Patents

Literature

144results about How to "Solve industry problems" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

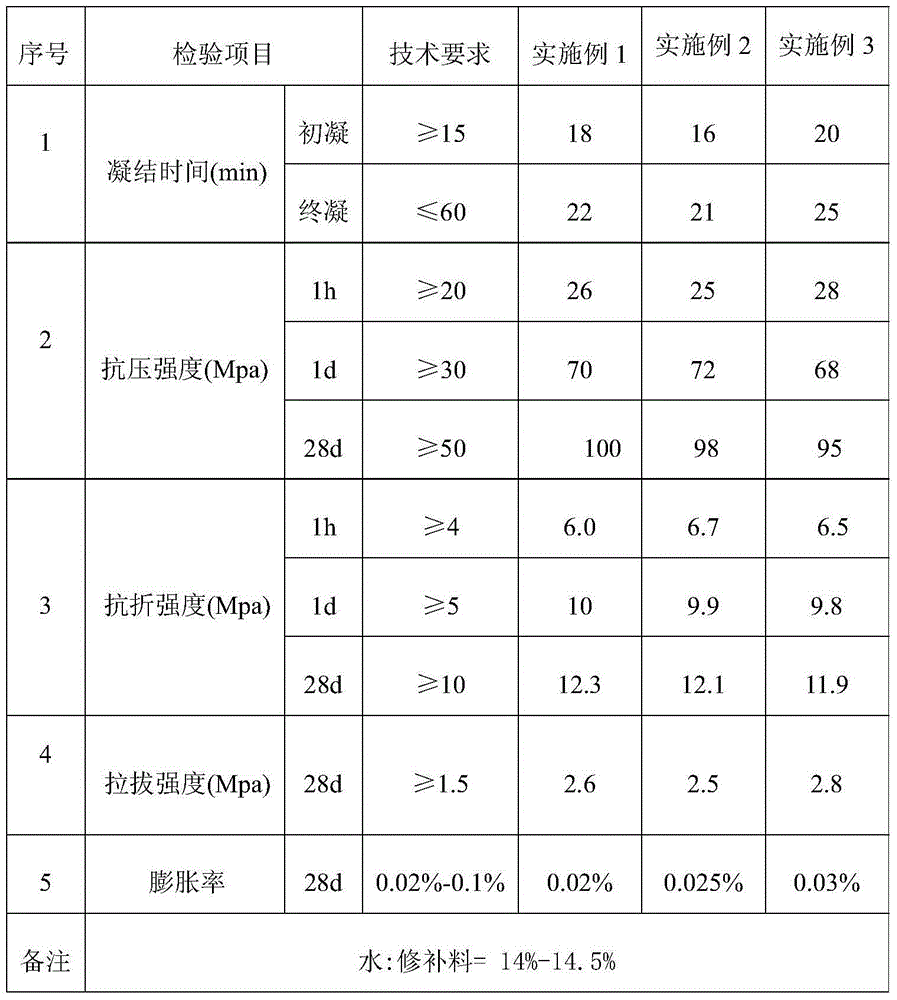

Pavement/bridge deck concrete fast mending material and application thereof

The invention relates to a pavement / bridge deck concrete fast mending material and application thereof. The mending material comprises the following raw materials by weight: 20 to 30 parts of sulphoaluminate cement, 8 to 10 parts of ordinary Portland cement 52.5, 5 to 10 parts of polymer powder, 0.5 to 1.5 parts of aluminium sulphate, 1 to 2 parts of water glass, 0.1 to 1 part of organic silicon, 1 to 2 parts of gypsum, 2 to 3 parts of slag, 0.1 to 0.5 part of silica micropowder, 0.5 to 1 part of an HPCA high-performance concrete expansive material, 3 to 5 parts of fly ash, 20 to 30 parts of washed-out and dried sand, 25 to 30 parts of corundum, 3 to 5 parts of composite fiber, 1 to 3 parts of a polycarboxylate superplasticizer, 0.1 to 0.5 part of boric acid, 0.1 to 0.3 part of sodium gluconate, and 0.2 to 1 part of lithium carbonate. The mending material is high in early strength, and has the advantages that traffic can be opened fast only 1 to 2 hours after mending is completed, so as to reduce traffic jams, and effectively reduce the generation of traffic accidents.

Owner:HENAN HUINENG ROAD & BRIDGE TECH CO LTD

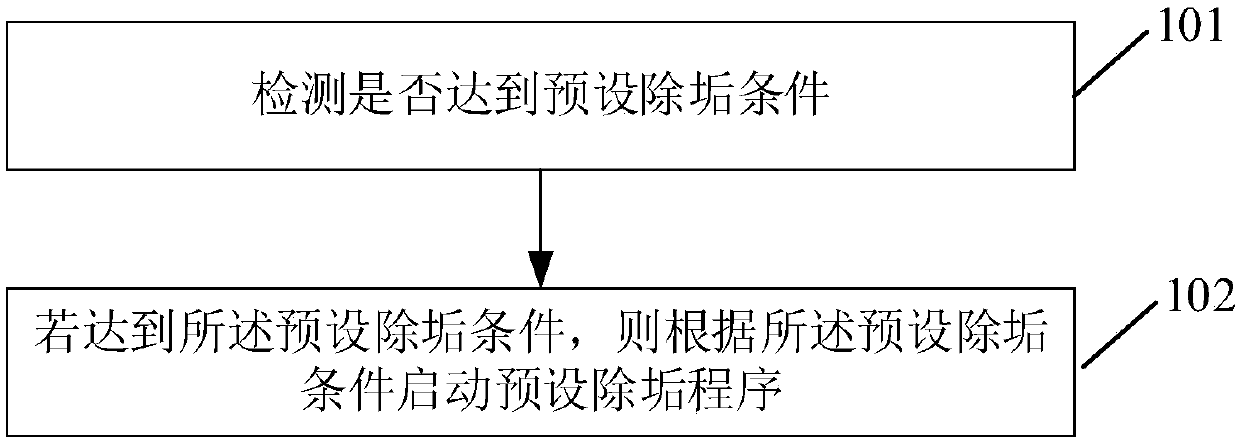

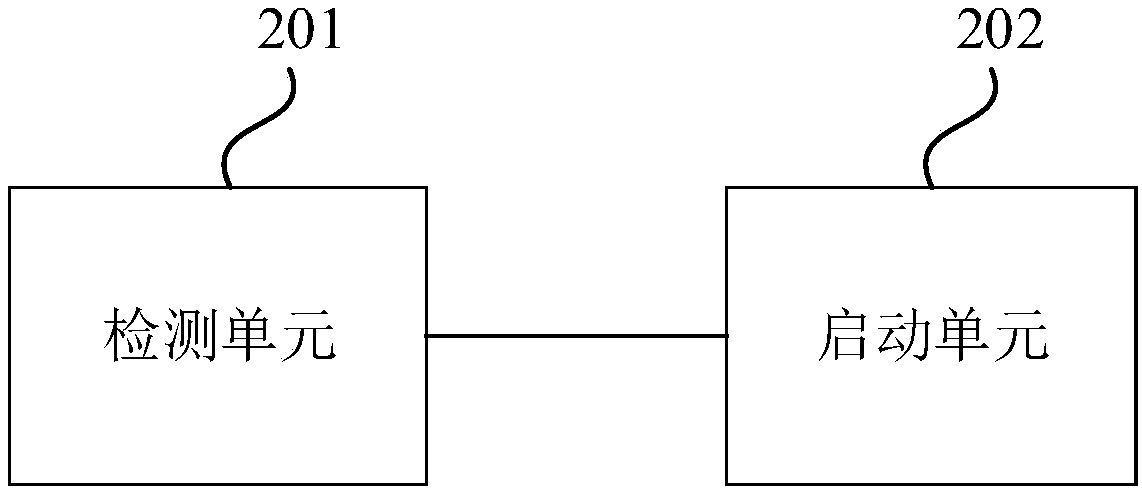

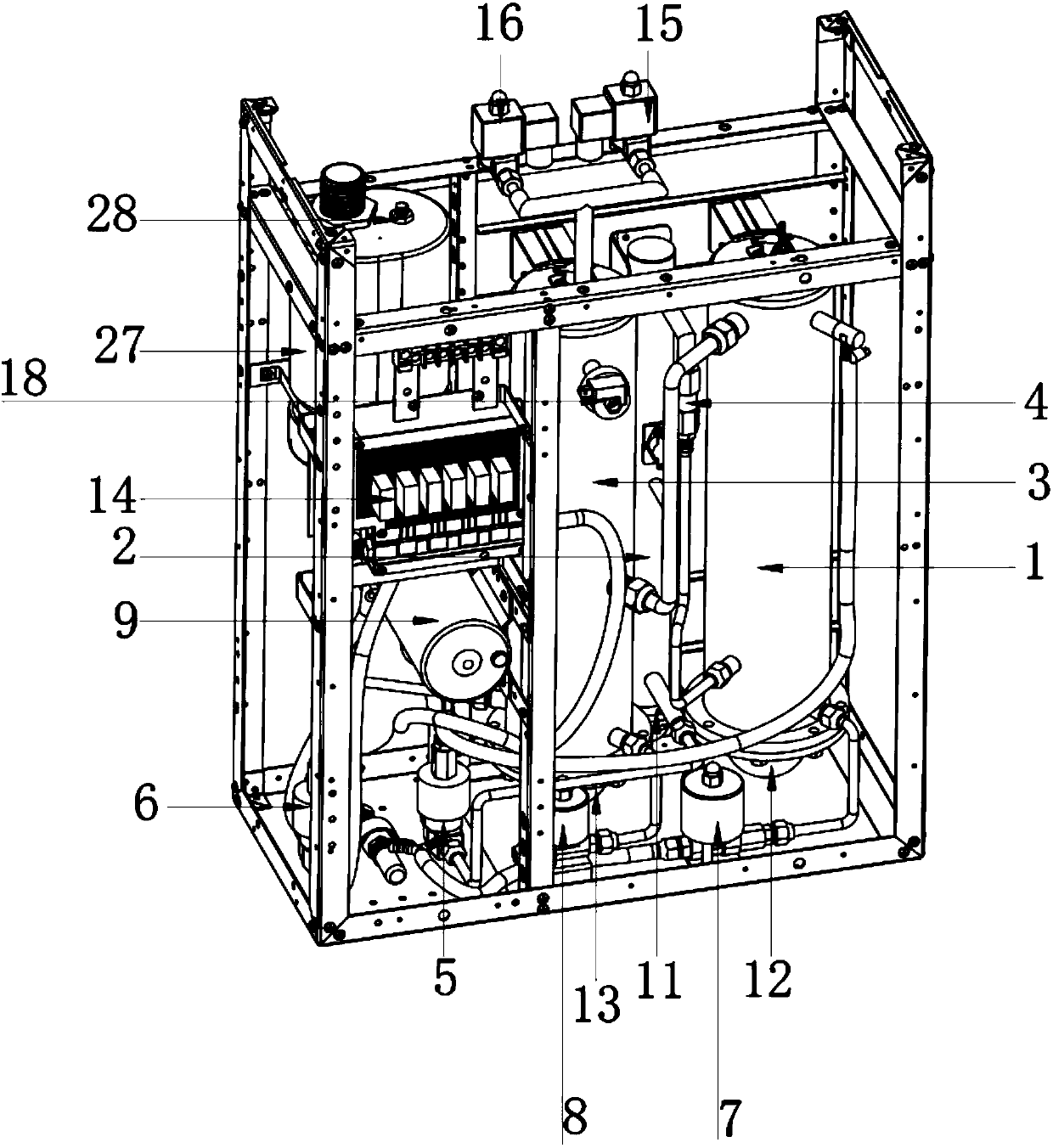

Automatic descaling method and device and system

ActiveCN107620950ARealize fully automatic descaling workReduce foulingSteam generation heating methodsBoiler cleaning apparatusDescaling agentFailure rate

The embodiment of the invention discloses an automatic descaling method and device and system of a steam generator. The automatic descaling method comprises the steps that whether preset descaling conditions are reached or not is detected, the preset descaling conditions comprise that the accumulated operating time of equipment reaches a preset time threshold value, the residue of a descaling agent reaches a preset standard, and an off-duty key OFF is triggered. If the preset descaling conditions are reached, a preset descaling program is started to conduct automatic descaling, so that full-automatic descaling work is achieved, equipment scaling is reduced, the failure rate is decreased, the service life of the equipment is prolonged, and the industry problem is solved.

Owner:深圳汉明威智能设备有限公司

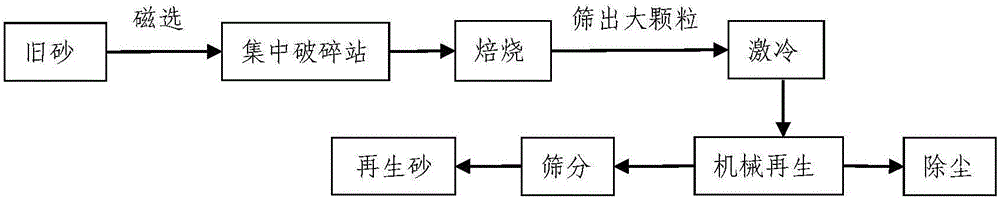

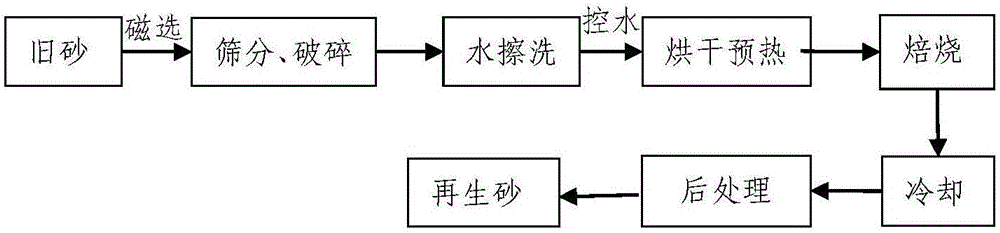

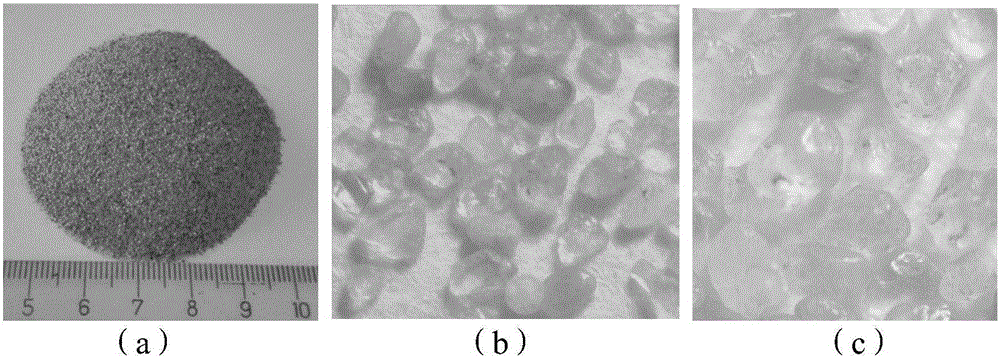

Regeneration method of casting wet type mixed old sand

ActiveCN105728641ASolve industry problemsLow gas productionMould handling/dressing devicesSocial benefitsPerformance index

The invention relates to a regeneration method of casting wet type mixed old sand. The regeneration method comprises the following steps: preprocessing casting wet type mixed old sand; wiping with water; drying; preheating; roasting; and post-processing. In the invention, components, such as bentonite, coal dust and ashes, in wet type old sand are effectively removed by a water wiping process, and a residual resin film in mixed old sand is thoroughly decomposed by a roasting process. The regeneration cost is low, and the regeneration effect is great. Actual production and verification show that the performance indexes of regenerated sand reach or surpass those of new sand. The regeneration method is successively applied to the core making production of cold boxes and has remarkable economical and social benefits.

Owner:WEICHAI POWER CO LTD

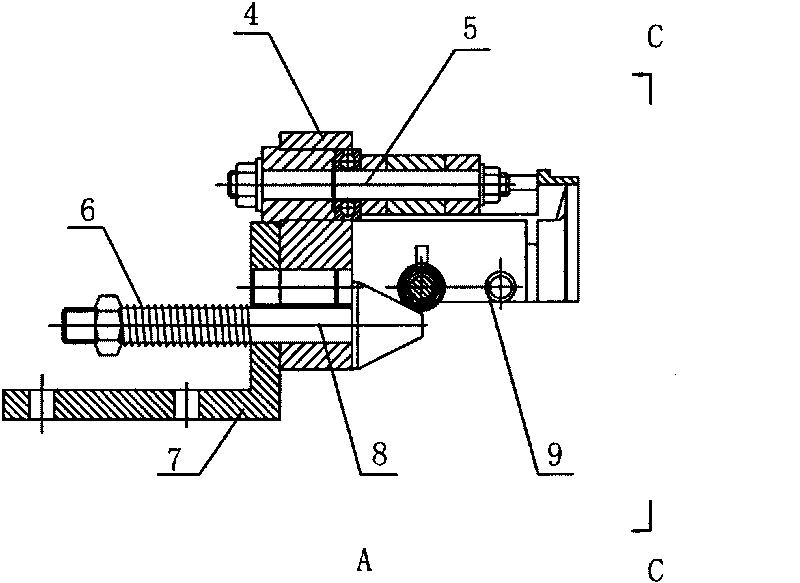

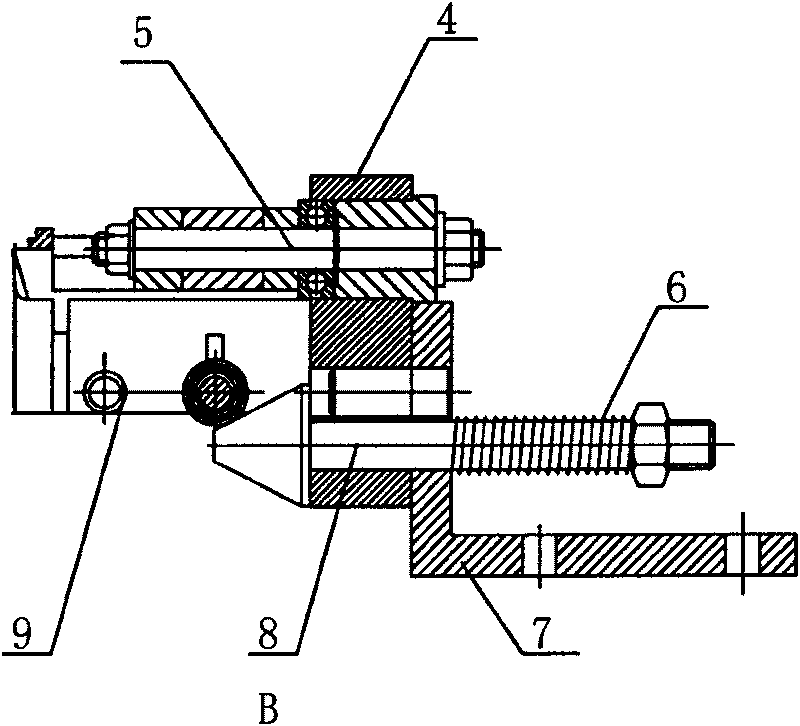

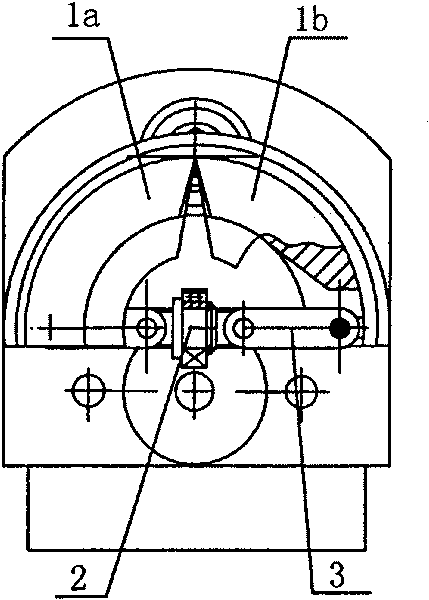

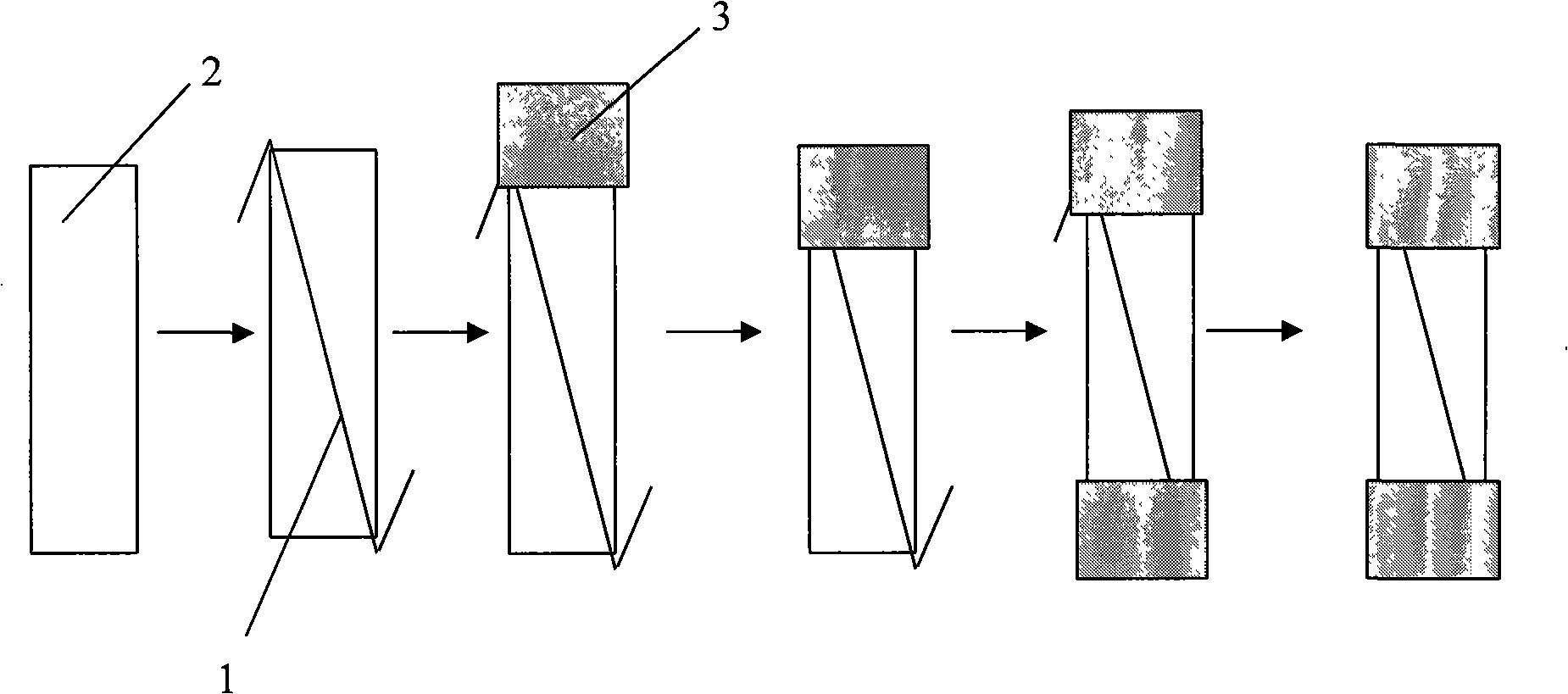

Translational compound paired mould of dumpling machine

InactiveCN101708012ASolve industry problemsReasonable designDough processingMaterials scienceConical surface

The invention discloses a translational compound paired mould of a dumpling machine, relating to a dumpling-processing translational compound paired mould assorted with a dumpling machine. The matched mould is particularly suitable for automatic production of traditional dumplings and different colors of dumplings and is a dumpling shaping module which does not need artificial reshaping. The translational compound paired mould of the dumpling machine consists of a group of translational compound paired moulds A and B; the compound paired moulds A and B consist of mould seats, angle plates, sub moulds 1a and sub moulds 1b; the upper parts of the sub moulds 1a and sub moulds 1b are connected by a spigot shaft in manner of a hinge; the lower parts of the sub moulds 1a and sub moulds 1b are connected to a connecting shaft provided with a bearing through a link joint; the bearing on the connecting shaft and the conical surface of a catch bar cooperate; the catch bar is provided with a main spring; the sub moulds 1a and sub moulds 1b are also provided with return springs; the compound paired moulds A and B are arranged on a lead rail pair through the angle plates; and the sub moulds 1a and sub moulds 1b are circular arc moving moulds.

