Patents

Literature

39results about How to "No emission" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fireproof insulation sheet material and processing technology thereof

A fireproof insulation sheet material and a processing technology thereof relate to a building decoration material. The fireproof insulation sheet material includes, by weight percentage, 8%-27% of foam insulation particles, 10%-30% of a resin adhesive agent, 2%-8% of an acid agent, 10%-20% of a quartz material, 10%-20% of expanded graphite, 10%-30% of a heat absorbing material, and 6%-18% of an insulation stone flour or insulation asbestos. The processing technology of the fireproof insulation sheet material is simple and practicable, the foam particles are provided with micropores, so as to facilitate infiltration of other raw materials into the foam particles. The prepared fireproof insulation sheet material has the advantages of safety, environment-friendliness, no pollution, excellent insulating performance, long service life, no smoke emission in high temperature, resistance to high temperature of 1000 DEG C, fire performance reaching A-level, and thermal conductivity less than 0.039 w / m.k.

Owner:YANCHENG ZHENXU NEW ENERGY

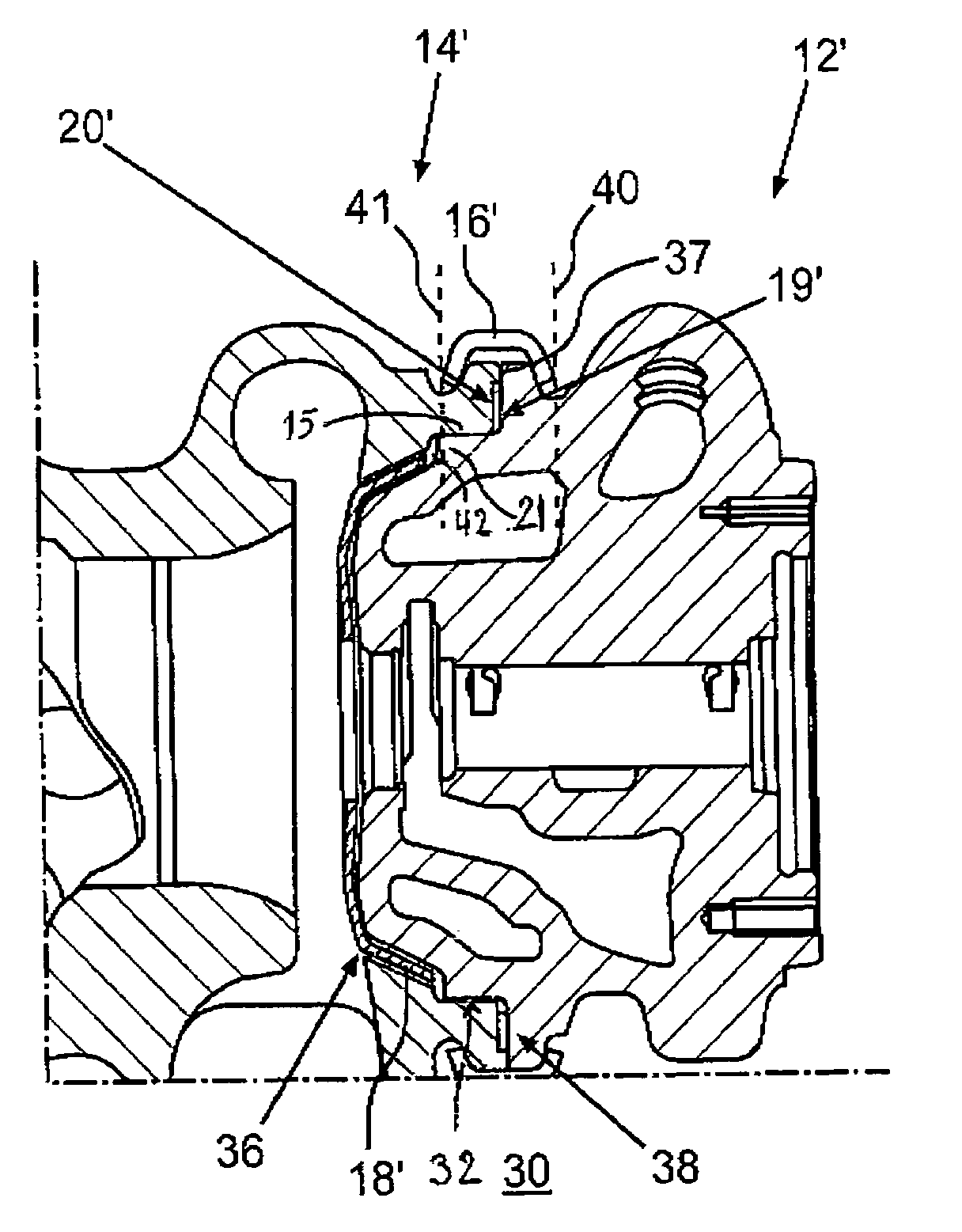

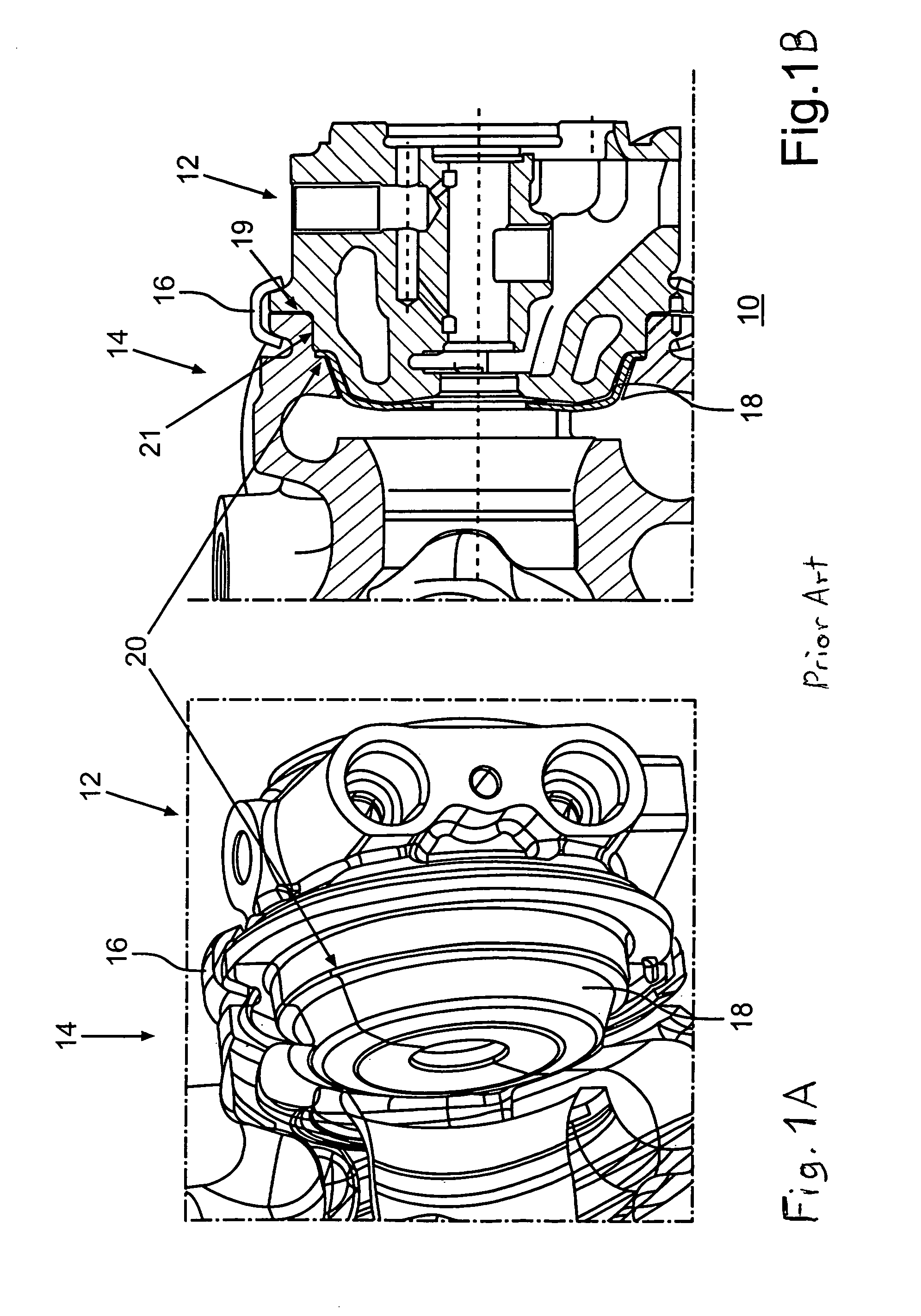

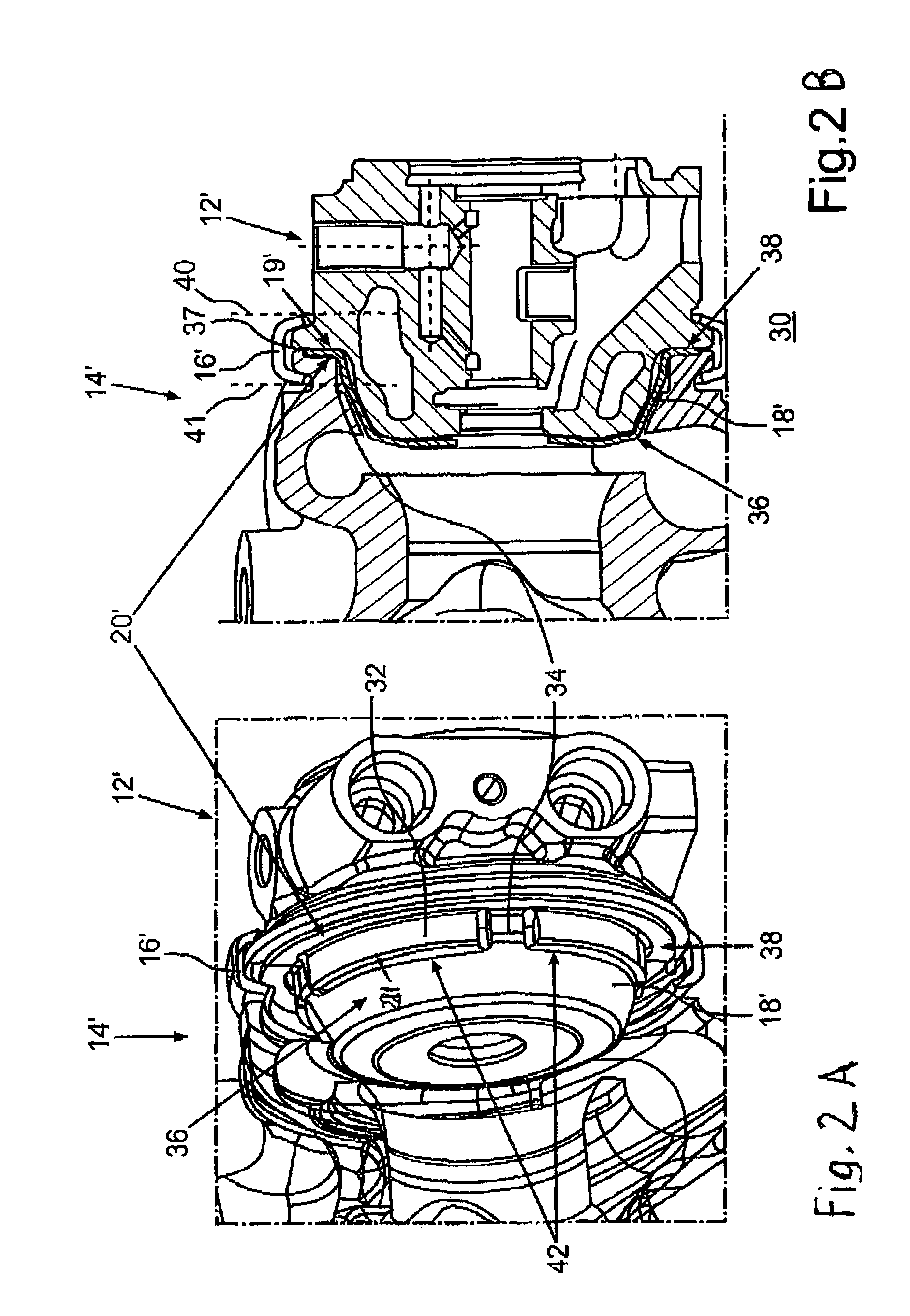

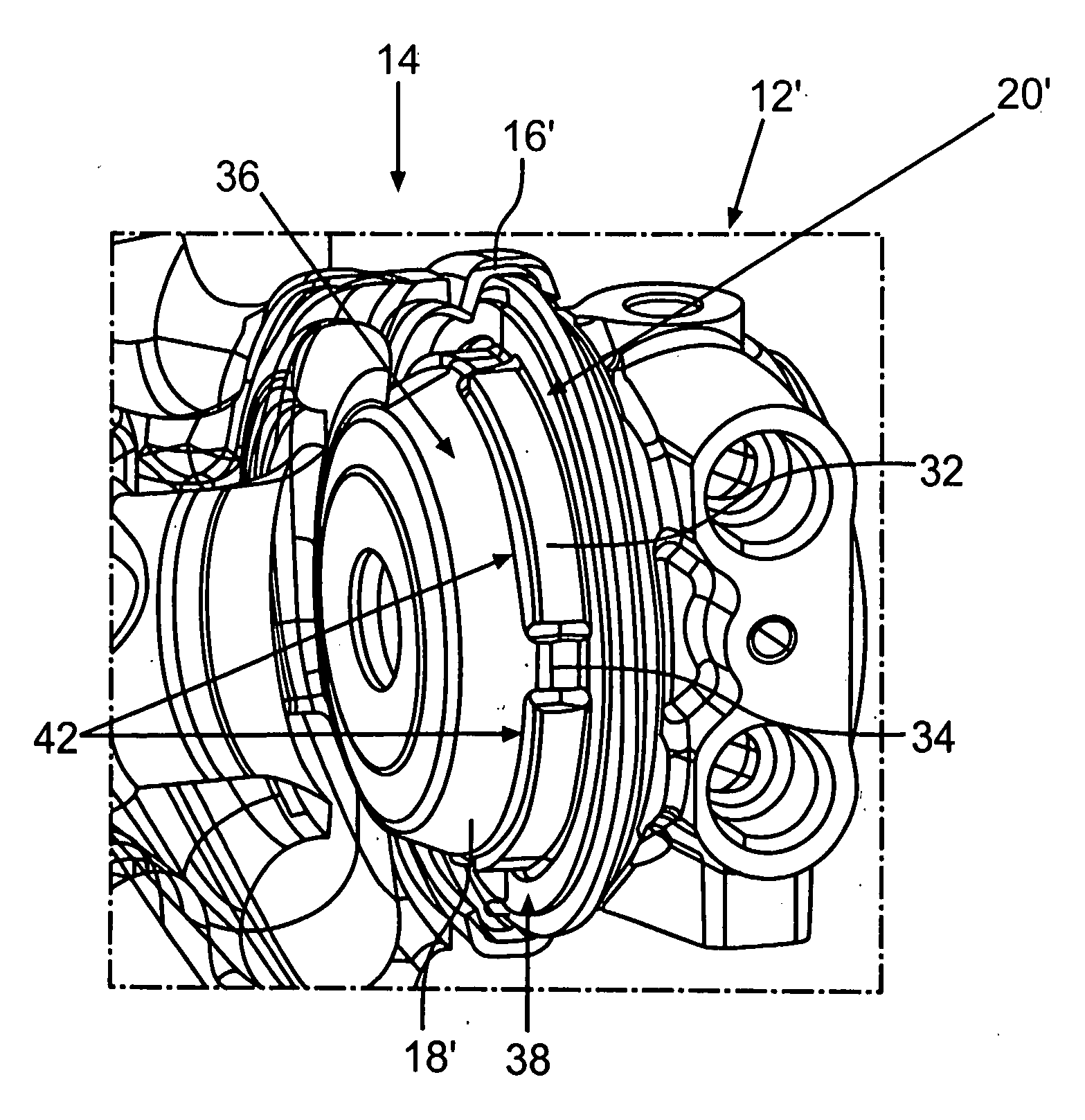

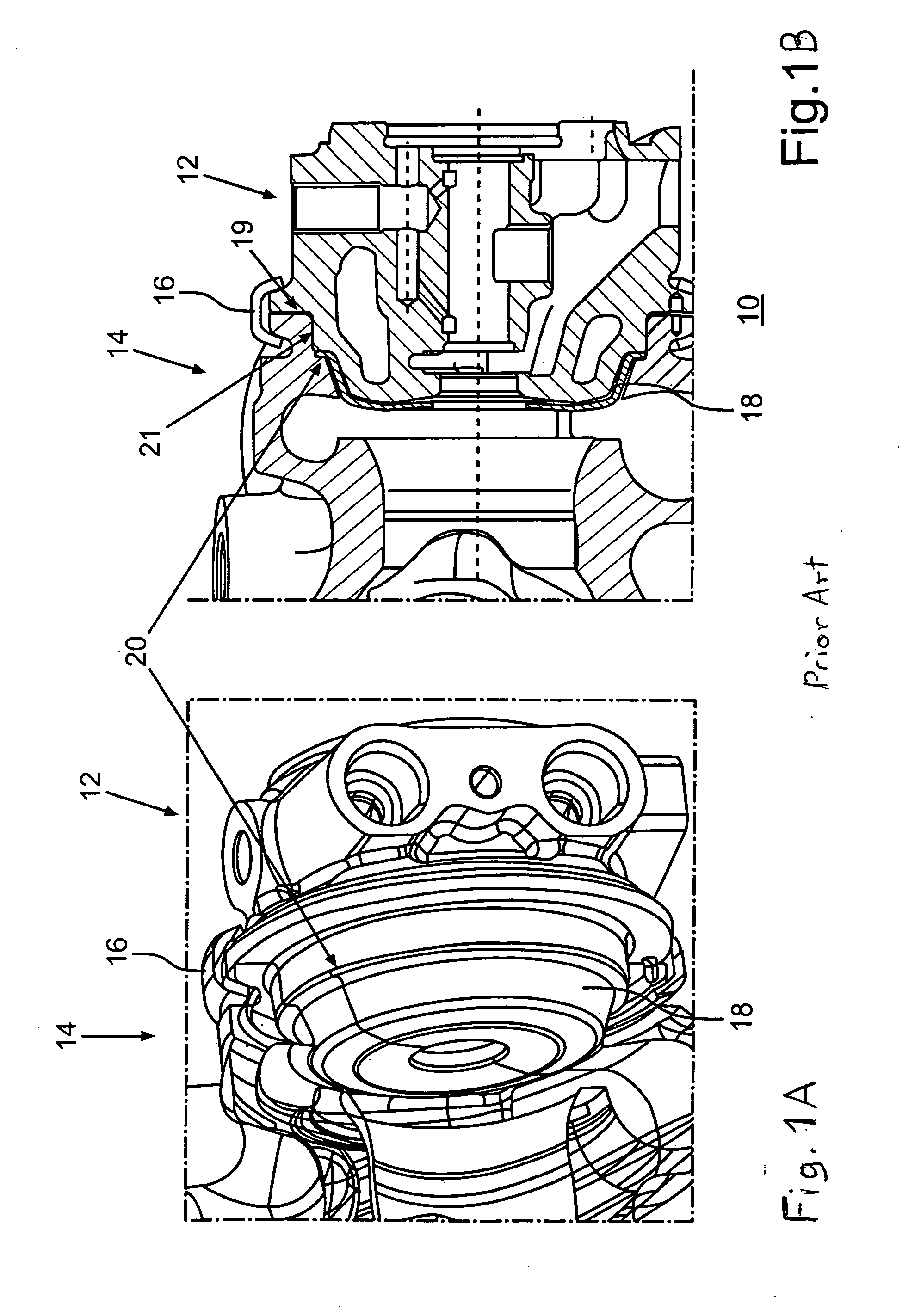

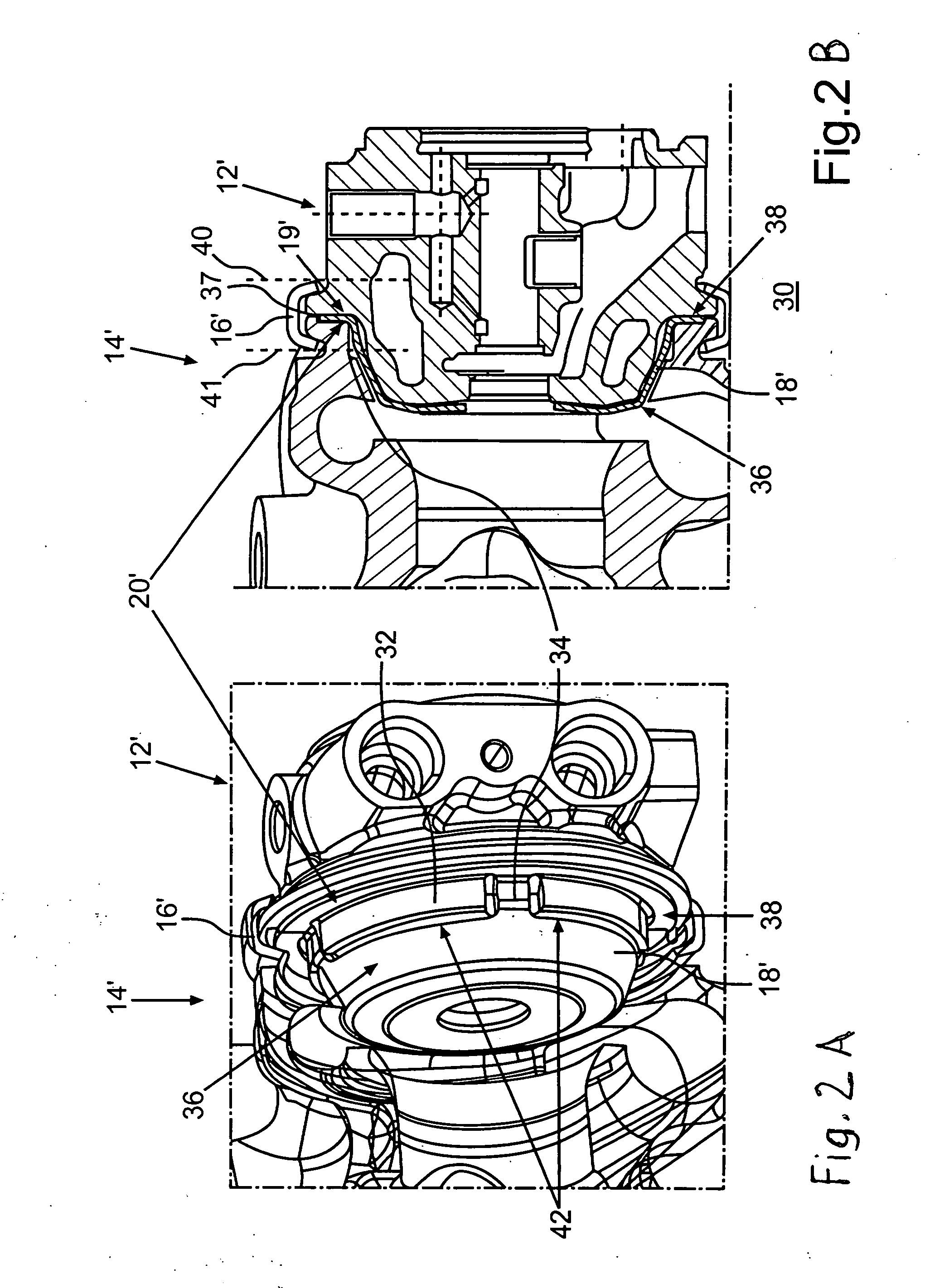

Connection assembly for joining a turbine housing and a bearing housing and exhaust gas turbocharger

InactiveUS8827638B2Prevent gas leakageNO emissionPump componentsGas turbine plantsTurbochargerEngineering

In a connection assembly of a turbine housing to a bearing housing of an exhaust gas turbocharger and to an exhaust gas turbocharger, wherein the turbine housing and the bearing housing are centered relative to each other and connected to each other in the region of a connection joint including a sealing assembly with a heat shield disposed between the turbine housing and the bearing housing, at least one cutout is provided in the heat shield for accommodating a centering means by way of which the turbine housing and the bearing housing are directly centered relative to one another.

Owner:IHI CHARGING SYST INT

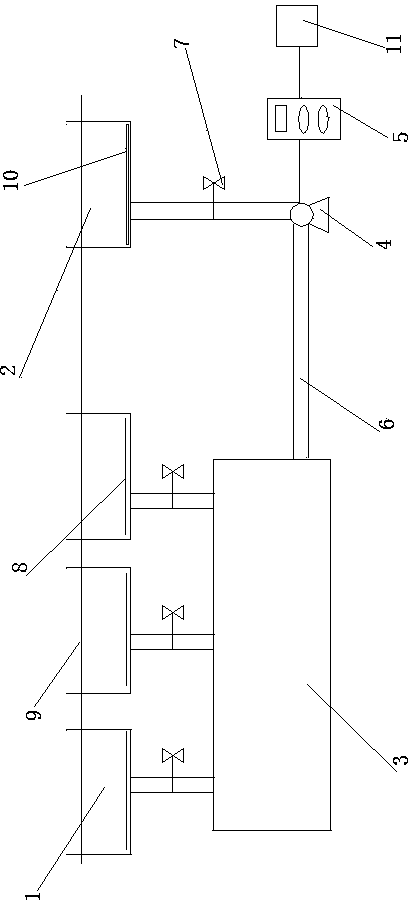

Automatic balance control device and method for copper ion concentration

InactiveCN104060319AReduce subsequent processing costsReduce the production of copper sludgeCellsPhysicsEngineering

