Patents

Literature

117results about How to "Refining solidified tissue" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

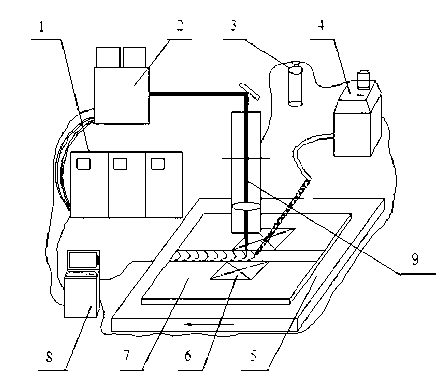

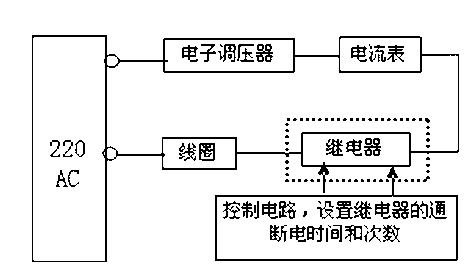

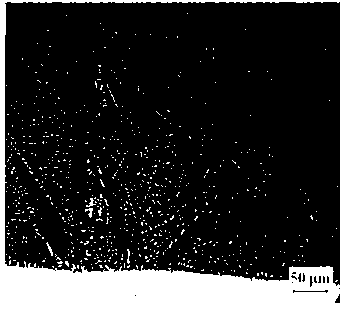

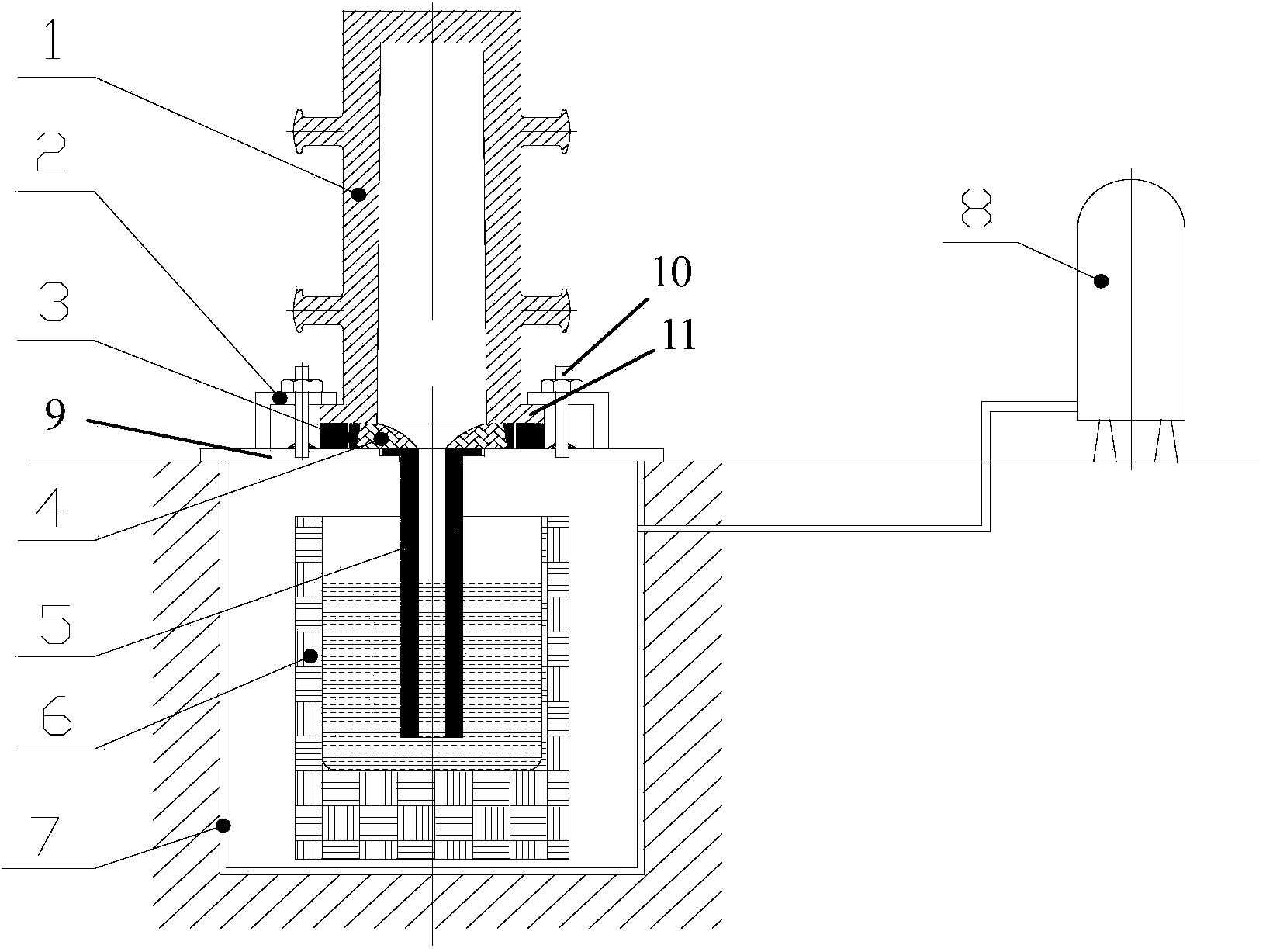

Method for refining solidified structure of laser cladding layer by using alternating magnetic field and device thereof

InactiveCN102703898ARefining solidified tissueChange shapeMetallic material coating processesNumerical controlAlternating current

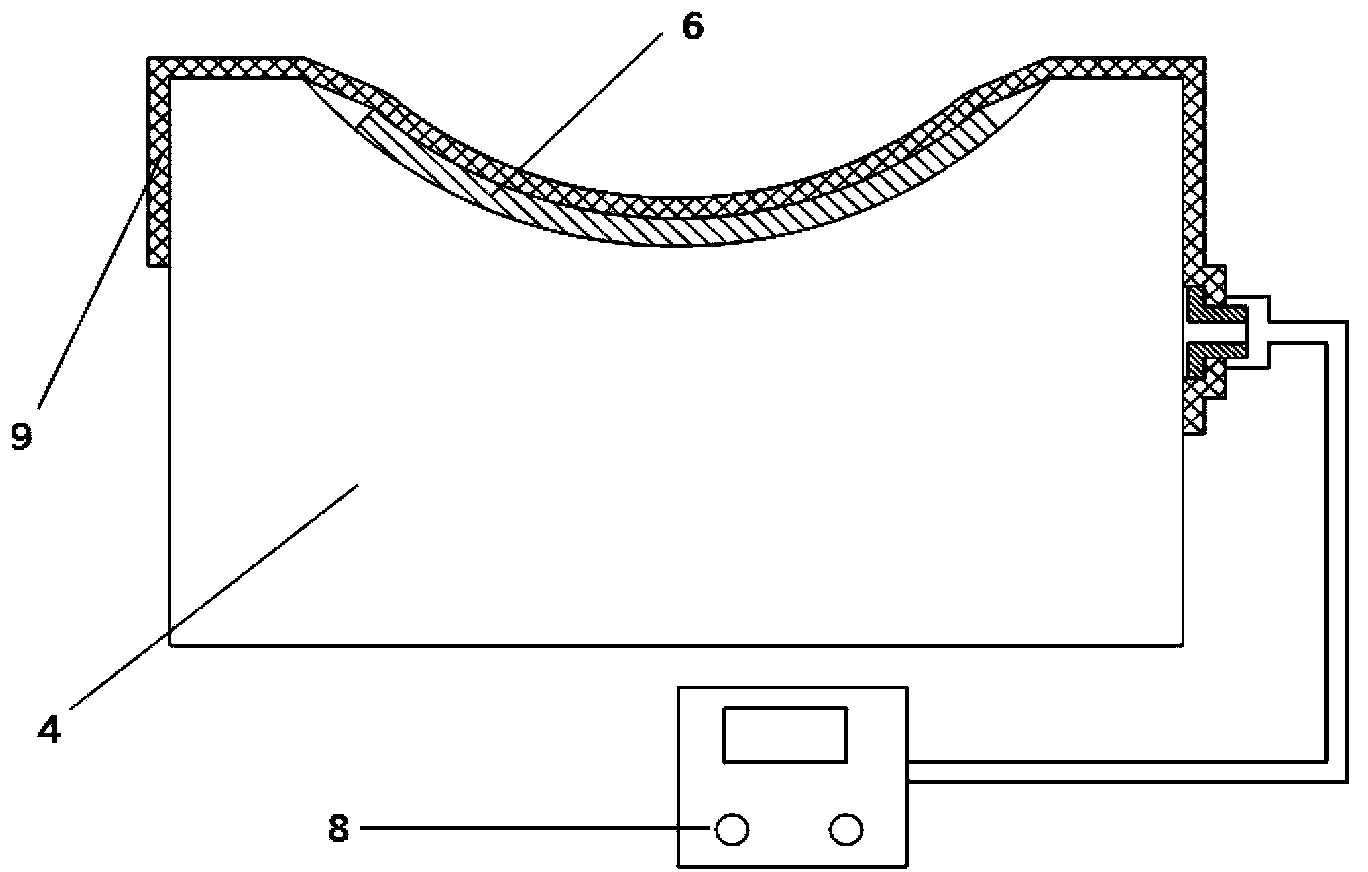

The invention relates to a method for refining a solidified structure of a laser cladding layer by using an alternating magnetic field and a device thereof, belongs to the technical field of laser processing. A compound coating is prepared on the surface of a substrate in a manner of conventional powder-feed laser cladding; the alternating magnetic field is applied to acting on a laser molten pool during the laser cladding; the powder-feed laser cladding process is carried out under the alternating magnetic field; and the direction of magnetic lines of force generated by the alternating magnetic field is perpendicular to the scanning speed direction of the laser cladding. The device for refining the solidified structure of the laser cladding layer by using the alternating magnetic field comprises a cooler, a CO2 laser, an argon protector, a synchronous powder feeder, a clamping device, an alternating magnetic field, a cladding substrate body and a numerical control operation floor. The method and the device provided by the invention are capable of obviously refining the solidified structure of the cladding layer; when alternating current with certain frequency is introduced into a coil, an alternating magnetic field can be generated between a metal melt and the magnetic field coil; and the intensity of the alternating magnetic field is controlled so as to change a form of the solidified structure of the cladding layer and refine crystalline grains through changing the intensity of an alternating magnetic field. The device provided by the invention is simple, low in investment cost, high in benefit, etc.

Owner:KUNMING UNIV OF SCI & TECH

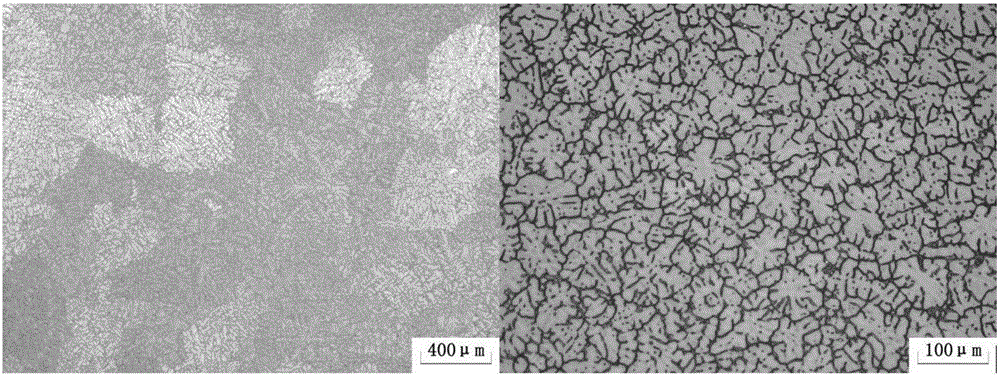

Method and device for preparing high-performance aluminum-base composite material under the action of pulsed magnetic field

The invention provides a method and a device for preparing high-performance aluminum-base composite material under the action of the pulsed magnetic field with the in situ crystallization method, belonging to the technical field of material preparation. The method comprises the following steps: smelting to synthesize compound material melt at the temperature of 10-200 DEG C higher than the compound material melt liquidus temperature and pouring the compound material melt into a specially-designed crystallizer to make the compound material melt solidify under the action of the pulsed magnetic field. The pulsed magnetic field has the key parameters of the pulse width of 1-500 ms and the amplitude strength of 0.1-50T. The pulsed electromagnetic force is applied to the process of solidifying the compound material melt under the action of the pulsed magnetic field so as to refine the matrix structure and the particle reinforced phase of the compound material at the same time, control the growth of the particle reinforced phase in cluster, increase the bonding strength of the interface of the particle reinforced phase and the matrix and obviously improve the performance of the composite material.

