Patents

Literature

47results about How to "Low vaporization temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

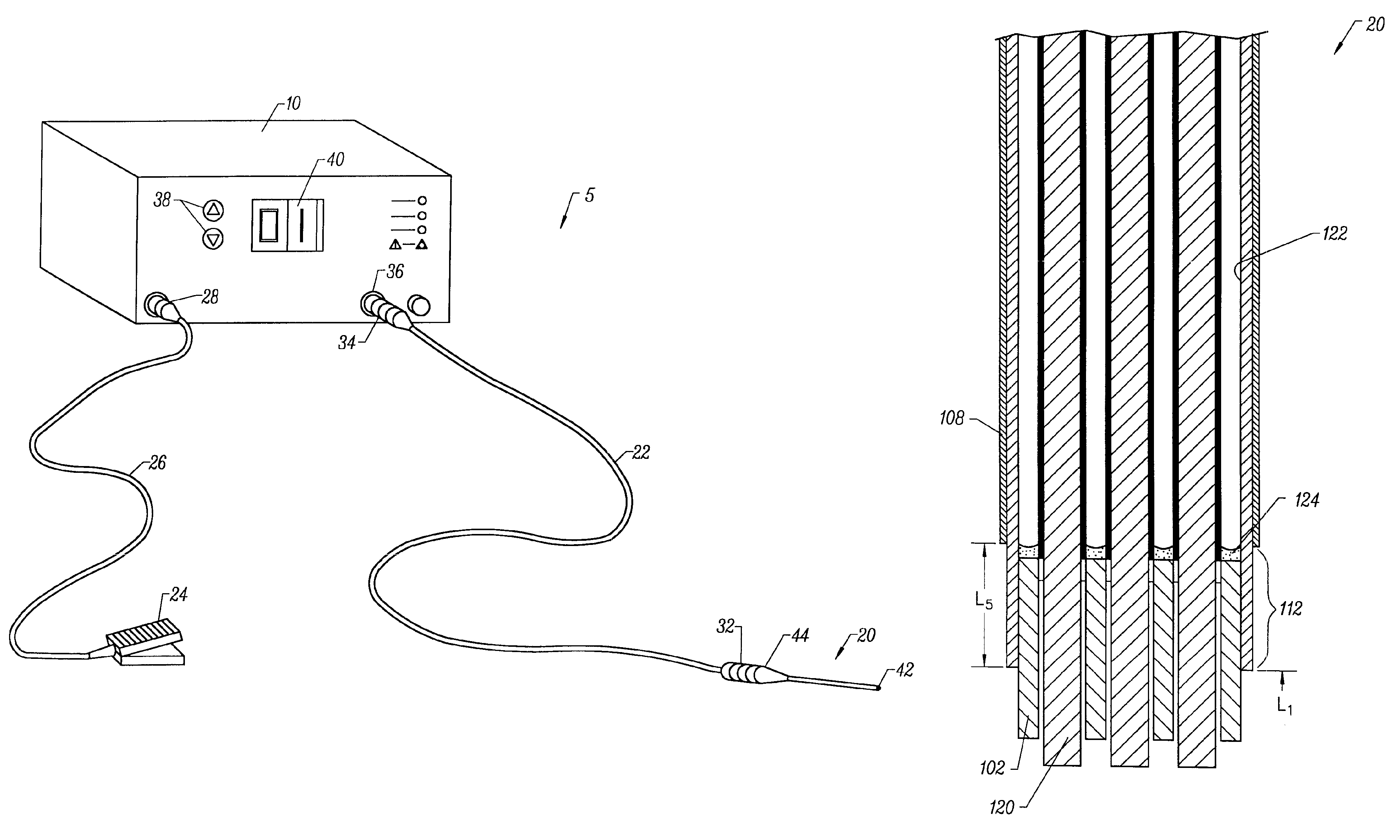

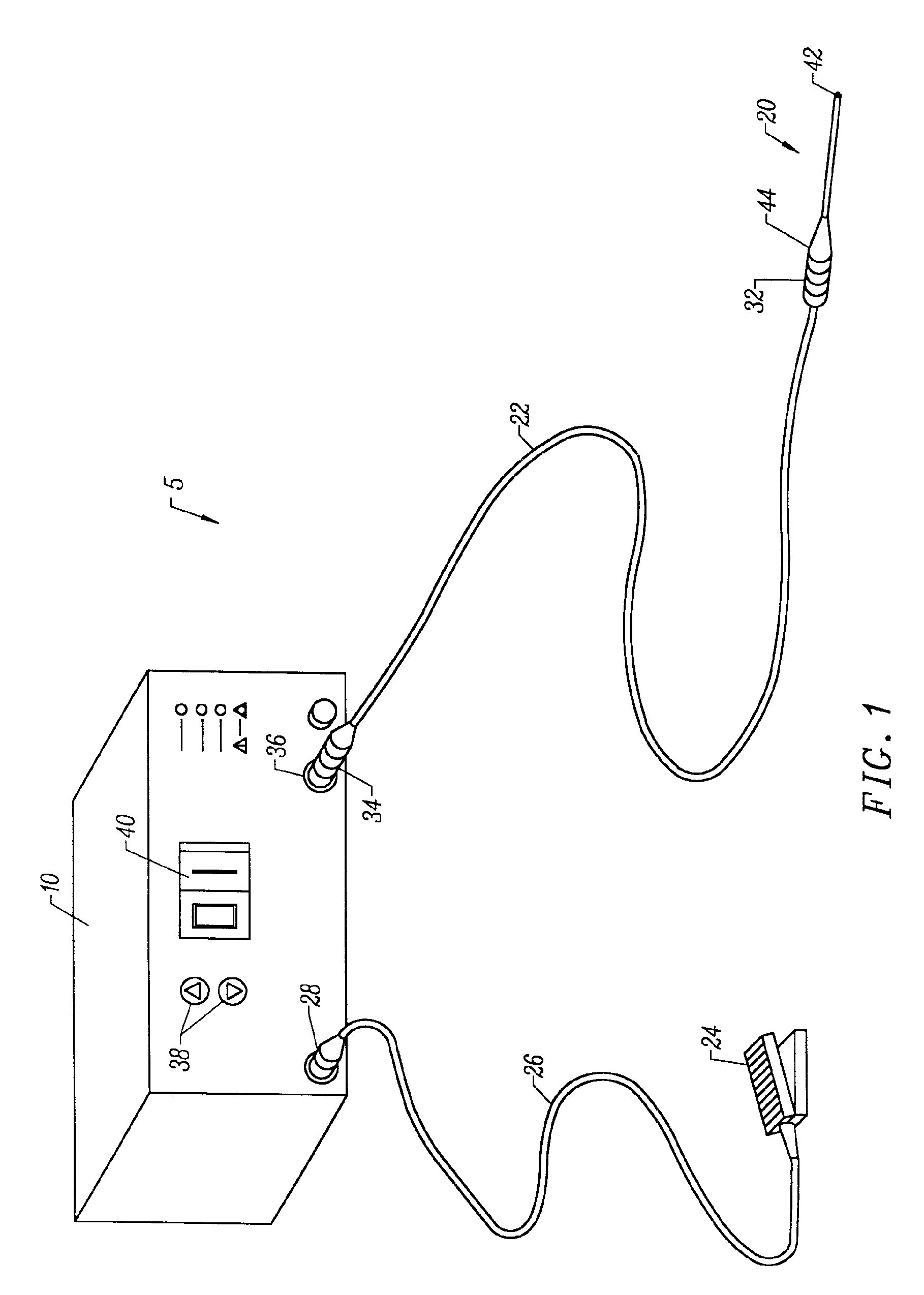

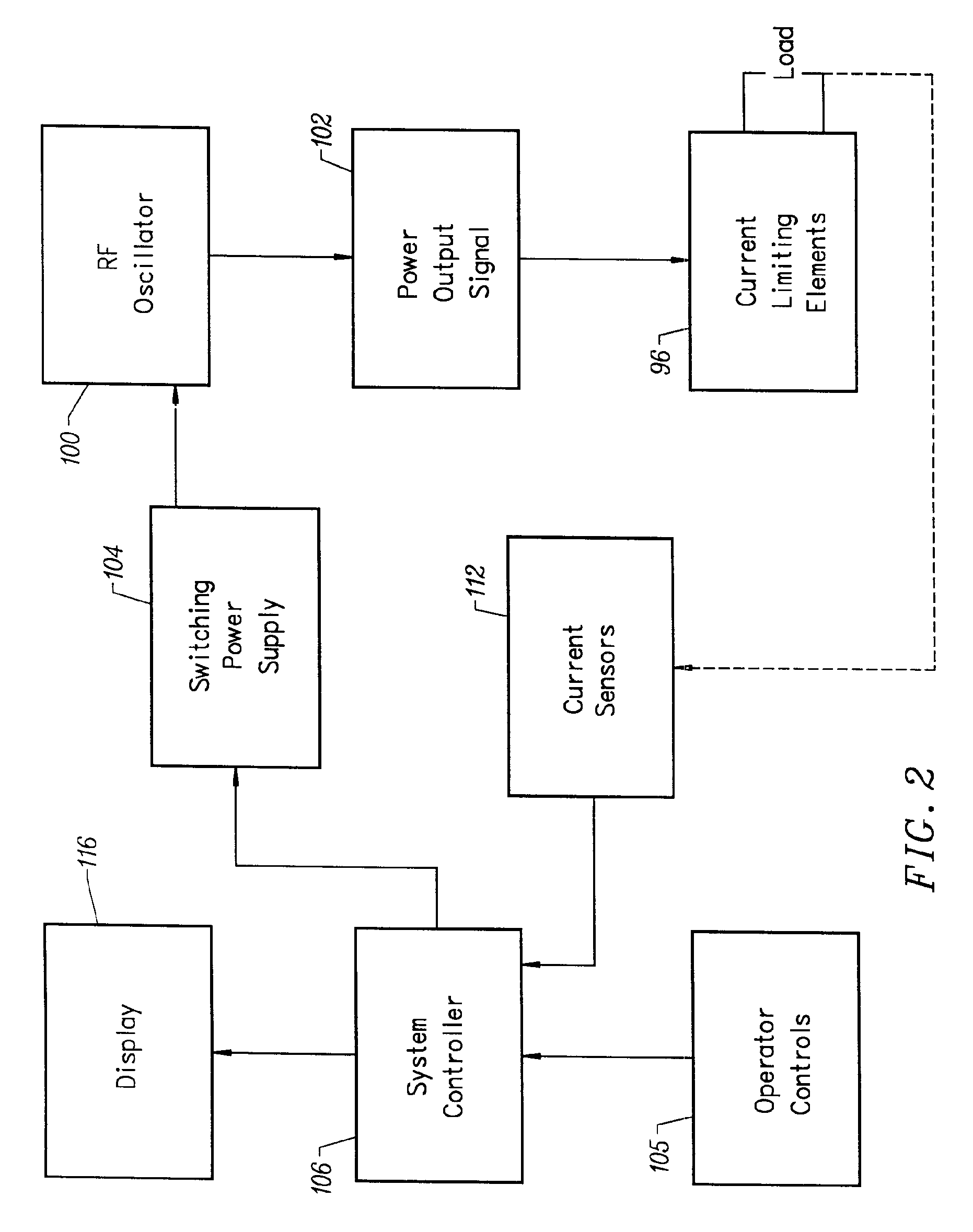

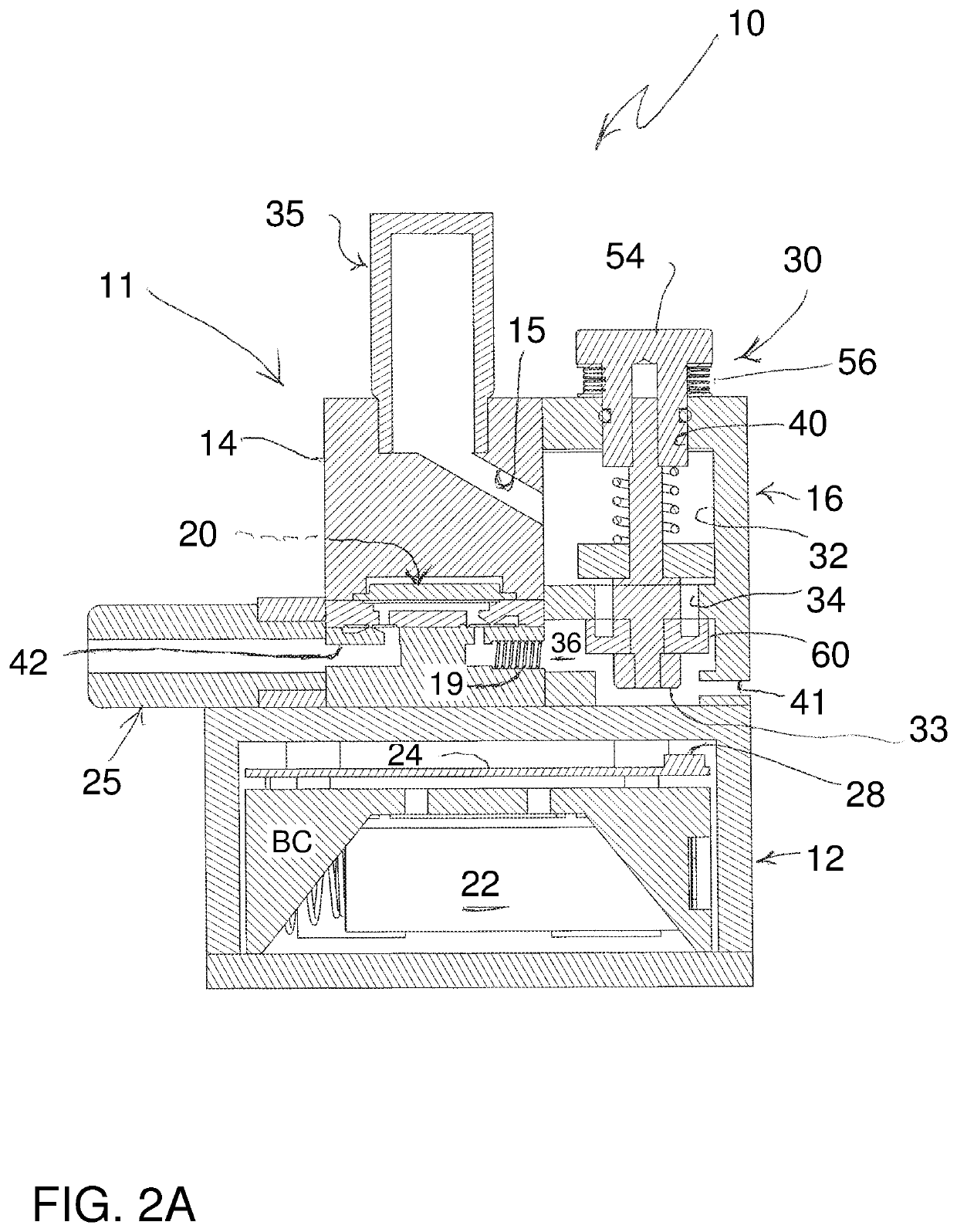

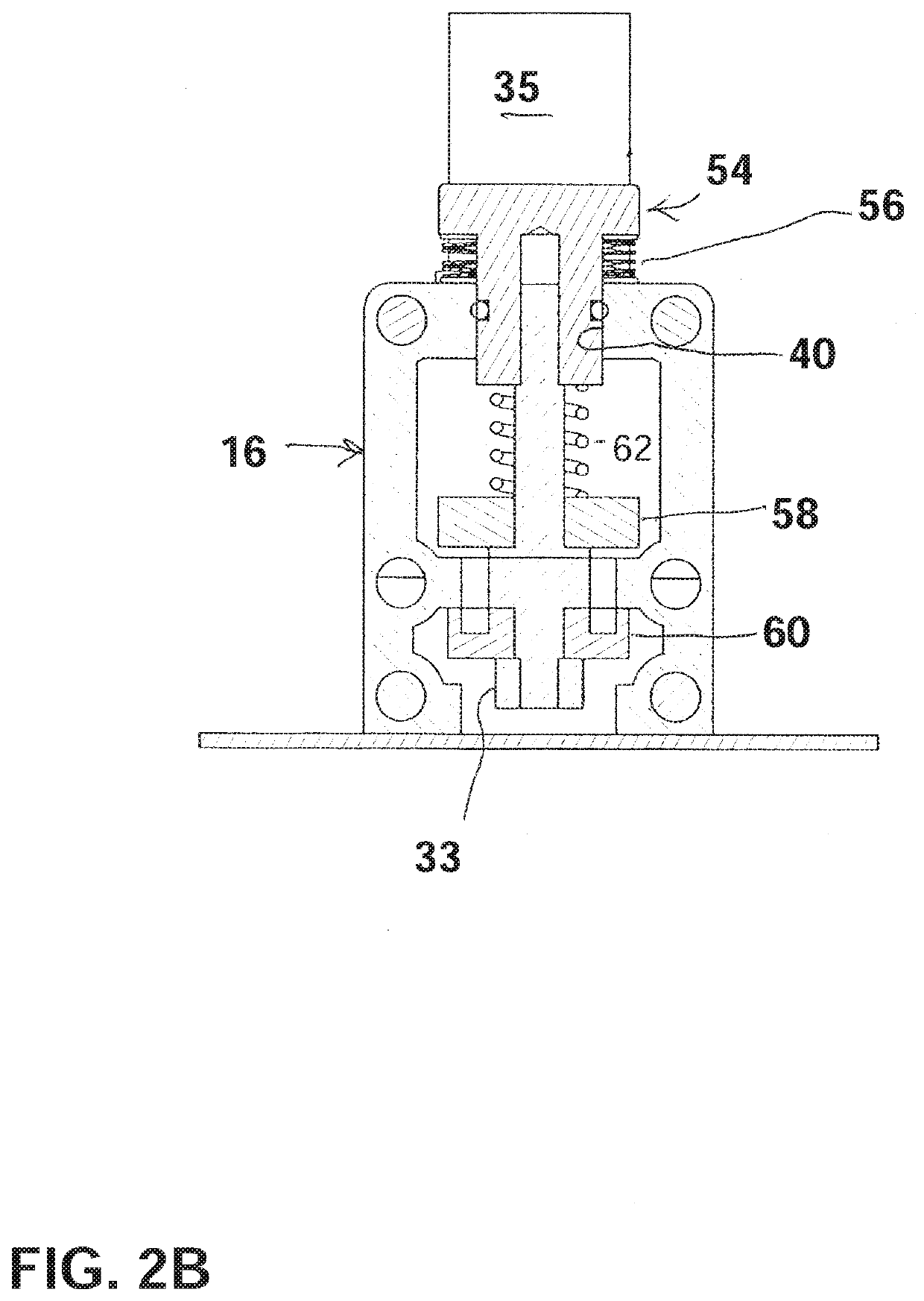

System for electrosurgical tissue treatment in the presence of electrically conductive fluid

InactiveUS7678069B1Quantity minimizationReduce the temperatureCannulasEnemata/irrigatorsEngineeringLow temperature plasma

Systems and methods are provided for applying a high frequency voltage in the presence of an electrically conductive fluid to create a relatively low-temperature plasma for ablation of tissue adjacent to, or in contact with, the plasma. In one embodiment, an electrosurgical probe or catheter is positioned adjacent the target site so that one or more active electrode(s) are brought into contact with, or close proximity to, a target tissue in the presence of electrically conductive fluid. High frequency voltage is then applied between the electrode terminal(s) and one or more return electrode(s) to generate a plasma adjacent to the active electrode(s), and to volumetrically remove or ablate at least a portion of the target tissue. The high frequency voltage generates electric fields around the active electrode(s) with sufficient energy to ionize the conductive fluid adjacent to the active electrode(s). Within the ionized gas or plasma, free electrons are accelerated, and electron-atoms collisions liberate more electrons, and the process cascades until the plasma contains sufficient energy to break apart the tissue molecules, causing molecular dissociation and ablation of the target tissue.

