Patents

Literature

62 results about "Industrial software" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

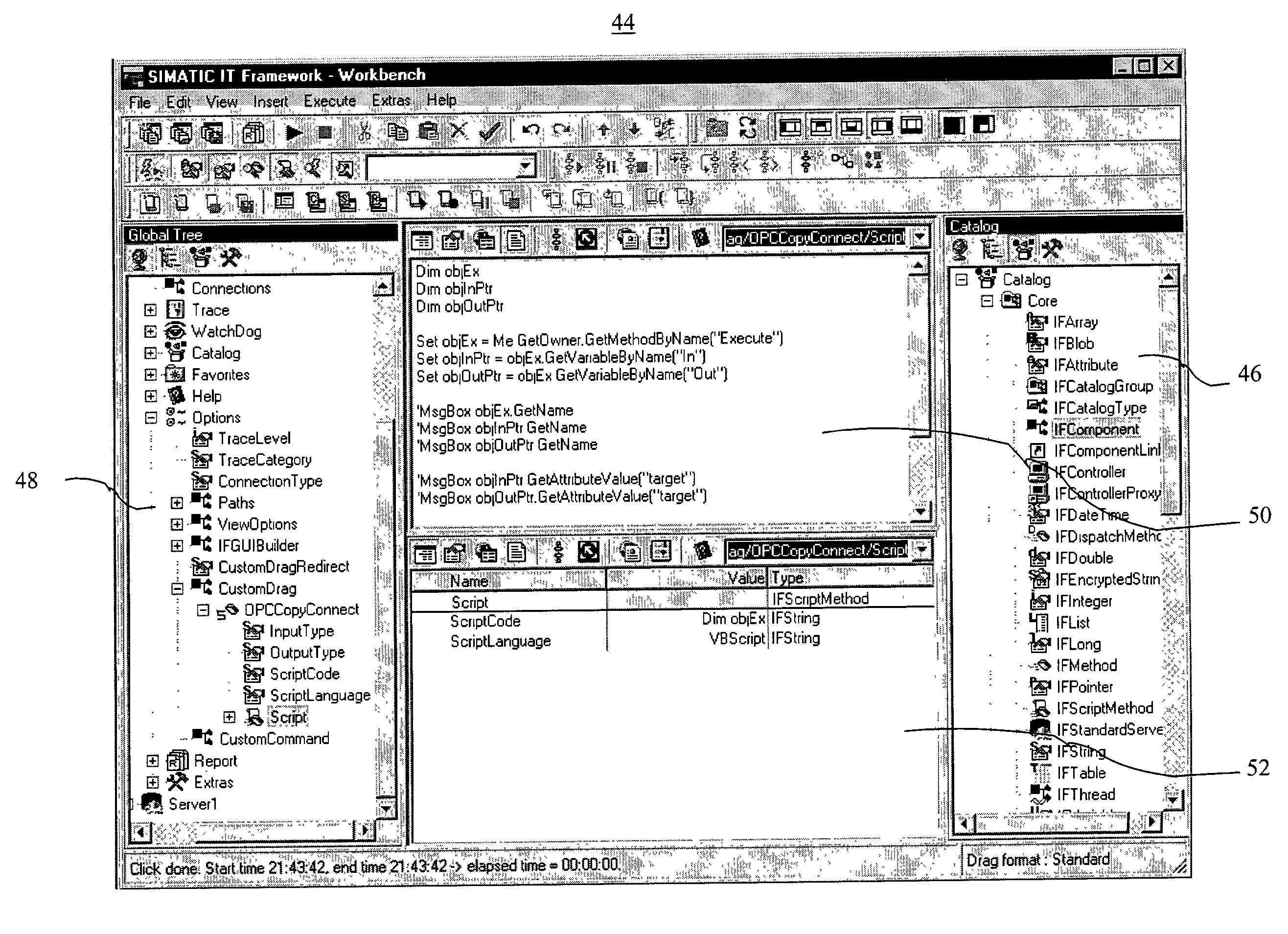

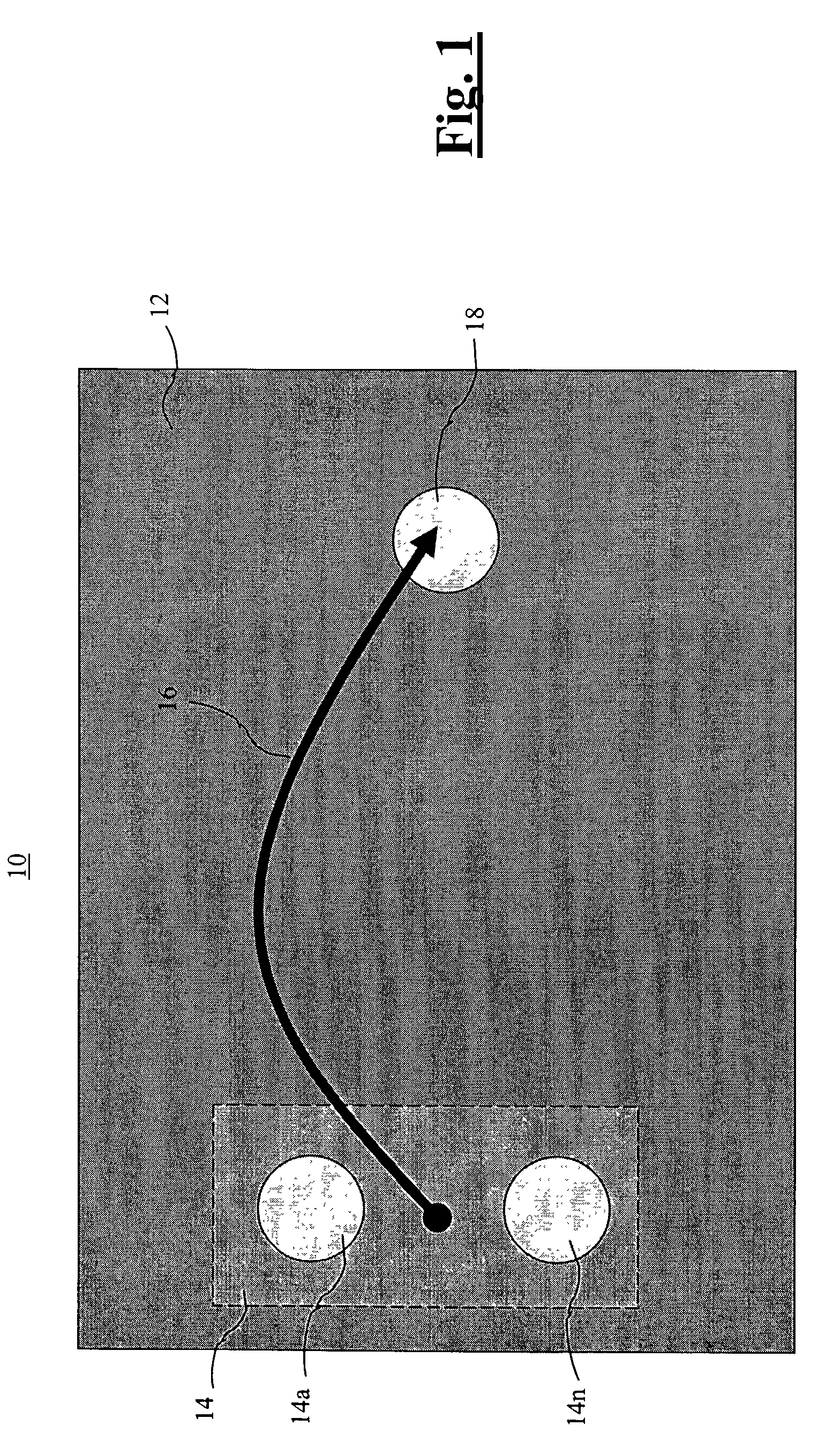

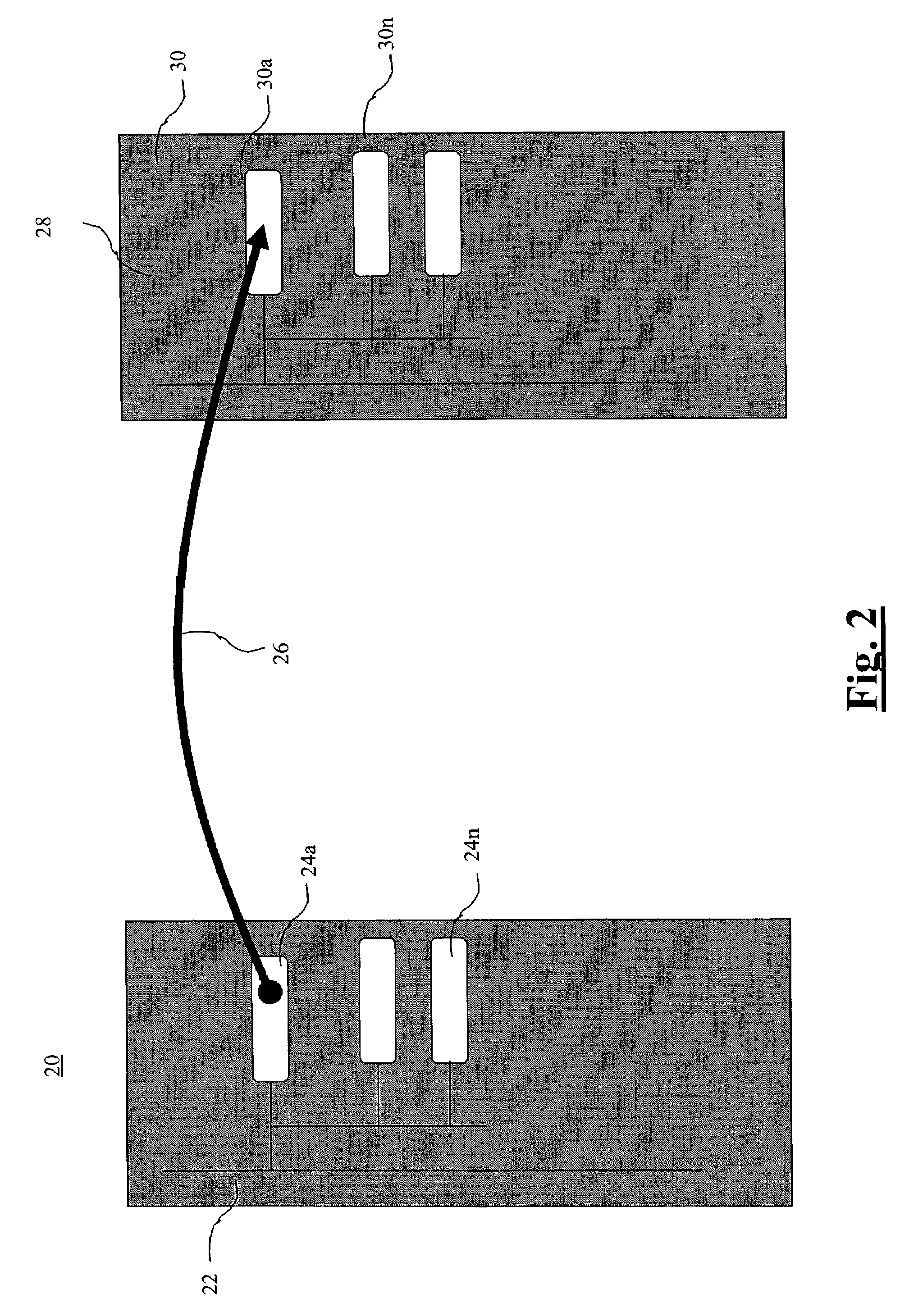

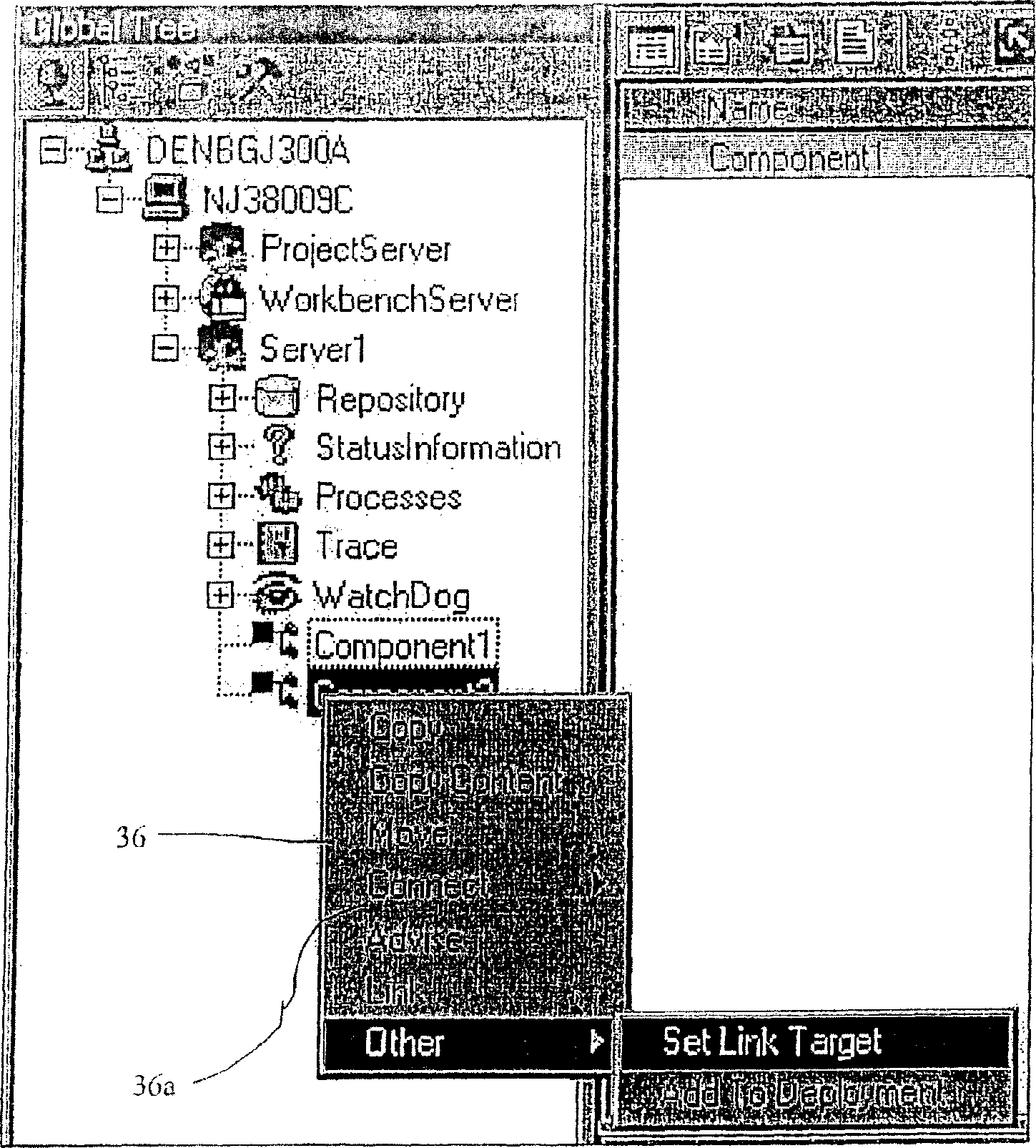

Customizable drag and drop for industrial software applications

ActiveUS7337409B2Extend semanticsCathode-ray tube indicatorsSpecial data processing applicationsDrag and dropSpecific function

Customizable Drag & Drop enables easy activation of user defined or project specific functions concerning two related objects: A user interface graphically displays objects of a particular module. An extending function extends the drag and drop operation to allow the user to define a new set of semantics that is applied when a drag and drop operation is executed. In this way communication can be established using Customizable Drag & Drop extended by a user defined function. Also definition and modification of the deployment of an industrial automation system and hyperlinking of objects in manufacturing execution systems is achieved by Customizable Drag & Drop.

Owner:SIEMENS AG

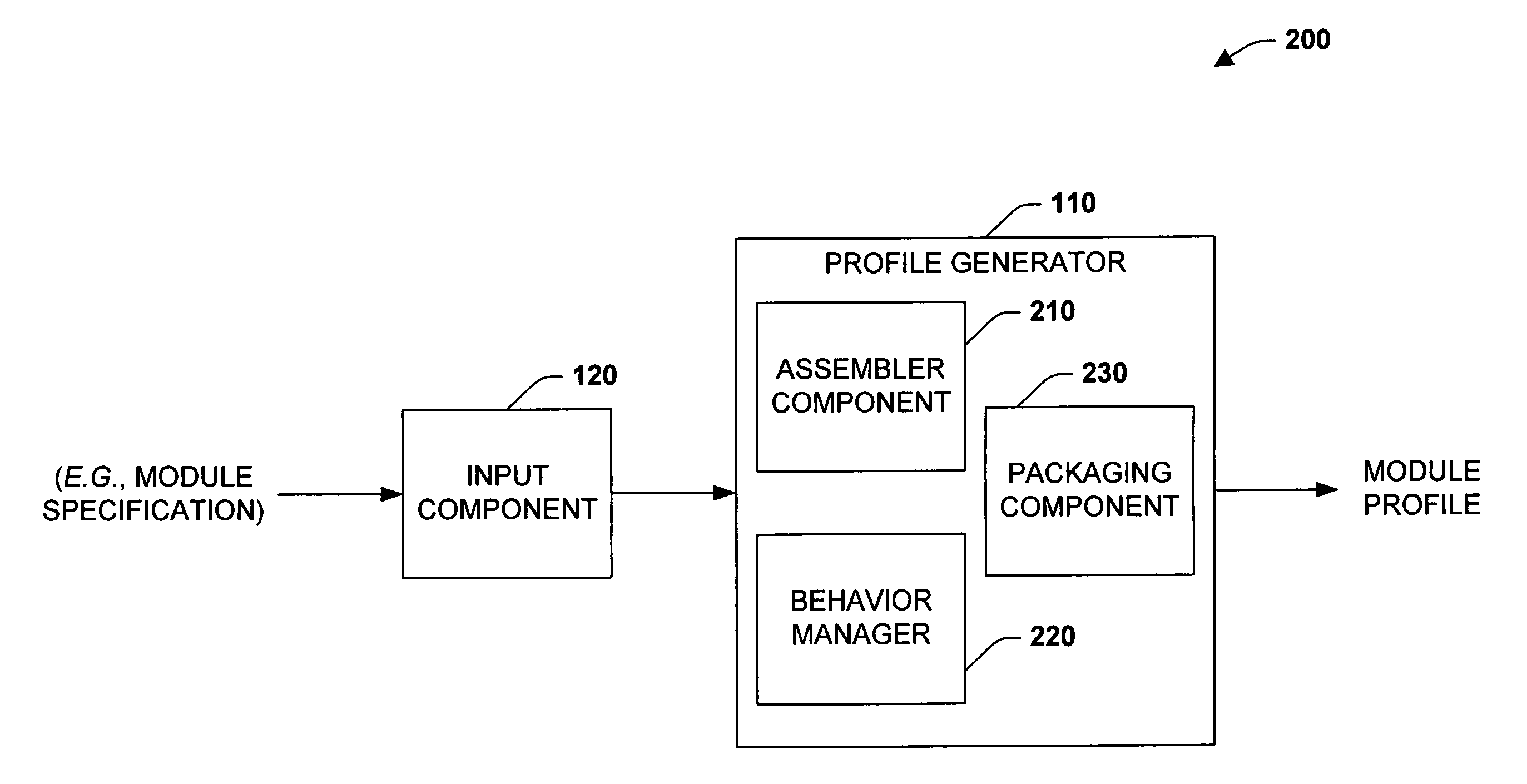

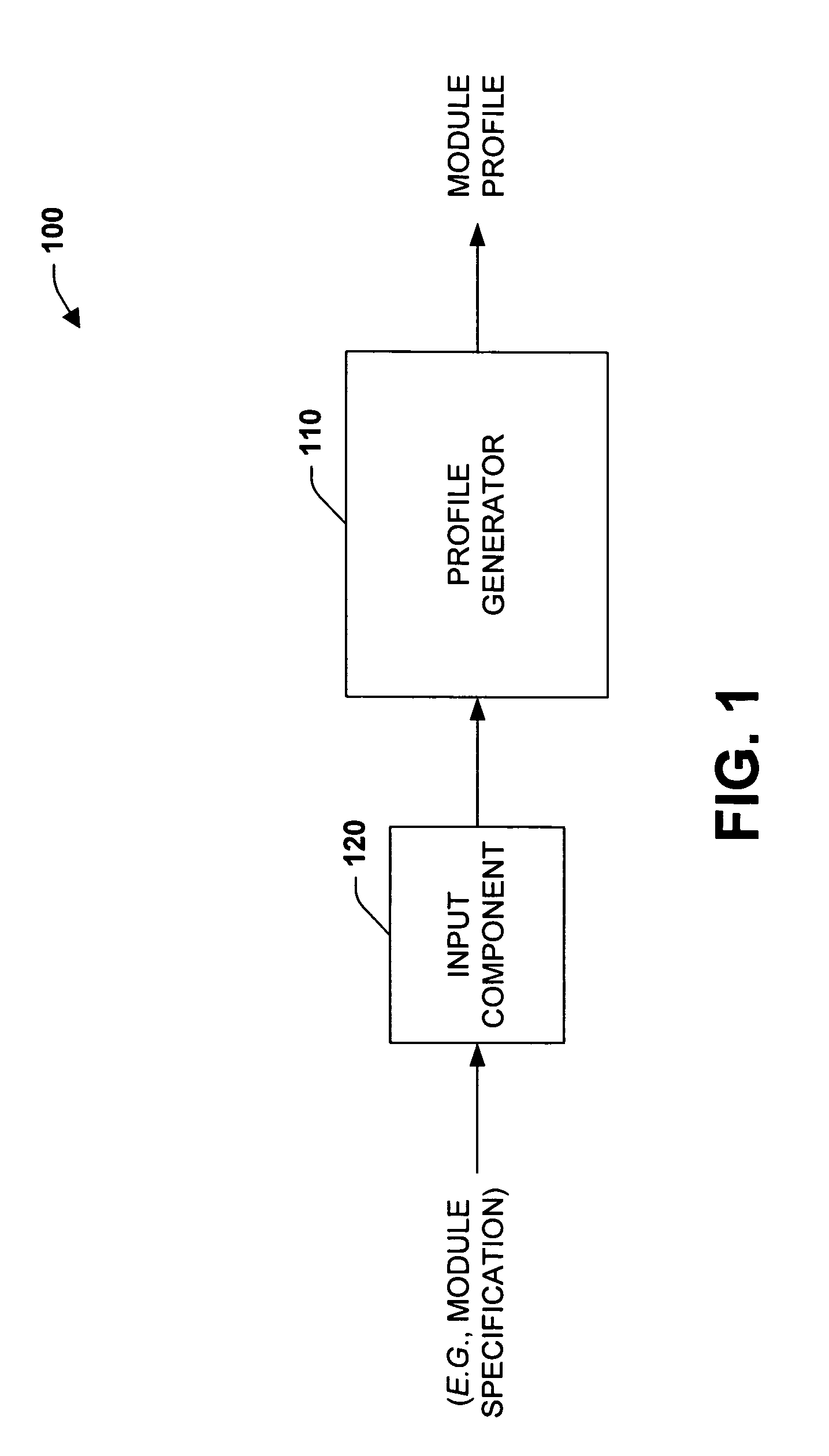

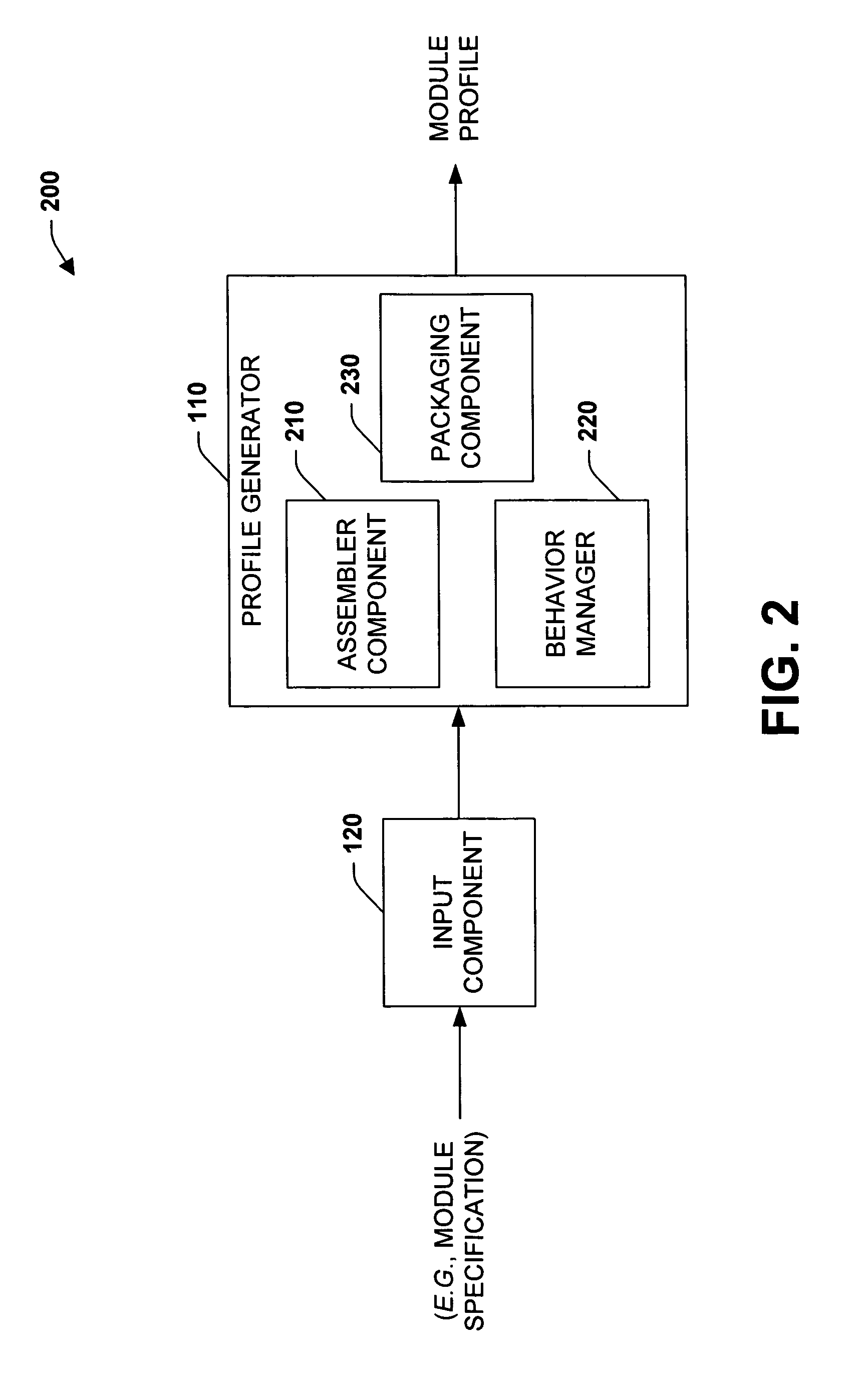

Systems and methods that employ an extensible architecture to define configuration functionality

ActiveUS7861223B1Improve development productivityEasy to determineProgramme controlSpecific program execution arrangementsGraphicsIndustrial software

The subject invention relates to systems and methods that generate modules profiles for industrial control modules (e.g., I / O, scanners, adapters . . . ). A module profile generally includes a set of components, interfaces and / or plug-ins that determine possible configurations for a module. Such entities are packaged in an XML based format to provide a dynamic module profile, wherein a definition type can be dynamically changed. Development and / or configuration of a module can be achieved through an industrial software development environment via a graphical hierarchical representation of configuration options defined in the module profile. In addition, the module profile provides for separately installable / release independent utilization via XML and COM based interfaces, wherein an end-user does not have to wait for a new software release in order to add a new module.