Owner:无锡孚德机械制造有限公司

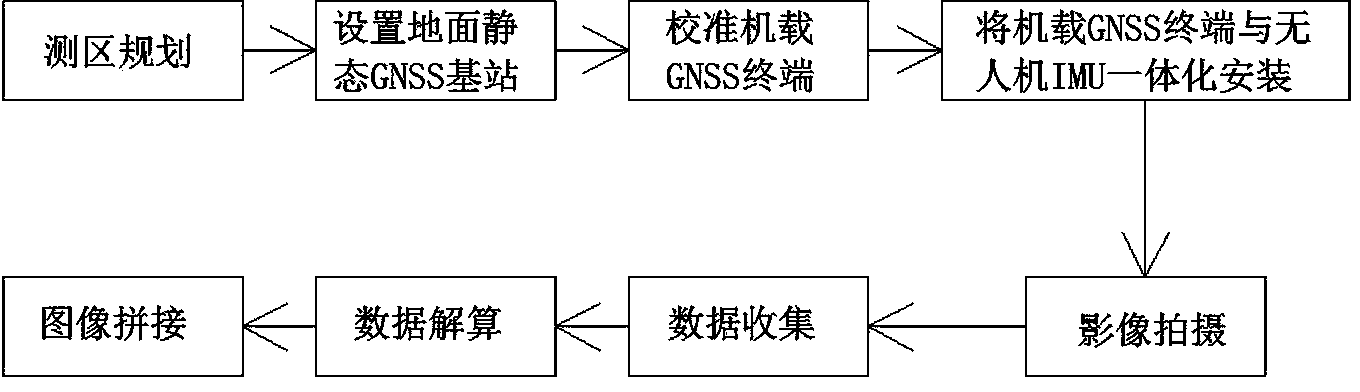

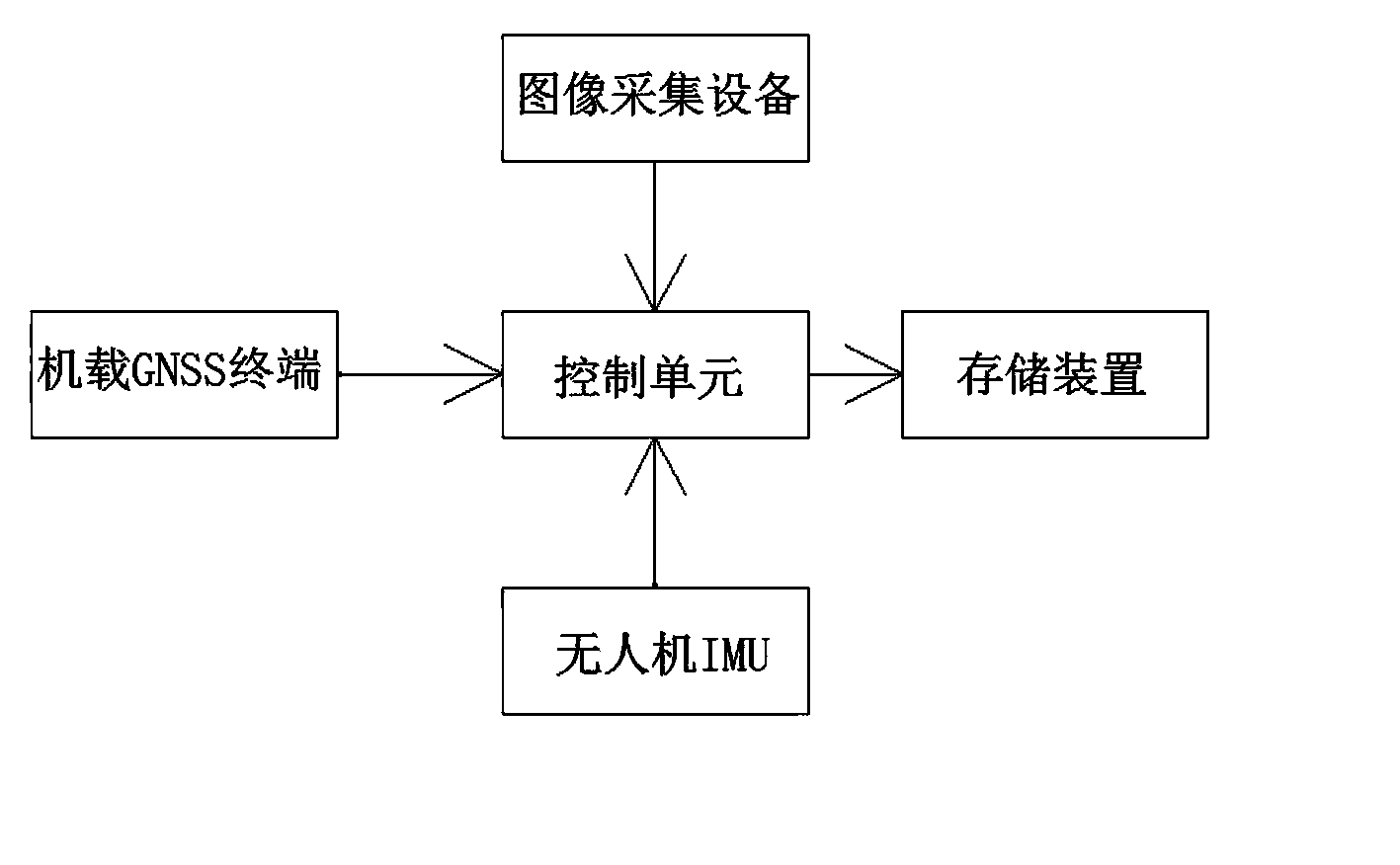

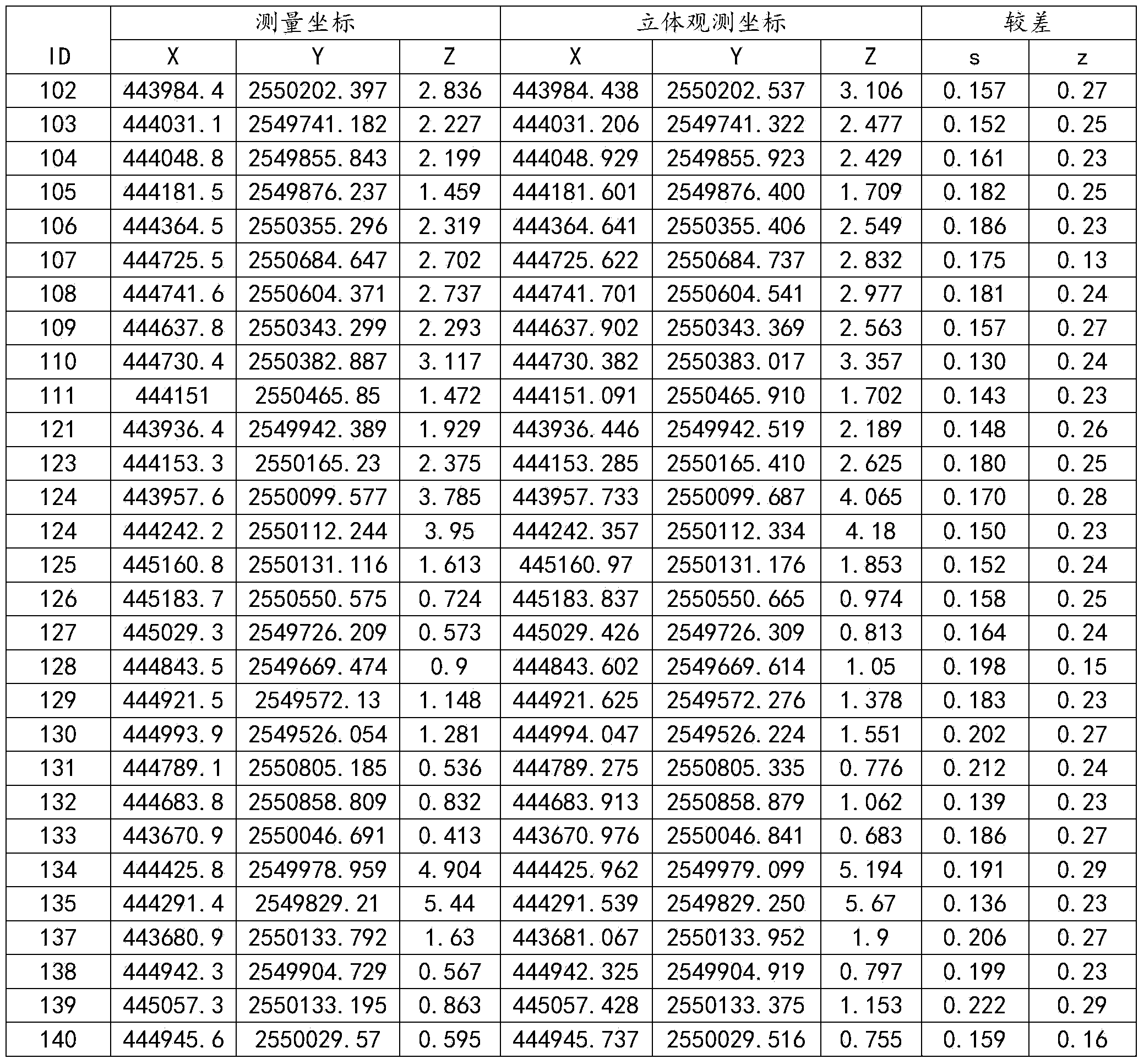

GNSS/IMU integrated unmanned aerial vehicle surveying and mapping method and system

InactiveCN104237922ALow resolutionHigh precisionSatellite radio beaconingTerrainAutomatic processing

The invention discloses a GNSS / IMU integrated unmanned aerial vehicle surveying and mapping method and system. A GNSS and an IMU system are integrated on an unmanned aerial vehicle, a ground static GNSS base station is arranged on a surveying and mapping area, parameters of the ground static GNSS base station, parameters of an airborne GNSS terminal and IMU parameters of the unmanned aerial vehicle are collected and recorded synchronously, the parameters are guided into conventional unmanned aerial vehicle surveying and mapping software for automatic processing, the requirement for surveying and mapping imaging precision of the unmanned aerial vehicle is met, and the problem that the surveying and mapping precision can not be ensured by setting a ground control point when surveying and mapping of the unmanned aerial vehicle are performed on bad terrain areas such as mountains and hills is solved.

Owner:CHINA GEOHARMONY TECH CO LTD

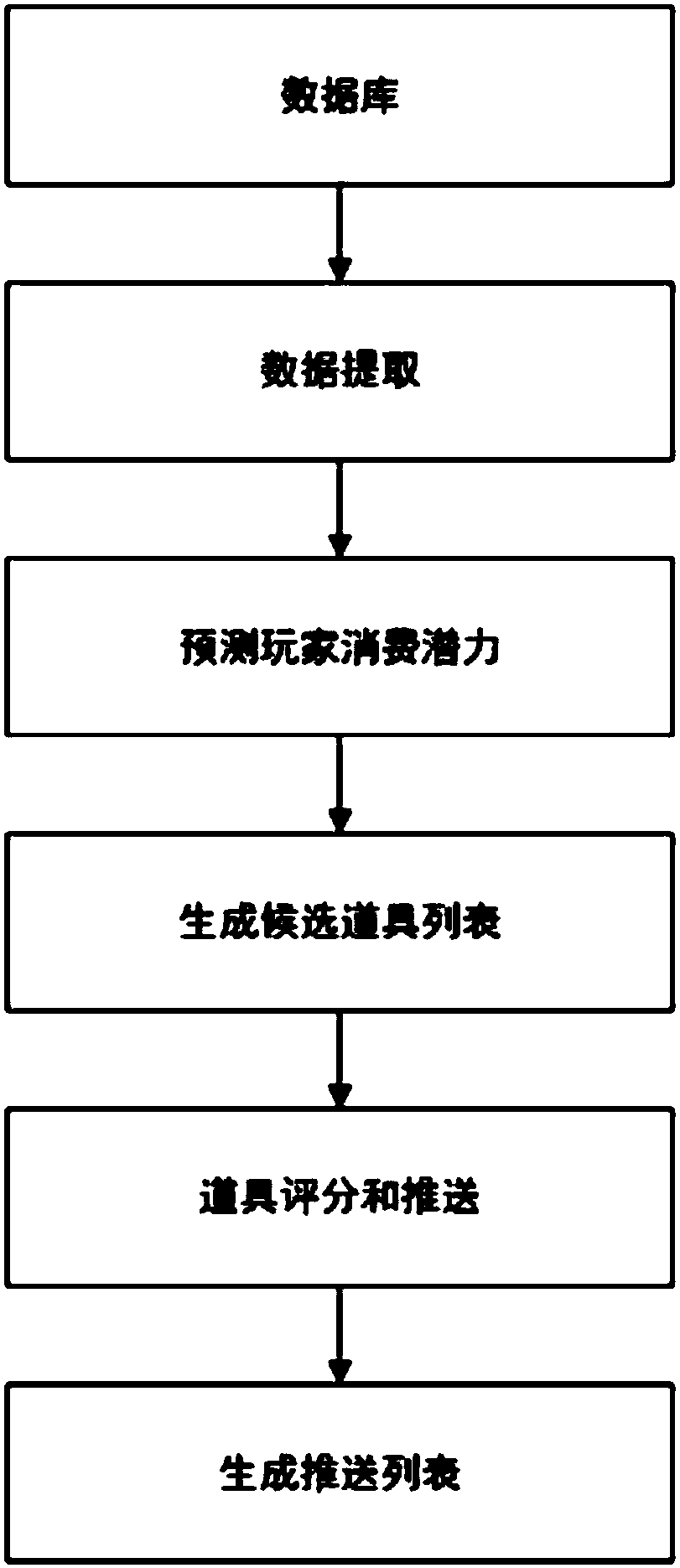

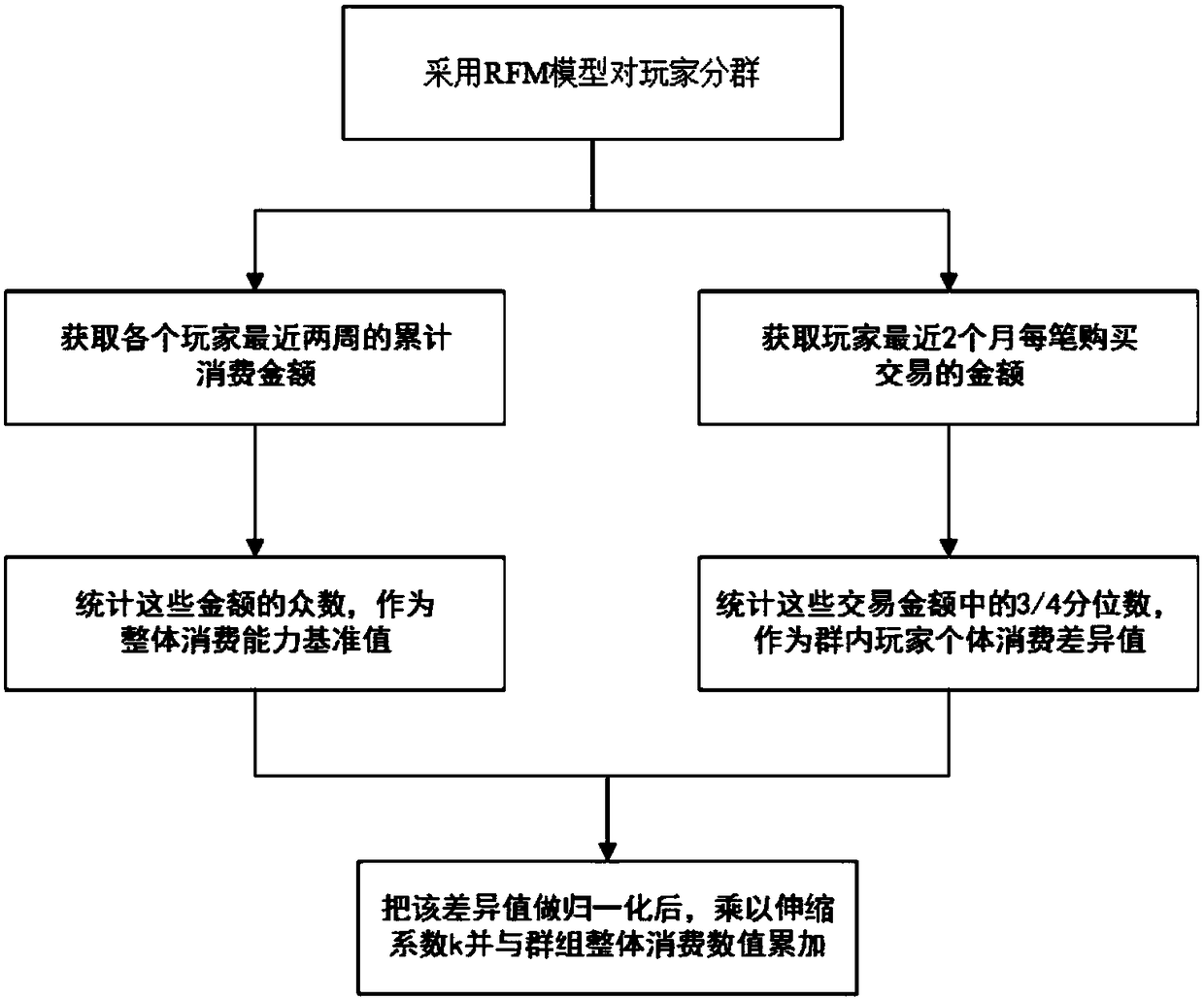

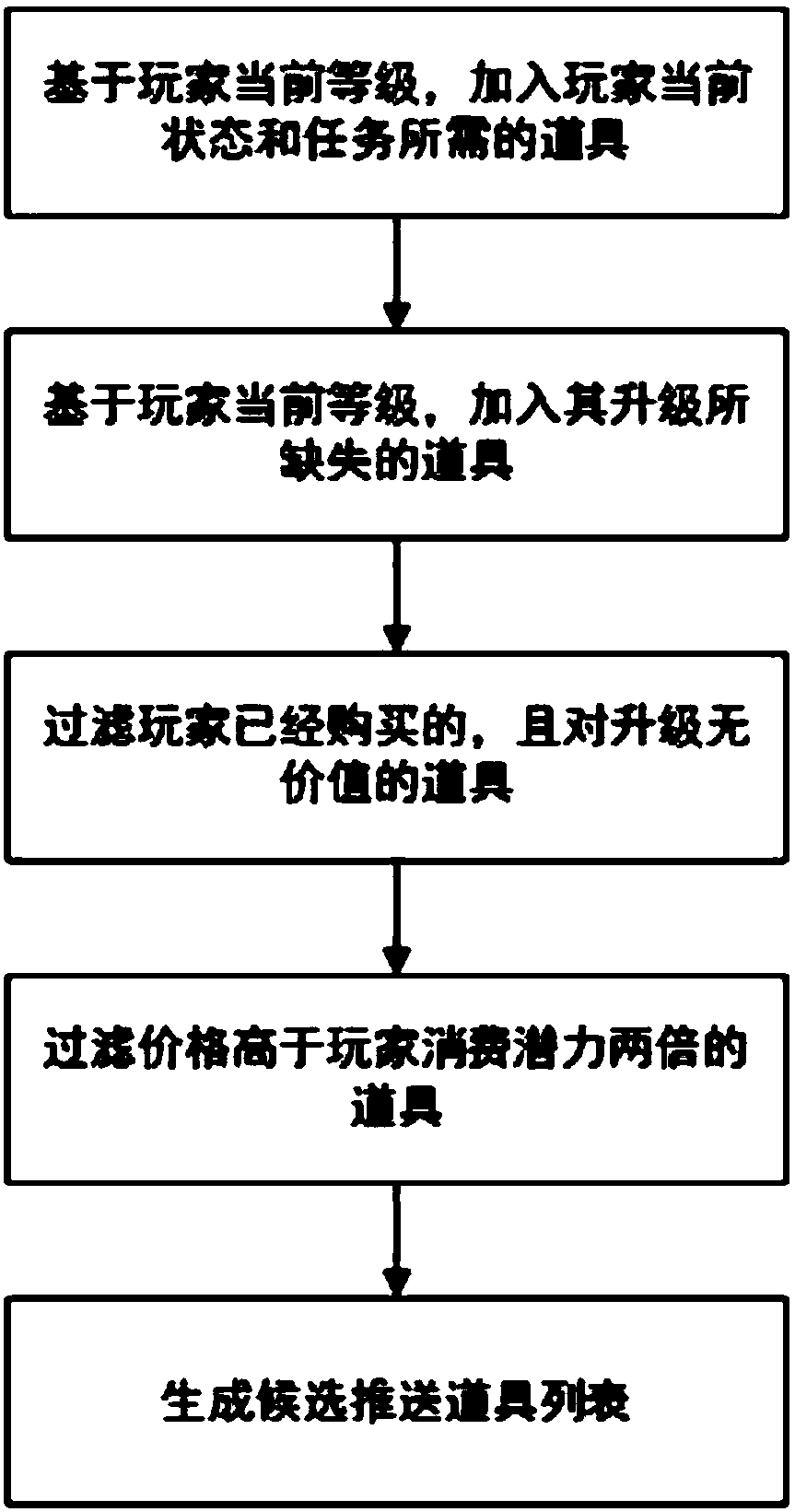

Player consumption potential-based game prop pushing method and device

ActiveCN108090800AImprove effective conversion rateSolve industry problemsBuying/selling/leasing transactionsVideo gamesData scienceOperations research

The invention provides a player consumption potential-based game prop pushing method and device. The method comprises the following steps that: the consumption data of players are extracted from a database; the players are grouped, the consumption ability of each player in each group is predicted; props matched with the consumption ability of the players are selected, and a prop candidate list isgenerated; and candidate props are sorted and pushed to the corresponding players. According to the player consumption potential-based game prop pushing method and device of the invention, the pushinglist of the game props is sorted and outputted on the basis of a plurality of factors; the game props that are matched with the consumption expectation of the players are pushed to the players; the effective conversion rate of conversion from pushing to transaction is significantly improved; and industrial problems are solved.

