Patents

Literature

312 results about "Double rotation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Double Rotation. Double rotation (DOR) spins a small inner rotor inside a larger outer rotor.

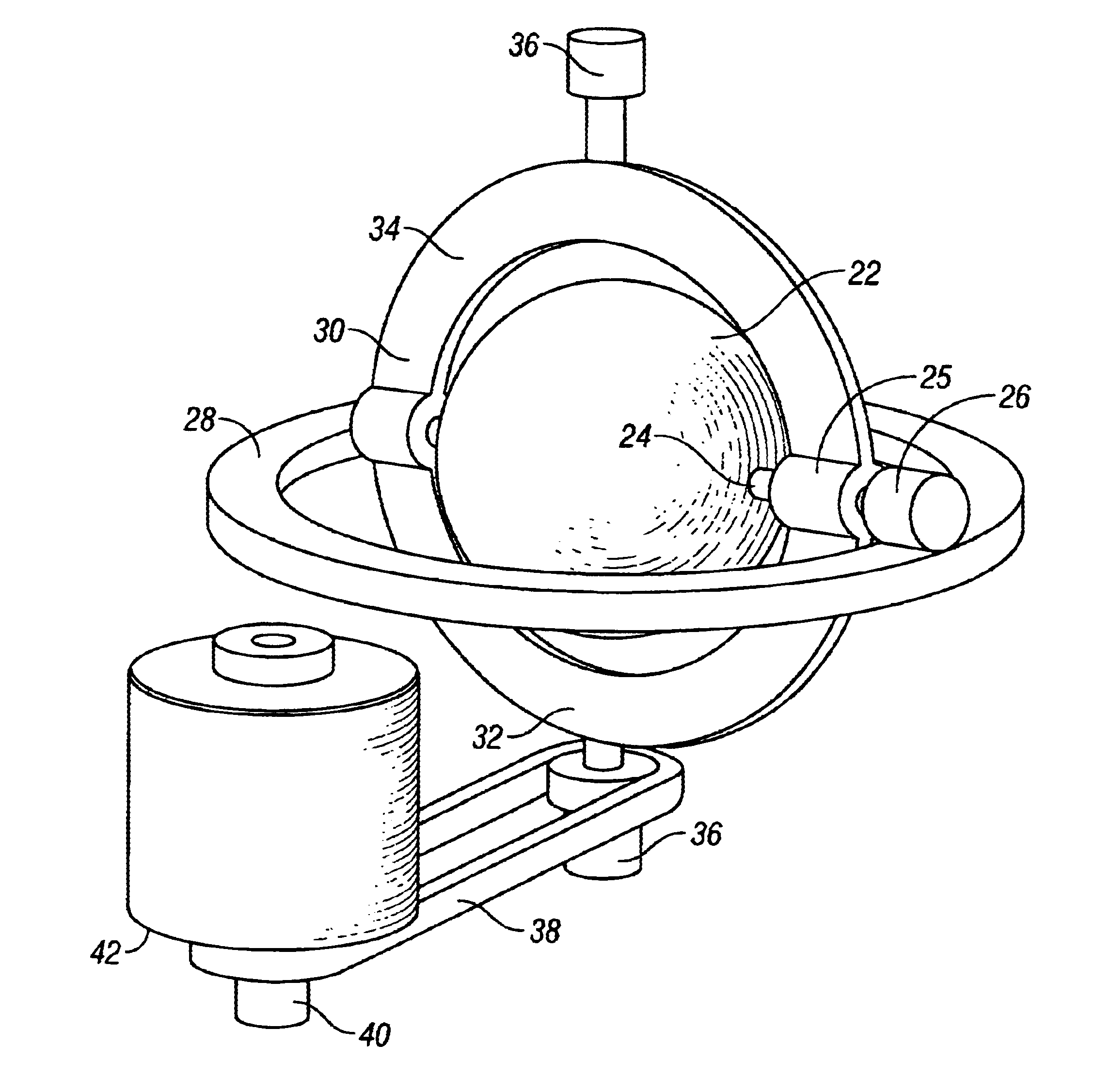

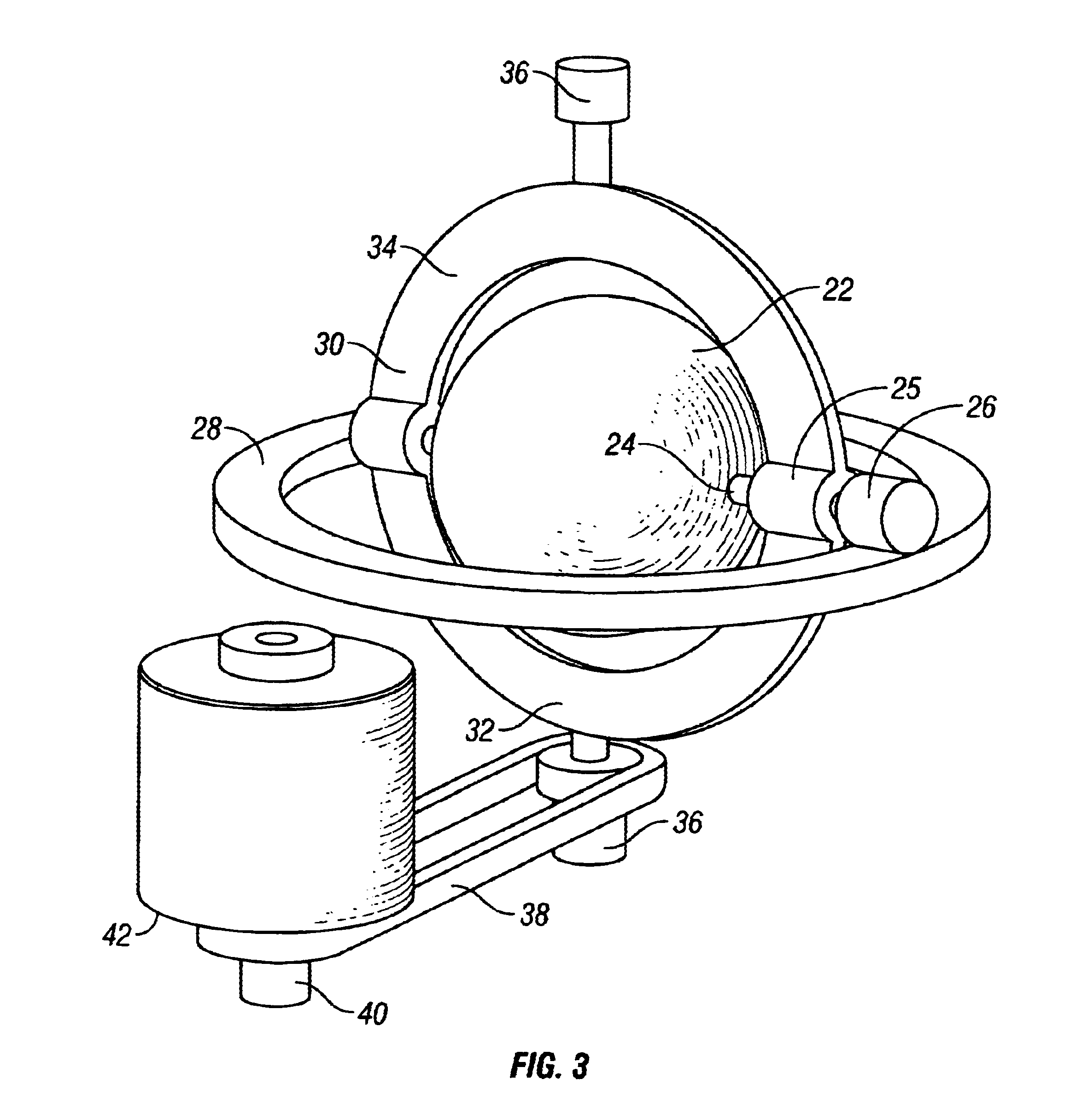

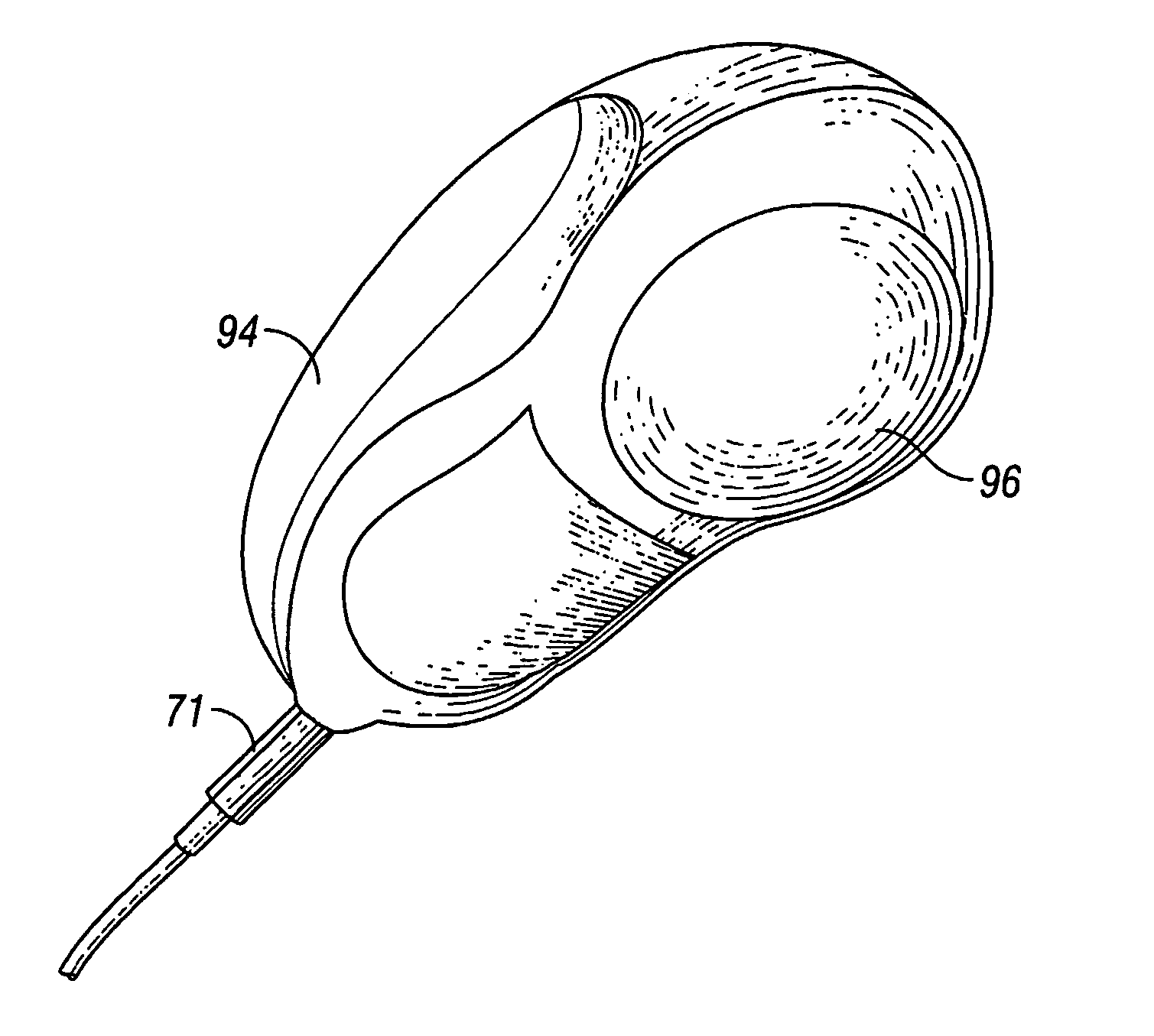

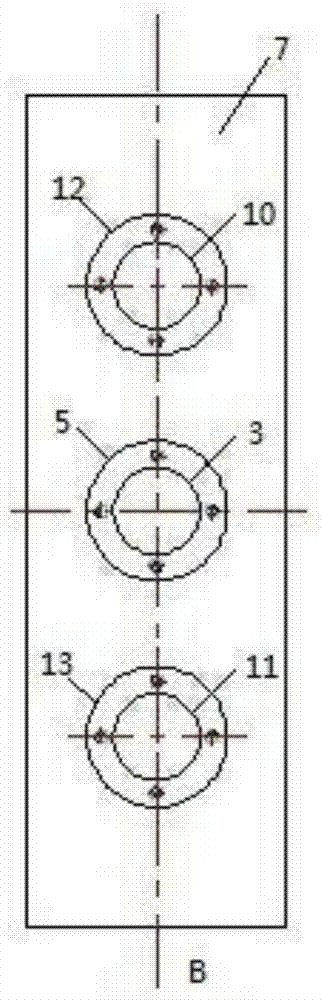

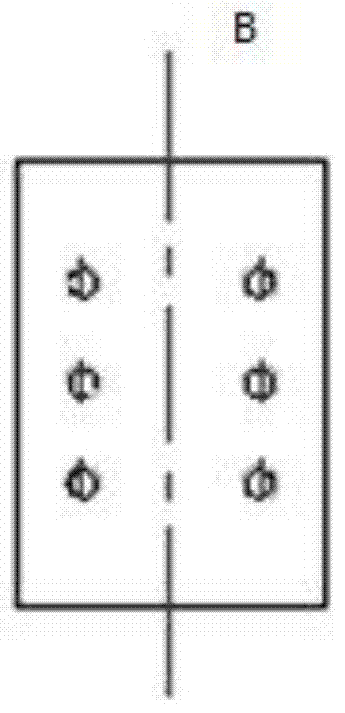

Bi-axial rotating magnetic therapeutic device

Owner:NYUU MAGUNETEIKUSU

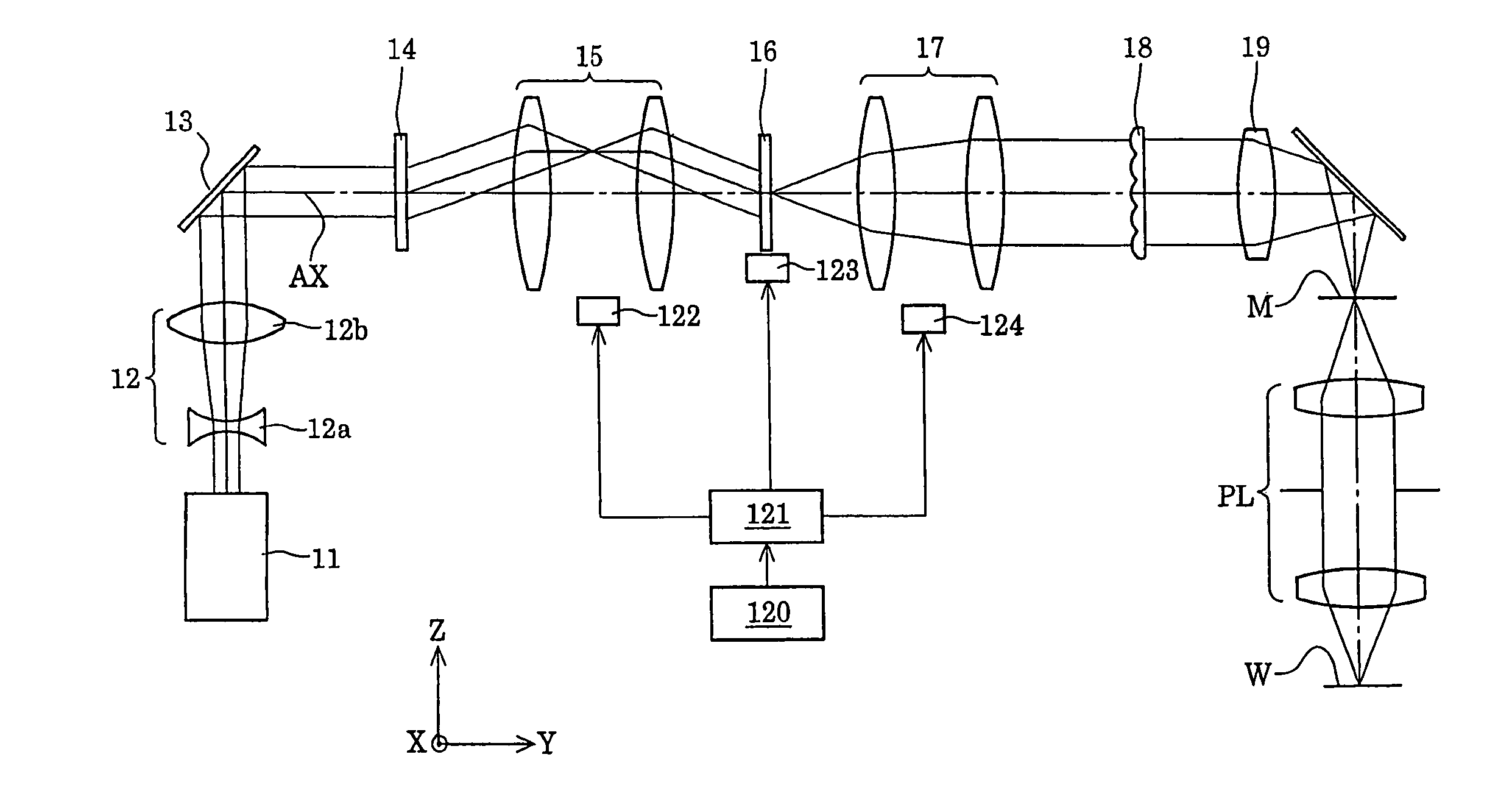

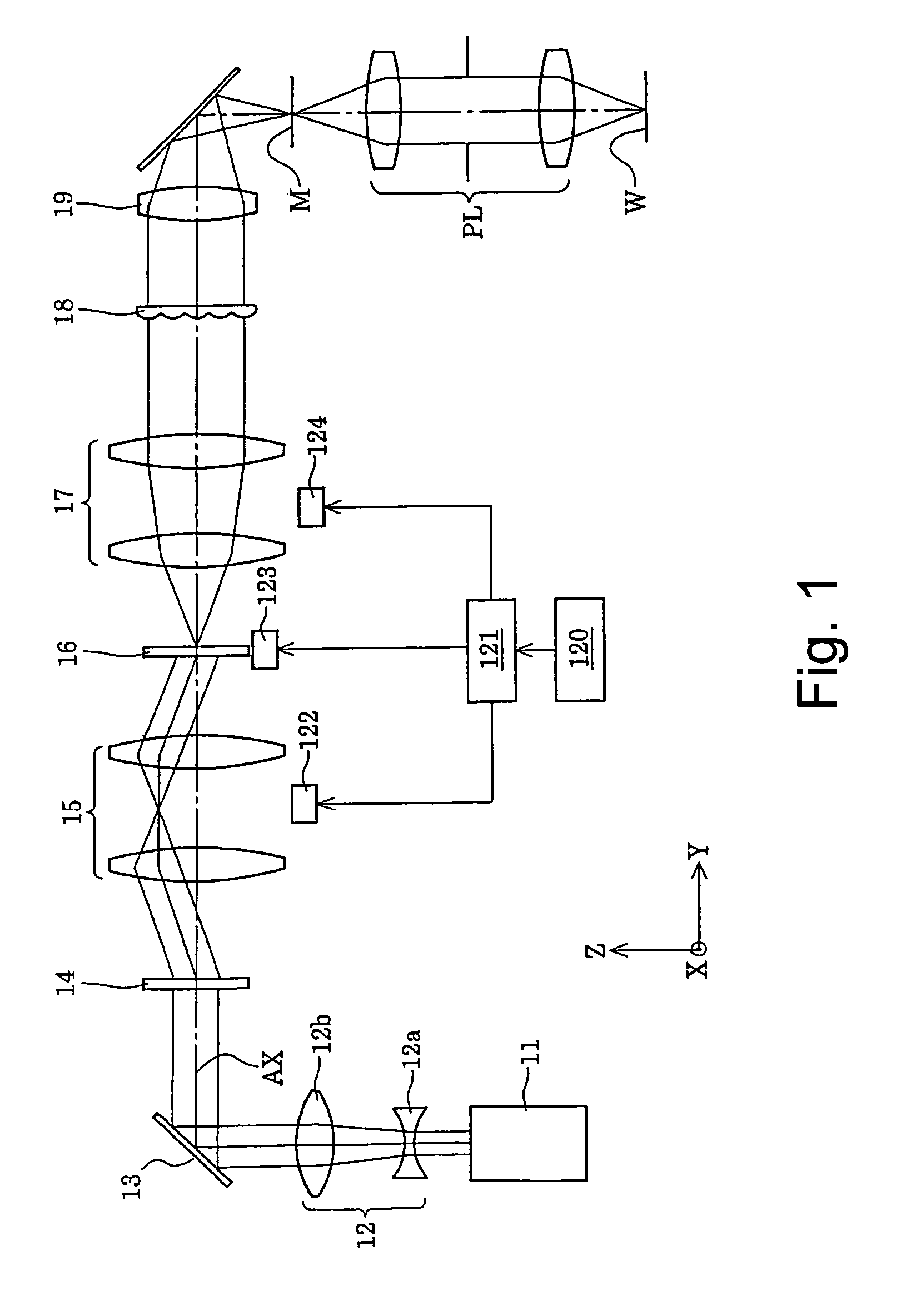

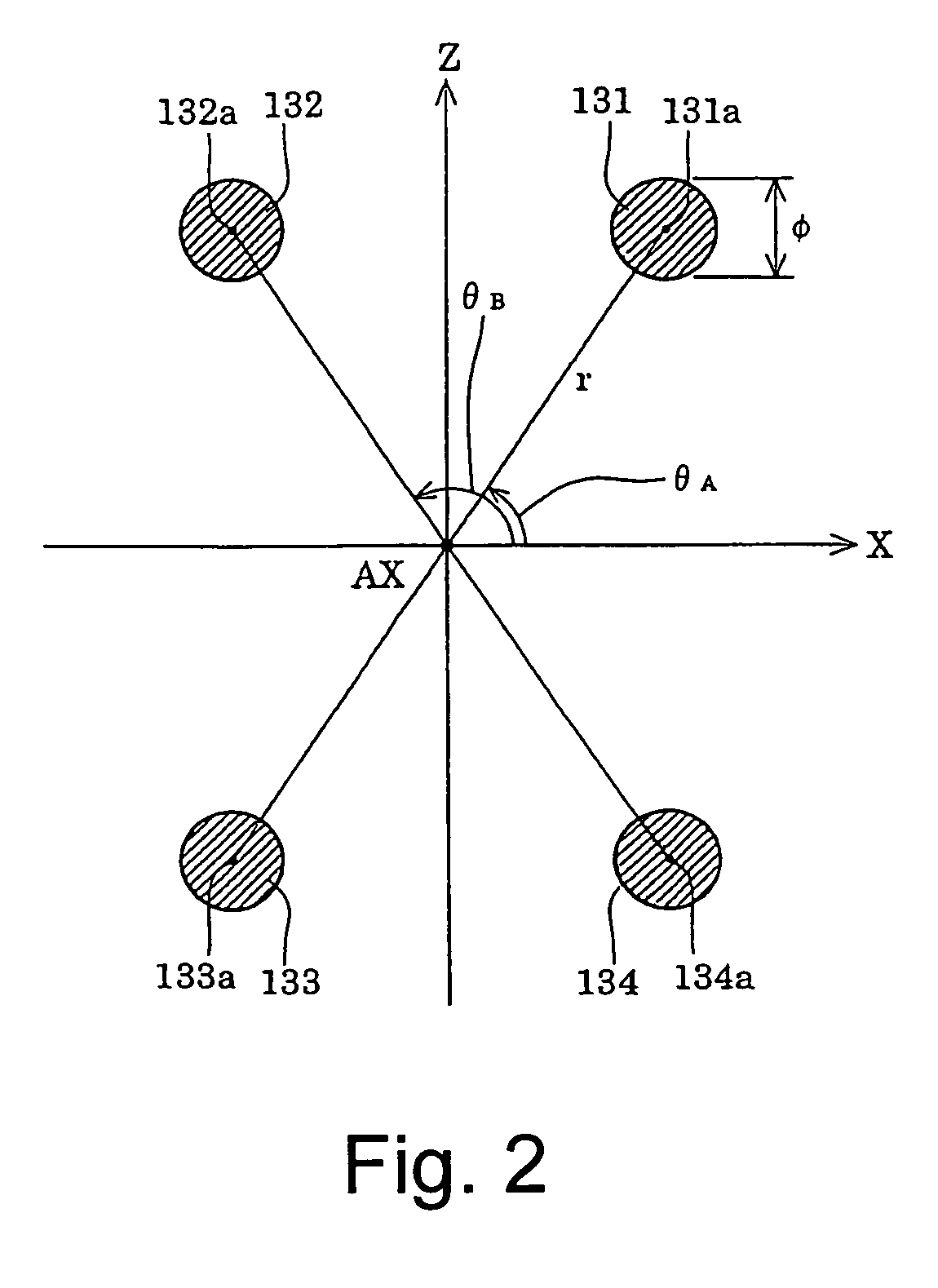

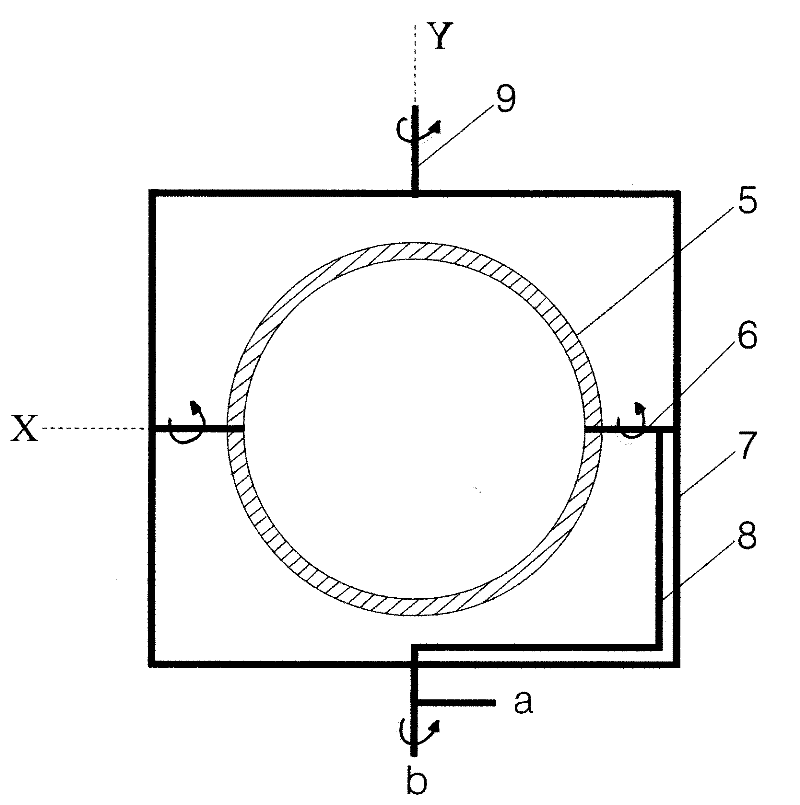

Diffractive optical device, refractive optical device, illumination optical system, exposure apparatus and exposure method

InactiveUS7095560B2Small sizeReduce in quantityDiffraction gratingsPhotomechanical exposure apparatusOptical axisLight beam

An illumination optical system having a more simplified structure forms various quadrupole-shaped secondary light sources with two-time rotational symmetry with respect to an optical axis. The apparatus can provide illumination conditions that differ in two perpendicular directions on a radiation-receiving plane. In order to form a secondary light source with a quadrupole-shaped light intensity distribution on an illumination pupil plane, a diffractive optical device is provided in which an entrance light beam is converted into four light beams, and a light beam having a shape of four points centered about the optical axis is formed in a far field. The diffractive optical device is provided with a first diffractive optical member that is rotatable about a first axis parallel to the optical axis, and a second diffractive optical member that is rotatable about a second axis parallel to the optical axis, and that is arranged adjacent to the first diffractive optical member. A refractive optical device having first and second refractive optical members accomplishes similar results.