Owner:ROCKWELL AUTOMATION TECH

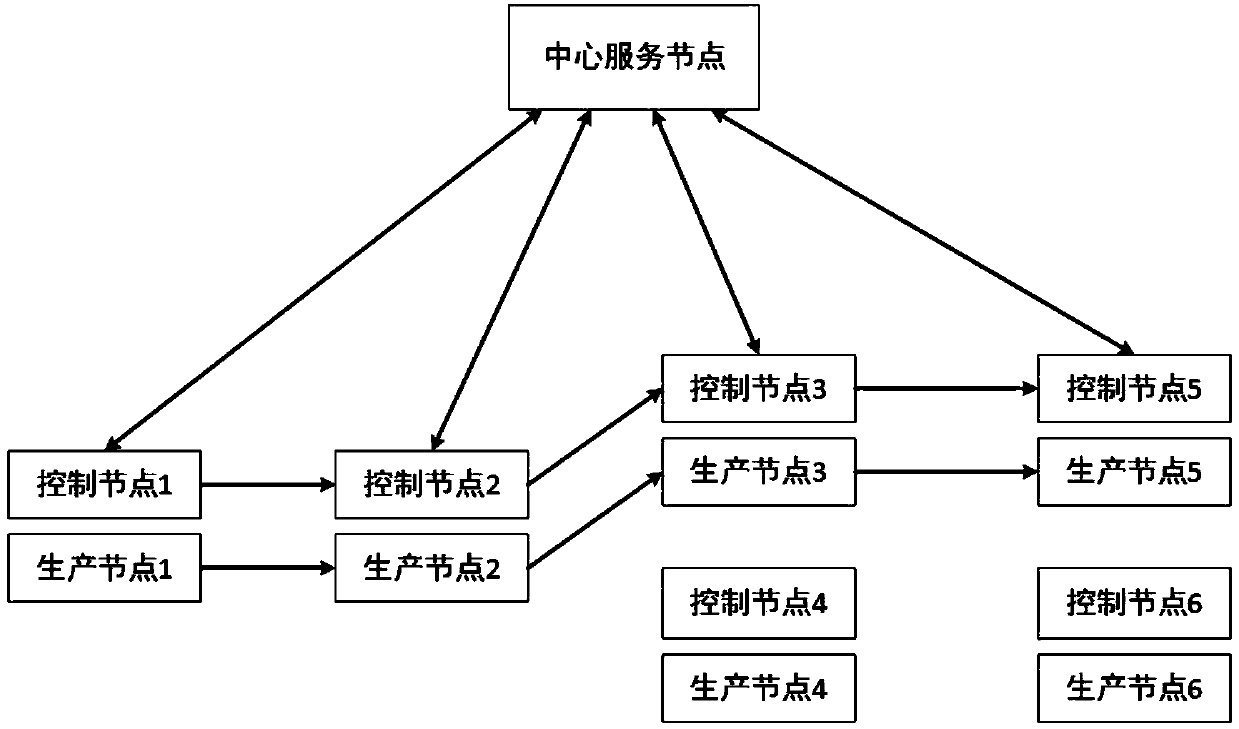

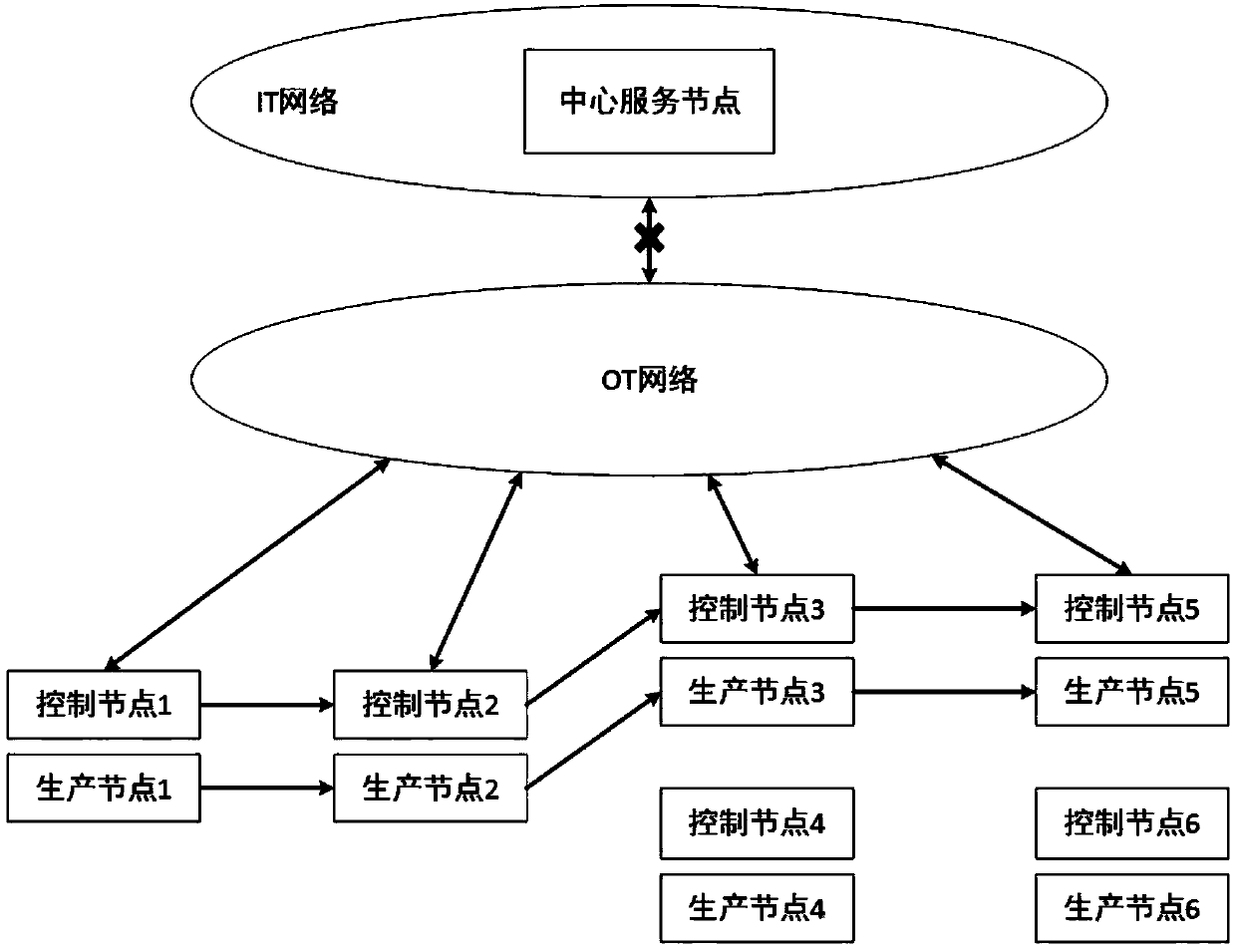

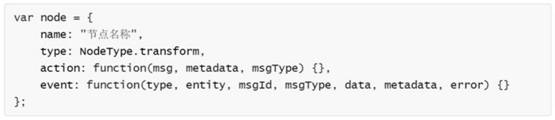

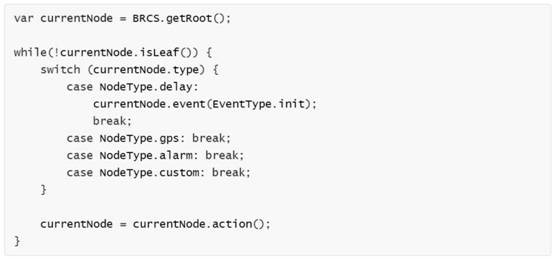

A real-time data collaboration method in an industrial internet of things

InactiveCN107657360AReduce acquisition timeMake sure to work togetherResourcesTransmissionReal-time dataData collaboration

The invention relates to a real-time data collaboration method in an industrial internet of things. The method provides a basic data coordination mechanism for application and implementation of industrial software in an industrial production site. The data collaboration method, through a pre-deployment mode, deploys data to nodes about to be used by the data before the data is used; meanwhile, themethod does not depend on a center service node, can realize data collaboration and information flow in a high-reliability network of a production environment better, improves data obtaining time andimproves data real-time processing performance; and meanwhile, the method improves data collaboration mode and flow path, and can improve data collaboration and flow reliability and performance.

Owner:浙江力太工业互联网有限公司 +1

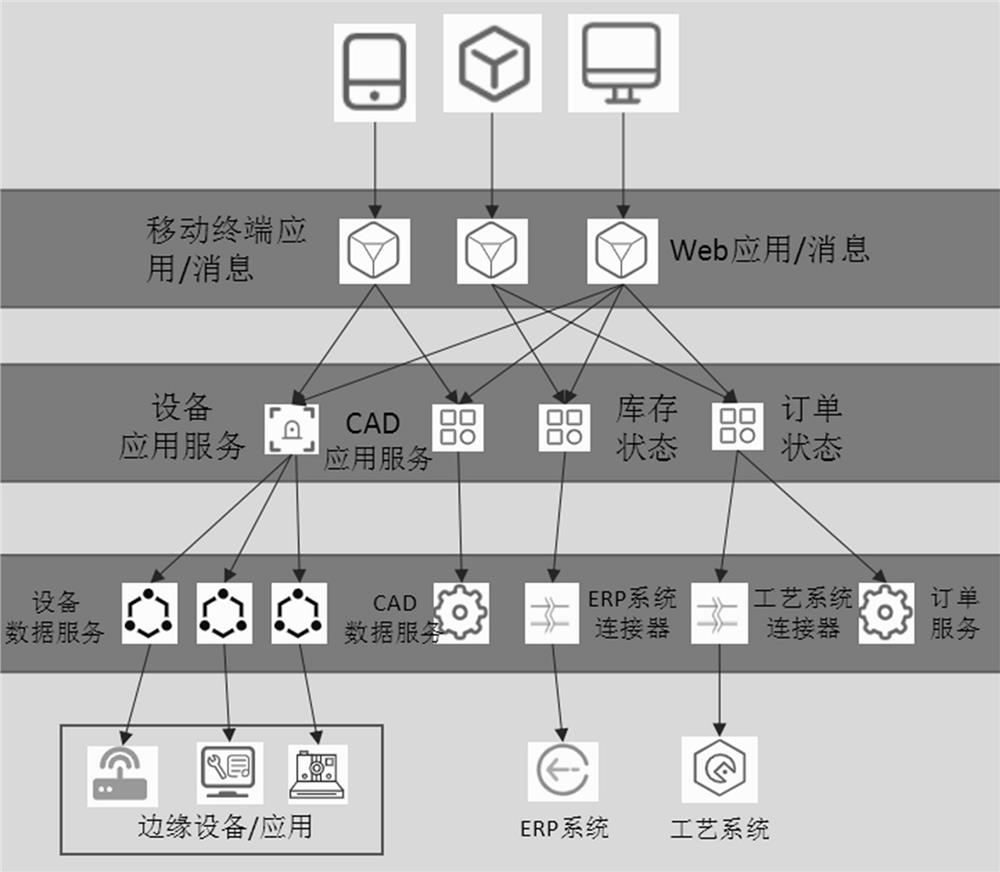

Industrial internet system based on industrial brain

ActiveCN113115241AQuick buildChange the construction modeParticular environment based servicesInterprogram communicationPersonalizationThe Internet

The invention belongs to the technical field of internet, and particularly relates to an industrial internet system based on an industrial brain. An industrial brain host not only can complete equipment docking, instruction issuing and data acquisition work, but also has the capability of docking and fusing heterogeneous industrial software, and the capability of business scheduling, edge calculation, business processing, big data analysis and platform interconnection. API can be comprehensively opened to the outside, business applications can be written at will, Handle identification analysis standards can be supported, and based on an industrial data chain technology and a business rule chain technology, personalized problems of different industries and different enterprises are solved through modularization and standardization of the industrial brain host, a personalized scheme is provided for the enterprises by using one set of industrial internet system, application industries and applicable enterprises are not definitely limited, and only one industrial brain host needs to be deployed in a machine room, and one or more industrial data gateways can be deployed in a production workshop, so that the system has the popularization advantage of universality.

Owner:QINGDAO RONGSHANG TIANXIA NETWORK CO LTD

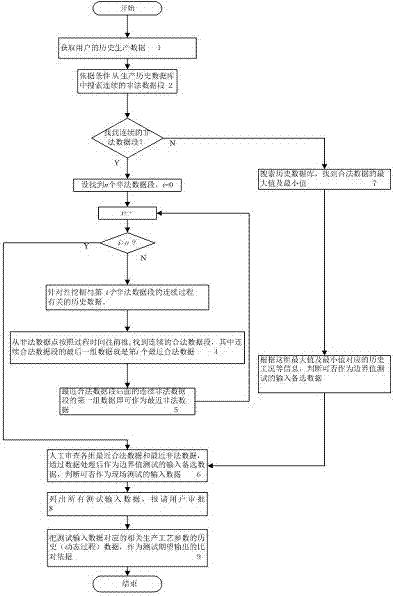

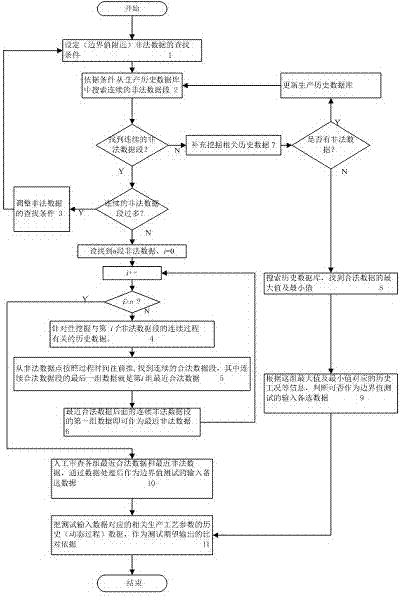

Boundary value testing method in industrial software site test based on user historical data

ActiveCN107967218AHigh efficiency of on-site implementationSoftware testing/debuggingTest efficiencyIndustrial software

The invention discloses a boundary value testing method in an industrial software site test based on user historical data, and belongs to the field of the software testing. A severe loss can be brought to the user site production by the site test of the industrial software, and a production accident is easily caused by just legal data and just illegal data near a boundary value. Recent illegal data and recent legal data near the boundary value are found out through the excavation to the historical data of the user production site, and production state information caused by the data is analyzedaccording to the corresponding historical process data, the related data is evaluated whether to be used as the input data of the boundary value testing, and the corresponding treating process data of abandonware in the historical data is used as the comparison evidence output by the tested new software site test. The method is capable of getting the boundary value testing data on the basis of the specific user production historical data processing. The boundary value testing data is closer to the practical situation of a user. The testing efficiency and sufficiency are improved under the precondition of effectively preventing an accident risk.

Owner:ZHONGYUAN ENGINEERING COLLEGE

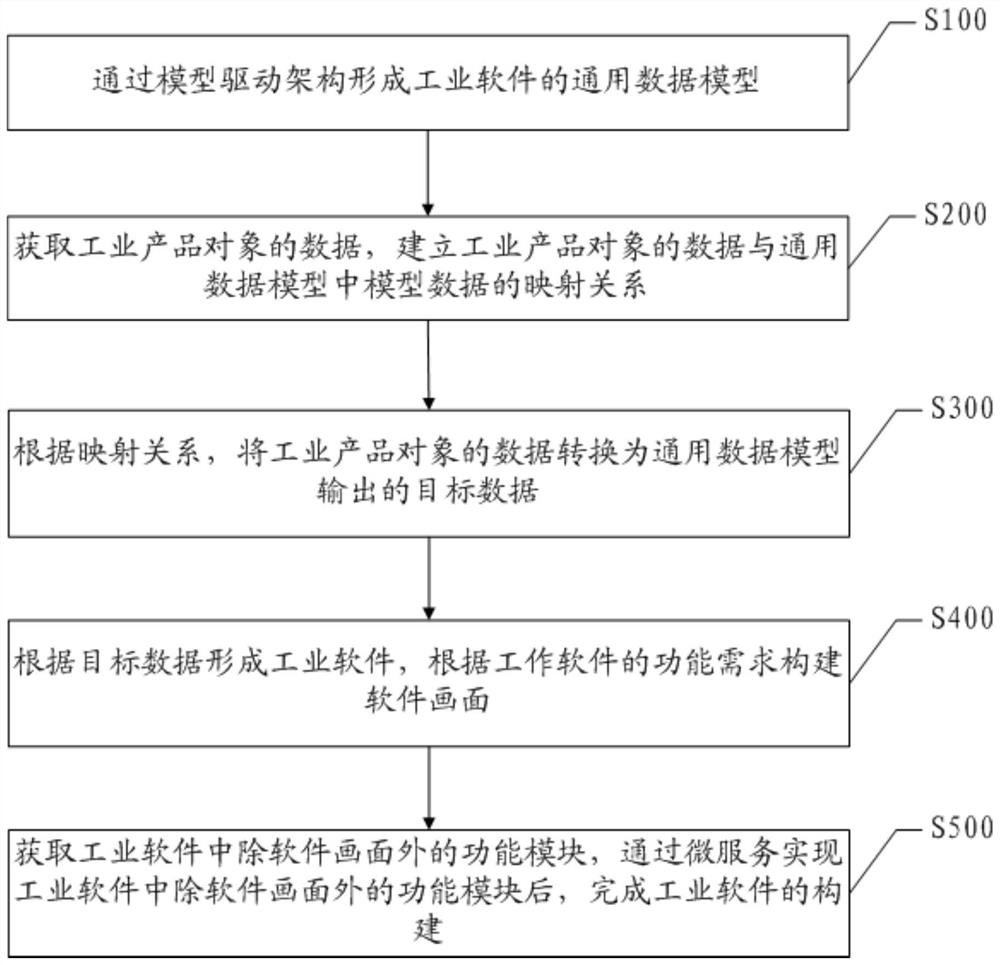

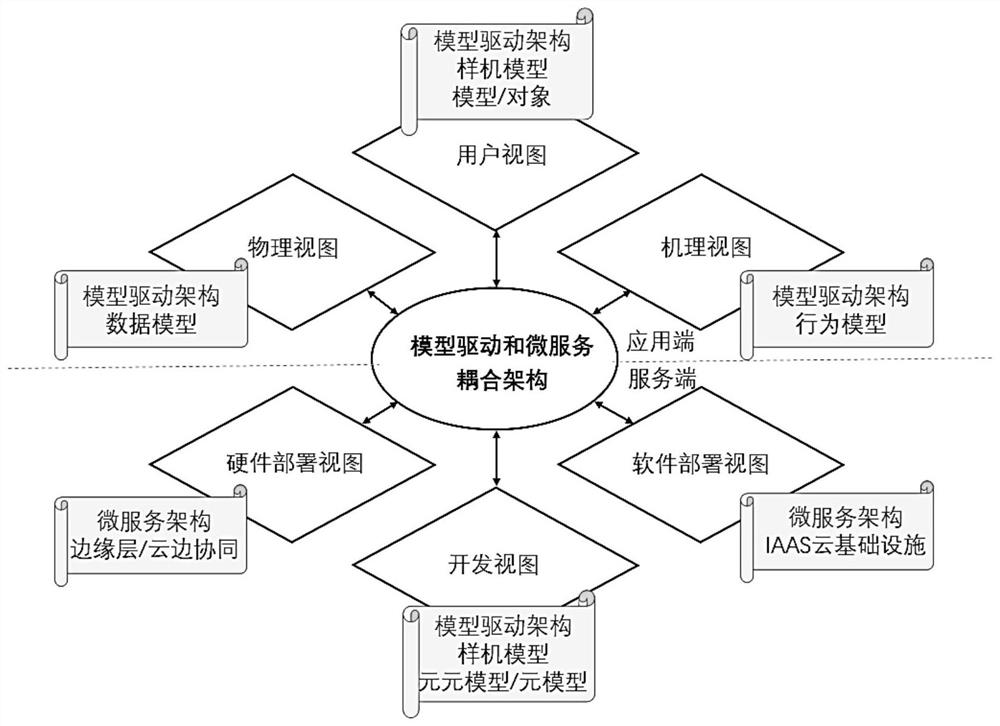

Industrial software construction method and system based on model driving and micro-service coupling

PendingCN112148255AResolve internal relationship issuesSoftware designData transformationIndustrial software

The embodiment of the invention discloses an industrial software construction method and system based on model driving and micro-service coupling. The method comprises the steps of forming a universaldata model of industrial software by a model driving architecture; acquiring data of an industrial product object, and establishing a mapping relationship between the data of the industrial product object and model data in the general data model; converting the data of the industrial product object into target data output by the general data model according to the mapping relationship; forming industrial software according to the target data, and creating a software picture according to functional requirements of working software; and obtaining functional modules except the software picture in the industrial software, and completing the construction of the industrial software after the functional modules except the software picture in the industrial software are realized through the micro-service. According to the embodiment of the invention, a model driving architecture and a micro-service architecture technology are combined, loose coupling related to industrial software is realizedthrough the micro-service architecture, and the problem of internal relations of complex industrial products is solved through model driving.

Owner:SUZHOU SHUSHE TECH CO LTD

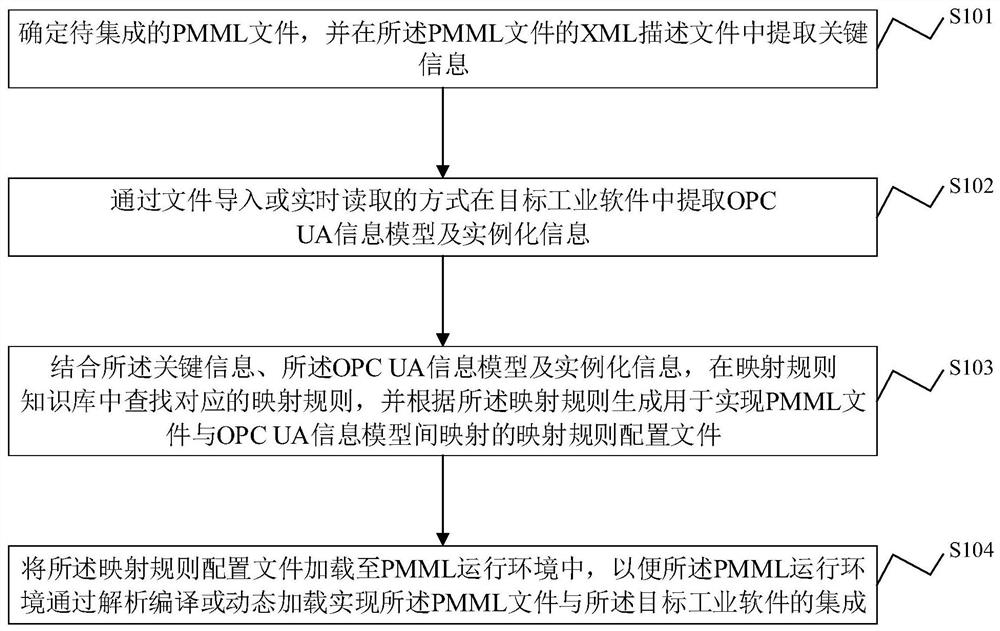

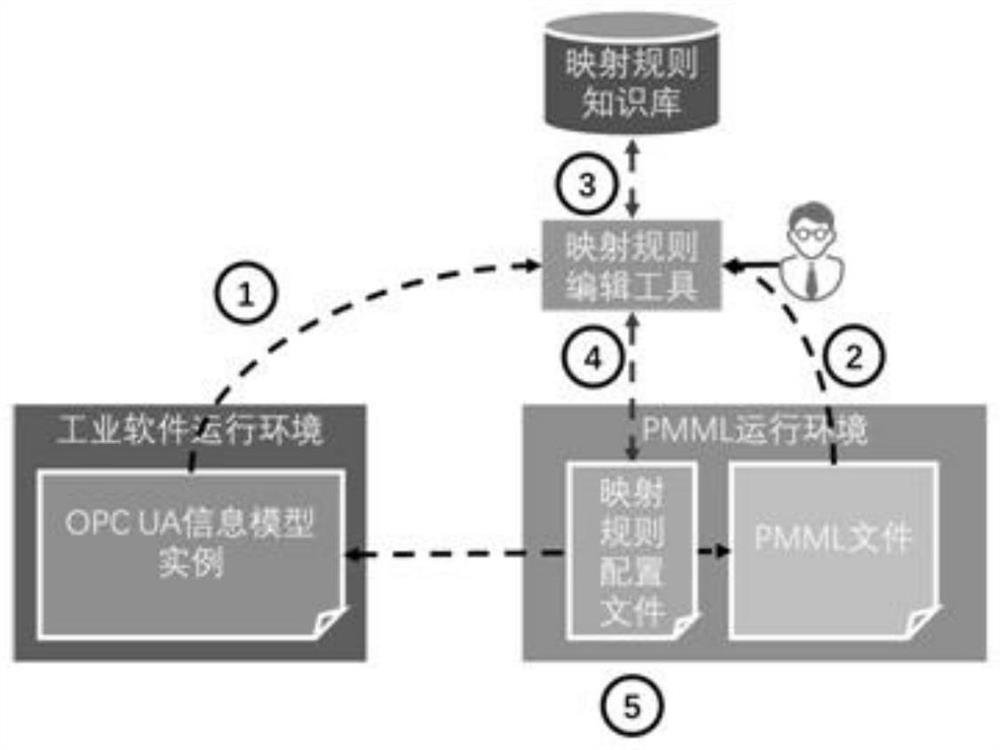

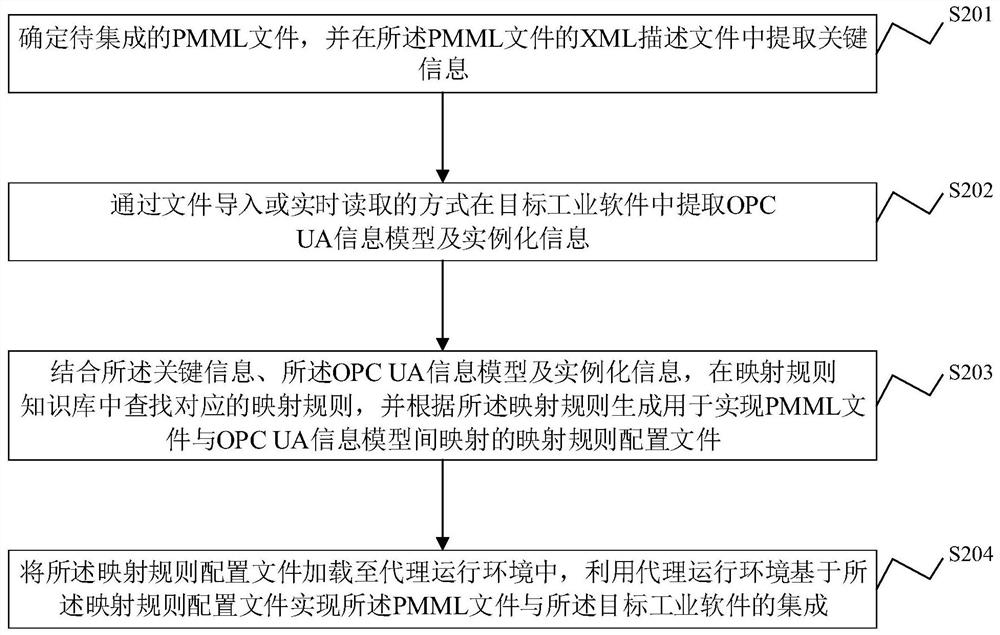

Method for integrating PMML file, operation environment thereof and industrial software

PendingCN112363695AAchieve integrationFast integrationSoftware designProgram loading/initiatingIndustrial softwareXML

The invention discloses a method for integrating a PMML file, an operation environment thereof and industrial software. The method comprises the steps: determining a PMML file to be integrated, extracting key information from an XML description file, and extracting an OPC UA information model and instantiation information from target industrial software; searching a rule knowledge base for matchedinformation model element mapping rule according to the OPC UA information model information and PMML file key information, and generating a mapping rule configuration file in combination with the obtained instantiation information; and loading the mapping rule configuration file into a PMML operation environment to realize data integration of the PMML file and the target industrial software. According to the method, rapid integration of industrial software and PMML files can be automatically realized, customized operation of traditional integration is avoided, and the manual configuration cost is reduced.

