Patents

Literature

114results about How to "Break down completely" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

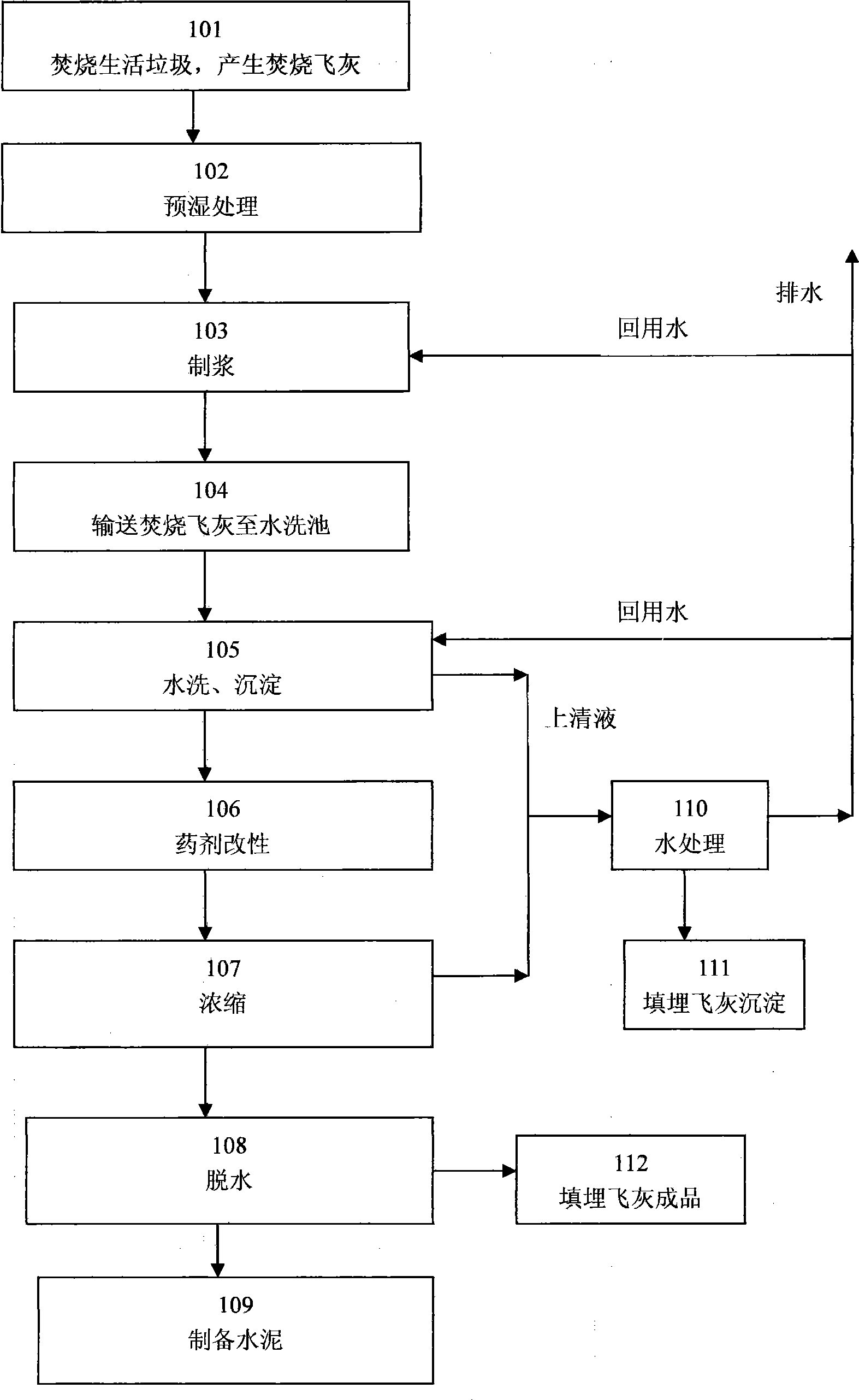

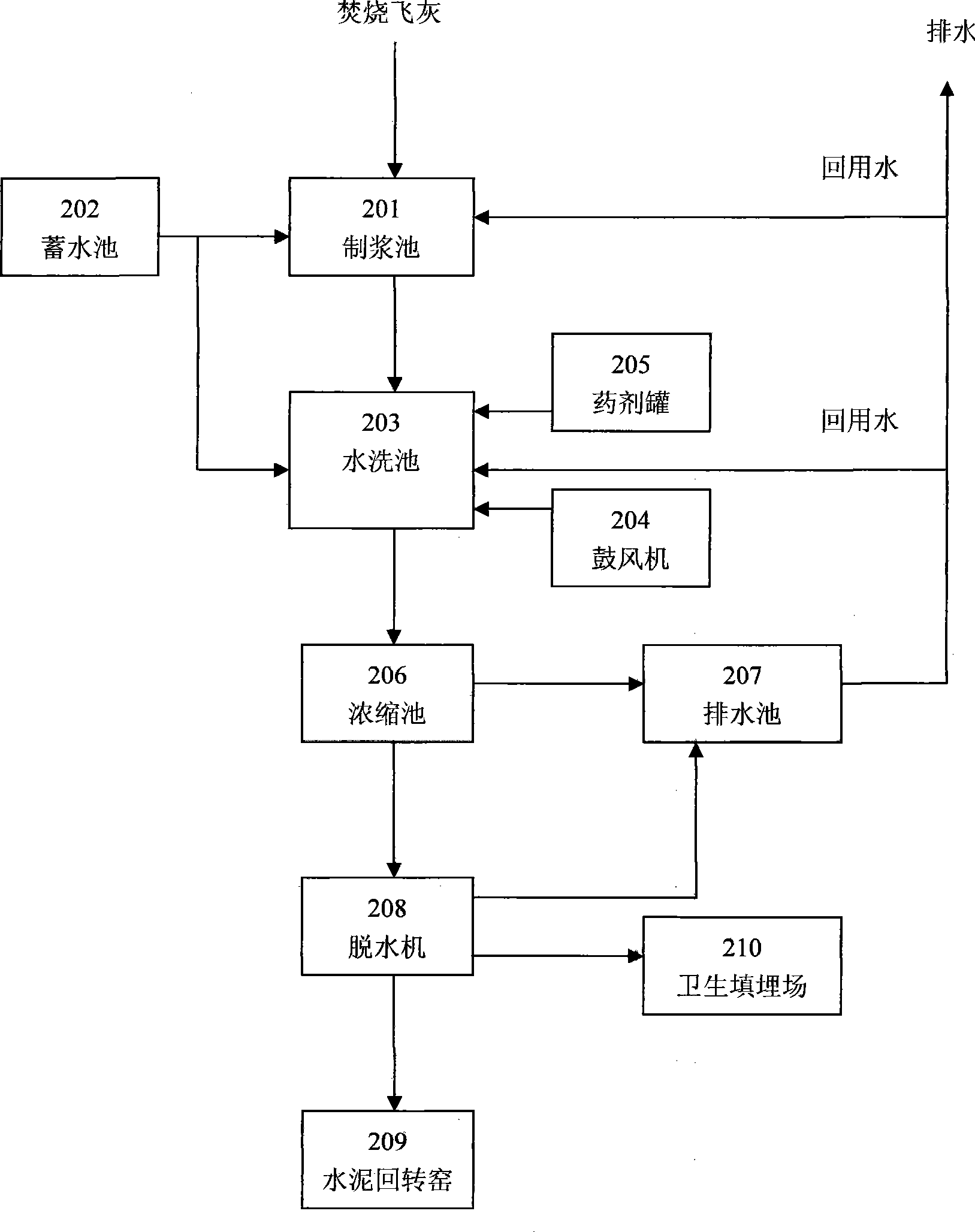

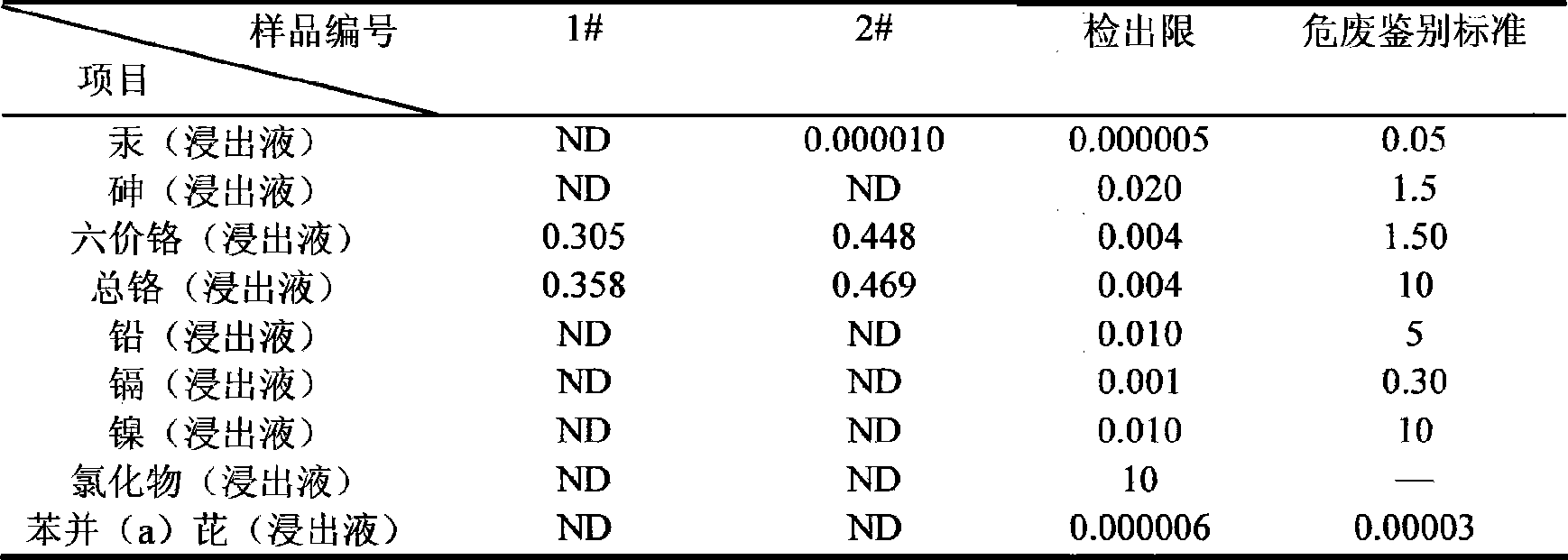

Innocent treatment method and apparatus for refuse burning flyash

ActiveCN101462835AReduce chlorine contentSolve the blockageSolid waste disposalCement productionWater qualitySlurry

The invention proposes a method for the innocent treatment of refuse burning fly ash. The method comprises the following steps: prewetting; pulping: mixing and stirring the fly ash and water in the proportion of 1:2 to 1: 20 to form ash slurry; water washing and precipitation: dissolving the soluble salts in the fly ash; modification through a reagent; concentration for reducing the water content of the ash slurry to 70 to 90 percent; dehydration for reducing the water content of the ash slurry to below 35 percent; water treatment: charging CO2 or acid to make the strongly basic supernatant with the pH value as high as 11 to 12 become the neutral water quality with the pH value of 6.0 to 8.5; flocculant addition for catching tiny particles and speeding up the precipitation process; cement preparation: heating up the fly ash end product in a cement rotary kiln to 1,000 to 1,450 DEG C, and decomposing dioxin and inhibiting the regeneration of the dioxin at the low temperature; and increase of the boiling point of heavy metals for passivating the volatility.

Owner:SHANGHAI SOLID WASTE DISPOSAL CENT +2

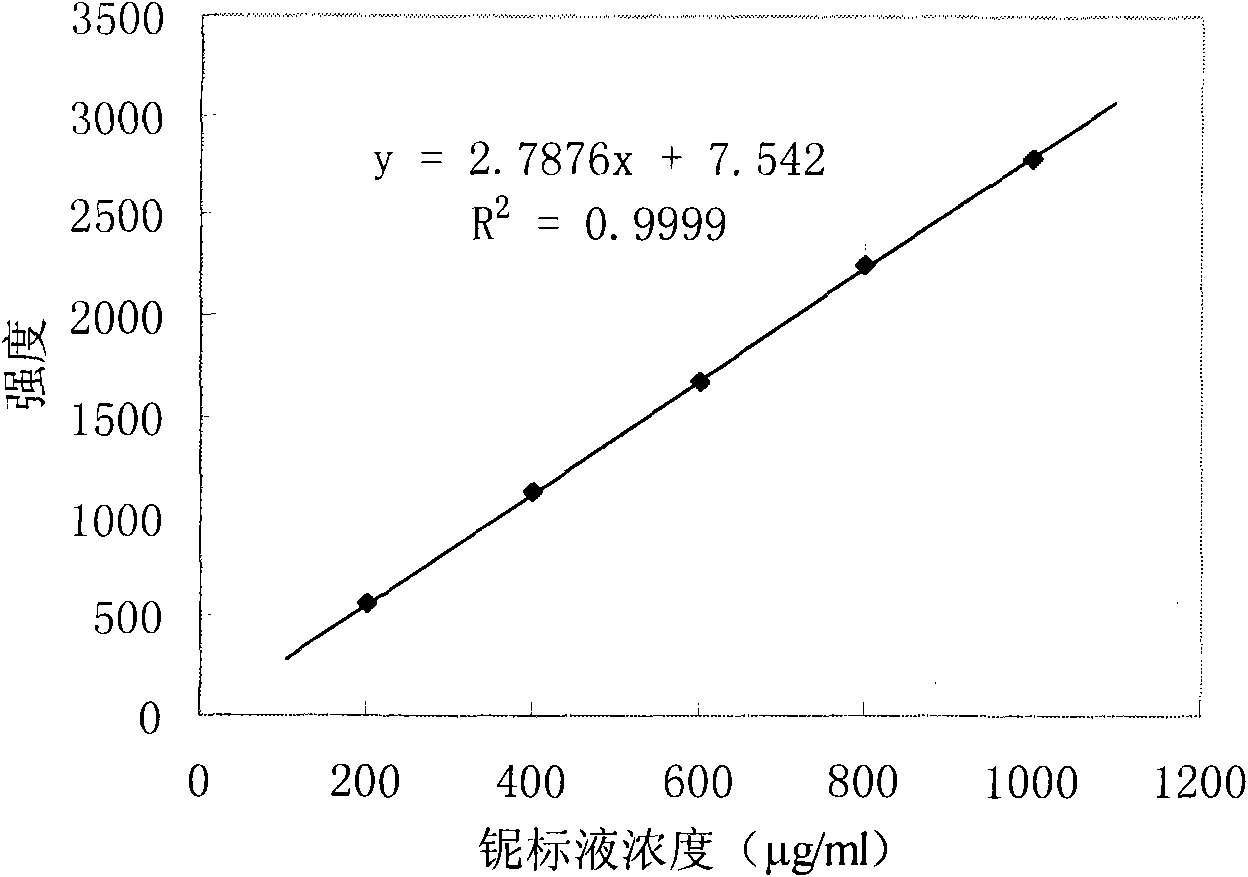

Method for determining niobium element content in ferroniobium

InactiveCN101609048AAvoid hydrolysisBreak down completelyAnalysis by thermal excitationPretreatment methodNiobium

The invention relates to a method for determining niobium element content in ferroniobium, which comprises the following steps: a sample is weighted and put in a polytetrafluoroethylene beaker and deionized water is added for humidifying the sample; hydrofluoric acid and nitric acid are added into the sample, and then are heated so that the sample is slowly dissolved; after the sample is completely dissolved, the breaker is taken down and cooled; after the sample is cooled to room temperature, the volume is metered; reagent blank without the sample is adopted, and then standard solution of niobium element with different volumes is added, and finally deionized water is added and the volume is metered; spectral line strength of niobium element in standard solution is determined under the working condition of a setting inductively coupled plasma atomic emission spectrometer and a working curve is drawn; the spectral line strength of niobium element in ferroniobium sample solution to be determined is determined, and then a computer automatically determines the concentration of niobium element in sample solution according to the working curve. The method mainly solves problems of long operational process, narrow measuring range and the like, determines appropriate sample processing methods and analytic conditions of instruments, and realizes effectively, rapidly and accurately measuring niobium element in ferroniobium.

Owner:武钢集团有限公司

Method for rapidly determining total iron in sulfur acid residue

InactiveCN101609078AAchieve complete decompositionReduce labor intensityAnalysis using chemical indicatorsChemical analysis using titrationTest sampleHigh energy

The invention provides a method for rapidly determining total iron in sulfur acid residue, which is as follows: reagent is used for analyzing in public and in a blank way volume difference of potassium dichromate standard titrimetric solution which is consumed by front and back titration, wherein the volume difference is blank valve (V0=V1-V2); milliliter quantity obtained by V1-V0 is used for calculating mass friction of total iron in sulfur acid residue test sample. The method overcomes shortcomings that the existing analytic method has poor accuracy, and a method of recycling and resolving sulfur acid residue test sample by alkali fusion or acid soluble is fussy, and has high energy consumption and the like. The method determining total iron in sulfur acid residue has the advantages of economy, environmental protection, simplicity, rapidness and accuracy.

