Method for determining niobium element content in ferroniobium

An element content and element technology, applied in the field of analytical chemistry, can solve the problems of long operation process and narrow measurement range, and achieve the effect of simple operation, enlarged measurement range and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Weigh 0.2000g sample (GSB 03-2202-2008 Sinosteel Jitie production) and place it in a 400mL polytetrafluoroethylene beaker, add 5mL of deionized water to wet the sample, add 5mL of hydrofluoric acid and 5mL of nitric acid, Heat on a 180°C electric heating plate to slowly dissolve the sample. After the sample is completely dissolved, remove it and cool it down. After cooling to room temperature, set the volume in a 100mL plastic volumetric flask, dilute to the mark with deionized water, and mix well.

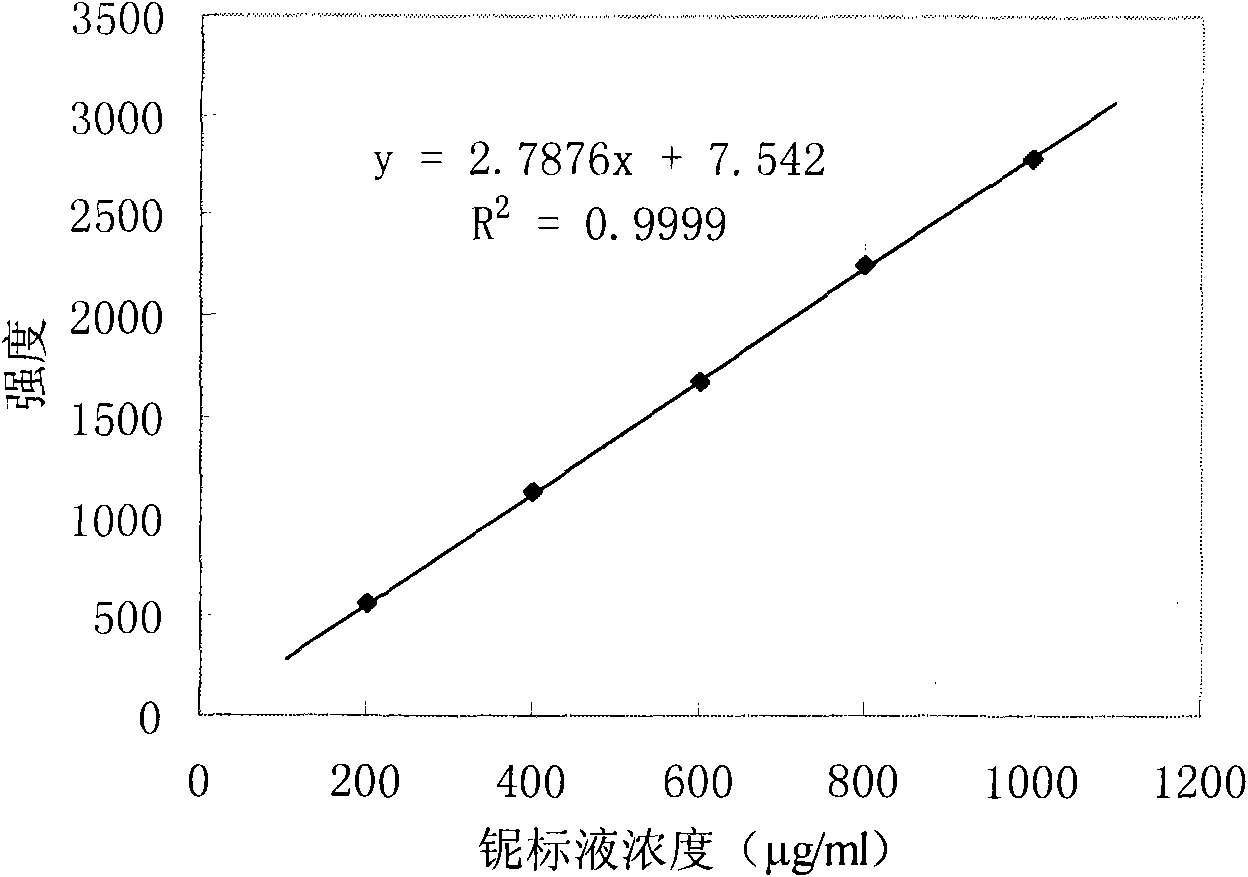

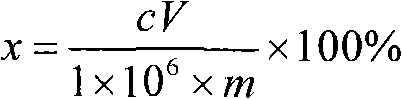

[0039] Treat the blank sample in the same way, add different concentrations of niobium standard solution, add water to make up to 100mL, measure the spectral intensity of niobium on the ICP emission spectrometer (see Table 1 for the measurement conditions of the spectrometer), and draw the working curve. Then measure the spectral intensity of niobium in the solution to be tested, obtain its concentration from the working curve, and obtain the content of niobium in the sample...

Embodiment 2

[0047] Weigh 1.0000g sample (unknown sample) and place it in a 400mL polytetrafluoroethylene beaker, add 10mL deionized water to wet the sample, add 10mL hydrofluoric acid and 10mL nitric acid, and heat on a 220°C electric heating plate to make The sample dissolves slowly. After the sample is completely dissolved, take it out and cool it down. After cooling to room temperature, set the volume in a 100mL plastic volumetric flask, dilute to the mark with deionized water, and mix well.

[0048] The blank sample is processed in the same way, adding different concentrations of niobium standard solutions, adding water to 100mL, measuring the spectral intensity of niobium on an ICP emission spectrometer (the measuring conditions of the instrument are the same as in Example 1), and drawing a working curve. Then measure the spectral intensity of niobium in the solution to be tested, obtain its concentration from the working curve, and obtain the content of niobium in the sample through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com