Owner:HANGZHOU HOLLYSYS AUTOMATION

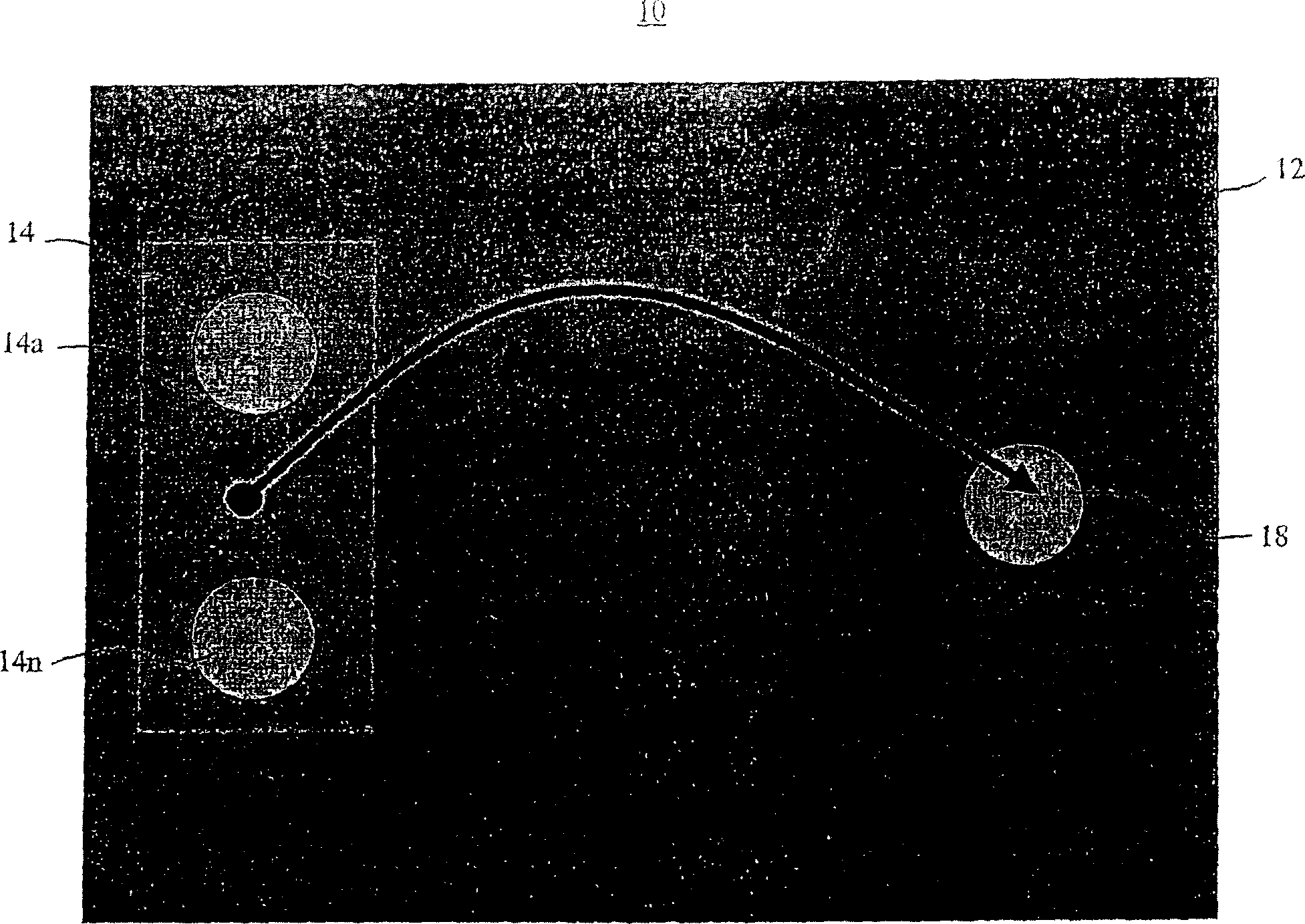

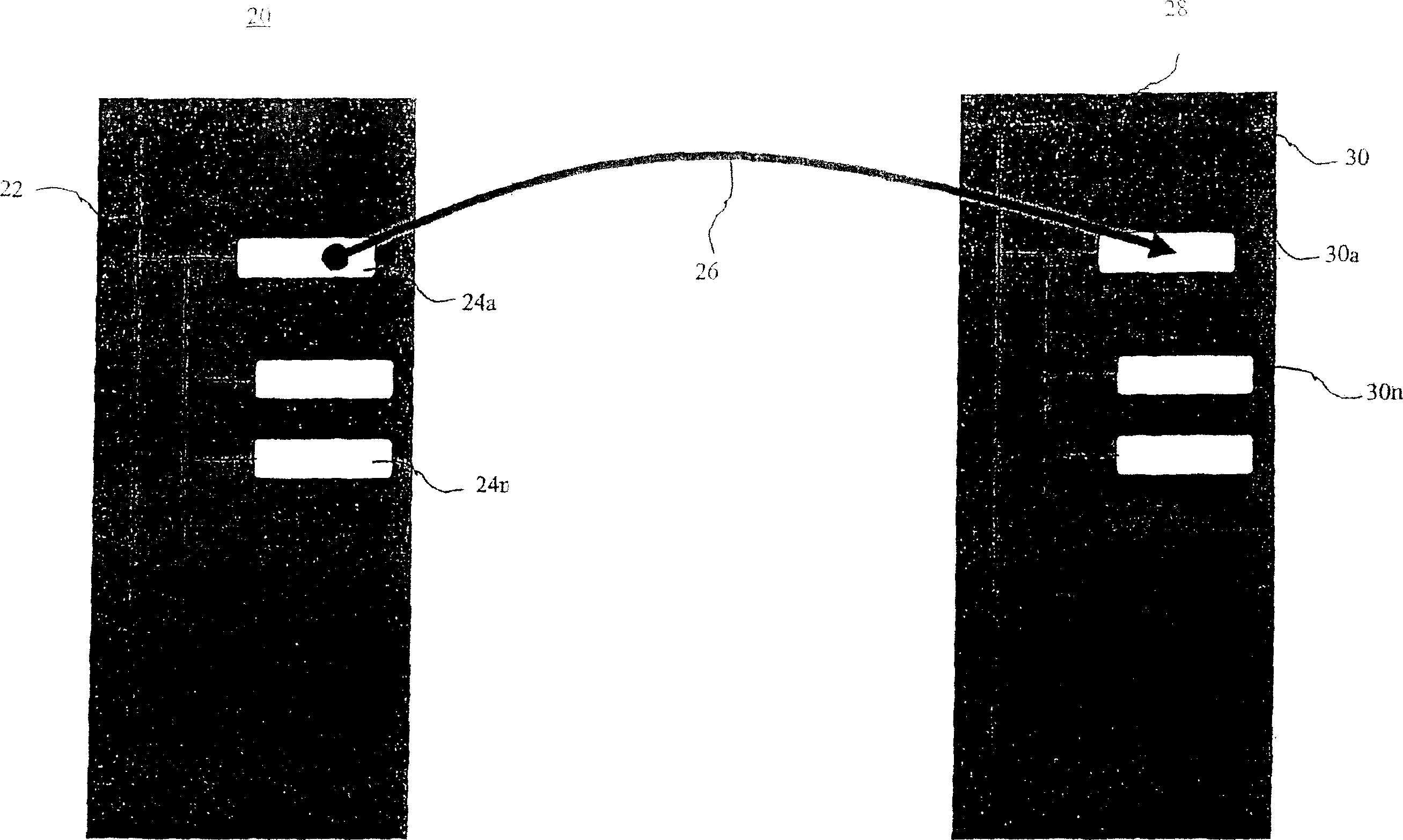

Customizable drag and drop for industrial software applications

InactiveCN1695108ASpecific program execution arrangementsInput/output processes for data processingManufacture execution systemDrag and drop

Customizable Drag & Drop enables easy activation of user defined or project specific functions concerning two related objects. A user interface graphically displays objects of a particular module. An extending function extends the drag and drop operation to allow the user to define a new set of semantics that is applied when a drag and drop operation is executed. In this way communication can be established using Customizable Drag & Drop extended by a user defined function. Also definition and modification of the deployment of an industrial automation system and hyperlinking of objects in manufacturing execution systems is achieved by Customizable Drag & Drop.

Owner:SIEMENS AG

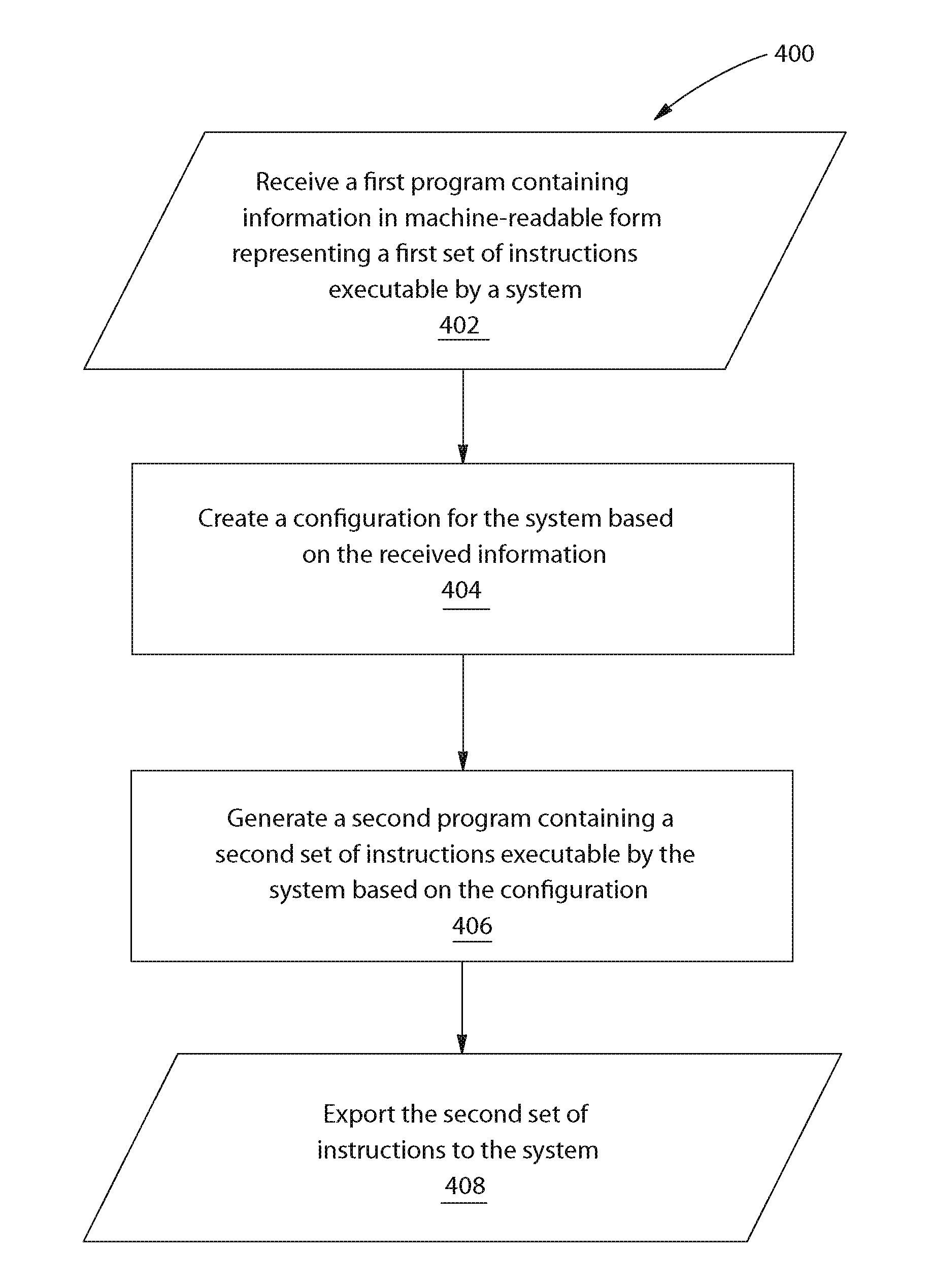

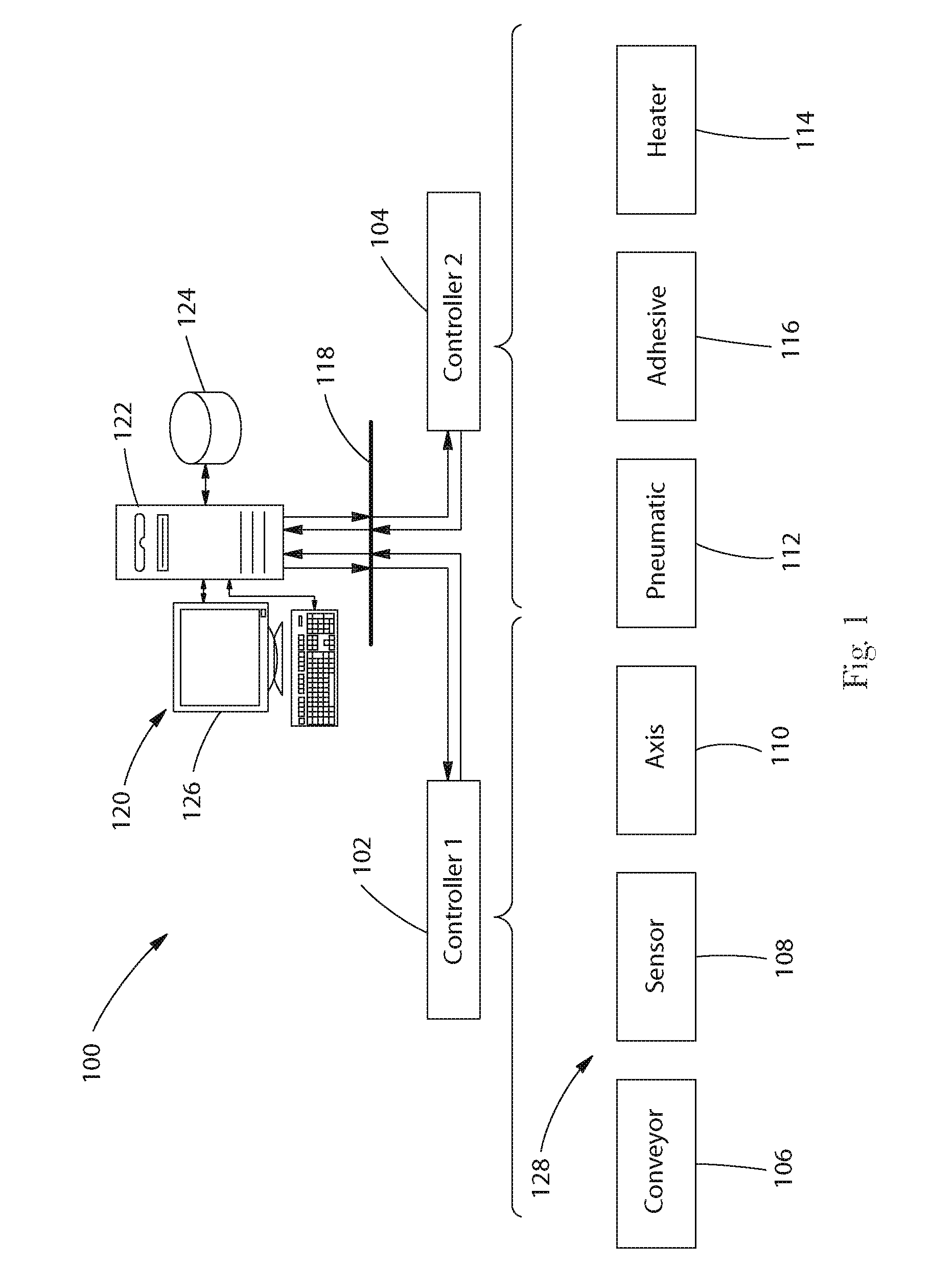

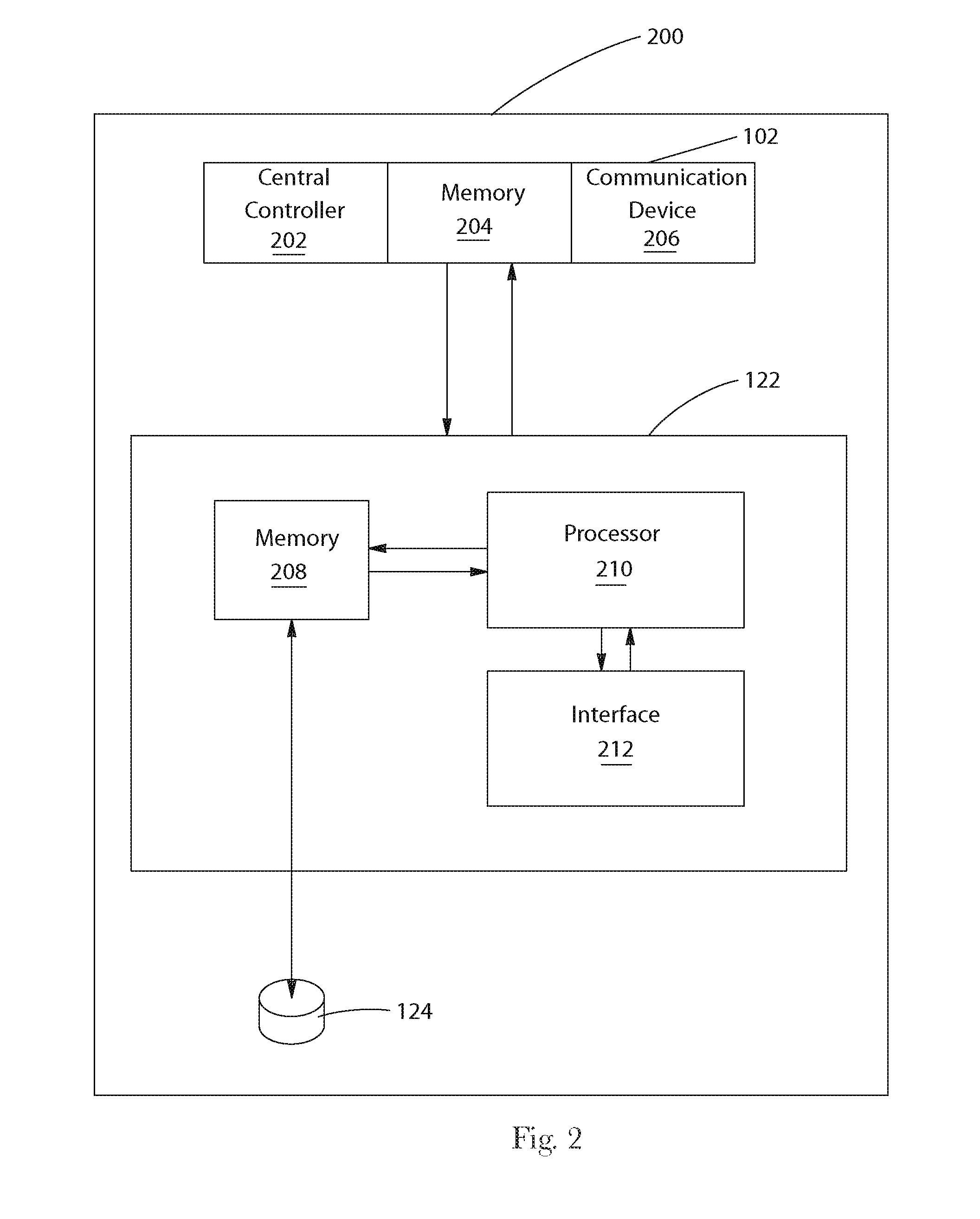

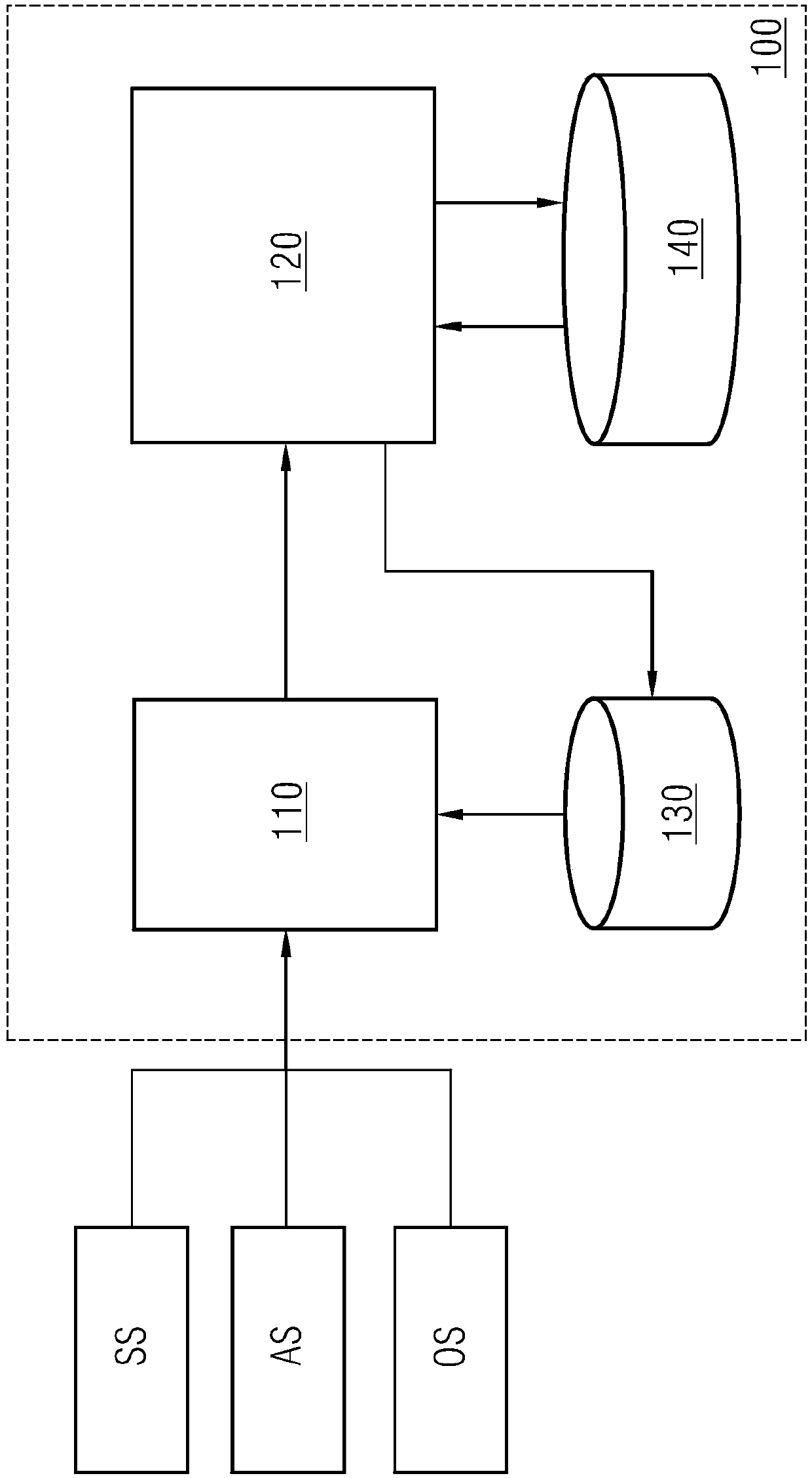

Apparatus, system, and method for managing industrial software configurations

An apparatus, system, and computer-implemented method of managing a software program. The computer comprises a processor, a memory, and an input / output interface for receiving and transmitting information to and from the processor, the computer providing a development environment for developing a set of instructions executable by a system. The processor receives a first program containing information in machine-readable form. The information represents a first set of instructions executable by the system. A configuration is created for the system based on the received information. The processor generates a second program containing a second set of instructions executable by the system based on the configuration. The second set of instructions corresponds to at least one algorithm assembled in a nested hierarchy.

Owner:PROCTER & GAMBLE CO

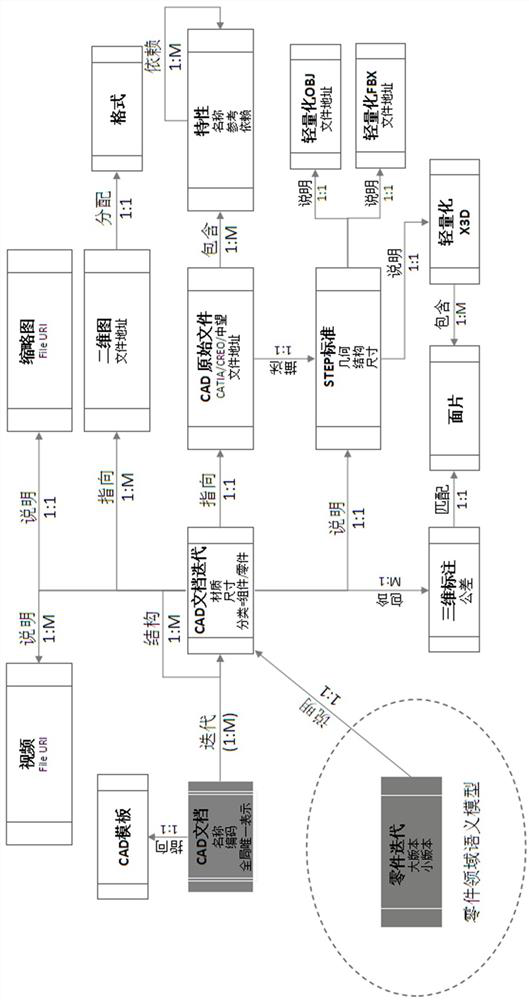

Product full-life-cycle management system

PendingCN111709702AEasy to shareImprove securityStill image data indexingOffice automationFull life cycleIndustrial software

The invention particularly discloses a product full life cycle management system. The system comprises industrial software or a browser installed in a client, a public cloud installed in a server anda private cloud installed in an enterprise server. The private cloud obtains update from the public cloud through the Internet, the public cloud publishes data to the private cloud through the Internet, and the industrial software or browser is connected with the private cloud and the public cloud through the Internet; the industrial software or browser controls the private cloud through the product management system; the product management system comprises an electronic warehouse management module, an authority management module, a document management module, a data query module, a version control module, a BOM extraction module, a workflow module, an electronic signature module and a CAD integration module. According to the drawing management system and method, the drawing sharing performance is improved, the drawing safety is improved, the drawing management efficiency is improved, and the BOM extraction module directly extracts product design data and process machining data according to drawings.