The invention relates to an automatic balance control device and method for copper ion concentration. The device and method are used for automatically adjusting the balance of the copper ion concentration in the process of producing an electroplated copper clad aluminum wire. The device comprises one or more electroplating grooves, a specific groove and an exchanging groove in a sequential connection mode. The specific groove is connected with the electroplating groove through a pipeline, the electroplating groove is connected to a buffering groove through a pipeline, the buffering groove is connected to the specific groove through a pipeline, an automatic pump is further arranged on the pipeline between the specific groove and the buffering groove, a Cu2+ on-line monitor is connected to the buffering groove, a PLC controller is connected to the Cu2+ on-line monitor, a central control module is used for controlling a high-frequency power source to output variable voltage through detecting the concentration of Cu2+ in the buffering groove within a regulated time section, and namely working currents in the specific groove are controlled. In this way, the varying rate of the concentration of Cu2+ in the specific groove is controlled in an adjustable mode, the concentration of copper ions in the electroplating groove is kept at a stable value needed for the technology for a long time, the groove liquid does not need to be kept in a dilution mode, waste liquid is not generated, follow-up processing cost is reduced, and no discharging is generated.

Owner:金华市大田线材有限公司

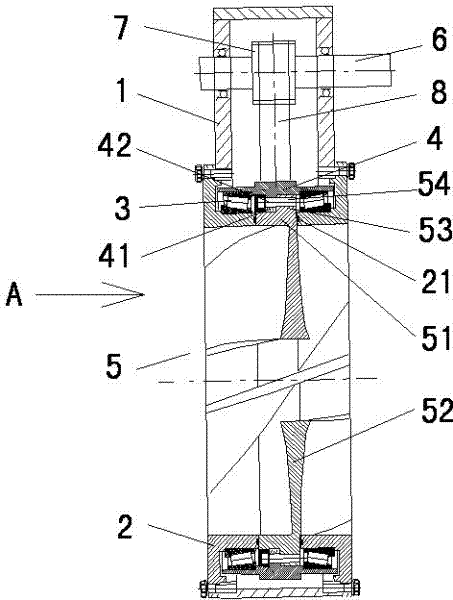

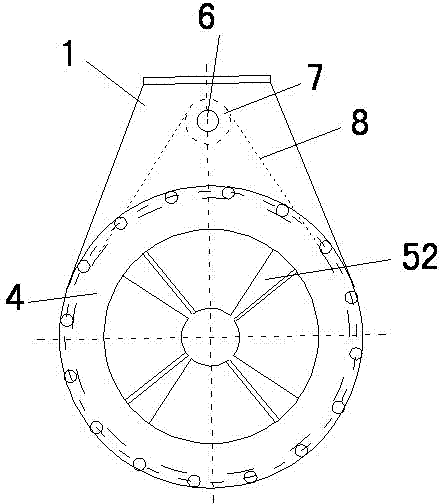

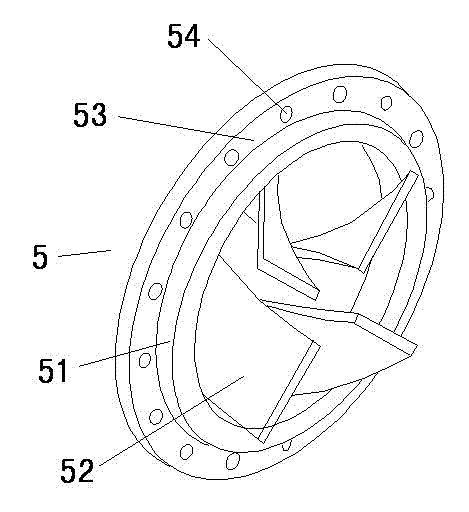

Shaftless propeller

InactiveCN102336261ARealize shaftless transmissionLarge thrustRotary propellersTransmission with mechanical gearingDrive wheelDrive shaft

The invention relates to a shaftless propeller which is characterized by comprising a shell (1), end covers (2), a rotating wheel (4), a propeller (5), a driving shaft (6), a driving wheel (7) and a toothed belt (8), wherein the two sides of the shell (1) are connected with the end covers (2); the rotating wheel (4) is connected between the end covers (2) by a rolling bearing (3); the rotating wheel (4) is internally and fixedly provided with the propeller (5); the shell (1) is also provided with the driving shaft (6) which is provided with the driving wheel (7); and the driving wheel (7) is connected with the rotating wheel (4) by the toothed belt (8). The propeller fixed on the rotating wheel is driven by the driving wheel arranged on the driving shaft through the toothed belt, so that the shaftless drive is realized by the shaftless propeller; and the shaftless propeller has the characteristics of being large in thrust, low in noise, free from winding, good in directionality and the like.

Owner:王仁夫

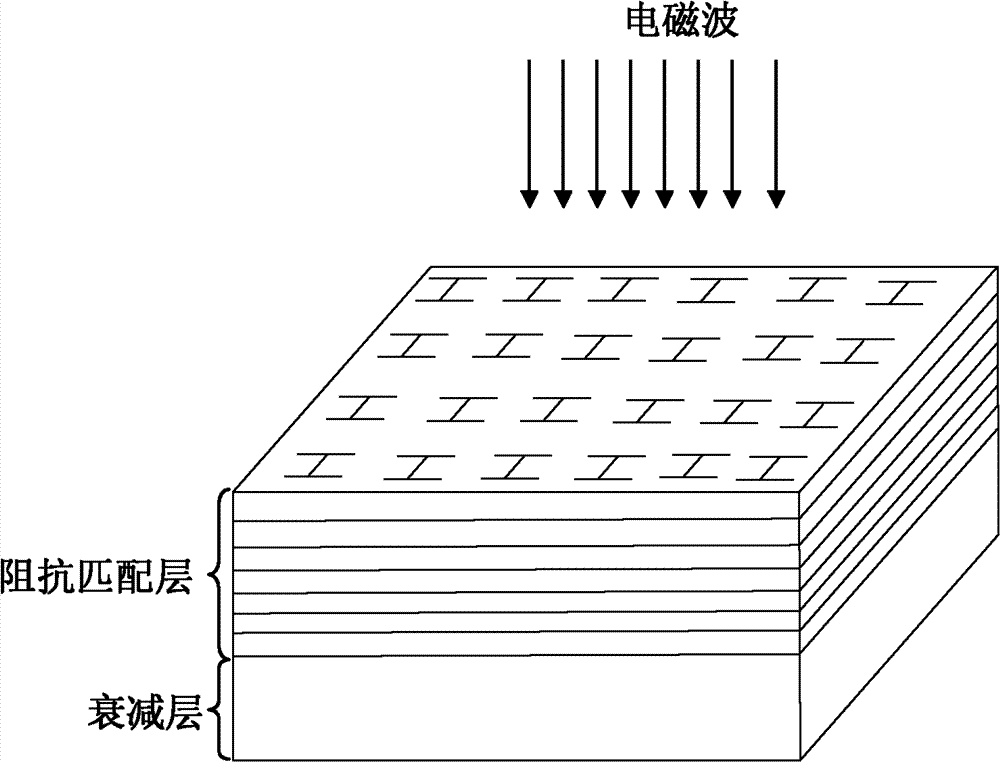

Mixed wave-absorbing material

ActiveCN102905508AImprove absorbing performanceNo emissionMagnetic/electric field screeningUltrasound attenuationEngineering