Owner:ZHUHAI KINGSOFT ONLINE GAME TECH CO LTD +1

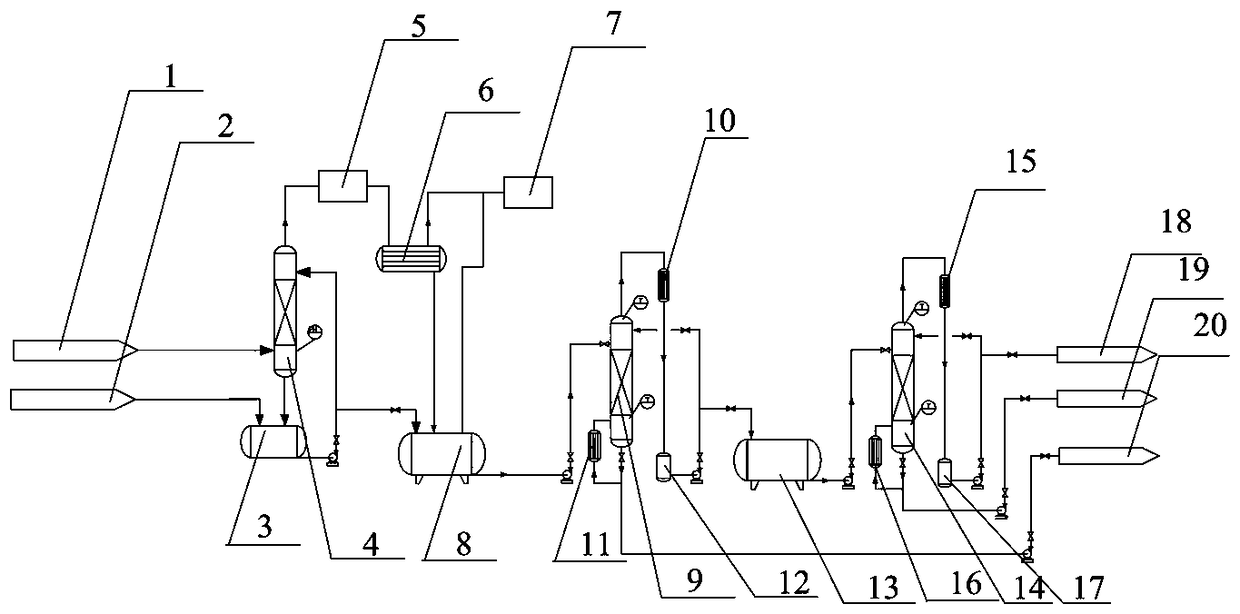

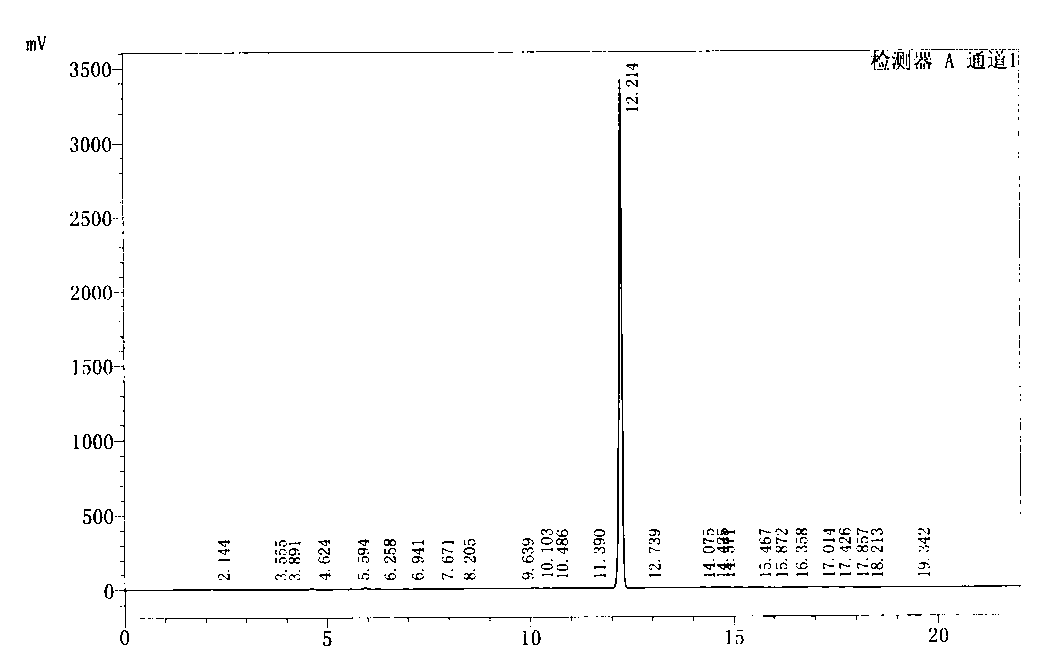

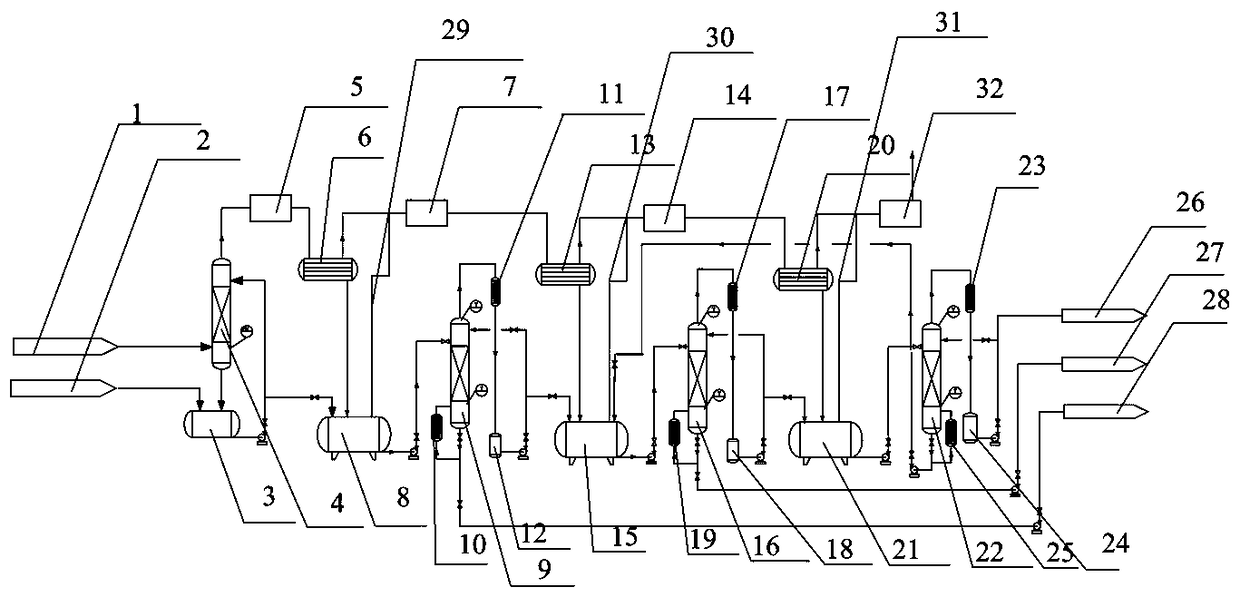

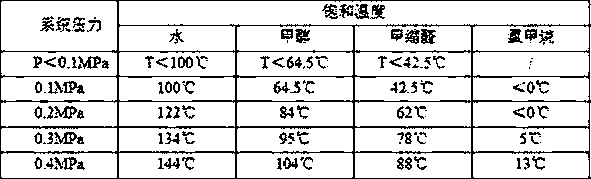

Alkyl ester method glyphosate solvent recovery system and process

PendingCN108380029AImprove intrinsic safetyReduce system pressureGas treatmentOrganic compound preparationSolventChemistry

The invention provides an alkyl ester method produced glyphosate solvent recovery method. A diluted methanol solution collection tank is connected with the upper part of a primary rectifying tower through a pipeline, and the primary rectifying tower is connected with a return tank I through a condenser I; the return tank I is connected with a methyl alcohol methylal solution intermediate tank; themethyl alcohol methylal solution intermediate tank is connected with a secondary rectifying tank, a return tank II is connected to a methyl alcohol methylal finished product tank, and the secondary rectifying tank is connected to a methyl alcohol finished product tank. The recovery process comprises the following steps: enabling diluted methanol inside the diluted methanol solution collection tank to enter into the primary rectifying tower, enabling gas inside the primary rectifying tower to condense through the condenser to return back to the return tank, and feeding to the methyl alcohol methylal solution intermediate tank; feeding to the methyl alcohol finished product tank from a secondary rectifying tower extraction pump, condensing liquid at the bottom of the tower through the condenser and then feeding to the methyl alcohol finished product tank. According to the equipment and process provided by the invention, the defect that a traditional liquid-phase recovery process highlydepends on a graphite condenser and the problem that a traditional gas-phase recovery process is unstable in operation are solved, the process has the characteristics of energy saving and economical efficiency, and the steam consumption of glyphosate is 1.2t.

Owner:HUBEI TAISHENG CHEM

Supply chain cooperative management method based on data sharing between different enterprises

PendingCN108090746AIncrease usageReduce operating costsOffice automationLogisticsProgram planningOpen platform

The invention discloses a supply chain cooperative management method based on data sharing between different enterprises. The cooperative method includes the following steps that S1, an ultra-transmission system is constructed, a standardized format of service data is created, and when different service systems are used, the enterprises which do not use the ultra-transmission system achieves standardized conversion of the data format through an ultra-transmission opening platform; S2, the external enterprises request a data sharing application from the ultra-transmission system and obtain a data sharing authorization of the ultra-transmission system opening platform; S3, after logging into the system, the external enterprises carry out data access based on a data authorization range of theultra-transmission opening platform; S4, the ultra-transmission system automatically generates supply chain plans and resource requirements according to the shared data obtain by the enterprises; S5,one party enterprise issues the application and can share the real-time inventory data and sales analysis of the other party after obtains an authorization from the other party enterprise; S6, a goods supply enterprise automatically generates a supply chain plan based on the inventory and sales analysis of a goods purchase enterprise.

Owner:郭笑楠

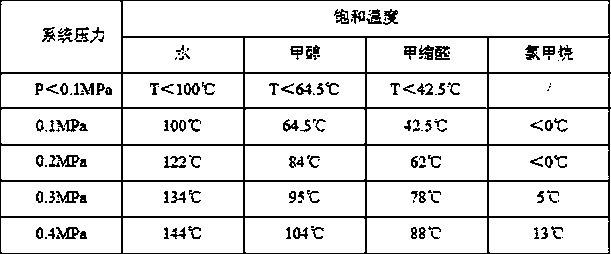

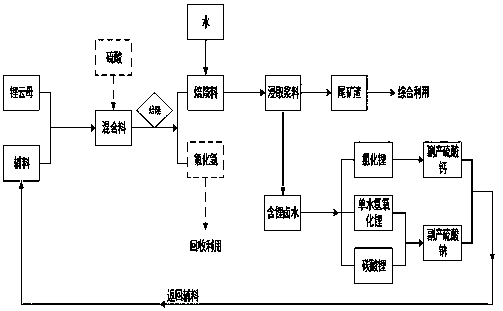

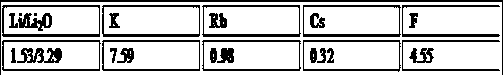

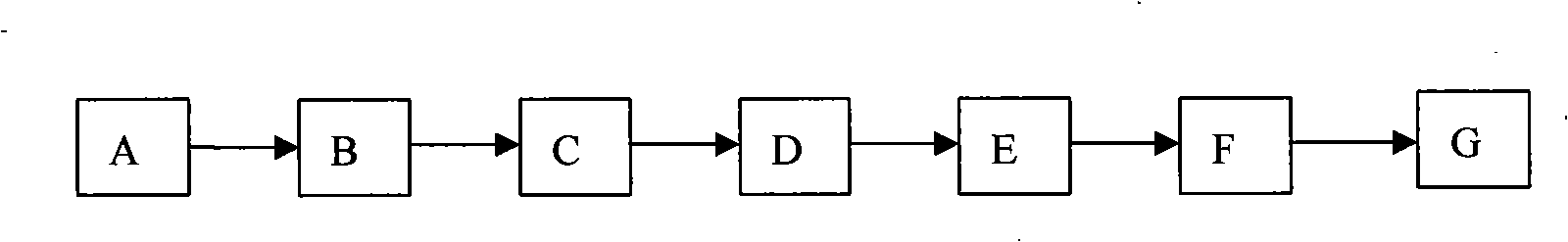

System method for extracting lithium-containing brine from lepidolite and manufacturing lithium salt

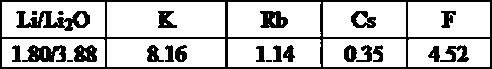

ActiveCN111137908AEasy to handleGood choiceAluminium silicatesCalcium/strontium/barium fluoridesLithium chlorideLithium carbonate

The invention discloses a system method for extracting lithium-containing brine from lepidolite and manufacturing lithium salt. The system method comprises the following steps: material mixing, roasting, brine preparation, lithium salt preparation and comprehensive utilization of tailing slag. According to the invention, sulfuric acid double salt and sulfuric acid (selected) are used as auxiliarymaterials to be mixed with the lepidolite for reaction; the system method is applicable to extraction of lithium in high-content and low-content lepidolite; good selectivity is achieved during extraction; the extraction rate of lithium is 95.5%-97.5%; and the extraction rates of K, Rb and Cs are smaller than 30%; the obtained brine is neutral and can be used for directly preparing lithium hydroxide monohydrate, lithium chloride or lithium carbonate, and the total yield of lithium is more than 92%; the process is high in flexibility, can produce single-variety lithium salt, and can jointly produce two or more varieties of lithium salt; and fluorine in the lepidolite can be separated and recovered, so the additional value is increased, and the lithium extraction tailing slag can be comprehensively utilized. The system method provided by the invention has the following advantages: the whole process is short in flow, low in cost and friendly to the environment; and the system method has good economic benefits and social benefits and good industrial application values.

Owner:CHANGSHA YUANPENG CHEM TECH

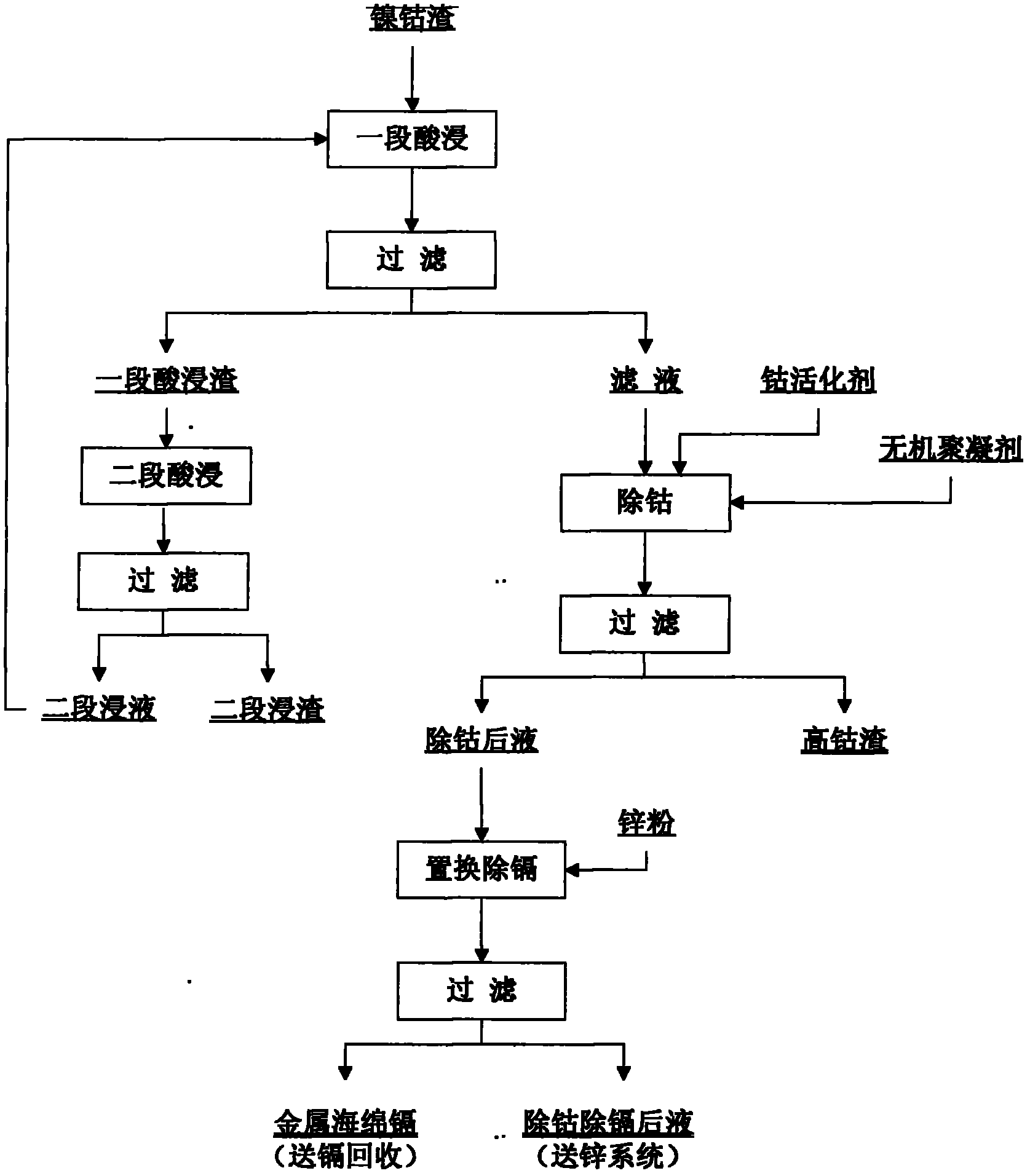

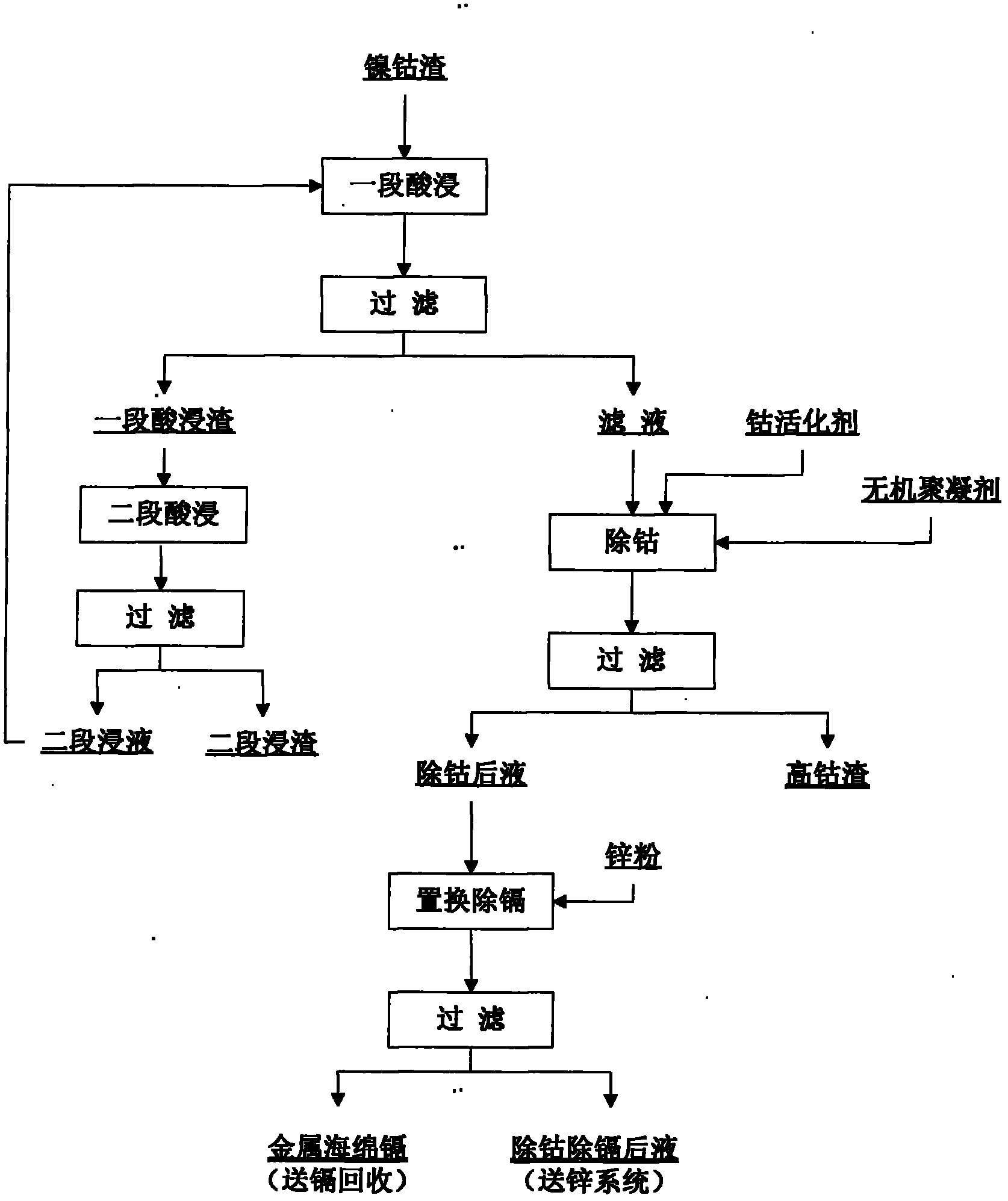

Novel process for separating zinc and cobalt from nickel and cobalt slag from zinc smelting and purification

ActiveCN101994008AEliminate the effects of pollutionRealize closed-loop operationProcess efficiency improvementBiological activationCobalt

The invention relates to a novel process for separating zinc and cobalt from nickel and cobalt slag from zinc smelting and purification, which comprises: separating cobalt from lixivium of nickel and cobalt slag by using a cobalt activation inorganic flocculation method, enriching the cobalt, recovering cobalt, removing cadmium from the cobalt-free lixivium by using the conventional zinc replacement method, obtaining sponge metal cadmium, delivering the sponge metal cadmium to a zinc smelting copper and cadmium processing step to recover metal cadmium. After cobalt and cadmium are removed, the lixivium is returned to a leaching step in a main zinc smelting system for recovering zinc. Thus, metals such as zinc, cobalt, cadmium and the like are recovered from the nickel and cobalt slag; meanwhile, the environmental pollution influence of the long-term piled up slag and the risk of irregular transfer of heavy metal pollutants such as cadmium in the zinc industry are eliminated, the closed-circuit operation of the recycling of the slag is realized, discharge of waste water and gas is avoided, valuable metals are comprehensively recovered, the requirement on pollution-free production is met and the problem of the industry is solved.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

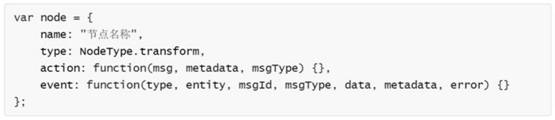

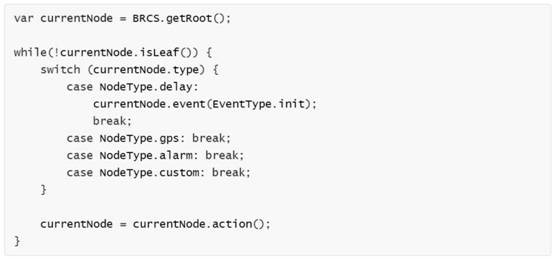

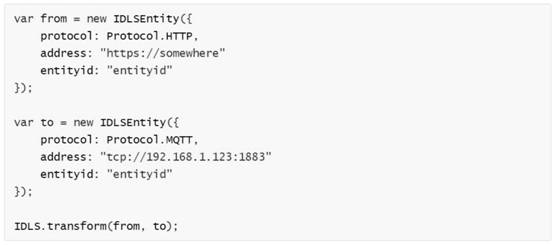

Industrial internet system based on industrial brain

ActiveCN113115241AQuick buildChange the construction modeParticular environment based servicesInterprogram communicationPersonalizationThe Internet

The invention belongs to the technical field of internet, and particularly relates to an industrial internet system based on an industrial brain. An industrial brain host not only can complete equipment docking, instruction issuing and data acquisition work, but also has the capability of docking and fusing heterogeneous industrial software, and the capability of business scheduling, edge calculation, business processing, big data analysis and platform interconnection. API can be comprehensively opened to the outside, business applications can be written at will, Handle identification analysis standards can be supported, and based on an industrial data chain technology and a business rule chain technology, personalized problems of different industries and different enterprises are solved through modularization and standardization of the industrial brain host, a personalized scheme is provided for the enterprises by using one set of industrial internet system, application industries and applicable enterprises are not definitely limited, and only one industrial brain host needs to be deployed in a machine room, and one or more industrial data gateways can be deployed in a production workshop, so that the system has the popularization advantage of universality.