Owner:NIKON CORP

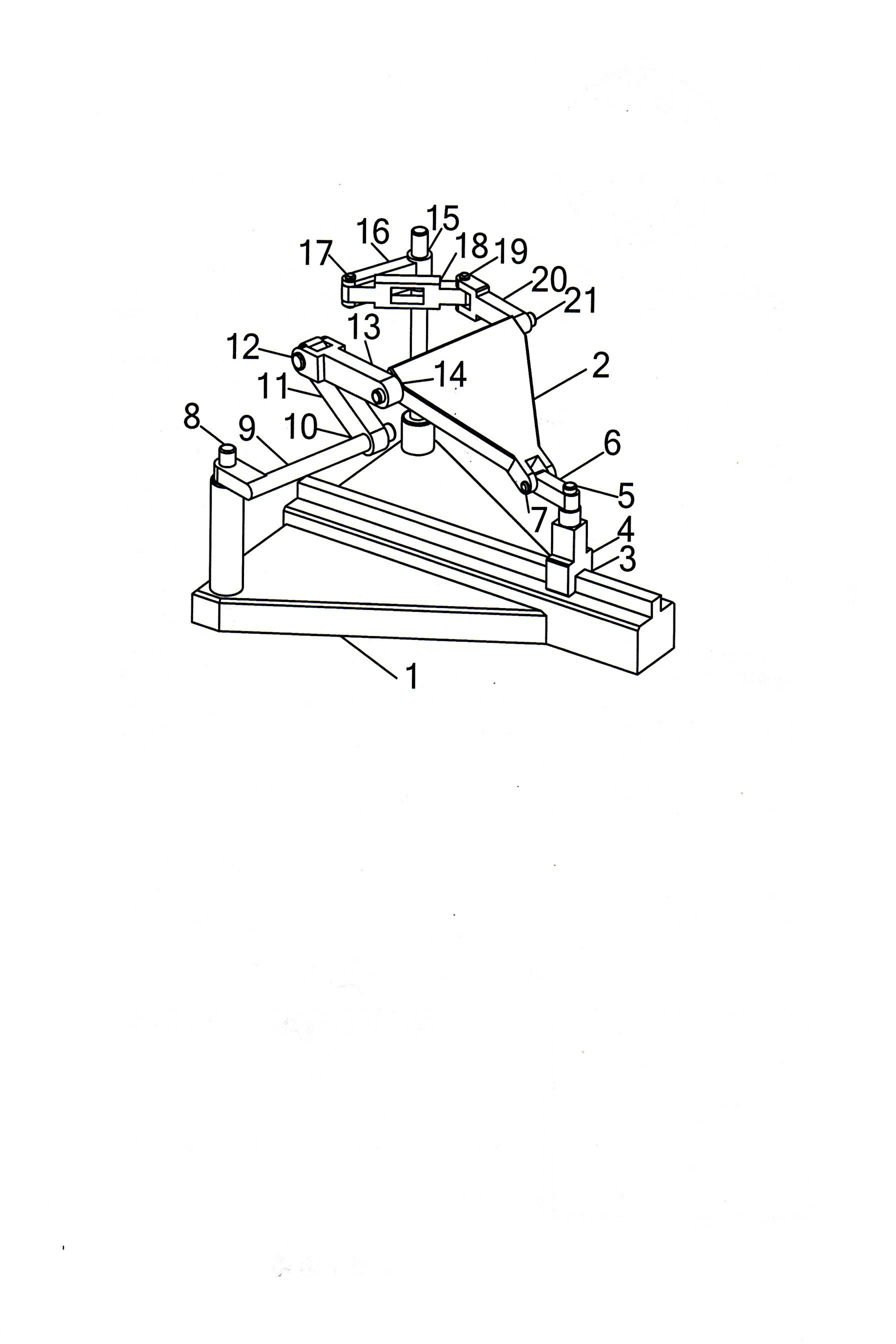

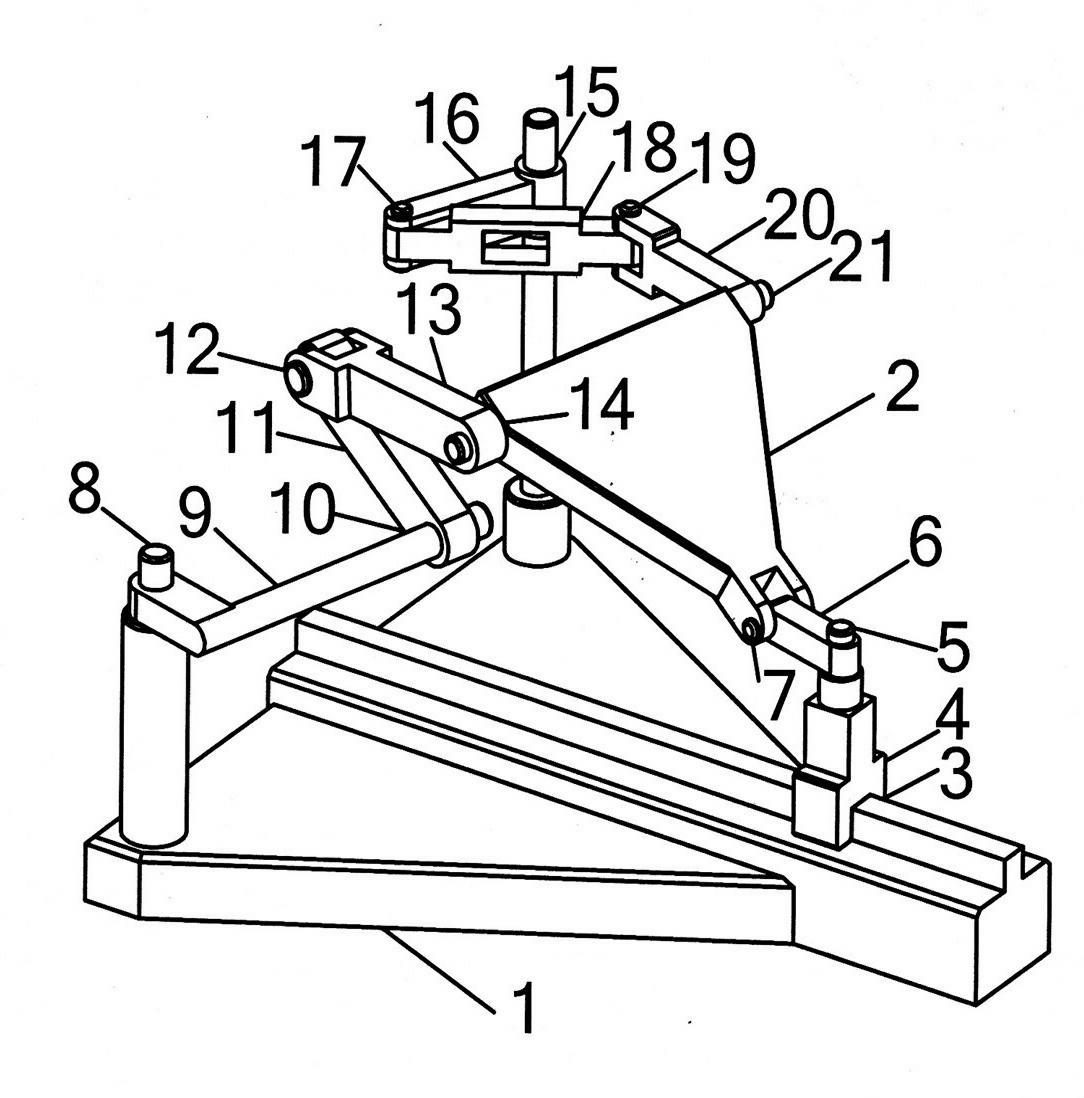

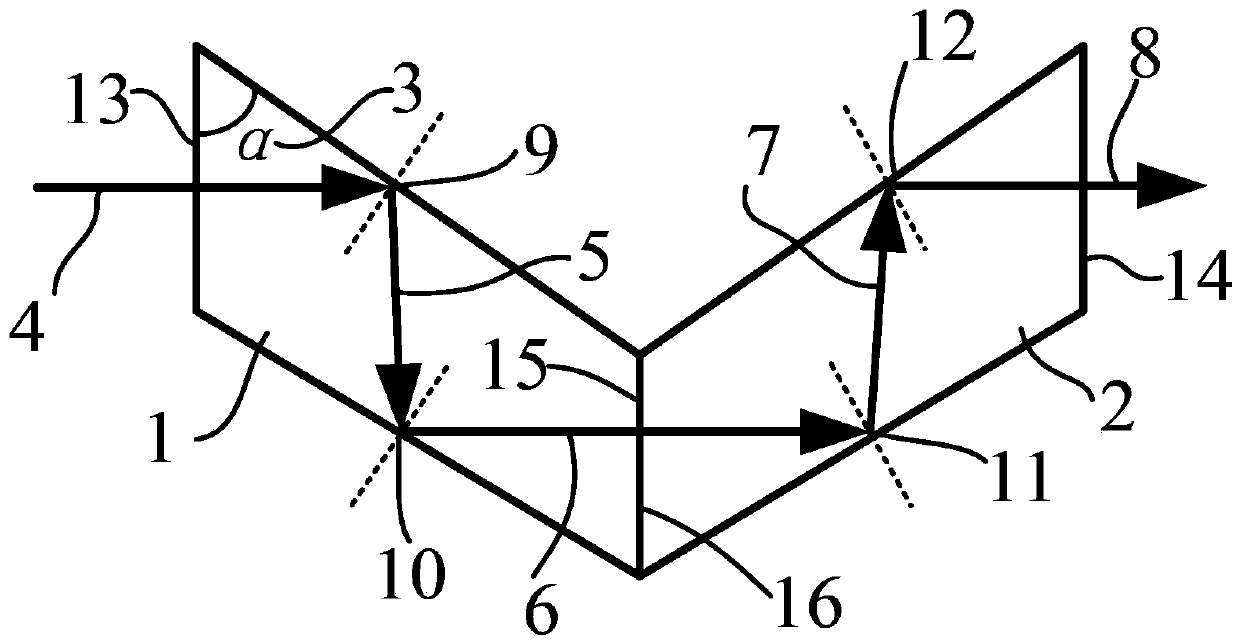

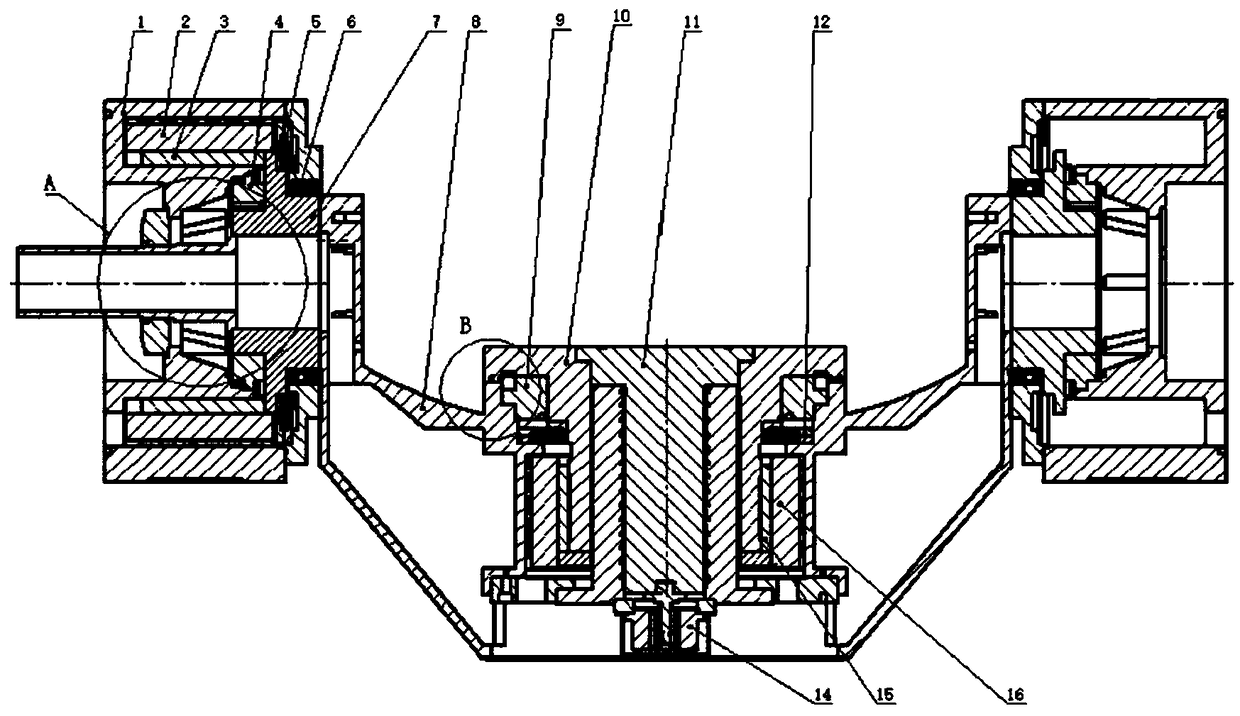

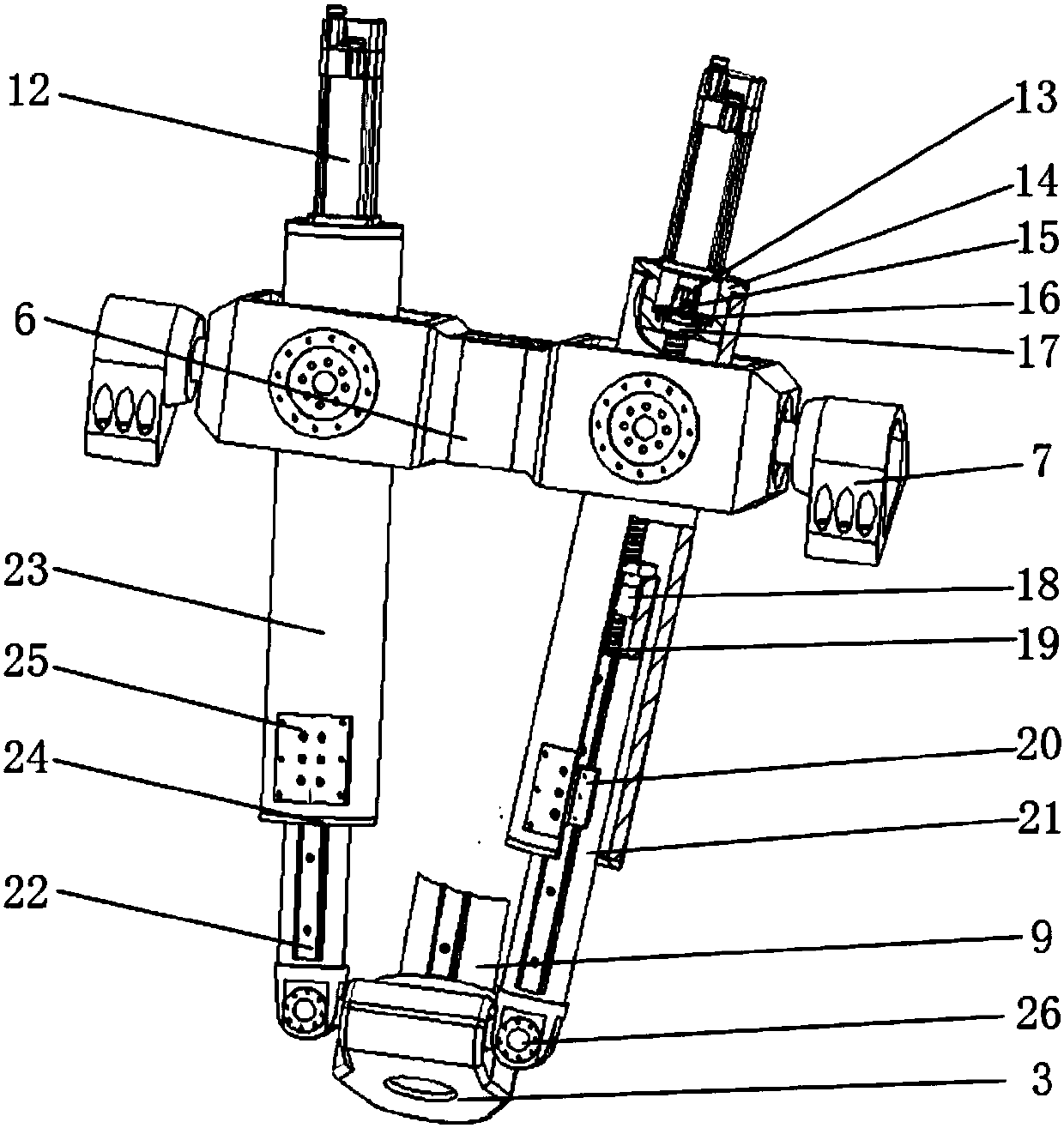

Decoupling parallel robot mechanism with single movement, double rotation and triple degree of freedom

ActiveCN102431028AIncrease flexibilityImprove developmentProgramme-controlled manipulatorControl systemDegrees of freedom

A decoupling parallel robot mechanism with single movement, double rotation and triple degree of freedom mainly comprises a fixed pedestal, a movable platform and three branches connected therewith. The first branch comprises two connecting rods which are connected by a reolute pair vertical to axis of a reolute pair connected with the movable platform and to direction of a movable pair connected with the fixed pedestal. The second branch comprises three connecting rods which are connected by a reolute pair and a column pair with parallel axes, axis of the column pair is vertical to axis of a reolute pair connected with the fixed pedestal and parallel to axis of the reolute pair connected with the movable platform. The third branch comprises three connecting rods which are connected by two reolute pairs with parallel axes and connected with the fixed pedestal by the column pair, axis of the column pair is vertical to axis of the reolute pair connected with the movable platform and parallel with axes of the other two reolute pairs. Three branches of the mechanism are parallel with three reolute pairs connected with the movable platform. The invention has movable decoupling, high movable platform flexibility, easily developed control system and more simple and convenient calibration.

