Al-Zn-Mg-Er rare earth aluminium alloy

A technology of aluminum alloy and rare earth, applied in the field of metal alloy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

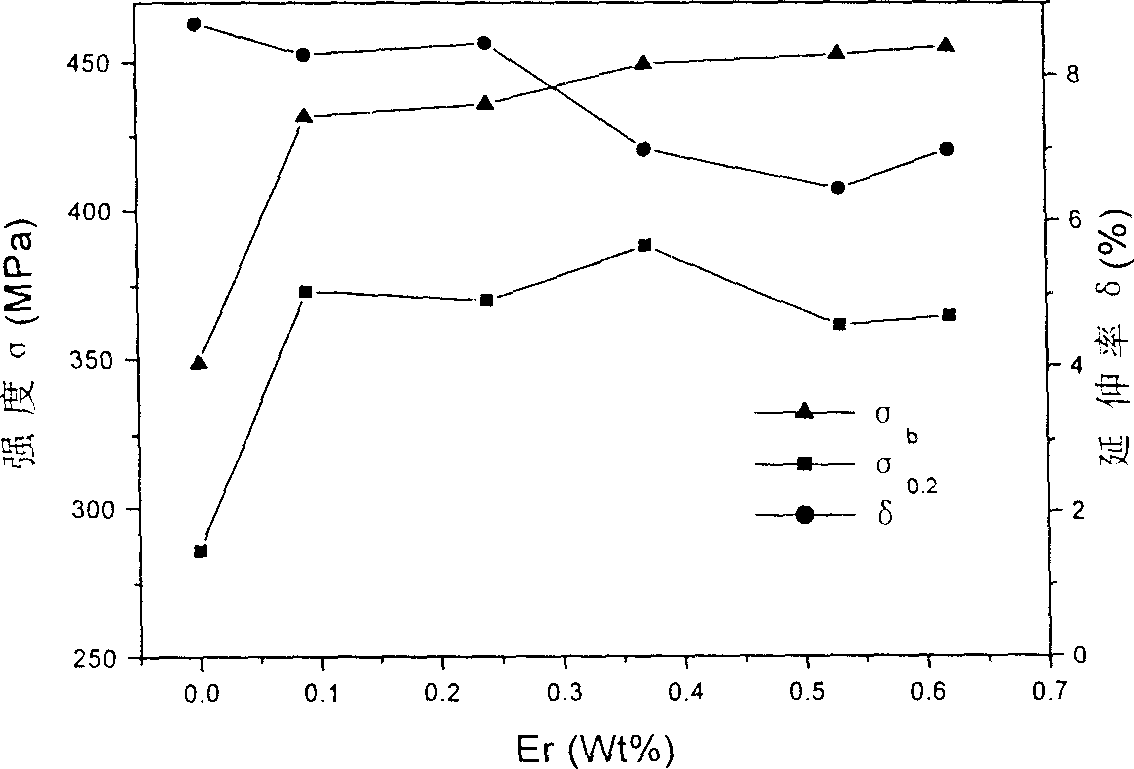

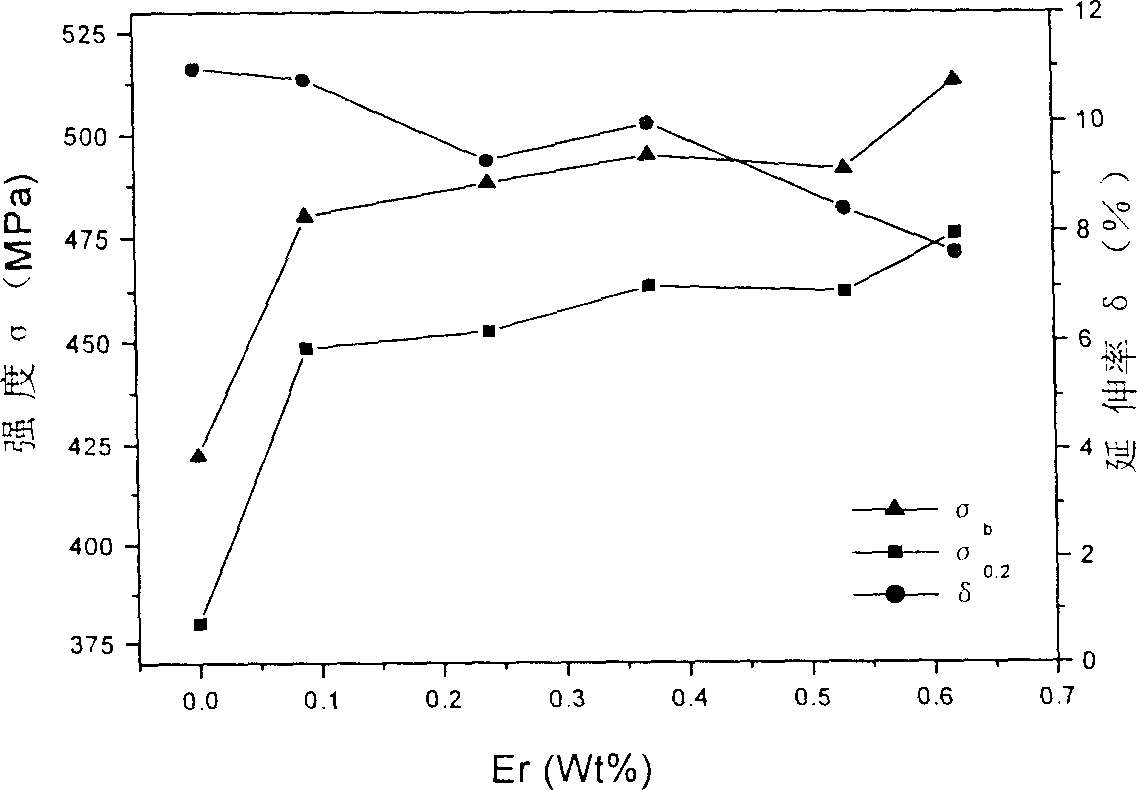

[0014] Example 1: Al-Zn-Mg-Er alloy is prepared by ingot metallurgy method. First, high-purity Al (purity up to 99.99%) and pure Er (purity up to 99.9%) are used as raw materials, and the mixing method (mixed melting method) is adopted. Melting and casting in a vacuum induction furnace to prepare Al-6.2Er master alloy. Then 1584.9 grams of high-purity aluminum and 27.4 grams of Al-6.2Er master alloy were added to the graphite clay crucible, and melted in a crucible resistance furnace at a melting temperature of 780 ° C. After the high-purity aluminum and Al-6.2Er master alloy were completely melted, Add pure Zn113.3 grams in the melt, after fully stirring, then add pure Mg38.6 grams, after stirring, add 3 grams of hexachloroethane (C 2 Cl 6 ) for degassing and slag removal, and finally the melt is poured into a rectangular iron mold, and demolded after cooling for 3 minutes. The size of each ingot is 120×90×32 (mm 3 ).

example 2

[0015] Example 2: Al-Zn-Mg-Er alloy is prepared by ingot metallurgy. First, high-purity Al (purity up to 99.99%) and pure Er (purity up to 99.9%) are used as raw materials, and the mixing method (mixed melting method) is adopted. Melting and casting in a vacuum induction furnace to prepare Al-6.2Er master alloy. Then add 1543.7 grams of high-purity