Patents

Literature

119 results about "Pre expansion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

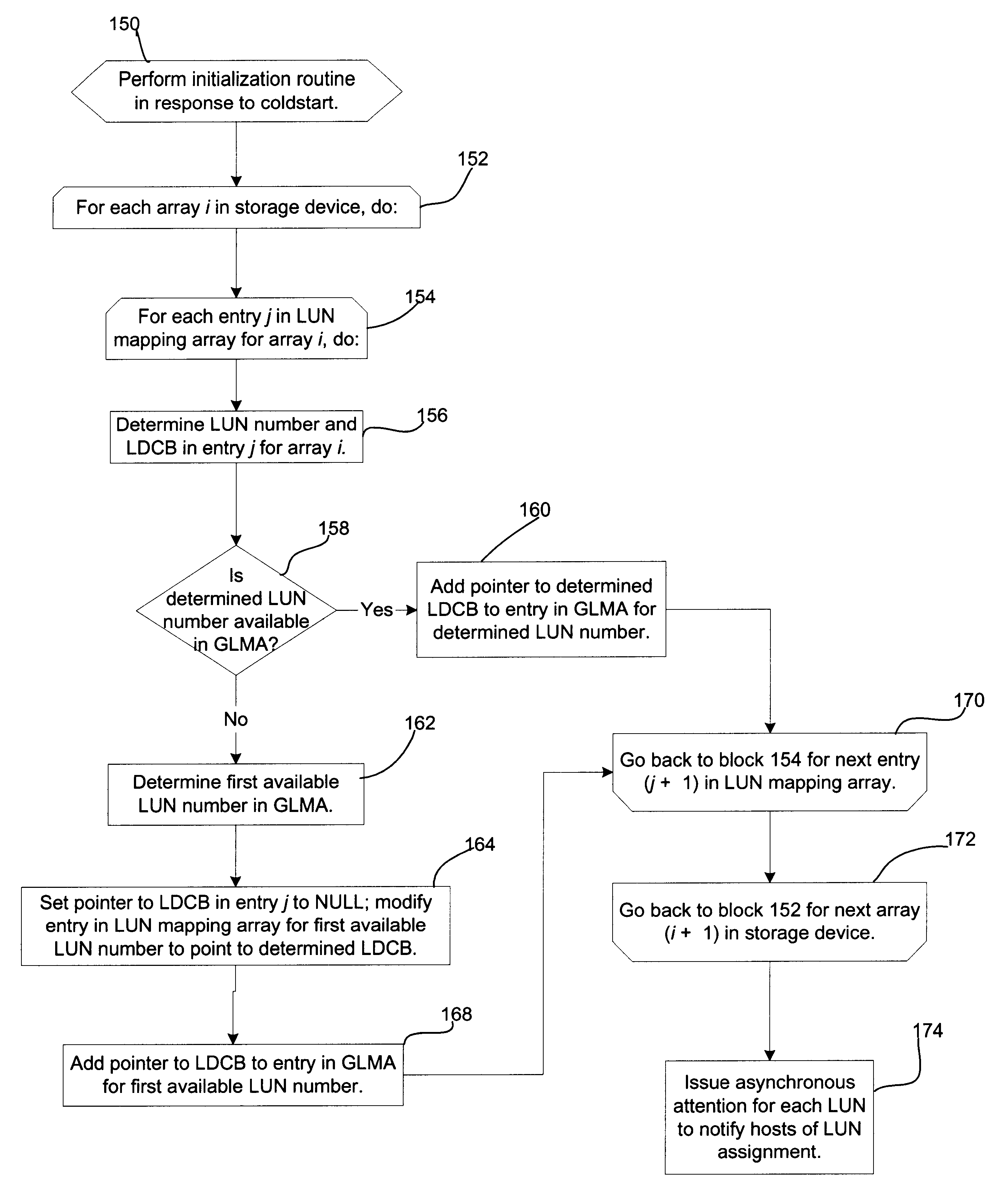

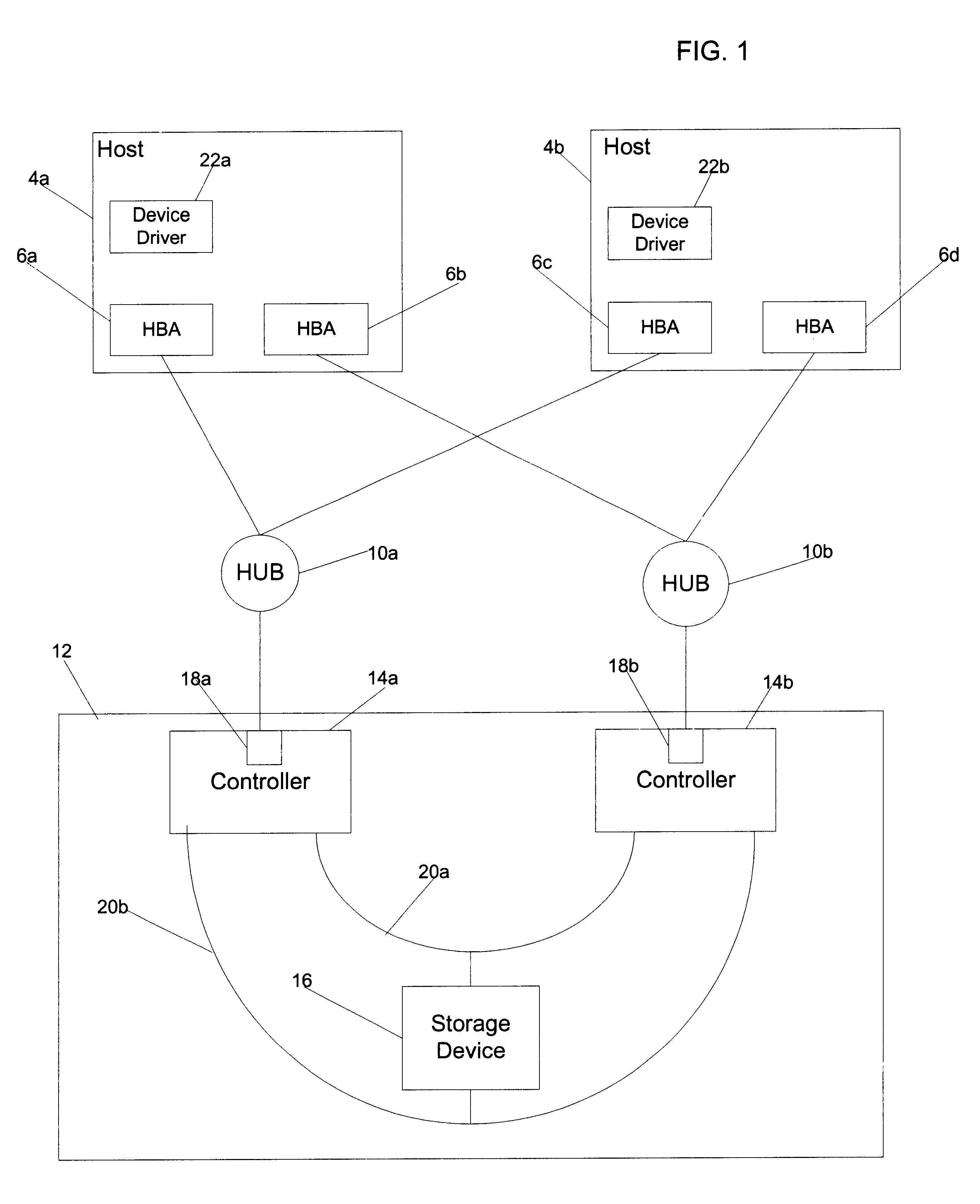

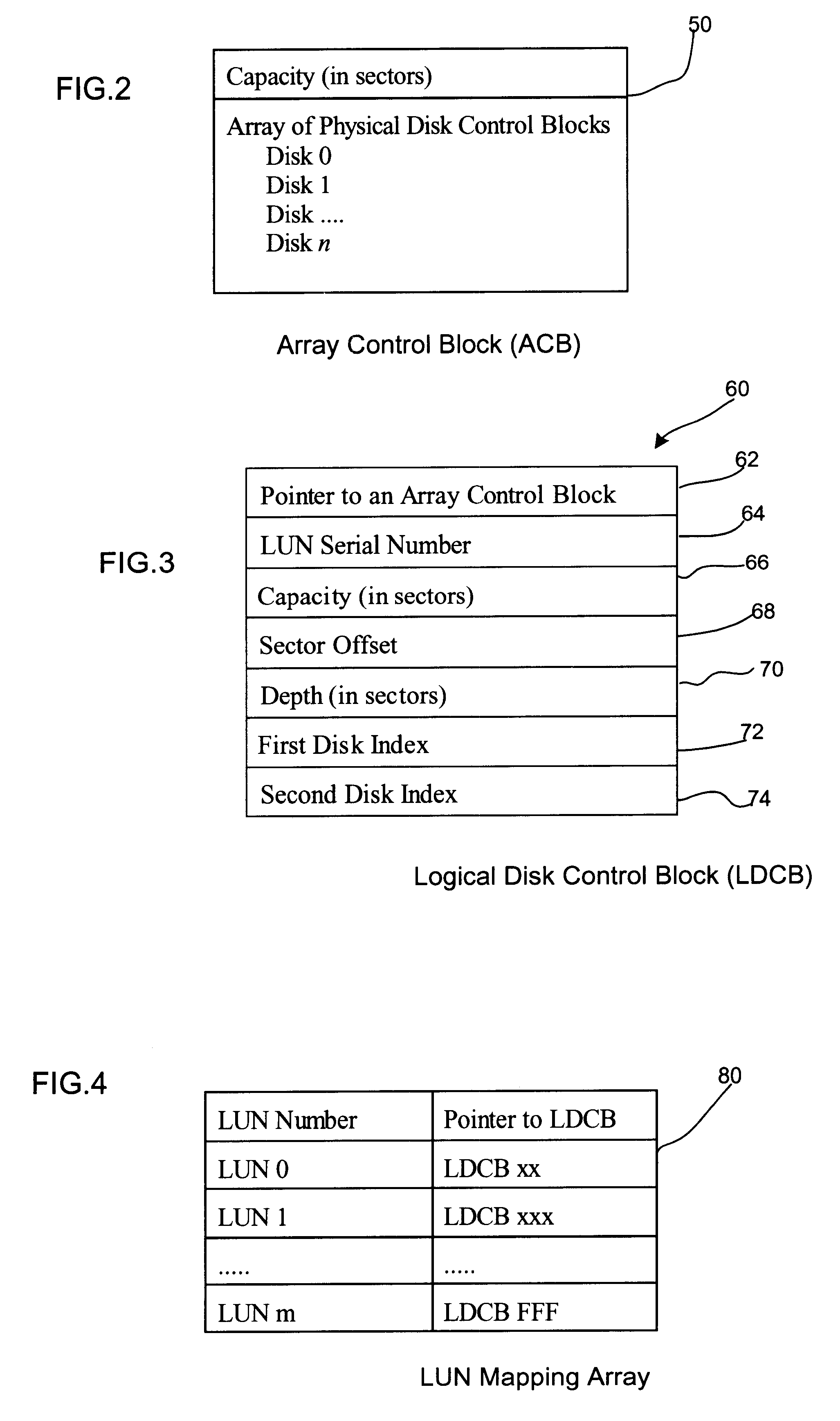

Method, system, and program for expanding the storage space in an array of storage units

InactiveUS6651154B1Increase storage capacityReduce stepsInput/output to record carriersRedundant data error correctionPre expansionEmbedded system

Owner:IBM CORP

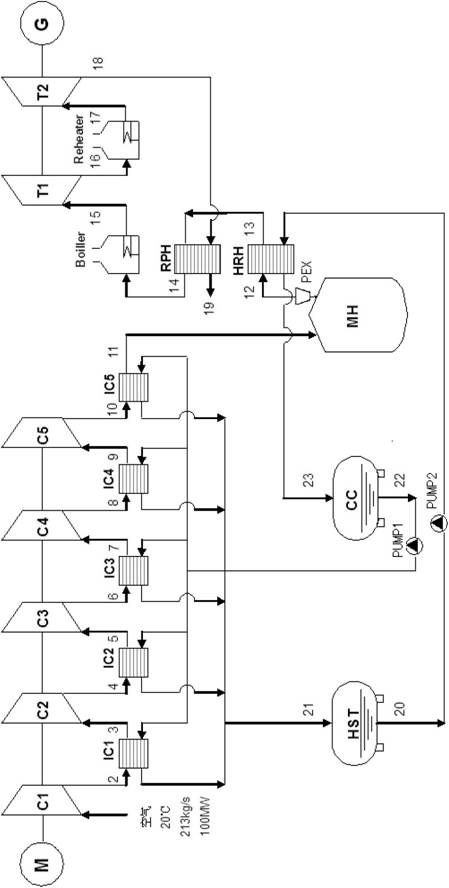

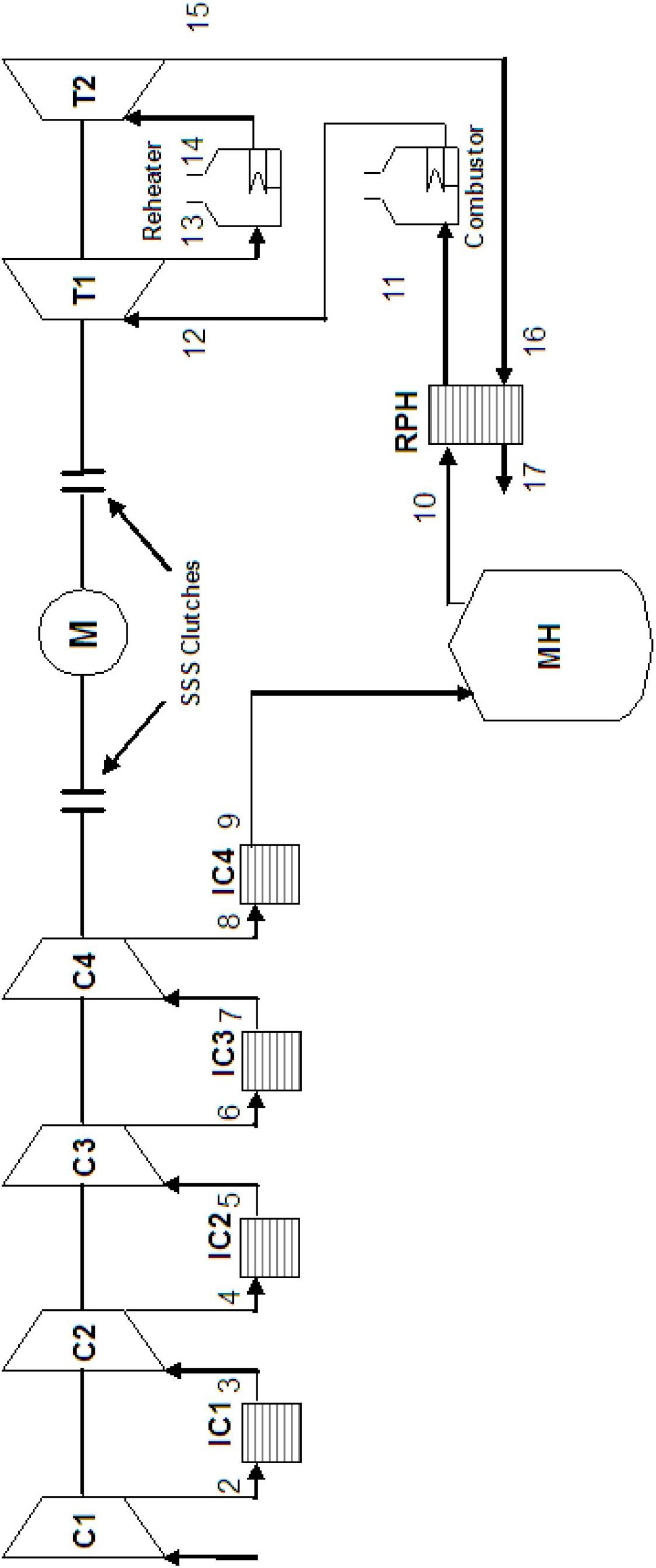

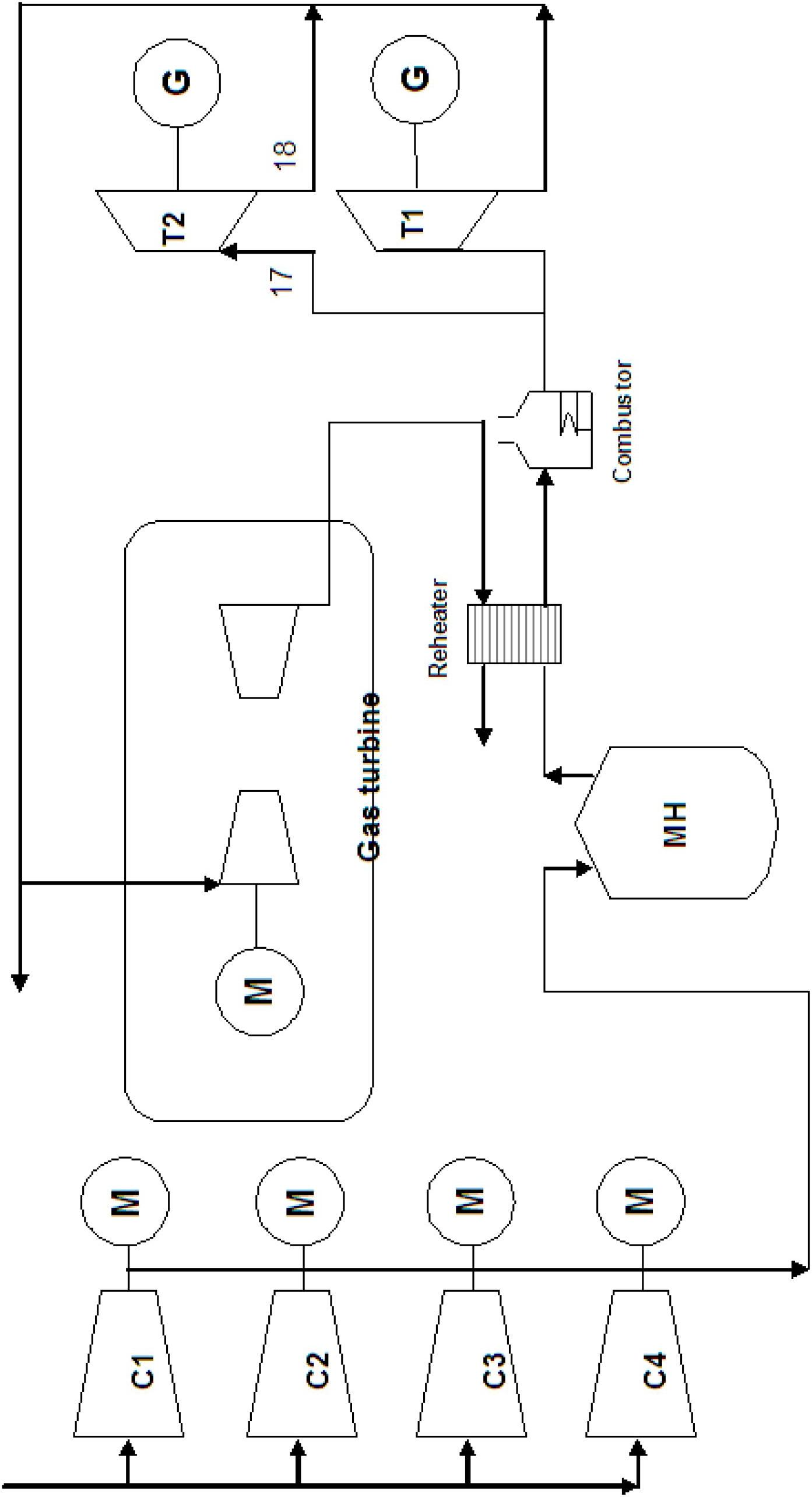

Compressed air energy storage system

InactiveCN102661175ATake advantage ofImprove energy conversion efficiencyPump componentsEngine componentsPre expansionThermal energy storage

The invention discloses a compressed air energy storage system, which comprises a compressor unit, a pre-expansion device, a turbine expansion machine, an intermediate cooler, an electric motor, a power generator, a hot water storage tank and a cold water storage tank, wherein the system utilizes electric energy which is not used up in the user electricity consumption valley period or wind power station power generation peak period for driving the compressor unit to work, the air at the normal pressure is compressed to high pressure, in addition, the part of air with rich pressure energy is stored into a high-pressure-resistance hole, in addition, the stored high-pressure air is released in the user electric consumption peak period or the wind power field generation valley period, an expansion unit is pushed to apply work, and the electric energy is output. The air pre-expansion device is additionally arranged at an outlet of an air storage chamber, so the air inlet pressure of the air turbine expansion machine is stable, the work stability of a power generation system is enhanced, low-temperature air at an outlet of the pre-expansion device is utilized for cooling hot water from the hot water storage tank, the temperature of the low-temperature air is raised through absorption of heat from the hot water, and the cooled water enters the cold water storage tank. The compressed air energy storage system is provided with the hot water storage tank and the cold water storage tank, the water is cyclically utilized in a closed loop, the water is not consumed, in addition, the heat discharged by the compressor is fully utilized and conveyed back to the high-pressure air at the outlet of the pre-expansion device. The high-pressure air at the outlet of the pre-expansion device is recovered through a heat recovering device (HRH).

Owner:XI AN JIAOTONG UNIV

Methods of manufacture of polylactic acid foams

A method of forming a composition of expanded polylactic acid (PLA) resin beads comprising impregnating PLA resin beads with CO2 and holding the impregnated beads at a temperature and pressure that prevents the beads from foaming while allowing the level of impregnated CO2 to reduce. The method may comprise pre-expanding the beads at a pre-expansion temperature. Promptly following pre-expansion or after a desired storage period, the method may comprise introducing the pre-expanded beads into a mould and further expanding and fusing the beads in the mould by application of a temperature greater than the temperature used for pre-expansion. Preferred moulded products include moulded blocks and shaped moulded products, especially blocks adapted to form packing material. Other preferred moulded products include convenience items such as containers including clamshell containers, pots, boxes, bowls, cups, plates and trays.

Owner:BIOPOLYMER NETWORK

Protection-sleeve-carrying paclitaxel drug balloon and preparation method thereof

The invention relates to a protection-sleeve-carrying paclitaxel drug balloon and a preparation method thereof. The protection-sleeve-carrying paclitaxel drug balloon comprises a drug balloon and a paclitaxel-containing degradable drug coating which is coated on a balloon work section. The drug balloon can be used as a pre-expansion balloon, a conveying balloon and a post-expansion balloon and the drug balloon comprises a HUB protection-sleeve handle, a near-end push rod, a transition section, a far-end push rod and a head end. The coating, which is configured by the paclitaxel and a contrast agent, or which includes the paclitaxel, a degradable polymer and a solvent of trichloroethane, acetone or tetrahydrofuran, can be layeredly coated on the balloon work section. Through the arrangement of a protection sleeve, the drug balloon is, during conveying processes from entering blood vessels to reaching diseased regions, in a protection state, so that drugs on the drug balloon may not be scoured, ineffective loss is avoided, initial drug loading capacity of the drug balloon can be reduced, the treatment effect can be meet and at the same time safety of the drug balloon is greatly improved.

