High-strength high-toughness AZ91 magnesium alloy strip eletrotoughening process method and system

A technology of AZ91, high strength and high toughness, applied in the field of toughening treatment of magnesium alloy strips, can solve the problems of high production cost, uneven material temperature, easy oxidation of magnesium alloy, etc., and achieve high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

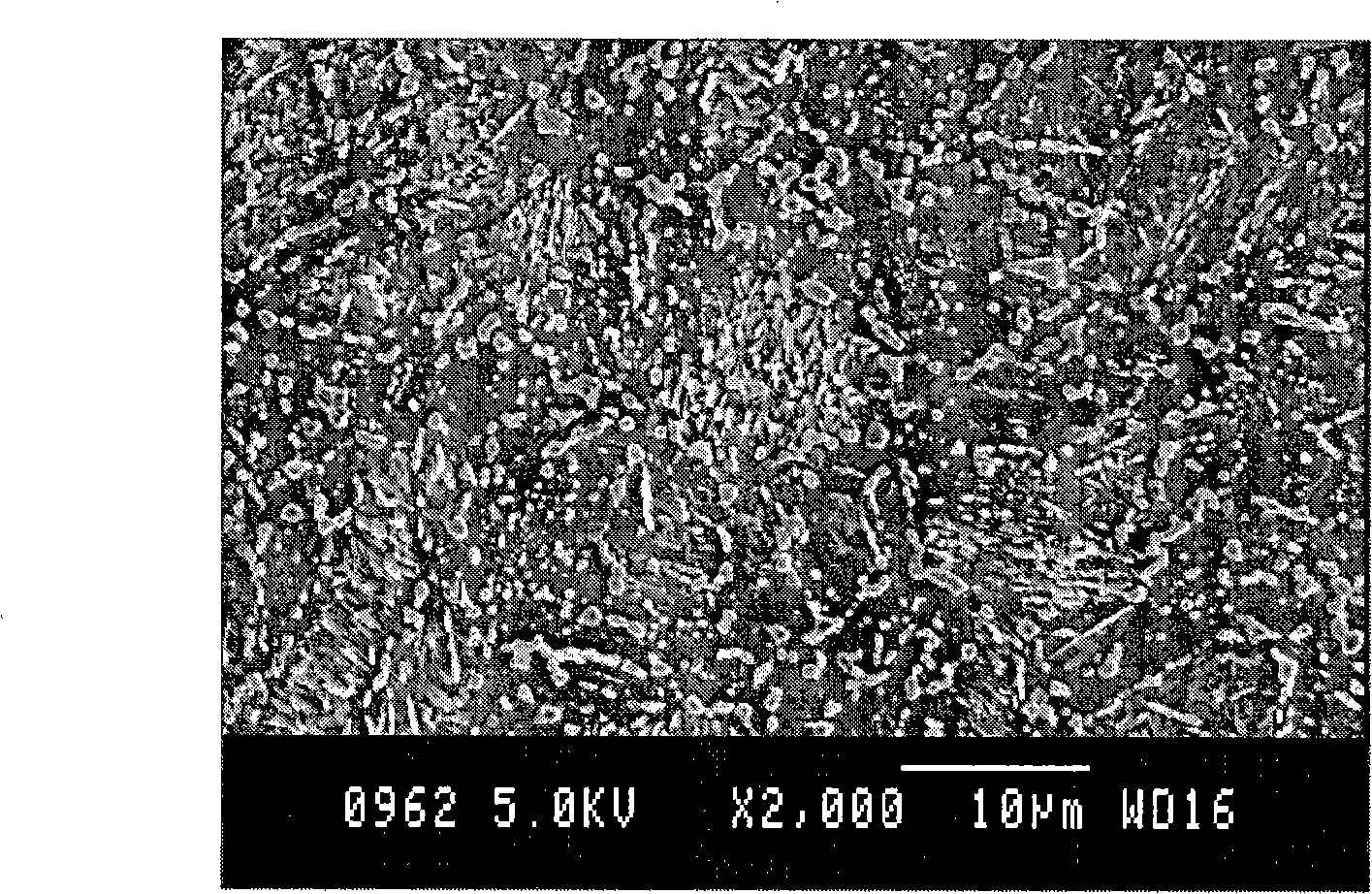

