Patents

Literature

668results about How to "Inhibition of recrystallization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Food preparation

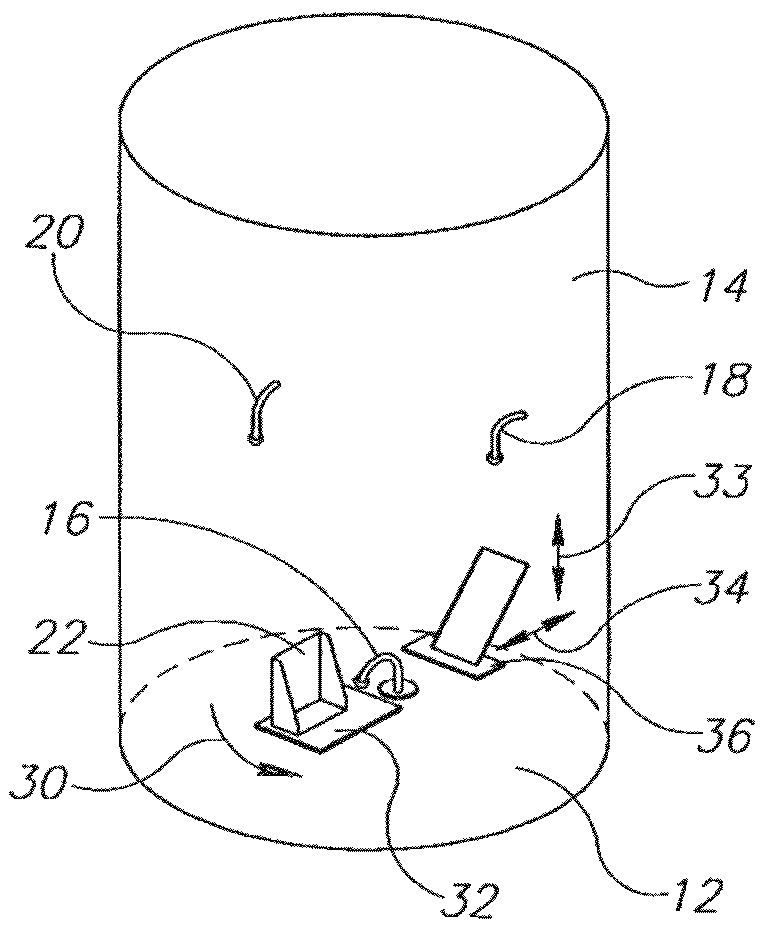

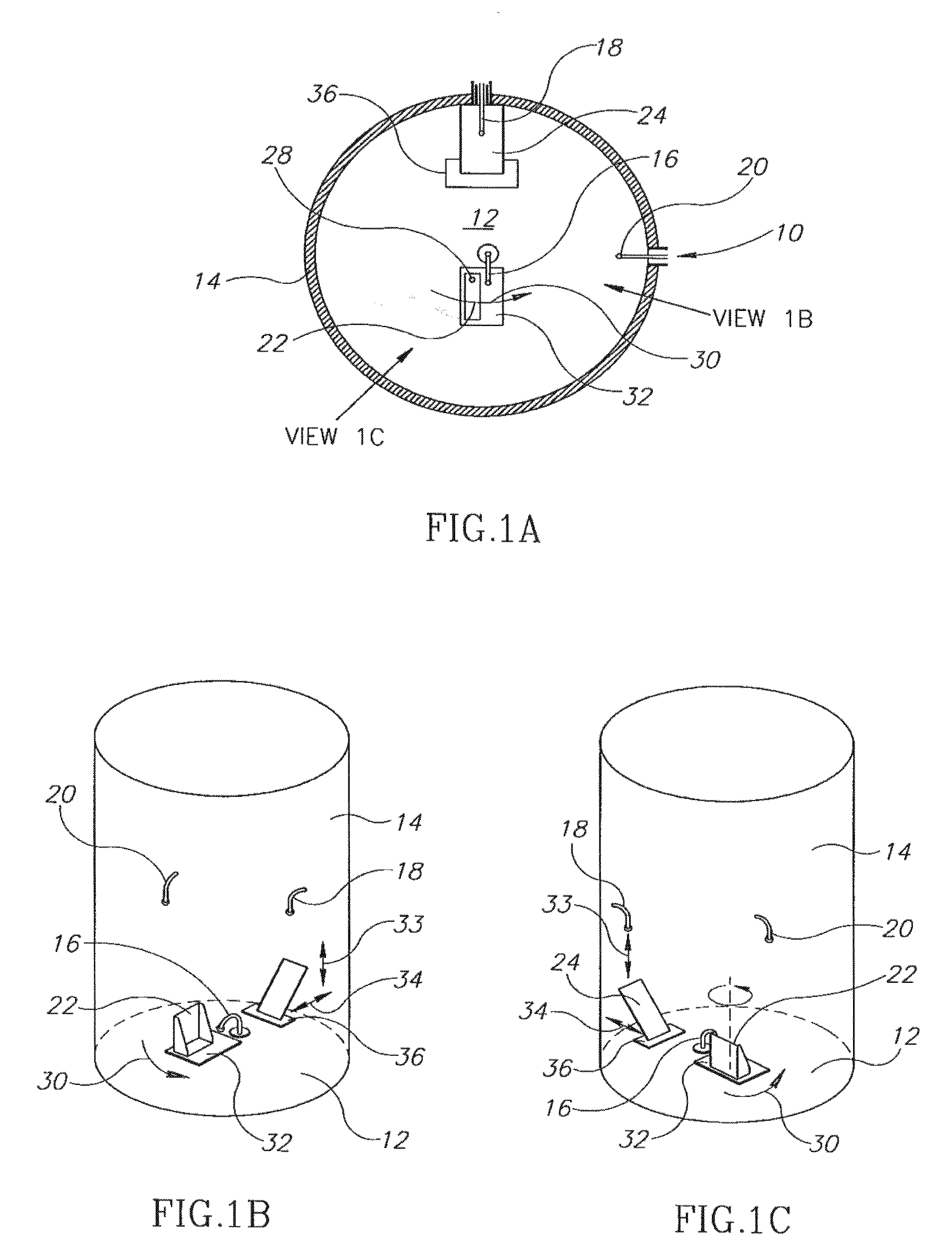

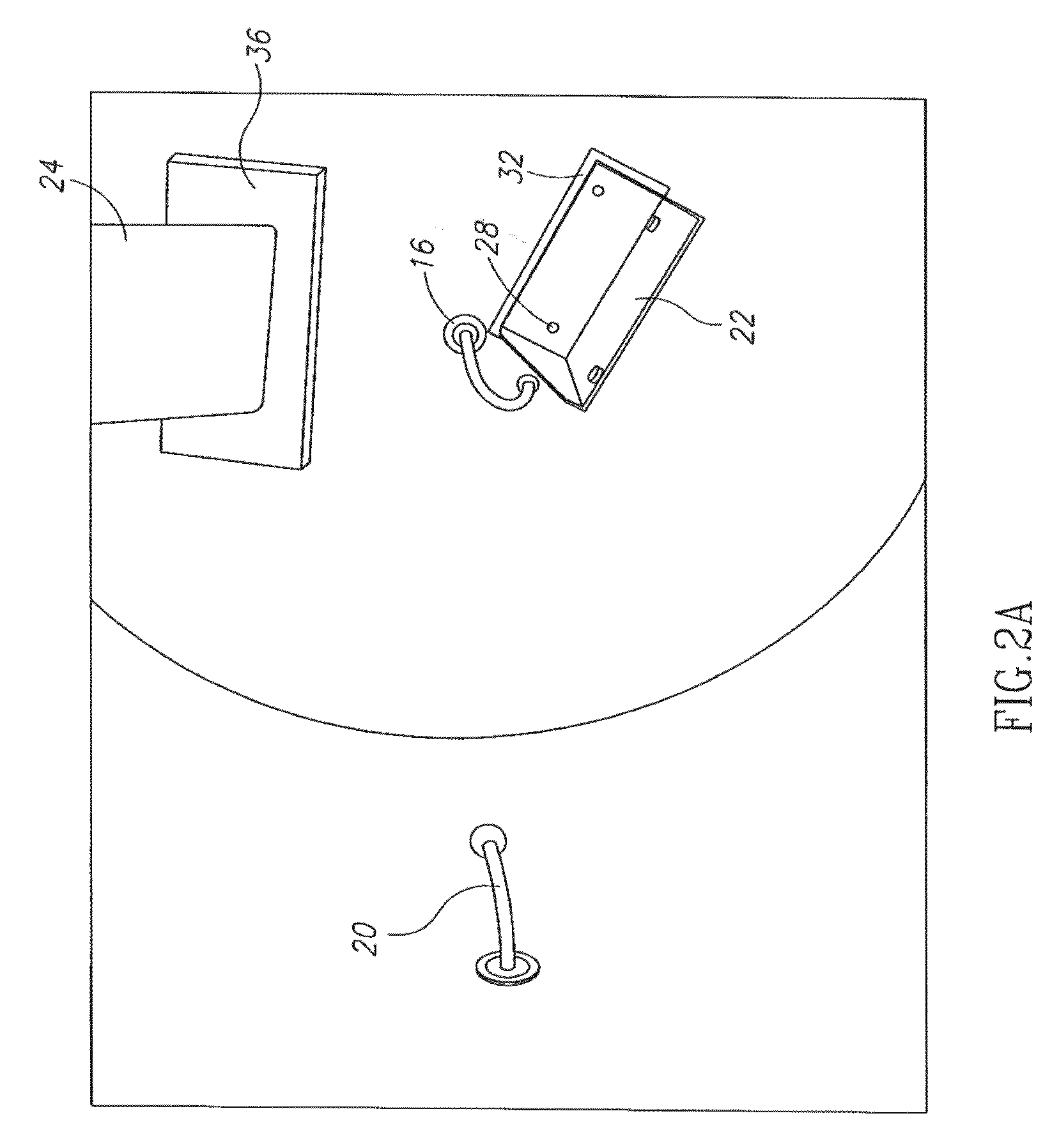

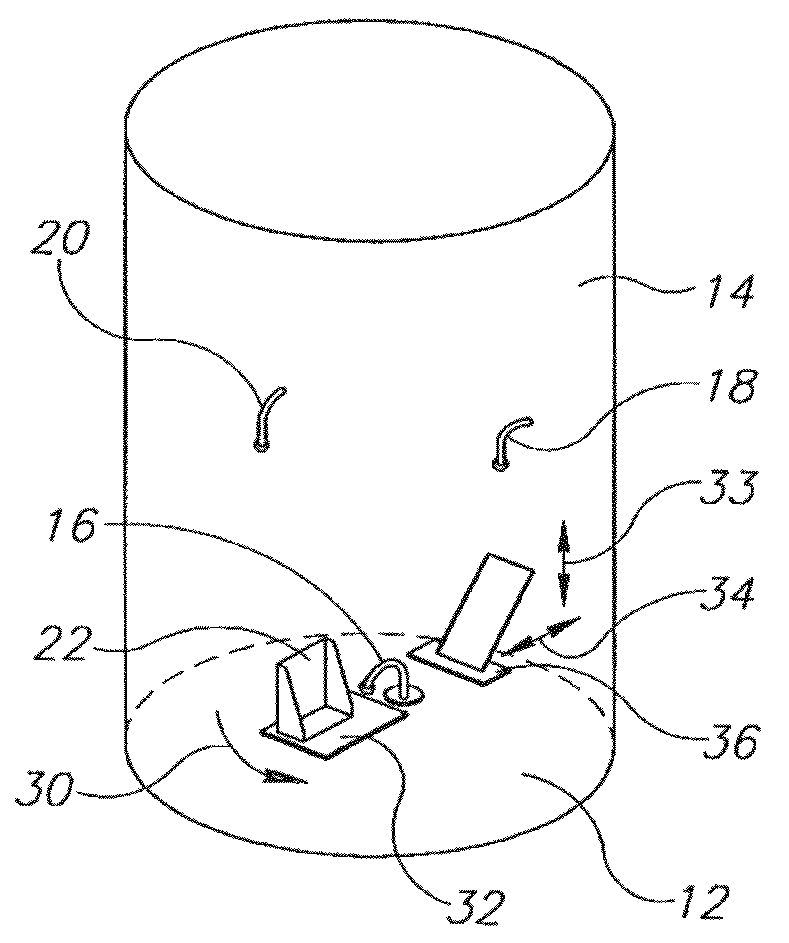

ActiveUS20090236335A1Improve efficiencyIncrease net powerContainer decorationsLevel indicationsEngineeringIngested food

Owner:JOLIET 2010 LTD

Food preparation

ActiveUS20090236333A1Improve efficiencyIncrease net powerContainer decorationsLevel indicationsEngineeringIngested food

