Method of applying electric field energy on molten steel to improve quality of silicon steel billet

A technology of electric field energy and molten steel, which is applied in the field of iron and steel metallurgy, can solve the problems of power supply system tripping, weak processing effect, and failure to work, so as to improve the quality and quality of silicon steel rolled products, eliminate corrugated plate shape defects, and avoid skin effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below through embodiments with reference to the accompanying drawings.

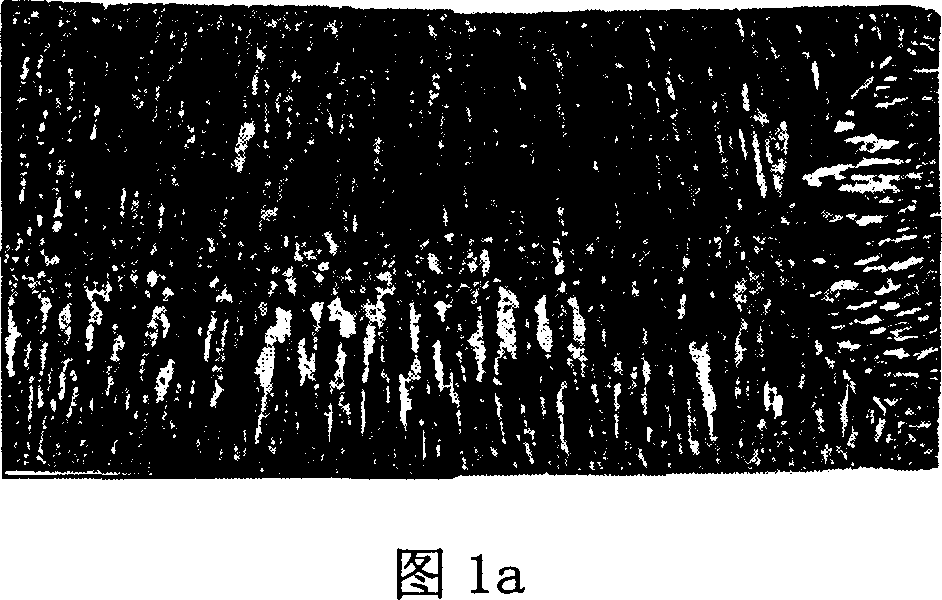

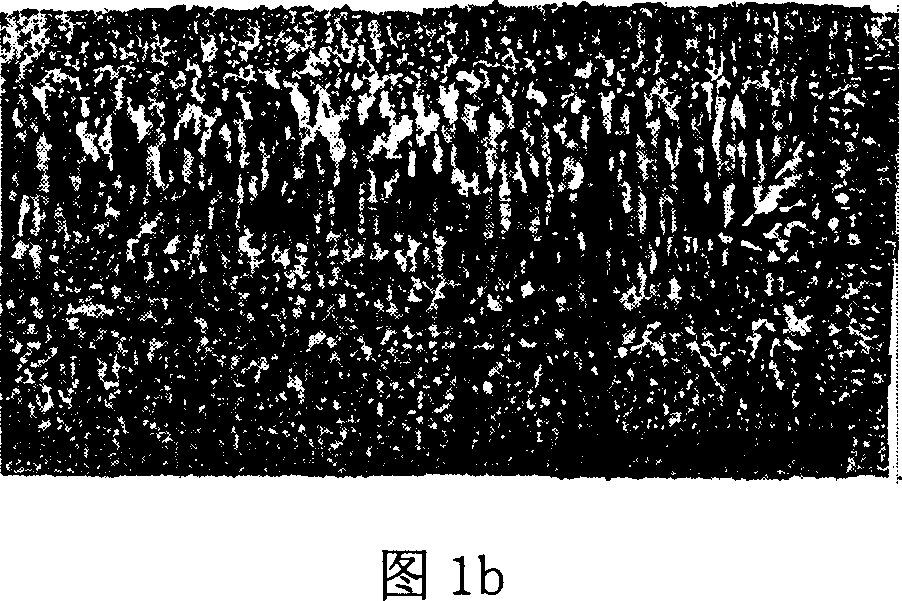

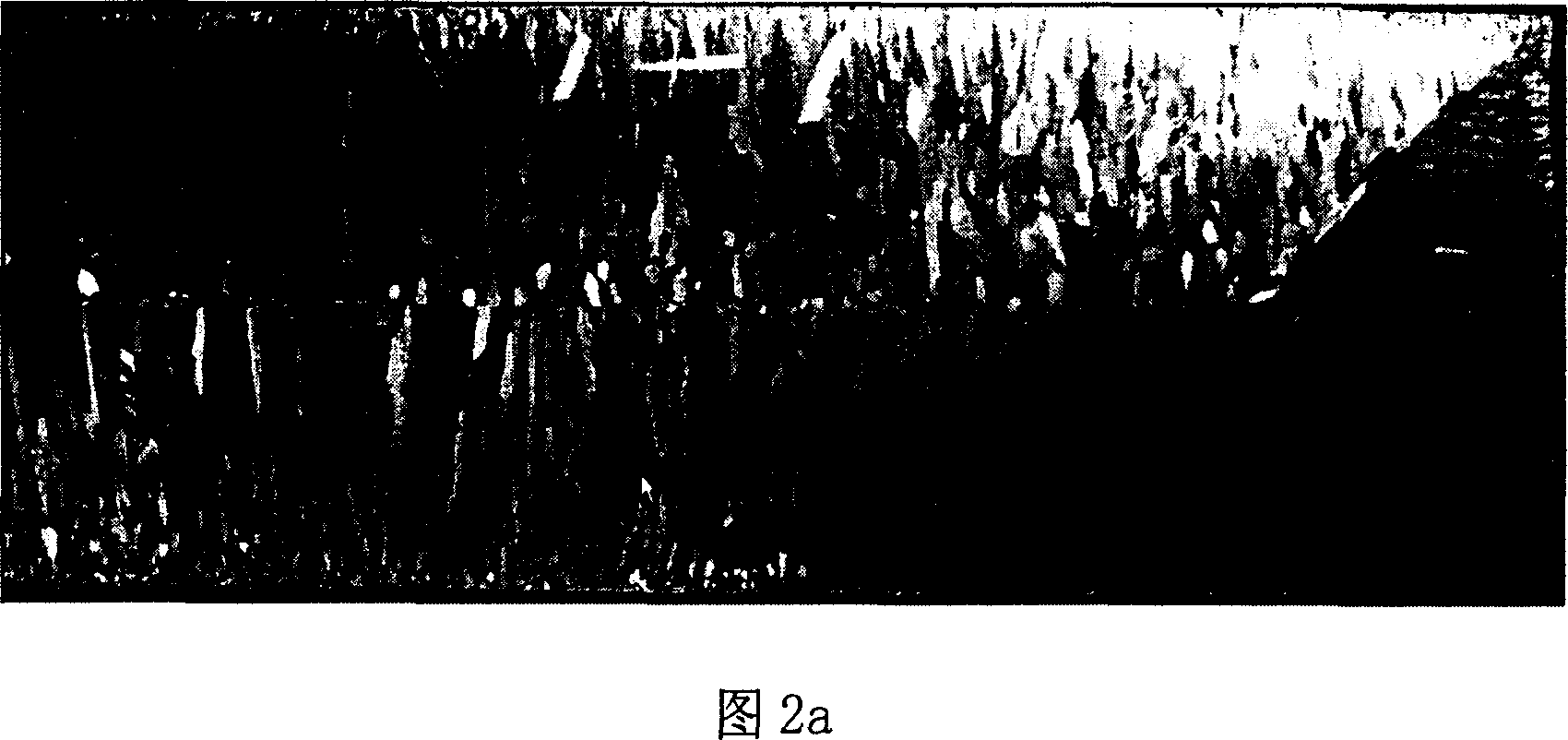

[0016] In the embodiment of the present invention, the electric field energy is applied to the liquid silicon steel molten steel of different steel types in the tundish of 5 tons to 80 tons respectively. The electric field energy is introduced into the molten steel, and the electrodes are inserted into the molten steel through the tundish cover, and the insertion depth is 200 mm to 1500 mm. The waveform of the electric field energy is a rectangular wave with variable duty ratio, the applied electric field energy is 1000J-170MJ, the voltage is 100V-1700V, the current is 100A-8KA, the frequency is ≤25Hz, and the duty ratio is 5%-90%.

[0017] The electric field energy applied by the present invention is 1000J-6000J, the voltage is 100V-500V, the current is 100A-800A, the frequency is ≤25Hz, and the duty ratio is 20%-50% when the liquid silicon steel mol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com