Owner:JIANGSU UNIV

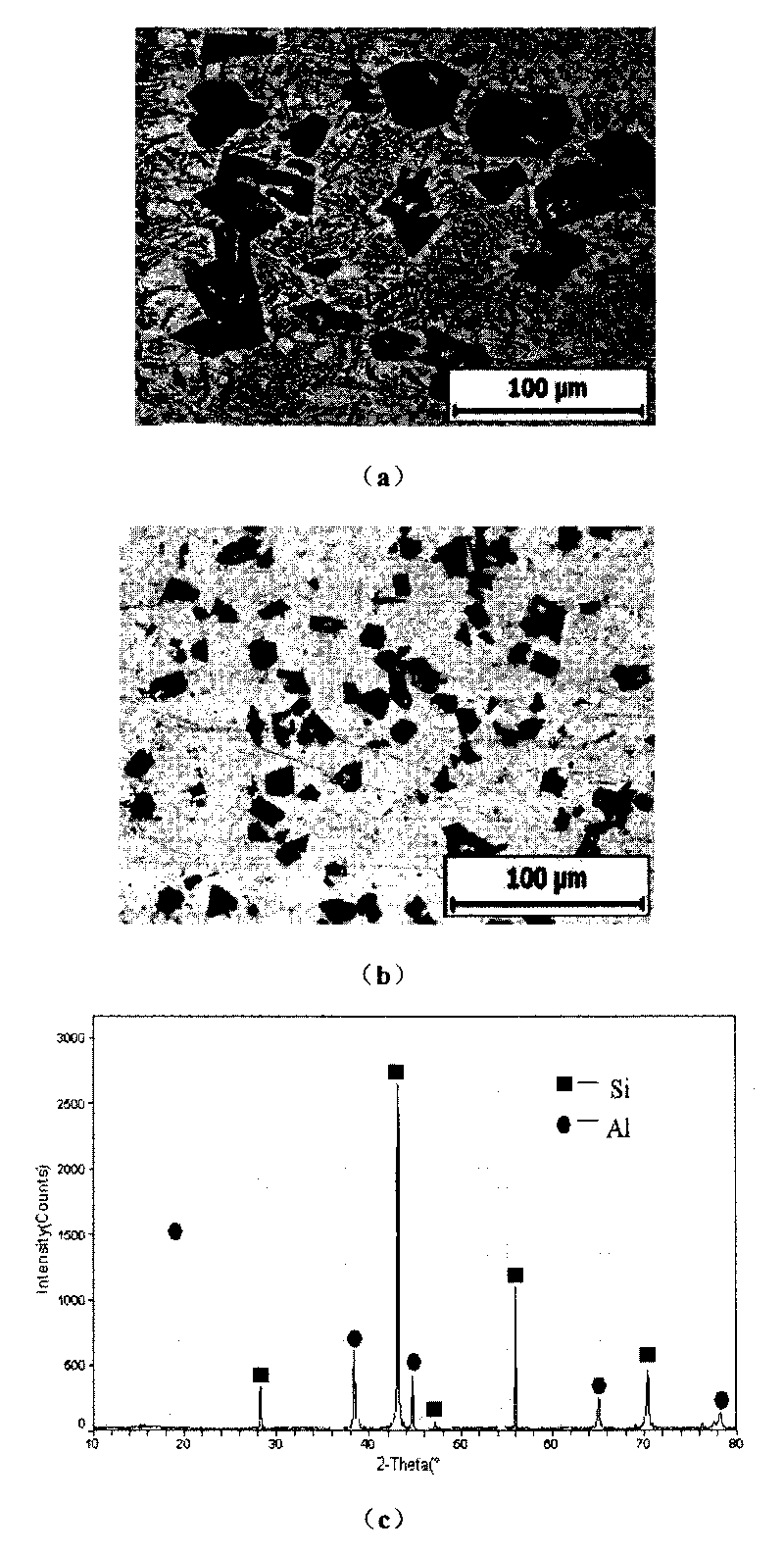

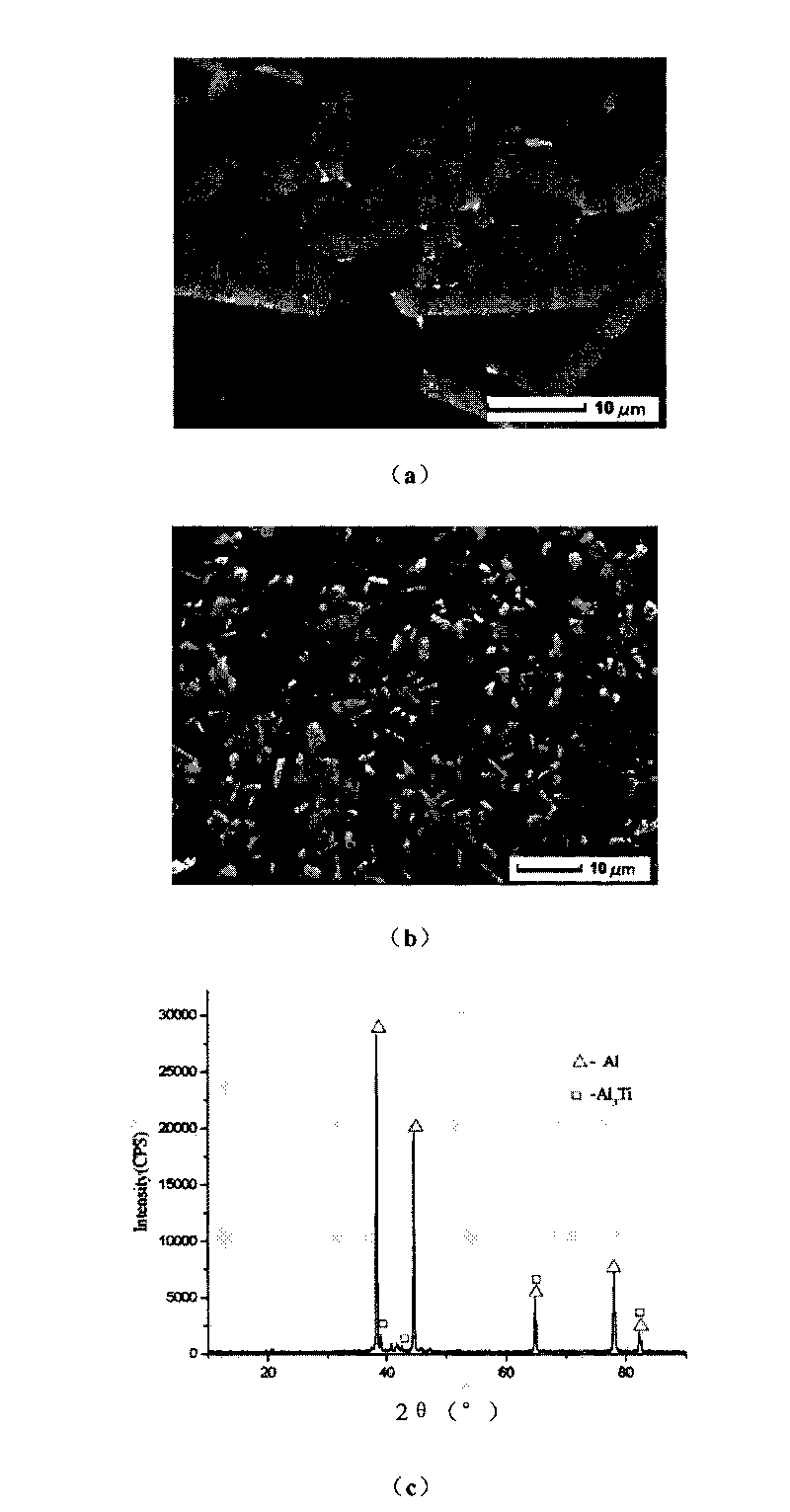

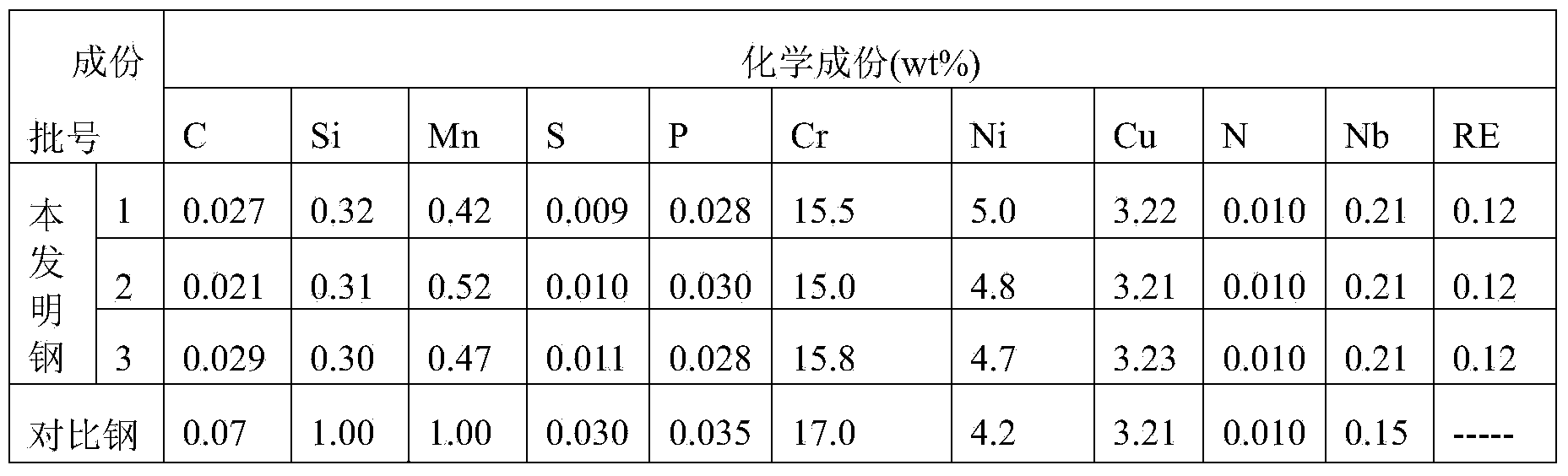

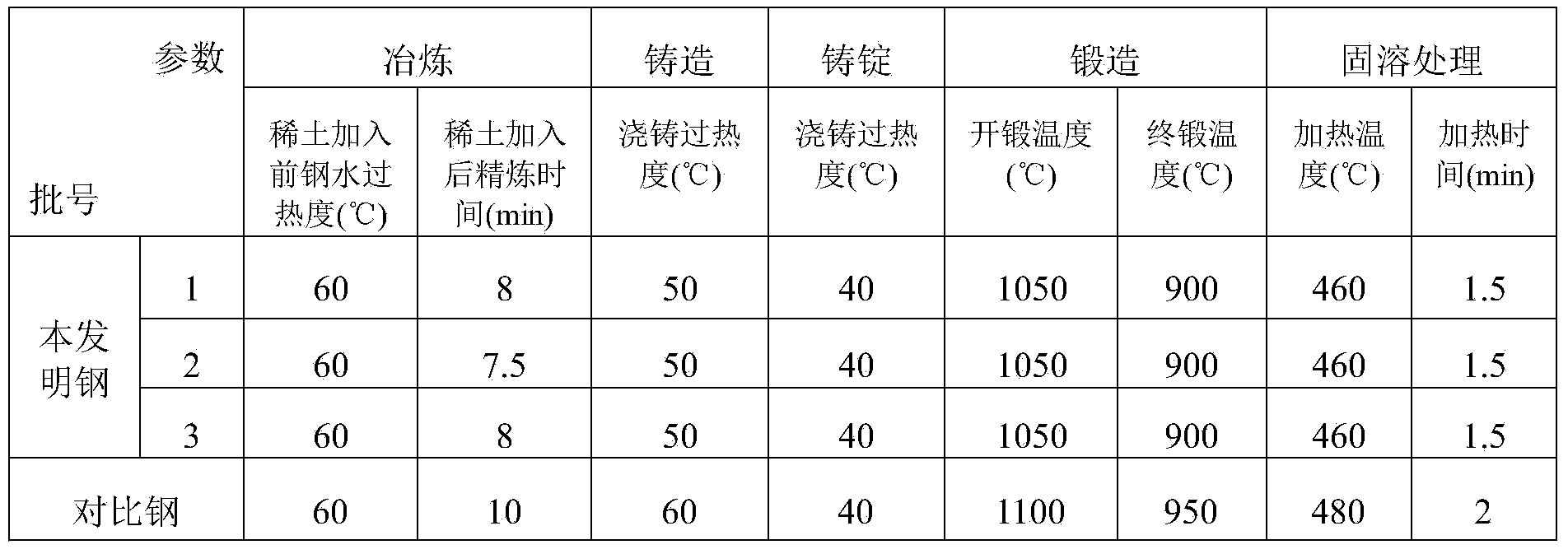

Rare-earth-type 0Cr17Ni4Cu4Nb martensitic precipitation-hardening stainless steel and preparation method thereof

ActiveCN104328353ARefining solidified tissueImprove performanceSolution treatmentMartensitic stainless steel

The invention discloses rare-earth-type 0Cr17Ni4Cu4Nb martensitic precipitation-hardening stainless steel. The rare-earth-type 0Cr17Ni4Cu4Nb martensitic precipitation-hardening stainless steel is characterized by comprising the following chemical components in percentage by weight: less than or equal to 0.07% of C, less than or equal to 1% of Si, less than or equal to 1% of Mn, less than or equal to 0.035% of P, less than or equal to 0.03% of S, 3.00-5.00% of Ni, 15.5-17.5% of Cr, 3.00-5.00% of Cu, 0.15-0.45% of Nb, 0.05-0.25% of Re and the balance of Fe and belongs to the field of alloy steels. The invention also discloses a preparation method of the rare-earth-type 0Cr17Ni4Cu4Nb martensitic precipitation-hardening stainless steel. The preparation method comprises the steps of smelting, casting, carrying out electroslag remelting, casting ingots, forging or rolling, carrying out solution treatment and the like. The rare-earth-type 0Cr17Ni4Cu4Nb special steel, which is disclosed by the invention, as one of precipitation-hardening martensitic stainless steel, has the characteristics of high strength, high hardness, corrosion resistance and the like and is suitable for various technical fields, such as chemical machinery, food machinery, papermaking machinery, aerospace and marine.

Owner:什邡新工金属材料有限公司

High low-temperature impact toughness thick steel plates for hydrogen-contacting equipment and production method thereof

ActiveCN102605297AImprove strength and toughnessMeet manufacturing requirementsFurnace typesHeat treatment furnacesHydrogenWater flow

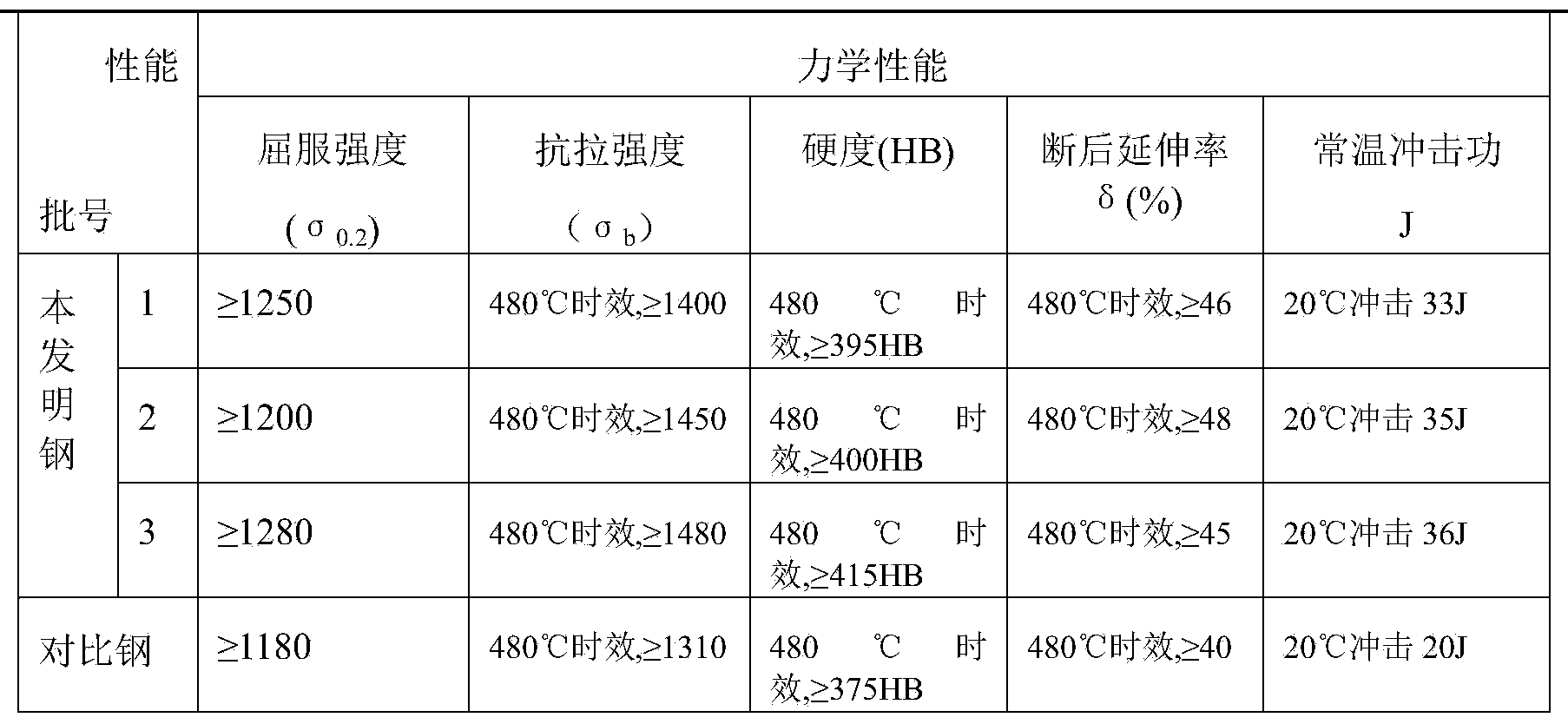

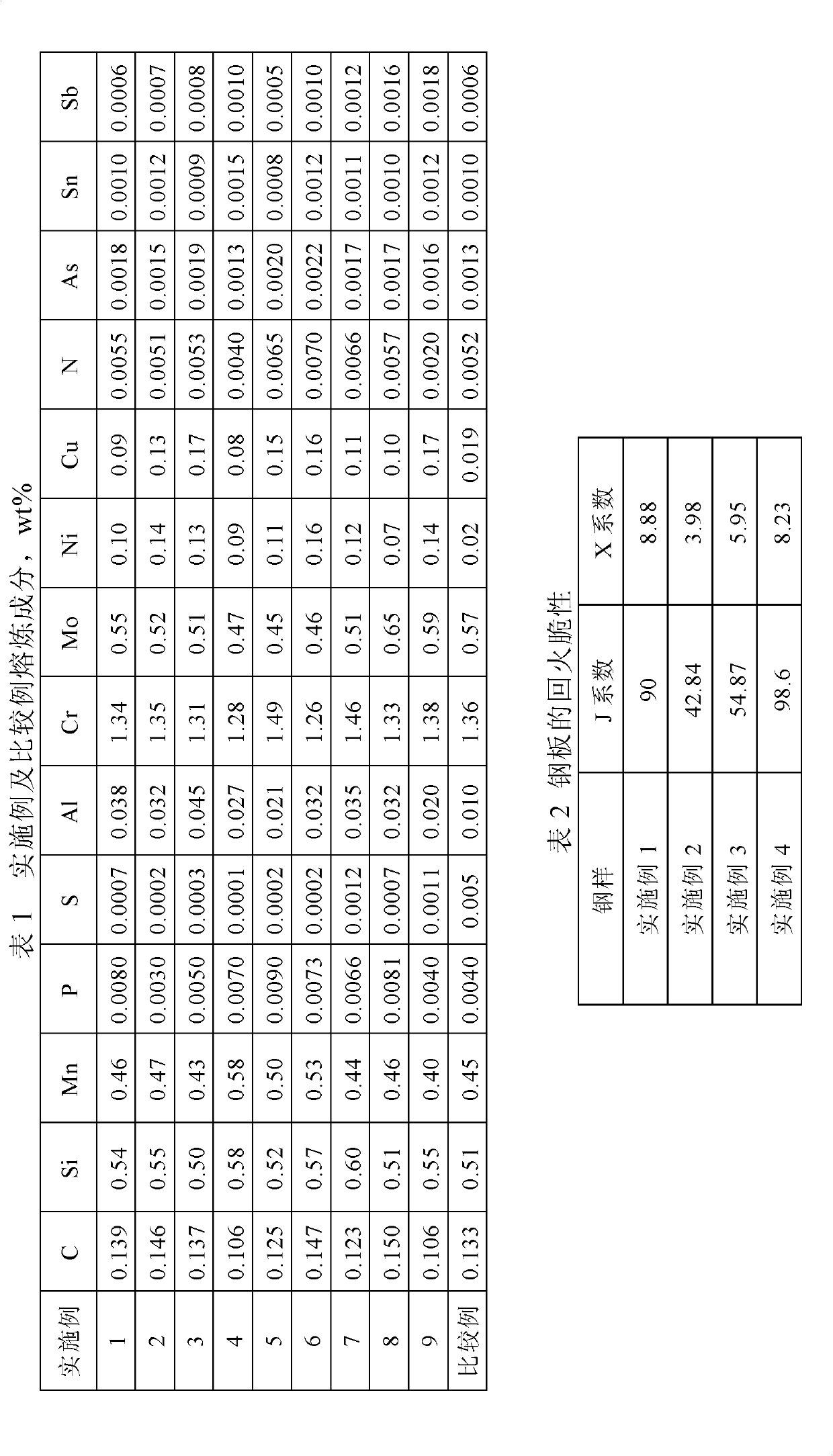

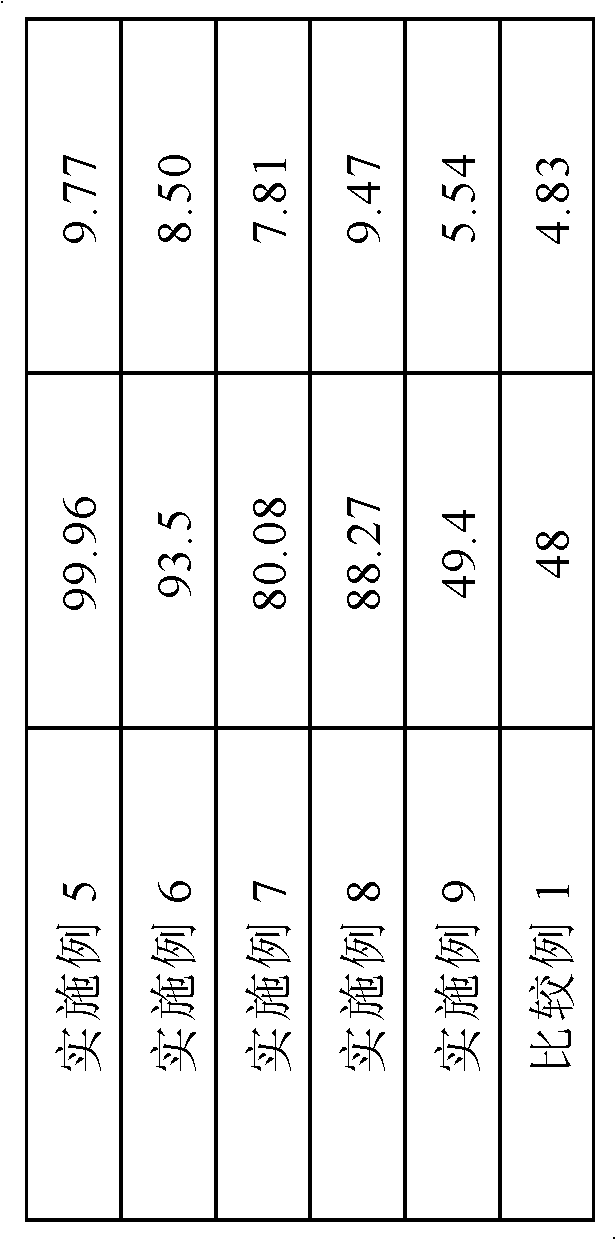

Disclosed are high low-temperature impact toughness thick steel plates for hydrogen-contacting equipment and a production method thereof. The production method includes the steps: firstly, smelting and casting; secondly, heating plate blanks at 1070-1210 DEG C and rolling the plate blanks according to a compression ratio of 2.7-6.4; thirdly, normalizing within an austenitization temperature range; fourthly, accelerated cooling with water for 4-15 minutes; and fifthly, tempering at 700-750 DEG C; and sixthly cooling, wherein the steel plates comprise, in weight percentage, 0.10-0.15% of C, 0.50-0.60% of Si, 0.40-0.60% of Mn, not more than 0.010% of P, not more than 0.003% of S, 1.25-1.50% of Cr, 0.45-0.65% of Mo, 0.08-0.18% of Cu, 0.07-0.17% of Ni, 0.020-0.045% of Al, not more than 0.003% of Sn, not more than 0.003% of Sb, not more than 0.003% of As, 0.0020-0.0070% of N, the balance of Fe and unavoidable impurities, low-pressure section water flow of a pressure quenching machine is 18-38m<3> / min, top-to-bottom water volume ratio of each steel plate is 1:1.0-1.3, and the surface temperature of the steel palate at an outlet of the pressure quenching machine is not more than 120 DEG C.

