Patents

Literature

124results about "Zig-zag/sinusoidal resistive elements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

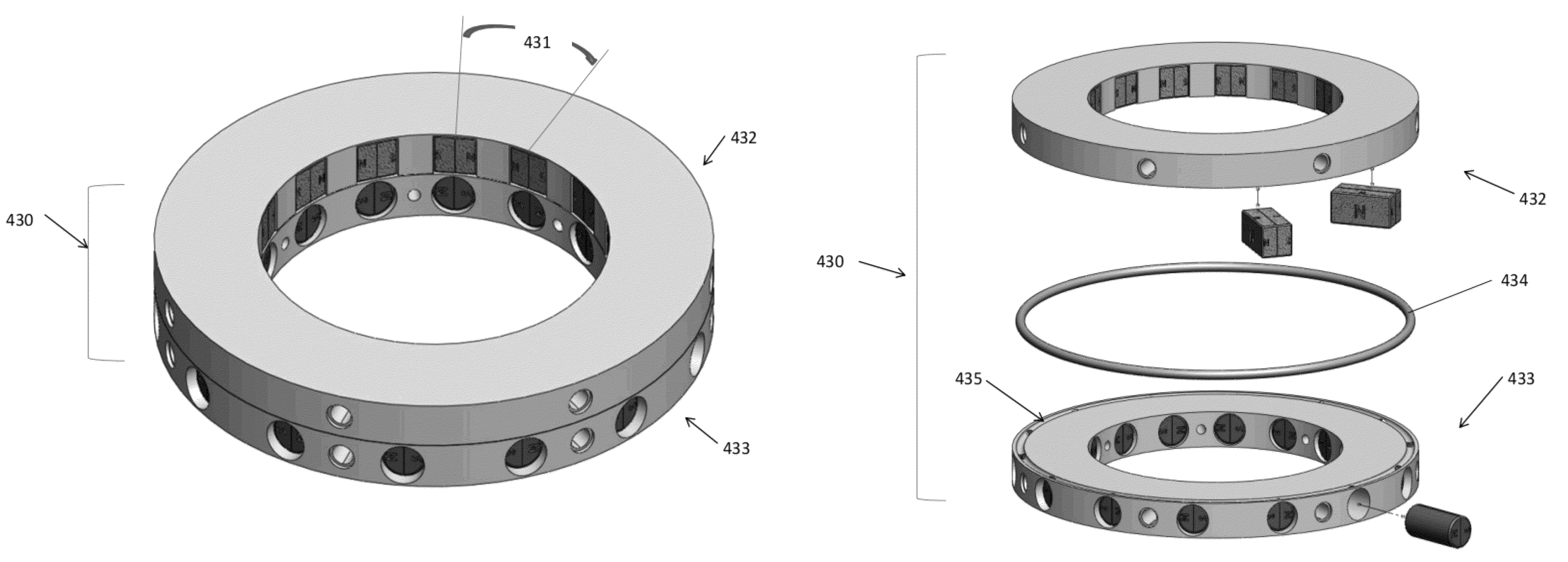

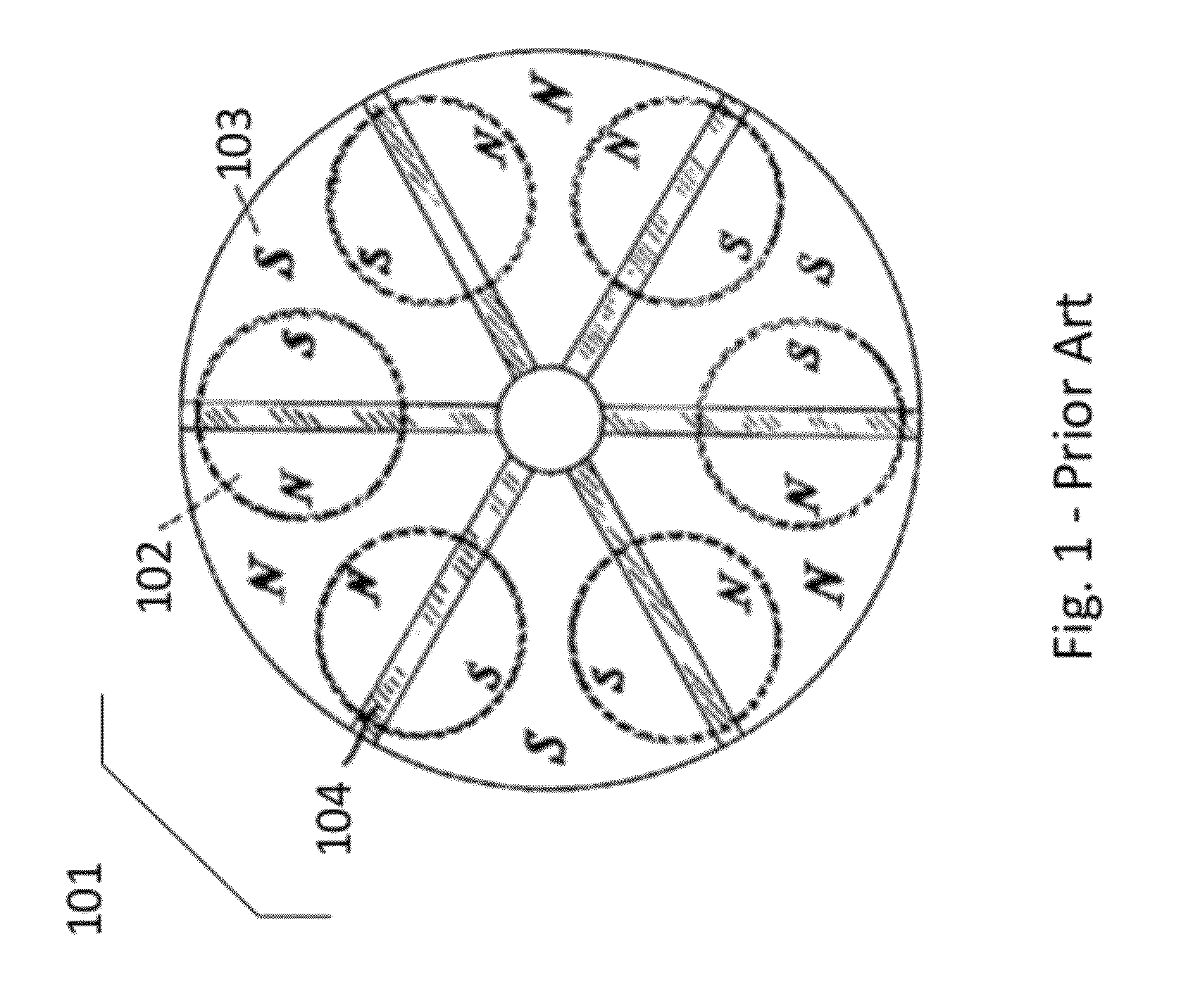

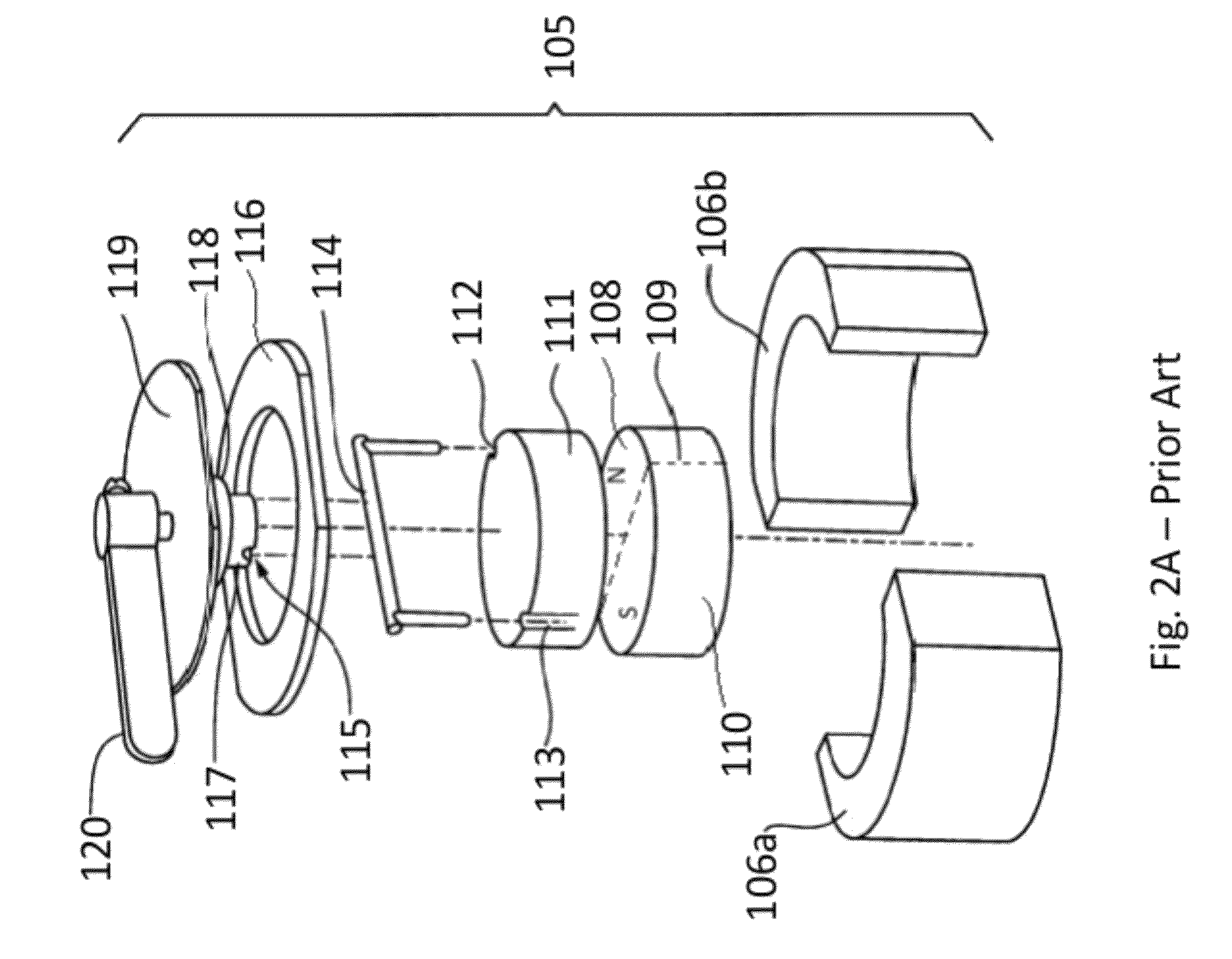

Rotary switchable multi-core element permanent magnet-based apparatus

ActiveUS8350663B1Low costRapid productionElectromagnets without armaturesElongated resistive elementEngineeringMagnet

A method for creating and a device for a rotary switchable multi-core element, permanent magnet-based apparatus, for holding or lifting a target, comprised of two or more carrier platters, each containing a plurality of complementary first and second core elements. Each core element comprises permanent magnet(s) with magnetically matched soft steel pole conduits attached to the north and south poles of the magnet(s). Core elements are oriented within adjacent carrier platters such that relative rotation allows for alignment in-phase or out-of-phase of the magnetic north and south fields within the pole conduits. Aligning a first core element “in-phase” with a second core element, that is, north-north / south-south, activates that core element pair, allowing the combined magnetic fields of the pole conduits to be directed into a target. Aligning the core element pair “out-of-phase,” that is, north-south / south-north, deactivates that core element pair by containing opposing fields within the pole conduits.

Owner:CREATIVE ENG SOLUTIONS

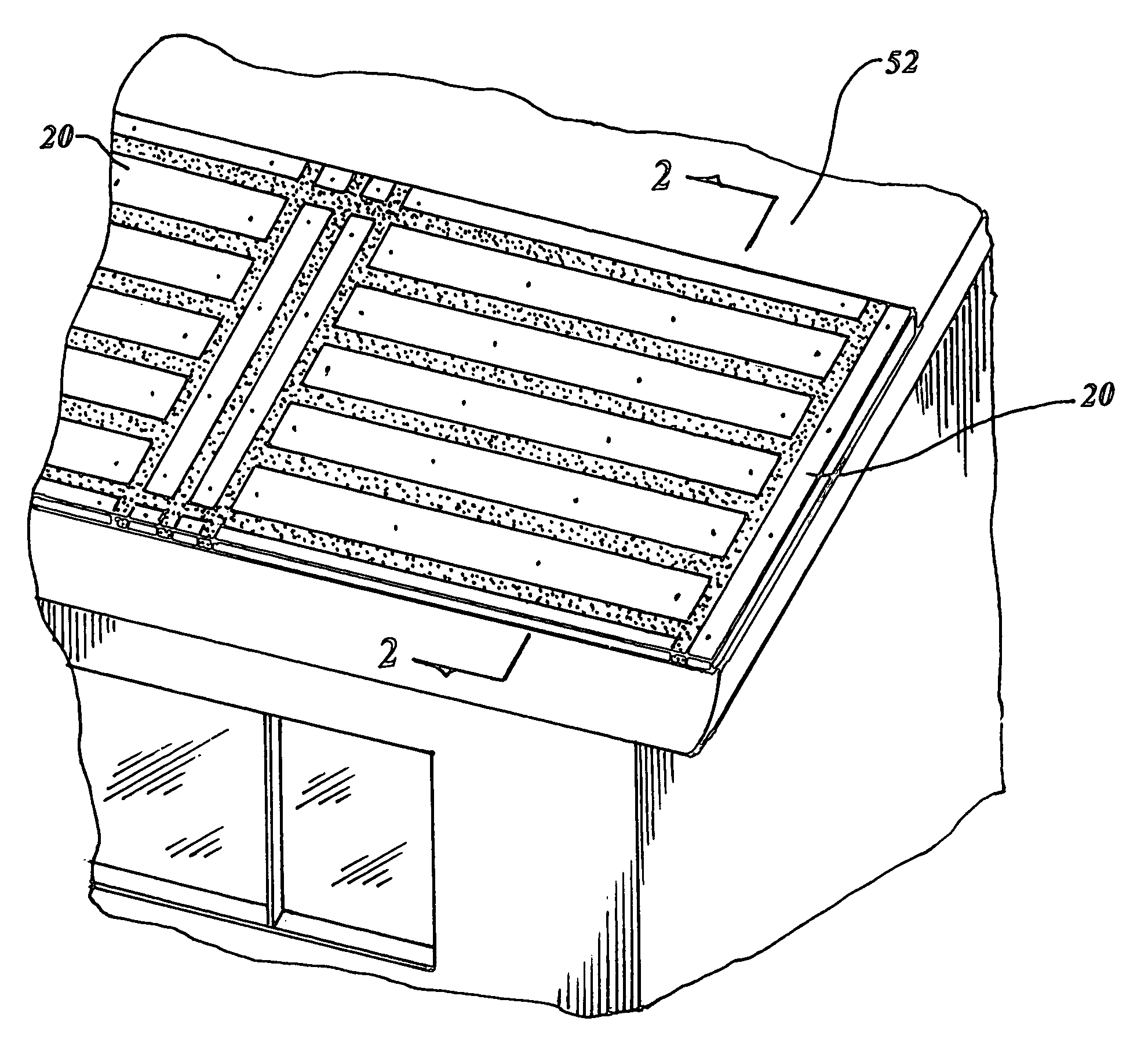

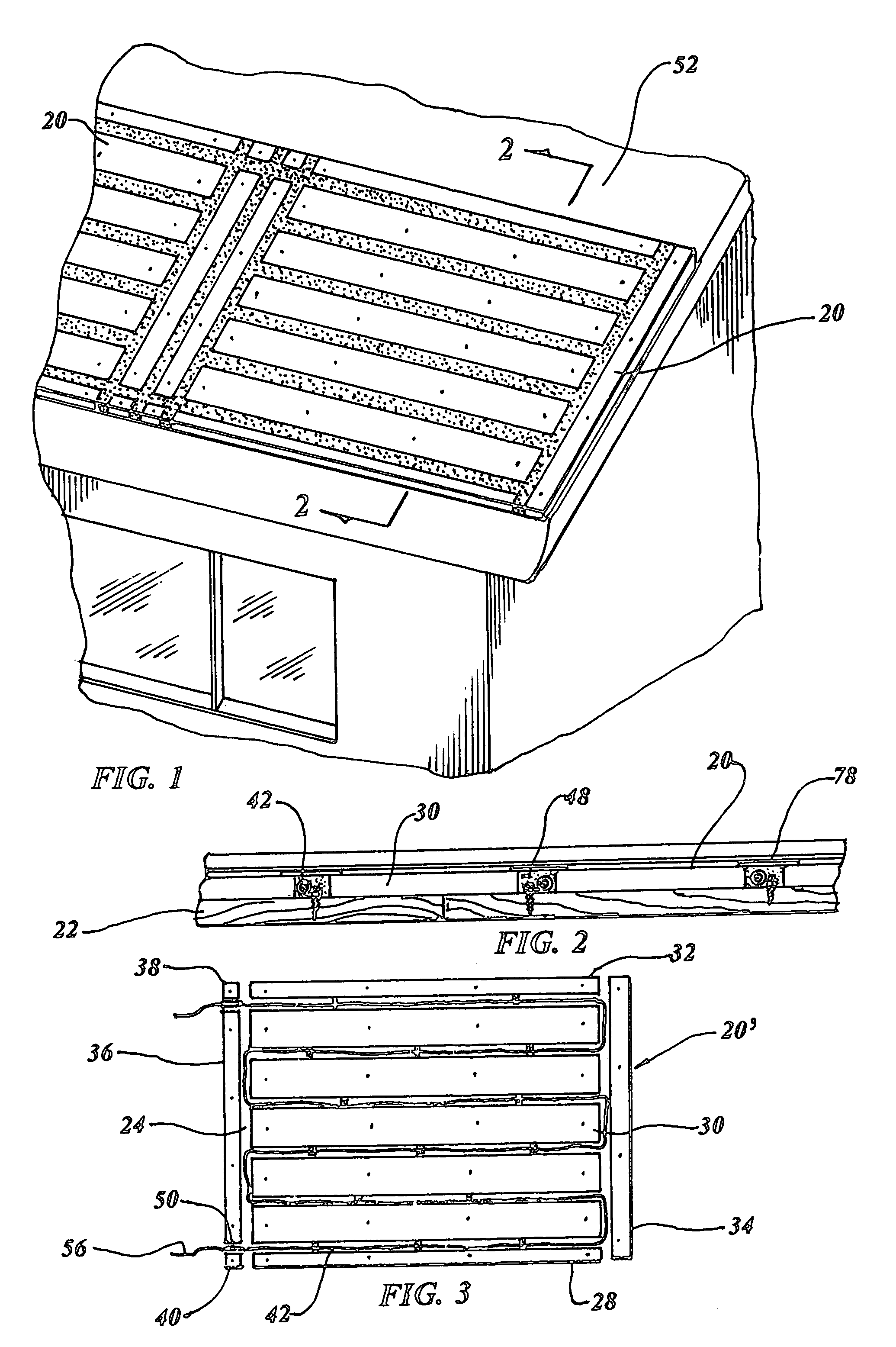

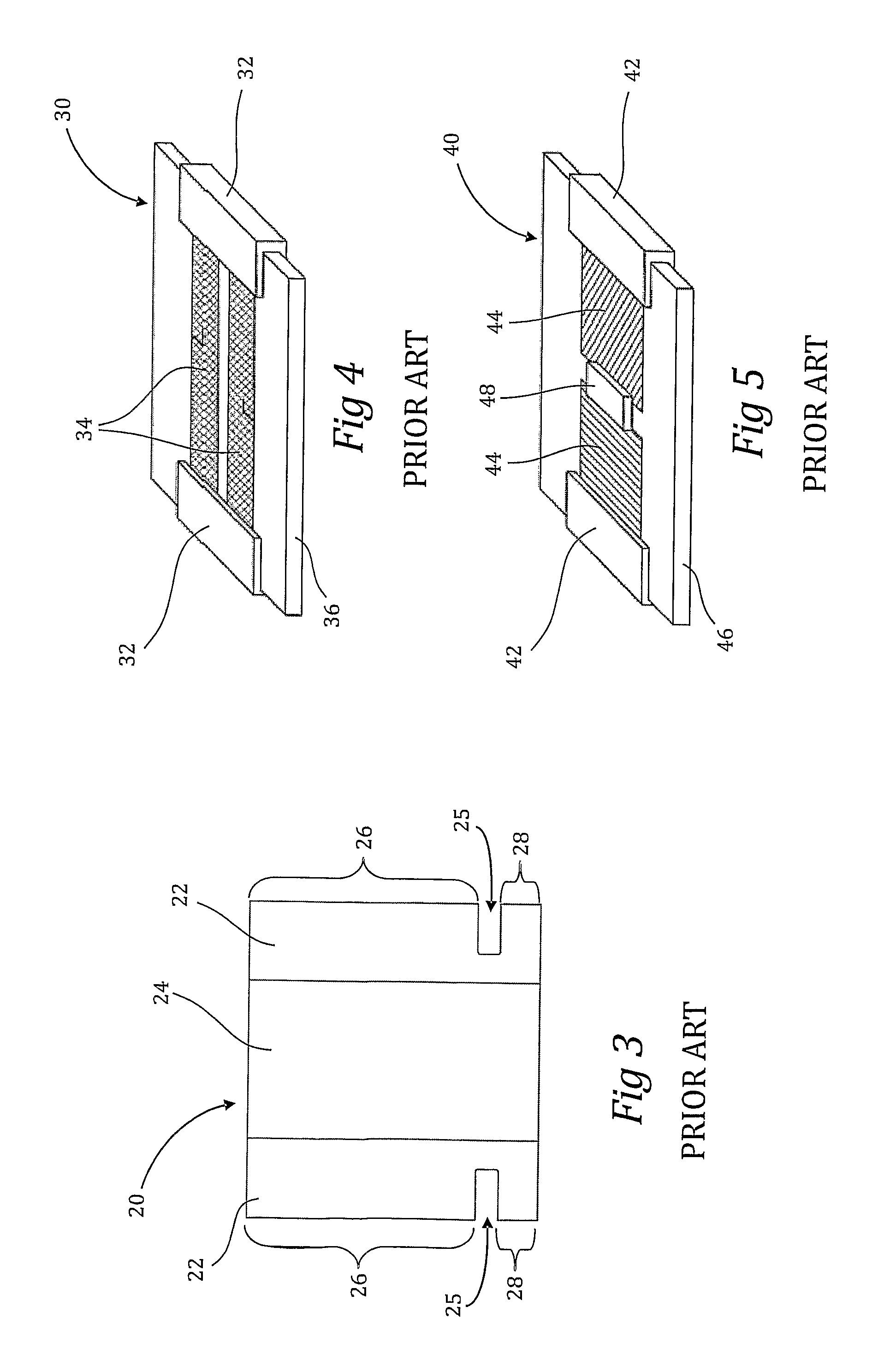

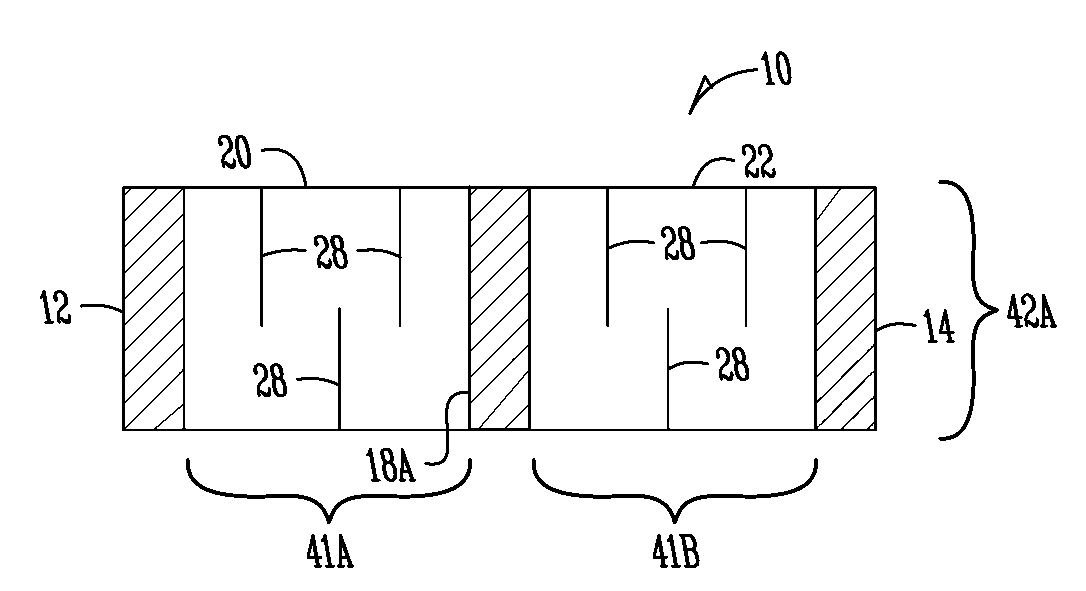

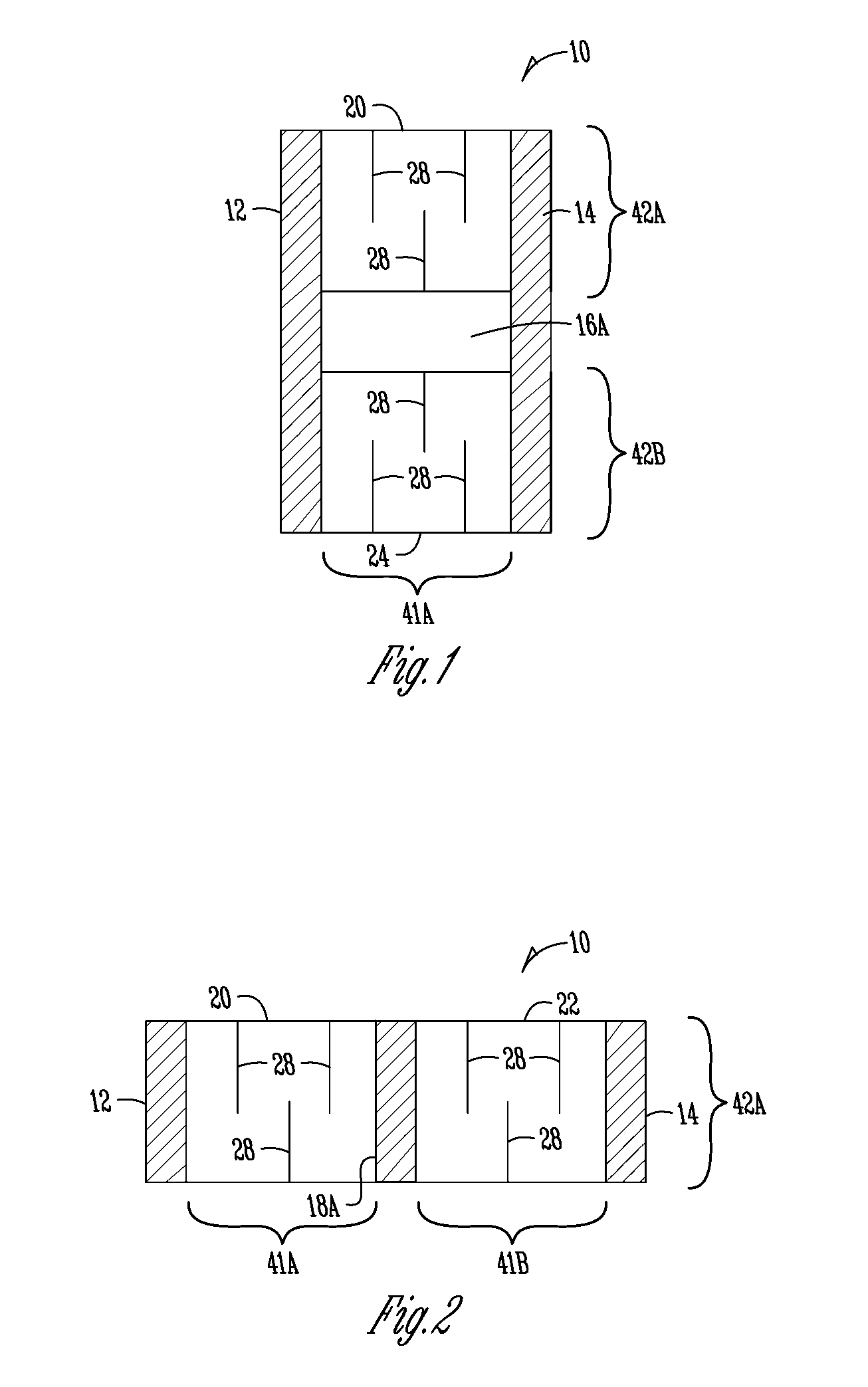

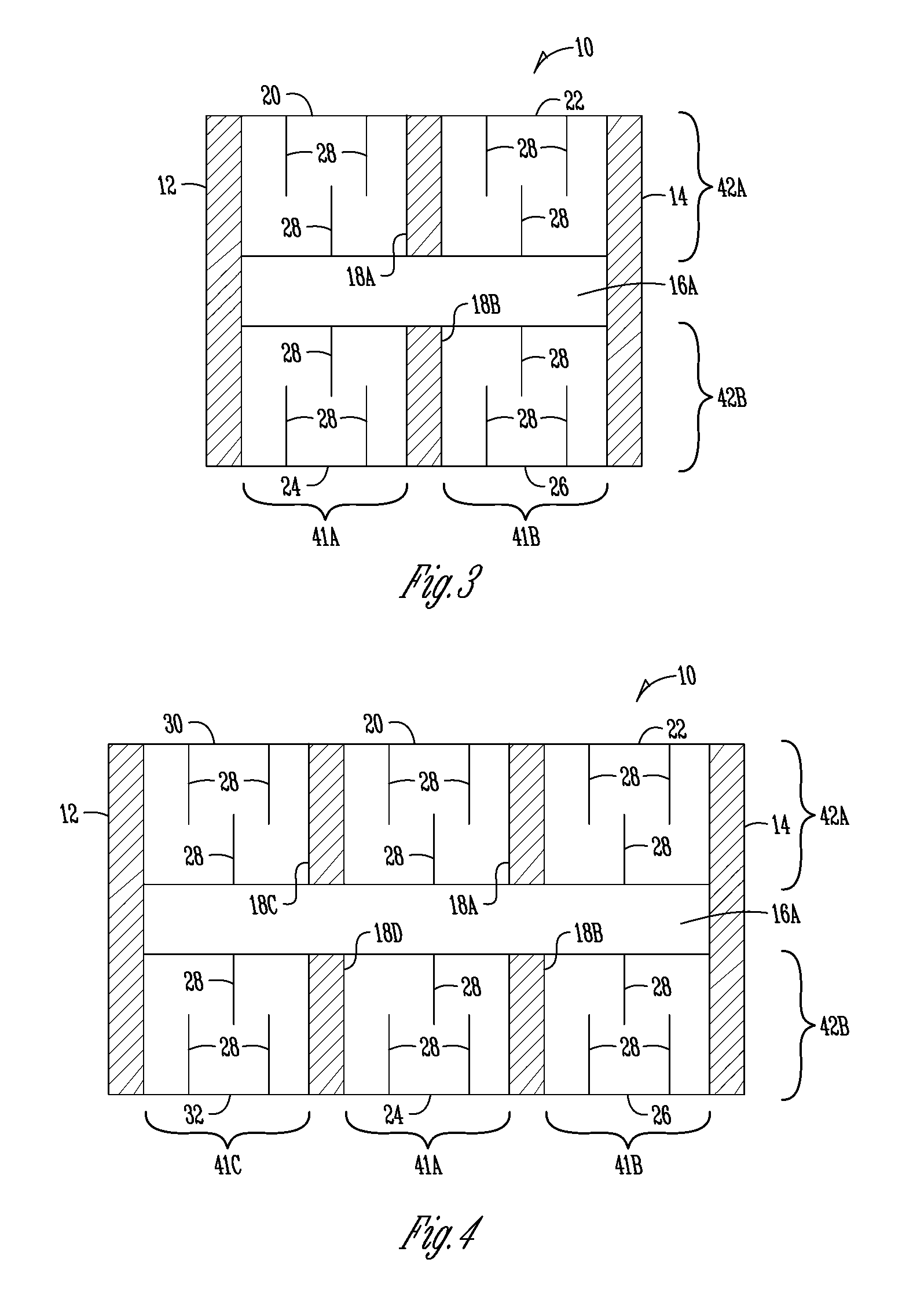

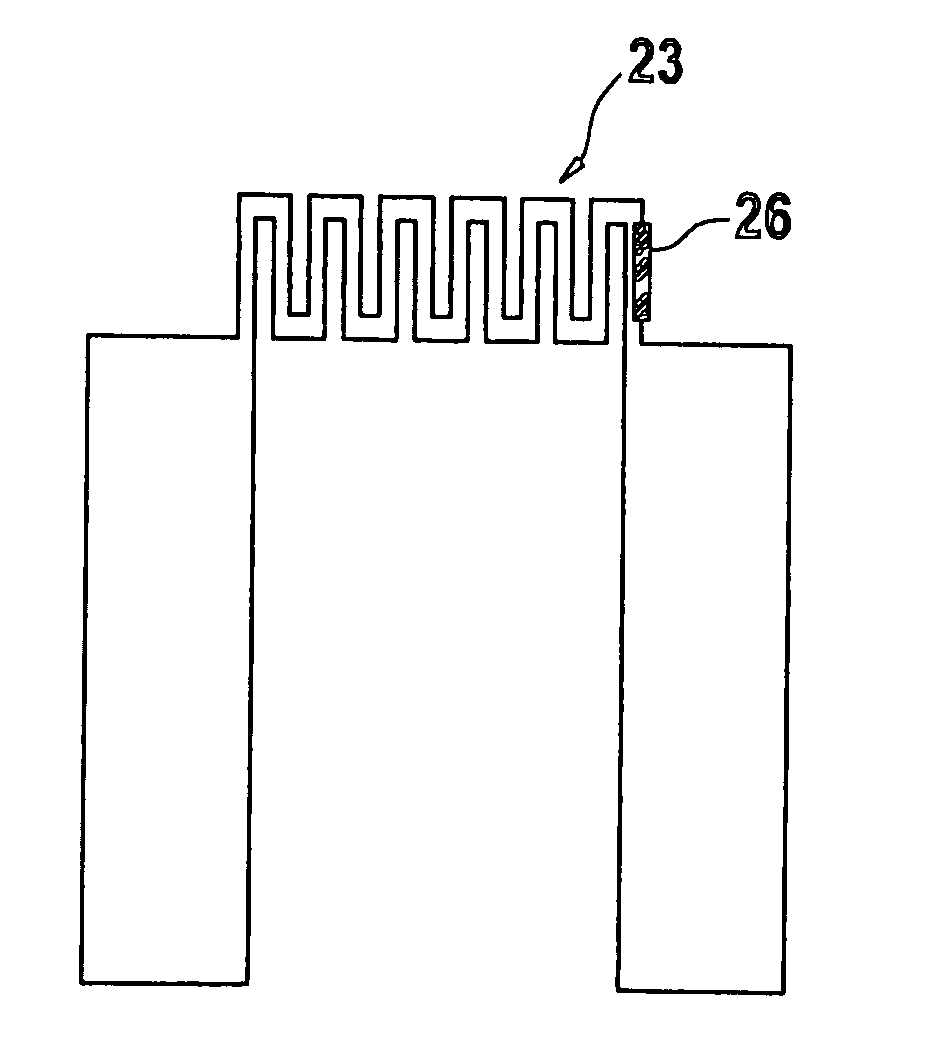

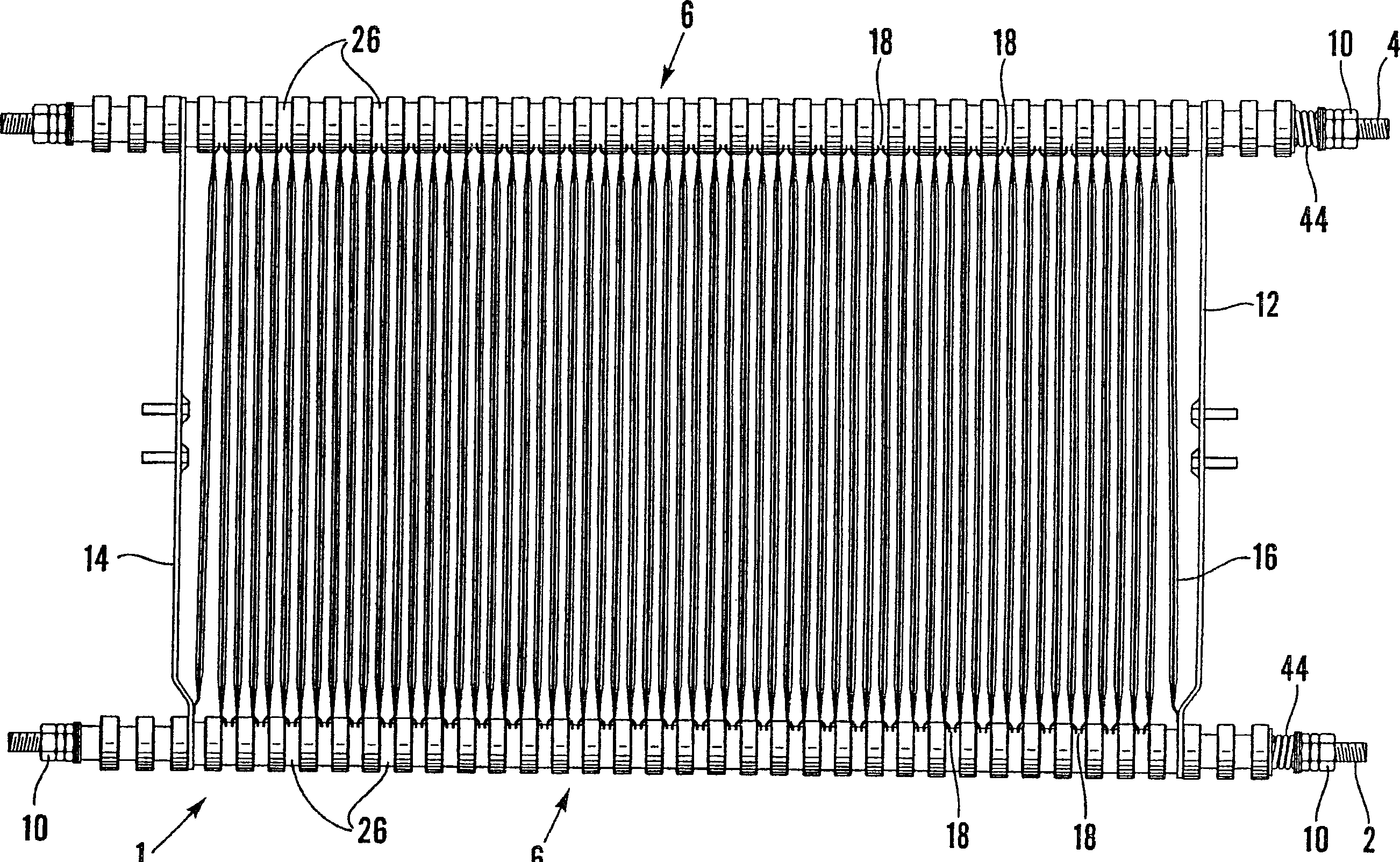

De-icing, snow melting and warming system

ActiveUS7071446B1Promote repairEasy to replaceRoof coveringElongated resistive elementTransformerLow voltage

A de-icing, snow melting and warming system is taught which utilizes a heatsink (20) consisting of a number of board strips disposed in a planer array positioned within a building structure between its exterior and interior surface. The heatsink board strips have a gap (24) therebetween in which a heating cable (42) is positioned in a continuous serpentine manner and held in place with loop clamps (44). A gap filler (48) encases the heating cable including the enclosed gap forming a homogenous closure. A low voltage power transformer (54) is attached to electrical mains providing electrical voltage reduction to the heating cable of 30 volts or less, and controls and self diagnostics regulate the power and detect anomalies within the system.

