Patents

Literature

67results about How to "Expand the range of species" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

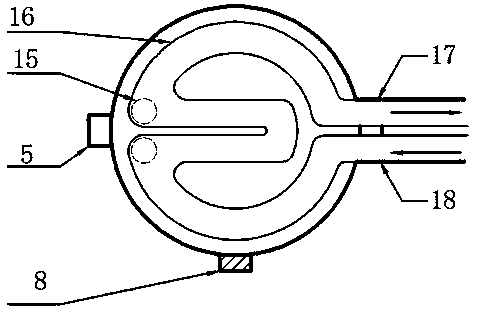

Hand-operated air pressure sample introduction method for microfluidic chips

InactiveCN102735864ANovel and practical manual mixed sampling methodSimple structureMaterial analysis by electric/magnetic meansEngineeringCost performance

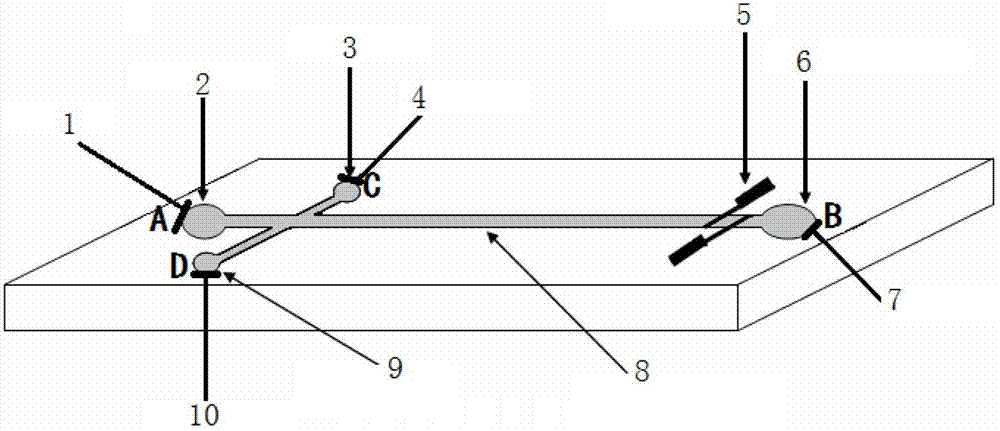

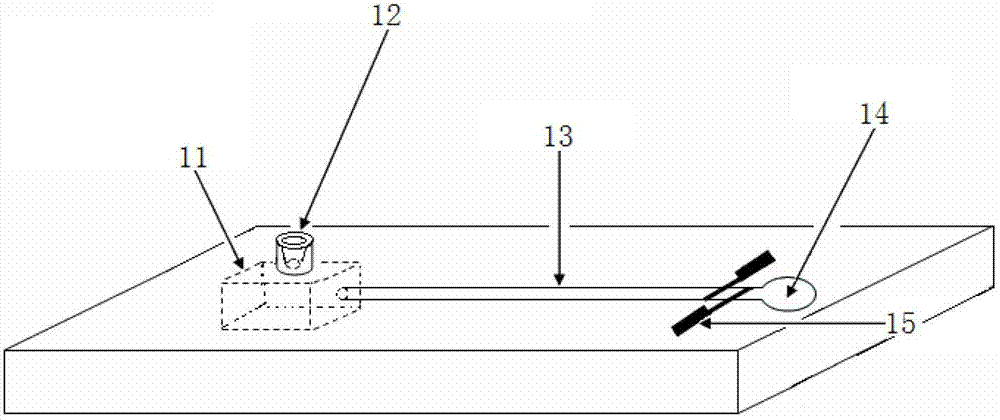

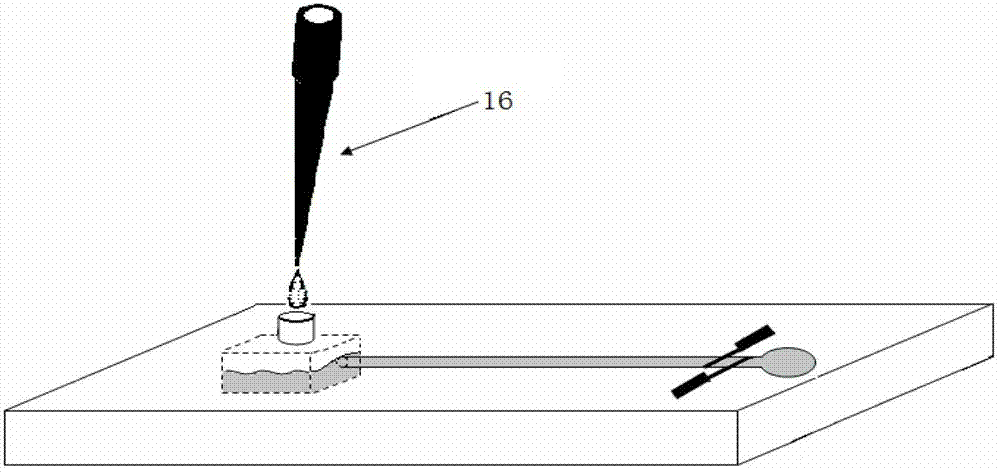

The invention belongs to a hand-operated air pressure sample introduction method for microfluidic chips. According to a hand-operated mixed sample introduction detection method for microfluidic chips, pressure generated by pushing of a section of enclosed air to another end is used as power to drive liquid in a chip detecting micro-channel circuit which forms an enclosed passage to flow along a designated target direction and to pass the position of a detector on a microfluidic chip so as to complete analysis and detection of substances; a cavity 11 is provided at a sample introduction inlet of the microfluidic chip for storage of a reaction solution and air used as a driving means, which is beneficial for people to control reaction and detection timing, and continuous air pressure is easily generated and is used as power needed in flowing of the liquid in the microfluidic chip, which enables driving to be realized. The hand-operated mixed sample introduction method provided in the invention has high cost performance and is simple and practical; the method is an optimal lightweight sample introduction scheme and is especially applicable to on-site detection and analysis in the field. The method can be widely applied to a variety of microfluidic chip detection apparatuses and has good versatility.

Owner:INST OF HYGIENE & ENVIRONMENTAL MEDICINE PLA ACAD OF MILITARY MEDICAL

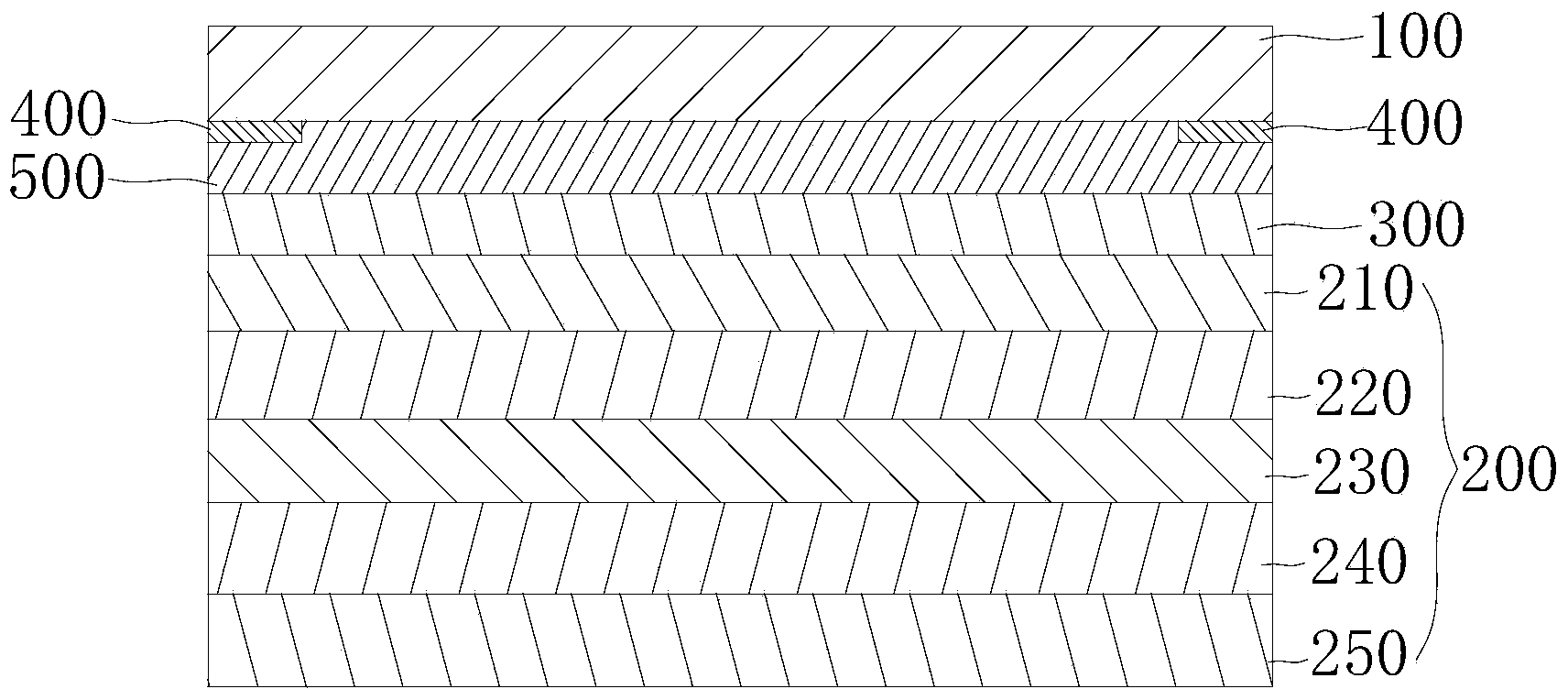

Secondary lithium battery and method for manufacturing the same

InactiveCN101431165AStable in natureReduce waterproof performance requirementsFinal product manufactureSmall-sized cells cases/jacketsOrganic solventLithium hydroxide

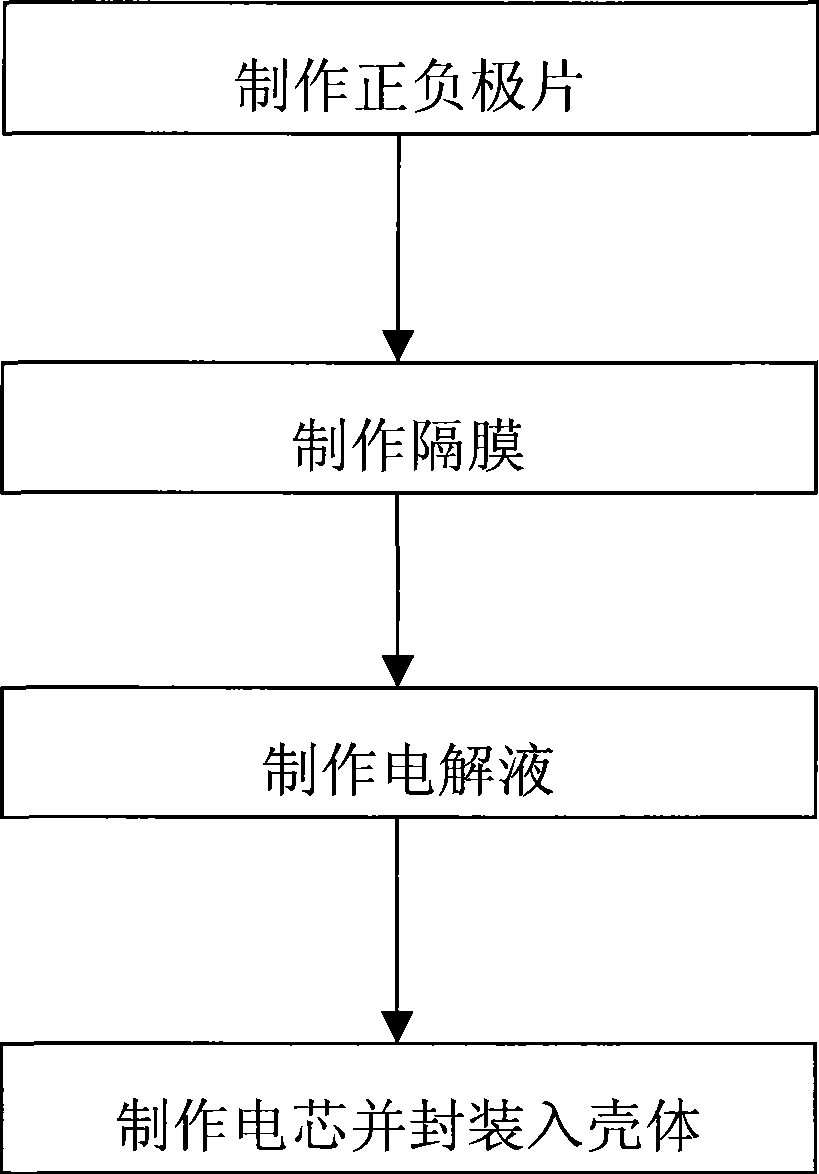

The invention relates to a lithium-ion secondary battery and a manufacturing method thereof. The battery comprises a positive electrode flake, a negative electrode flake, a diaphragm, electrolyte and a packaging shell body; positive electrode materials of the positive electrode flake comprise lithium salt with the positive electrode reversible extraction of lithium ions, a carbon conductive agent and a binding agent; the weight percentage of the three positive electrode materials is as follows, the lithium salt is 80 percent-98 percent, the carbon conductive agent is 0.5 percent-18.5 percent, and the binding agent is 1.5 percent-19.5 percent; negative electrode materials of the negative electrode flake comprise one of the lithium salt with the negative electrode reversible extraction of lithium ions, oxides with reversible extraction of lithium ions and sulfides with reversible extraction of lithium ions or the combination thereof, the carbon conductive agent and the binding agent; the weight percentage of the three negative electrode materials is as follows, the lithium salt is 80 percent-98 percent, the carbon conductive agent is 0.5 percent-18.5 percent, and the binding agent is 1.5 percent-19.5 percent; the electrolyte of electrolyte fluid is soluble lithium salt or lithium hydroxide which can not react with water, and the solvent is water or the organic solvent. The method comprises the steps of producing and packaging the positive and the negative electrode flakes, the diagram, the electrolyte and a battery cell and into the shell. The invention reduces the manufacturing difficulty and the production cost of the lithium-ion secondary batteries and expands the types and the scope of application of the lithium-ion secondary batteries.

