Patents

Literature

159results about How to "Low thermal efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

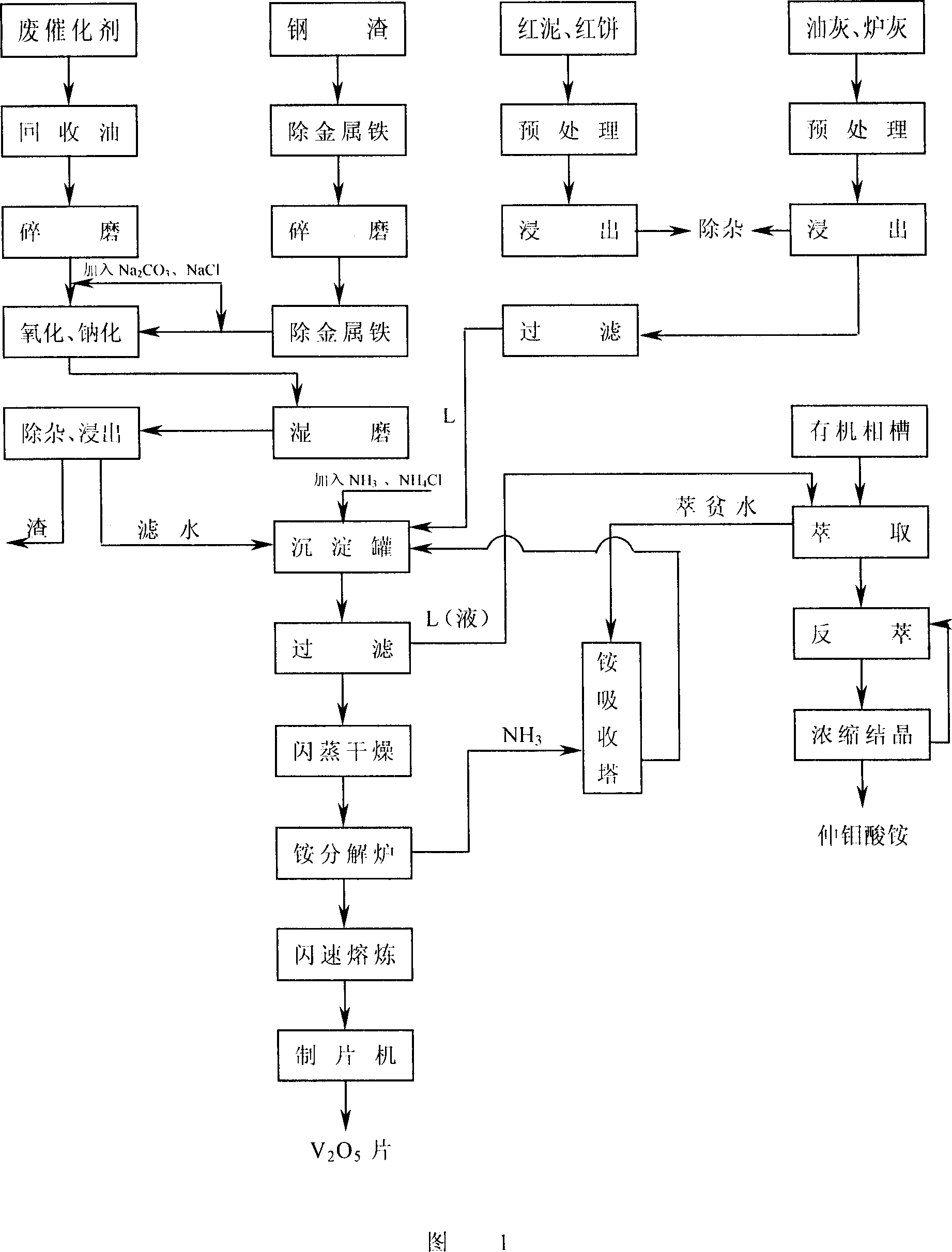

Extraction of vanadium and molybdenum compound from refused materials containing vanadium and molybdenum etc. multiple elements

InactiveCN1940096APrecipitation completeStable pHVanadium oxidesProcess efficiency improvementSodium molybdateMolybdenum compounds

Extraction of vanadium and molybdenum from waste materials is carried out by physically or chemically pre-treating for raw materials by recovered oil, leaching out at a certain pH value, generating soluble sodium metavanadate and sodium molybdate, removing impurities, filtering, solid-liquid separating, precipitating ammonium metavanadate by amine salt, filtering, drying, decomposing, tabletting by smelting furnace to obtain sheeted vanadic anhydride, precipitating ammonium metavanadate filtrate, pouring it into vanadium extraction tank, extracting by organic phase, cleaning by saturated organic phase, reversed extracting, concentrating and crystallizing. It has better vanadium recovery rate and quality and more product yield.

Owner:HUARUI VANADIUM IND SHENYANG

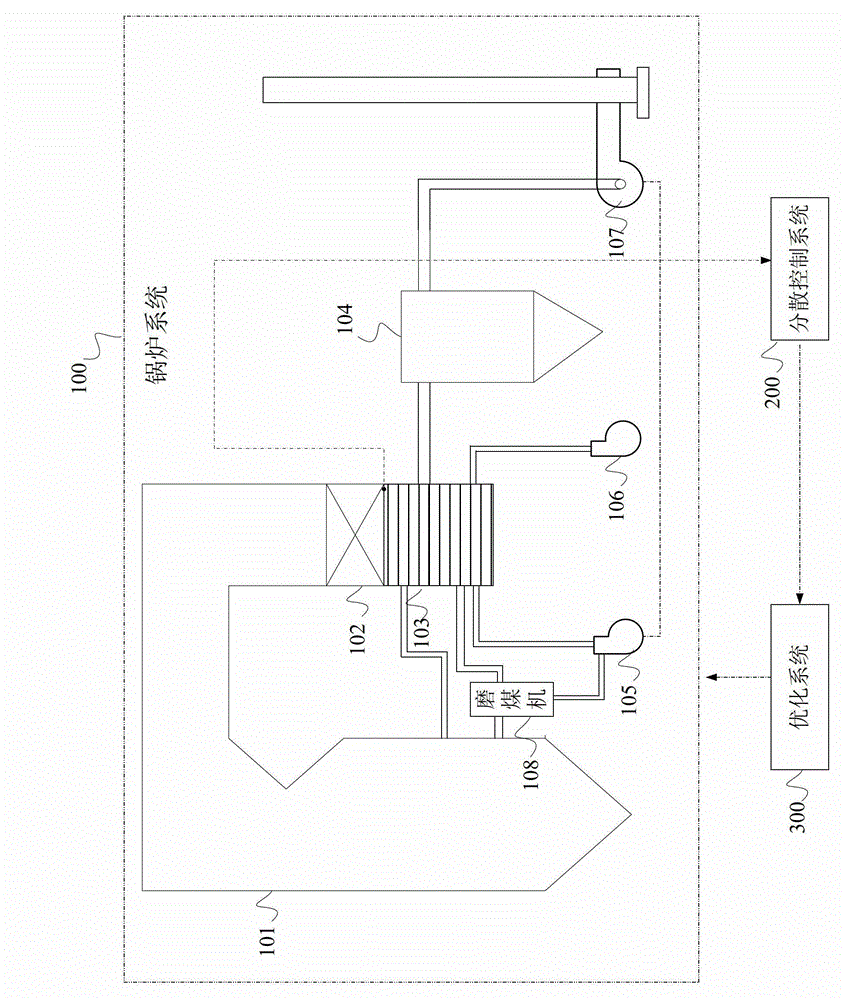

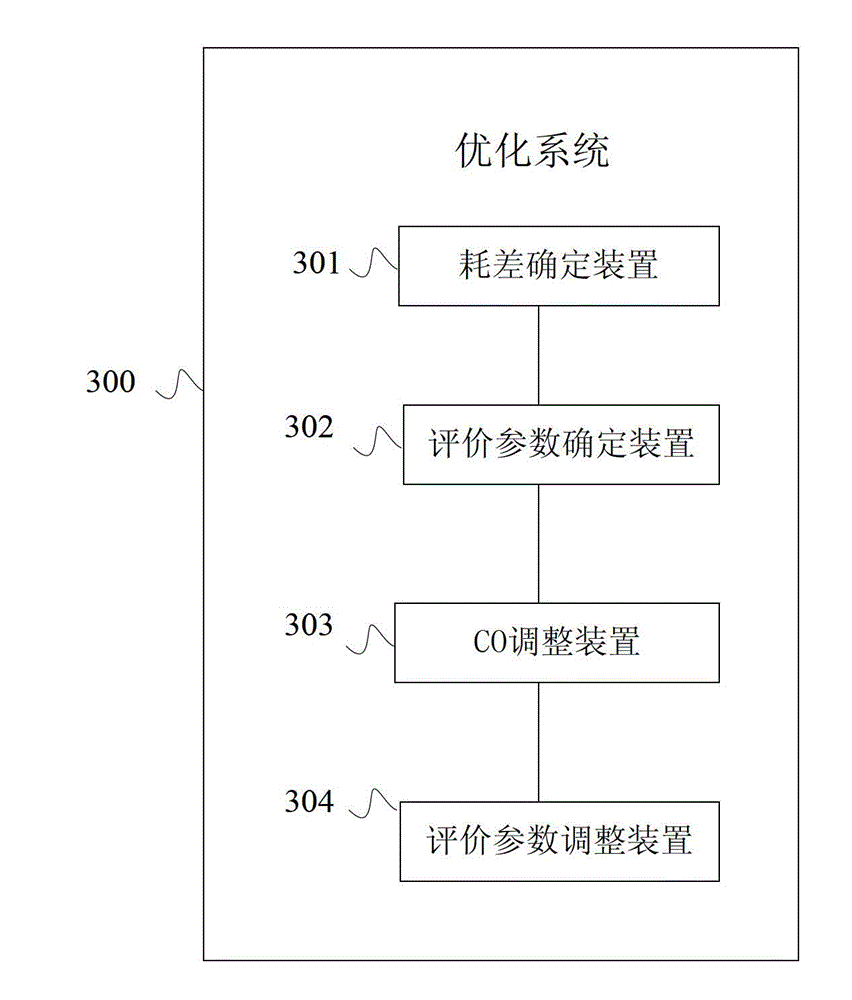

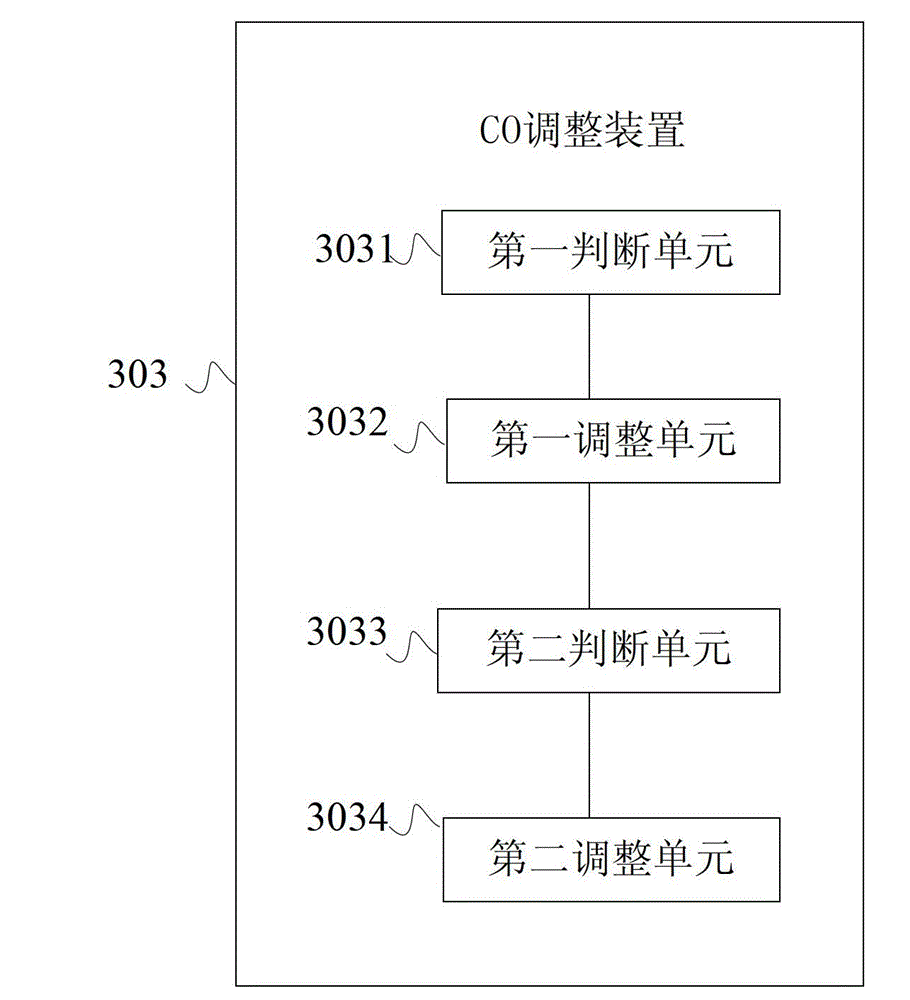

Optimal operation method and system for utility boiler based on CO

ActiveCN103148473ALow thermal efficiencyHigh thermal efficiencyBoiler controlAir preheaterAir volume

The embodiment of the invention provides an optimal operation method and a system for a utility boiler based on CO. The method comprises the steps of collecting CO concentration of an inlet of an air preheater, acquiring exhaust smoke temperature, an oxygen content of exhaust smoke, a carbon content of fly ash and fan power consumption of the currently operating boiler, determining the exhaust smoke temperature, the CO concentration, the oxygen content of the exhaust smoke, the carbon content of the fly ash and corresponding consumption difference of the fan power consumption respectively, determining operating evaluation parameters of the boiler according to the exhaust smoke temperature, the CO concentration, the oxygen content of the exhaust smoke, the carbon content of the fly ash and the corresponding consumption difference of the fan power consumption, adjusting secondary air volume of a boiler system to control the CO concentration to be in a preset scope, and adjusting coal quantity and primary air volume of the boiler system to allow the operating evaluation parameters of the boiler to be approximate to preset values. The method and the system can effectively improve operating economy and safety of the boiler, are in accordance with the current energy conservation and emission reduction policies, and have a great significance in the safe and economical operation of the utility boiler.

Owner:NORTH CHINA ELECTRICAL POWER RES INST +3

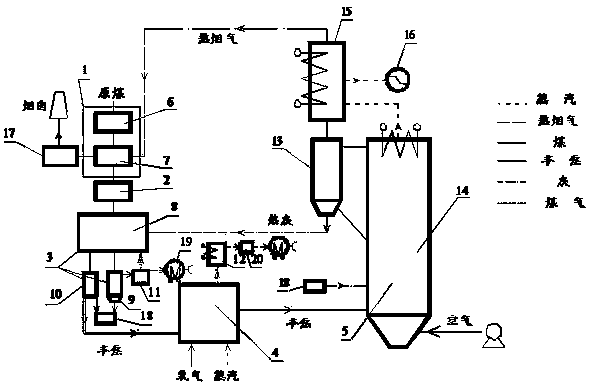

Polygeneration technology for gradient utilization of low-rank coal

InactiveCN103740389AIncrease added valueEmission reductionDirect heating destructive distillationSpecial form destructive distillationWaxBrown coal

The invention discloses a polygeneration technology for gradient utilization of low-rank coal. According to the polygeneration technology, a circulating fluidized bed combustion boiler, a circulating fluidized bed dry distillation reactor and a circulating fluidized bed gasification reactor are taken as cores; series power generation equipment achieves gradient cyclic utilization of low metamorphic coals; the low-rank coal is firstly subjected to lignite wax extraction after crushing and drying, and then enters a brown coal pyrolysis reactor; a raw gas of the gasification reactor is adopted as a fluidizing agent; tar and the raw gas are obtained after dry distillation; semicoke enters the gasification reactor to carry out partial gasification; a part of coal gas is generated as a fluidizing agent of a dry distillation reactor; incompletely gasified semicoke enters the combustion boiler as a fuel; heat and steam generated by combustion are applied to power generation; a by-product low-pressure steam can be used as a raw material of the gasification reactor; the high-temperature semi-coke and hot ashes obtained by combustion enter the dry distillation reactor and the gasification reactor as heat carriers, so as to finish a cycle. By adopting the polygeneration technology, the economic value of the low-rank coal can be obviously improved, emission of pollutants can be significantly reduced by gradient cyclic utilization, and the technology is safe and reliable.

Owner:BEIJING TIANSU SUNLIGHT LOW CARBON TECH

Processing method of paper-making pulping black liquor

The invention discloses a processing method of paper-making pulping black liquor, and the method comprises polycondensation, acid precipitation, aging, precipitation, solid-liquid separation and drying of the pulping paper-making black liquor, and in the black liquor, the solid phase which mainly comprises lignin and the liquid phase which mainly comprises sodium salt solution are separated; and the Baume degree of the black liquor is larger than or equal to 15 Be degrees. The method has simple process, low cost and wide application range. The obtained lignin can be used as multiple industrial and agricultural raw materials; the chroma, CODcr and BOD5 of the obtained liquid phase are greatly reduced.

Owner:张仲伦

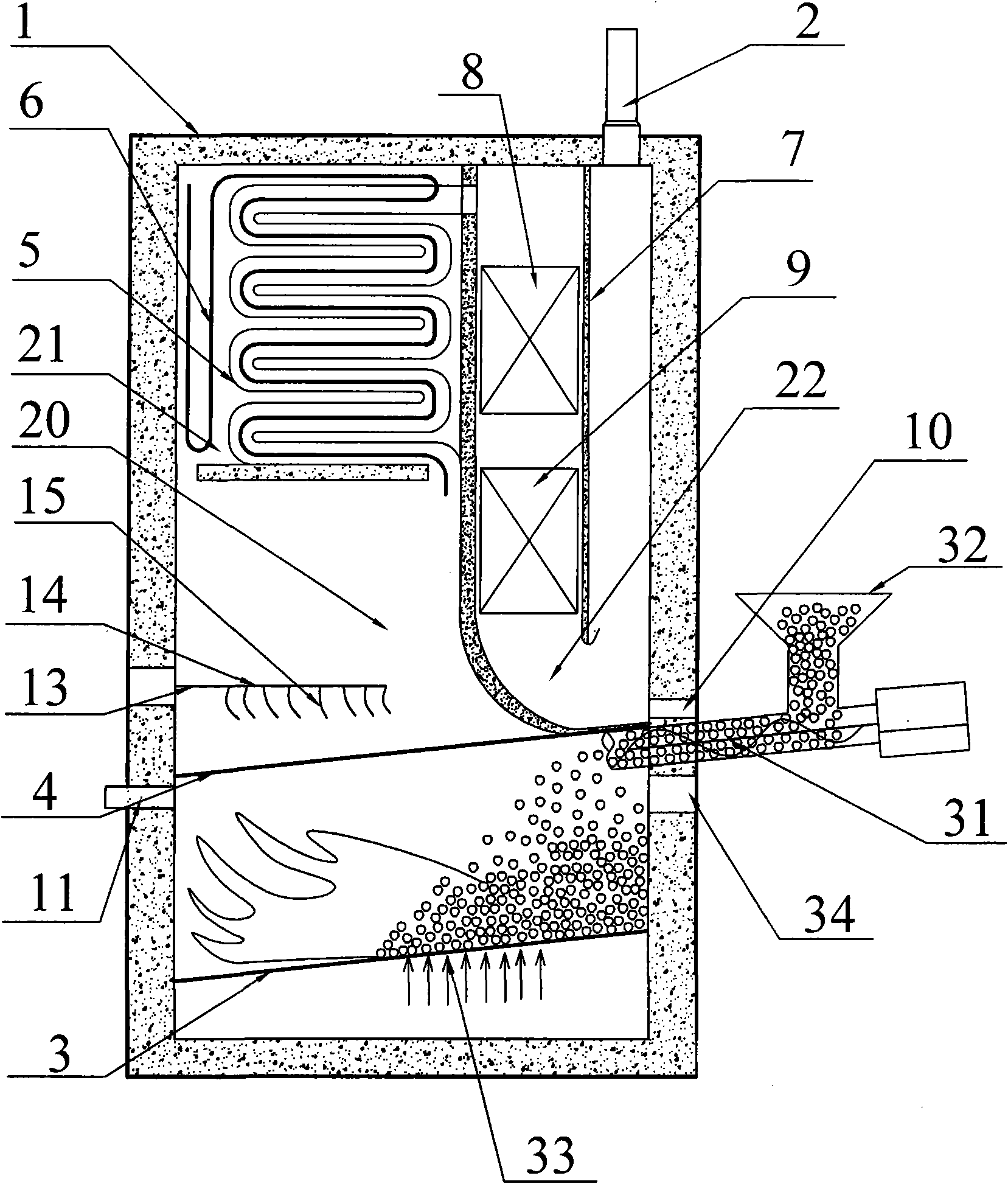

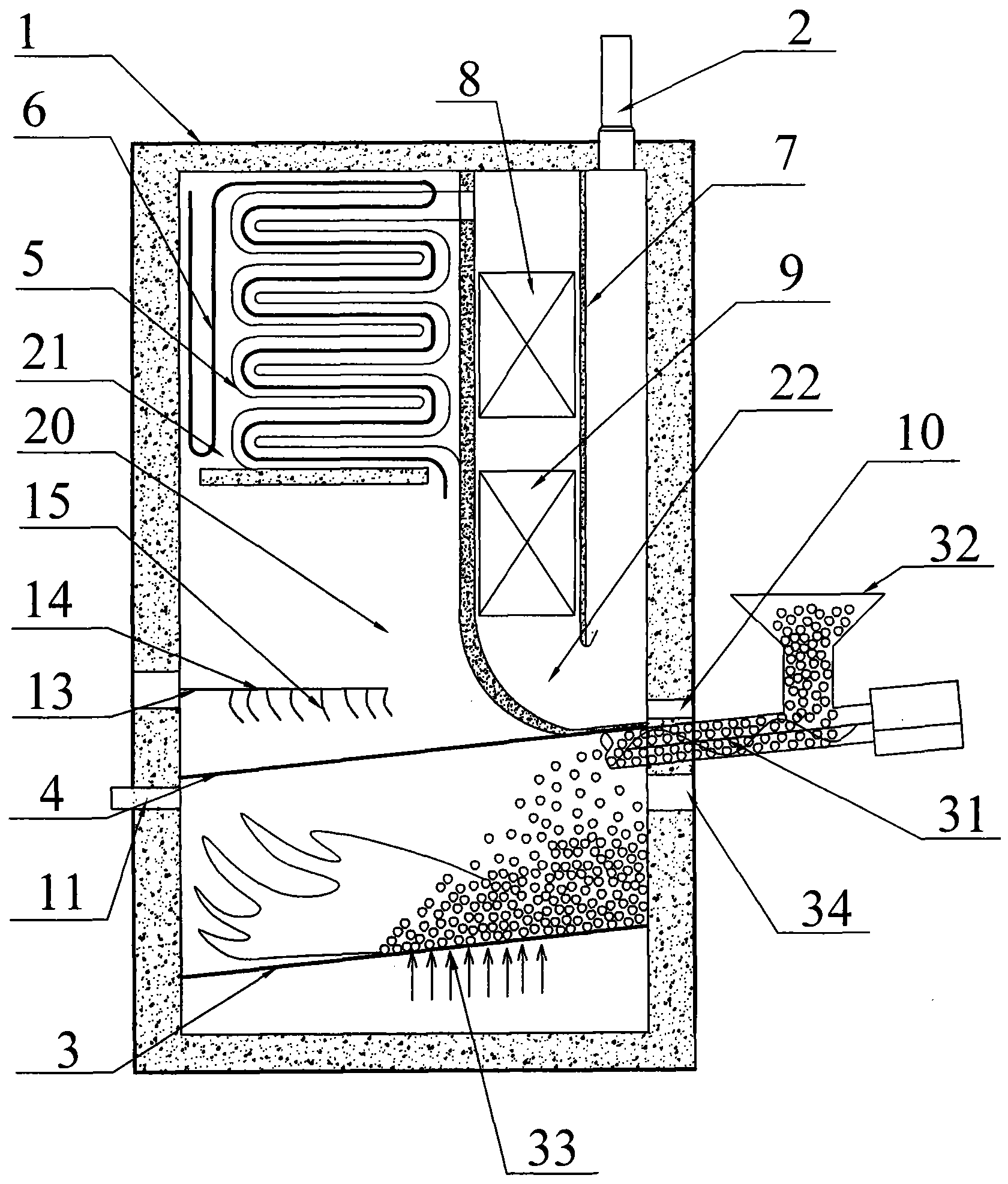

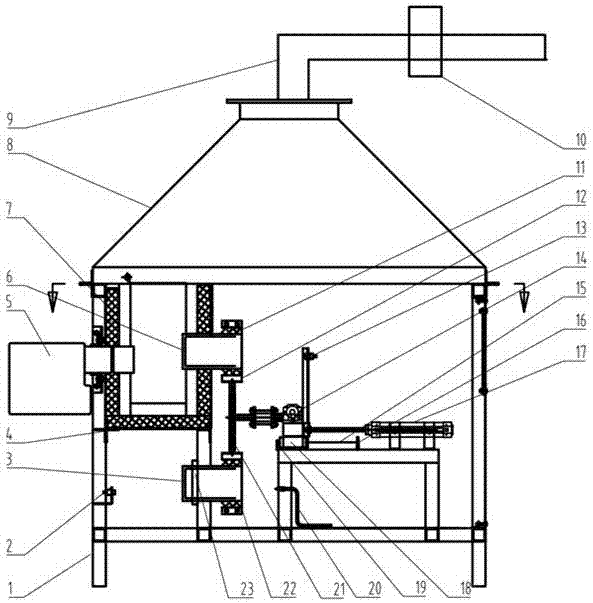

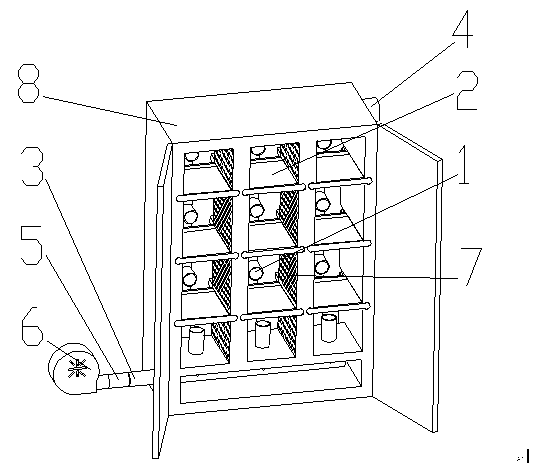

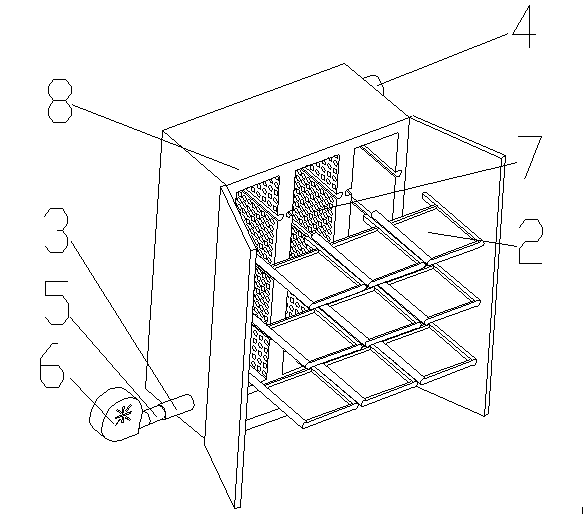

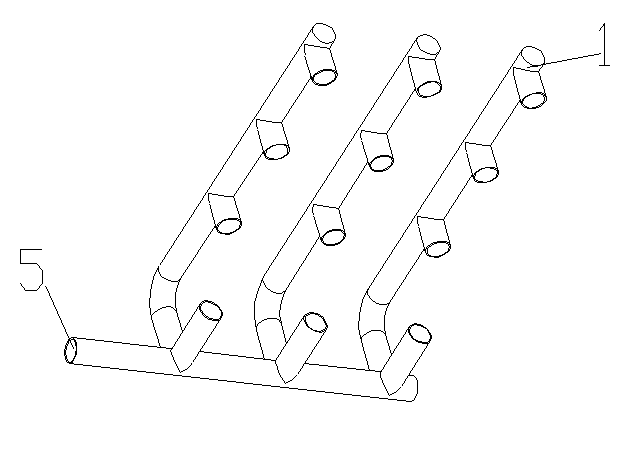

Biomass fuel combustion device

ActiveCN101839475ASlight disturbancePromote combustionDouble grateSolid fuel combustionCombustion chamberPollutant emissions

The invention discloses a biomass fuel combustion device, and provides a biomass fuel combustion device which has the advantages of high combustion efficiency and less pollutant discharge. The biomass fuel combustion device of the invention comprises a vertical combustion furnace (1), wherein a smoke discharging channel (2) is arranged on the vertical combustion furnace (1); a combustion chamber (20) and a heat exchange chamber (21) are arranged in the vertical combustion furnace (1); an upper grate (3) and a lower grate (4) are arranged in the combustion chamber (20); the combustion chamber (20) is provided with a feeding device which is positioned on the side wall of the vertical combustion furnace (1) and is communicated with the combustion chamber (20); a primary air inlet (33), a secondary air inlet (34) and a tertiary air inlet device are respectively arranged in the corresponding positions of the vertical combustion furnace (1); a smoke pipe (5) and a hot water pipe (6) are arranged in the heat exchange chamber (21); and the smoke pipe (5) is respectively communicated with the combustion chamber (20) and the smoke discharging channel (2) through gas flow. The invention can be widely applied to the field of boilers.