Owner:BIOVAS (WUHAN) MEDICAL TECH CO LTD

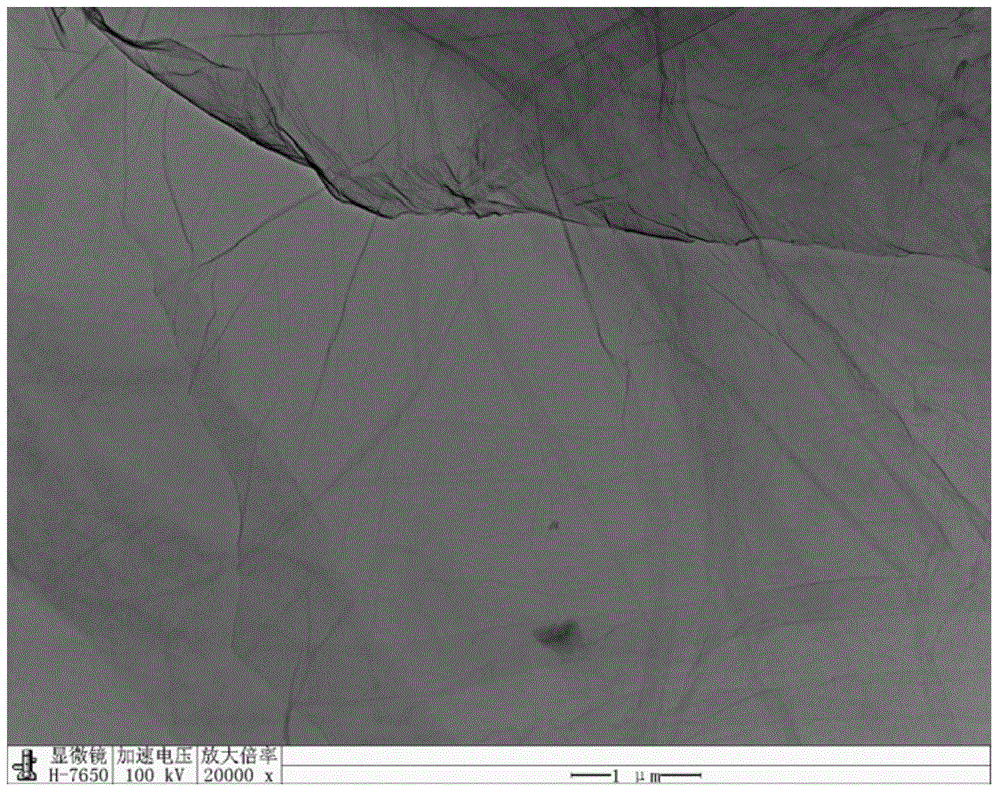

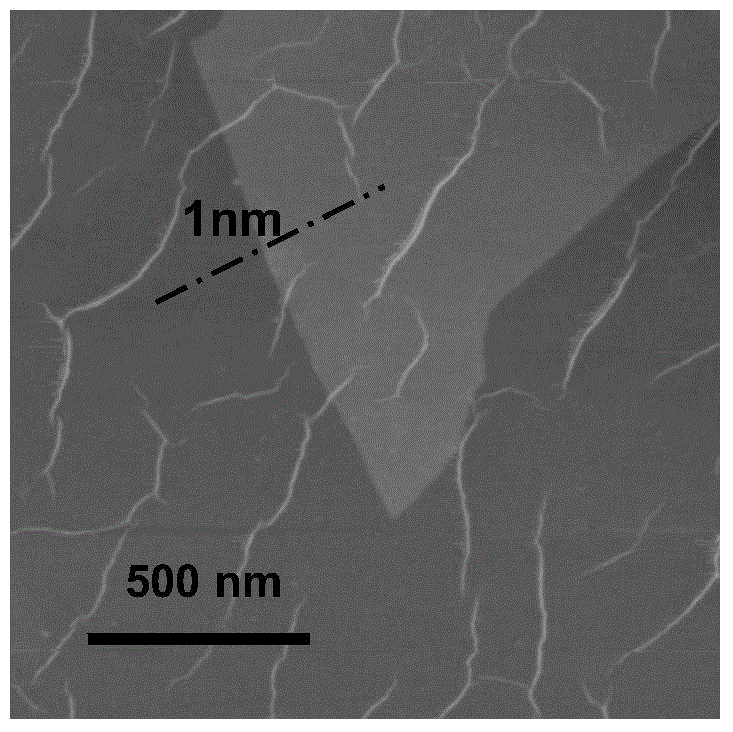

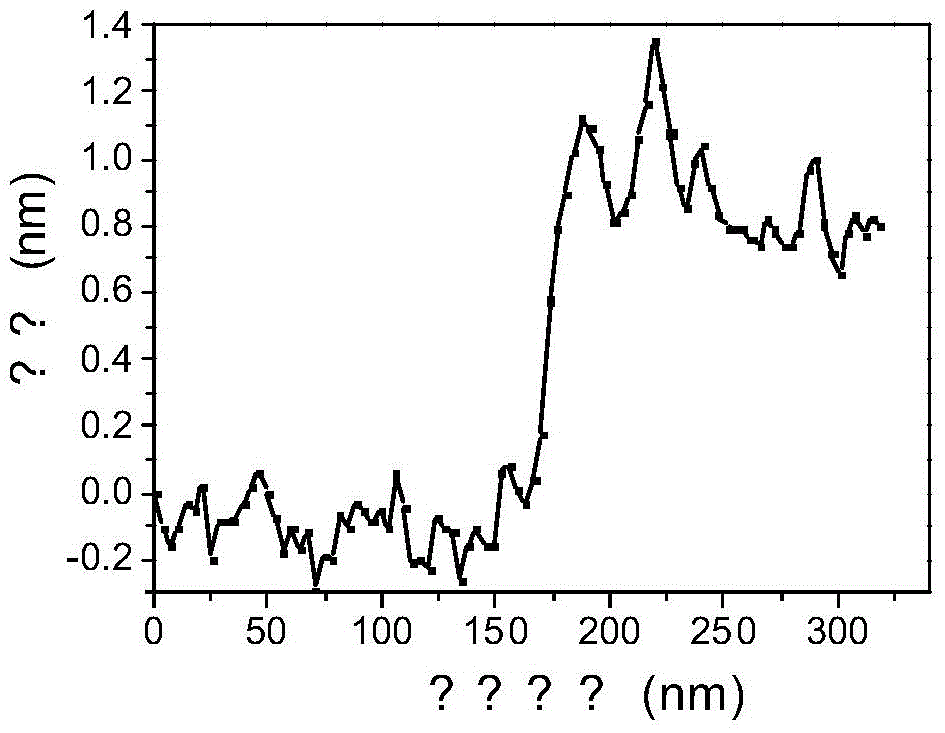

Graphene oxide solution for wet spinning and preparation method thereof, graphene fiber and preparation method of graphene fiber

ActiveCN105088415AEasy qualityQuality improvementInorganic material artificial filamentsWet spinning methodsFiberPre expansion

The invention provides a preparation method of a graphene oxide solution for wet spinning; the preparation method includes the following steps: carrying out centrifugal concentration on a graphene oxide solution, to obtain the graphene oxide solution for wet spinning. The graphene oxide solution is subjected to centrifugal concentration so as to obtain the graphene oxide solution for wet spinning finally. The preparation method of the graphene oxide solution for wet spinning simplifies operation processes, and omits ultrasound, dialysis and pre-expansion processes and the like; the experimental preparation process is simple, the conditions are easy to control, and large-scale production can be realized. In addition, the graphene oxide solution used for wet spinning and prepared by the preparation method provided by the invention has the advantages of stable quality, good water solubility, controllable concentration, and easy adjustment of the size of obtained graphene fiber.

Owner:UNIV OF SCI & TECH OF CHINA

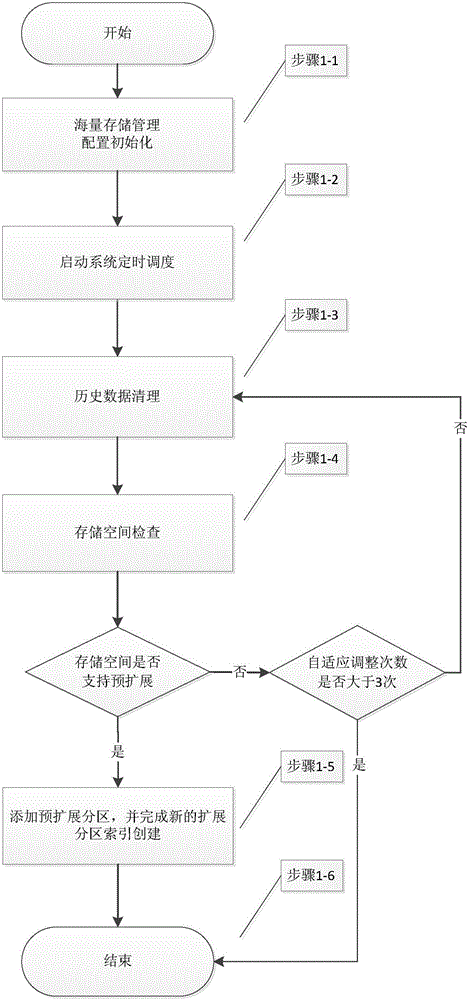

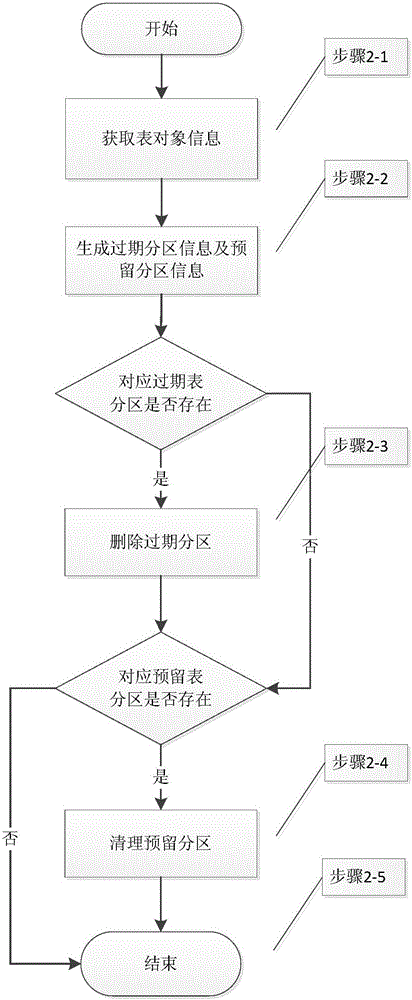

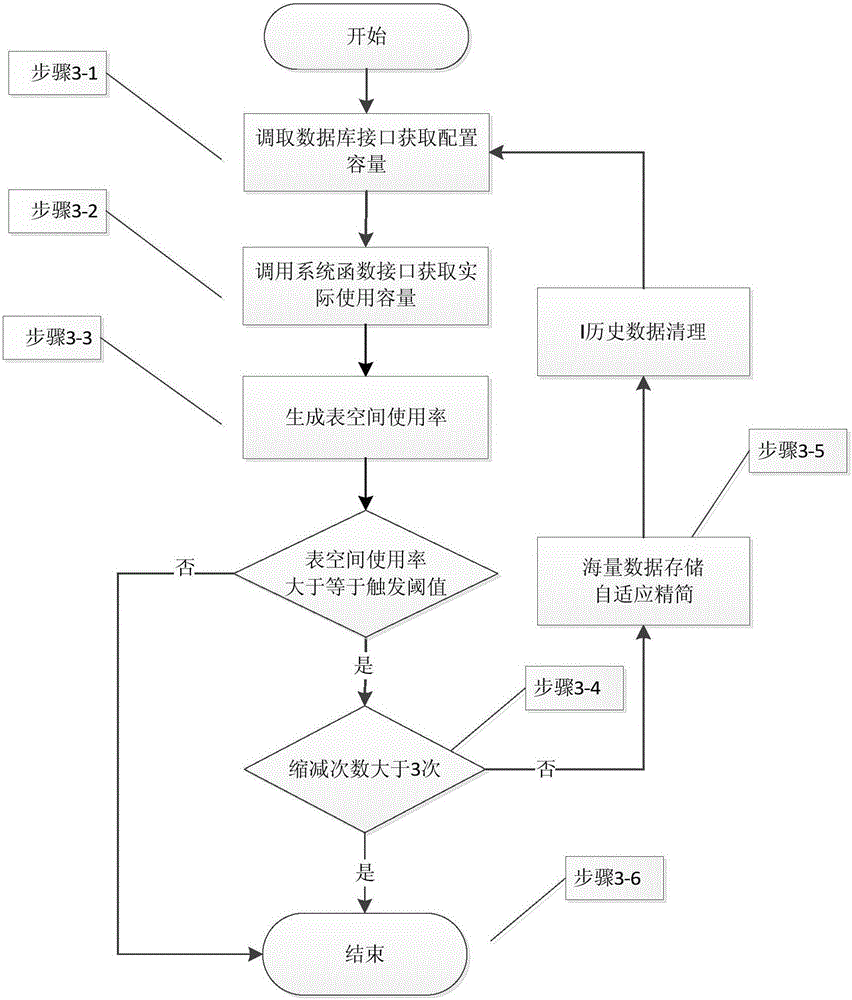

PostgreSQL database mass data management method and system

ActiveCN105893531AGuaranteed validityGuaranteed availabilityInput/output to record carriersSpecial data processing applicationsMass storagePre expansion

The invention provides a postgreSQL database mass data management method and system. The method is implemented based on a Linux platform and includes the steps that mass storage management configuration initialization is performed, and system timing scheduling is started; stale data partitions beyond a reserved time quantum are deleted, and then partition data, within a reserved time quantum and beyond an actual storage cycle, in non-stale data partitions is cleared away; storage space checking is performed, whether a storage space supports pre-expansion or not is judged, if yes, partition pre-expansion operation and index establishment are performed, and otherwise, an adaptive simplification mechanism is triggered. According to the postgreSQL database mass data management method and system, the validity, availability and expandability of data are guaranteed, a numerical basis is provided for data expansion, the maintenance efficiency of database administrators is effectively improved, the database management and maintenance cost is greatly reduced, and the postgreSQL database mass data management method and system have significant market value.

Owner:WUHAN HONGXIN TECH SERVICE CO LTD

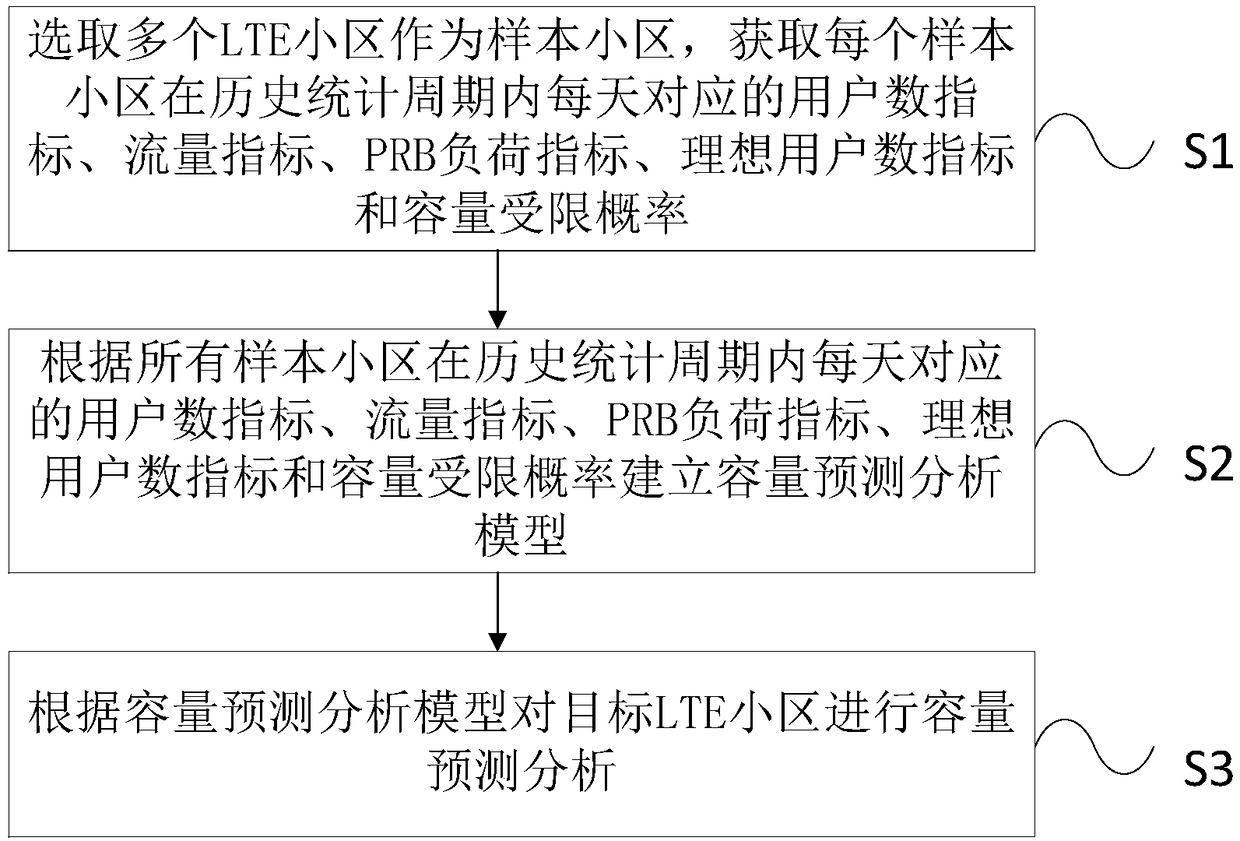

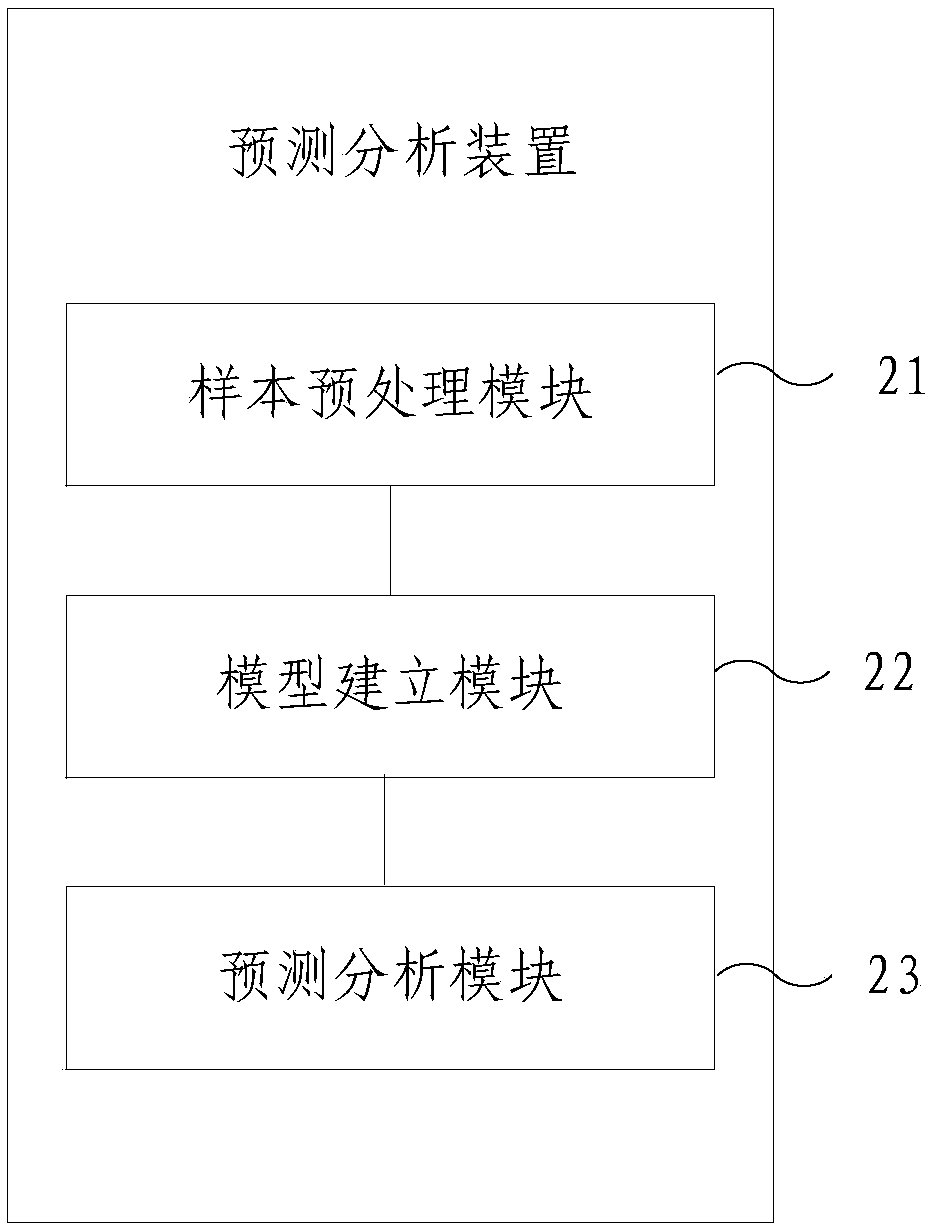

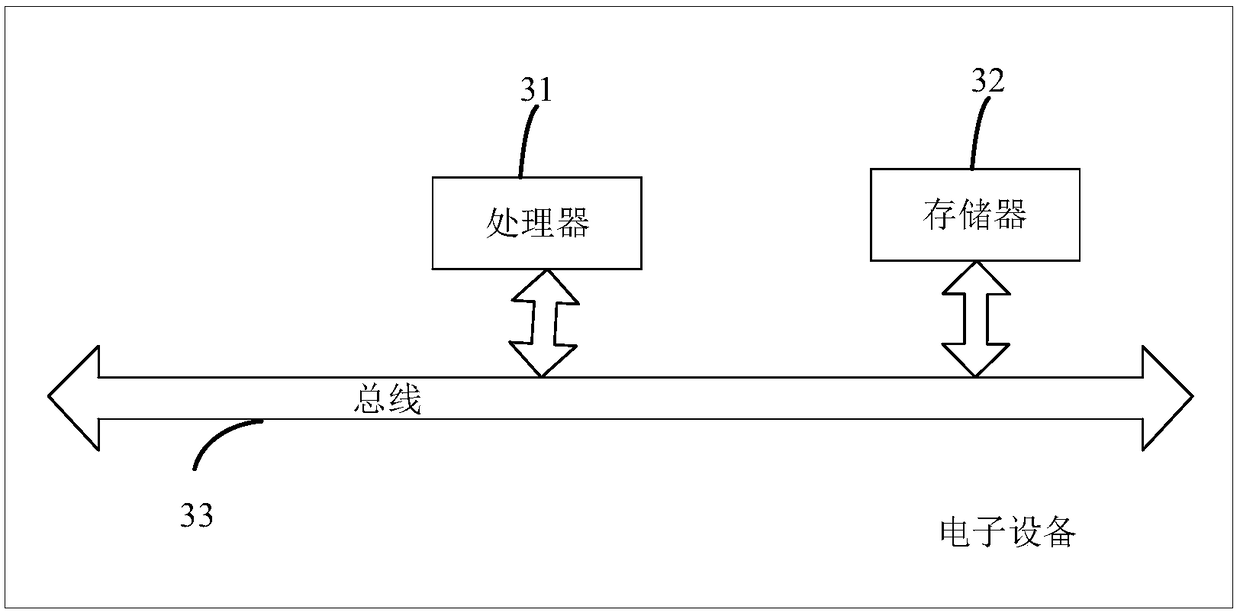

LTE cell capacity prediction analysis method and device

The embodiment of the invention provides an LTE cell capacity prediction analysis method and device. A plurality of LTE cells are selected as sample cells, and a corresponding user number index, flowindex, PRB load index, ideal user number index and capacity limited probability of each sample cell each day in a historical statistical period are acquired; according to the corresponding user numberindexes, flow indexes, PRB load indexes, ideal user number indexes and capacity limited probabilities of all the sample cells each day in the historical statistical period, a capacity prediction analysis model is established; and according to the capacity prediction analysis model, capacity prediction analysis is carried out on a target LTE cell. According to the method and the device, various indexes such as a user number, flow, a PRB load, an ideal user number and the like, are comprehensively considered, and the capacity prediction analysis model is established to implement capacity prediction analysis on the target LTE cell, so that a capacity limited cell is subjected to capacity pre-expansion, the cell capacity problem can be predicted and processed in advance, and daily optimization and the emergency guarantee working ability of a wireless network can be effectively promoted.

