Patents

Literature

32results about How to "Reduce the cost of performance testing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

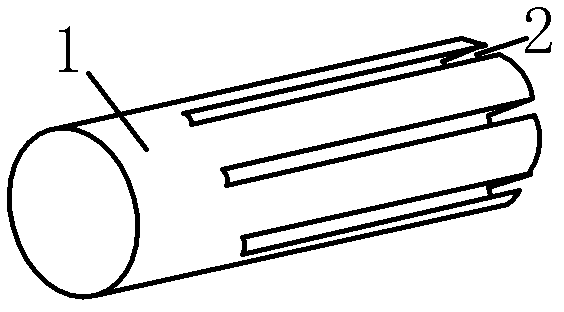

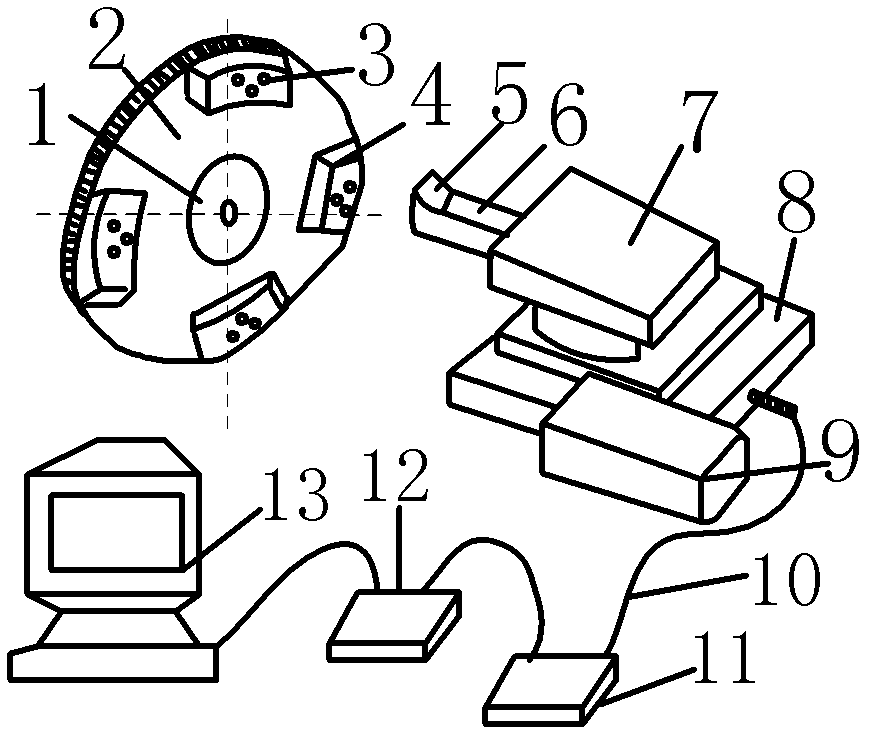

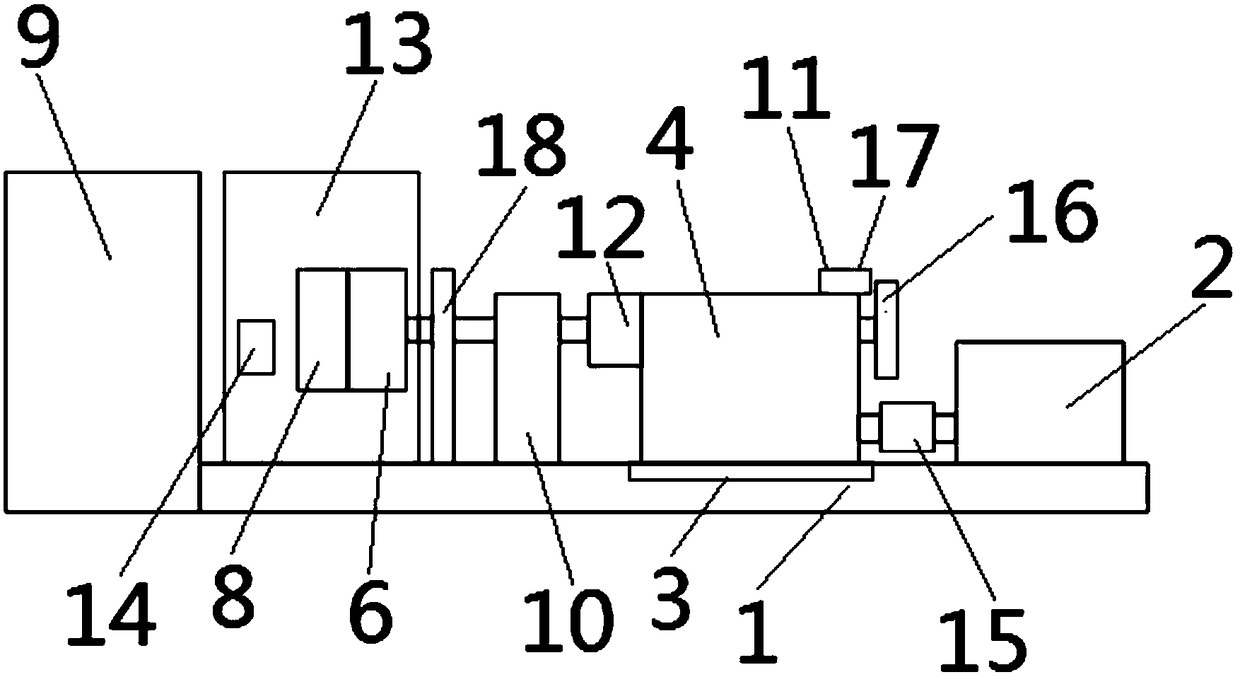

Device for evaluating and testing interrupted cutting performance of tools at high speed

InactiveCN102490084ARealize online measurementHigh speedMeasurement/indication equipmentsAudio power amplifierData acquisition

The invention provides a device for evaluating and testing interrupted cutting performance of tools at a high speed. The device comprises a rotary disk body, a tool bar, a tool rest, a piezoelectric type dynamometer, an infrared temperature detector, an electric charge amplifier and a computer, wherein the tool bar is arranged on the tool rest, the piezoelectric type dynamometer and the infrared temperature detector are fixed on the tool test, the piezoelectric type dynamometer is connected with the electric charge amplifier through a connecting wire, the electric charge amplifier is connected with a data acquisition card in the computer; a clamping part is arranged above the rotary disk body, and an even number of workpiece block installation locations symmetrically distributed at intervals on the same circumference by taking the center of rotation of the rotary disk body as a center, are arranged on the rotary disk body. The testing device can realize the interrupted cutting on the circumference and the cylindrical end face, can be used for the test evaluation of the interrupted cutting performance of the tools, and can realize the tool cutting performance evaluation test at different interrupted degrees and the on-line measurement of the cutting force, the cutting temperature and the service life of indexable blades to be evaluated, thus realization process and method are simple and convenient.

Owner:SHANDONG UNIV

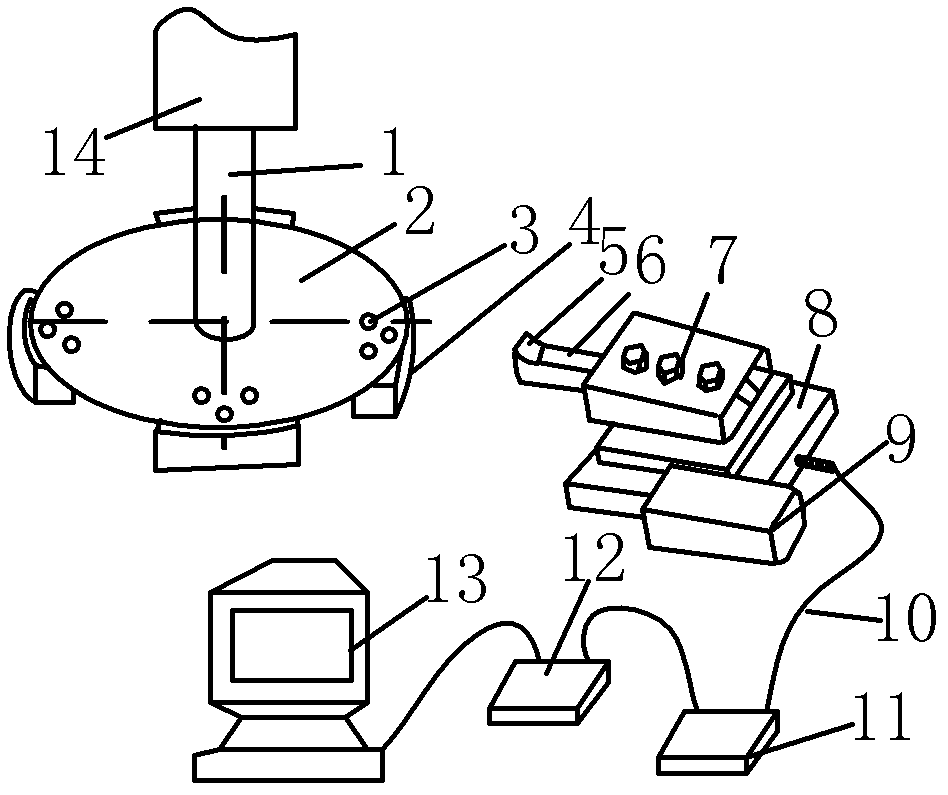

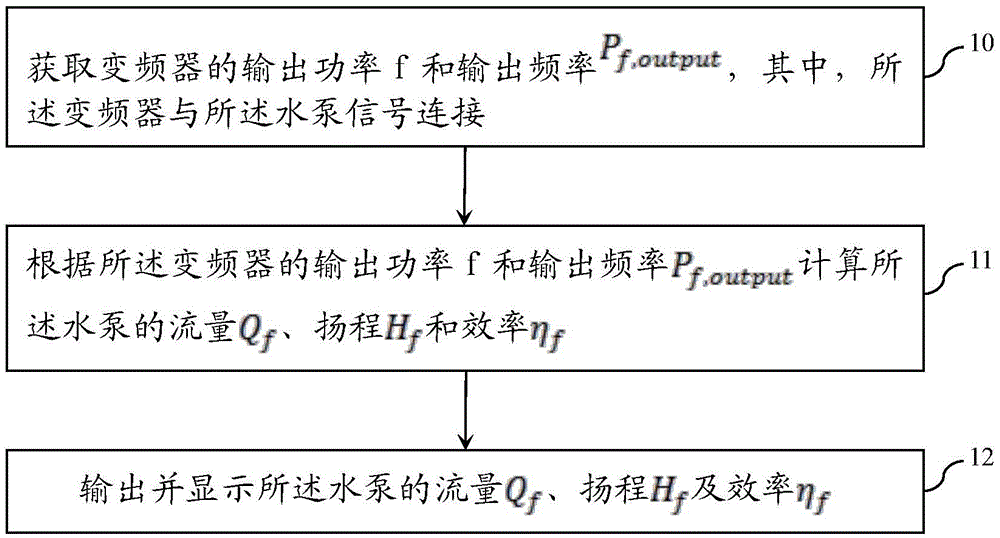

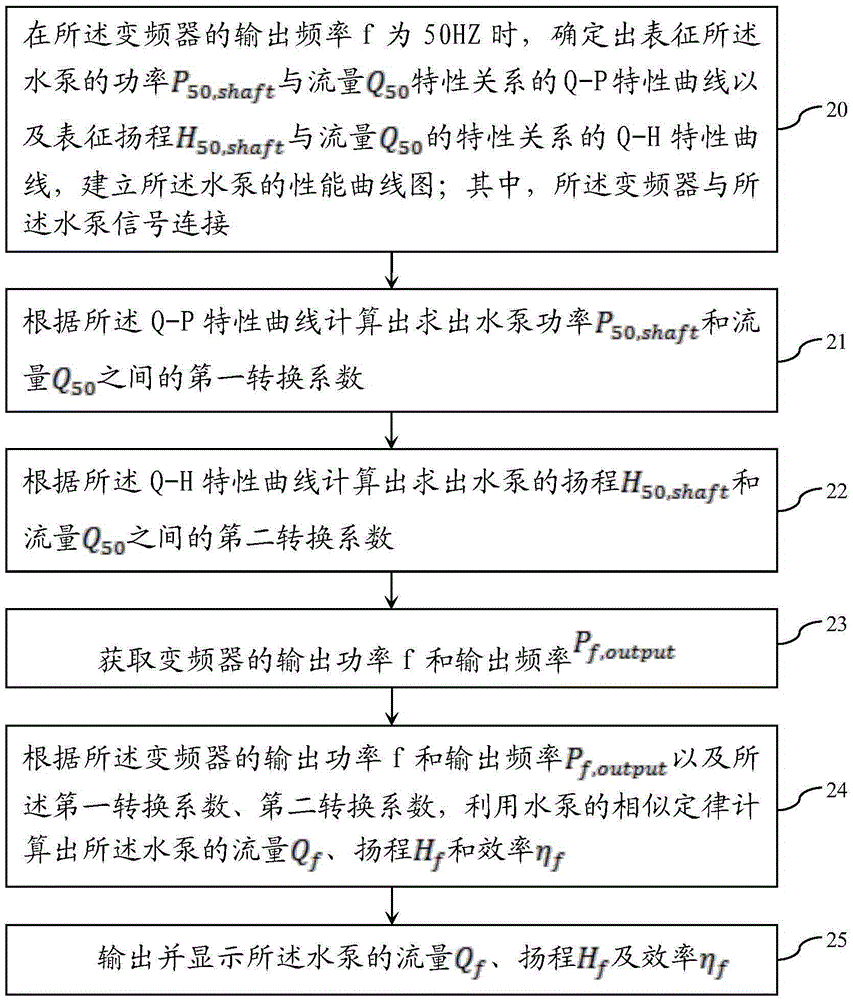

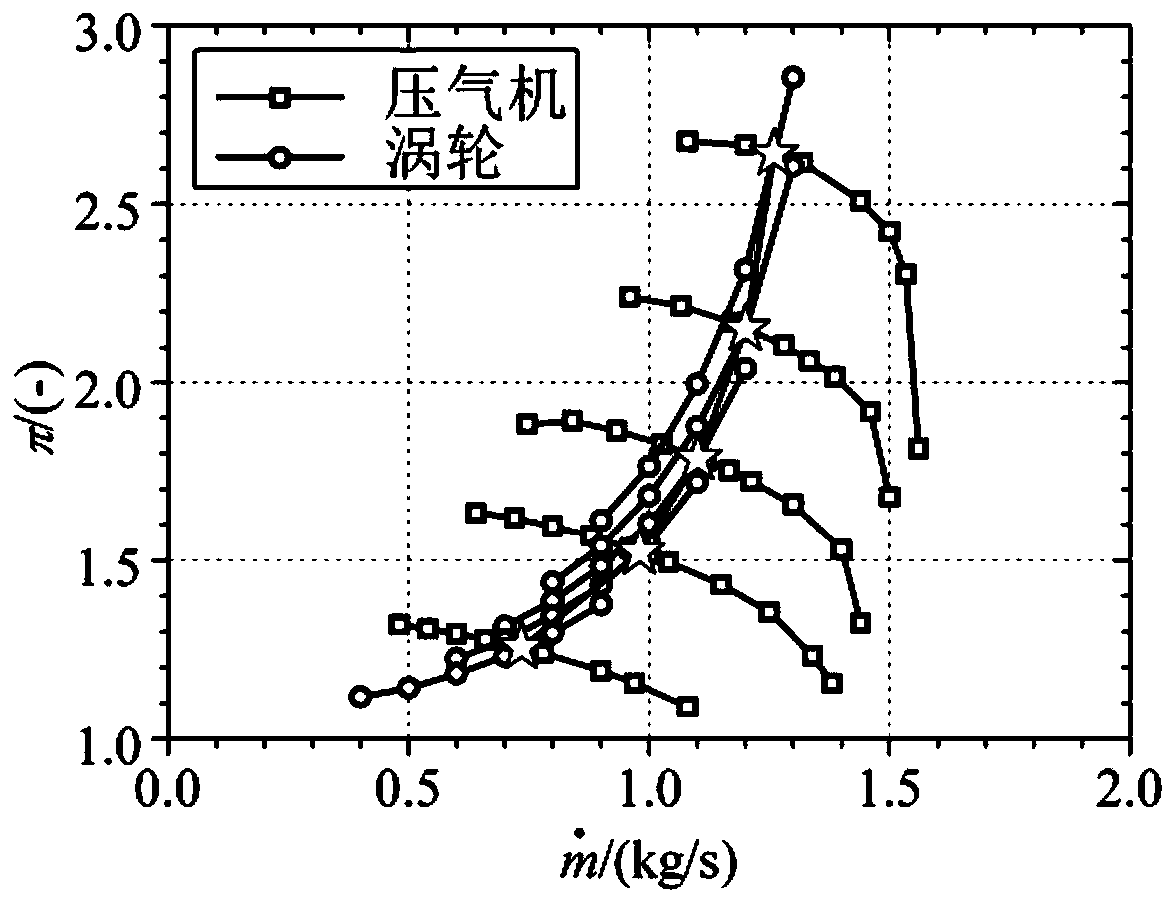

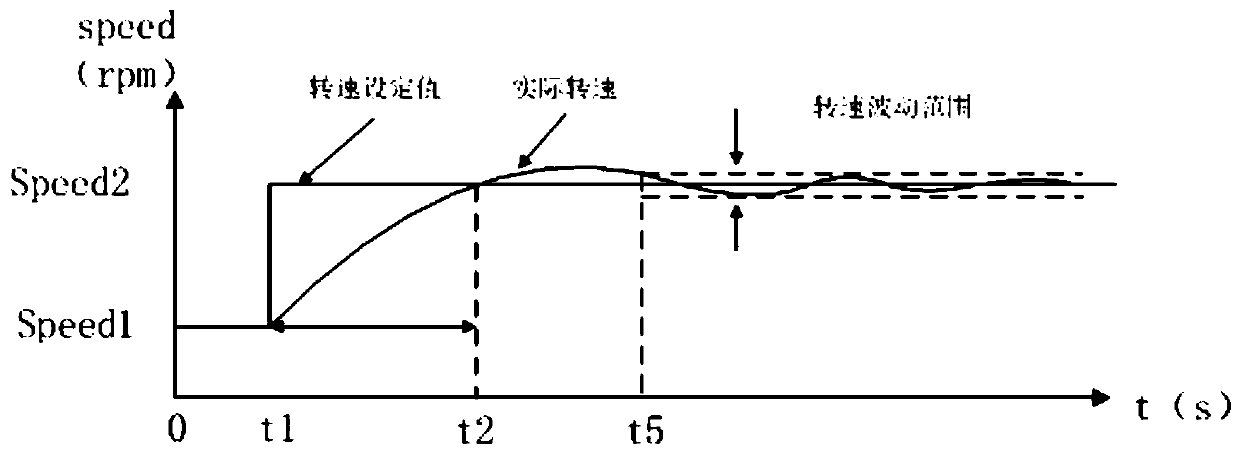

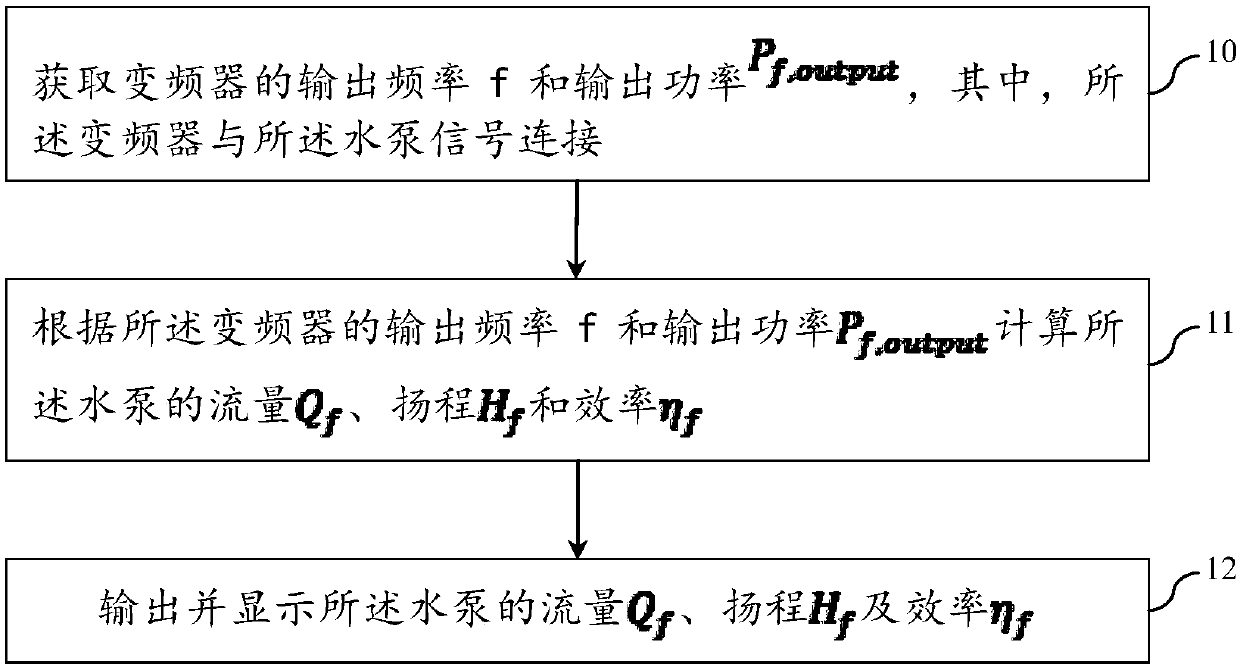

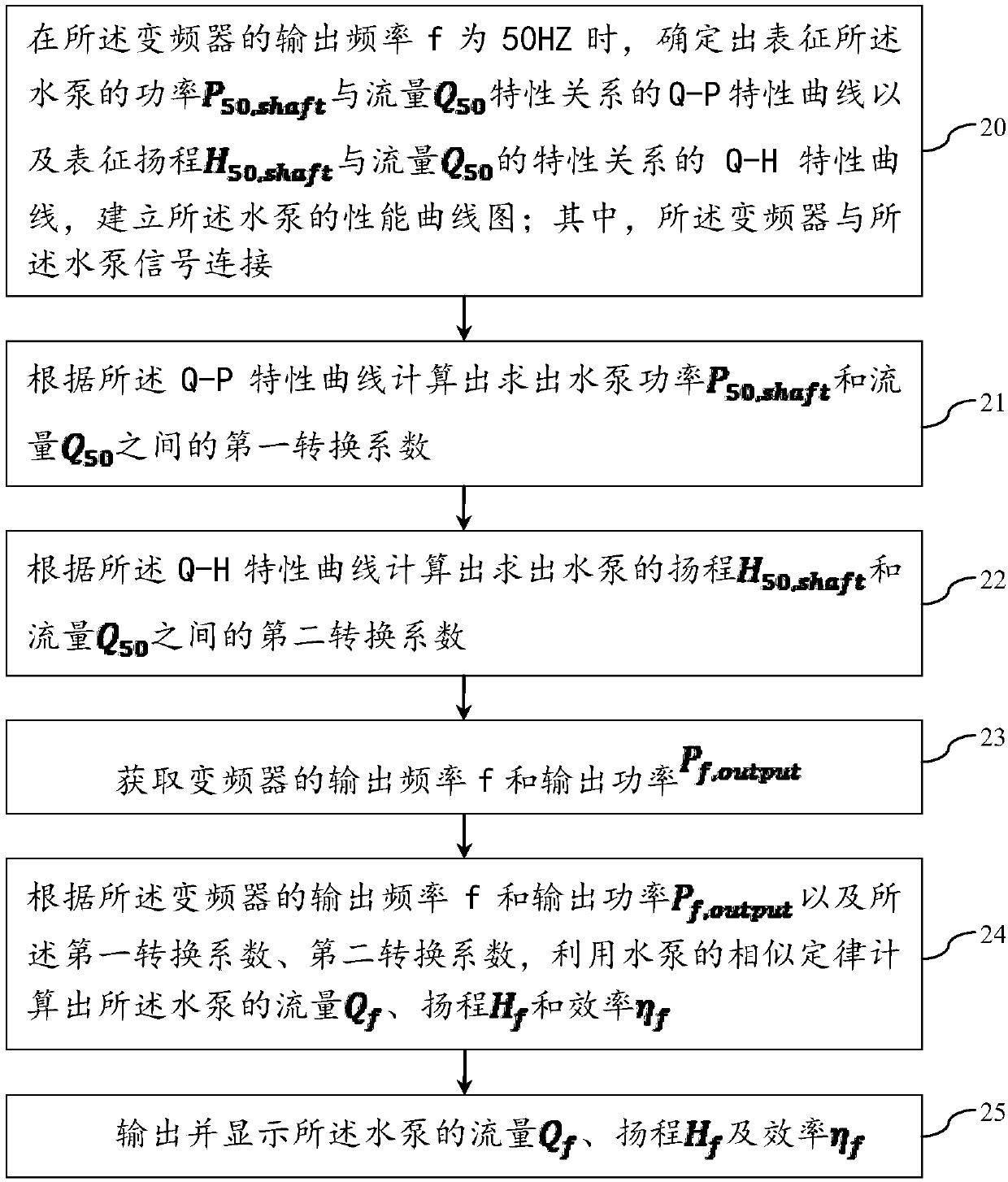

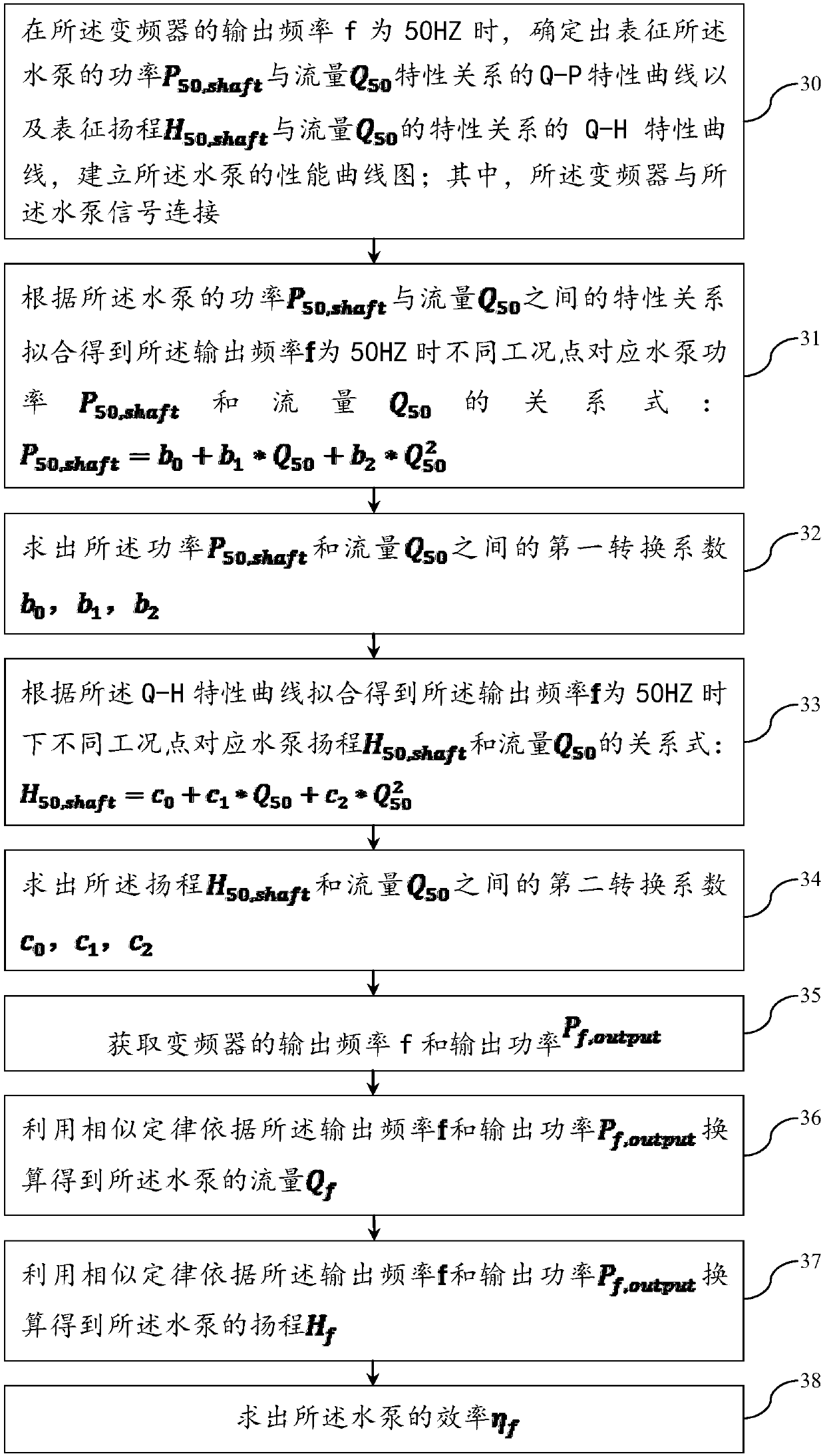

Water pump efficiency, flow and lift detection method and system

ActiveCN105673474AReduce the cost of performance testingHigh precisionPump testingPump controlTraffic volumeFrequency changer

The invention relates to a water pump efficiency, flow and lift detection method and system. The method comprises the steps of obtaining the output power f and the output frequency P<f>, <output>, of a frequency changer, wherein the frequency changer is in signal connection with a water pump; and according to the output power f and the output frequency P<f>, <output>, of the frequency changer, calculating the flow Qf, the lift Hf and the efficiency Eta f of the water pump. According to the water pump efficiency, flow and lift detection method and system, a controller reads the output power and the output frequency of the frequency changer; and according to the output power and the output frequency of the frequency changer, the flow, lift and efficiency of the water pump can be calculated. The structure is simple, and measurement can be achieved without installing of a pressure sensor and a flow meter; meanwhile, through PID real-time control and measurement display, the precision of measured water pump performance data is high, errors brought by manual measurement and treatment are overcome, the measurement efficiency is improved, high precision and high automation of the water pump performance measurement are achieved, the water pump performance measurement cost is reduced, and the measurement time is shortened.