Owner:湖南兆丰新能源技术有限公司

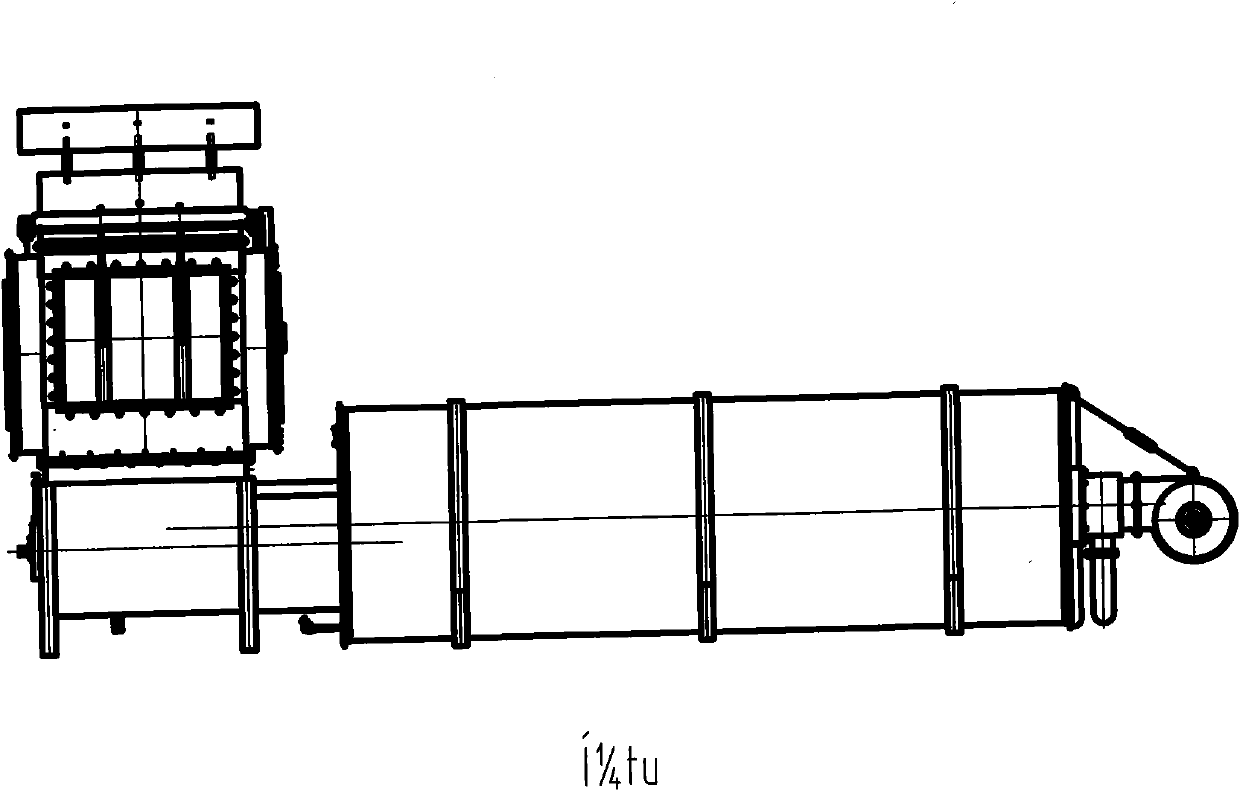

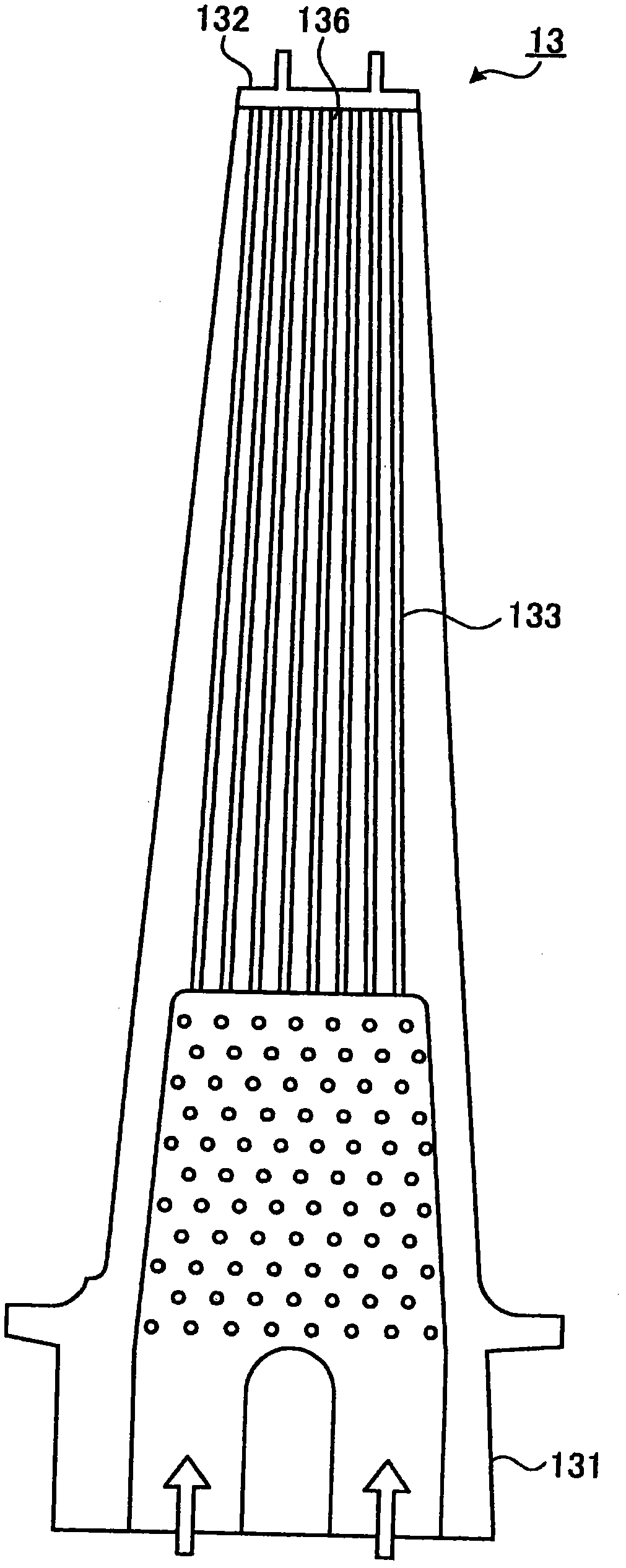

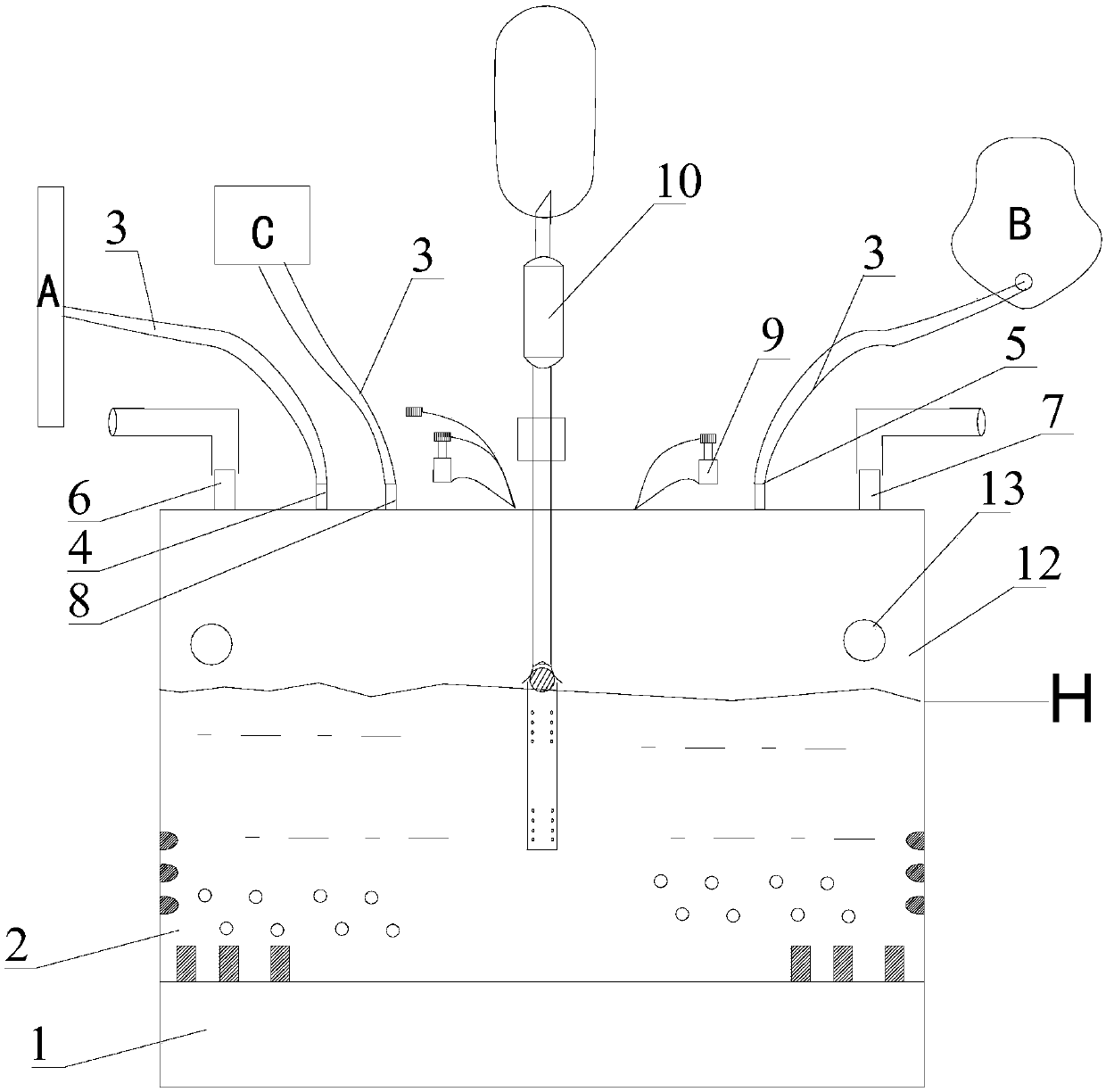

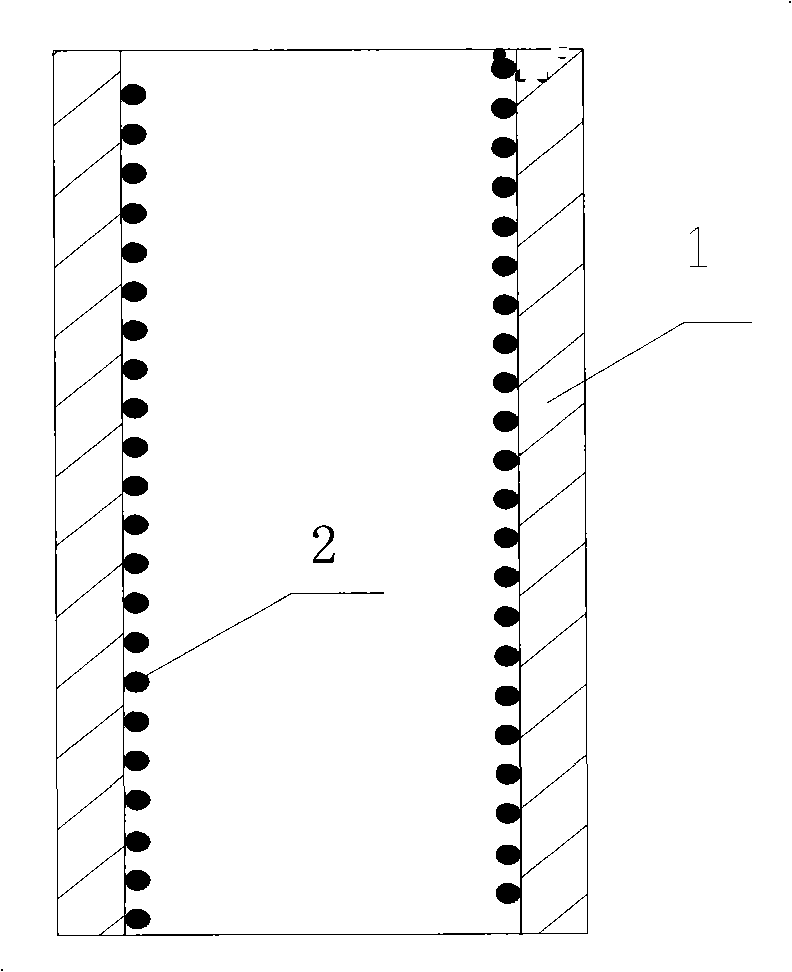

Offshore platform thermal recovery fuel oil or fuel gas steam injection boiler

ActiveCN101865450ALow thermal efficiencyReduce drynessFluid removalWater-tube boilersAutomatic controlFuel oil

The invention relates to an offshore platform thermal recovery fuel oil or fuel gas steam injection boiler used in the thermal recovery operation of an offshore oilfield platform. The invention mainly solves the problems that land petroleum thermal recovery devices can not meets the demands of the offshore platform on devices such as compact layout, light weight, safety, mental protection, high efficiency and high degree of automation. The boiler mainly comprises a boiler main body and auxiliary equipment, wherein the main body mainly contains a radiant section, a convection section and a water heat exchanger; and the auxiliary equipment mainly contains a steam-water system, a ventilation system, a combustion system and an automatic control system. All the parts of the boiler main body are assembled in the vertical mode and all the water channels and tube bundles in the boiler main body are arranged in a vertical structure and use the high-strength tubing with small wall thickness, thus the floor space of the boiler of the invention can be reduced by about one third and the weight can be reduced by about 20% compared with the conventional boiler used on land; the special insulating layer and insulating material are adopted simultaneously so that the economic and technical norms of the boiler such as heat efficiency, dryness, safety and environmental protection are all higher than the existing norms of the land boiler; and the boiler is combined with the automatic control system so that the boiler is safe, environmentally friendly and efficient, and has high degree of automation.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

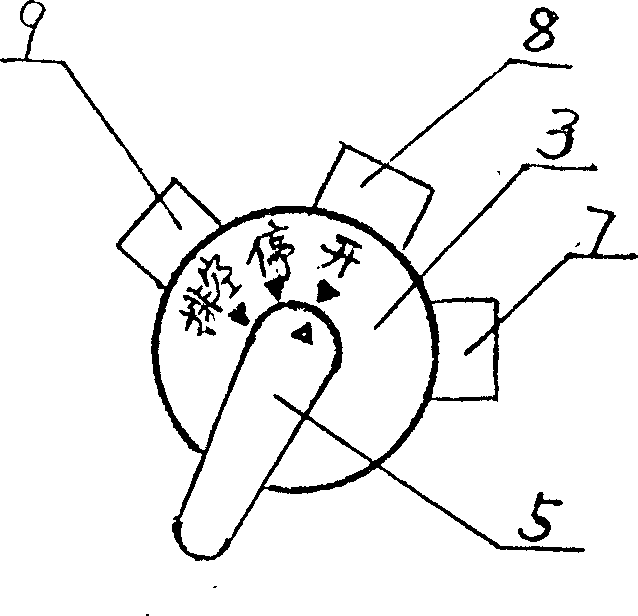

Solar water heater and basin with automatic temperature regulating mechanical valve

InactiveCN1421658AWon't blow upLow thermal efficiencySolar heat devicesSpace heating and ventilation detailsSolar waterEngineering

The present invention is solar water heater and basin with automatic temperature regulating mechanical valve. The valve installed on the basin has water inlet port, water outlet port and emptying port, and its water outlet port and emptying port are connected via pipe to the two sides of the solar heater separately. When the valve is set in the "open" position, the upper and the lower water pipe passage is communicated; when the valve is in the "close" position, the passage is emptied. When the heater is in use, the hot water is mixed with tap water in the valve to proper temperature. The water tank in the water heater has water pressure resisting, heat pressure resisting and heat insulating functions.

Owner:耿玉顺

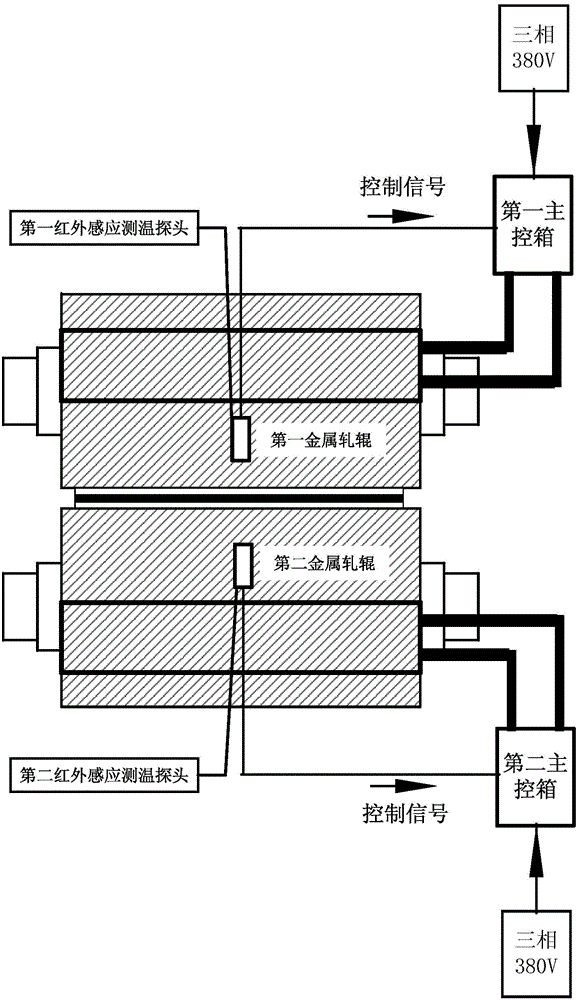

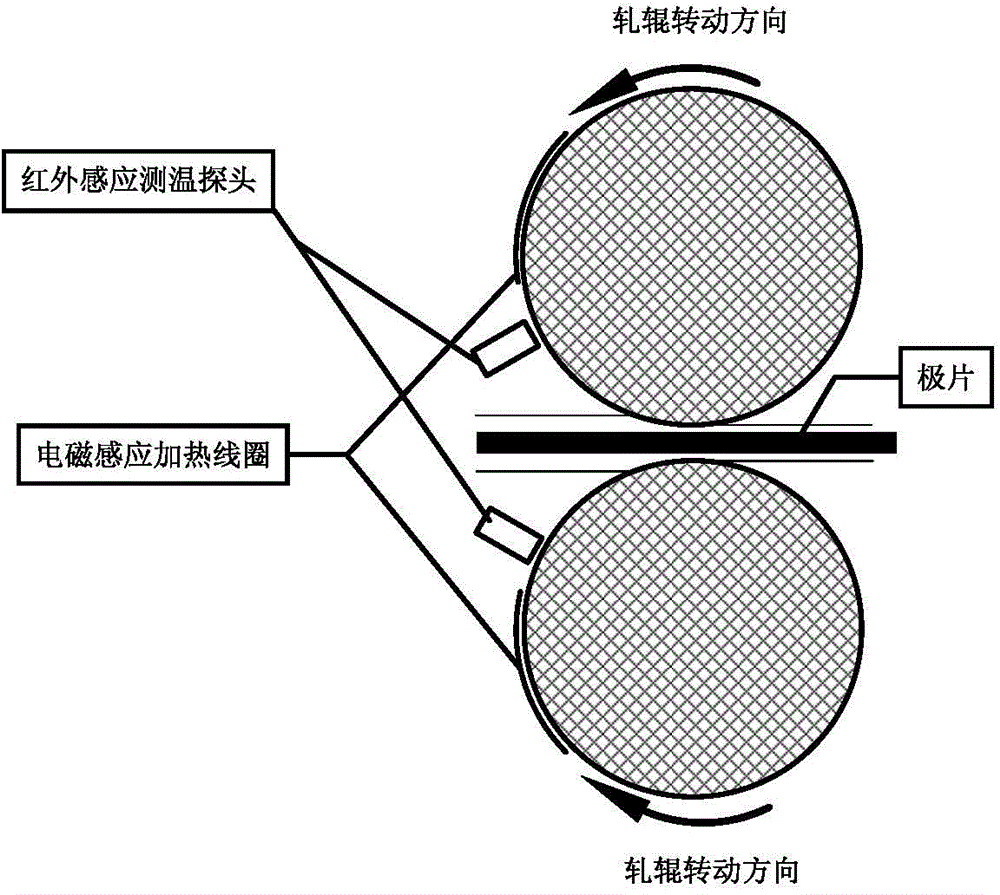

Method and system for induction heating of hot-rolling mill rollers for lithium battery pole pieces

InactiveCN104858234AImprove thermal efficiencyOvercome energy consumptionTemperature control deviceRollsHigh energyPole piece

The invention discloses a method and a system for induction heating of hot-rolling mill rollers for lithium battery pole pieces. The method mainly comprises steps as follows: one medium-frequency or high-frequency AC (alternating current) induction heating coil is additionally mounted on the surface of each pole piece roller, each pole piece roller is loaded with an alternating electromagnetic field by the aid of the corresponding induction heating coil, and same-frequency induction currents are produced on superficial layers of corresponding parts of each pole piece roller and the corresponding induction heating coil, so that the corresponding part of each pole piece roller is heated to the required heating condition temperature; a non-contact infrared temperature measuring probe is mounted in the range where each pole piece roller rotates out of the corresponding induction heating coil, and each probe is used for measuring the heating temperature of the corresponding pole piece roller. The method and the system for induction heating of the hot-rolling mill rollers for the lithium battery pole pieces can overcome defects of low heating efficiency, high energy consumption and the like in the prior art and have the advantages of high heating efficiency and low energy consumption.

Owner:RISESUN MENGGULI NEW ENERGY SCIENCE & TECHNOLOGY CO LTD

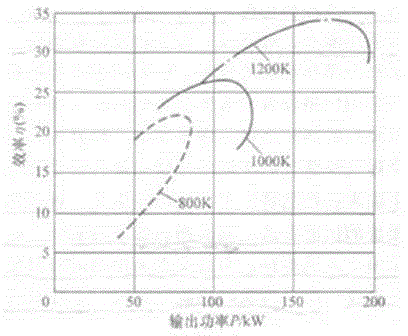

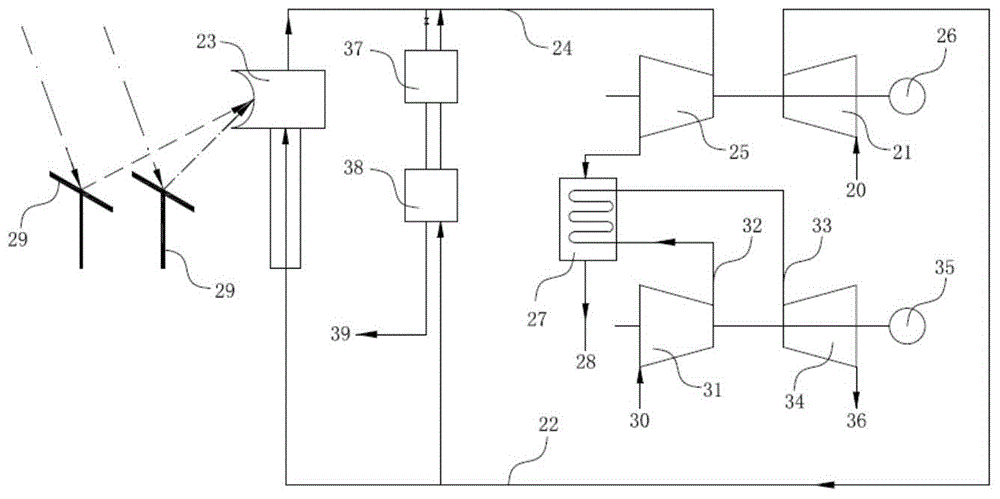

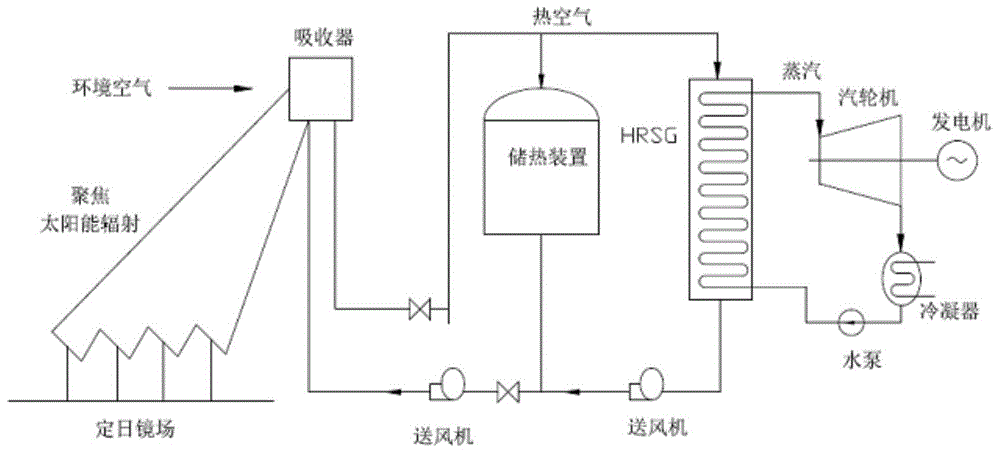

Solar thermal power generation method and device

InactiveCN104896764AReduce exhaust temperatureImprove efficiencyFrom solar energySolar heat devicesEngineeringAtmospheric sciences

The invention relates to a solar thermal power generation method and device. The method adopts an operation mode of overlapping top Britten circulation and bottom Britten circulation, and adopts air as a circulation working medium. After the air is pressurized by a top circulation air compressor, the air is fed into a cavity type receiver of a solar heat collecting device for absorbing heat; and the air, with higher temperature, discharged by a high-temperature air turbine in the top Britten circulation is used as a heat source of the bottom Britten circulation, thereby to forming an overlapped solar thermal power generation system. The device can effectively improve the solar thermal power generation efficiency, is excellent in unit safety and economy, and is specifically suitable for water-deficient areas.