Owner:BEIJING MATARNET TECH

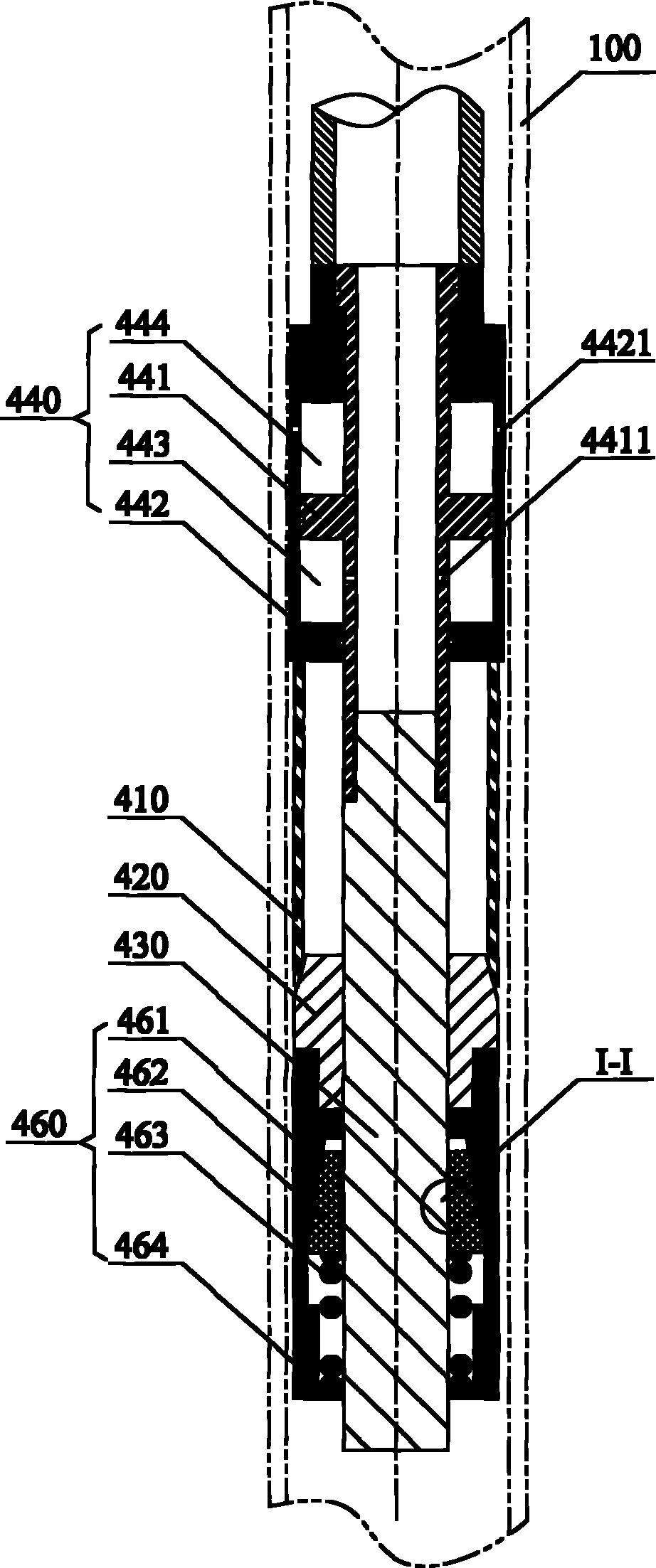

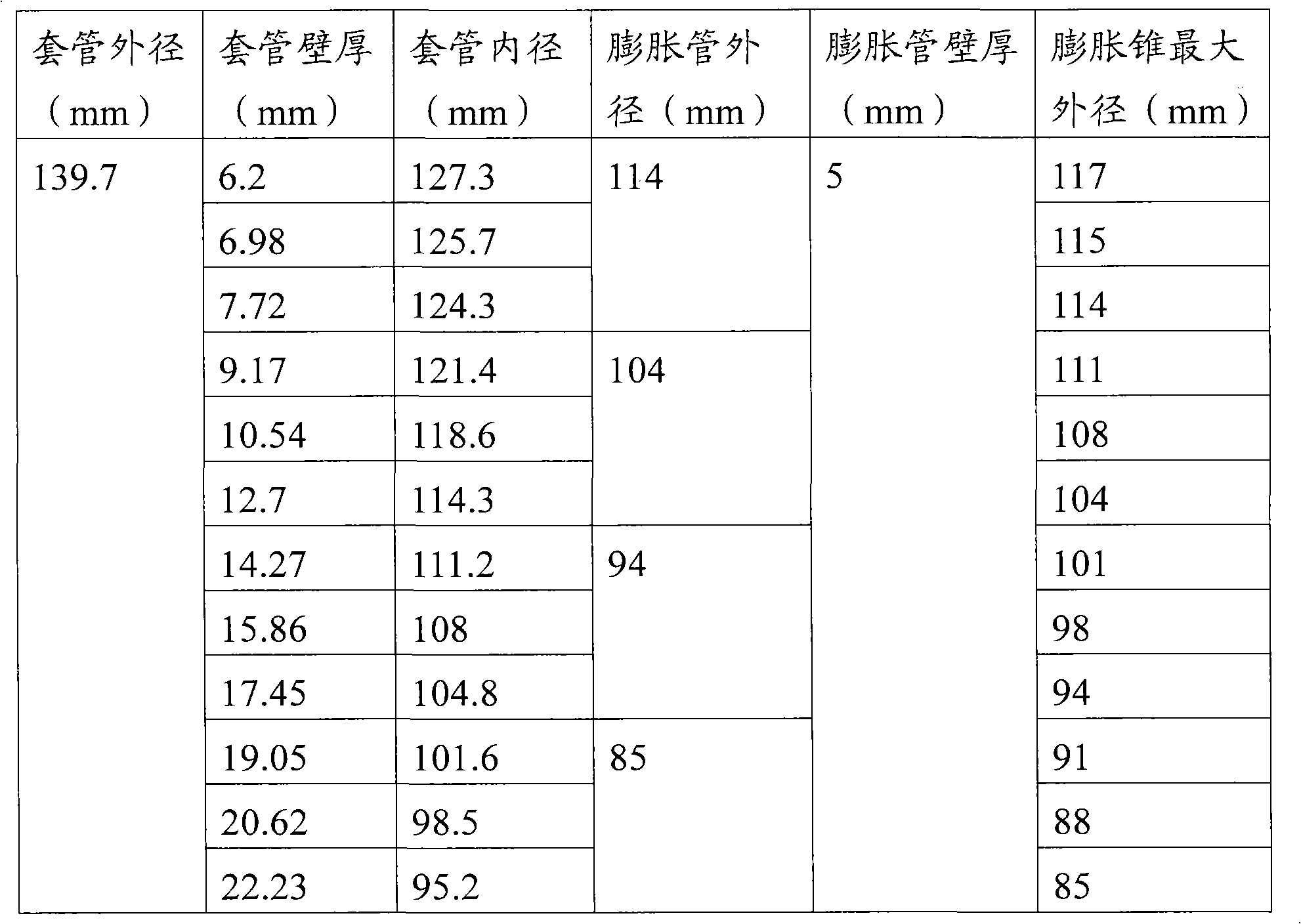

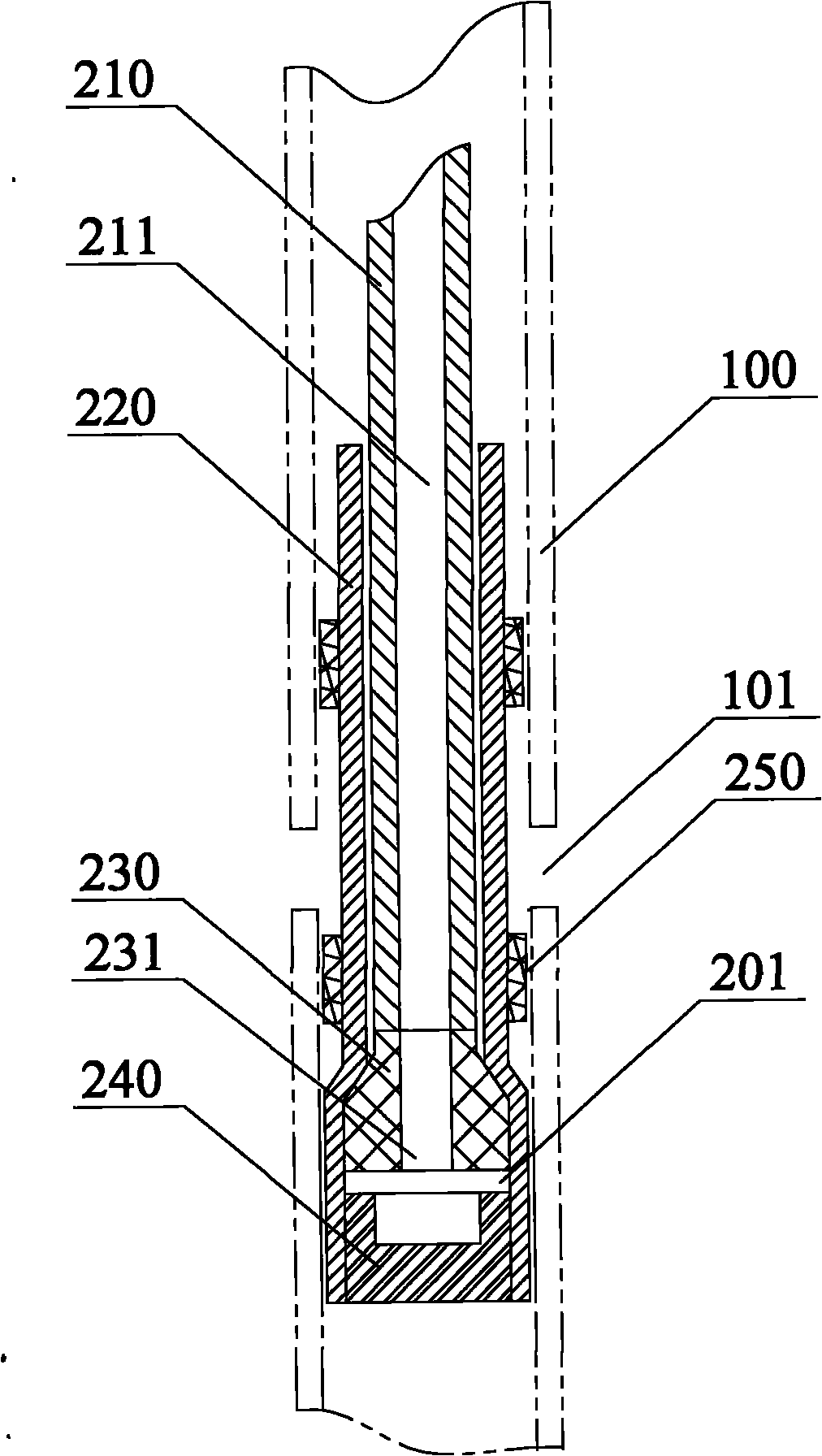

Expansion tube assembly, oil well subsidy construction mechanism and construction method

ActiveCN101812980AReduce thicknessLarge diameterBorehole/well accessoriesPre expansionMaximum diameter

The invention discloses an expansion tube assembly, an oil well subsidy construction mechanism with the expansion tube assembly, and an oil well subsidy construction method. The disclosed expansion tube assembly comprises an expansion tube, an expansion cone, a central rod and a power cylinder, wherein the expansion cone is installed on the central rod; the power cylinder comprises a cylinder barrel and a piston; the piston rod of the piston can be respectively in sliding fit with the upper end part and the lower end part of the cylinder barrel; the piston body of the piston is installed on the piston rod and is matched with the inner wall surface of the cylinder barrel; a first pressure chamber and a second pressure chamber are formed in the cylinder barrel; the central rod is connected with the lower end of the piston rod; the expansion tube is sleeved outside the central rod and is positioned between the cylinder barrel and the expansion cone; the piston is provided with a pressurization channel; and the cylinder barrel is provided with a pressure relief vent. Compared with the existing expansion tube assembly, the expansion tube assembly disclosed by the invention does not have a pre-expansion part bearing high pressure, so that the expansion tube can have smaller thickness, the maximum diameter of the expansion cone is increased, the subsidy position has a larger drift diameter, and the influence of subsidy construction on an oil well is reduced.

Owner:华鼎鸿基石油工程技术(天津)有限公司

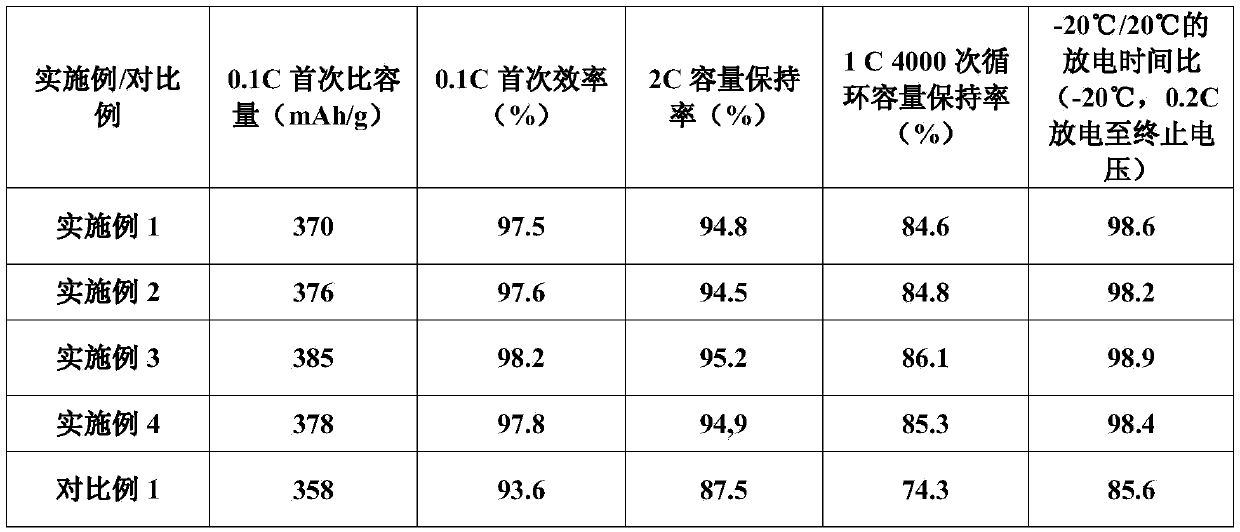

Preparation method of low-temperature and high-rate graphite anode material for power battery

ActiveCN105375030AImprove low-temperature lithium intercalation performanceImproved magnification performanceCell electrodesPre expansionHigh rate

The invention discloses a preparation method of a low-temperature and high-rate graphite anode material for a power battery. The method comprises the following steps: carrying out agglomeration pelletizing by a simple and efficient spray drying process and obtaining a porous graphite secondary particle cluster; and carrying out secondary surface coating and obtaining a low-temperature graphite anode material for a lithium-ion battery. In the anode material structure, a certain pre-expansion space is prefabricated in each particle of graphite which is modified by a micro-expansion technology, so that damage to a 'core-shell' structure due to graphite expansion is effectively inhibited in charge and discharge processes; the 'core-shell' structure is relatively well maintained; and particularly, the graphite anode material has good cycling stability in quick charge and discharge processes. After micron graphite is pelletized, primary graphite particles are agglomerated into secondary particles in a porous carbon matrix in the core; the isotropic degree is high; and single-direction expansion and shrinkage caused by charge and discharge are small, so that the low-temperature lithium intercalation performance and rate capability of the low-temperature and high-rate graphite anode material are greatly improved.

Owner:FUJIAN XFH NEW ENERGY MATERIALS CO LTD

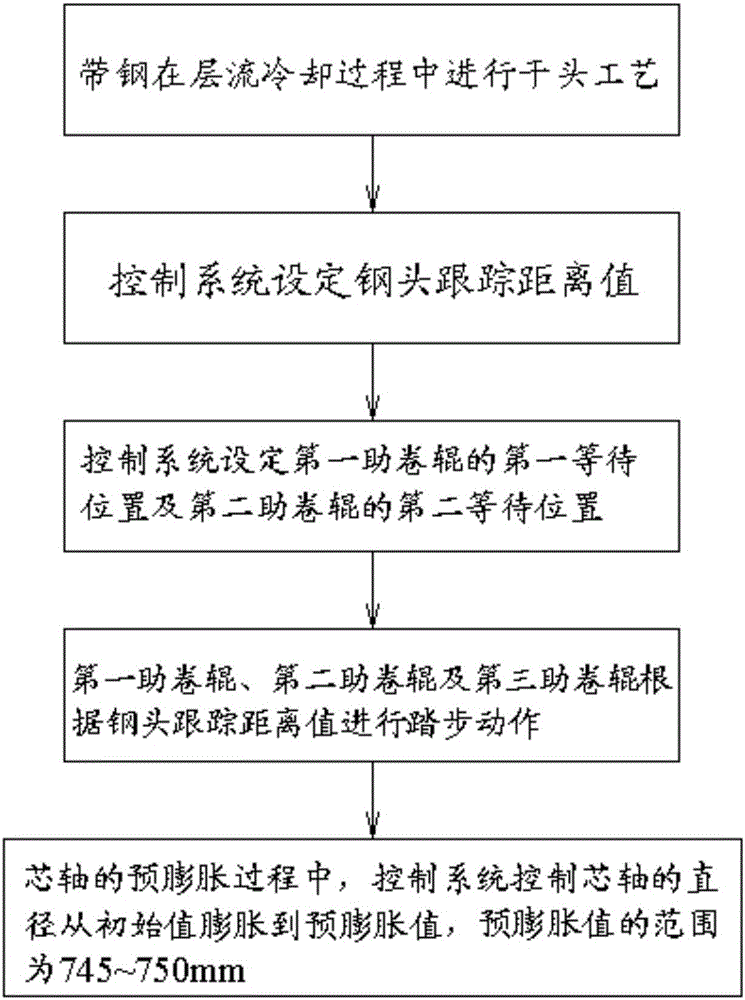

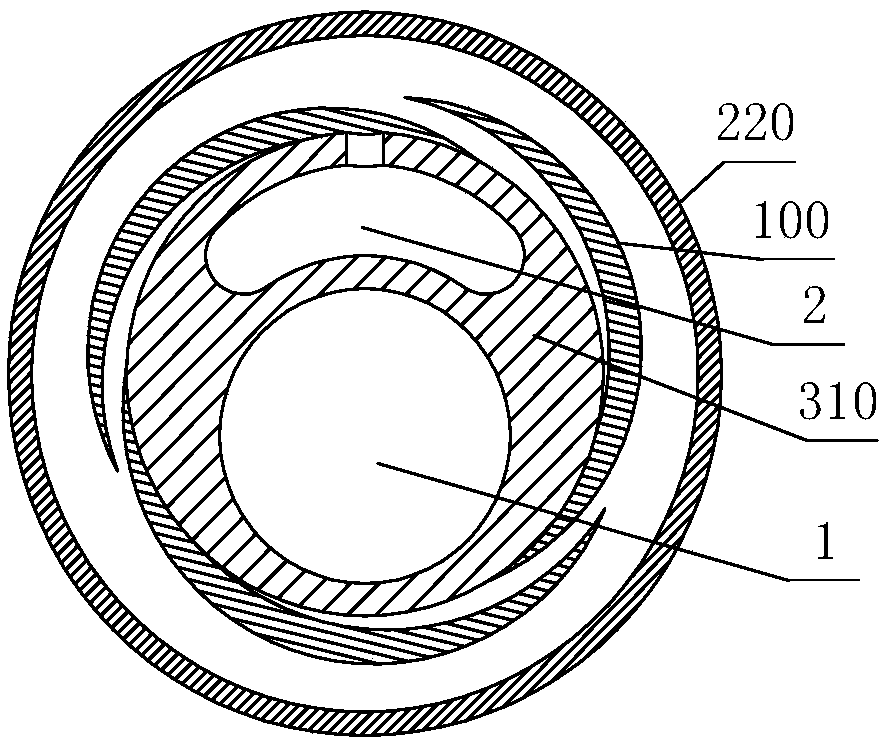

Control method for stable coiling of head of hot-rolled high-strength steel

ActiveCN105013860ASolve the problem that the temperature is relatively low and the bending performance is not idealImproved bending propertiesRoll mill control devicesMetal rolling arrangementsPre expansionControl system

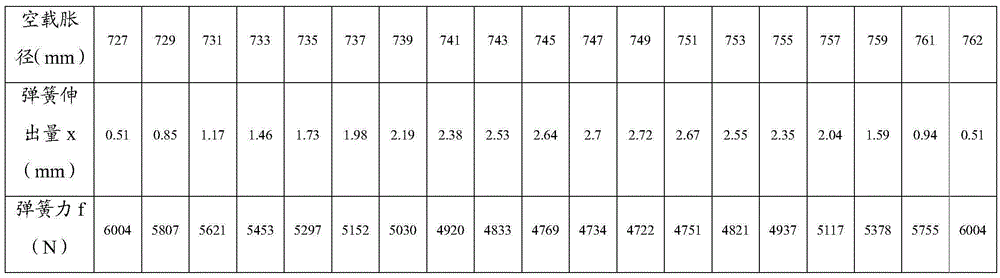

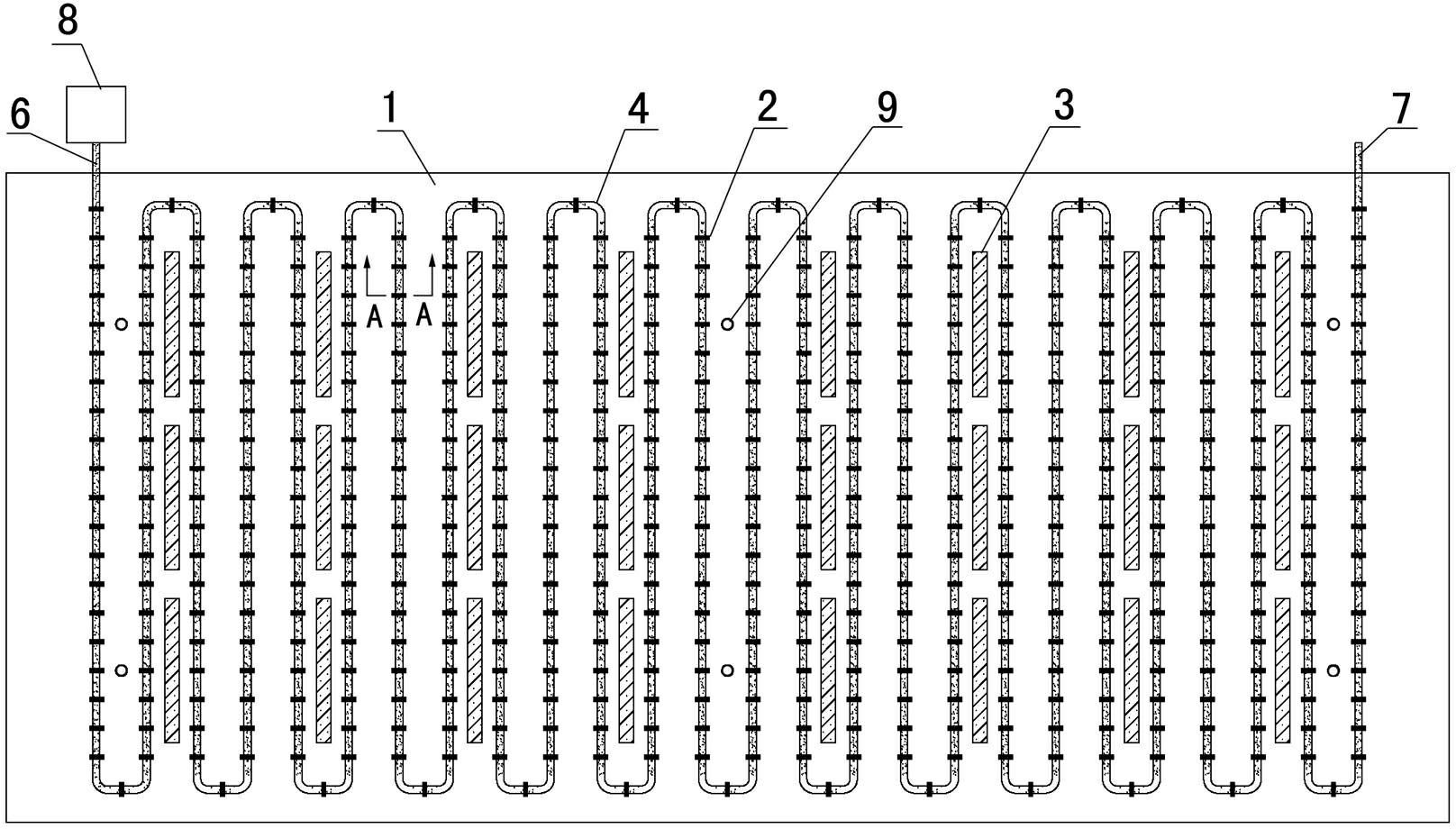

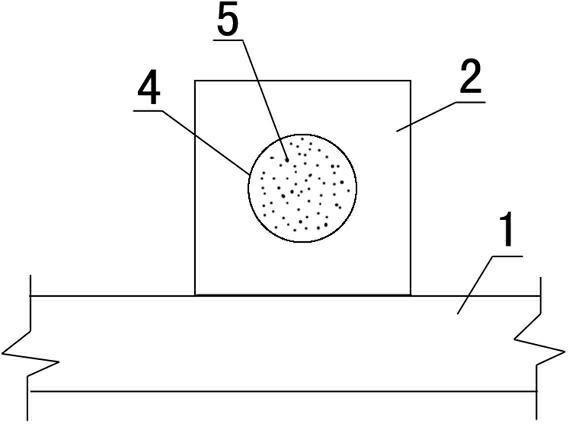

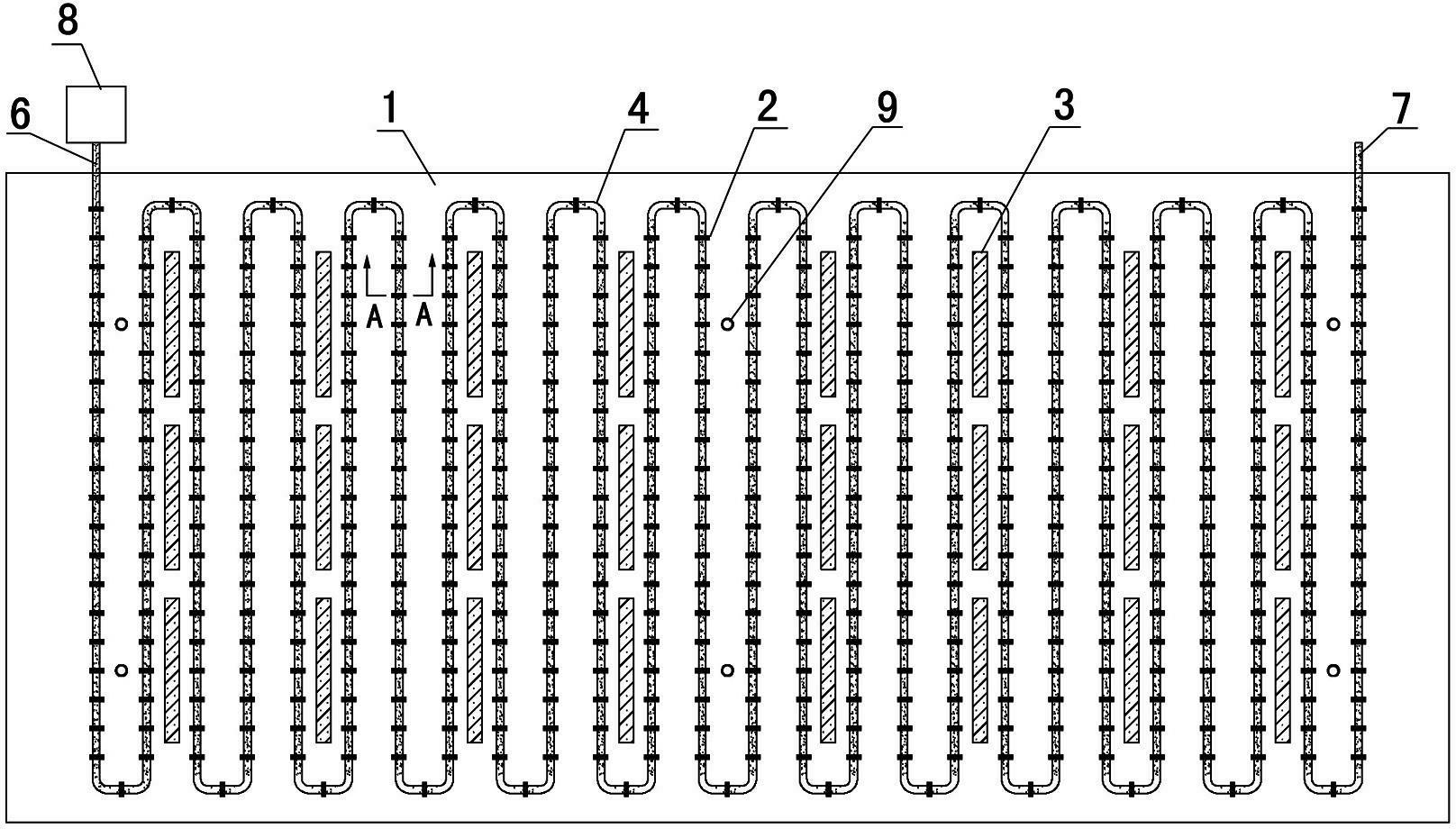

The invention relates to a control method for stable coiling of the head of hot-rolled high-strength steel. The method includes the following steps that head drying is performed on the strip steel in the laminar cooling process; a control system sets steel head tracking distance values; the control system sets the first waiting position of a first assistant coiling roll and the second waiting position of a second assistant coiling roll; the first assistant coiling roll, the second assistant coiling roll and a third assistant coiling roll conduct stepping according to the steel head tracking distance values; and in the pre-expansion process of a central spindle, the control system controls the central spindle to expand to a pre-expansion diameter value ranging from 745 mm to 750 mm from an initial diameter value. By means of the control method, it can be guaranteed that the head of the high-strength steel enters a coiling machine stably and smoothly, the situation that the head is abutted or rubs against relevant equipment, and consequently the steel strip halts is avoided, and therefore the steel heaping accident is avoided.