Owner:昆山夏洛特智能科技有限公司

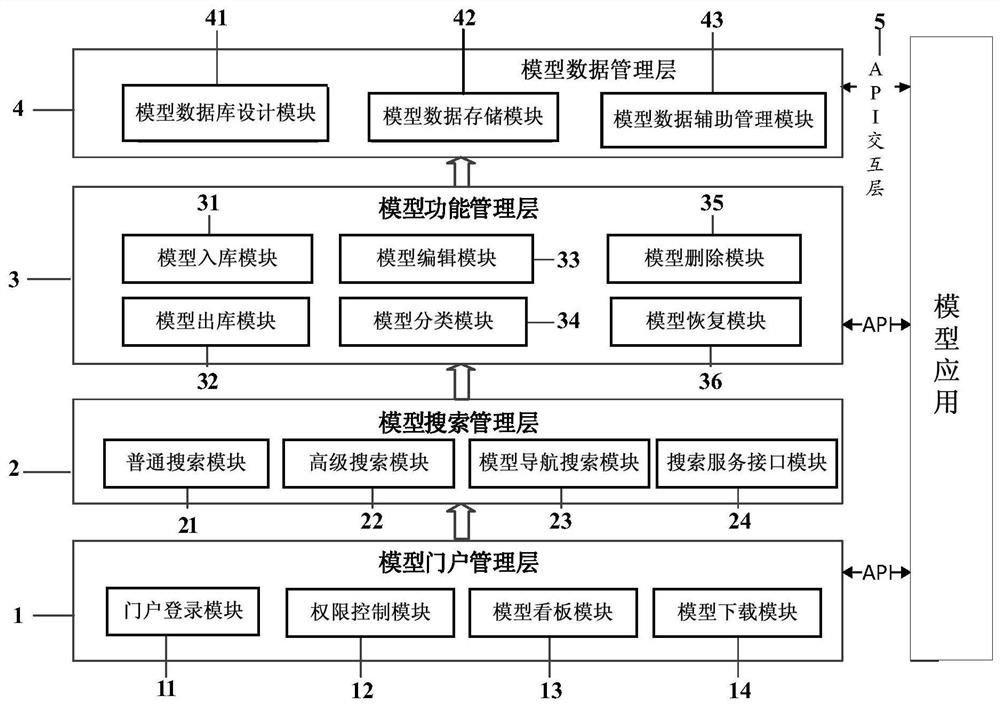

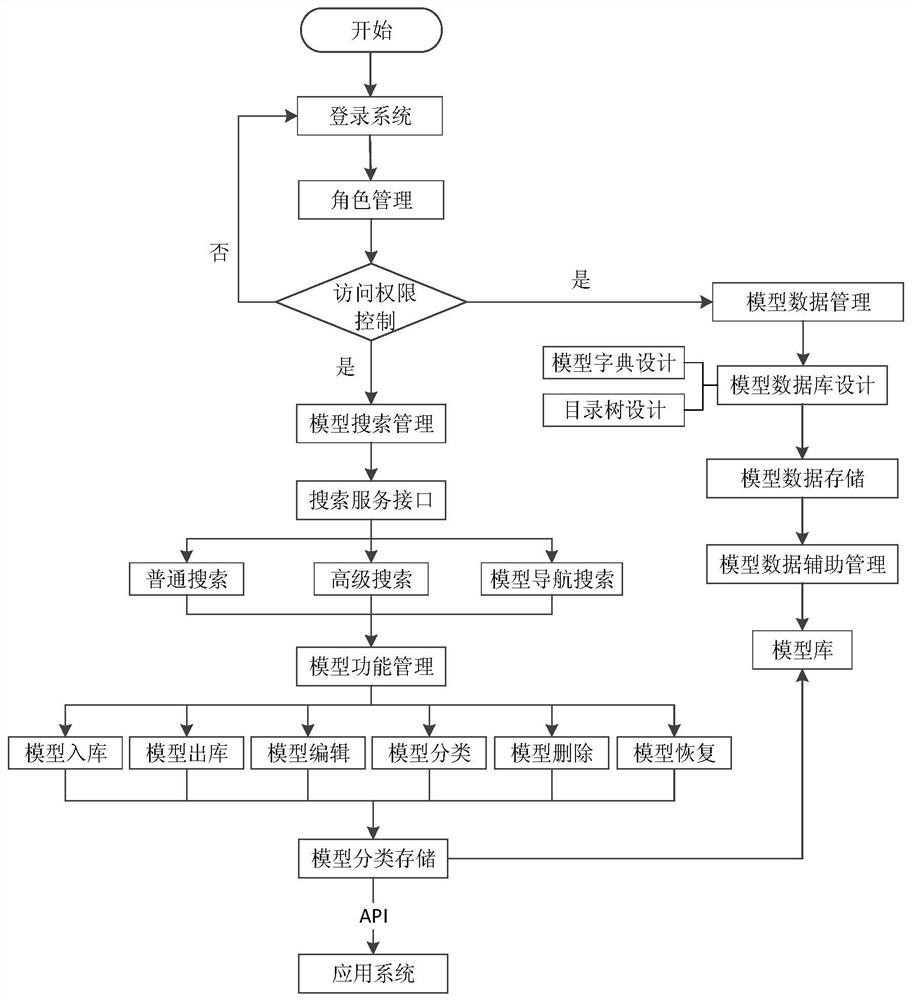

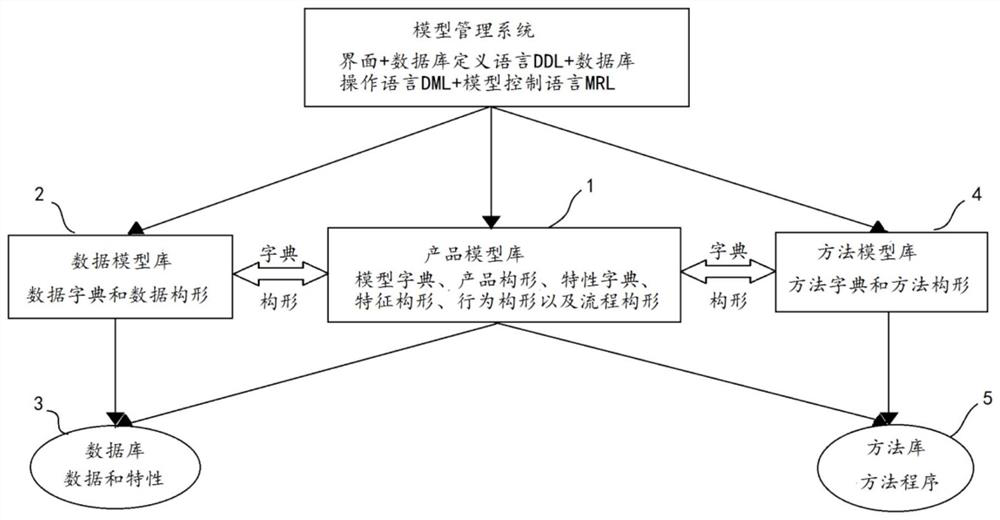

Management system and method for industrial mechanism model

PendingCN112232672AMerit Management SystemMerit methodResourcesManufacturing computing systemsModel managementUser needs

The invention provides a management system and method for an industrial mechanism model. The management system comprises a model portal management layer, a model search management layer, a model function management layer, a model data management layer and an API interaction layer. The model portal management layer is used for endowing users of different roles with different authorities; the modelsearch management layer is used for carrying out search management on the existing model of the model library; the model function management layer is used for editing the model searched by the model search management layer; and the model data management layer is used for designing a model database, classifying and storing the models and quickly calling the models according to user requirements. According to the industrial mechanism model management system and method provided by the invention, a model search mechanism, a model data storage mechanism and a model classification mechanism are designed and optimized, so the problem that massive industrial mechanism models are difficult to manage is solved, the utilization rate and the popularity rate of the industrial mechanism models are improved, and the development efficiency and quality of industrial software are further improved.

Owner:北京中船信息科技有限公司

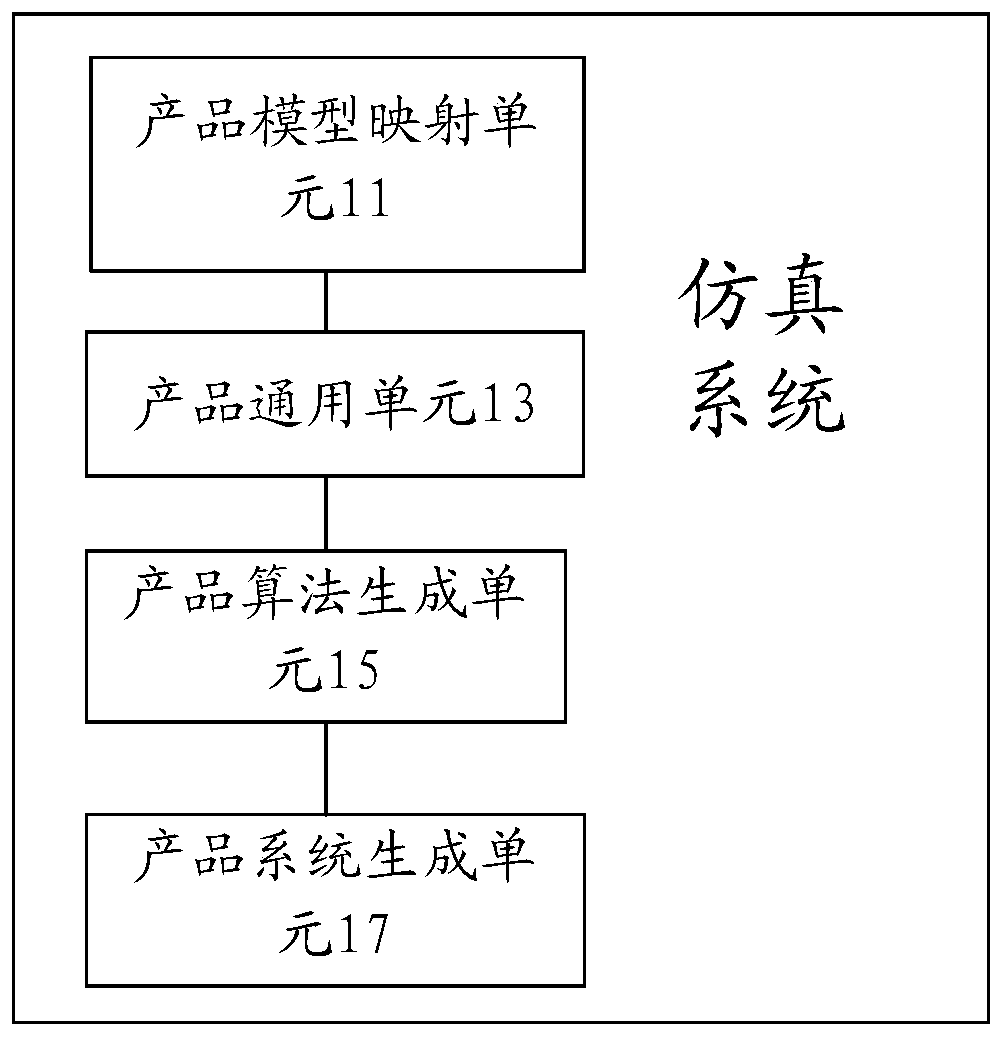

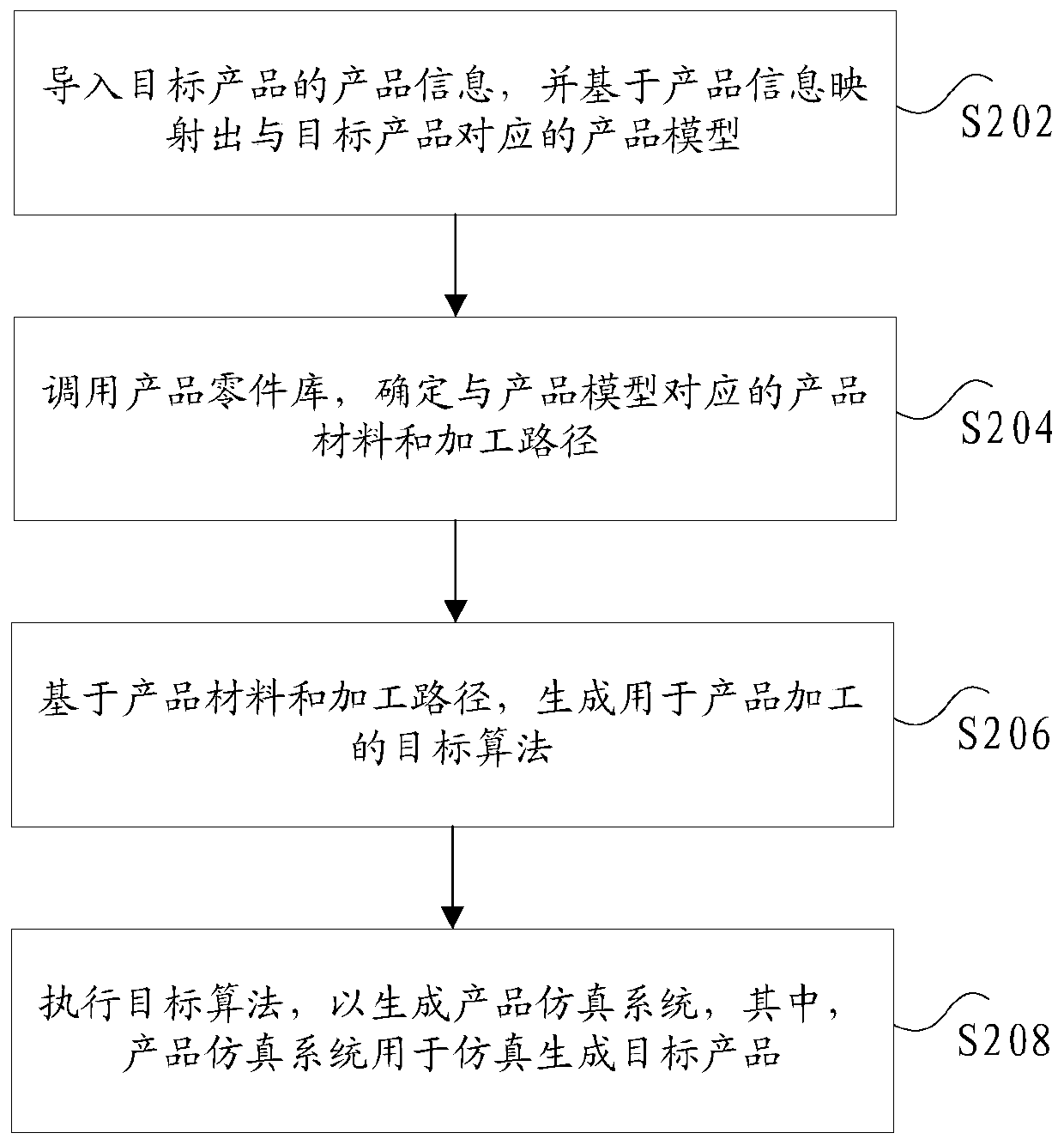

Simulation method and system based on industrial development software and electronic equipment

ActiveCN111199062AInhibition of differentiationGeometric CADDesign optimisation/simulationProduct systemProcessing

The invention discloses a simulation method and system based on industrial development software and electronic equipment. The simulation system comprises a product model mapping unit used for importing product information of a target product and mapping a product model corresponding to the target product based on the product information; a product generalization unit connected with the product model mapping unit and used for calling a product part library and determining a product material and a processing path corresponding to the product model; a product algorithm generation unit used for generating a target algorithm for product processing based on the product material and the processing path; and a product system generation unit used for executing the target algorithm to generate a product simulation system, and a product simulation system used for simulating and generating a target product. The technical problems that production products and simulation products cannot be unified and the use of the products is influenced due to the differentiation of industrial software in related technologies are solved.

Owner:SUZHOU SHUSHE TECH CO LTD

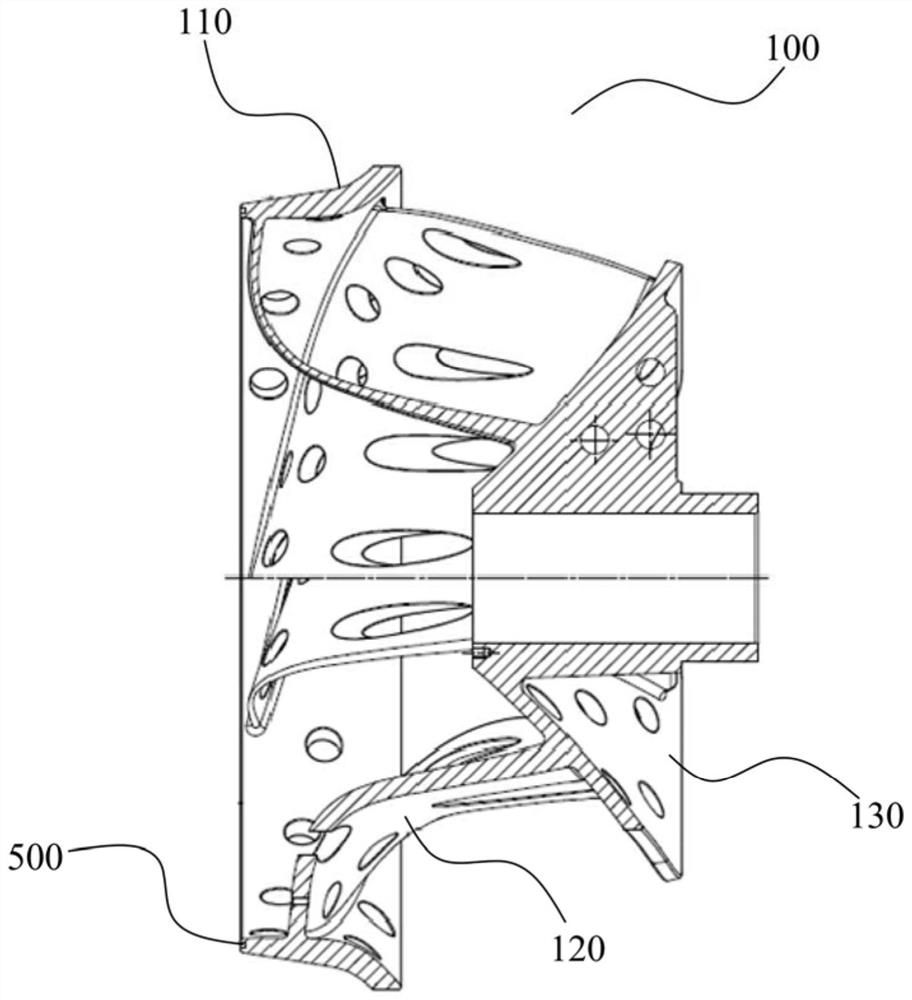

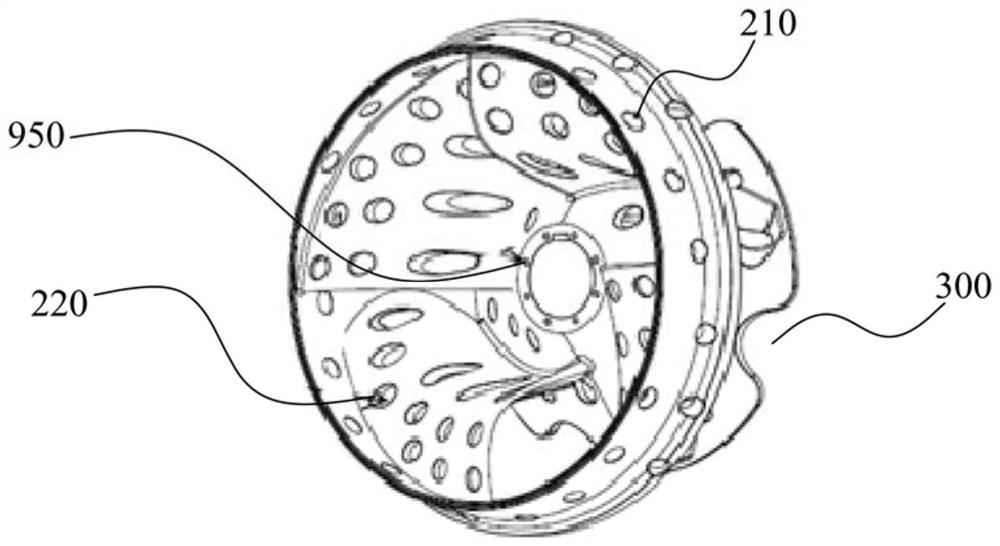

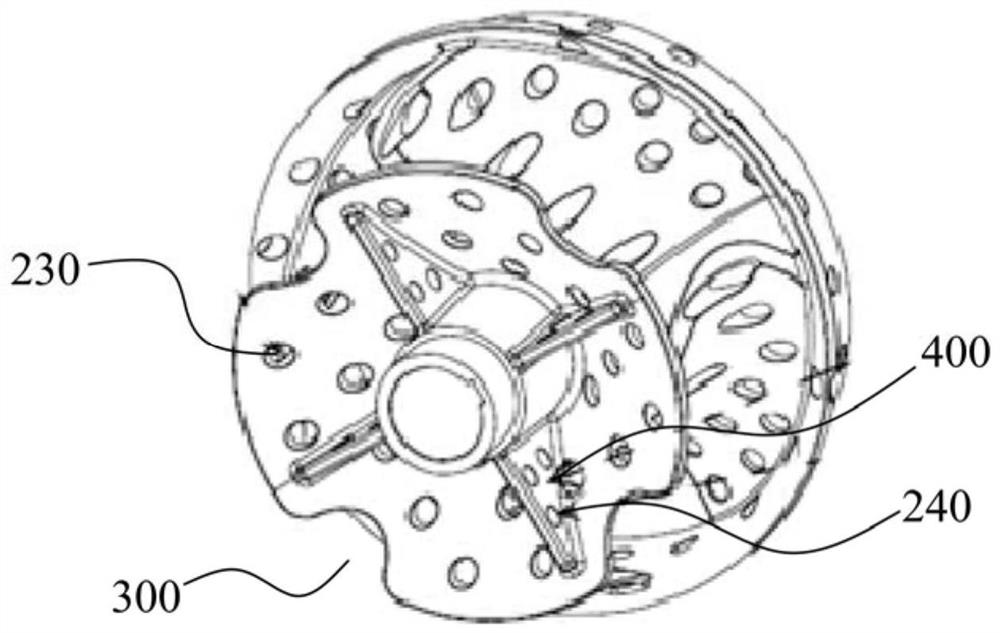

Ceramic impeller fixing device, ceramic impeller, and manufacturing method and detachment method for ceramic impeller

The invention relates to a ceramic impeller which comprises a metal framework and a ceramic layer formed on the metal framework in a vacuum casting mode. The metal framework comprises a front cover plate, a rear cover plate and blades arranged between the front cover plate and the rear cover plate; the front cover plate, the rear cover plate and the blades of the metal framework are provided withthrough holes respectively, and the through holes are used for fixedly holding the ceramic layer of the ceramic impeller; the front cover plate or the rear cover plate of the metal framework is also provided with at least one of reinforcing ribs, notches and grooves for fixedly holding the ceramic layer poured on the metal framework. The invention also relates to a manufacturing method for the ceramic impeller. The manufacturing method comprises the following steps of carrying out three-dimensional modeling on the metal framework in industrial software, wherein it is ensued that the strength and stress of the ceramic impeller runs are met all the time when a pump through simulation calculation and analysis of different working conditions; providing the metal framework analyzed through simulation calculation; and vacuum-casting the ceramic layer on the metal framework.

Owner:ANDRITZ CHINA

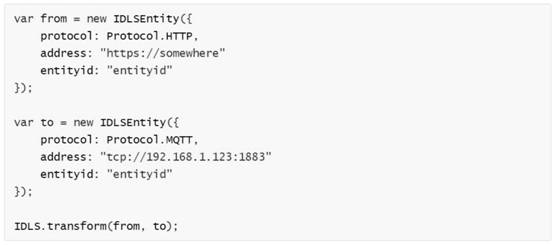

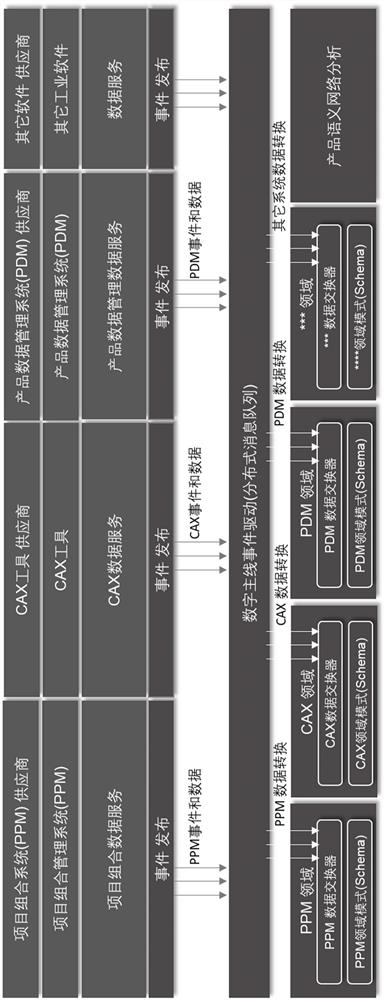

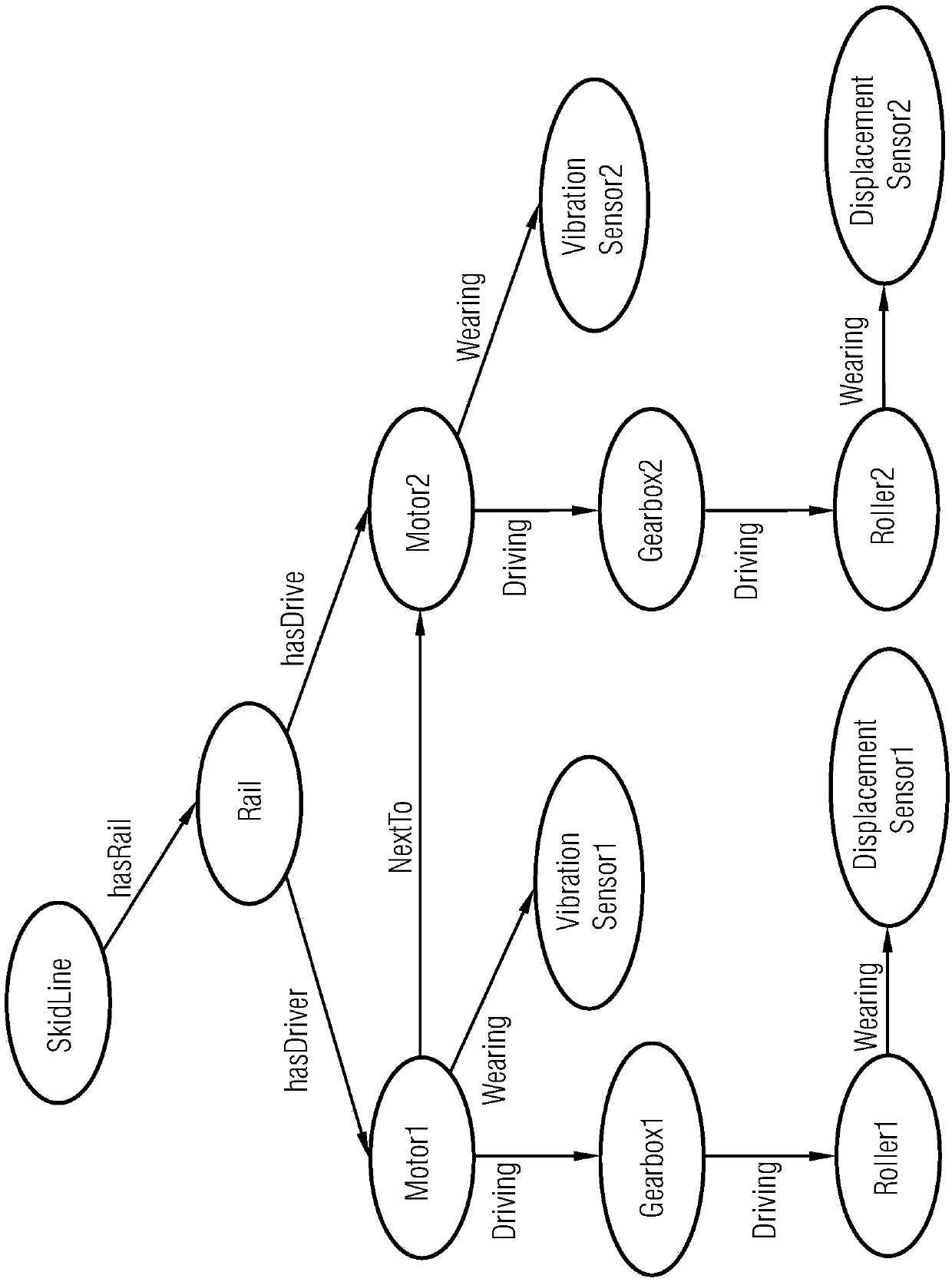

Distributed industrial software construction method of application and data service separation architecture

ActiveCN114756226ASpeed up iterationImprove digitizationModel driven codeManufacturing computing systemsIndustrial softwareBusiness enterprise

The invention relates to the field of industrial software system architecture, in particular to a distributed industrial software system architecture design and construction method, and particularly discloses a distributed industrial software construction method of an application and data service separation architecture. Comprising the steps of semantic model establishment, semantic model modeling tool construction, standardized data service establishment, application and data service arrangement and semantic event driving. Through the construction method disclosed by the invention, iteration, popularization and maturity of the industrial software suite are accelerated; the domain semantic model and the data service are polished, so that more data mining and intelligent data services are provided for enterprises and customers, and the business development of the enterprises is accelerated; a product digitization chain is developed based on data service, semantic traceability of product data is established, and change impact analysis and dynamic supplier impact analysis are effectively solved.