Owner:ARTHROCARE

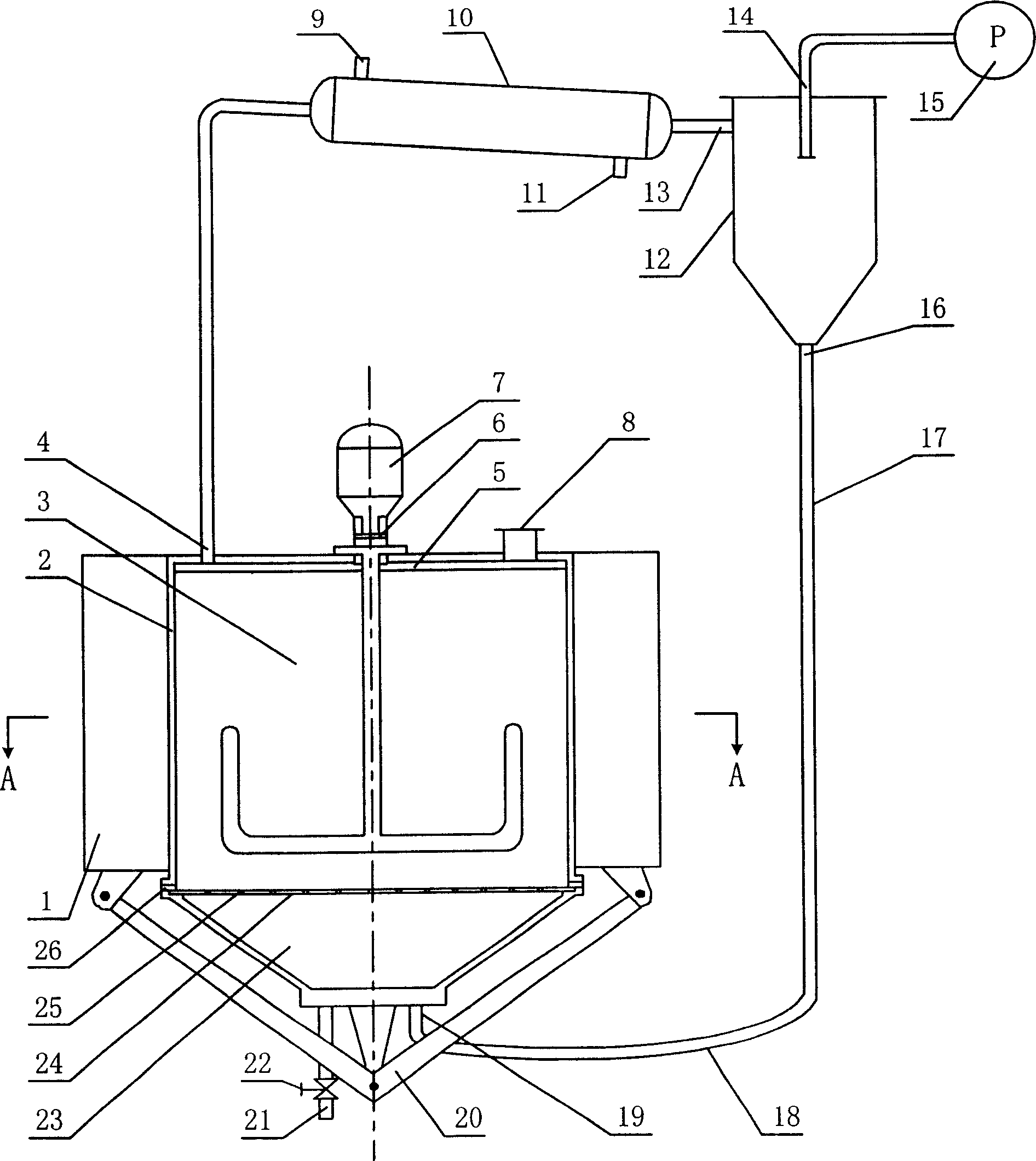

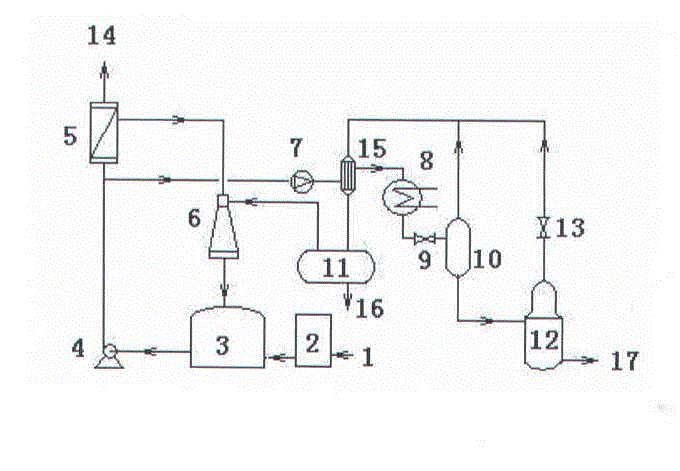

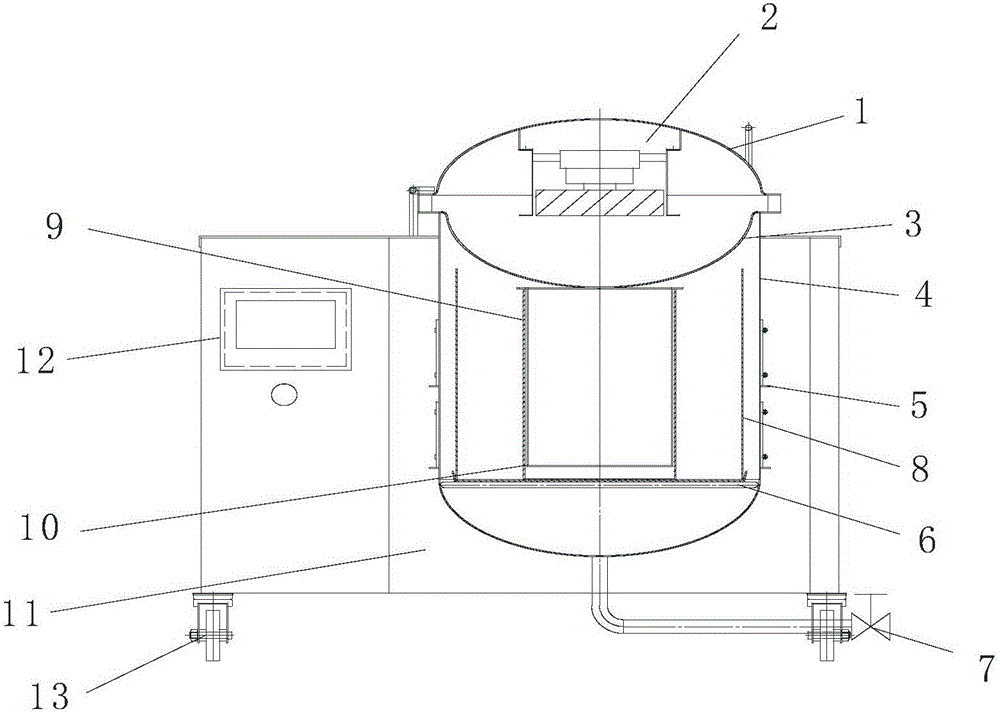

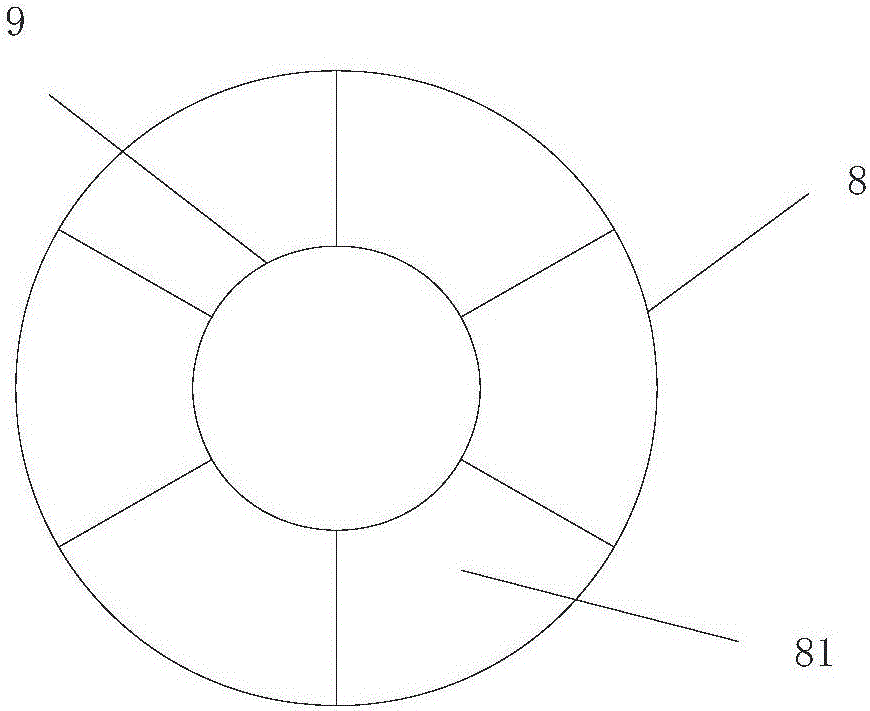

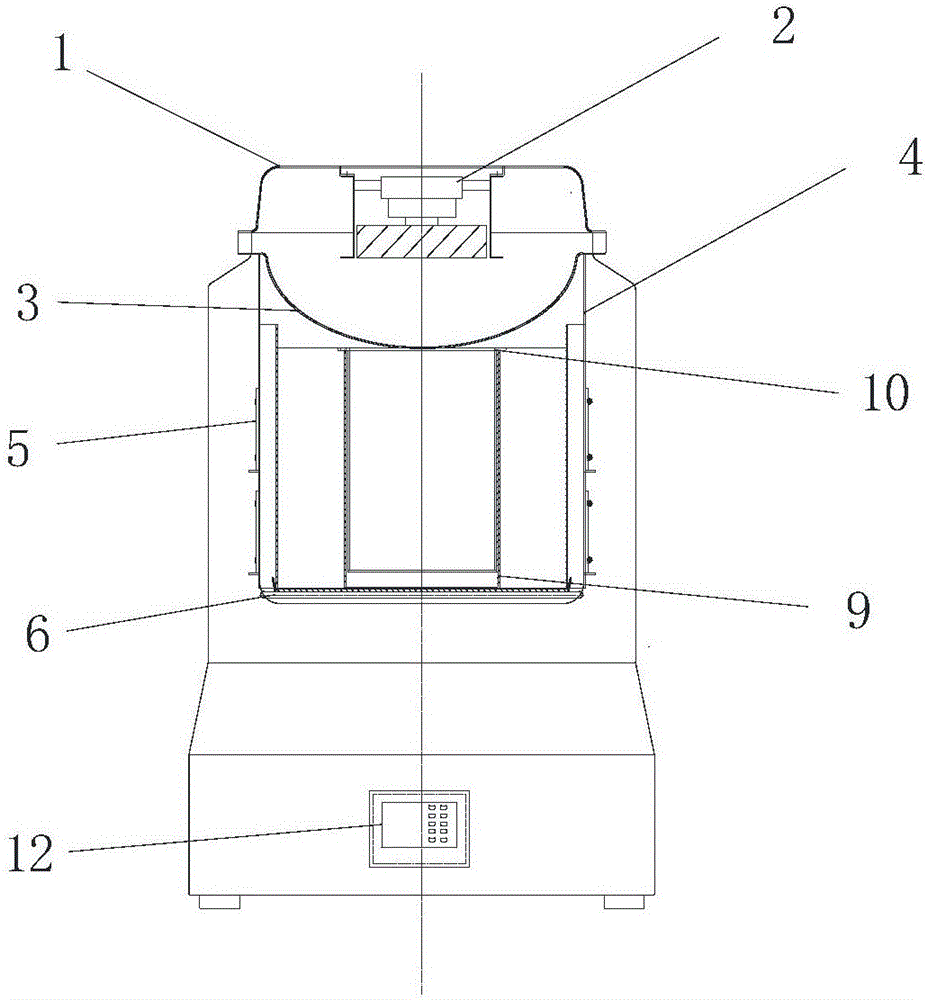

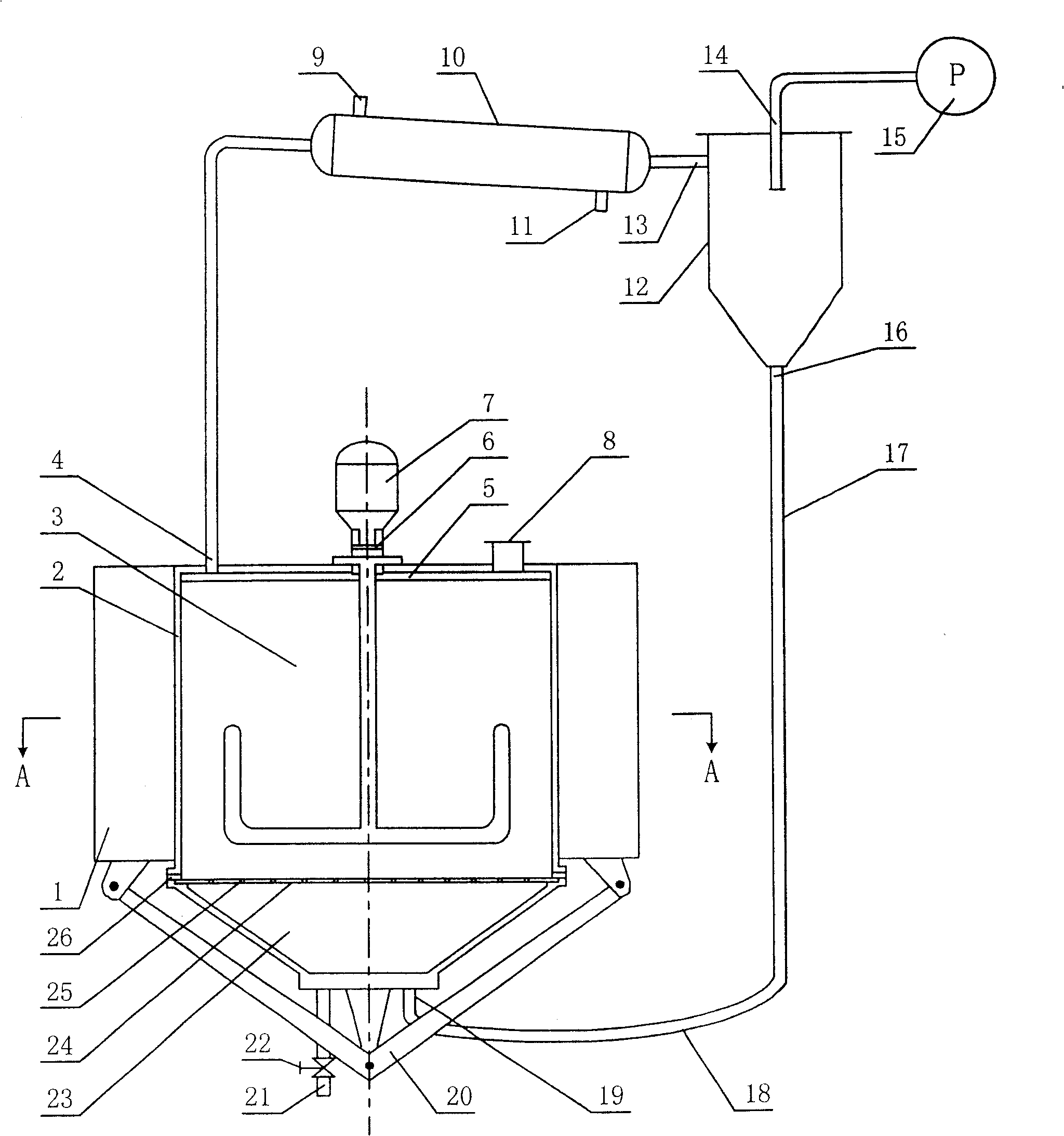

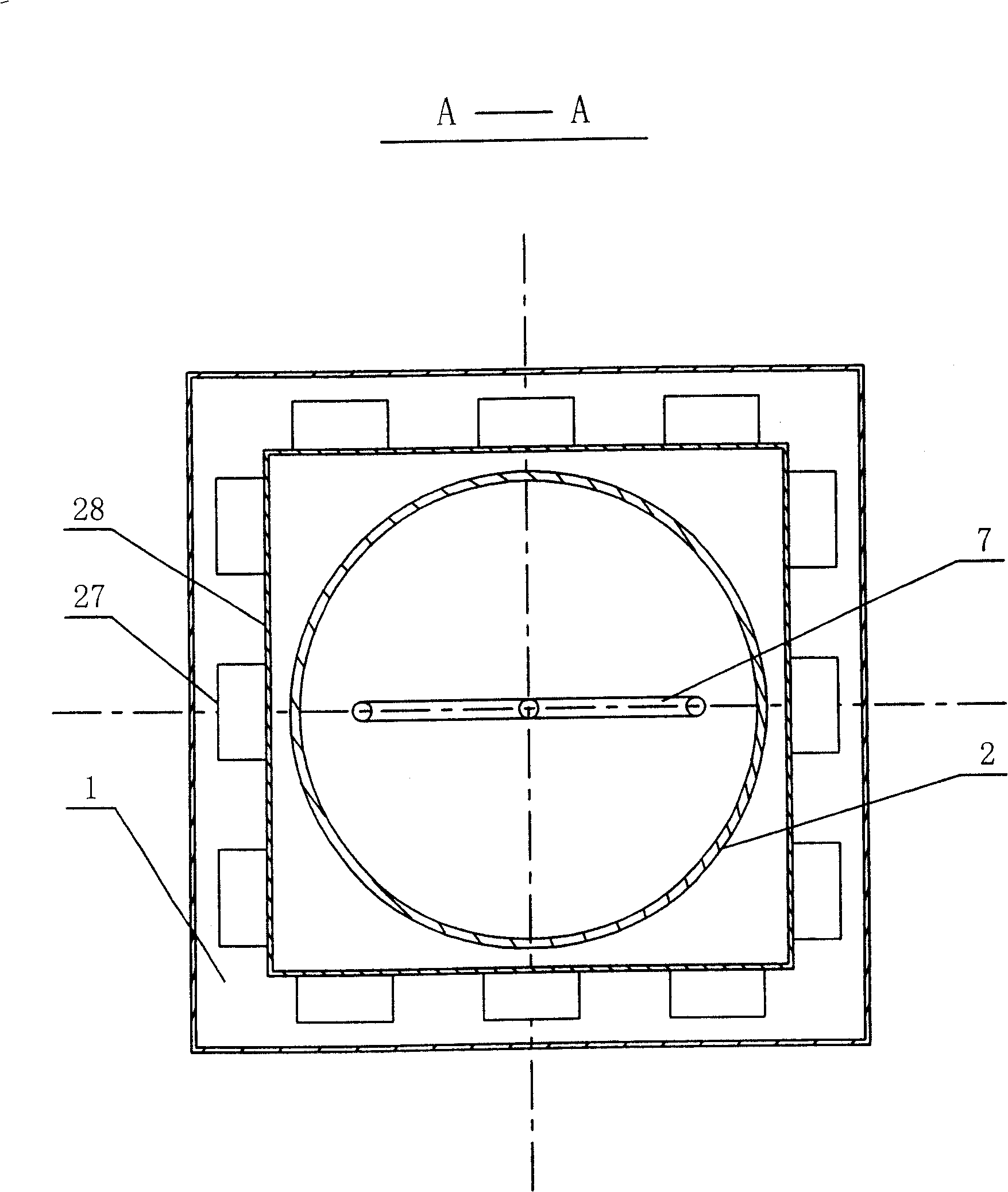

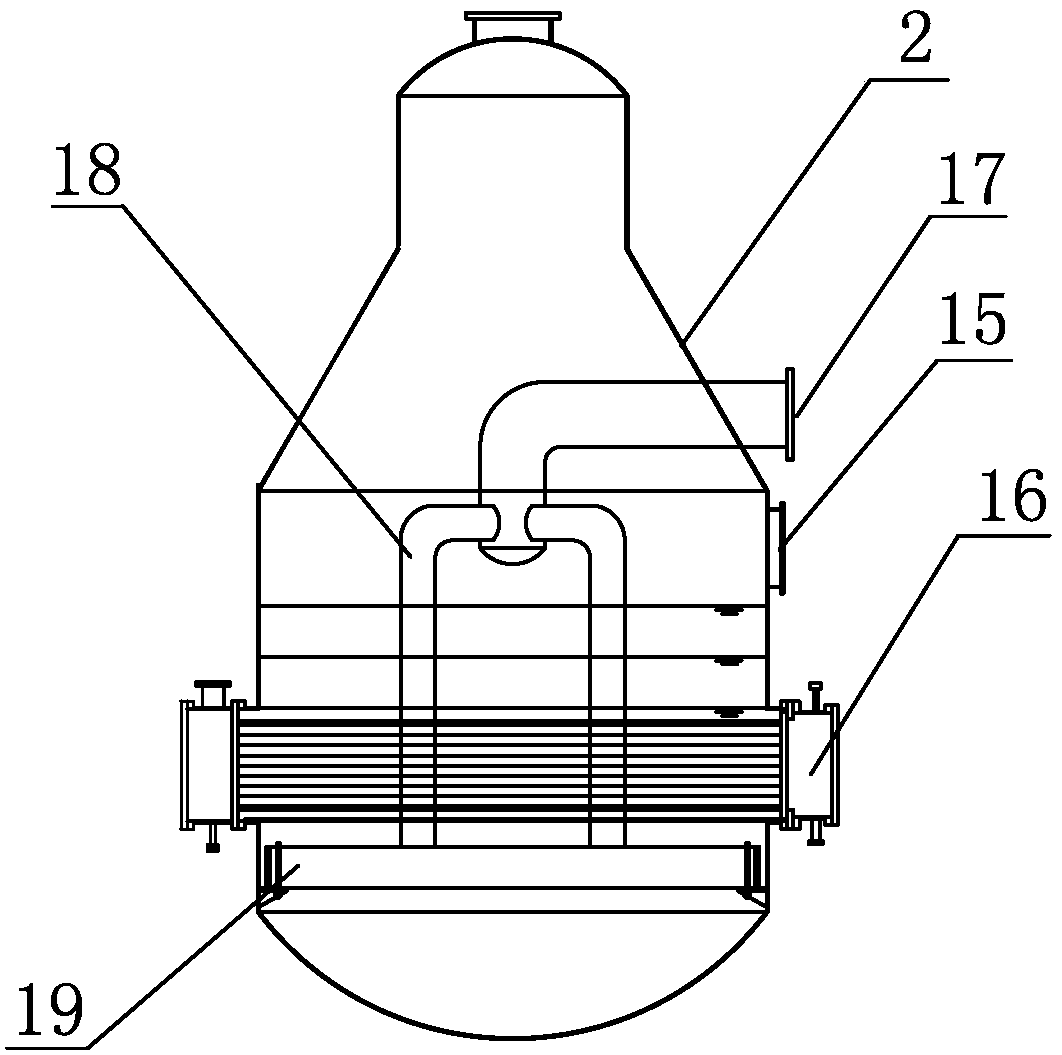

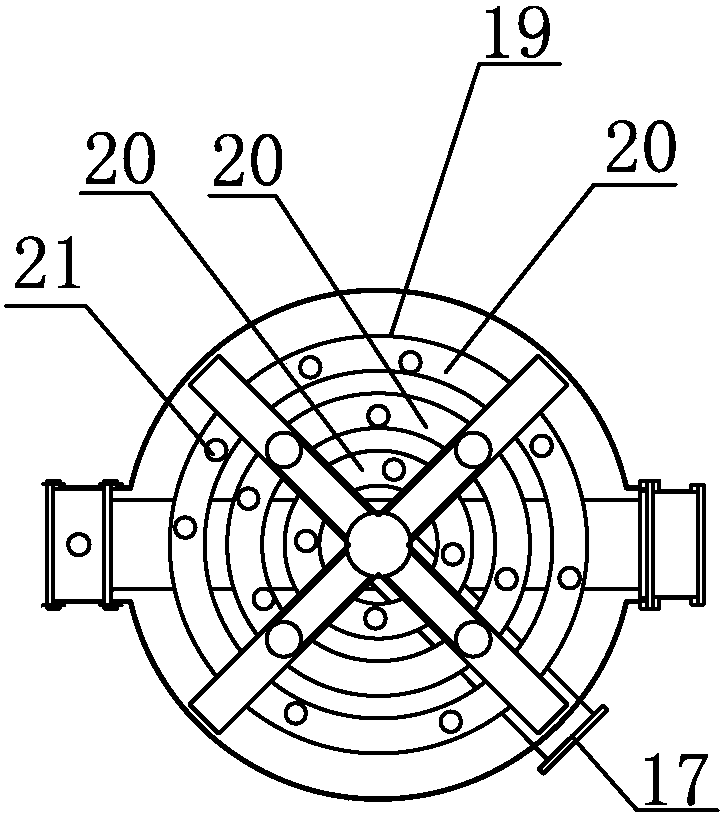

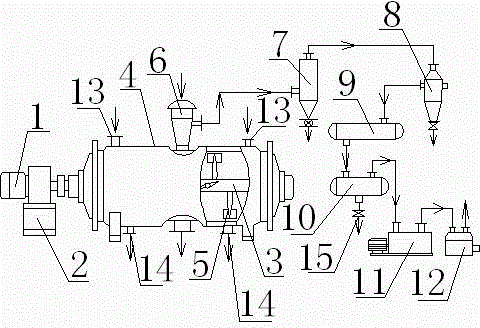

Decompressed microwave extraction device and method for extracting plant effective ingredient