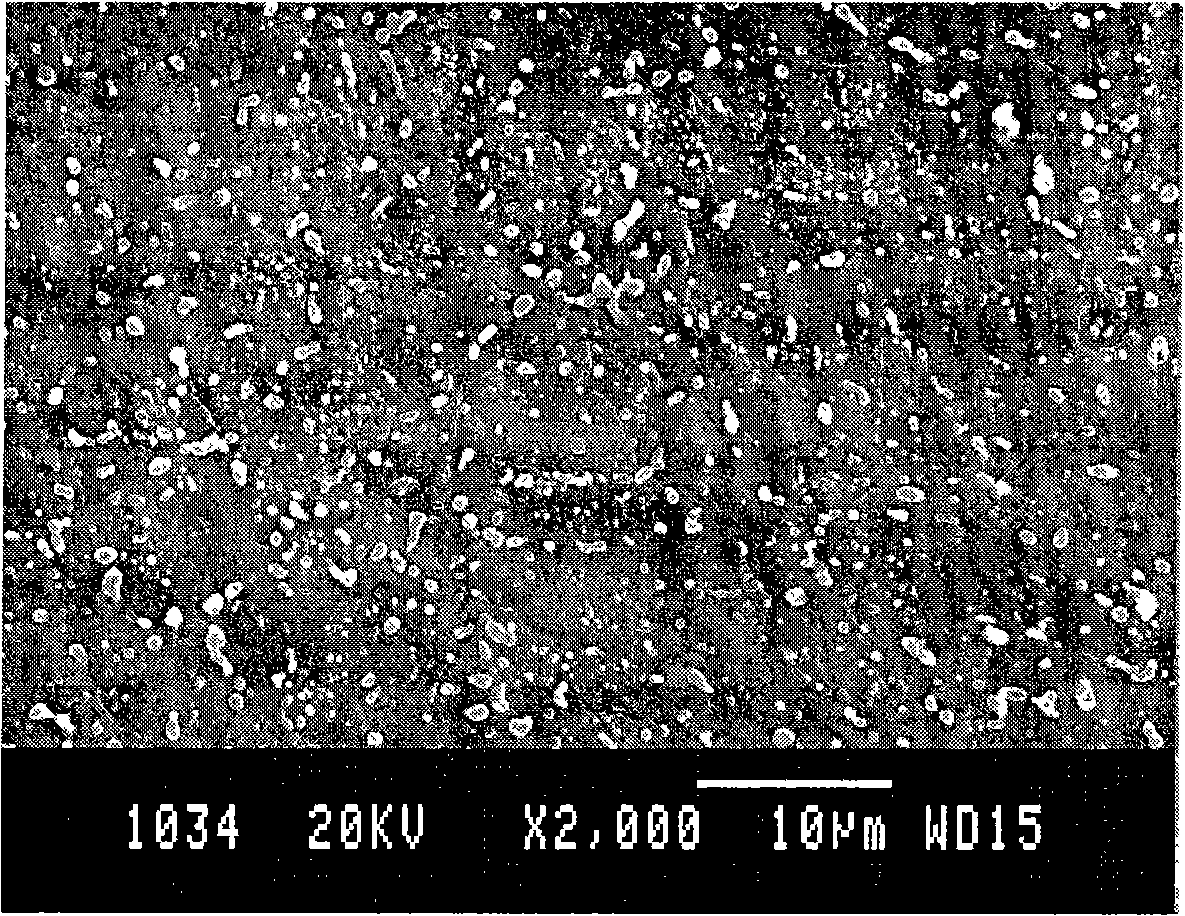

[0040] Embodiment: incoming material is the AZ91 magnesium alloy strip material after suitable deformation through aging, and thickness is 1.0mm, and width is 3.5mm, and the microstructure through aging after this AZ91 magnesium alloy deformation is as follows figure 2 , the magnesium strip was subjected to electro-toughening treatment, and compared with conventional heat treatment.