Owner:JOLIET 2010 LTD

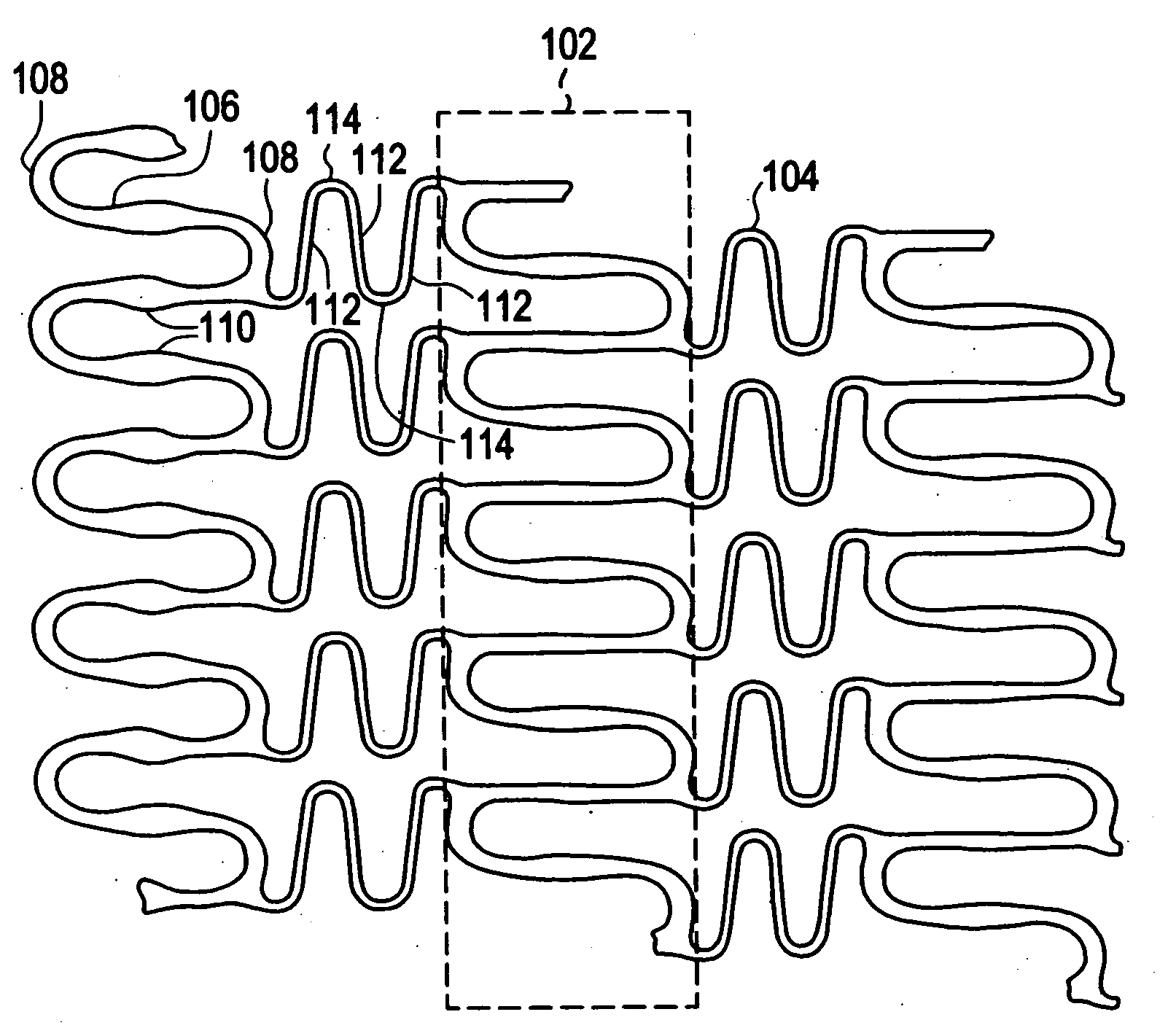

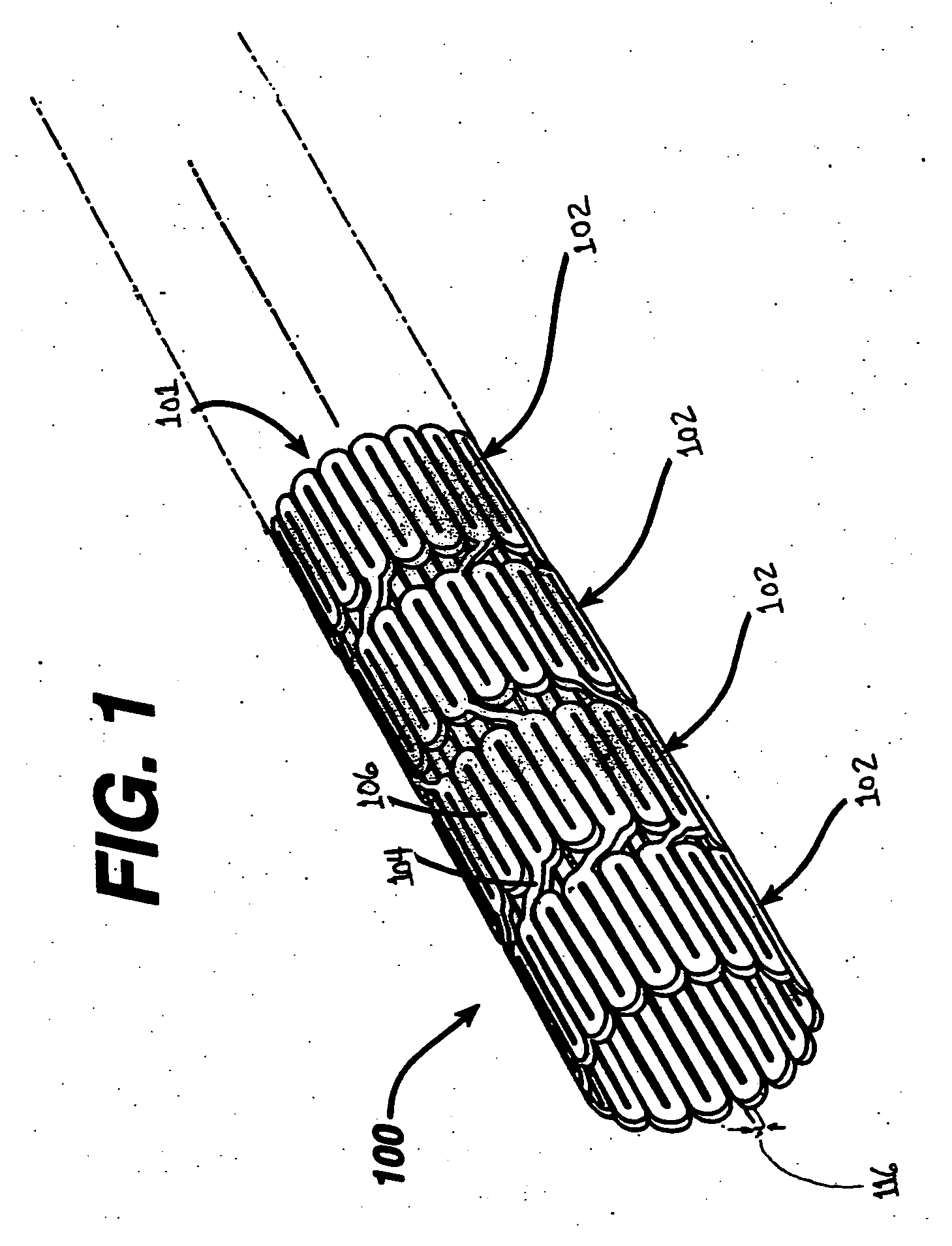

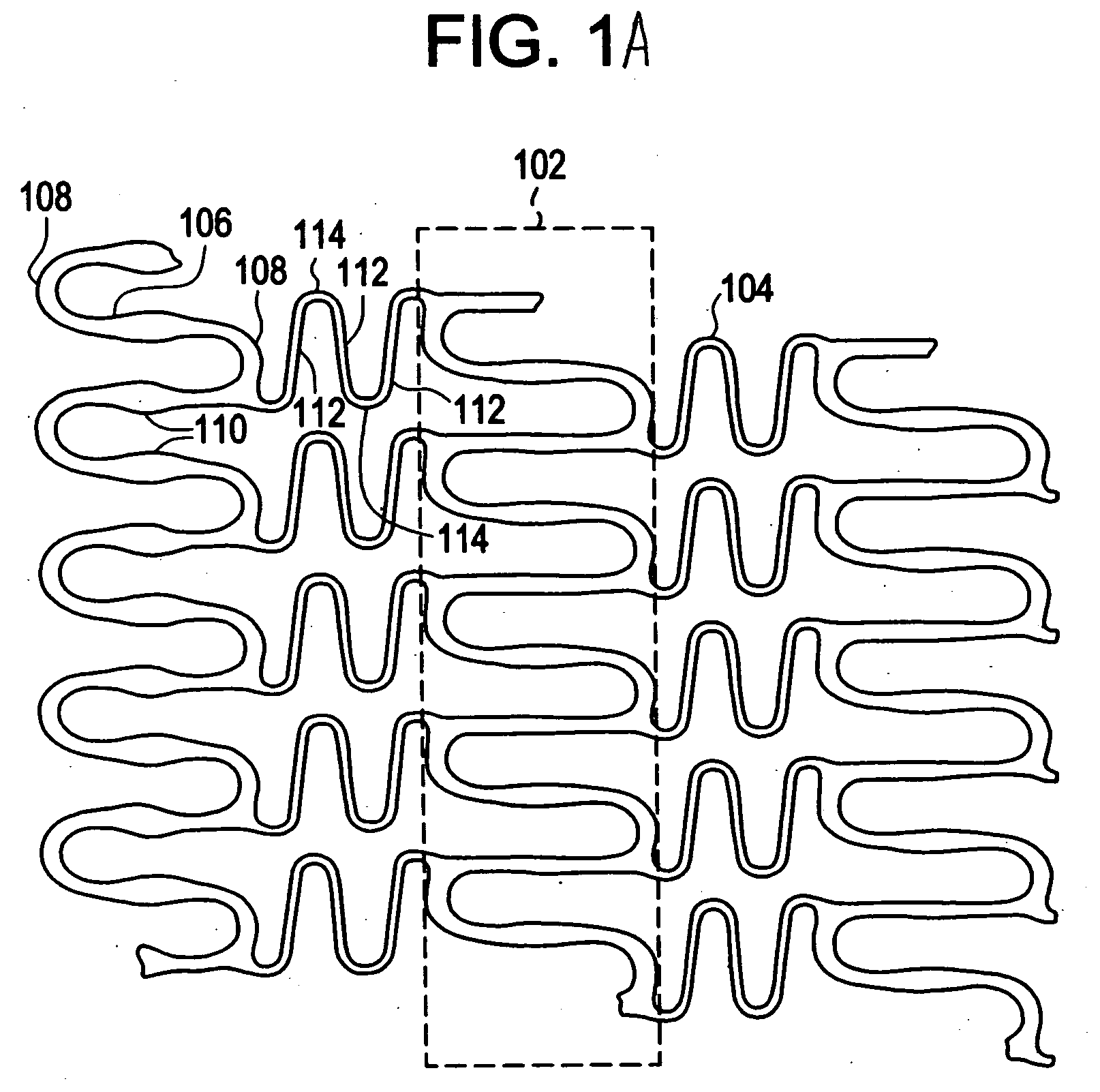

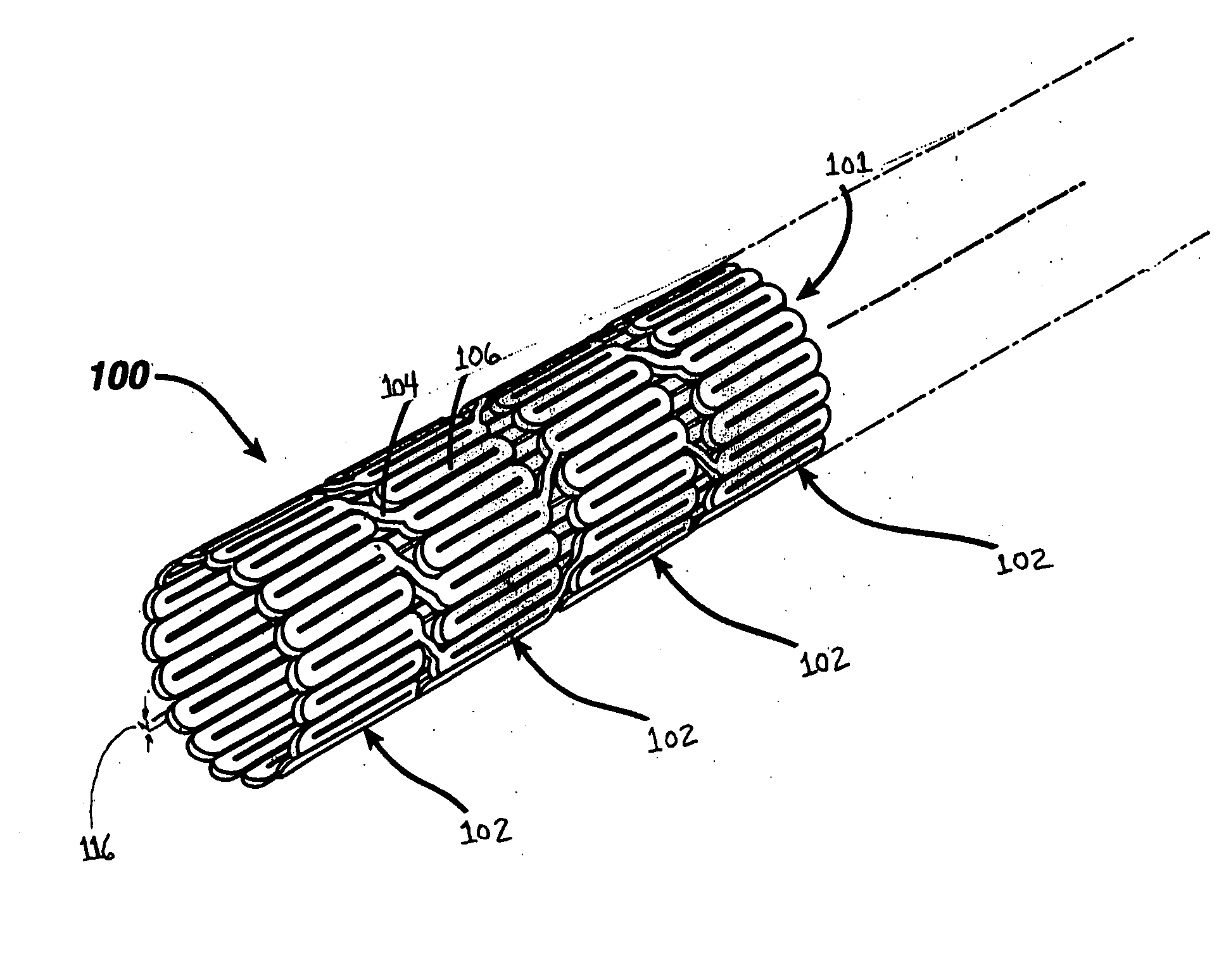

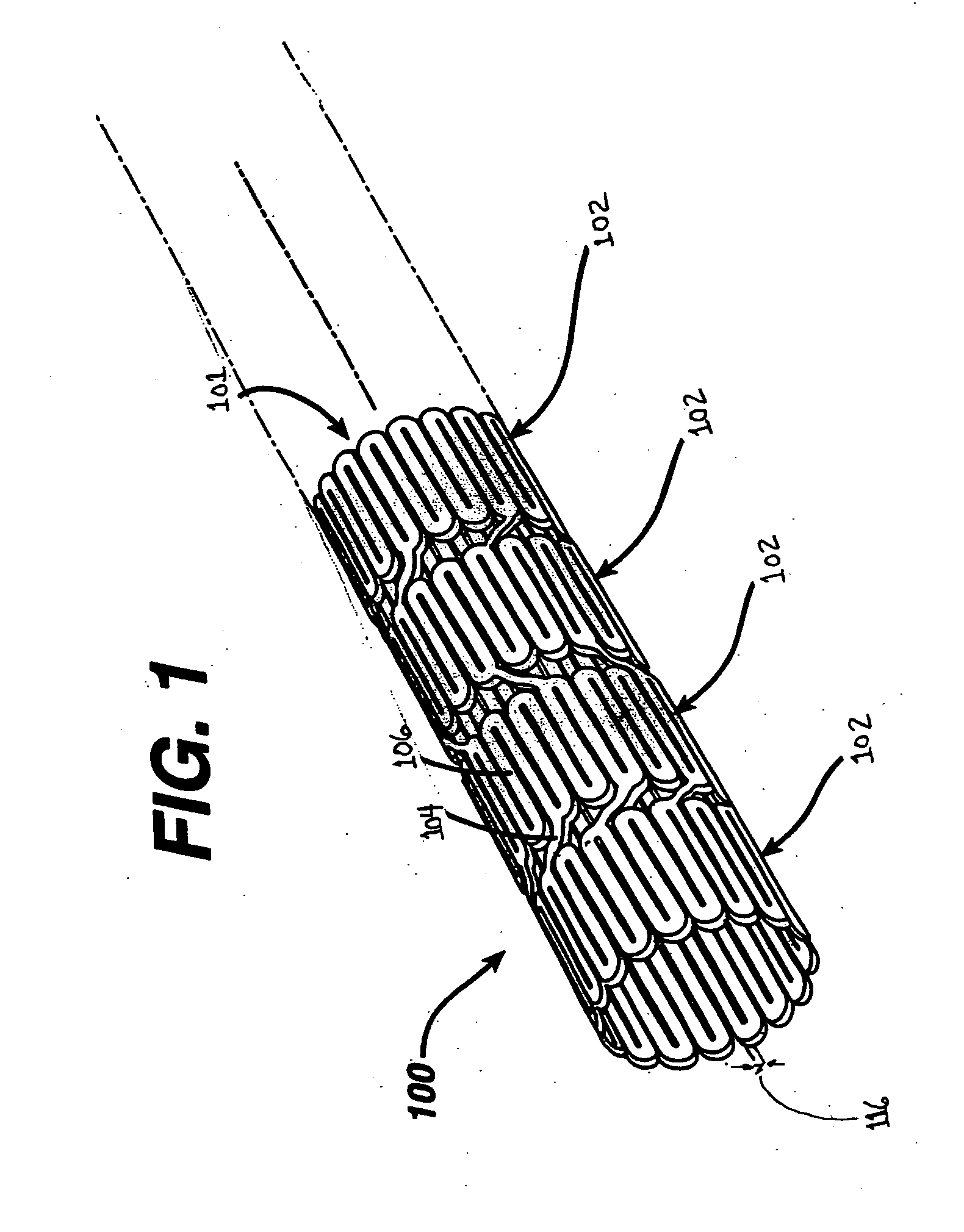

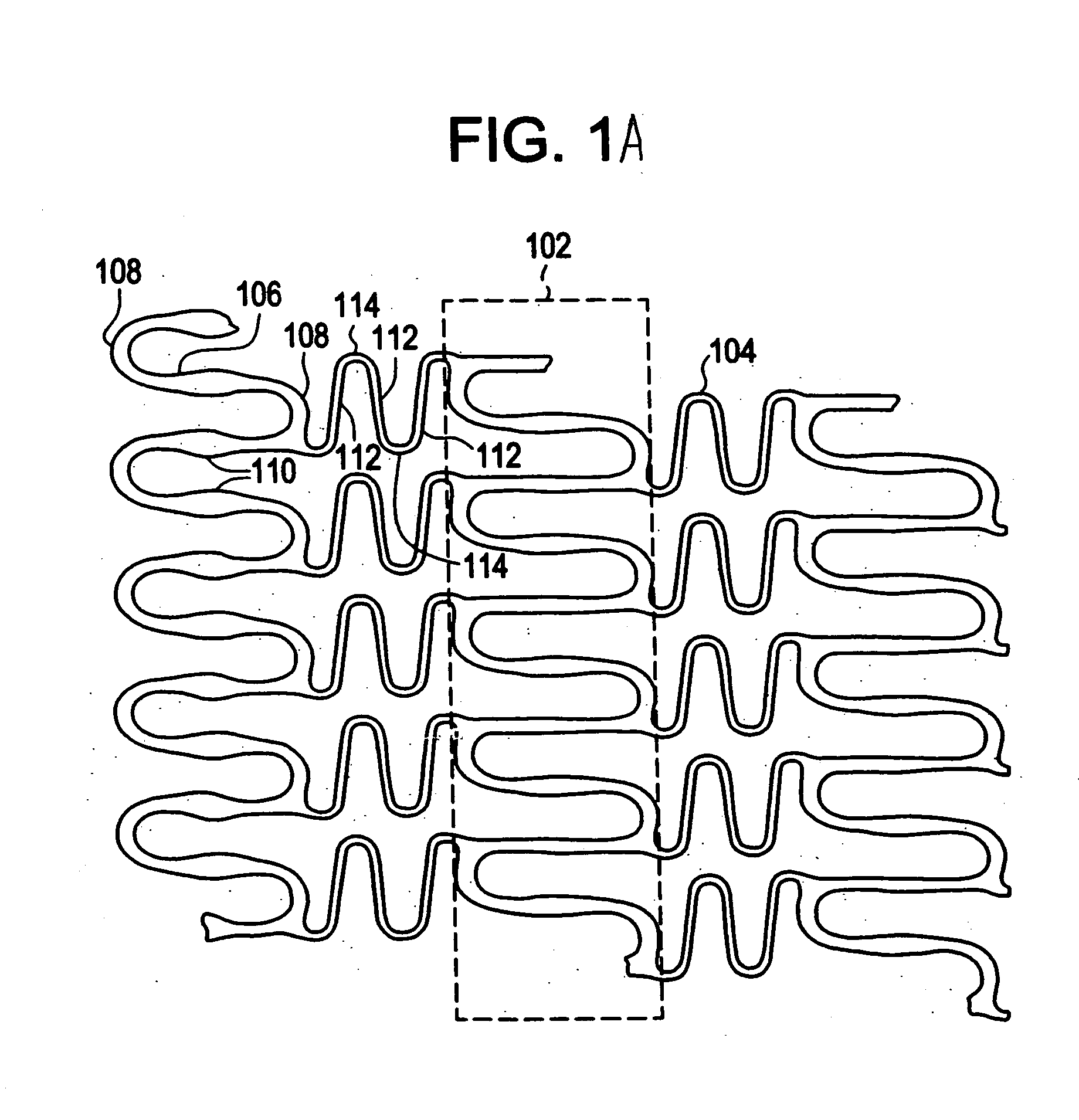

Morphological structures for polymeric drug delivery devices

InactiveUS20080097580A1Enhance performance characteristicHigh radial stiffnessStentsBlood vesselsBiomedical engineeringCrystallinity

An implantable medical apparatus includes a structure formed from bioabsorbable polymers. The apparatus also contains a therapeutic agent dispersed throughout the structure or coated on the structure in such a manner as to elute the therapeutic agent when implanted in an anatomical conduit. The apparatus can be constructed from a blend of polymers and other agents. The apparatus is implanted into the conduit by expansion with a balloon or some other expandable means. The morphology or arrangement of the polymeric structure ensures that the device maintains its shape characteristics to ensure proper modeling of the vessel. In particular, the crystallinity of the polymeric structure is adjusted so as to resist recoil.

Owner:CORDIS CORP

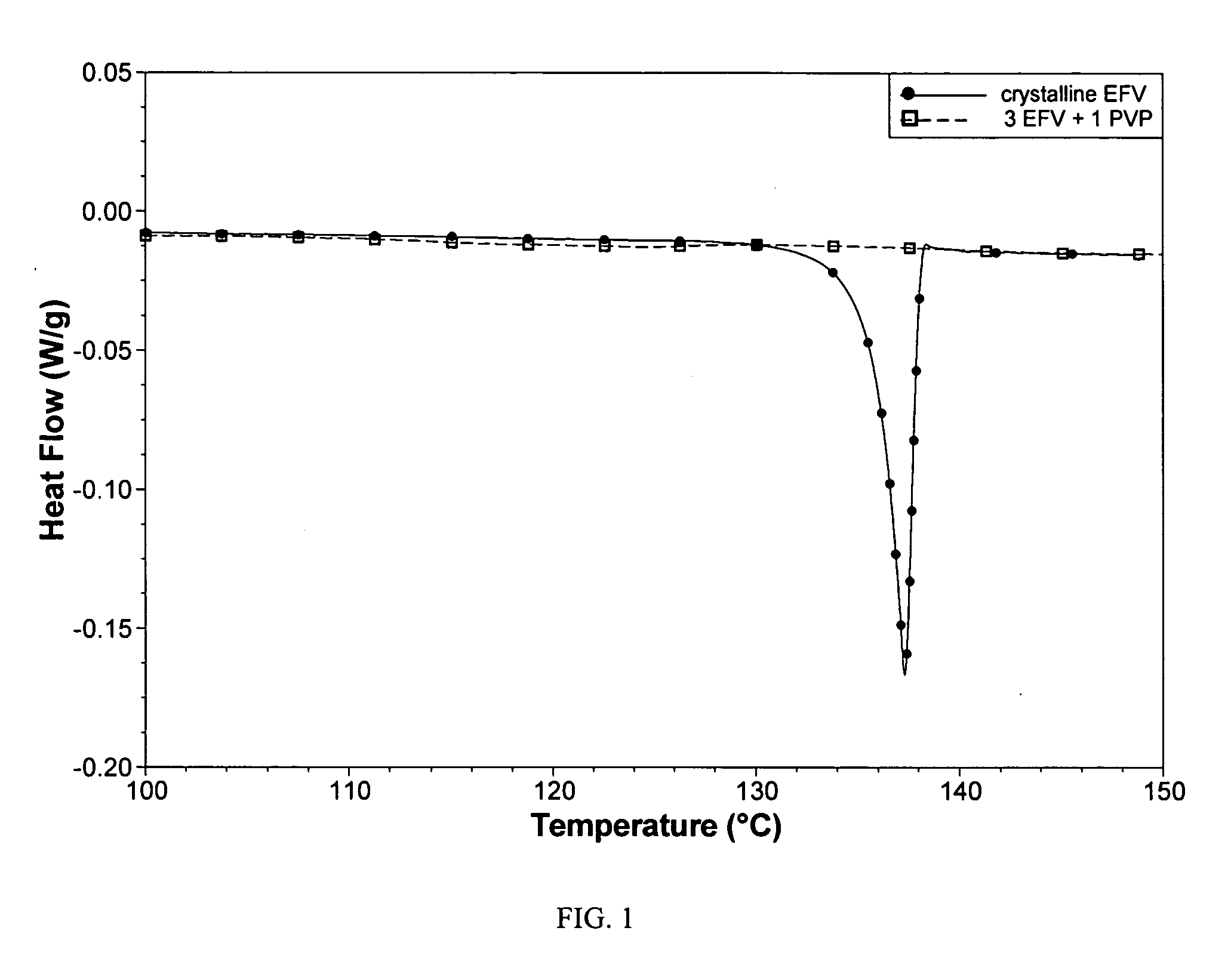

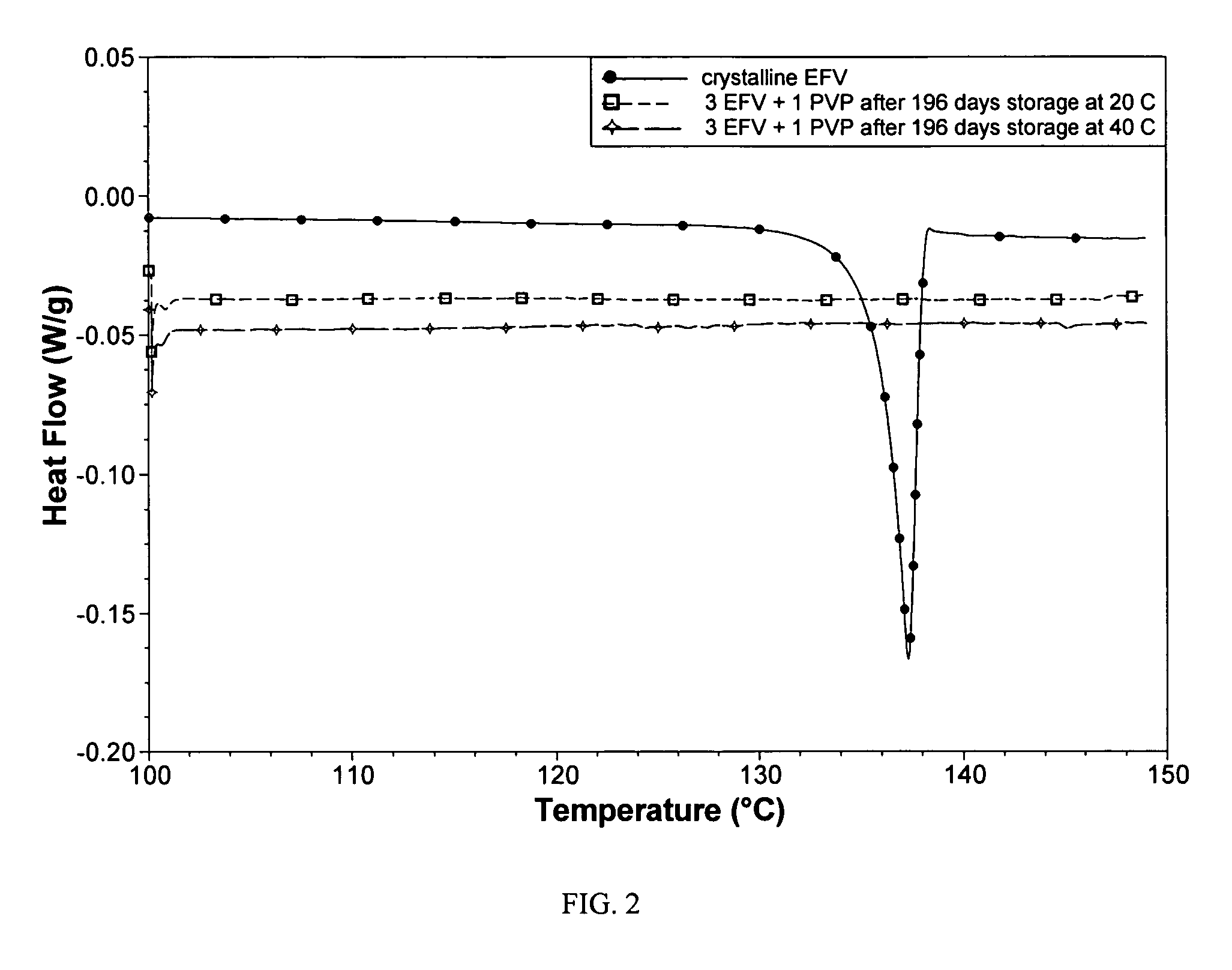

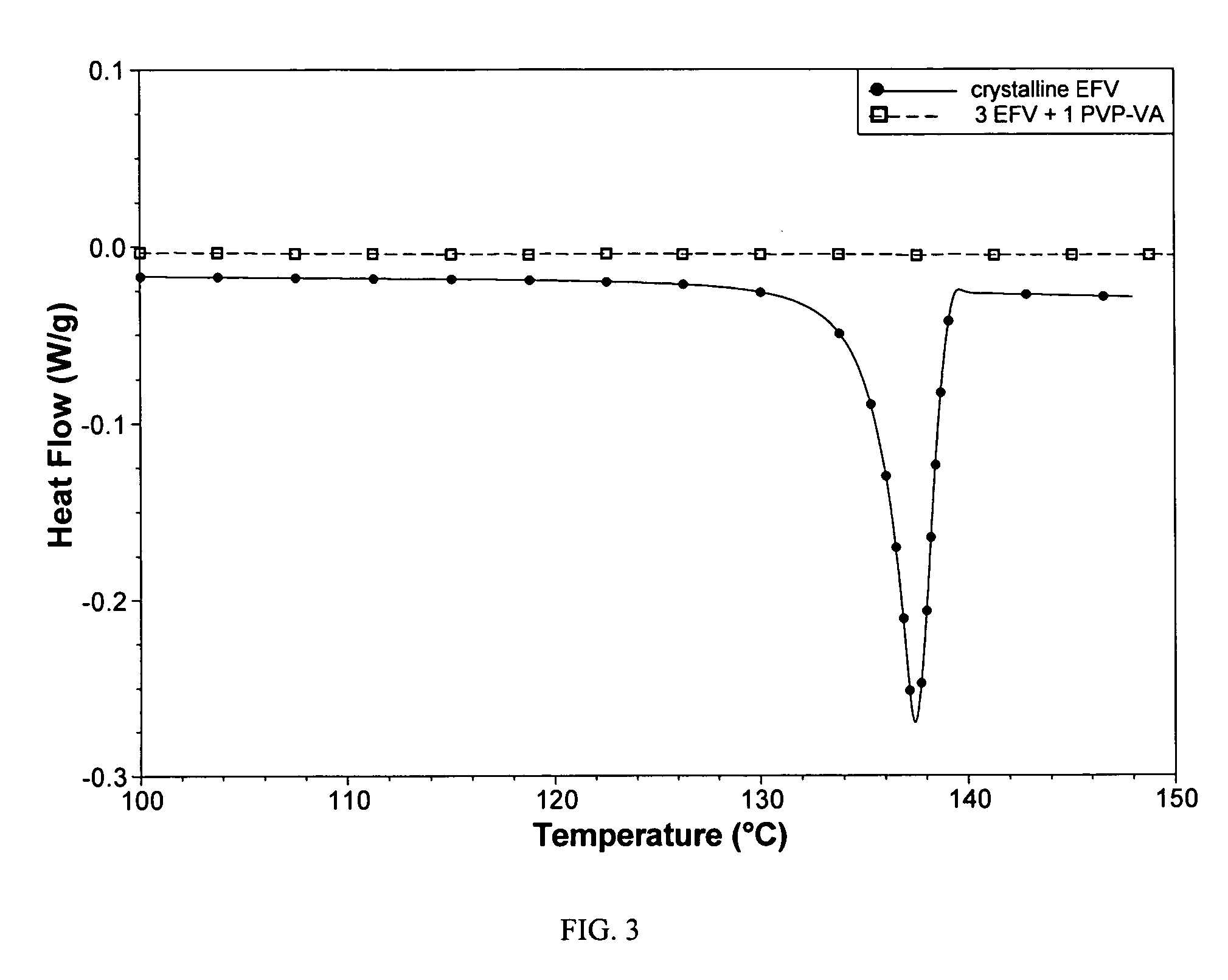

Amorphous efavirenz and the production thereof

InactiveUS20070026073A1Reducing residual solvent contentIncrease in bulk powder densityOrganic active ingredientsPowder deliverySolubilityPolymer chemistry

Efavirenz compositions of enhanced bioavailability are described that contain efavirenz with at least one solubility-enhancing polymer. Described methods to produce the bioenhanced products comprise solvent spray drying. One aspect of the method includes the steps of providing a mixture comprising efavirenz, a solubility-enhancing polymer and a single solvent, a solvent blend or solvent / non-solvent blend removing and then evaporating the mixture to form amorphous efavirenz.

Owner:ISP INVESTMENTS INC

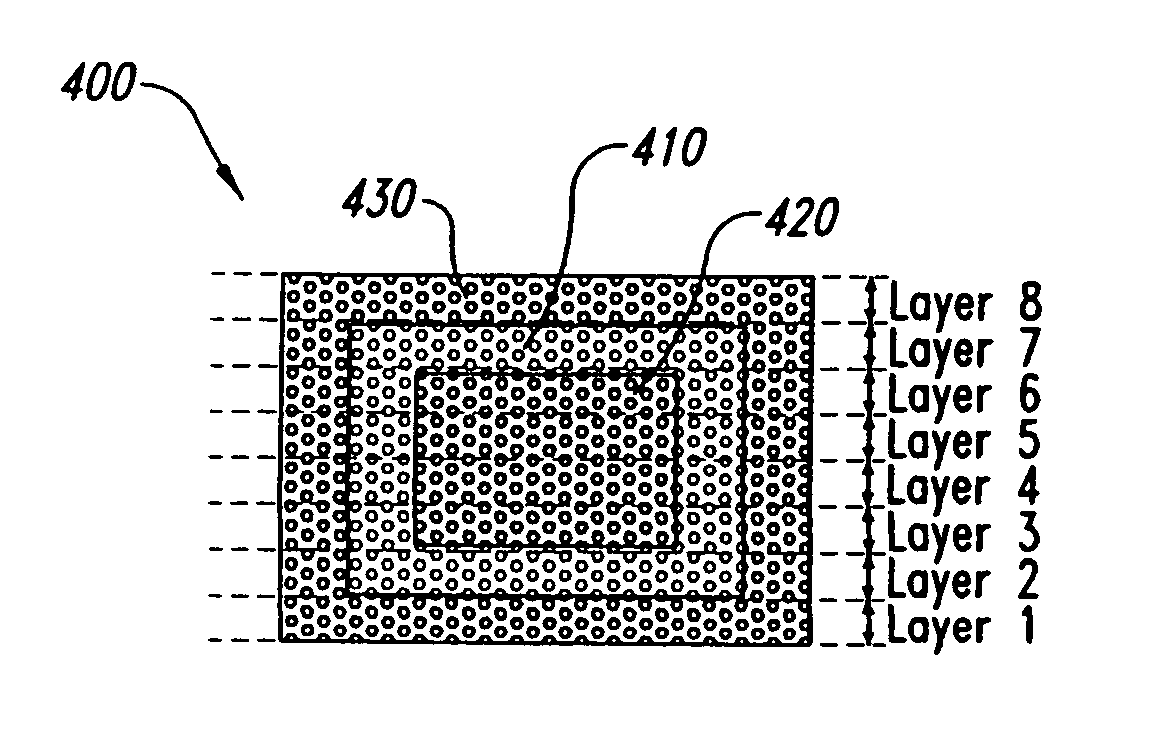

Method and form of a drug delivery device, such as encapsulating a toxic core within a non-toxic region in an oral dosage form

InactiveUS7276252B2Promote absorptionSmall crystal sizeBiocideAdditive manufacturing apparatusHazardous substanceBioavailability

A drug delivery device such as an oral dosage form (ODF) with a toxic or potent core encapsulated by a non-toxic region. The non-toxic region may be a region including multiple layers, coatings, shells, and combinations thereof, which provides protection to and isolation from the toxic or potent core. The drug in the toxic or potent core is incorporated into the dosage form via, for example, three-dimensional printing, as a solution, solubilization or suspension of solid particles in liquid, rather than by the more conventional handling and compressing of dry powder. This minimizes the likelihood of creating airborne particles of the toxic drug during manufacturing, hence controlling and minimizing the exposure of manufacturing personnel to the hazardous substance. Wet dispensing of the toxic or potent drug further provides greater bioavailability of the drug to the patient.

Owner:APRECIA PHARMA LLC +1

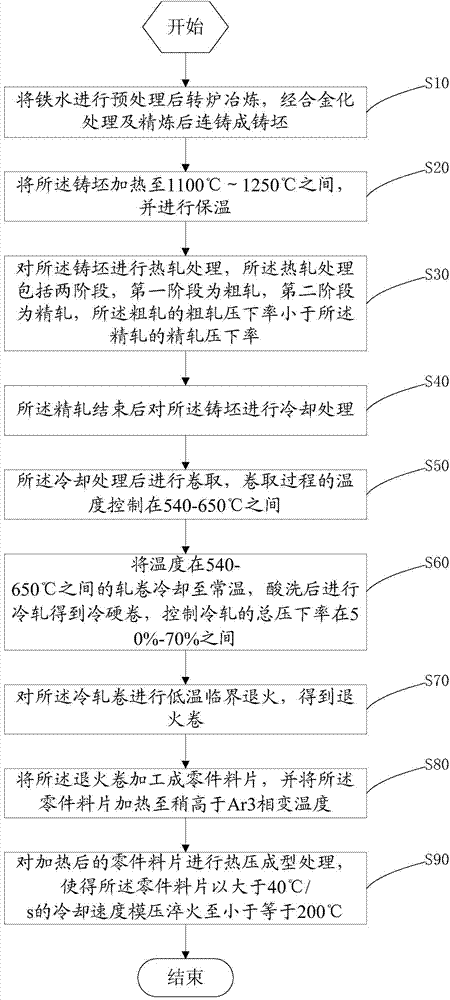

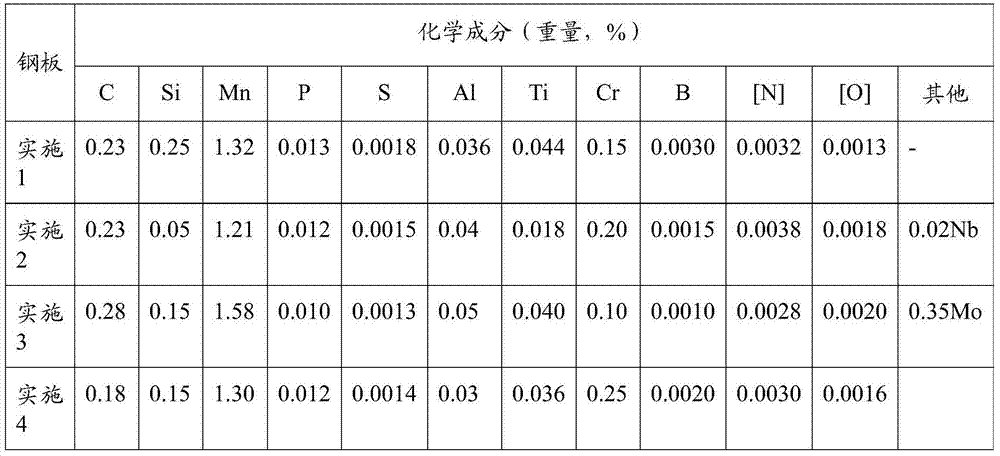

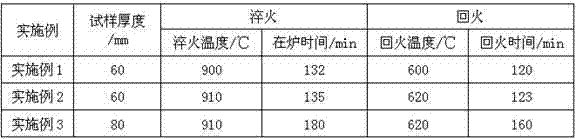

High-flexural-behavior hot-formed steel used for automobiles and manufacturing method thereof

The invention belongs to the technical field of steel rolling, and particularly relates to high-flexural-behavior hot-formed steel used for automobiles and a manufacturing method thereof. The steel comprises following trace elements by mass: 0.18-0.3% of C, not more than 0.3% of Si, 1-1.6% of Mn, not more than 0.015% of P, not more than 0.002% of S, 0.1-0.3% of Cr, 0.02-0.06% of Ti, 0.02-0.06% of Al, 0.0005-0.004% of B, not more than 0.004% of [N] and not more than 0.003% of [O]. The manufacturing method includes: heating a casting blank at a low temperature, performing controlled rolling in two stages, rapidly cooling, reeling up at a low temperature, preparing a steel coil by cold rolling and low-temperature critical annealing, shearing to prepare component tablets and performing hot press molding. By the manufacturing method, steel crystal grains are refined and ductility and toughness of the steel are enhanced, so that more energy is absorbed during deformation of the steel and automobile safety performance is enhanced.