Owner:NANJING RECLAIMER ENVIRONMENTAL TEKNIK

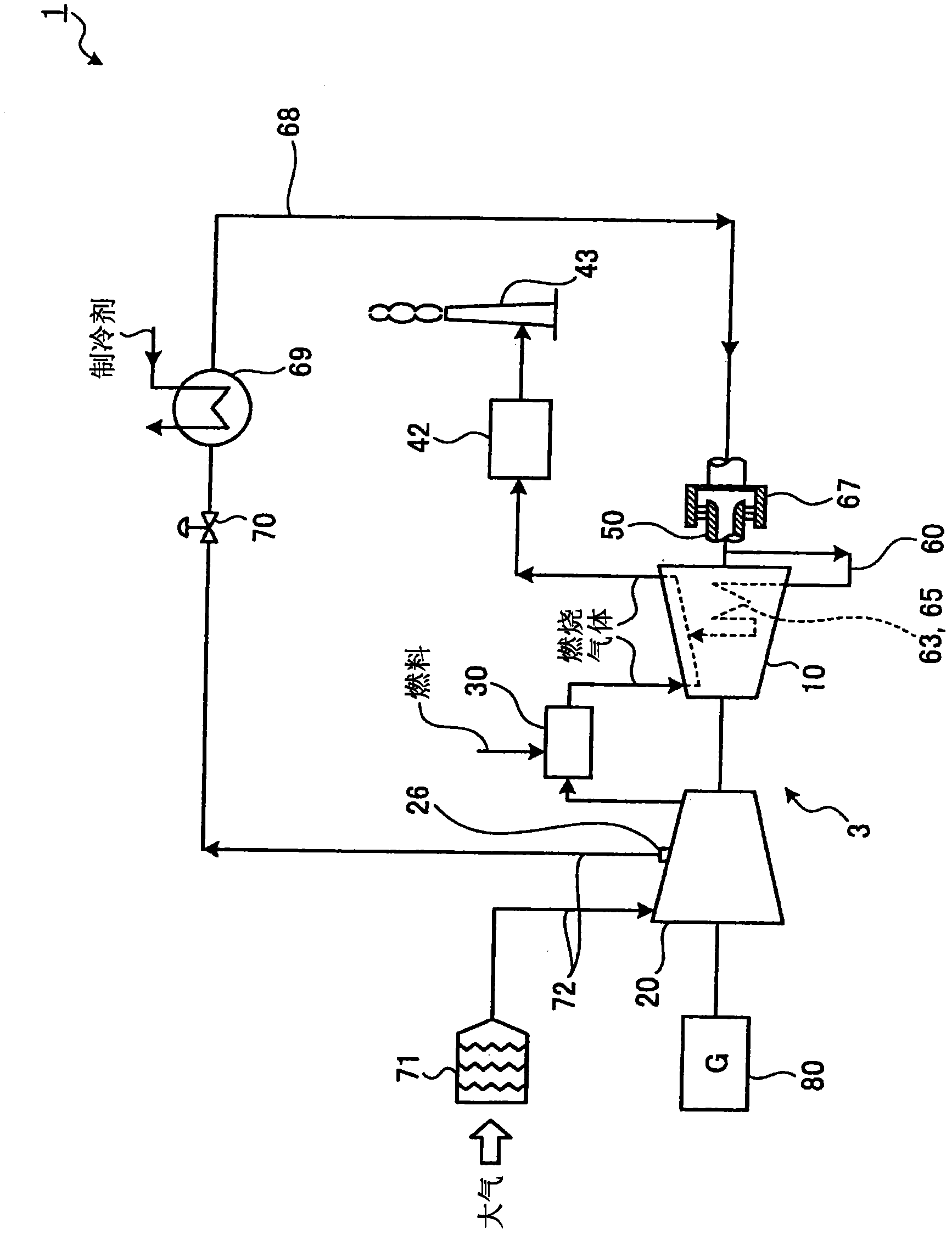

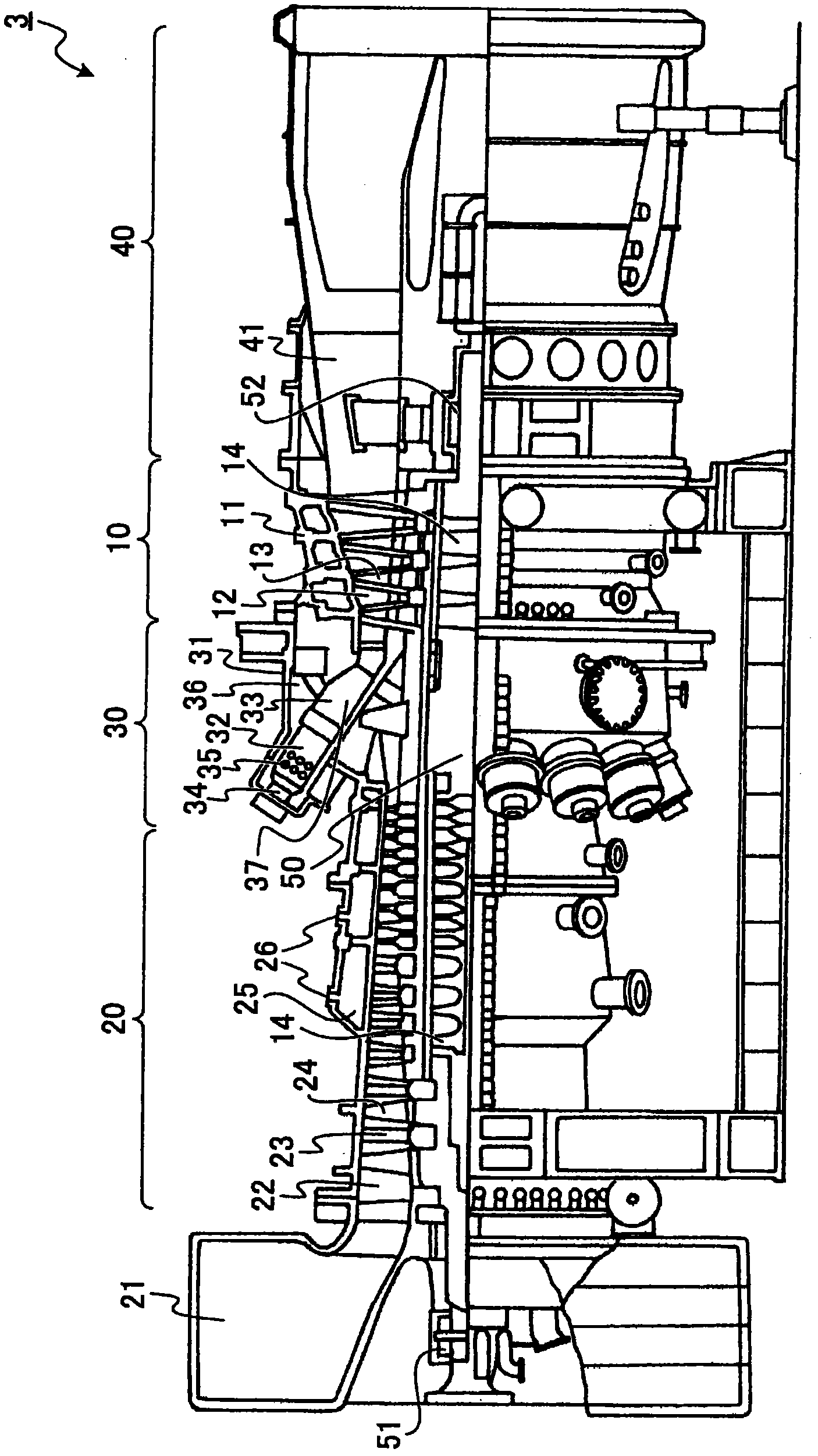

Gas turbine and method of operating gas turbine

ActiveCN102076940ALow thermal efficiencyEngine fuctionsTurbine/propulsion engine coolingAir volumeGas turbines

The present invention relates to a gas turbine and a method of operating a gas turbine. The gas turbine has an axial path provided in a rotating member which extends along the center axis, or the rotation axis, of a rotor and rotates about the center axis and allowing cooling air to flow therein along the center axis of the rotor; radial paths circumferentially arranged in the rotating member so as to extend outward from the center of the rotor, compressing the cooling air, and each having one end communicating with the axial path and the other end communicating with the outside of the rotating member; and an external path provided with an air volume regulating means and having one end communicating with an air source from which the external path takes in air and the other end communicating with the axial path to introduce the cooling air into the external path.

Owner:MITSUBISHI POWER LTD

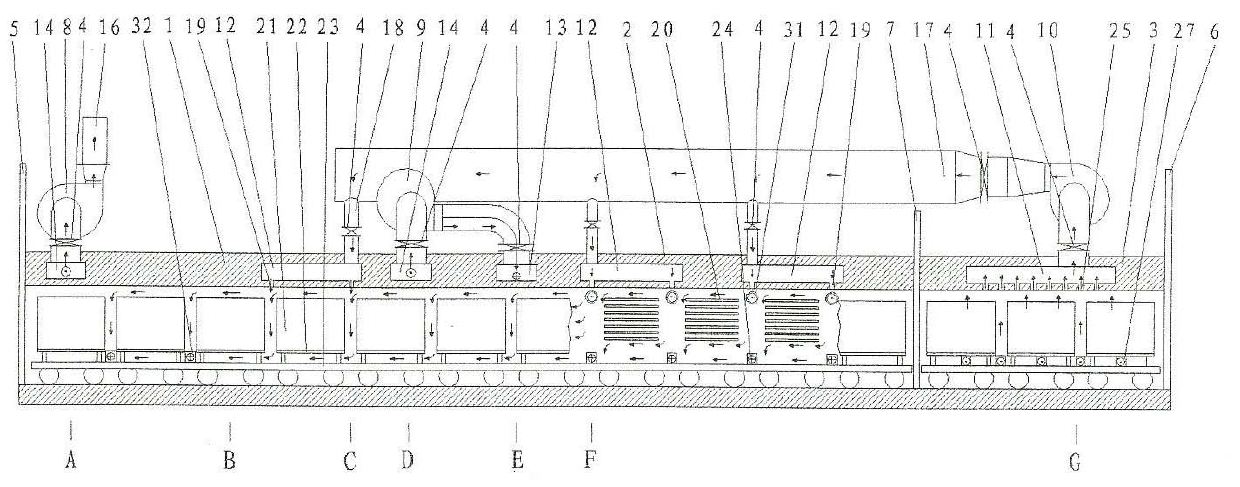

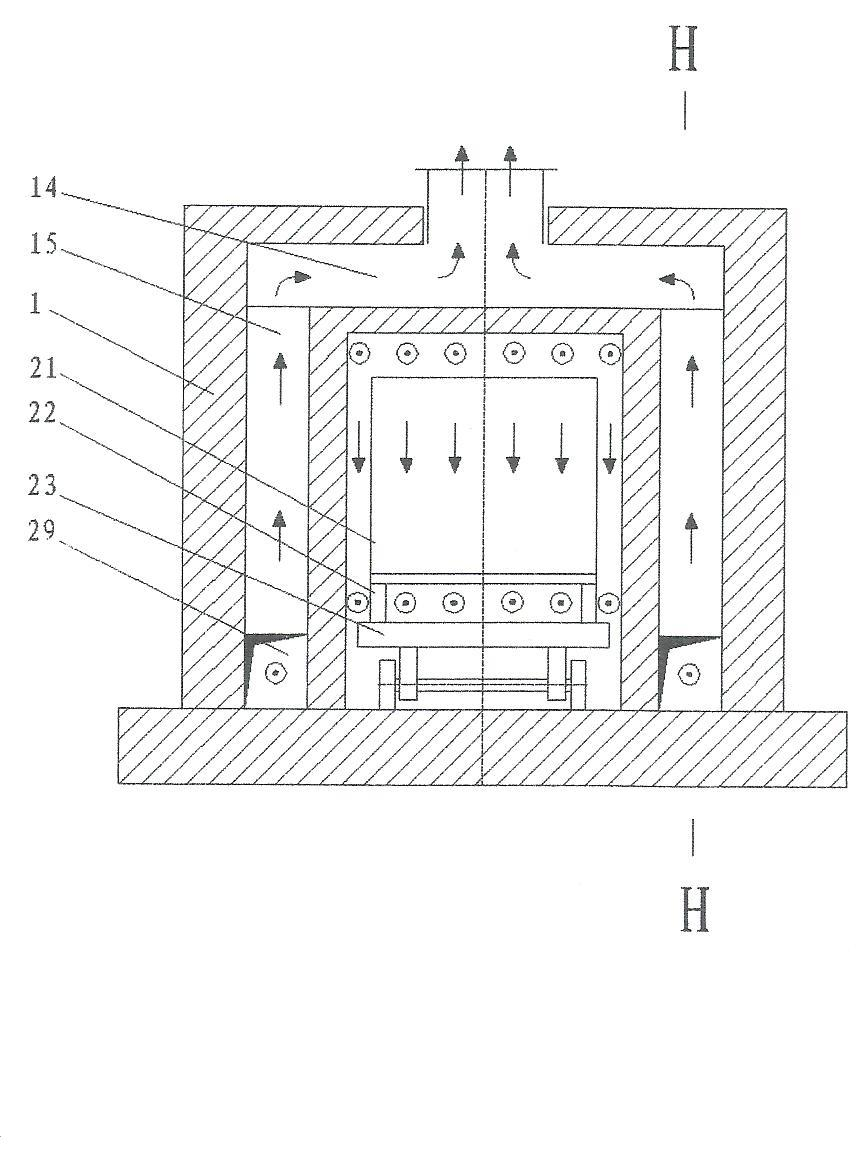

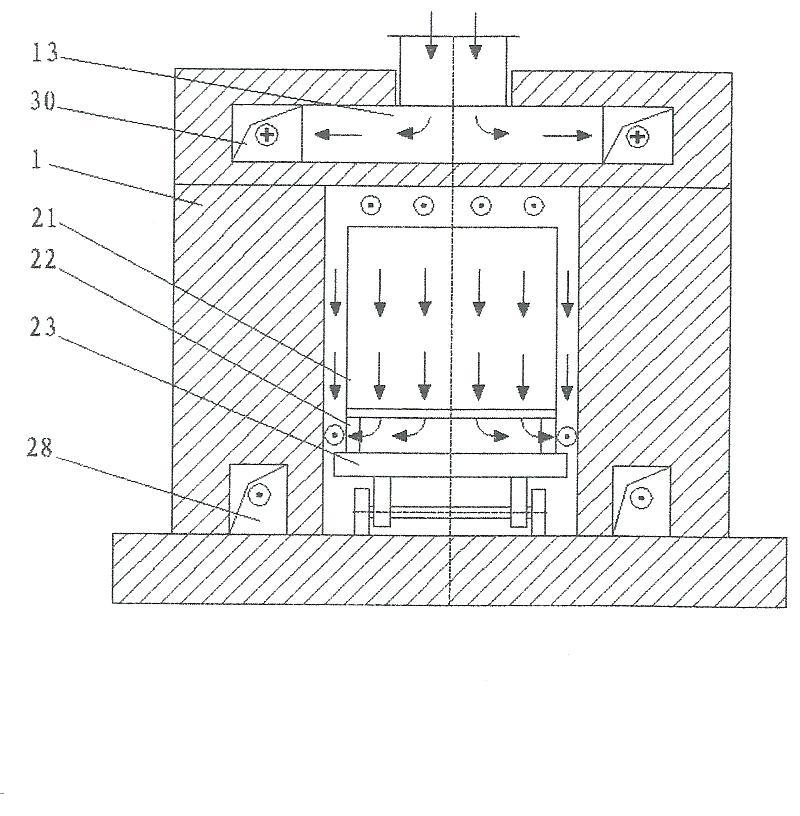

Energy-saving electrothermal tunnel kiln

InactiveCN102042750ALow thermal efficiencyReduce heat lossFurnace typesWaste heat treatmentTunnel kilnRadiation loss

The invention relates to an energy-saving electrothermal tunnel kiln, which is characterized in that: a circulating fan is arranged on the kiln top in a heating and thermal-insulation zone of the tunnel kiln; the air inlet of the circulating fan is connected with a valve, an air suction chamber, an air suction vertical duct, a lower circuiting air duct and a circulating air suction hole in turn; the air outlet of the circulating fan is connected with a valve, a circulating air inlet chamber, an upper circulating air duct and a circulating air spray nozzle in turn; electrical heating elements are arranged besides the sides walls in the kiln in the heating and thermal-insulation zone; a blower is arranged on the kiln top in a cooling zone of the tunnel kiln; and an exhaust fan is arranged on the kiln top in an preheating zone of the tunnel kiln. In the energy-saving electrothermal tunnel kiln, the kiln body is made of a high-quality thermal-insulation material to reduce the radiation loss on the surface of the kiln body, the thermal efficiency is 3 percent lower than that of an intermittent kiln, the after heat of products subjected to heat treatment in the tunnel kiln is recovered to preheat kiln products to raise the temperature of the kiln products by 50 DEG C, and the power saving rate reaches 16 percent.

Owner:袁锐

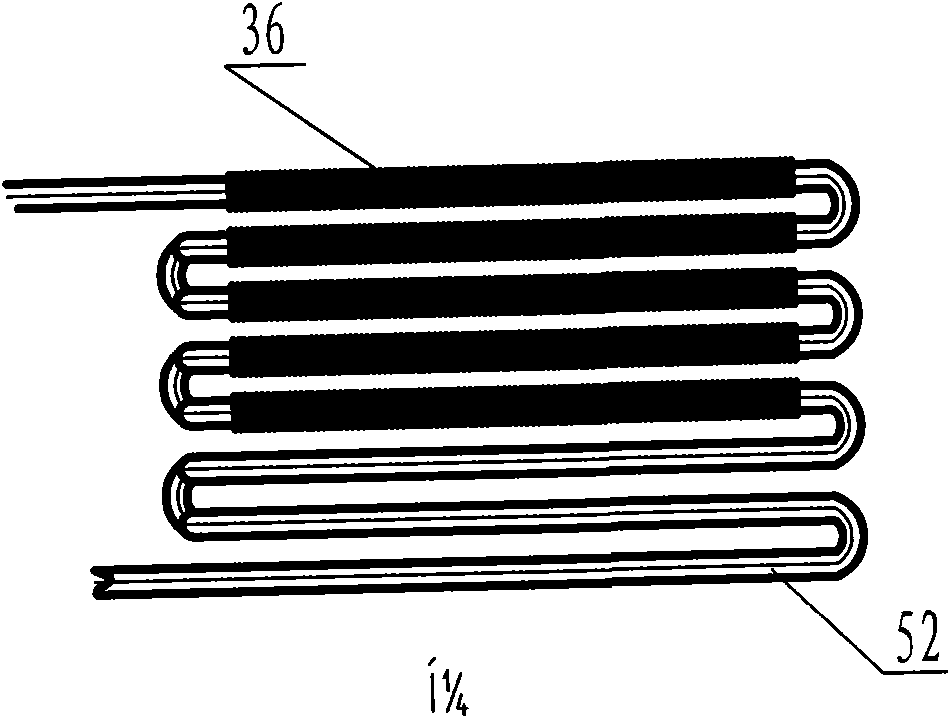

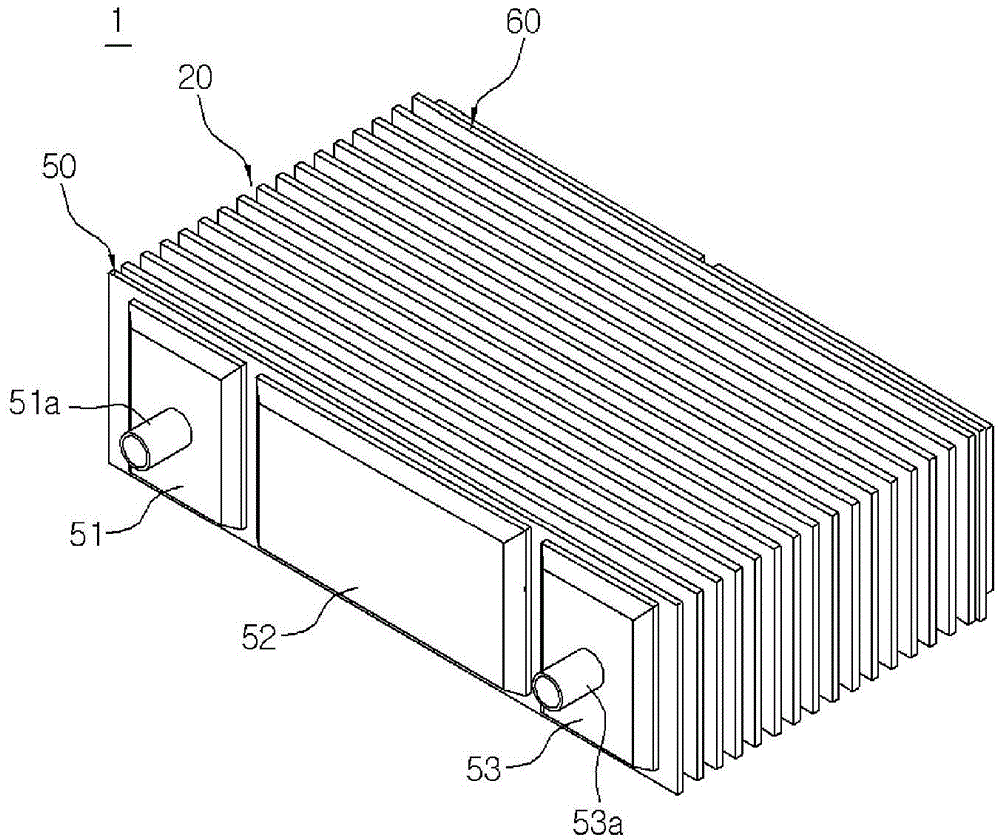

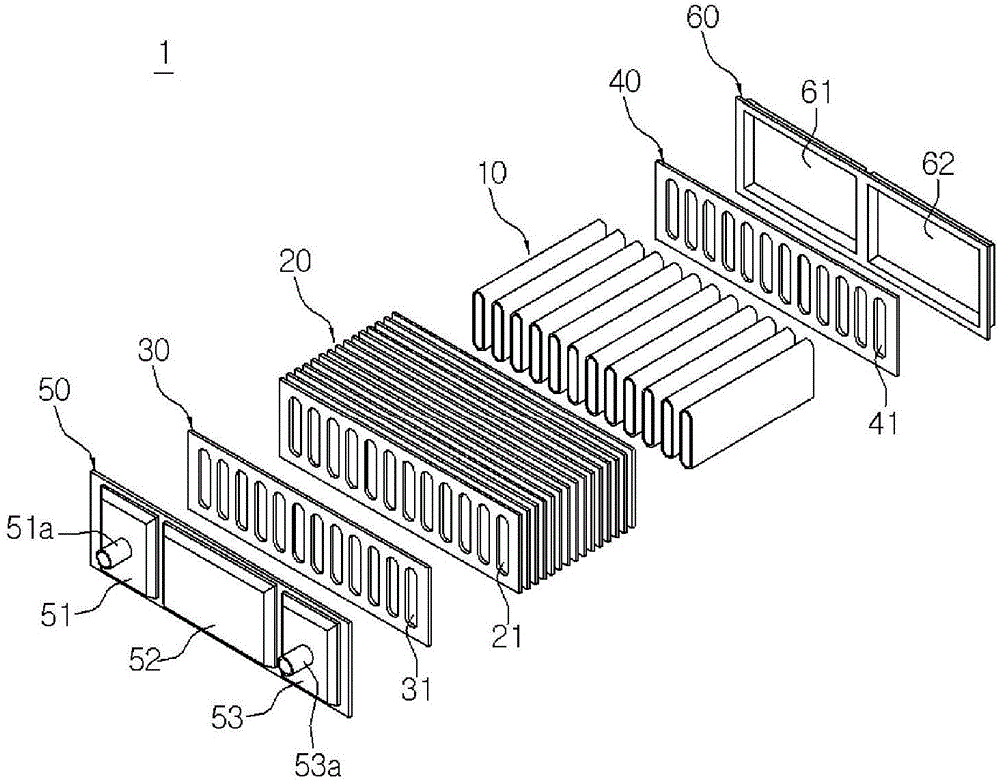

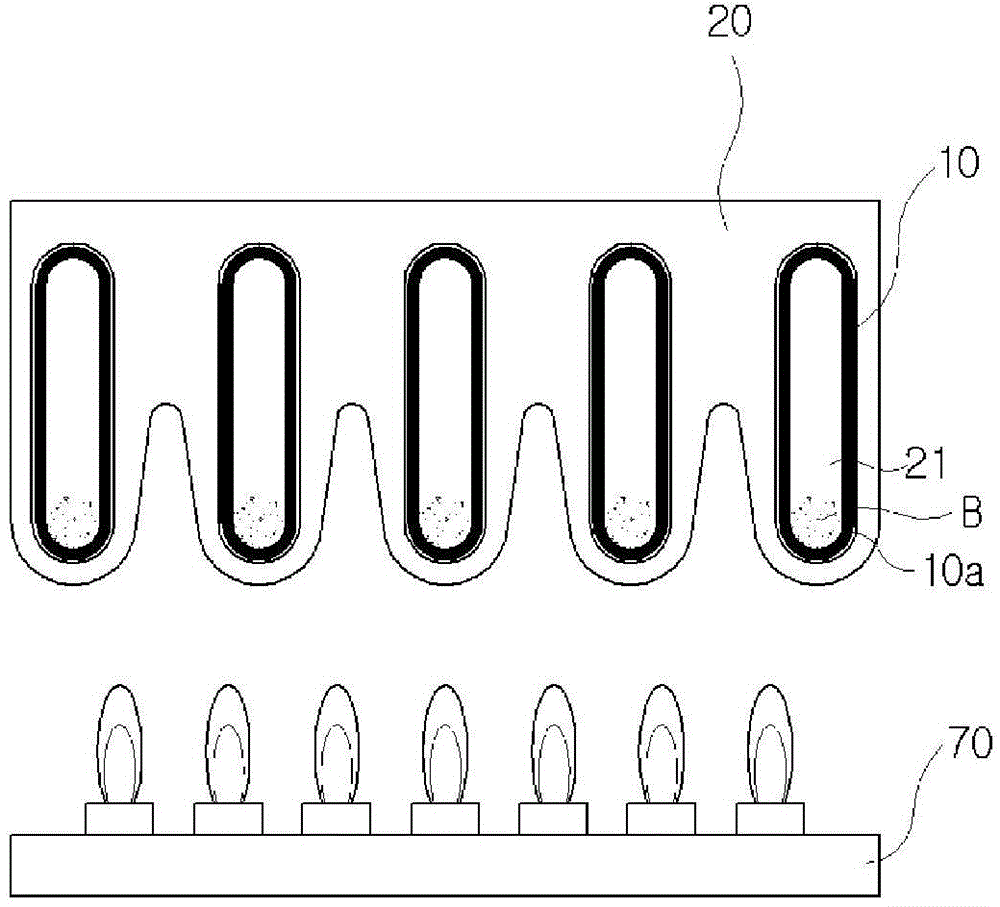

Fin-tube type heat exchanger

ActiveCN104884889APrevent localized overheatingIncreased turbulenceRecuperative heat exchangersHeat exhanger finsInterior spaceTubing types

The present invention relates to a pin-tube type heat exchanger, comprising: tubes through the inside of which a heat medium flows and which are arranged in parallel with a uniform distance therebetween, so that a combustion product can pass through space between the tubes; and heat transfer fins which are separately coupled to the outer surface of the tubes along the lengthwise direction thereof, so as to be parallel to the direction of flow of the combustion product, wherein inside the tubes a first turbulent flow-generating member is installed for creating turbulence in the flow of the heat medium, wherein the first turbulent flow-generating member comprises a flat plate portion, arranged in the lengthwise direction of the tubes, for dividing the inner space of the tubes into two sides, and first guide pieces and second guide pieces which are protrudingly provided at a tilted angle and are separately and alternately provided along the lengthwise direction of both sides of the flat plate portion.