Owner:BAOSHAN IRON & STEEL CO LTD

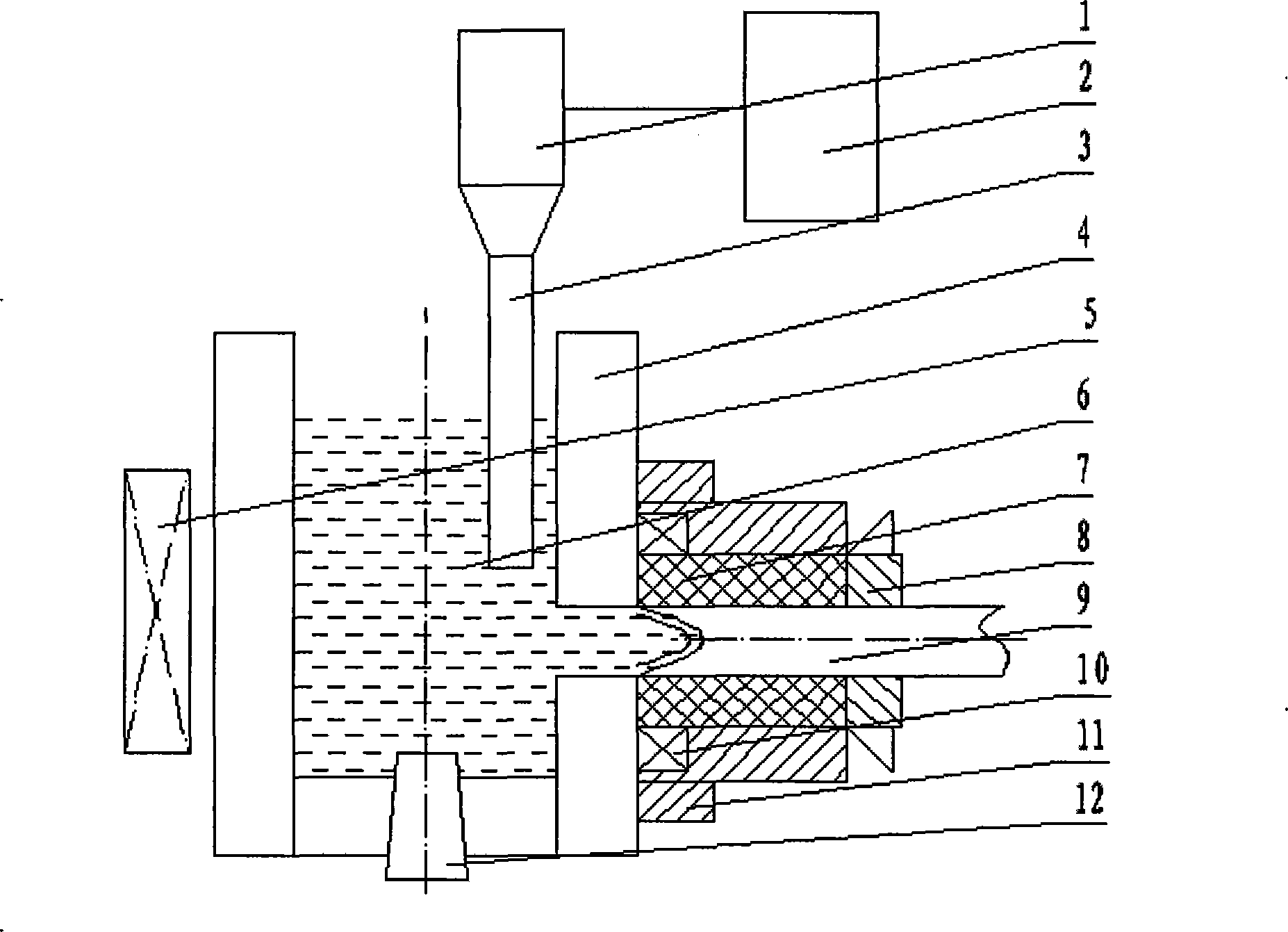

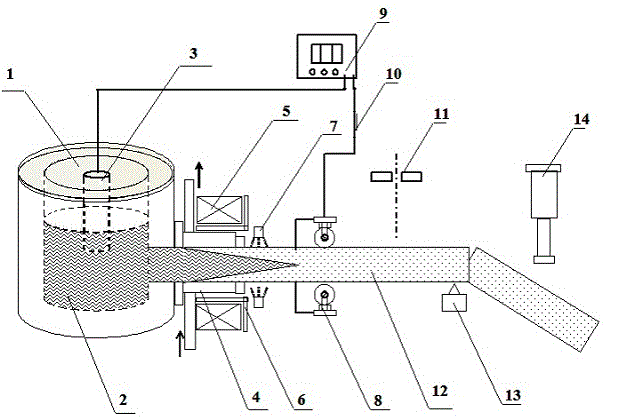

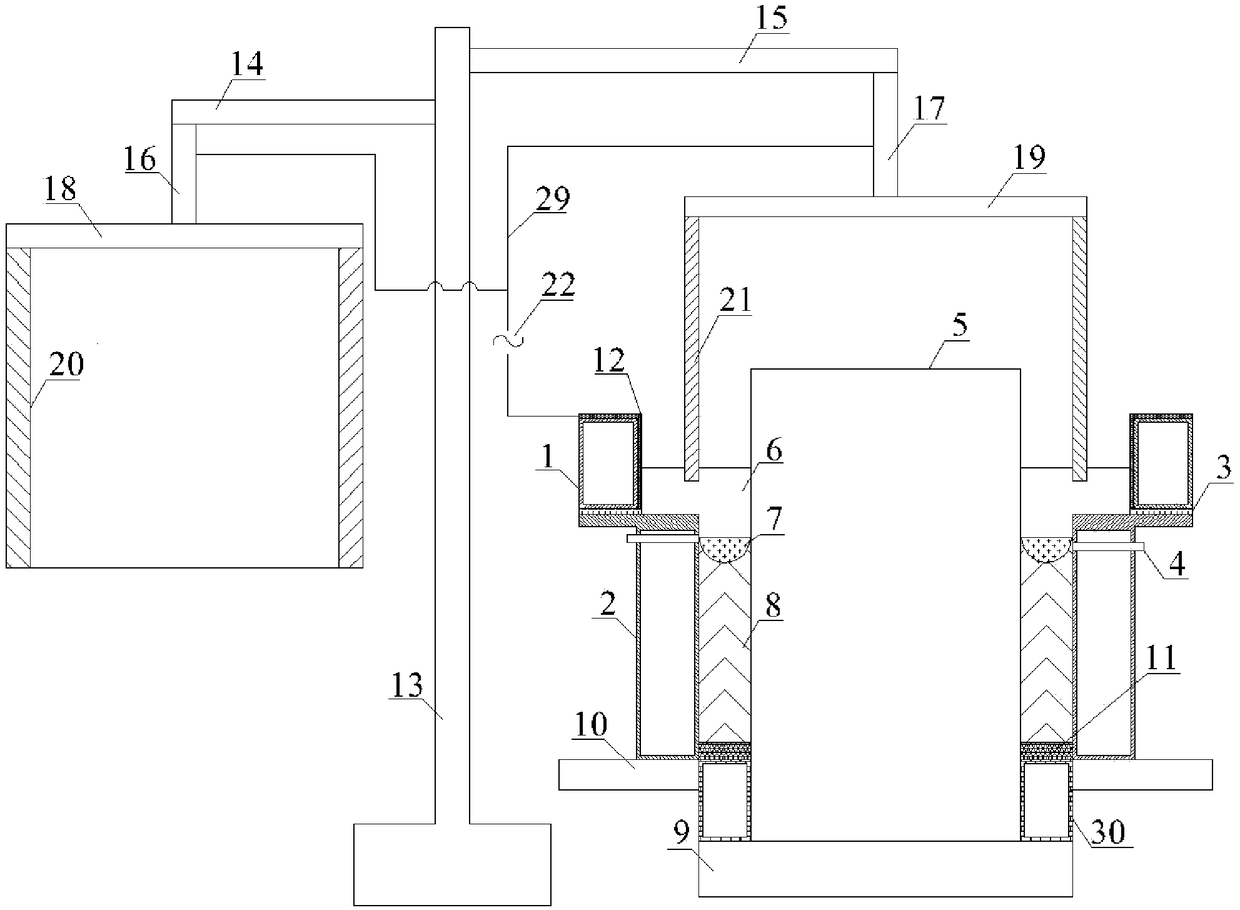

Method and apparatus for improving horizontal continuous casting billet quality by applying composite field

The invention relates to a quality improving method for horizontal continuous casting blanks by applying complex field and the device, belonging to the technical field of preparation of metal material, in particular to the technology of applying complex electromagnetic field and ultrasonic field in the continuous casting process of metal casting blanks. The device is characterized in that a generator of inert gas is arranged at the center of the bottom of a holding furnace; a generator of traveling wave magnetic field is arranged on the side of the holding furnace; a power ultrasonic device is arranged on the holding furnace close to the water port; a restriction electromagnetic coil is arranged on the outer side of a crystallizer. The device has the advantages that: firstly, the production technology is simple, the operation is easy, and the efficiency is high; secondly; the disadvantages of easy broken in rolling and drawing process of casting blank due to more impurity and pores is solved; thirdly, the solidification structure of the casting blanks is uniform, the crystal grain is fine, and the casting blanks can be rolled directly at casting state. The quality improving method and the device are mainly used for the field of metal continuous casting.

Owner:DALIAN UNIV OF TECH

H13 die steel and preparation method thereof

The invention relates to H13 die steel and a preparation method thereof, and belongs to the technical field of wear-resistant materials. The H13 die steel comprises the following chemical elements in percentage by weight: 0.40 to 0.46 percent of C, 6.00 to 6.30 percent of Cr, 0.50 to 0.65 percent of V, 0.30 to 0.45 percent of Mo, 0.85 to 1.05 percent of Mn, 1.25 to 1.55 percent of Si, 0.12 to 0.25 percent of W, 0.008 to 0.018 percent of Nb, 0.008 to 0.015 percent of Ta, 0.08 to 0.12 percent of Ti, 0.003 to 0.006 percent of B, 0.08 to 0.15 percent of Al, 0.03 to 0.06 percent of N, 0.06 to 0.12 percent of Y, less than 0.025 percent of S, less than 0.030 percent of P and the balance of Fe. The H13 die steel has the advantages that: the content of precious alloy elements, namely molybdenum and vanadium is low, the H13 die steel is not required to be forged, and forging can be replaced by casting, so that the cost of the H13 steel is obviously reduced; the performance of the H13 steel can be obviously improved, and a tungsten slag iron alloy is recycled; a solidification structure can be obviously refined, and the mechanical property of the H13 steel is improved; and the H13 steel has high wear resistance and is used as a hot working die, and the service life is prolonged.

Owner:江苏环立板带轧辊有限公司

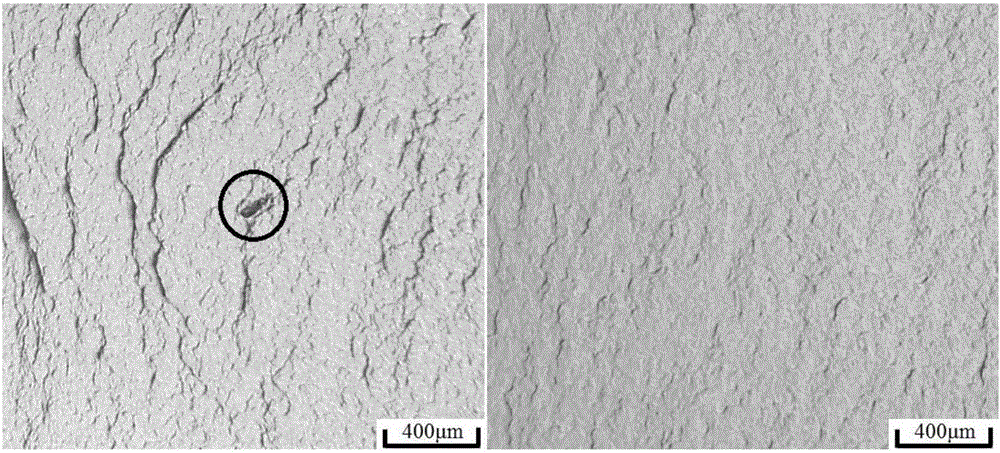

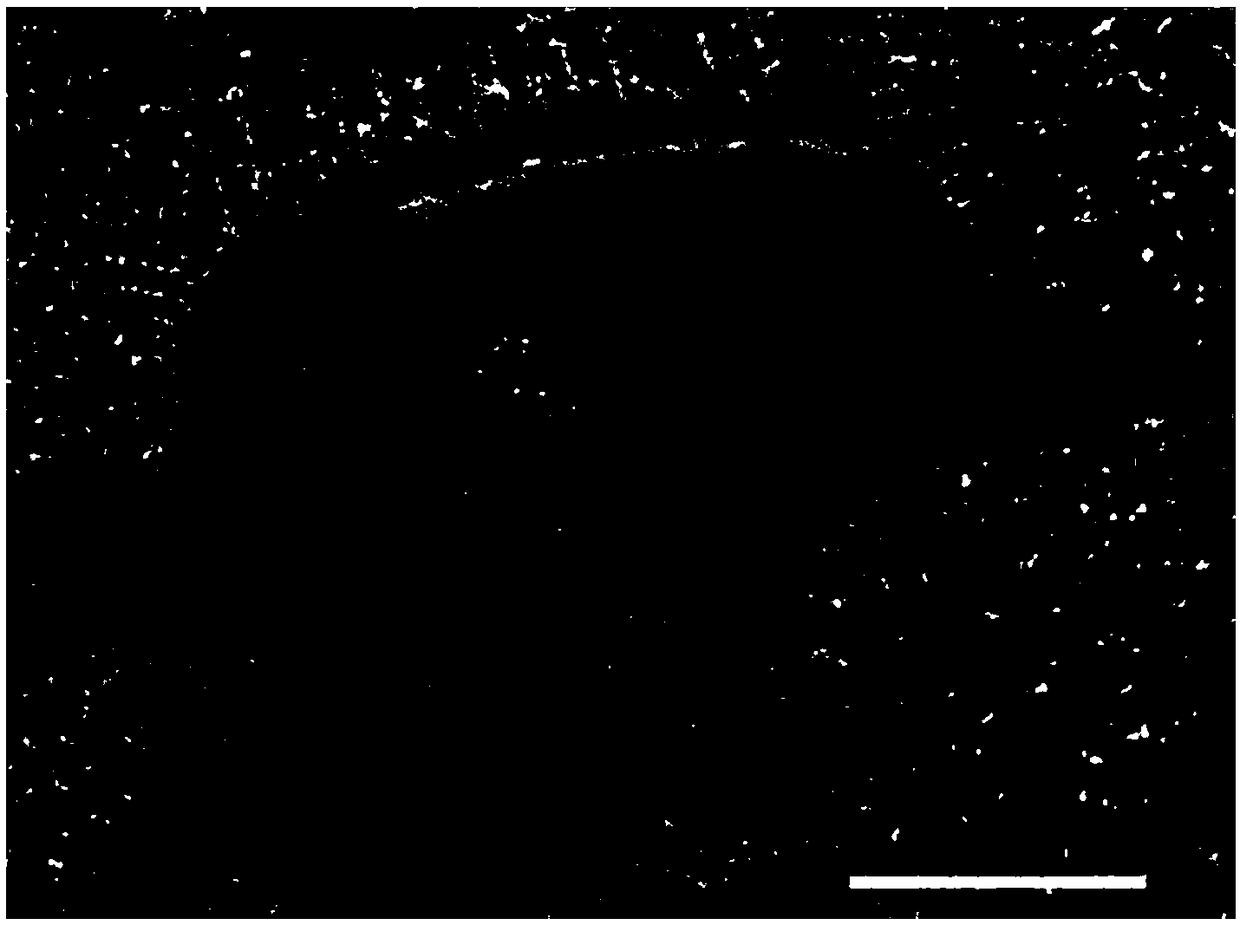

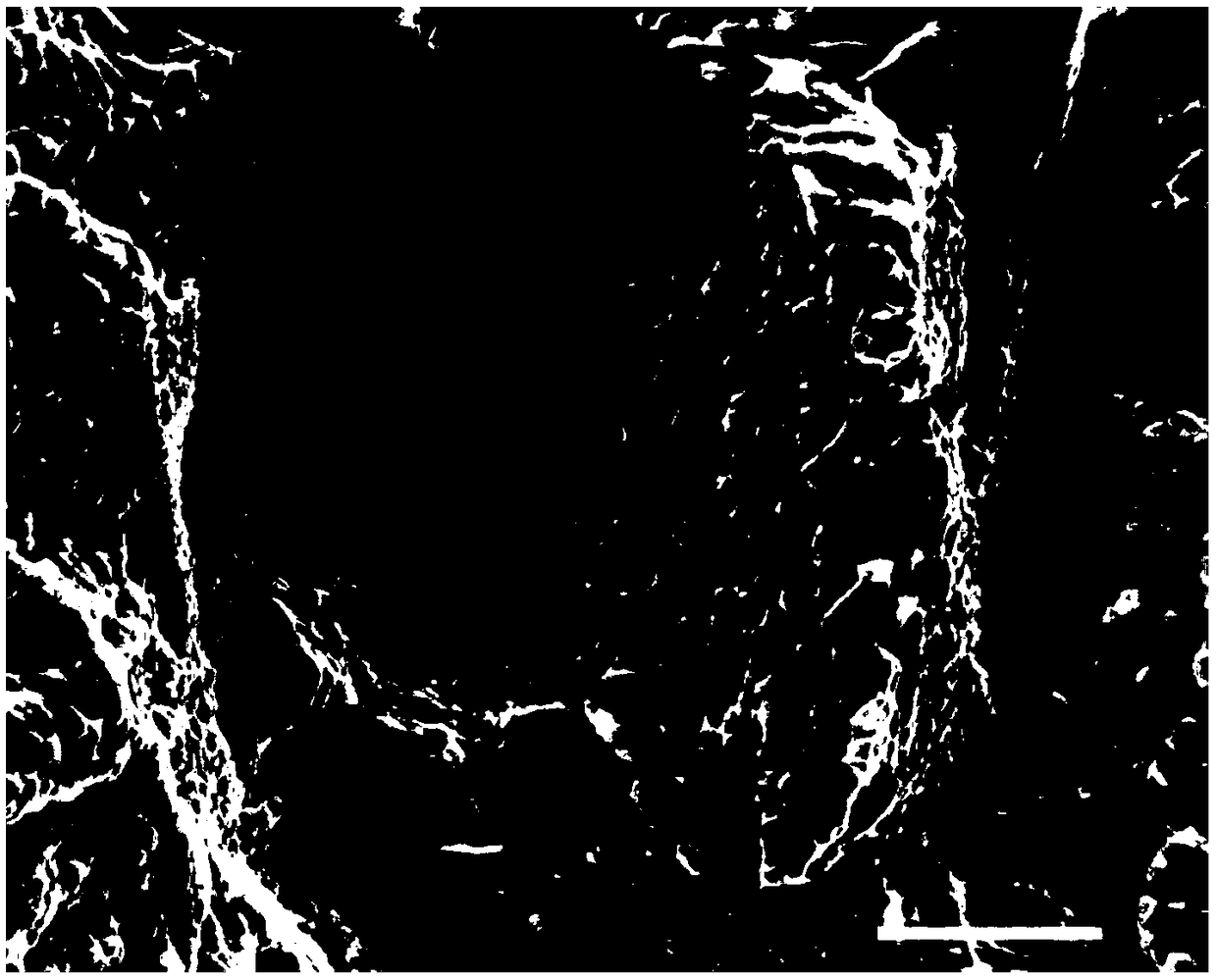

Middle-chromium rare earth-containing high-purity ferrite wrinkle-resistant stainless steel and manufacturing method thereof

InactiveCN101148739AImprove wrinkle resistanceImprove wrinkle defectsRoll mill control devicesHeat treatment process controlChemical compositionRare earth

The RE-containing medium Cr wrinkling resistant ferritic stainless steel has the chemical components including C not more than 0.02 wt%, N not more than 0.02 wt%, Si not more than 0.50 wt%, Mn not more than 0.50 wt%, P not more than 0.03 wt%, S not more than 0.02 wt%, Cr 16-20 wt%, Ni not more than 1.00 wt%, Mo not more than 2.00 wt%, Ti not more than 0.30 wt%, Nb not more than 0.40 wt%, O not more than 0.015 wt%, RE 0.01-0.20 wt%, and Fe and inevitable impurity for the rest. The ferritic stainless steel features low C and N contents, medium Cr content, containing RE, high wrinkling resistance, etc. It is suitable for punching formation to make product.

Owner:BAOSHAN IRON & STEEL CO LTD

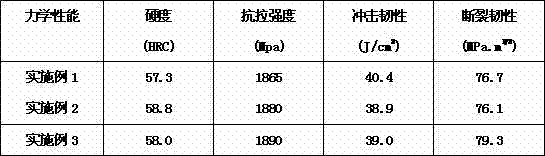

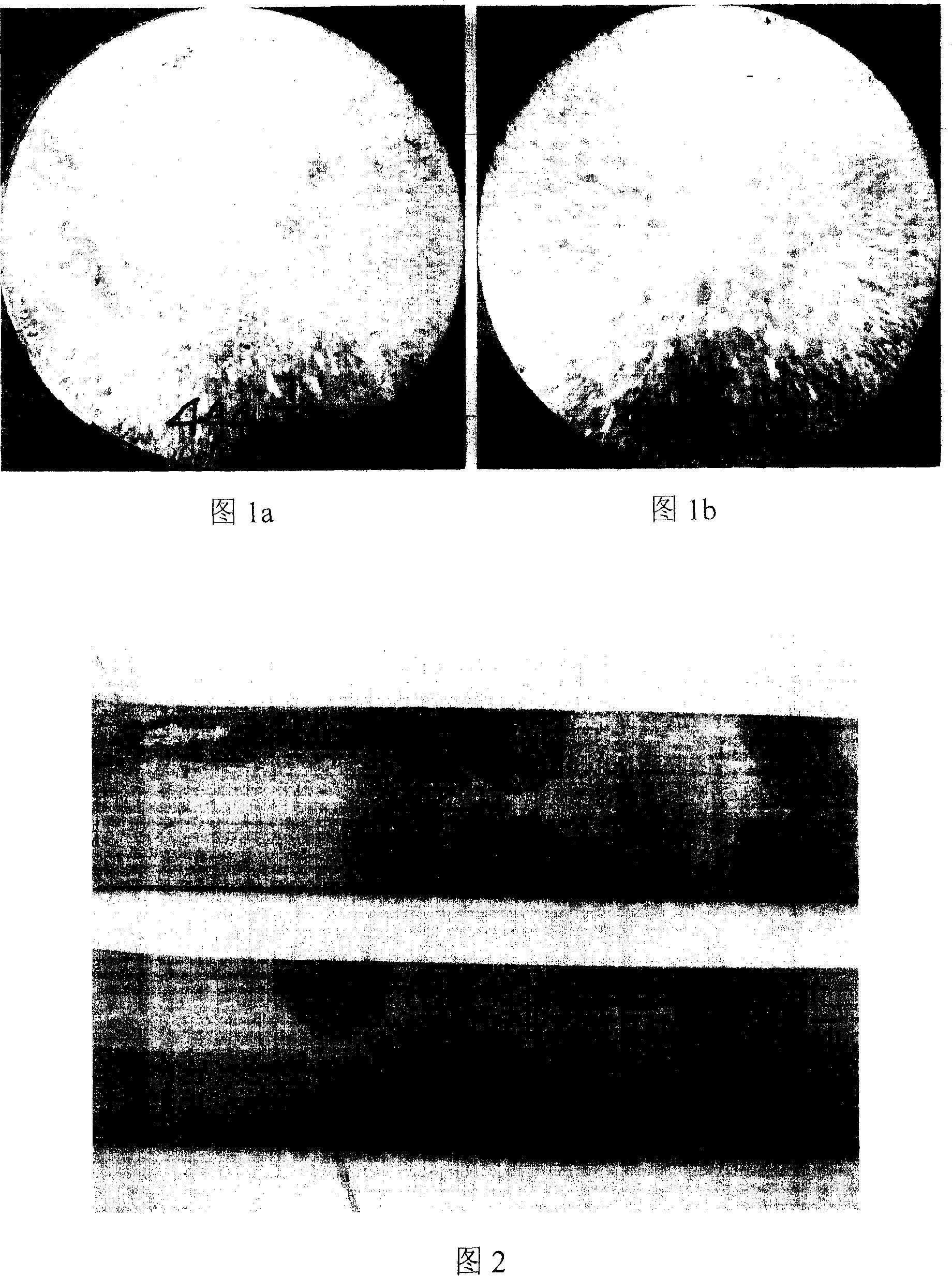

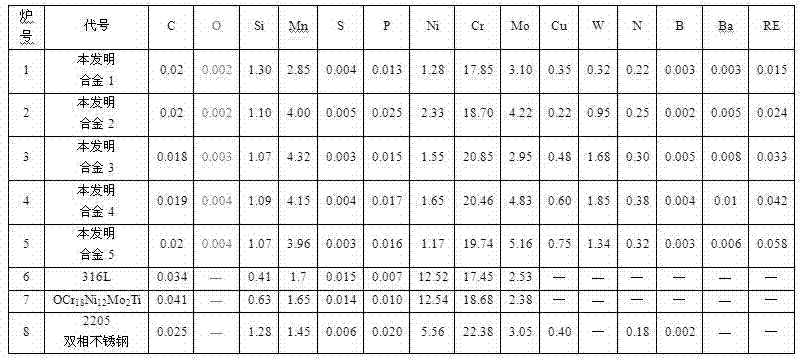

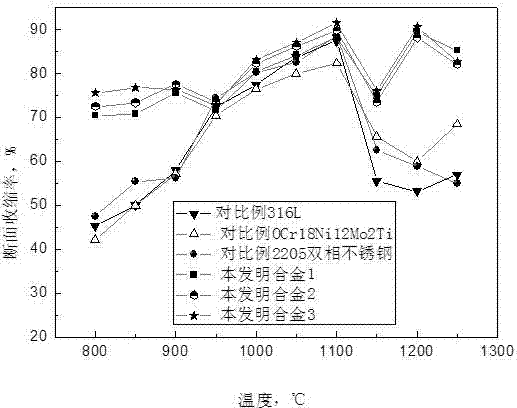

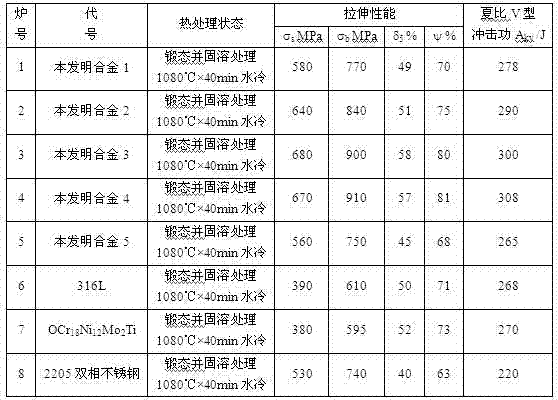

Nickel-saving rare-earth/barium-containing biphase stainless steel alloy material and preparation method thereof

The invention relates to a nickel-saving rare-earth / barium-containing biphase stainless steel alloy material and a preparation method thereof. The alloy material is composed of the following components in percentage by mass: at most 0.025% of C, at most 0.005% of O, at most 0.006% of S, at most 2.00% of Si, at most 0.025% of P, 2.00-5.00% of Mn, 17.0-21.0% of Cr, 1.0-2.5% of Ni, 0.1-2.0% of W, 0.1-1.0% of Cu, 2.0-5.5% of Mo, 0.2-0.40% of N, 0.001-0.01% of B, 0.0005-0.01% of Ba, 0.01-0.2% of lanthanum-cerium mixed rare earth RE and the balance of Fe. The preparation method comprises the following steps: smelting, casting, cast ingot or casting blank cogging, hot rolling and solution treatment. The method has the advantages of nickel saving and low production cost, obviously enhances the mechanical strength, and improves the hot working properties, corrosion resistance and the like.