Owner:SHOUGANG JINGTANG IRON & STEEL CO LTD

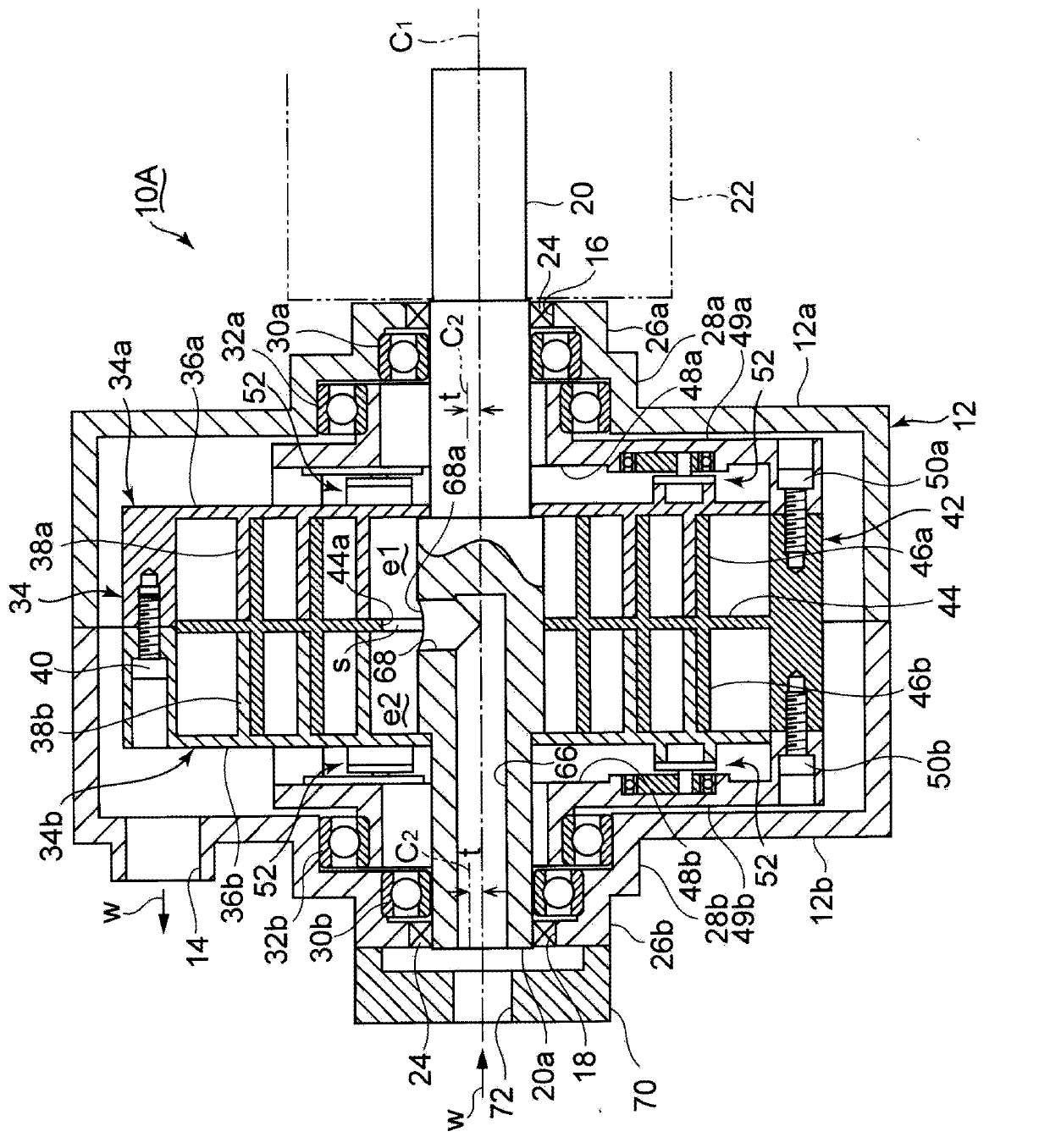

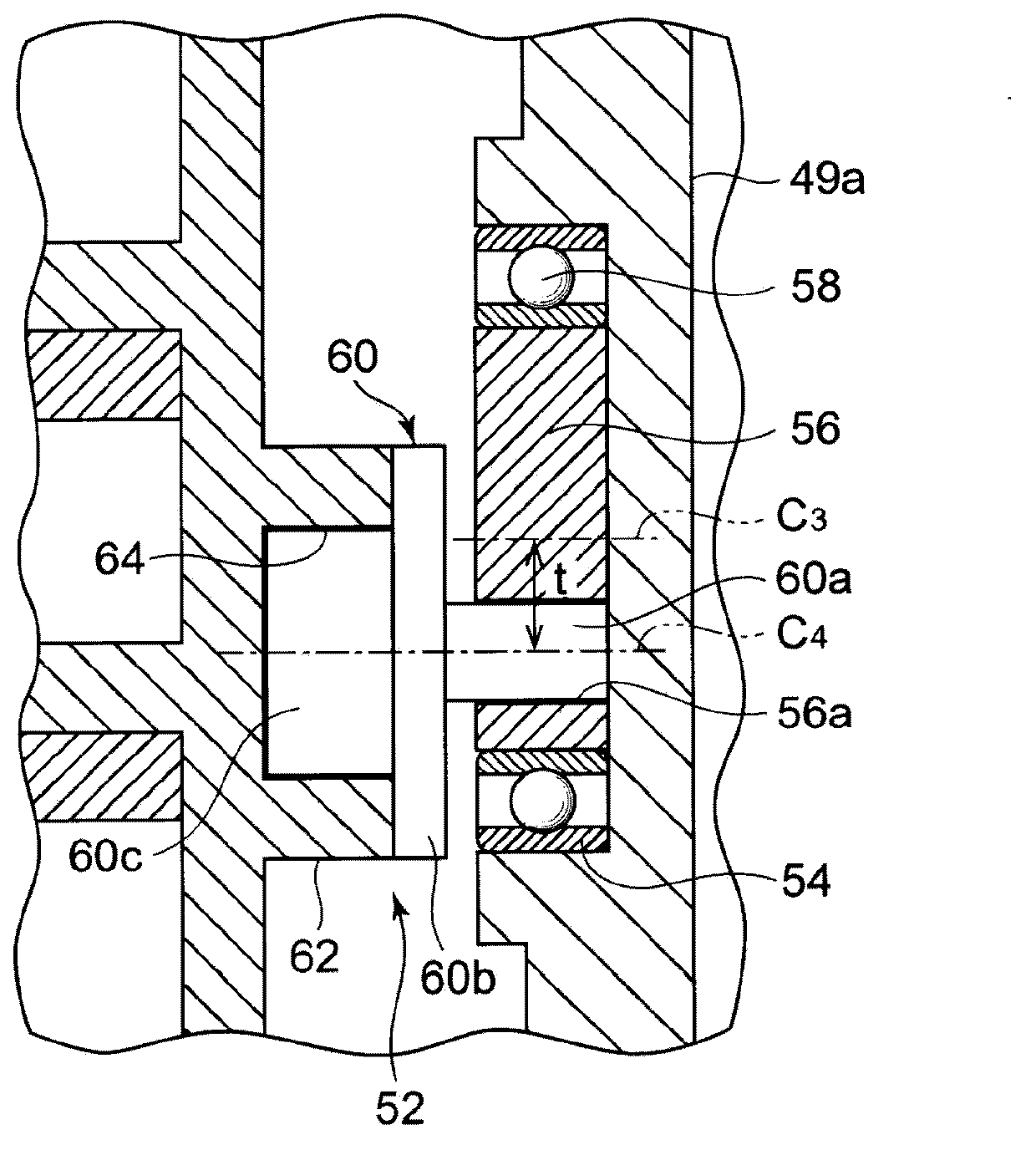

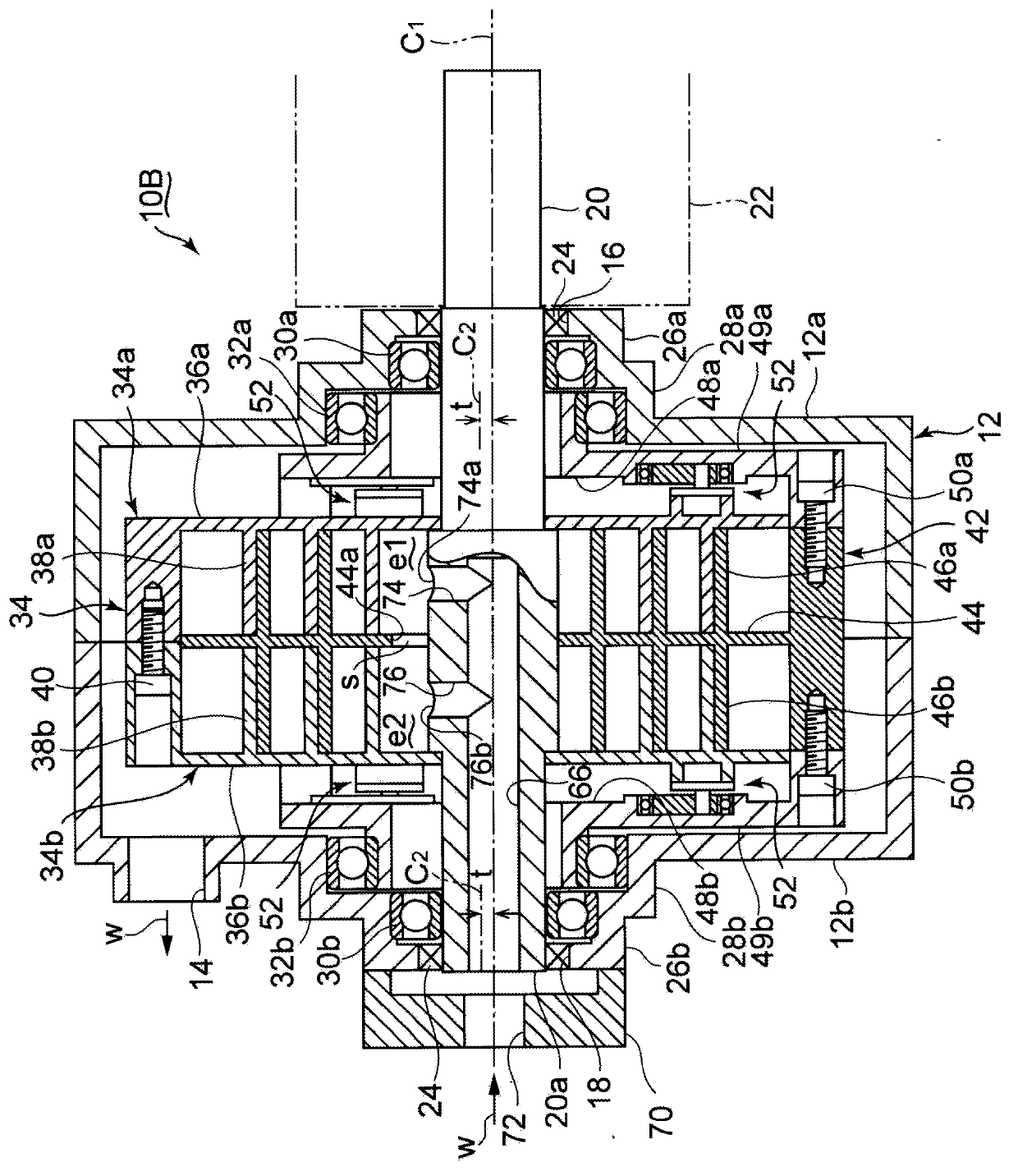

Scroll expander

InactiveCN103375174AImprove sealingPrecise positioningEngine of arcuate-engagement typeRotary piston pumpsPre expansionDrive shaft

Owner:ANEST IWATA CORP

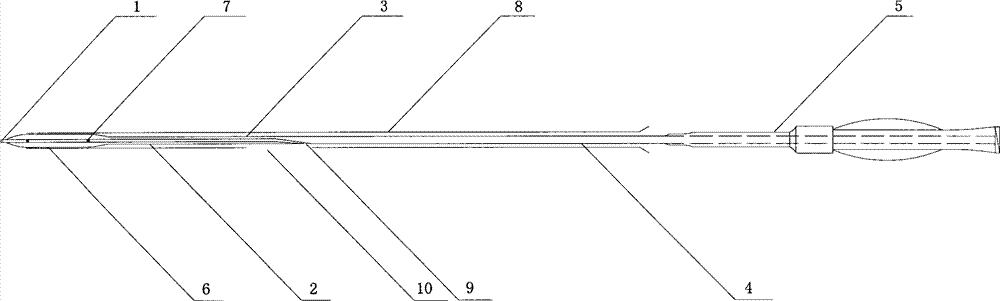

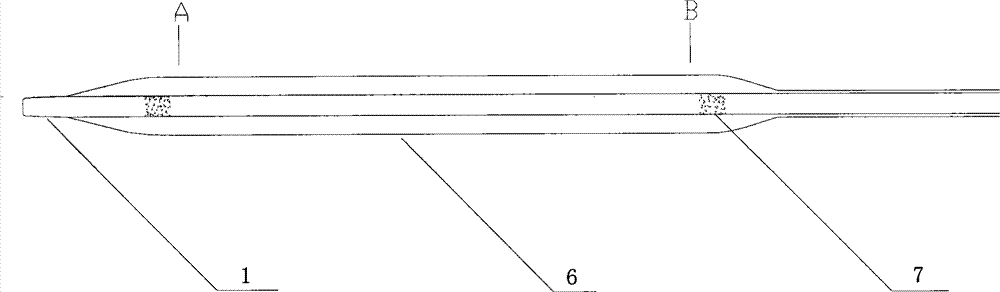

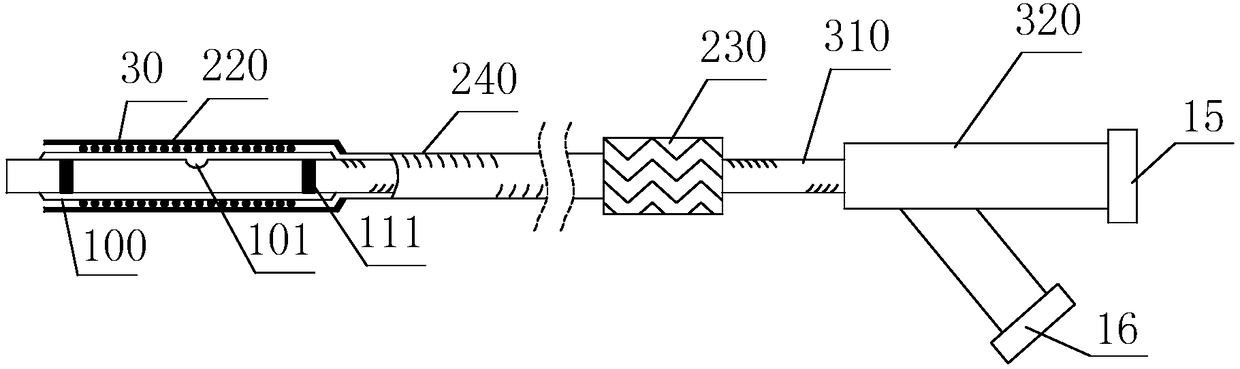

Medicine-coated balloon catheter

PendingCN109381780ALarge doseSmooth entryBalloon catheterMulti-lumen catheterPre expansionBalloon catheter

The invention discloses a medicine-coated balloon catheter comprising a push catheter, at least one expandable first balloon at a distal end of the push catheter, and a pre-expansion mechanism. At least a portion of the surface of the first balloon is covered with a drug coating. The pre-expansion mechanism comprises an expandable first expansion sleeve that is movably sleeved outside the first balloon, and a first expansion sleeve connector that is coupled to the proximal end of the first expansion sleeve. The first expansion sleeve connector is sleeved outside the push catheter and moves relative to the push catheter in the axial direction. The medicine-coated balloon catheter of the invention can not only effectively pre-expand the diseased part, but also effectively avoid the loss of the medicine-coated balloon in the conveying process, and the operation process is simple, the operation time is short, and the cost is low.

Owner:HANGZHOU WEIQIANG MEDICAL TECH CO LTD

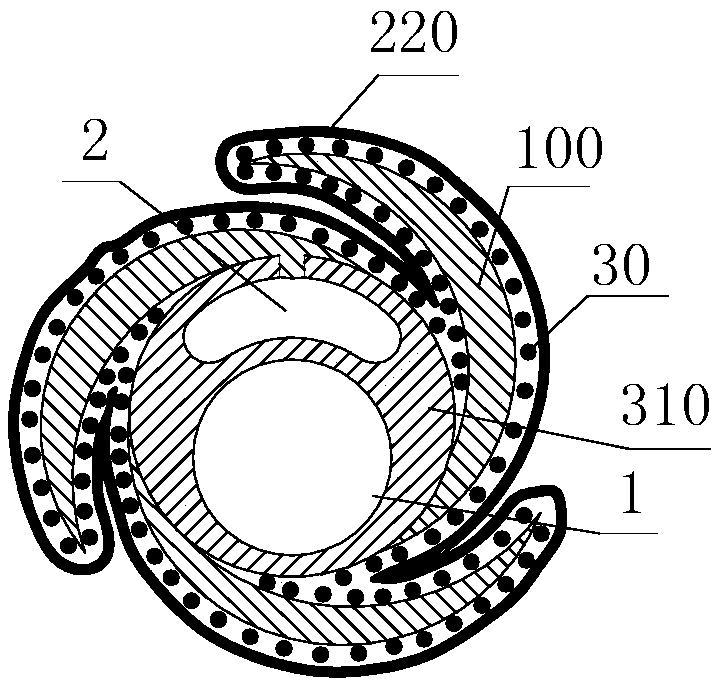

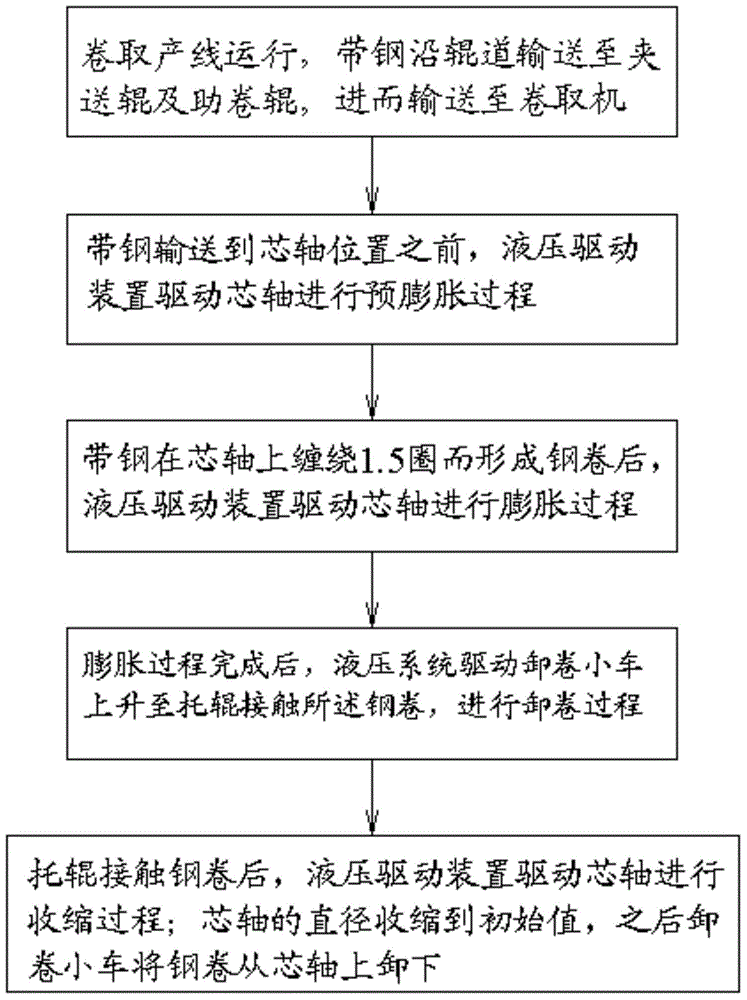

Control method for preventing telescopic discharged hot-rolled pipeline steel coils

The invention relates to a control method for preventing telescopic discharged hot-rolled pipeline steel coils. The control method comprises the following steps: operating a coiling production line, conveying band steel to a pinch roll and a pinch roll along a roller way, and further conveying to a coiling machine; driving a mandrel to carry out pre-expansion process by a hydraulic driving device before the band steel is conveyed to the position of the mandrel; winding 1.5 circles of band steel on the mandrel to form a steel coil and driving the mandrel to carry out expansion process by the hydraulic driving device; driving a coil discharging trolley to ascend until a carrier roller is contacted with the steel coil by a hydraulic system after the expansion process is finished, so as to carry out coil discharging process; driving the mandrel to perform contraction process by the hydraulic driving device after the carrier roller is contacted with the steel coil; and discharging the steel coil from the mandrel by the coil discharging trolley when the diameter of the mandrel is contracted to be minimum. The control method can ensure that the expanded diameter of the mandrel is reasonable, the coil contact height of the coil discharging trolley is appropriate, the telescopic discharging coil caused by rubbing of the mandrel and the inner wall of the steel coil is thoroughly reduced, the coil discharging operation is enabled to be carried out smoothly and the stable batch pipeline steel production is realized.

Owner:SHOUGANG JINGTANG IRON & STEEL CO LTD

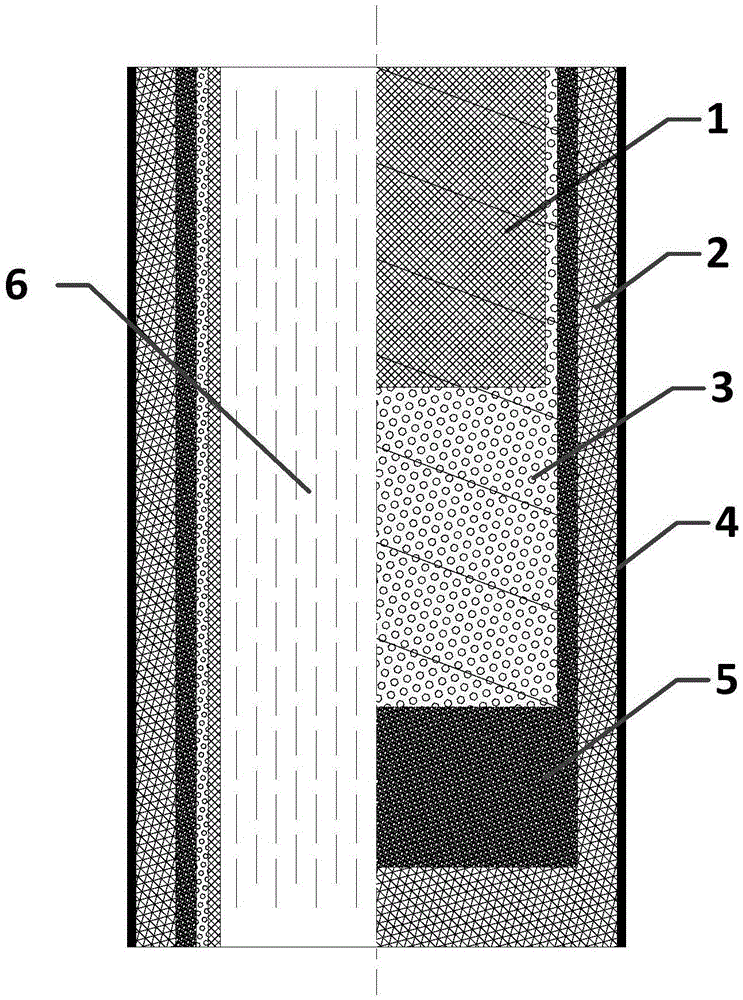

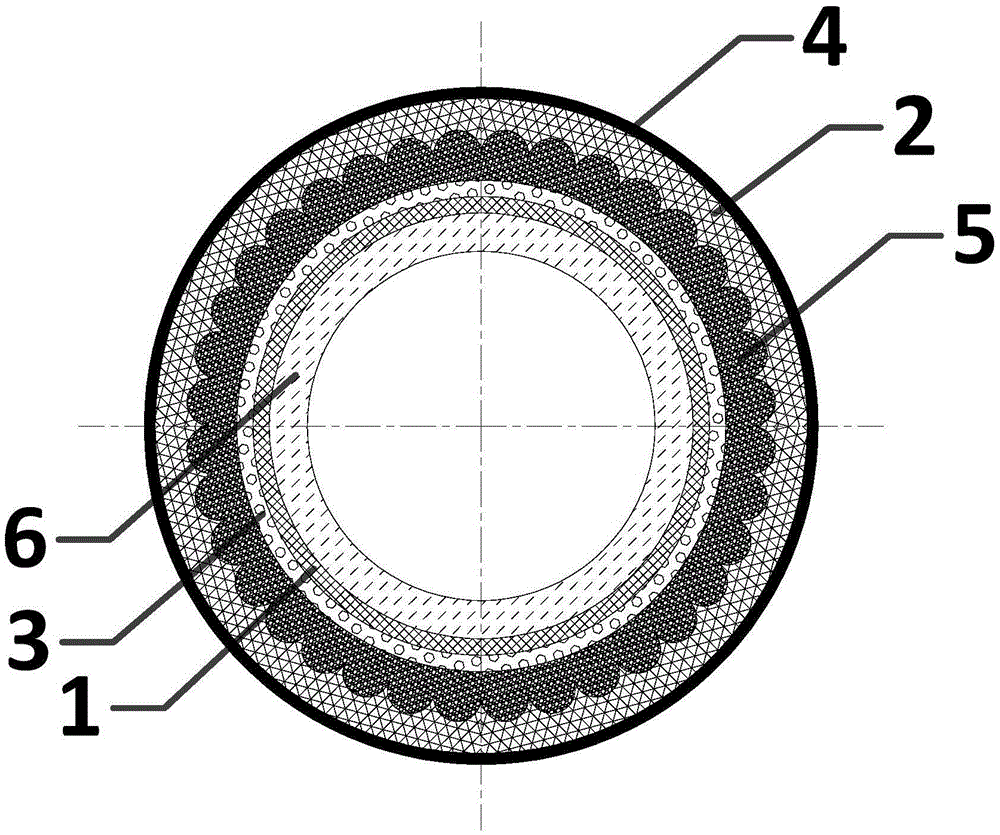

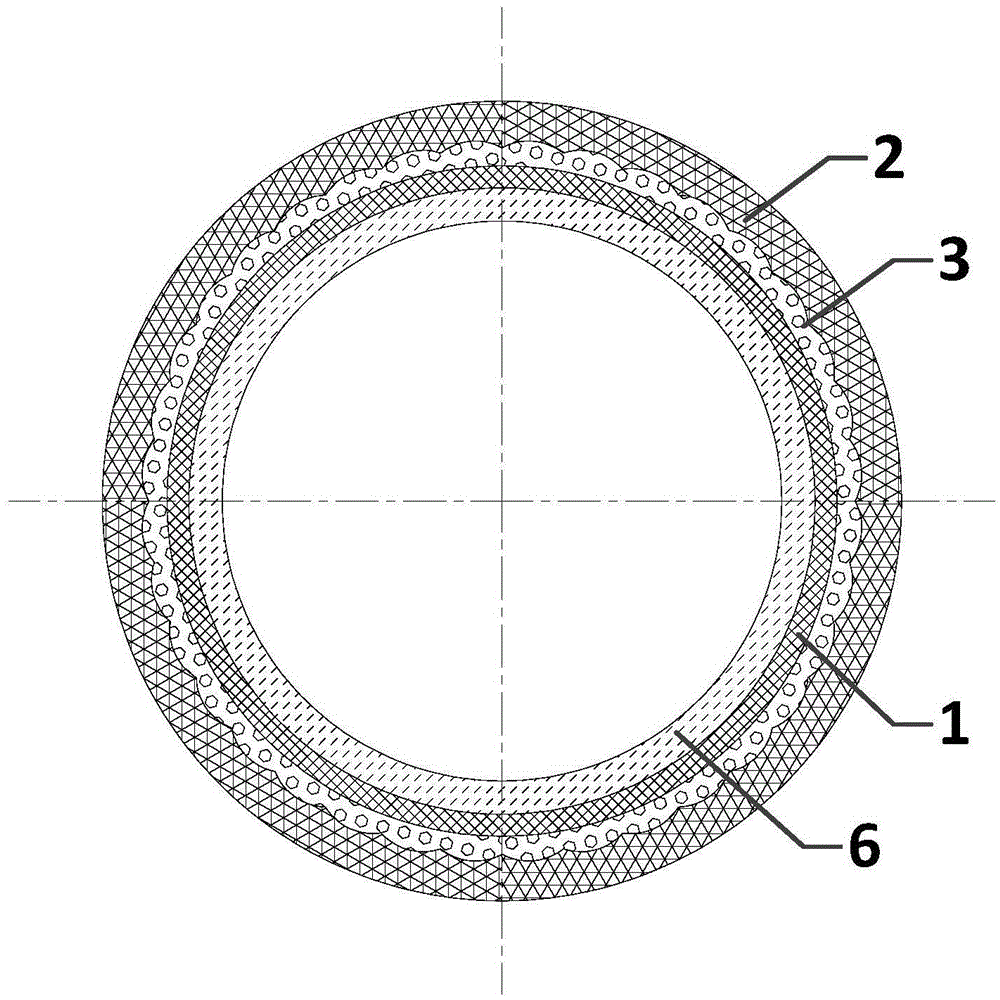

Novel self-expansion screen pipe

The invention provides a novel self-expansion screen pipe, comprising a shape memory alloy slotted base pipe, a metal screen pipe, a water-soluble filler layer, a shape memory polymer layer and a water-soluble protective layer sequentially from inside to outside. The shape memory alloy slotted base pipe is made of shape memory alloy, contracts to a pre-expansion shape at high temperature and self-expands under temperature effect after being tripped in to a specified position; the shape memory polymer layer contracts to a pre-expansion state at high temperature and never changes in shape at normal temperature. Compared with the prior art, the novel self-expansion screen pipe has the advantages that the diameter is increased through the expansion pipe technology; multiple producing layers can be subjected to sand prevention treatment at a time; gravel filling is not required so that the influence of insufficient filling on sand prevention effect is avoided; fewer string trips-in are required so that operation cost is reduced; double filtration with the screen pipe and the shape memory polymer layer is achieved, improving the sand prevention effect; a well wall can be effectively supported so that wall collapse due to sand discharge is prevented.

