Patents

Literature

452results about How to "Prevent slagging" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

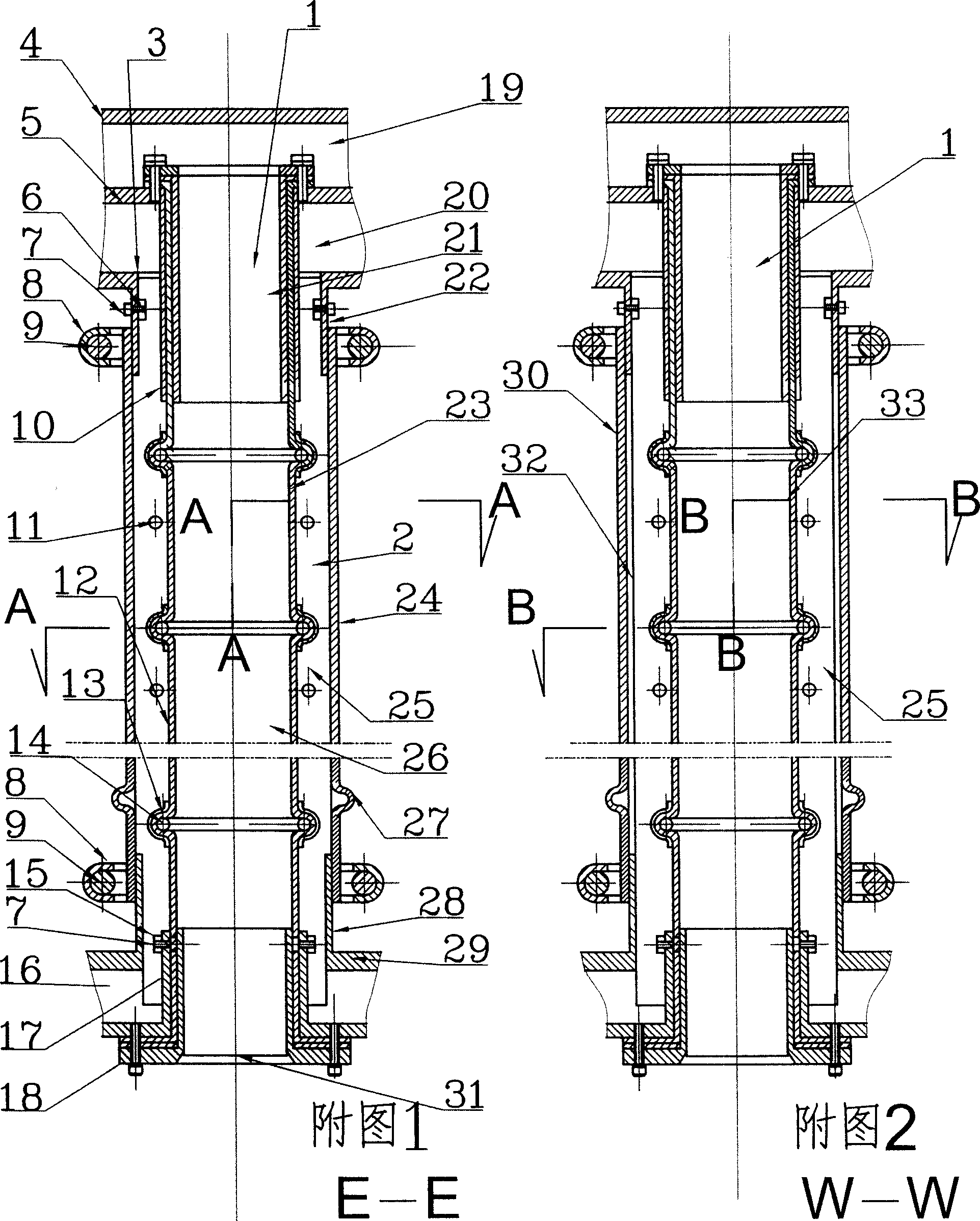

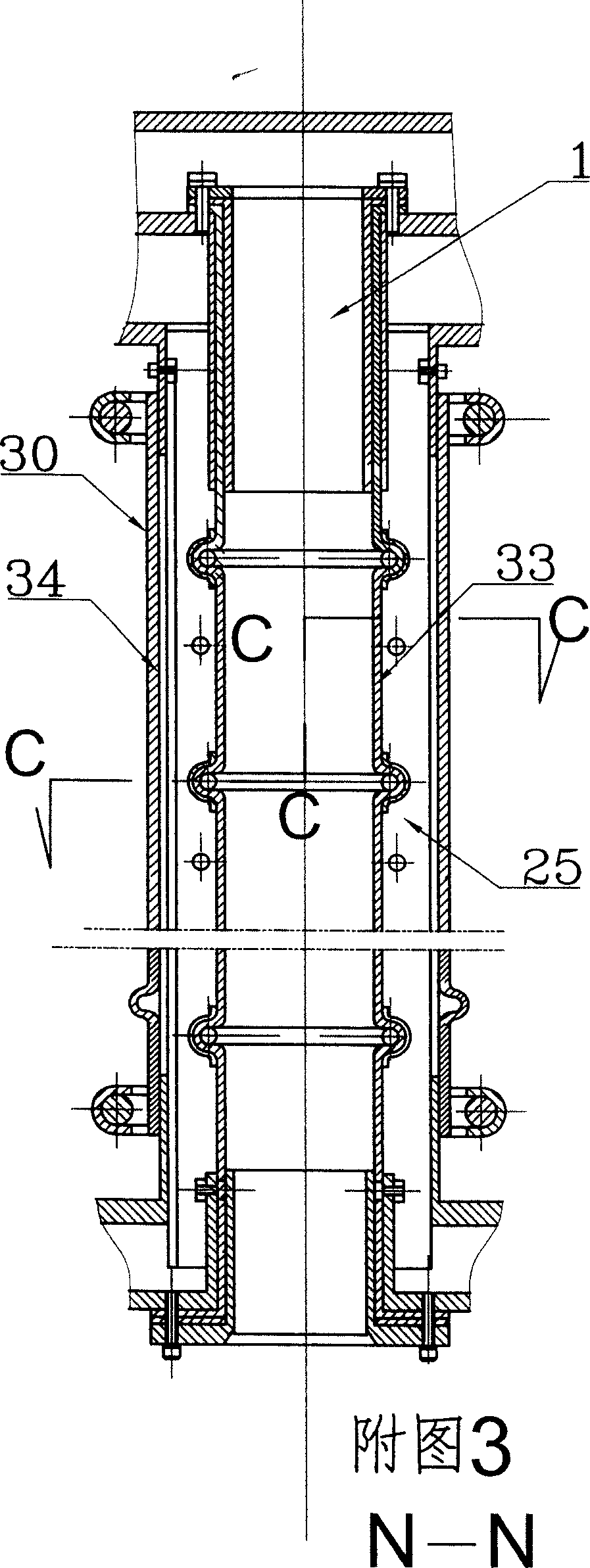

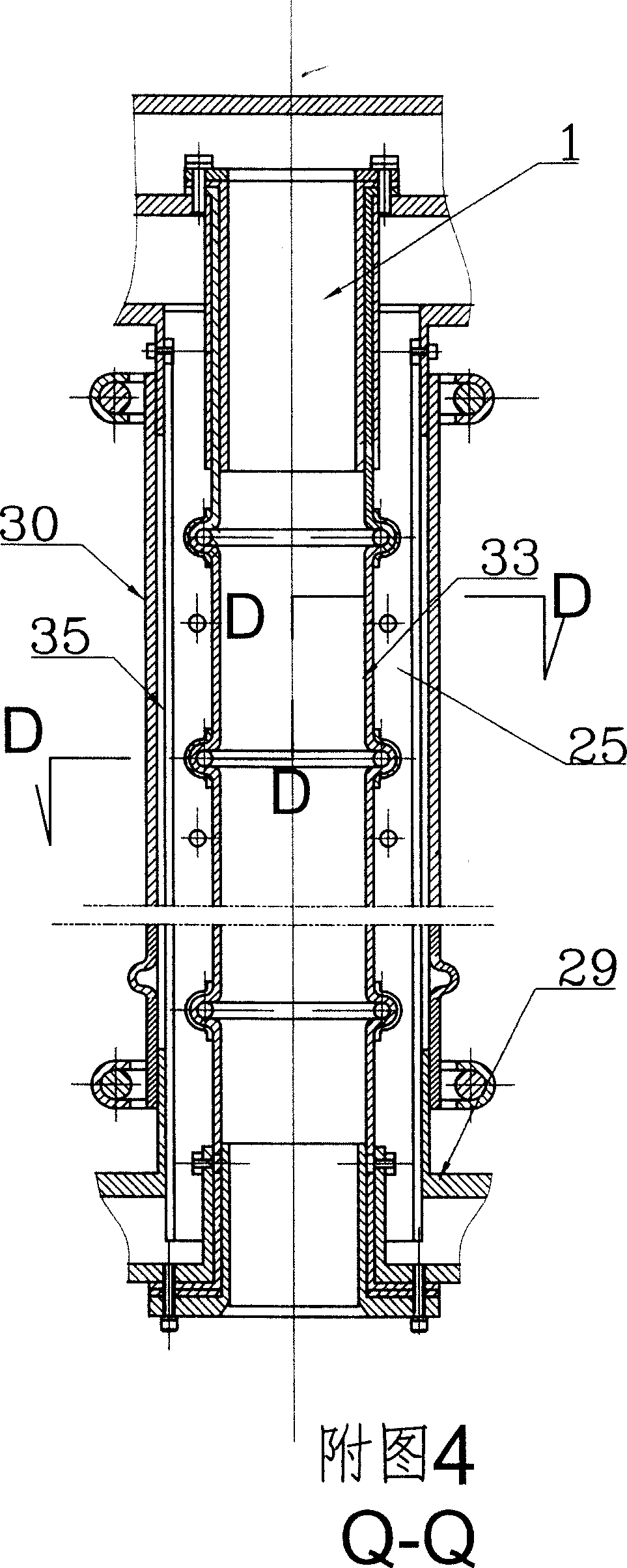

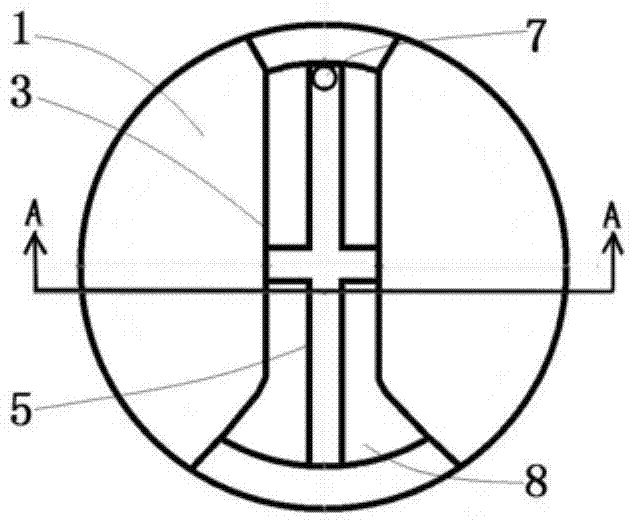

Flexible tube type solid-liquid processing machine with filtering, heat-exchange and hot compression function

InactiveCN1966129ALow costSimplify equipment componentsSemi-permeable membranesStationary filtering element filtersSlagEngineering

The invention relates to a flexible tubular solid liquid processor, with filter, heat exchange and thermal extraction functions, wherein the filter element at least comprises one flexible tubular membrane unit, upper flange room and lower flange room; the hydraulic extracting system comprises pressure container, extract pump and tubes; the material liquid of container can be filtered by the tubular filter membrane of membrane unit, and said material liquid can be used as work medium to extract the concentrated material liquid in the filter room of membrane unit and discharge filter slag; the pressure container or the filter room of membrane unit can be filled with medium to exchange heat, to realize thermal filter or extraction; the filter element is arranged on the bearing base inside the pressure container; the filter rotator can rotate the filter element to realize cross-flow filter; and the invention can be arranged with gas or water reverse tube and vacuum filter tube; the slag discharge system comprises slag discharger or tubular inner / outer membrane scraper, or vibration slag discharger, or compression slag discharger.

Owner:张民良

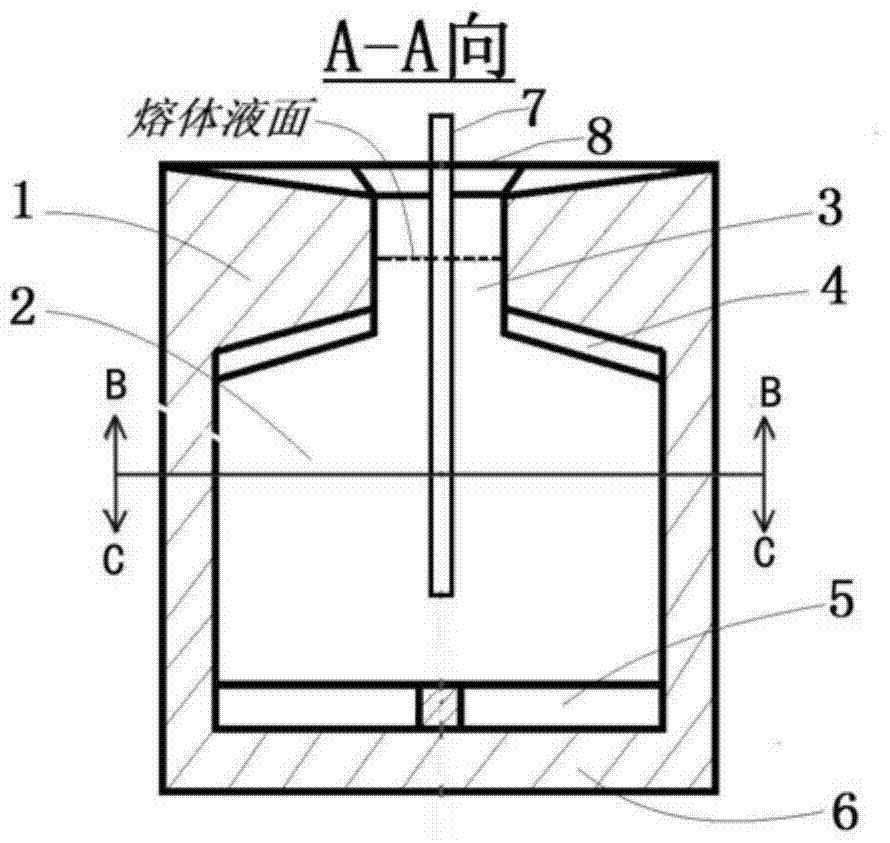

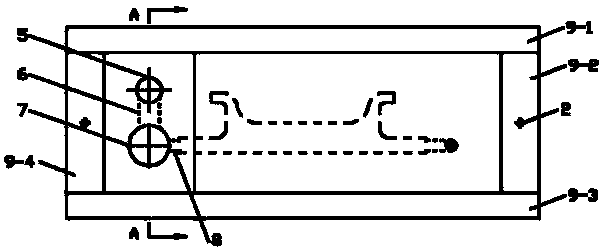

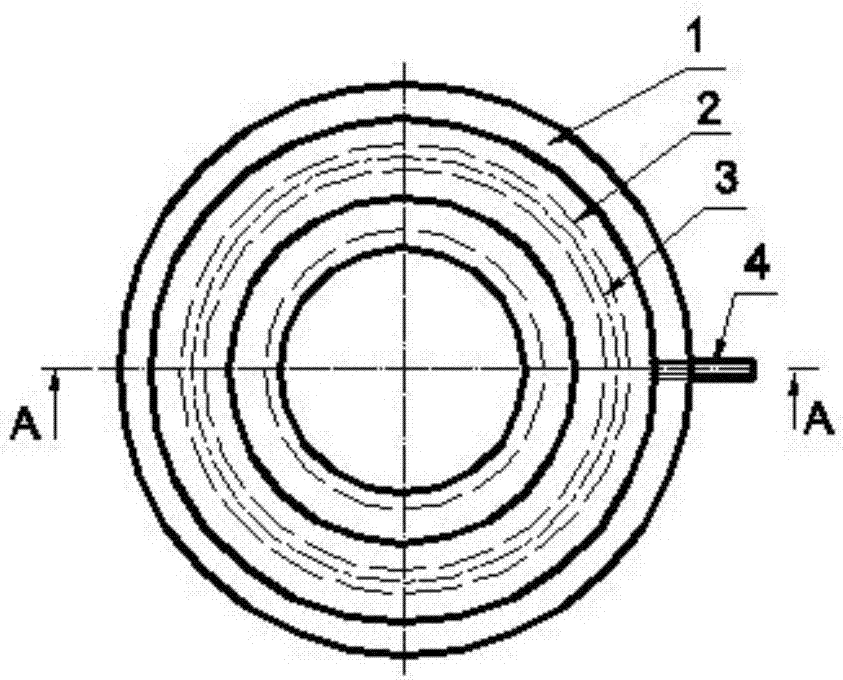

Stirring chamber for stirring molten metal and using method thereof

The invention discloses a stirring cavity used for stirring metal melt and a use method thereof, which belong to the field of material processing apparatuses for metallurgy, casting, chemical engineering and the like. The stirring cavity structurally consists of a melt container, a stirring cavity body, an upper stop opening, an upper blocking flange, a lower blocking flange, a lower bottom, a temperature sensor and a liquid taking / pouring port. According to the stirring cavity, the melt liquid level inside the stirring cavity is narrowed, so the stirring effect is effectively stopped from transferring to the liquid level, and the problems of melt oxidation and entrapped air risk are solved. The stirring cavity can be applied to various metal melt stirring and casting occasions; when the stirring cavity is used for batch-type casting such as pressure casting, the stirring cavity is adopted as the internal cavity structure of a pouring ladle; when the stirring cavity is used for continuous casting, the stirring cavity is adopted as the internal cavity structure of a melt hot top and can be directly connected with a continuous casting crystallizer; and full automation is realized in the whole process of melt stirring, chemical refining and casting in a pressure casting site.

Owner:GRIMAT ENG INST CO LTD

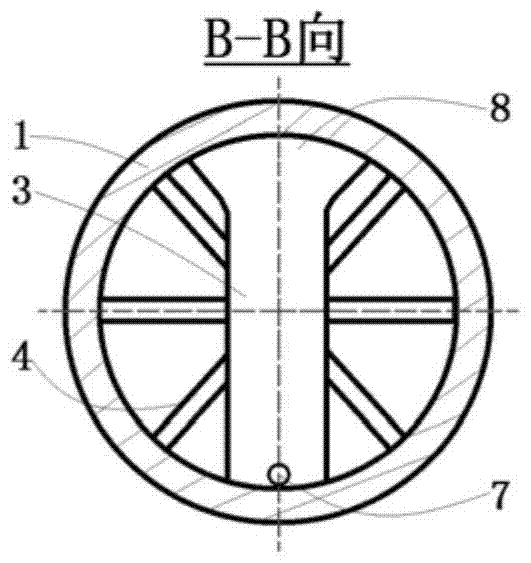

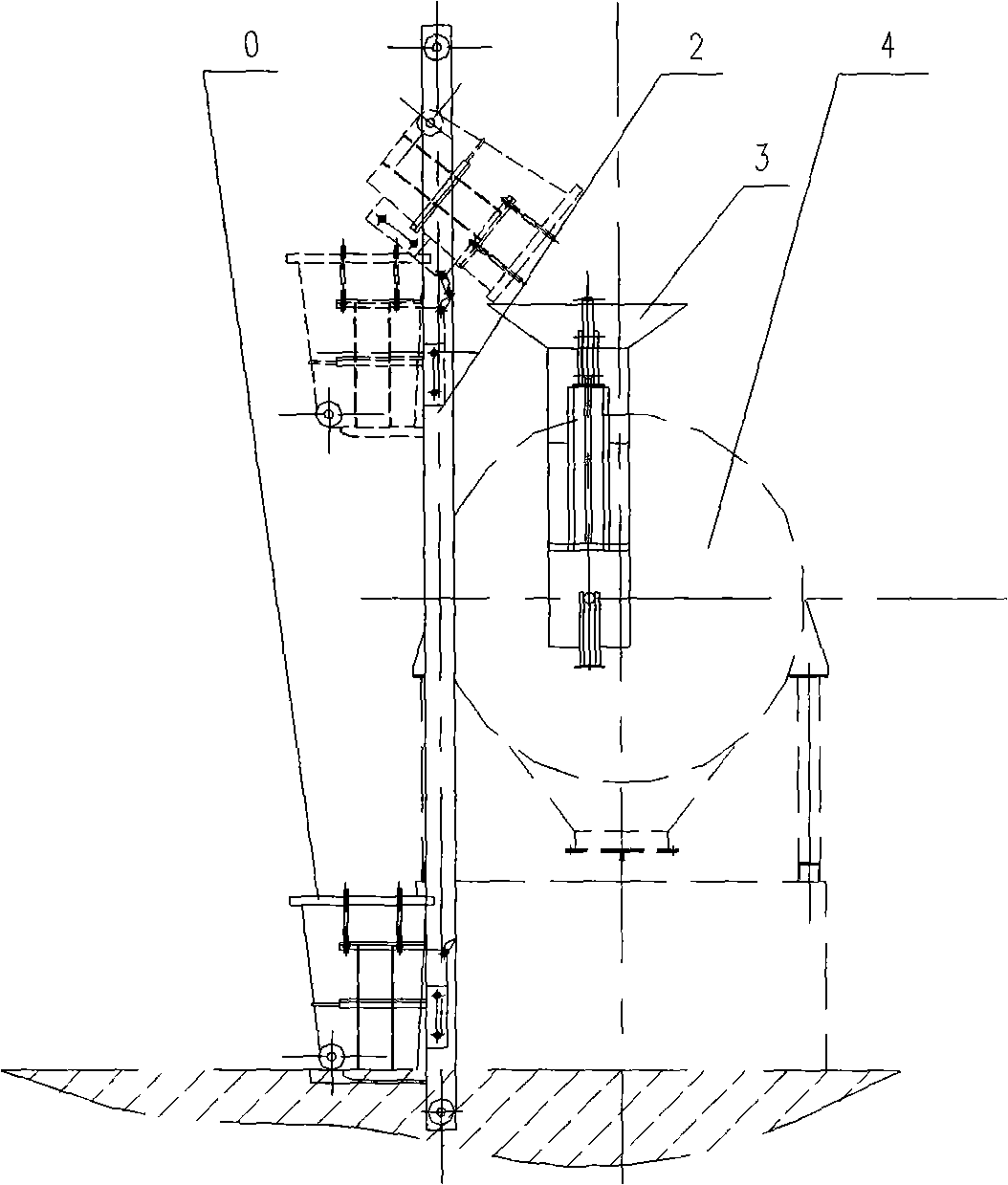

Pneumatic medical waste burning process for rotary kiln and device therefor

InactiveCN101285577AAvoid destructionAchieve turbulent combustionIndirect carbon-dioxide mitigationIncinerator apparatusCombustion chamberAtmospheric air

The invention discloses a process and a device for incinerating rotary kiln gas-controlled medical waste, relating to the environmental protection technical field. The process of the invention comprises the following steps of: collecting the whole packet of medical waste refuse bag and feeding into a feeding hopper, then feeding into a rotary kiln initial combustion chamber by a feeding mechanism which is closed by chain, and completing the processes of drying, pyrolyzing and air controlled anoxycausis of the medical waste. Waste gas generated by the rotary kiln initial combustion chamber enters to a secondary combustion chamber to undergo the process of air controlled oxygen-enriched complete combustion, wherein bottom ash with a little redial carbon is flamed at an inclined fire grate which is arranged in an ash well at the lower part of the secondary combustion chamber. The smoke gas at an outlet of the secondary combustion chamber is exhausted into the atmosphere by a draft fan through a chimney after surplus heat utilization of a surplus heat boiler, smoke gas sharp quenching of a quench tower, a dry-type deacidification and cloth-bag dust removal of a bag-type duster. Compared with the prior art, the process and the device for incinerating rotary kiln gas-controlled medical waste have the advantages of good operating economical efficiency, automatic safety continuous feeding, fluent slag tapping system and low index of pollution emission.