Owner:BENCH STEVEN D

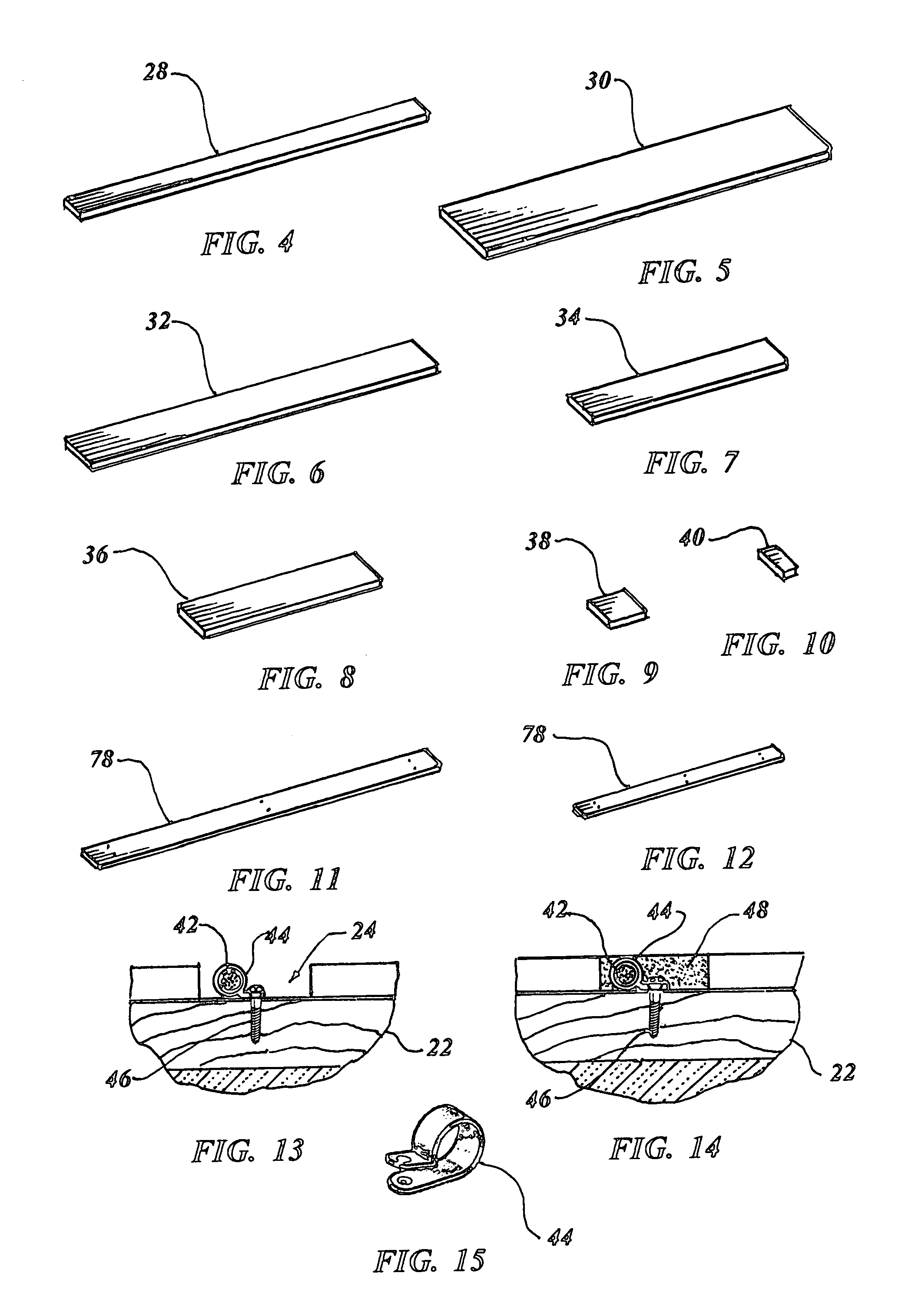

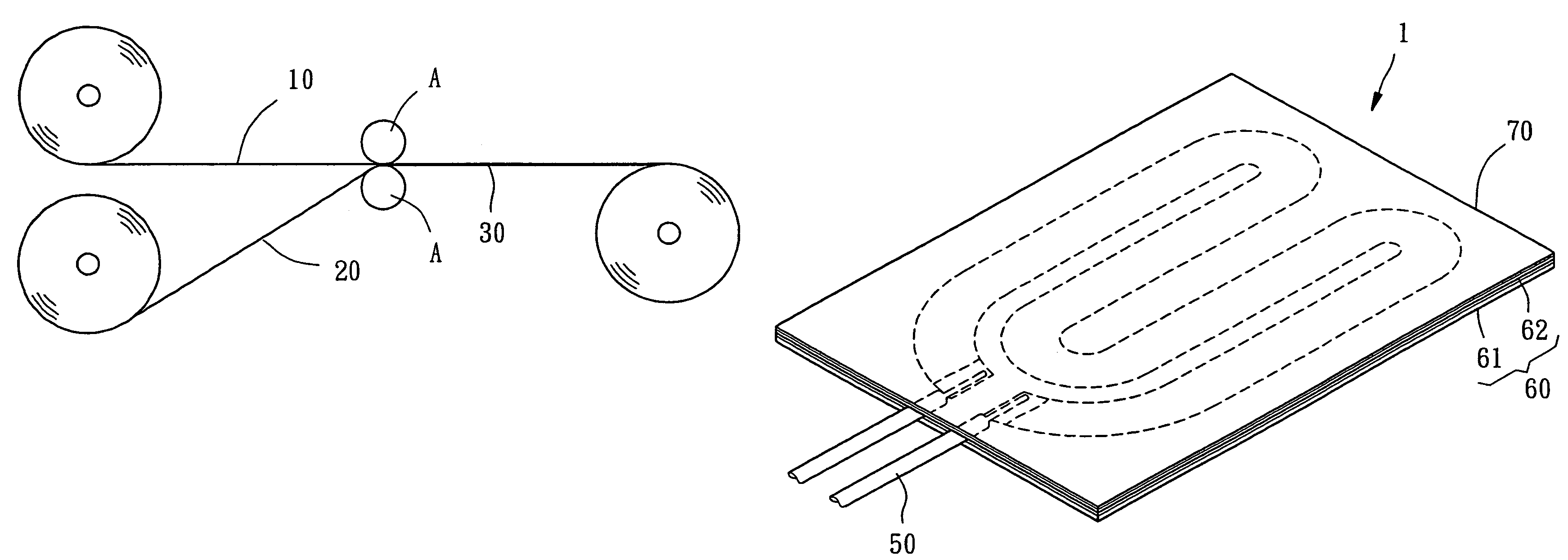

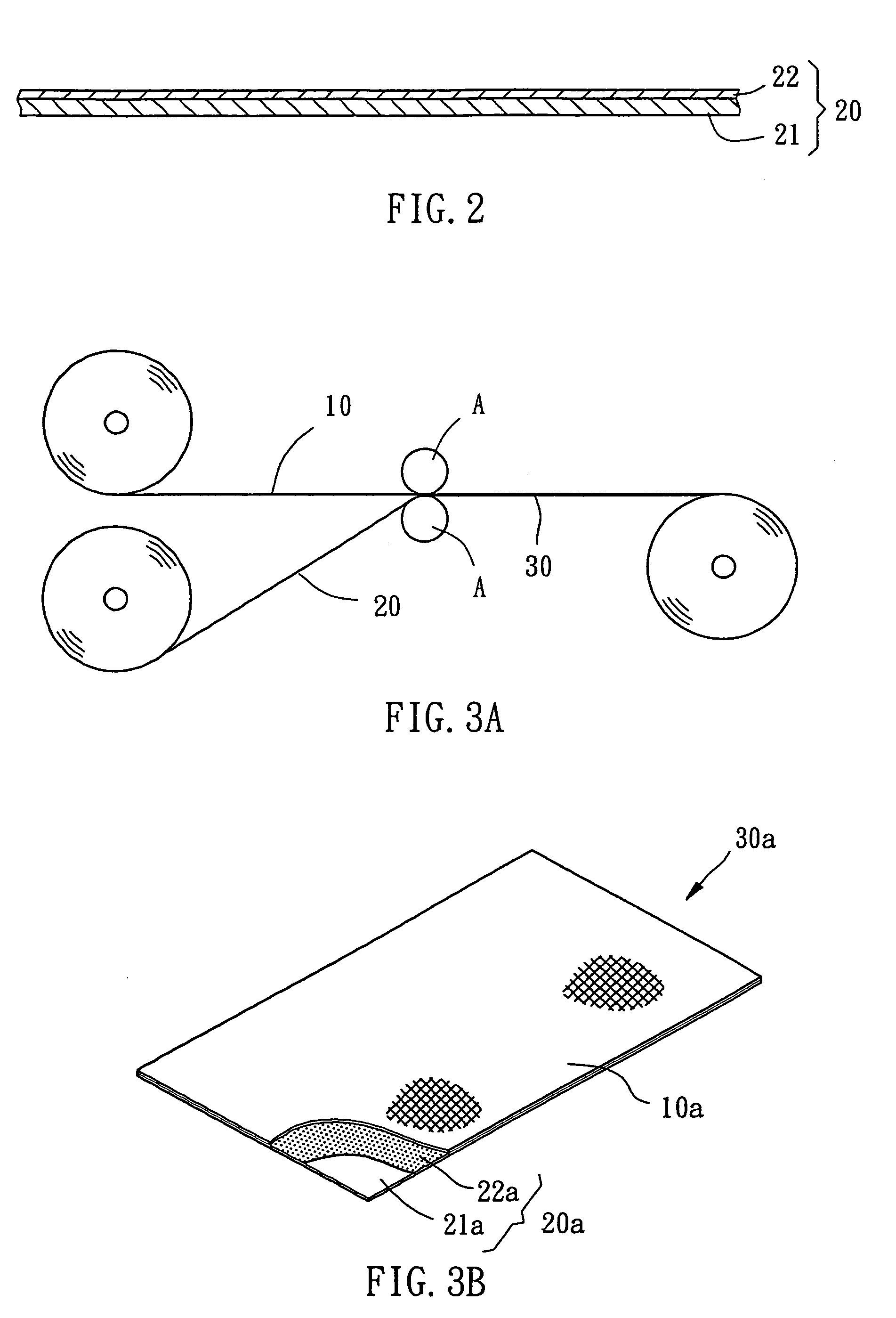

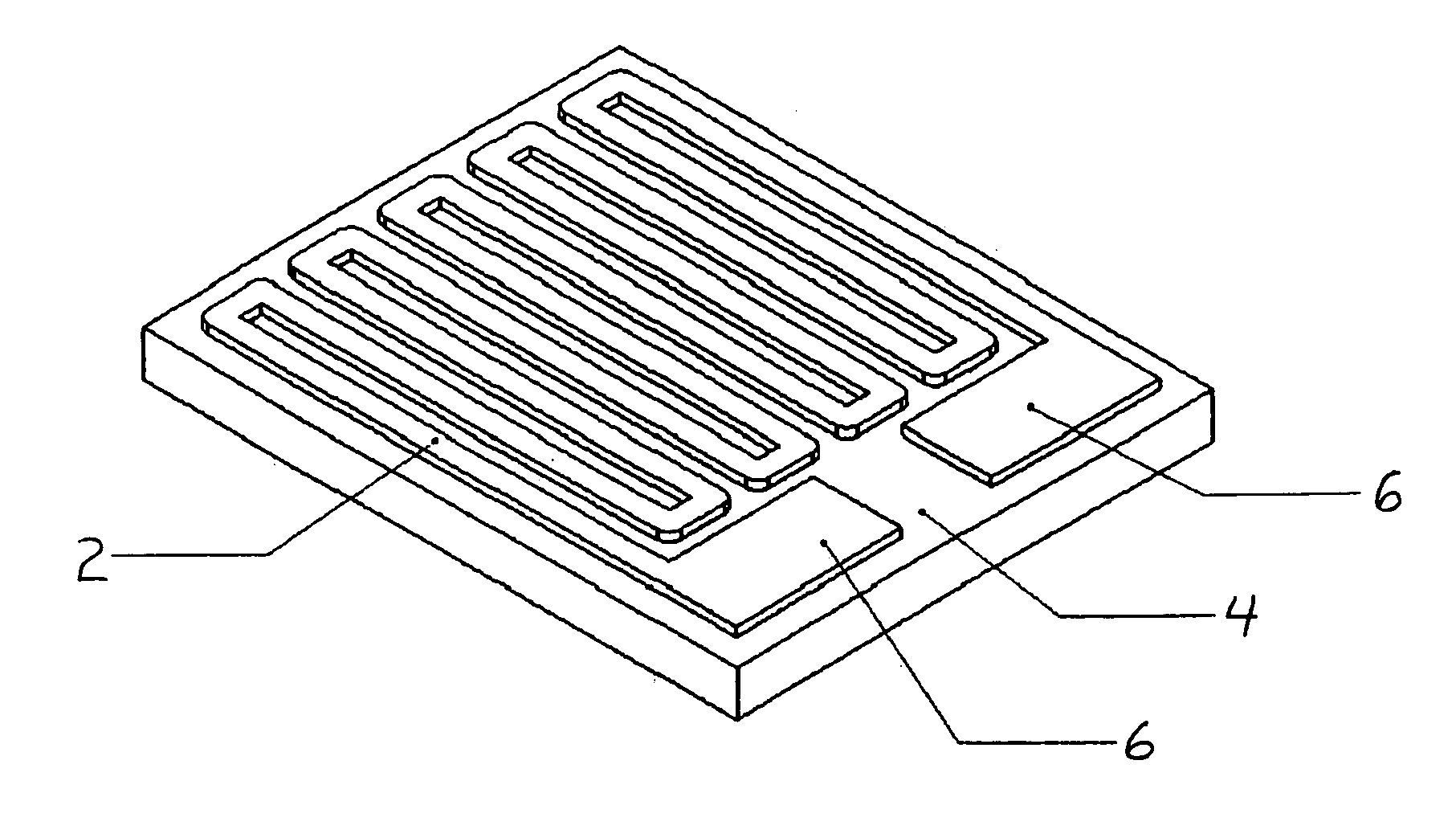

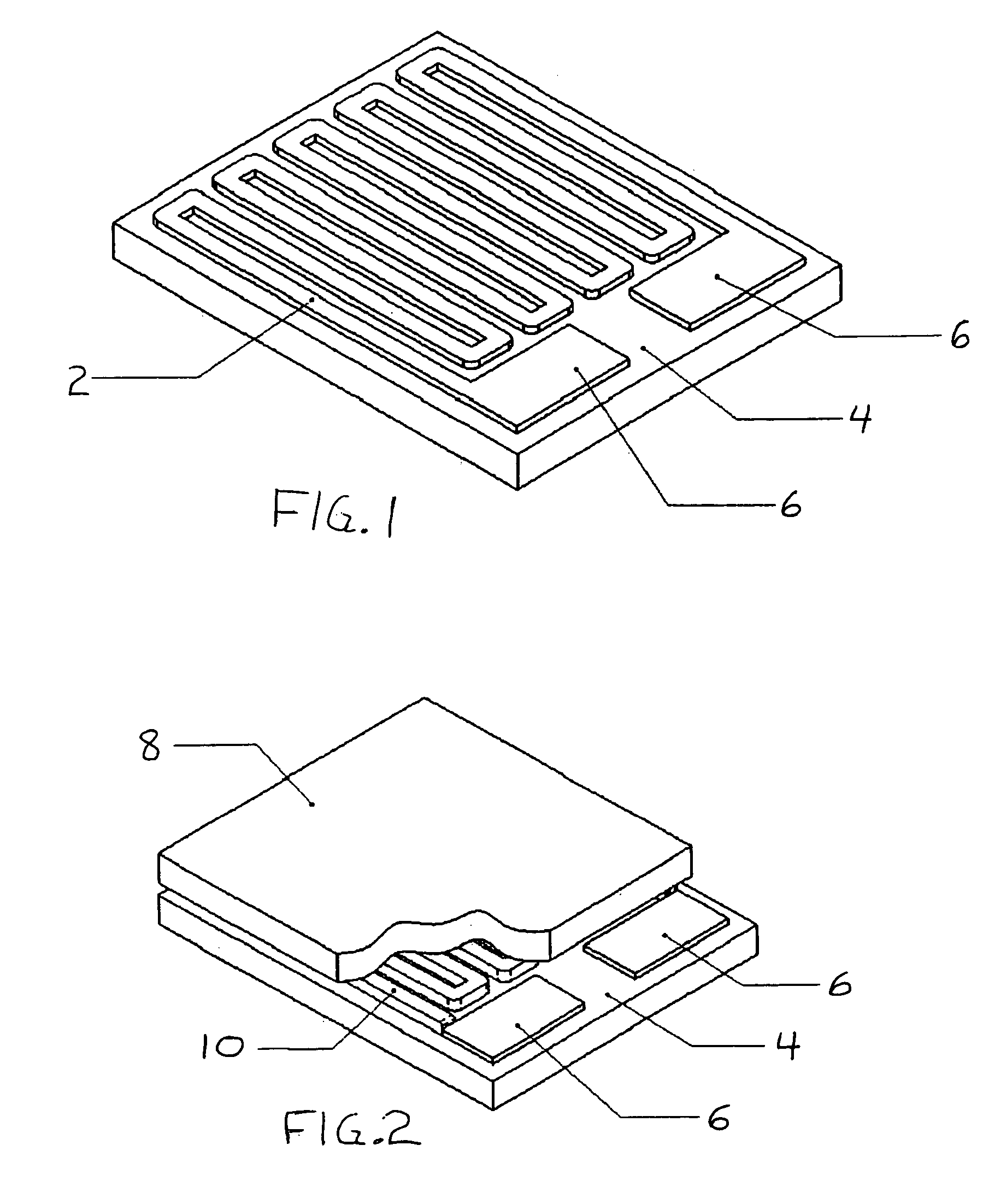

Method of making flexible sheet heater

ActiveUS7268325B1Rapidly and smoothly sandwichedHeating element shapesPower to electric heating circuitsEngineeringElectrically conductive

A method of making a flexible sheet heater includes the steps of (i) bonding an electrically conductive fabric and an support member formed of a PET film and a layer of acrylic together, ii) stamp-cutting the electrically conductive fabric to form a heating element having a predetermined loop, iii) attaching two electrical terminals to two distal ends of the heating element respectively, iv) bonding a first flexible protective sheet member to one side of the heating element opposite to the PET film, v) removing the PET film from the heating element; and vi) bonding a second flexible protective sheet member to the other side of the heating element opposite to the first flexible protective sheet member so that the heating element is sandwiched between the first and second flexible protective sheet members.

Owner:LINKWIN TECH

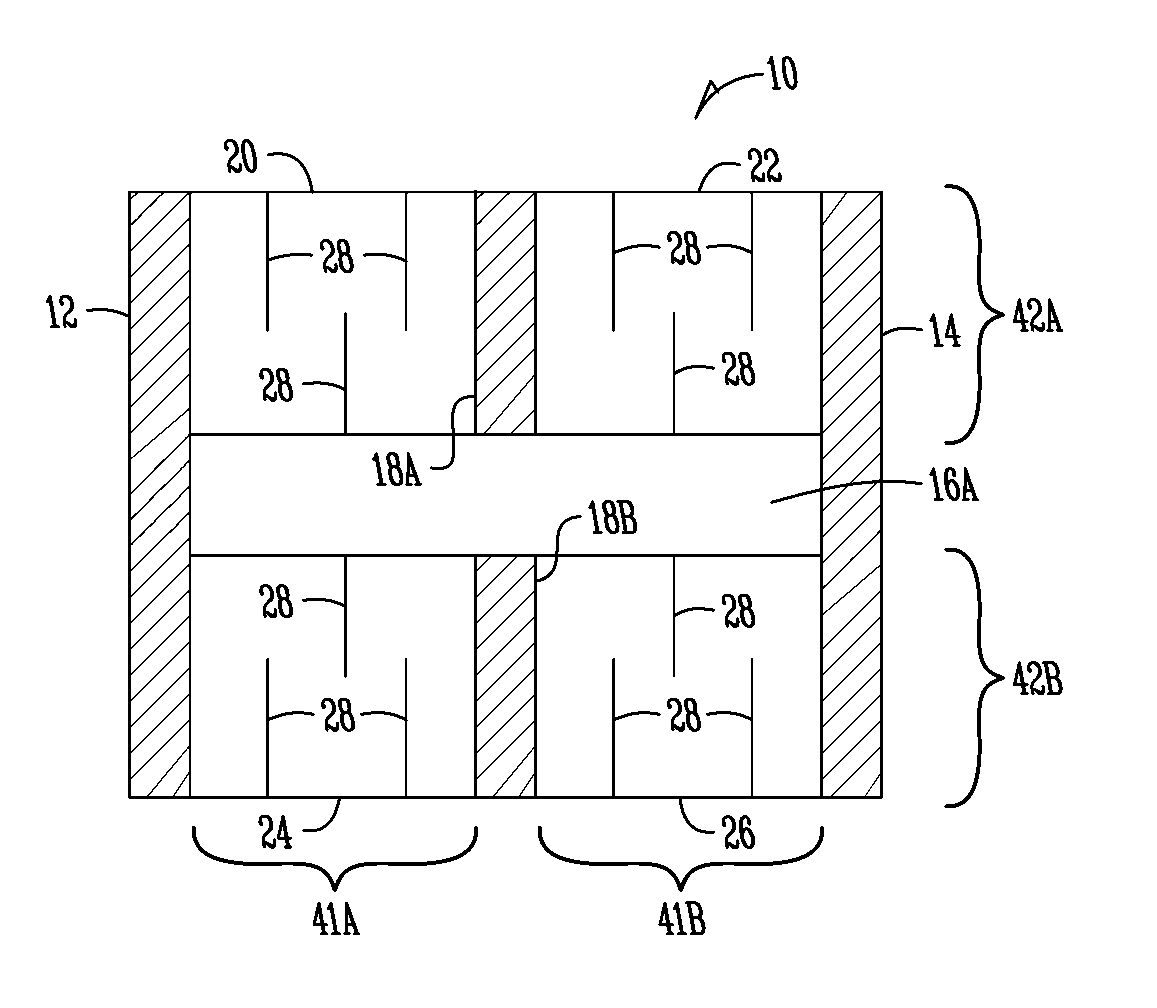

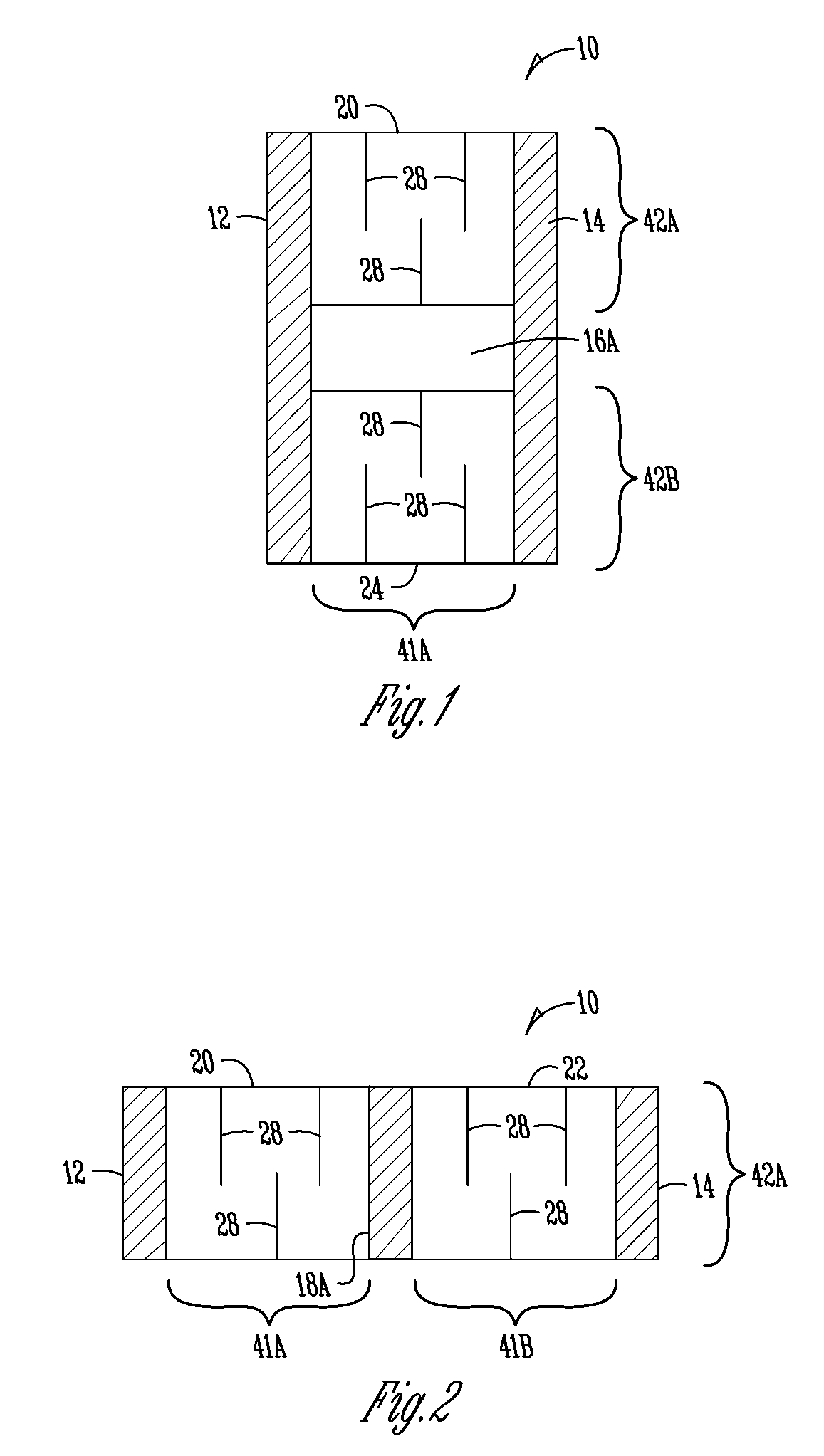

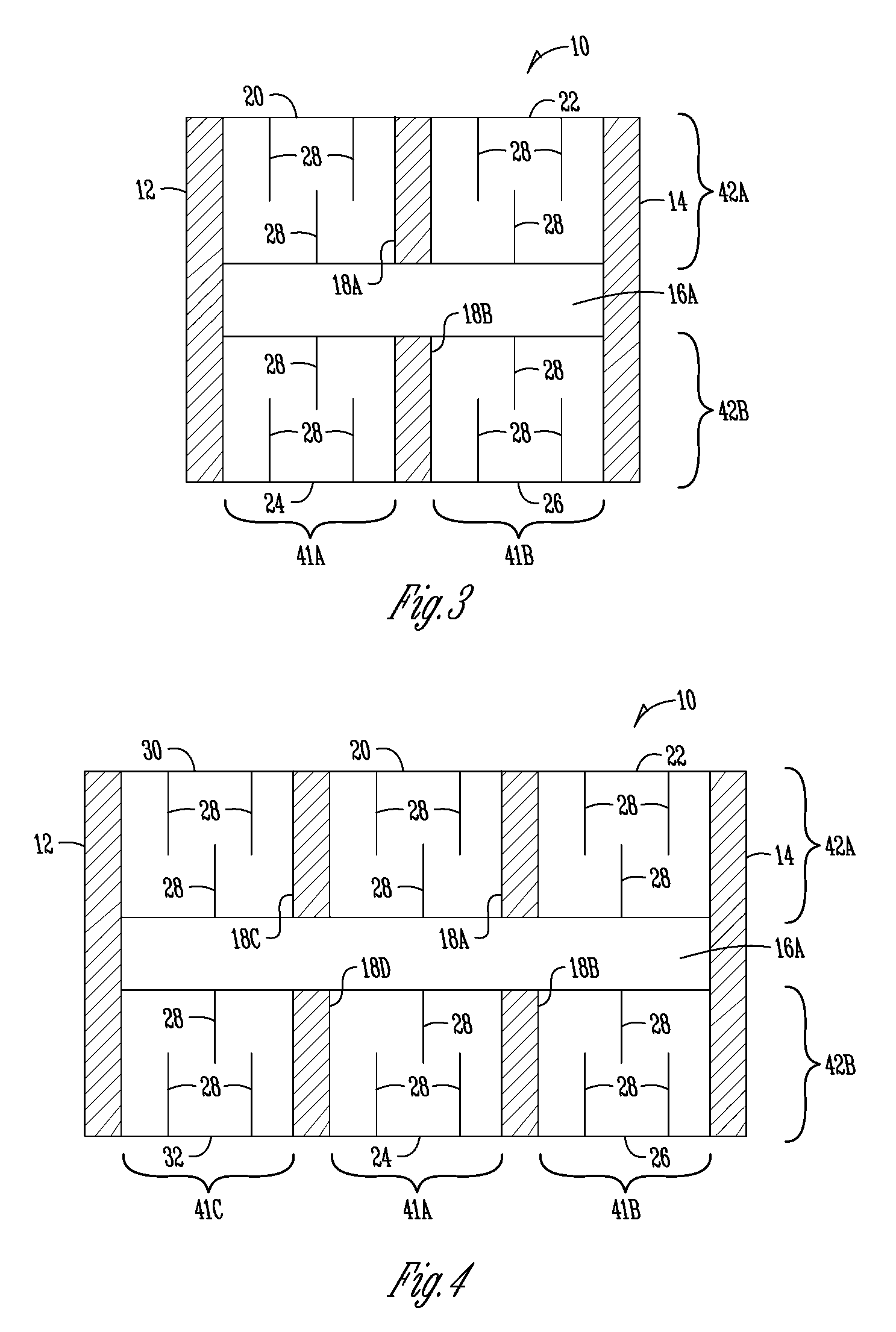

Power resistor

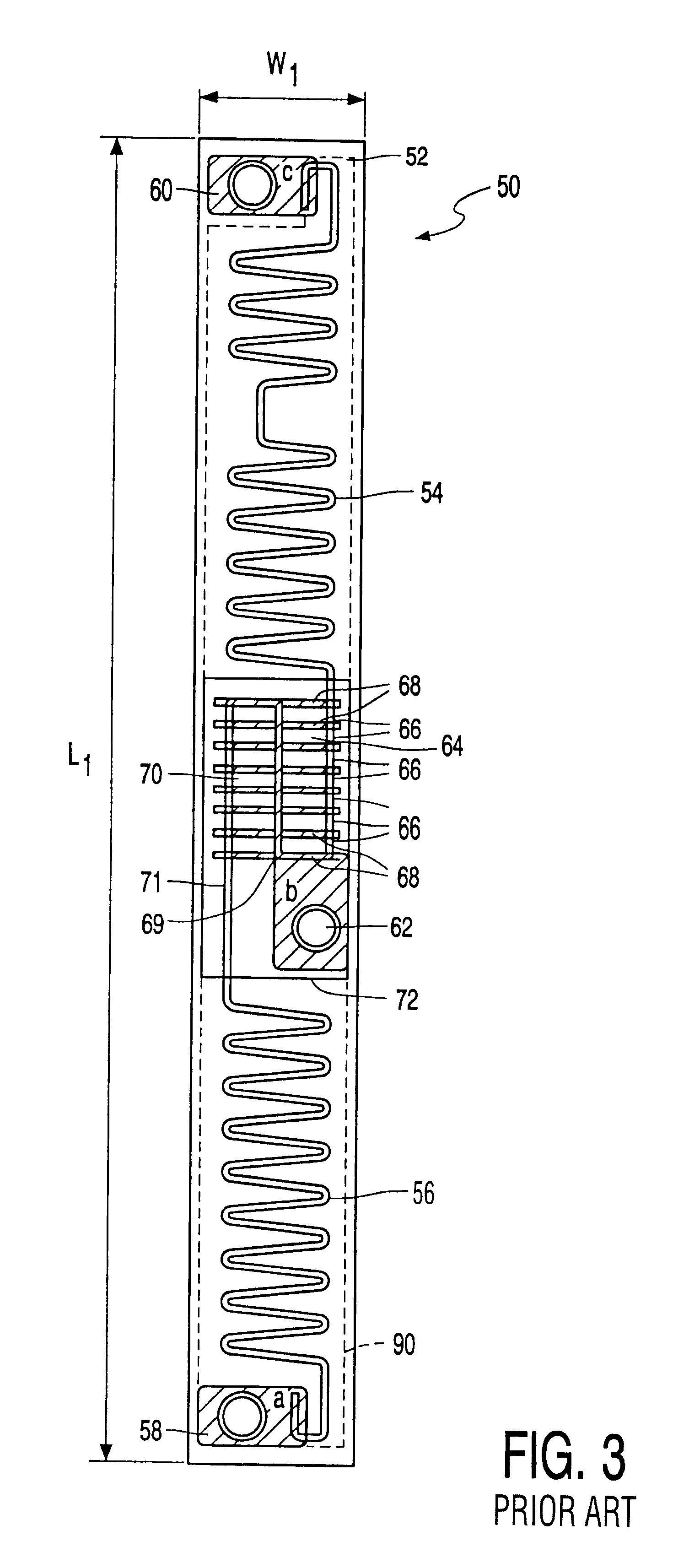

InactiveUS7843309B2Spread heatElongated resistive elementResistor cooling/heating/ventillationMetal stripsElectrical resistance and conductance

A resistor includes first and second opposite terminations, a resistive element formed from a plurality of resistive element segments between the first and second opposite terminations, at least one segmenting conductive strip separating two of the resistive element segments, and at least one open area between the first and second opposite terminations and separating at least two resistive element segments. Separation of the plurality of resistive element segments assists in spreading heat throughout the resistor. The resistor or other electronic component may be packaged by bonding to a heat sink tab with a thermally conductive and electrically insulative material. The resistive element may be a metal strip, a foil, or film material.

