Patents

Literature

311 results about "Joule heating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Joule heating, also known as Ohmic heating and resistive heating, is the process by which the passage of an electric current through a conductor produces heat. Joule's first law, also known as the Joule–Lenz law, states that the power of heating generated by an electrical conductor is proportional to the product of its resistance and the square of the current: P∝I²R Joule heating affects the whole electric conductor, unlike the Peltier effect which transfers heat from one electrical junction to another.

Smoking article incorporating a conductive substrate

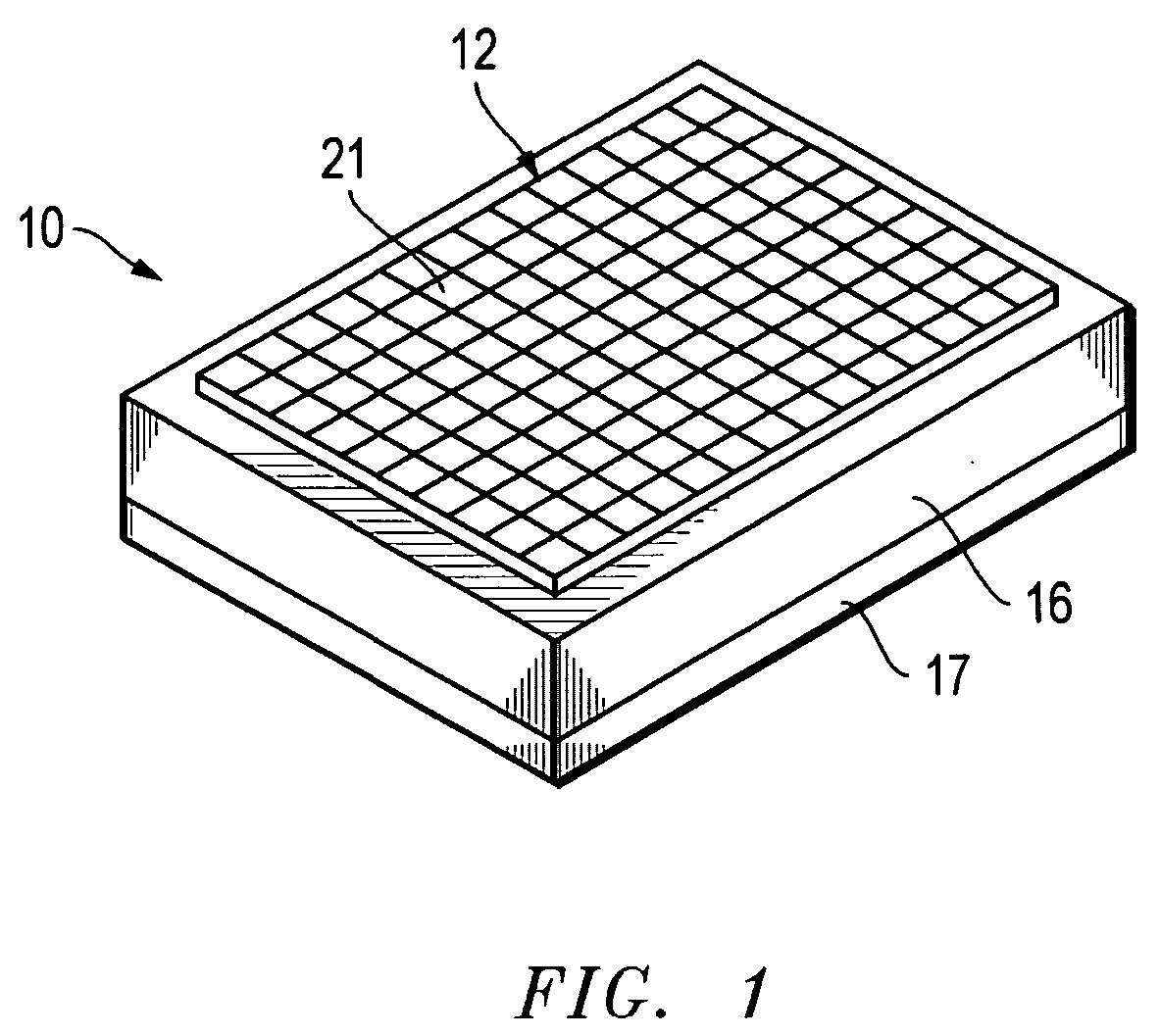

The present invention provides a conductive substrate useful for Joule heating, such as in an electronic smoking article. Particularly, the invention provides a resistive heating element formed of a conductive substrate. The conductive substrate comprises an electrically conductive material and a carbonaceous additive, such as a binder material. The conductive substrate is carbonized in that it is subjected to calcining conditions to effectively reduce the carbonaceous additive to its carbon skeleton. It has been found that such carbonized substrate has surprisingly improved resistance properties in relation a substrate of the same formulation that is not carbonized. The carbonized substrate can include an aerosol precursor material. The formed resistive heating element can be included in an electronic smoking article to simultaneously provide resistive heating and aerosol formation with a single, unitary component.

Owner:RAI STRATEGIC HLDG INC

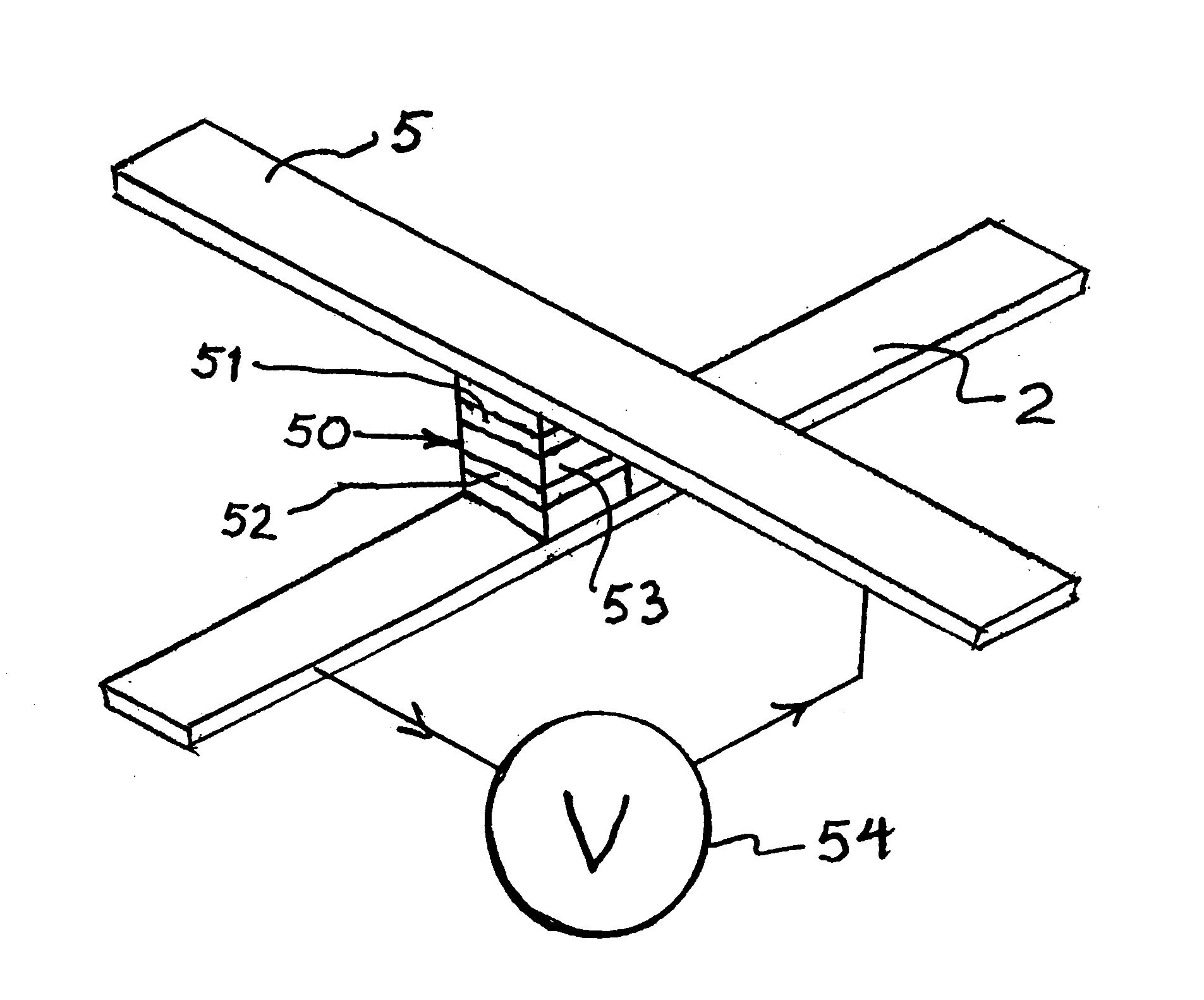

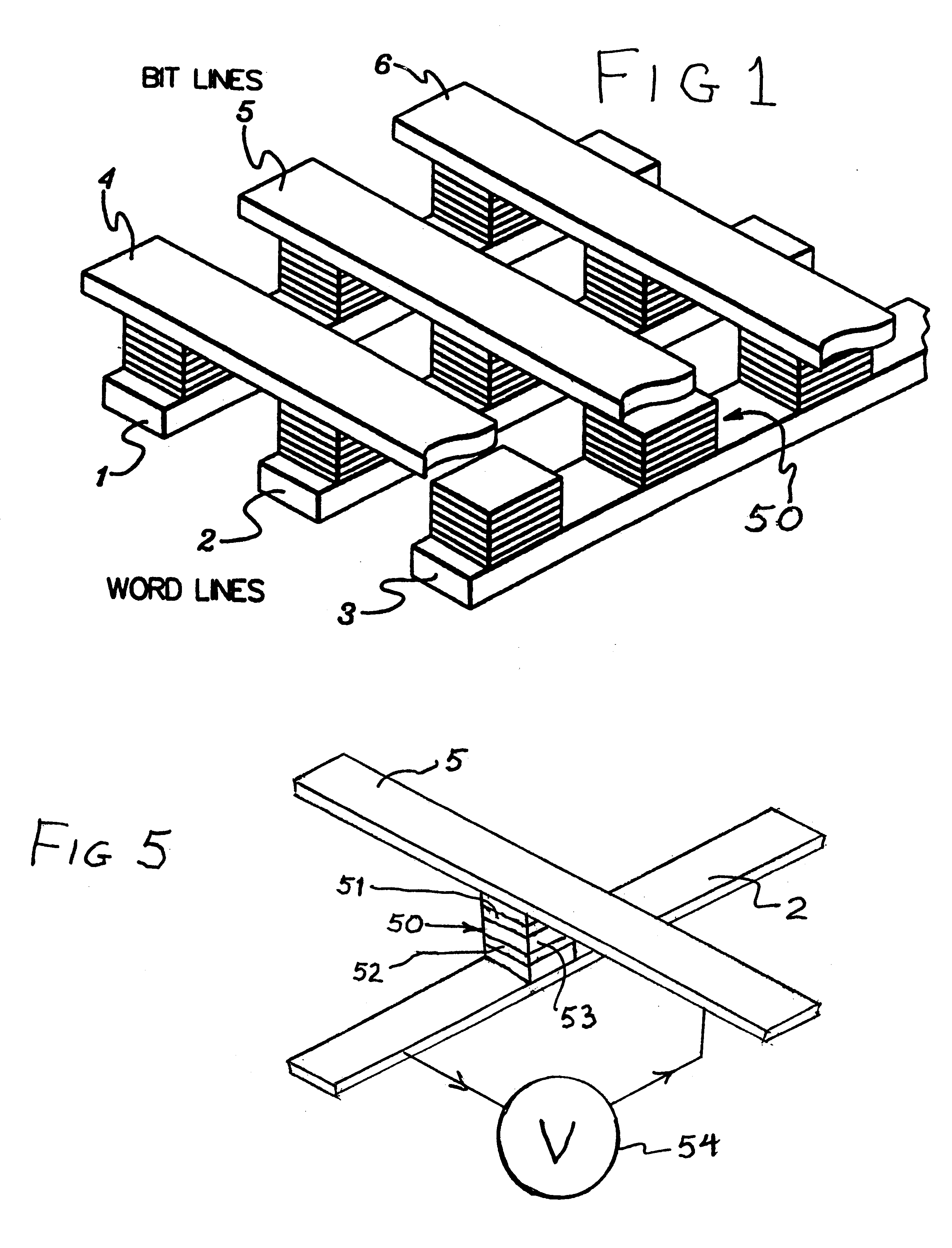

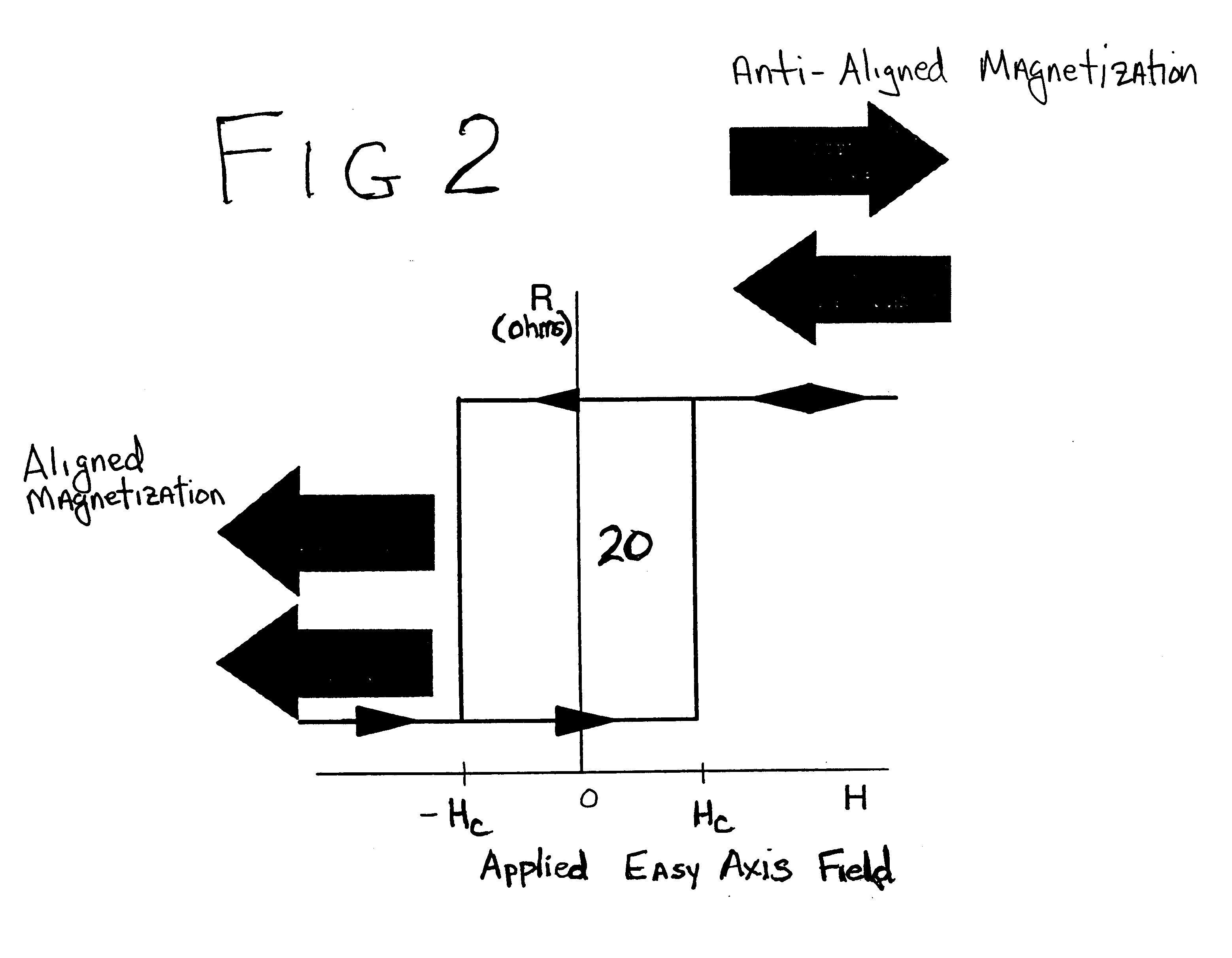

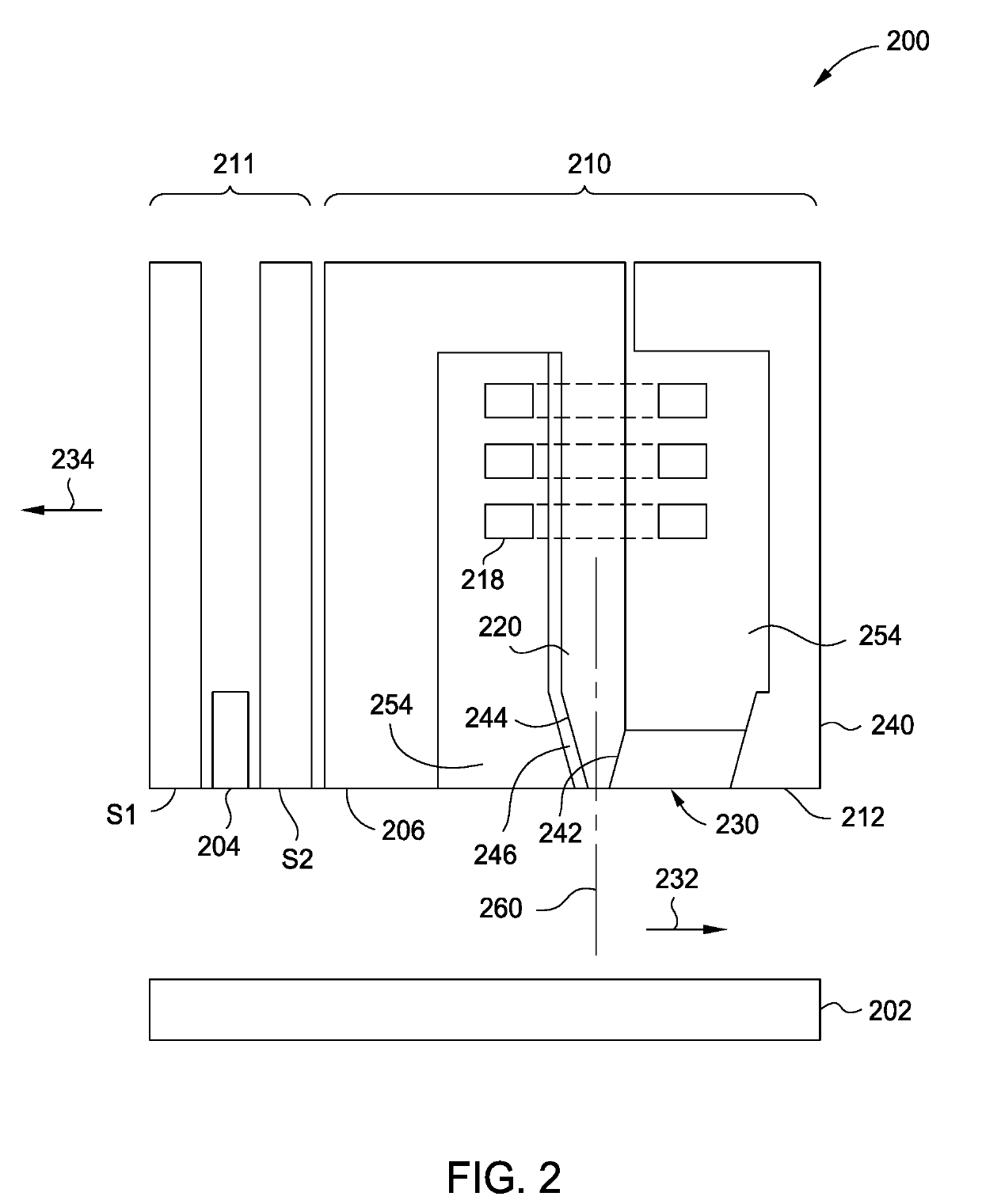

Thermally-assisted magnetic random access memory (MRAM)

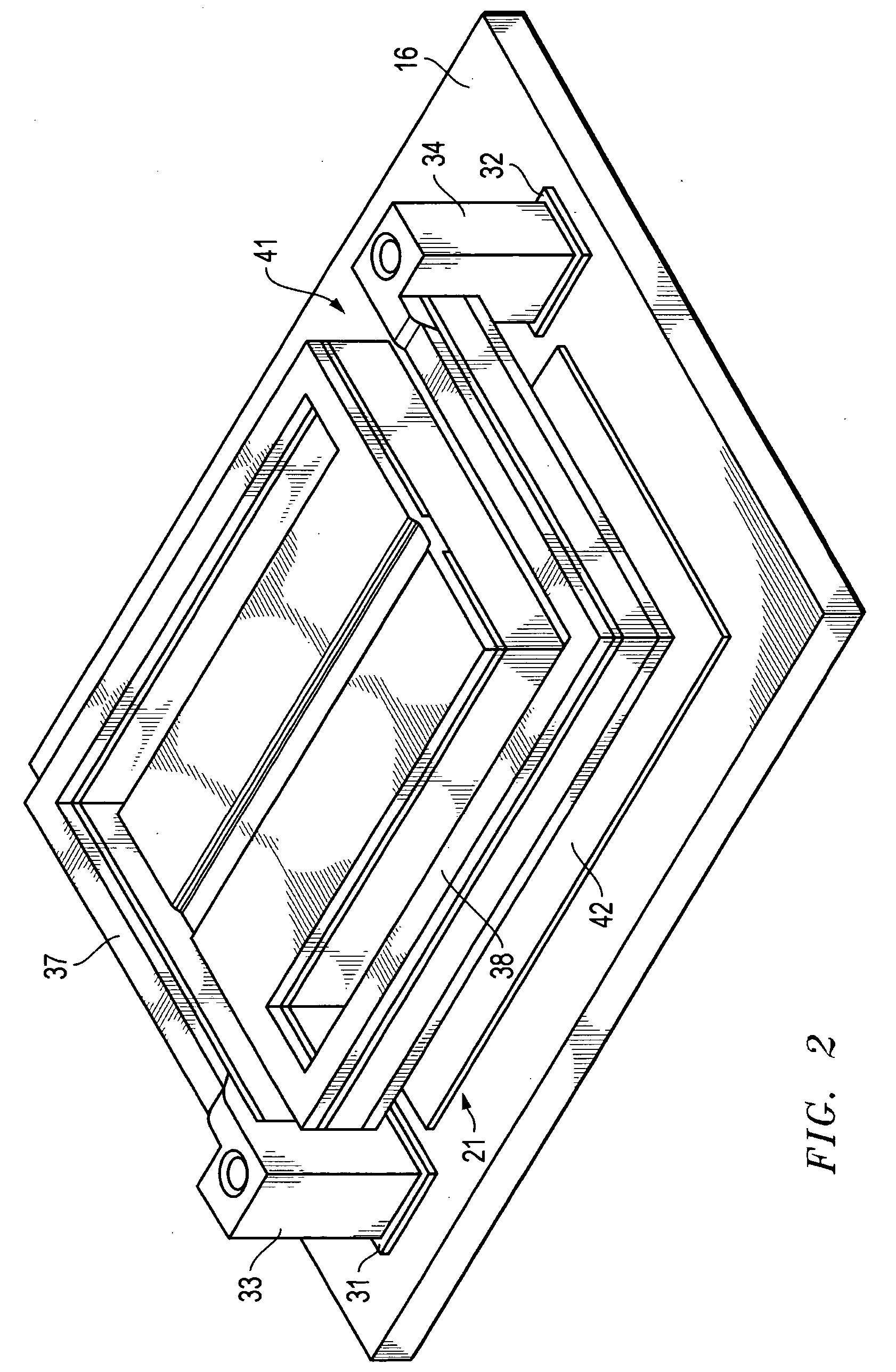

It is important to ensure good selectivity of a single magnetic tunnel junction storage cell within a memory array without affecting nearby storage cells. For this purpose, this memory array of storage cells preferably comprises a) an array of electrically conducting bit lines and electrically conducting word lines which form intersections therebetween, b) a storage cell disposed at each of said intersections, each storage cell comprising at least one reversible magnetic region or layer characterized by a magnetization state which can be reversed by applying thereto a selected external magnetic field, said reversible magnetic layer comprising a material whose magnetization state is more easily reversed upon a change in the temperature thereof, and c) a temperature change generator for changing the temperature of said reversible magnetic layer of only a selected one of said array of storage cells at any moment. To select a cell, it is preferable to select a cell by using a brief pulse of tunnelling current between the intersecting bit and word lines at that cell in order to provide sufficient Joule heating to facilitate a change in the magnetization state of its reversible magnetic layer, which preferably comprises a ferrimagnetic material.