Owner:TSINGHUA UNIV +1

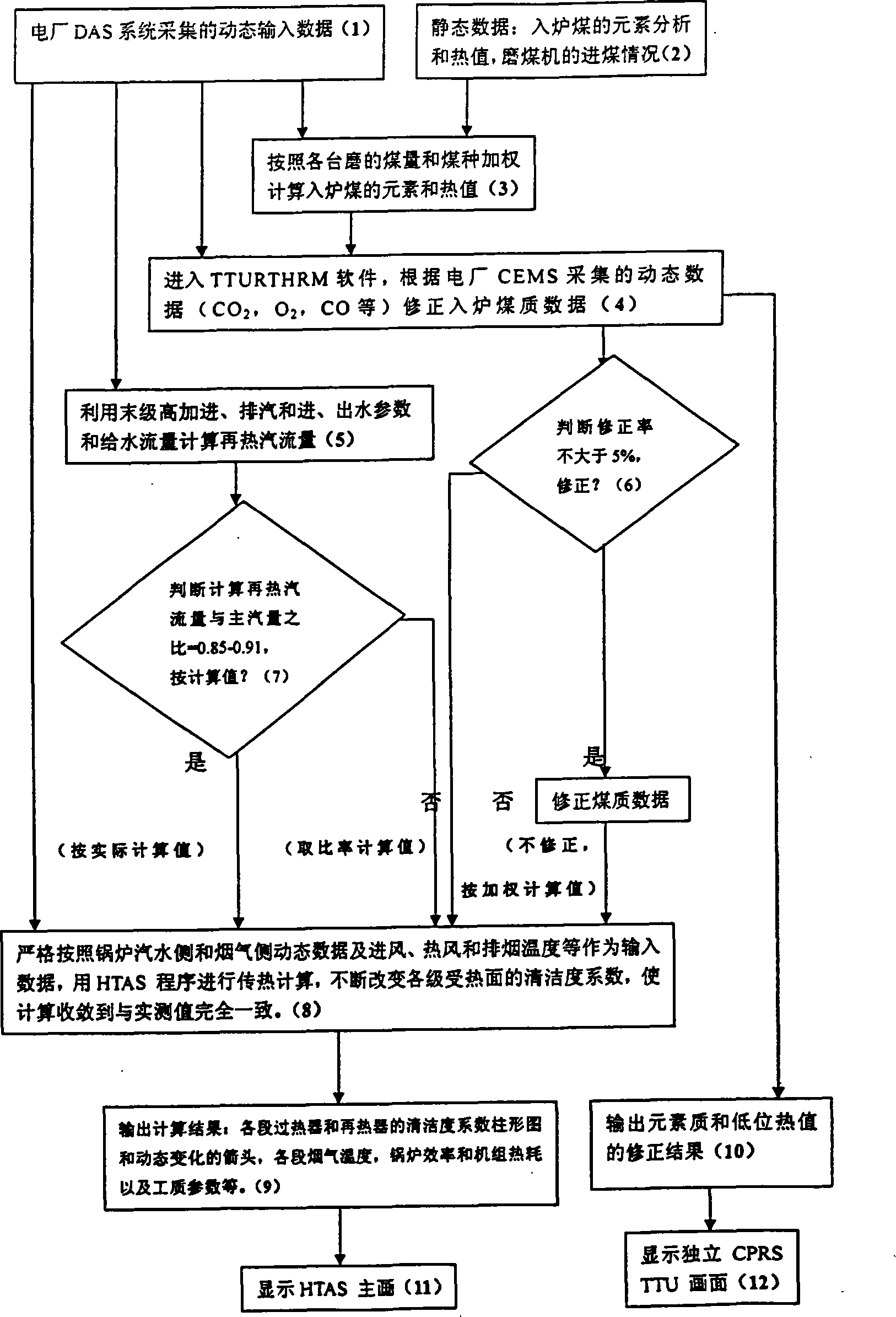

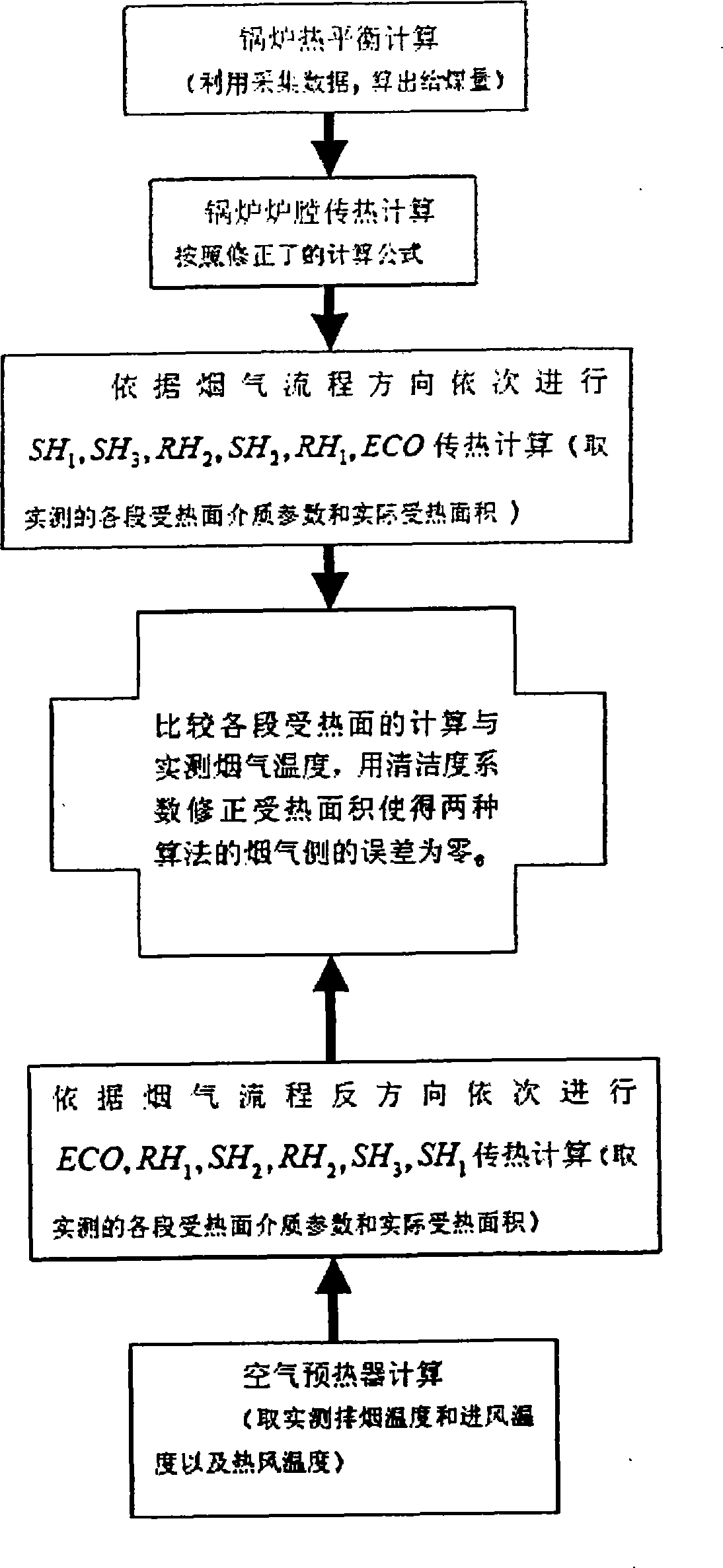

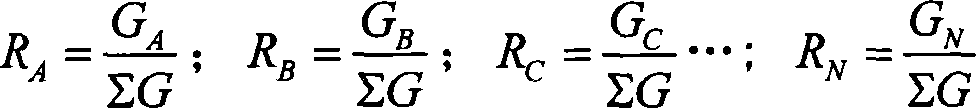

Online detecting, soot blowing and optimal energy-saving method for large coal-fired boiler

InactiveCN101034009AAccurate calculationSave fuelRadiation pyrometryBoiler indication operationsEngineeringSoot

This invention relates to a energy-saving method of large coal burning boiler's on-line measuring and soot blowing optimizing. The feature lays: the invention takes new developed HTAS procedure as main, combine with TTURTHERM procedure and infrared fume pyroscope, to form a integrated system that is able to accuracy and significance monitor and count large boiler heating surface cleanness degree, so to realize soot blowing-optimizing and energy-saving.

Owner:SHANGHAI POWER EQUIP RES INST

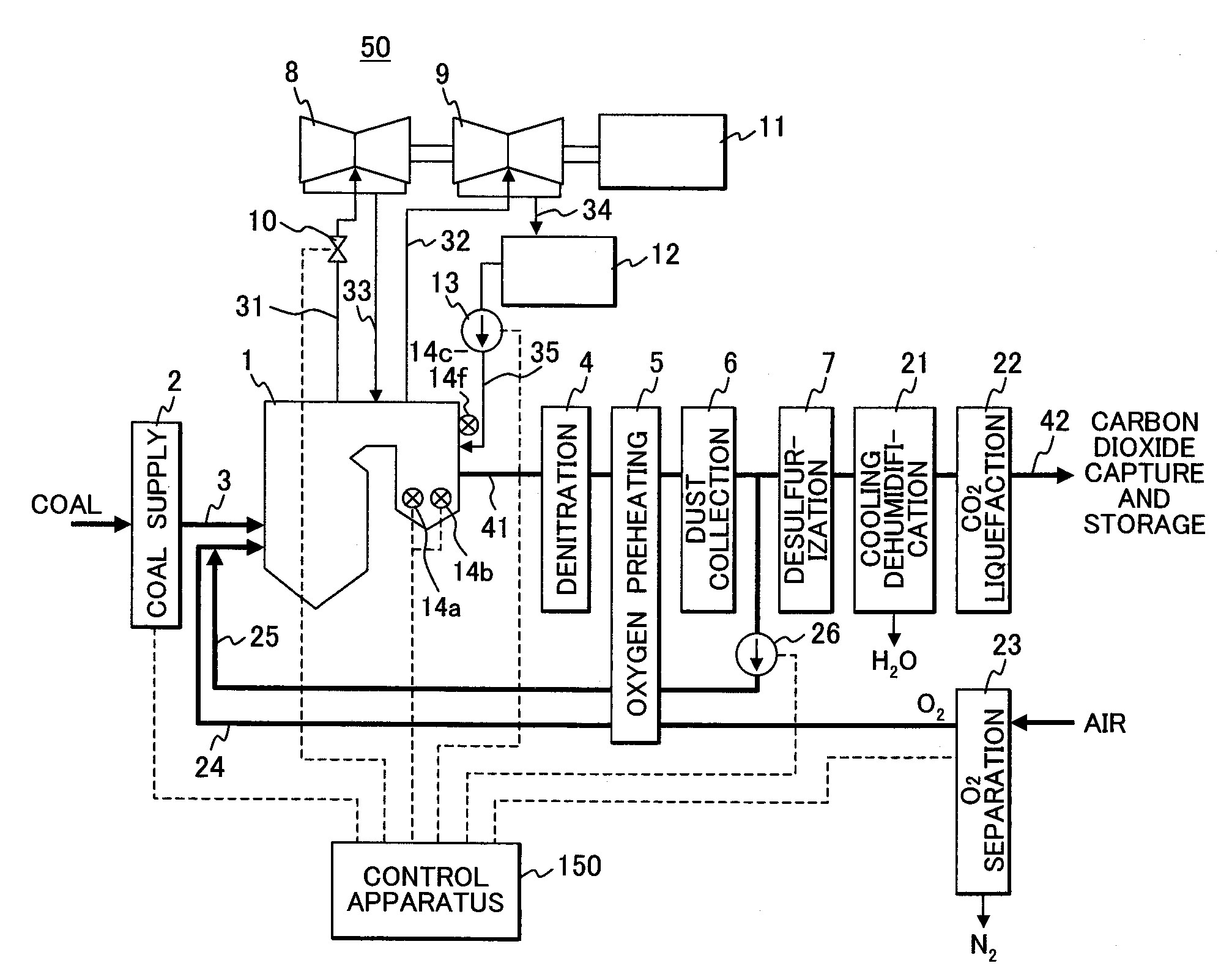

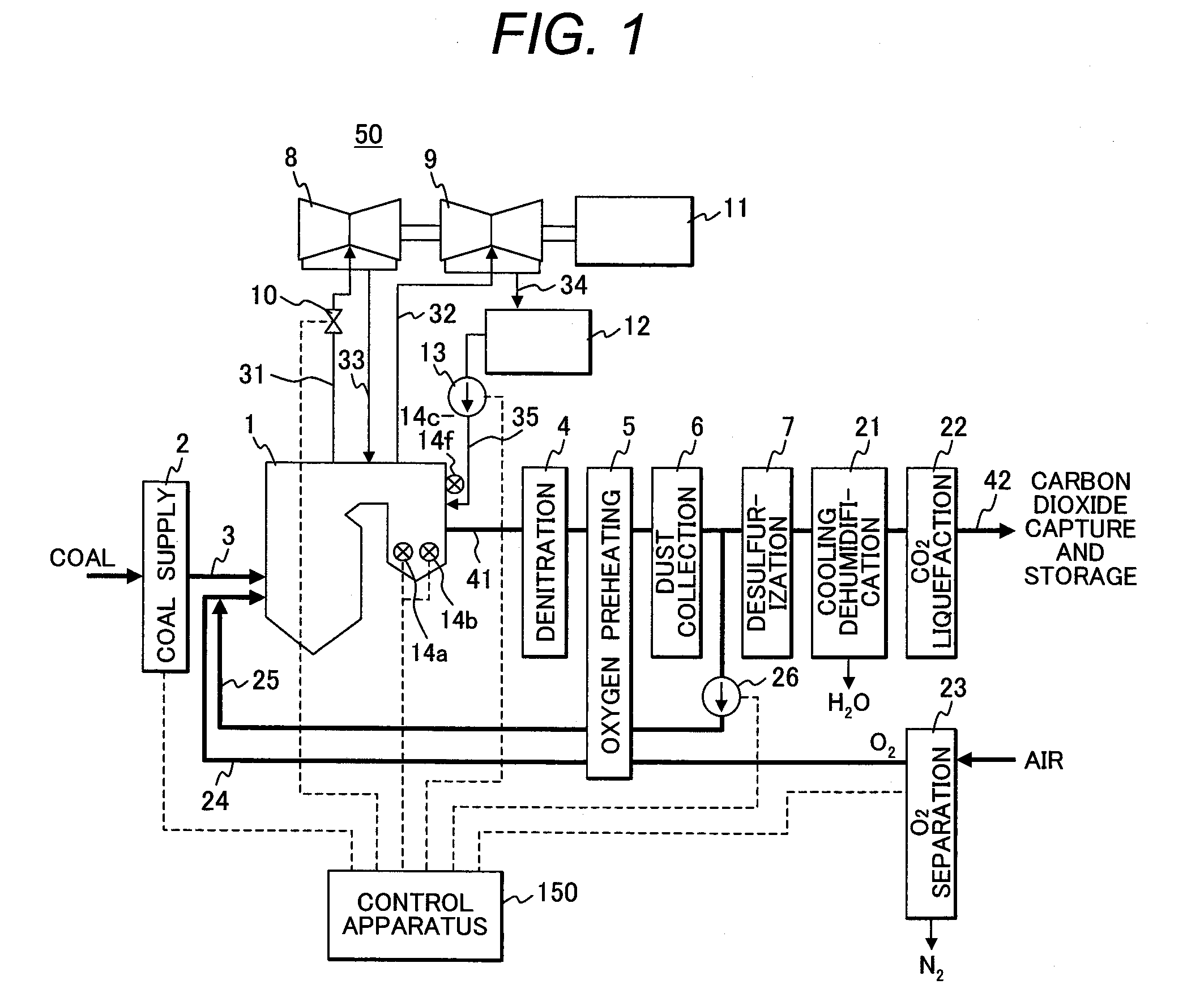

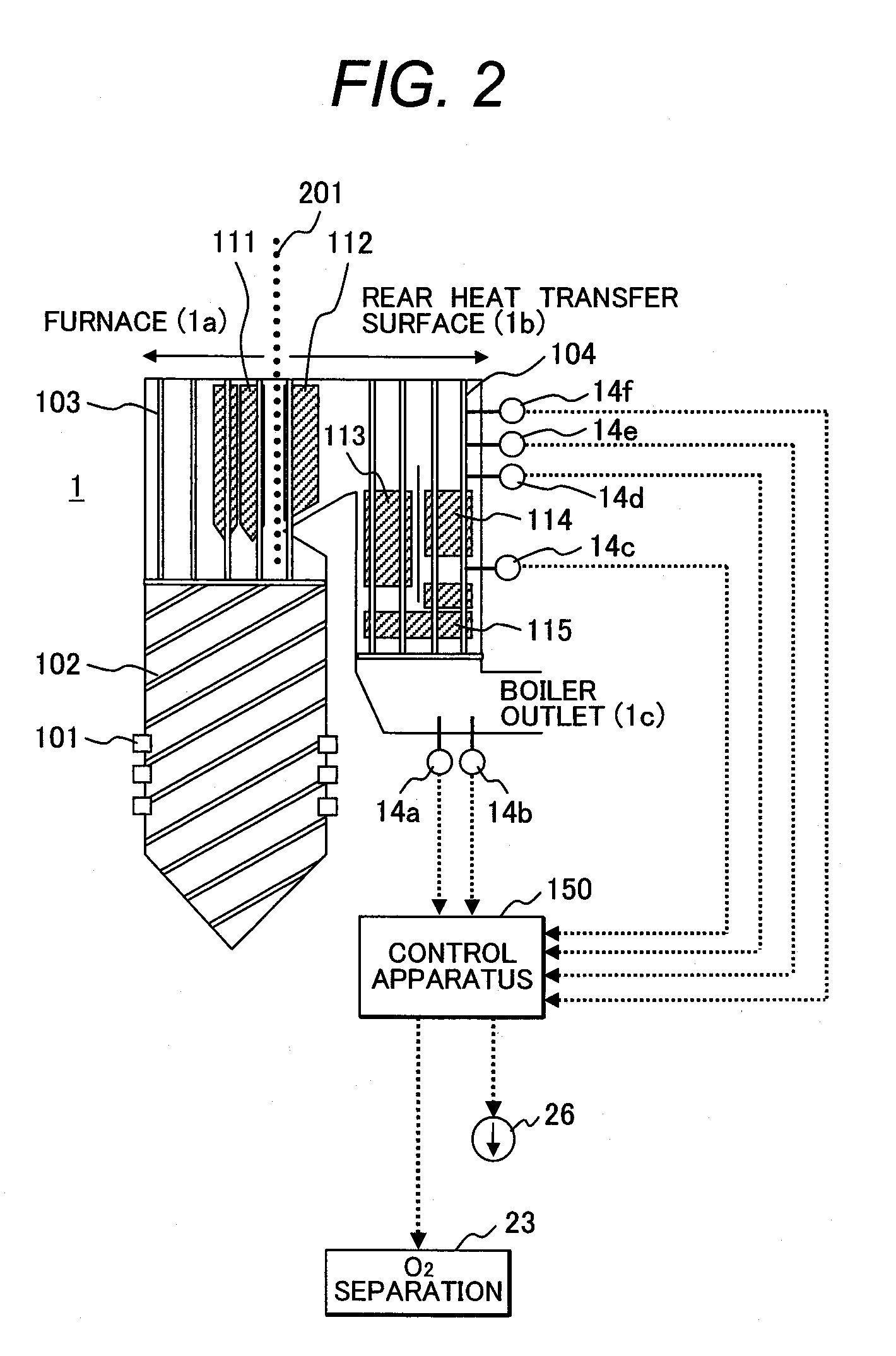

Oxyfuel Boiler and a Method of Controlling the Same

ActiveUS20100101462A1Cost reductionHigh reliabilityFluegas recirculationDirect carbon-dioxide mitigationBoiler furnaceProcess engineering

An oxyfuel boiler 1 is equipped with an oxygen separation apparatus 23 to produce oxygen by separating oxygen from the air, a recirculation fan 26 to supply a portion of combustion flue gas branched from the combustion flue gas discharged from the boiler to the oxyfuel boiler 1, a temperature sensor 14a to detect gas temperature at a boiler outlet 1d in the oxyfuel boiler 1, and a control apparatus 150 to calculate gas temperature at a furnace outlet 1c in the boiler from the gas temperature at the boiler outlet 1d detected by the temperature sensor 14a and control the operating condition of the recirculation fan 26 so that the calculated gas temperature at the furnace outlet 1c becomes a desired preset gas temperature.

Owner:MITSUBISHI POWER LTD

Control method for preventing nozzle clogging in casting process of ultra-low carbon-aluminium deoxidized molten steel

InactiveCN103451349AAvoid secondary oxidationImprove pourabilityMelt-holding vesselsManufacturing convertersSteelmakingCastability

The invention relates to a control method for preventing nozzle clogging in a casting process of ultra-low carbon-aluminium deoxidized molten steel, and belongs to the technical field of a steelmaking technology. The technical scheme is that a process path of molten iron desulfurization treatment, converter smelting, converter steel tapping, Rheinstahl Heraeus (RH) vacuum treatment, and continuous casting of a dual-flow slab is adopted to smelt ultra-low carbon steel, so that the castability of the ultra-low carbon-aluminium deoxidized molten steel is improved; the oxygen content of the molten steel of a converter blowing end-point, the carbon content and the temperature of the endpoint are reasonably controlled; a favorable condition is provided for RH vacuum decarburization; pouring is protected in a continuous casting manner; secondary oxidization of the molten steel is prevented by adopting blowing-argon sealing protection of a long-nozzle and a submersed nozzle; secondary oxidization of the molten steel is prevented by using an alkaline covering agent; an occluded foreign substance in the molten steel is well adsorbed; the castability of the ultra-low carbon-aluminium deoxidized molten steel is improved; the targets of no choking of the submersed nozzle and no change of the submersed nozzle in a complete multi-furnace continuous casting process are achieved. Thus, the effect on a casting blank caused by replacement of the submersed nozzle is avoided.