Owner:JIANGSU XIHU SPECIAL STEEL

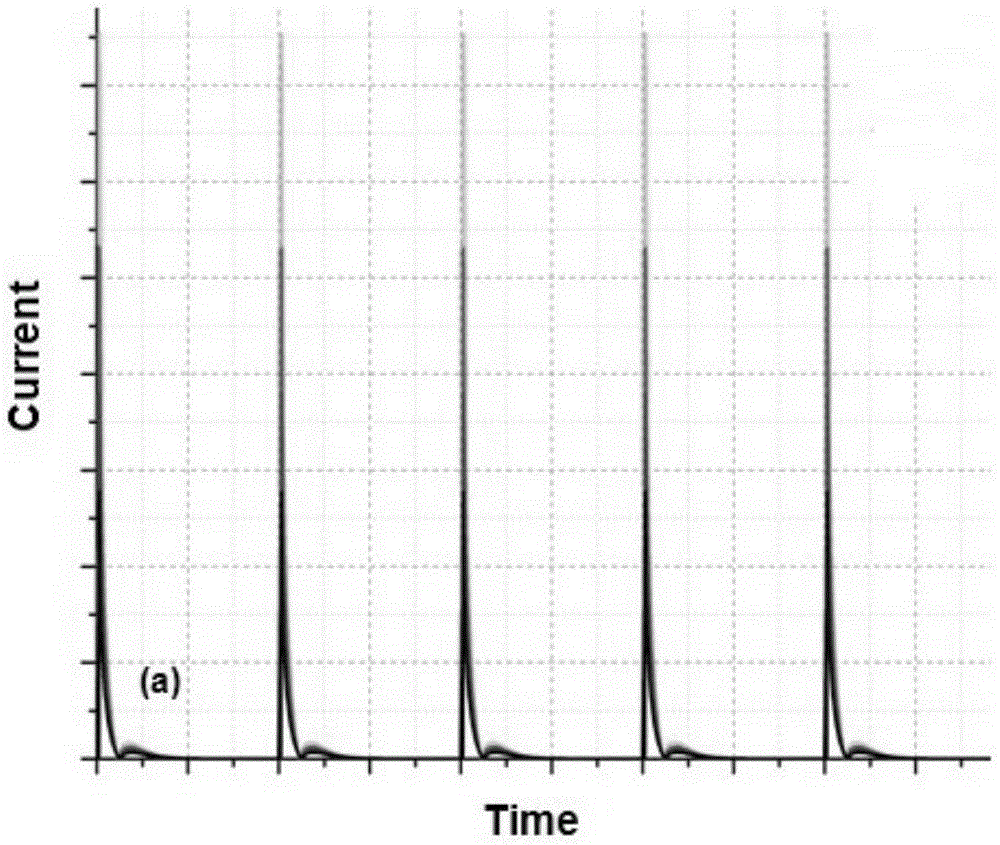

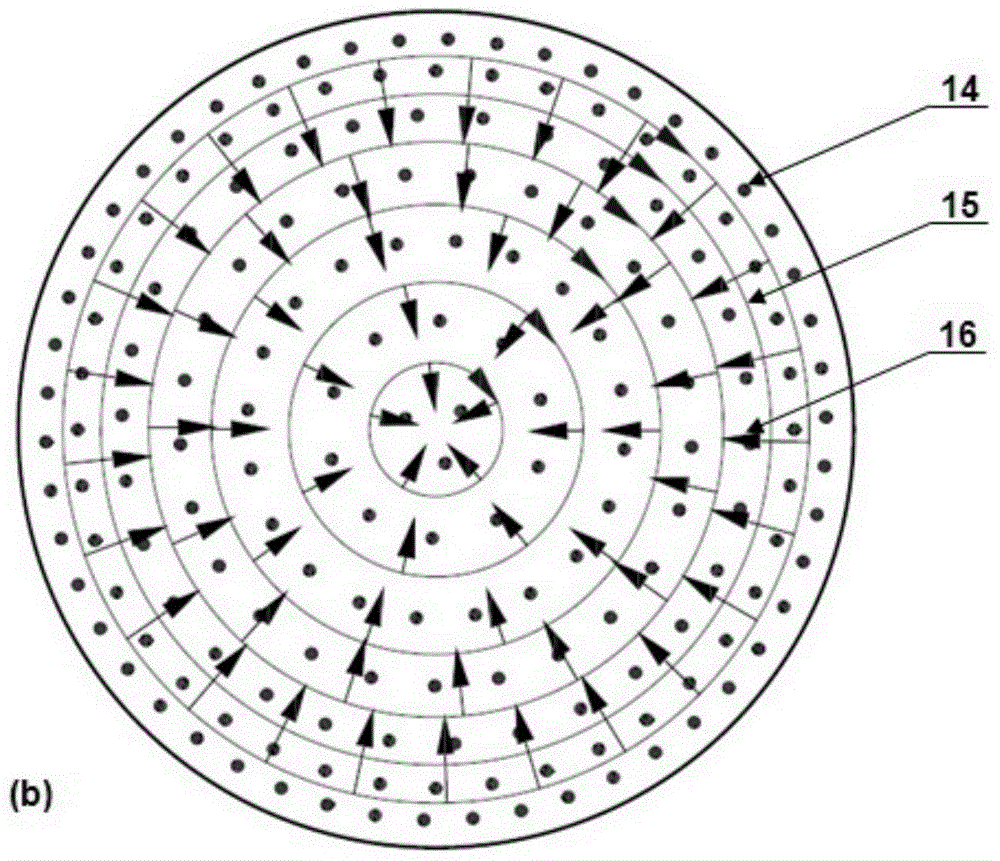

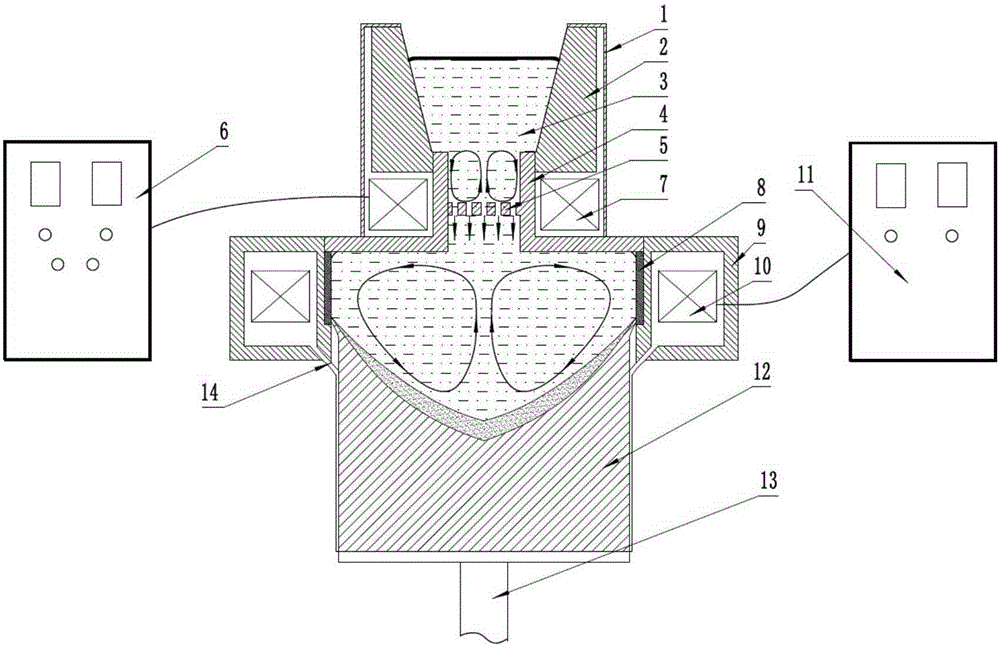

Method for controlling metal solidification phase texture in combined mode through external rotating magnetic field and current and fusion casting device of method

The invention discloses a method for controlling metal solidification phase texture in a combined mode through an external rotating magnetic field and current and a fusion casting device of the method. In a metal solidification process, firstly, the rotating magnetic field is exerted on a metal melt area on the front edge of a metal melt solidification interface, and meanwhile the current is exerted on metal melt nearby a solid-liquid interface area of a whole continuously cast bloom through an external power supply. Under the combined action of the rotating magnetic field and the current, electromagnetic combined stirring is conducted on metal liquid nearby the metal melt solidification interface, so that collision, friction and scour occur among primary grains of the metal melt and between the primary grains and the metal melt, fragmentation of the primary grains can be caused, and therefore the solidification texture of the continuously cast bloom is refined. The method is used for preparing high-quality metal materials.

Owner:SHANGHAI UNIV

Melt treating method of high-vanadium high-speed steel roller material for various rolling machines

The invention discloses a melt processing method of high-speed steel rolls containing high vanadium used for various rolling mills. When molten steel in transportation, ferrovanadium granules are added with flowing, the addition amount of the ferrovanadium granules is 0.80-1.20 percent of total weight of the molten steel. Before the molten steel is poured over a pouring ladle, yttrium based rare earth magnesium alloy, nitriding ferrochrome, potassium salt and metal aluminum are added into the pouring ladle in advance; wherein, the addition amount of the yttrium based rare earth magnesium alloy is 0.30-0.80 percent of the weight of the molten steel, the addition amount of the nitriding ferrochrome is 0.20-0.50 percent of the weight of the molten steel, the addition amount of the potassium salt is 0.30-0.80 percent of the weight of the molten steel and the addition amount of the metal aluminum is 0.30-0.60 percent of the weight of the molten steel. When the temperature of the molten steel reaches between 1450-1480 DEG C, the molten steel in a centrifuge is directly cast into rollers; during the process of casting molten steel, the ferrovanadium granules and ferrotitanium granules with granule dimension between 5mm-8mm are added with flowing, wherein, the addition amount of the ferrovanadium granules and the ferrotitanium granules is respectively 0.30-0.80 percent and 0.40-1.00 percent of the total weight of the molten steel. The centrifugal casting high-speed steel rolls containing high vanadium of the invention has less segregation, no casting cracks, high rigidity and good abrasion resistance.

Owner:XI AN JIAOTONG UNIV

Rare-earth heat-resistant aluminum alloy guide wire material and preparation method thereof

InactiveCN110343912AHigh strengthImprove heat resistanceConductive materialMetal/alloy conductorsHeat resistanceRare earth

The invention provides a rare-earth heat-resistant aluminum alloy guide wire material and a preparation method thereof. The aluminum alloy guide wire material consists of the following elements in percentage by weight: 5.00%-15.00% of Ce, 0.15%-0.70% of Zr, 0.01%-0.50% of Y, 0.01%-5.00% of Fe, 0.10%-5.00% of Mg, 0.05%-8.00% of Si, 0.001%-5.00% of Cu, 0.001%-0.40% of Co, 0.001%-0.85% of B, 0.001%-0.2% of Ti, 0.001%-0.15% of V, 0.001%-0.12% of Cr, 0.001%-0.12% of Mn, 0.001%-0.15% of Ni and the balance of aluminum. The high-strength high-conductivity heat-resistant aluminum alloy has high conductivity and high heat resistance.