Owner:耀安电池电源科技(深圳)有限公司

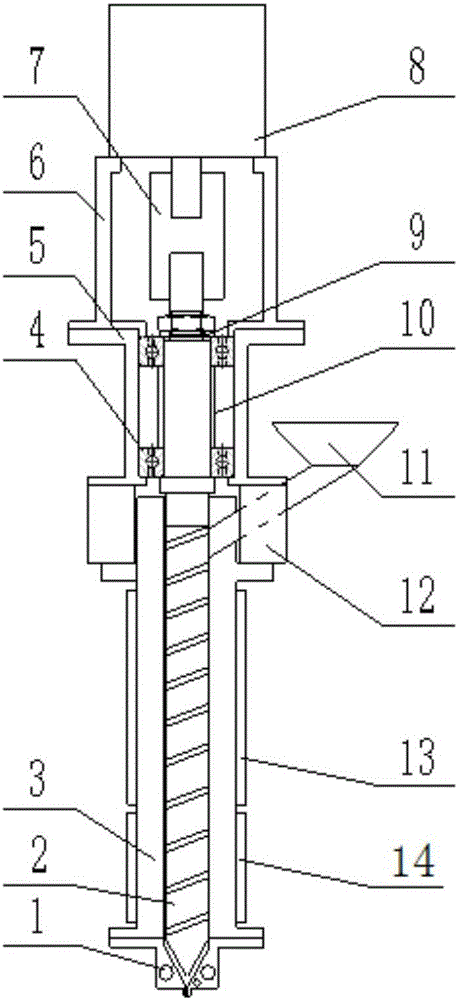

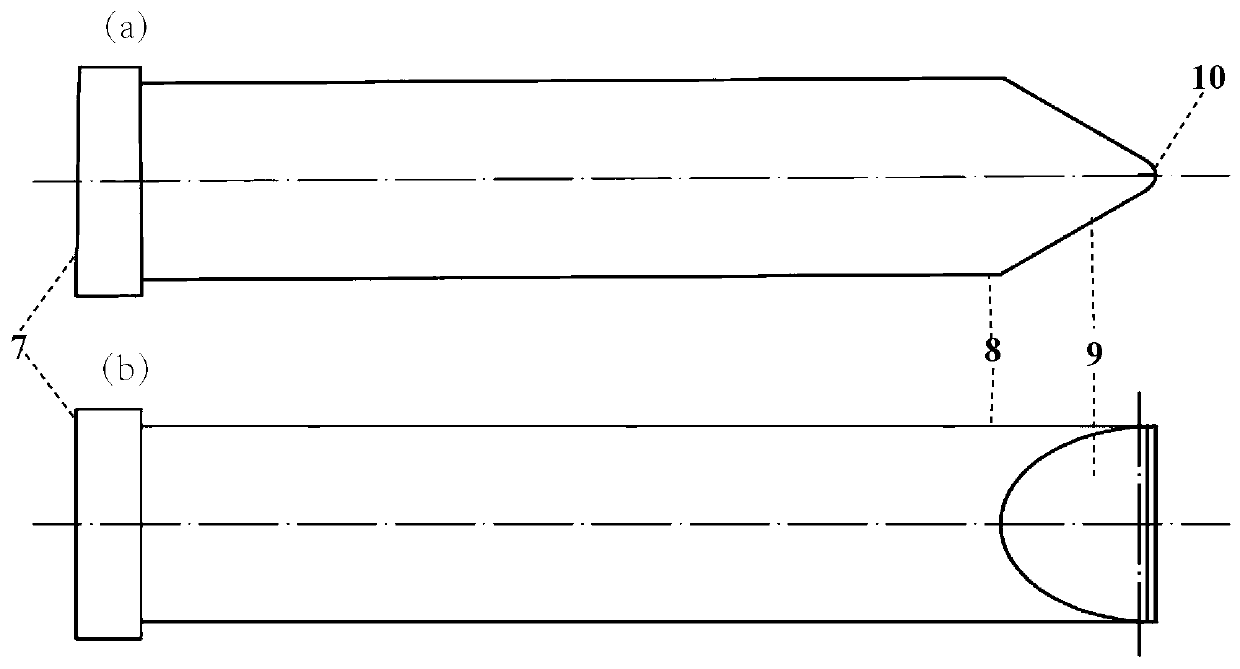

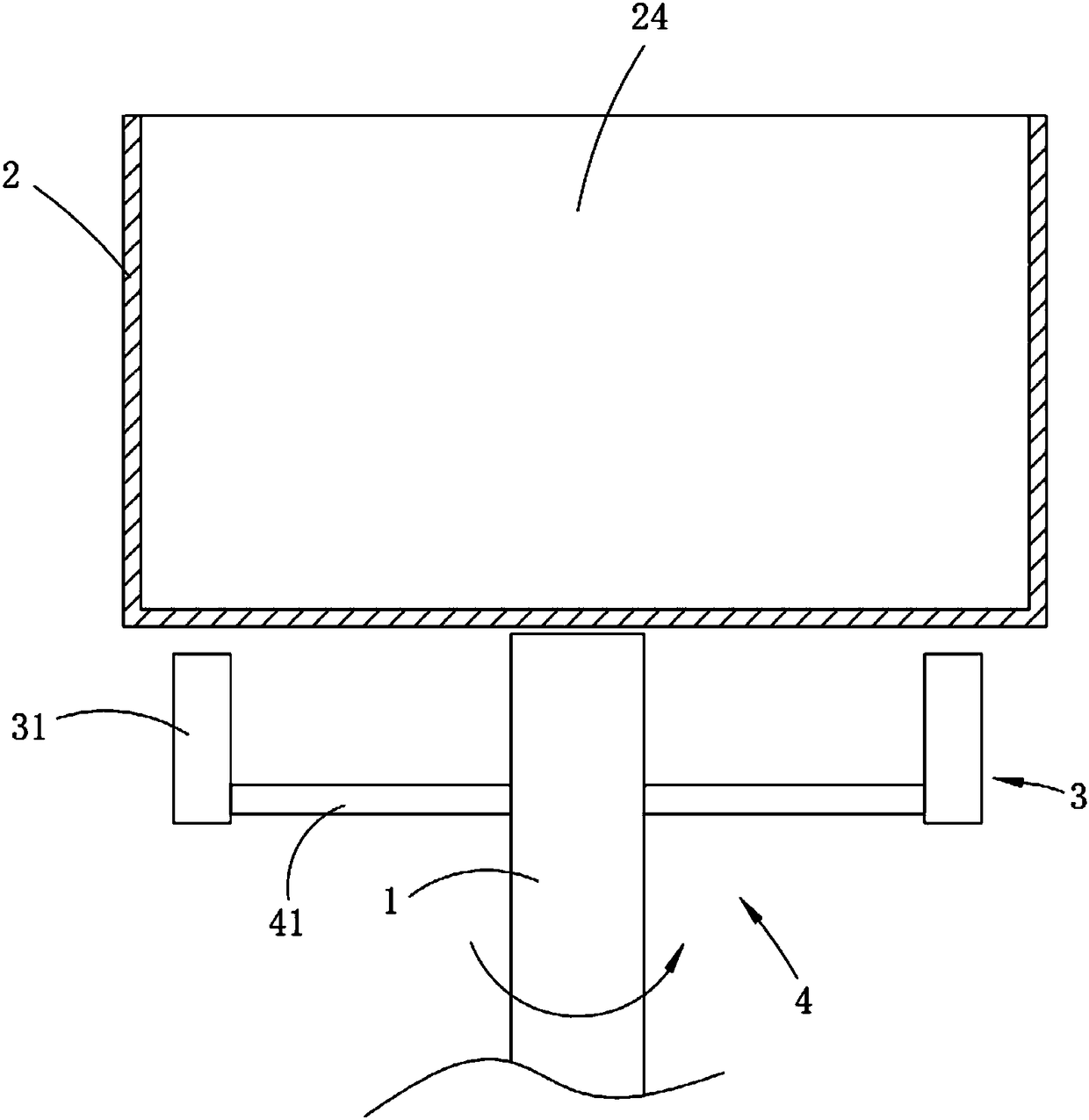

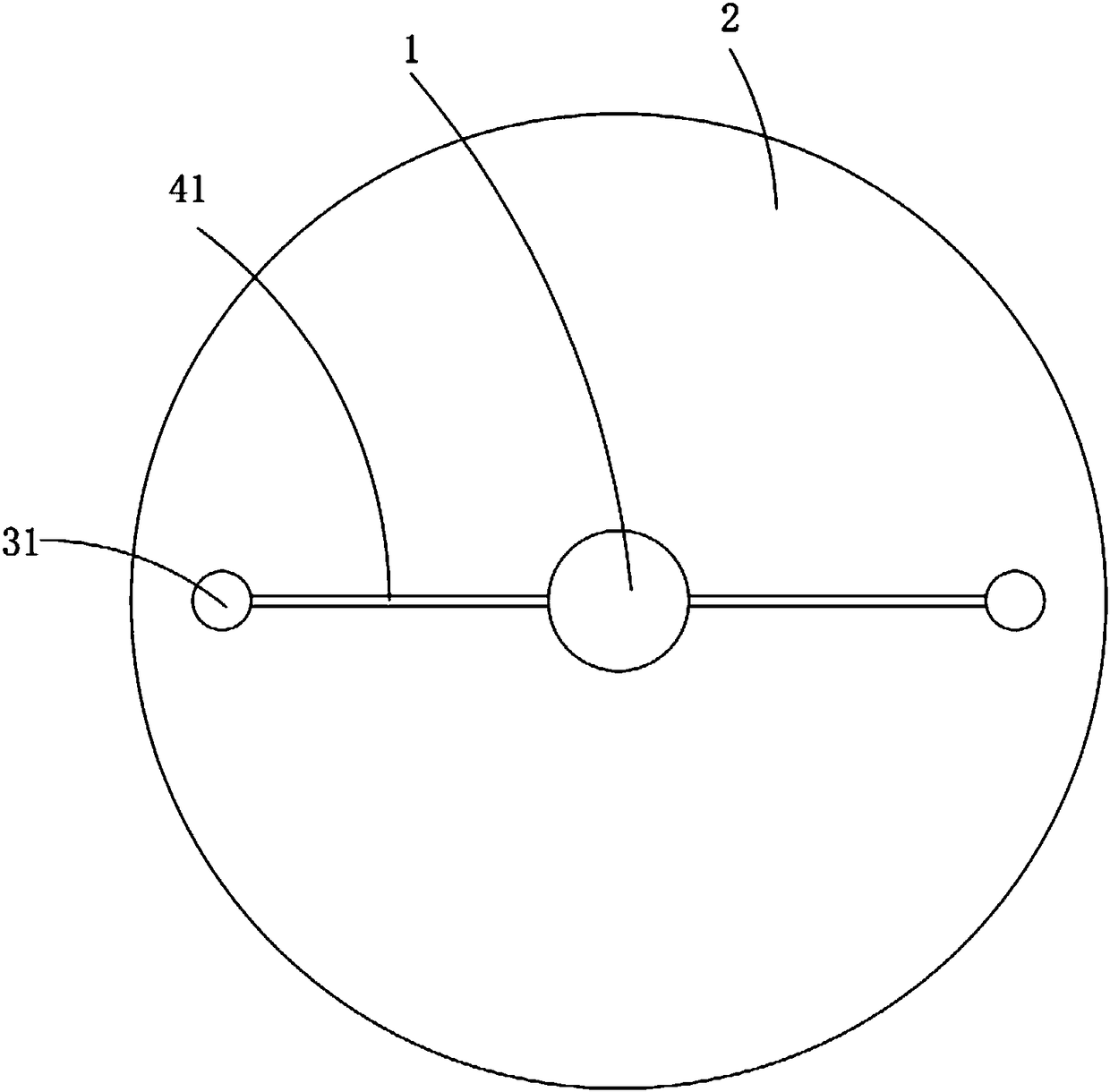

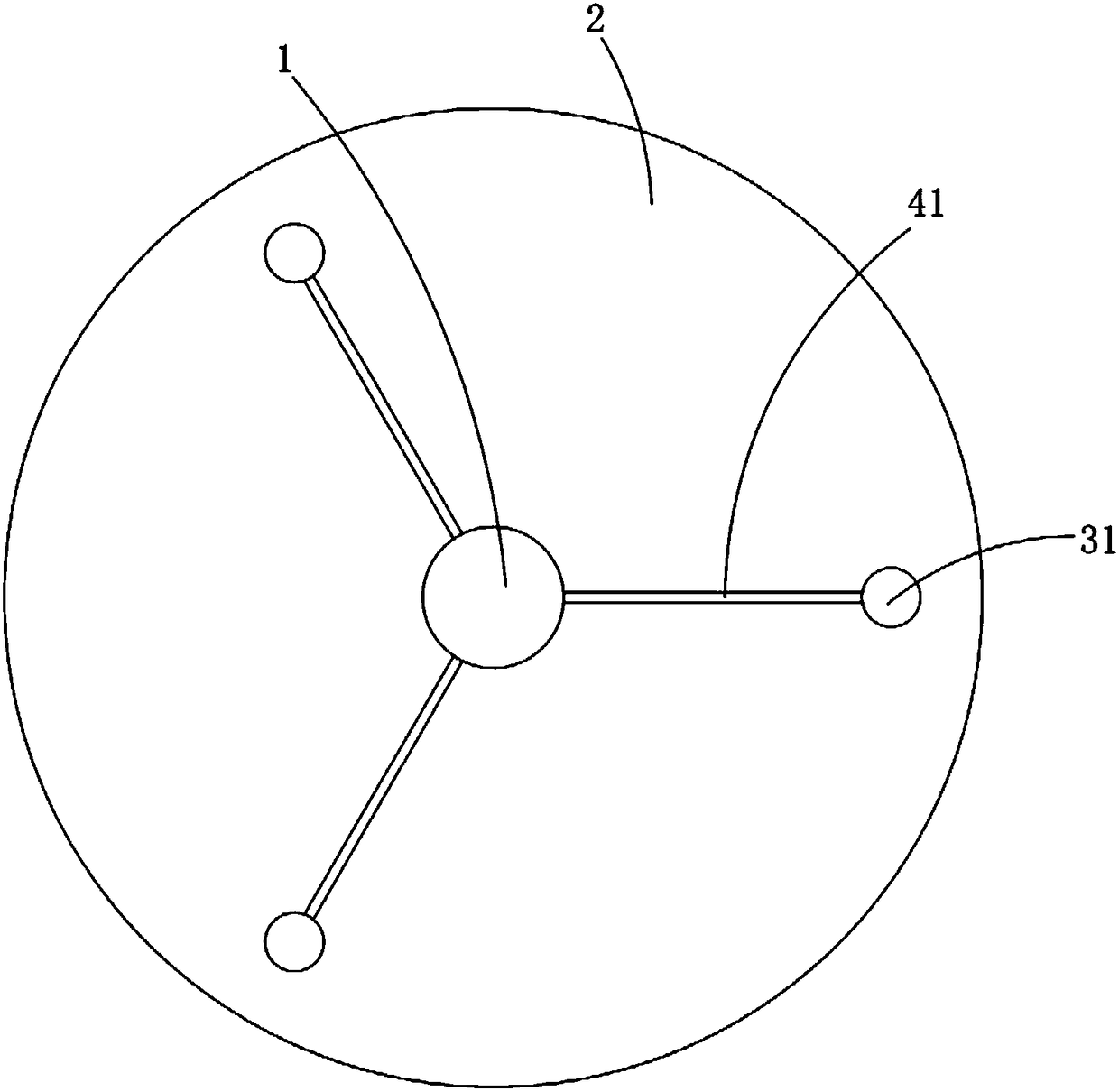

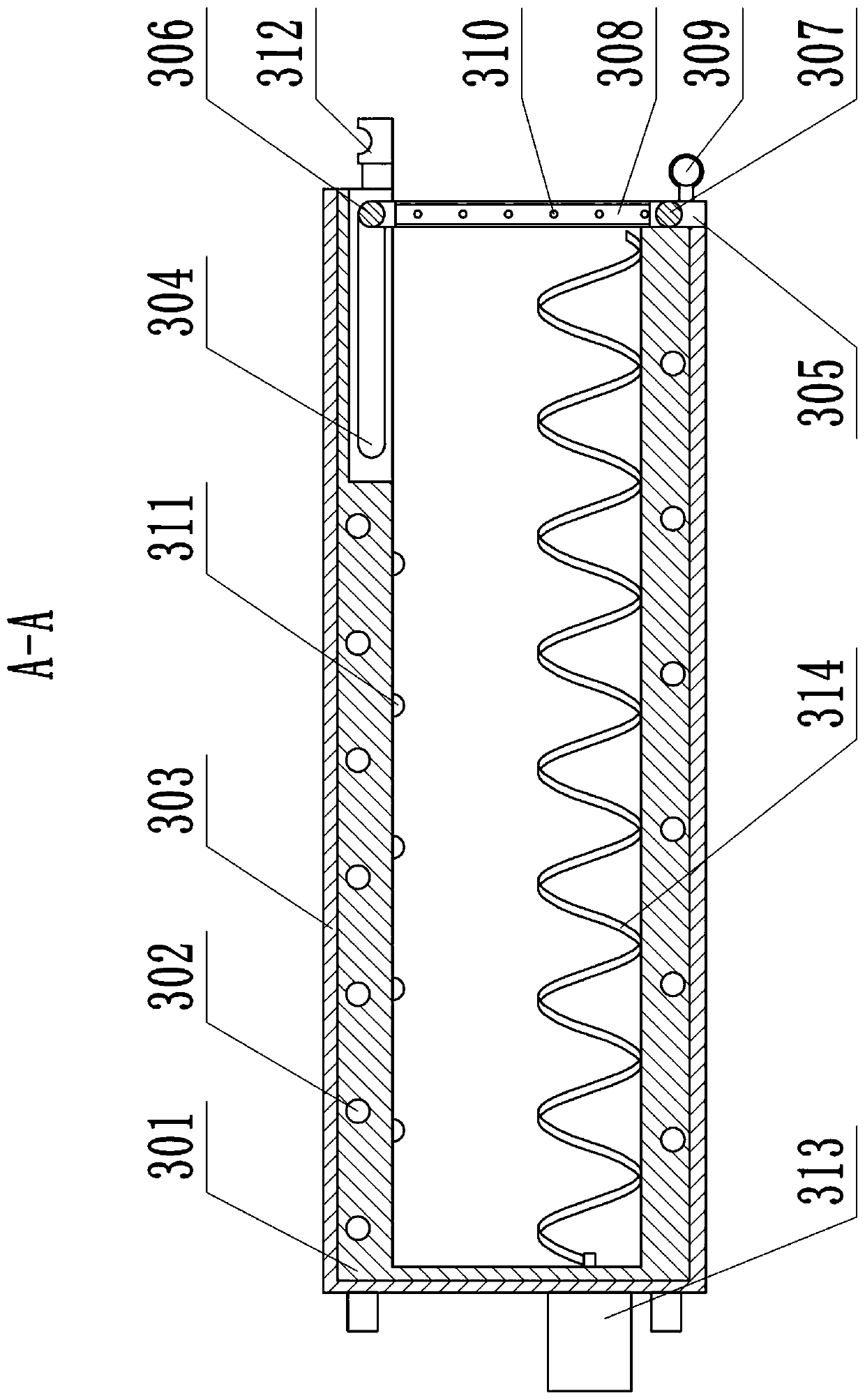

Screw type additive manufacturing spray head

InactiveCN106217867AEasy to useLow costAdditive manufacturing apparatusHeater RodPulp and paper industry

The invention discloses a screw type additive manufacturing spray head. Particles of the conventional size can be used as a raw material, the material extrusion process is stable, the extrusion force is large, and the forming efficiency is high. The screw type additive manufacturing spray head comprises a machine barrel, a nozzle fixed to the front end of the machine barrel, a screw arranged in the machine barrel and a drive motor fixed to the rear end of the machine barrel. The tail end of the screw is arranged in a cone shape. The front end of the screw is connected with the output end of the drive motor. The part, provided with a thread, of the screw is sequentially provided with a feeding segment, a compression segment and a metering segment from the front end to the tail end according to threaded groove depths. The groove depth of the feeding segment is the maximum, and the feeding segment is arranged in an equal groove depth manner. The groove depth of the metering segment is the minimum, and the metering segment is arranged in an equal groove depth manner. The groove depth of the compression segment is gradually changed into the minimum groove depth from the maximum groove depth. A feeding opening is formed in the position, corresponding to the feeding segment of the screw, of the machine barrel. A first heating ring is arranged at the position, corresponding to the compression segment, of the machine barrel, and a second heating ring is arranged at the position, corresponding to the metering segment, of the machine barrel. The interior of the nozzle is arranged in the manner of a conical face matched with the tail end of the screw. A set of heating bars is arranged on the nozzle in an inserted manner.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

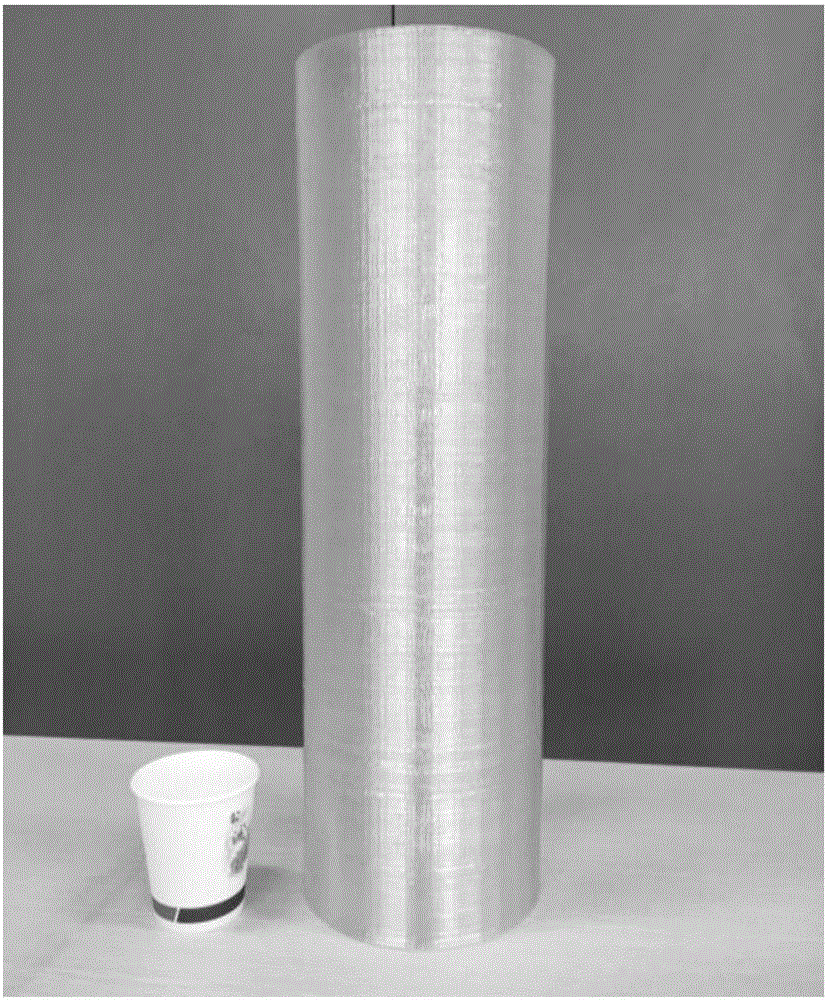

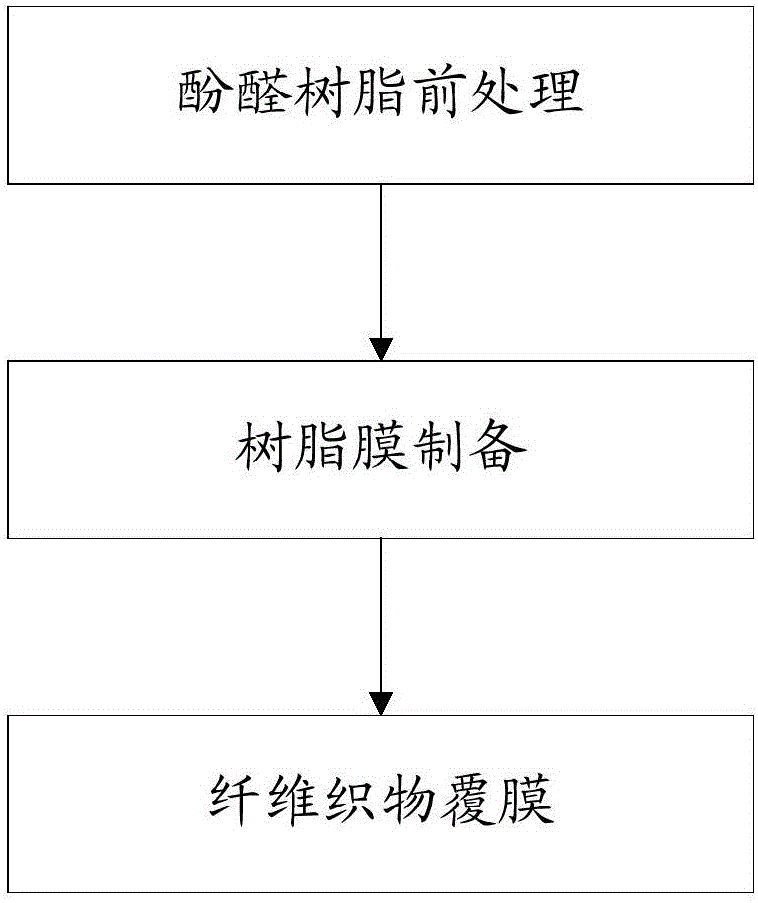

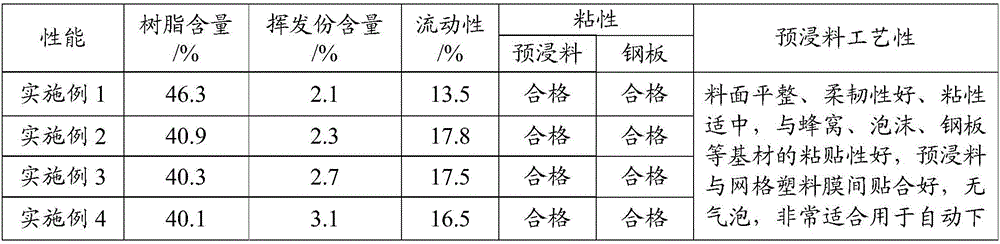

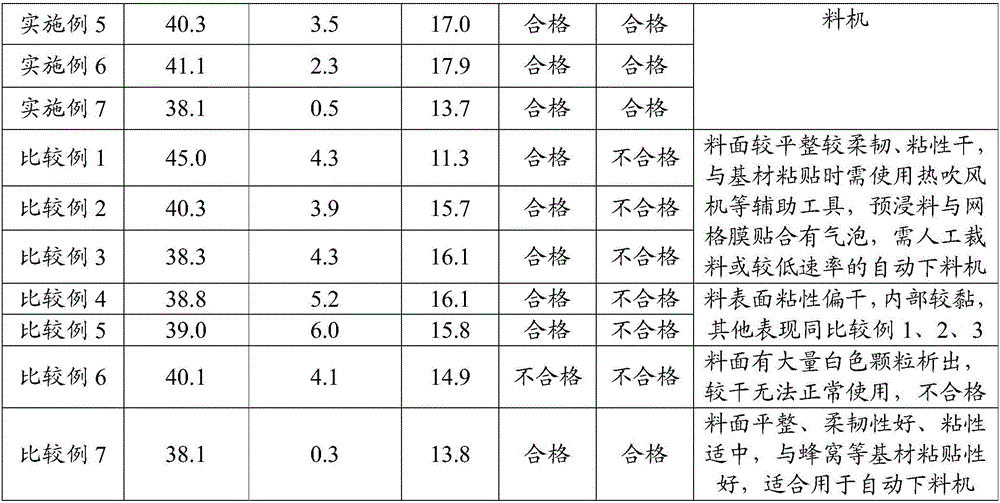

Method using coating technology to prepare solution-method phenolic aldehyde prepreg

ActiveCN105882077AImprove performanceIncrease flexibilitySynthetic resin layered productsLaminationFiberFiltration

The invention relates to a method using the coating technology to prepare solution-method phenolic aldehyde prepreg. The method includes: performing suction filtration pretreatment on a phenolic resin solution to discharge the solvent in the phenolic resin solution; using a coating machine to evenly coat a high-temperature-resistant plastic film with resin after pretreatment, and thermally drying to form a resin film; covering the upper surface and the lower surface of fiber fabric with the resin film through continuous operations, and performing rolling compaction to obtain the phenolic aldehyde prepreg. The method has the advantages that the phenolic aldehyde prepreg prepared by the method is excellent in comprehensive performance, the resin content and the volatile matter content, lower than 1.5%, of the prepared phenolic aldehyde prepreg are easy to control as compared with those of traditional solution-method prepreg, the viscosity and process operability of the prepared phenolic aldehyde prepreg are equivalent to those of prepreg prepared by a hot-melt method, the whole cloth surface is smooth and flat, fit, free of bubbles and the like, and the prepared prepreg is especially applicable to an automatic discharge machine; in addition, the equipment cost of the used coating machine is 1 / 3-1 / 2 of that of an impregnator used in the hot-melt method, production energy consumption of the method is greatly lower than that of a solution method, high production efficiency is achieved, and accordingly the production cost of the finished product can be lowered evidently.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

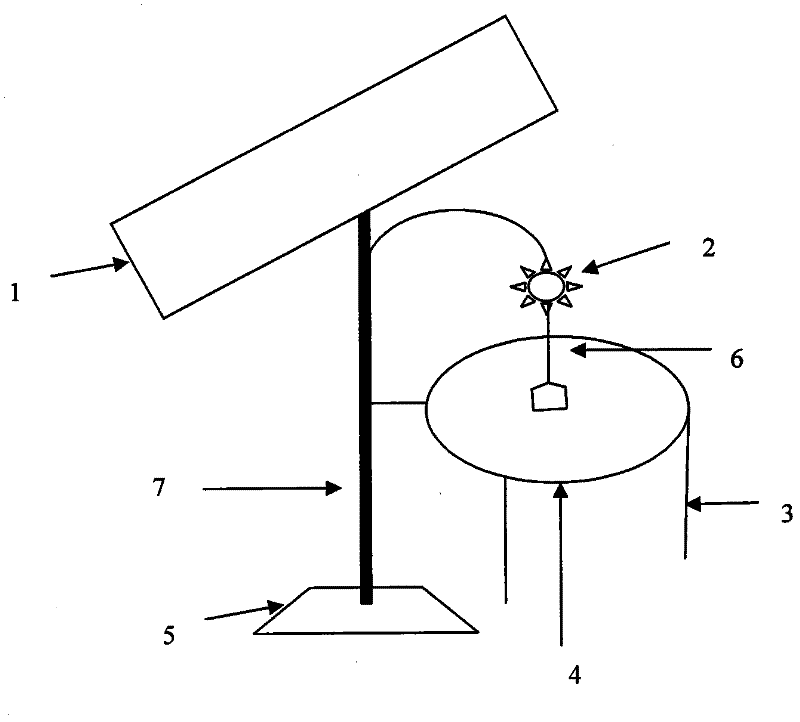

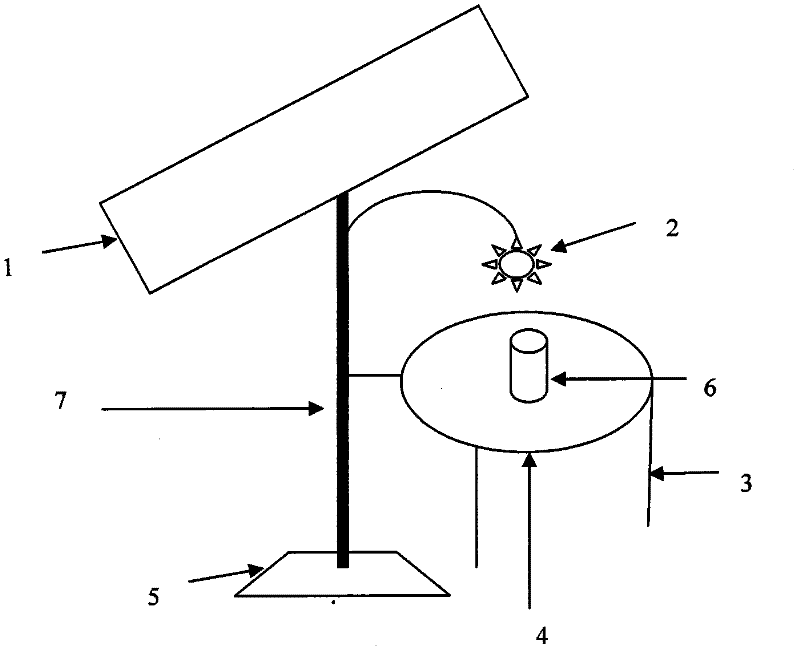

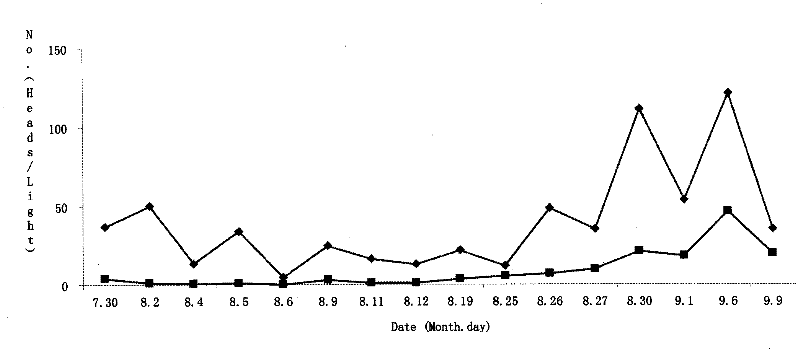

Method for trapping and killing pests by integrating pest killing lamp and attractant

InactiveCN102388848AExpand the range of speciesHigh trapping rateInsect catchers and killersOrganic farmingTrapping

The invention relates to a method for trapping and killing pests by integrating a pest killing lamp and an attractant. In the method, the pest killing lamp (solar or frequency-vibration pest killing lamp and the like) and the attractant (sex pheromone, sweet and sour liquid and other inducing substances) are integrated for trapping and killing pests; the trapping and killing with light is organically combined with the trapping and killing with smell and sex hormone; and the pests are trapped and killed through the mutual effect between the phototaxis and chemotaxis of the pests. According to the invention, multiple types of pests can be effectively attracted to monitor the occurrence rule of the pests, the attraction rate is improved, and the range of attracted types is widened; the method can be used as a physical prevention means to control the damage caused by the pests; pesticide is not used, and the use amount of pesticide in the comprehensive prevention and control of pests is reduced, thereby being environmentally-friendly; and therefore, the method provides technological support for rapidly developing organic agriculture in future.

Owner:XINJIANG AGRI UNIV

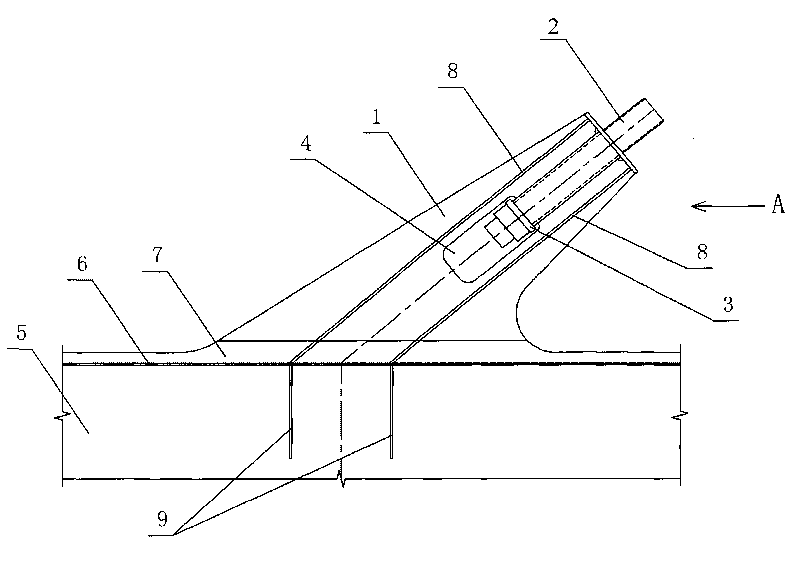

Anchor drawplate type cable-beam anchorage structure for cable-stayed bridge

InactiveCN101713166ASolve the problem of low fatigue strengthImprove fatigue strengthCable-stayed bridgeBridge structural detailsCable stayedUltimate tensile strength

The invention discloses an anchor drawplate type cable-beam anchorage structure for a cable-stayed bridge, which comprises a main steel beam and an anchor drawplate component, wherein the anchor drawplate component is arranged on the top surface of the main steel beam; the anchor drawplate component comprises an anchor drawplate, an anchor pipe and an anchor backing plate, wherein the anchor pipe is used for penetrating a stayed-cable; the anchor backing plate is arranged at the bottom of the anchor pipe and installed vertically to the anchor pipe; a counter bore-shaped groove is arranged in the top center position of the anchor drawplate along a central axis direction; the anchor pipe is installed at the upper part of the groove; a through hole corresponding to a pipe orifice of the anchor pipe is arranged on the anchor backing plate; a stayed-cable anchor head connected with a stayed-cable end head is installed at the lower part of the groove; a longitudinal web plate of the main steel beam extends upwards; an extending section on the longitudinal web plate corresponding to the bottom edge of the anchor drawplate protrudes out of a top plate of the main steel beam to form an outer web plate; and the bottom edge of the anchor drawplate is connected with the edge of the upper end of the outer web plate. The invention uses a connection structure of the outer web plate and the anchor drawplate and solves the problem of low fatigue strength of a cross welding structure; the top plate of the main steel beam is not required to have a Z-direction tear resisting characteristic, thus the material purchase and inspection charges are notably reduced and the structure stress is safer and more reliable.