Owner:SHENZHEN XINHUANNENG TECH

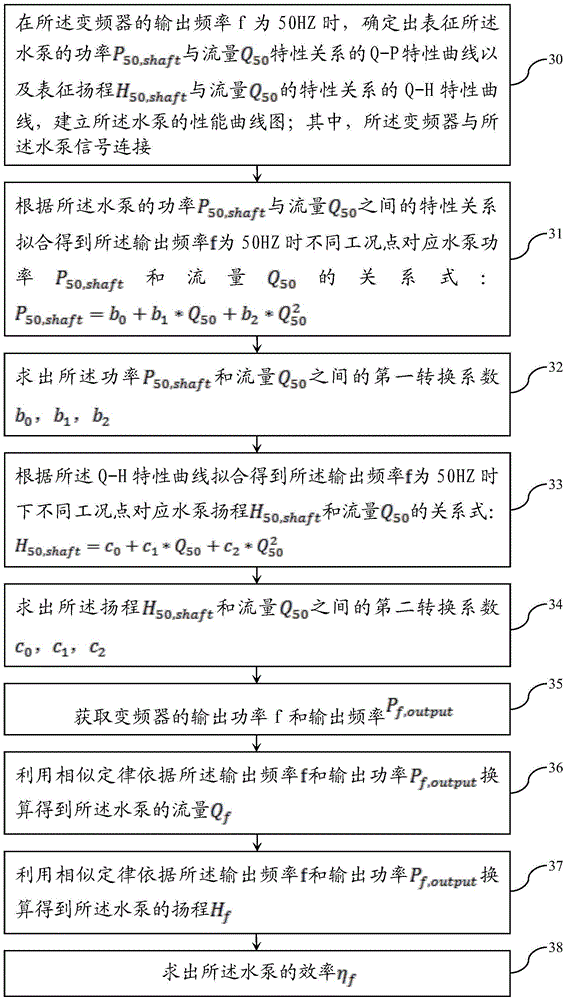

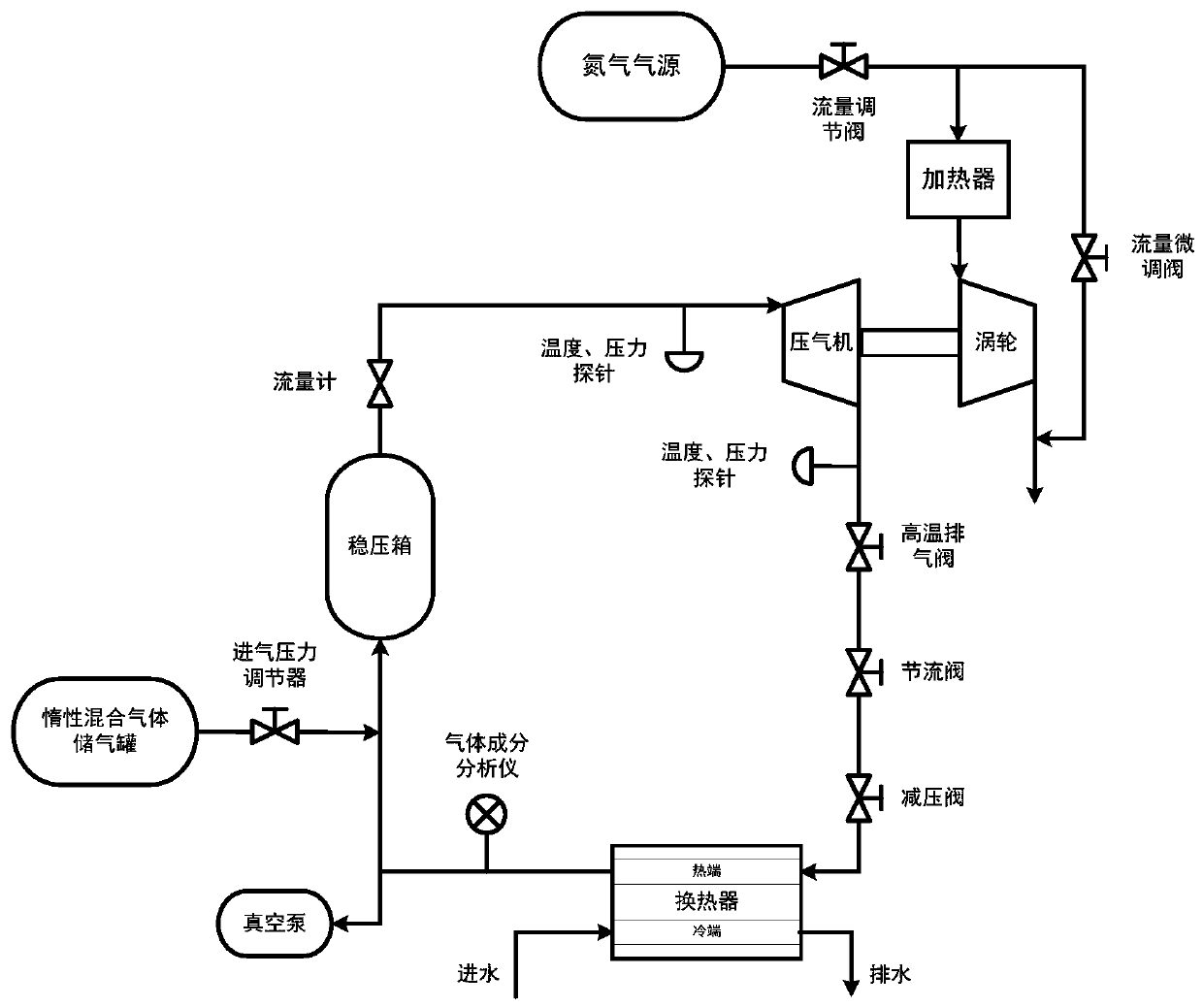

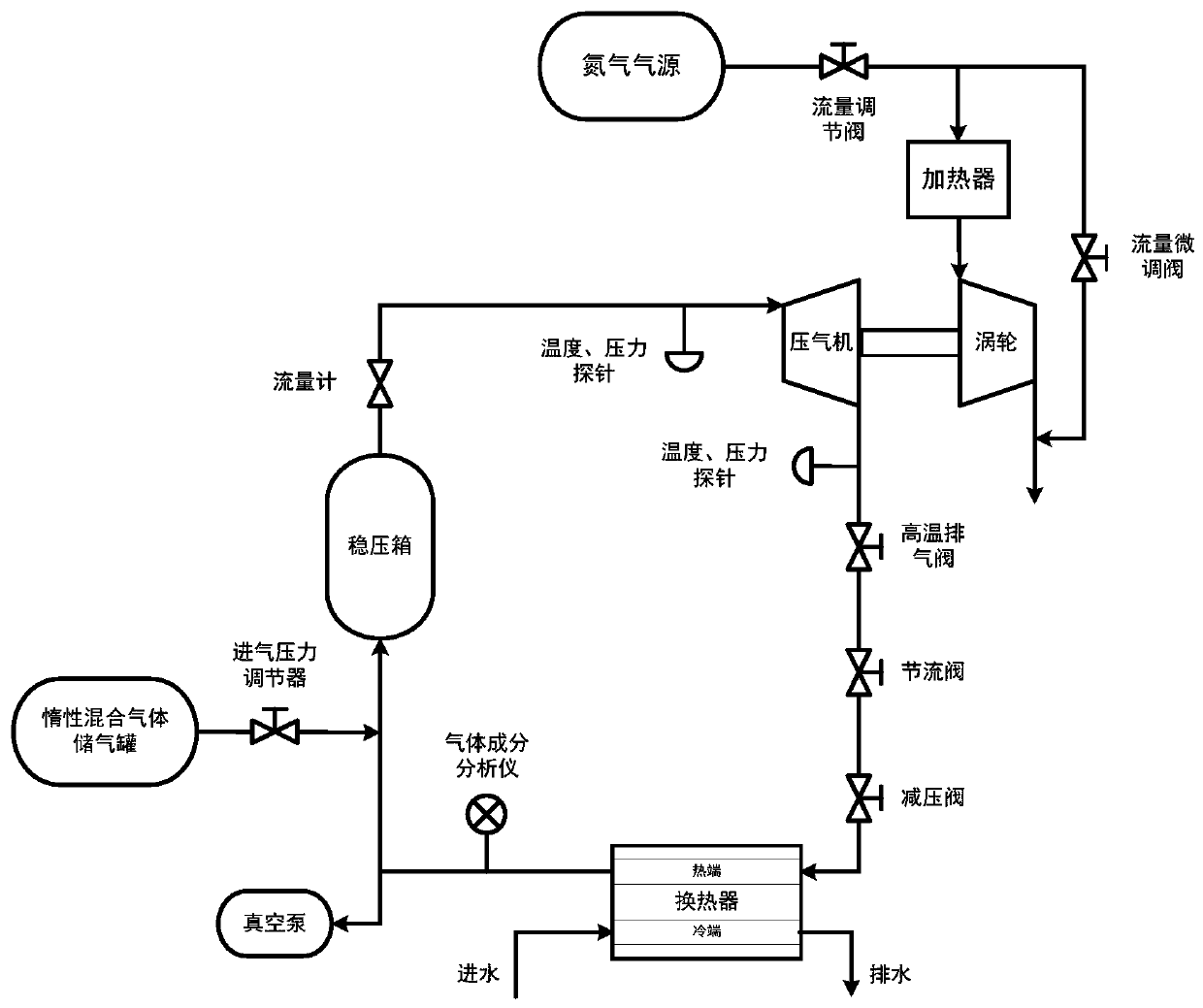

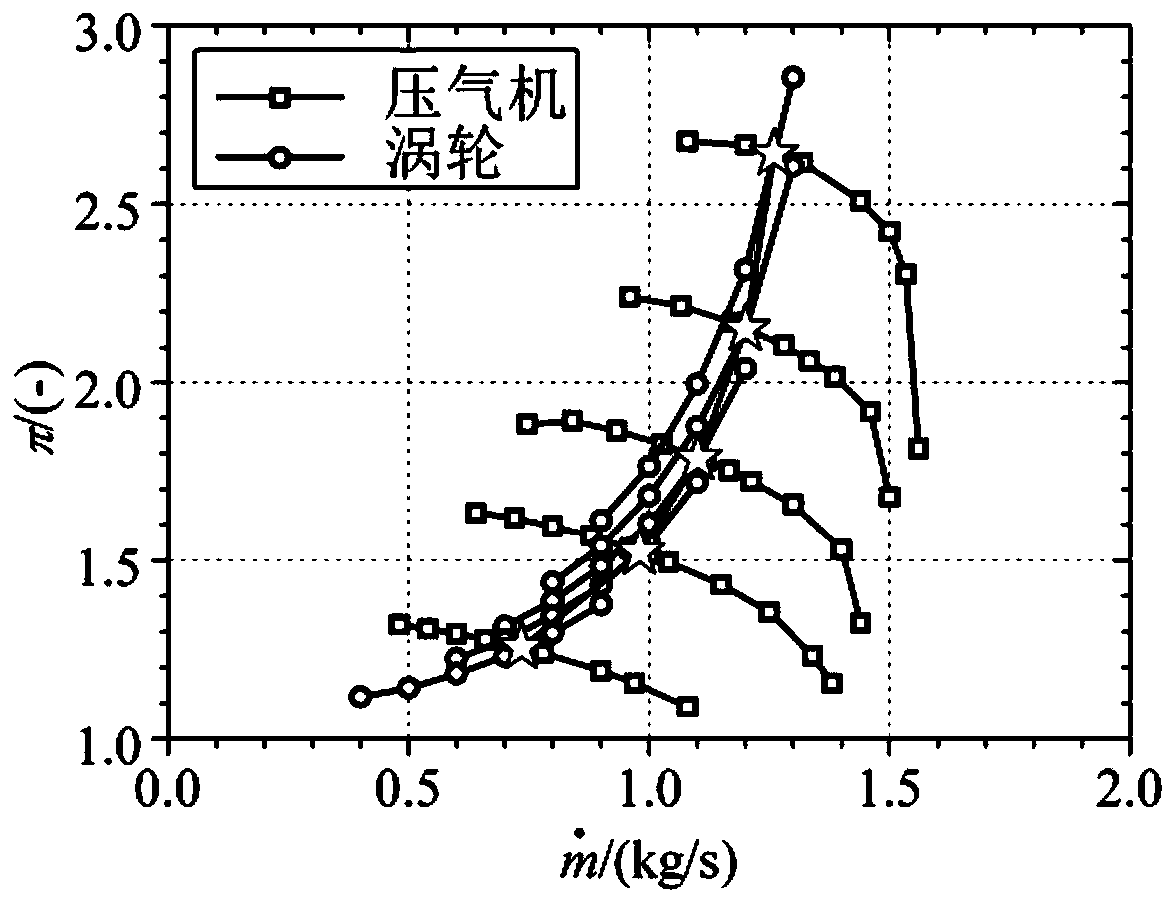

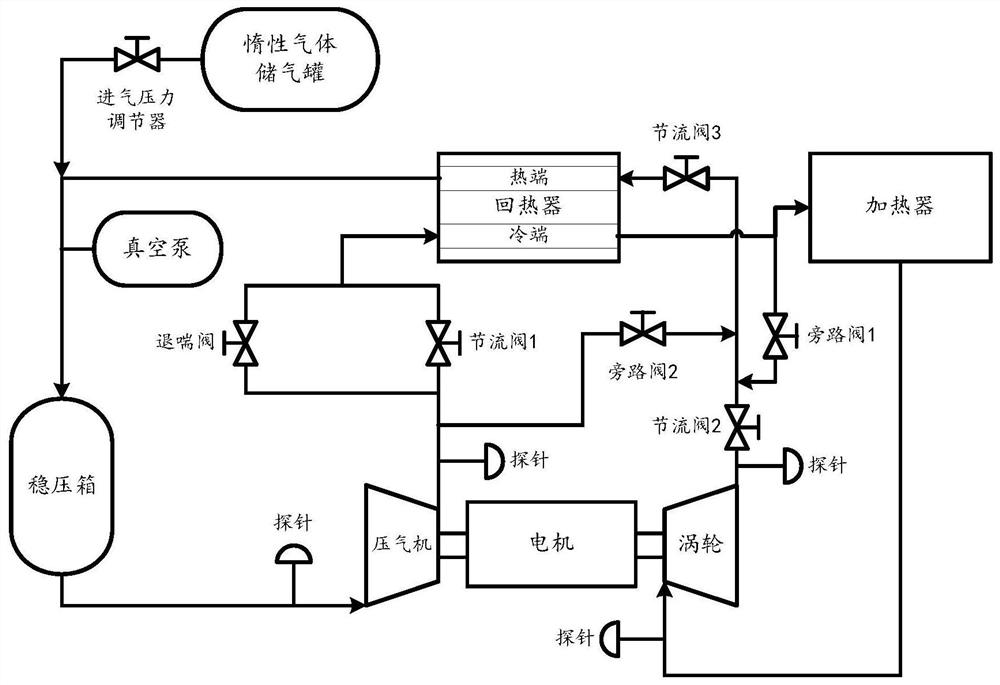

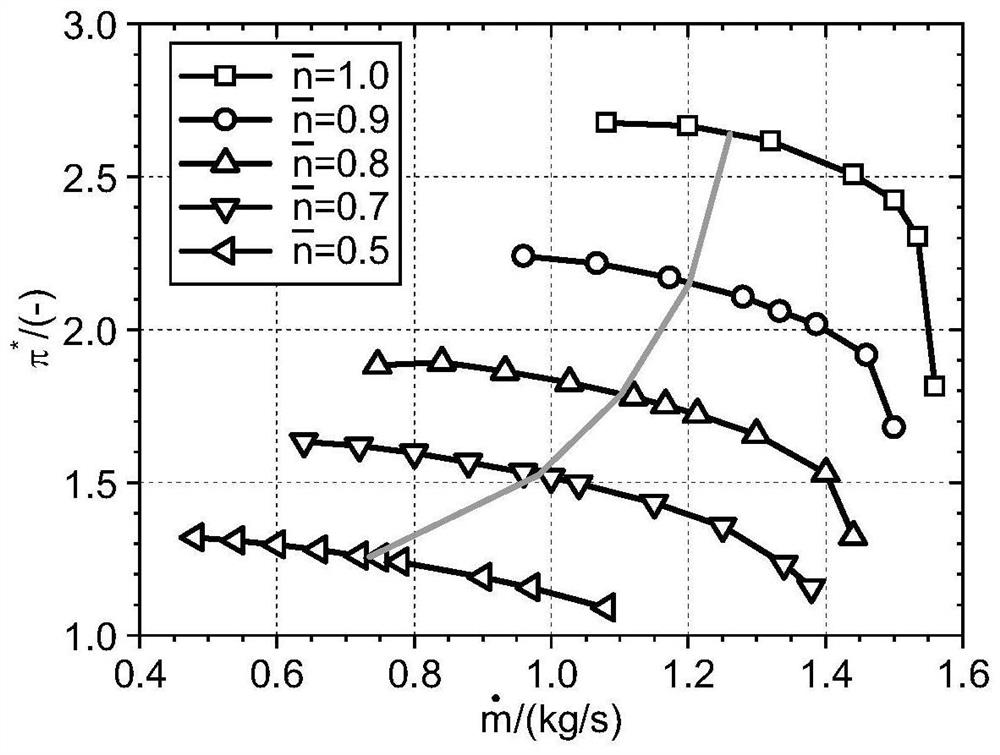

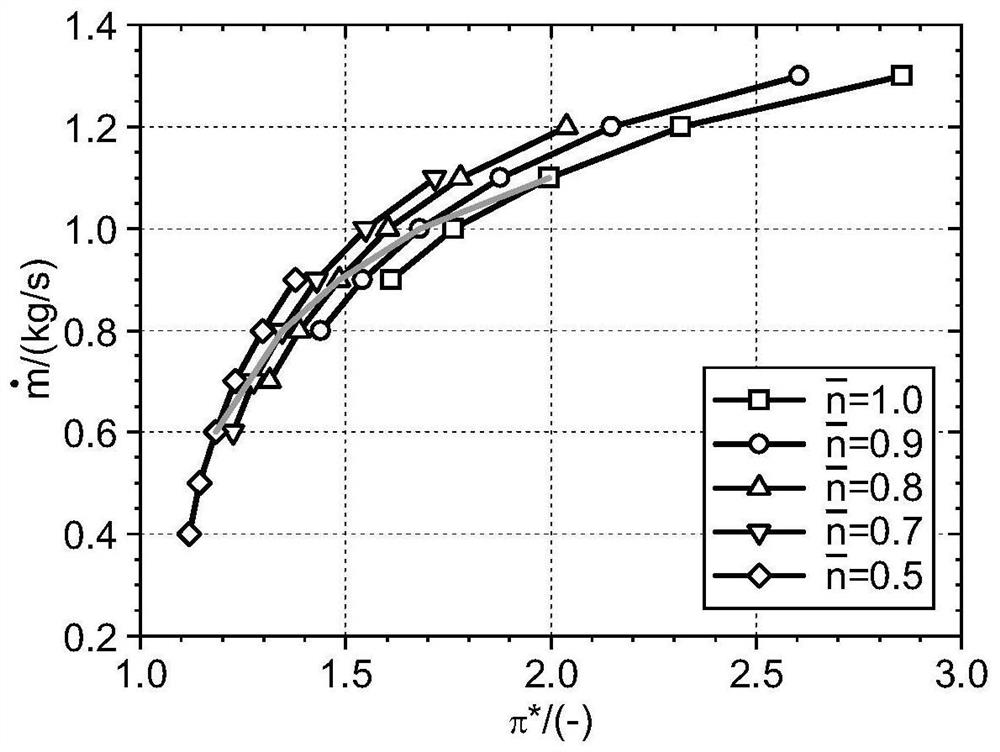

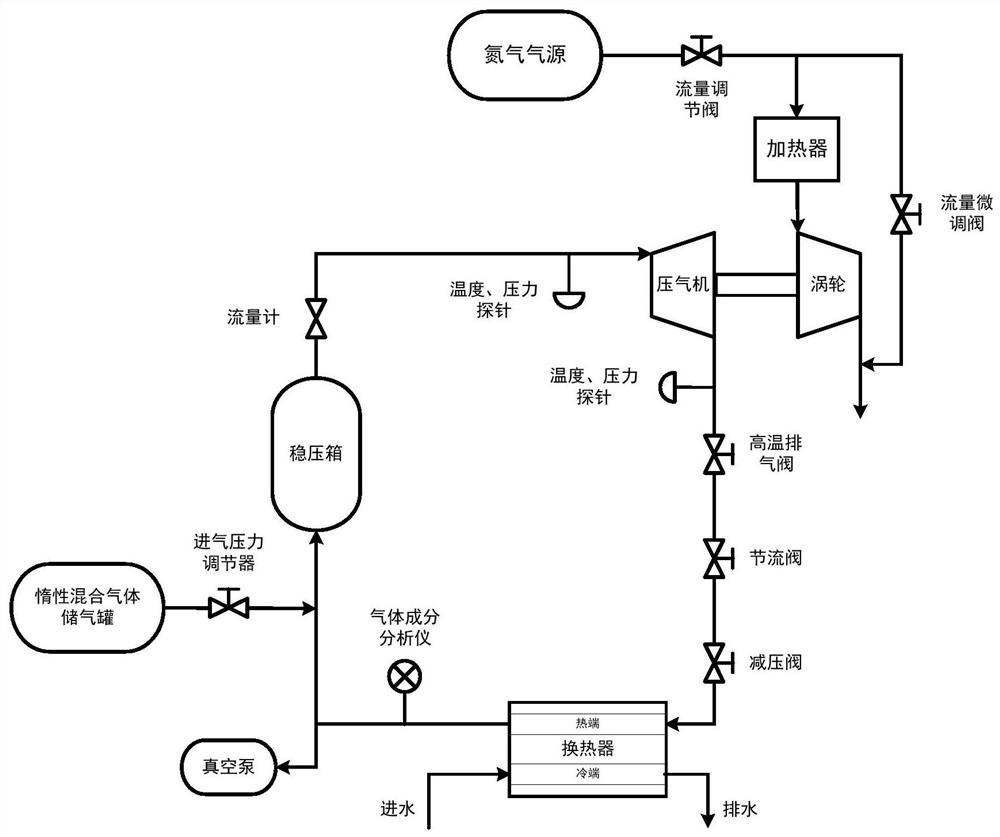

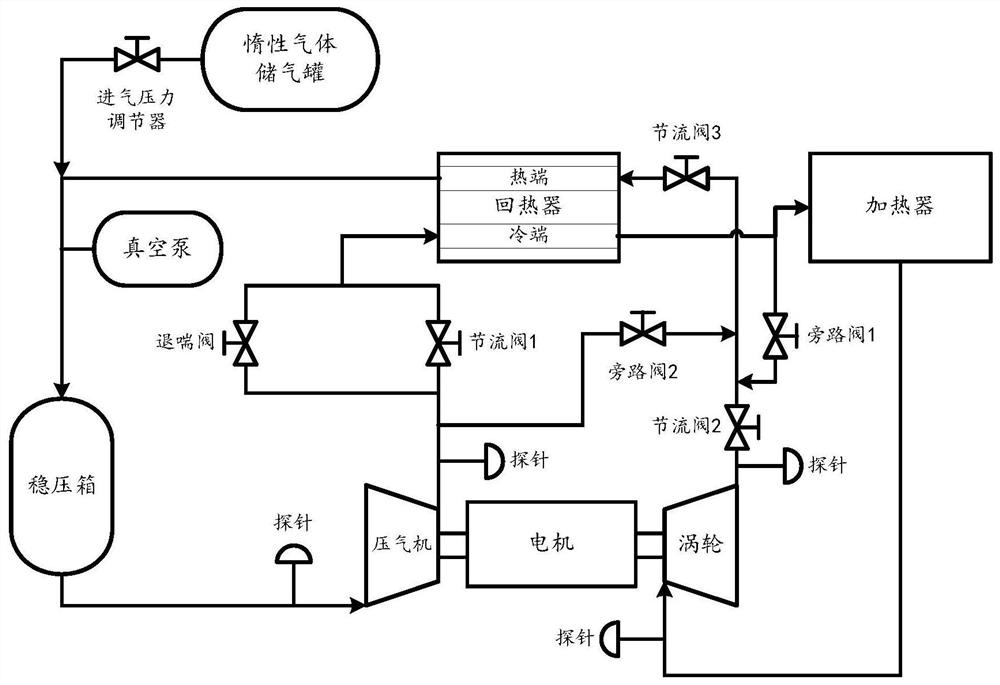

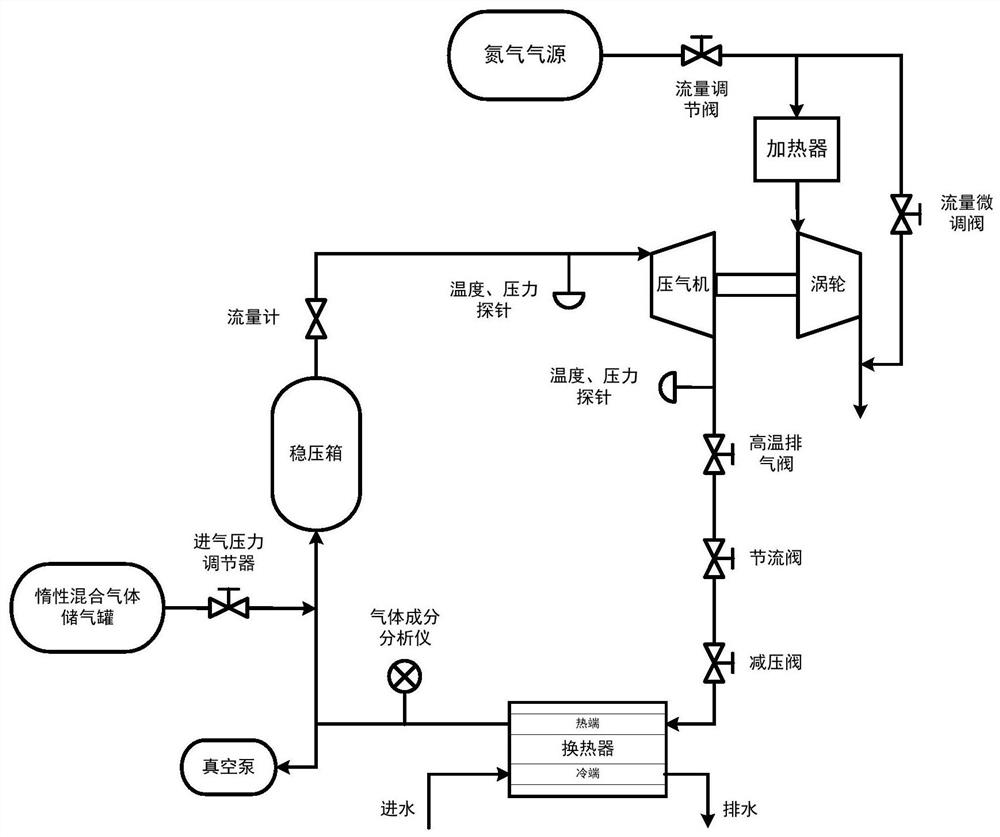

Closed circulation centrifugal compressor characteristic test device

ActiveCN111379728AAchieve recyclingSave energyPump controlNon-positive displacement fluid enginesExhaust valveEngineering

The invention discloses a closed circulation centrifugal compressor characteristic test device. The device comprises an inert mixed gas storage tank, a gas inlet pressure regulator, a pressure stabilizing tank, a flow meter, an intake and exhaust temperature and pressure probe, a compressor tester, a high-temperature exhaust valve, a throttle valve, a pressure reducing valve, a cooling water and water inlet and drainage device, a heat exchanger, a gas composition analyzer and a vacuum pump which are sequentially connected to form a closed circulation loop, inert mixed gas is used as a workingmedium, a low pressure air source, a flow regulating valve, a flow fine adjusting valve, a heater and a centripetal turbine are connected to form an open circulation loop, and air is used as a working medium. The device has the obvious characteristics of simple and reasonable structural design, resource conservation and the like, and is easy for large-scale popularization and application.

Owner:BEIJING POWER MACHINERY INST

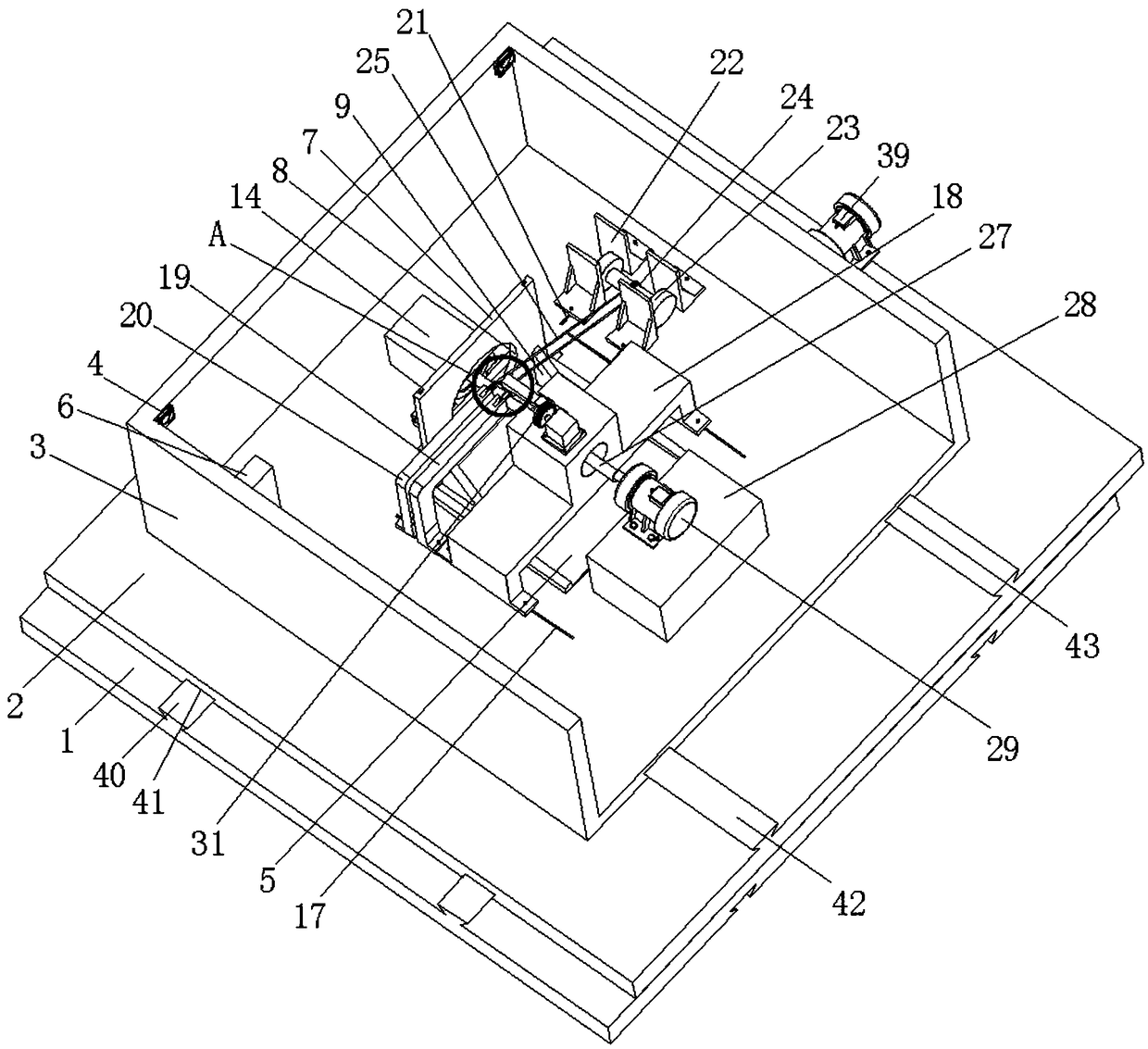

Loading device for reliability test of servo motor and using method of loading device

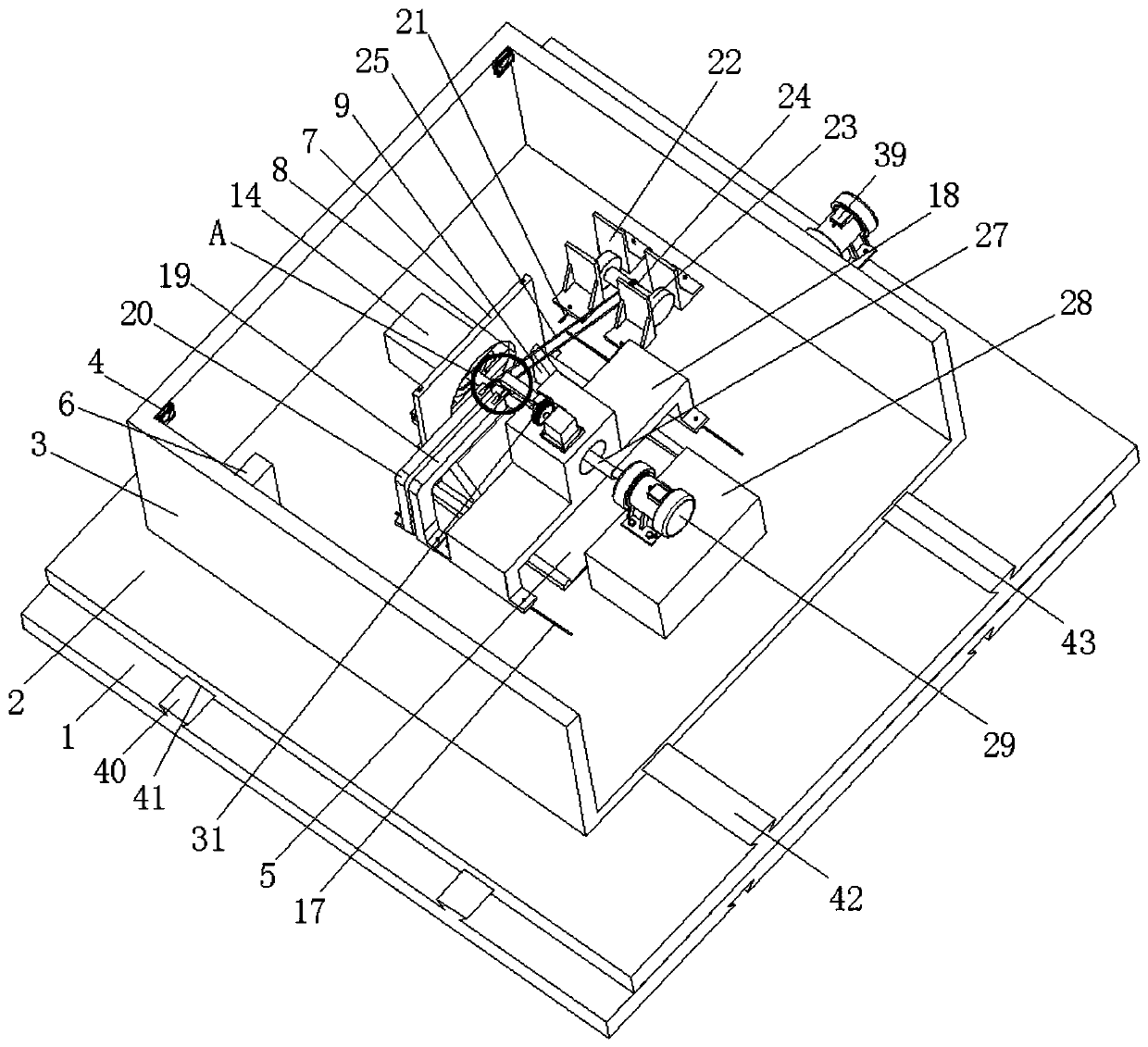

ActiveCN108983091AImprove performanceReduce the cost of performance testingDynamo-electric machine testingCouplingWorking environment

The invention discloses a loading device for reliability test of a servo motor and a using method of the loading device. The loading device comprises a lower base plate, an upper base plate, a casing,a fan, a plate seat, a humidifier, a vertical plate, a large through hole, an insertion board, a first chute, a long slide block, a second chute, a short slide block, the servo motor, a first ring, asecond ring, a third chute, a direction-Y sliding platform, a first ring column, a second ring column, a fourth chute, a friction plate, a rotating shaft with a belt, a belt pulley, a belt, a coupling, a connecting shaft, an exciter pedestal, a first exciter, a small motor, a gear, a first shaft, a level rotating arm, a toothed bar, an installation plate, a second shaft, a pulley and a second exciter. The bearing condition and working environment of the servo motor in the practical processing process can be simulated vividly in the test process, object materials and processing cutters are notconsumed, the excellent performance of the servo motor is ensured, the servo motor performance test cost is reduced effectively, the damage mechanism of the servo motor is analyzed by test, and the using performance of the servo motor can be improved.

