Patents

Literature

113 results about "Hydrogen Nitrate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Chemical compound containing the nitrate (NO3) radical. Nitrates are salts or esters of nitric acid, HNO3, formed by replacing the hydrogen with a metal (e.g., sodium or potassium) or a radical (e.g., ammonium or ethyl). .....

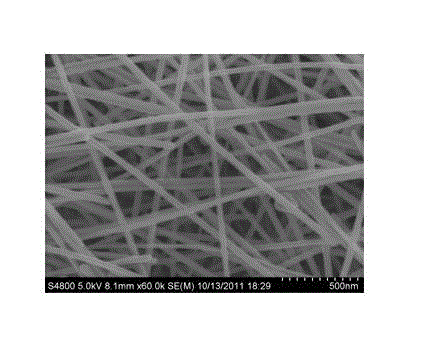

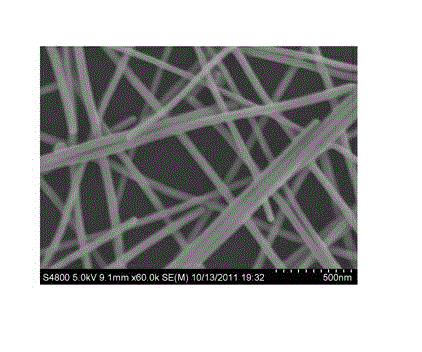

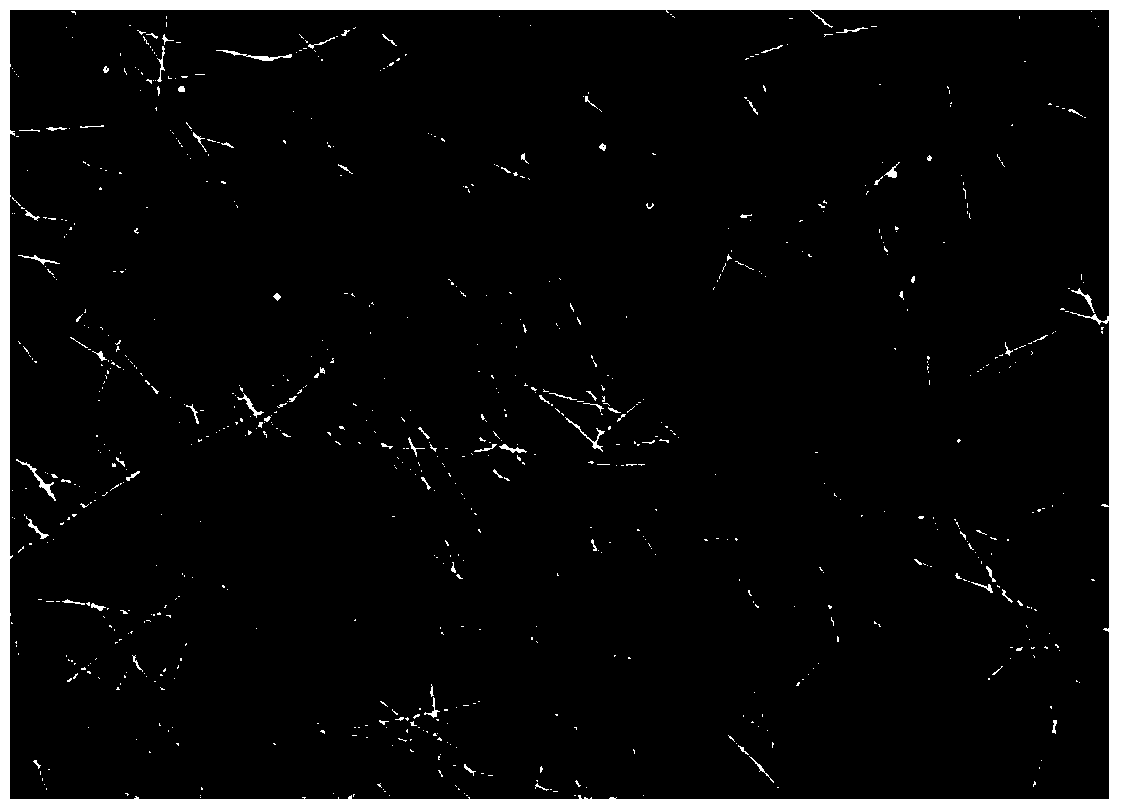

Method for preparing nano-silver wire with high length-diameter ratio

ActiveCN102744417AQuality improvementSimple preparation processPolycrystalline material growthFrom normal temperature solutionsHydrogen NitrateMicrowave method

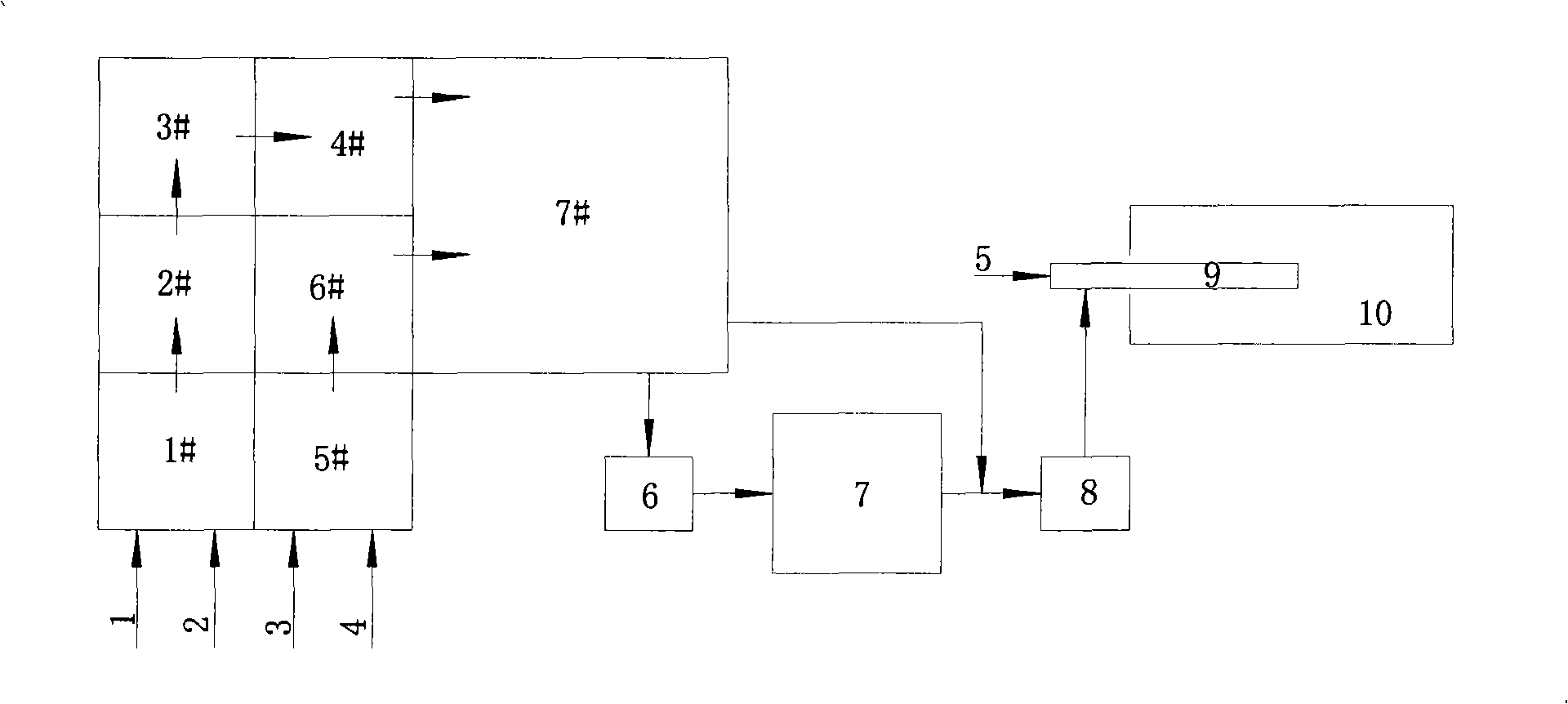

The invention provides a method for preparing a nano-silver wire with high length-diameter ratio. At least one polyhydroxy liquid organic (1), silver nitrate (2), polyvinylpyrrolidone (PVP) with a K value equal to or larger than 30 (3), at least one hydrogen nitrate compound or one hydrogen-containing compound (4) and at least one chloride for a reaction solution, wherein the chloride can be dissolved in the polyhydroxy liquid organic and can produce chloride ions after dissolved. Reaction is perform for more than 10 minutes under the condition that the reaction temperature is lower than the boiling temperature of the polyhydroxy liquid organic or a part of ingredients is subjected to chemical reaction to form a nano-silver wire solution containing length-diameter ratio exceeding 200, and solid-liquid separation is performed to obtain the nano-silver wire or nano-silver wire dispersing liquid. The nano-silver wire prepared by means of the method is high in length-diameter ratio and yield, few in impurities and good in thickness and length uniformity, and the shortcomings including complicated preparing technology process by means of a traditional polyol method, many impurities and non-uniformity by means of a microwave method and the like are overcome.

Owner:JIANGSU NANOWELL ADVANCED MATERIALS SCI&TECH

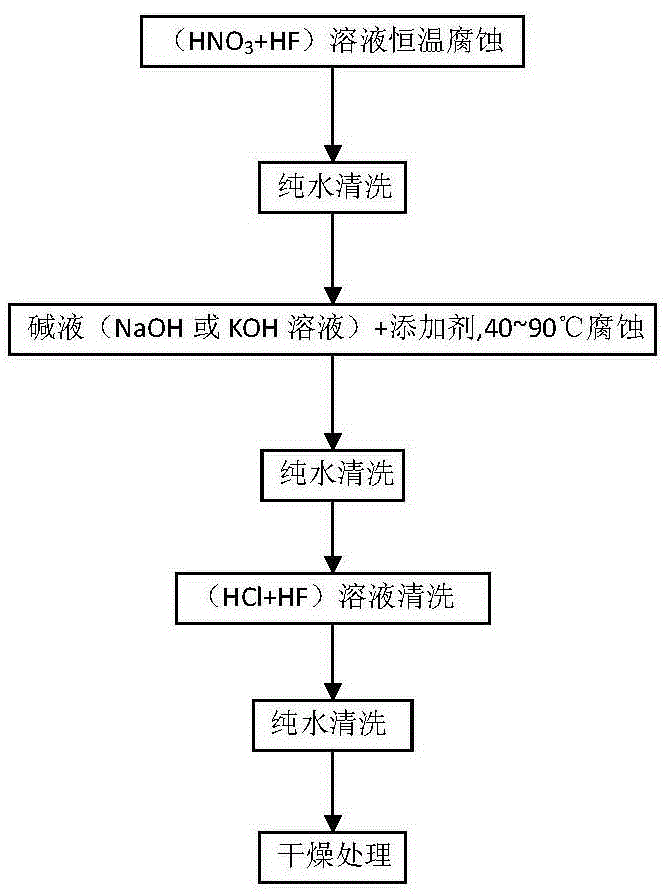

Texturing and cleaning process method of polysilicon wafer

ActiveCN103151423AImproving the effect of wool cleaningEasy to cleanAfter-treatment detailsFinal product manufactureHydrogen fluorideHydrogen Nitrate

The invention discloses a texturing and cleaning process method of a polysilicon wafer. The method comprises the following steps of 1, firstly, putting the polysilicon wafer in a mixing solution of HF (hydrogen fluoride) and HNO3 (hydrogen nitrate), and soaking; 2, putting the polysilicon wafer corroded by acid into pure water, and cleaning; 3, putting the polysilicon wafer in an alkaline solution, carrying out alkaline corrosion treatment, adding a texturing additive into the alkaline solution, and carrying out secondary texturing on the polysilicon wafer; 4, putting the polysilicon wafer corroded by alkali into the pure water, and cleaning; 5, putting the polysilicon wafer in a mixing solution of HCl (hydrogen chloride) and HF, and soaking; 6, putting the polysilicon wafer corroded by the acid into the pure water, and cleaning; and 7, drying the treated polysilicon wafer. The process method has the advantages that on the premise of not changing other processes, the final converting efficiency of the polysilicon wafer is improved by 0.2% to 0.3%, and the purpose of final efficiency stacking of a battery sheet is realized.

Owner:CHANGZHOU S C EXACT EQUIP

A nitric oxides (NOX) waste pollution control in industrial process and resource reclaiming method

InactiveCN1864812AGood governanceSimple processDispersed particle separationHydrogen NitrateHigh concentration

The invention relates to a method for treating and reusing waste gas containing nitrogen oxide generated in industrial process. It comprises following steps: mixing waste gas containing nitrogen oxide with air according to a certain proportion, plural serial adsorbing it in tower by introducing it from bottom of head tower, discharging it from top of tail tower, discharging generated hydrogene nitrate of low concentration from bottom of head tower, proceeding decompressing and thickening process in thickening tower, which includes bleaching and dewatering; hydrogen nitrate of low concentration is introduced from top of thickening tower, hydrogen nitrate of high concentration being 45-65% is discharged from bottom; supercharging nitrogen oxide extracted from thickening tower top with vacuum system, then introducing it into adsorbing process again; the water or diluted acid from thickening tower is used as adsorbent and is added from top of tail tower in adsorbing process and counter current contacts with gas in tower for mass transferring. The waste gas treatment effect is good, and the discharging concentration of nitrogen oxide in exhaust gas is less than 50 ppm; all the nitrogen oxide in exhaust gas is recycled to generate aqua fortis with mass concentration being more than 55%.

Owner:NANJING UNIV

Chemical etching liquid for metals and etching method

The invention provides a chemical etching liquid for metals. The chemical etching liquid comprises ferric chloride, hydrochloric acid, phosphoric acid, hydrogen nitrate, a corrosion inhibitor and a surface active agent. The corrosion inhibitor is at least one of hexamethylene tetramine, ethidene diamine, triethanolamine and heptadecane amide; and the surface active agent is one or two of sodium lauryl benzenesulfate and dodecyl alcohol amine. The invention further discloses a chemical etching method for metals; with the method, the metals are etched through spraying the etching liquid; and the etching liquid is provided by the invention. The etching liquid provided by the invention can be applied to surface etching of various metals, particularly stainless steel, copper and aluminum alloy; and since the metals can be etched with the same etching liquid, the consumption of equipment is reduced.