Owner:GUANGDONG PROVINCE COMM PLANNING & DESIGN INST

Self-assembled layers composite membrane and preparation and application thereof

ActiveCN104143613AHigh selectivityAchieving pore size distribution controlSynthetic resin layered productsCell component detailsPolymer resinPorous membrane

The invention relates to a self-assembled layers composite membrane. According to preparation of the composite membrane, a porous membrane prepared by using one or more than two of organic polymer resins or sulfonated organic polymer resins as raw materials is used as a matrix; the matrix undergoes swelling by the use of a swelling agent; and the cationic and anion polymer resins are self-assembled through electrostatic attraction on the surface of the matrix and are successively alternately arranged so as to prepare the self-assembled layers composite membrane. The number of the self-assembled layers is 1-60, and each self-assembled layer is composed of a single-layer cationic resin assembly layer or a single-layer anion resin assembly layer. In comparison with an original porous membrane, the composite membrane has advantages as follows: on the basis of maintaining ionic conductivity of the porous membrane, selectivity of hydrogen ion and vanadium ion is raised; and a battery assembled by the use of the composite membrane has higher efficiency.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

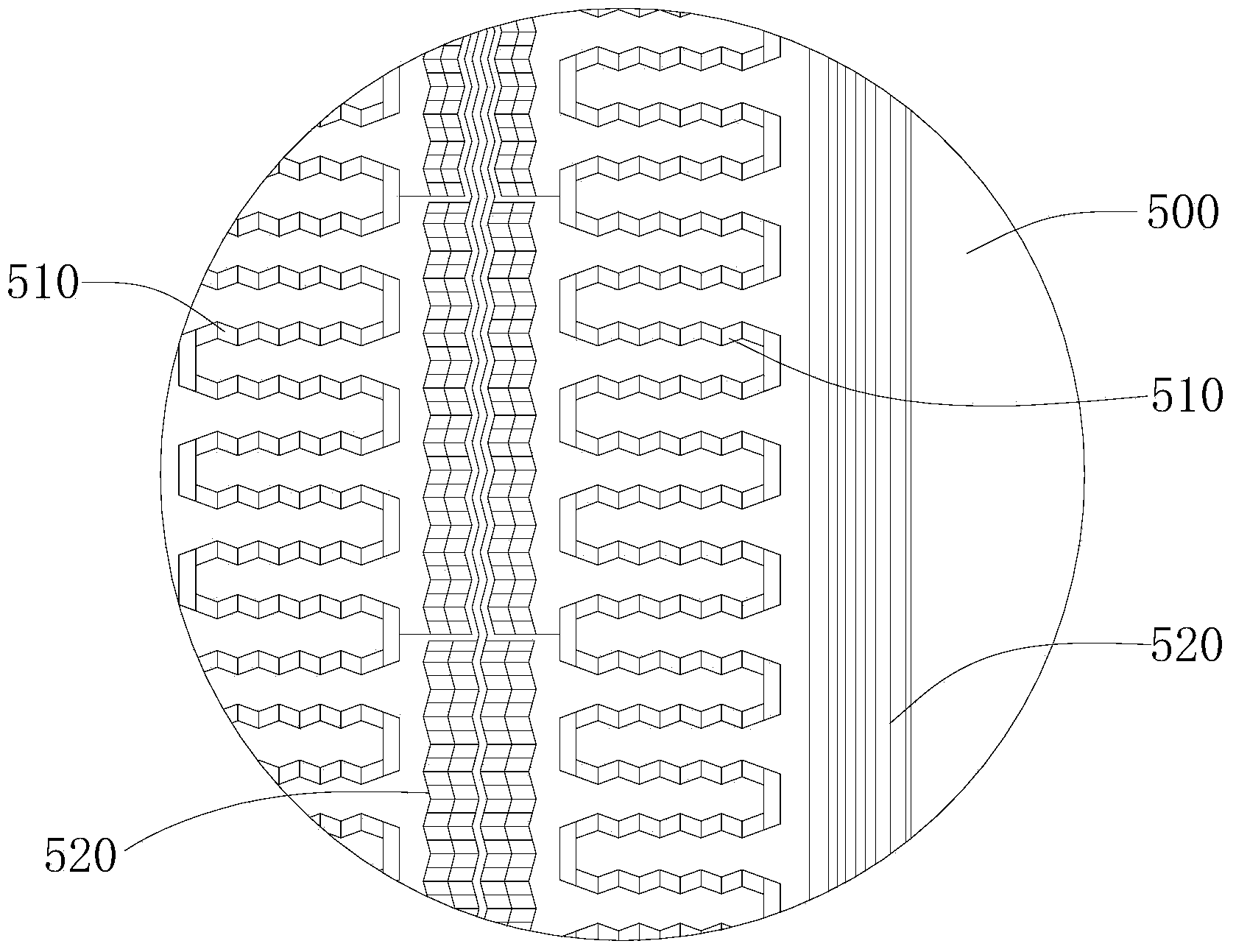

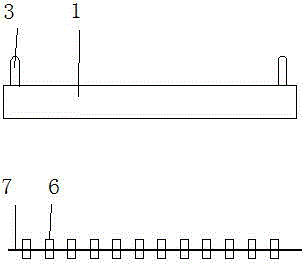

Electronic equipment and manufacturing method for single-layered multipoint capacitive touch screen and touch layer

InactiveCN103761017AImprove accuracyExpand the range of speciesInput/output processes for data processingEngineeringTouchscreen

The invention discloses electronic equipment and a manufacturing method for a single-layered multipoint capacitive touch screen and a touch layer thereof. The single-layered multipoint capacitive touch screen comprises a panel and a screen module, wherein a transparent optical adhesive layer is arranged between the panel and the screen module; a BM (basement membrane) frame layer is arranged on the frame of the panel; the screen module comprises an upper polaroid, an upper glass substrate, a lower glass substrate, a lower polaroid and a backlight plate which are sequentially arranged in a stacked manner from top to bottom and are adhered to one another; a metal conductive ink circuit layer is arranged between the panel and the screen module or in the screen module and comprises a plurality of touch units which are arranged in parallel; and each touch unit is independently provided with a lead connected with a processor. The single-layered multipoint capacitive touch screen is sensitive in touch, high in accuracy and wide in application range; the manufacturing method for the touch layer of the single-layered multipoint capacitive touch screen is simple; the touch layer is low in cost, and is energy-saving and environment-friendly; and the using convenience and the reliability of the electronic equipment with the touch screen are improved.

Owner:SHENZHEN SUCCESS ELECTRONICS LTD

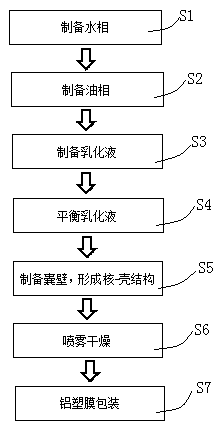

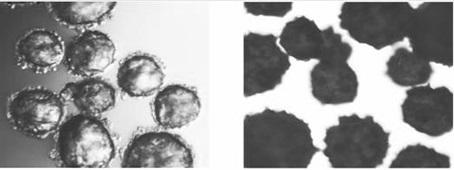

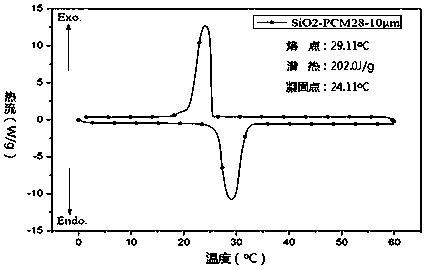

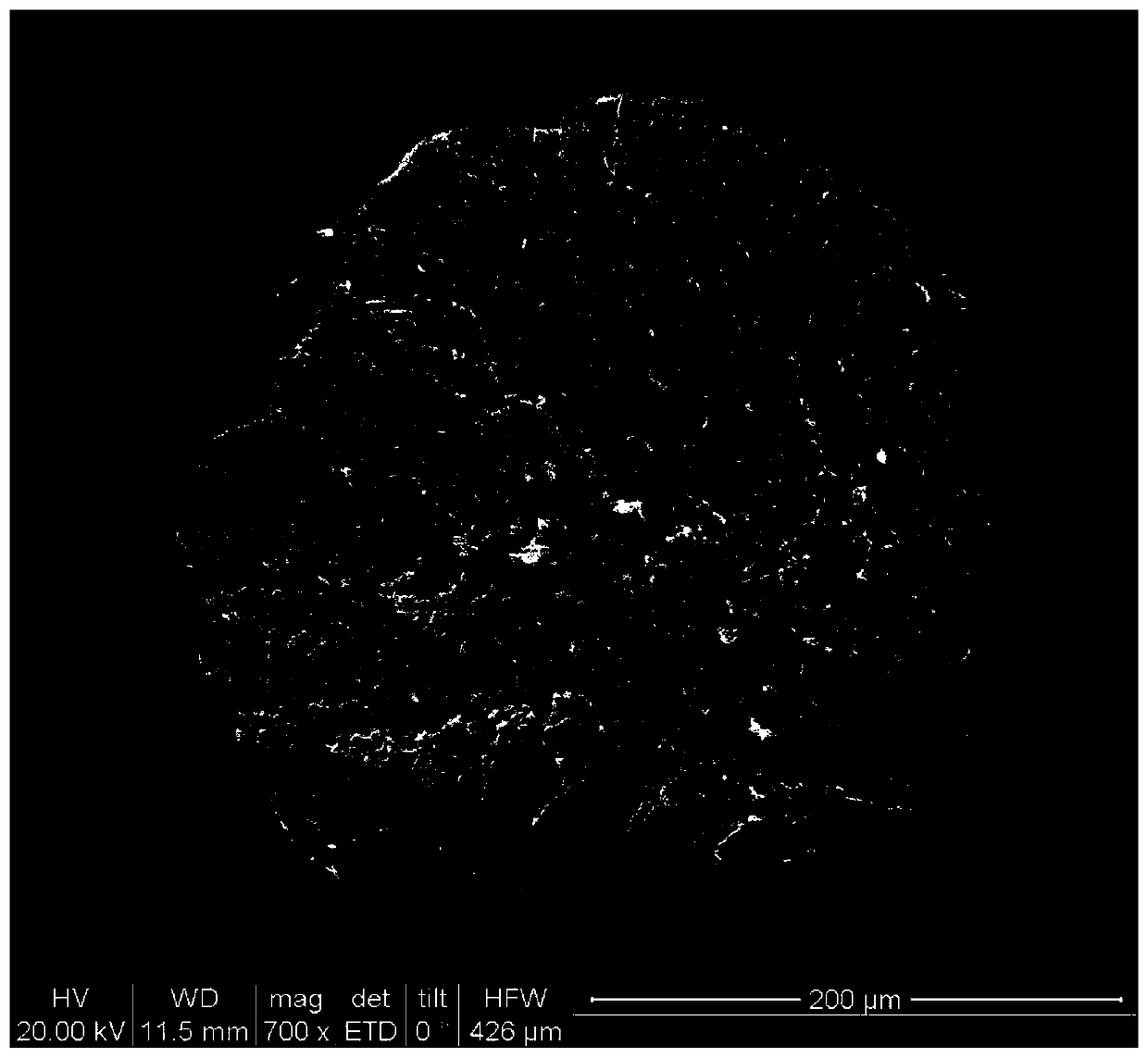

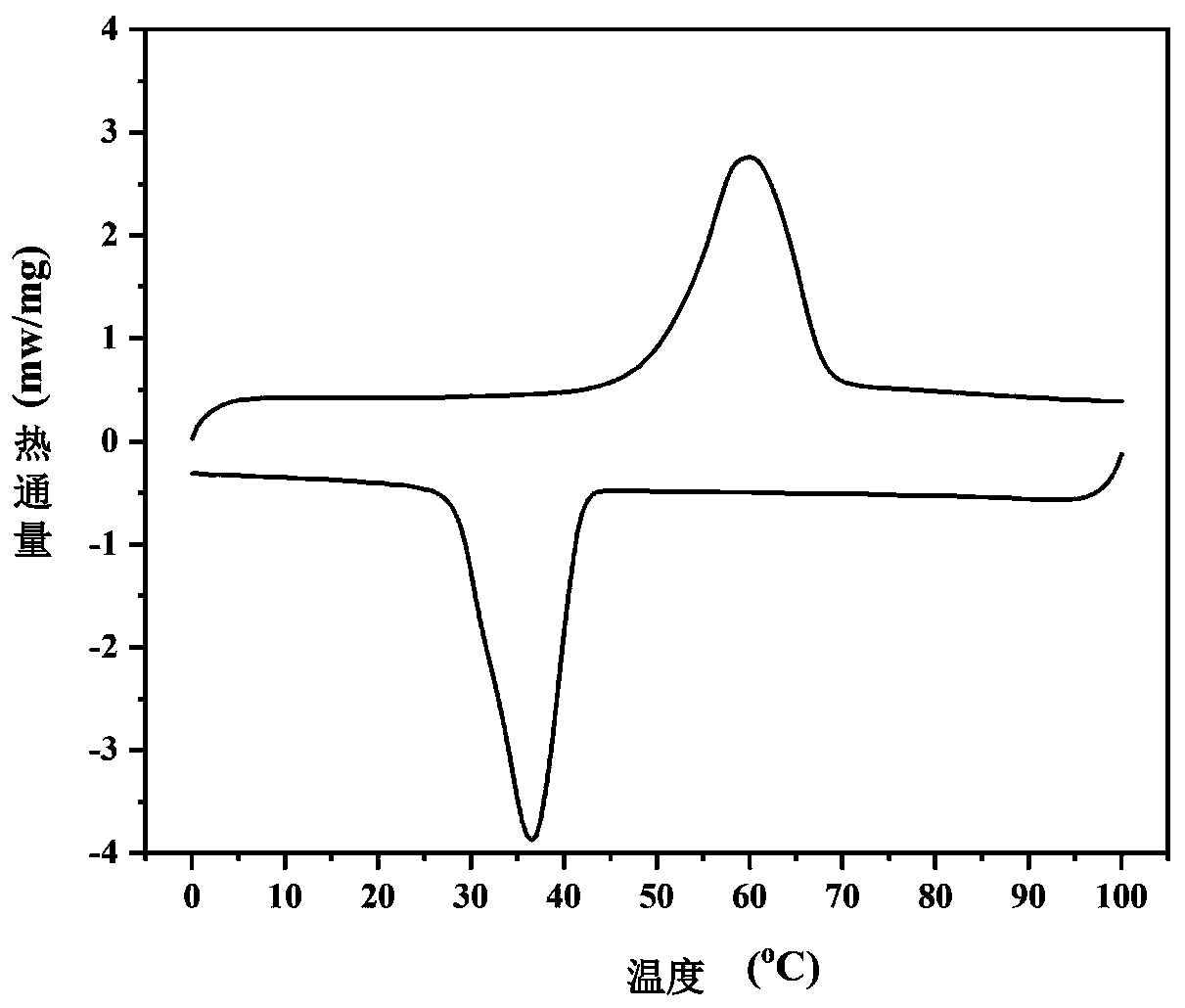

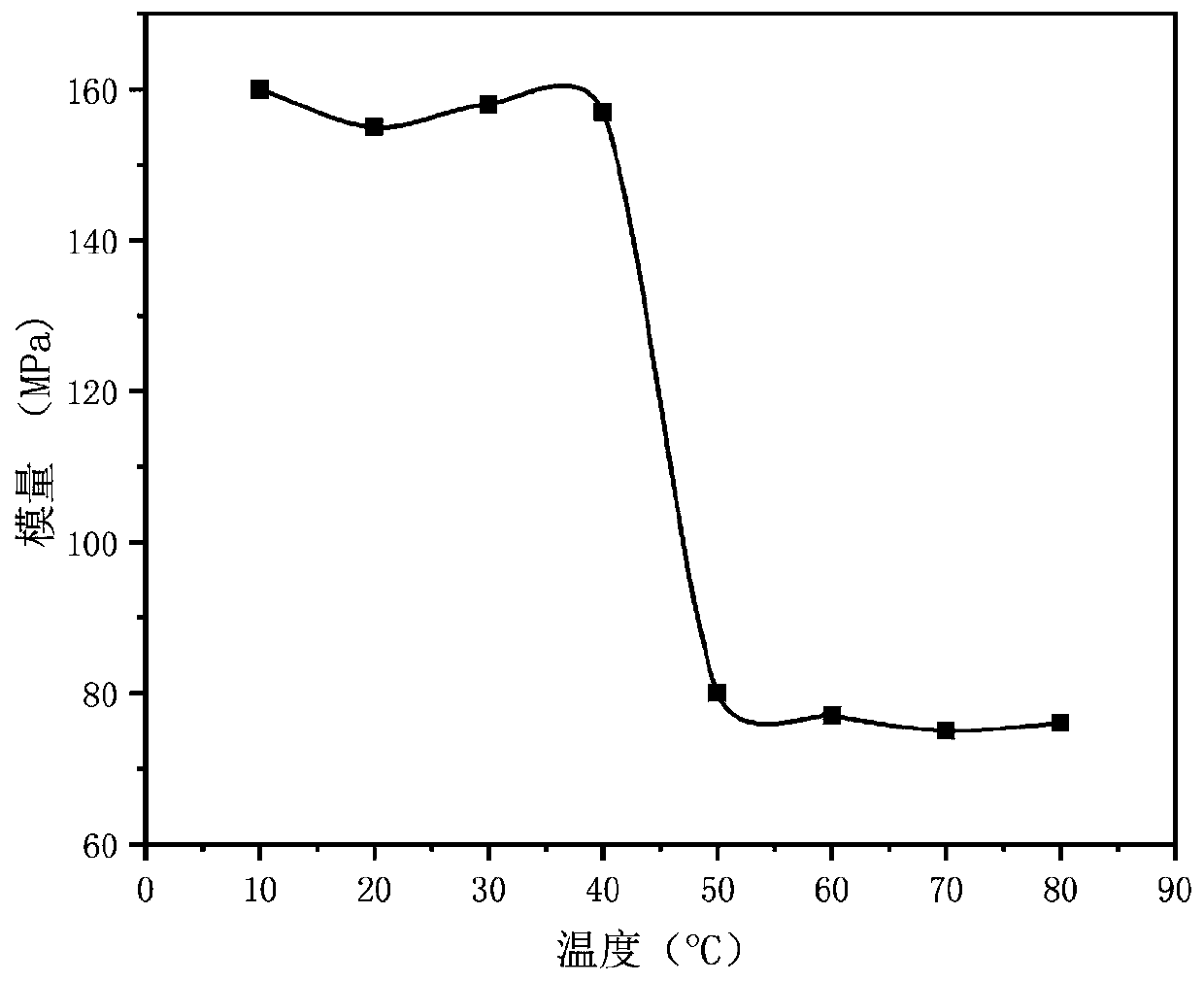

Organic phase change microcapsule, organic phase change microcapsule composite heat dissipation material and preparation method thereof

InactiveCN111518517AHigh thermal conductivityPrevent leakageHeat-exchange elementsPhase change enthalpyParaffin wax

Firstly, the invention provides an organic phase change microcapsule. The phase change microcapsule has a core-shell structure, the core is a capsule core, and the capsule core comprises one or more components of paraffin, n-octadecane and n-tetradecane; the shell is a capsule wall and comprises a silicon dioxide component; the particle size of the phase change microcapsule is 100-200 [mu] m, thephase change enthalpy is 120-200 KJ / Kg, and the phase change temperature is 29-40 DEG C. Secondly, the invention provides an organic phase change microcapsule composite heat dissipation material whichcomprises an aluminum plastic film and the organic phase change microcapsule, and the organic phase change microcapsule is coated with the aluminum plastic film so that the unstable capsule core material can be protected from being eroded by the external environment. Finally, the invention provides a preparation method of the organic phase change microcapsule composite heat dissipation material.The preparation method sequentially comprises the following steps: preparing a water phase, preparing an oil phase, preparing an emulsion, preparing a capsule wall, carrying out spray drying, packaging with the aluminum plastic film and the like, and has the advantages of simplicity and rapidness in operation and suitability for industrial production.

Owner:惠州德赛信息科技有限公司 +1

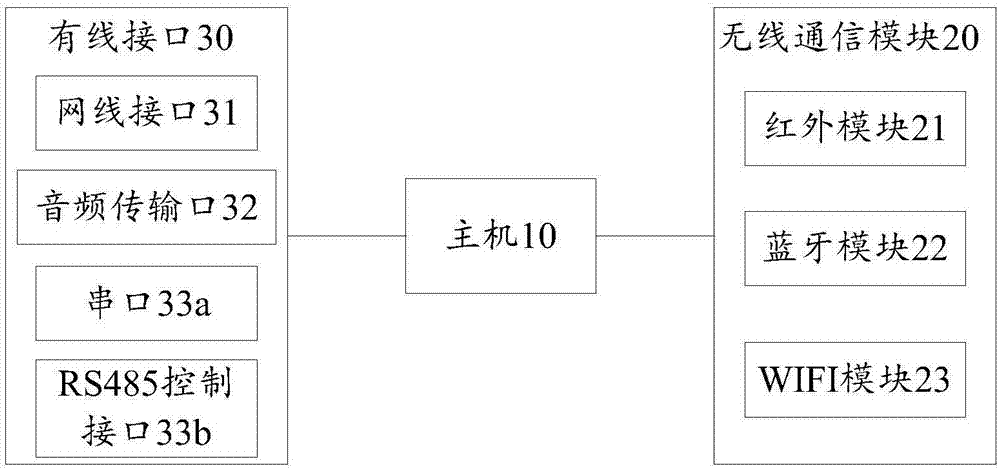

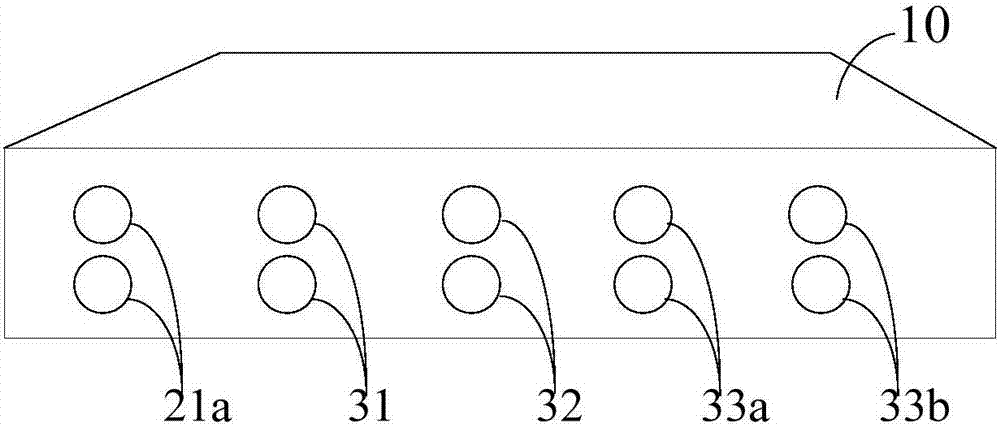

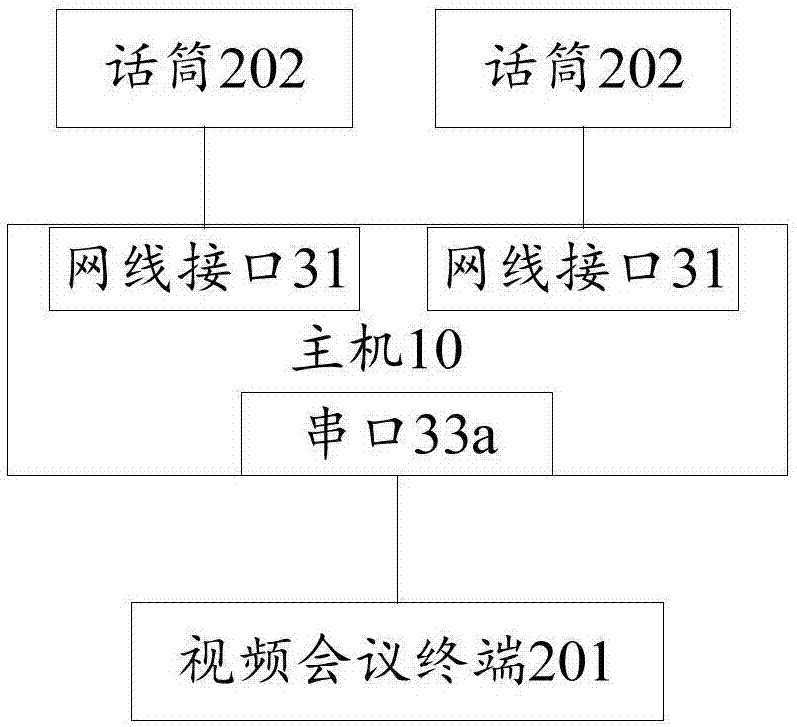

Audio and video linkage control device and audio and video linkage system

ActiveCN107580192AExpand the range of speciesImprove experienceTelevision system detailsTelevision conference systemsSERCOS interfaceComputer module

The invention provides an audio and video linkage control device and an audio and video linkage system, relating to the field of audio and video control equipment technology. The audio and video linkage control device comprises a host, and a wireless communication module and wired interfaces arranged on the host, wherein each wired interface includes a network cable interface, an audio transmission port and a data transmission port, and multiple wired interfaces are arranged; the wireless communication module comprises one or more of an infrared module, a Bluetooth module and a WIFI module; and the data transmission port includes a serial port and / or an RS485 control interface. According to the audio and video linkage control device and the audio and video linkage system, the host can be connected with external equipment through various types of interfaces, the connection mode is more flexible, and thus each external equipment can cooperatively work under the control of the host, the labor cost can be effectively saved, and the user experience can be improved.