Owner:IBM CORP

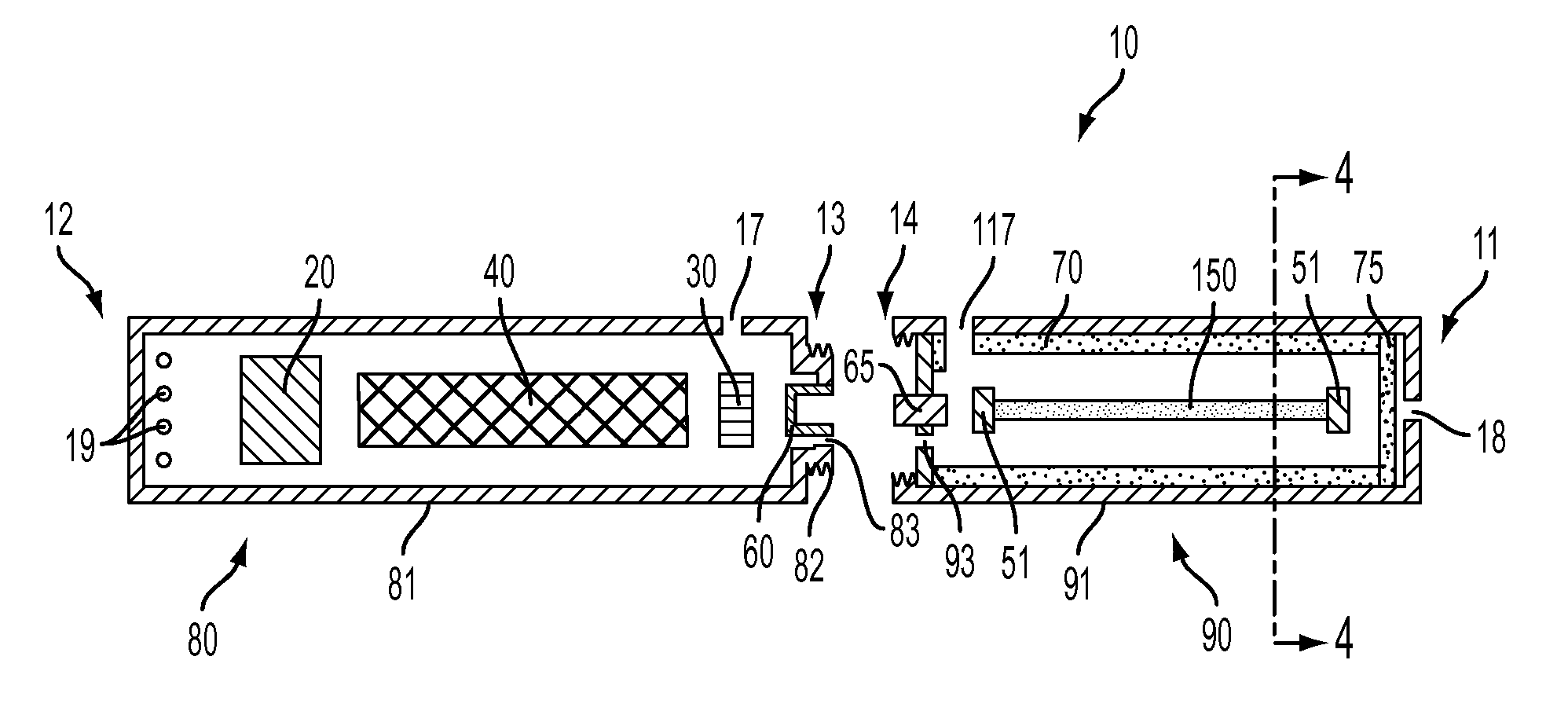

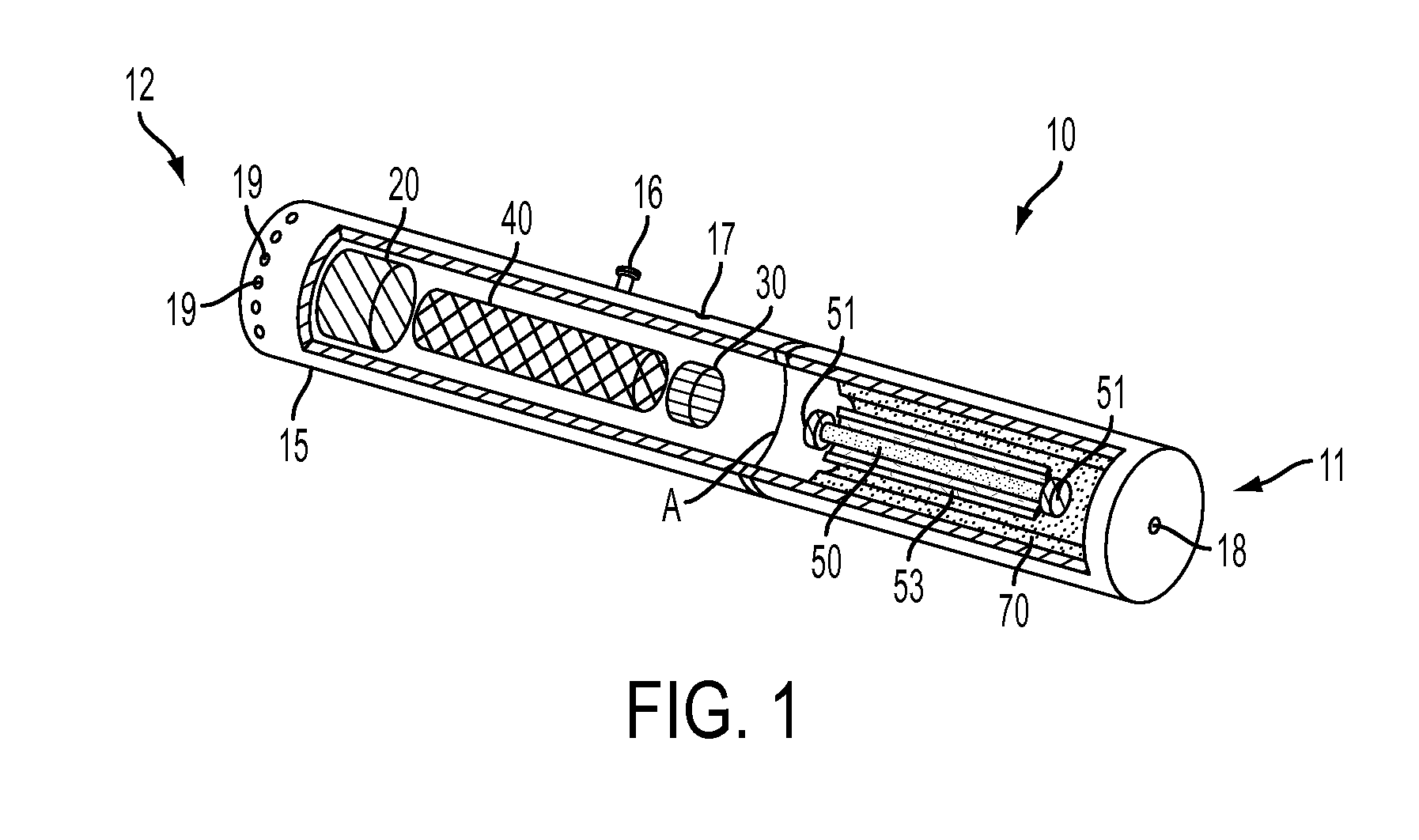

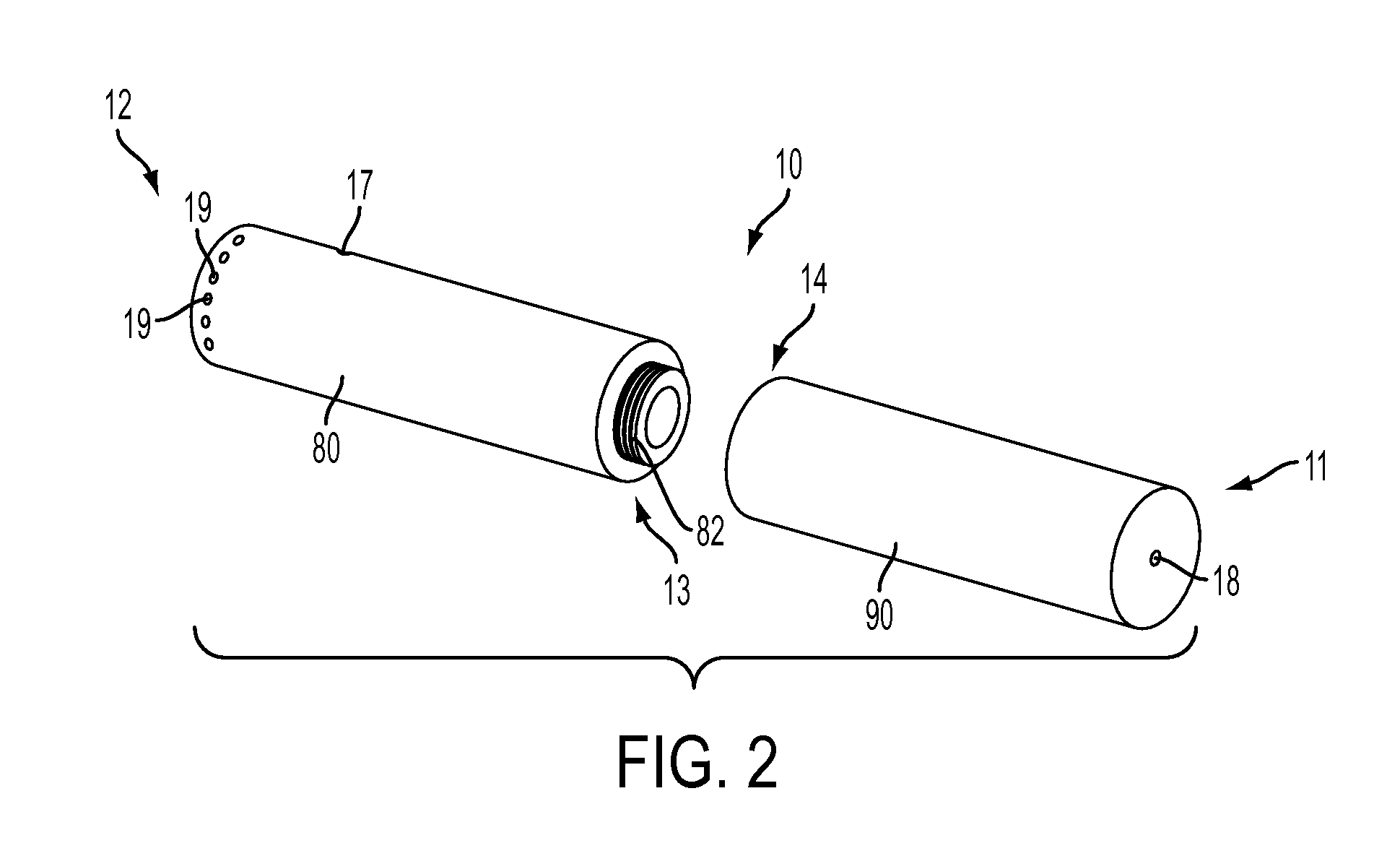

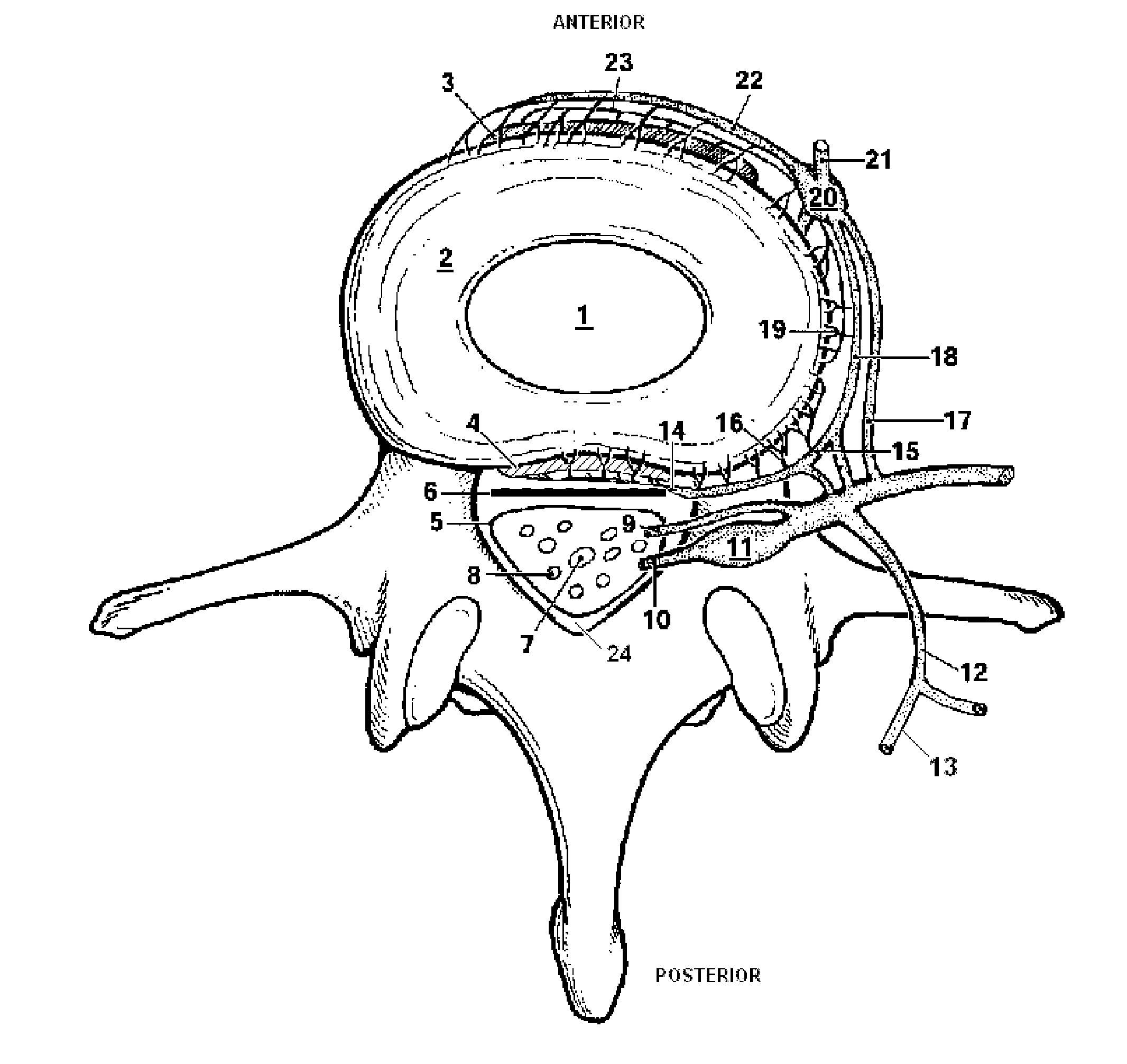

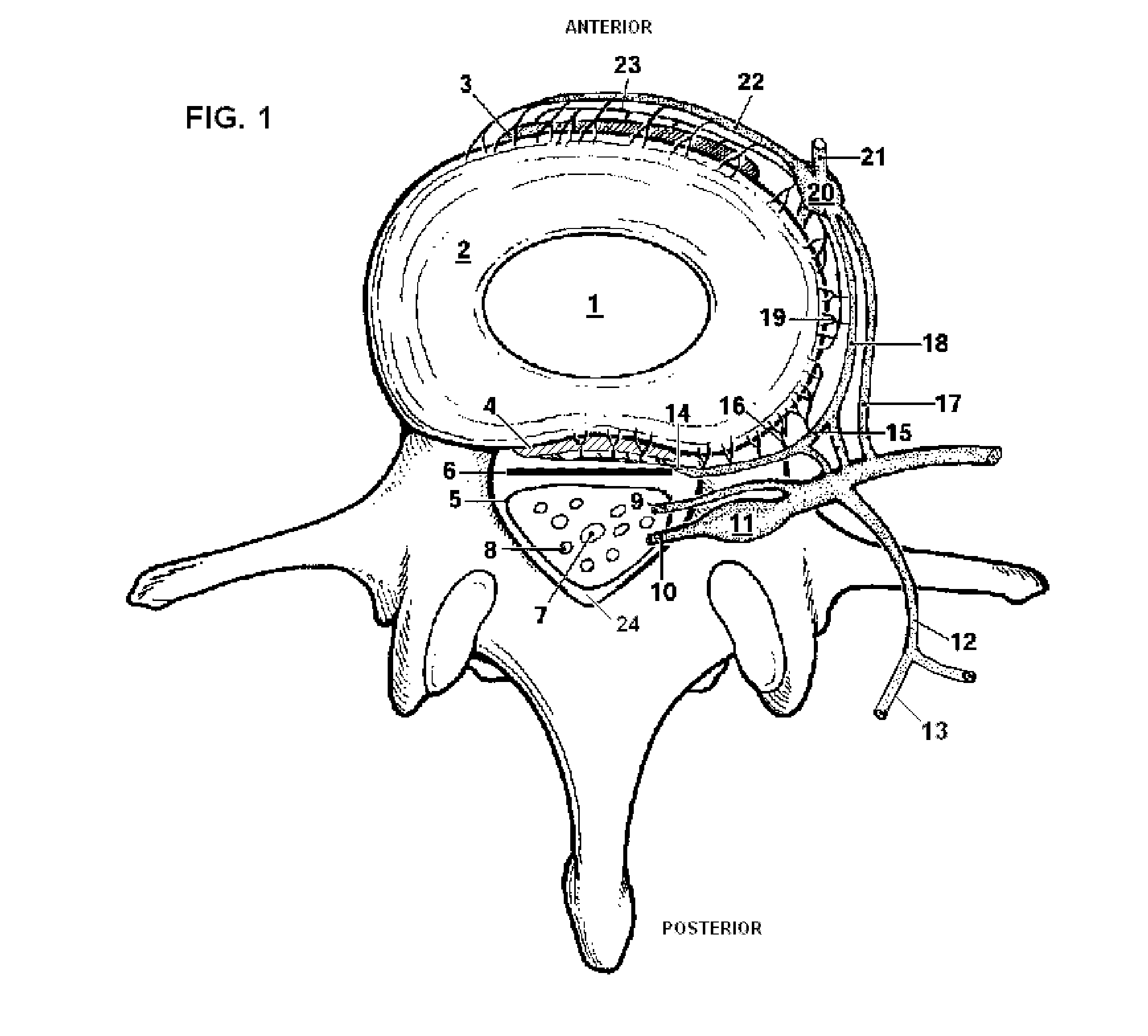

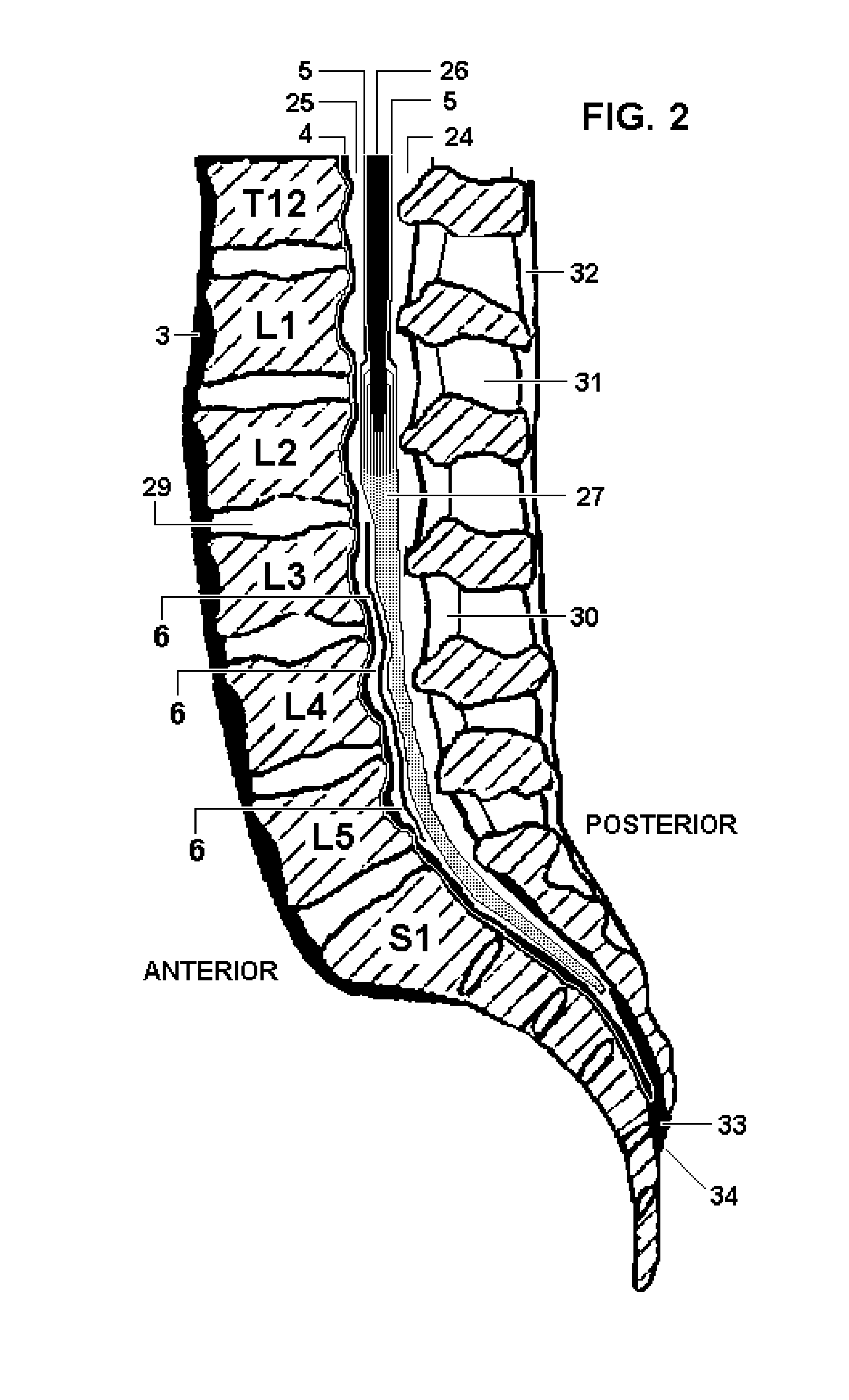

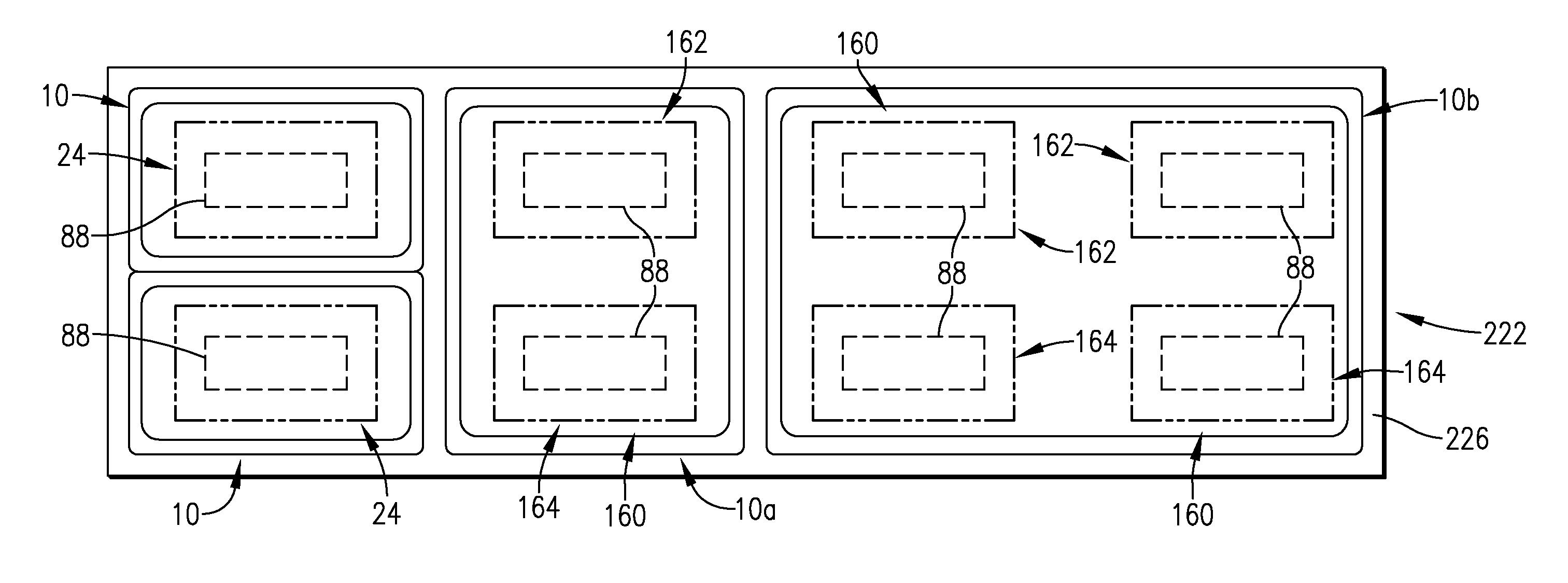

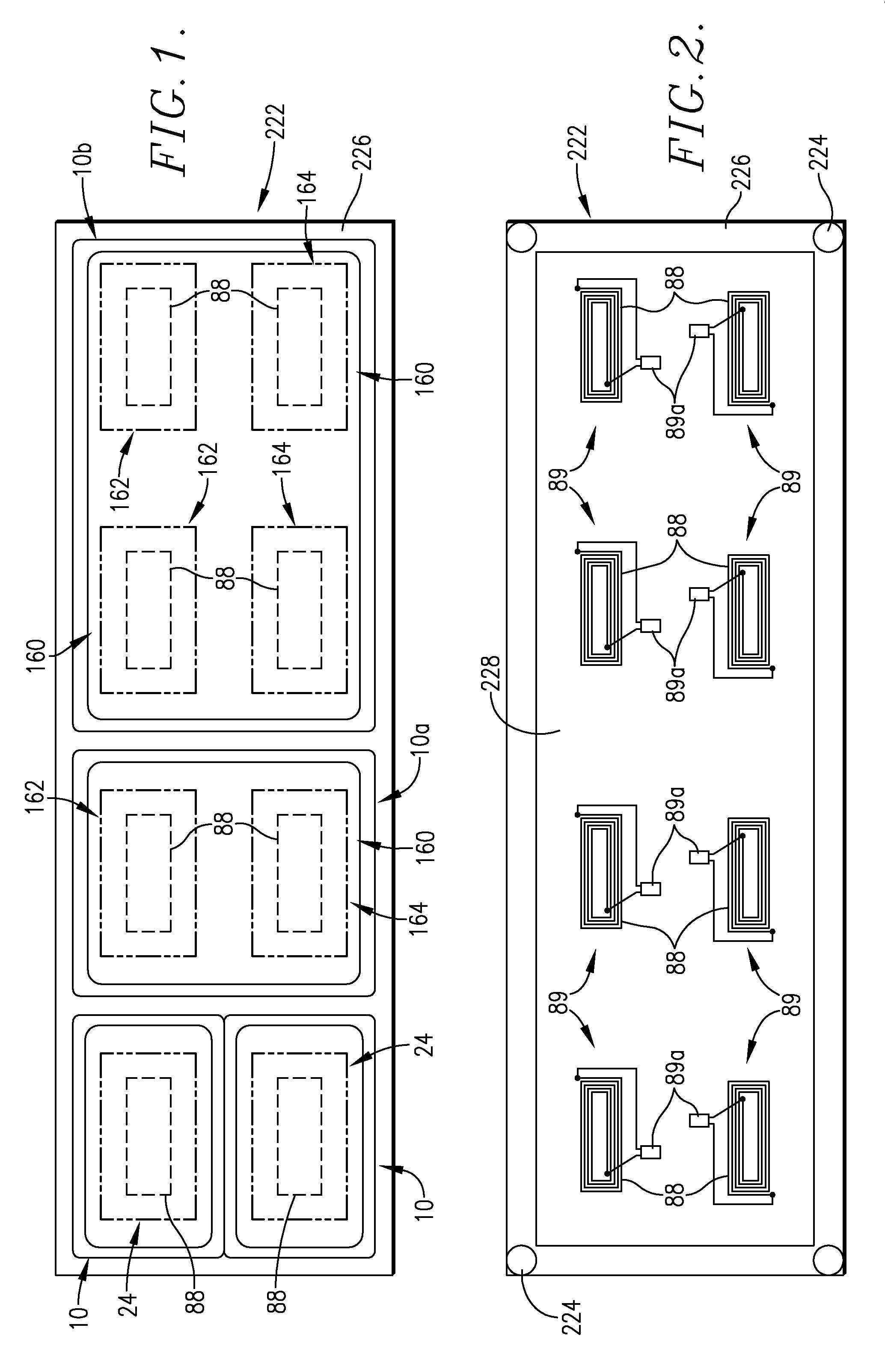

System and Method for Electrical Stimulation of the Lumbar Vertebral Column

ActiveUS20120215218A1Inhibit migrationPrevent rotationSpinal electrodesSurgical instruments for heatingElectrical impulseElectrical stimulations

Disclosed methods and devices treat chronic lower back pain from degenerated or injured intervertebral discs. Electrodes connected to a pulse generator deliver electrical impulses to nerves located within the posterior longitudinal ligament and annulus fibrosus of lumbar intervertebral discs. The stimulation reduces back pain reversibly, adjustably, and with almost complete coverage of the pain-generating region. A temporary percutaneous lead and a permanent paddle lead are used. The percutaneous lead, designed to prevent inappropriate stimulation of the thecal sac, is inserted using a specially-designed introducer cannula and lead blank. The paddle lead is configured individually for implantation in the anterior epidural space of each patient. Electrical stimulation parameters may also be selected so as to ablate the nerves, using non-thermal irreversible electroporation, or using joule heating wherein a thermal insulator covers substantially all of the thecal sac, thereby shielding the thecal sac from potential heat damage.

Owner:LIPANI JOHN D

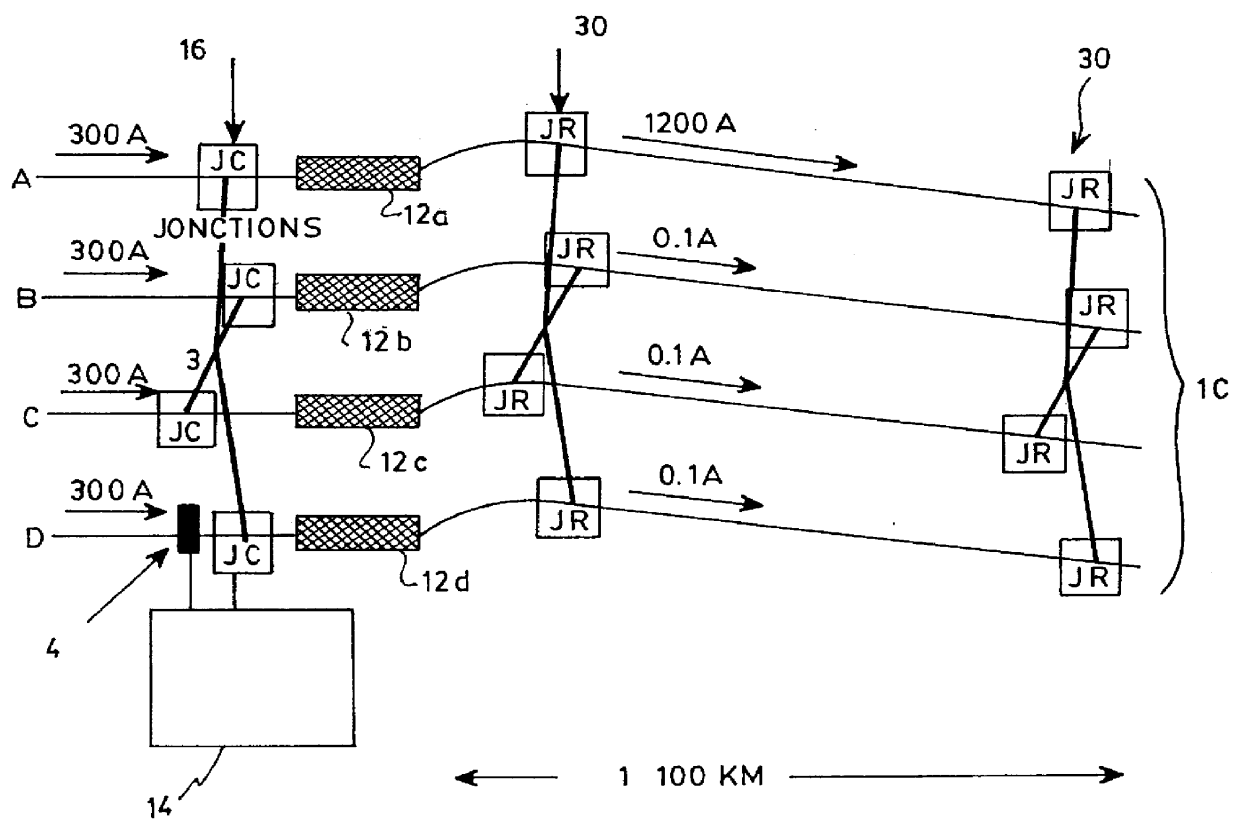

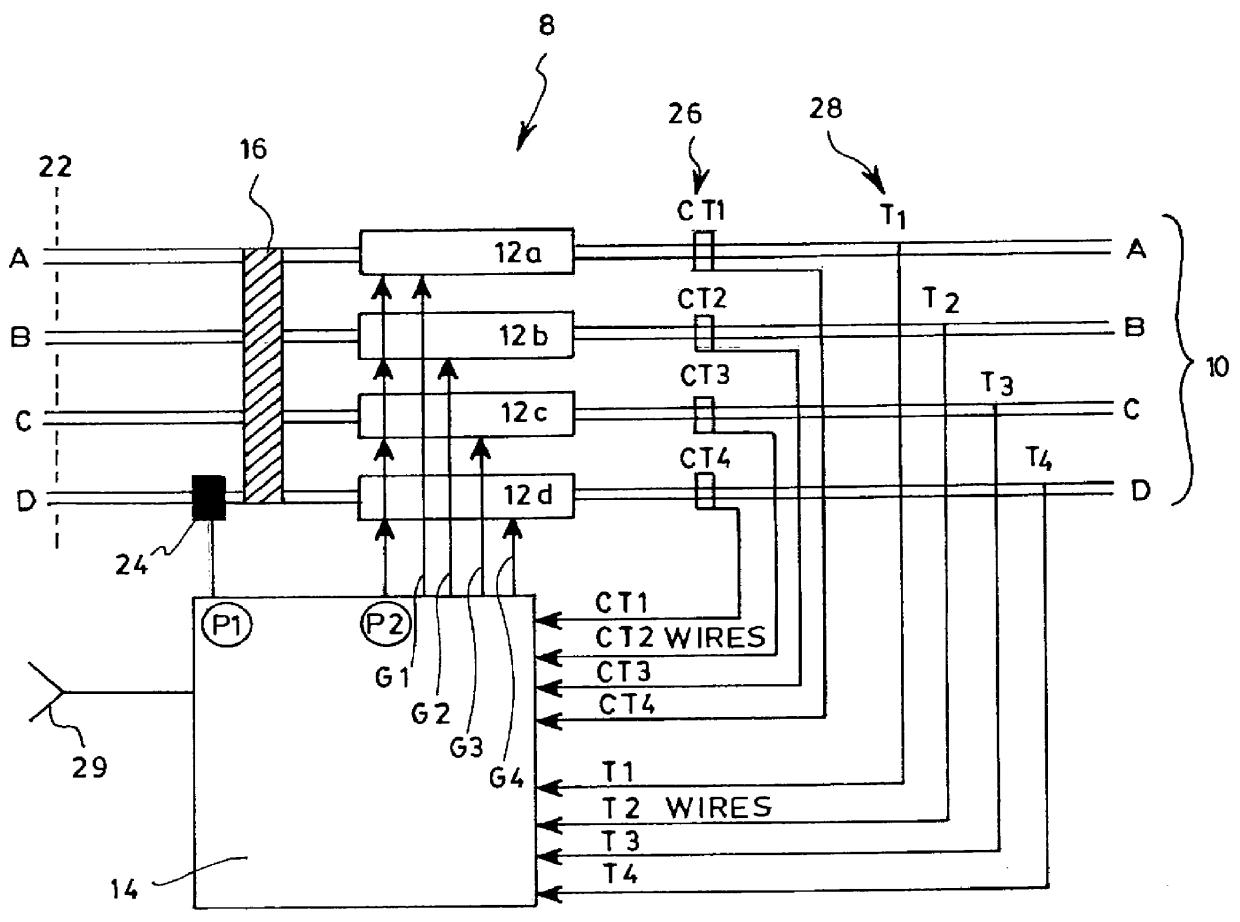

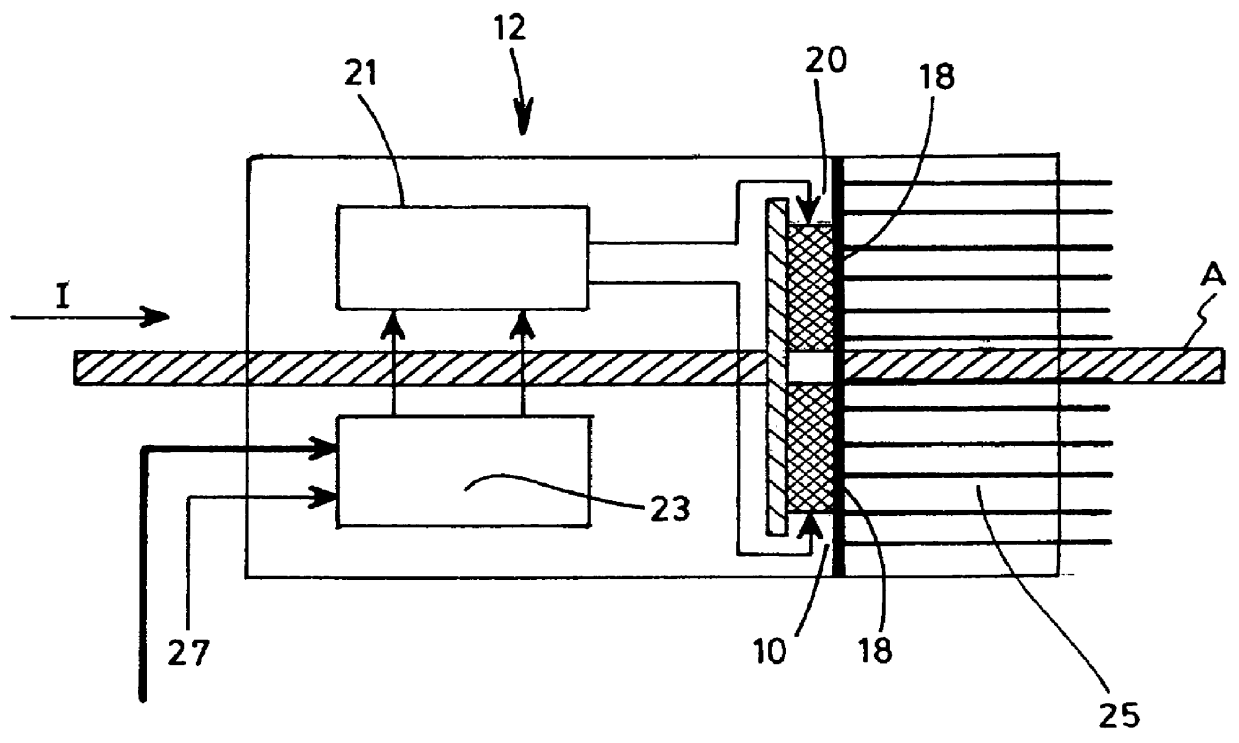

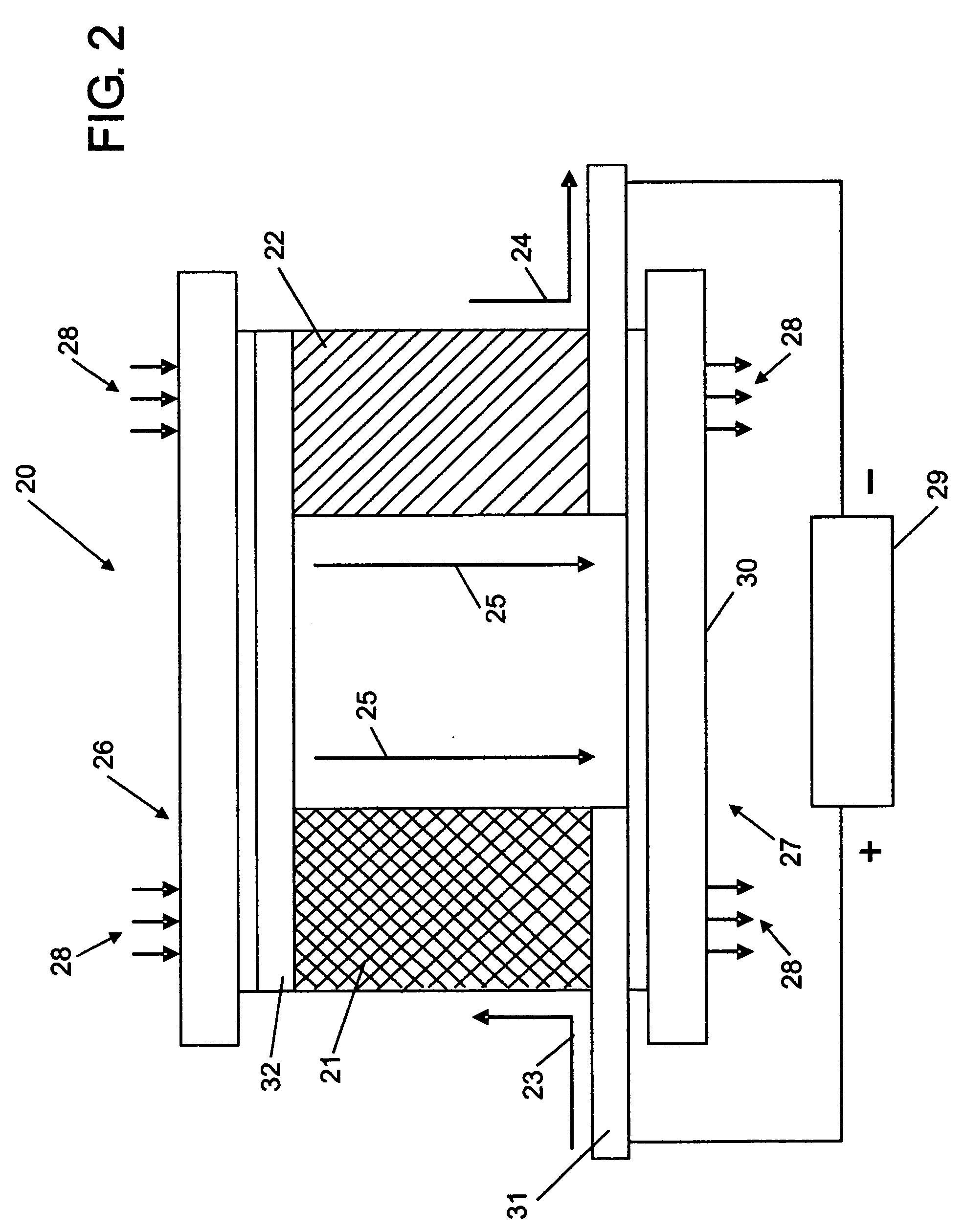

Method and device for de-icing conductors of a bundle of conductors

InactiveUS6018152AThe process is simple and effectiveOverhead installationBus-bar/wiring layoutsCurrent loadElectrical conductor

A method and device for removing ice from overhead conductors of a bundle of conductors or preventing an accumulation of ice on these conductors. The method includes forcing the entire current load of the line in one or a portion of the conductors, the excessive power dissipated in this manner de-ices the conductor by Joule heating. The method is repeated for different conductors of the bundle until they have all been de-iced or for the entire duration of an ice storm. Electric power units are provided on each conductor to control the current circulation as needed, and a command module controls the entire system. Conducting elements are provided at the beginning and at the end of the line to allow a distribution of the current as needed.

Owner:ALLAIRE MARC ANDRE +1

Thermoelectric devices with controlled current flow and related methods

InactiveUS20060048809A1Improve thermoelectric performanceReduce joule heatingThermoelectric device with peltier/seeback effectNanoinformaticsThermal energyElectrical resistance and conductance

Thermoelectric devices comprising at least a first conductive material, a first semiconductive material, a second conductive material, and a third conductive material. The second conductive material may be contacting, disposed within, or operably connected to the first semiconductive material. Semiconductive materials may be depleted, undoped, p-doped, or n-doped, nanotubes, nanowires, and others. Conductive materials may be metals, alloys, conductive materials, nanotubes, nanowires, and others. The effective electrical resistance between the first conductive material and the third conductive materials is reduced below the series electrical resistance of the first semiconductive material by design, reducing the associated Joule heating. Peltier cooling and Peltier heating counteract each other within the second conductive material as electrical current flows. Heat exchanged between the first conductive material and the third conductive material creates a temperature differential therebetween. Thermoelectric devices can reversibly heat or cool, and use the Seebeck effect to generate electrical power from thermal energy.