Owner:SHANGHAI JIAO TONG UNIV

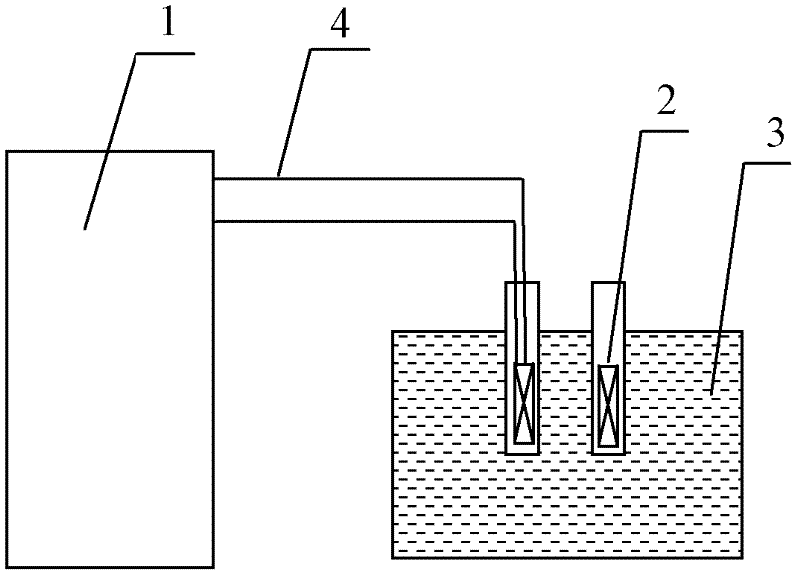

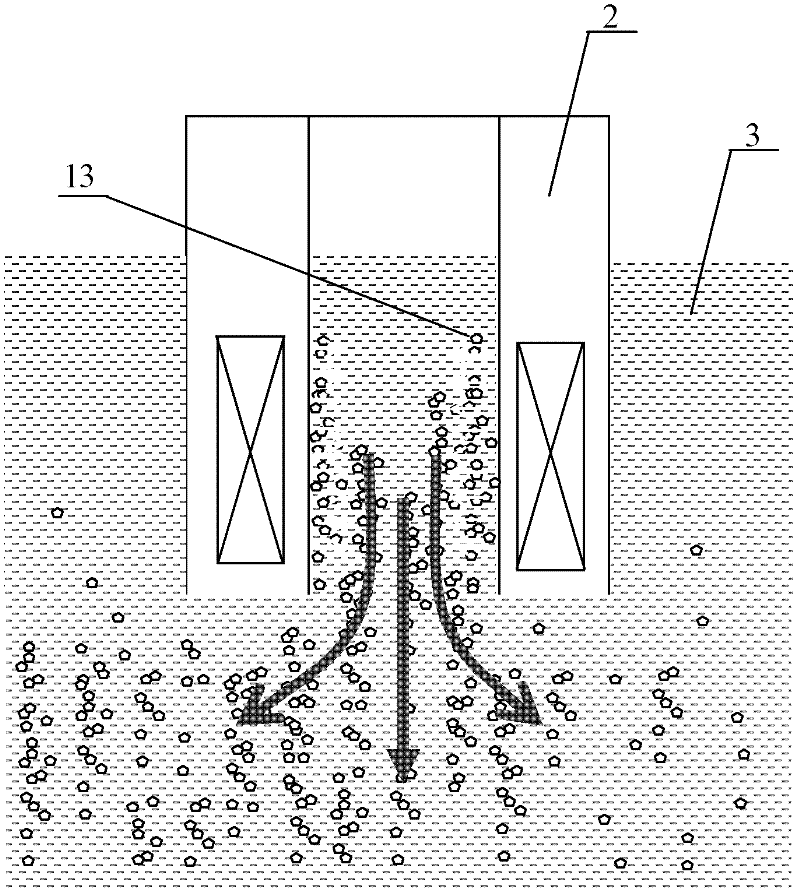

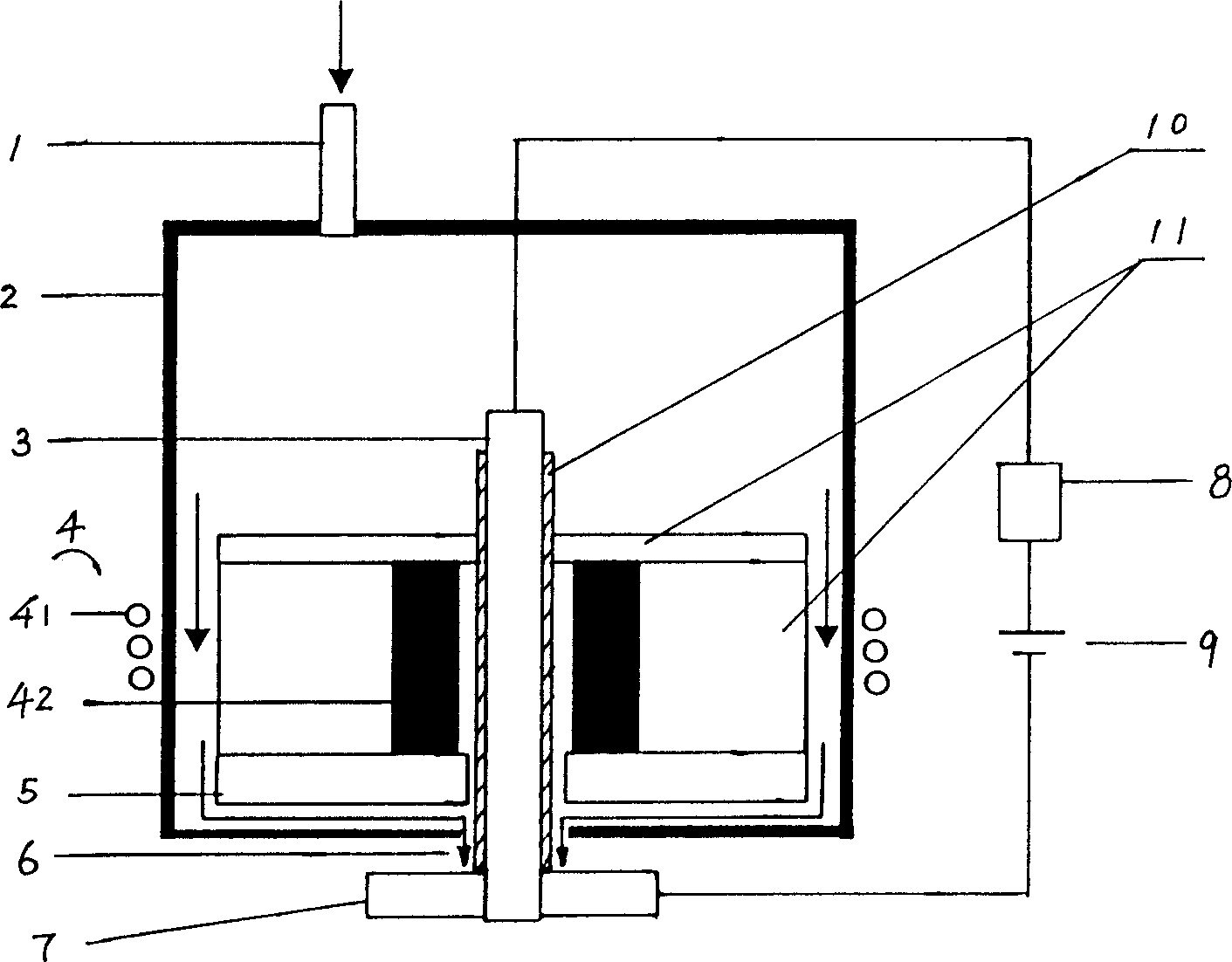

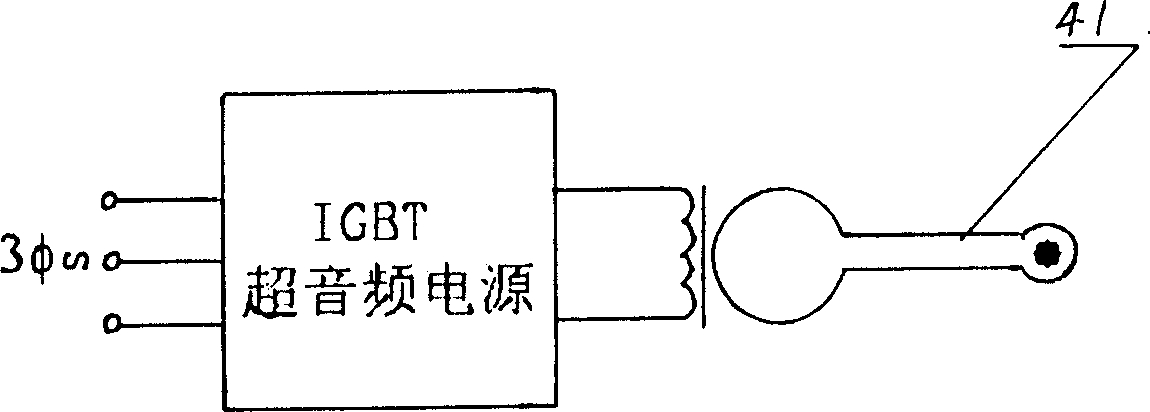

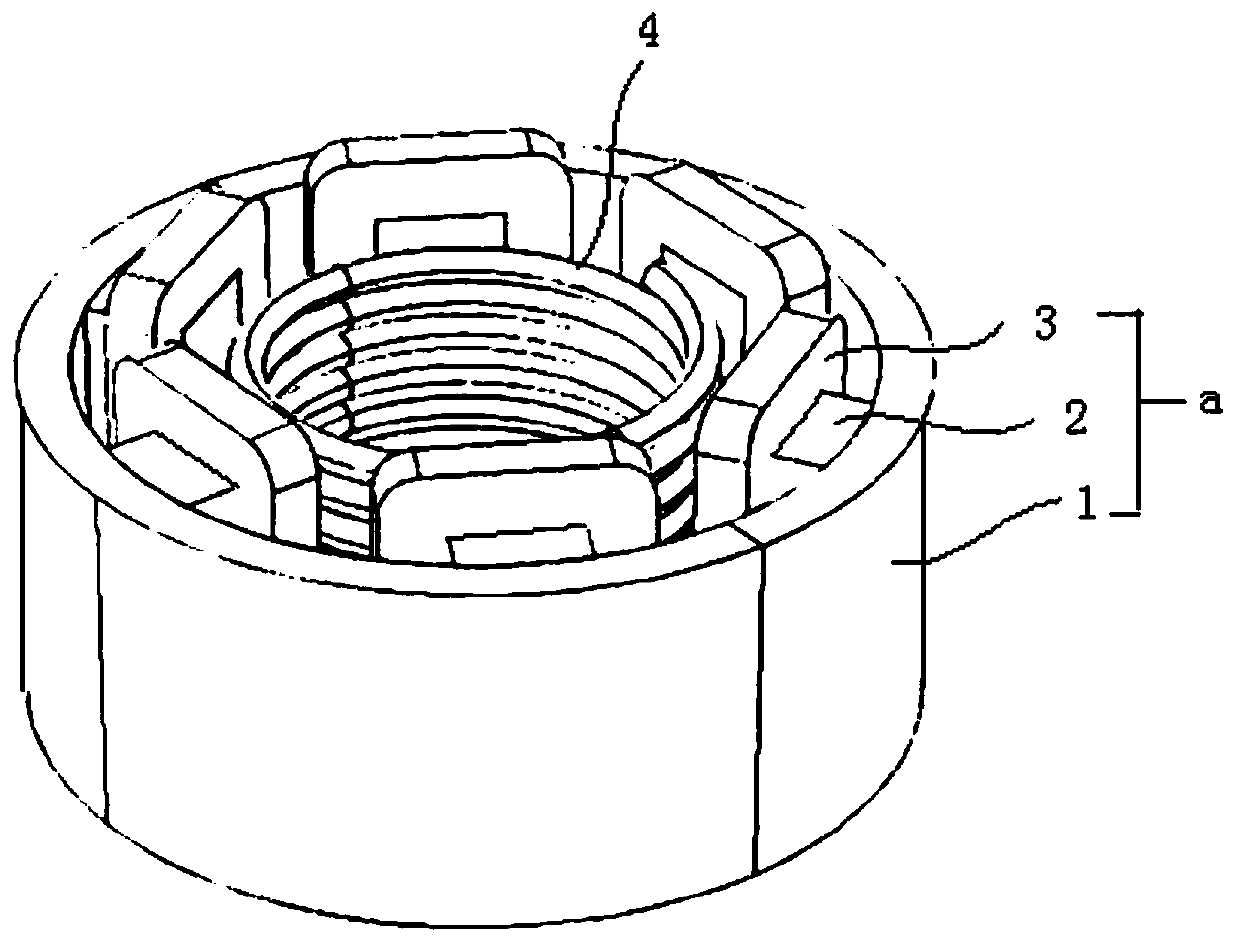

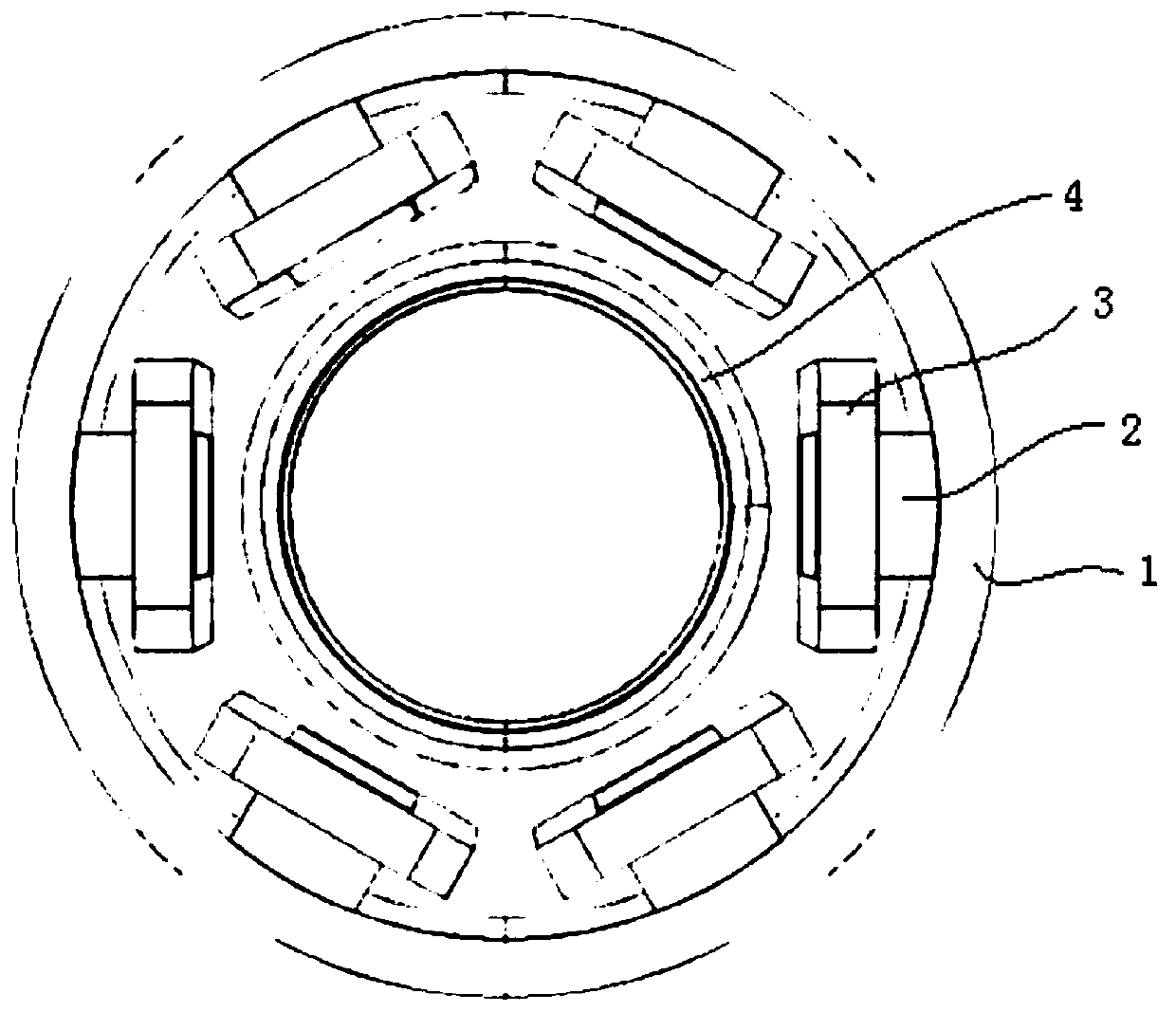

Method and device for improving metal solidification defects and refining solidification textures

ActiveCN102310174AImprove solidification defectsRefining solidified tissueNon-ferrous metalJoule heating

The invention relates to a method and a device for improving metal solidification defects and refining solidification textures. The method and the device comprise an excitation power supply and a magnetic field generating device, wherein the magnetic field generating device is immersed into casting piece (casting blank) and continuous casting metal liquid, crystal nucleuses on the inner surface of the magnetic field generating device are stripped in the metal liquid through electromagnetic force and the joule heating effect, melt vibration and convection are caused by the magnetic field, a large number of crystal nucleuses are continuously dispersed into the metal liquid so as to shorten the feeding distance in a metal solidification process, restrain casting piece and casting blank (ingot) central defects, relieve A segregation and refine the solidification textures, and simultaneously the surface is prevented from being rolled inside in mingling way. The method and device disclosed by the invention are used for preparing casting pieces, continuous casting blanks, mold casting ingots, mold casting blanks and hollow blanks of black metal and non-ferrous metal under vacuum and non-vacuum conditions.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