Owner:SHOUGANG CORPORATION

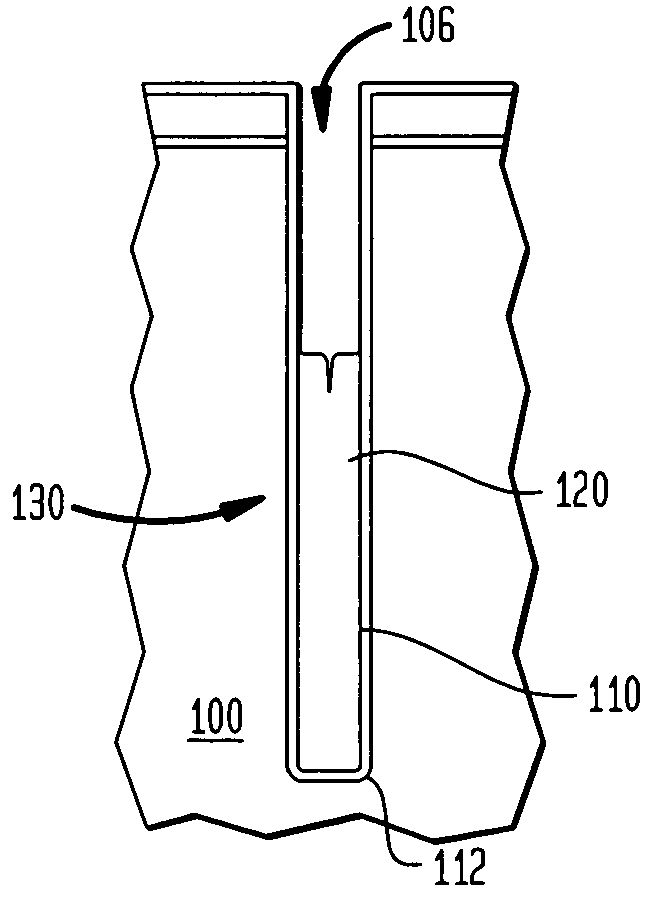

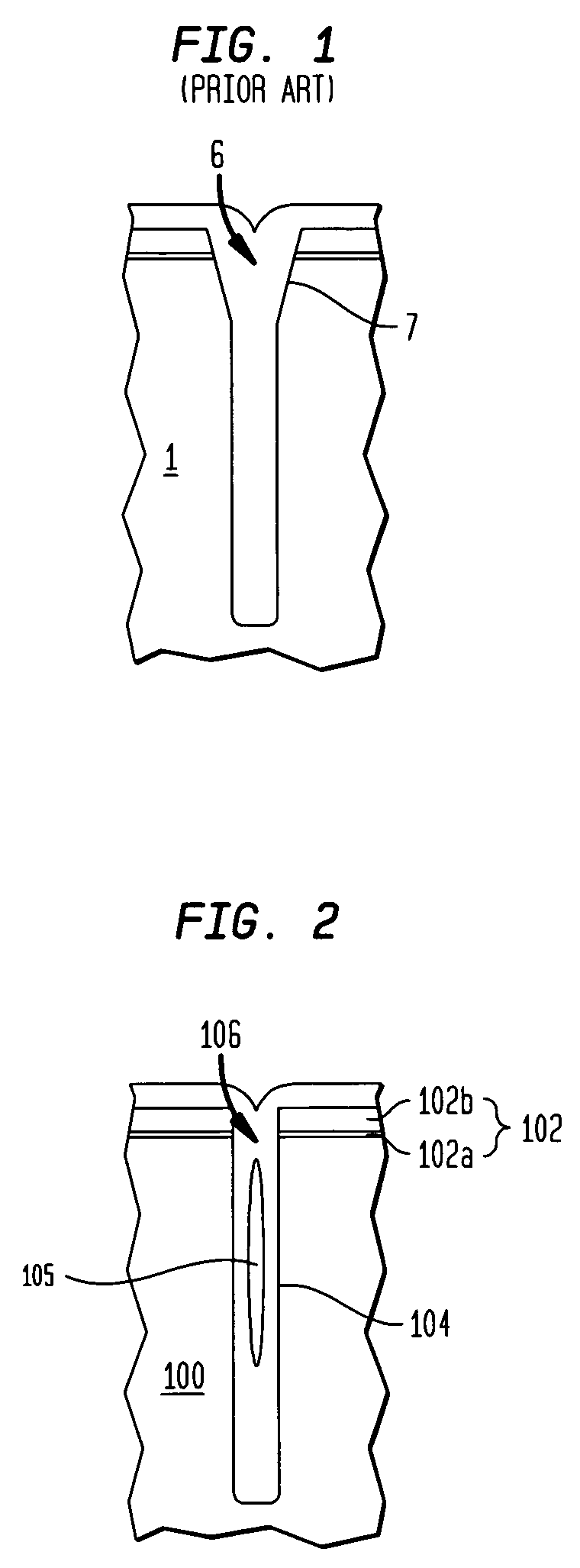

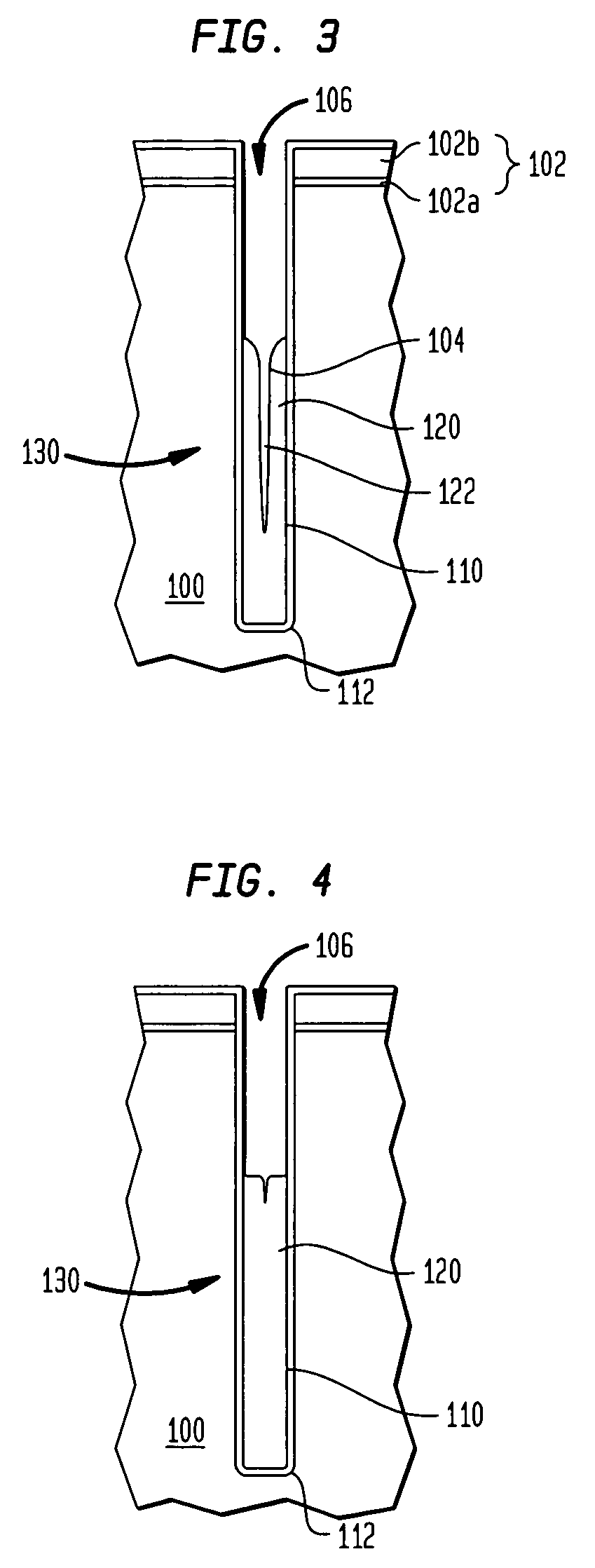

Void free, silicon filled trenches in semiconductors

InactiveUS7157327B2Inhibition of recrystallizationSolid-state devicesSemiconductor/solid-state device manufacturingSemiconductorMaterials science

The present invention provides methods of producing substantially void-free trench structures. After deposition of an a-Si or polysilicon layer in a trench formed in a semiconductor, the a-Si or polysilicon is exposed to hydrogen at an elevated temperature.

Owner:POLARIS INNOVATIONS LTD

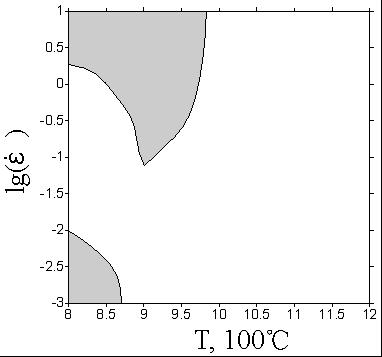

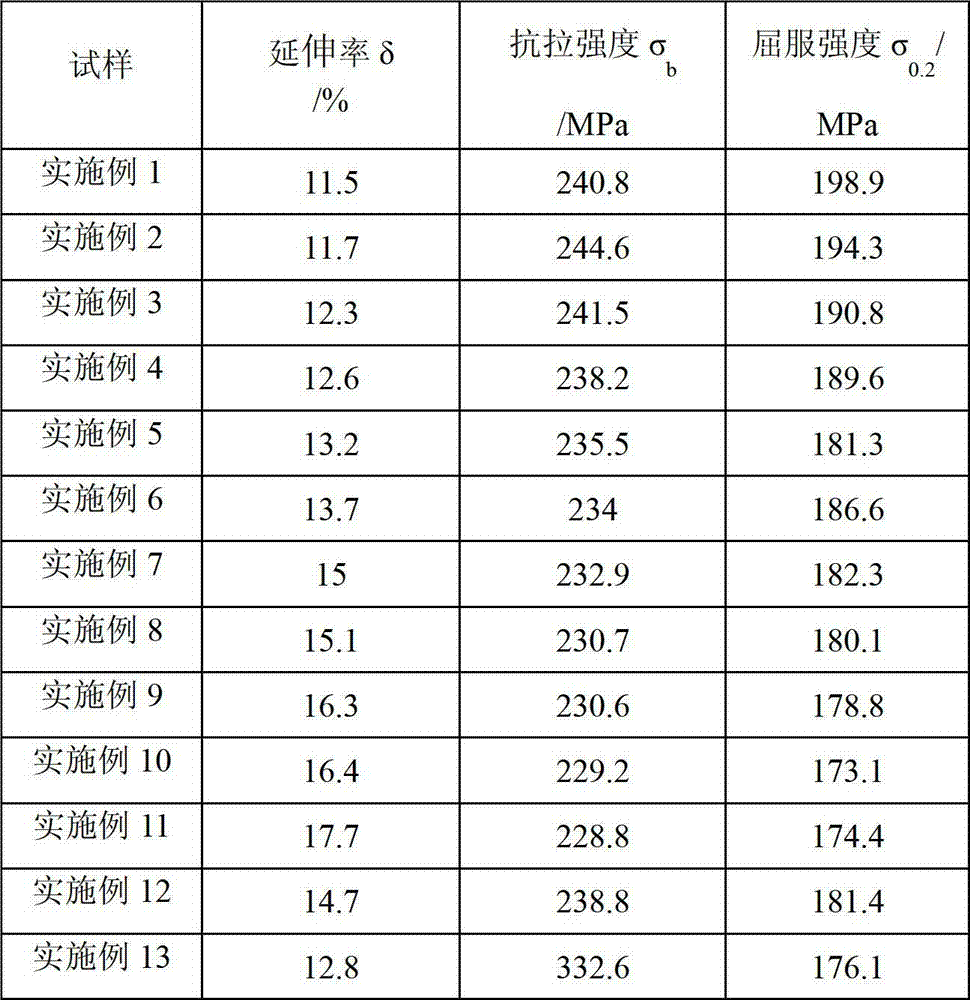

Aluminum alloy and aluminum alloy extruded profile machining method

The invention discloses aluminum alloy and an aluminum alloy extruded profile machining method. The aluminum alloy comprises, by weight, 0.6-1.4% of Si, 0.7-1.3% of Mg, 0.1-1% of Cu, 0.1-1% of Mn, 0.01-0.15% of Ti, 0-0.2% of Zr, 0-0.5% of Cr, 0-0.4% of Fe, 0-0.25% of Zn and the balance Al. The aluminum alloy also meets the requirements that the weight percentage range of Mg+Si+Cu is 1.4-3.7%, themole ratio of Mg to Si is 0.7-1.5, and the weight percentage range of Mn+Cr+Zr is 0.1-1.5%. The machining method comprises the steps that (1) a cast ingot of the alloy is subjected to homogenization treatment; (2) the cast ingot is extruded into aluminum profile; (3) extrusion production is conducted; (4) on-line quenching is conducted; (5) tension leveling is conducted; and (6) artificial aging is adopted. According to the aluminum alloy and the aluminum alloy extruded profile machining method, the technology is simple, and the production cost is low.

Owner:CHINALCO MATERIALS APPL RES INST CO LTD

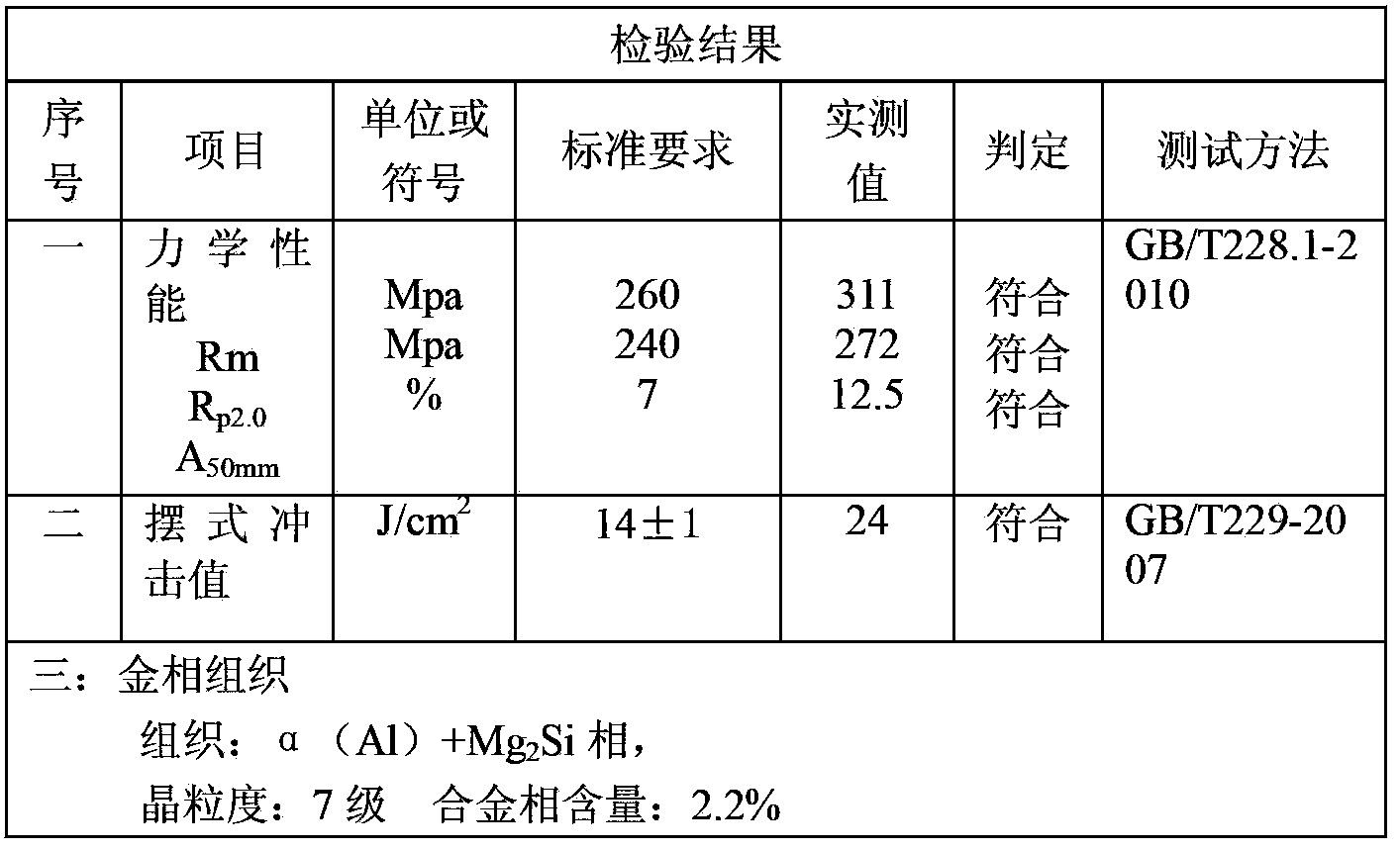

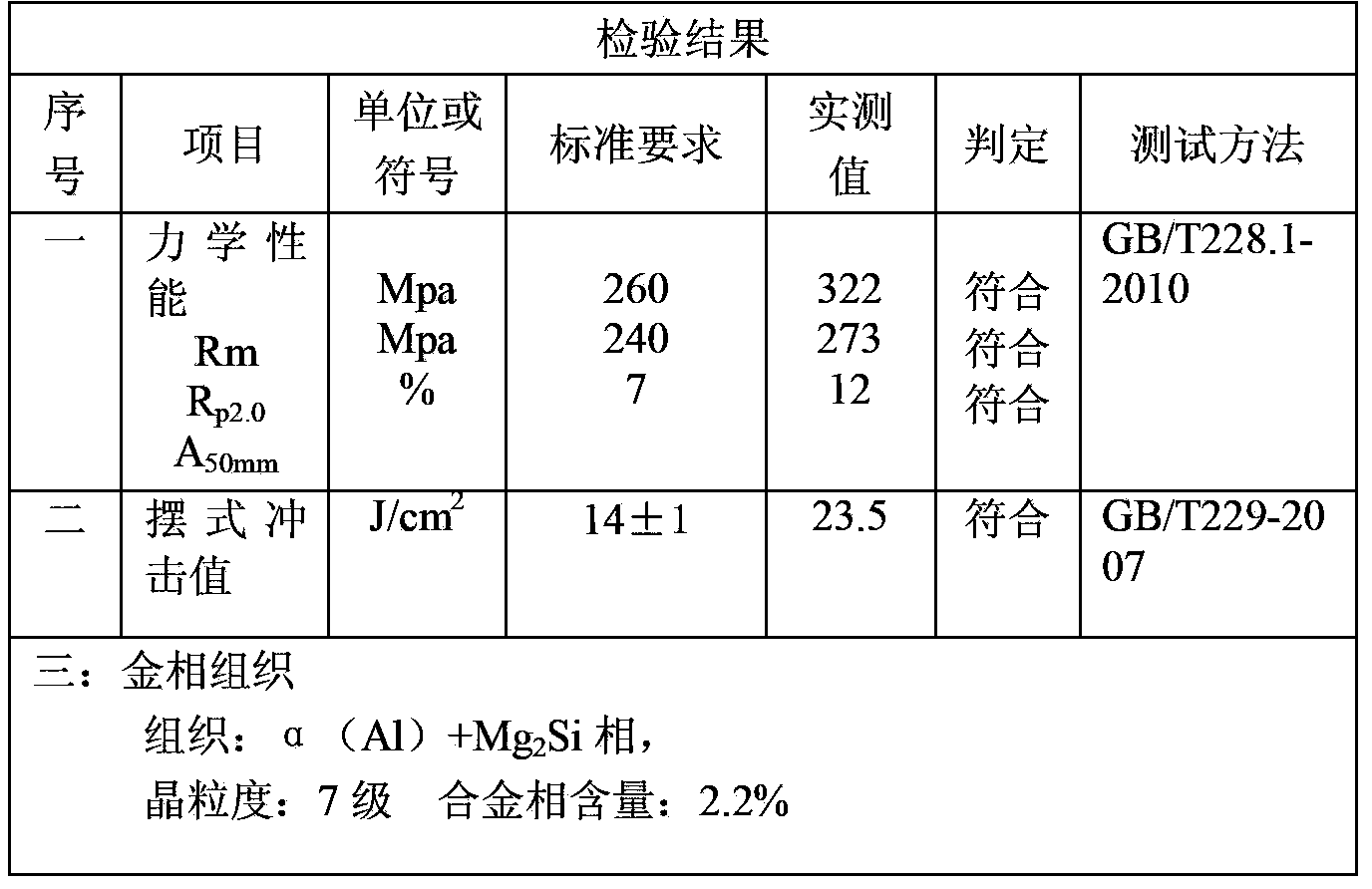

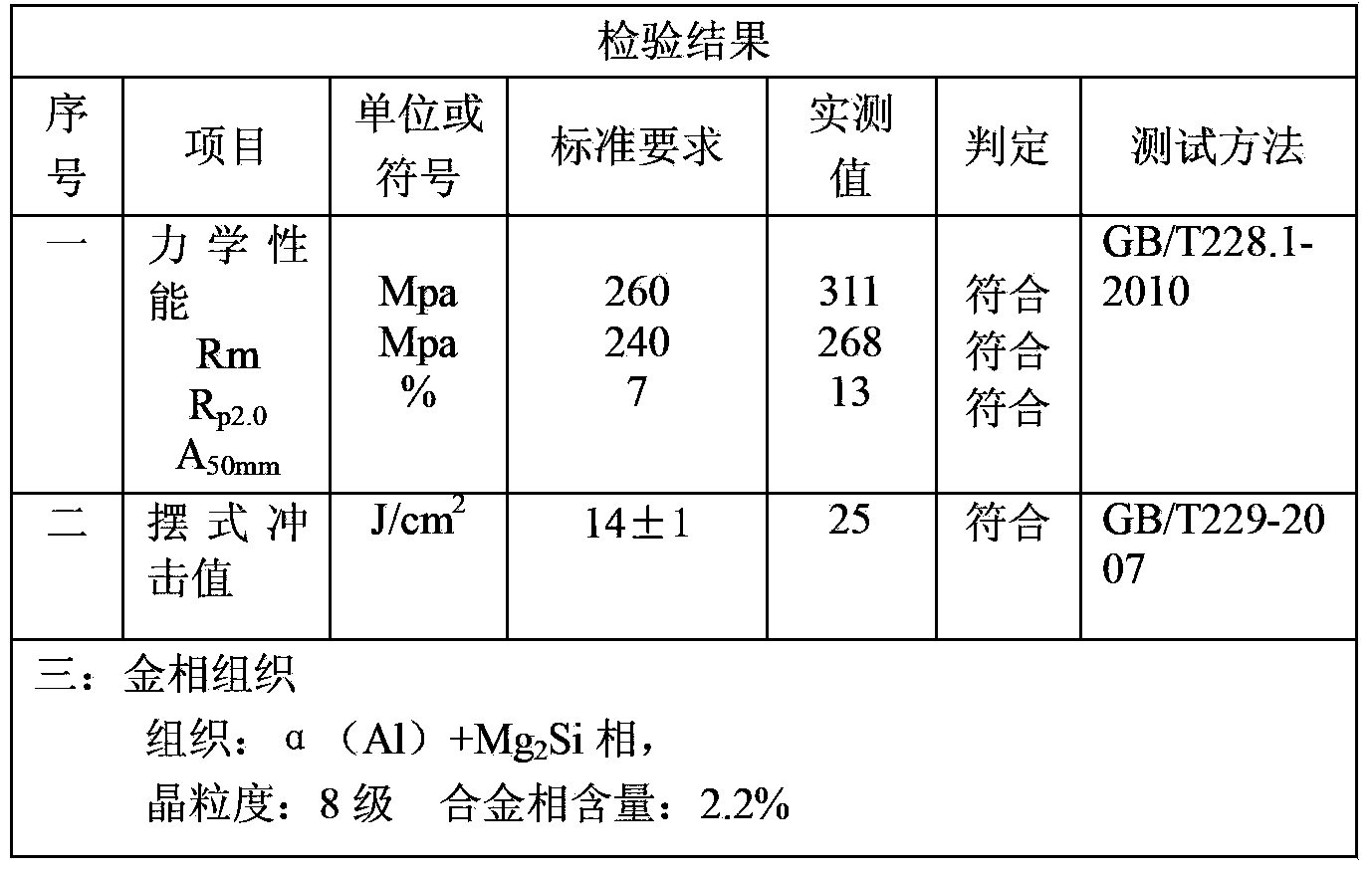

Aluminium alloy profile for building template, and preparation method thereof

The invention discloses an aluminium alloy profile for a building template, and a preparation method thereof. The aluminium alloy profile comprises the following components in percentage by weight: 0.85-0.95 percent of magnesium, 0.06-0.65 percent of silicone, 0.15-0.20 percent of copper, 0.05-0.08 percent of manganese, 0.03-0.05 percent of zirconium, 0.04-0.06 percent of chromium, 0.008-0.012 percent of titanium, 0-0.2 percent of iron, 0-0.10 percent of zinc and the balance of aluminium. The aluminium alloy profile provided by the invention has the advantages that the tensile strength is more than 300 MPa, the yield strength is more than 260 MPa, the breakage elongation percentage is more than 12 percent, the tenacity, the weldability and the corrosion resistance are obviously improved compared with that of an original 6061 alloy, the pendulum impact value is more than 20 J / cm<2>, the welding coefficient is not less than 0.6, smaller quench sensitivity is provided, and critical quenching speed is dropped from 10 DEG C / S of the original alloy to 7 DEG C / S; during the processing of the aluminium alloy profile, air cooling is adopted to process an extrusion outlet with the temperature of 450 DEG C in a high-temperature segment as well as an extrusion outlet with the temperature of being smaller than or equal to 25 DEG C in a low-temperature segment, while a moderate-temperature segment, namely a quench sensitive area with the temperature of 450-250 DEG C utilizes water mist to replace direct water-cooling, so that the difficulty for controlling cross section deformation of the profile in the production field is greatly reduced.

Owner:GUANGDONG WEIYE ALUMINUM FACTORY GRP

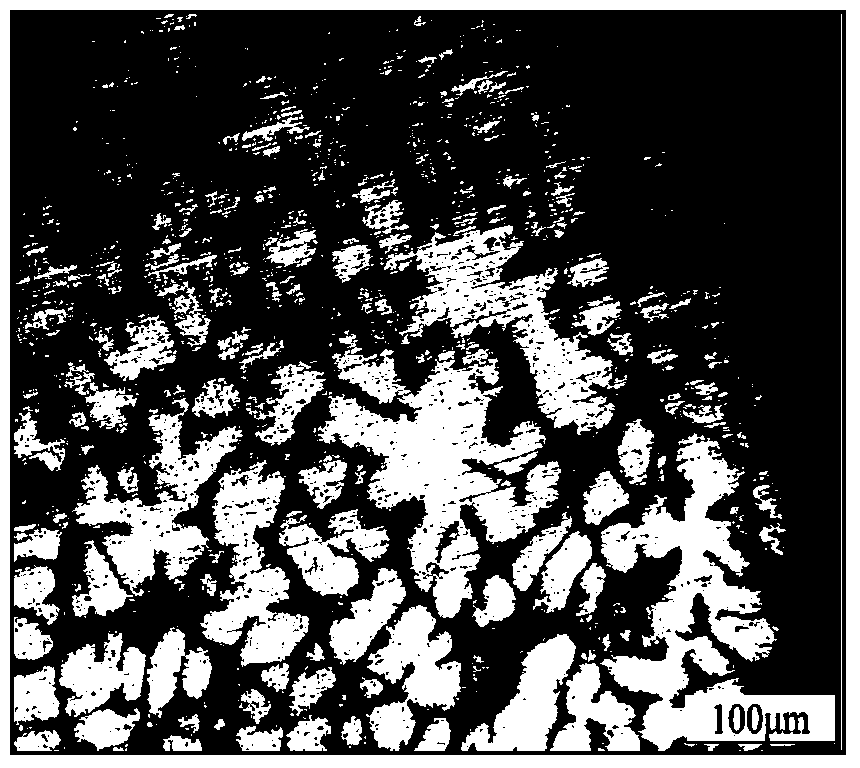

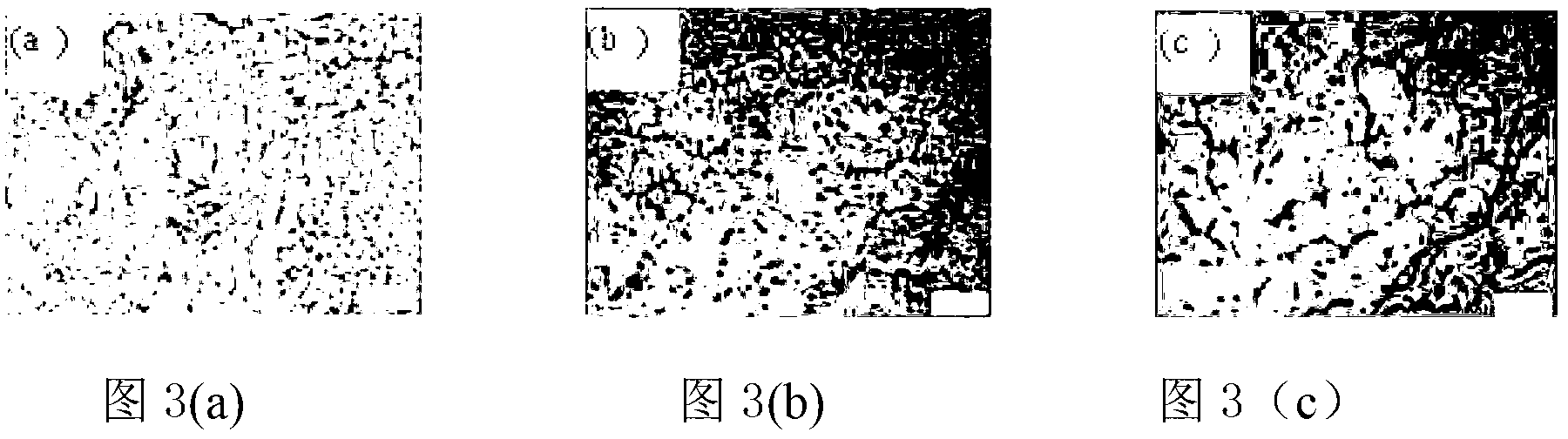

Grain-refined extruded aluminum alloy tubular product with large wall thickness and preparation method thereof

The invention discloses a grain-refined extruded aluminum alloy tubular product with large wall thickness and a preparation method thereof. The tubular product comprises the following metallic substances in percentage by weight: 1.0-1.15% of Mg, 0.60-0.75% of Si, 0.20-0.35% of Cu, 0.35% of Fe, 0.10% of Mn, 0.05-0.08% of Cr, 0.15% of Zn, 0.10% of Ti and the balance of aluminum. The invention further discloses a preparation method of the grain-refined extruded aluminum alloy tubular product with large wall thickness. The grain-refined extruded aluminum alloy tubular product with large wall thickness provided by the invention solves the problem that the grains of the base and surface of a 6061 alloy extruded aluminum alloy tubular product with great wall thickness are thick and big, the deficiency of bulky crystal spots generated after anodic oxidation can be eliminated and indexes of the final product, such as inner welding quality and mechanical performance, can satisfy the GB / T6892-2006 standard requirement.