Owner:VISHAY DALE ELECTRONICS INC

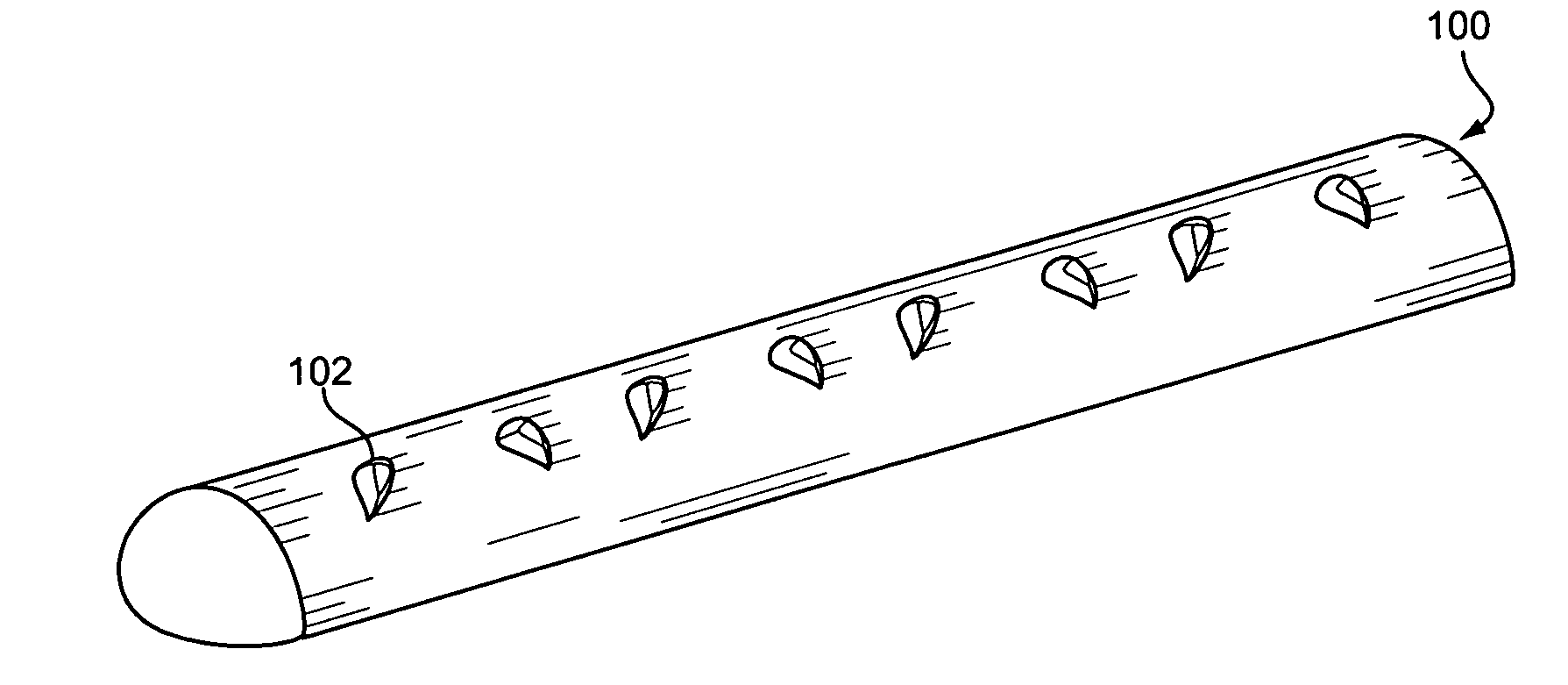

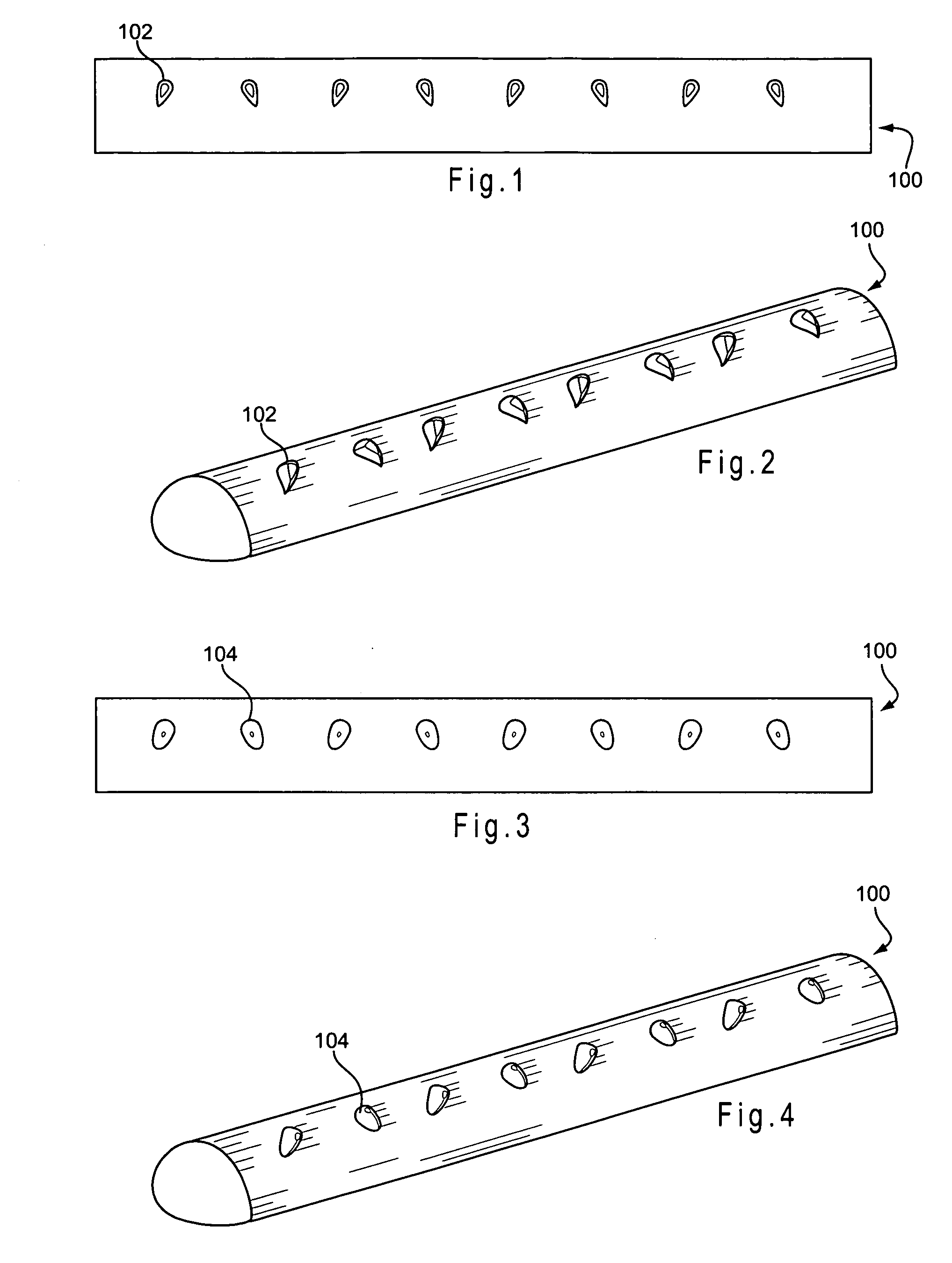

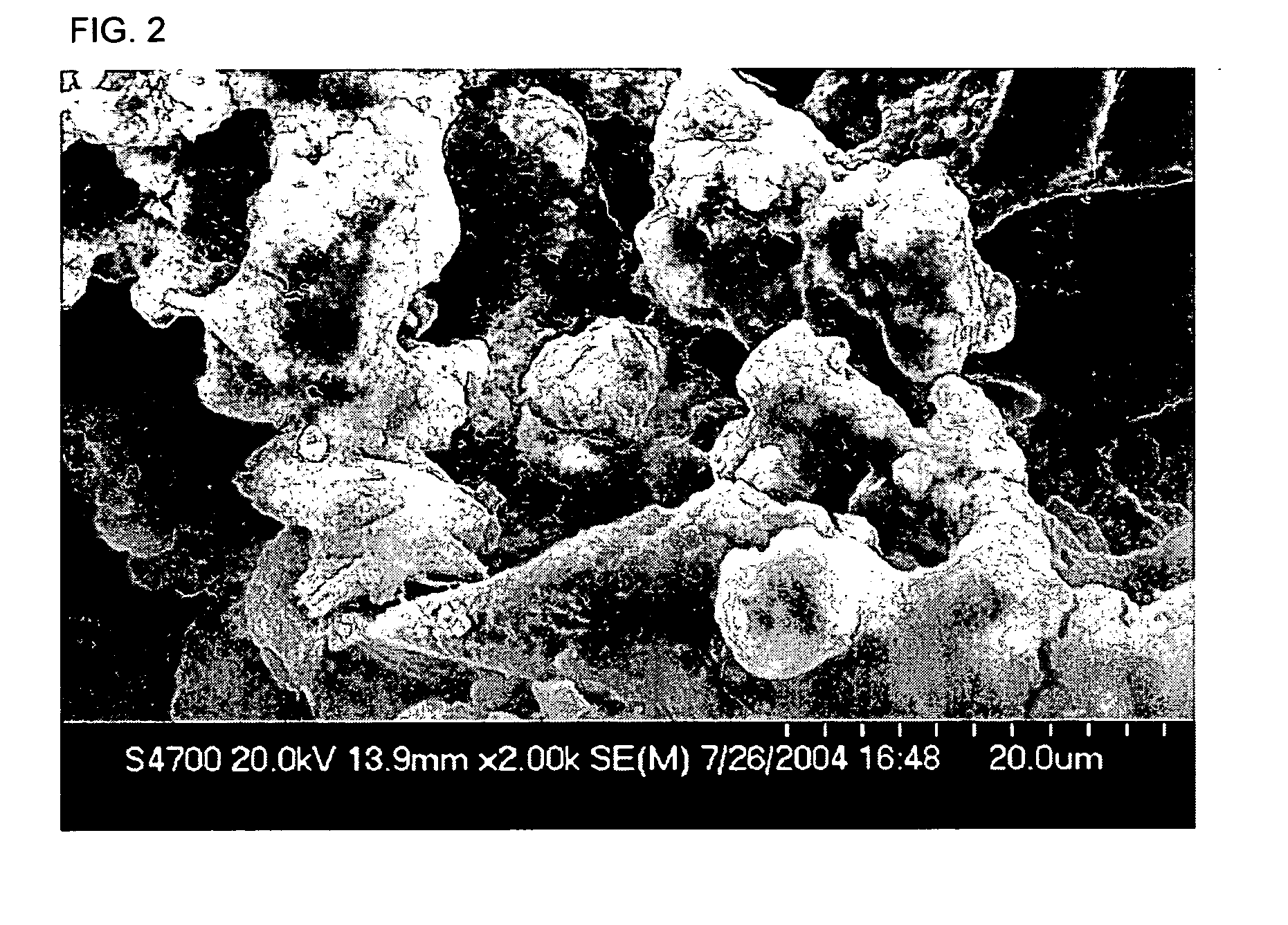

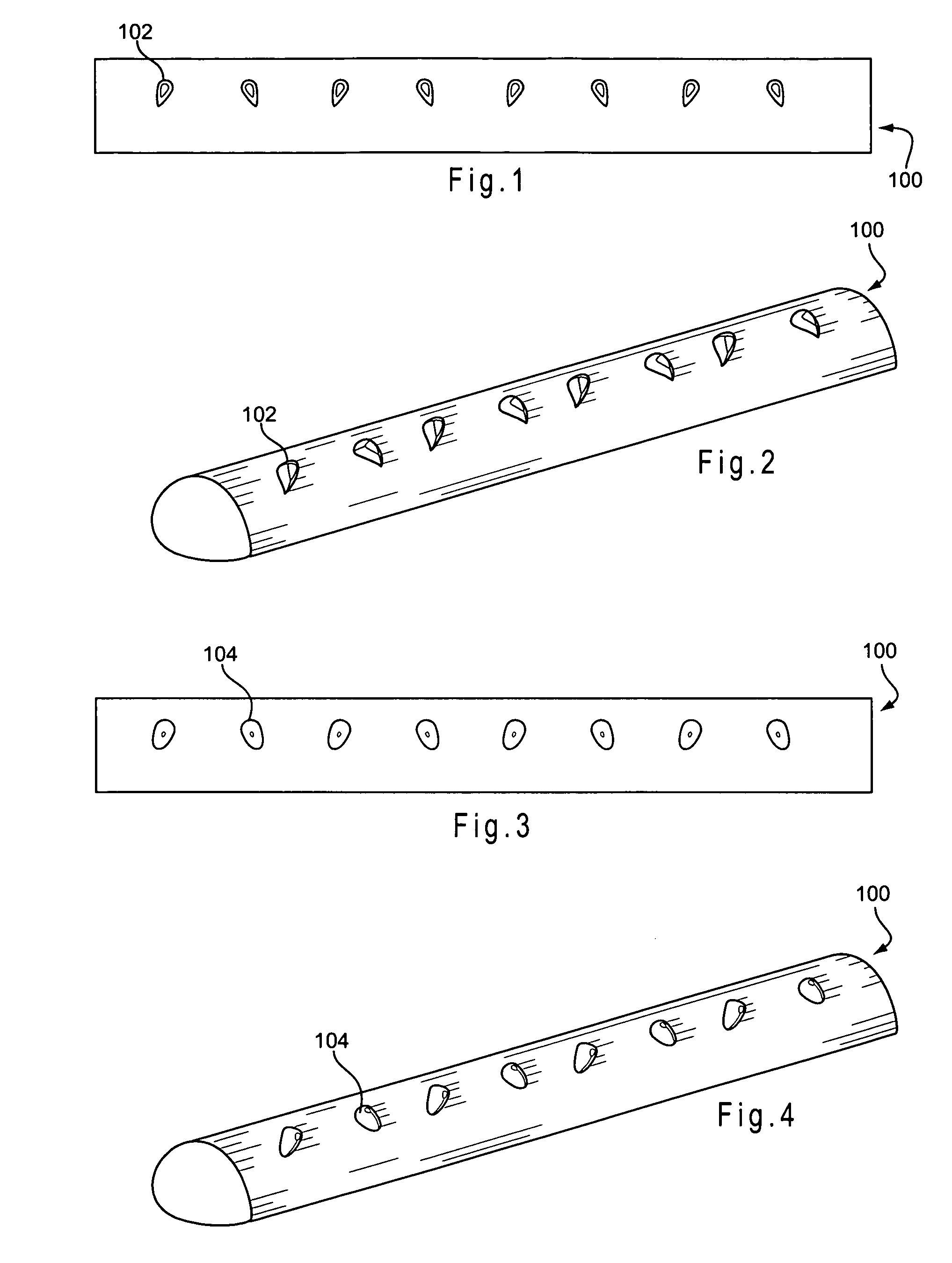

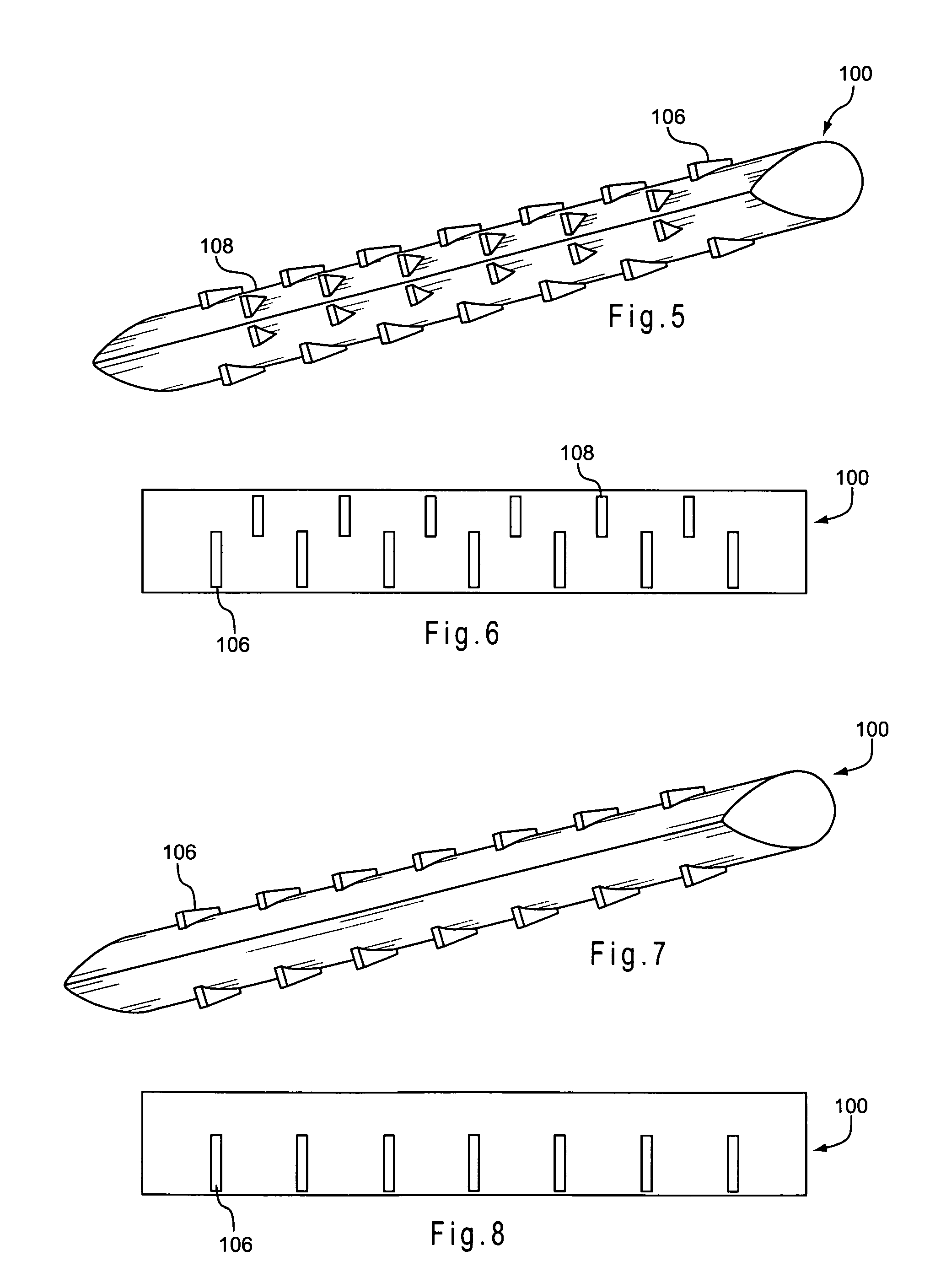

Wake generating solid elements for joule heating or infrared heating

ActiveUS20100132921A1Reduce dragReduce pressure dropMetal-working apparatusIndirect heat exchangersEngineeringJoule heating

An improved solid heat transfer element composed of an elongate member having a generally cylindrical surface with male vortex generating protrusions is provided. The vortex generating protrusions, which may be referred to as “turbulators,” provide improved heat transfer by convection to a flow of air transverse to the elongate members without substantially increasing the pressure drop in the flow of air passing over the members. Advantageously, a plurality of the heat transfer elements, or of straight portions of a single serpentine heat transfer element, may be arranged in an aligned or staggered array of elements or straight portions. Many advantageous profile shapes of the element and vortex generators are provided, including aerodynamic profile shapes that are symmetrical with respect to a fluid flow to provide low drag and pressure drop. Heat in the element may be generated by means of electrical resistance or absorption of radiation.