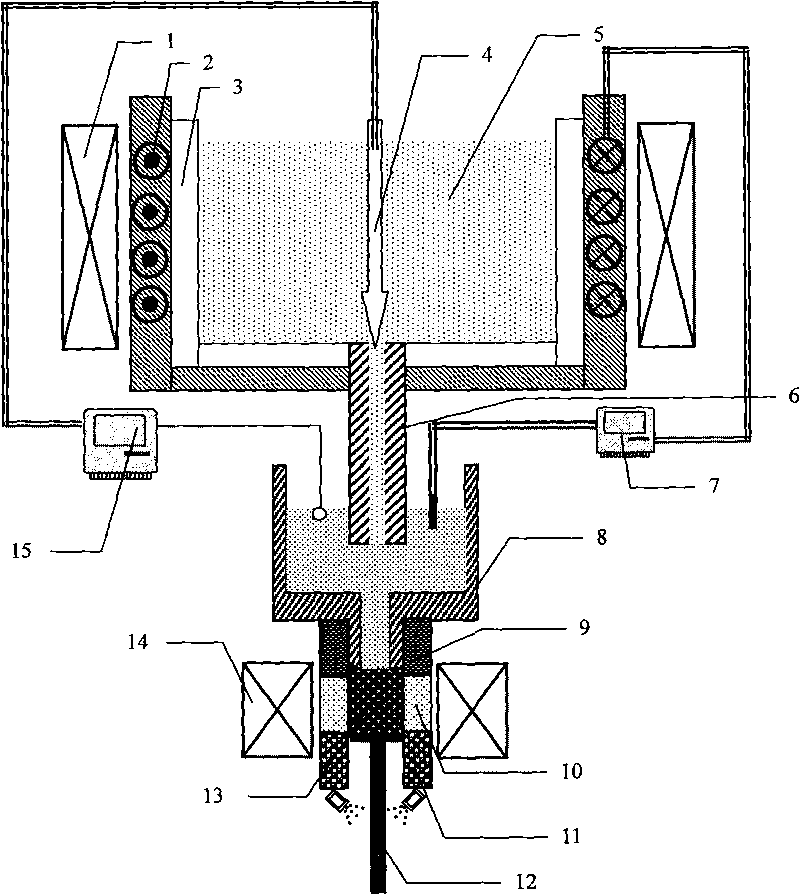

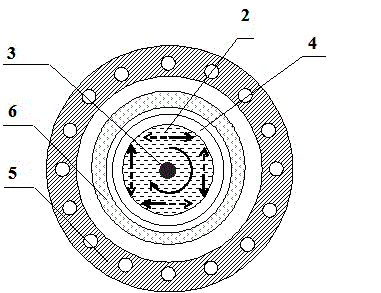

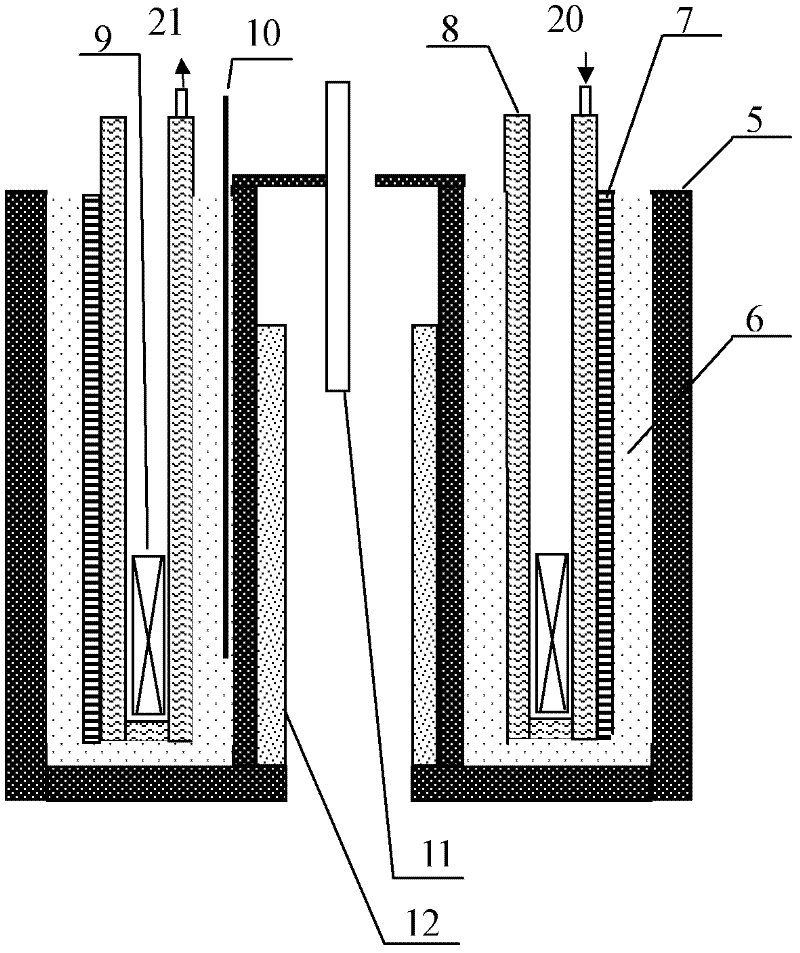

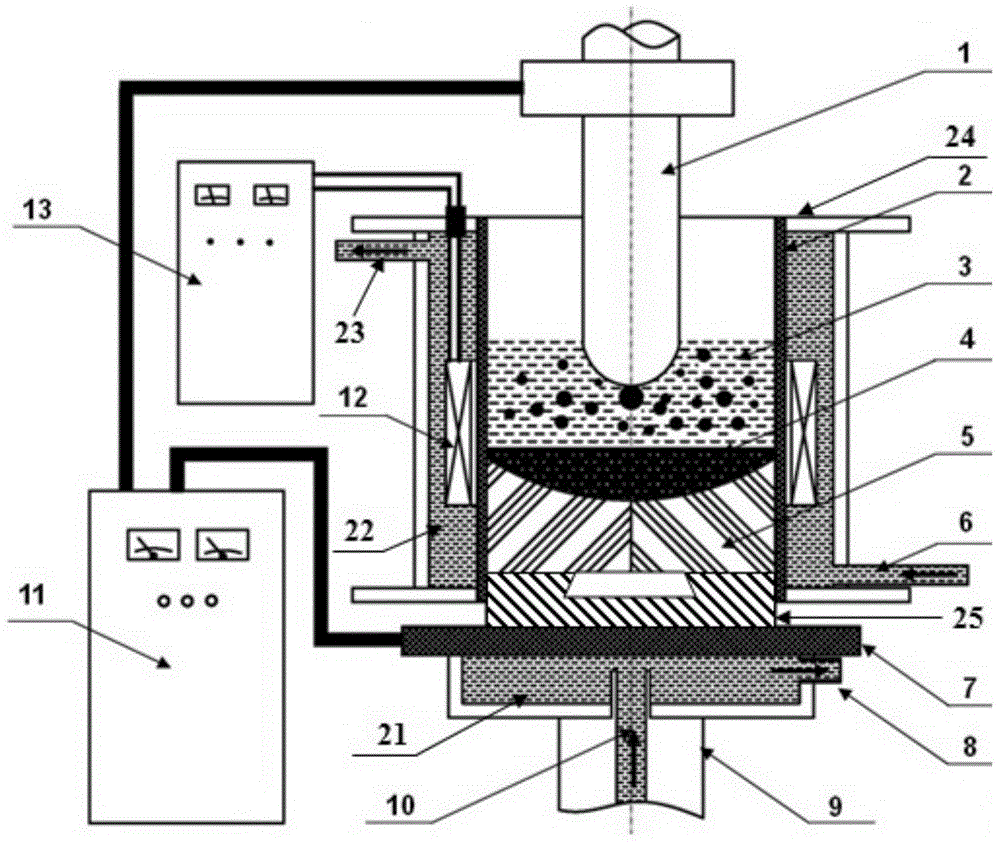

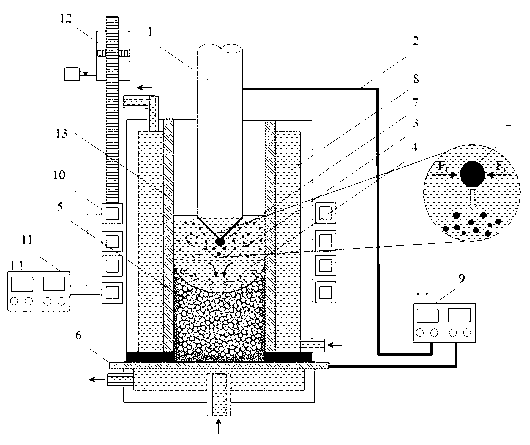

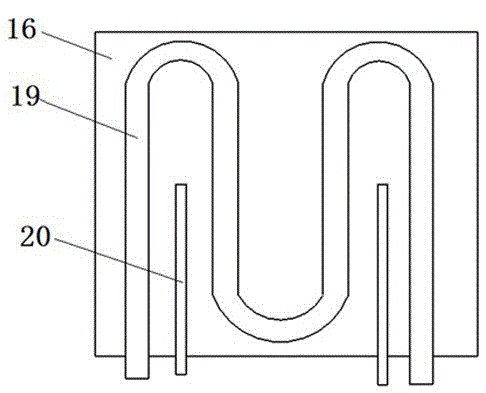

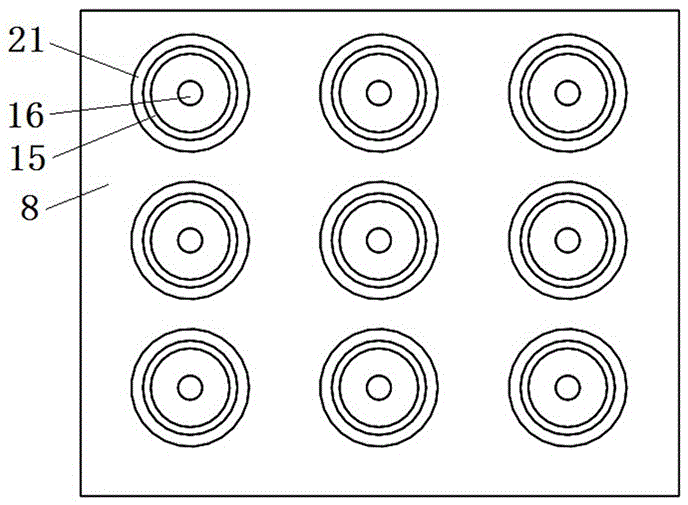

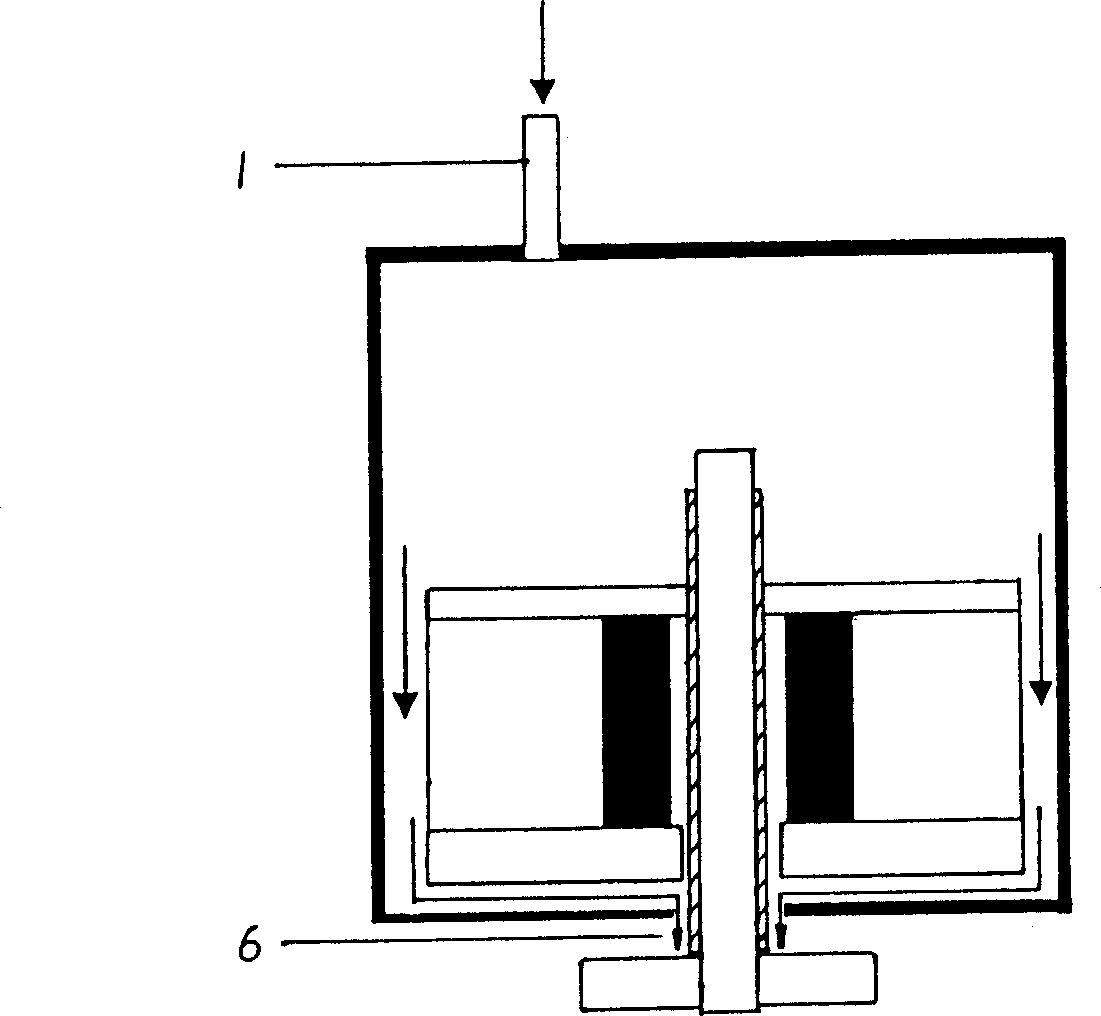

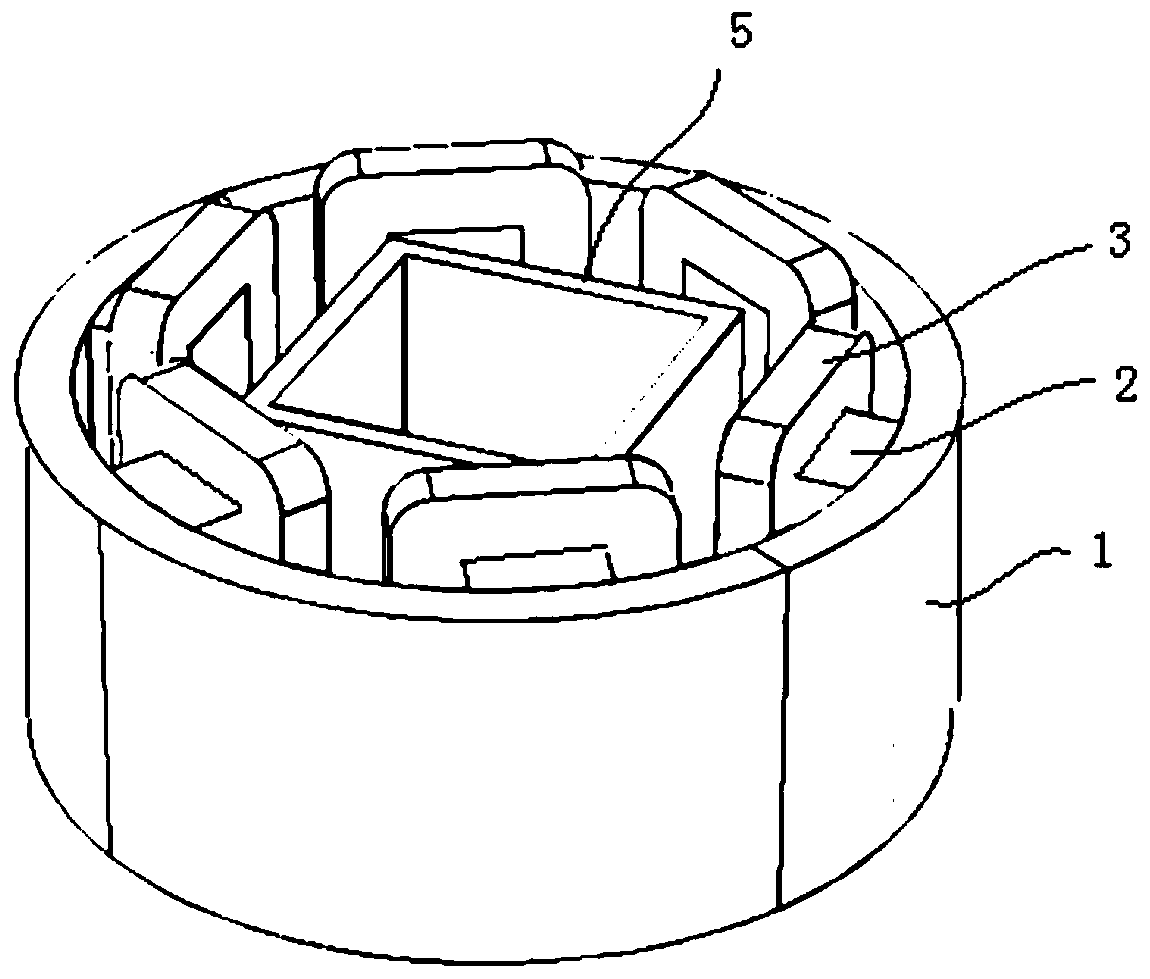

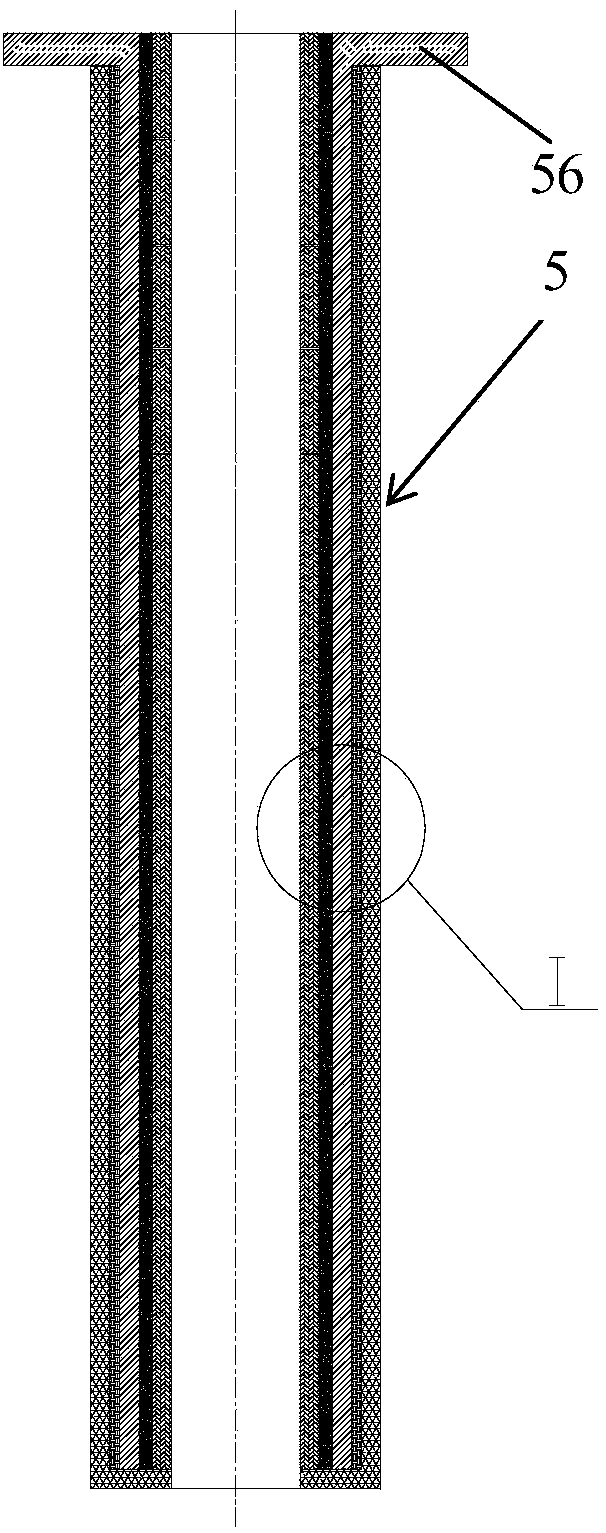

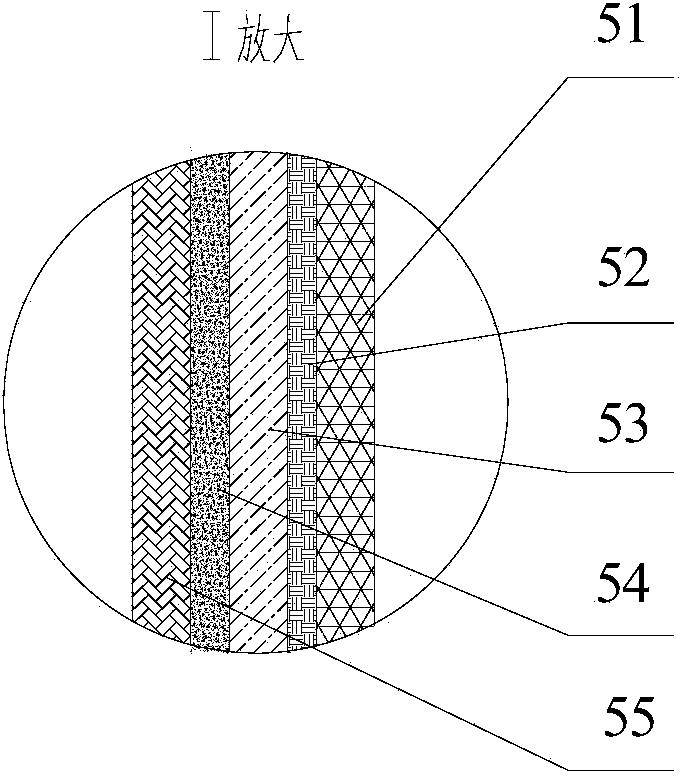

Method and device for casting electromagnetic compound control electroslag remelting fine grains

The invention relates to a method and a device for casting electromagnetic compound control electroslag remelting fine grains, and belongs to the field of preparation of metal materials. According to the method, metallic melt generates forced convection by using the action of exerted pulse magnetic field and periodic electromagnetic force which is generated by compounding of induced current in the melt and electroslag remelting current; a metal material solidification structure is fined; and composition segregation is reduced. Metal droplets can be crushed into fine liquid drops under the action of the electromagnetic force with direction and size in periodic change; the contact area and the contact time of the metal droplets and slag liquid are improved; and a good purification effect is achieved. The device comprises an electroslag remelting work power supply, a pulse power supply and an electromagnetic compound control electroslag remelting crystallizer, wherein the crystallizer is provided with a crystallizer red copper inner sleeve, a side cooling jacket, a bottom cooling jacket and a magnet exciting coil. The method and the device can be applied to electroslag remelting and refining of metal materials such as high-temperature alloy and high alloy steel; the alloy solidification structure can be fined; the segregation is reduced; the refining effect of the electroslag remelting process is improved.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Semi-steel roll and preparation method thereof

InactiveCN101537428AReasonable compositionEasy to shapeFurnace typesRollsChemical compositionCarbide

The invention relates to a semi-steel roll and a preparation method thereof, belonging to the technical field of steel rolling. The semi-steel roll contains the following chemical components according to the mass percent: 1.65-1.90 of C, 0.80-1.15 of Cr, 0.35-0.65 of Si, 0.60-1.00 of Mn, 0.30-0.60 of Mo, 0.20-0.80 of Ni, 0.05-0.10 of K, 0.05-0.10 of Na, 0.05-0.15 of Ti, 0.05-0.15 of Nb, 0.08-0.15 of Y, 0.03-0.08 of Mg, 0.02-0.04 of Zn, 0.06-1.00 of Al, less than 0.04 of P, less than 0.03 of S, and the balance of Fe. The semi-steel roll has reasonable chemical component, prolonged service life, the hardness of 55-58 HS and the tensile strength of 900-950 MPa and the impact toughness of 10-12 J / cm2; the invention can save the nickel resource, reduce the cost, simplify the heat treatment, shorten the production period, improve the heat treatment efficiency, save the energy, thin the solidified organization, improve the forms and the distribution uniformity of carbides and inhibit the aliquation of alloy elements;.

Owner:江苏环立板带轧辊有限公司

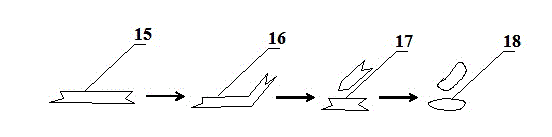

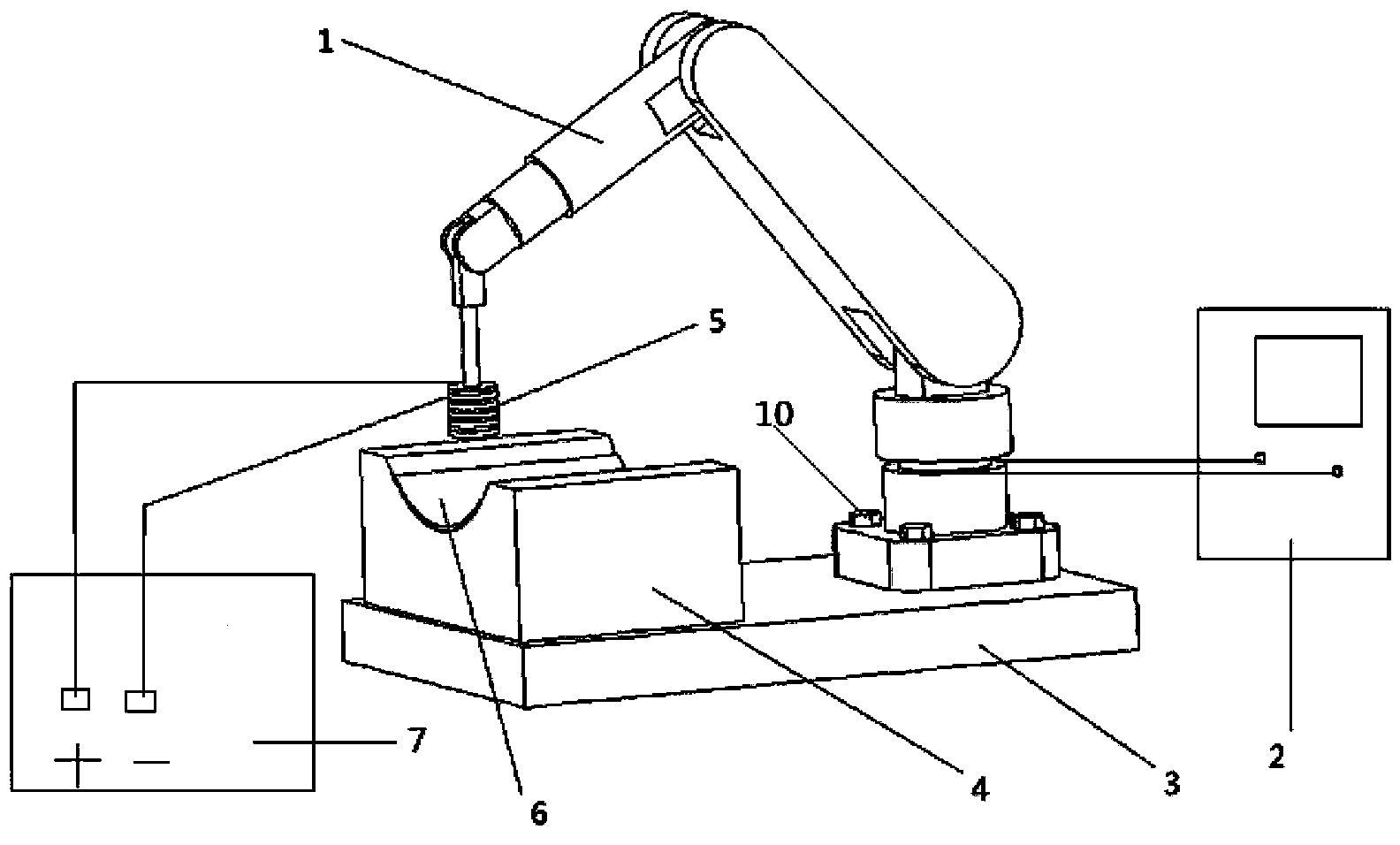

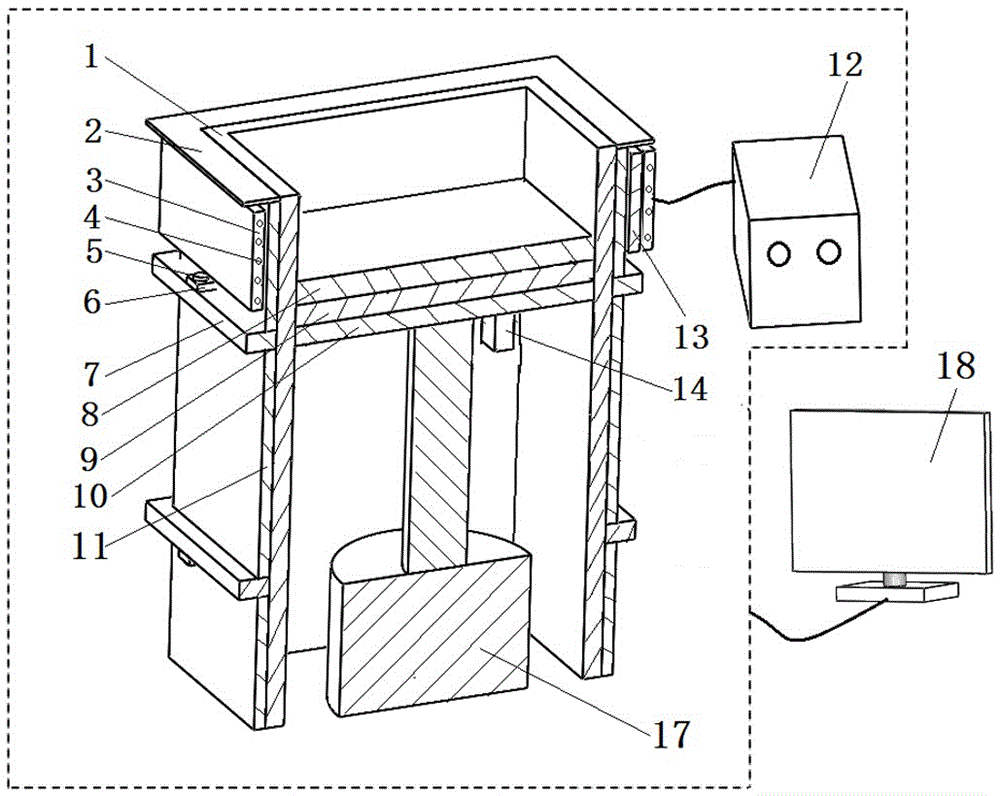

Forming device and forming method of electromagnetic induction assisting prestress

InactiveCN103406419AEasy to transformAchieving Electroplastic Bending FormingMetallic materialsEngineering

The invention discloses a forming device and a forming method of electromagnetic induction assisting prestress. A forming mold and a manipulator are fixed on the upper portion of a base. An electromagnetic coil is mounted at the chuck part of the manipulator, wire connecting of an electromagnetic induction control system is completed correspondingly, the electromagnetic coil is ensured to generate a pulsed magnetic field successfully in the forming process, and induced current is generated on a sheet material. The sheet material is placed on the mold, and a vacuum bag is placed on the sheet material and is evacuated through an evacuating device, so that the sheet material is pressed on the mold tightly, and effect of vacuum compaction is achieved. A computer control system is operated to form the electromagnetic induction assisting prestress. According to the forming device, when the pulsed magnetic field of the inducing coil penetrates a workpiece, the workpiece generates the induced current, plastic deformation capacities of metal materials are improved by the current, crystallizing process of amorphous alloy is promoted, solidification structure of the alloy is refined, deforming resistance during the forming process is reduced, springback amount is reduced, forming accuracy and comprehensive mechanical properties are improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