Owner:KYUNGDONG NAVIEN

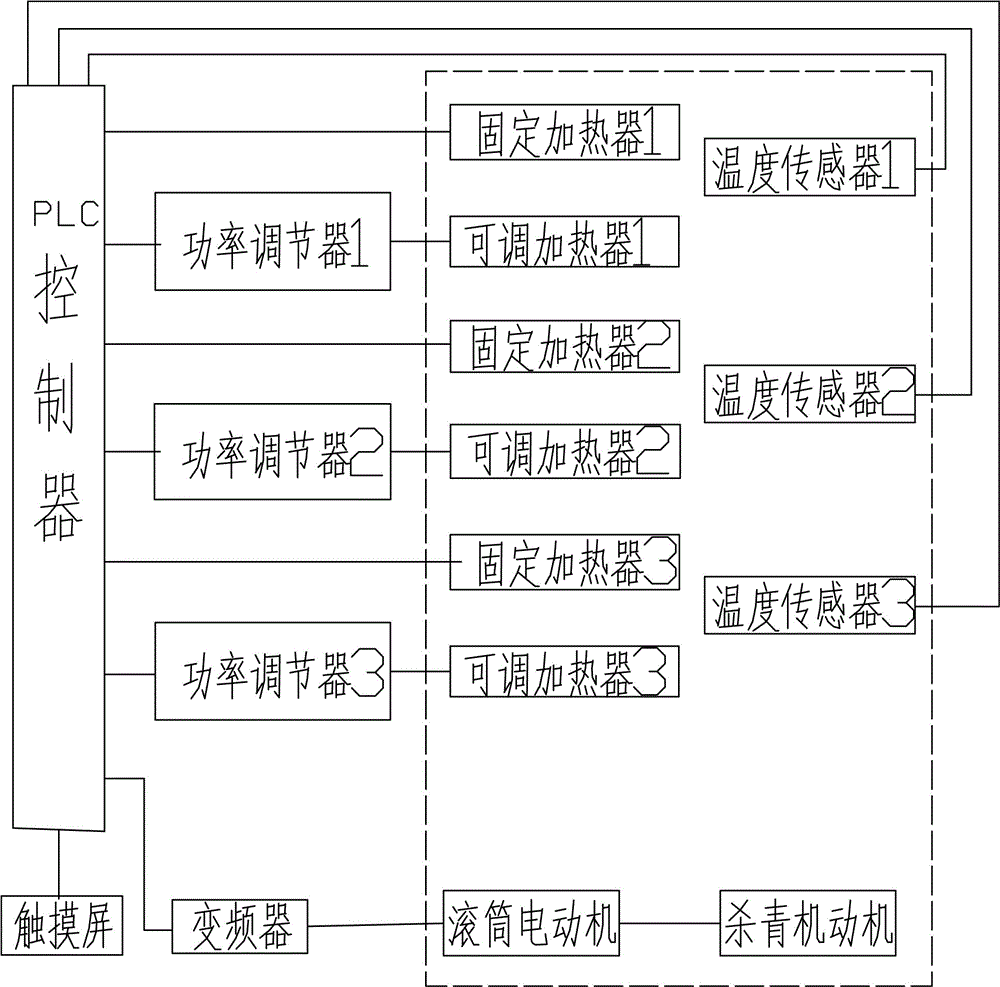

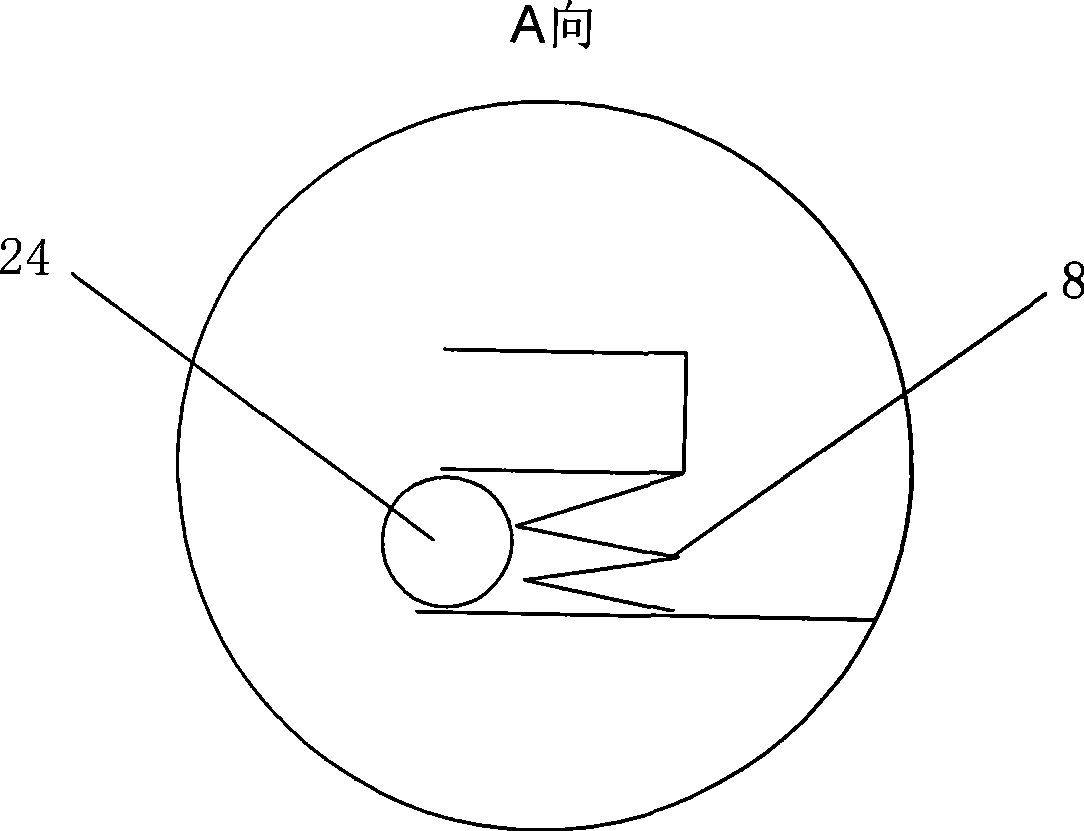

Segmented constant-temperature modular electrothermal tea leaf fixation machine

InactiveCN104904887AImprove thermal efficiencyImprove efficiencyPre-extraction tea treatmentChange controlEngineering

The invention relates to a segmented constant-temperature modular electrothermal tea leaf fixation machine. A motor is mounted on a stander; a roller base is mounted on the stander; a roller is mounted on the roller base; a speed reduction box is mounted on an output shaft of the motor; a gear is mounted on an output shaft of the speed reduction box and drives a belt wheel mounted on a supporting seat; the belt wheel drives a friction wheel meshed with the roller so as to enable the roller to rotate; an inlet funnel is arranged at the left end of the roller; a ventilating hole and a box cover are arranged at the top of the roller; a temperature control system is arranged on the box cover; an electric heating plate is mounted on the outer surface of the roller and is connected with the temperature control system. According to the fixation machine, the conventional heating mode is changed, and a PLC control technology, a modern control theory and a frequency change control technology are combined; the temperature control system of an electric heating roller fixation machine based on PLC control is designed, so that the temperature control precision, the automation degree and the interference resistance of the fixation machine are improved, and influence caused by manmade factors in actual production is reduced.

Owner:CHINA THREE GORGES UNIV

Highly effective liquid fuel evaporation combustion device

InactiveCN101149149AOvercoming weak vaporization abilityImprove leakageLiquid fuel evaporation burnersGaseous fuel burnerCombustion chamberEvaporation

This invention is a high efficiency liquid fuel vaporizing combustion device. It includes air chamber, vaporizing chamber and combustion chamber. There is combustion barrel is arranged between air chamber and combustion chamber. Its superior edge extends along horizontal radial direction and forms a ring shaped flange. The lower part of flange connects to air chamber barrel body, the bottom of which connects to air pipe. The radial wall of combustion barrel is arranged with air hole. The center of combustion barrel bottom has vaporizing tank, the center of which is arranged with fuel conveying pipe and nozzle. The internal wall of vaporizing tank has division plate, on which has the communicating hole communicating to the vaporizing chamber. The radial wall of vaporizing tank has fuel releasing hole. There is supporting gasket between vaporizing tank and combustion barrel bottom. Heat transferring medium is arranged inside of vaporizing chamber. This invention is adequate for equipment coordination such as boiler, kitchen range and air conditioner.

Owner:傅学正

Variable-temperature drying device of medium and high temperature heat pump

InactiveCN104807318AAchieve dryingMeet the requirements of different drying processesDrying gas arrangementsHeat sensitiveMoisture

The invention discloses a variable-temperature drying device of a medium and high temperature heat pump. According to the variable-temperature drying device, the technical advantages of wide drying temperature zone (0 to 80 DEG C) and controllable humidity of a drying media (air) of the medium and high temperature heat pump are utilized, an electric temperature and moisture control air valve is regulated to obtain a controllable sealed, semi-open or fully-open heat pump system, the variable-temperature and variable-moisture segmental drying of agricultural products is realized, and the purposes of low energy consumption of a drying process and high quality of dried products can be achieved. Materials can be prevented from thermal destruction in a high moisture environment by variable-temperature drying, and variable-moisture drying can be used for preventing the surfaces of materials from crusting or hardening and is favorable for inside moisture from transferring to the surfaces. The variable-temperature drying device adopts an intermittent drying mode. Compared with hot air drying equipment which gives priority to power consumption, the variable-temperature drying device has prominent energy efficiency, and the quality of a product dried by the variable-temperature drying device can be more easily controlled. The variable-temperature drying device can be widely applied to the drying of heat sensitive materials, such as agricultural products and aquatic products, and can be used for drying in industries, such as biological products, Chinese patent medicines and chemical engineering.

Owner:江西省科学院食品工程创新中心

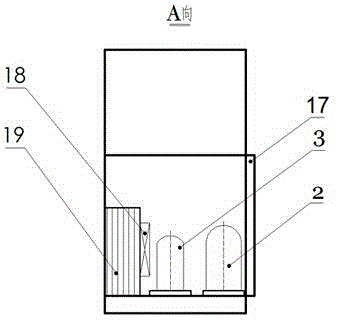

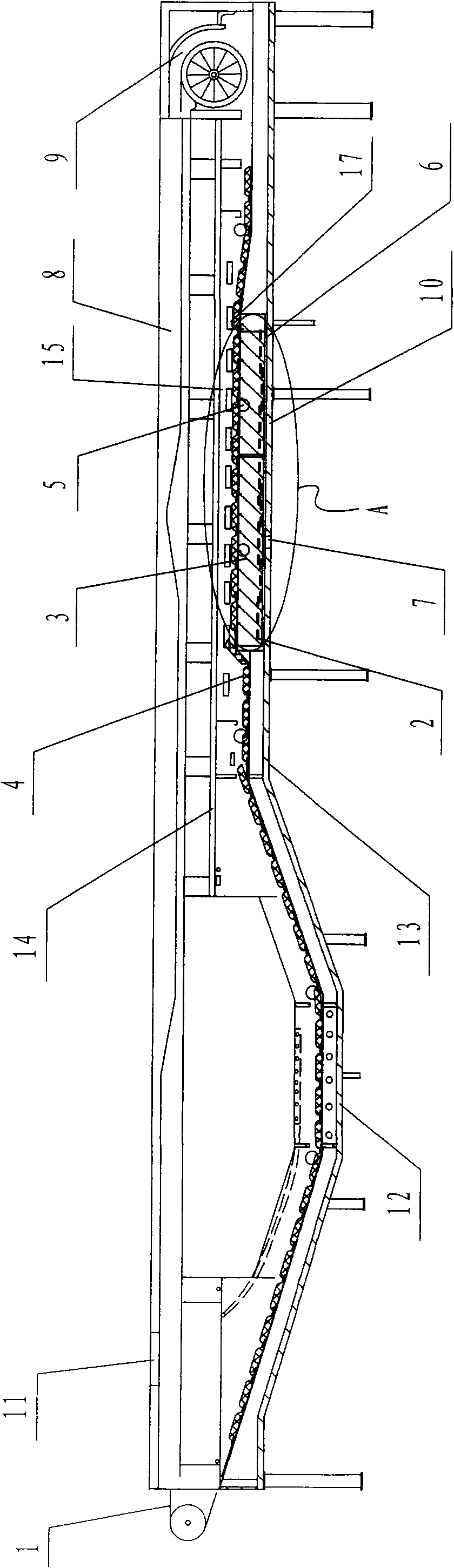

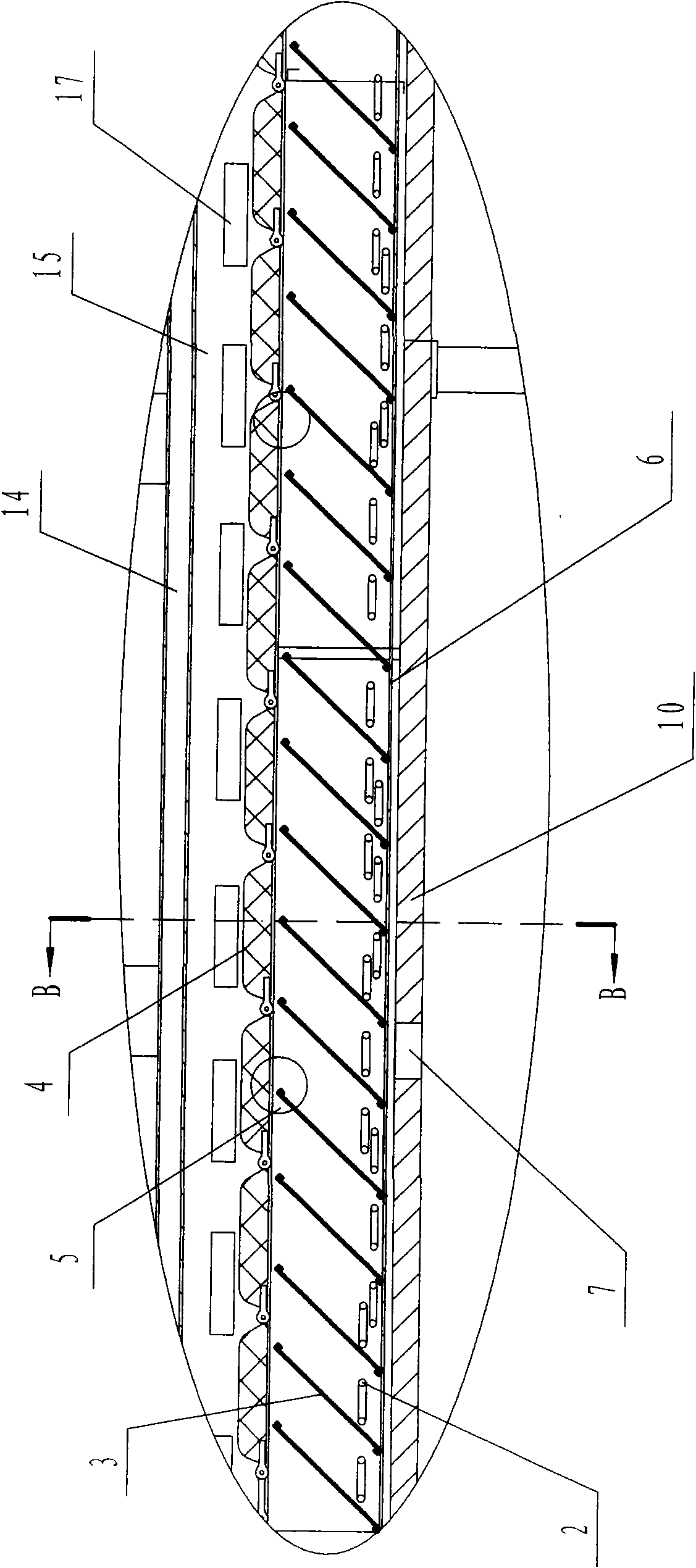

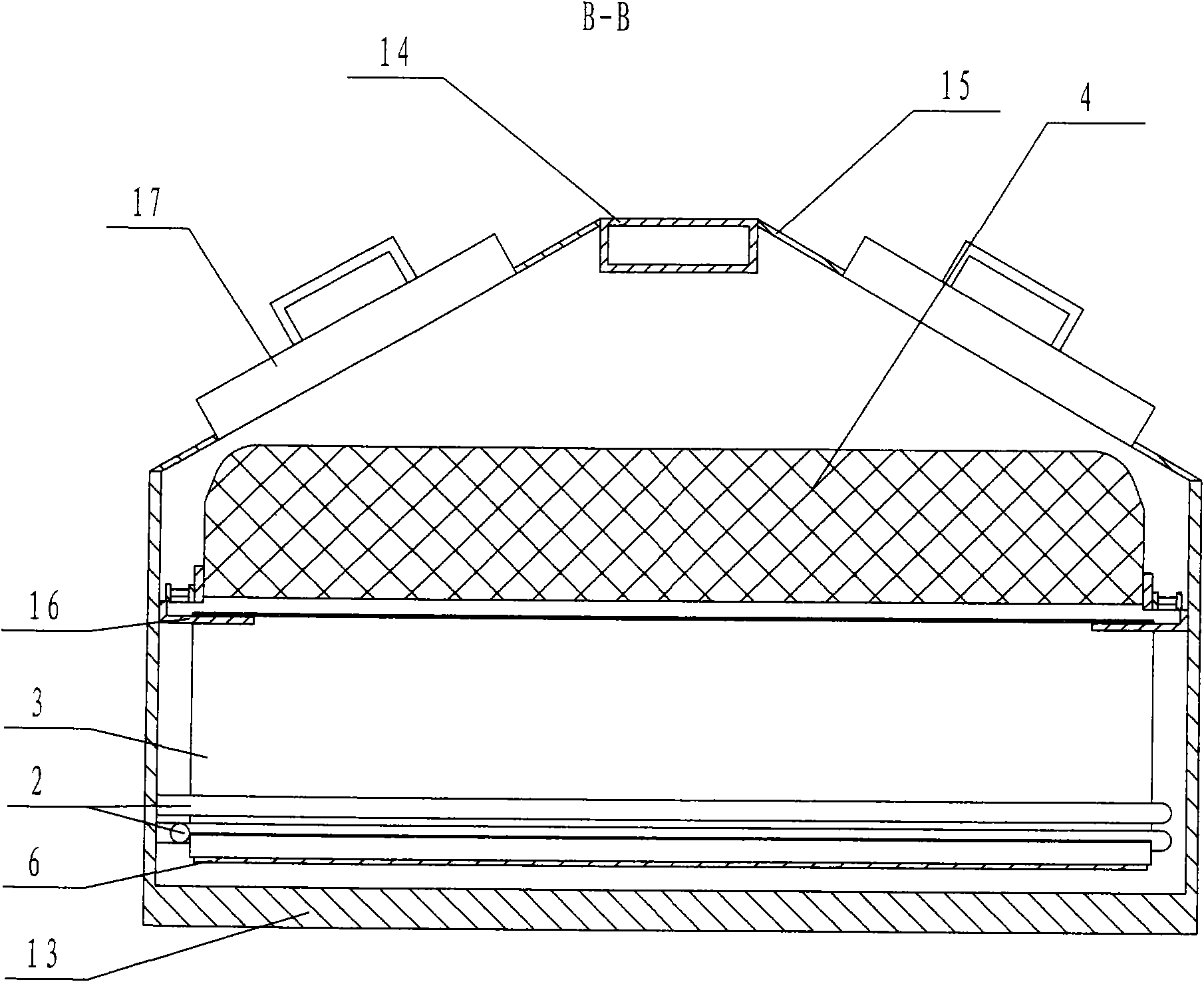

Cooking part device of cocoon cooking machine

InactiveCN101629321AGood adhesionUniform temperatureSilk filament obtainingEngineeringMechanical engineering

The invention relates to a cooking part device of a cocoon cooking machine. A plurality of symmetrical hooks (16) are arranged on both straight walls of a cooking chamber (10) along the length direction, each pair of hooks (16) is respectively positioned on the two straight walls, and inclined plates (3) are hooked on each pair of hooks (16); both the upper ends and the lower ends of all the inclined plates (3) are provided with two folding edges in the same direction; the inclined directions of all the inclined plates (3) are consistent, and the bottoms of all the inclined plates (3) are butted on the upper surface of a reflecting plate (6). Because the guide inclined plates are arranged above a steam elbow pipe, when steam mixed with steam dropping water moves to the positions of the inclined plates, the steam continues to upwards move along the inclined plates due to the function of the inclined plates, and the steam dropping water moves downwards along the inclined plates so as to achieve the aims for separating the steam from the steam dropping water and enabling the steam dropping water to be difficultly attached on silkworm cocoons; the inclined plates and the horizontal plane are in an included angle, and the steam can form circular flow in the cooking chamber, therefore, the temperature in the cooking chamber is more uniform, and the silkworm cocoons in a cocoon cage are uniformly cooked so as to be beneficial to reeling silk.

