Patents

Literature

42results about How to "Consistent dryness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process for drying fresh momordica grosvenori

InactiveCN102763846ANot easy to regain moisture and deteriorateReduce lossFood preparationPlant ingredientsCuticleMomordica grosvenori

The invention discloses a process for drying fresh momordica grosvenori, comprising the following steps: (1) selecting and cleaning fresh momordica grosvenori without being damaged on skins, and disposing holes on the top stems and the corresponding bottom areolas of the momordica grosvenori; (2) putting the momordica grosvenori with holes in water of 80-100 DEG C, deactivating, boiling for 30-40 seconds, taking out and draining; and (3) putting the deactivated momordica grosvenori into vacuum microwave drying equipment, drying in vacuum at the frequency of 850-900MH and the low temperature of 40-50 DEG C for 5 minutes, starting an infrared heater to heat the skins of the momordica grosvenori for 10-15minutes, and repeating the step (3) for 4-5 times to obtained the dried momordica grosvenori. The detection shows that the momordica grosvenori dried by adopting the process contains water of 1.5% or less, is light yellow, bright and attractive, retains the nutrients of more than 75%, has high content of momordica grosvenori enzyme, tastes good, has no smell of scorching and is not bitter.

Owner:GUILIN PURUI BIOLOGICAL SCI & TECH DEV

Air-drying method for improving quality of alfalfa

InactiveCN102228132AIncrease flow spaceHigh trafficDrying solid materials with heatAnimal feeding stuffLoss ratePositive interaction

The invention discloses an air-drying method for improving the quality of alfalfa. The method comprises the following steps of: 1) ridging; 2) selecting materials and treating; and 3) air-drying. The method has the advantages that: 1, the ridging increases the air flow space on the bottom of a grass layer; 2, the fracture of stalks accelerates the evaporation rate of the moisture in the stalks, so that the drying time is shortened; 3, the combination of field ridging and fracturing and air-drying of the stalks has a positive interaction effect on the loss of the moisture of fresh alfalfa forage; 4, the loss rate of the moisture of the fresh alfalfa forage is remarkably and negatively correlative with the residual amount of crude proteins in green hay; 5, the aims of accelerating the drying of the alfalfa, uniformly drying and improving the quality of the green hay are fulfilled; and 6, operation steps are simple and easy, the drying cost is low, and the efficiency is high.

Owner:GANSU AGRI UNIV

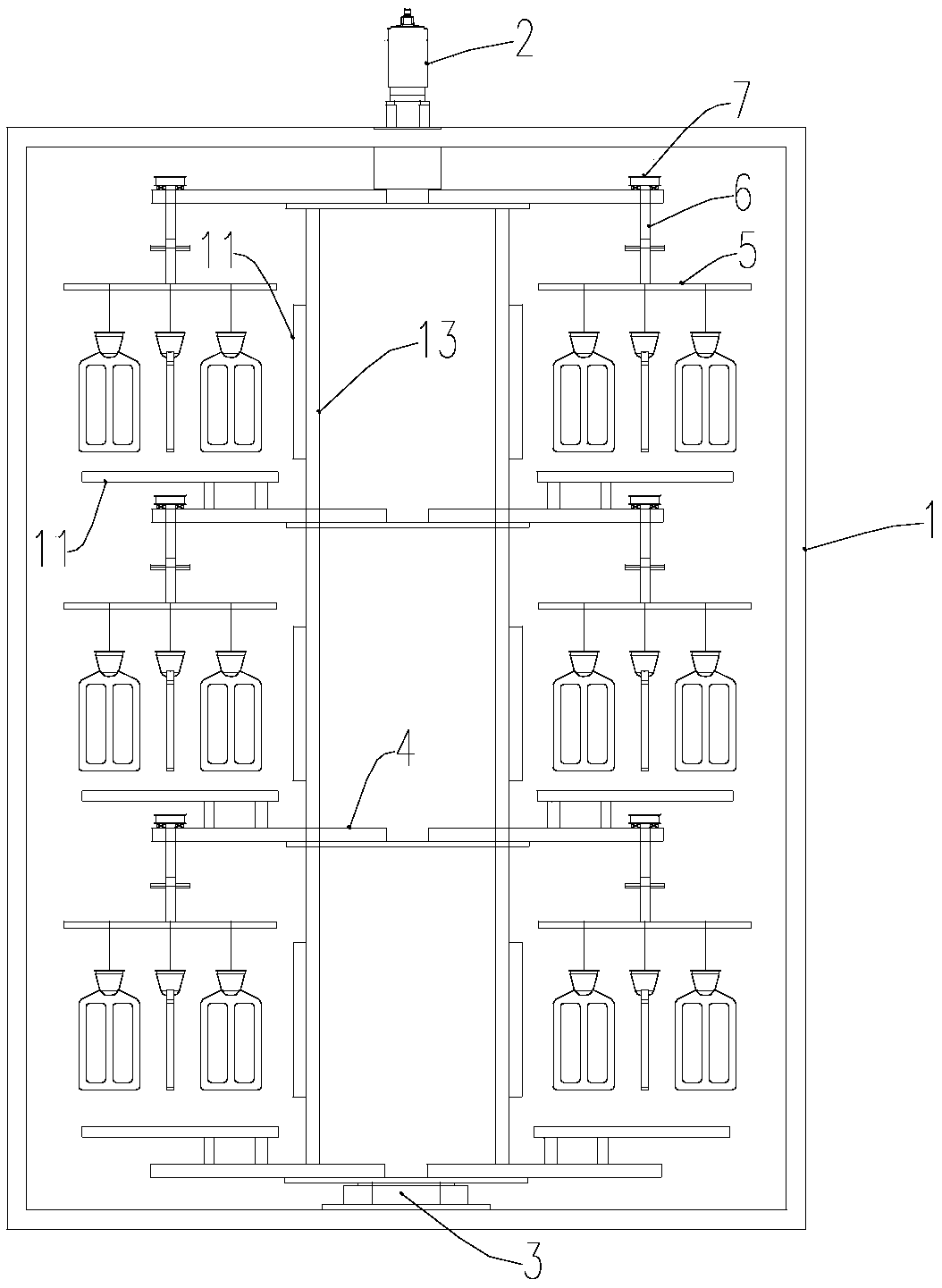

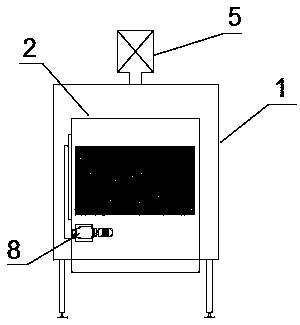

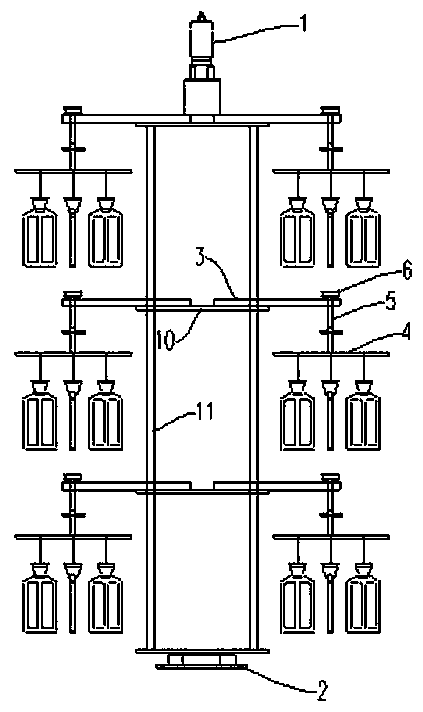

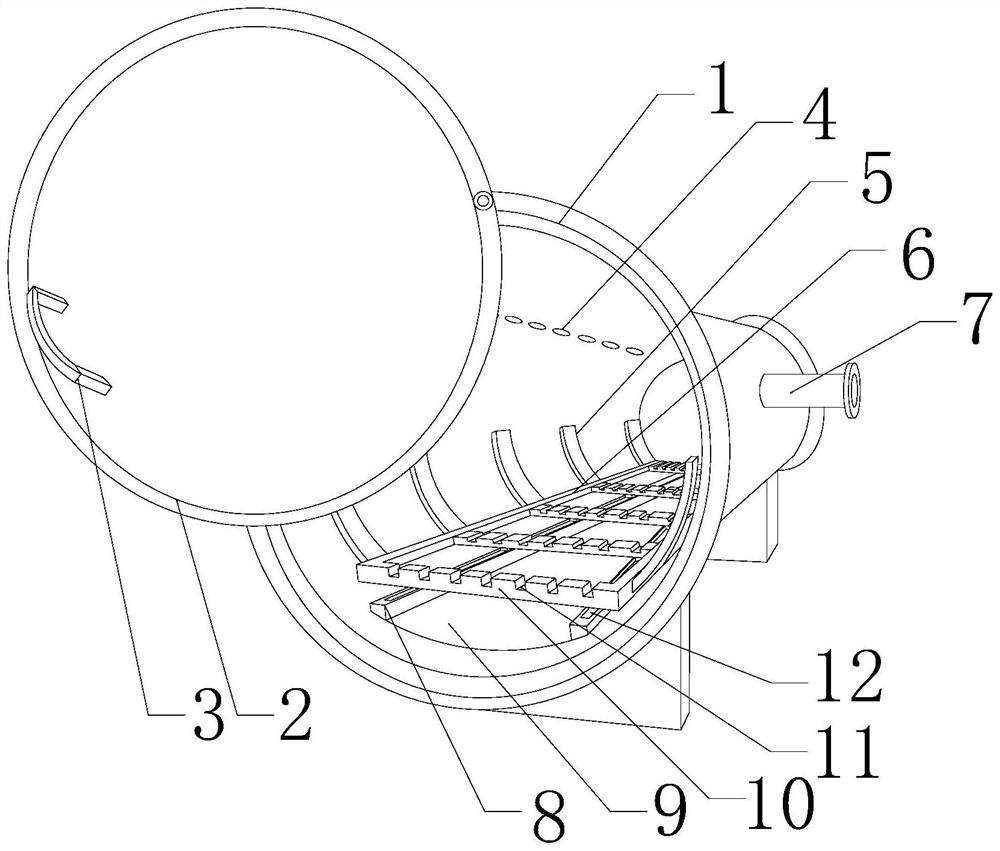

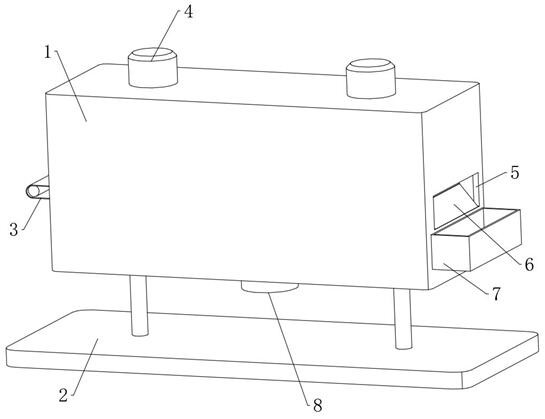

Intelligent adjustable formwork drying box suitable for intelligent robot formwork manufacturing line

PendingCN109341292AIncrease or decrease the dehumidification effectEnhance or reduce thermal radiation powerDrying gas arrangementsDrying machines with non-progressive movementsDrive motorThermal radiation

The invention relates to an intelligent adjustable formwork drying box suitable for an intelligent robot formwork manufacturing line. The intelligent adjustable formwork drying box comprises a box body, a revolution mechanism and a rotation mechanism, and the revolution mechanism and the rotation mechanism are located in the box body. The rotation mechanism comprises a plurality of rotation units,and a plurality of formworks to be dried can be suspended on each rotation unit. The revolution mechanism comprises a first drive motor fixed to the top of the box body, and when the revolution mechanism revolves, the rotation units can be driven to rotate. A plurality of thermal radiation air supply assemblies are fixed to the revolution mechanism. The side portion and the bottom of each rotation unit are each provided with a thermal radiation air supply assembly correspondingly. Each thermal radiation air supply assembly comprises an electric heat regulator and a blast regulator. The firstdrive motor, the electric heat regulators and the blast regulators are all electrically connected with a PLC. The intelligent adjustable formwork drying box has the advantages that on the one hand, itis ensured that the formworks in the box are dried uniformly, on the other hand, personalized selection and program control of drying conditions of the formworks at the different rotation units in the box can also be achieved, the flexibility is good, and the degree of automation is high.

Owner:WUHAN ZONKING METAL PRODS

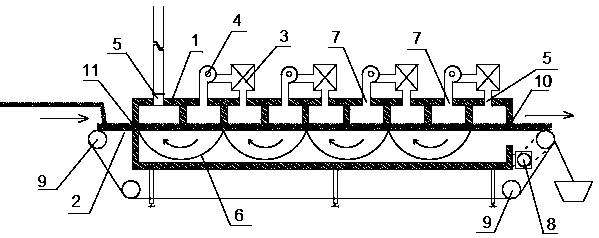

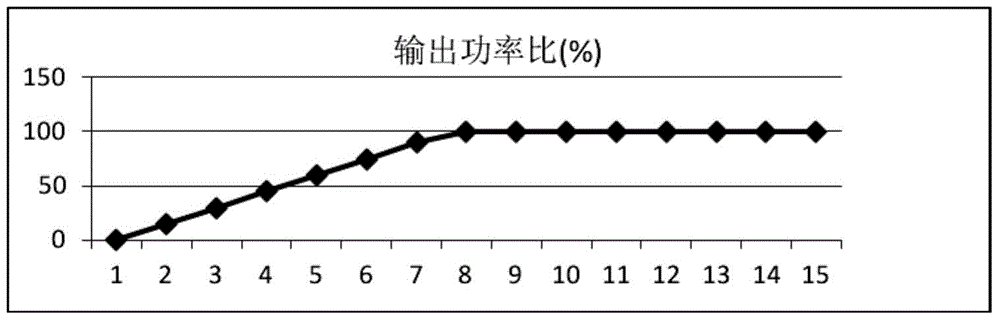

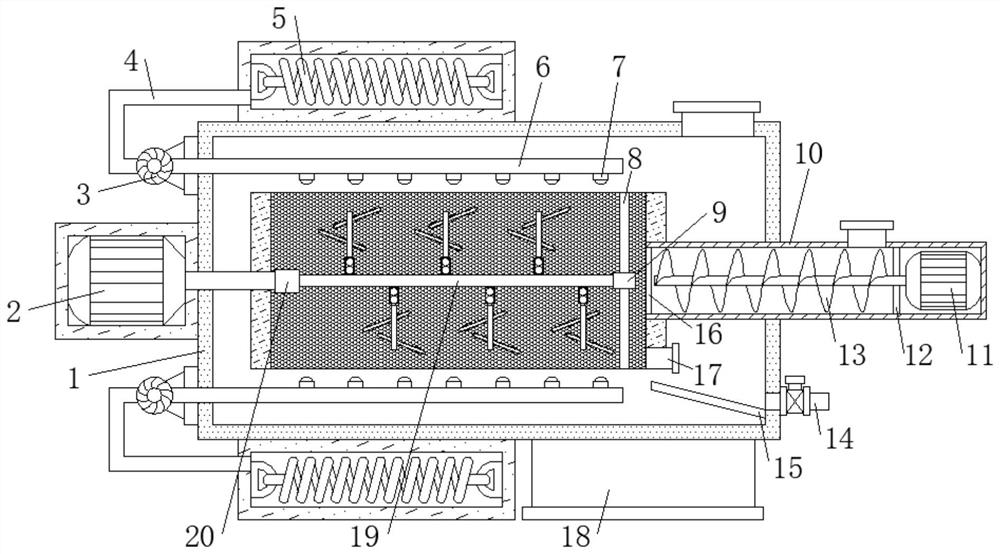

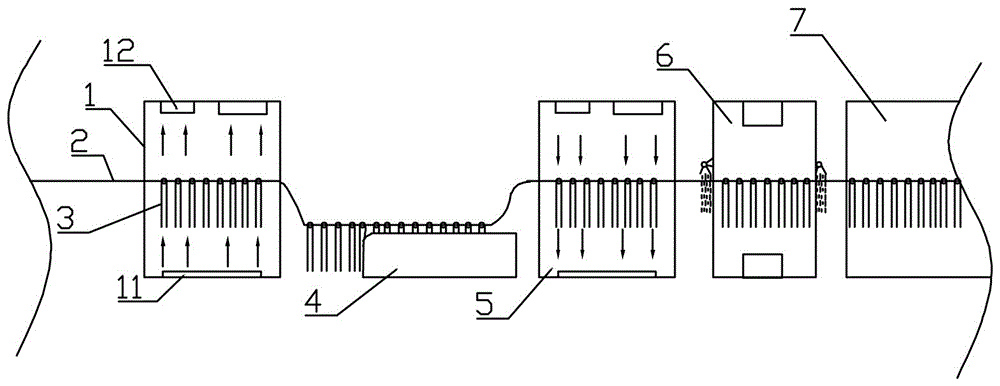

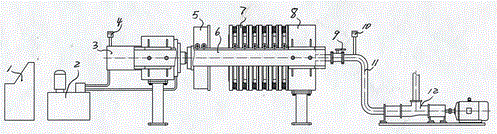

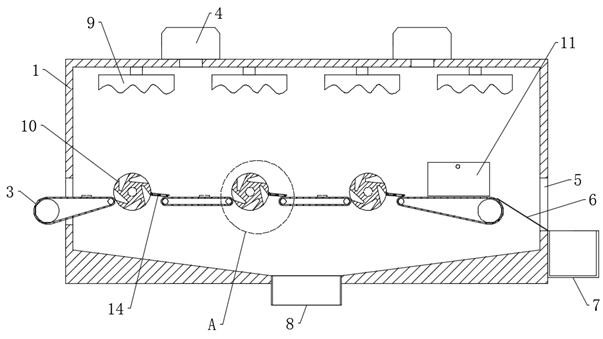

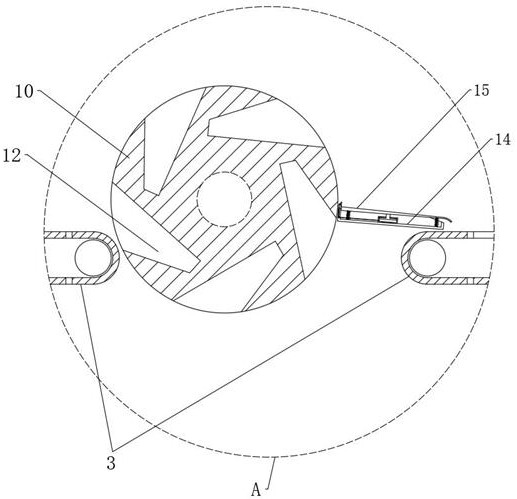

Drying method and equipment capable of realizing concentrated dehumidification, vertical alternate air-blowing and hot air recycling

PendingCN108050816AImprove drying effectConsistent drynessDrying solid materials with heatDrying gas arrangementsProcess engineering

The invention discloses a drying method capable of realizing concentrated dehumidification, vertical alternate air-blowing and hot air recycling. Dry hot air passes through a final cavity at a discharge port to heat and dry products, then passes through adjacent cavities sequentially to perform the same heating and drying process and finally is discharged to the outside of a workshop through a first cavity at a feeding port, and concentrated dehumidification and complete recycling of hot air are realized. The invention further provides drying equipment capable of realizing concentrated dehumidification, vertical alternate air-blowing and hot air recycling. The drying equipment comprises a casing, wherein the multiple sequentially adjacent cavities are formed in the casing, and the number of the cavities is odd. According to the method and the equipment, concentrated dehumidification and vertical alternate air-blowing can be realized, hot air is collected continuously, all hot air is recovered, product drying effect is good, drying cost is low, and drying efficiency is greatly improved.

Owner:张培森

Ultrahigh-voltage oilpaper capacitive bushing capacitor core drying method

ActiveCN104795254AEfficient removalLow dielectric lossDrying/impregnating machinesCapacitanceHeating time

Owner:沈阳和新套管有限公司

Fruit dehydrator with energy-saving rotating function

InactiveCN108362102AIncrease profitAdjustable tilt angleDrying gas arrangementsDrying machines with non-progressive movementsEngineeringEnergy source

The invention discloses a fruit dehydrator with an energy-saving rotating function. The fruit dehydrator with the energy-saving rotating function comprises a drying box, a rotating shaft is arranged in the middle of the bottom of the drying box, a first cavity is formed in the rotating shaft, and the rotating shaft extends upwards into the drying box. The rotating shaft is connected to a pluralityof material disks, second cavities are formed in the middle of the material disks, and the first cavity communicates with the second cavities. Multiple air holes are evenly formed in the upper surfaces of the material disks, and the outer ends of the material disks are connected with baffle blocks. Multiple disturbance rods are fixedly arranged on the left side of the drying box, and the disturbance rods are provided with multiple disturbance protrusions. An air collector and a solar panel are used for effectively using solar energy without consuming other energy sources, the disturbance rodsare arranged inside to turn over larger fruit, and the drying of the larger fruit is move even; hot air can be discharged from the air holes evenly formed in the material disks, the degree of the drying of the fruit remains the same, and the control over the drying process is facilitated.

Owner:胡冬冬

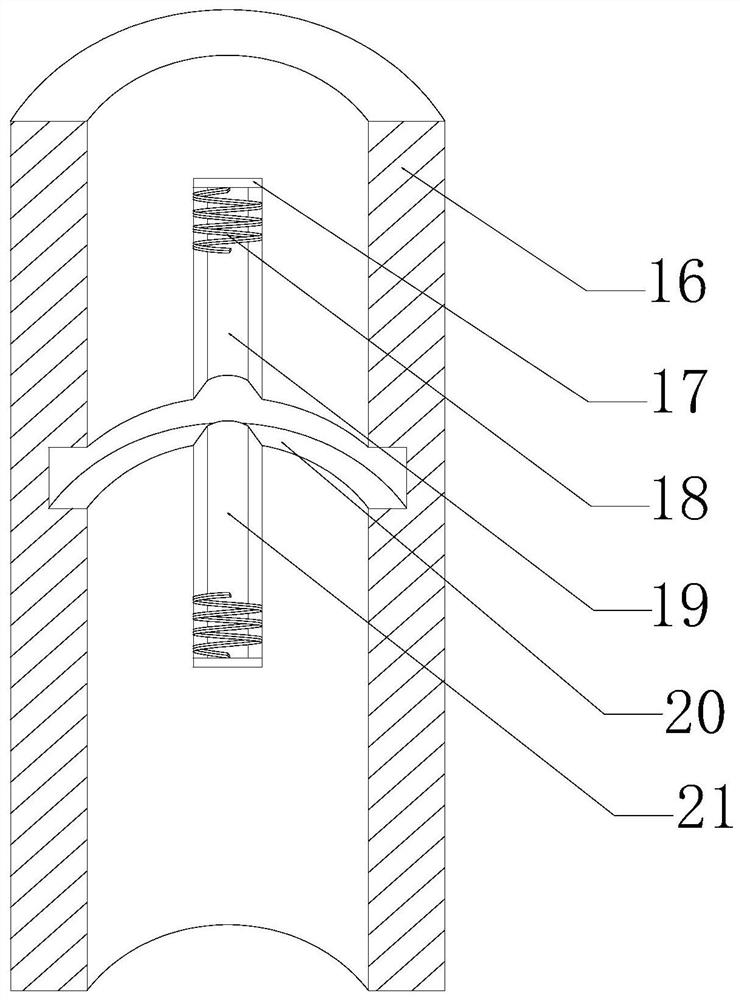

Circumfluent cooling dehumidifying barn

InactiveCN102626019AGuaranteed circulationSolve the problem of ventilation dead angleAgriculture tools and machinesClimate change adaptationThermodynamicsEngineering

The invention relates to a circumfluent cooling dehumidifying barn mainly solving the technical problems in the prior art that ventilation is not thorough and dead corner exists in the ventilation. The circumfluent cooling dehumidifying barn comprises a barn main body and a barn frame; the barn main body comprises a barn top cover and a cabin body; a cabin body grain outlet is arranged on the bottom part of the cabin body, and a grain outlet sealing plate is arranged on the cabin body grain outlet; a temperature-humidity probe is arranged on the inner wall of the cabin body; and the circumfluent cooling dehumidifying barn is characterized in that a spiral ventilation pipeline which is screwed upwards along the central line of the cabin body is arranged on the inner wall of the cabin body; a plurality of through holes are arranged on the wall of the spiral ventilation pipeline; the bottom end of the spiral ventilation pipeline is communicated with one end of a blowing pipeline which is arranged outside the cabin body on the bottom part of the cabin body; the other end of the blowing pipeline is communicated with an air outlet side of a blowing fan; an air outlet is arranged on the top part of the cabin body, and the air outlet is communicated with one end of an air outlet pipe which is arranged outside the cabin body; and the other end of the air outlet pipe is communicated with an air return pipe through a pipeline air outlet changeover switch, and the air return pipe is communicated to the air inlet side of the blowing fan.