aluminum and 68.5 grams of Al-6.2Er master alloy into a graphite clay crucible, and melt in a crucible resistance furnace at a melting temperature of 780 ° C. After the high-purity aluminum and Al-6.2Er master alloy are completely melted, Add pure Zn113.3 grams in the melt, after fully stirring, then add pure Mg38.6 grams, after stirring, add 3 grams of hexachloroethane (C 2 Cl 6 ) for degassing and slag removal, and finally the melt is poured into a rectangular iron mold, and demolded after cooling for 3 minutes. The size of each ingot is 120×90×32 (mm 3 ).

example 3

[0016] Example 3: Al-Zn-Mg-Er alloy is prepared by ingot metallurgy method. First, high-purity Al (purity up to 99.99%) and pure Er (purity up to 99.9%) are used as raw materials, and the mixing method (mixed melting method) is adopted. Melting and casting in a vacuum induction furnace to prepare Al-6.2Er master alloy. Then add 1502.5 grams of high-purity aluminum and 109.7 grams of Al-6.2Er master alloy into a graphite clay crucible, and melt in a crucible resistance furnace at a melting temperature of 780 ° C. After the high-purity aluminum and Al-6.2Er master alloy are completely melted, Add pure Zn113.3 grams in the melt, after fully stirring, then add pure Mg38.6 grams, after stirring, add 3 grams of hexachloroethane (C 2 Cl 6 ) for degassing and slag removal, and finally the melt is poured into a rectangular iron mold, and demolded after cooling for 3 minutes. The size of each ingot is 120×90×32 (mm 3 ).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com