Owner:CNPC BOHAI DRILLING ENG

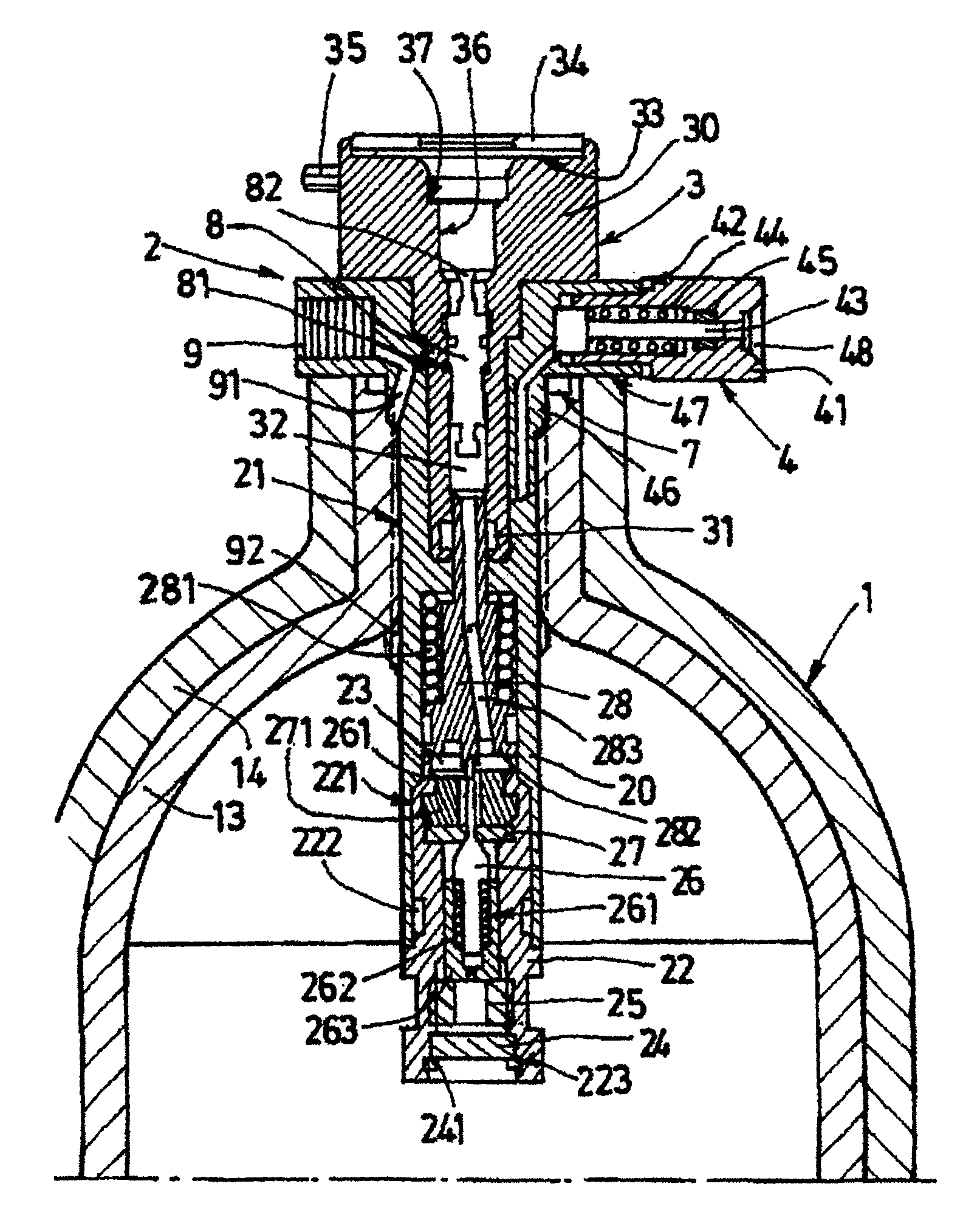

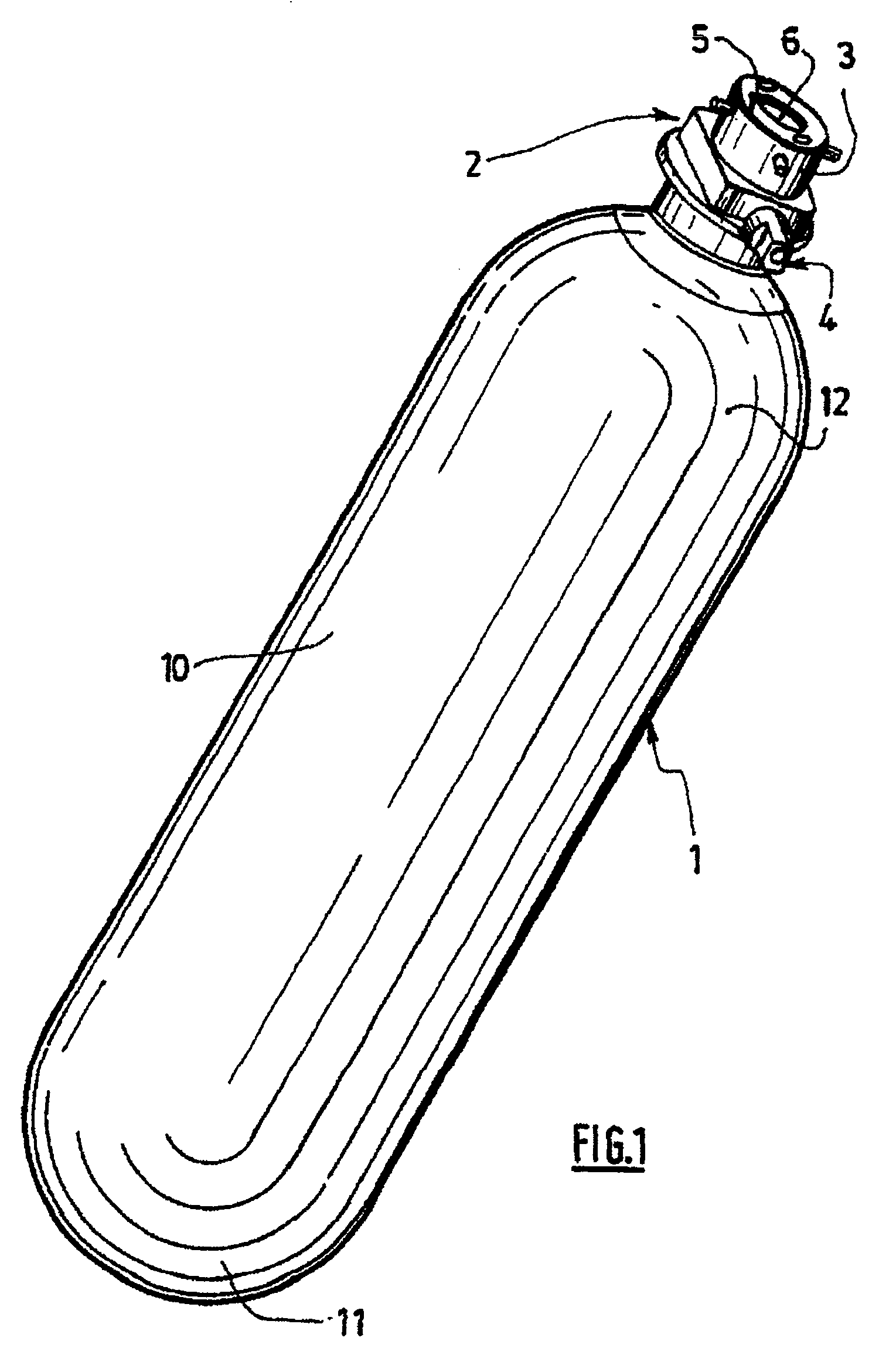

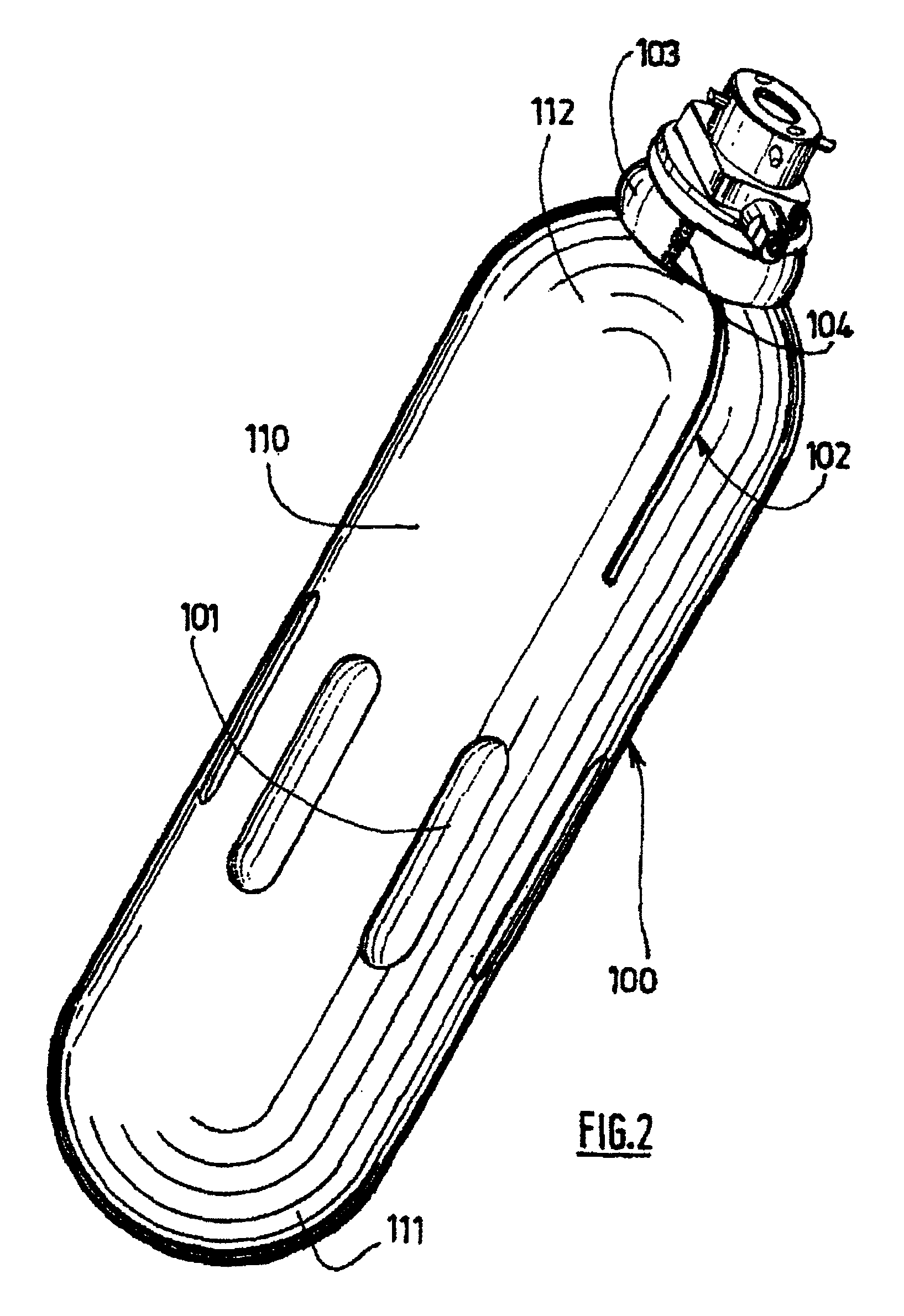

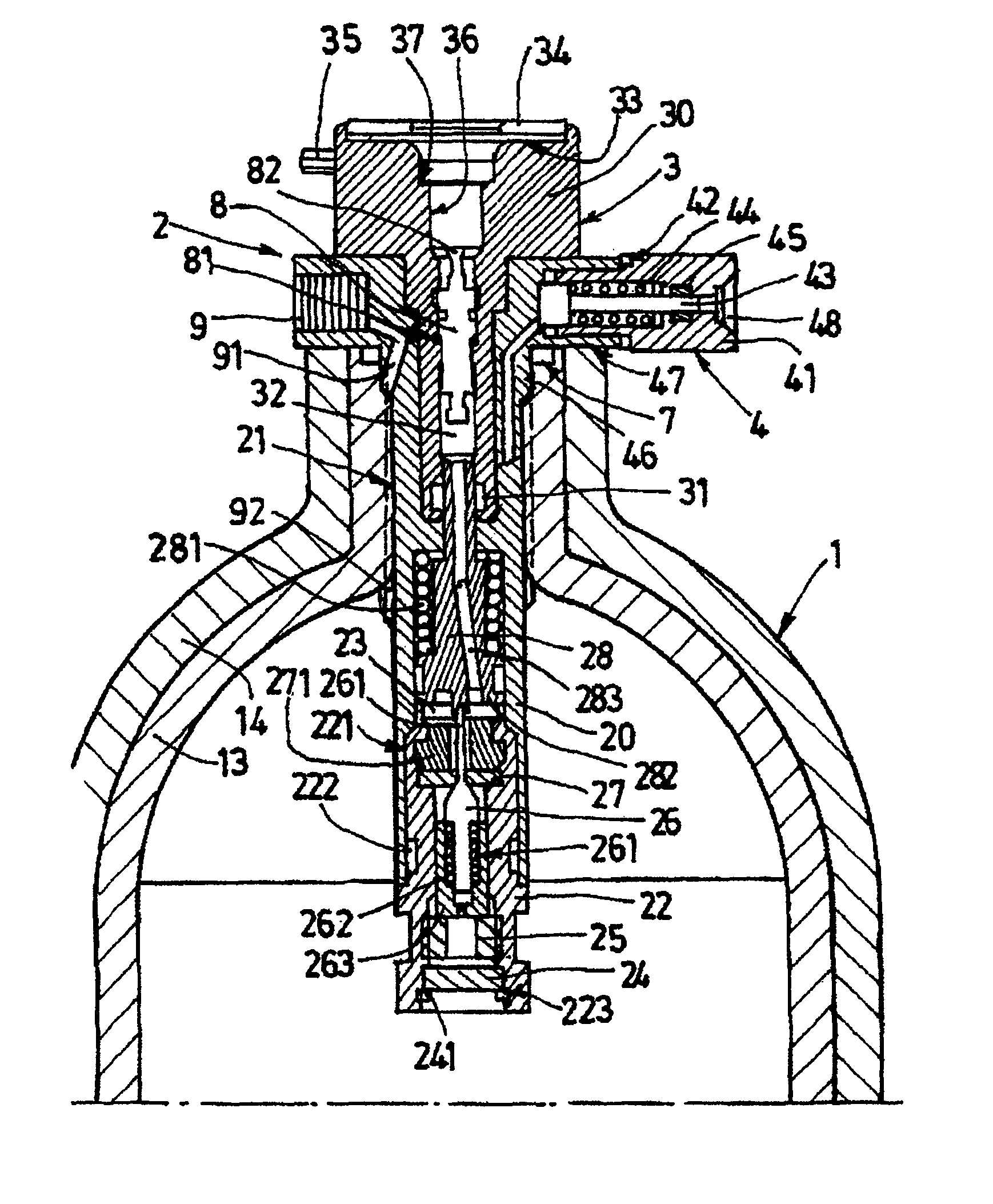

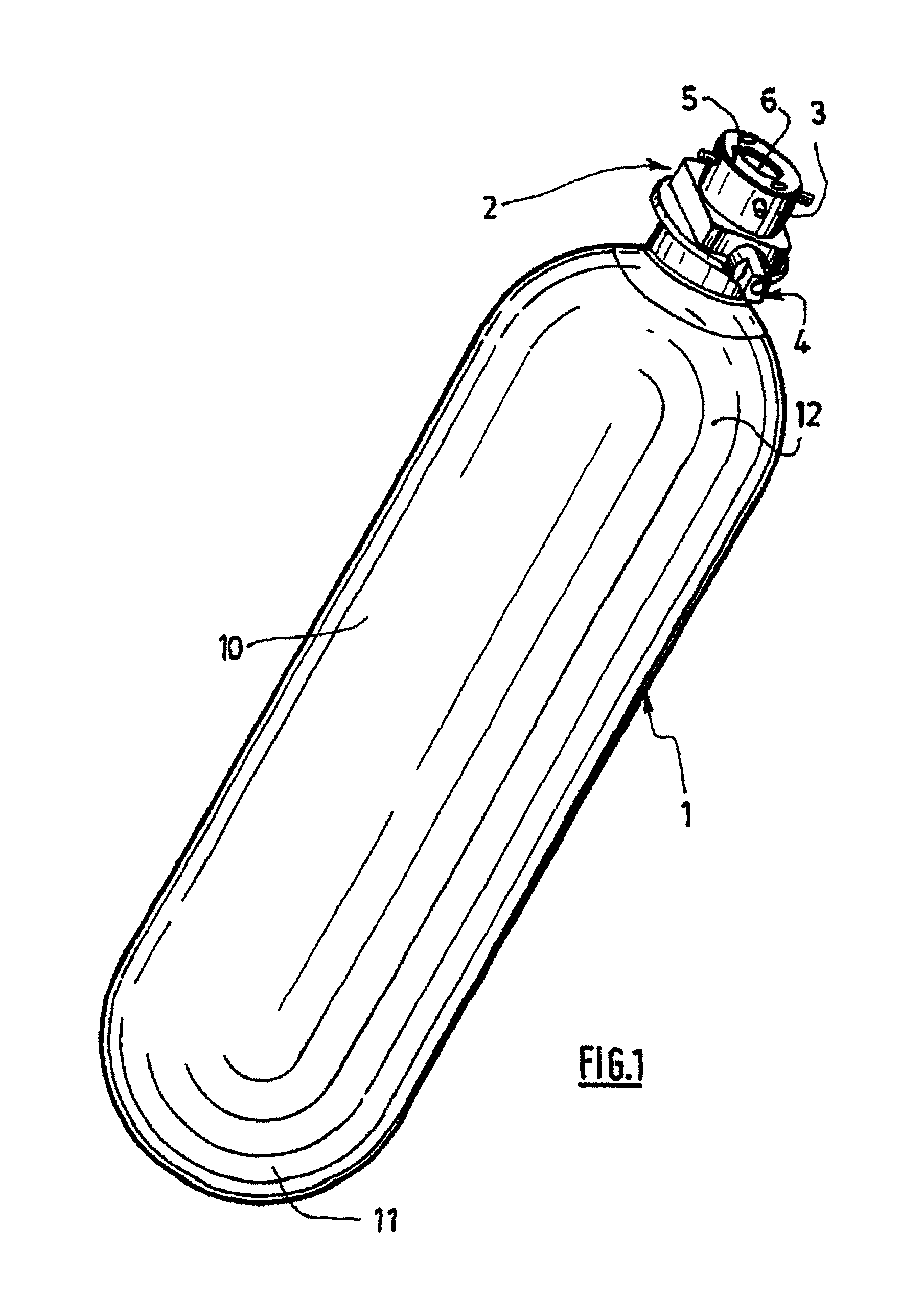

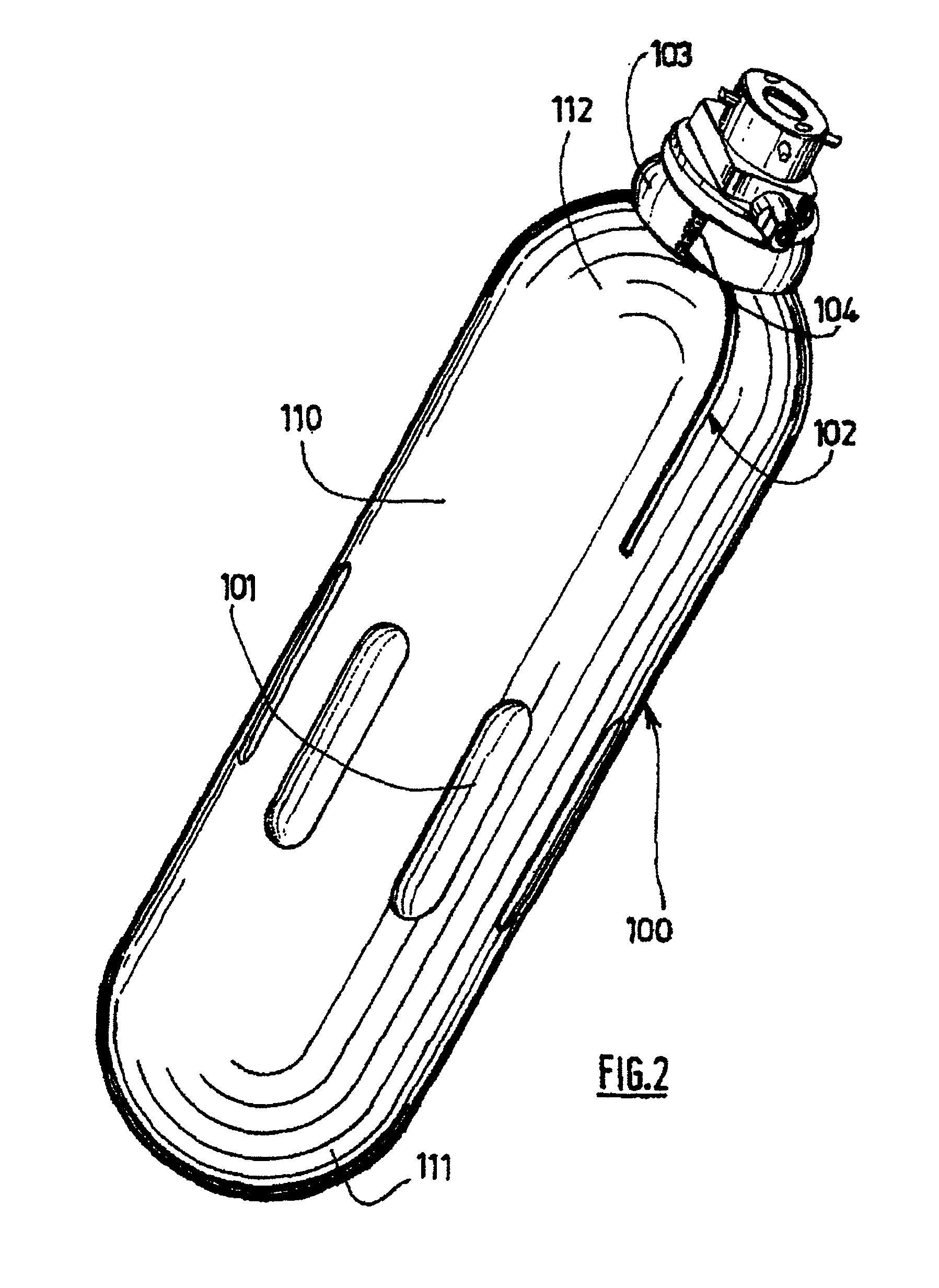

Assembly including a pressurized gas storage tank and a control device for filling the tank with gas and/or extracting gas therefrom

The invention relates to an assembly including a pressurized gas storage tank and a control device for filling the tank with gas and / or extracting gas therefrom. The aforementioned tank includes: a hole which communicates with the interior of the tank, a filling and distribution head which is disposed at the hole and which includes a pre-expansion device which is at least partially integrated inside the volume of the tank, and a connection interface which is removably engaged with the gas supply and / or extraction control device such as to co-operate therewith. The invention is characterized in that the head includes an isolation member, such as a valve, which is housed at least partially inside the volume of the head and which can be accessed by an opening member that is external to the head through an access hole that is provided in the head. The above-mentioned control device includes a body having a connection end which is intended to be removably engaged with the connection interface, an opening member which can move in relation to the body and an actuation element which can move the opening member selectively between a retracted rest position and an operating position in which one end of the opening member projects out from the body beyond the connection end, such that the opening member can extend into the access hole in the head in order to open the isolation member.