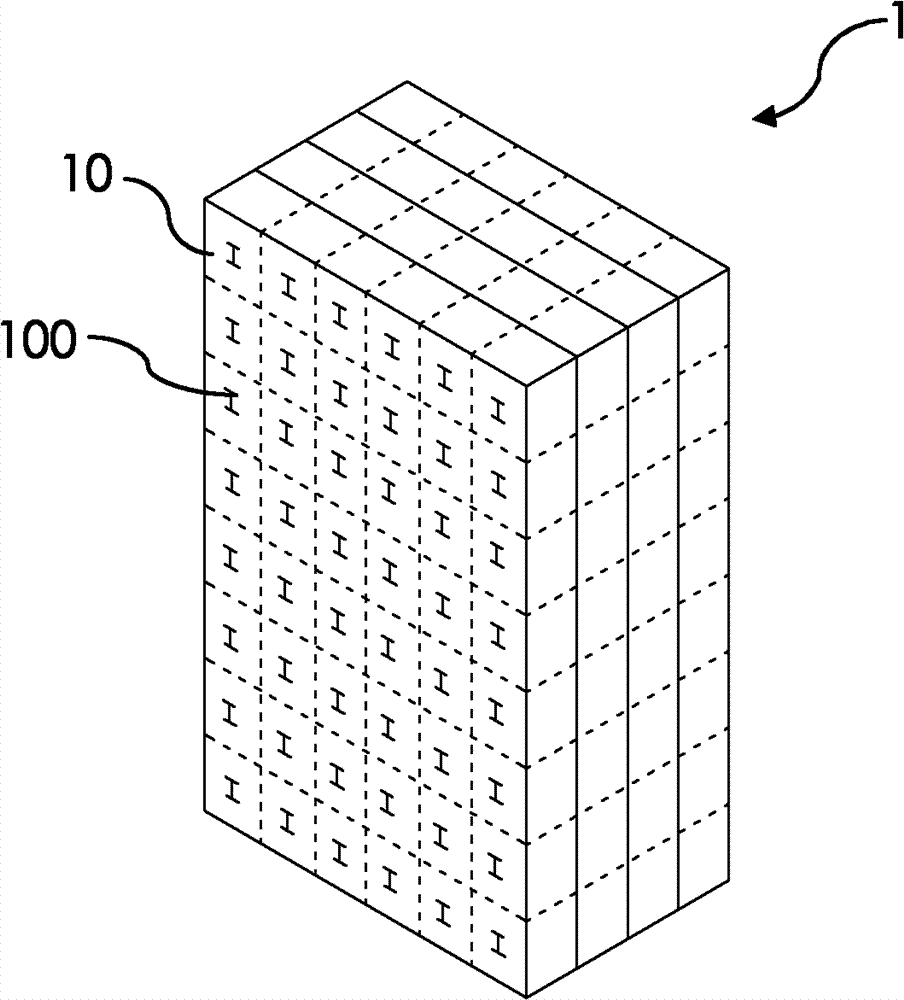

The invention relates to a mixed wave-absorbing material which comprises an attenuation layer and an impedance matching layer. The impedance matching layer consists of a plurality of uniform metamaterial sheet layers which are vertically and integrally stacked along the direction perpendicular to the surfaces of the metamaterial sheet layers, impedances of the metamaterial sheet layers are gradually changed along the stacking direction of the metamaterial sheet layers, the impedance of the outmost metamaterial sheet layer is identical to that of a free space, and the impedance of the innermost metamaterial sheet layer is identical to that of the attenuation layer. The mixed wave-absorbing material prevents reflection of incidence electromagnetic waves on the surface of the mixed wave-absorbing material and is better in wave absorbing performance.

Owner:KUANG CHI CUTTING EDGE TECH LTD

Anti-corrosion graphene coating and use method thereof

InactiveCN109181476AIncrease productivityIncrease salesFireproof paintsAnti-corrosive paintsEpoxySlurry

The invention discloses an anti-corrosion graphene coating. The anti-corrosion graphene coating is characterized by containing the following raw materials in parts by weight: epoxy resin, deionized water, graphene sheets, graphene dispersion liquid, a leveling agent, a wetting and dispersing agent, pigments, an ethanol solvent, an anionic acrylic emulsion, a defoaming agent, an Rs preservative, acuring agent, polyaniline, a film forming aid, isooctyl ester, a thickener, dimethyl fumarate, a mold release preservative, a toughening agent and a silane coupling agent. The preparation method comprises the following steps: (1) mixing, and stirring; (2) adding ingredients, and stirring at a high speed, so as to obtain slurry; (3) adding the slurry into a sand mill, and carrying out sand milling;and (4) putting the slurry into a size mixing tank, and stirring at a high speed, so as obtain the anti-corrosion graphene coating. By utilizing environment-friendly materials, the quality of a product is substantially improved; the time and the materials are saved, the anti-corrosion graphene coating is convenient to use only through thin coating and has excellent properties of water resistance,heat resistance, corrosion resistance, weather resistance, stability and the like.

Owner:EVERPOWER SHENG TIE (XIAMEN) GRAPHENE TECH CO LTD

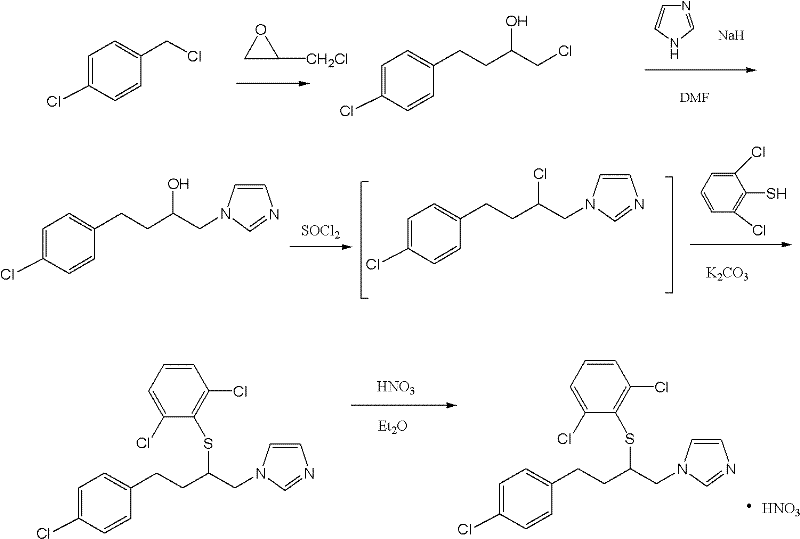

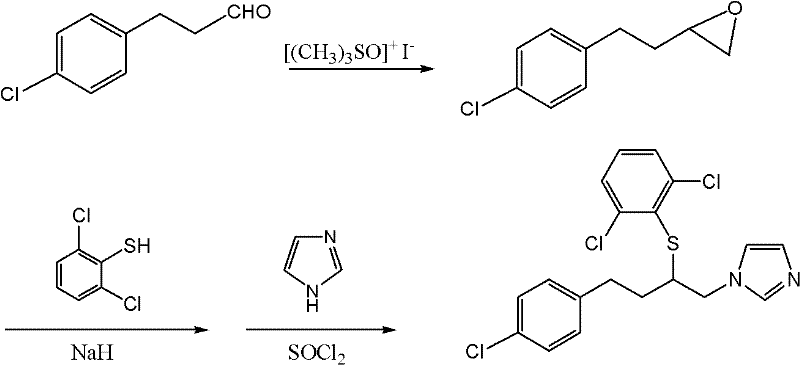

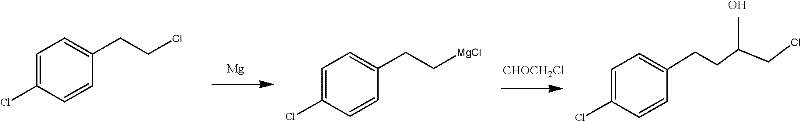

Preparation method for important intermediates of butoconazole nitrate

InactiveCN102649796AReaction is easy to controlSafe operating environmentMagnesium organic compoundsSolventPhenyl group

The invention discloses a preparation method for novel Grignard reagents, namely 4-chlorobenzylmagnesium chloride and 1-(2-chlorine-4-(4-chlorophenyl)-normal-butyl) imidazole. The method comprises the steps as follows: the 4-chlorobenzylmagnesium chloride is prepared from a mixed solvent of ethyl ether and MTBE (Methyl Tertiary Butyl Ether) by taking p-chlorobenzyl chloride as a raw material; and the 1-(2-chlorine-4-(4-chlorophenyl)-normal-butyl) imidazole is prepared from a methylene chloride solvent by taking 1- (4-(4-chlorophenyl)-2-hydroxy-normal-butyl) imidazole as a raw material. The 4-chlorobenzylmagnesium chloride and the 1-(2-chlorine-4-(4-chlorophenyl)-normal-butyl) imidazole are important intermediates for preparing butoconazole nitrate.

Owner:SICHUAN DIHON MEDICAL DEV +1

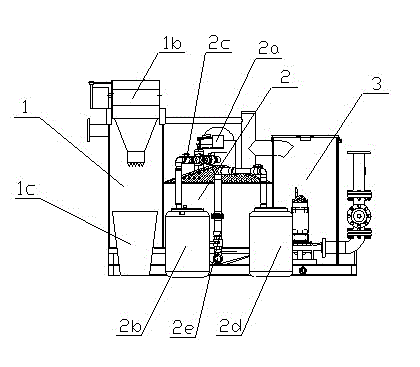

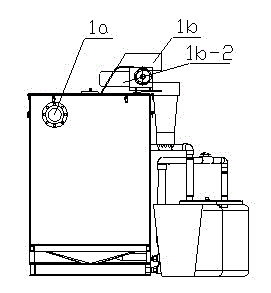

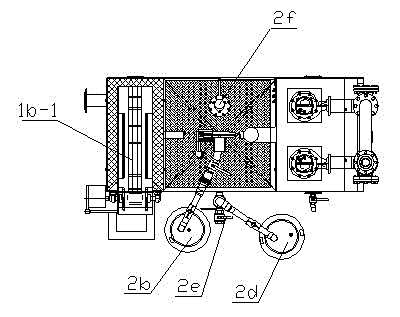

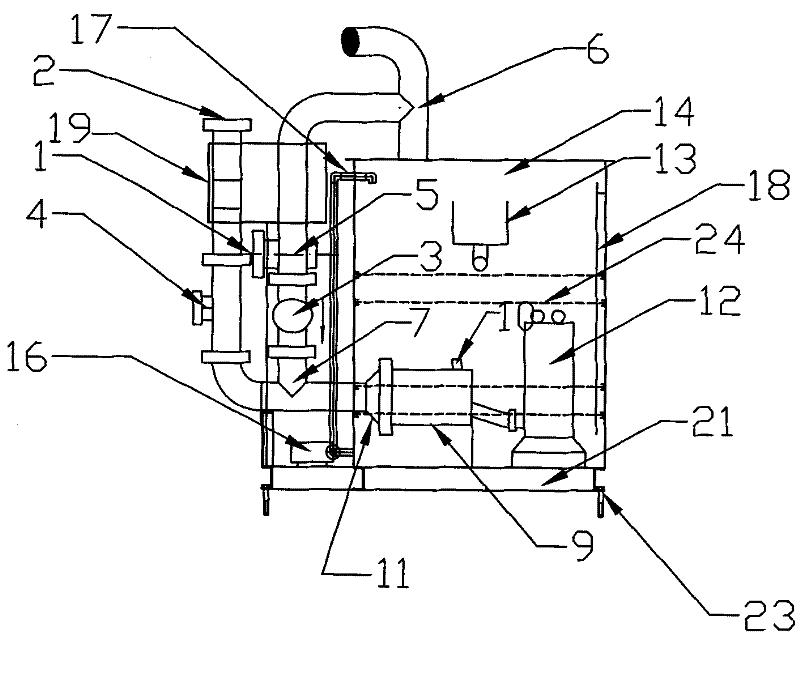

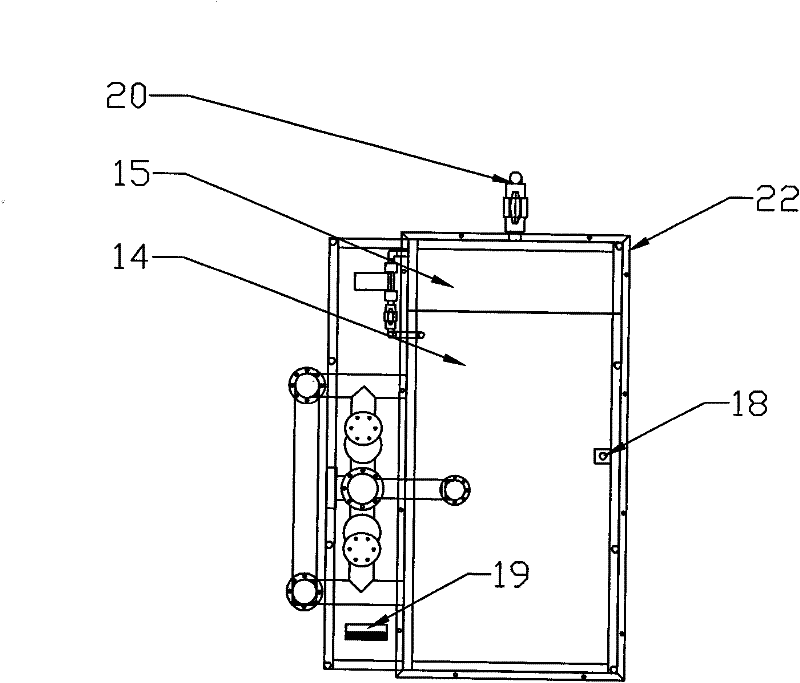

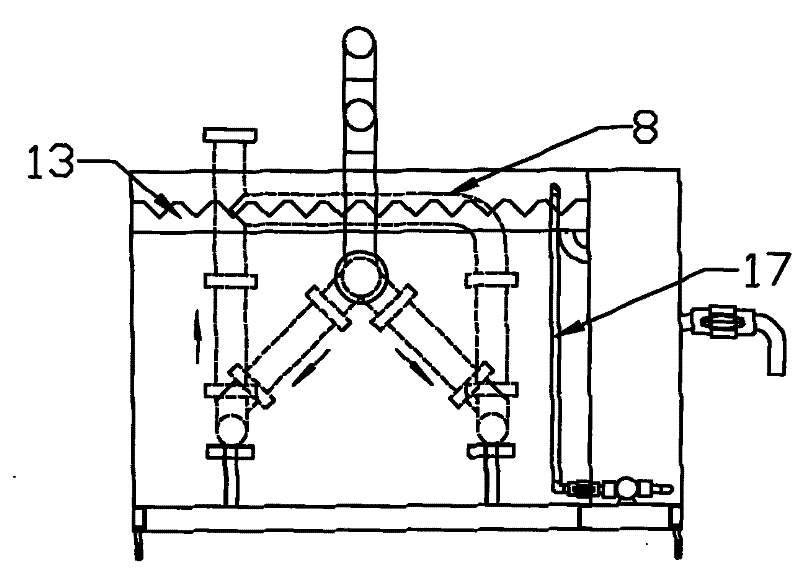

Full-automatic oil separation lifting integrated device

The present invention discloses a full-automatic oil separation lifting integrated device, including a debris separation tank, an oil-water separation tank and a sewage lifting tank which are communicated. The debris separation tank is connected with a sewage inlet pipe. The water inlet of the debris separation tank is provided with a mechanical grid which can automatically remove solid debris. The top of the oil-water separation tank is provided with an automatic oil wiper. The automatic oil wiper is communicated with an oil collection barrel. The bottom end of the oil-water separation tank is provided with a mud collection barrel communicated with the oil-water separation tank. The integrated device is compact in structure, saves civil construction, has the functions of efficient oil separation, automatic debris clearing, efficient mud discharging and automatic sewage lifting and discharging, and has the advantages of environmental protection, health, energy conservation, and small space occupation.

Owner:ANHUI TIANJIAN ENVIRONMENTAL PROTECTION

Composite reed-plastic material

The present invention relates to composite reed-plastic material comprising reed 44-70 wt%, thermoplastic plastic 18-44 wt%, assistant 6-8 wt% and stuffing 2-4 wt%. The said assistant includes one of the following components or their composition: lubricant, plasticizer, ultraviolet resisting agent, antioxidant, stuffing, reinforcer, fire retardant, antistatic agent, compatilizer, couplant and adhesive. The stuffing is powdered mineral(s). The production process includes cutting, stoving and crushing reed to form 20-300 mesh powder, mixing reed powder with other components, mixing in mixing apparatus, extruding through hole die, pelletizing in a pelletizer, quenching and curing to form the section of the composite material.

Owner:上海铭新环卫工程科技有限公司

Wheat straw plastics composite material

The present invention relates to a wheat straw plastics composite material, and its composition includes 49%-79% of wheat straw, 19%-49% of thermo-plastic plastics and 2%-4% of adjuvant. The described wheat straw can be wheat straw and wheat straw leaf of fruiting body or their mixture, and the described adjuvant is one kind of the following components: lubricating agent, plasticizer, UV-ray-resisting agent, anti-oxidant, filling agent, reinforcing agent, fire-retardant, anti-static agent, coupling agent and binding agent. Its production method includes the following steps: cutting wheat straw, drying, pulverizing to 20-300 meshes, adding the wheat straw power into high-speed mixer, mixing it with adjuvant and plastic powder, homogenizing, further mixing, extruding, granulating, cooling, solidifying and making them into the invented wheat straw plastics composite material.