Owner:龙口市丛林铝材有限公司

Method for manufacturing and tempering bainite wear-resistant steel and steel pipe

InactiveCN102534432AImprove stabilityGuaranteed recrystallizationFurnace typesHeat treatment furnacesWear resistantAlloy

The invention provides a method for manufacturing and tempering bainite wear-resistant steel and steel pipe. The bainite wear-resistant steel contains the following main ingredients of: C, Mn, Si, Cr, Ni, Cu, V, Al, P, S and the balance of Fe. The method for manufacturing the bainite wear-resistant steel pipe comprises the following steps of: alloying the raw material ingredients of bainite wear-resistant steel to form an alloy, refining the alloy by using a refining furnace, forming a pipe blank by using continuous casting, then, heating up the pipe blank, carrying out heat insulation to homogenize, then, perforating, carrying out tandem rolling, and sizing; carrying out pipe-making by using on-line rolling, then, carrying out air cooling or accelerated cooling; and after air cooling or accelerated cooling, carrying out tempering and heat insulation for 1-48 hours at the tempering temperature of 180-380 DEG C. Compared with the prior art, the method has the advantages that: the occurrence of mixed-metal texture is avoided, the recrystallization is fully guaranteed after the alloy is homogenized, two difficult problems in composite pipes internationally and domestically are solved, and a pipeline formed by directly adopting the bainite wear-resistant steel pipe is pressure-proof and wear-resistant.

Owner:TSINGHUA UNIV +1

Manufacture method of extremely thick ocean engineering steel plate with low compression ratio and super high-strength strain age

ActiveCN103031498AReduce the compression ratioReduce rolling passesUltimate tensile strengthMechanical engineering

The invention discloses a manufacture method of an extremely thick ocean engineering steel plate with low compression ratio and super high-strength strain age, which performs reasonable setting and optimization to controlled rolling and controlled cooling technology through converter smelting, LF and RH refining, so as to perform quenched-tempered heat treatment. The steel plate has good performance, the tensile strength is 780 to 850 MPa, the yield strength is 720 to 800 MPa, the percentage of elongation is 18 to 21 percent, the low-temperature transverse impact at minus 40 DEG C is larger than or equal to 120J, the low-temperature aging impact property at minus 40 DEG C is larger than or equal to 100J, the steel plate has ultrahigh strength, high tenacity and excellent low temperature aging tenacity, and the production technology is stable.

Owner:NANJING IRON & STEEL CO LTD

Aluminum alloy for 480 MPa-class aluminum alloy oil pipe and pipe manufacturing method thereof

The invention discloses an aluminum alloy for a 480 MPa-class aluminum alloy oil pipe. The aluminum alloy comprises the following components by weight percent: 5.10-6.90% of Zn, 1.10-1.80% of Mg, 0.05-0.20% of Cu, 0.10-0.30% of Mn, 0.10-0.30% of Cr, 0.01-0.02% of Ti, 0.15-0.2% of Zr and the balance of Al and unavoidable impurities, wherein in the unavoidable impurities, the content of the Si is not greater than 0.15 of the total weight of the aluminum alloy and the content of Fe is not greater than 0.15 of the total weight of the aluminum alloy. The manufacture method of the aluminum alloy pipe comprises the following steps: (1) smelting the raw materials according to the weight percentage, performing external refining and casting to obtain a pipe blank; (2) performing three-stage homogenization treatment; (3) squeezing under high temperature; (4) performing twin-stage solid solution treatment, quenching and cooling; (5) prestretching and deforming; and (6) performing twin-stage artificial aging treatment.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

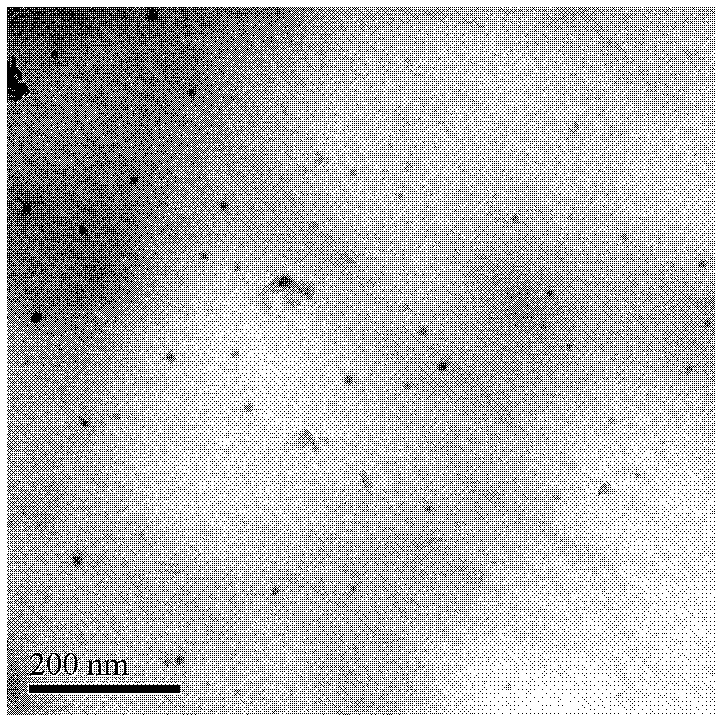

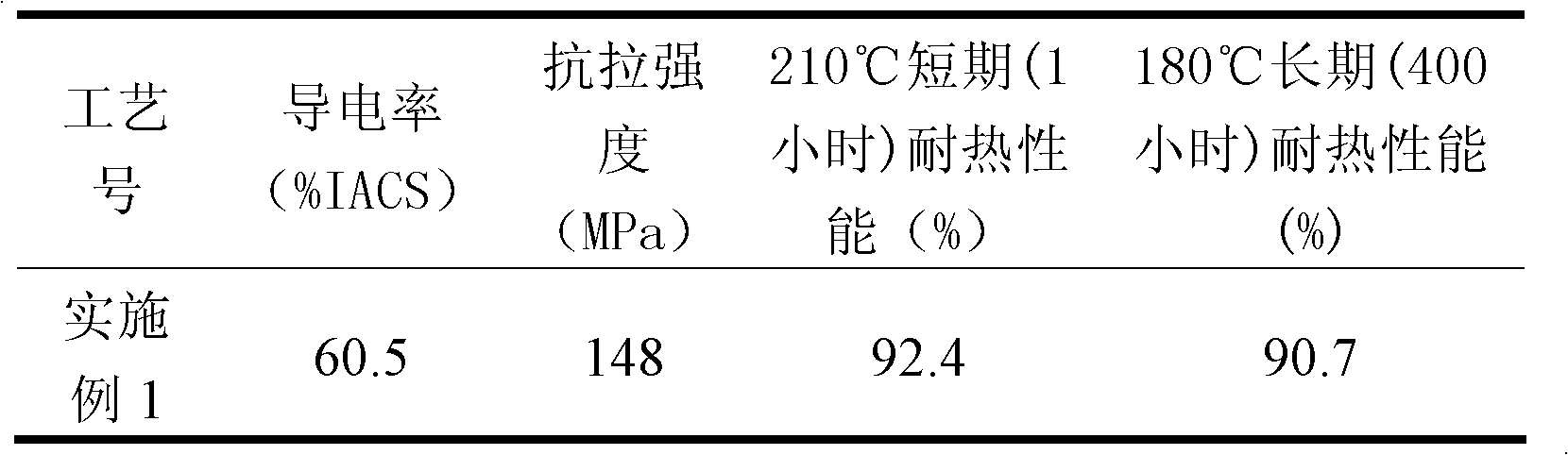

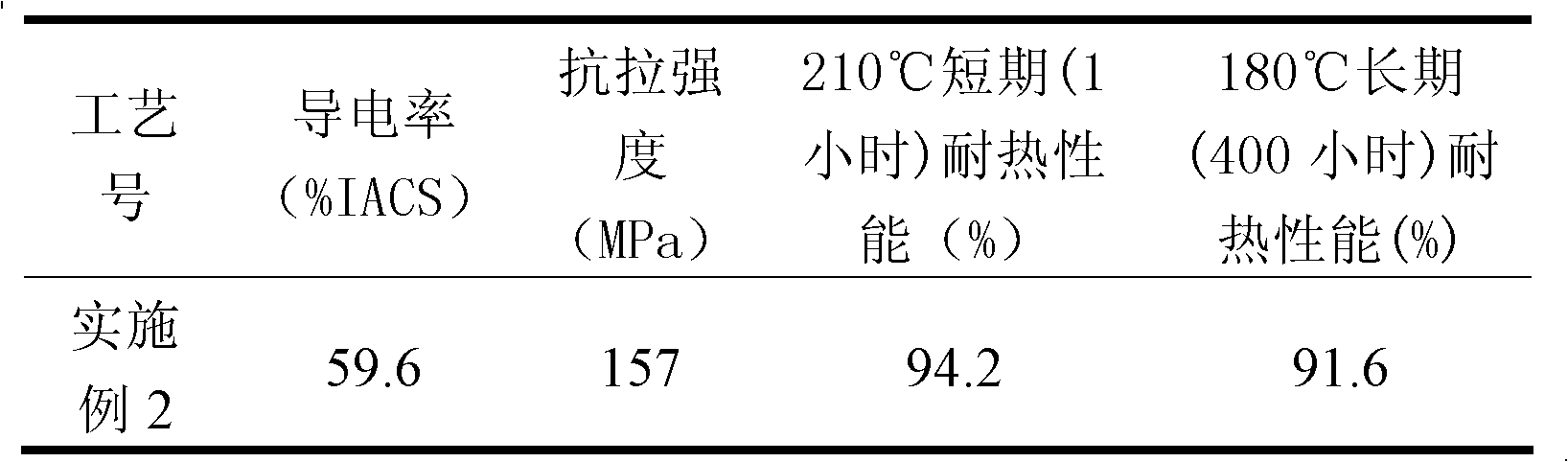

Heat resistant aluminum alloy conductor material and preparation method thereof

ActiveCN102230113AImprove conductivityLow conductivityMetal/alloy conductorsCable/conductor manufactureElectrical conductorManganese

The invention provides a heat resistant aluminum alloy conductor material and a preparation method thereof. The heat resistant aluminum alloy conductor material comprises the following components of 0.06-0.15 % of zirconium, 0.15-0.30 % of erbium, 0.10-0.20 % of iron, less than 0.05 % of silicon, less than 0.01 % of inevitable impurities like titanium, vanadium, chromium, manganese and the like and the balance of aluminum. According to the preparation method, the heat resistant aluminum alloy conductor material is directly rolled after each component is fused and cast. The conductor material can realize that the electric conductivity can reach 59.5-60.5 % IACS (International Association Of Classification Societies), the long-term heat resistance temperature can reach 180 DEG C and the short-term heat resistance temperature can reach 210 DEG C without heat treatment; therefore, the conductor material is an electric wire and cable conductor material with great potential. The conductor material can be widely used for construction and capacity expansion reconstruction of electric power engineering; and by using the conductor material, the transmission line capacity is largely increased, the transmission line loss is reduced, the distance between poles of the transmission line can be increased, the line building cost is reduced, the tense corridor resources are saved and obvious economic benefit and energy-saving and environment-friendly significance are obtained. The heat resistant aluminum alloy conductor material provided by the invention has the advantages of reasonable component mixing ratio, simple preparation process, convenience for realizing continuous production and suitability for industrial application; and the production cost and the energy consumption of the heat resistant aluminum alloy can be effectively reduced.

