Heat-treatment-free grade 8.8 fastener-use cold forging steel and manufacturing method thereof

A heat-free treatment and manufacturing method technology, which is applied in the field of cold heading steel manufacturing, can solve the problems of poor cold deformation ability of wire rods, hinder dislocation slippage, and large strength fluctuations, and achieve good cold workability, promote lattice distortion, and reduce production. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

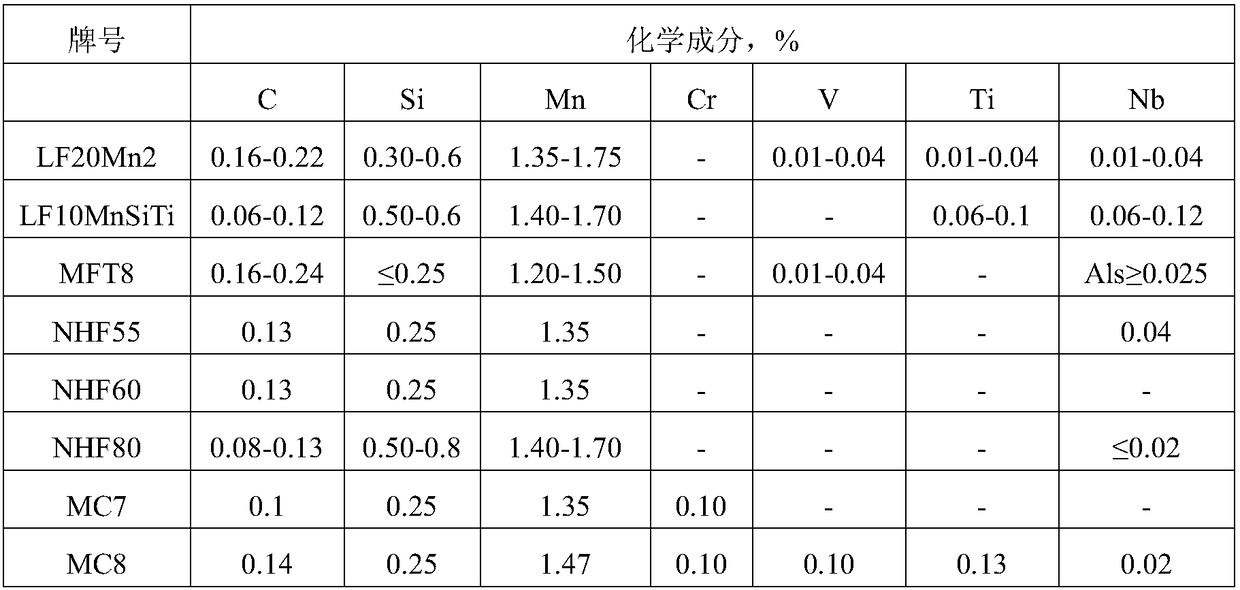

[0057] According to the chemical composition of embodiment 1~8 steel shown in table 3, with the blank sample that does not contain V, Ti, N as comparative example, carry out smelting and refining: rough refining with electric arc furnace or converter; LF refining furnace slag alkalinity is controlled at 4.0~6.5, if necessary, the molten steel should be degassed by VD or RH vacuum refining; use N-containing ferroalloy or LF or VD or RH bottom blowing nitrogen process, pay attention to the degassing efficiency of VD or RH when LF nitrogen alloying, to ensure that the molten steel N content.

[0058] The fully calmed molten steel is poured into steel ingots or billets under the condition of no oxidation protection.

[0059] High wire rolling: after being heated at 1080°C, it is rolled in the hot rolling experimental rolling mill. Conventional processing, the 8.8-grade cold heading steel for high-strength fasteners is obtained, and the mechanical properties are shown in Table 4. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com