Owner:INST OF AGRO FOOD SCI & TECH SHANDONG ACAD OF AGRI SCI

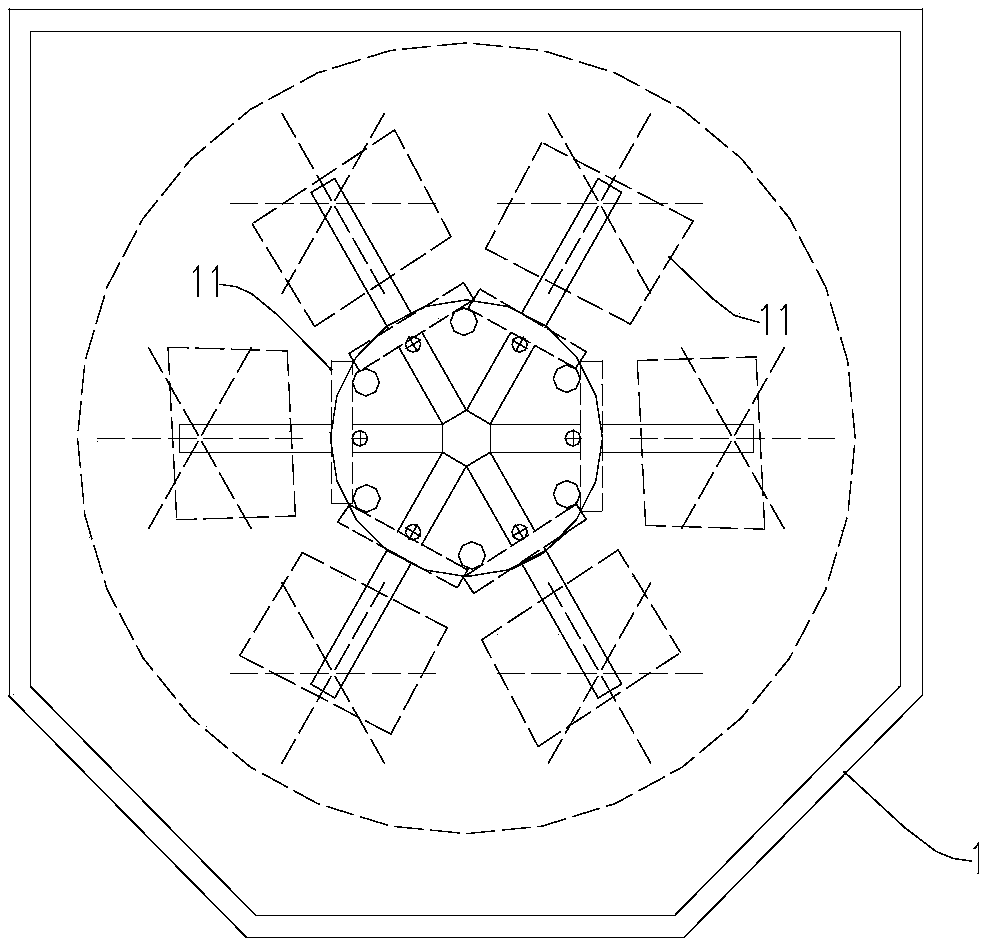

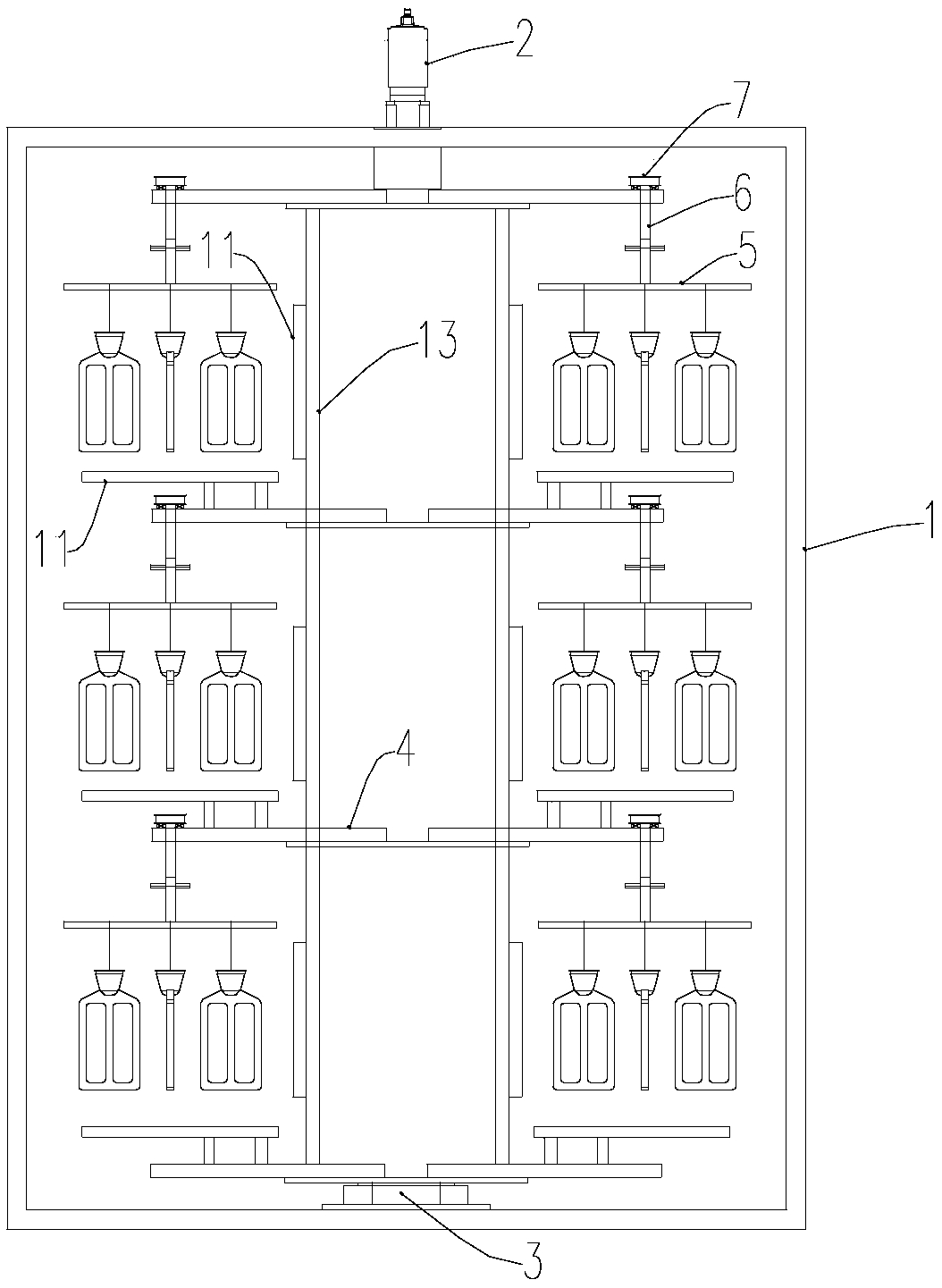

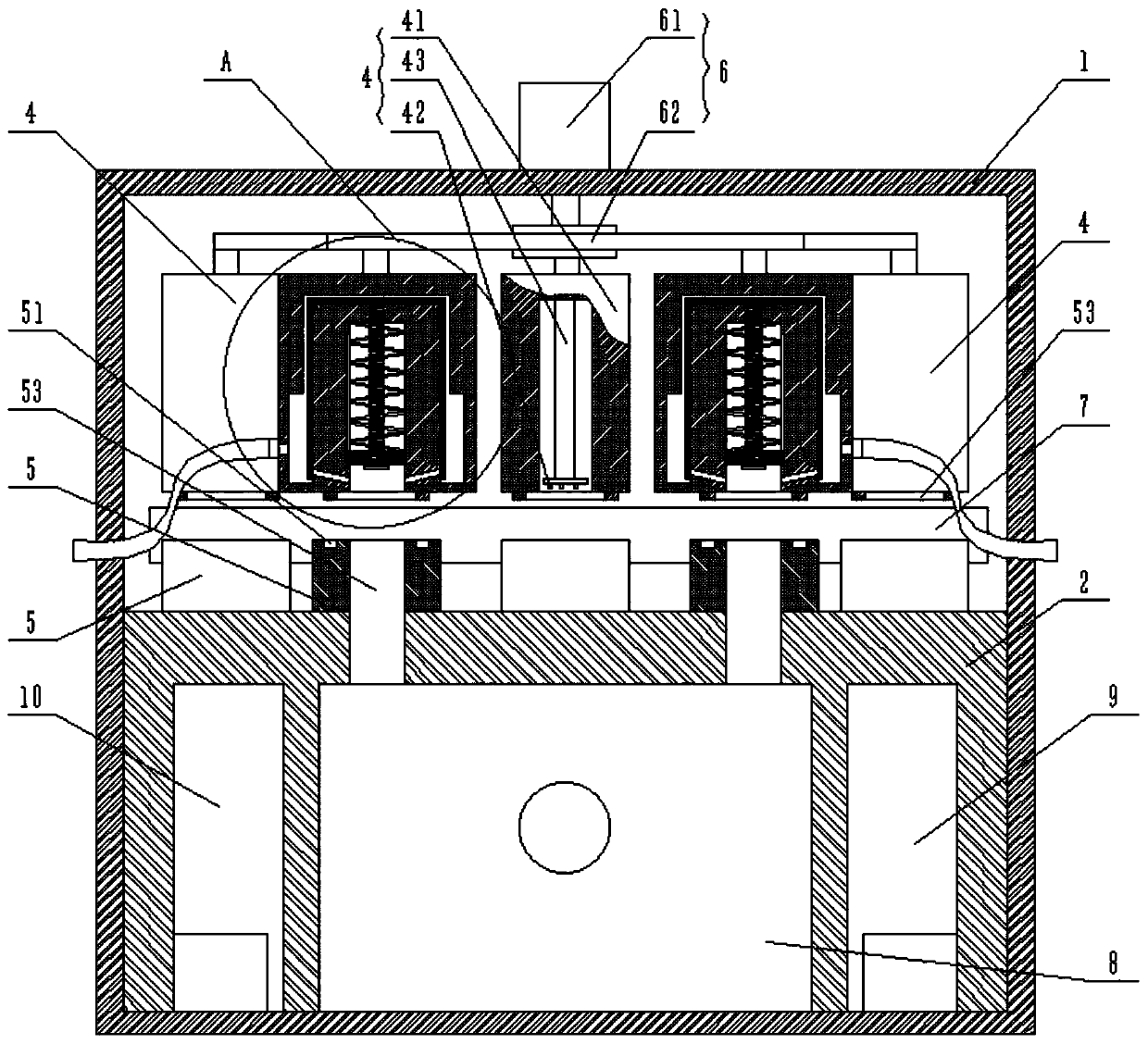

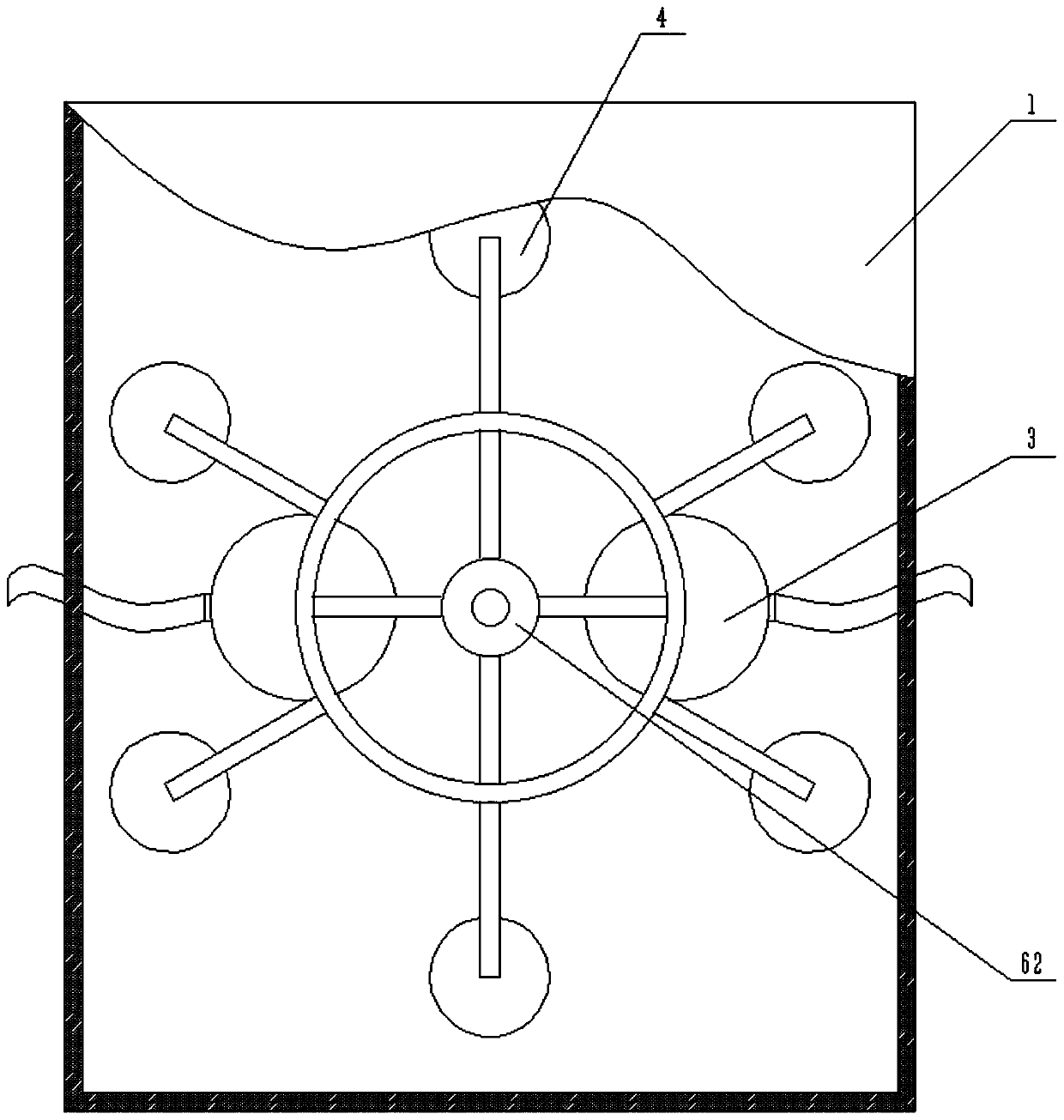

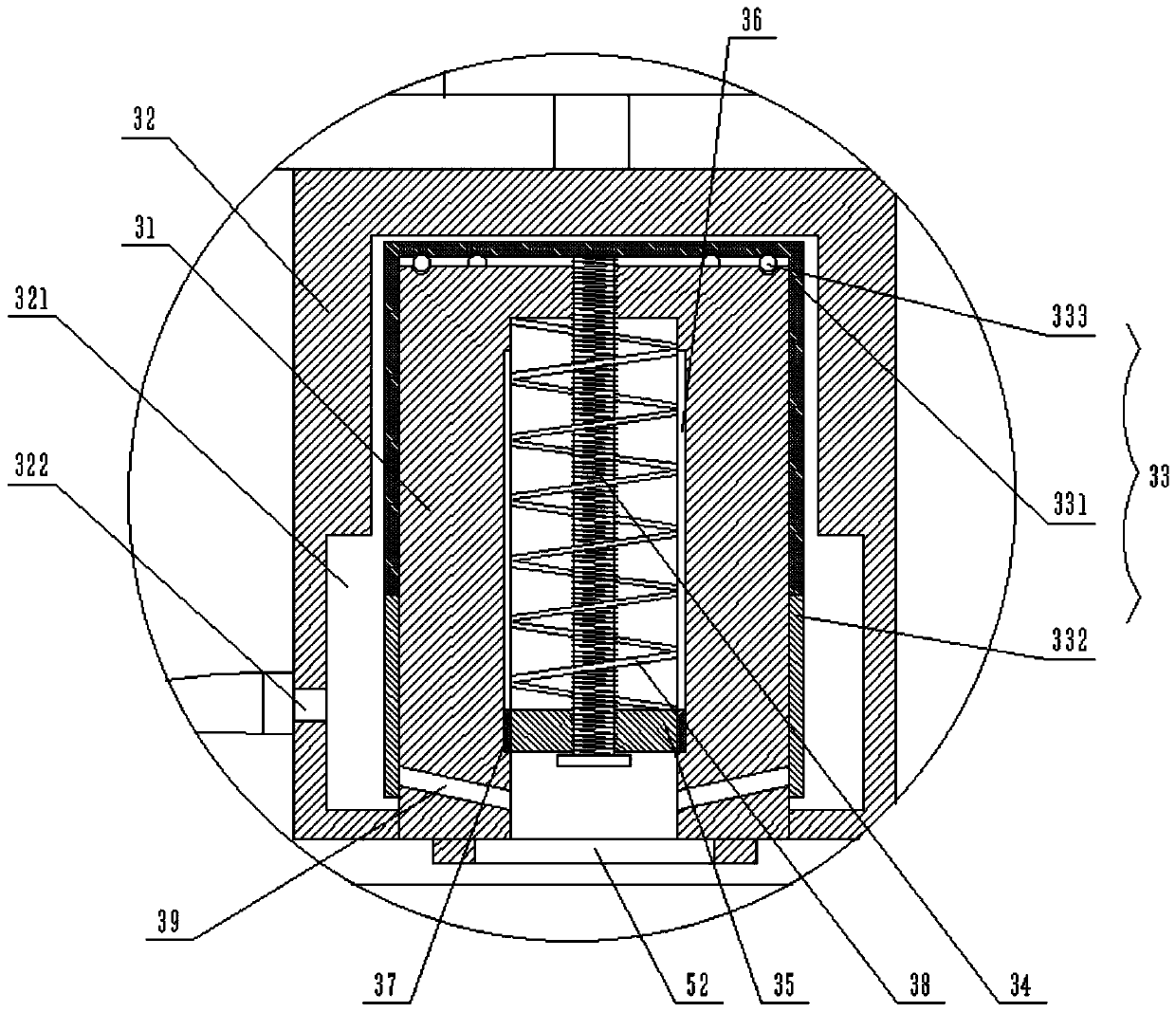

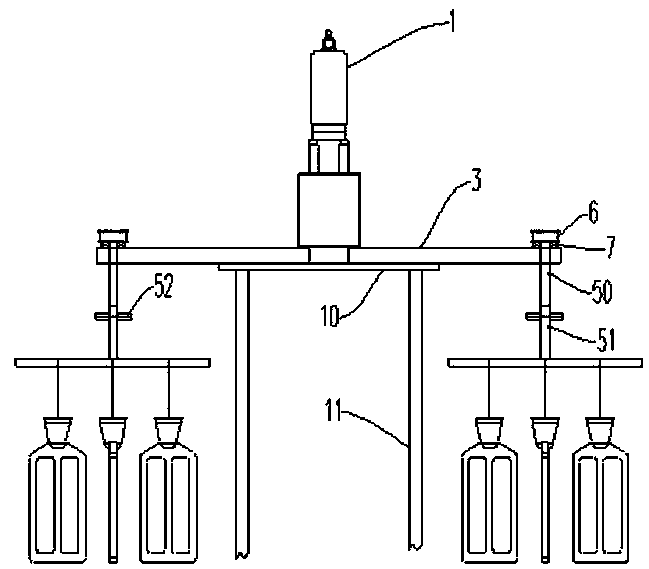

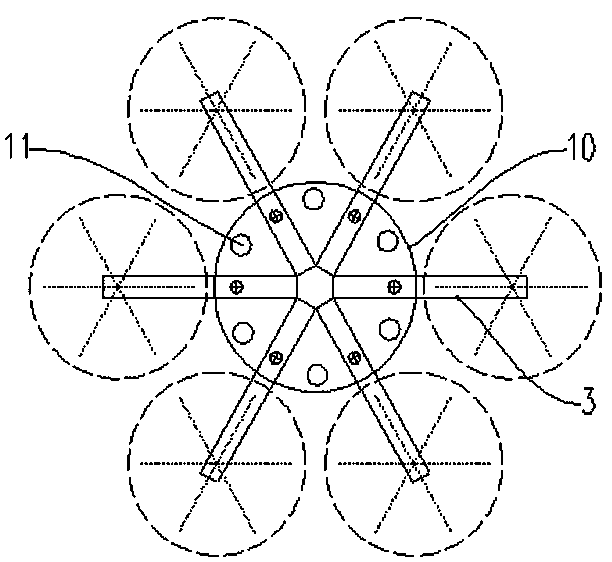

Formwork drying box with autorotation and revolution functions

PendingCN108855820AImprove qualityIncrease productivityPretreated surfacesCoatingsElectric machineryEngineering

The invention relates to a formwork drying box with autorotation and revolution functions. The formwork drying box comprises a box body, a drying mechanism, a revolution mechanism and an autorotationmechanism, the drying mechanism, the revolution mechanism and the autorotation mechanism are positioned in the box body, the autorotation mechanism comprises multiple autorotation units, the revolution mechanism comprises a first driving motor, a spindle and rotating support, a plurality of beam frames are vertically fixed on the spindle, each beam frame is composed of multiple cross beams, one end of each cross beam is correspondingly connected with an autorotation unit, each autorotation unit comprises a disc, a rotating shaft and multiple horizontal connecting rods, the upper end of each rotating shaft is fixedly connected with the center of a synchronous belt wheel after penetrating a through hole formed in one end of the cross beam, and multiple synchronous belt wheels are in transmission connection with a synchronous belt; the drying mechanism comprises multiple drying units fixed on the inner wall of the box or / and on the revolution mechanism. The formwork drying box has the advantages that the drying box can realize autorotation and revolution of multiple to-be-dried formworks during drying in the drying box in one time, and unfavorable impact of nonuniform temperature in the drying box and fixed wind direction during air blowing on formwork drying can be effectively eliminated.