Owner:WUHAN IRON & STEEL (GROUP) CORP

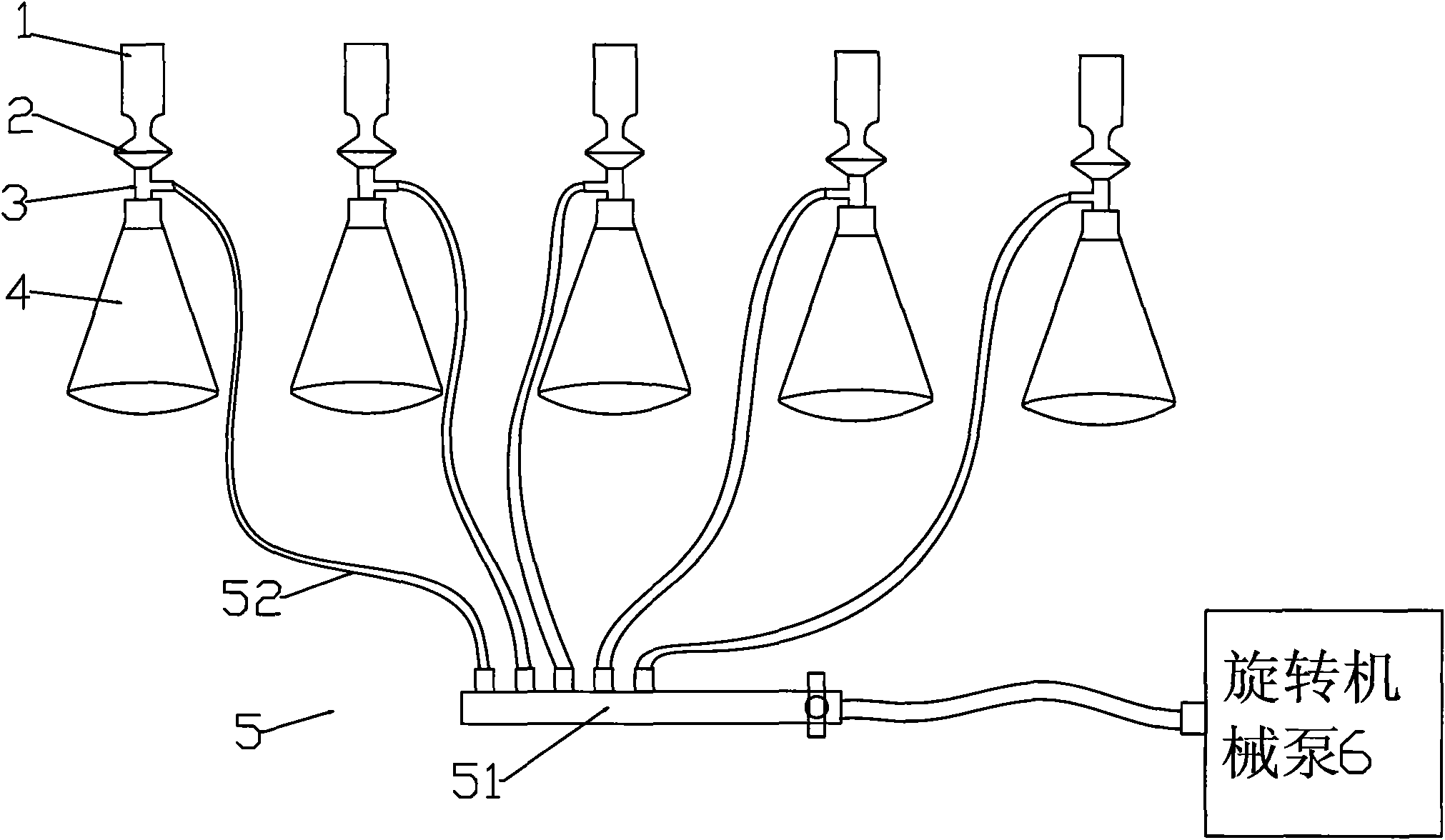

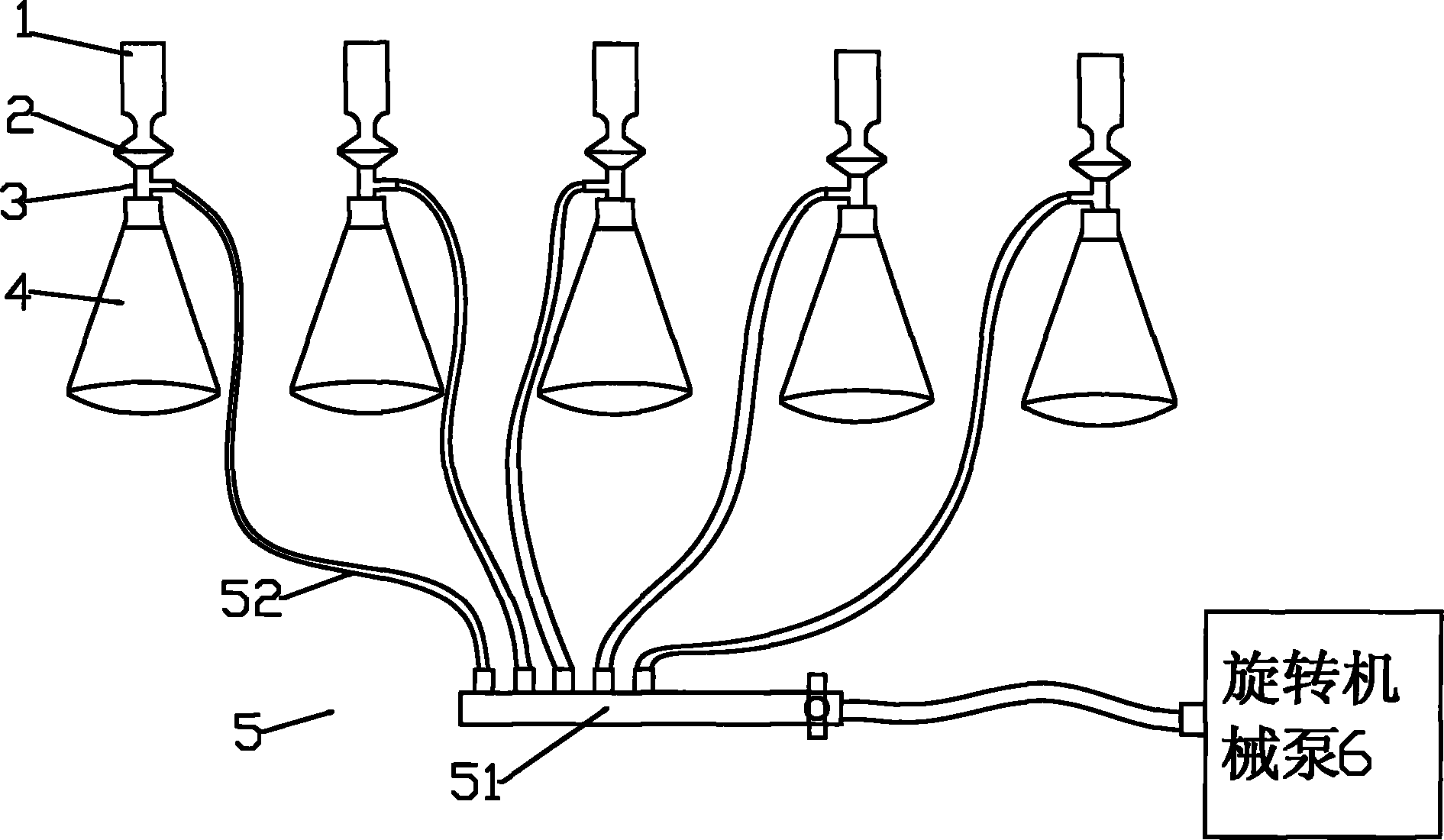

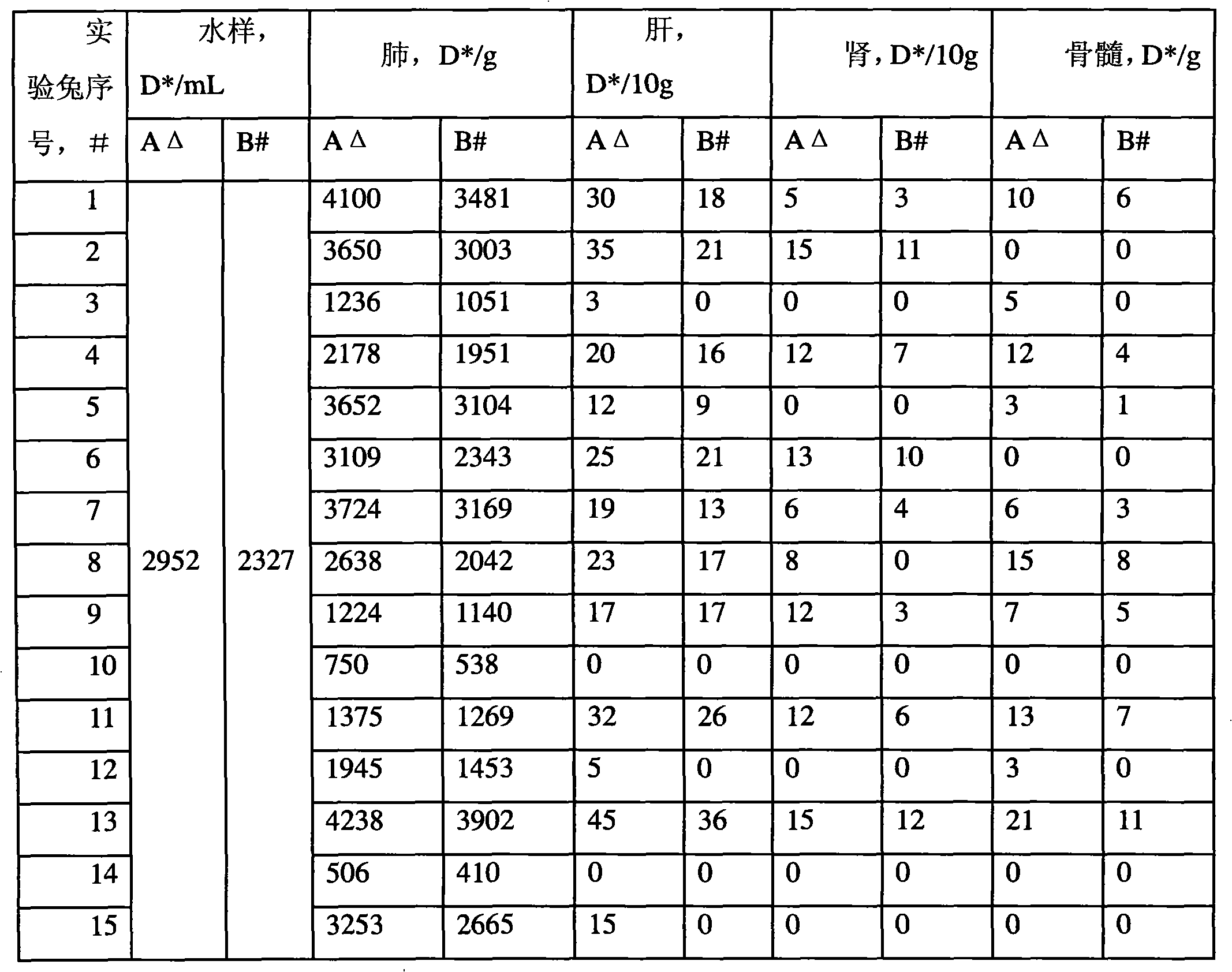

Diatom inspection method in medical jurisprudence

ActiveCN101776623ADoes not affect detectabilityDoes not affect species identificatioMaterial analysis using wave/particle radiationPreparing sample for investigationFiltrationScanning electron microscope

The invention relates to the field of medical jurisprudence inspection, in particular to a diatom inspection method in medical jurisprudence. The method at least comprises the following steps: (1) microwave digestion: adding concentrated nitric acid and hydrogen peroxide solution into the inspected sample to carry out microwave digestion; (2) vacuum filtration: carrying out vacuum filtration on the digestion solution, adding ultrapure water, carrying out vacuum filtration continually until the surface of the filter membrane is approximately neutral, adding absolute ethyl alcohol, and carrying out vacuum filtration to remove moisture from the filter membrane; (3) a scanning electron microscope automatically takes pictures and stores the pictures; and (4) qualitative and quantitative analysis on diatom: carrying out inspection, classification and statistic treatment on the diatom in the on-spot pictures in an artificial identification way or computer automated identification way. The invention has the advantages of high detection sensitivity, high accuracy of qualitative and quantitative analysis, simpleness, high efficiency and environmental protection, can effectively avoid pollution, greatly improves the working environment for diatom inspection technicians in medical jurisprudence, and reduces the labor intensity, thereby having wide application prospects in drowning diagnosis practice in medical jurisprudence.

