Device for evaluating and testing interrupted cutting performance of tools at high speed

A technology of cutting performance and testing equipment, which is applied in the direction of manufacturing tools, measuring/indicating equipment, metal processing equipment, etc., can solve the problems of inability to cut the cylindrical end face intermittently, difficult to realize cutting test, and high production cost, so as to reduce the test cost, The effect of quick replacement, material and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

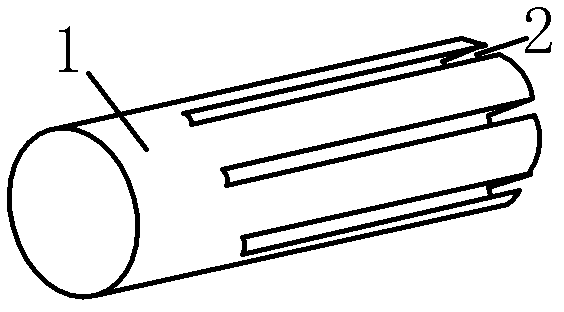

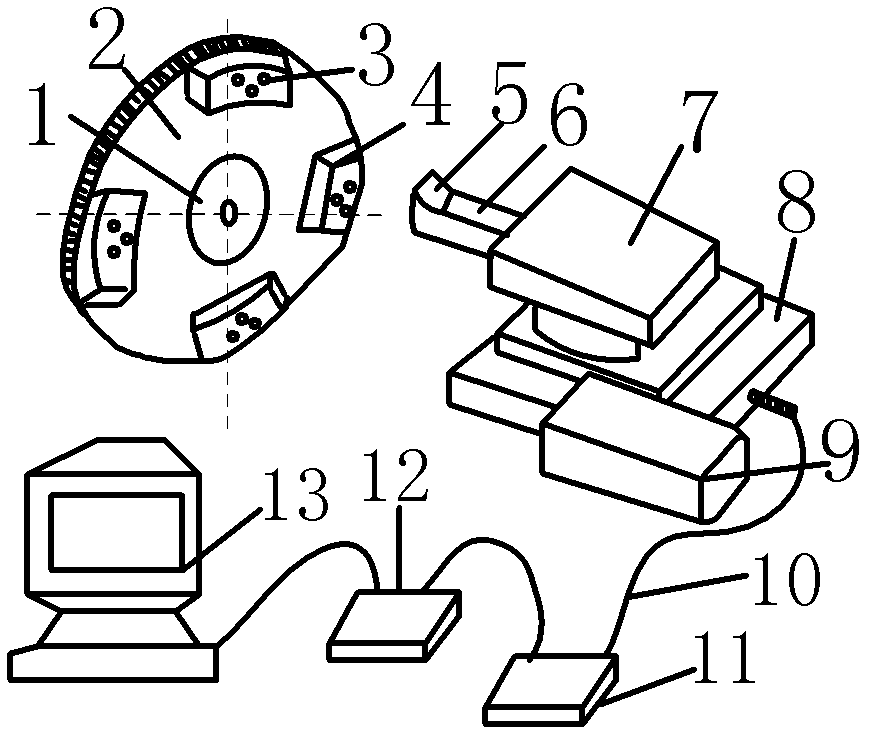

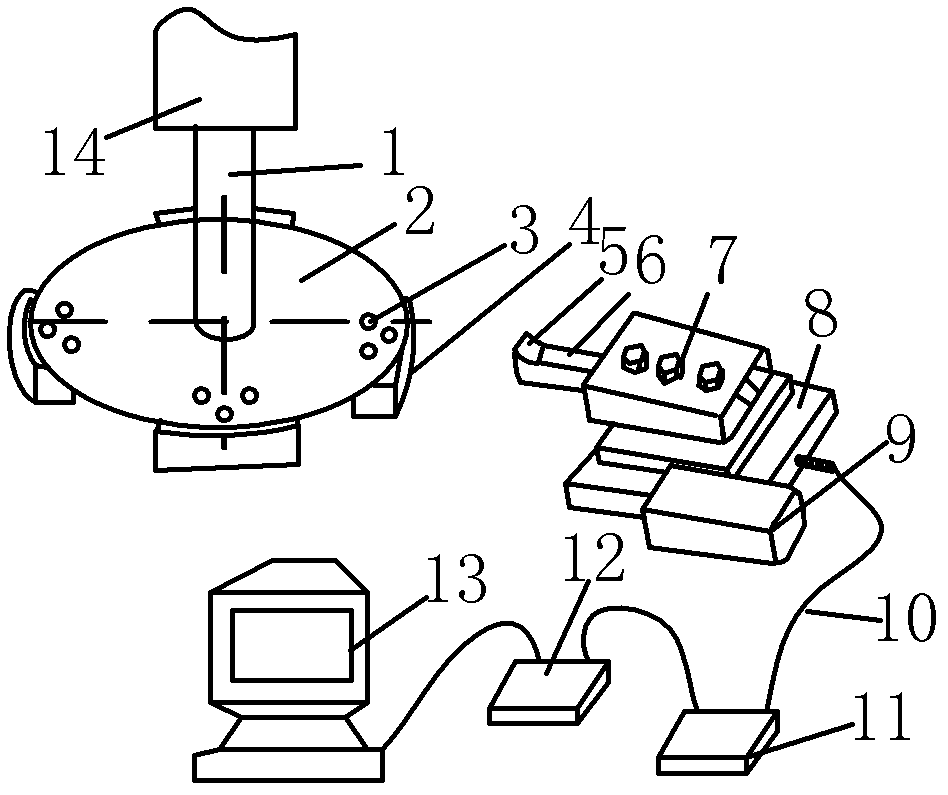

[0013] The tool high-speed interrupted cutting performance evaluation test device of the present invention is as follows: figure 1 and figure 2 As shown, it includes a rotary disc body 2, a tool bar 6, a tool holder 7, a piezoelectric force gauge 8, an infrared thermometer 9, a charge amplifier 11 and a computer 13. The tool bar 6 is installed on the tool holder 7, and the piezoelectric Type dynamometer 8 and infrared thermometer 9 are fixed on the tool rest 7, piezoelectric dynamometer 8 is connected with charge amplifier 11 through connection line 10, and charge amplifier 11 is connected with data acquisition card 12 in computer 13. The rotary disk body 2 is provided with a clamping part 1, and on the rotary disk body 2, an even number of workpiece block installation positions are symmetrically distributed at equal intervals on the same circle centered on the center of rotation. The locking screw 3 fixes and installs the workpiece block 4, which is reliable in positioning,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com