InactiveCN1843552AAccelerated extraction and dissolutionReduce concentrationEnergy based chemical/physical/physico-chemical processesSolid solvent extractionMicrowaveVapor–liquid separator

The invention discloses a decompression micro-wave extraction device and method on the plant effective component, which is formed by a micro-wave oven, an extraction pot, a condenser, a liquid-gas separator, and a decompression device. Wherein, the micro-wave oven is arranged outside the extraction pot, while the micro-wave generators are uniformly arranged inside the micro-wave oven; the extraction pot is mounted with electric mixer, while its top is mounted with magnetic eraser; the upper part of extraction pot is a extraction chamber, the lower part is mounted with a solvent warehouse, and they are separated by a baffle plate with uniform solvent penetrate holes. Via decompression and micro-wave, the gas solvent is condensed into liquid solvent via the condenser and fed back into the solvent warehouse via the cycle tubes; the plant via micro-wave radiation is discharged via the discharge device at the lower part of extraction pot; since said invention uses decompression and solvent cycle devices, the process that extracting plant effective components is accelerated; said components will not thermal deteriorated via high temperature; and the extraction rate and quality are improved to apply the industrial production.

Owner:QILU UNIV OF TECH

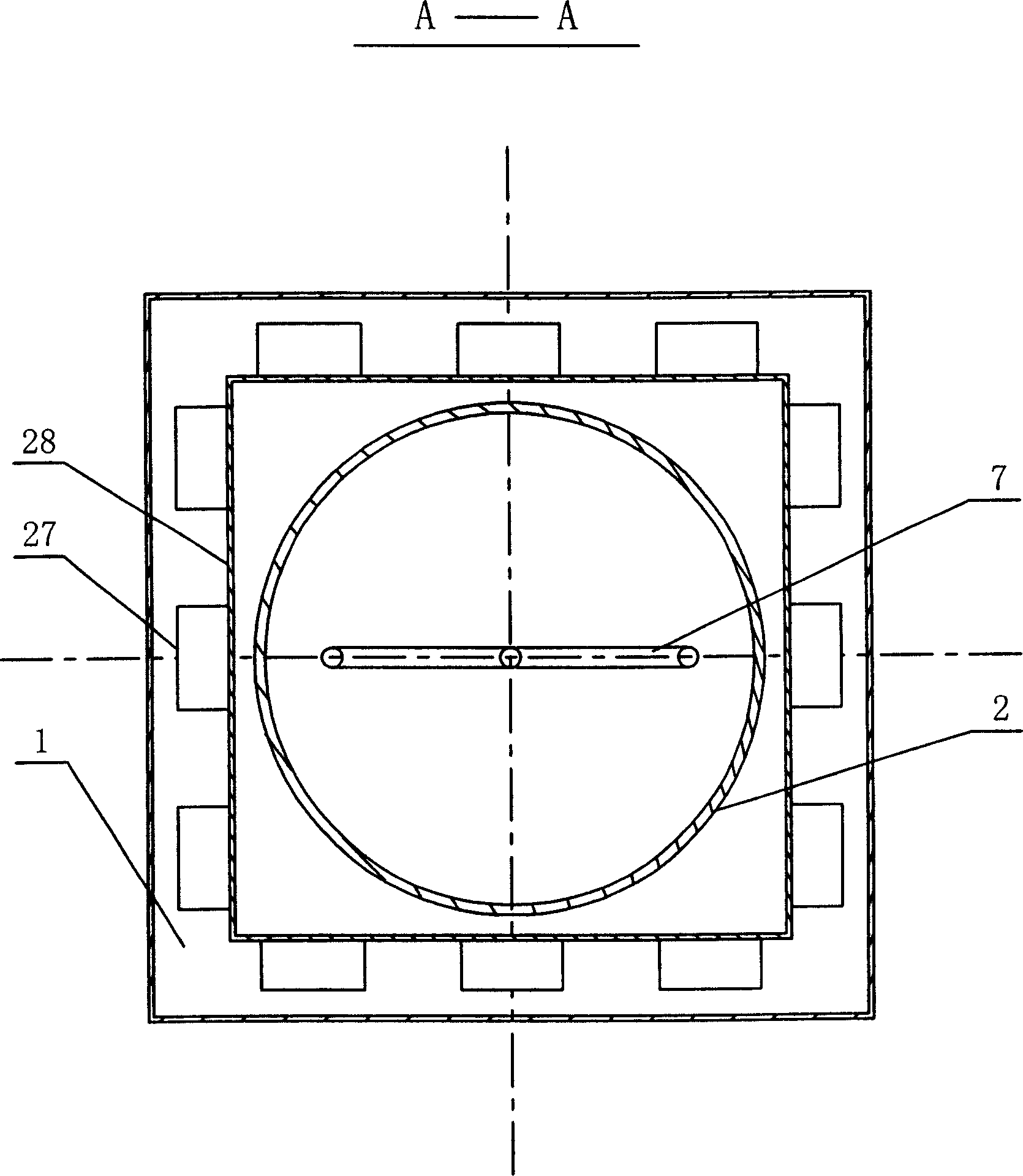

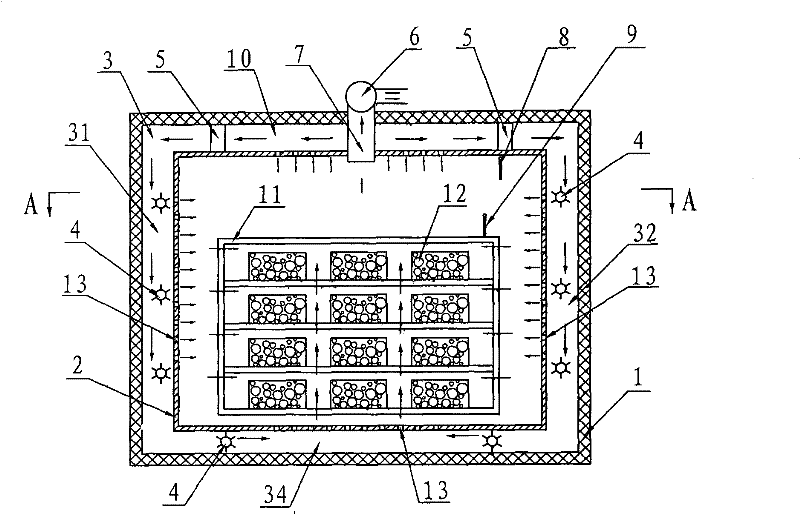

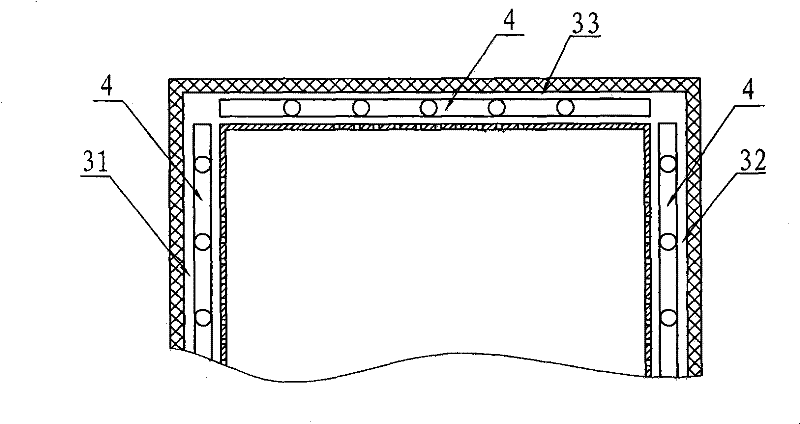

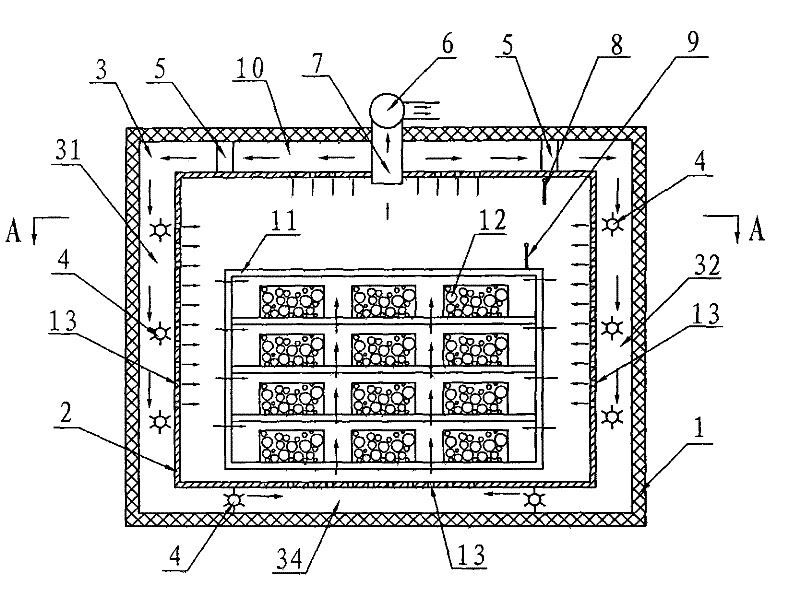

Special baking oven for silicon material

InactiveCN101749929AFully drawn outPulled out in timeDrying solid materials with heatDrying gas arrangementsCooking & bakingWater vapor

The invention relates to a special baking oven for a silicon material, comprising a thermal insulation shell, an inner container, a high temperature air cavity, a hot air duct, a heater, a circulating fan, a dehumidifier, a dehumidification pipe, a humidity sensor and a temperature sensor, wherein the high temperature air cavity is arranged on top of the inner container, the hot air duct is arranged around the inner container, the heater is arranged in the hot air duct, the circulating fan is arranged between the high temperature air cavity and the hot air duct, the dehumidifier is communicated with the inner chamber of the inner container, the humidity sensor and the temperature sensor are arranged to realize automation control of the baking oven, hot air in the baking oven can form backflow to facilitate full contact of hot air and silicon material, and the dehumidifier can discharge water vapor in the baking oven in time and form proper vacuum in the baking oven to reduce moisture vaporization temperature and improve baking speed. The invention has obvious energy-saving effect and can greatly reduce energy consumption and labor cost.

Owner:EGING PHOTOVOLTAIC TECHNOLOGY CO LTD

Method for blasting plant biomass walls with oxygen

InactiveCN102206928ADecompose thoroughlyBreak down evenlyRaw material divisionProcess engineeringOxygen

The invention discloses a method for blasting plant biomass walls with oxygen, comprising the following steps of: firstly, adding ethanol, hydrogen peroxide with concentration of 30% and water to crushed plant biomass, mixing the materials to oxidize and soak the materials, and conveying the oxidized and soaked materials to an oxygen blasting tank via a feeding port of the oxygen blasting tank; secondly, sealing the feeding port of the oxygen blasting tank, regulating the temperature of the gas in the oxygen blast tank at 80-150 DEG C and the pressure within 1-4 MPa by conveying pressure air to the oxygen blasting tank, preserving heat and keeping pressure for 20-200 seconds to soak the plant biomass into ethanol, hydrogen peroxide with concentration of 30%, steam and water; and finally, completely opening the discharge port of the oxygen blasting tank within 3 seconds to reduce the pressure in the oxygen blasting tank to the normal pressure. The invention aims to provide the method for blasting plant biomass walls with oxygen, which can be used for completely and uniformly decomposing the plant biomass and realizing industrialization production and has high production efficiency.