Owner:杰为软件系统(深圳)有限公司

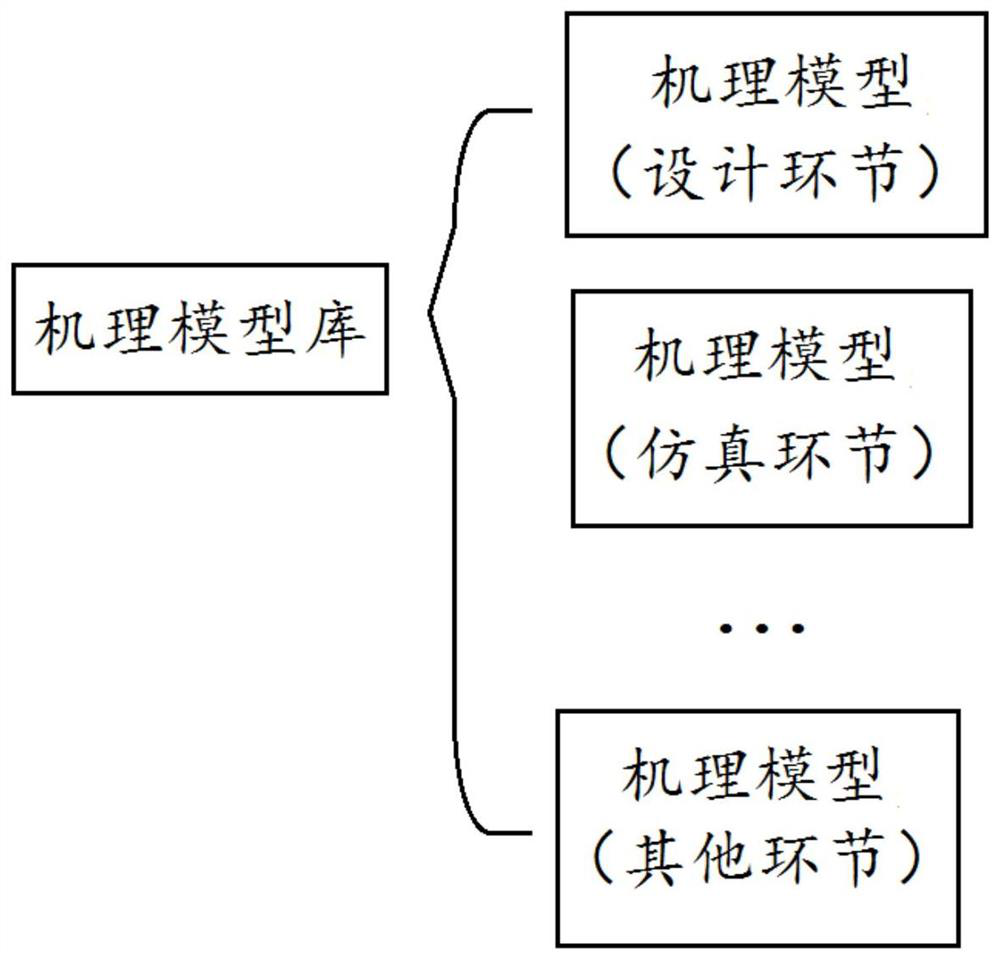

Mechanism model library in industrial software framework and calling method thereof

PendingCN112380727AEasy to buildIntuitive lookupDigital data information retrievalDesign optimisation/simulationPERQAnalysis data

The invention discloses a mechanism model library in an industrial software framework and a calling method of the mechanism model library, the mechanism model library is used for constructing a mechanism view, the mechanism model library comprises at least one mechanism model, and one mechanism model corresponds to one link of industrial software; each mechanism model comprises the following contents: unit data, characteristic data, load data, analysis data and result data. The invention discloses a mechanism model library for constructing a mechanism view, so that the construction of the mechanism view is more convenient, the content of the mechanism view and the meaning represented by the mechanism view in each link can be looked up more visually, the calling of the mechanism model library disclosed by the invention is realized by virtue of a model library management system, and the calling method is simple and rapid.

Owner:SHANGHAI GONGFANG SOFTWARE CO LTD

Template extraction system, device and method

PendingCN110399597AImprove experienceReduce power consumptionSpecial data processing applicationsManufacturing computing systemsIndustrial softwareTemplate based

The invention provides a template extraction system, device and method, and the method comprises the steps: receiving source knowledge from a plurality of pieces of industrial software in the industrial Internet of Things, converting the source knowledge information into a standard model, wherein the standard model comprises a model template or a model instance in a unified format; and comparing the model template or the model instance in the unified format with an existing template in a knowledge base, and extracting a new template from the model template or the model instance in the unifiedformat. The template extraction mechanism provided by the invention automatically acquires the template based on the standard keyword group, and is more effective and low in power consumption. In addition, the template extraction system, device and method can provide rich specific domain knowledge, which provides a specific domain template to support industrial applications.

Owner:SIEMENS AG

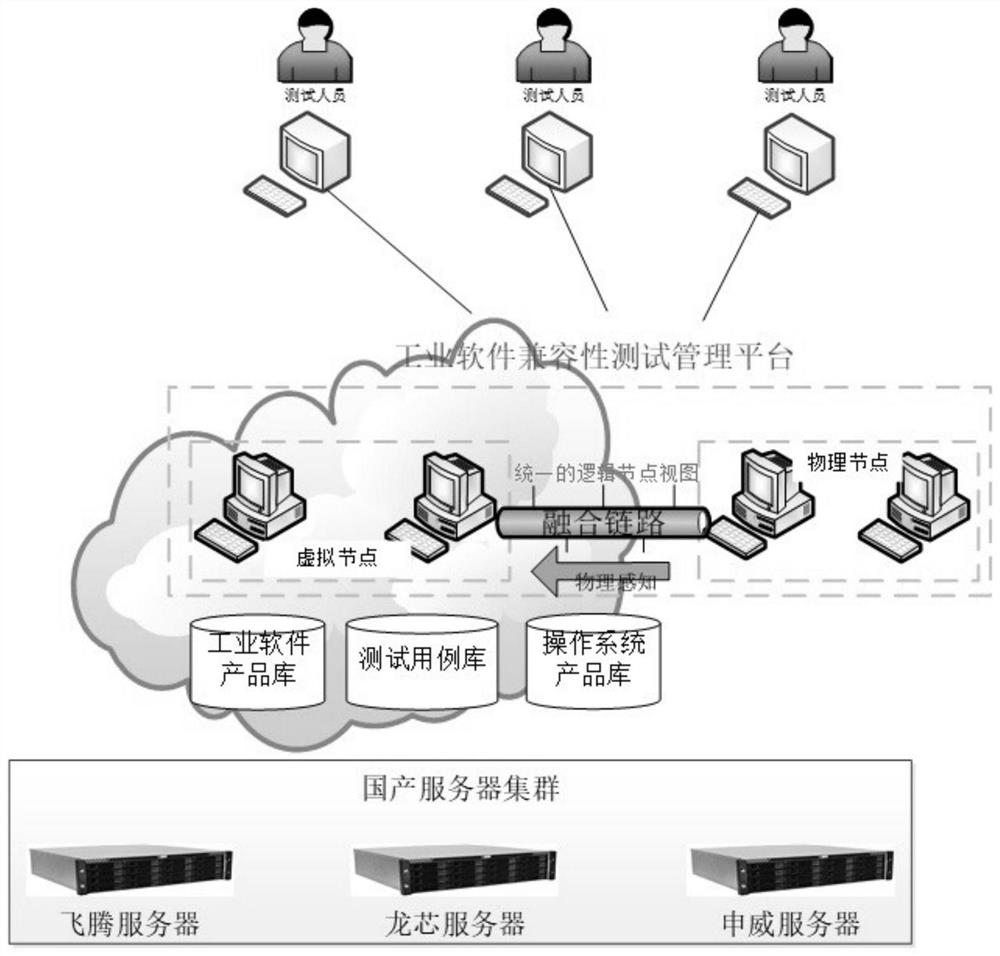

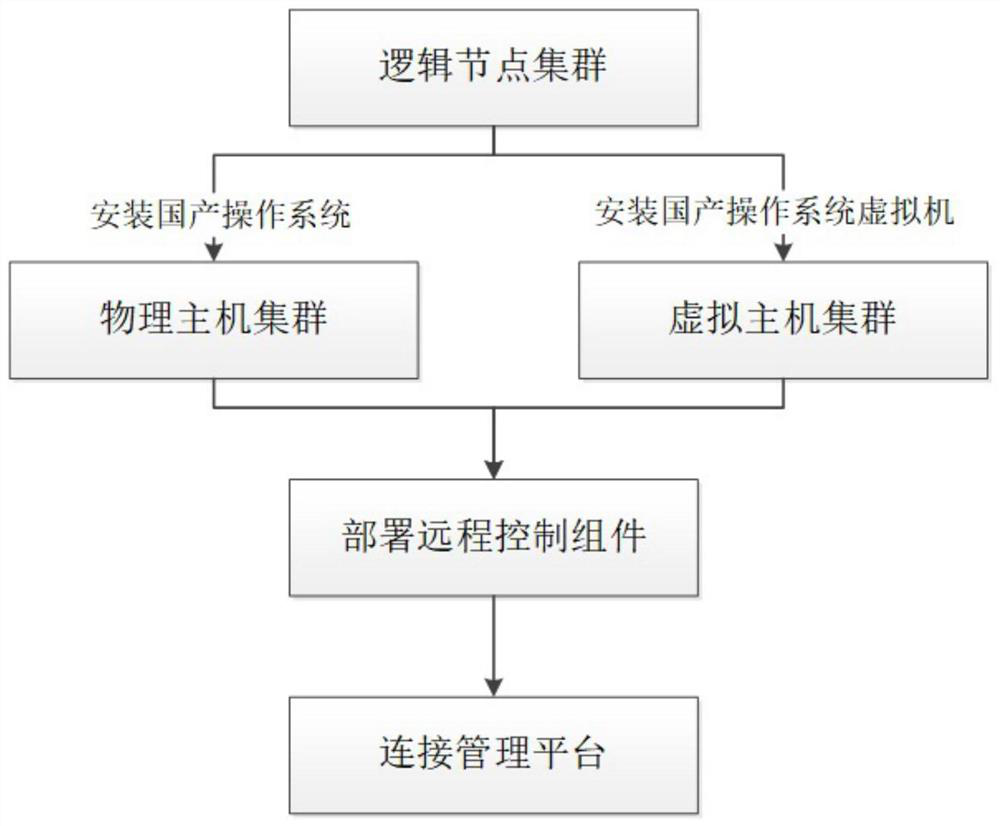

Industrial software compatibility testing method under multiple localization platforms

PendingCN113918452AImprove test efficiencyImprove sufficiencySoftware testing/debuggingAuto-configurationInterface (computing)

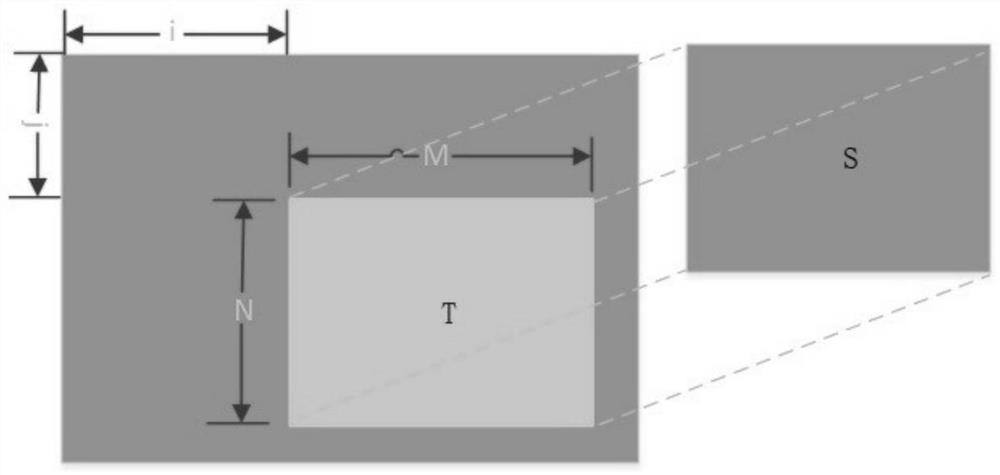

The invention relates to an industrial software compatibility testing method under multiple localization platforms, and belongs to the field of testing. According to the method, a domestic industrial software product library and a test case library are constructed; virtualized computing nodes and real physical computing nodes are automatically configured, and a visual graphical interface test environment cluster is provided for a test demand side; test requirements are collected through a compatibility test unified management and control management platform, a to-be-tested software installation package is matched from a software product library, a test environment is matched, an industrial software installation package is distributed to virtual nodes and physical nodes meeting the requirements, and the nodes are controlled to complete automatic deployment and installation of industrial software; an automatic test tool and a test case matched with the target environment architecture are distributed to the test node, and the execution of the automatic test is driven through a command; and when the node executes the test case, the test state and the test result of the test case can be checked on the management platform, and a test report is generated. The testing process is simplified, and the testing cost is reduced.

Owner:BEIJING INST OF COMP TECH & APPL

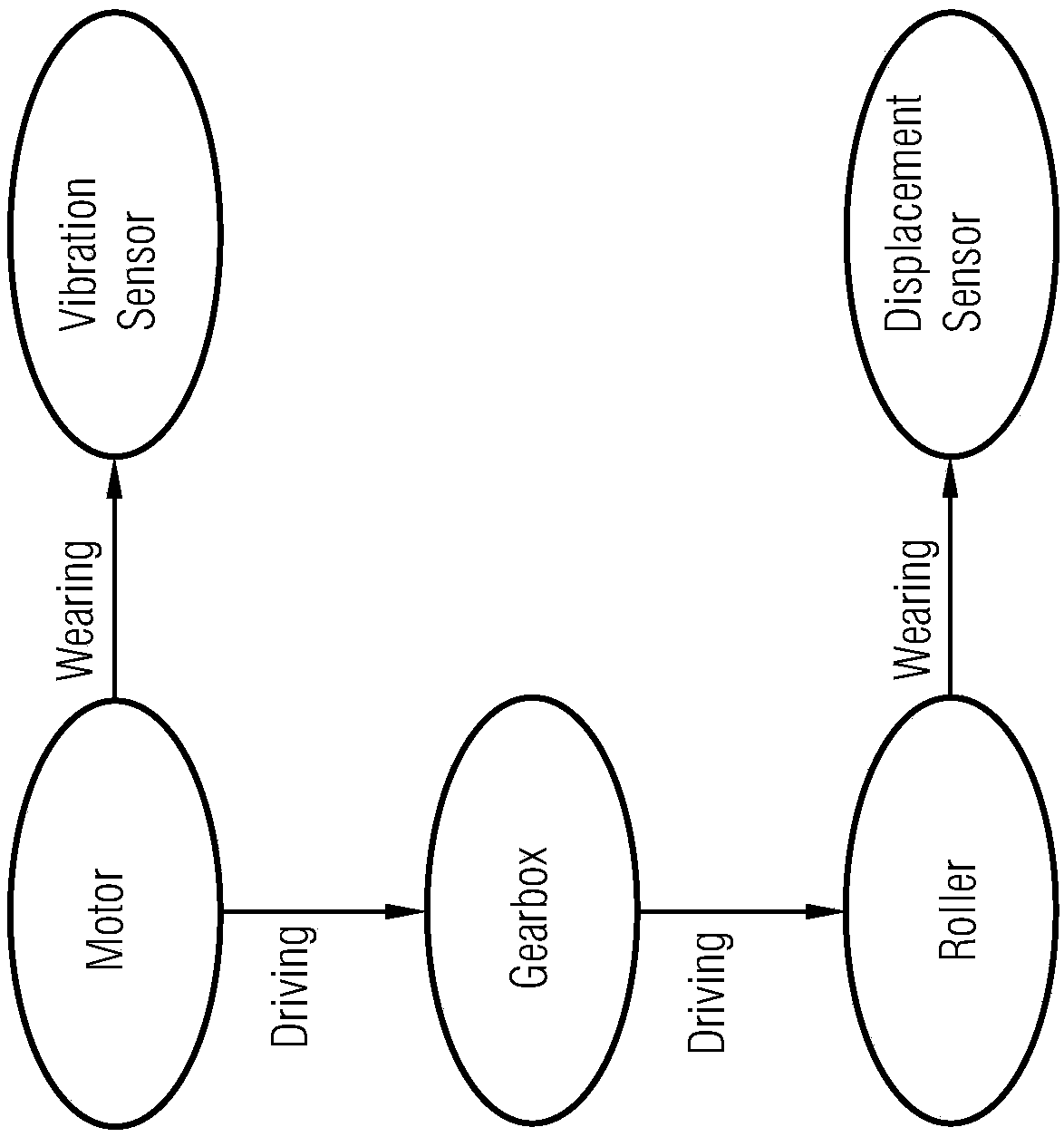

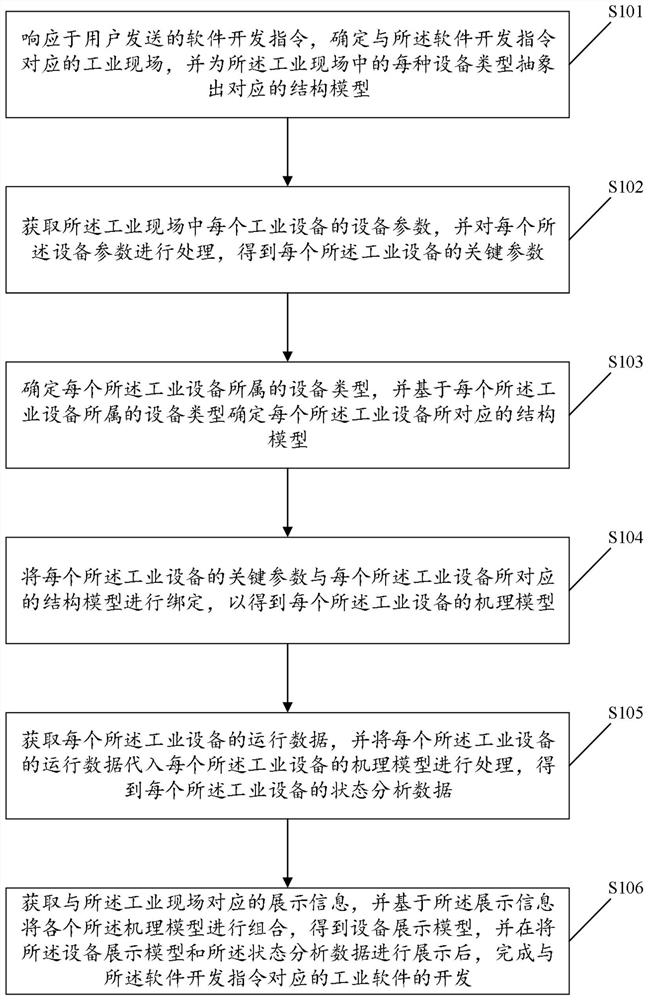

Industrial software development method and device

PendingCN112965696APromote rapid developmentEase complexitySoftware designModel driven codeDevice typeIndustrial software

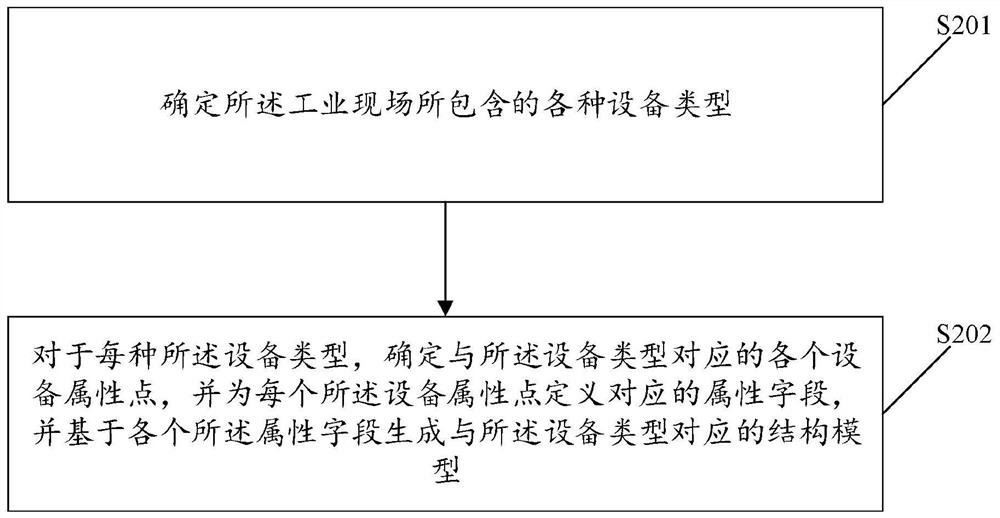

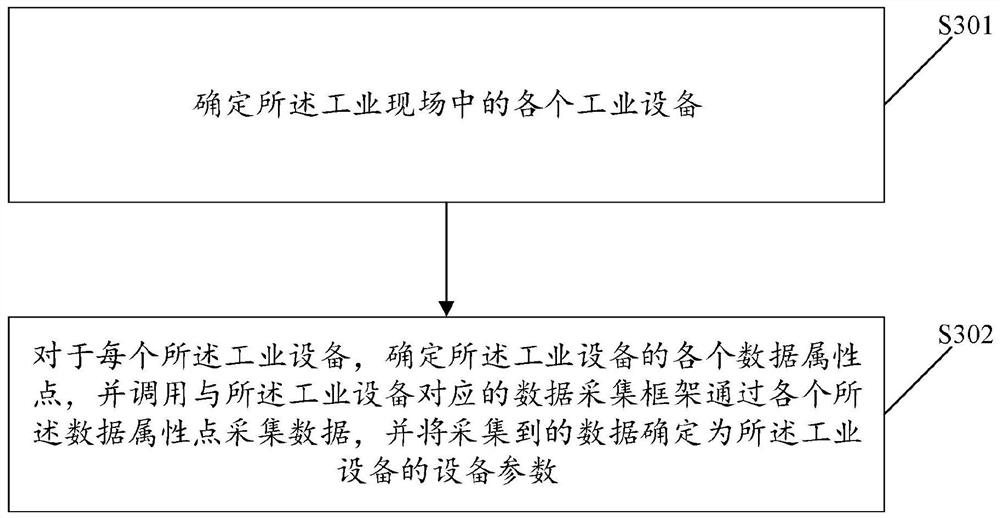

The invention provides an industrial software development method and device, and the method comprises the steps: determining an industrial site in response to a software development instruction sent by a user, and abstracting a corresponding structure model for each equipment type in the industrial site; processing the equipment parameters of each piece of industrial equipment in the industrial field to obtain key parameters of each piece of industrial equipment; for each piece of industrial equipment, determining a structure model based on the equipment type to which the industrial equipment belongs, binding the key parameters of the industrial equipment with the structure model to obtain a mechanism model, and substituting the operation data of the industrial equipment into the mechanism model for processing to obtain state analysis data of the industrial equipment; and combining the mechanism models based on the obtained display information to obtain an equipment display model, and displaying the equipment display model and the state analysis data to complete development of the industrial software. By applying the mode provided by the invention, the complexity of software development is reduced, the development efficiency can be improved, and various development requirements can be met.

Owner:ZHEJIANG SUPCON TECH

Mapping method and device for prototype model of development view and mechanism view framework products

PendingCN111950048AMeet development needsMeet engineering requirementsGeometric CADData centerIndustrial software

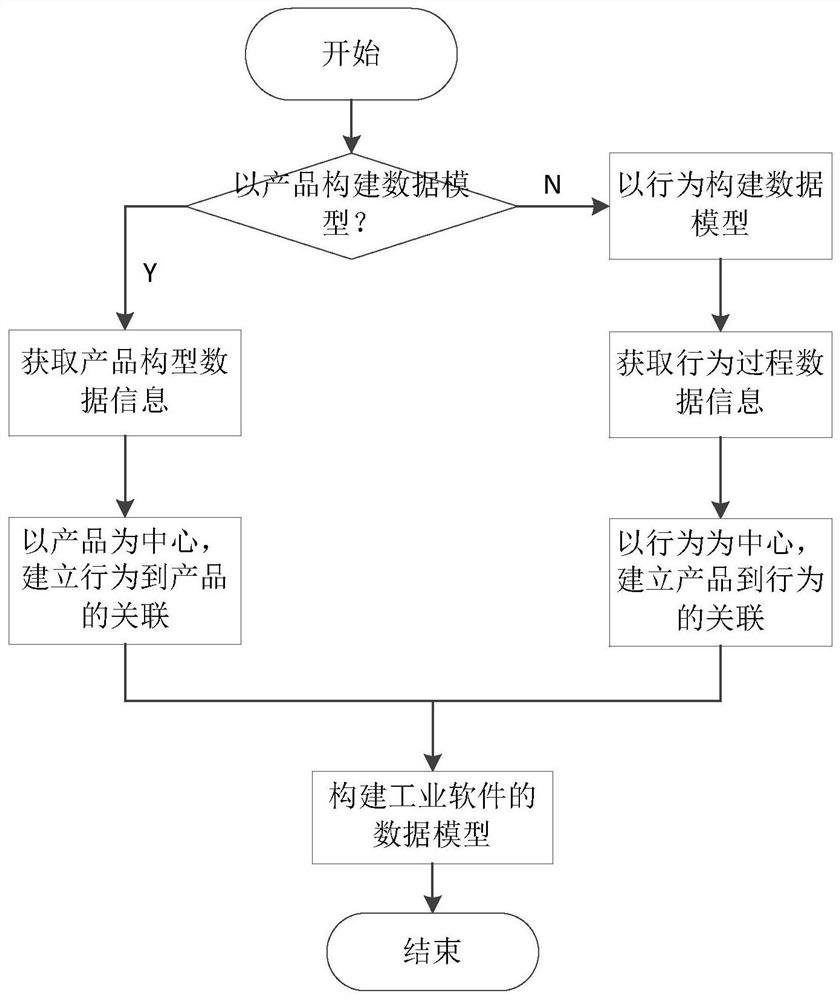

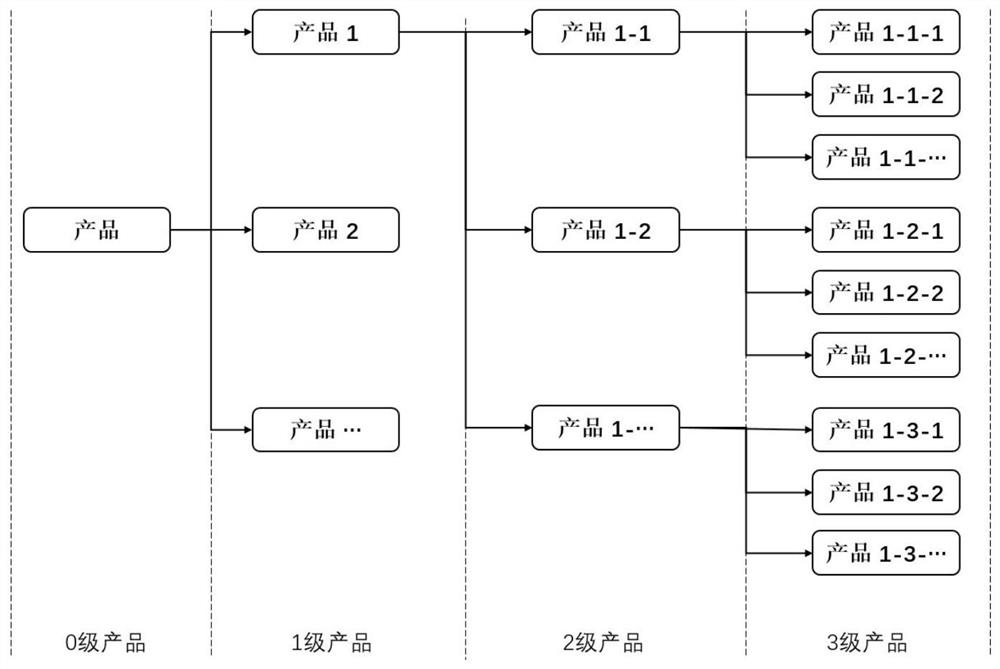

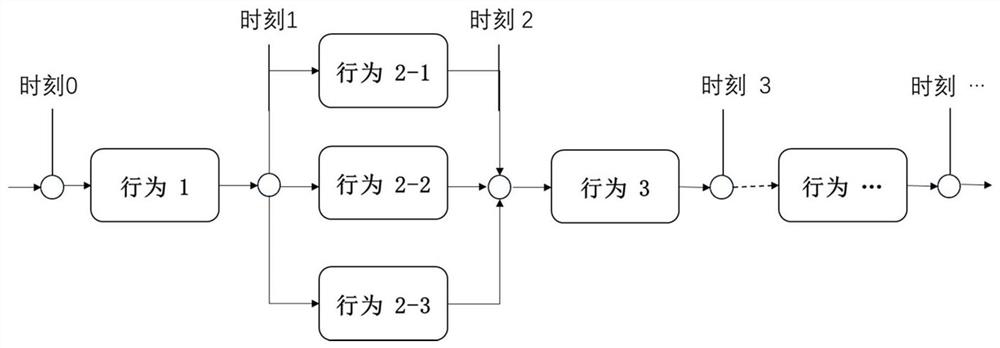

The invention relates to a mapping method and device for a prototype model of a development view and mechanism view architecture products, and the method comprises the steps: building correlations from behavior attributes of each hierarchy to product attributes through taking the hierarchy divided by product configuration as a main line and taking the product of each hierarchy as a data center, and building a data model of industrial software; or, by taking the behavior process execution moment as a main line and the behavior at each moment as a data center, establishing association from eachproduct attribute to the behavior attribute at the corresponding moment, and constructing a data model of the industrial software. The problem that in the prior art, a traditional development mode cannot meet the requirements of a software system and the development requirements of industrial software can be solved.