Owner:CENT SOUTH UNIV

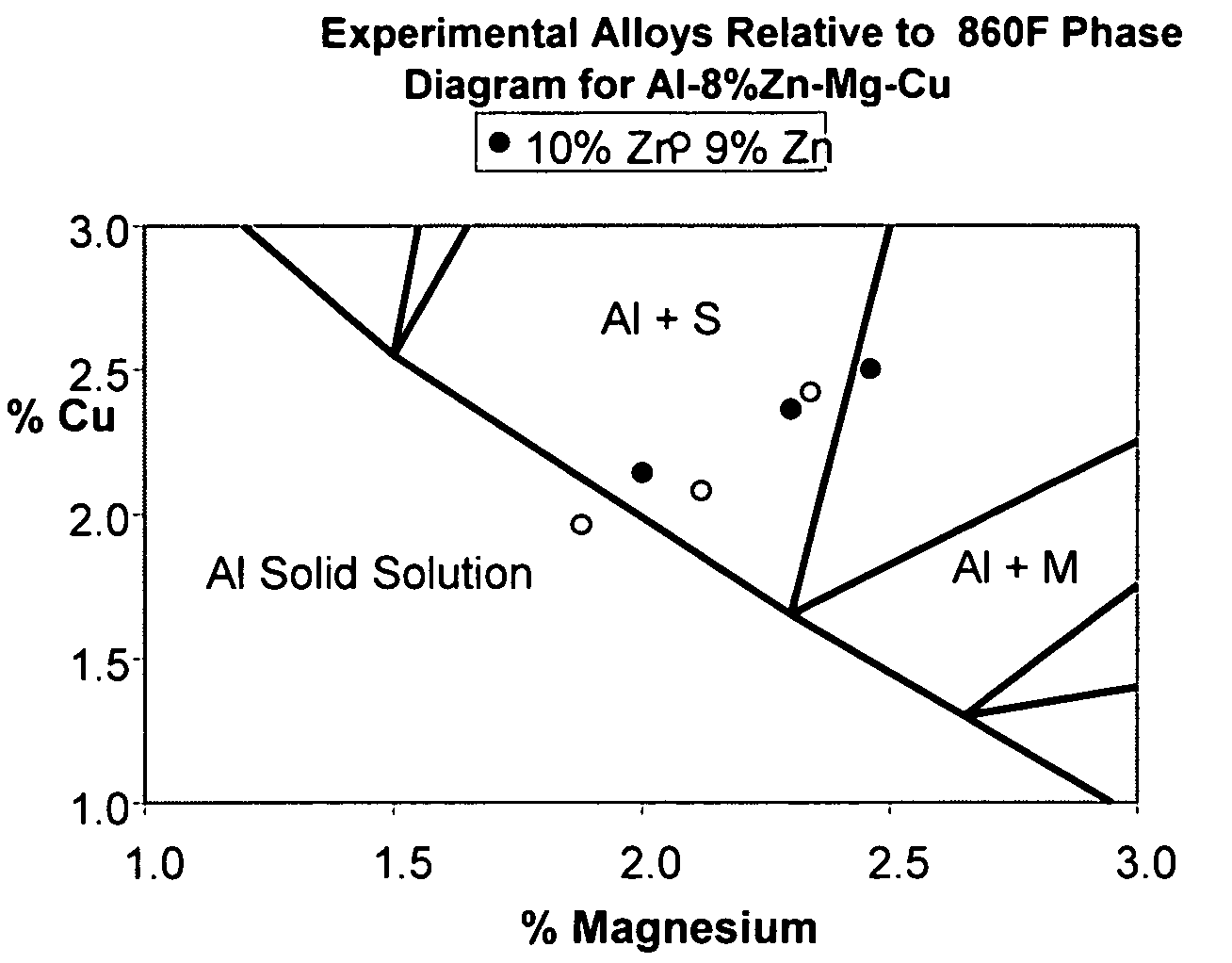

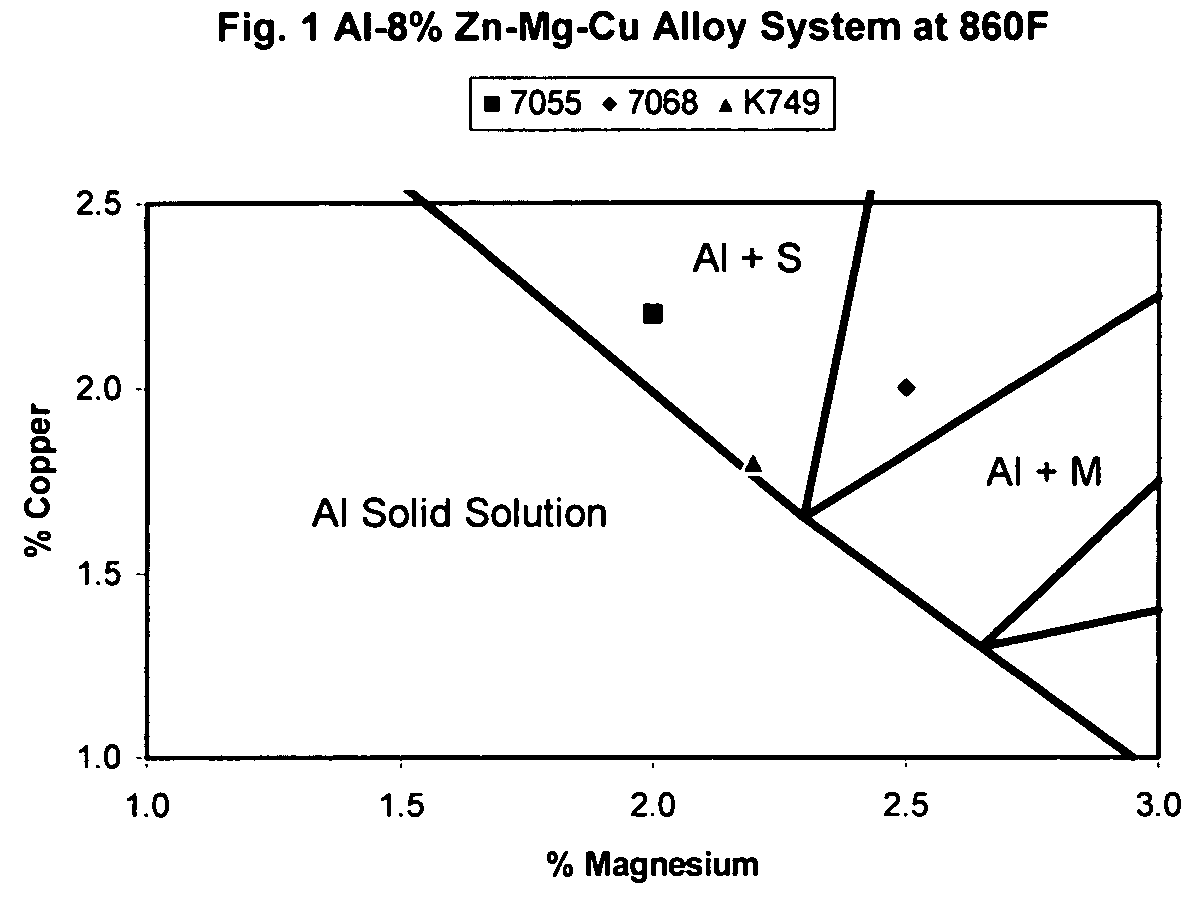

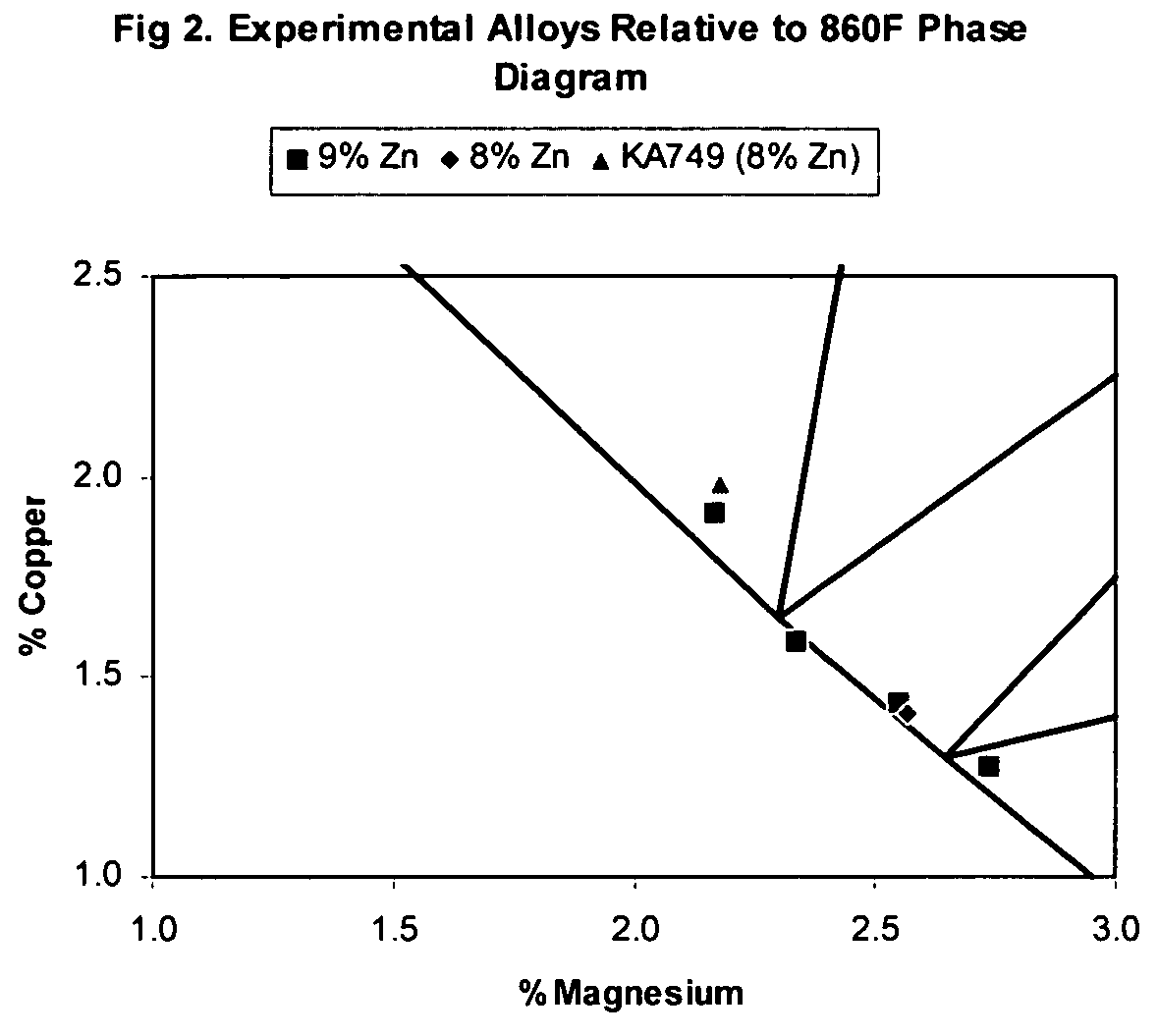

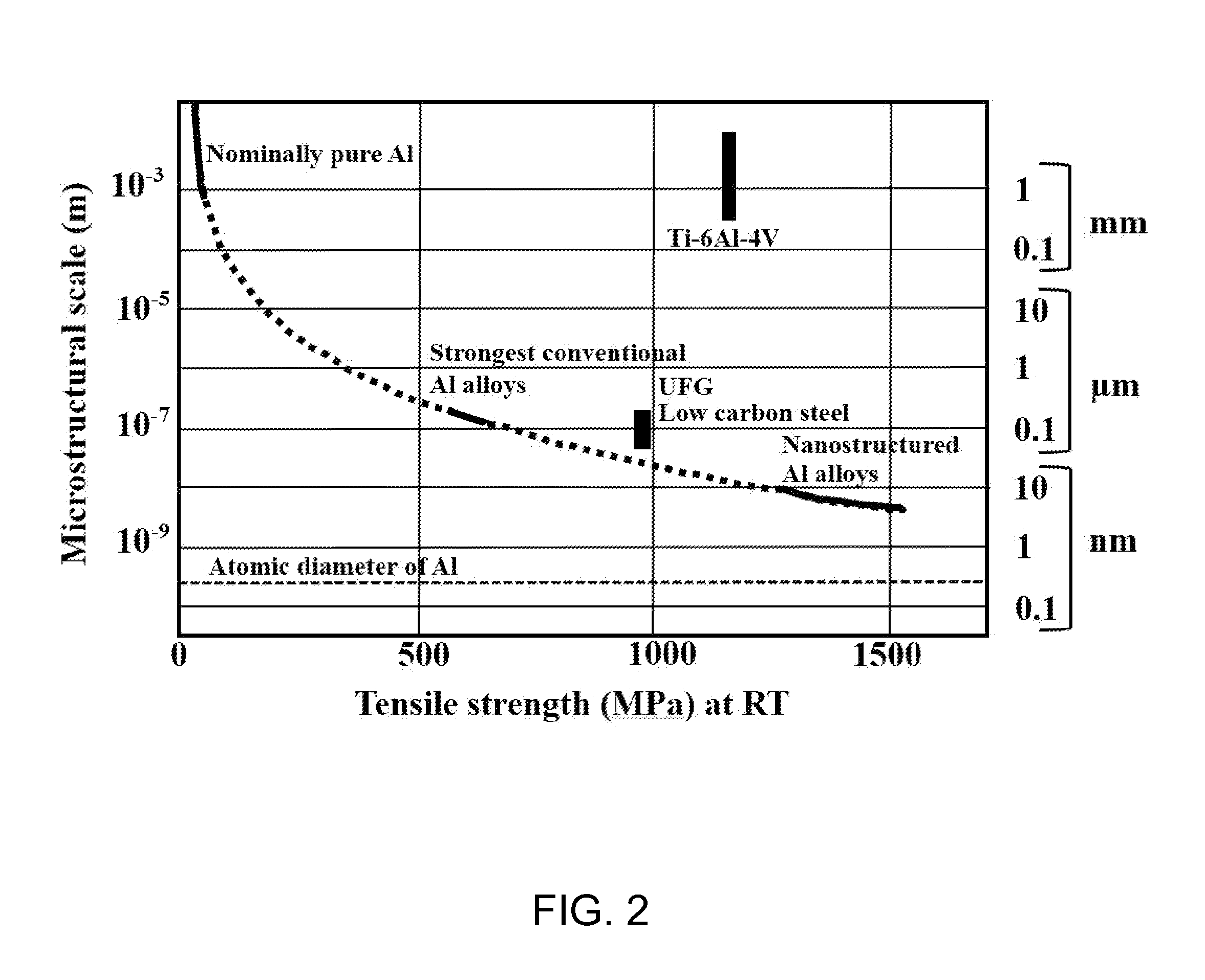

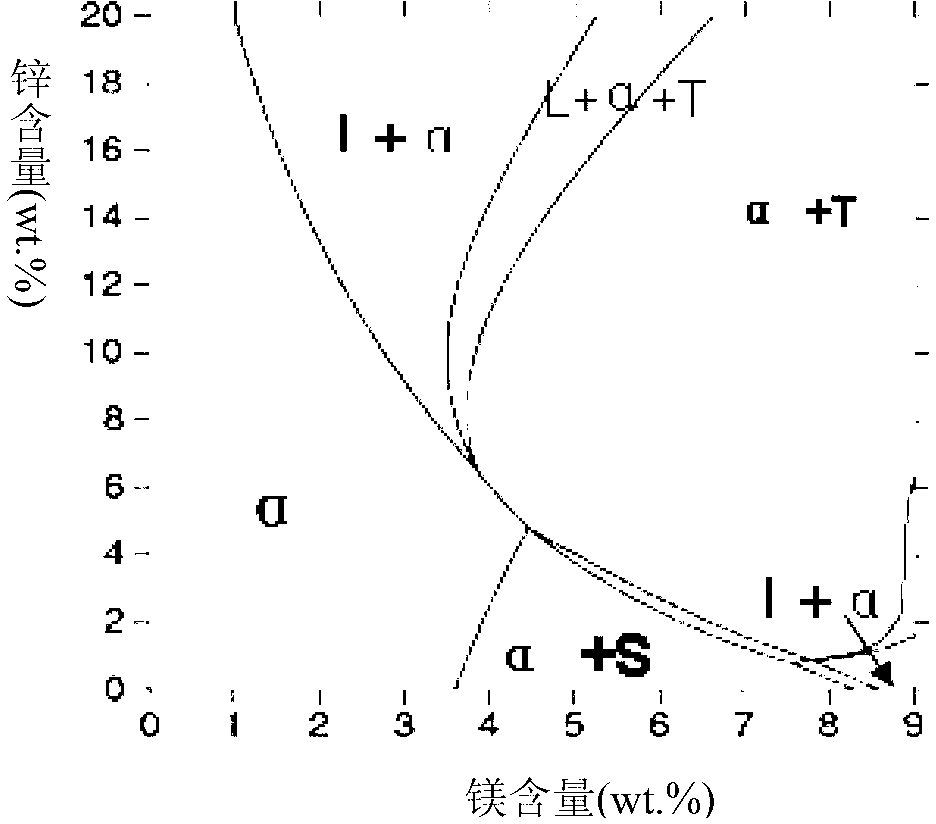

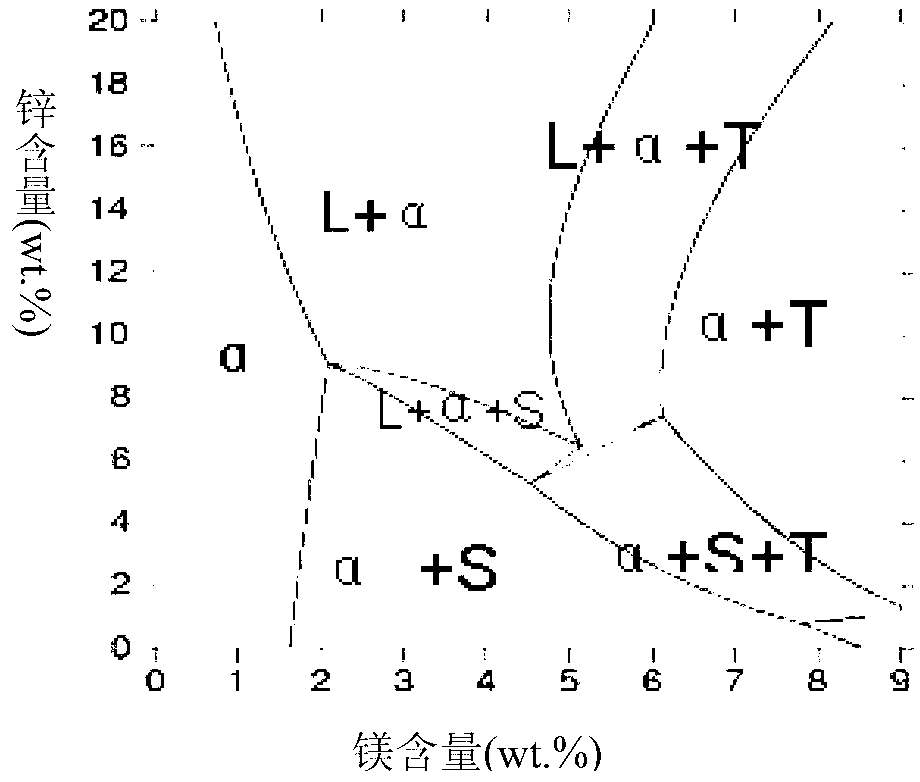

High strength aluminum alloys and process for making the same

High strength aluminum alloys based on the Al—Zn—Mg—Cu alloy system preferably include high levels of zinc and copper to provide increased tensile strength without sacrificing toughness. In addition, small amounts of scandium are also preferably employed to prevent recrystalization. Preferred ranges of the elements include by weight, 8.5-11.0% Zn, 1.8-2.4% Mg, 1.8-2.6% Cu, 0.05-0.30% Sc and at least one element from the group Zr, V, or Hf not exceeding about 0.5%, the balance substantially aluminum and incidental impurities. During formation of the alloys, a homogenization process is preferably employed after alloy ingot casting in which a slow rate of temperature increase is employed as the alloy is heated as near as possible to its melting temperature. For the last 20-30 F below the melting temperature, the rate of increase is limited to 20 F / hr. or less to minimize the amount of low melting point eutectic phases and thereby further enhance fracture toughness of the alloy.

Owner:KAISER ALUMINUM FABTED PRODS

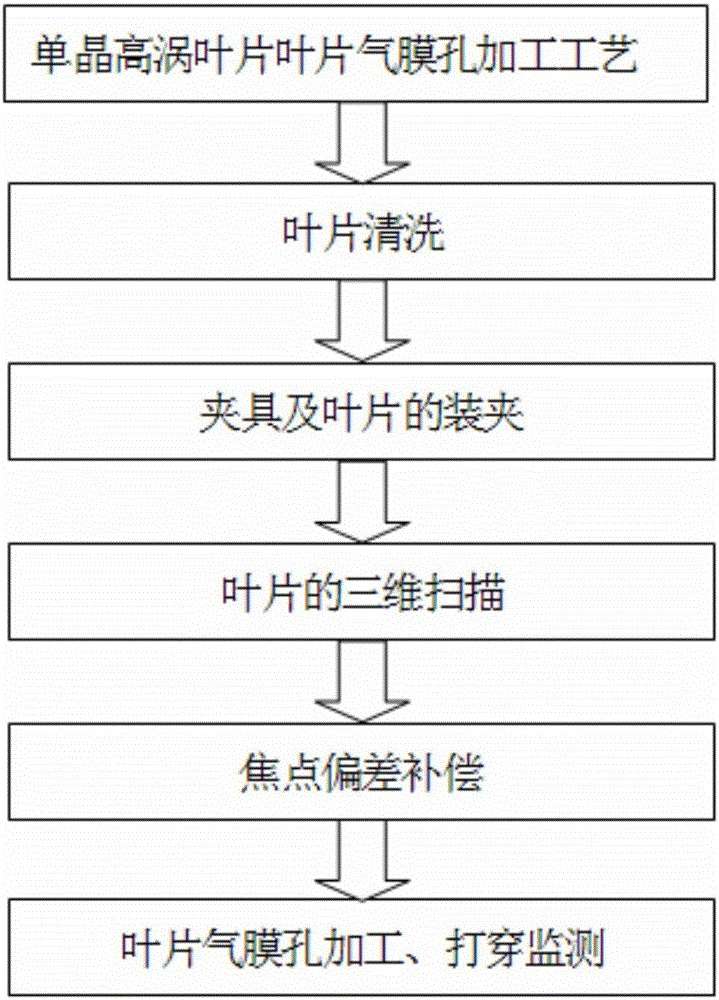

Low-damage processing method of film holes in single crystal high-pressure-turbine hollow blade of aircraft engine

ActiveCN106583949AExtend the life cycleExtended processing cycleLaser beam welding apparatusAviationEngineering

The invention provides a low-damage processing method of film holes in a single crystal high-pressure-turbine hollow blade of an aircraft engine. The low-damage processing method comprises the following steps: wiping the surface of the blade through degreasing cotton with absolute alcohol; transferring into a drying box to dry; arranging a clamp on a machine table, and aligning; assembling the dried blade on the clamp and locking; presetting scanning system parameters; scanning the blade; saving axis moving coordinate value of each hole to be processed under an automatically-generated machine coordinate system as a *.xls file; importing and generating a hole position file; performing compensative correction on the deviation value of a focus position of the hole to be processed; and setting the optimized laser processing technological parameters through a main processing interface. With the adoption of the low-damage processing method, the processed hole is outstanding in quality; a remelting layer, microcacks and recrystallization can be avoided after the single crystal material is processed, so that subsequent processing can be saved, and as a result, the fatigue life and the processing cycle of the blade can be prolonged and improved; the ablation threshold of the single crystal material can be effectively reduced; the recrystallization of the single crystal material can be avoided.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

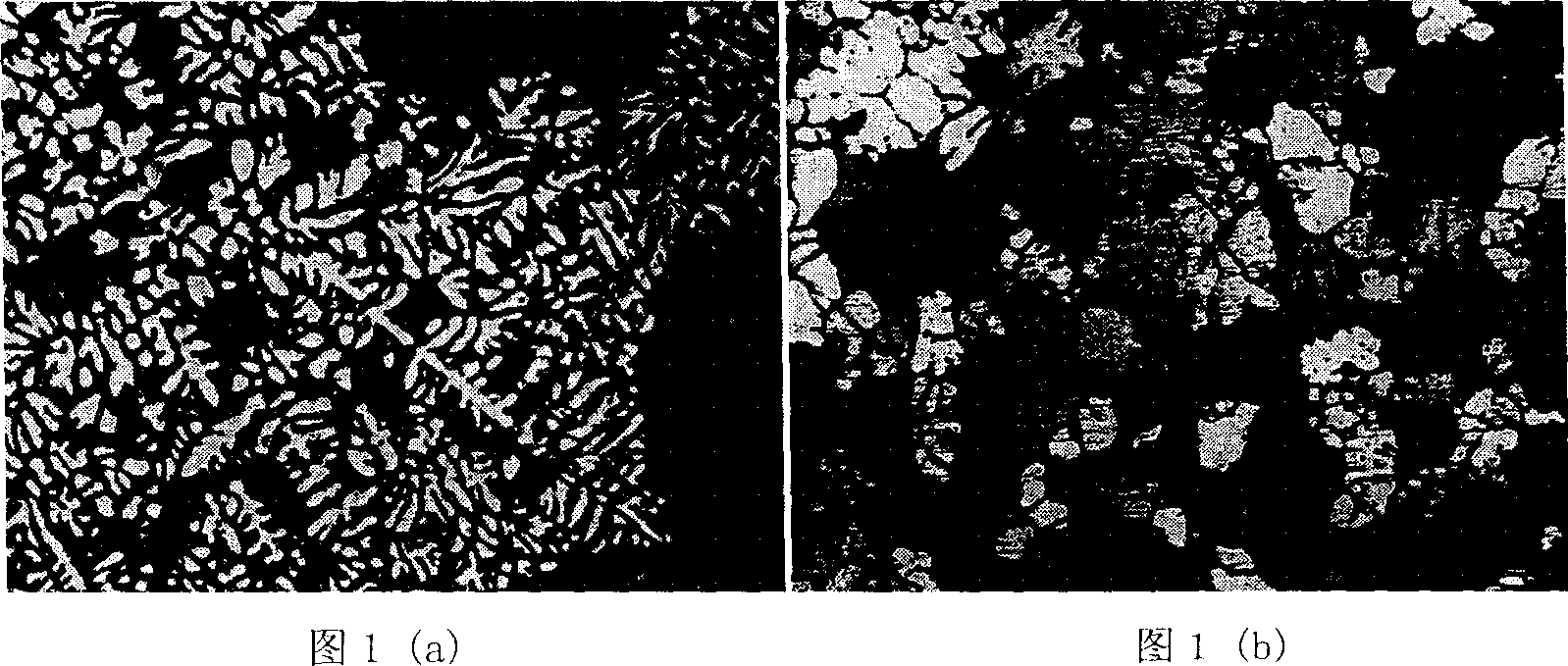

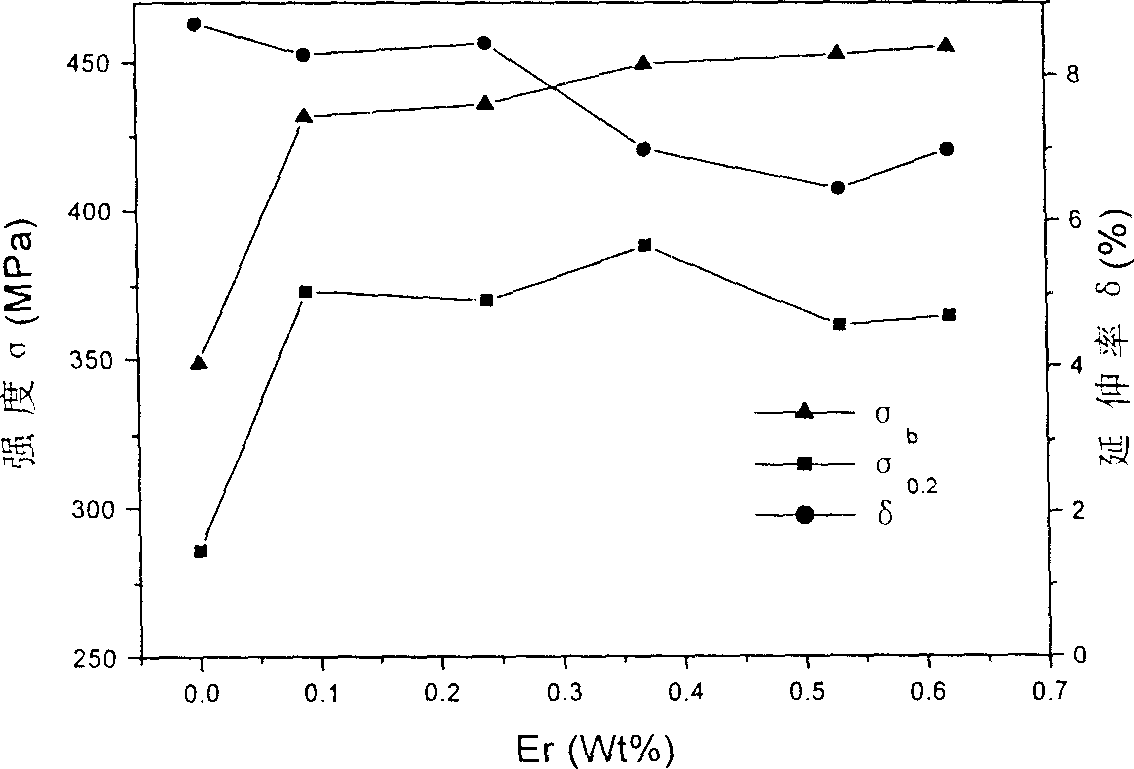

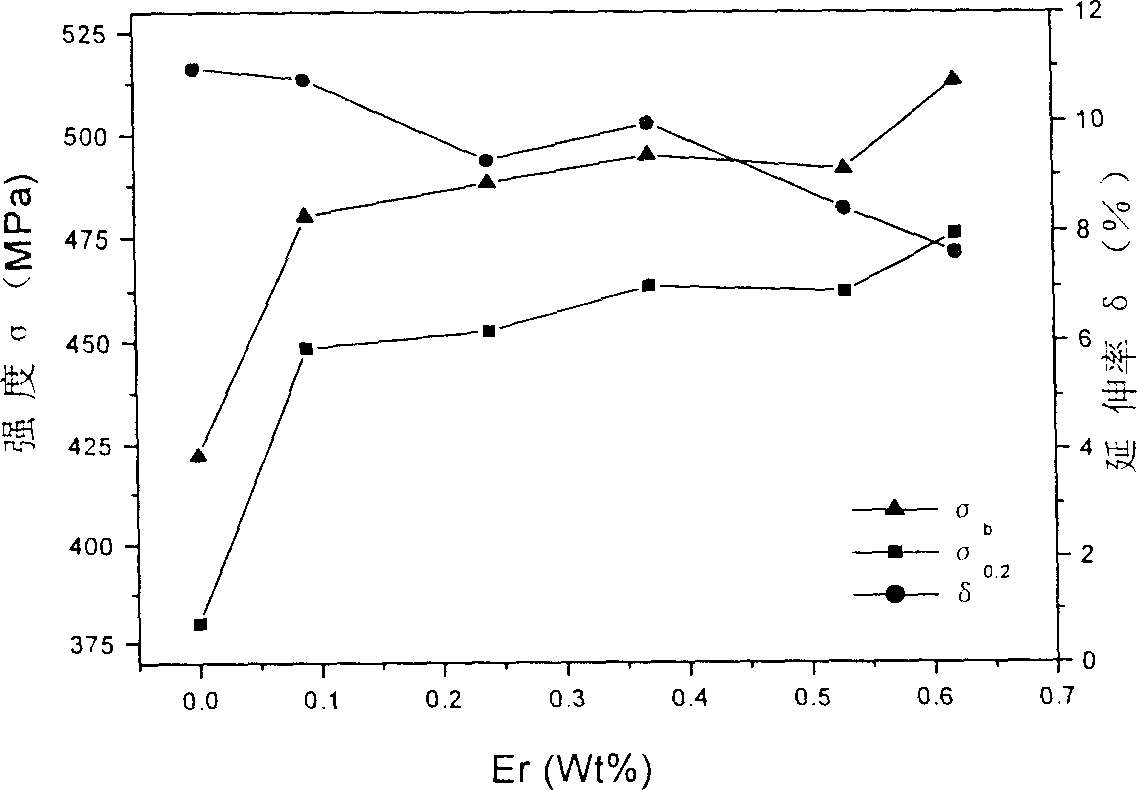

Al-Zn-Mg-Er rare earth aluminium alloy

The present invention relates to metal alloy technology. The key of the present invention is the addition of RE element Er in the experiment determined amount 0.1-0.7 wt% into the alloy. During the preparation process of the Al-Zn-Mg-Er alloy, Al-Er intermediate alloy through vacuum smelting is added into Al-Zn-Mg alloy. The addition of Er can fine obviously the alloy grains, raise alloy strength greatly and suppress re-crystallization. In addition, Er is relatively cheap and its addition has no significant increase in production cost. On the basis of Al-Zn-Mg alloy as one of the typical industrial Al alloy, one series of Er containing Al-RE alloy may be developed and used in astronautics, aeronautics, traffic and other fields.

Owner:BEIJING UNIV OF TECH

Rapid solidification Al-Ti-B-Sc intermediate alloy refiner and preparation method thereof

InactiveCN103589916AImprove grain refinement effectImprove adsorption capacityRare-earth elementMulti element

The invention provides a rapid solidification Al-Ti-B-Sc intermediate alloy refiner. The refiner is intermediate alloy and comprises, by mass, 3.75%-5% of Ti, 0.75%-1% of B, 0.1%-0.5% of Sc, and the balance Al. The cast structure of the refiner comprises particulate alpha-Al, TiAl3, TiB2, AlB2 and Al3Sc. The aluminum alloy refiner is an Al-Ti-B-Sc multi-element alloy refiner which comprises the rare earth element Sc and is acquired through rapid solidification. When the refiner is added to aluminum alloy, the aluminum alloy can be molten within a short time and can be evenly distributed more easily. When the refiner is applied, melting time can be shortened, and electric energy losses can be reduced.

Owner:HEBEI UNIV OF TECH

High-strength corrosion-resistant aluminum alloy profile and preparation method thereof

The invention discloses a high-strength corrosion-resistant aluminum alloy profile and a preparation method thereof. The aluminum alloy profile comprises an aluminum alloy base body and a ceramic coating. The aluminum alloy base body is prepared from Cu, Si, Fe, Cr, Mg, Mn, Zn, Ti, Li, Ni, Zr, Y, W, V and the balance Al. The ceramic coating is prepared from SiC, Cr2O3, NiO, Cr3C2, Al2O3 and Si3N4. According to the high-strength corrosion-resistant aluminum alloy profile, ceramic powder is arranged on the surface of the aluminum alloy base body through plasma cladding, and then laser remelting is conducted, so that the obtained aluminum alloy profile has good mechanical performance such as strength, hardness and impact toughness; and meanwhile, the high-strength corrosion-resistant aluminum alloy profile has the beneficial effects of being resistant to corrosion, good in abrasion resistance, long in service life and the like.