Owner:GUANGZHOU CRIMINAL SCI & TECH RES INST

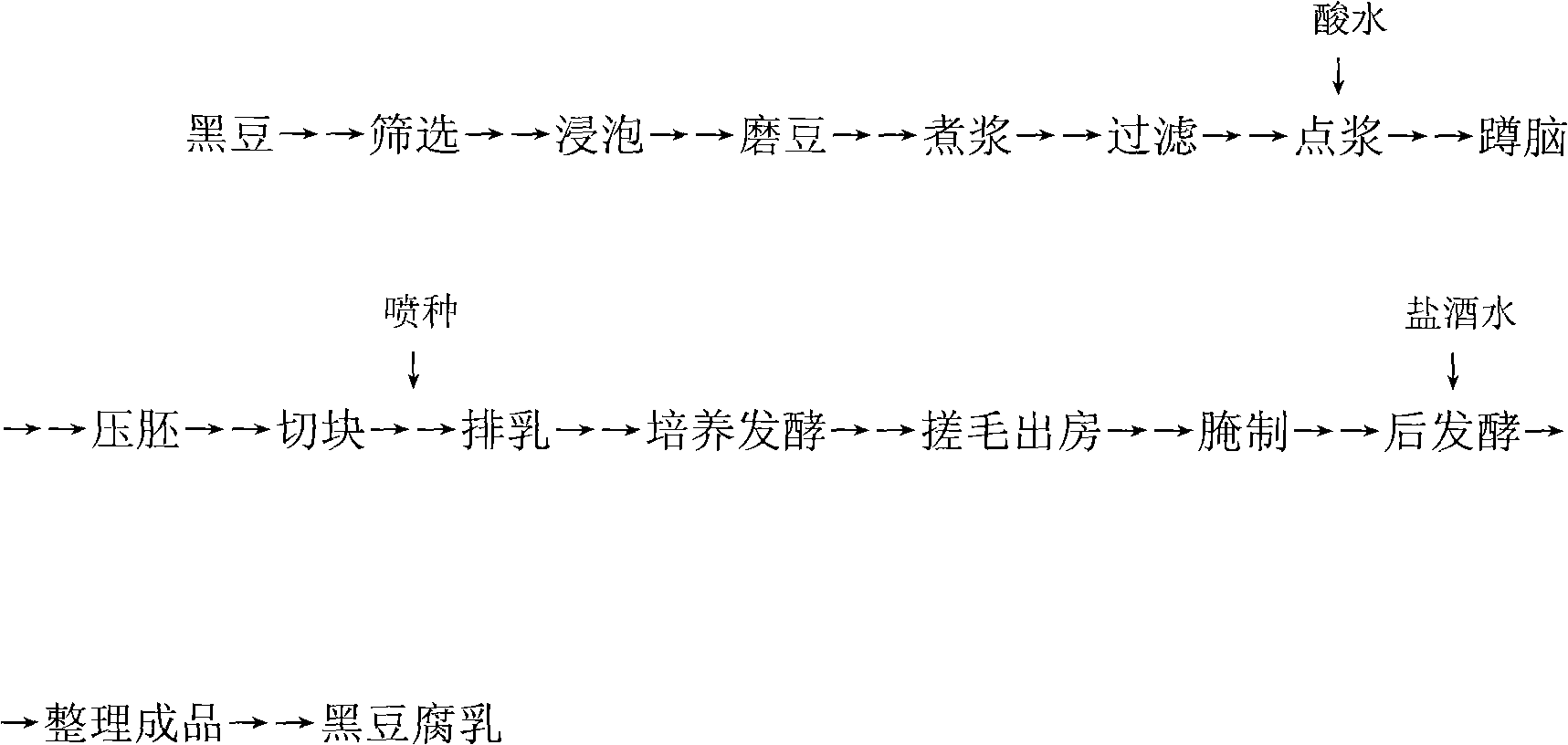

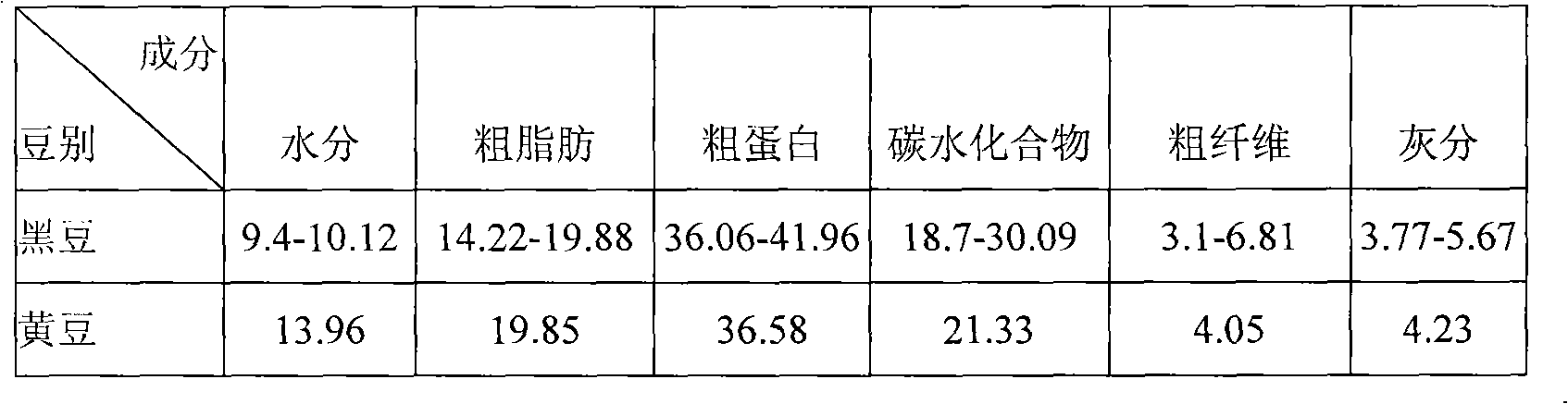

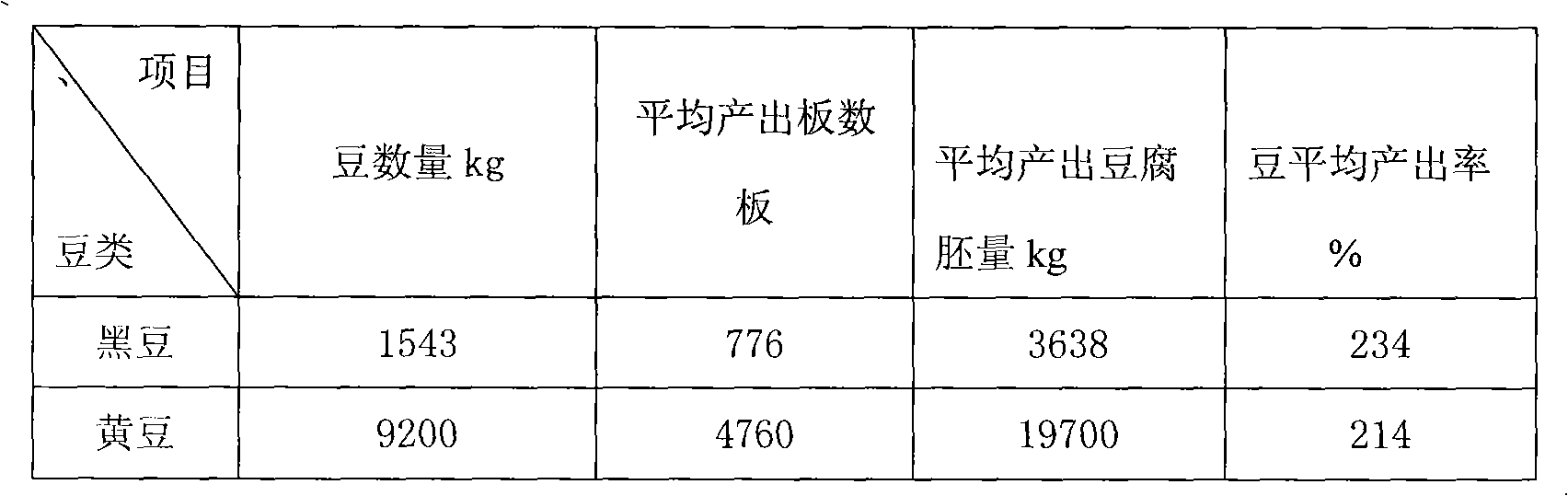

Preparation of preserved beancurd

The invention relates a method for producing preserved beancurd, which is characterized in that black beans are used as main raw materials and the product is produced by using a preserved beancurd process, compared with a common process, the coagulant used for shaping beancurd in the slurry curdling process according to the invention is 1% acid water; in the primary cultivation and fermentation process, the low-temperature bacterium cultivation process is used, the room temperature is controlled at 20-24 DEG C all around the year, the cultivation time is 36-40 hours; in the secondary fermentation process of the post production process, the concentration of the recombined salt wine is lower than the common concentration, so the content of the protein and aminoacid in the produced black preserved beancurd is higher, and the product has salt-fragrant, fresh sweet and soft glutinous mouth feelings.

Owner:开平广合腐乳有限公司

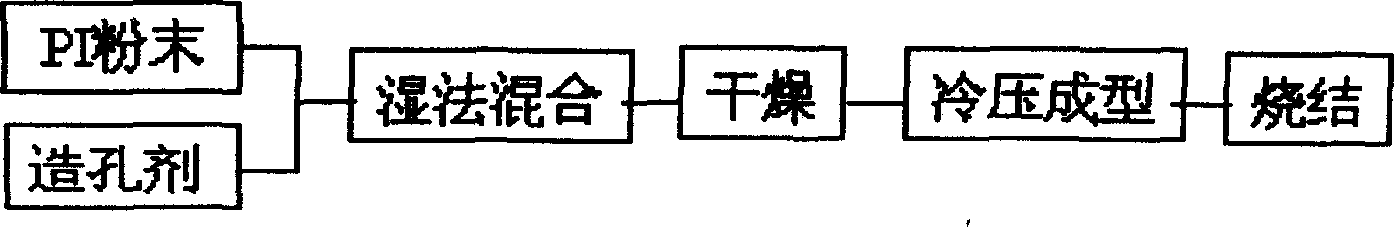

Thermoplastic polyimide microporous material and its preparation process

This invention is related to the manufacturing technologic field of a micropore polymeric material, esecilly related to a thermoplastic polyimide micropore material and its preparation technology. Its raw materials and their percentage contents are as belows: thermoplastic polyimid(TPI): 70%-95%; pore former: 5%-30%. The micropore material is prepared by sintering humid mixed powder of polyimide and solid pore former. Its technological process is simple and it costs little. Multi-stage thermostatic sintering makes the mixed powder decompose completely and blend well with the polyimide particles. This improves material's strength and the factor of porosity. Micropore material's property can be adjusted by controlling the contend of the pore former, so it is very easy to adjust the bore diameter and the factor of porosity.