Owner:NORTHEASTERN UNIV

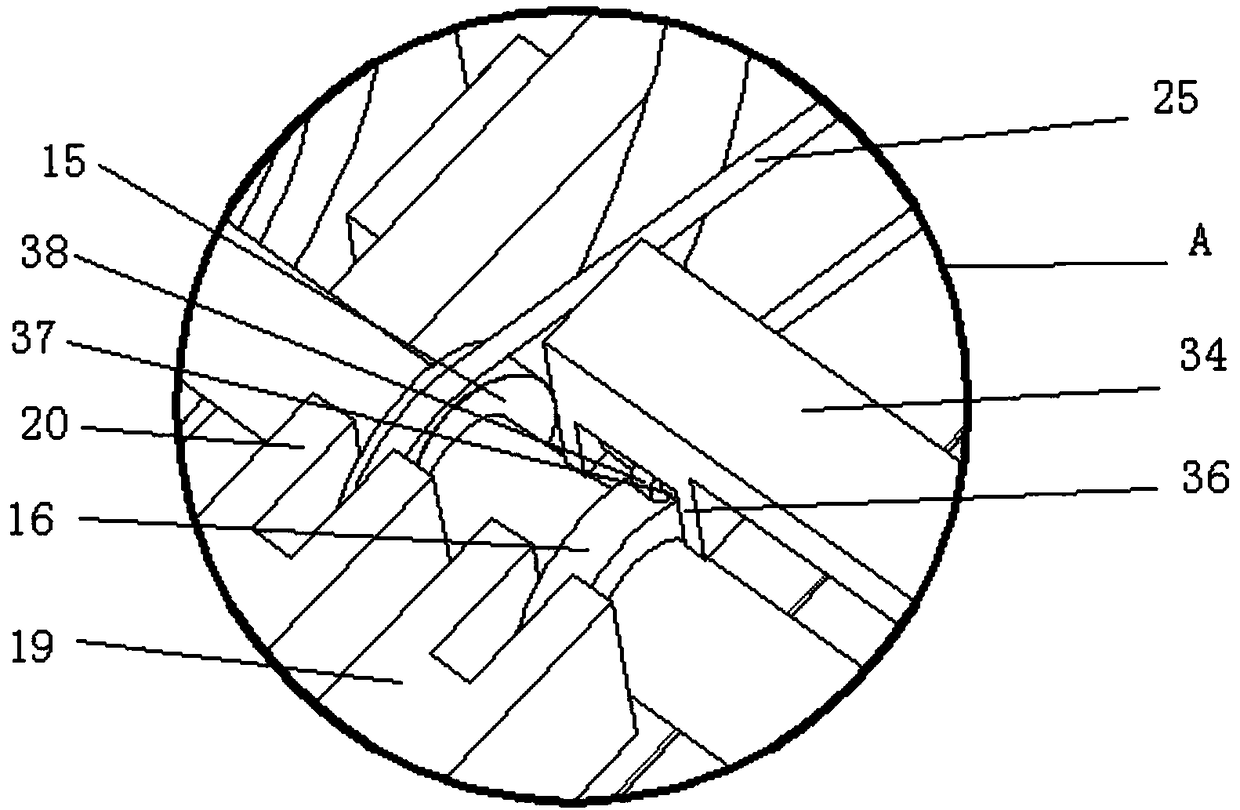

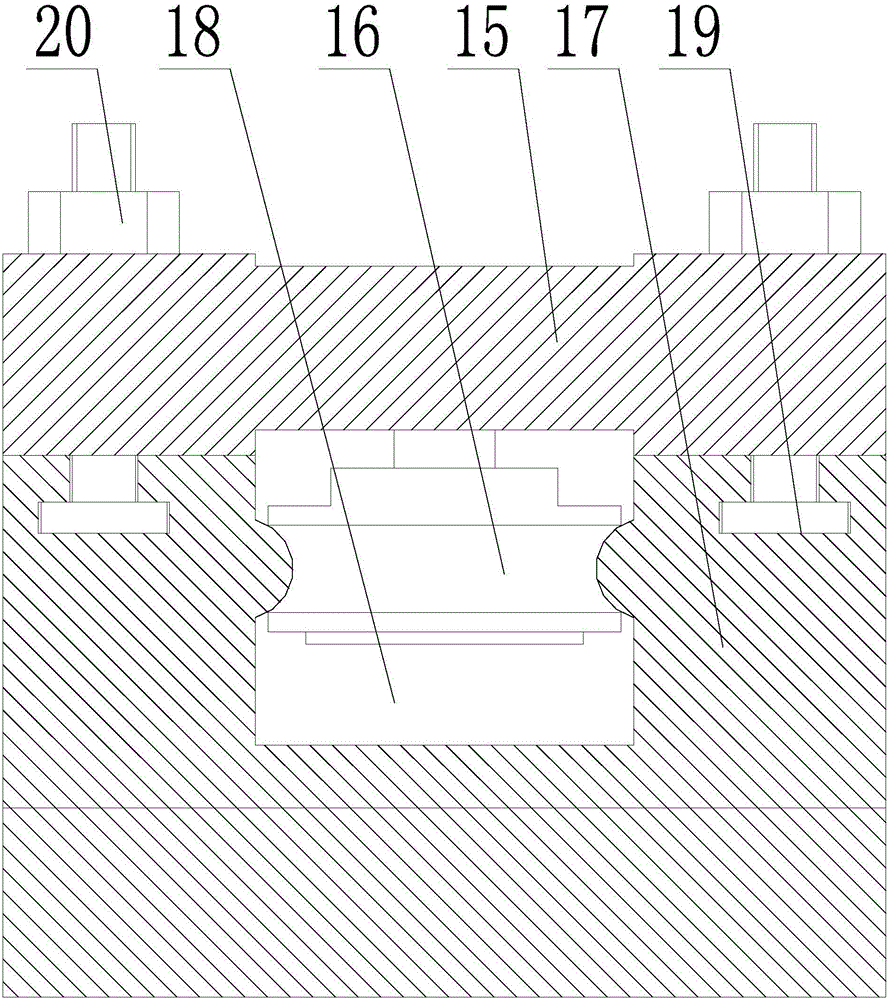

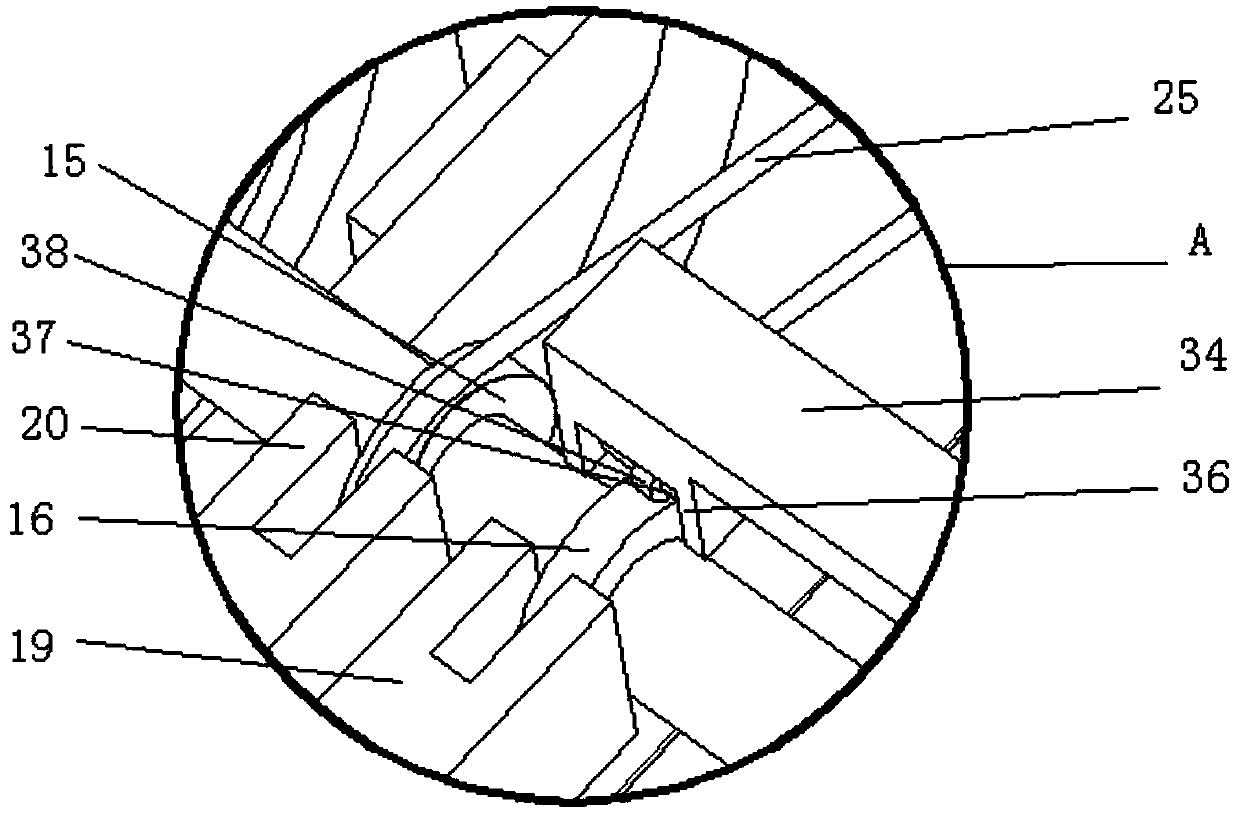

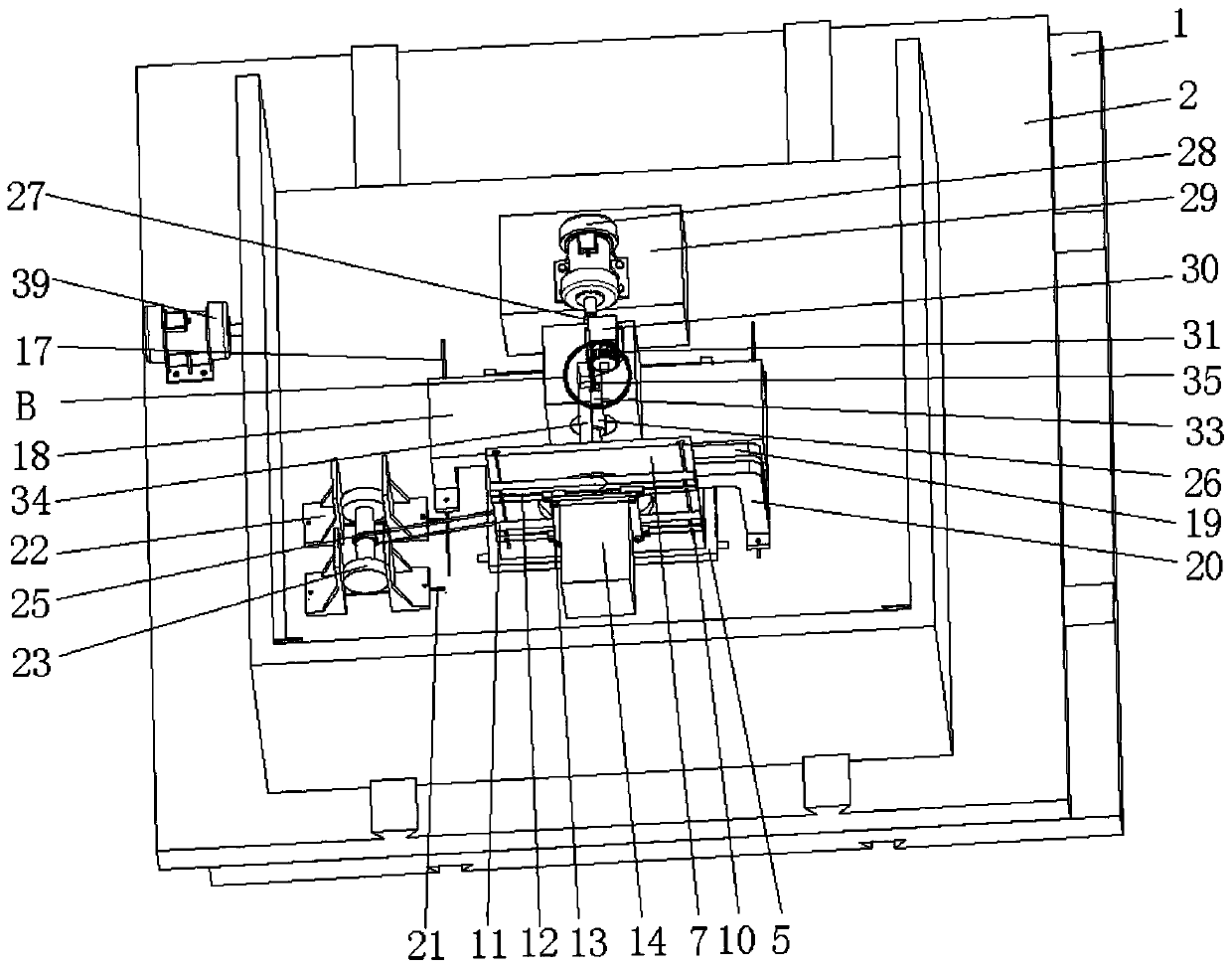

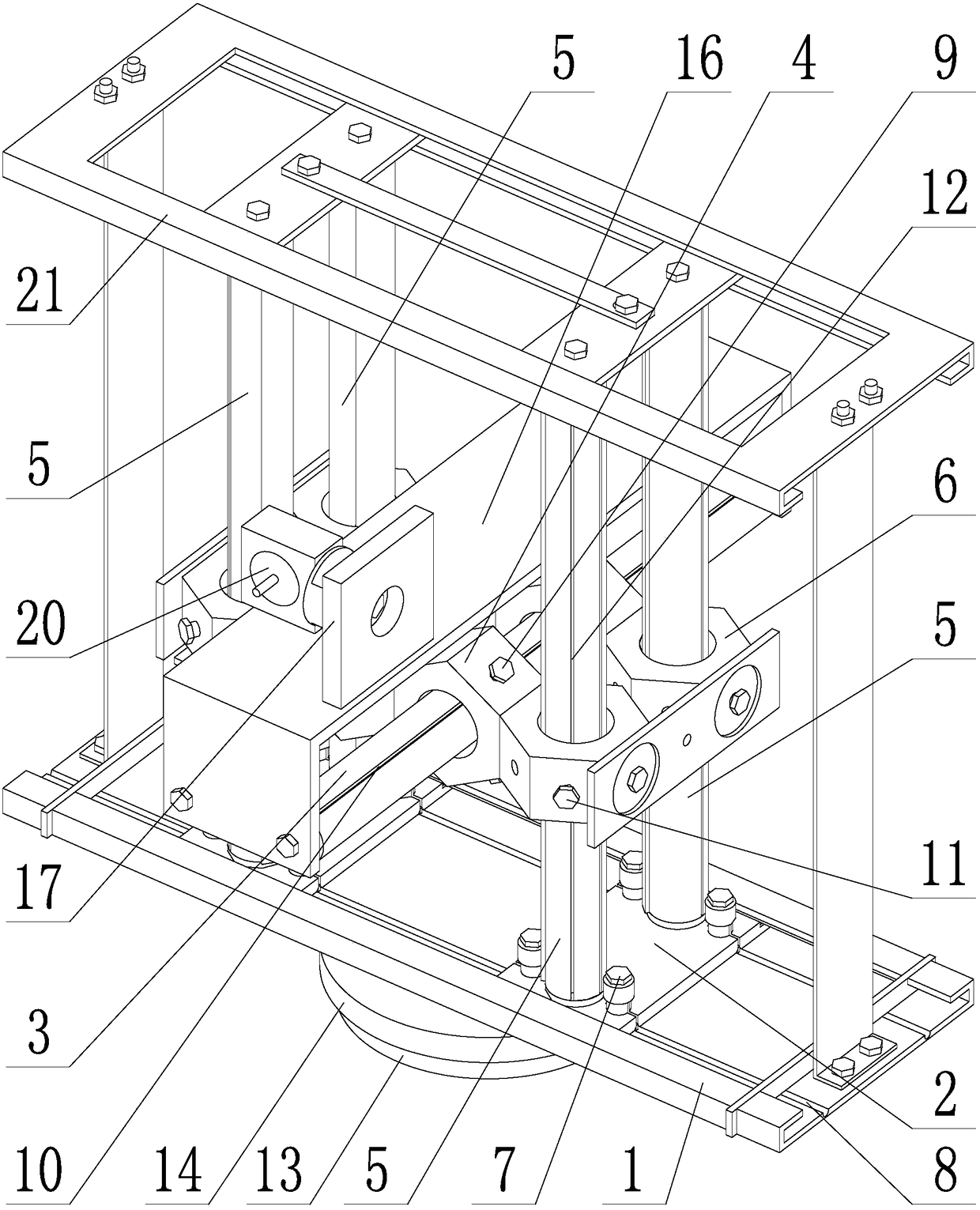

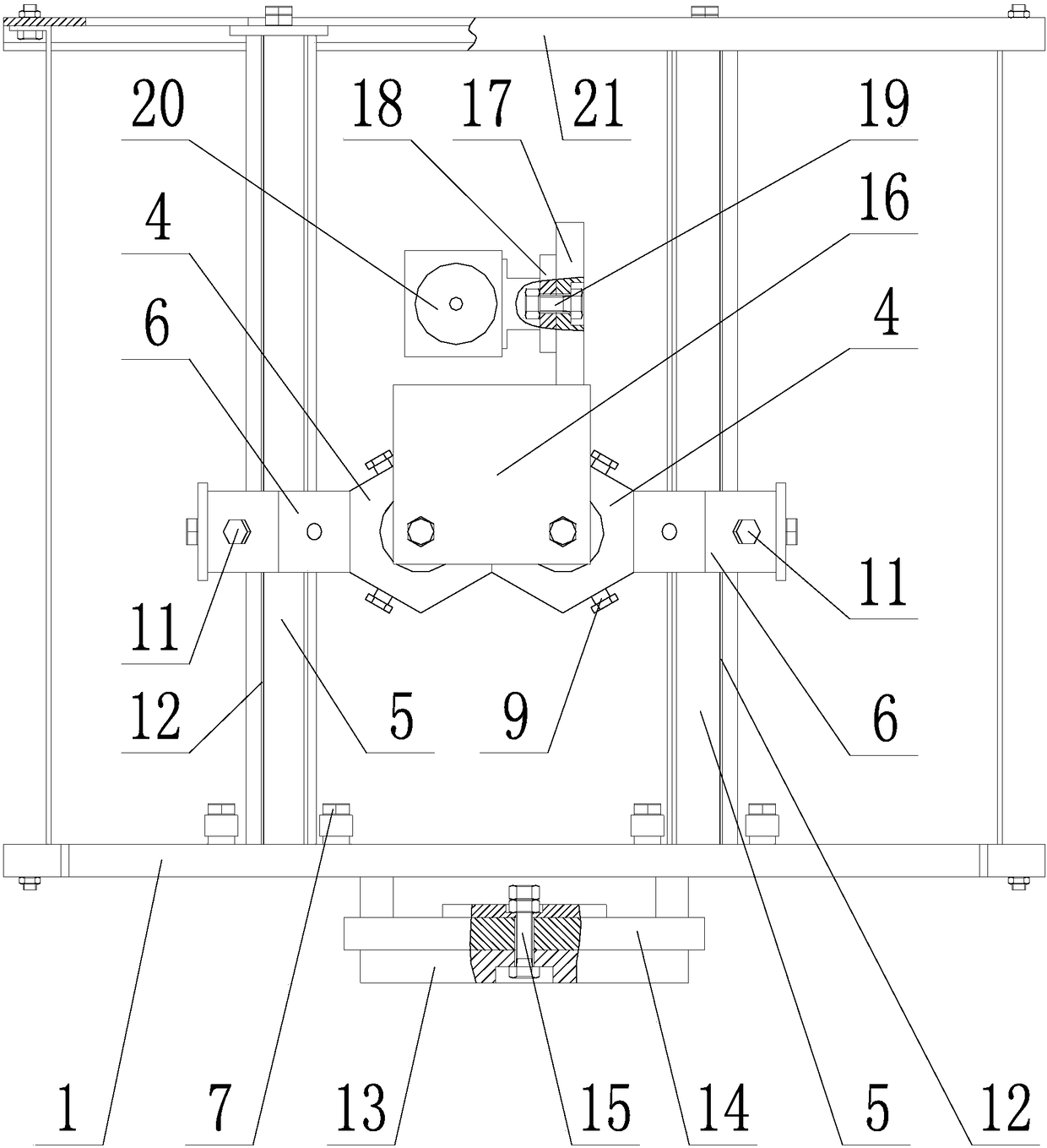

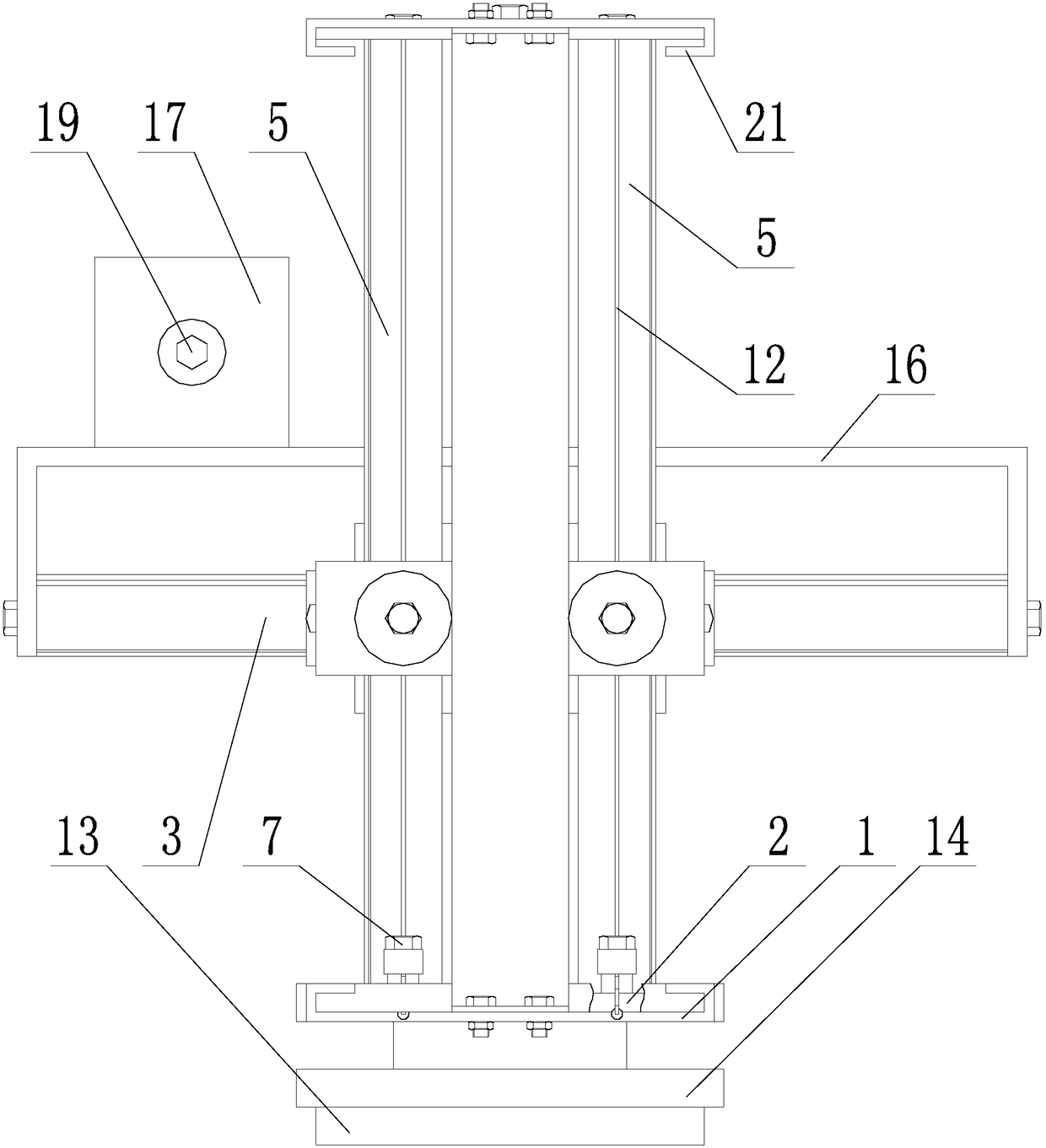

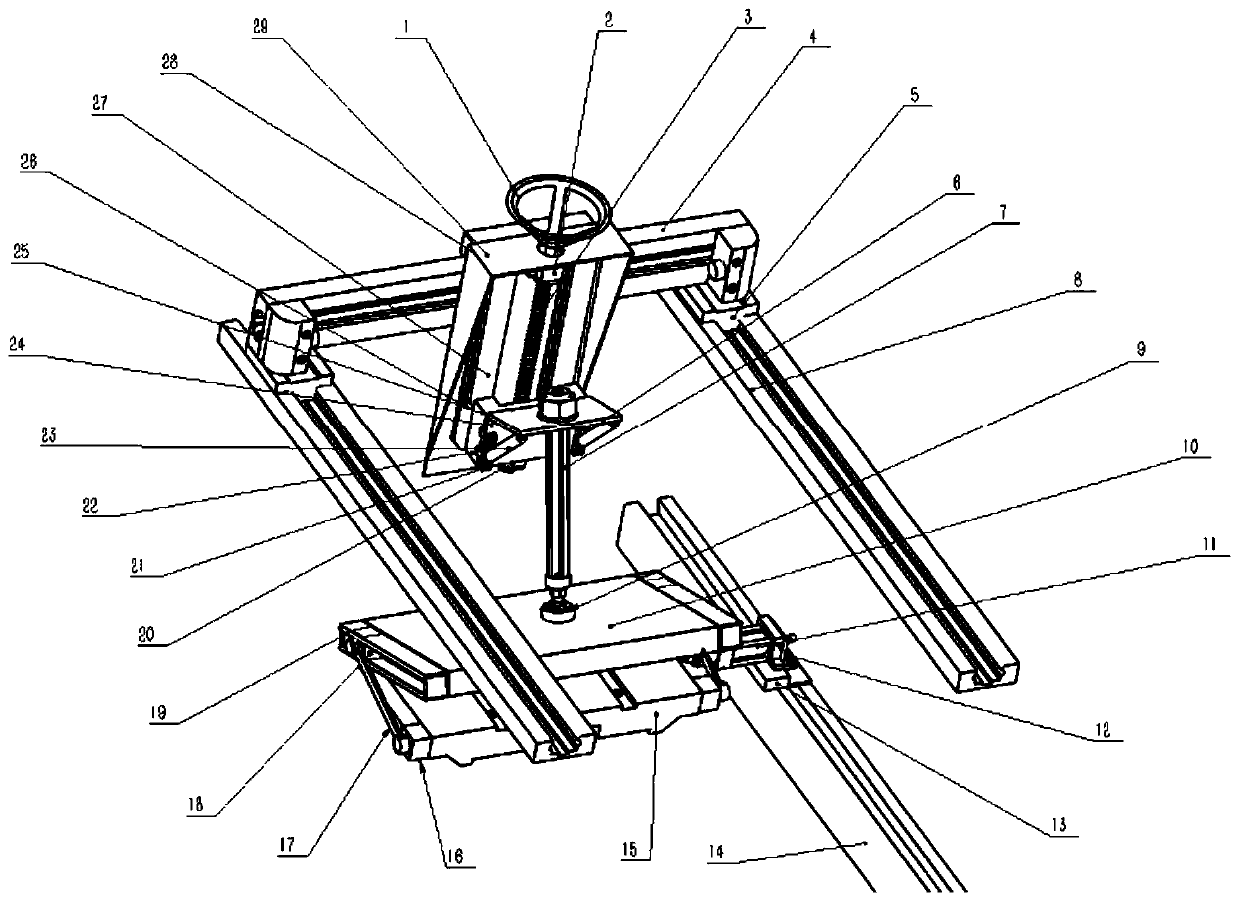

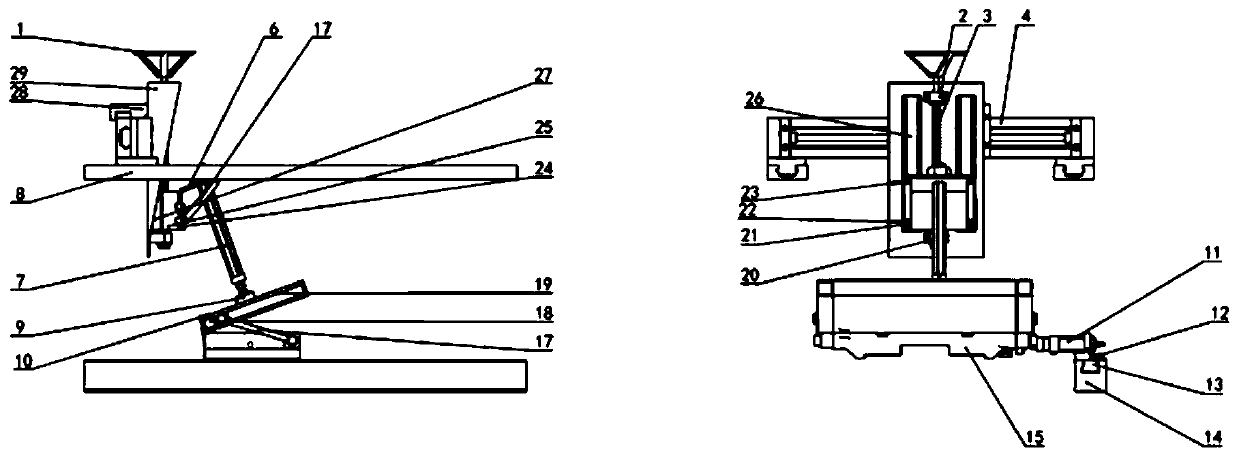

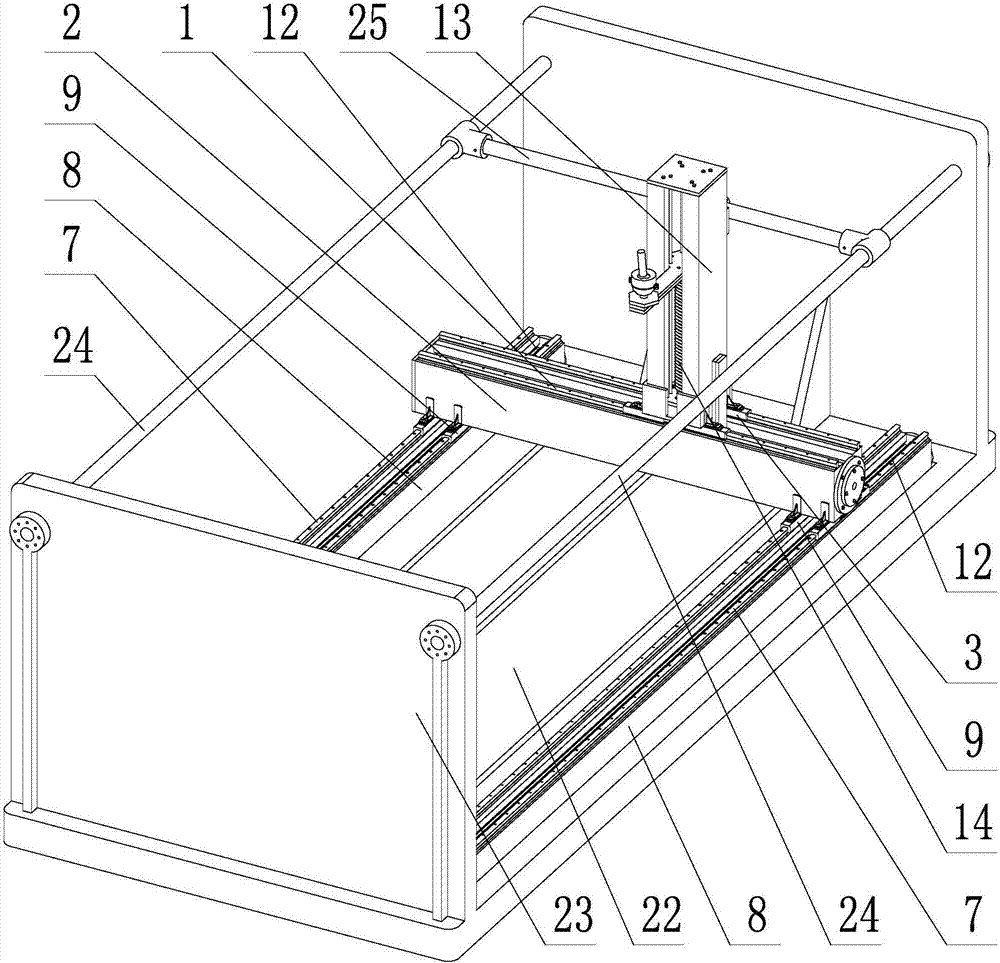

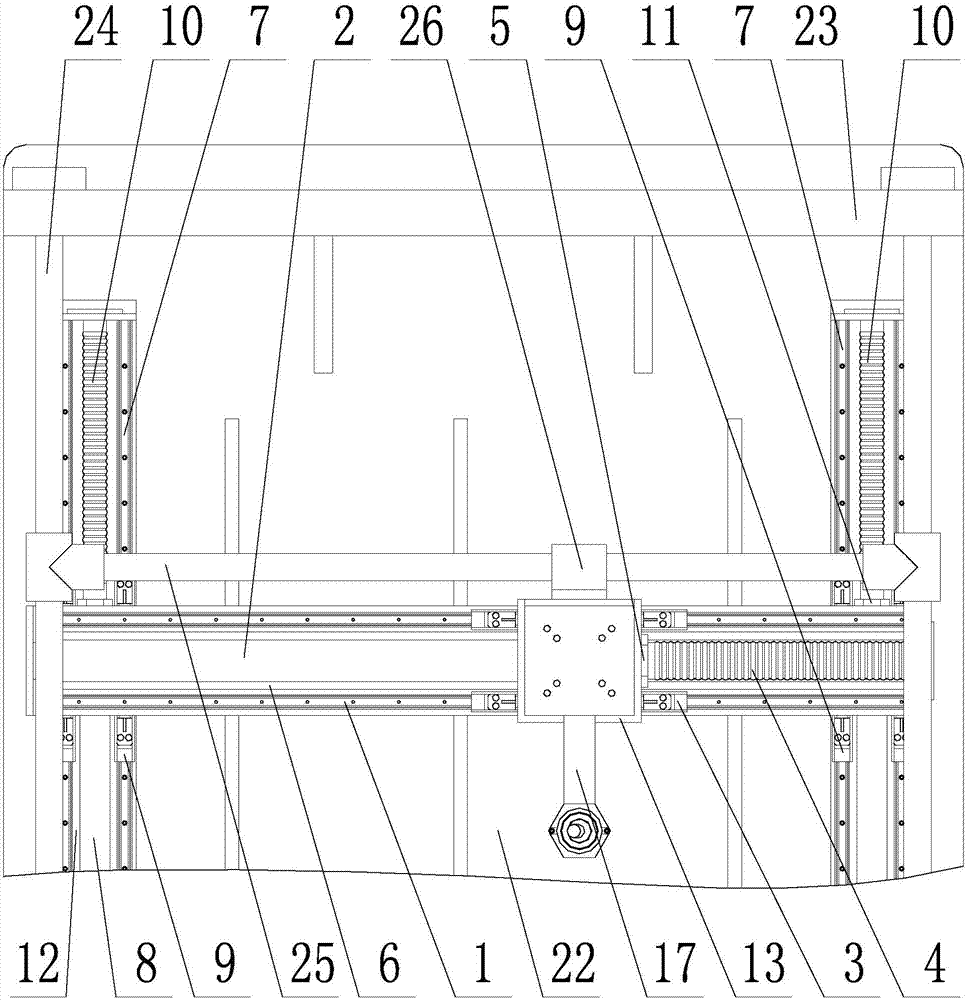

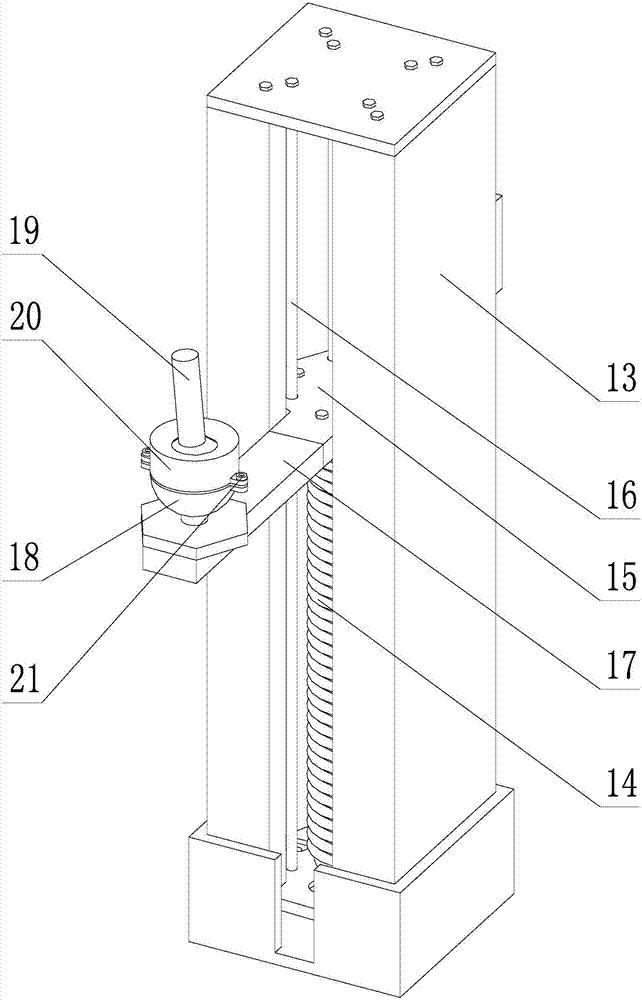

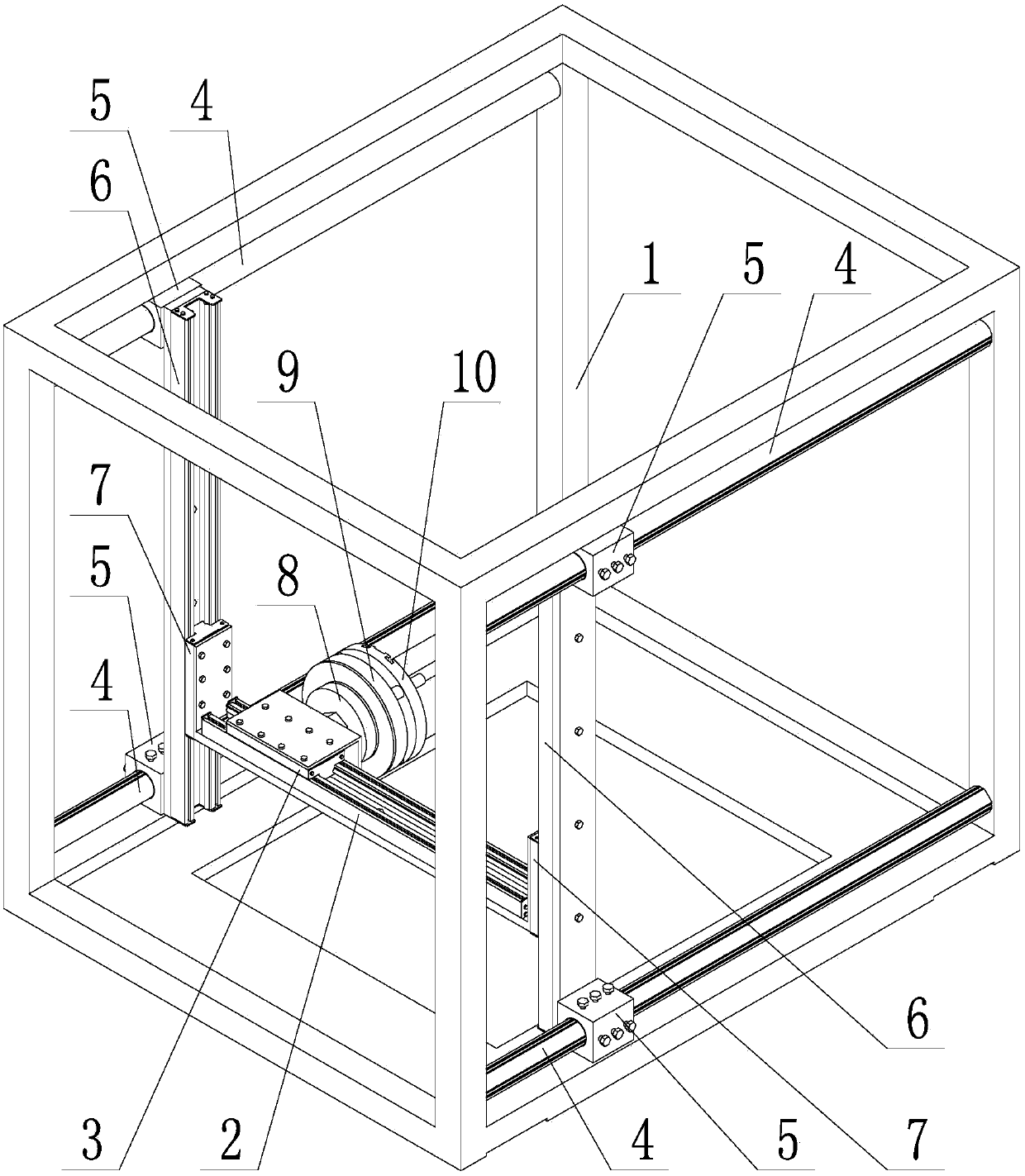

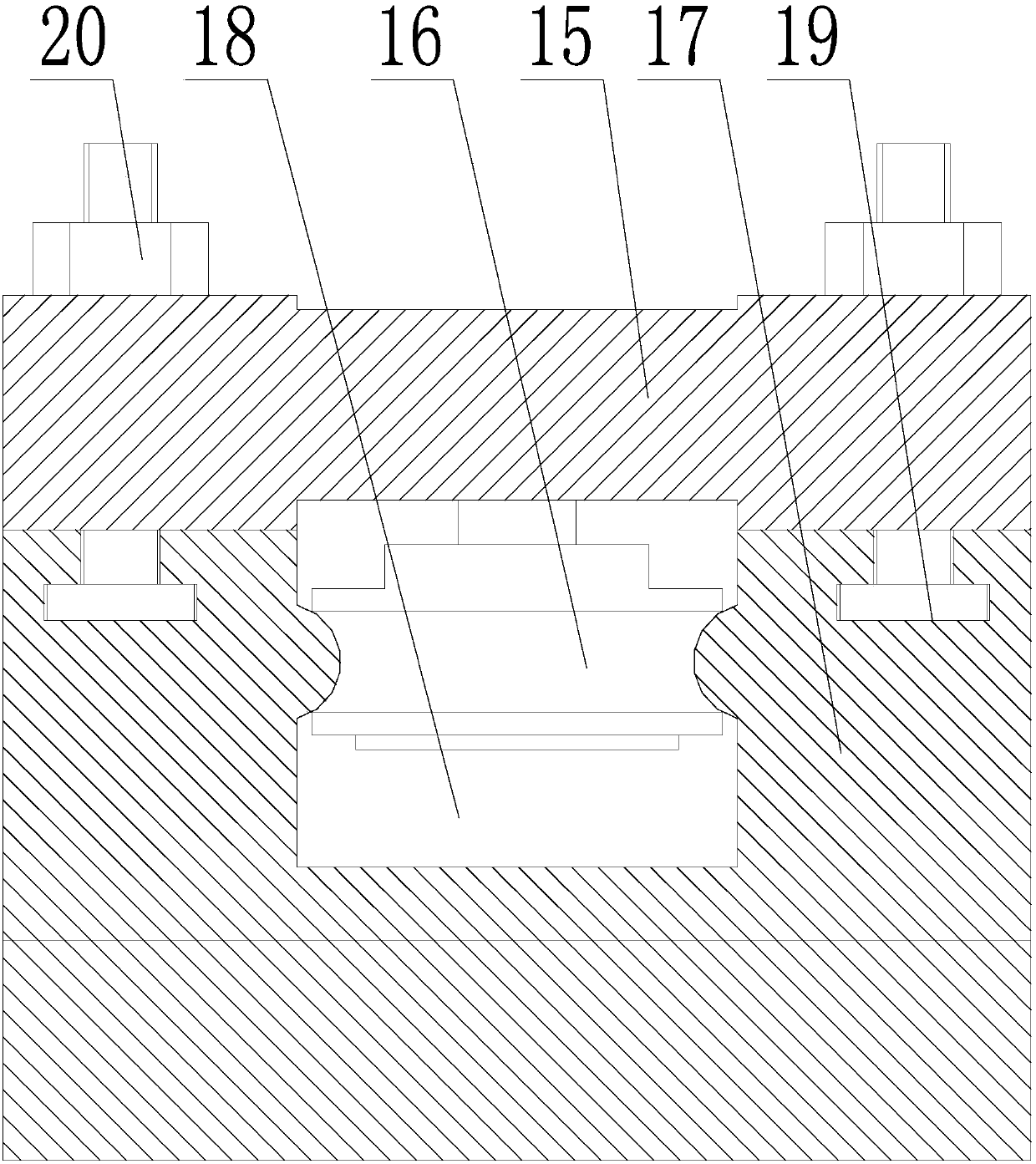

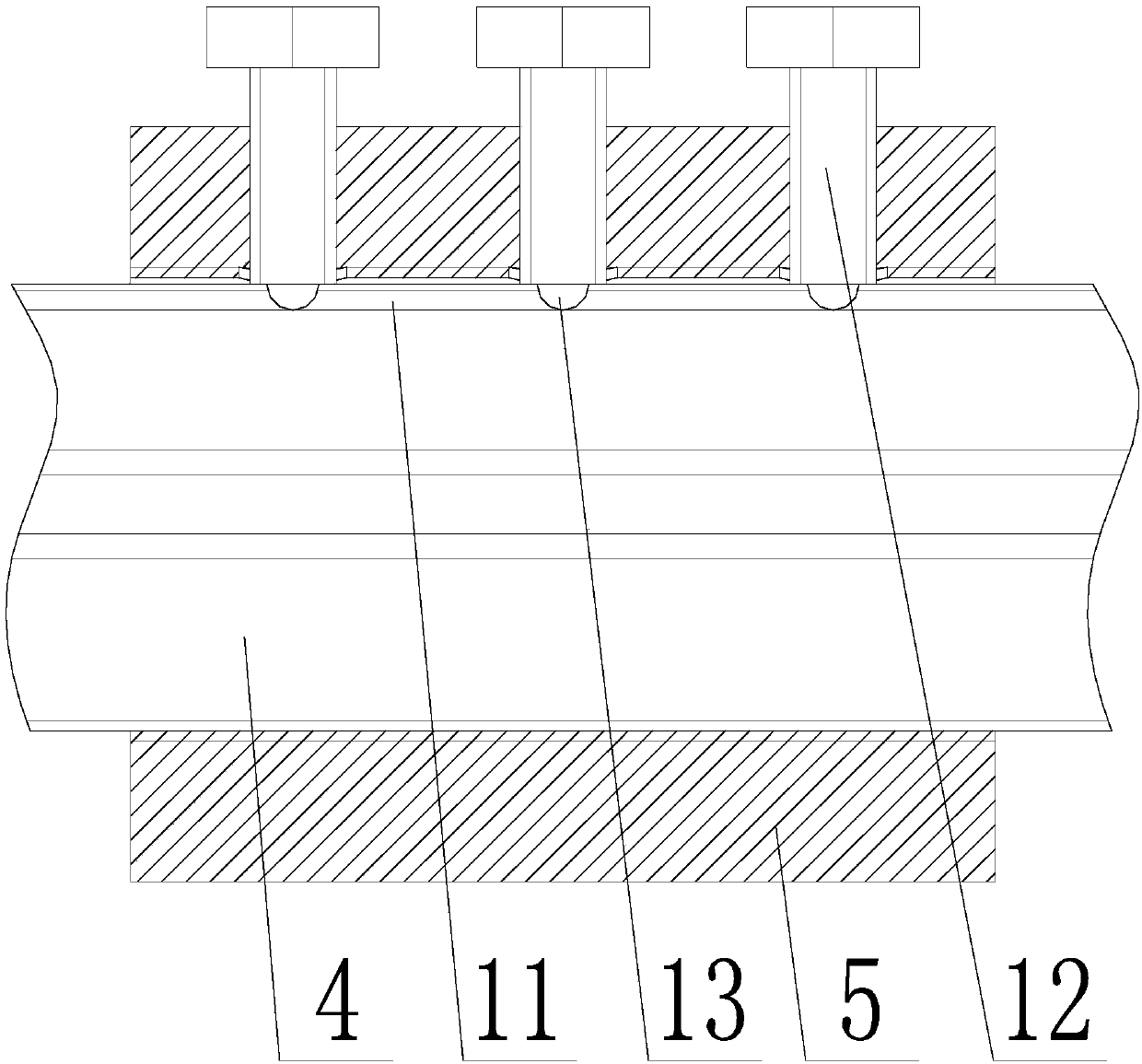

Simulated cutting force loading device for three-axis boring mill and use method

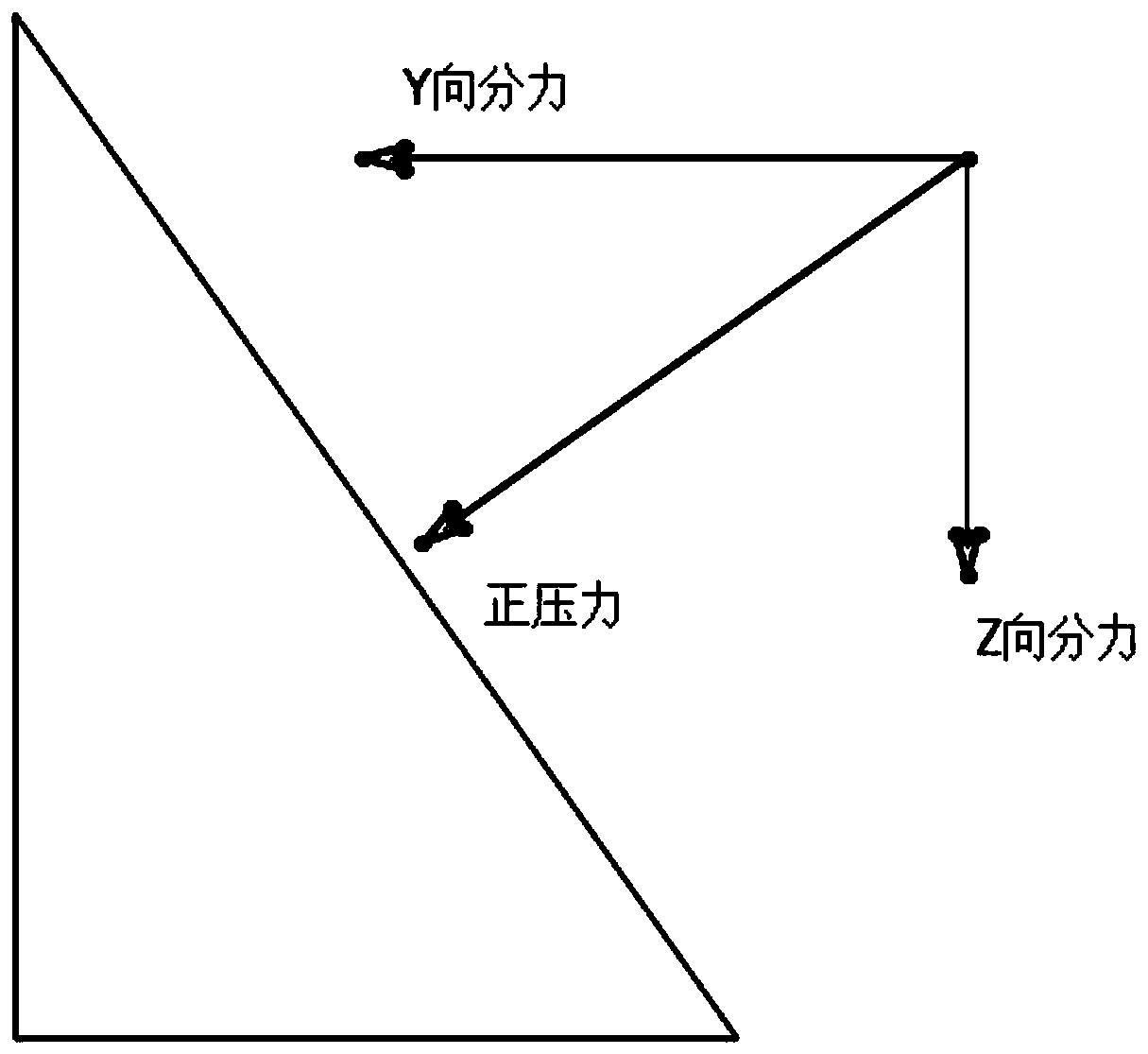

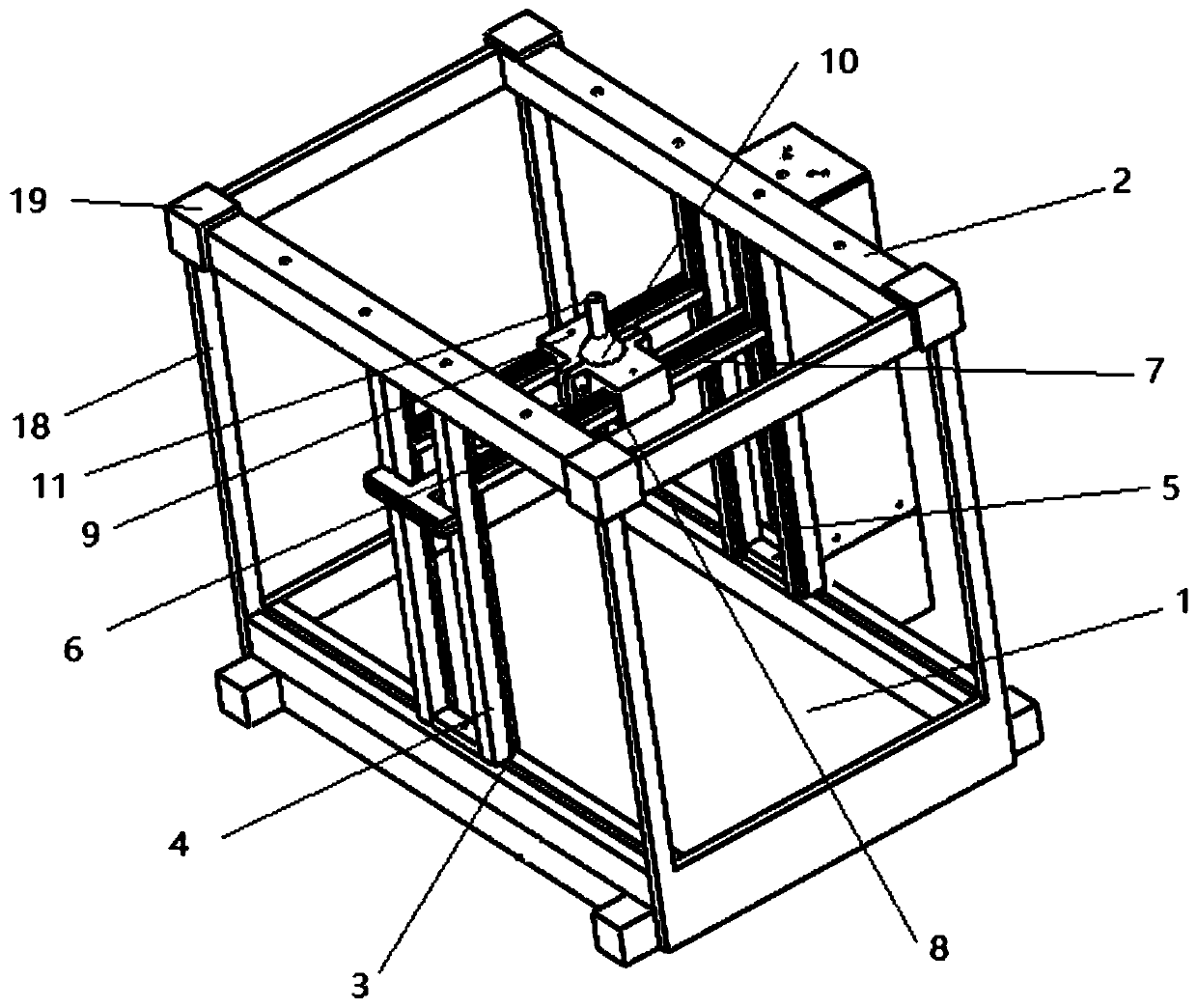

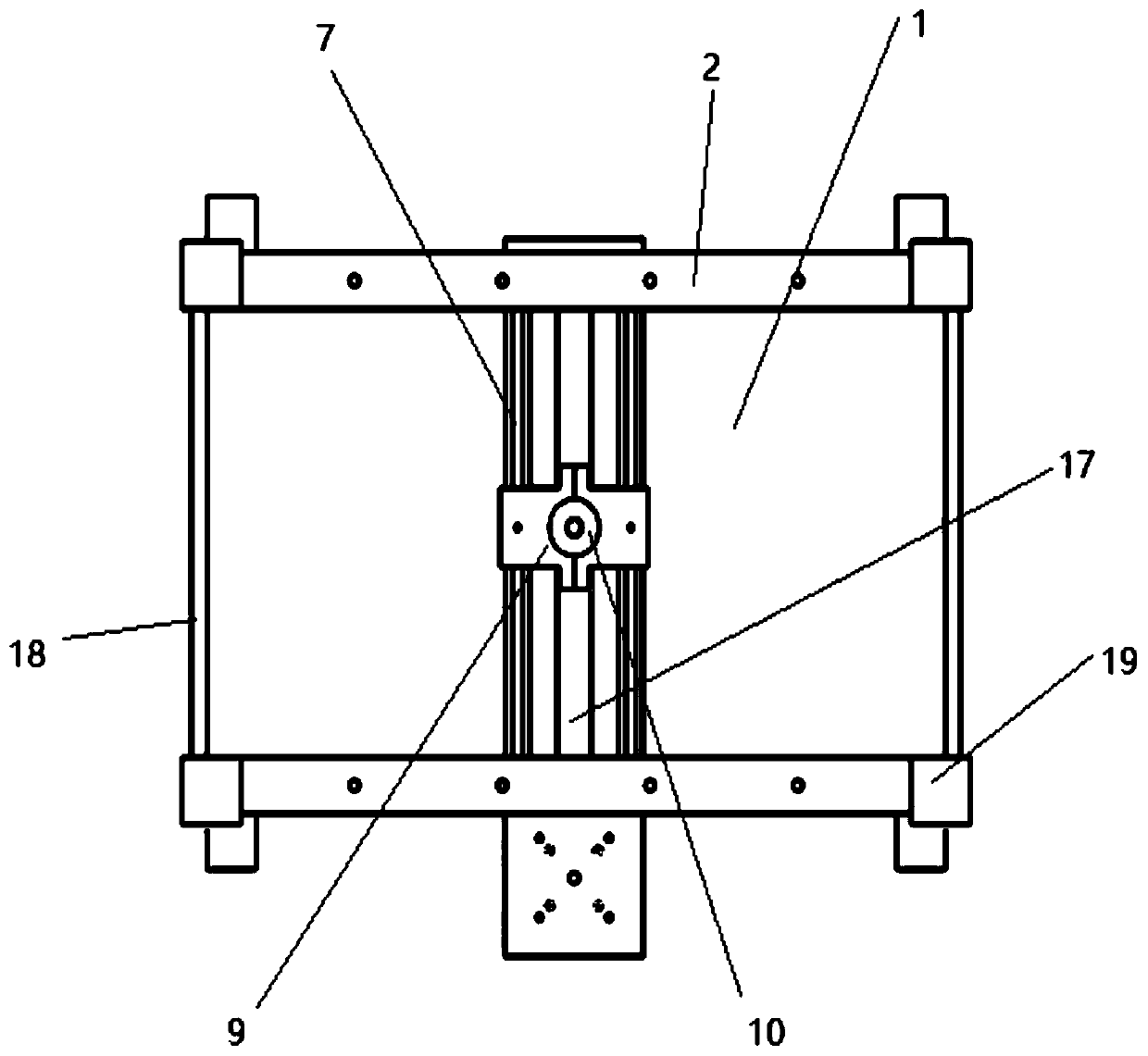

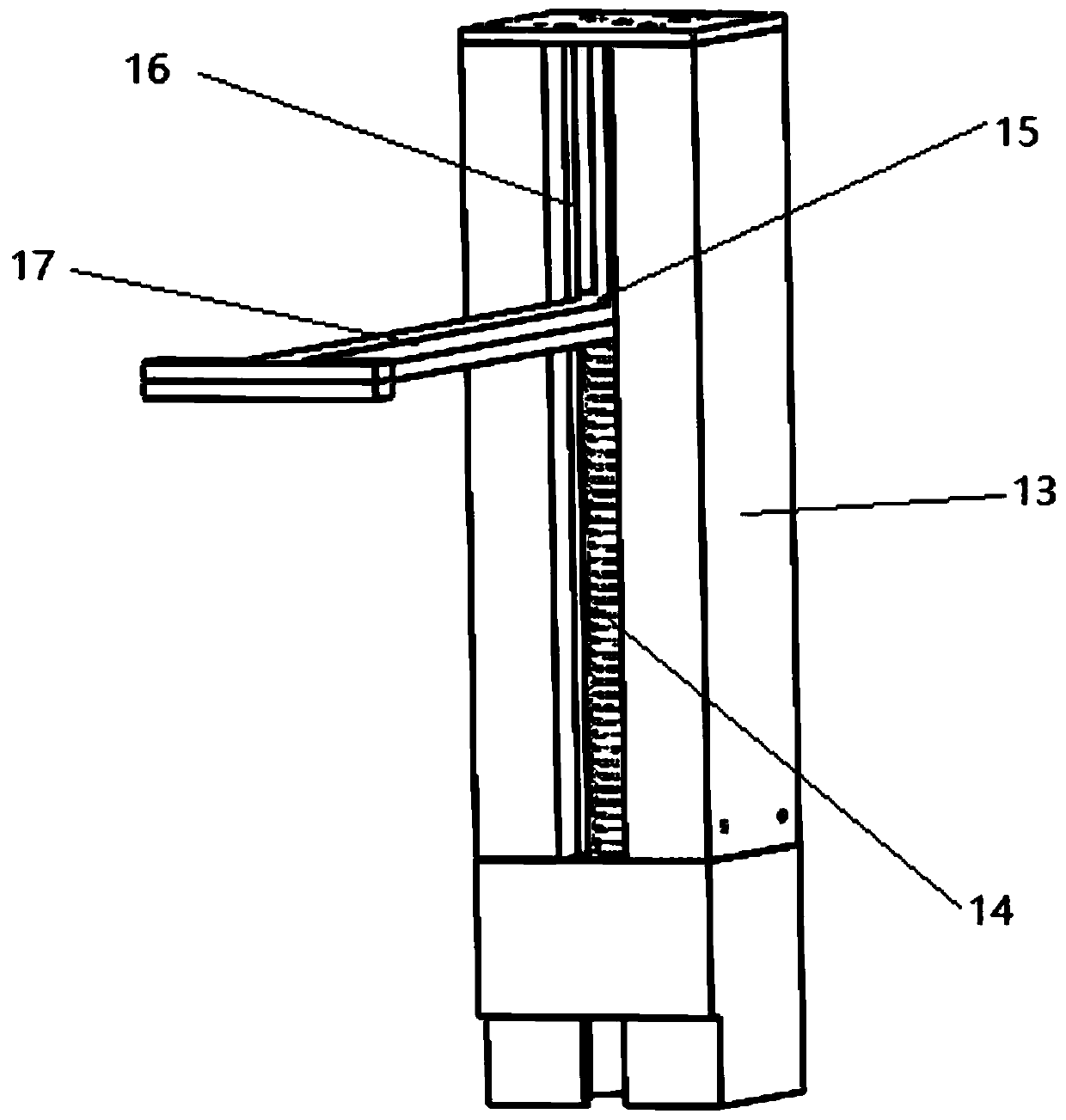

ActiveCN105865823AReduce the cost of performance testingMaintain good performanceStructural/machines measurementCutting forceMachine tool

The invention provides a simulated cutting force loading device for a three-axis boring mill and a use method. The device comprises a rigid framework, an X-direction position adjustment assembly, a Y-direction cutting force loading assembly, an X-direction position adjustment assembly and a cutter rotation-direction cutting force loading assembly. The method comprises steps as follows: the simulated cutting force loading device is hoisted on a bench of a machine tool, the position of a simulating facing head is adjusted through the X-direction position adjustment assembly and the Y-direction position adjustment assembly and fixed, and a boring bar on the simulating facing head and a boring bar on the facing head of the machine tool are fixedly connected; a group of cutting force is set, pretightening bolts in the Y-direction cutting force loading assembly and the cutter rotation-direction cutting force loading assembly are tightened through a torque wrench, so that friction force in the cutting force loading assemblies is equal to the set cutting force, and friction force needs to be read out after the tightening torque is calculated according to the formula M=KFd / mu due to the fact that the friction force cannot be directly read; the machine tool is started and runs machining programs, the actual operation state of the machine tool is simulated really under the force bearing condition, and the performance of the machine tool under the current cutting force condition is tested.