Owner:南通麦特隆新材料科技有限公司

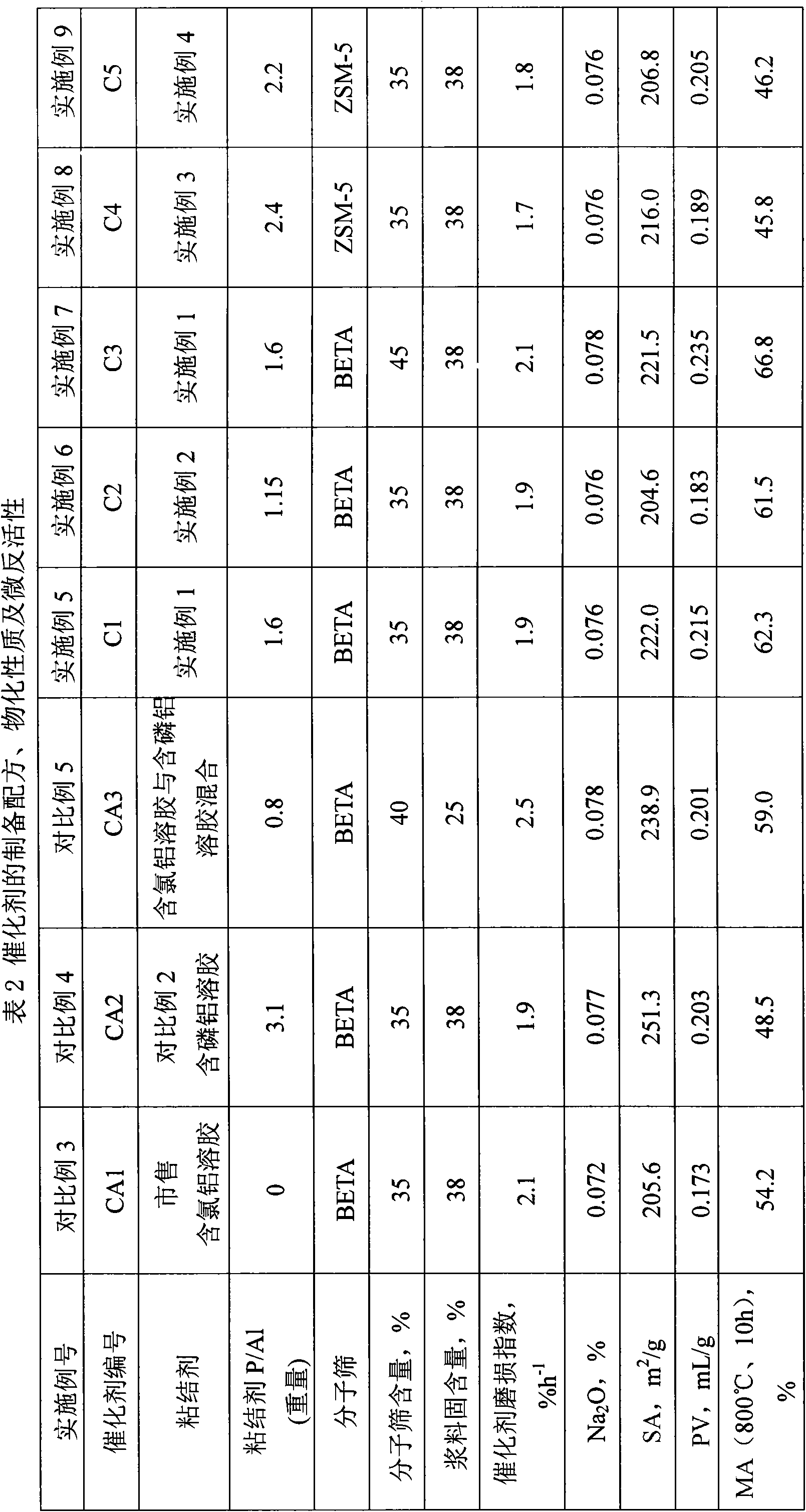

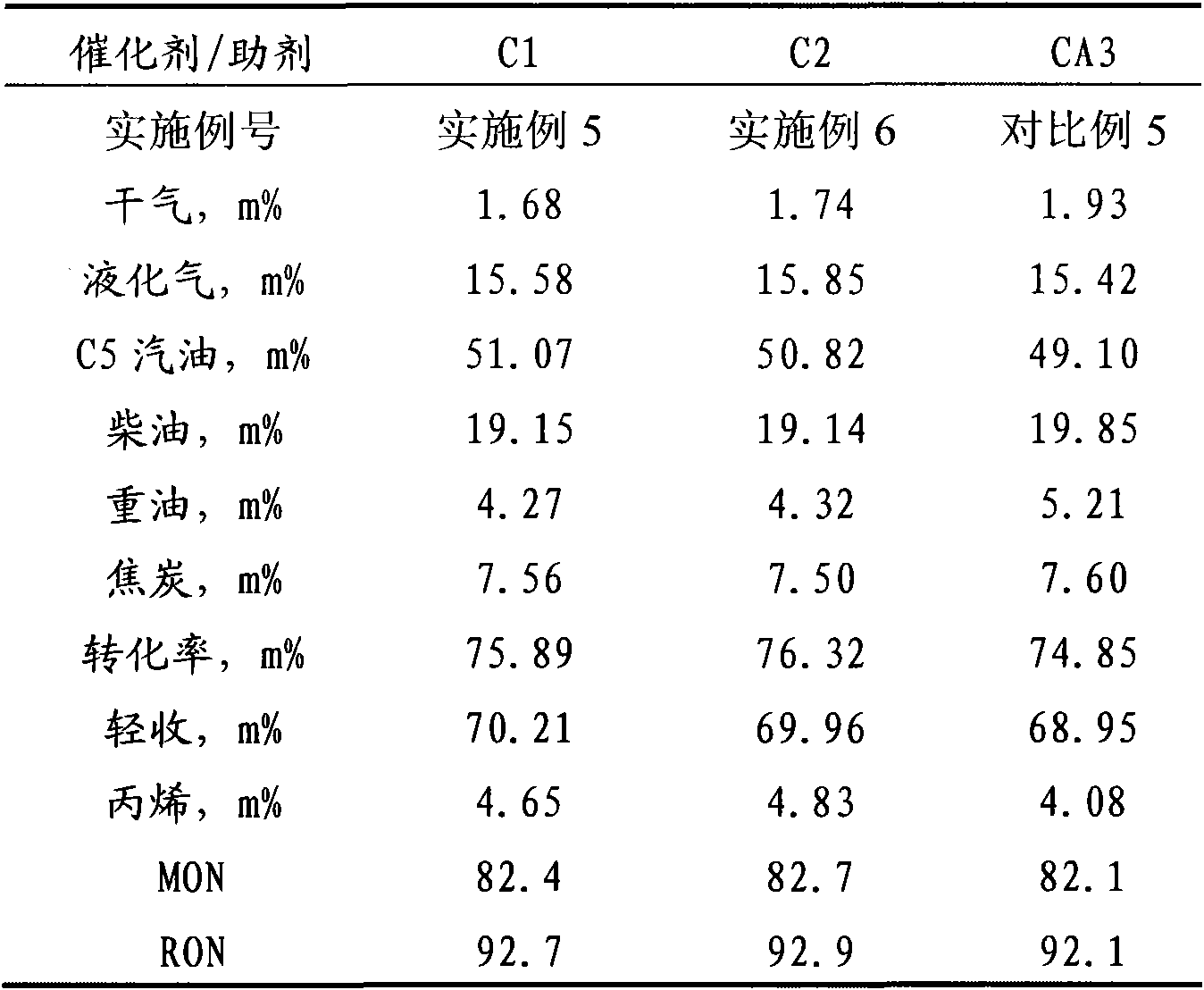

Aluminium phosphate sol used for catalyst and preparation method thereof

ActiveCN102050434AHigh activityHigh yieldPhysical/chemical process catalystsCatalytic crackingHydrogen NitratePhosphoric acid

The invention relates to a preparation method of aluminium phosphate sol used for a petroleum hydrocarbon cracking catalyst, which is characterized by comprising the steps of: mashing and dispersing an acid soluble aluminum precursor and decationed water into serous liquid with solid content of 15-35 percent, slowly adding phosphoric acid with concentration of 60-98 percent into the serous liquidunder the stirring according to the weight proportion of P / Al=1.0-2.5; then adding hydrogen nitrate with concentration of 40-98 percent according to the weight proportion of HNO3 / Al2O3=0.2-2.0, rapidly reacting and releasing a large quantity of heat; and generating colorless transparent thick liquid after the reaction. The microactivity of the catalytic cracking catalyst prepared by adopting the aluminium phosphate sol bonder provided by the invention is remarkably improved. The selectivity of the aluminium phosphate sol is improved, the yields of gas and coke are remarkably reduced, and the yields of light oil and propylene are improved.

Owner:PETROCHINA CO LTD

Preparation method of silicon dioxide/silver core-shell composite powder for high temperature electronic paste

ActiveCN103231072AGood dispersionUniform sizeConductive layers on insulating-supportsLiquid/solution decomposition chemical coatingDispersityHydrogen Nitrate

The invention provides a preparation method of silicon dioxide / silver core-shell composite powder for high temperature electronic paste and belongs to the technical field of electronic paste. The preparation method includes: manufacturing silicon dioxide nano-particles firstly, adding a hydrogen nitrate solution to adjust pH value, adding a stannous chloride solution after centrifugal cleaning, adding silicon dioxide microspheres in a silver ammonia solution to be soaked under the condition of ultrasound and then performing centrifugal separation, and enabling a layer of silver nano-particles to be generated on the surfaces of the silicon dioxide microspheres; adding silver nitrate and a dispersing agent under the condition of stirring, and then adding ascorbic acid to obtain silver-plated silicon dioxide composite powder; and removing reaction residues by using a deionized water centrifugal sedimentation and ultrasonic dispersion cycle cleaning mode to obtained the silicon dioxide / silver core-shell composite powder. The preparation method of the silicon dioxide / silver core-shell composite powder for the high temperature electronic paste is simple to operate and low in cost, and particles obtained by the preparation method are remarkable in core-shell structure, even in particle size, high in solid content, ordered in height, good in dispersity and have various application prospects in the aspects of biological sterilization, chemistry, optical materials, electronic paste and the like.