Owner:NANJING UNIV OF TECH

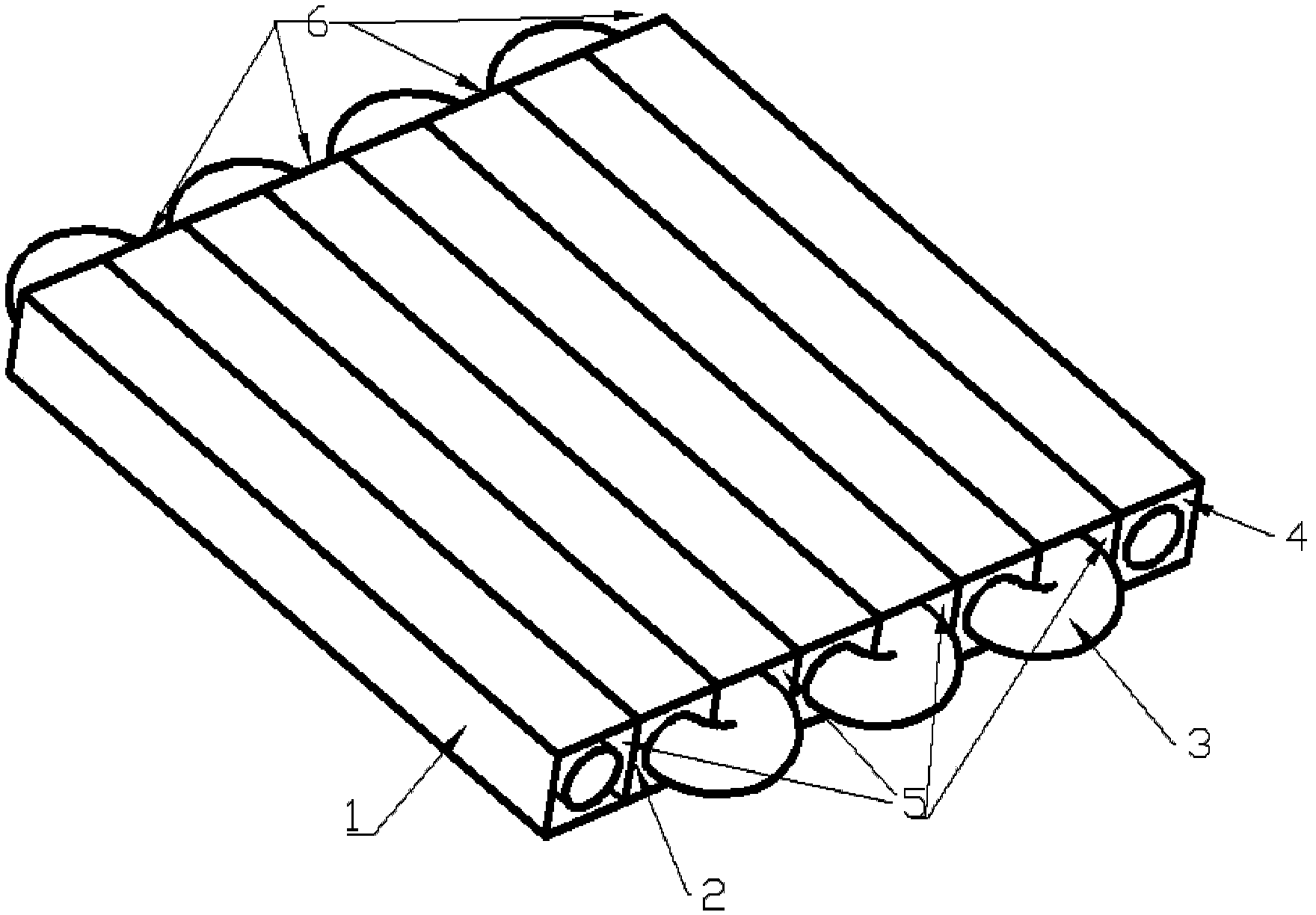

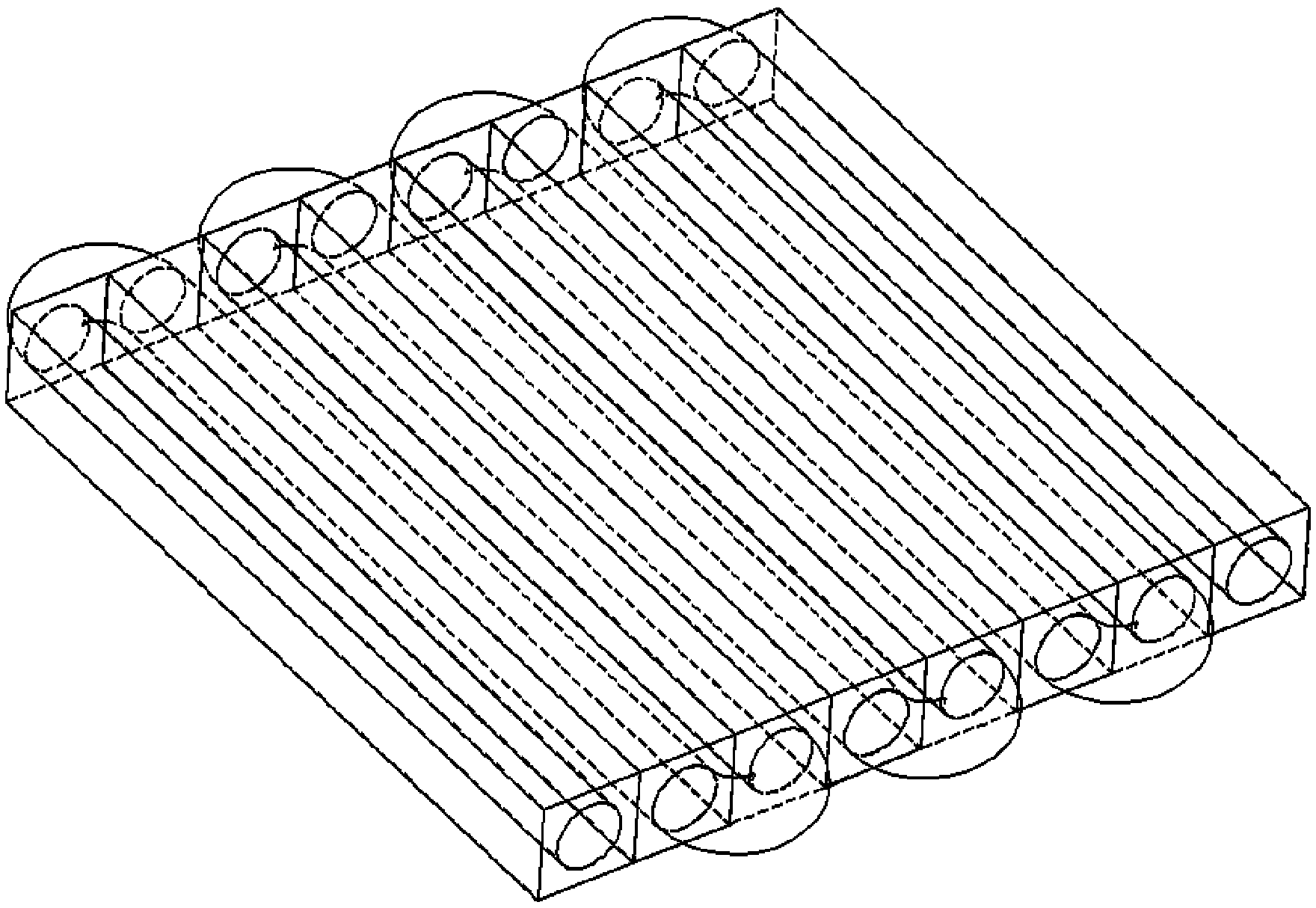

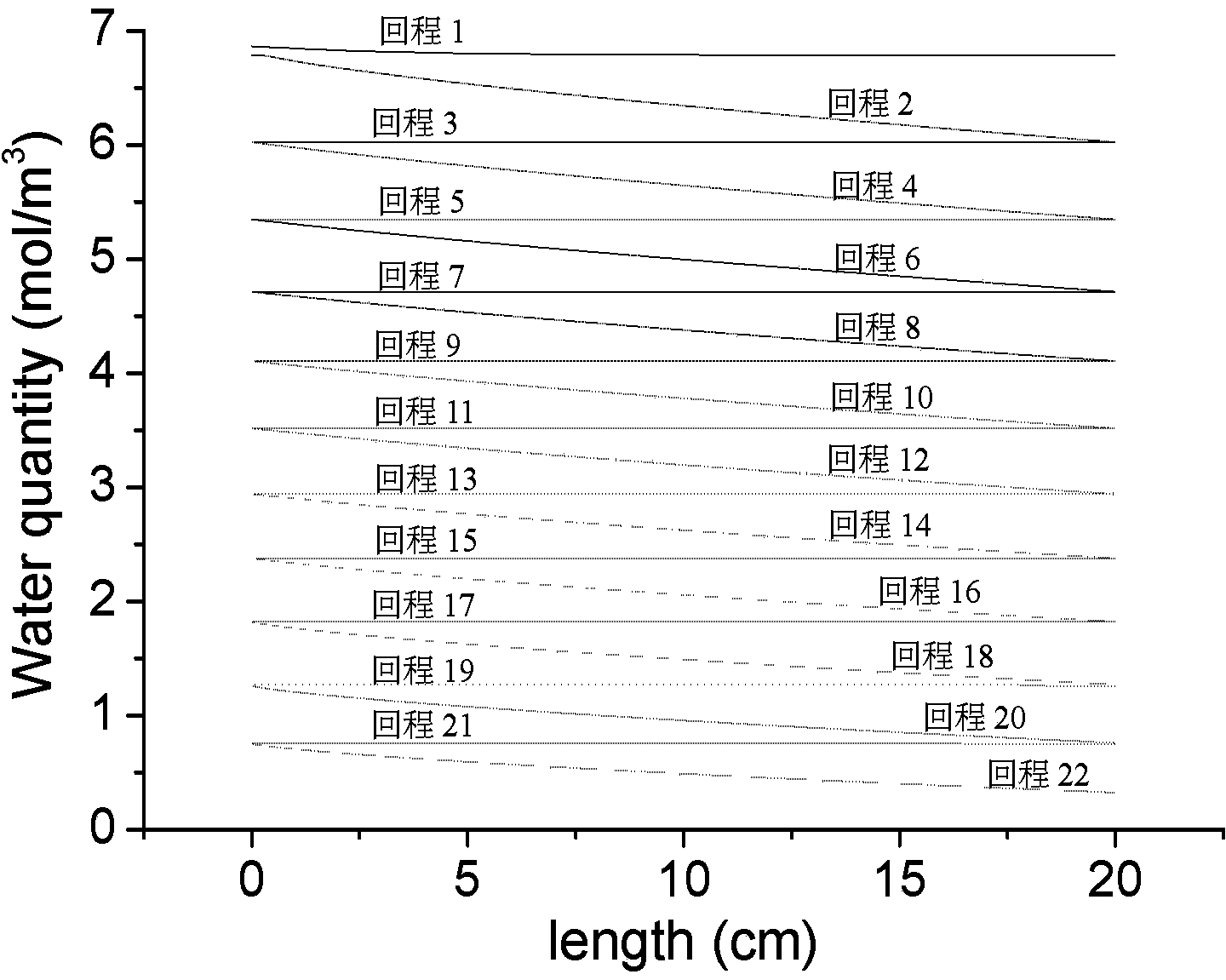

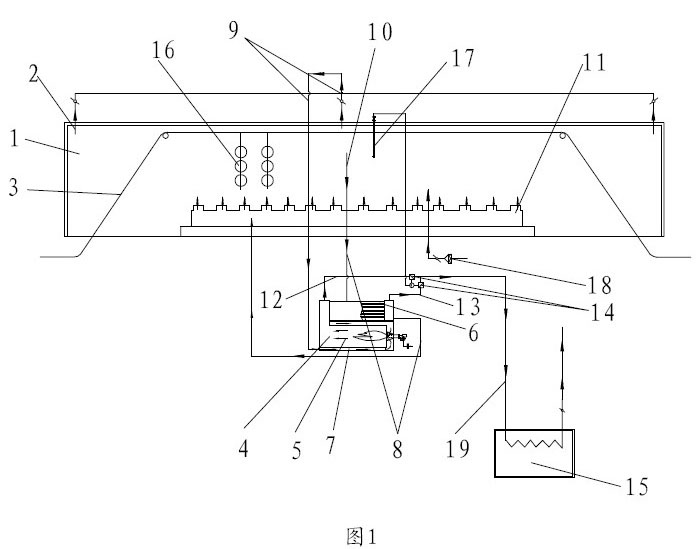

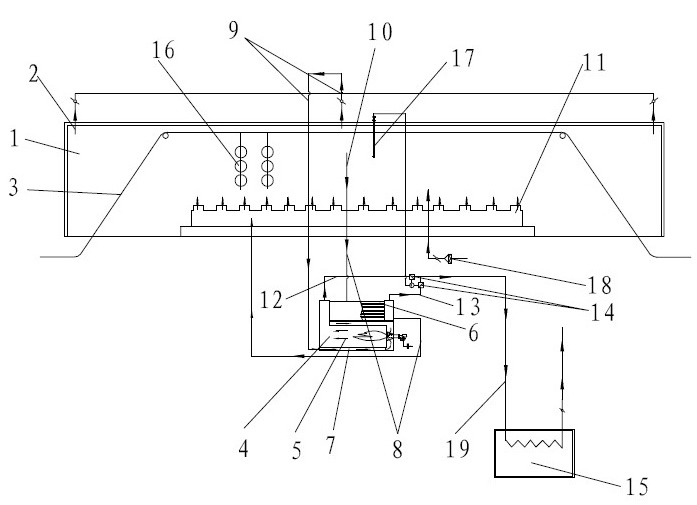

Device for alternately decomposing water to make hydrogen by oxygen permeating membranes and hydrogen permeating membranes

ActiveCN104163399AReduce heat lossImprove efficiencyHydrogen productionDecompositionChemical potential

The invention provides a device for alternately decomposing water to make hydrogen by oxygen permeating membranes and hydrogen permeating membranes. The device comprises a flat box body and inner pipelines, wherein the internal part of the flat box body is divided into a plurality of oxygen permeating chambers and hydrogen permeating chambers which are arranged at intervals; the inner pipelines extend inside all the oxygen permeating chamber and hydrogen permeating chamber; the inner pipelines of the adjacent chambers are connected with each other end to end through an outer pipeline; the inner pipelines and the outer pipeline form communicated serpentine steam channel; the inner pipelines in the oxygen permeating chambers are made of the oxygen permeating membranes; the inner pipelines in the hydrogen permeating chambers are made of the hydrogen permeating membranes; chemical potential difference exists between the inner and outer sides of the hydrogen permeating membranes of the inner pipelines in the hydrogen permeating chambers and chemical potential difference also exists between the inner and outer sides of the oxygen permeating membranes of the inner pipelines in the oxygen permeating chambers; and oxygen and hydrogen respectively enter the regions between the inner pipelines and the inner walls of the corresponding chambers through the oxygen permeating membranes and the hydrogen permeating membranes under the action of the chemical potential differences. According to the device, the steam channel is formed by alternate connection of the inner pipelines of the oxygen permeating membranes and the hydrogen permeating membranes, and the water vapor decomposition rate is much higher than that the situation of use of only oxygen permeating membranes or hydrogen permeating membranes.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

Titanium dioxide content measurement method

InactiveCN104034680AFully digestedPromotes fast digestionPreparing sample for investigationColor/spectral properties measurementsPolyesterTitanium metal

The invention relates to a titanium dioxide content measurement method. The titanium dioxide content measurement method comprises the following steps: (1) digesting a polyester sample by a wet-acid soluble decomposition system; (2) reacting a dilute acid mixture of hydrochloric acid and nitric acid with non-titanium metal salt in a sample to obtain a digestion sample liquid; (3) masking metal ions, which interfere with a main reaction, by ascorbic acid, and preparing a dilute solution to be measured with the absorbance value in the range of 0.2 to 0.8 by taking hydrogen peroxide as a color developing agent; (4) measuring the absorbance value A of the dilute solution to be measured, and measuring the blank absorbance value A0; (5) preparing standard solutions of titanium with a series of ladder concentration, measuring the absorbance values of the standard solutions, and then drawing a standard working curve Y=KX by taking the difference values of the measured absorbance values and the blank absorbance value as horizontal coordinates X and taking the titanium content corresponding to the standard solutions of titanium with a series of ladder concentration as vertical coordinates Y, thereby obtaining the slope value K of the standard working curve; and (6) calculating the percentage of titanium dioxide TiO2. By the measurement method disclosed by the invention, the content of titanium dioxide in polyester can be measured accurately.

Owner:TAICANG ZHENHUI CHEM FIBER

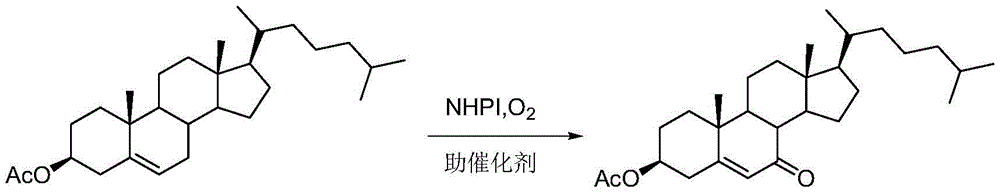

Synthesis method of vitamin D3 intermediate 7-ketocholesteryl acetate

ActiveCN105669813APromote decompositionBreak down completelySteroidsChemical recyclingSynthesis methodsDecomposition

The invention discloses a synthesis method of a vitamin D3 intermediate 7-ketocholesteryl acetate, and relates to 7-ketocholesteryl acetate. The method comprises the following steps: adding cholesteryl acetate to a mixed solvent, introducing oxygen as an oxidant, adding a main catalyst and a nonmetal cocatalyst, carrying out a catalytic allylic oxidation reaction, and purifying the obtained reaction product to obtain the vitamin D3 intermediate 7-ketocholesteryl acetate. No complex post-treatment processes are needed; a quaternary ammonium salt is adopted as the cocatalyst, so decomposition of peroxides is effectively promoted; tetrahydrofuran azeotropic water removal is adopted to remove water generated in the decomposition process of the peroxides, so the decomposition is complete, and the reaction is fast and mild; and he main catalyst and the cocatalyst are nonmetal catalysts respectively, and are cheap and easily available, the main catalyst can be reused 5 or more times, the conversion rate and the selectivity are respectively high, and the reaction yield reaches 85% or above, so the synthesis method has the advantages of high efficiency and low cost.

Owner:XIAMEN KINGDOMWAY VI TAMIN INC +1

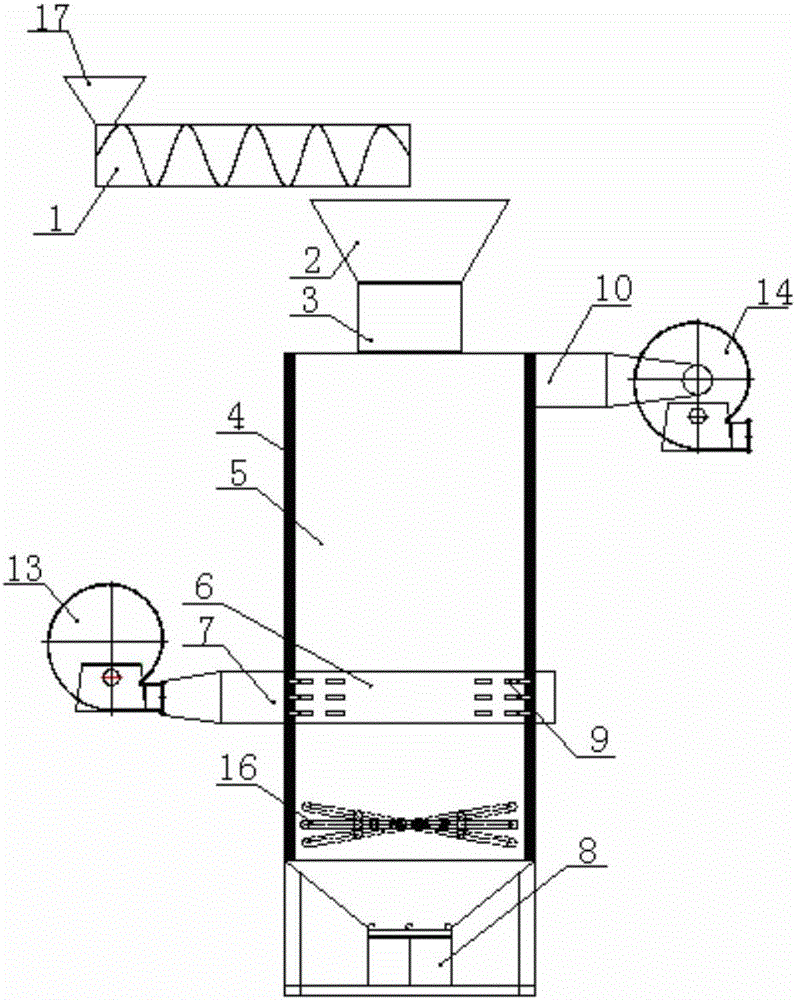

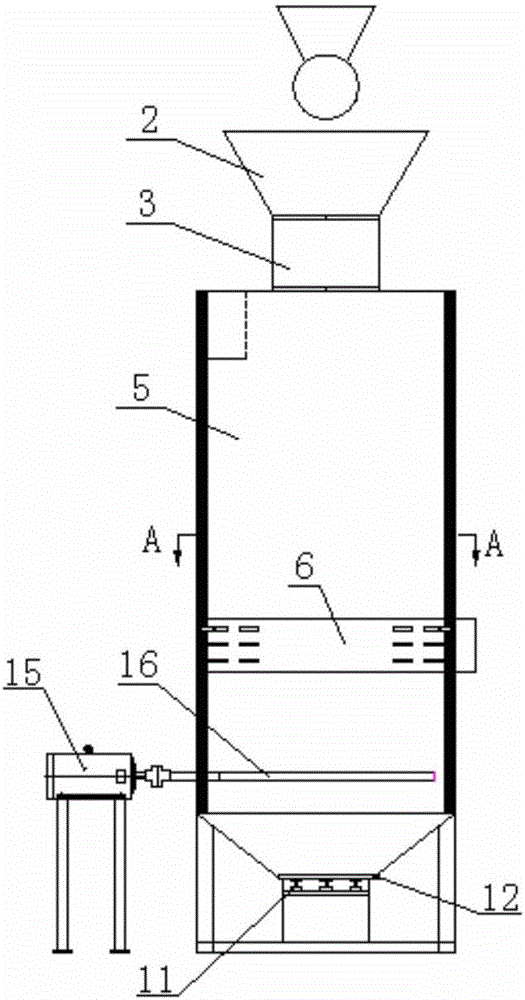

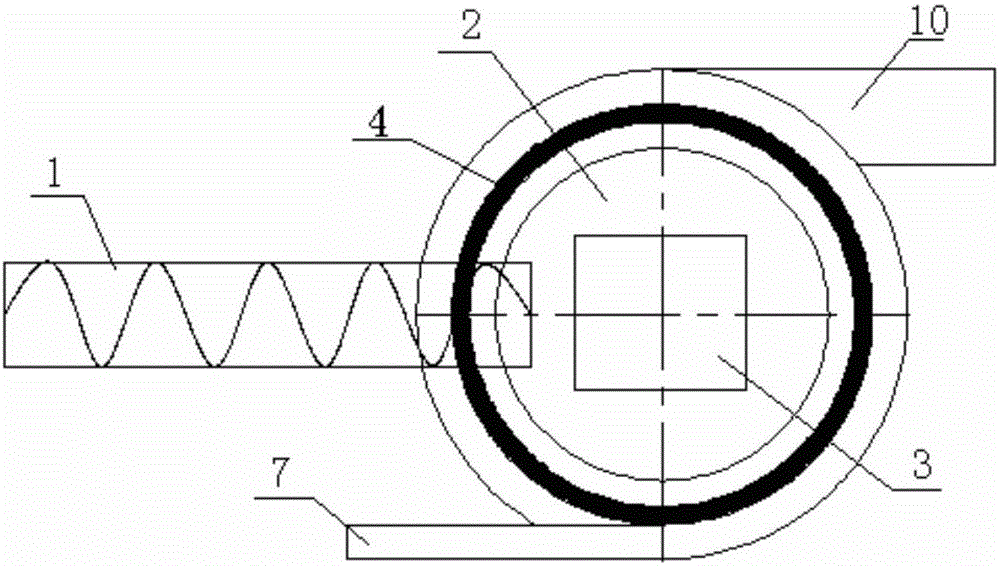

Household garbage incinerator

ActiveCN106122975AUniform temperature distributionIncrease temperatureTravelling grateBlast-producing apparatusCombustionSlag

The invention discloses a household garbage incinerator. A furnace door is arranged at the top of a furnace cavity of the incinerator. Materials are put into the furnace cavity through a feeding system. At least two rows of fire grates used for carrying garbage are arranged in the furnace cavity. The garbage entering the furnace cavity is dried and combusted on the fire grates. A slag discharging and dust removing door is arranged at the bottom of the furnace cavity. A plurality of injection pipes are arranged on the side wall of the furnace cavity. The injection pipes are connected with an air blower and used for injecting air to the interior of the furnace cavity. An exhaust port is formed in the top of the furnace cavity, arranged in the tangential direction of the furnace cavity, connected with an induced draft fan and used for pumping smoke in the furnace cavity. According to the household garbage incinerator, the movable fire grates are adopted, layered combustion is achieved, the garbage is evenly distributed, and the purpose of controlling the combustion condition in the incinerator can be achieved by controlling the induced air amount and air blowing amount. Through the arrangement of the injection pipes, the smoke temperature in the incinerator can be distributed more evenly, the retention time of the smoke is greatly prolonged, harmful matter such as dioxin can be completely decomposed, and sufficient combustion of the garbage is achieved.

