A kind of plastic mold steel and its manufacturing method

A technology of plastic mold steel and chemical composition, applied in the field of large-scale pre-hardened plastic mold steel and its manufacturing, to achieve the effects of improving performance, increasing stability, and reasonable chemical composition ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

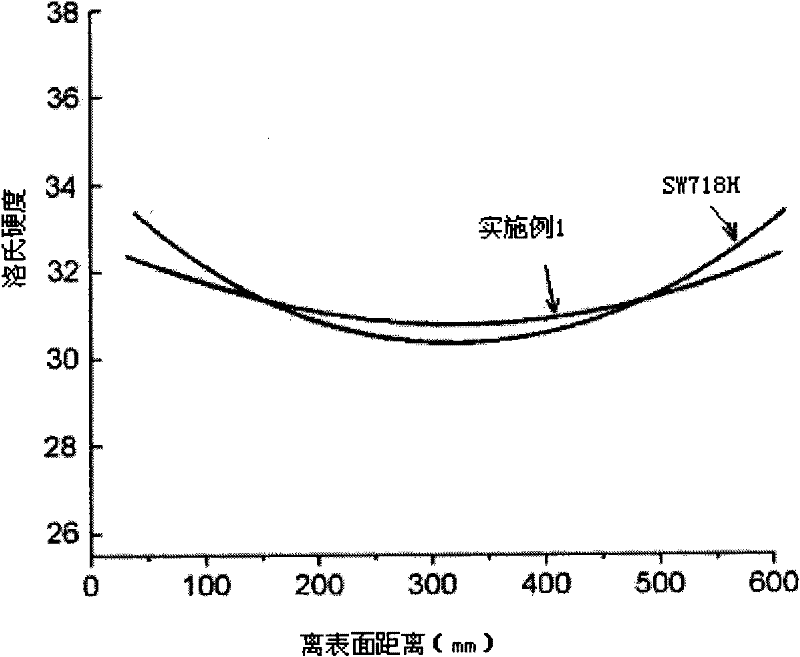

[0051] The chemical composition weight percentage of the plastic mold steel in this embodiment is: C 0.28wt%, Si0.49wt%, Mn 1.44wt%, Cr 1.40wt%, Mo 0.46wt%, Nb 0.035wt%, Ni 0.13wt%, Cu 0.11 wt%, S 0.003wt%, P 0.013wt%, N 0.0098wt%, and the balance is Fe and inevitable impurities.

[0052] According to the above chemical composition ratio, after the initial smelting in the electric arc furnace and the refining outside the furnace, the ingot is cast into a 25-ton steel ingot; then the steel ingot is heated to 1165 ℃ at a heating rate of 80 ℃ / hour to 120 ℃ / hour in the forging heating furnace, and the temperature is kept warm. For 5.5 hours, the steel ingot was forged, the forging temperature was 1110 °C, and the forging temperature was 930 °C; after forging, a forged module with a thickness of 660 mm was obtained; the above forged module was directly placed in the air and cooled to room temperature to obtain the thickness 660mm pre-hardened plastic mould steel.

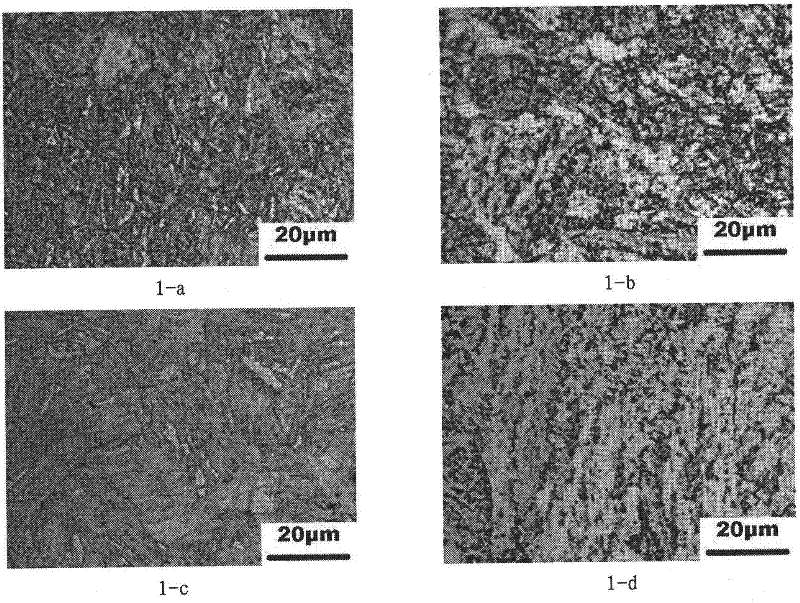

[0053] The plas...