Owner:童华波

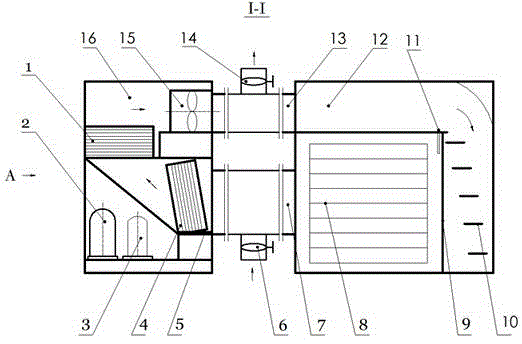

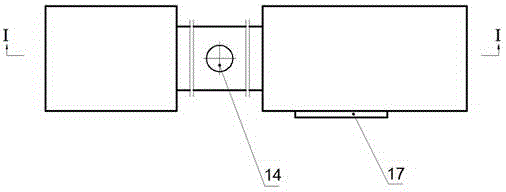

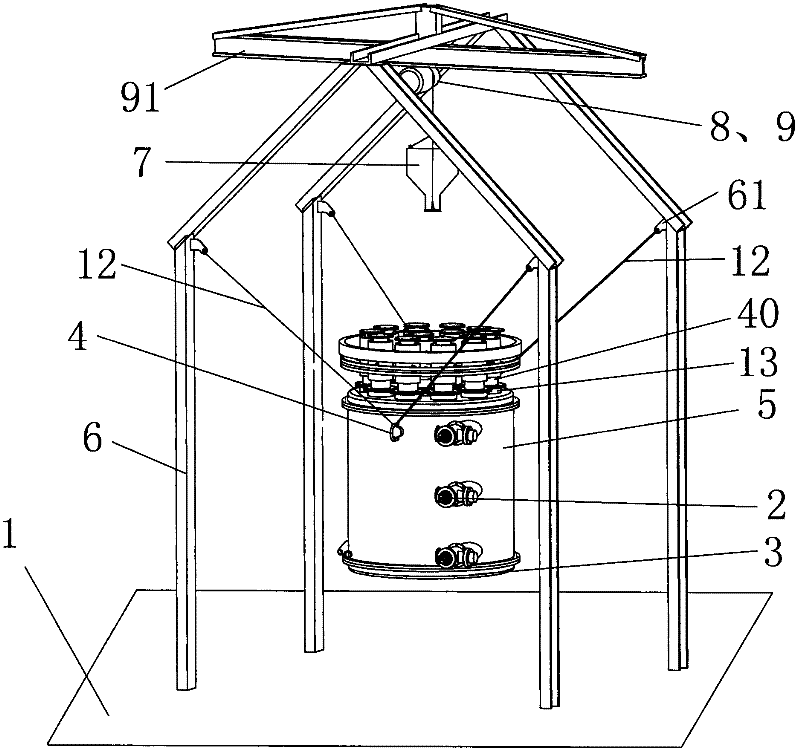

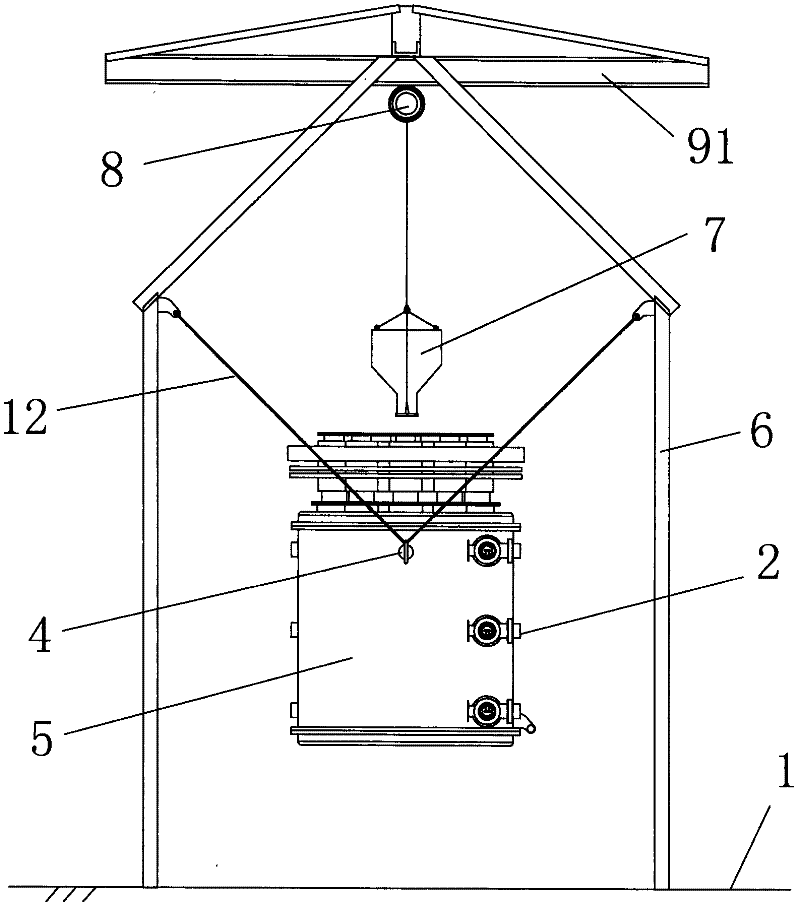

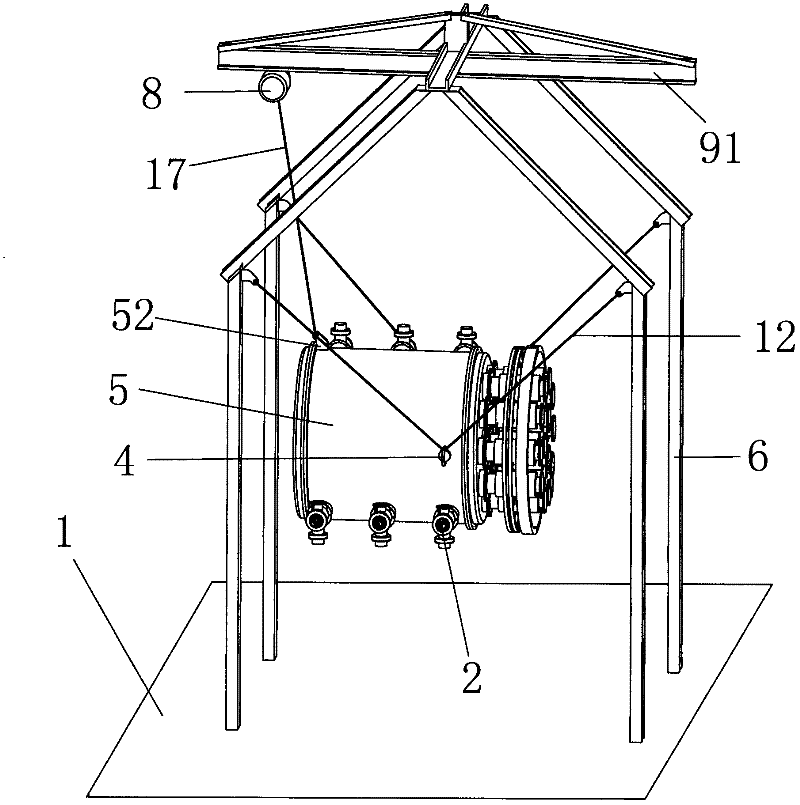

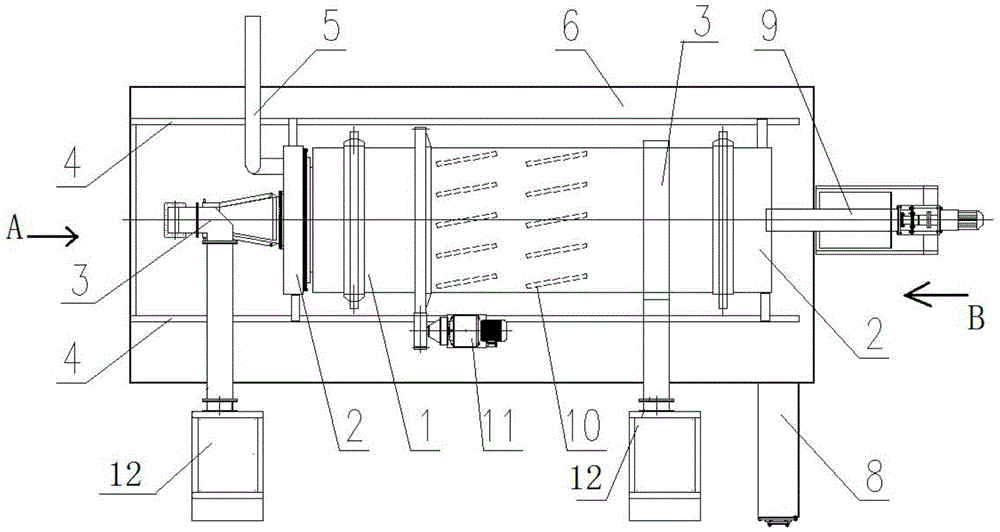

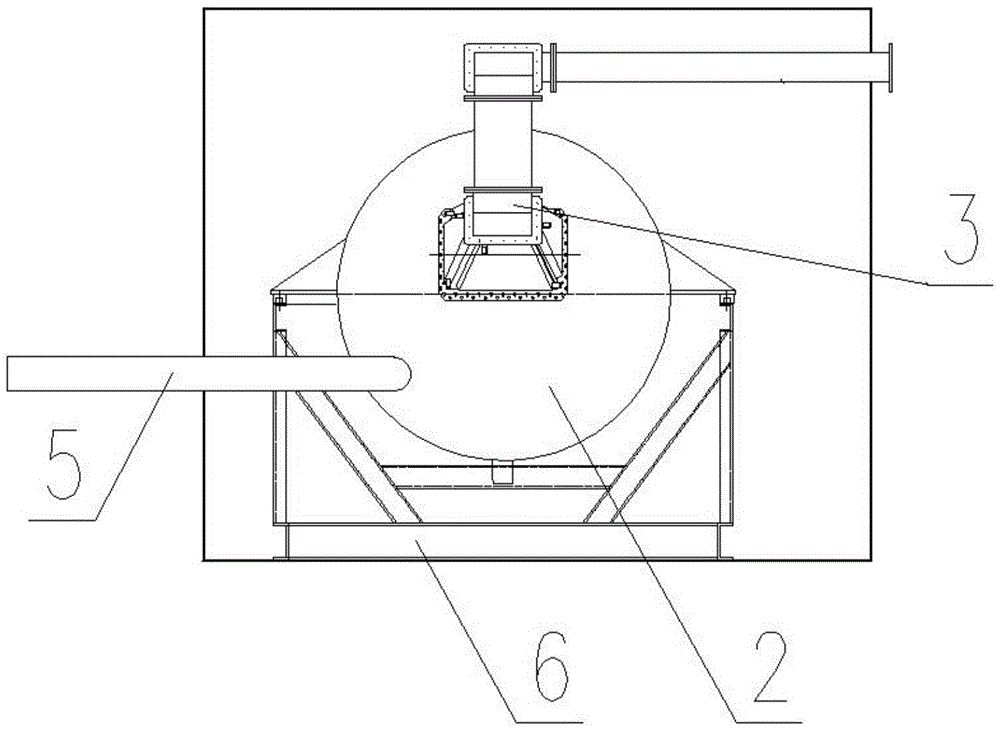

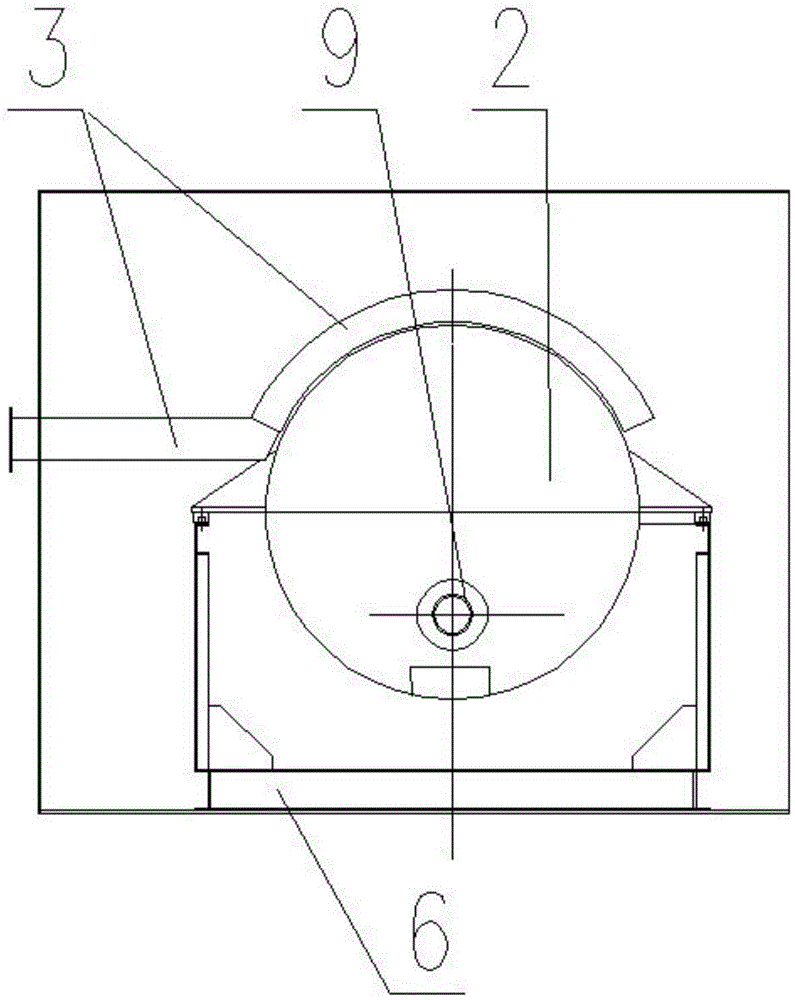

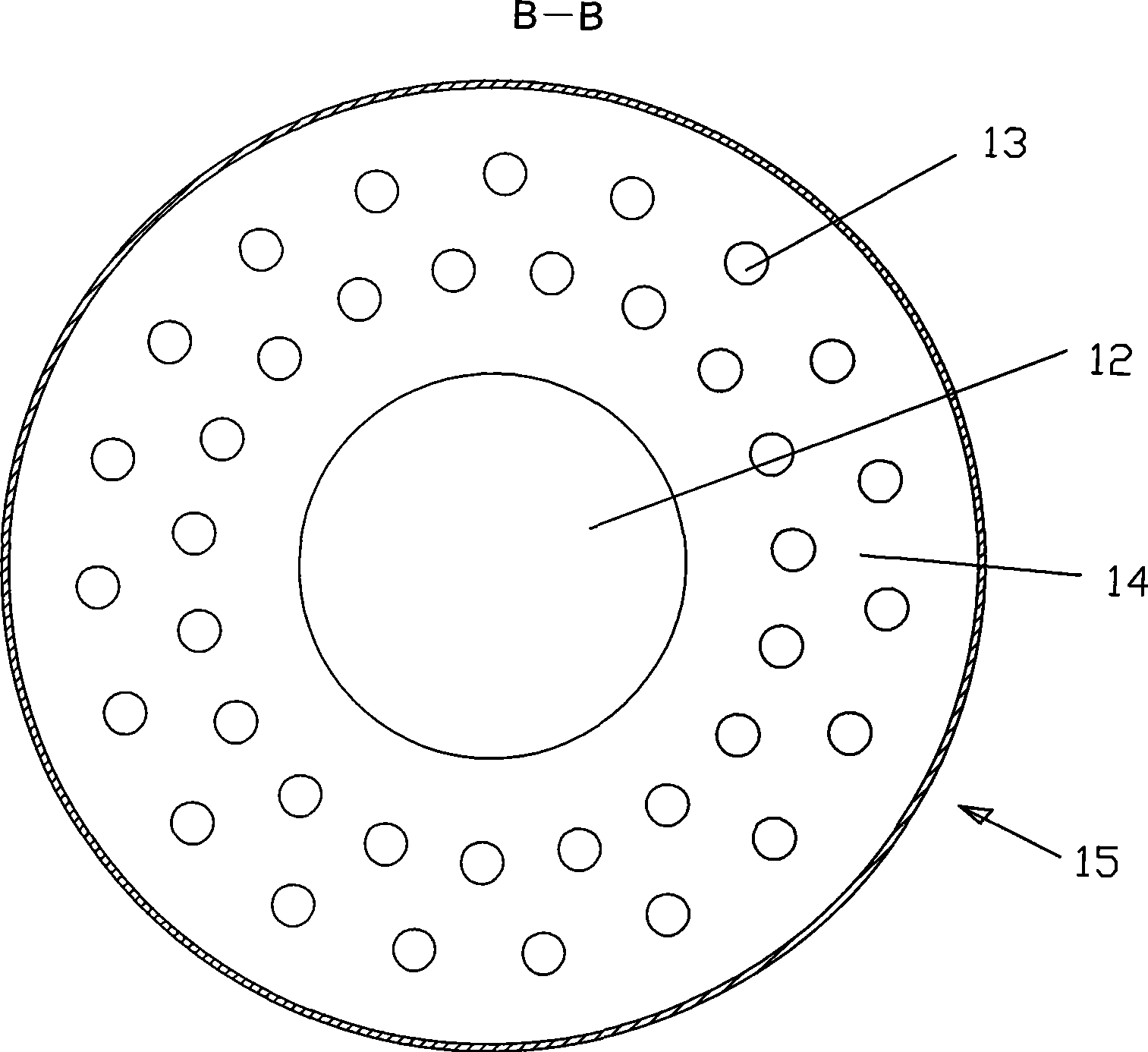

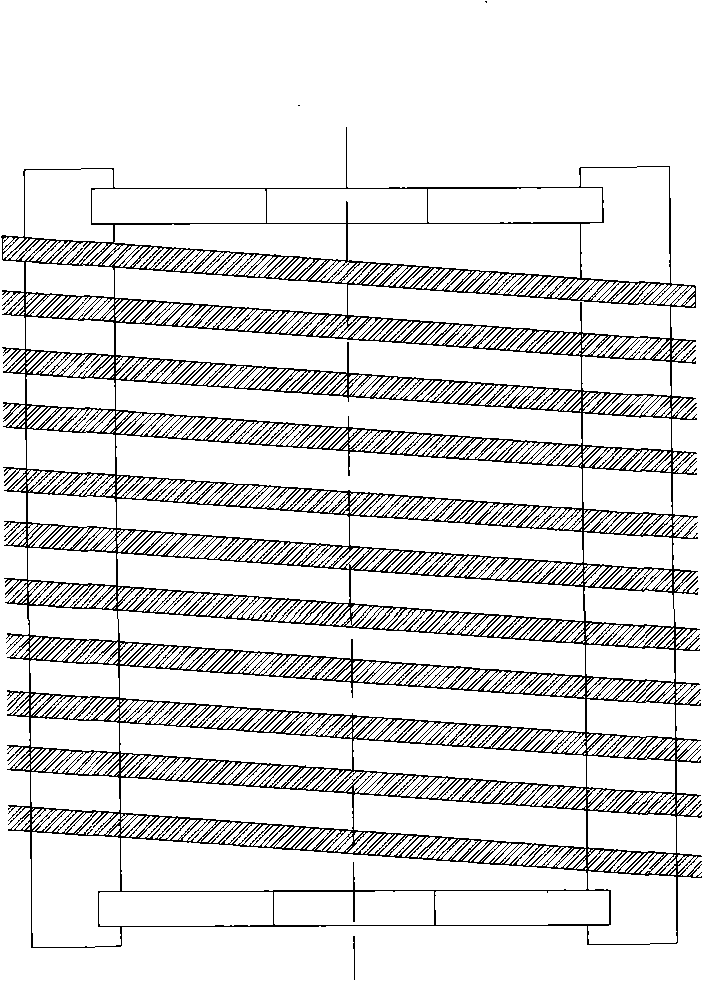

Suspension type automatic blanking vertical and horizontal dual-purpose heat accumulation energy-saving reduction furnace

InactiveCN102393140AIncrease the areaLow thermal efficiencyMuffle furnacesRetort furnacesCombustorDual purpose

The invention provides a suspension type automatic blanking vertical and horizontal dual-purpose heat accumulation energy-saving reduction furnace which comprises a metal furnace body of the reduction furnace, reduction pots, heat accumulation type burners and a suspension device, wherein one end of the metal furnace body of the reduction furnace is connected with a seal head, and the other end of the metal furnace body is connected with a reduction pot fixing flange; the reduction pots are uniformly distributed in the metal furnace body; the heat accumulation type burners are also symmetrically arranged on the circumference; a point of the center of gravity or a point of the eccentric center of gravity is also provided with a universal suspension ring; a suspension wire rope is suspended on the universal suspension ring; two ends of the suspension wire rope are obliquely pulled on the suspension device; a turnover suspension ring is also arranged on the metal furnace body of the reduction furnace near the seal head; the turnover suspension ring is connected with an electric block through a turnover wire rope; the metal furnace body of the reduction furnace turns under the pulling and relaxing operation of the turnover wire rope by taking the universal suspension ring of the furnace body as a center; and the suspension device comprises a portal frame, and the metal furnace body of the reduction furnace, the electric block, a running mechanism and a feeding mechanism are suspended on the portal frame.

Owner:李恒杰 +3

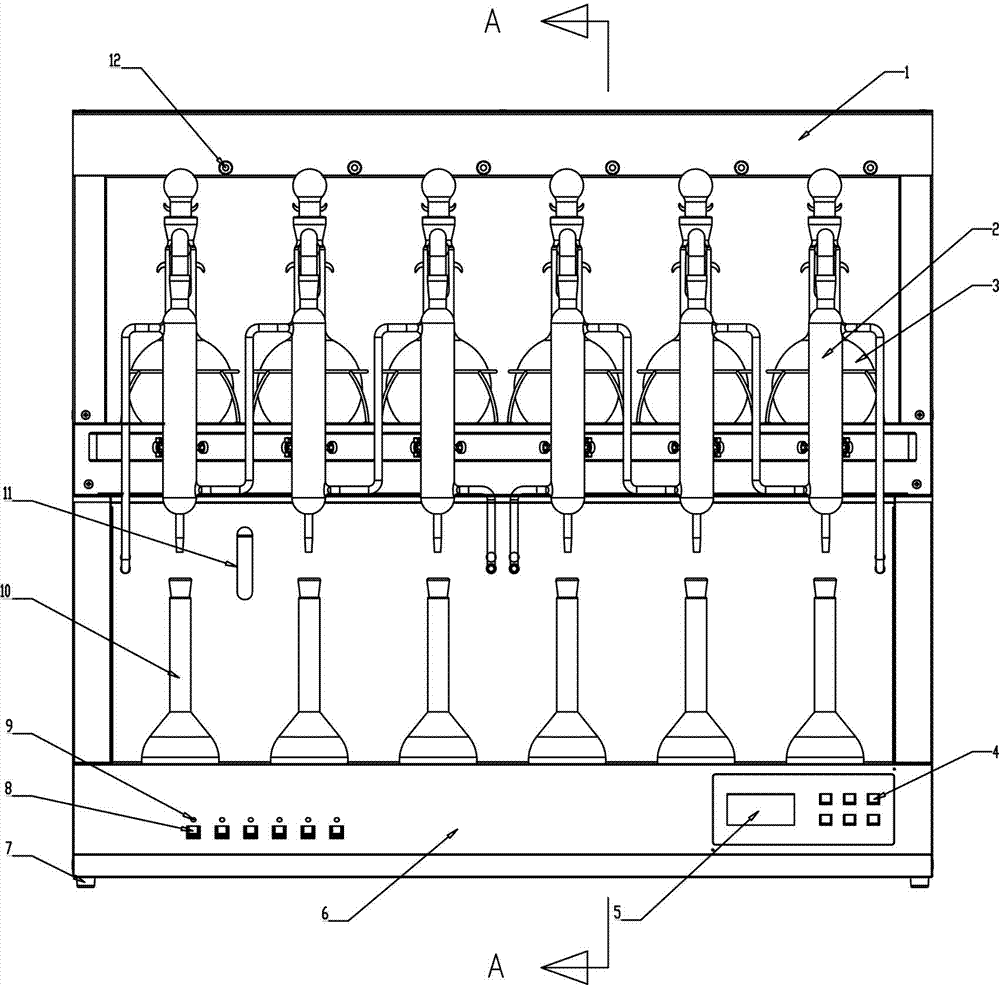

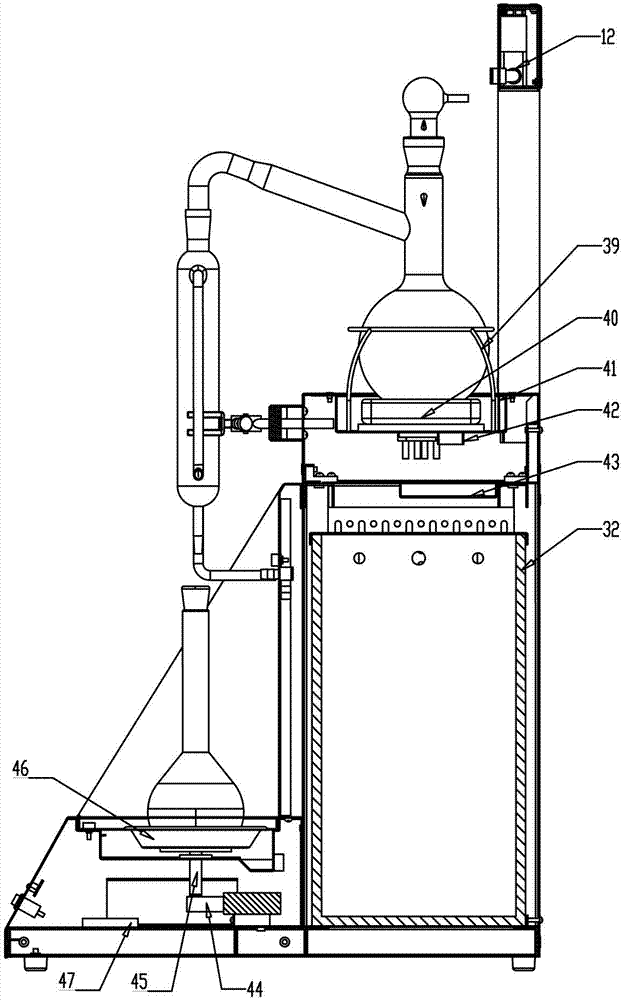

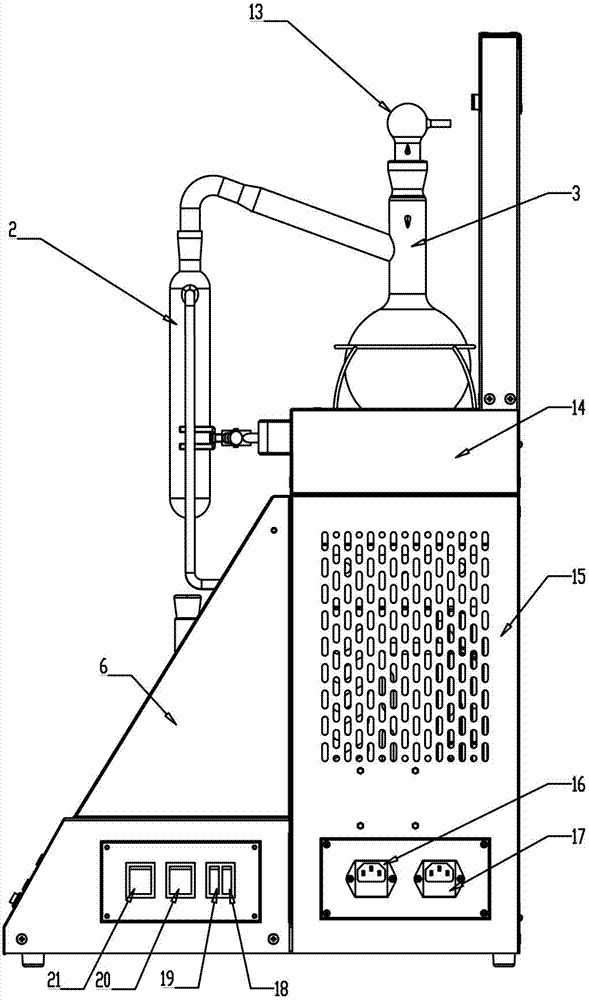

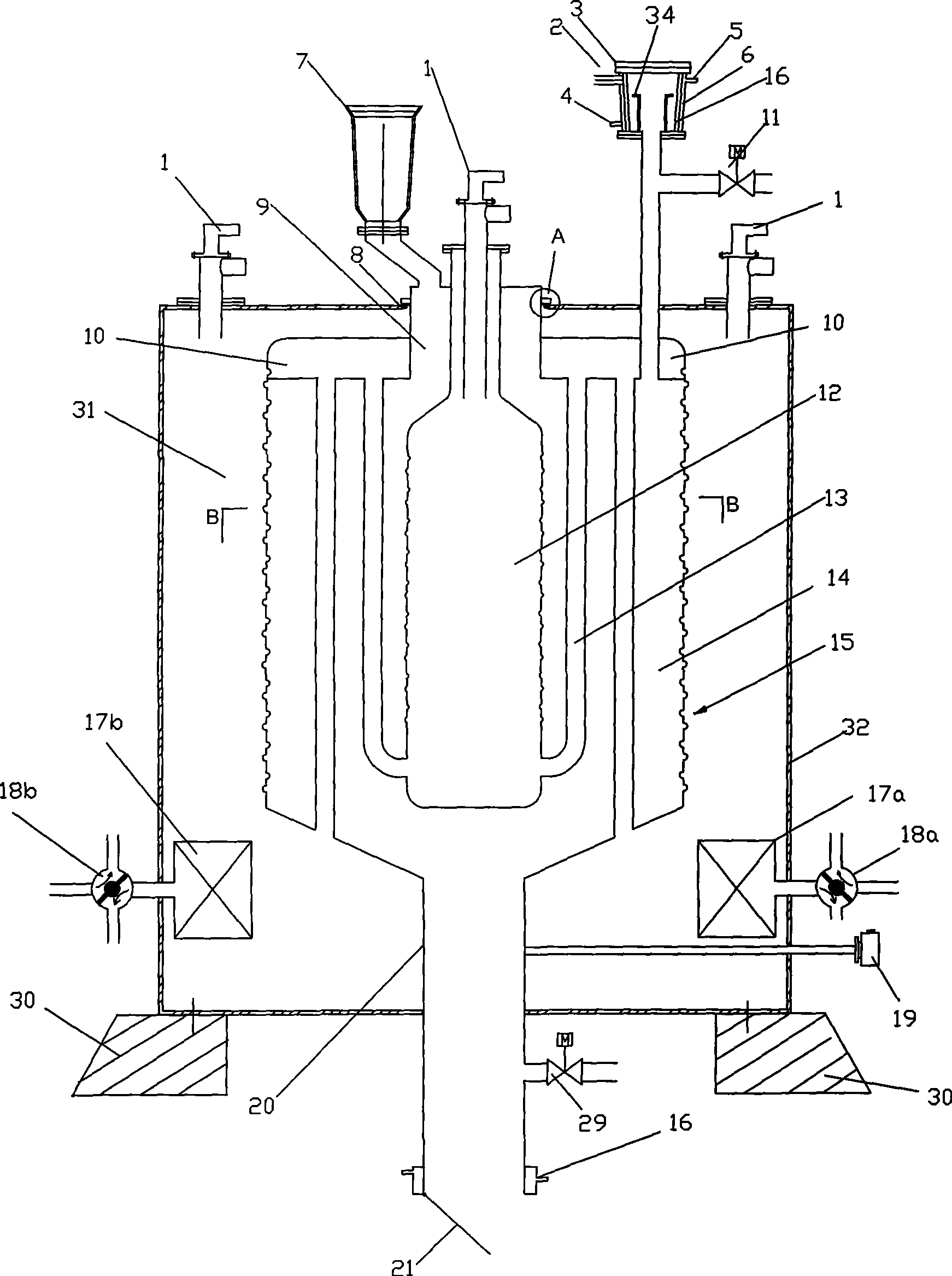

Integrated universal distiller

ActiveCN103566991AGood safety performanceHeating up fastLaboratory glasswaresAutomatic controlPrevention control

The invention discloses an integrated universal distiller. The integrated universal distiller comprises a heating device, a cooling device, a shell and a support, wherein the heating device is provided with a plurality of independent heating units; a ceramic electric heater is installed on a furnace frame of a heating box body; a furnace cover and a distilling bottle are arranged on the ceramic electric heater; the distilling bottle is installed in the furnace cover; the shell is provided with a plurality of heating control buttons corresponding to the plurality of heating units, heating state indicating lamps, functional regulating buttons as well as a liquid crystal display; the heating units are connected with the cooling device; the distilling bottle is connected with a condensing bottle connected with a water tank; the cooling device is connected with a control system; a volume bottle is arranged below the condensing bottle of the cooling device. The device integrates heating, distillation, condensation and receiving design; the ceramic electric heater is adopted by the heating device so as to achieve the functions of independent power regulating of a single furnace, automatic circulation of cooling water, automatic control of distillation terminal, automatic sucking-back prevention control and the like; the integrated universal distiller is practical, convenient, saves energy, protects the environment, and solves multiple defects of a traditional device.