Owner:上海铭新环卫工程科技有限公司

Rice strah plastic composite material

The composite material consists of rice straw 49-79 wt%, thermoplastic plastic 19-49 wt% and assistant 2-4 wt%. The rice straw may be rice straw and / or husk; and the assistant may be one or several of lubricant, plasticizer, uvioresistant agent, antioxidant, stuffing, reinforcer, fire retardant, antistatic agent, coupling agent and adhesive. The production process of the composite material includes stoving and crushing rice straw into 20-300 mesh; mixing straw powder is plastic powder and assistant in a high speed mixer; extruding via mold hole; pelletizing in the pelletizing machine; fast cooling, curing, and making into shaped material.

Owner:上海铭新环卫工程科技有限公司

Connection assembly for joining a turbine housing and a bearing housing and exhaust gas turbocharger

InactiveUS20110299983A1Affecting costImprove pollutionPump componentsGas turbine plantsExhaust gasEngineering

In a connection assembly of a turbine housing to a bearing housing of an exhaust gas turbocharger and to an exhaust gas turbocharger, wherein the turbine housing and the bearing housing are centered relative to each other and connected to each other in the region of a connection joint including a sealing assembly with a heat shield disposed between the turbine housing and the bearing housing, at least one cutout is provided in the heat shield for accommodating a centering means by way of which the turbine housing and the bearing housing are directly centered relative to one another.

Owner:IHI CHARGING SYST INT

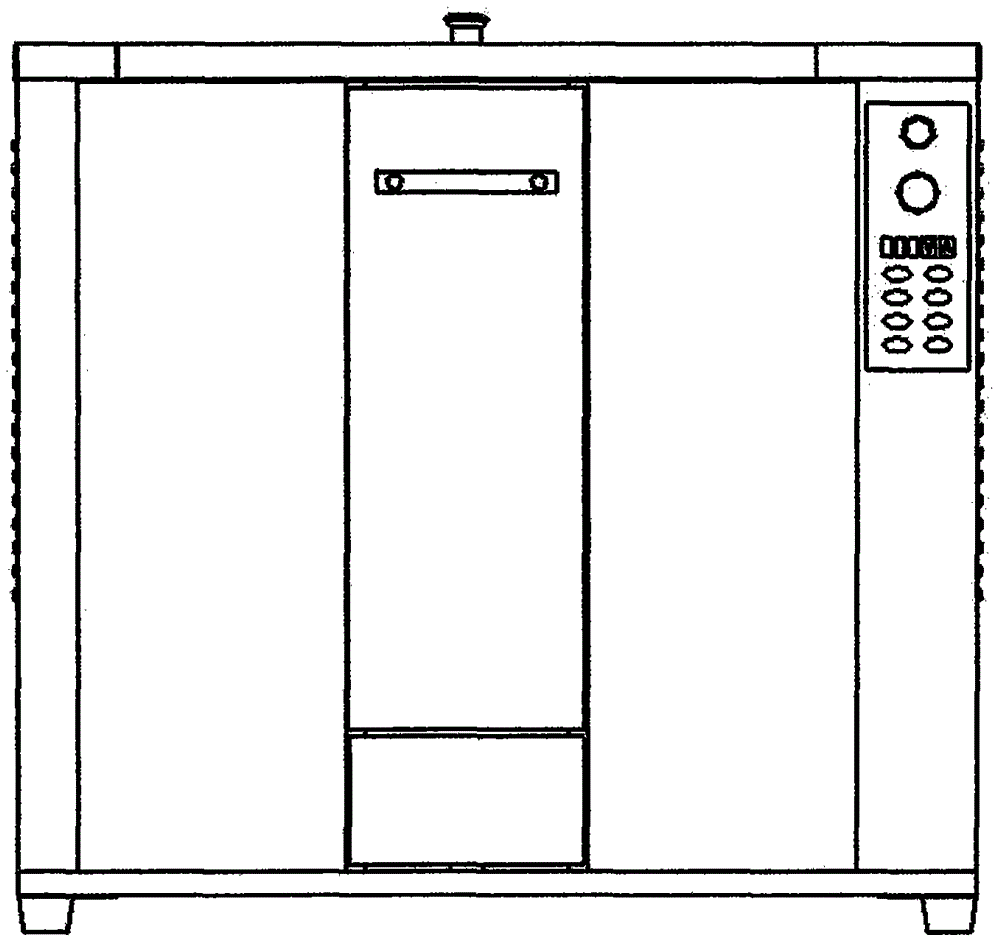

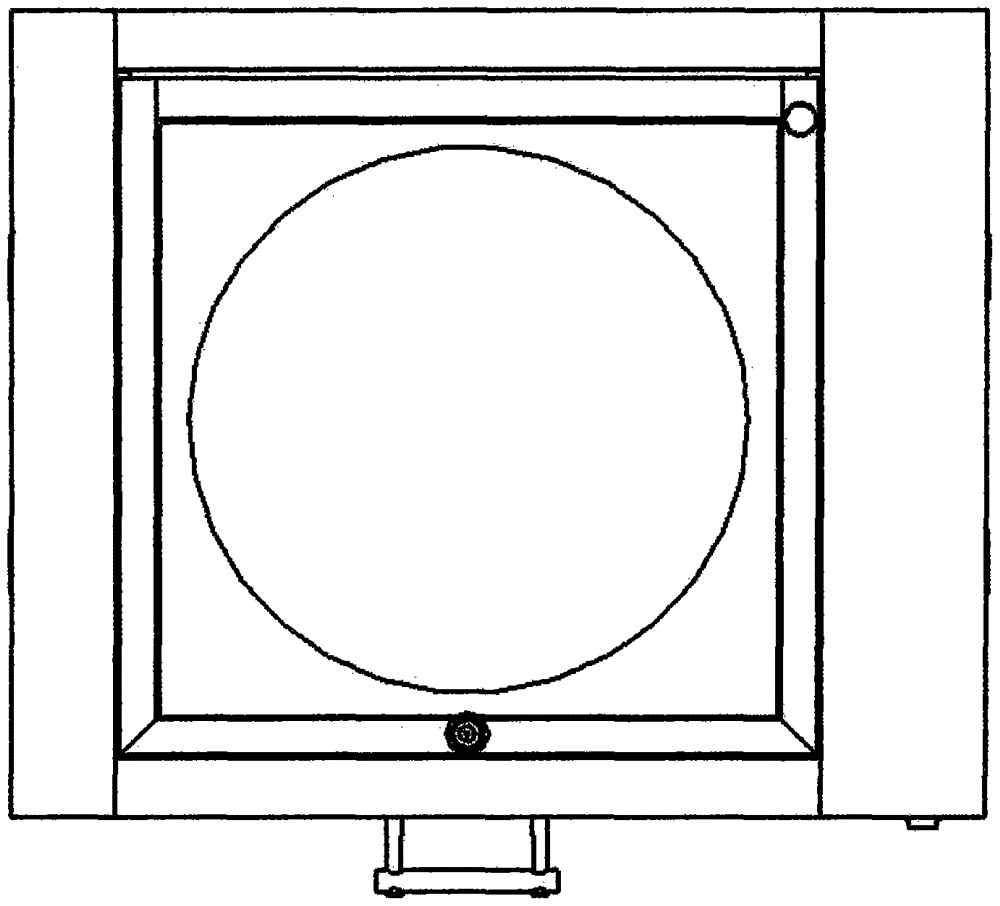

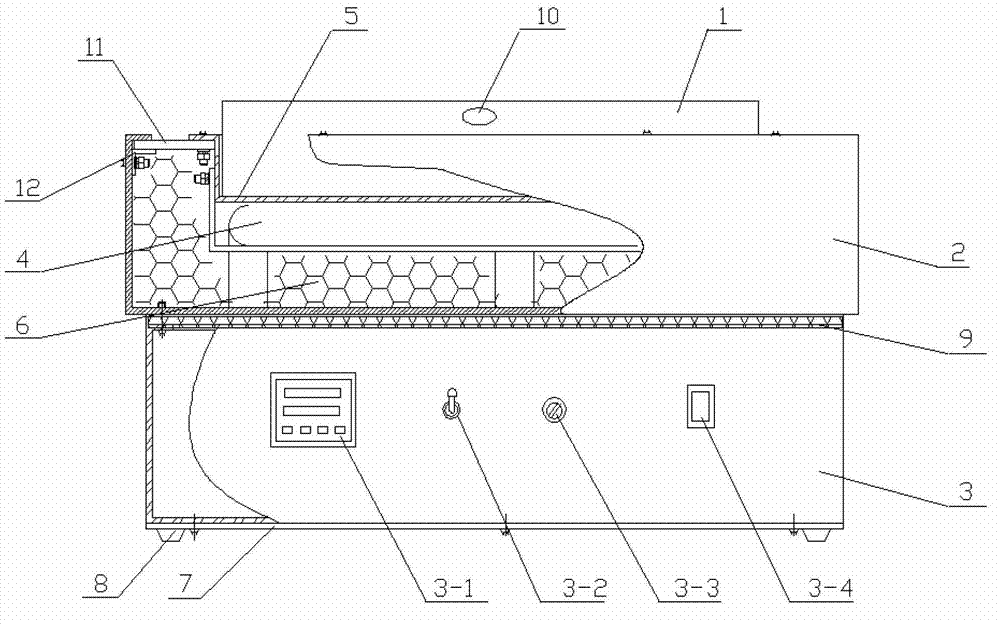

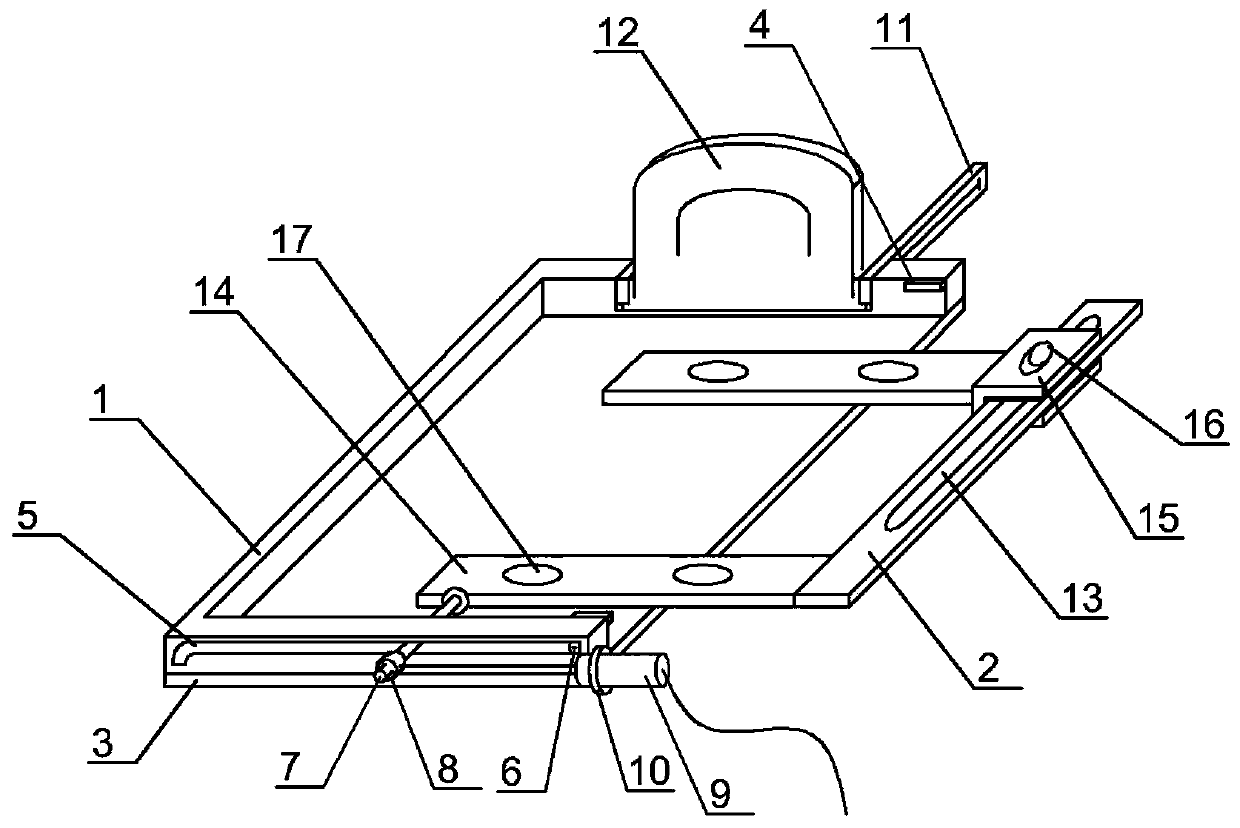

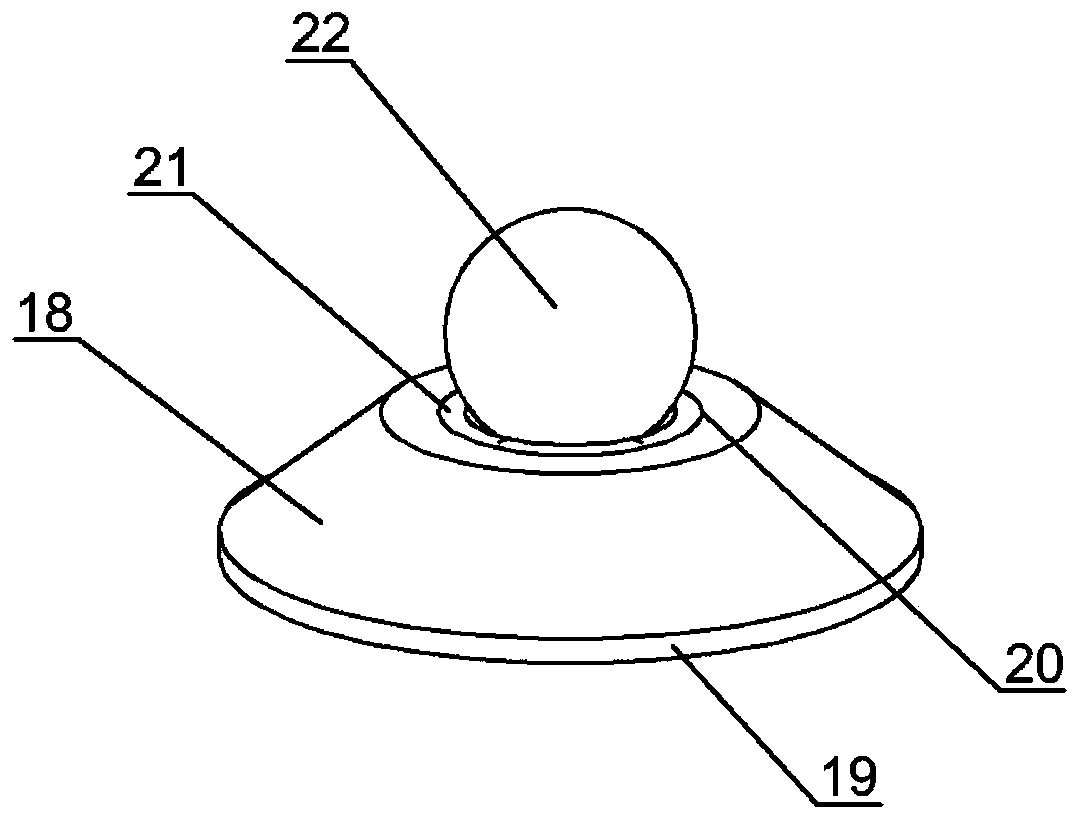

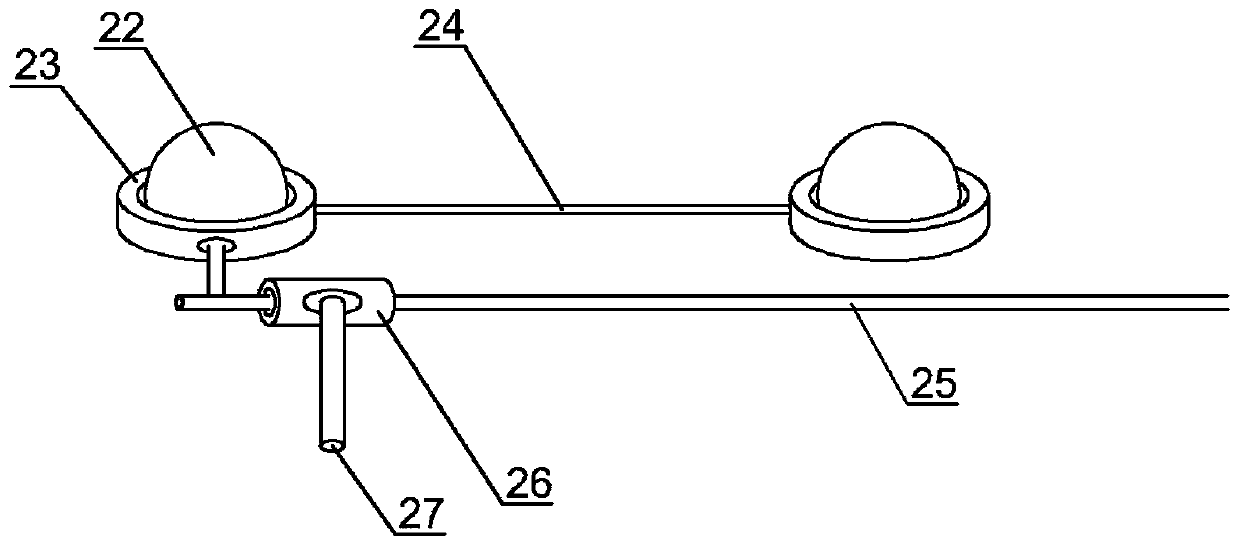

A far-infrared barbecue oven

ActiveCN105686684ASimple and efficient operationReduce power consumptionBaking ovenHigh-frequency/infra-red heating bakingThermal insulationAutomatic control

The invention provides a far-infrared food barbecuing oven which can be used for barbecuing such food as sesame seed cakes, skewered meat, vegetables and potatoes. The multifunctional far-infrared food barbecuing oven comprises a thermal insulation box body, a food rotating tool mechanism, an oil and water storage mechanism, a safe closing and opening door, an operation panel, an intelligent electric control system, a far-infrared heating mechanism, a temperature control mechanism, a hot air inner circulation mechanism, a motor transmission mechanism, a smoke outlet and an observation window. Through the operation panel mechanism, the types of barbecued food can be selected and the corresponding food barbecuing time, temperature and heat power parameters can be set; the intelligent electric control system automatically controls the food rotating tool mechanism, the far-infrared heating mechanism, the temperature control mechanism, the hot air inner circulation mechanism, and the motor transmission mechanism. The far-infrared barbecue oven is multifunctional in food barbecuing, is convenient to control when the food is cooked, is clean and hygienic, saves energy and is environmentally-friendly, is safe to operate, prevents workers from being scalded and is high in efficiency.