Owner:BEIJING ZHONGNUO DERUI IND TECH

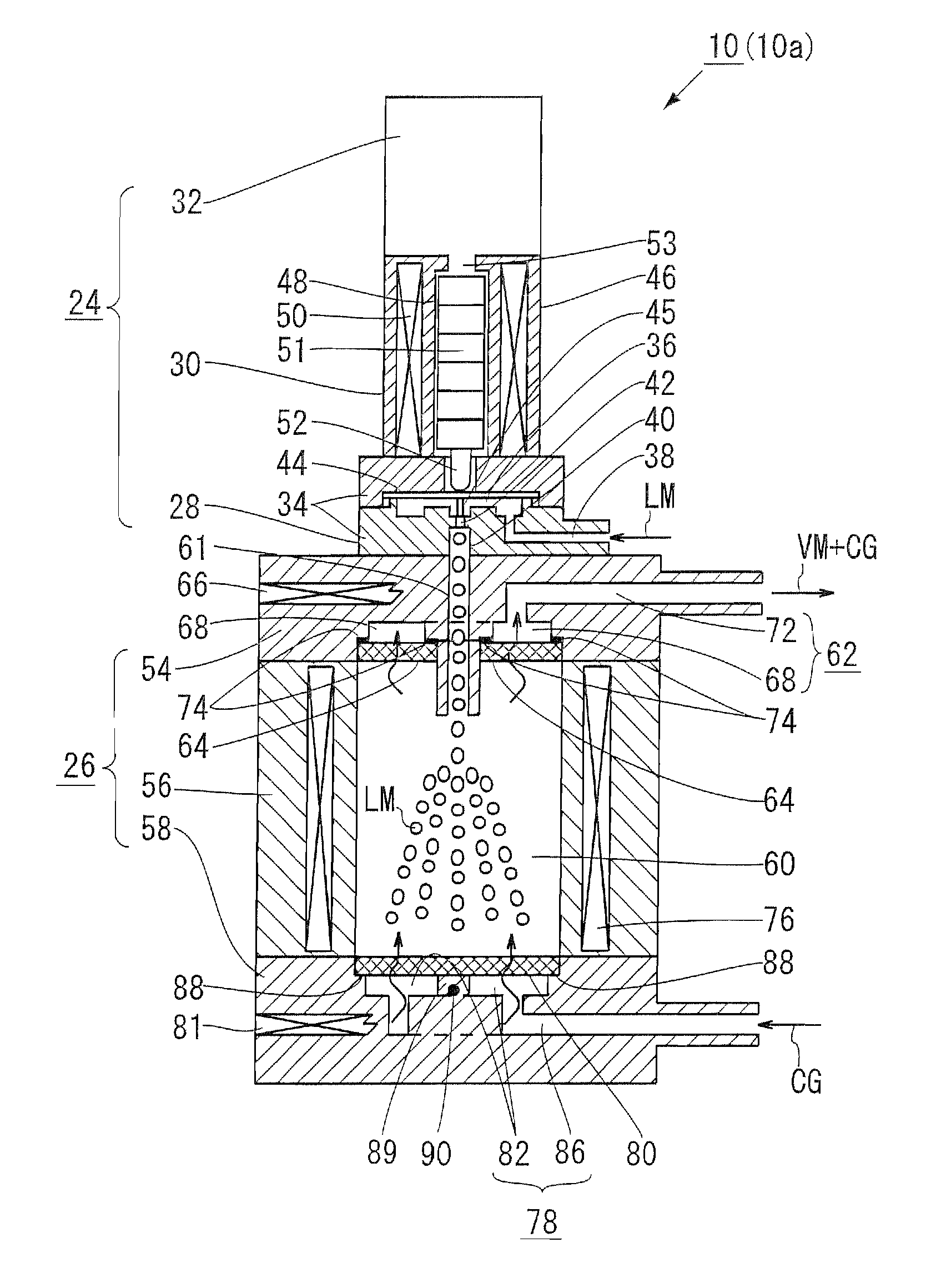

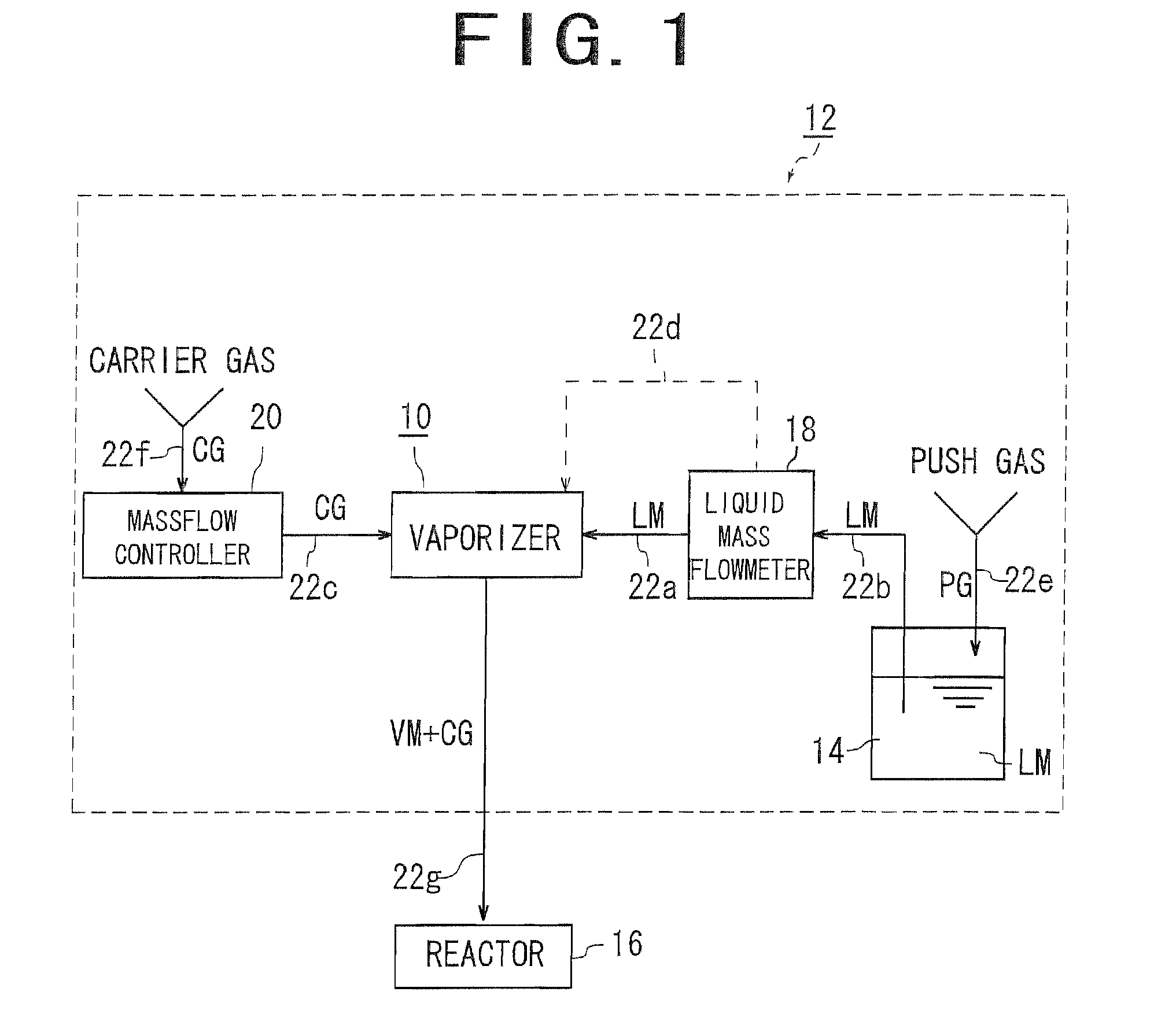

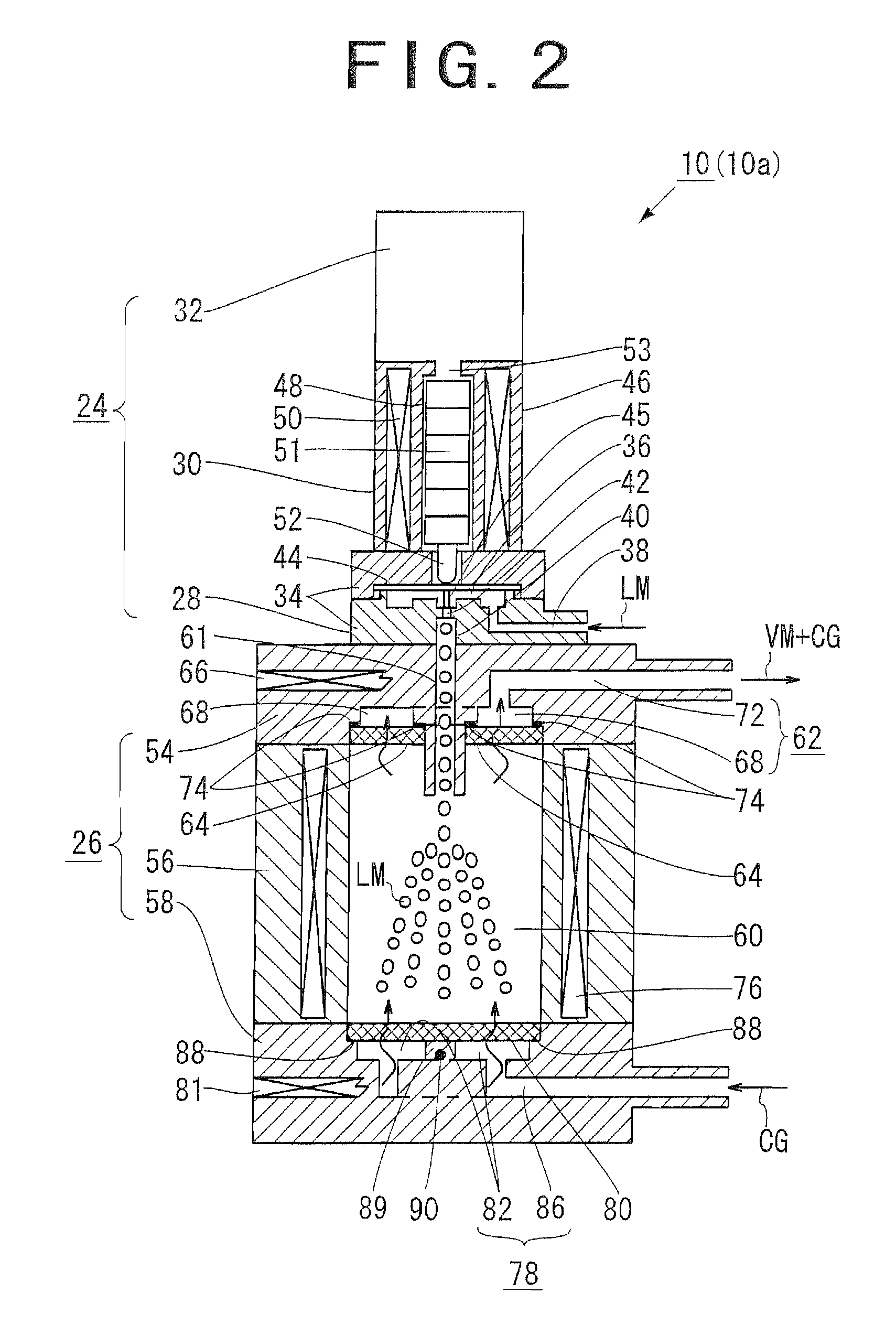

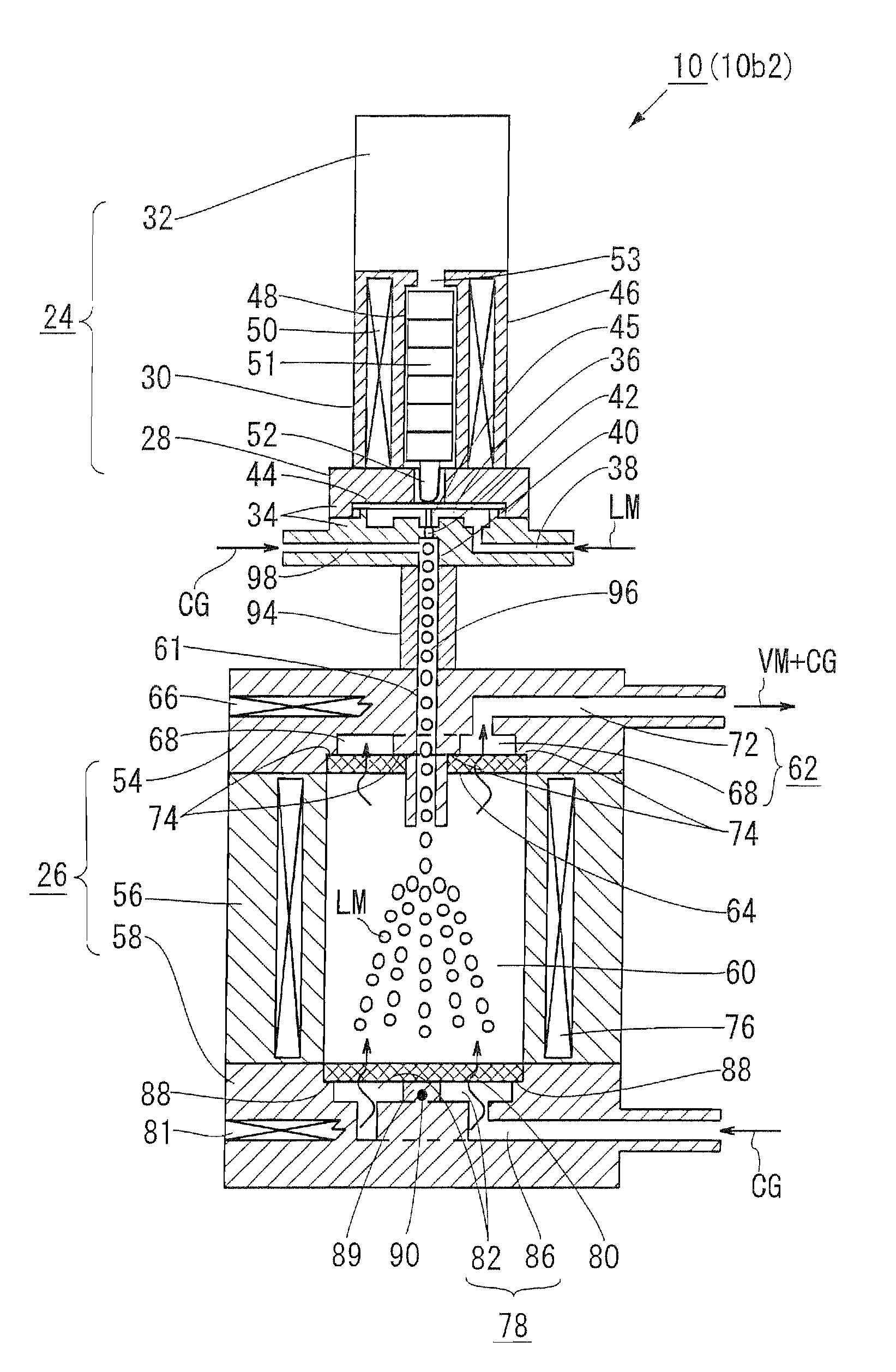

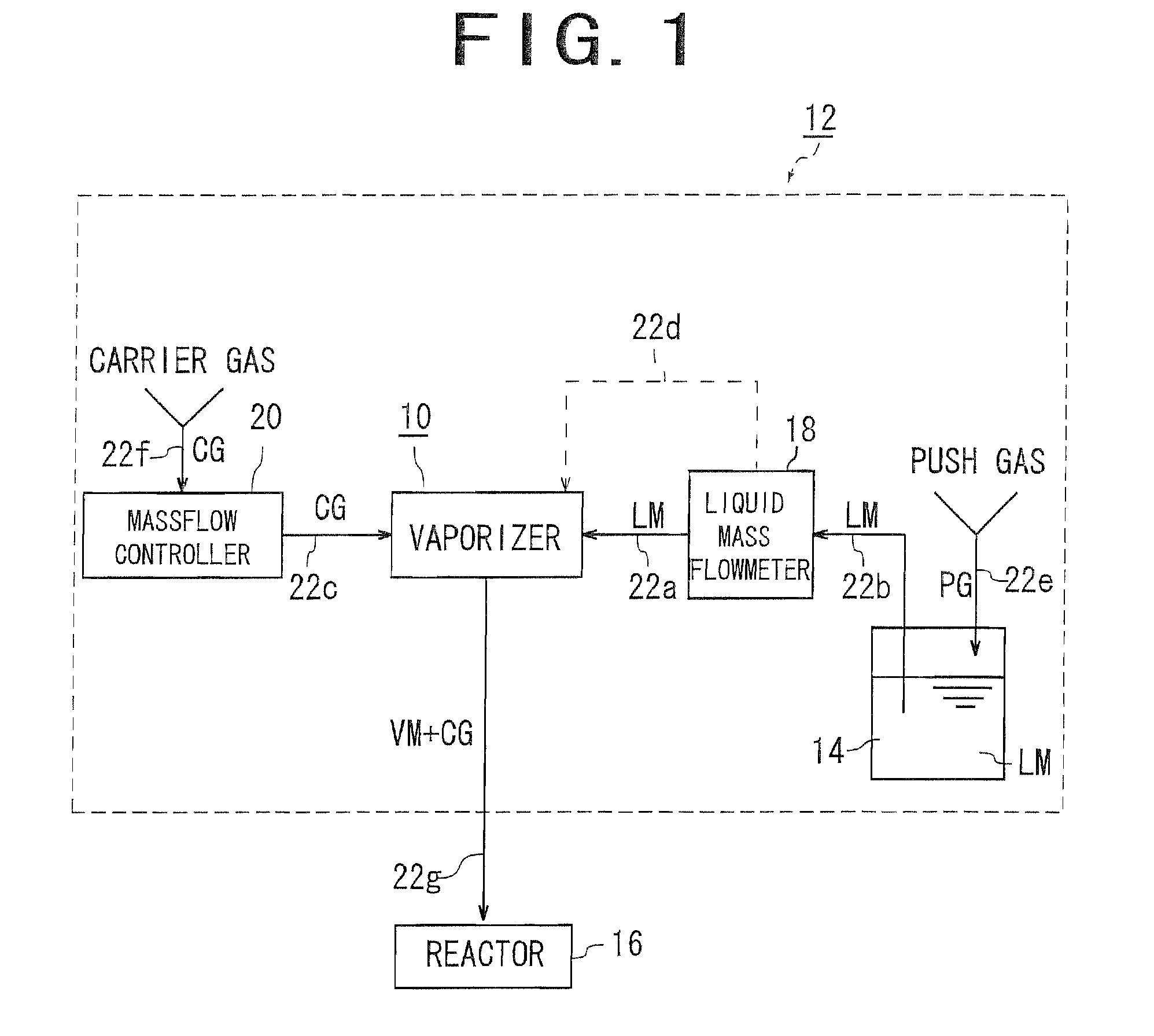

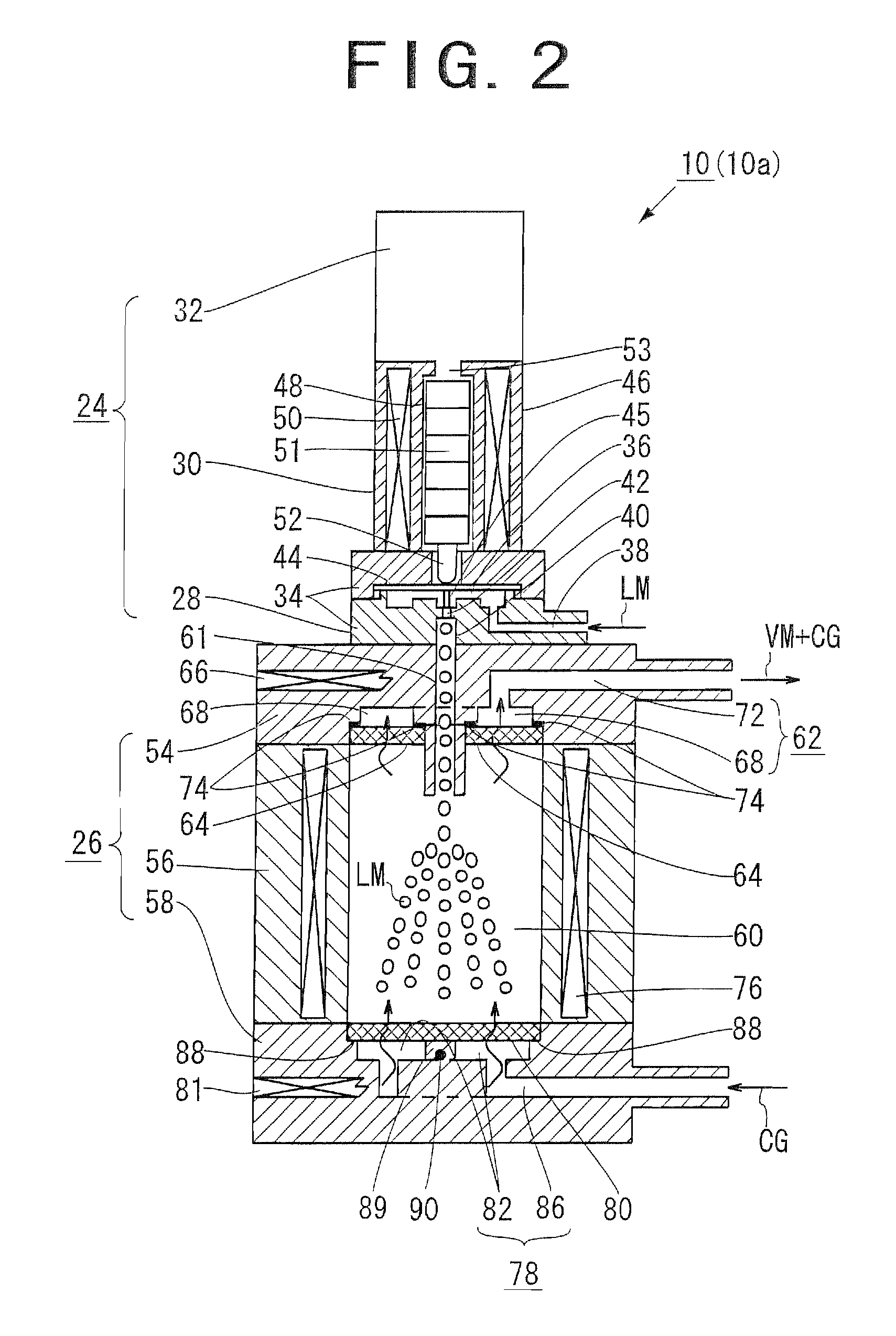

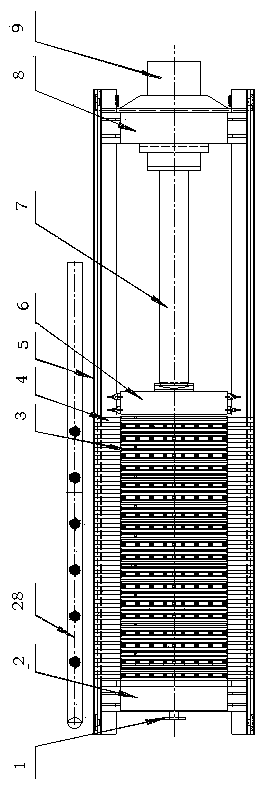

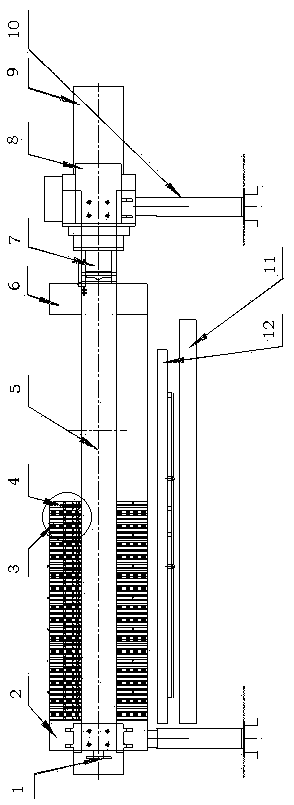

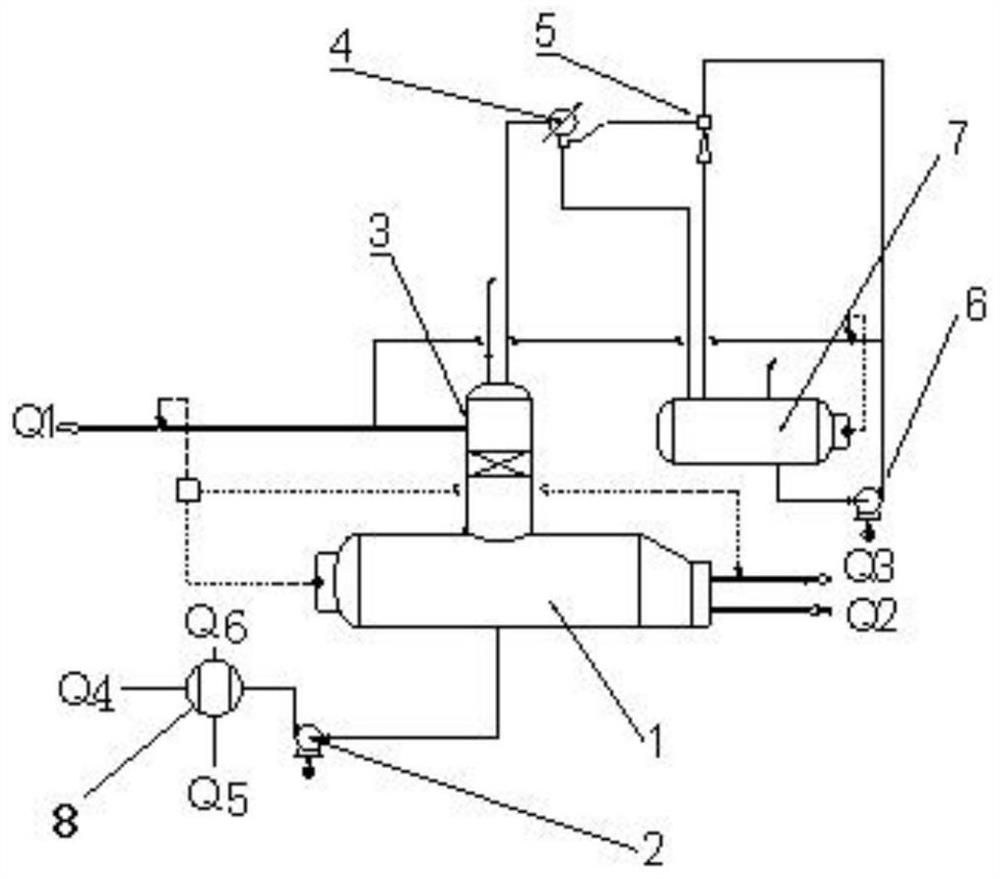

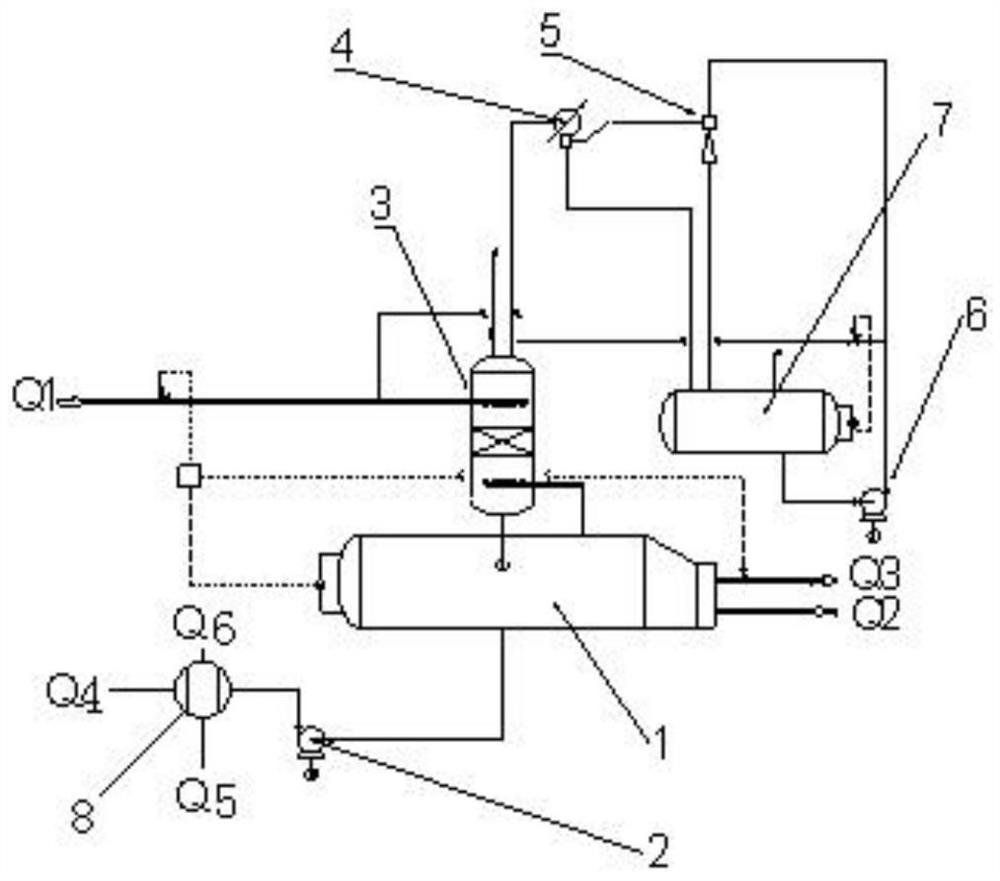

Method for vaporizing liquid material capable of vaporizing liquid material at low temperature and vaporizer using the same

ActiveUS20090065066A1Low vaporization temperatureAvoid accumulationLighting and heating apparatusUsing liquid separation agentProduct gasMaterial supply

A vaporizer is provided with a vaporizing chamber heated by heaters; a primary filter positioned in a bottom end portion of the vaporizing chamber and heated by the heater; a liquid material supply portion for dropping down a flow-controlled liquid material from upper portion of the vaporizing chamber toward the primary filter; a carrier gas guiding passage for guiding a carrier gas into the underside of the primary filter; and a material delivering passage for discharging a mixed gas including the carrier gas and a vaporized liquid material from the top of the vaporizing chamber. The liquid material dropped down onto the primary filter is partially vaporized, while the rest thereof is atomized by being subjected to bubbling effect provided by the carrier gas flowing from underneath.