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE

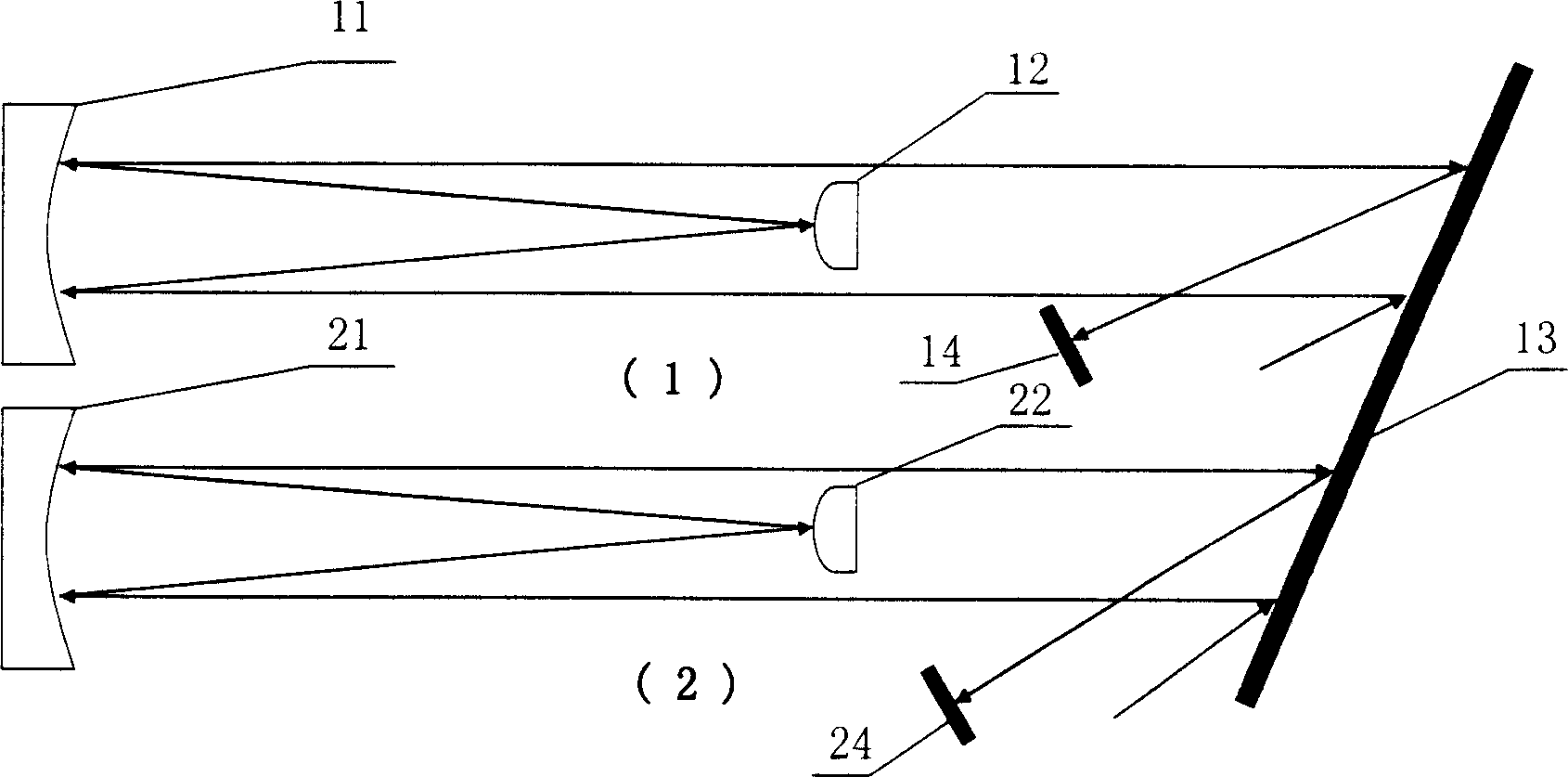

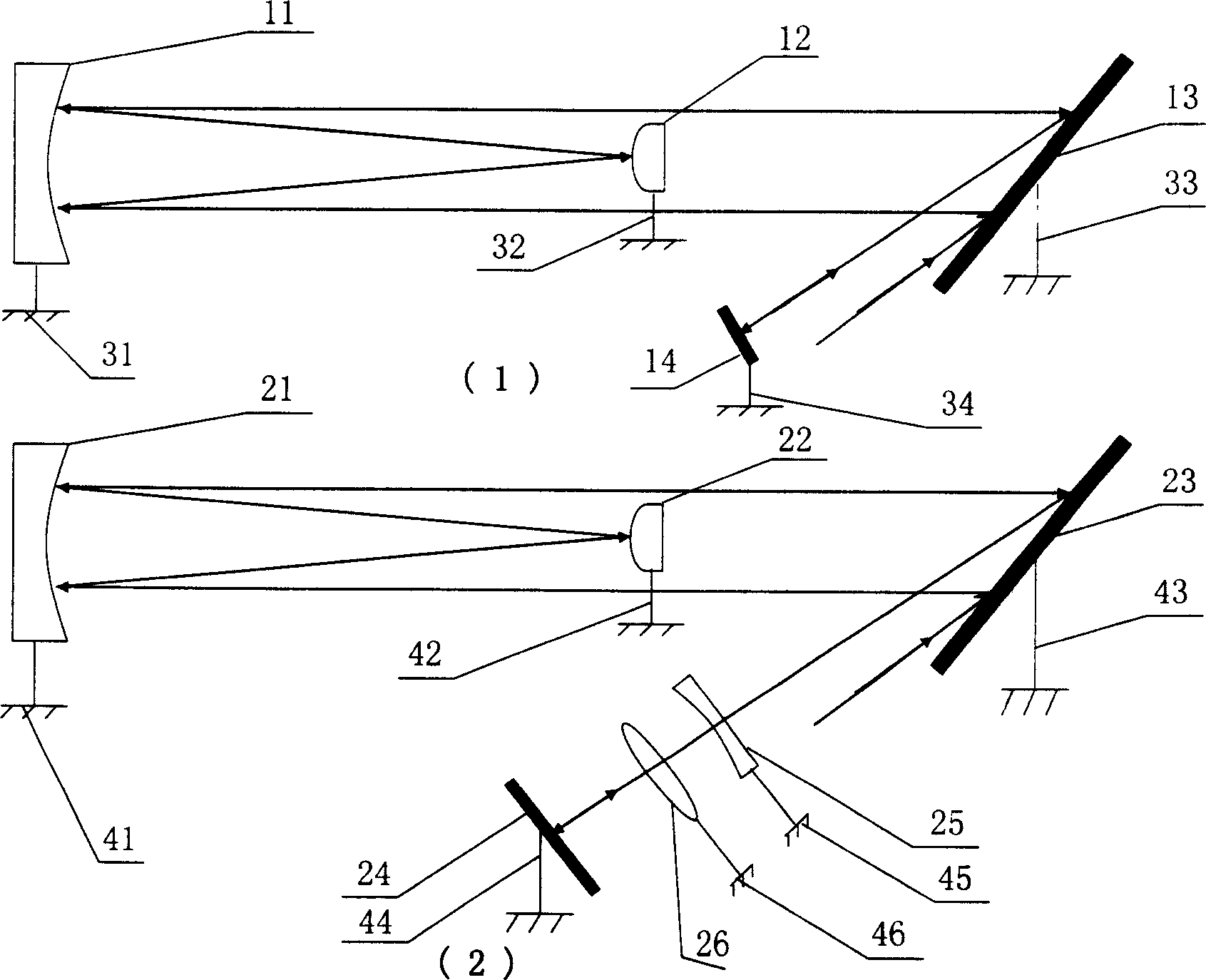

Superpower high-energy ultra-short laser pulse stretching device and its regulating method

InactiveCN1909305ARequirements for achieving widening with a large aspect ratioMeet the requirements of large aspect ratioLaser detailsNon-linear opticsPre expansionGrating

The invention relates to a high-power high-energy ultra-short laser impulse expander and a relative adjusting method, wherein said device is formed by two expanders, while the first is after the seed laser, and the expand ratio is fixed, and the second expander is after the pre-expansion of OPA, to continuously adjust resonance on secondary, third and fourth chromatic aberrations. The invention is characterized in that: it can realize large expand ratio, and the laser impulse width is expanded from 50-200fs to 2-5ns; at the same time, since the continuous resonance adjustment of second expander, the adjustment hardness of large-scale grating of compressor can be reduced, and the adjustment is completed by the second expander, or not adjusting after the adjustment of compressor.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

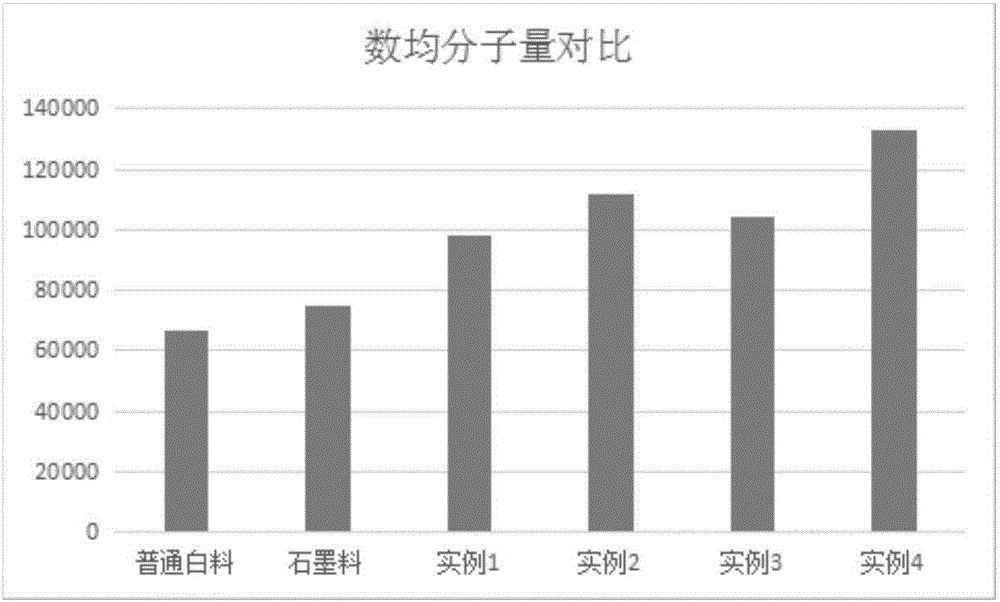

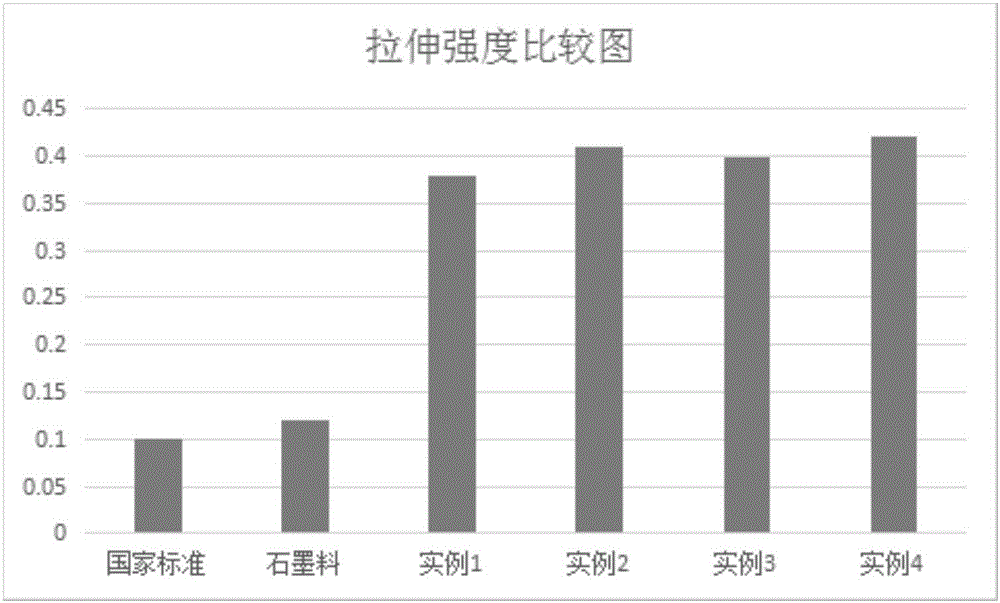

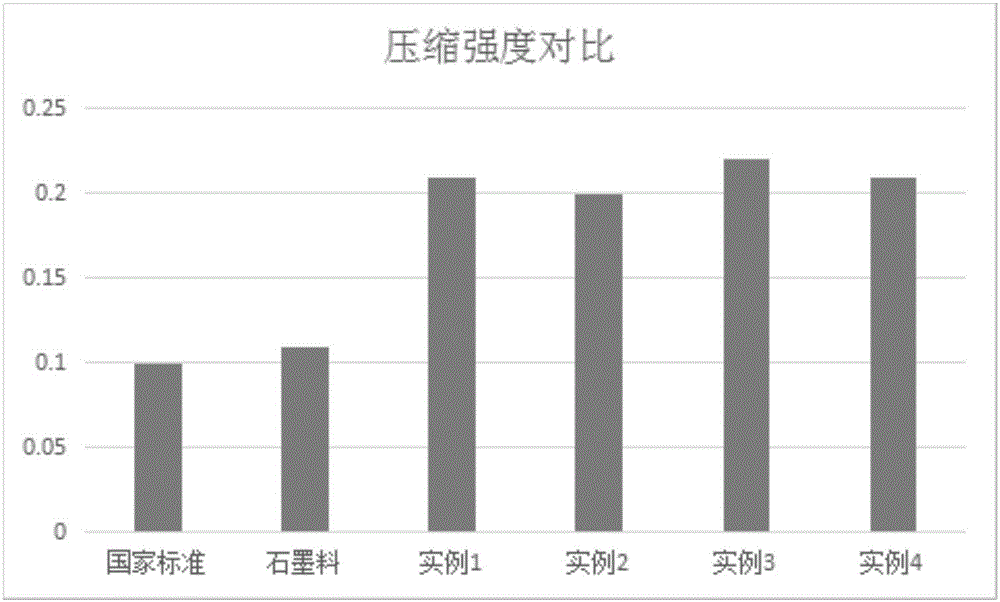

Preparation method of high-strength graphene expandable polystyrene board

InactiveCN106674783AHigh strengthThe polymerization process is stablePre expansionPolystyrene particle

The invention relates to a preparation method of a high-strength graphene expandable polystyrene board. The prepared product has the mechanical strength higher than that of other existing expendable polystyrene boards. The method comprises the several steps as follows: preparing a modified graphene pre-dispersion liquid; adding an oily dispersant to prepare an oily mixed liquid; preparing graphene polystyrene particles through suspension polymerization in a reaction kettle; finally, measuring mechanical properties after molding with pre-expansion, curing and board making processes. The prepared graphene expandable polystyrene board has excellent mechanical properties, has the tensile strength 400% higher than the national standard and has the compressive strength 200% higher than the national standard. With the adoption of the method, the application of expandable polystyrene in the packaging industry is expanded, expandable polystyrene is suitable for packaging industries with higher mechanical properties, such as packaging of precise instruments, packaging of spaceflight navigation parts and the like, and the advantages of polystyrene as a packaging material are played.

Owner:JILIN YUNTING ENERGY SAVING TECH CO LTD

Molten iron slag collecting agent and preparation method thereof

ActiveCN103589826AImprove adhesionGood adhesion to residuesProcess efficiency improvementPre expansionSlag

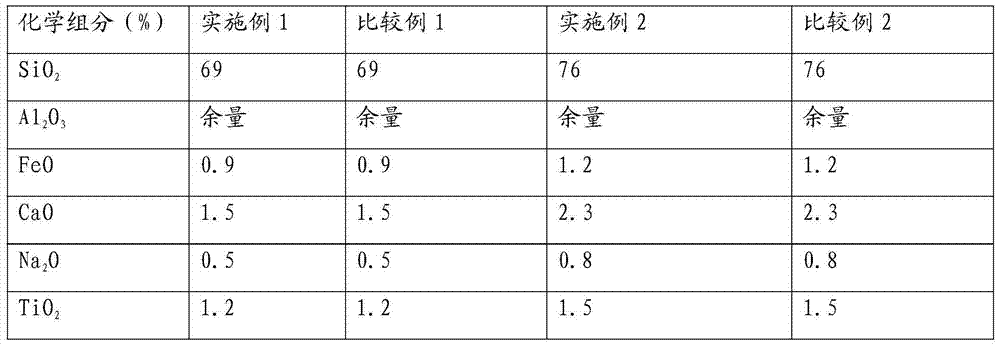

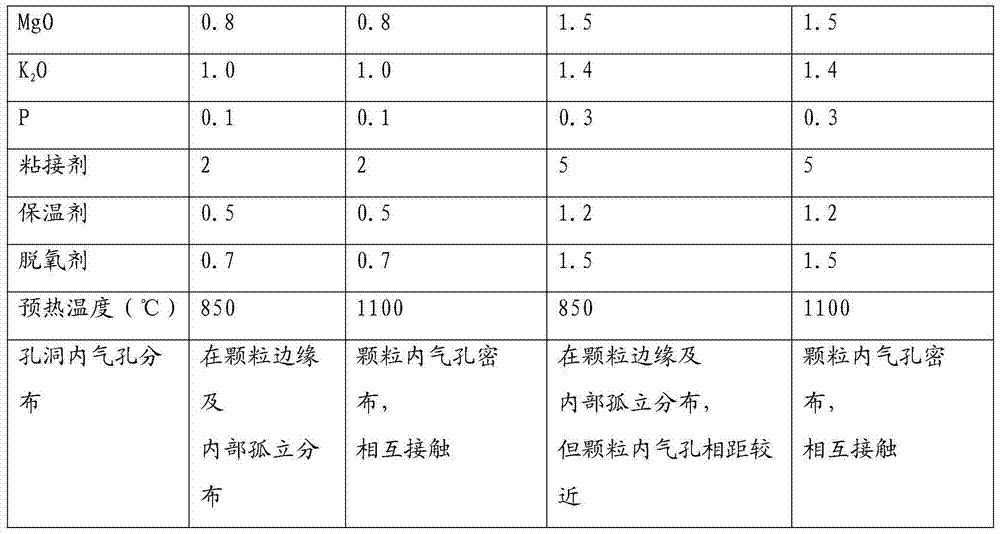

The invention provides a molten iron slag collecting agent; expanded perlite is used as a substrate, the components and mass percentages (%) of the slag collecting agent are as follows : 69 ~ 76% of SiO2, 0.6 ~ 1.2% of FeO, 1.5 ~ 2.3% of CaO, 0.2 ~ 1.2% of Na2O, 1.0~1.8% of TiO2, 0.8 ~ 1.5% of MgO, 1.0 ~ 1.4% of K2O and 0.1 ~ 0.3% of P, the slag collecting agent also includes by mass percentage (%), 2 ~ 5% of an adhesive , 0.5 ~ 1.2% of a heat insulating agent, 0.3 ~ 2.0% of a deoxidizing agent, and the balance of Al2O3. The invention also provides a preparation method of the slag collecting agent, and the preparation method includes the following steps: (1) preparation of an expanded perlite sample, to be more specific, collecting and selecting blocky perlite ore of 5 to 8cm, crushing into granules by a crusher, screening and picking broken granules to 0.9 ~ 1.7mm, then adding a cosolvent solution to the screened granules for soaking for 10 ~ 15s, performing pre expansion treatment, draining away water, putting into an oven of 750DEG C, drying for 2 ~ 3min to remove the water adsorbed on the surface of granules to obtain a perlite sample with a micro-hole structure, and raising the temperature of the oven to 850 ~ 1100 DEG C for pre heating to expand pores in micro holes to obtain an expanded perlite sample with the micro-hole structure; (2) preparation of slag collecting agent slurry; and (3) preparation of the slag collecting agent. The slag collecting agent of the invention has the characteristics of low cost, low dispersion, good fluidity, and strong slag adhesive capacity.