Owner:QINGDAO RONGSHANG TIANXIA NETWORK CO LTD

Reductive calcining process of ferrous sulfate as byproduct of titanium dioxide

InactiveCN103193278AEliminate pollutionSolve industry problemsSulfur compoundsFerric oxidesSulfite saltSulfur dioxide

The invention relates to a reductive calcining process of ferrous sulfate as a byproduct of titanium dioxide. The reductive calcining process comprises the following steps of: adding reductive substances, namely coke powder, sulphur and pyrite concentrate according to a certain proportion in a process of calcining ferrous sulfate to obtain solid substances, namely iron oxide red, wherein sulfur dioxide as a main component in waste gases can be used for producing concentrated sulfuric acid and anhydrous sodium sulfite after being purified, converted and absorbed, so that sulphur and iron resources in ferrous sulfate can be comprehensively recovered; and meanwhile the pollution to environment caused by long-term stockpiling of the ferrous sulfate as the byproduct in the titanium dioxide industry is eliminated, the ferrous sulfate residues can be recycled, valuable resources, such as sulphur and iron can be comprehensively recycled, the clean production requirement is achieved and the difficulties in the titanium dioxide industry are solved.

Owner:甘肃恒源硕化工科技有限公司

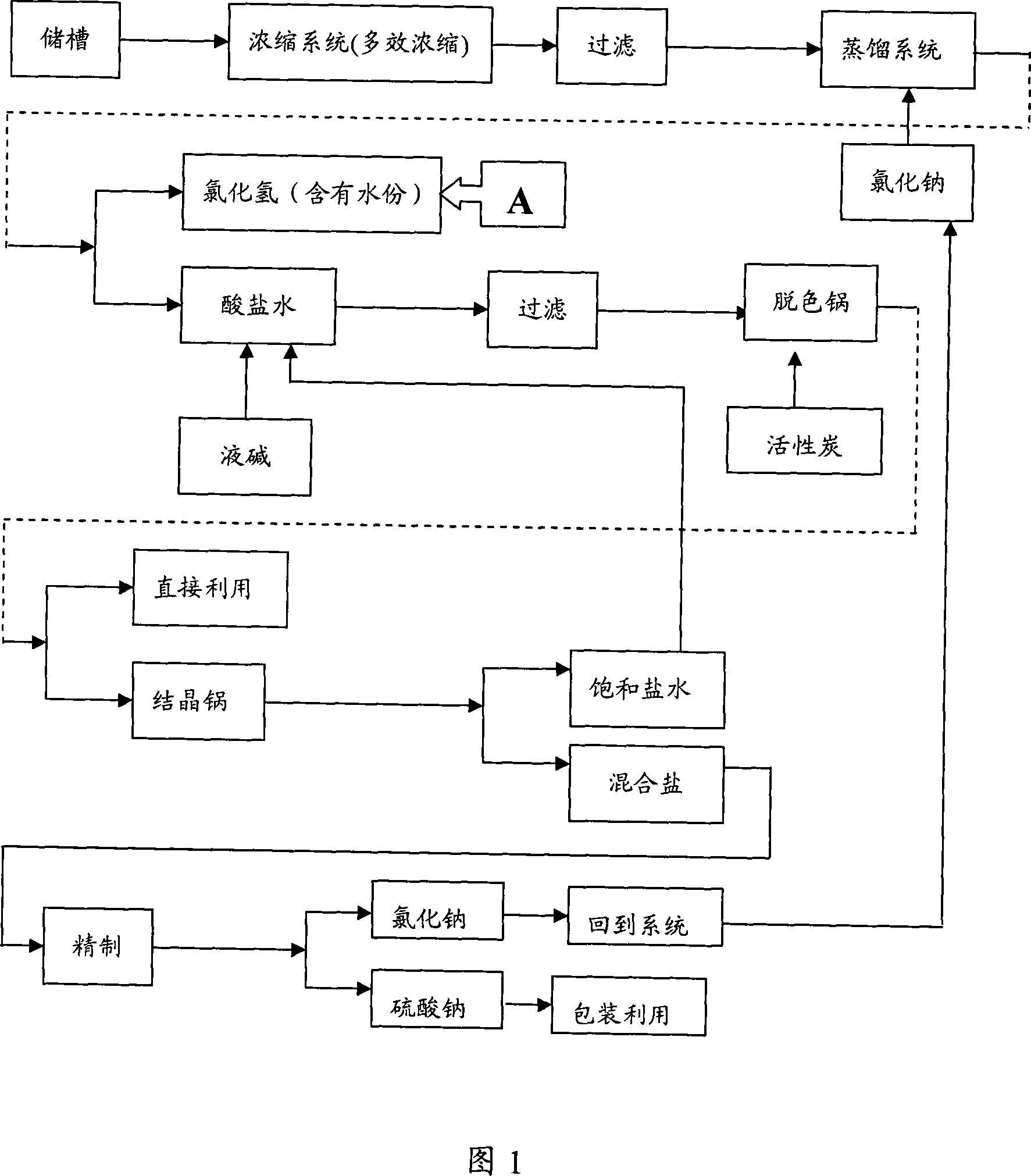

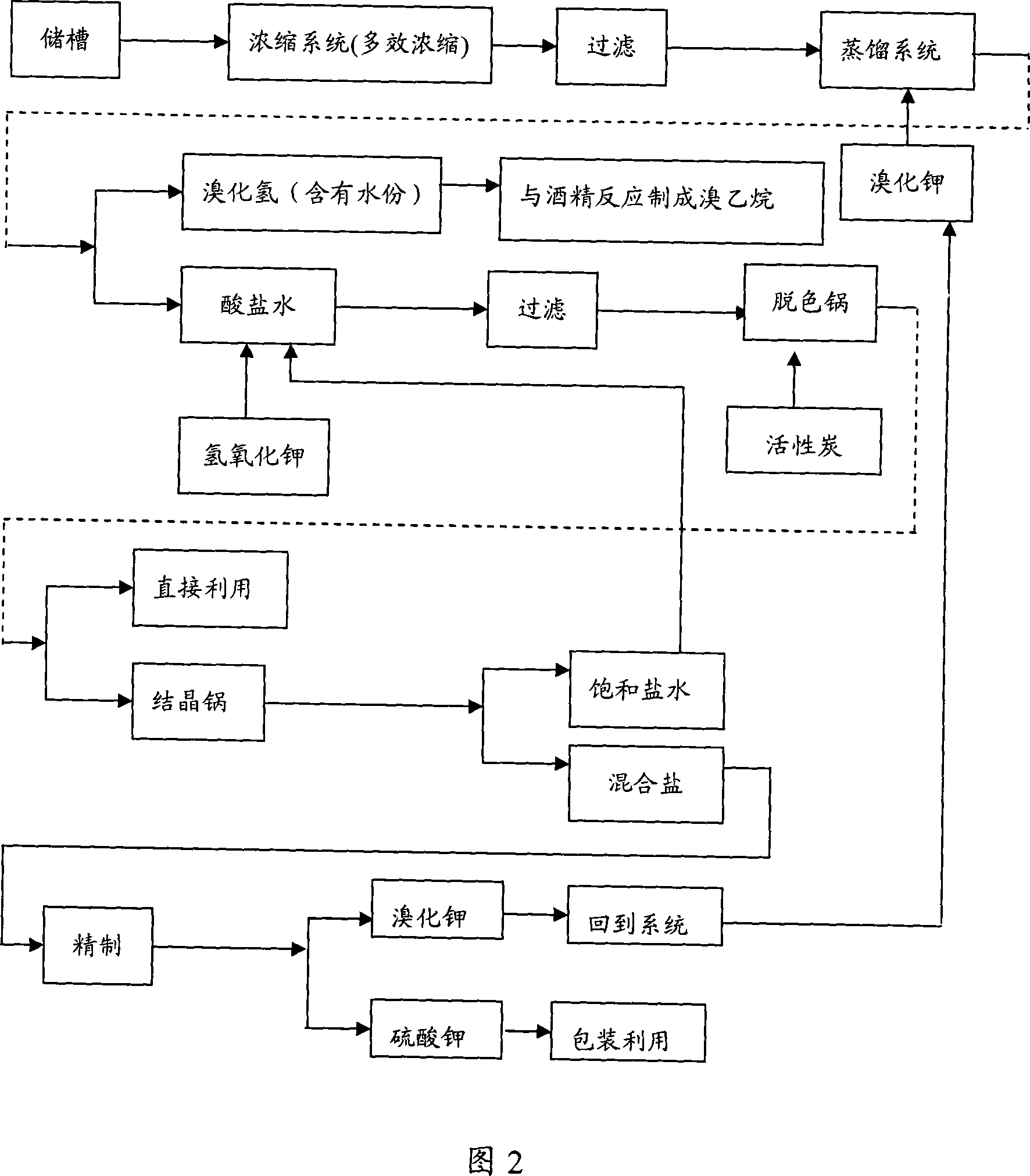

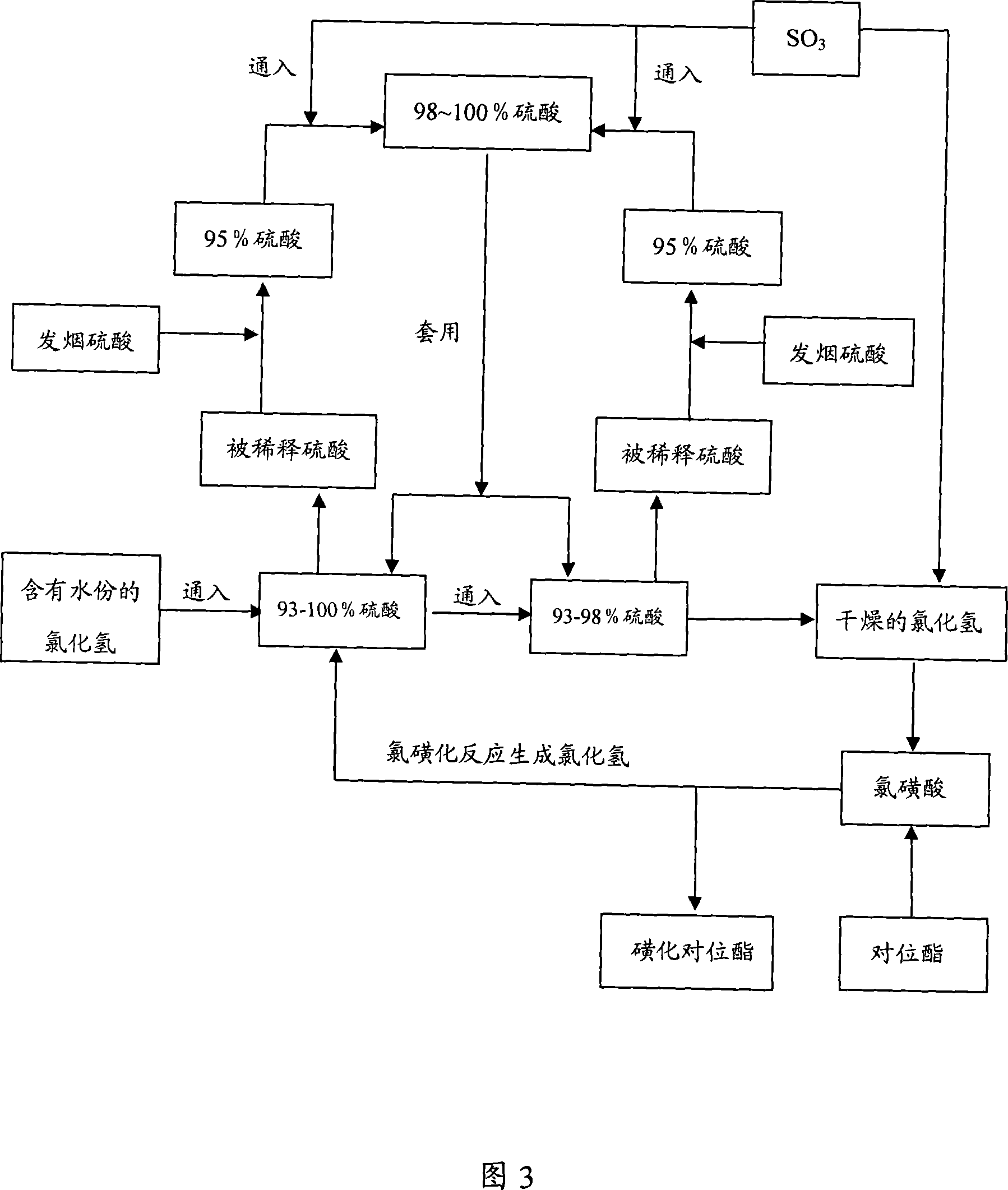

Process of recovering and utilizing pollutant waste acid liquid

ActiveCN101066817AReduce processing costsRealize comprehensive utilizationMultistage water/sewage treatmentWater/sewage treatment by neutralisationInorganic saltsSulfate radicals

The process of recovering and utilizing high polluted and low concentration waste acid liquid includes the following steps: multieffect concentrating and filtering waste water containing sulfuric acid; adding inorganic salt MX, where, X is Cl- or Br- and M is cation capable of forming soluble salt with sulfate radical, to react with the sulfuric acid to produce gas and mixed acid salt; and treating the mixed acid salt through neutralizing, depurating, decolorizing, refining and separating. The present invention provides one new way for treating and utilizing chemical waste water.

Owner:JIANGSU YUANZHENG CHEM

Method for preventing cracking of ceramic shell

ActiveCN106853508ANo more cracksSolve industry problemsFoundry mouldsFoundry coresThermal insulationMetallurgy

The invention discloses a method for preventing cracking of a ceramic shell. The method for preventing the cracking of the ceramic shell is characterized by comprising the following steps: 1) adopting a fabrication process of the ceramic shell to obtain the ceramic shell with a certain thickness; 2) covering a certain thickness of materials which can melt or thermal insulation materials which cannot melt in the dewaxing process on the outer surface of the ceramic shell which has a crack easily occurring part in the common crack direction; 3) putting the ceramic shell into a dewaxing device, using high-temperature and high-pressure steam to perform dewaxing. The method is suitable for any parts of the shell, so that the ceramic shell no longer cracks, thereby not having any impact on the shell and the subsequent process, and the method requires low cost, has high efficiency and greatly reduces the labor intensity of an operator.

Owner:DONGFANG TURBINE CO LTD

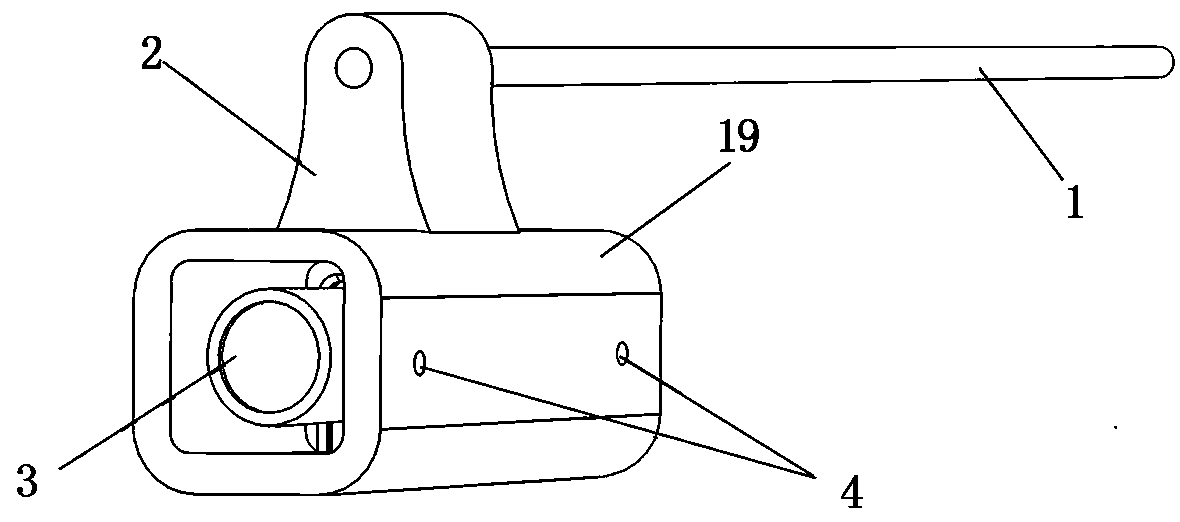

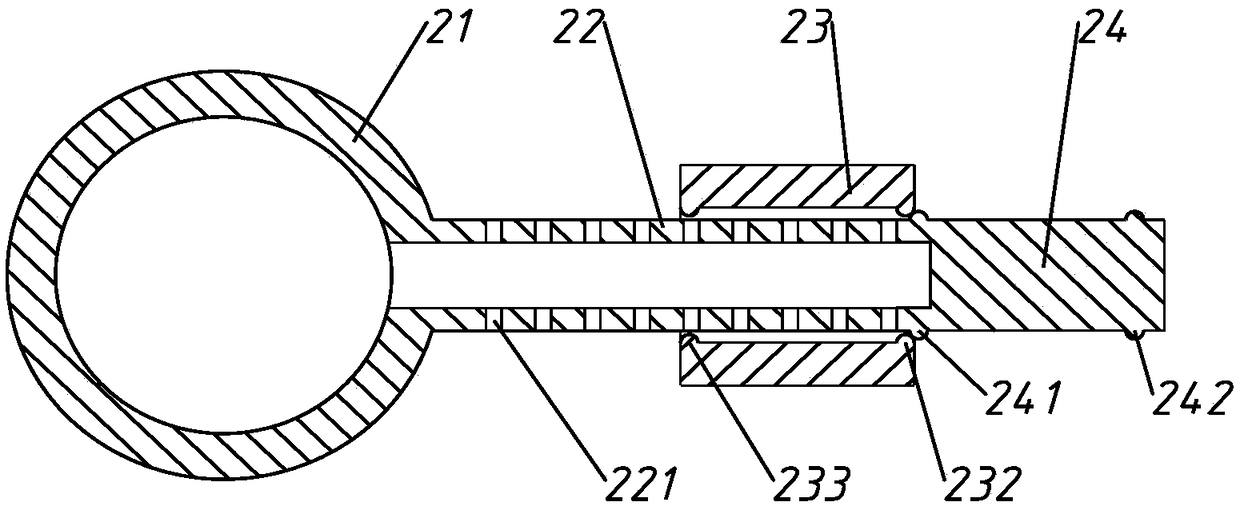

Firearm laser calibrator, method for demarcating firearm laser calibrator, method for calibrating firearm and method for determining target point of bore axis

The invention discloses a firearm laser calibrator, a method for demarcating the firearm laser calibrator, a method for calibrating a firearm, and a method for determining the target point of the boreaxis. The firearm laser calibrator comprises an inserted rod, a laser fixing frame and a laser generator, wherein the inserted rod is in a straight-handle rod shape, the diameter of the inserted rodis slightly less than the sunny side inner diameter of a gun barrel inner rotation line of a calibrated firearm, so that the inserted rod is smoothly inserted and connected into a gun barrel from a gun muzzle; the laser fixing frame includes a positioning cylinder for fixing the laser generator and an inserted rod positioning piece arranged on the upper side of the positioning cylinder, and the front end of the inserted rod is fixedly connected to the inserted rod positioning piece; and the laser generator is arranged in the positioning cylinder of the laser fixing frame. By means of the firearm laser calibrator, the purpose of calibrating the firearm can be achieved, and the accurate positioning of the extension line on the bore axis can also be achieved, the firearm laser calibrator is simple in structure, and convenient to use, the calibration work of the general light weapons such as rifles without live firing can be achieved, the calibration process is fast and accurate, and the firearm laser calibrator is very suitable for the use of the gun application unit of a basic level which lacks the special gun calibrator equipment.

