Ni-based alloy magnetic microwave absorbing material and preparation method thereof

A magnetic wave-absorbing, base alloy technology, applied in the field of Ni-base alloy magnetic wave-absorbing materials and its preparation, can solve the problems of low saturation magnetization, small microwave permeability, poor wave-absorbing ability, etc., and achieve good temperature stability , Strong anti-oxidation ability, good wave-absorbing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

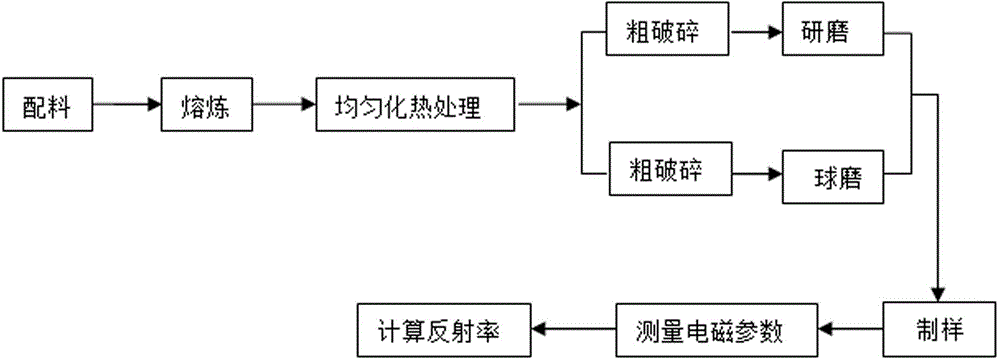

Method used

Image

Examples

Embodiment 1

[0030] Preparation of Pr 16.67 Ni 83.33 The specific implementation steps of the atomic percentage magnetic wave-absorbing material:

[0031] 1) The Pr and Ni metals with a purity ≥ 99.50% are classified as Pr 16.67 Ni 83.33 Stoichiometric ratio ingredients of molecular formula;

[0032] 2) Smelting in a standard electric arc furnace under the protection of argon, in order to ensure that the composition of the alloy is uniform, repeatedly turning and melting for 3 to 4 times;

[0033] 3) Heat the smelted ingot at 1000°C for 120 hours under vacuum protection, and then quench it in ice water;

[0034] 4) breaking the obtained alloy ingot into a coarse powder with particle size less than 0.5mm, and then sieving under a 300-mesh sieve;

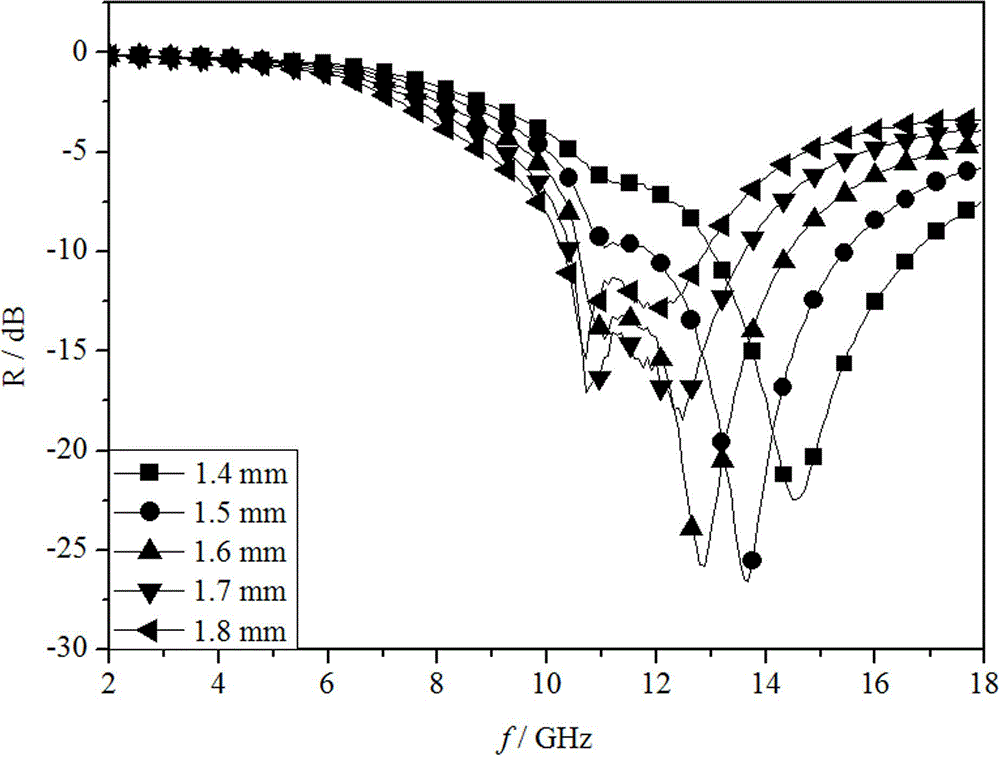

[0035] Product testing: mix according to the ratio of alloy powder: paraffin wax = 4:1 (mass ratio), make coaxial samples with inner diameter and outer diameter of 3mm and 7mm respectively, and thickness of about 3.0-4.0mm, using HP8722ES mic...