Owner:WUHAN ZONKING METAL PRODS

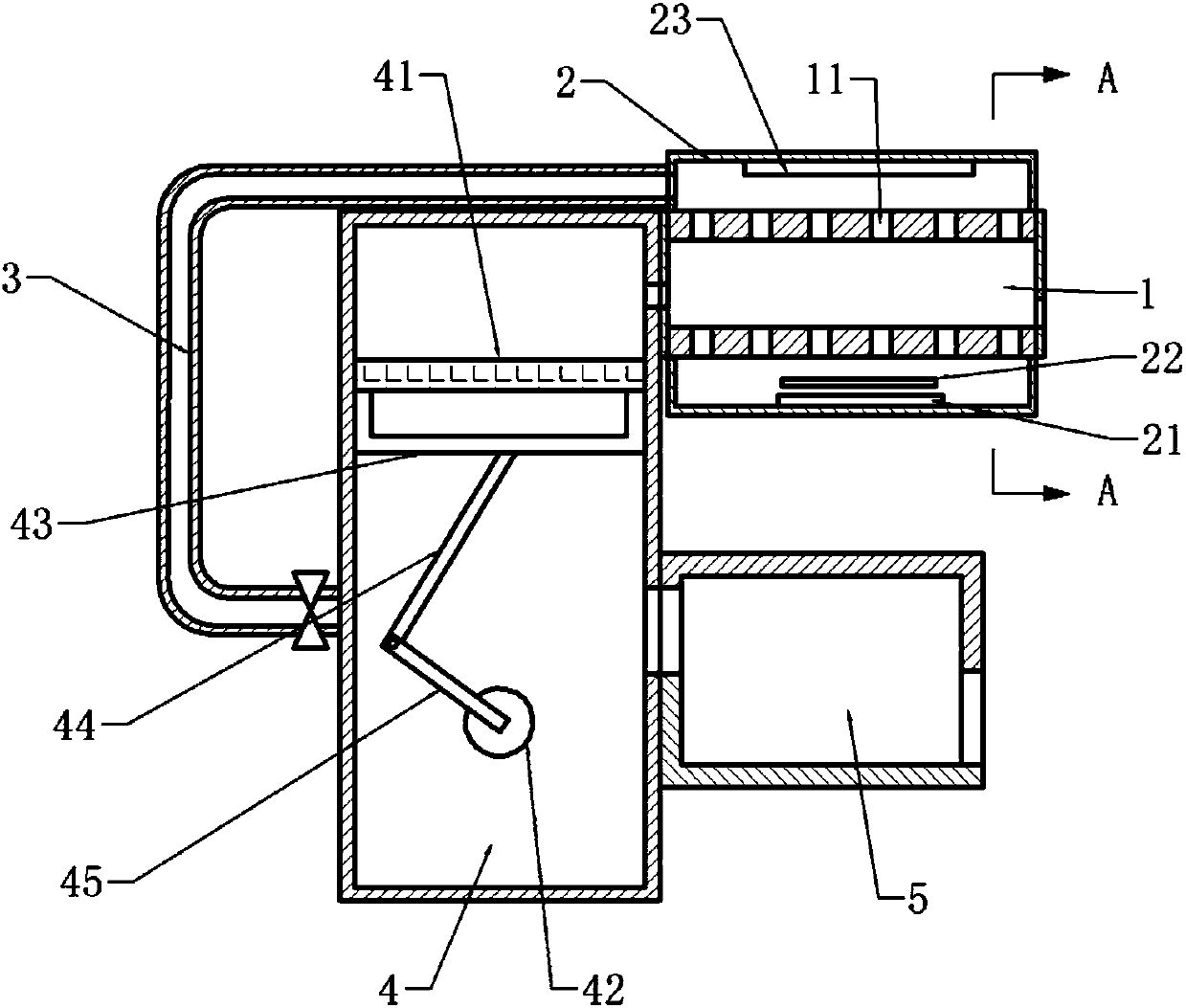

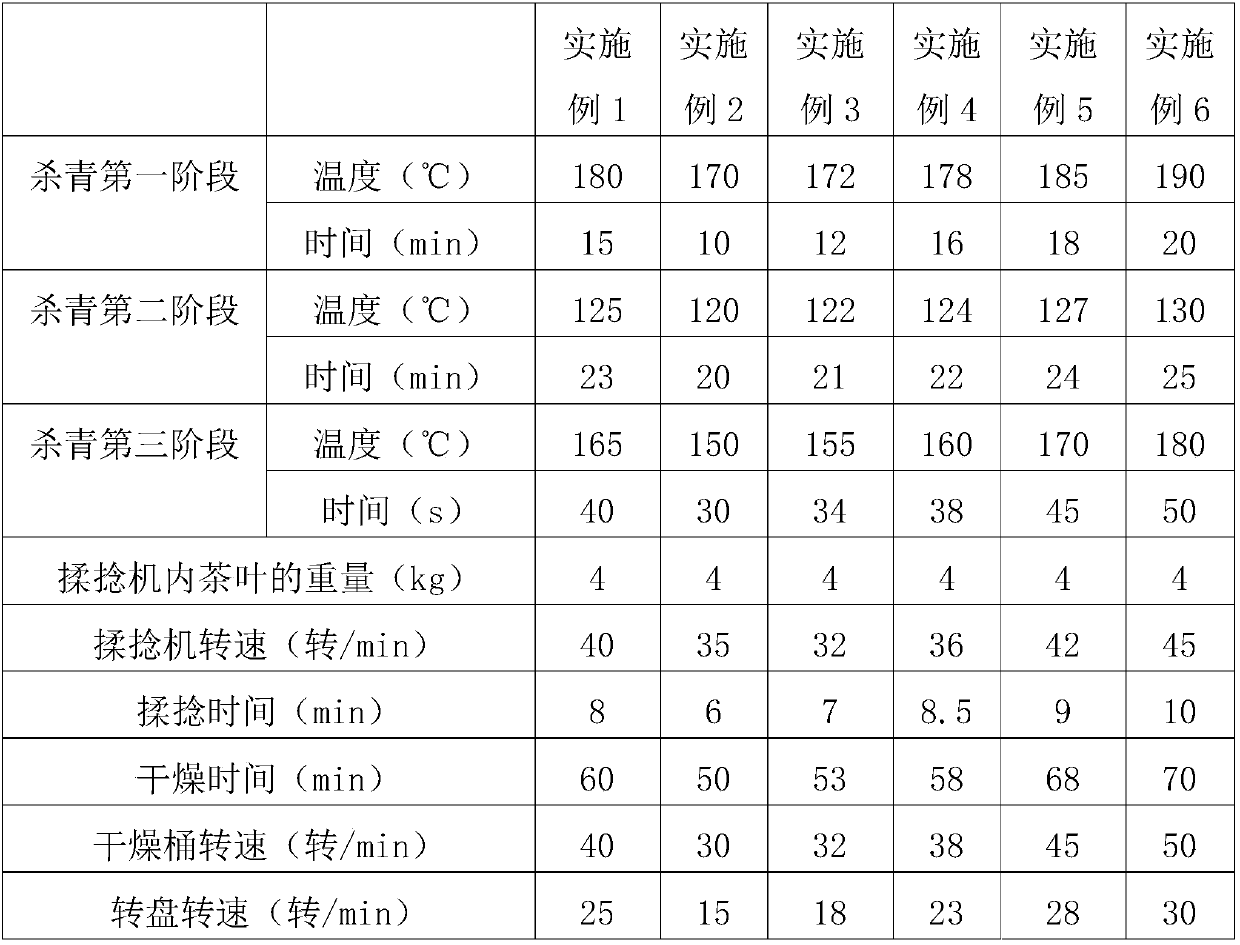

Tea leaf processing method

InactiveCN107647002APrevent mildewAvoid dripping condensationPre-extraction tea treatmentDrying gas arrangementsFixation timeThree stage

The invention belongs to the technical field of processing and producing of tea leaves, and discloses a tea leaf processing method. The tea leaf processing method comprises the steps of performing fixation, performing rolling and performing drying. The step of performing fixation comprises three stages, and the fixation temperature and the fixation time of different stages are collocated, so thatthe fixation effect is better; during rolling, the rotational speed and the rolling time of a rolling machine are collocated, so that the rolling degree of tea leaves is basically consistent; and during drying, a drying device is used for drying, when the tea leaves are dried, the tea leaves are sieved, the tea leaves which are not completely dried are sieved out, and drying is performed once again. Through the adoption of the tea leaf processing method disclosed by the invention, the problem that in the prior art, poor ventilation exists in a drying machine, steam generated by the dried tea leaves can be not liable to exhaust, when the drying machine stops heating, the steam in the drying machine condenses to be in contact with the tea leaves, the water content of the tea leaves is too high, and the tea leaves are easy to mildew is solved.

Owner:湄潭县渝乾茶叶有限公司

Building coiled material detection device

InactiveCN111458283AEasy to acceptReduce the risk of non-complianceWeather/light/corrosion resistancePermeability/surface area analysisWater storage tankTester device

The invention relates to the field of building material detection equipment. The invention particularly relates to a building coiled material detection device. The device comprises a box body, a detection platform is arranged in the box body, and a pressure detector and a weather-proof detector are arranged above the detection table. Detection bases are correspondingly arranged right below the pressure detector and the weather-proof detector. The pressure detector and the weather-proof detector are connected with a same height adjusting device. A coiled material inlet is formed in the side wall of the box body. A water storage tank is arranged in the detection table, and a high-pressure water chamber, a low-temperature water chamber and a high-temperature water chamber are arranged in thewater storage tank and communicated with the detection bases corresponding to the pressure detector and the weather-proof detector respectively. Compared with the prior art, the water seepage performance of a waterproof coiled material in high and low temperature environments can be effectively detected at the same time; multiple positions of the coiled material are detected at the same time basedon different temperatures, so that the continuity of the waterproof coiled material in use is ensured, and the waterproof effects of all parts are kept consistent; and the drying degree of the detection bases is effectively improved, corrosion is avoided, and the service life of the tester is prolonged.

Owner:重庆传策科技有限公司

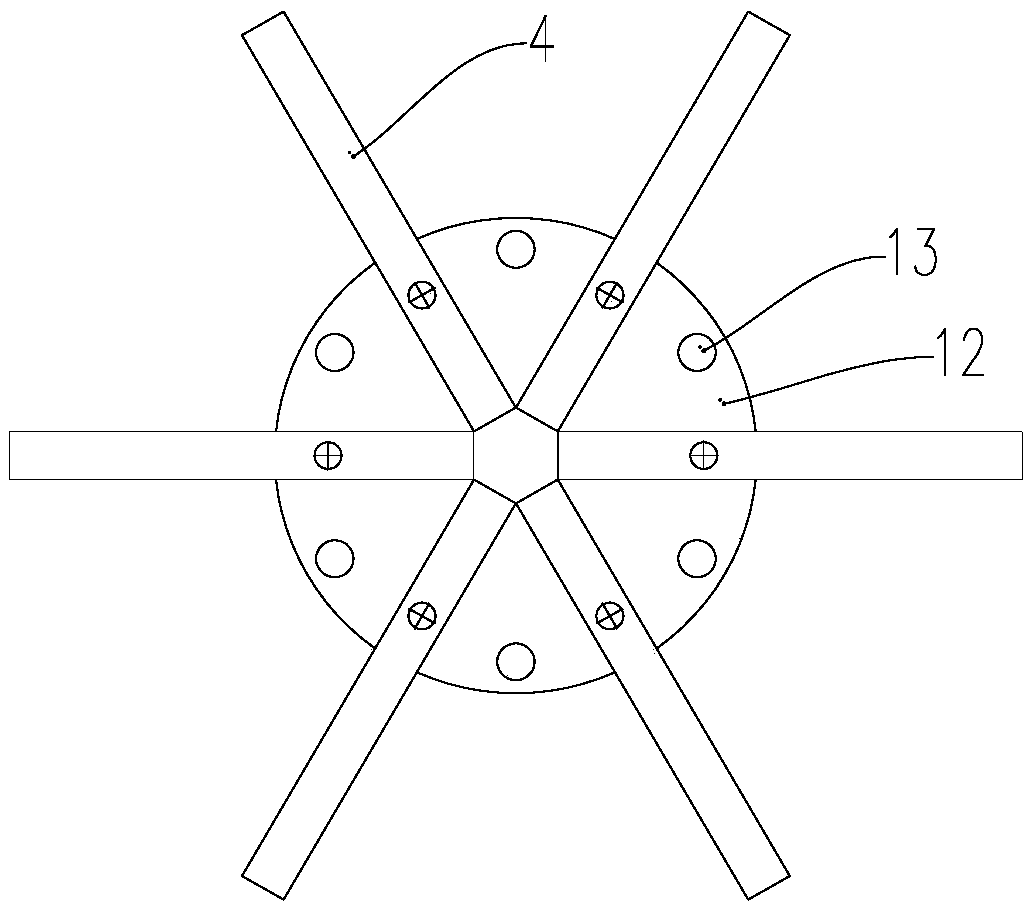

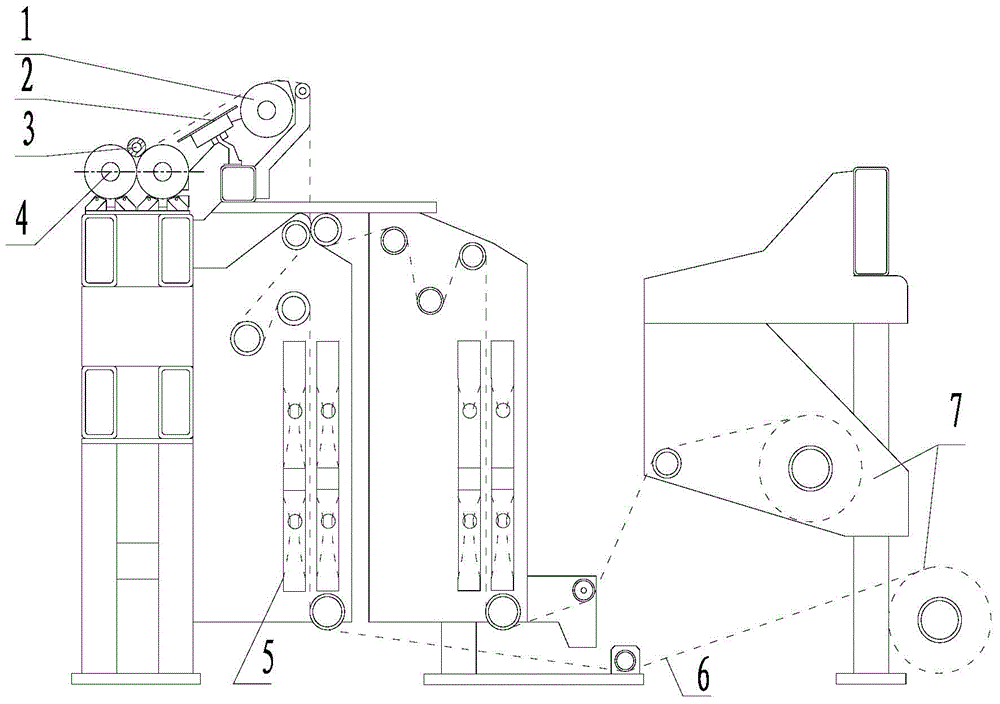

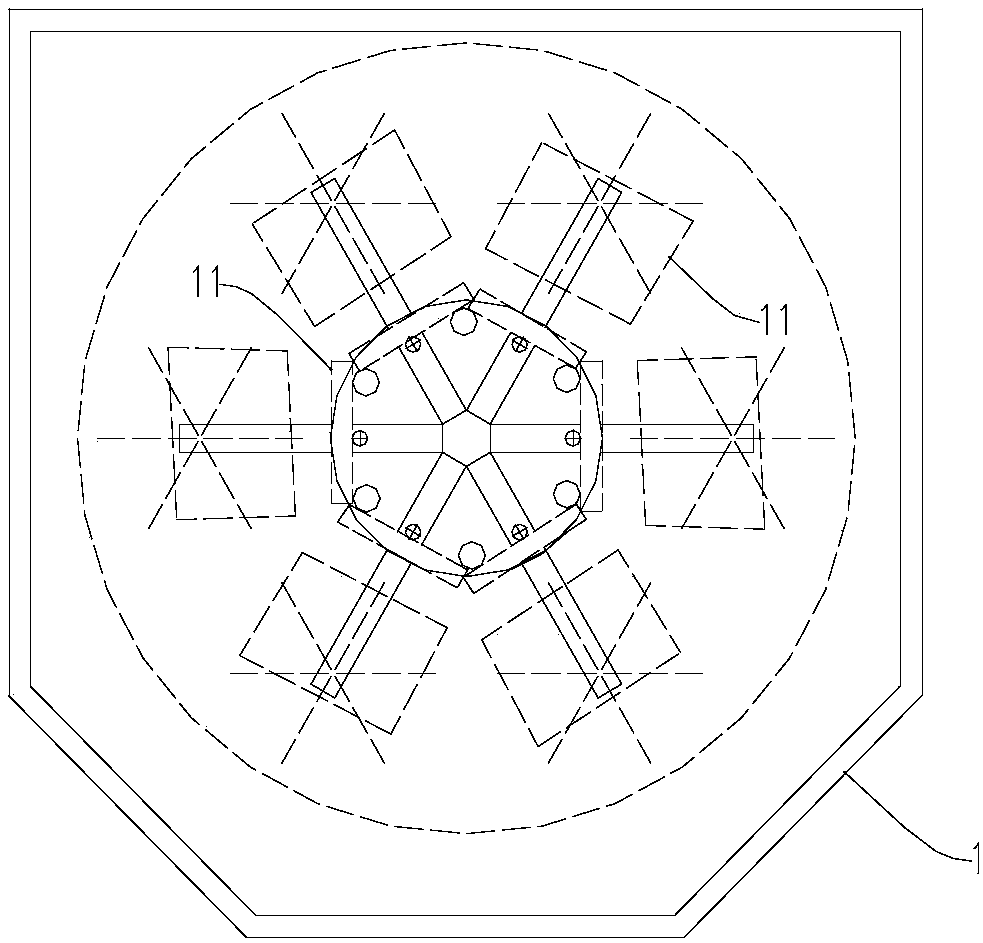

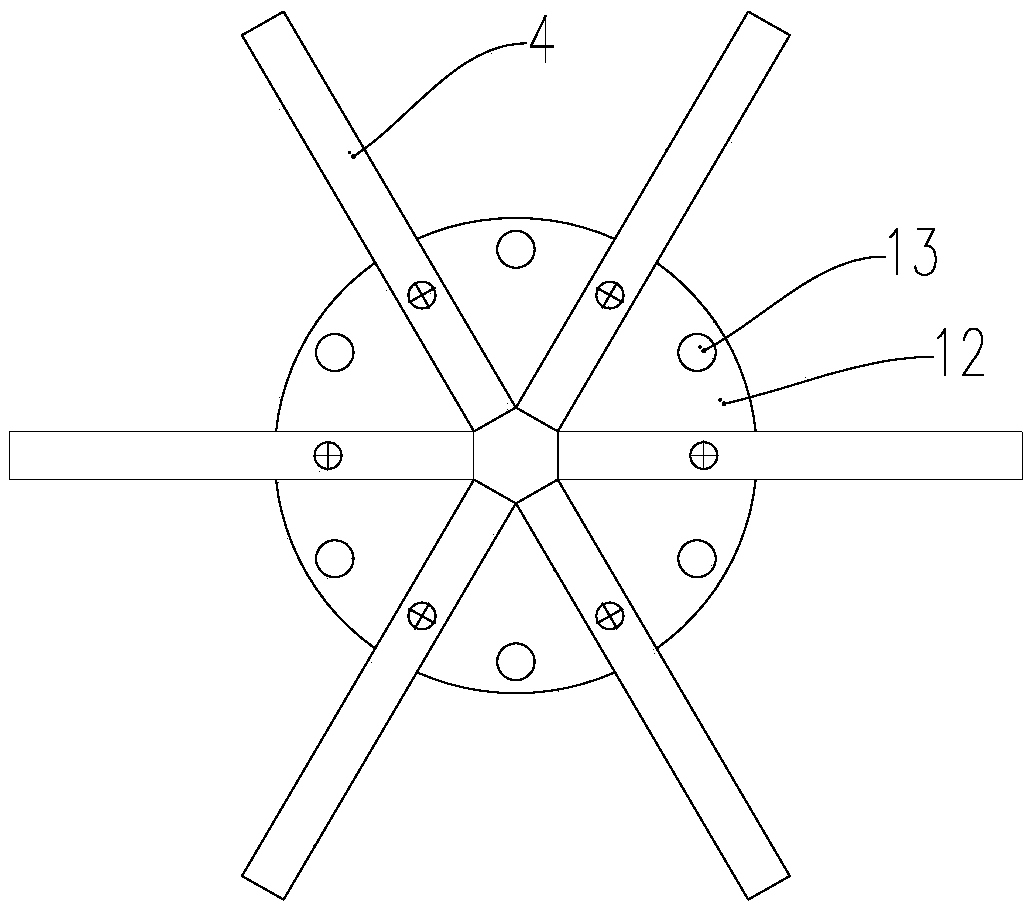

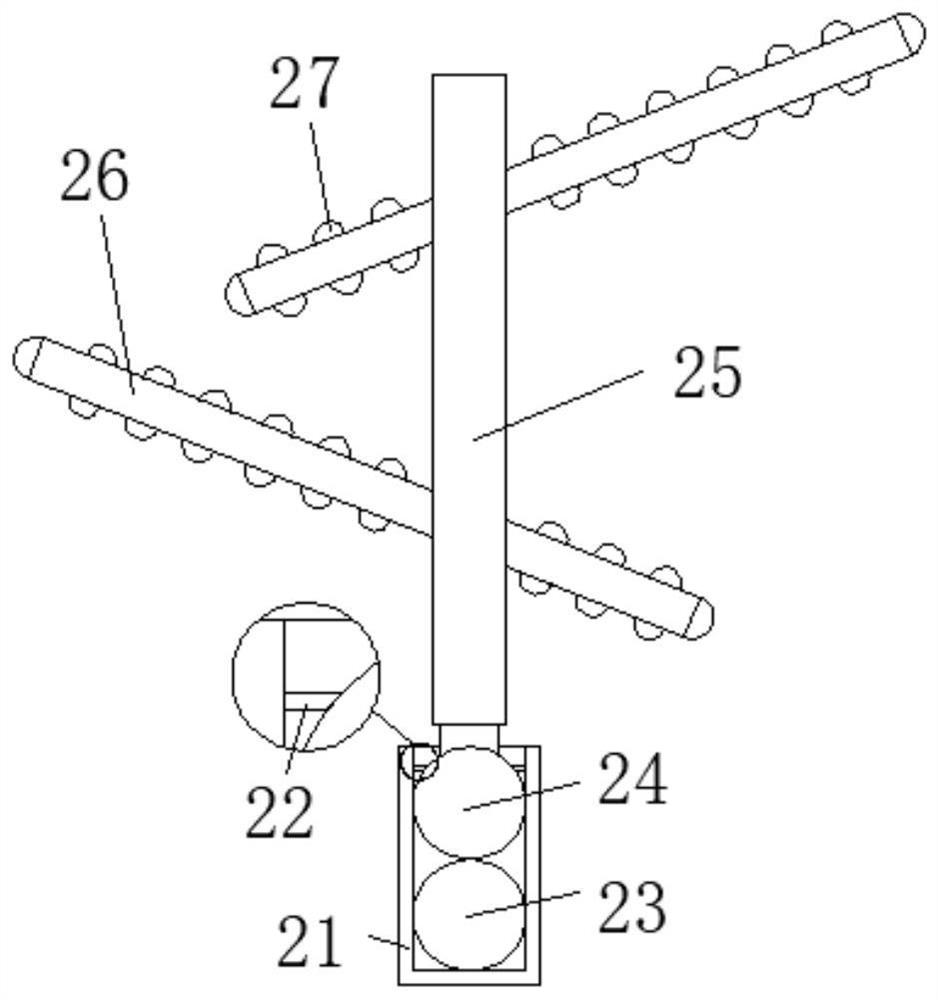

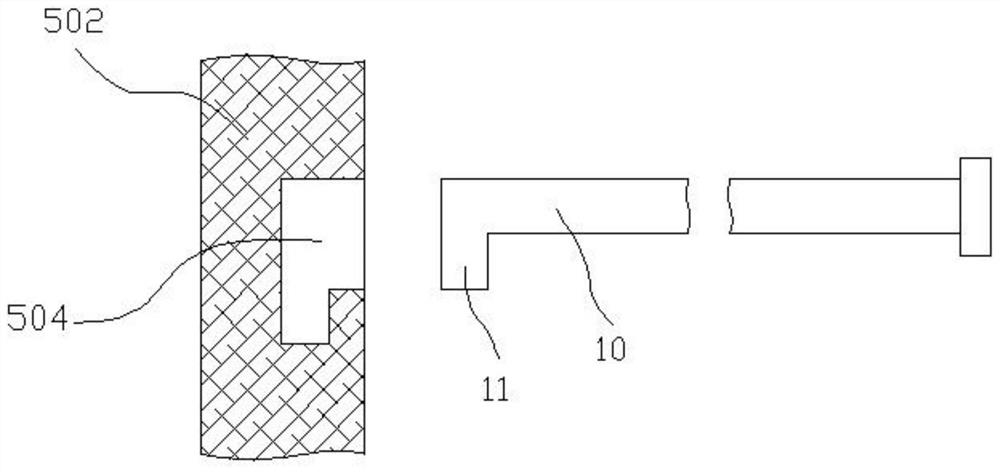

Hanging mechanism capable of rotation and revolution for mold shell drying

PendingCN109047674AConsistent drying speedConsistent drynessFoundry mouldsFoundry coresEngineeringSlewing bearing

The invention relates to a hanging mechanism capable of rotation and revolution for mold shell drying. The hanging mechanism comprises a revolution unit and a plurality of rotation units; the revolution unit comprises a first driving motor, a vertically arranged main shaft and a slewing bearing; the output end of the first driving motor is fixedly connected to the upper end of the main shaft, theslewing bearing is fixed on the bottom wall of a drying box, and the lower end of the main shaft is tightly pressed on the upper surface of the slewing bearing; a plurality of layers of beam frames are vertically fixed on the main shaft, each layer of beam frame is composed of a plurality of cross beams, and one end of each cross beam is correspondingly connected to one rotation unit; and the rotation units comprise disc bodies and rotating shafts, the upper ends of the rotating shafts penetrate through through holes formed in one ends of the cross beams and then are fixedly connected to centers of synchronous belt wheels, and a plurality of synchronous belt wheels are in transmission connection with the same synchronous belt. According to the hanging mechanism, rotation and revolution ofthe multiple batches of to-be-dried mold shells for drying in the drying box can be realized, so that the adverse effect on the drying of the mold shells due to the fact that the temperature in the drying box is not uniform and the wind direction is fixed during blowing can be overcome.

