Scroll expander

一种涡旋膨胀机、涡旋的技术,应用在旋转活塞式机械、旋转活塞式发动机、旋转或摆动活塞发动机等方向,能够解决压力损失、重量增加、大驱动力等问题,达到定位容易、密封性良好的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

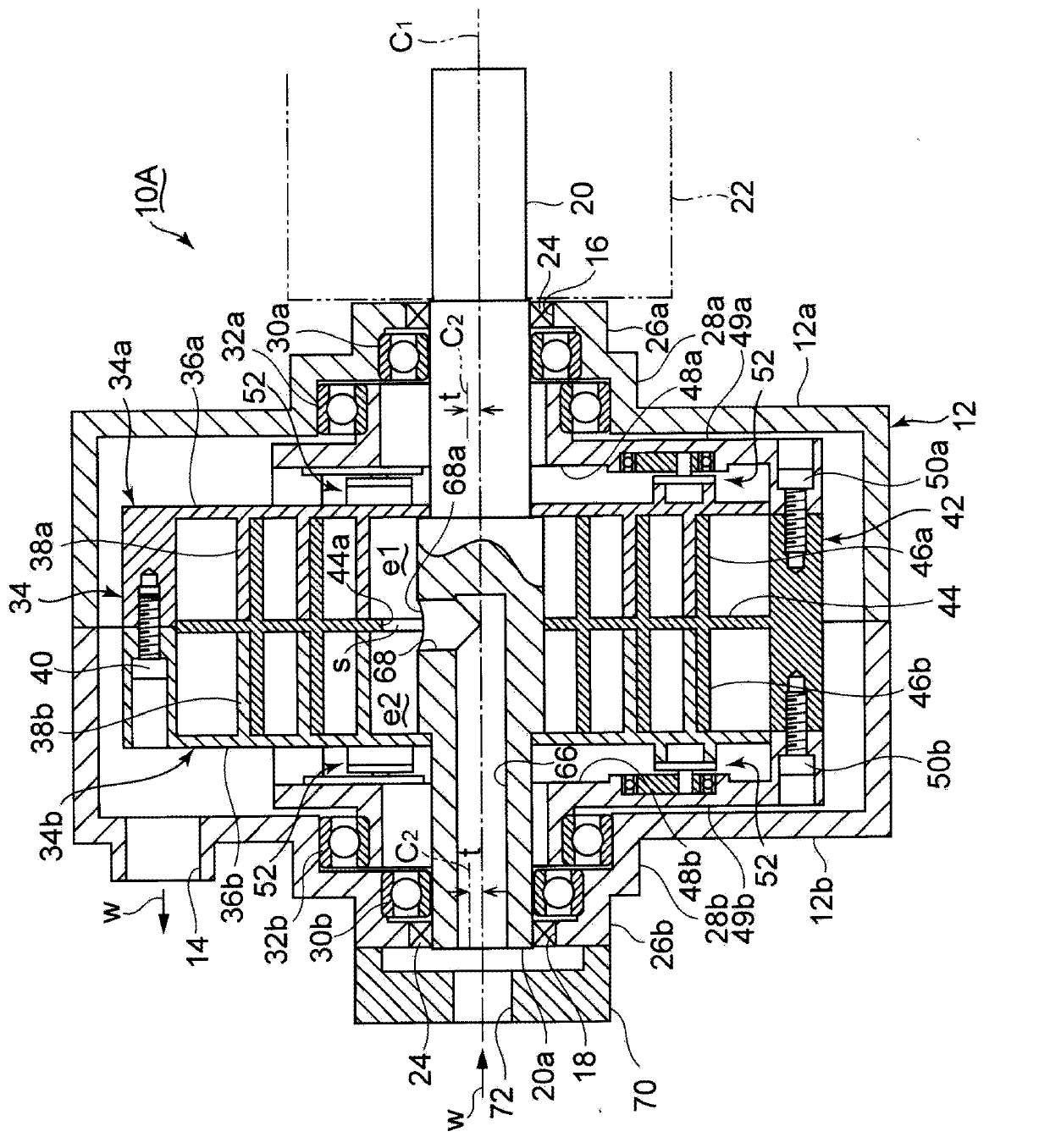

[0030] according to figure 1 and figure 2 A first embodiment of the device of the present invention will be described. The scroll expander of this embodiment can be applied to, for example, the above-mentioned dual-fuel power generation system. In this power generation system, a pressurized working medium with a low boiling point is introduced into a scroll expander, the drive shaft of the scroll expander is rotated by the expansion force of the working fluid, and power is generated by a generator connected to the drive shaft. exist figure 1 Among them, the casing 12 of the scroll expander 10A includes a pair of hollow cylindrical housings 12a and 12b. The ends of the casings 12a and 12b are butted against each other, and a hollow space is formed inside. A discharge port 14 for discharging the expanded working medium w to the outside of the casing 12 is provided on the outer peripheral portion of the end surface of the housing 12b.