Embodiment 2

[0041] Preparation of Pr 16.67 Ni 80 Fe 3.33 The specific implementation steps of the atomic percentage magnetic wave-absorbing material:

[0042] 1) Pr, Fe, Ni metals with a purity ≥ 99.50%, according to Pr 16.67 Ni 80 Fe 3.33 Stoichiometric ratio ingredients of molecular formula;

[0043] 2) Smelting in a standard electric arc furnace under the protection of argon, in order to ensure that the composition of the alloy is uniform, repeatedly turning and melting for 3 to 4 times;

[0044] 3) heat the smelted ingot at 1050°C for 72 hours under vacuum protection, and then quench it in ice water;

[0045] 4) breaking the obtained alloy ingot into a coarse powder with particle size less than 0.5mm, and then sieving under a 300-mesh sieve;

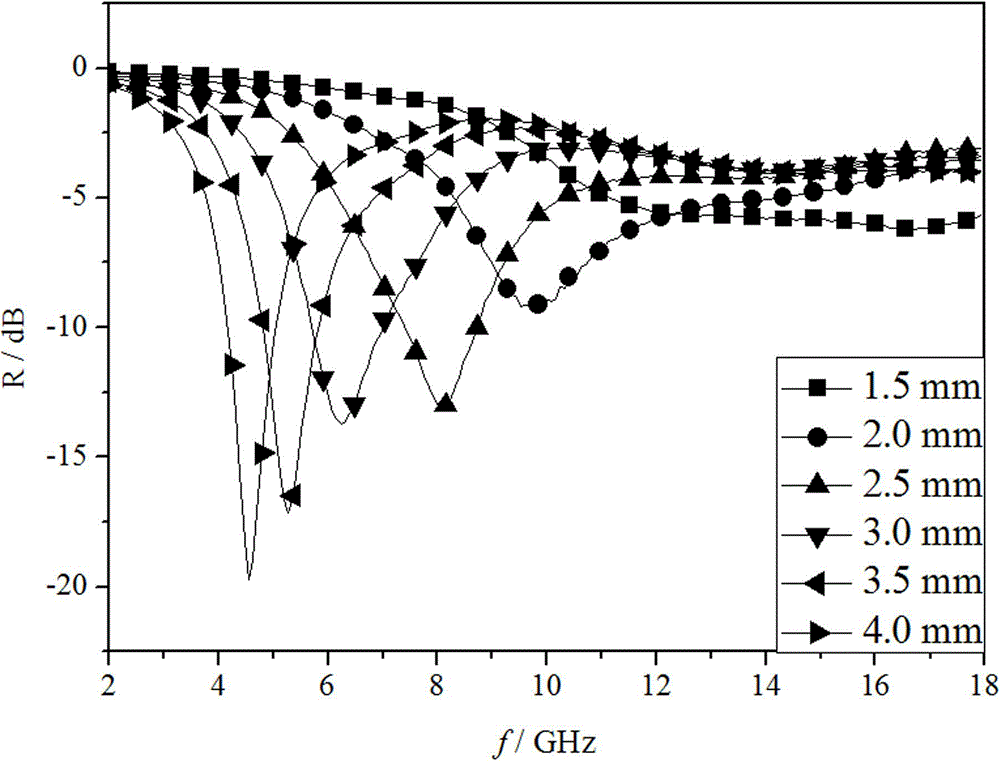

[0046] Product testing: mix according to the ratio of alloy powder: paraffin = 4:1 (mass ratio), make a coaxial sample with outer diameter and inner diameter of 7mm and 3mm respectively, and a thickness of about 3.0-4.0mm, measure and cal...

Embodiment 3

[0050] Preparation of Pr 16.67 Ni 75 Fe 8.33 The specific implementation steps of the atomic percentage magnetic wave-absorbing material:

[0051] 1) Pr, Fe, Ni metals with a purity ≥ 99.50%, according to Pr 16.67 Ni 75 Fe 8.33 Stoichiometric ratio ingredients of molecular formula;

[0052] 2) Smelting in a standard electric arc furnace under the protection of argon, in order to ensure that the composition of the alloy is uniform, repeatedly turning and melting for 3 to 4 times;

[0053] 3) heat the smelted ingot at 1050°C for 90 hours under vacuum protection, and then quench it in ice water;

[0054] 4) breaking the obtained alloy ingot into a coarse powder with particle size less than 0.5mm, and then sieving under a 300-mesh sieve;

[0055] Product testing: mix according to the ratio of alloy powder: paraffin = 4:1 (mass ratio), make a coaxial sample with outer diameter and inner diameter of 7mm and 3mm respectively, and a thickness of about 3.0-4.0mm, measure and cal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com