Owner:WUHAN ZONKING METAL PRODS

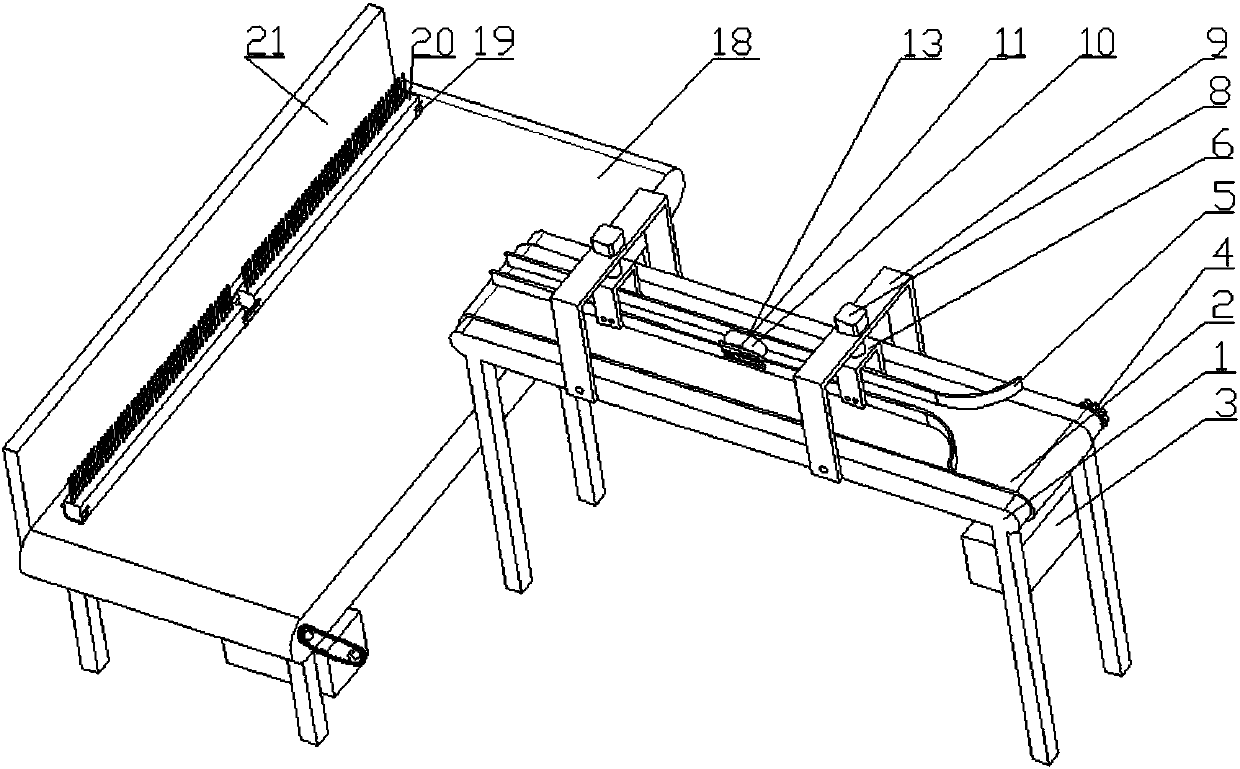

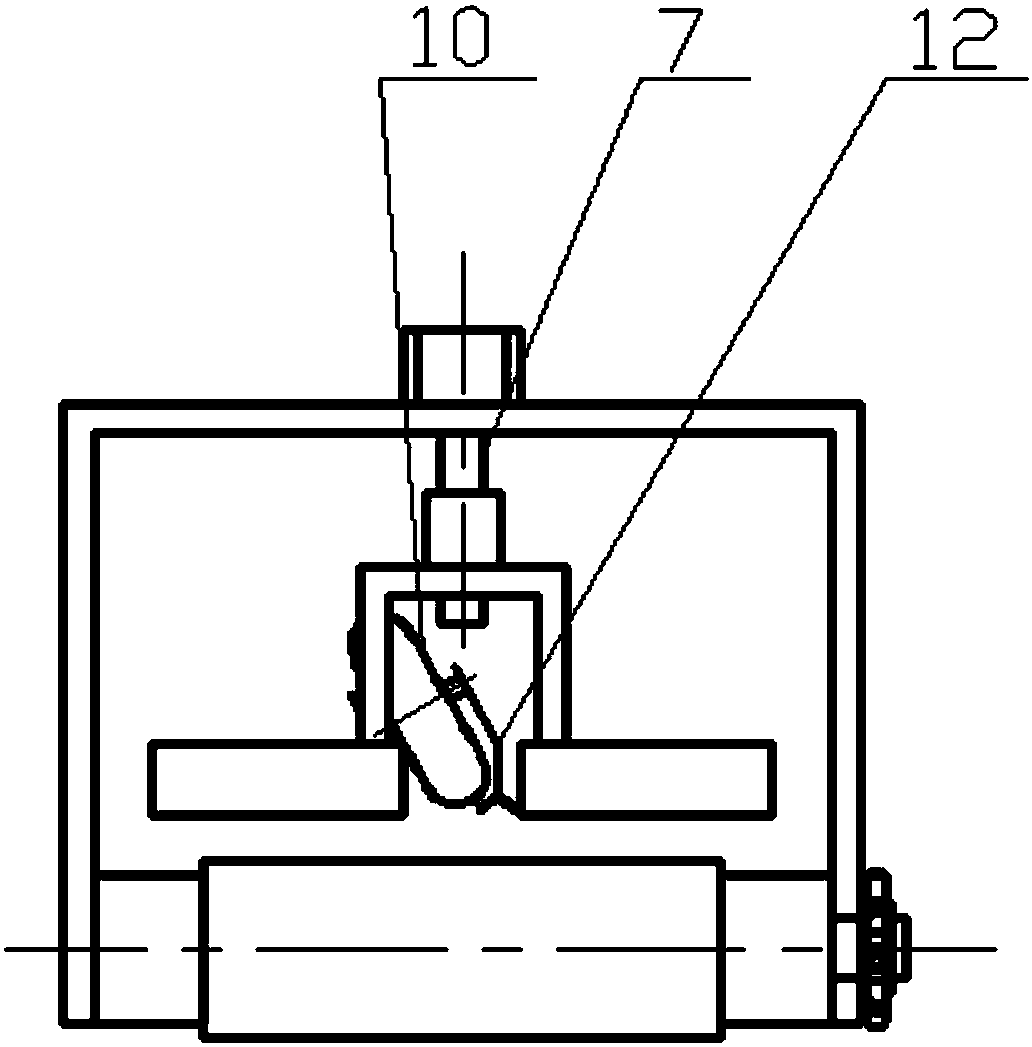

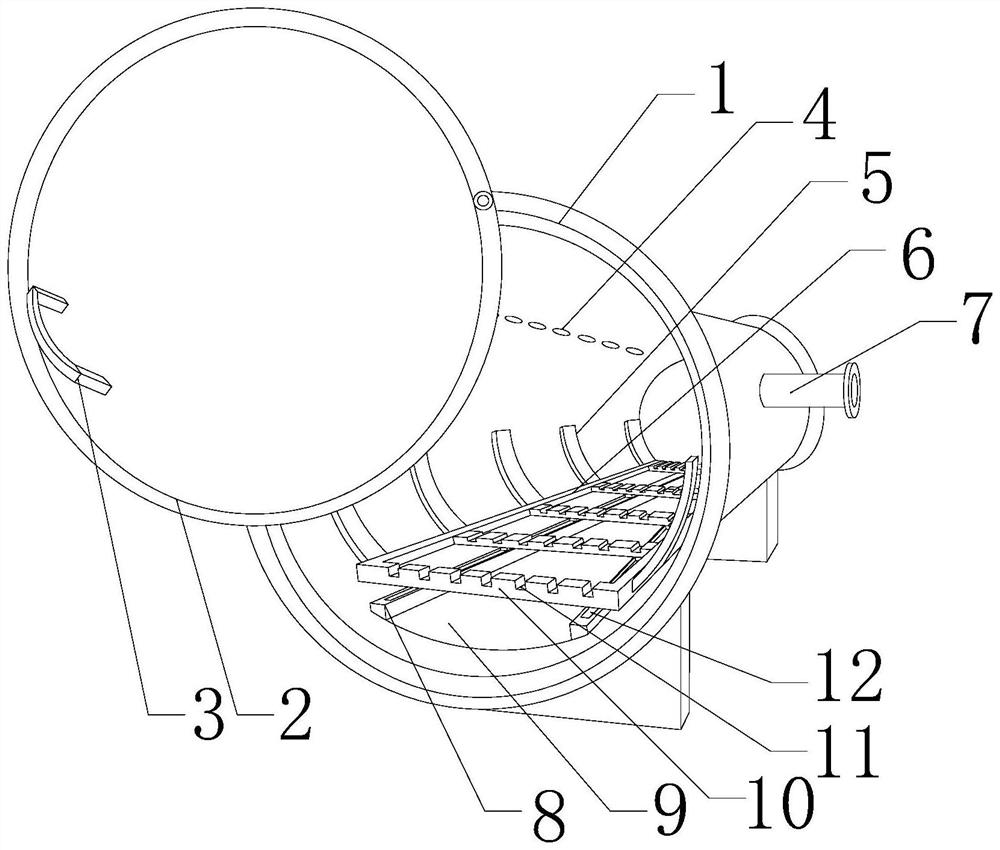

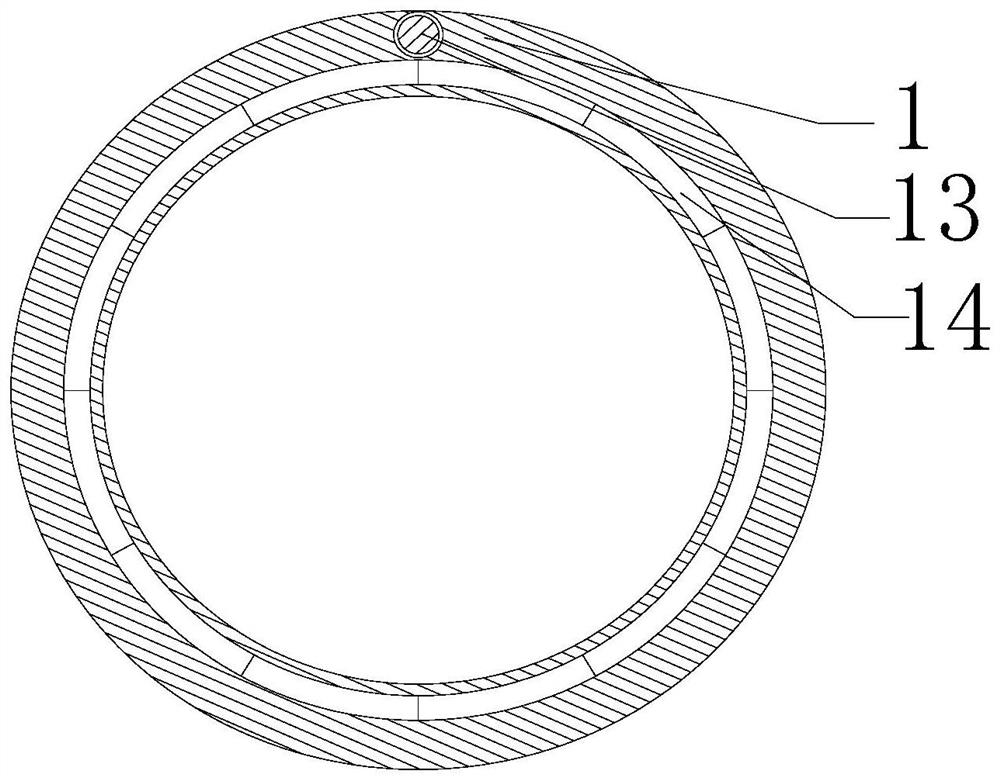

Fresh tobacco leaf stalk sectioning and orderly-clamping device and sectioning and clamping method thereof

The invention discloses a fresh tobacco leaf stalk sectioning and orderly-clamping device and a sectioning and clamping method thereof. Leaf stalks and tobacco leaves are different in flue-curing degree, and accordingly the flue-curing quality is affected. The fresh tobacco leaf stalk sectioning and orderly-clamping device comprises a positioning adjusting assembly, a first belt conveying mechanism, guiding plates, a compressing contour wheel, a Y-shaped cutter, a photoelectric sensor, a second belt conveying mechanism, a fastener, a tobacco clamp and a baffle. The Y-shaped cutter begins to cut main veins from the end faces of tobacco leaf stalks, and the compressing contour wheel is adjusted through a spring to adapt to the different height situations at different positions of the tobaccoleaf main veins. Sectioned tobacco leaves are throwed and conveyed through the first belt conveying mechanism, and leaf stalks fall between two adjacent clamping columns of the tobacco clamp after being in contact with the baffle; when n tobacco leaves are stacked between the two adjacent clamping columns, the tobacco clamp is stepped for one station; when the tobacco clamp is full of tobacco leaves, a motor is driven to stop rotating, the tobacco clamp is taken down and put in a flue-curing room, then a new tobacco clamp is clamped on two fasteners located at an upper tobacco leaf clamping station. The fresh tobacco leaf stalk sectioning and orderly-clamping device achieves automatic and orderly clamping of fresh tobacco leaves and makes the leaf stalk flue-curing time approximate to leaf flue-curing time.

Owner:西安智财全技术转移中心有限公司

Method for pest-proof treatment of wood

InactiveCN107351209AEffect on mechanical propertiesAvoid corrosionRadiation/waves wood treatmentWood treatment detailsMaterials scienceFumigation

The invention relates to a treatment method for preventing insects of wood, which specifically comprises the following steps: (1) heating wood to kill insects; (2) fumigation of wood; (3) painting after drying. Through experiments, the wood insect-proof treatment method provided by the invention effectively improves the resistance of wood to moths, greatly prolongs the use time of wood, and has a remarkable effect.