Owner:NORTHEASTERN UNIV LIAONING

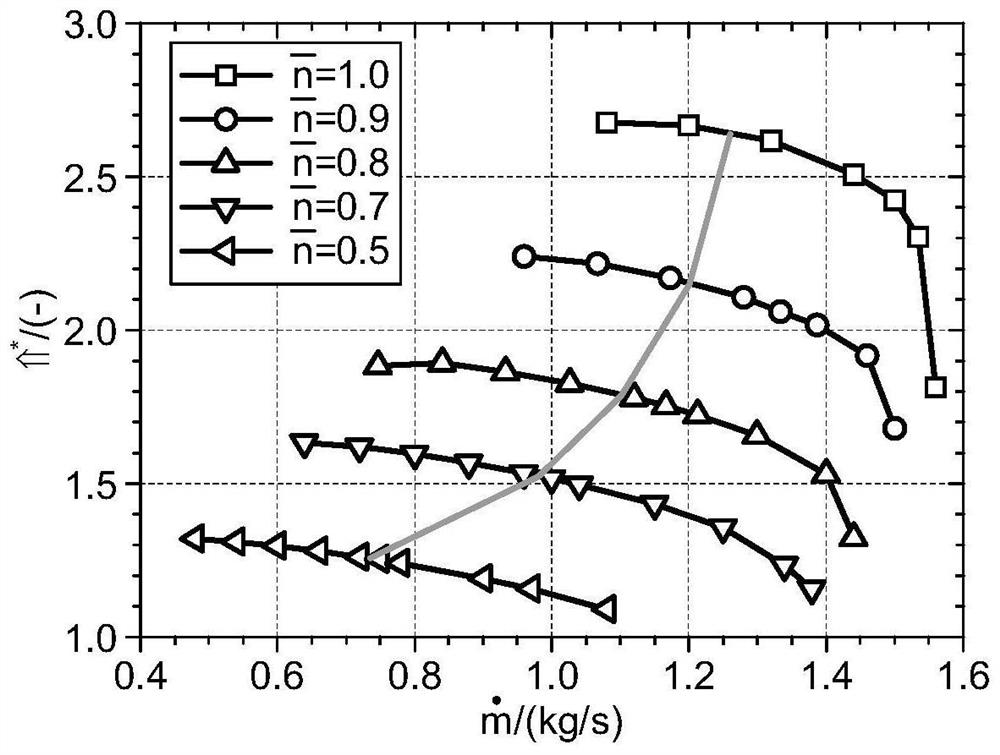

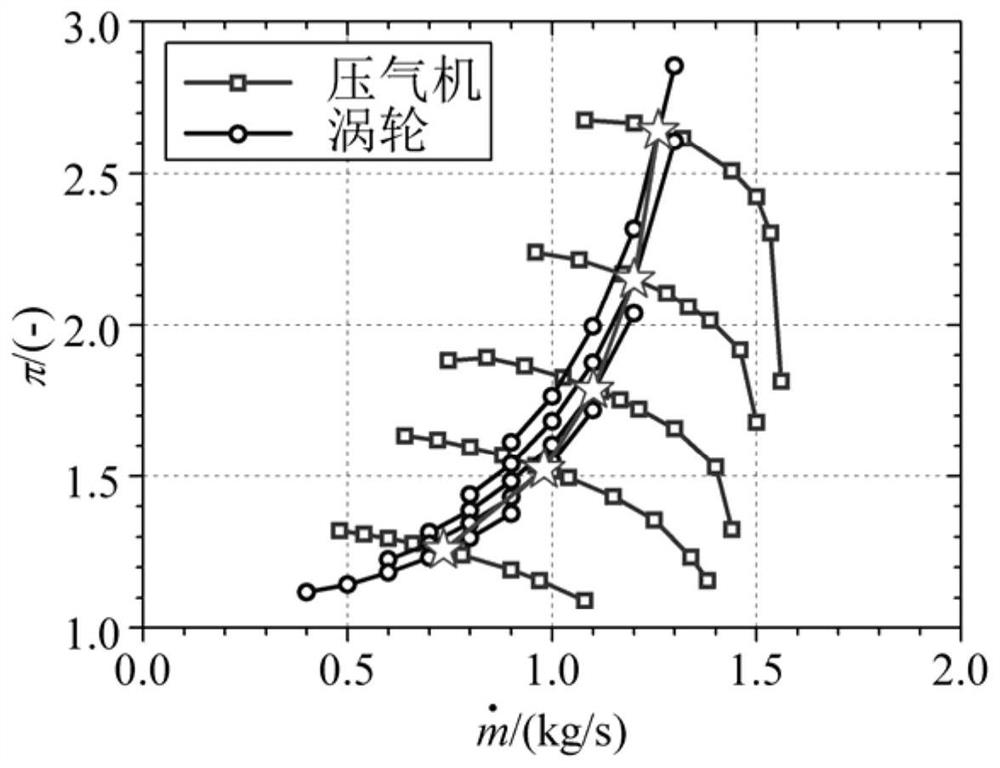

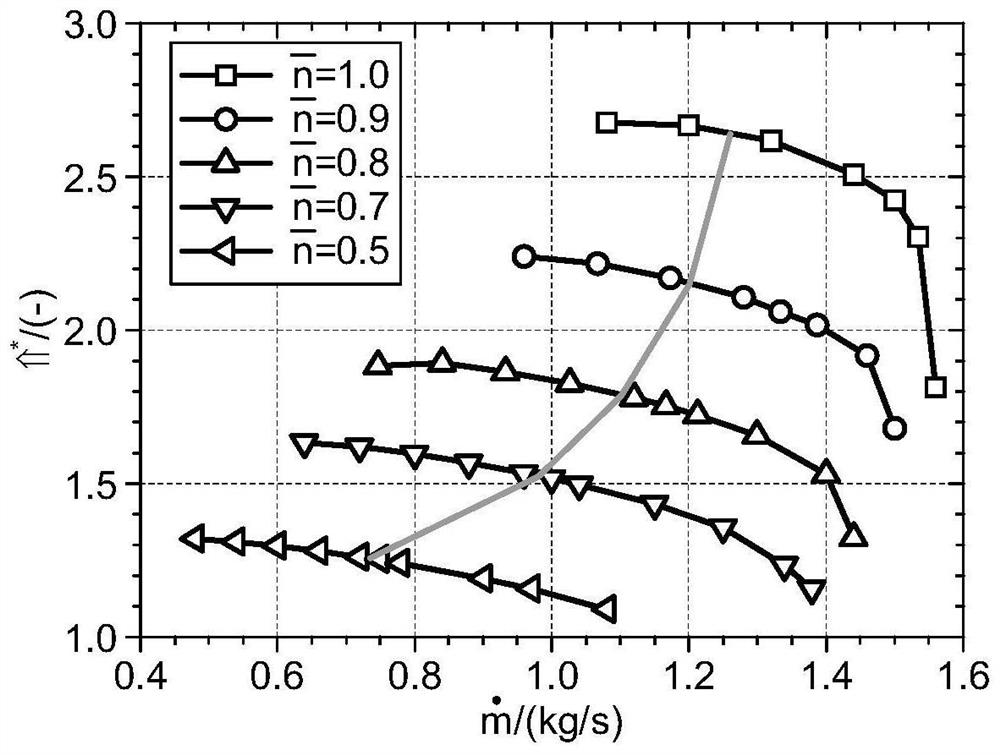

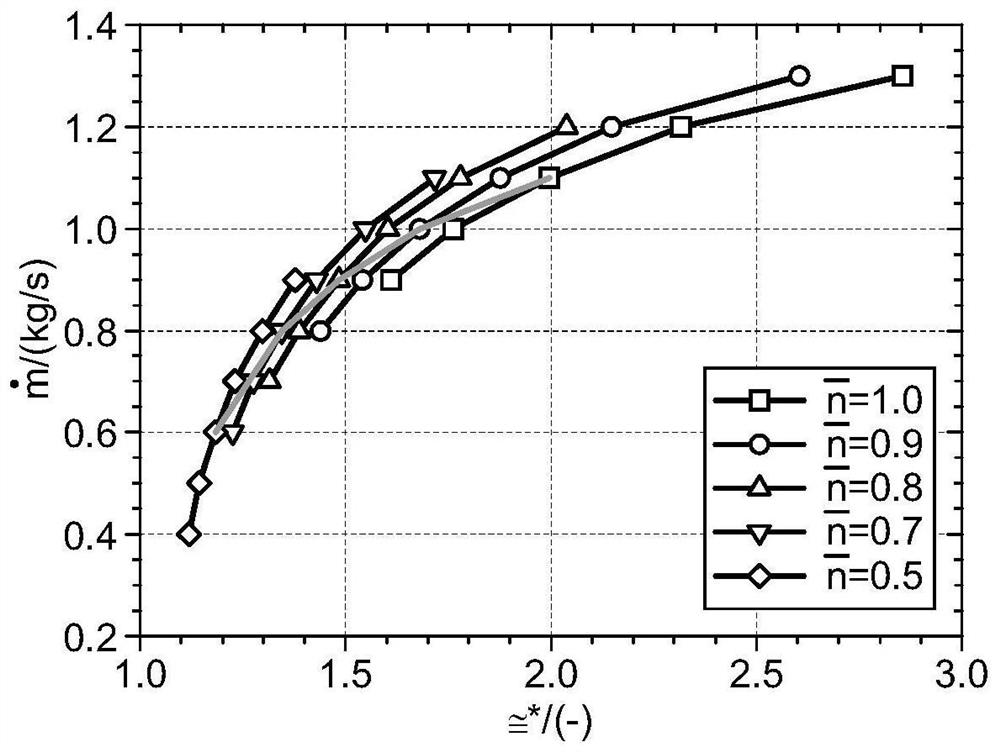

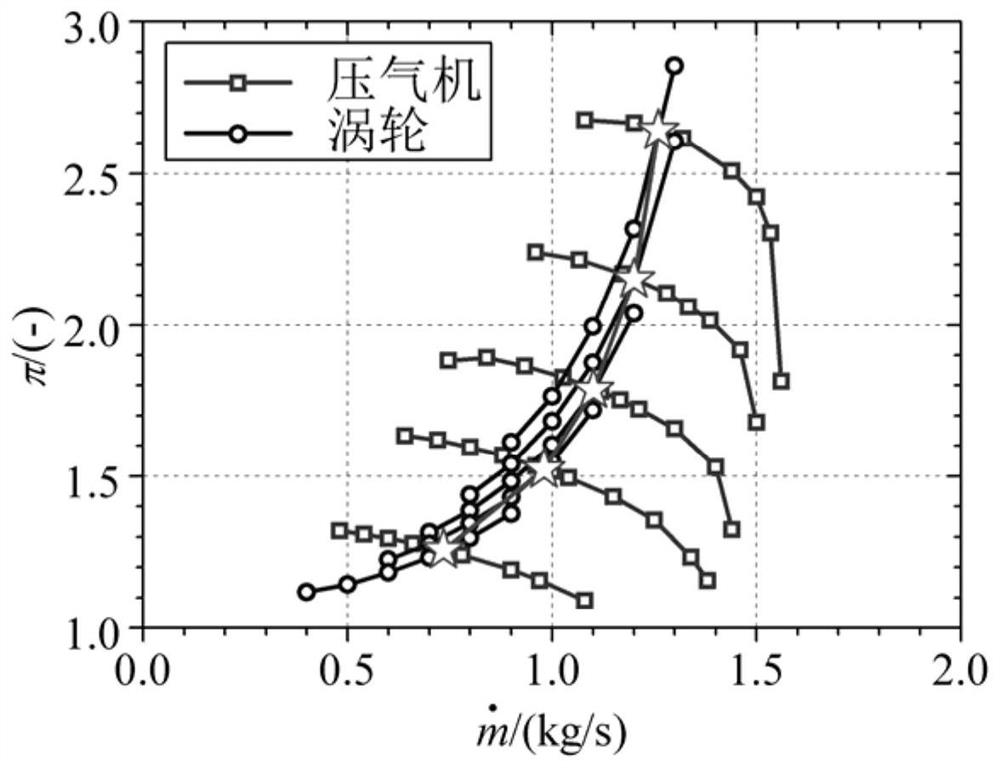

Closed circulation centrifugal compressor characteristic test method

ActiveCN111379727AAchieve recyclingSave energyPump controlNon-positive displacement fluid enginesLoop controlEngineering

The invention discloses a closed circulation centrifugal compressor characteristic test method. The method comprises the following process that inert mixed gas is injected into a closed circulation loop, air supplied by an air source is adopted to push a centripetal turbine, and a compressor tester coaxial with the centripetal turbine is driven to rotate by the centripetal turbine; according to the set working condition, a rotating speed of the centripetal turbine is adjusted, so that an open circulation loop enters a rotating speed closed-loop control state; after inlet and outlet airflow parameters of the compressor tester are stable, inlet and outlet thermodynamic parameters thereof are measured; and by adjusting a rotating speed of the centripetal turbine in the open circulation loop,the compressor tester is synchronously adjusted to other to-be-detected rotation speeds, and measurement and recording work of all characteristic line data points are completed in sequence. Accordingto the method, matching change of the reduced flow rate and the reduced rotation speed of the compressor tester can be achieved, the variable working condition requirement of a performance test of a centrifugal compressor is met, and the adjustment control difficulty of the performance test of a centrifugal compressor part is greatly reduced.

Owner:BEIJING POWER MACHINERY INST

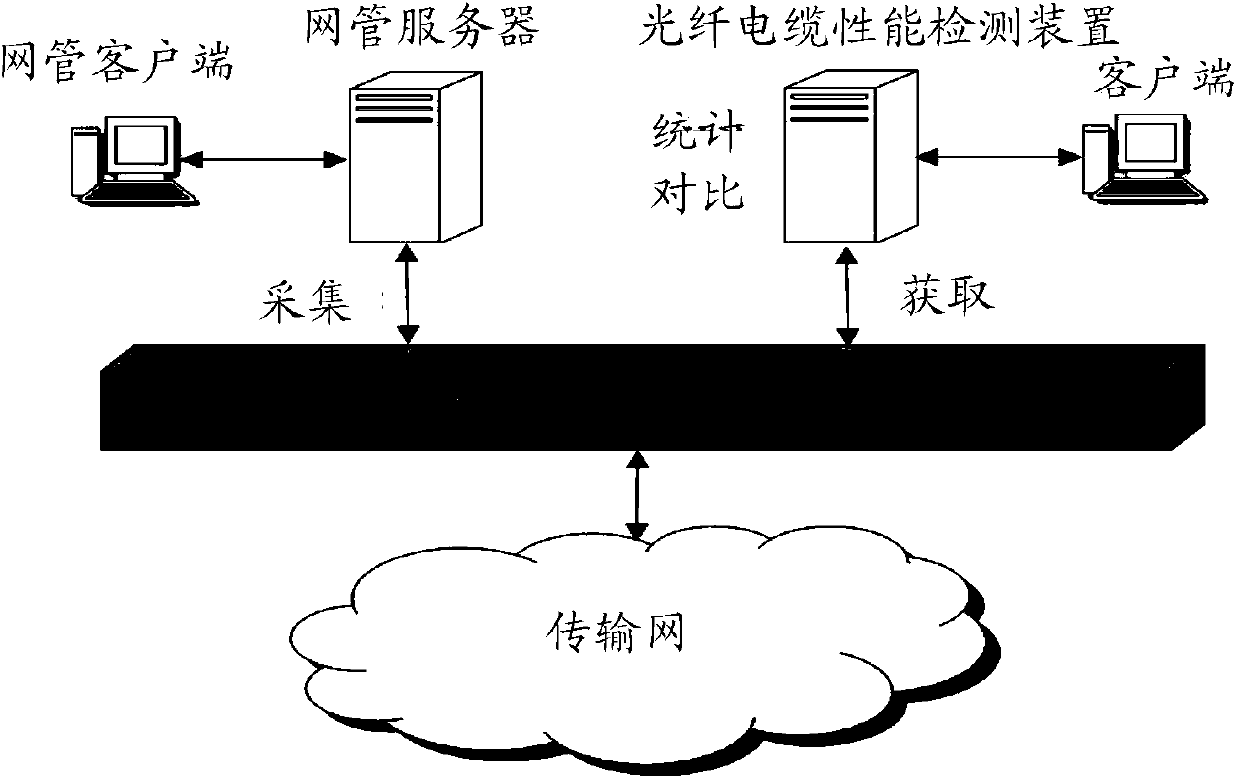

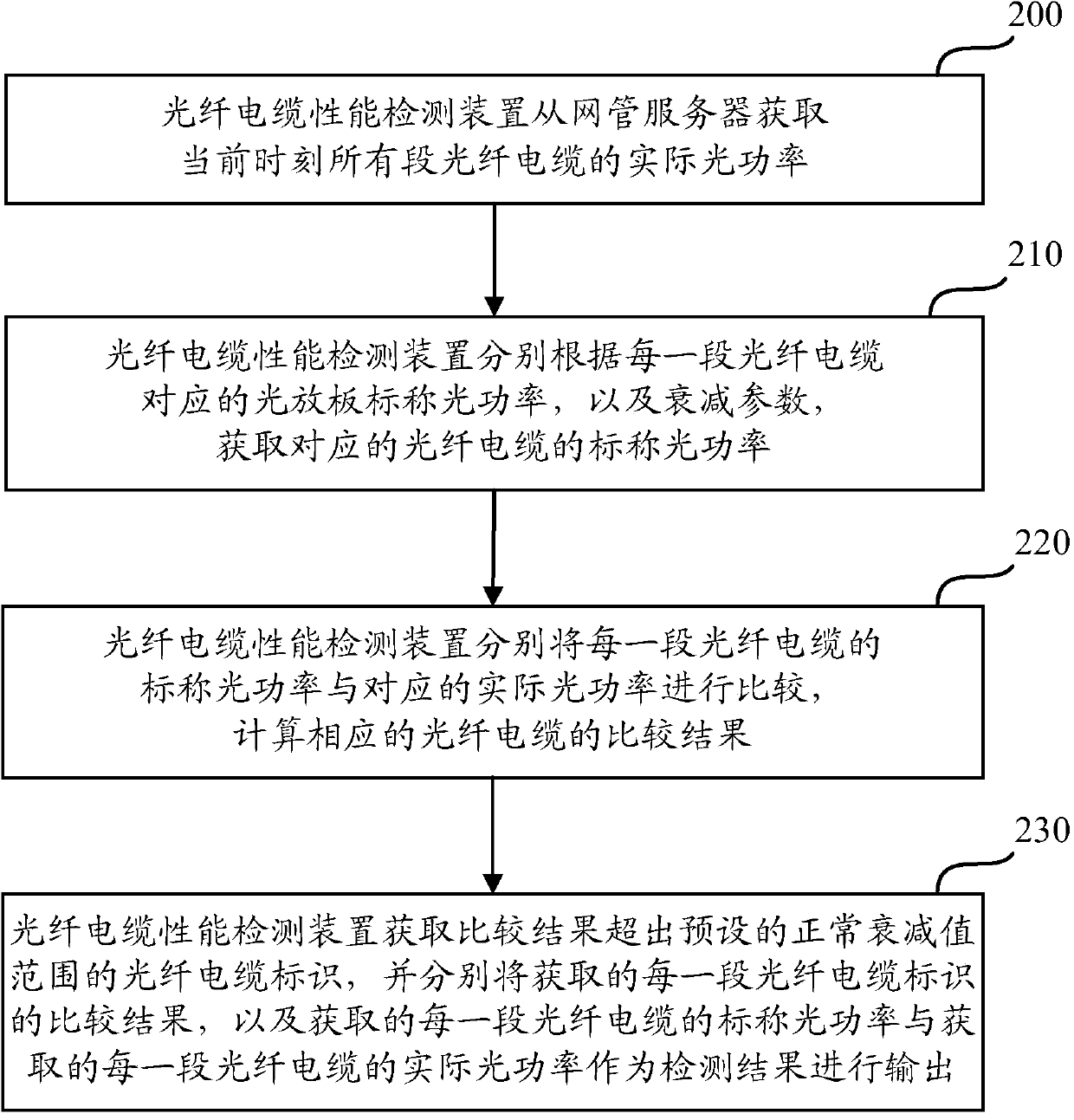

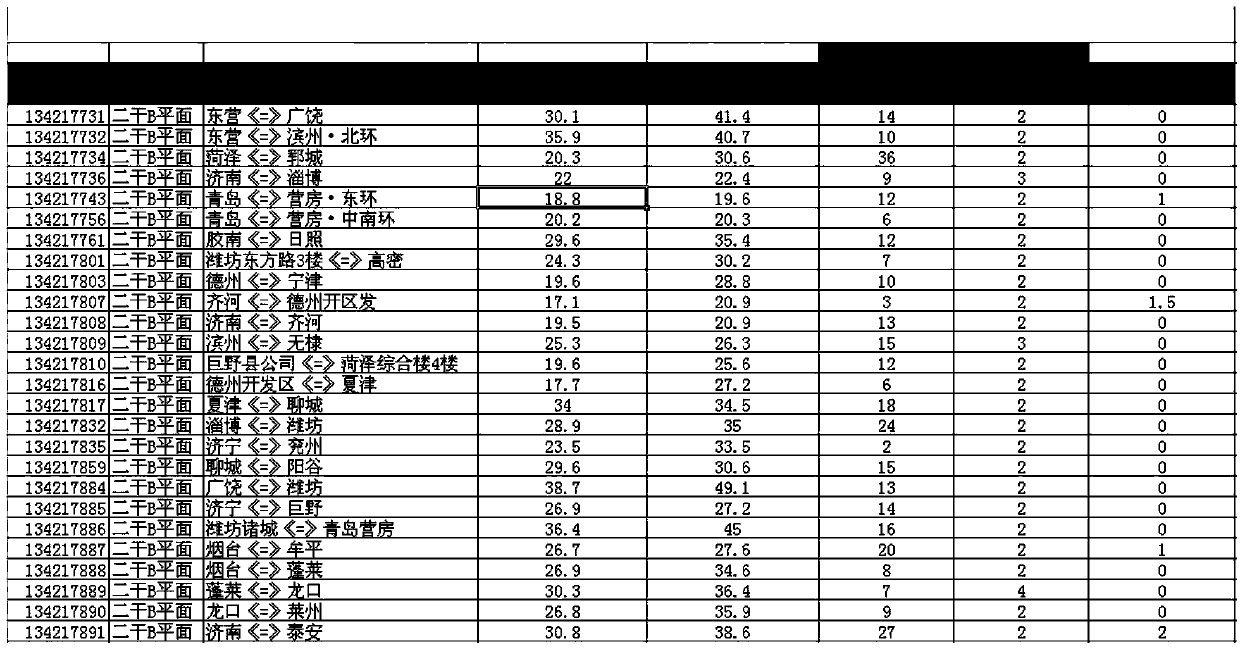

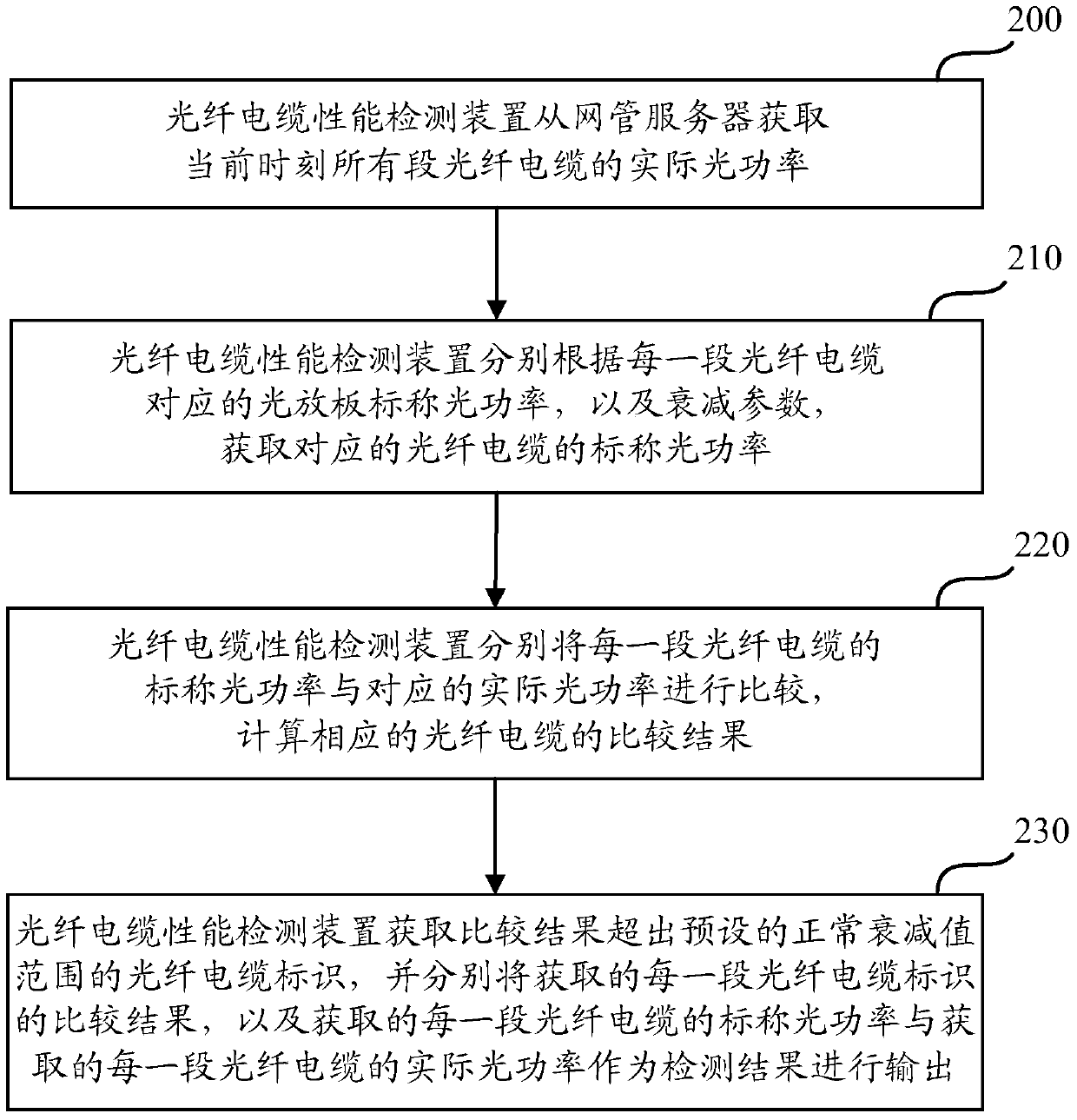

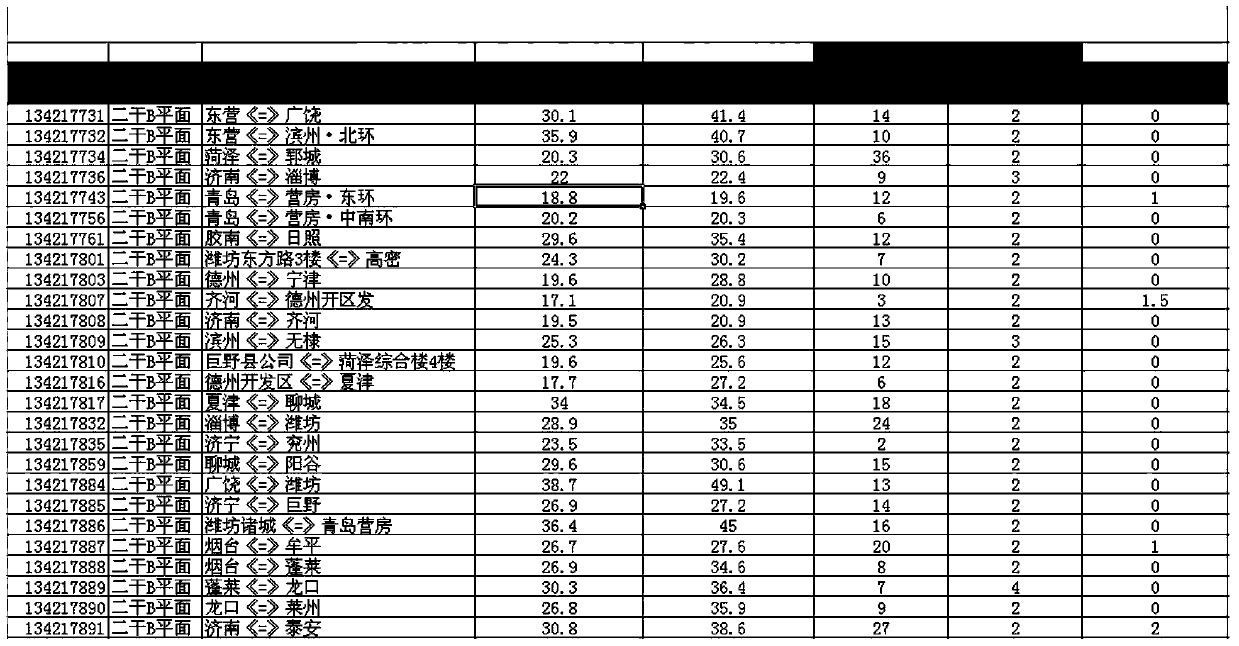

Optical cable performance detection method and device

ActiveCN105515649AImprove performance detection efficiencyImprove performance detection accuracyElectromagnetic transmissionUltrasound attenuationOptical power

The invention discloses an optical cable performance detection method and a device. The method comprises steps that an optical fiber performance detection device calculates the normal optical power of the corresponding optical fiber according to an optical amplification plate normal optical power and attenuation parameters corresponding to each optical fiber, compares the actual optical power of each optical fiber at this moment obtained from a webmaster server with the normal optical power of the corresponding optical fiber, regards the optical fiber whose comparison result is not in the preset normal attenuation value range as an optical fiber with a hidden performance danger and outputs a detection results of optical fibers with the hidden performance dangers. In this way, via the optical fiber performance detection device, identifications of the optical fiber with the hidden performance dangers are determined with no need for manual calculation and determination on the optical fibers with the hidden performance dangers, thereby effectively increasing performance detection efficiency of the optical fibers, greatly reducing cost of performance detection and increasing accuracy rate of the performance detection.