Owner:SHANGHAI GONGFANG SOFTWARE CO LTD

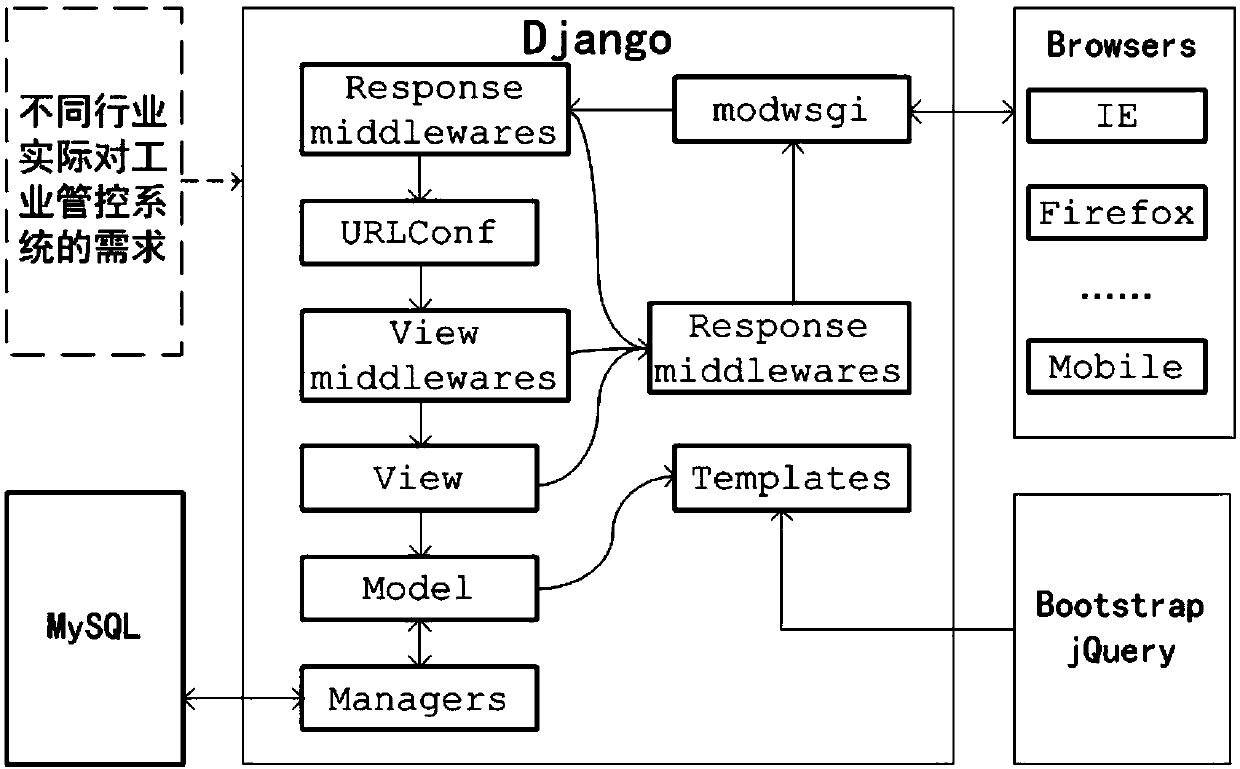

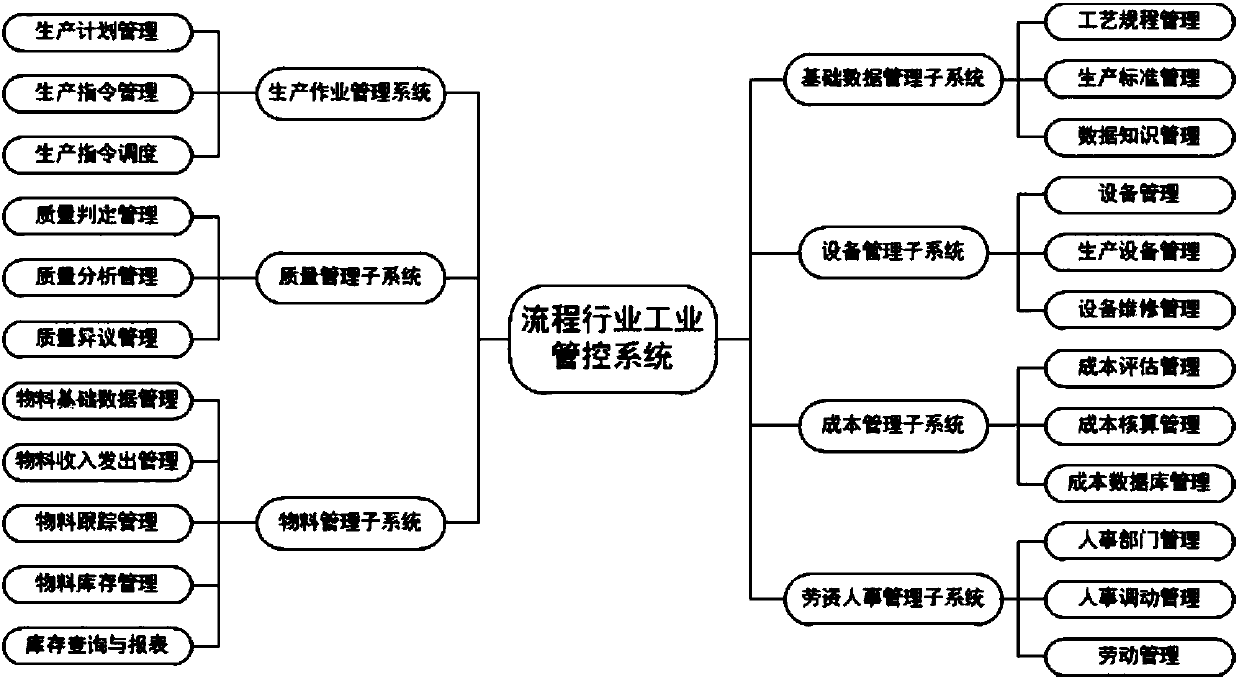

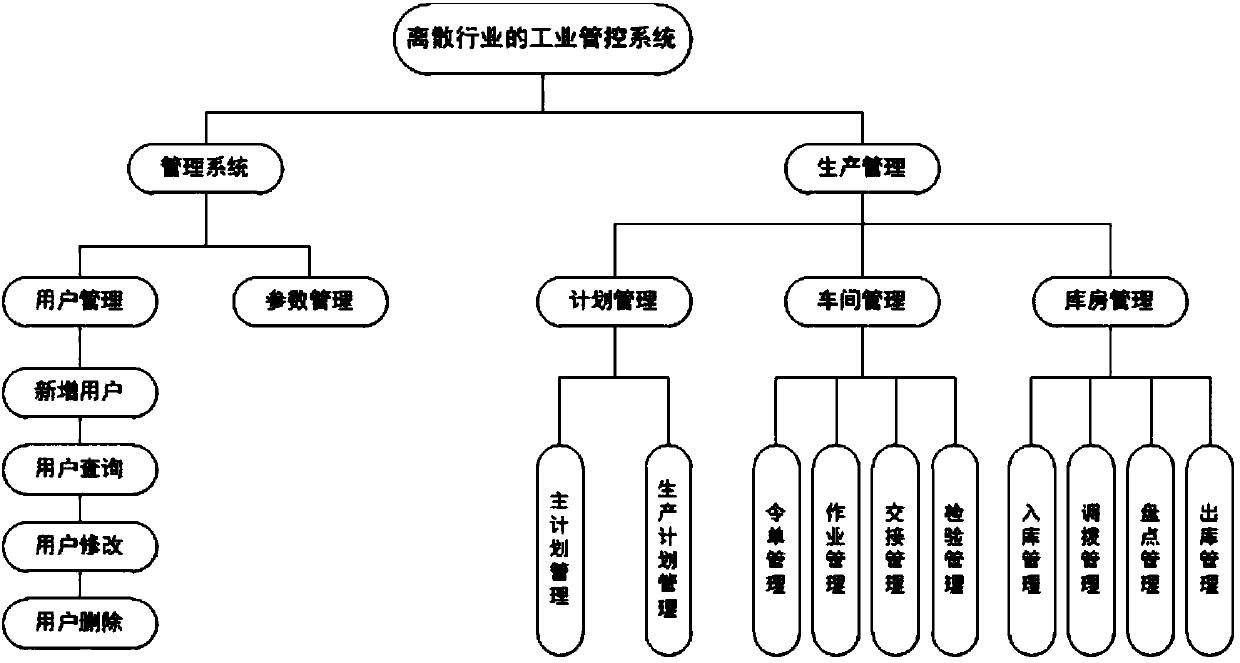

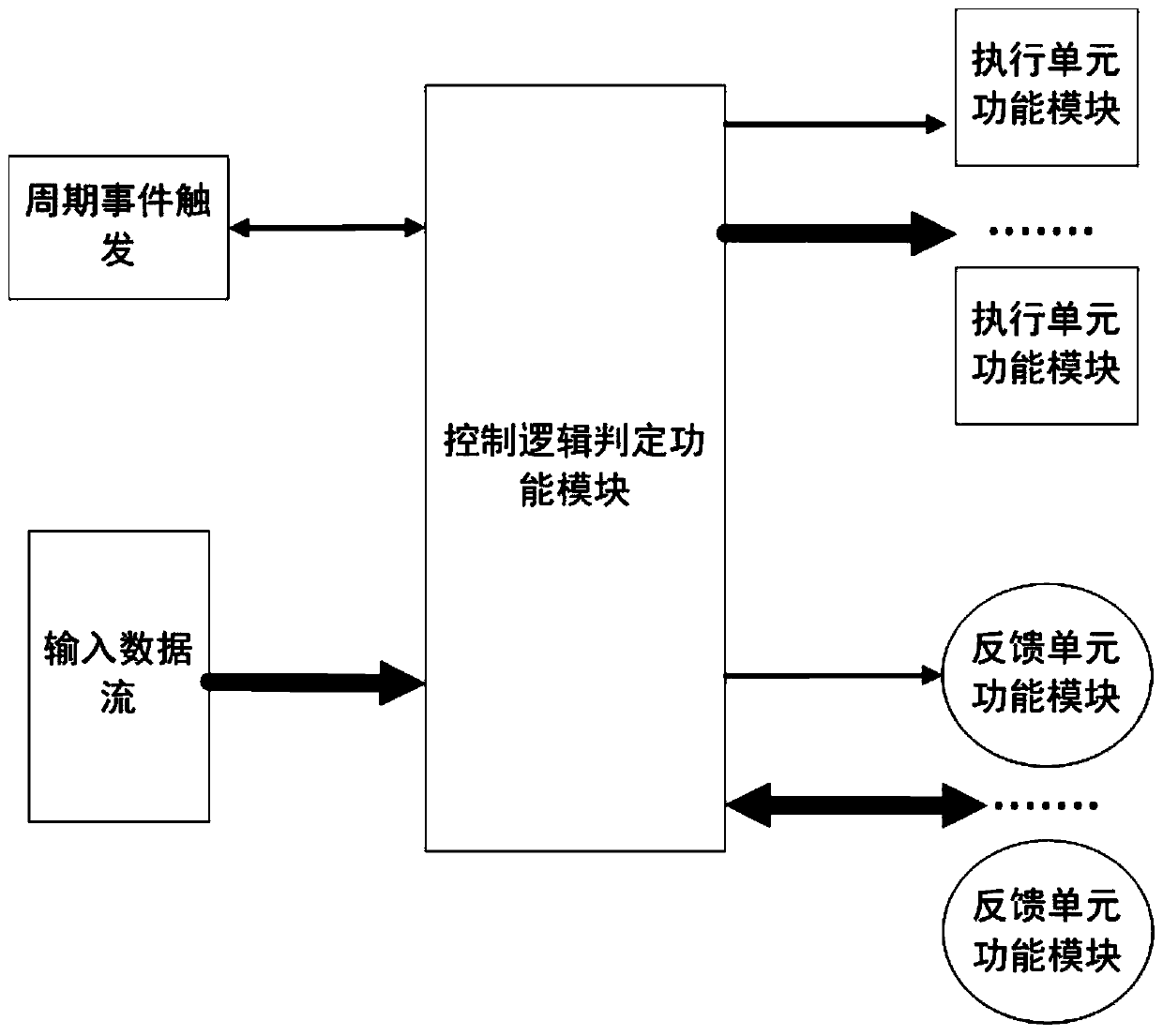

An implementation method for gamification of industrial management and control software

InactiveCN109725883AImprove usabilityImprove dynamic capabilitiesSoftware designExecution for user interfacesReal-time dataIndustrial software

The invention discloses an implementation method for gamification of industrial management and control software. Based on the MTV mode of Django, a discrete manufacturing industry management and control software system or a flow manufacturing industry management and control software system meeting actual requirements is built. real-time data access is carried out by accessing an open source database MySQL; gamification elements such as a feedback mechanism of the user, Integrating mechanism, an index mechanism and a grade progress are added; the jQuery is used for providing event drive and related plug-ins to dynamically implement the template module of the Django; Bootstrap is used for finishing the response type layout so as to meet the interaction requirements of different browser users, gamification and dynamic performance of industrial management and control software are achieved, the usability of the industrial software is enhanced, the enthusiasm of enterprise employees is improved, and enterprise benefits are increased.

Owner:林良煌

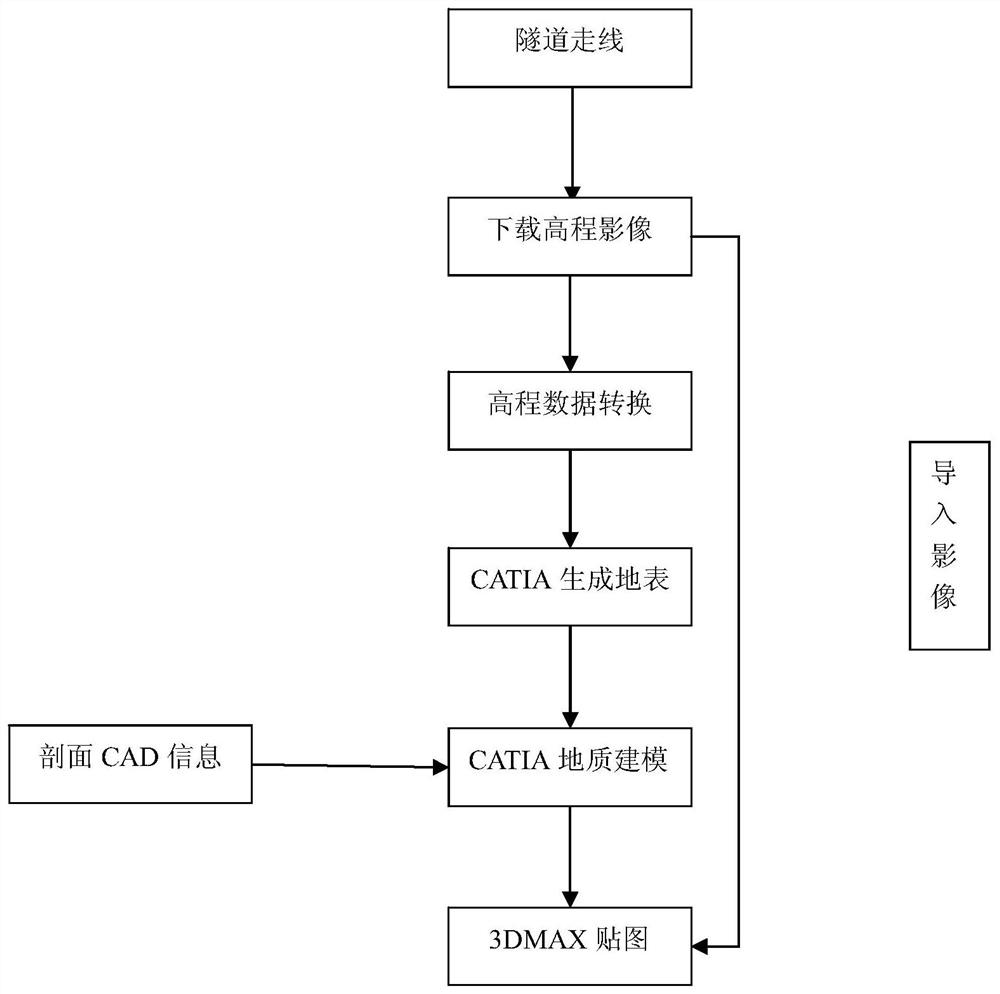

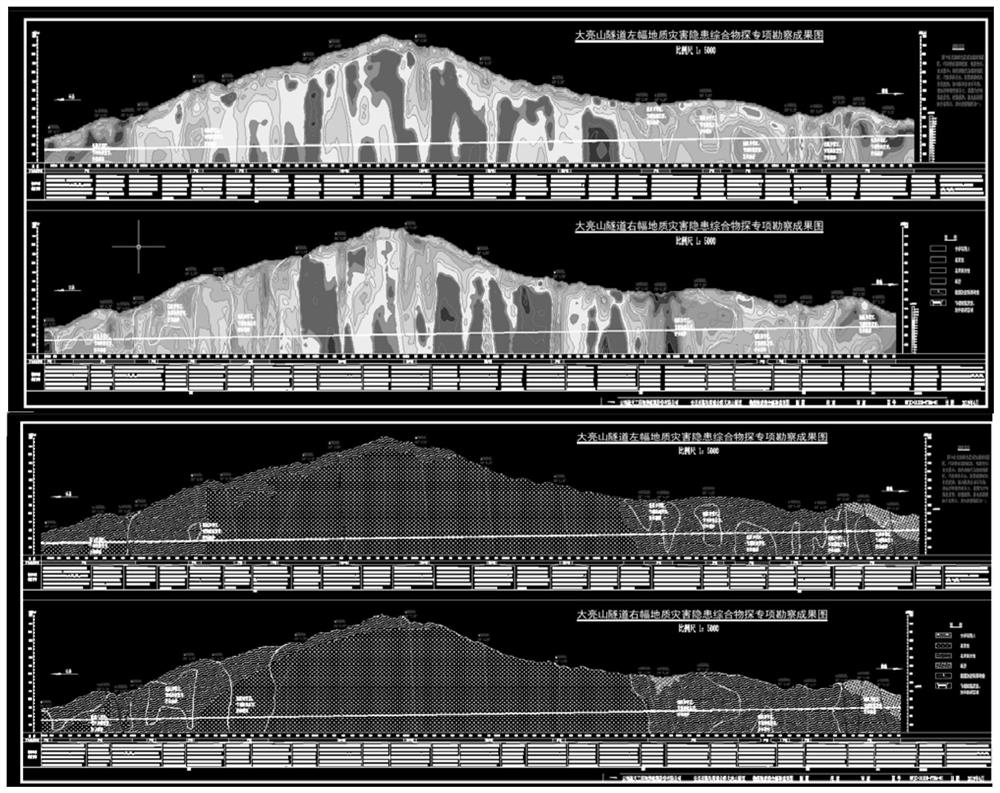

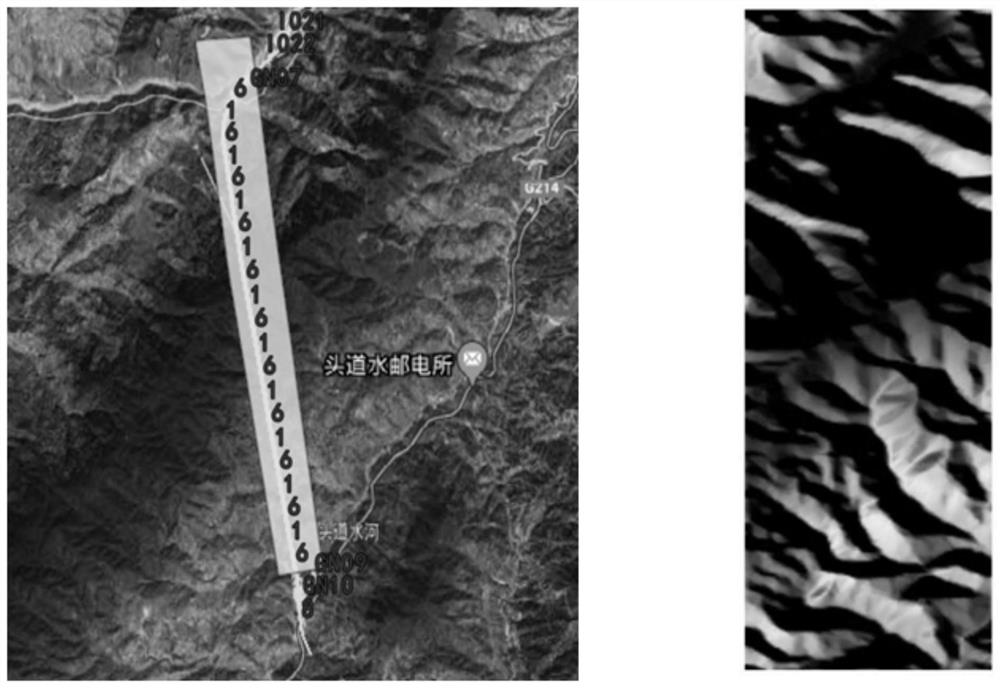

BIM three-dimensional geological modeling method based on two-dimensional profile and CATIA

The invention provides a BIM three-dimensional geologic modeling method based on a two-dimensional profile and CATIA. The method comprises the following steps: downloading a surface elevation image map of a geologic body; converting the surface elevation image map; performing geologic body section geophysical prospecting information processing; carrying out CATIA three-dimensional geological modeling; and carrying out 3DMAX mapping. The method has the following advantages that drilling data is not needed, the three-dimensional geologic body is established only through the two-dimensional cad section and the tunnel position, the characteristics of high precision degree and high compatibility of industrial software are utilized, the industrial software is applied to the geologic field, so that a geologic model is finer, the characteristic of high visualization of animation software is also utilized, the three-dimensional geologic body is more visual, and therefore, a new thought is provided for construction of the tunnel BIM system.

Owner:YUNNAN AEROSPACE ENG GEOPHYSICAL SURVEY INSPECTION

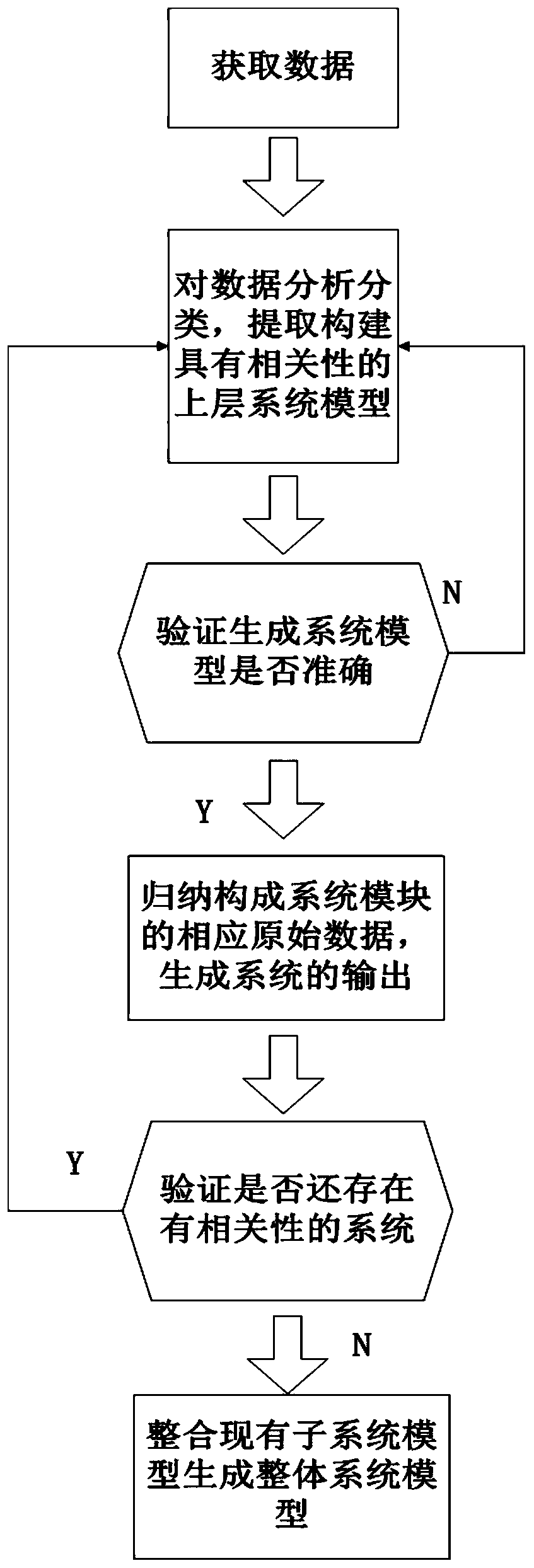

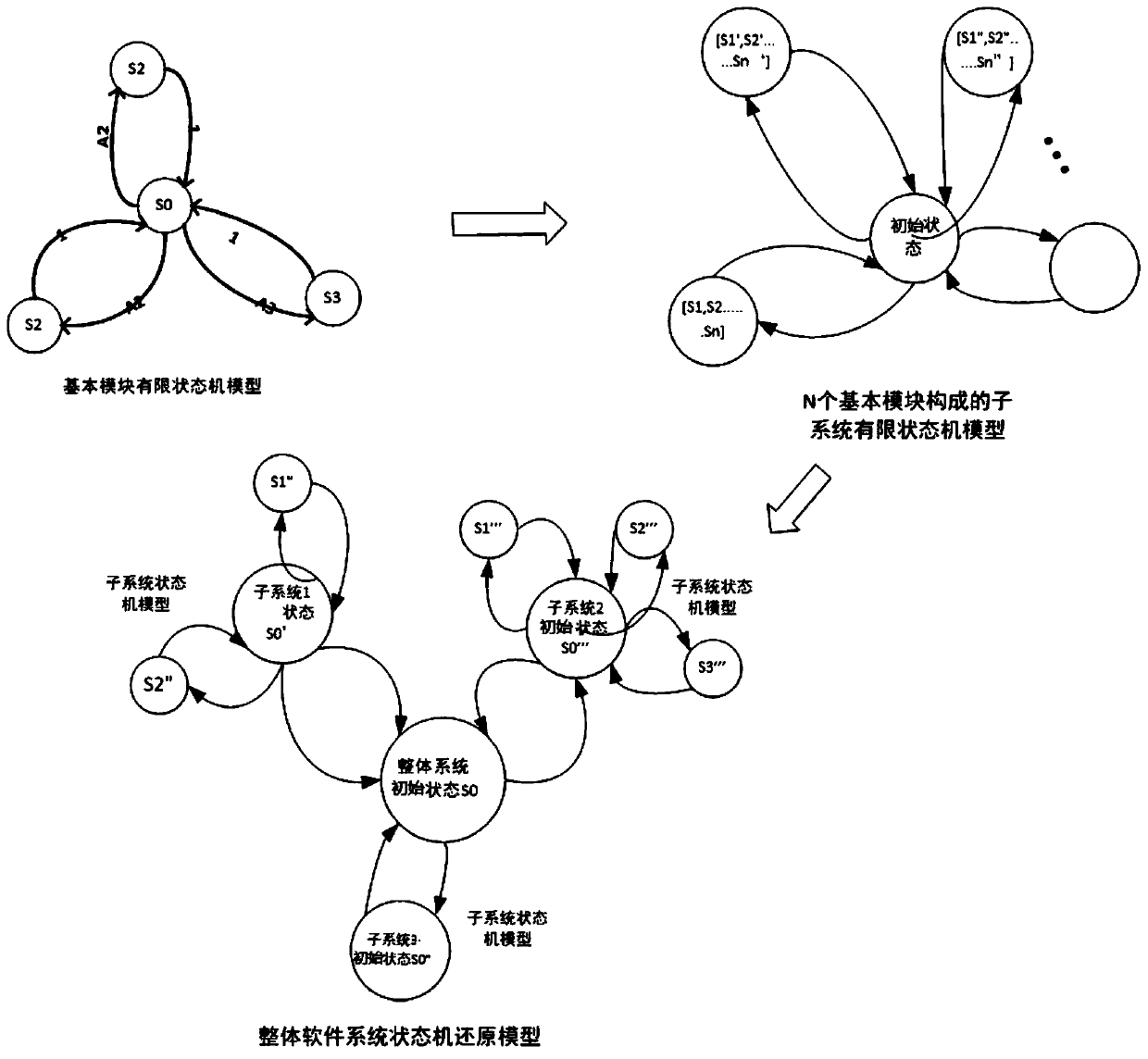

Behavior model restoration method for data-based industrial software system

ActiveCN110531963AFast and accurate complete buildShrink state spaceSoftware designModel driven codeSoftware systemIndustrial systems

The invention discloses a behavior model restoration method for a data-based industrial software system, which belongs to the field of industrial software, and comprises the following steps of: obtaining operation feedback data; analyzing and classifying the data, and extracting and constructing an upper-layer system model with correlation; verifying whether the generated system model is accurate;summarizing the corresponding original data forming the system module, and generating the output of the system; verifying whether a system with correlation exists or not; and integrating the existingsubsystem models to generate an integral system model. Based on existing industrial control software operation feedback data, an industrial system software model can be rapidly, accurately and completely constructed. The state space of the finite-state machine model of the whole software system is reduced, and the process of reversely constructing the finite-state machine of the system by data issimplified. The method is high in universality, can be widely applied to industrial system modeling, and can be quickly converted into an industrial system control code in combination with a basic unit code driving function block packaging technology.