Owner:上海启诺信息科技有限公司

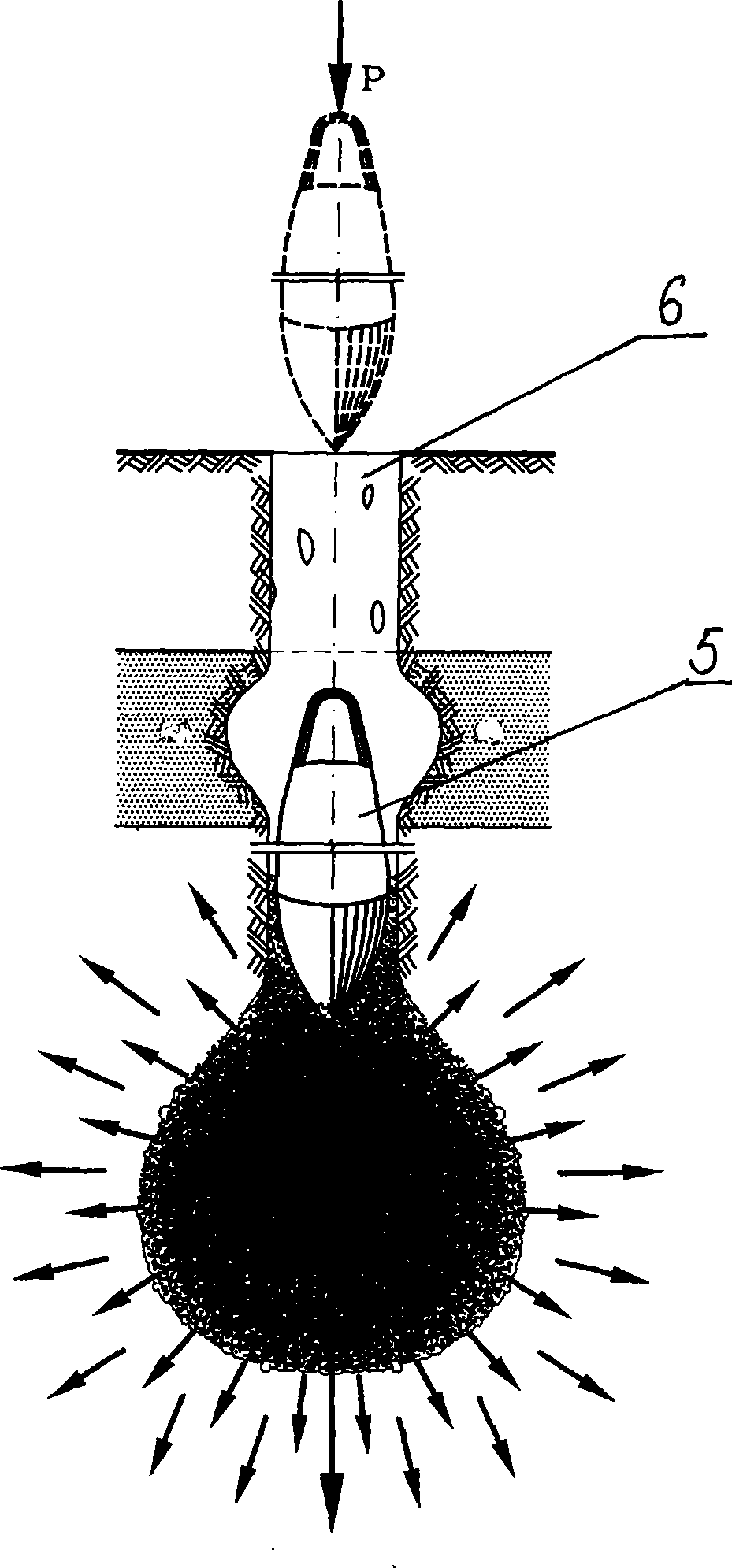

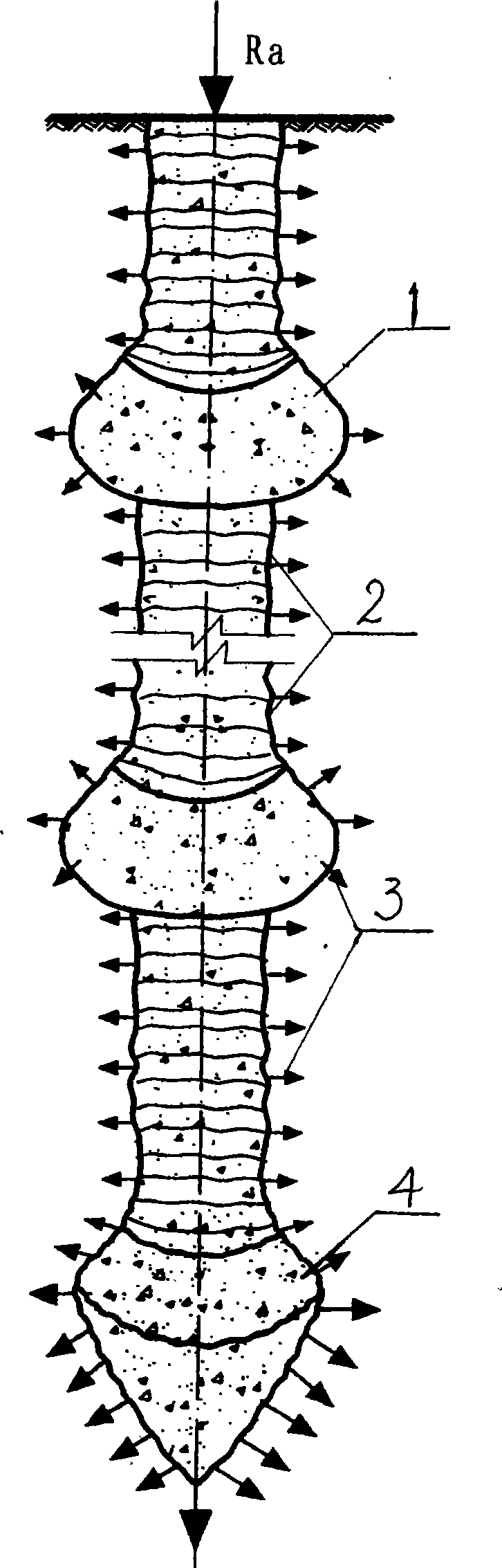

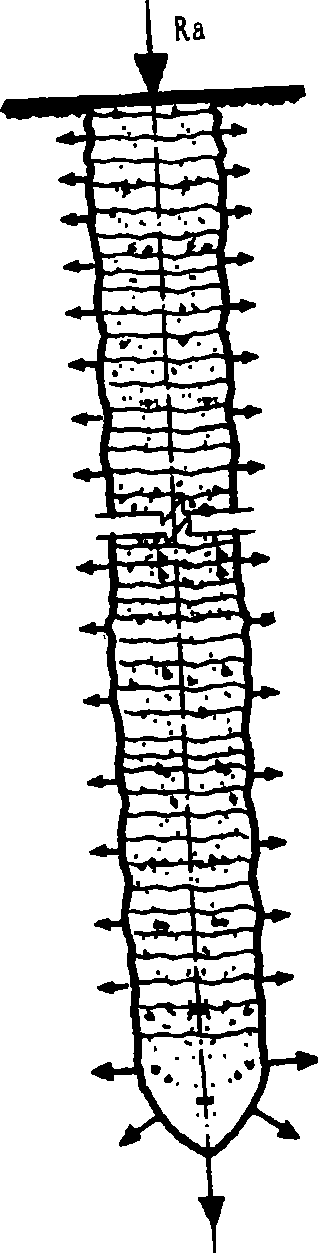

Five in one pre-expansion ecological pile body processing foundation method

The invention relates to a five-in-one pre-expanding ecological pile treating foundation method suitable for foundation, foundation collapse, gold ore dressing and construction application of environment-friendly field. The method comprises: after the foundation is drilled with holes, filling the holes, injecting hammer blocks into the holes, carrying out five-in-one power consolidation of vertically and transversely pre-expanding, extruding, transmitting and propelling by super-pressure kinetic energy through impacting, smashing, extruding, pressing and chopping; then filling the holes repeatedly and carrying out forced ramming and piling consolidation of vertically and transversely pre-expanding, extruding, transmitting and propelling for the super-pressure kinetic energy hammer blocks through impacting, smashing, extruding, pressing and chopping; and finally manufacturing a deep foundation of a composite foundation of a pre-expanding ecological pile with high bearing capacity, a specific pile foundation and the pre-expanding ecological pile. The method is advanced, has low construction cost, effectively solves problems of various thick difficult foundations, can eliminate pollution of pollutant to environment, and make human live on the foundation of firmness, safety and free pollution.

Owner:司炳文 +2

Soil-less culture tray for allium ascalonicum

InactiveCN105660343AAchieve soilless cultivationExpand the range of speciesAgriculture gas emission reductionCultivating equipmentsAllium ascalonicumWater jet

The invention discloses a soil-less culture tray for allium ascalonicum. The soil-less culture tray comprises a culture tray and a culture frame, wherein sponge is placed at the bottom of the culture tray, locating sticks are respectively arranged at four corners of the culture tray, the culture frame is provided with locating holes, water jets and culture tubes, the locating holes are formed in four corners of the culture frame and are in fit with the locating sticks, the water jets are located in two narrow sides of the culture frame and are trapezoidal, the culture frame may be of different types, including culture tubes of different pore sizes, different spacing and different tube length, and the culture tray can also be used for planting leafy vegetable plants such as fragrant-flowered garlic and Apium graveolens. The soil-less culture tray has the beneficial effects that the soil-less culture tray for the allium ascalonicum, disclosed by the invention, achieves the soil-less culture of the allium ascalonicum in a balcony or indoors and is applicable to the planting of the plants such as the fragrant-flowered garlic and the Apium graveolens.

Owner:CHENGDU CHUANGWEIKAI TECH INFORMAITON CONSULTING CO LTD

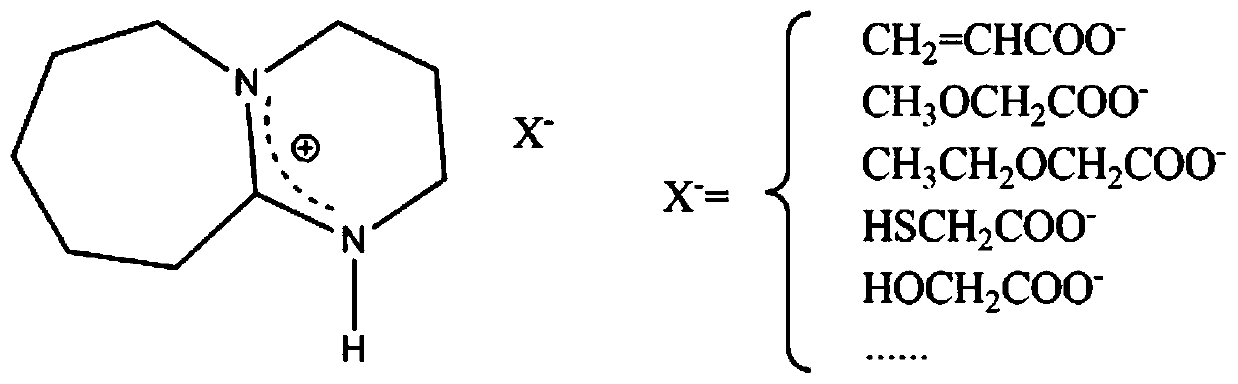

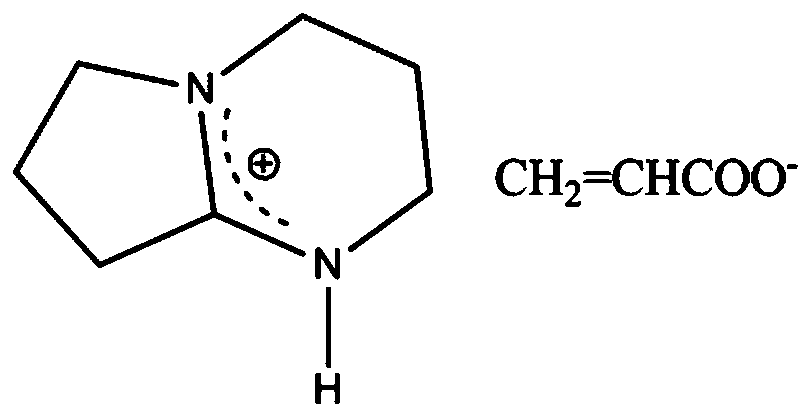

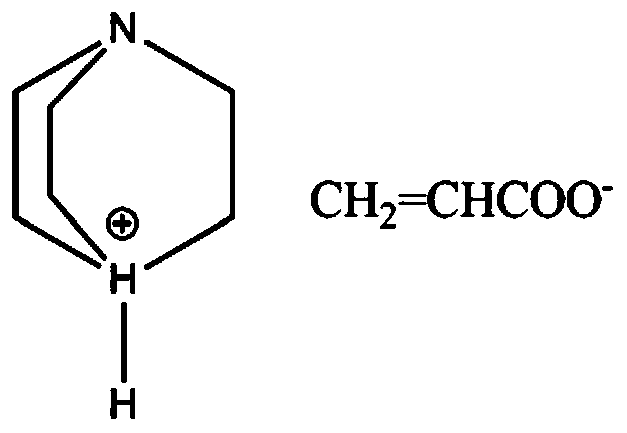

Cellulose solvent, and preparation method and application thereof

ActiveCN110256698AShorten the range of speciesShorten the scope of useBulk chemical productionCelluloseSolubility

The invention relates to a cellulose solvent, and a preparation method and application thereof. The preparation method for the cellulose solvent comprises the following steps of: mixing an organic base having a heterobicycle in its chemical structure with an organic solvent, placing the formed mixture in a three-necked flask, introducing nitrogen, dropwise adding an acidic reagent to a reaction system under magnetic stirring, and allowing a temperature to be kept at 30 DEG C or below in the whole reaction process so as to obtain a transparent mixture; continuing stirring the mixture at room temperature to realize full reaction of the mixture, allowing non-imidazole ionic liquid to be precipitated from an organic phase, and carrying out separation to obtain the non-imidazole ionic liquid; and heating the non-imidazole ionic liquid under the protection of an inert gas so as to obtain the dried cellulose solvent. According to the invention, the dissolution effect of cellulose in the relatively-inexpensive non-imidazole ionic liquid is improved through the preparation and utilization of the non-imidazole ionic liquid cellulose solvent; and in particular, the maximum solubility of cellulose is increased, the dissolution time of cellulose is shortened, and the degradation rate of cellulose is remarkablely reduced.

Owner:BEIJING FORESTRY UNIVERSITY

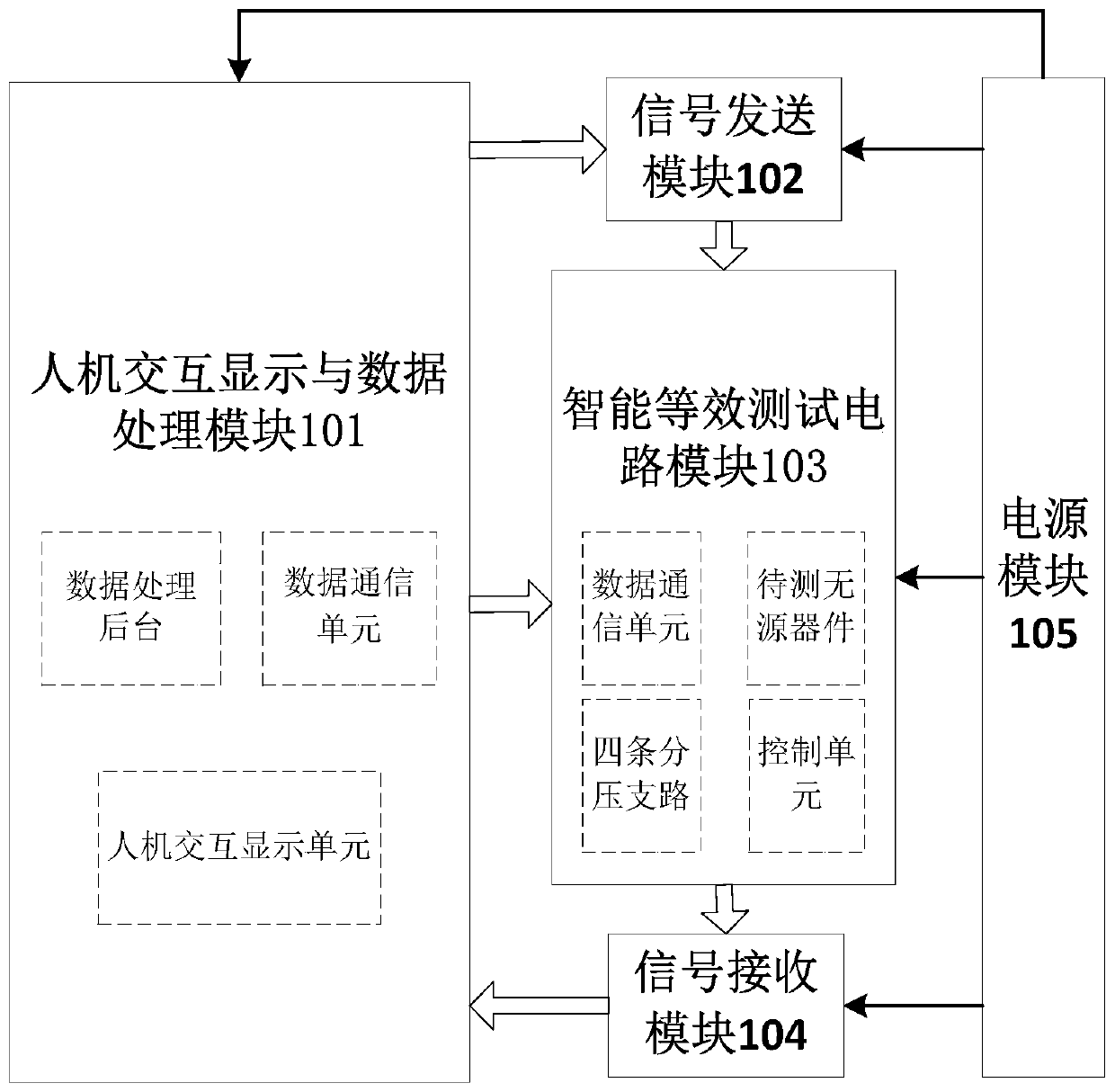

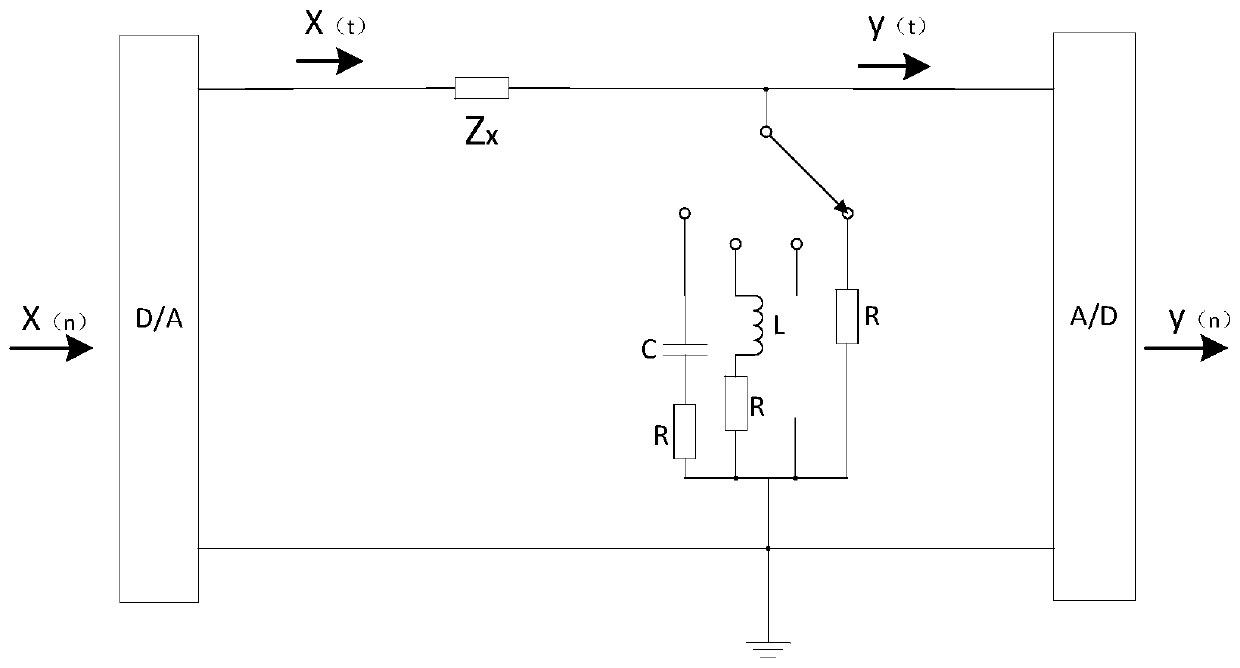

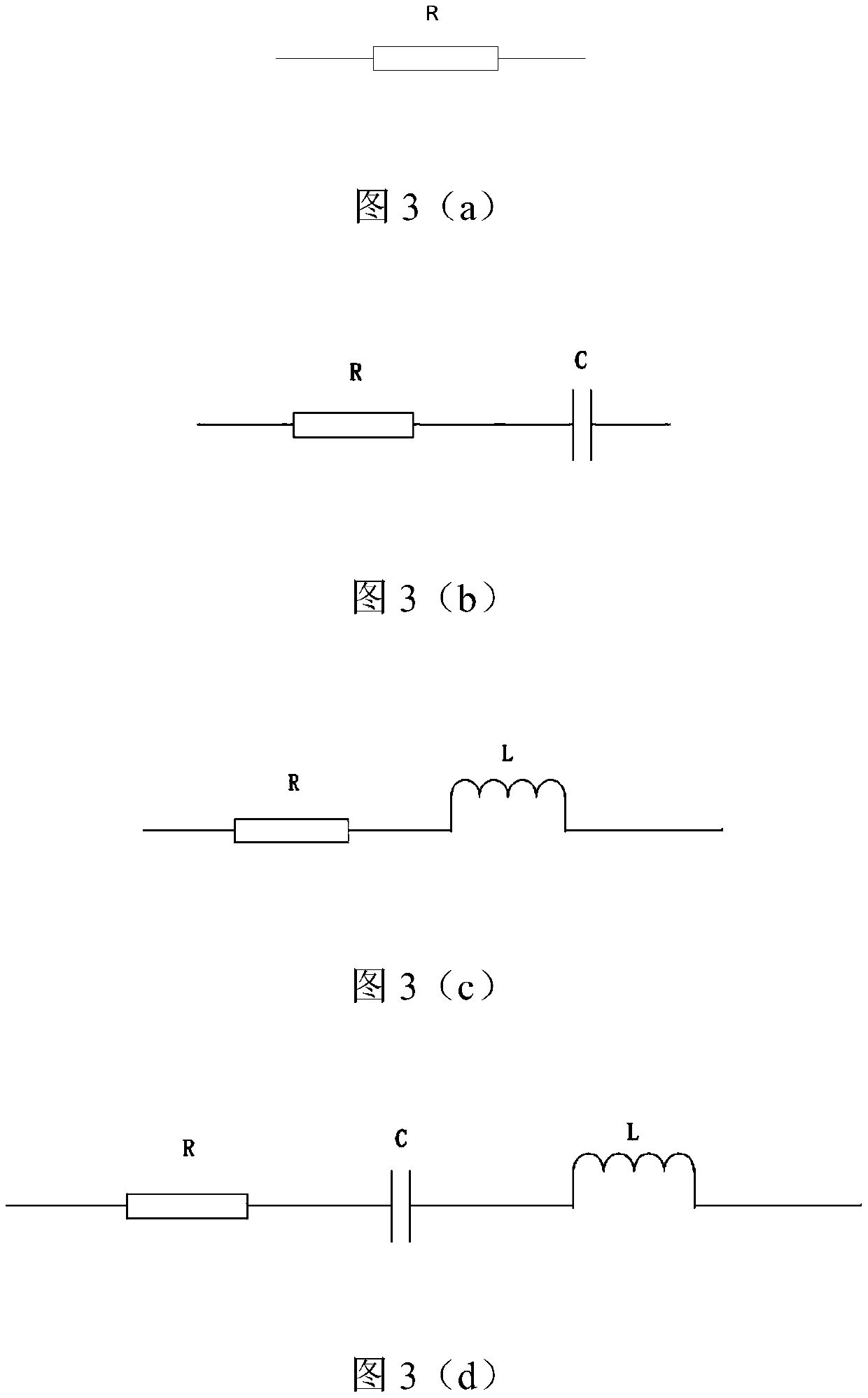

Passive device intelligent equivalent circuit model and parameter measuring device and working method

ActiveCN110542793ARealize intelligent divisionSwitch smartCapacitance measurementsFrequency bandRecognition algorithm

The invention discloses a passive device intelligent equivalent circuit model and parameter measuring device and a working method. The device comprises a man-machine interaction display and data processing module, a signal sending module, an intelligent equivalent test circuit module, a signal receiving module and a power supply module. The method is characterized by connecting a passive device inseries to an intelligent equivalent test circuit module through a lead wire and measuring initial frequency response; intelligently dividing the whole frequency band into a plurality of segmented frequencies by utilizing a mode recognition algorithm; intelligently selecting an optimal test circuit and an optimal equivalent circuit model for each segmented frequency; and finally, through an intelligent equivalent computing method, obtaining an optimal RLC equivalent circuit model of the passive device under different frequency bands and element parameters thereof and displaying the element parameters in a segmented frequency band manner. The device disclosed by the invention is relatively simple in circuit; the measurement result is intelligently and equivalently calculated in different frequency bands; and the device is high in speed, wide in application range, high in precision and higher in practical application value.