Owner:OROBRIDGE

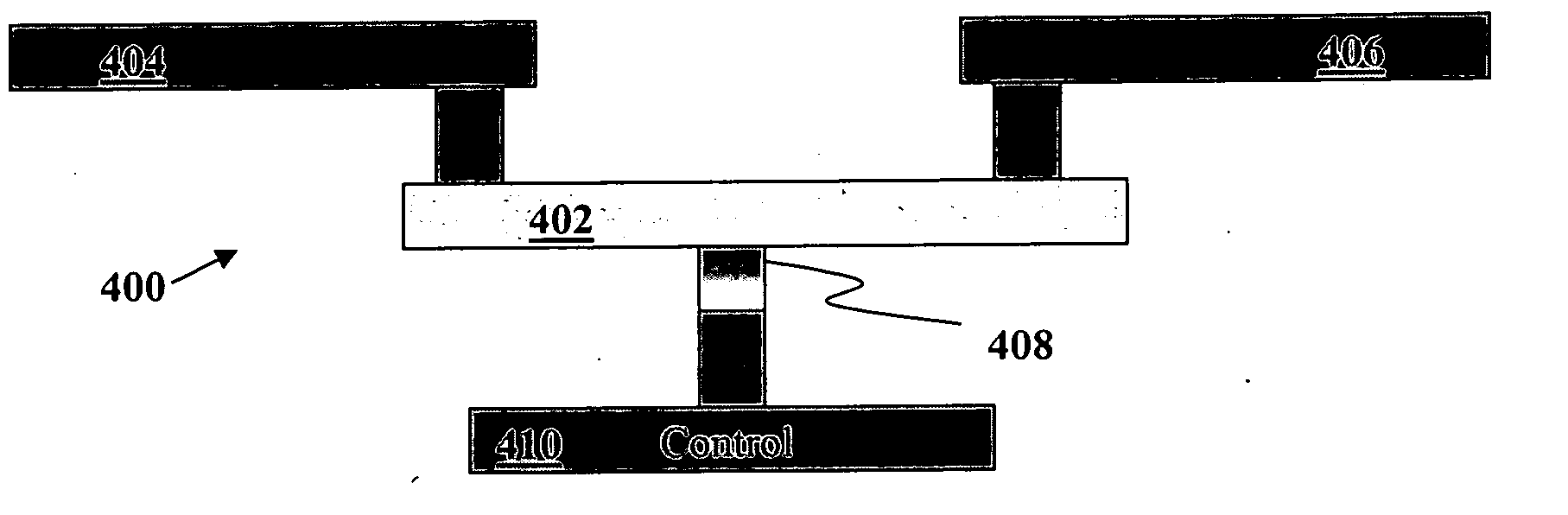

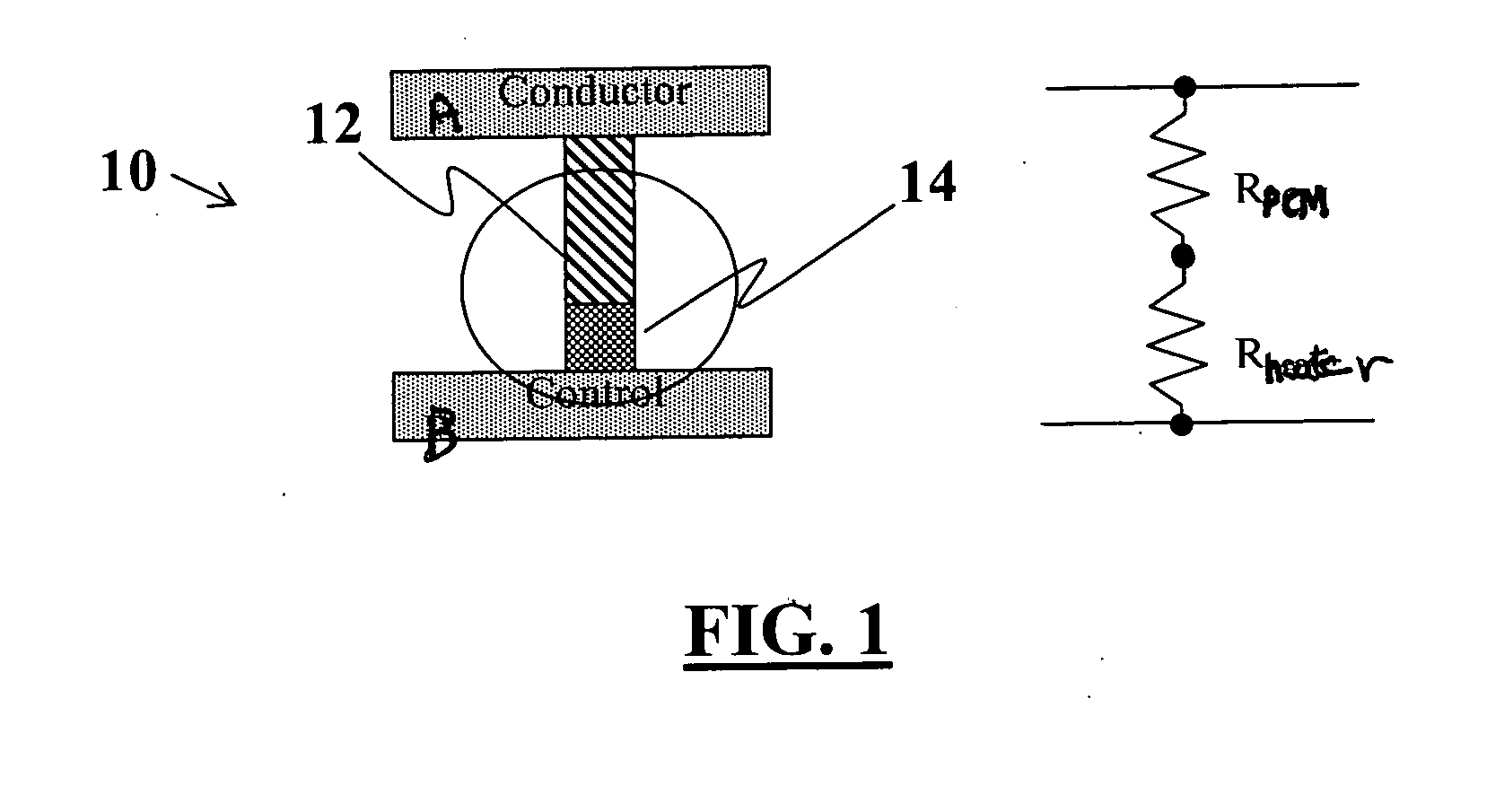

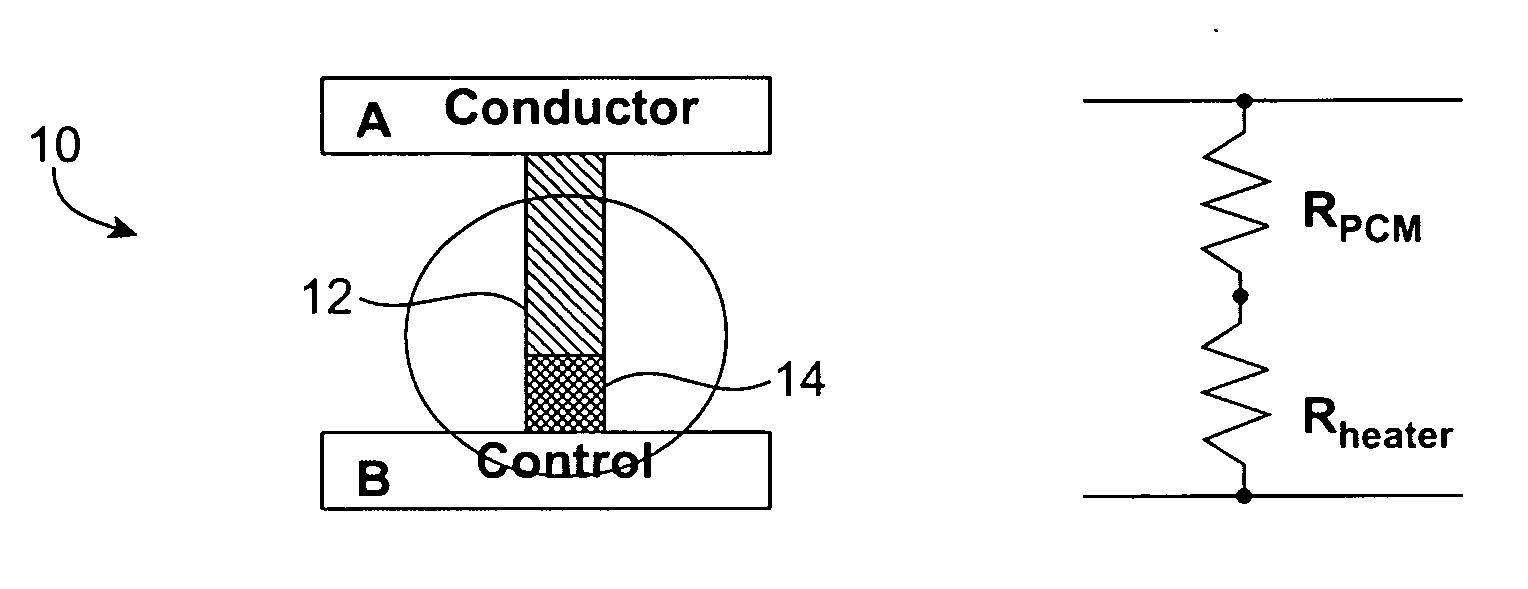

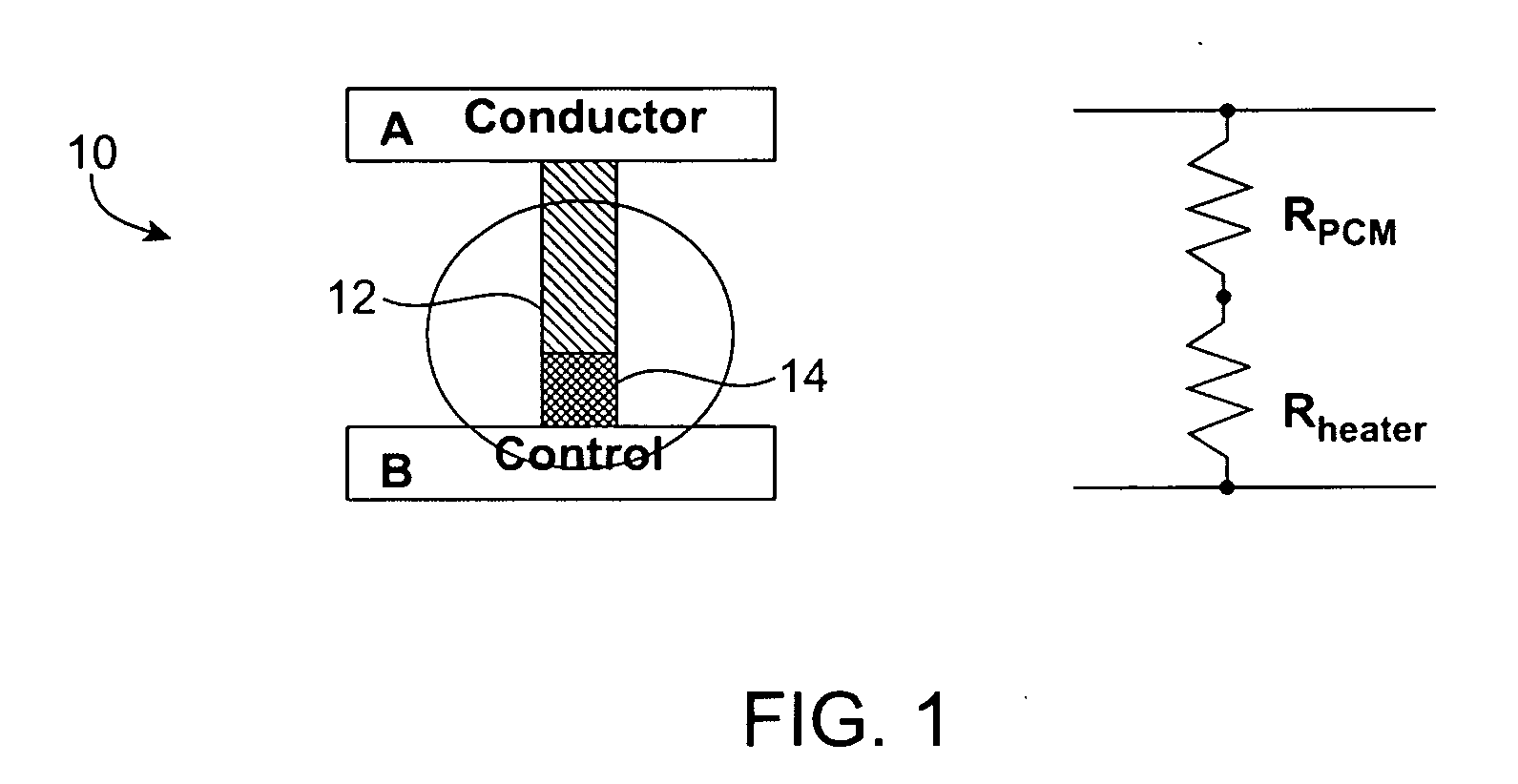

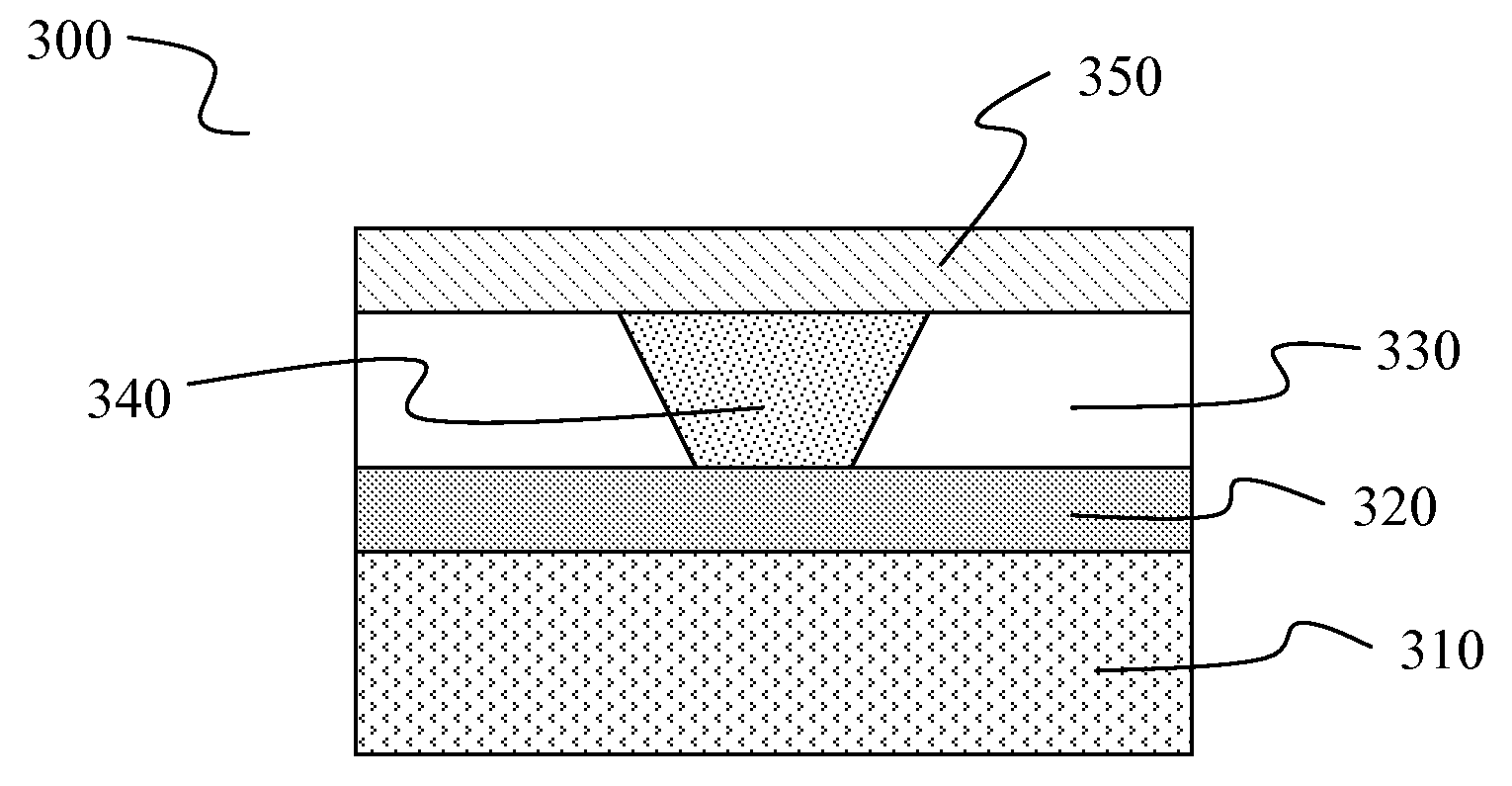

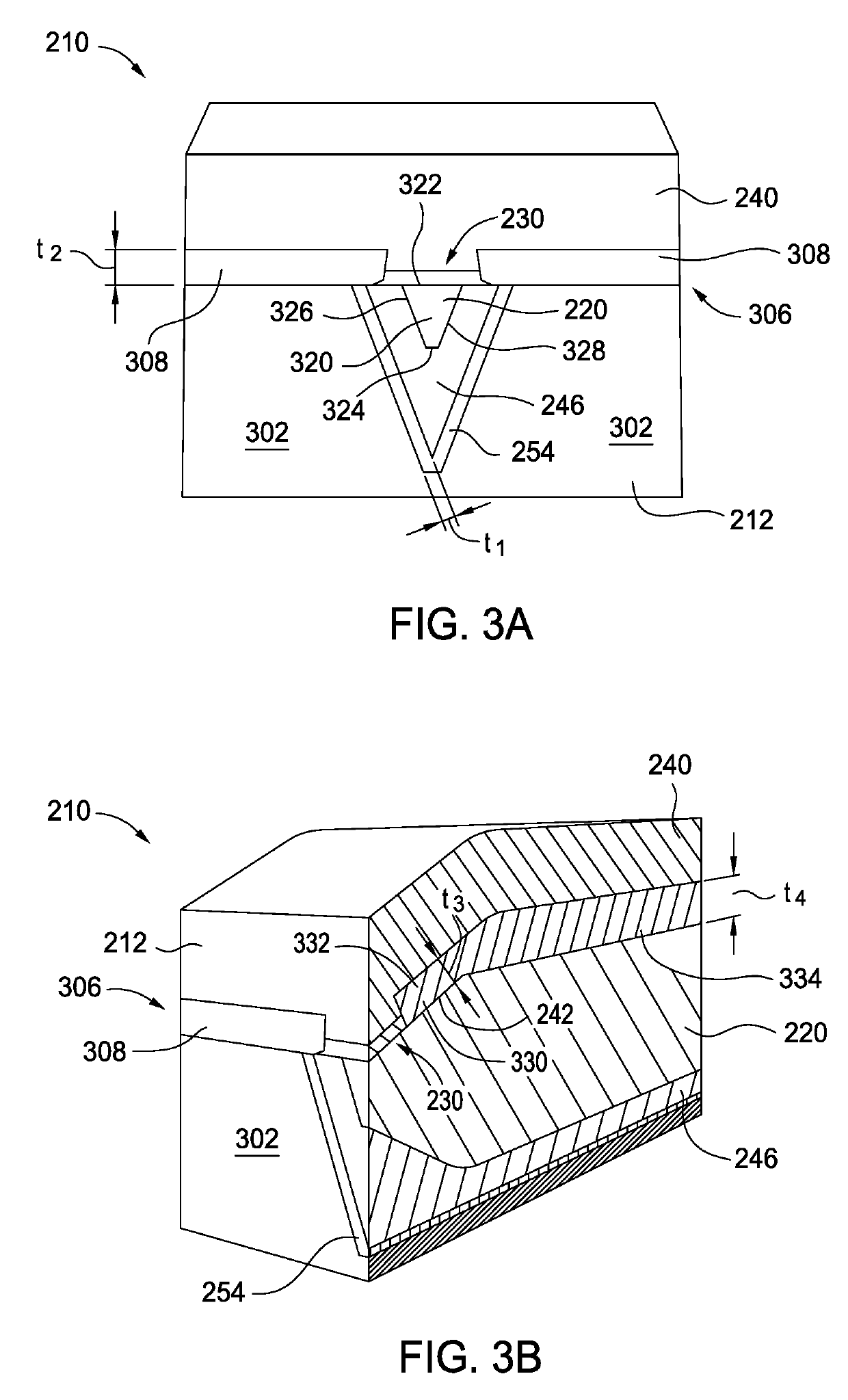

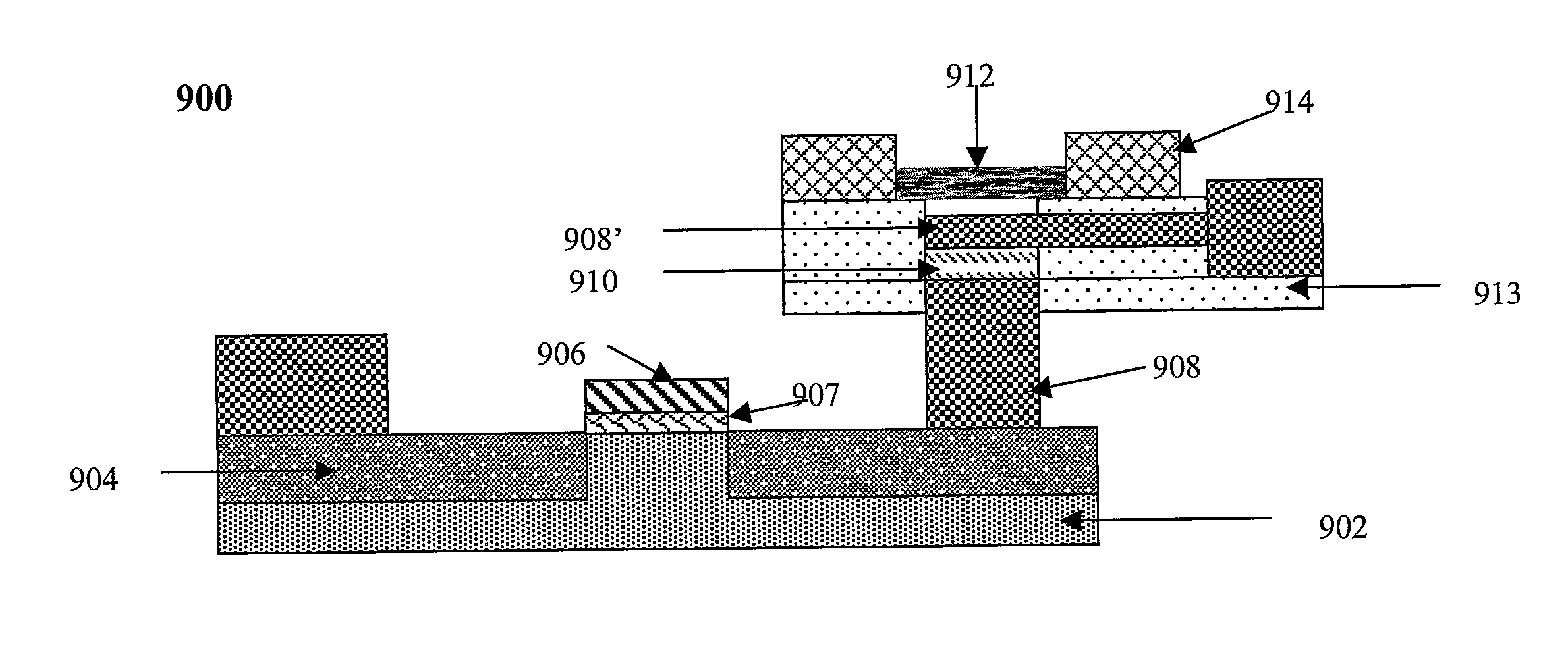

Methods for fabricating multi-terminal phase change devices

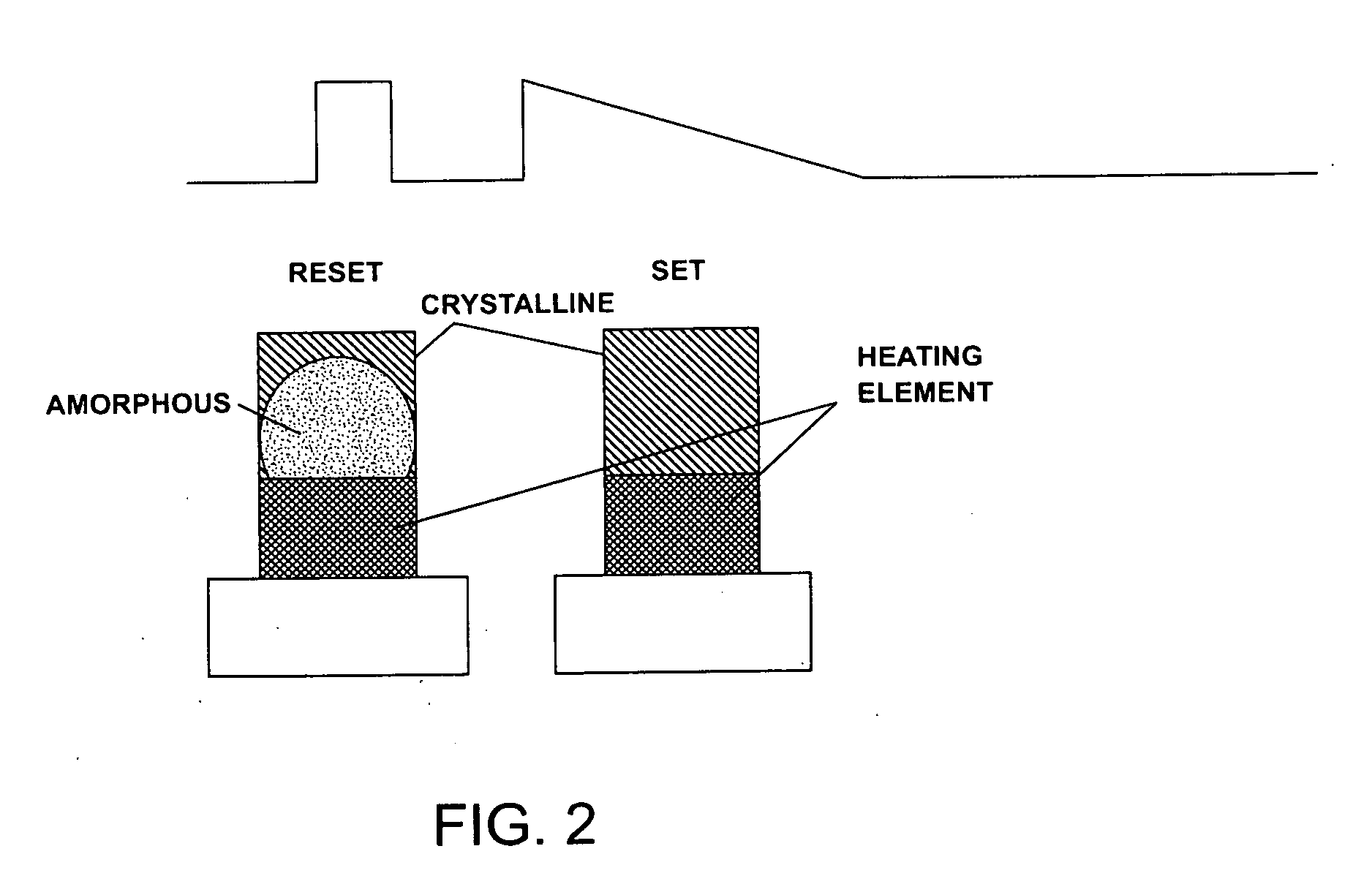

InactiveUS20070099405A1Reduce capacitanceReduce resistanceSemiconductor/solid-state device manufacturingCapacitanceControl signal

Phase change devices, and particularly multi-terminal phase change devices, include first and second active terminals bridged together by a phase-change material whose conductivity can be modified in accordance with a control signal applied to a control electrode. This structure allows an application in which an electrical connection can be created between the two active terminals, with the control of the connection being effected using a separate terminal or terminals. Accordingly, the resistance of the heater element can be increased independently from the resistance of the path between the two active terminals. This allows the use of smaller heater elements thus requiring less current to create the same amount of Joule heating per unit area. The resistance of the heating element does not impact the total resistance of the phase change device. The programming control can be placed outside of the main signal path through the phase change device, reducing the impact of the associated capacitance and resistance of the device.

Owner:AGATE LOGIC BEIJING

Multi-terminal phase change devices

InactiveUS20070096071A1Reduce capacitanceReduce resistanceDigital storageBulk negative resistance effect devicesCapacitanceElectrical resistance and conductance

Phase change devices, and particularly multi-terminal phase change devices, include first and second active terminals bridged together by a phase-change material whose conductivity can be modified in accordance with a control signal applied to a control electrode. This structure allows an application in which an electrical connection can be created between the two active terminals, with the control of the connection being effected using a separate terminal or terminals. Accordingly, the resistance of the heater element can be increased independently from the resistance of the path between the two active terminals. This allows the use of smaller heater elements thus requiring less current to create the same amount of Joule heating per unit area. The resistance of the heating element does not impact the total resistance of the phase change device. The programming control can be placed outside of the main signal path through the phase change device, reducing the impact of the associated capacitance and resistance of the device.

Owner:AGATE LOGIC BEIJING

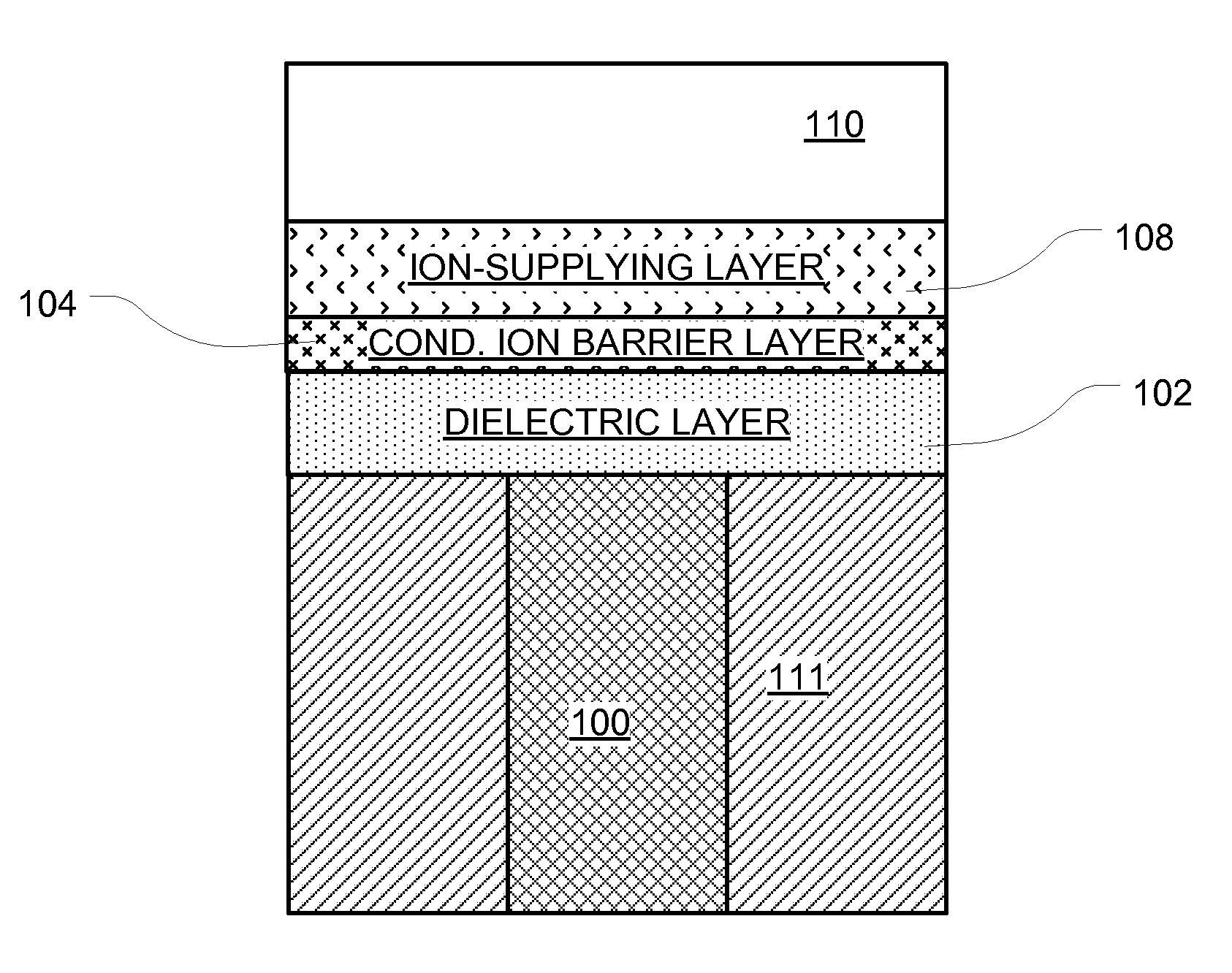

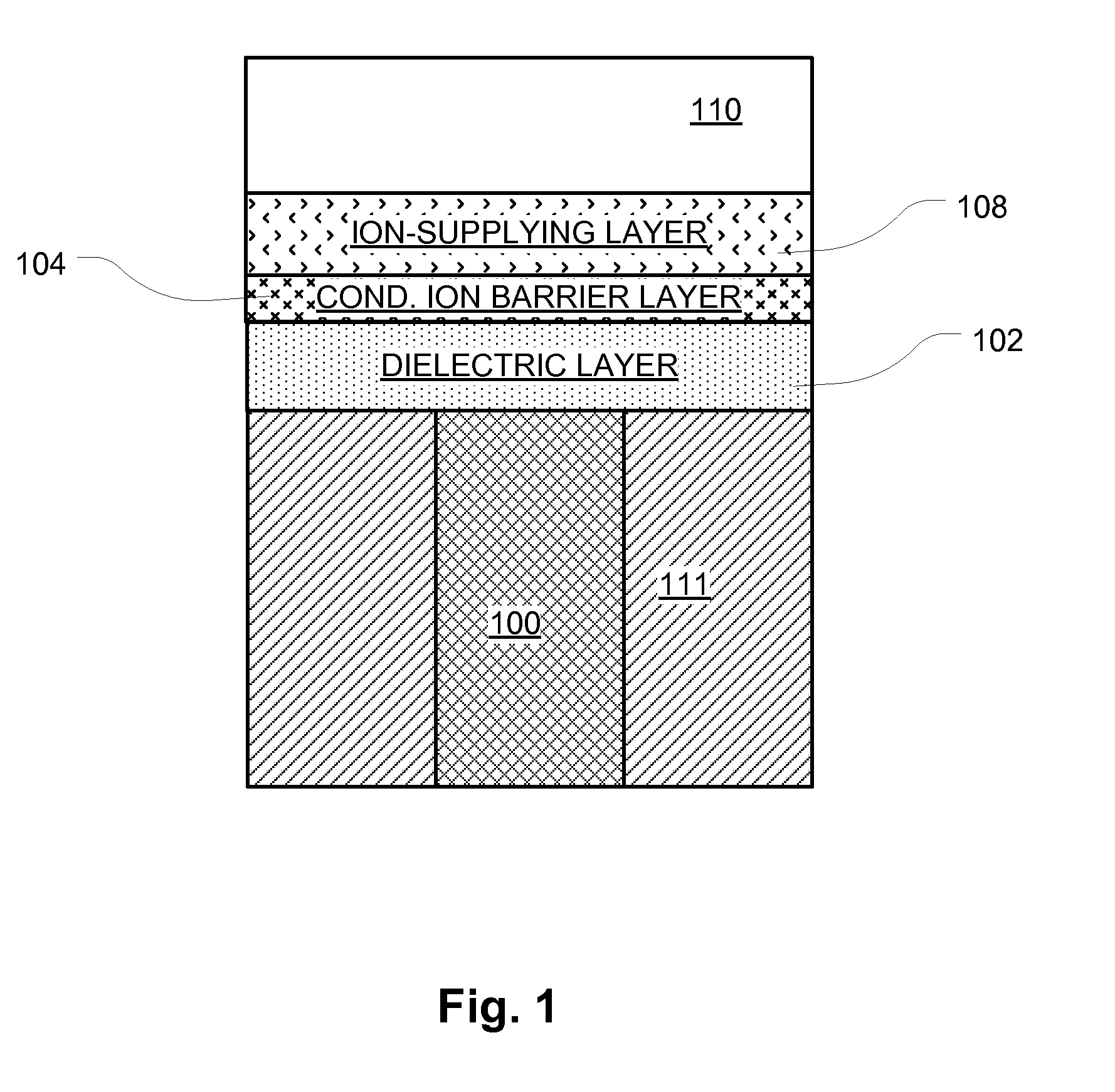

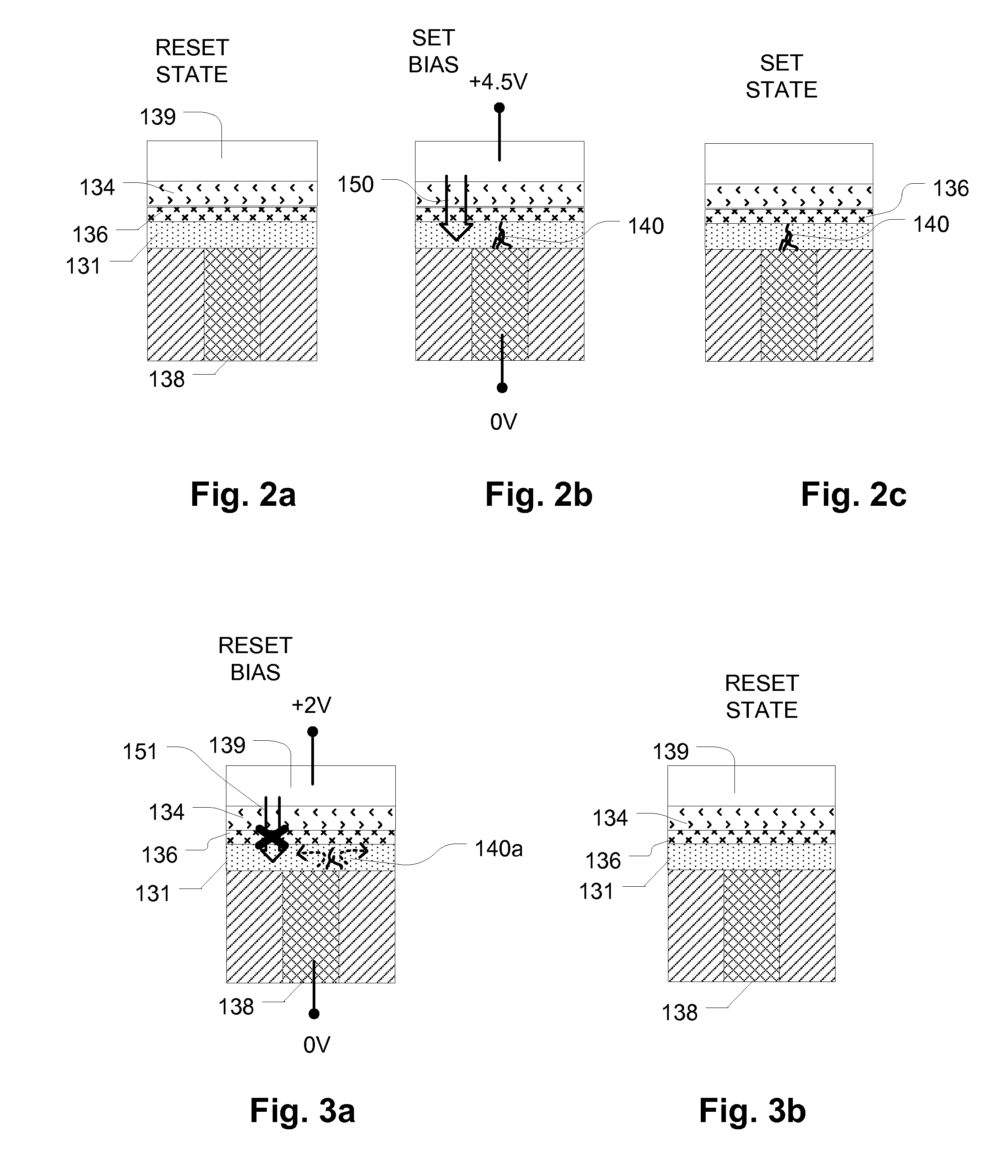

Unipolar programmable metallization cell

ActiveUS20140131653A1Semiconductor/solid-state device manufacturingDigital storageProgrammable metallization cellElectrical polarity

A programmable metallization device comprises a first electrode and a second electrode, and a dielectric layer, a conductive ion-barrier layer, and an ion-supplying layer in series between the first and second electrodes. In operation, a conductive bridge is formed or destructed in the dielectric layer to represent a data value using bias voltages having the same polarity, enabling the use of diode access devices. To form a conductive bridge, a bias is applied that is high enough to cause ions to penetrate the conductive ion-barrier layer into the dielectric layer, which then form filaments or bridges. To destruct the conductive bridge, a bias of the same polarity is applied that causes current to flow through the structure, while ion flow is blocked by the conductive ion-barrier layer. As a result of Joule heating, any bridge in the dielectric layer disintegrates.

Owner:MACRONIX INT CO LTD

Optical detectors for infrared, sub-millimeter and high energy radiation

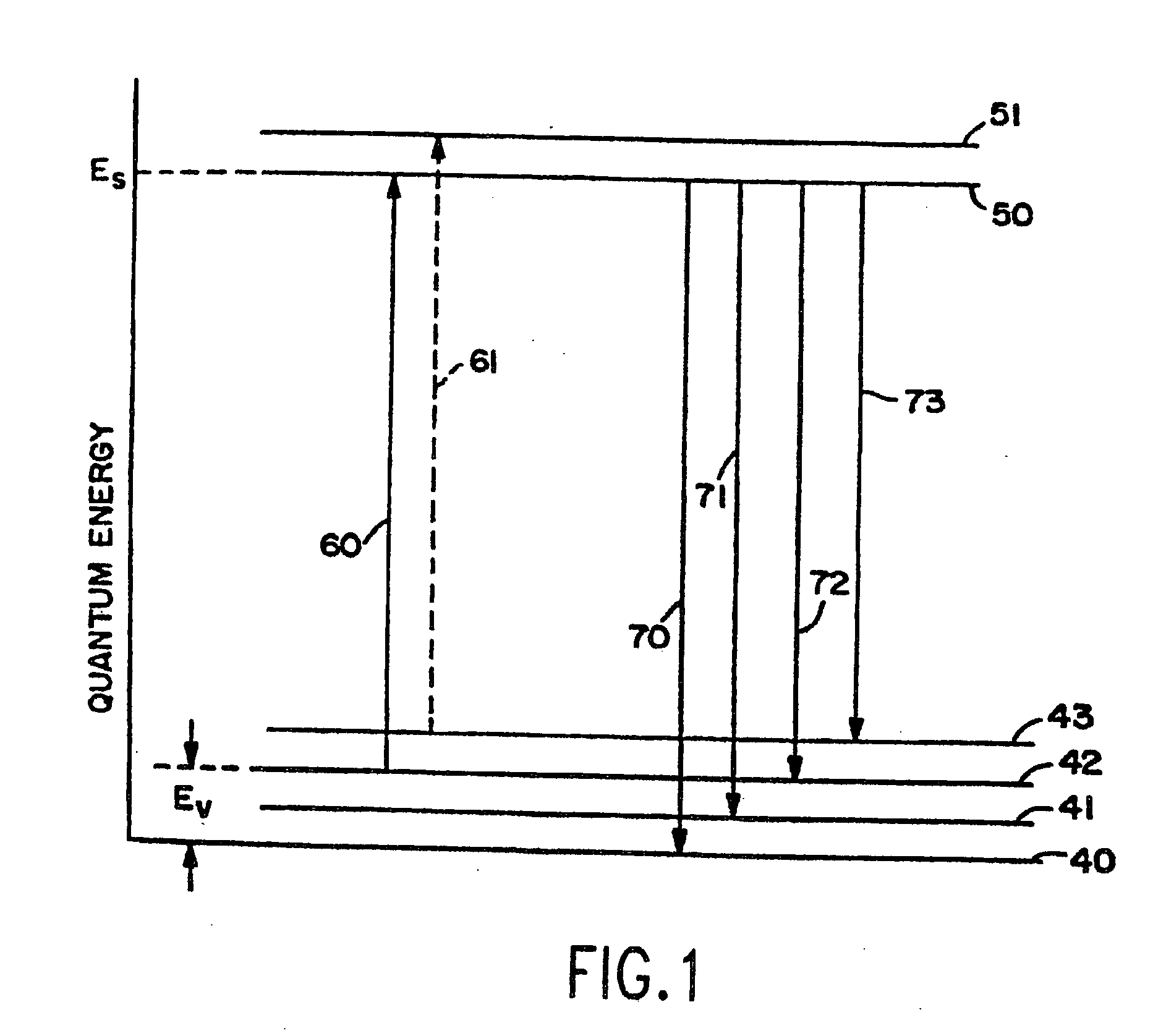

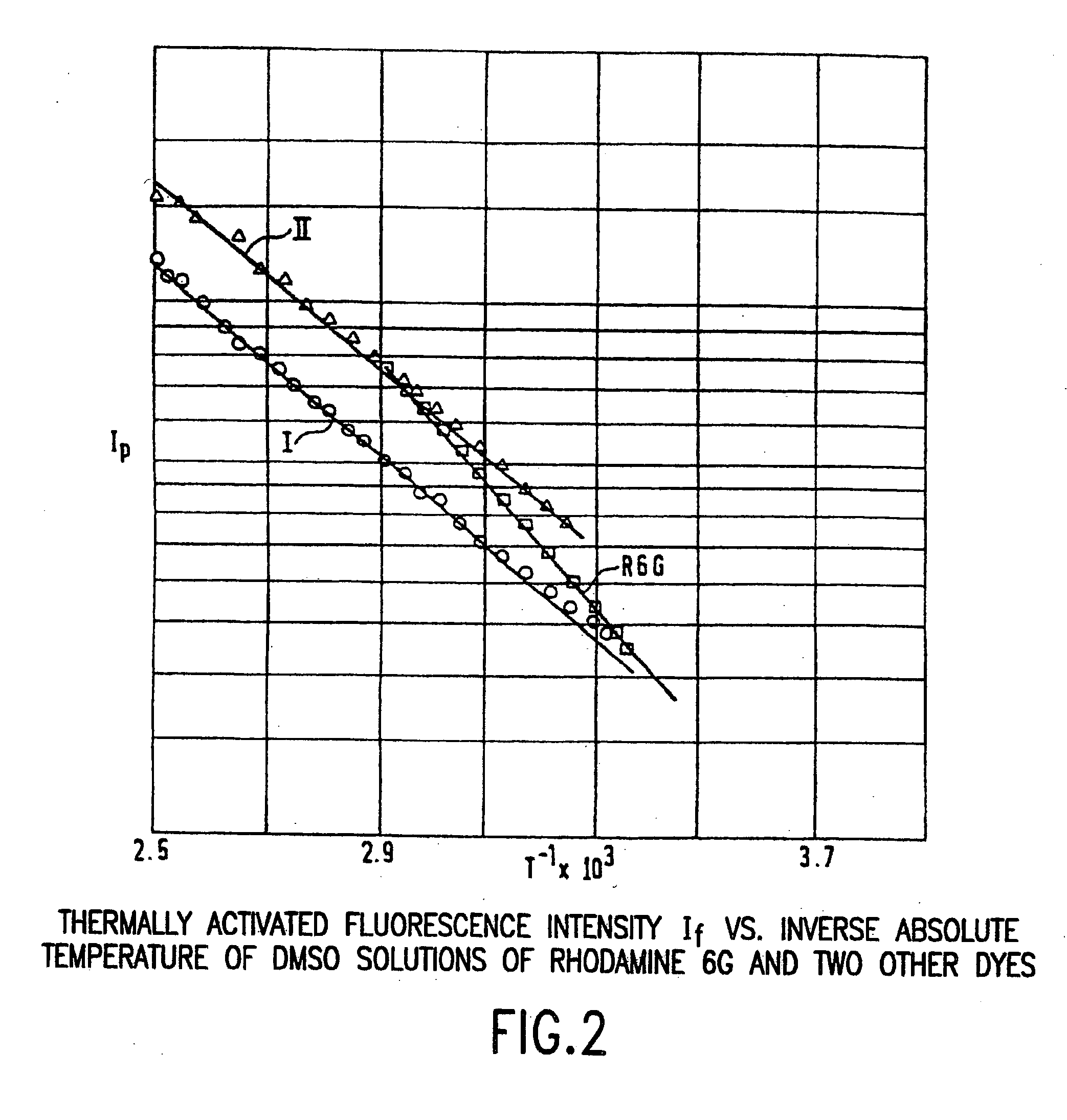

InactiveUS20060214113A1Reduce the total massSimpler and less-costlyRadiation pyrometryPhotometryHigh energyGram

Optical methods and devices for the thermal detection and imaging of infrared, sub-millimeter, millimeter and high energy radiation, wherein the thermal mass of the detector is minimized by the use of microscopic photoluminescent temperature probes having a weight mass which can be of the order of 10−11 grams or smaller. Used for detection of high energy radiation, including quantum calorimetry, said temperature probes allow non-contact measurements free of electrical sources of noise like Johnson noise or Joule heating.

Owner:KLEINERMAN MARCOS Y

Optically blocked reference pixels for focal plane arrays

ActiveUS20060124831A1Minimize divergenceIncreasing scene temperature temperatureRadiation pyrometrySemiconductor/solid-state device detailsThermal isolationBlock structure

Methods for making optically blind reference pixels and systems employing the same. The reference pixels may be configured to be identical to, or substantially identical to, the active detector elements of a focal plane array assembly. The reference pixels may be configured to use the same relatively longer thermal isolation legs as the active detector pixels of the focal plane, thus eliminating joule heating differences. An optically blocking structure may be placed in close proximity directly over the reference pixels.

Owner:DRS NETWORK & IMAGING SYST

Combined gasification and vitrification system

ActiveUS20070261303A1Lower cost of capitalMinimizes energyMuffle furnacesTransportation and packagingVitrificationCombustion

An optimized gasification / vitrification processing system having a gasification unit which converts organic materials to a hydrogen rich gas and ash in communication with a joule heated vitrification unit which converts the ash formed in the gasification unit into glass, and a plasma which converts elemental carbon and products of incomplete combustion formed in the gasification unit into a hydrogen rich gas.