[0031] Openings 16 and 18 are formed ...

Embodiment approach 2

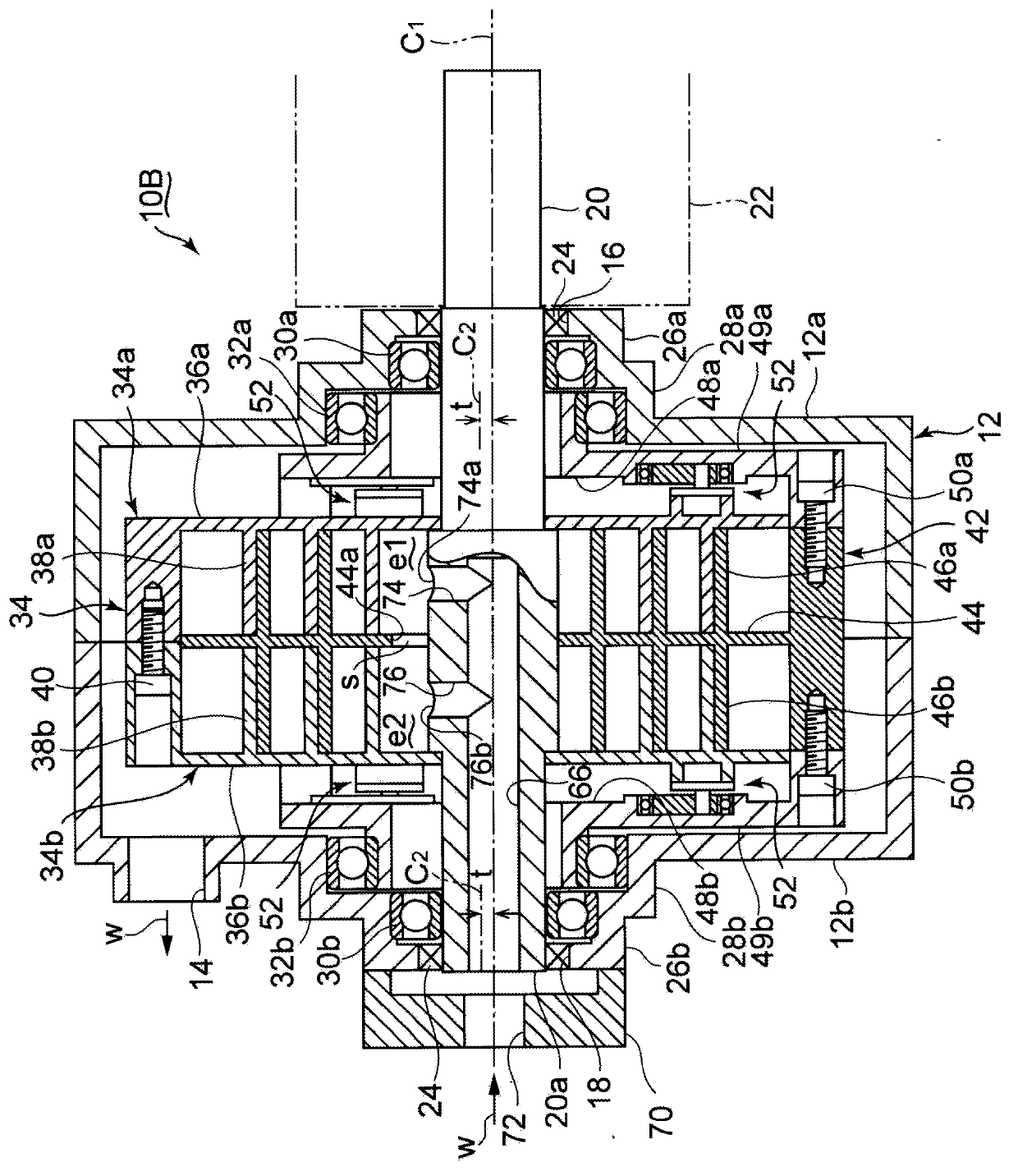

[0043] Next, according to image 3 A second embodiment of the device of the present invention will be described. In the scroll expander 10B of the present embodiment, two radial holes 74 and 76 respectively opening to the expansion chambers e1 and e2 are connected to the working medium introduction hole 66 . The opening 74a of the radial hole 74 opens toward the axial center of the expansion chamber e1, and the opening 76a of the radial hole 76 opens toward the axial center of the expansion chamber e2. The opening area of the opening 74a is the same as that of the opening 76a. Other structures are the same as those of the first embodiment.

[0044] According to the present embodiment, the supply amount of the working medium w supplied from the radial holes 74 to the expansion chamber e1 and the supply amount of the working medium w supplied from the radial holes 76 to the expansion chamber e2 can be made uniform. In addition, there is no need to arrange the opening 68 tow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com