Owner:AEROSPACE KAITIAN ENVIRONMENTAL TECH CO LTD

Drying oven for spraying

InactiveCN101829649ALess investmentHigh recovery ratePretreated surfacesCoatingsThermal energyDecomposition

The invention relates to a drying oven for spraying, which comprises a drying passage and an exhaust gas incinerator. The drying passage is communicated with the exhaust gas incinerator through an exhaust gas pipeline and an air return pipeline; the wall of the drying passage is provided with an air return outlet, an exhaust gas inlet and an air return inlet; the exhaust gas inlet is communicated with the exhaust gas pipeline; the air return inlet and the air return outlet are communicated with the air return pipeline respectively; the exhaust gas incinerator comprises a heat exchanger which is communicated with the air return pipeline, and a preheater and an incineration chamber which are communicated with the exhaust gas pipeline; and the inlet of the incineration chamber is communicated with the outlet of the preheater, and the outlet of the incineration chamber is communicated with the inlet of the heat exchanger. The drying oven saves a large amount of equipment investment; an exhaust gas heat energy recovery and heat exchange process is introduced based on a hot blast stove with an original drying passage, and the heat energy generated by incinerated exhaust gas is fully utilized, so the heat energy recovery rate is high, energy resources required by the drying oven and the incinerator are greatly saved, and the operating cost is reduced; and the drying oven has the advantages of high exhaust gas treatment efficiency, high incineration temperature, complete exhaust gas decomposition and high purifying rate.

Owner:ZHEJIANG HUALI INTELLIGENT EQUIP CO LTD

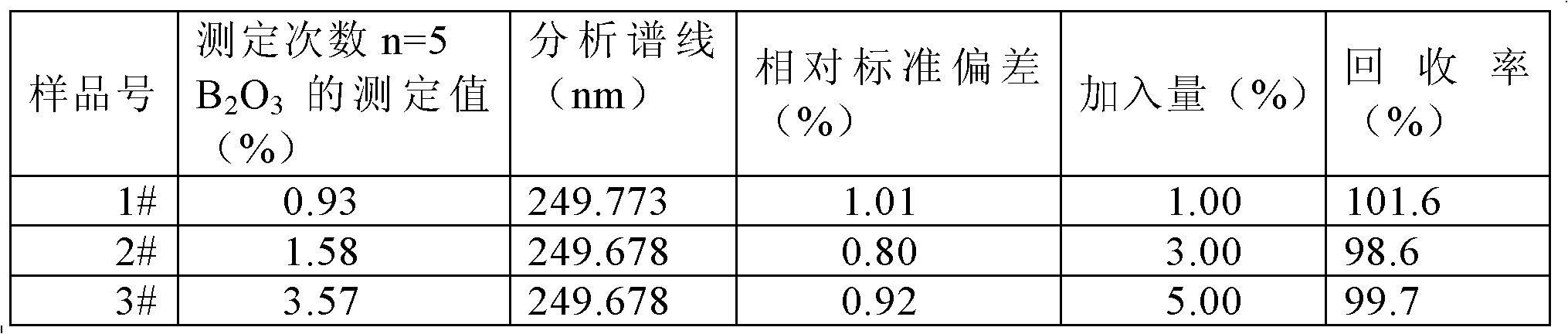

Method for measuring content of diboron trioxide in casting powder

InactiveCN101988891ABreak down completelyRapid determinationColor/spectral properties measurementsHydrogen NitrateInductively coupled plasma

The invention relates to a method for measuring the content of the diboron trioxide in casting powder in the smelting technology, which comprises the following steps of: 1. weighing 0.1-1g of sample accurately to 0.0002g, adding the constant quantity of the hydrochloric acid, the hydrogen nitrate and the hydrofluoric acid, adding 0.5-2.0g of mannitol into a beaker, and heating until that the sample is completely dissolved; 2. respectively preparing at least four parts of working curve standard solution for measuring the content of the diboron trioxide in volumetric flasks by the boron standard solution under the same acid medium; and 3. selecting the analysis spectral line of the boron in the medium on the inductively coupled plasma spectrometer (ICPS), measuring the spectral intensity of the boron in the standard solution and the test solution of the working curve at the same time, and computing an analysis result by a computer by means of autoregression. The method dissolves the sample by mixing the hydrofluoric acid with the other acids, and leads the sample to be complexed with the boron by adding the mannitol to lead the boron not to be volatilized and not to be completely decomposed, thereby being applied to measuring the diboron trioxide in the casting powder with the mass fraction within the range from 0.005% to 20%, and being fast in measuring speed and high in accuracy.

Owner:武钢集团有限公司

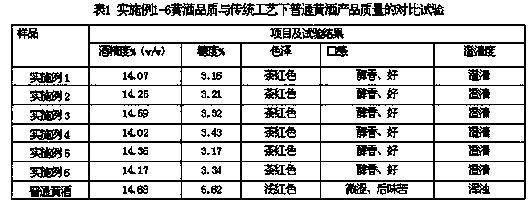

Preparation method for yellow rice wine

ActiveCN103695247AShorten the soaking timeSufficient soaking timeMicroorganism based processesAlcoholic beverage preparationFlavorFiltration

The invention discloses a preparation method for yellow rice wine and belongs to the technical field of yellow rice wine production processing. The preparation method comprises the following steps of (1) smashing, immersing, stewing and cooling coix lacryma-jobi and millets which serve as raw materials; (2) adding cooled rice into distilled yeast, uniformly mixing and stirring the materials for diastatic fermentation, adding yeast and purified water to implement constant-temperature fermentation, performing ultrasonic treatment after fermentation is executed, performing squeezed filtration, collecting filtrate, sterilizing the filtrate, and storing the filtrate in a sealed manner to obtain the yellow rice wine. The preparation method for the yellow rice wine is low in production cost and simple in technology; the yellow rice wine has good color, fragrance and flavor, tastes delicious and mellow and does not contain any additive and pigment; by virtue of long-time drinking, the yellow rice wine has good effects for resisting fatigue, enhancing the immunity of a human body, tonifying Yang and kidney and the like.

Owner:福建老福洲酒业股份有限公司

High-strength high-conductivity aluminum-scandium alloy as well as preparation method thereof and use thereof

ActiveCN106676334ABreak down completelyLong holding timeSingle bars/rods/wires/strips conductorsConductive materialManganeseImpurity

The invention provides a high-strength high-conductivity aluminum-scandium alloy as well as a preparation method thereof and a use thereof. The alloy consists of the following components in percentage by weight: 0.2-0.4 wt% of scandium (Sc), 0.01-0.15 wt% of zirconium (Zr), 0.1-0.3 wt% of manganese (Mn), less than or equal to 0.1% of other impurity elements, and the balance Al. The preparation method for the high-strength high-conductivity aluminum-scandium alloy comprises the following steps of: taking a pure Al ingot, an AlSc intermediate alloy, an AlZr intermediate alloy and an AlMn intermediate alloy as raw materials, putting the raw materials into a smelting furnace in proportion, and performing casting to obtain a cast ingot after performing stirring, refining, purifying, degassing, slagging-off and standing on melt; extruding the cast ingot into an aluminum alloy rod in an extrusion ratio of 25; and performing staged thermal treatment on the rod, and drawing the rod into a high-strength aluminum alloy wire through a wire drawing machine. The Sc-containing aluminum alloy wire has conductivity greater than or equal to 61% IACs, has alloy tensile strength greater than 240 MPa, has yield strength greater than 160 MPa, has ductility of 8%, and has a long-term operation temperature which can be up to 200 DEG C.

Owner:SHANGHAI JIAO TONG UNIV

Extraction method of passionflower seed oil

The invention discloses an extraction method of passionflower seed oil from passionflowers. The extraction method comprises the following steps: raw material treatment; compound enzyme treatment; supercritical CO2 fluid extraction; and vacuum drying to obtain a finished product. Compared with the prior art for directly carrying out supercritical CO2 fluid extraction on a passionflower raw material, the extraction method disclosed by the invention has the advantage of high content.

