Amorphous efavirenz and the production thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example # 1

A. Example #1

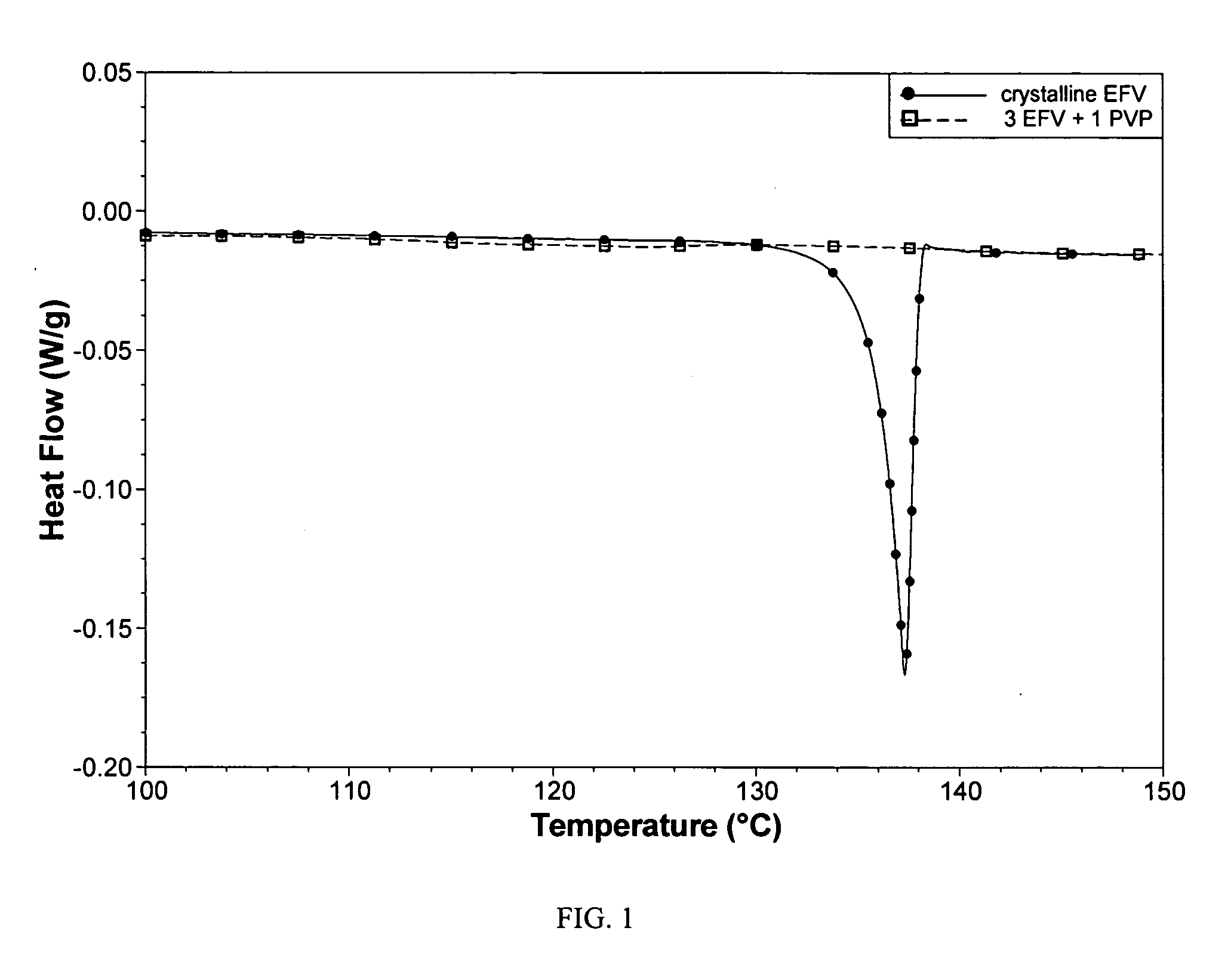

[0081] 1. Efavirenz was spray dried with polyvinylpyrrolidone (PVP) (Plasdone® K-29 / 32, ISP) from 100% dichloromethane in the ratio 3 efavirenz: 1 PVP. Dichloromethane is a solvent for both efavirenz and PVP. [0082] 2. Analysis of efavirenz crystallinity by differential scanning calorimetry (DSC) (Q1000®, TA Instruments) showed the complete absence of an efavirenz melt endotherm. The spray dried powder contained only completely amorphous efavirenz (FIG. 1).