Owner:秦皇岛燕盛智能科技有限公司

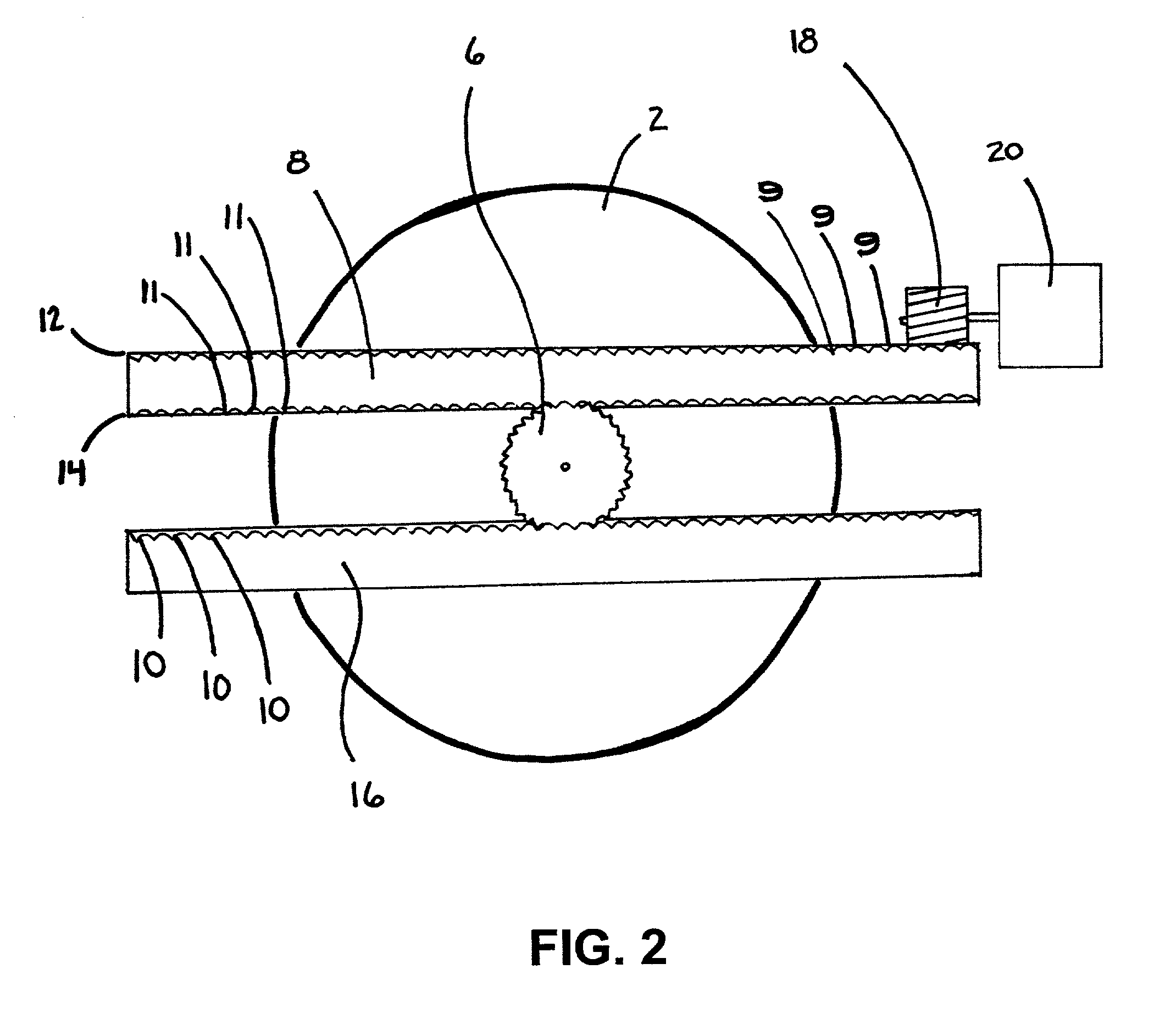

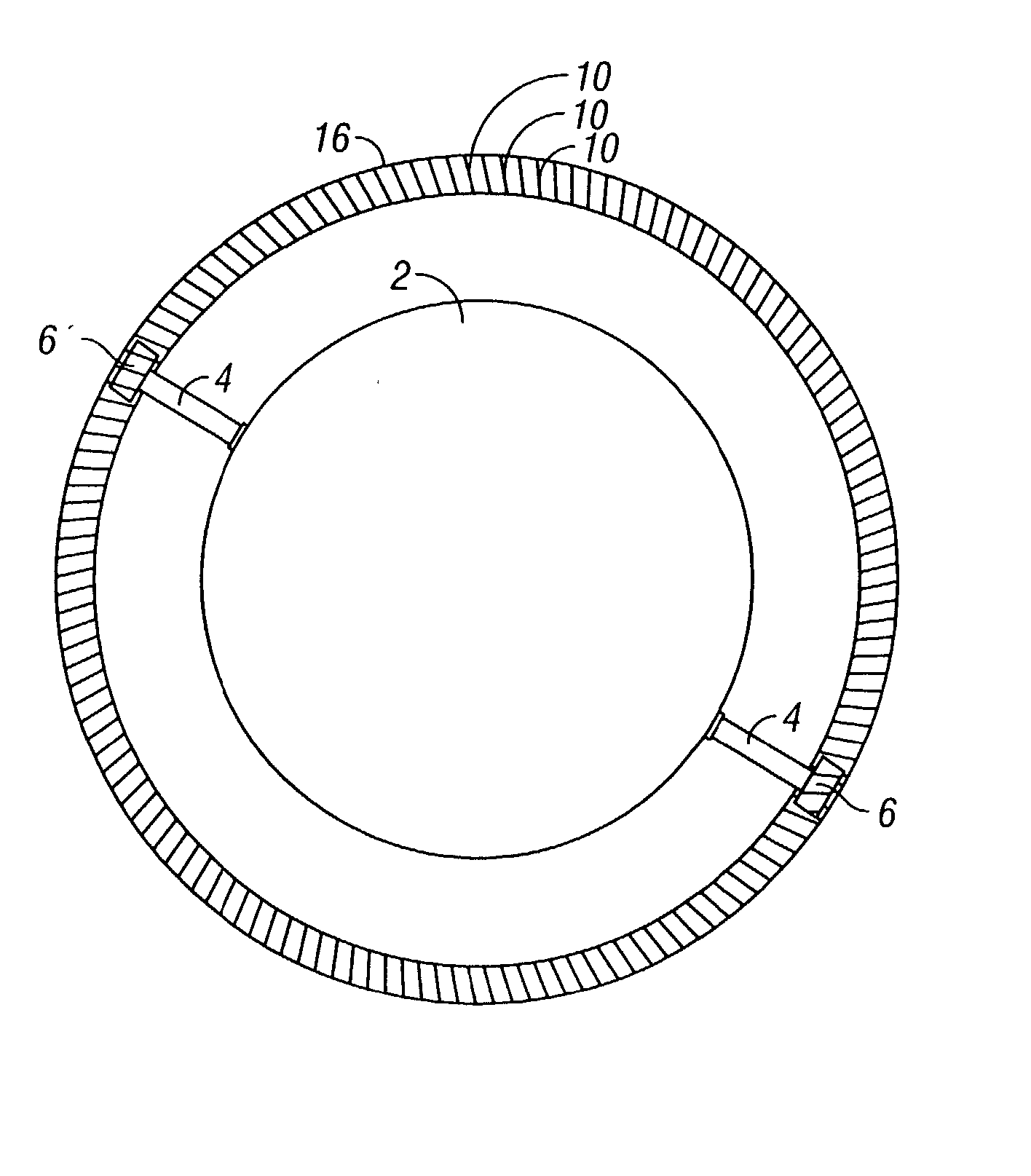

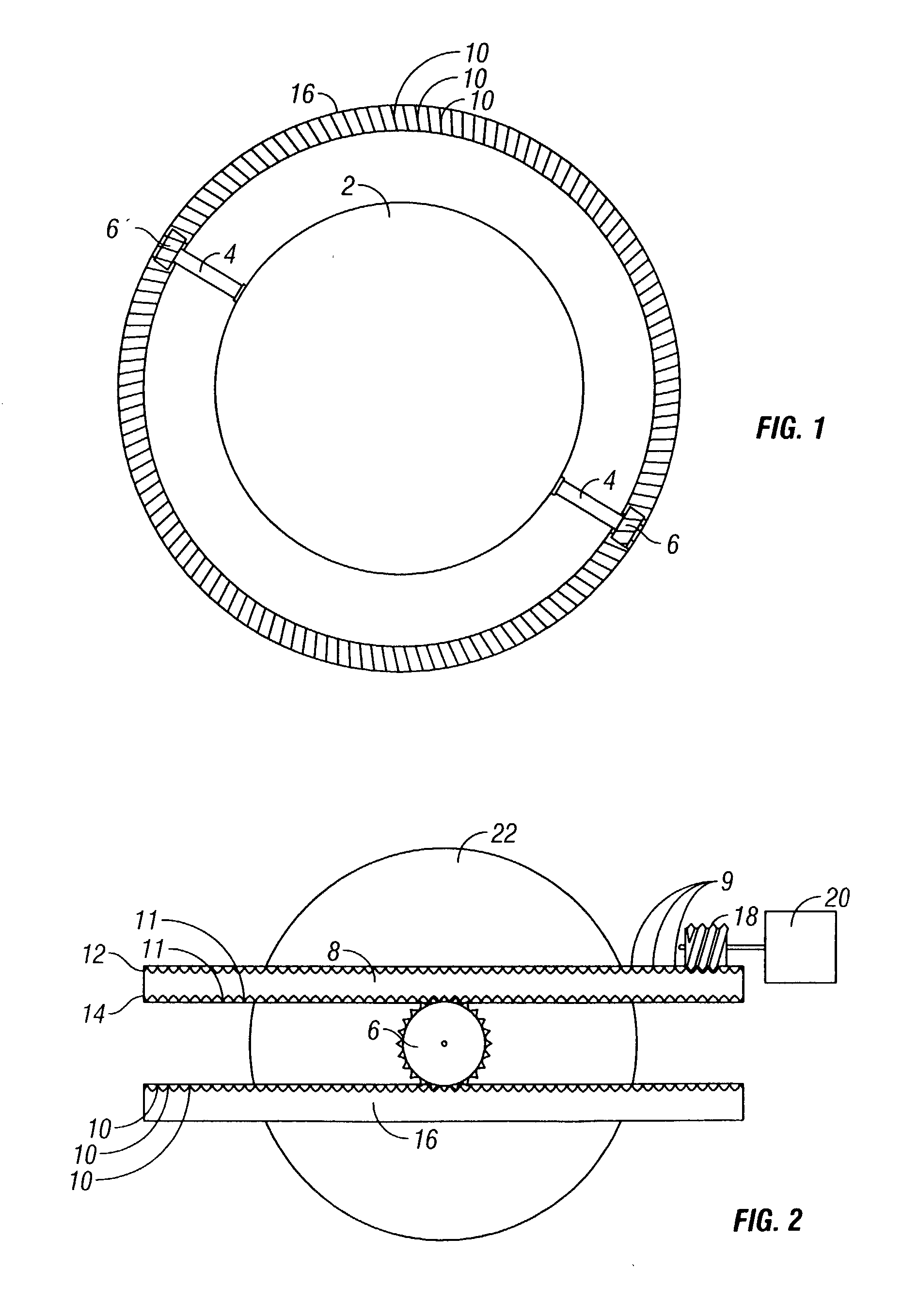

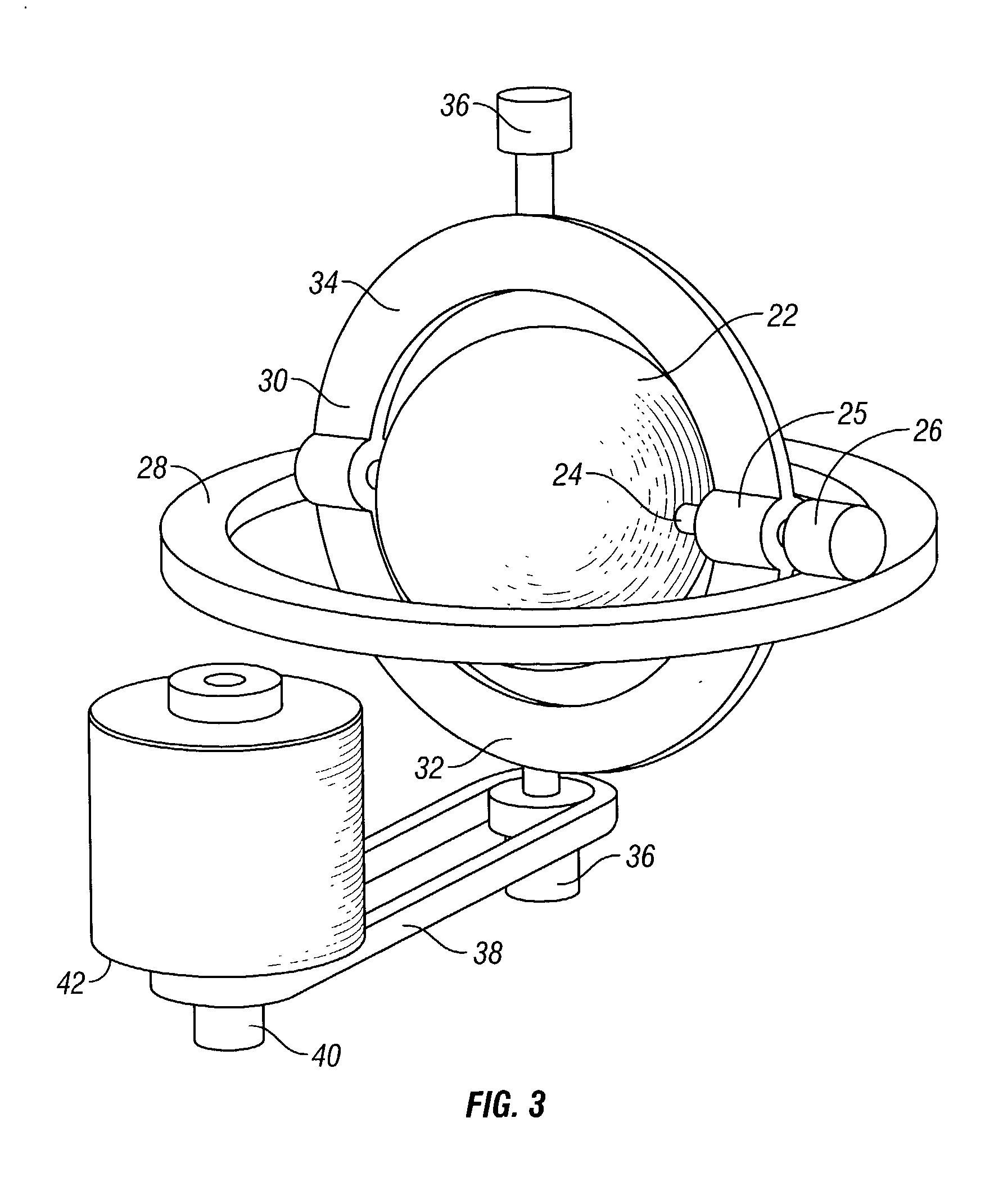

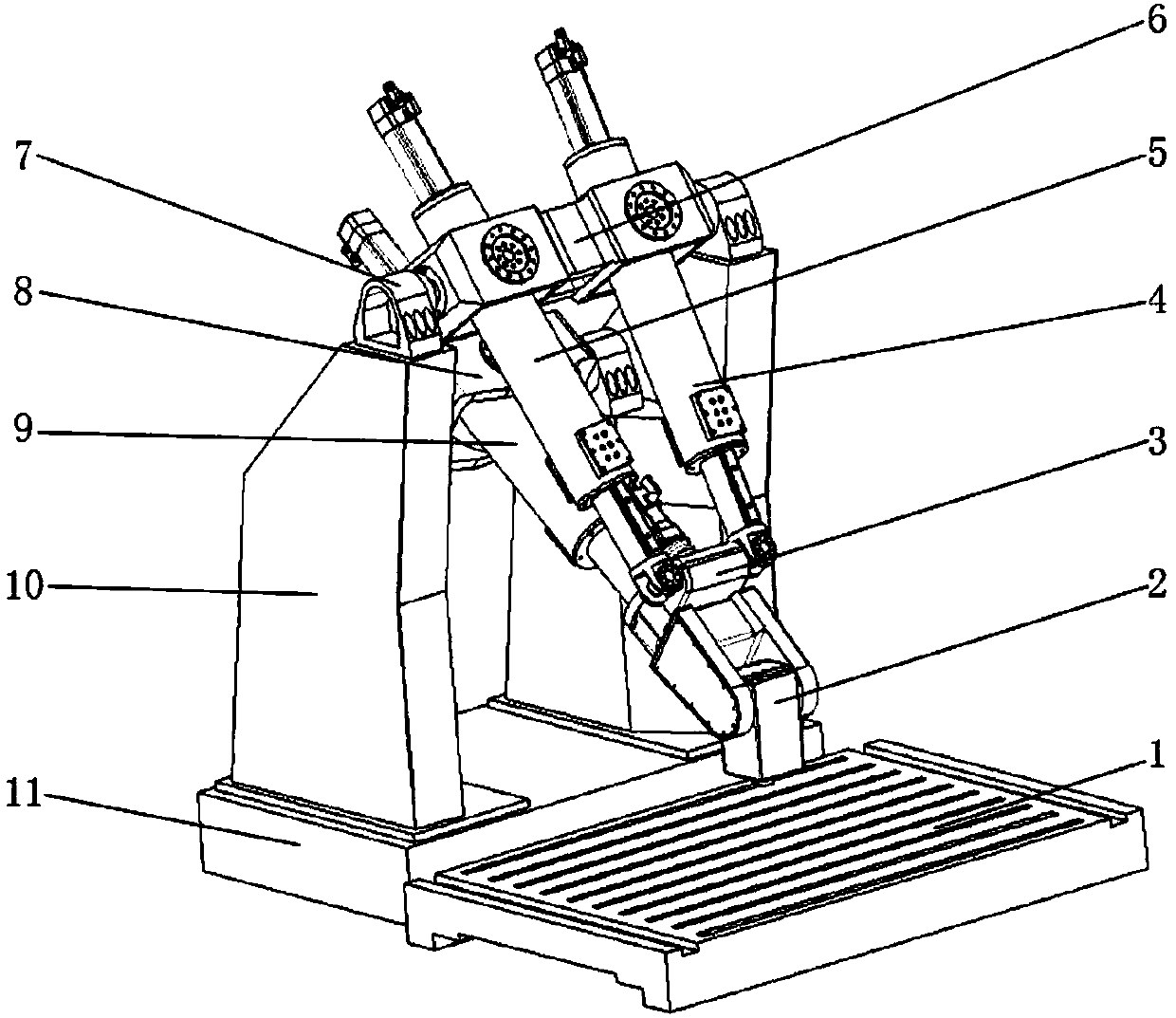

Bi-axial rotating magnetic therapeutic device

A device for applying a time-varying magentic field to a human or animal body for therapeutic purposes comprising a magnetic body (72), housed in a free moving member (80), which is it-self housed within the device. The device is powered by a small electric motor that drives the free moving member (80) and magnetic body (72) to rotate about an exis of first rotation. The magnetic body is further caused to rotate around an axis of second rotation through angular forces imparted on it either mechanically or magnetically. Mechanical angular force is imparted by a gear and tooth arrangement or other similar tactile interaction with a roller member (106). Magnetic angular force is imparted by stationary magnets (110) as the magnetic body (72) rotates past them. The two rotational movements of the magnetic body (72) are oblique to one another and produce both a time-varying field of magnetic flux density and a time varying field of angular flux displacement.

Owner:ARDIZZONE VINCENT +1

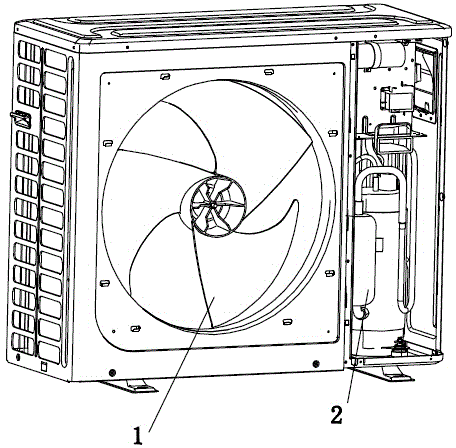

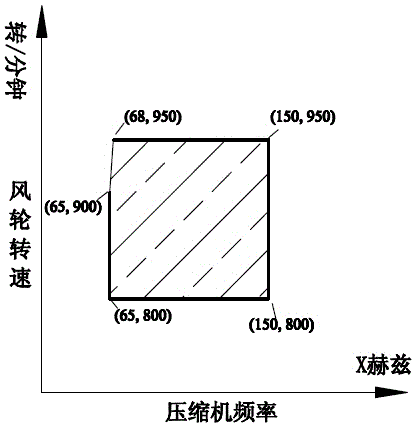

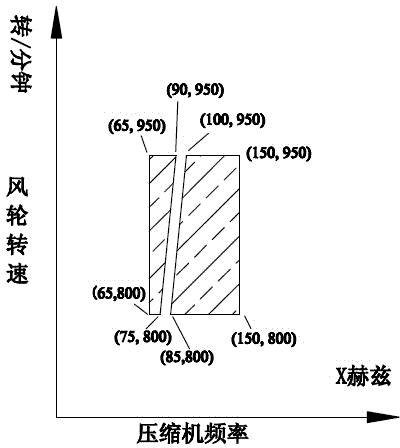

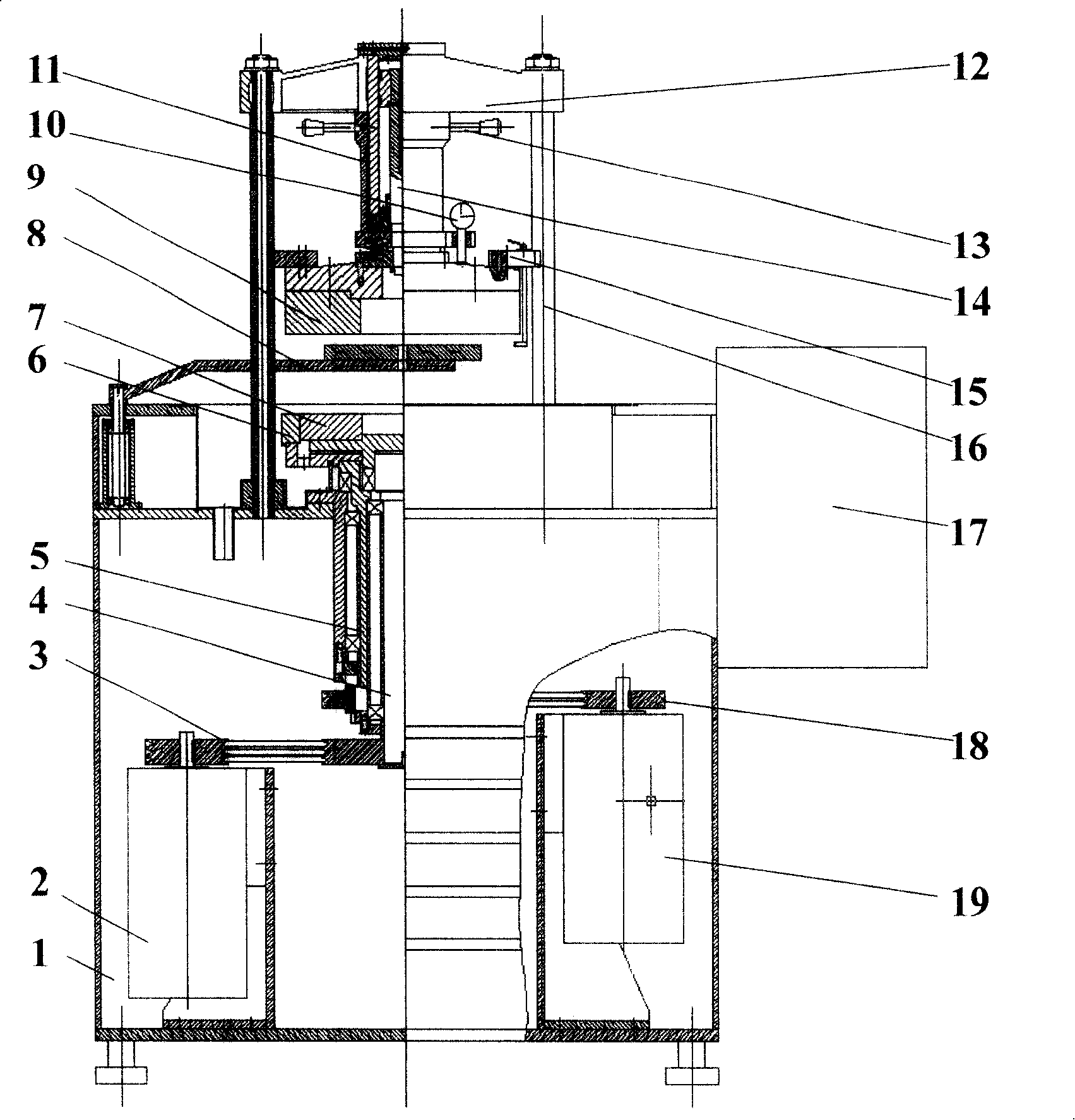

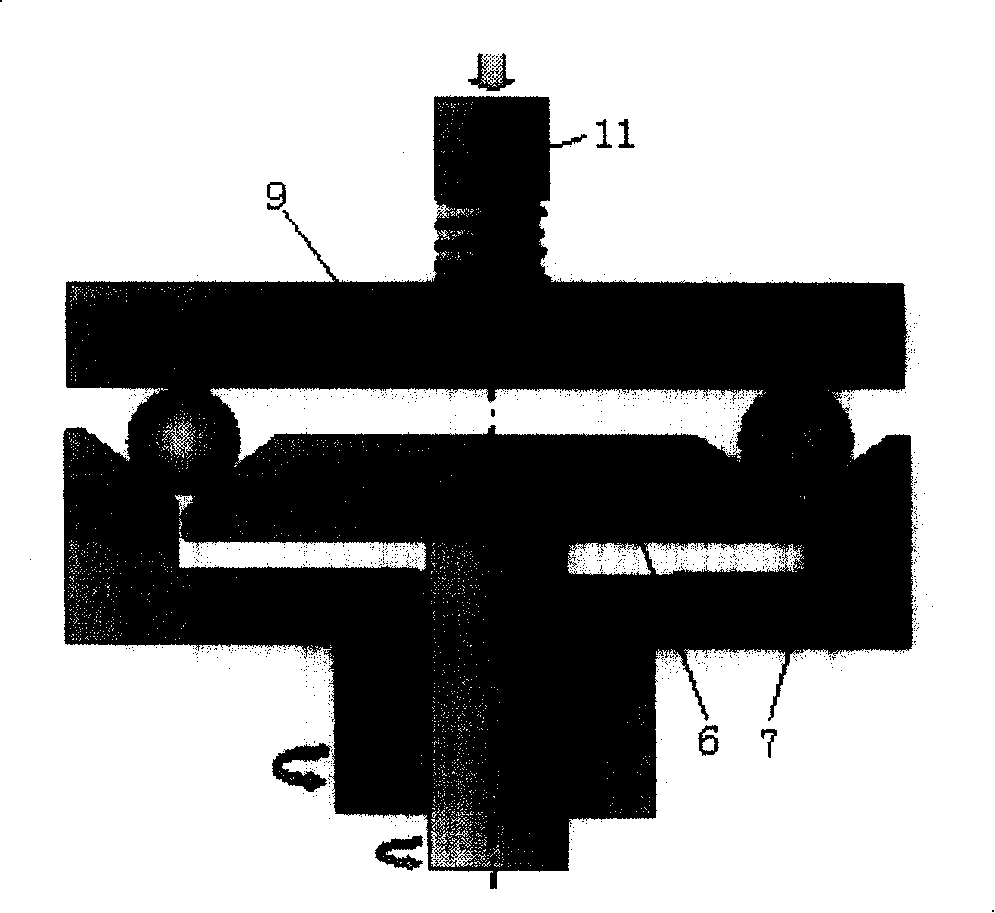

Method for controlling frequency inverter air conditioner outdoor fan and compressor vibration noise