Owner:张福龙

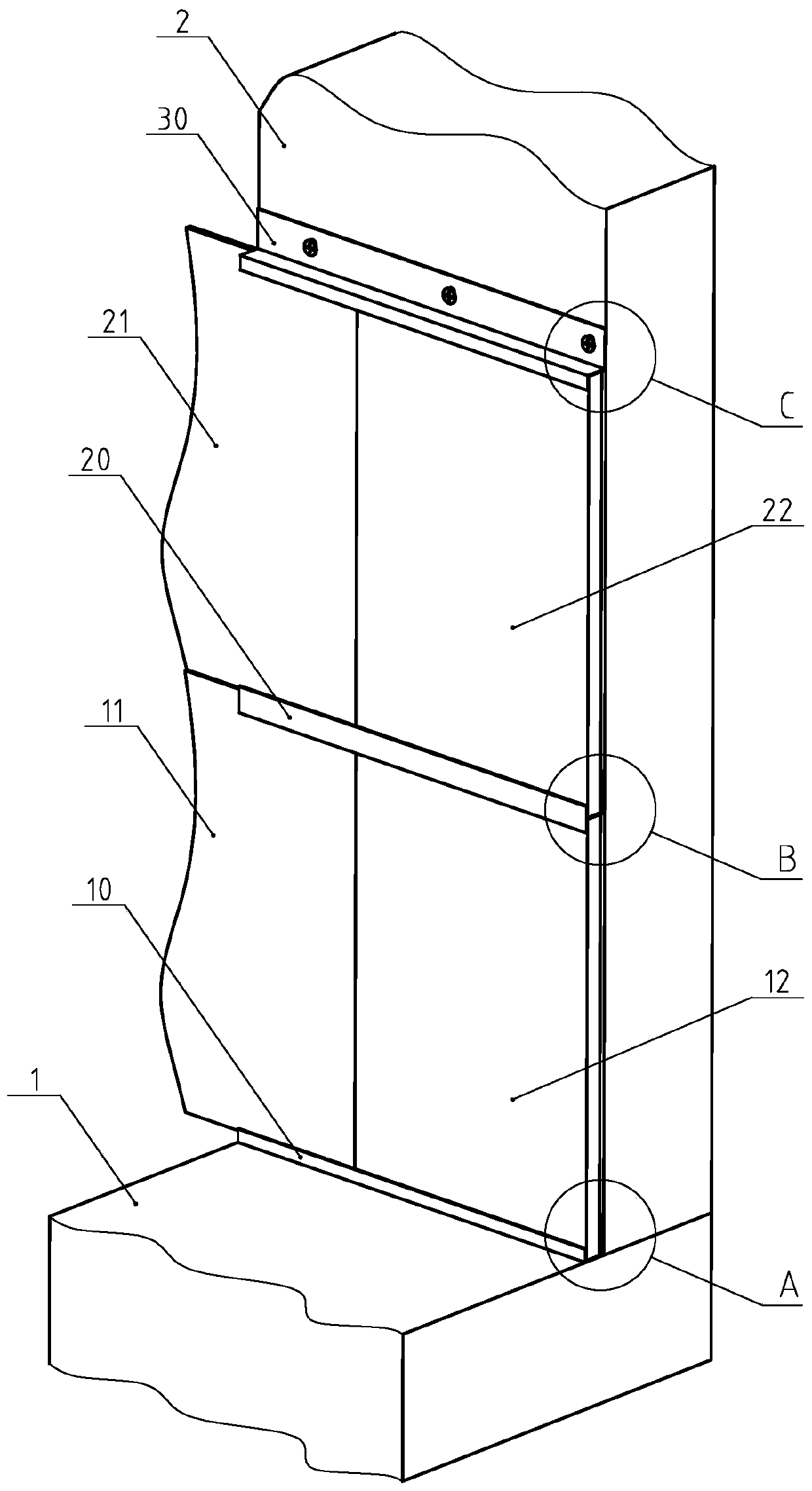

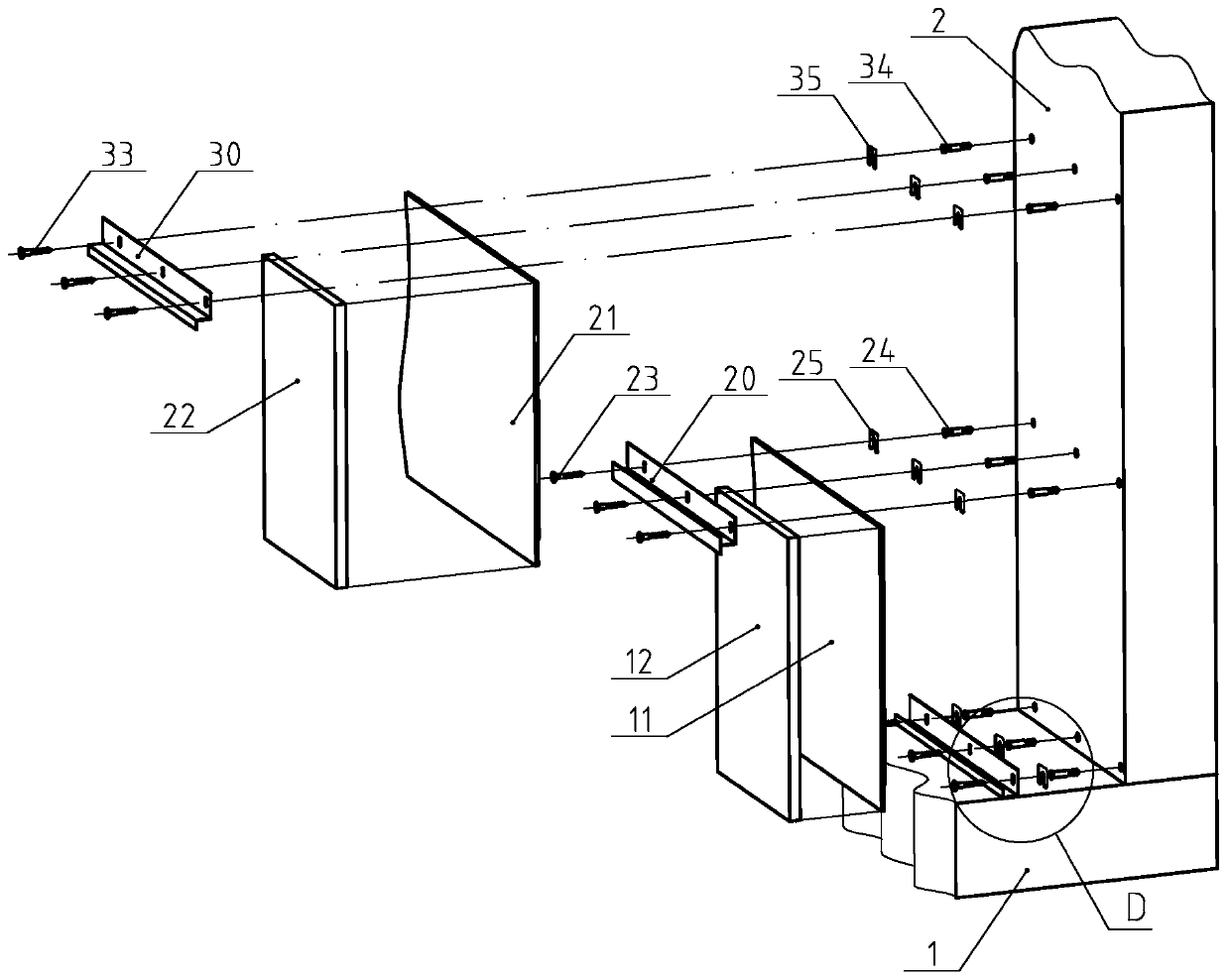

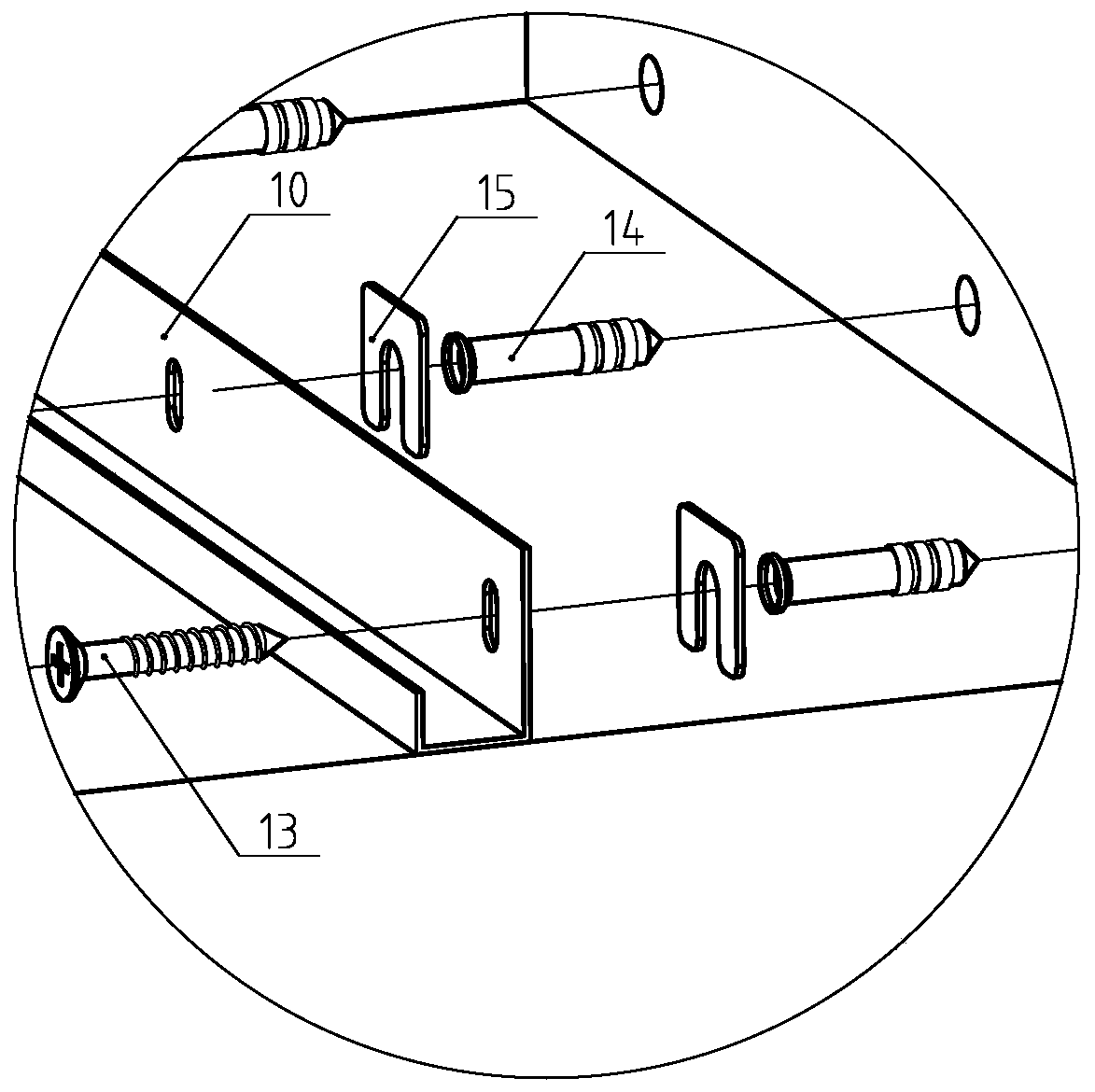

Paving method of wall covering plate

ActiveCN109736520APut an end to the hidden danger of falling and hurting peopleAvoid hollowingCovering/liningsEngineeringMoisture

The invention discloses a laying method of a wall covering plate, and belongs to the field of decoration. The method comprises the following steps: 1, placing an auxiliary line; 2, placing and fastening a first pressing strip; 3, placing first pearl wool; 4, placing a first wall surface covering plate; 5, placing and fastening a second pressing strip; 6, placing second pearl wool; 7, placing a second wall surface covering plate; and 8, placing and fastening a second pressing strip. By adopting the method disclosed by the invention, the following beneficial effects can be achieved: 1, the hidden danger that the ceramic tile falls off to hurt people due to hollowing is completely eradicated; 2, no moisture is emitted indoors, and no moisture is generated; 3, no formaldehyde pollution exists;4, the ceramic tile has no load concentration point, so that the ceramic tile is not easy to crack when being impacted; 5, secondary utilization of the ceramic tile is facilitated, resources are efficiently utilized, and resource waste is eradicated; 6, the heat preservation performance and the sound insulation performance of the wall body are improved; 7, the wall body is thinner and lighter, sothat the load of a floor beam body is reduced; and 8, the loss of the use area in a building is reduced.

Owner:QUANZHOU RUILANG MECHANICAL & ELECTRIAL TECH CO LTD

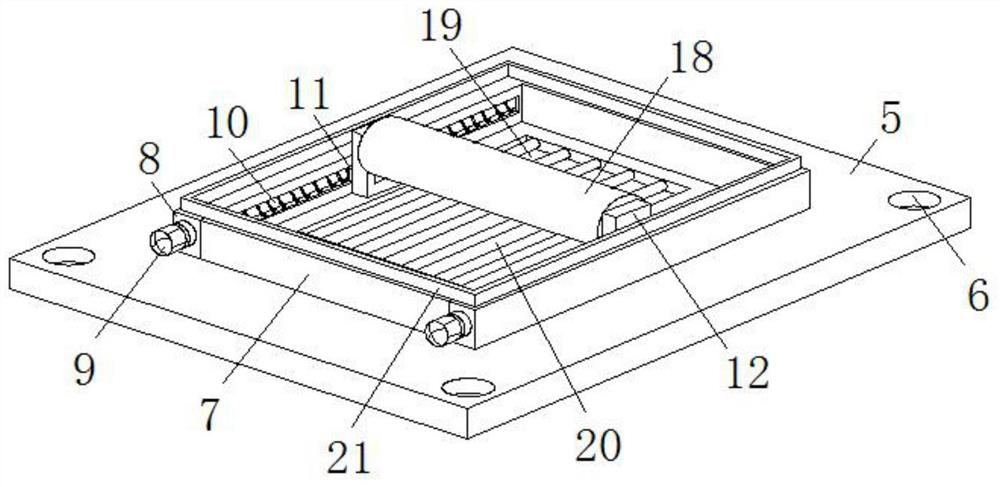

Equipment for producing latex mattresses by adopting high-frequency vulcanization and production process

The invention discloses equipment for producing latex mattresses by adopting high-frequency vulcanization and a production process, and belongs to the technical field of latex mattress production. A high-frequency heater is adopted as a heating source in the latex vulcanization process; and acute collision is caused in dried objects by using polarity motions of water molecules under high-frequencyelectric field effect to realize internal evaporation of the water molecules, so that such advantages as high efficiency, uniform drying, wide applicability, low damage to the dried objects and accurate control of the moisture regain are achieved; a lower mold baseplate is directly used as a cathode of the high-frequency heater for heating the latex mattresses in molds from inside to outside, sothat the products are uniformly heated; the mold opening and closing operations can be automatically realized; the opened molds are continuously conveyed to a mold closing process section for reuse, so that the automation and the continuity of the production process are realized, and the production efficiency is high; and the corner parts of the latex molds are made of nylon or plastic, so that the problem of generation of sparks due to mutual collision of electromagnetic waves is effectively prevented, and the safety is high.