Owner:MOSKAL DANIEL

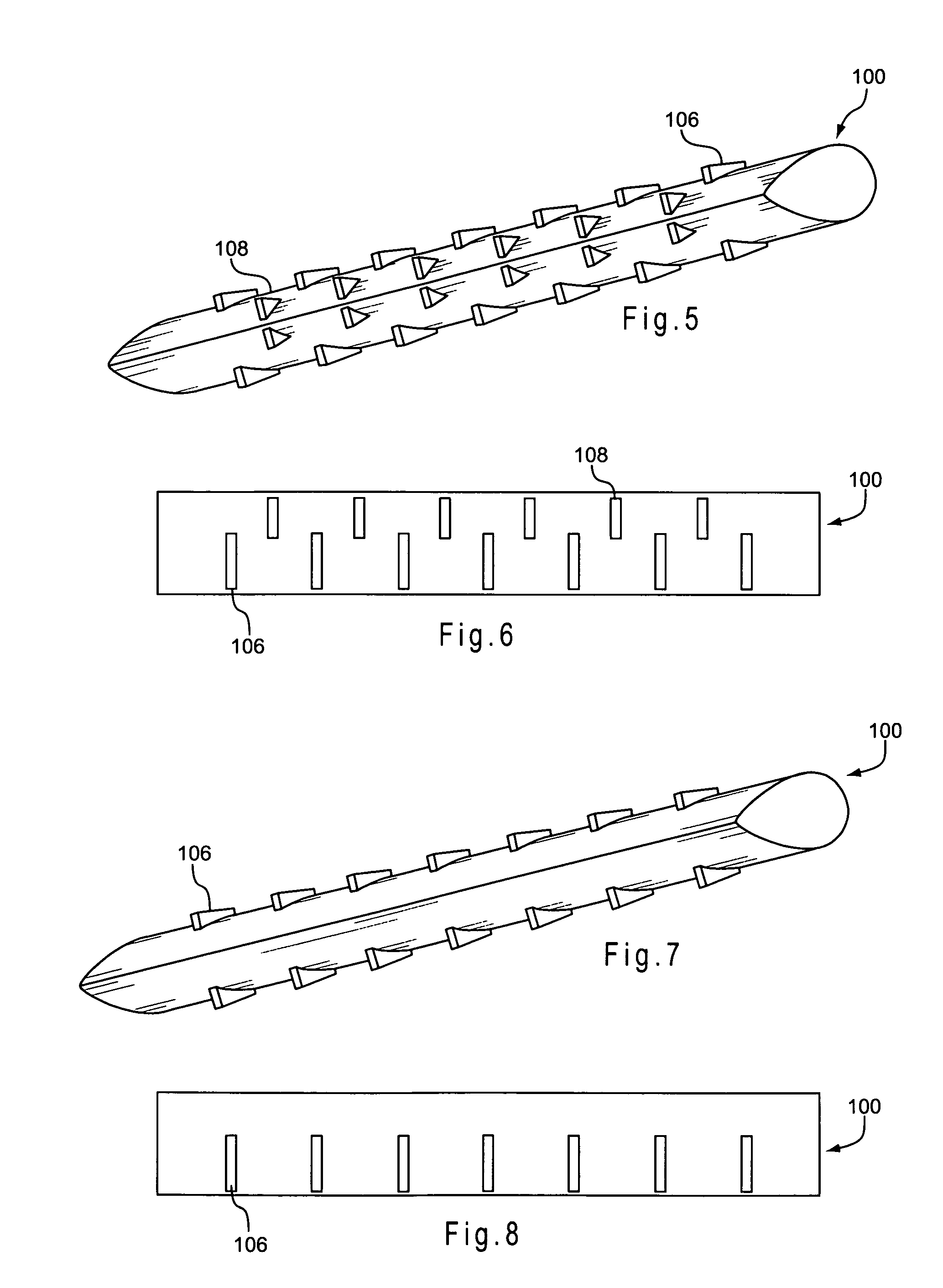

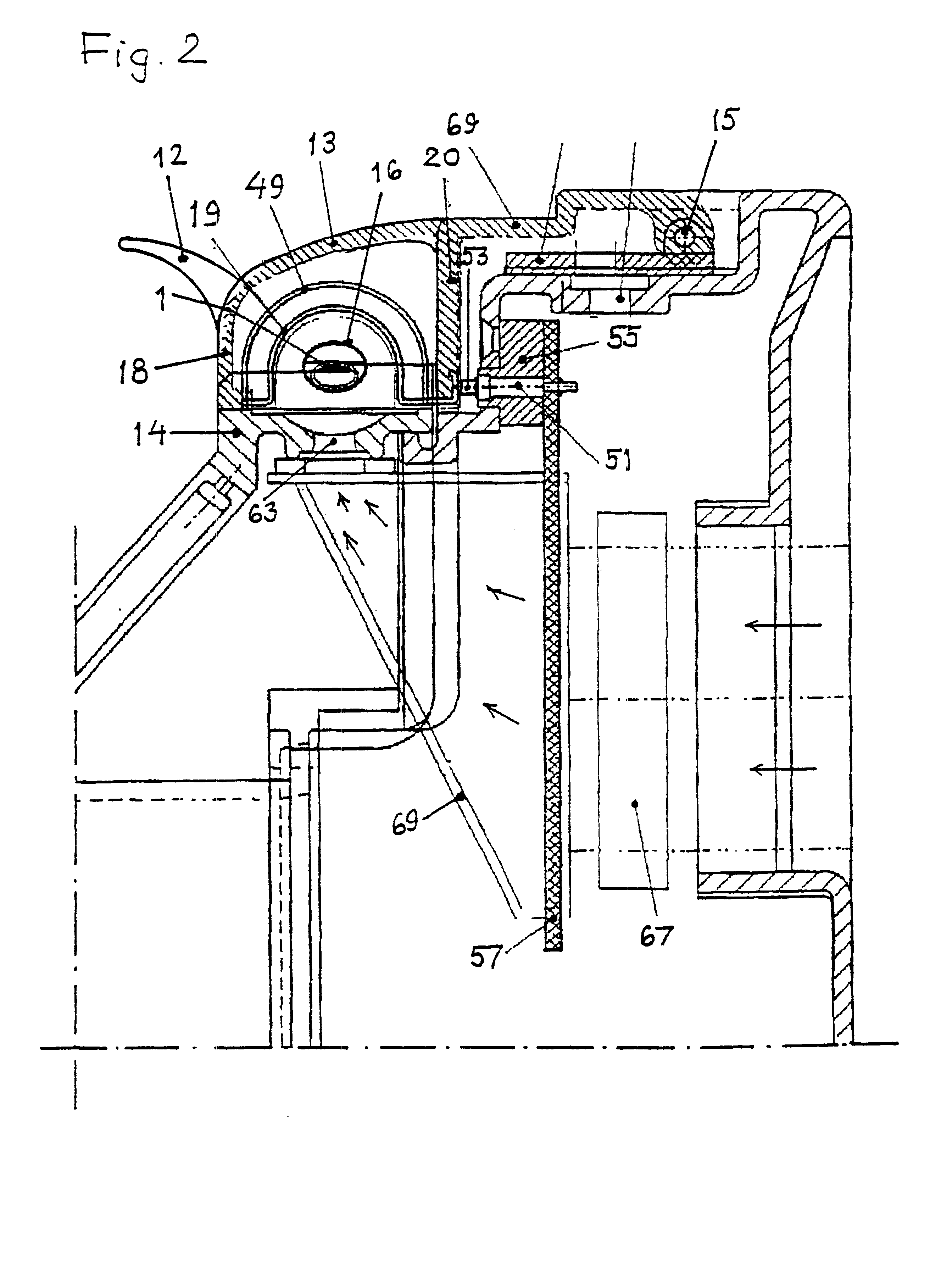

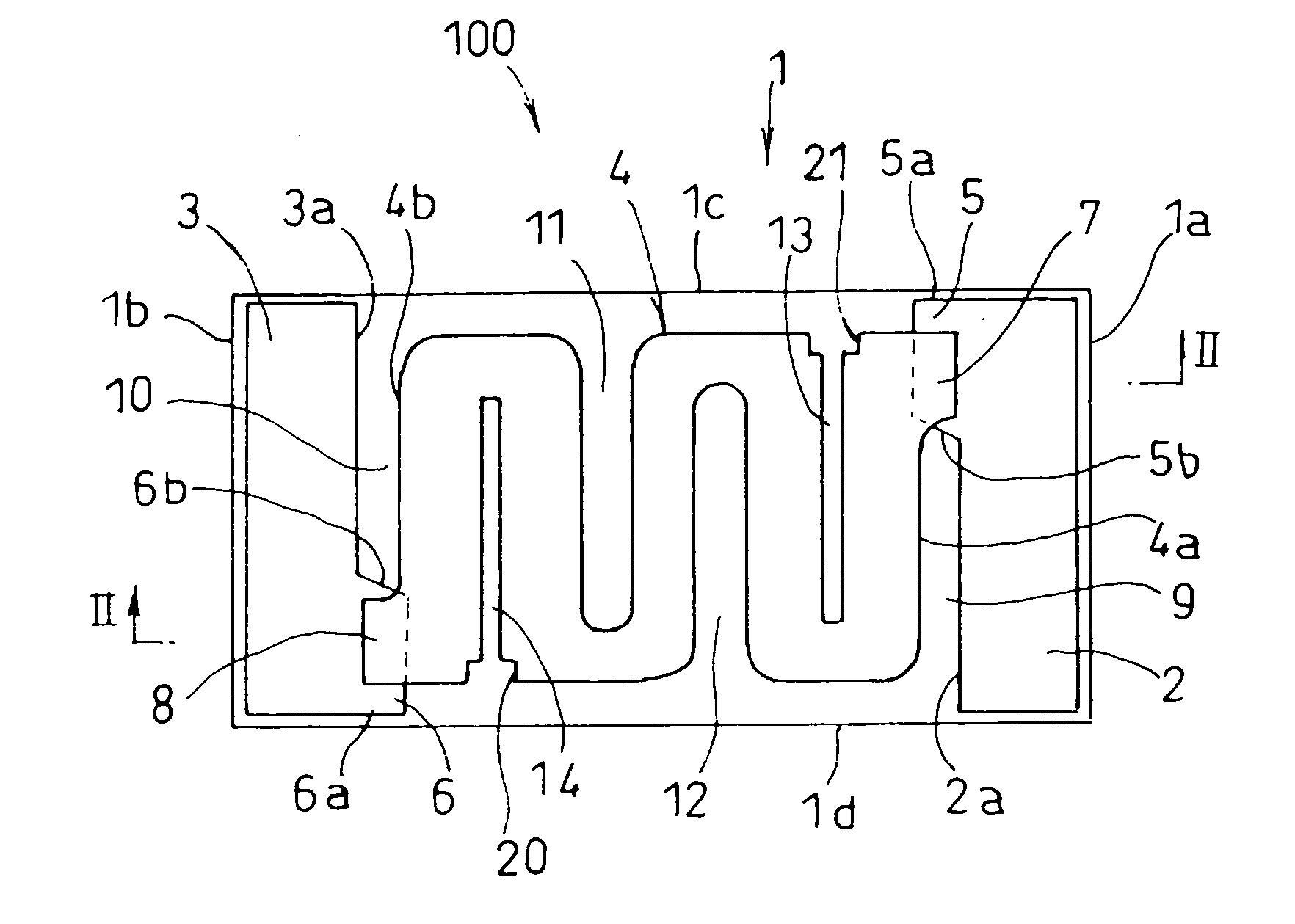

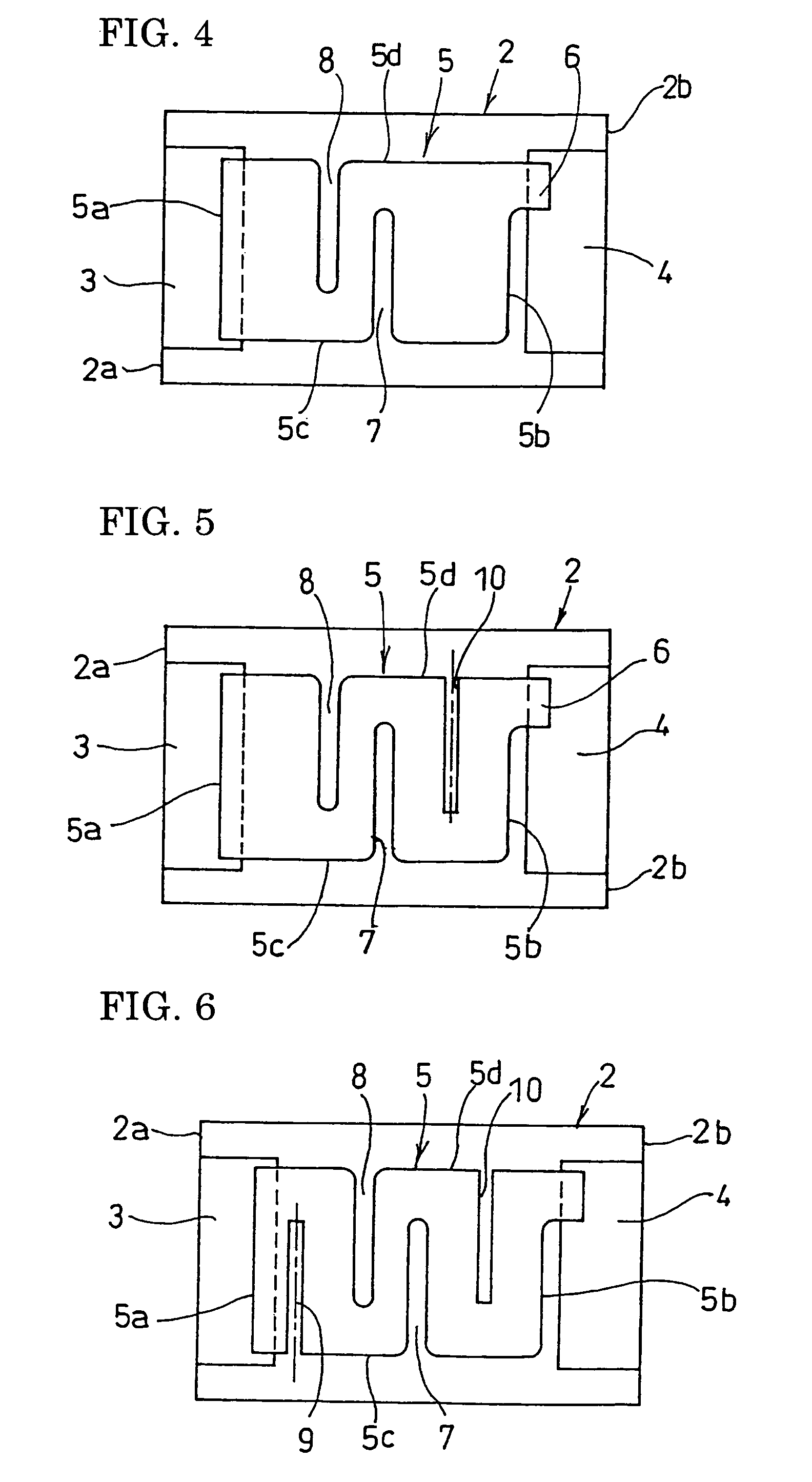

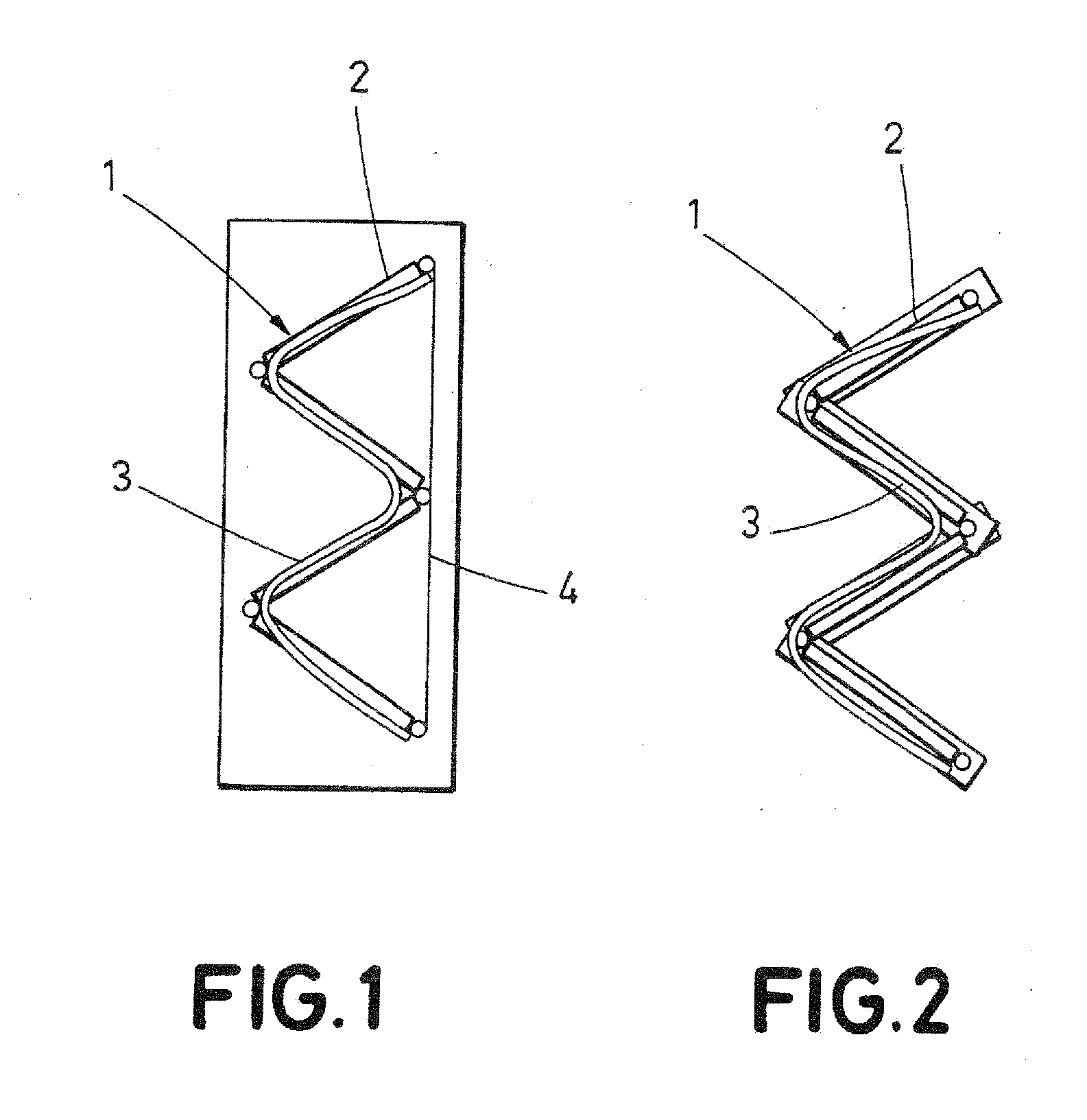

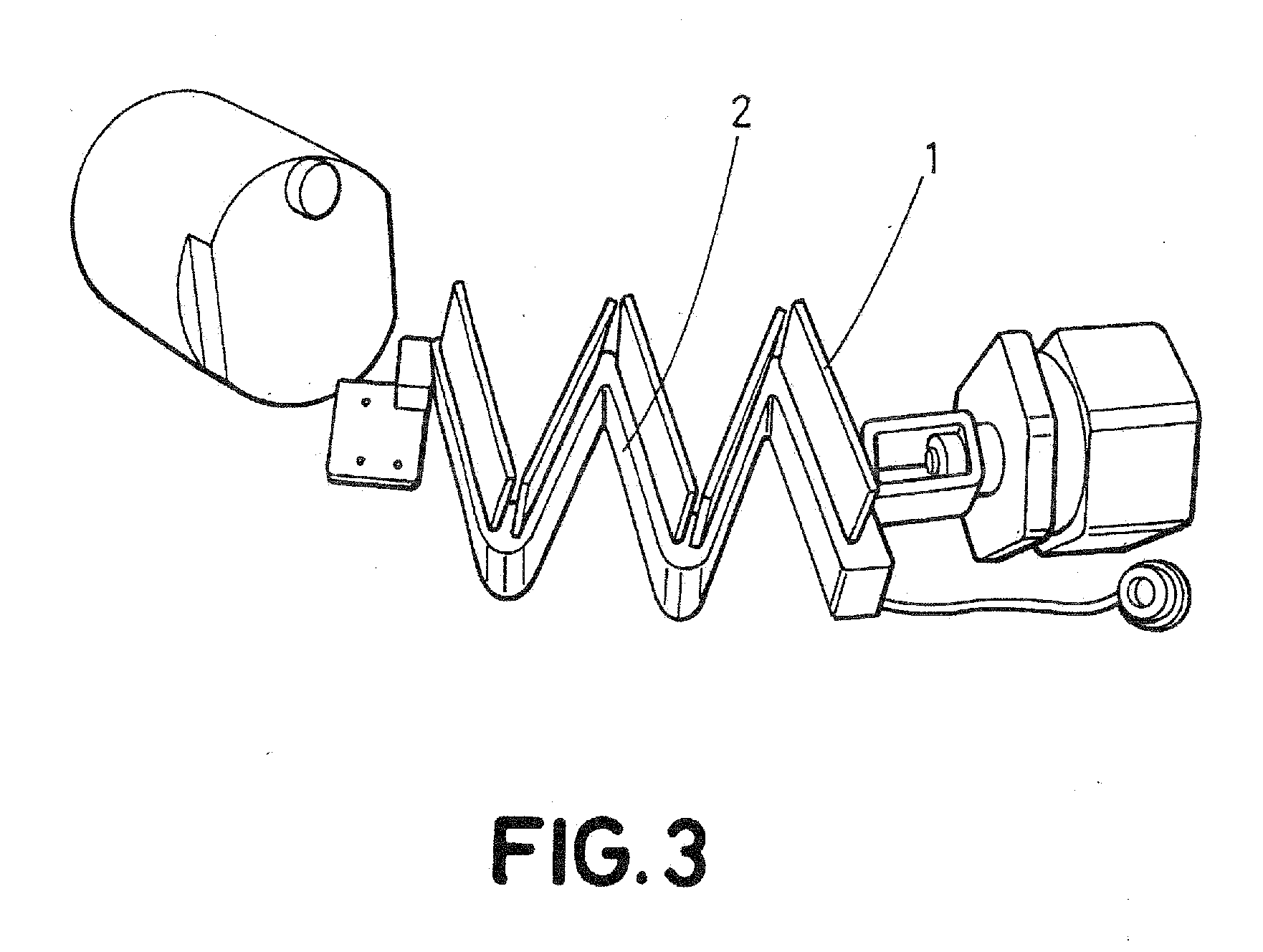

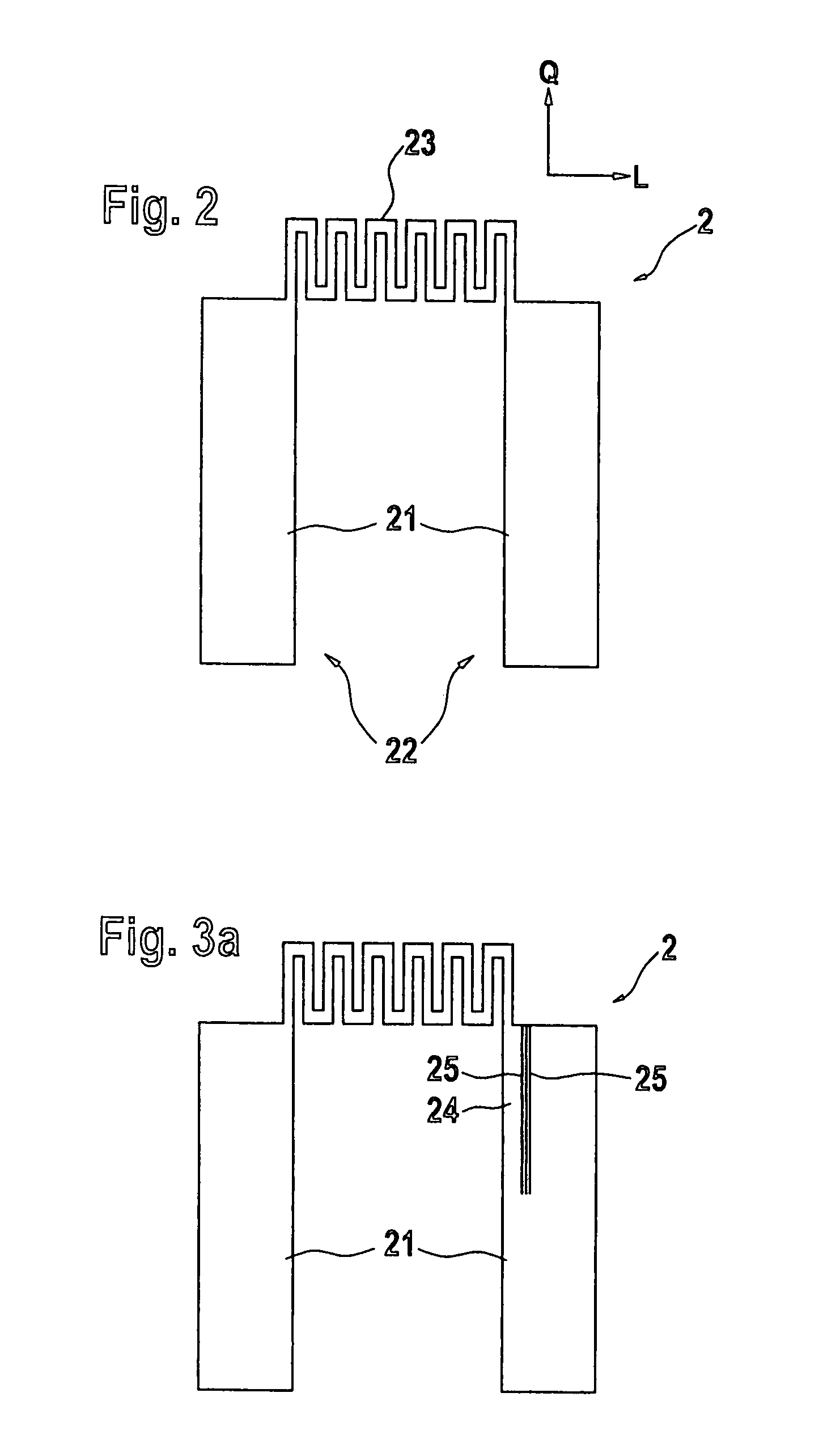

Device for heating shrinkable sleeves

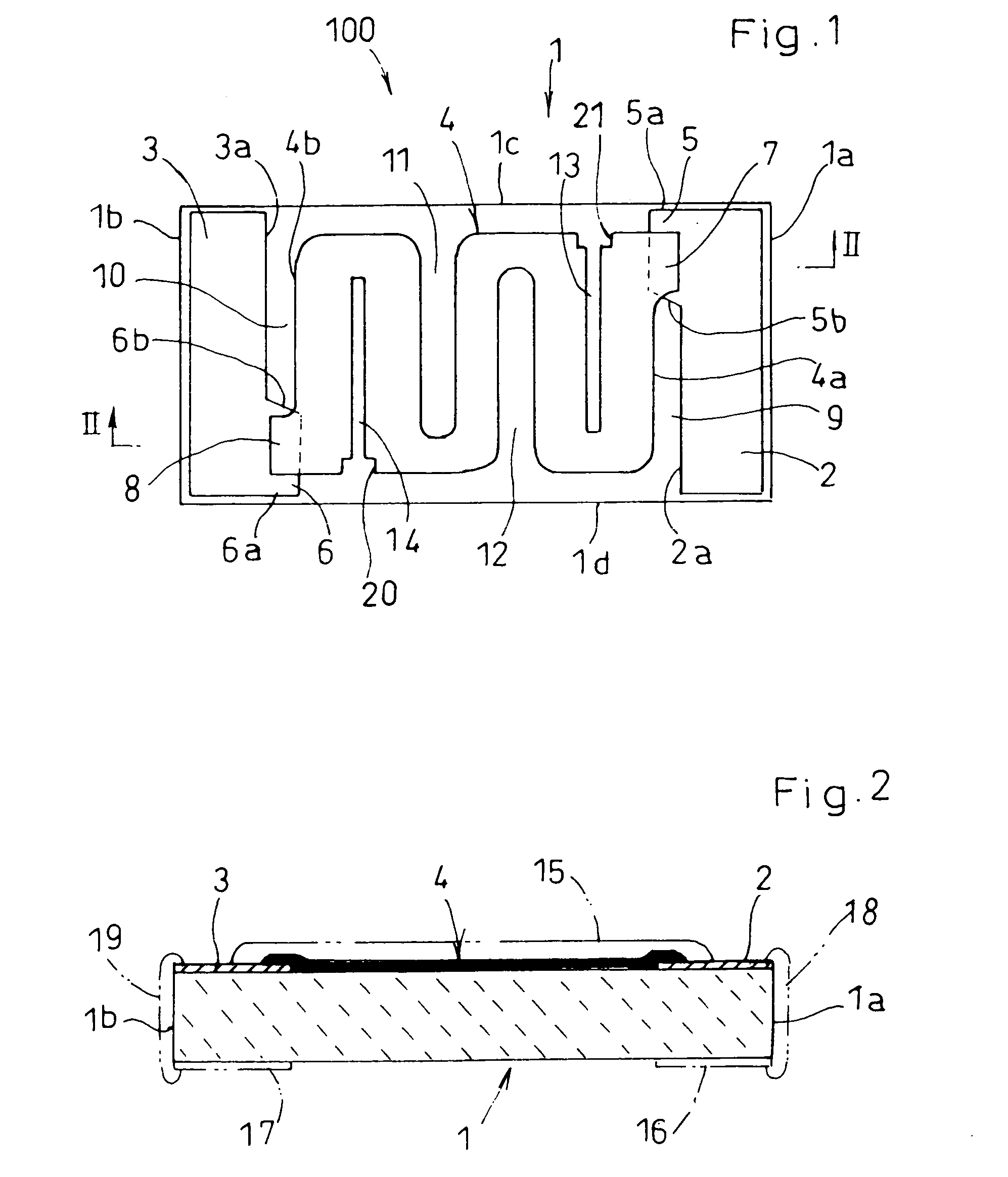

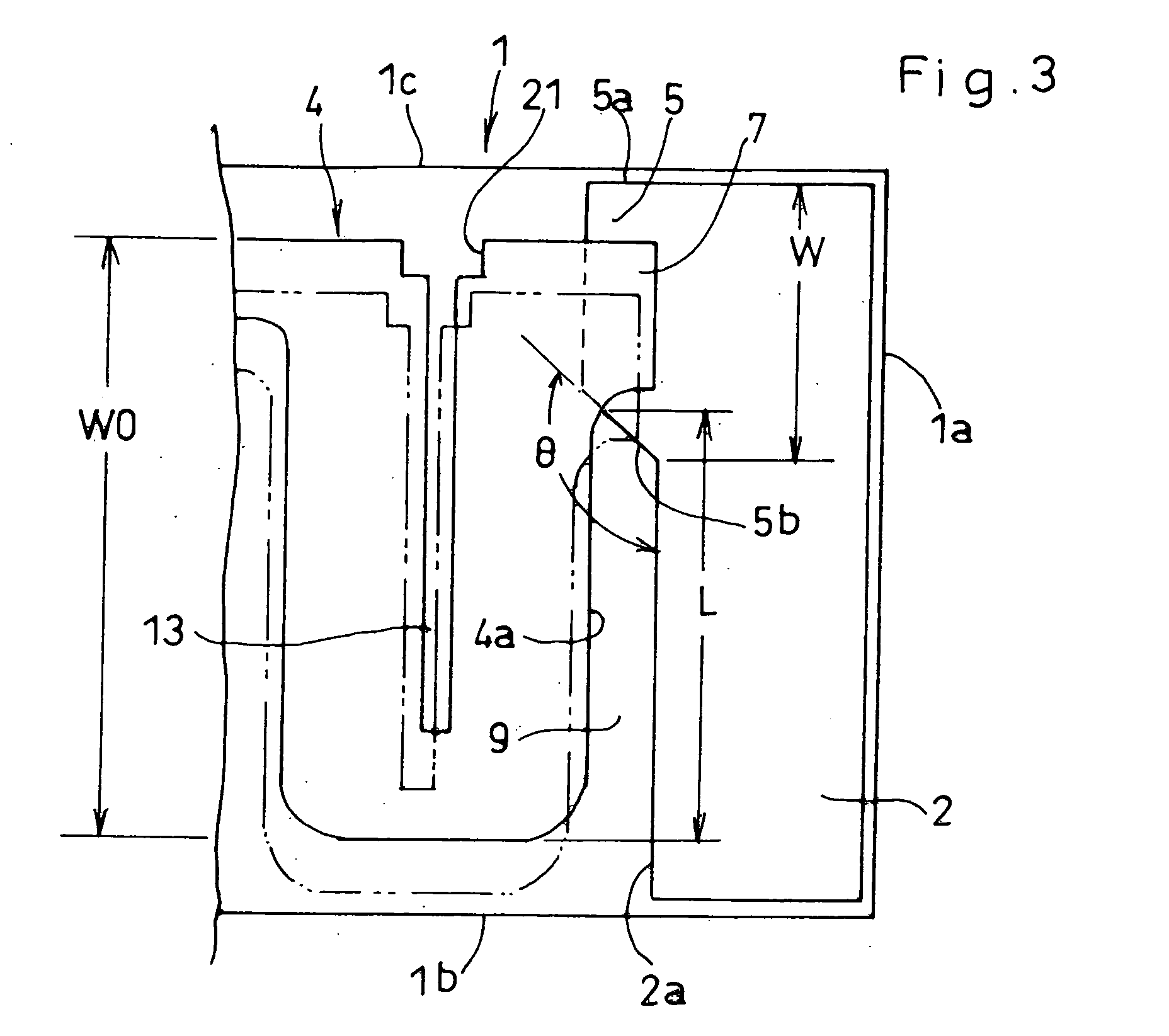

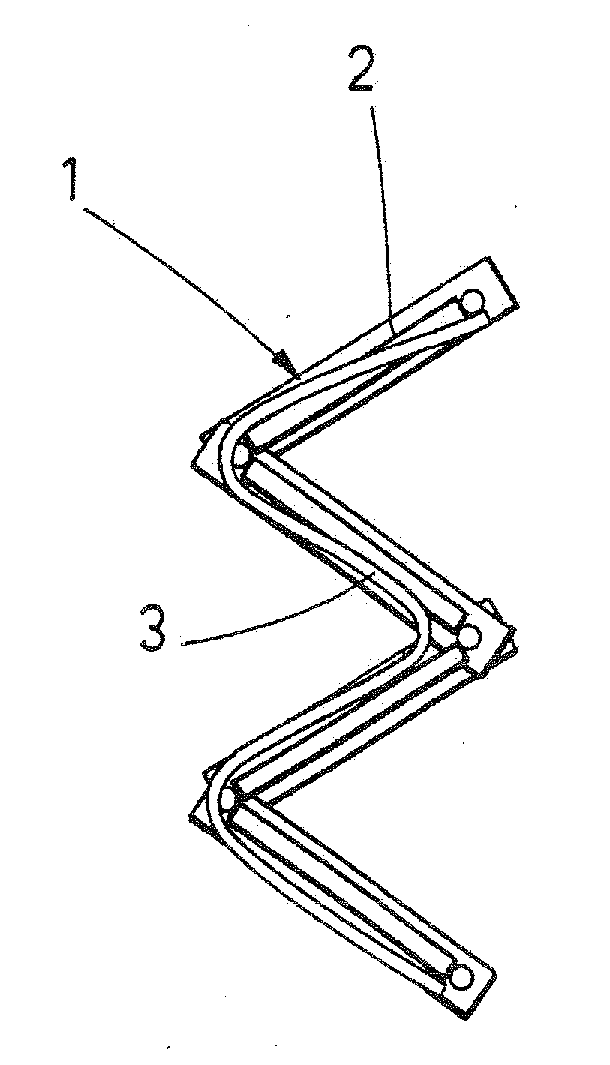

InactiveUS20020088796A1Simple mounting attachmentIncrease contactElongated resistive elementHeater elementsHeat-shrinkable sleeveElectrical resistance and conductance

A resistance element (19) for a device for shrinking shrinkable sleeves comprises an elongate electrical conductor extending in a zigzag pattern and bent to a tunnel shape. The shrinkable sleeve including for example an optical fiber enclosed therein is placed in that region of the resistance element (19), which corresponds to approximately the geometric axis of the upper semi-cylindric portion of the tunnel shape. The resistance element (1) has attachment pins (33) and contact and attachment pins (35) at its front and rear sides respectively intended to be placed in corresponding recesses in a lid of the device. The rear contact and attachment pins (35) have portions (39) intended for contact with elastic, electrically conducting contact pins with which the resistance element (19) comes in contact, when the lid is folded down to perform the shrinking operation. The open and freely suspended design of the resistance element (19) including only small contact areas to the lid result in that the resistance element can be rapidly heated and thereafter rapidly cooled implying that a shrinking operation can be executed in a minimum of time.

Owner:TELEFON AB LM ERICSSON (PUBL)

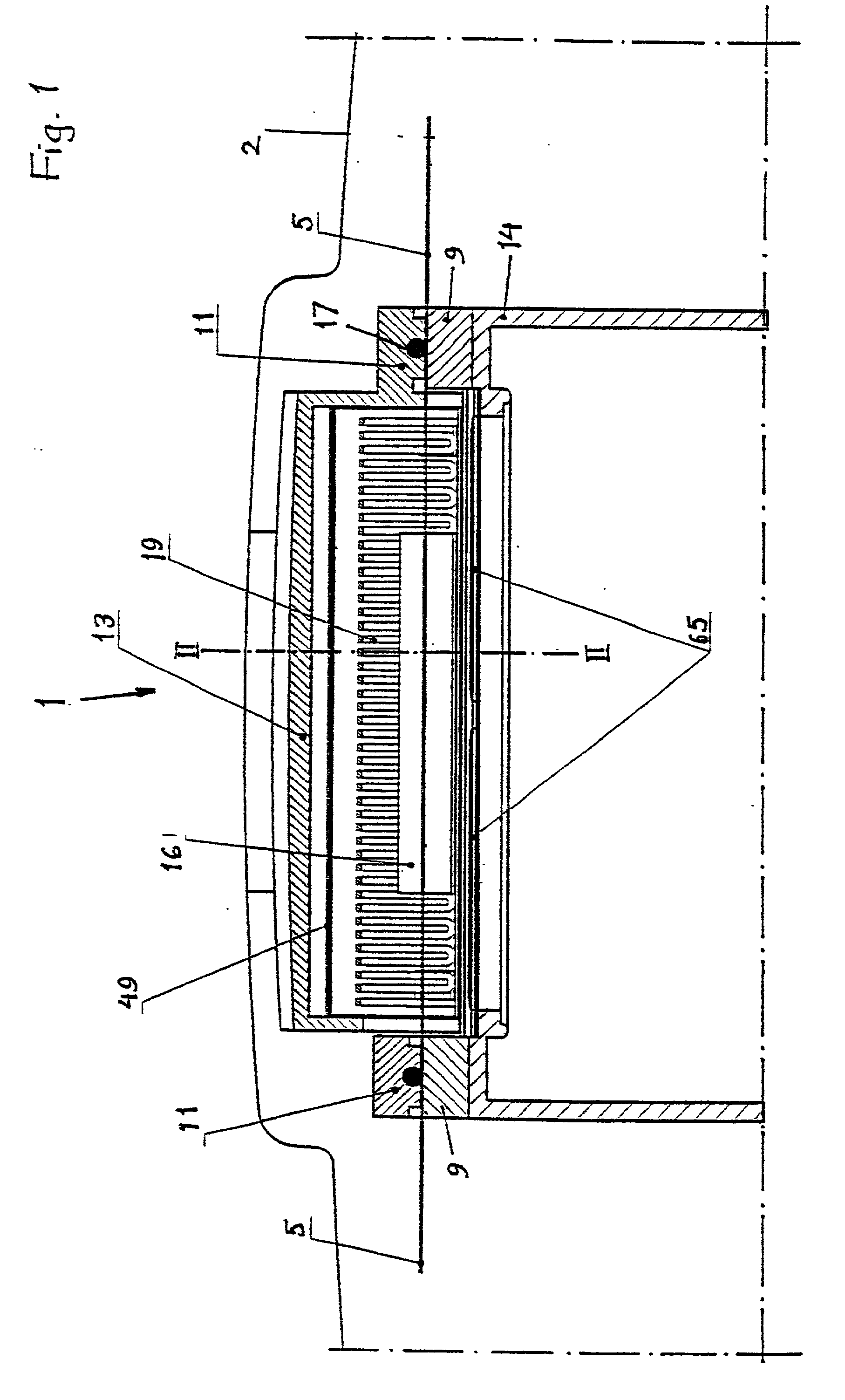

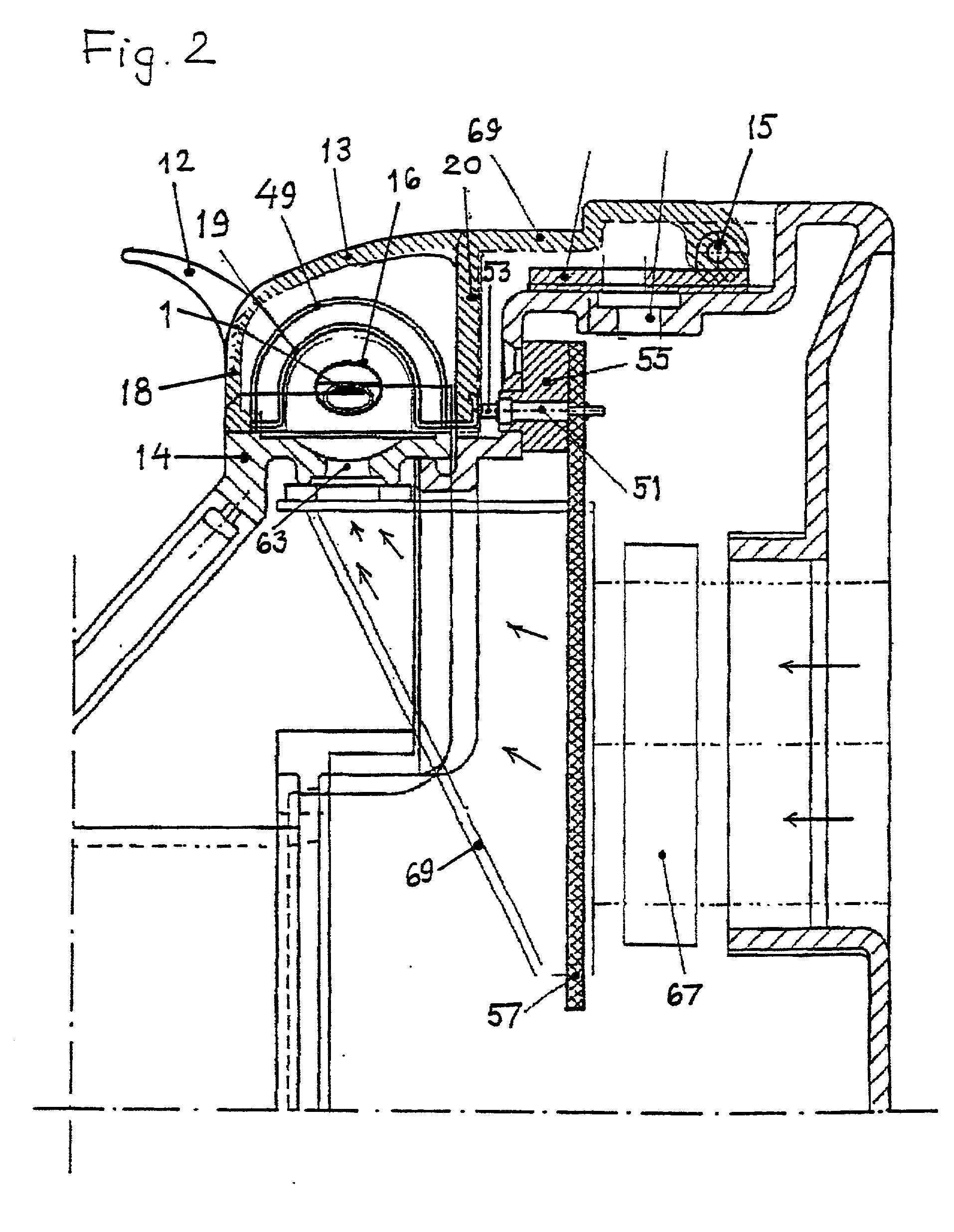

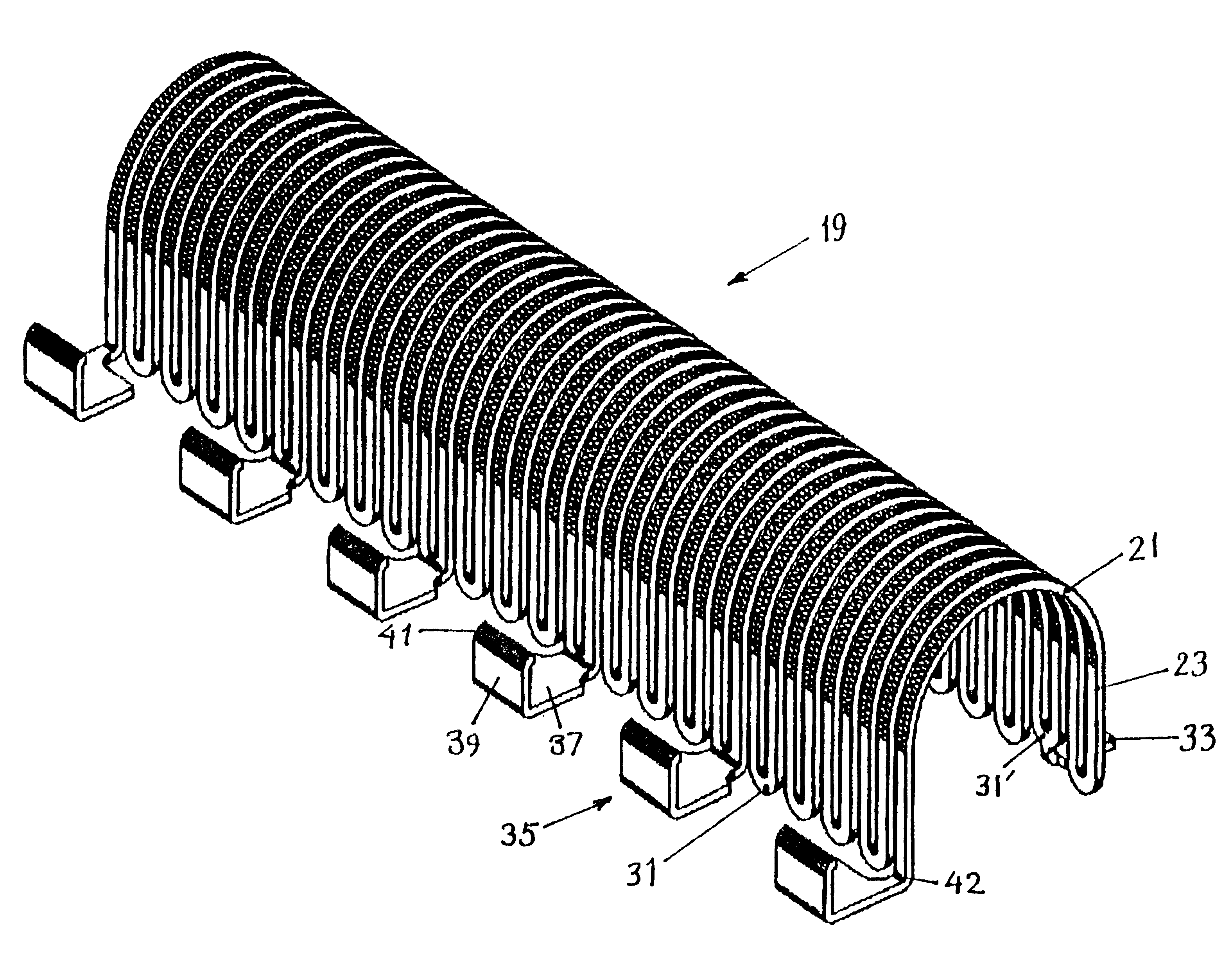

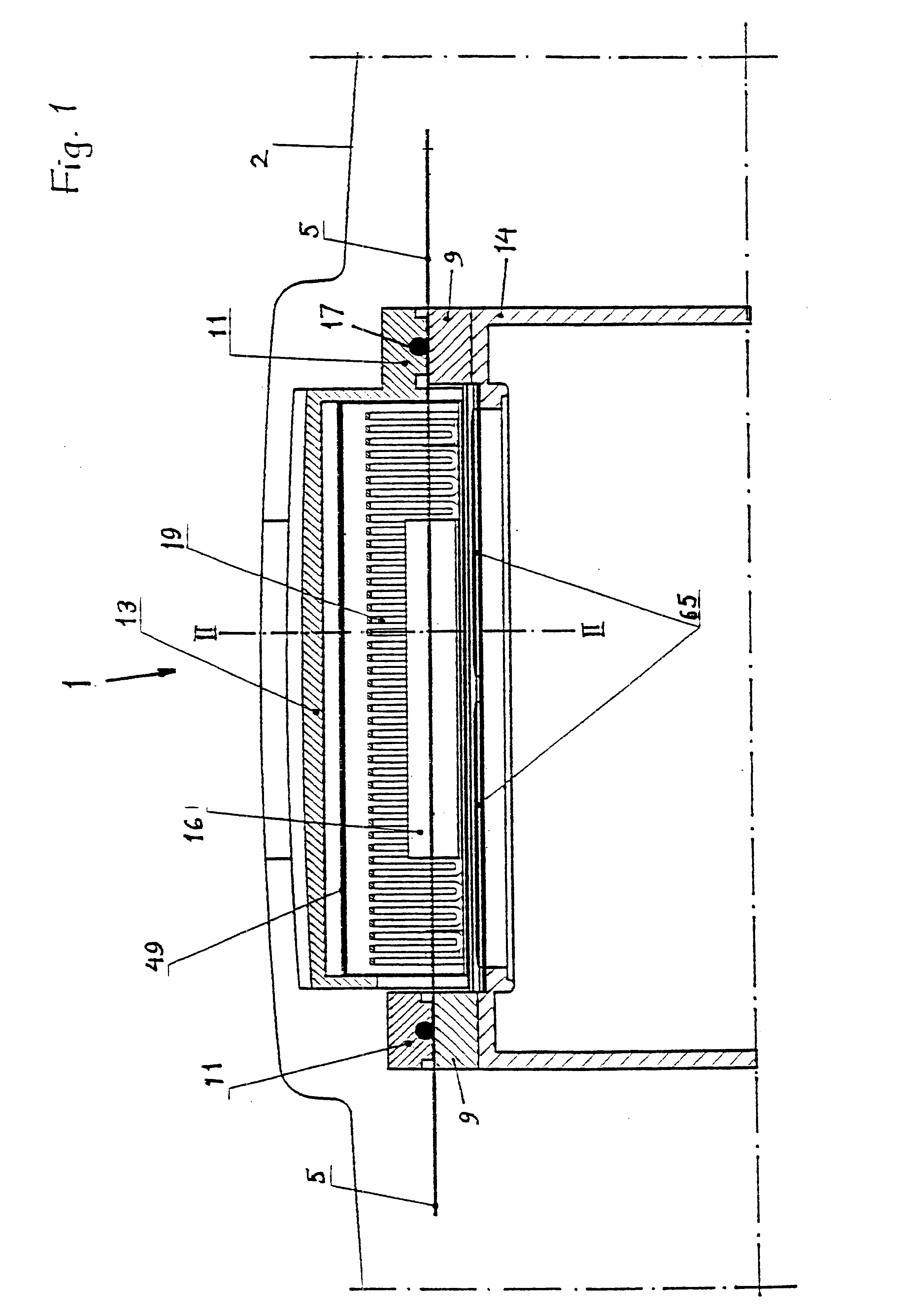

Device for heating shrinkable sleeves

InactiveUS6570140B2Simple mounting attachmentIncrease contactElongated resistive elementHeater elementsHeat-shrinkable sleeveElectrical resistance and conductance

A resistance element (19) for a device for shrinking shrinkable sleeves comprises an elongate electrical conductor extending in a zigzag pattern and bent to a tunnel shape. The shrinkable sleeve including for example an optical fiber enclosed therein is placed in that region of the resistance element (19), which corresponds to approximately the geometric axis of the upper semi-cylindric portion of the tunnel shape. The resistance element (1) has attachment pins (33) and contact and attachment pins (35) at its front and rear sides respectively intended to be placed in corresponding recesses in a lid of the device. The rear contact and attachment pins (35) have portions (39) intended for contact with elastic, electrically conducting contact pins with which the resistance element (19) comes in contact, when the lid is folded down to perform the shrinking operation. The open and freely suspended design of the resistance element (19) including only small contact areas to the lid result in that the resistance element can be rapidly heated and thereafter rapidly cooled implying that a shrinking operation can be executed in a minimum of time.