example # 2

B. Example #2

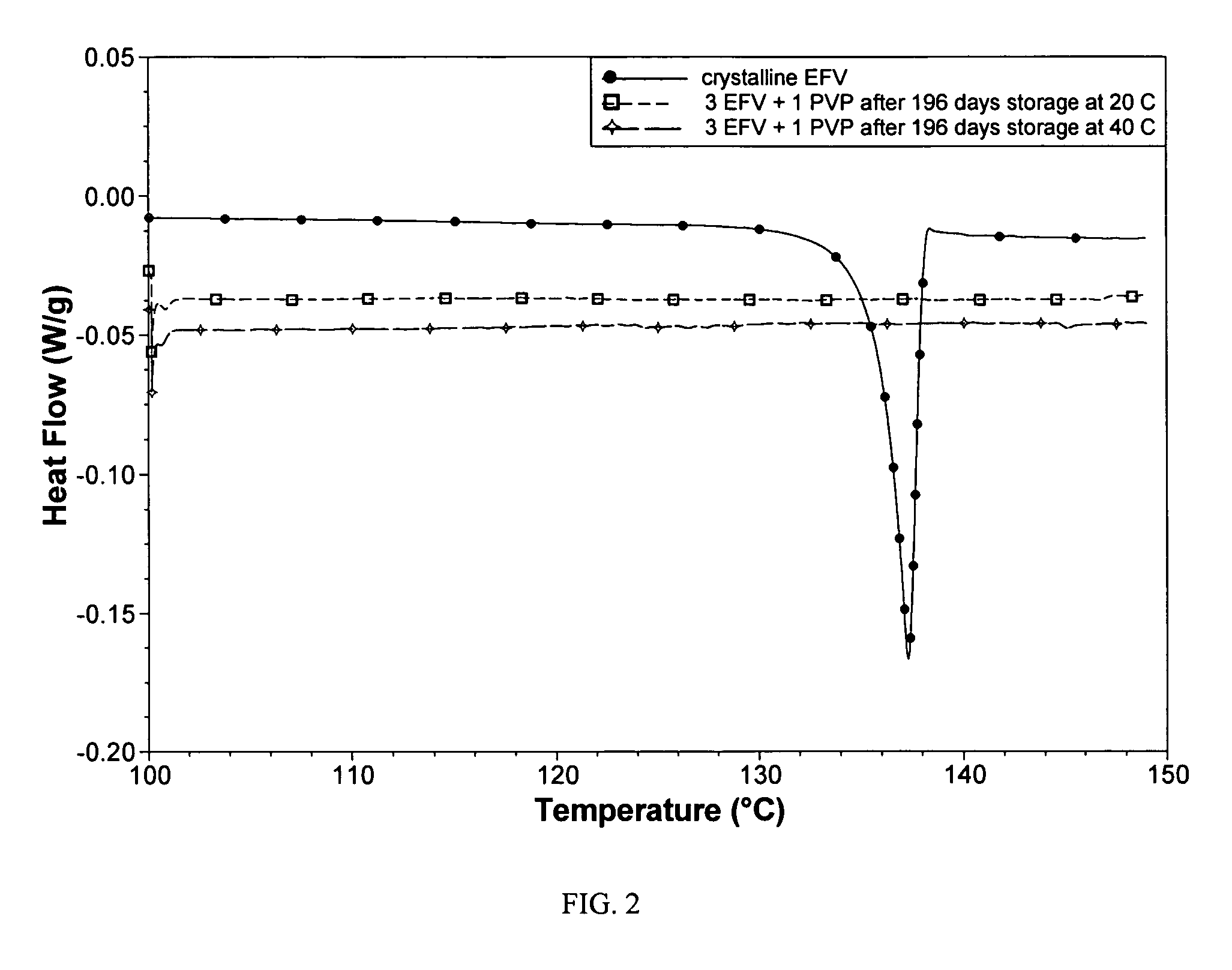

[0083] The efavirenz composition of Example #1 was placed on storage at 20° C. and 40° C. After 196 days of storage the sample show no amount of efavirenz crystallinity and contained only completely amorphous efavirenz at both storage temperatures (FIG. 2).

