Method for carrying out wet-method phosphorous diffusion and texturing on substrate and acid solution for texturing

A technology of phosphorus diffusion and acid solution, which is applied in the fields of final product manufacturing, sustainable manufacturing/processing, semiconductor/solid-state device manufacturing, etc. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

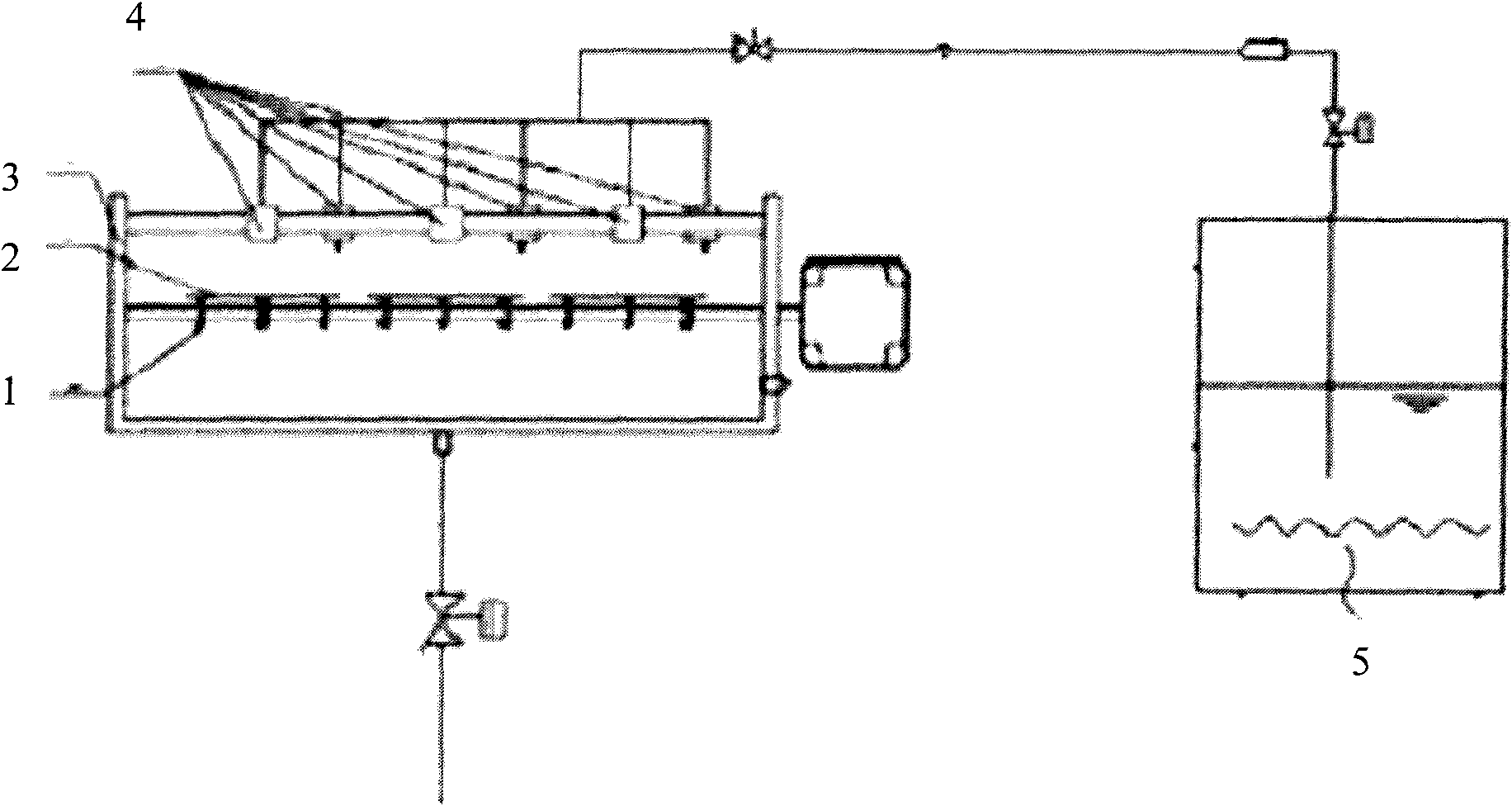

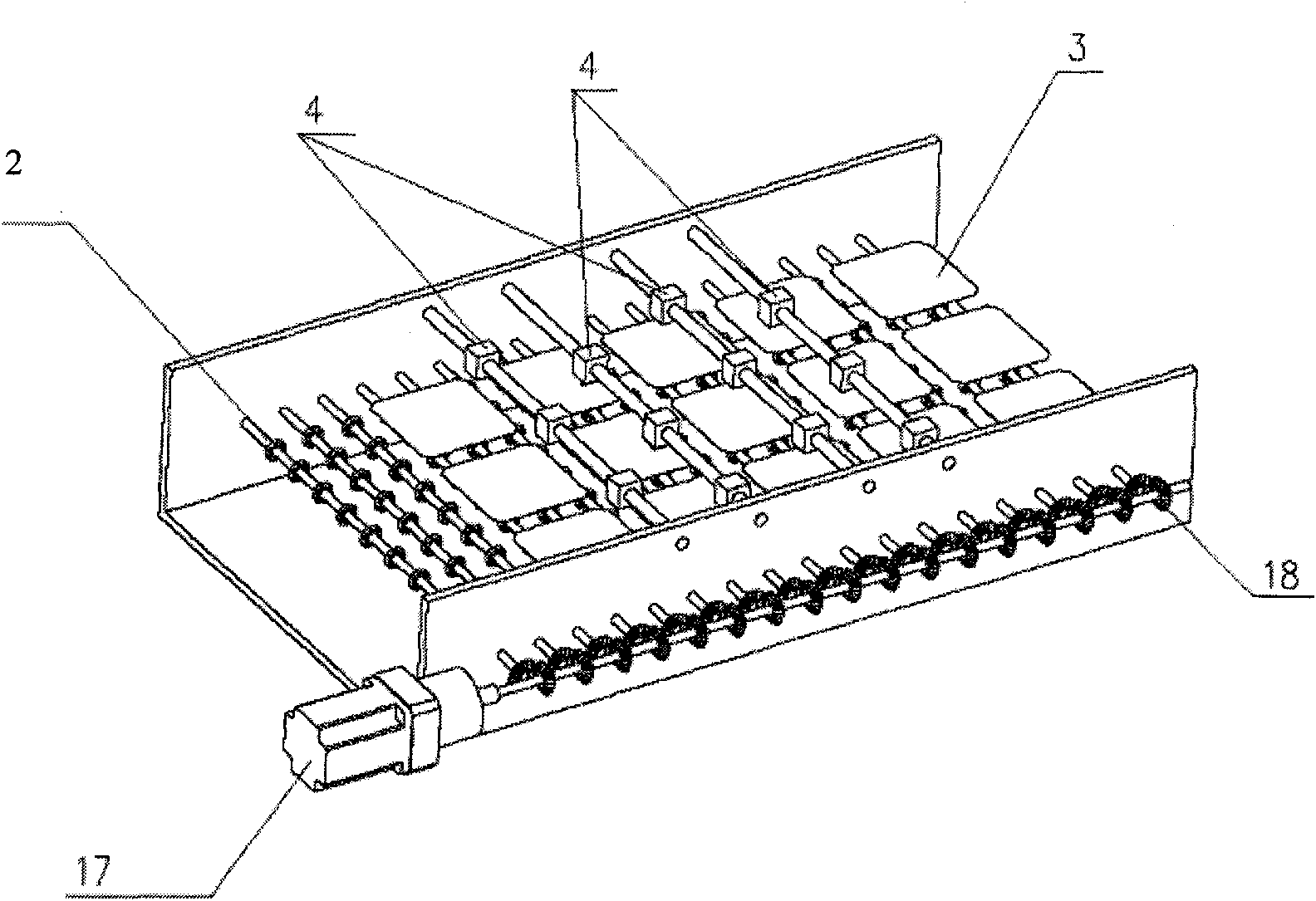

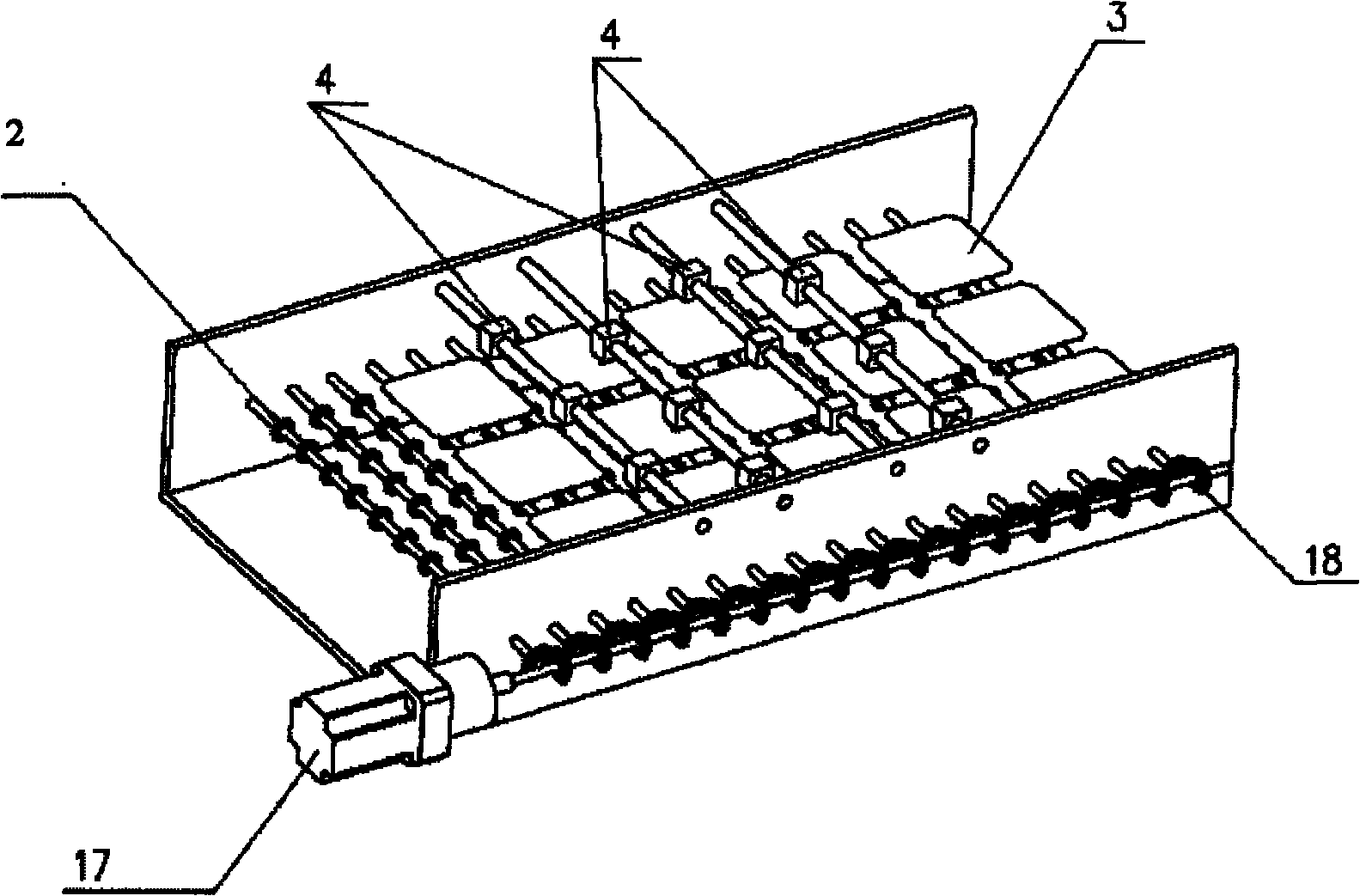

[0024] The method for wet phosphorus diffusion and texturing of substrates of the present invention can be used for polycrystalline silicon solar battery substrates, or components that require chemical wet treatment in other semiconductor integrated circuits. Taking solar cell substrates as an example, the features and advantages of the method for wet phosphorus diffusion and texturing of substrates according to the present invention will be described in detail below.

[0025] The method for carrying out wet phosphorus diffusion and texturing to the substrate of the present invention mainly comprises

[0026] (1) using phosphoric acid to carry out wet treatment to the substrate in the wet treatment chamber;

[0027] In step (1), preferably, the phosphoric acid is treated with heated atomized phosphoric acid through the atomization technology of the applicant's submitted patent application (200910054460.1), that is, the phosphoric acid is atomized through an atomizer After spr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com