Owner:TELEFON AB LM ERICSSON (PUBL)

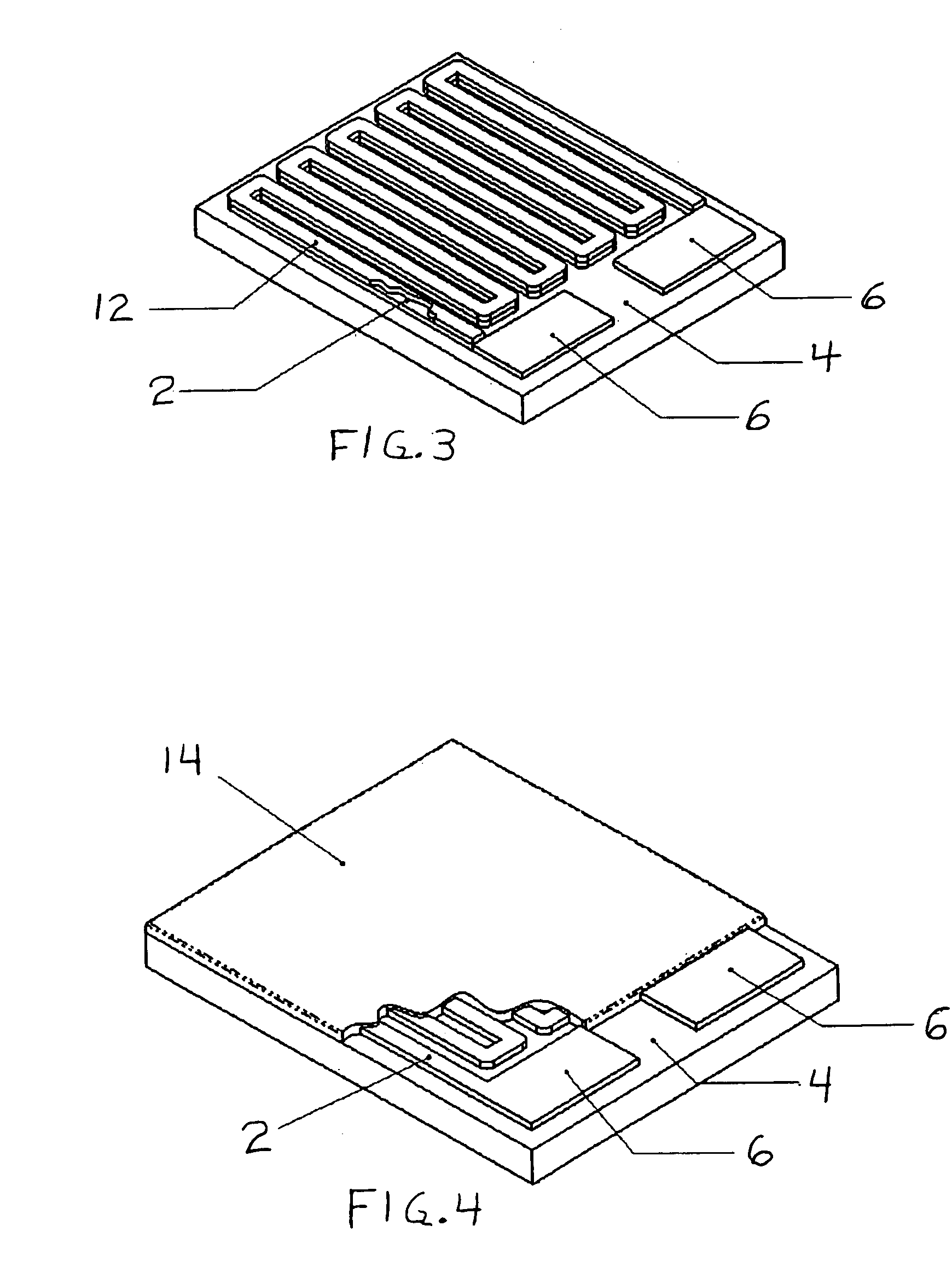

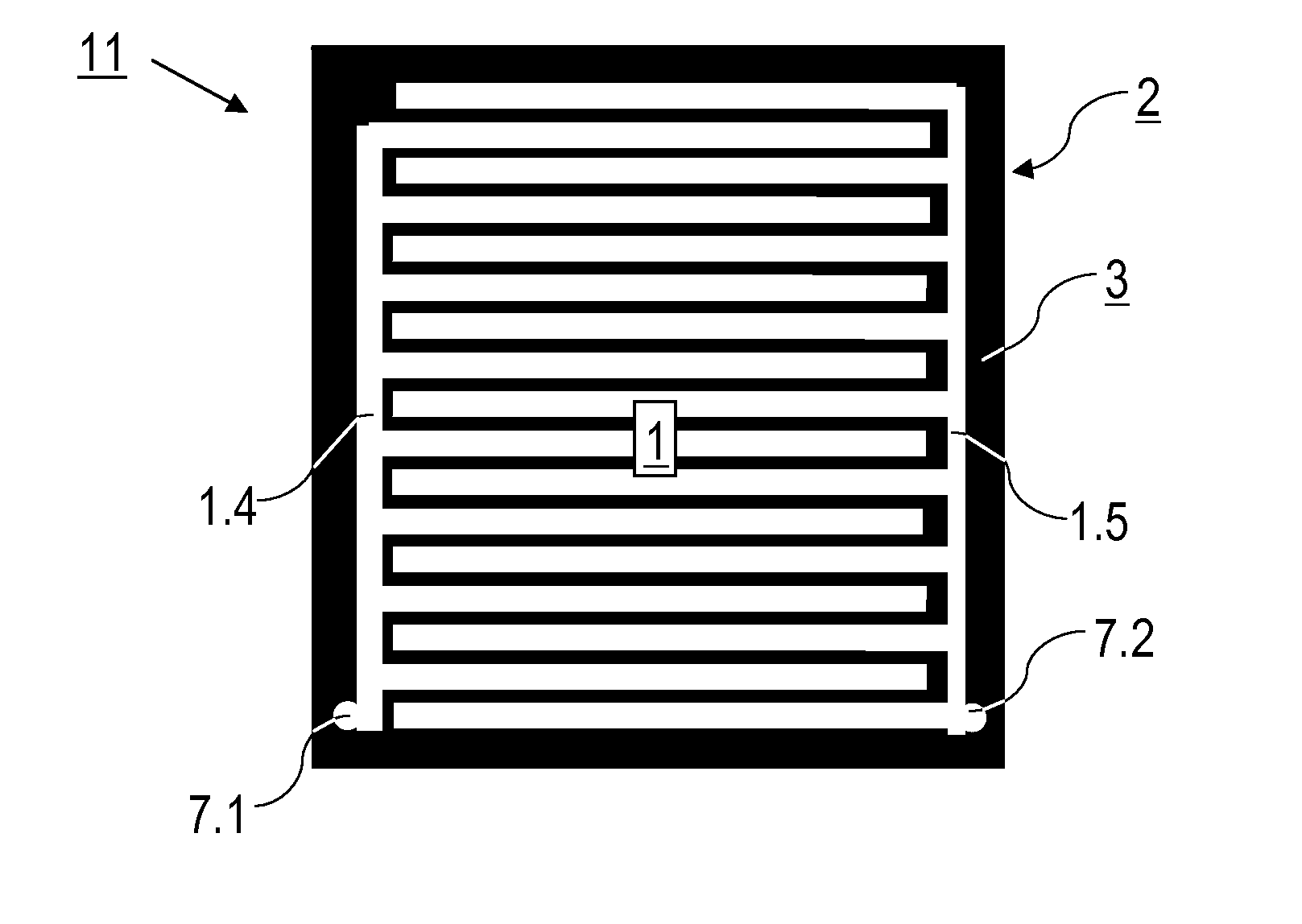

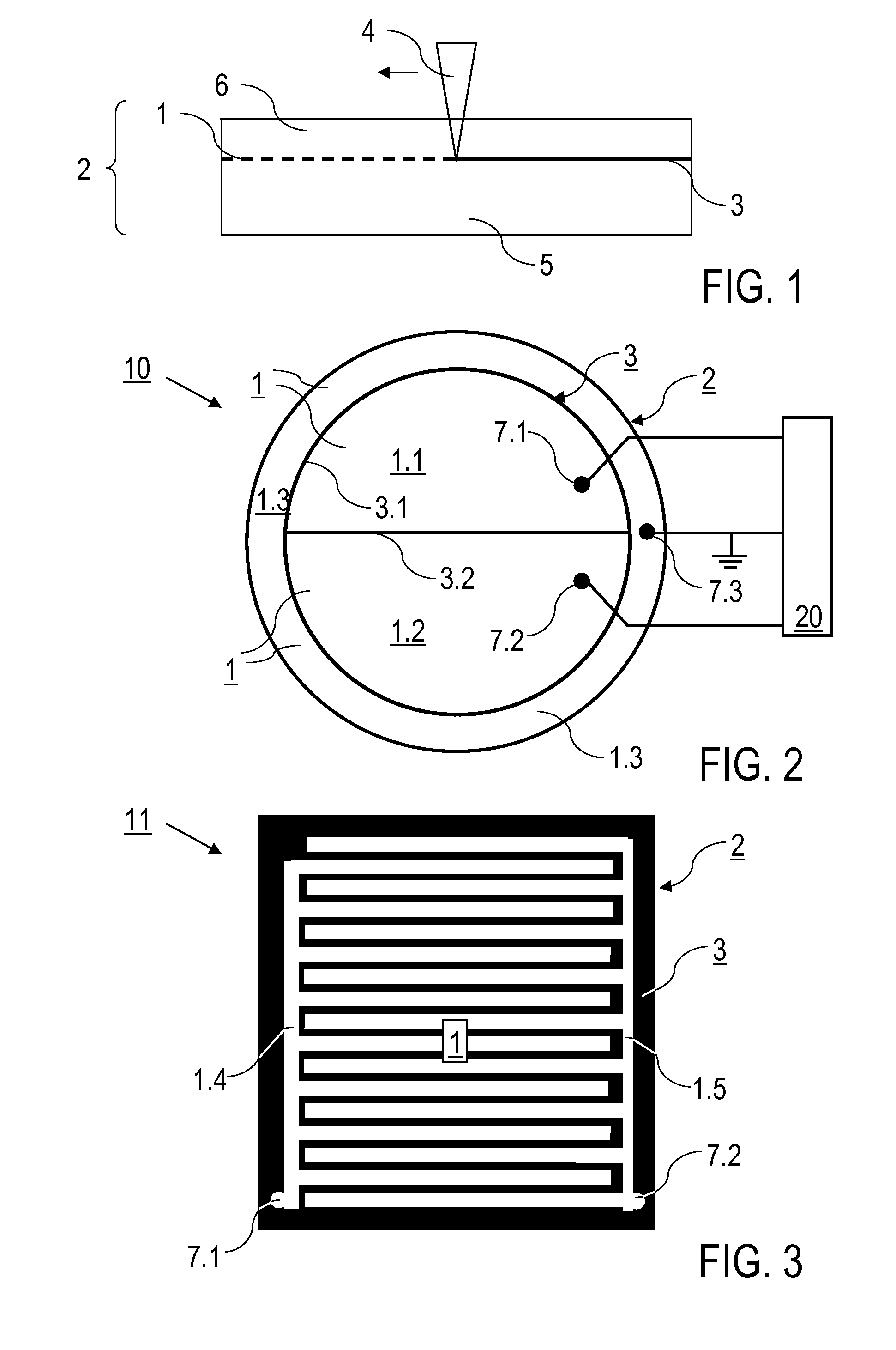

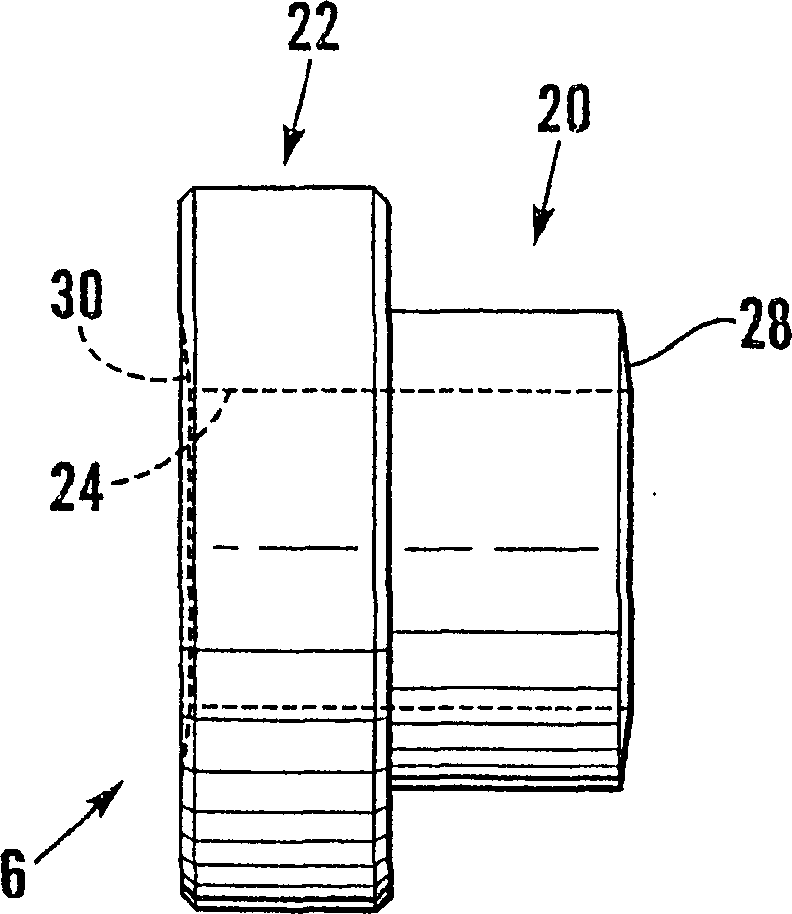

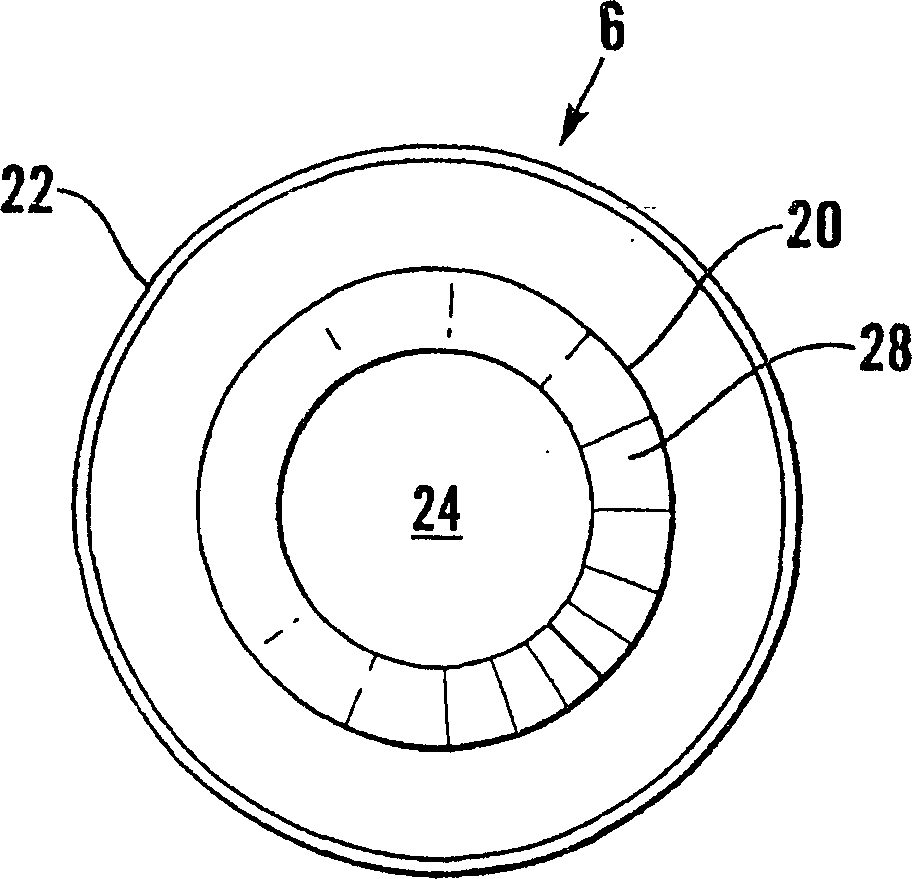

Stable high temperature sensor system with tungsten on AlN

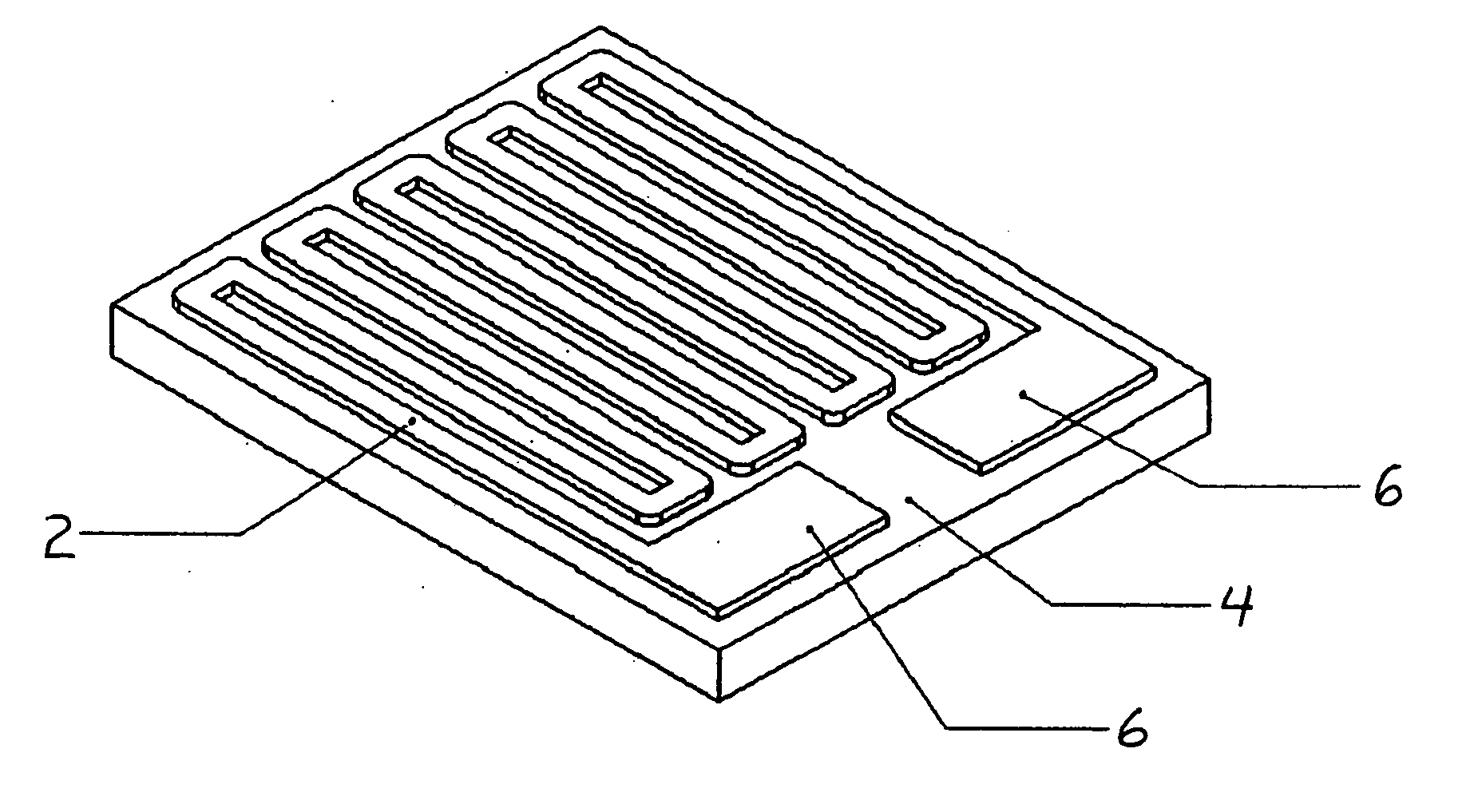

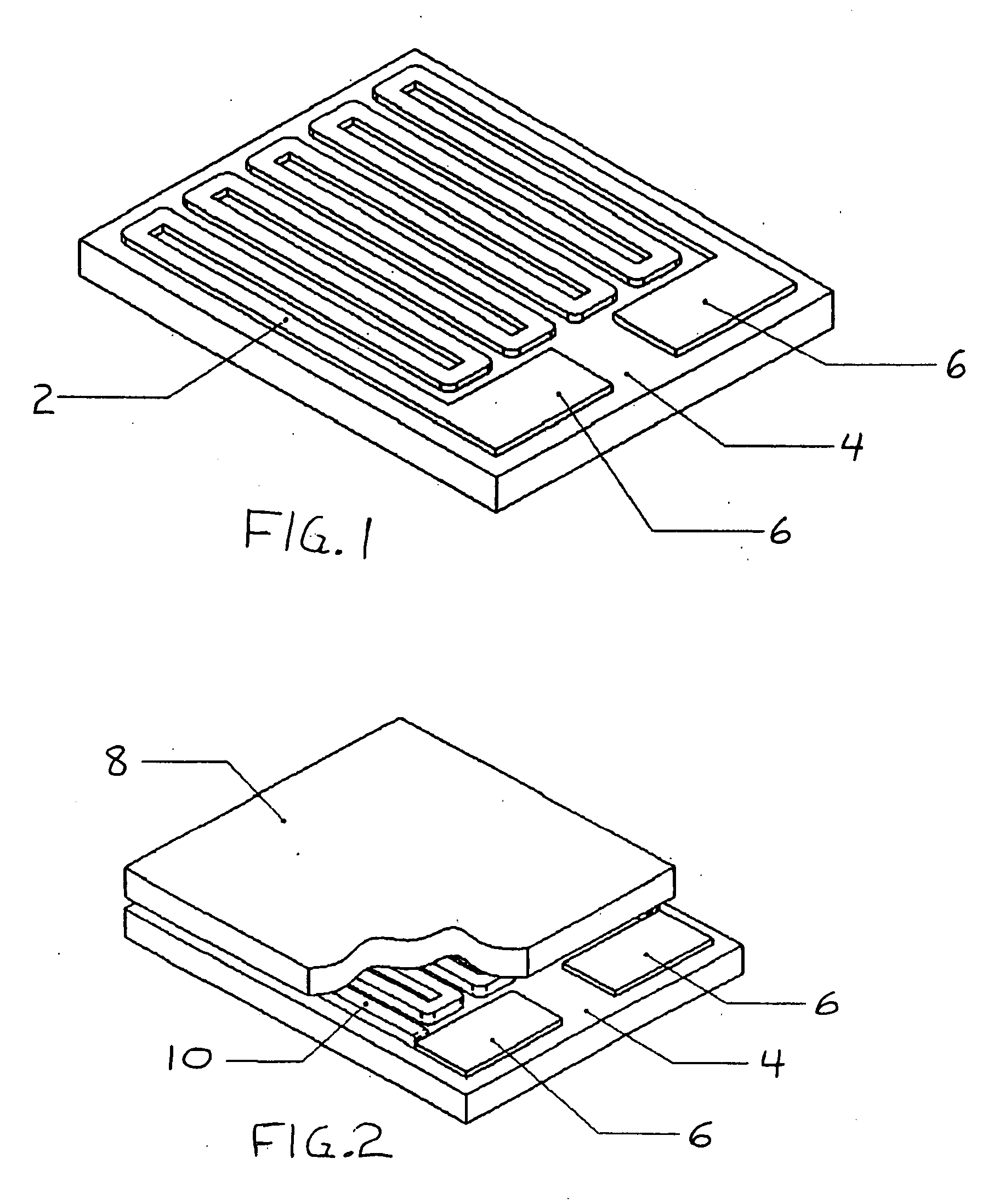

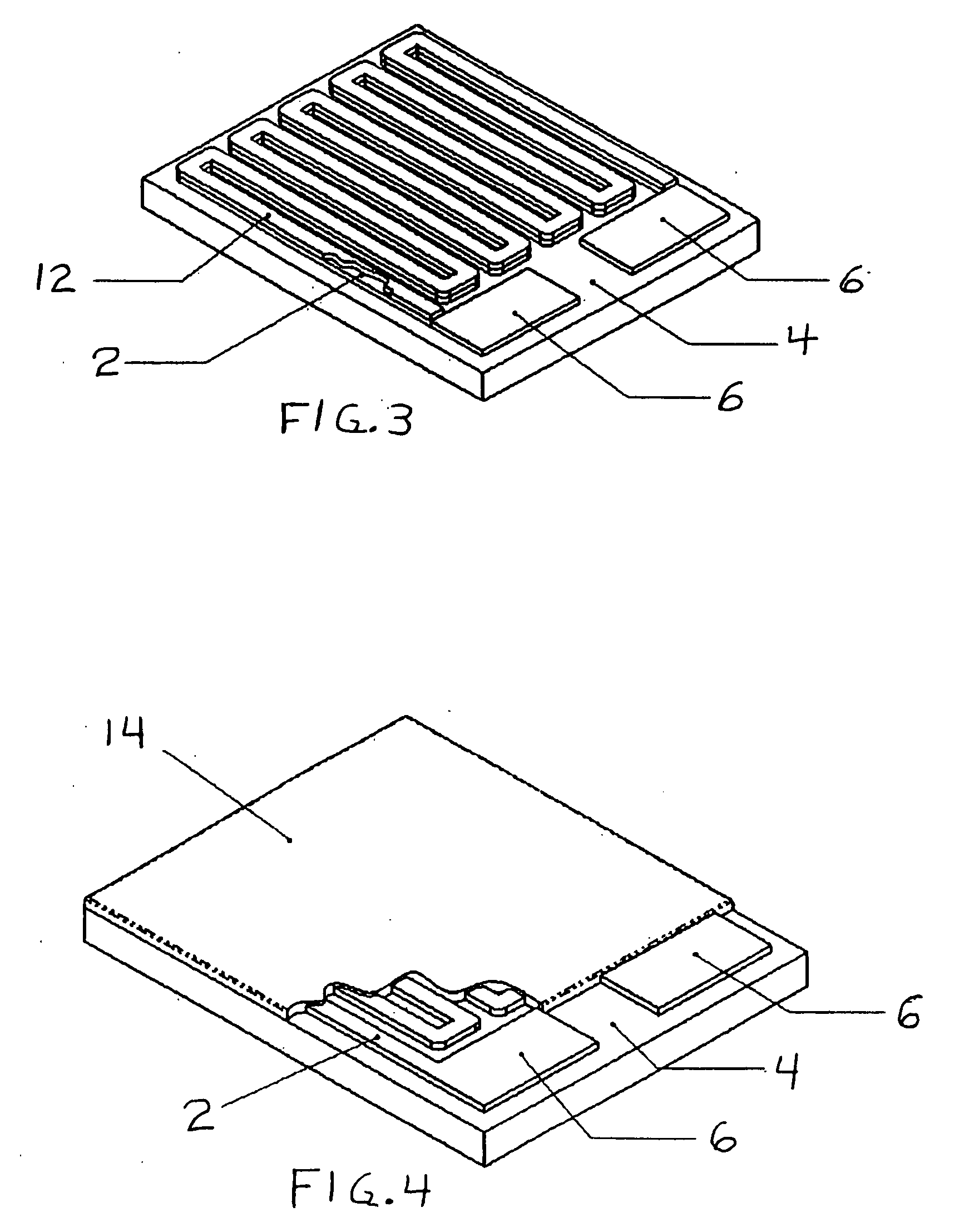

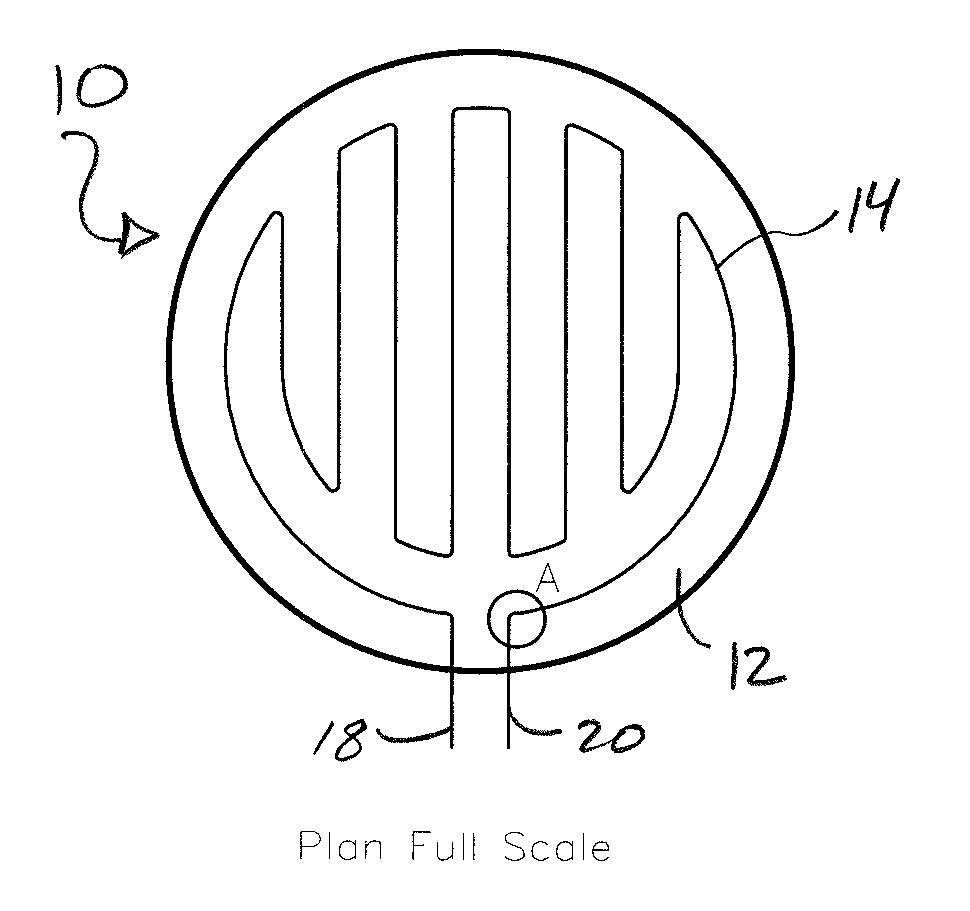

InactiveUS7106167B2Fast response timeHigh sensitivityAcceleration measurement using interia forcesThermometers using electric/magnetic elementsOptoelectronicsFluid level

A sensor system has an AlN substrate, a W layer on the substrate, a signal source adapted to apply an electrical actuating signal to the W layer, and a sensor adapted to sense the response of the W layer. The W layer can comprise a thin film, with various types of optional protective layers over the film. Applications include sensing temperature, fluid flow rates, fluid levels, pressure and chemical environments. For a planar heater, the W layer comprises a plurality of conductive strands distributed on the substrate, with the strands generally parallel and serpentine shaped for a rectangular substrate, and extending along respective lines of longitude that merge at opposite poles of the substrate for a circular substrate.

Owner:HEETRONIX

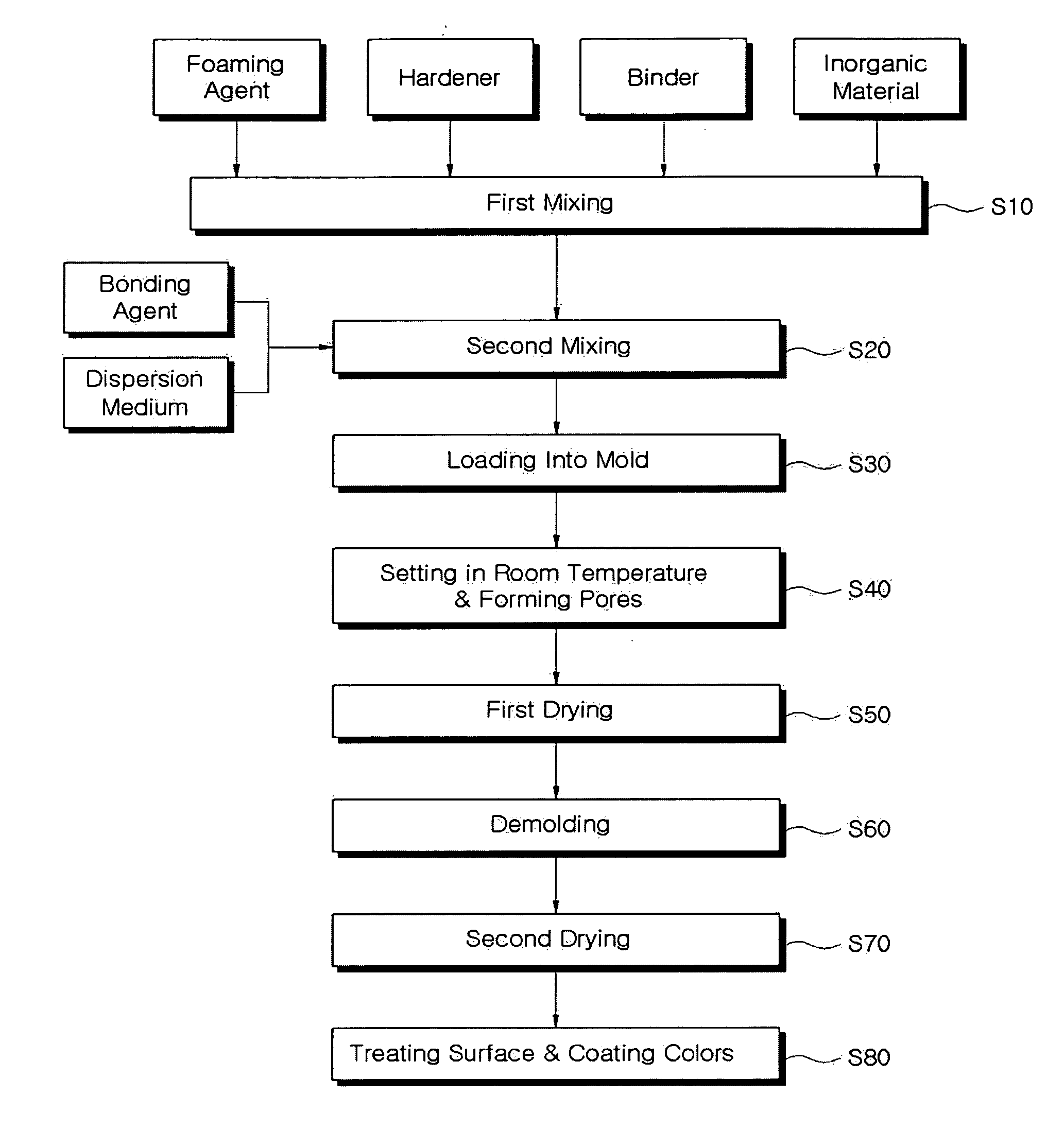

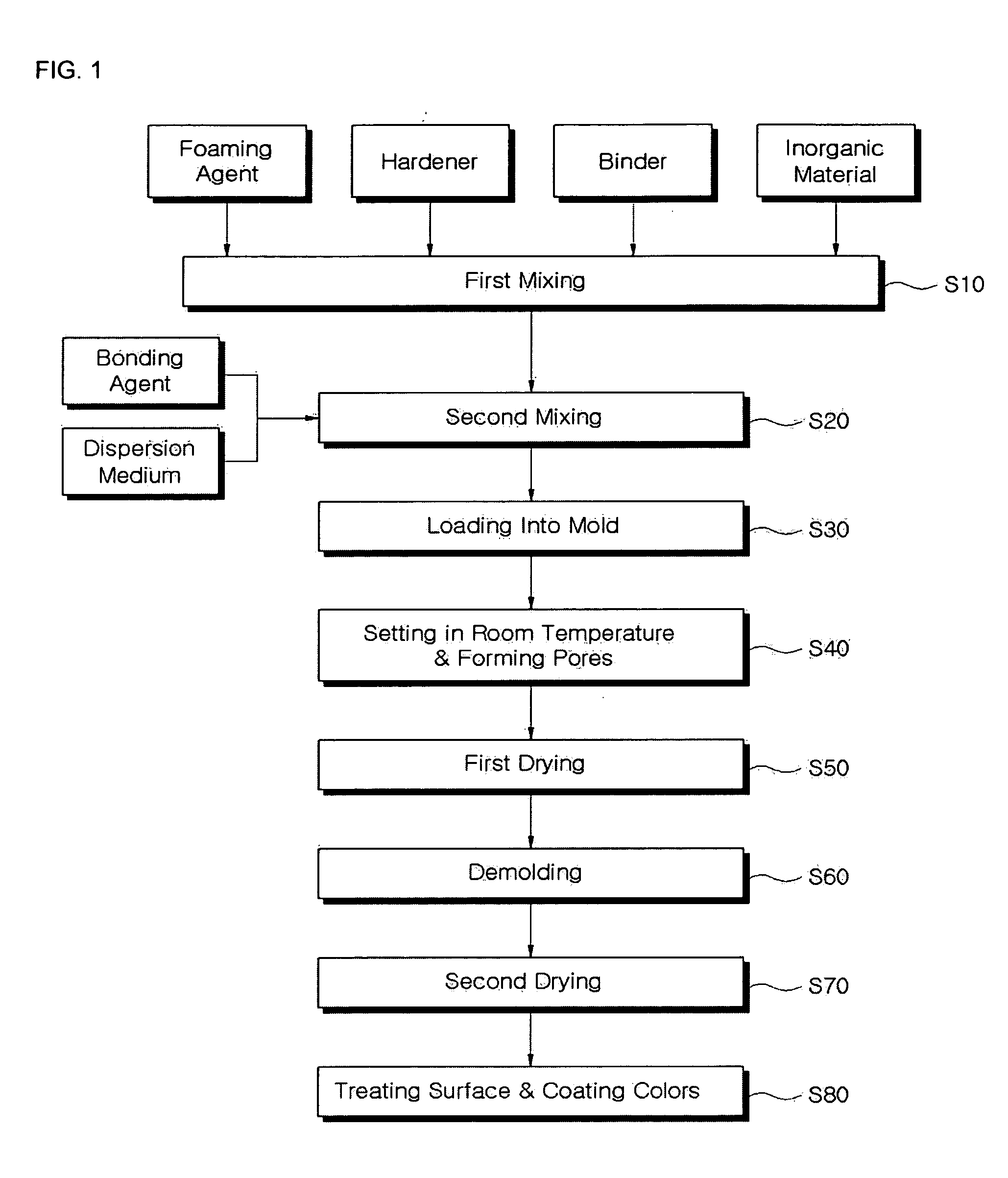

Porous ceramic heating element and method of manufacturing thereof

InactiveUS20070003750A1High bonding strengthAccelerating formation of foamIncandescent ignitionMaintainance of heating chambersFoaming agentMetallurgy

The present invention provides a porous ceramic heating element wherein 0.08 to 1.00 wt % of a foaming agent is added in 99.00 to 99.92 wt % of a mixture of an inorganic material, a binder, a conductive material, a hardener, a bonding agent and a dispersion medium and mixed with the mixture. According to the porous ceramic heating element, the bonding strength of porous foam formed in the ceramic heating element becomes strong, thereby providing an effect that the entire structure is hardened.