Owner:ARMY ENG UNIV OF PLA

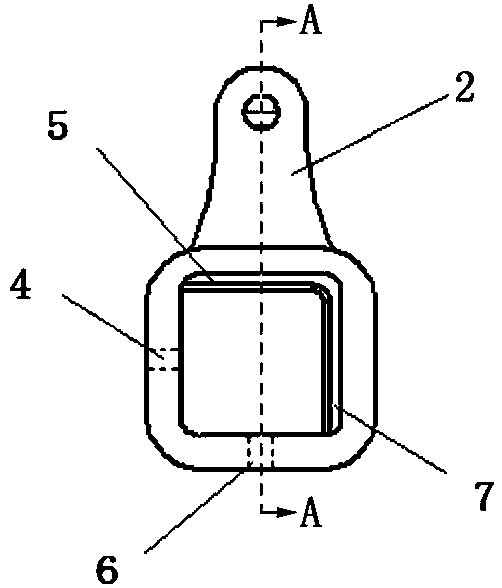

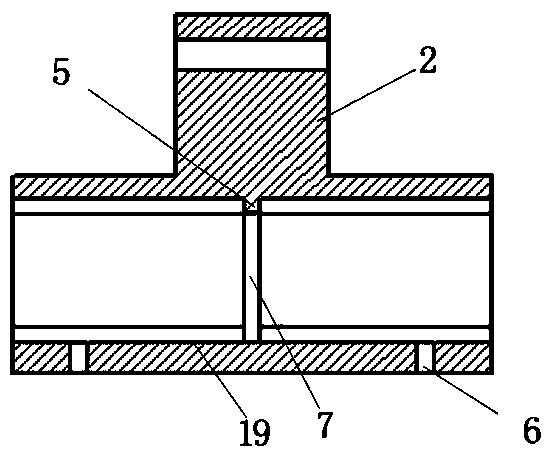

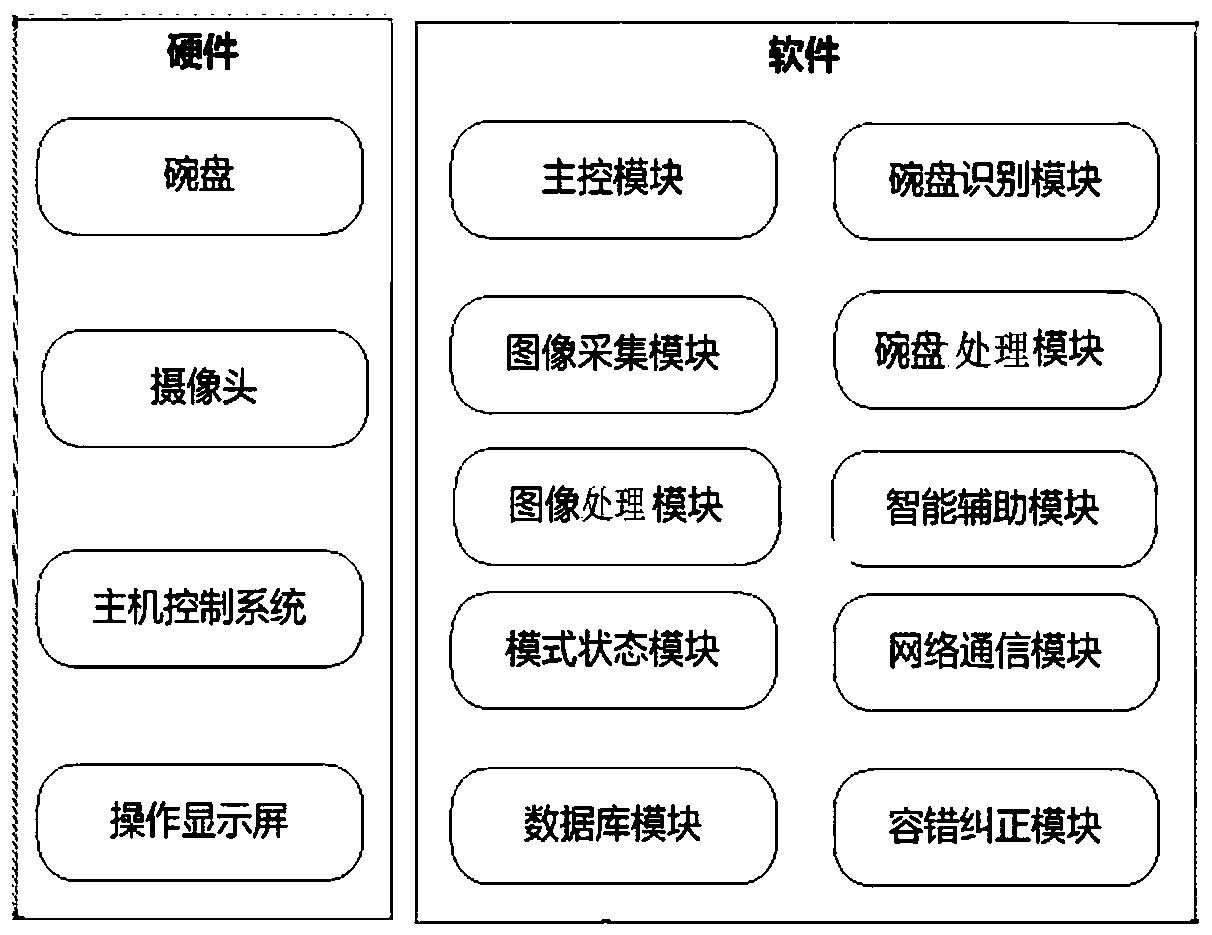

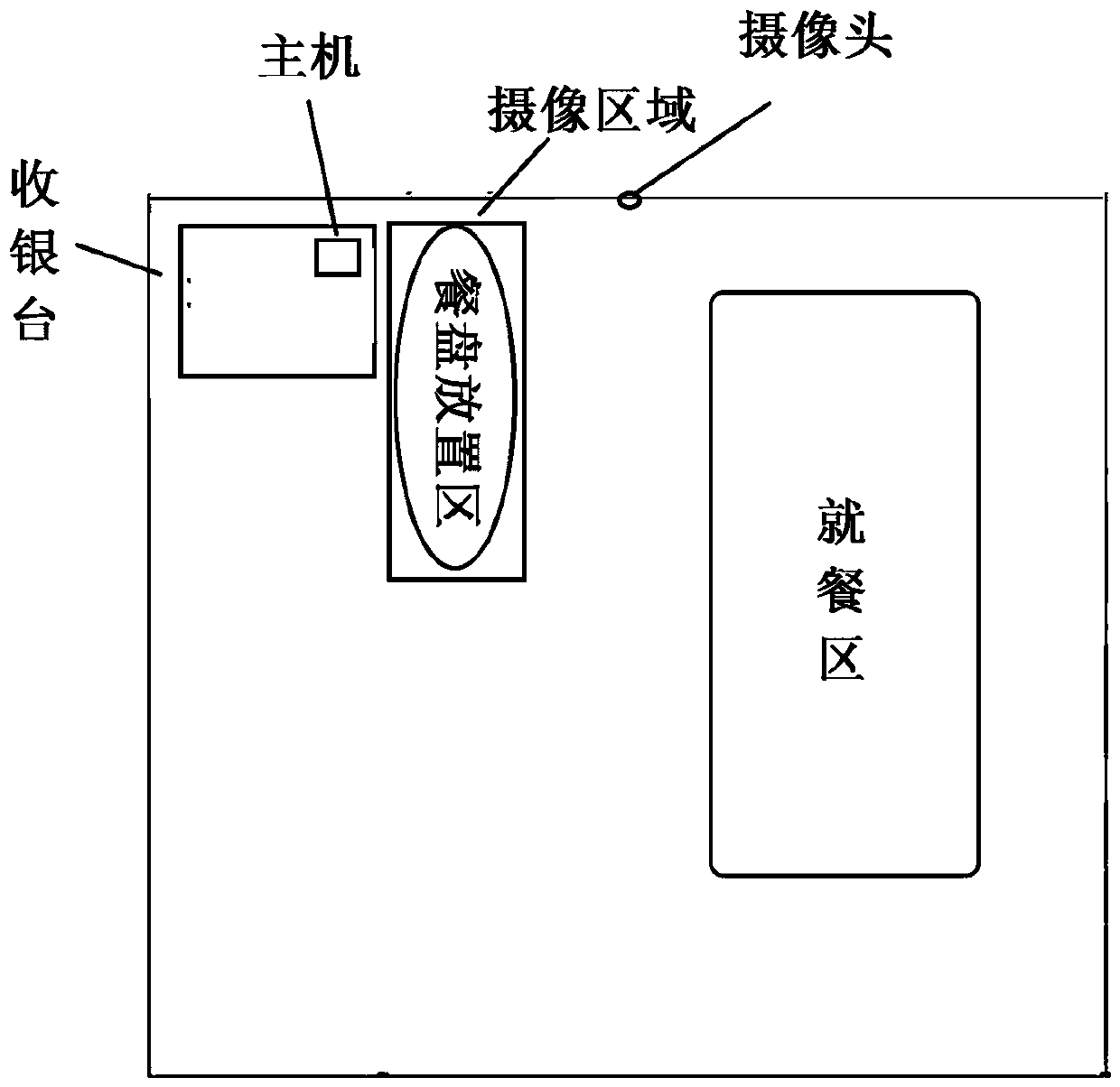

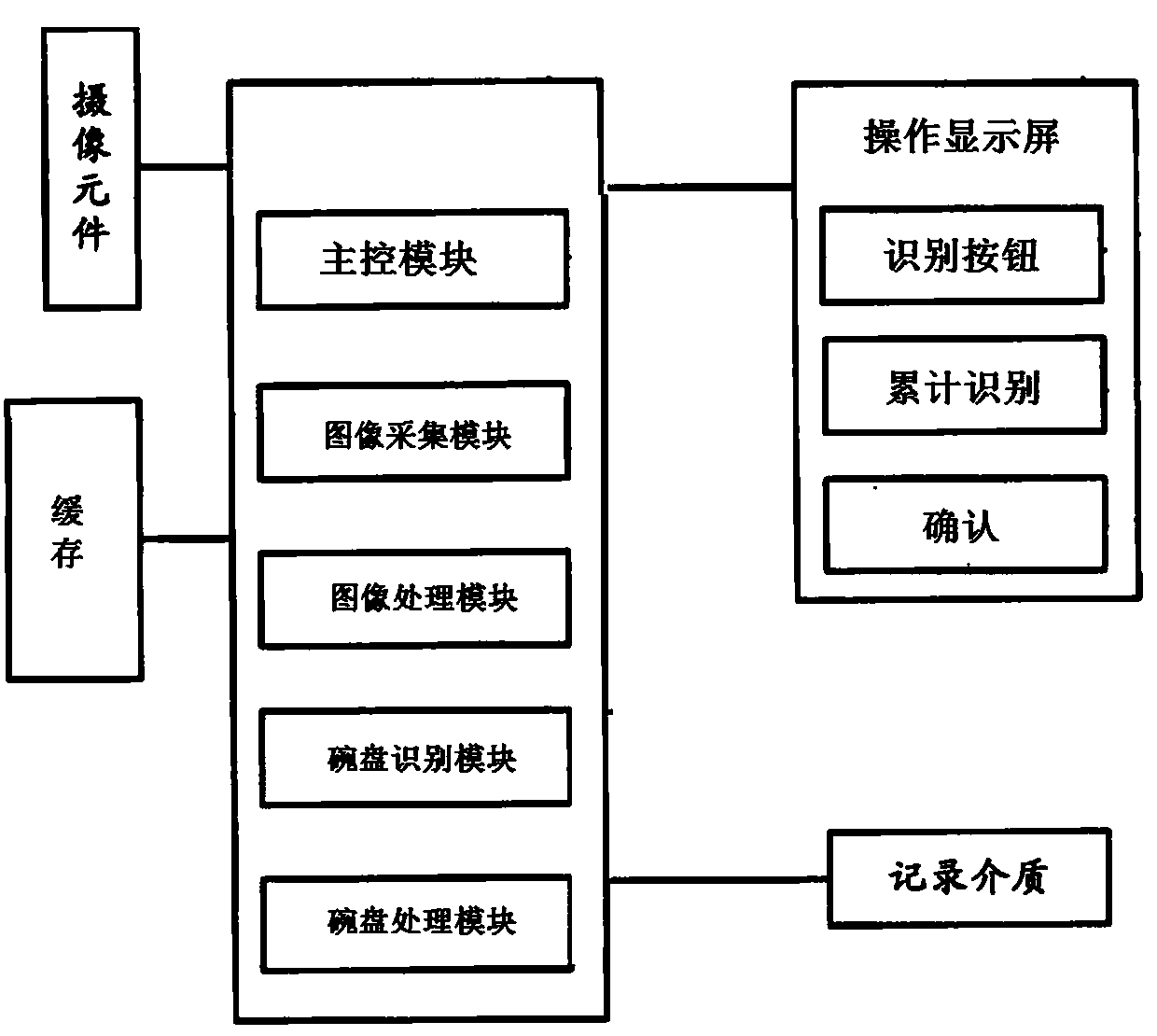

A fast food cashier system based on intelligent bowl and dish recognition

PendingCN109740579ASolve industry problemsLower performance requirementsCharacter and pattern recognitionCash registersPattern recognitionImaging processing

The invention discloses a fast food cashier system based on intelligent recognition of bowls and dishes. The device is used for canteens / restaurants / fast food restaurants and the like. The system comprises a main control module, an image acquisition module, an image processing module, a bowl and dish recognition module, a bowl and dish processing module, an intelligent auxiliary module, a mode state module, a network communication module, a database module and a fault-tolerant correction module, and is used for recognizing bowls and dishes with different types, different colors and different shapes and sizes and containing a breakfast / lunch / supper / night food multi-mode; according to the fast food cashier system based on intelligent recognition of bowls and dishes, intelligent recognition and manual input can be combined, application is flexible, different client requirements are met, and by means of the fast food cashier system based on intelligent recognition of bowls and dishes and dish classification management, a large amount of settlement cashier time is saved, and the queuing waiting time of users is shortened; meanwhile, a good solution is provided for restaurant standardized management, reduction of cashier requirements and rapid training on work.

Owner:上海柏珍信息科技有限公司

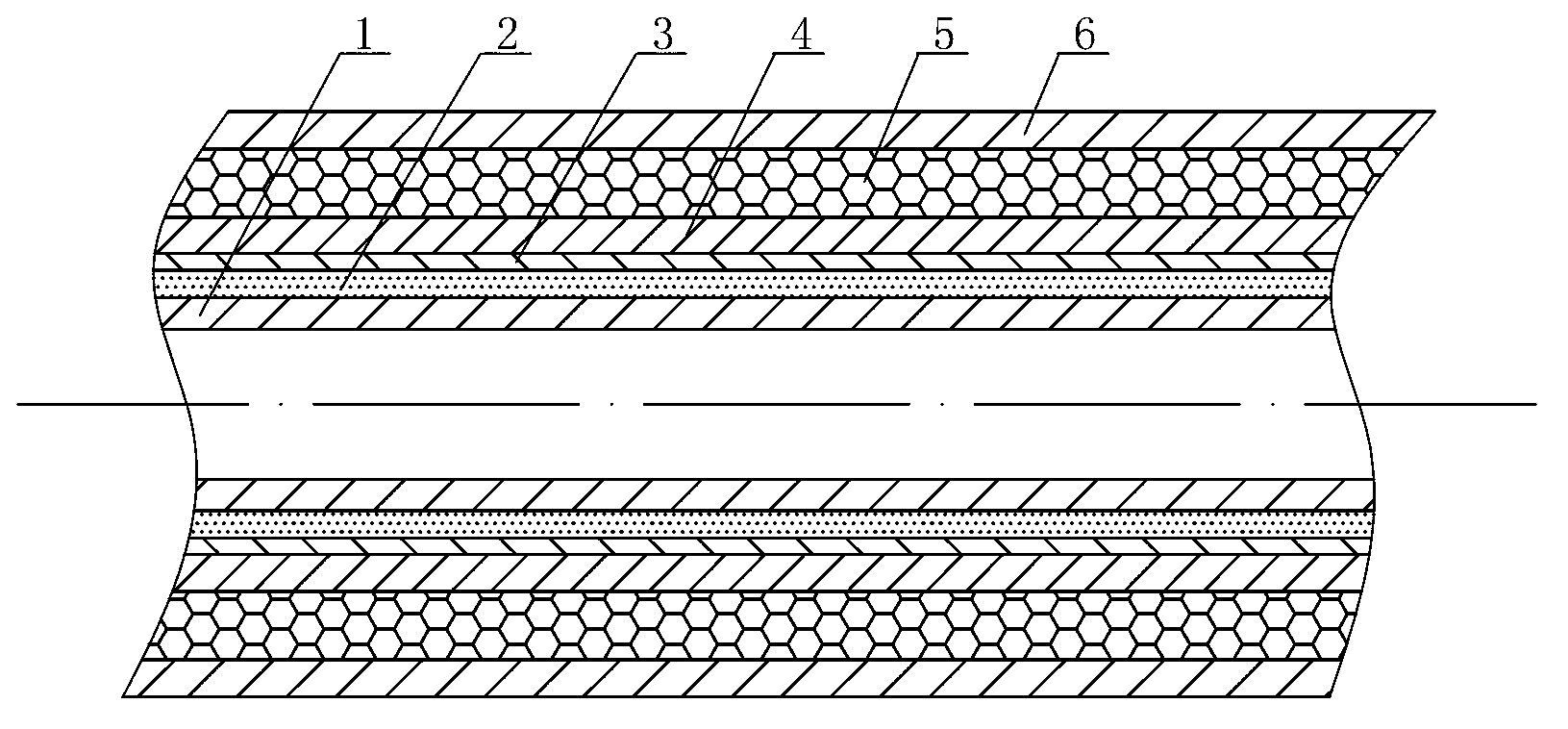

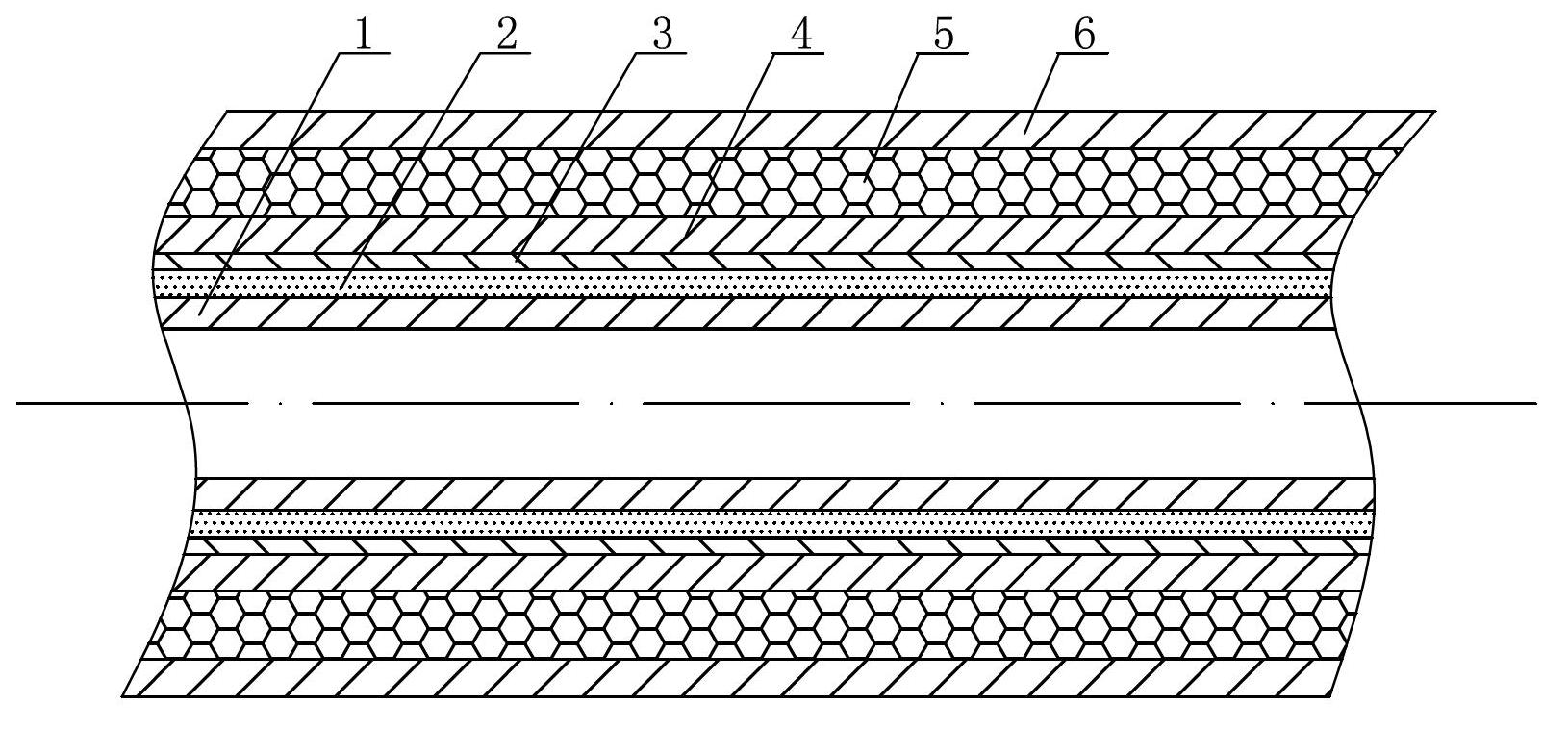

High shearing force three-layered polyolefin anti-corrosive thermal insulation steel pipe and manufacturing process thereof

InactiveCN102705633ASolve the difficult problem of making large shear force insulation pipeCorrosion protectionThermal insulationCorrosion preventionPolyolefinThermal insulation

The invention belongs to the field of anti-corrosive thermal insulation steel pipes, and particularly relates to a high shearing force three-layered polyolefin anti-corrosive thermal insulation steel pipe and a manufacturing process thereof. The steel pipe includes a three-layered polyolefin anti-corrosive pipe, which sequentially includes a steel pipe body, an epoxy resin layer, a glue adhesive layer and a polyolefin layer from inside to outside, wherein a polyethylene jacket pipe is jacketed outside the anti-corrosive pipe, and a polyurethane foaming material layer is arranged between the anti-corrosive pipe and the polyethylene jacket pipe. The manufacturing process is mainly used for the compound treatment of shot blasting and flame heating polarization on the polyolefin layer. The process not only enhances the adhesive properties of the polyurethane foaming material layer and the polyolefin layer on the 3PE anti-corrosive pipe surface, so as to improve the shearing strength of the 3PE anti-corrosive foaming jacket pipe, but also doesn't damage the anti-corrosive performance of the epoxy powder layer in the 3PE anti-corrosive pipe, so as to break through the limit of manufacturing big-shearing force thermal insulation pipe through utilizing the 3PE anti-corrosive pipe, so as to solve the difficulties of the industry, and provide a reliable anti-corrosive thermal insulation steel pipe product for crossing special areas as marsh and mire.