Owner:HBIS COMPANY LIMITED HANDAN BRANCH COMPANY

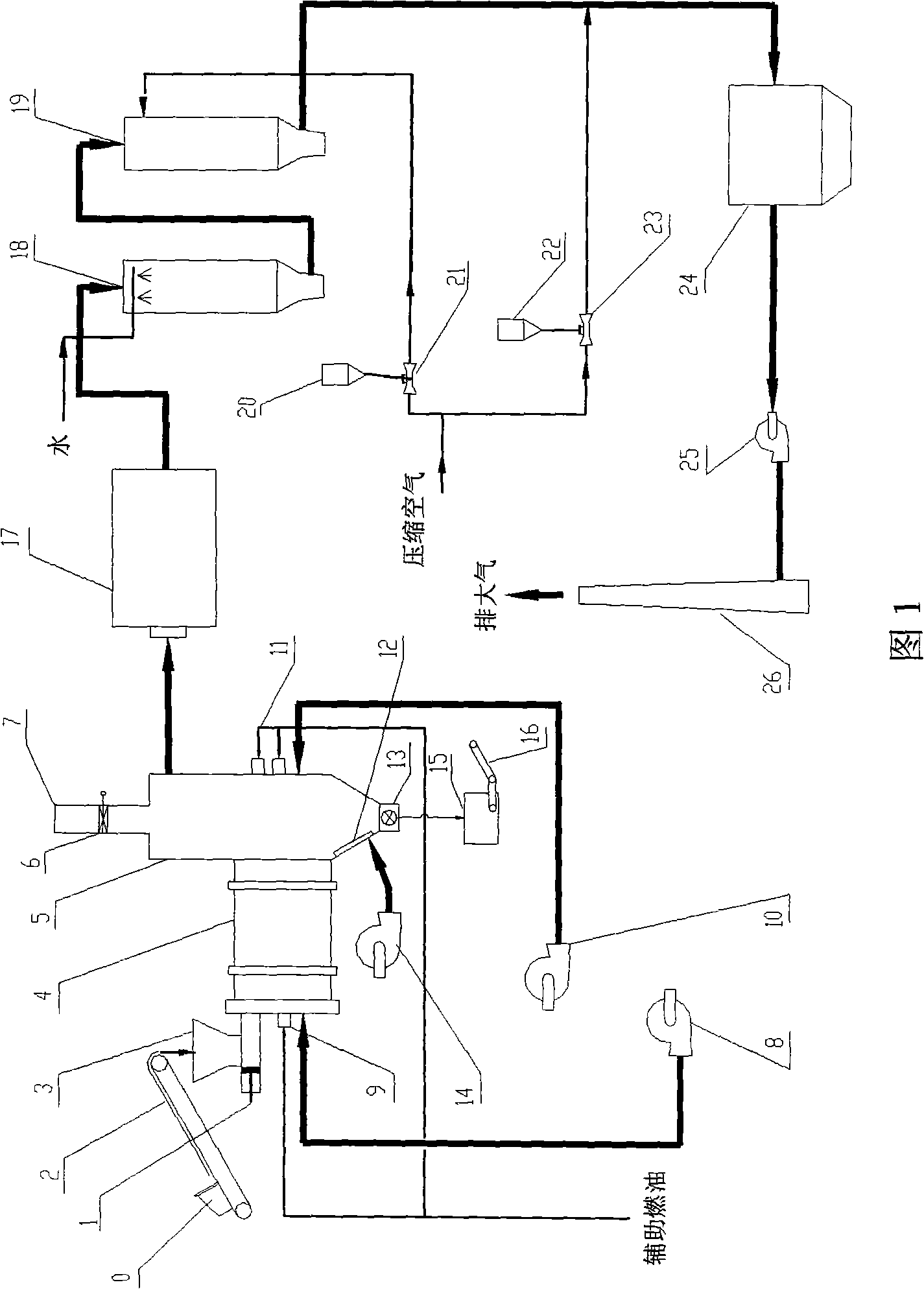

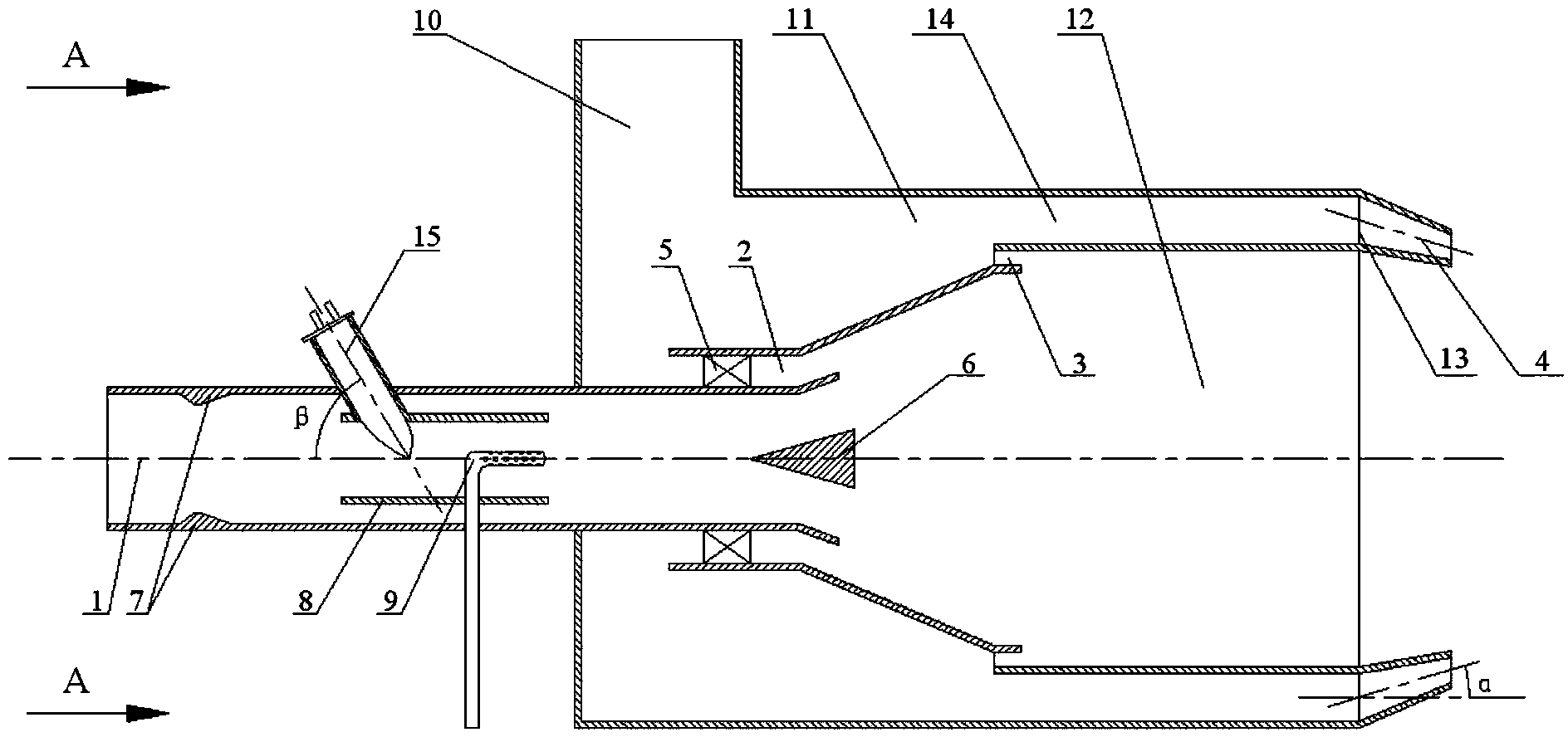

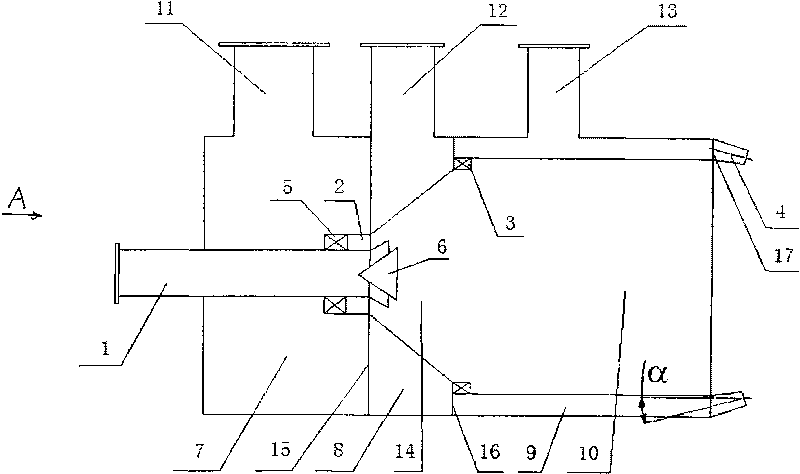

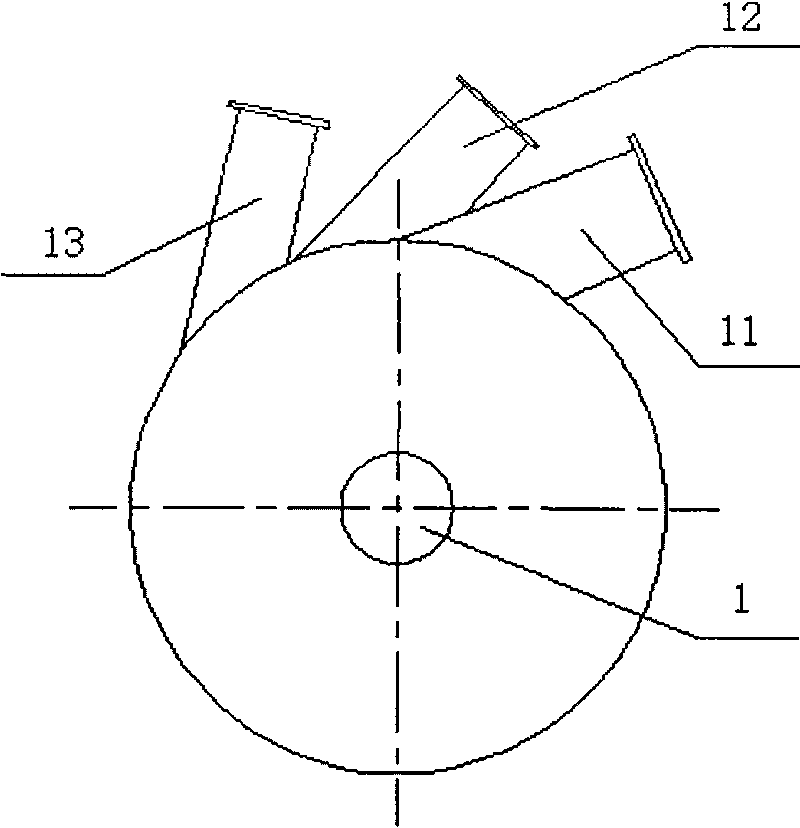

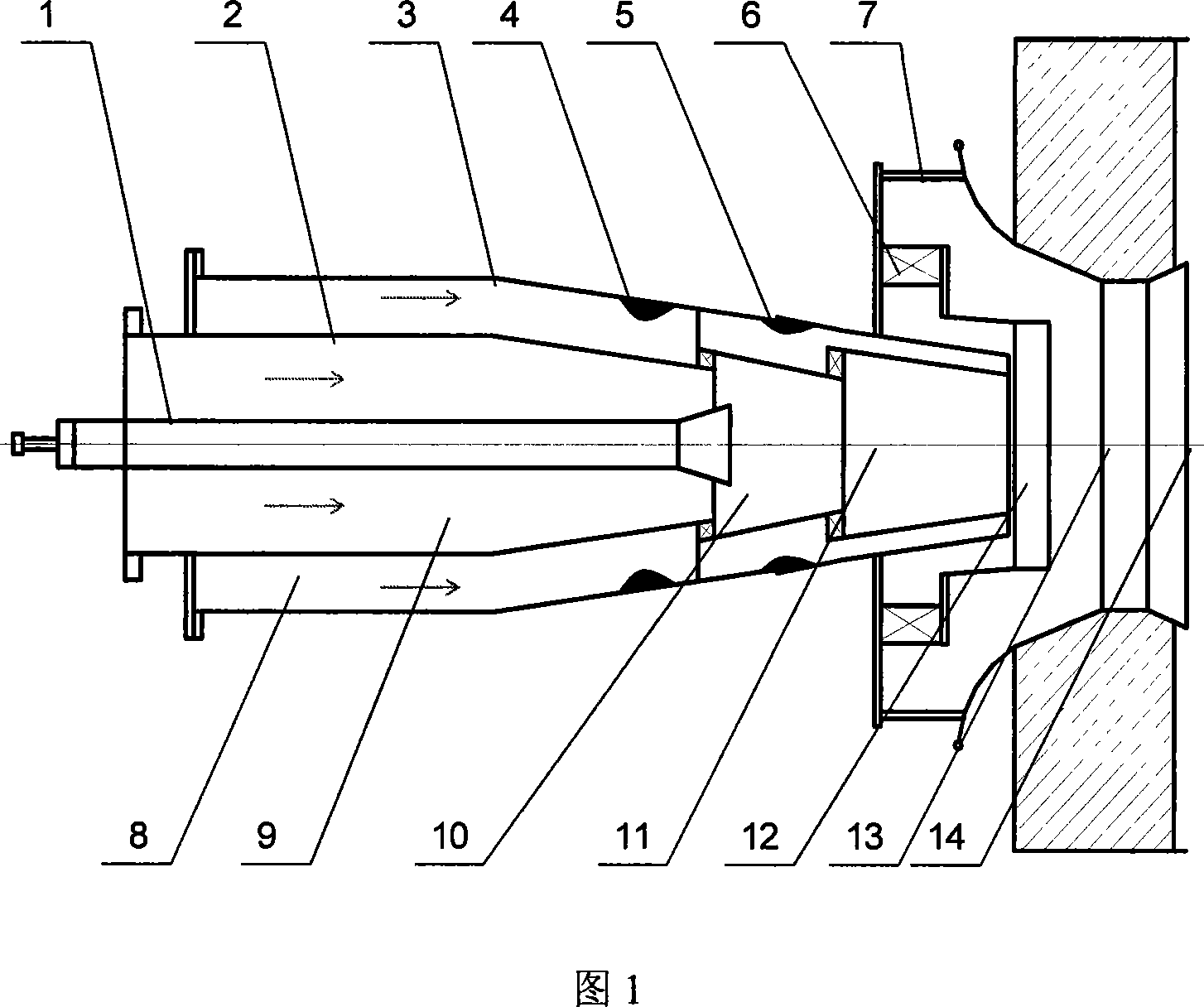

Novel oxygen enrichment tiny-oil ignition and ultralow load stable-combustion combustor

ActiveCN103615717AWith low load stable combustion functionProvide in timePilot flame ignitersPulverulent fuel combustion burnersCombustion chamberCombustor

The invention discloses a novel oxygen enrichment tiny-oil ignition and ultralow load stable-combustion combustor. The novel oxygen enrichment tiny-oil ignition and ultralow load stable-combustion combustor comprises an oxygen enrichment guide pipe, a primary air pipe, a cylindrical oil-coal mixed combustion chamber, a secondary air pipe, a secondary air box and a pre-combustion chamber, wherein the central axes of the primary air pipe, the cylindrical oil-coal mixed combustion chamber, the secondary air pipe, the secondary air box and the pre-combustion chamber coincide. A secondary air inlet inclining in the circumferential direction is formed in the pipe wall of the secondary air box; the primary air pipe penetrates through the secondary air box in the axial direction, the oil-coal mixed combustion chamber is coaxially arranged in the primary air pipe, and a high-energy tiny-oil ignition oil gun and the oxygen enrichment guide pipe are arranged in the oil-coal mixed combustion chamber; the secondary air pipe with a rotational flow impeller is coaxially arranged outside the primary air pipe in a sleeved mode and an outlet end is provided with a bluff body; the pre-combustion chamber is arranged in the secondary air box, the inlet end of the pre-combustion chamber is provided with a graded air duct, and a plurality of disturbance air nozzles are installed in an outlet of the combustor. The ignition fuel saving ratio reaches over 90% and the novel oxygen enrichment tiny-oil ignition and ultralow load stable-combustion combustor has the function of low load stable combustion and the function of ultralow load stable combustion; the technologies of oxygen enrichment, coal dust concentration, graded air feeding and the like are adopted, so that the novel oxygen enrichment tiny-oil ignition and ultralow load stable-combustion combustor has the advantages of being high in coal dust burn-off rate, low in NOx discharge and the like.

Owner:CHINA JILIANG UNIV

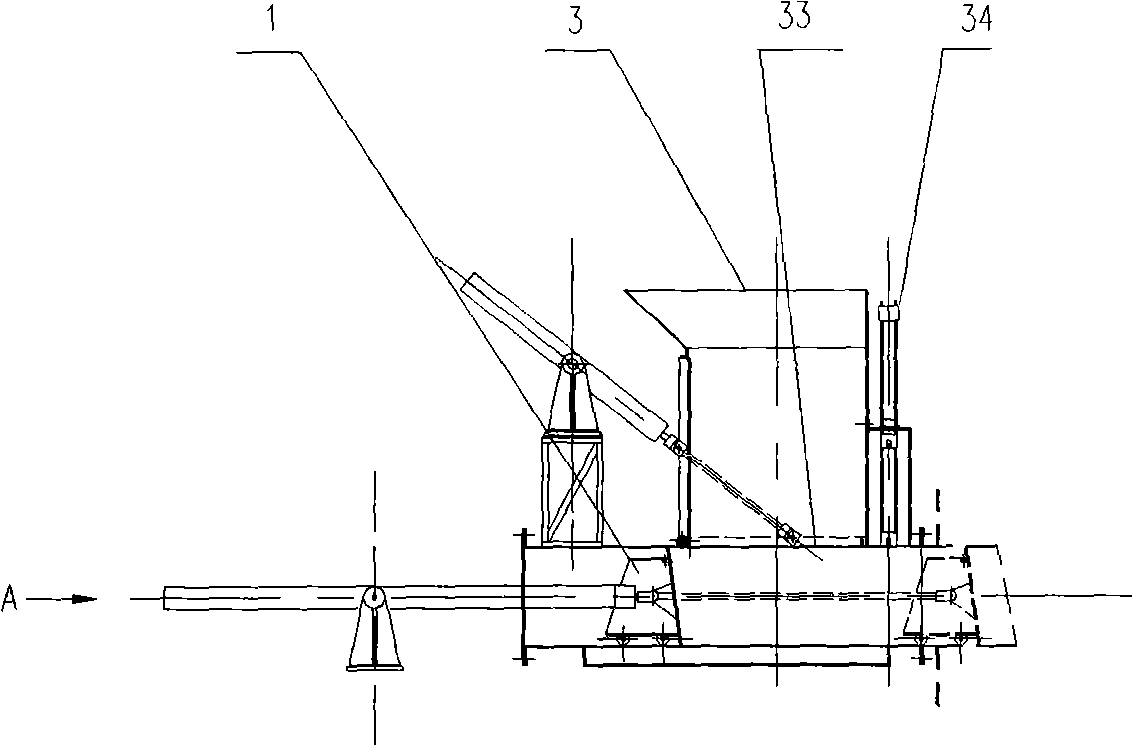

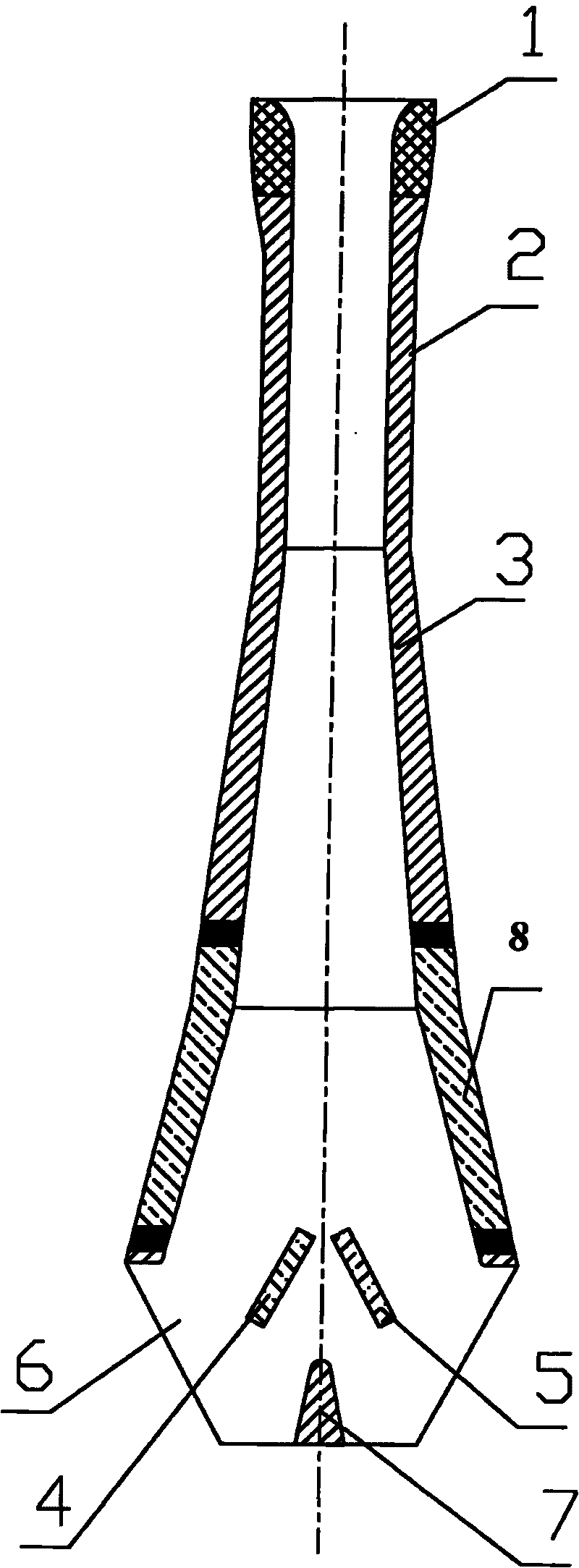

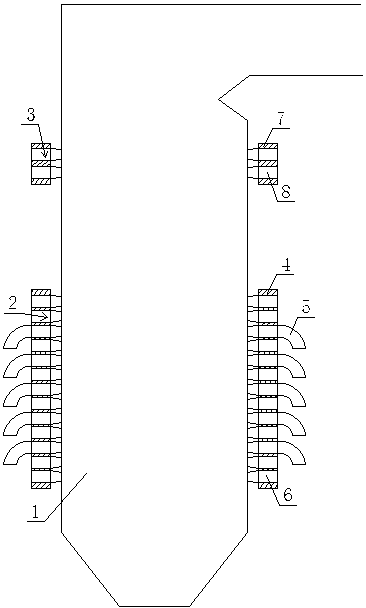

W-shape flame boiler for preventing side wall water cooling wall slagging scorification

ActiveCN101050854AAccelerated slagging problemReduce the temperatureSteam boilersCombustion chambersScarificationWing wall

A W type of flame boiler enabling to prevent water-cooled wall of wing walls from slagging scarification is prepared for setting four wall-wind fans separately on external sides of four wing walls and arranging ventilation gap on each of four wing walls.

Owner:HARBIN INST OF TECH

Slag-free flux-cored wire

ActiveCN101780609AIncrease the combinationImprove toughnessWelding/cutting media/materialsSoldering mediaSlagFerrosilicon

The invention provides a novel process for a formula of a slag-free flux-cored wire, and relates to a welding material. The manufacturing method adds the combination of molybdenum powder, nickel powder and rare earth silicon to a formula of raw materials, eliminates mineral powder in a common formula, and optimizes the proportion of various types of metal powder in the formula. According to the formula, the welding material comprises the following components: 4 to 8 parts of micro carbon ferrochromium, 12 to 18 parts of low carbon ferromanganese, 56 to 67 parts of iron powder, 2 to 6 parts of molybdenum powder, 0.1 to 0.4 part of ferroboron, 2 to 5 parts of rare earth silicon, 1 to 3 parts of ferrosilicon, 2 to 3 parts of ferrotitanium, 2 to 3 parts of sodium fluoride, 3 to 7 parts of ferroaluminum, 1 to 3 parts of aluminum to magnesium powder and 4 to 8 parts of nickel powder. The invention improves the toughness, strength and anti-fatigue performance of welding seams and thins welding-seam grains by adding the combination of molybdenum powder, nickel powder and rare earth silicon into the raw materials of the formula, eliminating the mineral powder in the common formula, and optimizing the proportion of various types of metal powder in the formula. Meanwhile, slagging on the surfaces of the welding seams is avoided, and welding efficiency is raised by 20 percent compared with slag-type processes.