Owner:SHANGHAI JIAO TONG UNIV

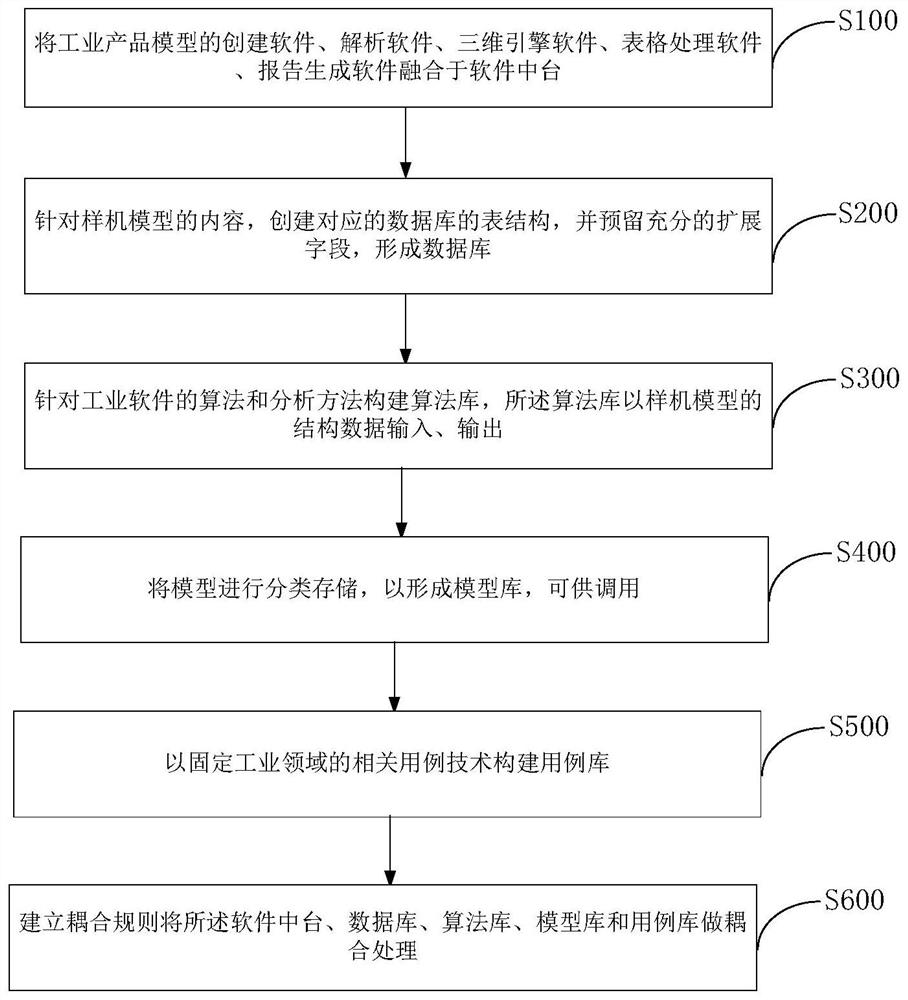

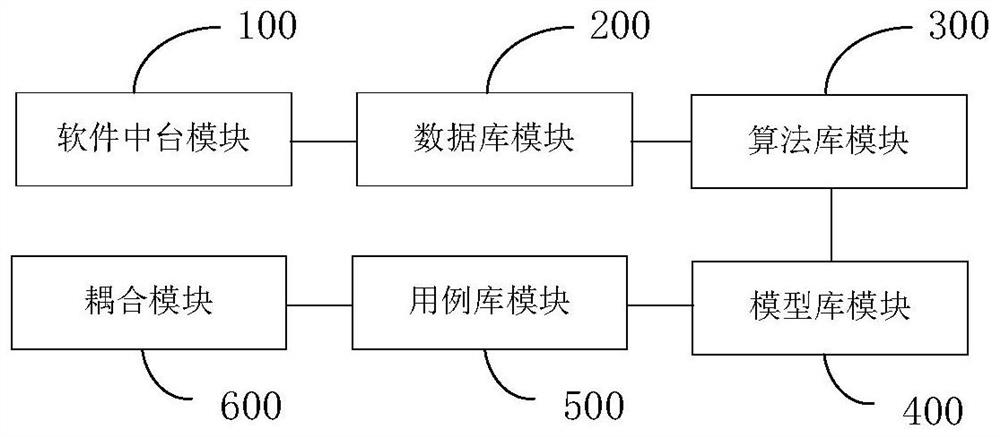

Technical console construction method and device

PendingCN112270077ADesign optimisation/simulationSpecial data processing applicationsTable (database)Industrial software

The invention discloses a technical console construction method and device. The method comprises the following steps: fusing creation software, analysis software, three-dimensional engine software, table processing software and report generation software of an industrial product model into a software console; aiming at the content of the prototype model, creating a table structure of a corresponding database, and reserving sufficient extension fields to form the database; constructing an algorithm library for algorithms and analysis methods of industrial software, wherein the algorithm libraryis used for inputting and outputting structural data of a prototype model; classifying and storing the models to form a model library for calling; constructing a case library by using a related casetechnology in the fixed industrial field; and establishing a coupling rule to perform coupling processing on the software console, the database, the algorithm library, the model library and the use case library.

Owner:SUZHOU SHUSHE TECH CO LTD

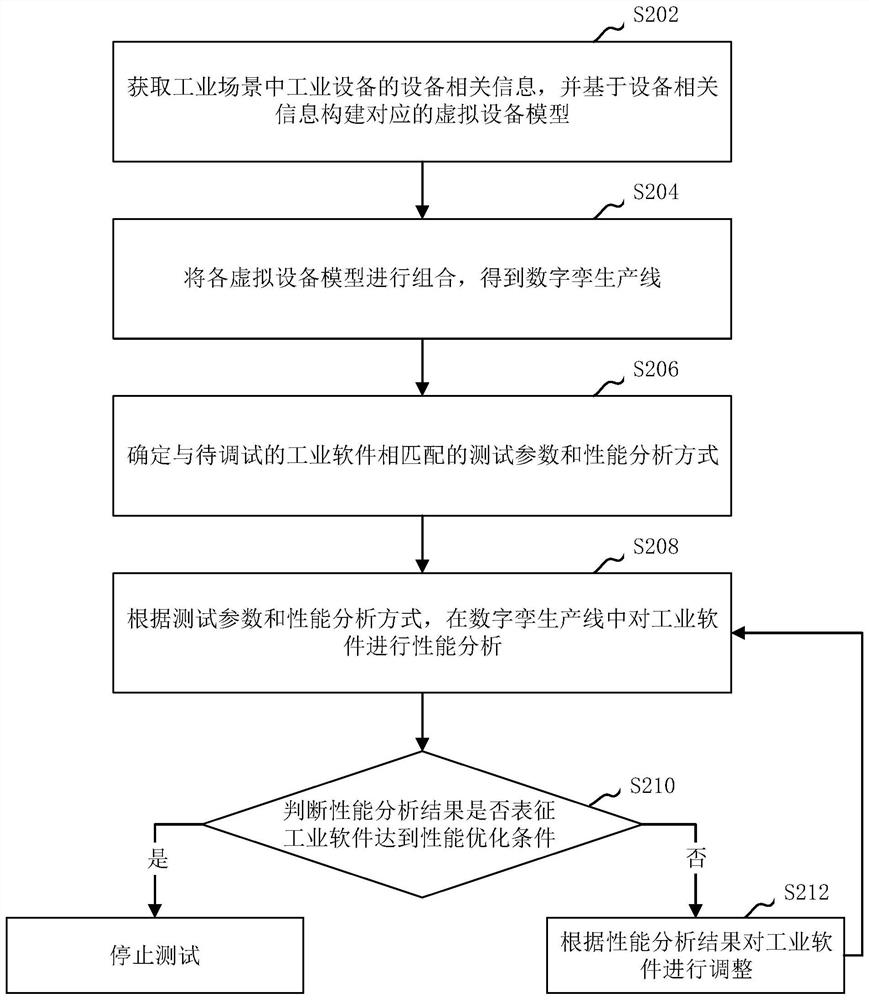

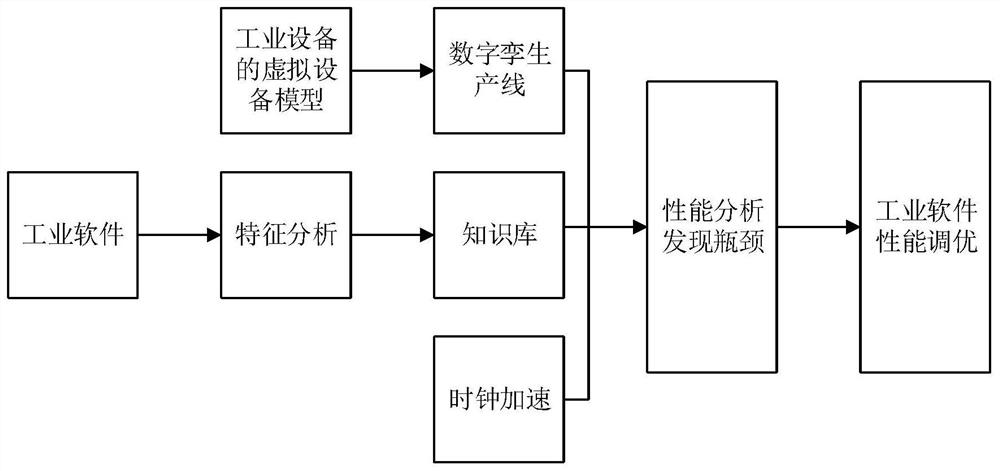

Industrial software debugging method and device, computer equipment and storage medium

PendingCN113868120AAvoid damageReduce the cost of performance testingSoftware testing/debuggingTotal factory controlIndustrial softwareIndustrial equipment

The invention relates to an industrial software debugging method and device, computer equipment and a storage medium. The method comprises the following steps: acquiring equipment related information of industrial equipment in an industrial scene, and constructing a corresponding virtual equipment model based on the equipment related information; combining the virtual equipment models to obtain a digital twin production line; determining test parameters and a performance analysis mode matched with the to-be-debugged industrial software; performing performance analysis on the industrial software in the digital twin production line according to the test parameters and the performance analysis mode; if the performance analysis result represents that the industrial software does not meet the performance optimization condition, adjusting the industrial software according to the performance analysis result; and based on the adjusted industrial software, returning to the step of performance analysis for continuous execution, and stopping until the adjusted industrial software reaches a performance optimization condition, thereby obtaining the optimized target industrial software. By adopting the method, the debugging efficiency of the industrial software can be improved.

Owner:CHINA ELECTRONICS PROD RELIABILITY & ENVIRONMENTAL TESTING RES INST

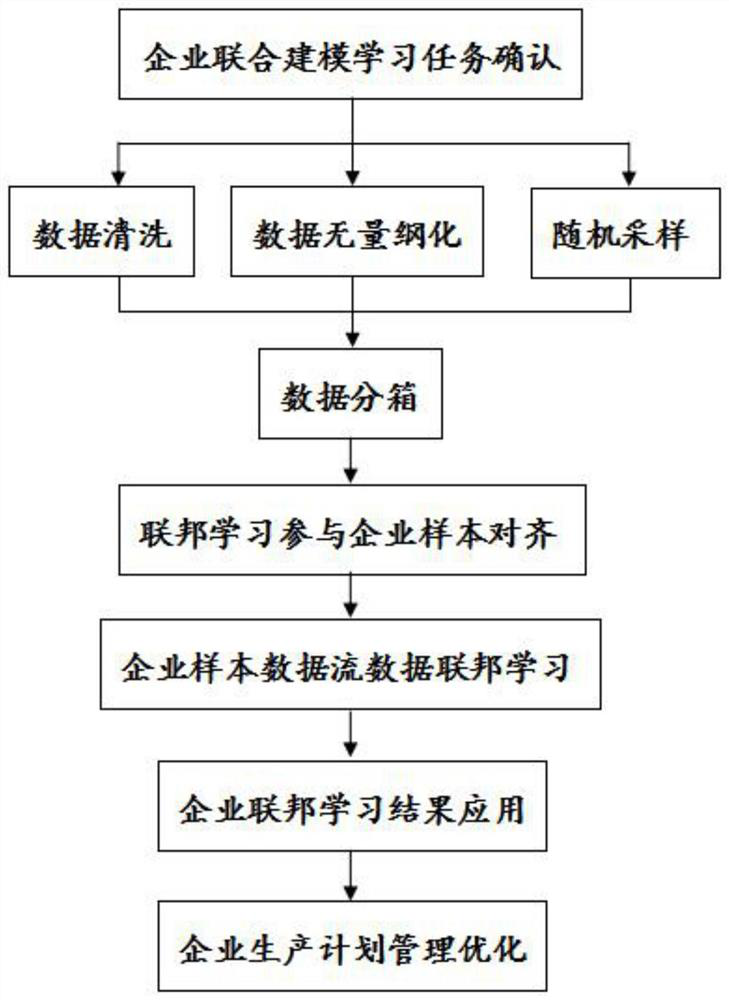

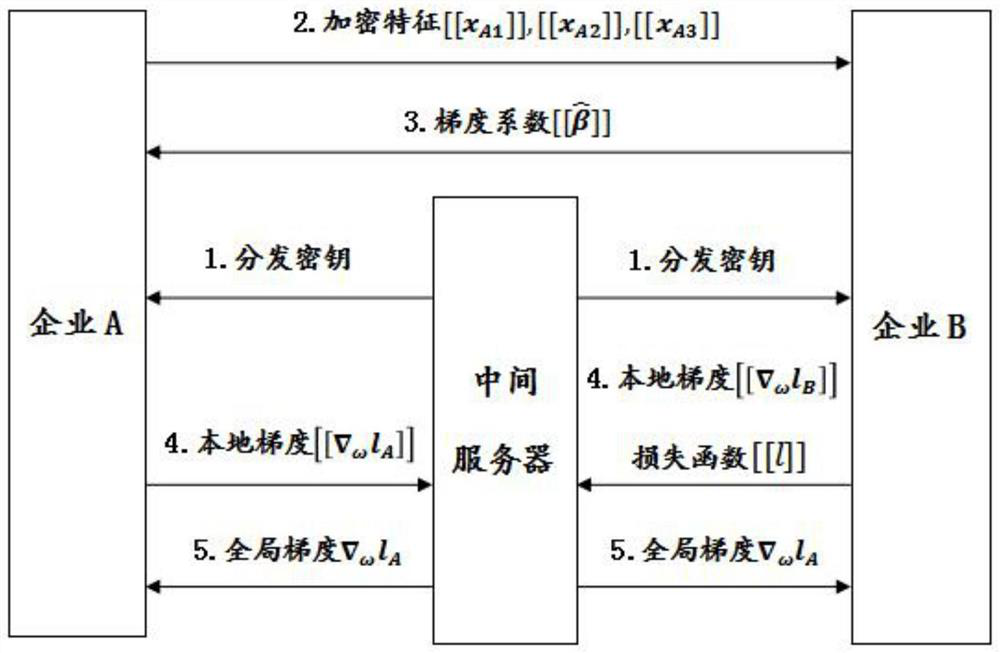

Production plan management optimization method based on longitudinal federated learning industrial software docking

PendingCN114358433AOvercoming hysteresisImprove performanceForecastingResourcesData streamSoftware system

The invention discloses a production plan management optimization method based on longitudinal federated learning industrial software docking, and the method comprises the steps: carrying out the joint modeling learning task confirmation of longitudinal federated based on the demands of an enterprise, carrying out the preprocessing of the data flow of federated learning participating enterprise samples, carrying out the sample alignment of the federated learning participating enterprises, and carrying out the optimization of the federated learning participating enterprises. Performing encrypted longitudinal federated learning of parameter exchange on federated learning participating enterprises, and finally performing enterprise production plan optimization management according to enterprise demand application federated learning prediction results. According to the method, the production plan optimal allocation condition of the next time period is obtained by applying a federal learning means, enterprise resources are comprehensively managed based on an industrial internet industrial software system, the enterprise productivity and production efficiency are improved, and a more powerful model is jointly established, so that the hysteresis quality of current enterprise production plan management is effectively improved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

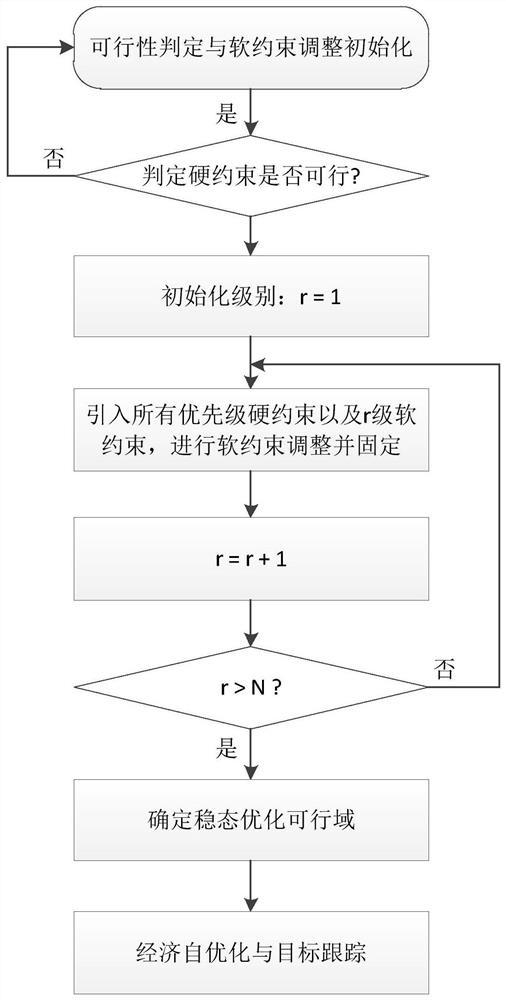

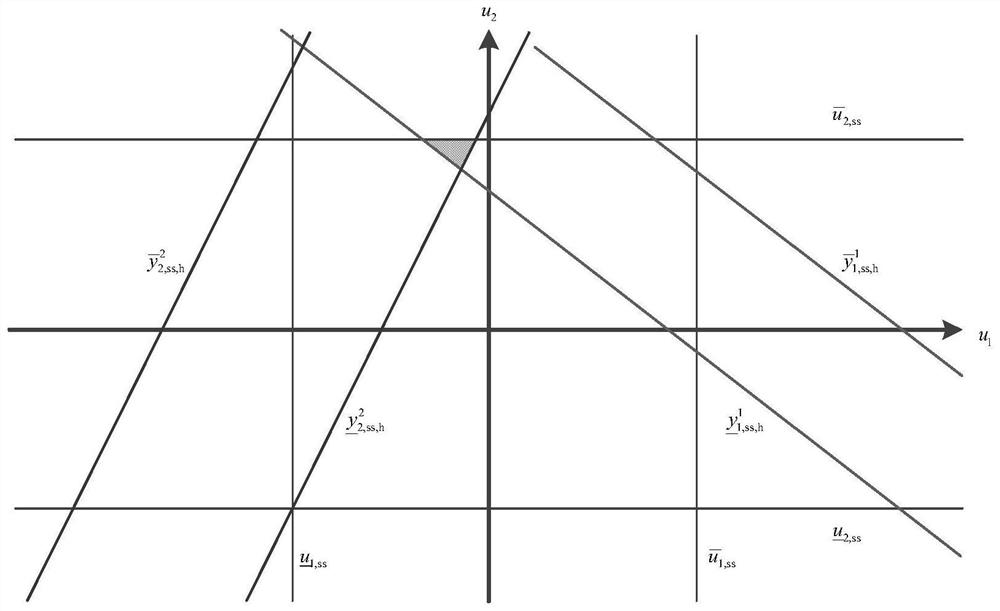

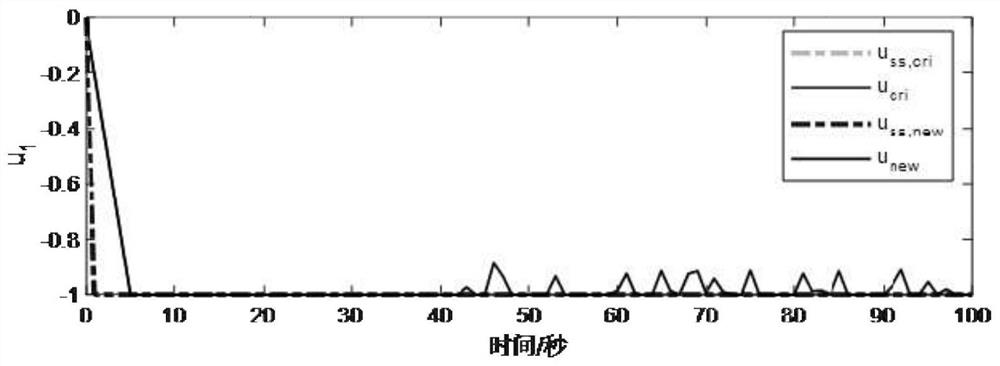

Chemical engineering-oriented priority ascending feasibility judgment and soft constraint adjustment method

PendingCN113917891AGuaranteed feasibilityAchieve Optimal Economic ControlTotal factory controlProgramme total factory controlIndustrial softwareProcess engineering

The invention relates to the field of process industrial control, in particular to a chemical engineering-oriented priority ascending feasibility judgment and soft constraint adjustment method, which comprises the following steps of initializing feasibility judgment and soft constraint adjustment; judging hard constraint feasibility; carrying out step-by-step soft constraint adjustment and solidification; and determining a steady-state optimization feasible region. In order to solve the problem of incompleteness of existing priority ascending feasibility judgment and soft constraint adjustment in the chemical process, under each priority, hard constraints of all priorities and soft constraints of the current priority are introduced at the same time for judgment and adjustment, and then judgment and adjustment are completed step by step until feasibility judgment and soft constraint adjustment are achieved for all priorities. According to the method, the problem of incompleteness of an existing priority ascending strategy is solved, the stability and the reliability of related process control industrial software can be effectively improved, and then guarantee is provided for stable operation of related chemical processes.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