Owner:INENTEC

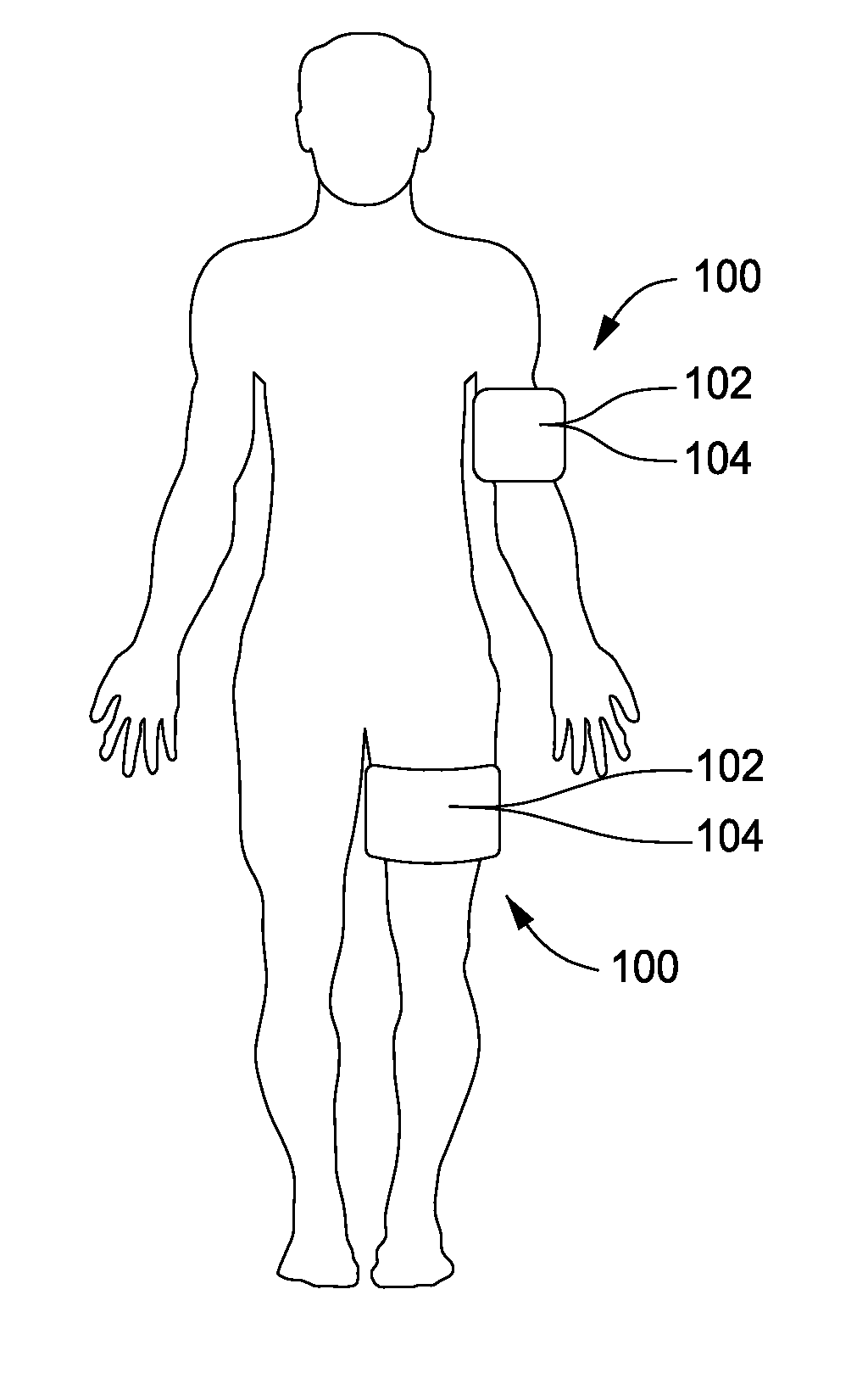

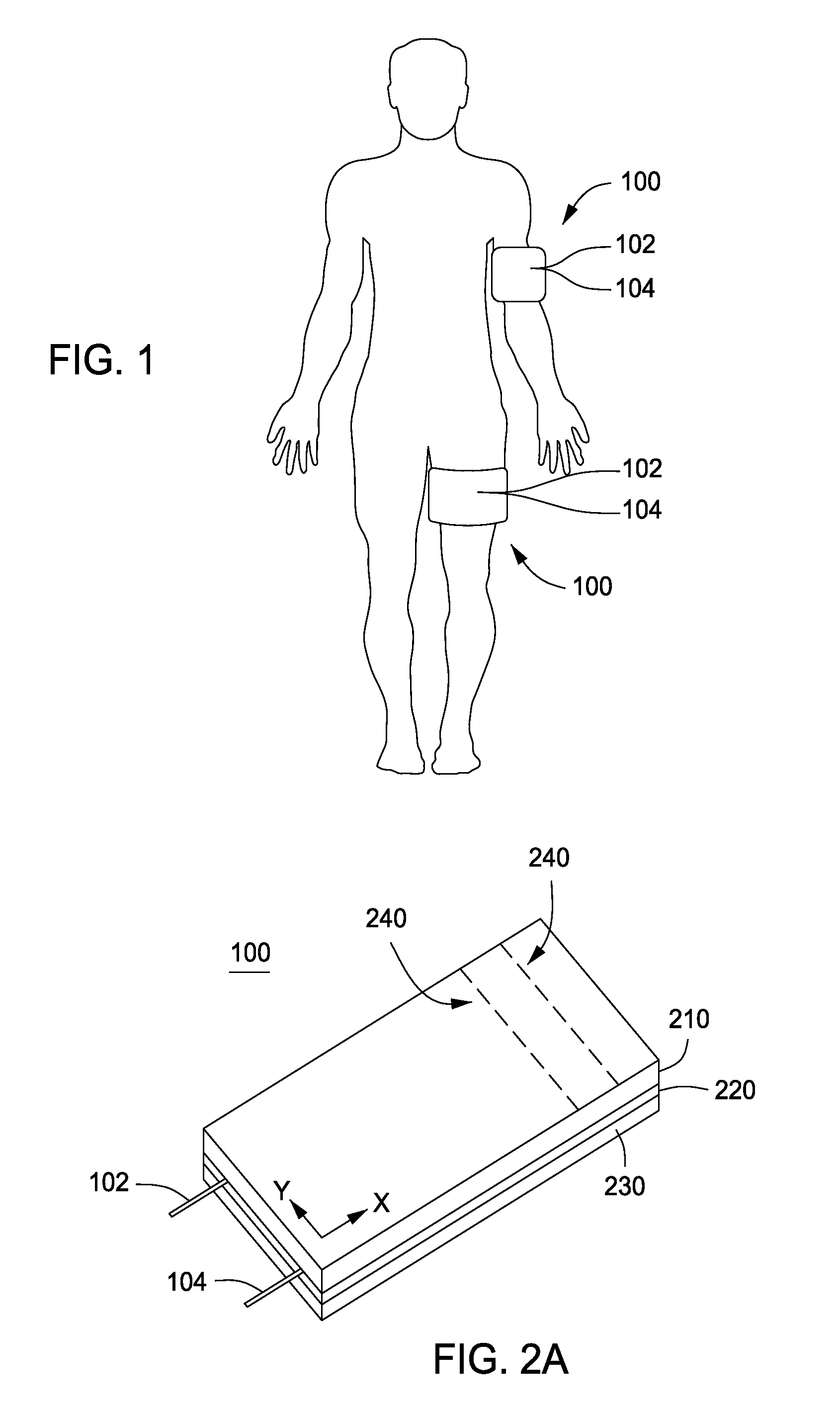

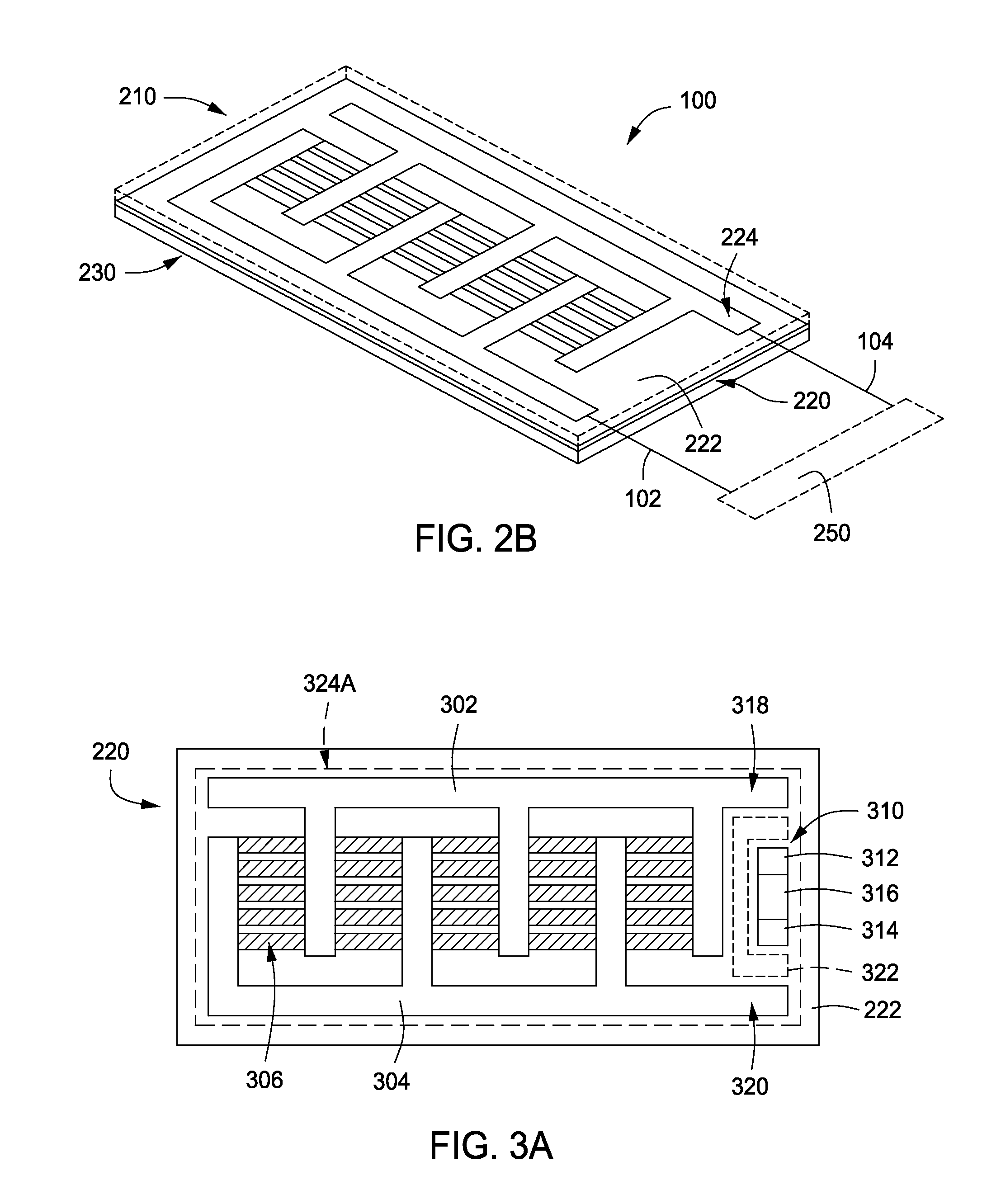

Methods and apparatus for active patient warming

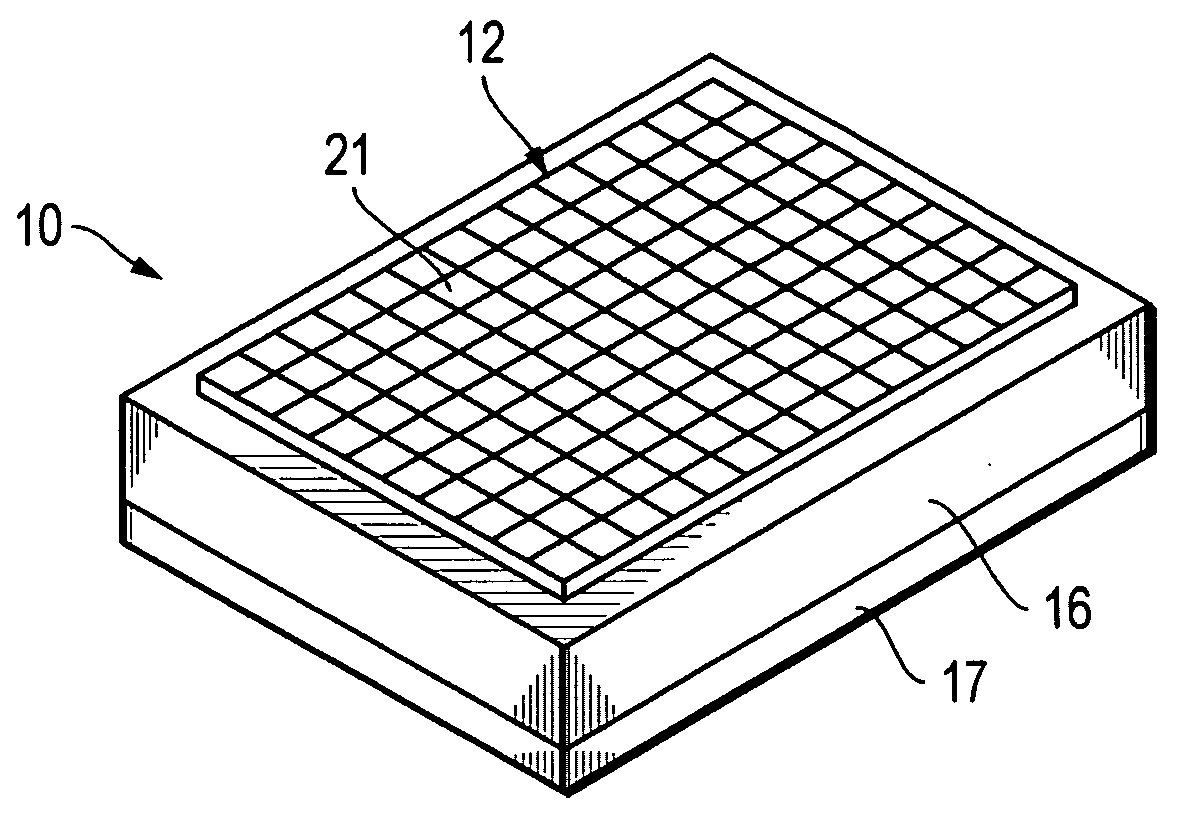

InactiveUS20110172750A1Suppress overheatingAccurate CalibrationTherapeutic coolingTherapeutic heatingEngineeringJoule heating

Methods and apparatus for warming a patient are disclosed herein. In some embodiments, a patient warming device may include a heater layer comprising a plurality of heater cells disposed on a flexible substrate; and a thermal conduction layer disposed on a patient side of the heater layer to transfer heat generated by the heater layer to a patient. The heater cells may comprise an electrical circuit to generate heat by Joule heating. The patient warming device is flexible to facilitate conforming the patient warming device to a patient during use.

Owner:VYAIRE MEDICAL CONSUMABLES LLC

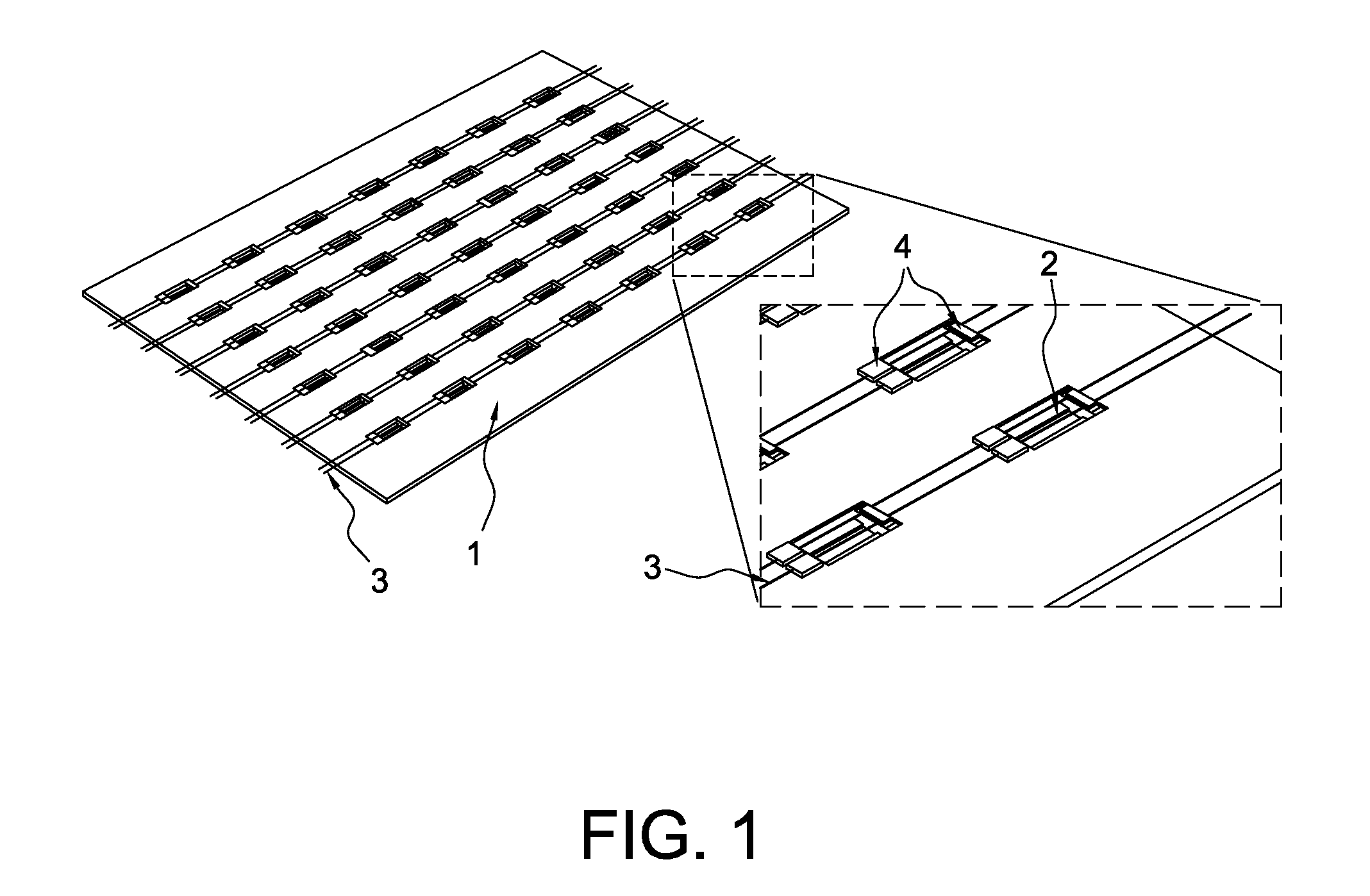

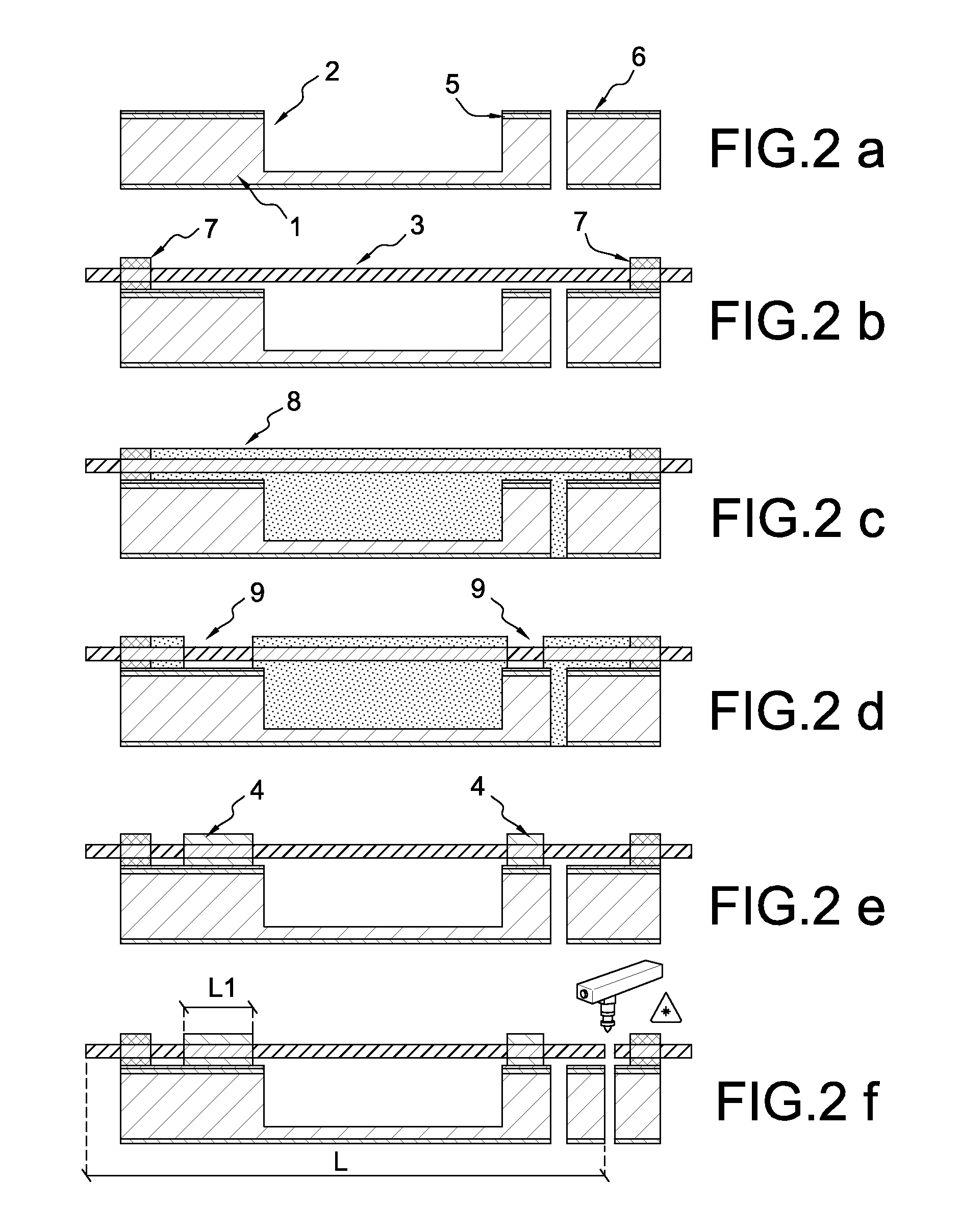

Method for mechanical and electrical integration of sma wires to microsystems

InactiveUS20120174572A1Cost-efficient manufacturing processLow costLine/current collector detailsMechanical power devicesElectrical connectionEngineering

The present invention relates to methods for the batch fixation and electrical connection of pre-strained SMA wires on a microstructured substrate using electroplating, providing high bond strength and electrical connections in one processing step. The integration process here developed relies on conventional micro machining techniques and it provides an efficient solution to some problems that have hindered the widespread diffusion of bulk SMA to MEMS, such as the lack of cost-efficient integration methods of bulk SMA and the difficult electrical contacting of the actuator material at small scale. Also disclosed herein is a Joule-heated SMA wire actuator on silicon MEMS.

Owner:X VALVE COMPANY +1

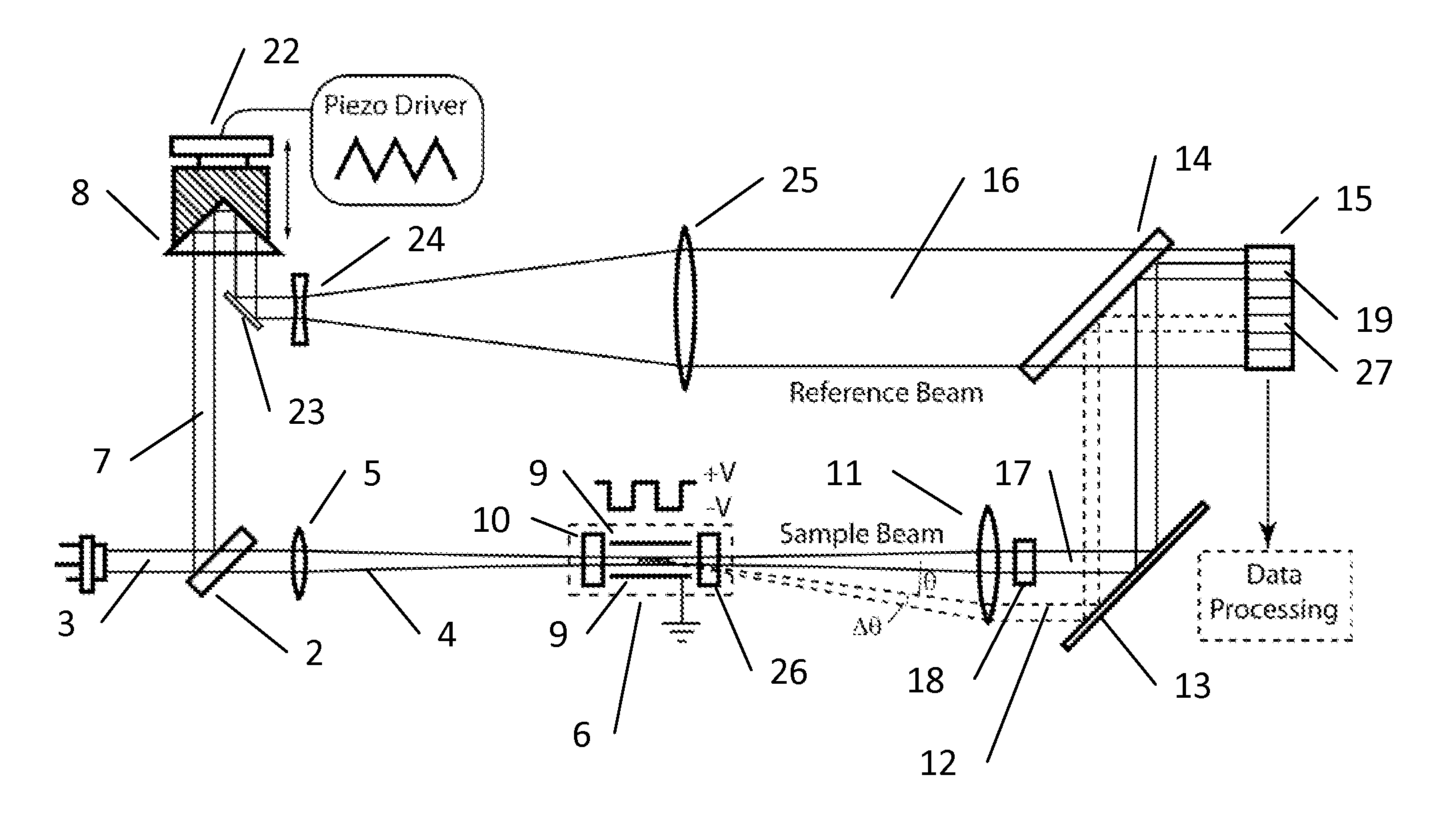

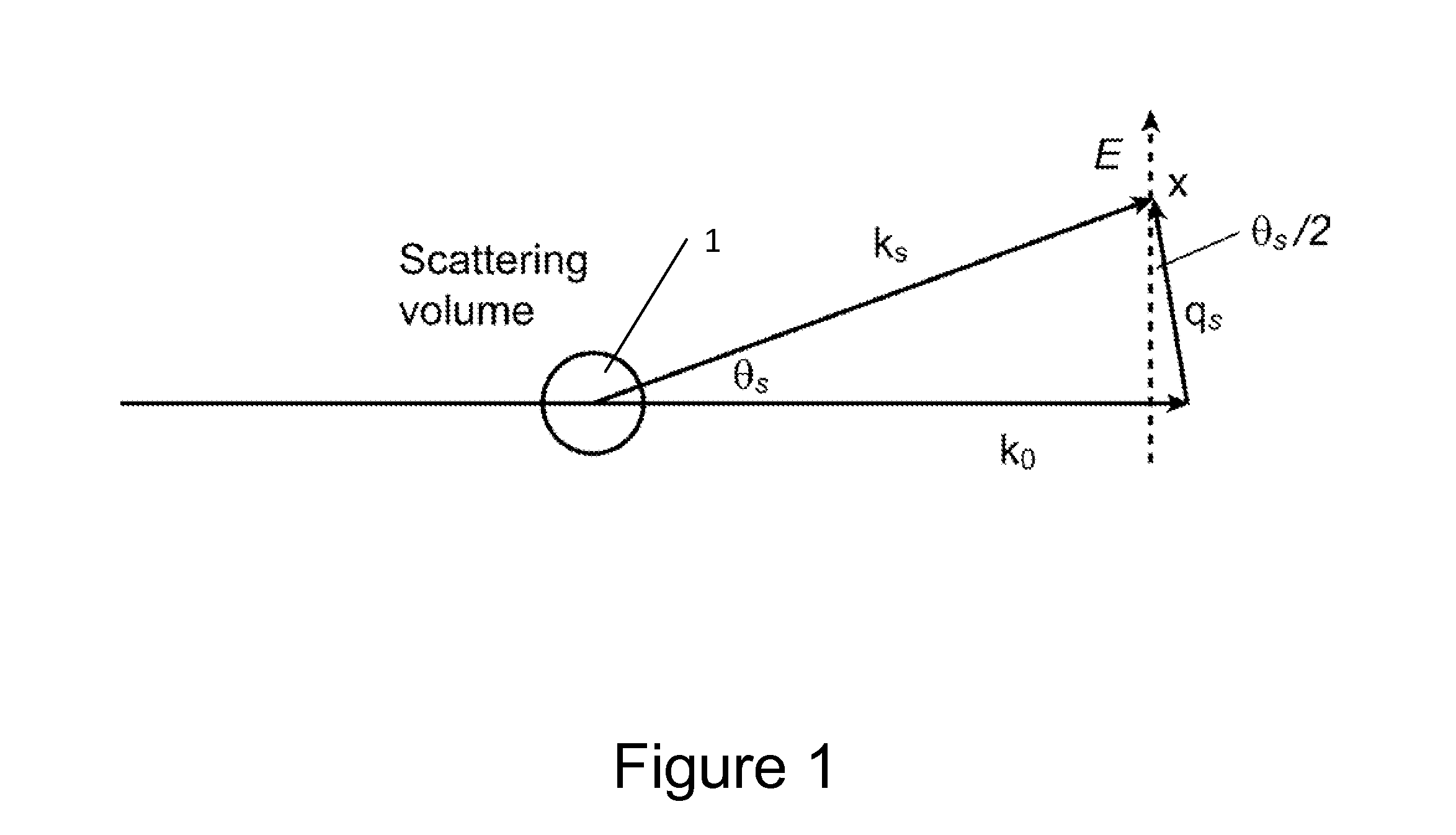

Method and apparatus to measure particle mobility in solution

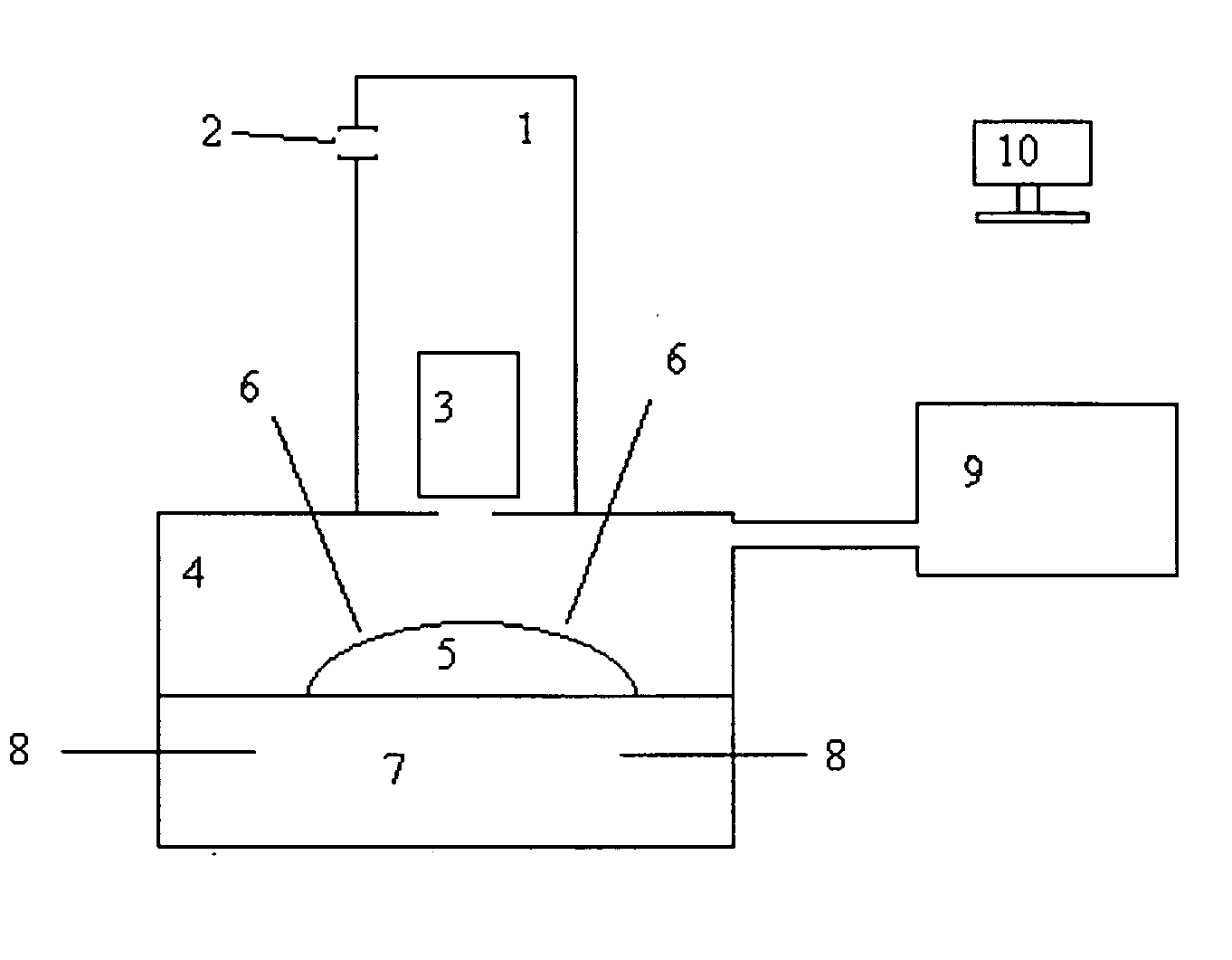

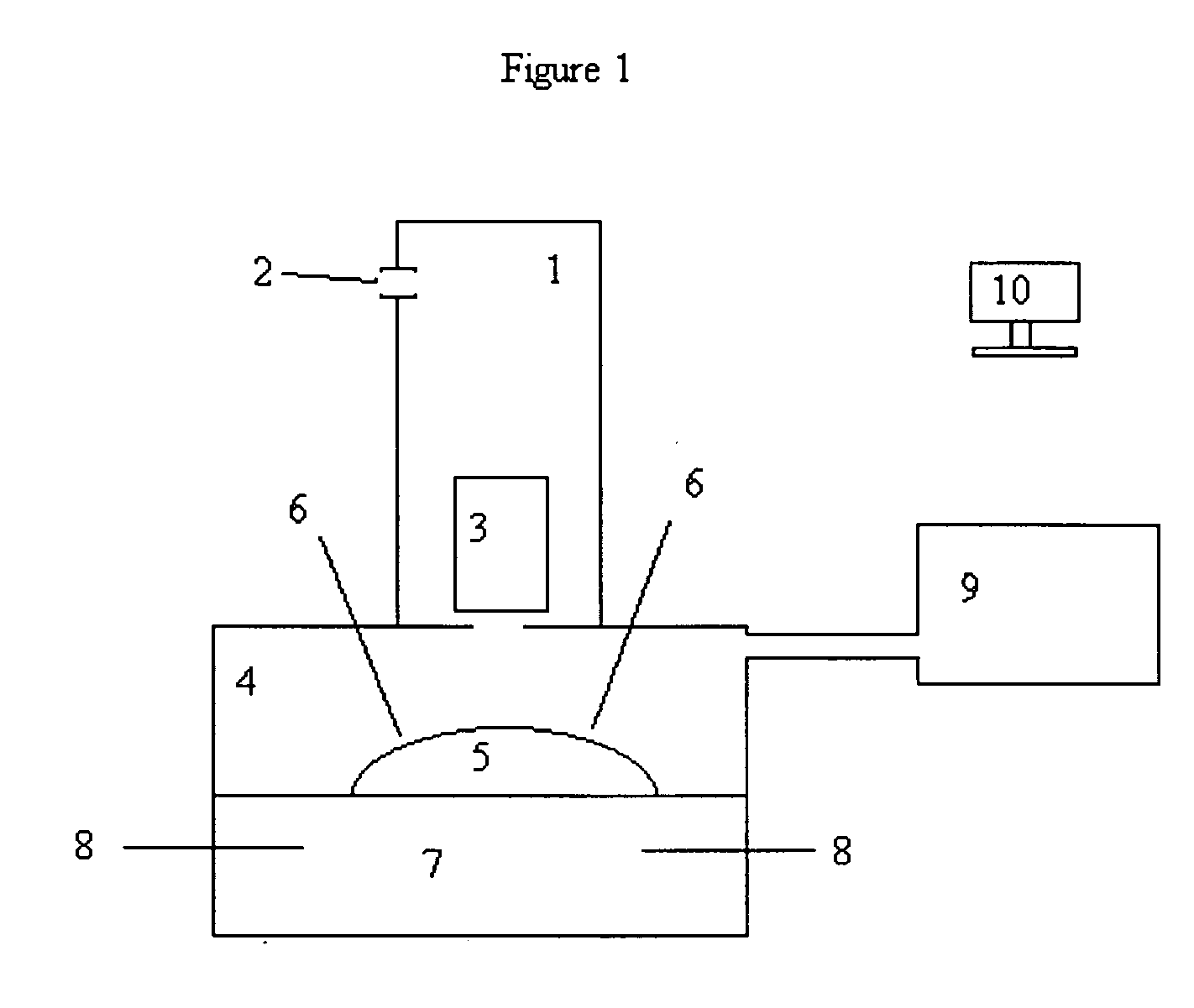

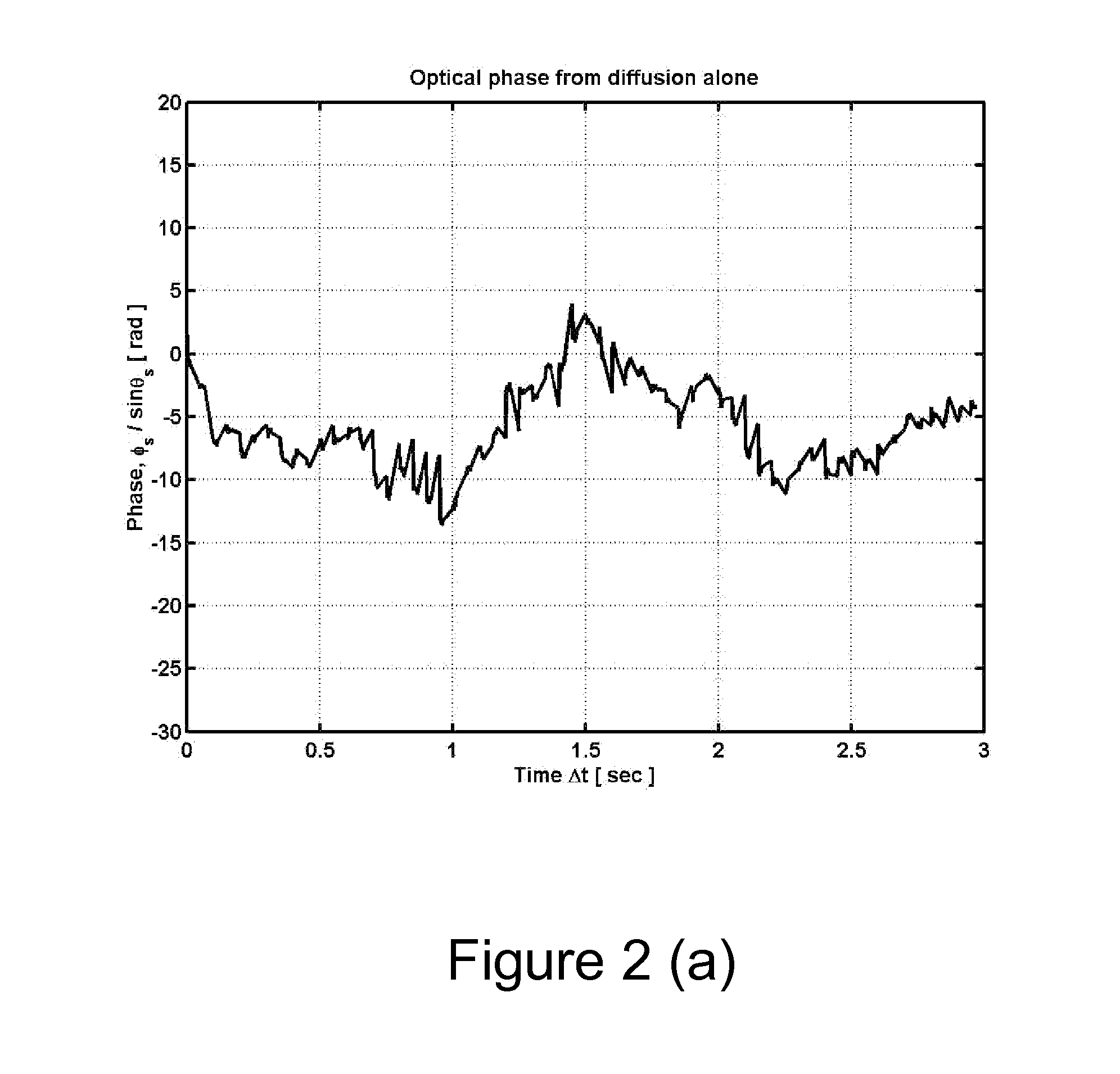

ActiveUS20110210002A1Reduce harmMinimizing electrochemical degradationSludge treatmentVolume/mass flow measurementPhotodetectorFree solution

A method and apparatus is disclosed for measurement of the electrophoretic mobility of particles and molecules in solution. A sample of particles is placed in a cell containing two electrodes that apply an alternating electric field. A monochromatic light beam passes through the sample. Light scattered by the particles, along with the unscattered beam, is collected and collimated as it exits the cell. This beam is combined in free space with a phase modulated reference beam. The interference forms a frequency modulated speckle pattern, which is detected by a photodetector array. Each array element collects a narrow range of well-defined scattering angles. The signal from each is demodulated to extract the optical phase information providing a first-principle measurement of the electrophoretic mobility of the scattering particles. Each detector element provides a simultaneous independent measurement. This inherent parallelism drastically increases the amount of information available in a given time. The resulting increased sensitivity extends the mobility measurement to particles below one nanometer, reduces the required concentration and electric field compared to previous methods. This minimizes damage to fragile samples, increases the electrode useful life, and reduces joule heating. Electrophoretic mobility is a critically important parameter for predicting the stability of nanoparticle suspensions and pharmaceutical formulations such as protein therapeutics. This invention enables reliable free-solution phase measurement of these samples.