Owner:山东聚力焊接材料有限公司

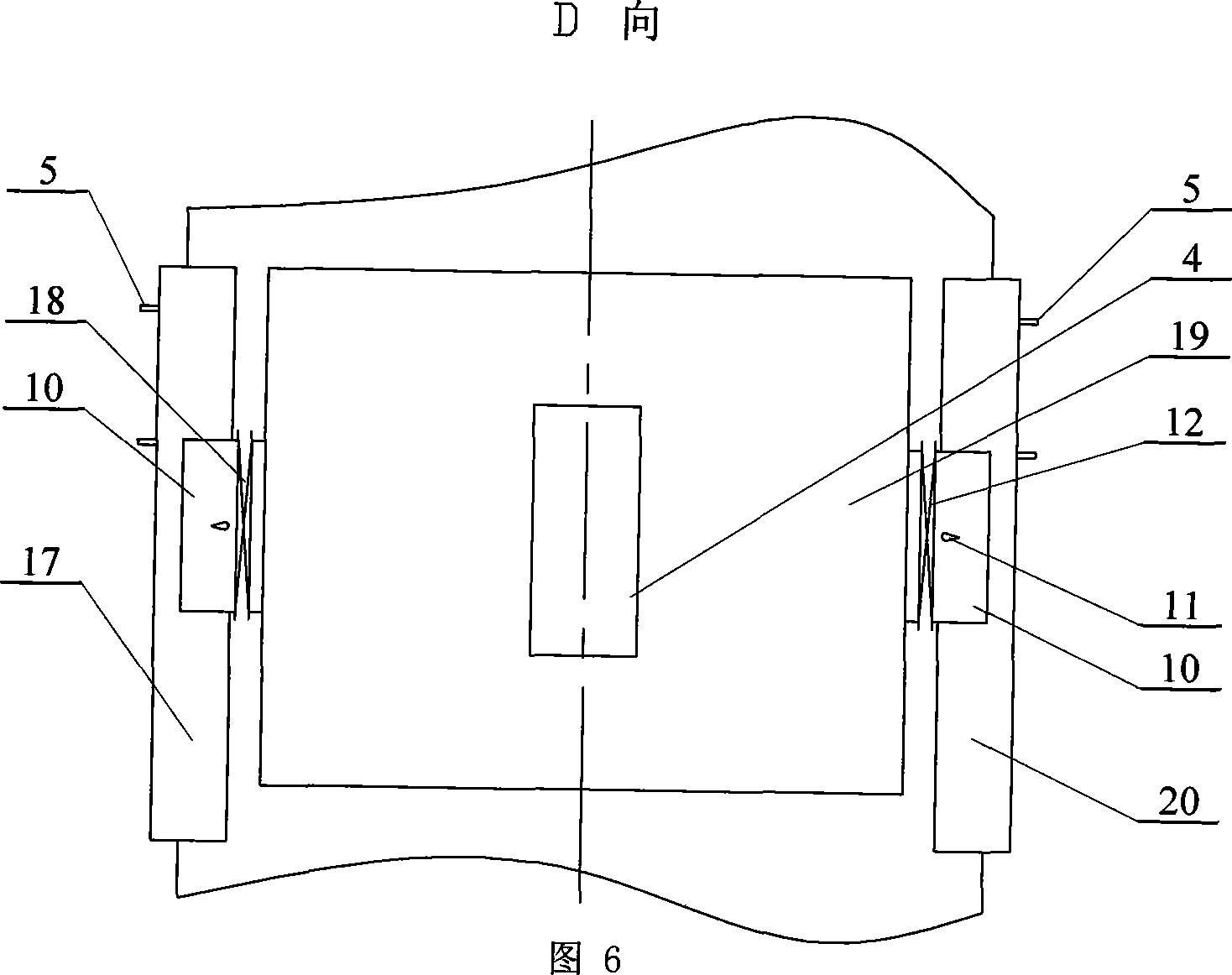

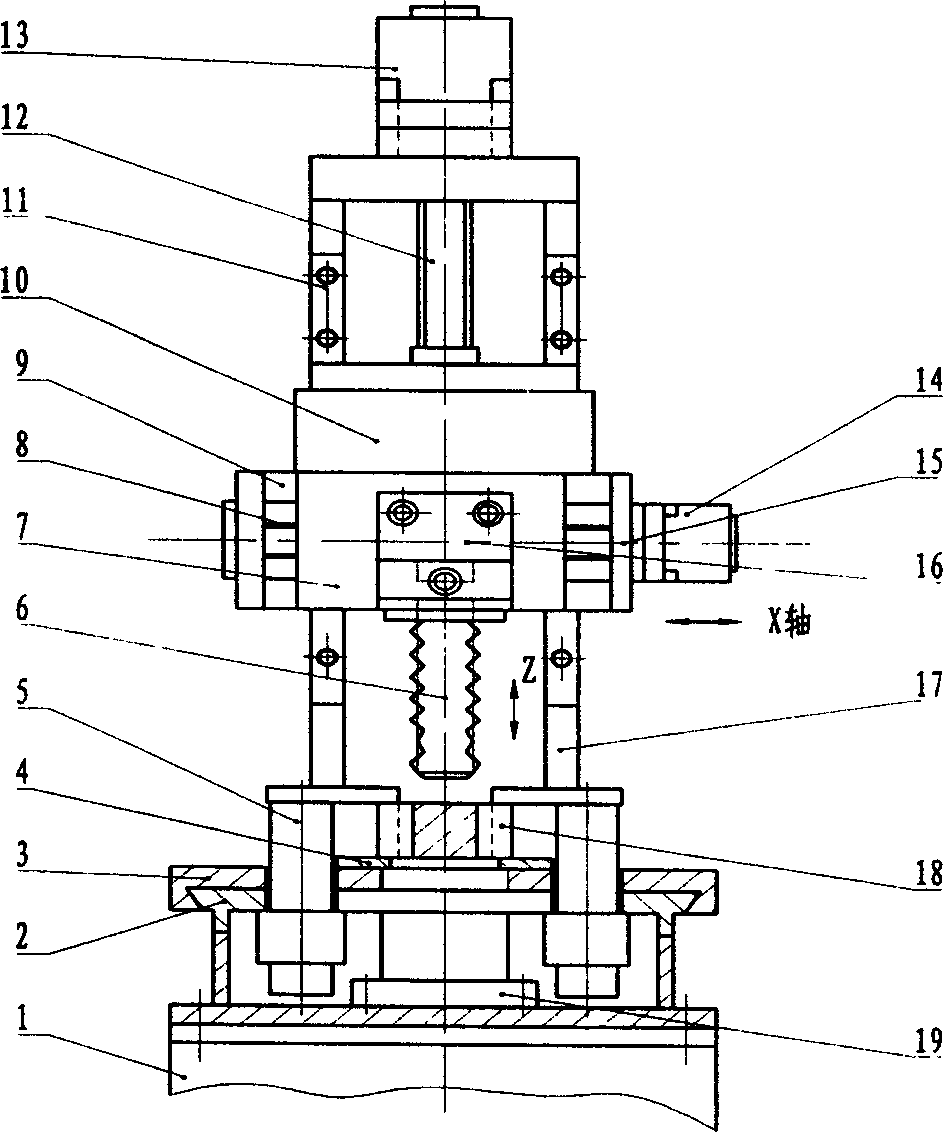

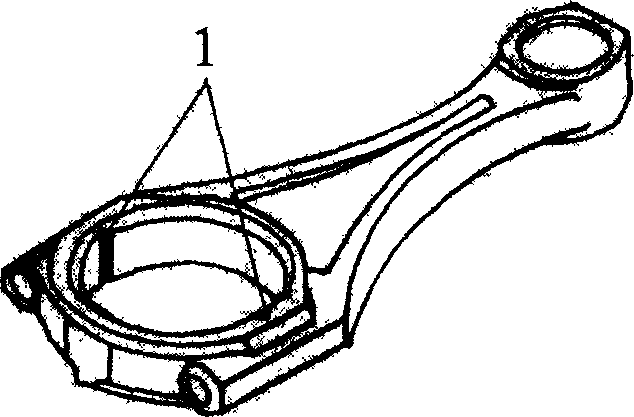

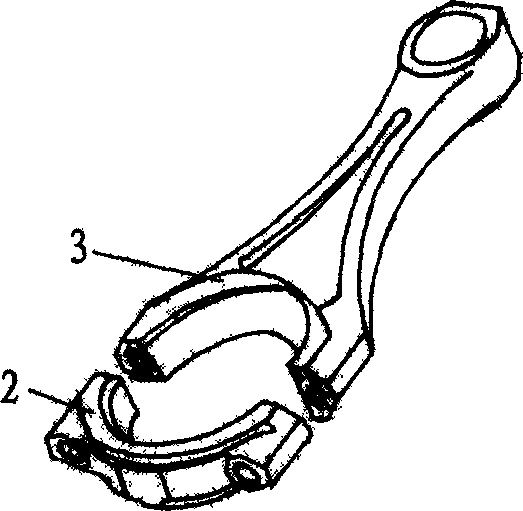

Processing apparatus for initial cracking tank for engine connecting rod

InactiveCN1569373AQuality improvementPrevent slaggingBroaching machinesEngineeringMechanical engineering

The invention relates to special device for motor link decomposing slot. The device mainly includes a host machine and piece clamping platform. . the host machine is assembled according to following meanings: there arranges with guiding track and sliding blocks along Z axis direction and X axis direction, the sliding block moves linearly on the guiding track; the platform is assembled according to following meanings: there has a sliding block which can moves linearly along y direction, the sliding block is arranged with three rotation pressing cylinders, and it has permutable fixing board.

Owner:JILIN UNIV

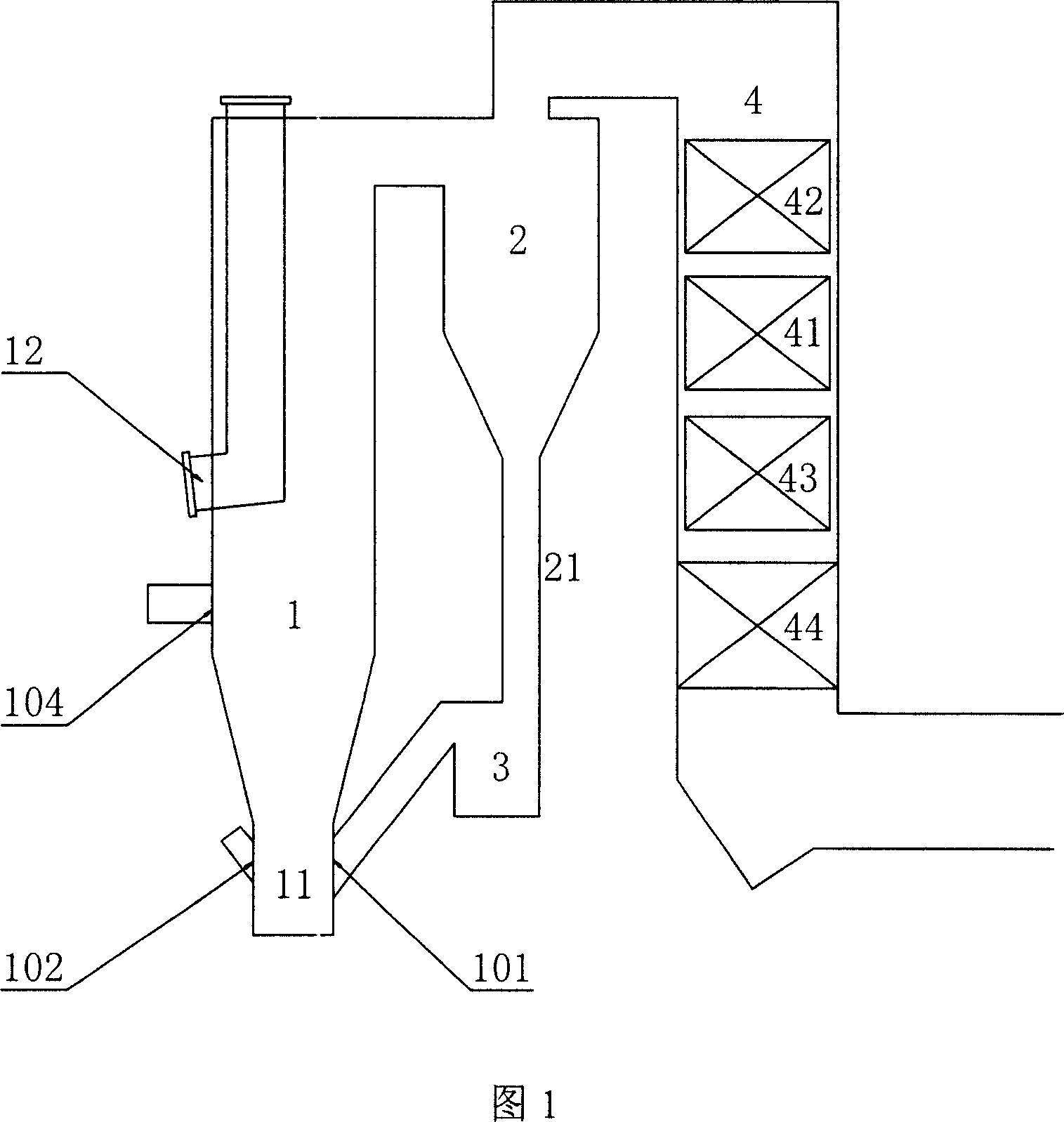

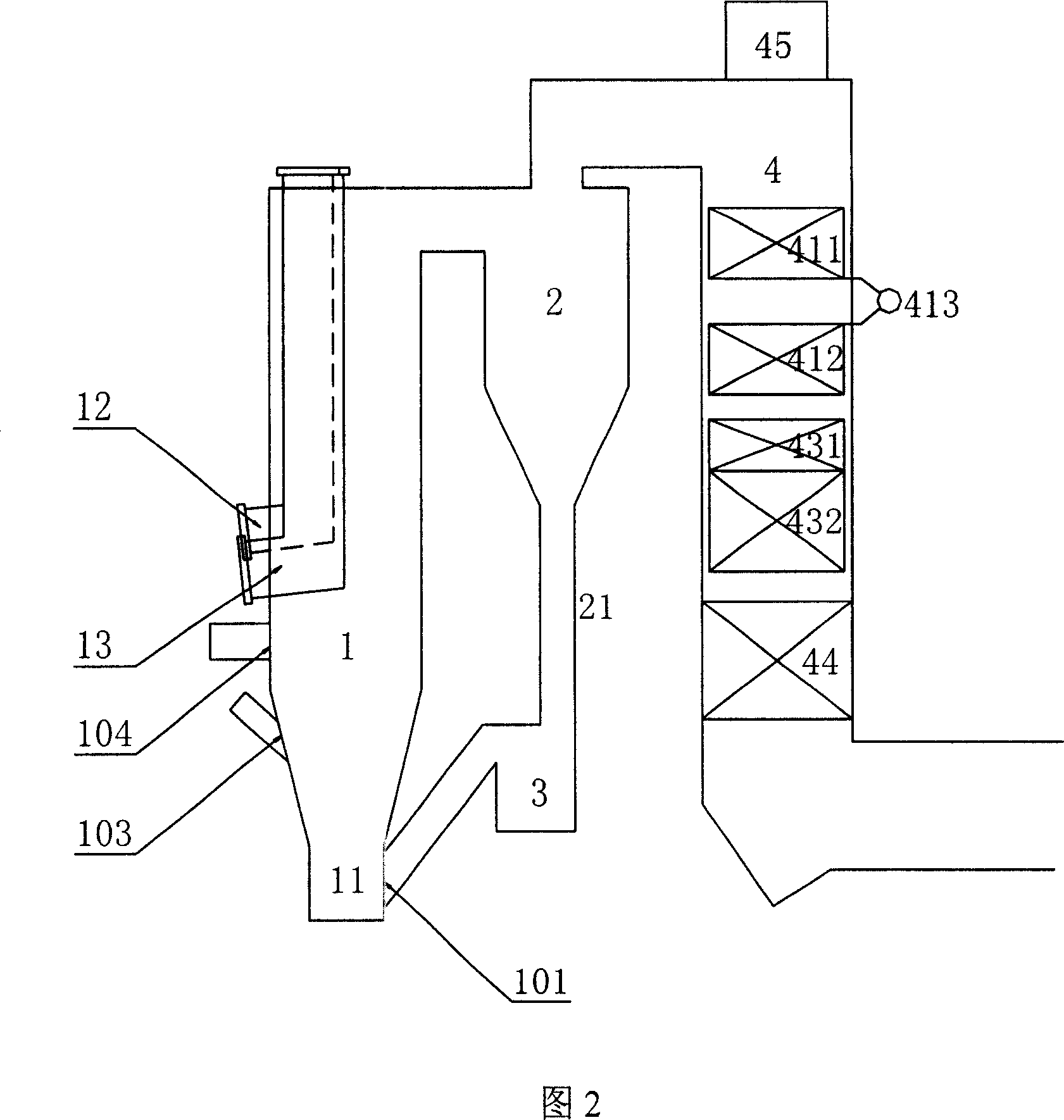

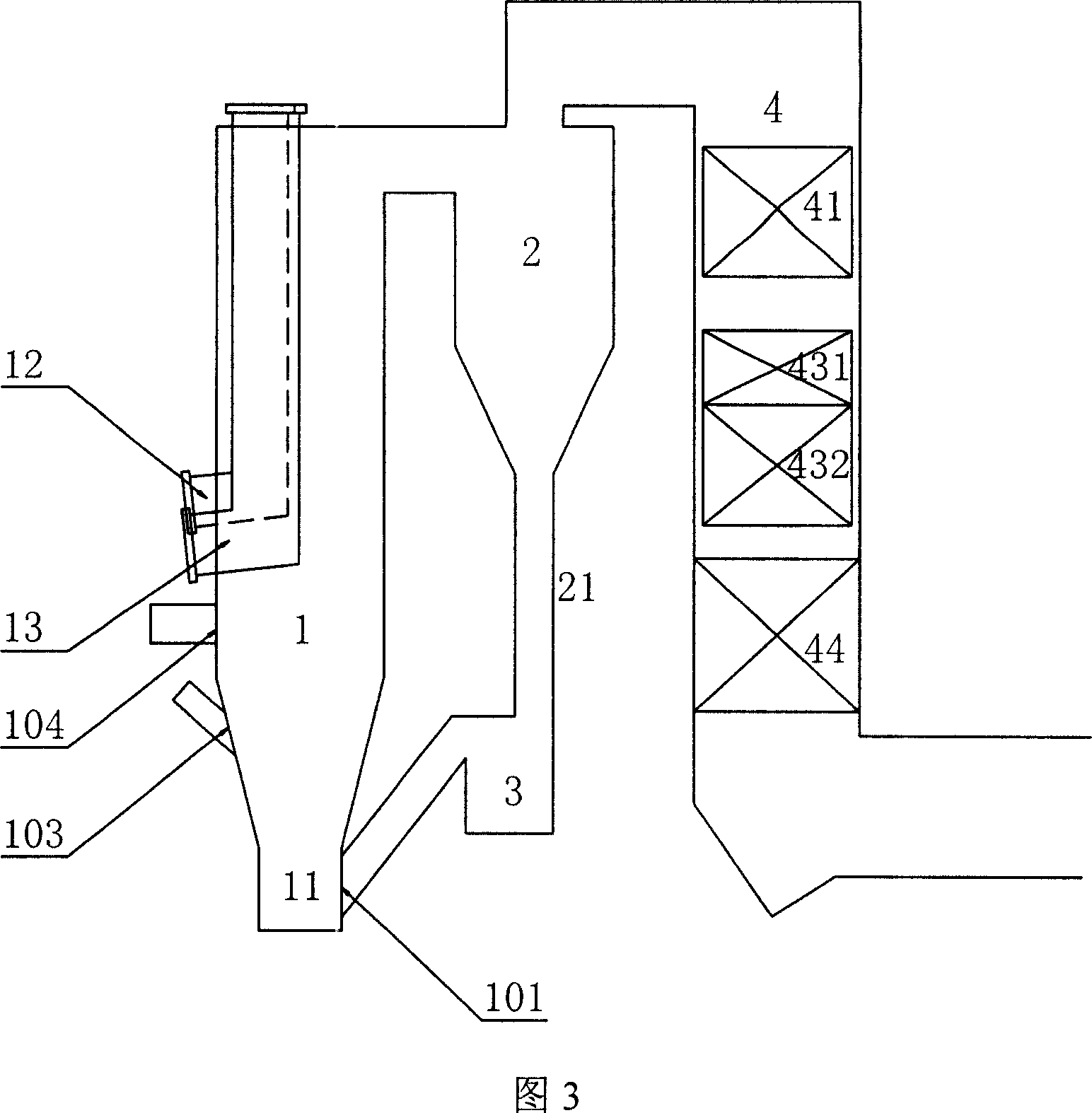

Biomass circulating fluid bed burning method and biomass circulating fluid bed boiler

ActiveCN101113816AReduce the temperatureImprove working environmentFluidized bed combustionApparatus for fluidised bed combustionTemperature controlSuperheater

The invention discloses a biological circulation fluidized bed combustion method and a biological fueled circulation fluidized bed boiler; the fluidized bed boiler comprises a boiler cavity, a clutch, a material refeeder, a tail chimney, wherein, the boiler cavity is provided with a superheater high temperature section, and the tail chimney is provided with a superheater low temperature section. Through the arrangement of heating surfaces of the boiler cavity and the tail chimney and other auxiliary measures, the temperature of the upper part of the boiler cavity is controlled at 550 to 800 DEG C, the outlet steam temperature of the tail heating surface is controlled at 350 to 400 DEG C, so as to solve the problem that: the temperature distribution of the boiler cavity is unreasonable, and the material concentration of the lower part of the boiler cavity is too low when the biological fuels are combusted in the circulation fluidized bed based on the stable fire, complete consumption of biological fuels , so that the temperature distribution in the boiler cavity tends to be equalized and the boiler cavity can be prevented from clinkering, and the accumulated ashes on the heating surfaces can also be prevented from being clinkered, furthermore, the boiler output capacity can be ensured, and a high steam parameter can also be achieved to ensure the generation efficiency.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

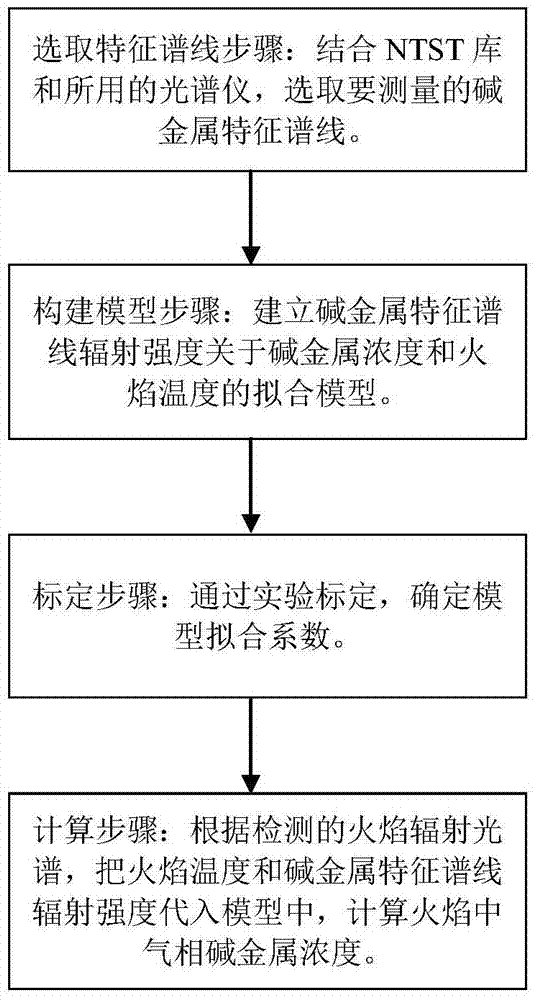

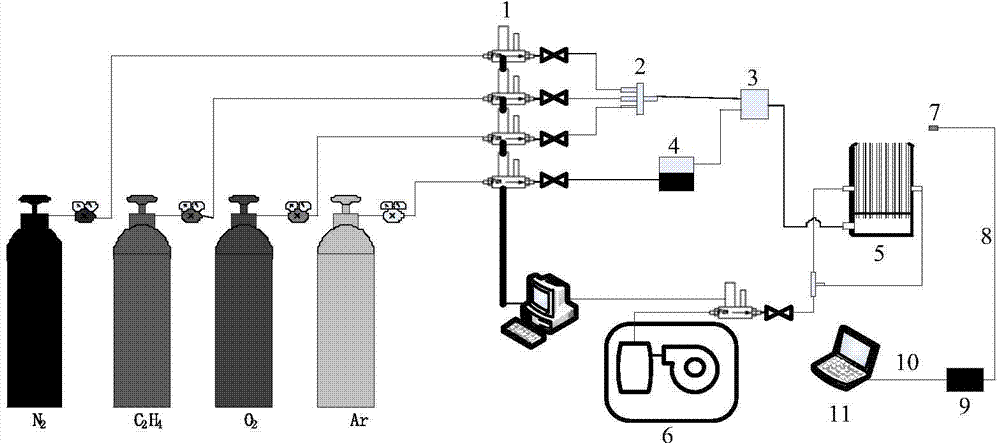

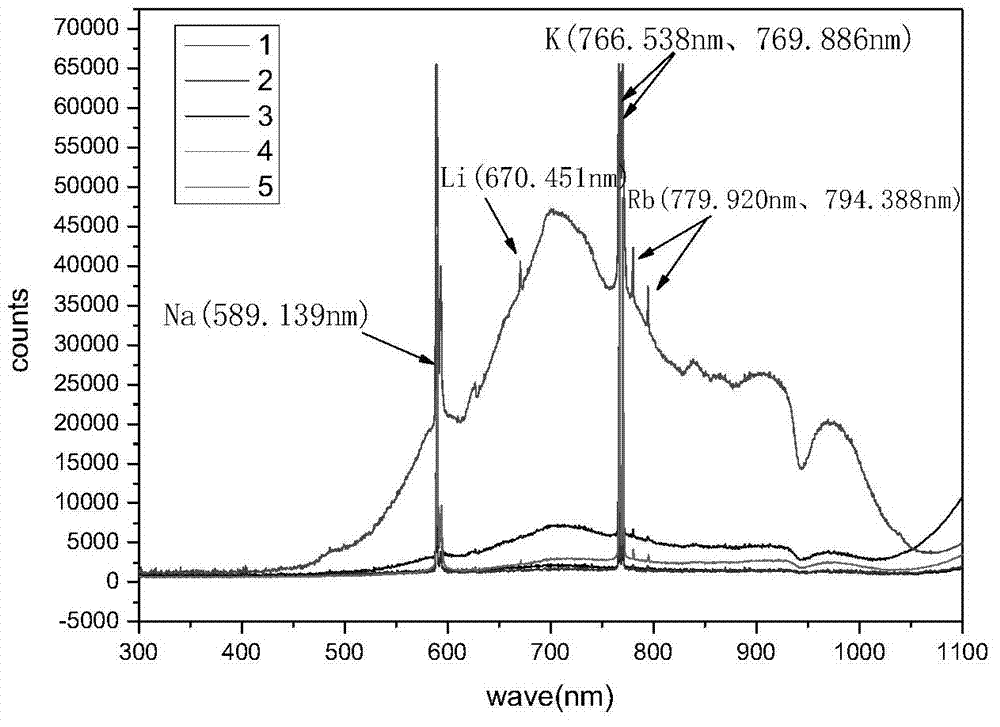

Online detection method of concentration of gas-phase alkali metal in boiler combustion flame

ActiveCN104849260AAvoid corrosionPrevent slaggingSpectrum investigationAnalysis by thermal excitationFiberCombustion

The invention discloses a method for detecting the concentration of gas-phase alkali metal in boiler flame on line by directly adopting flame emission spectral analysis. The method comprises the steps of firstly, selecting a characteristic spectral line of to-be-measured alkali metal, then constructing a fitting model of the radiation intensity of the characteristic spectral line relative to flame temperature and the concentration of the gas-phase alkali metal, then determining a fitting coefficient through experimental calibration, finally, measuring a radiation spectrum of a flame object by a portable fiber-optic spectrometer, so as to obtain the flame temperature and the radiation intensity of the characteristic spectral line of the alkali metal, substituting into the established fitting model of which the fitting coefficient is known, and calculating to obtain the concentration of the gas-phase alkali metal in the flame. The method has the advantages of simple equipment, low cost and convenience in industrial field measurement, the concentration of the gas-phase alkali metal in the boiler-inside combustion flame can be conveniently and precisely detected on line, and the contents of various kinds of alkali metal can be simultaneously detected.