Owner:LINTEC CO LTD

Highly effective liquid fuel evaporation combustion device

InactiveCN101149149AOvercoming weak vaporization abilityImprove leakageLiquid fuel evaporation burnersGaseous fuel burnerCombustion chamberEvaporation

This invention is a high efficiency liquid fuel vaporizing combustion device. It includes air chamber, vaporizing chamber and combustion chamber. There is combustion barrel is arranged between air chamber and combustion chamber. Its superior edge extends along horizontal radial direction and forms a ring shaped flange. The lower part of flange connects to air chamber barrel body, the bottom of which connects to air pipe. The radial wall of combustion barrel is arranged with air hole. The center of combustion barrel bottom has vaporizing tank, the center of which is arranged with fuel conveying pipe and nozzle. The internal wall of vaporizing tank has division plate, on which has the communicating hole communicating to the vaporizing chamber. The radial wall of vaporizing tank has fuel releasing hole. There is supporting gasket between vaporizing tank and combustion barrel bottom. Heat transferring medium is arranged inside of vaporizing chamber. This invention is adequate for equipment coordination such as boiler, kitchen range and air conditioner.

Owner:傅学正

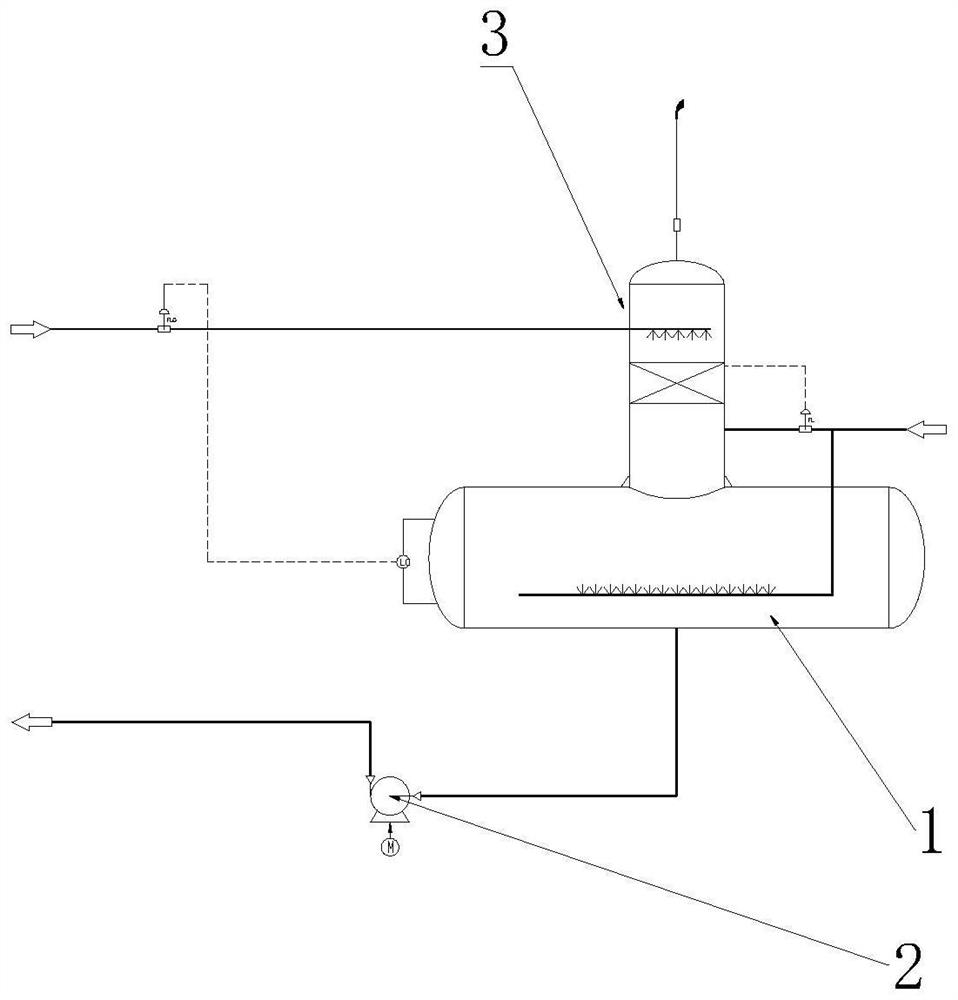

Brine-desalination method

InactiveCN102745852ALow vaporization temperatureLow costGeneral water supply conservationWater/sewage treatment bu osmosis/dialysisChemistryInjection pump

The invention aims to provide a brine-desalination method, which organically combines a distillation method and a membrane method for brine desalination, the high pressure of the strong brine of the membrane method is utilized to drive the negative pressure of a Venturi injection pump for lowering the subsequent evaporating pressure, so the evaporating process is carried out under the atmospheric pressure, the evaporating temperature can be effectively reduced, the evaporating energy consumption is saved, the concentration of the evaporating raffinate is high, and moreover, the heat of the evaporating raffinate is utilized for the subsequent crystallization; and the latent heat of the evaporated steam is effectively utilized to heat the brine to be evaporated, the heat energy is further recovered, and the energy consumption is lowered.

Owner:XINJIANG TECHN INST OF PHYSICS & CHEM CHINESE ACAD OF SCI

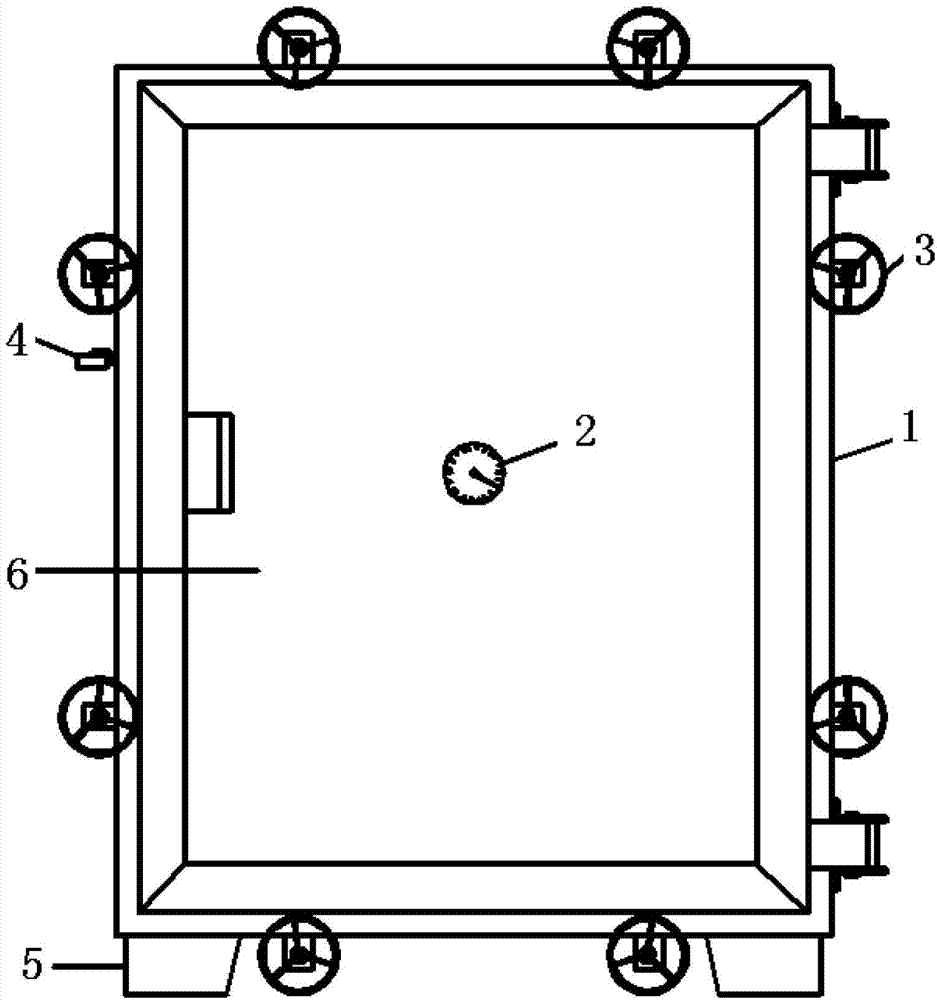

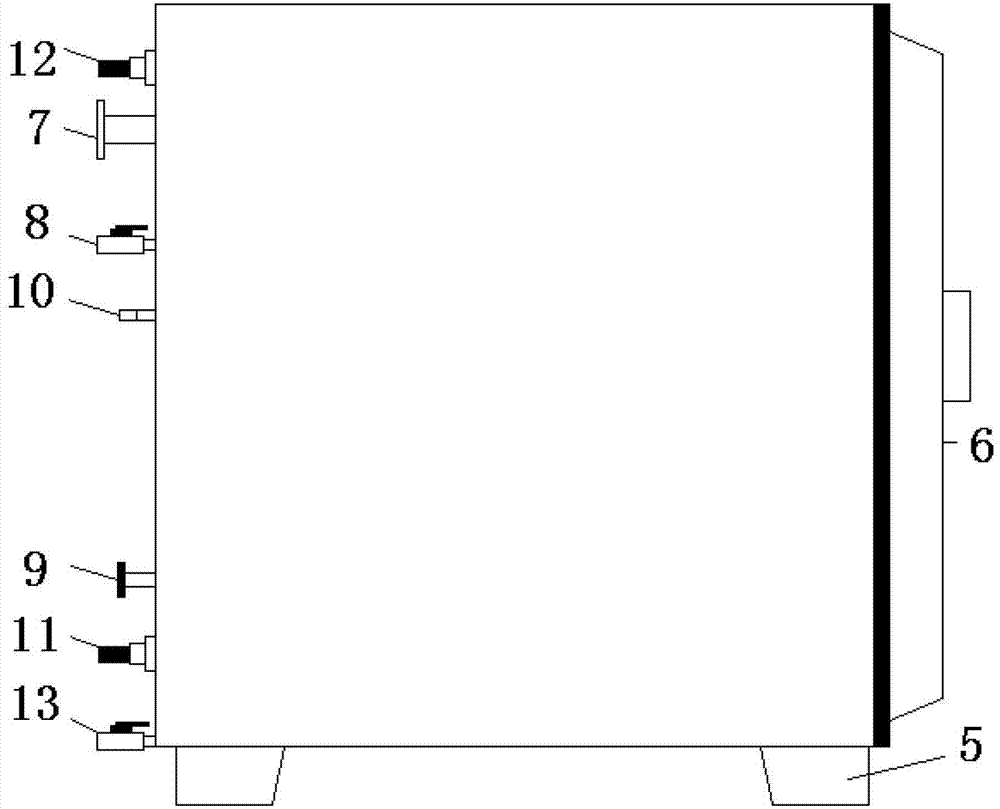

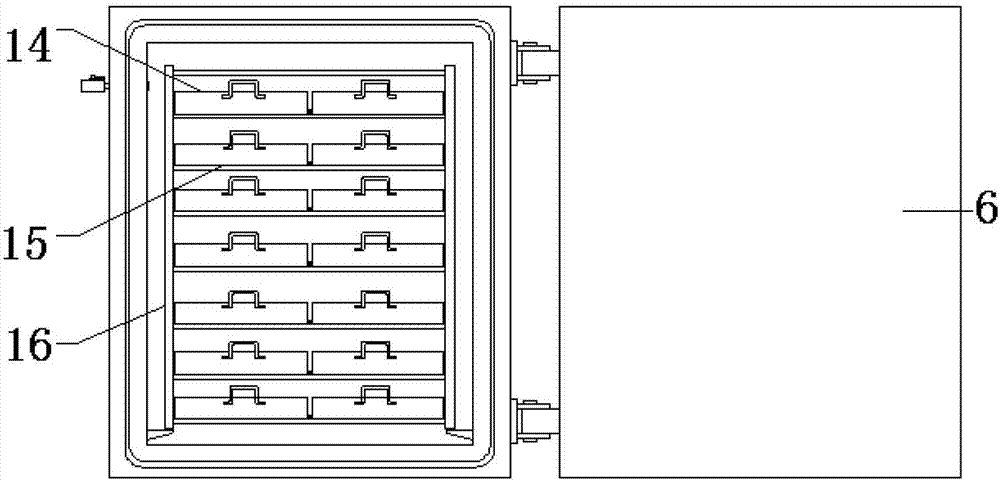

Drying device and drying method for high-purity silicon materials

ActiveCN102818439AEvenly heatedSimple structureDrying using combination processesDrying chambers/containersEngineeringVacuum pump

The invention discloses a drying device for high-purity silicon materials. The drying device comprises a case. The case is a sealed case with a sealing door, multiple layers of drying plate supports are arranged in an inner cavity of the case, toothed rails are arranged on each layer of drying plate supports, and drying plates are disposed on the toothed rails; two vacuum breaking ports are respectively arranged on side walls of the case; the case is communicated with a vacuumizing device via a vacuumizing port on a side wall, is communicated with a vacuum gauge via a vacuum verifying hole on the side wall and is communicated with a medium circulating heating device via a heat-conduction medium inlet and a heat-conduction medium outlet on the side wall simultaneously; and the vacuumizing device and the medium circulating heating device are respectively connected with a control device via signals. The invention further discloses a drying method for the high-purity silicon materials. The drying method includes placing the to-be-dried high-purity silicon materials in the sealed case; vacuumizing the case by a vacuum pump; heating to dry the high-purity silicon materials; detecting a drying effect in real time; and heating the high-purity silicon materials until technical requirements are met. The drying device and the drying method have the advantages of simple structure and high drying efficiency.

Owner:LONGI GREEN ENERGY TECH CO LTD

Method for vaporizing liquid material capable of vaporizing liquid material at low temperature and vaporizer using the same

ActiveUS7975993B2Low vaporization temperatureAvoid accumulationLighting and heating apparatusUsing liquid separation agentEngineeringMaterial supply

A vaporizer is provided with a vaporizing chamber heated by heaters; a primary filter positioned in a bottom end portion of the vaporizing chamber and heated by the heater; a liquid material supply portion for dropping down a flow-controlled liquid material from upper portion of the vaporizing chamber toward the primary filter; a carrier gas guiding passage for guiding a carrier gas into the underside of the primary filter; and a material delivering passage for discharging a mixed gas including the carrier gas and a vaporized liquid material from the top of the vaporizing chamber. The liquid material dropped down onto the primary filter is partially vaporized, while the rest thereof is atomized by being subjected to bubbling effect provided by the carrier gas flowing from underneath.

Owner:LINTEC CO LTD

Preparation method of breaded shrimps

The invention provides a preparation method of breaded shrimps. The preparation method comprises the following steps: uniformly wrapping the surfaces of shrimp meat with a layer of wrapping paste and treating the shrimp meat wrapped with breadcrumbs by adopting a low-temperature and low-pressure frying technology; preparing the wrapping paste: adding 1.2 weight times of water into the wrapping paste powder, wherein the temperature of the water is 3 to 5 DEG C, uniformly stirring to obtain dilute wrapping paste, wherein the wrapping paste powder is prepared from the following main raw materials in parts by weight: 20 to 30 parts of cassava starch, 20 to 30 parts of gluten powder, 2 to 4 parts of edible salt, 5 to 10 parts of spice, 1 to 5 parts of white granulated sugar, 2 to 6 parts of acetylated distarch phosphate, and 1 to 5 parts of a leavening agent; the low-temperature and low-pressure frying technology is that the pressure is 2 to 5 kPa, the temperature is 60 to 80 DEG C and the frying time is 2.5 to 3 minutes. According to the preparation method provided by the invention, the oil absorption amount of the fried breaded shrimps can be reduced, the quality of a product is improved, and the shelf life of the product is prolonged.

Owner:福清朝辉水产食品有限公司

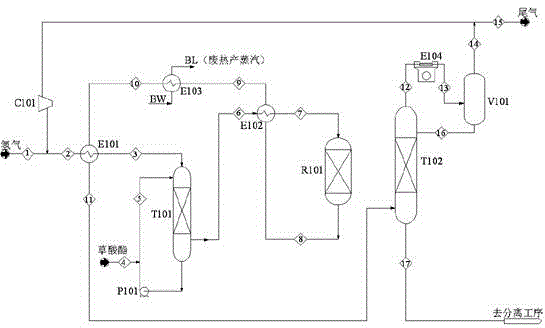

Optimized reaction technology producing ethylene-glycol by adding hydrogen in oxalate

InactiveCN104355966AGuaranteed purityReduce energy consumptionOrganic compound preparationHydroxy compound separation/purificationOxalateHydrogen

The invention belongs to the field of chemical engineering, and relates to a production technology for ethylene-glycol, in particular to an optimized reaction technology producing ethylene-glycol by adding hydrogen in oxalate. The technology comprises the following steps: adding a raw material oxalate in a vaporization tower directly first; circulating the oxalate in the tower; enabling the oxalate and heated circulating gas in the tower to conduct continuous gas-liquid contact; gradually increasing temperature to a vaporization temperature; taking the oxalate after vaporization and the circulating gas as reaction gas for preheating; pumping the oxalate and the circulating gas in a reactor; heating reaction gas by the product gas after reaction; generating vapor as a byproduct by surplus heat after temperature reduction; reducing the temperature to the temperature required by the inlet of a circulating compressor through air cooling or water cooling. Through the adoption of the technology, equipment investment can be reduced effectively; energy consumption and cost are reduced.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