ActiveCN102721120AImprove sound qualityImprove reliabilityLighting and heating apparatusAir conditioning systemsResonanceSuperimposition

The invention relates to a method for controlling frequency inverter air conditioner outdoor fan and compressor vibration noise. The rotation speed of a wind wheel (1) of an air conditioner outdoor fan is Y r / min. The number of the blade of the wind wheel (1) is Z. The rotation fundamental frequency of the blade of the wind wheel (1) is F1:F1=Z*Y / 60 Hz. The rotation frequency of a compressor (2) is X Hz. The method is characterized in that when the operation frequency of the compressor (2) X is between 65 Hz and 150 Hz, the rotation speed of the wind wheel (1) is in the range of 800 r / min to 950 r / min, and the following relationships exist: the absolute value of the difference between the rotation frequency of the compressor X and double rotation fundamental frequency of the blade of the wind wheel (1) is greater than 5 Hz, namely |X-2*F1|>5 Hz. The method provided by the invention can greatly weaken or completely eliminate the vibration formed by the superimposition of the wind wheel and the compressor rotation noise, thereby the sound quality the noise of the air conditioner outdoor unit is significantly improved, the sheet metal structure resonance can be effectively avoided, the vibration can be reduced, the sound quality can be improved, the noise can be reduced, and the reliability of the whole machine can be improved.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD

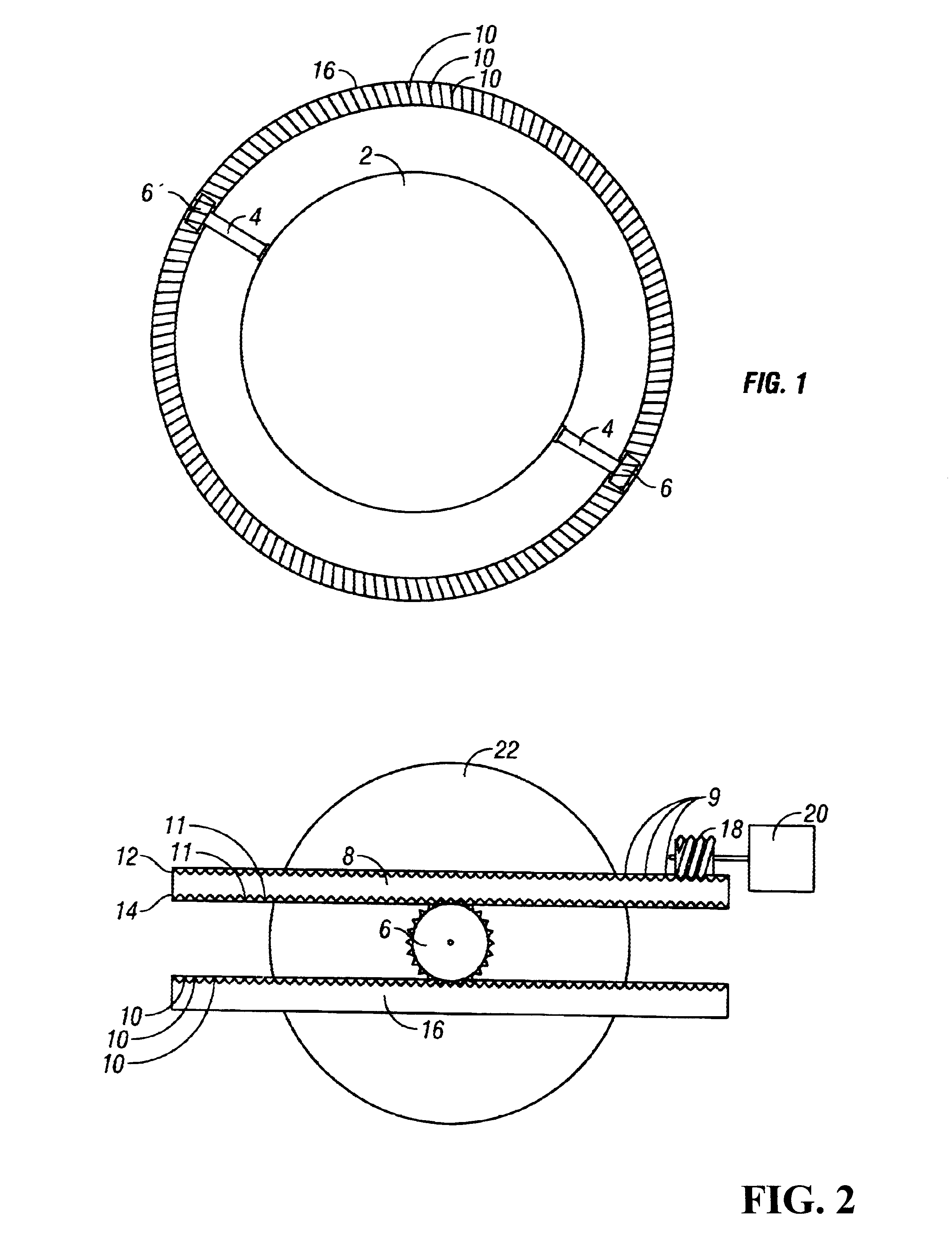

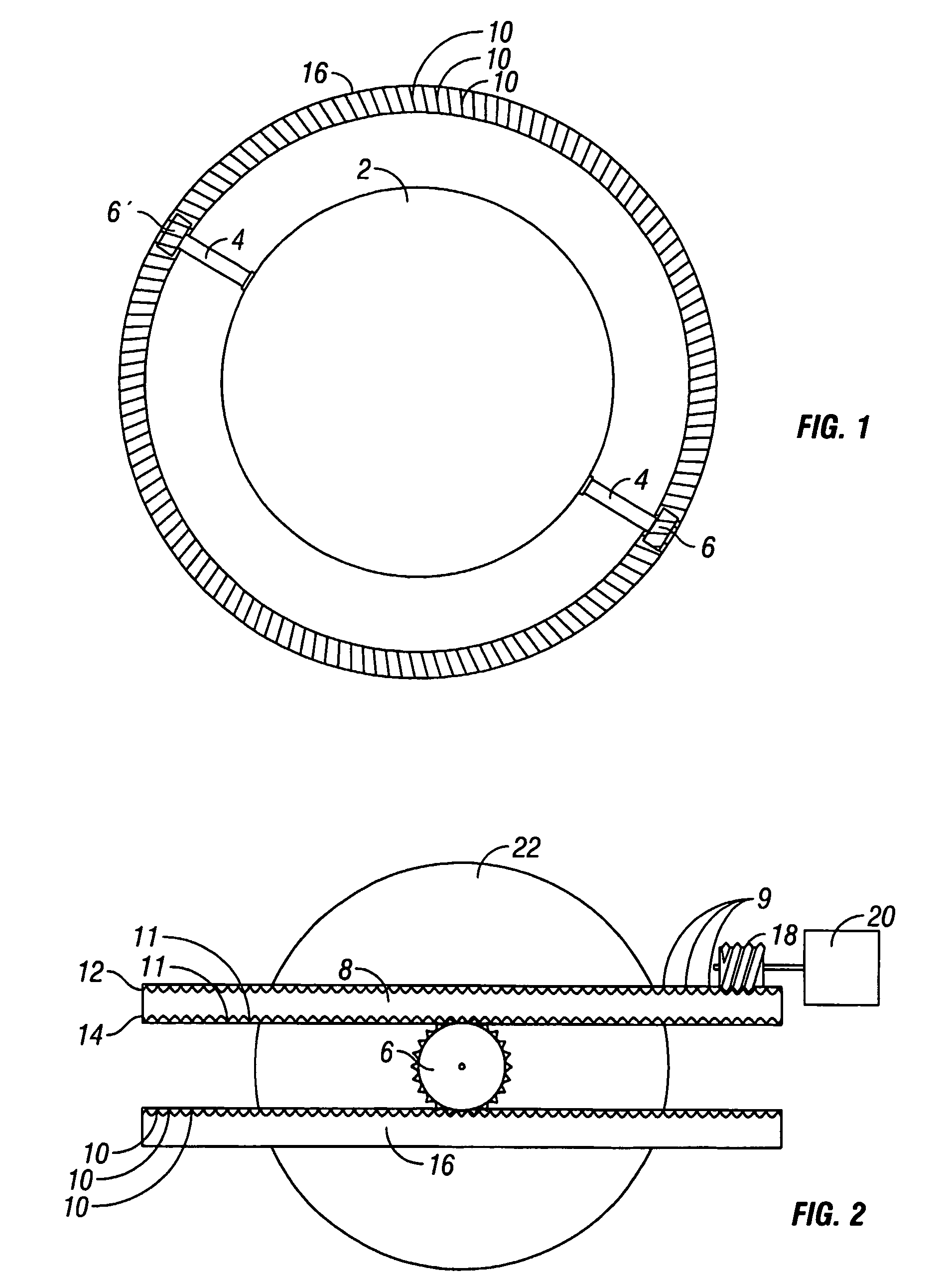

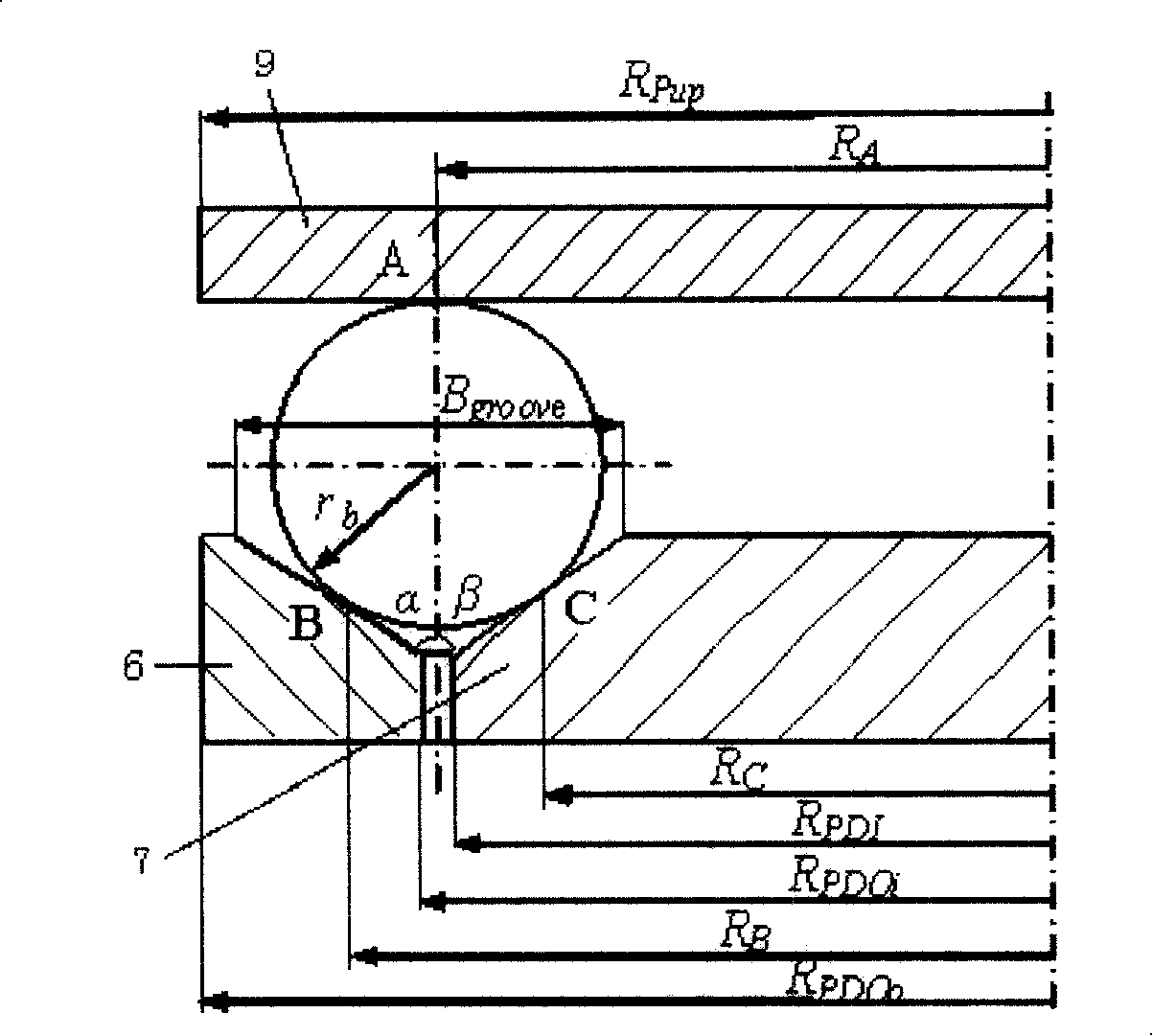

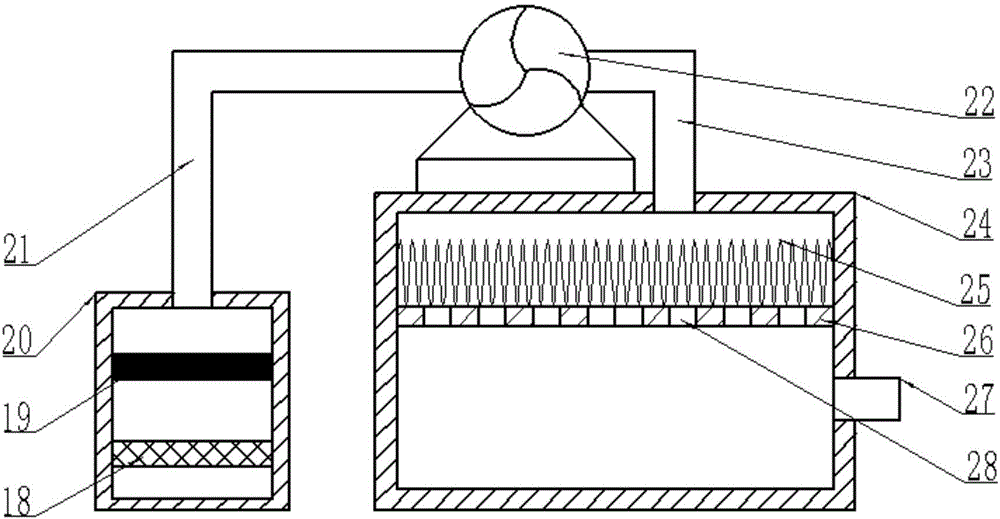

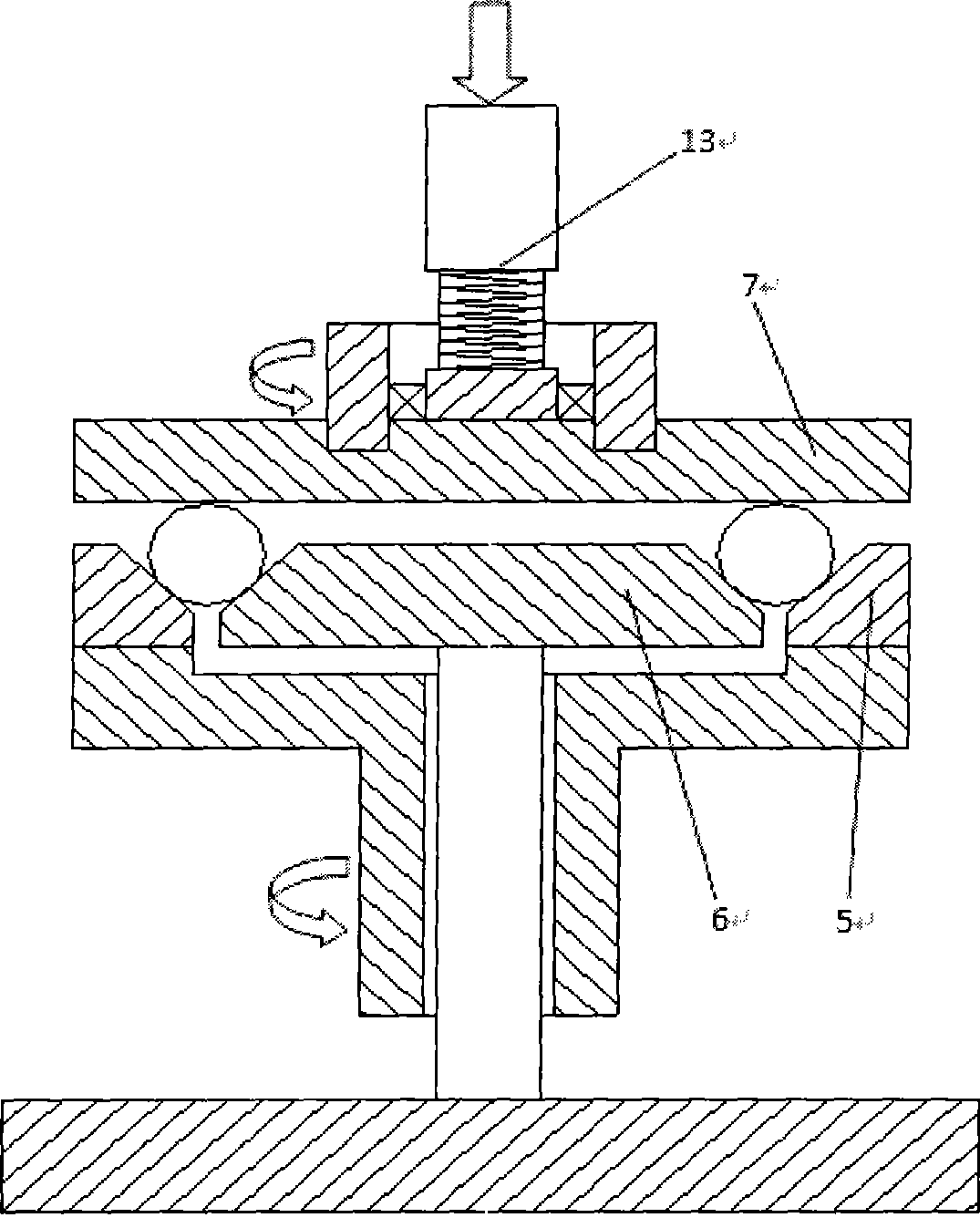

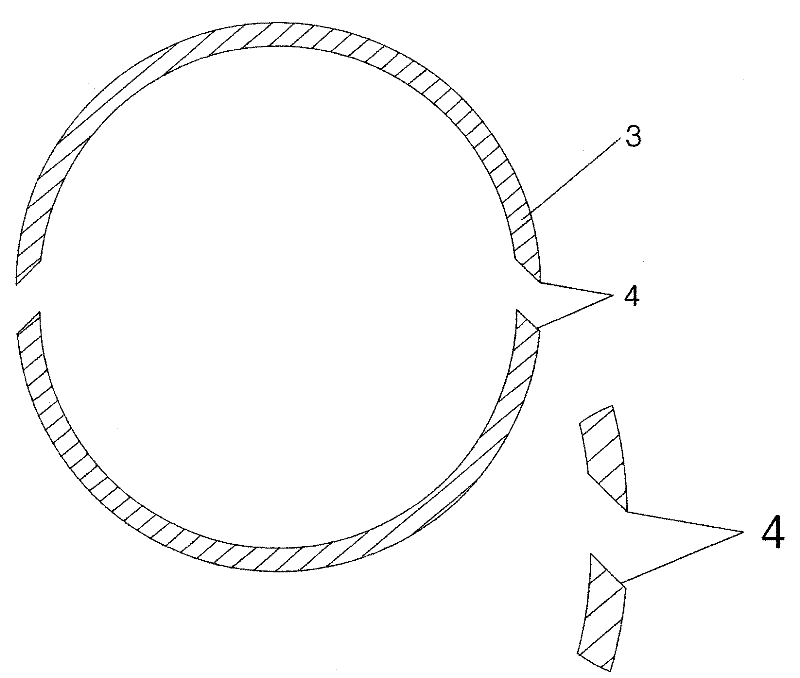

High accuracy ball double autorotation grinding tray high-efficiency grinding device

InactiveCN101204786AImprove grinding precisionImprove grinding efficiencySpherical surface grinding machinesRough surfaceDrive motor

A high precision ball double rotation abrasive disk high efficiency grinding unit includes an upper abrasive disk, a lower abrasive disk and an inner disk of the lower abrasive disk arranged on a frame. The cone abrasive surface at the outer side of the inner disk of the lower abrasive disk and the cone abrasive surface at the inner side of an outer disk of the lower abrasive disk form a V-shaped slot structure which together with the upper abrasive disk forms three machining contact points of a grinding ceramics ball. The drive axes of any two parts in the upper abrasive disk, the outer disk of the lower abrasive disk and the inner disk of the lower abrasive disk are selected to be connected with an electric motor. The parts not connected with a drive motor machine a loading device. The invention can realize the relative orientation adjustment of a rotating axis and a revolution axis for a ball rough and realizes uniform grinding / polishing of the ball rough surface. The invention has the advantages of high machining precision, machining efficiency and machining consistency, and simultaneously the drive and transmission devices have been reduced from 3 to 2. The invention has a simple structure and is a grinding unit with less requirements for machining and assembling precisions.