Owner:山东益源环保科技有限公司

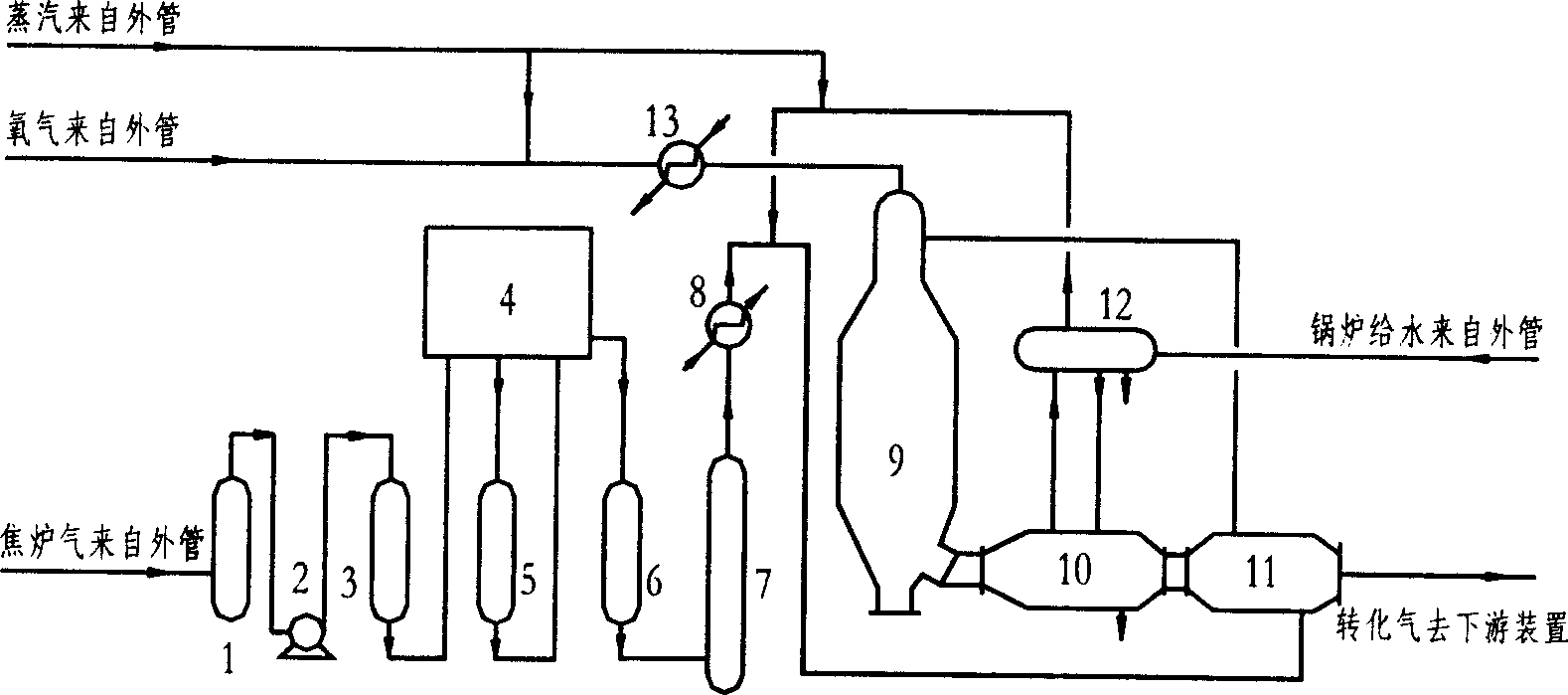

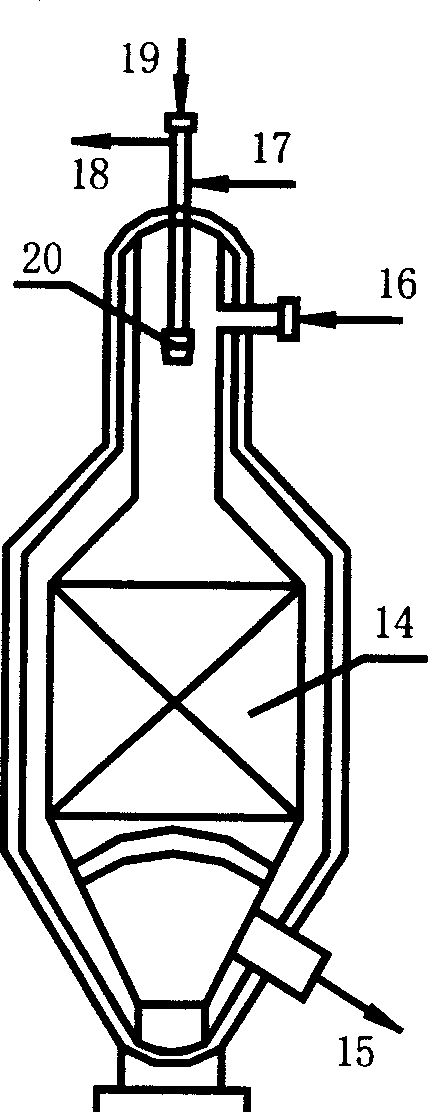

Process for pretreatment of coke oven gas and partial oxidation preparation of synthetic raw gas

ActiveCN1844327AMeet the requirements of oxidation reactionImprove thermal efficiencyCombustible gas chemical modificationPartial oxidationFlue gas

The invention provides a technique for preparation of synthesis raw gases by pretreating coking gas and partial oxidation of coking gas and its devices to reach the purpose of producing large-scale synthesis ammonia and methanol device. The said technique mainly includes electrical tar collecting of coking gas, naphthalene-removing, deoxidation, desulfuration, pretreatment of coking gas, partial oxidation of coking gas, steam conversion and reaction heat utilization of reformed gases. The invention pretreats coking gas containing 20 %-30 % methane to get the coking gas, oxygen and water vapour to perform partial oxidation and steam conversion in converter according the purpose of synthesis raw gases by selecting oxidants with different components and reach a balance of selfheat. After the conversion reaction, the synthesis raw gases containing less than 0.5 % of methane content are obtained. The consumption of the coking gas reduces by 15 %-20 % compared with traditional conversion process, the consumption of the vapor reduces by 50 %-55 %, the investment reduces by 10 %-15 %, which can eliminate the discharge of the flue gas and protect the environment.

Owner:WUHUAN ENG

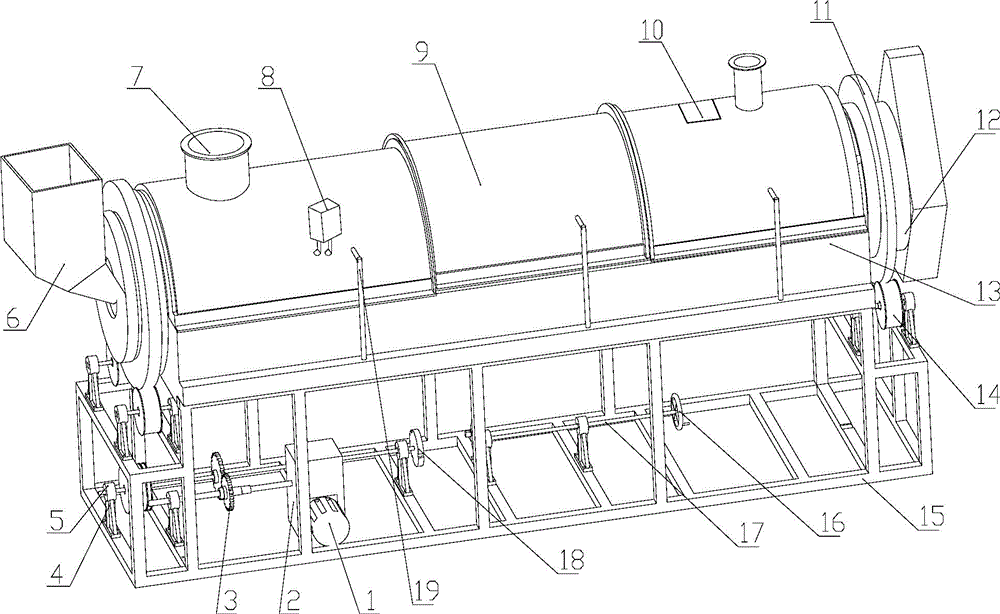

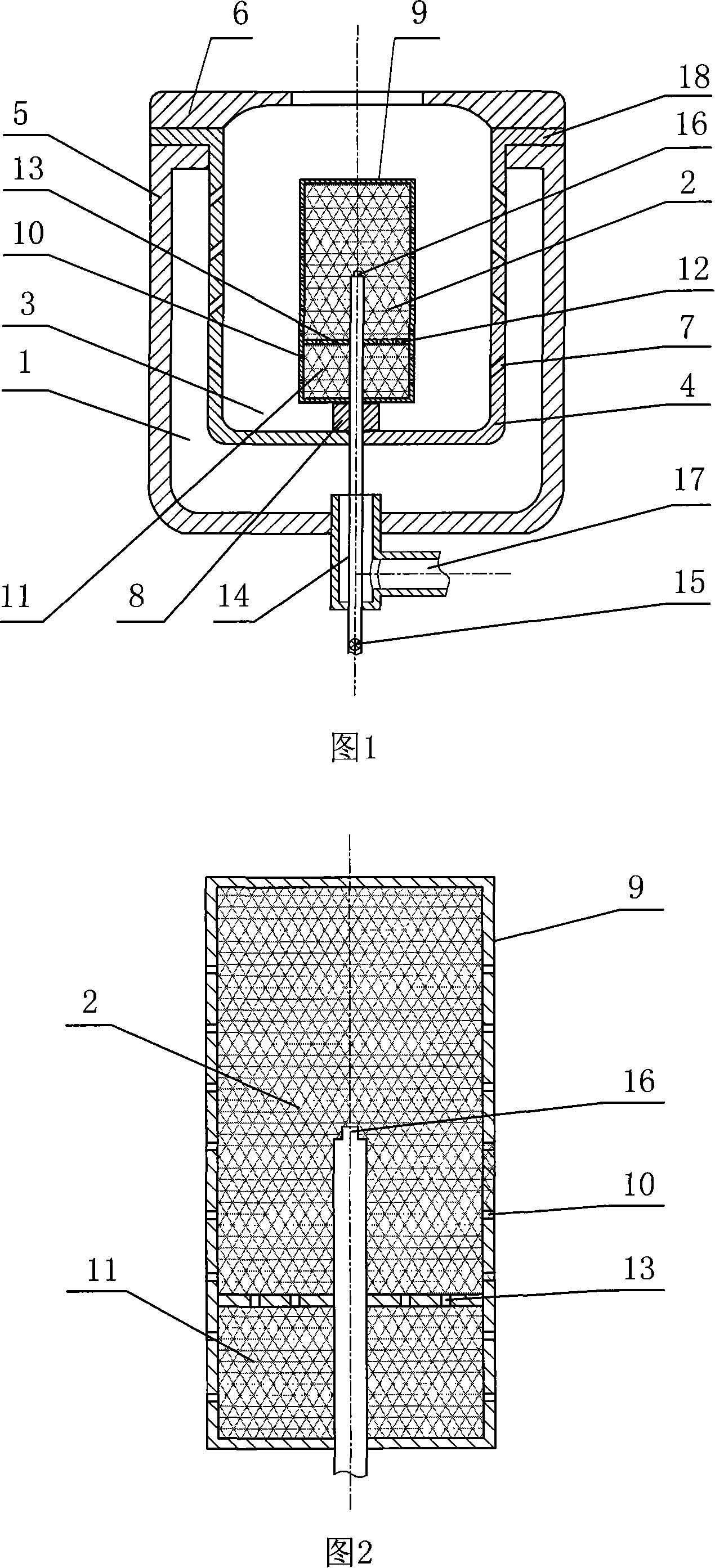

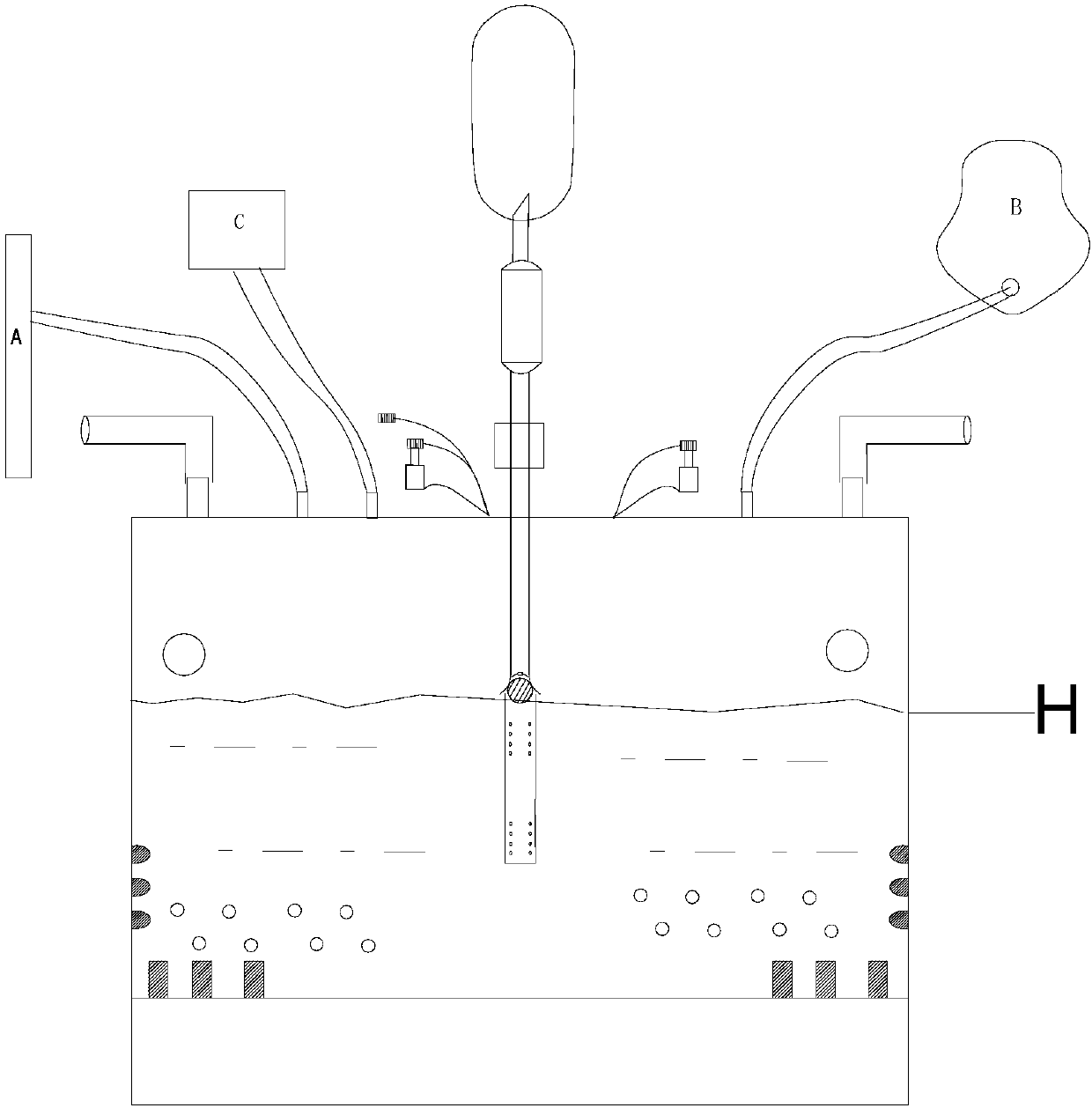

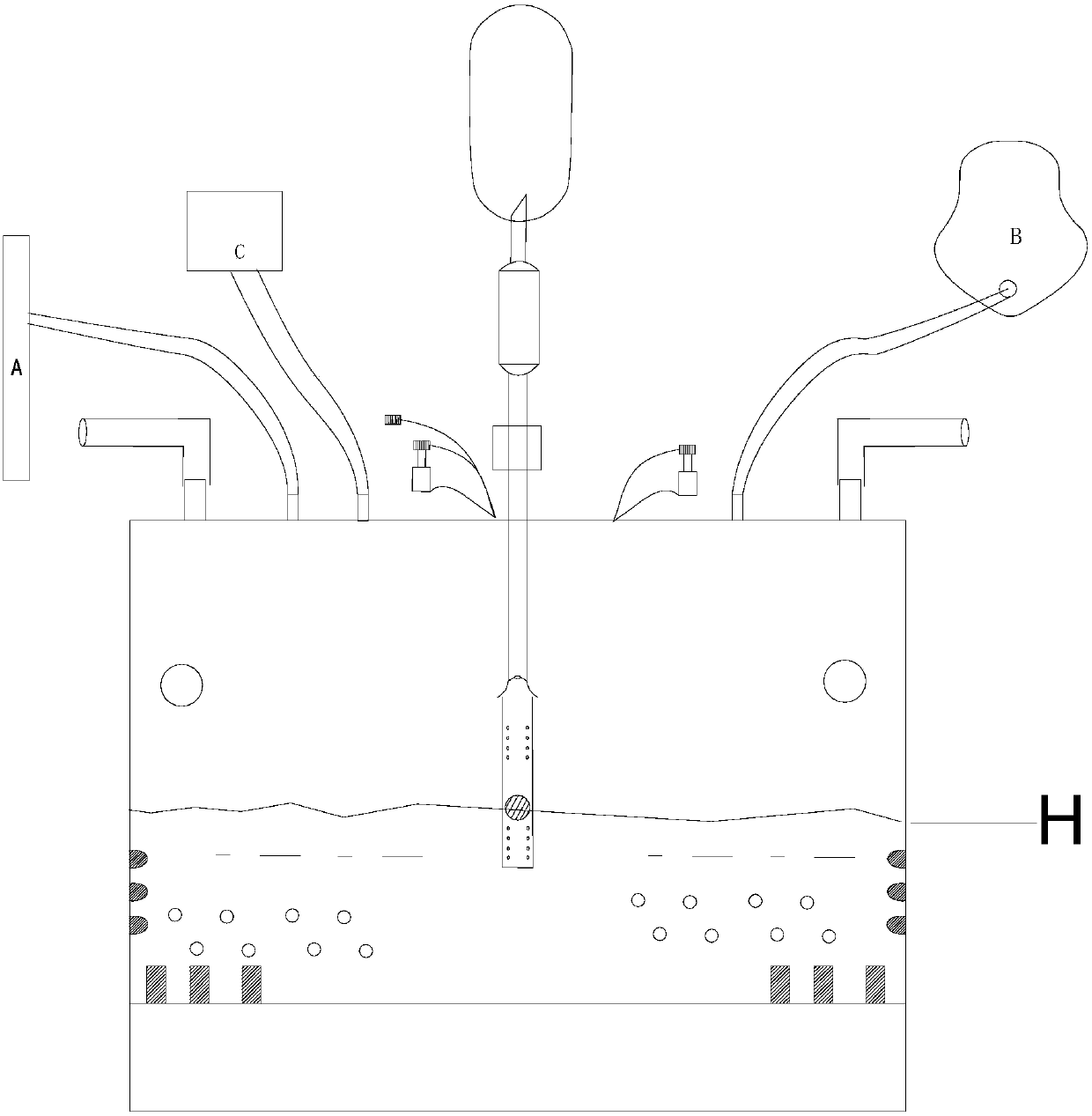

Vacuum type microwave rotary roller drying device

InactiveCN105466197ARealize heating and dryingFast heating and dryingSludge treatment by de-watering/drying/thickeningWater/sewage treatment by irradiationMicrowaveElectric machine

The invention discloses a vacuum type microwave rotary roller drying device. The drying device comprises a sealed box body (6), a rotary roller (1) mounted in the sealed box body (6), sealing covers (2) mounted at the two ends of the rotary roller (1) and a material inlet opening (9) formed in one end of the rotary roller (1); microwave feed openings (3) are formed in the axial direction and the radial direction of the rotary roller (1), and are connected with a microwave generator (12), and the rotary roller (1) is driven by a motor (11) to rotate; a vacuum exhaust opening (5) and a material discharging opening (8) are formed in the rotary roller (1), and the vacuum exhaust opening (5) is connected with a condenser; and the condenser is connected with a storage tank. The drying device is reasonable in design and convenient to operate, under the vacuum negative pressure, axial and radial microwave heating is adopted, flammable substance is prevented from combusting and exploding, the safety performance is good, the heat utilization efficiency is high, the heating work efficiency is high, and the application range is quite wide.

Owner:NANJING SANLE MICROWAVE TECH DEV +1

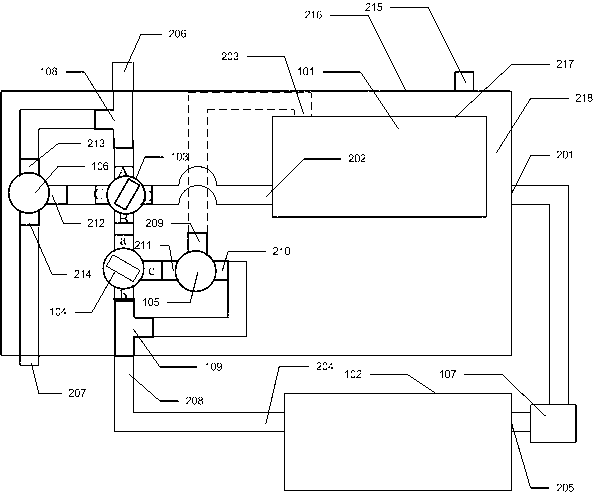

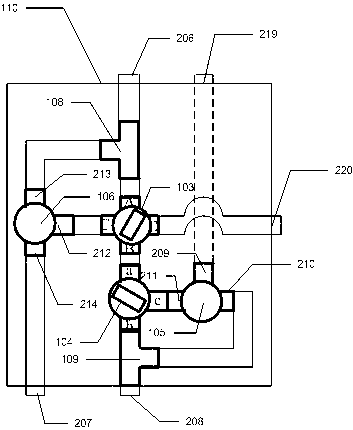

Double-burning and double thermal heat storing type energy-saving high efficiency furnace and tank integrated reducing furnace system

The invention discloses an integrated reducing furnace system of a dual-combustion and dual-heating regenerative energy-saving and high-efficiency retort. The integrated reducing furnace system comprises a furnace body part and a heating part. The furnace body part comprises: a reduction pot in which a central combustion chamber and a charging chamber are arranged, wherein, a high-temperature fume exhaust radiant heat tube is arranged in the charging chamber; a feed port which is connected with the charging chamber; a magnesium crystal collector; a sullage pipe; a combustor which is connected to the top of the central combustion chamber; an insulating shell and an outer fume chamber, wherein, the insulating shell is arranged outside the reduction pot, and an external heating combustor is arranged on the top surface of the insulating shell. Air in the combustor is preheated and premixed by a regenerator and fuel, then is jetted into the central combustion chamber by electrical high tension ignition and combusts in the central combustion chamber. The integrated reducing furnace system has the most significant innovation of being compatible for internal combustion and external combustion, having higher efficiency and more obvious benefit.

Owner:邓小宝 +3

Medical humidifier

PendingCN107596531AImprove compatibilityImprove the humidification effectRespiratorsCycloneWater storage tank

The invention discloses a medical humidifier. The medical humidifier comprises a heater, a water storage tank, a plurality of connection ports and a plurality of connection pipes. Each connection portis provided with an adapter substitute. A liquid supplying machine is arranged at the top of the water storage tank. The heater comprises a heater body and cooling fins. Each cooling fin is in an S shape. A separation plate perpendicular to the bottom of the water storage tank is further arranged in the water storage tank, and the separation plate is in an S shape. Air vents are formed in the twoends of the top of the separation plate. The directions of the openings of the air vents in the two ends are used for jointly guiding the air flow flowing out in the air outlet direction to form a clockwise cyclone or an anticlockwise cyclone in the water storage tank. The medical humidifier has the technical advantages that the multiple connection ports can be compatibly used, the compatibilityof the medical humidifier is higher, the humidifying efficiency is high, and the humidifying effect is obvious.

