Method for preparing multi-wall carbon nanotube-palladium composite material and use thereof

A technology of multi-walled carbon nanotubes and composite materials, which is applied in the field of preparing multi-walled carbon nanotubes-palladium composite materials, and achieves the effects of mild reaction conditions, improved dispersion, and simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with the accompanying drawings and embodiments of the present invention are described in further detail:

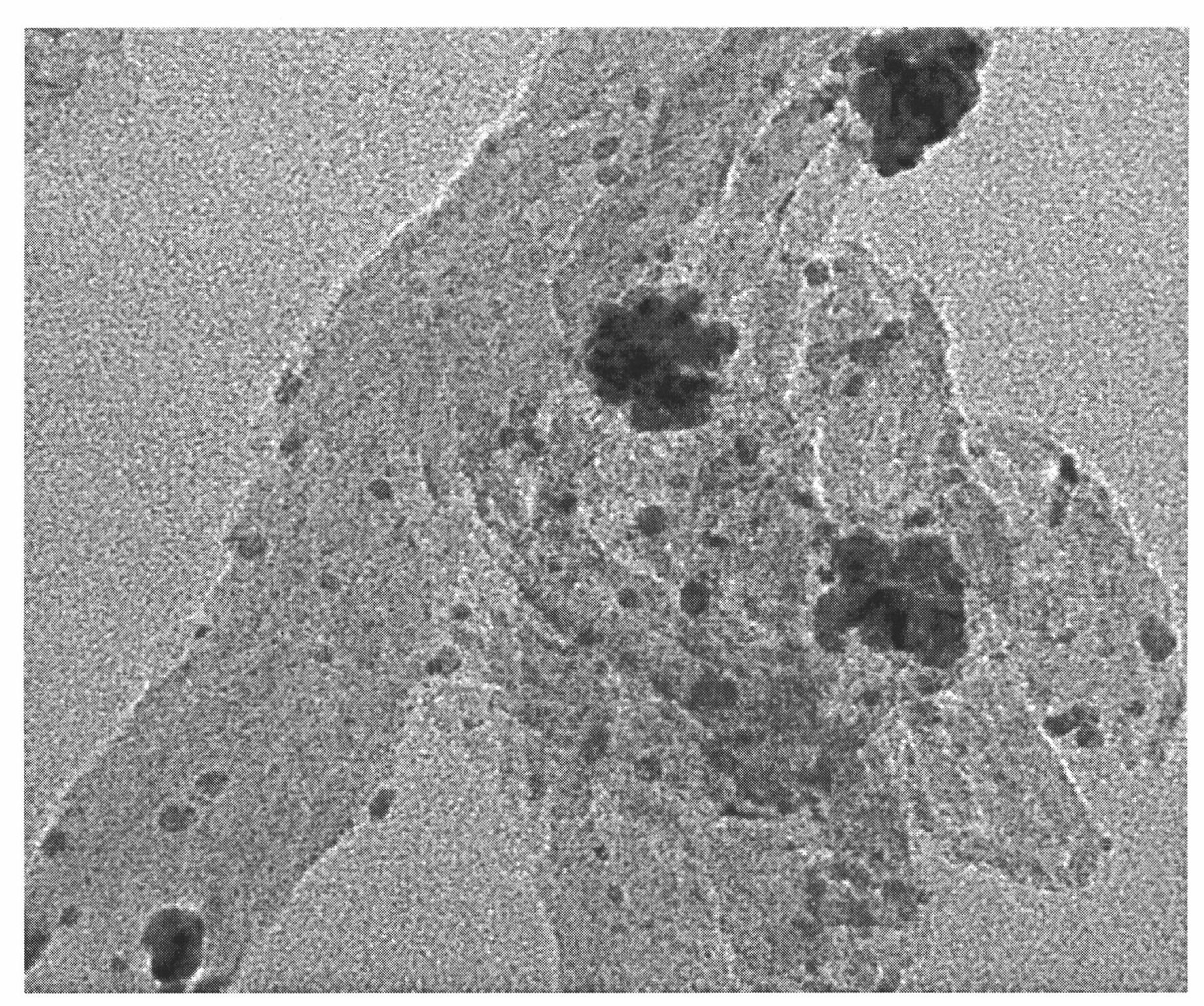

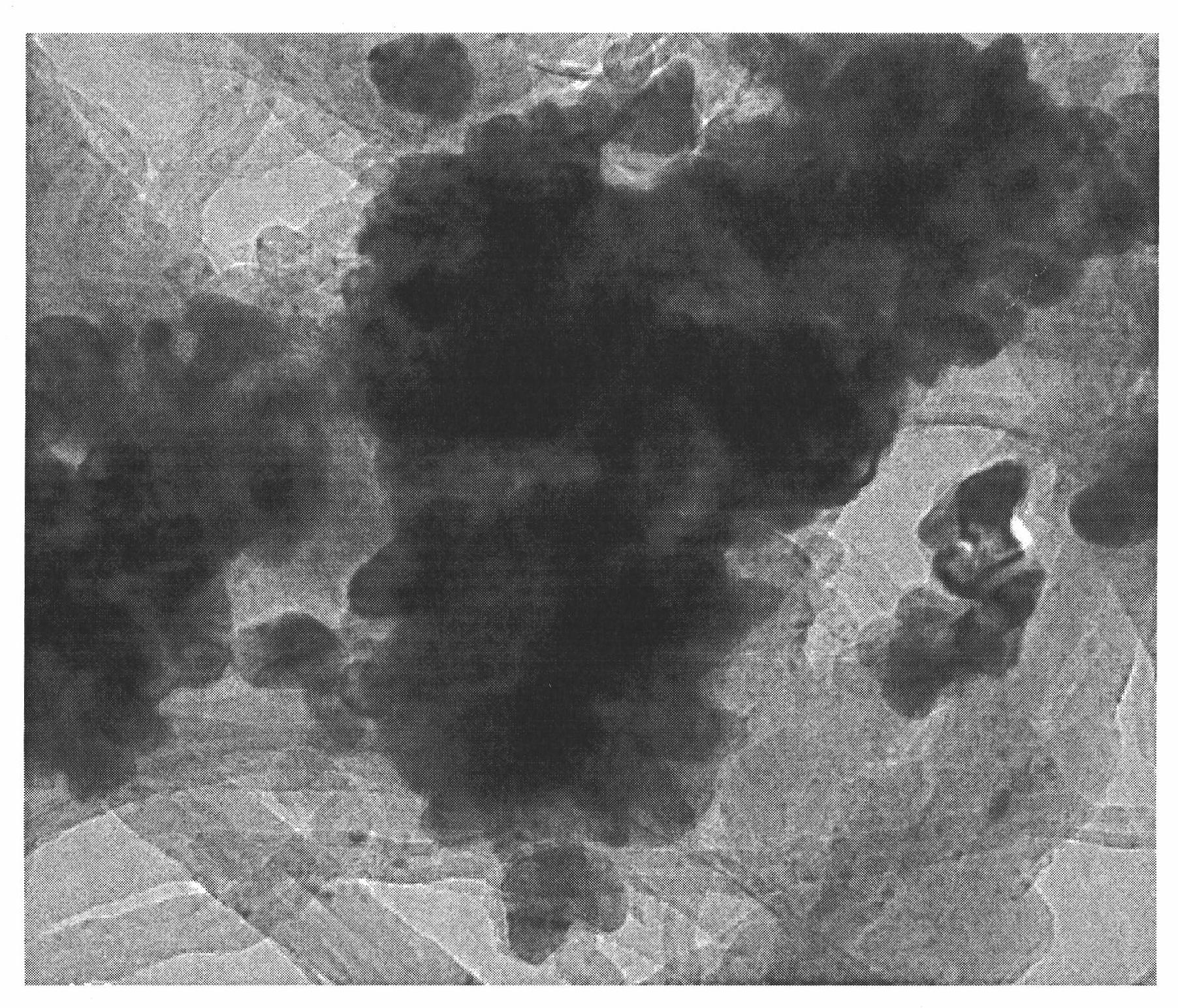

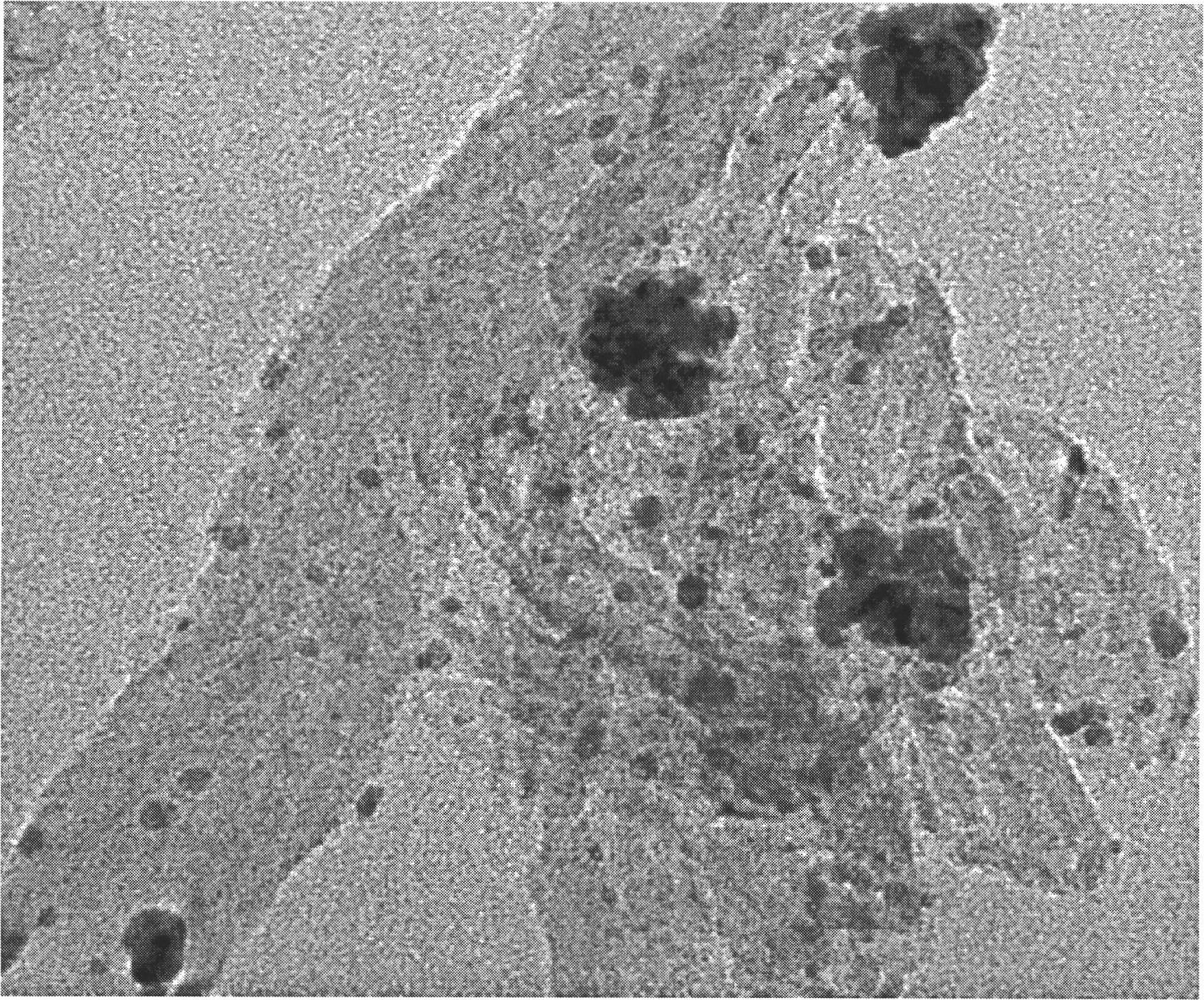

[0021] The invention provides a method for preparing multi-walled carbon nanotube-palladium composite materials. During the test process, X-ray powder diffraction is tested with Bruker D8 X-ray diffractometer; transmission electron microscope is tested with JEOL2001TEM microscope under 200KV, and the attached Test electron energy spectrum; gas chromatography-mass spectrometer is hp 6890 and hp 5973 respectively; H-NMR is tested by JNM-MY60FT instrument at 300MHz, CDCl3 condition. The rest of the medicines used were obtained from commercial sources and used directly without treatment.

[0022] Take 1.0 g of carbon nanotubes in 50 ml of nitric acid and reflux at 150 degrees Celsius for two hours. After stopping the reaction, pour the above uniform black system into a centrifuge test tube. min, centrifuged and washed 4 times with distilled water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com