Owner:SOUTH CHINA UNIV OF TECH

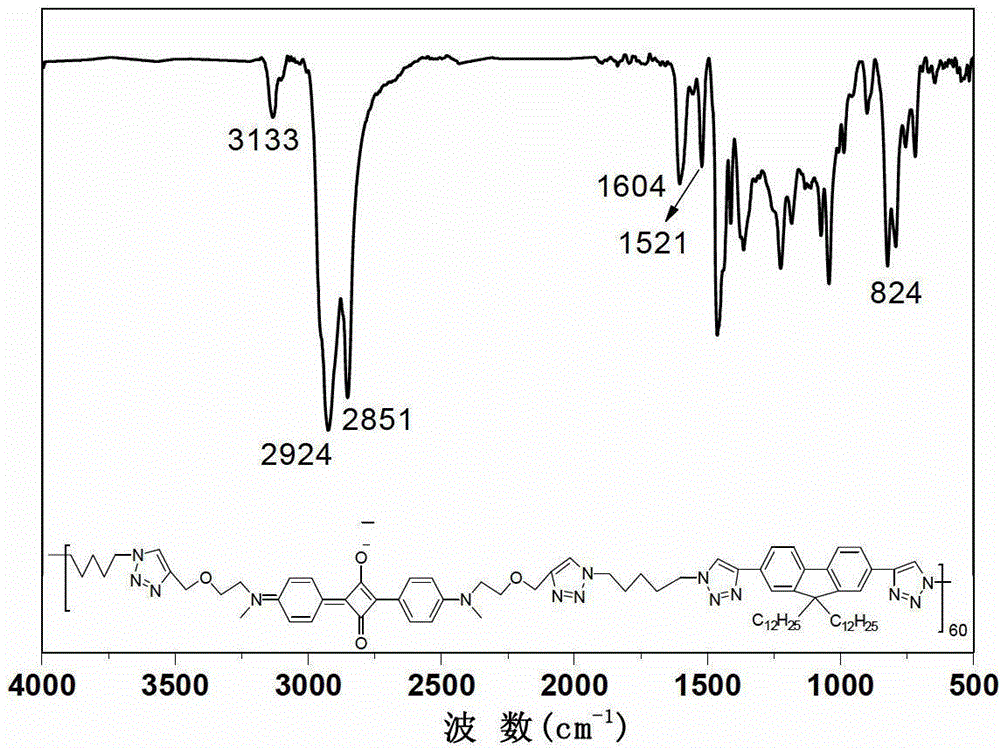

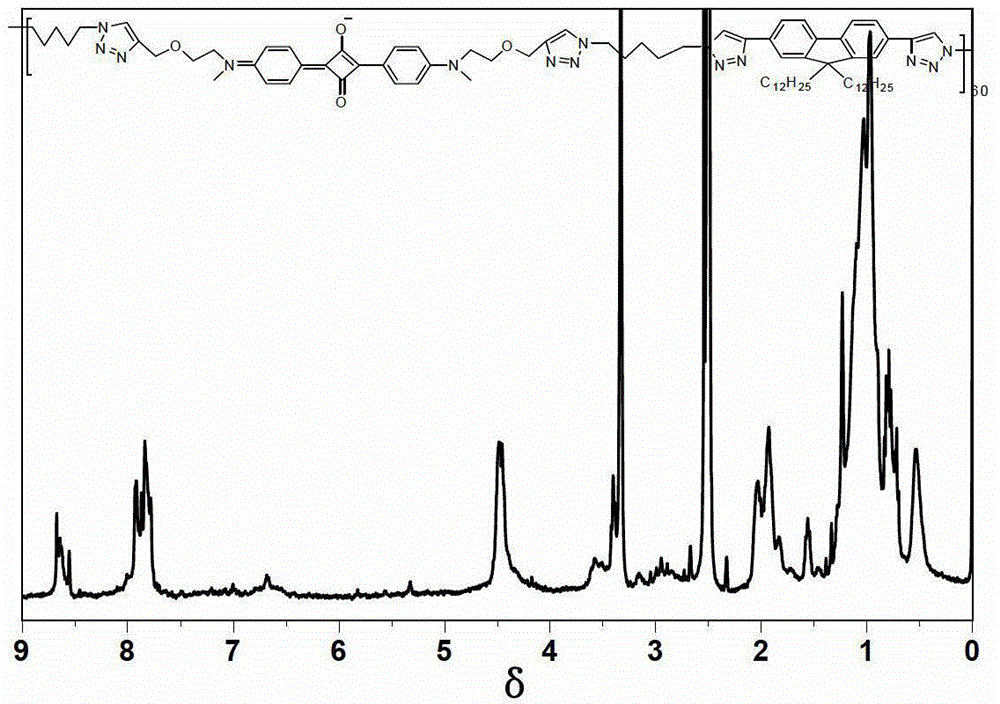

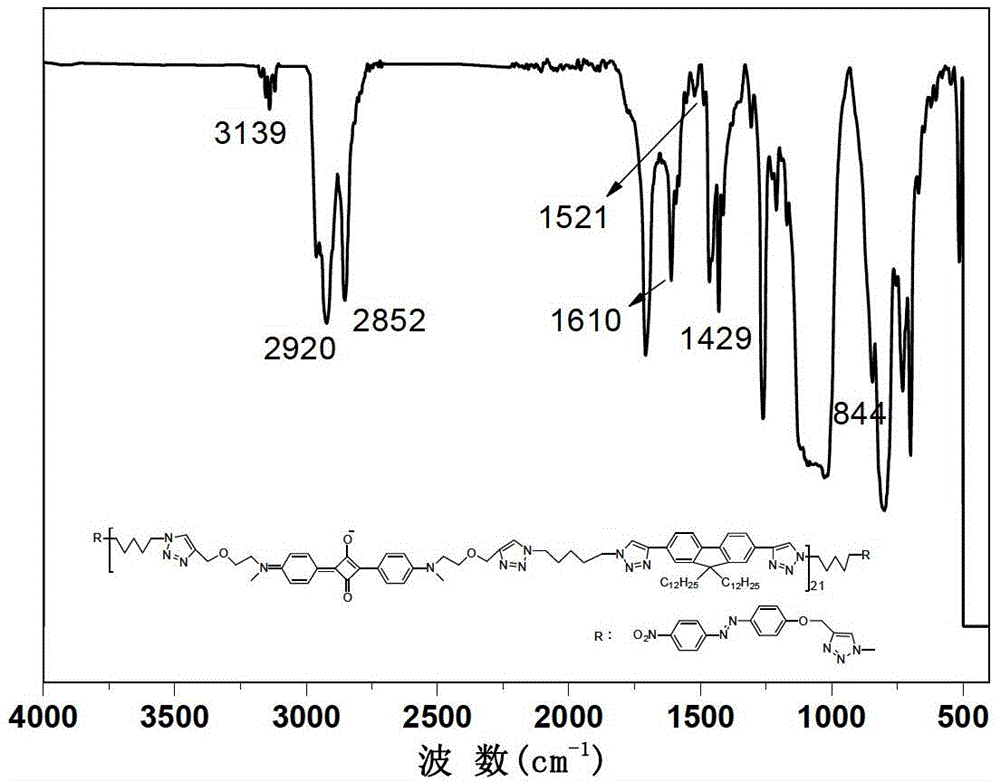

Squaraine polytriazole with near-infrared optic absorption, and preparation method thereof

The invention relates to a squaraine polytriazole with near-infrared optic absorption, and a preparation method thereof. The squaraine polytriazole is polytriazole which is prepared from at least two different diacetylene monomers and diazido monomers through click reaction; the preparation method comprises the steps of: in nitrogen atmosphere, adding the at least two diacetylene monomers and diazido monomers into a mixed system containing a catalyst, a ligand and an organic solvent, performing polymerization reaction for 24-48h at 40-45 DEG C, filtering, washing and vacuum-drying after the reaction is finished, thereby obtaining the squaraine polytriazole. The materials for preparation have good dissolubility, stronger optic absorption property of near-infrared regions and excellent thermal stability, and the temperature range of 5% of thermal weight loss ranges from 300 DEG C to 400 DEG C; by adopting click chemistry, the preparation method is simple and easy to operate, is not required for catalysis of heavy metal, and is good in economic benefits; and the materials can be applied in the fields of optic-dynamics treatment, data storage, light-emission field effect transistors, solar batteries and the like.

Owner:DONGHUA UNIV

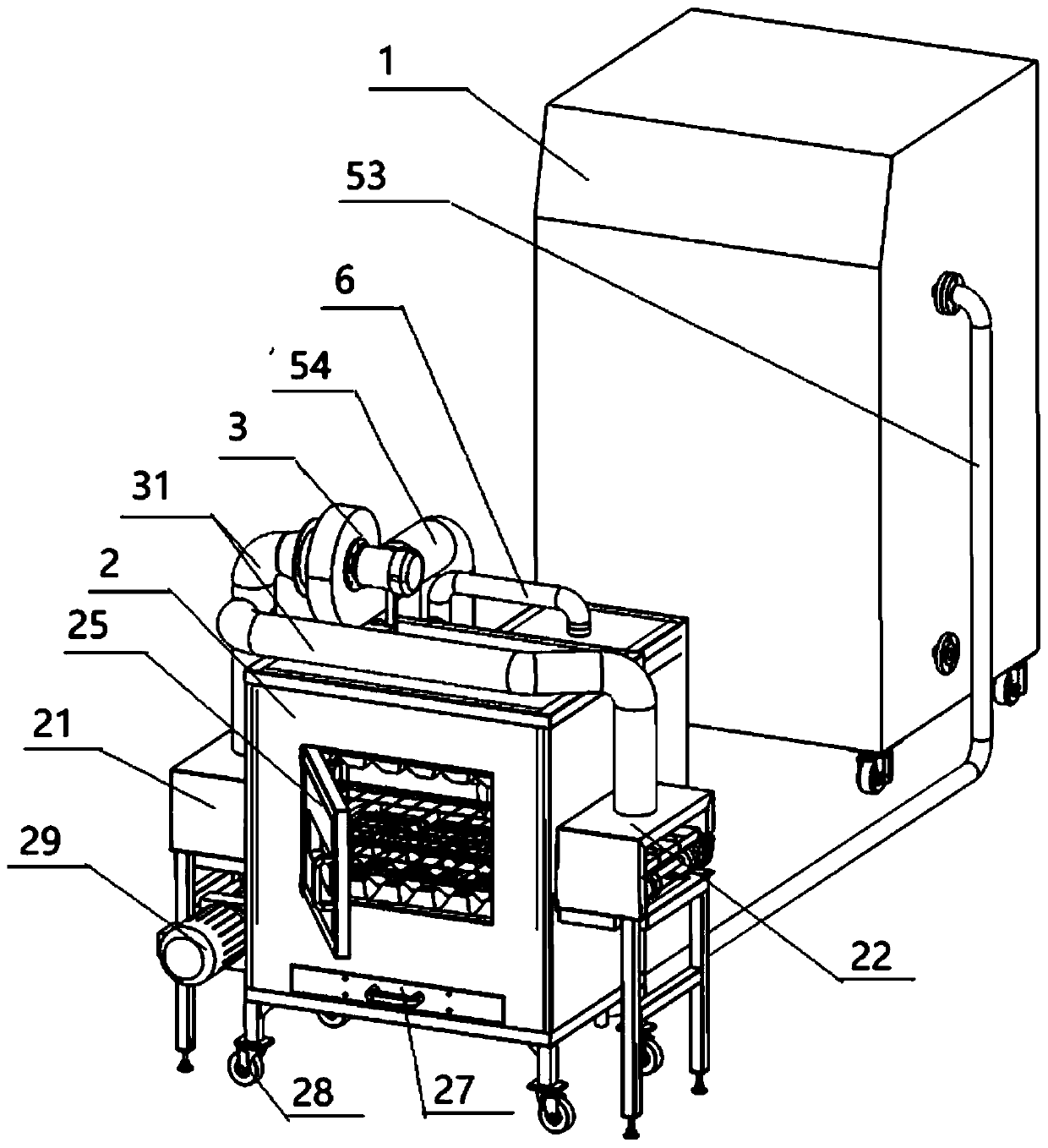

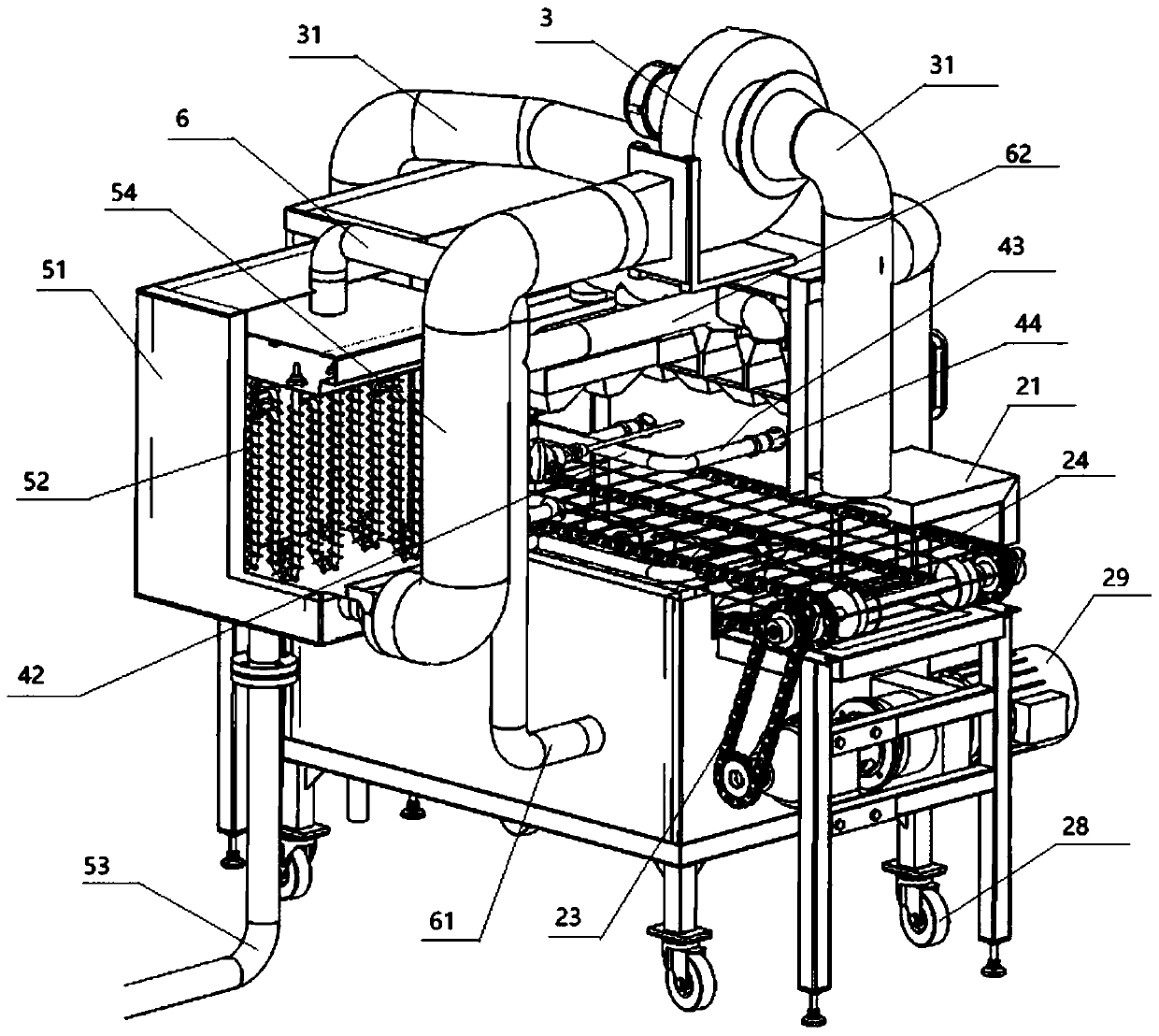

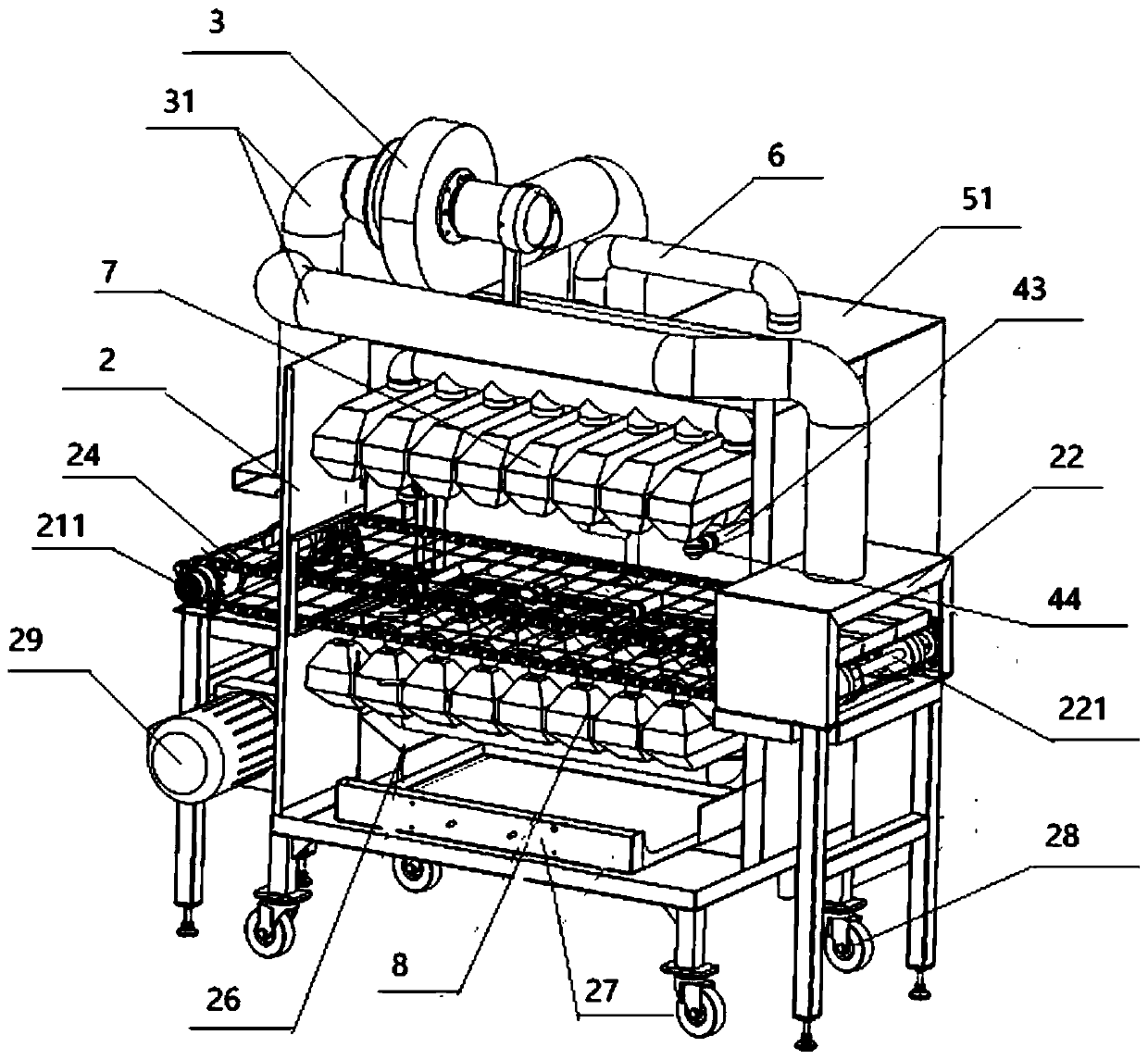

Device for flexibly processing food through superheated steam

The invention discloses a device for flexibly processing food through superheated steam. The device comprises a steam generator, a steaming oven and a cleaning mechanism, wherein the upper portion andthe lower portion of the steaming oven are both communicated with a steam outlet of the steam generator, the middle of the steaming oven is communicated with an air inlet of an exhaust fan, the opposite first side face and second side face of the steaming oven are provided with a feeding port and a discharging port respectively, the cleaning mechanism comprises a water guide pipeline located in the steaming oven, a water inlet pipe for making the water guide pipeline communicated with the outside world, and a high-pressure rotary spraying nozzle rotationally sleeving one end of the water guide pipeline. By arranging the cleaning mechanism capable of rotationally spraying water in the steaming oven, oil stains in the steaming oven can be regularly and automatically cleaned away, and cleaning is convenient and efficient.