example # 3

C. Example #3

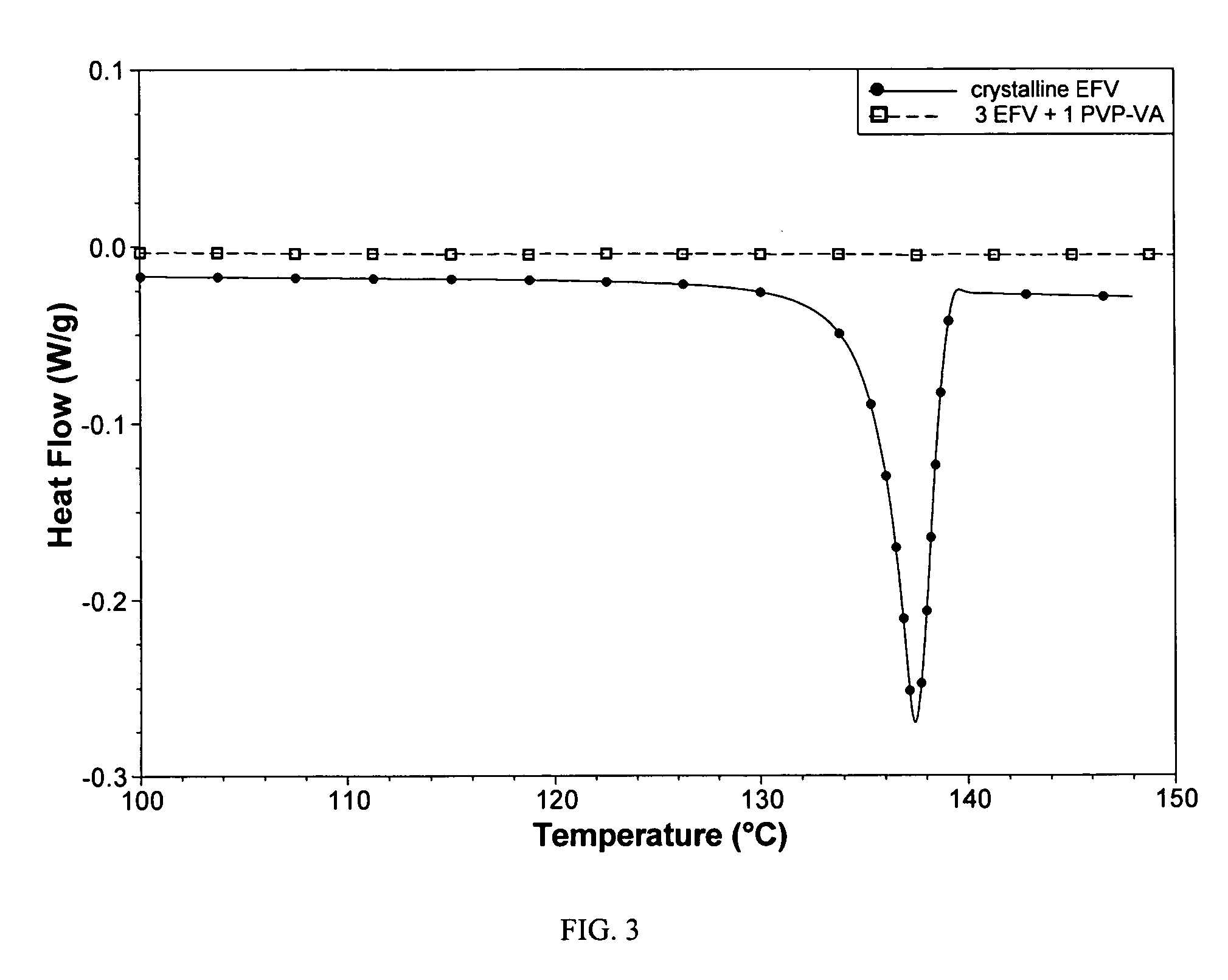

[0084] 1. Efavirenz was spray dried with polyvinylpyrrolidone-co-vinyl acetate (PVP-VA) (Plasdone® S-630, ISP) in the ratio 3 efavirenz:1 PVP-VA from 100% acetone. Acetone is a solvent for both efavirenz and PVP-VA. [0085] 2. Analysis of efavirenz crystallinity by DSC (Q1000®, TA Instruments) showed the complete absence of an efavirenz melt endotherm. The spray dried powder contained only completely amorphous efavirenz (FIG. 3).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com