Owner:昆明高聚科技有限公司

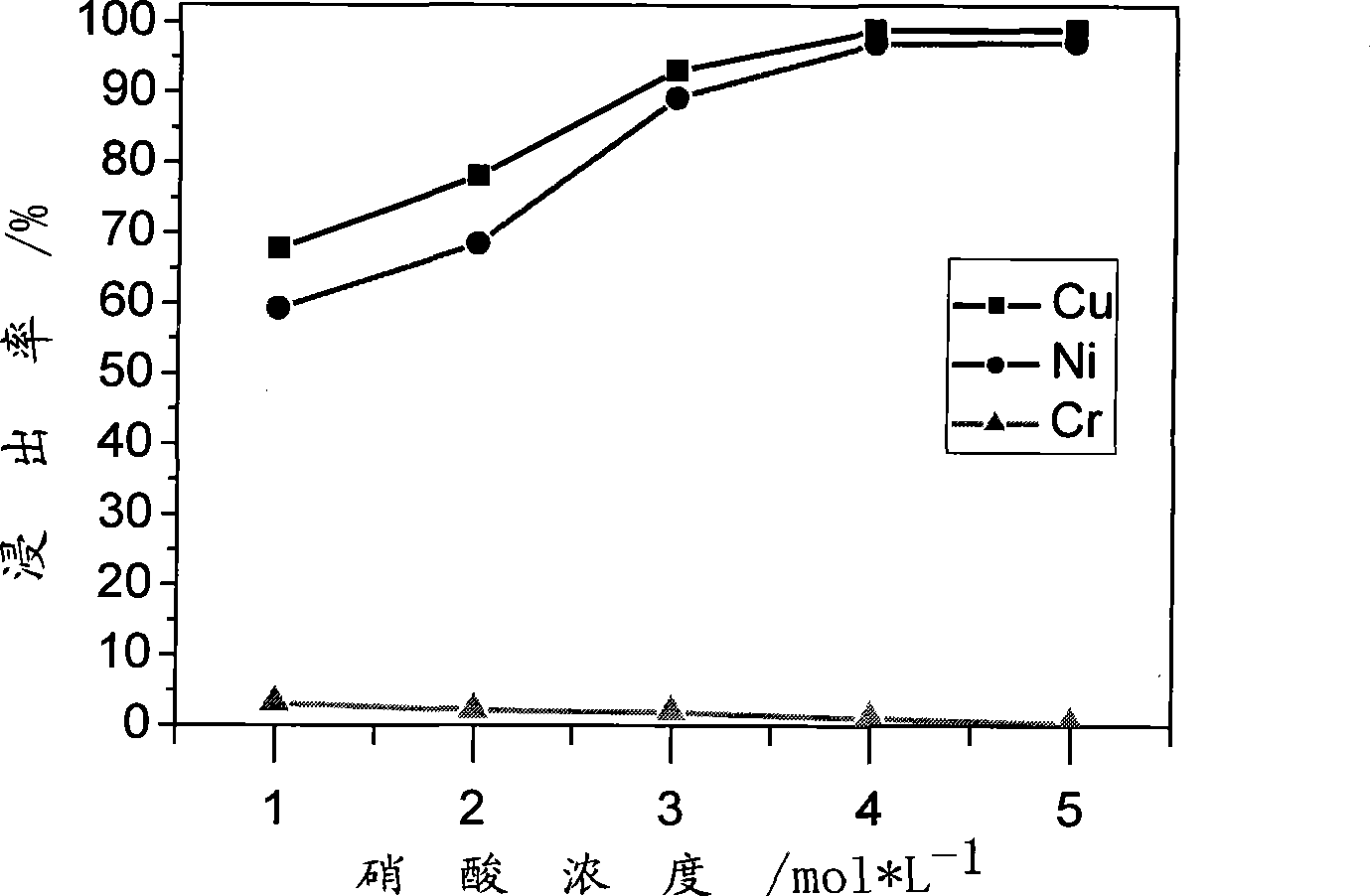

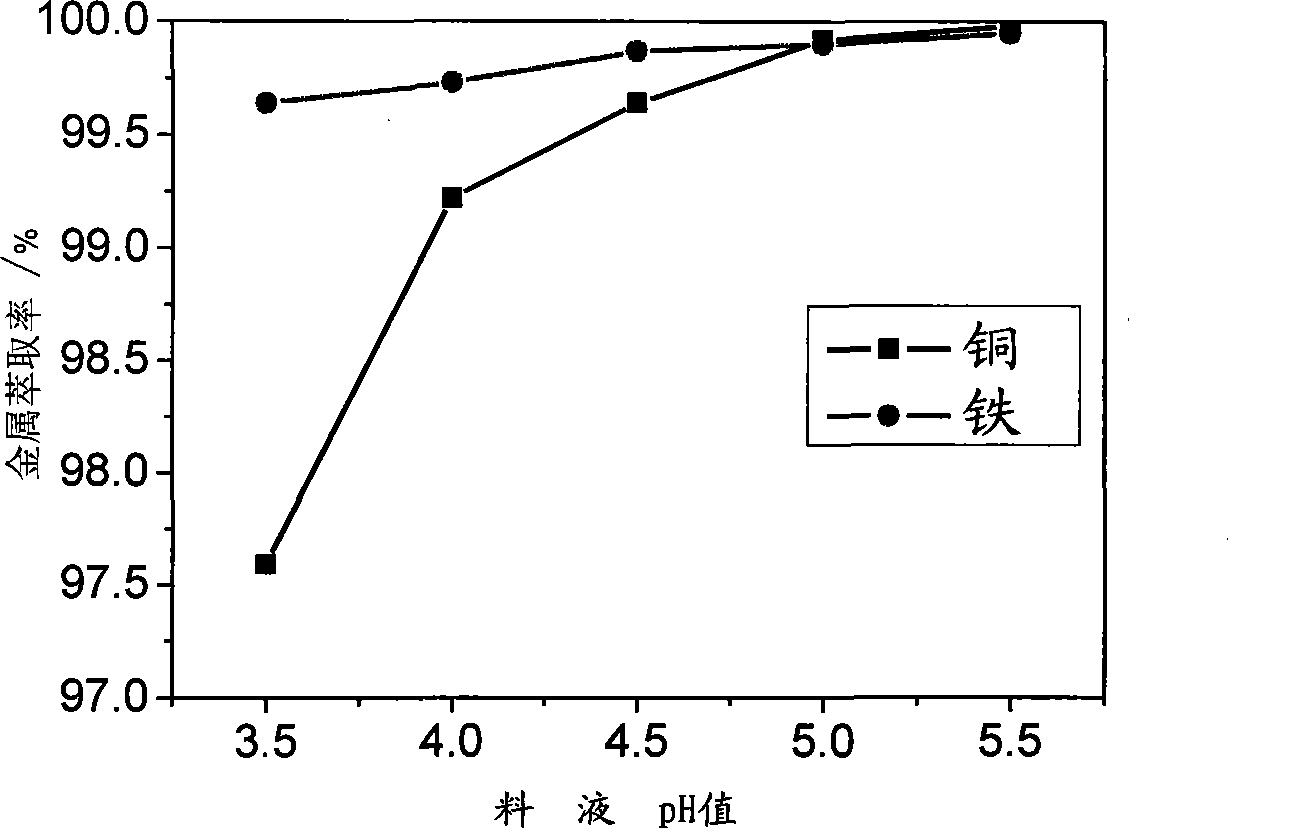

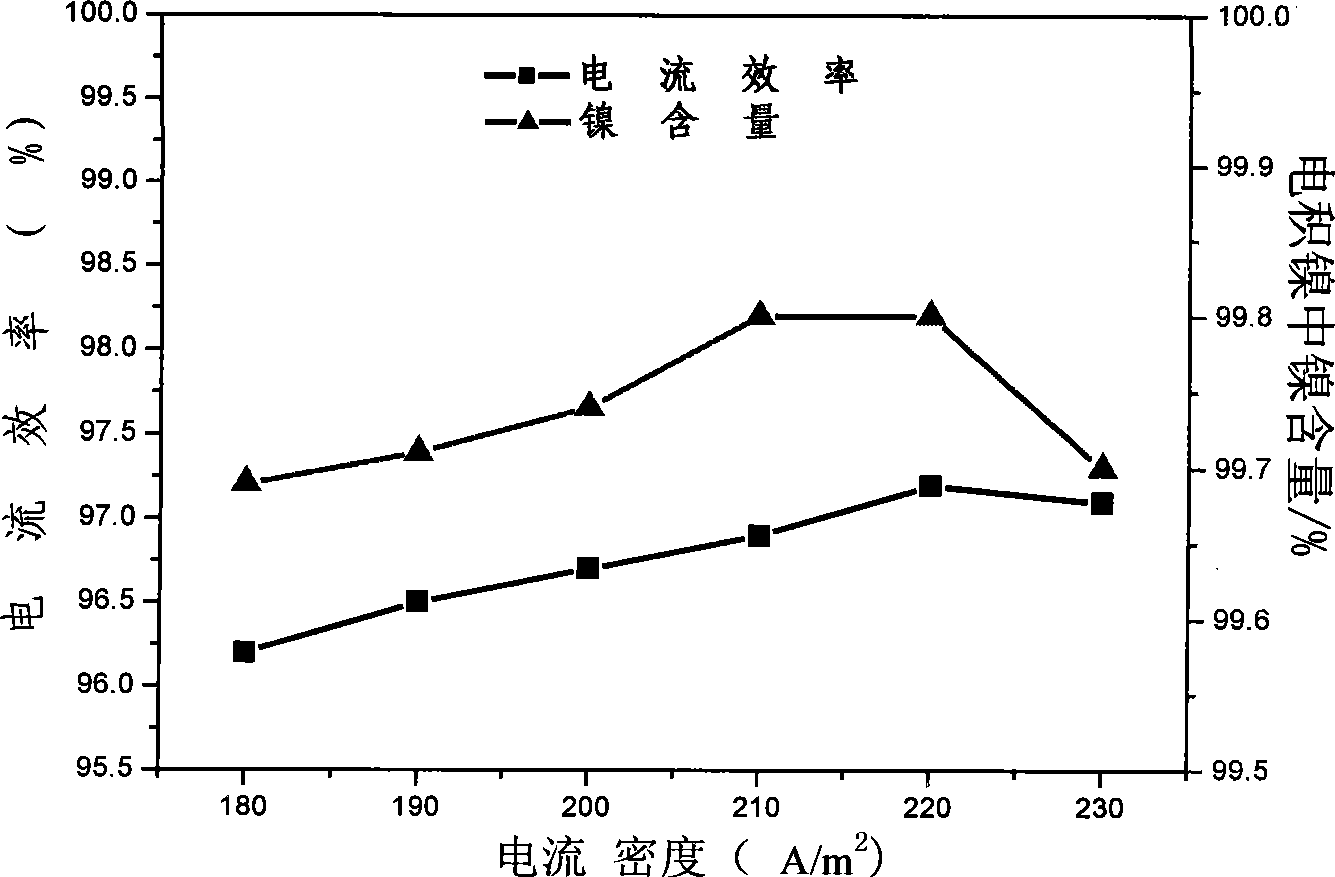

Method for separating and recycling copper, nickel and regenerative plastic from waste electroplating plastic

ActiveCN101476041AHigh purityIncrease incomePhotography auxillary processesPlastic recyclingHydrogen NitrateNitrate

The invention discloses method of isolating and recovering cuprum and nickel from the waste plating plastics and regenerating plastics.The method is characterized in that metals of cuprum, nickel and the like on the surface of waste plating plastics after being pulverized by a pulverizer are dissolved by hydrogen nitrate, undissolved substances are filtered and washed, then pure plastics can be obtained for regeneration; the solution containing cuprum and nickel is displaced by powdered iron to obtain a high purity spongy copper; the rest liquid is performed with iron removal by using a amarillite method, a pure nickel nitrate solution can be obtained after foreign ions of copper, iron and the like are removed by P204 extraction, metallic nickel plates can be produced by an electrodeposition process.The invention has characteristics of simple technique, cheap original supplementary materials and high added value of products.

Owner:GUANGDONG BRUNP RECYCLING TECH +1

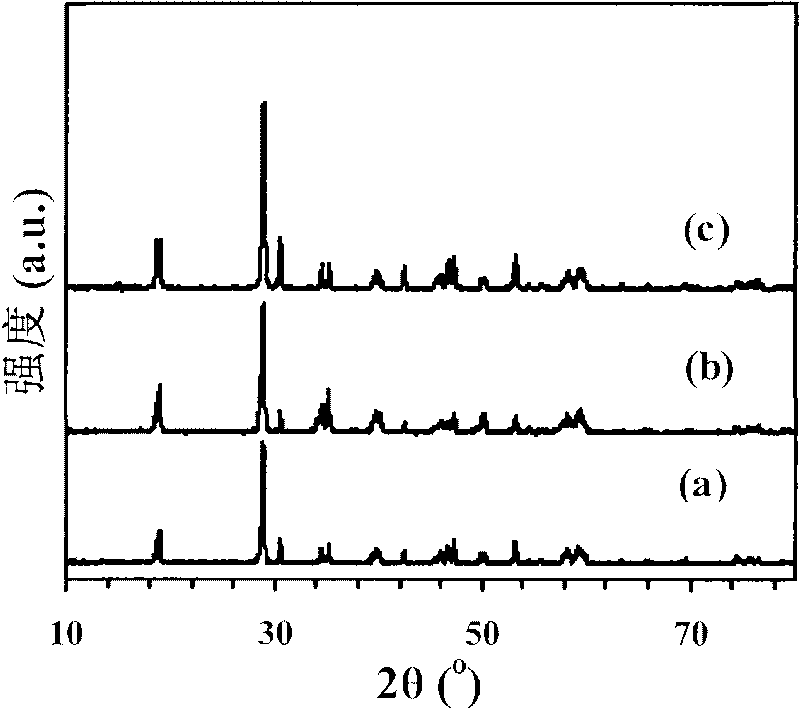

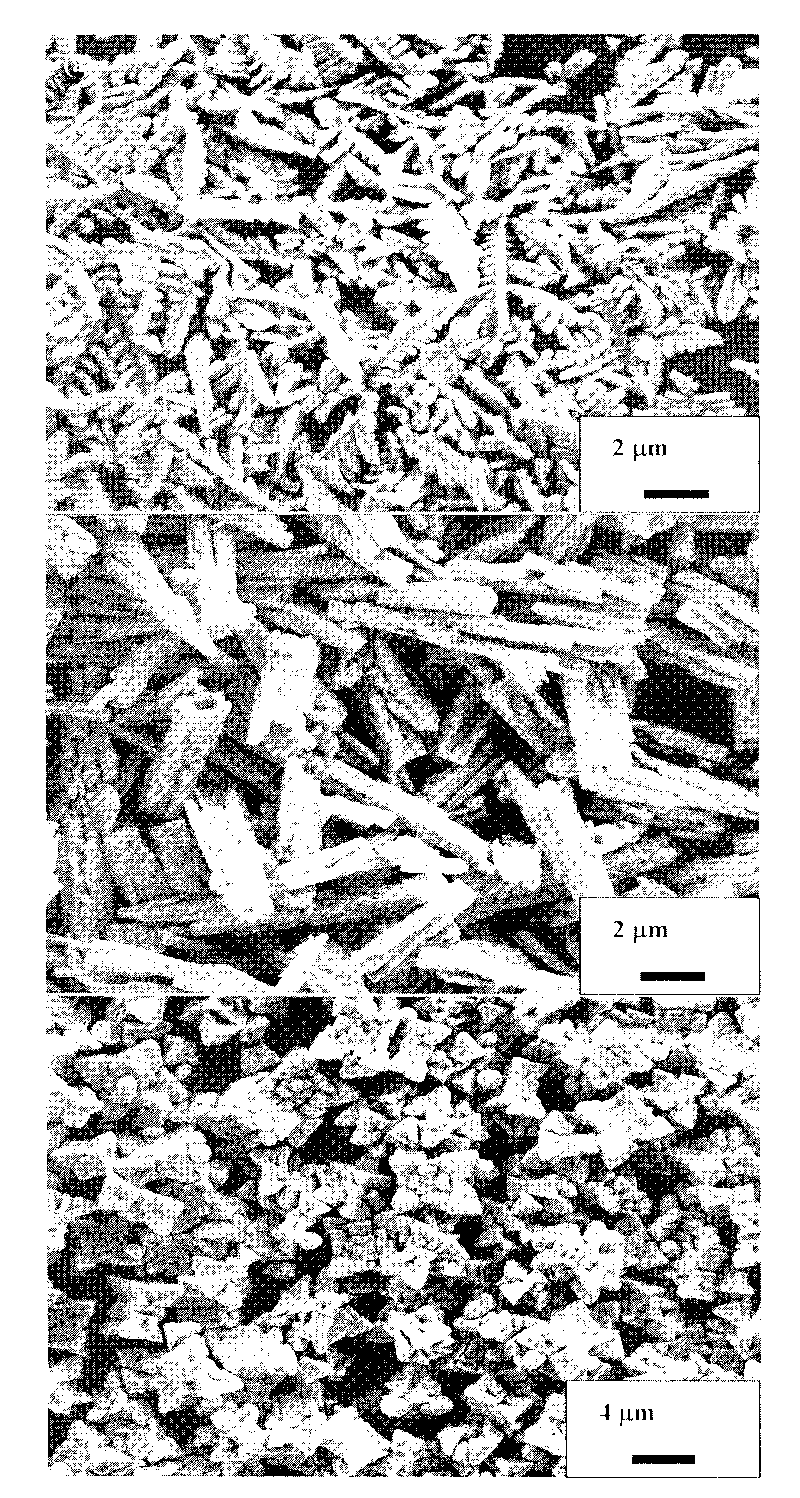

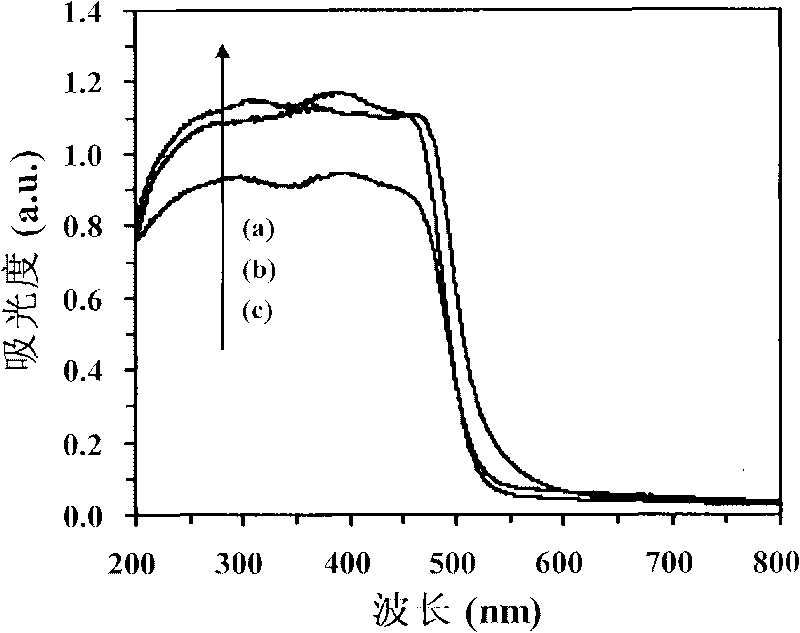

Surfactant hydrothermal method for preparing leaf-shaped, tubular and paraphlomis-kwangtungensis-shaped BiVO4

InactiveCN101746823ASave raw materialsSimple processVanadium compoundsHydrogen NitrateAmmonium metavanadate

The invention discloses a surfactant hydrothermal method for preparing leaf-shaped, tubular and paraphlomis-kwangtungensis-shaped BiVO4. The method comprises the steps that: bismuth nitrate, ammonium metavanadate, hydrogen nitrate, and triblock copolymer P123 are resolved in hydrogen nitrate aqueous solution with a concentration of 2mol / L under the stirring condition, then 14 percent of ammonia water by weight is added drop by drop, the pH of the obtained solution is adjusted to 9, the solution containing yellow precipitate is transferred to a stainless steel gravity reactor the lining of which is made from polyfluortetraethylene and is placed and treated in an incubator at a temperature of 180 DEG C for 6 hours, the solution naturally cools down to the room temperature after being taken out, the product obtained after treatment is dried at a temperature of 60 DEG C for 12 hours and then is sintered to obtain the leaf-shaped BiVO4 micron particles with monocline scheelite structure. In the surfactant hydrothermal method, the obtained samples when treated with a pH of 10 in the incubator at a temperature of 180 DEG Care tubular pucherite micron particles with monocline scheelite structure; the obtained samples when treated with a pH of 3 in the incubator at a temperature of 80 DEG C are paraphlomis-kwangtungensis-shaped pucherite micron particles. The surfactant hydrothermal method for preparing leaf-shaped, tubular and paraphlomis-kwangtungensis-shaped BiVO4 are characterized by cheap raw materials, simple process, controllable target product particle shape and crystalline structure, etc.

Owner:BEIJING UNIV OF TECH

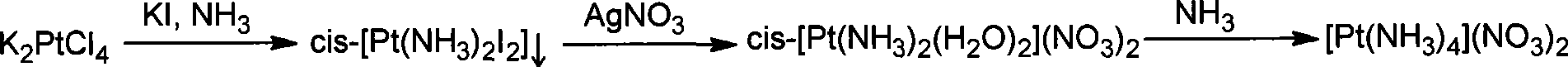

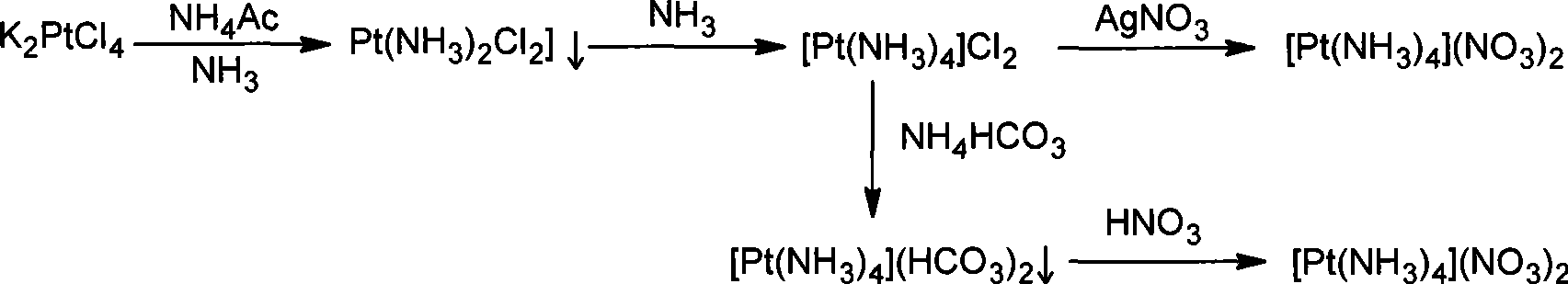

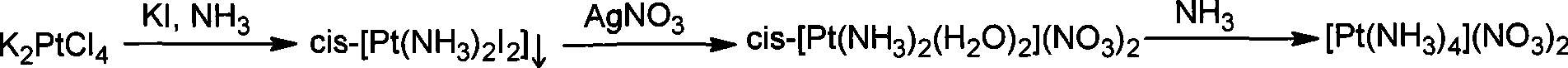

Novel method for synthesis of tetrammine platinum hydrogen nitrate (II)

InactiveCN101367557AEasy to operateHigh yieldRuthenium/rhodium/palladium/osmium/iridium/platinum compoundsPlatinumHydrogen Nitrate

The invention relates to a novel process for synthesizing the tetraammineplatinum (II) nitrate, and comprises the following steps: (1) K2PtCl4 is reacted with KI and ammonia to generate the intermediate body of the maleinoid-form diiododiammine platinum; (2) the intermediate body is reacted with silver nitrate to get the hydrate nitrate maleinoid-form-dihydrate-diamminine platinum; (3) the hydrate is reacted with strong aqua ammonia to get the target product of the tetraammineplatinum (II) nitrate. The productivity of the method is high (more than 90 percent); the purity of the product can reach 99.0 percent (calculating at metal platinum); the operation is simple and is easy to be controlled; the production cost is low, thereby being applicable to the mass production.