Owner:CHINA MOBILE GROUP SHANDONG

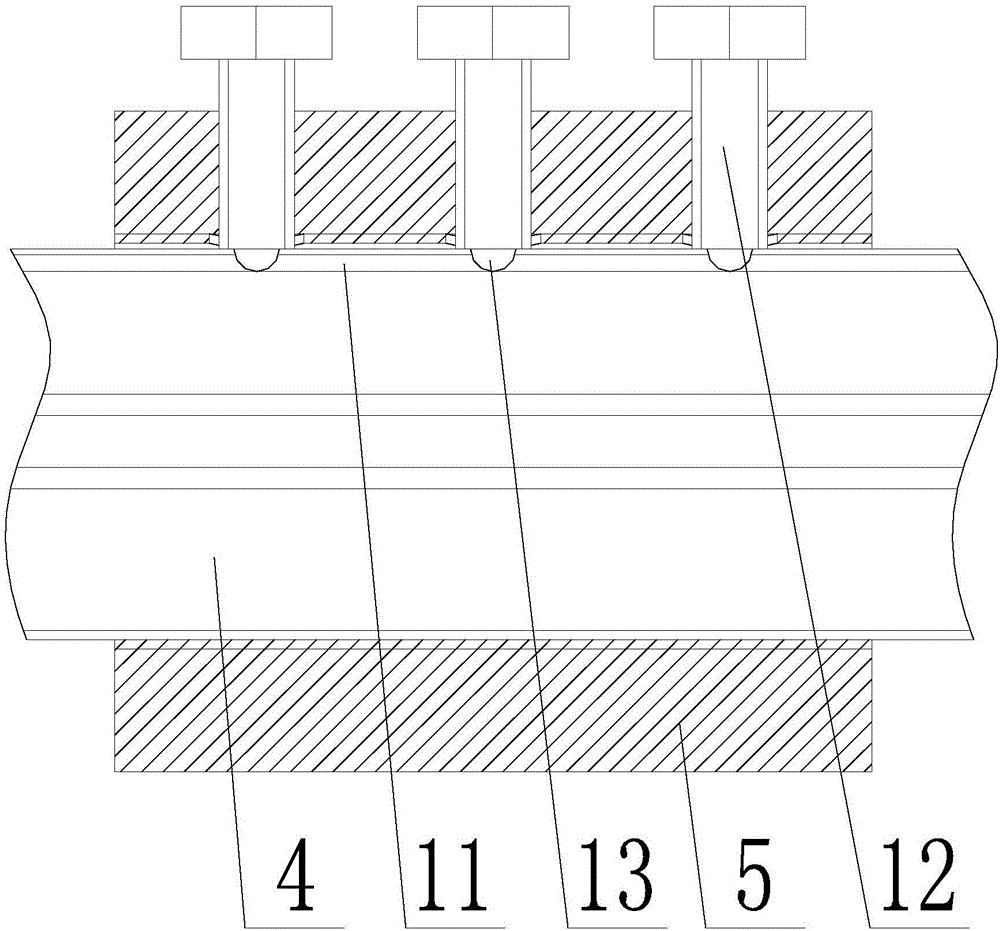

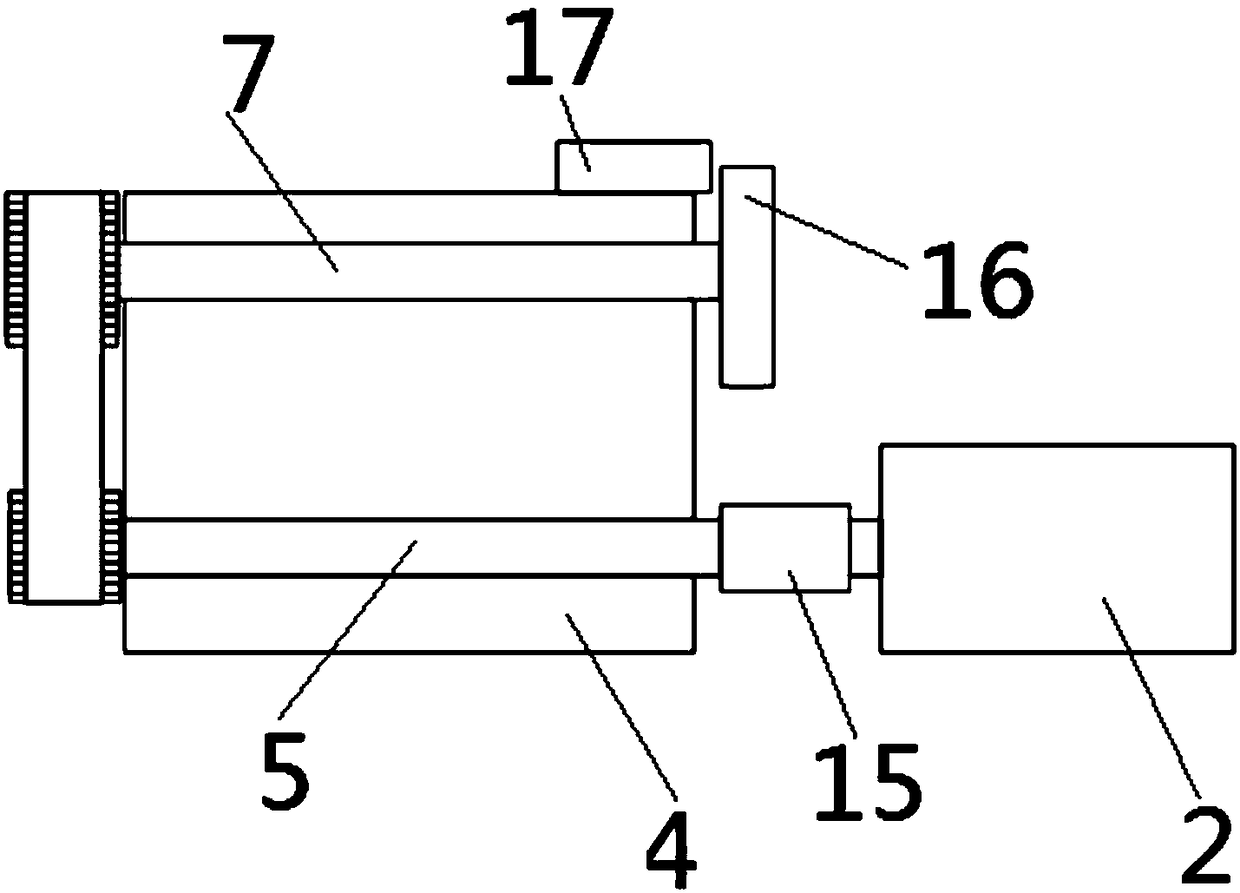

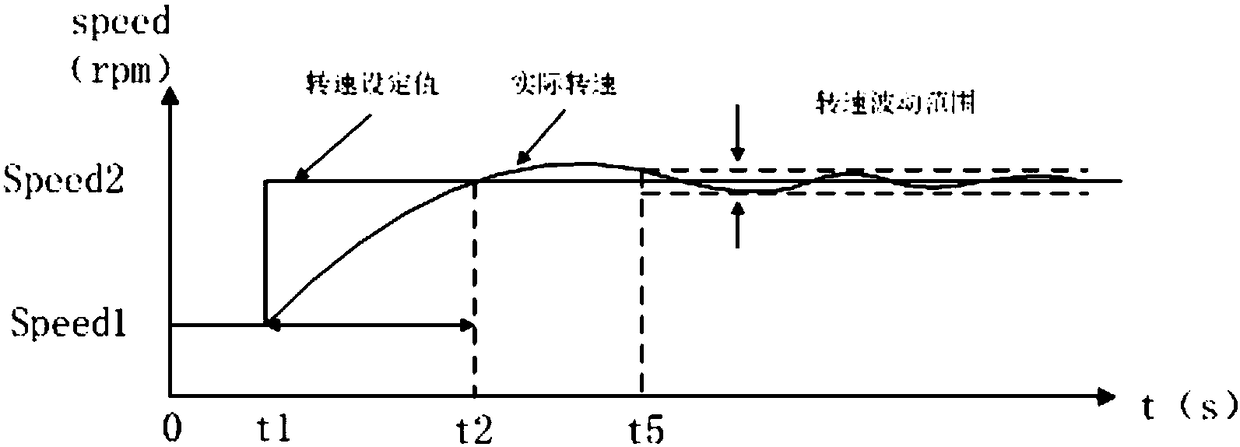

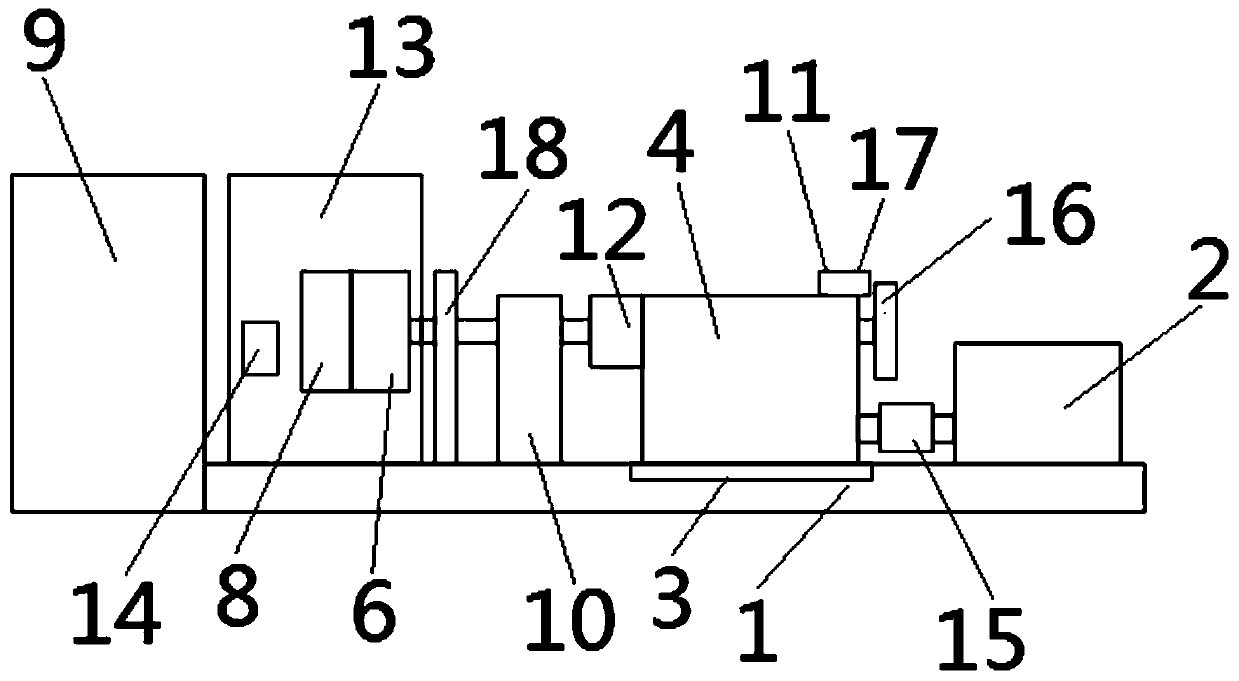

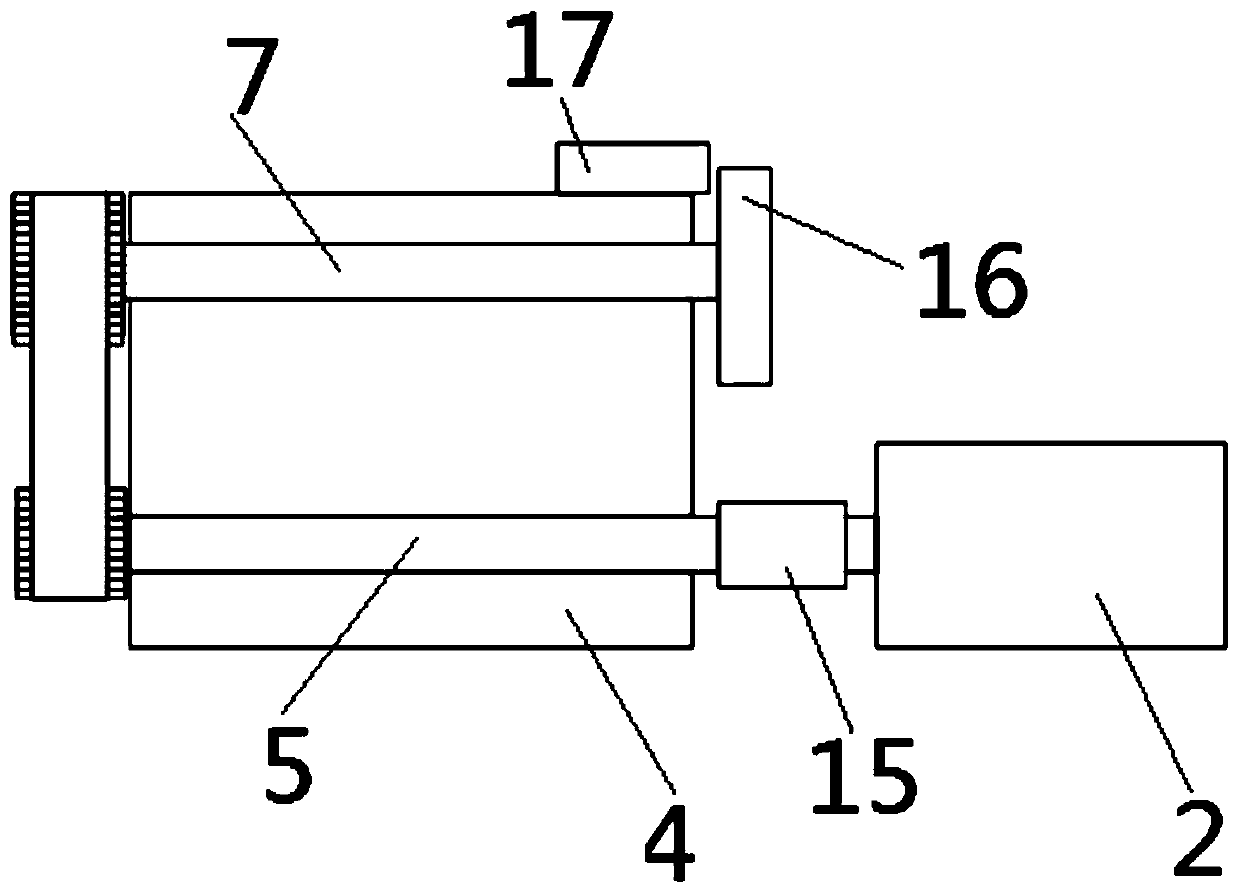

Electronic variable valve timing system function testing device and testing method thereof

ActiveCN108106853AMeet the needs of mass productionEfficient and accurate performance testingEngine testingFunctional testingVariable valve timing

The invention provides an electronic variable valve timing system function testing device applied to the technical field of variable valve timing system testing. In the electronic variable valve timing system function testing device, a drive motor (2) is connected with an engine crankshaft (5), a cam shaft speed sensor (11) is connected with an acquisition control module (9), an adjustment motor (6) is connected with a motor control component (8), the motor control component (8) is connected with the acquisition control module (9), the acquisition control module (9) is connected with a rotational speed torque sensor (10), and the drive motor (2) is connected with the acquisition control module (9). The electronic variable valve timing system function testing device and a performance test method of the invention can accurately and quickly simulate the actual working conditions of the electronic variable valve timing system used in the engine to judge the product performance of the timing system and contribute to performance optimization.

Owner:JAPHL POWERTRAIN SYST

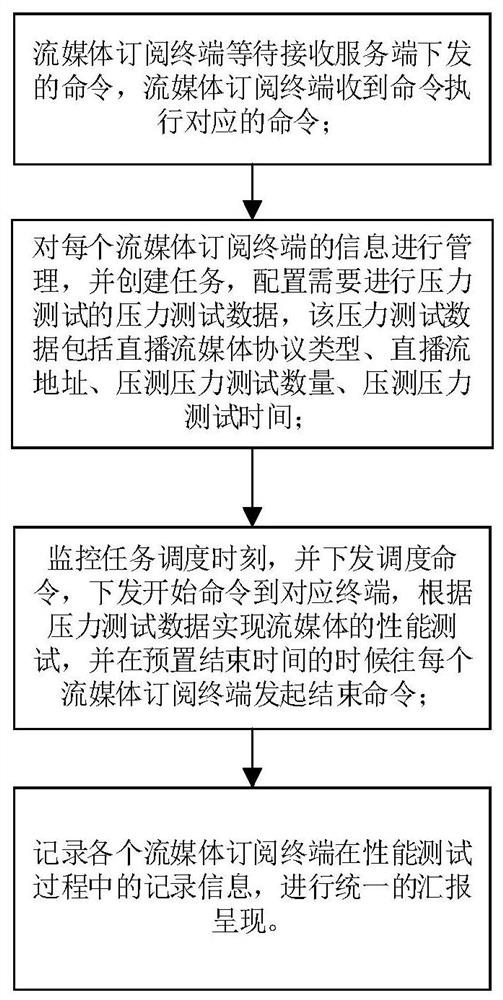

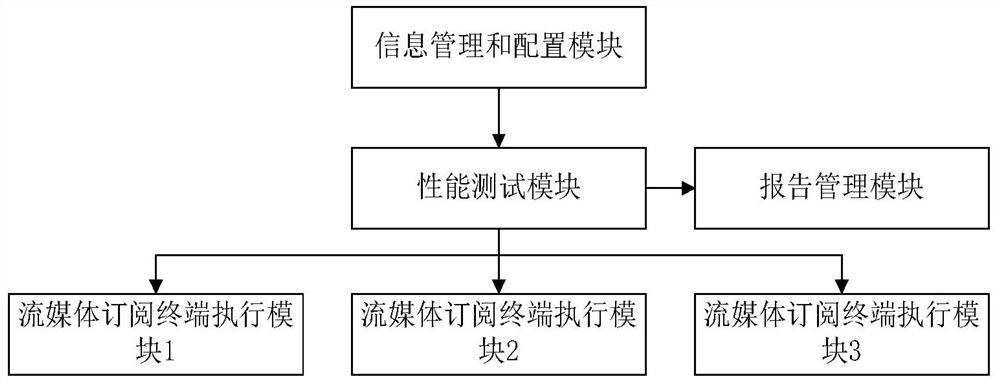

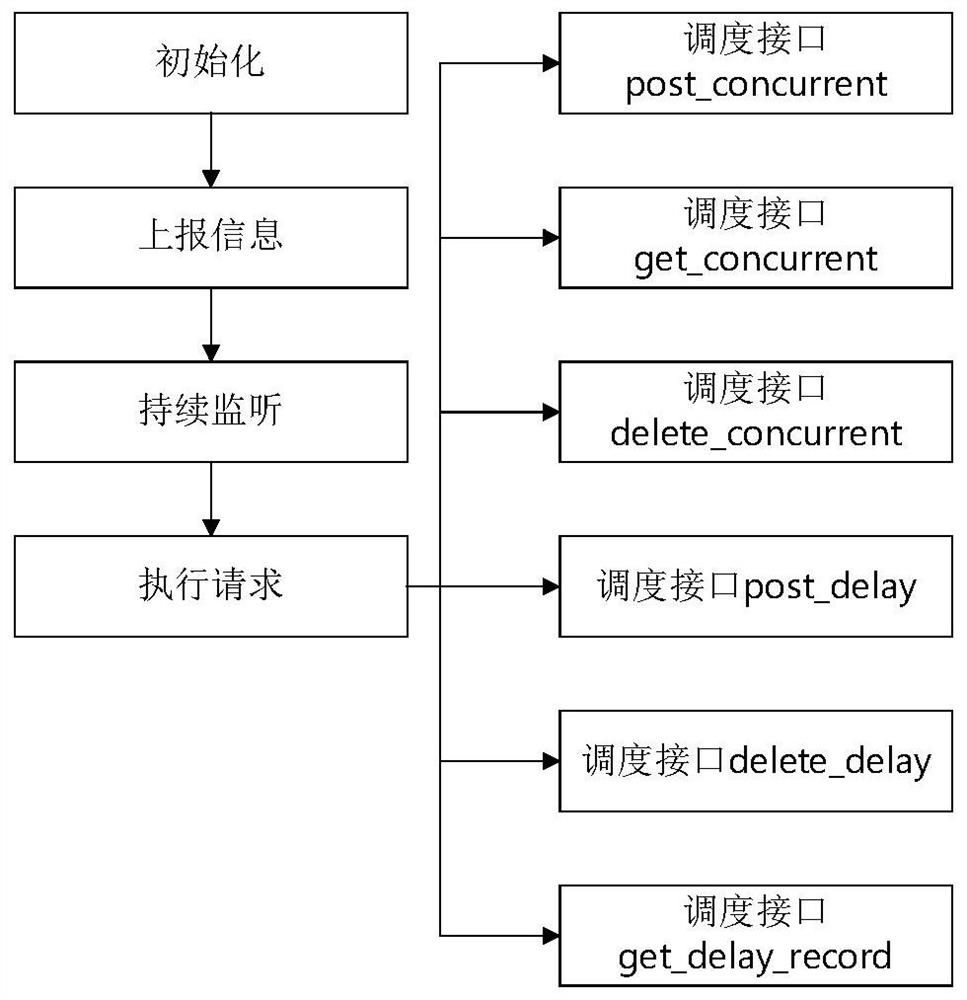

Performance test method and system for live streaming media

ActiveCN112954311ARealize high concurrent performance testingPerformance testing supportTelevision systemsSelective content distributionEngineeringData needs

The invention provides a live streaming media performance test method, which comprises the following steps that: S1, a streaming media subscription terminal waitting for receiving a command issued by a server, and the streaming media subscription terminal receiving the command and executing the corresponding command; S2, managing information of each streaming media subscription terminal, creating a task, and configuring pressure test data needing to be subjected to pressure test; S3, monitoring task scheduling time, issuing a scheduling command, issuing a start command to the corresponding terminal, and testing the performance of the streaming media according to the pressure test data, and initiating an ending command to each streaming media subscription terminal at preset ending time; S4, recording the recorded information of each streaming media subscription terminal in the performance test process, and performing unified report presentation. The performance pressure test is realized, the performance test cost can be effectively reduced, and even the idle bandwidth can be commercially realized.

Owner:FUJIAN TQ DIGITAL

A servo motor reliability test loading device and using method

ActiveCN108983091BImprove performanceReduce the cost of performance testingDynamo-electric machine testingGear wheelElectric machine

Owner:NORTHEASTERN UNIV LIAONING

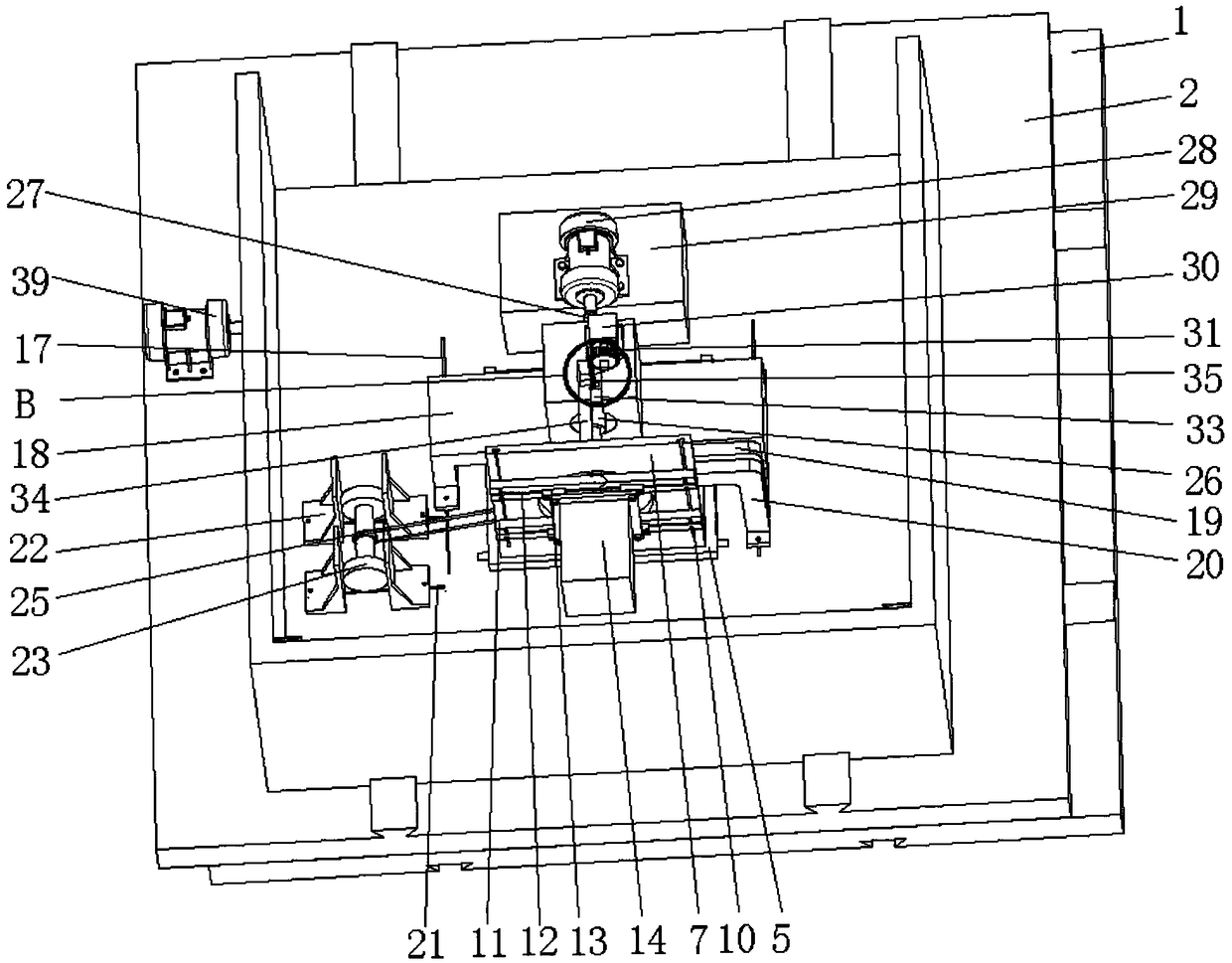

A swinging head rotary table five-axis machine tool simulating cutting force loading device and using method

ActiveCN105845015BImprove performanceReduce the cost of performance testingCosmonautic condition simulationsStructural/machines measurementElectric machineEngineering

A swing-head turntable five-axis machine tool simulated cutting force loading device and a method of use. The device includes X-direction, Y-direction, Z-direction, turntable rotation steering and swing-head rotation cutting force loading components. By tightening the X-direction and Y-direction respectively , Z-direction, turntable rotation and swing head rotation pre-tightening bolts to achieve cutting force loading. The method steps are: hoist the device to the machine tool turntable, fix the turntable rotation fixed plate to the machine tool turntable, and connect the machine tool tool spindle and The motor shafts of the damping motor are firmly connected; set a set of cutting forces, and tighten the pretightening bolts in the five cutting force loading components with a torque wrench, so that the friction forces in the five cutting force loading components are respectively consistent with the set The specified cutting force is equal. Since the friction force cannot be read directly, the tightening torque needs to be calculated through the formula M=KFd / μ and then read; start the machine tool and run the processing program to truly simulate the actual operating status of the machine tool under stress conditions. , test the machine tool performance under current cutting force conditions.

Owner:NORTHEASTERN UNIV LIAONING

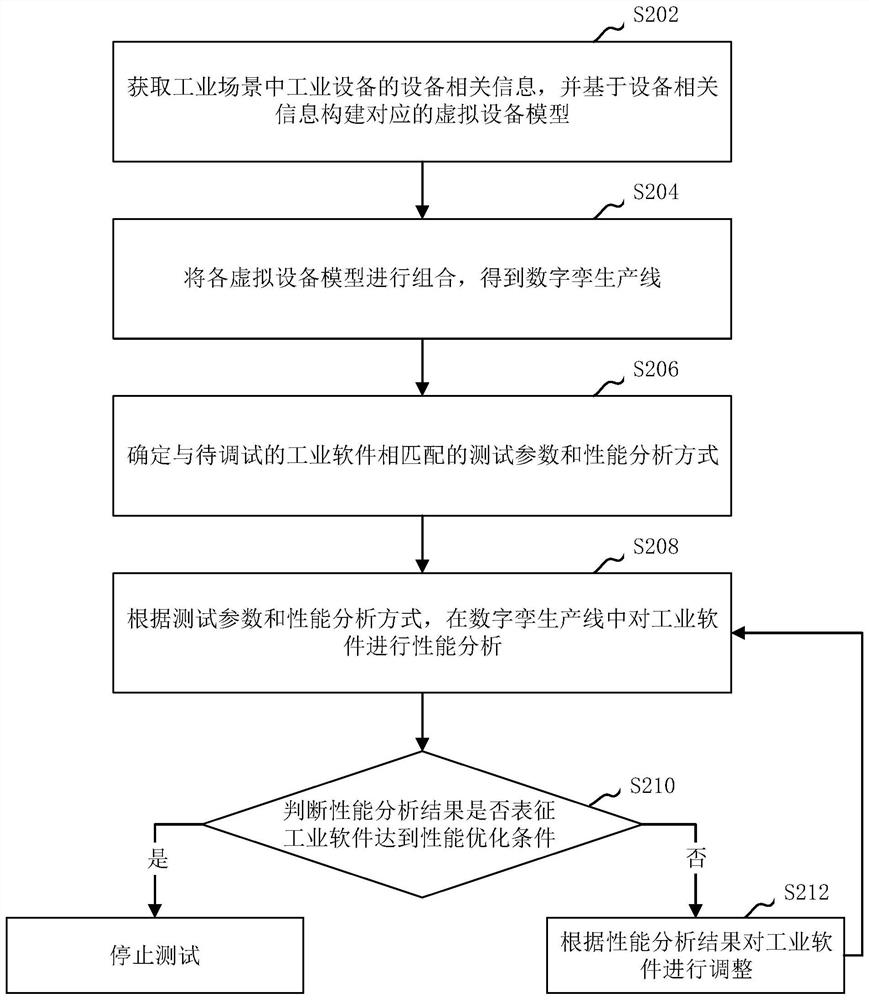

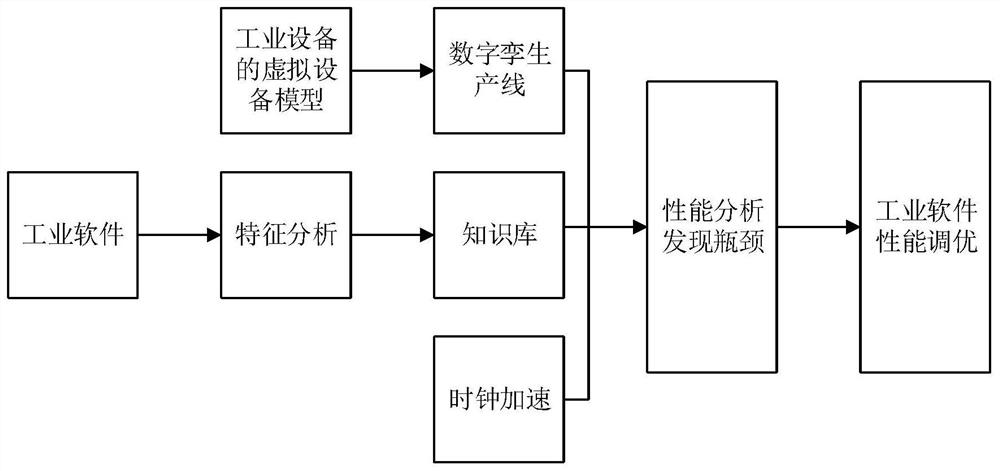

Industrial software debugging method and device, computer equipment and storage medium

PendingCN113868120AAvoid damageReduce the cost of performance testingSoftware testing/debuggingTotal factory controlIndustrial softwareIndustrial equipment

The invention relates to an industrial software debugging method and device, computer equipment and a storage medium. The method comprises the following steps: acquiring equipment related information of industrial equipment in an industrial scene, and constructing a corresponding virtual equipment model based on the equipment related information; combining the virtual equipment models to obtain a digital twin production line; determining test parameters and a performance analysis mode matched with the to-be-debugged industrial software; performing performance analysis on the industrial software in the digital twin production line according to the test parameters and the performance analysis mode; if the performance analysis result represents that the industrial software does not meet the performance optimization condition, adjusting the industrial software according to the performance analysis result; and based on the adjusted industrial software, returning to the step of performance analysis for continuous execution, and stopping until the adjusted industrial software reaches a performance optimization condition, thereby obtaining the optimized target industrial software. By adopting the method, the debugging efficiency of the industrial software can be improved.