Owner:SHANDONG SHENGLI STEEL PIPE

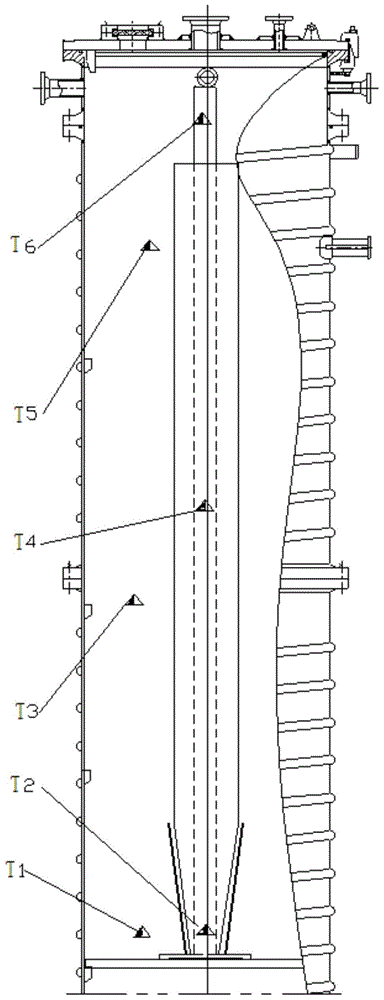

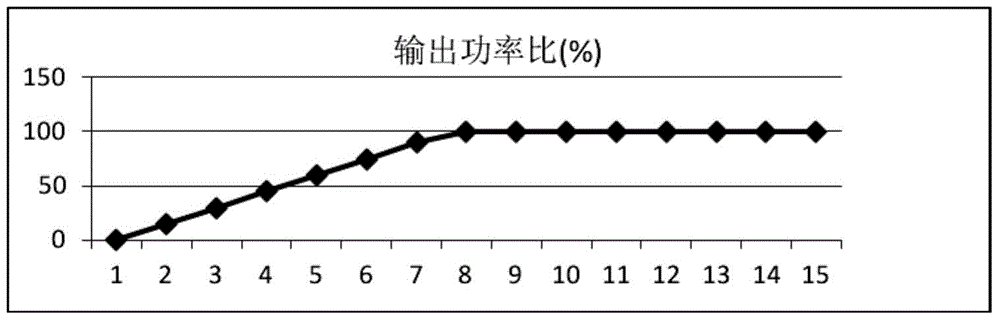

Ultrahigh-voltage oilpaper capacitive bushing capacitor core drying method

ActiveCN104795254AEfficient removalLow dielectric lossDrying/impregnating machinesCapacitanceHeating time

Owner:沈阳和新套管有限公司

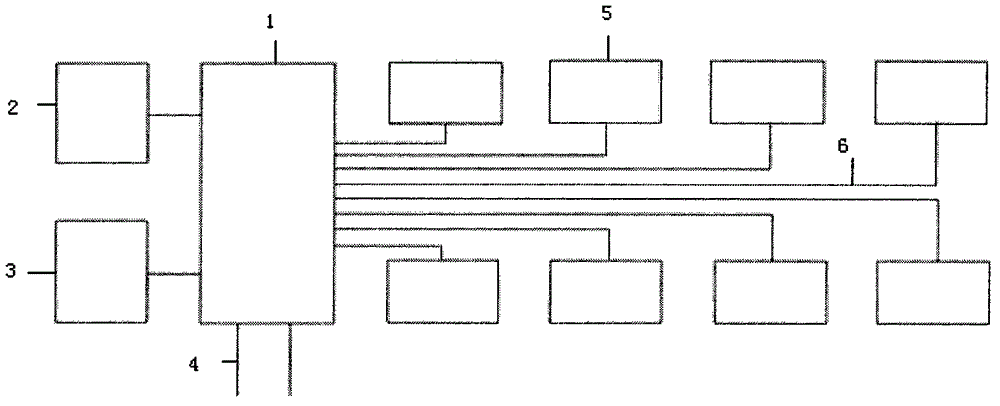

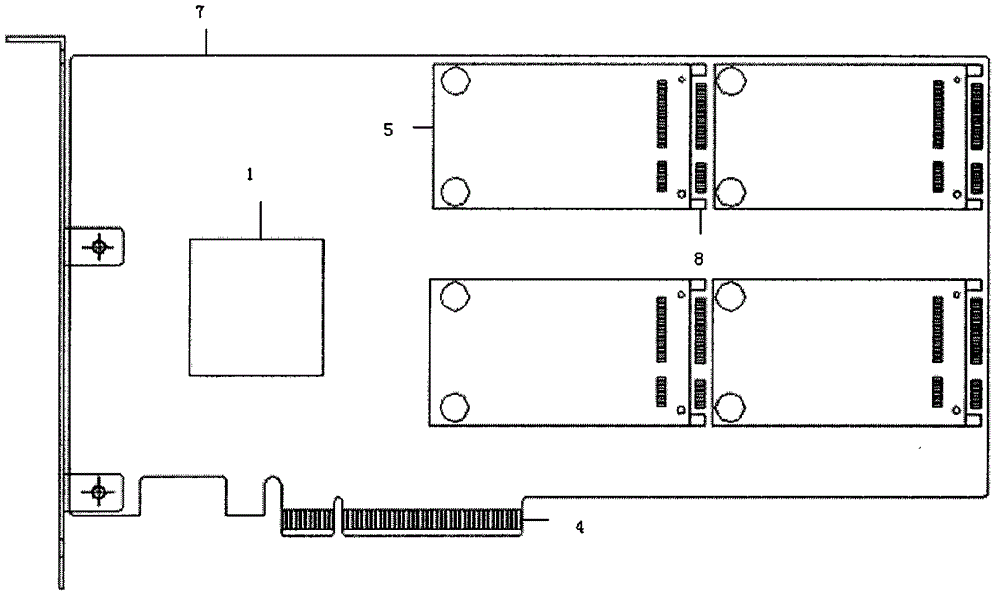

Integrated solid array storage card

The invention provides an integrated solid array storage card. The integrated solid array storage card is composed of an RAID control chip with a PCIE 3.0 bus interface, and a plurality of high-density SSD modules with SATA3 or SAS3 interfaces. A BIOS of the RAID control chip is set to operate in an RAID0 mode, so that the speed and capacity are respectively the sum of single SSD modules; all hardware members are integrated to one card (such as a standard PCIE card or a VPX card), so that the large capacity is realized by only a small size (a single PCIE card is 16 TB, and a single VPX card is 48TB); the speed is high (4000 MB / S for reading, 4000 MB / S for writing); and the power consumption is low (smaller than 40 W).

Owner:詹雨明

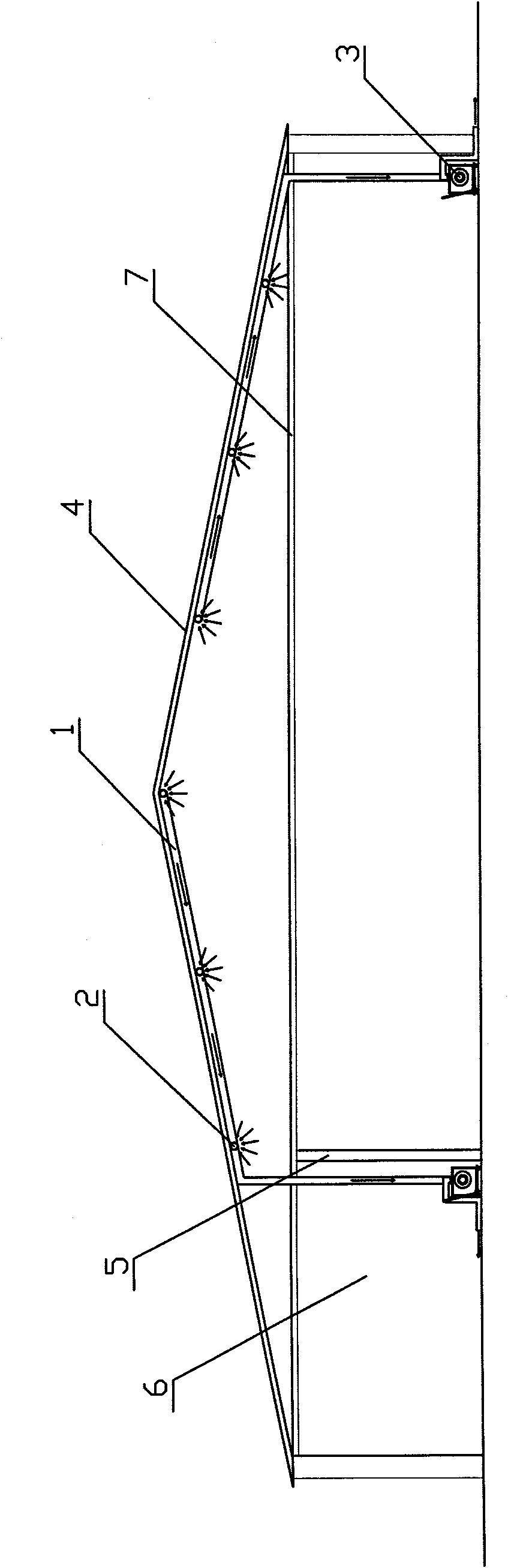

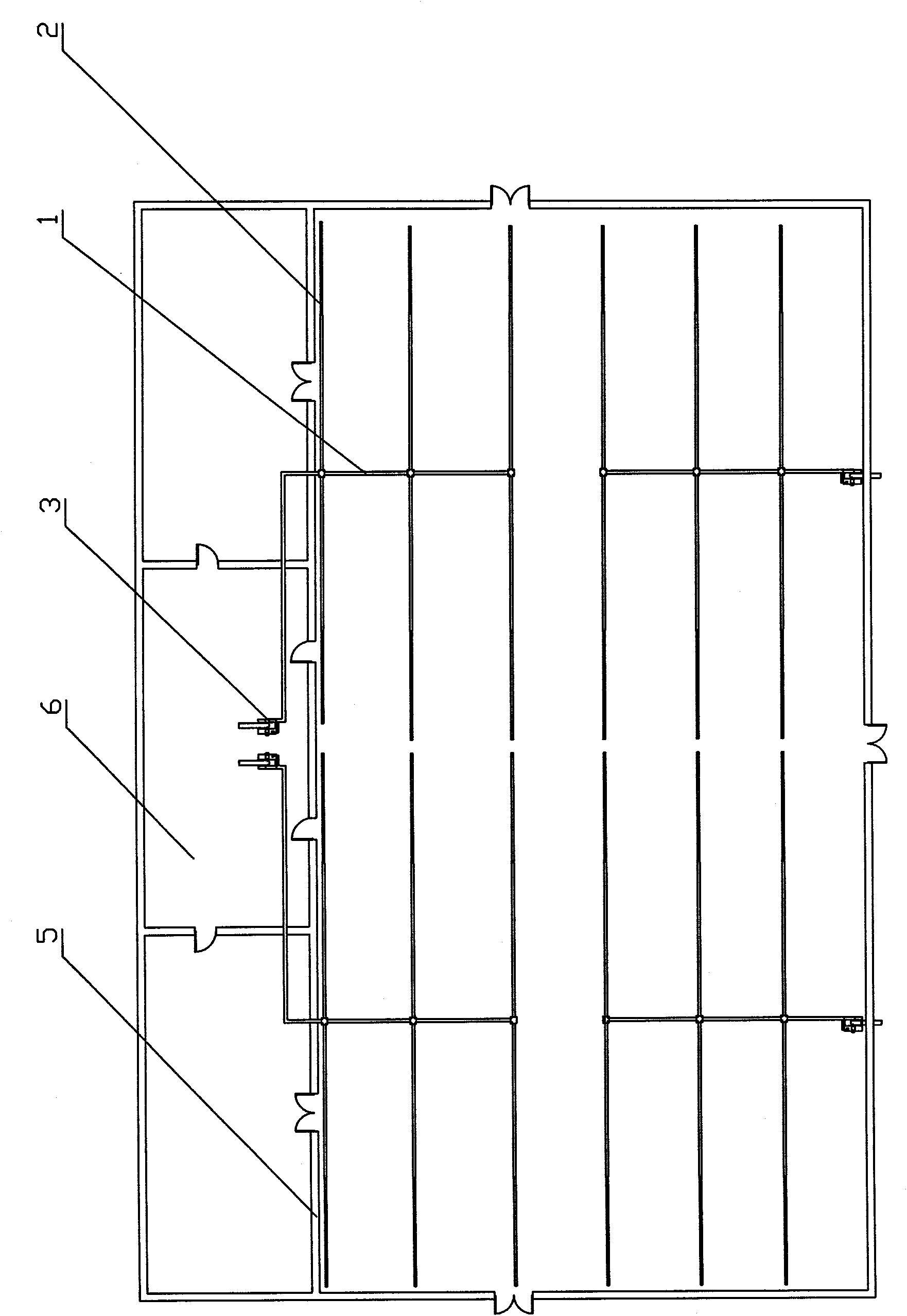

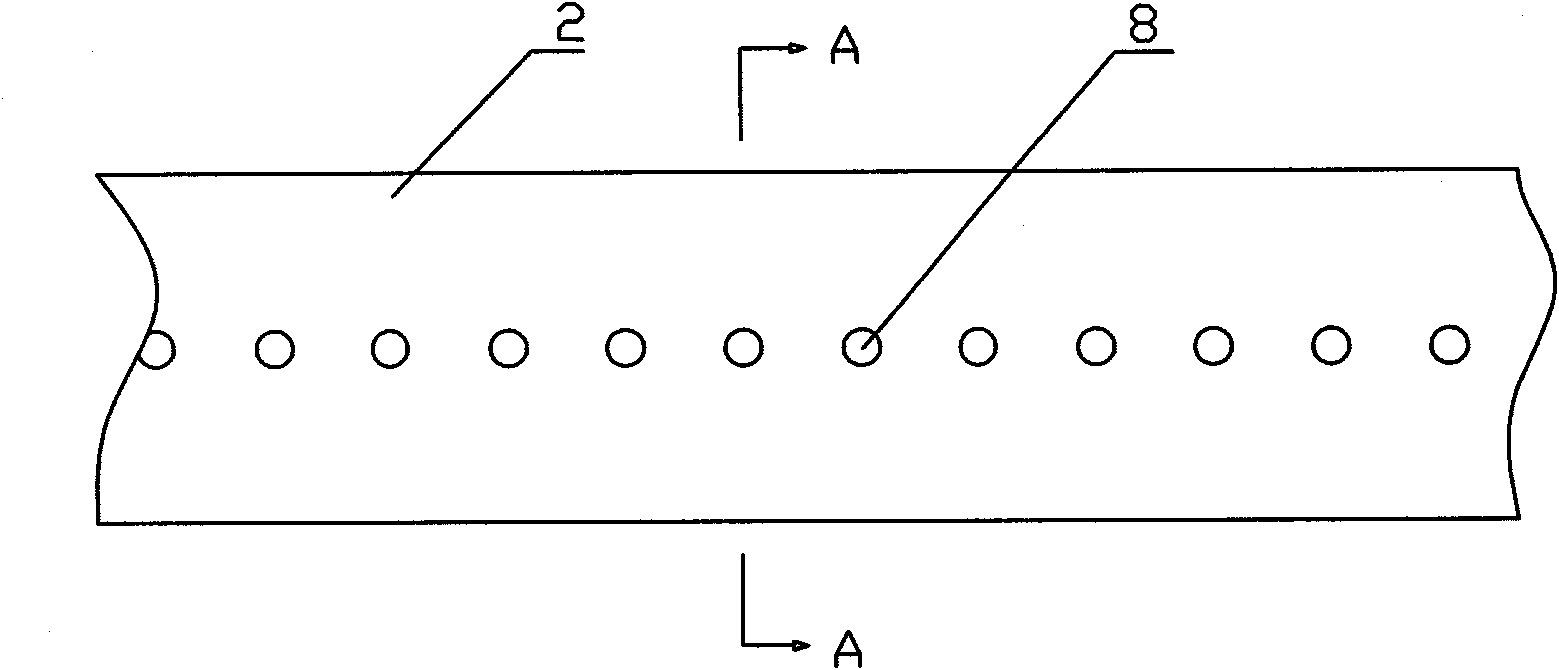

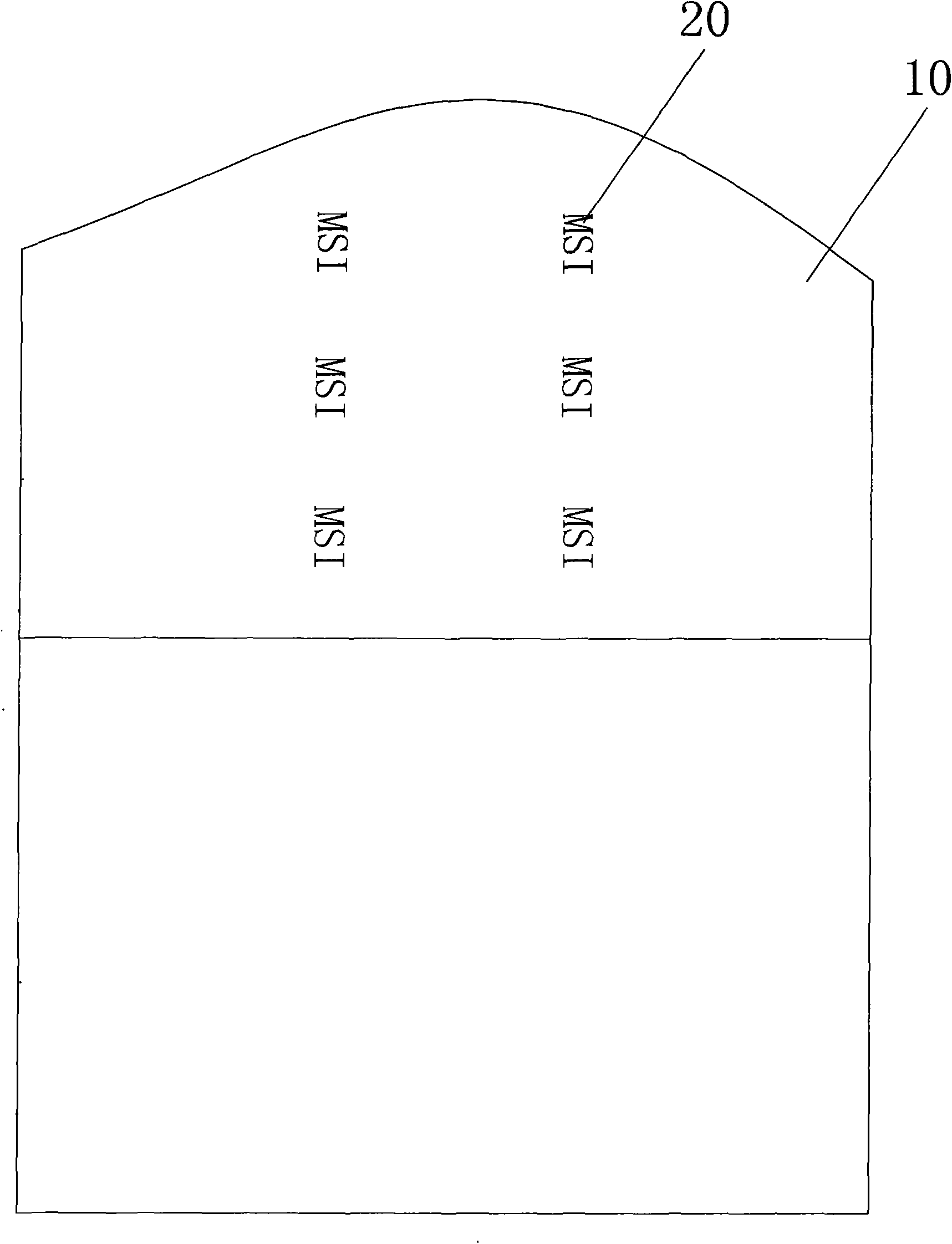

Method and device for preventing moisture condensation of roof of textile workshop

InactiveCN101818550AImprove anti-condensation effectSolve condensationDucting arrangementsSpace heating and ventilation safety systemsAutomatic controlRelative humidity

The invention discloses a method and a device for preventing moisture condensation of a roof of a textile workshop. The method comprises the following steps of: using an exhausting and dehumidifying fan in winter: starting the exhausting and dehumidifying fan when the air humidity of the roof reaches the highest limit value of the given relative humidity through an exhausting and dehumidifying pipe net fixed at the lower surface of the roof of the textile workshop, and extracting the humid air around the lower surface of the roof. The device comprises the exhausting and dehumidifying pipe net at the lower surface of the roof of the textile workshop, a humidity sensor, the exhausting and dehumidifying fan and an anti-fogging automatic control circuit; the exhausting and dehumidifying pipe net consists of at least one exhausting and dehumidifying main pipe and a certain quantity of exhausting and dehumidifying branch pipes arranged by a certain regular way; the two sides of each exhausting and dehumidifying branch pipe are at least respectively provided with a row of exhausting and dehumidifying holes or seams arranged uniformly. The invention has good effect of preventing moisture condensation, low cost of application, simple structure and convenient use; and the operation fee is only 4% of the traditional method. The invention can save energy and reduce the power consumption, has good environmental-friendly performance and provides great economic benefits and social benefits in the textile industry.