Owner:KUNMING INST OF PRECIOUS METALS

Method for preparing antimony doped stannic oxide nano powder

InactiveCN101597022AEvenly distributedReduce reunionNanostructure manufactureHydrogen NitrateAntimony trioxide

The invention relates to a method for preparing antimony doped stannic oxide nano powder and belongs to the field of nanometer materials. The nanometer material is prepared by the following steps that: stannum granules, antimonous oxide powder and an antimony compounding agent in a certain mixing ratio are dissolved in hydrogen nitrate at certain concentration to form light cyan transparent solution; the transparent solution and ammonia water at certain concentration are dripped into a base solution doped with a dispersing agent in a cocurrent flow mode to undergo a coprecipitation reaction; and the ATO nano powder is prepared by washing, azeotropic distillation, drying and calcining of the product of the coprecipitation reaction. The method is characterized in that: the stannum granules and the antimonous oxide powder are used as basic raw materials, the antimony compounding agent is added in a preparation process to process a precursor together with an azeotropic distillation method to prepare the ATO nano powder. The method is easy in accurate measurement, effectively suppresses the early hydrolysis of the antimony, realizes even doping of the ATO nano powder, effectively removes moisture in the precursor and free hydroxyls on the surface, reduces the conglobation of the powder, simplifies a preparation process, reduces preparation period and expends the application range of the ATO nano powder.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

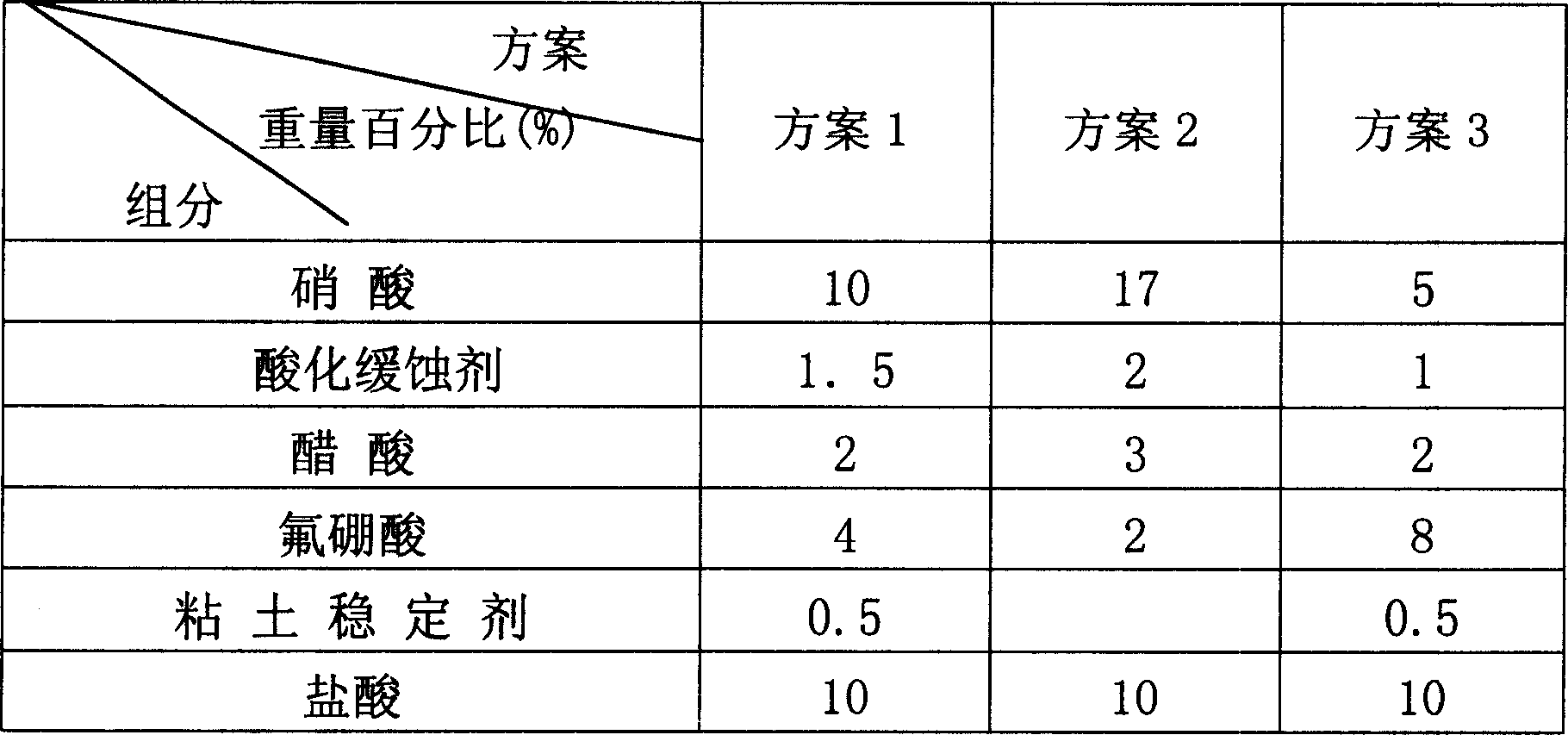

Compound acidifying liquid containing nitric acid and boratofluroic acid and its use method

InactiveCN1528854AUnblockRestore or increase water injection capacityFluid removalHydrogen NitrateAlcohol

The invention is a kind of compound acidification liquid which contains hydrogen nitrate, fluoboric acid and the manufacturing method, it solves the problem that the blocking effect to formation which has large quantity of clay and low temperature. The character lies in: the compound acidification liquid includes hydrogen nitrate, fluoboric acid and acidification inhibitor and whose content is 2%-25%, 1%-15% and 0.5%-5%, the acidification inhibitor is made up of nitrogen compound, potentiating agent, surface activating agent and solvent waterless alcohol; when using the acidification liquid to be inserted into the formation, the usage is 1-6 m3 in each meter, the time in formation can exist for 4-12 hours, the reacted acidification liquid residue can return to the ground.

Owner:LIDA OIL FIELD CHEM REAGENT WORKS SAERTU DISTRICT DAQING CITY

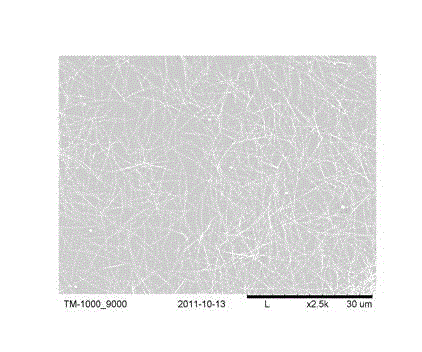

Multilayer structure composite transparent conducting thin film based on silver nanowires and preparation method thereof

ActiveCN103730194AImprove adhesionPrevent oxidationConductive layers on insulating-supportsCable/conductor manufactureHydrogen NitrateFlexible electronics

The invention discloses a multilayer structure composite transparent conducting thin film based on silver nanowires and a preparation method thereof. A lower AZO conducting layer, a silver nanowire conducting layer, an upper AZO conducting layer and another silver nanowire conducting layer are sequentially prepared on a flexible substrate, wherein in the process that a polyol process is adopted to prepare the silver nanowire conducting layers, the molar ratio of polyvinylpyrrolidone to metal salt to hydrogen nitrate to silver nitrate is 1.5-6 to 1.5*10-3-3*10-3 to 0.01-0.5 to 1. Adhesivity and stability of the multilayer structure composite transparent conducting thin film based on the silver nanowires are improved, improvement of stability and electrical conductivity of the composite transparent conducting thin film based on the silver nanowires is facilitated, the AZO thin film and the flexible substrate are adopted, preparation cost is reduced, and flexibility of materials is increased. The composite transparent conducting thin film based on the silver nanowires is applied to flexible electronic devices, device integration is easy to achieve, the preparation technology is simple, and the composite transparent conducting thin film based on the silver nanowires is suitable for industrial production.

Owner:CHANGZHOU HUAWEI ADVANCED MATERIAL

Carbon emission material for renovation of nitrogen hydrogen nitrate pollution groundwater and production method

InactiveCN101219832AReduced release rateAvoid churnTreatment with anaerobic digestion processesHydrogen NitrateOxygen

The invention relates to a carbon release material for purifying groundwater polluted by nitrate nitrogen, which substantially comprises a carbon release agent, an oxygen capture agent, a KH2PO4, trace elements, coarse sand, cement and water, in which the carbon release agent provides carbon for the denitrification degradation process of the microorganism; the oxygen agent is used for capturing and consuming the dissolved oxygen in the groundwater to create an anaerobic environment; the KH2PO4 and the trace elements provide the required nutrient elements for metabolism of the microorganism; the coarse sand is used for promoting permeability of the carbon release material; the cement and the water adhere other components together in the carbon release material. A contrast test of denitrification degradation of nitrate nitrogen in the groundwater proves that the nutrition compound carbon release material in the invention can allow concentration of the dissolved oxygen in the water to decrease from 4.1mg / L to about 0.1mg / L as well as the concentration of the nitrate nitrogen to decrease from 103.4mg / L to 2.5mg / L; the degradation rate is as high as 97.6 percent while the degradation rate of the degradation rate in the contrast text is only up to 50.2 percent.

Owner:TIANJIN UNIV

Method for detecting manganese in carbon manganese alloy

ActiveCN102128836AUniform densityImprove uniformityMaterial analysis by observing effect on chemical indicatorPreparing sample for investigationN-phenylanthranilic acidHydrogen Nitrate

The invention relates to a method for detecting manganese in carbon manganese alloy and belongs to the technical field of elementary analysis. The method for detecting manganese in carbon manganese alloy comprises the following steps: 1) firing a sample: weighting a sample, firing the sample and measuring the mass of the fired sample; 2) dissolving the sample: weighting a right amount of the fired sample, adding in phosphoric acid and hydrogen nitrate, heating till the fired sample completely is dissolved, and then adding ammonium nitrate for fully oxidizing divalent manganese; 3) titration: titrating with ferrous ammonium sulphate solution till the solution becomes light pink, dropping in N-phenylanthranilic acid indicator, and continuing to titrate till the solution becomes bright green; 4) confirming the titer: weighting ferromanganese standard matter, operating according to the same method, and solving the titer of ferrous ammonium sulphate solution to manganese; and 5) calculating the content: the content (%) of manganese = (the titer of ferrous ammonium sulphate solution to manganese) * (the volume of consumed ferrous ammonium sulphate solution) * (the mass percent of the fired sample to the sample) / (sample weight. The method provided by the invention is simple and is convenient to operate and has the advantages of accurate terminal point judgment, good repeatability and the like, and the data is accurate.

Owner:TIANJIN IRON & STEEL GRP

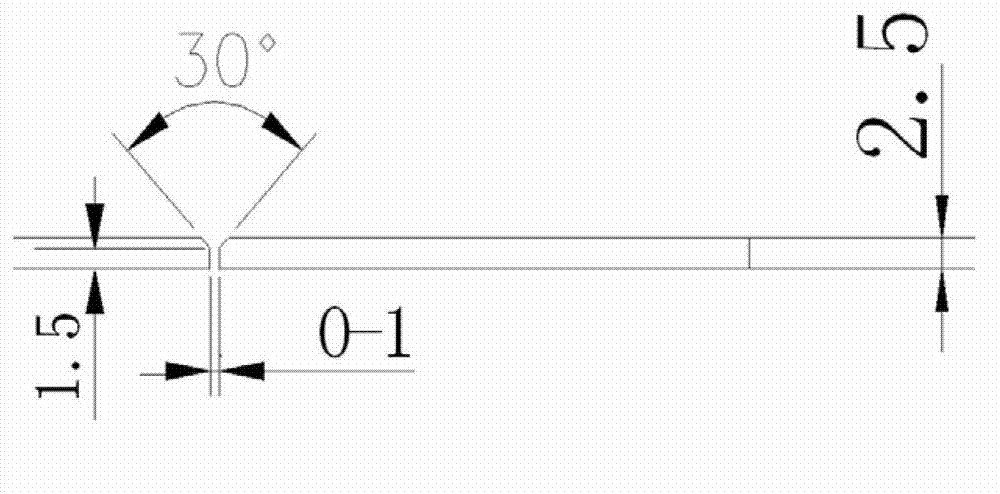

Welding method for longitudinal butt joint of thin-wall aluminum alloy non-profile long pipes

InactiveCN103111731AGuaranteed surface forming qualityGuarantee internal qualityArc welding apparatusPorosityHydrogen Nitrate

The invention discloses a welding method for longitudinal butt joint of thin-wall aluminum alloy non-profile long pipes. Firstly, grooves are formed in to-be-welded portions of parts, cleaned mechanically and then subjected to chemical cleaning through a solution of sodium hydroxide (NaOH) and a solution of hydrogen nitrate (HNO3); and then a gas metal arc welding (GMAW) process is carried out, and welding parameters include current, voltage, current polarity, protective gas, the flow rate of the protective gas, backing gas, and the flow rate of the backing gas, wherein the current is 65-95 amperes, the voltage is 18+ / -3 volts, the current polarity is alternating current, the protective gas is argon gas with purity more than or equal to 99.99%, the flow rate of the protective gas is 16+ / -3 liters per minute, the backing gas is argon gas with purity more than or equal to 99.99%, and the flow rate of the backing gas is 16+ / -3 liters per minute. Through the welding method for the longitudinal butt joint of the thin-wall aluminum alloy non-profile long pipes, the surface forming quality and the inside quality of a double-sided welded joint can be guaranteed, welding defects such as bad shape, lack of penetration, porosity, incomplete fusion, burning-through, collapse and inclusions are avoided, production efficiency is improved, the repair rate is lowered, and quality of products is guaranteed.

Owner:BEIJING CED RAILWAY ELECTRIC TECH

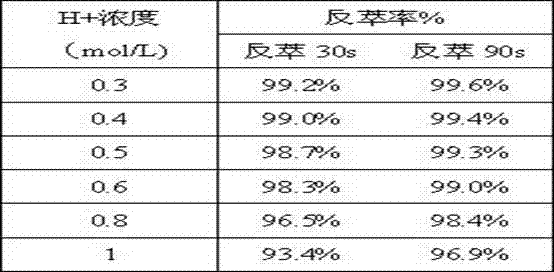

Method for separating U (uranium) from Pu (plutonium) in Purex process

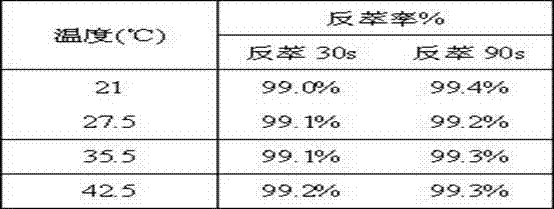

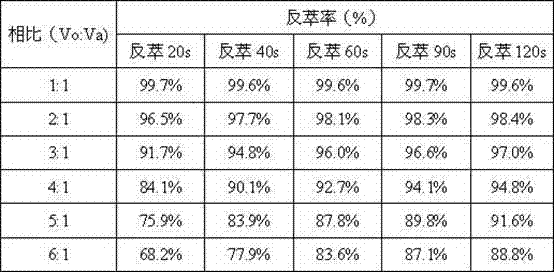

The invention which belongs to the technical field of radioactive post-treatment concretely relates to a method for separating U from Pu in a Purex process. The method comprises the following steps: 1, removing nuclear reaction splinters except U and Pu; 2, coextracting codecontaminated U and Pu to a TBP (tributyl phosphate) / kerosene mixed liquor with a volume percentage of 30%; and 3, adding a reducing agent HSC (hydroxysemicarbazide) to the mixed liquor in step 2, and fully mixing to back-extract Pu (III) which is reduced from Pu (IV) in an organic phase to an aqueous solution of hydrogen nitrate, wherein the ratio of the molar concentration of the HSC in an aqueous phase solution to the molar concentration of Pu in an organic phase solution is 5-60, the volume ratio of the organic phase solution to the aqueous phase solution is 1:1-6:1, the temperature is 21-42.5DEG C, and the concentration of H<+> is 0.3-1mol / L. A technical scheme provided by the invention allows Pu (IV) in the organic phase to be rapidly reduced and back-extracted to the aqueous phase, the reaction time is two magnitudes shorter than the reaction time of the prior art, the technological process is simplified, and the separation efficiency is improved.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

A method for preparing nitro compounds using nitrogen suboxides

ActiveCN102276471AIncrease profitAtom economy is highNitro compound preparationNitro compoundHydrogen Nitrate

The invention discloses a method for preparing a nitro compound from a low-valent nitric oxide. The method comprises that a low-valent nitric oxide such as nitric oxide, nitrogen dioxide, nitrous oxide, nitrogen trioxide, dinitrogen tetroxide and the like react with an alicyclic compound, an aromatic compound or a heterocyclic compound through promoting effects of molecular oxygen and effects of catalysts comprising a transition metal oxide, a triphenylphosphine metal organic complex, transition metal ion clay and heteropoly acid salts such as aluminosilicate, silicoaluminophosphate, sodium phosphomolybdate and the like. The method can replace the traditional industrial method for preparing a nitro compound from a high-valent (V-valent) nitrogen compound such as nitrogen pentoxide, hydrogen nitrate, nitric acid salts, nitric acid esters and the like. The method improves an atom utilization rate of a reaction in industrial nitration preparation of a nitro compound, and has atom economic characteristics of industrial preparation of a nitro compound.

