Mixed wave-absorbing material

A technology of absorbing materials and composite materials, applied in the field of absorbing materials, can solve the problems of high reflectivity and poor impedance matching characteristics of composite absorbing materials, and achieve the effect of improving the absorbing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

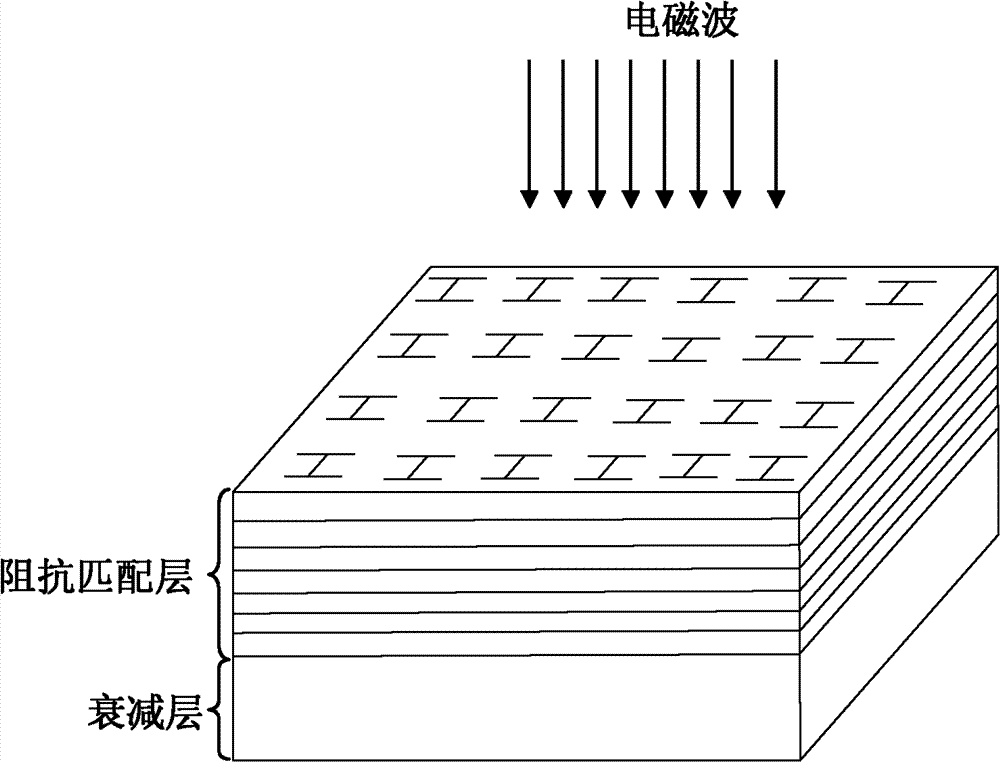

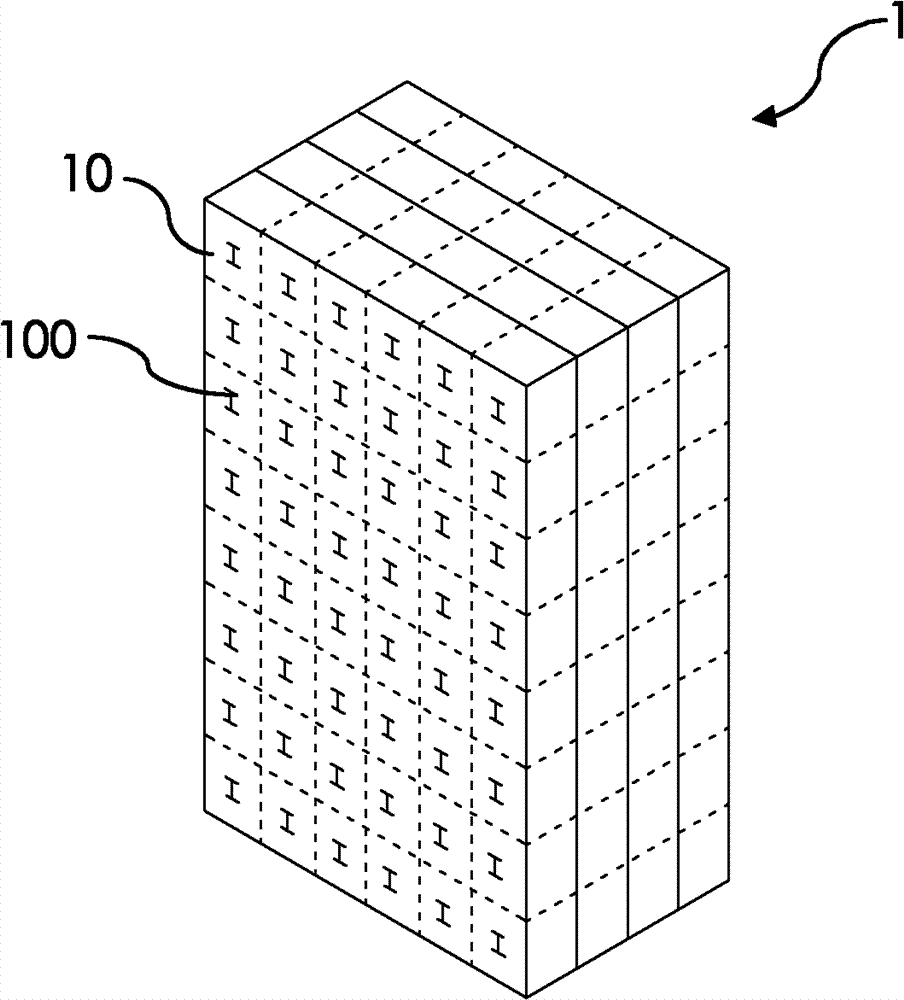

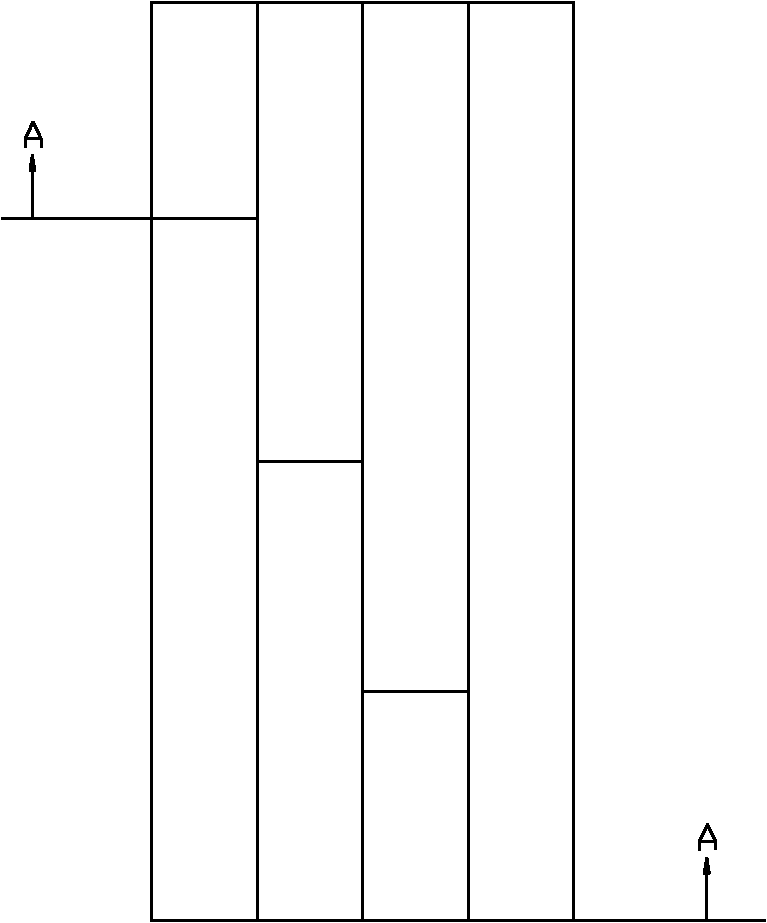

[0027] Please refer to figure 1 , figure 1 It is a schematic diagram of the structure of the hybrid absorbing material of the present invention. The hybrid absorbing material of the present invention uses the traditional absorbing material as the attenuation layer and uses the traditional absorbing material as the substrate to build an impedance matching layer with impedance matching function. The setting of the impedance matching layer makes the traditional absorbing material only need to consider its attenuation characteristics when configuring. Therefore, the traditional absorbing material in the present invention refers to various common absorbing materials with high loss factors, including those with high magnetic dielectric loss. ferrite, conductive polymer with high resistance loss, carbon black with high dielectric loss, B a T i o 3 , F e T i o 3 ,P b T i o 3 Wait. The attenuation layer is not limited to the examples of traditional absorbing materials mentio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com