Owner:JIANGSU AIDEFU LATEX PROD

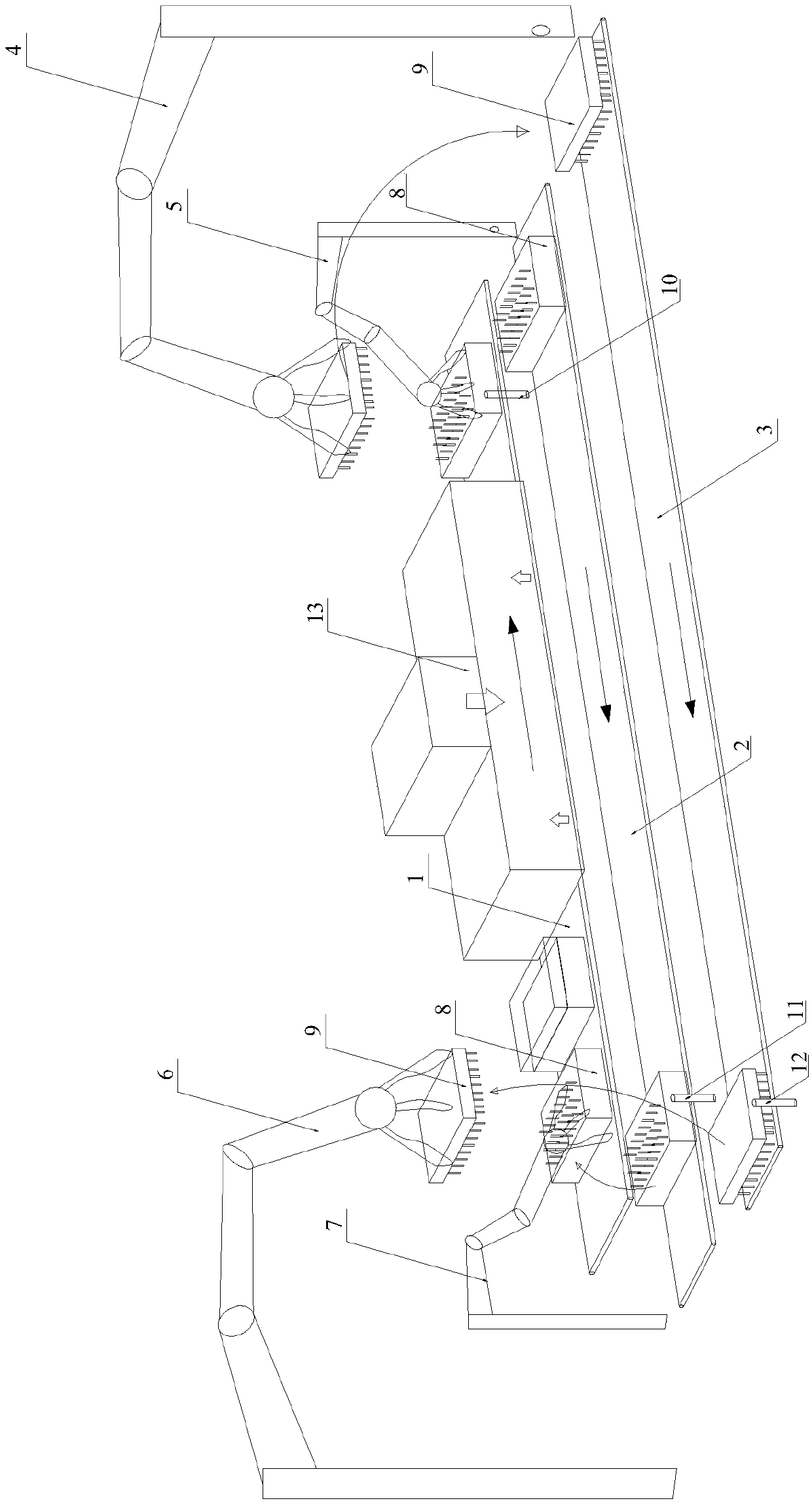

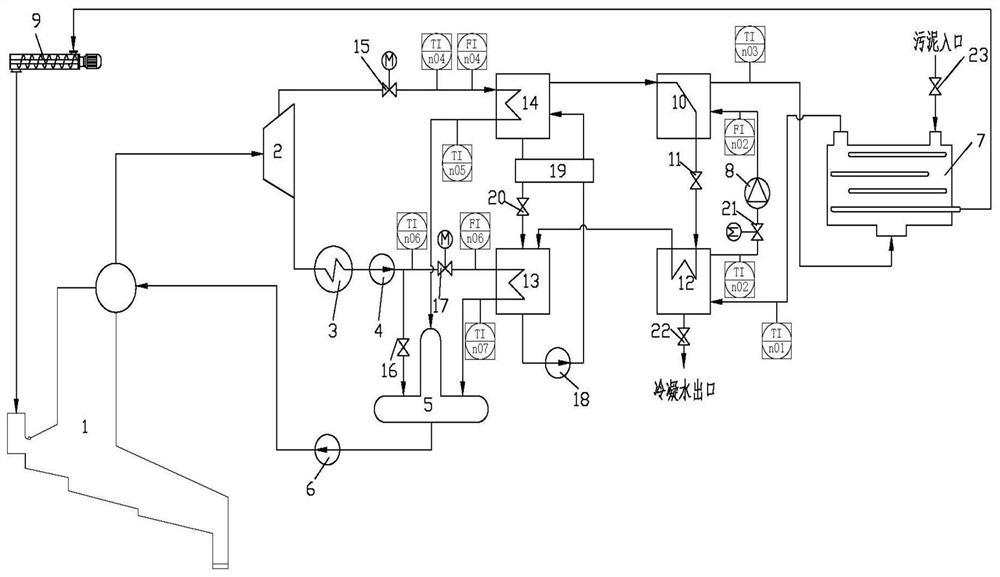

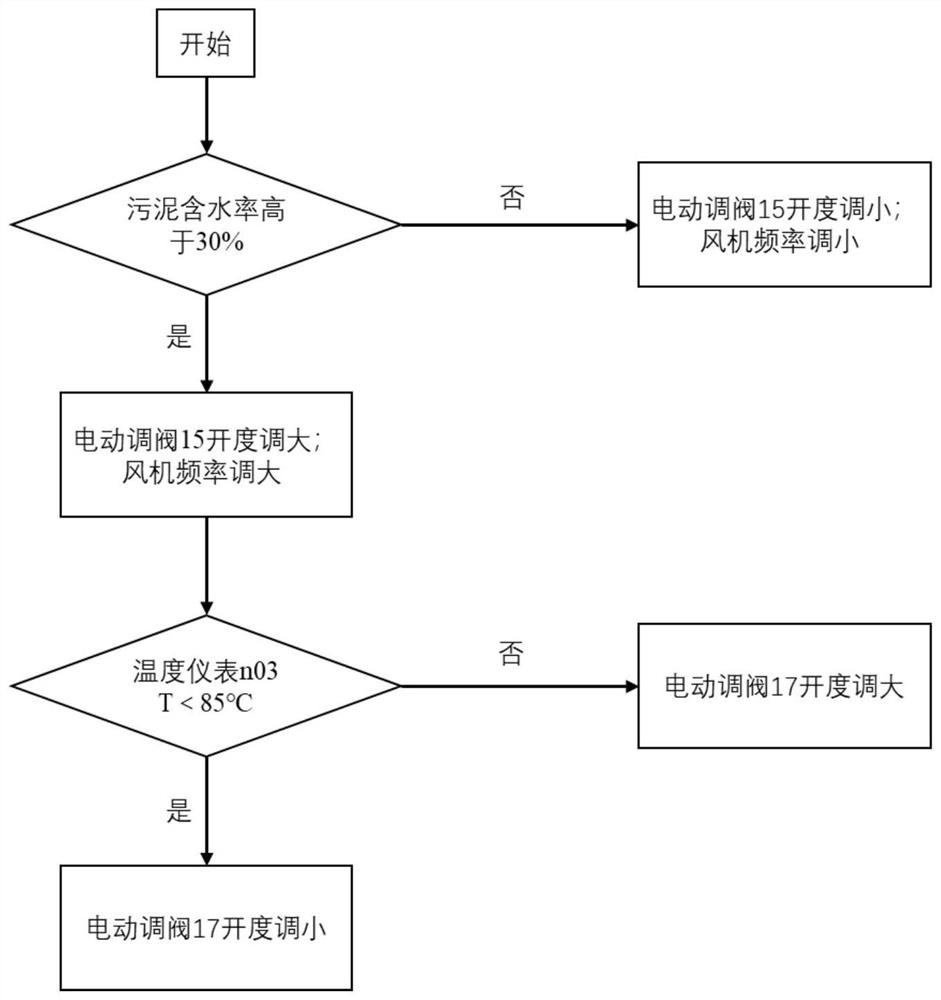

Waste incineration plant coupled sludge low-temperature drying treatment system

ActiveCN112520974AAchieving deep reductionImplement resourcesSludge treatment by de-watering/drying/thickeningLiquid degasificationSludgeAbsorption heat pump

The invention provides a waste incineration plant coupled sludge low-temperature drying treatment system, which comprises a waste incineration power generation system, a belt type drying machine, a first-class absorption heat pump, a circulating fan and a sludge conveyor. A steam turbine is used for low-pressure steam extraction to drive a first-class absorption heat pump, heat in the sludge condensation and dehumidification process is recycled while low-temperature sludge drying is achieved, and the dried sludge is conveyed to an incinerator to be incinerated cooperatively. The system is safe, reliable, free of odor emission in the drying process and environmentally friendly in a plant area, and the steam consumption in the drying process can be reduced by 0.53 t / t wet sludge (the moisture content is 80%); therefore, the deep reduction, harmlessness and resource utilization of the sludge are achieved while the safety, environmental friendliness and economical efficiency of a waste incineration plant are improved.

Owner:SHANGHAI SUS ENVIRONMENT

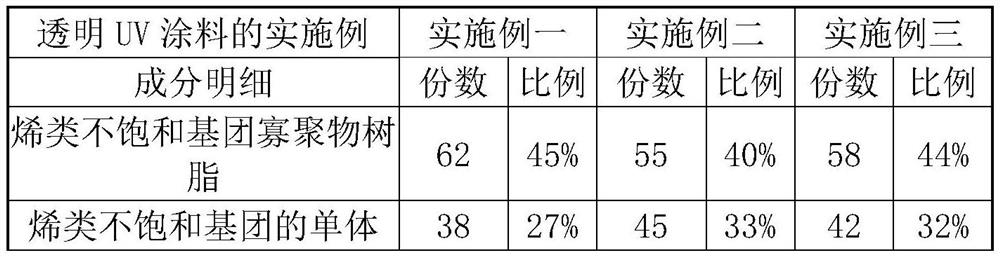

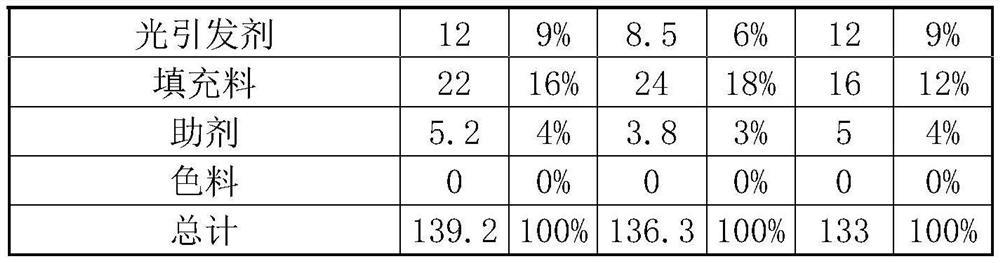

UV coating material and edge sealing process thereof

InactiveCN111944391AReduce gapAvoid breedingAntifouling/underwater paintsPretreated surfacesPolymer scienceHazardous substance

The invention belongs to the technical field of plate edge sealing, and particularly relates to a UV coating material and an edge sealing process thereof, wherein the UV coating material comprises thefollowing raw materials in percentage by weight: 25-65% of alkene unsaturated group oligomer resin, 10-40% of alkene unsaturated group monomer, 3-15% of a photoinitiator, 5-25% of a filler, 0.5-5% ofan assistant and 0-20% of a pigment, and the sum of the components is 100%. The UV coating material has the following advantages that 1, the periphery of a base material is sealed by a photocuring edge sealing process, the photocuring edge sealing process and the base material combining are integrated, glue and edge sealing strips are not used, gaps between the edge sealing strips and the panel are avoided, and dirt and bacteria can be prevented from breeding; 2, the UV photocuring production speed is far higher than the edge sealing speed of the traditional edge sealing strip, the UV photocuring time only needs several seconds, the glue curing time does not need to be waited, the packaging can be realized after the glue is cured, and the productivity can be greatly improved; 3, the UV coating material is safe and environment-friendly, and does not emit harmful substances; and 4, local scratches and damages can be repaired for the second time, so that the phenomenon of abutted seams is avoided after repairing, and the overall service life is effectively prolonged.

Owner:JETCOAT SHANGHAI CO LTD CHINA

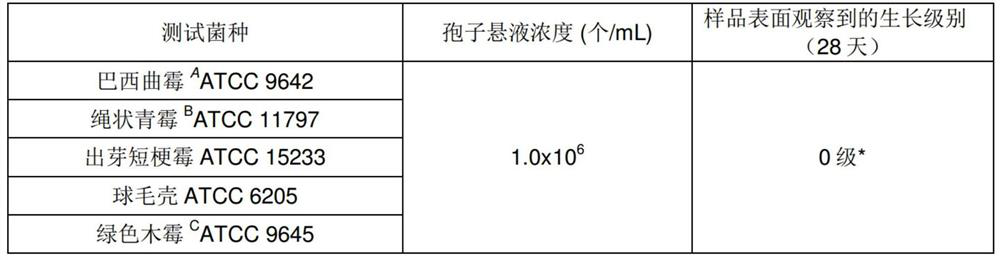

Energy-saving temperature controlling heating stage and constant temperature controlling method thereof

ActiveCN103256708AHeating up fastHigh control precisionAir heatersTemperature controlThermal insulation

The invention relates to an energy-saving temperature controlling heating stage and a constant temperature controlling method of the energy-saving temperature controlling heating stage. The energy-saving temperature controlling heating stage and the constant temperature controlling method of the energy-saving temperature controlling heating stage solve the problems that a conventional temperature controlling box is slow in temperature increase and temperature of a conventional electric heating plate can not be stably controlled. The energy-saving temperature controlling heating stage comprises a thermal insulation box cover, a heating cavity and an electric control operation box, wherein the thermal insulation box cover, the heating cavity and the electric control operation box are sequentially connected from top to bottom. A heating device and a soaking plate are arranged in the heating cavity. The upper surface of the heating device is tightly connected with the lower surface of the soaking plate. Heat insulating and preserving materials are filled in a cavity of the lower surface of the heating device. An automatic sealed ring controlling regulator, a heating switch, a power supply switch and a fuse cutout are arranged on the electric control operation box.

Owner:BEIJING JIEYALI ELECTRONICS TECH

Composition for preparing ceramic cubbyhole

The invention discloses a composition for preparing a ceramic cubbyhole. The composition for preparing the ceramic cubbyhole is made from, by weight, 60% of foamed aluminum powder, 30% of silicon carbide, 2% of active calcium, 5% of bovine-derived bone and 3% of a binding agent. According to the composition for preparing the ceramic cubbyhole, formulation is simple, the cost is relatively low, a traditional single material is changed, the composition for preparing the ceramic cubbyhole is processed with ceramic materials, so that performance of finished products is stable, no toxic and harmfulsubstances are scattered, and attractiveness is high.

Owner:ANHUI QINGHUAFANG FINE BONE PORCELAIN

Automatic sewage lifting device with oil-separating apparatus

InactiveCN102235029ASave civil construction investment costsEasy to installFatty/oily/floating substances removal devicesSewerage structuresOil separationCheck valve

The invention discloses an automatic sewage lifting device with an oil-separating apparatus, which has the functions of automatic sewage lifting and simple oil separation. The automatic sewage lifting device disclosed by the invention is characterized in that a water inlet is in butt joint with a water outlet by a flange; a feed water check valve and a four-way water distributor are connected by a special hole and a flange; a discharge water check valve is in flanged joint with a discharge pipe; a solid-fluid separator is in flanged joint with a pipe; and the bottom of the solid-fluid separator is provided with a hole, welded with the pipe and then in flanged joint with a submersible sewage pump. The automatic sewage lifting device disclosed by the invention has the advantages of environment friendliness, health and space saving.

