Highly effective liquid fuel evaporation combustion device

A liquid fuel and combustion device technology, applied in the direction of evaporating liquid fuel burners, gas fuel burners, burners, etc., can solve the problems of inconvenient maintenance, low fuel vaporization temperature, low combustion efficiency and thermal efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

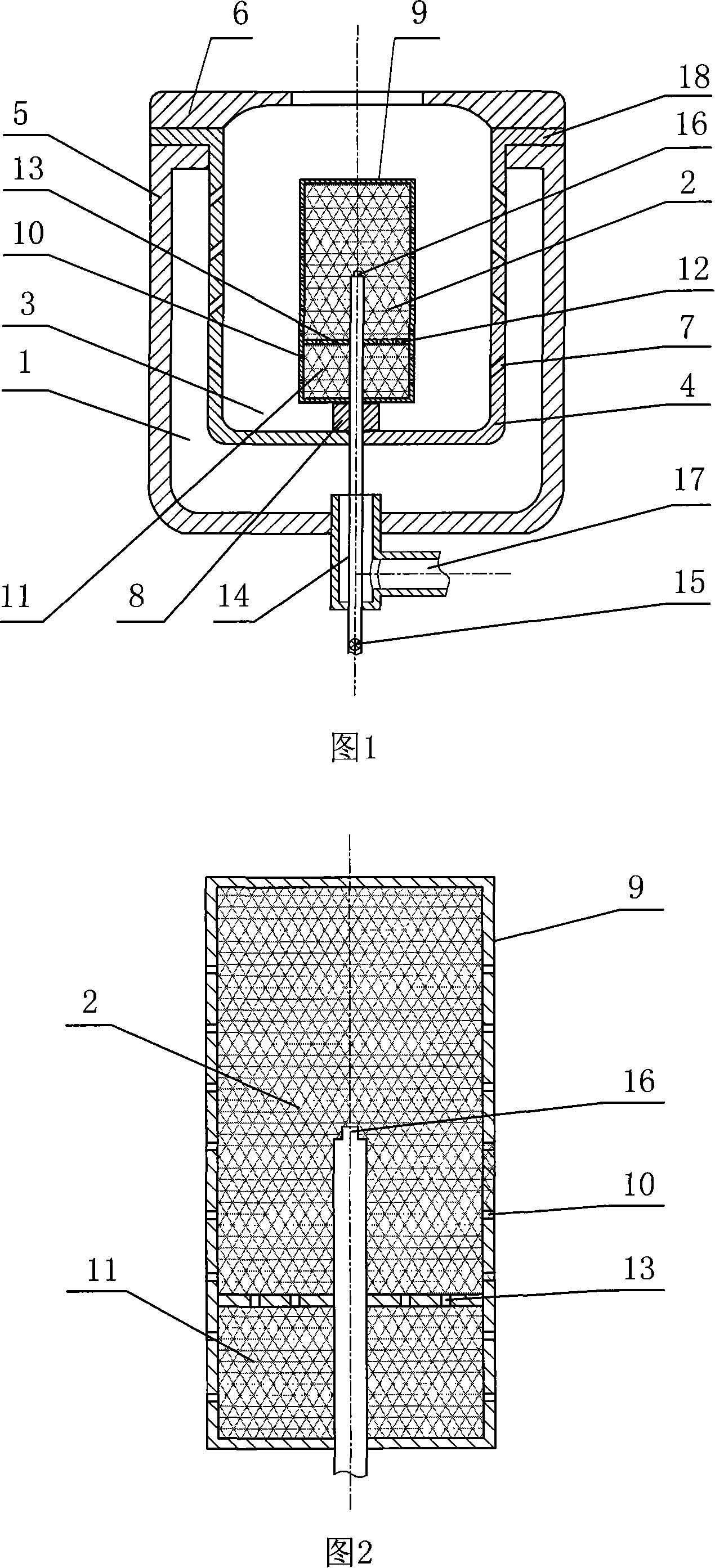

[0021] Referring to the accompanying drawings, a high-efficiency liquid fuel vaporization combustion device includes a gas chamber 1, a vaporization chamber 2 and a combustion chamber 3. There is a combustion cylinder 4 between the gas chamber 1 and the combustion chamber 3, and its upper edge extends horizontally and radially Form an annular flange 18; in order to make the combustion flame more concentrated, the top of the annular flange 18 is movably connected to the fire cover 6, and the bottom of the annular flange 18 is connected to the gas chamber cylinder 5, and the gas chamber cylinder 5 and the combustion cylinder The area surrounded by 4 is the air chamber 1, and the bottom surface of the air chamber cylinder 5 is connected to a fan through the ventilation pipe 17. In order to facilitate maintenance, the vaporized fuel can be mixed with the air faster and more fully, and the combustion is more complete. The ventilation pipe 17 connected to the bottom surface of the ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com