Owner:彭新华

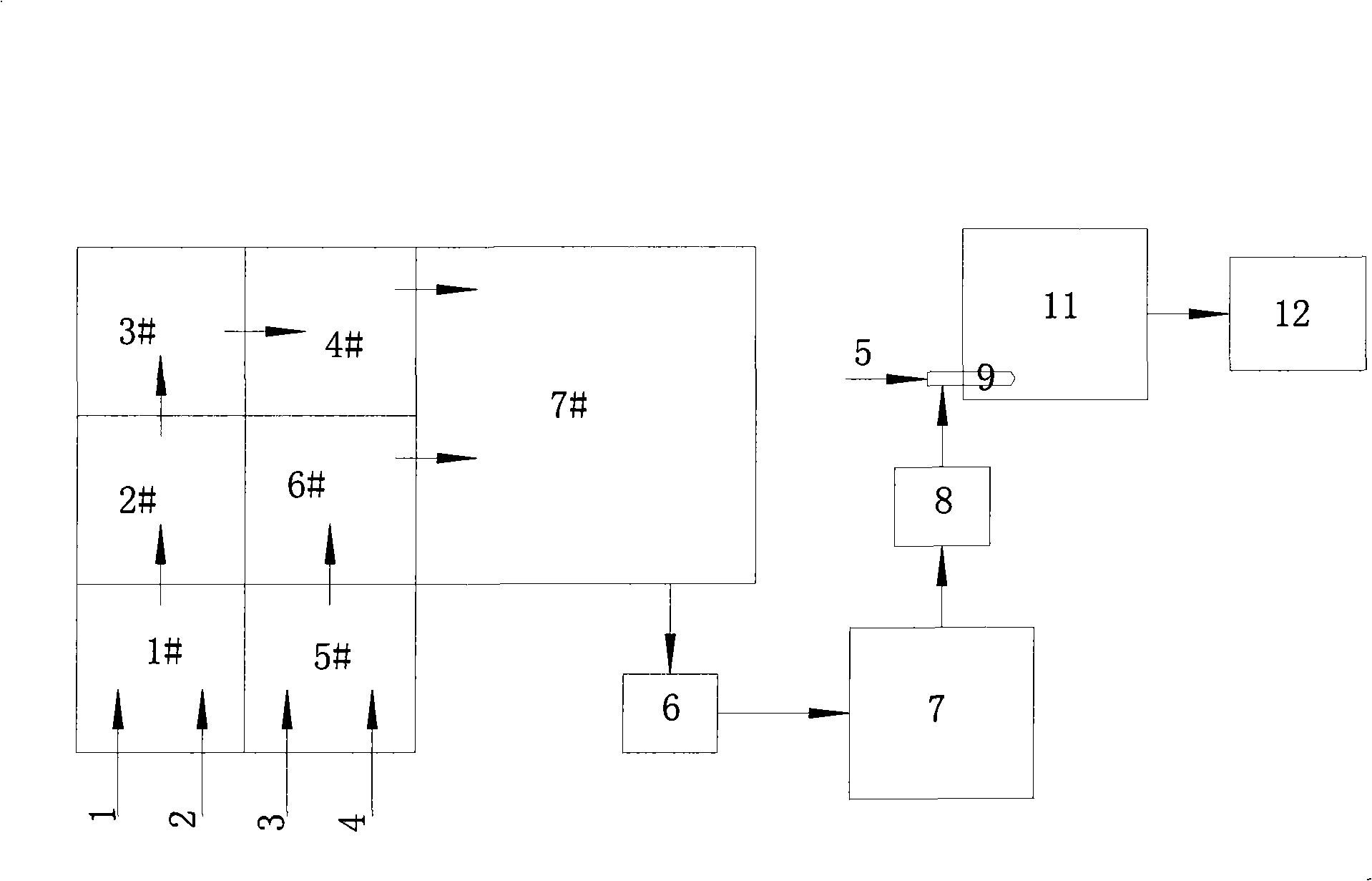

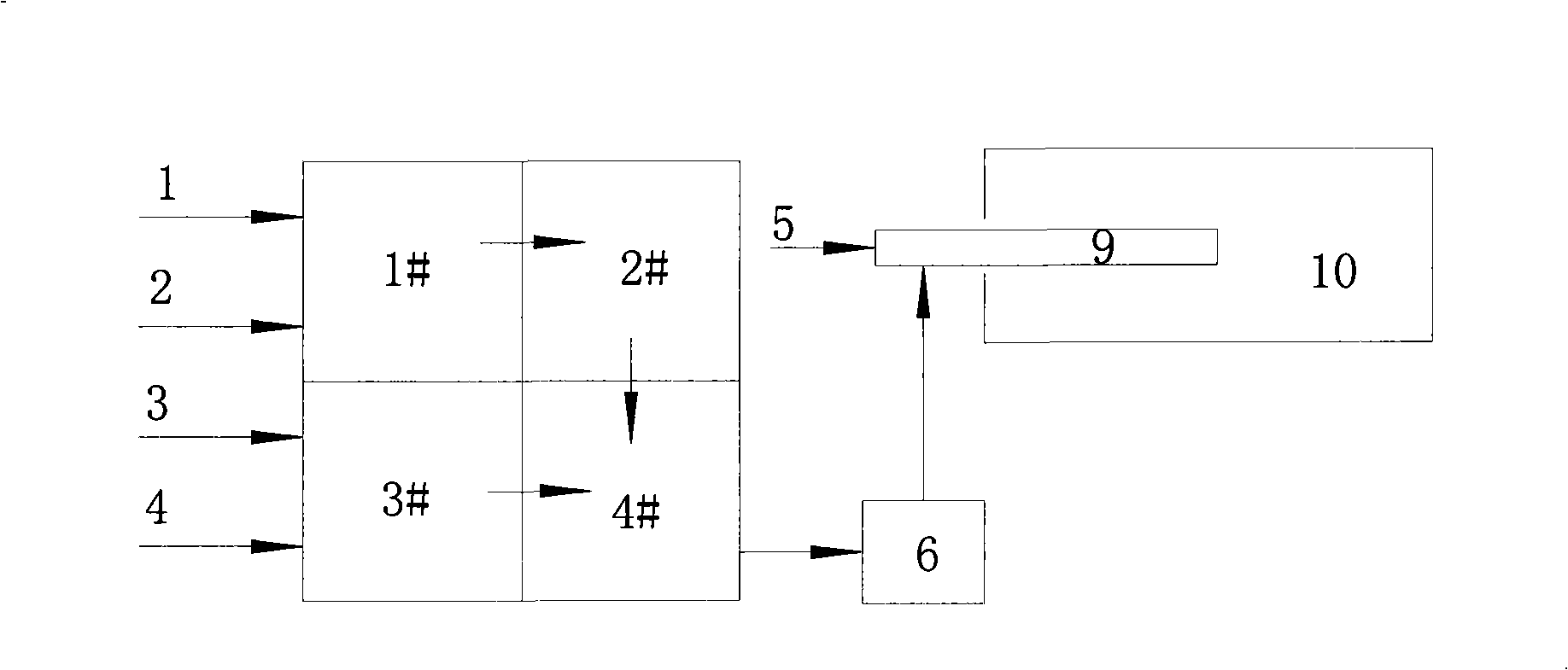

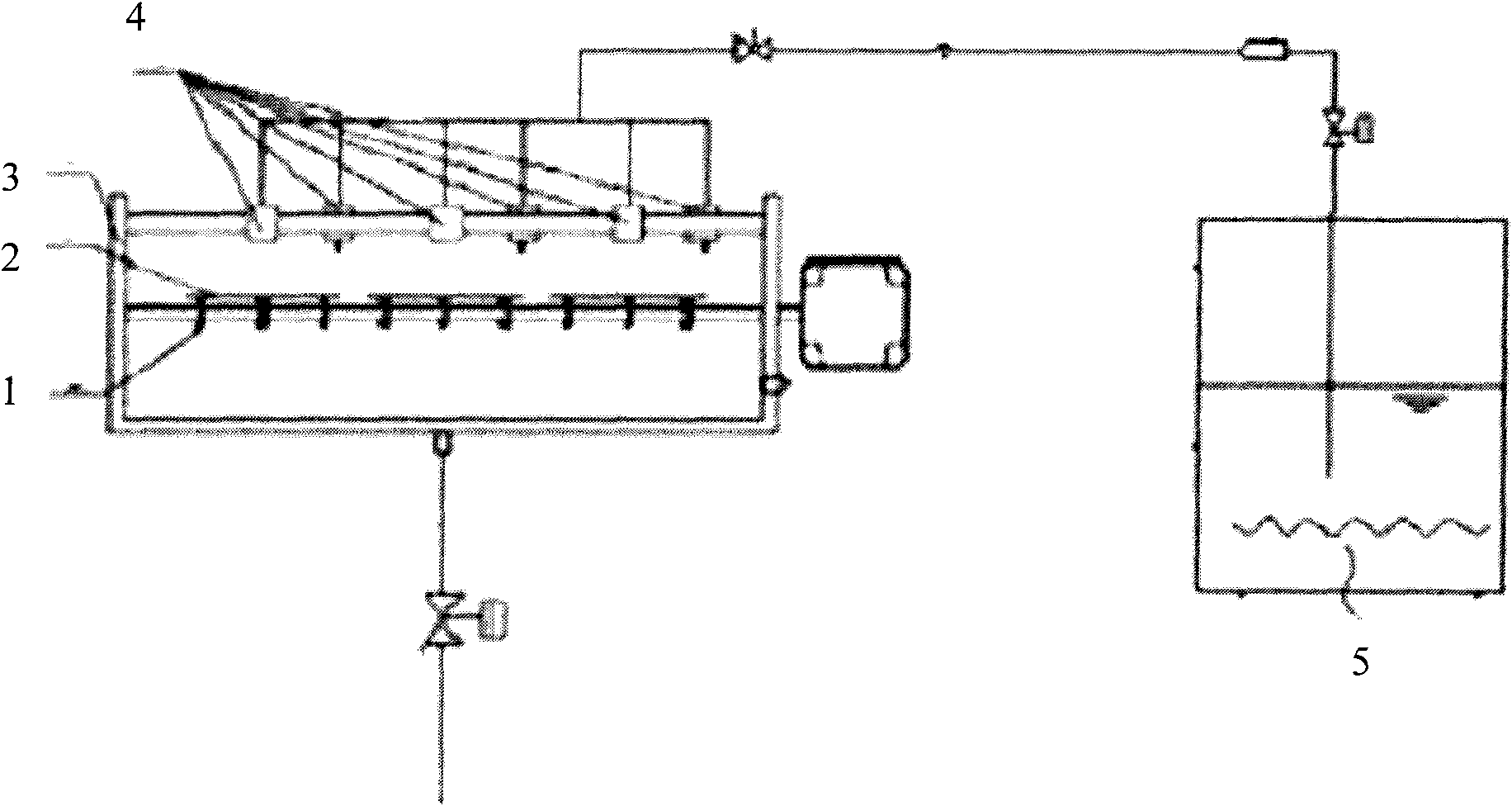

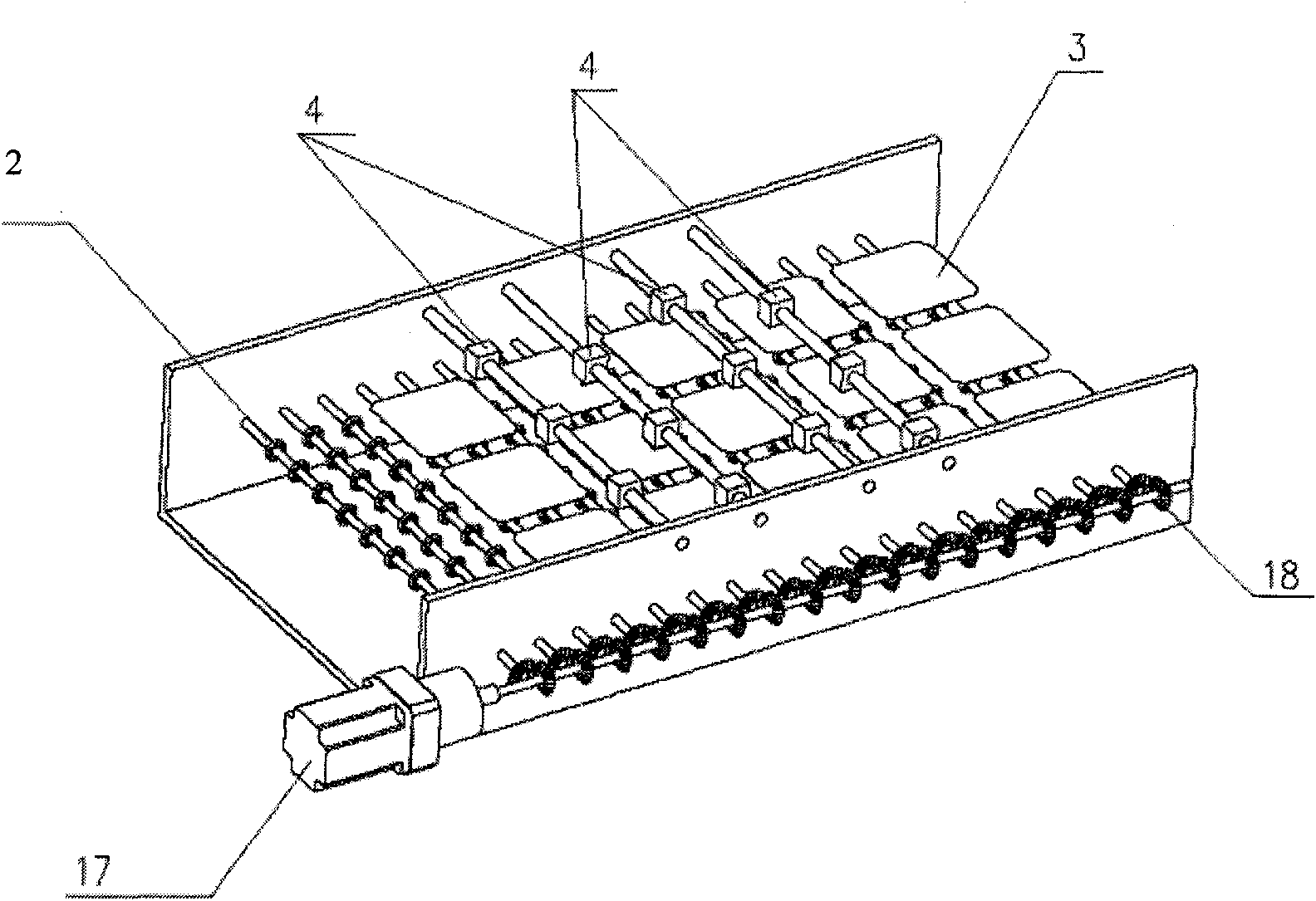

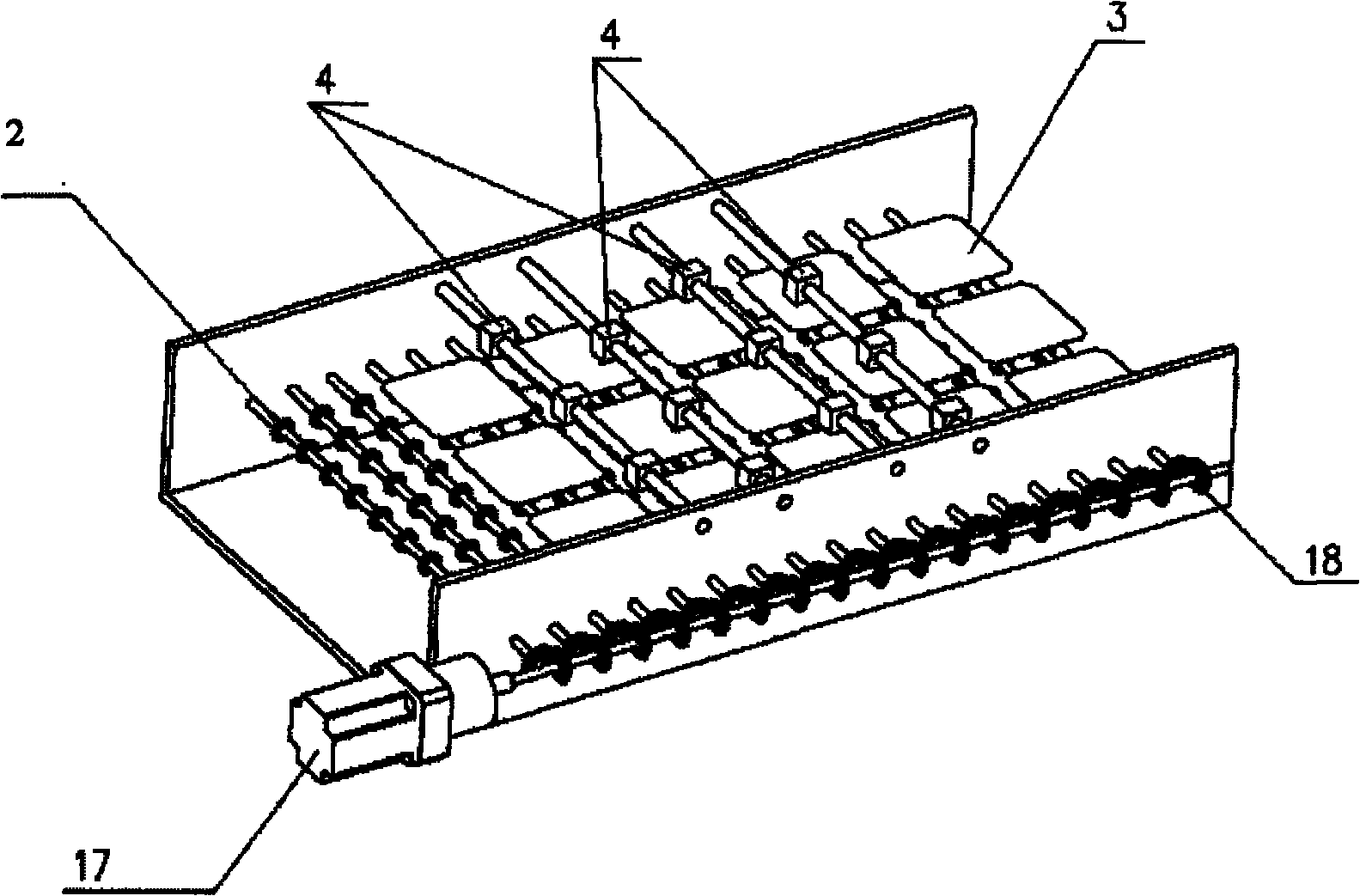

Method for preparing sulphur based compound fertilizer by decomposing rock phosphate with hydrogen nitrate and system thereof