Owner:郑州宏大纺纱新技术咨询有限公司

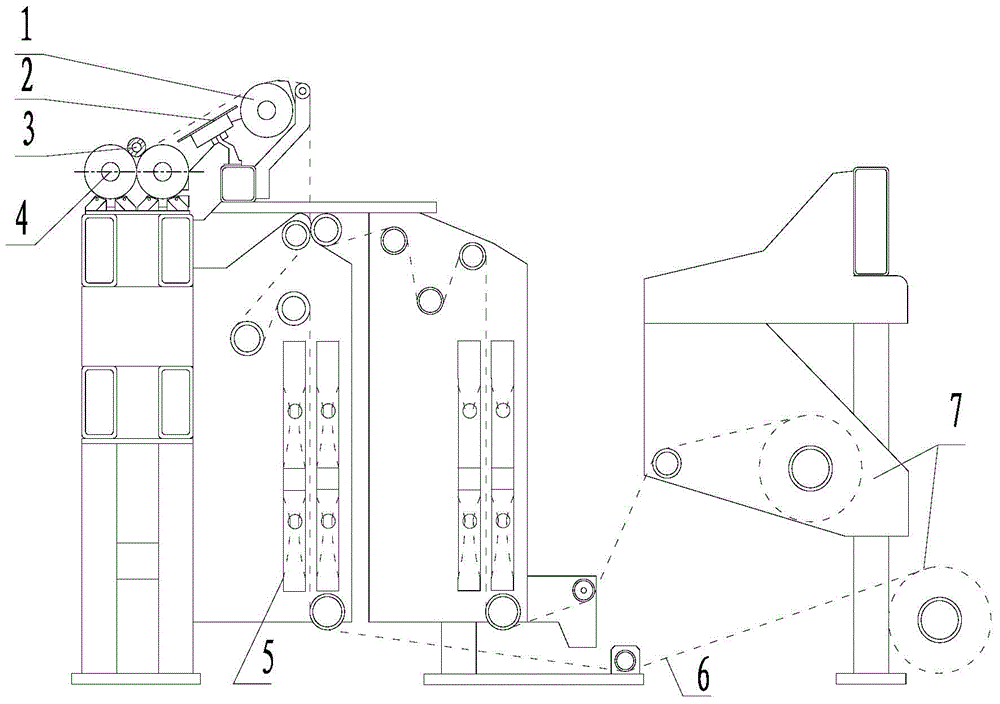

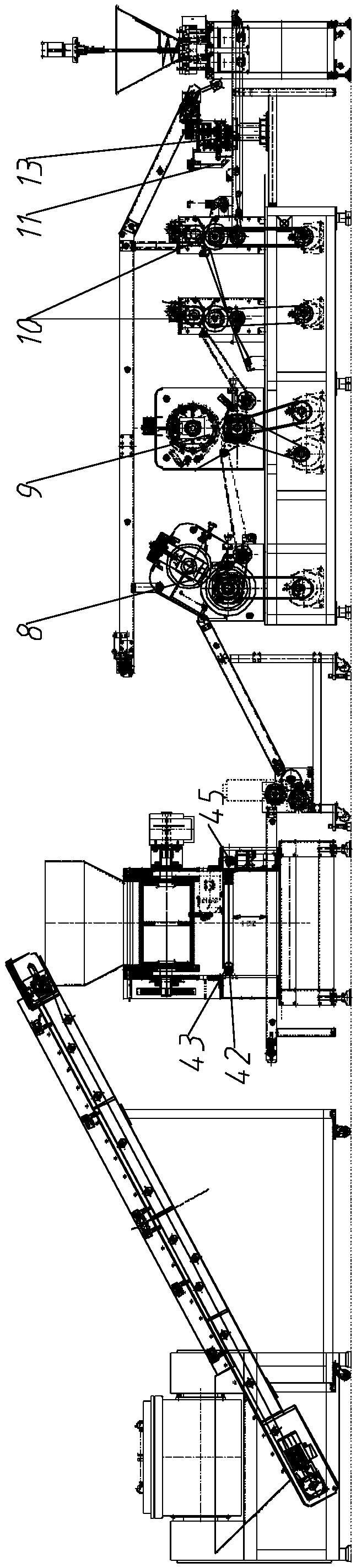

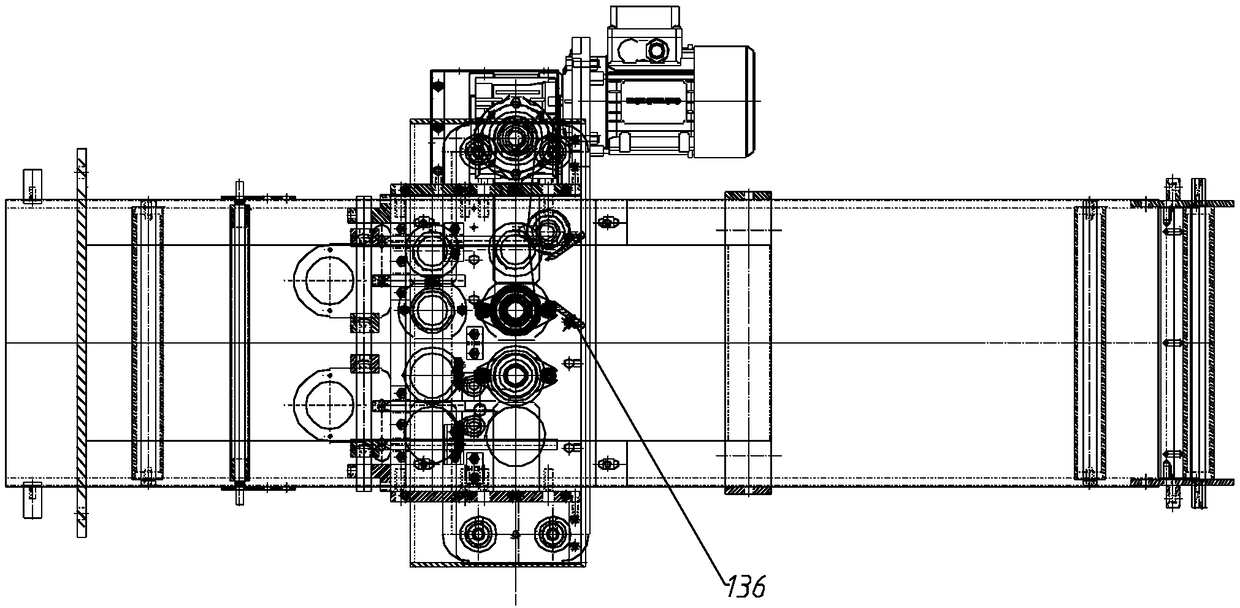

Wrapper making device and dumpling automatic making line

ActiveCN109362823AAvoid stuck damageImprove biteDough-sheeters/rolling-machines/rolling-pinsDough shaping and cutting apparatusProduction lineReciprocating motion

The invention belongs to the technical field of food processing, and provides a wrapper making device and a dumpling automatic making line. The wrapper making device comprises a machine frame, whereina feeding hopper, a wrapper making roller group, a wrapper piling device and a conveyer belt are sequentially arranged on the machine frame; an opposite pressing device is also arranged on the machine frame, and comprises lower pressing plates which are oppositely arranged; the lower pressing plates are located at one end close to the feeding hopper, of the wrapper making roller group, and are used for enabling dough to be extruded to be flat before the dough enters the wrapper making roller group; the wrapper piling device comprises a material guiding hopper which is in reciprocating motion;the moving direction of the material guiding hopper is perpendicular to the transporting direction of the conveyer belt; and wrappers pressed by the wrapper making roller group are subjected to positive and negative piling after being guided by the material guiding hopper. The invention further comprises a quick-frozen dumpling automatic production line. A rough pressing device, a beating device,a fine pressing device, a filling injecting device, a guiding device, a shaping device and a recovering device are sequentially arranged on the quick-frozen dumpling automatic production line. Through the adoption of the wrapper making device and the quick-frozen dumpling automatic production line disclosed by the invention, the problems that in the prior art, the speed of manually making dumplings is too low, and the requirements of people cannot be met are solved; and the technical problem that problems exist in some dumpling making machines, so that the dumpling making machines are difficult to popularize and use, is solved.

Owner:石家庄市汉普食品机械有限公司

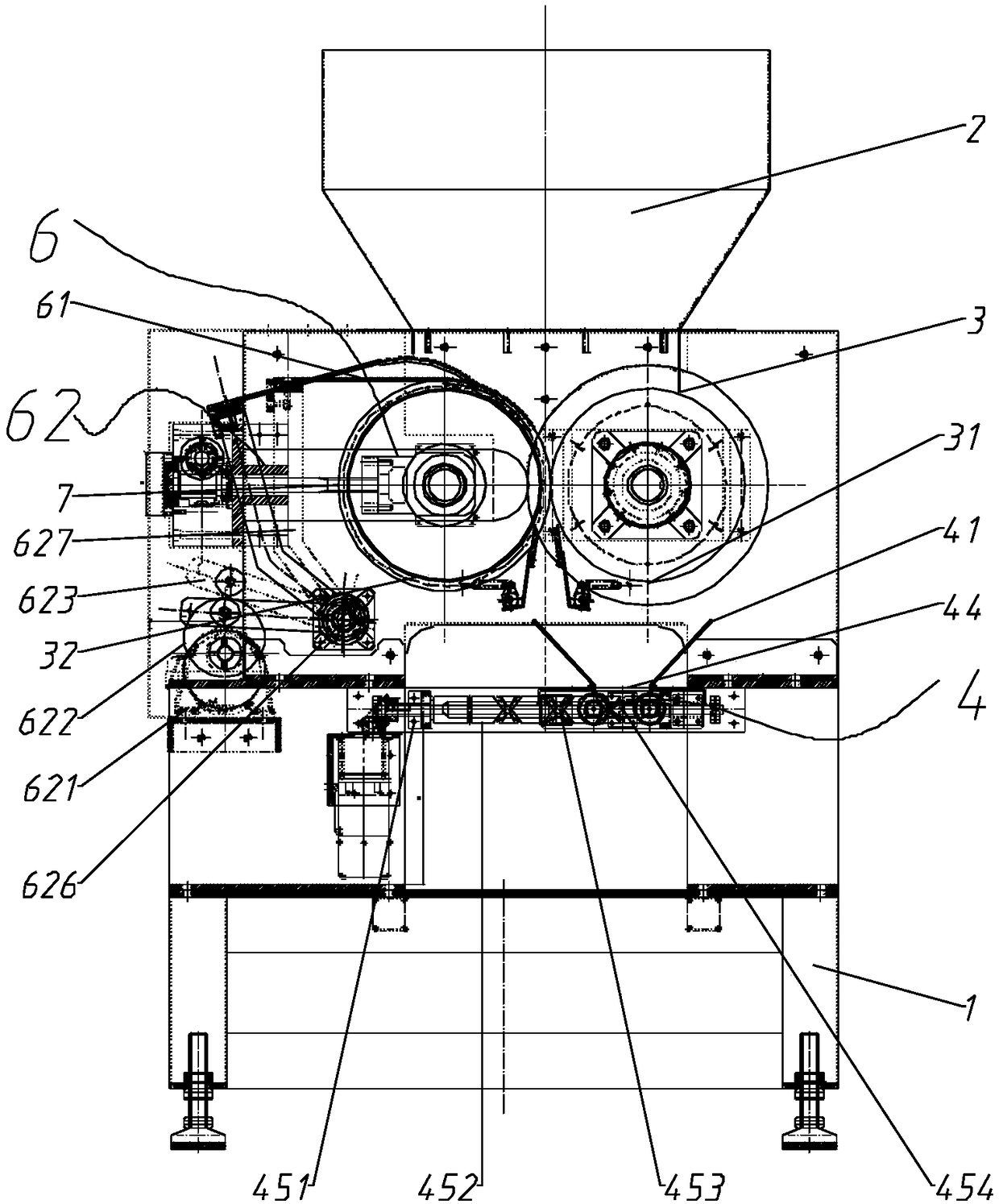

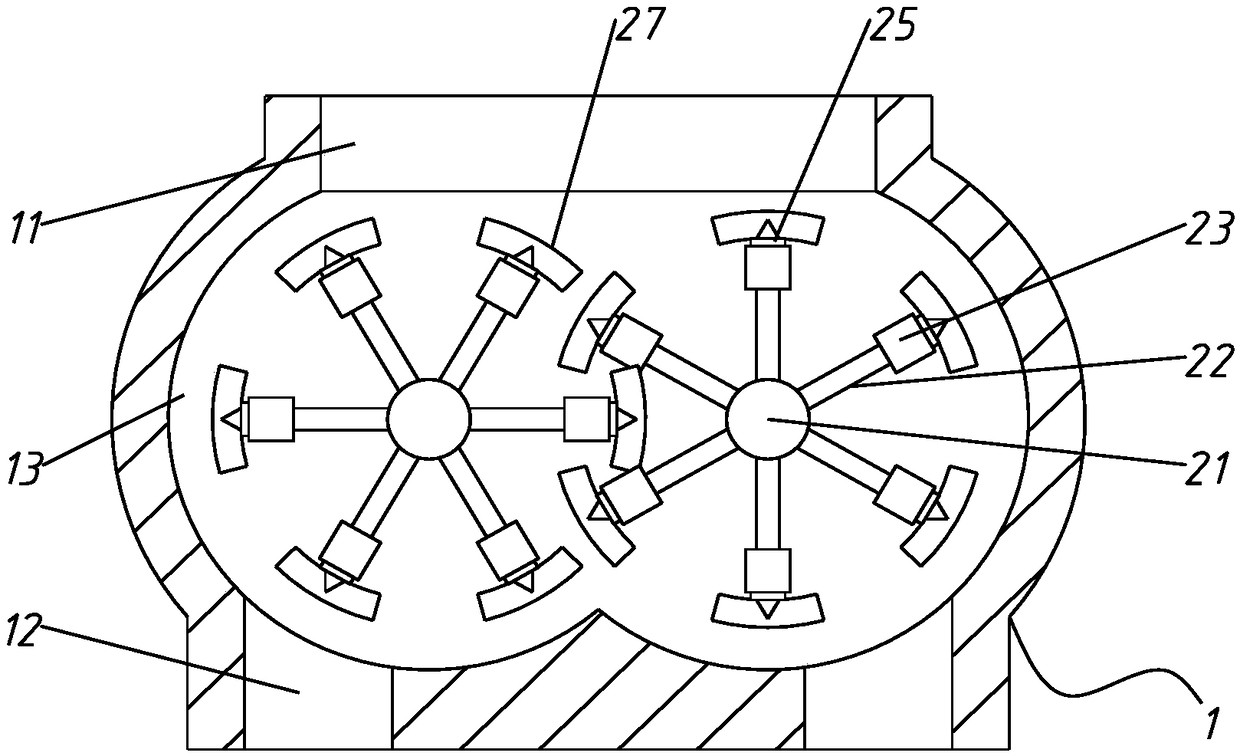

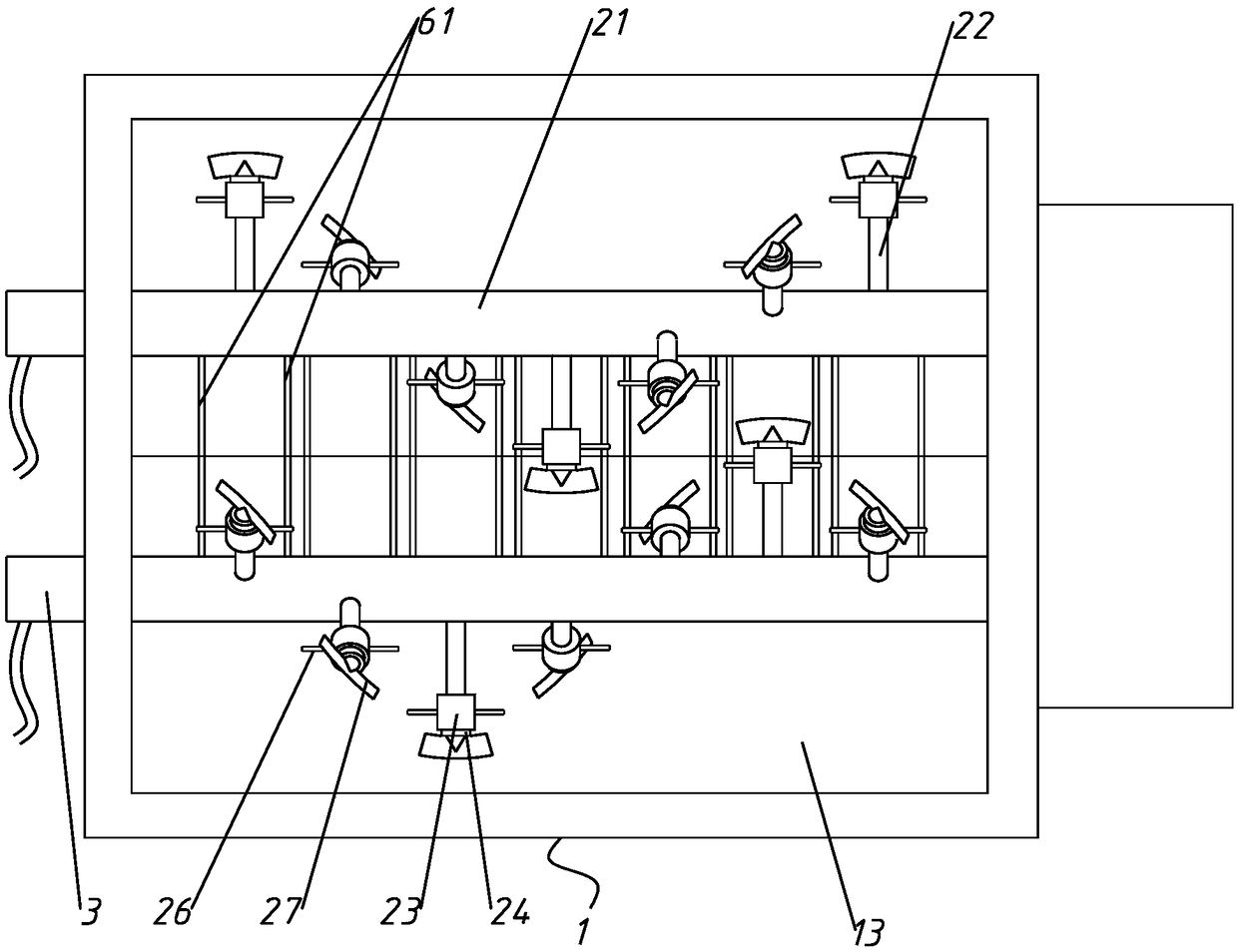

Double-shaft horizontal type mixer for mixing concrete

InactiveCN108789826AIncrease freedomLow failure rateCement mixing apparatusLiquid ingredients supply apparatusMixing effectHollow core

The invention belongs to the technical field of mixers, and provides a double-shaft horizontal type mixer for mixing concrete. The double-shaft horizontal mixer comprises a machine shell, a stock binis arranged inside the machine shell, a feeding inlet is formed in the upper part of the machine shell, and a discharge port is formed in the lower part of the machine shell. The feeding inlet and thedischarge port both communicate with the stock bin, and mixing main shafts are rotatably arranged in the stock bin. The mixing main shafts are each provided with a plurality of mixing rods in the radial direction of the mixing main shafts, the mixing main shafts are of hollow core structures, and first cavities are formed in the inner portions of the mixing main shafts. One ends of the first cavities are sealed, and liquid supply pumps are connected to the other ends of the first cavities through rotary joints. The mixing rods are of hollow core structures, and second cavities are formed in the inner portions of the mixing rods. The first cavities communicate with the second cavities. The mixing rods are each provided with a plurality of first through holes, and the first through holes communicate with the second cavities. Mixing blocks are slidably arranged on the mixing rods. Through the double-shaft horizontal mixer, the technical problem that the mixing effect is affected due to the fact that the structure of a mixing mechanism of a mixer in the prior art is limited due to the poor internal environment of a stock bin is solved.

Owner:高碑店市天筑新型建材有限公司

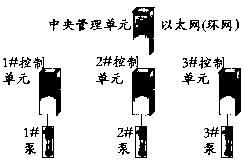

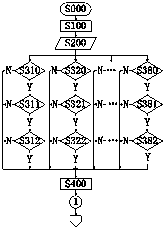

Distributed redundant constant-pressure water supply control system

ActiveCN110764481ASolve industry problemsImprove reliabilityEnergy industryService pipe systemsControl mannerControl cell

The invention discloses a distributed redundant control system. According to the system, pump revolution speed is dynamically adjusted based on the pressure, flow, temperature and other variables of fluid so as to achieve an expected control objective. The product is composed of one central management and coordination unit and n distributed control units which are independent and redundant from one another and can run autonomously, wherein each unit is in whole-network information transmission and modular design; the central management and coordination unit is only responsible for managing andcoordinating the control units, and the right of control is handed over to each control unit; and the central management and coordination unit can perform cascading in the same network segment or across network segments. In a pressure-maintaining standby state based on a multi-variable weight algorithm, the system does not do idle work due to dynamic flow compensation. The system has the advantages of high reliability, high continuity, distributed running, strong extensibility and energy preservation, therefore, the defects that through a traditional central control mode, reliability is poor,and equipment overhaul requires shutdown and water supply cut-off are overcome, and the problems that water supply continuity is not high, and the scale is not large in the industry are solved. In this way, the after-sales service pattern in the current industry is changed, and after-sales cost is greatly lowered.