Owner:ANHUI TIANJIAN ENVIRONMENTAL PROTECTION

Smokeless anti-fatigue moxa-moxibustion stick and preparation method thereof

InactiveCN106727833AGood adhesionNo emissionAntinoxious agentsOil/fats/waxes non-active ingredientsChemistryRaw material

The invention discloses a smokeless anti-fatigue moxa-moxibustion stick and a preparation method thereof. The smokeless anti-fatigue moxa-moxibustion stick comprises, by weight, moxa carbon powder, chrysanthemum extract, Siberian elm bark powder, epimedium herb powder and rubber powder. Chrysanthemum is treated by matching various processes, and effective components including linarin in the chrysanthemum are extracted at the highest extraction rate. Compared with a general traditional extraction method, the matched various processes can maximally extract the linarin and other effective components in the chrysanthemum, the chrysanthemum extract serving as a raw material is added in the preparation process of the moxa-moxibustion strip, efficacy can be maximally played, and moxibustion heat enters a human body when the moxa-moxibustion stick enters is combusted, so that an anti-fatigue function is achieved.

Owner:河南忠澜艾瓷文化开发有限公司

High-strength environment-friendly outer shell for home distribution box and processing method

The invention discloses a high-strength environment-friendly outer shell for a home distribution box. The high-strength environment-friendly outer shell is characterized by being prepared from, by mass, 58% of waste polyurethane, 5% of polyvinyl chloride paste resin, 5% of glass powder, 1% of graphite, 2% of silane coupling agents, 1% of epoxy curing agents, 2% of antioxidants, 2.5% of epoxy resin, 3% of reinforcing agents, 2% of nanometer silicon carbide, 1% of surfactants, 5% of titanium dioxide, 2% of brightening agents, 1% of modified starch, 3% of transparent agents, 0.5% of lime powder, 0.5% of magnesium carbonate, 0.5% of dolomite powder and 5% of everbright fast red. The processed outer shell is attractive in color, harmonious in color matching, stable in performance, free of harmful smells, good in overall strength, small in mass and quite suitable for modern home decoration.

Owner:安徽卓越电力设备有限公司

Environment-friendly household wallboard

InactiveCN105256943AImprove insulation effectWith fire performanceRosin coatingsBuilding componentsEngineeringEnvironmentally friendly

The invention discloses an environment-friendly household wallboard. The environment-friendly household wallboard sequentially comprises a coating board, an insulating board and a concrete fireproof board from the inner layer to the outer layer. The insulating board is arranged between the coating board and the concrete fireproof board, and the coating board, the insulating board and the concrete fireproof board are arranged from thin to thick. The environment-friendly household wallboard is environmentally friendly, free of smells and good in insulating effect, and has fireproof capacity.

Owner:无锡阿炯创意科技有限公司

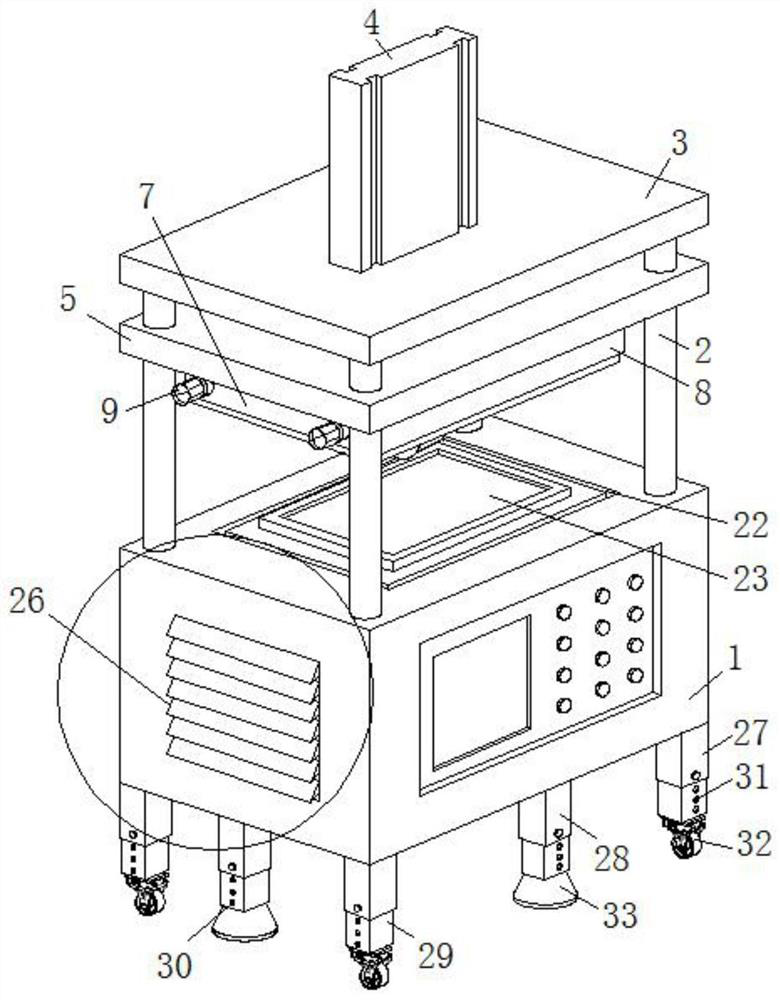

Constant-temperature reciprocating type hot press for touch screen machining

The invention discloses a constant-temperature reciprocating type hot press for touch screen machining. The constant-temperature reciprocating type hot press for touch screen machining comprises a hot press body, the upper end of the hot press body is fixedly connected with a connecting rod, the lower end of the hot press body is fixedly connected with an adjusting supporting leg, the adjusting supporting leg internally comprises a sleeve, the sleeve is internally and movably connected with a movable rod, a fixed screw hole is formed in the interior of the movable rod, a fixed screw is detachably connected to the interior of the sleeve, the fixed screw penetrates through the outer side of the sleeve to be matched with the fixed screw hole in a clamped mode, and the lower end of the adjusting supporting leg is fixedly connected with a fixed supporting leg and a universal trundle in sequence from inside to outside. According to the constant-temperature reciprocating type hot press for touch screen machining, overall resource consumption is reduced, and therefore overall hot pressing is facilitated, a lead screw sliding block drives a hot pressing roller in the interior of an automatic adjusting frame to carry out repeated hot pressing on a touch screen, the overall hot pressing effect is improved, meanwhile, overall moving and fixing are facilitated, and the overall practicability is improved.