Owner:WUJIANG HYDRAULIC COMPONENTS FOUNDRY

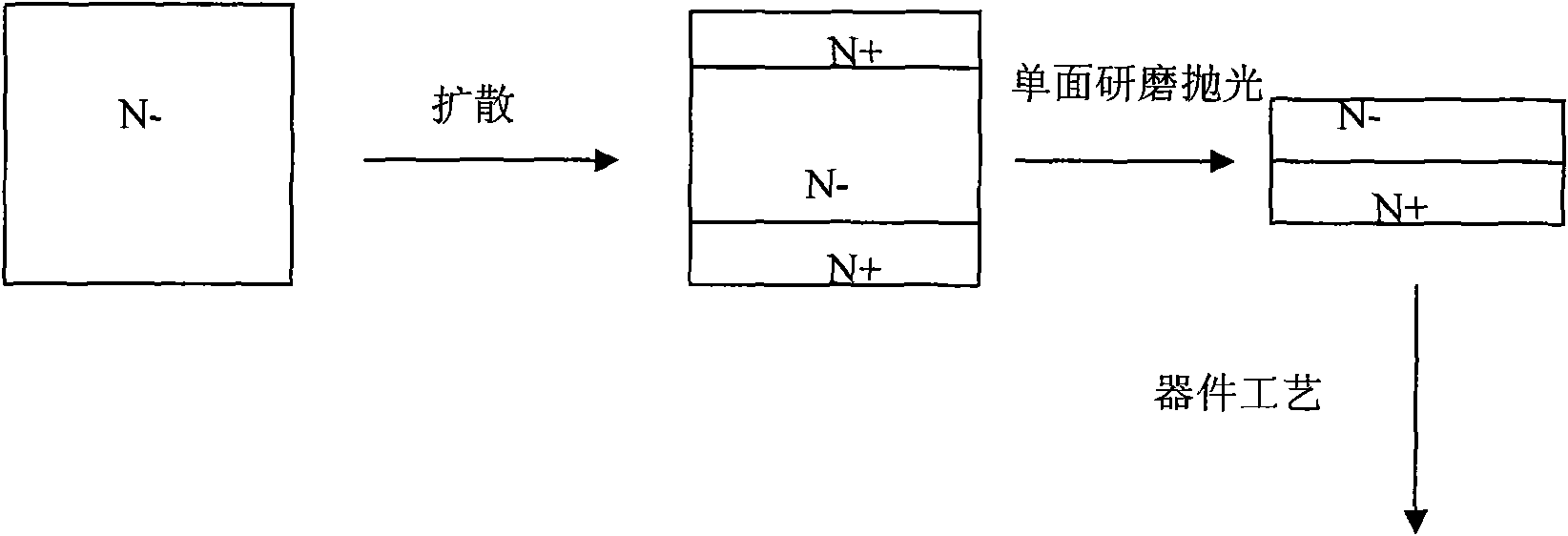

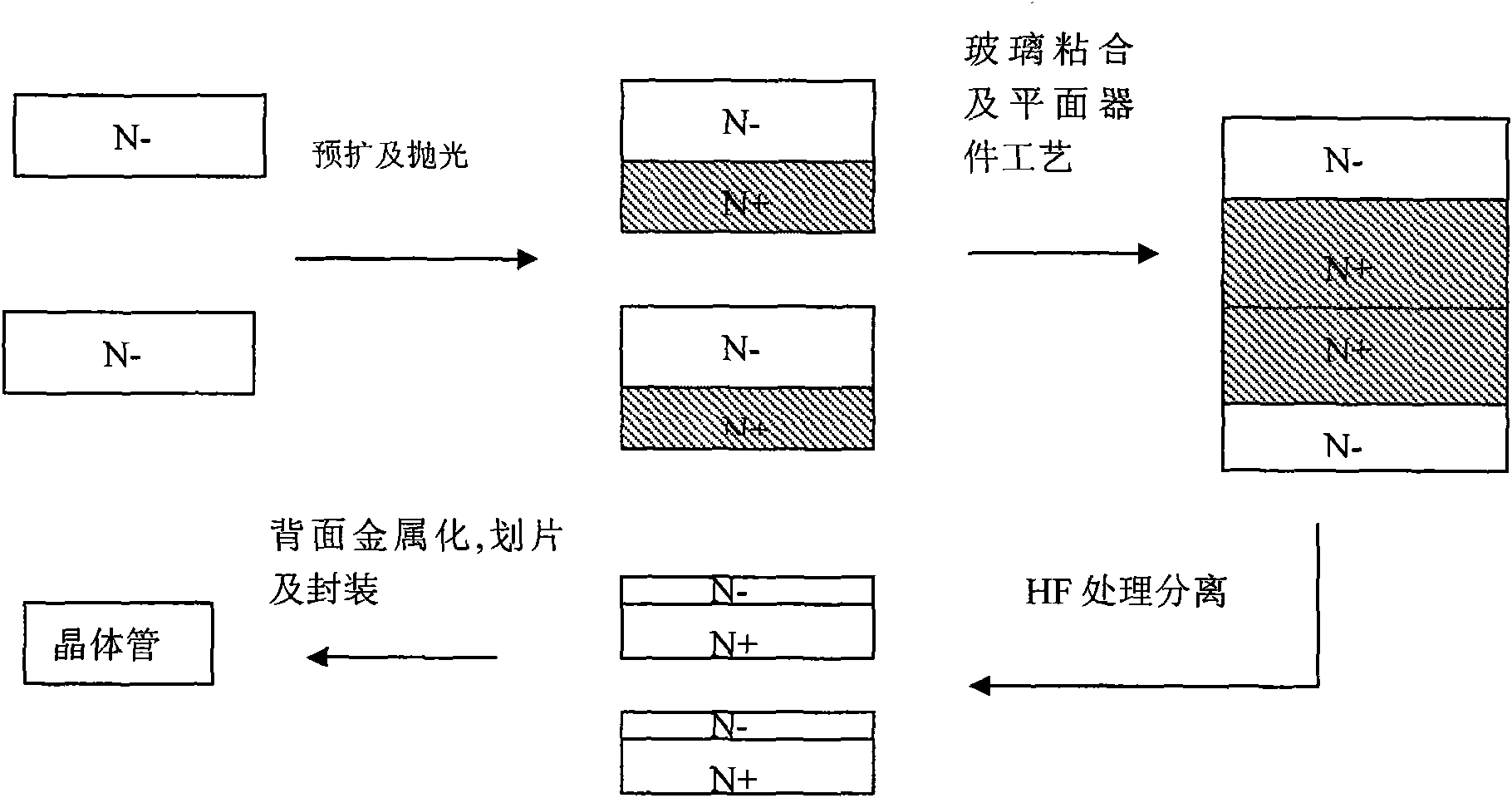

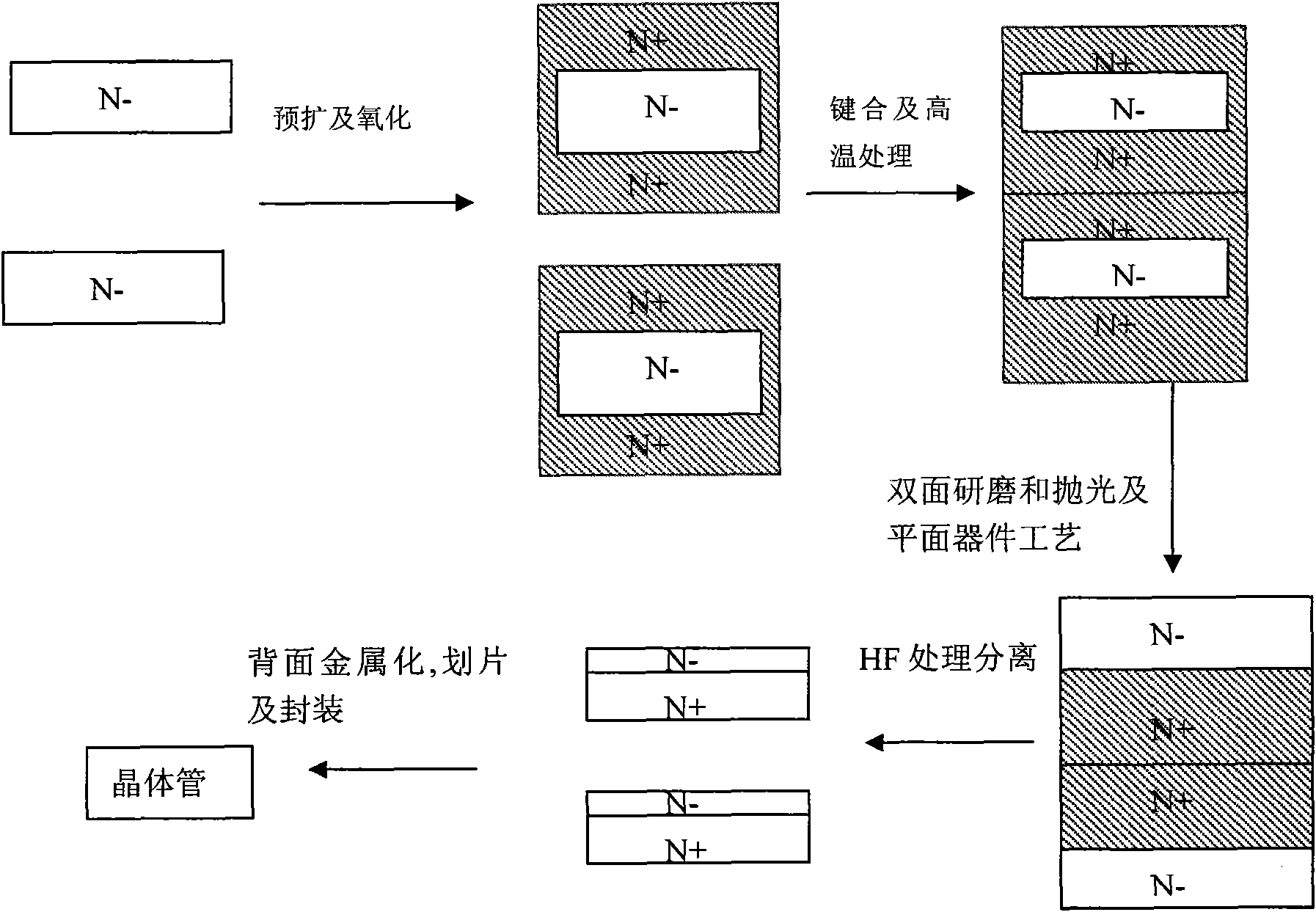

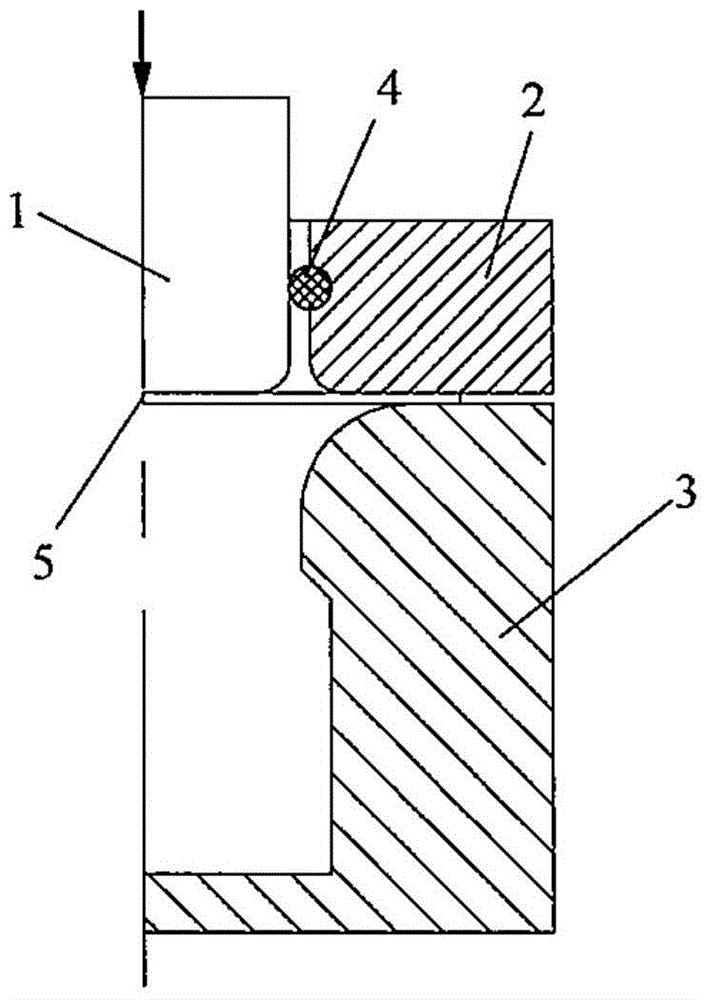

Method for manufacturing transistor by using silicon single crystal slices

ActiveCN101661884AImprove performanceReduces defects caused by interfacial stressSemiconductor/solid-state device manufacturingPre expansionResist

The invention discloses a method for manufacturing a transistor by using silicon single crystal slices, which comprises the steps of: 1) selecting two light-doped polished silicon slices, wherein thefront surfaces thereof are the polished surfaces; 2) conducting N+ or P+ pre-expansion on each silicon slice and then arranging an oxide layer on the front surface of the pre-expanded polished siliconslice; 3) causing the front surfaces of the two polished silicon slices with the oxide layers to face to each other for bonding at room temperature, and putting the obtained bonded silicon slice group into a high-temperature furnace for high-temperature processing; 4) conducting mechanical grinding and polishing on the two surfaces of the obtained silicon slice group; 5) manufacturing a transistor chip on the two surfaces of the silicon slice group respectively; 6) putting the silicon slice group obtained in the Step 5) into an HF solution to separate the silicon slices; and 7) metallizing the surfaces of the silicon slices without the transistor chip, and then removing optical resist, scribing and packaging, thus obtaining the transistor. The method for manufacturing the transistor by using silicon single crystal slices can guarantee the performance of the transistor.

Owner:ZHEJIANG HAINA SEMICON CO LTD

Preparation method for adsorbing material for removing cadmium from slightly-polluted water body

InactiveCN104148027AIncrease productionEasy to operateOther chemical processesWater/sewage treatment by sorptionWater bathsPre expansion

The invention relates to a preparation method for an adsorbing material for removing cadmium from a slightly-polluted water body, and belongs to the field of wastewater treatment. The preparation method comprises the following steps: manually cutting fresh bagasse into small strips; putting the small strips into a pressure cooker, adding distilled water and boiling to remove soluble substances, such as sugar; drying the boiled small strips into a hot air oven; crushing the dried small strips by using a Chinese herbal medicine crushing machine; putting the crushed bagasse into a container, and adding a NaOH solution into the crushed bagasse to obtain a mixture; stirring the mixture uniformly at room temperature by using a glass rod until the mixture is fully alkalified; pouring alkalified bagasse into a filtration funnel, and drying the bagasse after the bagasse is leached to be neutral; putting dried cellulose in a container, adding an aqueous solution of H3PO4 into the container for performing pre-expansion; adding the aqueous solution of the H3PO4 after the pre-expansion is performed; reacting the mixture in a water-bath kettle, wherein urea is used as a catalyst and methylbenzene is used as a solvent; washing a reaction product by using an alkali until the reaction product does not contain phosphate anions; converting an esterification reactant into an H-type ion exchanger by using an aqueous solution of HCl; and drying the H-type ion exchanger to obtain the adsorbent disclosed by the invention. According to the preparation method, the cost is low, the secondary pollution is avoided, and the requirement on resource recovery of solid waste is met.

Owner:CHANGZHOU UNIV

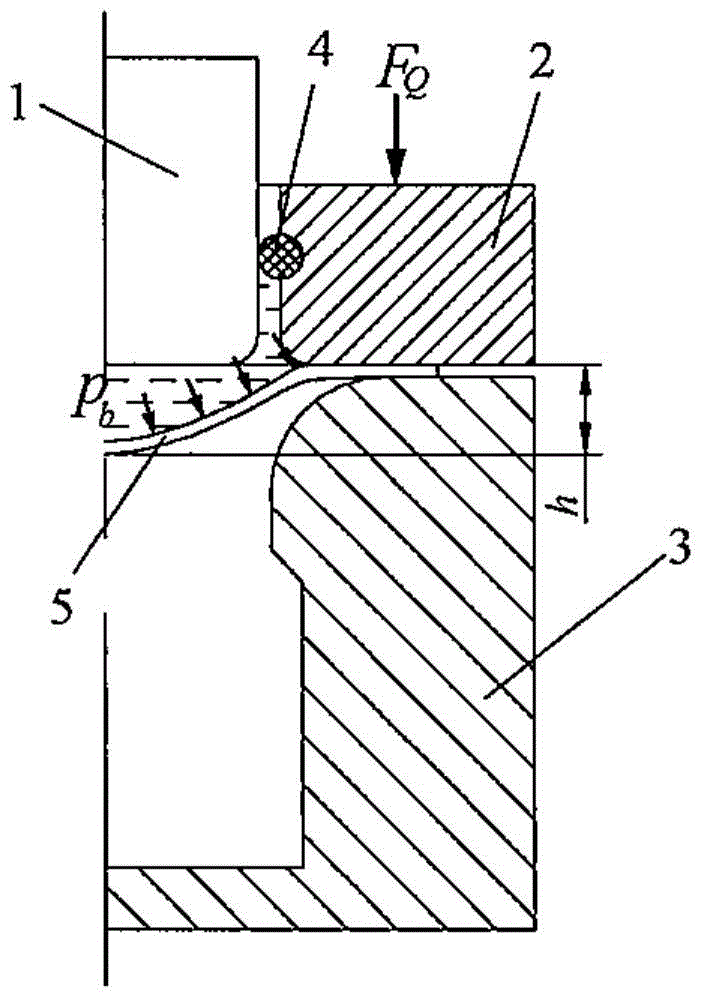

Hydro-mechanical deep drawing forming method for sheet metal component with uniform deformation

The invention provides a hydro-mechanical deep drawing forming method for a sheet metal component with uniform deformation. The method includes the following steps of (1), placing a sheet; (2), applying blank holder force; (3), conducting forward expansion forming; (4), setting the pressure of a liquid filling chamber; (5), conducting hydro-mechanical deep drawing forming; and (6), picking up a component. Hydro-mechanical deep drawing forming with component uniform deformation is achieved through the change of the pre-expansion direction of the sheet; and the method breaks through the limitation of the pre-expansion amount in reverse expansion hydro-mechanical deep drawing, and the deformation uniformity of the component can be greatly improved.

Owner:COMAC +1

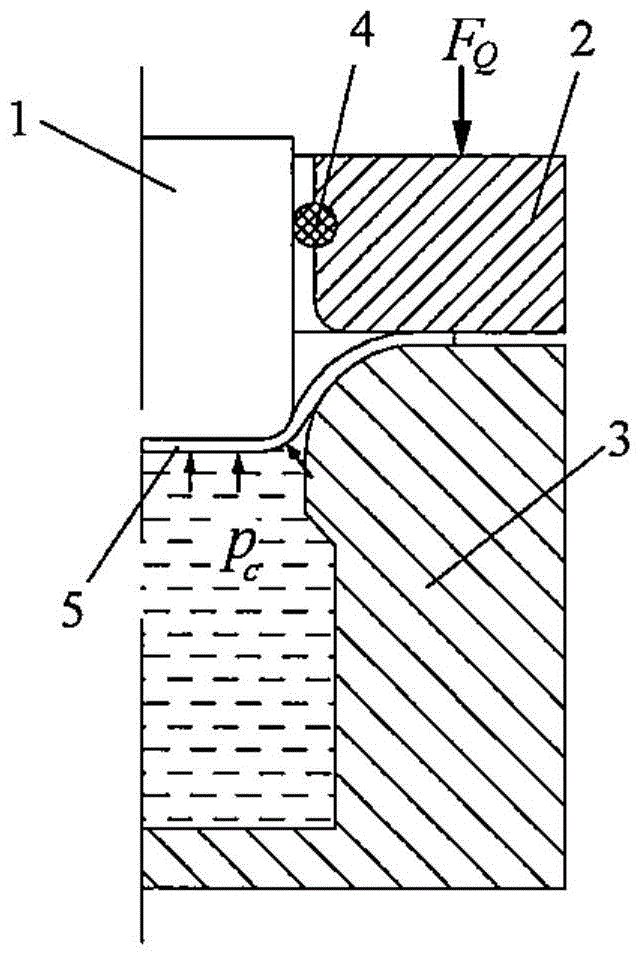

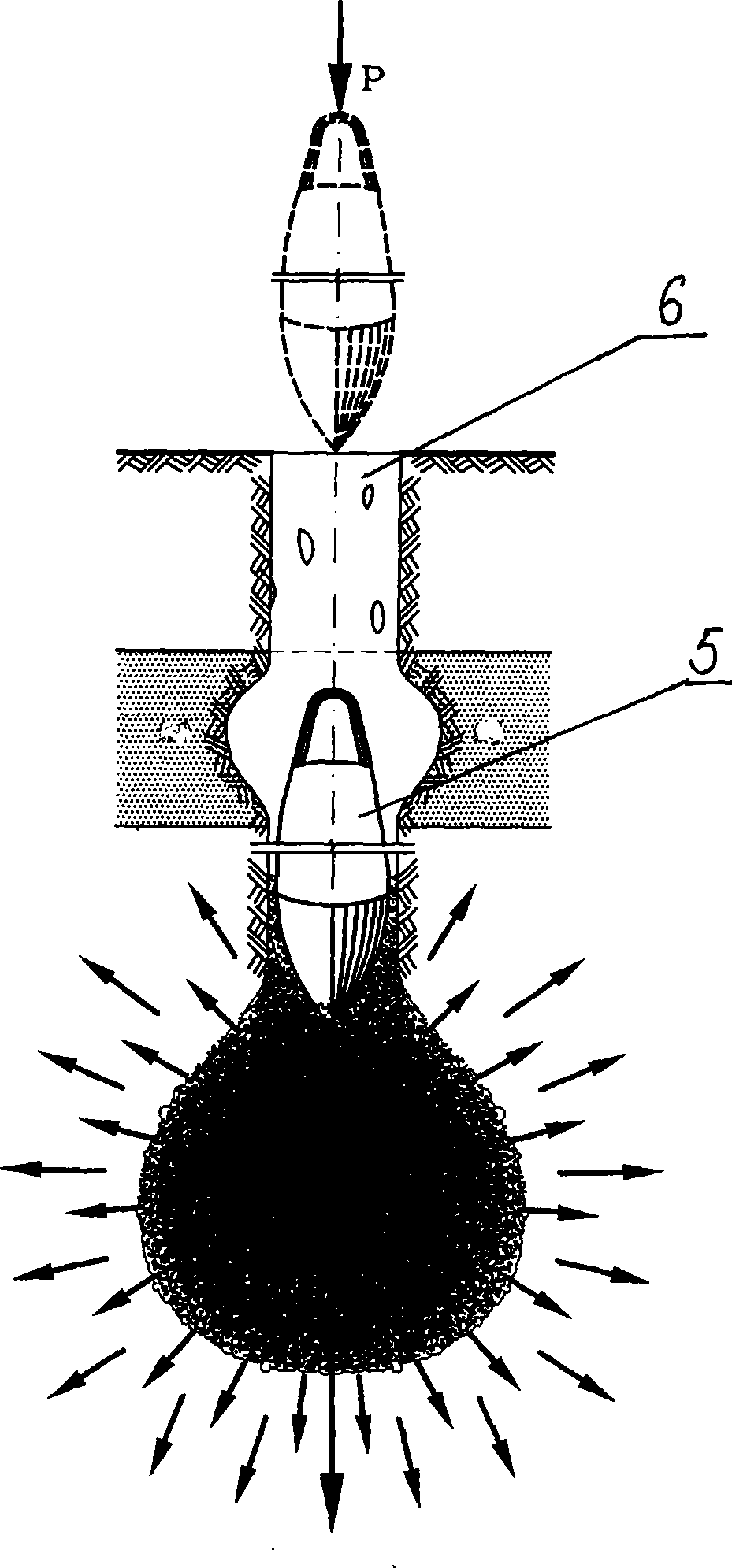

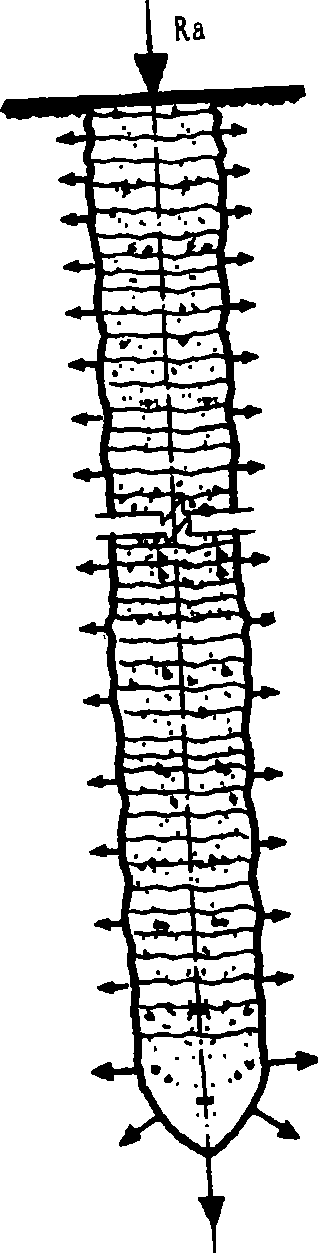

Five in one pre-expansion ecological pile body processing foundation method

The invention relates to a five-in-one pre-expanding ecological pile treating foundation method suitable for foundation, foundation collapse, gold ore dressing and construction application of environment-friendly field. The method comprises: after the foundation is drilled with holes, filling the holes, injecting hammer blocks into the holes, carrying out five-in-one power consolidation of vertically and transversely pre-expanding, extruding, transmitting and propelling by super-pressure kinetic energy through impacting, smashing, extruding, pressing and chopping; then filling the holes repeatedly and carrying out forced ramming and piling consolidation of vertically and transversely pre-expanding, extruding, transmitting and propelling for the super-pressure kinetic energy hammer blocks through impacting, smashing, extruding, pressing and chopping; and finally manufacturing a deep foundation of a composite foundation of a pre-expanding ecological pile with high bearing capacity, a specific pile foundation and the pre-expanding ecological pile. The method is advanced, has low construction cost, effectively solves problems of various thick difficult foundations, can eliminate pollution of pollutant to environment, and make human live on the foundation of firmness, safety and free pollution.

Owner:司炳文 +2

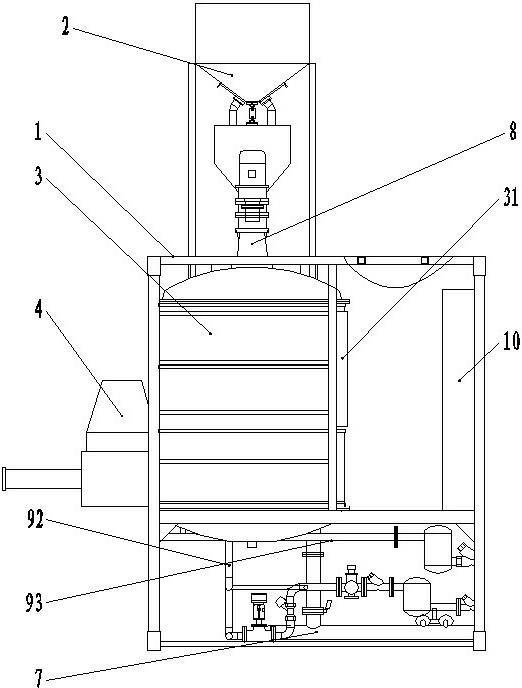

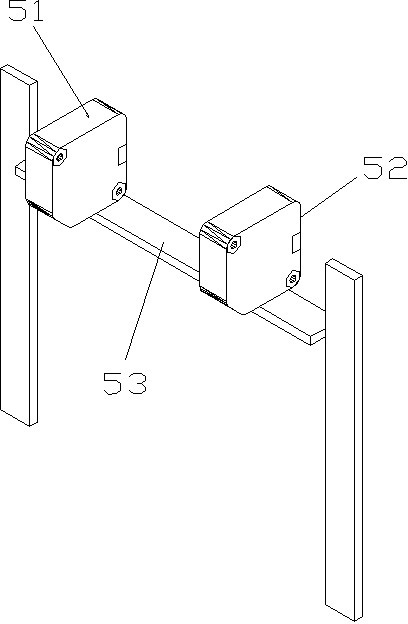

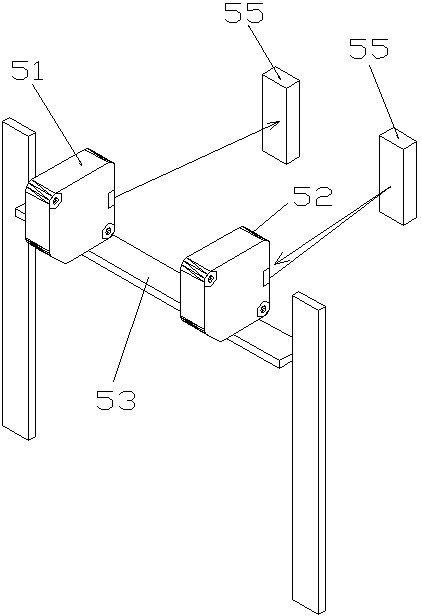

Pre-expansion machine of foam

The invention relates to a pre-expansion machine of foam, which is mainly used for producing plastic foam. The pre-expansion machine of the foam with a reasonable structural design and reliable performances is not existed at present. The pre-expansion machine of the foam comprises a machine frame, a material loading device, a barrel body, a material door device, a material level control device, a scraper device, a sewage discharge device, a stirring device, an electrical box, a steam pipeline and a compressed air pipeline; the barrel body and the electrical box are both arranged on the machine frame; the material loading device, the material door device and the material level control device are all arranged on the barrel body; the scraper device is arranged at the bottom of the stirring device; the stirring device is arranged in the barrel body; and the sewage discharge device, the steam pipeline and the compressed air pipeline are all connected with the barrel body. The invention is characterized in that the scraper device comprises a scraper base, a left long scraper, a right long scraper, a front short scraper and a back short scraper; and the left long scraper and the right long scraper are both fixedly arranged on the scraper base, and the front short scraper and the back short scraper are both fixedly arranged on the scraper base. As the pre-expansion machine of the foam has the reasonable structural design, the materials cannot be collected at the bottom of a barrel, and a material leakage phenomenon cannot be generated on a material door.

Owner:HANGZHOU FUYANG DONGSHAN PLASTIC MACHINERY

A modified graphite polystyrene board and a preparing method thereof

The invention relates to a modified graphite polystyrene board and a preparing method thereof. Raw materials comprise expandable polystyrene beads, expandable graphite, phenolic resin and a curing adhesive. The preparing method includes: subjecting the expandable polystyrene beads to pre-expansion and curing, mixing with the expandable graphite and a part of the curing adhesive, mixing with the phenolic resin and the rest of the curing adhesive, and moulding and cutting by a board machine. The modified graphite polystyrene board has advantages of high flame retardance, thermal insulation, no melt trickling, and no dripping.