Owner:安徽省煜灿新型材料科技有限公司

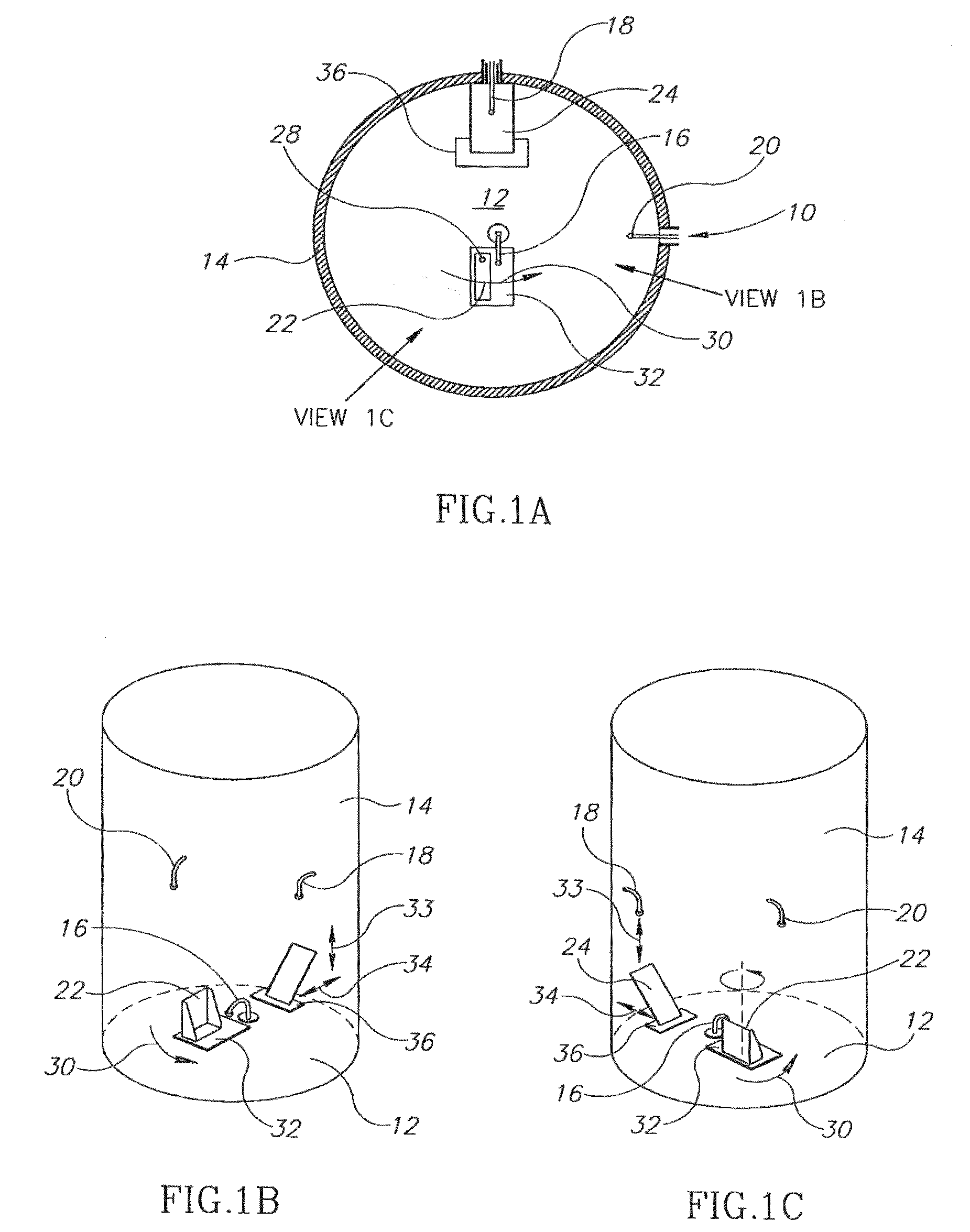

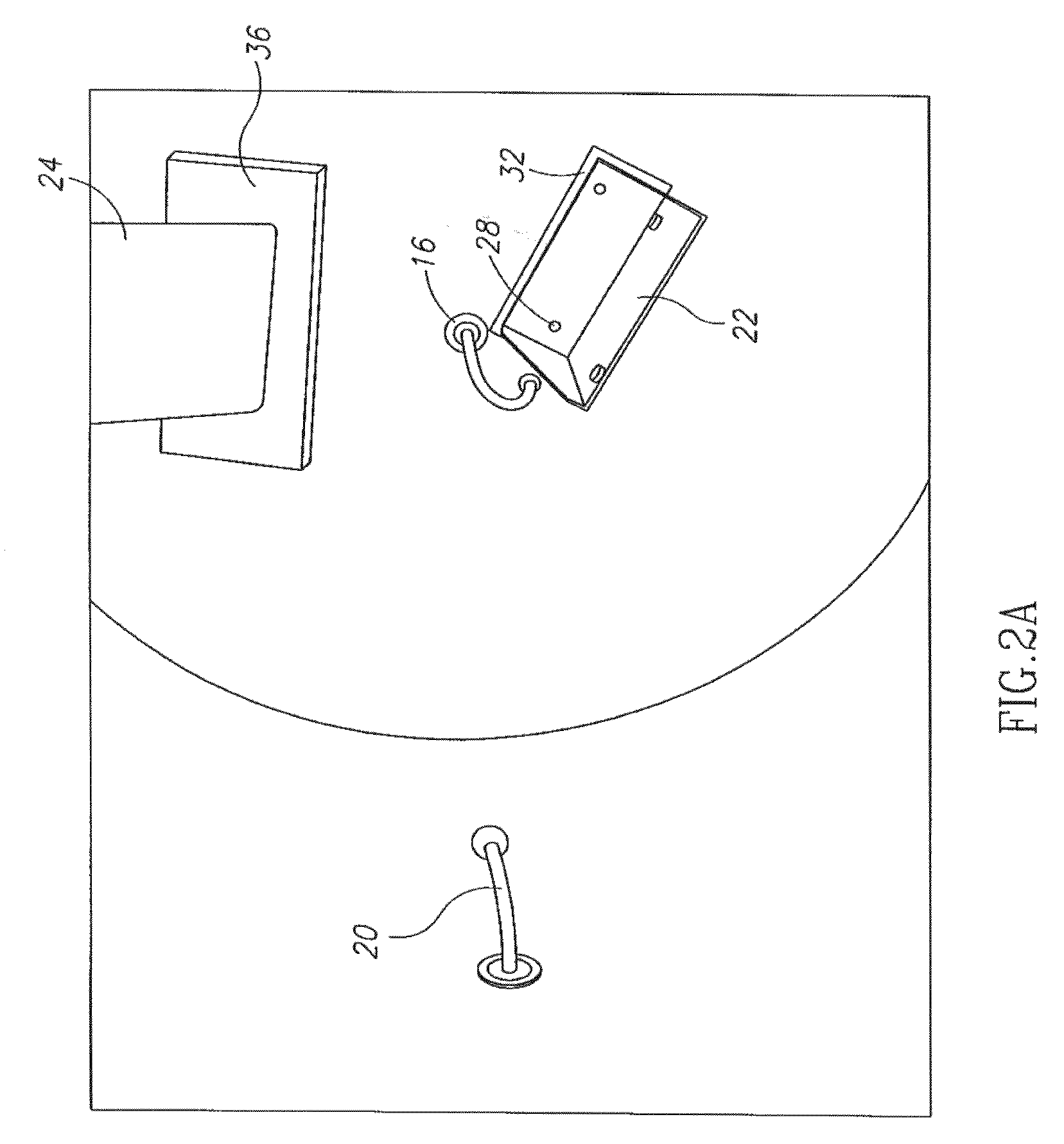

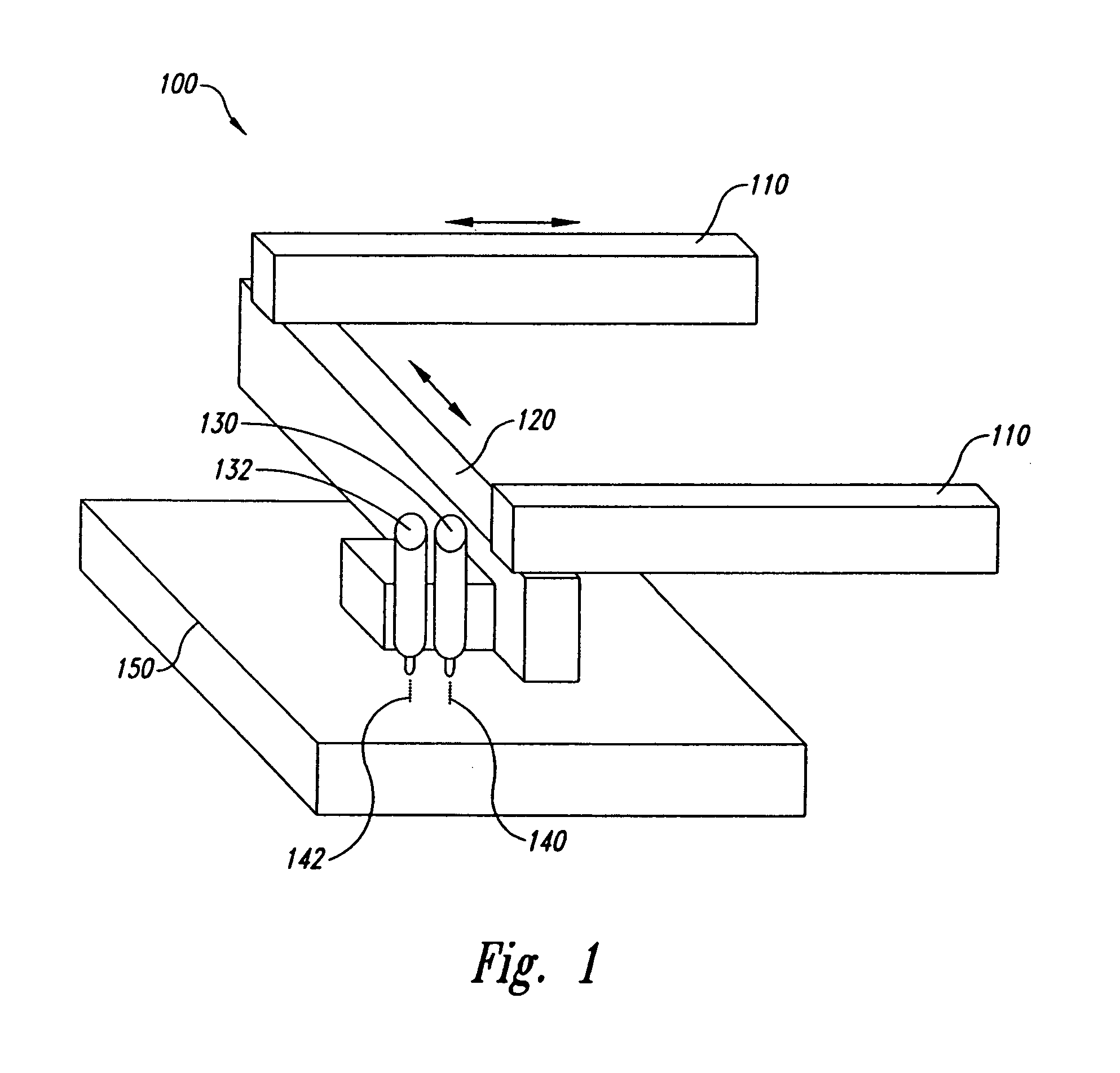

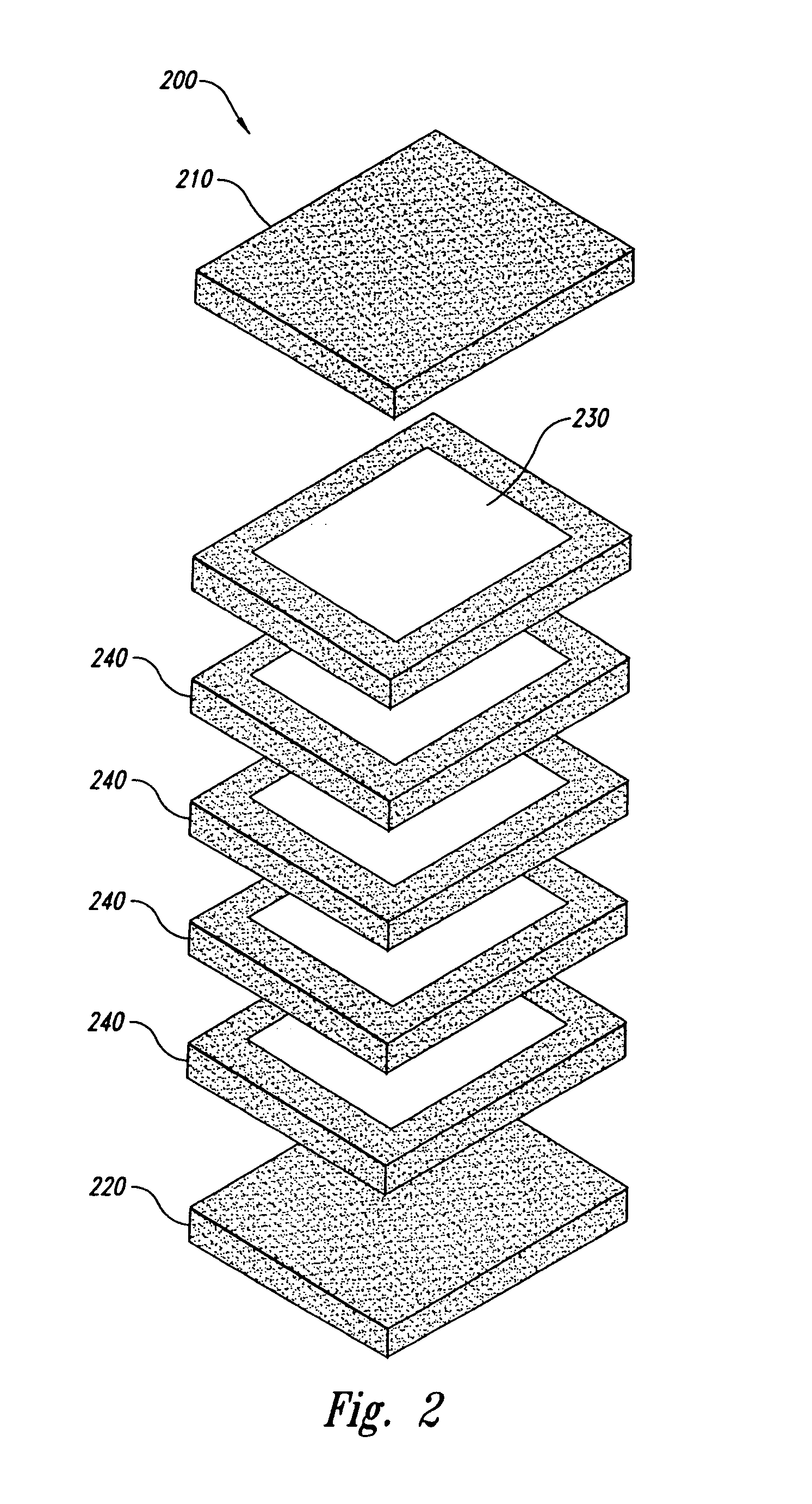

Method and apparatus for making polymeric drug delivery devices having differing morphological structures

InactiveUS20080169582A1Wide rangeEasy to manufactureWood working apparatusDomestic articlesAnatomical conduitPlasticizer

A polymeric medical device is constructed from bioabsorbable polymers. The device is constructed from a tube comprised of at least one polymer. The polymer is treated at pre-determined heating and cooling temperatures to obtain a desired morphology. The morphology or arrangement of the polymeric structure ensures that the device maintains its shape characteristics to ensure proper modeling of the vessel. In particular, the crystallinity of the polymeric structure is adjusted so as to resist recoil. The device can also contain a therapeutic agent dispersed throughout the structure or coated on the structure in such a manner as to elute the therapeutic agent when implanted in an anatomical conduit. The device can also be constructed from a blend of polymers and other agents such as plasticizers.

Owner:CORDIS CORP

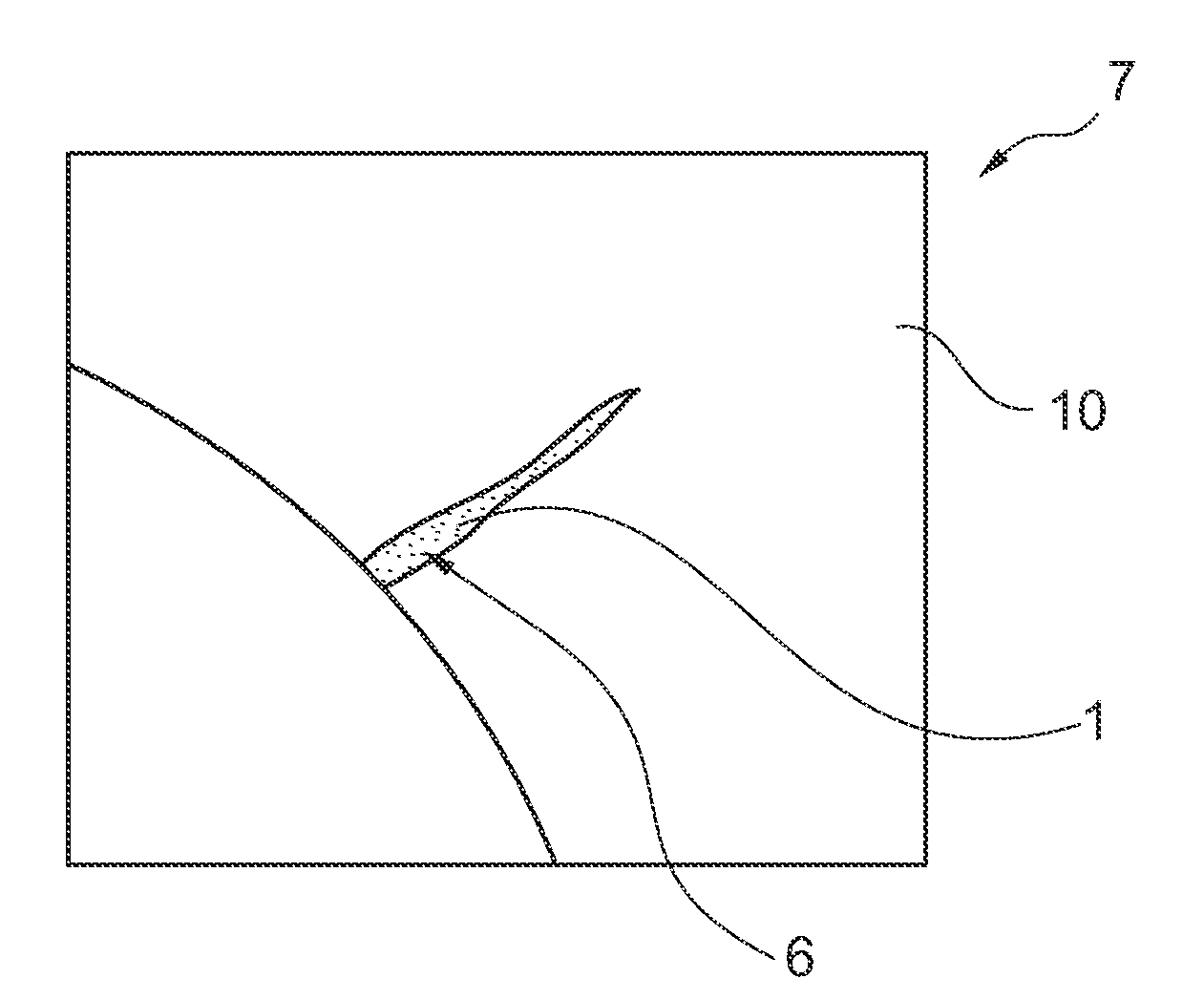

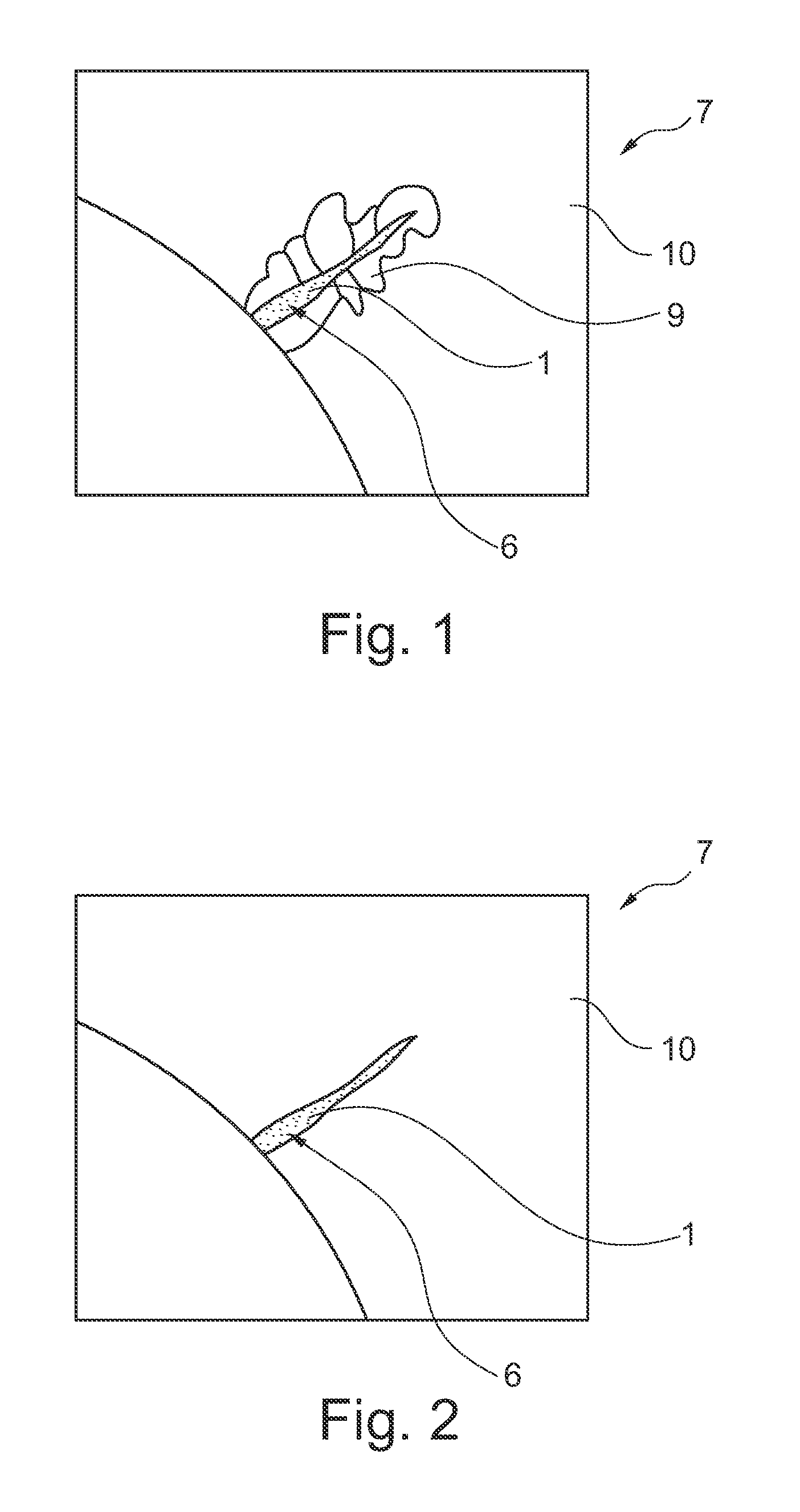

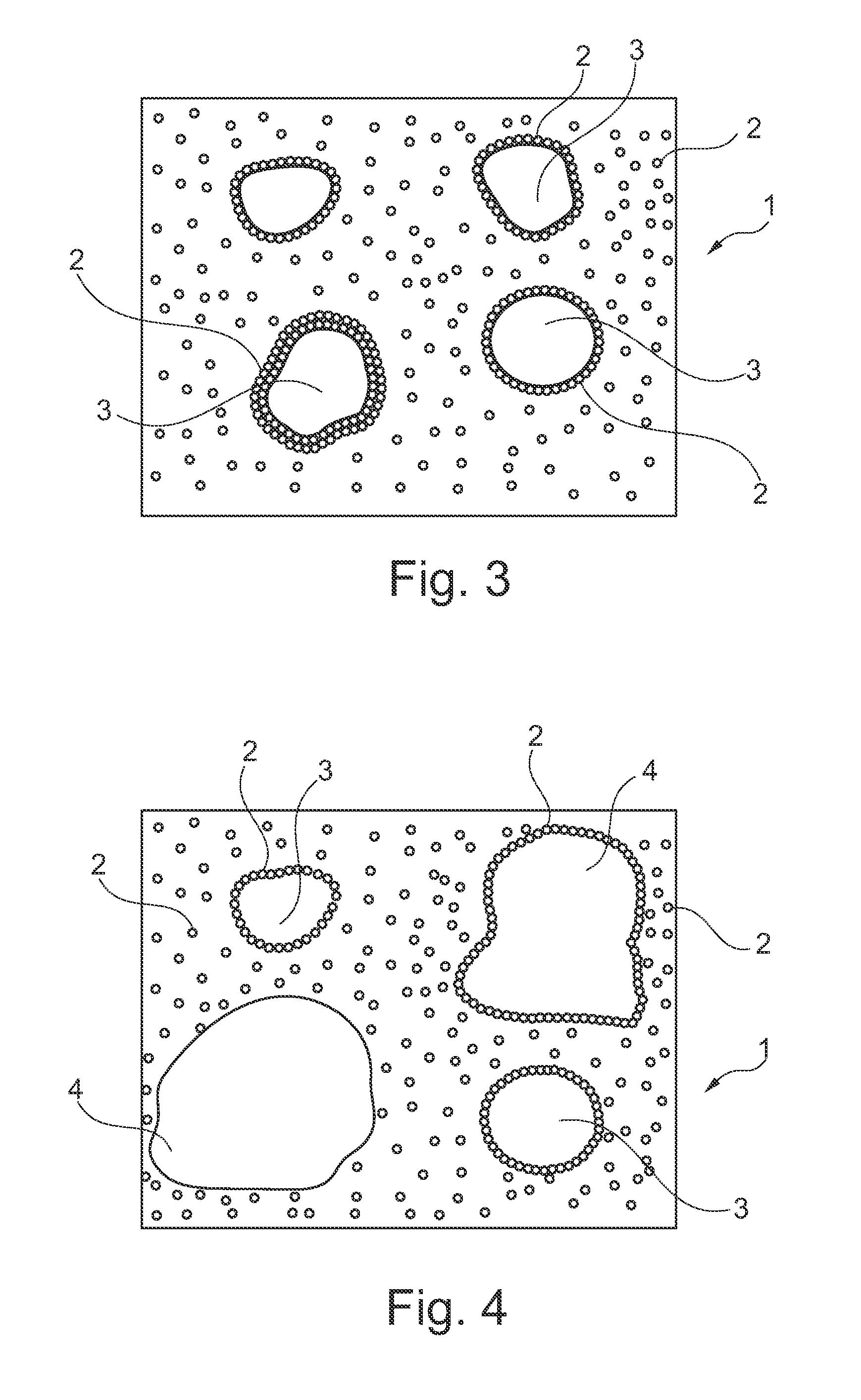

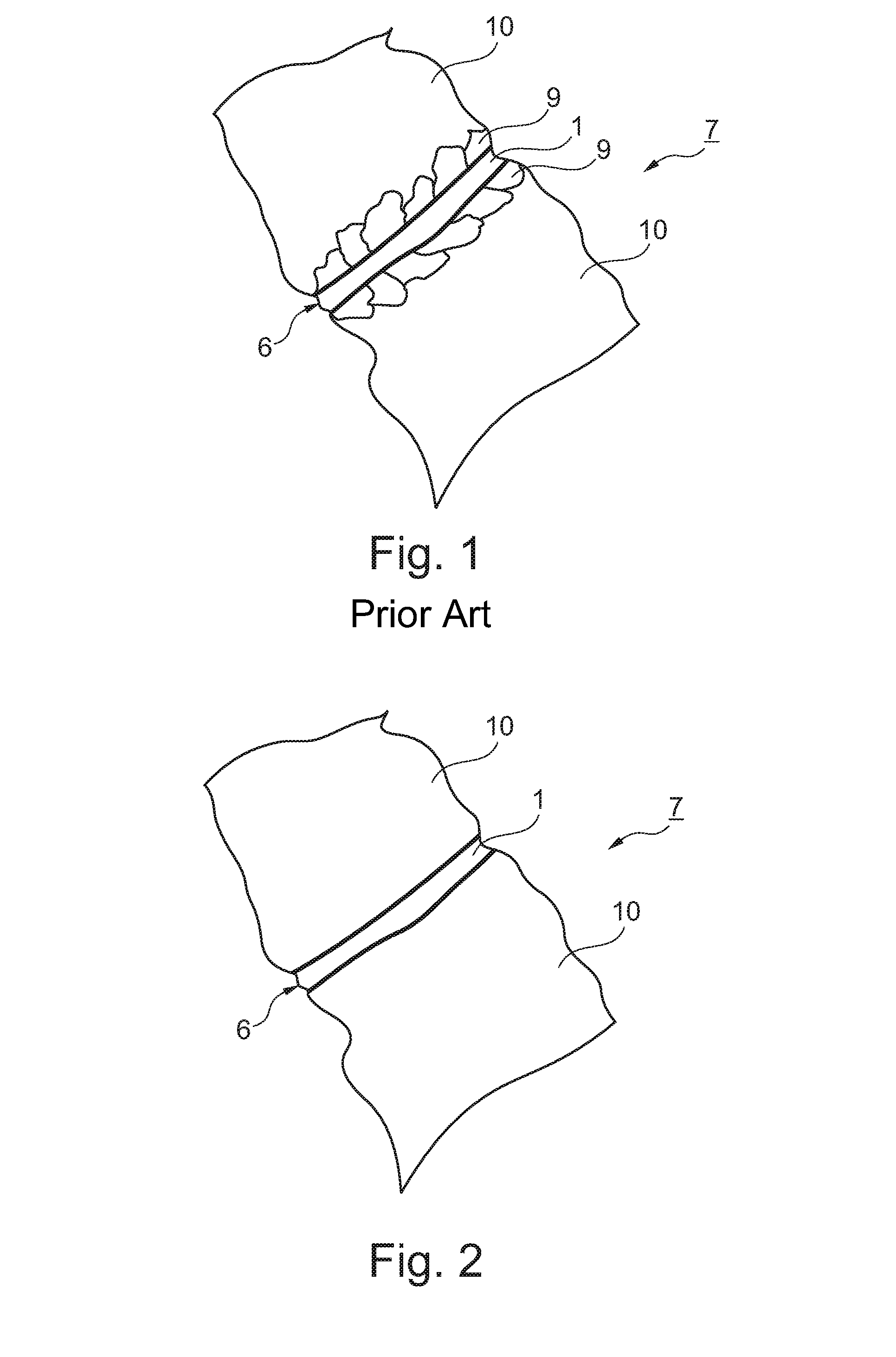

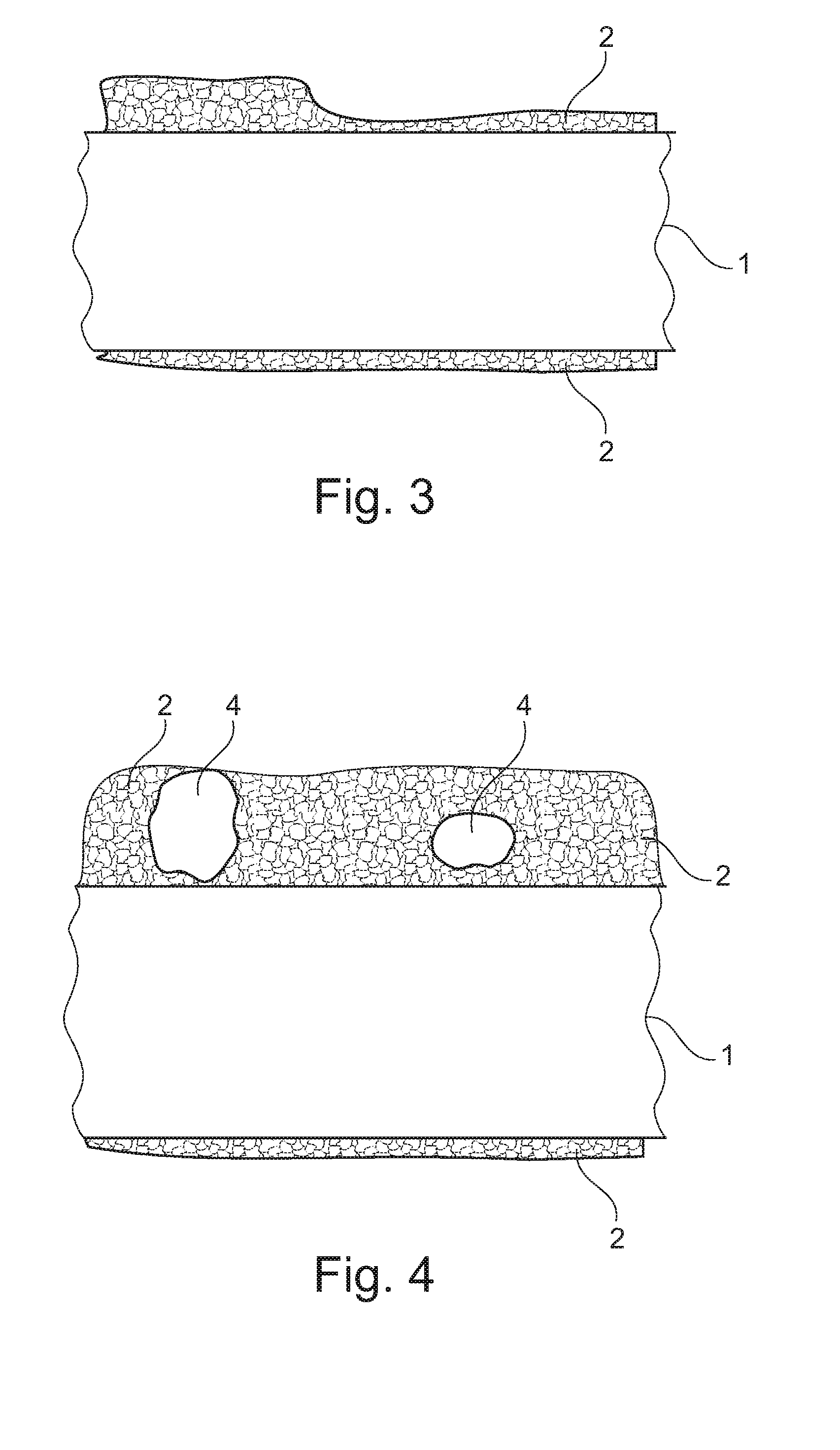

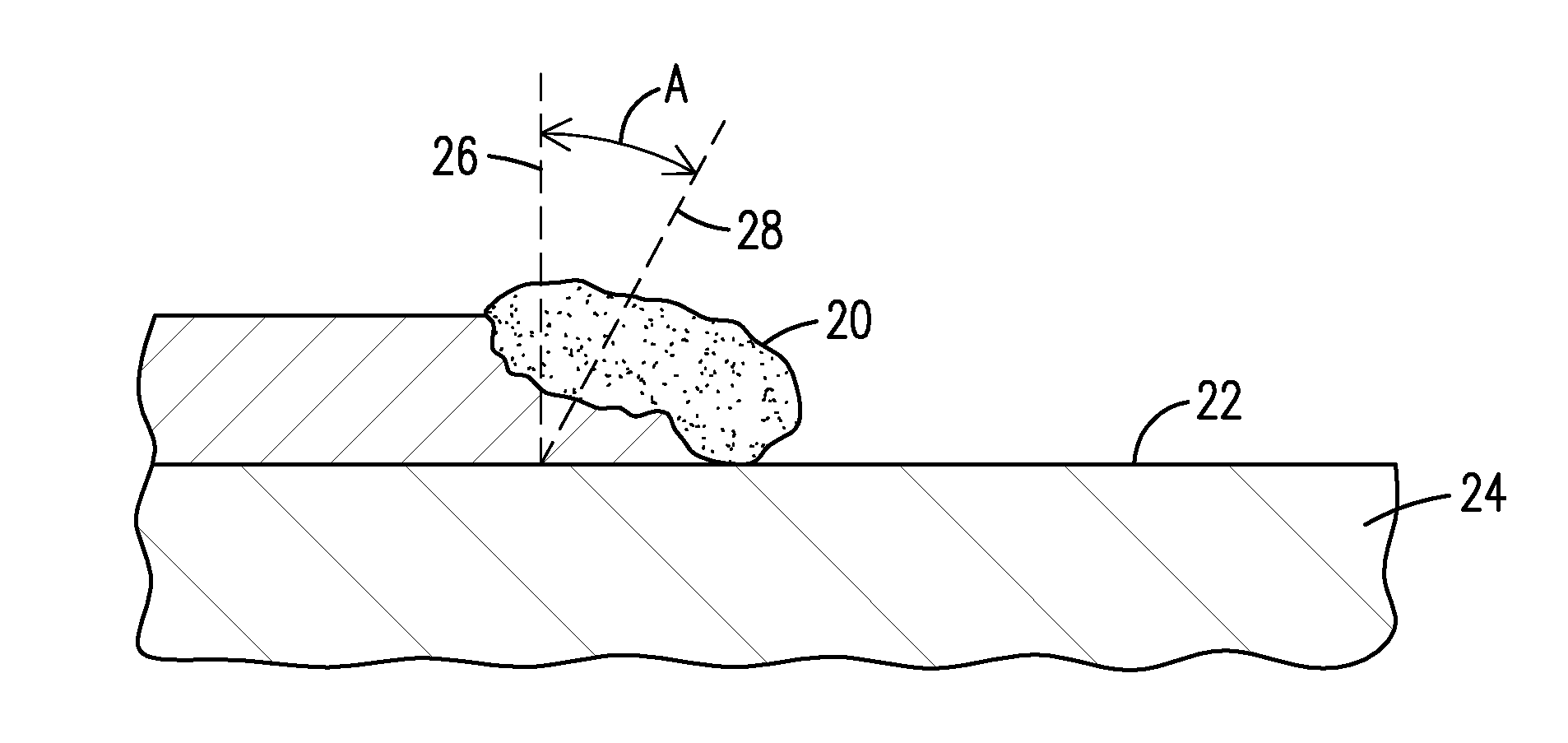

Braze alloy for high-temperature brazing and methods for repairing or producing components using a braze alloy

In a Ni-based, Co-based, or Ni—Co-based braze alloy (1) for high-temperature brazing of components (7) of modular structure and for repairing damaged components (7) which are formed of single crystal or directionally solidified superalloys using said braze alloy (1), the braze alloy has a first metallic powder component (2) having particle sizes in the nanometer range and a second metallic powder component (3) having particle sizes in the micrometer range. The surface of the particles of the second powder component (3) is thinly coated with particles of the first powder component (2). The braze alloy (1) additionally includes grain boundary stabilizing elements as alloying elements. In addition, melting point depressants can be present in the braze alloy (1) in a commercially common quantity or with a considerably increased proportion. Both the melting temperature of the braze alloy (1) and the probability of recrystallization are advantageously reduced.