Owner:CHINA ELECTRONICS PROD RELIABILITY & ENVIRONMENTAL TESTING RES INST

A kind of inert gas closed circulation radial impeller mechanical performance test method

ActiveCN112610520BAchieve recyclingSave energyPump controlSafety/regulatory devicesWorking fluidTurbocharger

The invention discloses a characteristic test method for a closed-loop radial-flow impeller based on the structure of a turbocharger. The turbocharger is used as the basic structure, and the original centripetal turbine or centrifugal compressor is replaced with a tester. And the centrifugal compressor of the turbocharger is used as the power consumption device, or the centrifugal turbine of the turbocharger is used as the power device; The closed loop with gas as the working fluid can realize the closed loop utilization of the inert gas by cooperatively controlling multiple test equipments. The present invention has remarkable features such as ingenious and reasonable structure design, resource saving and the like, and is easy to popularize and apply on a large scale.

Owner:BEIJING POWER MACHINERY INST

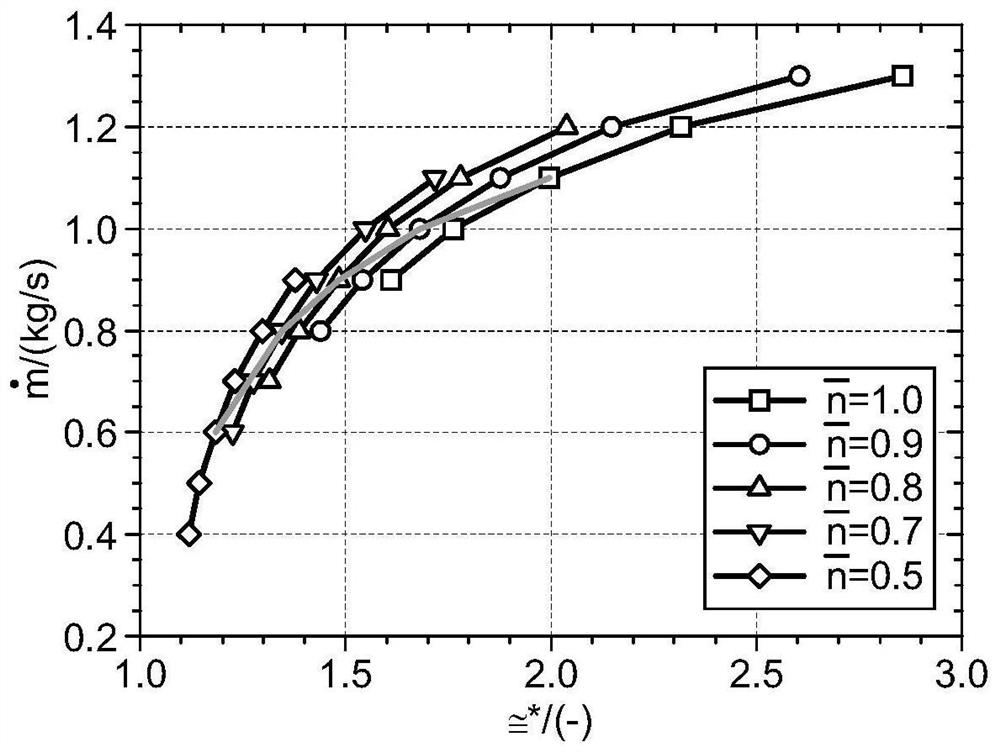

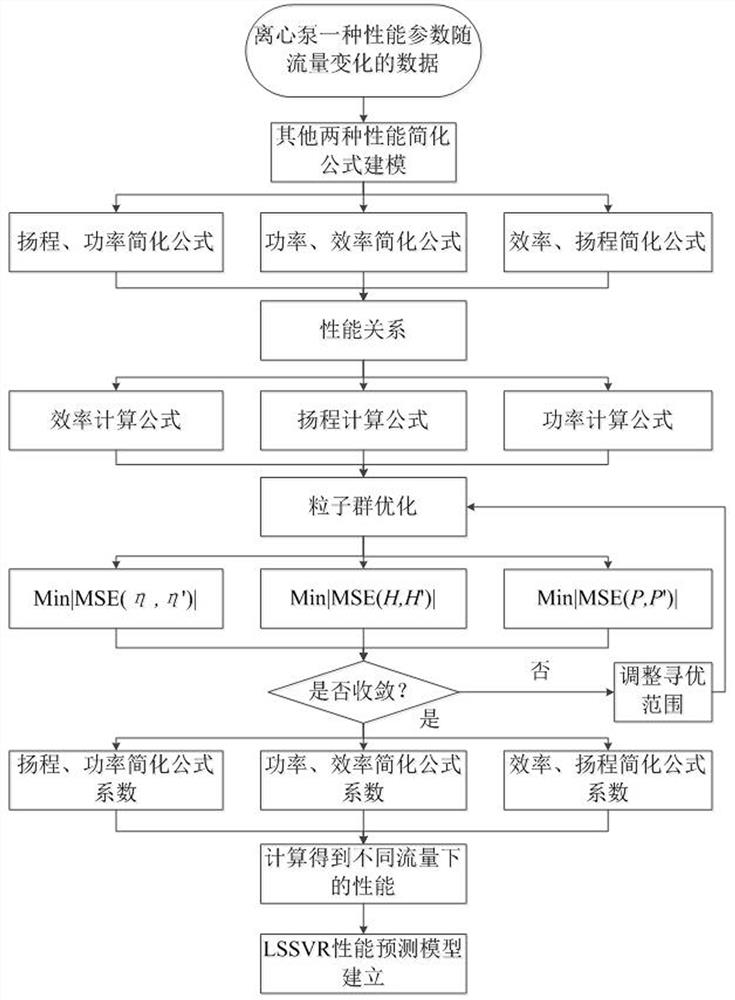

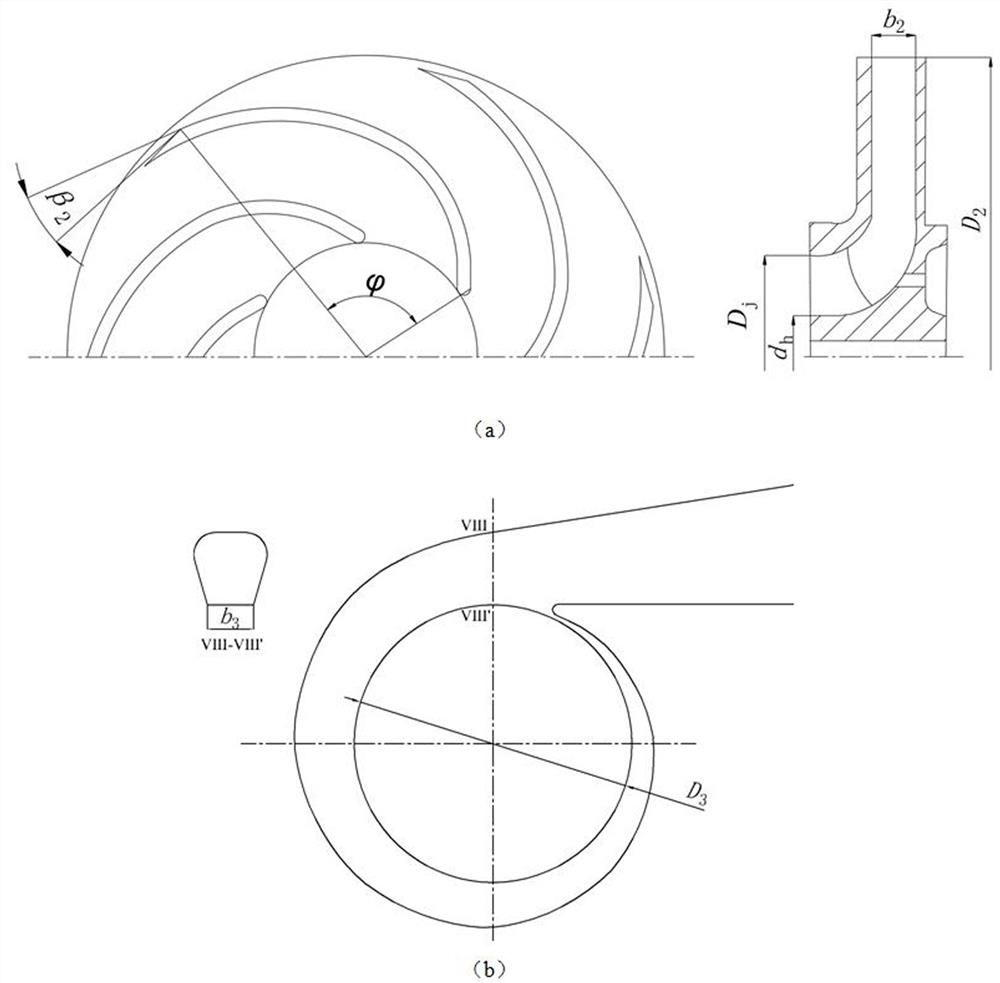

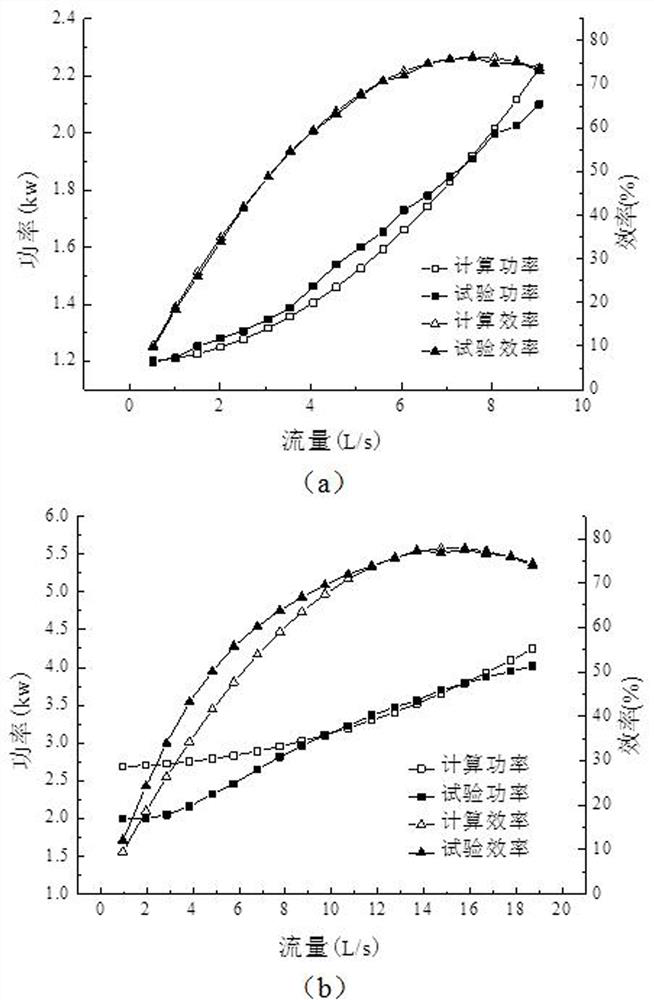

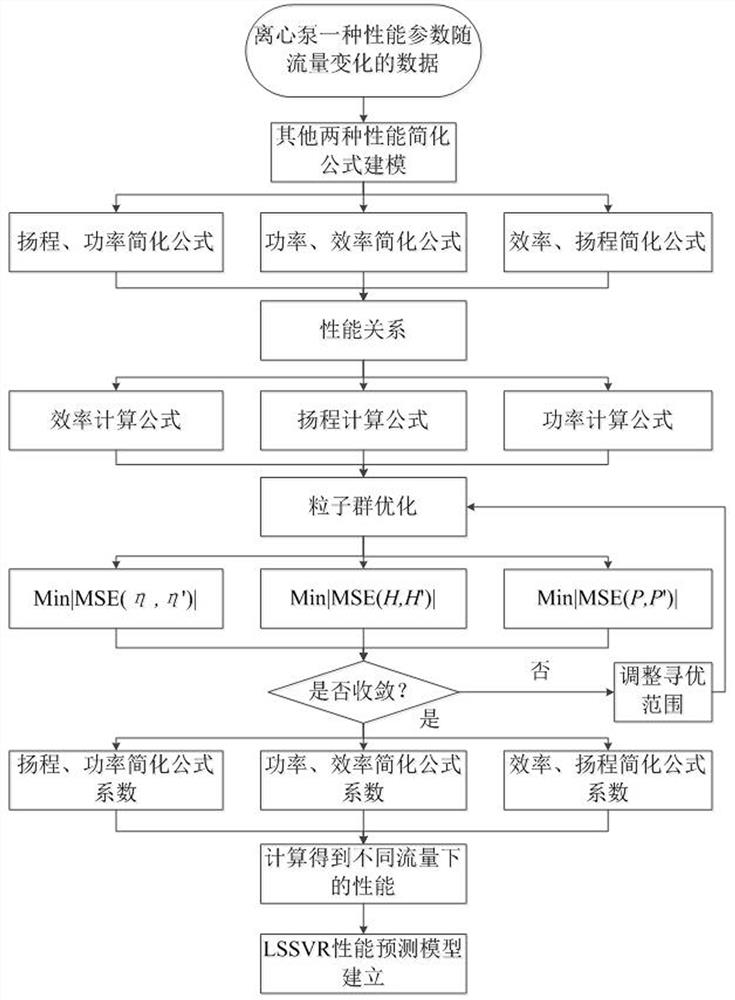

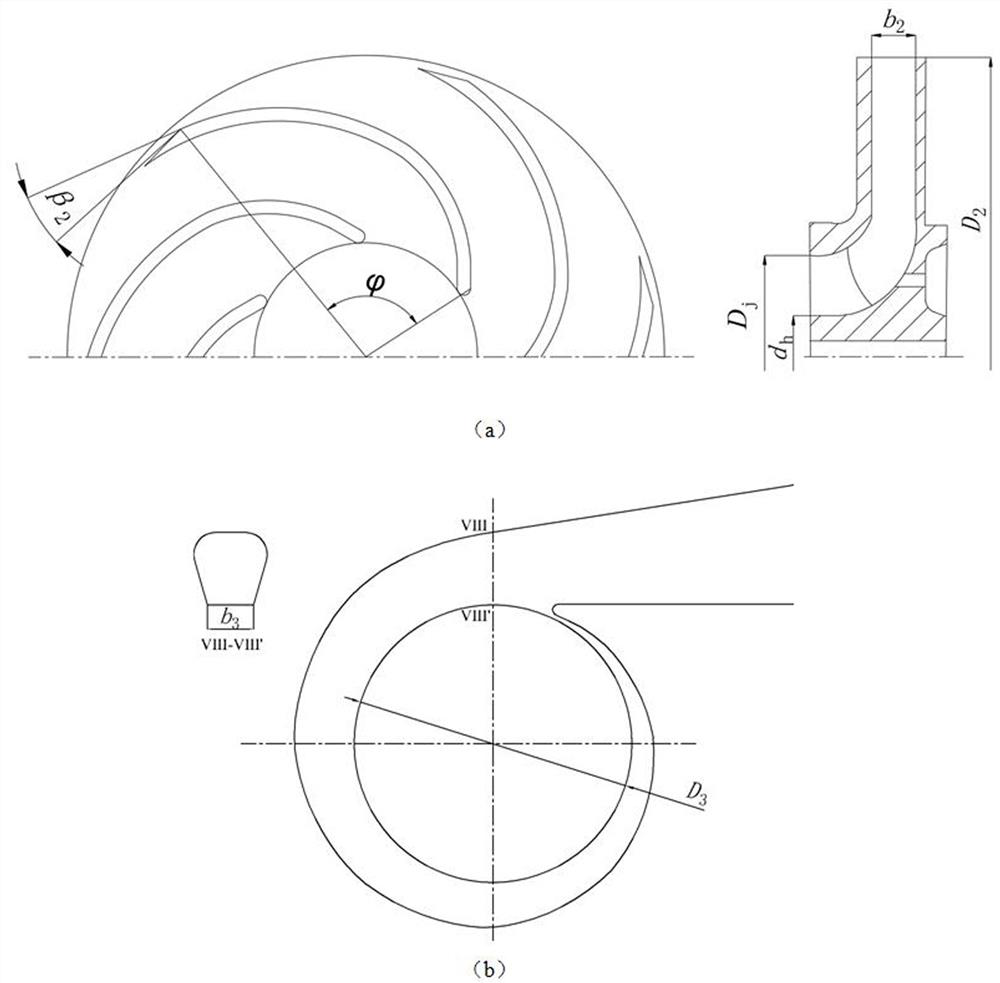

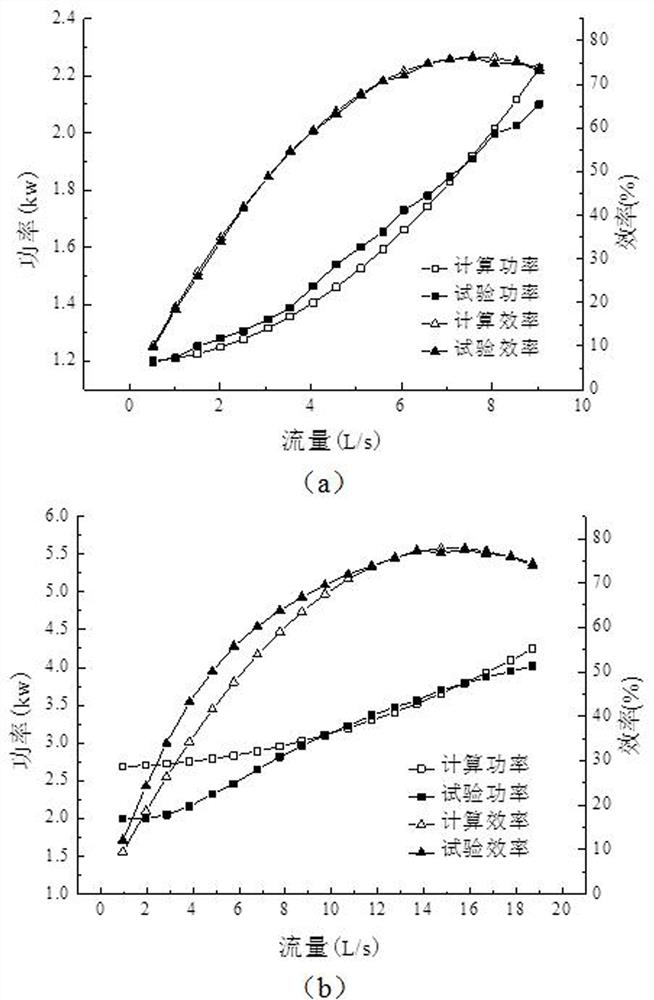

Centrifugal pump performance curve sample acquisition method and its application in machine learning

ActiveCN114201926BReduce the cost of performance testingSpeed up the design processKernel methodsCharacter and pattern recognitionEngineeringMachine learning

The invention discloses a centrifugal pump performance curve sample acquisition method and its application in machine learning. The method first collects the data of one of the performance parameters of various centrifugal pumps changing with the flow rate; Modeling to obtain the simplified formula of the unknown performance parameters; then based on the relationship between the performance parameters and the simplified formula of the unknown performance parameters, the calculated value of the known performance parameters is calculated; finally, the real value of the known performance parameters and the calculated value The mean square error is used as the objective function of the differential evolution optimization algorithm to optimize the coefficients of two unknown performance parameter calculation formulas; finally, the unknown performance parameter values under different flow rates are calculated. This method can quickly and conveniently obtain a large number of performance parameter samples. The method is further combined with the machine learning model, and the performance prediction results of different centrifugal pumps can be obtained based on the geometric parameters of the centrifugal pump. The calculation time is short and the implementation is convenient, thereby speeding up the research and development progress.

Owner:CHINA JILIANG UNIV

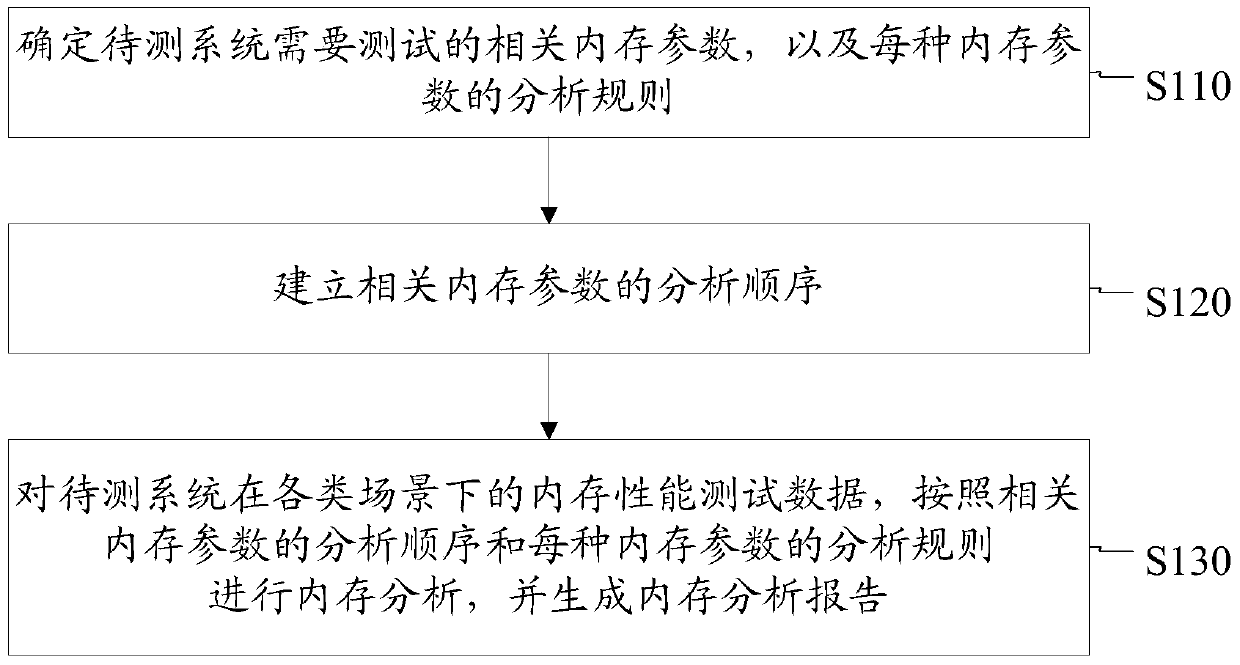

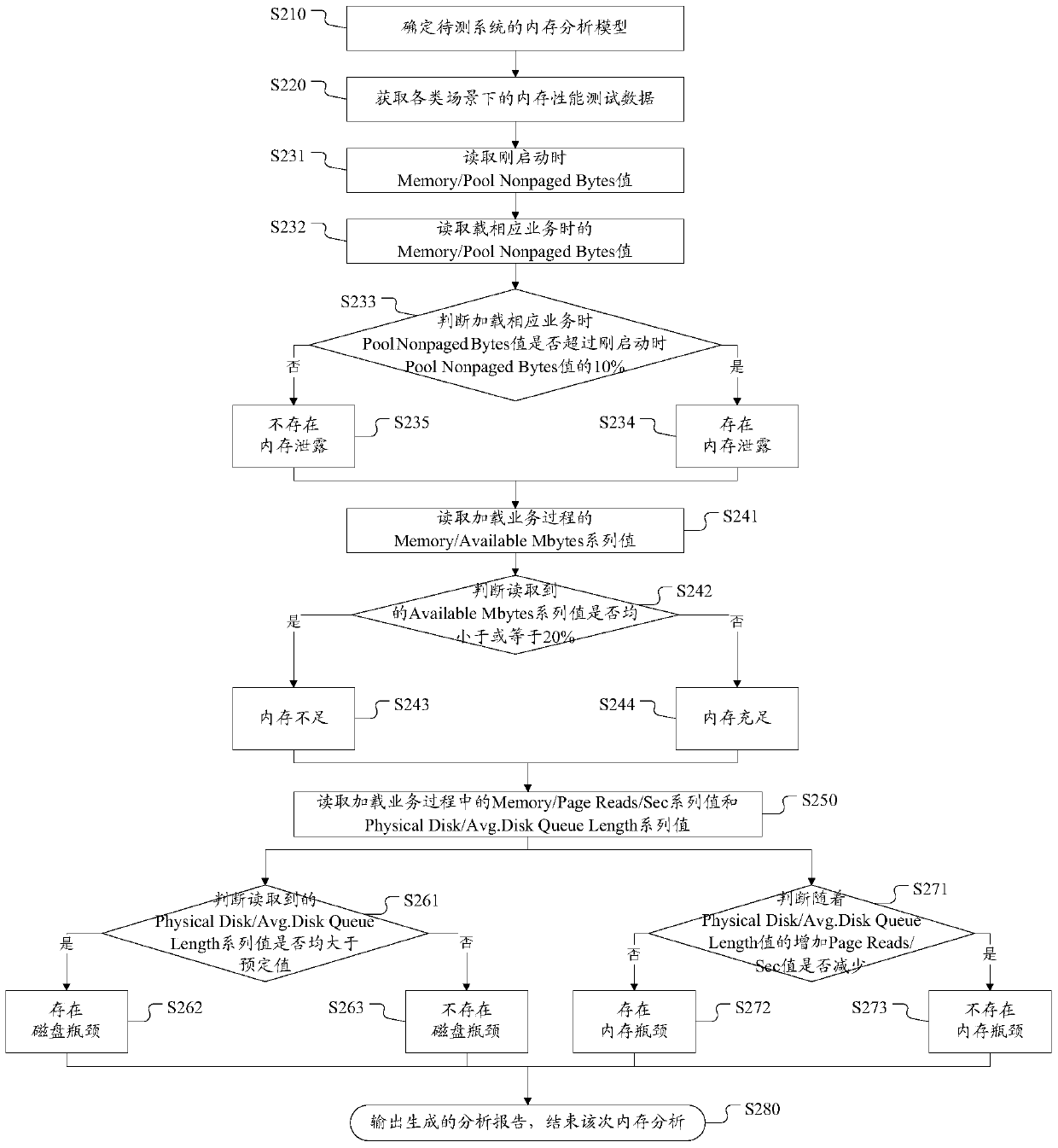

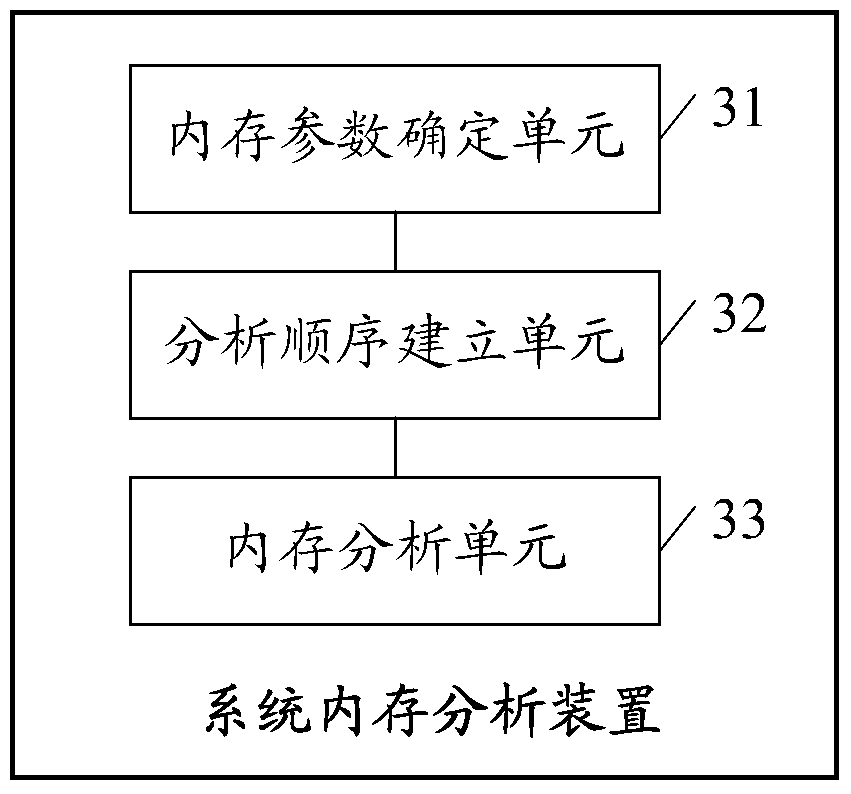

A system memory analysis method and device

ActiveCN106855841BImprove analysis efficiencyQuality improvementHardware monitoringMemory profilingAlgorithm

The invention discloses a system memory analysis method and device. The method comprises the steps that related memory parameters needing to be tested by a to-be-tested system and analysis rules of all the memory parameters are determined; an analysis sequence of the related memory parameters is established; memory analysis is conducted on memory performance test data of the to-be-tested system under various scenes according to the analysis sequence of the related memory parameters and the analysis rules of all the memory parameters, and a memory analysis report is generated. According to the technical scheme, the performance situation of a to-be-tested system memory can be accurately analyzed, the test difficulty of a performance test is lowered, the efficiency of performance test analysis and the quality of the performance test are improved, and evaluation of the system performance and positioning and analysis of system defects are effectively guided.

Owner:ULTRAPOWER SOFTWARE

An inert gas closed circulation radial impeller mechanical performance test device

ActiveCN112610519BAchieve recyclingSave energyPump controlSafety/regulatory devicesWorking fluidTurbocharger

Owner:BEIJING POWER MACHINERY INST

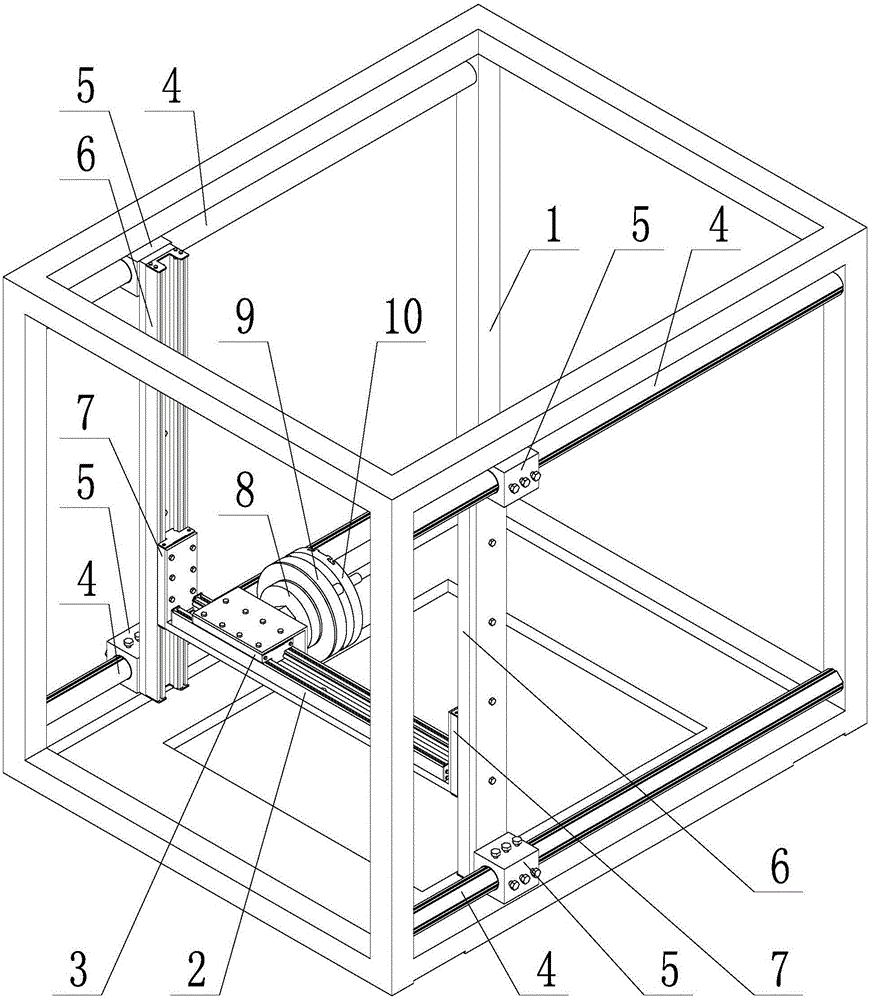

Loading device and method for reliability test of rolling linear guide rail and ball screw system

ActiveCN109000903BReduce the cost of performance testingMaintain good performanceMachine part testingBall screwStructural engineering

The invention provides a rolling linear guide and ball screw system reliability test loading device and a method of use, including: , and implement sliding loading. The invention provides a new machine tool performance testing method. After the test loading device is assembled and used with the machine tool to be tested, it can truly simulate the load applied to the linear guide rail and the ball screw pair in the linear feed motion of the machine tool, completely There is no need to consume physical materials and processing tools, which effectively reduces the cost of machine tool performance testing. While ensuring the excellent performance of the machine tool, it also effectively reduces the cost of machine tool manufacturing.