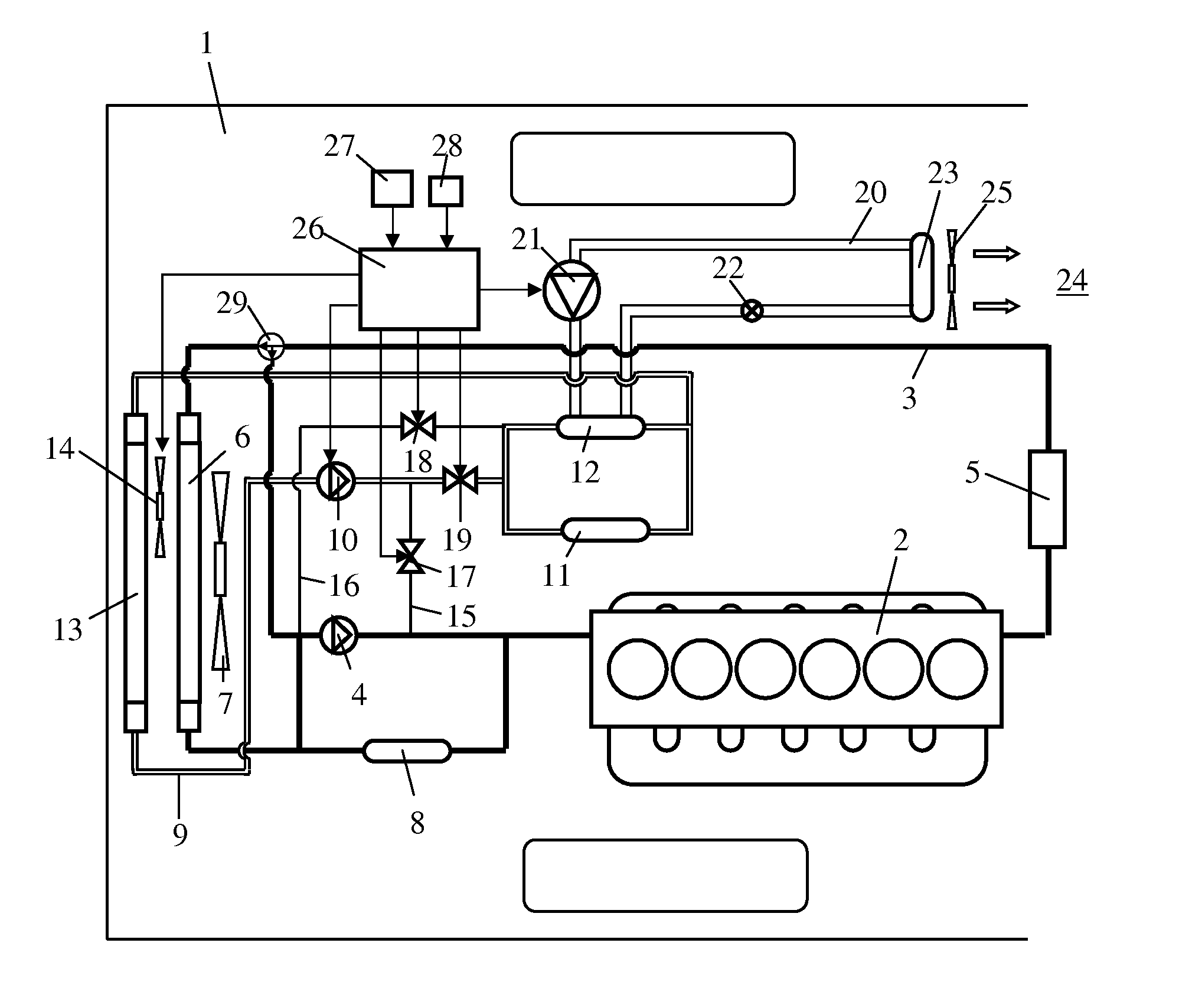

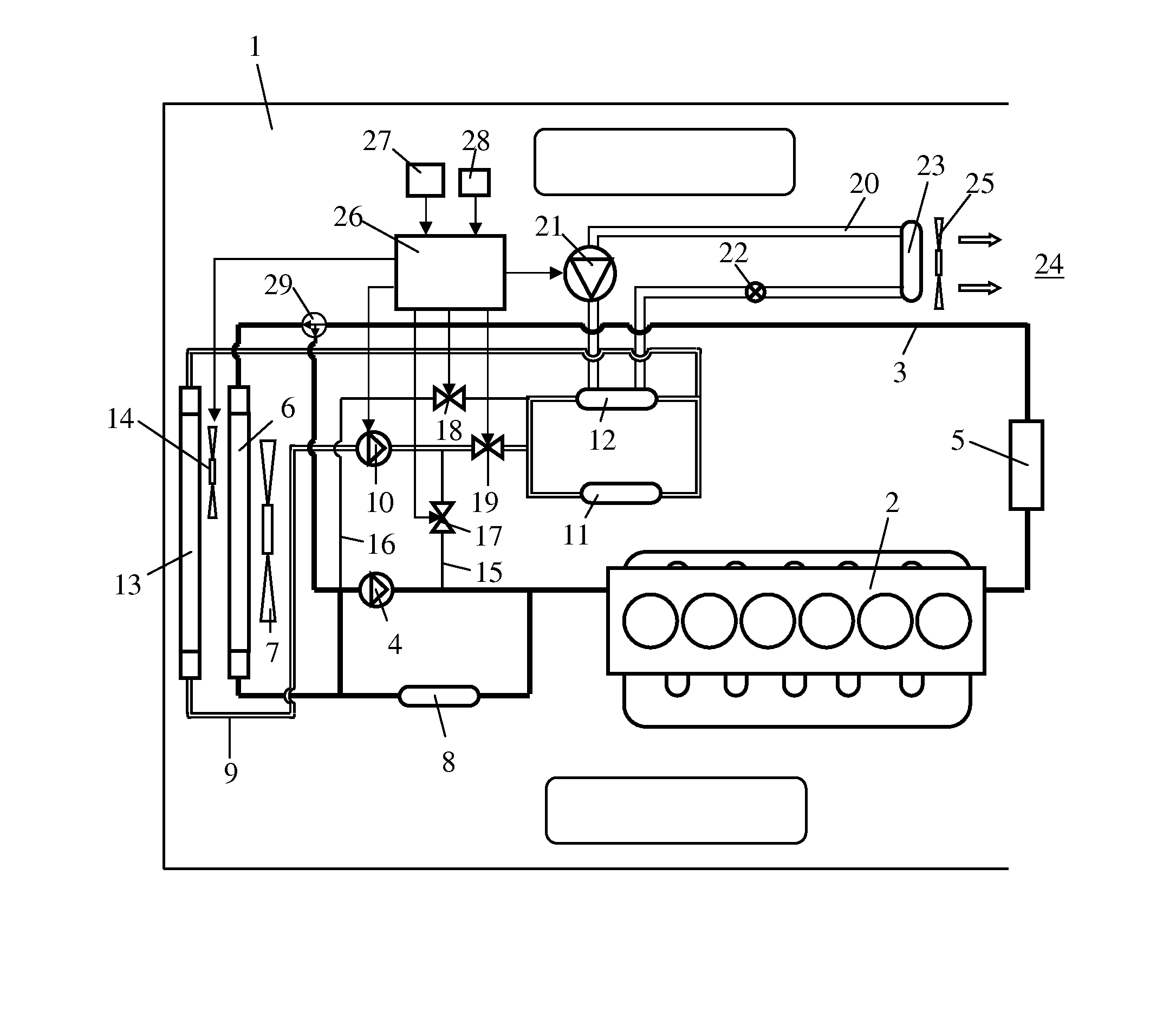

Radiator arrangement in a vehicle powered by a combustion engine

InactiveUS20130255296A1Easy transferImprove cooling effectAir-treating devicesVehicle heating/cooling devicesThermal energyCombustion

A radiator arrangement in a vehicle (1) powered by a combustion engine (2). The arrangement includes an AC system (20) with a circulating refrigerant which gives off heat in a condenser (12) and absorbs heat in an evaporator (23) and the evaporator is in contact with air close to a cab space (24) in the vehicle (1). A line circuit in which circulating coolant comes into heat-transferring contact with the engine (2). The condenser (12) is in heat-transferring contact with coolant which circulates through the line circuit. An activator for the AC system (20) causes coolant to be circulated through the line circuit when the engine (2) is not in operation. When the engine (2) is cold, coolant in the line circuit delivers thermal energy it acquires in the condenser (12).

Owner:SCANIA CV AB

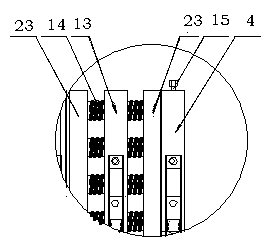

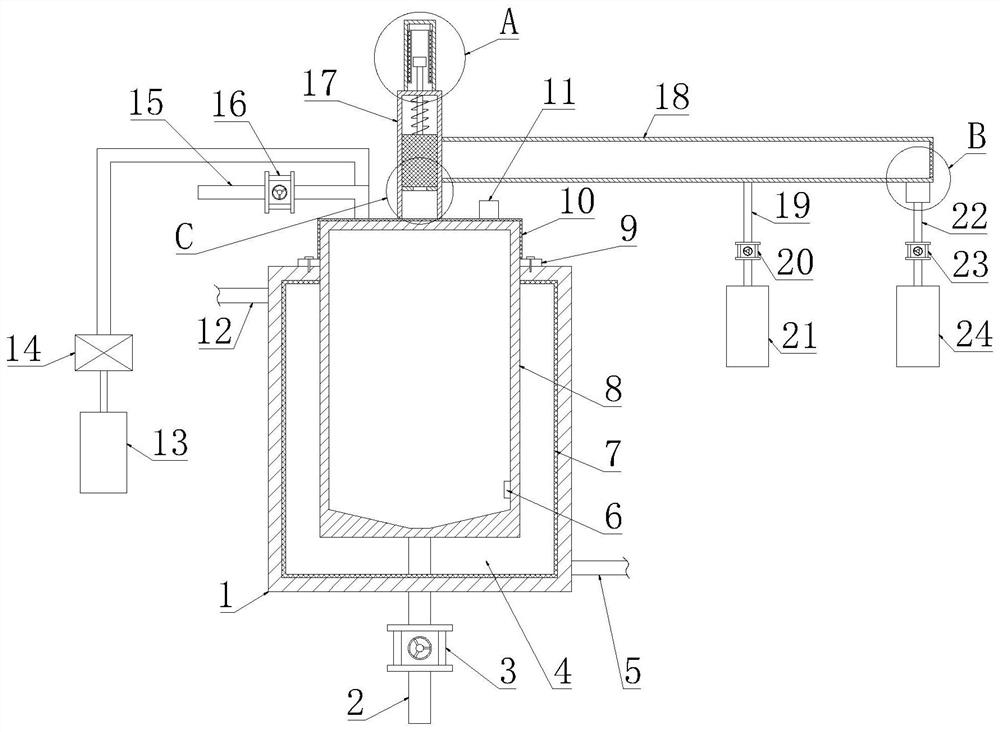

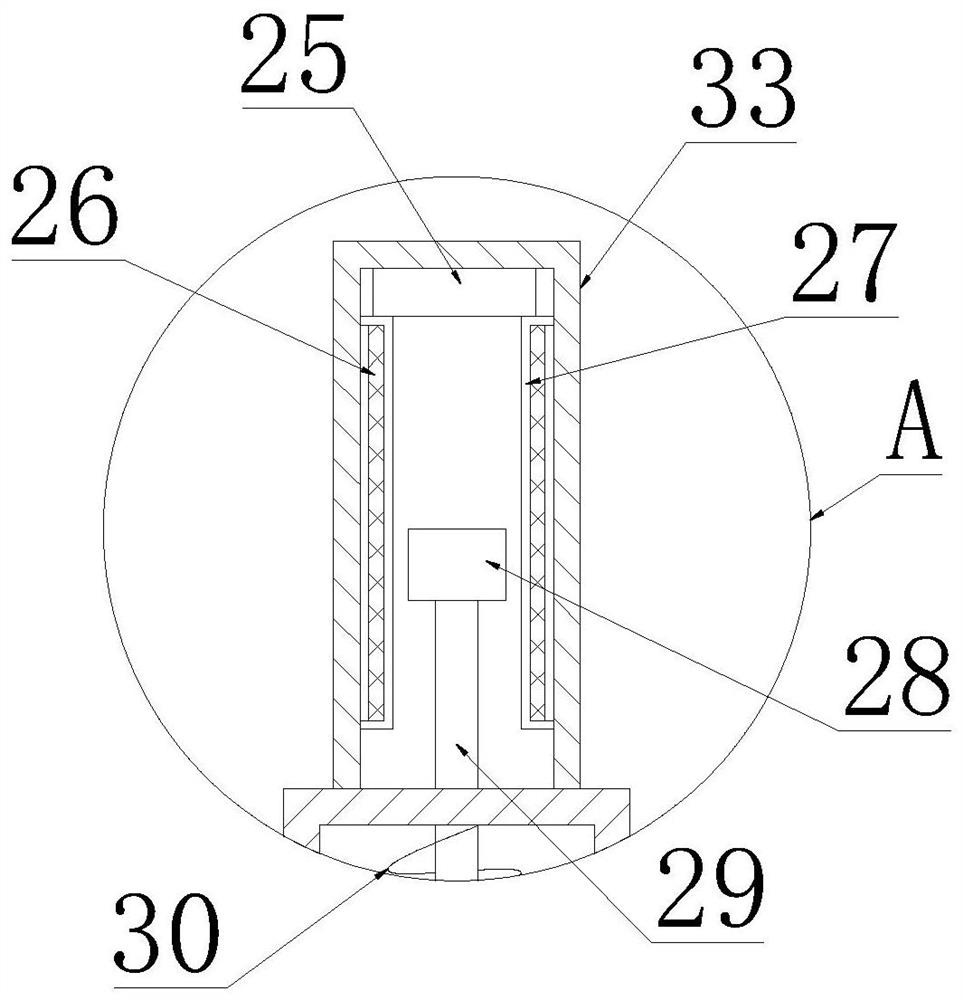

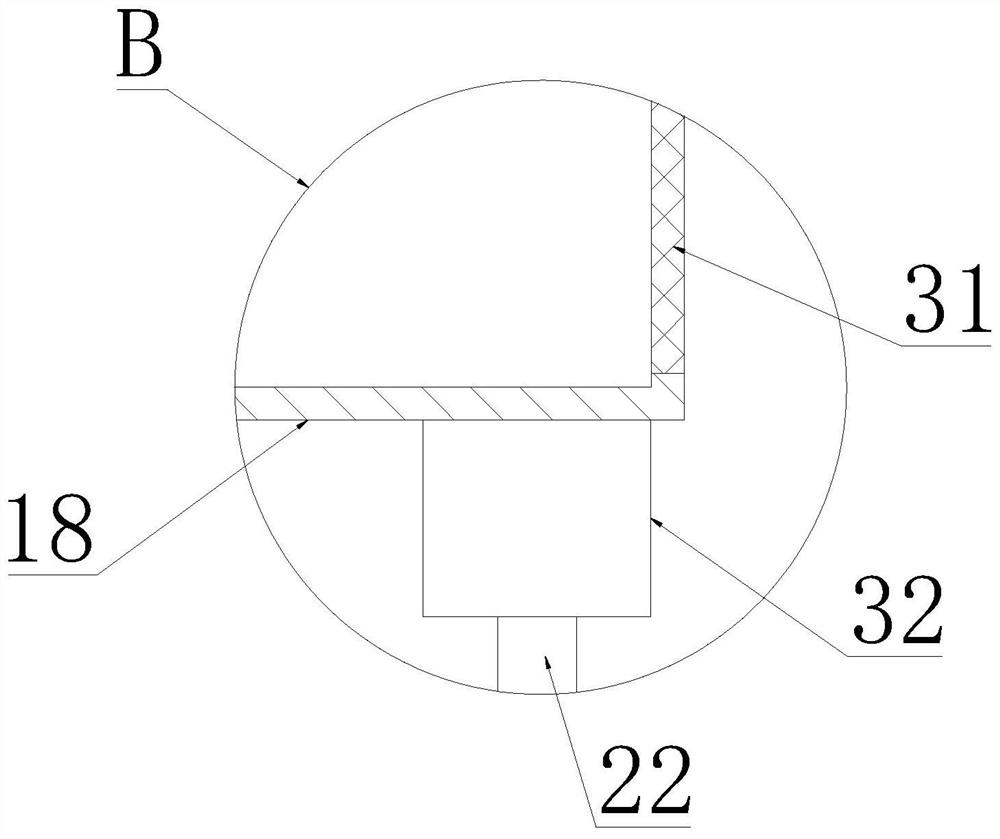

Plant essence extracting machine and extracting process

InactiveCN105999762APromote precipitationPrevent spoilageSolid solvent extractionPulp and paper industryNutrient

The invention belongs to the field of component extracting devices, and particularly relates to a plant essence extracting machine and an extracting process. The plant essence extracting machine comprises a cylinder. A heating device is arranged on the surface of the cylinder. The plant essence extracting machine is characterized in that a material barrel is arranged in the cylinder and internally provided with an extraction cylinder, a cover body for sealing the upper end of the cylinder is hinged to the cylinder and comprises an upper cover, an air inlet is formed in the upper cover, an air blowing device is arranged at the position, located at the air inlet, of the lower surface of the upper cover, and the cover body further comprises a lower cover in a spherical or conical surface shape. By designing the plant essence extracting machine, various components in raw materials are effectively extracted, nutrient components in the raw materials are protected, and the nutrient components and concentration of an obtained plant essence extraction solution are increased.