Owner:ANSALDO ENERGIA IP UK LTD

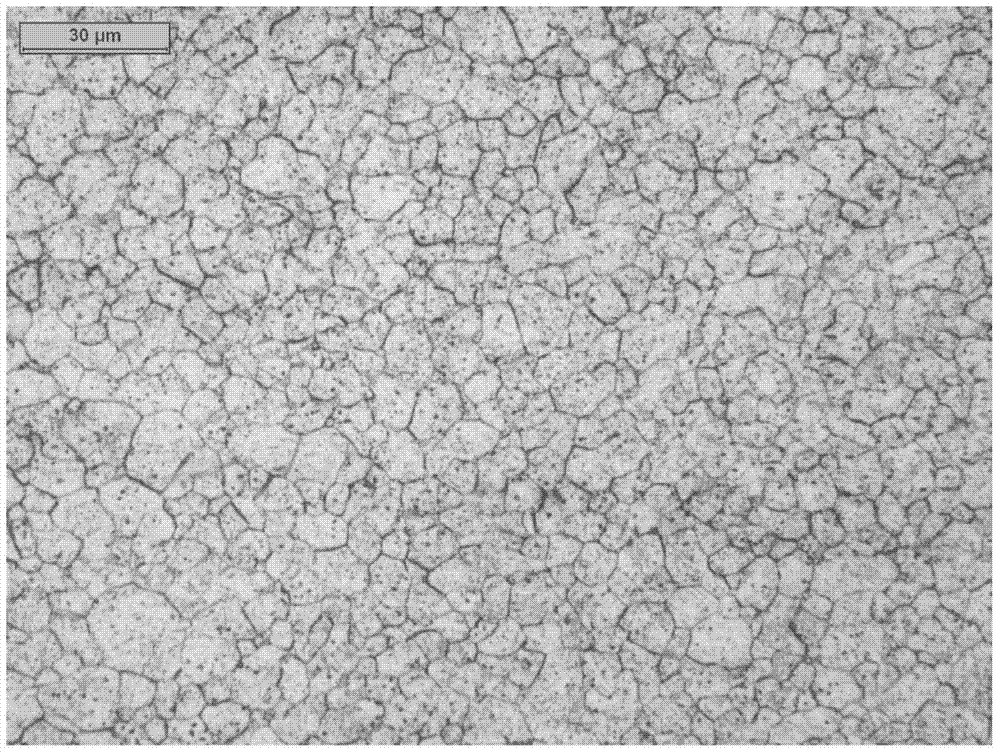

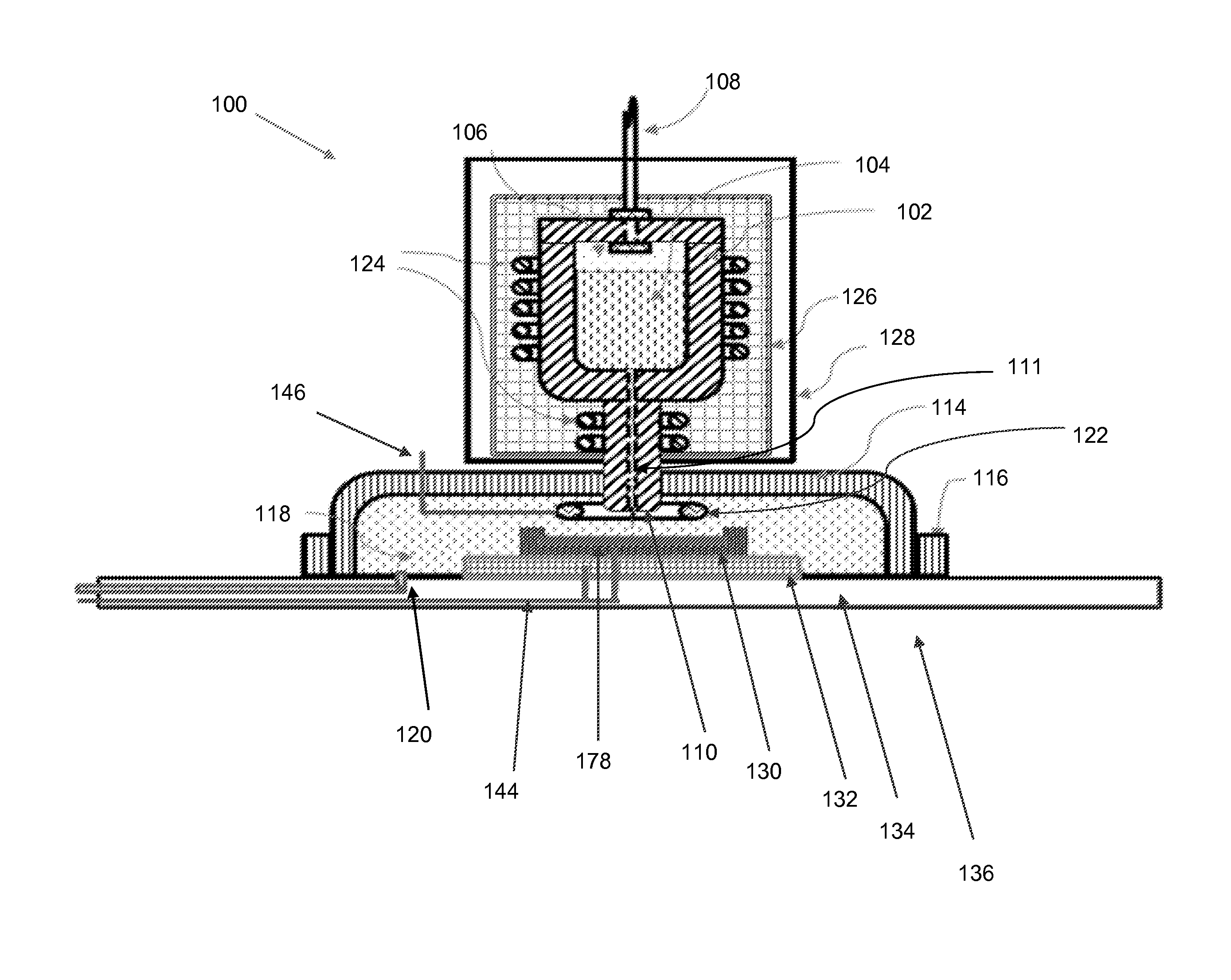

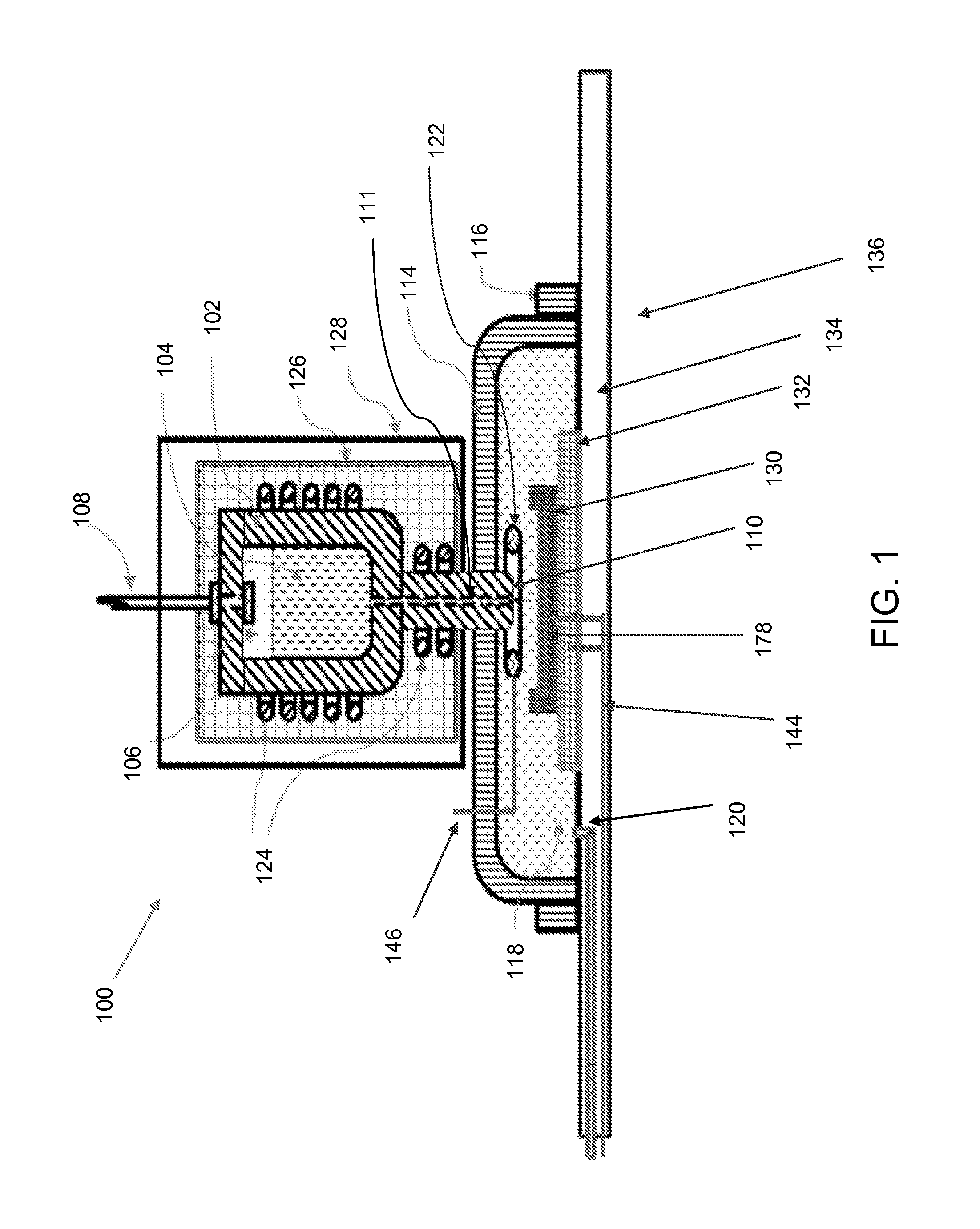

Electrospray pinning of nanograined depositions

ActiveUS20150251213A1Inhibition of recrystallizationEnhanced nucleationLiquid surface applicatorsAdditive manufacturing apparatusGrain growthElectric field

A method and apparatus for fabrication of objects retaining nano-scale characteristics. A composition is provided comprising grain growth inhibitor particles in solution with a binding agent in a molten phase. An electric field and a magnetic field are generated with a combined extraction electrode. The composition is electrosprayed from a nozzle with the electric field to form a stream of droplets. The electric field drives the droplets toward a moving stage holding an object comprising successive deposition layers. The magnetic field limits dispersion of the stream of droplets. The stage is moved laterally as the stream of droplets impacts the object to form a current deposition layer of the object. The stage is moved vertically as necessary to maintain a target stand-off distance between the nozzle and a previous deposition layer of the object, based on profile data of the previous deposition layer.

Owner:Q21 CORPORATION +1

High-Zn, high-Mg and low-Cu ultrahigh-strength corrosion-resisting aluminum alloy and heat treatment method

The invention discloses a high-Zn, high-Mg and low-Cu ultrahigh-strength corrosion-resisting aluminum alloy and a heat treatment method. The alloy comprises the following components by mass percentage: 6.5-8.3% of Zn, 2.3-3.0% of Mg, 0.8-1.2% of Cu, 0.1-0.2% of Zr, less than 0.15% of Fe, less than 0.1% of Si, and the balance of Al. A preparation method of the alloy comprises the steps of blending, smelting, semi-continuous casting, homogenizing, thermoplastic deformation, short time solid solution, and ageing heat treatment. For the high-Zn, high-Mg and low-Cu ultrahigh-strength corrosion-resisting aluminum alloy prepared with the method, the hardness (HV) is 185-209, the tensile strength sigma b is greater than or equal to 650Mpa, the percentage elongation delta is greater than or equal to 7%, the pitting resistance is high, the cast ingot yield is high, and the stress corrosion resistance is further improved while the mechanical property is kept after multiple regression reageing treatment. The alloy and the heat treatment method solve the problems that the cast ingot yield in the existing high-copper Al-Zn-Mg-Cu ultrahigh-strength aluminium alloy is low, and the strength, toughness and corrosion resistance cannot be compromised. The heat treatment method is simple to operate, and the industrial production is facilitated.

Owner:CENT SOUTH UNIV

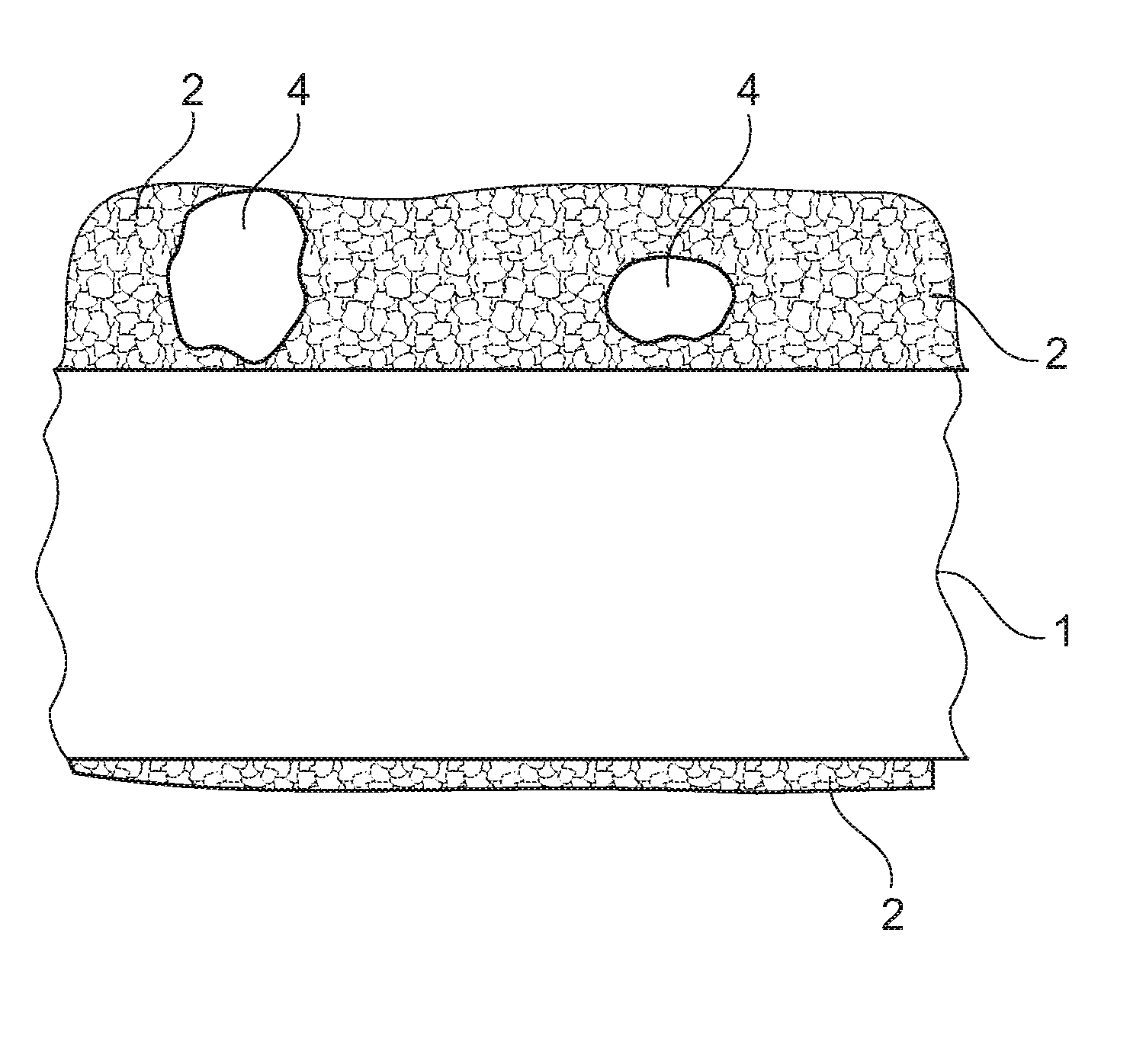

Braze foil for high-temperature brazing and methods for repairing or producing components using a braze foil

An amorphous braze foil (1) produced by a melt-spin process has an upper side and a lower side. The upper side and the lower side are thinly coated with a film of metallic Ni-based, Co-based, or Ni—Co-based braze powder (2) with a particle size in the nanometer range, wherein both the braze foil (1) and also the braze powder (2) additionally include grain boundary stabilizing elements as alloying elements. In addition, melting point depressants can be present in the braze foil or in the nano braze powder (2) in a commercially common quantity or with a considerably increased proportion. With the braze foil (1) coated in this manner, both the melting temperature of the braze material and also the probability of recrystallization are advantageously reduced when brazing in the adjacent base material (10).

Owner:ANSALDO ENERGIA IP UK LTD

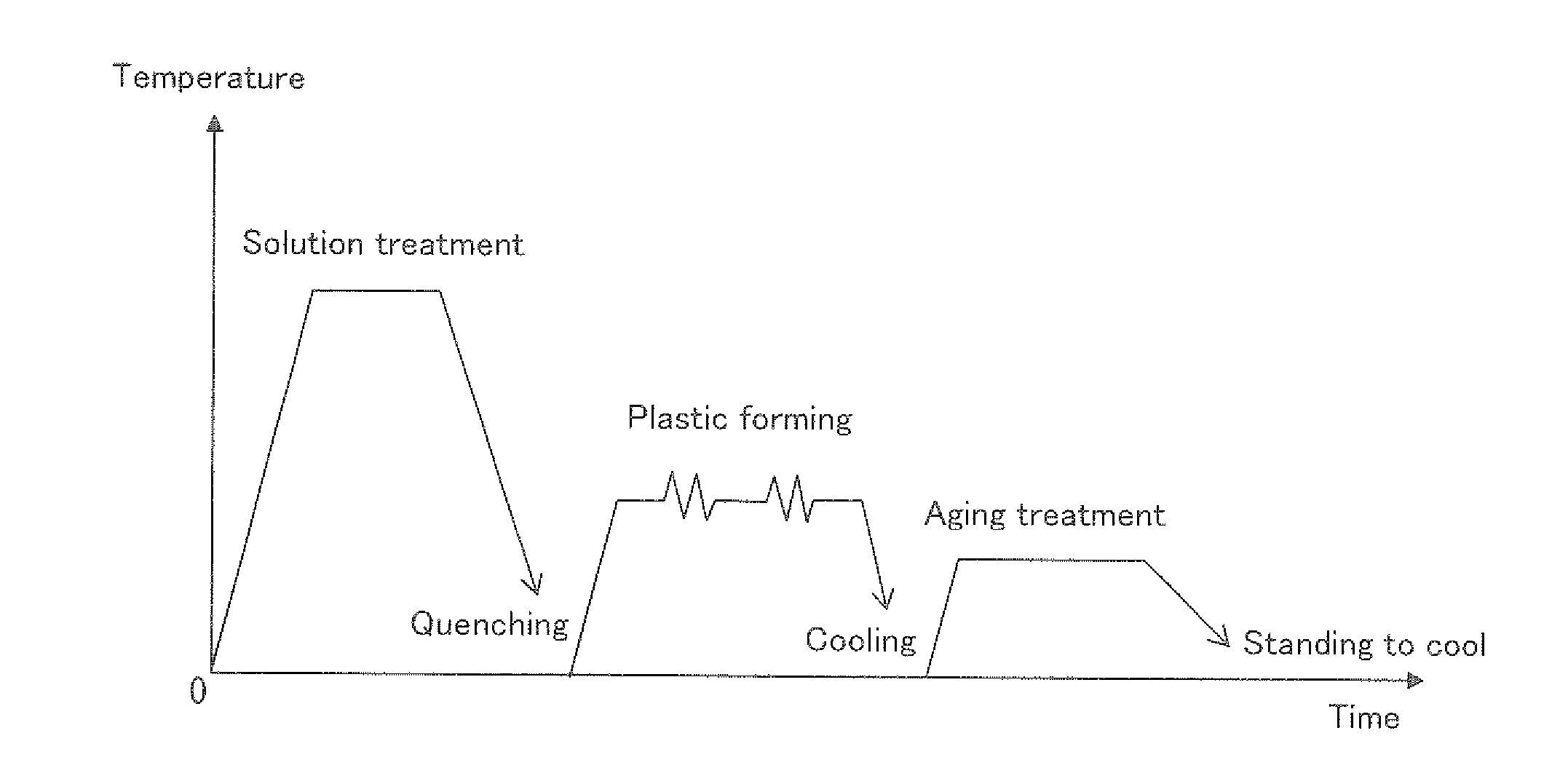

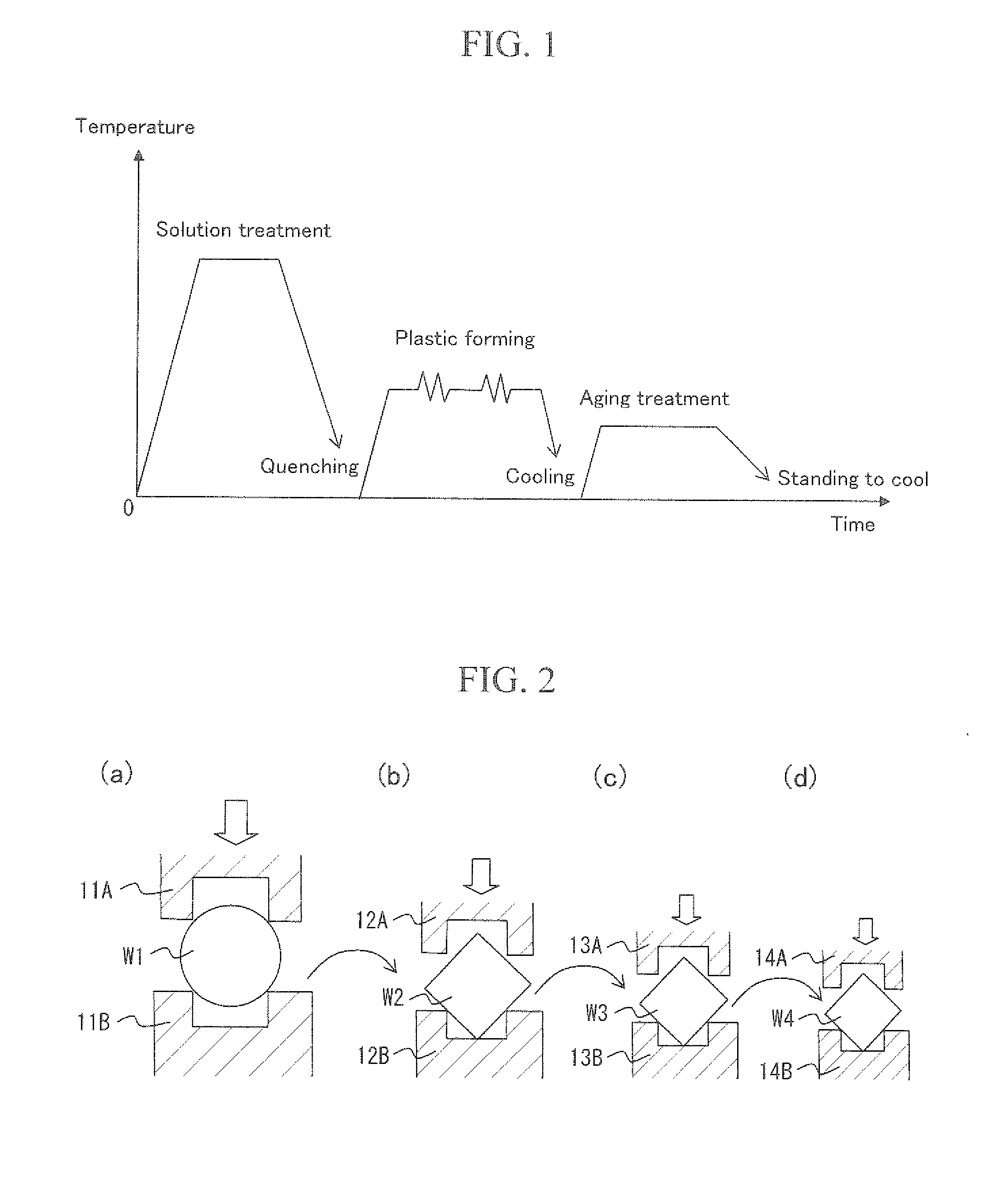

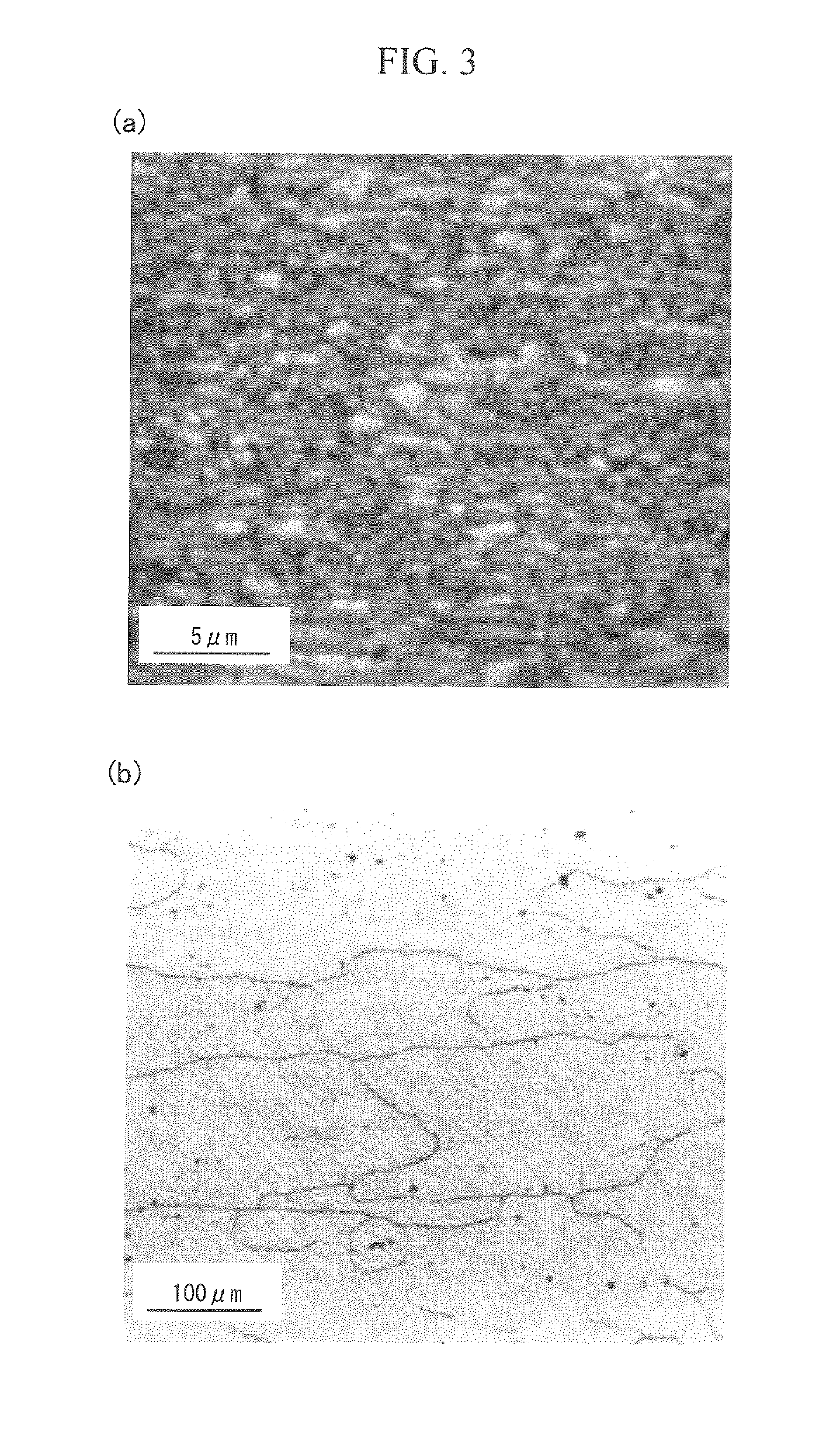

Process for producing aluminum alloy material and heat treated aluminum alloy material