Owner:许刚

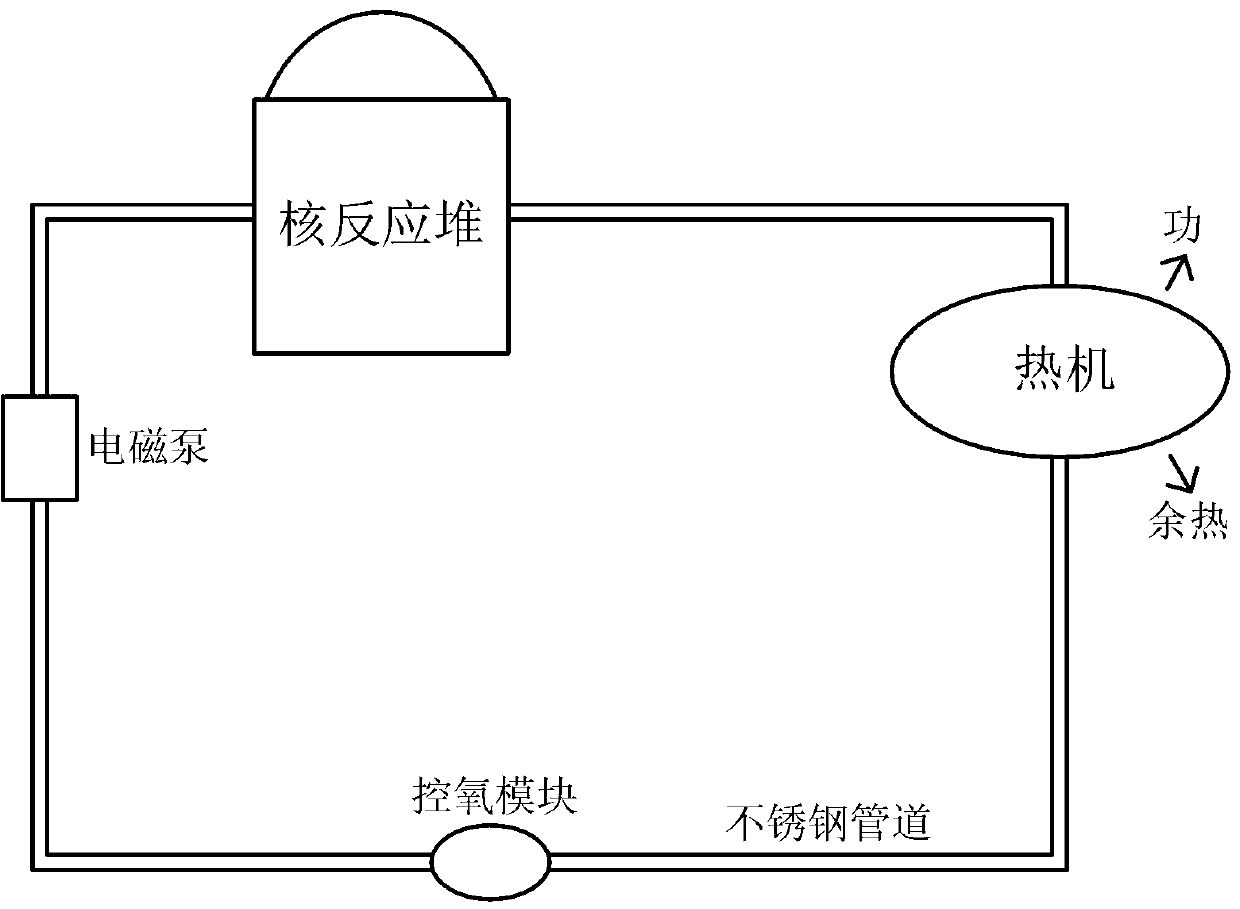

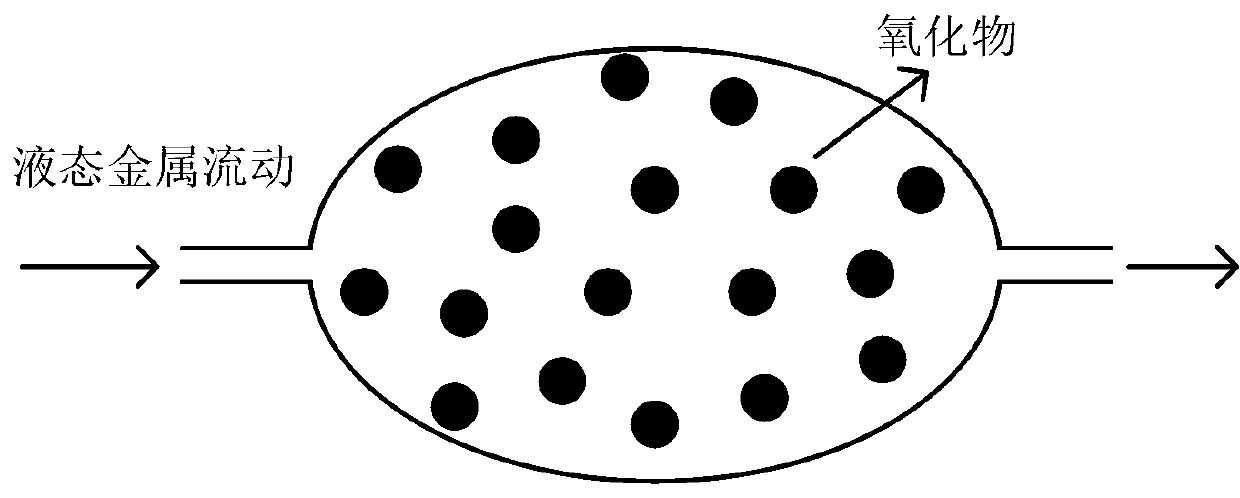

Nuclear reactor oxygen control type liquid metal used under 200-300 DEG C and compatibility process thereof

InactiveCN110284043AGuaranteed safe operationReduce corrosionNuclear energy generationCooling arrangementNuclear reactorNuclear power

The invention discloses a nuclear reactor oxygen control type liquid metal used under 200-300 DEG C and a compatibility process of the nuclear reactor oxygen control type liquid metal used under 200-300 DEG C. The nuclear reactor oxygen control type liquid metal comprises, by weight percentage, 0.2-0.4 wt.% of Ag, 3.0-5.0 wt.% of Sb, 1.0-2.0 wt.% of Mn, 10.0-15.0 wt.% of Bi, 8.0-12.0 wt.% of Cd, 2.0-3.0 wt.% of Ga, 20.0-30.0 wt.% of Pb and the balance tin. The oxide composition for controlling the oxygen activity is composed of 10.0-12.0 wt.% of PbO, 2.0-5.0 wt.% of CuO, 1.0-4.0 wt.% of Sn2O3, 5.0-8.0 wt.% of AgO, 10.0-20.0 wt.% of ZnO and the balance Fe2O3. When the scheme is applied to liquid metal and pipeline design in the field of nuclear power, the equipment is simple, the construction cost is low, and the heat transfer performance is good; and under the working temperature of 200-300 DEG C, the structure (liquid metal plus oxygen control module plus stainless steel pipeline) can be used for 10 years without major overhaul.

Owner:深圳市兴荣晟物业管理有限公司

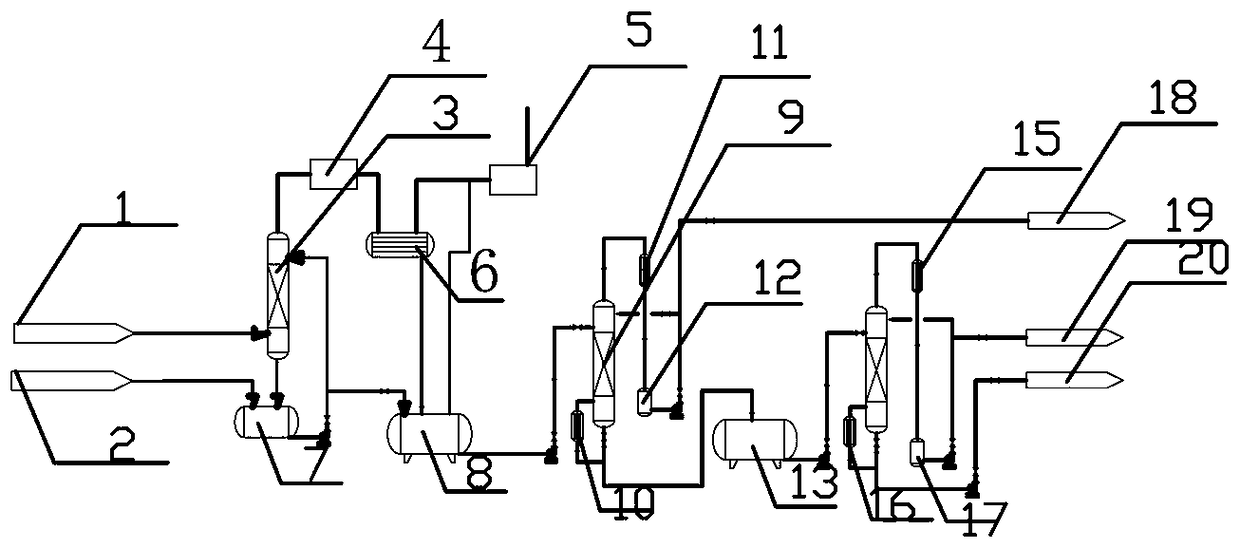

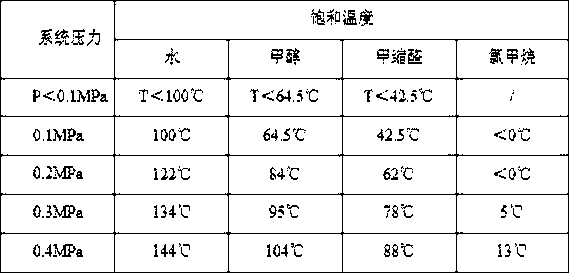

Pressure control recovery equipment and process for glyphosate hydrolysis tail gases produced by alkyl ester method

PendingCN108727160AImprove intrinsic safetyImprove stabilityOrganic compound preparationHydroxy compound separation/purificationSolventHydrolysis

The invention relates to pressure control recovery equipment and process for glyphosate hydrolysis tail gases produced by an alkyl ester method. A pretreatment system for glyphosate hydrolysis tail gases produced by the alkyl ester method is connected with a dilute methanol solution collection tank; the dilute methanol solution collection tank is connected with the upper part of a methylal rectifying column by virtue of a pipeline; the top of the methylal rectifying column is connected with a methylal rectifying column return tank by virtue of a condenser I; the methylal rectifying column return tank is connected to a methylal finished product tank; the bottom of the methylal rectifying column is connected with a methanol aqueous solution intermediate tank by virtue of a pipeline; the methanol aqueous solution intermediate tank is connected with a methanol rectifying column by virtue of a pipeline; the top of the methanol rectifying column is connected with a methanol rectifying columnreturn tank by virtue of a condenser III; and the methanol rectifying column return tank is connected to a methanol finished product tank. Meanwhile, the invention discloses specific process steps. The energy consumption for solvent recovery is reduced by virtue of pressure control condensation and reduced pressure gasification measures, the hydrolysis tail gas recovery stability is improved, anda highly dependent damageable graphite condenser in an original liquid phase recovery process is not used.

Owner:HUBEI TAISHENG CHEM

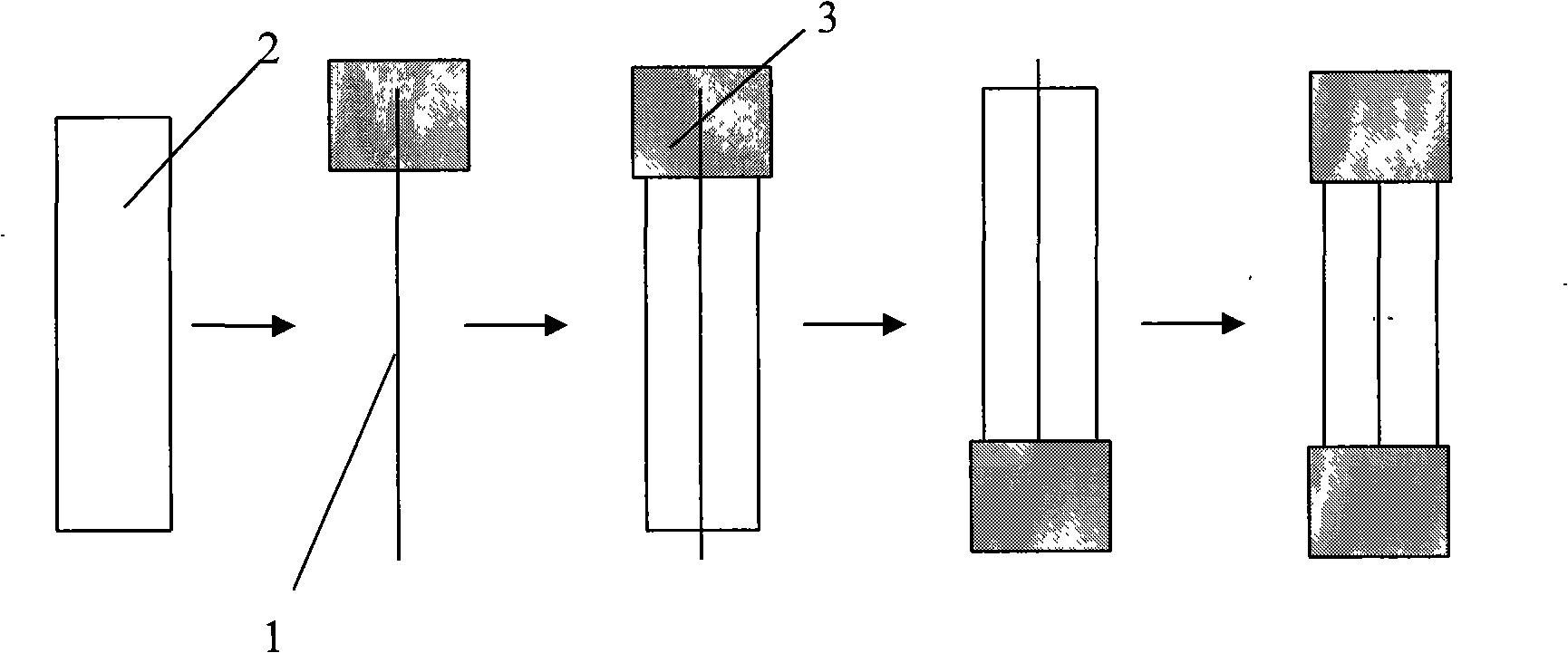

Vacuum cartridge fuse and process for manufacturing the same

ActiveCN101281838AImprove overall lifespanExtend your lifeFuse device manufactureHigh frequency current welding apparatusEngineeringSoldering

The present invention relates to a cartridge fuse and a manufacturing technique for the cartridge fuse, in particular to a vacuum cartridge fuse and a manufacturing technique for the cartridge fuse. The interior of main body of the cartridge fuse is in vacuum state. The present invention utilizes high frequency welding technique to solder a fuse, a tube, and a tinned copper cap together as follows: high frequency current is provided by a high frequency welding machine, an enclosed soldering cavity that can be opened is arranged, alternating magnetic field is produced by the high frequency current in the enclosed soldering cavity, the frequency and time of the high frequency current is controlled, so that the tin on the tinned cap is melted and therefore the soldering is completed in the enclosed soldering cavity. The copper cap on one end is soldered with high frequency welding technique; before the other end is soldered, the cavity is pumped into vacuum state to attain the purpose of protecting the finished product of cartridge fuse.

Owner:DONGGUAN BETTER ELECTRONICS TECH +1

Production technology of stretching film

The invention relates to a stretching film, in particular to a production technology of stretching film provided with a printing procedure. The invention comprises a feeding procedure in which raw material solid LDPE granules are delivered to the sequential procedures through a feeding orifice, the sequential procedures comprise: 1) high temperature melting procedure; 2) die orifice extruding procedure; 3) pulling and cooling procedure; 4) printing procedure; and 5)rolling and packaging procedure. The invention has the beneficial effects that: (1) the stretching film produced by a stretching film machine can be used for printing company trademarks and other contents according to the requirements of customers and can be demounted conveniently; (2) when the stretching film is produced, the pattern printing procedure can be finished in one step at the same time, exerting no impact on the productivity; and (3) various patterns can be printed according to the requirements of customers and can be used in advertisements.

Owner:孙和永

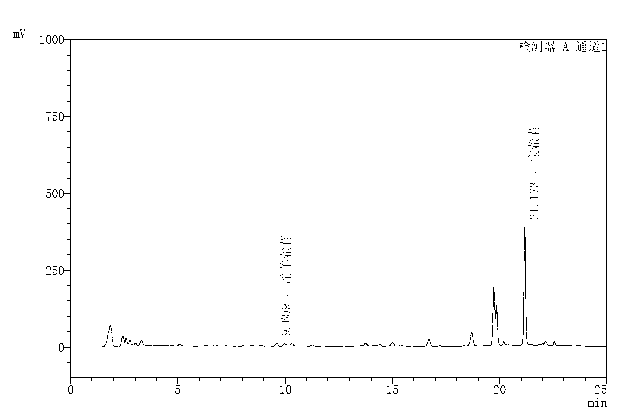

Method for producing baohuoside I through herba epimdii

ActiveCN103305572AHigh yieldLow costMicroorganism based processesFermentationSilica gelEthyl acetate

The invention discloses a method for producing baohuoside I through herba epimdii. The method comprises the following steps of: S1. expanding propagating and diluting saccharomyces cerevisiae in culture medium; S2. mixing and evenly stirring culture solution and herba epimdii, and carrying out close and static anaerobic fermentation in a fermentation tank; S3. when the herba epimdii is entirely hydrolyzed, extracting fermenting raw materials with an extraction solvent; S4. washing with extract dichloromethane, and extracting ethyl acetate; and S5. filtering ethyl acetate through an alumina column, then carrying out silica gel adsorption column chromatography to obtain pure baohuoside I. The method has the beneficial effects of being simple and convenient to operate, easy to implement, high in efficiency, fast, low in cost, high in yield, pollution-free by adopting microbial solid-state anaerobic fermentation to hydrolyze herba epimdii-containing raw materials, thus being suitable for large-scale industrial production.

Owner:XICHANG DANYANG BIOLOGY TECH CO LTD

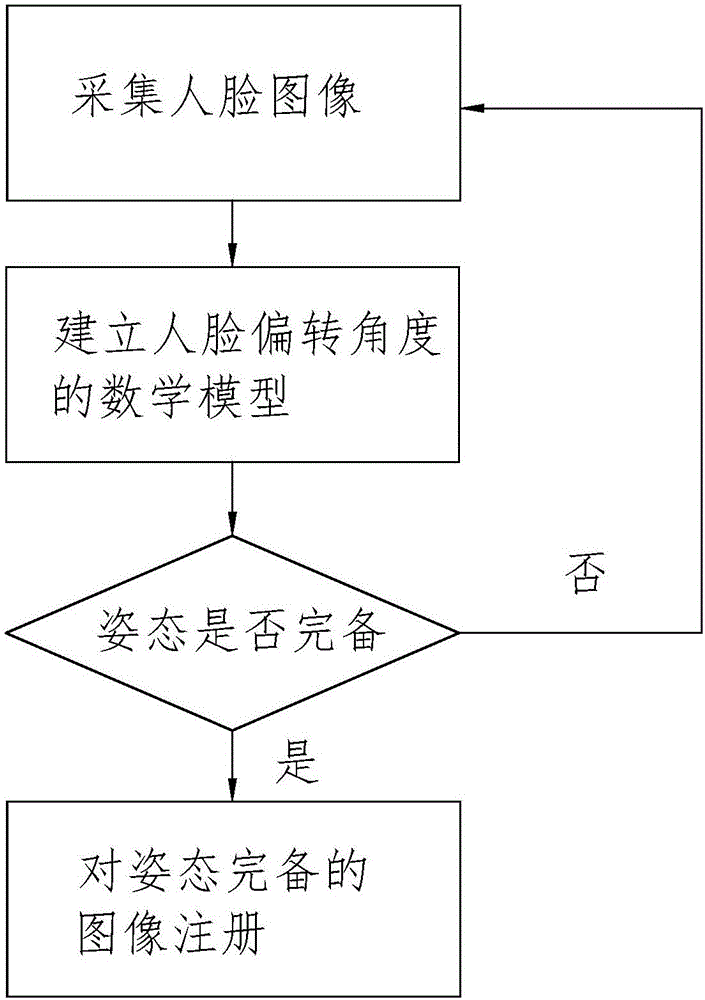

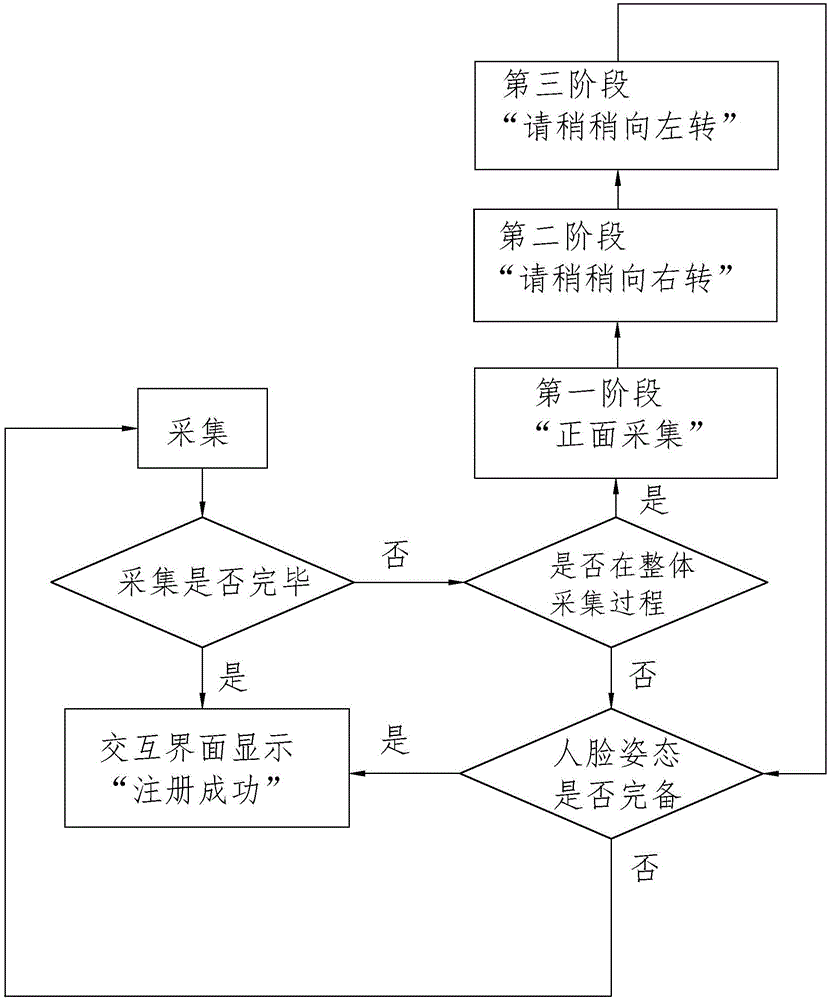

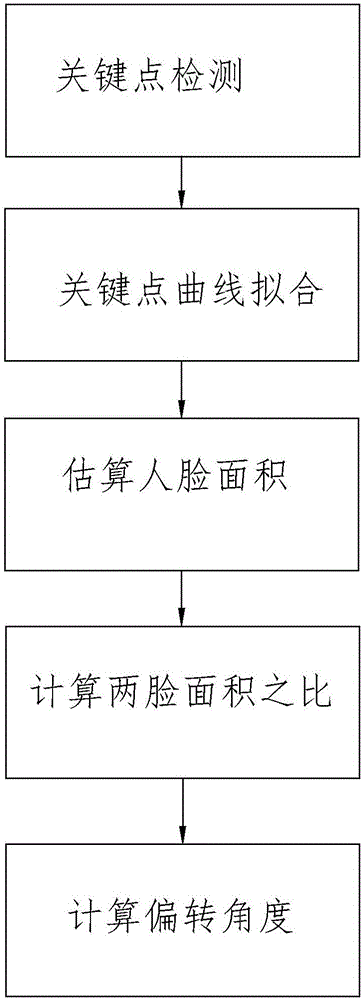

Automatic face registration method and device with super-complete attitude of face identification

ActiveCN106778925ASolve industry problemsCharacter and pattern recognitionPattern recognitionComputer graphics (images)

The invention discloses an automatic face registration method and device with a super-complete attitude of face identification. A mathematical model of face deflection angle is established, a face image with complete attitude is discriminated according to the model, face images in which the attitude is incomplete are eliminated during registration, face images with super complete attitudes are obtained, and industrial difficulties are overcome. The automatic registration device comprises an image collection module, a face attitude discriminating module, a registration module and a display module; and the four modules cooperate with one another to obtain the face images with super-complete attitudes, and the industrial difficulties are overcome.

Owner:未来航空科技(江门)有限公司

Alkyl ester method glyphosate solvent recovery system and process based on three-stage condensation

PendingCN108358763AImprove intrinsic safetyReduce system pressureOrganic compound preparationHydroxy compound preparationSolventChemistry

The invention belongs to an alkyl ester method glyphosate solvent recovery system and method, and particularly relates to recovery equipment and process for tail gas with the major ingredients of hydrogen chloride, methylal, methanol, methyl chloride and water generated after the synthesis liquid hydrolysis in the alkyl ester method glyphosate production process. The equipment and the process provided by the invention thoroughly weed out a graphite condenser highly relied in the conventional liquid phase recovery process. Compared with a conventional gas phase recovery process, the equipment and the process provided by the invention have the stable system pressure. Compared with a liquid phase recovery process, the equipment and the process provided by the invention have the advantage thatthe ton glyphosate steam consumption is reduced by 2.6t; safety and energy-saving benefits are obvious.

Owner:HUBEI TAISHENG CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com