Owner:GUILIN TECH ENTERPRISE DEV CENT

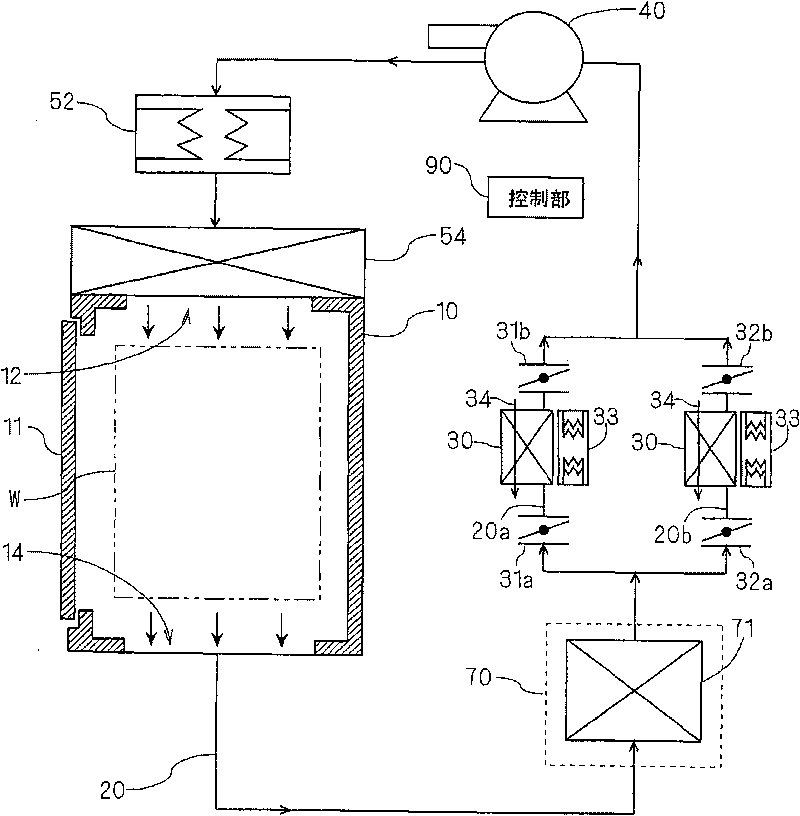

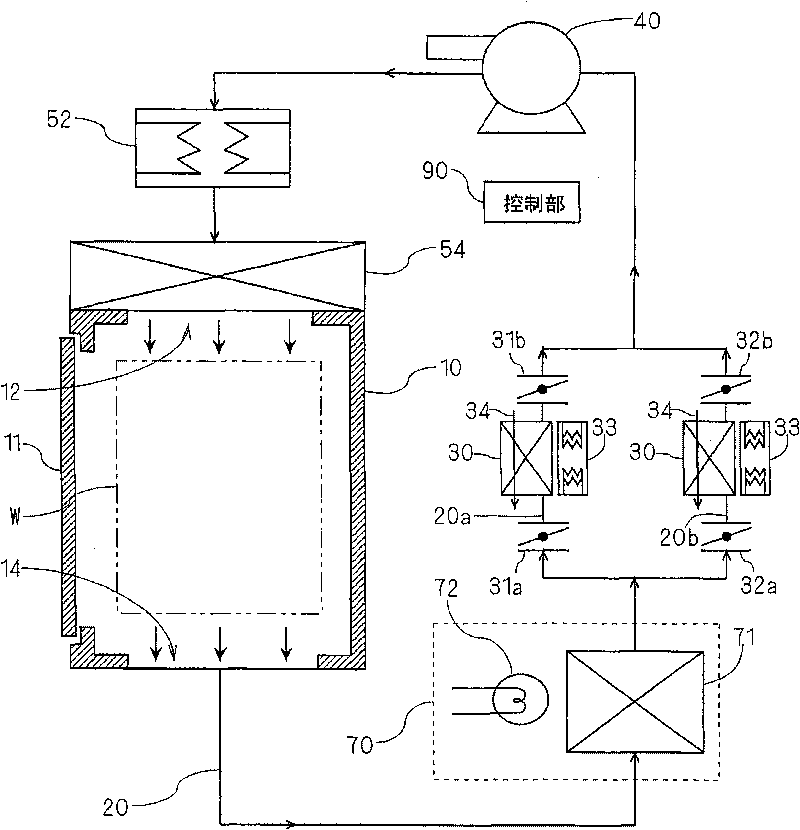

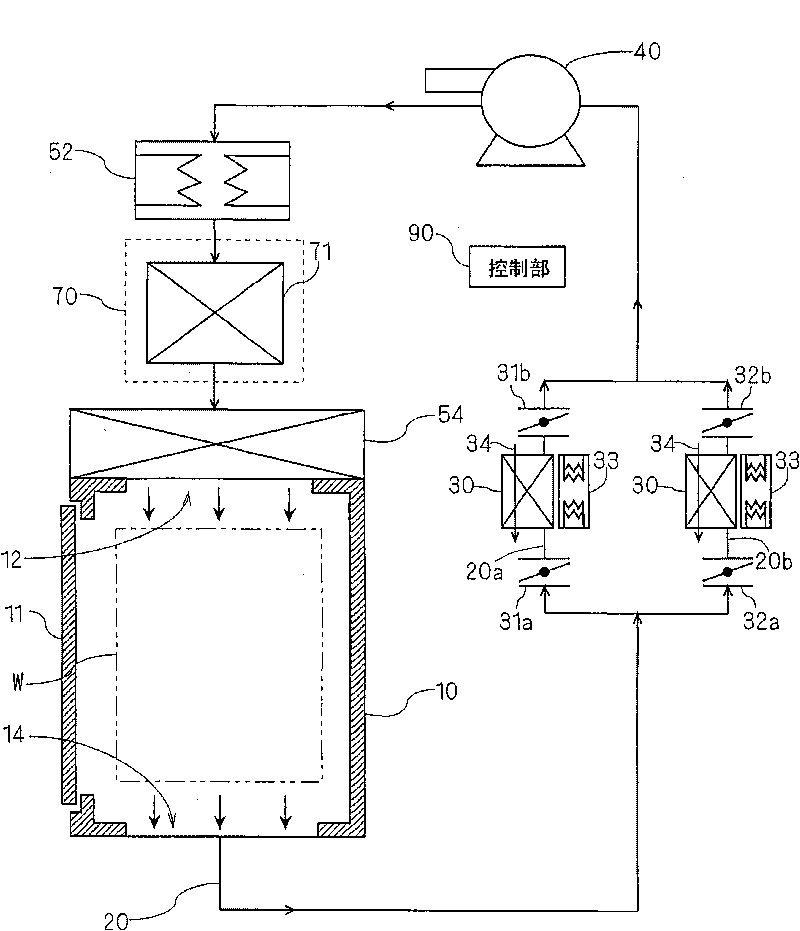

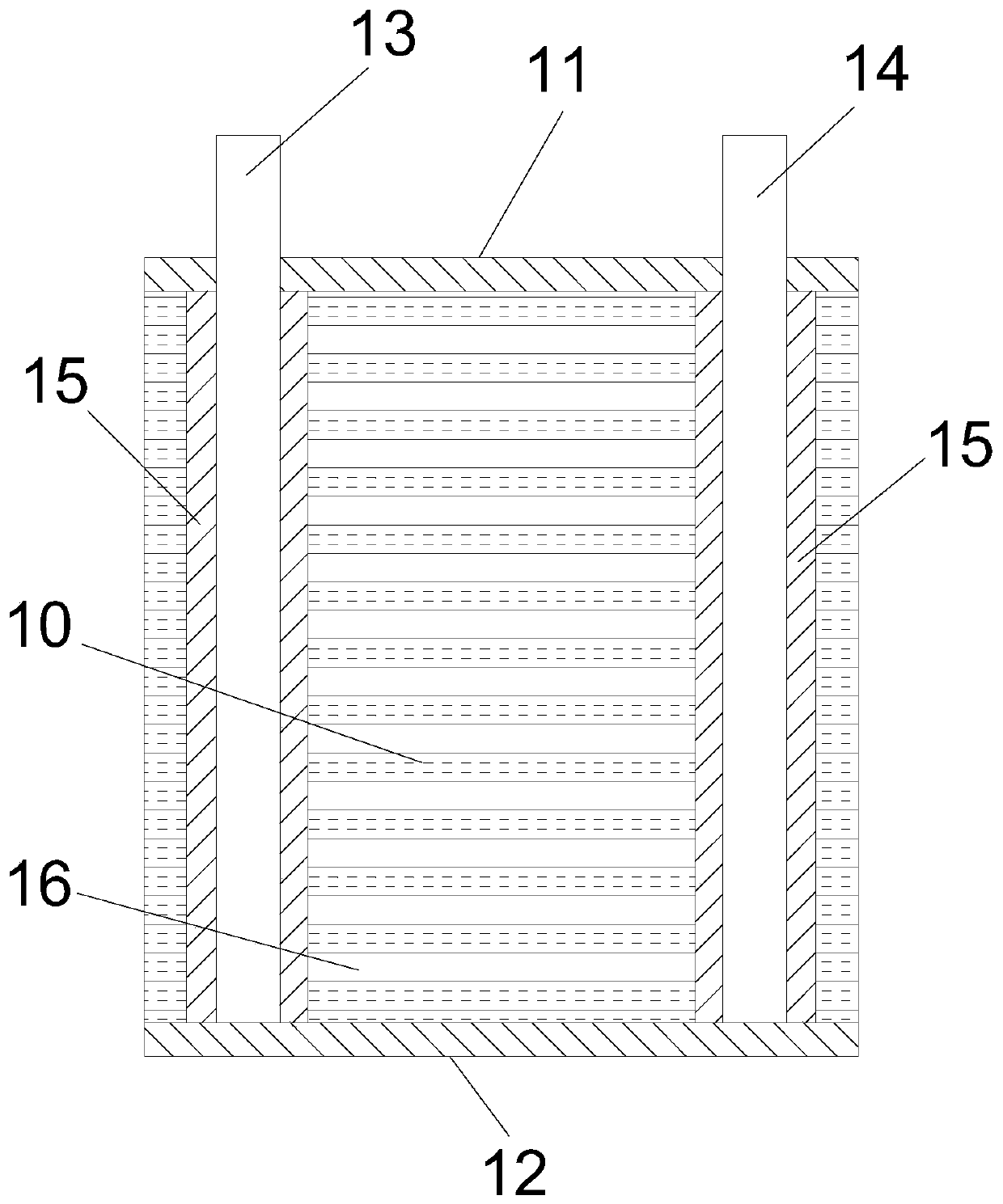

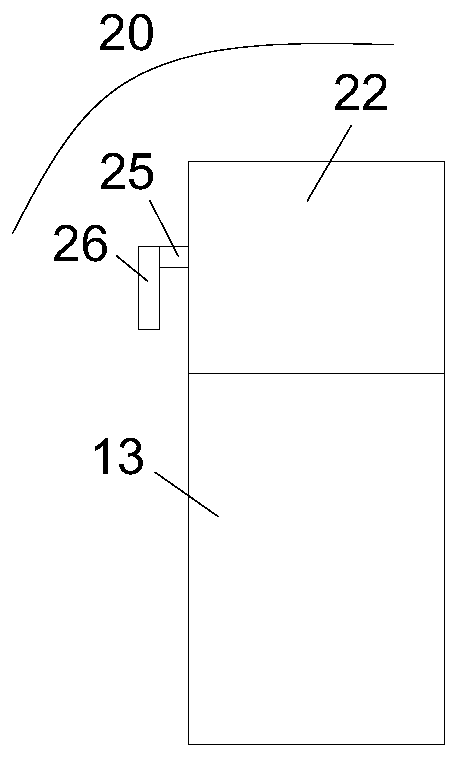

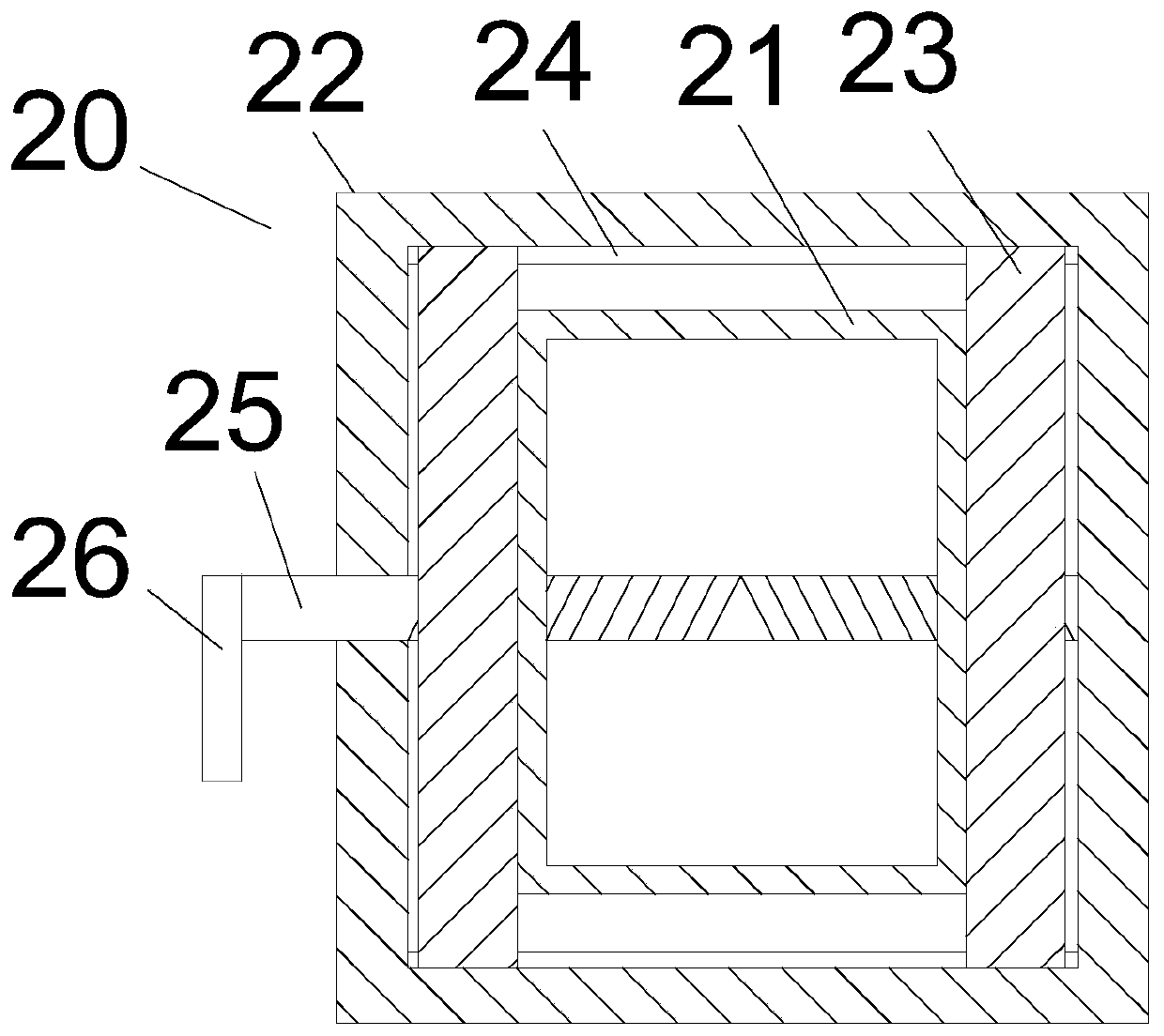

Circle substrate firing furnace

InactiveCN101749949AReduce heat lossEasy to control temperatureSemiconductor/solid-state device manufacturingFurnace typesHot blastOrganic compound

The invention provides a circle substrate firing furnace which can reduce the heat loss and obtain the steady sintering temperature. The sintering treatment of a glass substrate (W) can be performed by blowing out the hot blast from a furnace main body part (10). the hot blast exhausted from the furnace main body part (10) cycles in a circulating path (20) by a circulating fan (40), passes through an adsorption tower (30) for adsorbing and decomposing the resultant from a catalyst filtering part (70) for decomposing the organic compounds, and is heated again in a main heater (52). The hot blast exhausted from the furnace main body part (10) directly flows into the catalyst filtering part (70), thereby the organic compounds contained in the hot blast can be decomposed, thus no additional single heater is needed for heating the catalyst, the heat loss can be reduced. In addition, the sintering temperature in the furnace main body part (10) can be adjusted by controlling the main heater (52), therefore the temperature can be easily controlled to obtain the steady sintering temperature.

Owner:FUTURE VISION

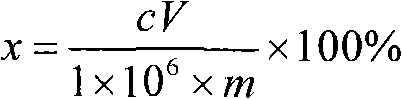

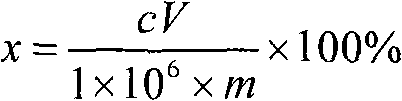

Method for accurately and quickly detecting manganese content in nitridation reinforcer

InactiveCN104502345AImprove stabilityGood reproducibilityMaterial analysis by observing effect on chemical indicatorPreparing sample for investigationBenzoic acidHydrofluoric acid

The invention discloses a method for accurately and quickly detecting manganese content in a nitridation reinforcer. The method comprises the following steps: pulverizing a test sample, weighing 0.2000g of test sample, evenly mixing with 10ml of 1.42 g / ml nitric acid, 12.0ml of 1.70 g / ml phosphoric acid and 5 drops of 1.15 g / ml hydrofluoric acid, heating to 80-100 DEG C until the test sample is completely dissolved, cooling for 2-3 minutes, adding 2.0ml of 1.67 g / ml perchloric acid into the obtained test solution, heating until small bubbles on the liquid level disappear, cooling to 70-80 DEG C, adding 50ml of water until the reaction salts are sufficiently dissolved, cooling to room temperature, titrating the test solution with a 0.03980-0.0400 mol / L ammonium ferrous sulfate standard solution until the solution turns pink, adding 5 drops of 2 g / L N-phenyl anthranilic acid solution, continuing titrating until the solution becomes brilliant green to reach the end point, and recording the volume of the consumed ammonium ferrous sulfate standard solution. The manganese content is calculated according to the following formula. The method can implement quick detection on the manganese content in the nitridation reinforcer, and has the advantages of accurate, stable and reliable detection result and high popularization and application value.

Owner:WUKUN STEEL

Porous cordierite ceramic prepared by taking walnut hull powder as pore former

InactiveCN104402515ADoes not affect pure phaseQuality improvementCeramicwareParticulatesPore distribution

The invention relates to a porous cordierite ceramic prepared by taking walnut hull powder as a pore former. The ceramic is prepared by mixing and grinding talcum, kaoline, calcined kaoline, alumina, aluminum hydroxide, quartz and MC (Methyl Cellulose) By weight percentage, putting into a body mold for forming, drying a formed body, roasting, and holding the temperature for a certain time. A method is used for the porous cordierite ceramic prepared by taking the walnut hull powder as the pore former; the ceramic meeting national standard requirements is obtained; at the same time, apparent porosity of the ceramic reaches above 50%; a pore size reaches about 2.5 micrometers; a pore size scope is 2.0-3.0 micrometers; and the pore distribution is uniform, so that PM2.5 (Particulate Matter 2.5) in gas is absorbed to achieve an effect of purifying air. A walnut hull has a higher decomposition temperature which is matched with a ceramic forming temperature of the cordierite ceramic, so that uniform pores can be formed in the ceramic body more easily; compared with an inorganic pore former, the walnut hull is decomposed more completely without any impurities, and a cordierite pure phase of the ceramic is unaffected.

Owner:JILIN UNIV

Method for preparing water gas from organic hazardous waste

InactiveCN108410505ABreak down completelyEliminate secondary pollutionWaste based fuelGasification processes detailsAmmoniaProduced water

The invention relates to a method for preparing water gas from organic hazardous waste. The method comprises the following steps: (1) removing strong oxidizing substances contained in the organic hazardous waste, and adjusting the pH to be 6 to 9; (2) blending different organic hazardous waste into a homogeneous mixture with a certain heat value; (3) preparing the organic hazardous waste and / or coal into a fluid or powder; (4) feeding the organic hazardous waste and / or coal into a gasifier, and carrying out a gasification and pyrolysis reaction under a high temperature condition to produce water gas; (5) chilling the obtained water gas of which the temperature is 1,000 DEG C or more with water of 100 to 250 DEG C to obtain small molecular water gas of 250 DEG C or less; (6) entering different processing procedures according to different subsequent processes to obtain methanol, ammonia, ethylene glycol or olefin. By adopting the method, the problems of low treatment efficiency for a part of organic hazardous waste, poor dioxin control effect, incapability of recycling resources and the like in the existing incineration technology are solved effectively.

Owner:绍兴凤登环保有限公司

Ecological and environment protecting livestock feeding method

InactiveCN104957095AReduce mortalityReduce infection rateAnimal feeding stuffAnimal housingMicroorganismAdditive ingredient

The invention provides an ecological and environment protecting livestock feeding method. The method comprises the steps that hog houses are isolated, an excreta resolving type floor is established; the hog house distribution density is set; a fodder batch mixture is prepared; the temperature of the hog houses is controlled; feeding is carried out on hogs; disinfecting and vaccinating are carried out. Due to the fact that natural fiber material layers are arranged in the hog houses, and hog excreta resolved by an aerobiotic microorganism is absorbed and converted into a hog fodder ingredient which can be utilized. Under the condition that the hog houses are guaranteed to be dry, the feeding cost is lowered, the ecology and the environment protecting can be achieved, hogs in the different growth stages are subjected to partition feeding in a remote mode, the epidemic situation is prevented from infecting, controlling is convenient to carry out, and when hog infectious diseases occur, the infectious rate and the death rate of the hogs are lowered.

Owner:郑日维

Method for preparing pickles

The invention discloses a method for preparing pickles. The method comprises the following steps of: (1) preparation of sweet flour paste juice: taking 1 weight part of flour, 1.15 to 1.3 weight parts of water, 0.1 to 0.2 weight part of soybean yeast or edible bean pulp, 0.025 to 0.04 weight part of edible alcohol and 0.015 to 0.025 weight part of salt, liquefying the flour by using alpha-amylase, then saccharifying the flour by using saccharifying enzyme, adding the soybean yeast or the edible bean pulp, the edible alcohol and the salt into the flour at the same time, stirring the mixture uniformly and fermenting the mixture for 10 to 20 days at the temperature of between 38 and 47 DEG C to form fermented paste, filter-pressing the fermented paste, and taking the juice, namely the sweet flour paste juice; and (2) preparation of the pickles: salting vegetables, cutting the vegetables and then desalting and dehydrating the vegetables, saucing the vegetables into the twice-used sweet flour paste juice for 24 hours, extruding the vegetables, then saucing the vegetables into the once-used sweet flour paste juice for 24 hours, extruding the vegetables again, and saucing the vegetables into the unused fresh sweet flour paste juice for 24 to 48 hours. The method has the advantages of short period, small floor area, low production cost, sanitation and reliability.

Owner:HEBEI BAODING HUAIMAO

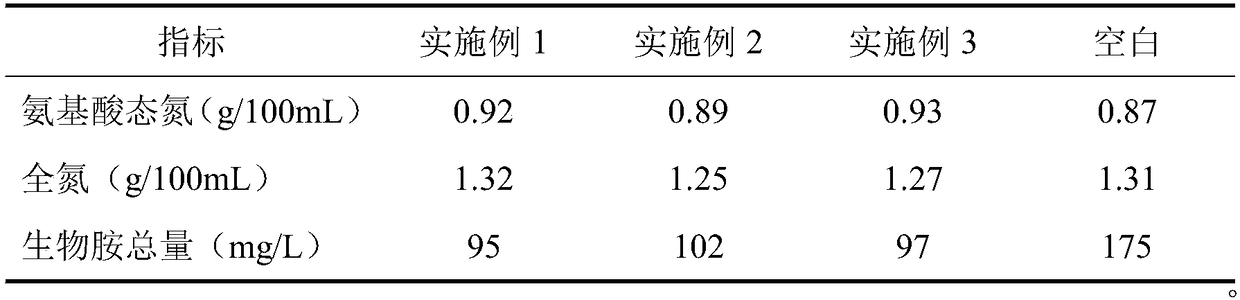

Method for reducing generation of biogenic amine in soy sauce by changing fermentation temperature

InactiveCN109363144ASimple and efficient operationDelay enzyme activityFood scienceMacromolecular SubstancesNutrient

The invention relates to a method for reducing generation of biogenic amine in a soy sauce by changing fermentation temperature. According to the method, the fermentation temperature after fermentation of 30 days is changed to reduce generation and accumulation of the biogenic amine in the fermentation process of a high-salt liquid-state soy sauce. The method is simple and convenient to operate, the temperature is reduced to effectively change the group and the quantity of microorganisms, and the activity of proteolytic enzymes and amino acid decarboxylase is reduced, so that the accumulationof the biogenic amine is influenced. Under the low-temperature condition, the explosion growth of the microorganisms can be controlled, nutrient substances of reducing sugar and the like in soy saucemash can be reserved as many as possible, and besides, the activity of enzymes can be delayed, so that macromolecular substances can be completely decomposed under slow fermentation condition, the utilization efficiency of the raw materials is improved, more flavor substances are generated, the generation of harmful microorganisms in the fermentation process can also be effectively prevented, andsafe production of a soy sauce is effectively guaranteed.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