Owner:安徽嘉美工艺品有限公司

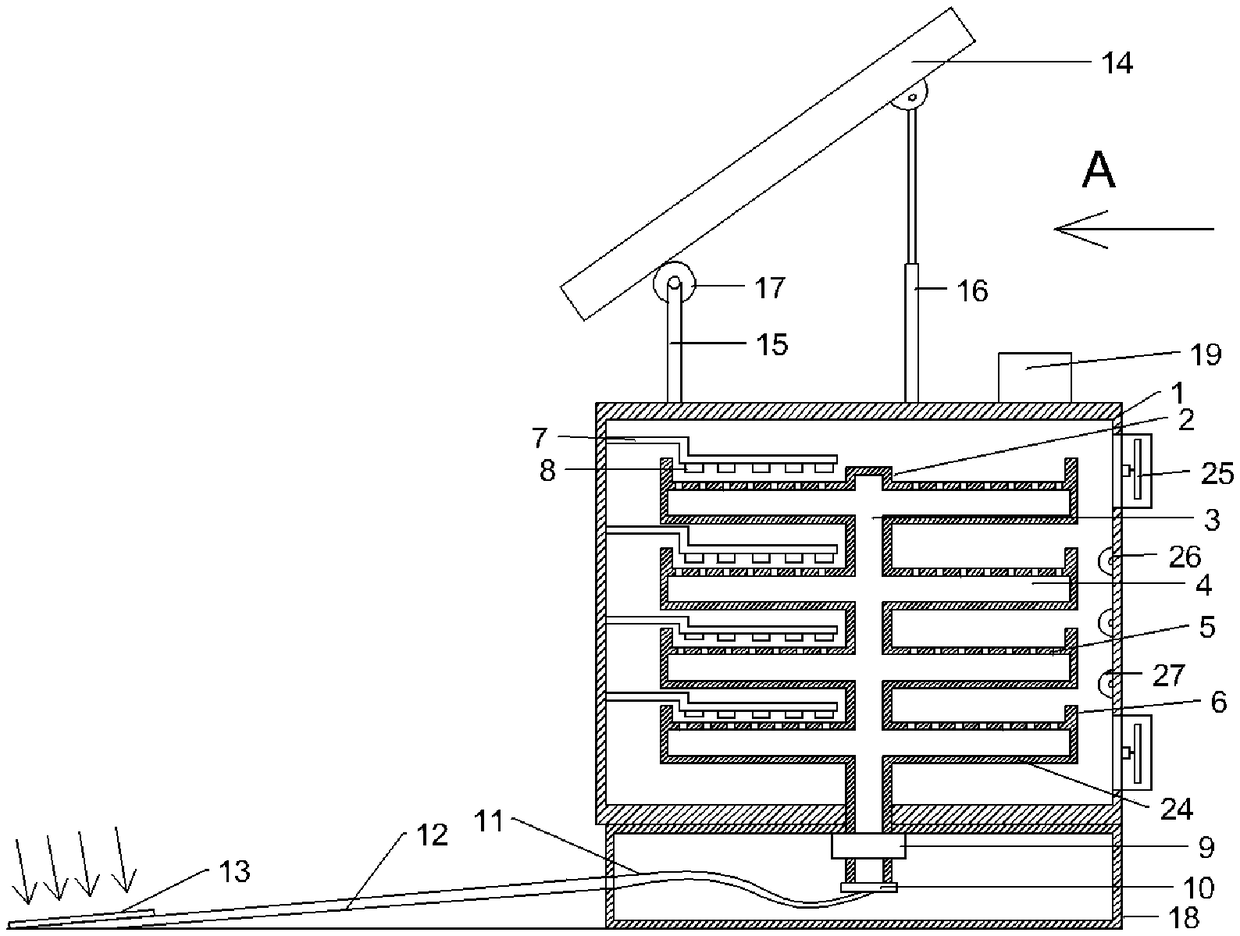

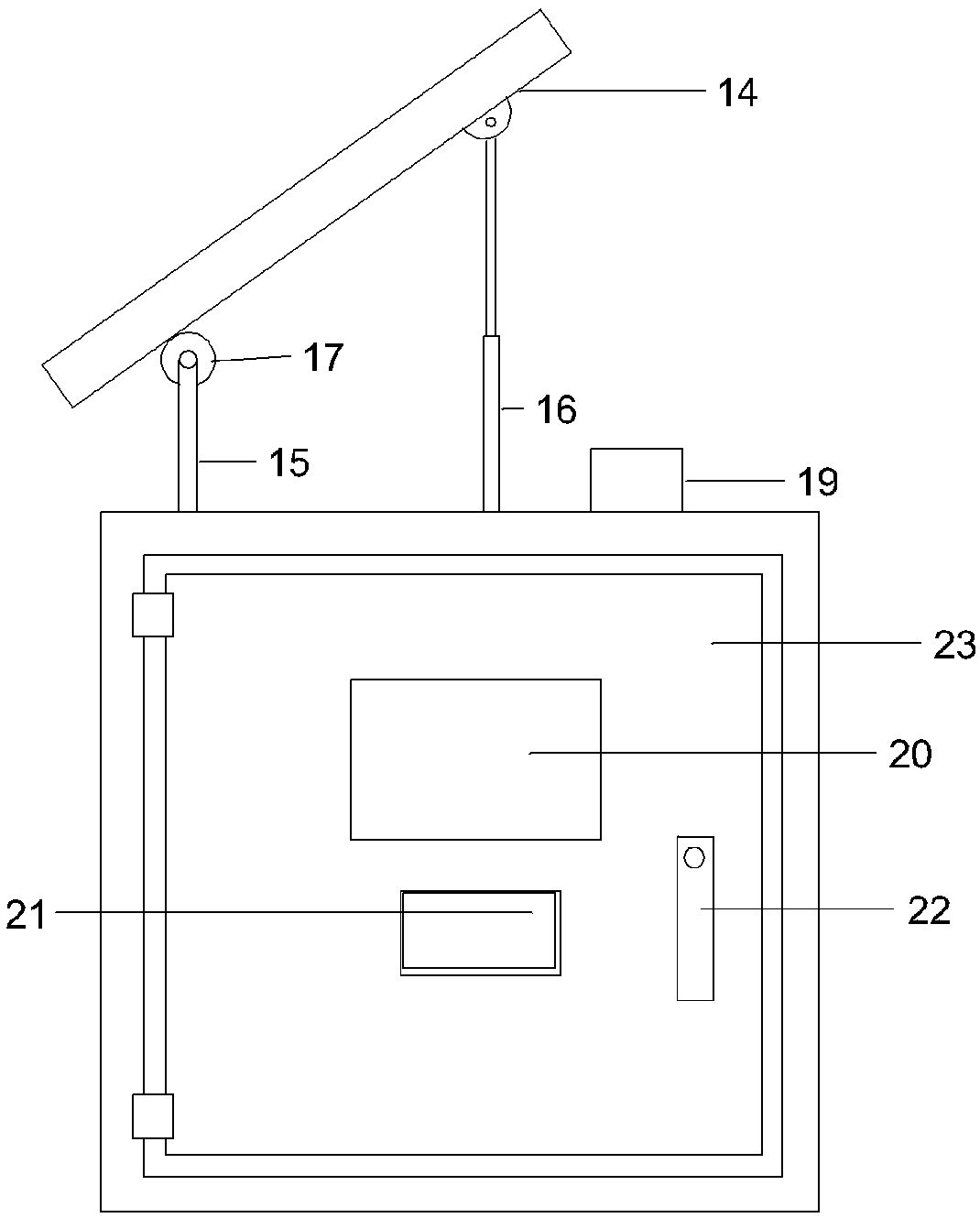

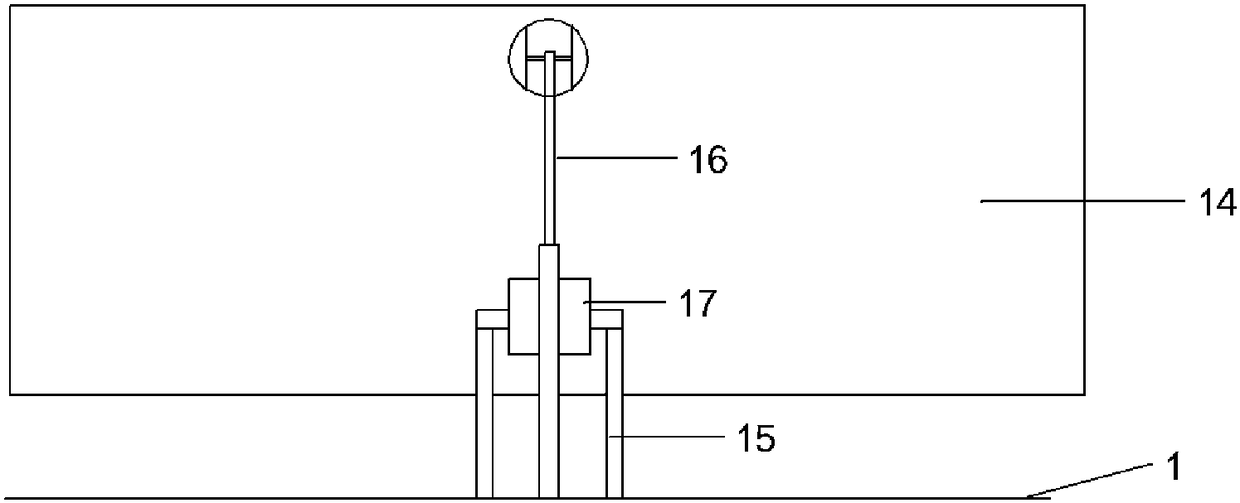

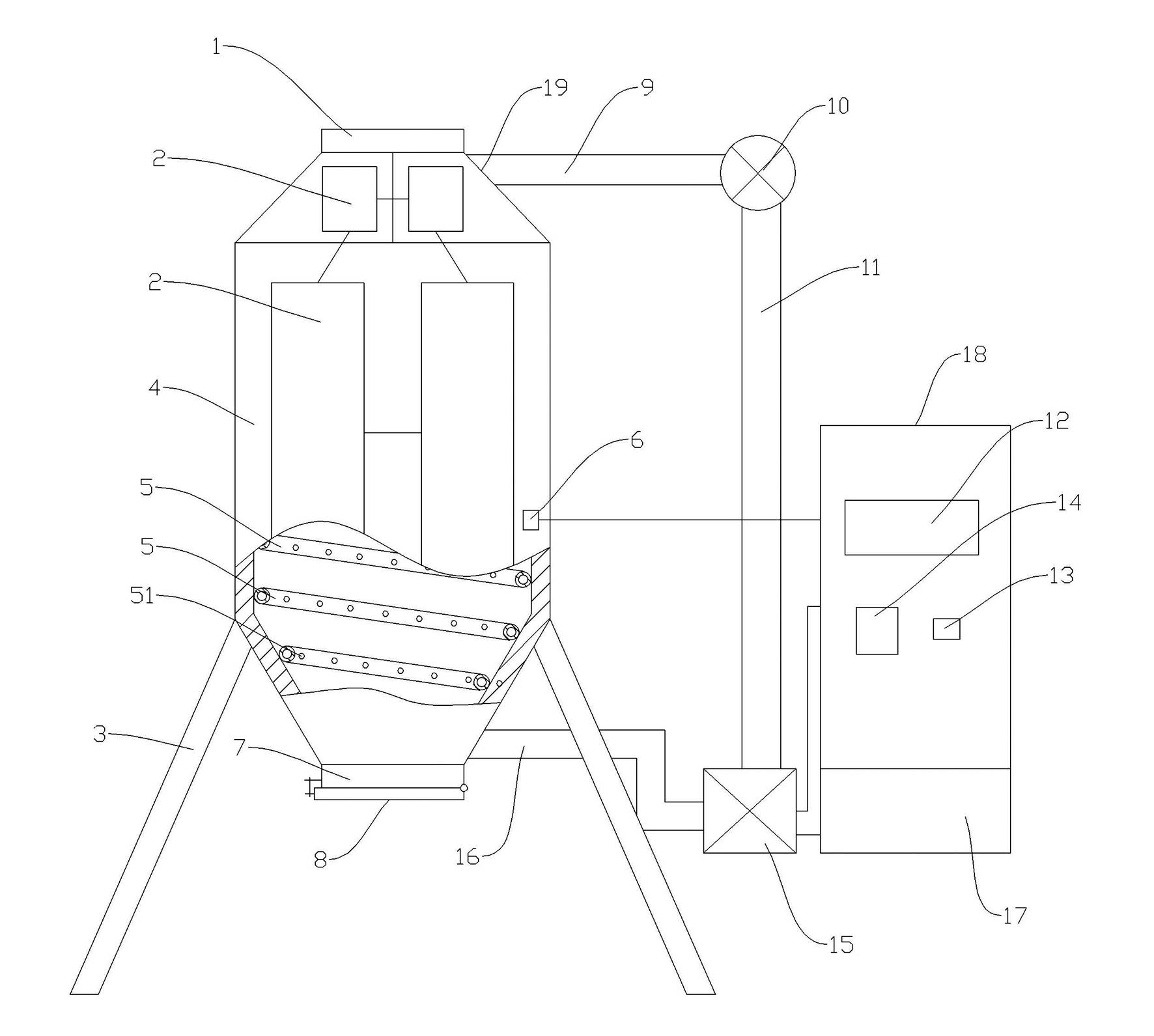

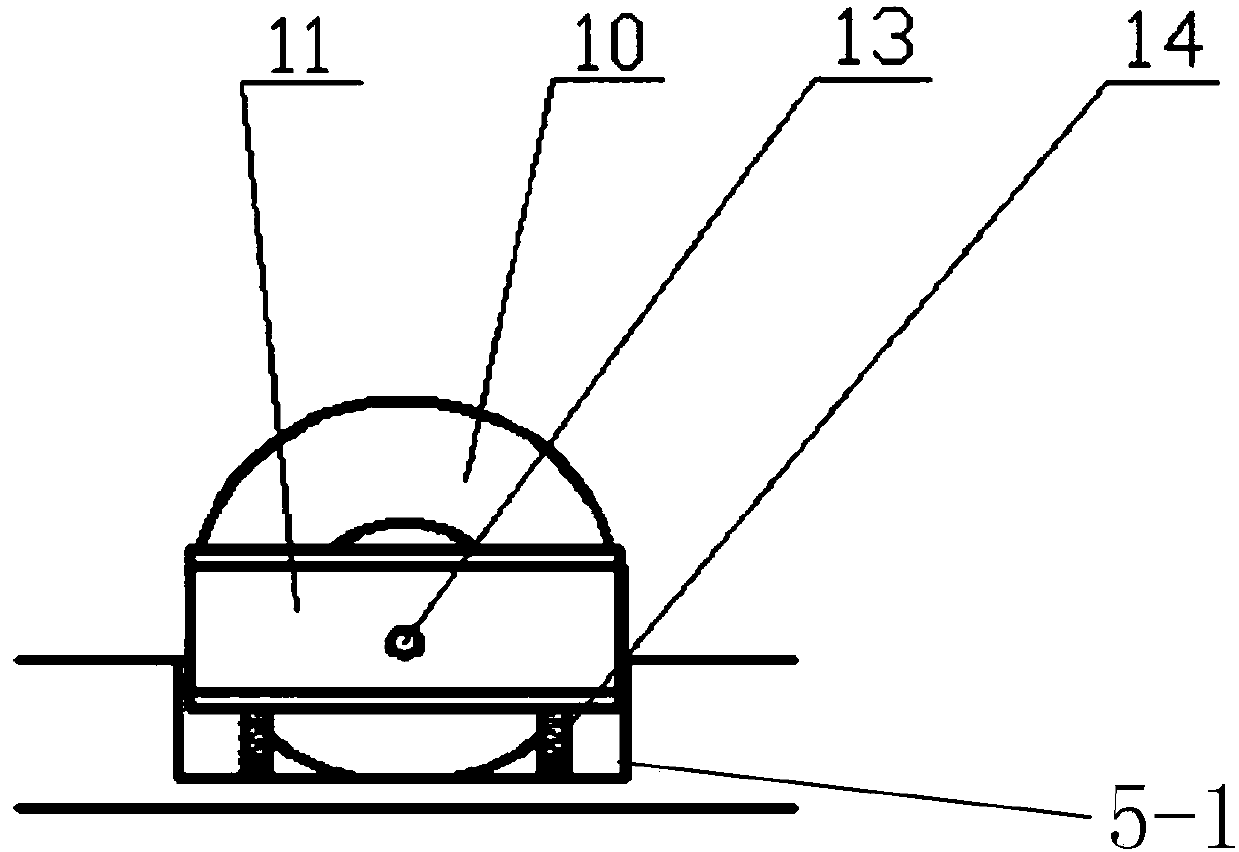

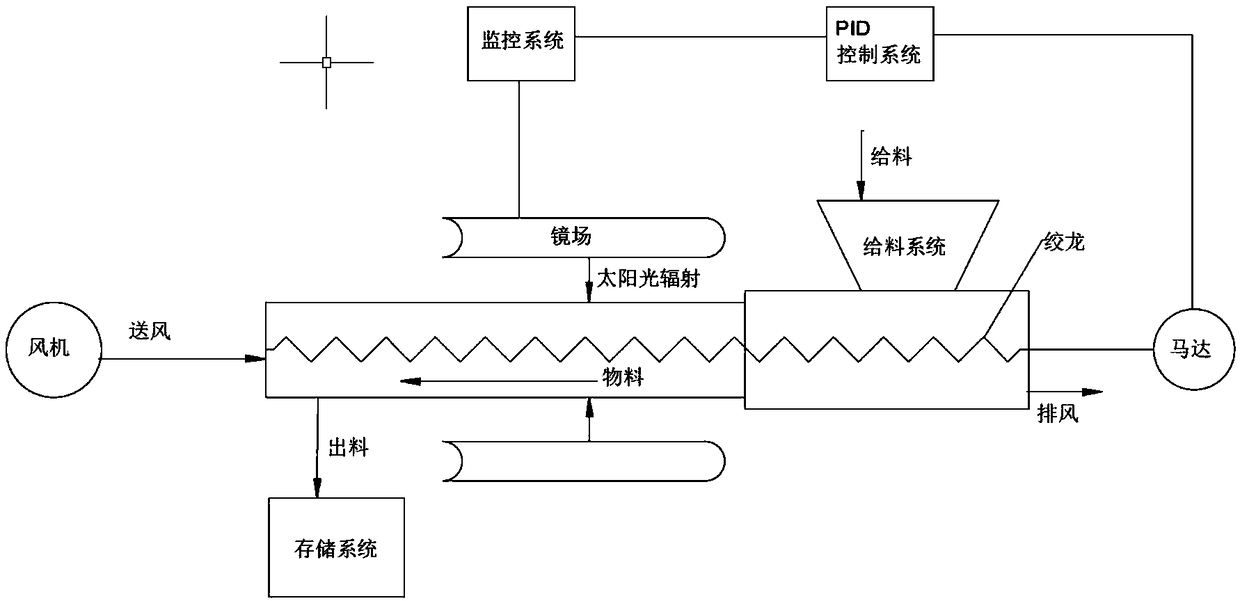

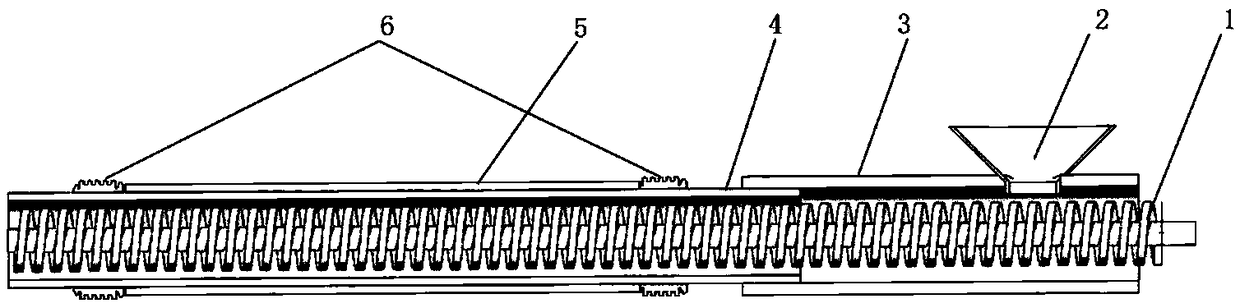

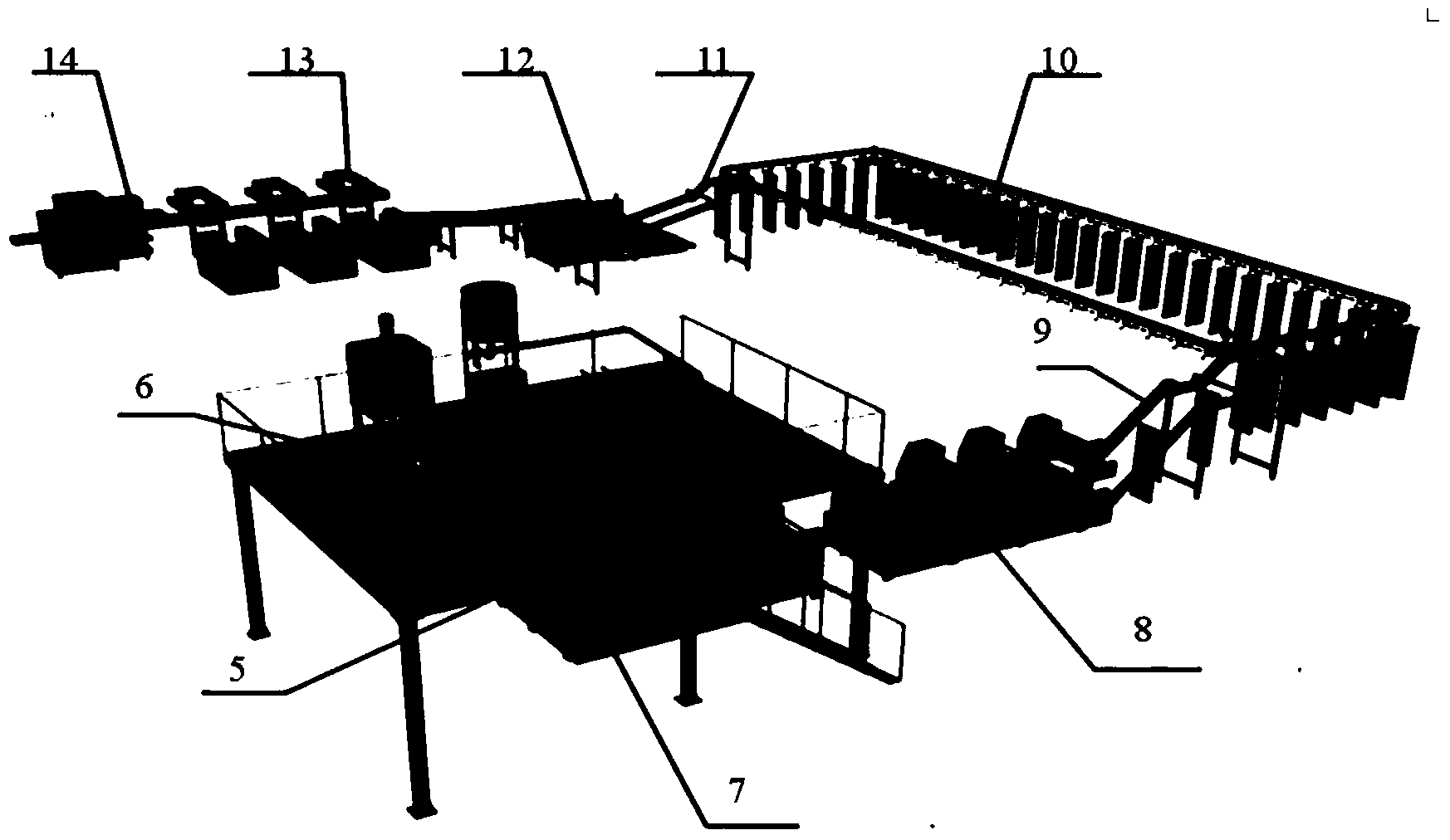

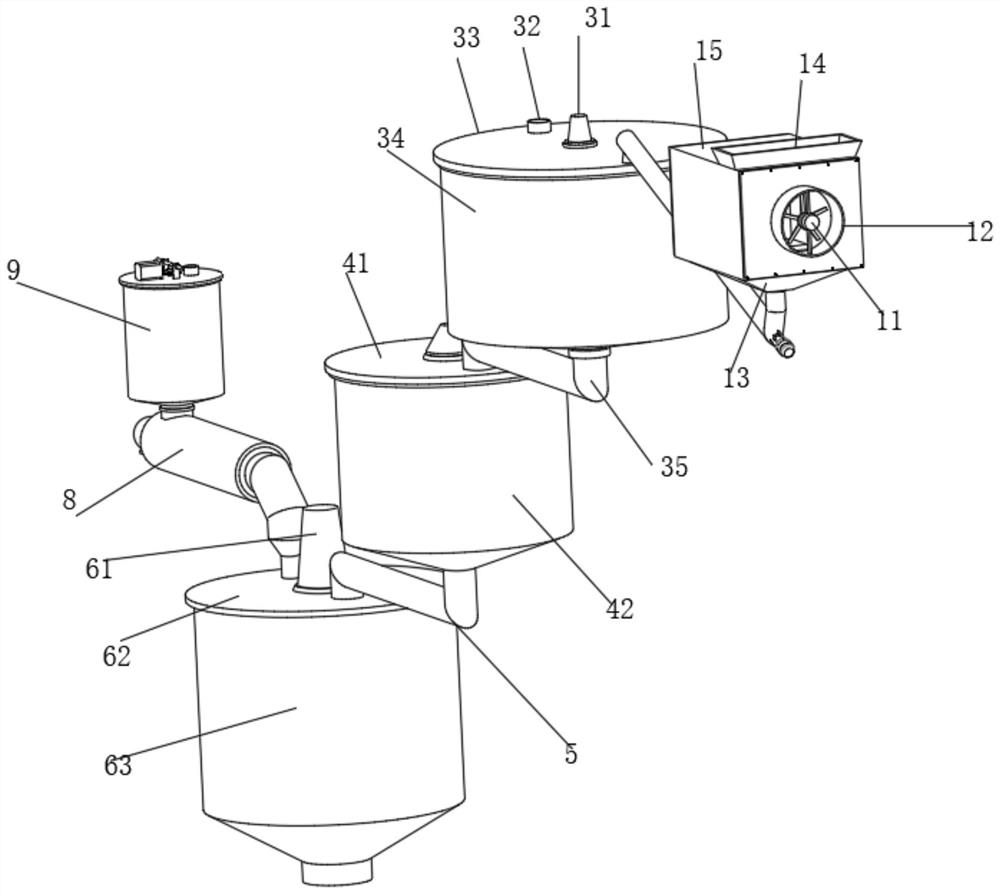

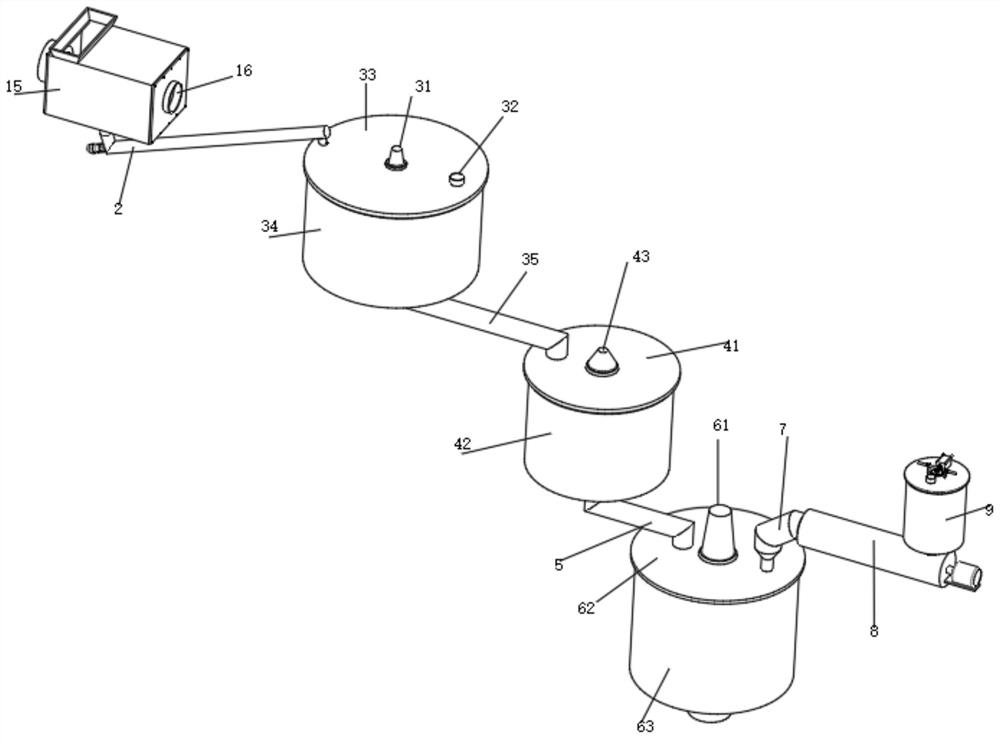

Biomass drying system based on concentrated solar energy

InactiveCN109489344AImprove energy utilizationImprove drying efficiencySolar heating energySolar heat collector controllersDouble tubeEngineering

The invention belongs to the technical field of biomass processing accessory related equipment, and discloses a biomass drying system based on concentrated solar energy. The biomass drying system based on the concentrated solar energy comprises a solar energy concentrating unit, a segmented drying unit, a feeding unit, an air supply unit and a control terminal, wherein the concentrating unit is used for guiding incident solar energy to a whole double-tube drying unit after focusing; and the drying unit comprises a preheating section pipe and a drying section pipe which are coaxially arranged,and a packing auger is arranged in the inner axial direction of the two section pipes, so that axial conveying of materials through the packing auger is achieved, and sunlight from the concentrating unit is simultaneously received to complete preheating and drying of the materials. In order to ensure the reliable operation of the system, the drying degree of the outlet materials is enabled to be consistent under different solar radiation intensities through the control terminal. Through the biomass drying system based on the concentrated solar energy, exhaust waste heat can be fully utilized,the energy utilization rate of the whole system is improved, the energy consumption in the drying process is reduced, and structural damage caused by uneven heating is avoided.