ActiveCN101343200AThe production process is straightforward and simpleReduce intermediate stepsFertilizer mixturesHydrogen NitratePhosphate

The invention relates to a method and a system for using nitric acid decomposed phosphate rock powder to produce a sulfur-based compound fertilizer, comprising the steps of: (1) preparing potassium bisulfate for obtaining a mixed acid I; (2) decomposing phosphate rock powder with nitric acid for acquiring a mixed acid II; (3) mixing the mixed acid I with the mixed acid II; and (4) having the mixed acid III obtained in the step (3) to react with liquid ammonia or gas ammonia for getting the sulfur-based compound fertilizer. The method and the system have a more direct and simple production process flow than that of the current nitryl sulfur-based fertilizer, and fully utilize the nitrate nitrogen and acidity of nitric acid and the heat of reaction, as well as low temperature dechlorination and sensible heat of concentrated sulfuric acid potassium chloride, thereby cutting the intermediate step, obviously reducing the energy consumption and corrosion, and lowering the capital construction and equipment investment.

Owner:中国-阿拉伯化肥有限公司

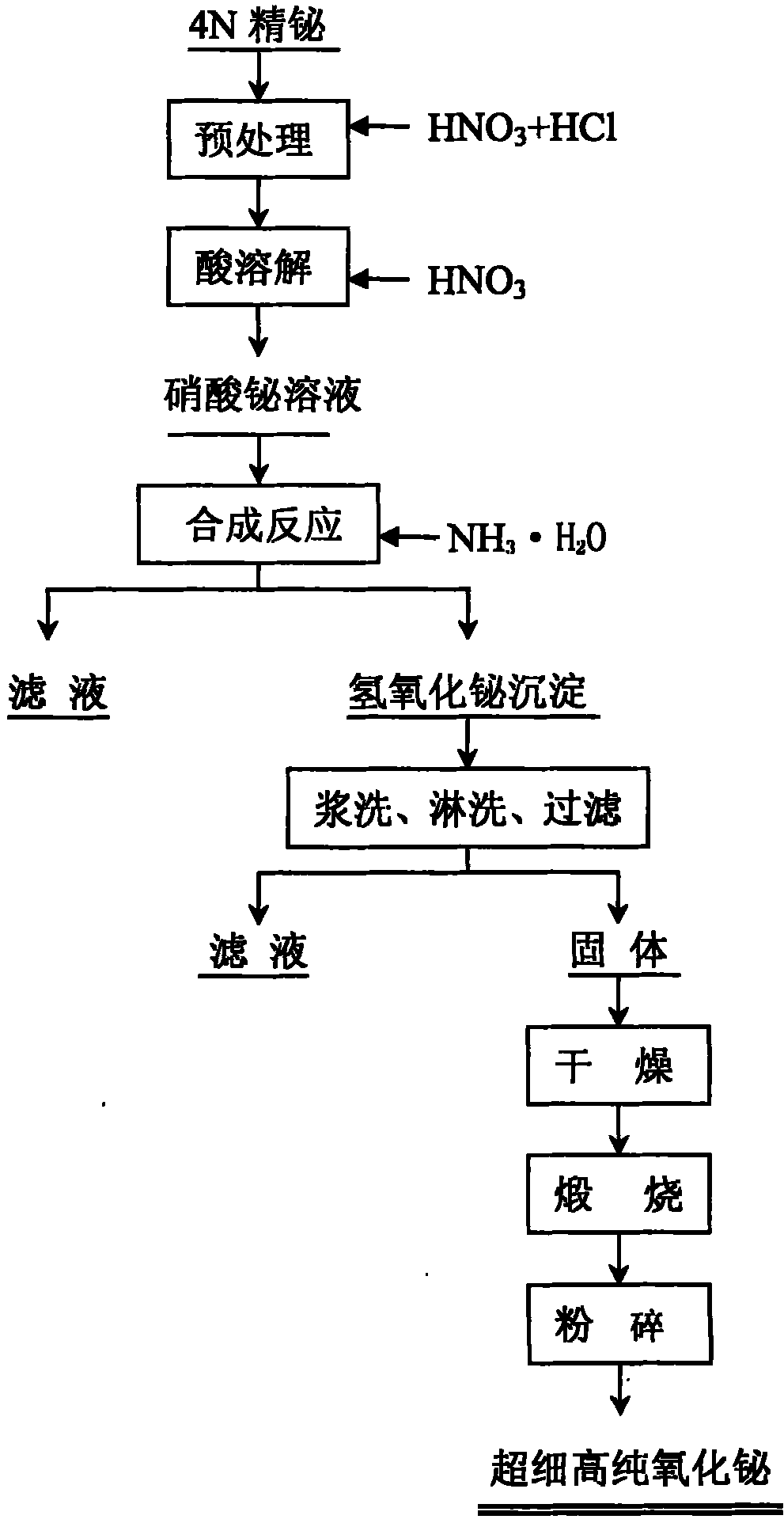

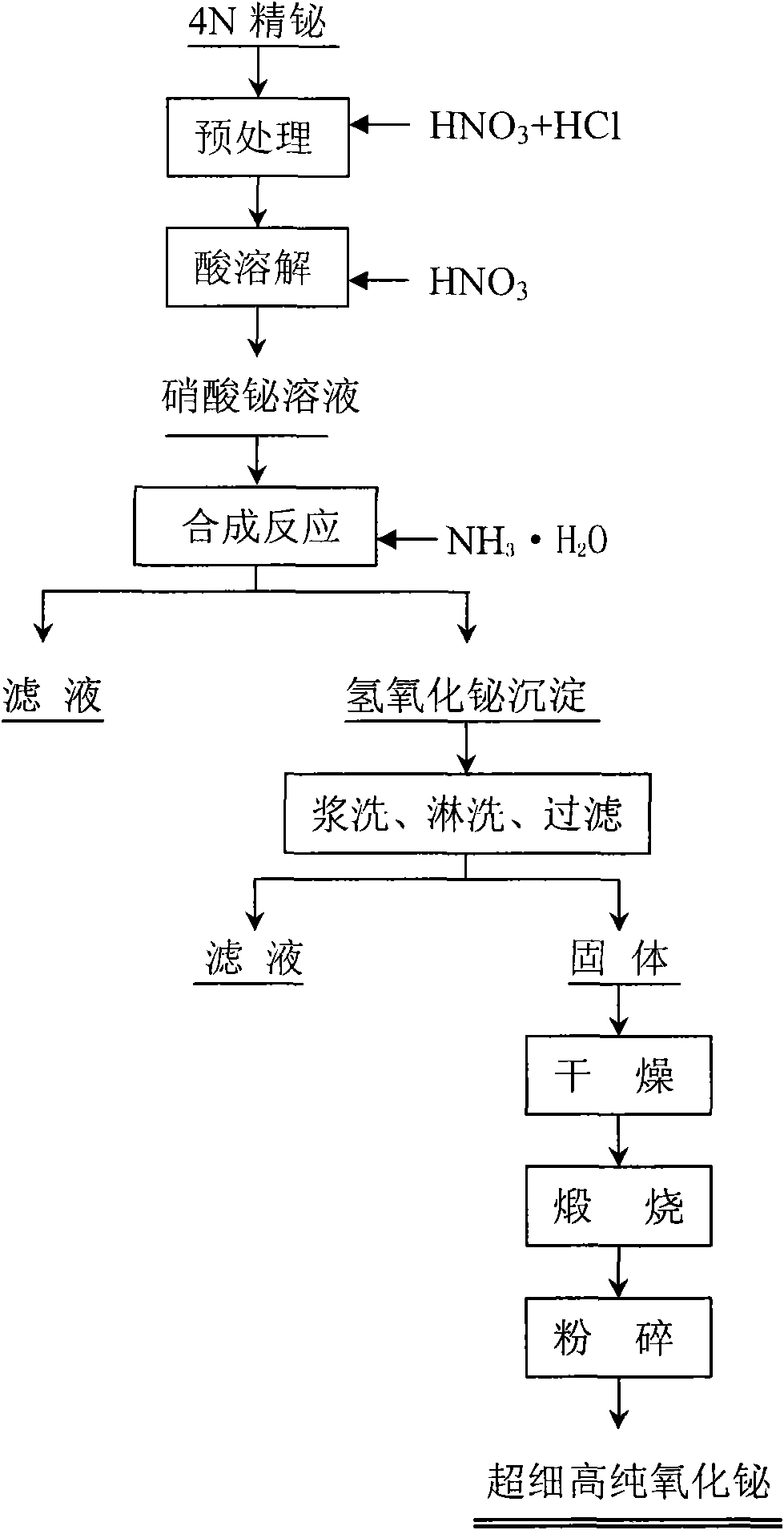

Superfine and high-purity bismuth oxide and preparation method thereof

InactiveCN101811732AProcess conditions are easy to controlImprove uniformityBismuth compoundsHydrogen NitrateGranularity

The invention relates to a superfine and high-purity bismuth oxide with the granularity of 10-1000nm and a preparation method thereof. The method takes the solid bismuth with the purity of 4N as a raw material to synthesize the superfine and high-purity bismuth oxide, and is characterized in comprising the following steps of: firstly, soaking the solid bismuth with the purity of 4N into mixed acid solution which is prepared by hydrogen nitrate and muriatic acid; taking out the soaked solid bismuth, and enabling the soaked solid bismuth to react with hydrogen nitrate solution to obtain the bismuth nitrate solution and keep the excessive status of the hydrogen nitrate; mixing the bismuth nitrate solution with the ammonia water solution to perform synthetic reaction; filtrating to obtain white bismuth hydroxide deposition; and washing, drying, calcining and preparing powder according to a conventional method to obtain the superfine and high-purity bismuth oxide with the phase of alpha-Bi2O3, the granularity of 10-100nm and the purity of 5N. The technological condition is easily controlled, has good product homogeneity, and does not need to an add dispersing agent, thereby being capable of obtaining the superfine bismuth oxide powder with even granularity, preventing impurity from being induced, and reducing the preparation cost.

Owner:ZHUZHOU SMELTER GRP

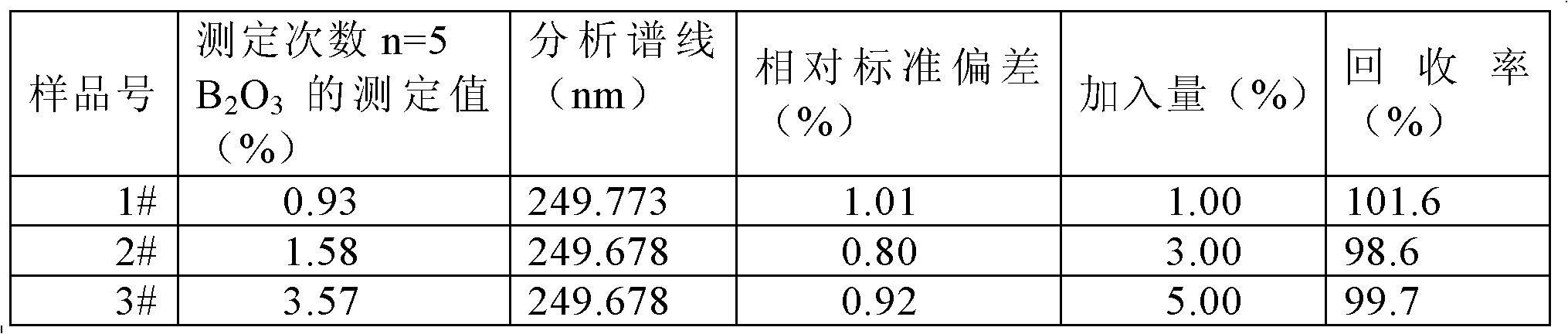

Method for measuring content of diboron trioxide in casting powder

InactiveCN101988891ABreak down completelyRapid determinationColor/spectral properties measurementsHydrogen NitrateInductively coupled plasma

The invention relates to a method for measuring the content of the diboron trioxide in casting powder in the smelting technology, which comprises the following steps of: 1. weighing 0.1-1g of sample accurately to 0.0002g, adding the constant quantity of the hydrochloric acid, the hydrogen nitrate and the hydrofluoric acid, adding 0.5-2.0g of mannitol into a beaker, and heating until that the sample is completely dissolved; 2. respectively preparing at least four parts of working curve standard solution for measuring the content of the diboron trioxide in volumetric flasks by the boron standard solution under the same acid medium; and 3. selecting the analysis spectral line of the boron in the medium on the inductively coupled plasma spectrometer (ICPS), measuring the spectral intensity of the boron in the standard solution and the test solution of the working curve at the same time, and computing an analysis result by a computer by means of autoregression. The method dissolves the sample by mixing the hydrofluoric acid with the other acids, and leads the sample to be complexed with the boron by adding the mannitol to lead the boron not to be volatilized and not to be completely decomposed, thereby being applied to measuring the diboron trioxide in the casting powder with the mass fraction within the range from 0.005% to 20%, and being fast in measuring speed and high in accuracy.

Owner:武钢集团有限公司

Method for carrying out wet-method phosphorous diffusion and texturing on substrate and acid solution for texturing

InactiveCN102157602AIncrease productionLow costFinal product manufactureSemiconductor/solid-state device manufacturingHydrogen NitratePhosphoric acid

The invention relates to a method for manufacturing a PN junction by carrying out wet-method chemical phosphorous diffusion on a substrate and texturing the substrate, mainly comprising the following steps of: (1) carrying out wet treatment on the substrate by using phosphoric acid; (2) transferring the substrate into a heating furnace for phosphorous diffusion, wherein the temperature inside the heating furnace is 800-900 DEG C, and the heating time is 20-30 minutes; (3) texturing the substrate by adopting an acid solution, wherein the acid solution is a mixed solution of hydrofluoric acid, hydrogen nitrate, phosphoric acid and a surface active agent; and (4) finally cleaning the substrate by using an alkali solution and deionized water, and drying. By means of the method disclosed by the invention, the single-surface diffusion and the texturing of the polycrystalline silicon substrate become easy and feasible, and the production quantity of high-quality PN junction substrates (such as solar cell substrates) through uninterrupted continuous production is greatly improved; and the invention has the advantages of simpleness, high efficiency, low cost and no toxicity.