Owner:CHANGZHOU WANJI DRYING ENG

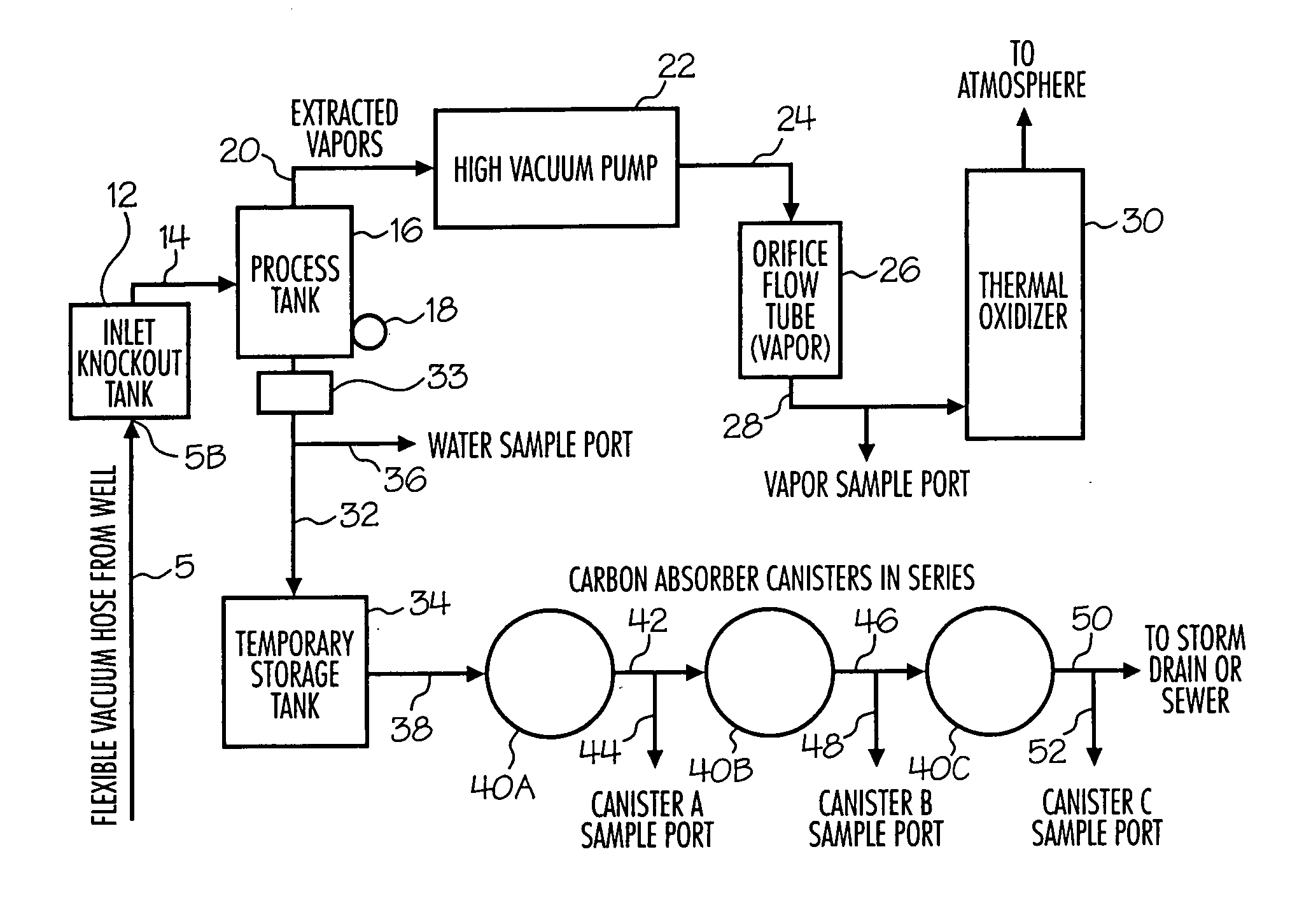

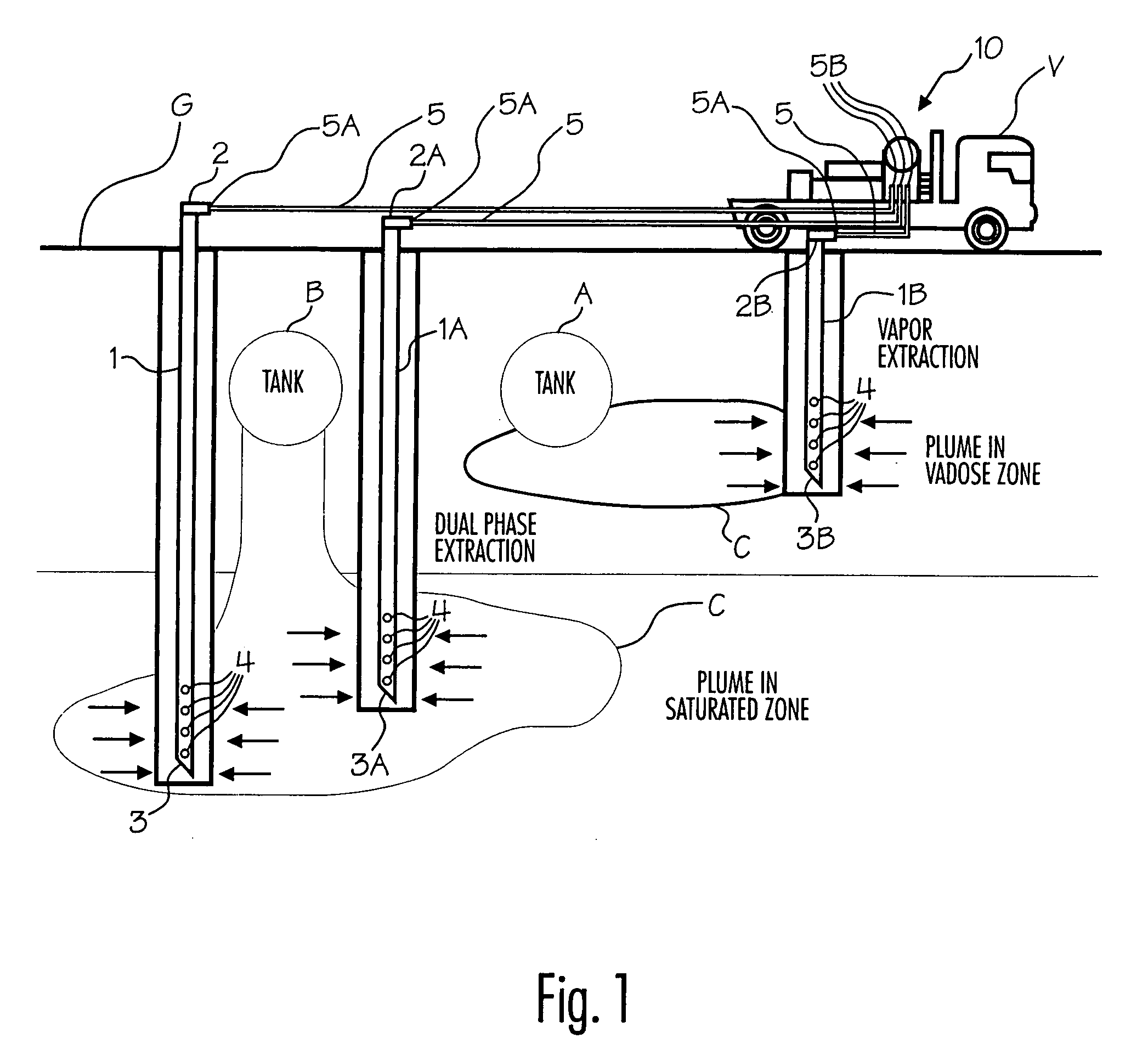

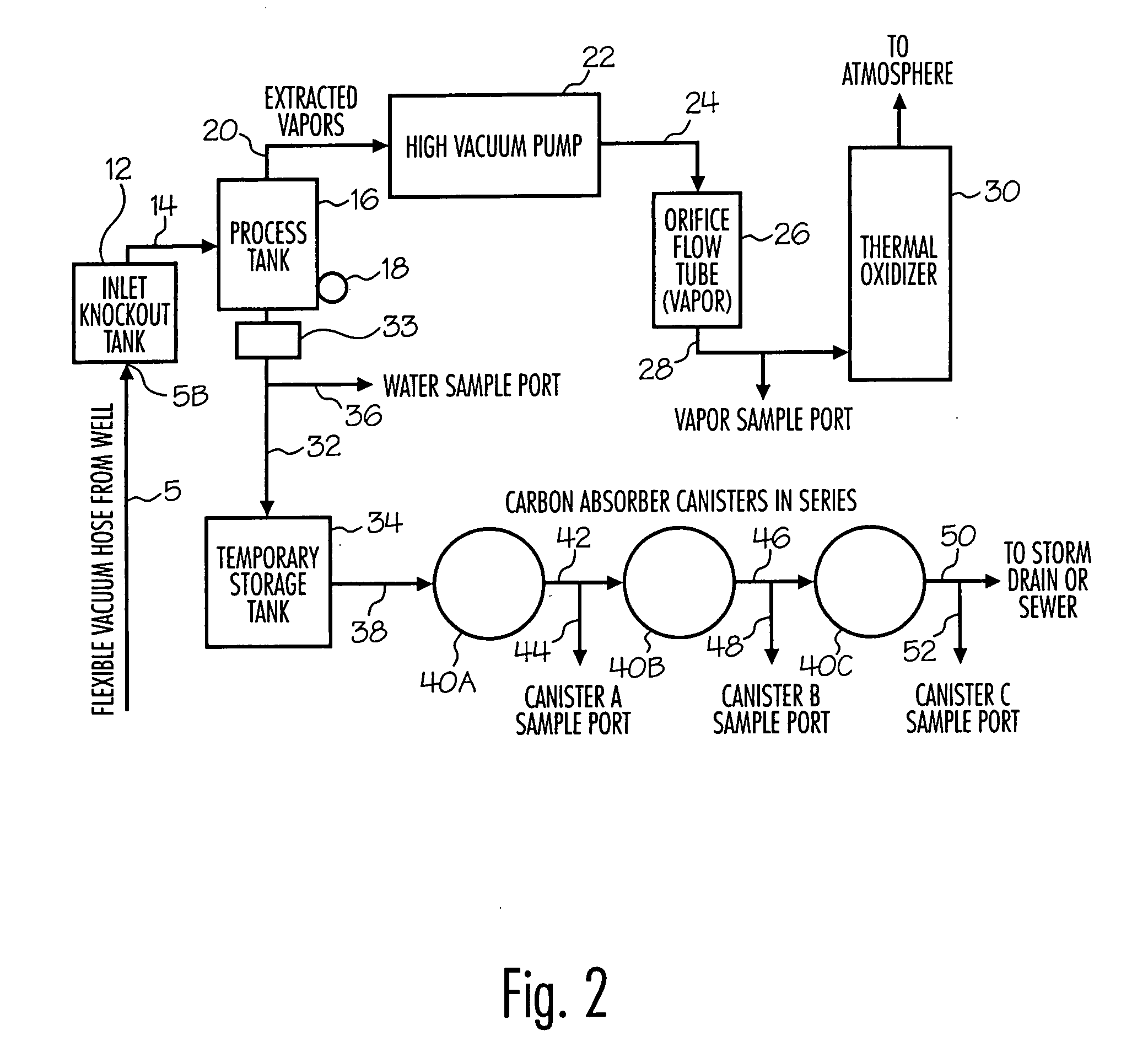

Removing contaminants from groundwater

InactiveUS20090107832A1Low vaporization temperatureCost effectivenessAuxillariesWater contaminantsActivated carbon filtrationCatalytic oxidation

A method and apparatus for removing hydrocarbon contaminants from groundwater. The apparatus preferably removes contaminants from groundwater by heating the groundwater to a temperature at which the contaminant vaporizes and separates from the liquid groundwater. Sparge air may be passed through the groundwater to assist in separating the vaporized contaminant. Further, a vacuum may be applied to lower the vaporization temperature of the contaminant. The extracted hydrocarbons are preferably destroyed in a thermal or catalytic oxidizer while the groundwater with the vaporized contaminant removed is preferably pumped through activated carbon filters to further reduce the amount of contaminants to governmental standards.

Owner:SHENOI NOEL A

Method for continuously producing 3-octanoyl thiopropyl triethoxysilane by virtue of tower type organic method

ActiveCN109517006ALow costEasy to operateGroup 4/14 element organic compoundsTriethoxysilaneChloride

The invention provides a method for continuously producing 3-octanoyl thiopropyl triethoxysilane by virtue of a tower type organic method and relates to a process for continuously producing 3-octanoylthiopropyl triethoxysilane. According to the method, the technical problem that the reaction needs to be carried out through a solvent and a catalyst in an existing rubber preparation method is solved. The method comprises the steps of introducing caprylyl chloride in a tower of a tower type reactor into a flash tank connected with the tower type reactor, when the temperature in the tower exceeds90 DEG C, starting a discharging valve of a 3-mercaptopropyl trialkoxysilane measuring tank, and conveying 3-mercaptopropyl trialkoxysilane into the tower type reactor by virtue of a measuring pump,so as to obtain 3-octanoyl thiopropyl triethoxysilane. The method has the beneficial effects that the raw materials can direct react without a solvent and a catalyst, so that the cost is saved, the operation is simplified, and the method is suitable for large-scale industrial production; and the product purity reaches over 96%, the yield reaches over 95%, and the waste gas produced in the reactionprocess can be circularly utilized.

Owner:江西宏柏新材料股份有限公司

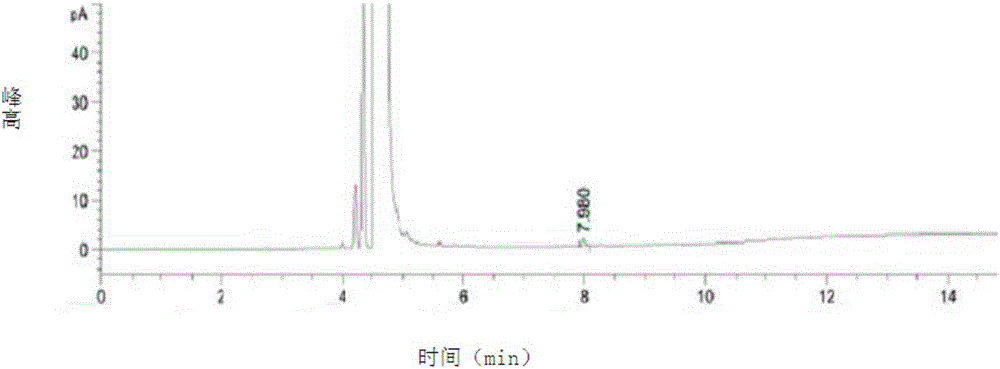

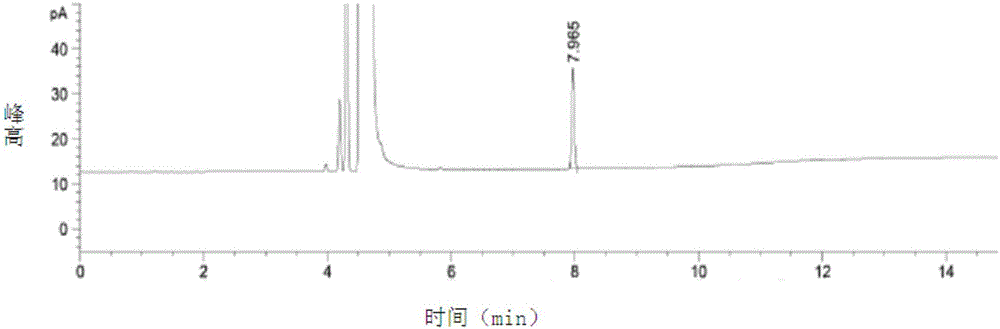

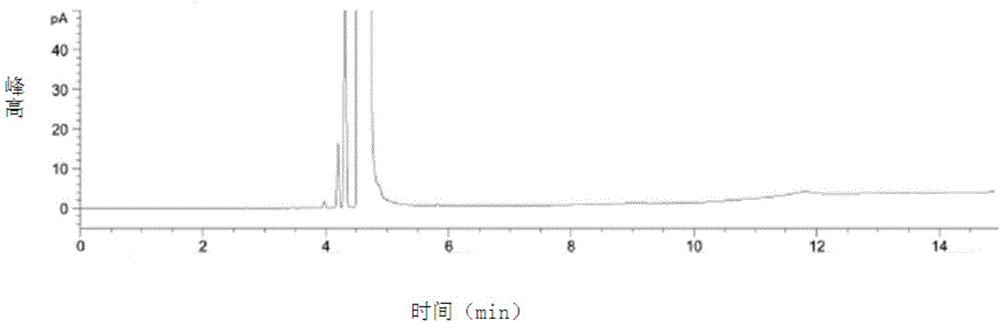

Capecitabine determination and application thereof

ActiveCN105823845ALow vaporization temperatureAffect accuracyComponent separationOrganic solventInjection port

The invention discloses capecitabine determination and application thereof. A direct injection method is selected, an organic solvent with the boiling point lower than 70 DEG C under the normal pressure is adopted as a solvent, the temperature of an injection port is 60-75 DEG C, degradation of capecitabine is effectively controlled, and the problem that a capecitabine sample disturbs determination of the content of n-amyl alcohol due to high-temperature degradation is solved. The verification test reproducibility is good, the linear relation is good, the average recovery rate is good, and n-amyl alcohol possibly remaining in the capecitabine sample can be accurately and quantitatively detected out. The content of n-amyl alcohol in the sample is accurately determined, and meanwhile the quality of capecitabine and safety of drug use are ensured.

Owner:HANGZHOU HUADONG MEDICINE GRP PHARMA RES INST

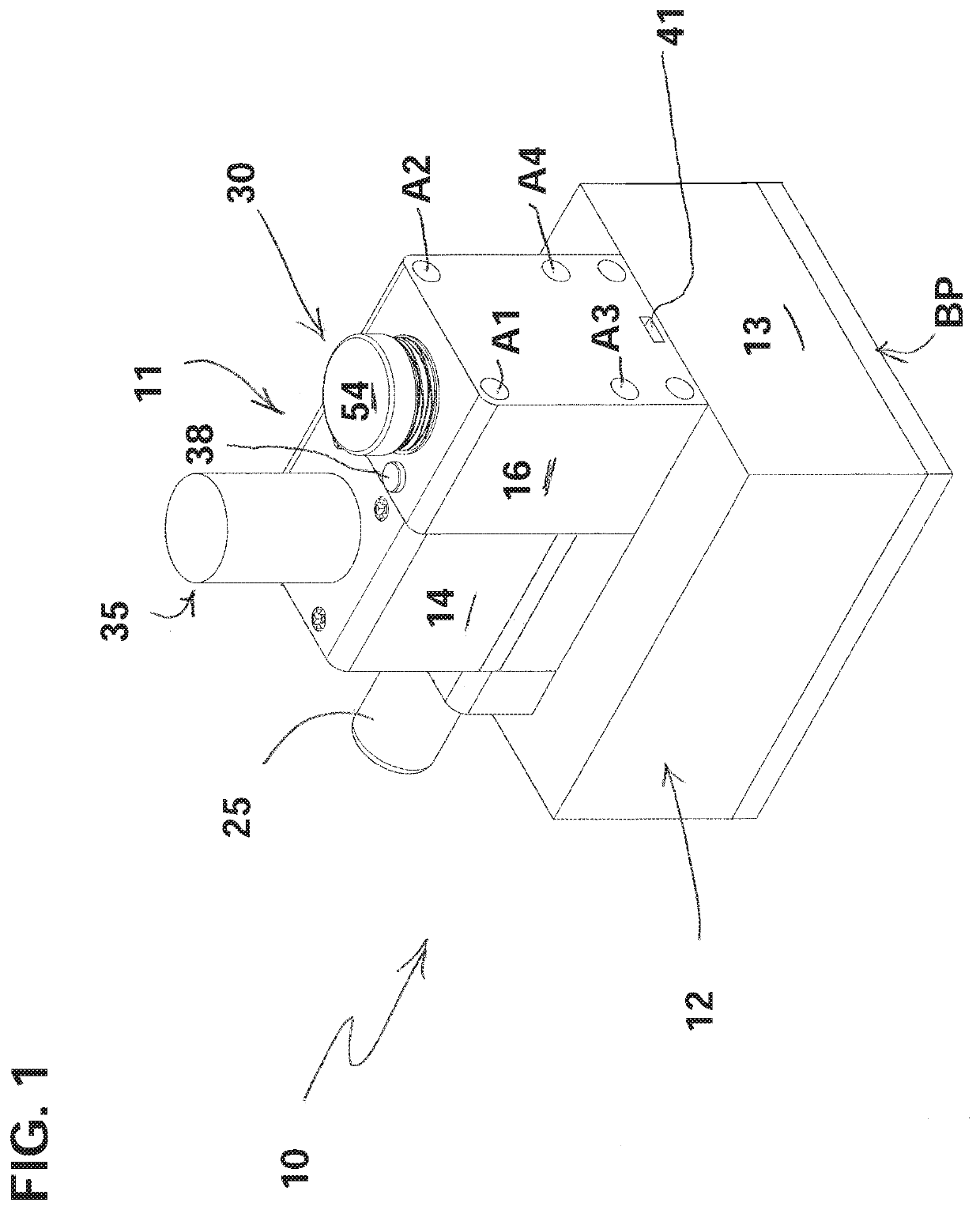

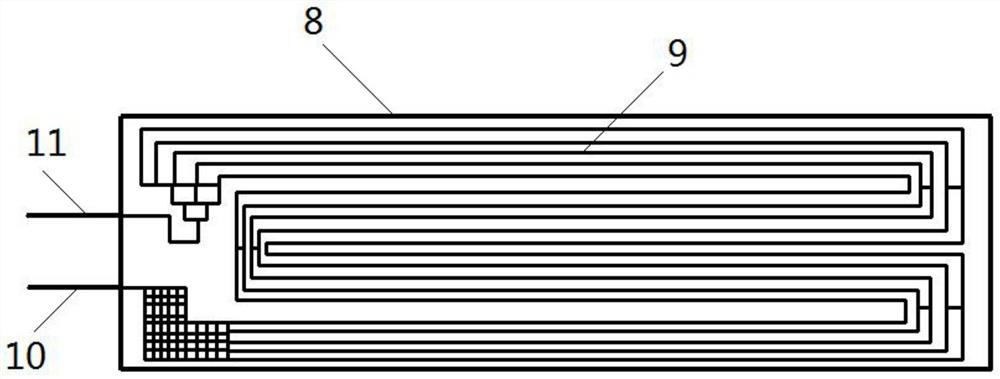

Vaporizer apparatus having both a vacuum pump and a heating element, and method of using same

ActiveUS20210052007A1Reduce the temperatureLow vaporization temperatureTobacco pipesVacuum pumpVaporizer

A vaporizer apparatus includes a pump housing, a main housing containing an evacuation chamber, and an operation unit attached to the main housing. The operation unit selectively isolates the evacuation chamber from communication with an air inlet. At least one vacuum pump is operable to generate a vacuum in the evacuation chamber, while a heating element also operates. A mouthpiece is attached to the main housing, and may be selectively placed in communication with the evacuation chamber. When oil is placed in the evacuation chamber and the operation unit is operated, the evacuation chamber is temporarily sealed off from the inlet, creating a vacuum sealed chamber connected with the pump(s). Then, the pump(s) is / are activated to reduce pressure in the evacuation chamber, and the oil is vaporized at reduced pressure and at an elevated temperature. When the operation unit is released, the evacuation chamber is emptied via the mouthpiece.

Owner:MABEE ENGINEERED SOLUTIONS INC

Titanium white gypsum suspension solid-liquid separation and hot-pressing drying equipment and production process thereof

InactiveCN105498320ALow vaporization temperatureStrengthen the function of mechanical dehydrationSolid waste disposalTransportation and packagingGypsumProcess engineering

The invention discloses titanium white gypsum suspension solid-liquid separation and hot-pressing drying equipment and a production process thereof, and solves the problems of single function, filter press plate deformation after long-term use and the like in the prior art. The equipment and the process are characterized in that: mechanical filter pressing and heating are combined, first a hydraulic system and a two-sided elastic water permeable plate are utilized to conduct filter pressing on a suspension so as to realize solid-liquid separation of the suspension, the solid material forms a filter cake in a filter chamber, when feeding is stopped, a heat source is employed to heat a drying plate clinging to the material, moisture in the compact material clinging to the drying plate is vaporized under heating, the volume increases, the generated driving force squeezes the non-vaporized material moisture out of one side of the water permeable plate, at the same time the elastic water permeable plate timely compresses the volume vacated due to moisture decrease under the action of the hydraulic system, thus realizing deep dewatering and drying of the filter cake within a short period of time. The equipment and the process provided by the invention combine mechanical filter pressing and heating drying, and improve the heat efficiency. The equipment provided by the invention has the advantages of small land occupation and low energy consumption, and existing plate and frame type filtration equipment can be transformed into high elasticity hot-pressing drying equipment.

Owner:武汉青江化工黄冈有限公司

Monoglyceride distillation and purification kettle

ActiveCN112807729AHigh purityEasy to operateChemical industryVapor condensationThermodynamicsMonoglyceride

A monoglyceride distillation and purification kettle comprises a shell, a liquid discharge pipe, a liquid storage barrel, two groups of condensers, two groups of vacuum generators, a liquid adding pipe, a mounting barrel, an air outlet pipe, an exhaust pipe and a collecting barrel; a liquid storage cylinder is arranged in the shell; a heating bin is defined by the peripheral face of the liquid storage cylinder and the inner wall of the shell; the heating bin is provided with a liquid inlet pipe and a liquid outlet pipe on the shell; one group of vacuum generators communicate with the liquid storage cylinder and one group of condensers through air pipes; the liquid discharge pipe hermetically penetrates through the shell and communicates with the interior of the liquid storage cylinder; the mounting barrel is connected with the upper end face of the liquid storage cylinder, a piston is slidably arranged in the mounting barrel, and a driving assembly for driving the piston to move is arranged on the mounting barrel; the air outlet pipe is arranged on the mounting barrel; the other end of the air outlet pipe is provided with a condensing plate and communicates with the other group of vacuum generators; the lower end surface of the air outlet pipe is provided with a collecting box and the exhaust pipe; the exhaust pipe communicates with the other group of condensers; and the collecting box communicates with the interior of the collecting barrel through a collecting pipe. The monoglyceride distillation and purification kettle is easy to operate and convenient to use, and the high-purity monoglyceride can be efficiently prepared.