Owner:HUAZHONG UNIV OF SCI & TECH

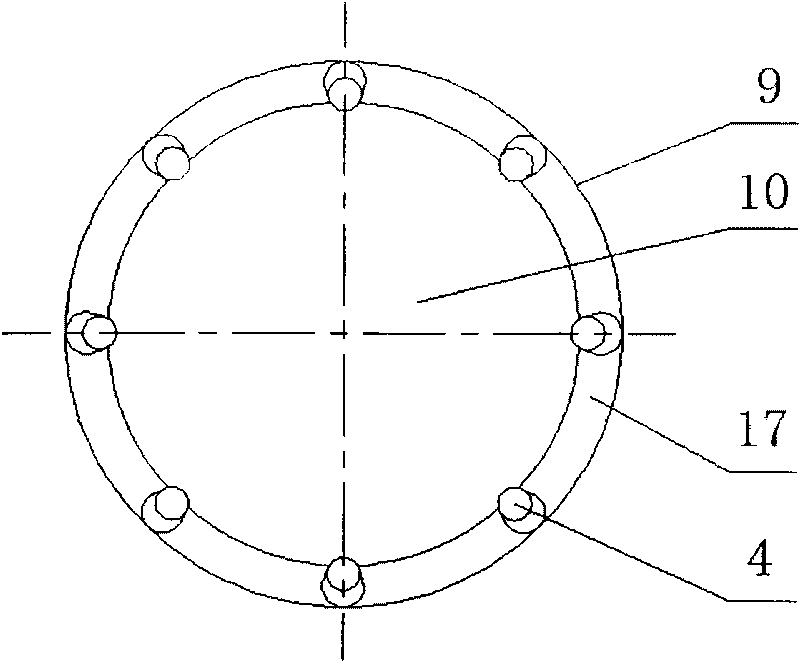

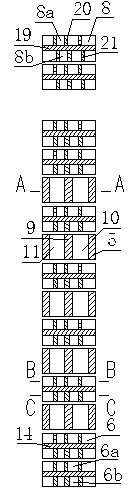

Low-NOx pulverized coal burner

The invention discloses a low-NOx pulverized coal burner, which comprises an inner secondary air box, a hierarchical air box and a disturbed air box. The inner secondary air box, the hierarchical air box and the disturbed air box are separated by a first clapboard and a second clapboard sequentially; the centers of the first clapboard and the second clapboard are provided with circular holes; each pipe wall of each of the three air boxes is correspondingly provided with an air inlet which inclines towards the circumferential direction; a primary air pipe axially passes through the inner secondary air box; an inner secondary air pipe with a swirl vane is coaxially sleeved outside the primary air pipe; the inner secondary air pipe is hermetically connected with the first clapboard; the inner secondary air pipe expands conicity and extends outwards to form a conical cylinder at the circular hole of the first clapboard; the conical cylinder is arranged in the hierarchical air box; the disturbed air box is coaxially provided with a precombustion chamber with two open ends; an annular channel is formed between the wall of the disturbed air box and the wall of the precombustion chamber; an annular end face is arranged at an outlet of the annular channel; a disturbed air nozzle is fixed at an opening of the annular end face; the inlet end of the precombustion chamber is hermetically connected with the second clapboard; an annular hierarchical air channel is formed at the root of the inlet of the precombustion chamber; and the conical cylinder is hermetically fixed with the inner wall of the hierarchical air channel.

Owner:ZHEJIANG JINGUO BOILER

Eddy flow powdered coal burner lit up by tiny oil

InactiveCN101093077ASave fuel for ignitionReduce outputPulverulent fuel combustion burnersHigh energyCoal

This invention relates to a wall-laid little oil ignition coal burner including a primary air pipe, a central air pipe, a high energy oil gun set horizontally in the central air pipe, inlet for inner secondary wind, an inlet for outer secondary wind, spouts of primary wind and secondary wind and a spout of a burner characterizing in setting one stage or multiple stages of diversion condensed rings on the internal wall of the primary air pipe and setting one or multiple stages of precombustion chamber at the front of the central pipe, which realizes four-stage ignition process with tiny oil and higher oil-saving rate when adjusting the peak deeply and has the function of stable and low NOx burning when the oil gun stops working.

Owner:TSINGHUA UNIV

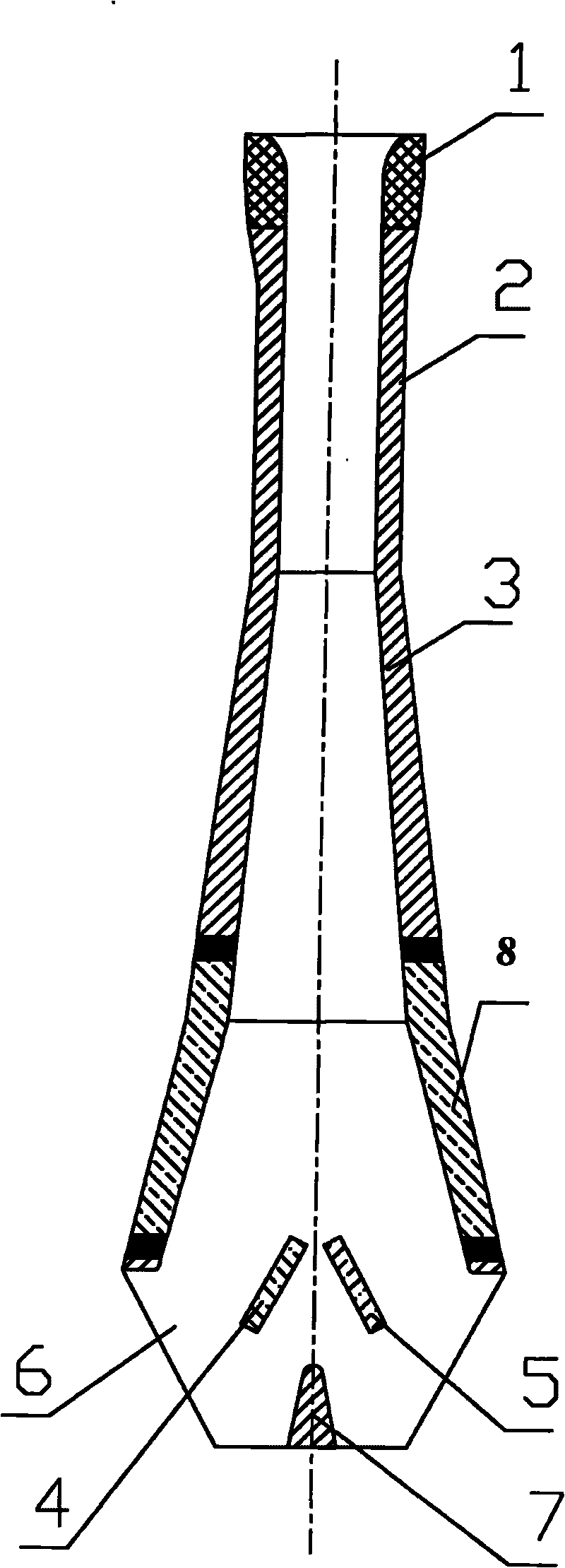

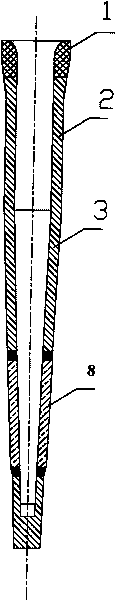

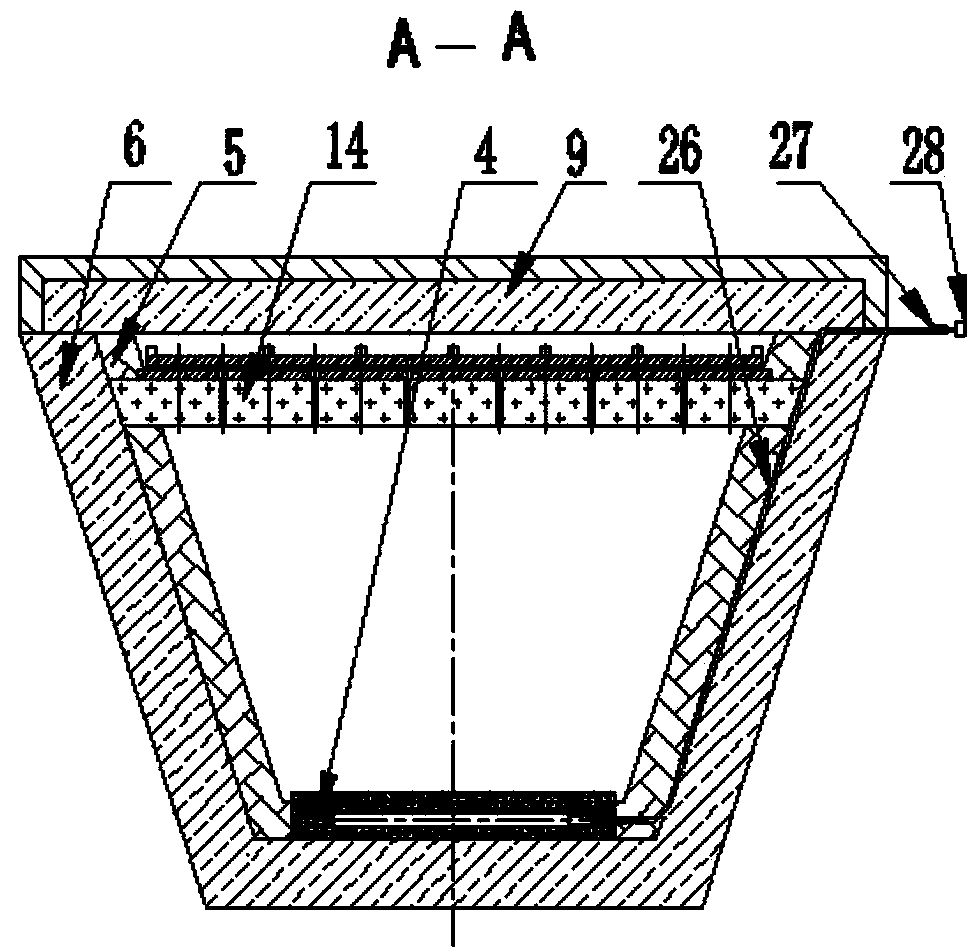

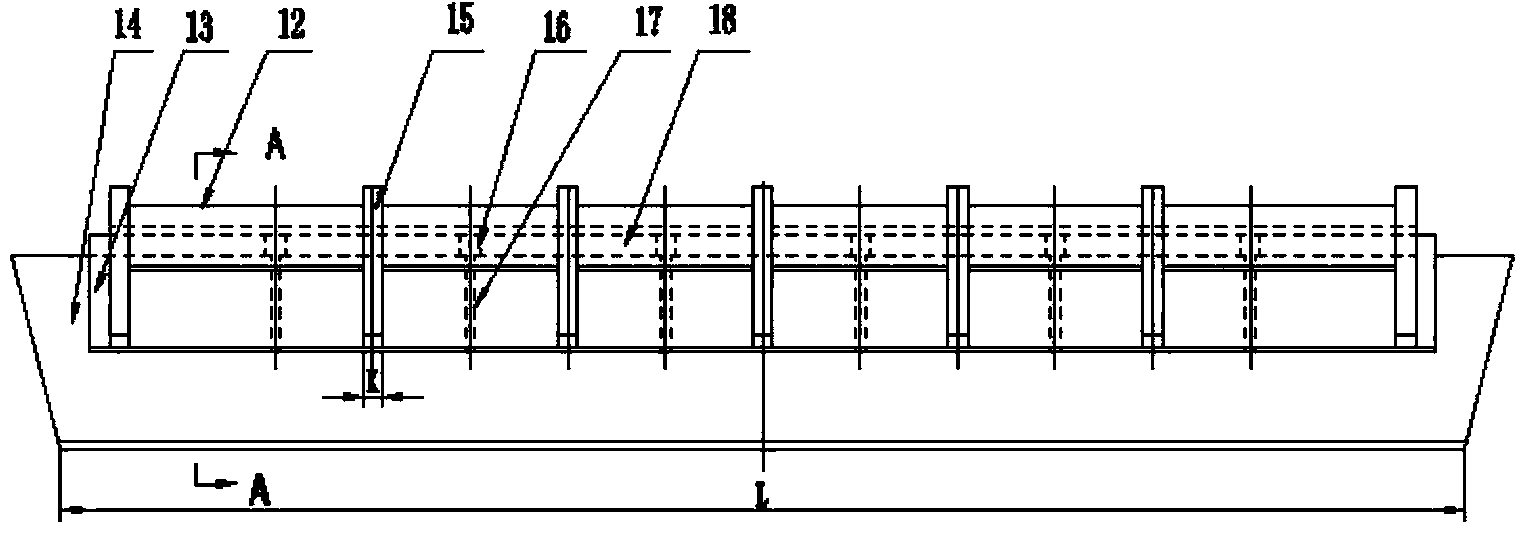

Submerged nozzle for sheet billet continuous casting crystallizer

The invention discloses a submerged nozzle for a sheet billet continuous casting crystallizer, which comprises an upper end and a transition section, wherein the transition section is positioned below the upper end, the transition section is in the shape of a cylindrical constant section, and an upper flat section and a lower flat section are positioned below the transition section; a first guide plate and a second guide plate which are symmetrical are arranged under the lower flat section, two nozzle outlets are formed between the lower end of the lower flat section and the first guide plate and between the lower end of the lower flat section and the second guide plate, and the first guide plate and the second guide plate are cuboid; and a conical flow splitting body is arranged at the middle position below the first guide plate and the second guide plate. The two guide plates are added into the submerged nozzle to perform the action of changing the angle and the speed of molten steel flowing out of the nozzle, so that the liquid level of the crystallizer keeps stable at a high flow speed to achieve the uniform distribution of protective slag, thereby effectively preventing slag entrapment and inhabiting the generation of cracks on a casting blank; and the molten steel can uniformly flow in the crystallizer and achieve reasonable liquid level speed and protective slag coverage.

Owner:CHONGQING UNIV +1

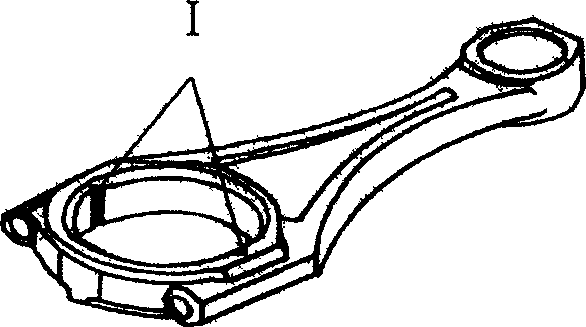

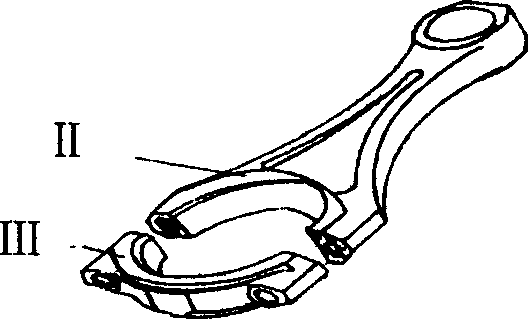

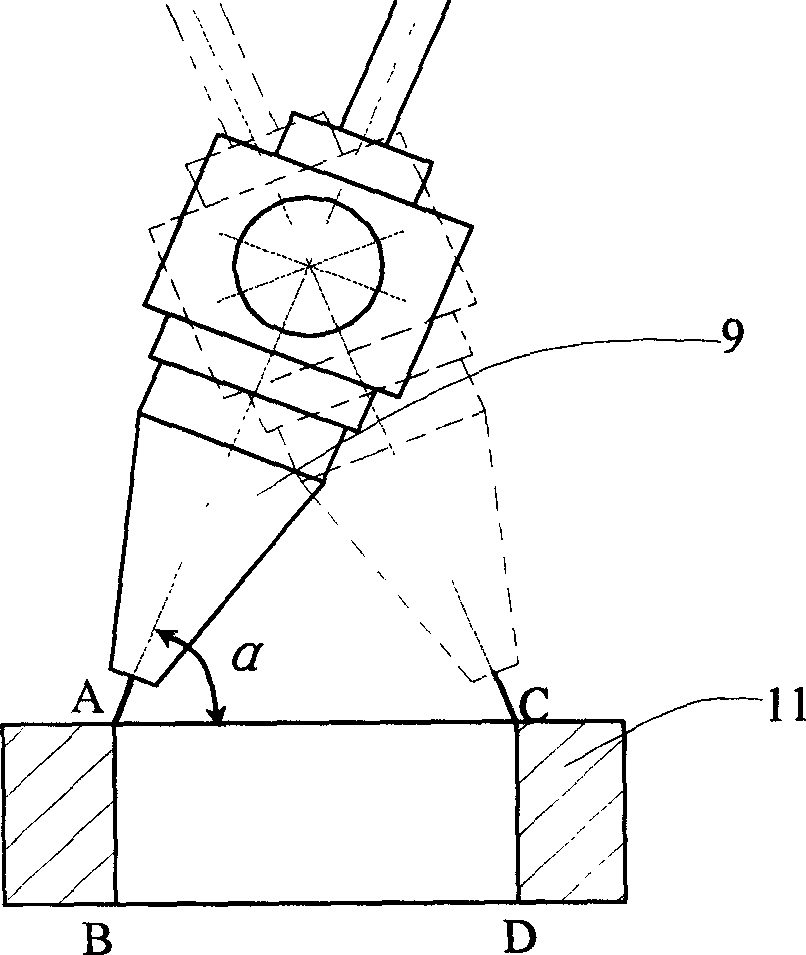

Laser processing method for connecting rod splitting groove and its equipment

InactiveCN1559744ANarrow kerfControllable depthConnecting rod bearingsShearing machinesLaser processingLaser cutting

A method for using laser to premachine the cracking slots before dividing connecting rods from each other includes such steps as fixing the laser cutting head above the position to be machined, which is near the hole on big end of connecting rod, regulating the incident angle of laser beam to 0-70 deg.C, turning on laser device, vertically moving the laser cutting head to machine the cracking slot to predefined depth, and repeating said steps to machine another cracking slot at another end of aconnecting rod.

Owner:JILIN UNIV

Lignite boiler combustion method capable of reducing nitrogen oxide emission

InactiveCN101482262AImprove operational reliabilitySimple structureAir supply regulationDispersed particle separationSlagBrown coal

The invention provides a brown coal boiler combustion method capable of reducing discharge of nitrogen oxide and relates to a method for boiler combustion of the brown coal. The method solves the problems that slag bonding is easy to appear in the boiler combustion of the brown coal by adopting air fractional combustion technology, a catalyst is needed, system investment is huge and operating cost is high in the boiler combustion of the brown coal by adopting selective catalytic reduction technology and denitration efficiency is low in the boiler combustion of the brown coal by adopting selective non-catalytic reduction technology. A brown coal boiler with the furnace being divided into a primary combustion zone (1) and a burnout zone (2) from bottom to top is adopted in the brown coal boiler combustion method capable of reducing discharge of nitrogen oxide. An amino group reducer is sprayed grade by grade during the combustion process of the brown coal. By the two methods of the invention, the discharge of the nitrogen oxide can be reduced by more than 60% and the combustion efficiency of the brown coal is up to more than 98%. By the two methods, no slag bonding appears during the combustion of the brown coal, no catalyst is needed and the operating cost is only around 30% of the operating cost of the selective catalytic reduction method.