Owner:WYATT TECH

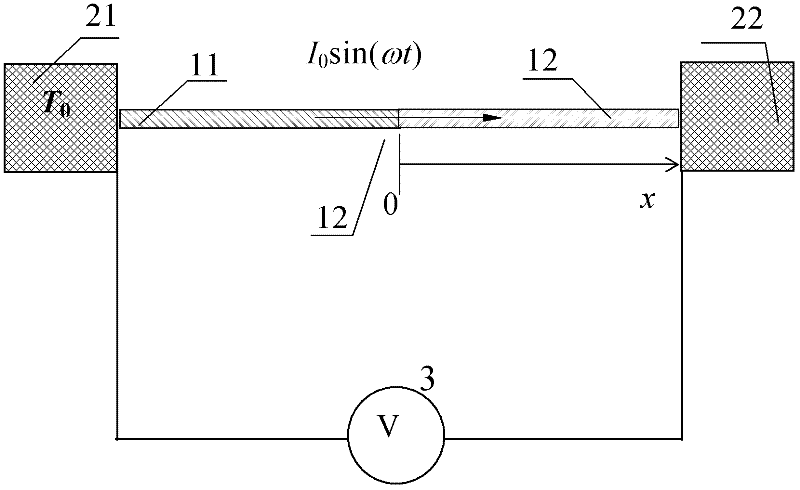

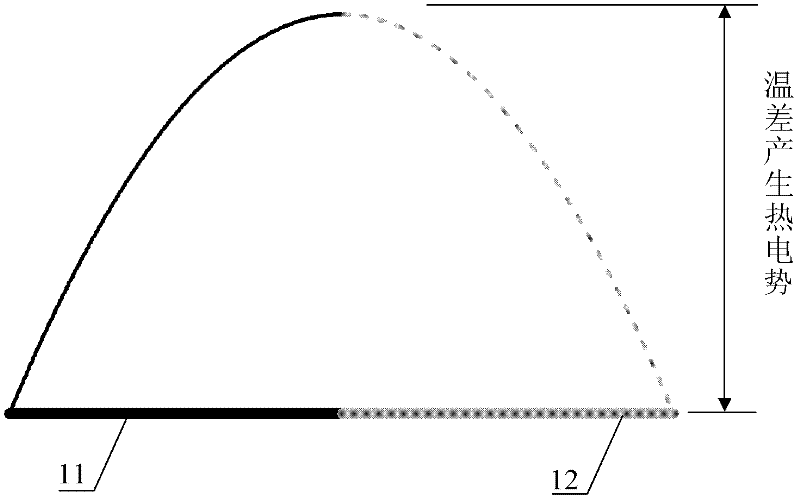

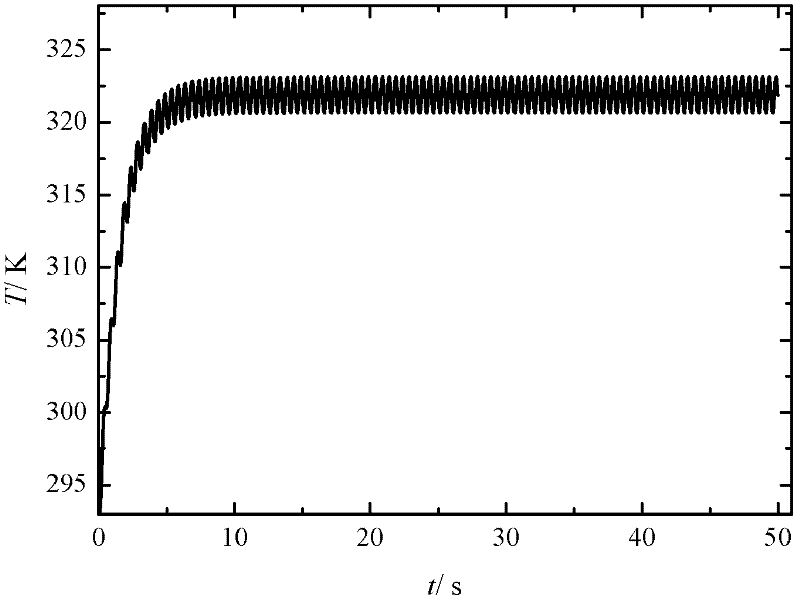

Method for measuring Seebeck coefficient of micro/nano thermoelectric materials or devices

ActiveCN102305807AHigh measurement accuracyThe experimental setup is simpleMaterial heat developmentElectrical testingThermoelectric materialsTemperature difference

The invention discloses a method for measuring the Seebeck coefficient of micro / nano thermoelectric materials or devices, which comprises the following steps of: connecting the two ends of a sample formed by connecting two thermoelectric materials with heat sinks, putting into a vacuum environment, introducing alternating current I0 sin(omega t) with frequency omega and amplitude I0, generating parabolic temperature distribution on the sample to be measured through a Joule heating effect, and adding one steady component and two harmonic components to obtain the temperature at a junction of the materials to be measured, wherein for the thermoelectric materials, the steady temperature component at the junction and a temperature difference formed at the heat sink ends can generate direct-current Seebeck thermal electromotive force due to a Seebeck effect; and acquiring a direct-current voltage signal and theoretically solving a steady temperature difference simultaneously, so that the Seebeck coefficient of the thermoelectric materials to be measured can be obtained. The method has the advantages of high measuring accuracy, simple experiment device, low test cost and the like, and iseasy to implement, and a new idea is provided for evaluating and representing a micro / nano scale thermoelectric conversion system.

Owner:TSINGHUA UNIV

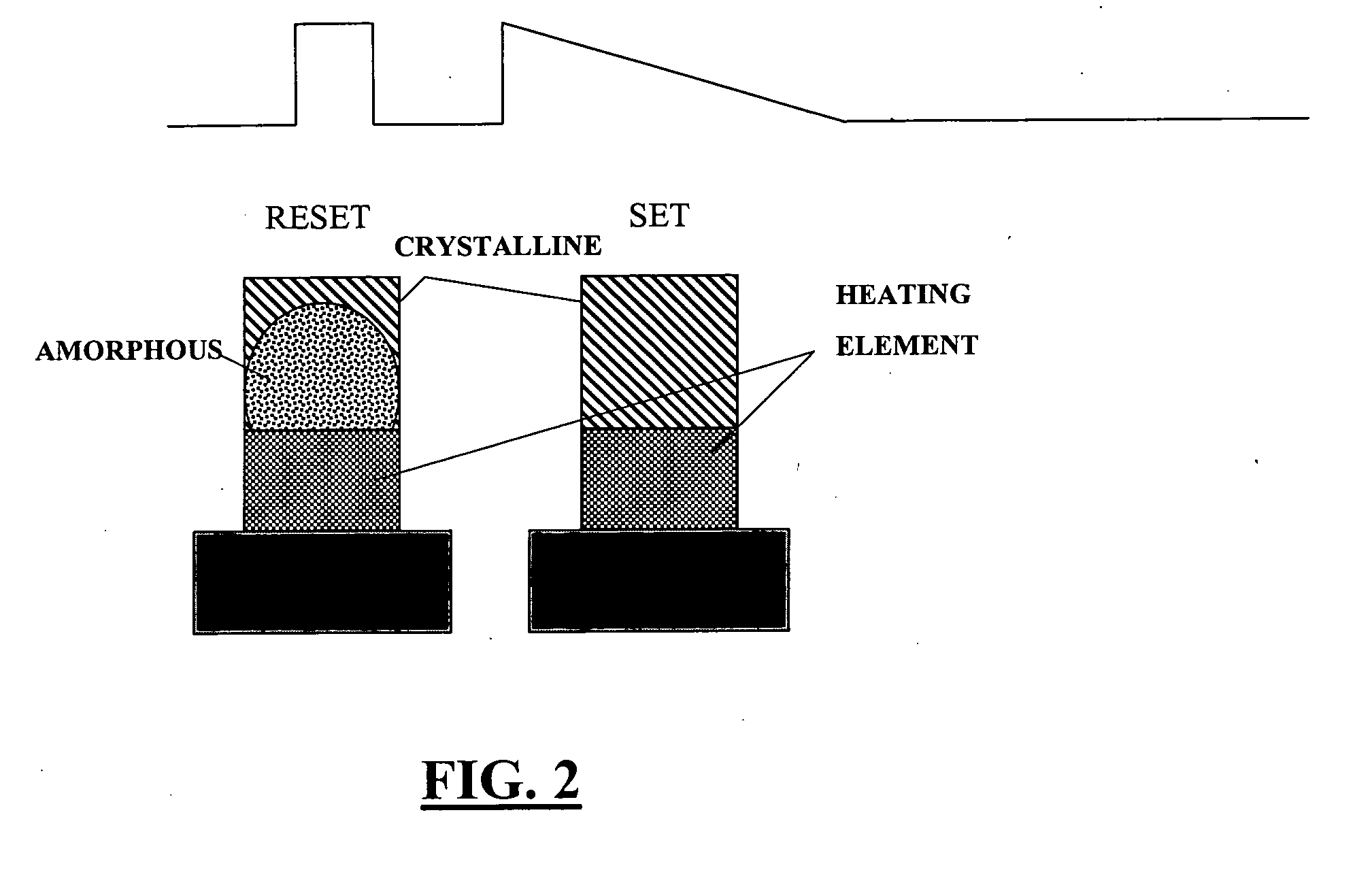

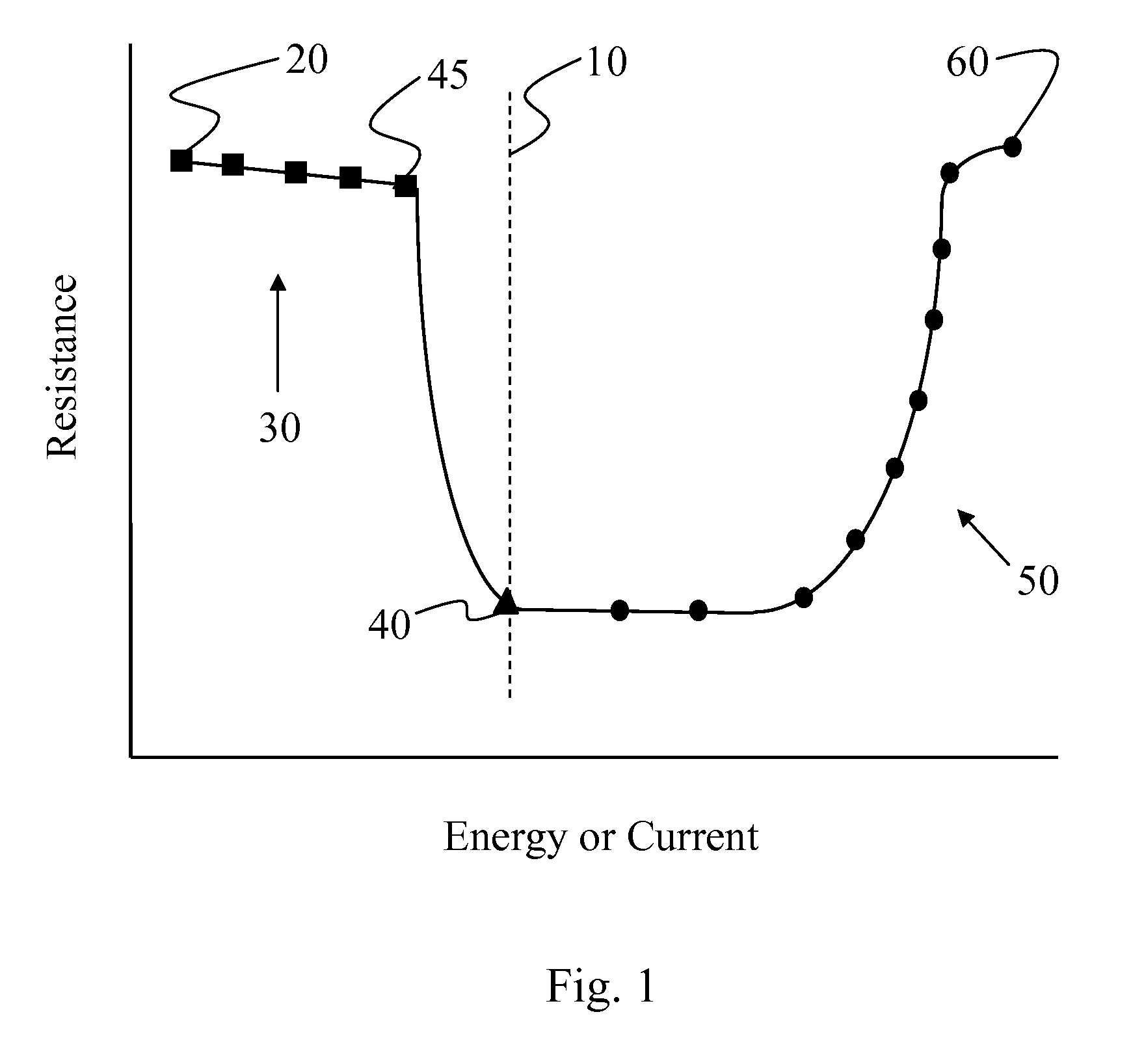

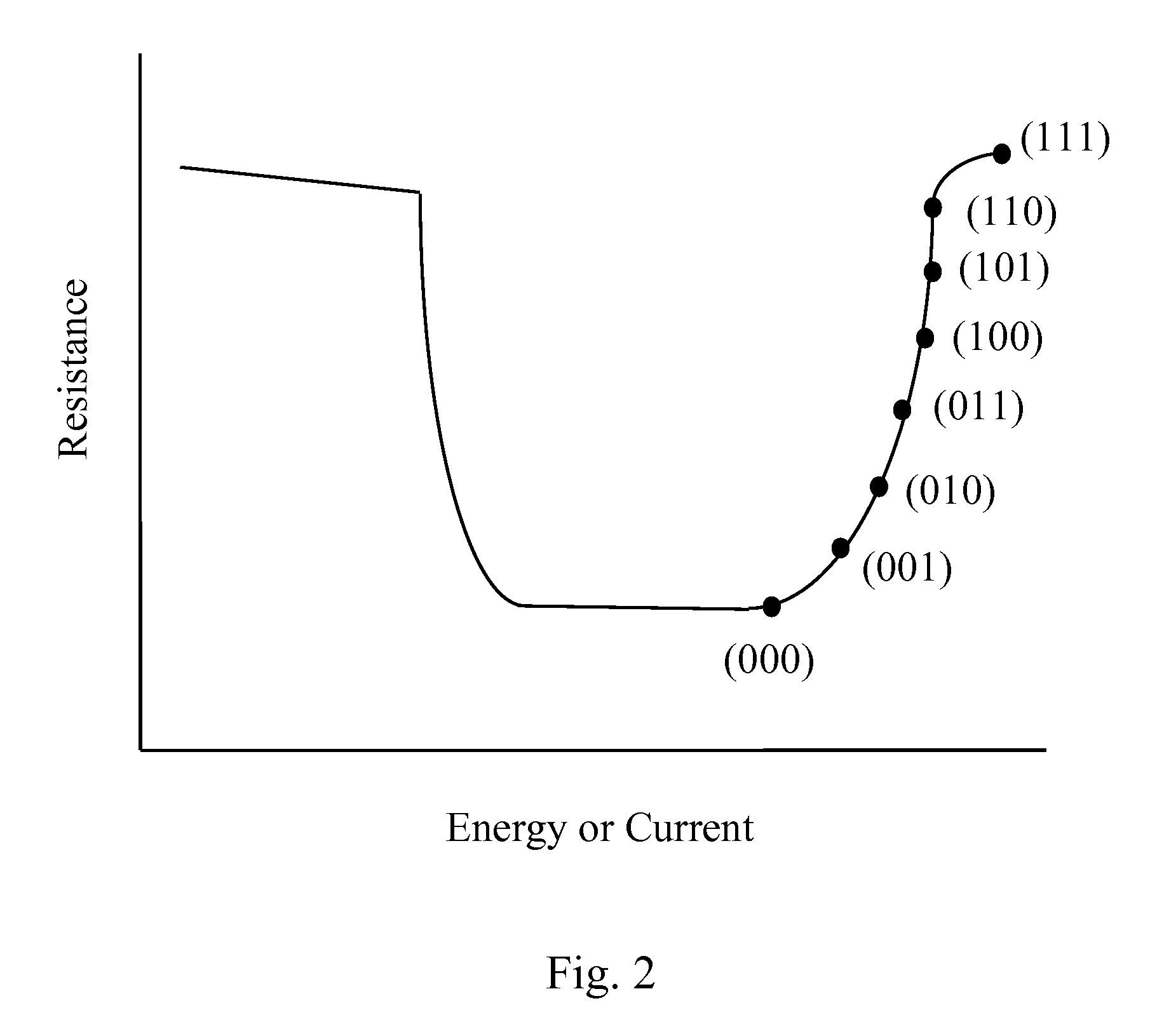

High Margin Multilevel Phase-Change Memory via Pulse Width Programming

InactiveUS20100182827A1Structure is limitedIncrease the number ofDigital storageThermal energyPhase-change memory

An electronic device and method of programming for binary and multilevel memory operation. The active material of the device is a phase-change material. The method includes utilization of the pulse duration of electrical pulses as a programming variable to program a phase-change device to two or more memory states that differ in the relative proportion and / or spatial arrangement of crystalline and amorphous phase regions. Pulse width programming, in conjunction with a device electrical contact having a resistivity within a particular range, enables fine control over the crystalline-amorphous phase-change process by facilitating control over the spatial distribution of thermal energy produced by Joule heating. The degree of control over the phase-change process enables reliable multilevel memory operation by providing for reproducible programming of memory states that are well-resolved in both resistance and programming variable.

Owner:OVONYX

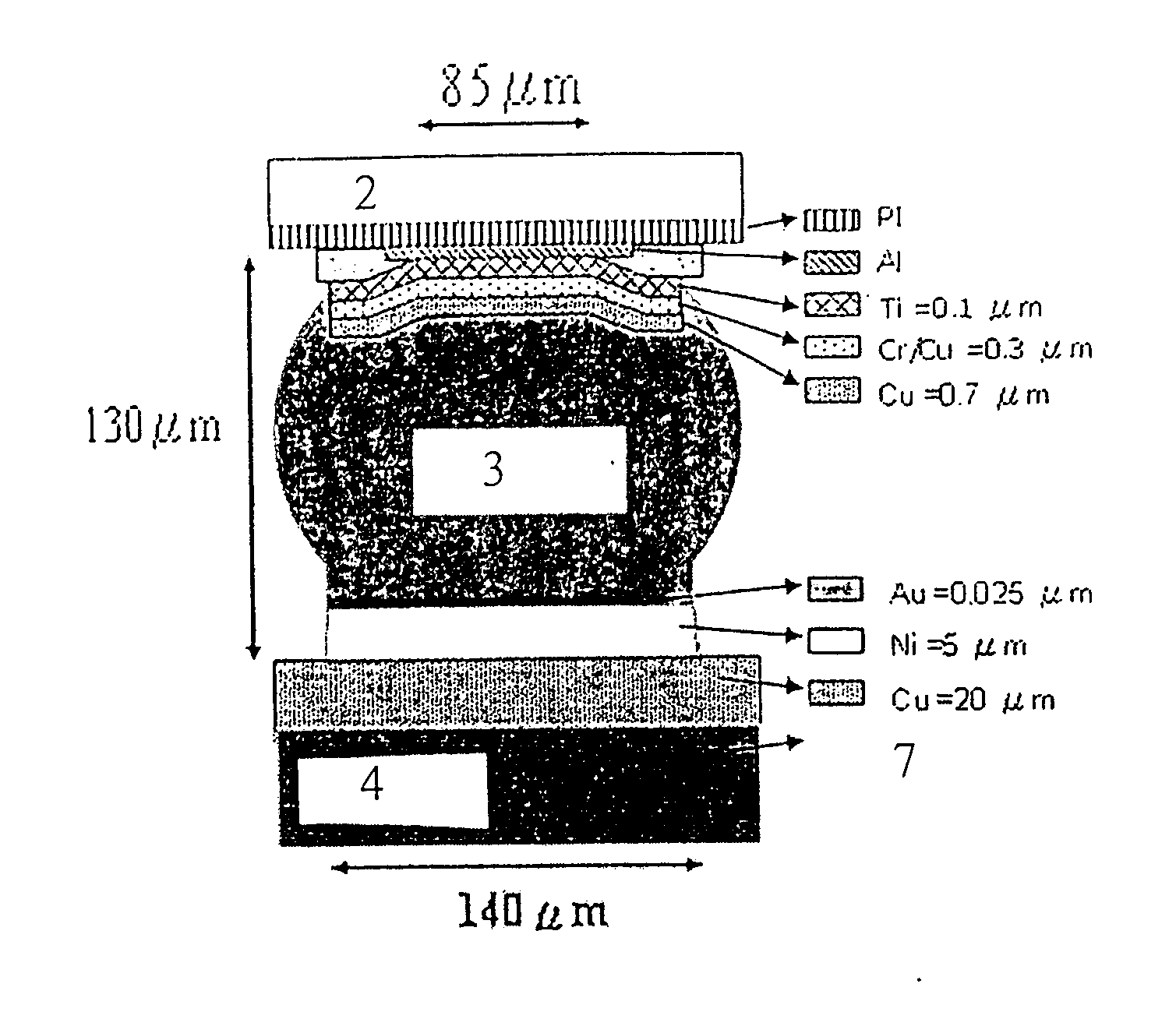

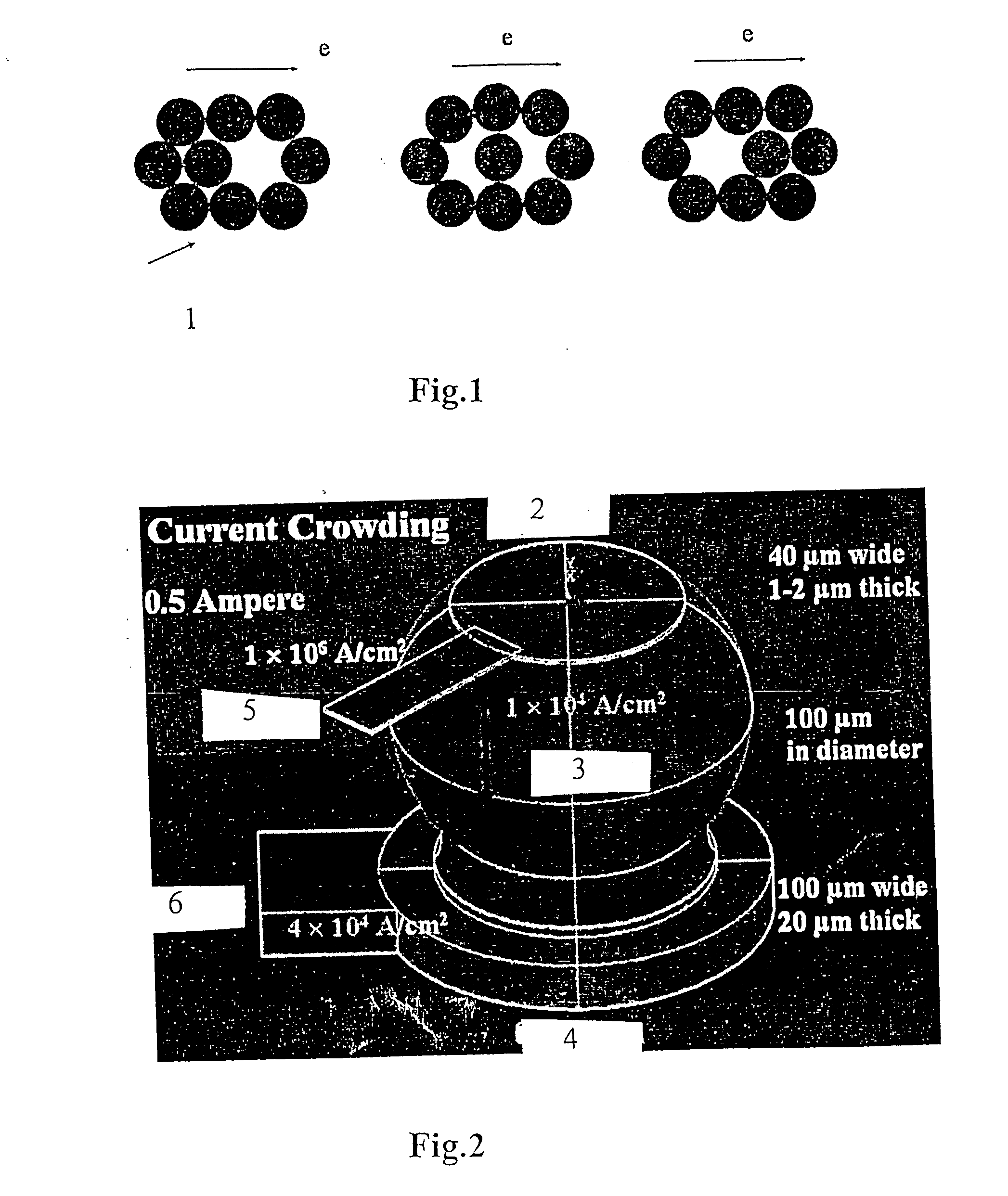

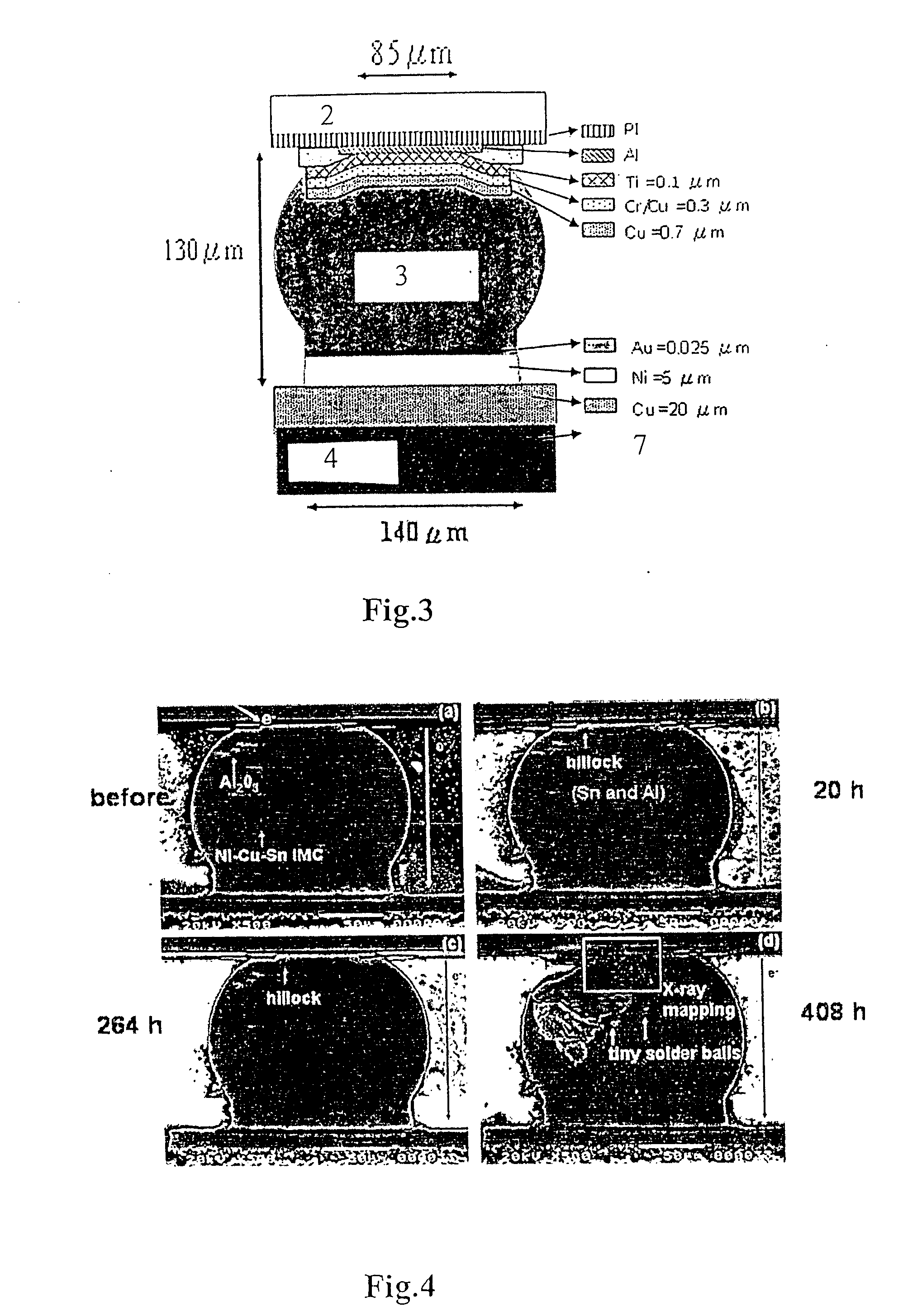

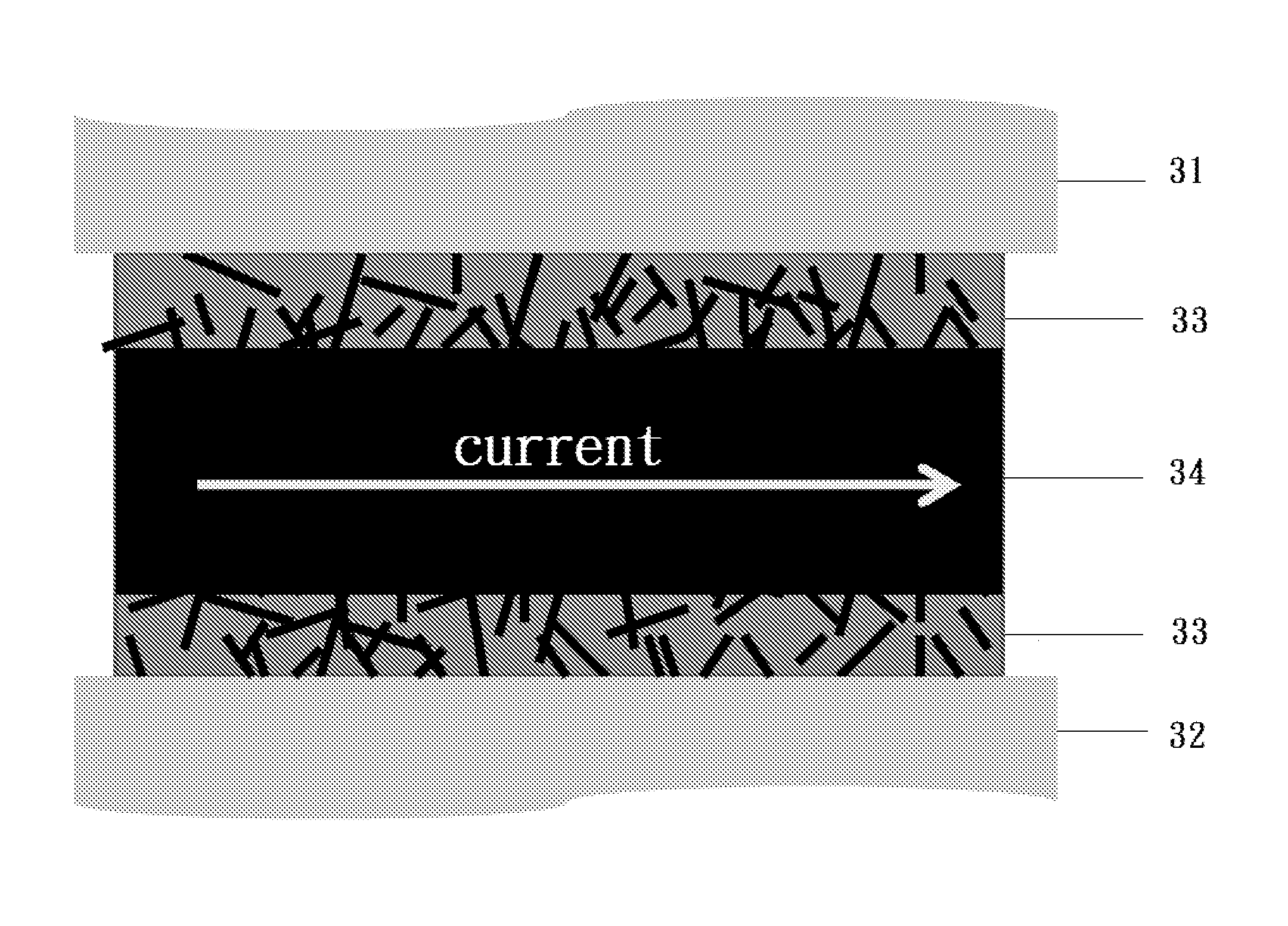

Process for protecting solder joints and structure for alleviating electromigration and joule heating in solder joints

InactiveUS20060027933A1Relieve electromigration damageAlleviate current crowding effectSemiconductor/solid-state device detailsSolid-state devicesMetallurgyCurrent distribution

This invention provides a process for protecting solder joints, comprising forming an UBM or pad metallurgy in solder joints and then further forming a small solder bump on UBM or pad metallurgy between substrate and chip. Wherein a material of high electric resistance is coated at the ends of UBM or pad metallurgy where substrate is connected to chip, as to equalize the current distribution of solder bump, therefore the electromigration resistance of solder joints is improved by suppressing the current crowding and joule heating phenomenon.

Owner:NAT CHIAO TUNG UNIV

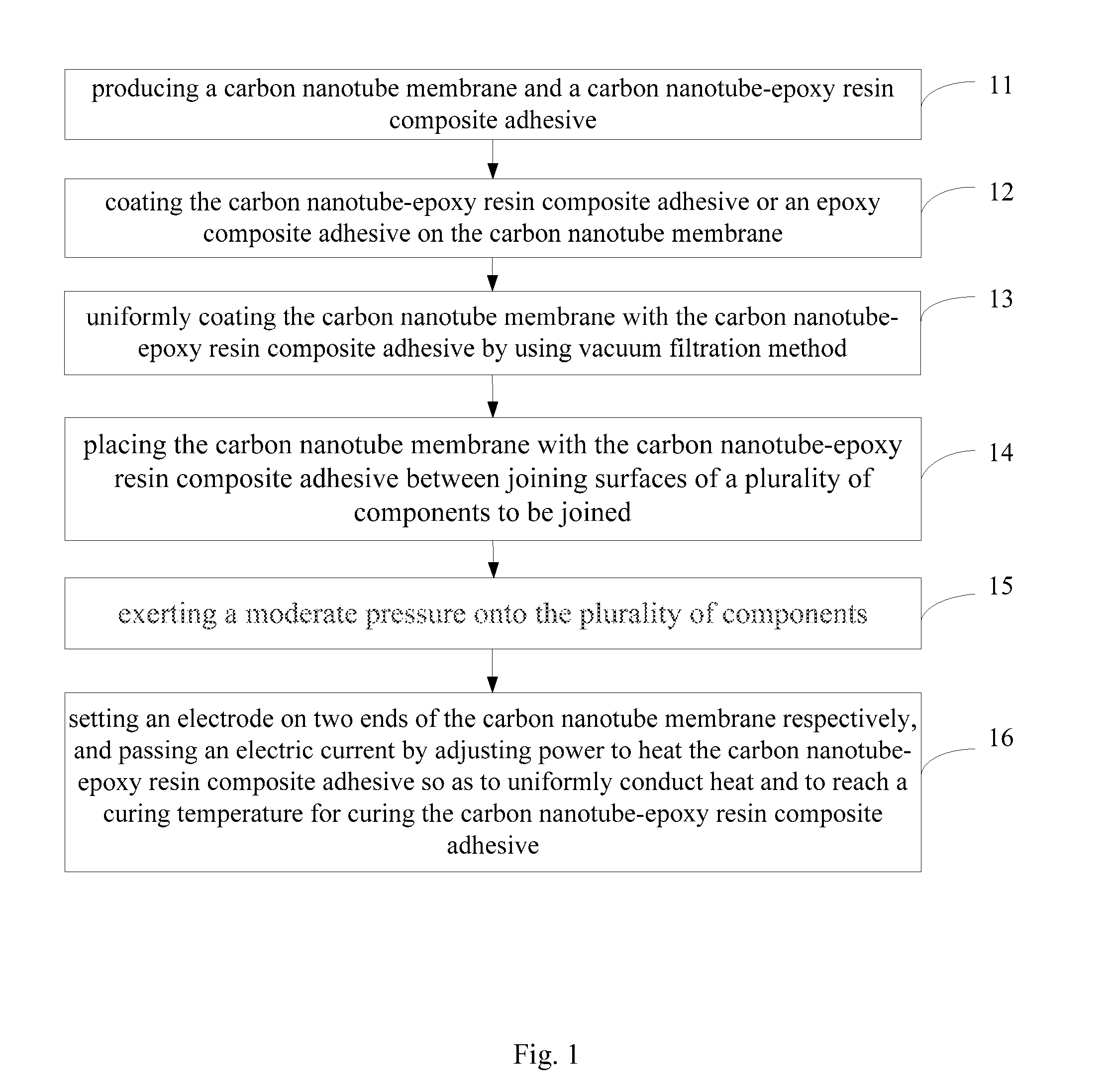

Method for bonding components by utilizing joule heating to cure carbon nanotube-epoxy resin composite adhesive

InactiveUS20130087278A1Achieve effectLow costMaterial nanotechnologyLamination ancillary operationsEpoxyBuckypaper

The using of carbon nanotubes to produce a thin film or buckypaper, hereafter referred to as carbon nanotube membrane, which is soaked with epoxy resin or a carbon nanotube-epoxy resin composite adhesive, and then placed between the joining edges of components, where after an electric current is passed through to heat up the carbon nanotube membrane. This leads to the curing temperature of the epoxy resin or carbon nanotube-epoxy resin composite adhesive, thereby hardening the epoxy resin or carbon nanotube-epoxy resin composite adhesive to achieve bonding. This invention utilizes simple equipment, and the method of an electric current passing through for heating, which can rapidly and uniformly heat the epoxy resin or carbon nanotube-epoxy resin composite adhesive, resulting in hardening and bonding. This method is not affected by the environment, and greatly reduces the time and resources required to harden the epoxy resin, and achieves a stronger effect additionally.