Owner:ZHEJIANG UNIV OF TECH

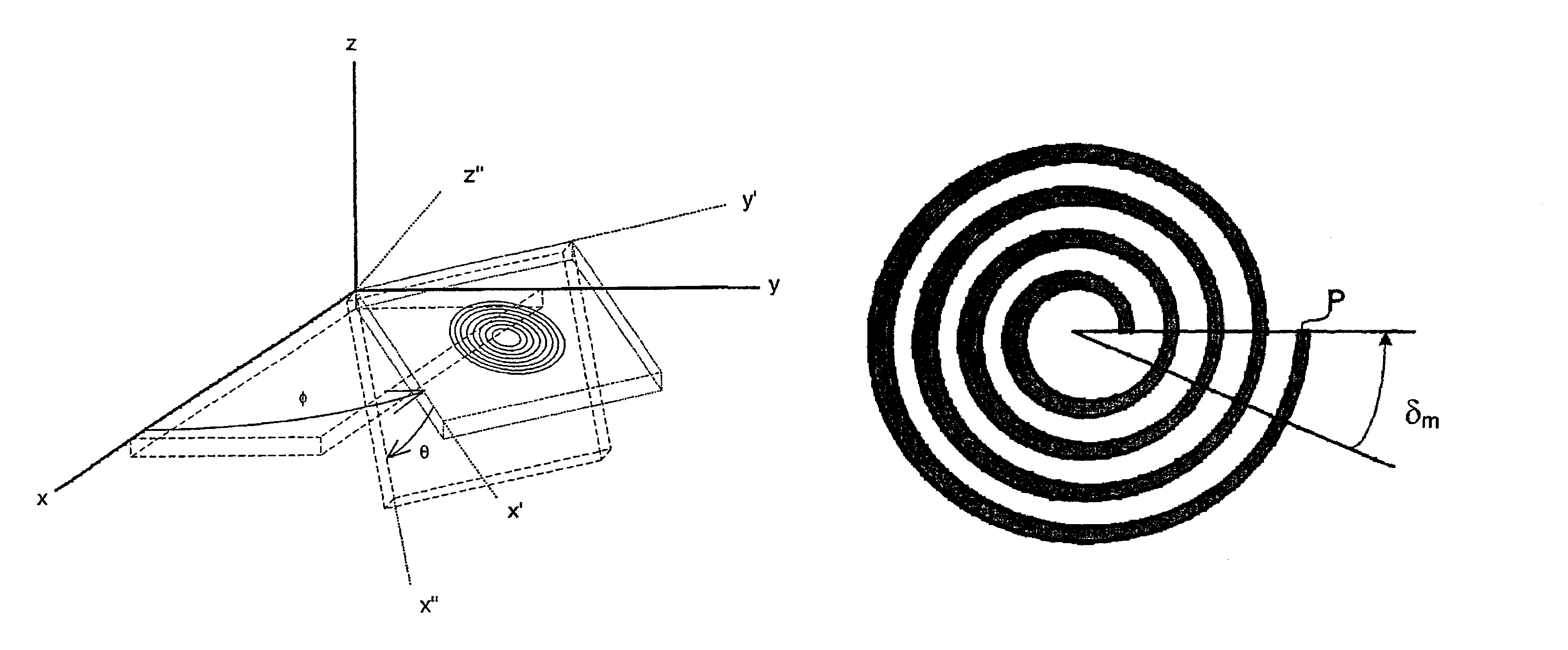

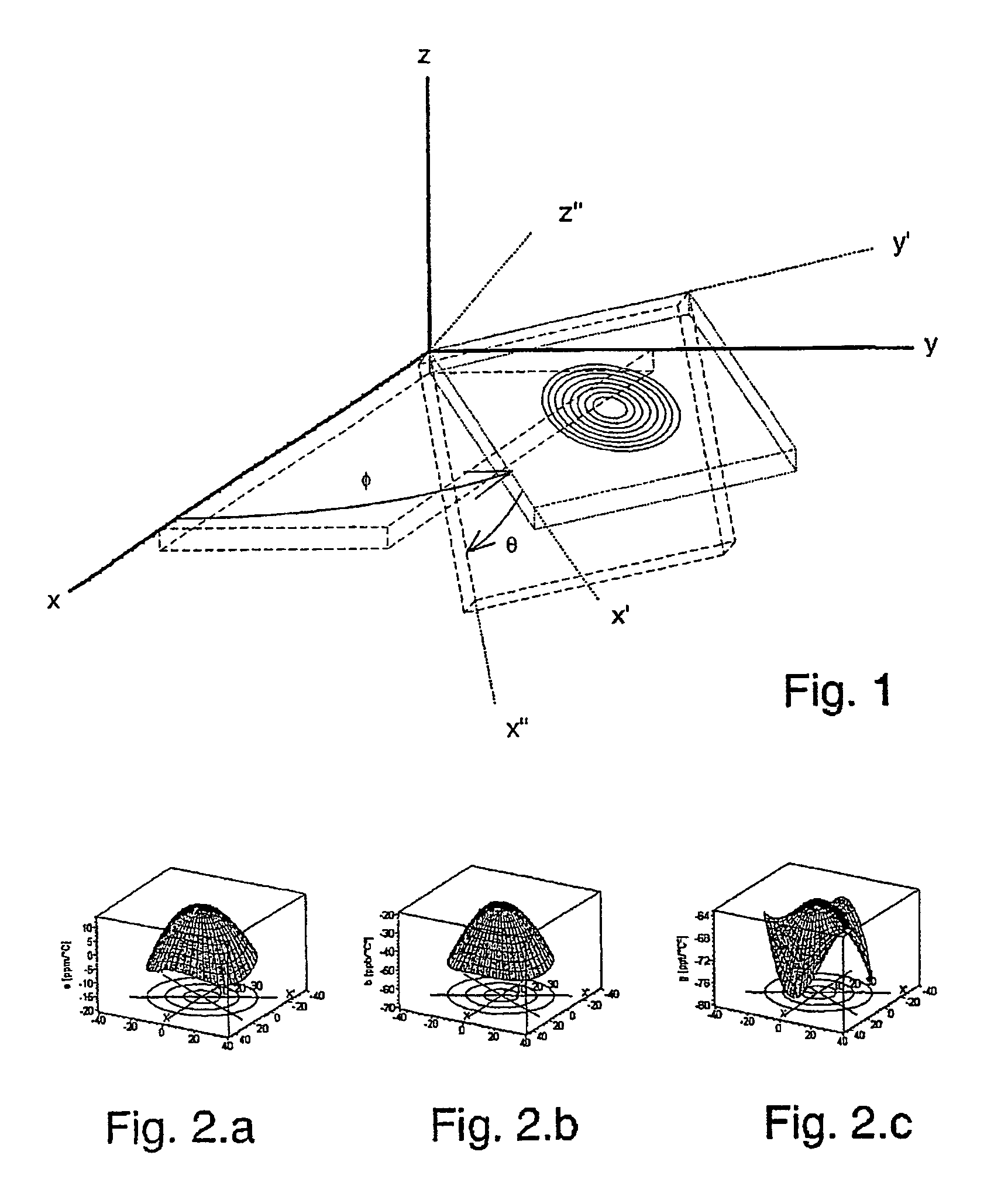

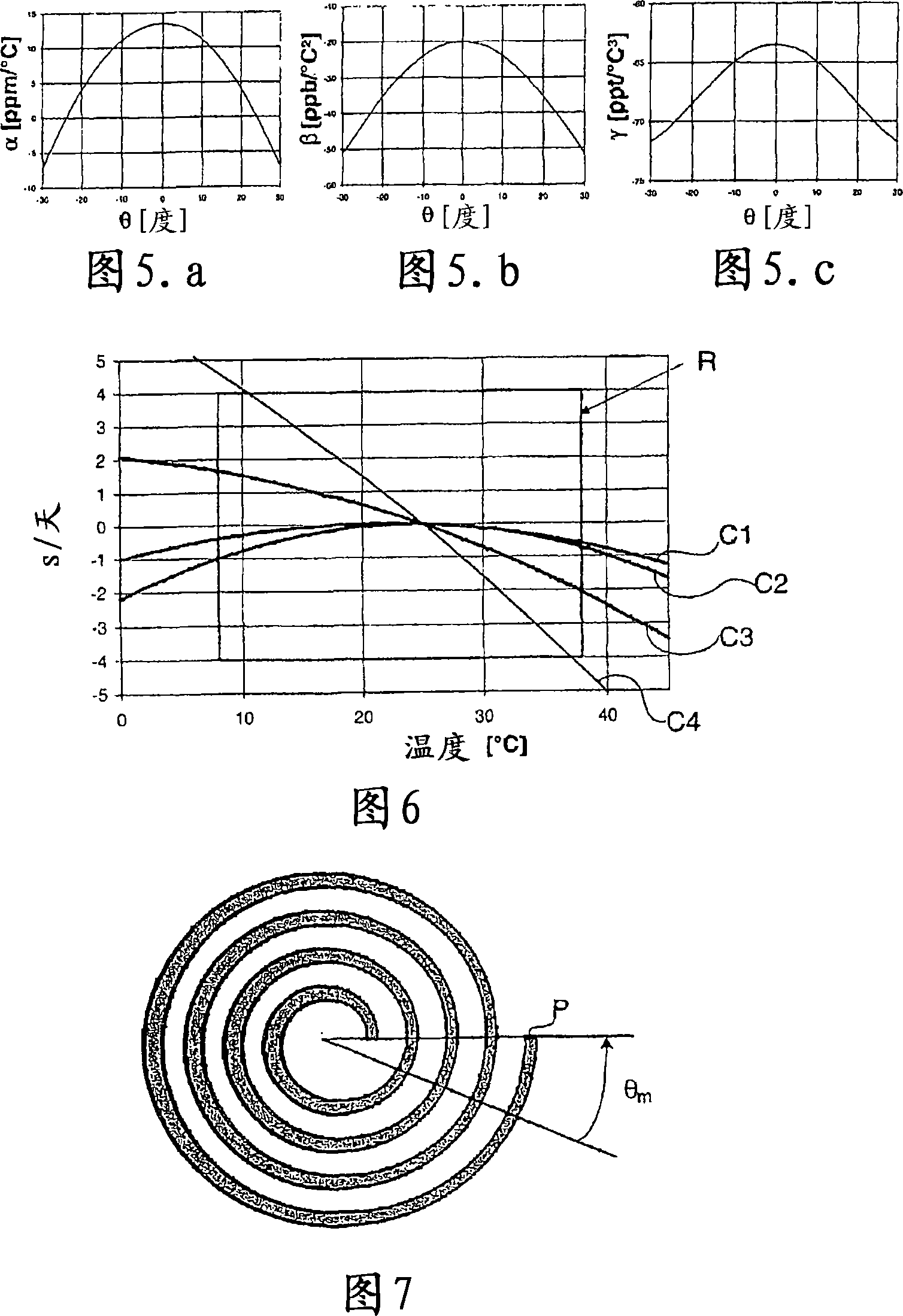

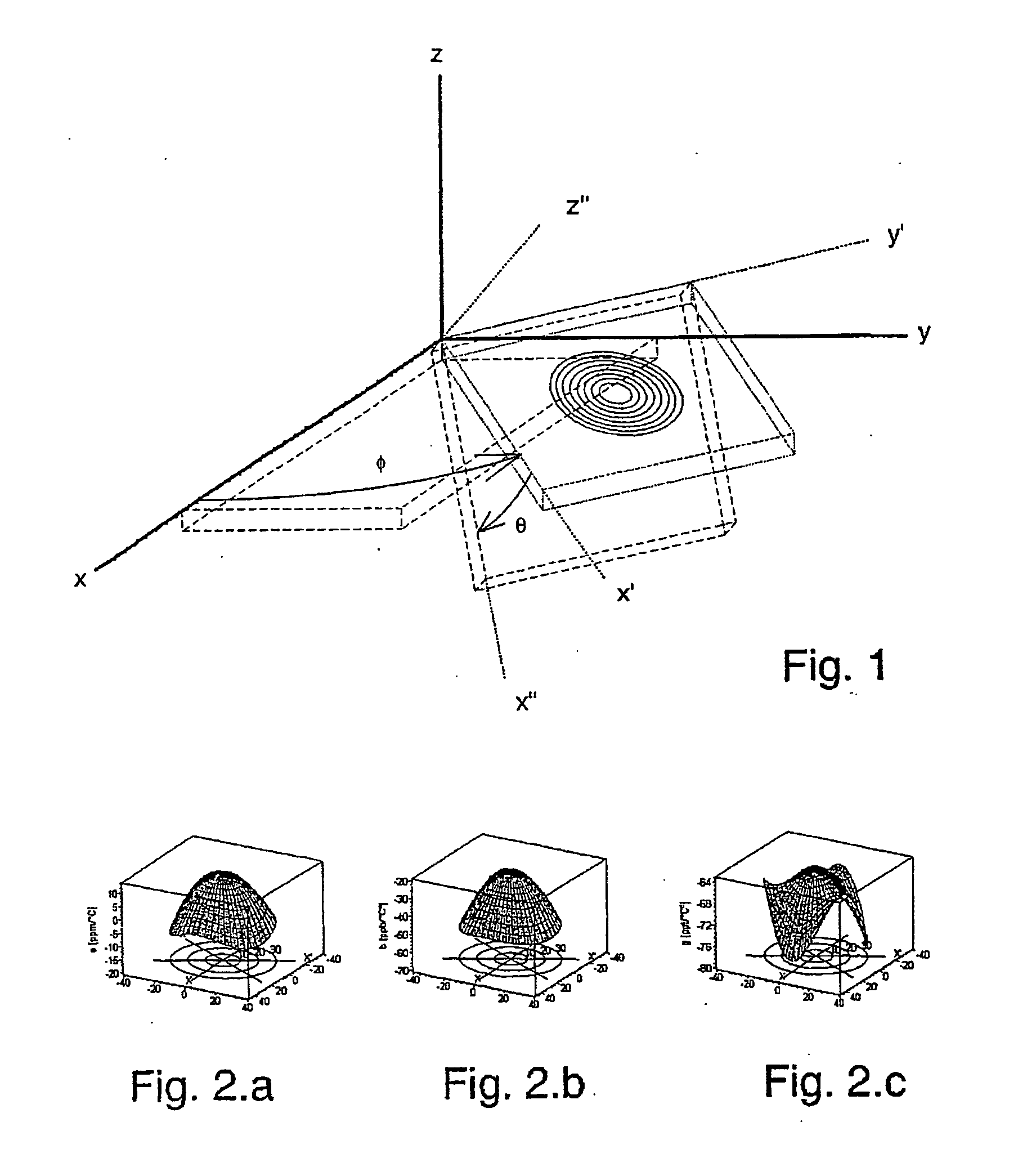

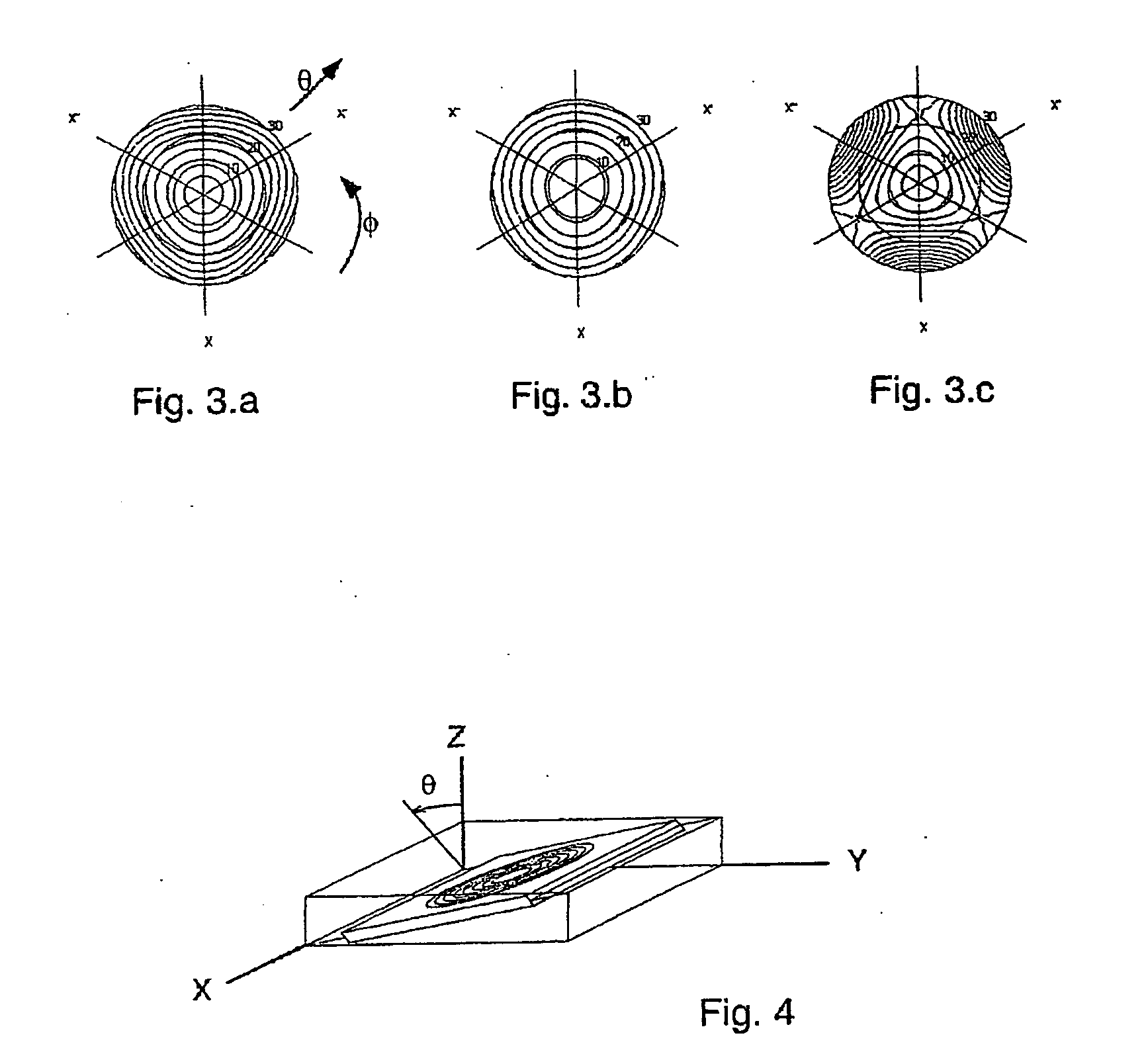

Temperature-compensated balance wheel/hairspring oscillator

ActiveUS7682068B2Assembly is smallFrequency stabilisation mechanismWound springsEngineeringDouble rotation

The invention relates to mechanical watch oscillators comprising an assembly consisting of a spiral and a temperature compensated balance. The spiral is embodied in a quartz substrate whose section is selected in such a way that the drifts of the spiral and of the balance associated therewith are thermally compensated. The substrate section can be embodied in the form of a section of single or double rotation.