Owner:HARBIN INST OF TECH

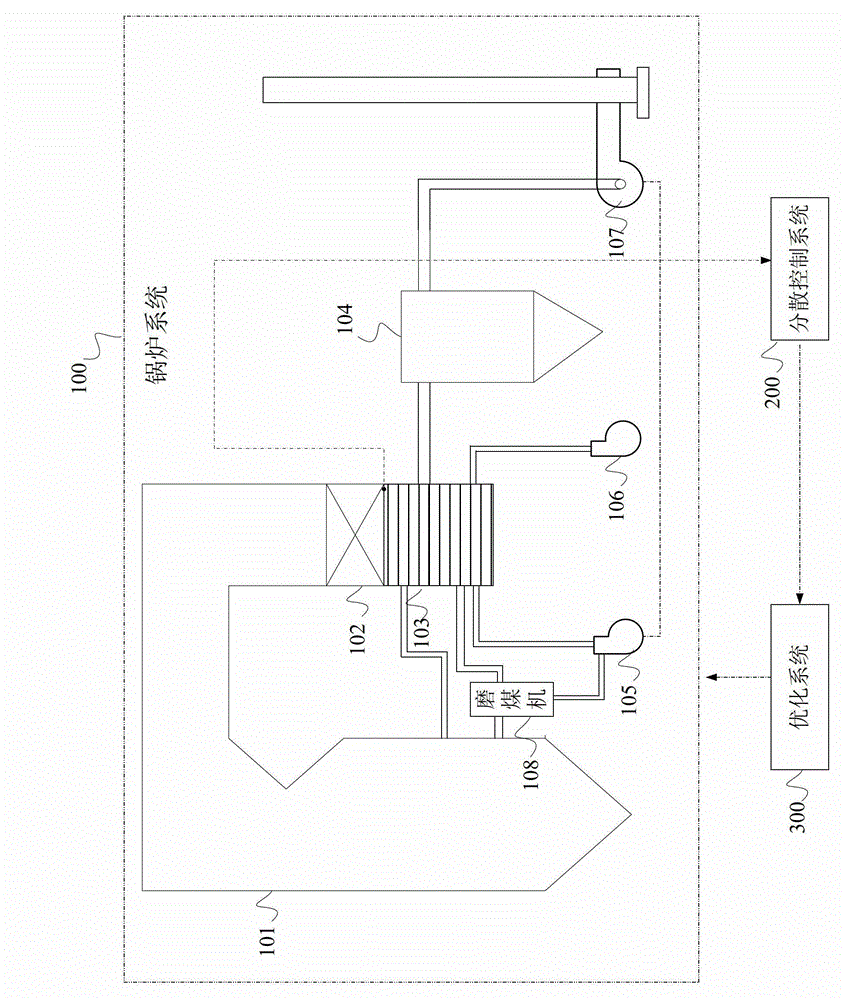

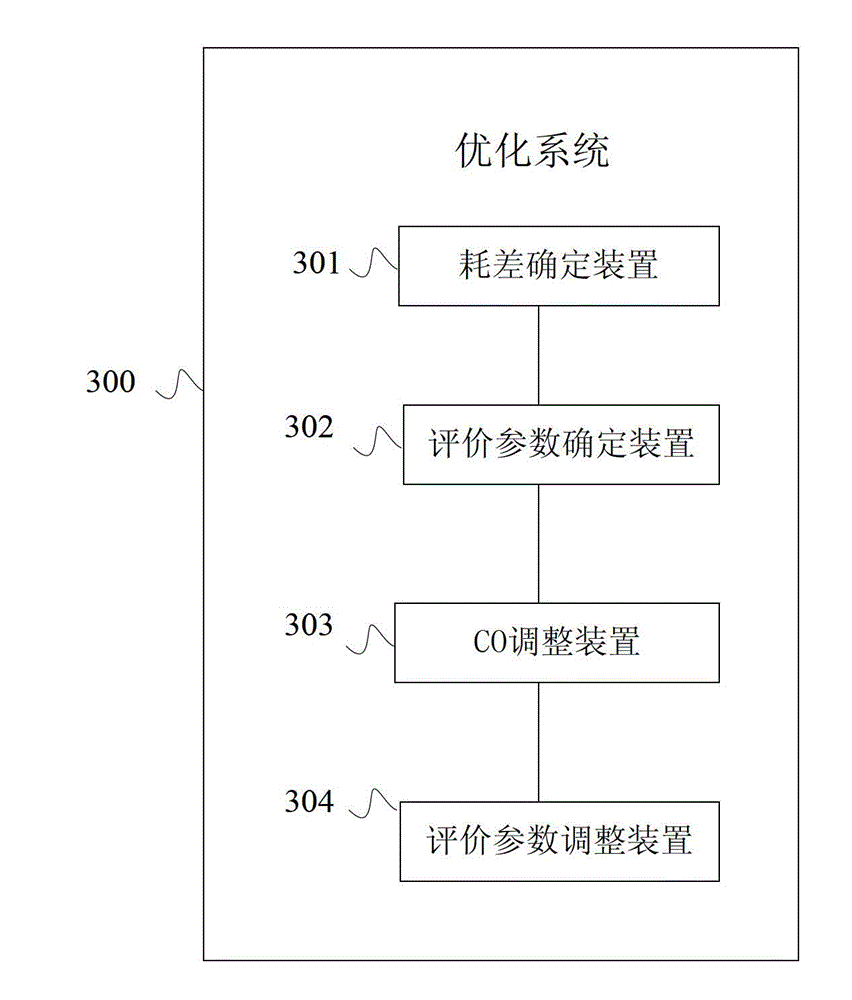

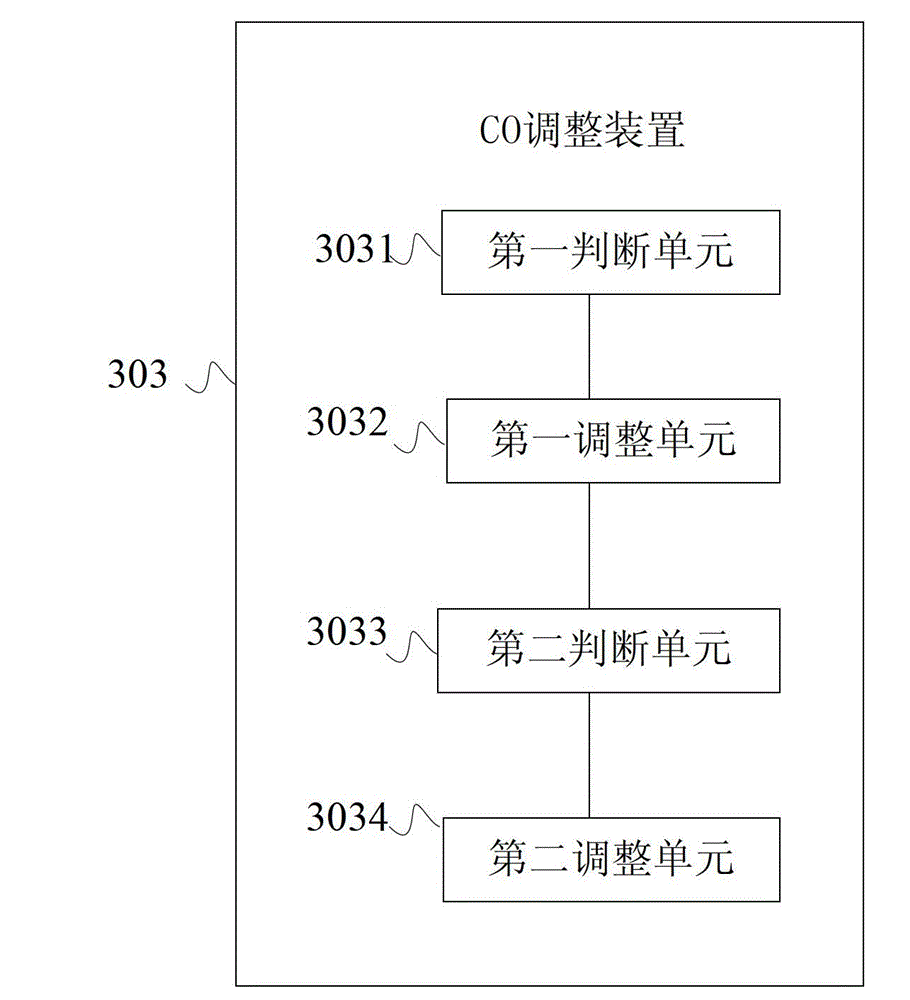

Optimal operation method and system for utility boiler based on CO

ActiveCN103148473ALow thermal efficiencyHigh thermal efficiencyBoiler controlAir preheaterAir volume

The embodiment of the invention provides an optimal operation method and a system for a utility boiler based on CO. The method comprises the steps of collecting CO concentration of an inlet of an air preheater, acquiring exhaust smoke temperature, an oxygen content of exhaust smoke, a carbon content of fly ash and fan power consumption of the currently operating boiler, determining the exhaust smoke temperature, the CO concentration, the oxygen content of the exhaust smoke, the carbon content of the fly ash and corresponding consumption difference of the fan power consumption respectively, determining operating evaluation parameters of the boiler according to the exhaust smoke temperature, the CO concentration, the oxygen content of the exhaust smoke, the carbon content of the fly ash and the corresponding consumption difference of the fan power consumption, adjusting secondary air volume of a boiler system to control the CO concentration to be in a preset scope, and adjusting coal quantity and primary air volume of the boiler system to allow the operating evaluation parameters of the boiler to be approximate to preset values. The method and the system can effectively improve operating economy and safety of the boiler, are in accordance with the current energy conservation and emission reduction policies, and have a great significance in the safe and economical operation of the utility boiler.

Owner:NORTH CHINA ELECTRICAL POWER RES INST +3

Multi-stage stratified combustion system and method for primary air and secondary air of boiler

ActiveCN103216821ARigid enoughWell mixedCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustion systemSpray nozzle

The invention discloses a multi-stage stratified combustion system and a multi-stage stratified combustion method for primary air and secondary air of a boiler. The multi-stage stratified combustion system comprises combustors and air after-combustion devices, which are arranged on the four corners of a furnace chamber; each combustor comprises a secondary air box, at least one primary air tube and at least one primary secondary air spray nozzle; each air after-combustion device comprises an after-combustion air box and at least one after-combustion air spray nozzle; the secondary air boxes and the after-combustion air boxes are connected with a main air duct by the respective air tubes; the primary air tube spray nozzle is divided into a thick primary air spray nozzle and a thin primary air spray nozzle; the primary secondary air spray nozzle is divided into a secondary direct-blowing air spray nozzle and a secondary deviation-blowing air spray nozzle; the after-combustion air spray nozzle is divided into an after-combustion direct-blowing air spray nozzle and an after-combustion deviation-blowing air spray nozzle; and an effect of covering powder by air is formed during the combustion process by virtue of the multi-stage stratification of the primary air and the secondary air. The multi-stage stratified combustion method and the multi-stage stratified combustion method for the primary air and the secondary air of the boiler not only can be used for ensuring the ultralow emission of NOx and improving the combustion efficiency of the pulverized coal, but also can be used for preventing the agglomeration and the high-temperature corrosion of the water-cooling wall and reducing the thermal deviation of the heating area at the outlet of the furnace chamber.

Owner:DONGFANG BOILER GROUP OF DONGFANG ELECTRIC CORP +1

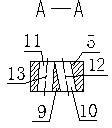

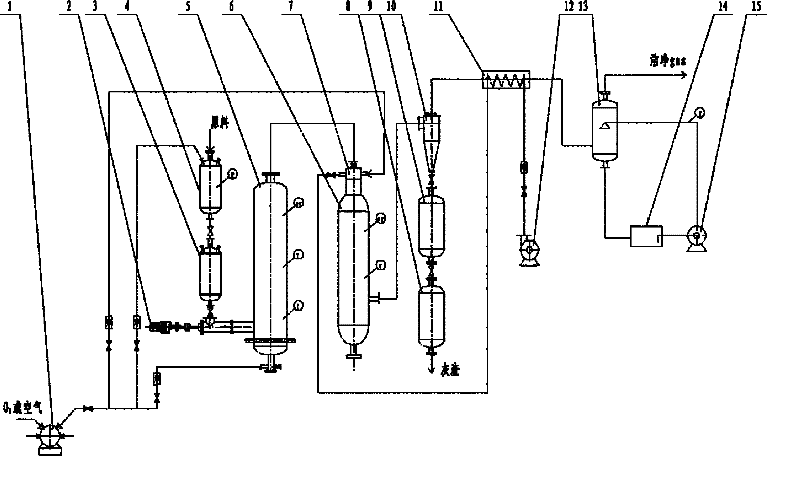

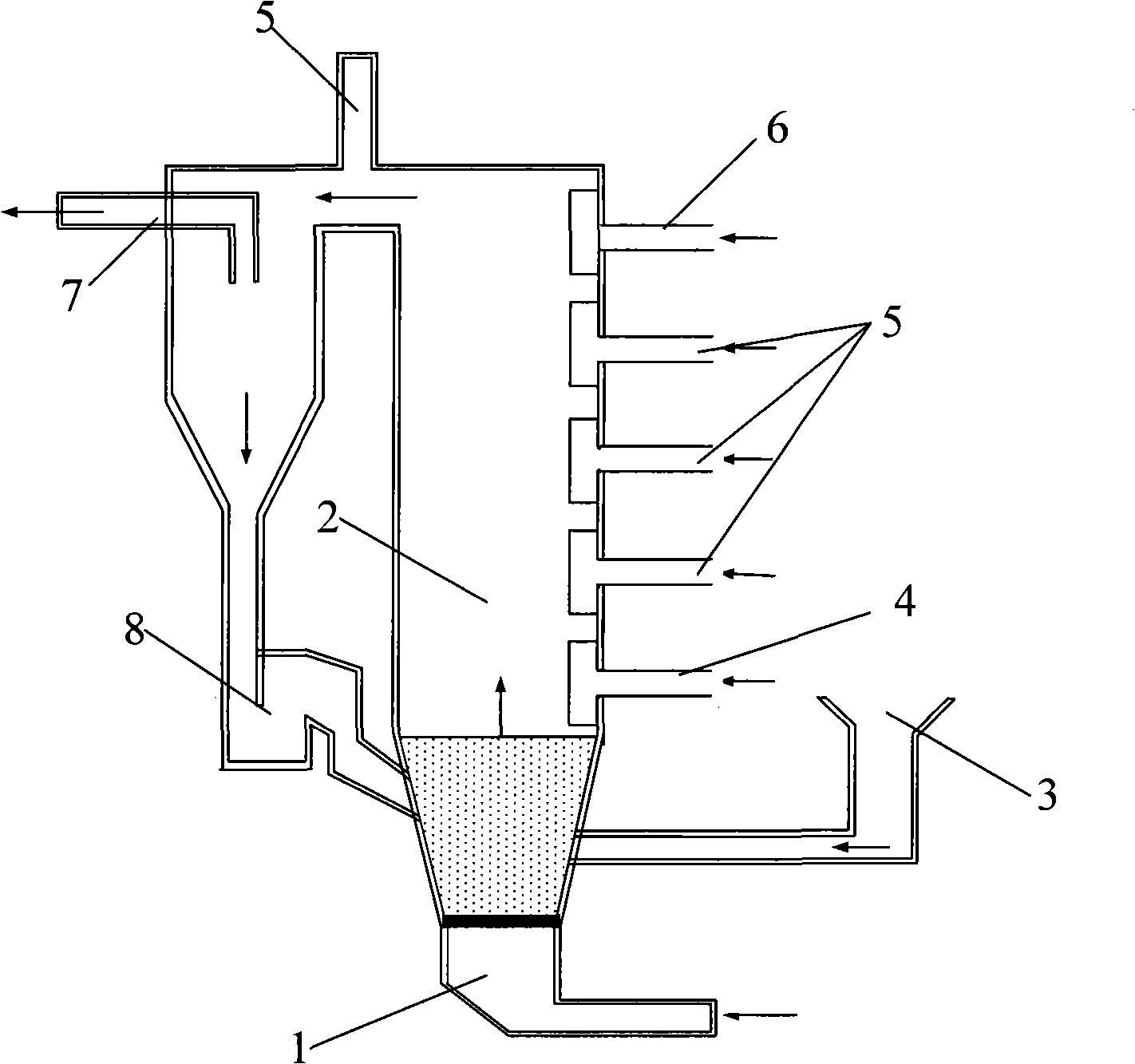

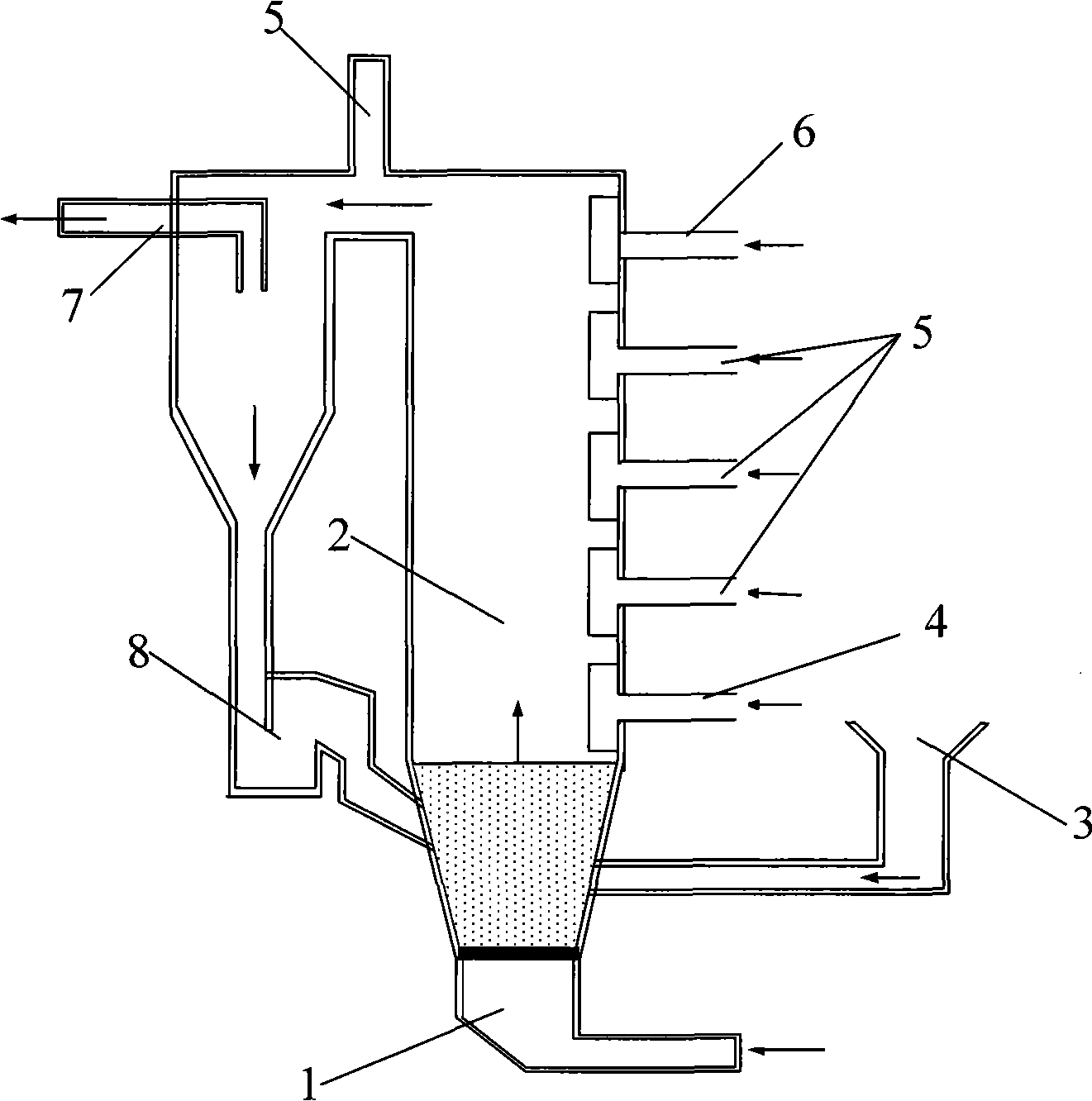

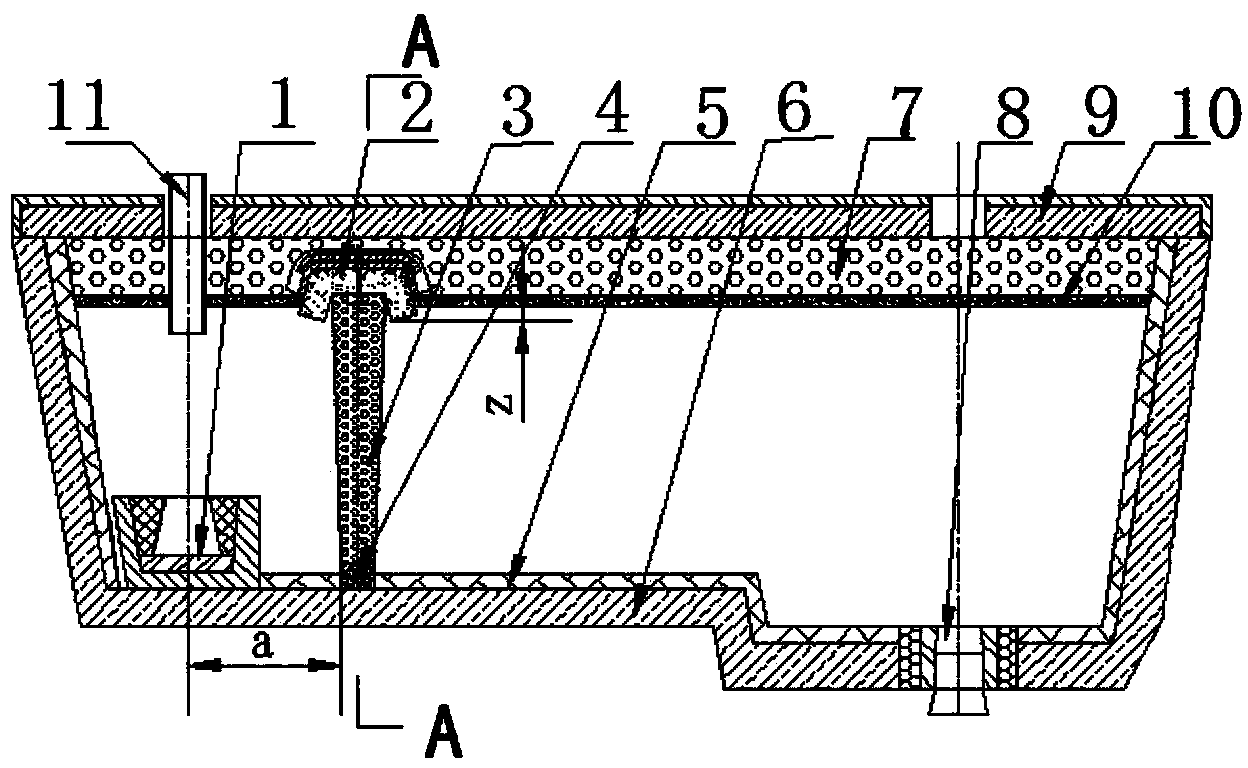

Technology and equipment for preparation of synthetic gas by two-stage high temperature biomass gasification

InactiveCN102226107AImprove equipment production capacityHigh calorific valueProductsReagentsTarCoal tar

The invention relates to a technology and equipment for preparation of synthetic gas by two-stage high temperature biomass gasification. Gasification in the technology is carried out in two stages, namely, primary gasification and high temperature gasification; biomass combustion gas, unreacted solids, tar and the like obtained in the primary gasification are directly delivered into a high temperature vapourizing furnace at high temperature and steam and air are also delivered into the vapourizing furnace so as to carry out high temperature gasification, thereby enhancing thermal efficiency, conversion rate of carbon and cracking rate of tar. In the process of the preparation, heat energy is self supplied, and heat is recovered to improve thermal efficiency; a thermal value of prepared synthetic gas can reach 7 to 8 MJ / m<3>. Equipment for realizing the technology comprises a biomass feed unit, gasification reactors, a dust collector, a heat reclaim unit, a washing unit, an air compressor, etc. The technology and equipment provided in the invention can be used to convert biomass raw materials like agricultural waste into synthetic gas with a high thermal value and low content of tar and are applicable to heat supply by biomass combustion gas, power generation by combustion gas or synthesis of liquid fuels.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

Biomass gasified gas re-burning mode and system for coal-fired fluidized bed

InactiveCN101915419AImprove combustion efficiencyImprove emission reduction efficiencyFluidized bed combustionApparatus for fluidised bed combustionSlagCoal dust

The invention belongs to the technical field of N2O emission reduction in a coal-fired fluidized bed, and particularly relates to a biomass gasified gas re-burning mode and a biomass gasified gas re-burning system for a coal-fired fluidized bed. The wall of a fluidized bed boiler is provided with a plurality of biomass gasified gas nozzles, biomass gasified gas is introduced into a hearth of the fluidized bed boiler, and the biomass gasified gas is reacted with N2O-containing smoke generated by burning of coal dust in the hearth to realize multi-stage re-burning so as to improve the burning efficiency of the whole fluidized bed and reduce the emission of N2O. Compared with pyrolysis and direct burning, the biomass gas rich in combustible substances such as H2, CH4, CO and the like has low ash content and extremely low sulfur content, has no sulfur removal problem, is ideal re-burning fuel and can effectively reduce the emission of nitrogen oxides by using mixed burning of the biomass gasified gas and the coal dust; and because of low alkali metal and chlorine content in the gasified gas, problems of slag formation and corrosion can be avoided, utilization of the coal dust is not affected and efficient clean utilization of the biomass can be realized.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