Owner:毕见龙

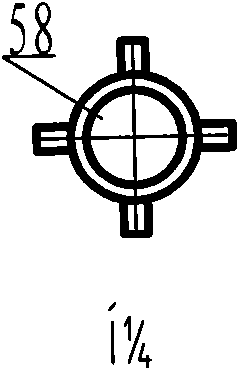

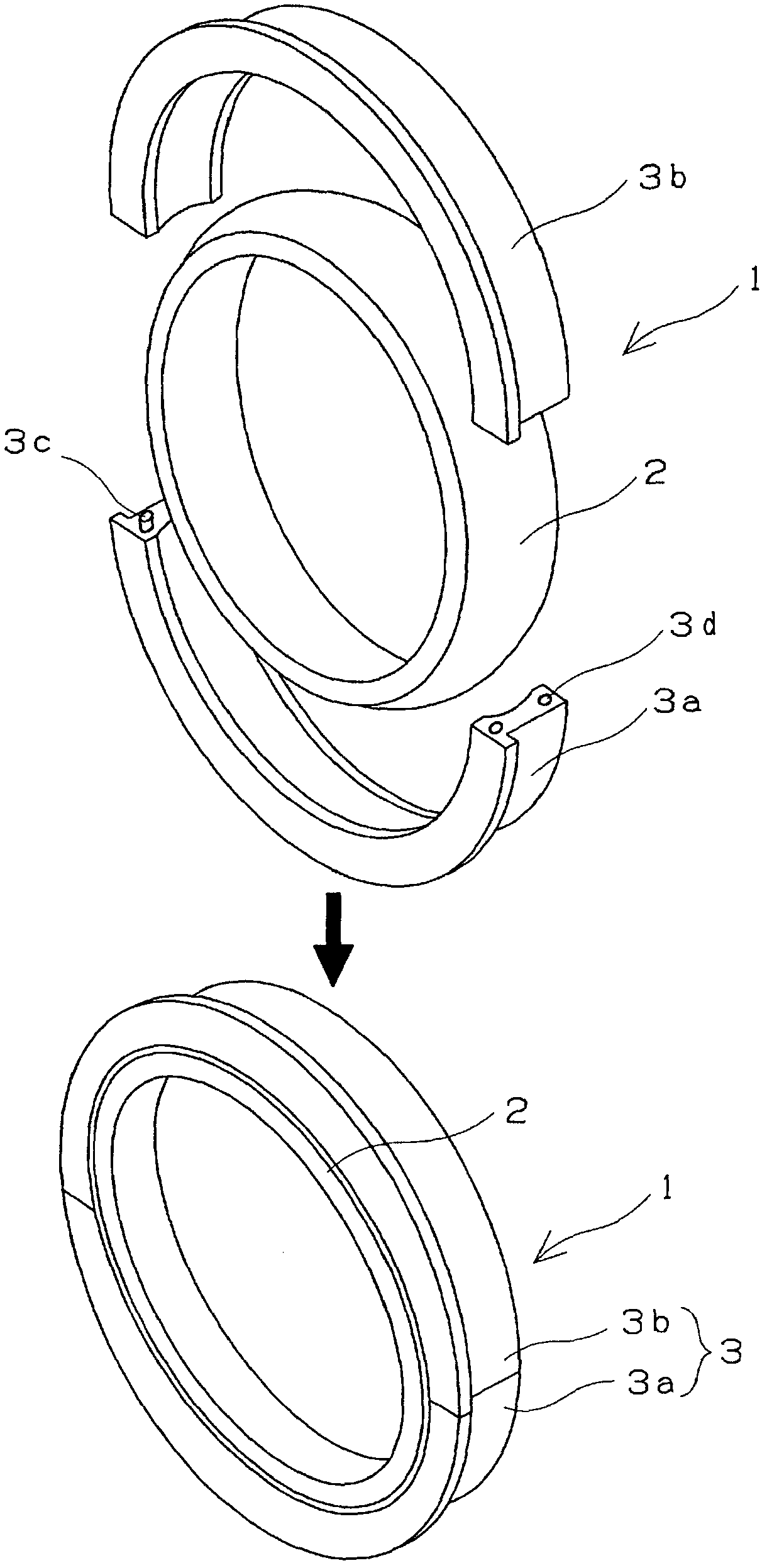

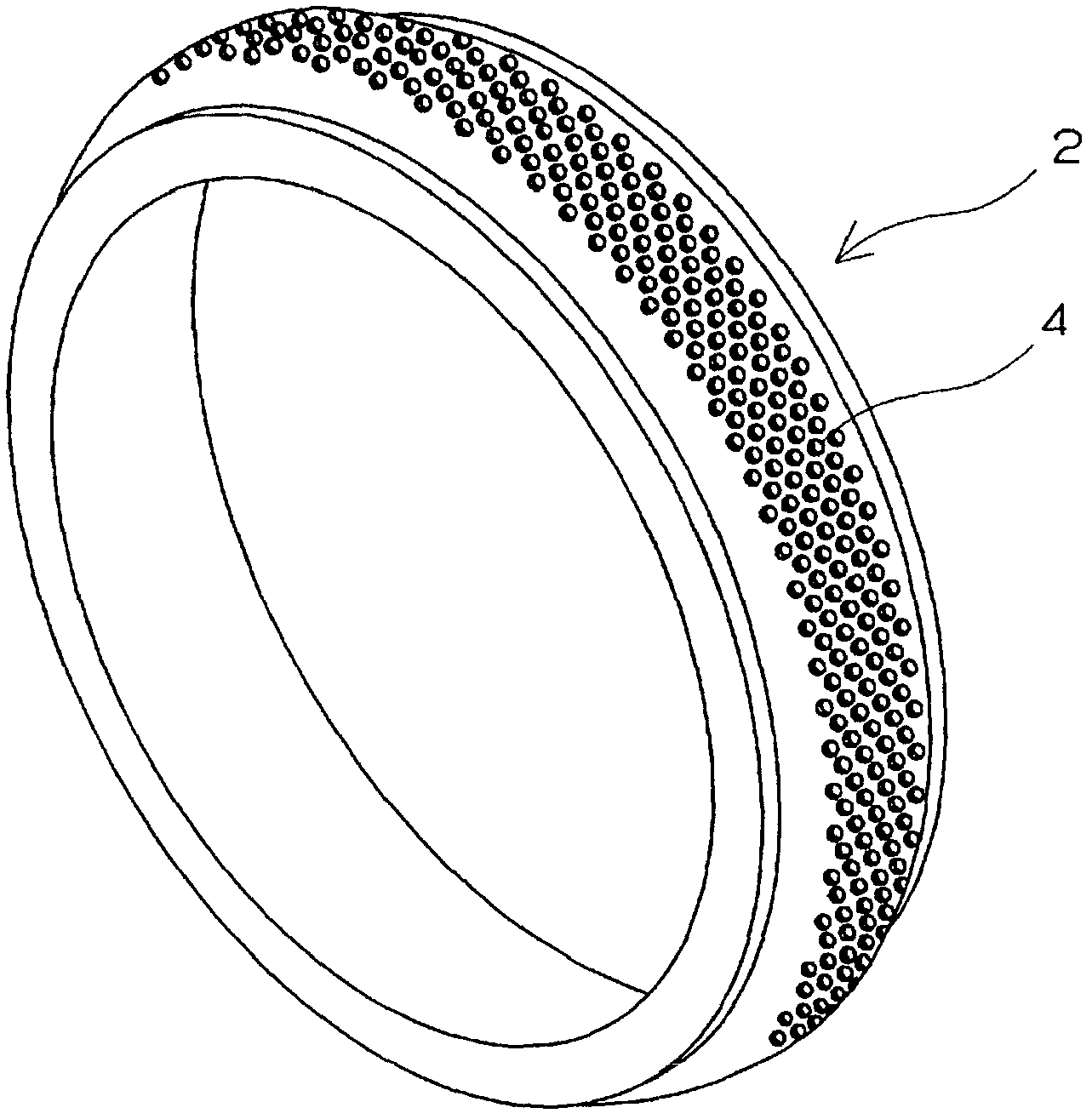

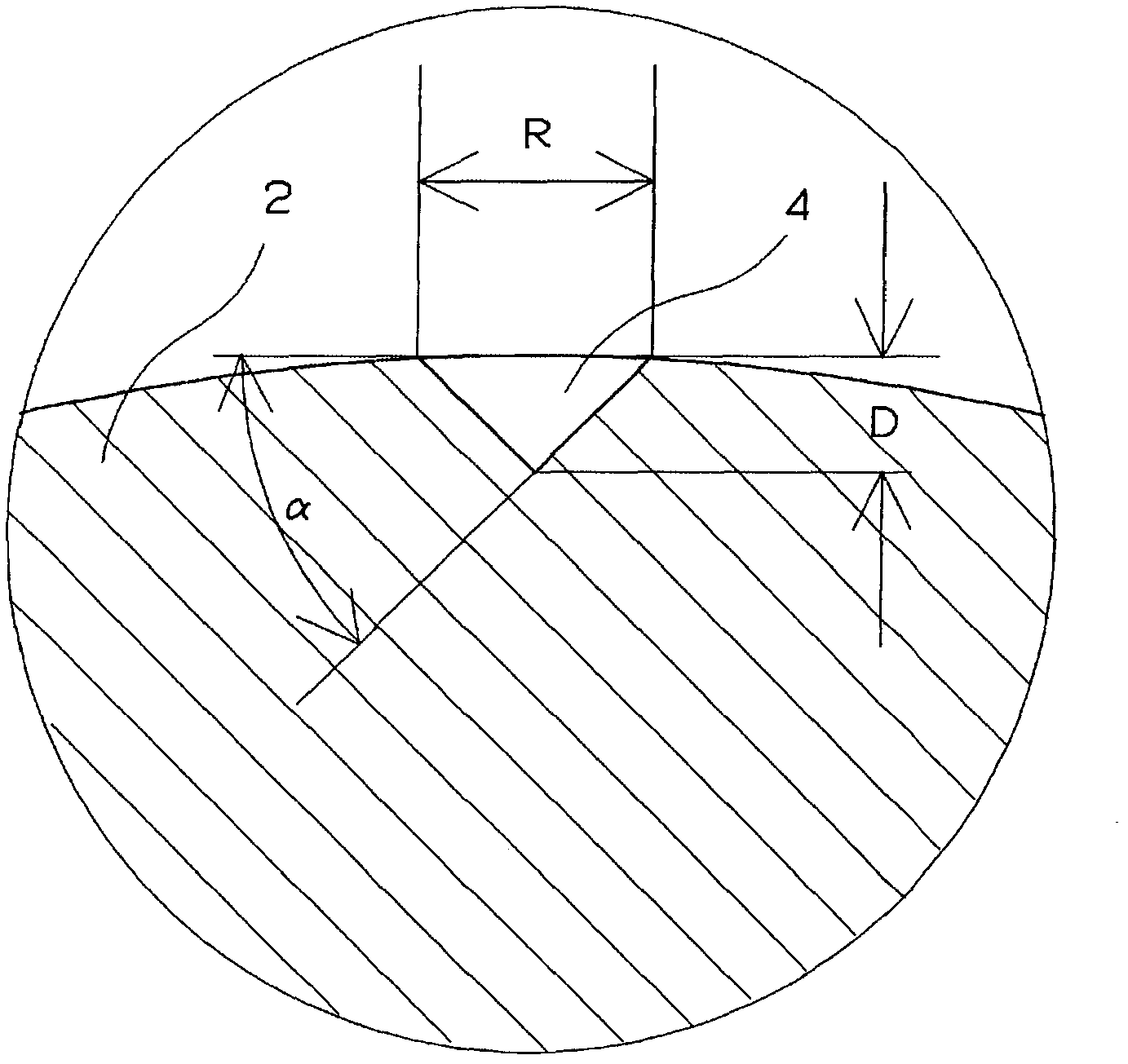

Slide bearing

InactiveCN102549281ASolution to short lifeLow thermal efficiencyShaftsBearing componentsEngineeringSliding contact

A slide bearing having a simple configuration and low friction torque. A slide bearing (1) for supporting heat rollers, such as a fixing roller and a pressing roller which are used for an image forming device, the slide bearing (1) comprising an outer ring (3) and an inner ring (2). Either the outer ring (3) or the inner ring (2) consists of resin, and the other consists of a sintered metal. The outer peripheral surface of the inner ring (2) is a convex surface, and the inner peripheral surface of the outer ring (3) is a concave surface corresponding to the convex surface. The outer ring (3) is bisected in the radial direction, and the inner ring (2) is sandwiched between the bisected halves of the outer ring (3). The inner peripheral surface of the outer ring (3) and the outer peripheral surface of the inner ring (2) are in sliding contact with each other.

Owner:NTN CORP

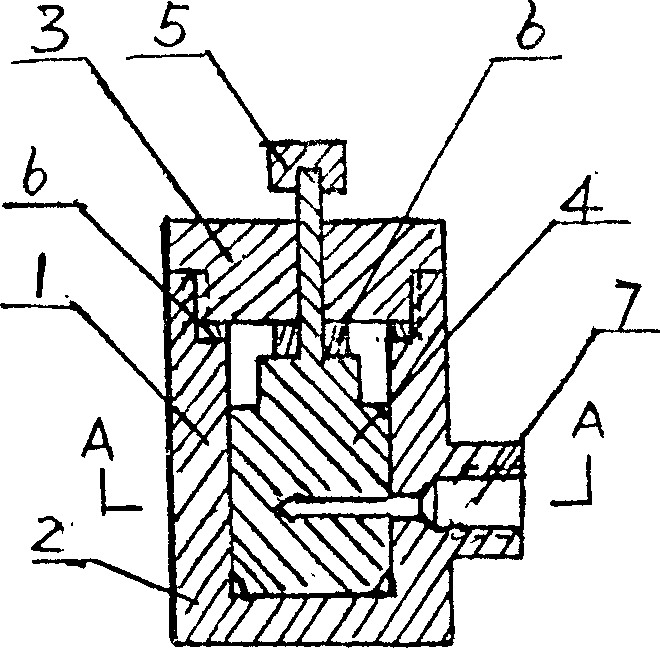

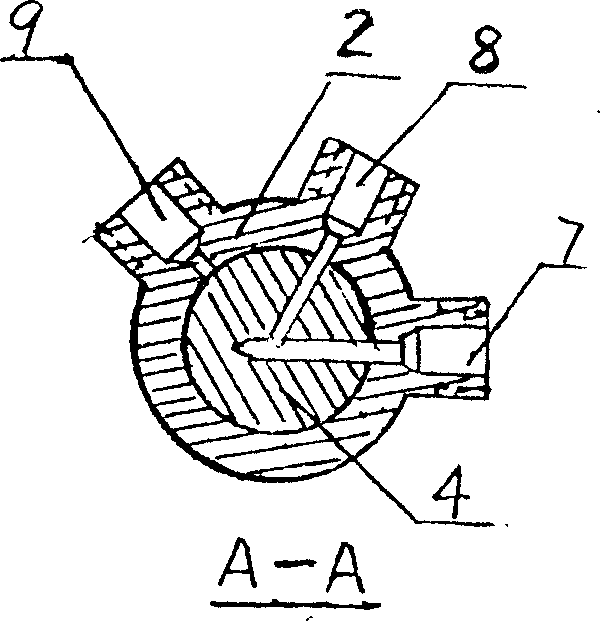

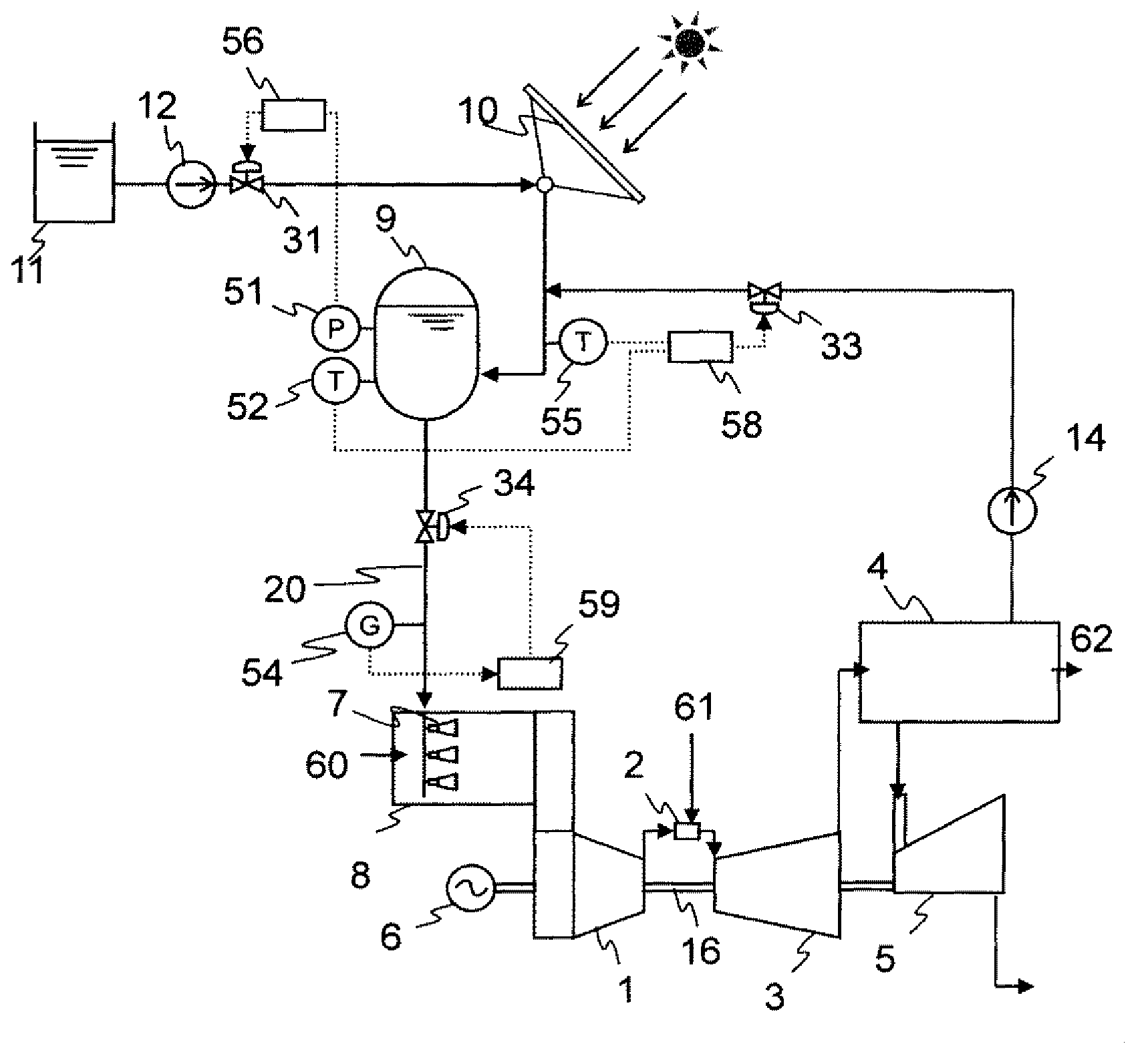

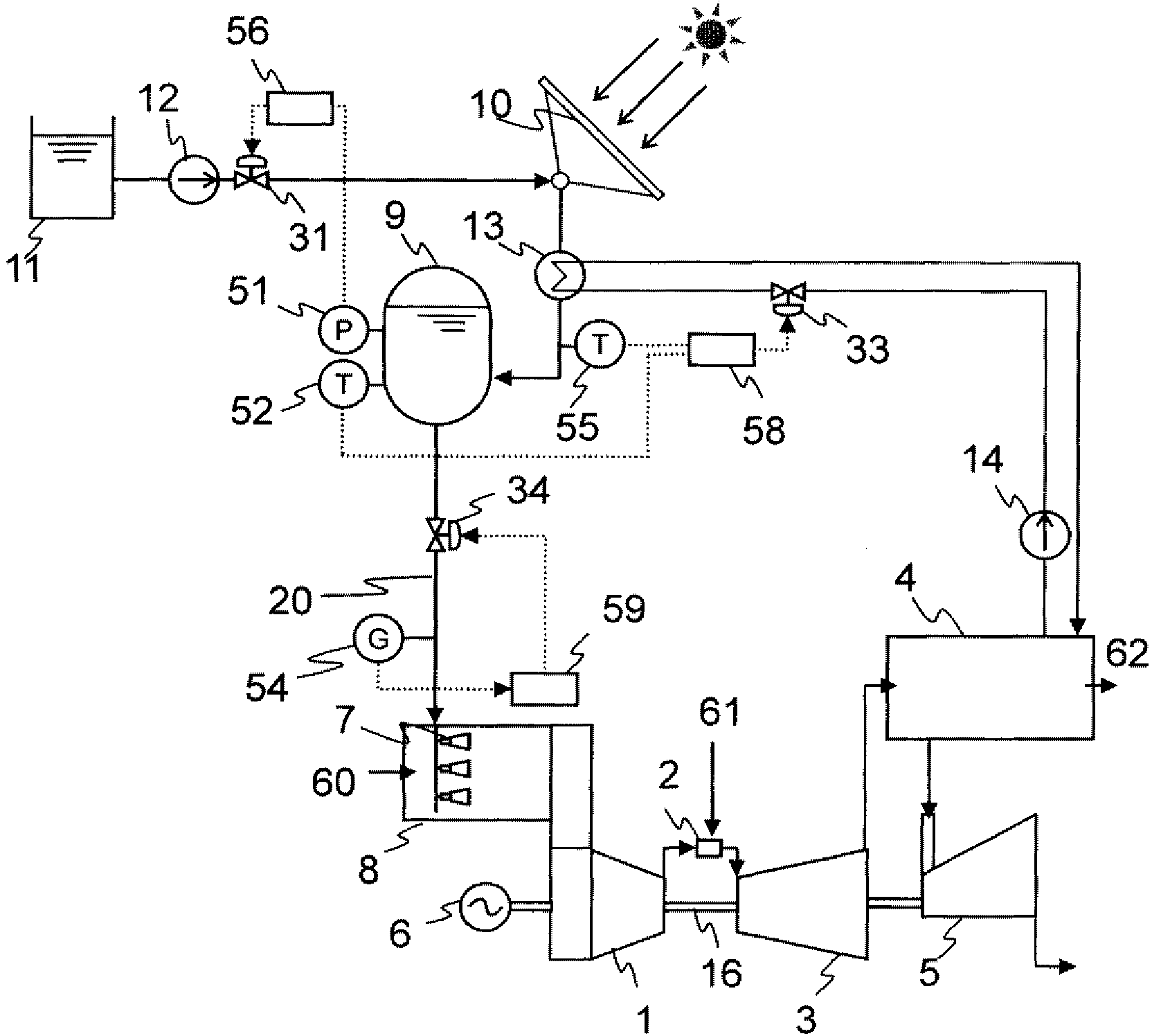

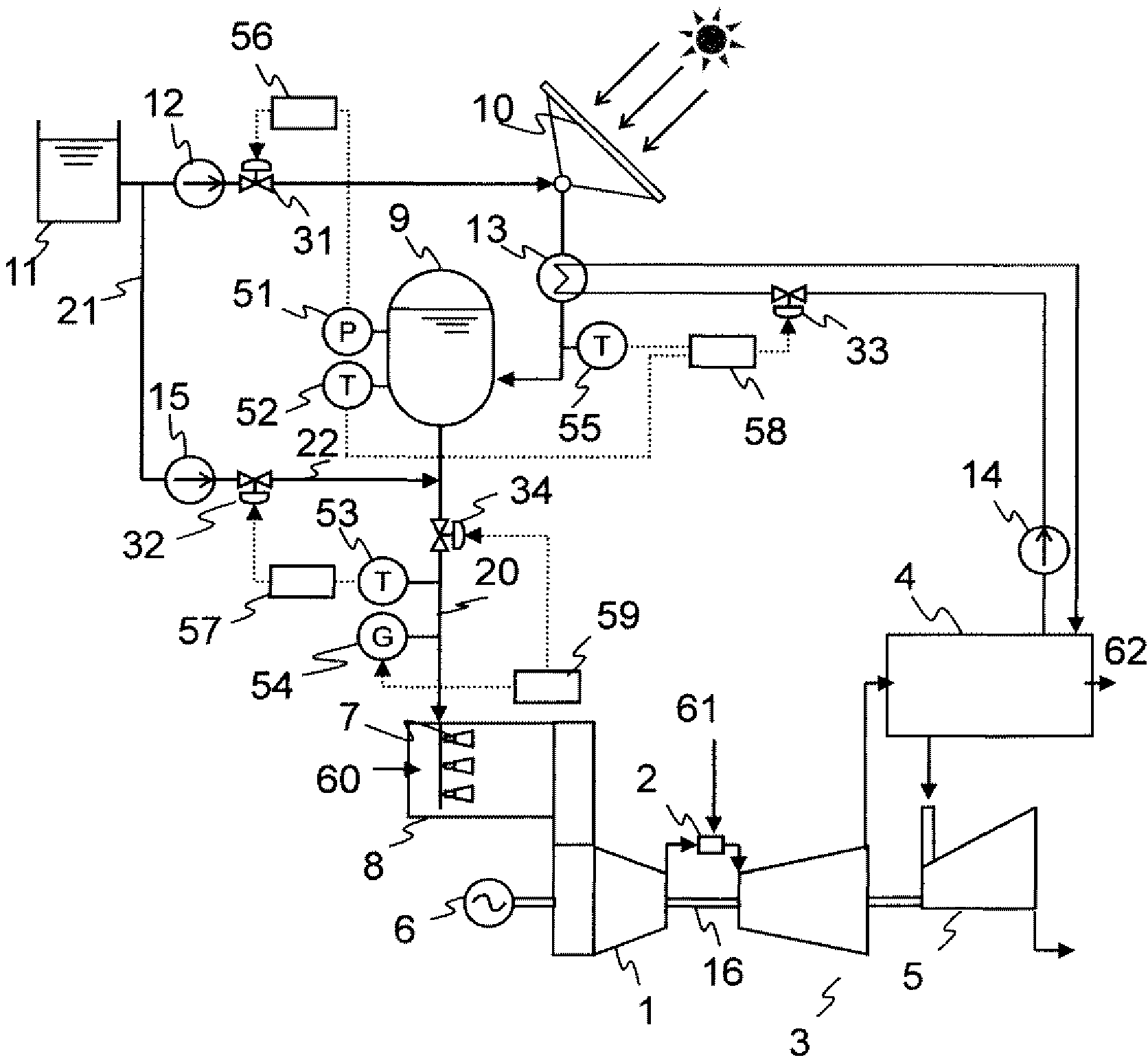

Combined cycle power generation plant utilzing solar heat

ActiveCN103080503ALow thermal efficiencyStable power generation outputSolar heating energyFrom solar energyCombustion chamberHigh pressure

A combined cycle power generation plant that uses solar heat and is equipped with: a compressor (1) that pressurizes air for combustion; a combustion chamber (2) that mixes / burns the aforementioned combustion air (60) and a gas turbine fuel (61) to generate high-temperature combustion gas; a gas turbine (3) that drives the compressor (1) using the aforementioned combustion gas; an exhaust heat recovery boiler (4) that obtains steam from the heat energy of the exhaust gas from the gas turbine (3); and a steam turbine (5) that is driven using steam obtained with the exhaust heat recovery boiler (4). The power generation plant is further equipped with: a heat collector (10) that converts feed water to high-temperature water by means of the heat energy of sunlight; a heat accumulator (9) that stores high-pressure, high-temperature water obtained from the heat collector (10) and the exhaust heat recovery boiler (4); and a spraying device (4) that sprays the high-pressure, high-temperature water stored in the heat accumulator (9) into the intake air of the compressor (1) as a water spray.