Owner:HUAZHONG UNIV OF SCI & TECH

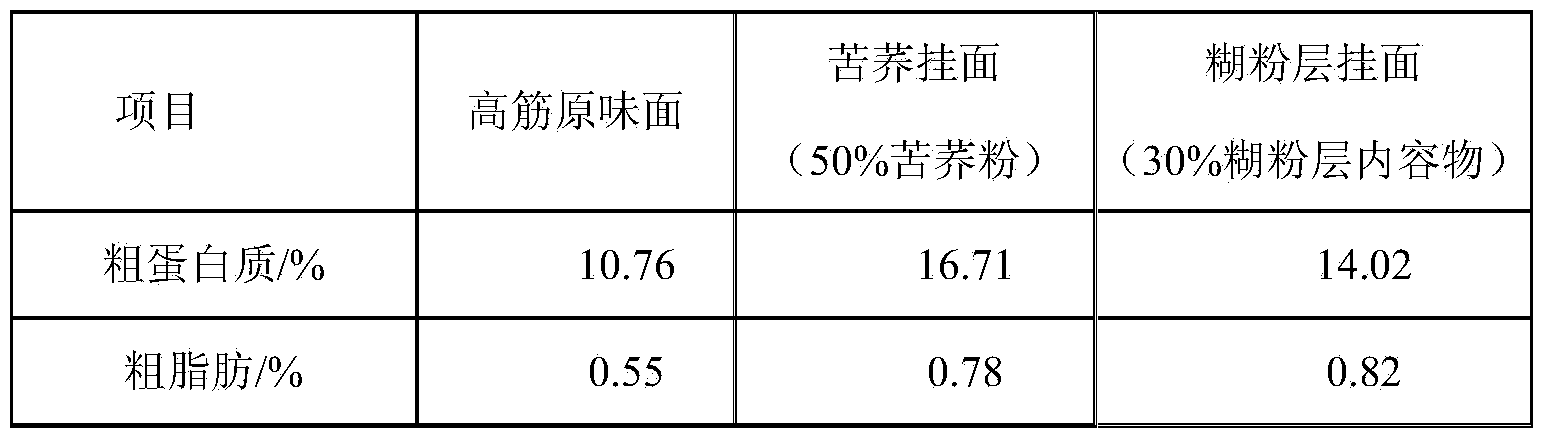

Aleurone-layer fine dried noodles and preparation technology thereof

InactiveCN104222819AAnti-cancerHigh in nutrientsFood ingredient functionsFood preparationPolyphenolVitamin

The invention discloses aleurone-layer fine dried noodles and a preparation technology thereof. The aleurone-layer fine dried noodles comprise components as follows: flour raw materials and auxiliary materials, wherein the flour raw materials comprise 50%-80% of high protein flour and 20%-50% of wheat aleurone layer contents, the added auxiliary materials comprise components accounting for the flour raw materials in percentage by mass as follows: 0.5%-2% of added salt, 0.5%-5.0% of wheat gluten, 0.05%-0.4% of xanthan gum and 20%-35% of added water. The aleurone-layer fine dried noodles are prepared by the steps as follows: mixing, dough kneading, curing, flour tape pressing, noodle cutting, hanging of noodles on rods, drying, cooling, taking off of the noodles on the rods, cutting, weighing and packaging. The aleurone-layer fine dried noodles are smooth, clean, fine, uniform, chewy and boil-proof, has good elasticity, contains nutrient substances such as dietary fiber, protein, mineral substances, vitamins, polyphenol and the like and can effectively improve the current dietary structure of people, if the aleurone-layer fine dried noodles are eaten for a long time, health of the digestive system can be kept, and the immune system is strengthened.

Owner:JIAXING HEXIN TECH VENTURE CAPITAL INVESTMENT

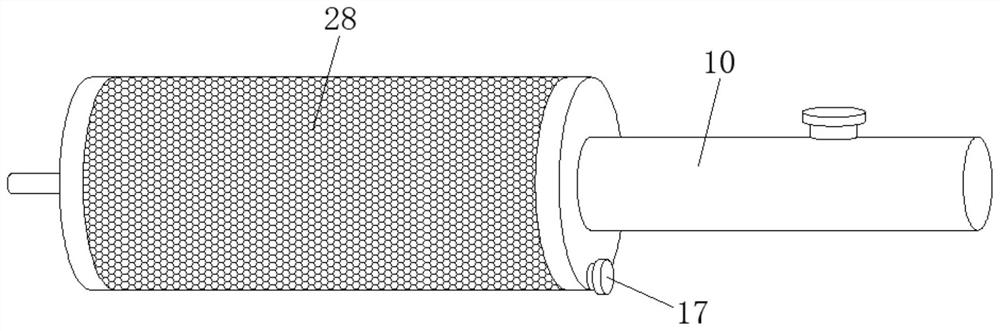

Floating drying device for agricultural cereal seeds

InactiveCN112378207AEvenly heatedConsistent drynessDrying gas arrangementsDrying safety systemsAgricultural engineeringMechanical engineering

The invention discloses a floating drying device for agricultural cereal seeds. The following scheme for solving the problem that the seeds are too dry or too wet is put forward now: the floating drying device comprises a box body, wherein a feeding mechanism is arranged on the outer wall of one side of the box body, one end of the feeding mechanism is located in the box body, a motor box is fixedto the outer wall of the side, away from the feeding mechanism, of the box body through bolts, a servo motor is fixed to the inner wall of one side of the motor box through bolts, one end of an output shaft of the servo motor is located in the box body, one end of the output shaft of the servo motor is sleeved with a net cylinder, and the feeding mechanism is rotatably inserted into the outer wall of one side of the net cylinder. By means of the floating drying device, the cereal seeds can be fed into the net cylinder capable of rotating, and the net cylinder rotates, so that the cereal seedscan continuously roll in the net cylinder; and air nozzles are arranged on the upper portion and the lower portion of the net cylinder, and the servo motor rotates rapidly, so that the cereal seeds float in the net cylinder, the surfaces of the cereal seeds make contact with hot air more easily, and balanced drying is achieved.

Owner:李克兰

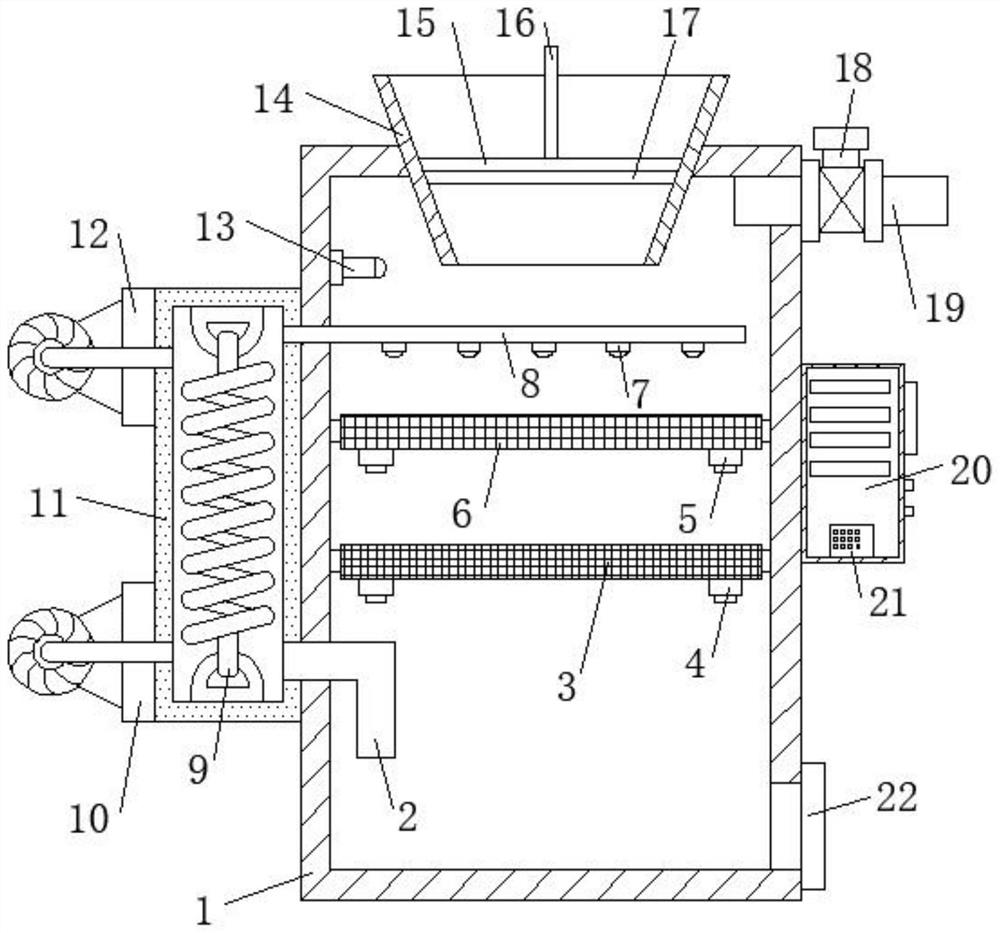

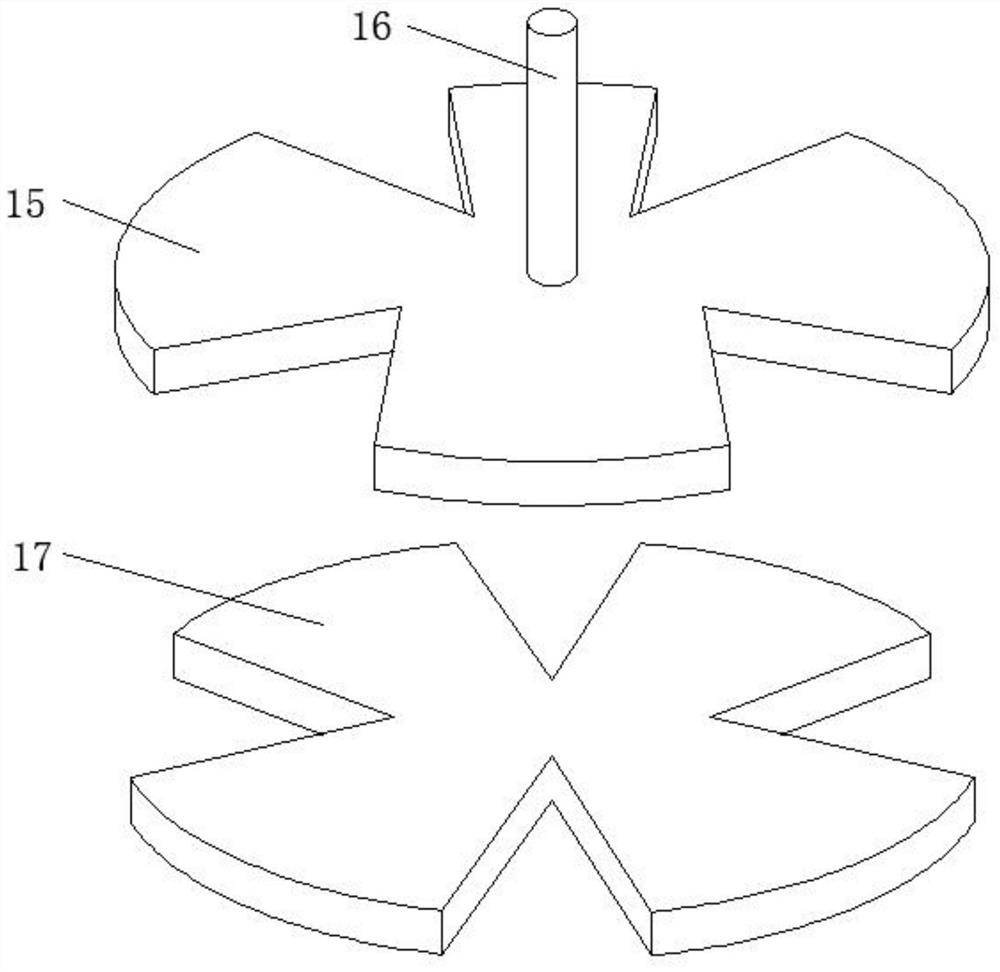

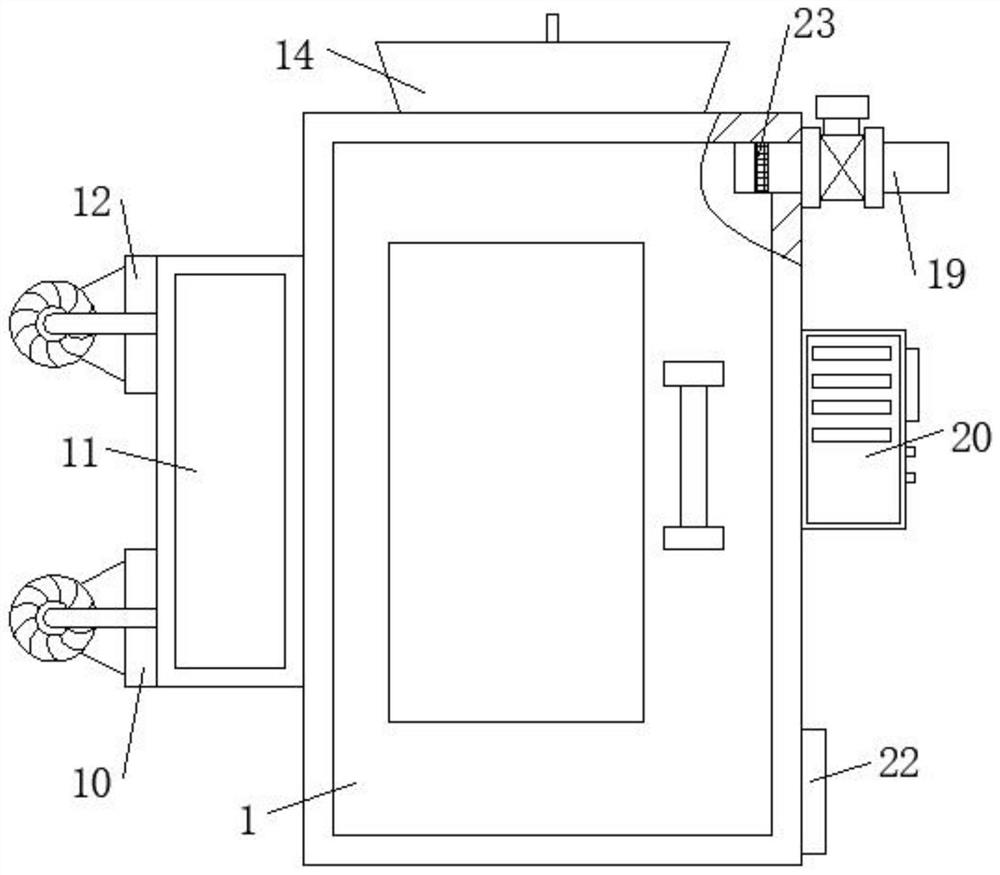

Tea sieving device for green tea processing

InactiveCN111842112ASame sizeDry completelySievingPre-extraction tea treatmentBiotechnologyGreen teas

The invention discloses a tea sieving device for green tea processing. Aiming at the problem that tea cannot be dried uniformly and the degree of drying of the tea is different, the invention proposesthe following scheme which comprises a box body, wherein a hopper is inserted near the middle of the outer wall of the top of the box body, a blanking mechanism is arranged on the inner wall of the hopper, a primary sieving mechanism and a secondary sieving mechanism are arranged on the inner wall of the box body from top to bottom, a fixing box is fixed on one side of the outer wall of the box body by bolts, a heater is fixed on the inner wall of the fixing box by bolts, and a first fan is fixed on one side of the outer wall, close to the top, of the fixing box by bolts. According to the teasieving device for green tea processing provided by the invention, the first fan blows downwards from above the tea to dry the upper surface of the tea, and a second fan blows from below the tea. According to the principle that hot air rises, the tea is dried from bottom to top, and as a result, the tea is dried more completely, and the upper surface and the lower surface are dried to the same degree.

Owner:华容县胜峰茶业有限公司

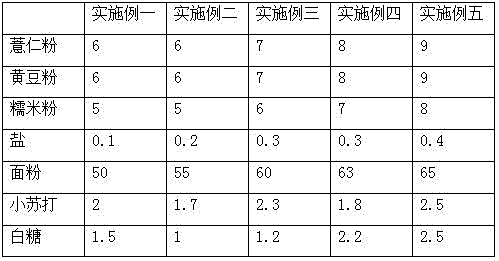

Lotus root noodles and drying method thereof

The present invention relates to fruit and vegetable noodles and particularly lotus root noodles. The lotus root noodles consist of the following components in parts by mass: 6-9 parts of coix seed flour, 6-9 parts of soybean powder, 5-8 parts of glutinous rice flour, 0.1-0.4 part of salt, 50-65 parts of flour, 1.6-2.5 parts of baking soda and 1.0-2.5 parts of white sugar. Pressed wet noodles are sent into a steam room, the wet noodles passed the steam room are soaked into a juice storage pool loaded with lotus root juice, the soaked noodles are hung up, the wet noodles after the step 2 are sent into a cold air room to be hung up, and the cold air flows from the upper side of the wet noodles to the lower side of the wet noodles; step 4: the dry flour is sprayed on the surfaces of the wet noodles in the step 3; and step 5: the dry flour sprayed wet noodles are put into a low-temperature and low-humidity room to conduct a hot air drying. The method solves the problem that during the drying process, the lotus root noodles are easily oxidized and discolored, and the present invention aims to provide the lotus root noodles which can avoid discoloration.

Owner:GUIZHOU PROVINCE FENGGANG COUNTY HETANGQIUYUN ORGANIC PROD CO LTD

Production method of strong fragrance rose odor type China black tea and produced China black tea

InactiveCN106306153AUnique aroma and tasteThe taste is mellow and sweetPre-extraction tea treatmentBlack teaPhyllotaxis

The invention discloses a production method of strong fragrance rose odor type China black tea. The production method sequentially comprises the following steps: selecting materials, blending, withering, rolling, fermenting, making into strips while hot and drying. The invention also discloses black tea produced by utilizing the production method. The production method disclosed by the invention has the advantages that multiple tea tree raw materials are carefully selected and are blended in a certain ratio, and a step of making into the strips while hot is also added in the traditional black tea processing method, so that the black tea is extremely unique in aroma and taste, thick but not bitter and sweet with aftertaste, the strips are tight and complete, the color and luster are black and moist, the liquor color is golden yellow and bright, flowers and fruits are fragrant and sweet, the taste is fragrant, mellow and sweet, and phyllotaxis is tender and bright.

Owner:YUNNAN DIANHONG GRP

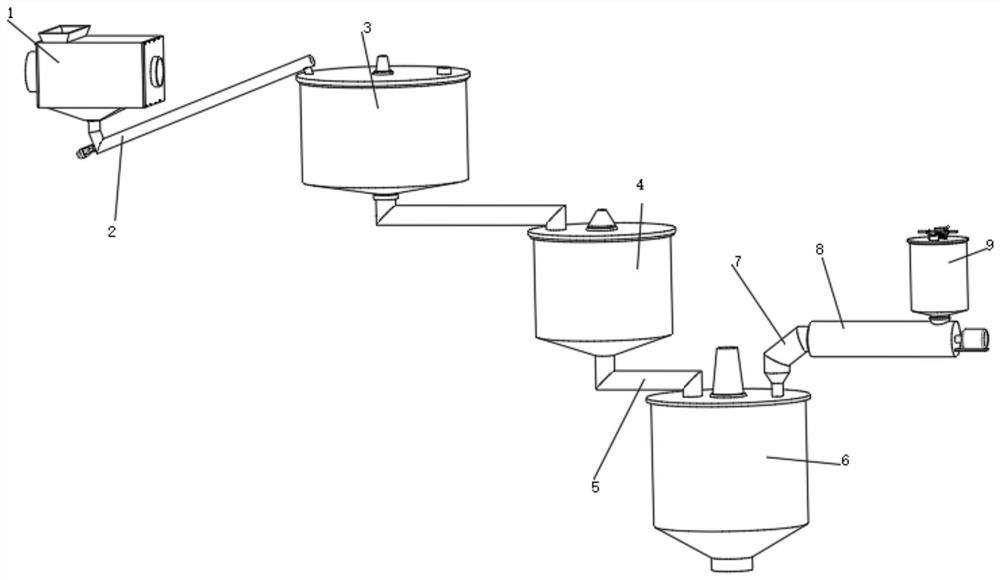

Whole wheat flour production process and processing device for intermediate extraction treatment of gluten materials

The invention relates to the technical field of wheat processing, in particular to a whole wheat flour production process and processing device for intermediate extraction treatment of gluten materials. The whole wheat flour production process and processing device comprise a winnowing structure, an auger discharging pipe, a wheat wetting structure, a smashing structure, a first connecting pipe, asecond connecting pipe, an extrusion bulking machine and a fermentation drying structure, wherein the wheat wetting structure is provided with the smashing structure, the bottom of a fourth box bodyis fixedly connected with the extrusion bulking machine for wheat bran extrusion bulking through a pipeline, and a discharging pipe of the extrusion bulking machine is fixedly connected with a secondconnecting pipe; and the first connecting pipe and the second connecting pipe are connected to a micro smashing mechanism for micro-smashing powder uniformly. The invention is beneficial to improve full contact of a fermentation liquor with wheat bran, so that the wheat bran is fermented quickly, the fermentation time is shortened, the fermented bran is dried, the drying degree of the bran is consistent, and the bran effect is exerted favorably.