Owner:合肥中农科泓智营养健康有限公司

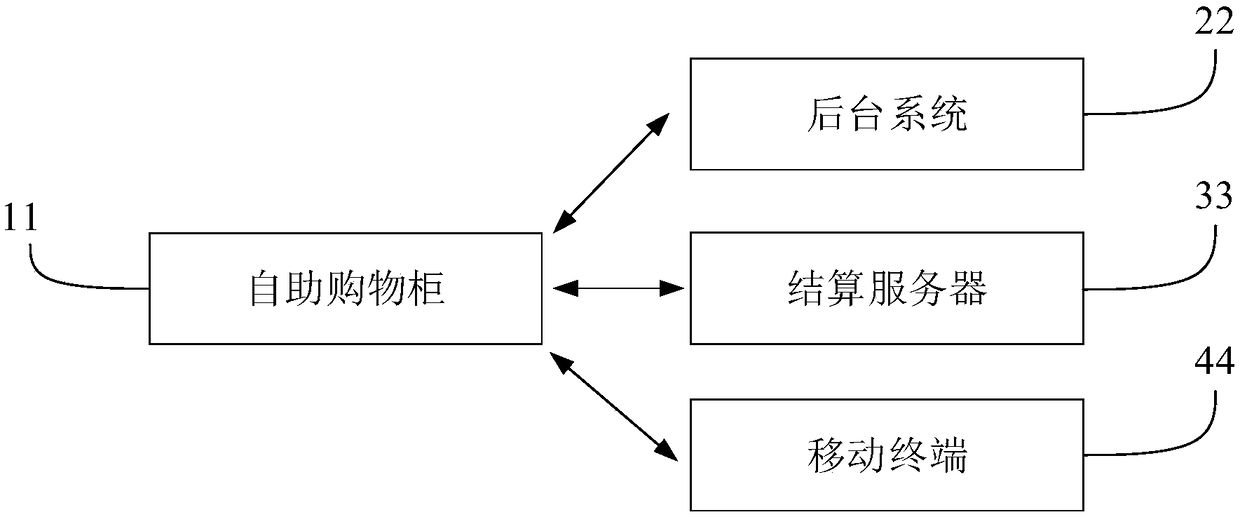

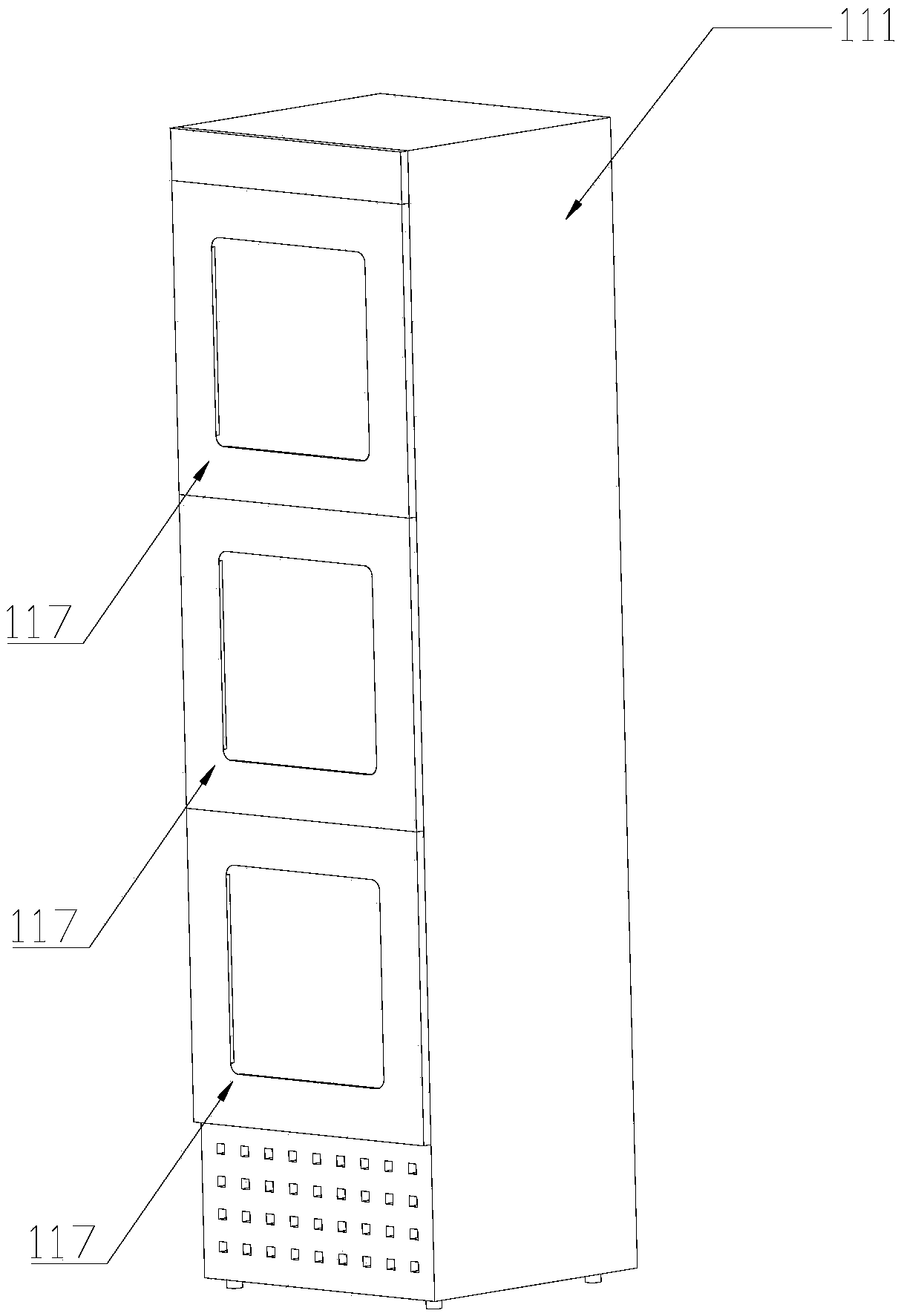

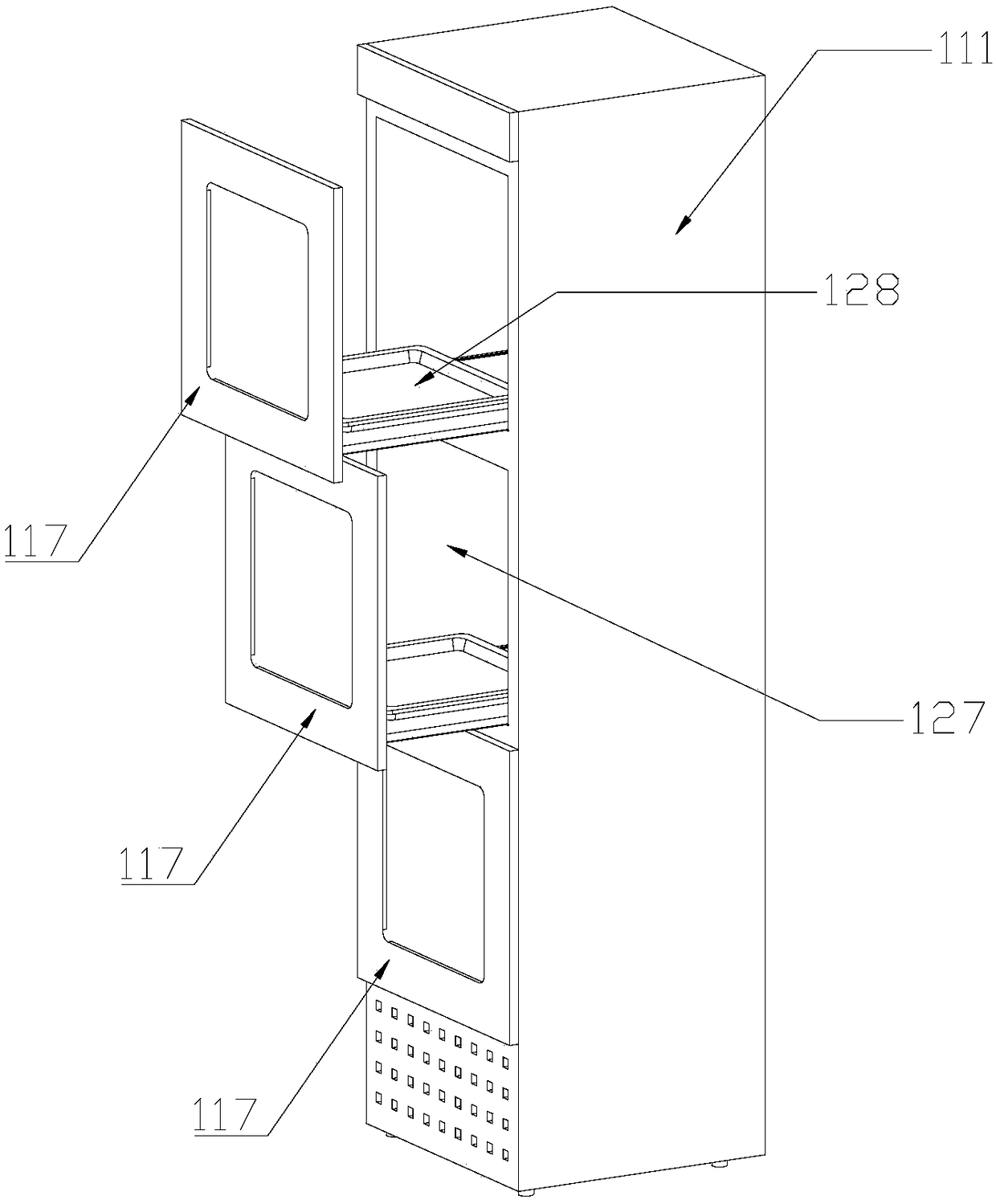

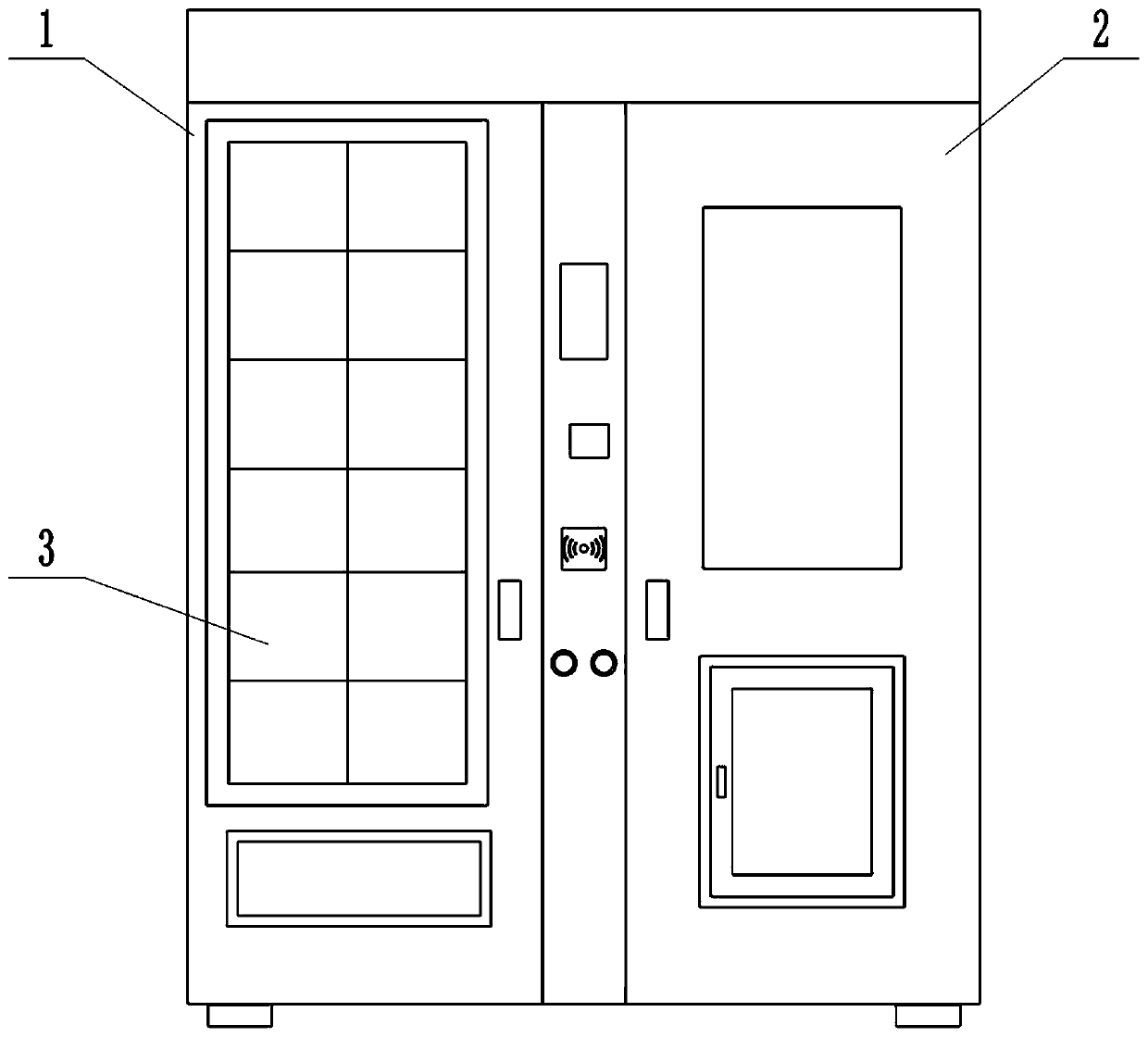

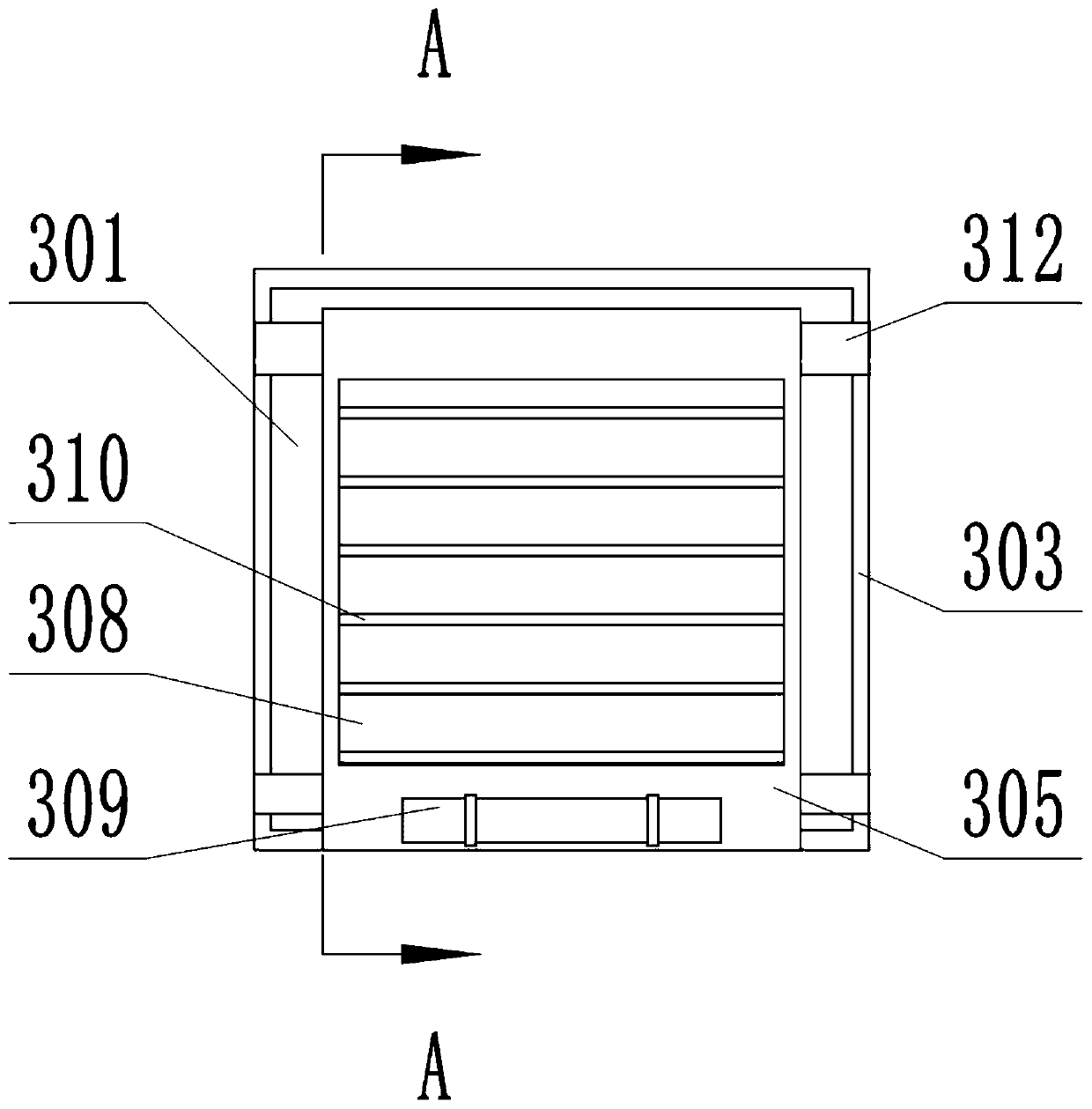

Self-service shopping cabinet and self-service shopping system and method

InactiveCN108734863AExpand the range of speciesEnsure safetyCoin-freed apparatus detailsOptical detectionStopped workPush pull

The invention provides a self-service shopping cabinet and a self-service shopping system and method. The self-service shopping cabinet comprises a cabinet body, a controller, a commodity weighing module, a cooling module, a temperature sensor, a locking device and a push-pull device and is characterized in that the controller receives the purchasing instruction of a user, generates an unlocking control instruction according to the purchasing instruction and transmits the unlocking control instruction to the locking device to allow the locking device to control the push-pull device to be pulled out in a direction away from the cabinet body according to the unlocking control instruction; the total price of the commodities is calculated according to the weight, measured by the commodity weighing module, of the commodity, taken out by the user, in each cell and the preset unit price of the commodity in each cell; the controller receives temperature, detected by the temperature sensor, inthe cabinet body and compares the temperature with a preset maximum temperature value, the controller controls the cooling module to work when the temperature is higher than the preset maximum temperature value, and the controller controls the cooling module to stop working when the temperature is lower than the preset maximum temperature value. The self-service shopping cabinet is high in automation level, rich in function and good in practicality.

Owner:北京旺发伟业商贸中心

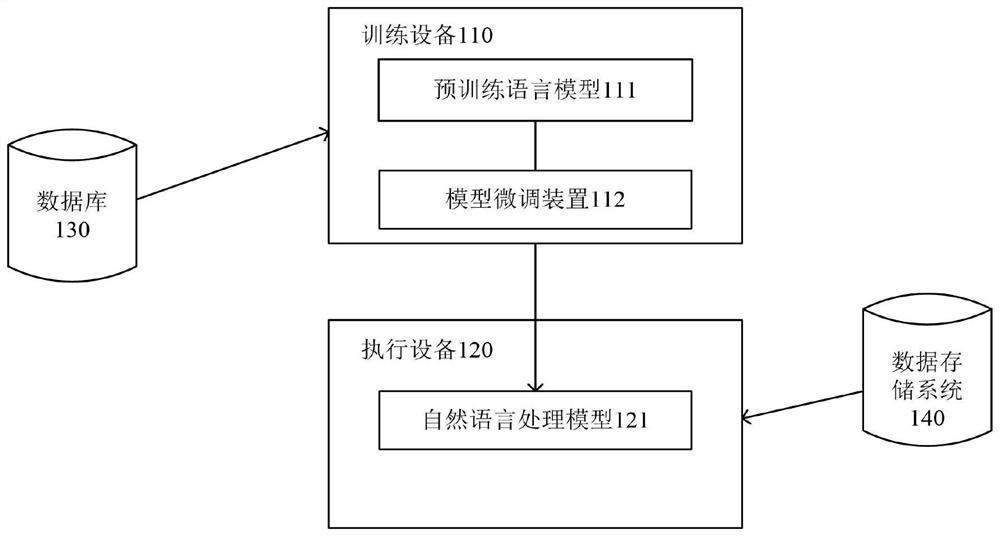

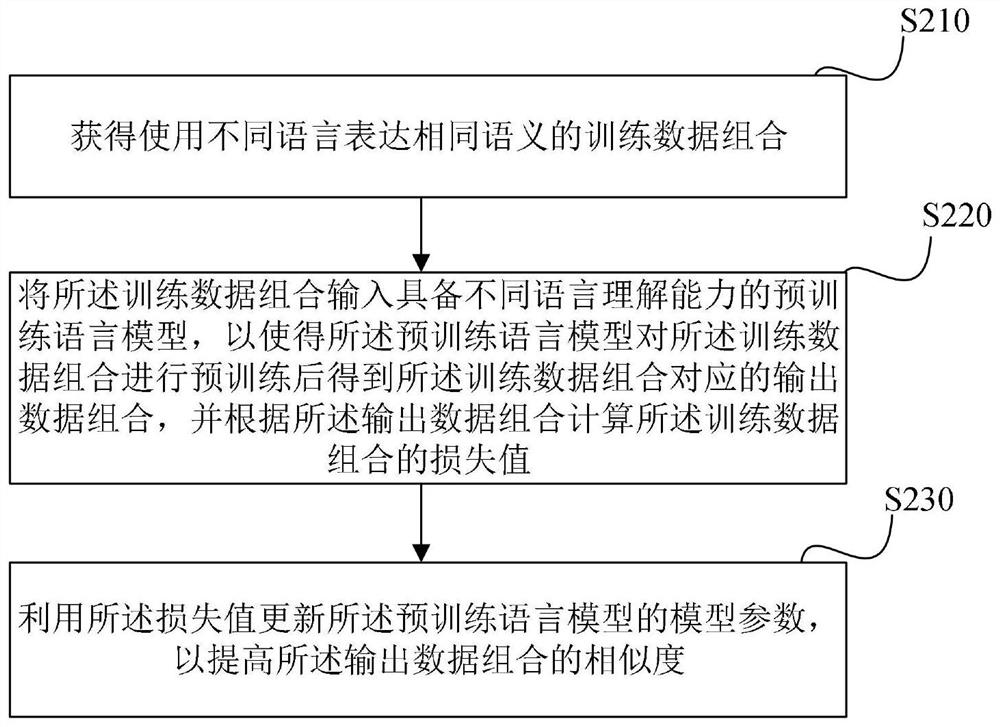

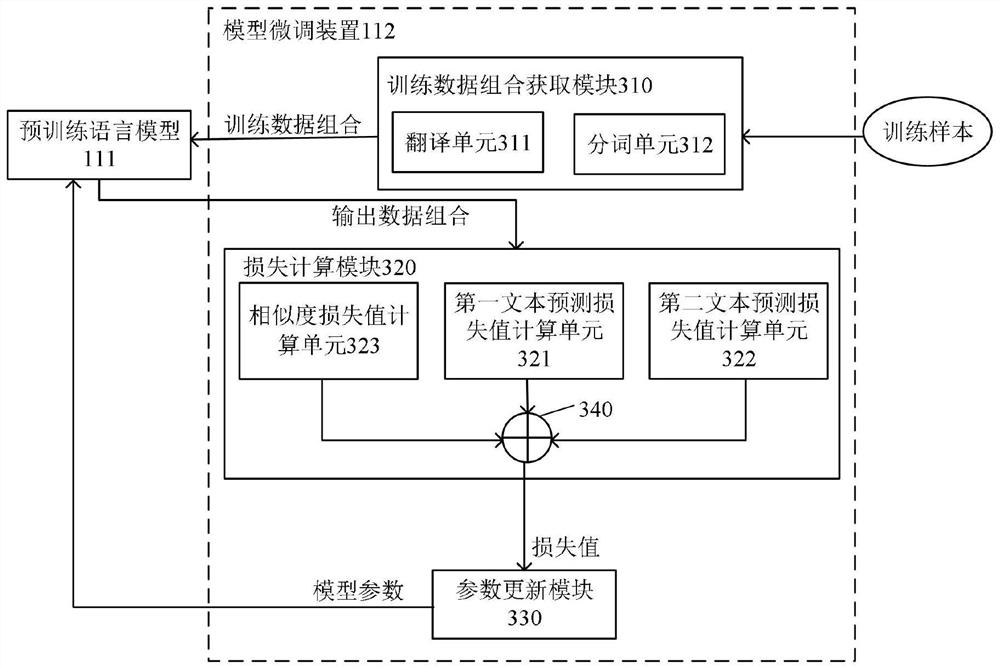

Training method and device of pre-training language model, computer equipment and medium

PendingCN114398899AHigh similarityImprove cross-language representation capabilitiesSemantic analysisCharacter and pattern recognitionLanguage understandingSimulation

The invention provides a training method and device of a pre-training language model, computer equipment and a medium. The method comprises the following steps: obtaining a training data combination for expressing the same semantics by using different languages; inputting the training data combination into a pre-training language model with different language understanding capabilities to enable the pre-training language model to pre-train the training data combination to obtain an output data combination corresponding to the training data combination, and calculating a loss value of the training data combination according to the output data combination; and updating model parameters of the pre-training language model by using the loss value so as to improve the similarity of the output data combination. According to the method, the downstream task processing performance of the natural language processing model in a low-resource language scene is improved, and the type range of downstream tasks applicable to the pre-training language model in a multi-language scene is widened.

Owner:ALIBABA DAMO (HANGZHOU) TECH CO LTD

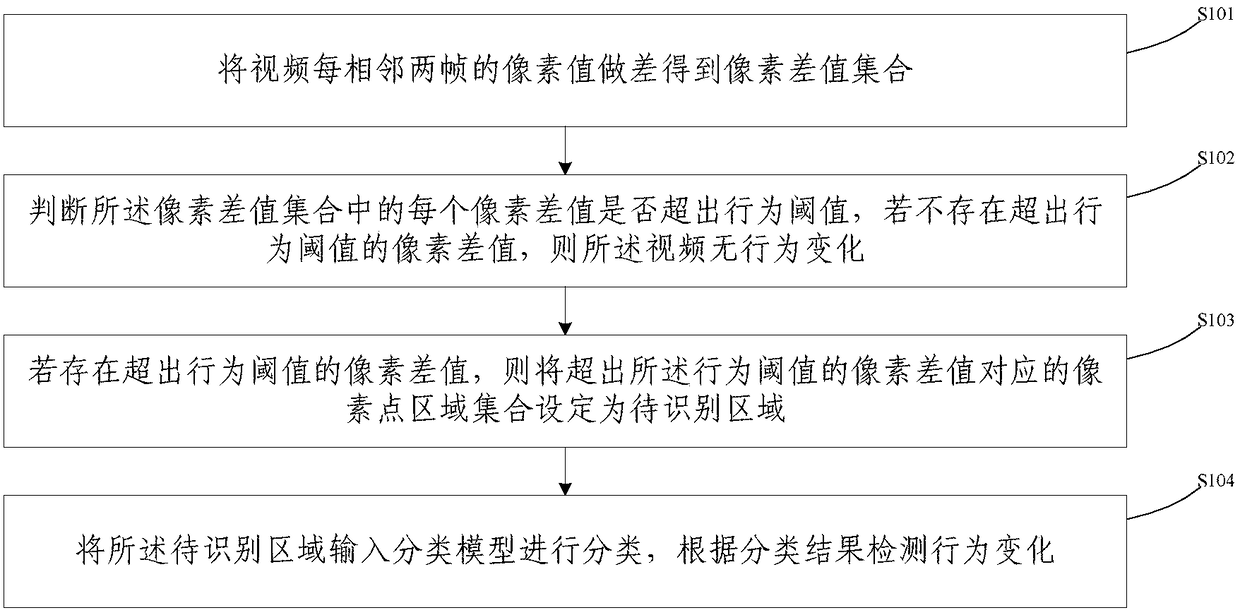

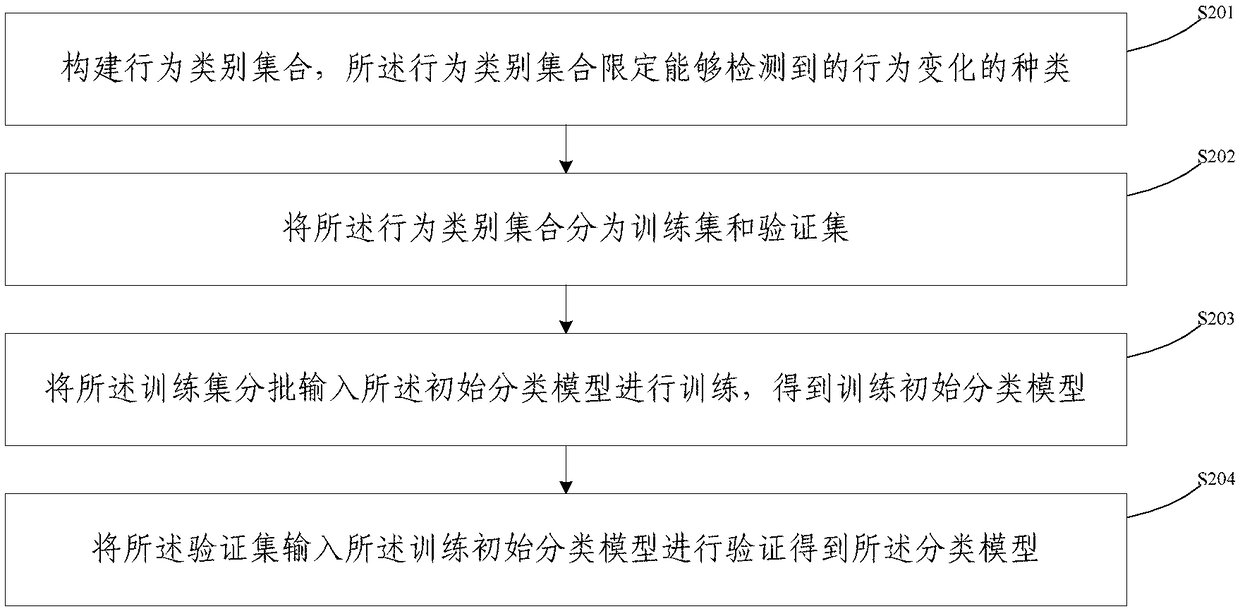

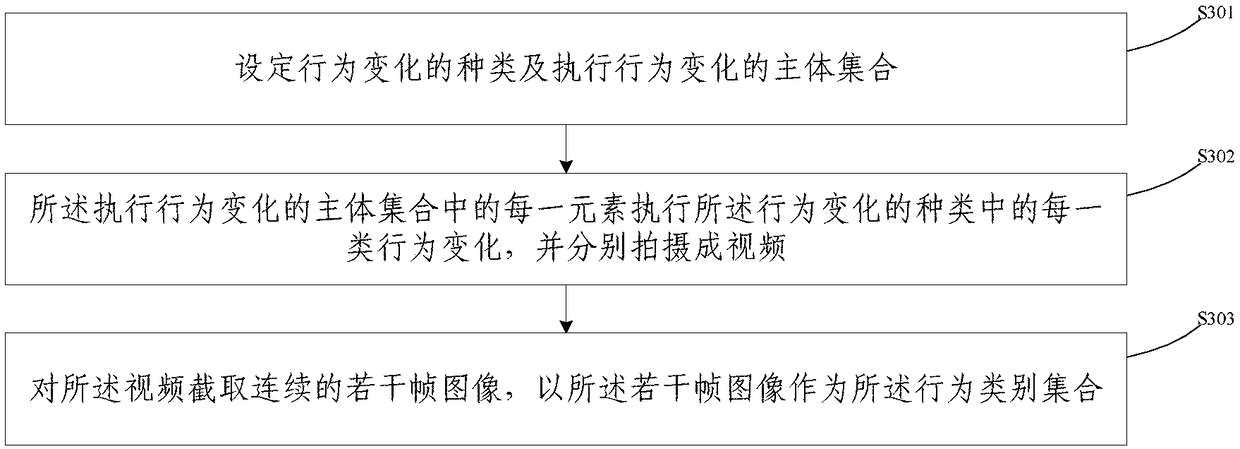

Method for detecting behavior change, equipment and storage medium

InactiveCN108416797AHigh sensitivityExpand the range of speciesImage enhancementImage analysisValue setInteraction device

The invention provides a method for detecting a behavior change. The method comprises: a difference between each two adjacent frames of pixel values of a video is calculated to obtain a pixel difference value set; whether each pixel difference in the pixel difference value set exceeds a behavior threshold is determined; if not, no behavior change exists in the video; if so, a pixel point region set corresponding to the pixel difference value exceeding the behavior threshold is set to be a to-be-identified area; and the to-be-identified area is inputted into a classification model for classification and a behavior change is detected according to the classification result. In addition, the invention also provides an active interaction device and a non-transitory readable storage medium for realizing the method. Therefore, sensitivity of detecting behavior changes is improved; and the range of types of behavior changes that can be detected is extended.