Embodiment 2

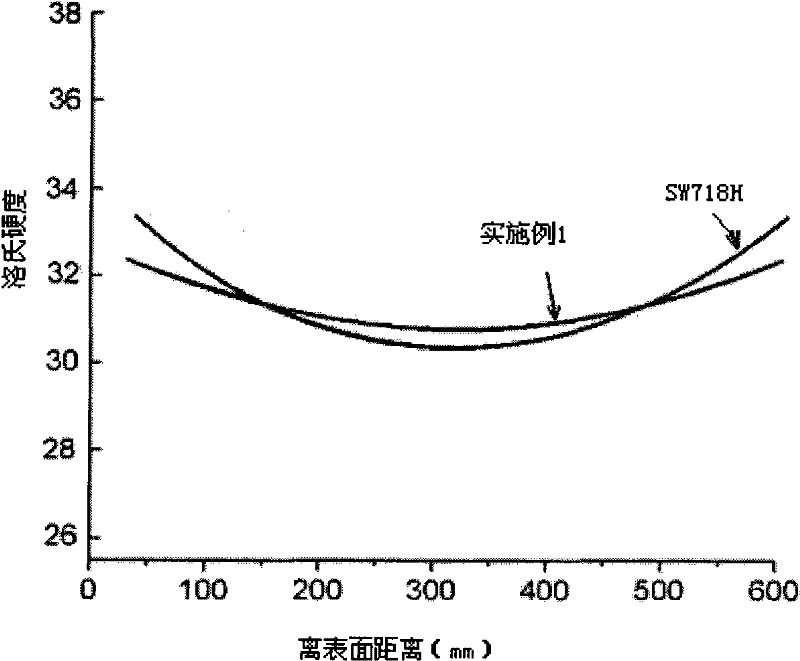

[0058] The chemical composition weight percentage of the plastic mold steel in this embodiment is: C 0.25wt%, Si 0.40wt%, Mn 1.50wt%, Cr 1.20wt%, Mo 0.50wt%, Nb 0.050wt%, Ni 0.11wt%, Cu 0.12 wt%, S 0.013wt%, P 0.020wt%, N 0.012wt%, and the balance is Fe and inevitable impurities.

[0059] According to the above chemical composition ratio, after the initial smelting in the electric arc furnace and the refining outside the furnace, the ingot is cast into a 35-ton steel ingot; then the steel ingot is heated to 1160 ℃ at a heating rate of 80 ℃ / hour to 120 ℃ / hour in the forging heating furnace, and the heat preservation is carried out. For 8.0 hours, the ingot was forged, the forging temperature was 1100°C, and the forging temperature was 850°C; after forging, a forged module with a thickness of 610 mm was obtained; the above-mentioned forged module was directly placed in the air and cooled to room temperature to obtain a thickness of 610 mm. 610mm pre-hardened plastic mould st...

Embodiment 3

[0062] The chemical composition weight percentages of the plastic mold steel in this embodiment are: C 0.25wt%, Si 0.60wt%, Mn 1.30wt%, Cr 1.40wt%, Mo 0.44wt%, Nb 0.020wt%, Ni 0.10wt%, Cu 0.11 wt%, S 0.012wt%, P 0.016wt%, N 0.009wt%, the balance is Fe and inevitable impurities;

[0063] According to the above chemical composition ratio, after the initial smelting in the electric arc furnace and the refining outside the furnace, the ingot is cast into a 25-ton steel ingot; then the steel ingot is heated to 1170 ℃ at a heating rate of 80 ℃ / hour to 120 ℃ / hour in the forging heating furnace, and the temperature is kept warm. For 6.0 hours, the ingot was forged, the forging temperature was 1120°C, and the stop forging temperature was 880°C; after the forging was completed, a forged module with a thickness of 620 mm was obtained; the above-mentioned forged module was directly placed in the air and cooled to room temperature to obtain a thickness of 620 mm. 620mm pre-hardened plastic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com