Owner:佳力士添加剂(海安)有限公司

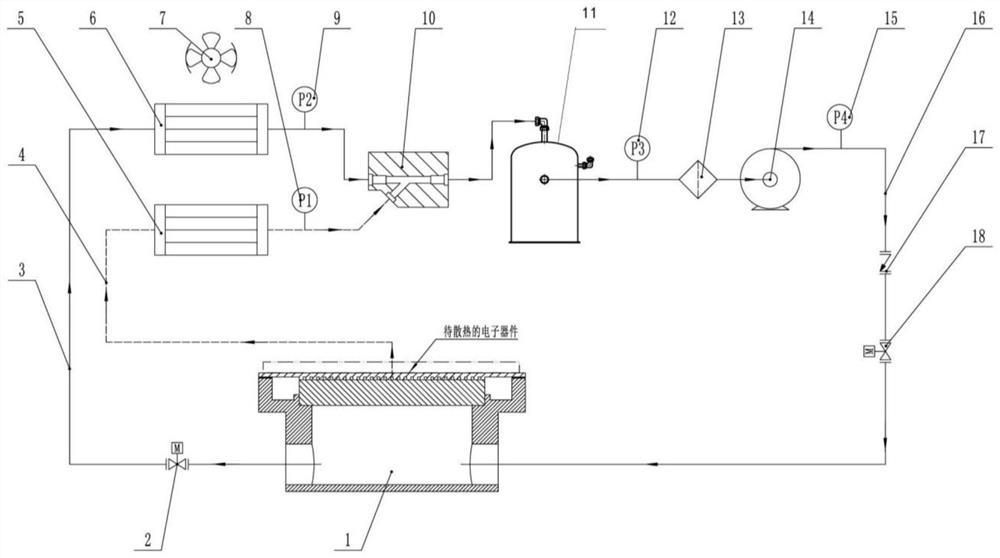

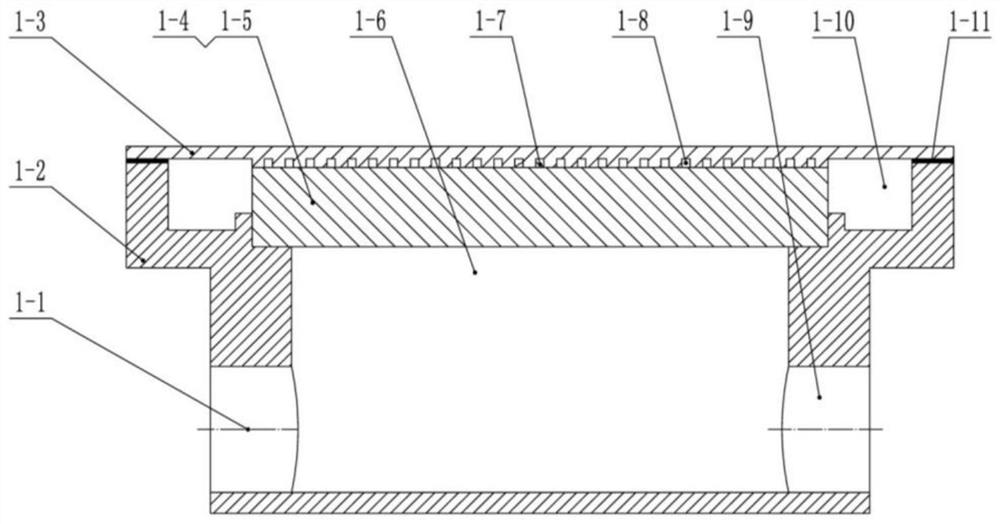

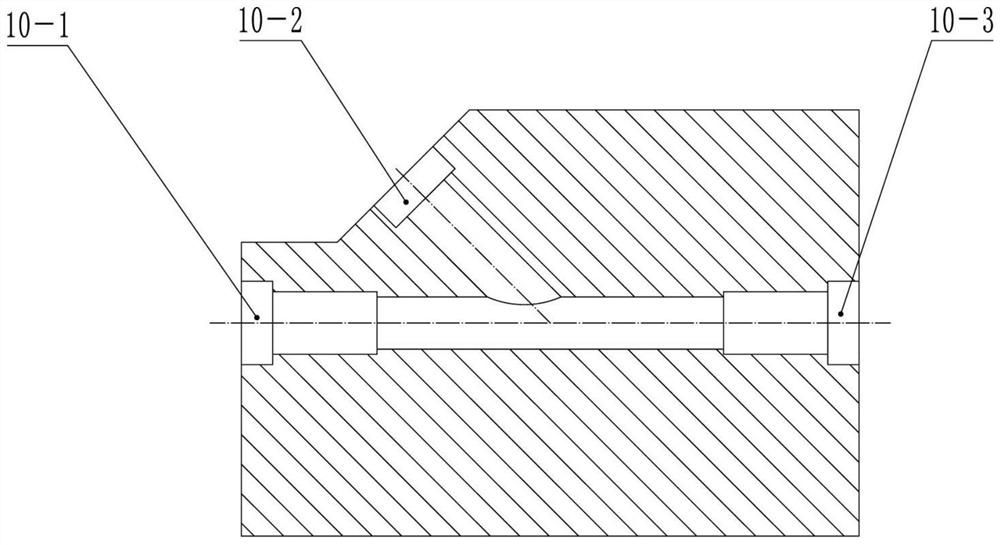

Heat dissipation system based on pump-driven capillary phase change loop

PendingCN112000206AGreat driving forceIncrease heat transfer distanceDigital data processing detailsEnergy efficient computingHeat flowEngineering

The invention discloses a heat dissipation system based on a pump drive capillary phase change loop. The heat dissipation system comprises a first liquid pipeline, a second liquid pipeline, a steam pipeline, an ejector and an evaporator. The first end of the second liquid pipeline is communicated with the first end of the first liquid pipeline through the ejector, and the second end of the secondliquid pipeline is communicated with the second end of the first liquid pipeline through the evaporator; the first end of the steam pipeline is communicated with the first end of the first liquid pipeline through an ejector; the second end of the steam pipeline is communicated with the second end of the first liquid pipeline through the evaporator; an active heat dissipation technology and a passive heat dissipation technology are combined; the heat exchange capability is improved by utilizing phase change latent heat of the working medium; the heat dissipation system meets the heat dissipation requirement of high heat flow density, has high heat transfer efficiency, improves the power of electric power and electronic devices, improves the working efficiency of the electric power and the electronic devices. The defects that a loop heat pipe and a capillary pump loop are small in transmission distance, difficult to start and the like are overcome, and the heat dissipation system adaptsto heat dissipation of the electronic devices with different heat flow densities.

Owner:包文隆 +1

Decompressed microwave extraction device and method for extracting plant effective ingredient

InactiveCN100421759CAccelerated extraction and dissolutionReduce concentrationEnergy based chemical/physical/physico-chemical processesSolid solvent extractionMicrowaveVapor–liquid separator

Owner:QILU UNIV OF TECH

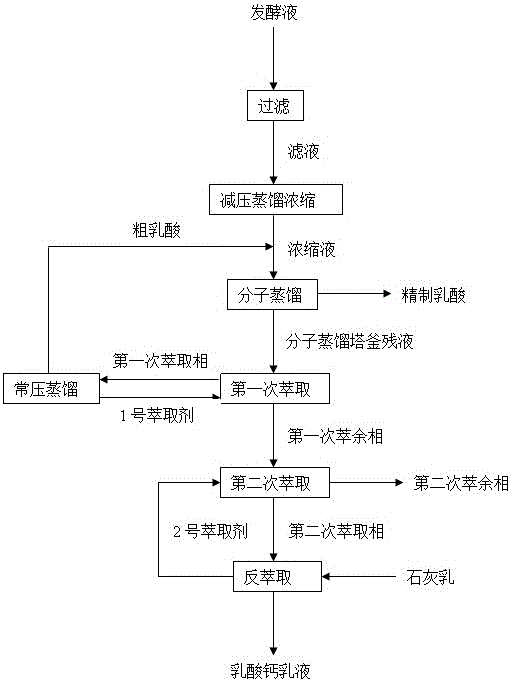

Method for extracting lactic acid from fermentation liquor through combination of molecular distillation and extraction

ActiveCN106431895ALow toxicityLow vaporization temperatureOrganic compound preparationCarboxylic acid salt preparationAlcoholEmulsion

The invention aims to solve the problem of high lactic acid content in residual liquid in a tower kettle according to a molecular distillation method for extracting lactic acid. The extraction is introduced into the molecular distillation method, a mixture of isopropyl ether and isopropyl acetate is taken as a No.1 extraction agent for extracting for the first time and recycling the lactic acid from the residual liquid in the tower kettle, and the rough lactic acid acquired after the extraction agent is recycled is returned into a molecular distillation device, so that the efficiency of recycling the lactic acid according to the molecular distillation method can be increased; and a mixture of tributyl phosphate, n-caprylic alcohol and hydrogenated kerosene is taken as a No.2 extraction agent for extracting for the second time, lime milk is adopted for carrying out reverse extraction so as to acquire calcium lactate emulsion, and the calcium lactate emulsion can be used for further preparing the lactic acid. The purity of the lactic acid acquired according to the method is above 95%, the recovery rate of the lactic acid (excluding the lactic acid recycled from the calcium lactate emulsion) is above 83%, and the method has the advantage of high recovery rate.

Owner:NINGBO UNIVERSITY OF TECHNOLOGY

Smokeless anti-fatigue moxa-moxibustion stick and preparation method thereof

InactiveCN106727833AGood adhesionNo emissionAntinoxious agentsOil/fats/waxes non-active ingredientsChemistryRaw material

The invention discloses a smokeless anti-fatigue moxa-moxibustion stick and a preparation method thereof. The smokeless anti-fatigue moxa-moxibustion stick comprises, by weight, moxa carbon powder, chrysanthemum extract, Siberian elm bark powder, epimedium herb powder and rubber powder. Chrysanthemum is treated by matching various processes, and effective components including linarin in the chrysanthemum are extracted at the highest extraction rate. Compared with a general traditional extraction method, the matched various processes can maximally extract the linarin and other effective components in the chrysanthemum, the chrysanthemum extract serving as a raw material is added in the preparation process of the moxa-moxibustion strip, efficacy can be maximally played, and moxibustion heat enters a human body when the moxa-moxibustion stick enters is combusted, so that an anti-fatigue function is achieved.

Owner:河南忠澜艾瓷文化开发有限公司

A special corrosion inhibitor for pyrolysis coking wastewater flue gas using converter high temperature flue gas

The invention relates to a special corrosion inhibitor for pyrolyzing and coking waste water flue gas by using high-temperature flue gas of a converter, and an application method of the special corrosion inhibitor. Chemical formulation range of catalyst is as followings in percent by weight: 1.0 to 8.0 percent of rosin imidazoline quaternary ammonium salt, 35.0 to 55.0 percent of oleinic acid imidazoline, 8.0 to 17.0 percent of alkylphenol polyoxyethylene, and 20.0 to 50.0 percent of ethylene-glycol, adding a certain quantity of ethylene-glycol after content weighing sequentially, fully resolving and stirring uniformly once a material is added and then adding next material, and stirring uniformly. The formula of the catalyst is simple, the effect is obvious, the cost is low, the application method is simple, the special corrosion inhibitor and the method are suitable for pyrolyzing and coking waste water by using high-temperature flue gas of converter, and the corrosion inhibitor can be effectively used for refraining and coking flue gas formed after pyrolyzing of waste water in high-temperature flue gas of the converter or corrosion to pipeline and equipment from converter gas.

Owner:北京泰和元环保科技发展有限公司

Method for producing deoxygenated water with low-temperature heat as heat source and negative-pressure thermal deaerator system with low-temperature heat as heat source

PendingCN114455660ALow vaporization temperatureImprove oxygen removal effectWater/sewage treatment by heatingWater/sewage treatment by degassingThermodynamicsPollutant emissions

The invention belongs to the technical field of chemical processes, and particularly relates to a method for producing deoxygenated water by taking low-temperature heat as a heat source, namely a negative-pressure thermal deaerator system taking low-temperature heat as a heat source. The method provided by the invention comprises the following steps: under a negative pressure condition, carrying out heat exchange on water by using a low-temperature thermal medium to produce steam, and stripping the demineralized water by using the steam to obtain the deoxygenated water. According to the method provided by the invention, the low-temperature heat production steam is used as a steam stripping medium to prepare the deoxygenated water, so that the fuel consumption can be effectively reduced, the operation cost of a refinery enterprise is reduced, the pollutant emission is reduced, and the method is green and environment-friendly. The invention finds a way for efficiently utilizing low-temperature heat for refinery enterprises.

Owner:肖立刚

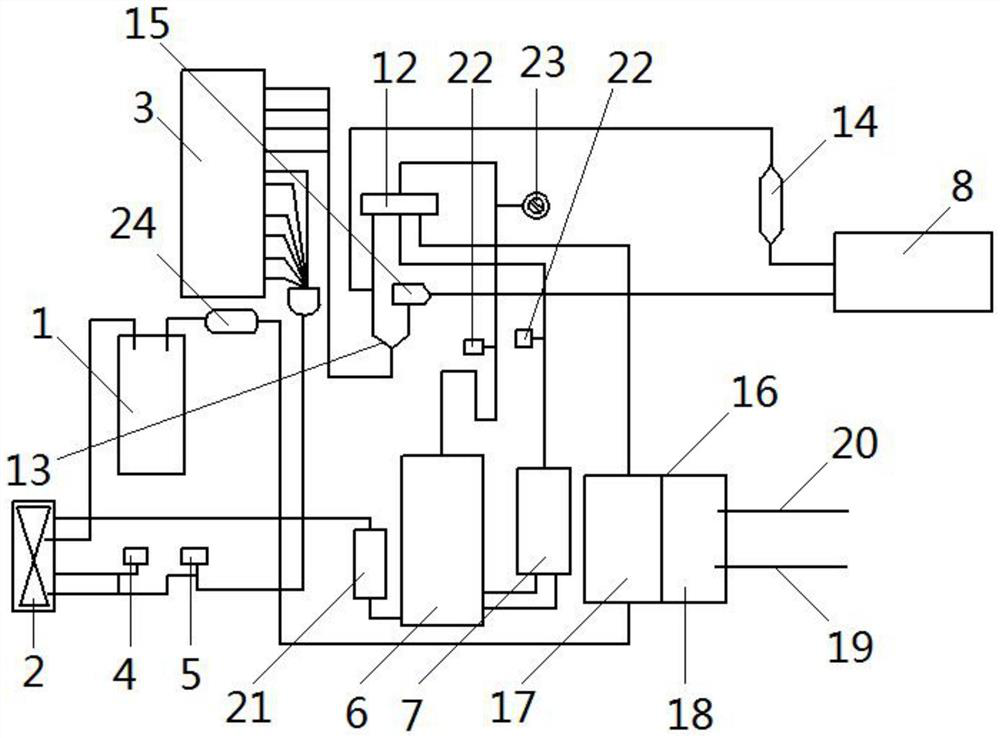

Photo-thermal different-energy-gathering heat pump integrated system

PendingCN114811707ALow vaporization temperatureSolve the problem of poor heating effectMechanical apparatusHeat pumpsPlate heat exchangerLiquid storage tank

The invention discloses a photo-thermal different-energy-gathering heat pump integrated system, and relates to the technical field of energy utilization. The plate heat exchanger is communicated with the liquid storage tank; the evaporator is communicated with the plate heat exchanger, and an enthalpy supplementing expansion valve and an electronic expansion valve are arranged between the evaporator and the plate heat exchanger; the compressor is communicated with the plate heat exchanger; the liquid storage separator is communicated with the compressor; a channel is formed in the heat collection panel, and the two ends of the channel communicate with the liquid inlet and the liquid outlet correspondingly. The four-way valve is communicated with the tee joint, a liquid inlet of the heat collection panel is communicated with the tee joint, a liquid outlet of the heat collection panel is communicated with the four-way valve, a one-way valve is arranged between the heat collection panel and the four-way valve, an electromagnetic valve is arranged between the heat collection panel and the tee joint, and the compressor and the liquid storage separator are both communicated with the four-way valve. The two ends of the refrigerant area communicate with the liquid storage tank and the four-way valve correspondingly, and the water area is provided with a water inlet and a water outlet. Therefore, the problem that in the prior art, a heat supply system is low in energy utilization rate, and consequently the heat supply effect is poor is solved.

Owner:耿丙义

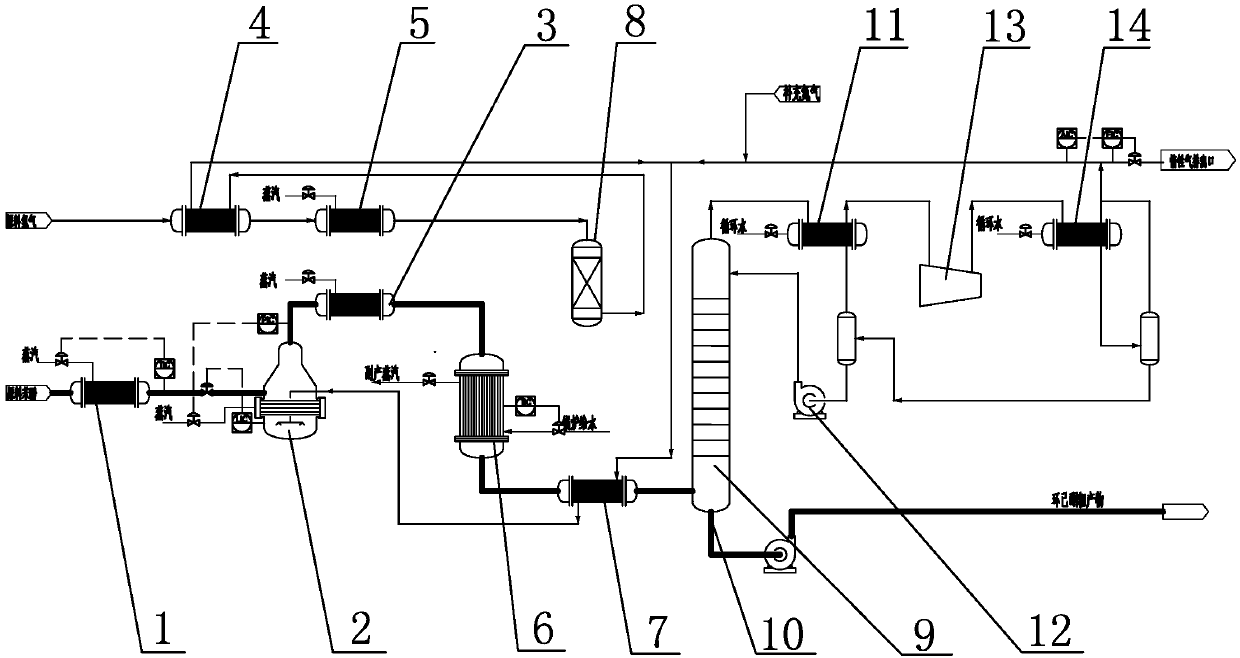

Method and system for producing cyclohexanone from phenol

ActiveCN105967984BExtend your lifeHigh selectivityPreparation by hydroxy compound hydrogenationOrganic compound preparationCyclohexanoneHydrogenation reaction

The invention discloses a method and system for producing cyclohexanone with phenol. The method is characterized by comprising the following steps that the raw material phenol is heated through a phenol preheater and then sent to a phenol vaporizer, mixed gas of the phenol and decarburized hydrogen is sent to a raw material superheater and sent to a hydrogenation reactor after superheating is conducted, in the hydrogenation reactor, hydrogen is added to the phenol to generate the cyclohexanone, a hydrogenation reaction product is sent to a hydrogenation reactor heat recovery heat exchanger for heat recovery and then sent to a dehydrogenation tower, hydrogen which does not react is separated, and a crude cyclohexanone product is obtained at the bottom of the dehydrogenation tower. The system comprises the phenol preheater, the phenol vaporizer, the raw material superheater, a hydrogen preheater, a hydrogen heater, the hydrogenation reactor, the hydrogenation reactor heat recovery heat exchanger, a decarburization reactor and the dehydrogenation tower. The system and method have the advantages that high-efficiency and high-selectivity hydrogenation preparation of the cyclohexanone with the phenol is achieved, the technological process is simple, and the product cyclohexanone is high in yield.

Owner:SEDIN NINGBO ENG

Vacuum rake dryer

InactiveCN104654755ALow vaporization temperatureImprove applicabilityDrying machines with non-progressive movementsDrying solid materialsReduction drivePulp and paper industry

The invention relates to a drying device, and in particular to a vacuum rake dryer which can be applicable to all materials in different states and with different properties. The vacuum rake dryer comprises a motor, and the motor is connected with a rotating shaft through a speed reducer; a cylinder is arranged outside the rotating shaft, and a plurality of stirring rods are arranged on the rotating shaft; and a feeding opening is formed in the upper portion of the cylinder. The vacuum rake dryer is characterized in that one side of the feeding opening is connected with a dry type dusting machine which is connected with a wet type dusting machine; the wet type dusting machine is connected with a condenser, and the condenser is connected with a condensate receiving groove which is connected with a vacuum pump; and the vacuum pump is connected with a steam-water separator. The vacuum rake dryer has the beneficial effects of being high in equipment applicability, wide in application range, good in product quality, convenient to operate, low in labor intensity and good in operation environment.

Owner:徐广敏

Method for STC vaporization and hydrogen mixing

InactiveCN110921672ALow vaporization temperatureReduce manufacturing costChemical industryHalogenated silanesFluid phaseProcess engineering

The invention provides a method for STC vaporization and hydrogen mixing, and relates to the technical field of cold hydrogenation processing. The method comprises: liquid-phase STC preheating pressurizing, STC heat preservation hydrogen bubbling, STC heating vaporization, preheated hydrogen mixing and other steps. According to the invention, the method overcomes the defects in the prior art, effectively reduces the industrial vaporization temperature of STC, enables STC to be more fully mixed and reacted with hydrogen after vaporization so as to achieves the energy-saving effect, and is simple to operate, lower in cost and suitable for large-scale production and use in factories.

Owner:南京合创工程设计有限公司

The method for continuous production of 3-octanoylthiopropyltriethoxysilane by tower organic method

The invention provides a method for continuously producing 3-octanoyl thiopropyl triethoxysilane by virtue of a tower type organic method and relates to a process for continuously producing 3-octanoylthiopropyl triethoxysilane. According to the method, the technical problem that the reaction needs to be carried out through a solvent and a catalyst in an existing rubber preparation method is solved. The method comprises the steps of introducing caprylyl chloride in a tower of a tower type reactor into a flash tank connected with the tower type reactor, when the temperature in the tower exceeds90 DEG C, starting a discharging valve of a 3-mercaptopropyl trialkoxysilane measuring tank, and conveying 3-mercaptopropyl trialkoxysilane into the tower type reactor by virtue of a measuring pump,so as to obtain 3-octanoyl thiopropyl triethoxysilane. The method has the beneficial effects that the raw materials can direct react without a solvent and a catalyst, so that the cost is saved, the operation is simplified, and the method is suitable for large-scale industrial production; and the product purity reaches over 96%, the yield reaches over 95%, and the waste gas produced in the reactionprocess can be circularly utilized.

Owner:江西宏柏新材料股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com