Owner:LUDONG UNIVERSITY

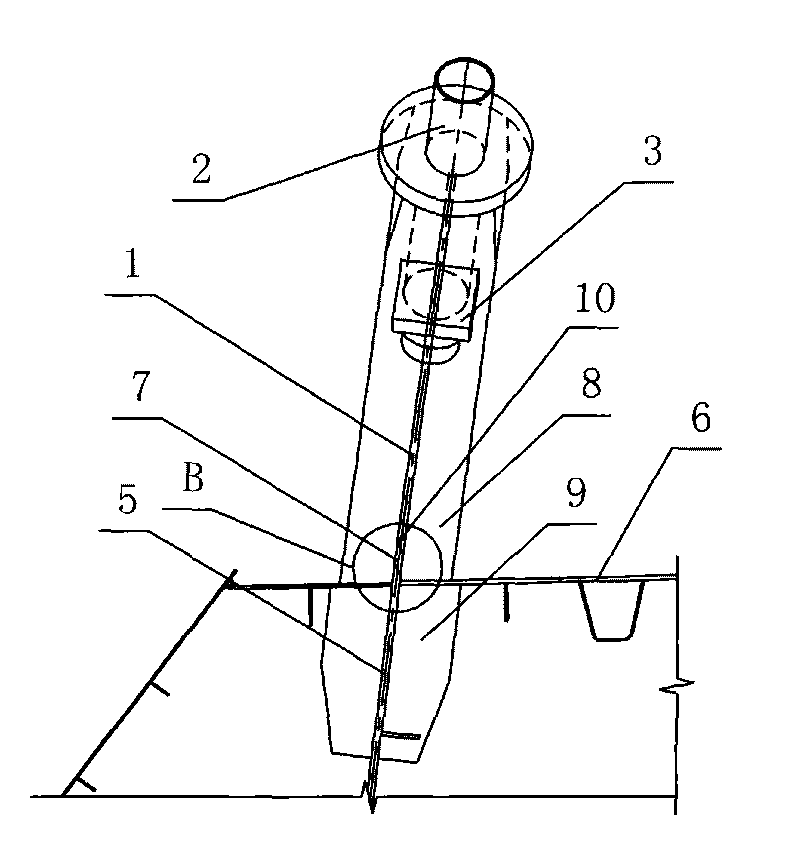

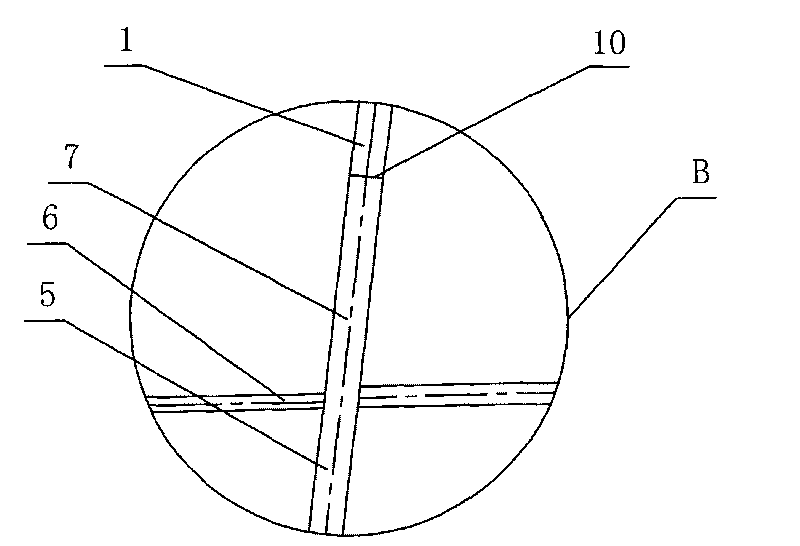

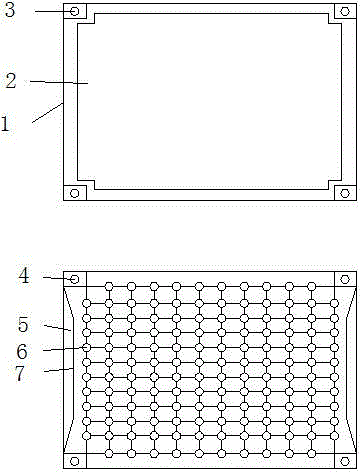

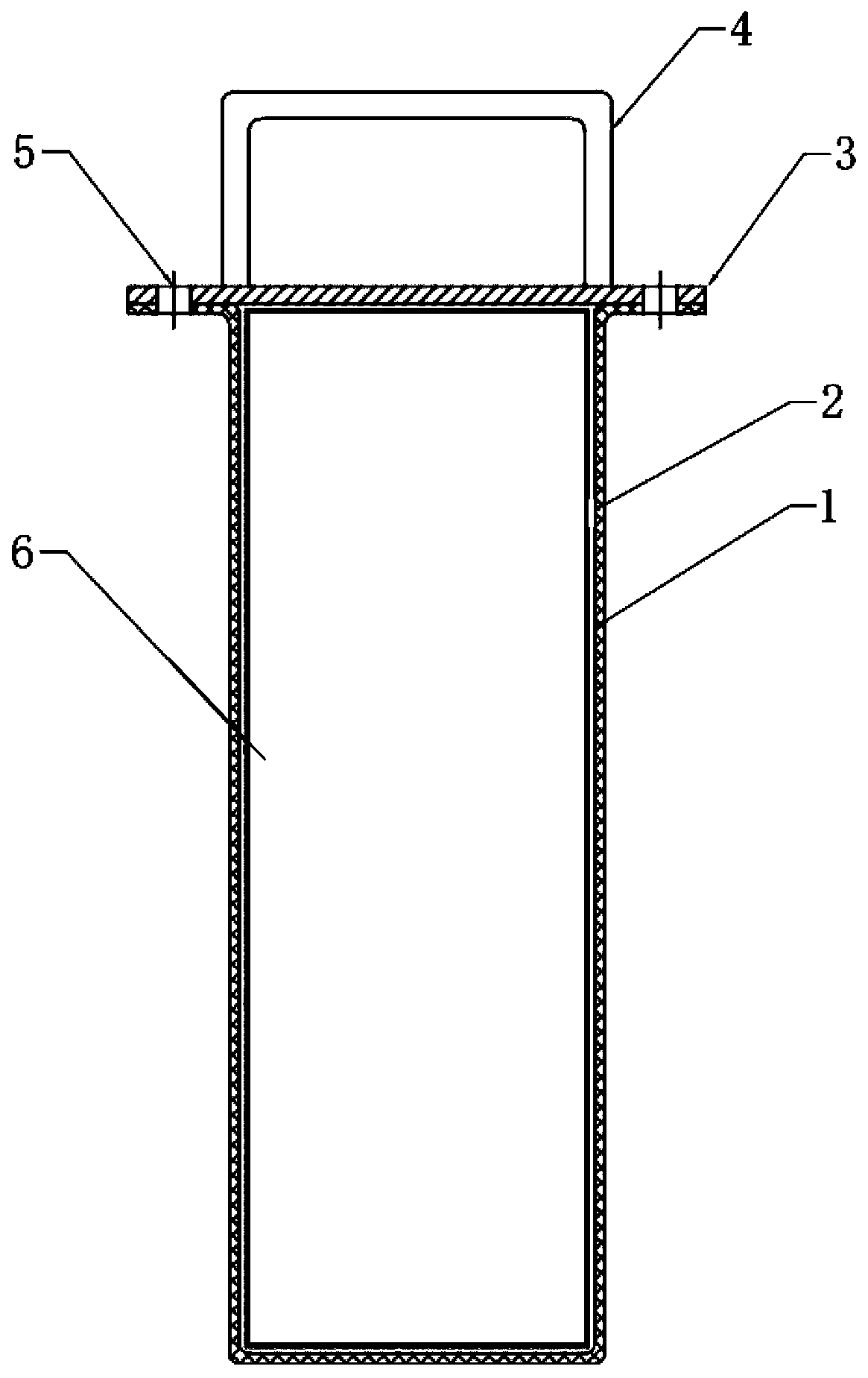

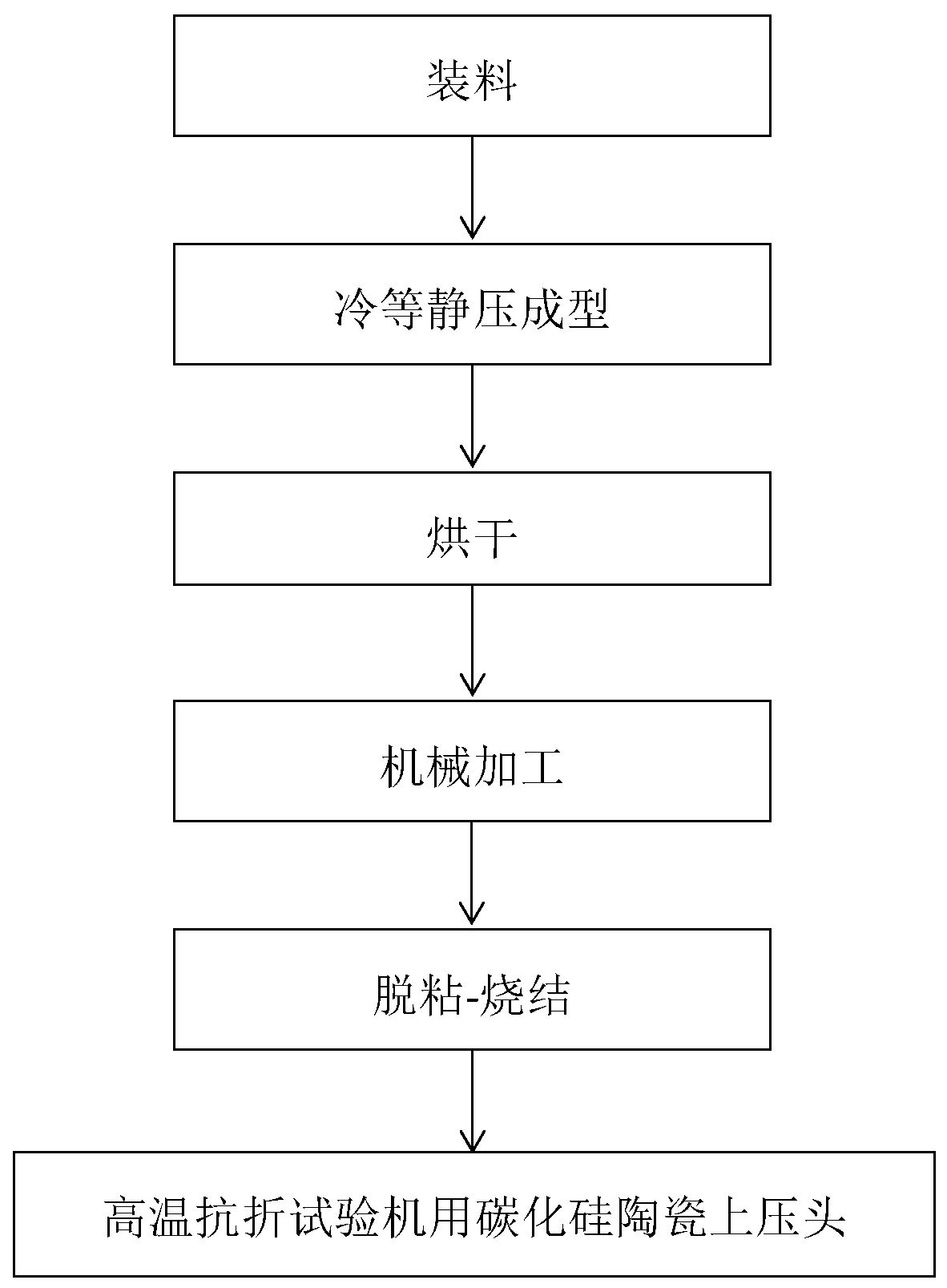

Silicon carbide ceramic upper pressure head of high-temperature bending resistance testing machine, preparation method thereof and die

The invention provides a silicon carbide ceramic upper pressure head of a high-temperature bending resistance testing machine, a preparation method thereof and a die, and particularly relates to an isostatic pressing die for a long rod-shaped ceramic biscuit. The isostatic pressing die comprises a die main body (1), a plastic film lining (6) closely attached to the inner surface of the die main body (1), and an upper cover plate (3) for sealing the die main body (1), wherein the plastic film lining is made of polyethylene; and the die main body is cylindrical barrel-shaped, sieve holes (2) areuniformly distributed in the whole die main body, and the lower end of the die main body is provided with a bottom.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

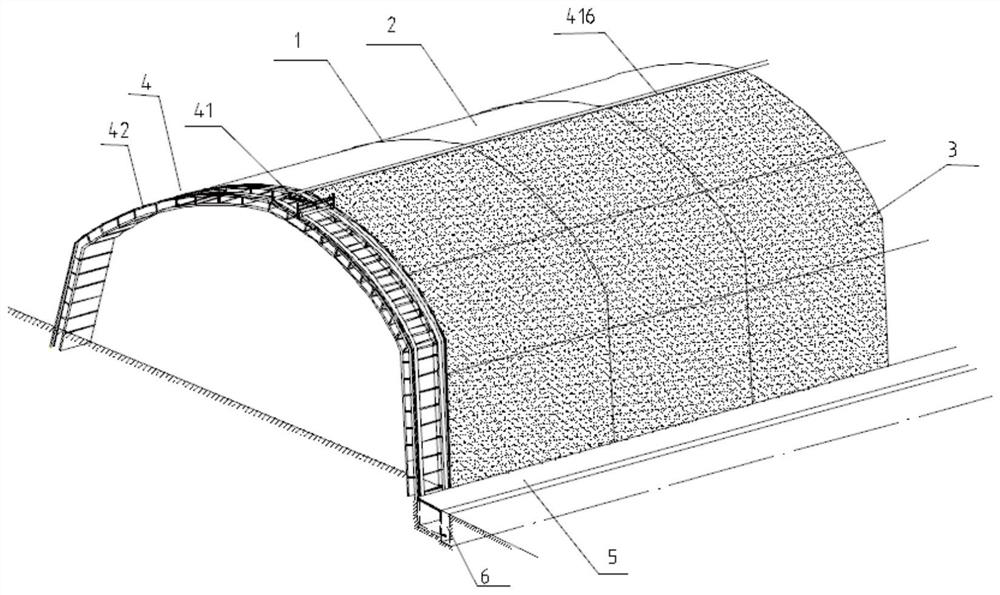

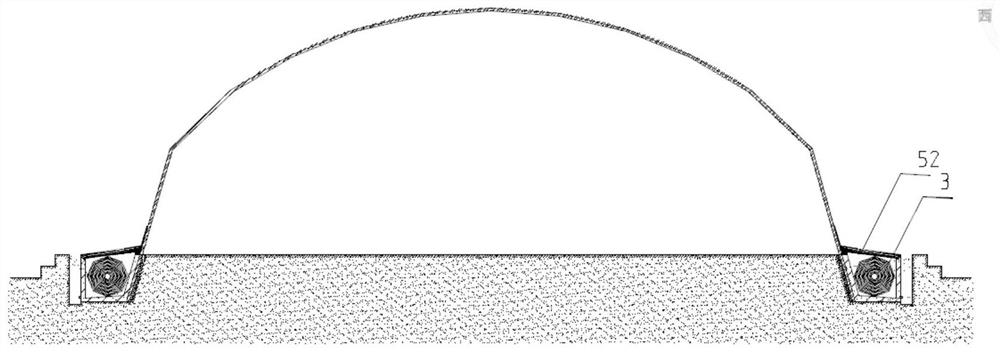

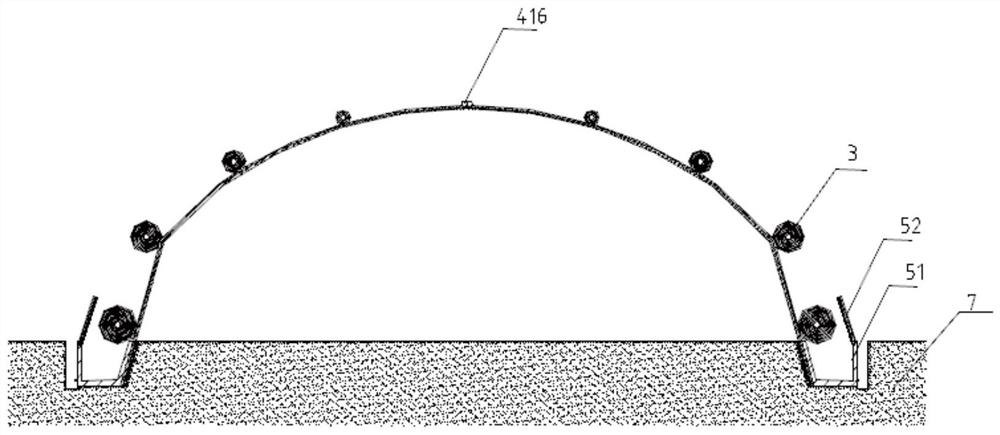

Plastic greenhouse with external heat preservation quilt stored underground

InactiveCN111802140AEliminate the effect of moving shading shadow volumesEliminate concentrated load effectsClimate change adaptationGreenhouse cultivationAgricultural scienceGreenhouse

The invention provides a plastic greenhouse with an external heat preservation quilt stored underground. The plastic greenhouse comprises a greenhouse framework, a greenhouse film, the heat preservation quilt, a roller shutter device and an underground storage device. The roller shutter device comprises a roller shutter machine and a roller shutter machine supporting frame. The roller shutter machine supporting frame is arranged at one end of the greenhouse framework. The roller shutter machine is connected with the roller shutter machine supporting frame. The roller shutter machine comprisesa quilt rolling shaft. The quilt rolling shaft is connected with the heat preservation quilt. Storage grooves are formed in two sides of the greenhouse framework. One end of the heat preservation quilt is fixed to the inner walls of the storage grooves. A groove cover is arranged above each storage groove. According to the plastic greenhouse, the heat preservation quilt can be rolled up and placedin the underground storage device when not used in the daytime, the heat preservation quilt is laid upwards from the east side and the west side of the plastic greenhouse along the greenhouse framework when heat preservation is needed in the greenhouse at night, the influence of a movable shading shadow body generated in the greenhouse when the heat preservation quilt is placed on the top is completely eliminated, the influence of illumination and temperature is reduced, and the range of the types of crops planted in the plastic greenhouse is enlarged.

Owner:QINGDAO AGRI UNIV

Water soluble low-temperature-solidification appliance insulating varnish and preparation method thereof

The invention discloses a water soluble low-temperature solidification appliance insulating varnish and a preparation method thereof. The water soluble low-temperature solidification appliance insulating varnish comprises a low-temperature latent initiator, wherein the low-temperature latent initiator accounts for 0.10 to 1.5 percent of the total weight of the water soluble low-temperature solidification appliance insulating varnish; and the low-temperature latent initiator is benzoyl peroxide. The preparation method comprises the following steps of: firstly, uniformly mixing acrylic ester, organic silicon resin, polyalcohol, the low-temperature latent initiator and 50 percent de-ionized water with slowly stirring at room temperature; secondly, adding a flatting agent, a curing agent, a defoamer and the other 50 percent de-ionized water in sequence and still stirring slowly; and finally, adding solution of alkylol amine dropwise, and adjusting pH to 8.0 to 9.0 to obtain the required product. When the preparation method is implemented, the baking, solidification and film molding temperature of the varnish is as low as only 80 to 90 DEG C; and a varnish film has high adhesion, high humidity, heat and slat-fog resistance and high water solubility and produces no harmful gas in use.

Owner:深圳市东方亮化学材料有限公司

Temperature-responsive fiber and method of preparing same

InactiveCN110607683AAchieve preparationExpand the range of speciesCarbon fibresVegetal fibresChemical reactionPorous fiber

The invention discloses a temperature-responsive fiber and a method of preparing the same. The method of preparing the temperature-responsive fiber comprises: impregnating a porous fiber with a liquidtemperature-responsive material or a temperature-responsive material solution, thereby encapsulating the temperature-responsive material in mesopores of the porous fiber to obtain the temperature-responsive fiber. According to the method of preparing the temperature-responsive fiber, a complex synthesis technology is not needed, no chemical reaction occurs in the whole preparation process, the process is simple, the flow is short, and large-scale preparation of the temperature-responsive fiber can be achieved; different temperature-responsive fibers can be obtained by adjusting the temperature-responsive material, so that the type and application range of the temperature-responsive fiber is greatly expanded.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

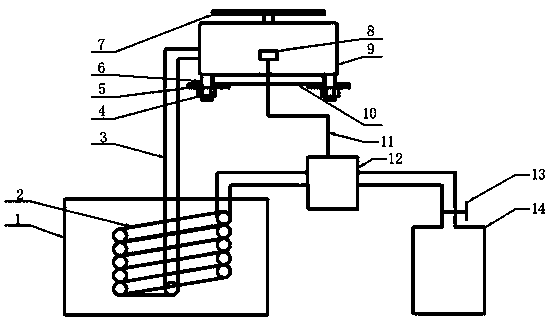

Heating and cooling portable sample stage equipment based on liquid nitrogen refrigeration

PendingCN111058008AExpand the range of speciesMeet the needs of processing temperatureVacuum evaporation coatingSputtering coatingDisplay deviceEngineering

The invention discloses heating and cooling portable sample stage equipment based on liquid nitrogen refrigeration. The equipment includes a cavity, a refrigeration device in the cavity, a cooling device outside the cavity, a control display device and a sample fixing device; the refrigeration device in the cavity includes supporting columns and an S-shaped copper coil pipe arranged on the supporting columns; and the cooling device outside the cavity includes a nitrogen tank, a liquid nitrogen tank, a copper coil pipe and a copper pipe, the copper coil pipe is arranged in the liquid nitrogen tank and communicates with the nitrogen tank through a connecting pipe, and the copper coil pipe communicates with the S-shaped copper coil pipe through the copper pipe. The equipment has the followingbeneficial effects: the equipment is ingenious in design, reasonable in structure, and convenient to use; and when the equipment is used to adjust the temperature of samples, the requirements of processing temperature for different substrates are conveniently met, the type range of the samples that can be processed by a vacuum coating machine is expanded, and the equipment has important significance in the field of research of vacuum coating.