Owner:KIM CHANGHEE +1

Wake generating solid elements for joule heating or infrared heating

ActiveUS8541721B2Lower overall pressure dropIndirect heat exchangersWater heatersEngineeringJoule heating

Owner:MOSKAL DANIEL

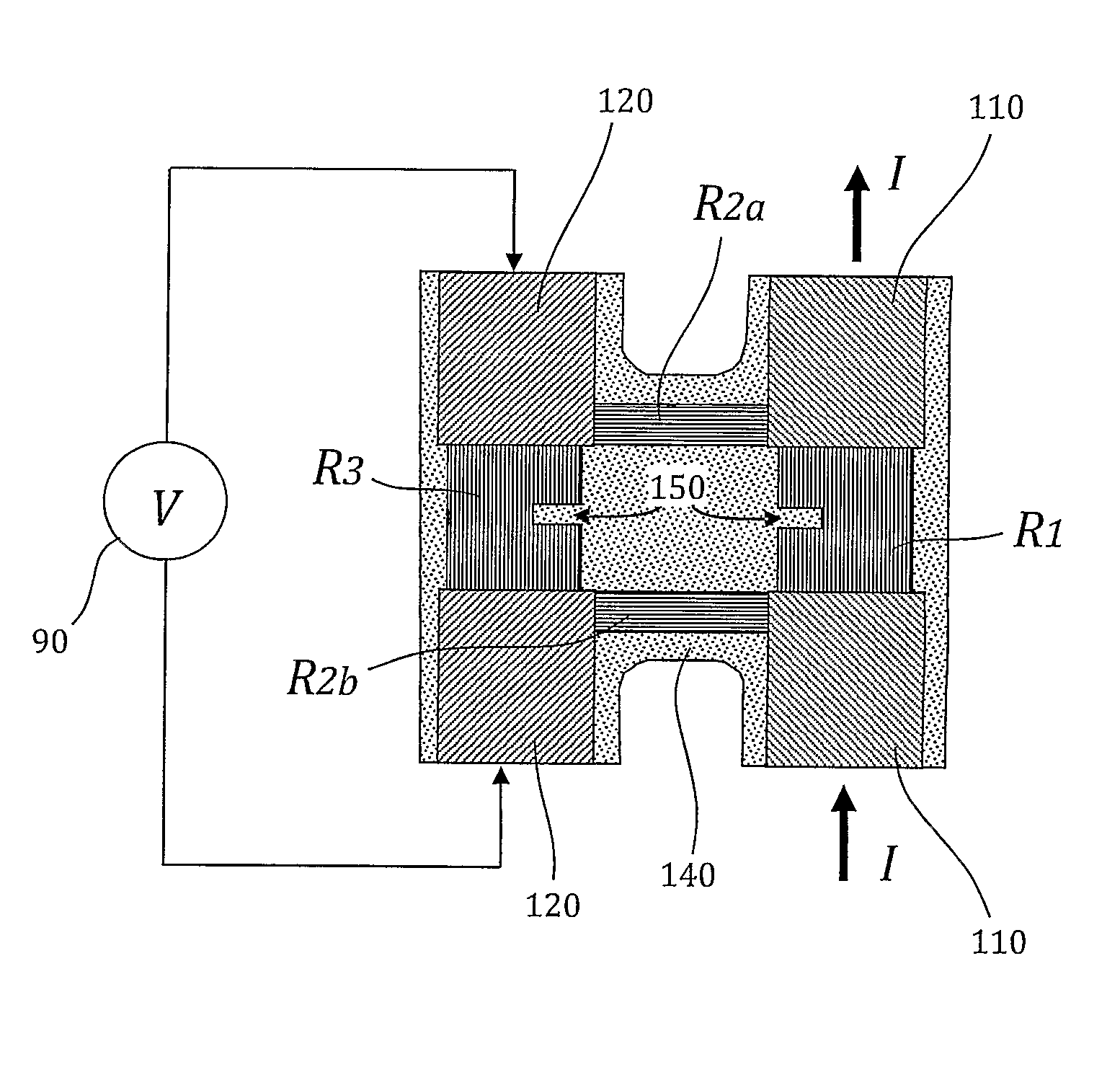

Four-terminal resistor with four resistors and adjustable temperature coefficient of resistance

Thermally stable four-terminal resistor (current sensor) is characterized by having the capacity to adjust both resistance and temperature coefficient of resistance (TCR), during manufacturing process. The four-terminal resistor includes 3 or 4 elementary resistors R1-R3 forming a closed loop. Resistor R1 is the principal low-ohmic value resistor. The terminals of resistor R1 serve as “Force” terminals of the four-terminal resistor. Resistors R2, R3 form a voltage divider intended to minimize the TCR of the four-terminal resistor and connected in parallel to resistor R1. The terminals of resistor R3 serve as “Sense” terminals of the four-terminal resistor. Resistor R2 may be split into two resistors: R2a, R2b to simplify the implementation of four-terminal resistor. Elementary resistors R1, R2 must have the same sign of TCR. Target resistance and TCR minimization in four-terminal resistor are reached by adjustment of resistance of the elementary resistors.

Owner:VISHAY DALE ELECTRONICS INC

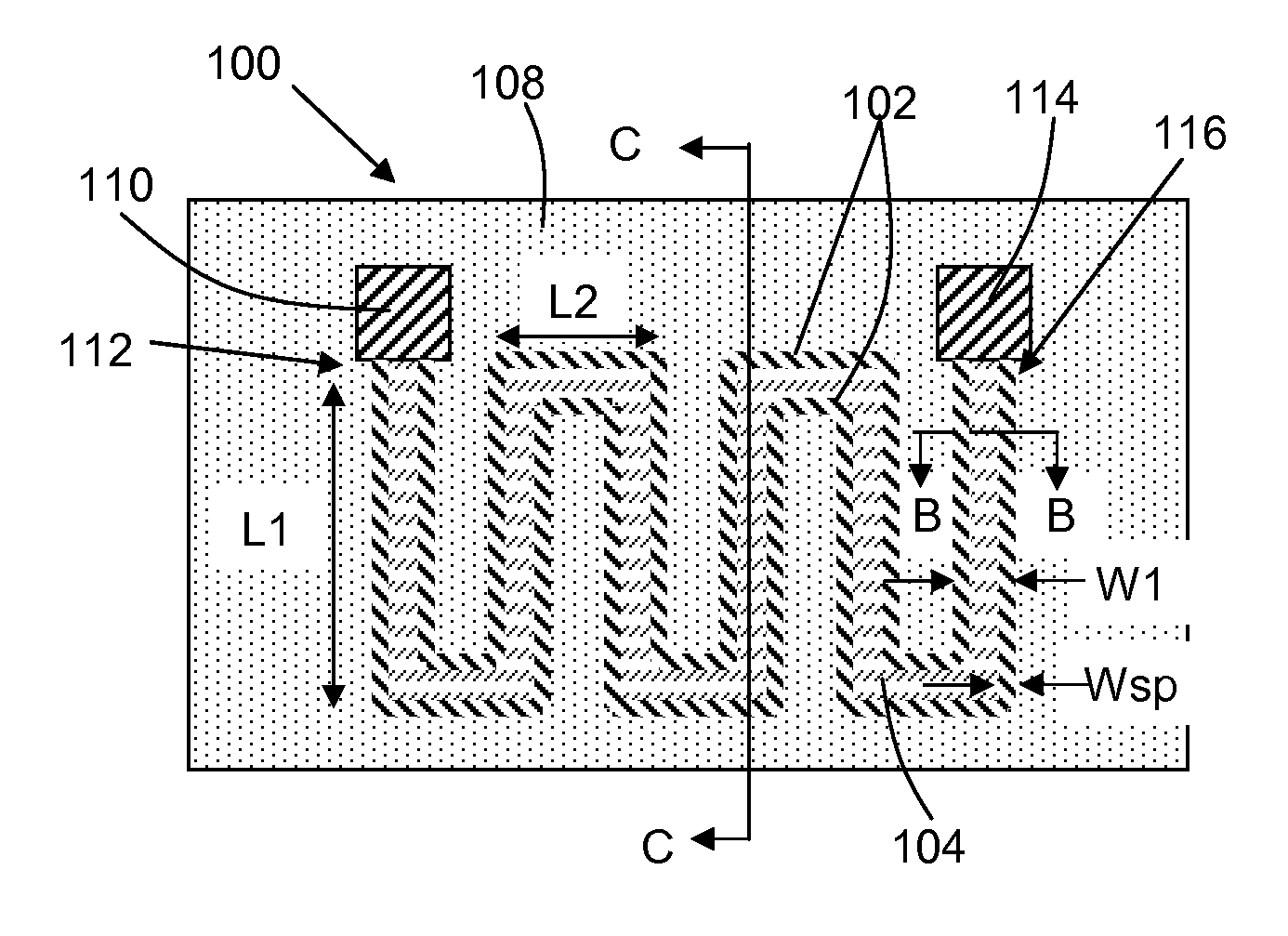

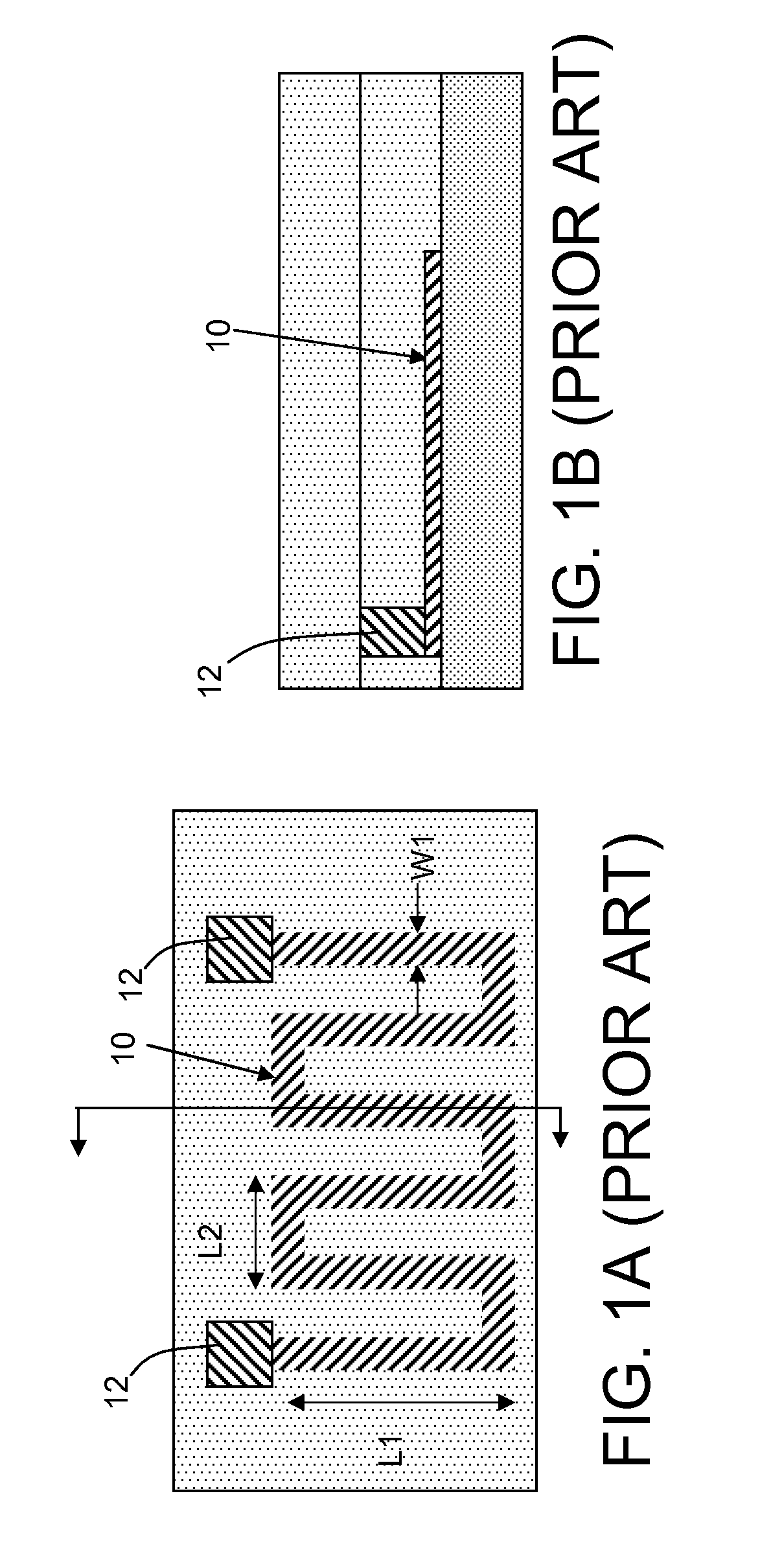

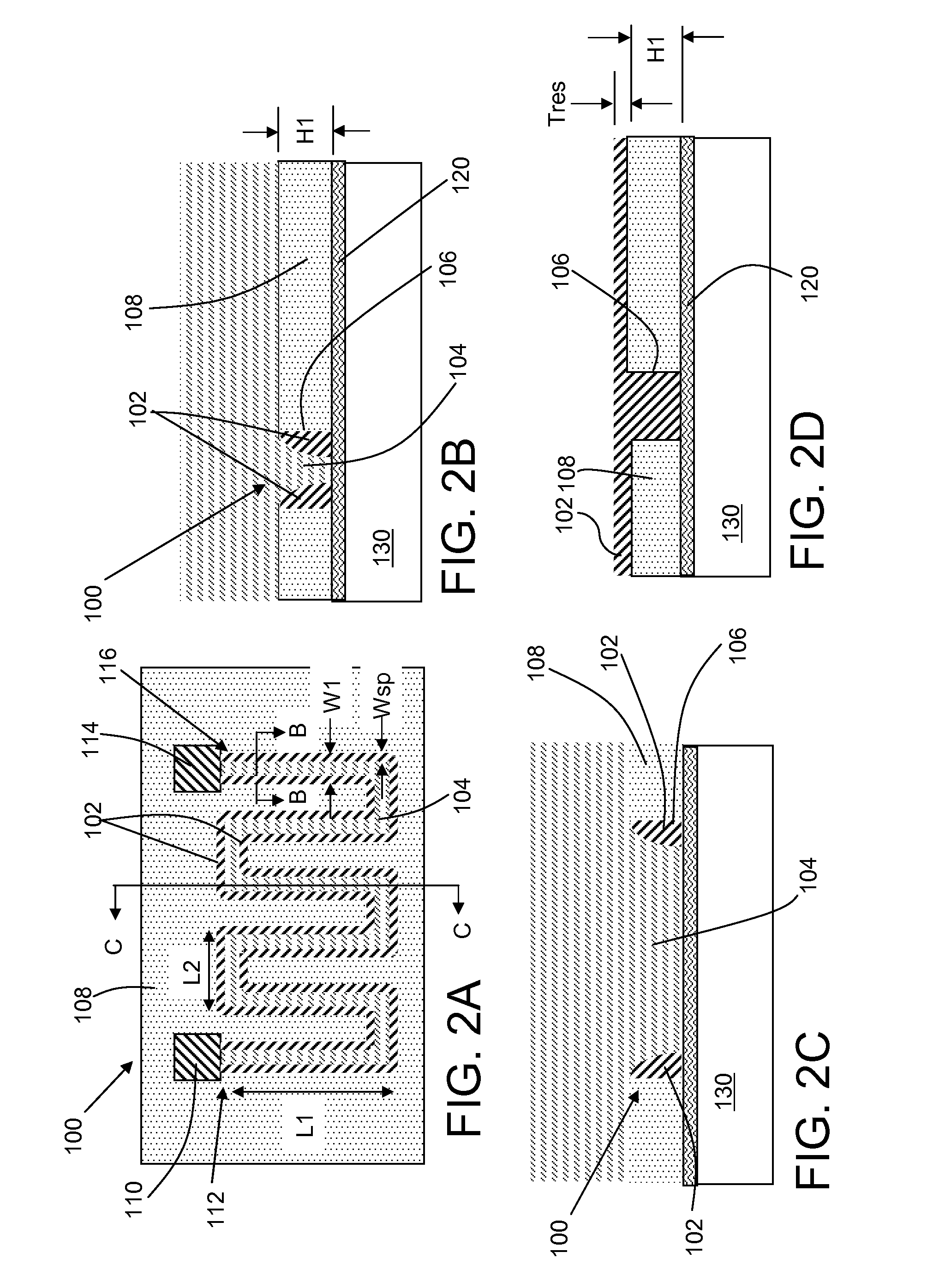

Resistor and design structure having substantially parallel resistor material lengths

A resistor and design structure including a pair of substantially parallel resistor material lengths separated by a first dielectric are disclosed. The resistor material lengths have a sub-lithographic dimension and may be spacer shaped.

Owner:GLOBALFOUNDRIES INC

Power resistor

InactiveUS20090085715A1Spread heatElongated resistive elementEnvelope/housing resistor manufactureElectrical resistance and conductanceMetal strips

A resistor includes first and second opposite terminations, a resistive element formed from a plurality of resistive element segments between the first and second opposite terminations, at least one segmenting conductive strip separating two of the resistive element segments, and at least one open area between the first and second opposite terminations and separating at least two resistive element segments. Separation of the plurality of resistive element segments assists in spreading heat throughout the resistor. The resistor or other electronic component may be packaged by bonding to a heat sink tab with a thermally conductive and electrically insulative material. The resistive element may be a metal strip, a foil, or film material.

Owner:VISHAY DALE ELECTRONICS INC

Chip resistor and method for manufacturing the same

ActiveUS20050275503A1Eliminate the problemUpgraded surge resistanceResistor chip manufactureResistor terminals/electrodesElectrical connectionFront edge

A chip resistor includes a chip substrate, a terminal electrode formed on an upper surface of the chip substrate in a region close to the respective end portions, and a resistant film formed in a zigzag-folded shape on the upper surface of the chip substrate between the terminal electrodes. An inner edge of at least one of the terminal electrodes includes a protrusion integrally formed so as to project from a portion close to a side edge of the chip substrate toward the resistant film, for achieving electrical connection between the resistant film and the protrusion. A side edge of the protrusion facing inward farther from the side edge of the chip substrate is inclined such that a front edge of the protrusion has a narrower width.

Owner:ROHM CO LTD

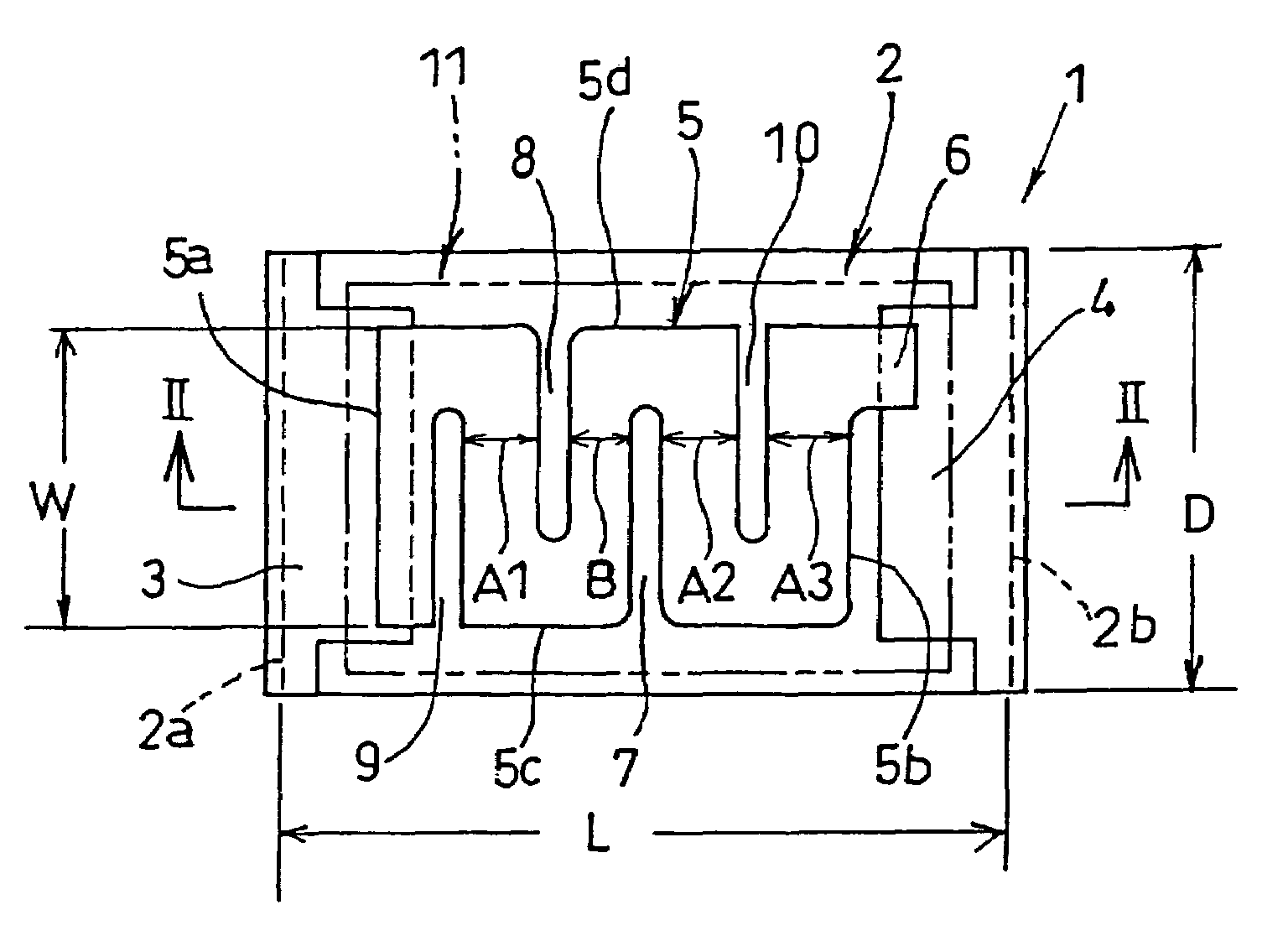

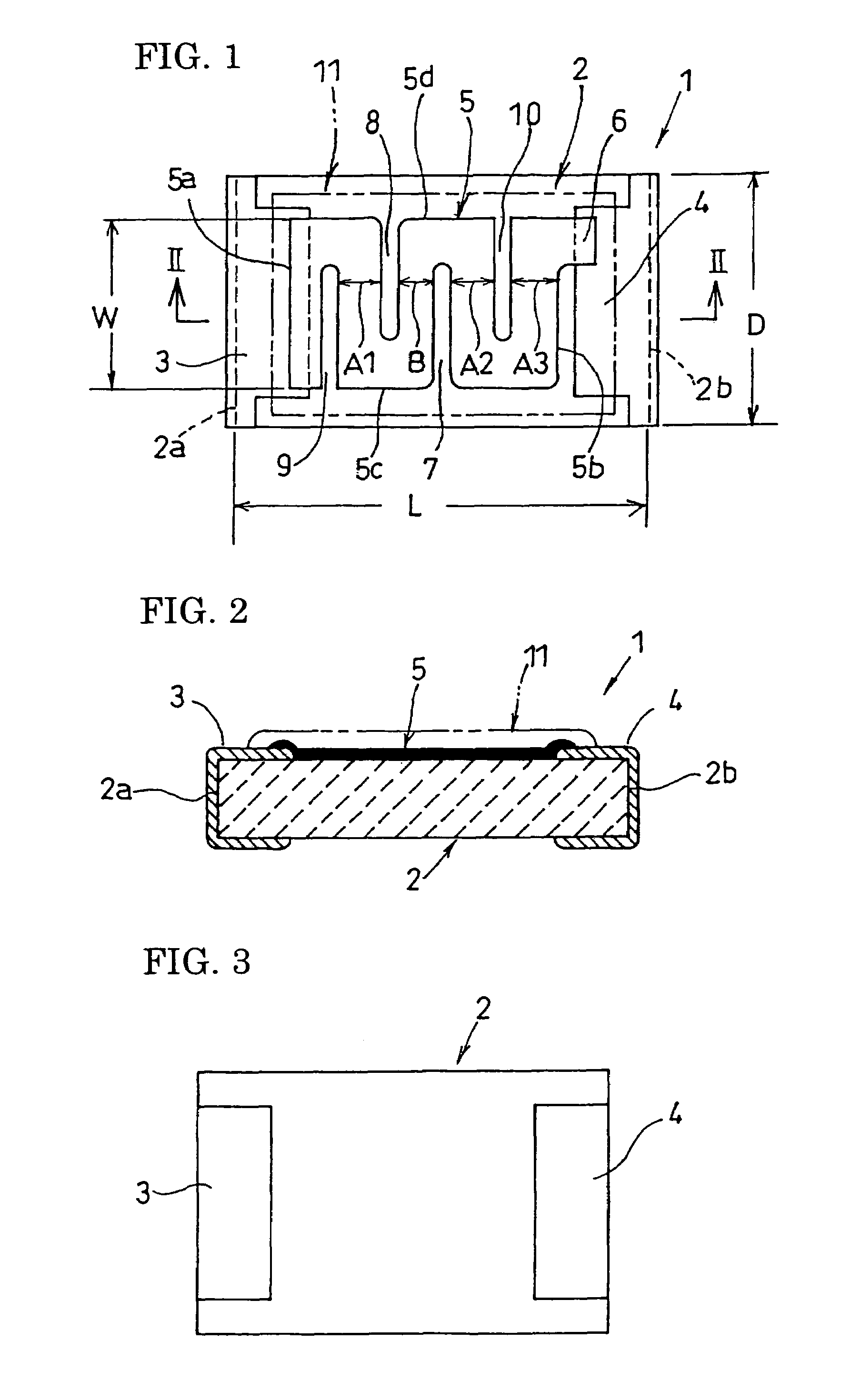

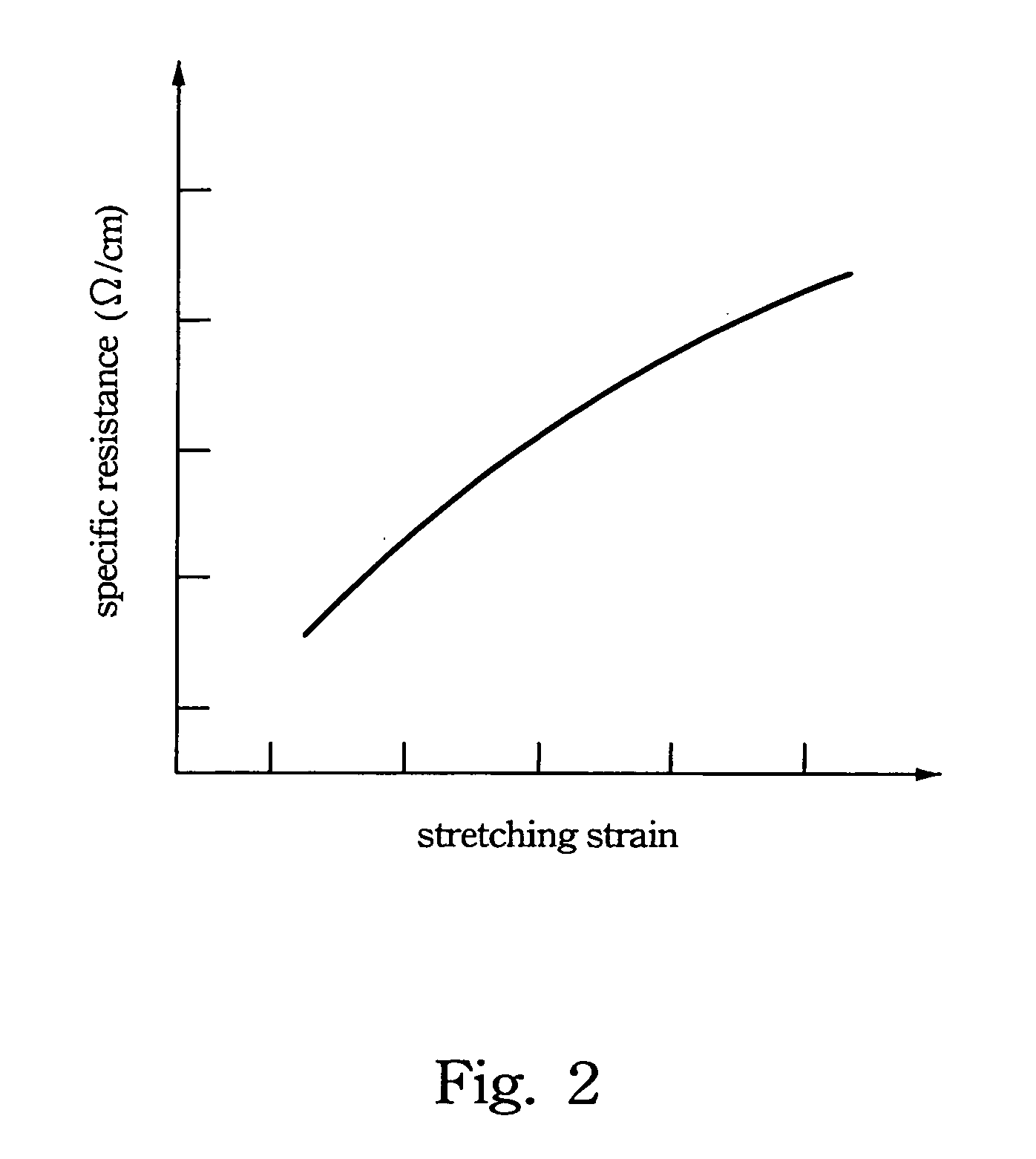

Chip resistor and method of manufacturing the same

ActiveUS7286039B2Increase the lengthImprove anti-surge performanceElongated resistive elementAlarmsElectrical and Electronics engineeringYield rate

A chip resistor is provided which includes a resistor film 5 formed between a pair of terminal electrodes 2 and 3 on an upper surface of an insulating substrate 2. The resistor film is formed with two inward grooves 7, 8 and two trimming grooves 9, 10 which are alternately provided for causing the current path in the resistor film to have a winding shape. The two inward grooves 7 and 8 are provided approximately at the midpoint between one end edge 5a and the other end edge 5b of the resistor film 5. The trimming groove 9 is provided between the inward groove 8 and the end edge 5a of the resistor film, whereas the other trimming groove 10 is provided between the inward groove 7 and the end edge 5b of the resistor film, whereby the time required for the trimming adjustment to adjust the resistance to a predetermined value is shortened, and the yield rate is reduced to reduce the cost.