Owner:张云路

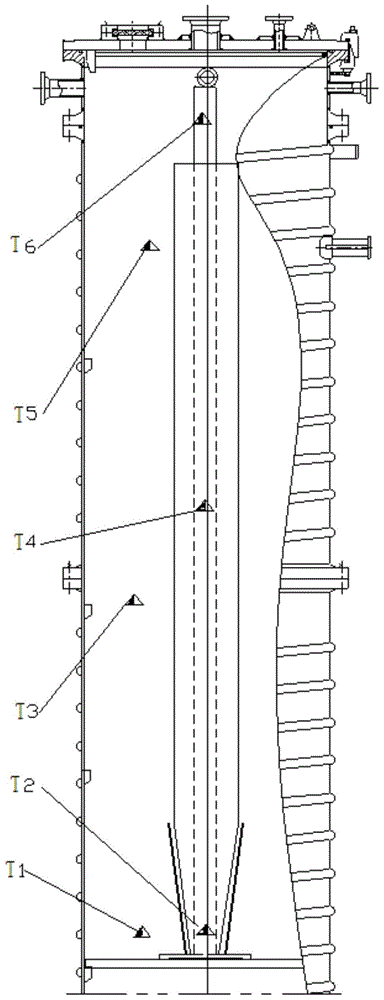

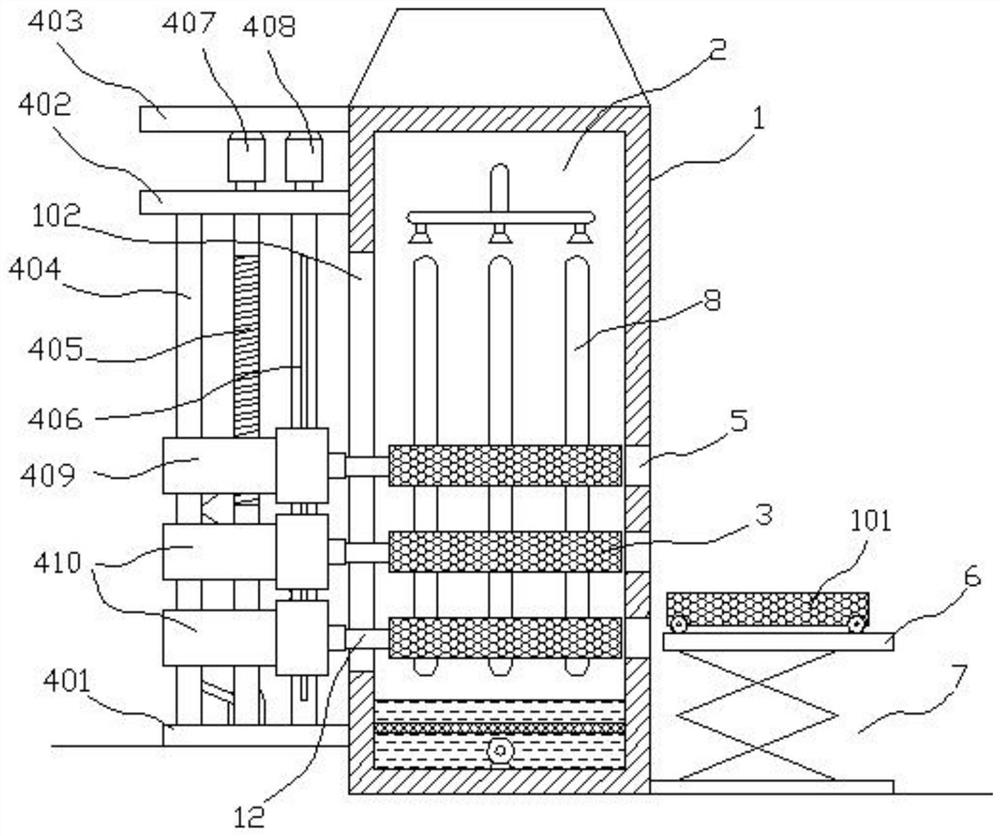

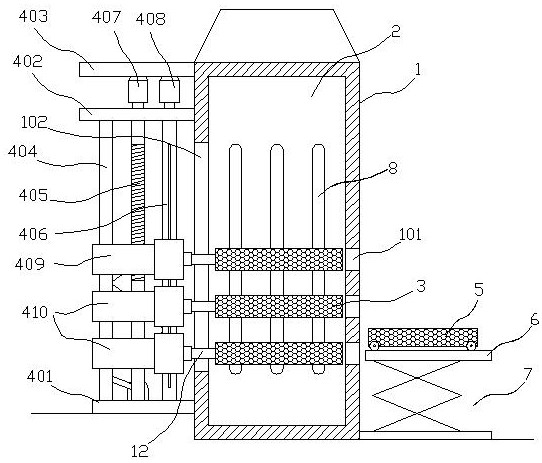

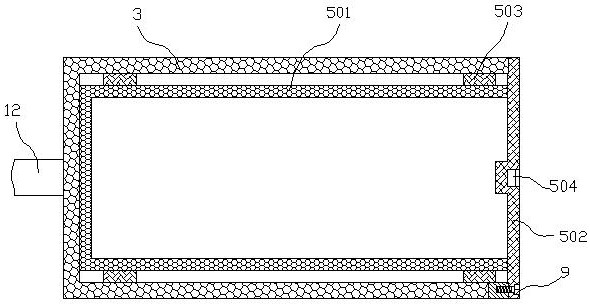

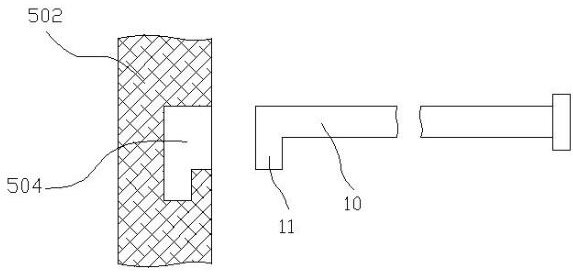

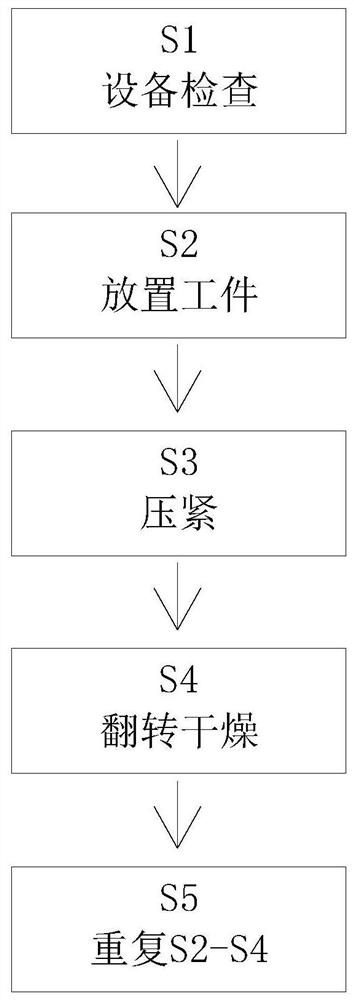

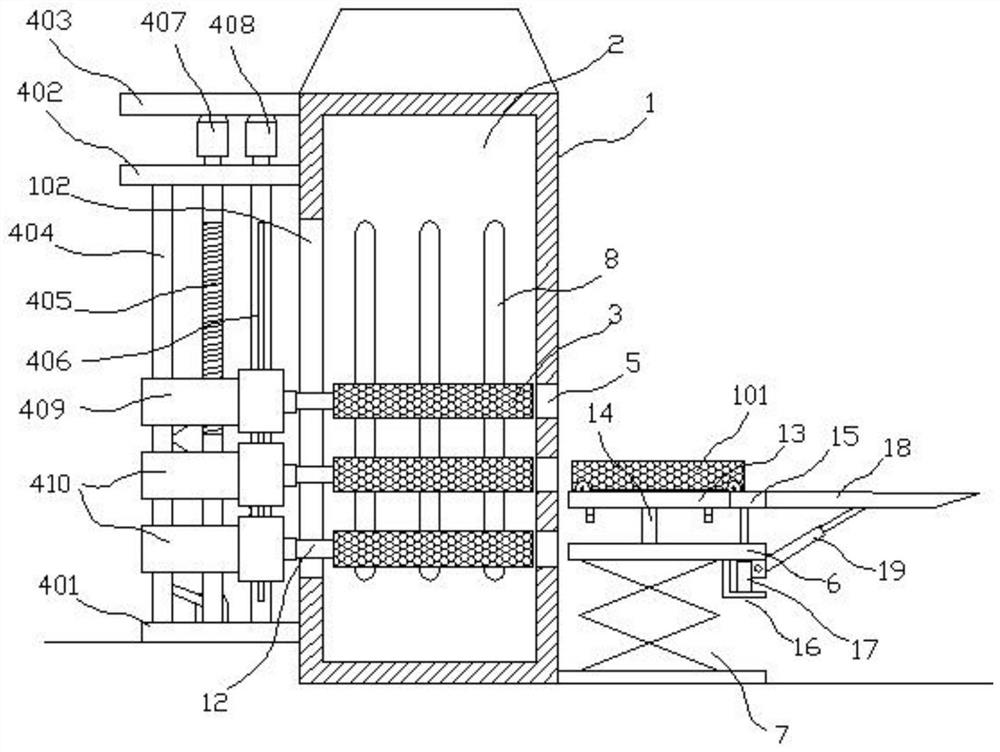

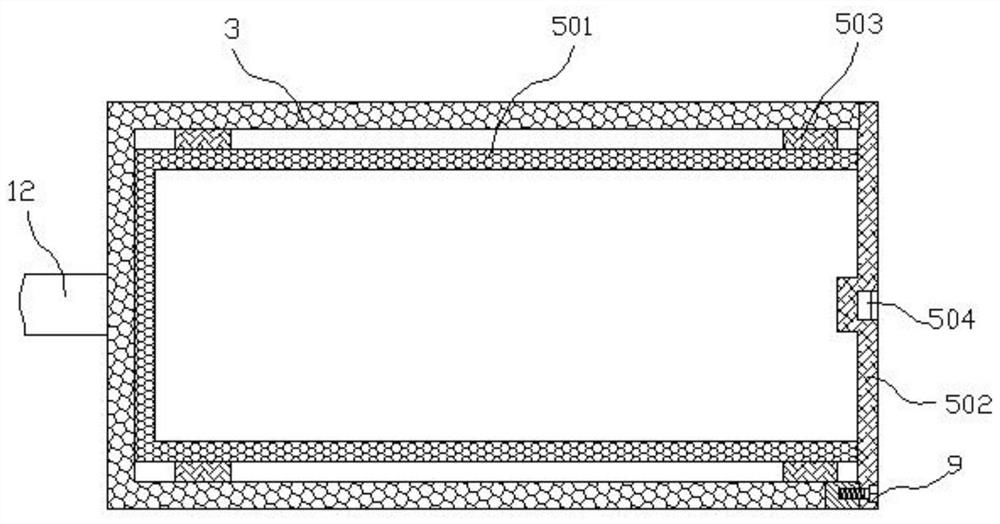

Tea seed cleaning and drying integrated equipment for camellia oil processing

ActiveCN113317528AImprove drying efficiencyImprove qualityFatty-oils/fats productionFood treatmentAgricultural engineeringWater pipe

The invention discloses tea seed cleaning and drying integrated equipment for camellia oil processing, and relates to the technical field of tea seed processing. The equipment comprises a drying tower, drying frames, frame vehicles, a driving mechanism for driving the drying frames to do up-and-down synchronous same-distance linear motion and to overturn and a lifting platform for feeding the frame vehicles into the frames. The multiple drying frames are driven by the driving mechanism which is uniquely designed, tea seed materials can be statically and dynamically dried, the drying efficiency and quality are improved, the automation degree is high, time and labor are saved, operation is convenient, the labor cost is greatly reduced, the dried tea seed materials are evenly heated, and the risk of reworking and secondary processing production is reduced. A water accumulating tank, a water suction pump, a water pipe and spraying heads are additionally arranged on a tower body, so that the equipment has the function of cleaning the tea seed materials in the frames, and then cleaning and drying operation on the tea seed materials can be sequentially completed by one set of equipment.

Owner:安徽东旭大别山农业科技有限公司

An efficient and environmentally friendly tea seed drying equipment for camellia oleifera processing

ActiveCN113324385BImprove drying efficiencyImprove qualityDrying solid materialsFatty-oils/fats productionAgricultural scienceCamellia oleifera

The invention discloses a high-efficiency and environment-friendly tea seed drying equipment for camellia oleifera processing, which relates to the technical field of camellia oleifera seed processing. The overturned drive mechanism and the above-mentioned frame car are sent into the frame to lift the platform, and the multiple drying frames are driven by the uniquely designed drive mechanism, which can achieve static and dynamic drying of tea seed materials. The two modes and switching can be Significantly speed up the drying efficiency of the material. During the drying period, the water and impurities in the tea seed material can be discharged, which significantly improves the quality of the dried material. The machine is used to arrange the space of the frame and the materials in it, and the degree of automation is improved. High, time-saving and labor-saving, convenient operation, greatly reduced labor costs, and the dried tea seed materials are heated evenly, and the drying degree can be kept consistent, which solves the common problems of uneven, incomplete and poor consistency of tea seed materials.

Owner:安徽东旭大别山农业科技有限公司

Automobile sheet metal process

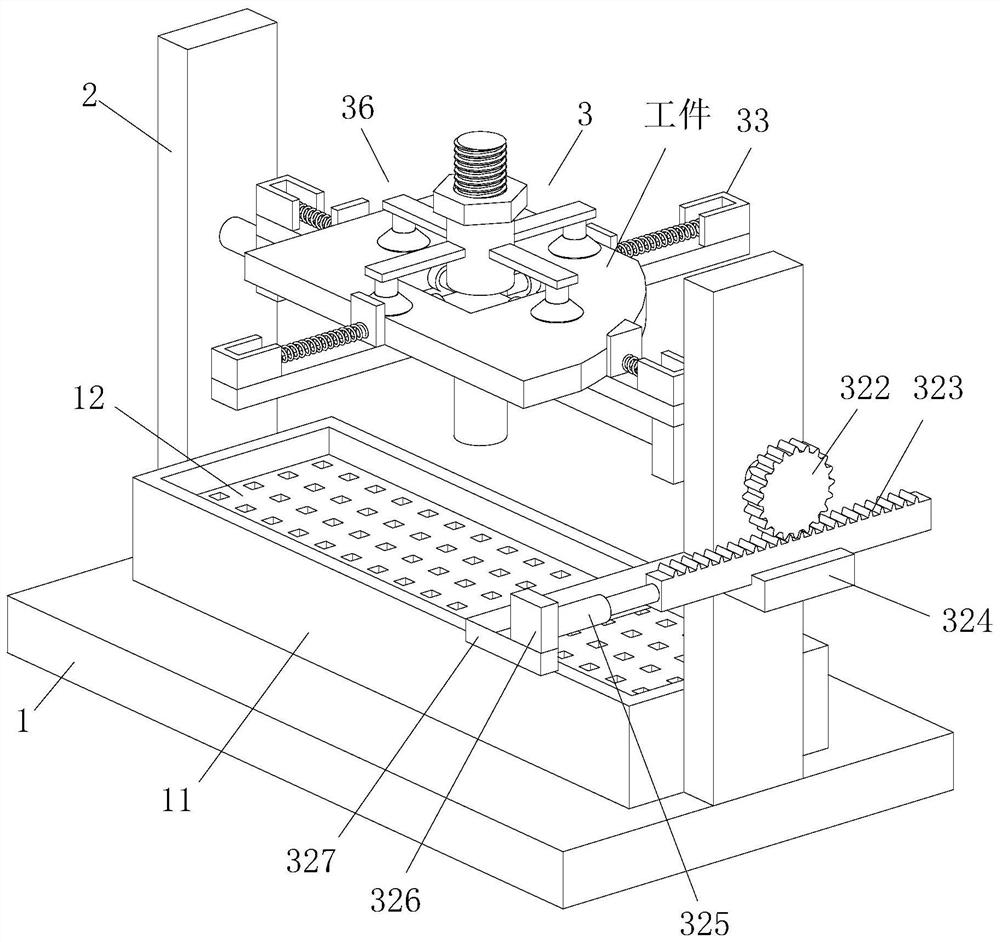

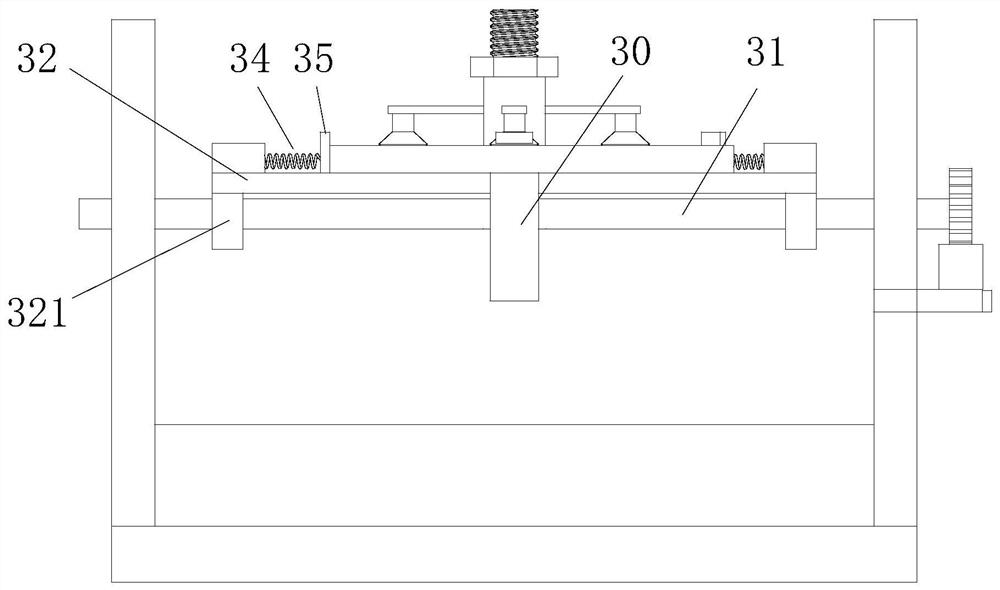

InactiveCN112588876ARealize the function of limit fixationImprove practicalityMetal-working feeding devicesPretreated surfacesBilateral symmetryIndustrial engineering

The invention provides an automobile sheet metal process which adopts the following equipment for treatment: the equipment comprises a base, support frames and a clamping device. The lower end of thebase is connected with the existing ground; the support frames are mounted on the upper end surface of the base in a bilateral symmetry manner; and the clamping device is arranged between the supportframes which are opposite to each other left and right. According to the automobile sheet metal process provided by the invention, through mutual cooperation of an inner supporting module, an extrusion plate, a spring and a [-shaped frame, the periphery of an automobile sheet metal workpiece can be limited; the position of the extrusion plate can be automatically adjusted by arranging the spring,so that the function of limiting and fixing the automobile sheet metal workpiece in an all-around mode is achieved; and meanwhile, the equipment can be used for fixing and machining the automobile sheet metal workpieces with different sizes and specifications, so that the practicability of the equipment is improved.

Owner:南京柯策商贸有限公司

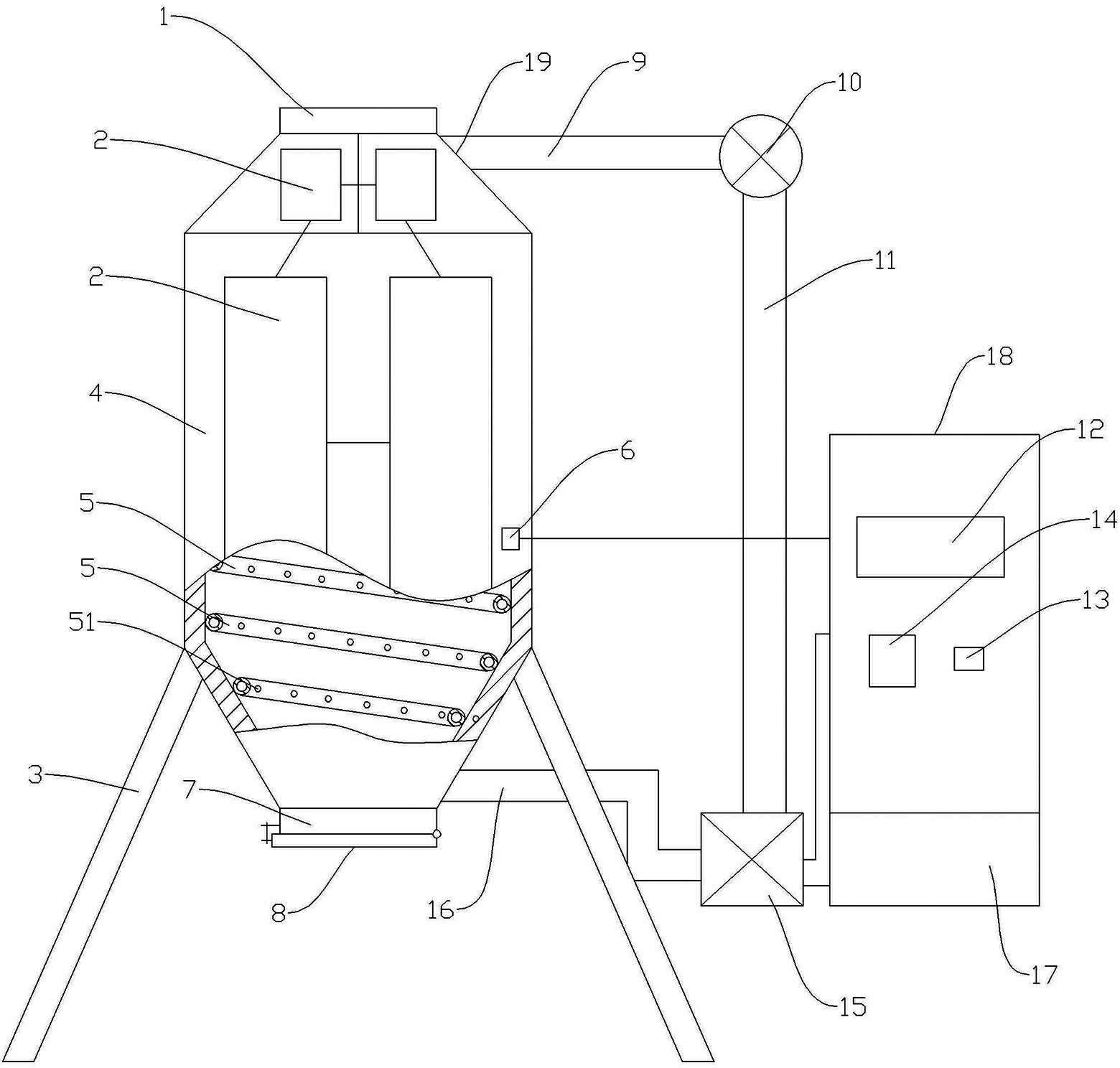

Camellia seed drying equipment for camellia oil cold pressing production

ActiveCN113324382AImprove drying efficiencyImprove qualityDrying chambers/containersDrying solid materialsAgricultural scienceAgricultural engineering

The invention discloses camellia seed drying equipment for camellia oil cold pressing production, and relates to the technical field of camellia seed processing. The camellia seed drying equipment comprises a drying tower, a plurality of drying frames, a frame vehicle, a driving mechanism for driving the drying frames to synchronously and linearly move up and down at the same distance and turn over, and a lifting platform for conveying the frame vehicle into the frames. The drying frame is driven by the driving mechanism which is uniquely designed, camellia seed materials can be statically and dynamically dried, the drying efficiency and quality of the materials are improved, the automation degree is high, time and labor are saved, operation is convenient, the labor cost is greatly reduced, the dried camellia seed materials are evenly heated, and through the improved design of the lifting platform, the frame vehicle is moved to the lifting platform through a first hydraulic oil cylinder and a second hydraulic oil cylinder, so that the frame vehicle is very convenient to enter and exit from the frame, and the labor cost is greatly reduced.

Owner:安徽东旭大别山农业科技有限公司

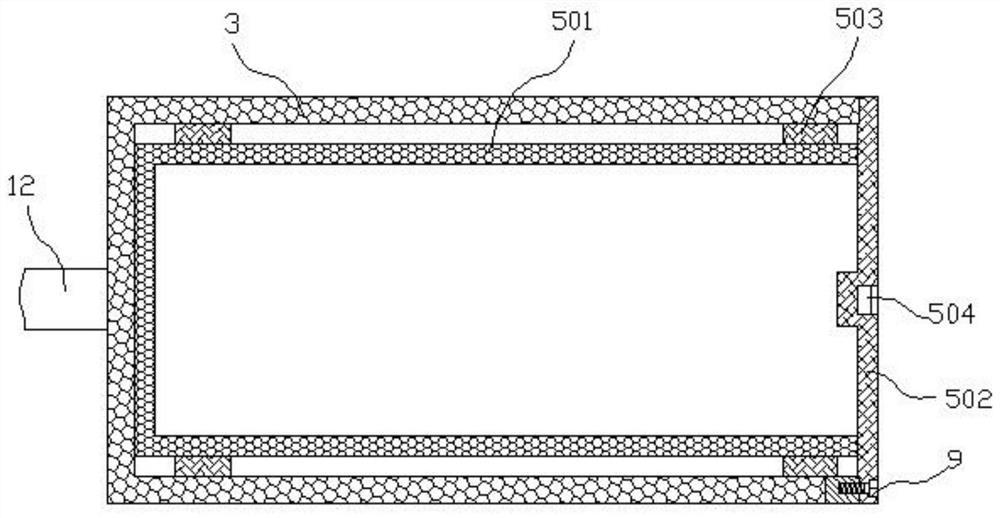

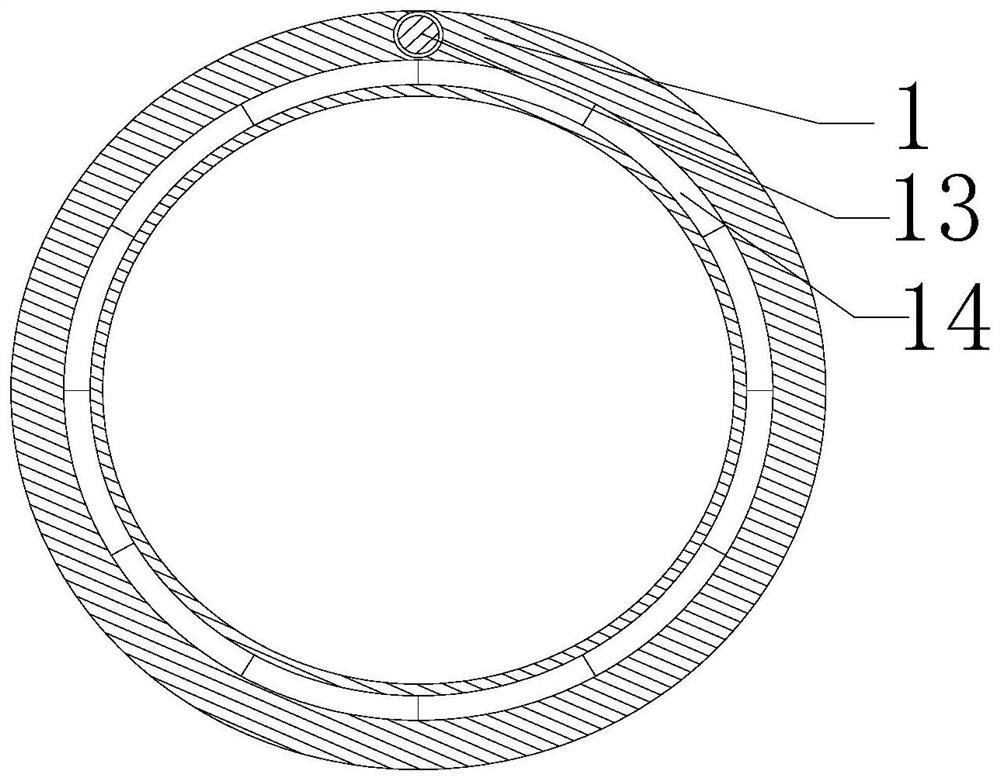

A drying structure for reducing the moisture content of log planks

ActiveCN108592538BEvenly heatedConsistent drynessDrying solid materials without heatDrying chambers/containersDry structureEngineering

The invention discloses a drying structure for reducing log board water content. The drying structure comprises a tank body and an end cover; a liquid collecting tank is formed in the inner wall of the bottom of the tank body along the axis of the tank body; guide rails are arranged at the two ends of the liquid collecting tank; chutes are formed in the upper surfaces of the two guide rails; multiple suction holes are formed in the inner wall of the top of the tank body along the axis of the tank body, and communicate with suction pipes arranged on the outer wall of the tank body; clamping grooves are formed in the upper surfaces of all longitudinal plates; and multiple slide blocks are arranged at the middle parts of the lower surfaces of all transverse plates. The drying structure heatslogs under vacuum environment, and timely exhausts steam in the tank body to guarantee uniform heating of the logs in the tank body, so that the drying degrees of the logs in different placing positions are the same, meanwhile, the drying efficiency and the drying cost of the logs are in positive correlation, and the maximum heat efficiency of the drying tank in log drying is achieved.