Owner:ZHEJIANG UNIV OF TECH

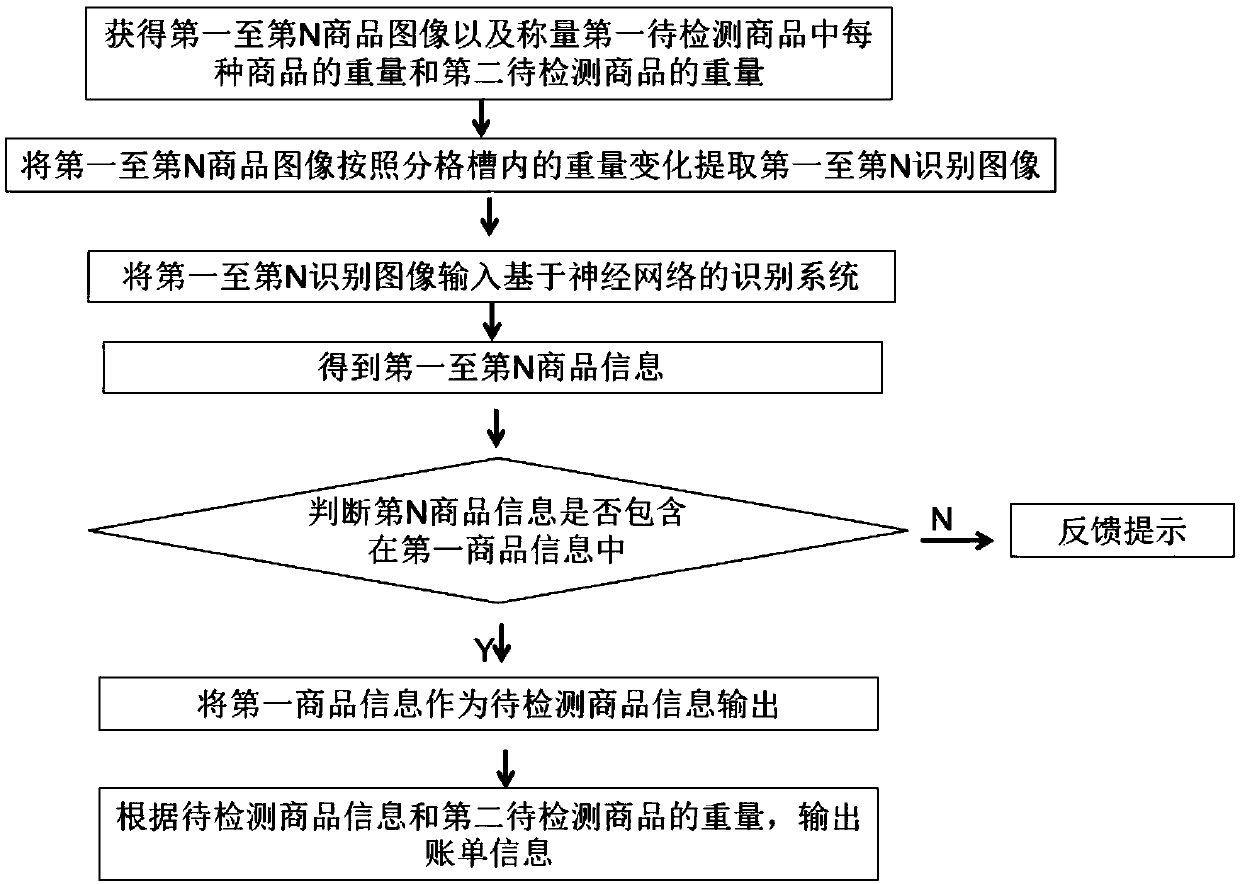

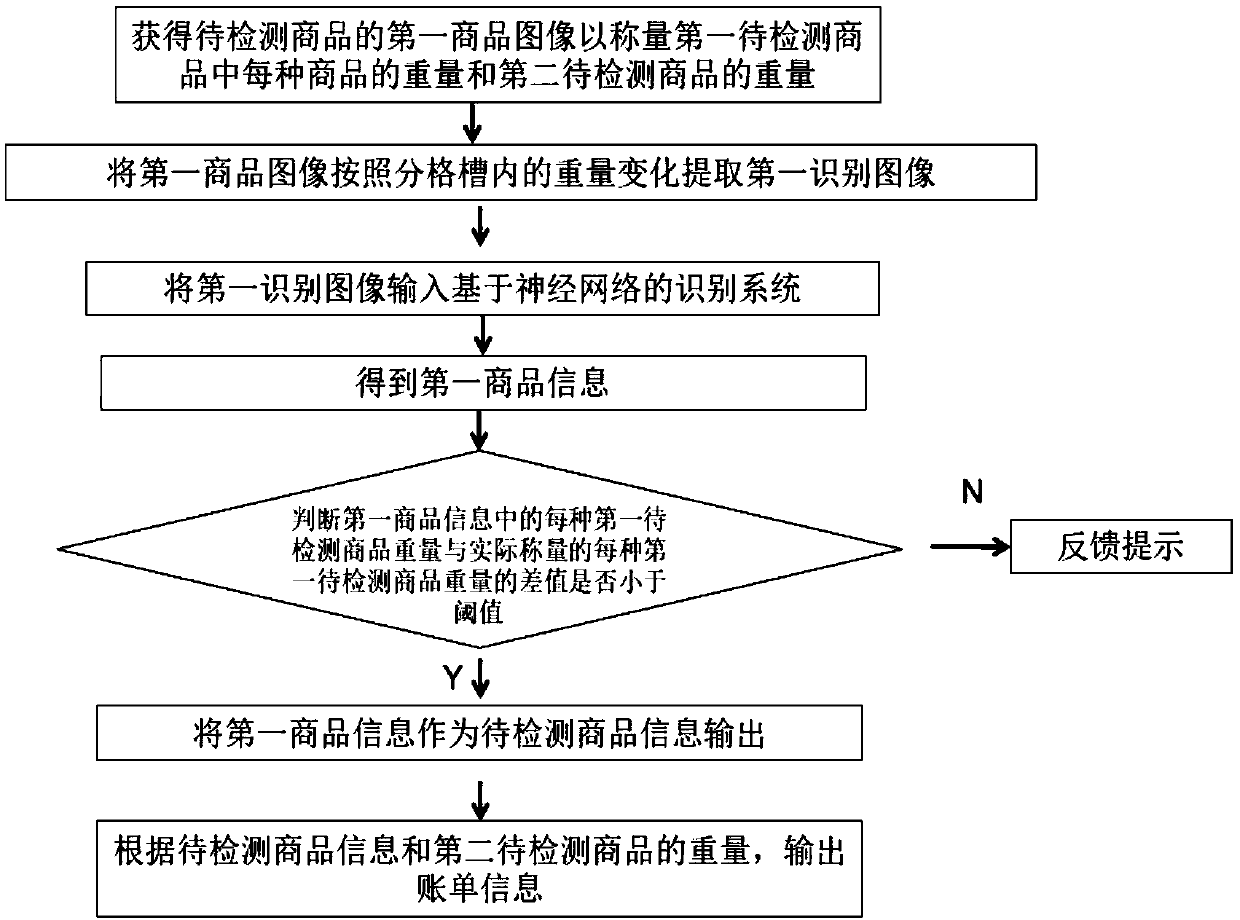

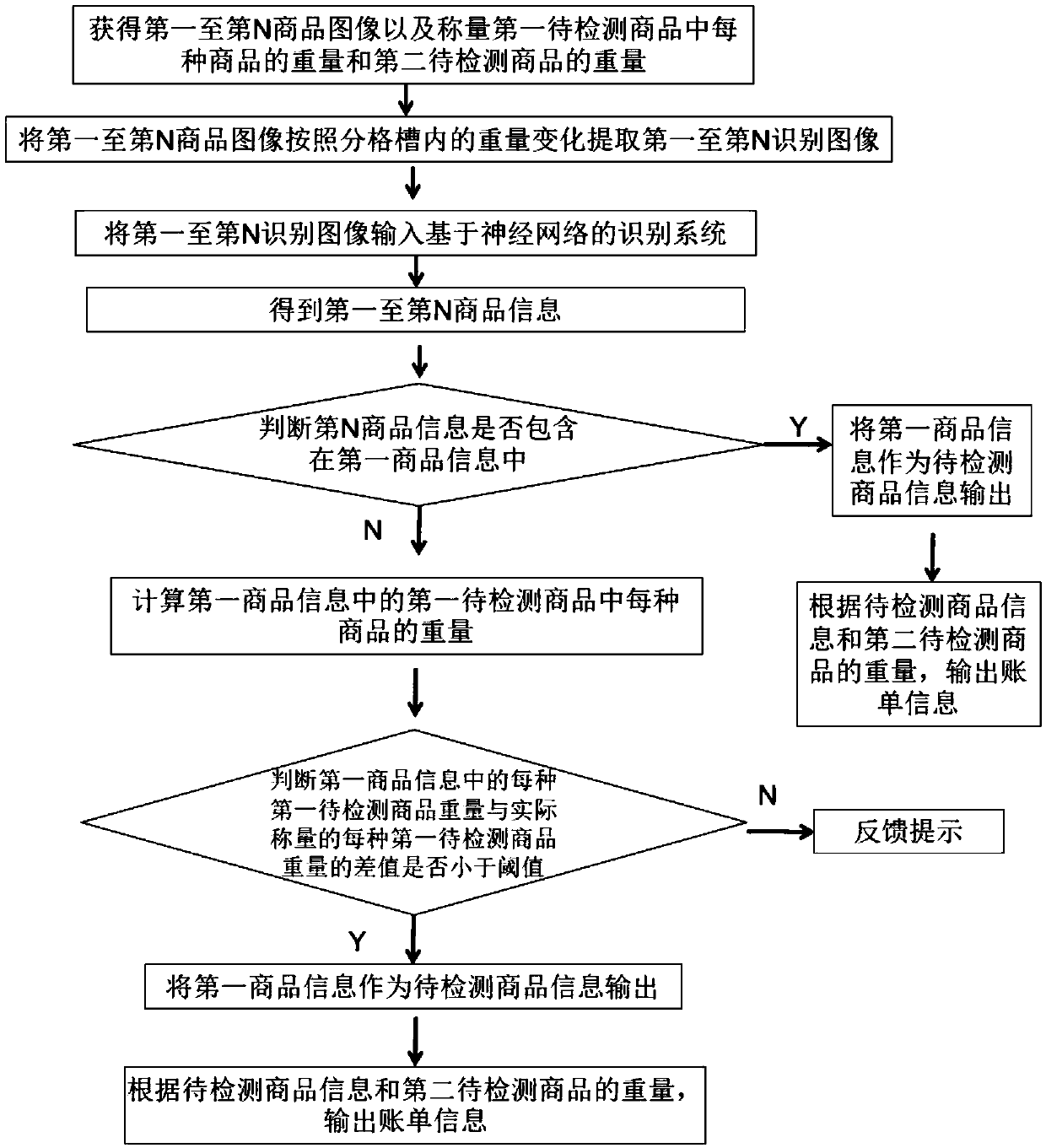

Cashiering method for identifying commodities based on neural network and self-service cashier desk

ActiveCN109559457AReduce training timeSave time and costCharacter and pattern recognitionCash registersNeural network systemNetwork output

The invention discloses a cashiering method for identifying commodities based on a neural network. The method comprises the following steps of acquiring commodity images of commodities to be detectedwhich are placed in different grid grooves, wherein each grid groove is used for containing commodities with the same kind; acquiring weighing weight of the commodity to be detected in at least one grid groove; inputting the commodity image into an identification system based on the neural network, wherein the identification system based on the neural network outputs commodity information in the commodity image; and outputting an identification result according to the weighing weight and the commodity information. According to the method, the commodities with the same category are identified by a neural network system, so that the identification accuracy can be improved; the weighing weight of the commodity to be detected can be applied to an identification process, so that the identification process can be simplified, and the identification efficiency can be improved; and furthermore, the weight of the commodity to be detected can also be verified, so that the identification accuracyis further improved.

Owner:BINGOBOX BEIJING TECH CO LTD

Efficient membrane-dissolution crystallization method of double-unit coupling circulation

InactiveCN107890686AReduce energy costsLow investment costMembranesSemi-permeable membranesPeristaltic pumpCoupling

The invention provides an efficient membrane-dissolution crystallization method of double-unit coupling circulation, and belongs to the technical field of crystallization engineering. When a raw material solution is added into a material solution tank and a dissolving agent is added into a storage tank, dissolving agent circulation is carried out until a system is stable; a peristaltic pump of theraw material tank is turned on, so that the dissolving agent fully contacts the raw material solution in a membrane assembly for generating a crystal product; and a mixed liquid carrying crystals flows into a filtering and drying device to form a solid and a mother liquor. The mother liquor passes through a pervaporation membrane assembly, and a pure solvent, a solute and a pure dissolving agentare separated out; the solvent and the solute are recycled; and the dissolving agent returns to the dissolving agent storage tank for secondary utilization. The addition amount of the dissolving agentand the pervaporation process are systematically regulated by controlling membranes and operation conditions, so that on the premise that the ideal crystal product is obtained, the efficiency, environment protection and greenness of the coupling process are further improved, the cost is reduced, and the recovery rate and yield of the crystal product are increased.

Owner:DALIAN UNIV OF TECH

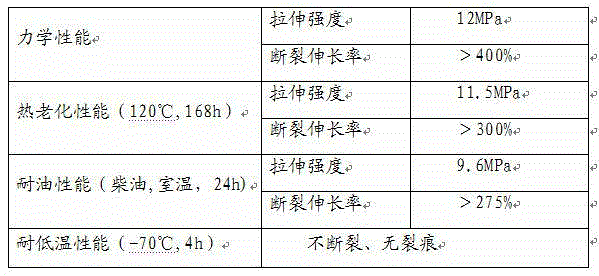

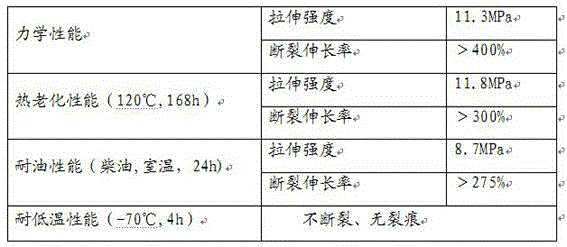

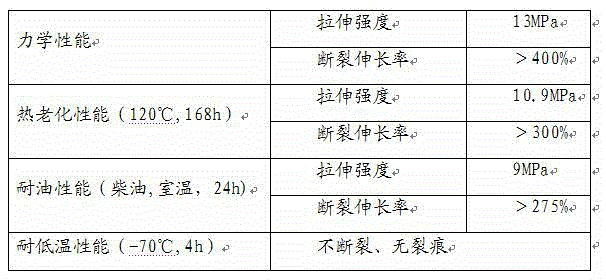

Radiation crosslinking chloroprene rubber heat shrinkage material and preparation method thereof

ActiveCN102977441AOpen up application spaceImprove performanceTubular articlesPolyolefinPolymer science

The invention discloses a radiation crosslinking chloroprene rubber heat shrinkage material which comprises the following components in parts by weight: 100 parts of polyolefin base material; 5-20 parts of chloroprene rubber; 5-20 parts of chlorinated polyethylene; 0.5-3 parts of antioxygen; 1-15 parts of plasticizer and 1-5 parts of color master batch. The radiation crosslinking chloroprene rubber heat shrinkage material has the advantages of low temperature resistance, oil resistance and thermal aging resistance.

Owner:CHANGYUAN ELECTRONICS DONGGUAN +3

Metal casting ultrasonic finishing batch production method and equipment

PendingCN108544306AImplement batch processingSimple methodEdge grinding machinesPolishing machinesMachining processMetal

The invention discloses a metal casting ultrasonic finishing batch production method. A grinding material and metal castings are freely placed in a finishing machining chamber, ultrasonic waves are provided by an ultrasonic tool head rotating relative to the grinding material, meanwhile, a rotating magnetic field with the magnetic field direction changing periodically is provided by a magnetic field generator rotating relative to the grinding material, and metal casting ultrasonic finishing batch production is completed. According to ultrasonic finishing batch production equipment, the ultrasonic tool head is rotationally mounted on the lower portion of a containing body, the magnetic field generator is fixed to the ultrasonic tool head, and the ultrasonic tool head and the magnetic fieldgenerator are driven to rotate at high speeds in the ultrasonic finishing machining process. The metal castings in any shape can be subjected to finishing machining and do not need to be clamped and fixed, an operator needs to put the magnetic conductive grinding material into the containing body only, the type range of the metal castings is further enlarged, and meanwhile, batch machining of themetal castings is achieved.

Owner:东莞市新玛博创超声波科技有限公司

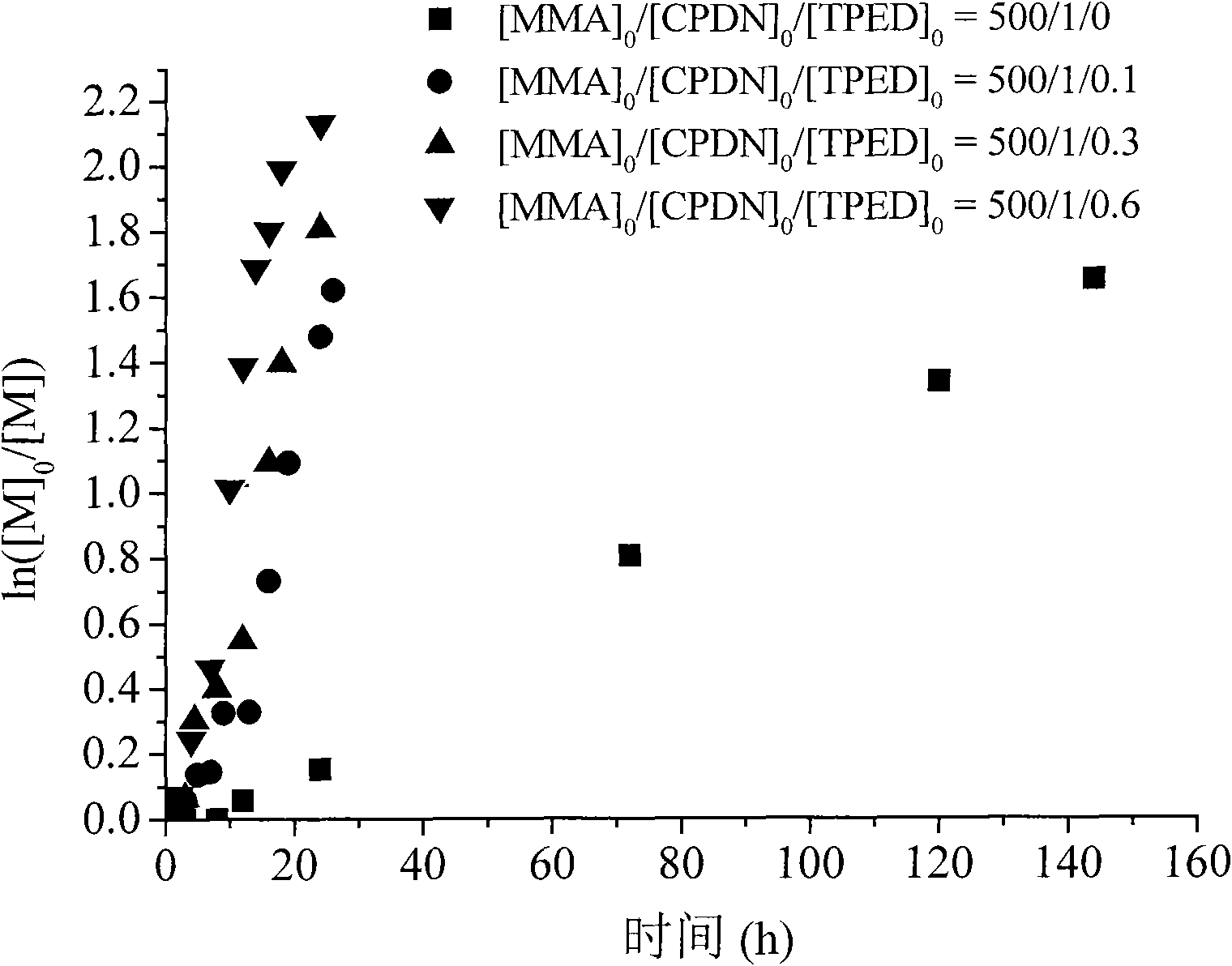

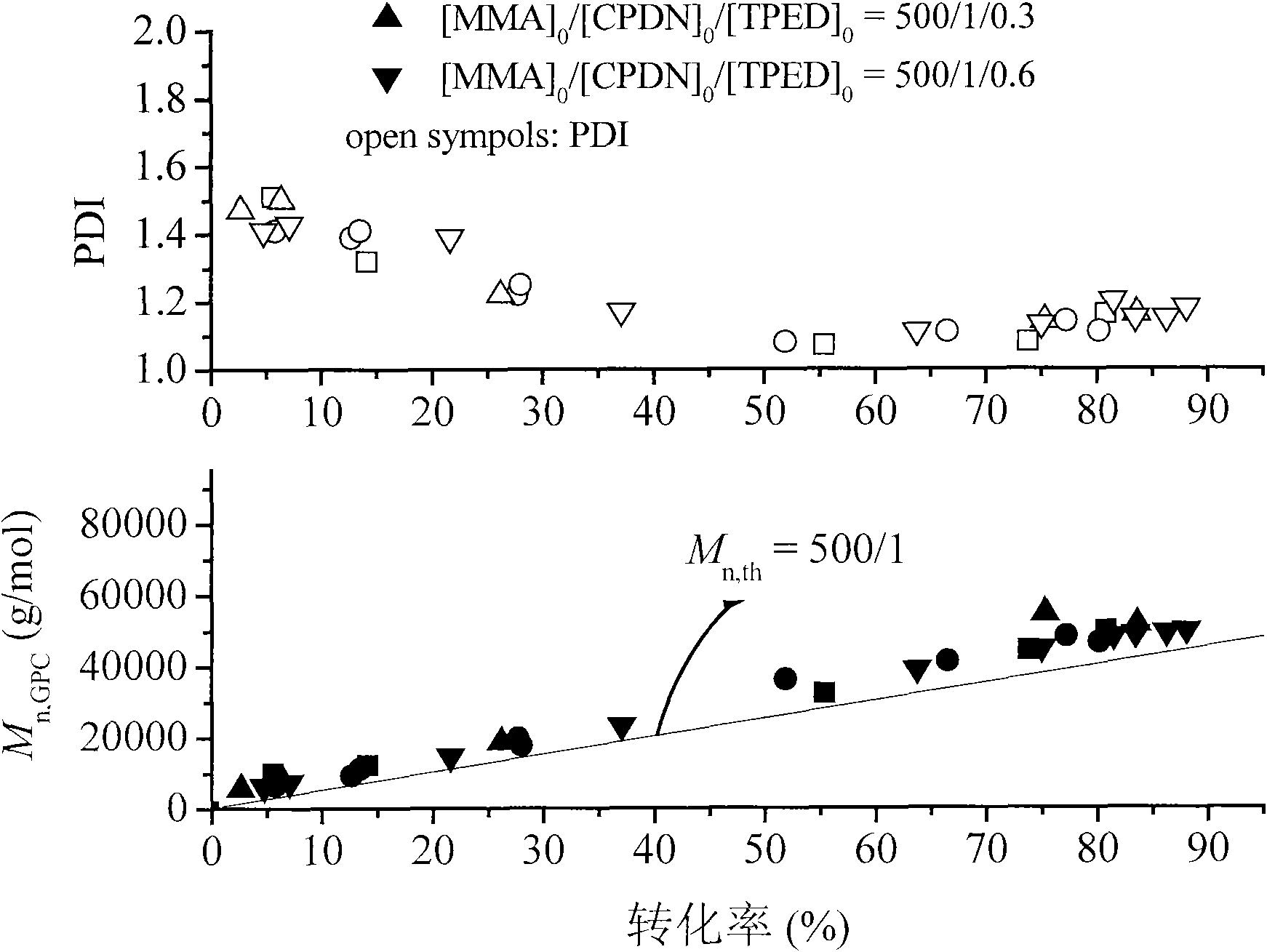

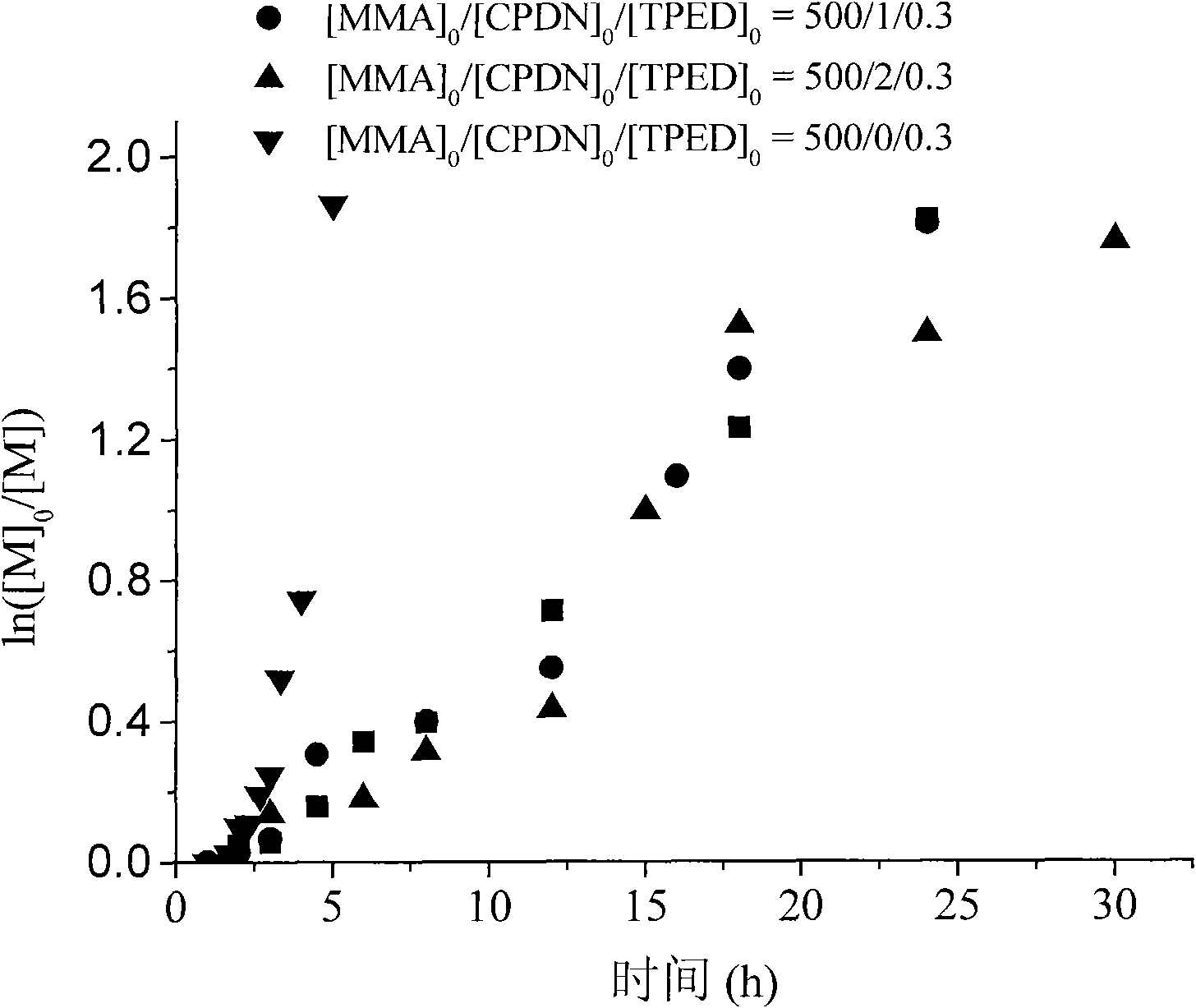

Application of 1,1,2,2-tetraphenylethylene glycol used as RAFT polymerization initiator

The invention discloses a new application of 1,1,2,2-tetraphenylethylene glycol used as RAFT polymerization initiator. The method of using 1,1,2,2-tetraphenylethylene glycol as RAFT polymerization initiator comprises the following steps: using monomer, initiator and chain transfer agent to form RAFT polymerization system in inert atmosphere and performing RAFT polymerization at 80-115 DEG C whilecontrolling the polymerization time to control the molecular weight of polymerization product. The molar ratio of monomer to initiator and chain transfer agent is 500:0.1-1:0.5-2, the chain transfer agent is one of CPDB and CPDN and the monomer is oil-soluble monomer corresponding to the chain transfer agent.

Owner:SUZHOU UNIV

Water and goods selling integrated machine with hot and cold drink selling function

InactiveCN109859395AExpand the range of speciesCoin-freed apparatus detailsApparatus for dispensing fluids/granular materialsTemperature controlEngineering

The invention relates to a water and goods selling integrated machine with a hot and cold drink selling function, which comprises a goods selling part and a water selling part, wherein the goods selling part includes a plurality of heat preservation units stacked in a warehouse, each heat preservation unit includes a housing, one end of the housing is provided with an opening, the wall of the housing is coiled with a temperature control pipe, the housing is externally coated with a heat preservation layer, the opening end of the housing is provided with slideways, two slideways are provided with a window frame therebetween, the window frame is internally and fixedly embedded with glass, the glass is internally coiled with an electric heating wire in a penetrating manner, the side wall of the housing is fixedly provided with a motor, and an output shaft of the motor is connected with a shifting rod. The water and goods selling integrated machine makes full use a refrigerant of the waterselling part to provide a cold source for the good selling part, so that the goods selling part can supply cold drinks and / or hot drinks on demand through the plurality of heat preservation units, thereby meeting the requirement of drinking hot and cold drinks of consumers, and expanding the type and range of products sold by the water and goods selling integrated machine.

Owner:TIANJIN QUANJIE TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com