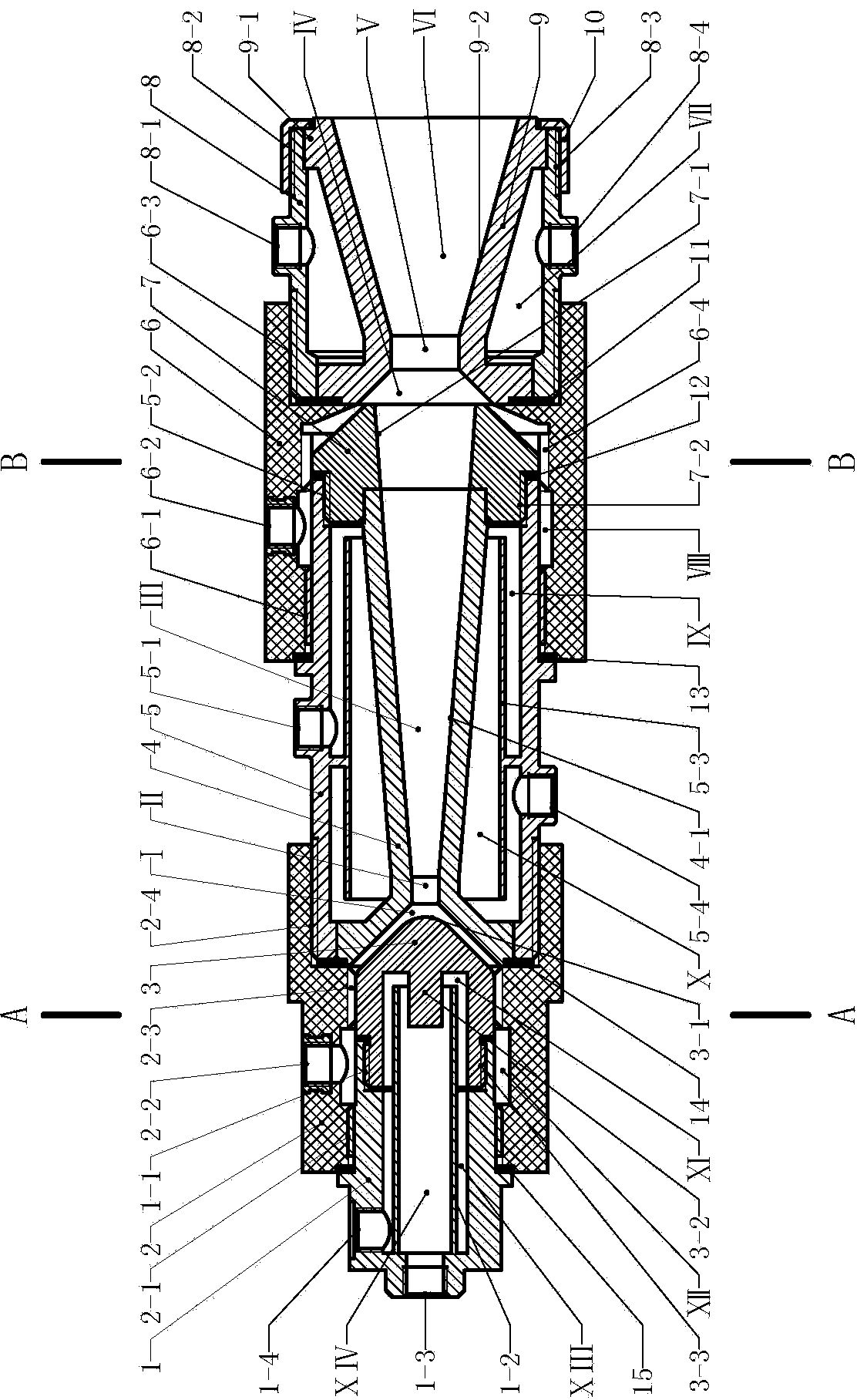

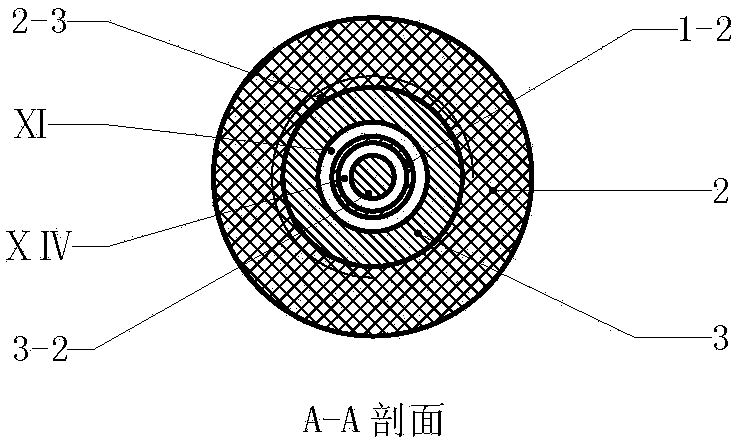

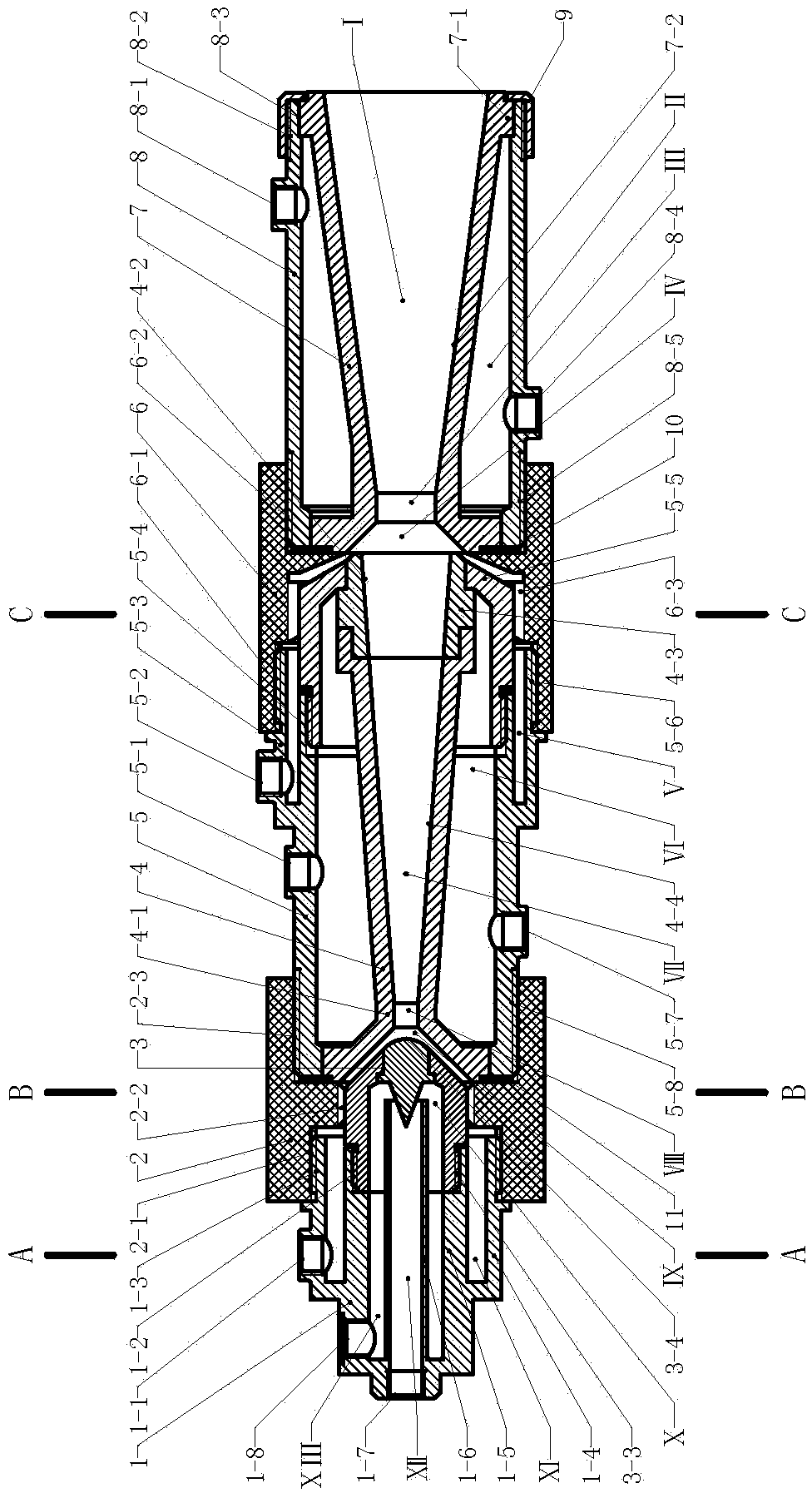

Two-stage arc plasma torch

The invention discloses a two-stage arc plasma torch, and relates to a plasma device. The two-stage arc plasma torch is composed of a back base, a first cathode, a first insulating torch frame, a first anode, a second cathode, a first pipe sleeve, a second insulating torch frame, a second anode and a second pipe sleeve, wherein the first cathode is installed in an installing spiral opening in the front end of the center of a rotating body of the back base, the second cathode is connected to the front end of the first anode, the first anode and the second cathode are embedded in the first pipe sleeve, the second anode is embedded in the second pipe sleeve, the back base and the first cathode are installed in a rear installing groove of the first insulating torch frame, the first pipe sleeve, the first anode and the second cathode are installed in a front installing groove of the first insulating torch frame and a rear connecting groove opening of the second insulating torch frame, and the second pipe sleeve and the second anode are installed in a front connecting groove opening of the second insulating torch frame (6). Two-stage high-temperature plasma arcs are generated in the plasma torch, the plasma torch can reach a higher processing temperature, and the heating efficiency and the decomposition capacity of the plasma torch are improved.

Owner:重庆顺雅电子科技有限公司

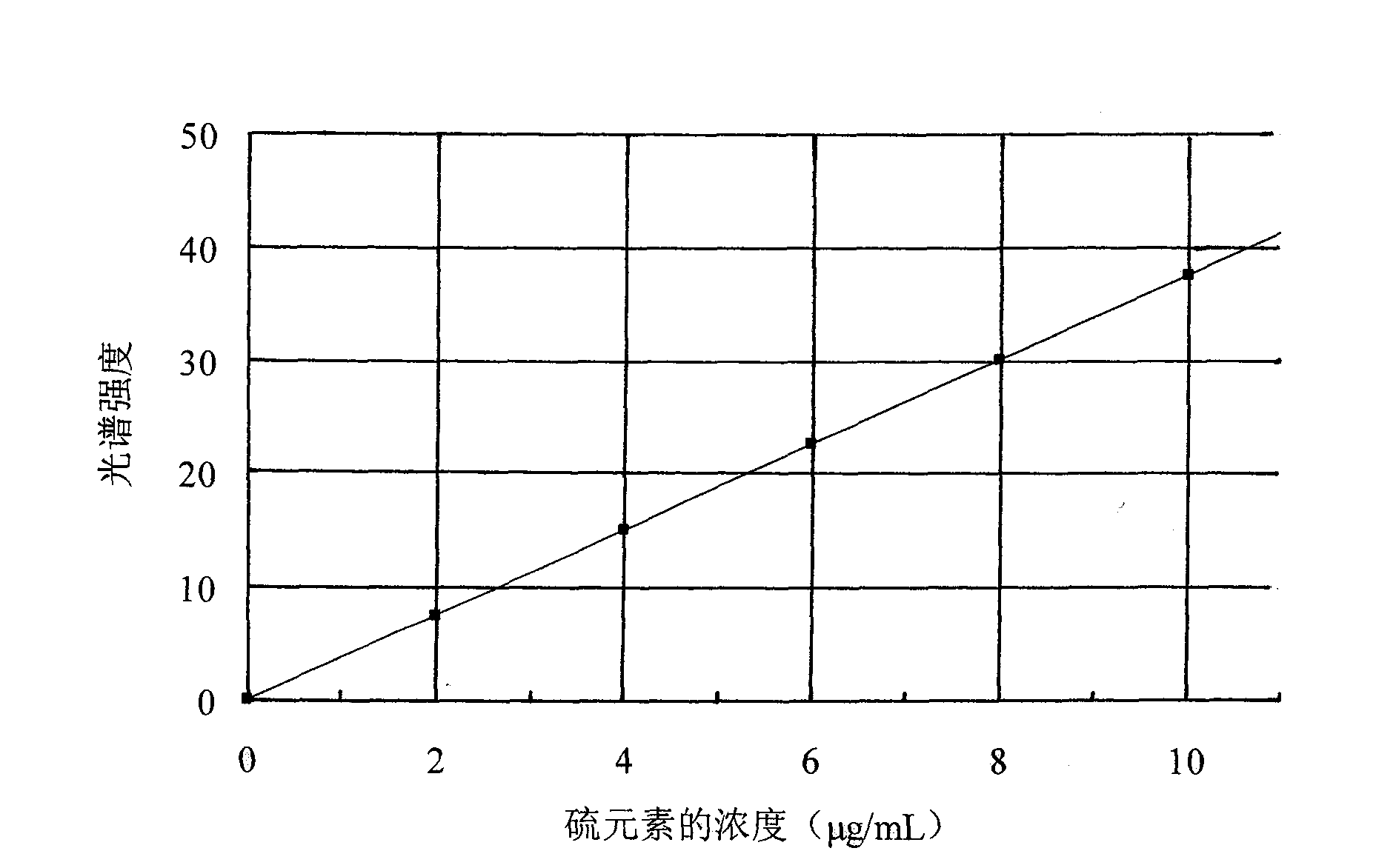

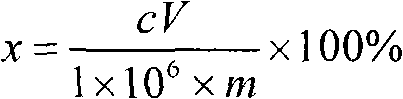

Method for rapidly and accurately determining sulphur element content in fluorite

InactiveCN101639443ABreak down completelySimple and fast operationAnalysis by thermal excitationLighting spectrumCalcium EDTA

A method for rapidly and accurately determining sulphur element content in fluorite mainly comprises the following steps: weighing a fluorite sample, adding deionized water, and then adding mixed acidto cause the fluorite sample to be fully converted into diffluent salt; adding deionized water and heating till the salt is completely dissolved; metering volume till 100mL; adopting reagent withoutthe sample for blanking, adding calcium standard solution equivalent to the fluorite sample, and then adding standard solution of sulphur element of different volumes; using sulphur element concentration as a horizontal ordinate and the intensity of a light spectrum as a vertical coordinate to draw a working curve; and then automatically determining the concentration of the sulphur element in thesample solution by a computer according to the working curve. The method uses an inductance coupling plasma body emission light spectrum, mainly solves the problems in the existing method of incompletely decomposed sample, the background interference of the light spectrum during measurement, spectral line interference and the like, determines appropriate operational parameters and steps and rapidly determines the sulphur elements in the fluorite in high effect.

Owner:武钢集团有限公司

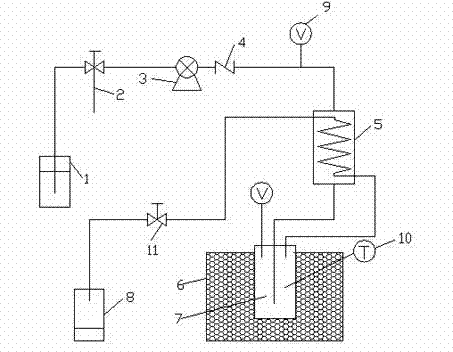

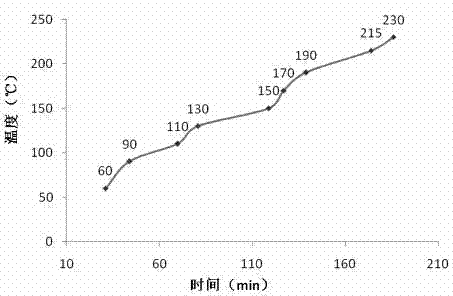

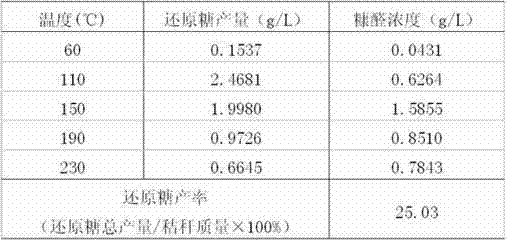

Hydrothermal saccharification method and device for cellulose biomass

InactiveCN102816877AThe source process is fastBreak down completelySaccharides productionCelluloseHydrolysate

The invention discloses a hydrothermal saccharification method for cellulose biomass, which comprises the following steps: pulverizing cellulose biomass; mixing the pulverized cellulose biomass and 0.05-1.00 wt% dilute acid solution in a reactor in a solid-to-liquid ratio of 1:(6-20); and heating the cellulose biomass and dilute acid mixture in the reactor while stirring to carry out reaction at 60-230 DEG C under the reaction pressure of 1-4MPa under sealed conditions, wherein the heating adopts a gradient heating mode, i.e. the temperature is divided into multiple temperature nodes of which the temperature intervals are 15-50 DEG C, the hydrolysate obtained by reaction is discharged and collected and new dilute acid solution is injected every time coming to a temperature node, and the hydrolysates at different temperature nodes are collected respectively. The saccharides obtained by decomposing cellulose biomass by using the method and device disclosed by the invention can be separated immediately after being generated, thereby effectively enhancing the saccharine yield, greatly lowering the toxic components in the saccharides and making a great step forward for industrialized production of saccharides from biomass.