Owner:SHANGHAI SNA ELECTRONICS TECH

Process for purifying and recovering boron nitride nanotube crude product

The invention relates to a process for purifying and recovering a boron nitride nanotube crude product, comprising the following steps: crashing the boron nitride nanotube crude product, soaking with acid which is hydrochloric acid or hydrogen nitrate, filtrating to obtain filter cake and filtrate, water washing and drying the filter cake to obtain purified boron nitride nanotube powder; adding ammonia in filtrate and precipitating to obtain byproducts, filtrating to obtain filter cake and filtrate, water washing and drying the obtained filter cake to obtain a recycle byproduct-alkaline-earth metal compound, filtering and water washing the obtained filtrate, evaporating the filtrate and waste washing liquid to remove moisture and volatiles, and performing oxidation reaction to obtain recycle transition metal oxide and rare-earth oxide. The beneficial effects of the invention are that: boron nitride nanotube purity can reach above 90wt.% by purifying, the recovery rate of catalyst and byproducts can reach above 95% and the recovered metal catalyst and byproducts can be recycled for preparing boron nitride nanotube.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

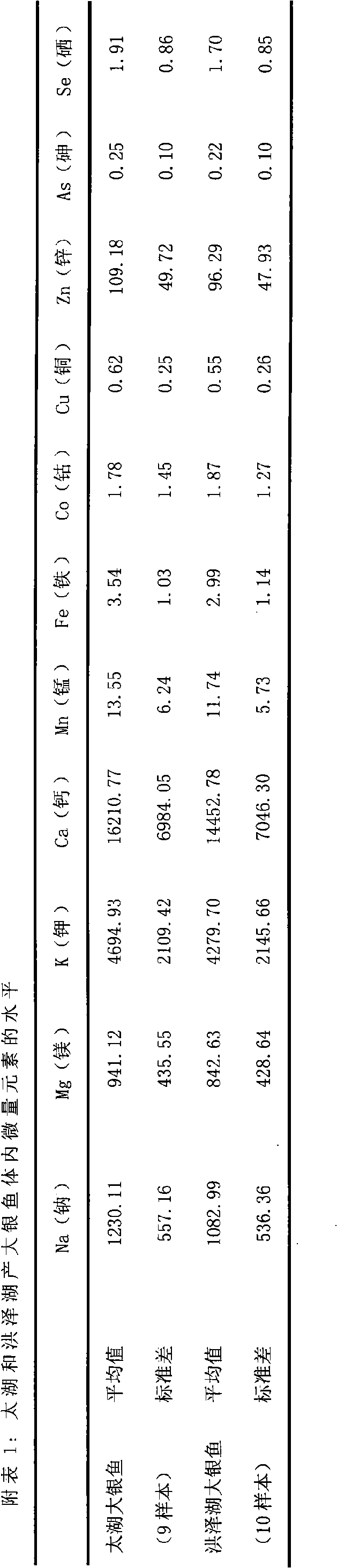

Method for discriminating different origins using multiple microelements in ice fish vivo

InactiveCN101275956AGood repeatabilityImprove stabilityPreparing sample for investigationMaterial analysis by electric/magnetic meansHydrogen NitrateMinor element

The present invention relates to a method for determining a plurality of minor elements in the body of the whitebait from different producing areas. The invention is characterized in that the specimen of the whitebait is transferred into a refrigerator for storing. The specimen of the whitebait is washed with after thawing and is baked to a constant weight in a drying cabinet. The dried specimen of large whitebait is grinded to powder and is arranged in a dryer in pickle. The dried specimen of large whitebait is taken into a Teflon decomposing container which is acid washed. The high purity hydrogen nitrate is added for preparing the acidolysis in room temperature. A microwave oven is used for resolution. Then hyperpure water is used for regulating the volume to a solution to be measured. The solution to be tested is leaded into an inductance coupling plasma velocitron to execute a concentration determination. The concentrations of 11 minor elements in the dried specimen of large whitebait are measured. A linear dicriminant function is established. The large whitebait generated in different waters can be effectively discriminated through the calculated value of the dicriminant function. The result obtained by the invention has the advantages of good stability, high repeatability, small systematical error and strong discriminability. Not only the localizations which can be discriminated by the methods of visual method, hereditism and the like are overcome, but also the predominance of high speed is displayed.

Owner:FRESHWATER FISHERIES RES CENT OF CHINESE ACAD OF FISHERY SCI

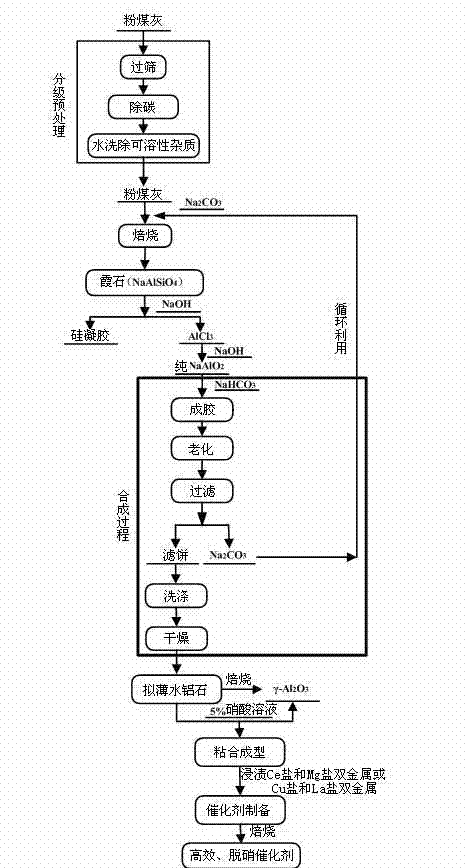

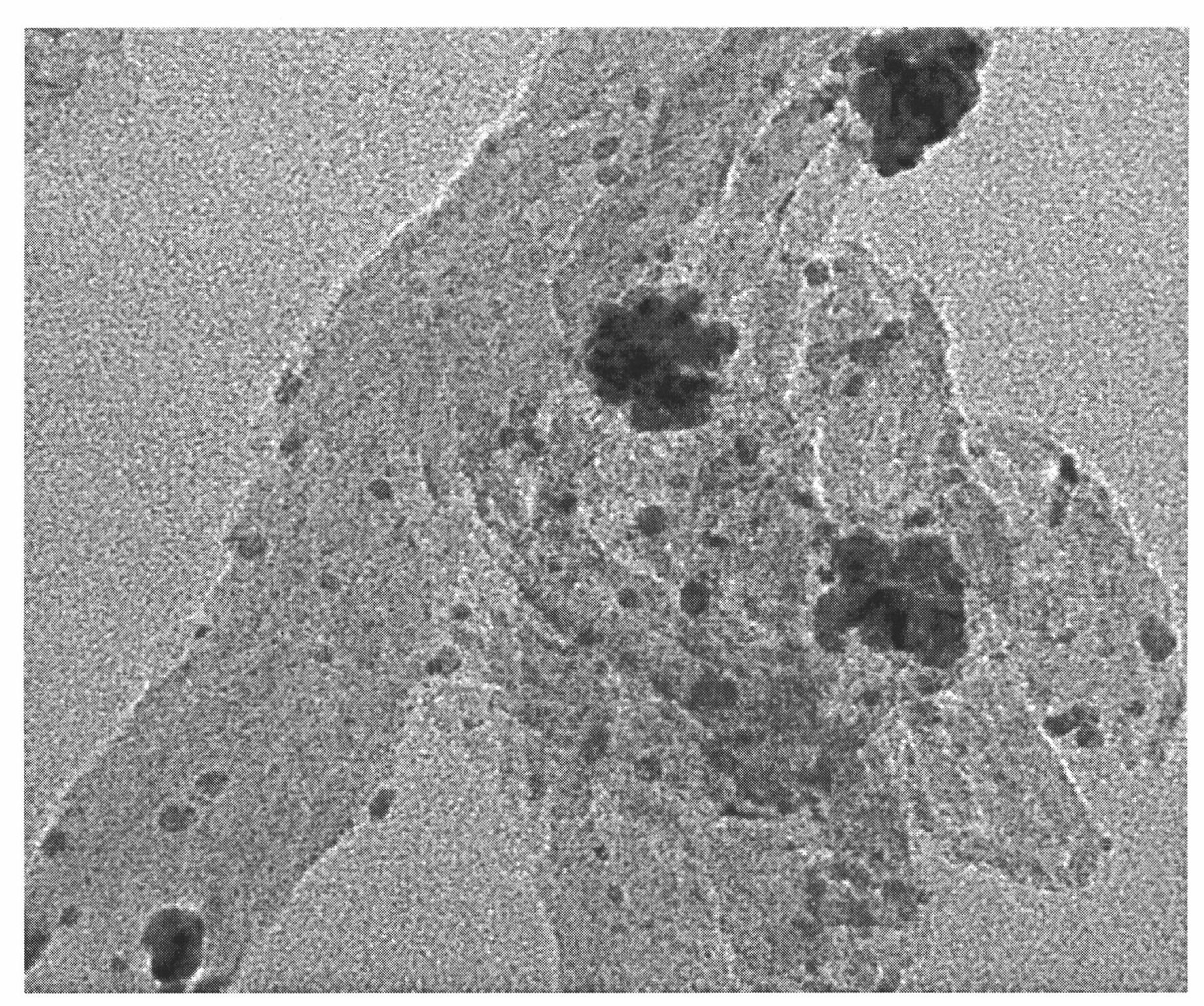

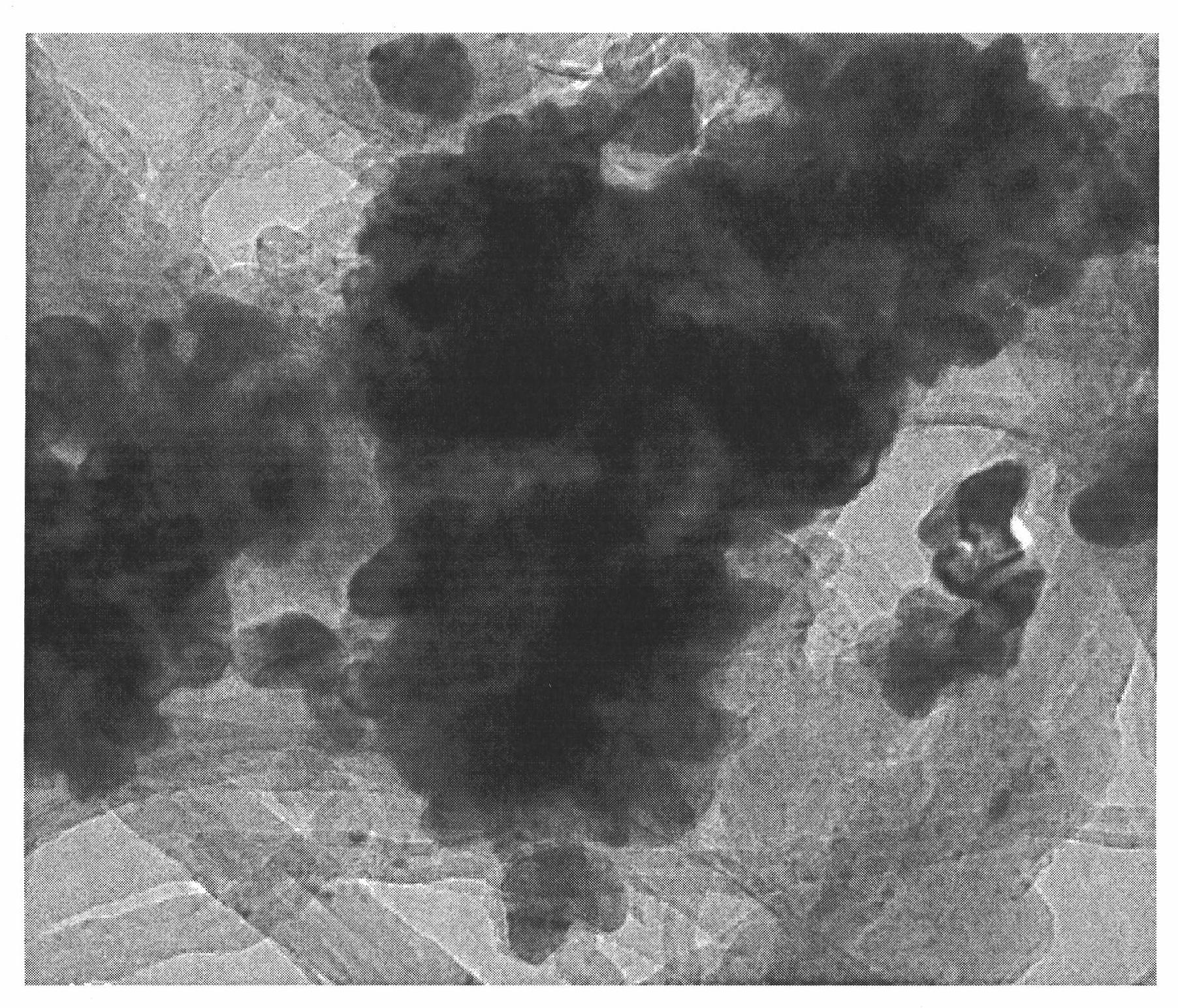

Method for preparing bimetallic denitration catalyst by using coal ash

InactiveCN102861566AIncrease added valueAddress underutilizationDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsHydrogen NitrateMolecular sieve

The invention relates to a method for preparing a bimetallic denitration catalyst by using coal ash. The method includes firstly, using the coal ash to prepare a coarse AlCl3 solution; secondly, using the coarse AlCl3 solution to prepare pseudo boehmite; thirdly, subjecting the obtained pseudo boehmite to high-temperature roasting at the temperature of 400-700 DEG C to obtain gamma-Al2O3, adding hydrogen nitrate to the pseudo boehmite and the gamma-Al2O3 to be evenly mixed, and crushing the pseudo boehmite and the gamma-Al2O3 into required shapes and sizes according to requirements after extrusion molding; fourthly, using Ce salt and Mg salt to prepare a stable mixed solution with mass percentage concentration of 1%-20%; and fifthly, immersing the gamma-Al2O3 obtained from the second step in the mixed solution prepared in the fourth step for 20-30 hours, draining the residual solution in a molecular sieve after the immersion is finished, and subjecting the drained residual solution to drying for 24 hours at room temperatures and then roasting at the temperature of 500-850 DEG C to obtain bimetallic denitration catalyst particles. Compared with existing denitration catalysts, the bimetallic denitration catalyst has the advantages that the specific area is larger, the thermal stability is better, and the conversion percentage of NOx reaches 60%-90%.

Owner:NORTHEAST GASOLINEEUM UNIV

Method for preparing multi-wall carbon nanotube-palladium composite material and use thereof

InactiveCN101862654AGood dispersionHigh yieldOrganic compound preparationCarboxylic acid esters preparationHydrogen NitrateNanotube

The invention relates to a method for preparing a multi-wall carbon nanotube-palladium composite material and use thereof. The method comprises the following steps: refluxing carbon nanotubes in hydrogen nitrate, and after the reaction is finished, pouring the reaction solution into a centrifugal test tube to perform centrifugal washing by using distilled water and ethanol, and drying the obtained product in an oven; and dissolving PdC12 in water, adding the multi-wall carbon nanotubes treated by the hydrogen nitrate into the solution, processing the solution in ultrasonic waves in a N2 atmosphere, adjusting the pH value of the solution to 8 to 9 by using ammonia water, slowing dripping the mixture into aqueous solution of NaBH4 in ultrasonic waves, performing ultrasonic wave treatment continuously after the dripping is finished, centrifuging the resulting product, washing the product with distilled water and then with absolute ethanol and drying the product. The key design point of the invention lies in that the ultrasonic wave treatment improves the dispersibility of the particles of the product metal. The method of the invention adopts simple steps, allows the reactions to be performed under mild reaction conditions and at normal temperature and saves energy.

Owner:SHANGHAI QIBAO HIGH SCHOOL

Method for extracting gold by using circuit board anode mud

InactiveCN101760624AHigh recovery rateProtect resourcesProcess efficiency improvementHydrogen NitrateElectrolysis

The invention relates to a method for extracting gold by using circuit board anode mud. The method comprises the following steps that: sulfuric acid, sodium chloride and sodium chlorate are added in anode mud, and leached liquid and leached residue are obtained through filtration; the leached liquid is cooled, crystals are precipitated and copper is recovered; sodium bromide, hydrogen chloride, sodium hypochlorite and sodium chloride are added in the obtained leached residue, and leached liquid containing gold and leached residue containing silver are obtained through filtration; ammonia water is added in the leached residue containing silver, and leached liquid containing silver and leached residue are obtained through filtration; hydrazine hydrate is added to reduce the leached liquid containing silver and silver powder is obtained; and sodium sulfite is added to reduce the obtained leached liquid containing gold, then hydrogen nitrate and sodium hydroxide are added and finally goldpowder is obtained. The invention solves the difficulty in China that precious metals are hard to be separated from the anode mud after cathode copper is extracted from waste circuit boards through miscellaneous copper alloy electrolysis, and has the advantages that the recovery rate of the precious metals is improved, the resources are protected and the economic benefit is improved.