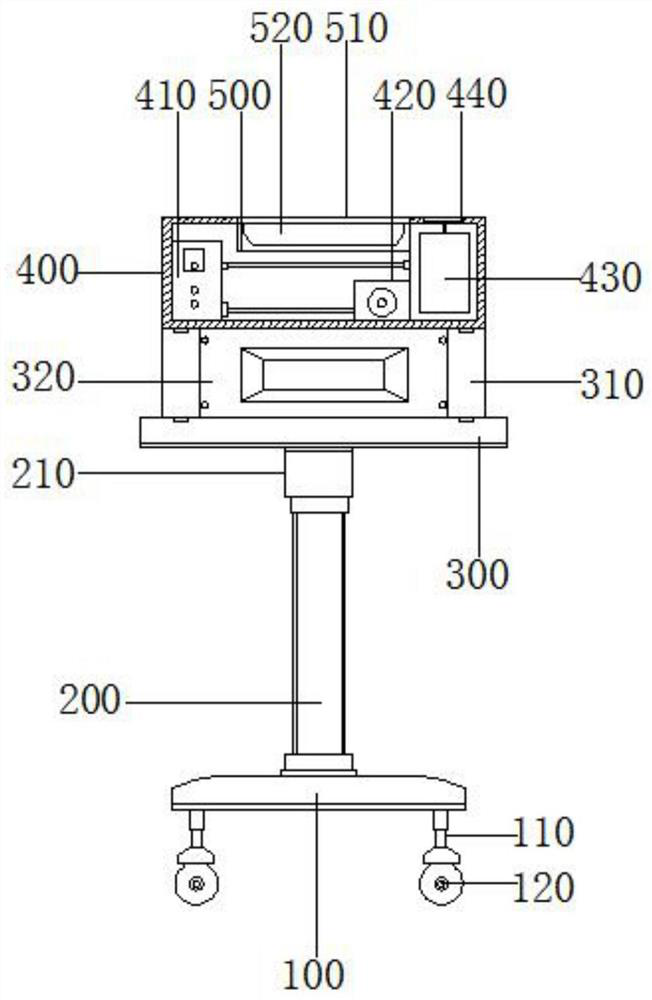

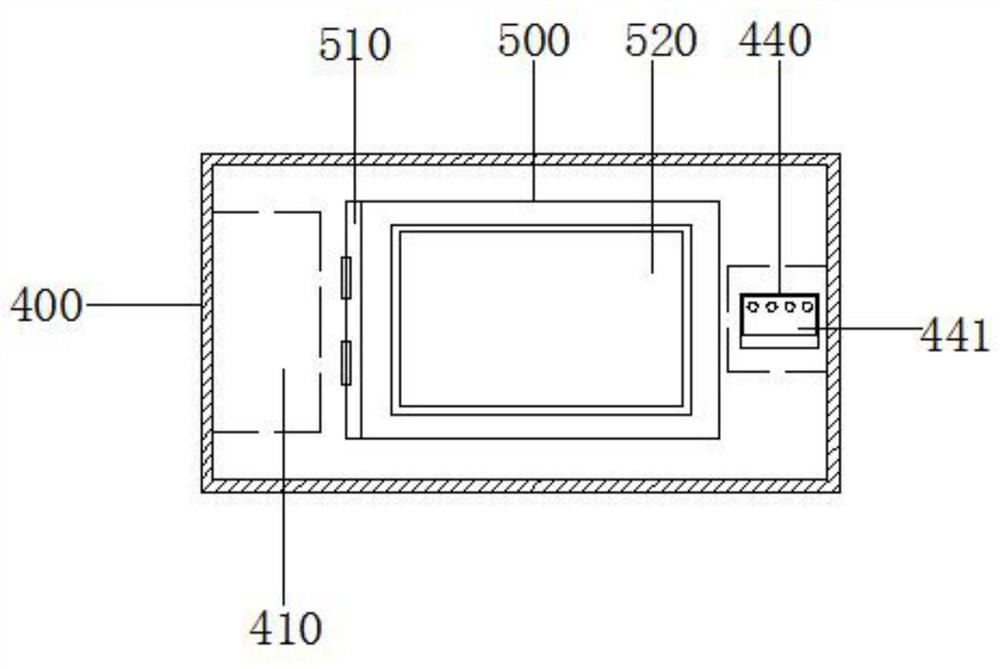

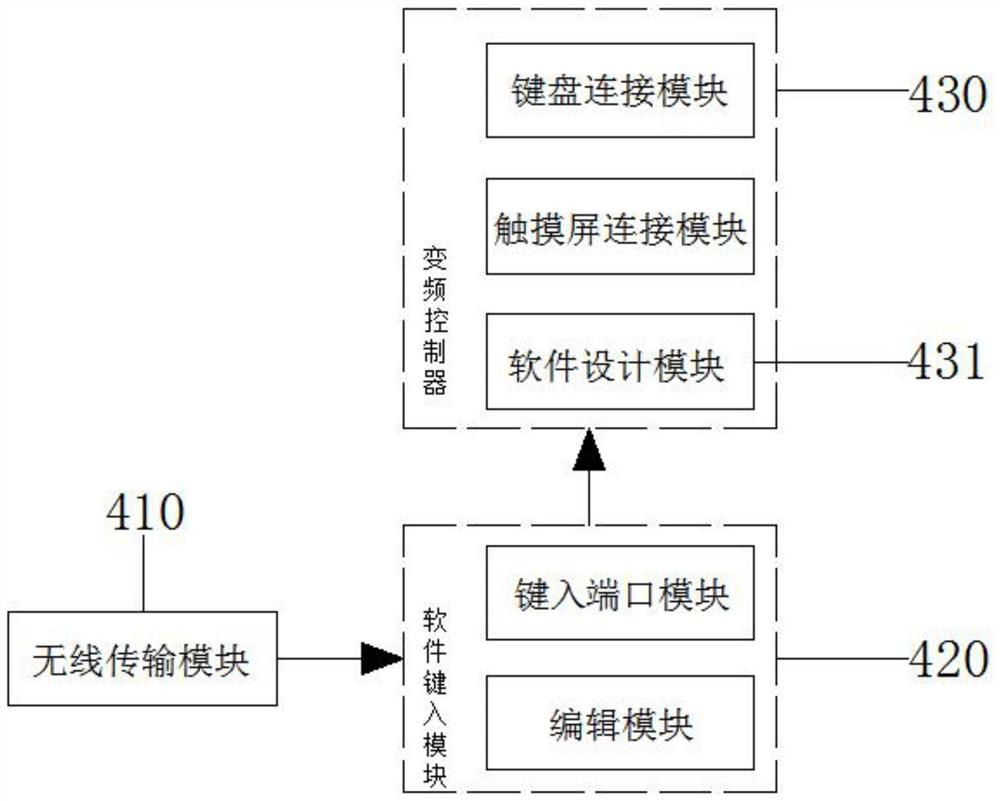

Industrial software design and application platform and use method thereof

PendingCN112835558AEasy to useEasy to moveSoftware designVisual/graphical programmingWireless transmissionIndustrial software

The invention belongs to the technical field of software design devices, and particularly relates to an industrial software design and application platform and a use method thereof.The industrial software design and application platform comprises a base, a movable frame, a combined plate, a platform body and a built-in cavity, the top of the base is fixedly connected with the movable frame through bolts, and the combined plate is arranged at the top of the movable frame; according to the industrial software design and application platform and the use method thereof, the wireless transmitter, the software typing module and the frequency conversion controller containing the software design module can be integrally arranged in the platform, overall movement is facilitated, flexibility is improved, the top of the platform is provided with the built-in cavity with the display device and while observation is conducted. the frequency conversion controller is used in cooperation with the software design module in the frequency conversion controller, industrial software design is carried out through the system process design module, the interface and the view design module in the software design module, implementation is carried out in cooperation with the implementation module, the overall process is simplified, the integration degree is high, and use is convenient.

Owner:武汉普来思信息技术有限公司

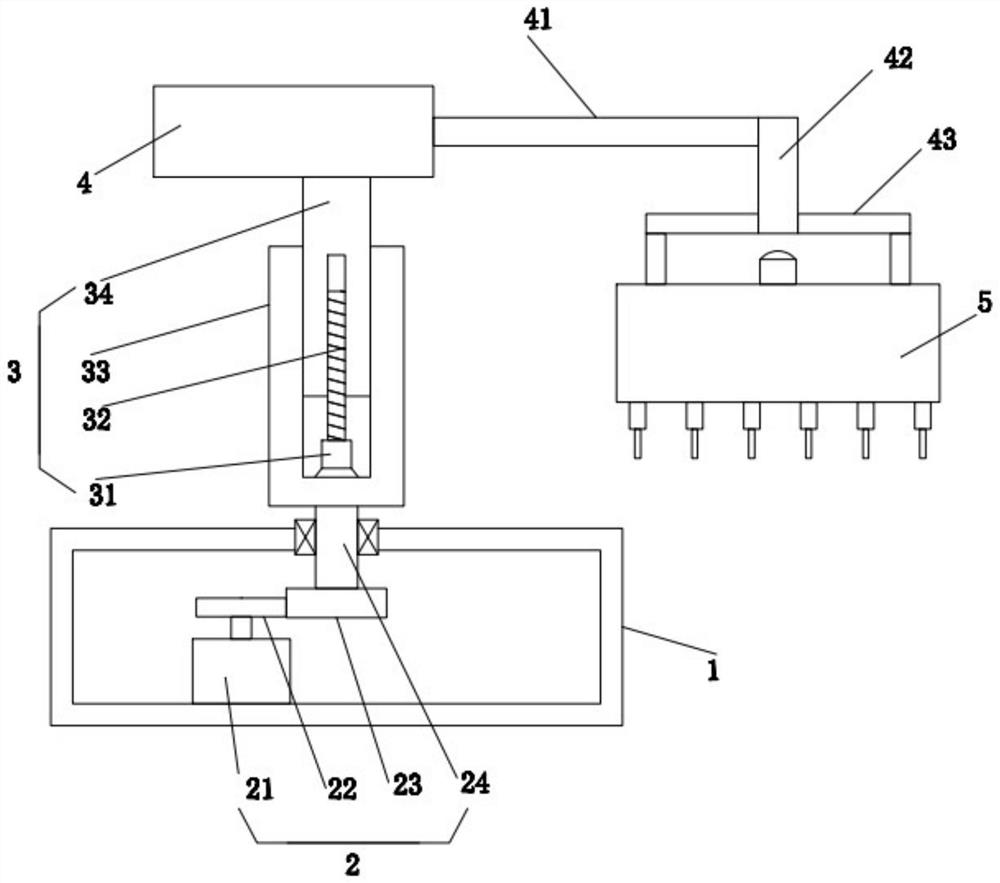

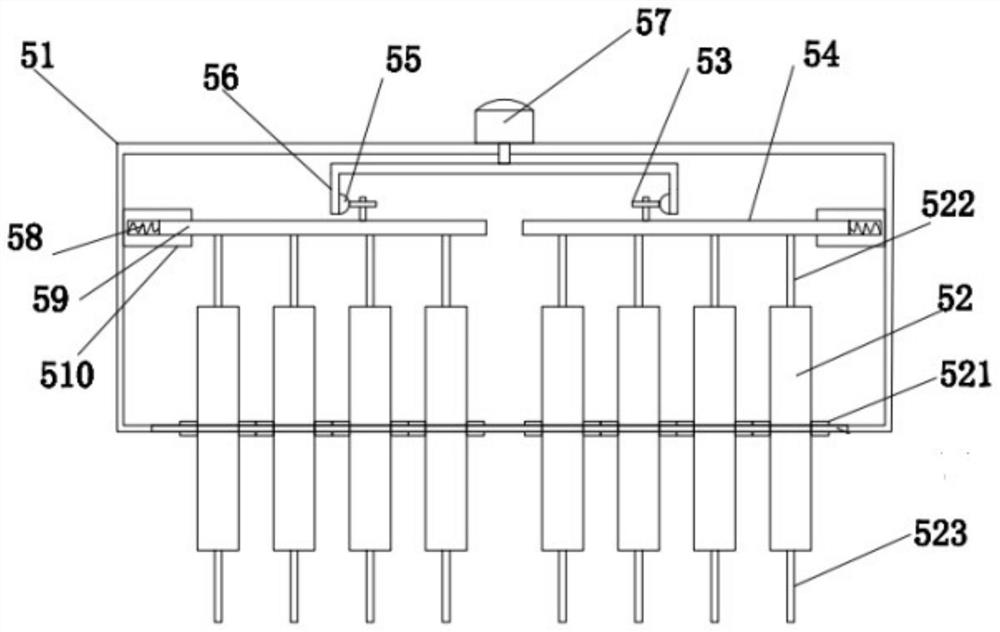

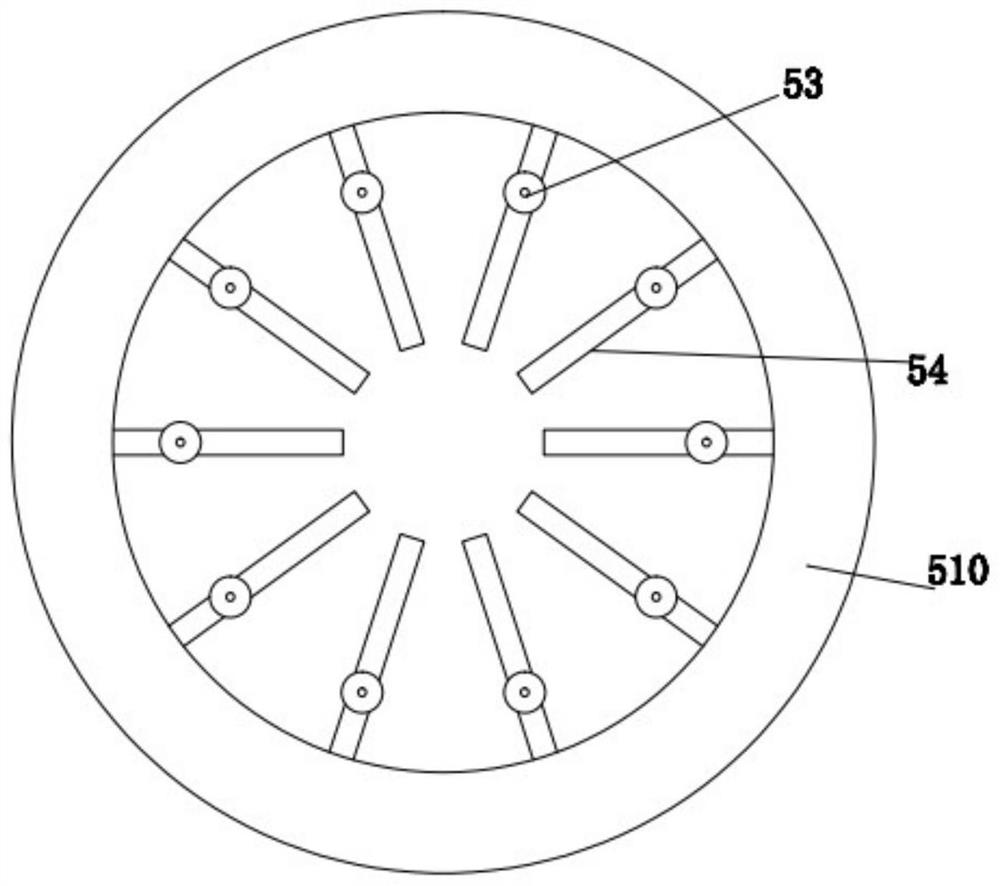

A kind of industrial software grasping robot and grasping method

ActiveCN110405732BLow costPracticalProgramme-controlled manipulatorGripping headsHydraulic cylinderIndustrial software

The invention discloses an industrial software grabbing robot and a grabbing method, comprising a base, a lifting assembly for adjusting the grabbing height is arranged above the base, and the bottom of the lifting assembly is connected with a jack for adjusting the circumferential position of grabbing Steering assembly, the output end of the lifting assembly is provided with a horizontal hydraulic cylinder for grasping the horizontal position movement, the output end of the horizontal hydraulic cylinder is provided with a horizontal telescopic rod, and the end of the horizontal telescopic rod is provided with a vertical The suspension rod is set, and the lower end of the suspension rod is connected to the software grabbing component through the connecting frame. The present invention improves on the existing needs, and designs a grabbing component that can grab objects of different shapes, and does not need a simulated human phone Reasonable, greatly reducing the cost, strong practicability.

Owner:NANJING YUSHENG ROBOT CO LTD

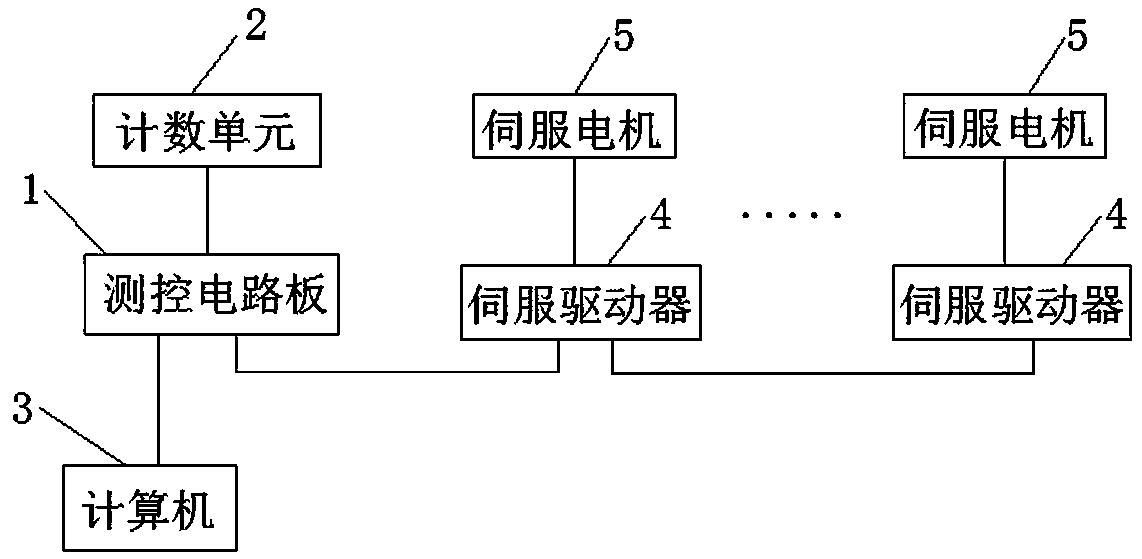

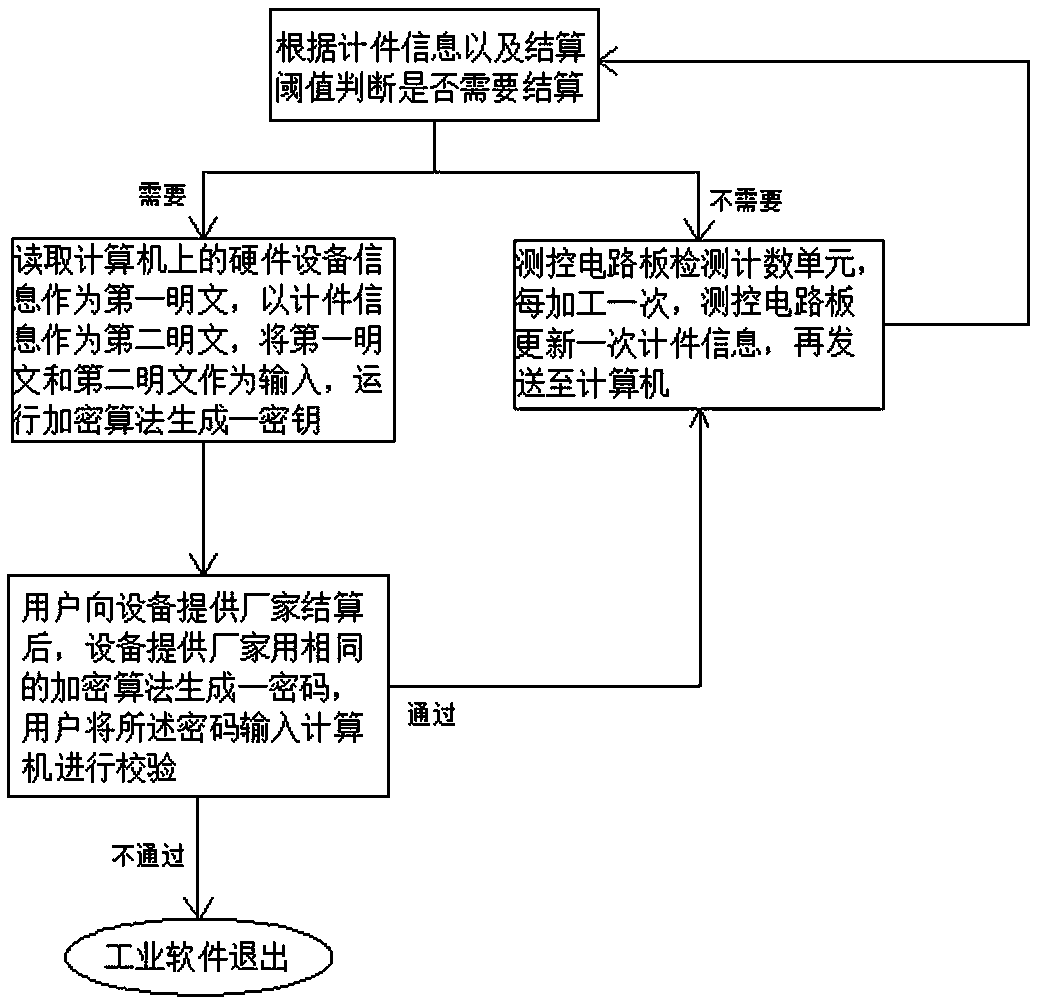

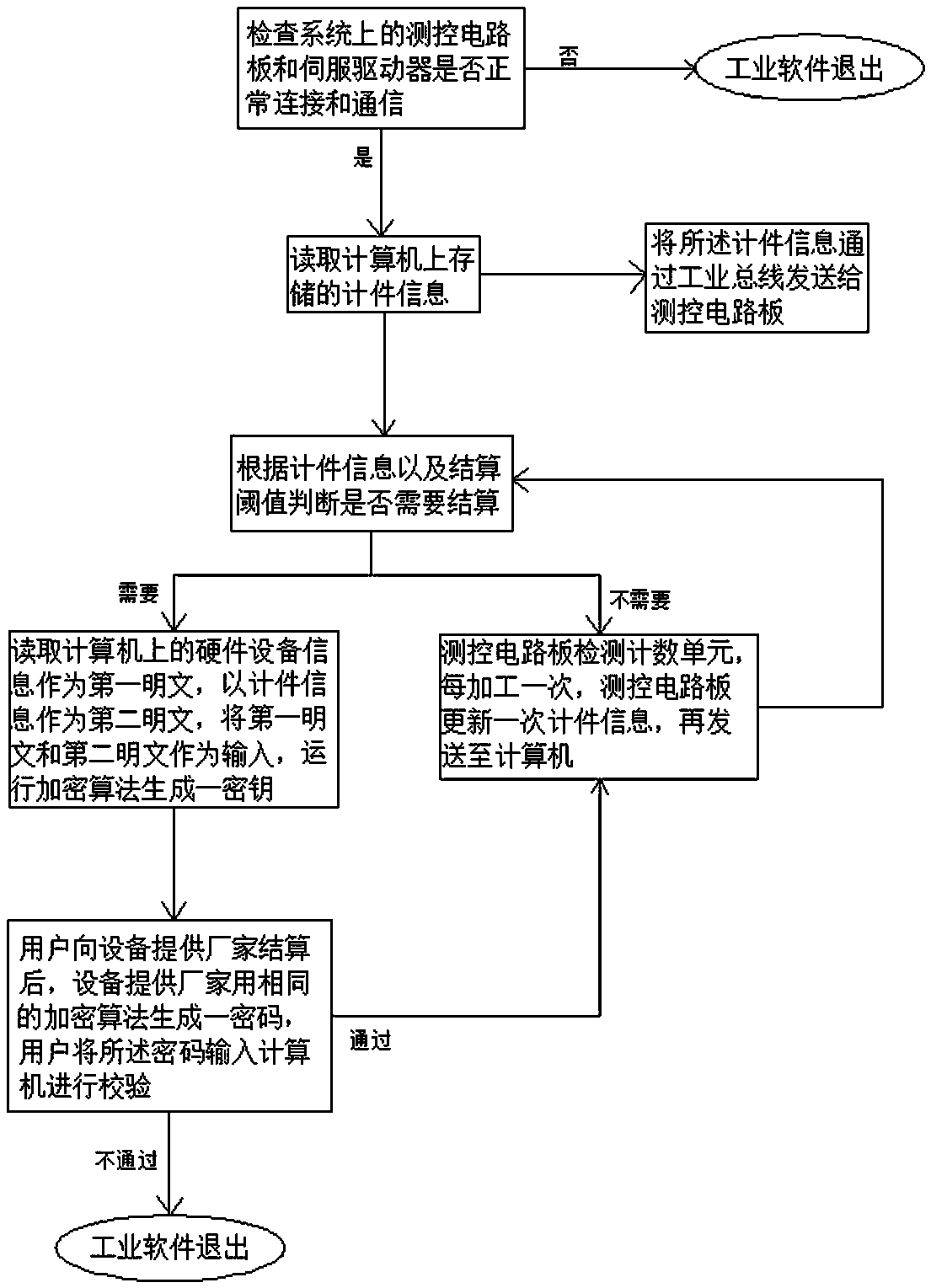

Industrial software number counting encryption method and system

ActiveCN108322312ASolve Billing IssuesAvoid economic lossProgramme controlKey distribution for secure communicationPaymentUser needs

The invention relates to an industrial software number counting encryption method and system; whether a user needs to settle a fee or not is judged according to number counting information and a settlement threshold value; if settlement is needed, the hardware information and the number counting information of a computer equipped with industrial software are taken as input, and an encryption algorithm is operated to generate a secret key; the user obtains a password after settling the fee with a device providing manufacturer; the generation mode of the password is the same as that of the private key; the password is consistent with the secret key, and the device can continue to work normally. The invention relates to an industrial software number counting encryption system. according to the method and the system in the invention, the industrial software can be encrypted, and the number encryption can be realized; after a certain number of workpieces are processed, the user needs to obtain the secret key to continuously use the device after payment settlement to the device manufacturer; and the method and the system can be widely applied to the fields of renting of industrial automatic devices, MES systems and the like.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY +1

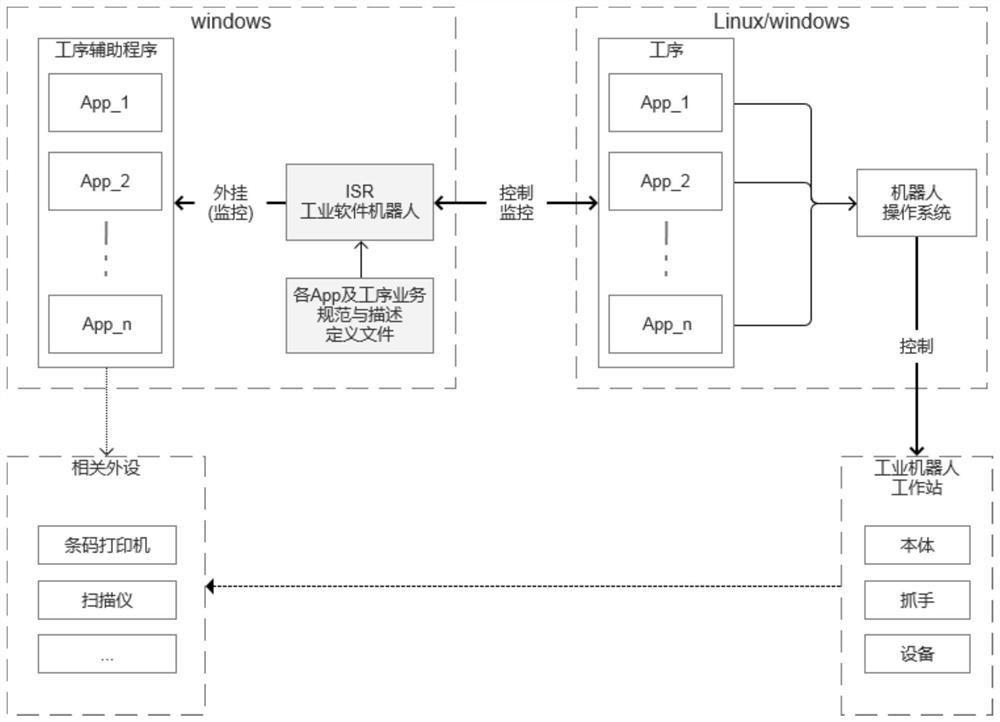

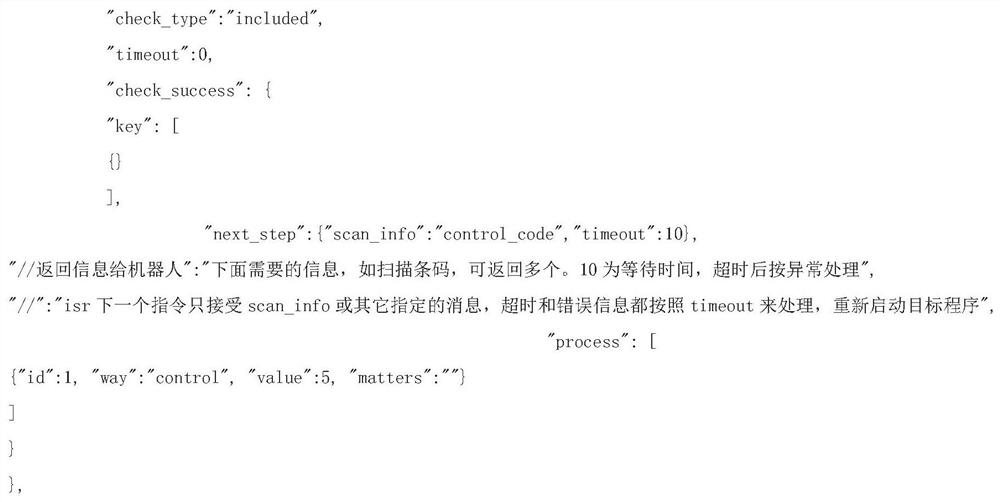

Industrial software robot system

ActiveCN111966055ASolve the technical problems of effectively interacting and working togetherTotal factory controlProgramme total factory controlIndustrial softwareApplication procedure

The invention provides an industrial software robot system, which comprises a production business system, an auxiliary business system and a software robot, wherein that the production business systemcomprises a process application program, and the process application program controls the industrial robot to complete a process and receives a process operation result returned by the industrial robot; the auxiliary business system comprises a process auxiliary application program, and the process auxiliary application program controls peripheral equipment to work; a process application program,a process and a business specification of a process auxiliary application program are stored in the software robot, the software robot is initialized by describing a definition file, and the softwarerobot monitors the production business system, acquires a process operation result from the production business system and controls the auxiliary business system to work. According to the industrialsoftware robot system provided by the invention, the technical problems of effective interaction and cooperative work among a plurality of business systems are solved.

Owner:雷蜂(东莞)科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com