Ultrahigh-voltage oilpaper capacitive bushing capacitor core drying method

A technology of bushing capacitor and drying method, applied in the direction of drying/dipping machine, etc., can solve the problems of incomplete drying, long drying time, affecting the service life of insulation, etc., and achieve complete drying, small decrease in polymerization degree, and high temperature heating. short time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further elaborated below in conjunction with the accompanying drawings of the description.

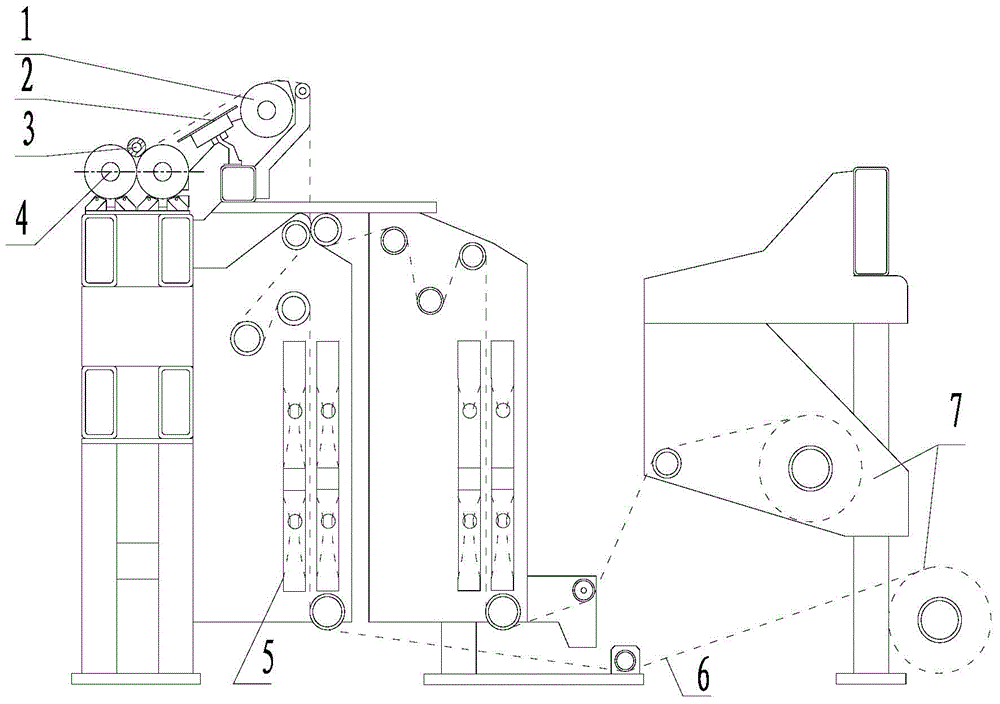

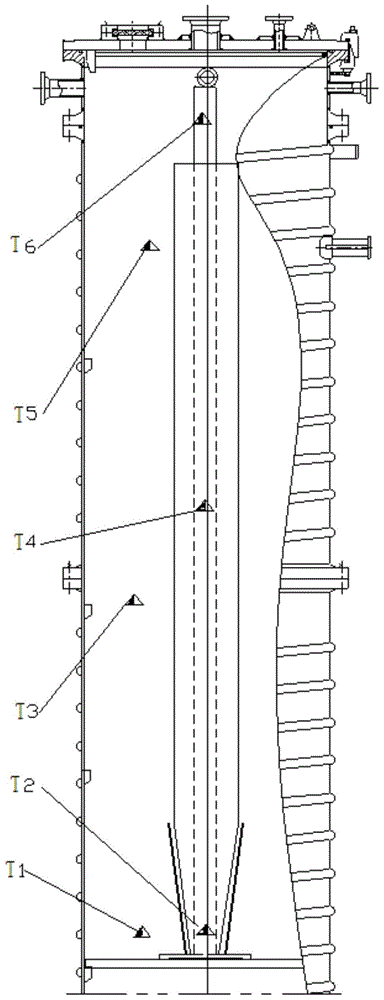

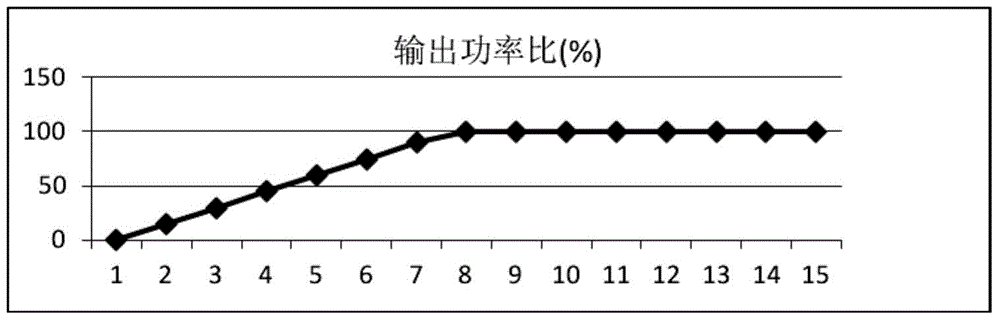

[0035] The method of the invention abandons the traditional way of drying the capacitor core as a whole after the coiling is completed, and each part cooperates with different drying equipment and drying processes to undertake different drying tasks. The first part (pre-drying) removes about 15% to 20% of the moisture in the insulation, reducing the moisture content of the insulating paper from 6 to 8% to 4 to 6%; the second part (main drying) during the rolling process Dry the single-layer insulating paper to reduce the moisture content of the insulating paper from 4 to 6% to less than 0.3%; the third part (auxiliary drying) is the drying and finishing after rolling. Good insulating paper absorbs moisture away. Specific steps are as follows:

[0036] Pre-drying before rolling: dry the insulating paper base paper bundle 7 in a drying room to remov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com