Owner:李福生

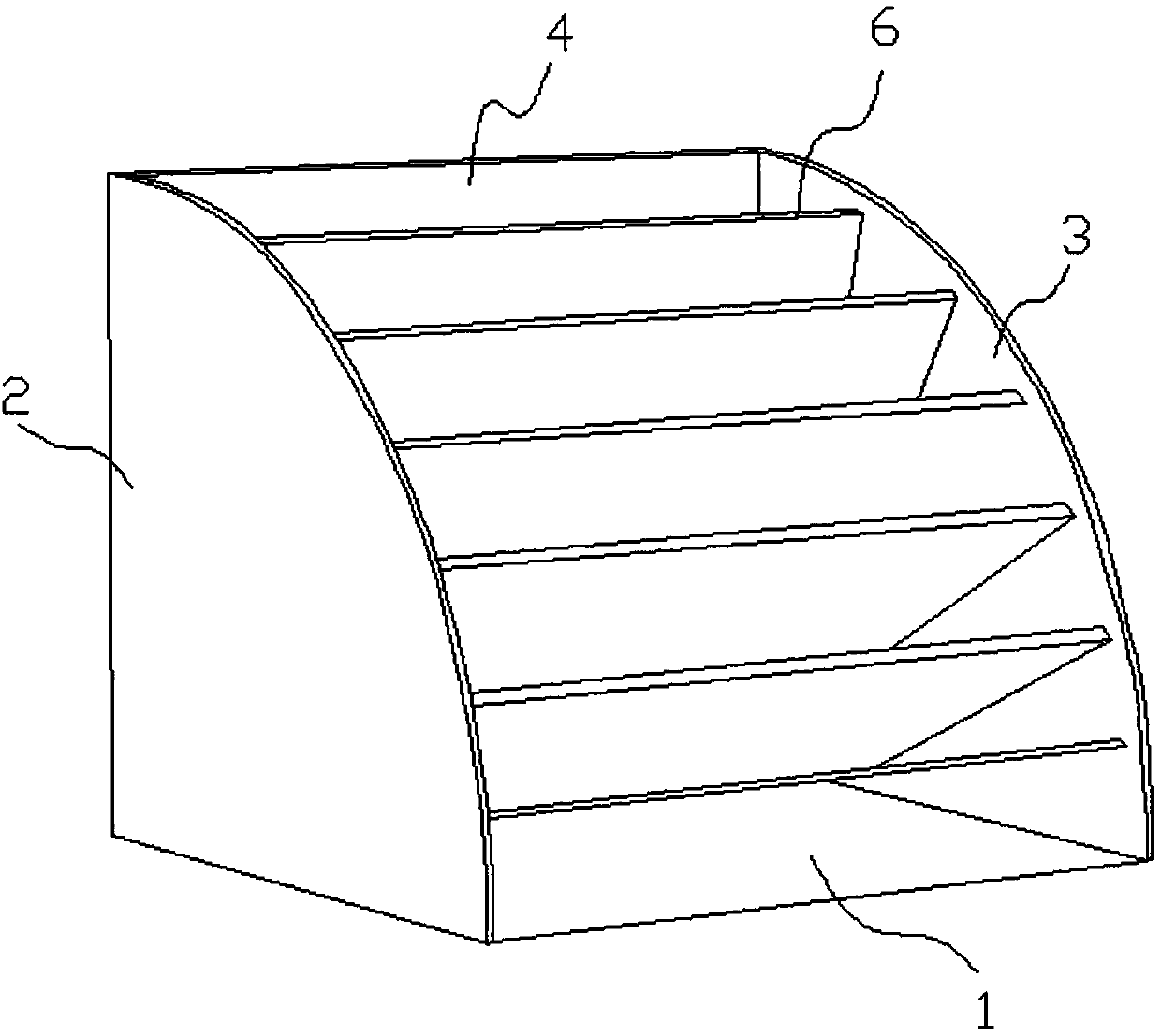

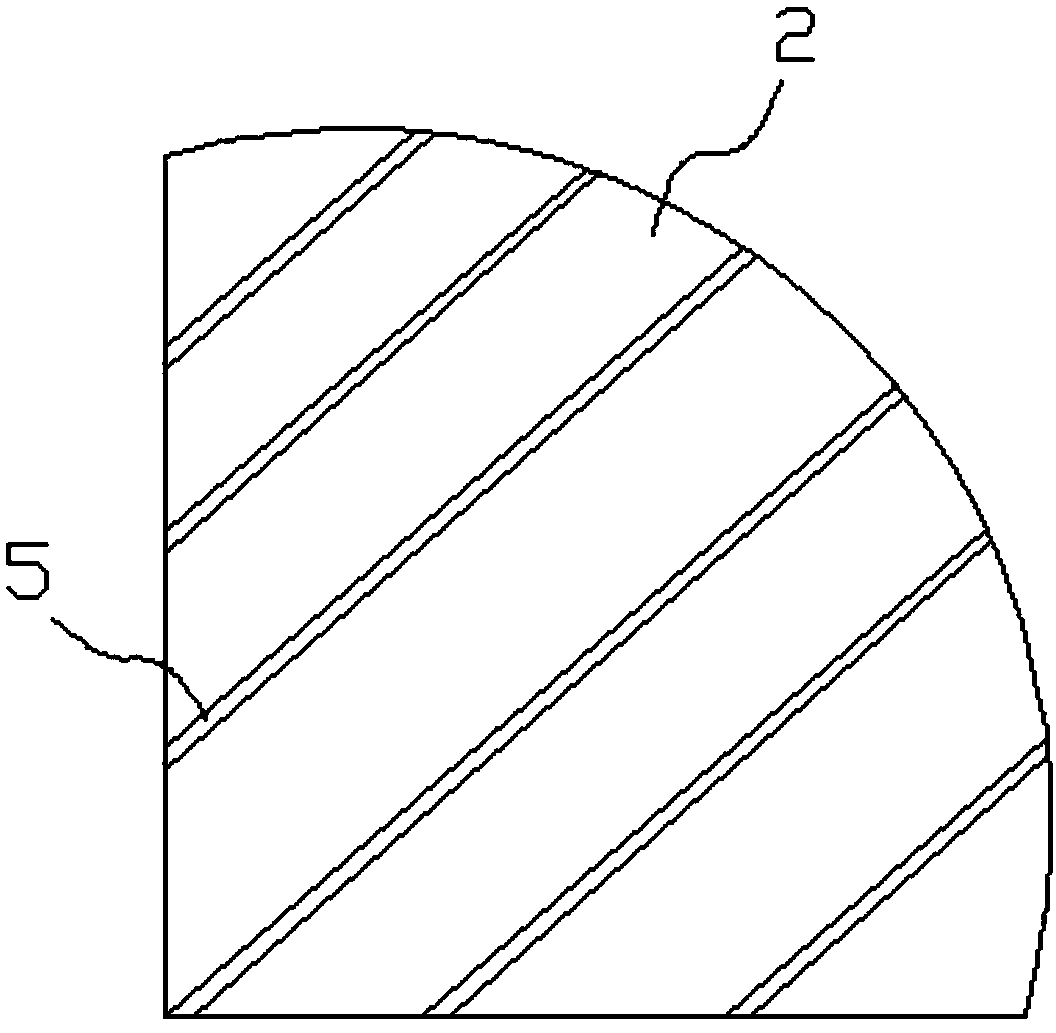

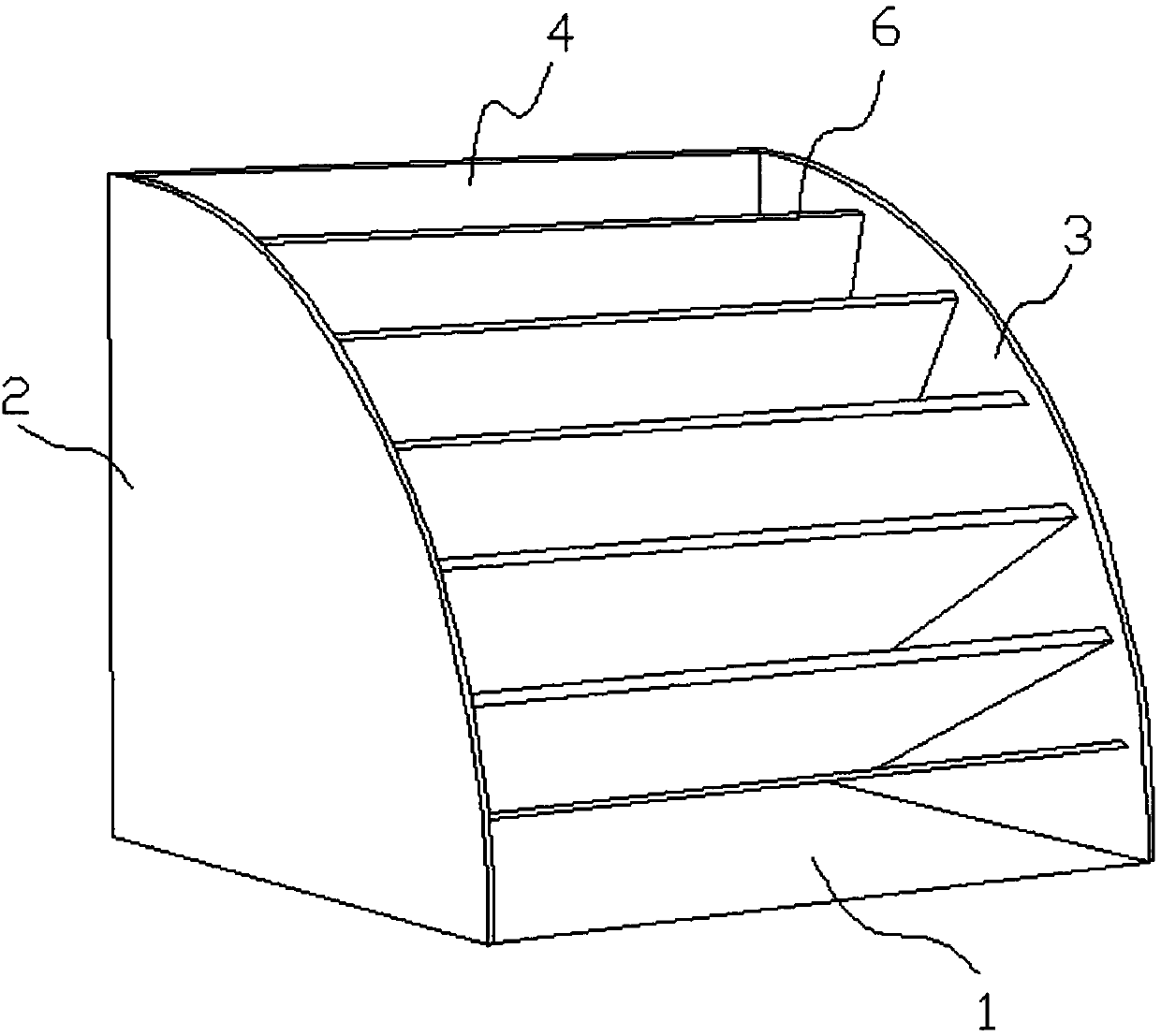

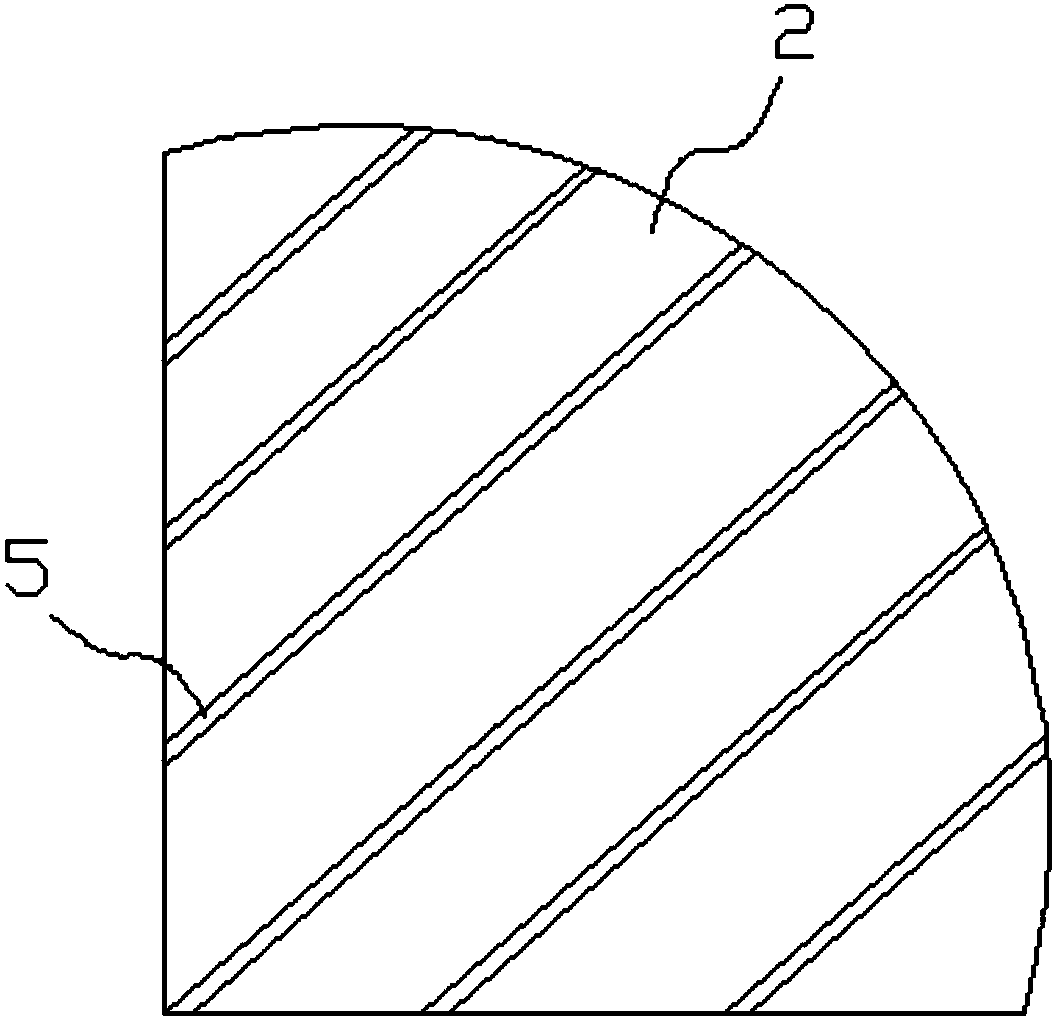

Combined ceramic file shelf

InactiveCN107692568ASimple structureInnovative designBook cabinetsFittingToxic materialArchitectural engineering

The invention discloses a combined ceramic file shelf. The combined ceramic file shelf includes a bottom plate, a left side plate, a right side plate, and a back baffle plate; a bottom edge of the back baffle plate is vertically connected to a back edge of the bottom plate; the left side plate and the right side plate are connected to right sides and right sides of the bottom plate and the back baffle plate respectively; the bottom plate, the left side plate, the right side plate and the back baffle plate are integrally formed through a die; clamping grooves are symmetrically formed in inner walls of the left side plate and the right side plate; sandwich plates are connected between the left clamping grooves and the right clamping grooves; two ends of the sandwich plates are clamped in theclamping grooves so as to achieve free combination. The combined ceramic file shelf is simple in structure, is novel in design, and can achieve free combination; and the combined ceramic file shelf is made of a ceramic material instead of the conventional single material, is stable in finished product performance, will not release toxic substances, and is high in beautiful degree.

Owner:ANHUI QINGHUAFANG FINE BONE PORCELAIN

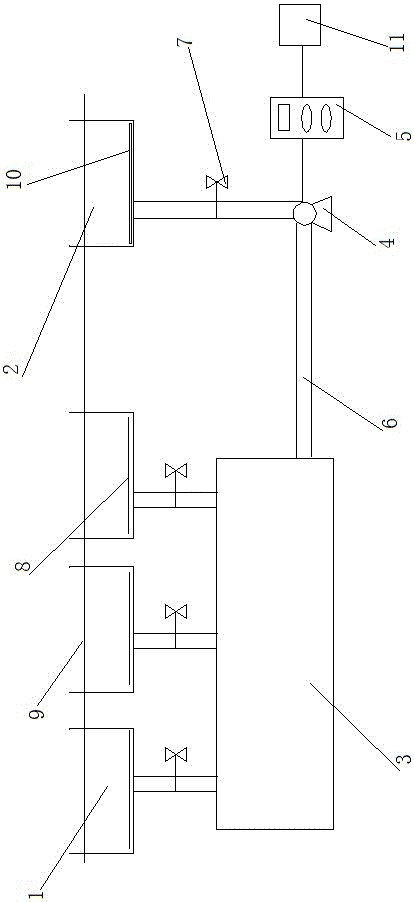

A copper ion concentration automatic balance control device and control method thereof

InactiveCN104060319BAdjustable rate of changeReduce subsequent processing costsCellsWire rodCu2 ions

The present invention involves an automatic balance control device and its control method for a copper ion concentration, which is used for self -regulating balance of copper ion concentration during the production process of electroplating copper bag aluminum wires.Including at least one electroplating groove and a specific slot, an exchange slot, the sequence of connection sequence is a specific slot connecting the electroplating groove through the pipeline. The electroplating groove is connected to the buffer slot through the pipeline. The buffer slot is connected to the specific slot through the pipeThere is also an automatic pump on the pipeline between the buffer groove. There is a CU2+online monitor connected to the buffer groove. A PLC controller is connected to the CU2+online monitor.The concentration controls the high -frequency power output variable voltage by the central control module, that is, control the working current in a specific slot, and achieve the adjustable control of the CU2+concentration change rate in a specific groove, so that the copper ion concentration in the electroplating groove is maintained for a long time onIn terms of the stability required by the process, the slot solution is not required to be diluted and maintained on a regular basis, and the waste liquid is not generated.

Owner:金华市大田线材有限公司

Improved metallic paint preparation process

The invention provides an improved metal paint production process, which comprises the steps of: mixing and stirring acrylic acid and pure acrylic emulsion to form a mixed emulsion; heating the mixed emulsion to 80-85°C and keeping it warm; putting epoxy resin and copolymerized emulsion into the mixed emulsion Wax liquid, stir evenly, and cool to 30~35°C; add glitter powder, sodium carboxymethyl cellulose, propylene glycol phenyl ether and stir evenly to make a metallic paint. The weight ratio of raw materials is 35-45 parts of pure acrylic emulsion, 30-45 parts of acrylic acid, 20-25 parts of epoxy resin, 10-13 parts of copolymerized wax liquid, 10-13 parts of glitter powder, sodium carboxymethyl cellulose 8‑9 parts, 8‑9 parts of propylene glycol phenyl ether.

Owner:何玉珍

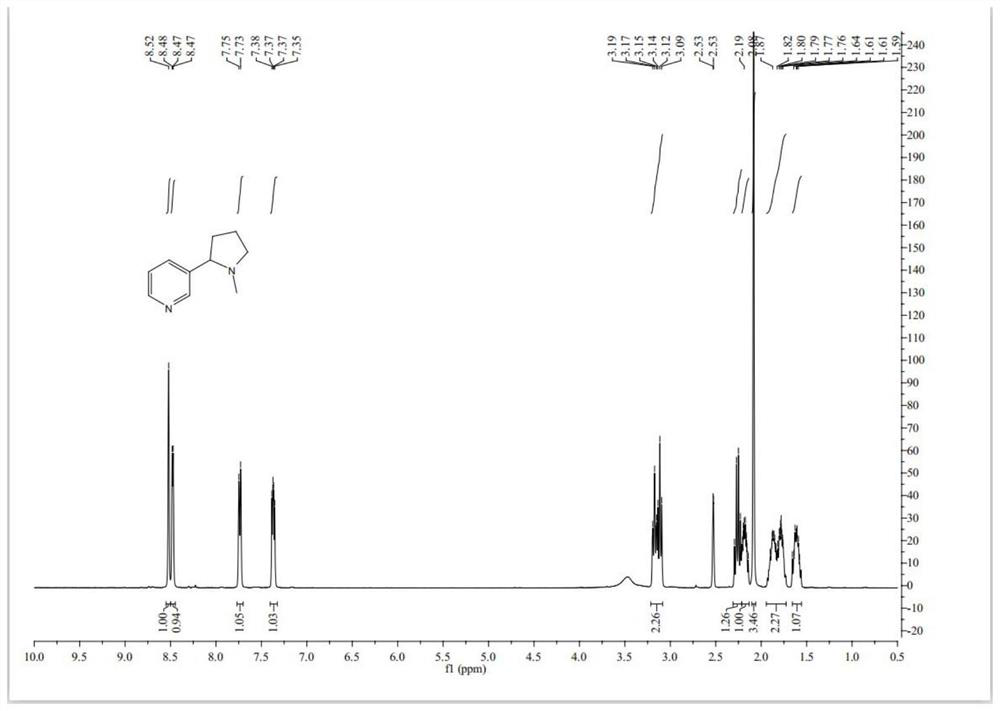

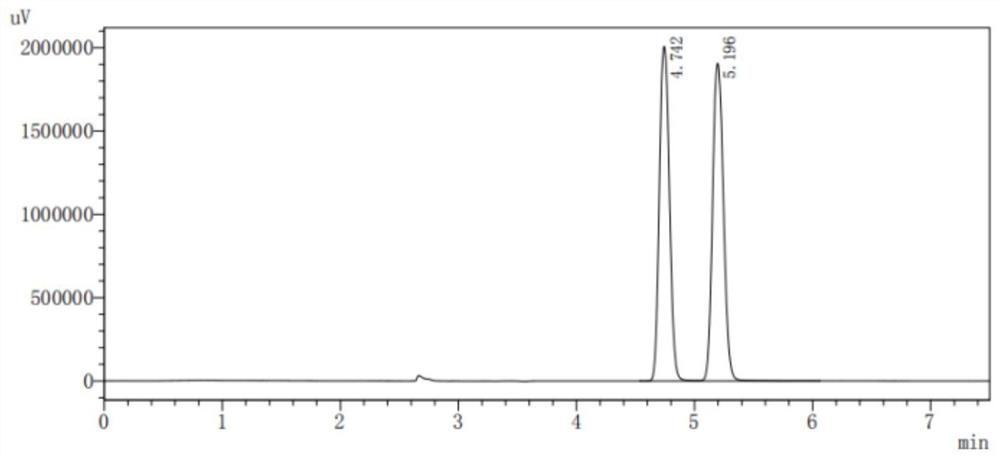

Preparation method of high-purity racemic nicotine

PendingCN114195758ASimple preparation processMild reaction conditionsOrganic chemistryStrong acidsPyridyne

The invention relates to a preparation method of high-purity racemic nicotine, which comprises the following steps: (1) reacting 4-(pyridine-3-yl)-1-butyraldehyde, a strong acid catalyst and 2, 2-dimethoxypropane to obtain a product 3-(4, 4-dimethoxybutyl) pyridine; (2) reacting and oxidizing the 3-(4, 4-dimethoxybutyl) pyridine obtained in the step (1) with an oxidizing agent to obtain a product 4, 4-dimethoxy-1-(pyridine-3-yl) butanone; and (3) dissolving the 4, 4-dimethoxy-1-(pyridine-3-yl) butanone obtained in the step (2) in an organic solvent, reacting under an acidic condition, concentrating under reduced pressure, adding methylamine hydrochloride and a reducing agent, reacting to obtain a racemic nicotine crude product, and refining to obtain the pure racemic nicotine. The method for preparing the racemic nicotine is simple in process, mild in reaction condition, free of gas emission in the reaction process, environment-friendly and high in yield, and is an industrial method which is expected to synthesize the racemic nicotine on a large scale.

Owner:上海零诺生物科技有限公司

An energy-saving temperature-controlled heating platform and its constant temperature control method

ActiveCN103256708BHeating up fastHigh control precisionAir heatersTemperature controlPower switching

Owner:BEIJING JIEYALI ELECTRONICS TECH

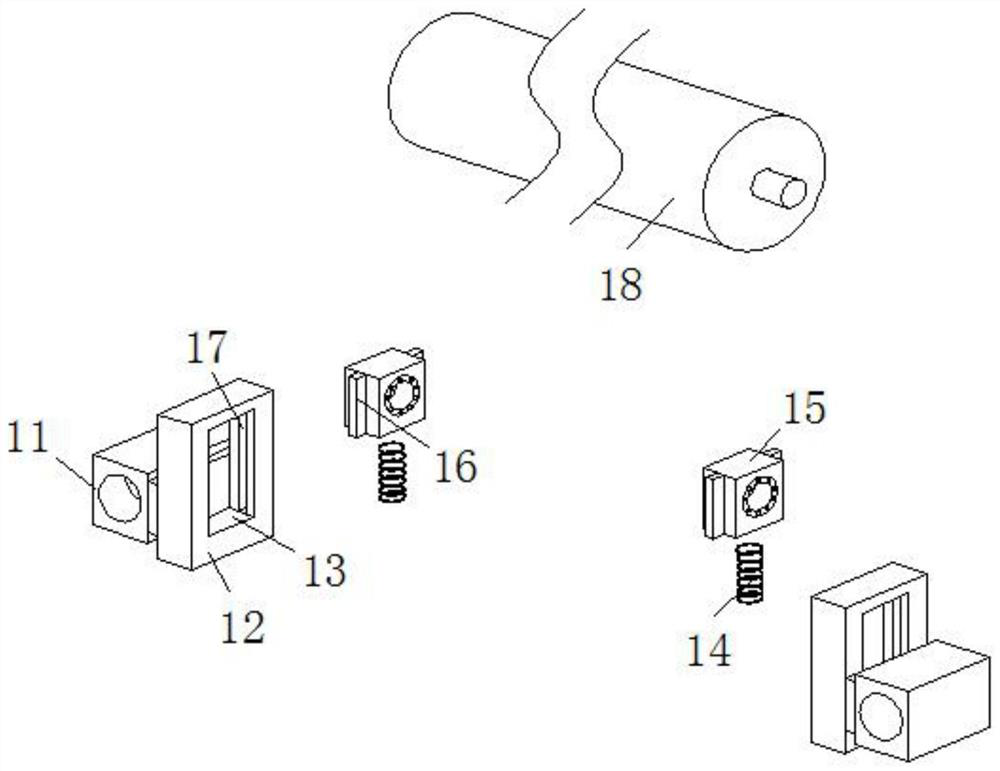

A single-page printing side shifting device

The invention discloses a lateral moving device for single page printing. The device comprises a lateral moving body and an attraction lateral moving body, wherein the lateral moving body is fixed ona single page support bottom plate, a single page spacer is arranged on the inner wall of the lateral moving body, a lateral moving sliding chute is formed in the front side of the lateral moving body, a spring extrusion piece is arranged at the right end in the lateral moving sliding chute, a lateral moving interlocking bar penetrates through the lateral moving sliding chute and sleeved with a lateral moving pipe sleeve, and the lateral moving pipe sleeve is connected with an electric telescopic pole. The more efficient and practical lateral moving device for single page printing is provided.The device laterally moves well printed paper in a negative pressure suction manner, in the lateral moving process, almost no noise or excessive heat dissipation is produced, and the long-term printing task can be met.

Owner:山东银广印务科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com