A kind of sheet-like ceramic wave-absorbing material and its preparation method

A wave-absorbing material and sheet-like technology, applied in the field of sheet-shaped ceramic wave-absorbing materials and their preparation, can solve problems such as difficult to achieve impedance matching, inability to provide high magnetic loss, low saturation magnetization, etc., to achieve improved impedance matching performance, Good microwave absorption characteristics, enhanced magnetic exchange effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

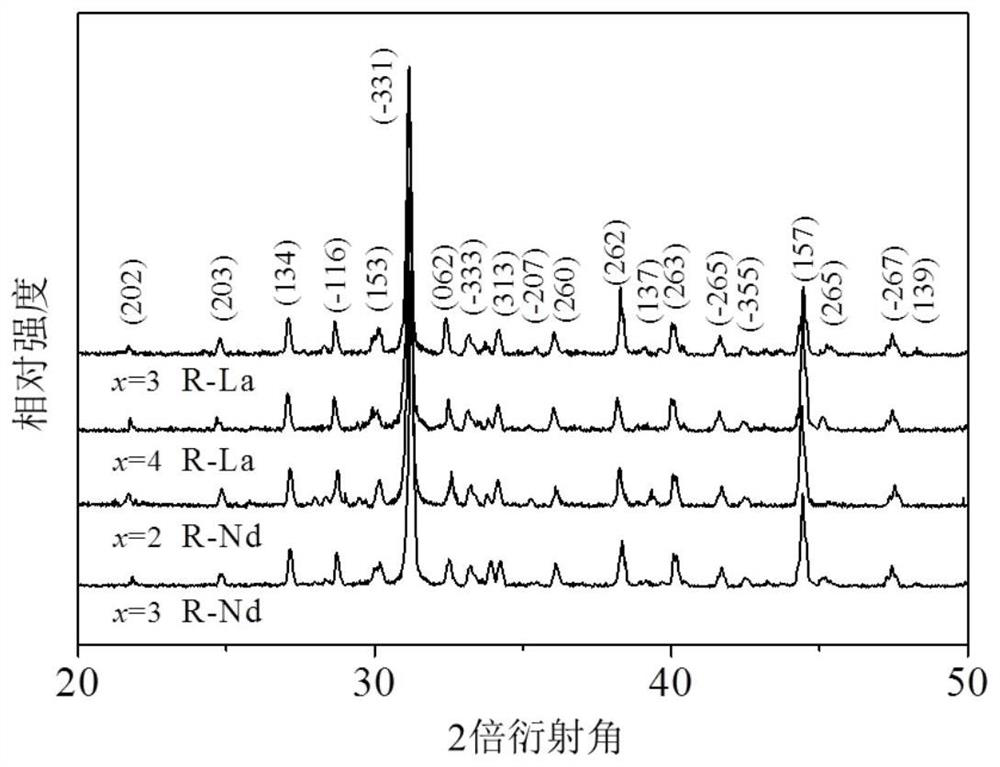

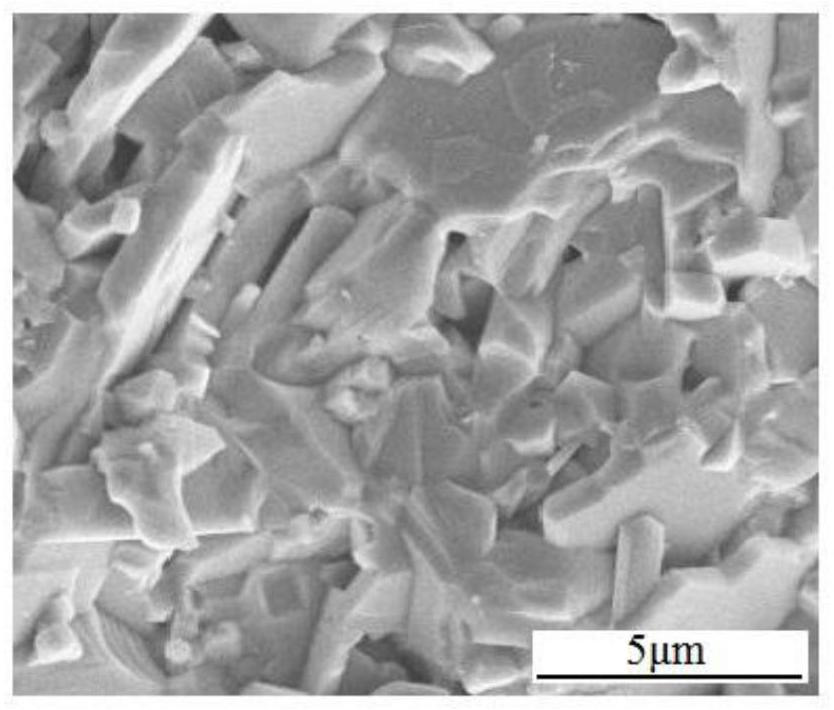

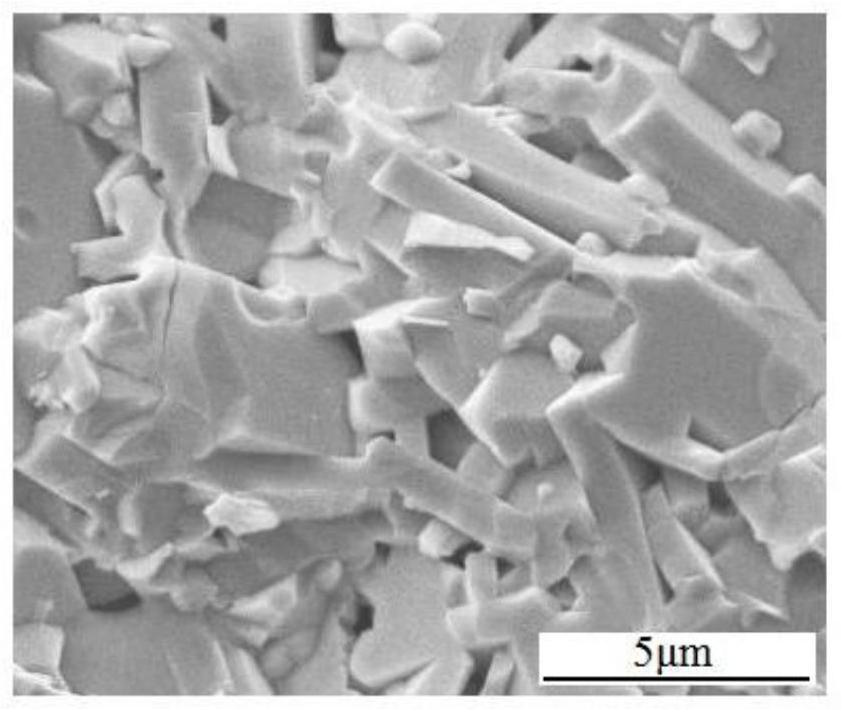

[0038] The present embodiment sheet ceramic absorbing material BA 12-x R x FE 28 Ti 15 O 84 ( x = 3, R is LA) is a class of monocluted crystal structure laminated oxides, and the spatial group is C 2 / m The single-oblique crystal structure is a randomly arranged sheet-like crystal grain, a diameter of 2 to 7 µ m, thickness 1 ~ 2 µ M.

[0039] Tablet ceramic absorbing material BA 12-x R x FE 28 Ti 15 O 84 ( x = 3, R is LA) preparation method, including the following steps:

[0040] (1) Preparation of Sol: Press BA: LA: Fe: Ti. The chemometrics ratio of Ti is called 11.76 g of nitrate (98.5% purity), 6.50 g of hexahydrate (purity is 99%) 48.48 g of nine hydrogen nitrate (purity was 98.5%), 25.53 g of titanate niutate (98% purity) was added to 700 ml of deionized water, 17.68 g of ethylenediamine tetracetic acid (98% purity) and 46.49g. Citric acid (purity was 98%), stirring, a uniform mixture; an ammonia water was added to the mixture, adjusted pH to 7, and then heated in a water ba...

Embodiment 2

[0050] The chemical formula of the sheet-shaped ceramic absorbing material is Ba 12-x R x FE 28 Ti 15 O 84 ( x = 4, R is LA), its preparation method includes the following steps:

[0051] (1) Preparation of Sol: Press BA: LA: Fe: Ti. The chemometrics ratio is 8: 4: 28: 15 (98.5% purity), 8.66 g of hexahydrate (purity is 99%) 48.48 g of nine hydrogen nitrate (98.5% purity), 25.53 g of titanate niutate (98% purity) was added to 700 mL of deionized water, 66.05 g of citric acid (98% purity), stirred, resulting in uniform mixing Liquid; then adding ammonia water to the mixture, adjusting pH to 7, a water bath placed at a constant temperature 90 ° C, heating for 5 h, 400 rpm / min, stirring for 5 h, stable and uniform precursor sol;

[0052] (2) Preparation of primary powder: The solution obtained by step (1) at 120 ° C drying tank, dried for 5 h, fluffy black dry gel; then use alcohol to sufficiently burn the dry gel, to coral shape Gray compound; collecting the ashing and ground, pla...

Embodiment 3

[0058] The present embodiment sheet ceramic absorbing material BA 12-x R x FE 28 Ti 15 O 84 ( x = 2, R is Nd) is a class of single-crosstal crystal structure laminated oxide, and the spatial group is C 2 / m The single-oblique crystal structure is a randomly arranged plate-like grain, a diameter of 3 to 7 µ m, thickness 1 ~ 2 µ M.

[0059] Tablet ceramic absorbing material BA 12-x R x FE 28 Ti 15 O 84 ( x = 2, R is ND) preparation method, including the following steps:

[0060](1) Preparation of sol: Press BA: ND: Fe: Ti chemometrics ratio 10: 2: 28: 15, 13.07 g of nitrate (purity is 98.5%), 4.38 g of six hydrogen nitrate (purity is 99%) 48.48 g of nine hydrogen nitrate (purity was 98.5%), 25.53 g of titanate niutate (purity 98%) was added to 700 ml of deionized water, 17.93 g of ethylenediamine tetracetic acid (98%) and 58.88g lemon The acid (purity was 98%), stirred, the uniform mixture was obtained; then an ammonia water was added to the mixture, and the pH value of 7 was adjust...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| optical bandwidth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com