InactiveUS20100319820A1Reduction in aluminum alloy material strengthInhibition of recrystallizationSolution treatmentUltimate tensile strength

According to the present invention, a process for producing an aluminum alloy material, whereby reduction in toughness and in fatigue strength of the aluminum alloy material can be inhibited even after solution treatment is provided. Also, the following is provided: a process for producing an aluminum alloy material comprising at least the steps of subjecting a heat treatable aluminum alloy material to solution treatment and applying aging treatment to the aluminum alloy material subjected to solution treatment, which further comprises the following step between the solution treatment step and the aging treatment step: the step of subjecting the aluminum alloy material to plastic forming in a manner such that a given amount of equivalent strain is imparted to the aluminum alloy material from at least two directions while the aluminum alloy material subjected to solution treatment is maintained under temperature conditions that do not cause softening of the aluminum alloy material by over-aging.

Owner:TOYOTA JIDOSHA KK

High-plasticity aluminum-silicon alloy for die casting and preparation method thereof

The invention provides high-plasticity aluminum-silicon alloy for die casting. The high-plasticity aluminum-silicon alloy comprises the following components in percentage by weight: 7.0 to 13.0 percent of silicon, 0.20 to 0.40 percent of magnesium, 0.20 to 0.50 percent of manganese, 0.01 to 0.15 percent of strontium, less than 0.15 percent of ferrum, less than 0.10 percent of copper, less than 0.10 percent of zinc and the balance of aluminum, wherein the sum of the mass percentage of each component is 100 percent. The aluminum-silicon alloy is light in weight, high in quality, strength and plasticity and high in flowing property, the elongation is more than 10 percent, and die casting pieces are easy to demold in the production process; and a preparation process is simple and low in cost.

Owner:南京宁铁有色合金科技开发有限公司

Glass-state storage method for modifying quick-frozen conditioning fruit-vegetable quality

InactiveCN1676006AAvoid generatingOvercome the problem of low temperature fractureFruits/vegetable preservation by freezing/coolingLiquid stateEngineering

The present invention relates to a vetrification storage method for raising quality of fast-frozen fruit and vegetable. Said method mainly includes the following steps: (1) selecting vegetable and fruit raw material, washing, peeling (coring) and slicing / block cutting; (2) scalding (100 deg.C, 15 sec.) and cooling; (3) conditioning (vacuum osmosis treatment); (4) measuring glass-transition temperature of said raw material; (5) making the conditioned raw material undergo the processes of liquid nitrogen or liquid state CO2 quick dip freezing treatment so as to make the temperature of said raw material be quckly reduced to the required temperature, then packaging; and (6). cold-storing the frozen raw material in freezer chest (temperature can be regulated below the glass transition temperature of said raw material.

Owner:JIANGNAN UNIV

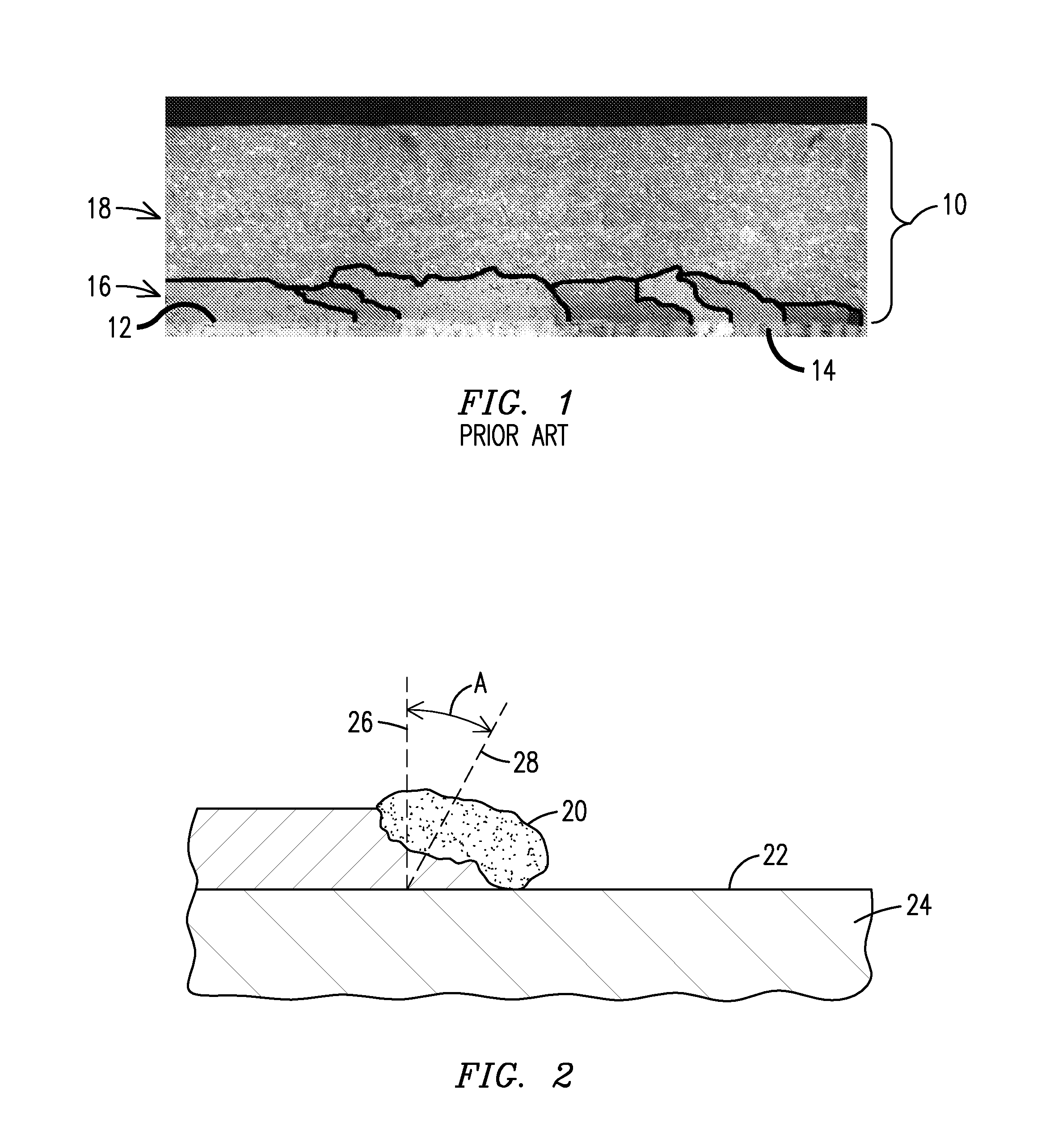

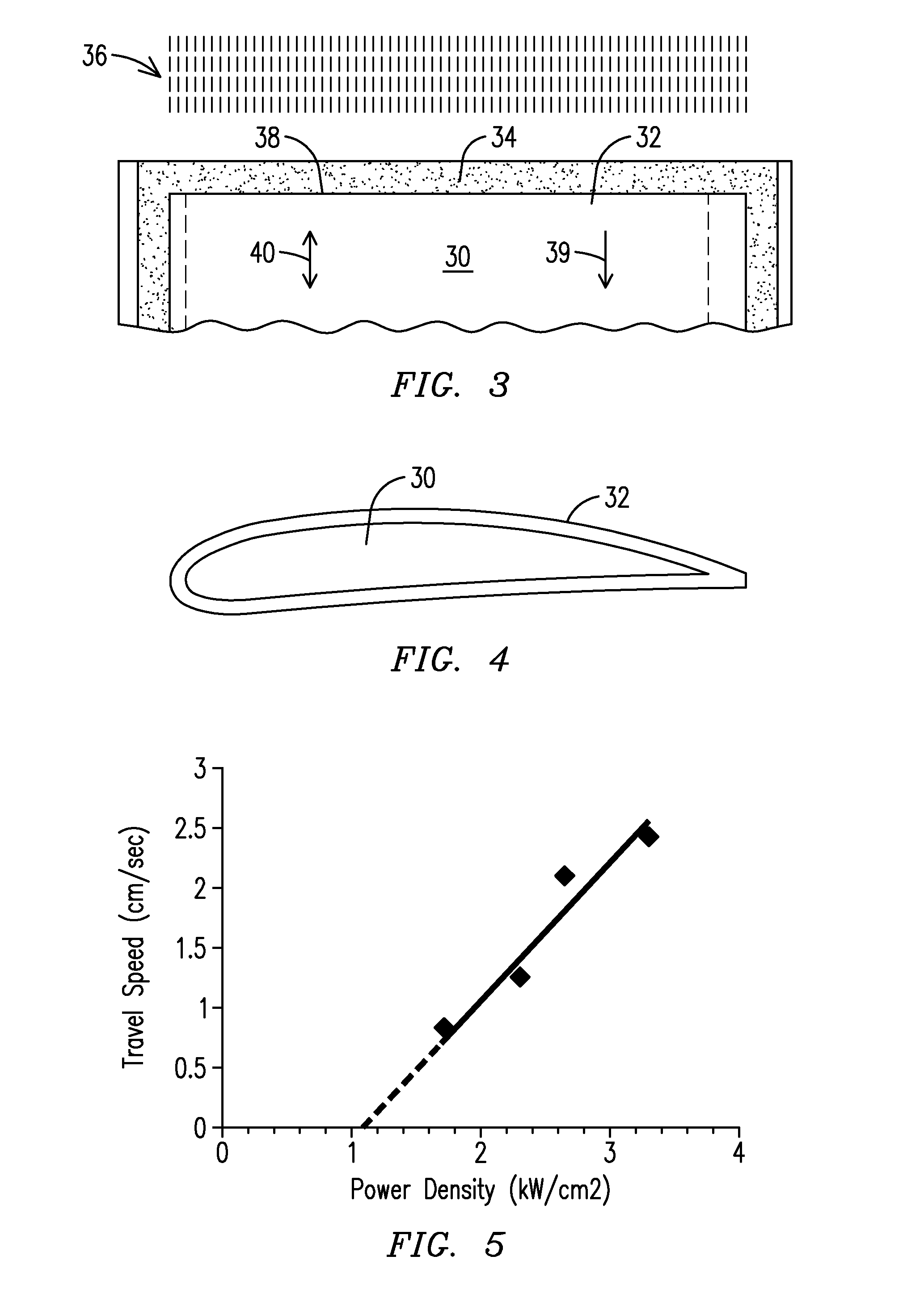

Repair of directionally solidified alloys

ActiveUS20130302533A1Inhibition of recrystallizationLess timeRadiation applicationsBlade accessoriesGratingFluidized bed

A method for epitaxial addition of repair material onto a process surface (38) of a directionally solidified component (30). The component is positioned in a fluidized bed (34) to drift particles of a repair material over the process surface as laser energy (36) is rastered across the surface to melt the particles and to fuse repair material onto the entire surface simultaneously. The component is moved downward (39) in the bed in a direction parallel to the grain orientation in the component as material is added to the surface, thereby providing continuous epitaxial addition of material to the surface without recrystallization.

Owner:SIEMENS ENERGY INC

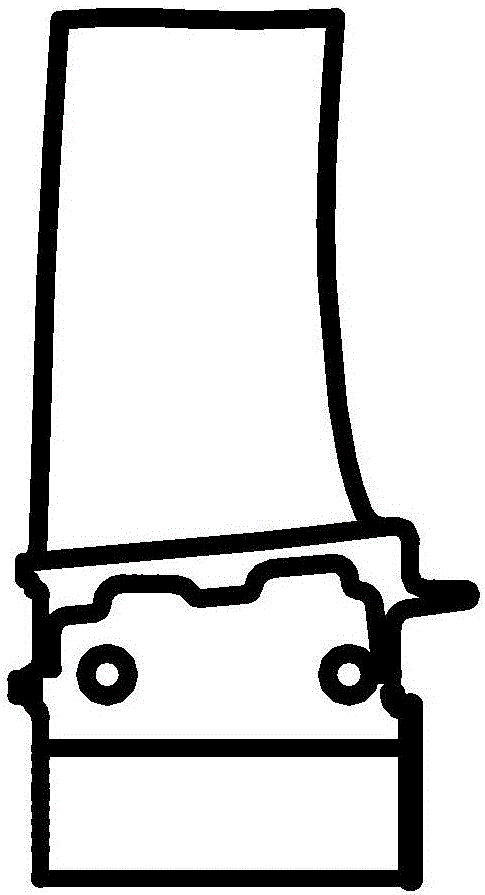

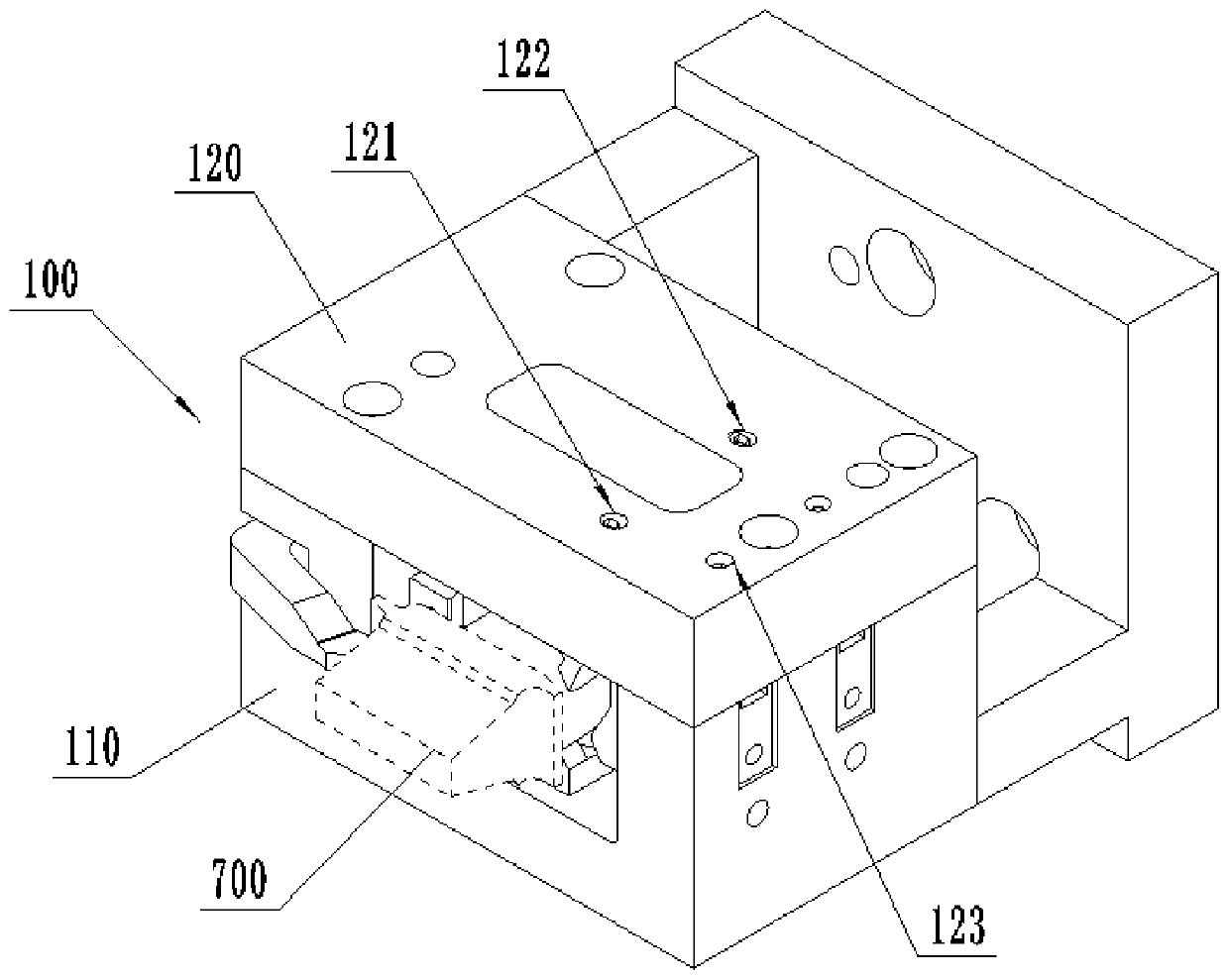

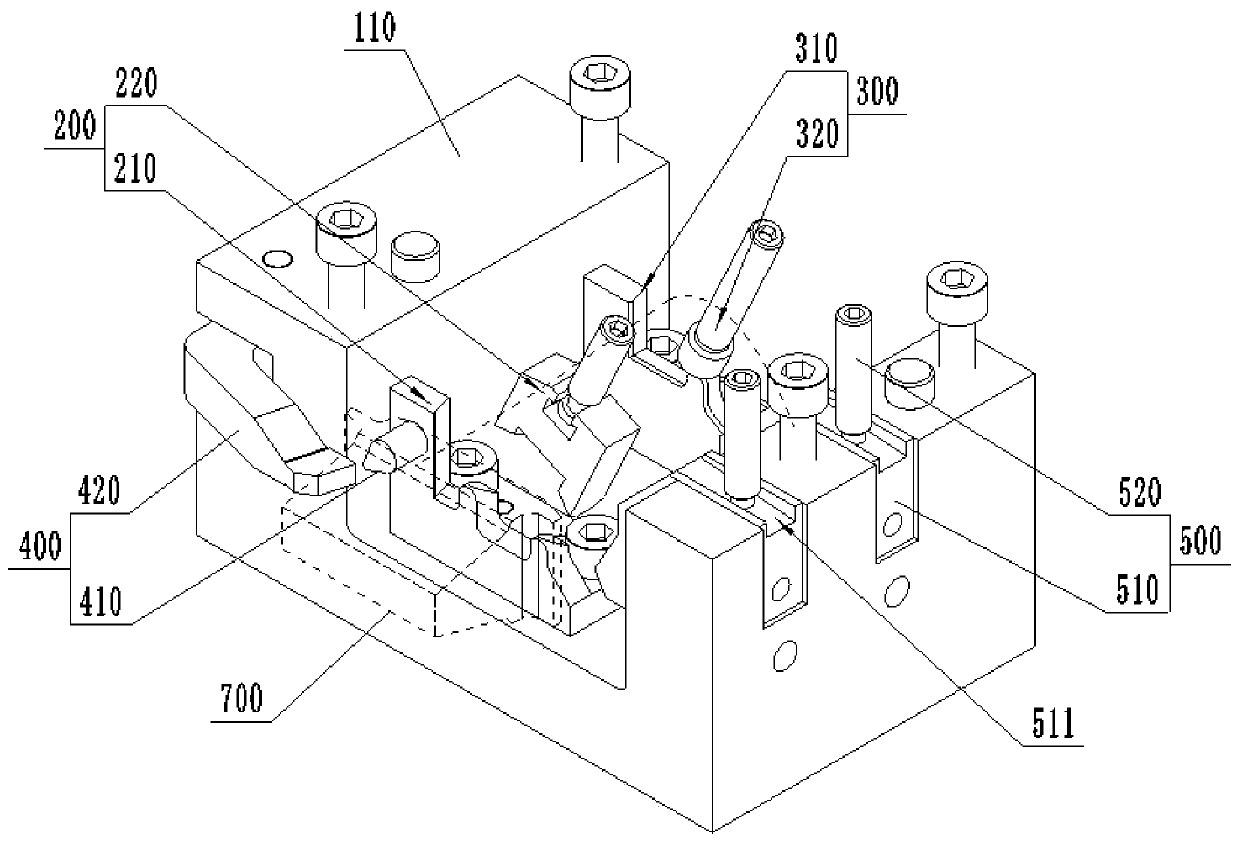

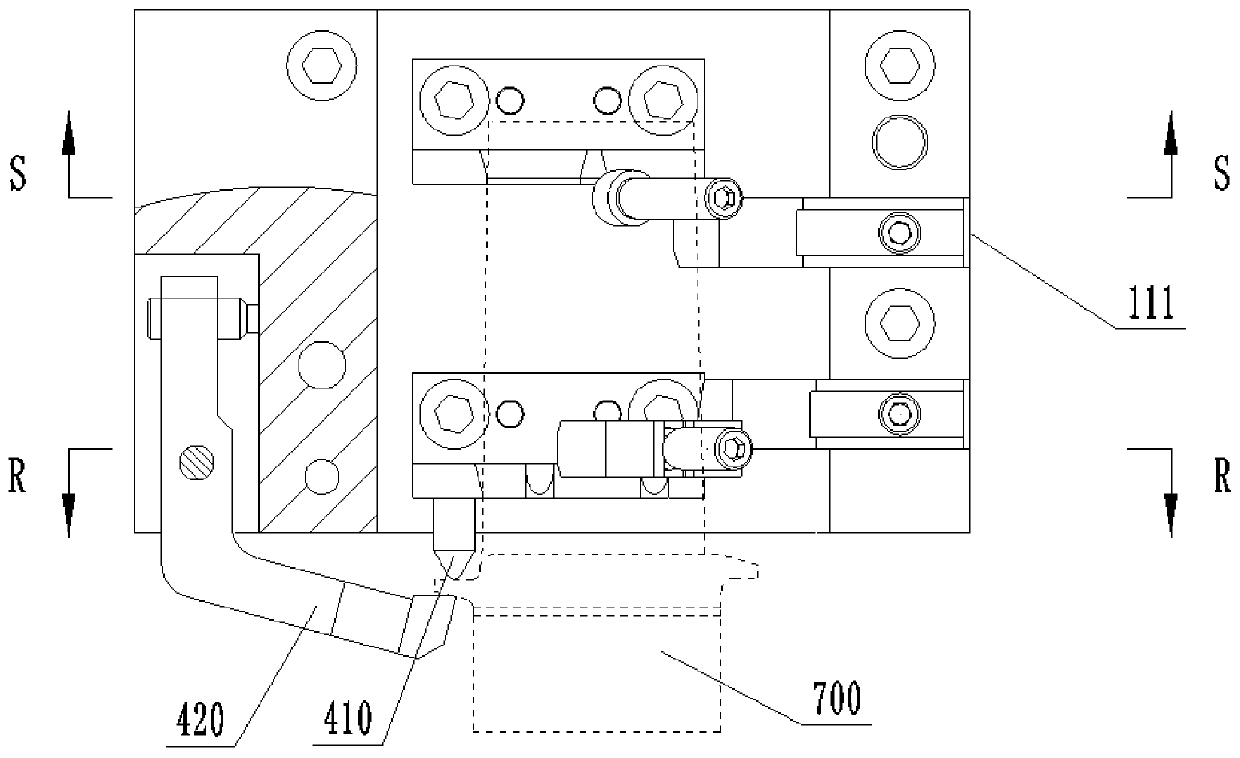

Tool clamp and method for clamping aero-engine turbine fine cast blade

InactiveCN110125701AEasy to fixInhibition of recrystallizationPositioning apparatusMetal-working holdersEngineeringMachining process

The invention relates to a tool clamp and a method for clamping an aero-engine turbine fine cast blade, and belongs to the technical field of aero-engine blade machining. The tool clamp comprises a square box, a blade body root positioning assembly, a blade body tail positioning assembly and an edge plate blade shoulder positioning assembly, wherein the blade body root positioning assembly, the blade body tail positioning assembly and the edge plate blade shoulder positioning assembly are fixedly arranged in the square box. By adopting the structure, the blade body root positioning assembly, the blade body tail positioning assembly and the edge plate blade shoulder positioning assembly which are fixedly arranged in the square box are used for positioning the root of a blade body, the tailof the blade body and an edge plate blade shoulder correspondingly, so that the blade is fixed in the square box, the position of the blade is firmly fixed during cutting machining, the machining precision is improved, all the positioning assemblies and the square box are integrally clamped, so that the defect that the datum conversion error is large is avoided, and the product percent of pass isimproved; and according to the method for clamping the aero-engine turbine fine cast blade, by using the tool clamp, it is guaranteed that the blade is positioned accurately, is pressed firmly and does not move in the machining process, so that the machining stability and the machining efficiency are further improved.

Owner:AECC AERO SCI & TECH CO LTD

Method to improve characteristics of spray dried powders and granulated materials, and the products thereby produced

ActiveUS20070026083A1Reducing residual solvent contentIncrease in bulk powder densityOrganic active ingredientsPretreated surfacesNon solventAverage size

A method for preparing solid materials is described. One aspect of the method includes the steps of providing a mixture comprising an organic material in a blend of a solvent and non-solvent for the organic material, distributing the mixture into either droplets or granules, and evaporating the solvent and non-solvent mixture to form particles having an average size of from about 0.5 μm to about 5000 μm.

Owner:ISP INVESTMENTS LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com