Owner:NORTHEASTERN UNIV LIAONING

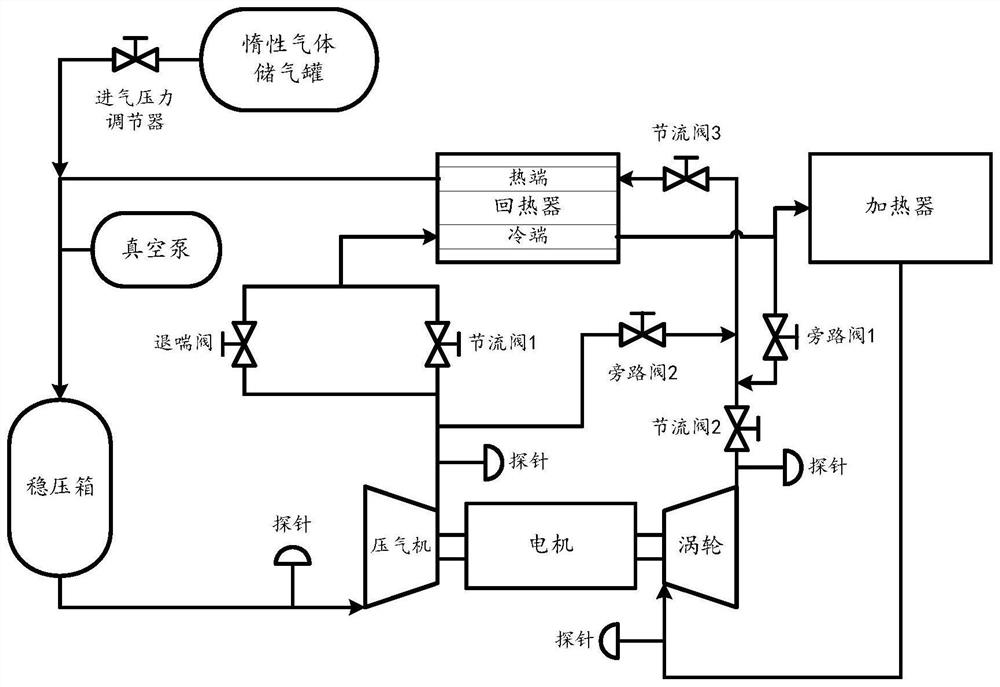

A Closed Cycle Centrifugal Compressor Characteristic Test Device

ActiveCN111379728BAchieve recyclingSave energyPump controlNon-positive displacement fluid enginesExhaust valveWorking fluid

The invention discloses a closed cycle centrifugal compressor characteristic test device, comprising: an inert mixed gas storage tank, an intake pressure regulator, a pressure stabilizing box, a flow meter, intake and exhaust temperature and pressure probes, and a compressor test The device, high temperature exhaust valve, throttle valve, pressure reducing valve, cooling water and water inlet and drainage device, heat exchanger, gas composition analyzer and vacuum pump are connected in sequence to form a closed loop, with inert mixed gas as the working medium; while the low pressure The air source, flow regulating valve, flow fine-tuning valve, heater and centripetal turbine are connected to form an open circulation loop, with air as the working medium. The invention has remarkable features such as simple and reasonable structural design, resource saving, etc., and is easy to be popularized and applied on a large scale.

Owner:BEIJING POWER MACHINERY INST

Centrifugal pump performance curve sample obtaining method and application thereof in machine learning

ActiveCN114201926AReduce the cost of performance testingSpeed up the design processKernel methodsCharacter and pattern recognitionEngineeringMachine

The invention discloses a centrifugal pump performance curve sample obtaining method and application of the centrifugal pump performance curve sample obtaining method in machine learning. The method comprises the steps that firstly, data of one performance parameter of multiple centrifugal pumps changing along with flow are collected; performing mathematical modeling on the other two unknown performance parameters to obtain a simplified formula of the unknown performance parameters; then, based on the relation between the performance parameters and a simplified formula of unknown performance parameters, calculation values of known performance parameters are obtained through calculation; and finally, taking a mean square error of a true value and a calculated value of the known performance parameter as an objective function of a differential evolution optimization algorithm, and optimizing to obtain coefficients of two unknown performance parameter calculation formulas. Finally, unknown performance parameter values under different flows are obtained through calculation. According to the method, a large number of performance parameter samples can be quickly and conveniently obtained. The method is further combined with a machine learning model, performance prediction results of different centrifugal pumps can be obtained based on geometric parameters of the centrifugal pumps, calculation time is short, implementation is convenient, and therefore the research and development progress is accelerated.

Owner:CHINA JILIANG UNIV

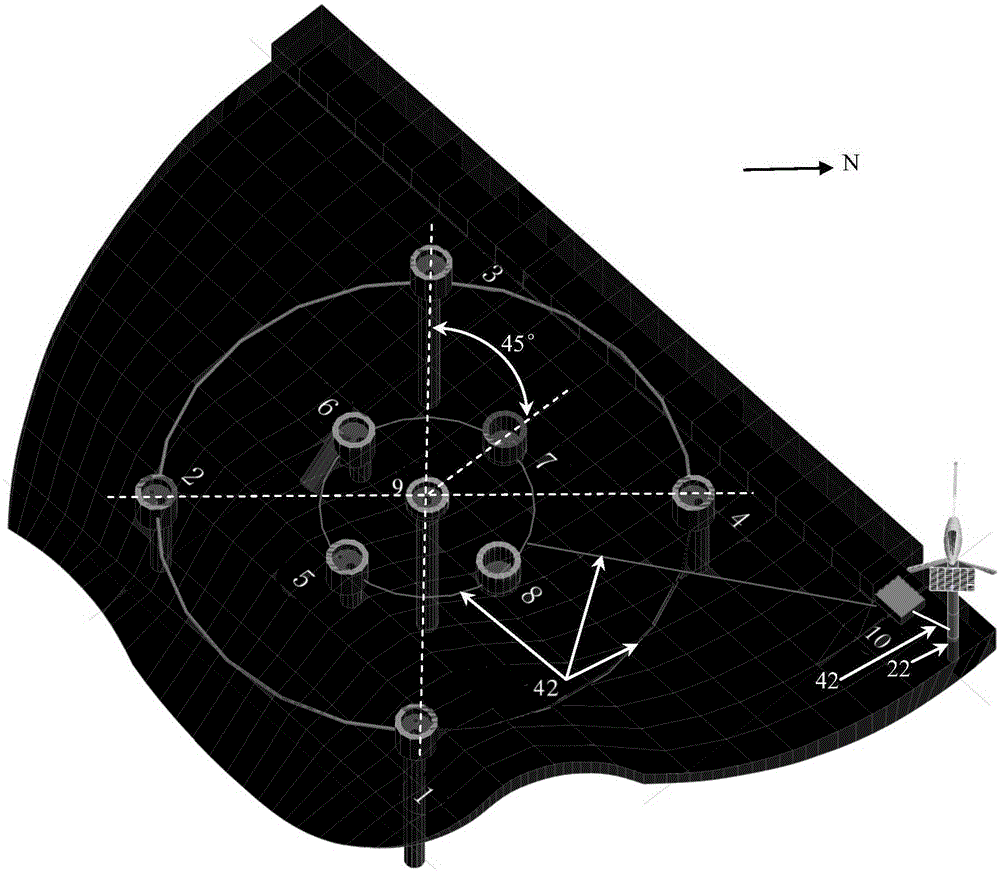

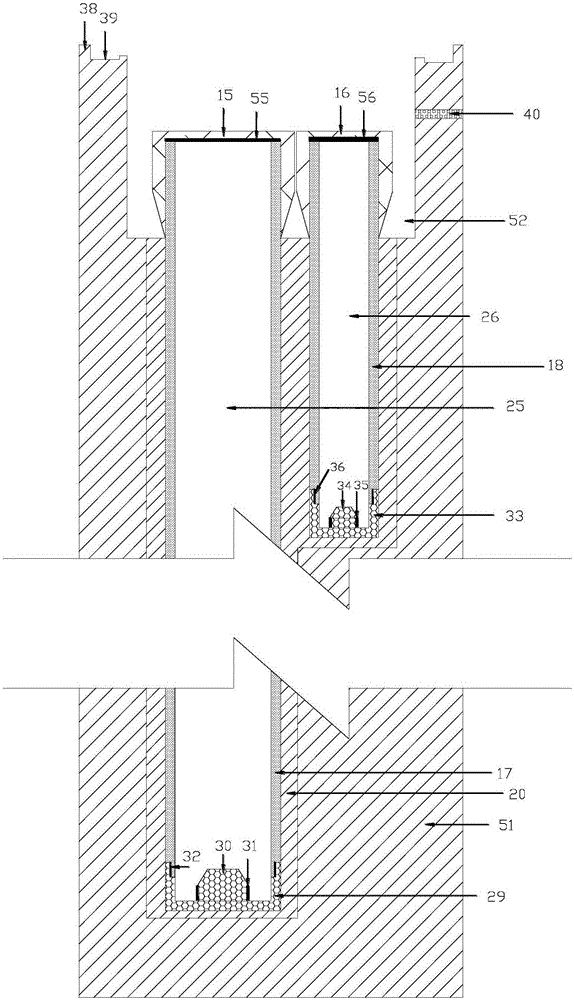

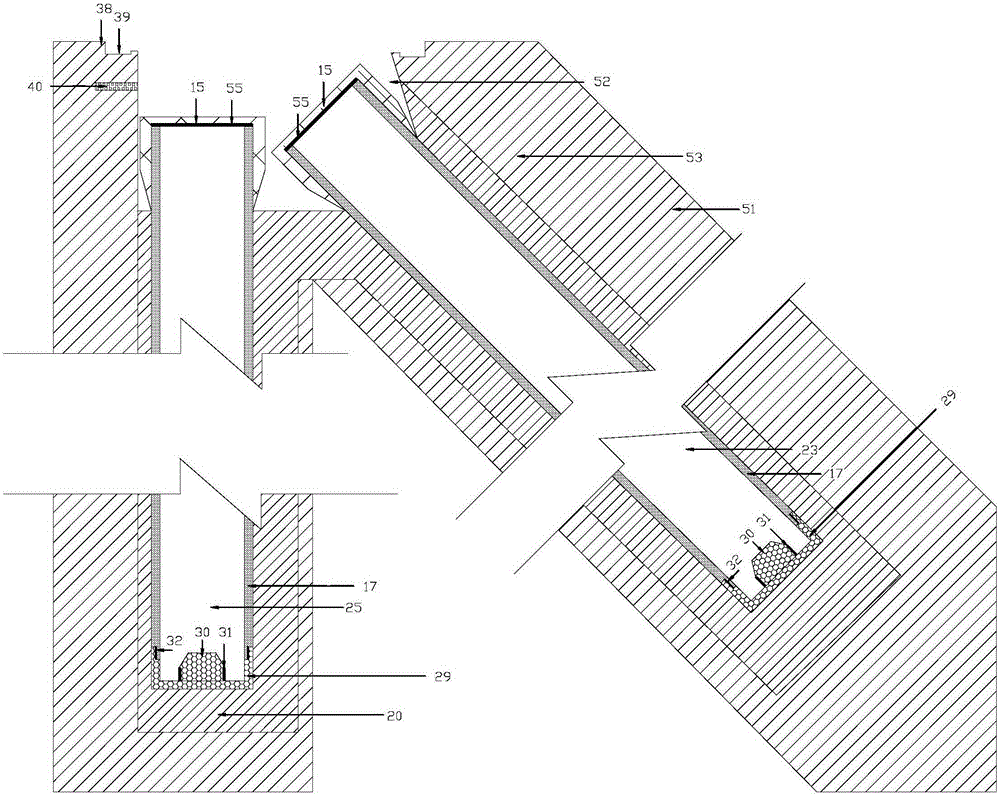

A multifunctional testing platform and testing method for a microseismic system

InactiveCN103558649BVerification accuracyVerify the impact of positioning accuracyGeological measurementsFunctional testingEngineering

The invention discloses a multifunctional testing platform for a microseismic system, which includes a microseismic signal collection and transmitting device, and further includes first to fourth microseismic monitoring wells arranged uniformly and clockwise on the outer circle sequentially, and sequentially arranged evenly and clockwise on the inner circle. For the fifth to eighth microseismic monitoring wells, the outer circle and the inner circle have the same center, and a microseismic signal transmission well is set at the center of the circle. The first microseismic monitoring well is located in the east of the microseismic signal transmission well, and the fifth microseismic monitoring well is located In the southeast of the vibration signal transmission shaft, the microseismic monitoring sensors installed in the first to eighth microseismic monitoring wells are respectively connected to the microseismic signal acquisition and transmission devices. The invention also discloses a method for testing the positioning accuracy of the microseismic source, which can use the positioning algorithm to be tested to locate the position of the vibration source according to the monitored microseismic signal, and compare it with the position of the real vibration source to determine the positioning accuracy of the microseismic source. Position the pros and cons of the algorithm and end the test.

Owner:INST OF ROCK & SOIL MECHANICS CHINESE ACAD OF SCI

An electronic variable valve timing system function test device and test method thereof

ActiveCN108106853BMeet the needs of mass productionEfficient and accurate performance testingEngine testingFunctional testingVariable valve timing

Owner:JAPHL POWERTRAIN SYST

Method for testing mechanical property of inert gas closed cycle radial flow type impeller

ActiveCN112610520AAchieve recyclingSave energyPump controlSafety/regulatory devicesTurbochargerProcess engineering

The invention discloses a method for testing mechanical property of an inert gas closed cycle radial flow type impeller based on a turbocharger structure. The method comprises the steps: by taking the turbocharger as a basic structure, replacing an original centripetal turbine or a centrifugal compressor of the turbocharger with the tester, and taking the centrifugal compressor of the turbocharger as as a power consumption device or taking the centripetal turbine of the turbocharger as a power device. The tester, a heater, a heat regenerator and a cooler form a closed loop with inert gas as a working medium through pipelines and valves, and closed cyclic utilization of the inert gas is achieved by cooperatively controlling a plurality of test devices. The method has the remarkable characteristics of ingenious and reasonable structural design, resource saving and the like, and is prone to large-scale popularization and application.

Owner:BEIJING POWER MACHINERY INST

A vertical numerically controlled milling machine simulating cutting force loading device and using method

ActiveCN109000947BReduce the cost of performance testingMaintain good performanceStructural/machines measurementNumerical controlStructural engineering

A vertical CNC milling machine simulated cutting force loading device and a method of use, including an X-direction cutting force loading component, a Y-direction cutting force loading component, a Z-direction cutting force loading component and a torque loading component. The steps to use it are: hoist the simulated cutting force loading device to the machine tool workbench for fixation, secure the machine tool tool spindle to the center piece rod, connect the Z-direction corrugated damping tube to the hydraulic system, and start the hydraulic pressure maintaining system. ; Set a set of cutting forces by adjusting the tightening of the bolts and sliders and adjusting the opening of the throttle valve, start the machine tool and run the processing program, truly simulate the actual operating status of the machine tool under stress conditions, and test the current Machine tool performance under cutting force conditions. The device and its use method can truly simulate the stress conditions during the actual processing of the machine tool without consuming physical materials and processing tools, effectively reducing the cost of machine tool performance testing, ensuring excellent machine tool performance while reducing machine tool manufacturing costs.

Owner:NORTHEASTERN UNIV LIAONING

Water pump efficiency, flow and head detection method and system

ActiveCN105673474BReduce the cost of performance testingHigh precisionPump testingPump controlFrequency changerTest efficiency

The invention relates to a water pump efficiency, flow and lift detection method and system. The method comprises the steps of obtaining the output power f and the output frequency P<f>, <output>, of a frequency changer, wherein the frequency changer is in signal connection with a water pump; and according to the output power f and the output frequency P<f>, <output>, of the frequency changer, calculating the flow Qf, the lift Hf and the efficiency Eta f of the water pump. According to the water pump efficiency, flow and lift detection method and system, a controller reads the output power and the output frequency of the frequency changer; and according to the output power and the output frequency of the frequency changer, the flow, lift and efficiency of the water pump can be calculated. The structure is simple, and measurement can be achieved without installing of a pressure sensor and a flow meter; meanwhile, through PID real-time control and measurement display, the precision of measured water pump performance data is high, errors brought by manual measurement and treatment are overcome, the measurement efficiency is improved, high precision and high automation of the water pump performance measurement are achieved, the water pump performance measurement cost is reduced, and the measurement time is shortened.

Owner:SHENZHEN XINHUANNENG TECH

A test method for the characteristics of a closed cycle centrifugal compressor

ActiveCN111379727BAchieve recyclingSave energyPump controlNon-positive displacement fluid enginesControl theoryTurbine

The invention discloses a method for testing the characteristics of a closed cycle centrifugal compressor. The process is as follows: inject an inert mixed gas into the closed cycle loop, drive a centripetal turbine through the air supplied by an air source, and drive the centripetal turbine coaxially with it. The compressor tester rotates; according to the set working conditions, adjust the speed of the centripetal turbine, so that the open loop enters the speed closed-loop control state; when the airflow parameters at the inlet and outlet of the compressor tester are stable, measure the thermodynamic parameters of the inlet and outlet; By adjusting the rotational speed of the centripetal turbine in the open circulation loop, the compressor tester is simultaneously adjusted to other rotational speeds to be tested, and the measurement and recording of all characteristic line data points are completed in sequence. The invention can realize the matching change of the equivalent flow rate and the equivalent rotational speed of the compressor tester, meet the requirement of variable working conditions in the performance test of the centrifugal compressor, and greatly reduce the adjustment and control difficulty of the performance test of the centrifugal compressor components.

Owner:BEIJING POWER MACHINERY INST

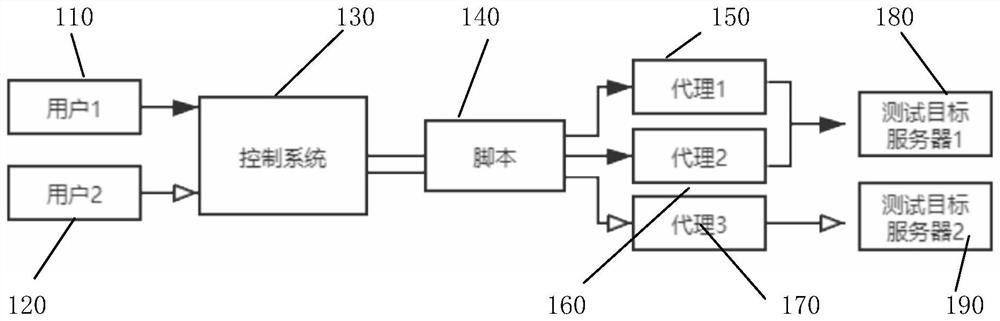

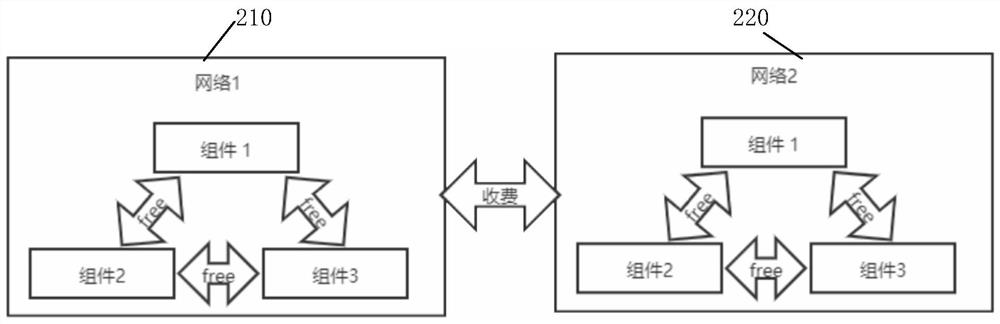

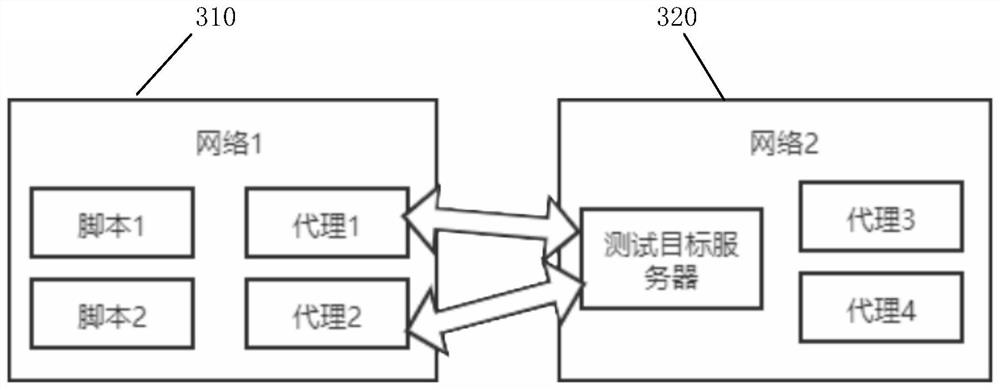

Test method and system for reducing performance test cost in cloud environment

InactiveCN112087340AReduce the cost of performance testingLow costData switching networksReal-time computingDistributed computing

The invention relates to the field of performance testing, aims to solve the problem of relatively high performance testing cost in an existing cloud environment, and provides a test method and systemfor reducing the performance test cost in a cloud environment. The technical scheme is summarized as follows: the method comprises steps of receiving network information input by a user, and selecting at least one agent in a network corresponding to the network information; and receiving target server information input by the user, verifying whether a server corresponding to the target server information exists in a network corresponding to the network information or not, if so, transmitting the target server information to the selected at least one agent, and otherwise, stopping access to the network or the server. Unnecessary cost caused by flow among networks and network changes can be reduced, more accurate performance test results and system stability can be provided, and the methodis suitable for performance test in a cloud environment.

Owner:SICHUAN CHANGHONG ELECTRIC CO LTD

A five-axis double swing head gantry milling machine simulating cutting force loading device and using method

ActiveCN105817954BReduce the cost of performance testingReduce manufacturing costMeasurement/indication equipmentsStress conditionsEngineering

Owner:NORTHEASTERN UNIV LIAONING

A three-axis boring machine simulation cutting force loading device and its use method

ActiveCN105865823BReduce the cost of performance testingMaintain good performanceStructural/machines measurementEngineeringCutting force

A three-axis boring machine simulated cutting force loading device and its use method. The device includes a rigid frame, an X-direction position adjustment component, a Y-direction cutting force loading component, a Z-direction position adjustment component and a tool rotation cutting force loading component. The method steps are: Lift the simulated cutting force loading device to the machine tool workbench, adjust and fix the position of the simulated flat rotating plate through the X-direction and Z-directed position adjustment components, and securely connect the simulated flat rotating plate and the boring tool bar on the machine tool flat rotating plate. ; Set a set of cutting forces, and use a torque wrench to tighten the pre-tightening bolts in the cutting force loading assembly in the Y direction and the tool rotation direction, so that the friction force in the cutting force loading assembly is equal to the set cutting force. Since the friction force cannot be read directly, the tightening torque needs to be calculated through the formula M=KFd / μ before reading; start the machine tool and run the processing program to truly simulate the actual operating status of the machine tool under stress conditions and test the current cutting force conditions. Lower machine tool performance.

Owner:NORTHEASTERN UNIV LIAONING

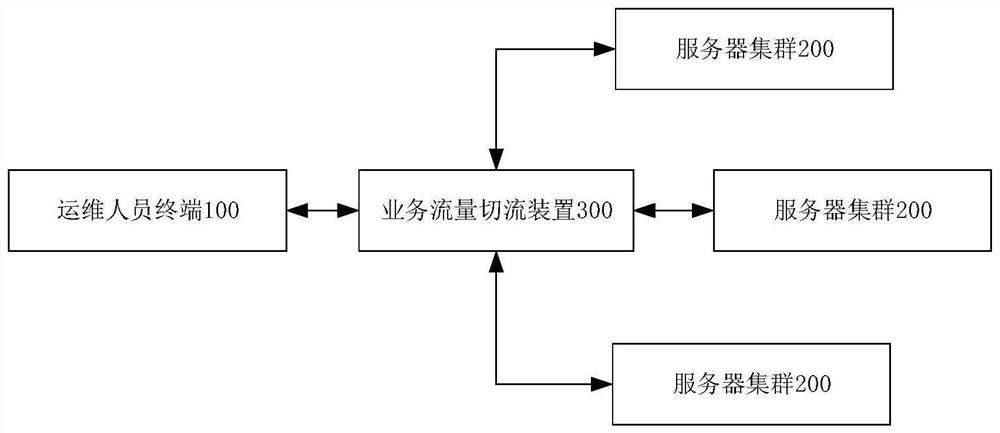

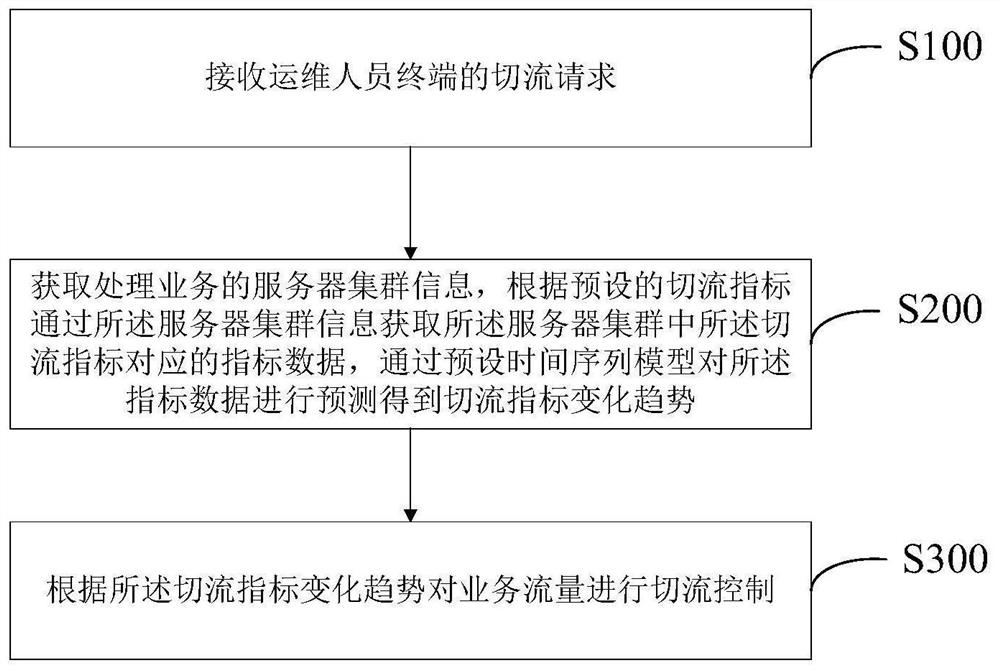

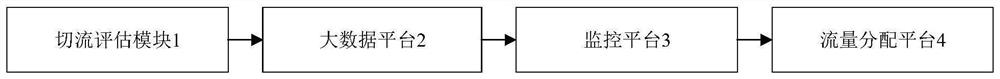

Service flow cutting method and device based on time sequence model

PendingCN114051000ARealize cutting flow controlImprove convenienceFinanceHardware monitoringService flowEngineering

The invention provides a service flow cutting method and device based on a time sequence model, which can be used in the technical field of artificial intelligence, and the method comprises the steps: receiving a flow cutting request transmitted by an operation and maintenance personnel terminal; obtaining server cluster information for processing a service, obtaining index data corresponding to a flow cutting index in a server cluster through the server cluster information according to the preset flow cutting index, and predicting the index data through a preset time sequence model to obtain a flow cutting index change trend; according to the flow switching control method and device, predicting the flow switching index change of the server cluster for service processing through the preset time sequence model to obtain the flow switching index change trend, so that the cost of performance testing is reduced; and the accuracy of predicting the change trend of the system flow switching index and the stability of server cluster service processing are improved.

Owner:INDUSTRIAL AND COMMERCIAL BANK OF CHINA

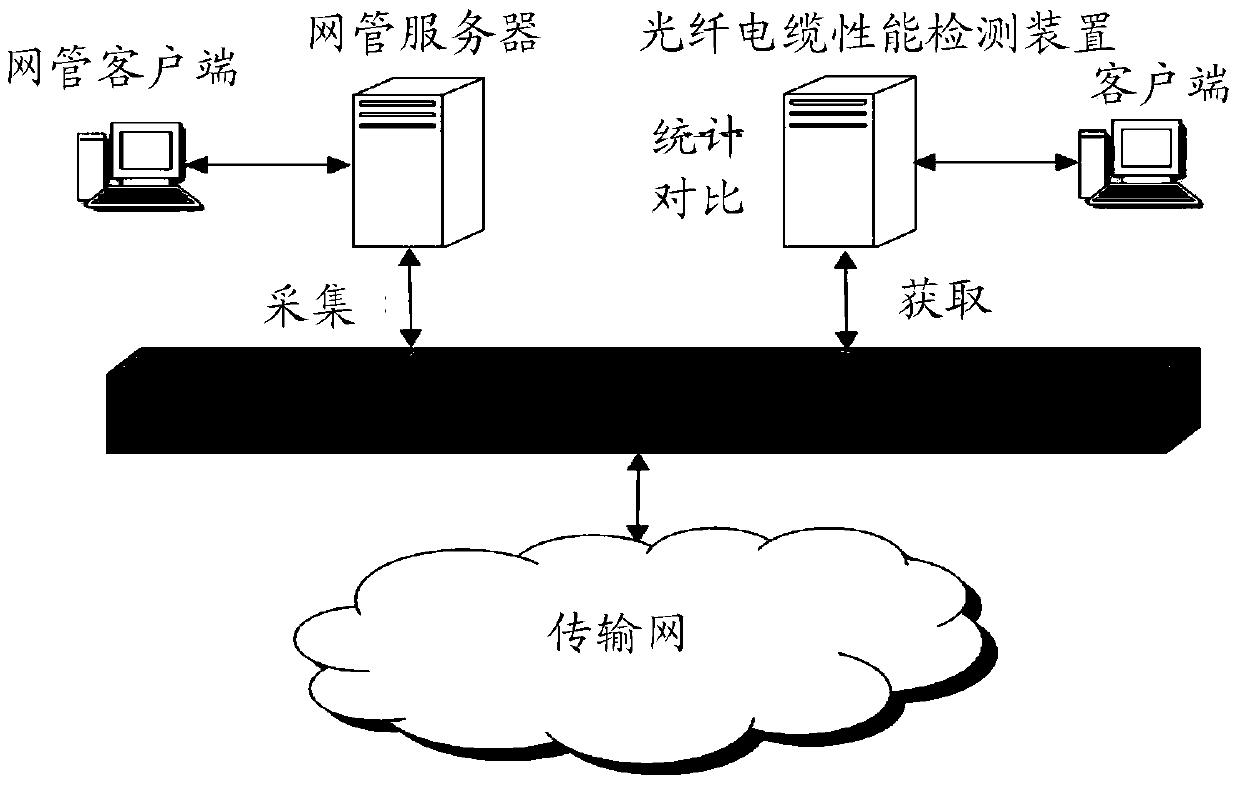

A method and device for detecting the performance of an optical fiber cable

ActiveCN105515649BImprove performance detection efficiencyImprove performance detection accuracyElectromagnetic transmissionUltrasound attenuationFiber

The invention discloses a method and device for detecting the performance of an optical fiber cable. The method is that the performance detecting device for an optical fiber cable calculates the nominal optical power of the corresponding optical fiber cable according to the nominal optical power and attenuation parameters of the optical amplifier board corresponding to each section of the optical fiber cable ; and compare the actual optical power of each section of optical fiber cable obtained from the network management server with the nominal optical power of the corresponding optical fiber cable respectively, and use the optical fiber cable whose comparison result is not within the preset normal attenuation value range as Optical fiber cables with performance hazards; output the detection results of all optical fiber cables with performance hazards. By adopting the technical solution of the present invention, through the optical fiber cable performance detection device, the identification of the optical fiber cable with potential performance hazards is determined, and no manual calculation is required to determine the optical fiber cables with potential performance hazards, thereby effectively improving the performance detection efficiency of optical fiber cables and greatly reducing the cost of performance detection. Improved performance detection accuracy.

Owner:CHINA MOBILE GROUP SHANDONG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com