Owner:广东奥美特集团有限公司

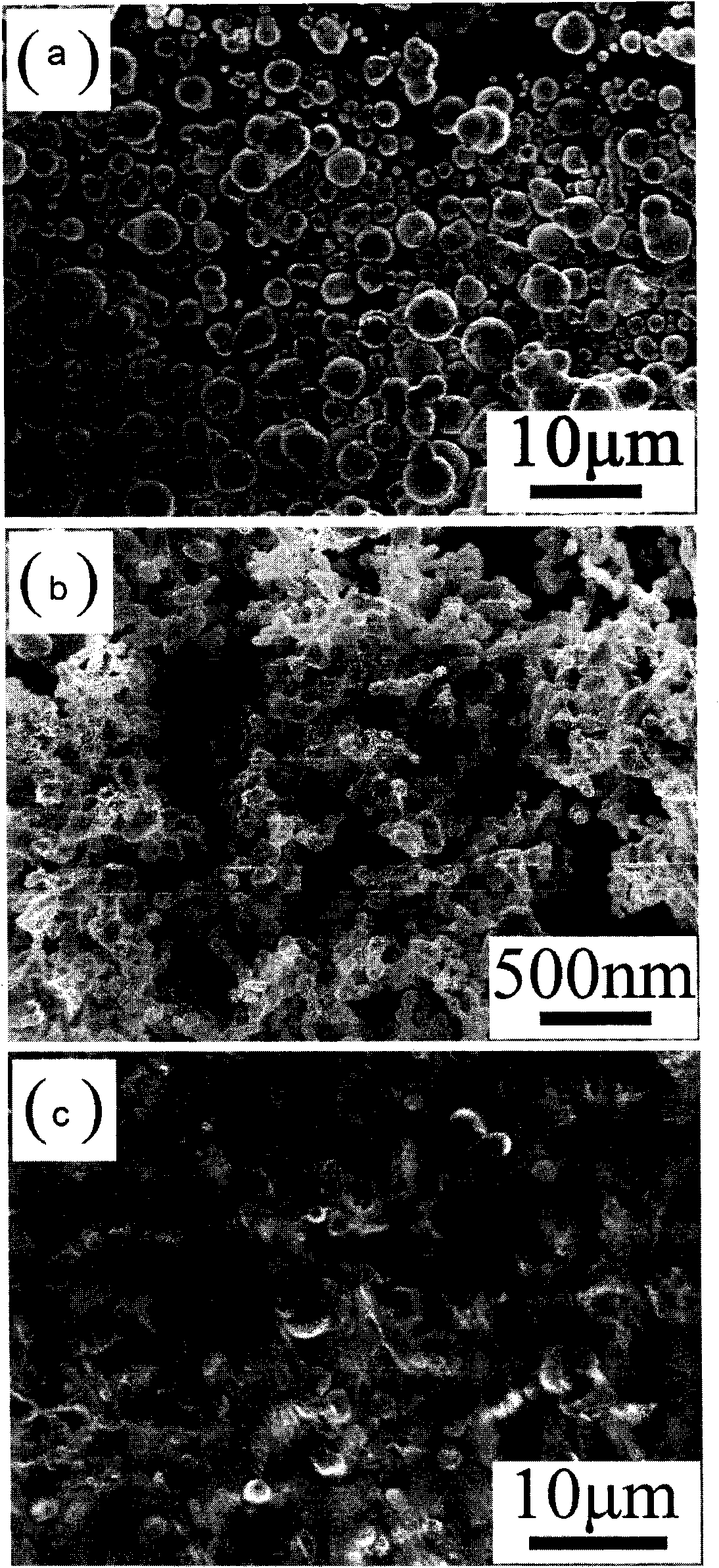

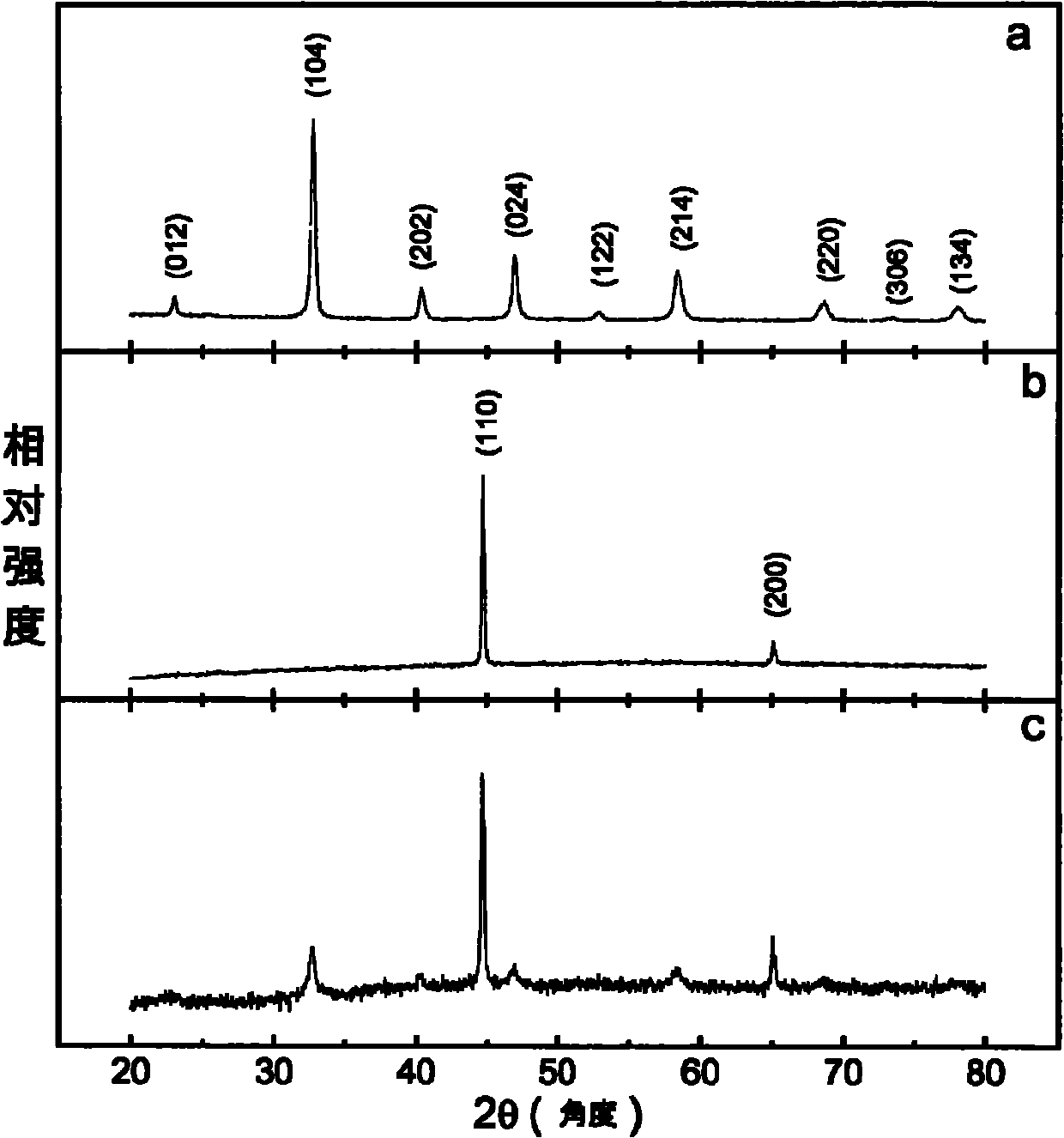

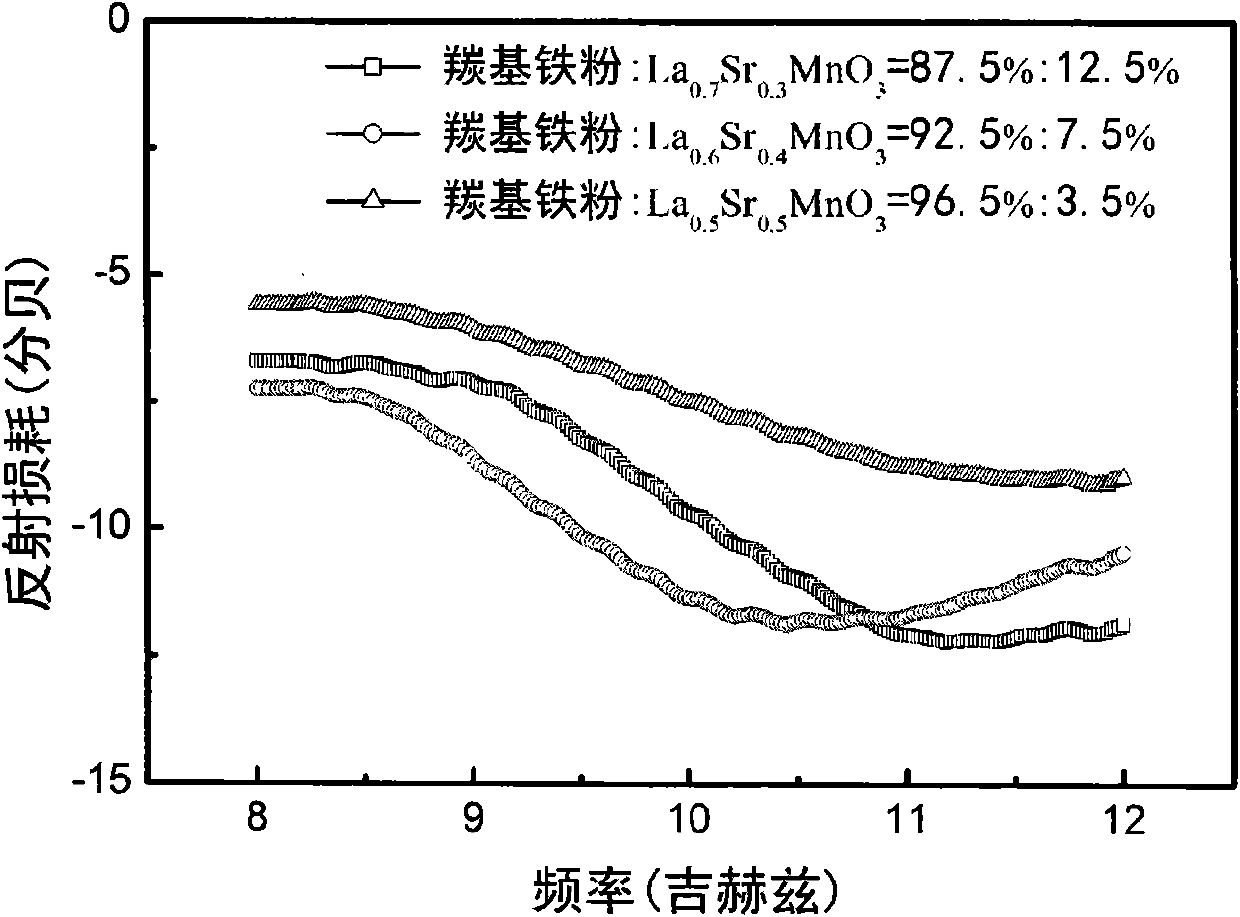

Carbonyl iron powder/lanthanum strontium manganate composite and preparation method thereof

InactiveCN102020974AImprove absorbing performanceDifferent absorbing propertiesOther chemical processesMagnetic/electric field screeningHydrogen NitrateManganese

The invention discloses a carbonyl iron powder / lanthanum strontium manganate composite and a preparation method thereof. The composite is formed by mixing the following components in percentage by weight: 7.25 to 98.75 percent of carbonyl iron powder and 1.25 to 22.75 percent of La1-xSrxMnO3 powder, wherein x in the La1-xSrxMnO3 powder is between 0.25 and 0.55. The method comprises the following steps of: adding lanthanum oxide, strontium carbonate and manganese carbonate into aqueous solution of hydrogen nitrate according to a stoichiometric ratio of La1-xSrxMnO3 to obtain mixed liquor, and adding citric acid into the mixed liquor at the temperature of between 60 and 95 DEG C to obtain intermediate liquor; adding ammonia water into the intermediate liquor dropwise until the pH value is between 6 and 7, stirring at the temperature of between 60 and 95 DEG C to form gel, and performing heat preservation on the gel at the temperature of between 100 and 150 DEG C to obtain gel dry powder; presintering the gel dry powder at the temperature of between 200 and 350 DEG C for 2 to 4 hours, and grinding to obtain powder; performing heat treatment on the powder at the temperature of between650 and 800 DEG C for 2 to 8 hours to obtain the La1-xSrxMnO3 powder; and mixing the carbonyl iron powder and the La1-xSrxMnO3 powder according to the required ratio to obtain the composite. The carbonyl iron powder / lanthanum strontium manganate composite can absorb electromagnetic waves uniformly and effectively within the frequency range of between 8 and 12 GHz under the condition that the thickness is less than 1 millimeter.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

High-performance liquid chromatography method for measuring nucleotide in milk powder

ActiveCN102680601AThe separation method is simpleEasy to separateComponent separationHydrogen NitrateFood additive

The invention relates to a high-performance liquid chromatography method for measuring nucleotide in milk powder, and belongs to the technical field of detection for food additives. The method comprises the following steps of: preparing a contrast solution by using a nucleotide standard substance; weighing a test sample, dissolving the test sample in distilled water through ultrasonic oscillation, so that the nucleotide in the milk powder is dissolved in the distilled water; adjusting the pH value of the test sample solution by hydrogen nitrate until the pH value is 3 to 4, precipitating proteins, filtering and removing the proteins, fixing the volume of a filtrate by using water to obtain a to-be-tested solution; measuring nucleotide chromatographic peak areas in the test solution and the contrast solution by high performance liquid chromatography; and calculating the nucleotide content in the test sample by an external standard method according to the concentration of the nucleotidein the contrast solution, the nucleotide chromatographic peak area in the test solution and the mass of the test sample. The method is simple, convenient to operate and high in precision; proteins can be completely separated, so that interference with the measurement for the nucleotide is eliminated; and a good condition is supplied to measurement of the nucleotide in the test sample.

Owner:SHANDONG KAISHENG NEW MATERIALS

Method for producing calcium nitrate by carbide slag

InactiveCN102115133AEfficient extractionSimple methodSolid waste disposalCalcium/strontium/barium nitratesHydrogen NitrateSlag

The invention provides a method for producing calcium nitrate by carbide slag, which comprises the steps of: grinding the carbide slag into coarse powders with 80-100 meshes, putting the coarse powders into a reactor to be abundantly mixed with the water, putting the excessive hydrochloric acid into a reactor, converting oxide in the carbide slag into soluble chloride, and filtering a reaction product to obtain filter liquor which takes calcium chloride as a main part; reacting the filter liquor which takes the calcium chloride as the main part with excessive carbonic acid solution, combining calcium ions with carbonate ions into calcium carbonate to be precipitated, and filtering to obtain a calcium carbonate filter cake, and reacting the calcium carbonate filter cake with hydrogen nitrate solution to obtain calcium nitrate precipitate and carbon acid solution mixture; and separating the calcium nitrate precipitate from the carbon acid solution mixture in a filtering way to obtain the carbonic acid filter liquor and the calcium carbonate filter cake, and drying and smashing the calcium carbonate filter cake to obtain a calcium carbonate product. The method is simple in operation and small in equipment investment, and the obtained calcium nitrate product is high in purity and economic value.

Owner:马艳荣

Method for manufacturing nylon conductive fibers

ActiveCN103173886AHas conductive propertiesEasy to processElectroconductive/antistatic filament manufactureMonocomponent polyamides artificial filamentHydrogen NitrateCarbon nanotube

The invention discloses a method for manufacturing nylon conductive fibers. The method comprises the following steps of: (1) uniformly mixing four-needle type zinc oxide crystal whisker and conductive potassium titanate crystal whisker, roasting, cooling, adding into deionized water, performing ultrasonic dispersion, filtering, and drying, and thus obtaining wrapped crystal whisker mixtures; (2) adding multi-wall carbon nano tubes into a hydrogen nitrate solution, performing ultrasonic dispersion, heating, oxidizing, cooling, filtering, drying and grinding; (3) stirring the crystal whisker mixtures, the multi-wall carbon nano tubes, stibium-doped tin oxide conductive powder, a coupling agent, polymethylene, an antioxidant and nylon sliced powder in a closed manner, and granulating the mixtures through a screw extruder, and thus obtaining nylon conductive mother particles; and (4) respectively putting the nylon conductive mother particles and polyamide 6 into the corresponding screw extruders, spraying from a composite spinneret plate, cooling and winding to obtain the nylon conductive fibers. The nylon conductive fibers have conductive characteristics and are high in processing property and spinning property.

Owner:JIANGSU ZJA NEW MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com