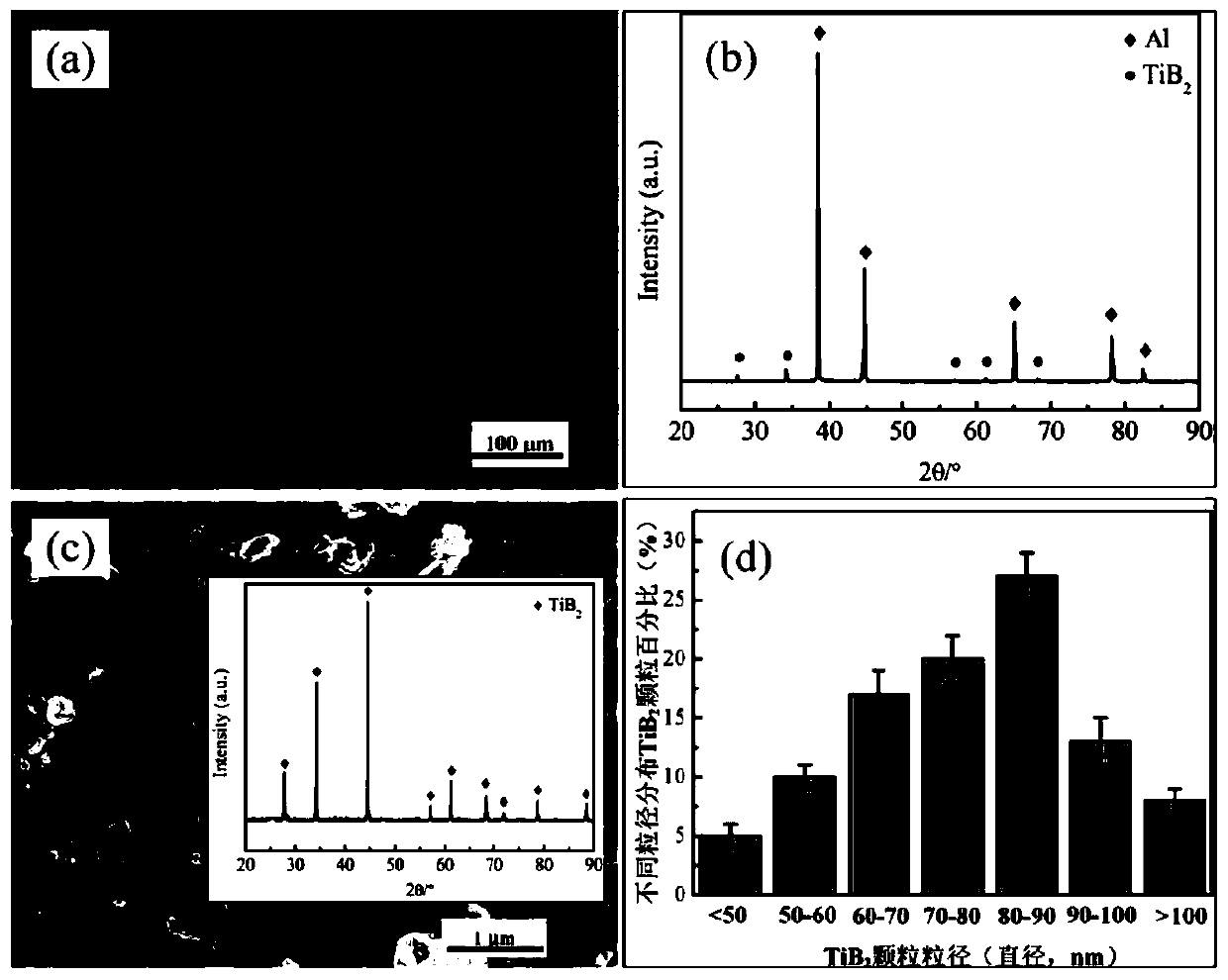

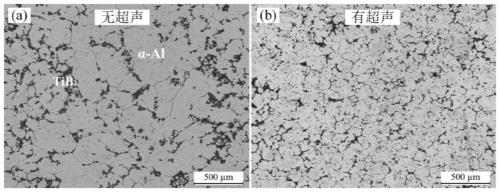

High-dispersive-distribution nano-titanium diboride particle reinforced aluminum matrix composite material and preparation method thereof

The invention discloses a high-dispersive-distribution nano-TiB2 particle reinforced aluminum matrix composite material and a preparation method thereof. Firstly, a uniform-structure Al-TiB2 intermediate alloy is prepared through an ultrasound assisted mixed salt reaction (K2TiF6 / KBF4-Al), wherein the average particle diameter of in-situ endogenous TiB2 particles is smaller than 100nm; the Al-TiB2 intermediate alloy and Al are used as raw materials, or Al-TiB2 intermediate alloy, Al and alloy elements are used as raw materials, the nano-TiB2 particles are introduced into an aluminum (alloy) matrix through an intermediate alloy dilution method, ultrasound agitation treatment is used as assistance, then pouring into a mold is performed, and ultrasound is applied during solidification (introduction through a bottom introduction method); and thus the high-dispersive-distribution nano-TiB2 particle reinforced aluminum matrix composite material is obtained.

Owner:咸阳瞪羚谷新材料科技有限公司

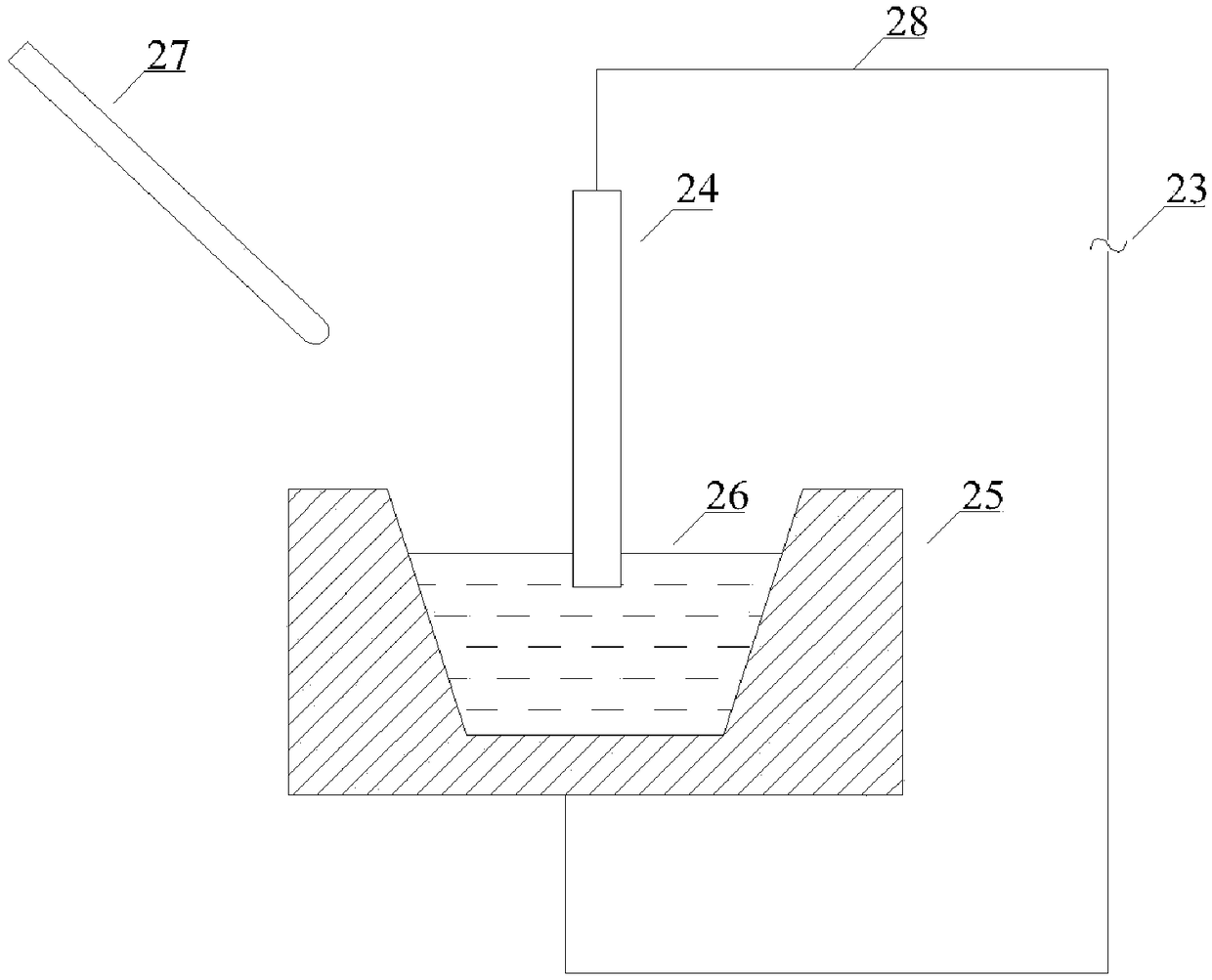

Method for controlling electroslag melting casting by added transient magnetic field and electroslag smelting casting device

The invention discloses a method for controlling electroslag melting casting by an added transient magnetic field. The method includes adding a transient magnetic field to a melting end of an electroslag remelting mother electrode, a liquid slag tank and a metal melting tank so that the transient magnetic field acts on large metal molten drops which are generated by initial melting at the tail end of the electrode and are converging to become big; under joint action of alternating lorentz force and pressure waves generated by the transient magnetic field, dispersing the metal molten drops in a burst manner into small metal molten drop groups, and randomly dispersing the small metal molten drop groups into the liquid slag tank to sufficiently contact with liquid slag after passing the liquid slag tank; after washing, enabling included foreign substances and impurities in the small metal molten drops to enter the liquid slag quickly, slowly settling and converging the foreign substances and impurities into the metal melting tank below the liquid slag tank, and finally crystallizing and solidifying to form solidified cast ingots. The invention further provides an electroslag melting casting device. By adding the transient magnetic field during electroslag melting casting and fining the molten drops by the aid of unique electromagnetic effect of the transient magnetic field, the purposes of improving refining efficiency, fining crystalline grains and reducing segregation of cast ingots are achieved, and industrial application value is realized.

Owner:SHANGHAI UNIV

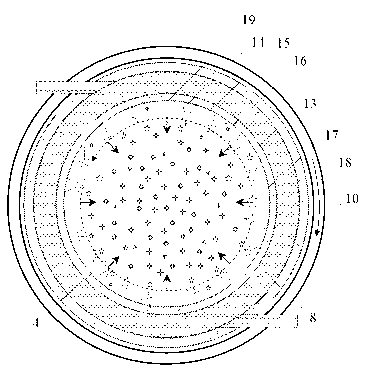

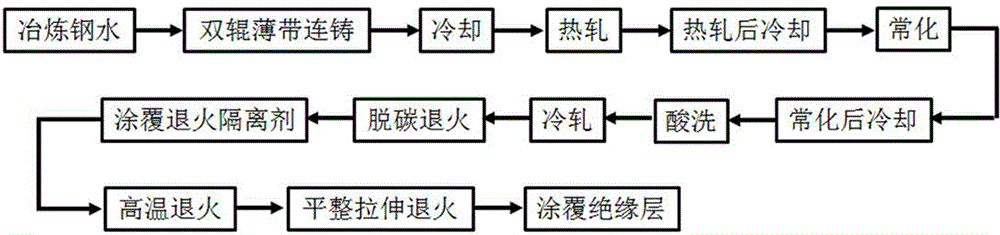

High magnetic induction oriented silicon steel and manufacturing method thereof

The invention relates to high magnetic induction oriented silicon steel and a manufacturing method thereof. The silicon steel comprises the following components in percentage by mass: 0.01-0.08% of C, 2.8-3.4% of Si, 0.02-0.30% of Mn, 0.010-0.04% of S, 0.005-0.05% of Als, 0.003-0.010% of N, 0.005-0.5% of TI, 0-0.6% of Cu, 0-0.2% of Sn, less than 0.004% of O, less than 0.01% of P and the balance of Fe. The manufacturing method comprises the following steps: (1) smelting molten steel; (2) carrying out continuous casting by adopting a twin-roll strip continuous casting device to obtain a cast strip; (3) cooling and then carrying out hot rolling, and then cooling and coiling; (4) carrying out normalizing annealing on a hot rolled coil, and carrying out controlled cooling to room temperature; (5) carrying out acid washing and then cold rolling, then carrying out decarburizing, and coating an annealing isolation agent; (6) annealing at high temperature, and then carrying out purification annealing. The manufacturing method disclosed by the invention is simple and effective and has the characteristics of short process, easiness in control and low energy consumption; the silicon steel has excellent properties.

Owner:NORTHEASTERN UNIV

Selective laser melting SLM formation cylinder in high-intensity magnetic field

InactiveCN106141185ARapid coolingUniform temperature distributionAdditive manufacturing apparatusIncreasing energy efficiencySelective laser meltingManufacturing technology

The invention relates to a selective laser melting SLM formation cylinder in a high-intensity magnetic field and belongs to the technical field of 3D printing material additive manufacturing. The invention provides the selective laser melting SLM formation cylinder in the high-intensity magnetic field, wherein parts and powder in the formation cylinder can be heated to prevent the thin-walled parts of the parts from being cooled too quickly, so that the internal temperature distribution of the parts is tend to be uniform. The technical scheme adopted is as follows: a hydraulic cylinder is arranged in the cylinder body, a bottom plate is arranged on a piston rod of the hydraulic cylinder, a heating tube and a first temperature-sensing galvanic couple are arranged in the wall body of the cylinder body, an insulating layer is arranged outside the cylinder body, an electromagnetic inductor and a magnetic field measuring instrument are arranged in the upper part of the cylinder body, a magnet exciting coil is arranged in the electromagnetic inductor, a medium-frequency power supply is connected to the electromagnetic inductor, a shielding hood is arranged on the top of the cylinder body, and the heating tube, the electromagnetic inductor, the medium-frequency power supply and the magnetic field measuring instrument are connected to a master control system. The selective laser melting SLM formation cylinder in the high-intensity magnetic field is widely applied to selective laser melting SLM processes.

Owner:ZHONGBEI UNIV

Semicontinuous casting device and method of aluminum alloy

The invention provides a semicontinuous casting device and method of an aluminum alloy, and belongs to the technical field of casting equipment of the aluminum alloy. The semicontinuous casting device and method are provided so as to improve the quality of aluminum alloy ingots, refine structures of cast ingots, and lower harmful effects generated by oxides gathering in molten aluminum on the aluminum alloy ingots and subsequent deep-processed products. The semicontinuous casting device consists of a flow supply system, a shearing system, a crystallization system, a stirring system and a traction system. The semicontinuous casting device is provided with the shearing system on the basis of conventional semicontinuous casting of the aluminum alloy; through an upper coil, a variable-frequency power source and a flow-guide-pipe partition board in the shearing system, the molten aluminum in a flow guide pipe flows intensely and quickly, and the generated powerful shearing force scatters gathered oxidation films in the molten aluminum; the stirring effect of a low-frequency electromagnetic field is utilized to uniformly scatter mass points of the scattered oxidation films to different positions in a crystallizer, so that solidification structures are refined, and the comprehensive performance of the aluminum alloy is improved.

Owner:NORTHEASTERN UNIV

3D-printing in-situ rare earth doped titanium matrix composite material activated bone implant and forming method

ActiveCN108705092AImprove service performanceImprove mechanical propertiesAdditive manufacturing apparatusIncreasing energy efficiencyTitanium matrix compositesArgon atmosphere

The invention discloses a 3D-printing in-situ rare earth doped titanium matrix composite material activated bone implant. The implant comprises an in-situ rare earth doped titanium matrix composite material formed by in-situ rare earth Re2O3, an in-situ TiB ceramic phase and a hydroxyapatite ceramic phase. A preparation method comprises the steps that B2O3 powder and rare earth Re powder are subjected to ball-milling mixing by adopting a high-energy ball milling technology under inert gas shielding, and B2O3 / Re mixed powder is obtained; the B2O3 / Re mixed powder, hydroxyapatite powder and 3D-printing dedicated spherical titanium alloy powder are weighed, a low-energy ball milling technology under inert gas auxiliary shielding is adopted, and titanium alloy composite material powder is obtained; and under the argon atmosphere, the in-situ rare earth Re2O3, in-situ TiB ceramic and hydroxyapatite ceramic reinforced titanium matrix composite material activated bone implant is formed by means of laser 3D-printing. According to the method, the service performance of the titanium alloy bone implant is improved through rare earth in-situ doping, and precision manufacturing of the high-performance complex-structure titanium alloy activated bone implant can be achieved.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

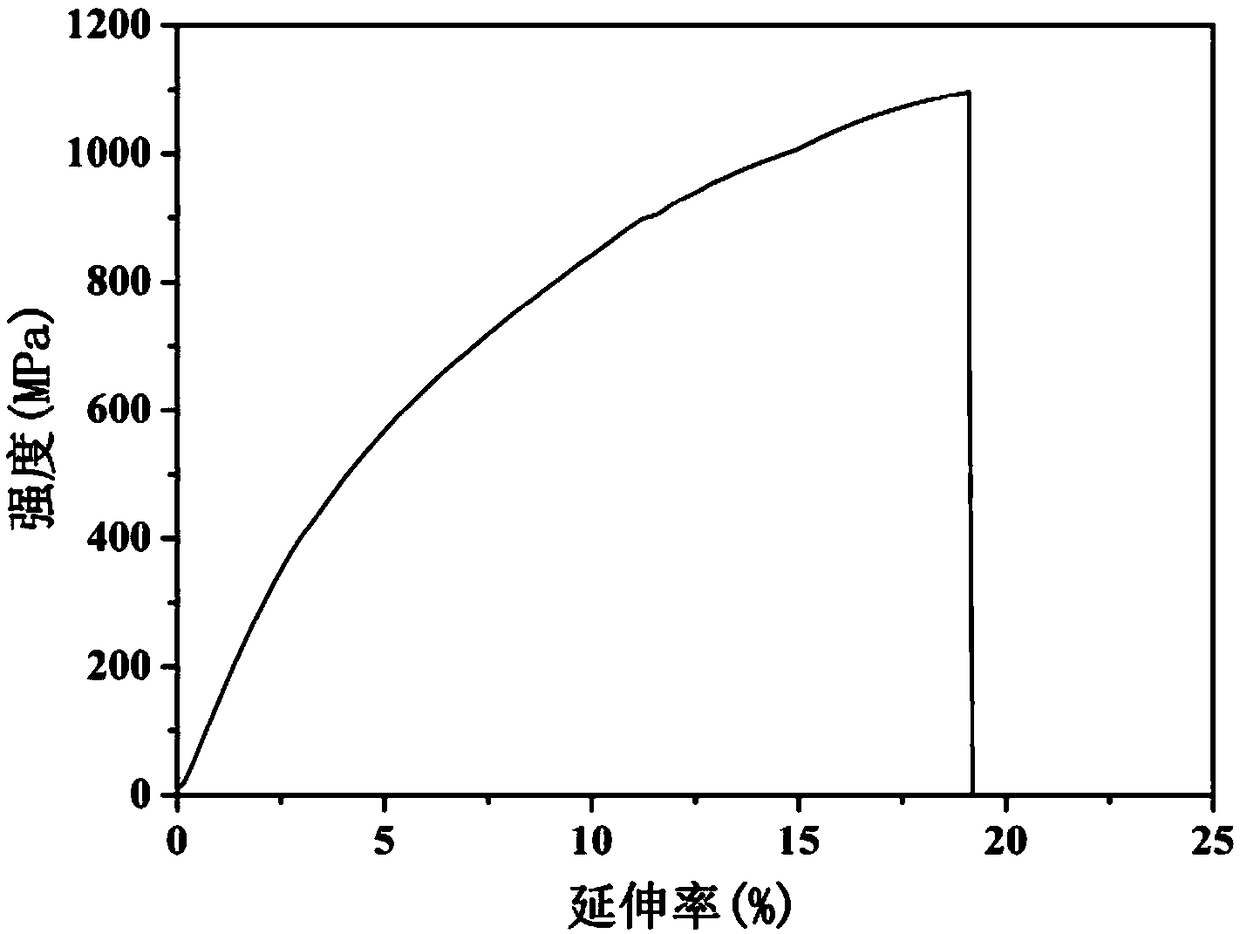

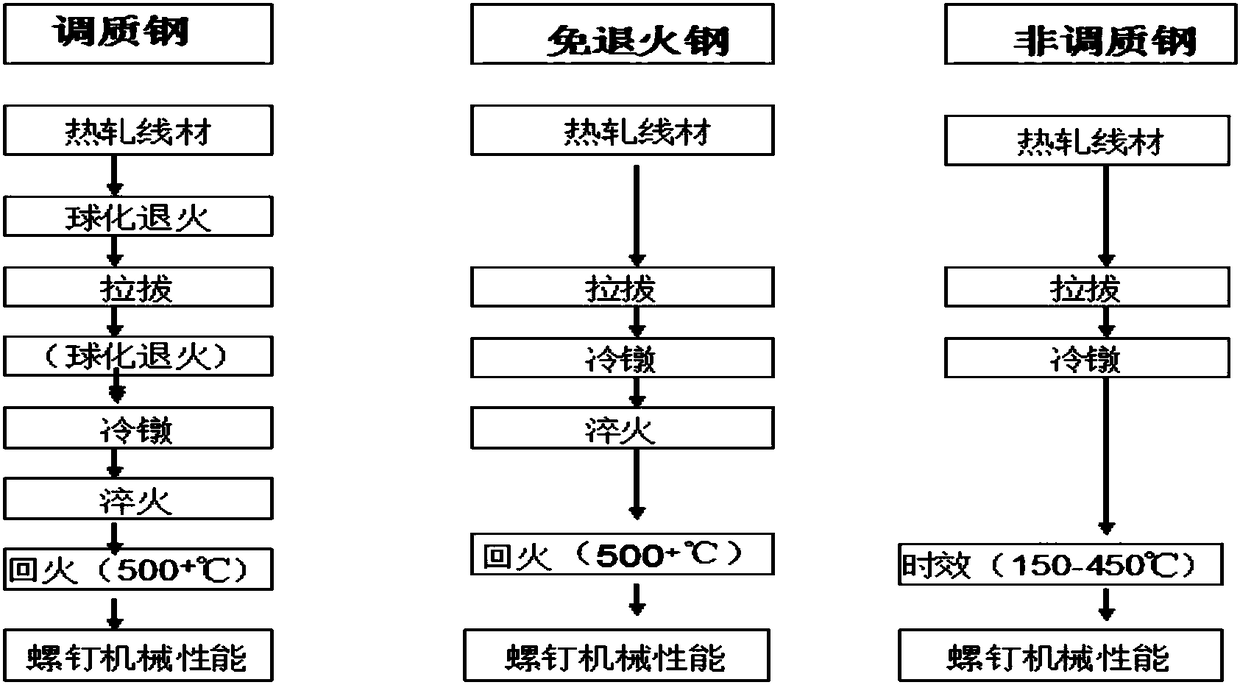

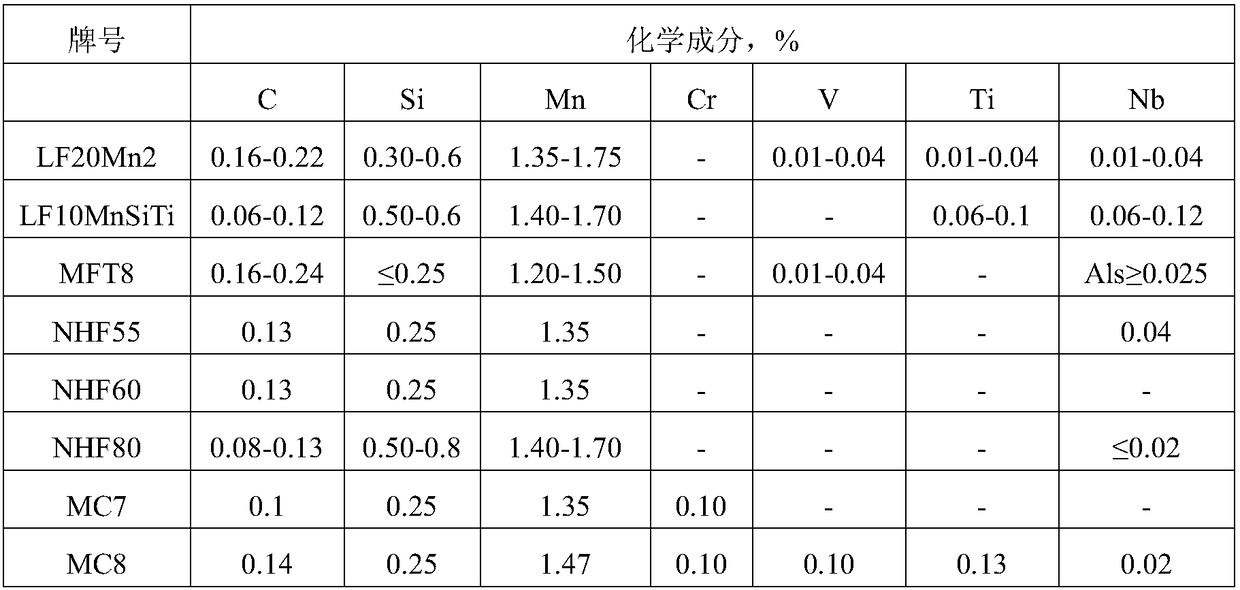

Heat-treatment-free grade 8.8 fastener-use cold forging steel and manufacturing method thereof