Owner:ROHM CO LTD

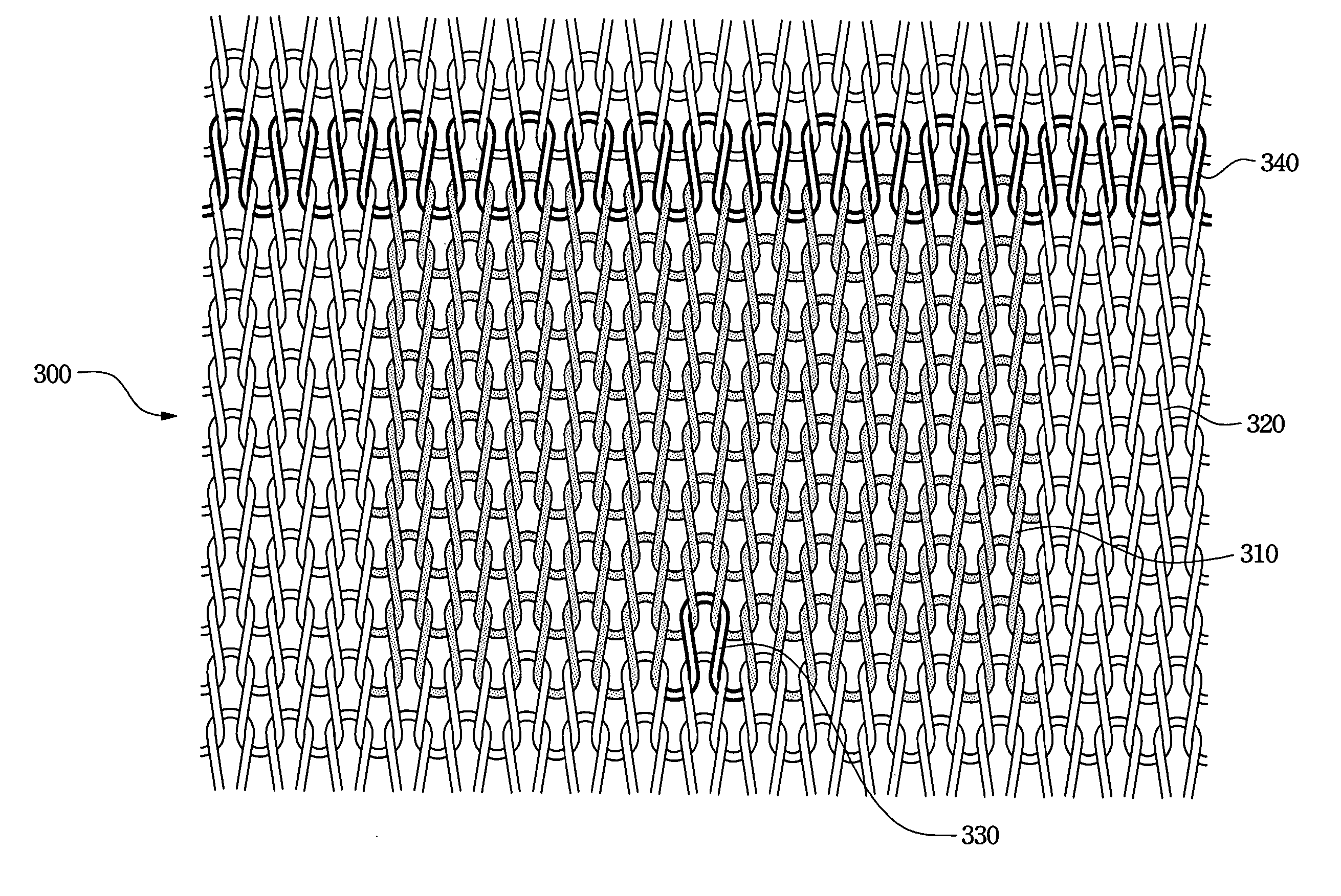

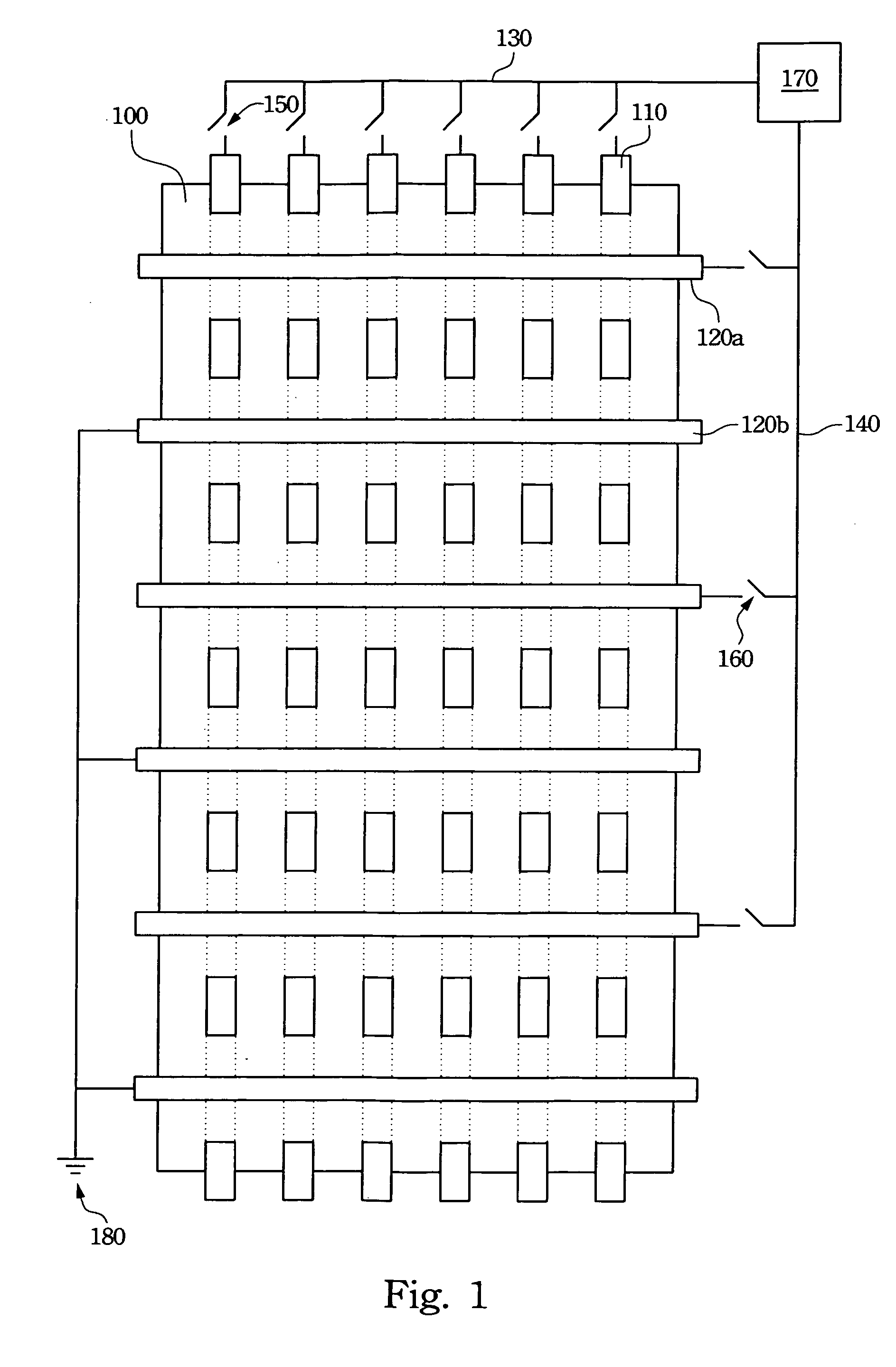

Pressure sensible textile and pressure sensible device thereof

ActiveUS20070080773A1High sensitivityReduce thicknessNegative temperature coefficient thermistorsPositive temperature coefficient thermistorsHigh resistanceElectrical resistance and conductance

A pressure sensible textile has at least a high-resistance conducting area and two groups of low-resistance conducting wefts or warps contacting the high-resistance area directly. The two groups of low-resistance conducting wefts or warps cross each other and do not contact with each other directly. Furthermore, two scanning circuits can be electrically connected to the two groups of low-resistance conducting wefts or warps. Then, a controller is added to the two scanning circuits to obtain a pressure sensible device.

Owner:TAIWAN TEXTILE RESEARCH INSTITUTE

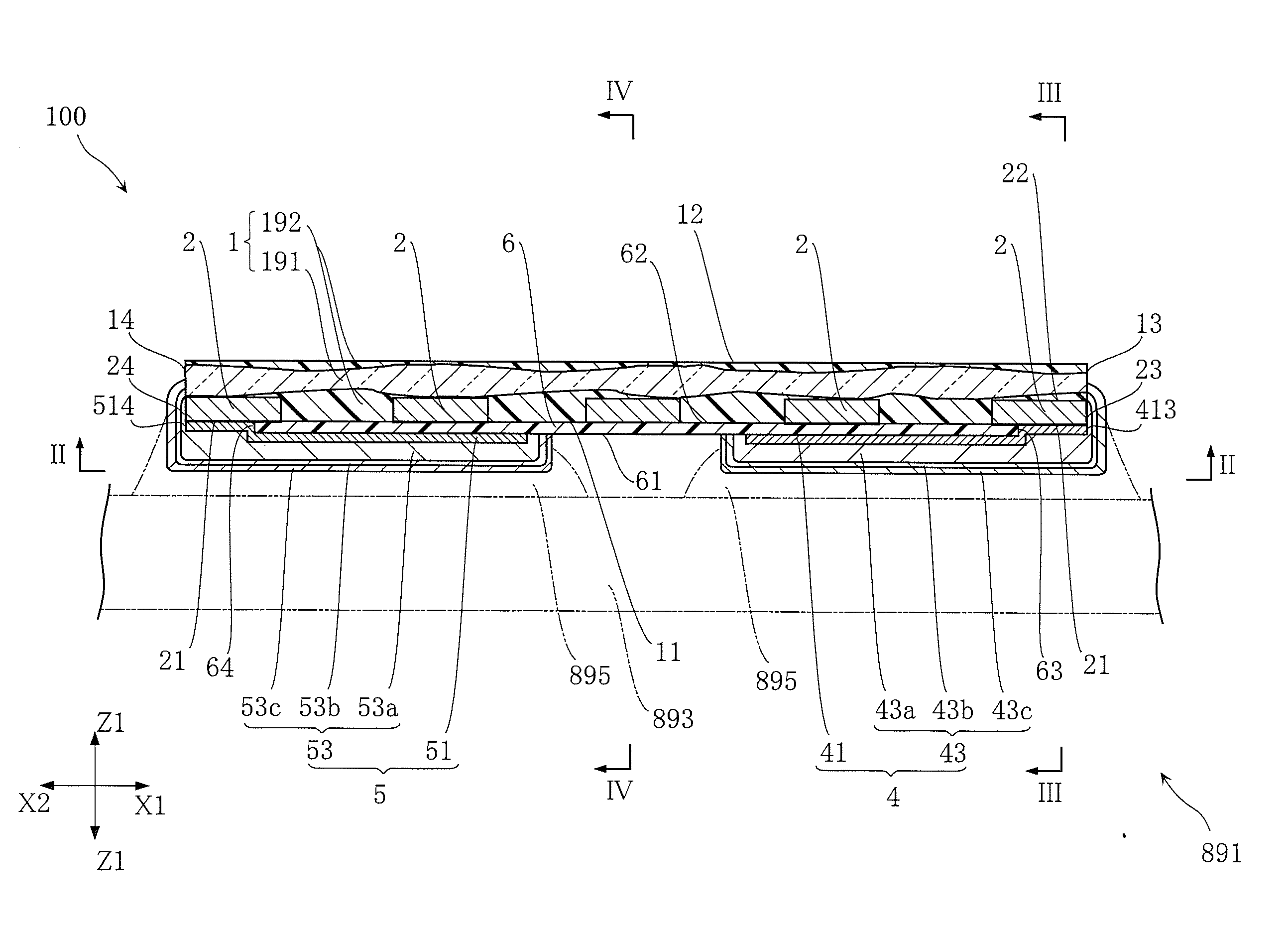

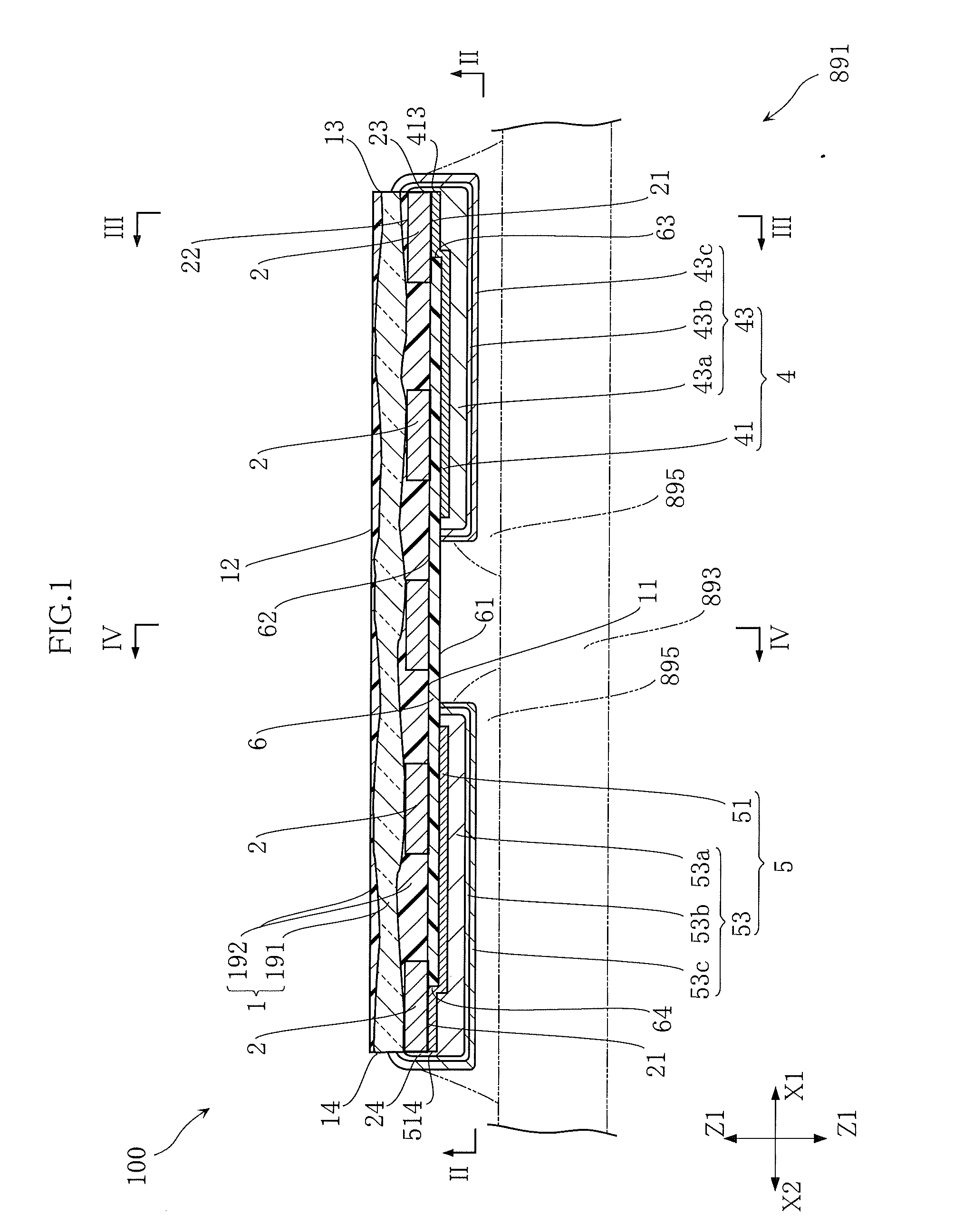

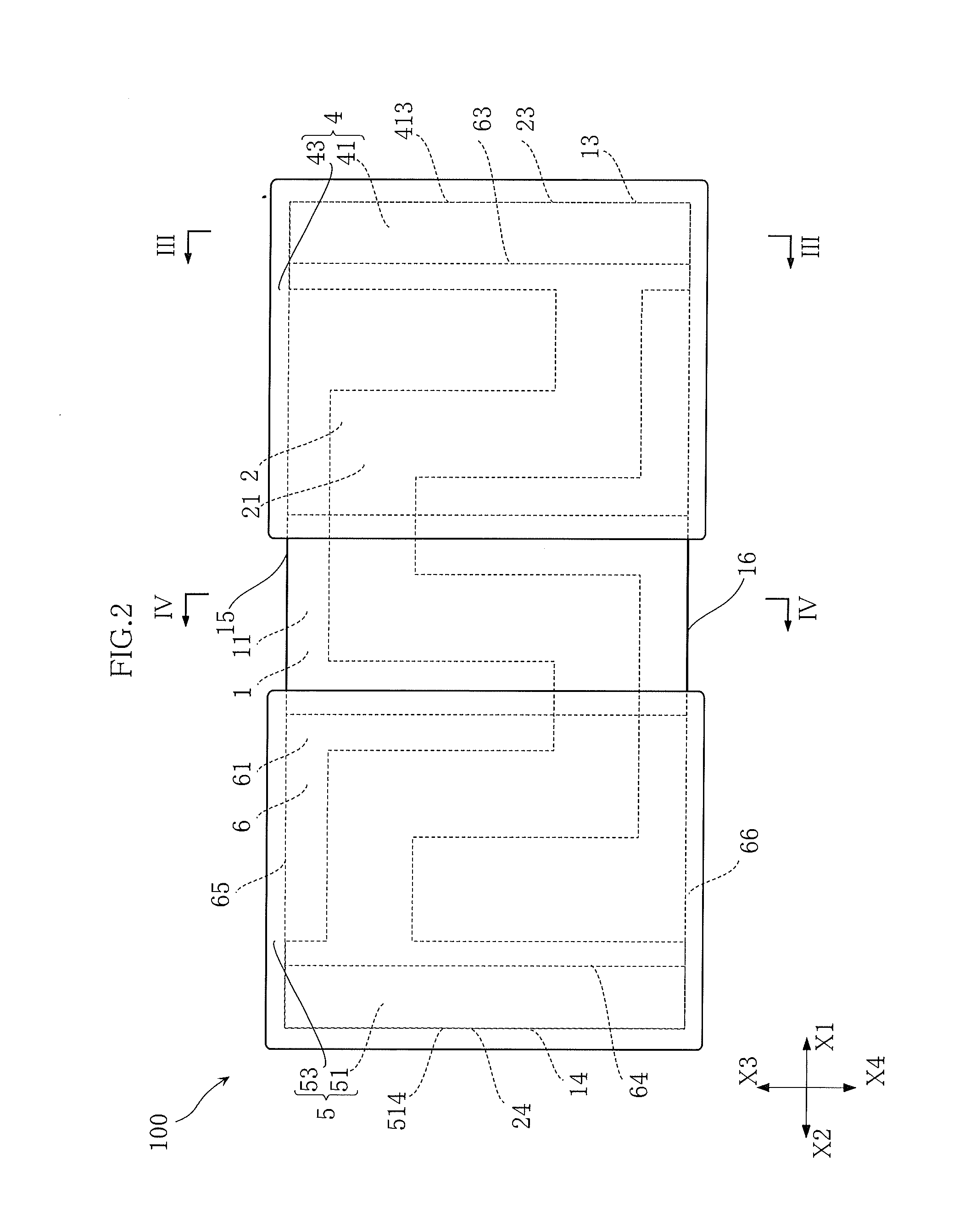

Chip resistor and mounting structure thereof

ActiveUS20140367153A1Reduce thicknessImprove cooling effectFinal product manufactureResistor terminals/electrodesElectrical and Electronics engineeringElectrode

A chip resistor with a reduced thickness is provided. The chip resistor includes an insulating substrate, a resistor embedded in the substrate, a first electrode electrically connected to the resistor, and a second electrode electrically connected to the resistor. The first electrode and the second electrode are spaced apart from each other in a lateral direction that is perpendicular to the thickness direction of the substrate.

Owner:ROHM CO LTD

High-voltage voltage divider and connector comprising said divider

InactiveUS20130169263A1Improve accuracySave spaceOther resistor networksMultiple-port networksElectrical resistance and conductanceVoltage divider

The present invention relates to a resistive voltage divider comprising a plurality n of resistive elements in a configuration wherein the angles m=n−1 between each pair of elements are between 180° and 10°, characterized in that the group of elements is supported by a dielectric the shape of which is such that it allows the creepage distance of the divider to be equal to or longer than the sum of creepage distances of the individual resistances. This arrangement allows a correct insulation of the device because it maintains the outer insulation since in the event of short-circuit the current will flow through the resistances and not through the support.

Owner:ARTECHE LANTEGI ELKARTEA

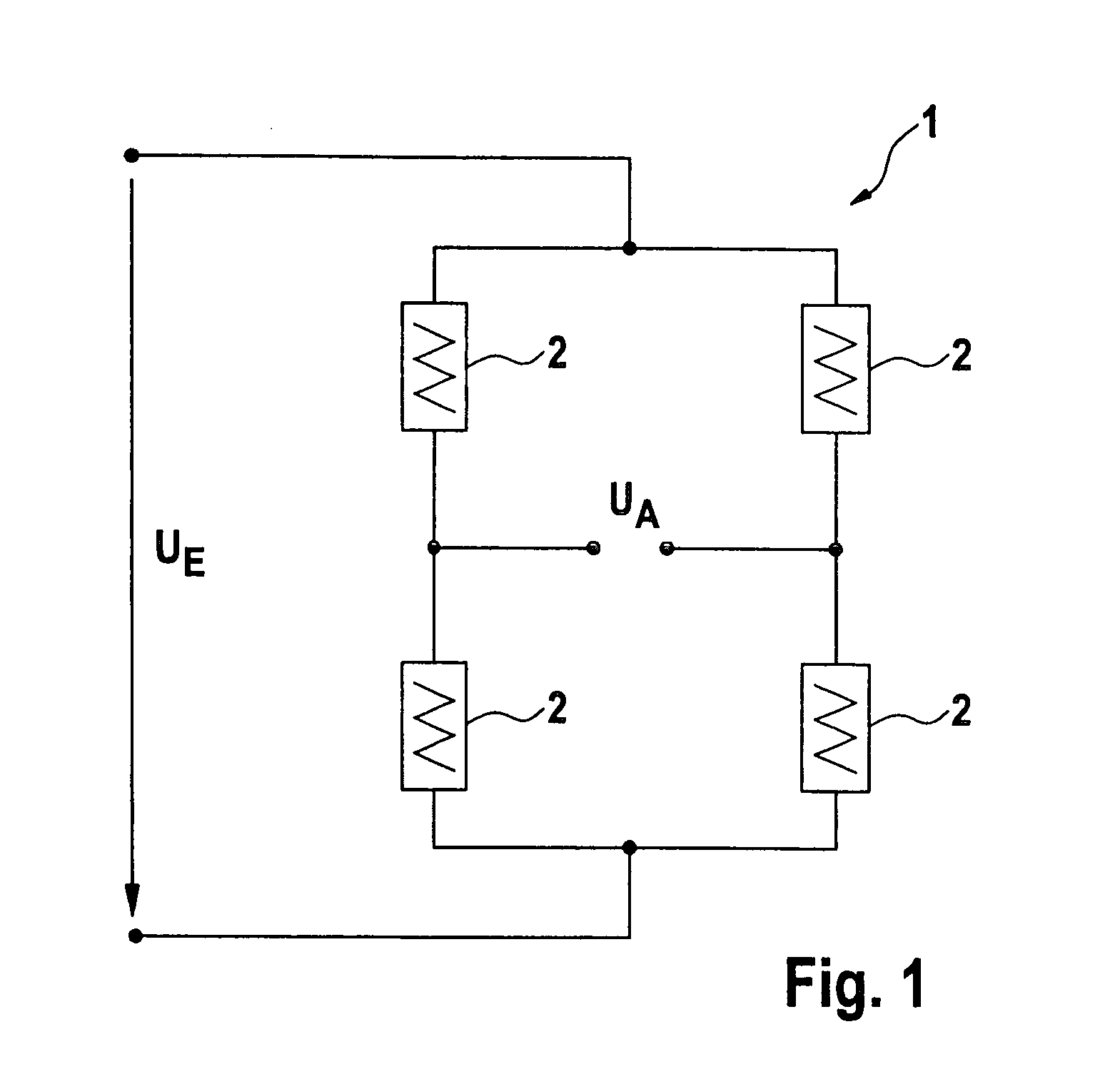

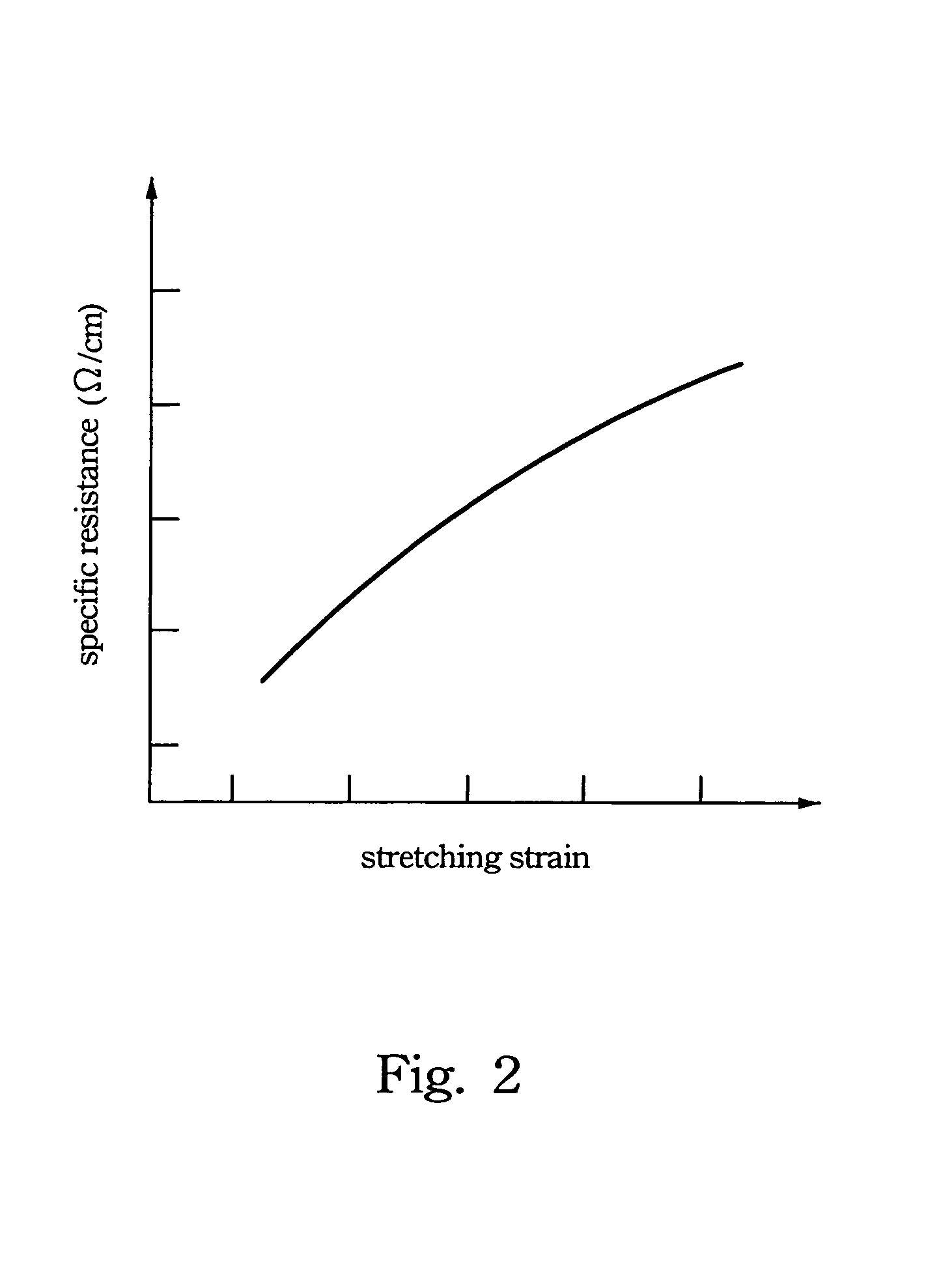

Method for adjusting a sheet resistor, a sheet resistor, and an expansion measuring element

InactiveUS20070013474A1Low temperature dependenceCompensation effectResistor terminals/electrodesResistor manufactureHigh resistanceElectrical resistance and conductance

A method for adjusting a sheet resistor, in particular in an expansion measuring element, is described, the sheet resistor having a low-resistance supply lead area and a high-resistance resistor area, which is electrically connected to the supply lead area, the method having the following steps: performing a first laser cutting step in the resistor area to modify the temperature coefficient of the offset voltage; performing a second laser cutting step to adjust the sheet resistor, so that an electric quantity of the sheet resistor and thereby the offset voltage is set as a function of a predefined setpoint value.

Owner:ROBERT BOSCH GMBH

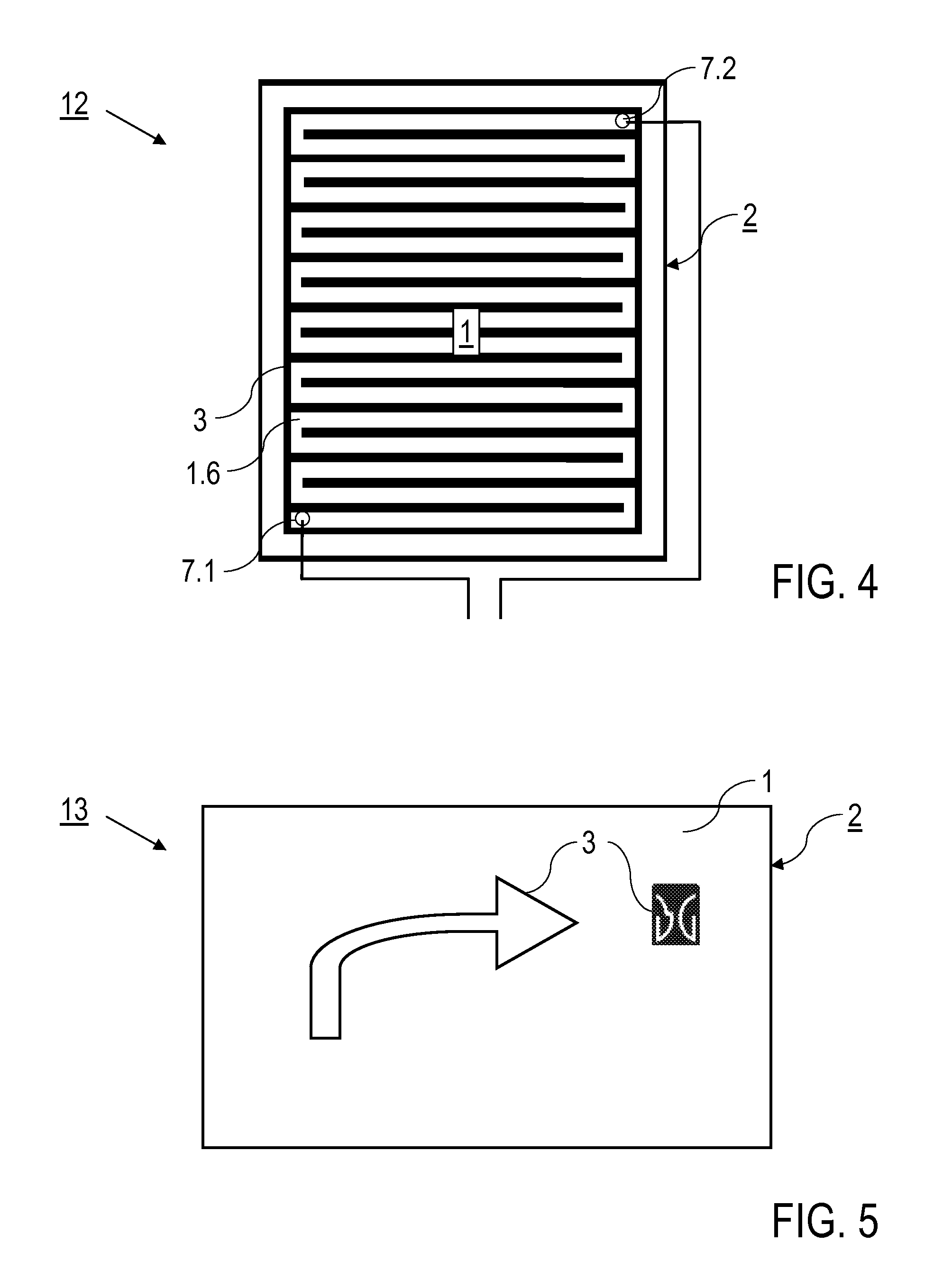

Processing an embedded metal film, and component with an embedded metal film

ActiveUS20120236458A1Improve spatial resolutionLocal heating is possibleElectric heatingSemiconductor/solid-state device manufacturingDisplay deviceOptoelectronics

A method for processing a metal film (1) embedded in a carrier (2) includes the step of heating the metal film (1) in such a way that the metal film (1) is transformed in a subregion into at least one insulator section (3). The metal film (1) is preferably locally heated by laser radiation (4). Also described is a component (10, 11, 12, 13) which is produced by the method and includes an electrostatic clamp, a drive mechanism which is adapted for moving a workpiece under the action of electrical fields, a resistor element or a display device, for example.

Owner:ASML NETHERLANDS BV

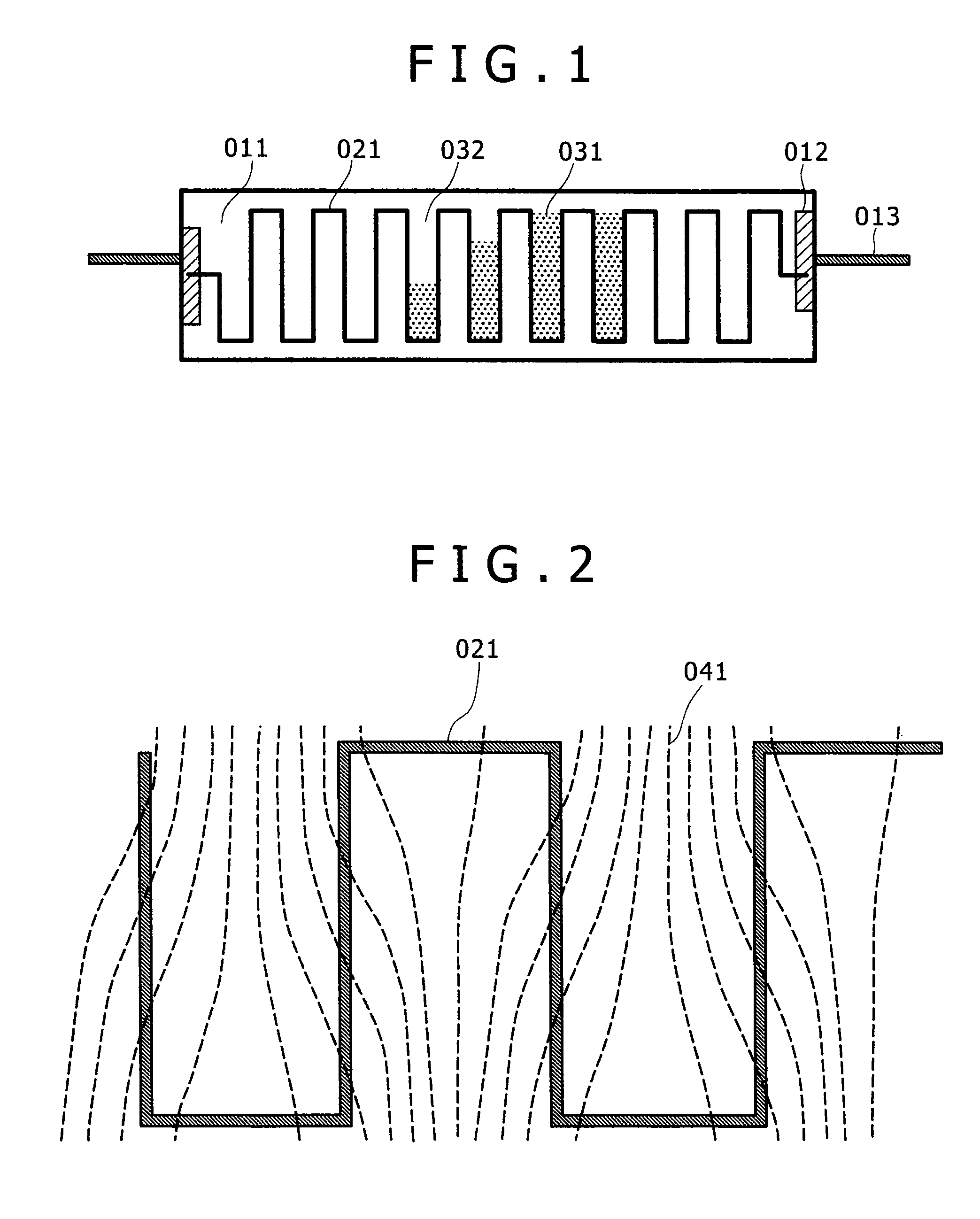

Thick film resistor

InactiveUS20090174523A1Improve stabilityImprove noise characteristicsElongated resistive elementCoil/loop resistive elementsCapacitanceElectrical resistance and conductance

In a flat plate type thick film resistor, an insulation performance is improved by excluding the nonuniformity of potential distribution on a wiring plane, which is generated when electric current flows in a resistance wire. Simultaneously, generation of noise depending on potential distribution and variation of stray capacitance around a resistor is suppressed. When the resistance wire having a constant thickness and uniform resistivity, which is formed on an insulating substrate, is connected to a pair electrode conductors that face to each other, in the way that the resistance wire is repetitively bent to the alternate side in zigzags, a potential gradient on the wiring plane, which is generated when electric current flows in the resistance wire, is constant by properly selecting the line width, the bending angle, and the spacing between bending vertexes of a resistance wire.

Owner:HITACHI HIGH-TECH CORP +1

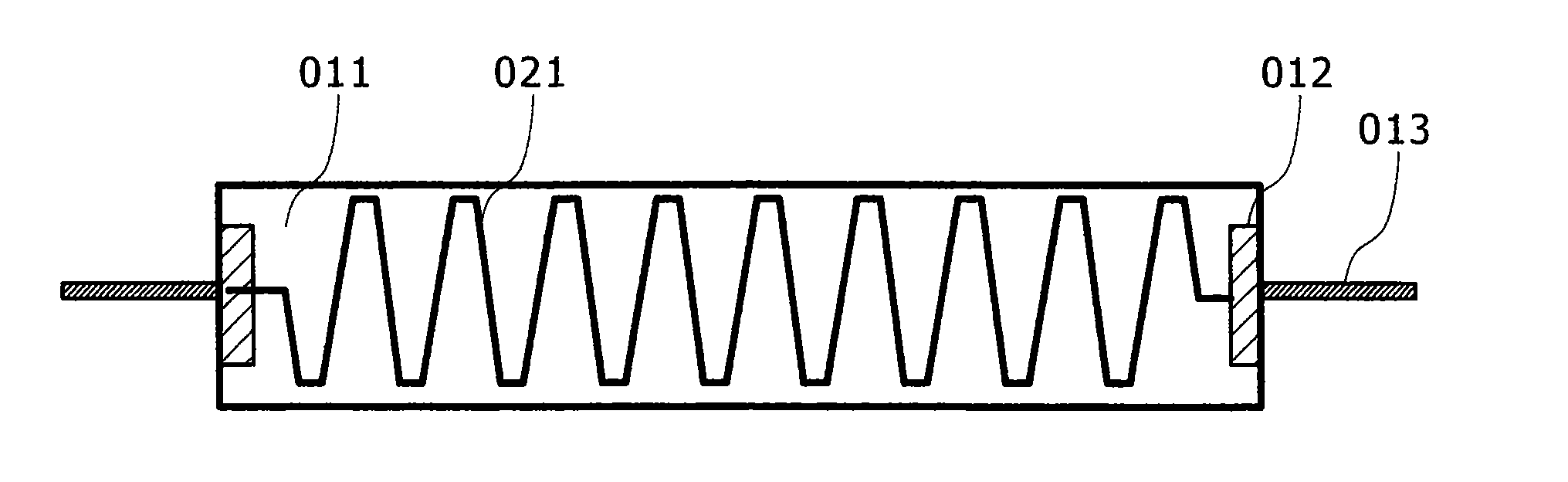

Meander resistor

ActiveUS20110241820A1Reliable and reliableMitigating ESD damageElongated resistive elementSemiconductor/solid-state device detailsElectrical resistance and conductanceMeander

The present invention relates in general to the field of integrated circuits, and more specifically to a meander resistor. Basically, a meander resistor can be considered as a bar resistor with the exception of the corner squares (right-angle bends). The Electrostatic Discharge (ESD) sensitivities of on-chip resistors can be a problem for both electronic manufactures and electronic component users. As others components, passive devices are known to be susceptible to ESD events. The context of this invention is to improve the reliability of the resistors during an ESD event. An ESD stress means that high current and high voltage levels are applied to the device. The device has to be able to dissipate this energy without failure.