Owner:MITSUBISHI POWER LTD

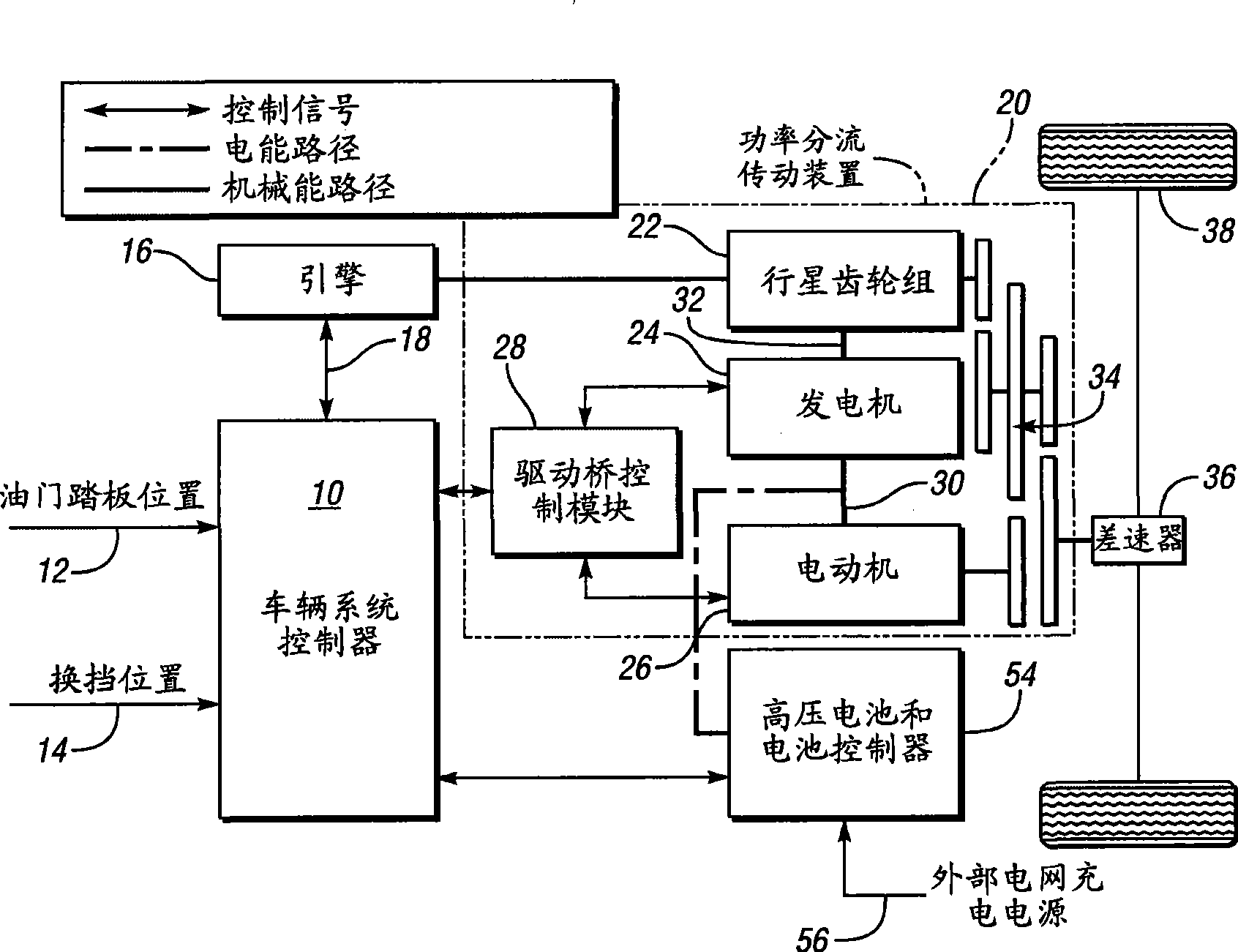

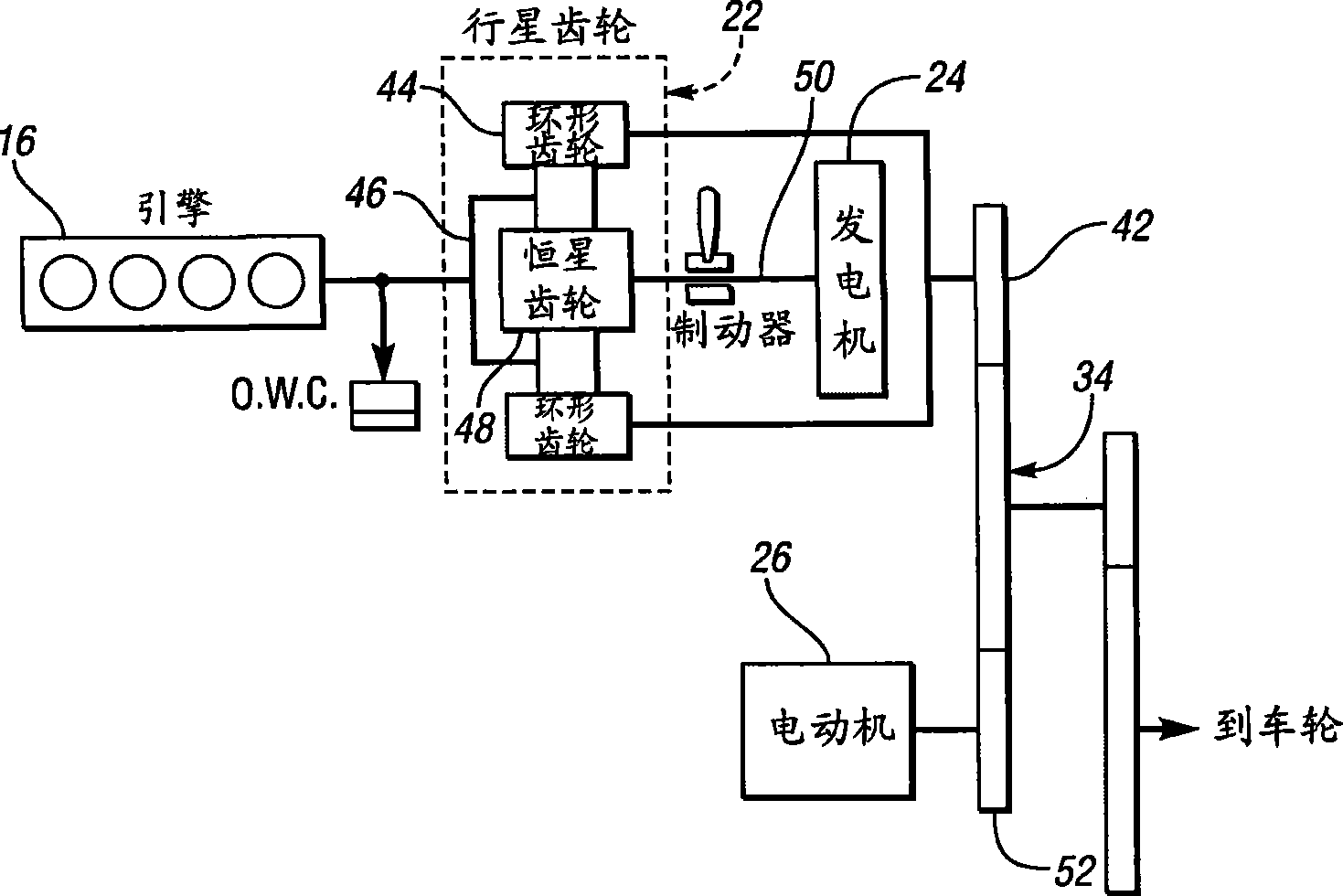

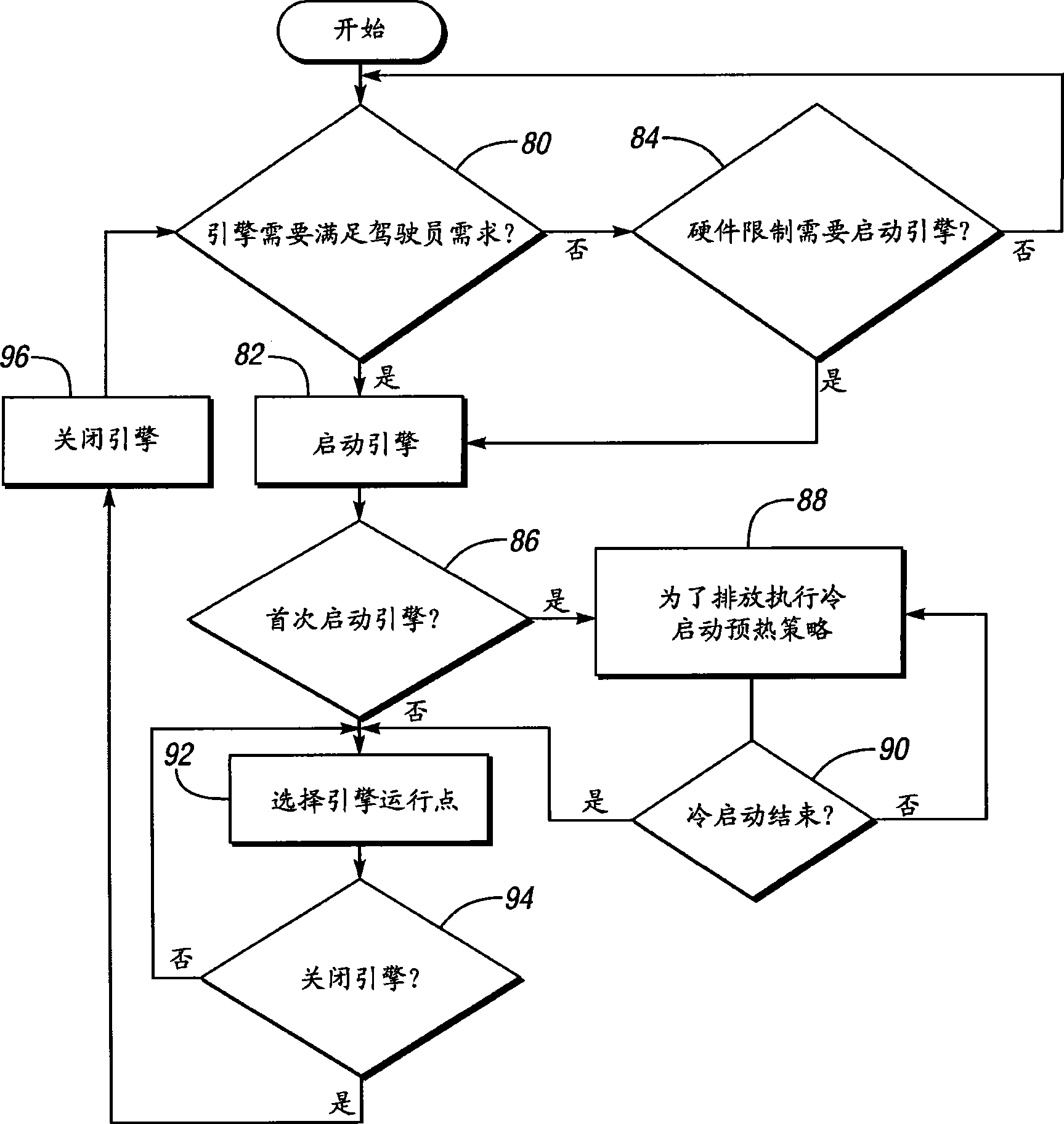

Charge depleting energy management strategy for plug-in hybrid electric vehicles

ActiveCN101456416AMeet power needsMeet needsHybrid vehiclesPlural diverse prime-mover propulsion mountingBattery state of chargeBattery charge

A method for managing power distribution from an engine and a battery in a plug-in hybrid electric vehicle whereby battery power is used to meet a driver demand for power and engine power complements battery power when either battery state-of-charge limit or battery discharge power limit would be exceeded, an external power grid being used to restore battery power following battery charge depletion.

Owner:FORD GLOBAL TECH LLC

Separated type solar water heater with freeze prevention and frost resisting functions

ActiveCN102706000AAntifreezeFunctionalSolar heat devicesSolar thermal energy generationFrostSolar water

The invention discloses a separated type solar water heater with freeze prevention and frost resisting functions, and relates to the separated type solar water heater which has a freeze protection function and a frost resisting function. The interchange and realization of the two functions are fully based on zero power consumption independent of any external electrical energy, and the two functions can be crossly used or selectively used in different districts or in different environments in the same district so as to bring great expedience for clients. The separated type solar water heater prevents freeze and does not consume power and resists the frost without an anti-freeze fluid; the system adopts a single circuit to directly replace heat transfer in a high efficiency manner, the heat efficiency is high, the system cost is low, and the cost performance is ultrahigh; the whole separated type solar water heater adopts a full mechanical structure and is safe and reliable, and the freeze prevention and frost resisting problems of a flat plate collector are thoroughly solved. The separated type solar water heater with freeze prevention and frost resisting functions is an all-weather solar water heater which is truly high in efficiency, is convenient and in a zero power consumption, and has large popularization and application values.

Owner:滁州市中诺设备模具制造有限公司

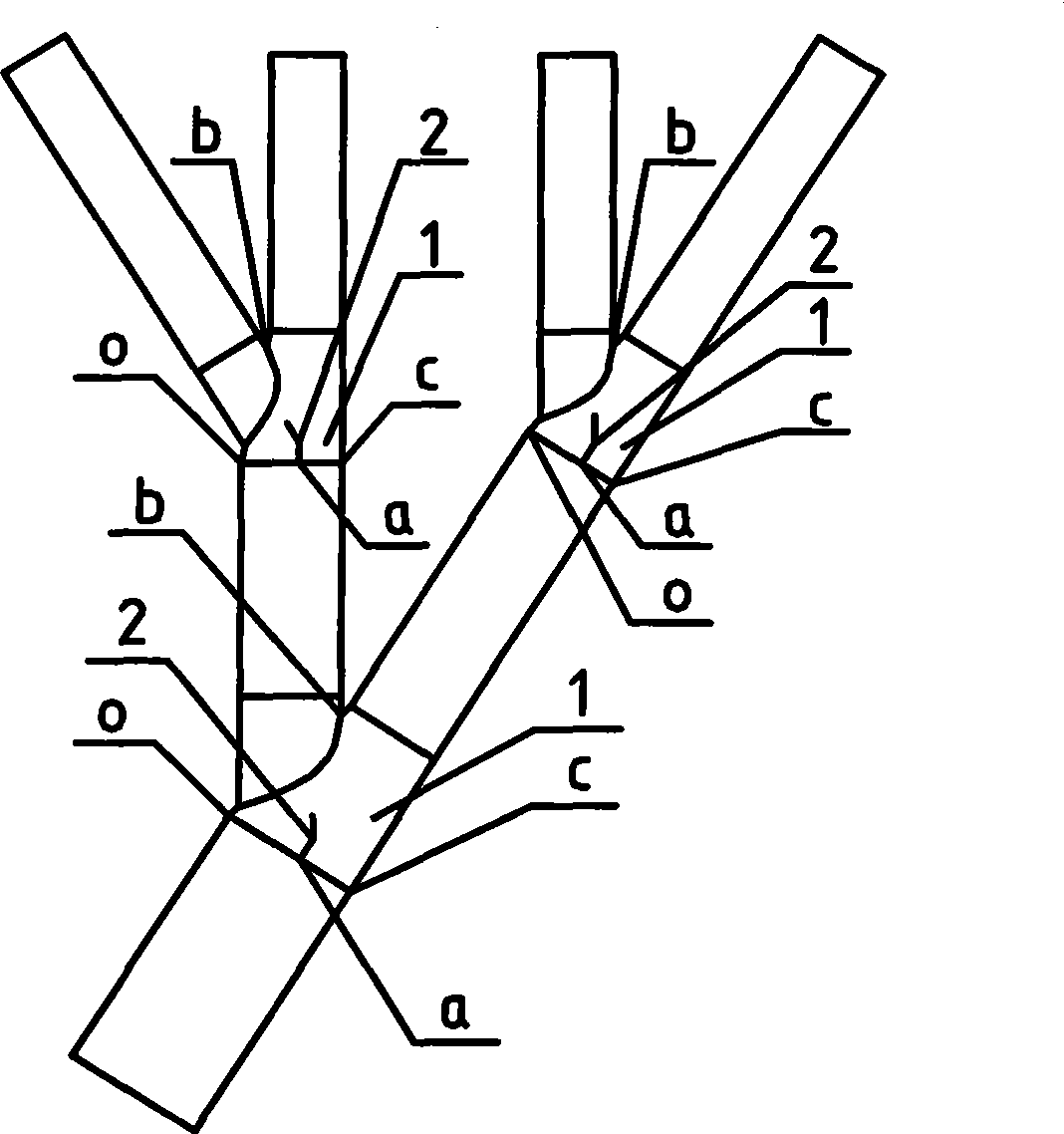

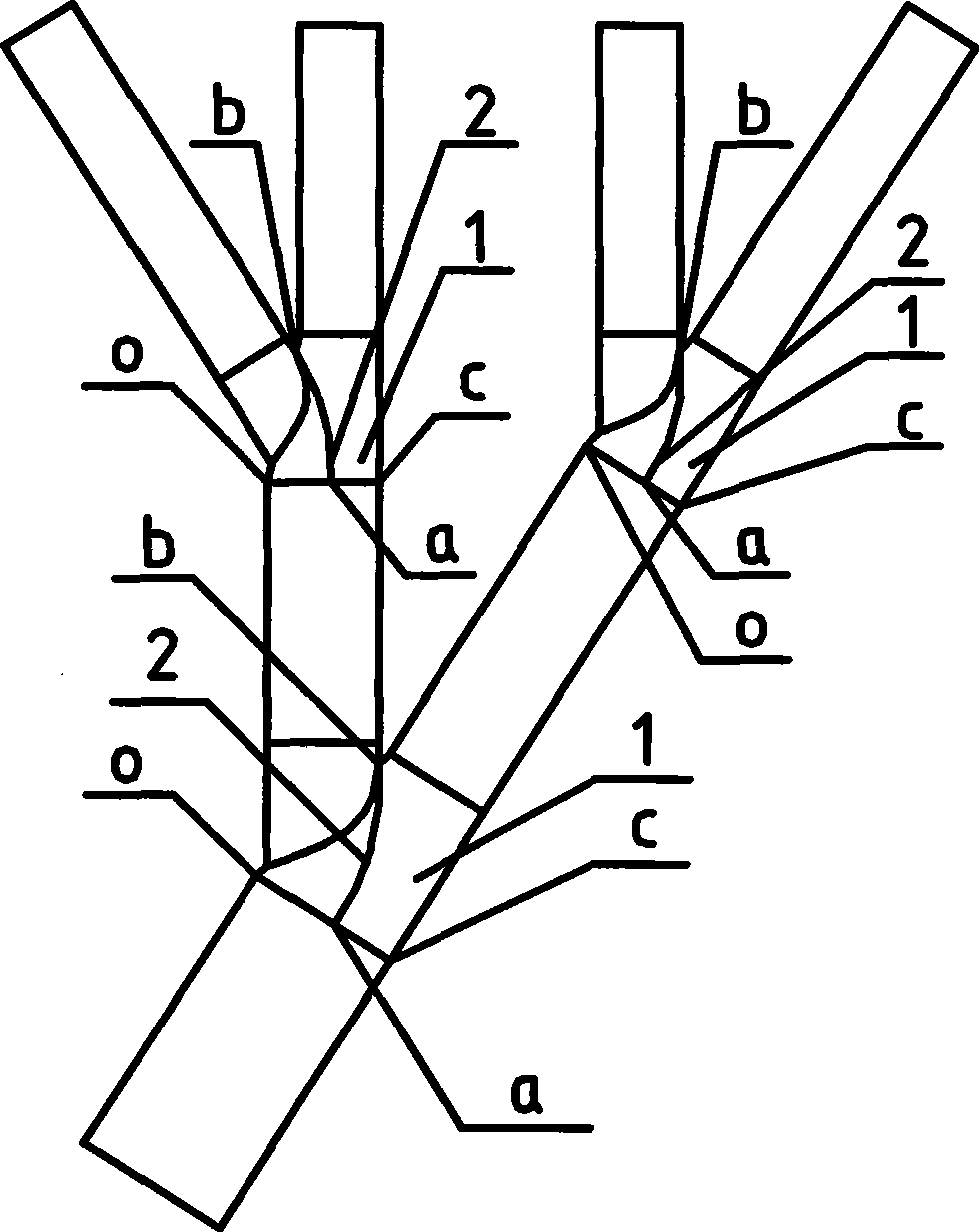

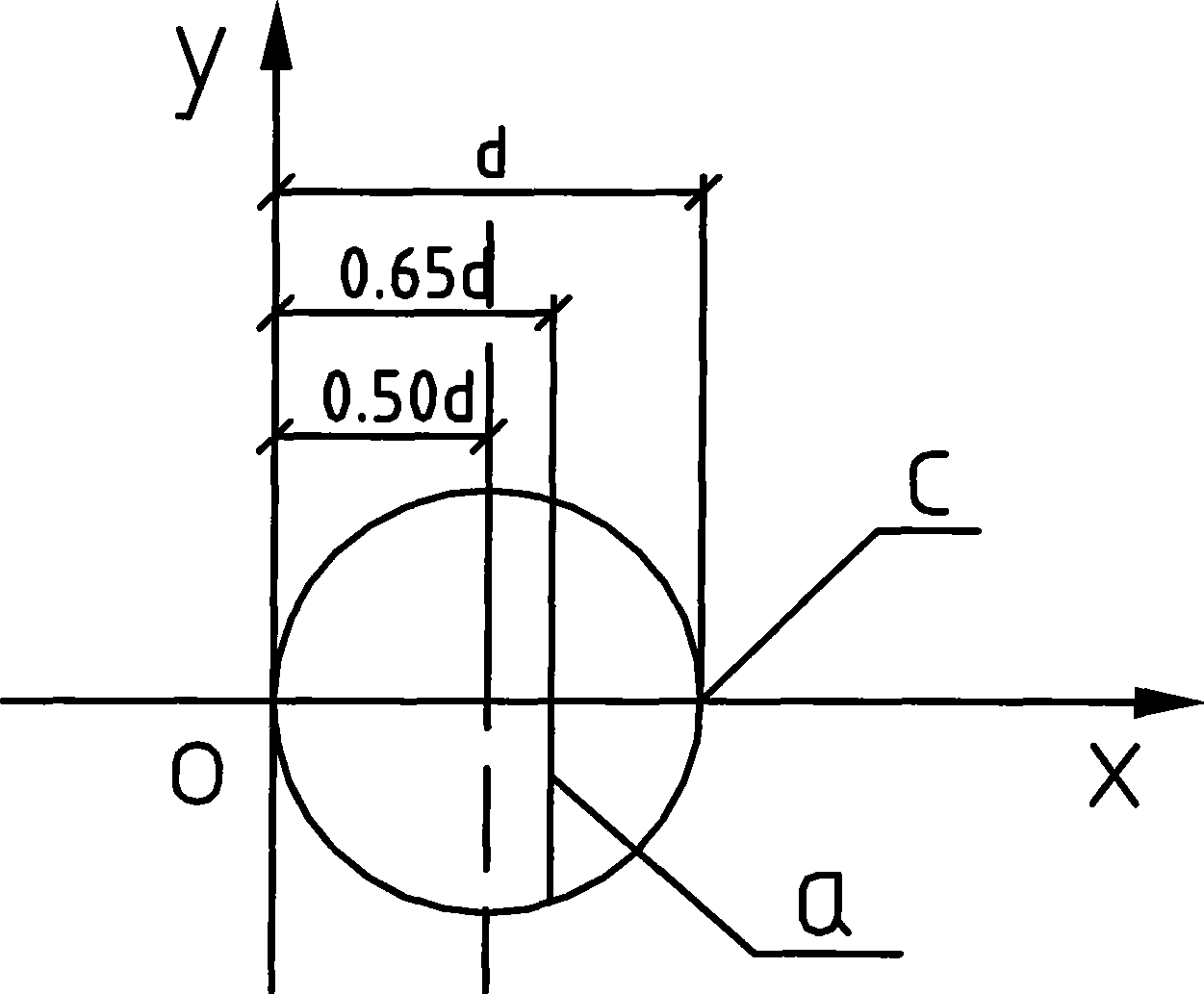

Internal steam conduction apparatus of direct air cooling branch-shaped exhaustion duct system

InactiveCN101476823AGuaranteed safe operationKeep the economy runningEnergy industrySteam/vapor condensersHigh resistanceThermal energy

The invention discloses a flow guide device in a direct air cooling branch-shaped exhaust duct system, which is applied in the field of heat energy power engineering. The device solves the problem of even flow distribution of steam exhaust of a steam turbine among various steam distribution pipes. The device prevents the danger of the freezing of a direct air cooled condenser which is possibly caused by the unreasonable design of the direct air cooling branch-shaped exhaust duct system, and ensures safe operation of the steam turbine in winter. The device ensures that a system prevents the pressure loss of water vapor from being overhigh and the supercooling area from being overlarge, prevents the reduction of heat exchange amount, and reduces the thermal efficiency of power plants when realizing the even distribution of the flow of water vapor. The device fully plays the cooling capacity of various parts of the direct air cooled condenser, and ensures that the steam turbine runs economically in other seasons. For realizing the even distribution of the flow of the water vapor, the distribution of the area of a diversion cross-section depends on the resistances of two branch pipe sections, and a branch pipe with a high resistance should obtain larger diversion area. The device is mainly used for steam diversion and cooling systems of power stations, petrochemical industry, and the like.

Owner:BEIJING JIAOTONG UNIV

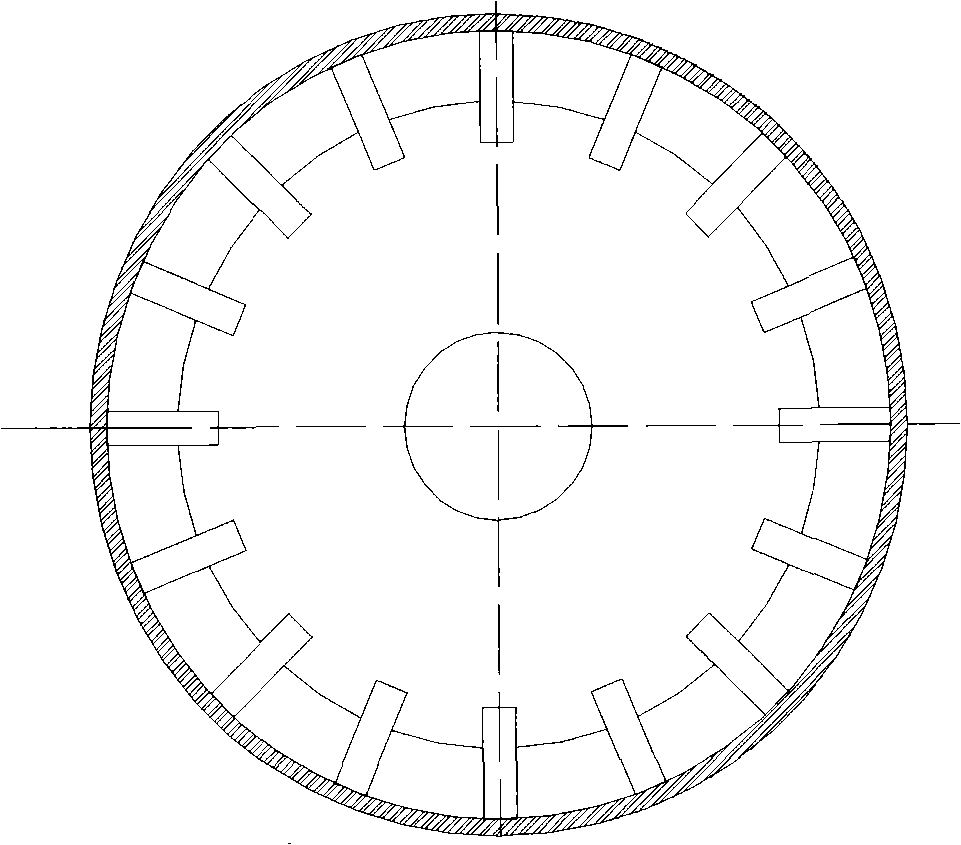

Electromagnetic internal heating type hot cover process for water-wheel generator rotor support

InactiveCN101291091AAvoid the problem of moving the lower end upwardsLow costCoil arrangementsManufacturing stator/rotor bodiesWater wheelEngineering

The invention relates to a method for internally-heating shrinkage fit by electromagnetic induction to a rotor field spider and a shaft of a hydraulic generator. The method has the advantages of even heating, convenient control, movable heating equipment, repeated use, energy conservation and high efficiency. The method comprises the following steps of: winding an electromagnetic wire on a support made of a special temperature resistant material; then, inserting the support into a wheel boss of the rotor field spider to perform electromagnetic induction heating; sleeving the rotor field spider on the shaft after the wheel boss reaches predetermined magnitude of interference; and fixing the rotor field spider on a platform through a lacing wire to prevent the lower end of the wheel boss from moving upwards during cooling process.

Owner:HARBIN ELECTRIC MASCH CO LTD

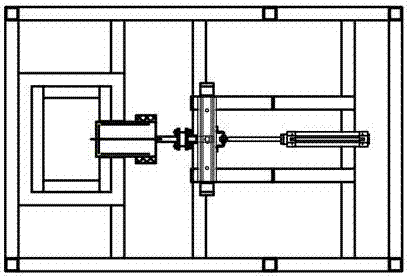

Turnover-type thermal shock and thermal fatigue test platform

ActiveCN107884165AThe experimental platform is simpleImprove work efficiencyMachine part testingPistonThermal shock

The invention relates to a turnover-type thermal shock and thermal fatigue test platform, which belongs to the technical field of test appliances. The turnover-type thermal shock and thermal fatigue test platform comprises a test platform support, a first infrared thermometer, a first test piece, a heat preservation cavity support, a heating device, a second test piece, a heat preservation cavity,a hood, an exhaust manifold, a high-temperature pipe fan, a first clamp, a second infrared thermometer, a swing cylinder, a linear guide rail, a first position sensor, a linear cylinder, a sliding block, a second position sensor, a third infrared thermometer, a T-type rod, a second clamp, a cooling device and a controller. Two test pieces can be tested at the same time, one is heated and the other one is cooled, the two test pieces turn over vertically for 180 DEG under driving of the swing cylinder, and the two test pieces can rotate together with a working platform to exchange working positions under driving of the swing cylinder. The turnover-type thermal shock and thermal fatigue test platform is simple, practical and high in working efficiency, and in the case of simulated experimental study on thermal shock and thermal fatigue of a piston in an internal combustion engine, the test cost can be saved, and the research and development period of related parts can be greatly shortened.

Owner:KUNMING UNIV OF SCI & TECH

Domestic tea drying box

InactiveCN102835480ANo deformationGood quality teaPre-extraction tea treatmentElectricityAgricultural engineering

The invention discloses a domestic tea drying box, comprising a box body, an electric heater and a fan. The domestic tea drying box is characterized in that a lower left corner and a lower right corner of the box body are respectively provided with an air inlet adapter and an air outlet adapter; a middle plate in the box body is provided with a plurality of movable trays and a ventilation pipe with a plurality of branch blast pipes; the air inlet adapter is provided with the electric heater; the fan is directly attached to an outer end straight pipe of the air inlet adapter; and the middle plate in the box body is provided with a plurality of radiating holes. According to the domestic tea drying box provided by the scheme of the invention, the tea does not need to be stirred in the drying process; and the dried tea has no deformation or breaking, and gains good quality. The domestic tea drying box has simple structure, good hot air delivery effect, high thermal efficiency, and low energy consumption, so as to greatly reduce the cost and realize good comprehensive performance.

Owner:SUZHOU XISHAN HONGYUN MATERIAL ARTICLES FACTORY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com