The invention relates to heat-treatment-free grade 8.8 fastener-use cold forging steel and a manufacturing method thereof. The heat-treatment-free grade 8.8 fastener-use cold forging steel is preparedfrom the following chemical ingredients in percentage by weight: 0.13 to 0.20 percent of C, 0.10 to 0.35 percent of Si, 1.40 to 1.80 percent of Mn, 0.03 to 0.10 percent of V, 0.01 to 0.03 percent ofTi, 0.008 to 0.02 percent of N, at most 0.02 percent of P, at most 0.015 percent of S and the balance of Fe and impurities, wherein the Ti and N meets the requirement that N-0.15Ti-0 .1V is greater than or equal to 0 .003 percent; the ratio of V to N is smaller than or equal to 10. In the rolling steps, the low-temperature heating is performed; the low-temperature rolling does not need to be executed; the equipment requirement and the production cost are reduced; the obtained grade 8.8 fastener-use cold forging steel has good cold deformation capability; after the drawing, cold forging and aging treatment, the high-intensity grade of a 8.8 fastener can be reached; the use requirement of the fastener can be met.

Owner:BAOSHAN IRON & STEEL CO LTD

Device and method for casting large-sized compound steel ingot by using graphite electrode ring for preheating electroslag

The invention provides a device and method for casting a large-sized compound steel ingot by using a graphite electrode ring for preheating electroslag. The device comprises a T-shaped electric conduction crystallizer, supporting arms and a lined electroslag furnace, wherein two transverse arms on a support are respectively used for lifting and dropping the graphite electrode ring and a self-consuming electrode ring; the lined electroslag furnace is used for slagging and pouring premelting slag into the T-shaped electric conduction crystallizer; and an annular bottom water tank is arranged onan ingot introducing plate. The method comprises the following steps of: (1) putting a core rod in the T-shaped electric conduction crystallizer, slagging the premelting slag in the lined electroslagfurnace, and forming a slag tank by pouring; (2) lowering the graphite electrode ring, and causing the graphite electrode ring, the slag tank, the upper crystallizer, a casting power source and the traverse arms to form an electric conduction loop, and heating the surface of the core rod and the slag tank by electrifying; and (3) when a preset temperature reaches, moving away the graphite electrode ring, inserting the self-consuming electrode ring into the slag tank, and carrying out electroslag casting. The method has high utilization rate of heat, can prevent interlayer slag from being generated on the compound interface of the steel ingot, facilitates the improvement of the quality of the steel ingot and simplifies the production equipment.

Owner:NORTHEASTERN UNIV LIAONING

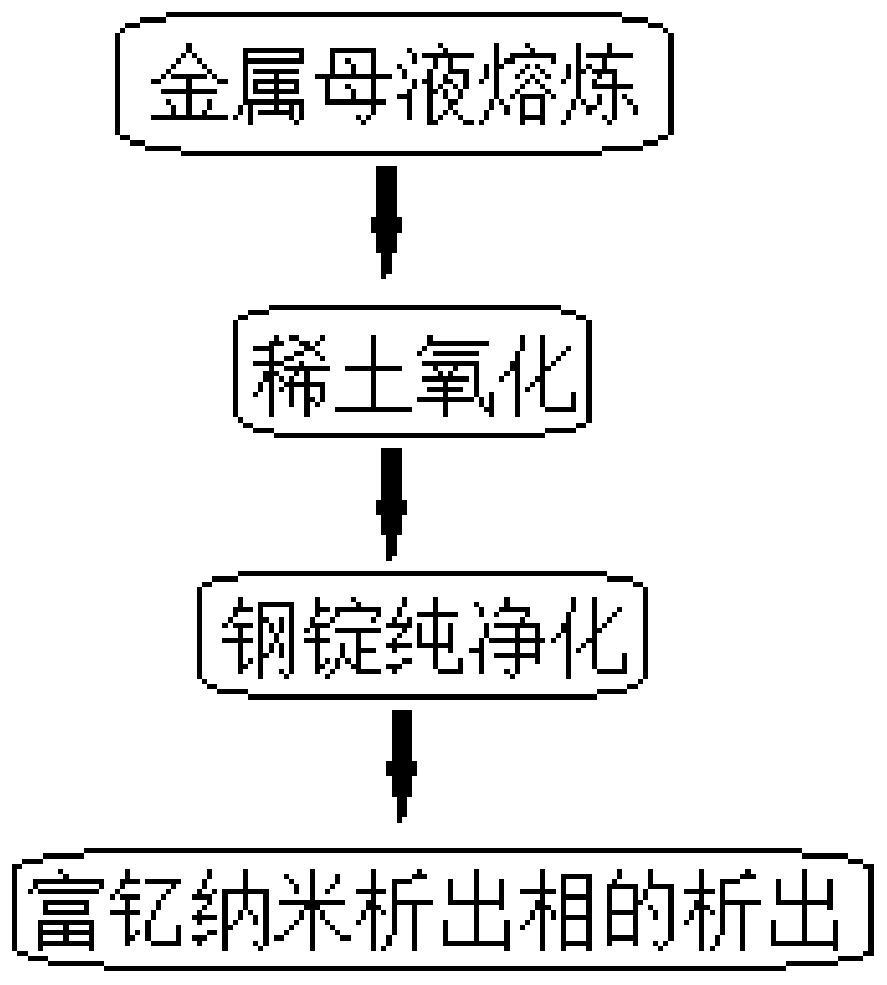

Rare earth steel and preparation method thereof

ActiveCN111705264AImprove high temperature mechanical propertiesSimple processYttriumOxidizing agent

The invention discloses rare earth steel and a preparation method of the rare earth steel. The rare earth steel comprises the following components of, in percentage by weight, 0.01%-0.05% of C, 0.15%-0.3% of Si, 0.4%-0.5% of Mn, 8%-10% of Cr, 2%-2.5% of W, 0.2%-0.25% of V, 0.05%-0.1% of Ta, 0.001%-0.01% of Zr, 0.3%-0.6% of Y<2>O<3> and the balance Fe; during preparation, Cr, W, Ta, Fe, Si, Mn andY are smelted into metal mother liquor, then mixed gas of CO<2> and Ar serving as an oxidizing agent is introduced into the alloy mother liquor, Y is oxidized into Y<2>O<3>, Zr, V and C are added, casting is performed after melting down; electroslag remelting is carried out on a cast ingot in a protective atmosphere, purifying is carried out; austenitizing is carried out on a purified steel ingot,then the steel ingot is subjected to pressure machining to form a steel plate, water cooling is carried out after pressure machining; and heat treatment is carried out on the steel plate obtained through pressure machining, a yttrium nanometer precipitated phase is precipitated from the steel plate, and the rare earth steel is obtained. According to the rare earth steel and the preparation methodof the rare earth steel, RAFM ( Reduced Activation Ferritic / Martensitic ) steel can be produced in a smelting and casting mode, the yield of the RAFM steel can be increased, and meanwhile the high-temperature mechanical property of the RAFM steel is improved.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Monocrystal high temperature alloy electric field directional freeze apparatus

InactiveCN1508297ARefining solidified tissueEasy to useFrom frozen solutionsSingle crystal superalloySingle crystal

The invention relates to the single crystal high-temperature alloy solidifying technique, including case, heating set, sample clamping framework and DC electric field generating set. The clamping framework is set under the case, composed of two clamping bars set on the bracket, one end of each clamping bar linked with the rotation shaft on the bracket, the other end linked through fastener, and the outer side of each clamping bar installed with tension spring, the other end of each tension spring fixed on the bracket, and the bracket opened with a through hole to make the sample pass through; the generating set is a close loop, formed by setting a programmable functional module in series between one end of the sample and one pole of the voltage-stailized source, and connecting the other end with the other pole through the clamping tool.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

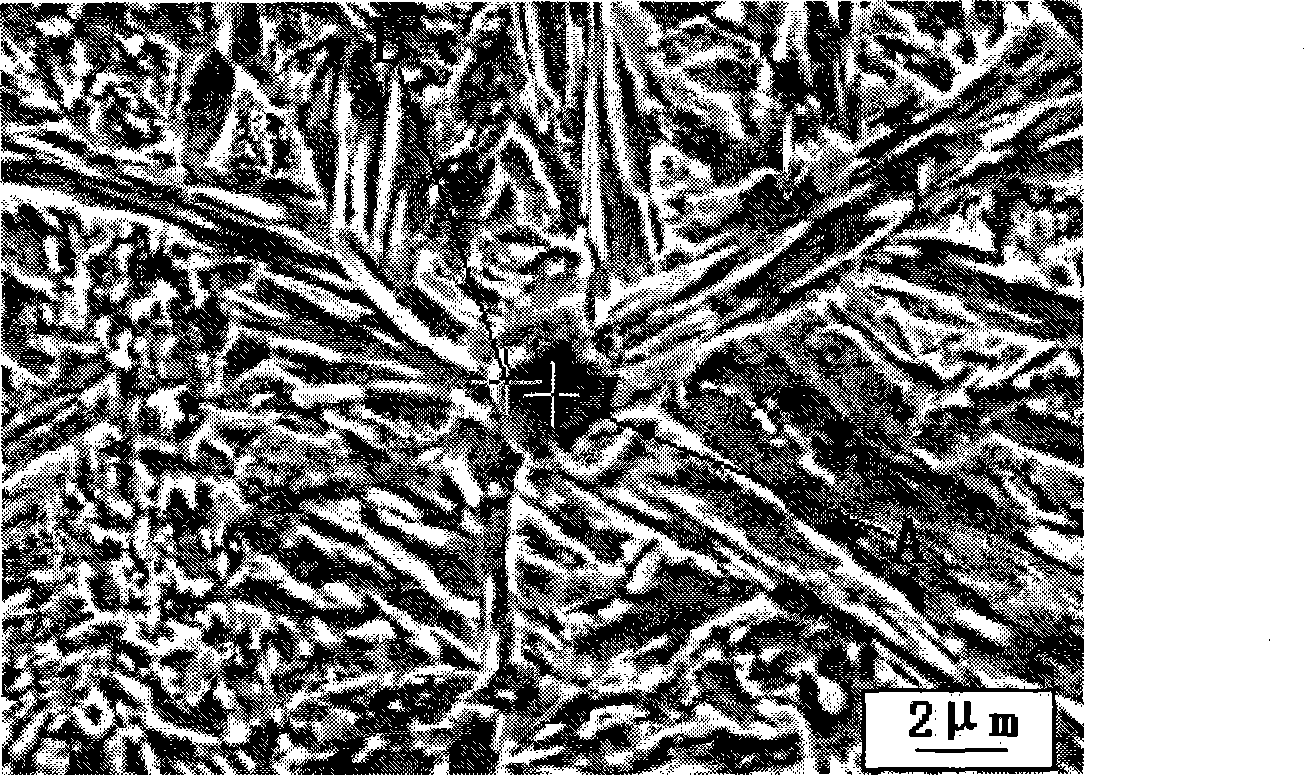

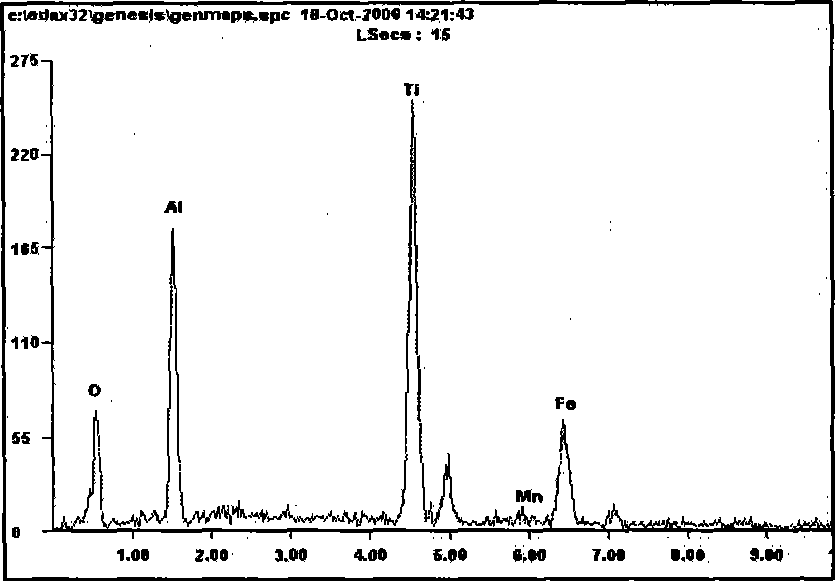

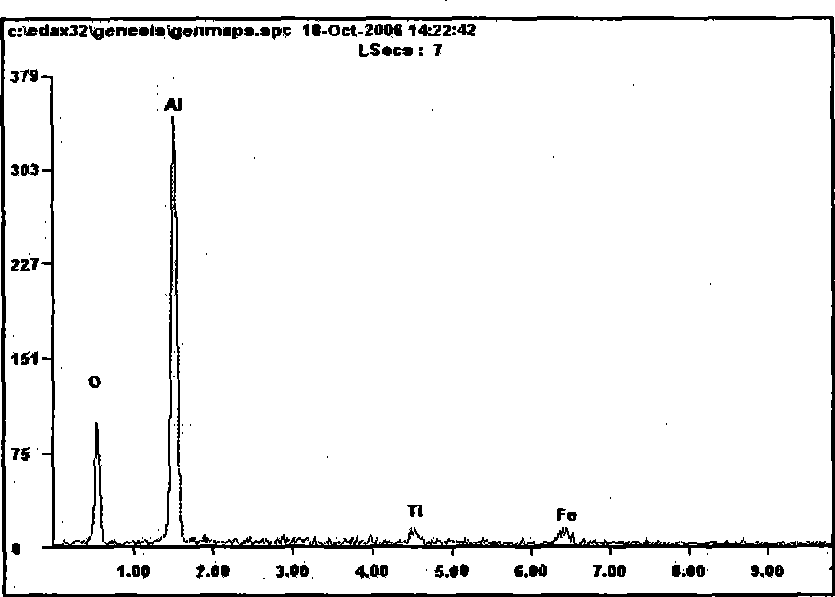

Molten steel deoxygenation method for thinning solidification structure

The invention provides a hot metal deoxidation method of a refinement and solidification structure, which comprises the following steps: proper amount of carbon powder, ferromanganese, ferrosilicon and other alloys are added into the molten steel to carry out deoxidizing and alloying. The method is characterized in that: before deoxidizing and alloying, proper amount of SiAlFe alloy is added to carry out pre-deoxidizing, the oxygen activity of the molten steel is controlled between 50 multiplied by 10<-6> and 100 multiplied by 10<-6> through pre-deoxidizing and deoxidizing and alloying and the temperature is controlled over 1550 DEG C; then proper amount of ferrotitanium is added to carry out final deoxidizing and aluminum content and titanium content of the steel deoxidized are respectively 0.003 percent to 0.012 percent and 0.015 percent to 0.050 percent. Under the conditions without changing the technique flow of steelmaking, adding equipment and increasing cost, the solidification structure of carbon steel can be obviously refined and isometric crystal proportion can be improved to more than 80 percent. Therefore, harmful function of alumina foreign impurities is eliminated, generation of large particles of single titanium oxide is avoided and blockage of a water gap is reduced.

Owner:ANGANG STEEL CO LTD

Electromagnetic stirring generating device, method and application of composite time-varying magnetic field

ActiveCN110252975AImprove fatigue performanceSmall mechanical propertiesPhysicsElectromagnetic stirring

The invention relates to an electromagnetic stirring generating device, method and application of a composite time-varying magnetic field. The device is a composite rotating magnetic field electromagnetic stirring generating device or a time-varying magnetic field generating device, or a traveling wave magnetic field electromagnetic stirring generating device. According to the method and the application, in the continuous casting, semi-continuous casting or die casting process, the electromagnetic stirring generating device of the composite time-varying magnetic field acts on a crystallizer for continuous casting or semi-continuous casting, a secondary cooling zone and any one position or multiple positions of the tail end or a riser in the mold casting production, liquid level and the like, so that the mechanical property of a casting blank is improved by improving the component segregation and the shrinkage porosity of the casting blank. Compared with the continuous casting or semi-continuous casting or die-casting production process, electromagnetic stirring or time-varying magnetic fields are independently applied, so that the shrinkage porosity and component segregation of the core of the casting blank are remarkably improved.

Owner:SHANGHAI UNIV

Pressure casting method of purified homogenized compacted fine-grained large steel blank

The invention relates to the field of manufacturing of large-section thick large blanks, in particular to a pressure casting method of a purified homogenized compacted fine-grained large steel blank. According to the method for improving quality of a large steel blank by pressure effect, the problems that the existing large-section blank experiences gross segregation, shrinkage cavity and porosity, inclusion and grain coarseness can be solved; the large steel blank can be purified, homogenized, compacted and fine grained during manufacturing; yield of the blank is significantly improved; on such basis, gravity riser feeding is replaced with pressure feeding to allow non-riser casting, and yield of the blank can be significantly increased. The pressure casting method is applicable to manufacturing of large-section steel blanks, including round billets, square billets and flat billets, is applicable to manufacturing of large blanks of aluminum alloy, magnesium alloy and high-temperature alloy and is also applicable to manufacturing of complex castings of ferrous metals and nonferrous metals.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Method of applying electric field energy on molten steel to improve quality of silicon steel billet

The method of applying electric field energy on molten steel to improve quality of silicon steel billet is to introduce electric field energy with the electric field energy generator and the electrodes into molten steel, the electric field energy waveform is duty ratio variable square wave of energy 1000 J-180 MJ, voltage 100-1800V, current 100A-8KA, frequency not higher than 25 Hz and duty ratio of 5-90 %. The electric field energy generator is suitable for use in industrial production and controllable in electric field energy parameters. The treated molten steel results in refined billet structure with obviously increased global crystal, less defaults and high quality.

Owner:ANGANG STEEL CO LTD

Vanadium-titanium-containing ductile cast iron material and thermal treatment process

ActiveCN105714183AUniform cast structureMake up for the defect of composition segregationQuenching agentsRare-earth elementCast iron

The invention relates to a vanadium-titanium-containing ductile cast iron material. The material comprises, by mass, 3.20%-3.90% of carbon, 2.30%-2.93% of silicon, 0.96%-2.80% of manganese, 0.20%-0.90% of chromium, 0.60%-0.90% of copper, 0.80%-1.20% of molybdenum, 0.54%-0.68% of vanadium, 0.3%-0.78% of titanium, 0.01%-0.09% of niobium, higher than or equal to 0 but lower than 0.05% of phosphorus, higher than or equal to 0 but lower than 0.03% of sulfur, 0.03%-0.05% of magnesium, 0.02%-0.03% of rare earth elements, and the balance iron. According to the material, the ingredients are properly proportioned, and the material has the advantages that grains are refined, hardness is increased, hardenability is enhanced, the Ms point is moved downwards, and lower-bainite ferrite can be formed more easily.

Owner:CHENGDE RONGMAO CAST STEEL +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com