Owner:NATIONAL TSING HUA UNIVERSITY

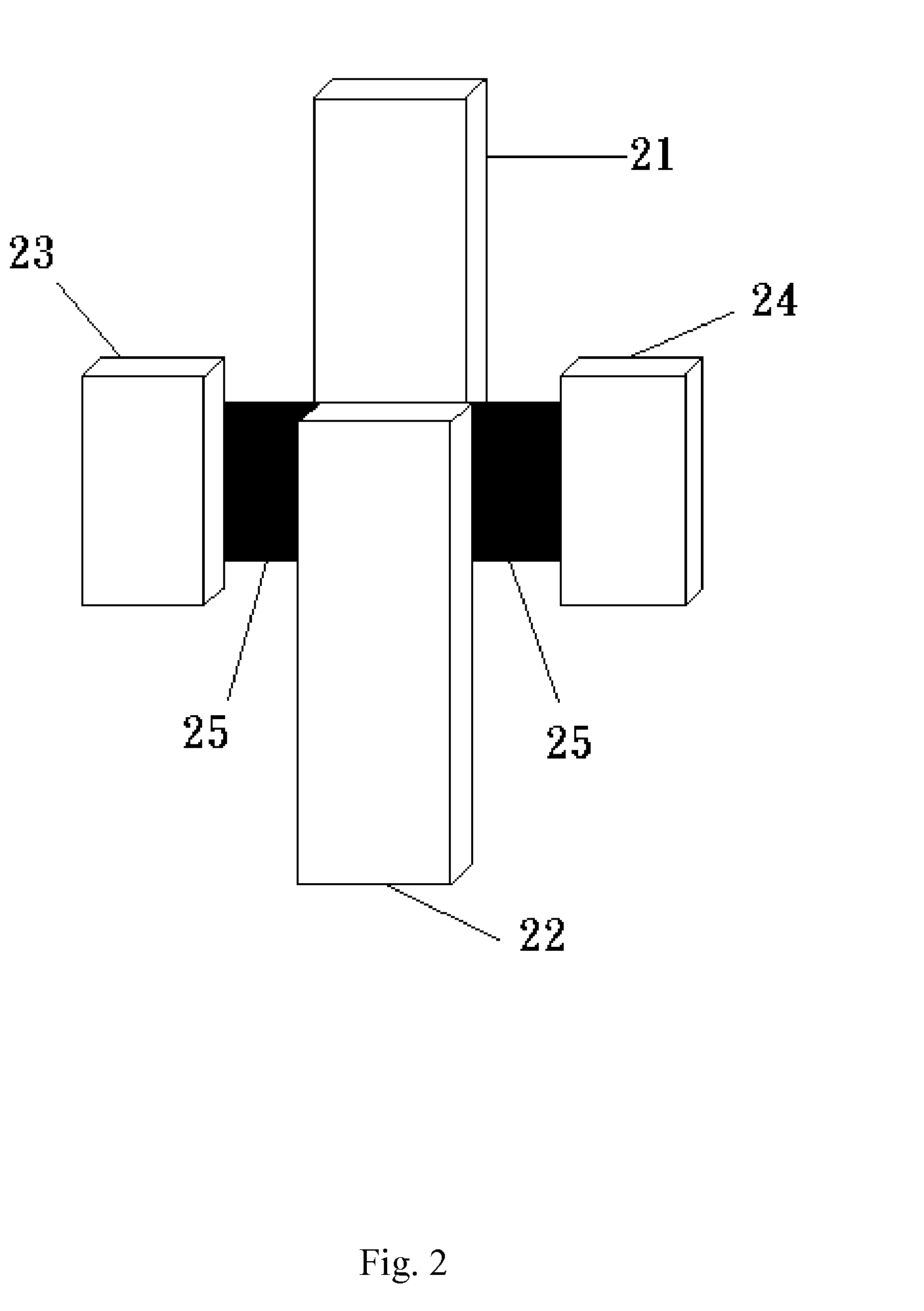

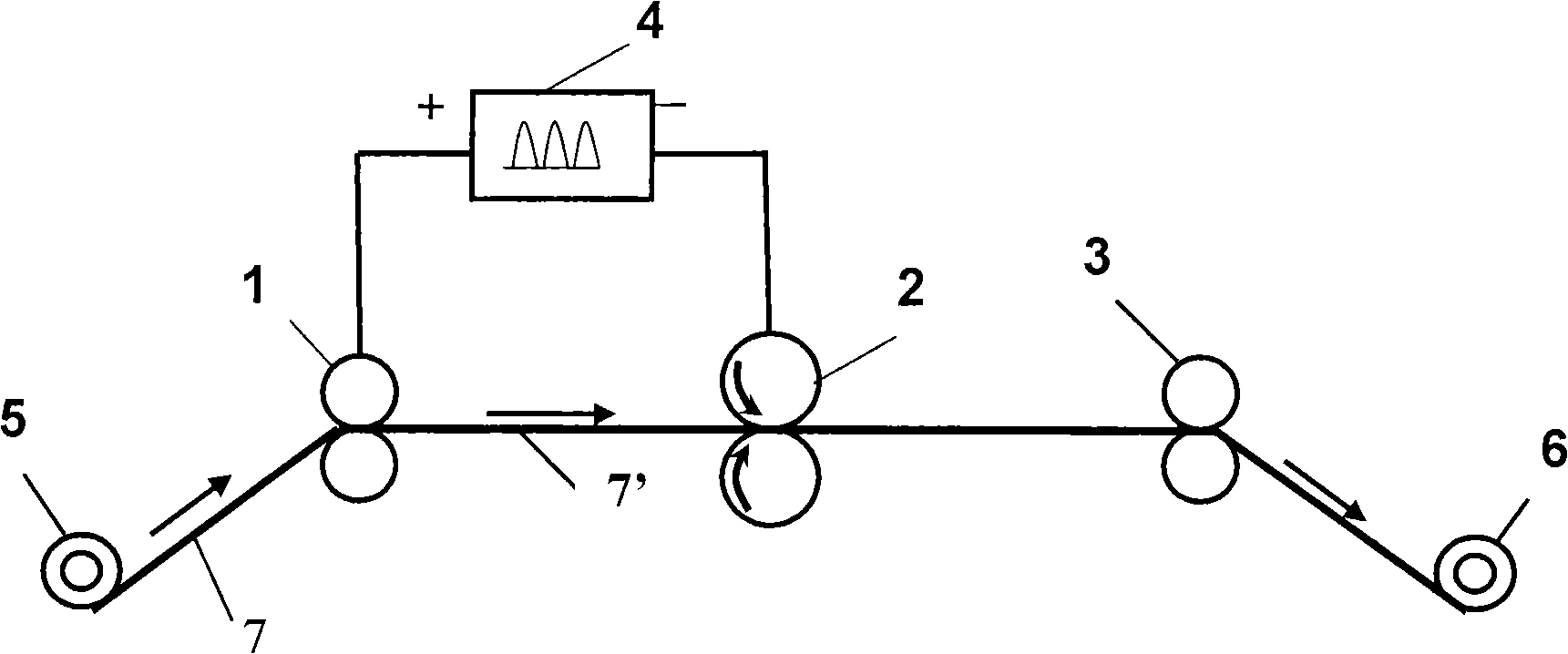

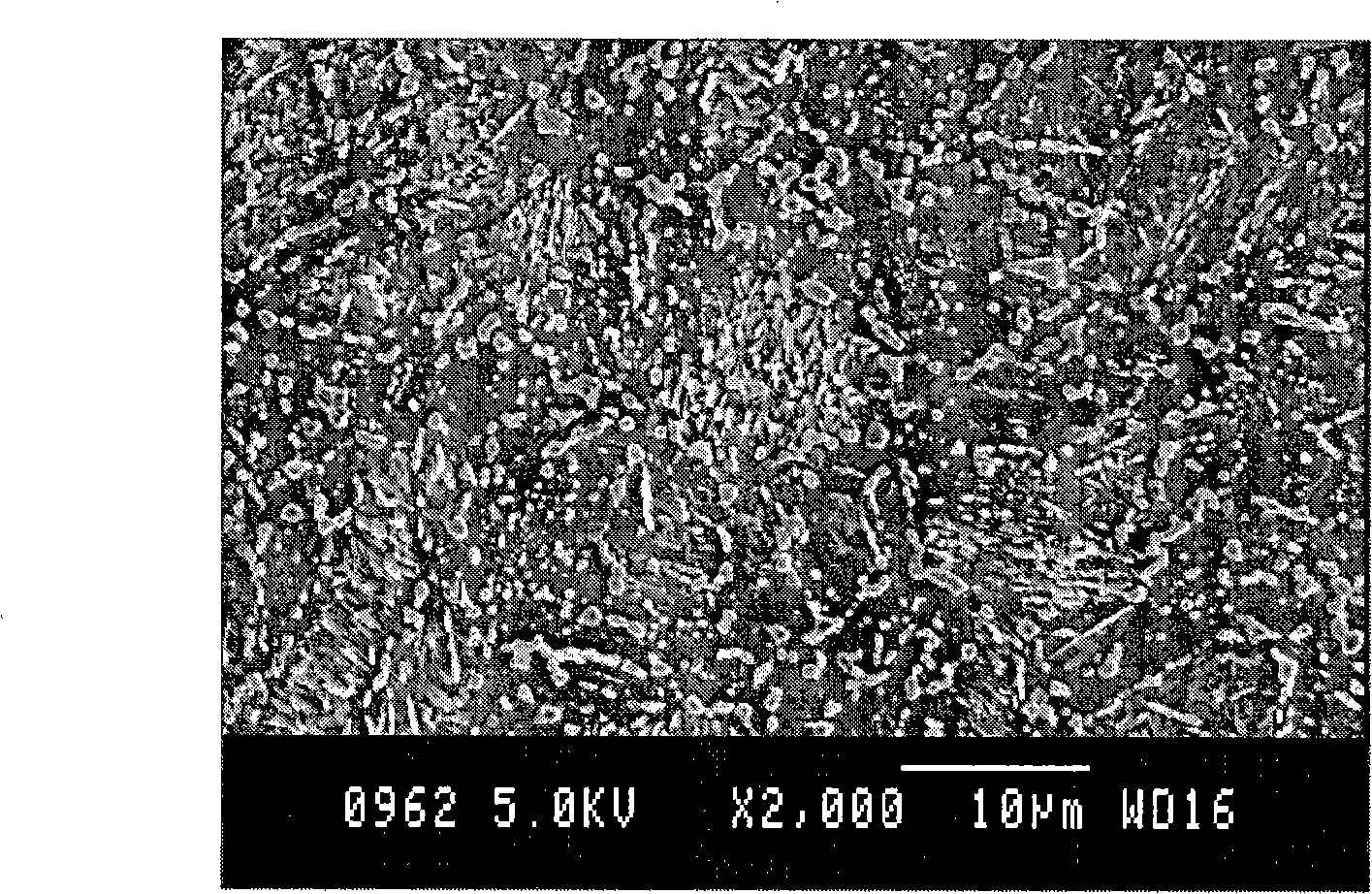

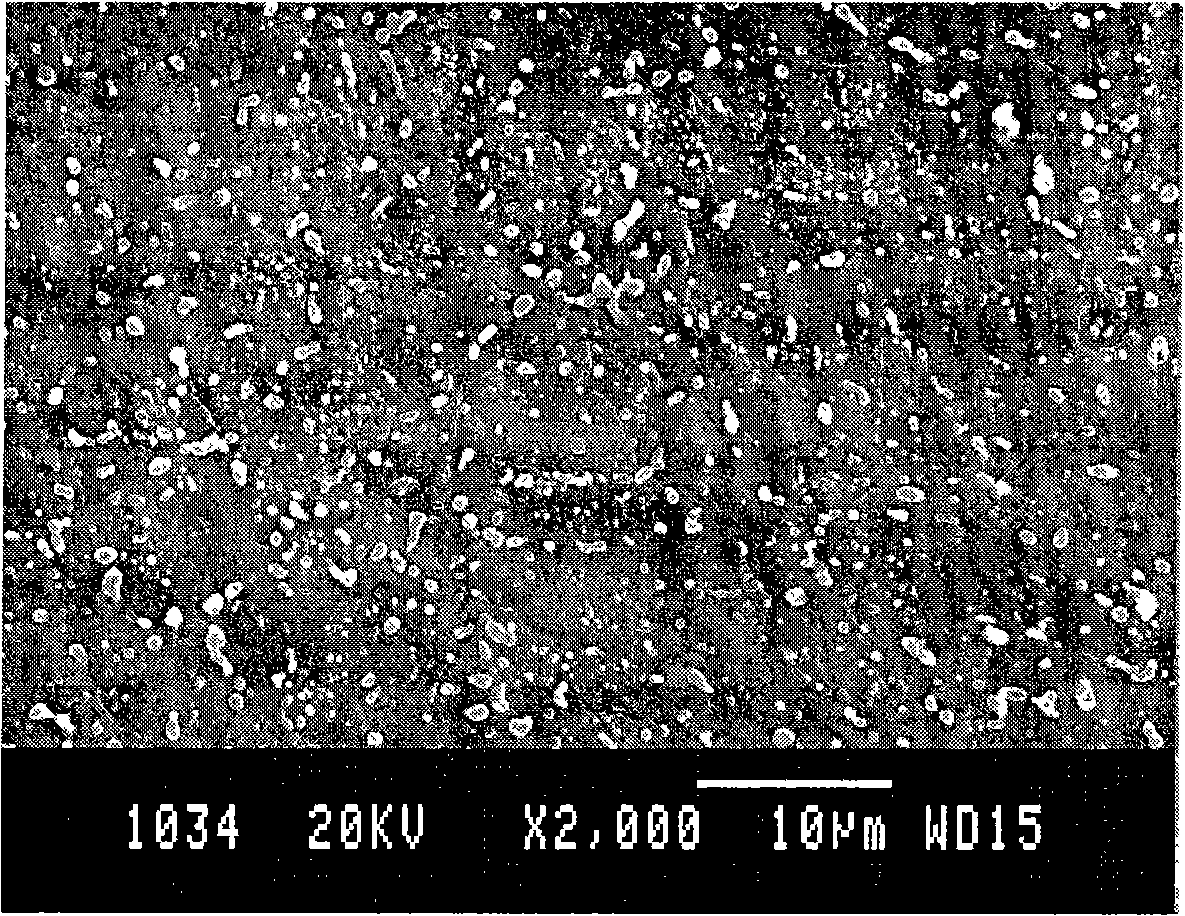

High-strength high-toughness AZ91 magnesium alloy strip eletrotoughening process method and system

InactiveCN101298653AOxidation does not occurToughening treatment is widely applicableHigh energyRoom temperature

The invention discloses an electro-strengthening and toughening processing method of a belt material of AZ91 magnesium alloy and a system thereof. The electro-strengthening and toughening processing method comprises following steps: when the belt material of magnesium alloy is transmitted at a certain speed which is driven by a roller on an electro plastic rolling machine, high-energy impulse current that is output by an impulse power source through an electrode is input into an electriferous region section of the moving belt material of magnesium alloy, and the Joule heating effect and the non-heating effect are generated in the electriferous region section, thus causing the phase transition of internal microscopic constitution from bulky lath-shaped Beta-Mg17Al12 that are gathering and agglomerating in an initial state to Beta-Mg17Al12 particles that are evenly distributed and approximately sphere-shaped, or causing the solid solution effect that leads Beta-Mg17Al12 to be dissolved in a substrate; the processed belt material can be naturally air cooled at room temperature. The electro-strengthening and toughening processing method of the belt material of AZ91 magnesium alloy has short processing time and high production efficiency, and simultaneously avoids the high-temperature oxidation of the magnesium alloy. After the electro-strengthening and toughening processing, the microscopic constitution of the belt material of magnesium alloy can be remarkably improved, the unit extension of the microscopic constitution is increased from 11.8 percent in the initial aging state to over 20 percent, and the tensile strength of the microscopic constitution is not dramatically lowered.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

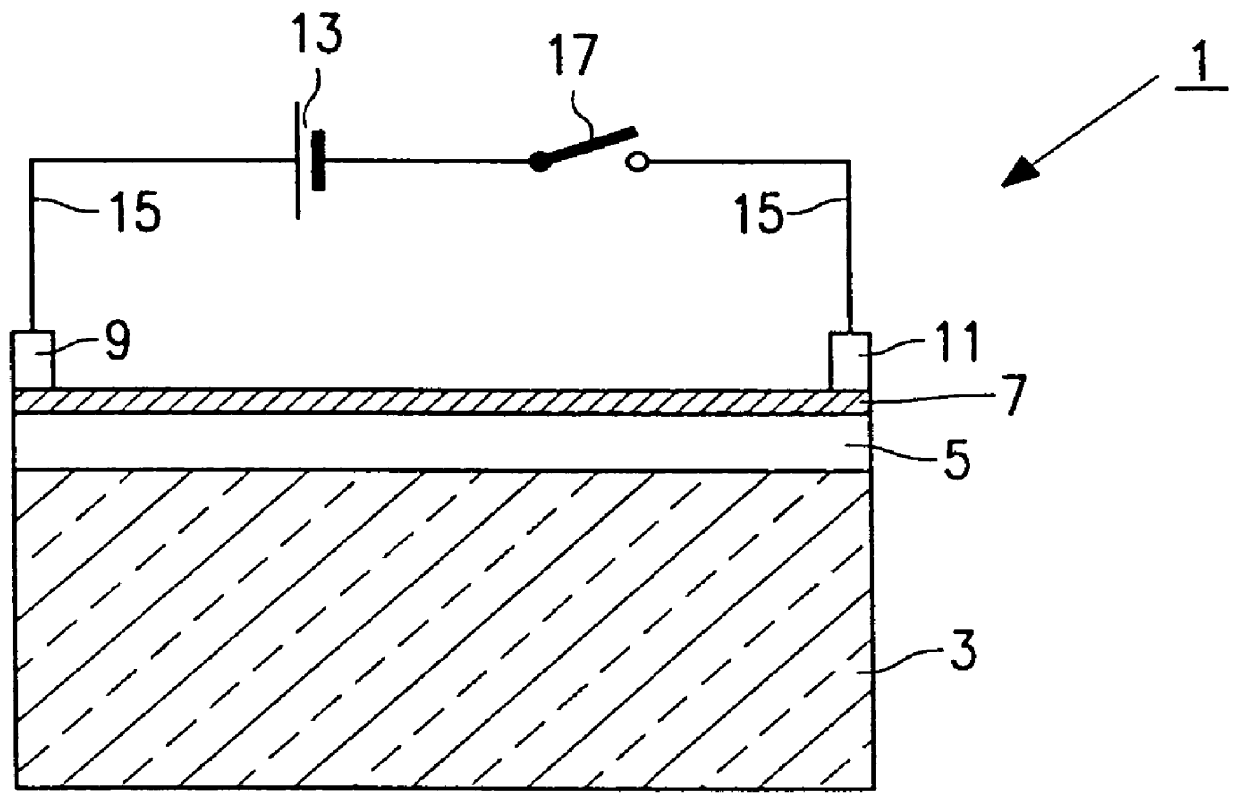

Optical switching device

InactiveUS6101298AIncrease chanceLayer structure is simpleElectronic switchingCoupling light guidesChemical compoundDisplay device

A description is given of an optical switching device (1) comprising a transparent substrate (3), a switching film (5) of a hydride compound of a trivalent transition or rare earth metal having a thickness of 300 nm, and a palladium capping layer (7) having a thickness of 30 nm. The capping layer is in contact with hydrogen. An electric current through the switching film (5) can be switched on and off between the terminals (9, 11). Joule heating of the switching film (5) causes a rapid transition from the transparent trihydride state to the absorbing dihydride state. By switching off the current, the switching film (5) cools down, which results in the formation of the absorbing dihydride state. The conversion between both states is reversible and can be repeated many times. The device can be used for controlling light beams, or it can be used in or for a display. Optionally, cooling of the switching film (5) is obtained with a Peltier element in thermal contact with the switching film (5).

Owner:U S PHILIPS CORP

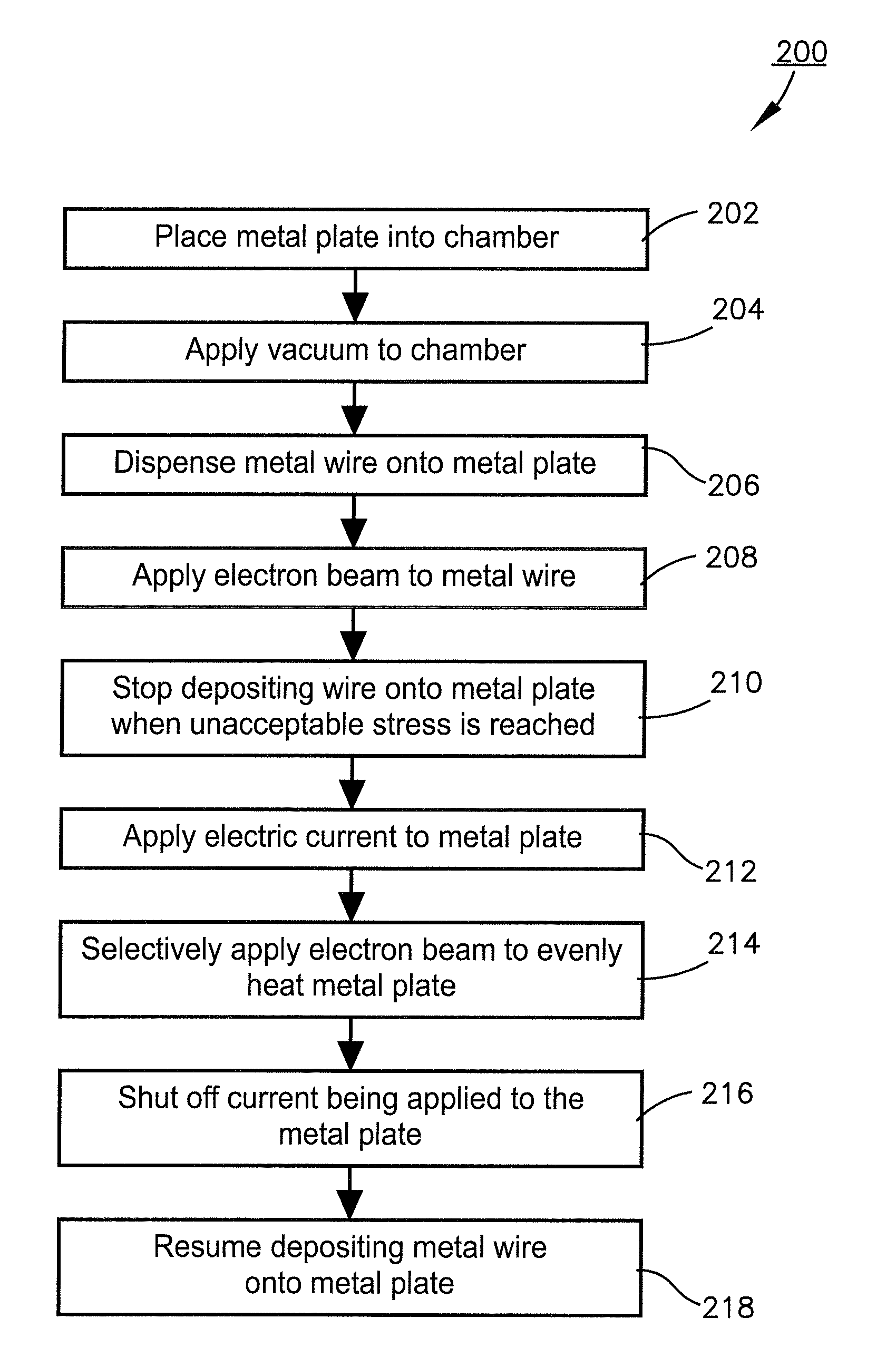

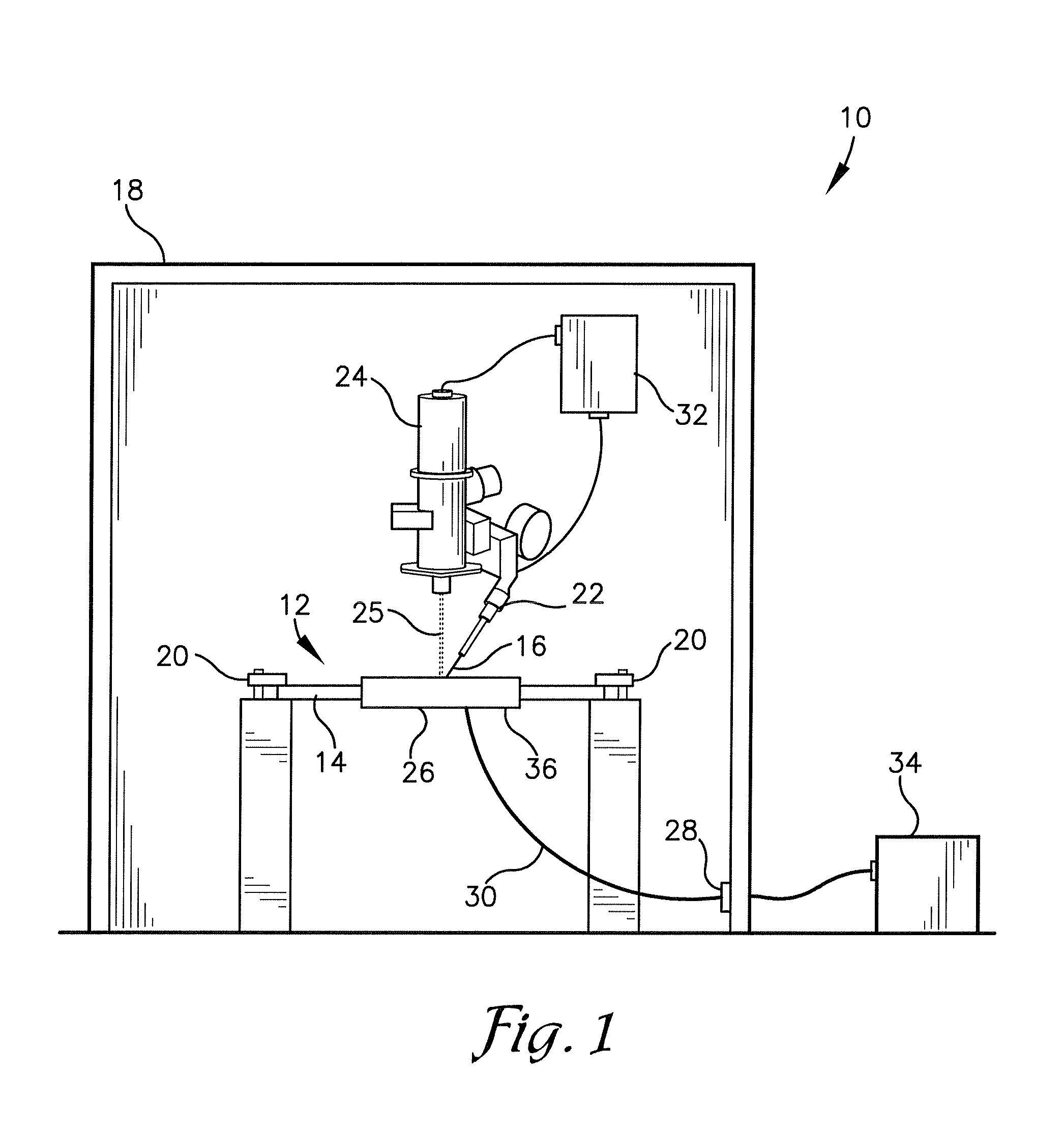

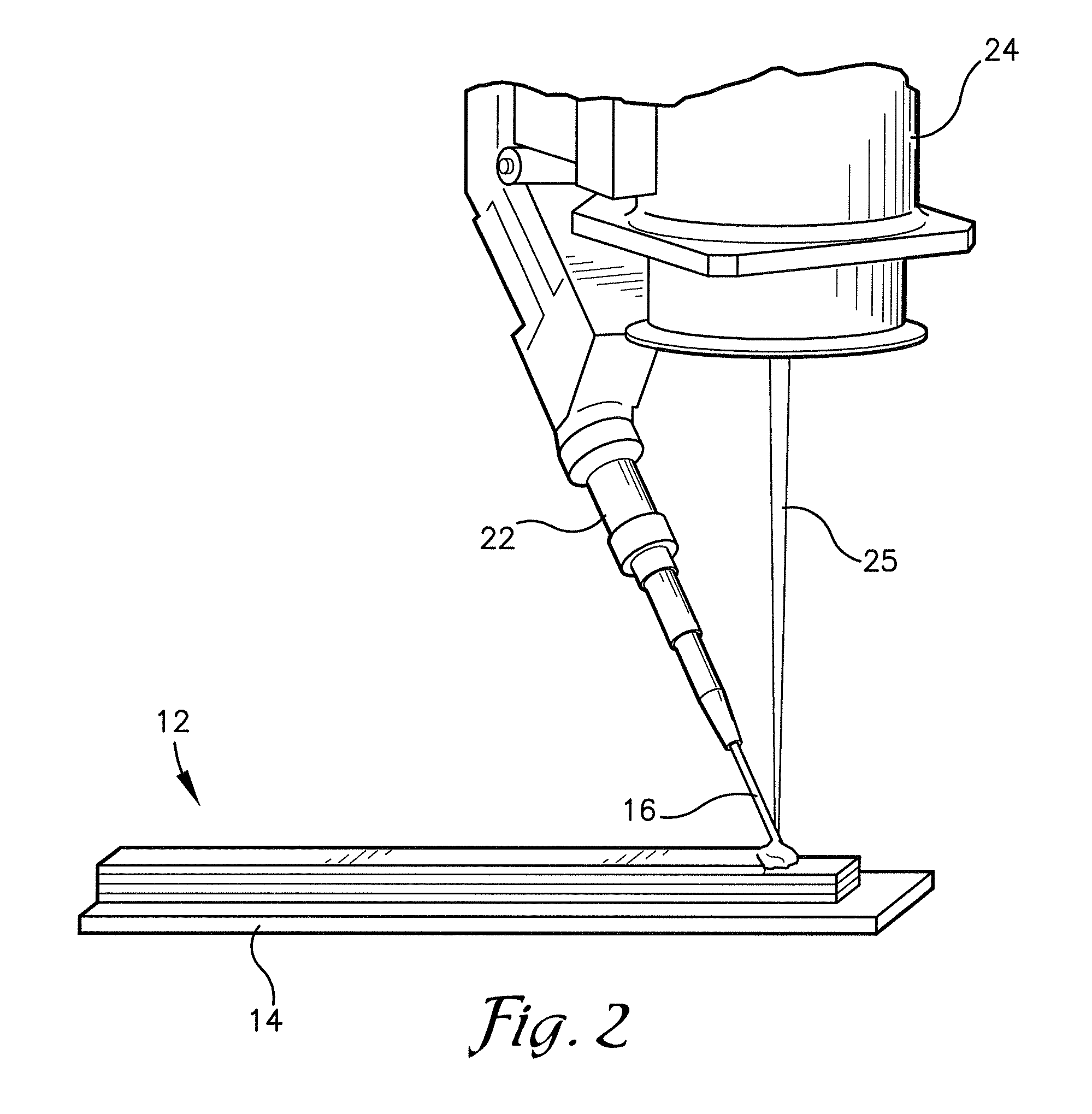

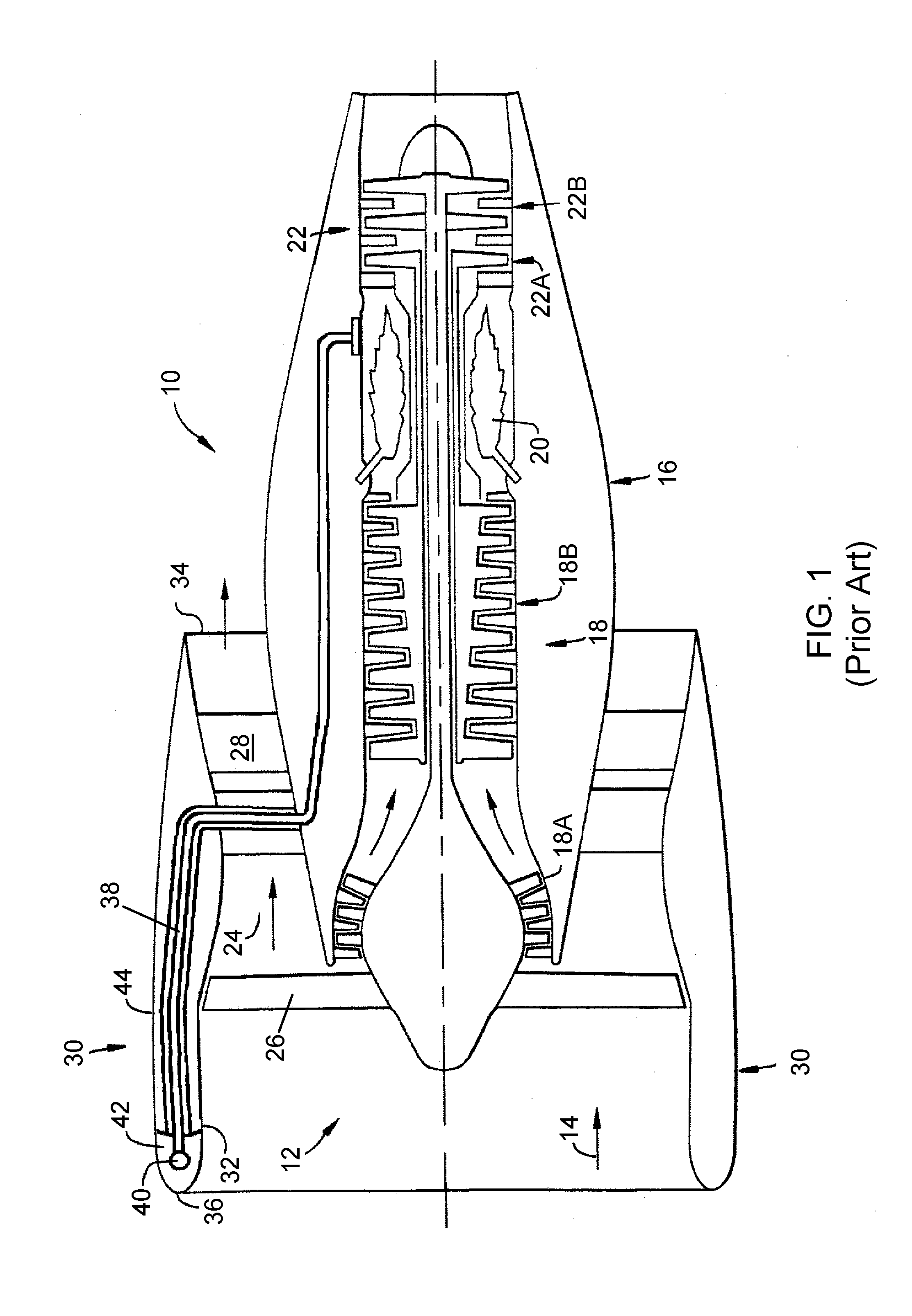

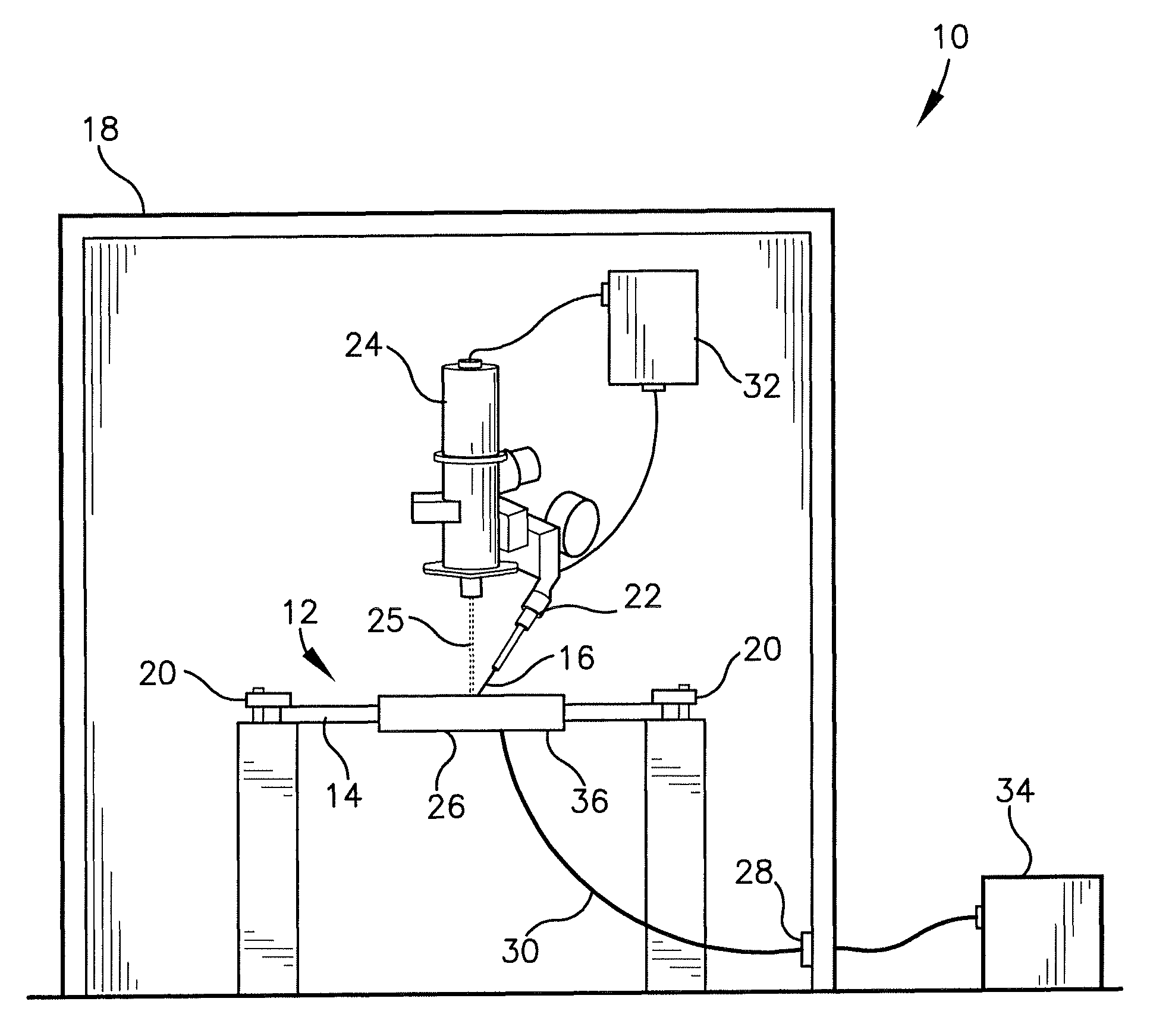

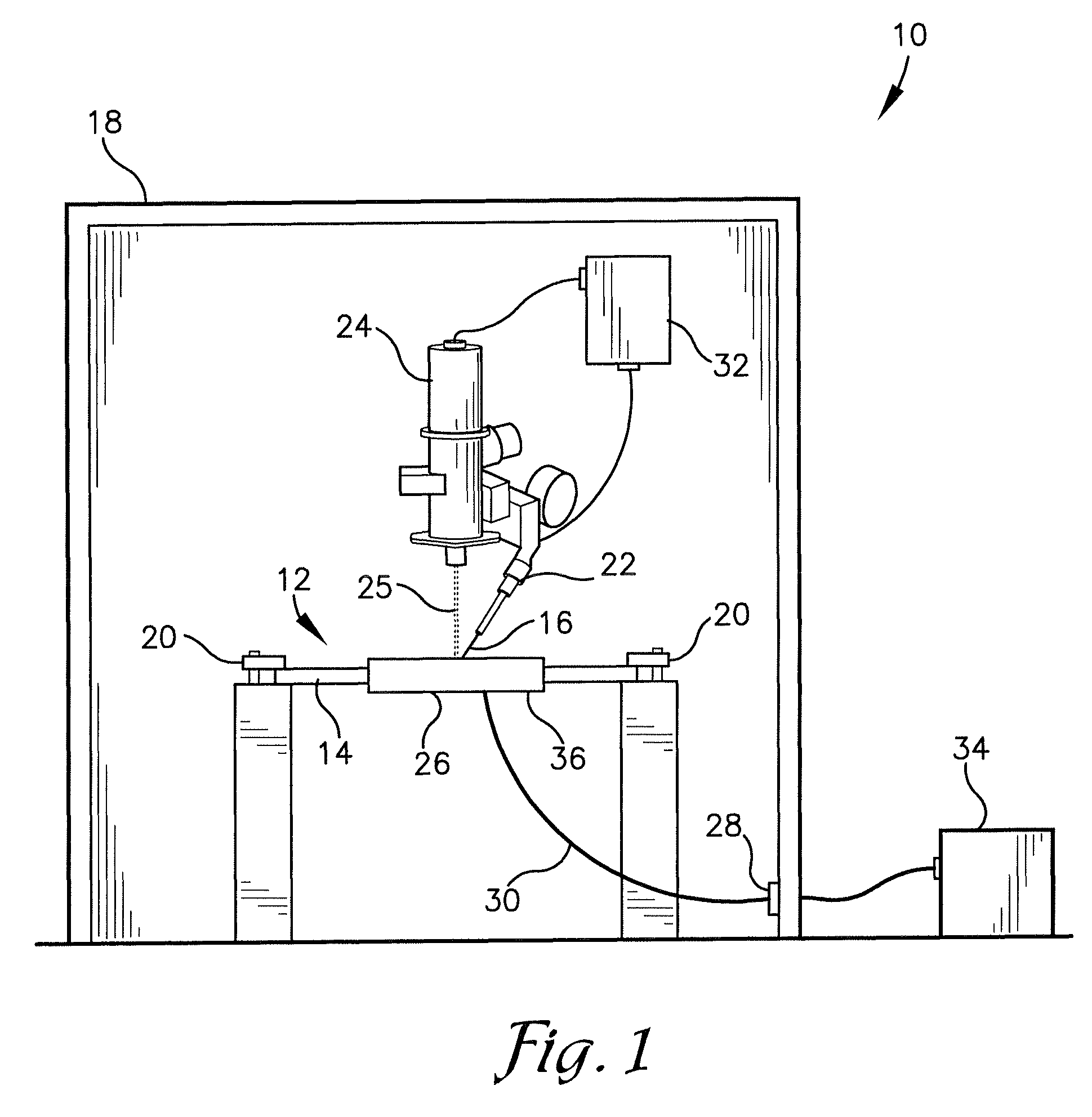

System and method to form and heat-treat a metal part

ActiveUS20110008530A1Evenly heatedAdditive manufacturing apparatusMolten spray coatingPower flowStress relieving

A system and method for direct manufacturing and stress relieving a metal part without removing the metal part from a vacuumed chamber. The system may comprise the chamber, a wire feeder for depositing a metal wire onto a metal plate, an electron beam (EB) source for providing an electron beam to melt the metal wire during deposition, and a current-providing apparatus for joule heating the metal plate to provide heat treatment to the metal part. The method may comprise depositing the metal wire onto the metal plate within the vacuumed chamber, then providing intermediate stress relief after a portion of the metal wire is deposited onto the metal plate by applying an electrical current to the metal part. The electron beam may also be set at a temperature below a melting point of a particular metal of the metal part for relieving stress in the metal part.