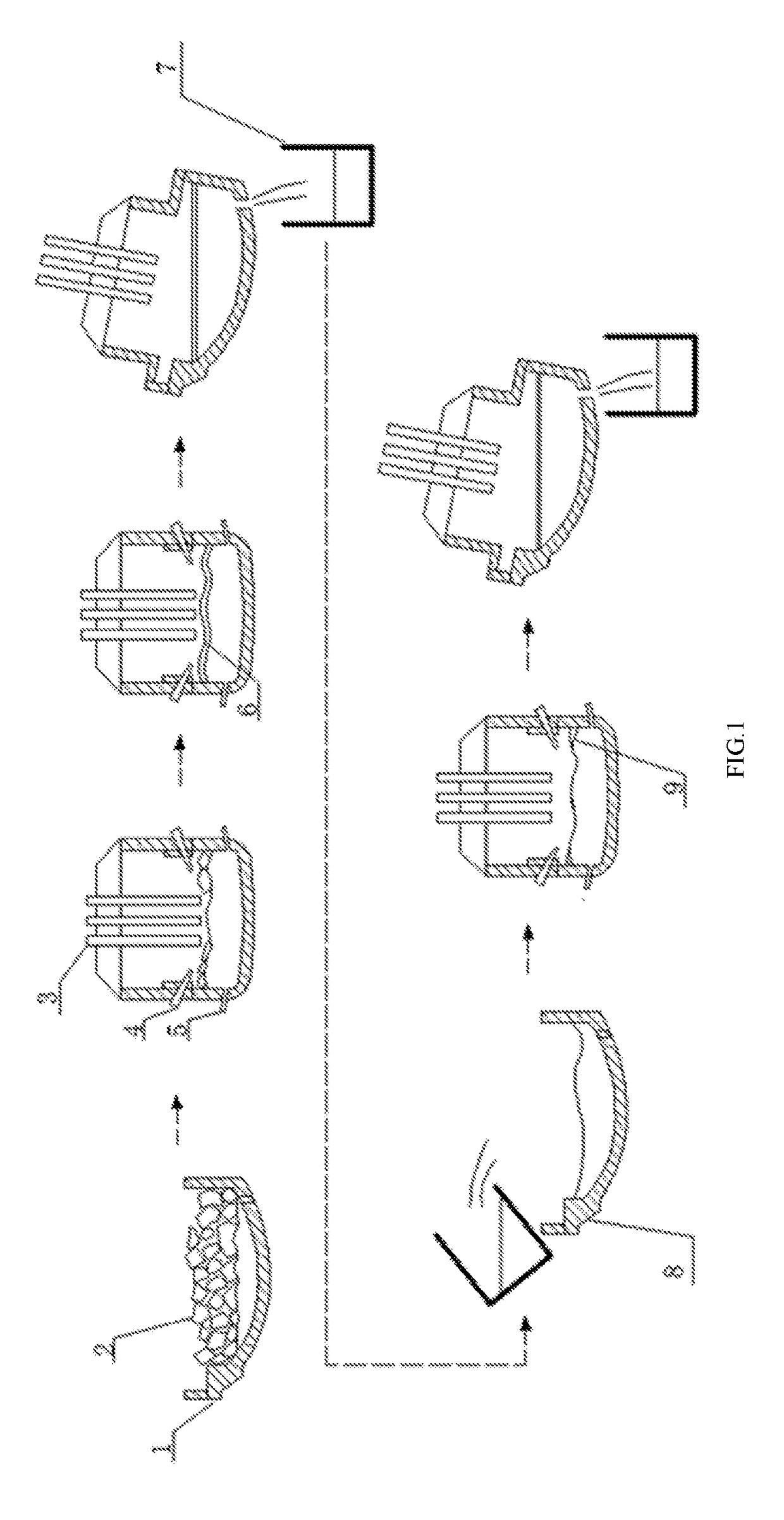

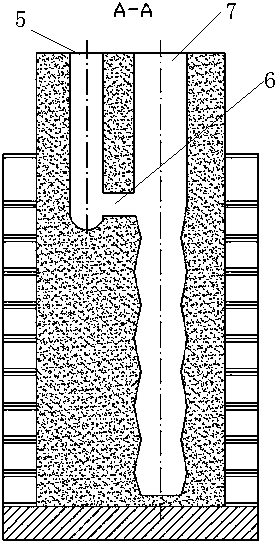

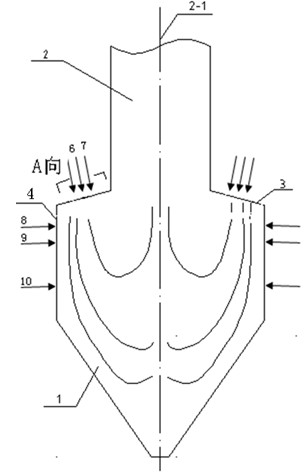

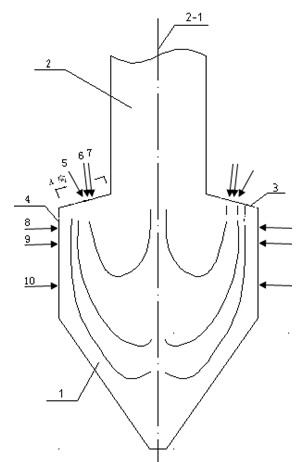

Refining device and method for removing liquid steel inclusions in continuous casting tundish

The invention relates to a refining device and method for removing liquid steel inclusions in a continuous casting tundish. The refining device comprises a turbulence controller, a refining cover and air curtain ventilation bricks. The two side ends of the refining cover are fixed to a permanent lining on the wall of the tundish, the lower end of the refining cover is immersed into liquid steel below a steel slag layer inside the tundish, the refining cover is located over the air curtain ventilation bricks and is opposite to the air curtain ventilation bricks, a gas channel is formed in the body of the refining cover, the two ends of the gas channel are communicated with a gap between a tundish cover and the steel slag layer inside the tundish, gas exhaust holes communicated with the gas channel are formed in the body of the refining cover and are opposite to the air curtain ventilation bricks, large-flow argon is blown in through the air curtain ventilation bricks, an air curtain barrier with the large continuous intensity is formed between the air curtain ventilation bricks and the refining cover, the inclusions are captured and are adsorbed and removed by the steel slag layer, the argon flows through the gas channel and forms argon seal between the steel slag layer inside the tundish and the tundish cover, the steel slag face is protected, secondary oxidation of liquid steel is avoided, the cleanliness of the liquid steel is greatly improved, and the 0.5 level of the four kinds of inclusions in LHG2 steel reaches more than 90%.

Owner:LAIWU STEEL YINSHAN SECTION CO LTD

Production method for smelting clean steel from full-scrap steel using duplex electric arc furnaces

ActiveUS20180363077A1Improve cleanlinessLow melting pointManufacturing convertersElectric furnaceSteelmakingElectric arc furnace

A production method for smelting clean steel from full-scrap steel using duplex electric arc furnaces, which belongs to the field of electric arc furnace steelmaking. This method makes electric arc furnaces located in two positions be connected in series, wherein the electric arc furnace in a first position is dephosphorization electric arc furnace, and the electric arc furnace in a second position is decarbonization electric arc furnace.

Owner:UNIV OF SCI & TECH BEIJING +1

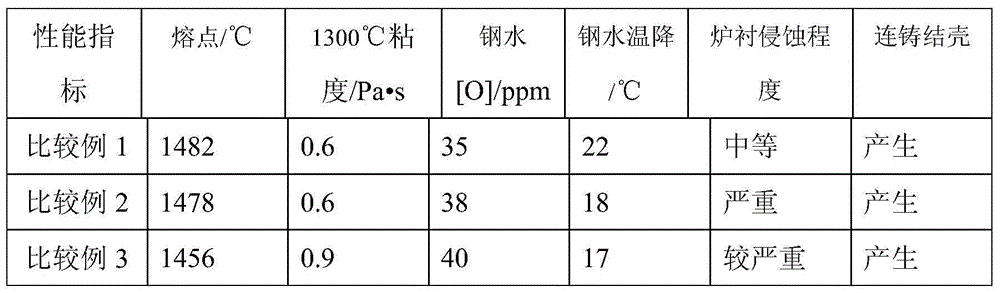

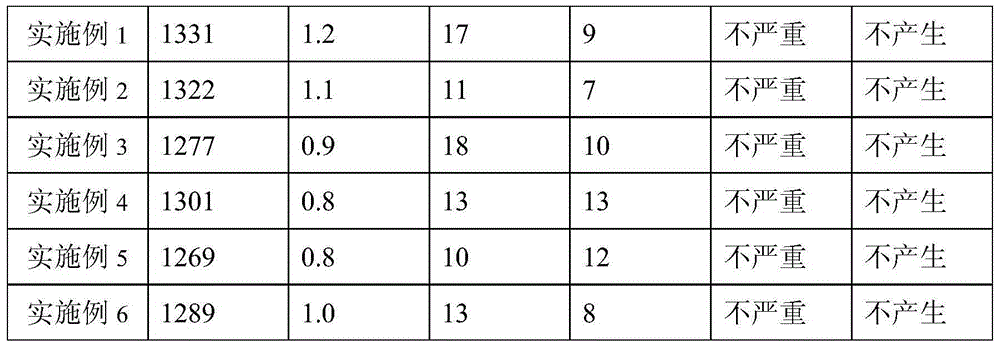

Tundish covering agent and application thereof

The invention relates to a tundish covering agent and application thereof and belongs to the technical field of tundishes in the continuous casting process. The tundish covering agent is mainly prepared from, by percentage content, 35-45% of CaO, 8-15% of SiO2, 25-30% of Al2O3, 5-15% of MgO, 5-12% of (Na2O+Li2O), 1-5% of B2O3 and 0.5-1% of TiO2. The tundish covering agent has the advantages that the melting point is low and is 1250-1350 DEG C, the viscosity is high and is 0.8-1.2 Pa*s at the temperature of 1300 DEG C, and the basicity is high and is 3-6. The tundish covering agent is applicable to the continuous casting production process, for producing the tundishes, of titanium-added steel. When the tundish covering agent is applied to the continuous casting production process of the titanium-added steel, produced TiO2, produced TiN and other produced inclusion can be effectively dissolved. The inclusion is prevented from entering a crystallizer, the cleanness degree of molten steel is improved, and therefore the quality of cast blanks is improved.

Owner:CENT SOUTH UNIV

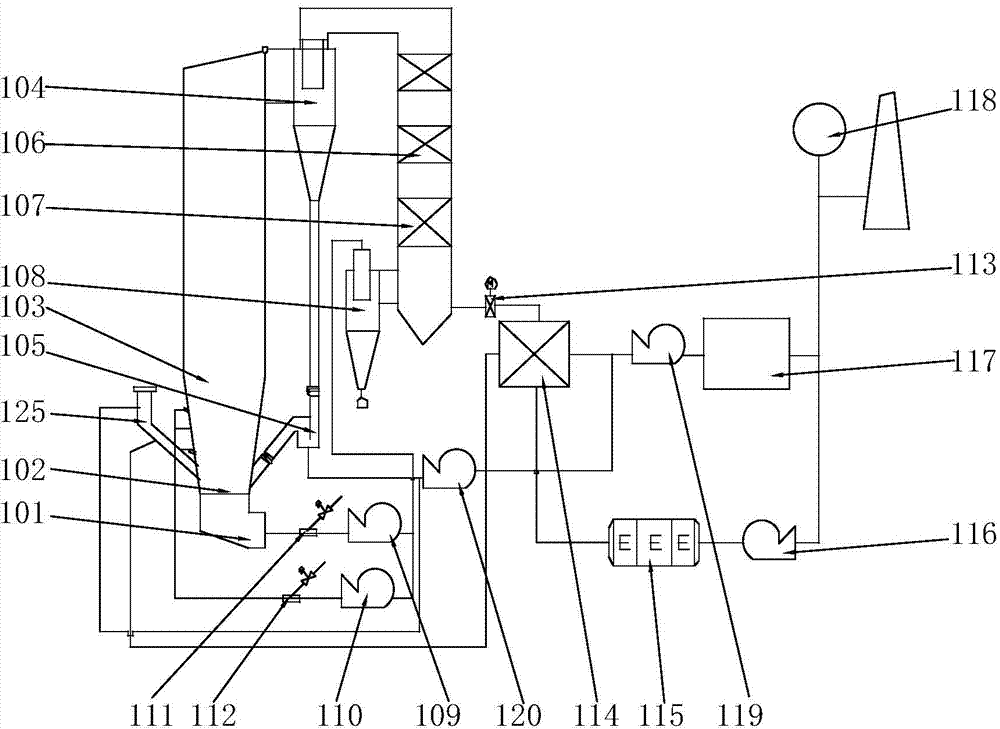

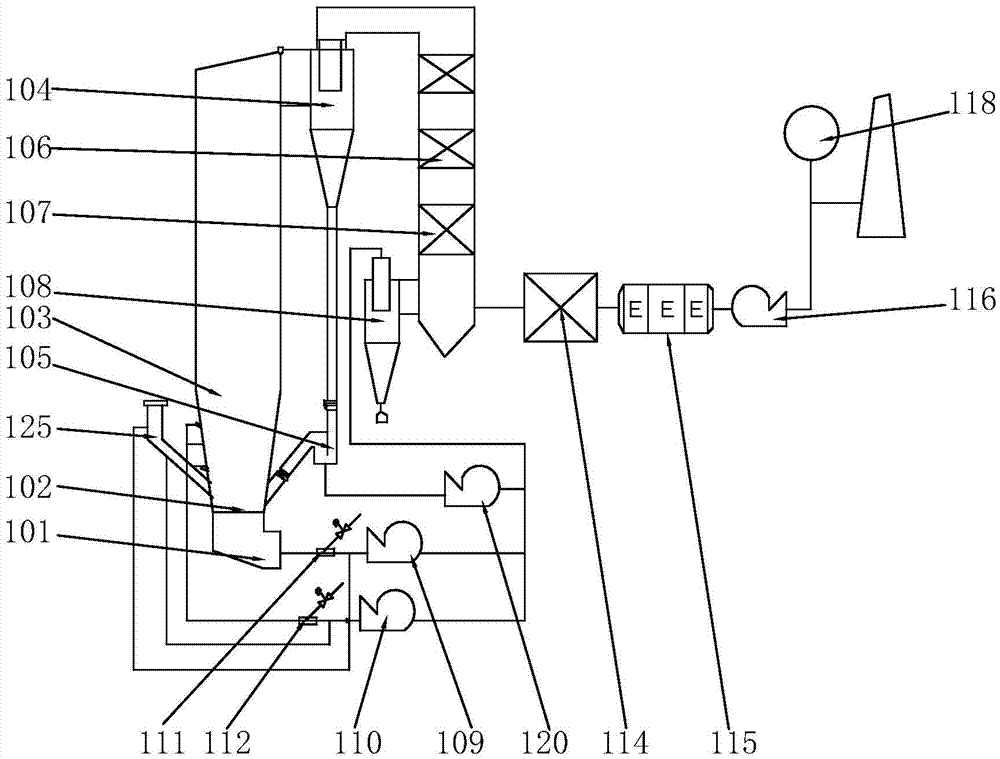

Recirculating fluidized bed oxygen-enriched combustion apparatus and operation method thereof

ActiveCN104848213AUniform fluidizationAvoid depositionFluidized bed combustionIndirect carbon-dioxide mitigationCycloneCombustion

The invention discloses a recirculating fluidized bed oxygen-enriched combustion apparatus, which comprises an air compartment, an air distribution device arranged above the air compartment and a hearth arranged above the air distribution device; the upper part of the hearth is connected with a high-temperature cyclone separator; the upper part of the high-temperature cyclone separator is connected with a heating surface; the lower part of the heating surface is connected with an economizer. The invention further discloses an operation method of the recirculating fluidized bed oxygen-enriched combustion apparatus. The recirculating fluidized bed oxygen-enriched combustion apparatus and the operation method thereof, disclosed by the invention, overcome the defects in the prior art, and intermediate temperature flue gas is used as primary air and secondary air which respectively enter the hearth to serve as recirculating air, in addition, oxygen is injected into the primary air and the secondary air, and the oxygen injection amount can be adjusted, meanwhile, an oxidizing agent is provided for combustion in the hearth, the concentration of CO2 discharged from a boiler of a recirculating fluidized bed can be enriched to more than 80%, and the capture of the CO2 in the flue gas after combustion of coal is facilitated.

Owner:DONGFANG BOILER GROUP OF DONGFANG ELECTRIC CORP

Foam slag inhibitor for converter

The invention relates to a foaming slag inhibitor special for a converter, in particular to a foaming slag inhibitor for a top and bottom combined blown converter. The invention aims to solve the technique problems of slow effect and not suitable for being added when tapping in the existing foaming slag inhibitor. The technical proposal is as following: a foaming slag inhibitor special for the converter mainly comprises the main components with weight percentage as follows: fiber pulp: 60 to 75 percent, carbonized rice husk: 5 to 15 percent, clay: 8 to 14 percent; and additives and caking agents in accordance with actual needs. The foaming slag inhibitor special for the converter is mainly used for controlling spraying in converter blowing process, inhibiting furnace slag from frothing for a second time when tapping and preventing furnace mouth from roughing slag.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

Grate bar material and production method thereof as well as combined pouring unit of sintering machine

ActiveCN103849819AReduce contentHigh hardnessFoundry mouldsFurnace typesChemical compositionBar product

The invention relates to a production method of a grate bar material of a sintering machine. The production method mainly solves the problems that a high-alloy grate bar is complex in production process, relatively high in production cost, difficult in casting flaw control, non-uniform in performance and the like in the prior art. The technical scheme of the invention is as follows: the grate bar material of the sintering machine comprises the following chemical components in percentage by mass: 1-1.5% of C, 1.5-2.5% of Si, 1.2-2.2% of Al, 2.5-3% of Mn, 11-15% of Cr, 0.3-0.8% of Mo, 0.01-0.03% of Nb, 0.01-0.03% of Ti, 0.03-0.1% of Re, less than or equal to 0.06% of P, less than or equal to 0.06% of S, and the balance of Fe and inevitable impurity elements. A sand casting process of 'one pouring with more molds' is applied, so that the aluminum content and the casting flaws of a silicon grate bar are reduced, and the production cost is reduced. A heat treatment furnace provided with a flow guide circulating fan is applied to low-temperature uniform heat treatment on a cast so as to improve the performance uniformity of casts of the same batch. By adopting the production method disclosed by the invention, a grate bar product of the sintering machine, which is good in process stability, good in performance and relatively low in production cost, can be obtained.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

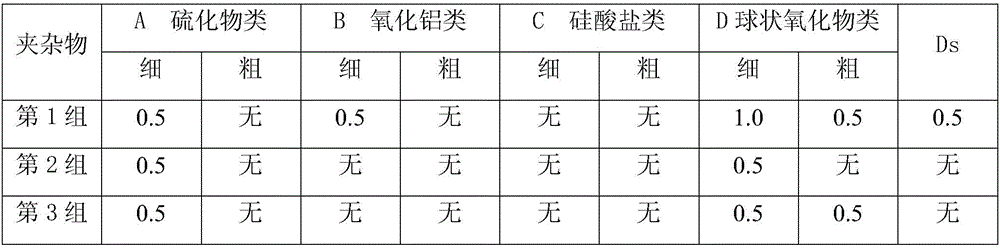

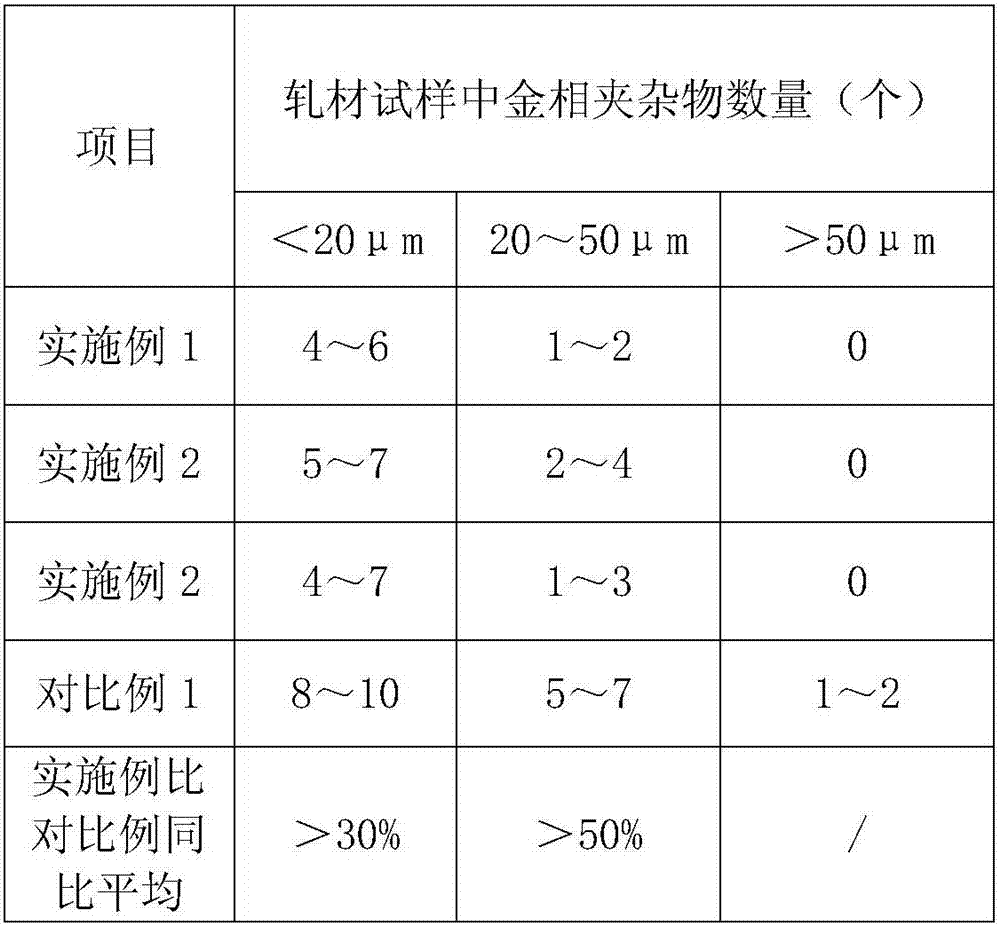

Production process for high-purity bearing steel

InactiveCN106591536ALow residual elementsReduce gas contentProcess efficiency improvementLow nitrogenSlag

The invention belongs to the technical field of steel preparation, and particularly relates to a production process for high-purity bearing steel. The production process comprises the following steps: firstly, adding blast-furnace molten iron and steel scrap in an electric converter and smelting; secondly, alloying a steel ladle by virtue of an alloy, an aluminium cake and a low-nitrogen carburant; thirdly, discharging molten steel into the steel ladle subjected to the alloying treatment after the smelting is completed, slagging and enabling the slagging result to meet the requirements of while slag in the earlier stage of refining, obtaining the while slag and then carrying out aluminium line feeding operation; fourthly, hoisting molten steel qualified after the refining into a vacuum tank and carrying out vacuum treatment; and finally carrying out continuous casting. Cancel of molten steel modification treatment is realized; and moreover, the molten steel is high in castability and meets the production requirements of high-standard bearing steel.

Owner:ZENITH STEEL GROUP CORP

Method for removing slag inclusion of continuous casting tundish purging upper nozzle seating brick through argon blowing

The invention provides a method for removing slag inclusion of a continuous casting tundish purging upper nozzle seating brick through argon blowing. The proper amount of high-alkalinity low-carbon tundish covering agent is added to the molten steel liquid face of the area over the continuous casting tundish purging upper nozzle seating brick per charge, the problem that due to argon blowing of the continuous casting tundish purging upper nozzle seating brick, the molten steel liquid face greatly fluctuates is solved, the problem of molten steel secondary oxidization and slag entrapment can be effectively prevented, the argon bubble capture inclusion floats to the tundish liquid face to be absorbed timely by the high-alkalinity low-carbon tundish covering agent and be removed more effectively, and the metallurgical results of argon blowing slag inclusion removal of the continuous casting tundish purging upper nozzle seating brick is improved.