Owner:HEBEI HAOSHI FOAM

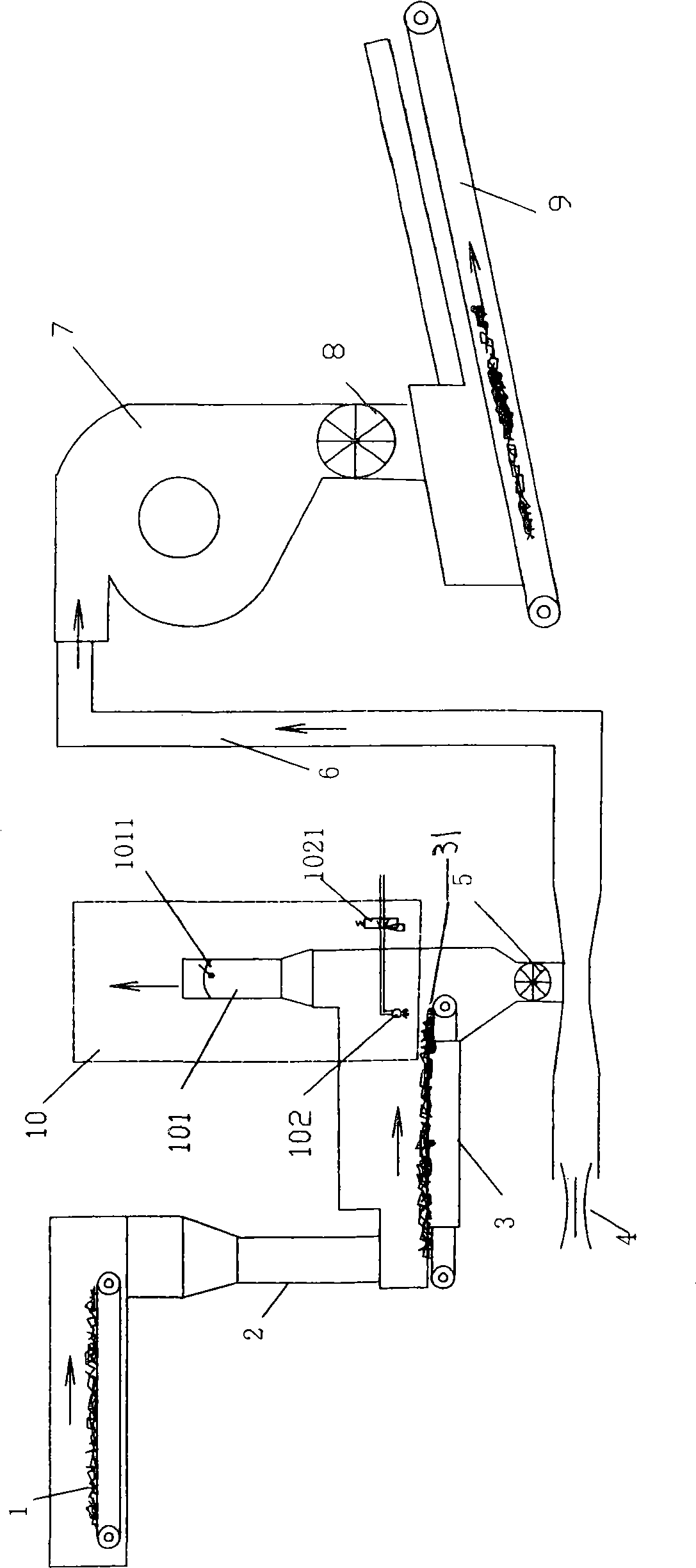

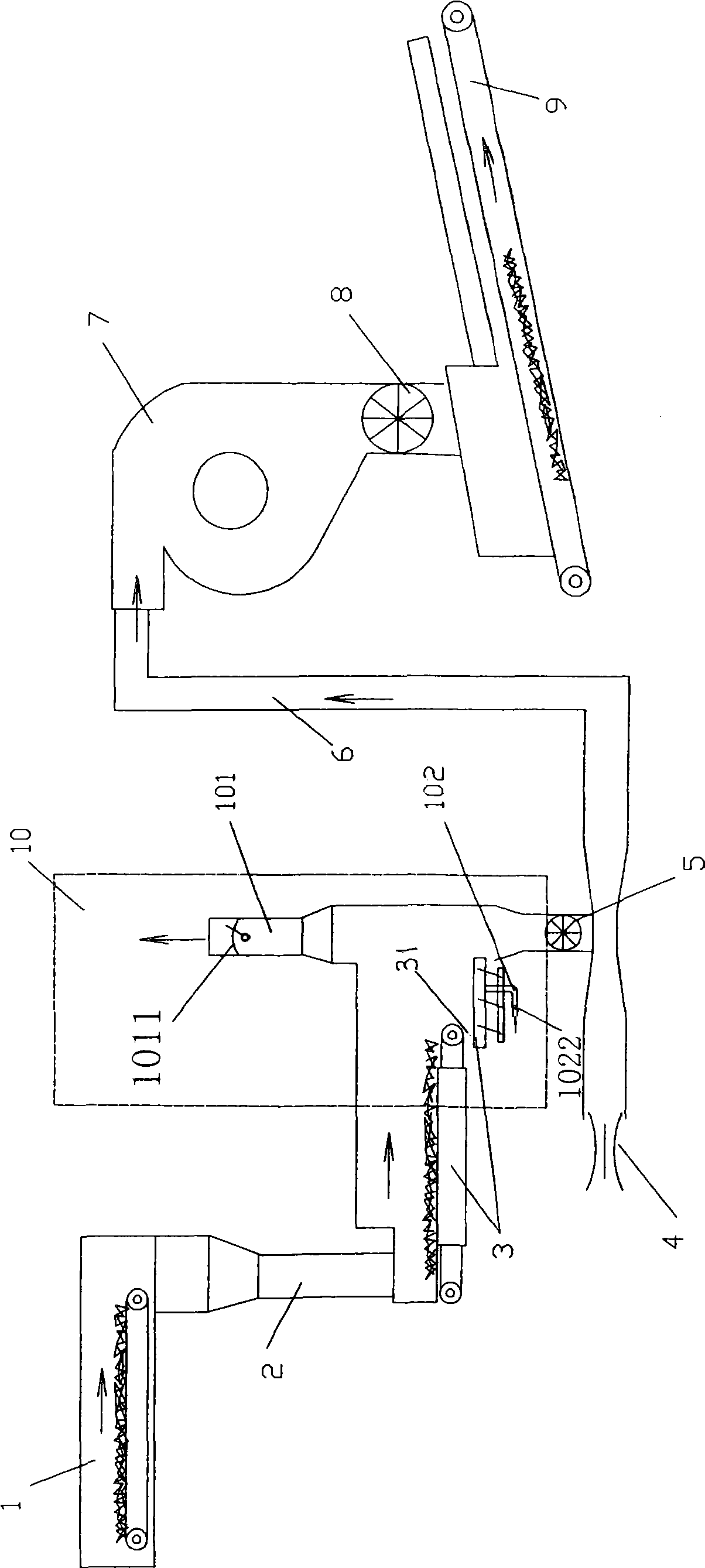

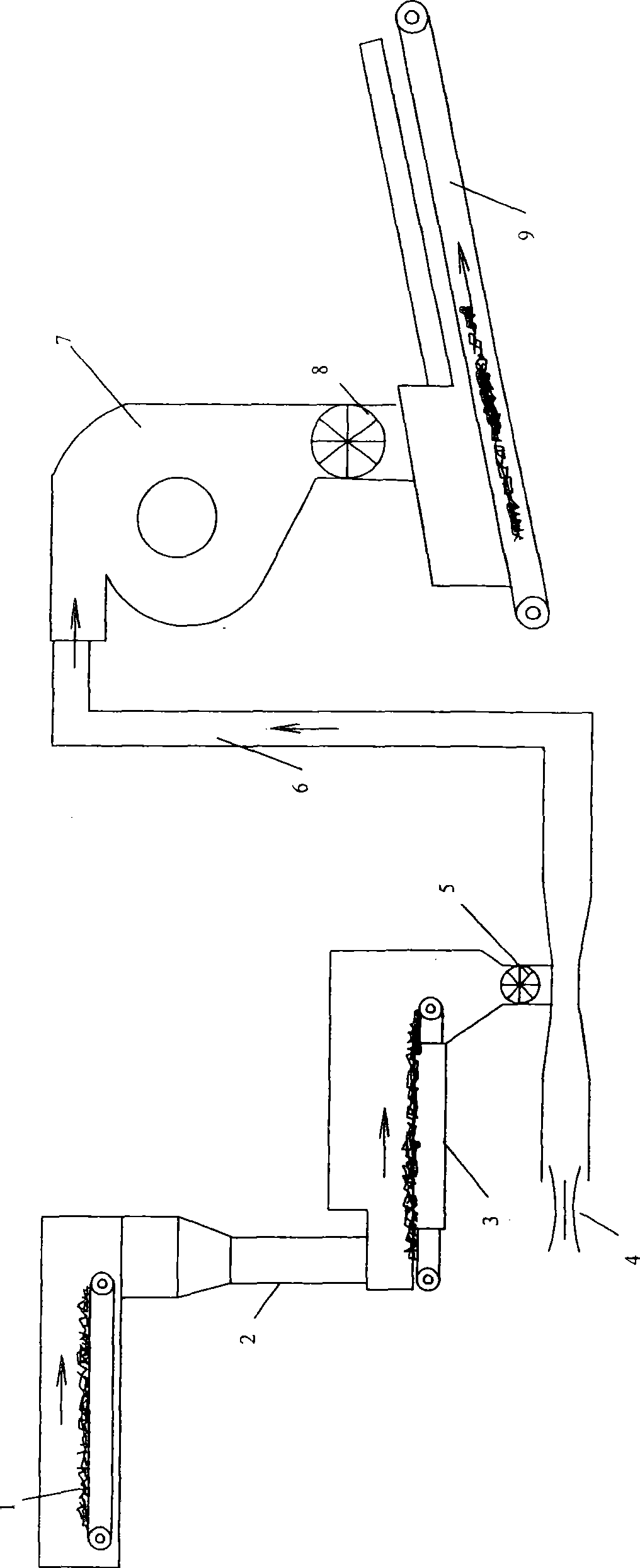

Method for expanding tobacco shred and equipment for the method

The invention relates to a method for expanding tobacco shreds and equipment used in the method. The method is characterized by comprising the following steps: (1) dipping; (2) loosening; (3) storing; (4) secondary loosening; (5) quantitative feeding; (6) pre-expanding, purification and air extraction: the tobacco shreds dipped by an expanding medium are pre-expanded in air blowing equipment, and the tobacco shreds dipped by the expanding medium are delivered to the air blowing equipment which blows air to the shreds dipped by the expanding medium; and miscellaneous gas volatilizing at the pre-expansion of the tobacco shreds and CO2 are pumped off by an exhaust tube; (7) expanding: the pre-expanded tobacco shreds are quickly delivered to a sublimator by a feeding air lock and is mixed with hot air flow in the sublimator for continuous expansion; and (8) cooling and shaping. The method has the advantages of improving the toughness, the whole cut rate and long shred rate of the expanded tobacco shreds, reducing the breakage of the expanded tobacco shreds, eliminating the miscellaneous gas and lowering energy consumption in the production process.

Owner:HONGTA TOBACCO GRP

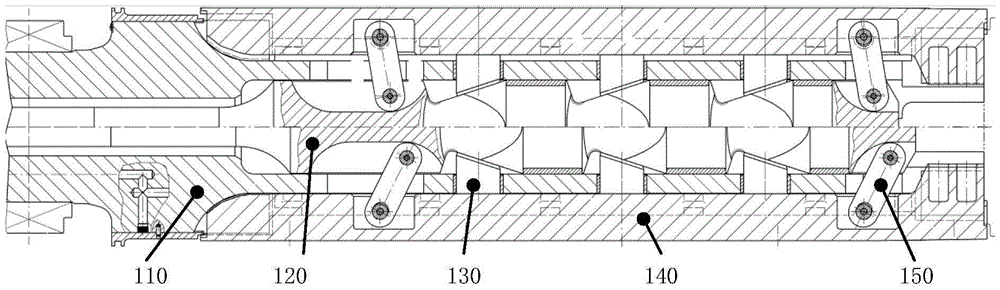

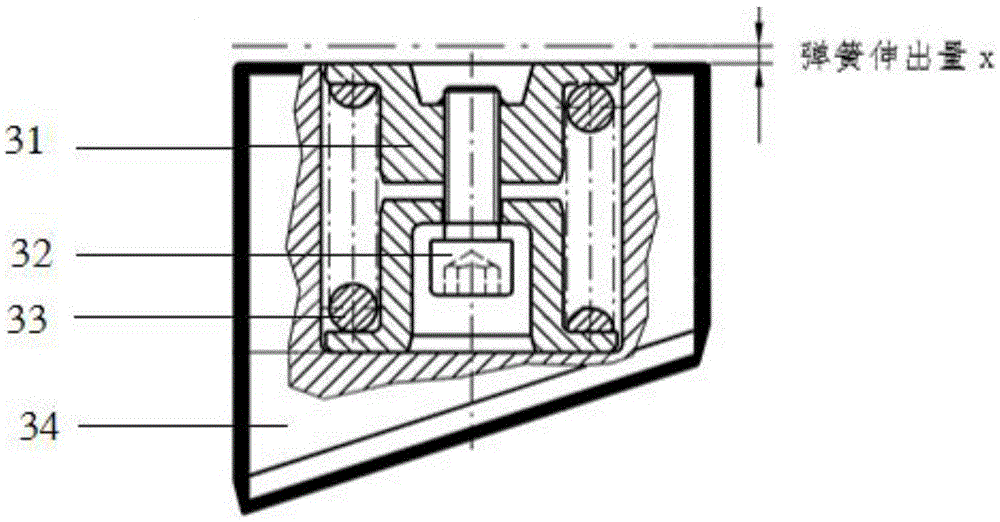

Pressurized gas filling and distribution head and tank equipped with one such head

The invention relates to a gas filling and distribution head (2) which is intended to be disposed in a hole in a pressurized gas storage tank. The inventive head (2) includes a mounting segment (21) which is intended to be housed in the hole in the tank and an expansion segment which houses a pre-expansion device (22), said pre-expansion device (22) being arranged in relation to the mounting segment (21) such as to be housed at least partially inside the tank when the head is in the mounted position. The head (2) also includes: a filling circuit which extends between a first end which is equipped with a filling hole (6) and a second end which is intended to communicate with the interior of the tank, and an extraction circuit which extends between a first end which is intended to communicate with the interior of the tank and a second end which is equipped with an extraction hole. The invention is characterized in that the filling hole (6) is aligned with the extraction hole.

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE

Internal wear clearance measuring and calculating method of winding drum of winding machine

ActiveCN105458037AExtended replacement cycleSolve the technical problem of waste of maintenance costMetal working apparatusPre expansionWinding machine

The invention discloses an internal wear clearance measuring and calculating method of a winding drum of a winding machine. The method comprises the steps that the zero wear rigidity expanding diameter and the zero wear no-load expansion diameter of the winding drum of the winding machine under the condition without wear are obtained; after the winding drum is used for a preset time period, the measuring rigidity expansion diameter of the winding drum is obtained by limiting the actual rigidity expansion diameter of the winding drum; the winding drum expands to the pre-expansion position, so that the measuring no-load expansion diameter of the winding drum of the winding machine is detected and obtained; and according to the measuring rigidity expansion diameter, the measuring no-load expansion diameter, the zero wear rigidity expansion diameter and the zero wear no-load expansion diameter, the internal wear clearance total amount of the winding drum is obtained. According to the technical scheme, the internal wear clearance total amount of the winding drum is obtained, and therefore replacement of the winding drum can be carried out when the internal wear clearance total amount approximates the maximum allowance wear clearance, the technical problems that in the prior art, according to the steel coiling amount, the winding drum is replaced, and the maintaining cost is wasted are solved, and the technical effects of prolonging the replacement period of the winding drum and reducing the maintaining cost are achieved.

Owner:BEIJING SHOUGANG CO LTD

Construction method for eliminating concrete shrinkage cracks of steel plate and concrete combined shear wall by preheating steel plate

ActiveCN102650165APrevent shrinkage crackingTemperature controlBuilding material handlingPre expansionSheet steel

The invention relates to a construction method for eliminating concrete shrinkage cracks of a steel plate and concrete combined shear wall by preheating a steel plate, which comprises the following steps: step 1, laying a heat conduction coil on the steel plate of the shear wall before the steel plate and concrete combined shear wall of a building is constructed; step 2, after the on-site installation of the steel plate of the shear wall is completed, injecting a heat conduction medium with a preset temperature into the heat conduction coil by a heat conduction metal injection system, simultaneously observing the temperature variation of the steel plate of the shear wall by a temperature measurement system to ensure the steel plate of the shear wall to reach a set temperature and generate a certain pre-expansion, and then carrying out concrete pouring construction in the steel plate and concrete combined shear wall; and step 3, after concrete is finally set, according to the shrinkage of the concrete, regulating the temperature and the flow of the heat conduction medium injected into the heat conduction coil by the heat conduction medium injection system so as to control the temperature of the steel plate of the shear wall. According to the method, the temperature of the steel plate of the shear wall can be effectively controlled and the concrete shrinkage cracks caused by inconsistence of deformation of the steel plate of the shear wall and the concrete are avoided.

Owner:CHINA CONSTR THIRD ENG BUREAU GRP CO LTD

Apramycin liposome and preparation method thereof

ActiveCN103565746AEasy reunionGood encapsulation effectOrganic active ingredientsPharmaceutical product form changePre expansionMass ratio

The invention discloses an apramycin liposome. The apramycin liposome is a composition with a spherical or ellipsoidal double-film structure, and is formed by encapsulating apramycin with a liposome film. A preparation method comprises the following steps: 1) dissolving the apramycin and the liposome film with ethanol to obtain a mixed solution, and dissolving the mixed solution into supercritical CO2 to obtain a supercritical solution, wherein the mass ratio of the apramycin to the liposome film is (1 : 1) to (1 : 30); the liposome film is phosphatidylcholine, or a mixture of phosphatidylcholine and cholesterol; 2) dissolving a stabilizer into an aqueous medium to obtain a stabilizer solution; 3) spraying the supercritical solution to the stabilizer solution at an expansion pressure of 15-30MPa and a pre-expansion temperature of 323-343K, dispersing and precipitating to obtain an apramycin liposome suspension.

Owner:HENAN SOAR VETERINARY PHARMA

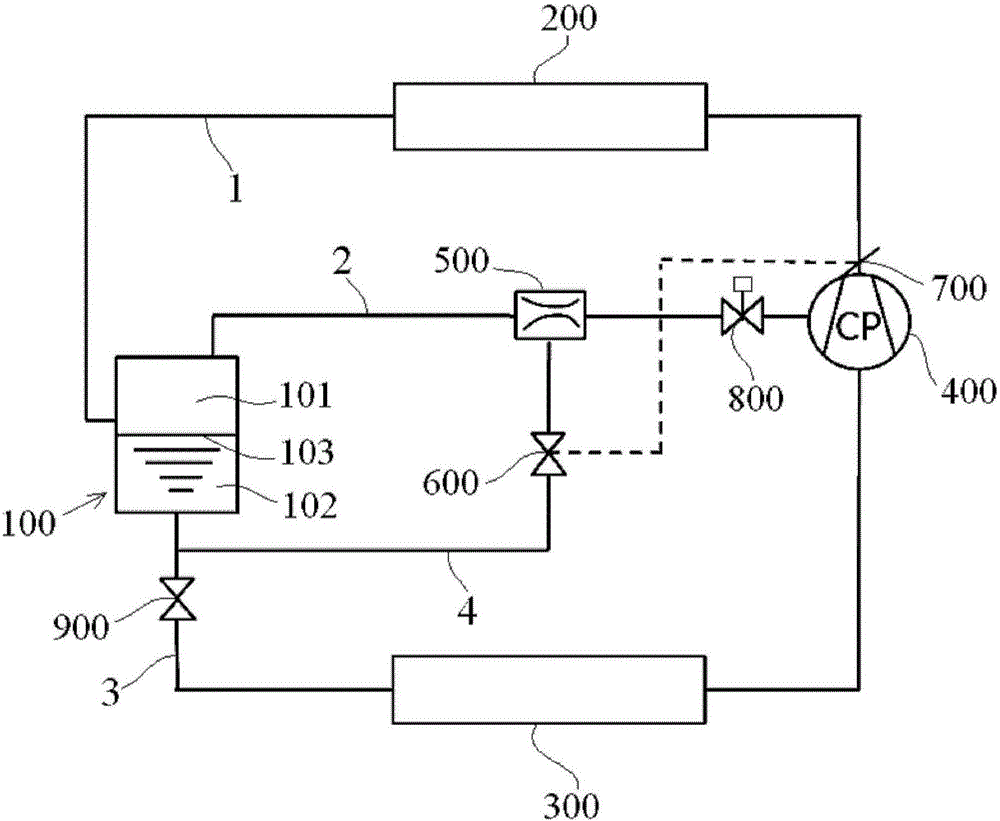

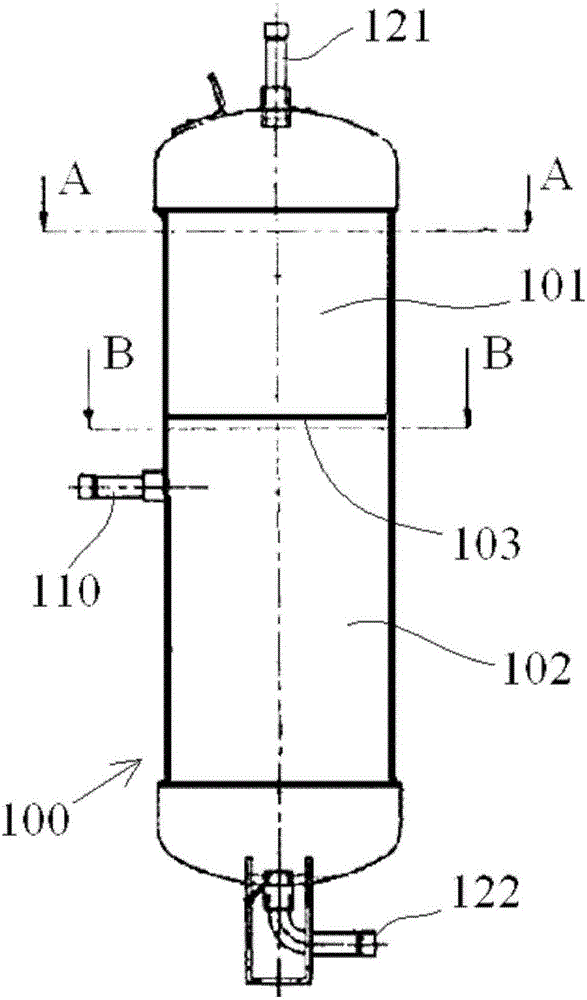

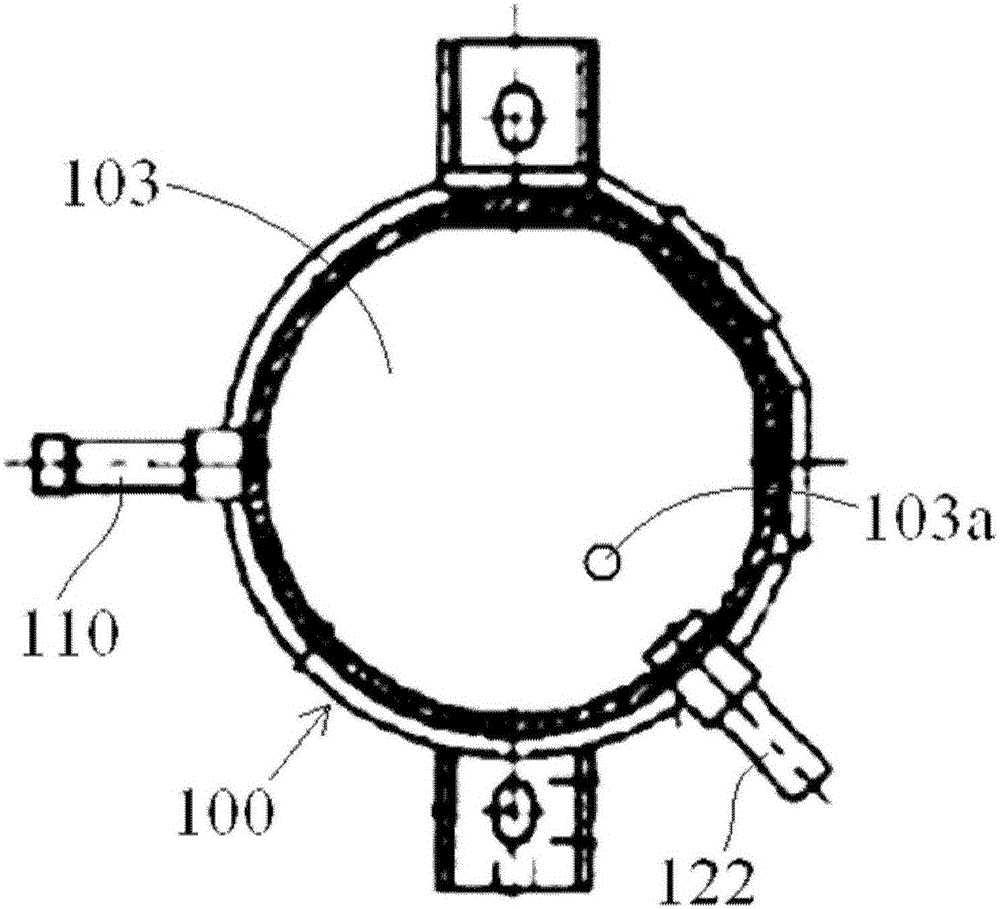

Flash tank and refrigerating system

InactiveCN106705508AControl exhaust temperatureSimple structureMechanical apparatusFluid circulation arrangementPre expansionRefrigerant

The invention discloses a flash tank which comprises an inlet, a first outlet, a second outlet and a pre-expansion element. Fluid flows into the flash tank from the inlet. The first outlet is located in the top of the flash tank. The second outlet is located in the bottom of the flash tank. The pre-expansion element is integrated in the inlet of the flash tank and is used for pre-expanding fluid flowing into the inlet of the flash tank. In the flash tank, the pre-expansion element used for pre-expanding a refrigerant flowing into the inlet of the flash tank is integrated in the inlet of the flash tank, and therefore an independent throttling valve does not need to be arranged in a fluid inlet pipeline connected with the inlet of the flash tank and the throttling valve does not need to be independently controlled; and thus, the structure of a refrigerating system and control over the refrigerating system are simplified, and the cost is reduced. In addition, the invention further discloses the refrigerating system comprising the above flash tank.

Owner:DANFOSS (TIANJIN) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com