Owner:SPIRIT AEROSYSTEMS

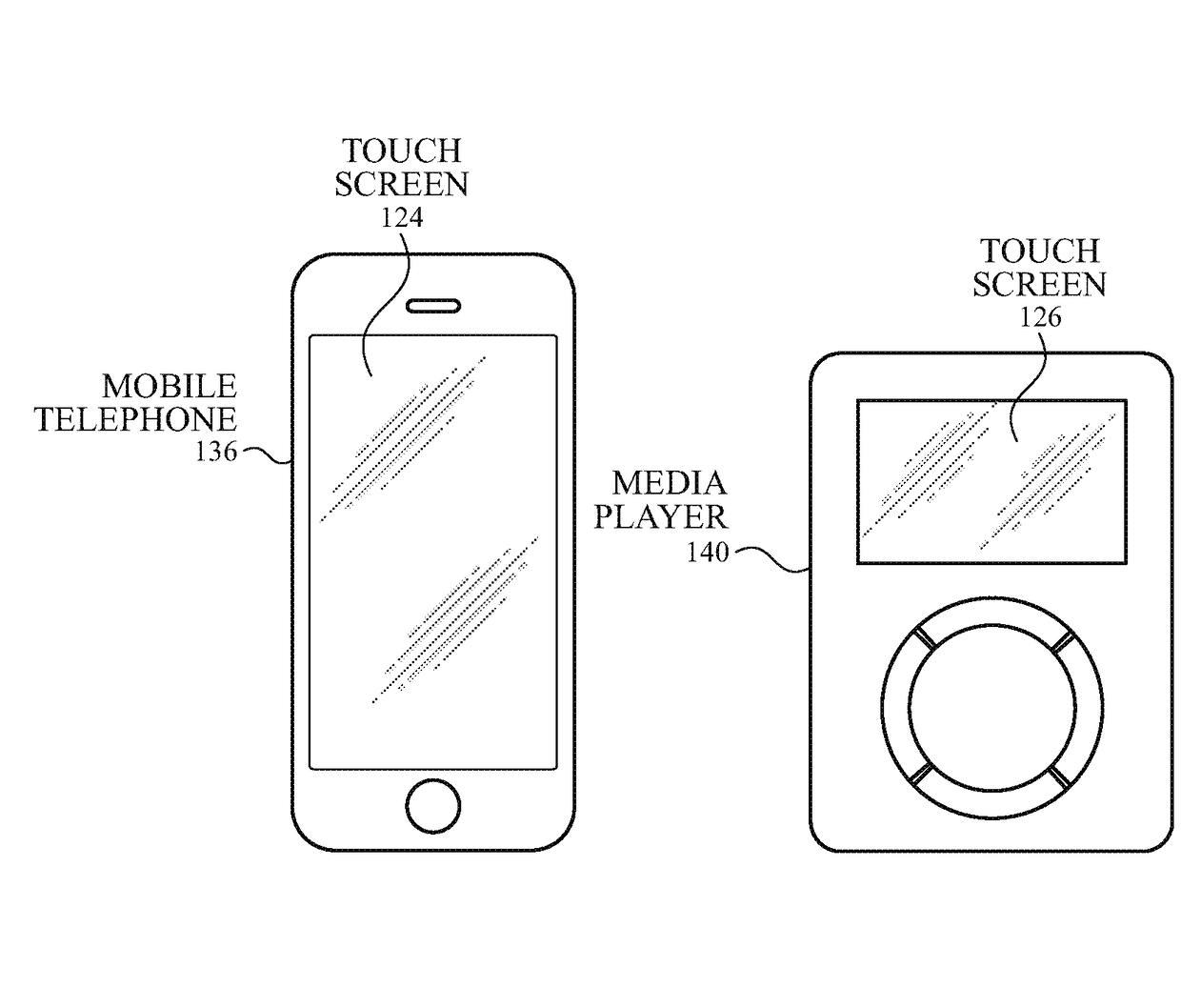

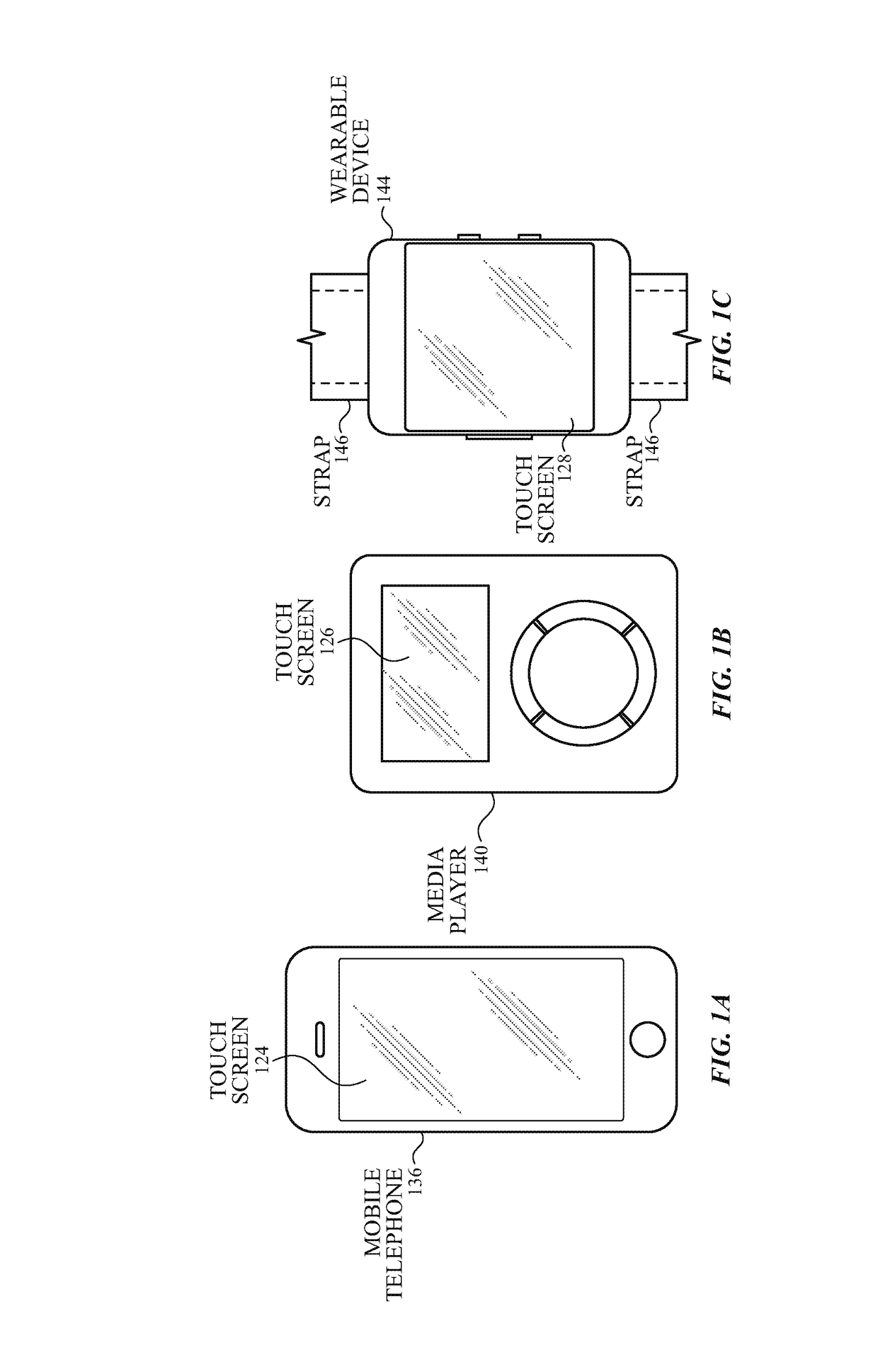

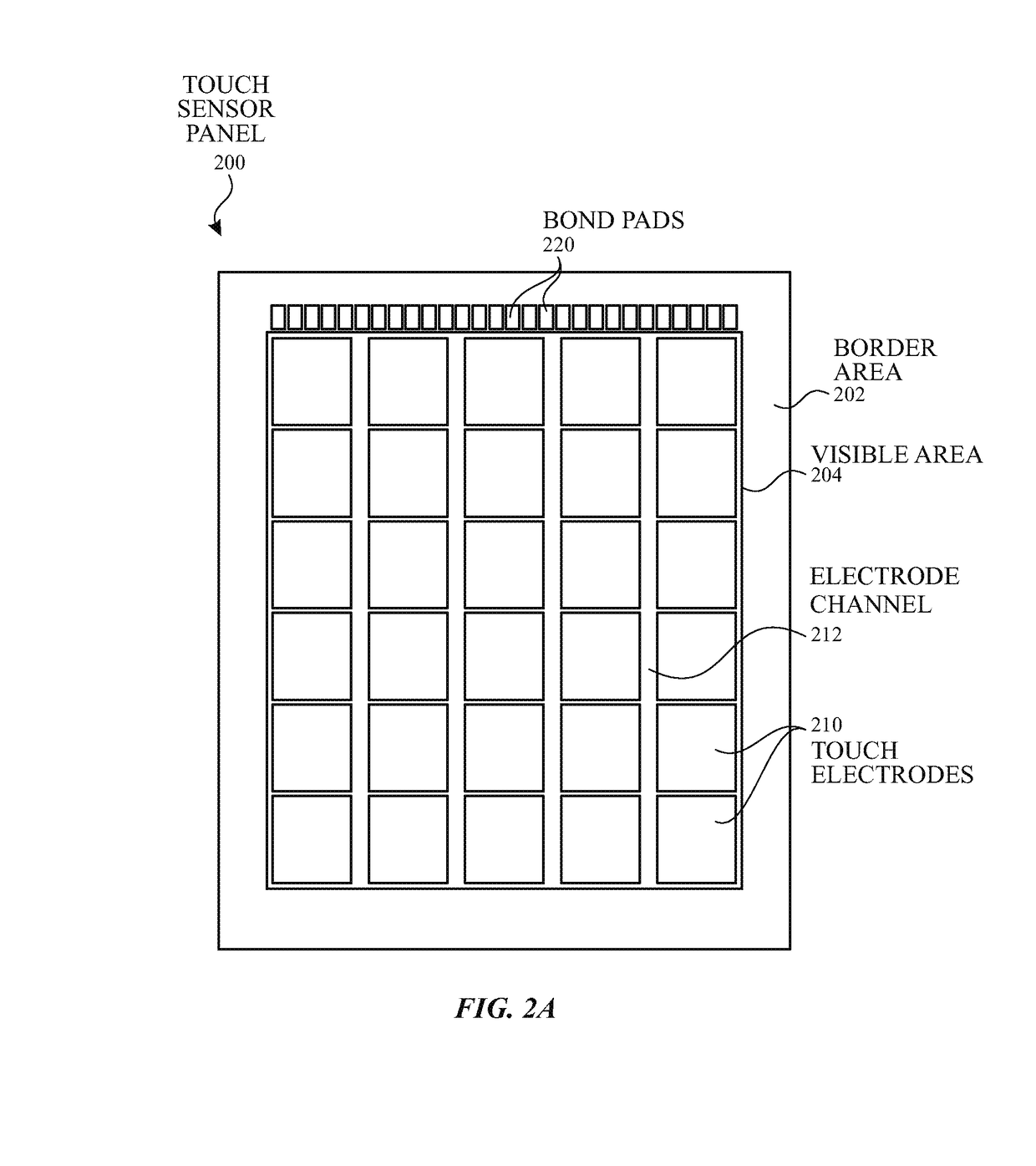

Back of cover touch sensors

ActiveUS20180067584A1Reduce electrostatic dischargeAffects overall performance of sensorDevices with sensorSubstation equipmentEngineeringBoundary region

Touch sensor configurations for reducing electrostatic discharge events in the border area of a touch sensor panel is disclosed. Touch sensors (e.g., electrodes formed on the cover material and / or the opaque mask) can be susceptible to certain events such as arcing and discharge / joule heating, which may negatively affect touch sensor performance. Examples of the disclosure can include increasing the trace width, spacing, and / or thickness in the border area relative to the trace width, spacing, and / or thickness in the visible / active area along one or more sides of the touch sensor panel. In some examples, touch electrodes can be located exclusively in the visible / active areas along one or more sides of the touch sensor panel, while dummy sections can be included in both the border and visible / active areas. Additionally or alternatively, one or more gaps between adjacent touch electrodes in the border area or serpentine routing can be included.

Owner:APPLE INC

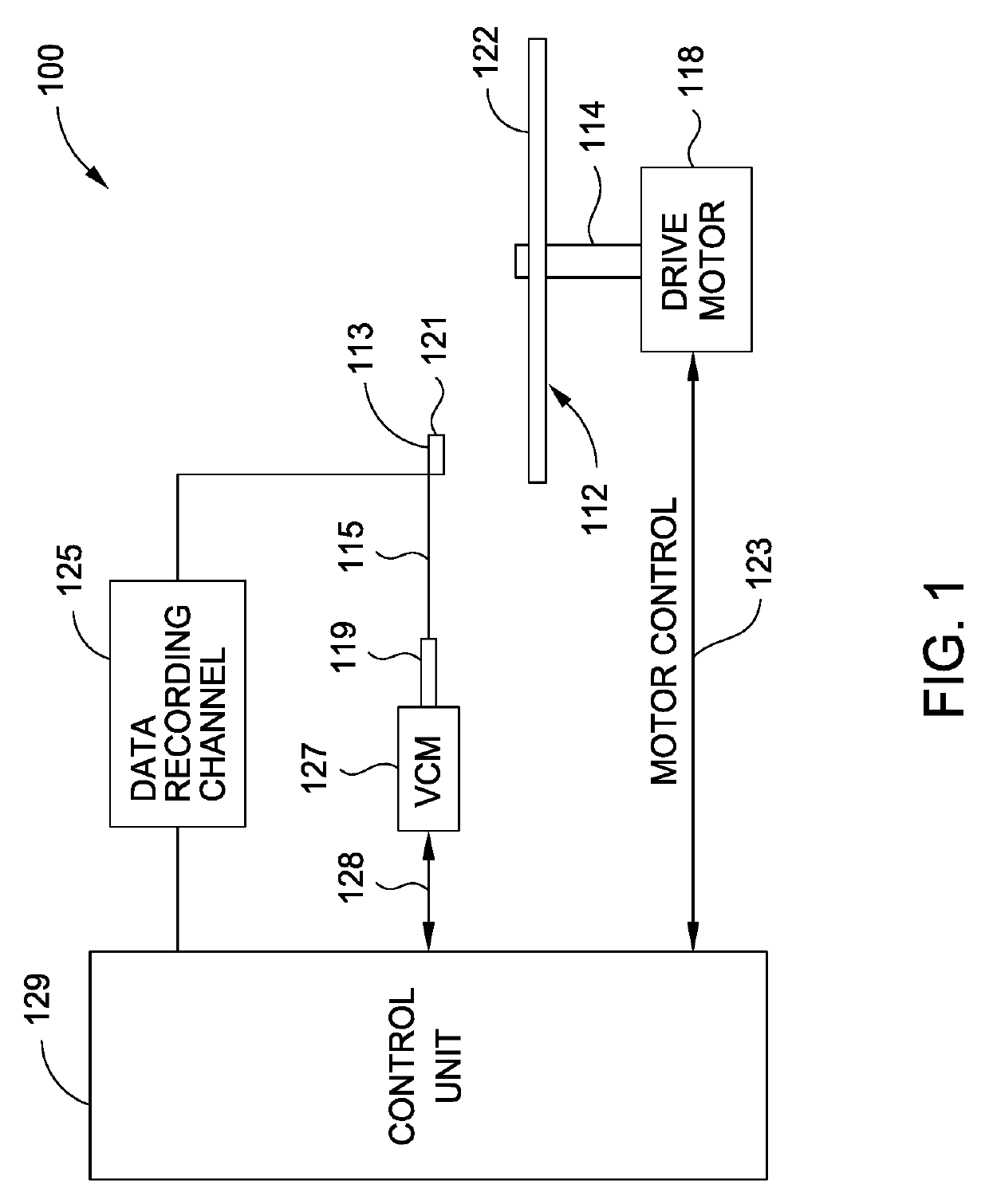

Mamr write head with thermal dissipation conductive guide

ActiveUS20190259413A1Heat dissipationReduce failureHeads using thin filmsRecord information storageElectricityMagnetic media

The present disclosure generally relates to data storage devices, and more specifically, to a magnetic media drive employing a magnetic recording head. The head includes a trailing shield, a main pole, a MAMR stack disposed between the trailing shield and the main pole, side shields surrounding at least a portion of the main pole, and a structure disposed between the side shields and the main pole at a media facing surface (WS). The structure is fabricated from a material that is thermally conductive and electrically insulating / dissipative. The material has a thermal conductivity of at least 50 W / (m*K) and an electrical resistivity of at least 105 Ω*m. The structure helps dissipate joule heating generated from either the main pole or the MAMR stack into surrounding area without electrical shunting, leading to reduced heating or break-down induced failures.

Owner:WESTERN DIGITAL TECH INC

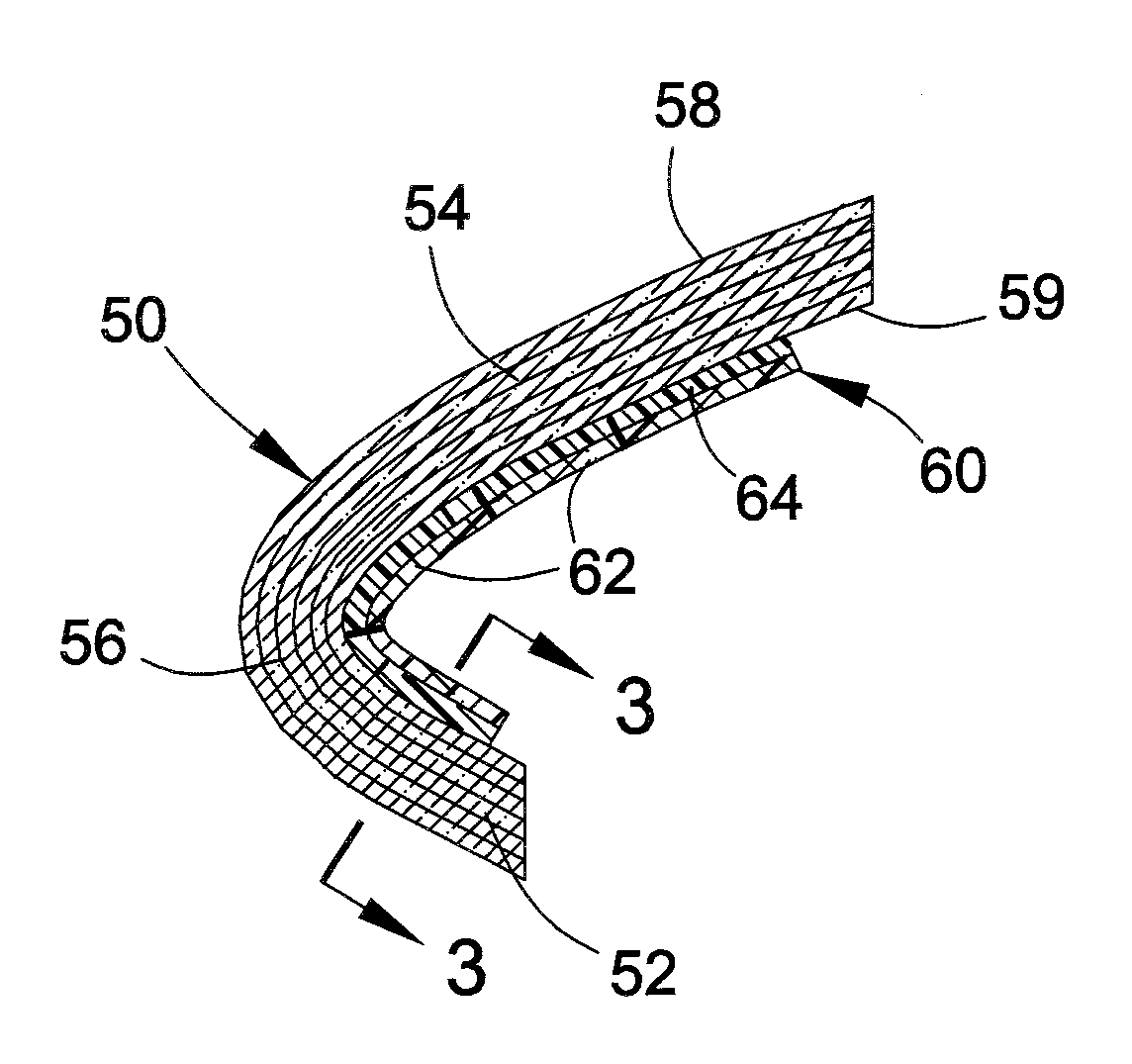

Turbomachine nacelle and Anti-icing system and method therefor

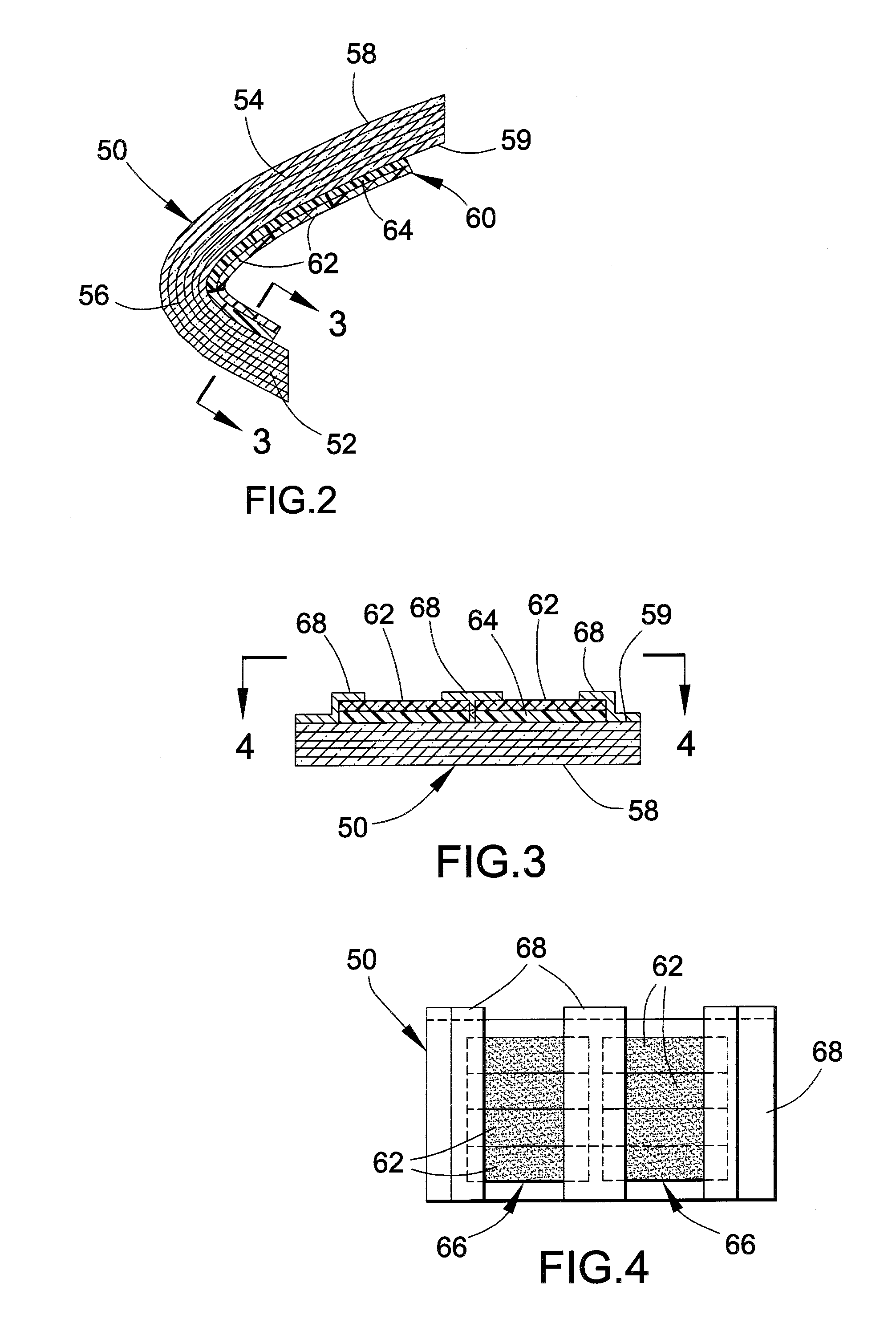

ActiveUS20110167781A1Preventing ice buildupPrevent removalMaterial nanotechnologyPower plant arrangements/mountingLeading edgeIce protection system

An anti-icing system and method for an aircraft engine nacelle. The nacelle has an inlet lip that defines a leading edge of the nacelle and has a cross-sectional shape and oppositely-disposed exterior and interior surfaces. An anti-icing system contacts at least the inlet lip of the nacelle. The anti-icing system includes at least one heating element having a cross-sectional shape that conforms to the cross-sectional shape of the inlet lip and in which carbon nanotubes are oriented and arranged to conduct electrical current through the heating element. Passing an electrical current through the heating element causes Joule heating of the heating element and heating of the inlet lip by thermal conduction.

Owner:MRA SYST LLC

System and method to form and heat-treat a metal part

ActiveUS8308876B2Evenly heatedAdditive manufacturing apparatusMolten spray coatingStress relievingStress relief

A system and method for direct manufacturing and stress relieving a metal part without removing the metal part from a vacuumed chamber. The system may comprise the chamber, a wire feeder for depositing a metal wire onto a metal plate, an electron beam (EB) source for providing an electron beam to melt the metal wire during deposition, and a current-providing apparatus for joule heating the metal plate to provide heat treatment to the metal part. The method may comprise depositing the metal wire onto the metal plate within the vacuumed chamber, then providing intermediate stress relief after a portion of the metal wire is deposited onto the metal plate by applying an electrical current to the metal part. The electron beam may also be set at a temperature below a melting point of a particular metal of the metal part for relieving stress in the metal part.

Owner:SPIRIT AEROSYSTEMS

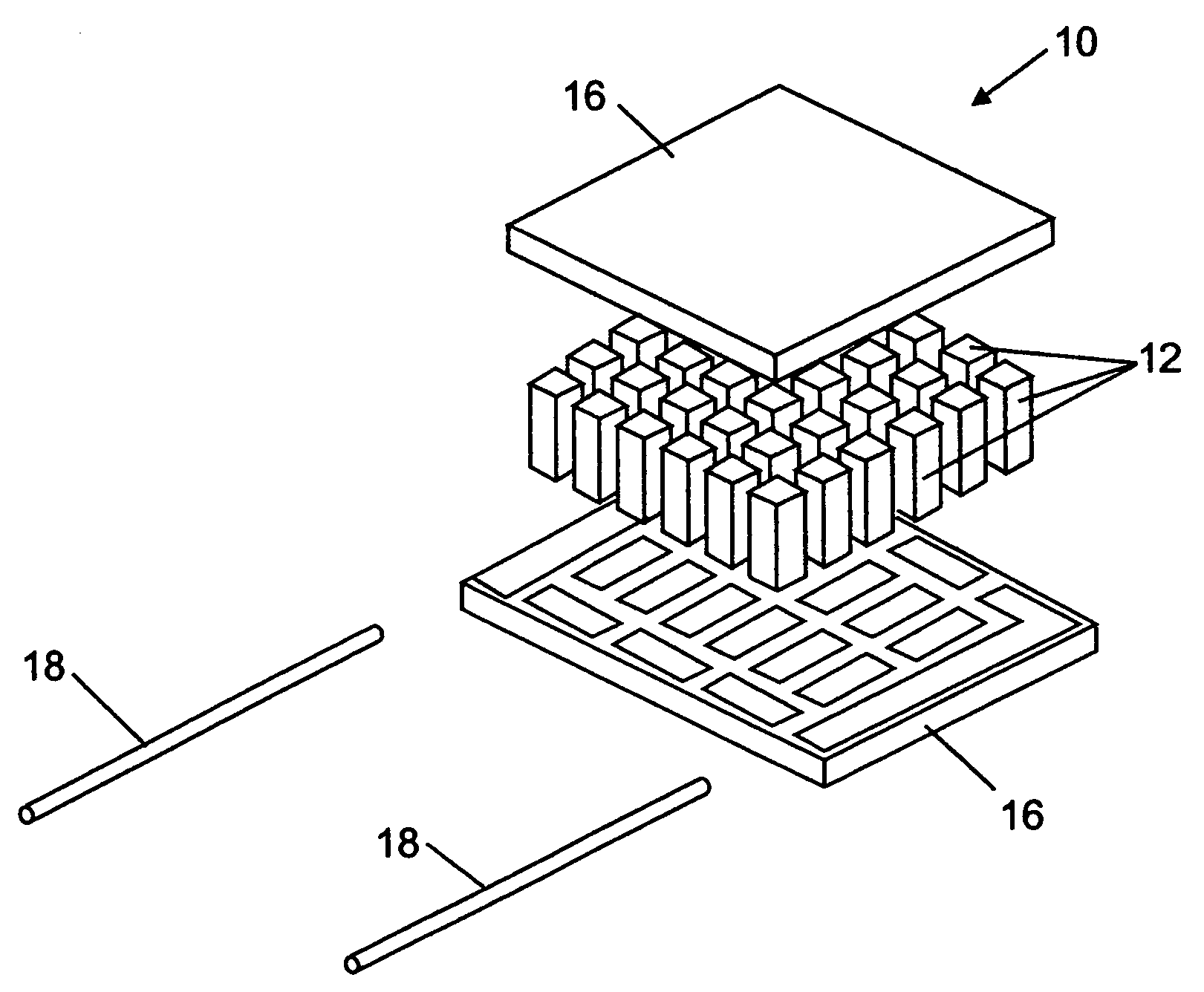

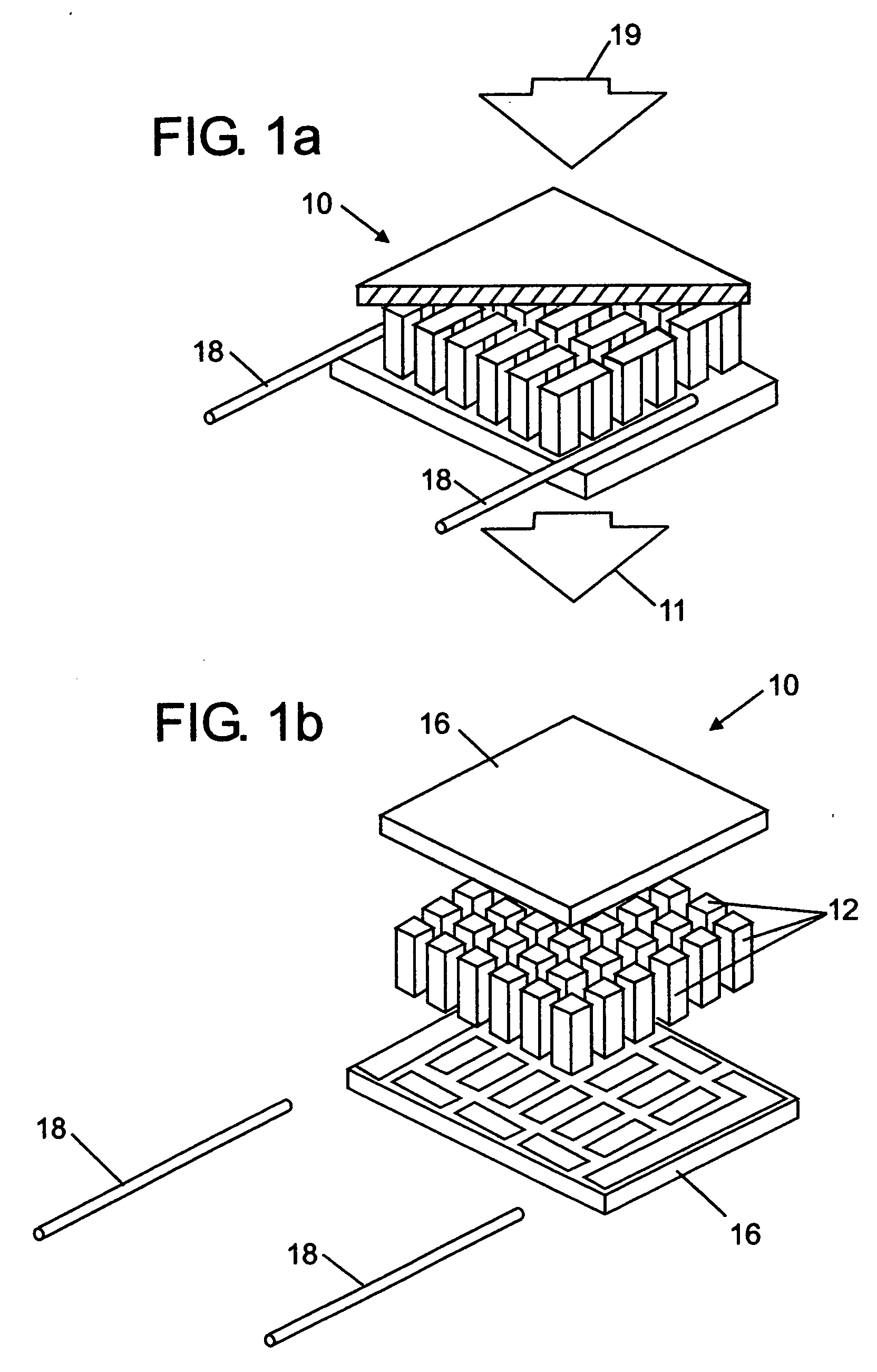

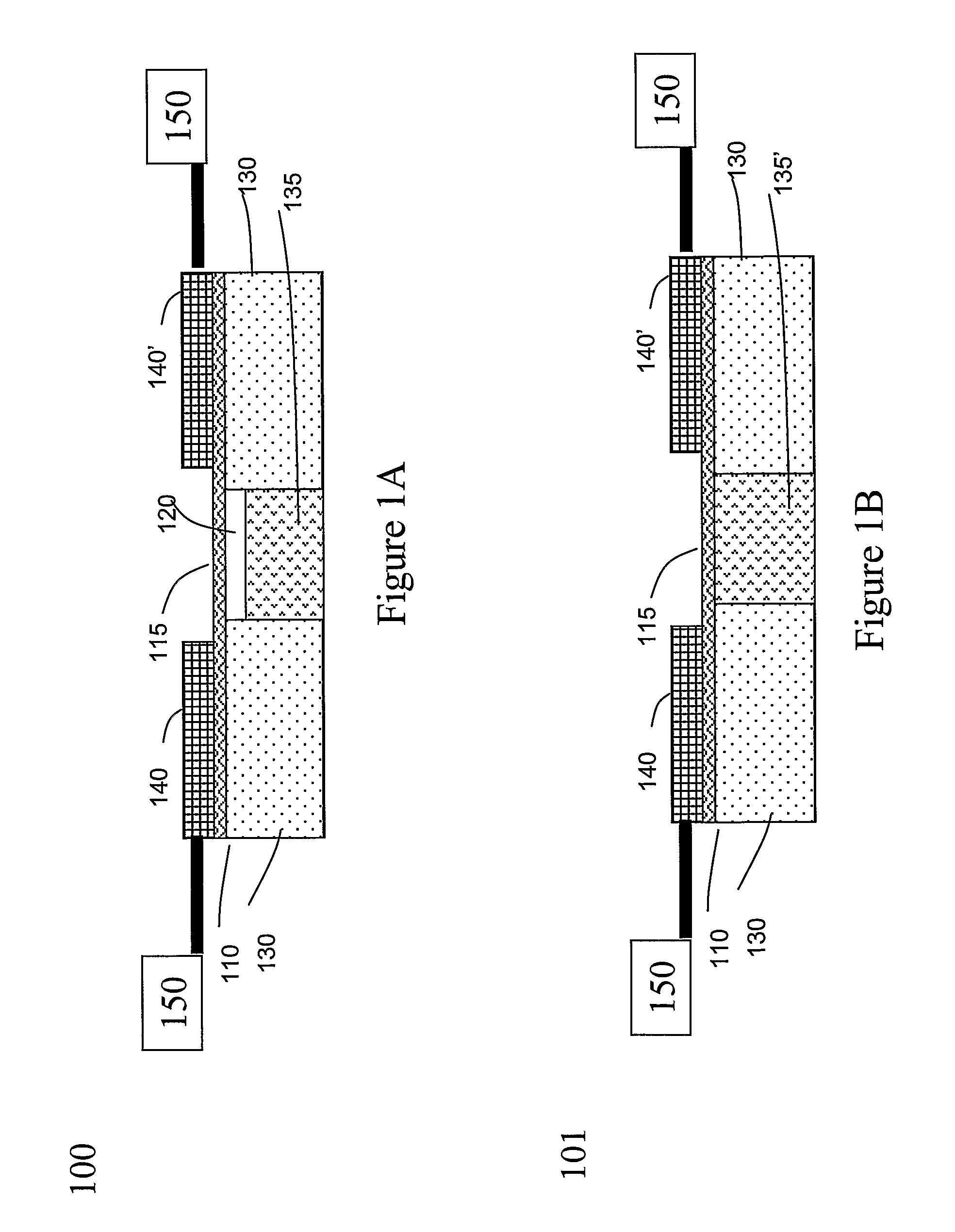

Method and system of using nanotube fabrics as joule heating elements for memories and other applications

Methods and systems of using nanotube elements as joule heating elements for memories and other applications. Under one aspect, a method includes providing an electrical stimulus, regulated by a drive circuit, through a nanotube element in order to heat an adjacent article. Further, a detection circuit electrically gauges the state of the article. The article heated by the nanotube element is, in preferred embodiments, a phase changing material, hi memory applications, the invention may be used as a small-scale CRAM capable of employing small amounts of current to induce rapid, large temperature changes in a chalcogenide material. Under various embodiments of the disclosed invention, the nanotube element is composed of a non-woven nanotube fabric which is either suspended from supports and positioned adjacent to the phase change material or is disposed on a substrate and in direct contact with the phase change material. A plurality of designs using various geometric orientations of nanotube fabrics, phase change materials, and drive and detection circuitry is disclosed. Additionally, methods of fabricating nanotube heat emitters are disclosed.