Owner:SHANGHAI JIAO TONG UNIV

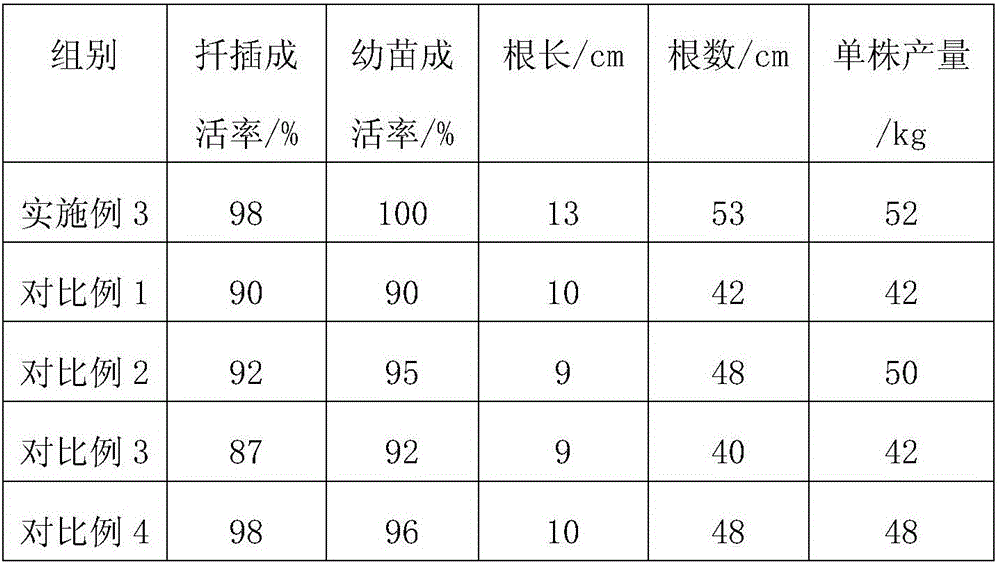

Seedling culturing method of pitaya

InactiveCN106577109AImprove stabilityImprove water retentionGrowth substratesCulture mediaAlcoholRoot growth

The invention provides a seedling culturing method of pitaya, and belongs to the technical field of agricultural planting. The method comprises management of cutting seedlings and management of seedlings. A specially prepared cutting matrix is adopted during cutting. Cutting stems are immersed in a rooting solution and then cut; the rooting solution is prepared from the following components with the following concentration: ABT rooting powder I with the concentration of 3.0 to 4.0 mg / mL, diethyl aminoethyl hexanoate with the concentration of 1.0 to 2.0 mg / mL, jasmonic acid with the concentration of 0.80 to 1.0 mg / mL and chlorethyl alcohol with the concentration of 0.22 to 0.28 mg / mL. According to the method, the soil is further improved through specially prepared base fertilizer during the management of the seedlings, so that the fertility of the soil is improved. The method greatly increases the rooting rate of pitaya cutting; the obtained seedlings are more robust in root growth; in the seedling stage, pitaya seedlings have better growth vigour; and a good foundation is laid for high yield of subsequently planted pitaya.

Owner:兴业县恩民农业科技有限公司

Novel methanol reformer

ActiveCN109950589AIncreased hydrogen productionImprove reforming efficiency and heat transfer efficiencyHydrogenFinal product manufactureHoneycomb structureMethanol

The invention provides a novel methanol reformer comprising a guiding mixing plate and catalyst coatings. The guiding mixing plate is a honeycomb structure. The inner and outer sidewalls of the guiding mixing plate are provided with the catalyst coatings. The novel methanol reformer provided by the invention, by means of the catalyst coatings on the inner sidewall and the outer sidewall of the guiding mixing plate, enables a fluid to flow through honeycomb holes in the guiding mixing plate. Thus, the fluid can be sufficiently mixed and can be in well contact with the catalyst coatings, therebycompletely decomposing methanol, increasing hydrogen production, improving reforming efficiency and heat exchange efficiency, and make the reformer compact, efficient and good in vibration resistance.

Owner:CHINA HYDROGEN NEW ENERGY TECH CO

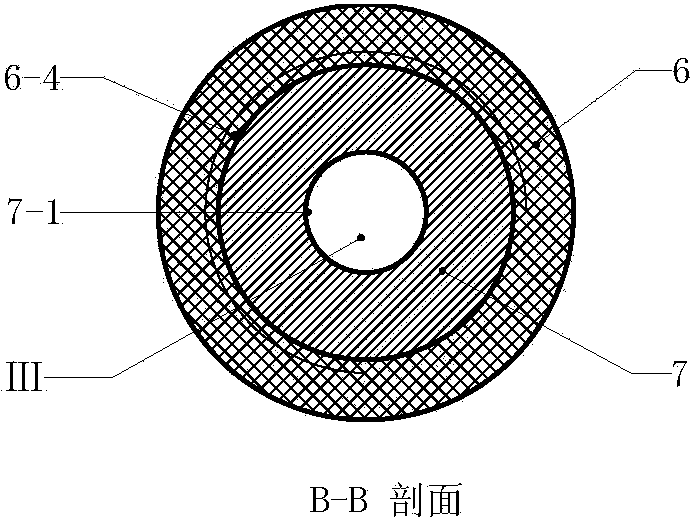

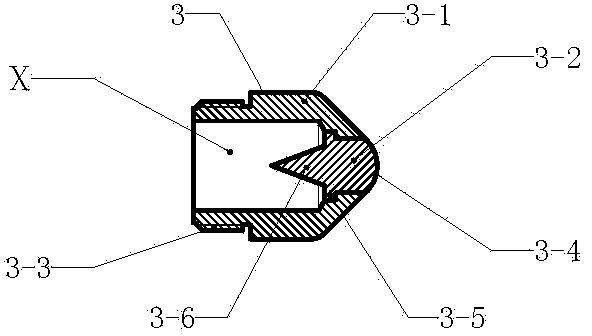

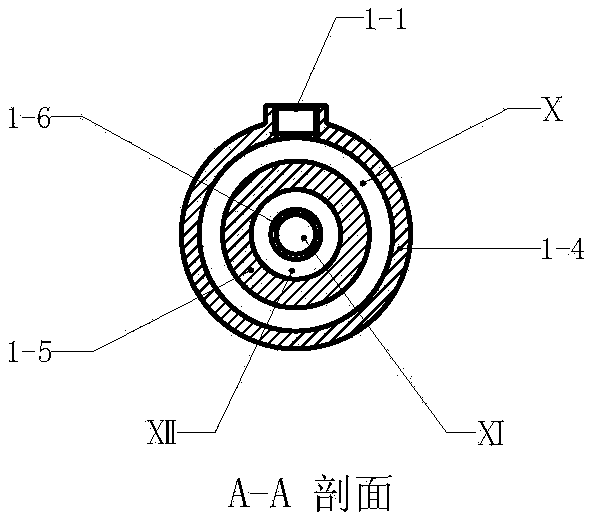

Plasma torch of double-stage nozzle structure

ActiveCN104363690AImprove heating efficiencyImprove decomposition ratePlasma techniqueEngineeringTorch

The invention discloses a plasma torch of a double-stage nozzle structure and relates to plasma equipment. The plasma torch is composed of a backseat, a cathode, a first insulating torch rack, a first nozzle, a first sleeve, a second insulating torch rack, a second nozzle and a second sleeve; the cathode is mounted at the front end of the center of the backseat, the first nozzle is mounted in the first sleeve, the second nozzle is mounted in the second sleeve, the backseat with the cathode is mounted in a rear mounting groove in the first insulating torch rack, the first sleeve with the first nozzle is mounted in a front mounting groove of the first insulating torch rack and a rear connecting slot of the second insulating torch rack, and the second sleeve with the second nozzle is mounted in a front connecting slot of the second insulating torch rack; the head of the cathode extends into a bell mouth space of the rear end of the first nozzle, and the bell mouth space of the first nozzle forms a first discharge area. Two-stage high-temperature plasma arc is generated in the plasma torch, so that heating efficiency and resolving capability of the plasma torch are improved, and application requirements on the fields of pyrolysis water hydrogen production, solid waste disposal and harmful gas treatment can be met.

Owner:重庆市璧山区涂鑫机械有限责任公司

Test sample treatment method for simultaneously measuring content of silicon and phosphor in silicon-manganese alloy by ICP

InactiveCN104502179AAvoid volatile lossBreak down completelyPreparing sample for investigationSolventTest sample

The invention discloses a test sample treatment method for simultaneously measuring content of silicon and phosphor in a silicon-manganese alloy by ICP. The test sample treatment method comprises the following steps: weighing 0.1000g of a silicon-manganese alloy test sample with particle size of 160-200mesh, putting the silicon-manganese alloy test sample into filter paper which is pre-filled with 2.0-2.5g of a mixed solvent of anhydrous sodium carbonate and boric acid in a ratio of 2 to 1, uniformly mixing, packaging and putting into an iron crucible with a graphite layer bottom for fusing for 12-18 minutes at 800-900 DEG C, cooling for 2-3 minutes to obtain a sample, putting the sample into a container which is pre-filled with 90-110ml of a diluted hydrochloric acid solution consisting of hydrochloric acid and water in a ratio of 1 to 3, dissolving clinkers, filtering the obtained sample through rapid quantitative filter paper into a 250ml volumetric flask, cleaning the sample containing container and the filter paper with deionized water, and adding deionized water to the scale after cooling the filtrate and washing liquor. According to the test sample treatment method, the silicon-manganese alloy test sample is fused and decomposed through an alkaline fusion method, thereby avoiding volatilization loss of silicon when hydrofluoric acid is added to dissolve the test sample through an acid dissolving method; the test sample is completely decomposed without interference or dissipation, so that the analyzed results are accurate and stable; moreover, an ICP spectrograph is used for simultaneously measuring the content of silicon and phosphor in the silicon-manganese alloy.

Owner:WUKUN STEEL

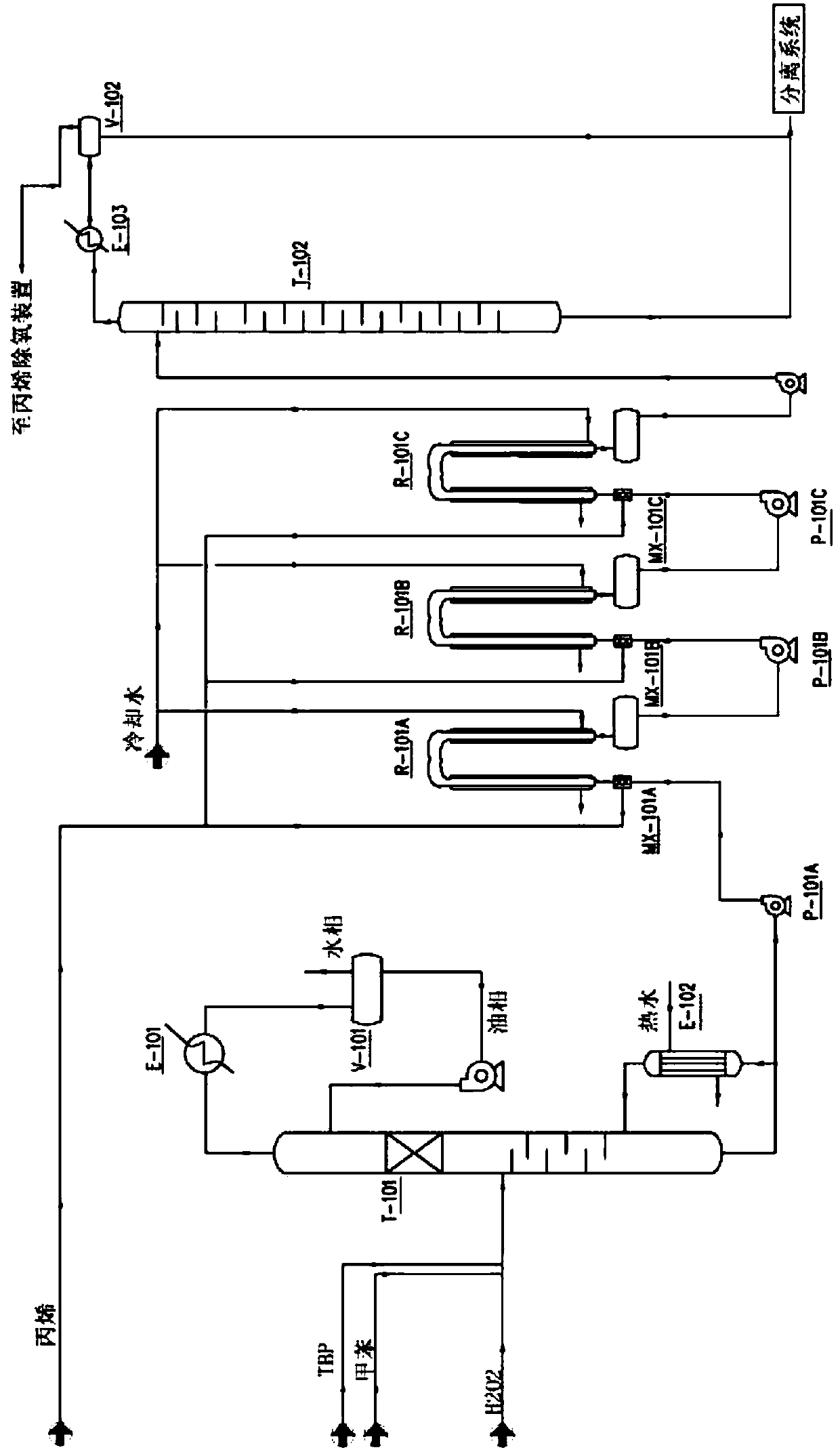

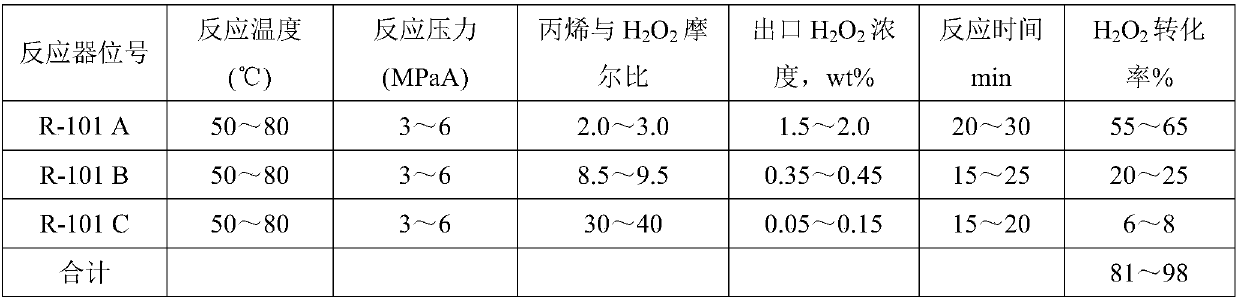

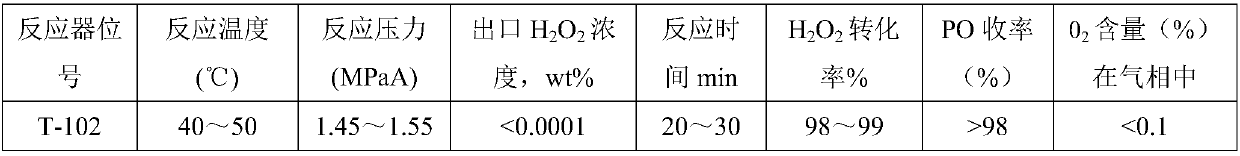

Method for continuous production of propylene oxide by direct oxidation of propylene with hydrogen peroxide through tubular reactors

InactiveCN109535102AReduce decompositionReduce contentProcess control/regulationOrganic chemistryReaction temperaturePetrochemical

The invention relates to the field of petrochemical industry, in particular to a method for continuous production of propylene oxide by direct oxidation of propylene with hydrogen peroxide through tubular reactors. The method comprises the steps: a catalyst, namely phosphotungstic acid quaternary ammonium salt is mixed with the hydrogen peroxide and an organic solvent, and the mixture is subjectedto azeotropic dehydration and then sequentially reacts through the multi-stage tubular reactors which are connected in series; and a raw material, namely the liquid propylene is divided into multiplestrands to be parallelly added into all the stages of tubular reactors, reacting mixed liquid flowing out from the tubular reactor of the last stage enters a tower reactor, and after reacting of thereacting mixed liquid in the tower reactor is completed, the reacting mixed liquid enters a separating system. The design is ingenious, through combination of the tubular reactors and the tower reactor and reasonable control over the reacting temperature and the reacting pressure, the atmosphere needing to be protected by N2 in the reactors in a laboratory process is omitted, and condensation filter tower devices which are additionally arranged in the reactors because of protection of the N2 and control over the oxygen content are omitted; the equipment investment and the tail gas treatment cost are saved greatly, tail gas emission of the reactors is less, and thus pollution to the environment is less; and the method has potential market value.

Owner:山东凯泰科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com