Owner:CHENGDU ZINAN FURNITURE

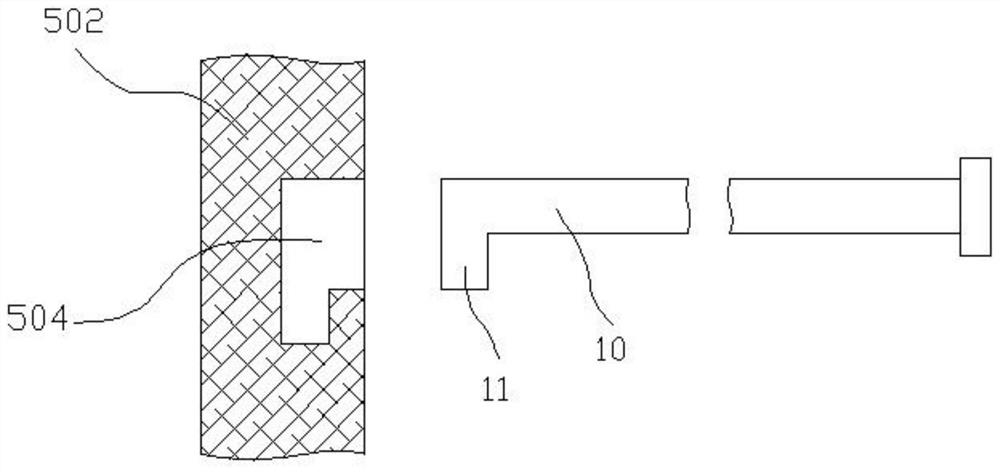

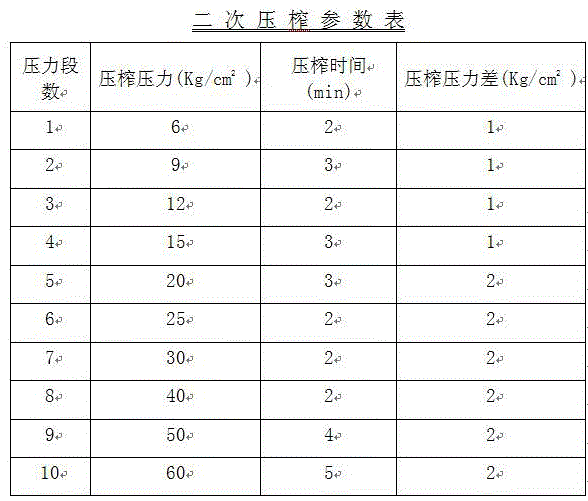

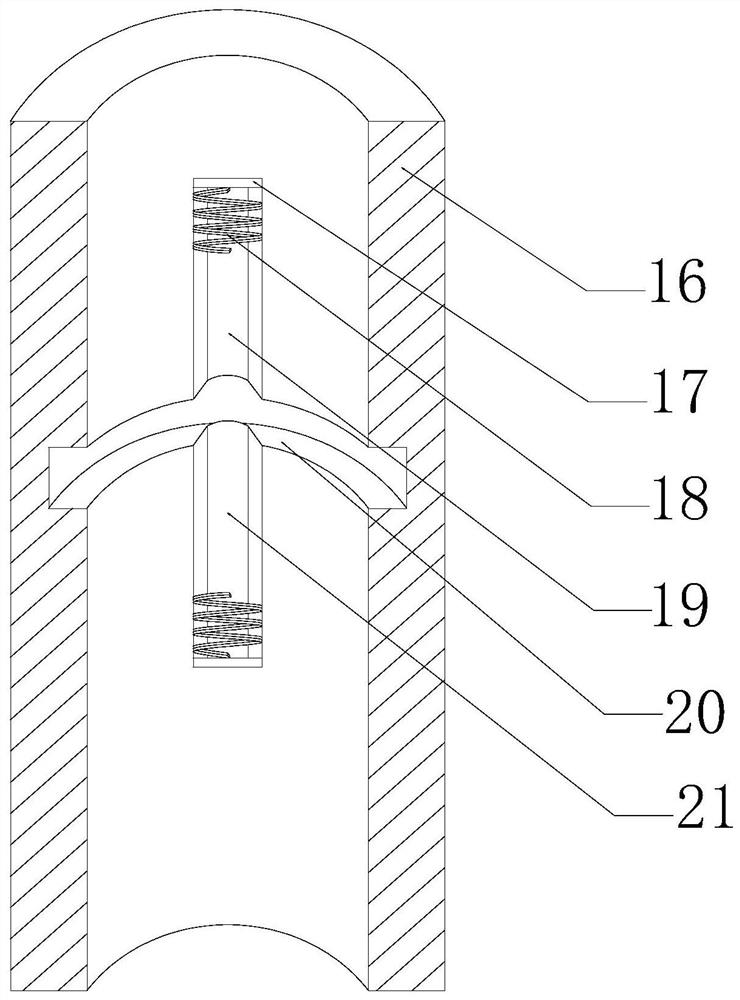

A pressing method of variable capacity filter press

InactiveCN104649561BImprove drynessConsistent drynessSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesHydraulic cylinderPressure difference

The invention discloses a squeezing method of a variable-volume press filter. The squeezing method comprises the following steps: pre-pressing, feeding, primary squeezing and dehydration and secondary squeezing and dehydration, wherein the secondary squeezing and dehydration process comprises a plurality of segmented squeezing and dehydration, each segmented squeezing and dehydration process comprises the following steps: maintaining pressure and dehydrating for certain time under the squeezing pressure value set in the segment, wherein squeezing pressure is reduced due to dehydration of squeezed objects, when the squeezing pressure value is reduced to a set pressure difference, a hydraulic cylinder acts to achieve the set squeezing pressure value to be continuously squeezed and dehydrated until set squeezing time at the segment is reached, then entering the next segmented squeezing and dehydration process until all the squeezing and dehydration time of all segments are over, then the next squeezing and dehydration process is allowed, and the squeezing pressure values in the squeezing and dehydration process of all segments are gradually increased from front to back. The squeezing method has the significant advantages that the material dryness is large, the internal and external dryness are consistent and the dehydration efficiency is high.

Owner:HENAN BAIHUI ENVIRONMENTAL PROTECTION TECH CO LTD

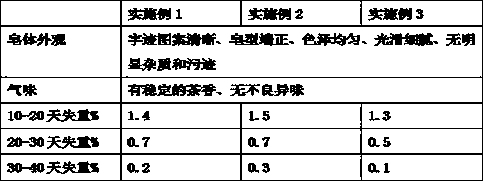

Processing method of matcha handmade soap and obtained matcha handmade soap

ActiveCN108559672BImprove completenessImprove efficiencyShaping soapDetergent compounding agentsProcess engineeringSaponification

The invention discloses a making method of handmade matcha soap and handmade matcha soap made via the making method, wherein the making method comprises: dispensing materials; quantitatively weighingoil, an alkali and water; performing saponifying, to be specific, dissolving the alkali in water, mixing the solution with the oil, adding matcha into the mixture, and allowing reacting; solidifying,to be specific, pouring the reacted liquid into a mold, and airing to obtain the handmade matcha soap. The handmade matcha soap with the matcha has a basic cleaning function, and a function of resisting and even eliminating computer radiation hazard.

Owner:贵州湄潭兰馨茶业有限公司

Filter cake drying and collecting device for 2-methyl-5-pyrazinecarboxylic acid production

ActiveCN114322521ARealize repeated tumble dryingConsistent drynessDrying chambers/containersDrying machines with progressive movementsPyrazinecarboxylic acidEngineering

The invention discloses a filter cake drying and collecting device for 2-methyl-5-pyrazinecarboxylic acid production, and relates to the field of filter cake drying. According to the technical scheme, the filter cake drying and collecting device comprises a drying box, penetrating grooves are symmetrically formed in the outer portion of the drying box, and a plurality of overturning mechanisms and a plurality of conveying belts are assembled in the drying box; the multiple overturning mechanisms and the multiple sections of conveying belts are distributed in a staggered mode, one side of each overturning mechanism is adjacent to the corresponding conveying belt, a buffering mechanism is adjacently arranged on the other side of each overturning mechanism, clamping rods are symmetrically installed in the drying box, and the outer portions of the clamping rods are slidably connected with mounting plates. A positioning mechanism used for dividing filter cakes into columns is arranged between the two mounting plates, guide plates are mounted outside the mounting plates, the distance between the column dividing plates can be adjusted by adjusting the positions of the mounting plates in the positioning mechanism, and then the filter cakes moving on the conveying belt can be evenly divided into columns. And the filter cakes can be conveniently collected through the collecting box.

Owner:东营曜康医药科技有限公司

Log high frequency vacuum drying tank

ActiveCN108582354BEvenly heatedConsistent drynessWood treatment detailsWood heatingEngineeringThermal treatment

The invention discloses a high-frequency vacuum drying tank for logs, which includes a tank body and an end cover, and a liquid collection tank is opened on the inner wall of the bottom along the axis of the tank body, and guide rails are respectively arranged at both ends of the liquid collection tank, and each guide rail There is a chute on the upper surface, and a plurality of suction holes are opened on the inner wall of the top along the axis of the tank body. The plurality of suction holes communicate with the suction pipes arranged on the outer wall of the tank body. A heating assembly is arranged on the outer wall; a card slot is opened on the upper surface of each longitudinal plate, and a plurality of sliding blocks are arranged in the middle of the lower surface of each transverse plate. The invention heats the log in a vacuum environment, and discharges the steam inside the tank in time to ensure that the wood inside the tank is heated evenly, the drying degree of the wood in different positions is consistent, and at the same time, the drying heat efficiency of the wood is guaranteed to be the same as that of drying The cost is positively correlated and the thermal efficiency of the drying tank is maximized while drying the wood.

Owner:CHENGDU ZINAN FURNITURE

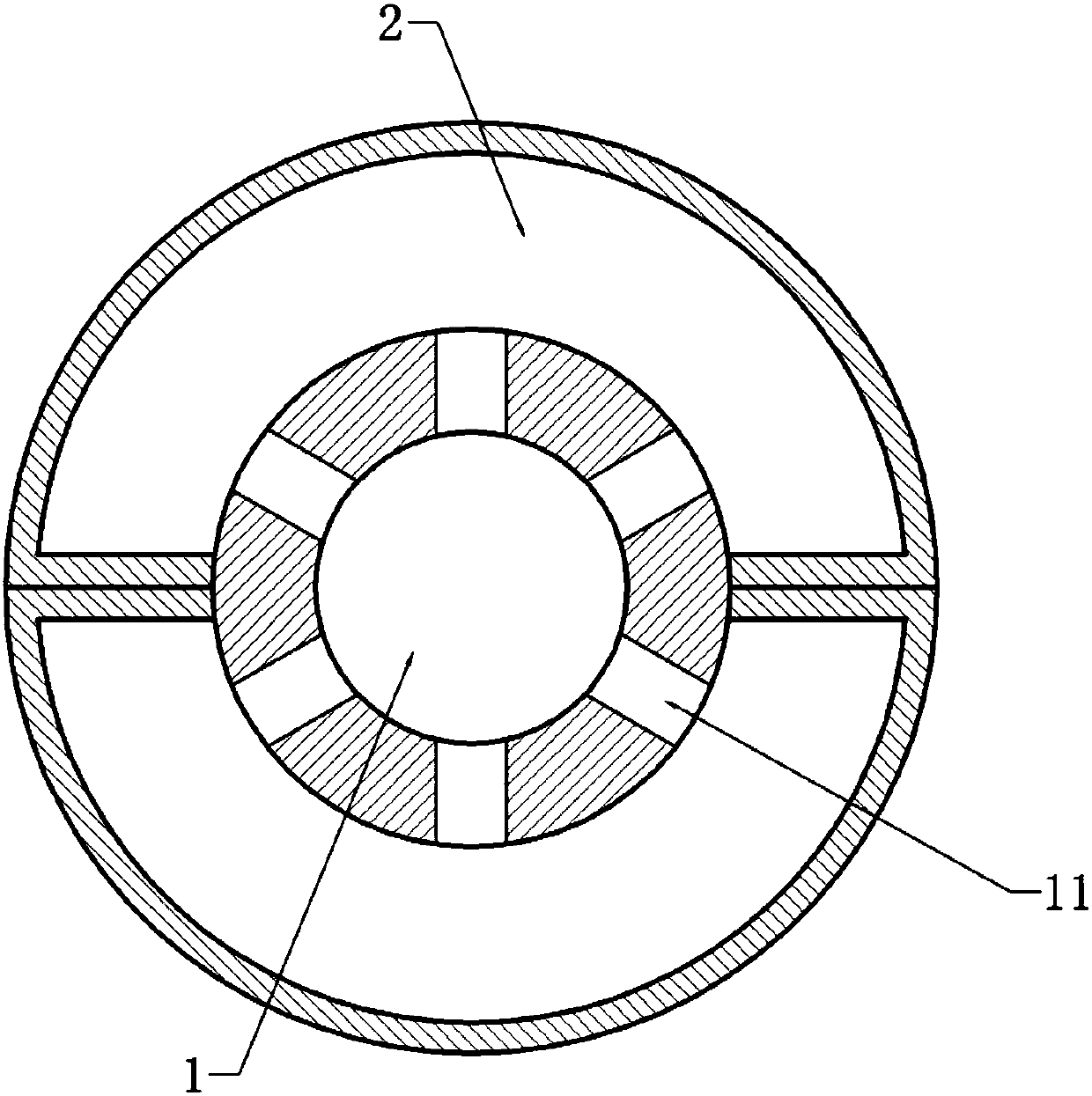

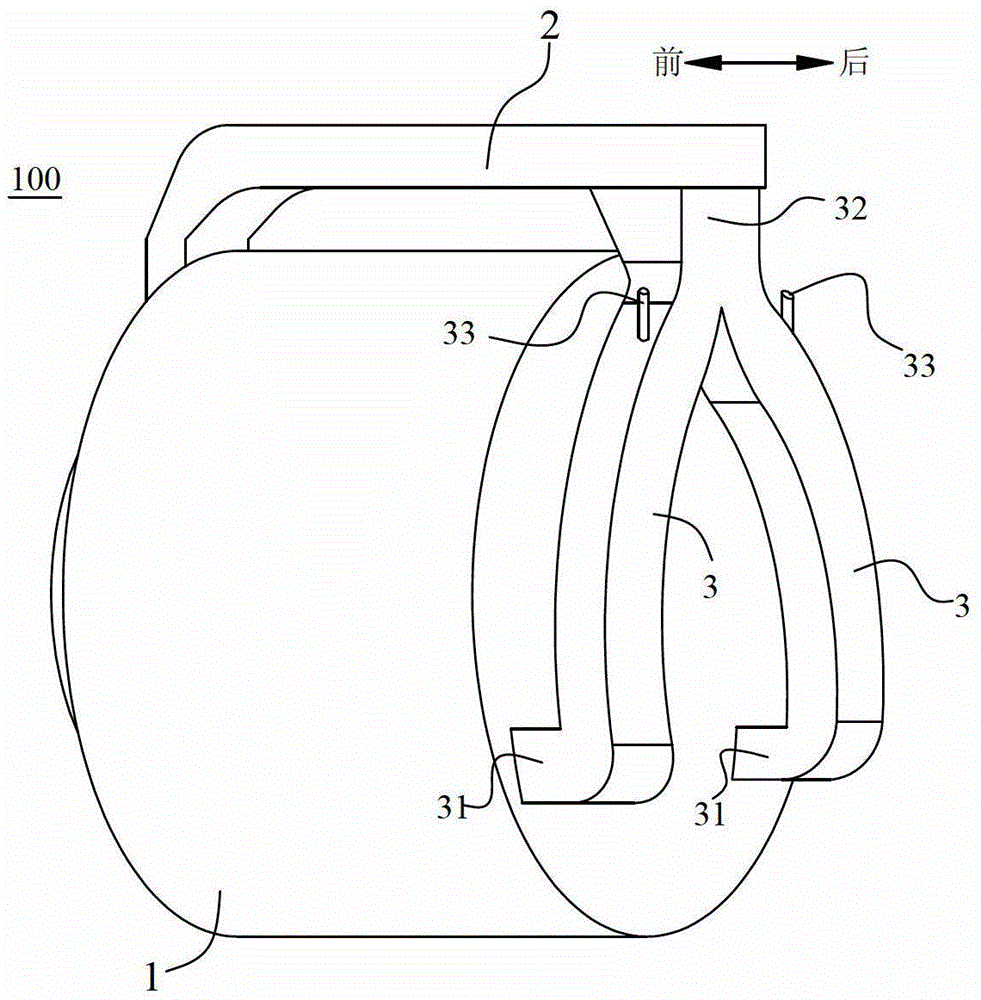

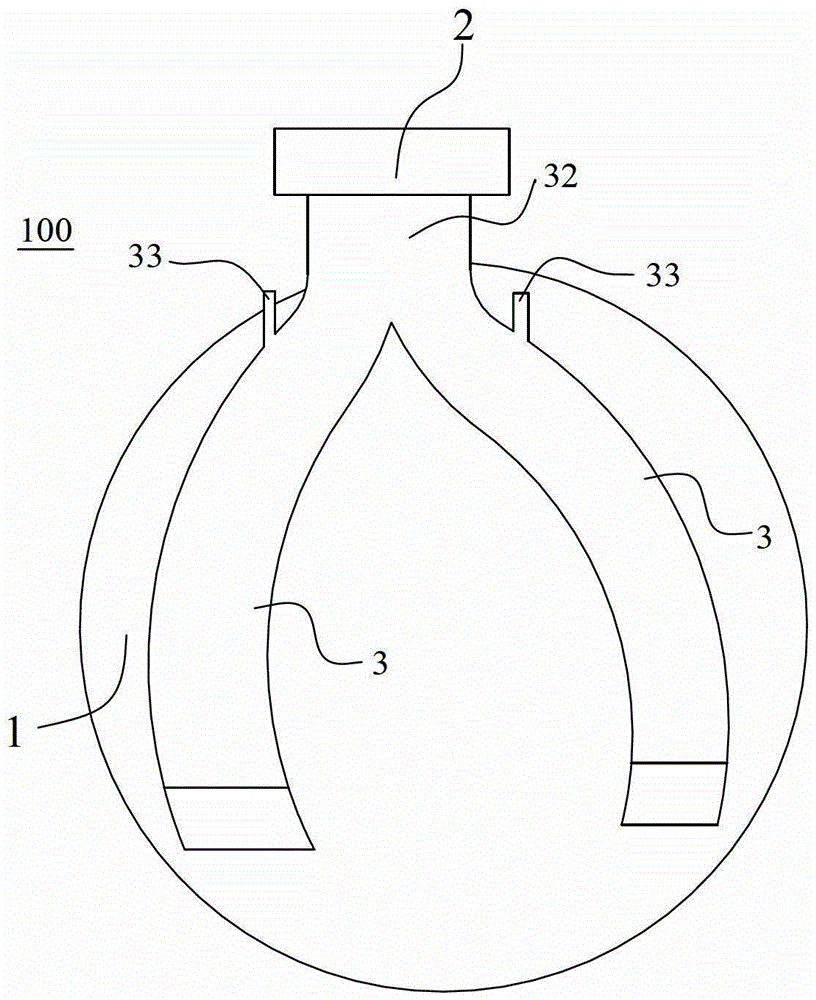

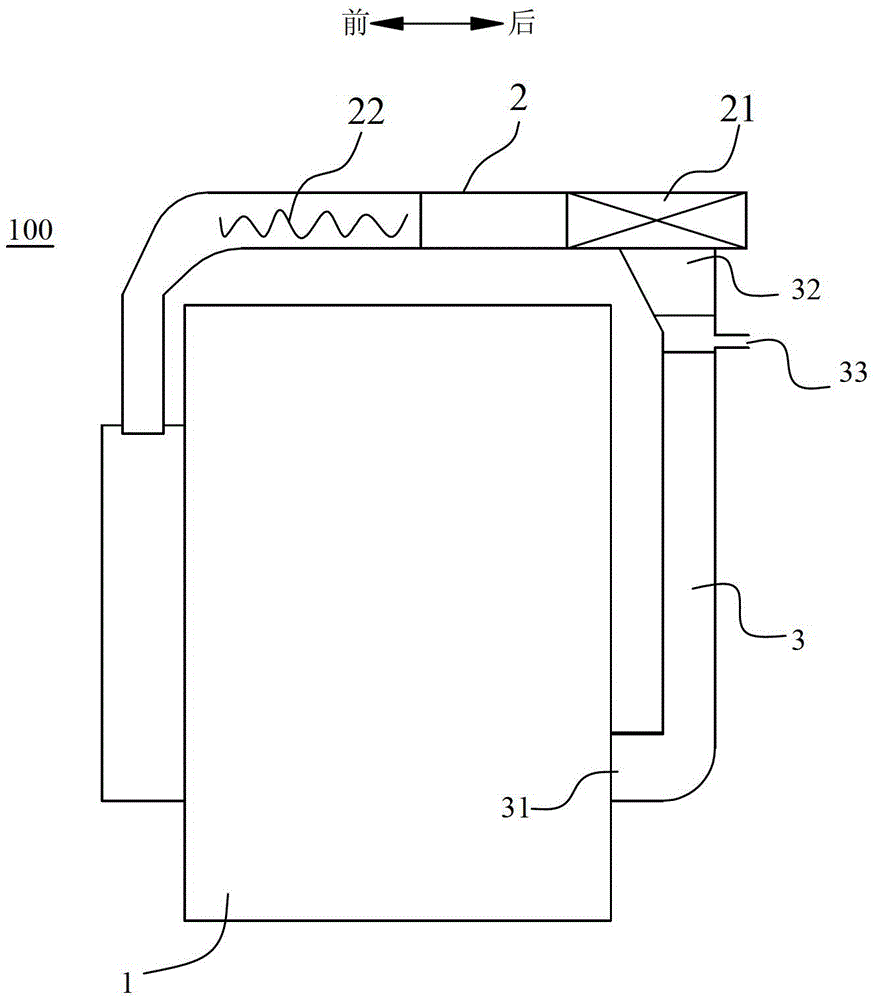

Drum of washing machine and drum washing machine having same

ActiveCN103266458BConsistent drynessIncrease condensation areaTextiles and paperLaundry driersAir volumeEngineering

The present invention discloses a washing machine and a drum washing machine having a drum thereof. The drum washing machine comprising: a barrel assembly, said barrel assembly having a receiving chamber for receiving laundry; drying duct, in communication with said receiving chamber of the drying channel; a plurality of condensation passages, said plurality the inlet end of the condensing passages communicating respectively receiving chamber, a plurality of condensation passages respectively communicating with the outlet end of the drying duct and the condensing passages each having a plurality of upper water inlet. The area of the washing drum condensed embodiment of the present invention, high heat transfer efficiency, return air resistance is small, drying air volume, more uniform degree of drying laundry.

Owner:WUXI LITTLE SWAN ELECTRIC CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com