Owner:NANTERO

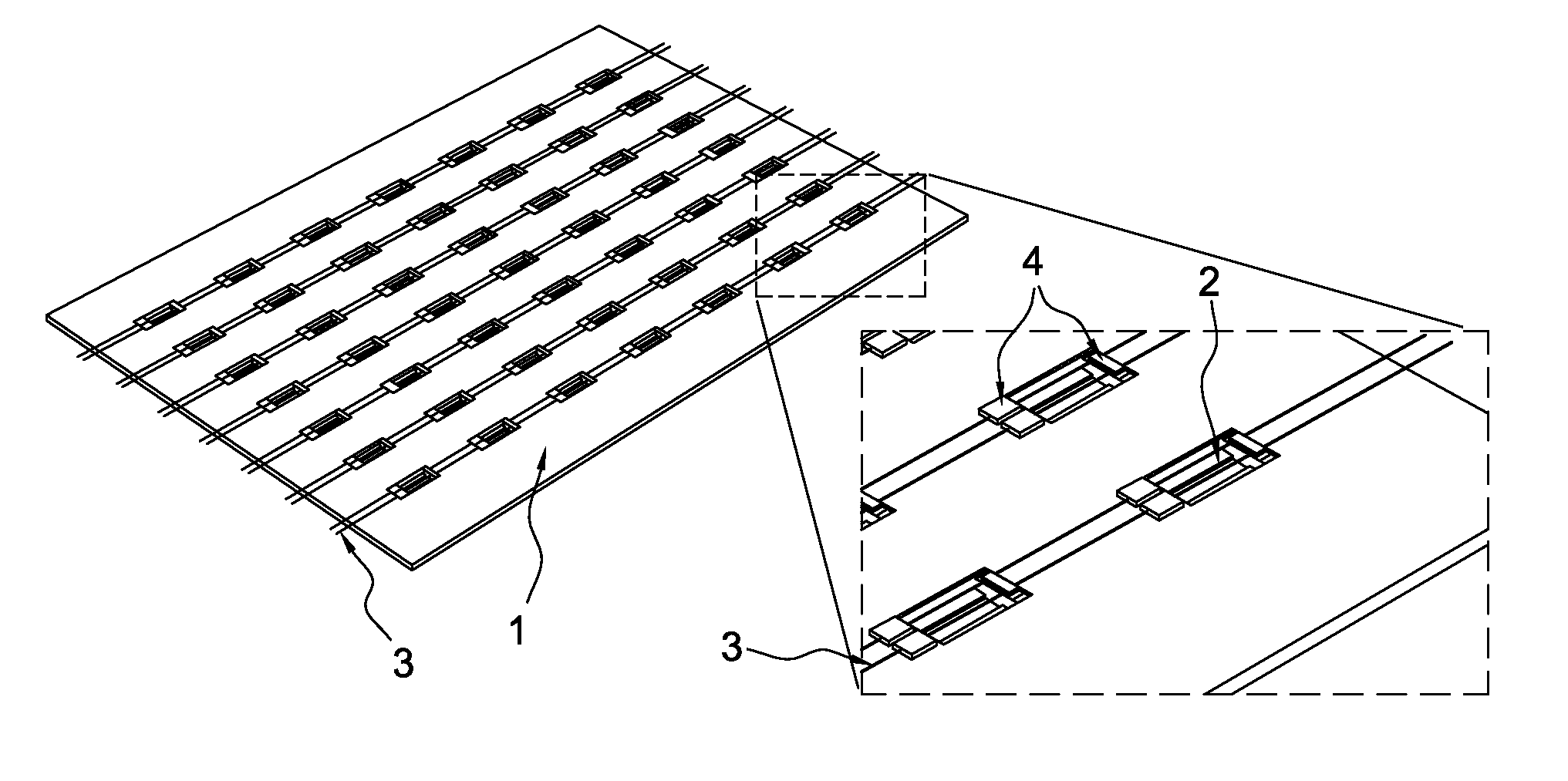

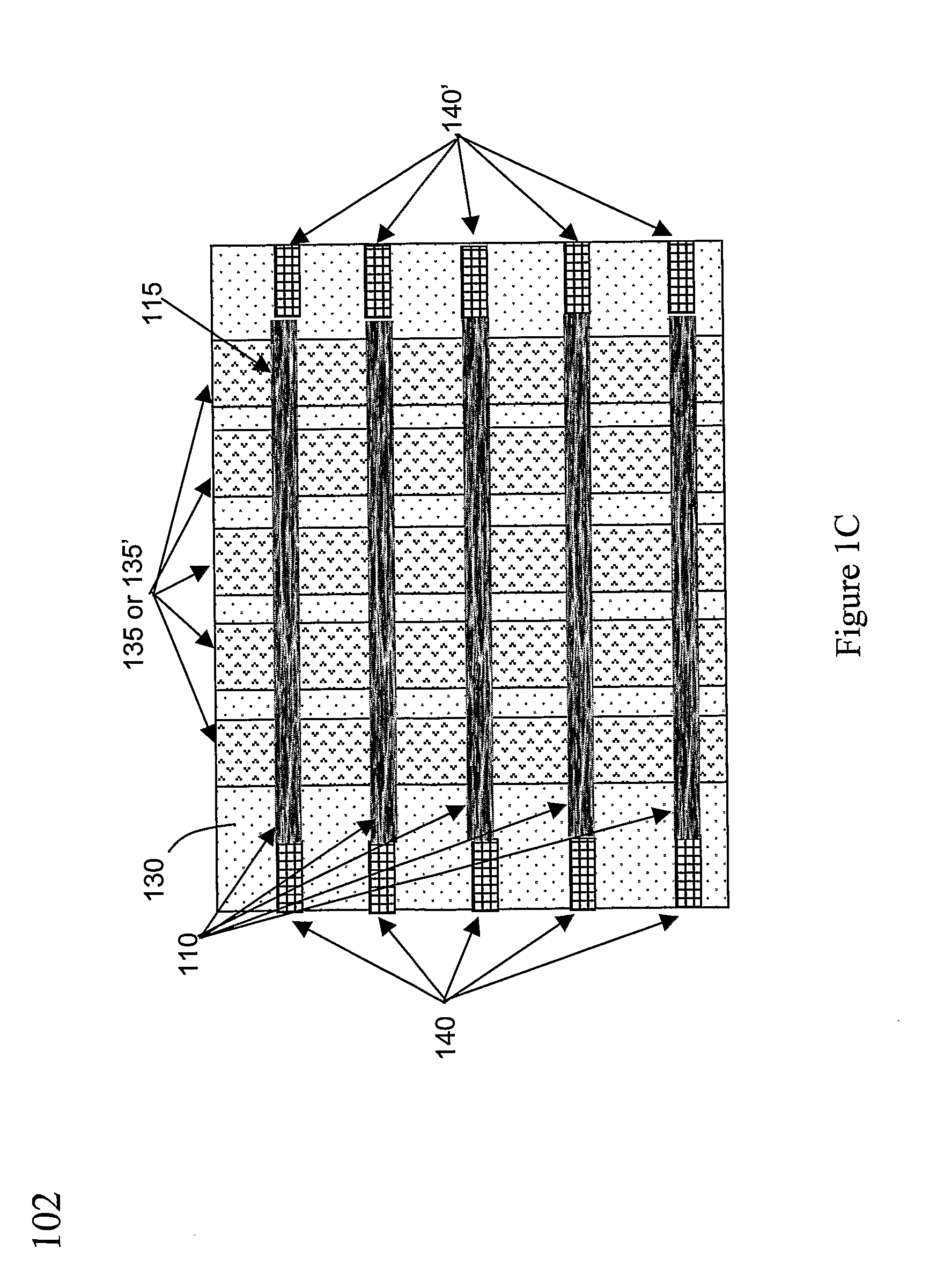

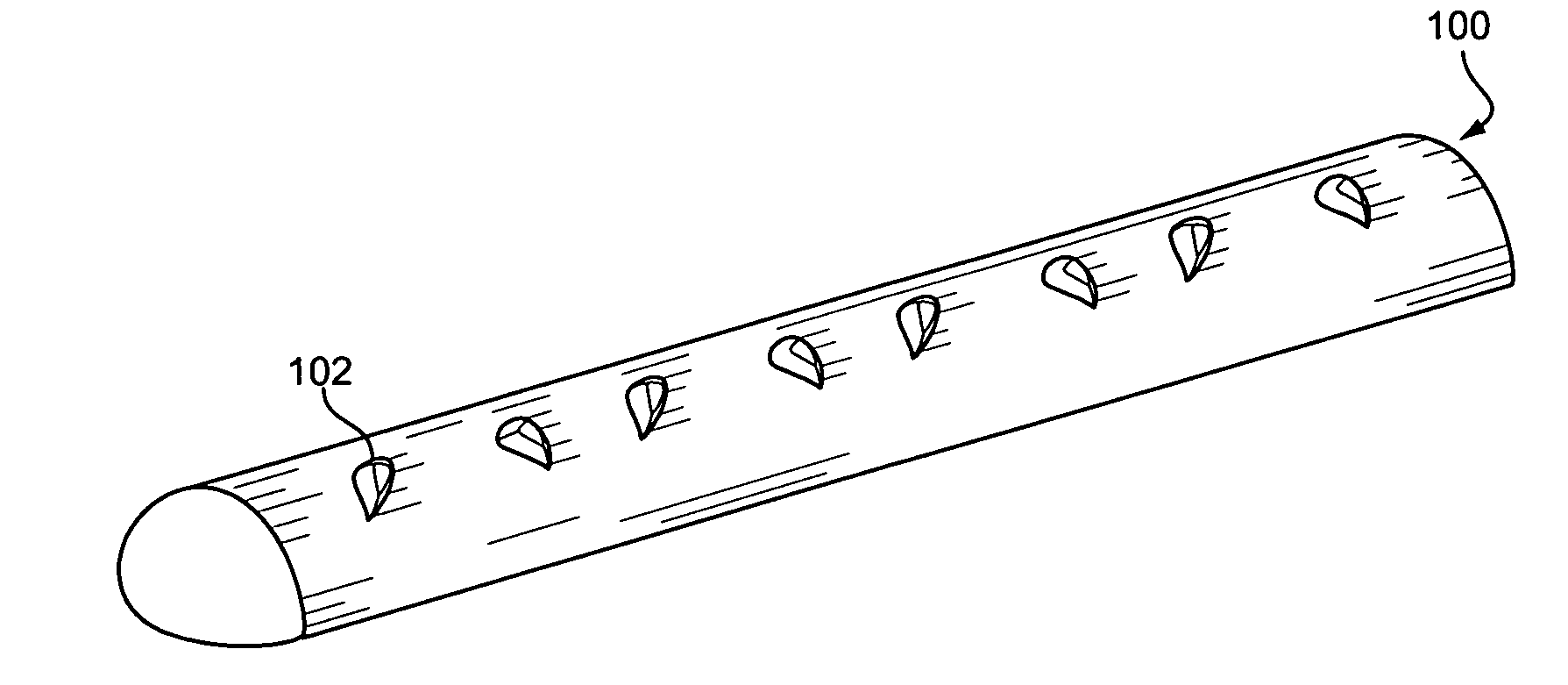

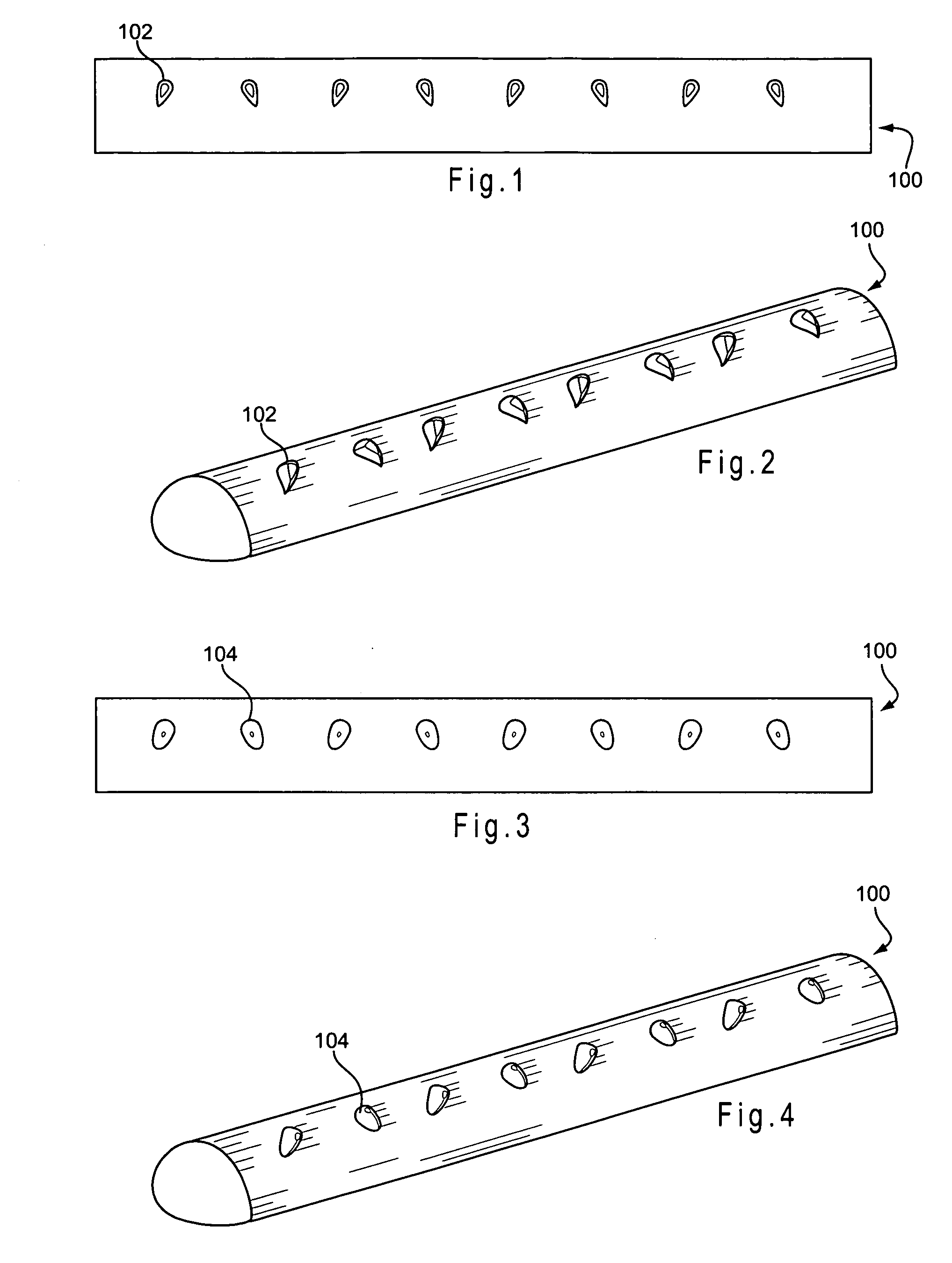

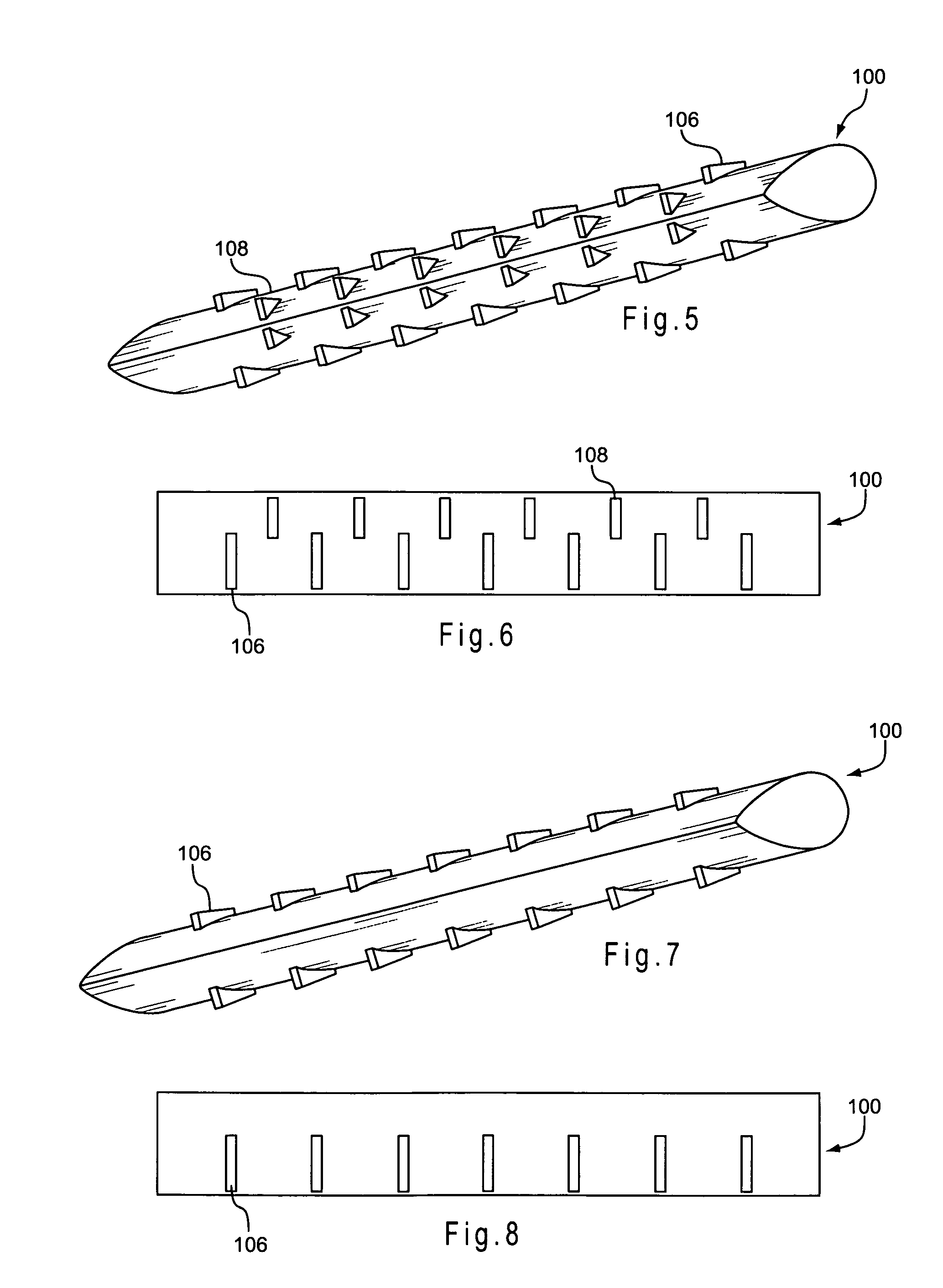

Wake generating solid elements for joule heating or infrared heating

ActiveUS20100132921A1Reduce dragReduce pressure dropMetal-working apparatusIndirect heat exchangersEngineeringJoule heating

An improved solid heat transfer element composed of an elongate member having a generally cylindrical surface with male vortex generating protrusions is provided. The vortex generating protrusions, which may be referred to as “turbulators,” provide improved heat transfer by convection to a flow of air transverse to the elongate members without substantially increasing the pressure drop in the flow of air passing over the members. Advantageously, a plurality of the heat transfer elements, or of straight portions of a single serpentine heat transfer element, may be arranged in an aligned or staggered array of elements or straight portions. Many advantageous profile shapes of the element and vortex generators are provided, including aerodynamic profile shapes that are symmetrical with respect to a fluid flow to provide low drag and pressure drop. Heat in the element may be generated by means of electrical resistance or absorption of radiation.

Owner:MOSKAL DANIEL

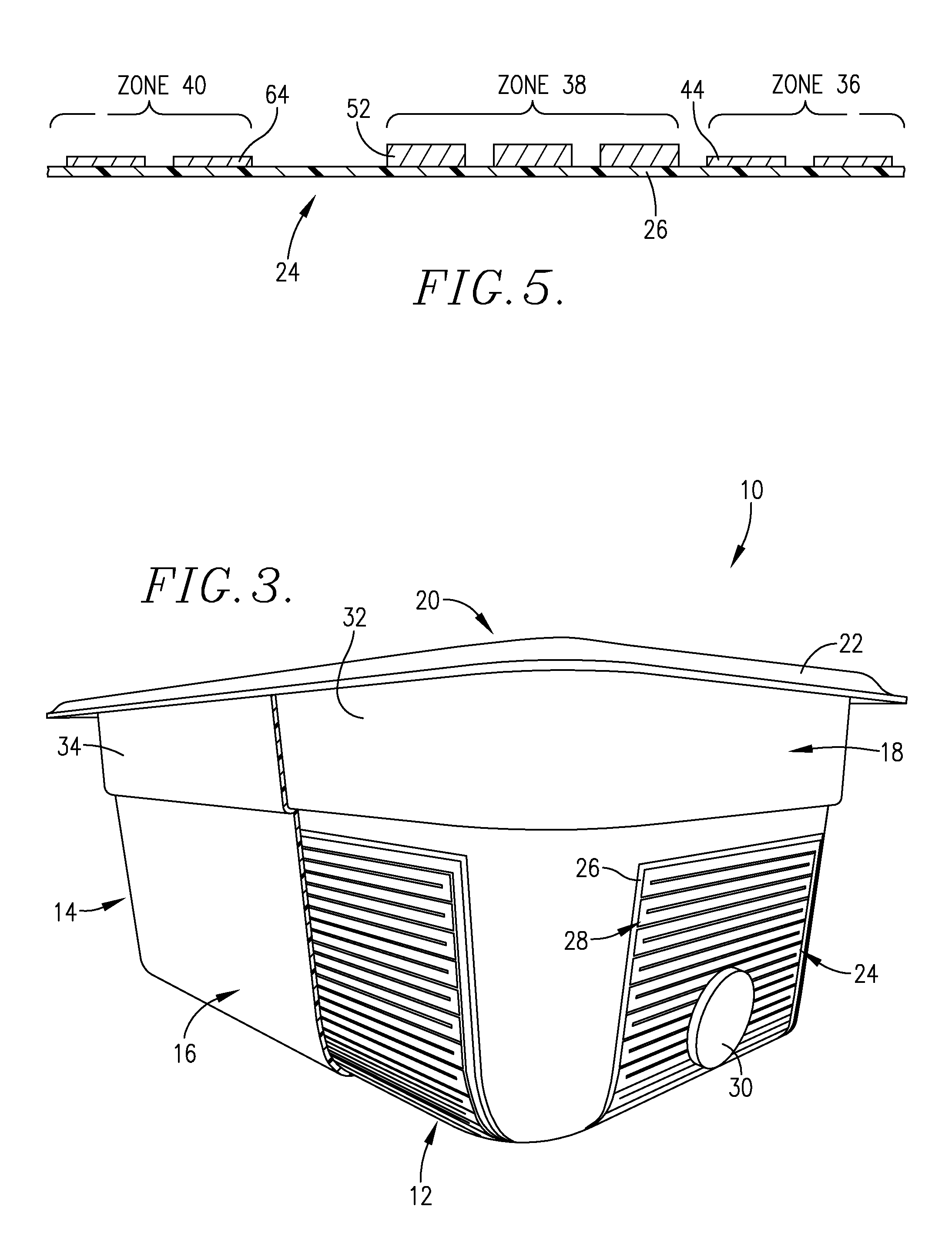

Induction heating system employing induction-heated switched-circuit vessels

An induction heatable article such as a pan is provided having a synthetic resin body with at least one susceptor coil secured to the body and operable under the influence of an induction field to generate Joule heating within the coil to thereby heat the body. The coil has a plurality of zones, each adjacent a different portion of the body and capable of providing respective, different magnitudes of Joule heating-derived energy per unit time in the zones. A multiple-pan, modular food heating / warming table includes a table supporting an array of individually controllable induction heaters with a plurality of synthetic resin, food-holding pans positionable on the table, wherein each pan has a zoned susceptor coil for induction heating of the pans

Owner:TSI TECH

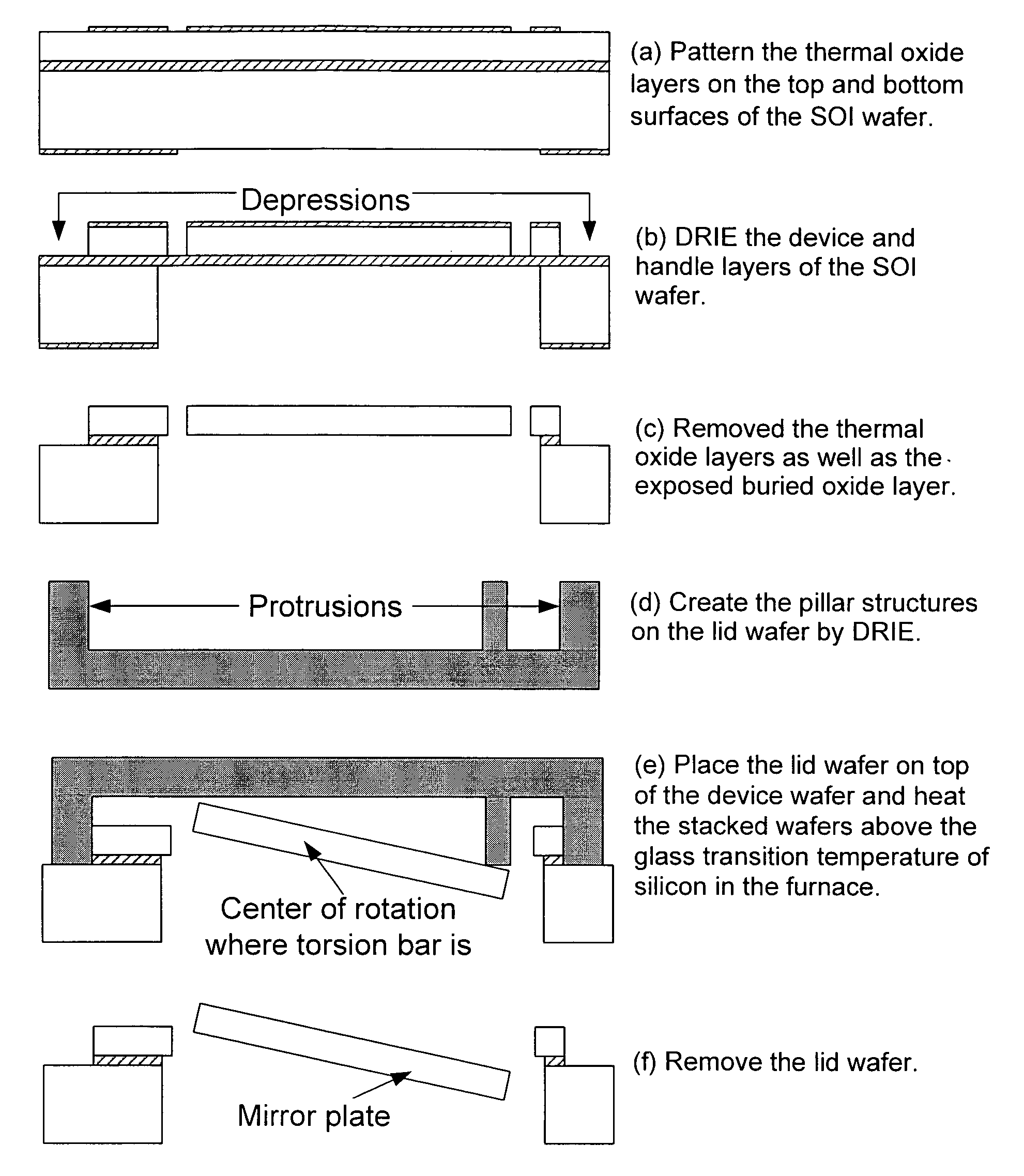

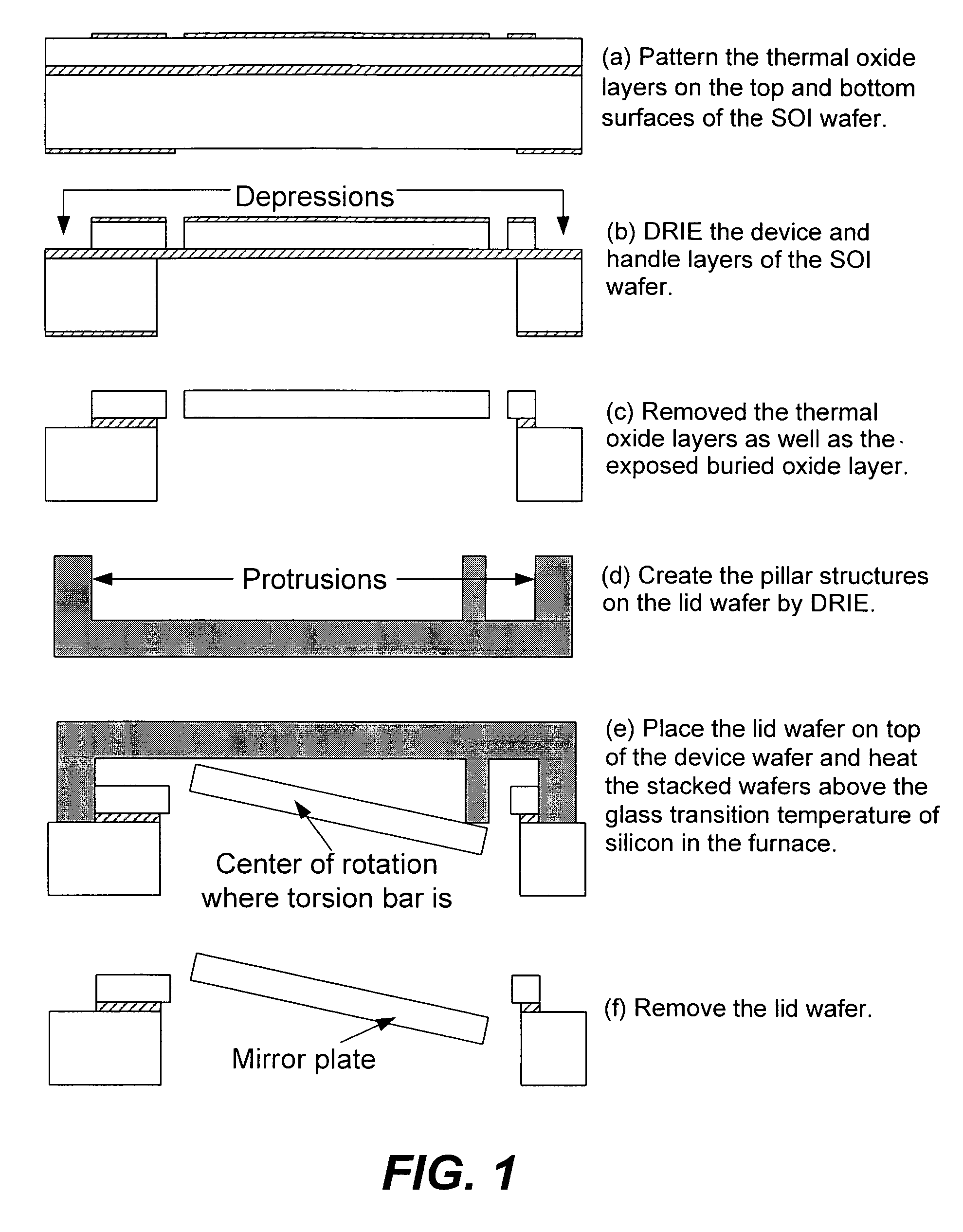

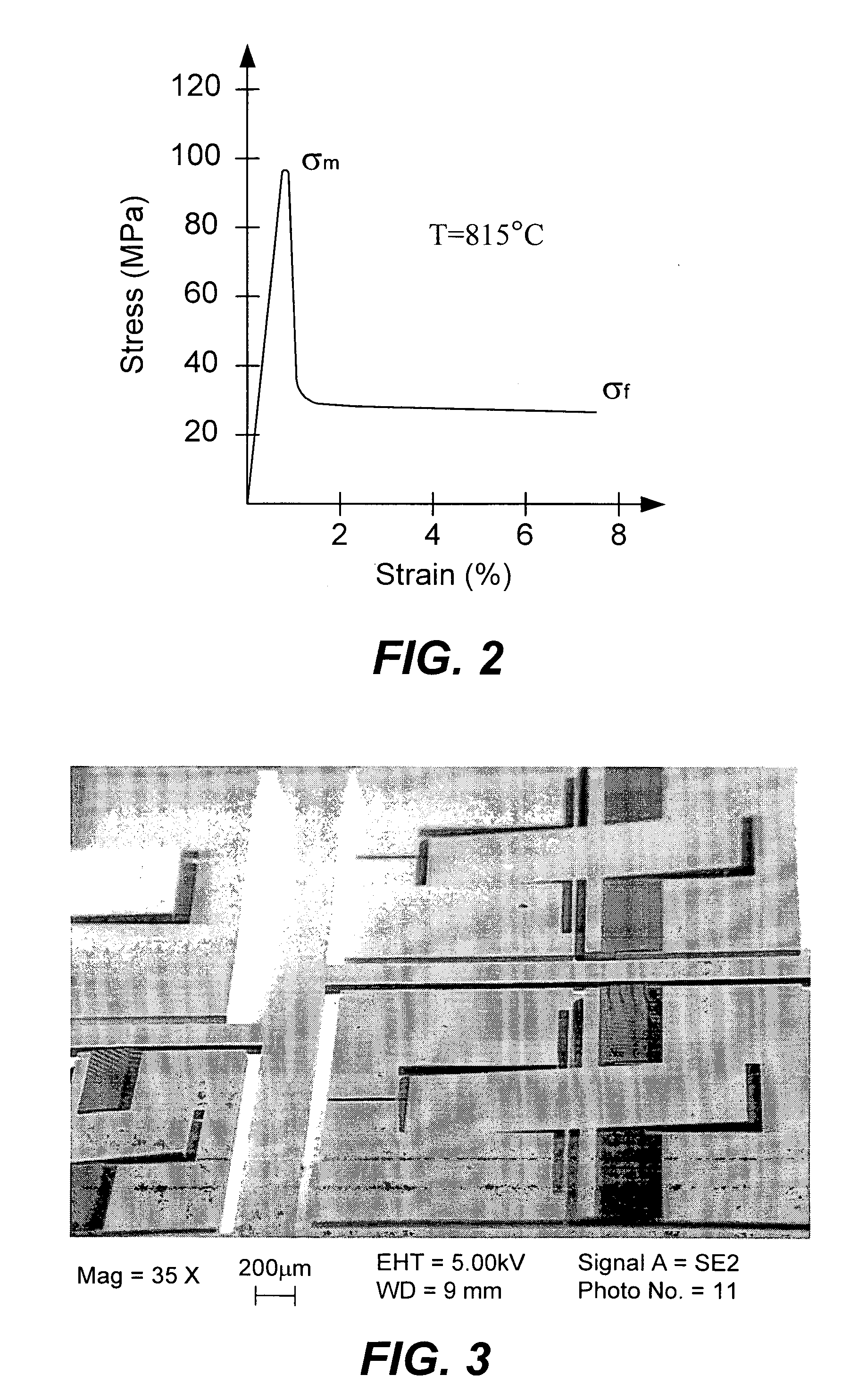

Microfabricated vertical comb actuator using plastic deformation

A microfabricated actuator of the vertical comb-drive (AVC) type or staggered vertical comb-drive type for torsional or linear applications includes torsion springs which permit self-aligned deformation of the device (micromirror) structure of the actuator through the heating of the torsional springs to plasticity. The torsional springs can include perpendicular-beam springs or double folded beams which allow axial movement of the spring when heated. Heating of the springs can be by bulk heating of the actuator structure or by Joule heating to the torsional springs by passing an electrical current therethrough.

Owner:RGT UNIV OF CALIFORNIA

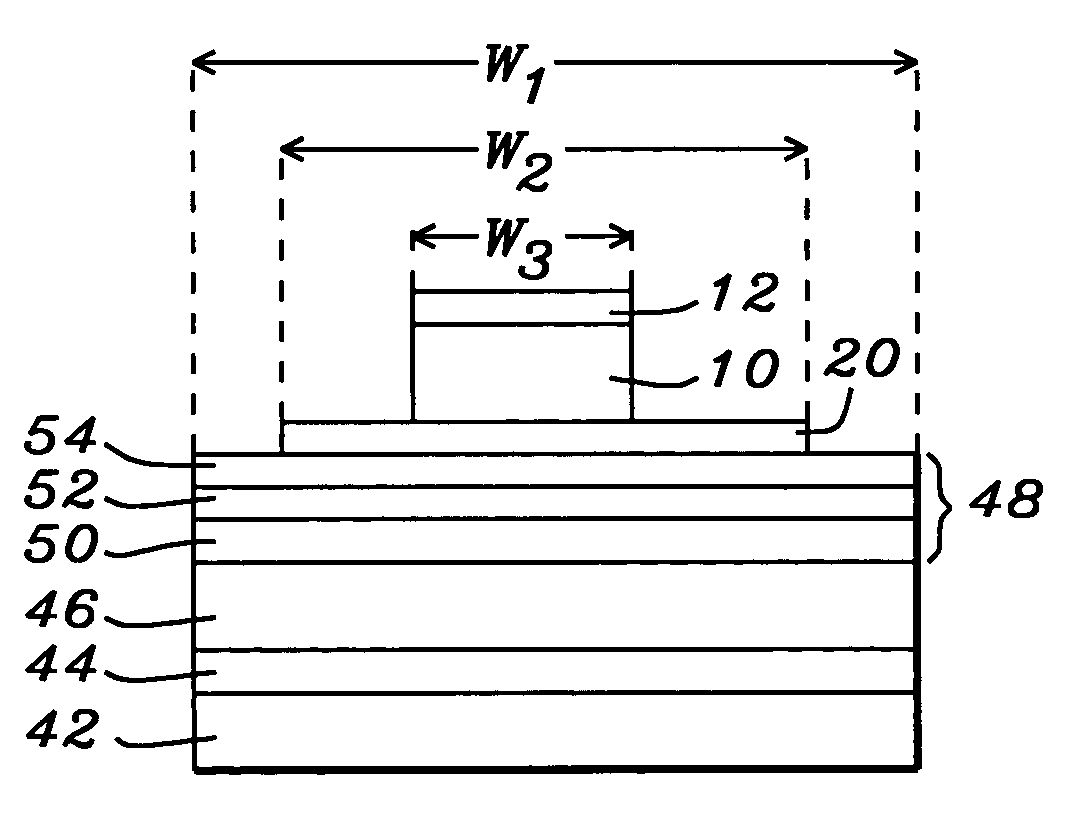

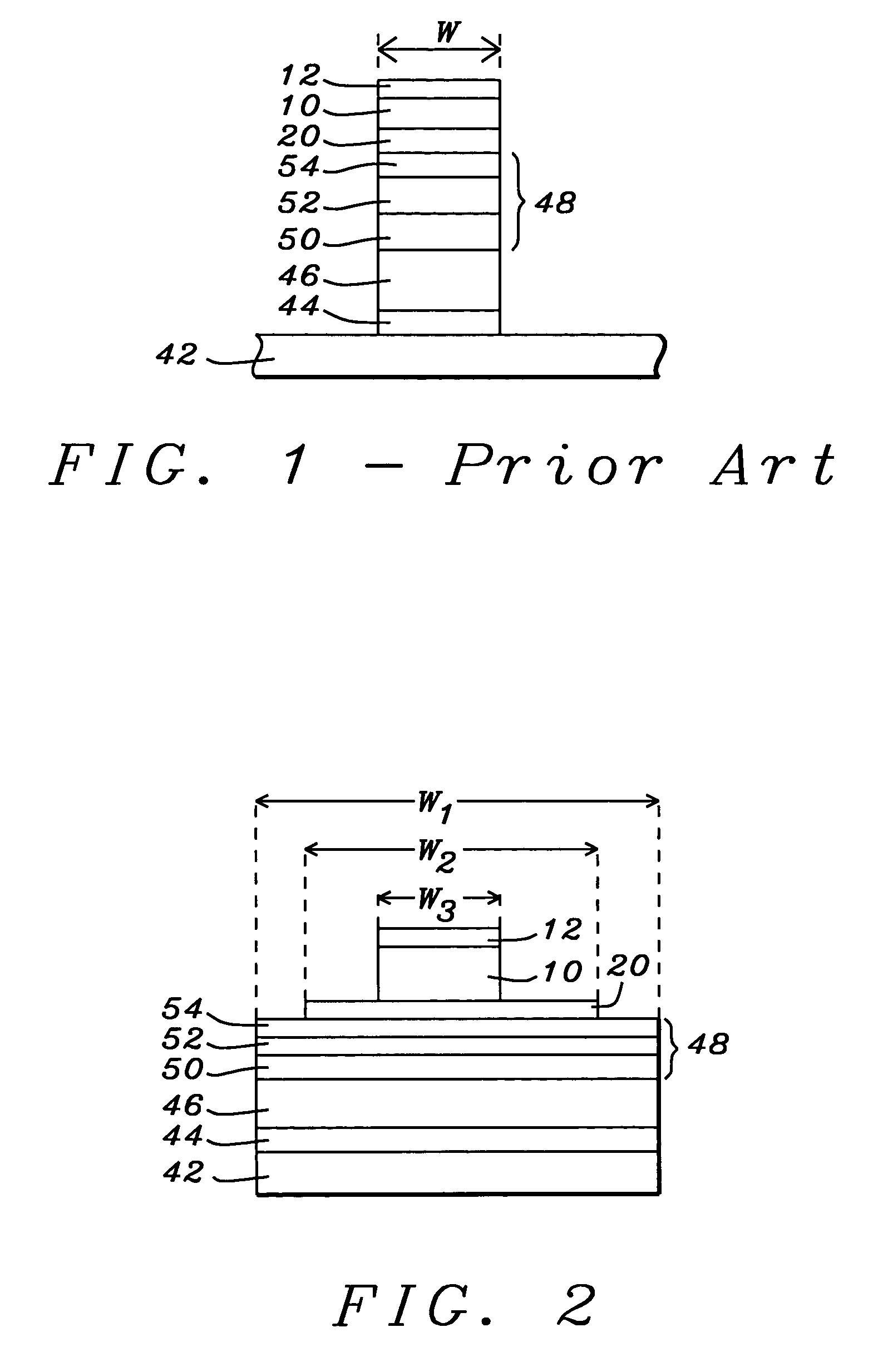

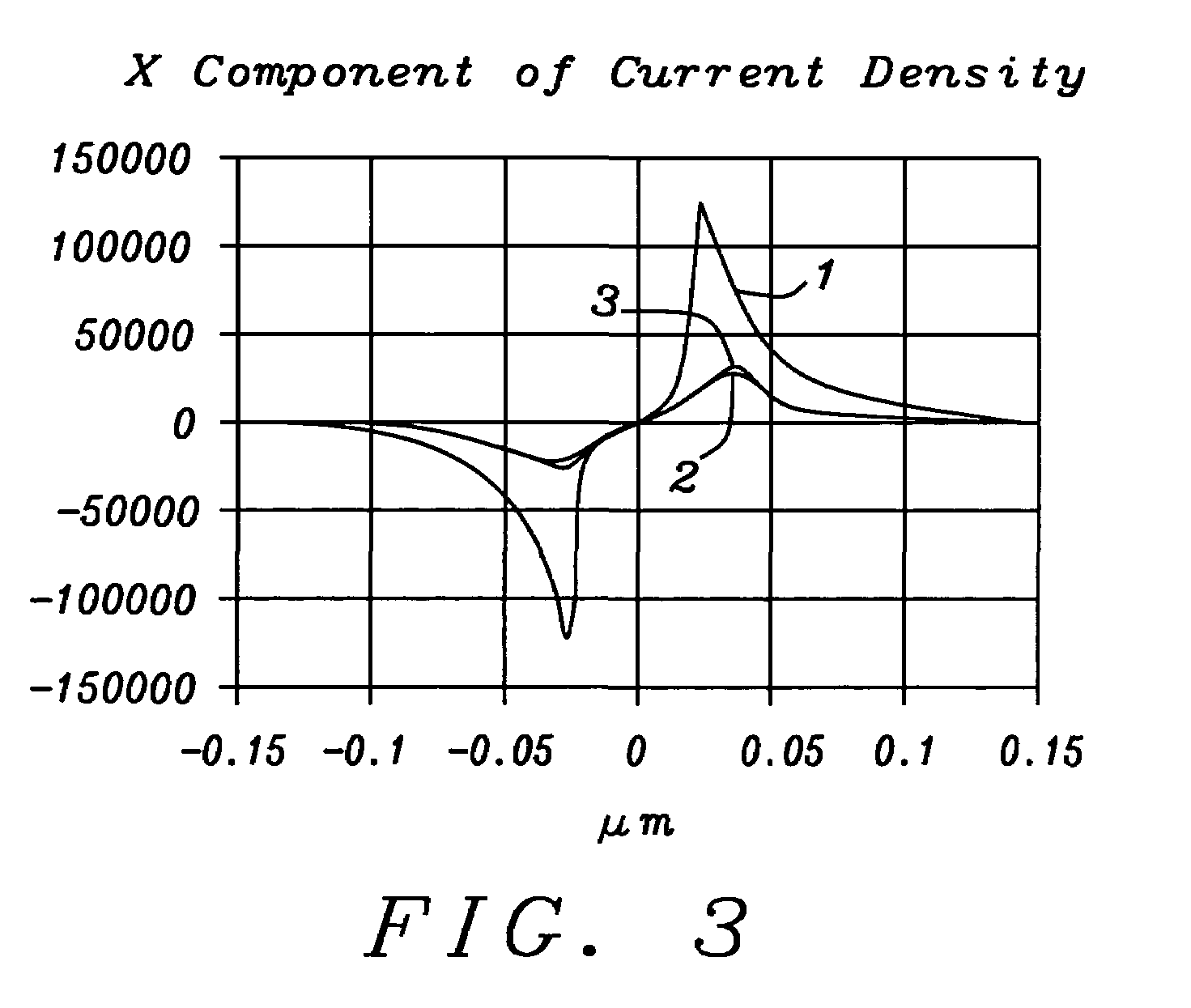

Method of increasing CPP GMR in a spin valve structure

ActiveUS7016168B2Reduce resistanceHigh sensitivityConstruction of head windingsNanomagnetismHigh resistanceSquare cross section

A current-perpendicular-to-plane (CPP) giant magnetoresistive (GMR) sensor of the synthetic spin valve type is provided, the sensor comprising a GMR stack having a substantially square lateral cross-section, a Cu spacer layer of smaller square cross-section formed centrally on the GMR stack and a capped ferromagnetic free layer of substantially square, but even smaller cross-sectional area, formed centrally on the spacer layer. The stepped, reduced area geometry of the sensor provides a significant improvement in its GMR ratio (DR / R), a reduced resistance, R, and elimination of Joule heating hot-spots in regions of high resistance such as the antiferromagnetic pinning layer and its seed layer.

Owner:HEADWAY TECH INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com