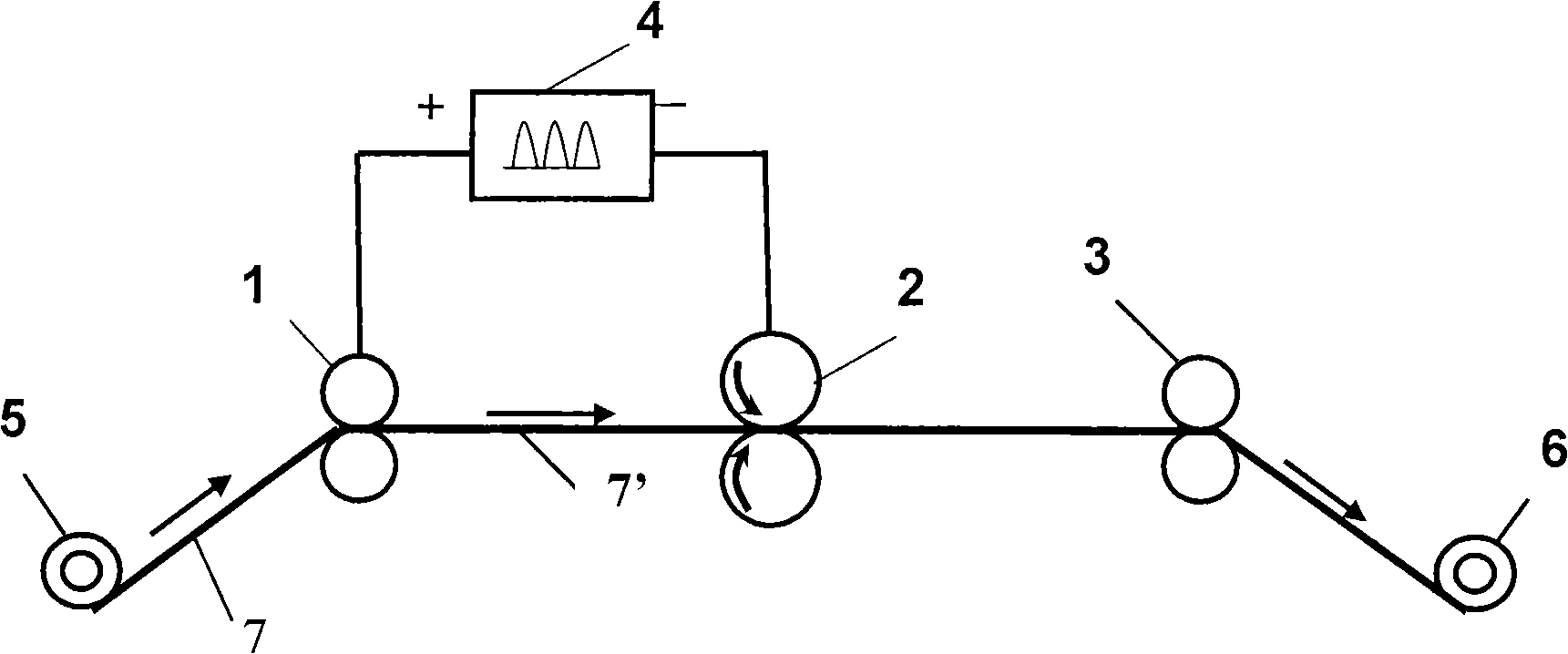

[0041] refer to figure 1 , the continuous AZ91 magnesium alloy strip 7 is controlled by the uncoiling device 5 and the winding device 6 and is driven by the rotating roll 2 at a speed of 4 mpm in the direction shown by the arrow in the figure. The distance between the roll 2 and the strip is only Close elastic contact, the roll does not produce obvious plastic deformation to the magnesium alloy strip, the positive and negative poles of the high-energy pulse power supply 4 are respectively connected to the moving magnesium from the first support roll 1 and roll 2 (the distance between the centers...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com