Owner:NEXPERIA BV

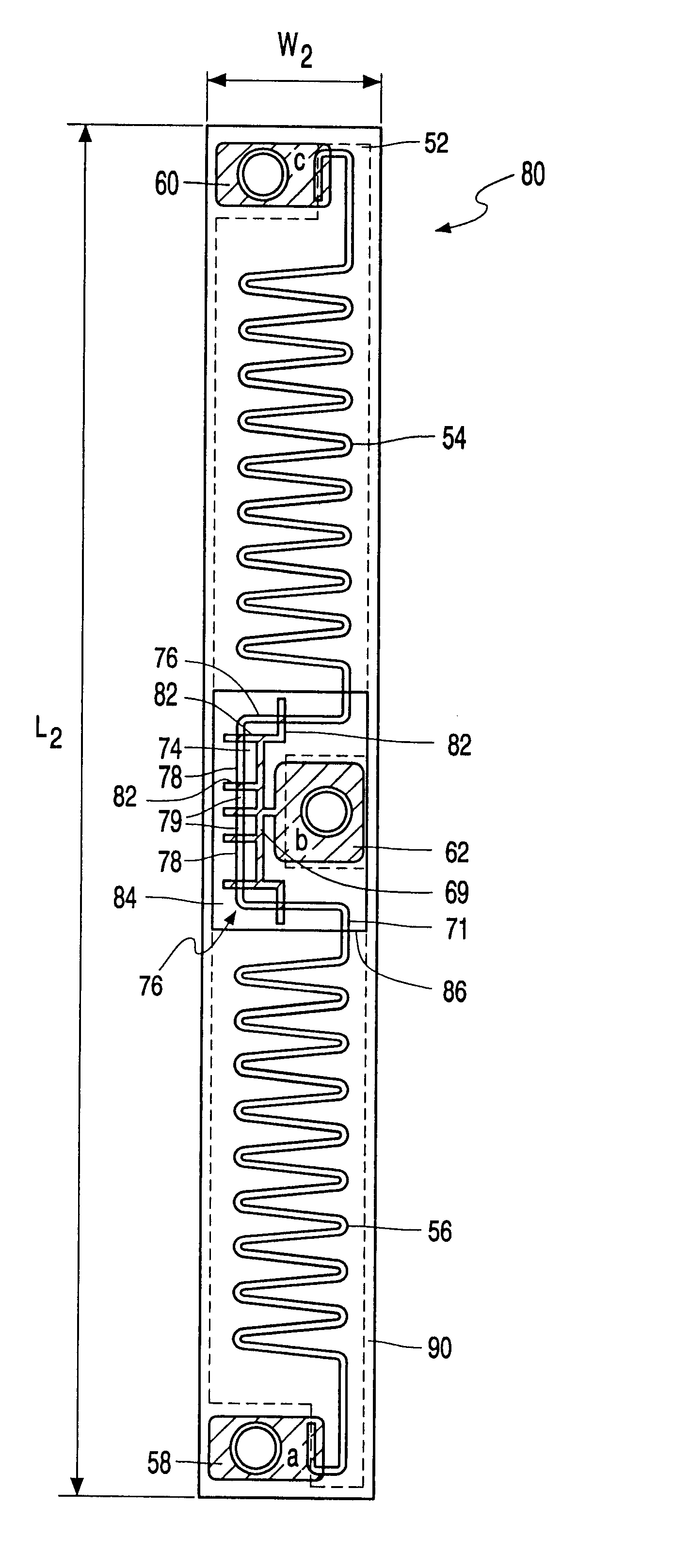

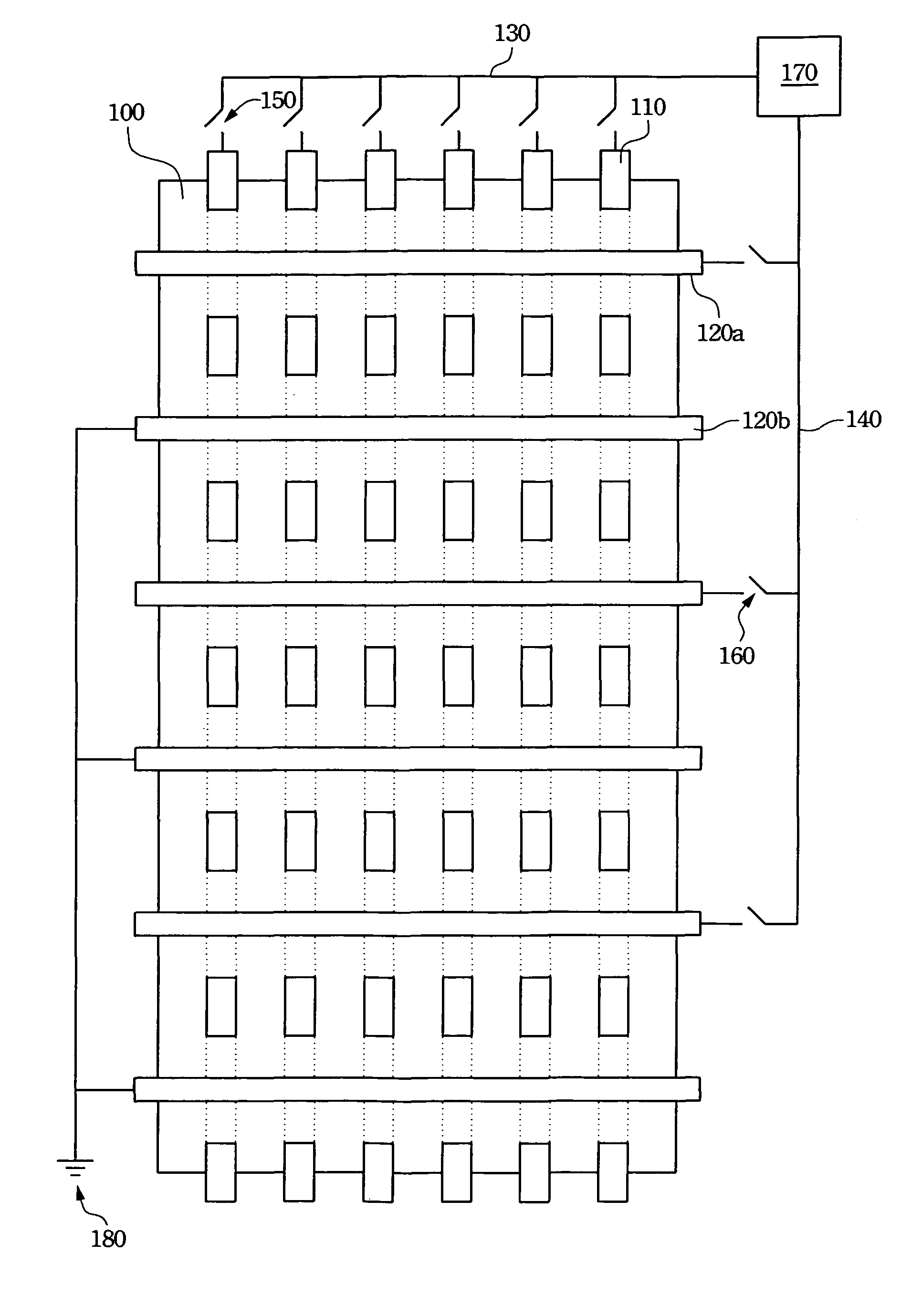

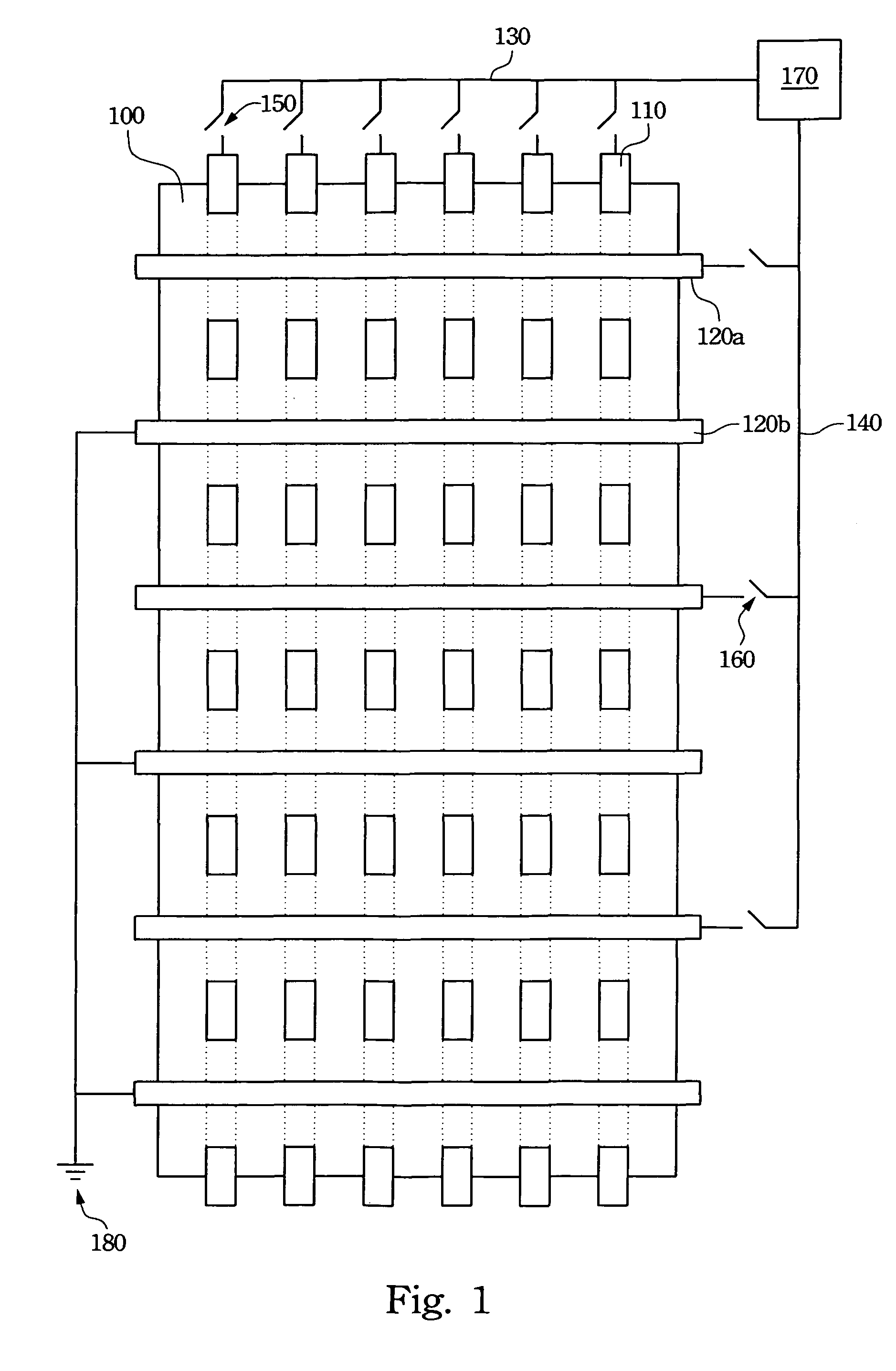

Resistor assembly and cathode ray tube

InactiveUS6593697B1Shorten the timeShorten the lengthElongated resistive elementElectrode and associated part arrangementsAnode voltageEngineering

The invention relates to a resistor assembly for dividing an applied voltage into an intermediate voltage being below the applied anode voltage in a cathode ray tube. The resistor assembly comprises an insulating substrate and a resistive voltage divider including a first and a second resistive layer provided on the insulating substrate, and an additional resistive network with a first network terminal and a second network terminal. The additional resistive network is coupled in series with the first resistive layer. Furthermore, the additional resistive network comprises first and second resistive portions which are releasably coupled to the network terminals via bridge connections. According to the invention, the first and second resistive portions have substantially different resistance values for selecting a predetermined resistance value from a range of resistance values of the additional resistive network.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

Resistor banks

Owner:CRESSALL RESISTORS

Stable high temperature with serpentine heating strands on insulative substrate

InactiveUS20060082433A1Fast response timeHigh sensitivityIncandescent ignitionVolume/mass flow measurementCompound (substance)Fluid level

A sensor system has an AlN substrate, a W layer on the substrate, a signal source adapted to apply an electrical actuating signal to the W layer, and a sensor adapted to sense the response of the W layer. The W layer can comprise a thin film, with various types of optional protective layers over the film. Applications include sensing temperature, fluid flow rates, fluid levels, pressure and chemical environments. For a planar heater, the W layer comprises a plurality of conductive strands distributed on the substrate, with the strands generally parallel and serpentine shaped for a rectangular substrate, and extending along respective lines of longitude that merge at opposite poles of the substrate for a circular substrate.

Owner:HEETRONIX

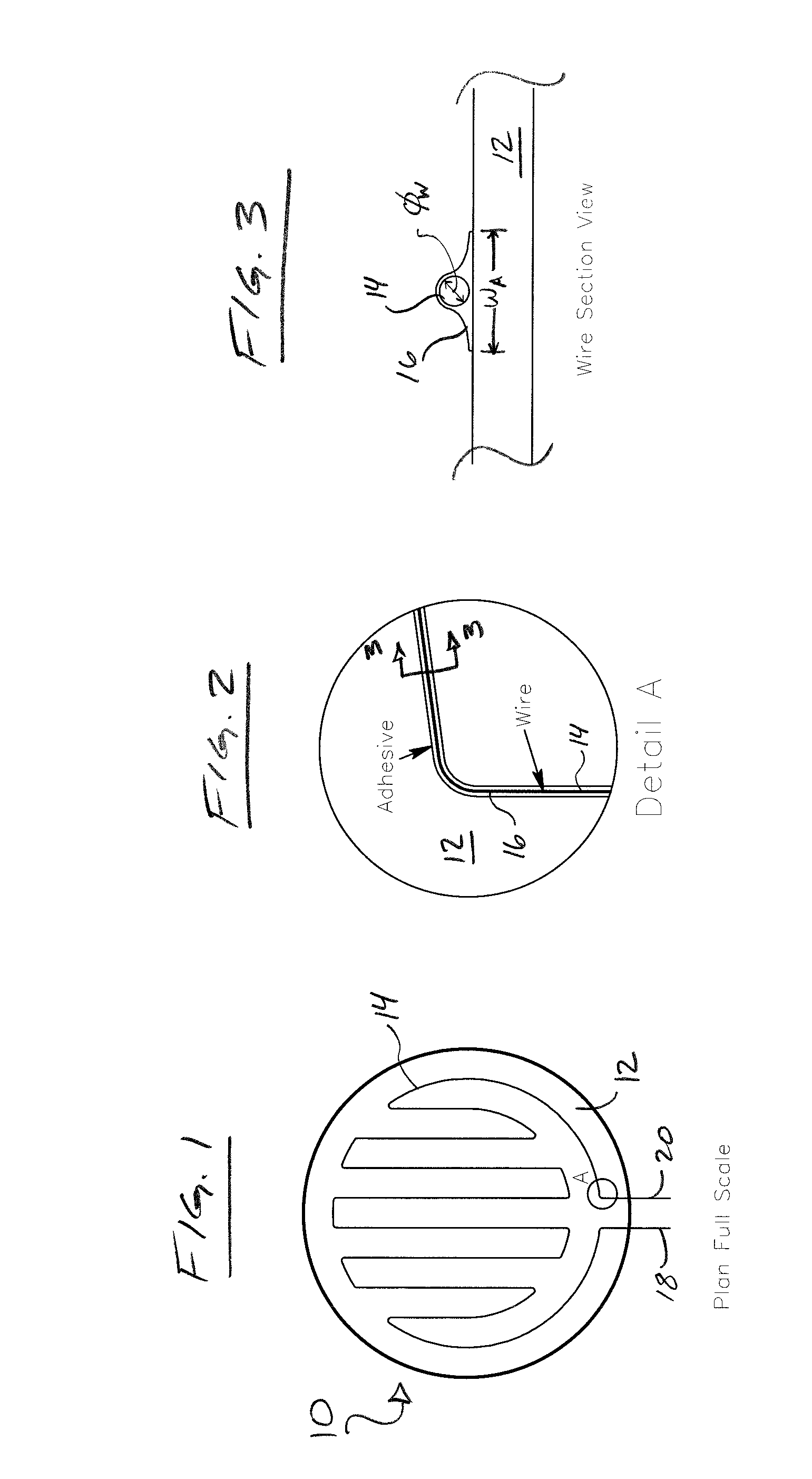

Thermally conditionable light transmitting subassembly

A non-film based, thermally conditionable light transmitting article is provided. The article includes an adhesively coated resistive wire and a substrate suitably selected for light transmittance. The adhesively coated resistive wire is solely and directly adhesively affixed to the substrate so as to be thereby supported upon and by the substrate. A layer of adhesive, in the form of an adhesive linkage originating from the adhesive of the adhesively coated resistive wire, is present between the resistive wire and the substrate.

Owner:MINCO PRODUCTS

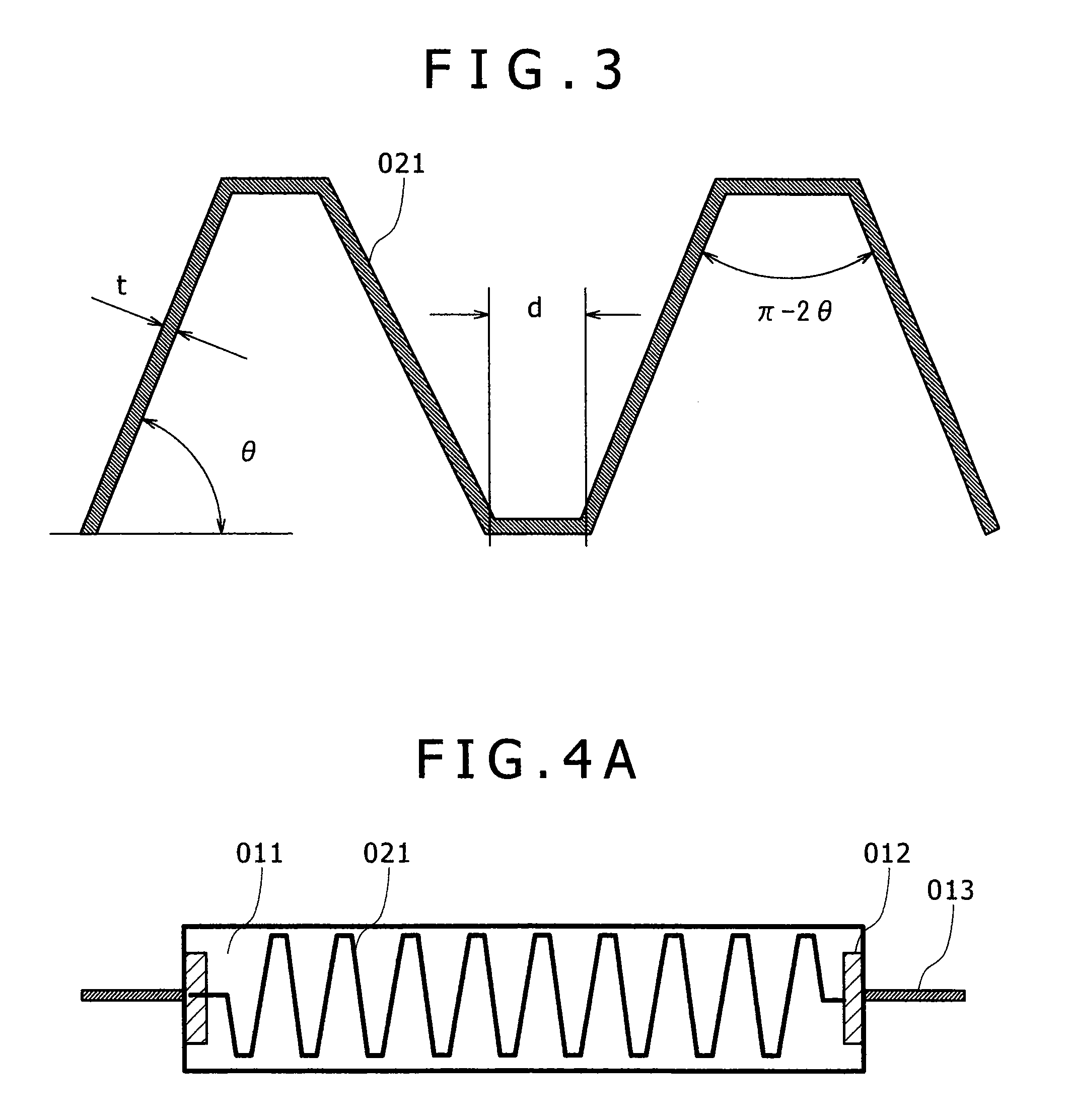

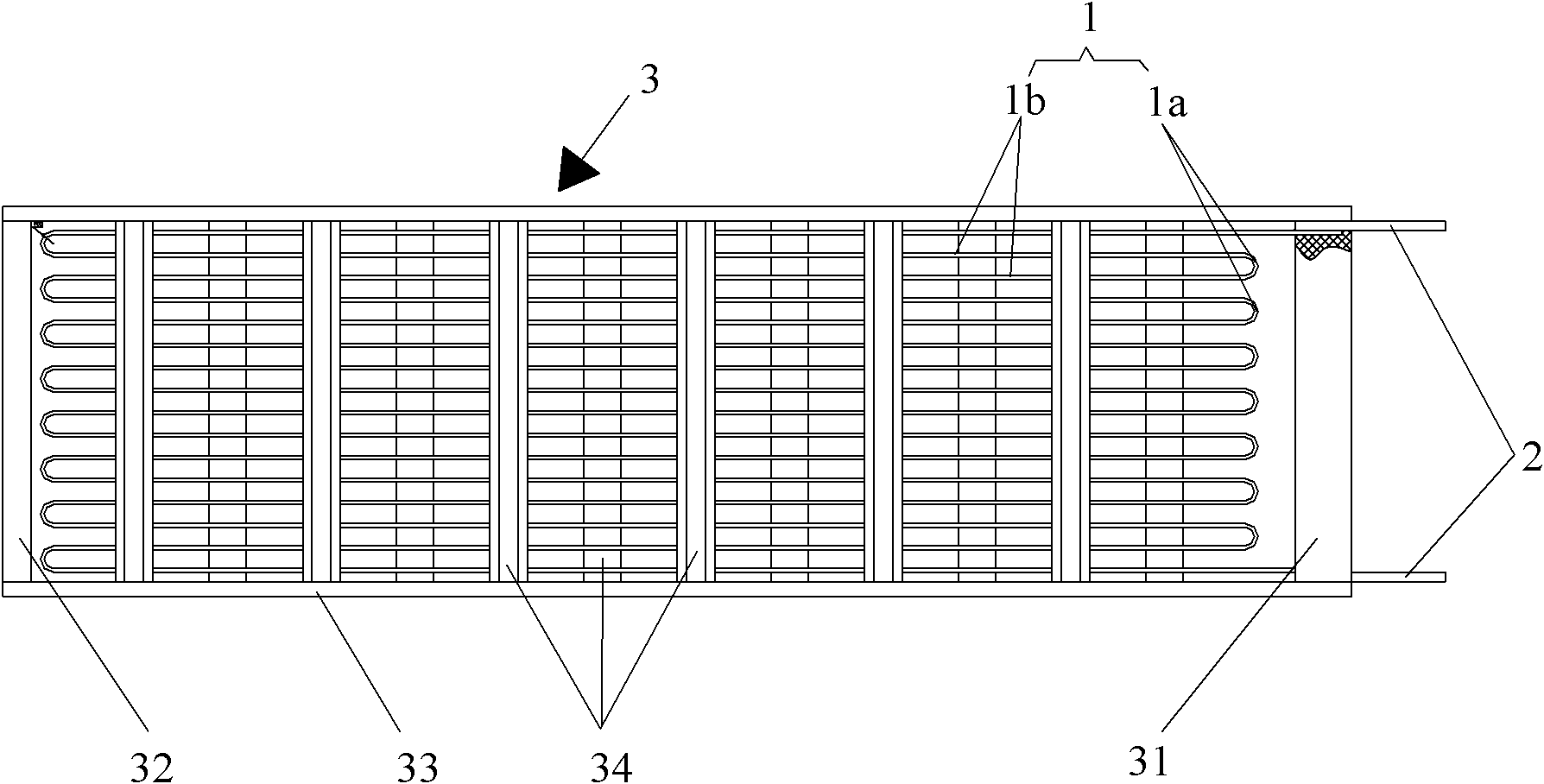

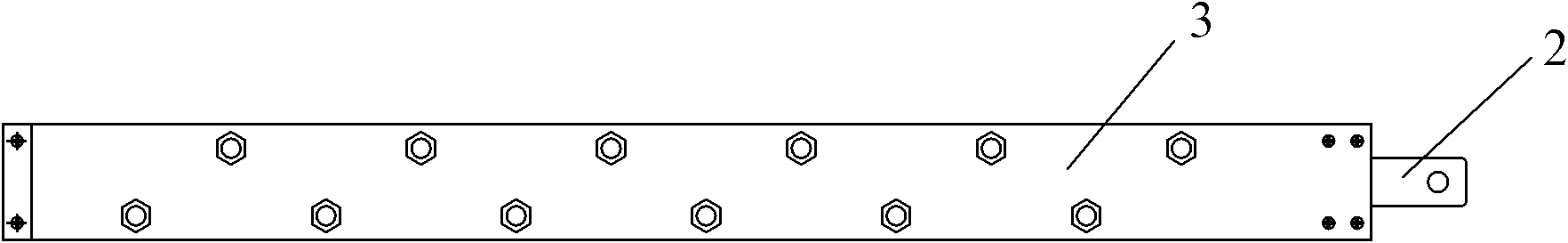

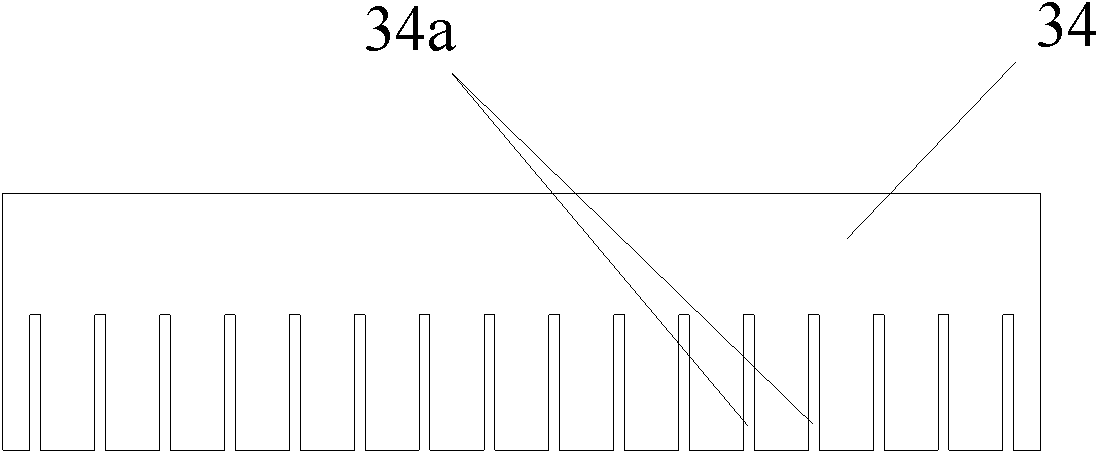

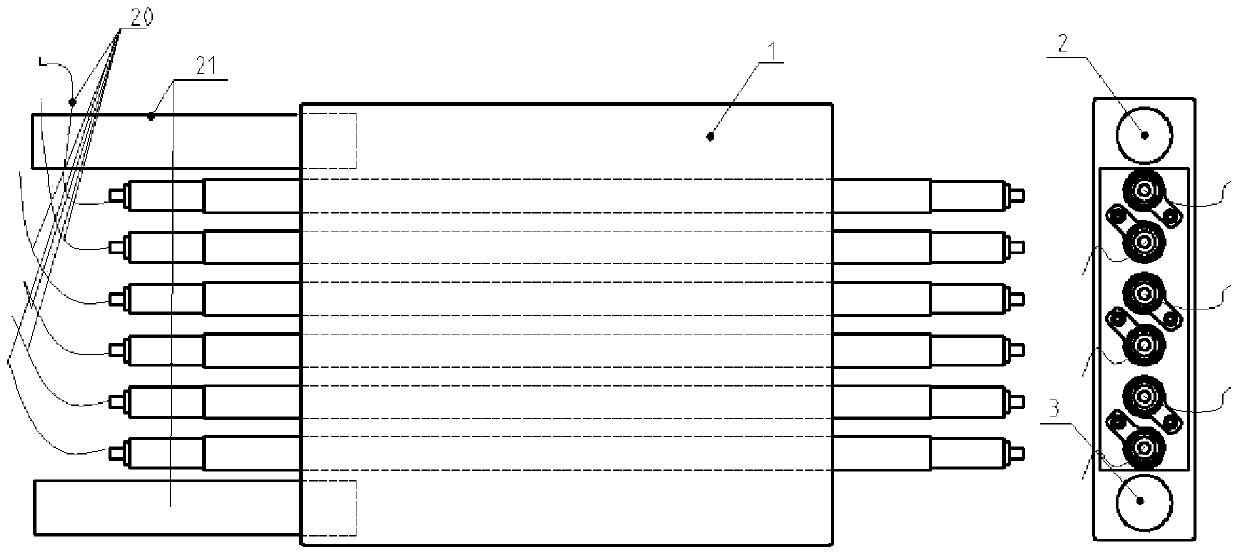

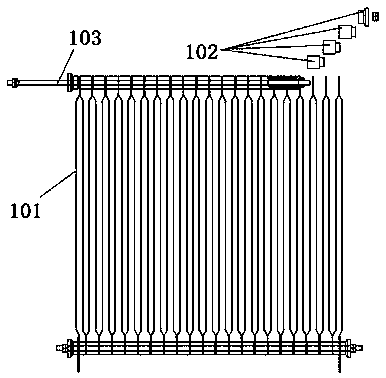

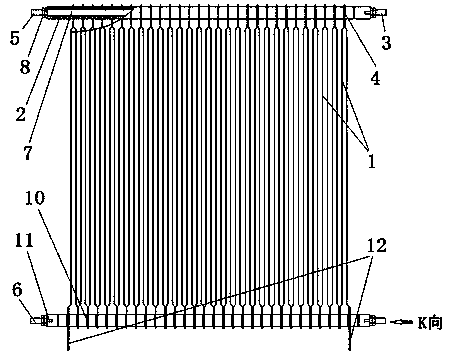

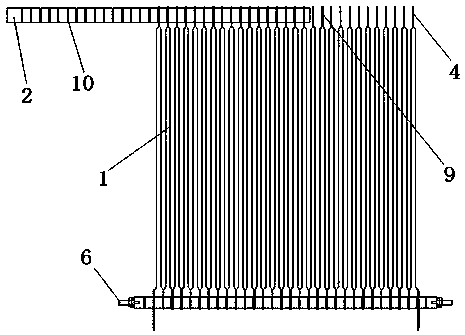

High-power pulse linear dummy load

ActiveCN101944414ASimple structureLow costZig-zag/sinusoidal resistive elementsElectrical resistance and conductanceDummy load

The invention discloses a high-power pulse linear dummy load, which comprises a resistor, outlet connectors connected to two ends of the resistor and an insulating frame for fixing the resistor. The resistor is formed by alternately connected a plurality of bending sections and a plurality of straight sections; the straight sections are parallelly arranged in the insulating frame at certain intervals; and the outlet connectors extend out of the insulating frame. The high-power pulse linear dummy load has the advantages of simple structure, good radiating performance, low manufacturing cost, and suitability for wide application.

Owner:HUAZHONG UNIV OF SCI & TECH

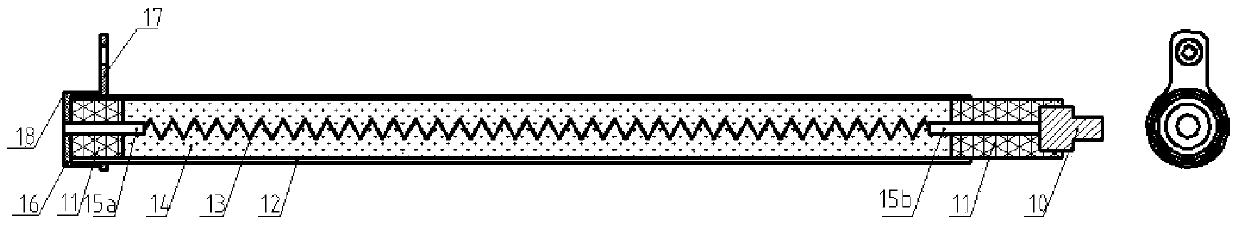

Resistor, radiator and combined equipment of resistor and radiator

ActiveCN104183341AShorten the lengthAchieve isolationCurrent collector arrangementsResistor terminals/electrodesElectric powerPower electronics

The invention discloses a resistor, a radiator and combined equipment of the resistor and the radiator, and belongs to the field of power electronics. The resistor is columnar in appearance and comprises a metal end, an insulation part, a shell, a metal bar, a resistance wire, thermally conductive insulating filler and a metal connecting mechanism, wherein the metal connecting mechanism of the resistor is connected with the radiator in a direct contact manner. By virtue of adoption of the structure and the connection manner, the length of the resistor can be reduced, and complete leakage isolation of an electrical loop of the resistor and a water inlet and outlet pipe of the radiator can be realized, so that the combined equipment of the resistor and the radiator is compacter in structure and tidier in connection.

Owner:NR ELECTRIC CO LTD +2

Pressure sensible textile and pressure sensible device thereof

ActiveUS9048013B2High sensitivityReduce thicknessNegative temperature coefficient thermistorsPositive temperature coefficient thermistorsHigh resistanceElectricity

Owner:TAIWAN TEXTILE RESEARCH INSTITUTE

Method of improving insulation performance of chip resistor unit

ActiveCN110289144AImprove insulation performanceMeet high pressure requirementsZig-zag/sinusoidal resistive elementsEngineeringMoisture

The invention discloses a method of improving the insulation performance of a chip resistor unit. Resistor strips or resistor chips are arranged together, adjacent resistor strips or resistor chips are isolated by an insulation material, an integral insulation tube is adopted to isolate the adjacent resistor strips or resistor chips, and through the integral insulation tube, isolation, insulation and positioning are carried out between adjacent resistor strips or resistor chips. Clamping grooves are opened in the integral insulation tube, all resistor strips or resistor chips are clamped in the clamping grooves in the integral insulation tube, and through the clamping grooves, isolation, insulation and positioning are formed among the resistor strips or resistor chips. The resistor strips or resistor chips are clamped through the integral insulation tube. The resistor strips or resistor chips can be effectively positioned, insulation and isolation between the resistor strips or resistor chips can be effectively realized, the creepage distance of the resistor strips or resistor chips is greatly increased, problems such as moisture to affect the insulation performance do not happen, and the insulation performance of the resistor unit is improved.

Owner:SHIDAI ELECTRIC FACTORY ZHUZHOU ELECTRIC LOCOMOTIVES INST MIN OF RAILWAYS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com