Owner:SHANDONG IRON & STEEL CO LTD

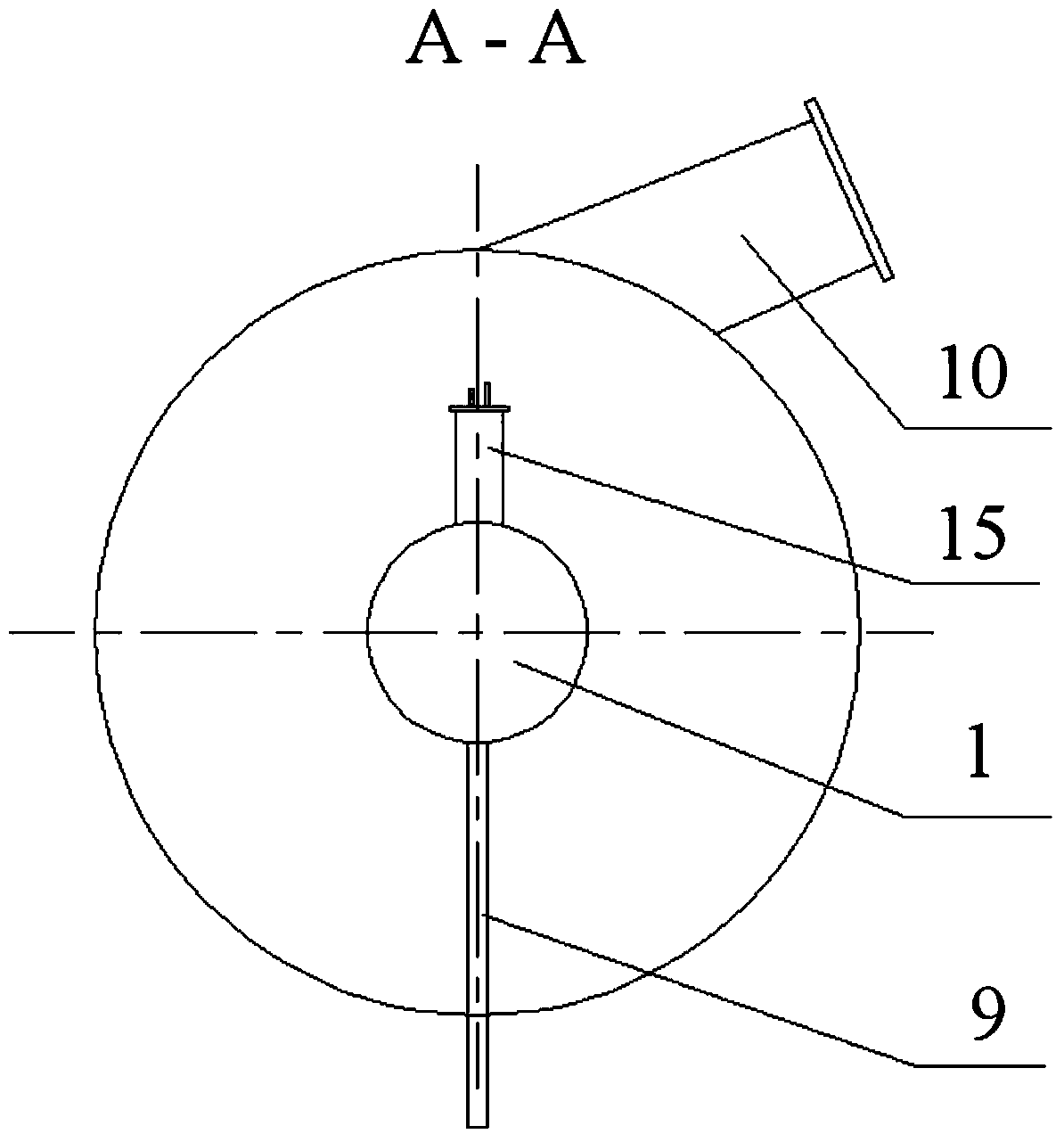

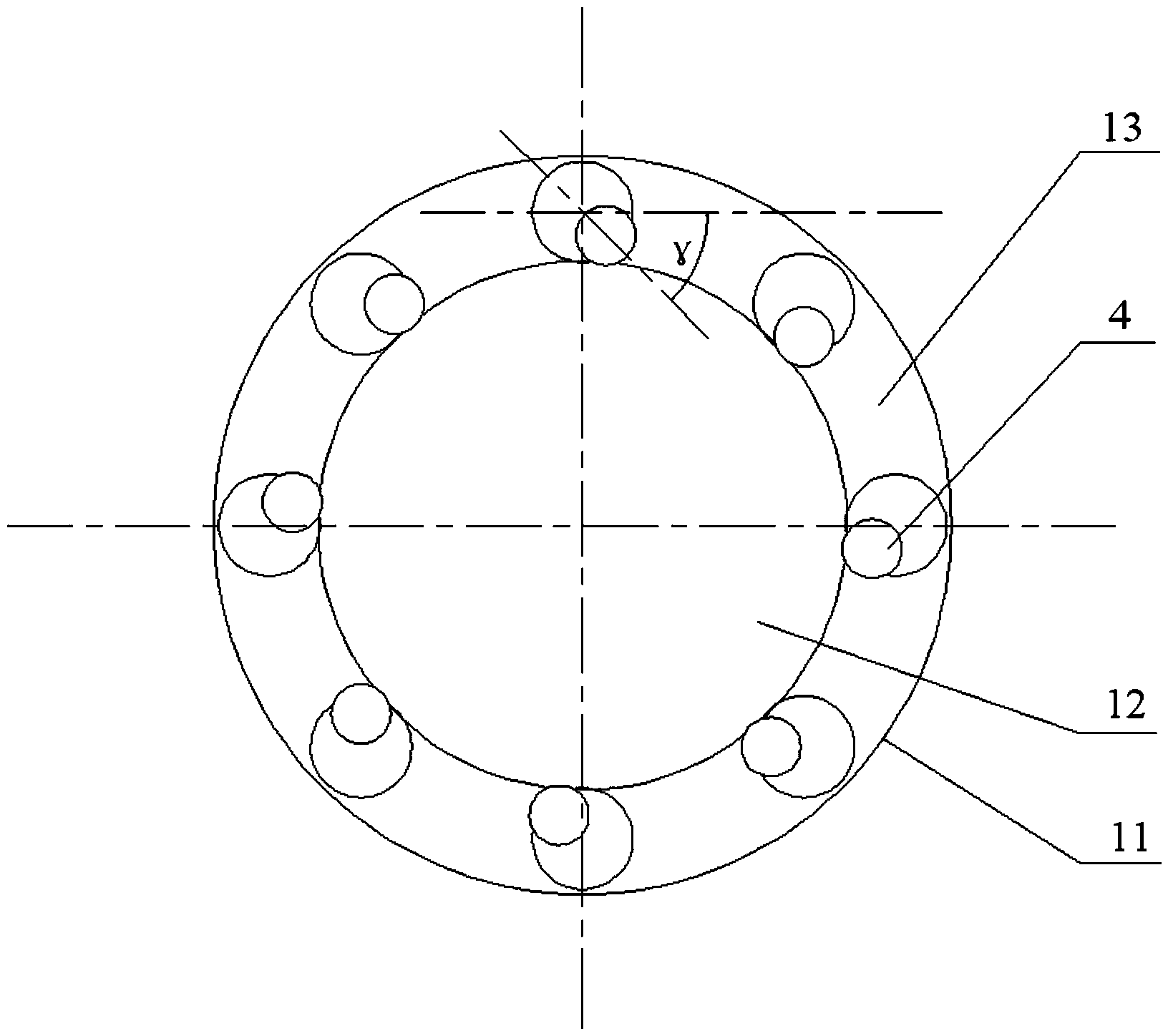

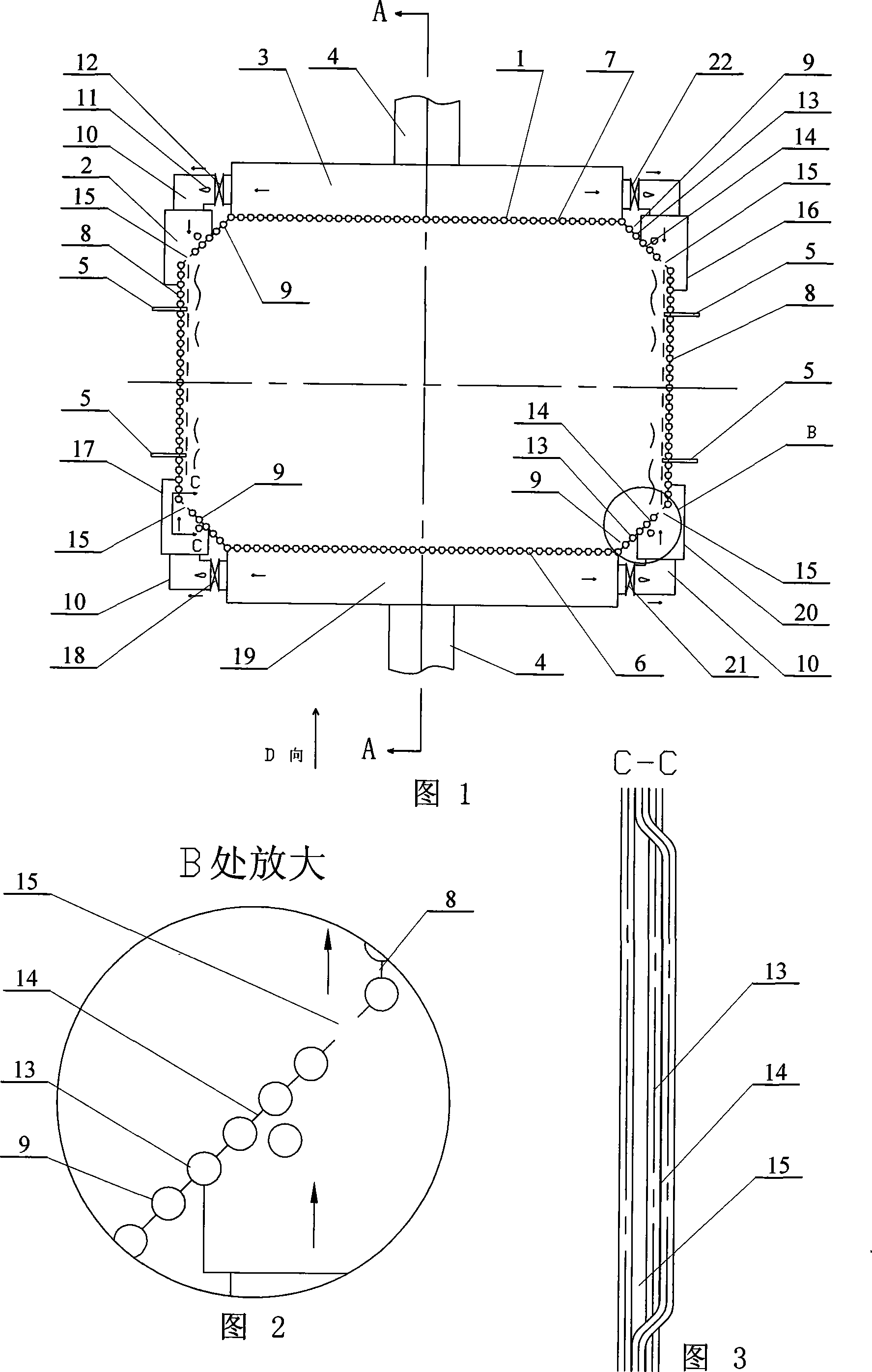

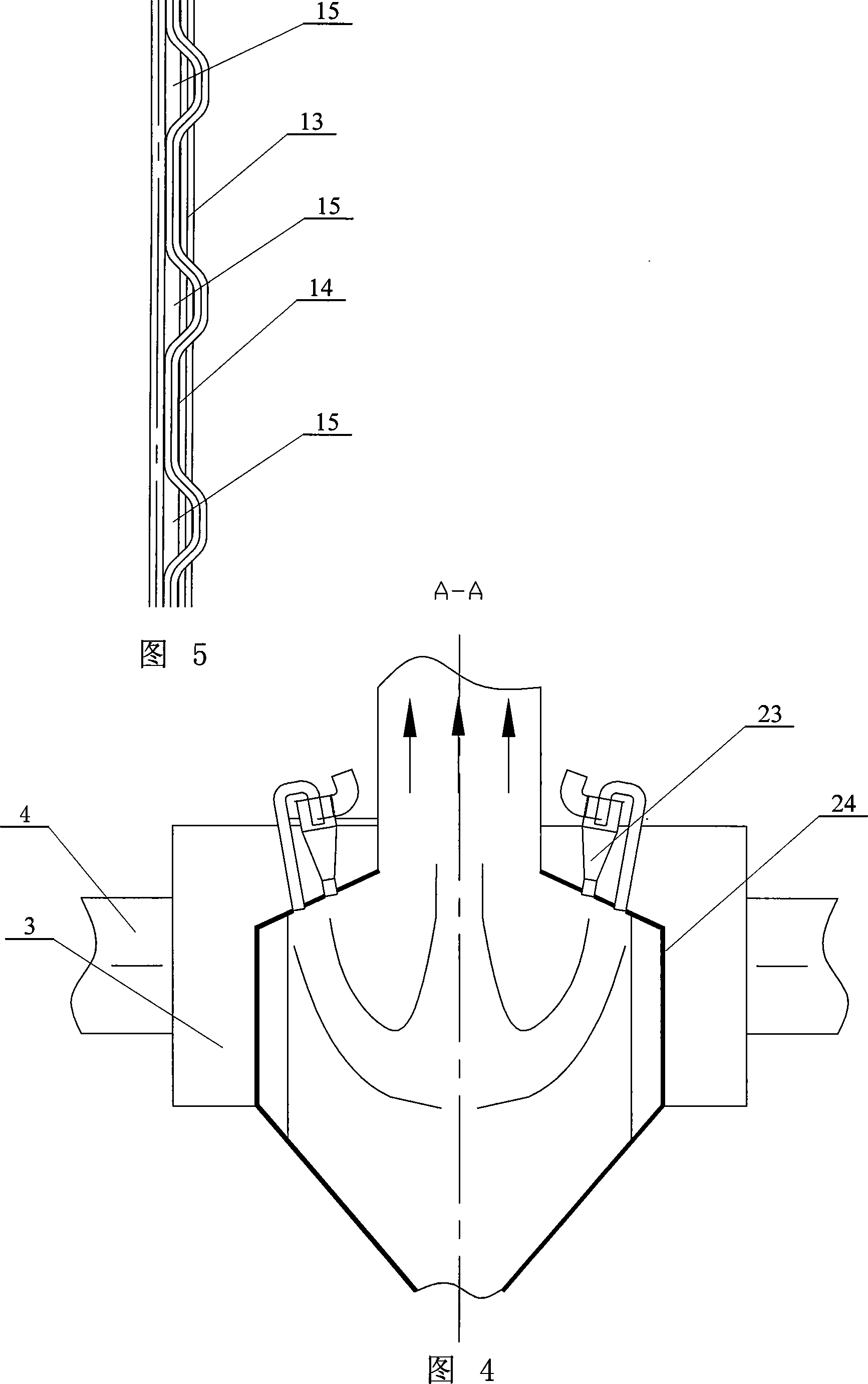

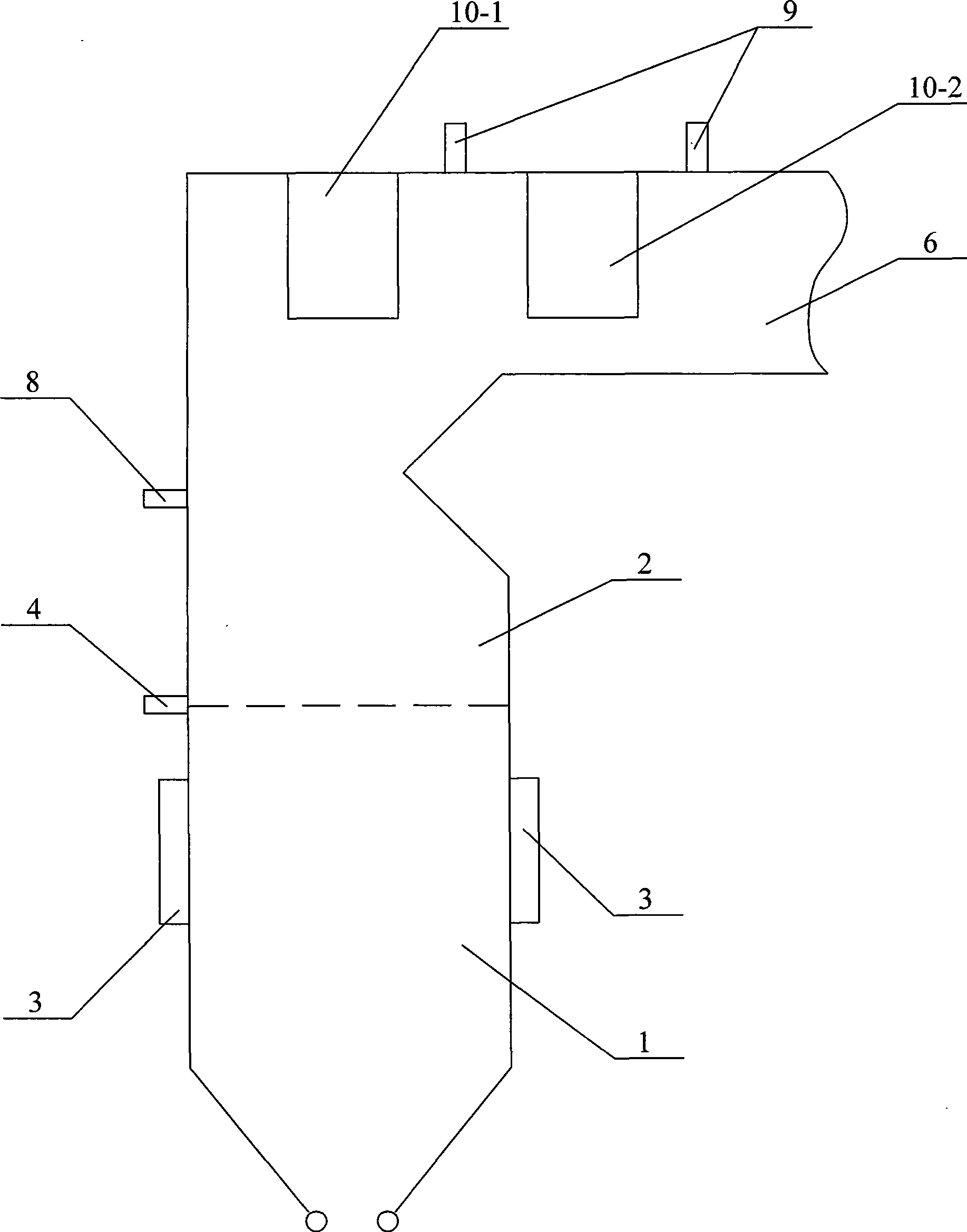

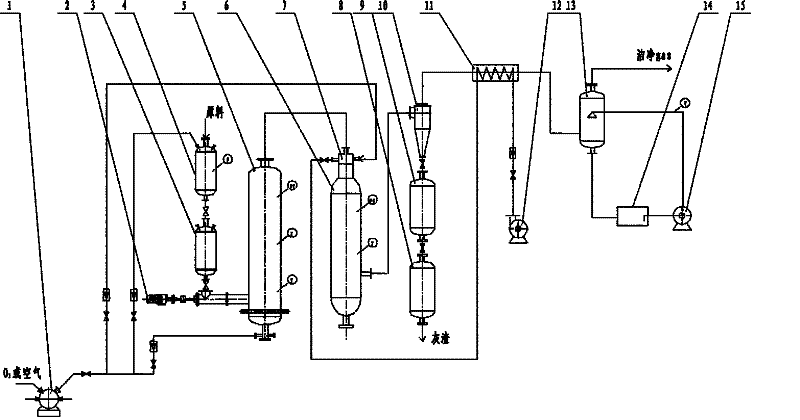

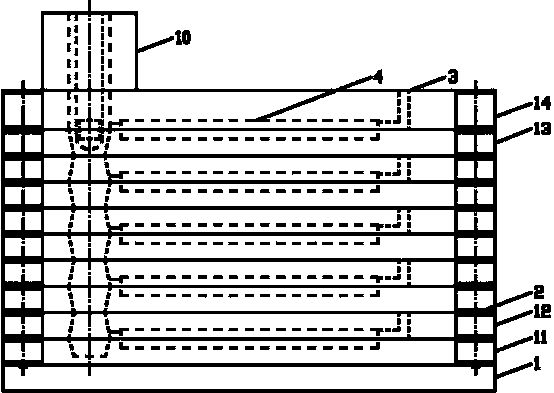

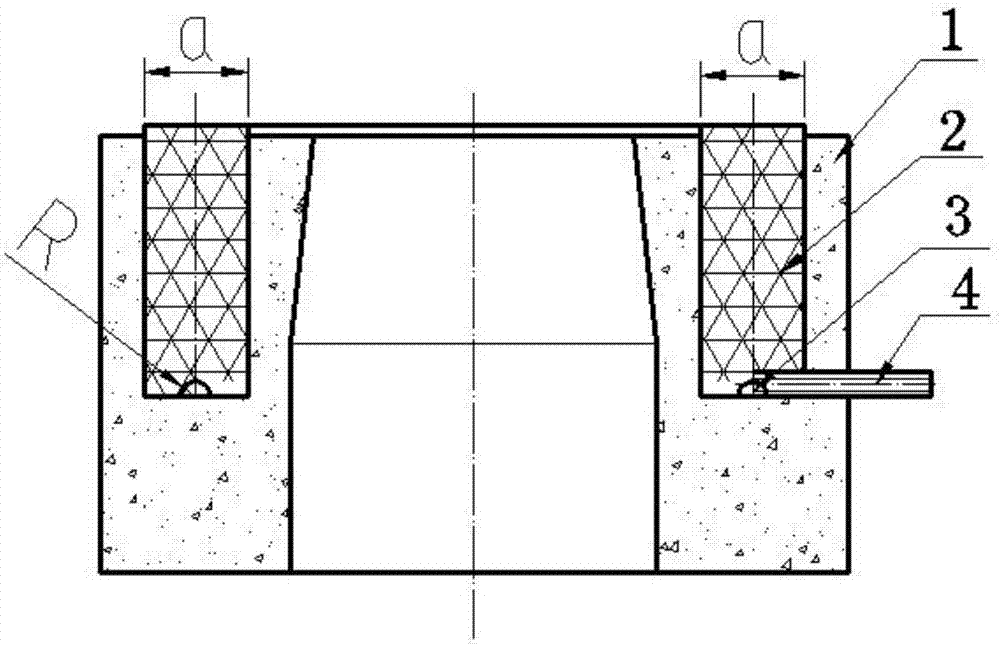

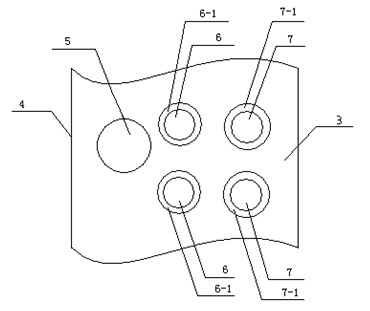

Double-cyclone cylinder burner W-shaped flame boiler capable of stably burning pulverized coal

InactiveCN102322631AReduce distractionsImprove stabilityNon-combustible gases/liquids supplyWater coolingCoal

The invention discloses a double-cyclone cylinder burner W-shaped flame boiler capable of stably burning pulverized coal. The boiler consists of a lower hearth (1), an upper hearth (2), a front-rear arch (3) and a front-rear wall water cooling wall (4); the lower part of the front-rear wall water cooling wall (4) is provided with a secondary air nozzle; the front-rear arch (3) is provided with a primary air nozzle (6), a gas exhaust nozzle (7) and a secondary air C nozzle (5); and the air outlet of the secondary air C nozzle (5) and the vertical direction form an included angle of 1-10 degrees. According to the invention, the secondary air C nozzle and the vertical direction form a fixed included angle and form a group of closely parallel air stream with the primary air, thus the interferences of the secondary air at the C nozzle to the main pulverized coal air stream of the primary air can be reduced, the burning stability is improved, also the secondary air entering from the secondary air C nozzle also can supply air in the course of burning of the main pulverized coal air stream under the tilting angle, and better burning rate is achieved.

Owner:ELECTRIC POWER SCI RES INST OF GUIZHOU POWER GRID CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com