Owner:CSEM CENT SUISSE DELECTRONIQUE & DE MICROTECHNIQUE SA RECH & DEV

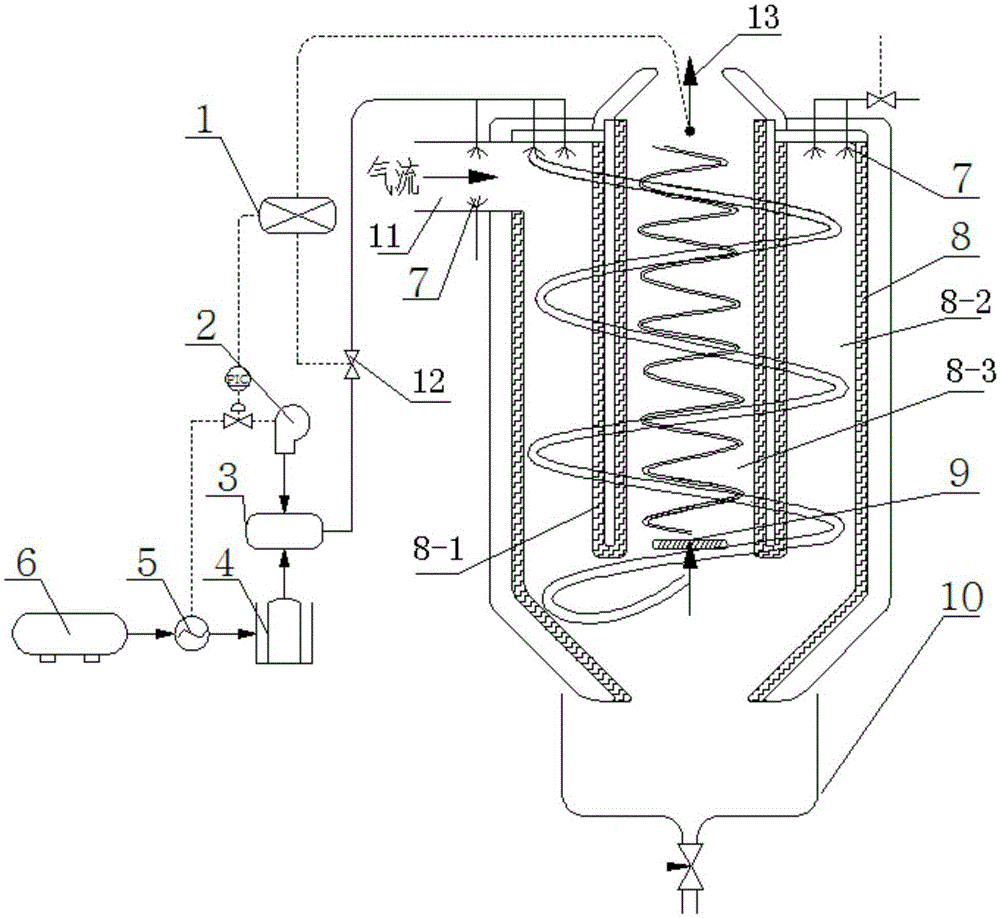

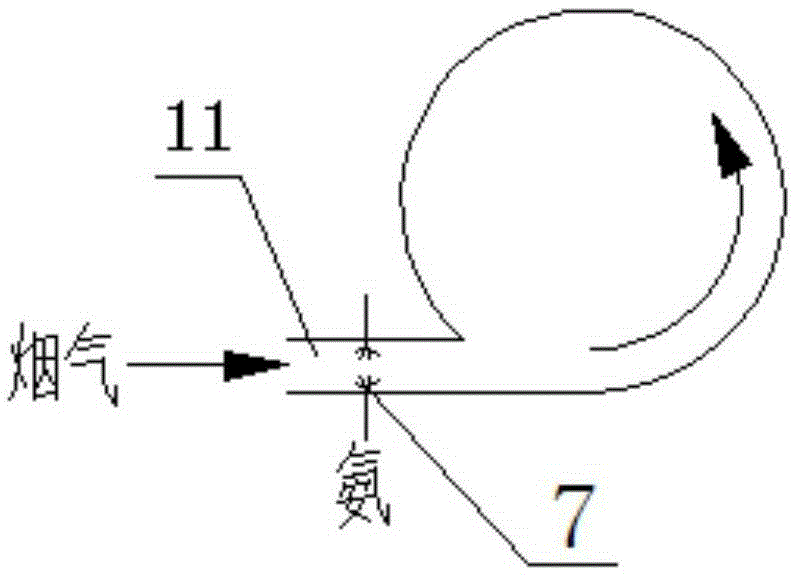

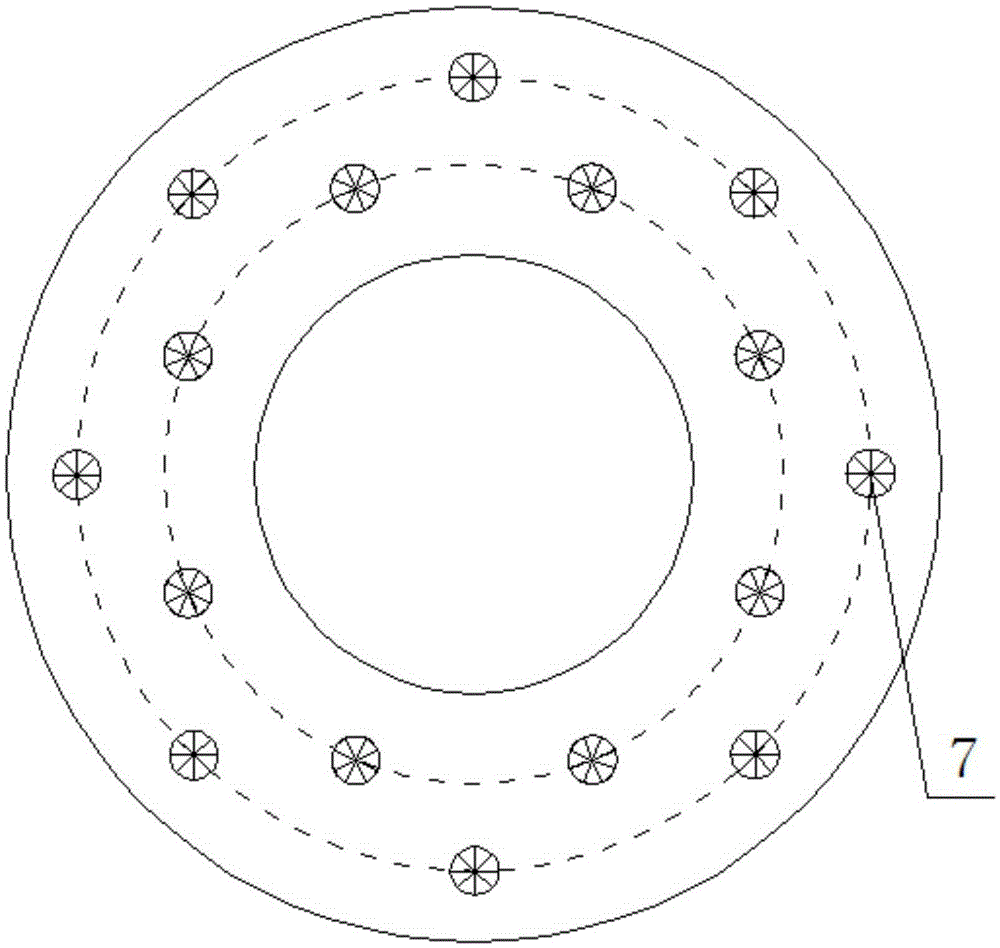

Double-rotation SCR denitration method and apparatus thereof

ActiveCN105289301AImprove denitrification efficiencyIncrease contact timeDispersed particle separationCycloneFlue gas

The invention discloses a double-rotation SCR denitration method and an apparatus thereof. According to the invention, a first eddy flow catalytic reaction chamber and a second eddy flow catalytic reaction chamber are arranged along a denitrating tower body; a flue gas introduction pipeline is arranged on a sidewall of the denitrating tower body; several eddy flow atomizing nozzles are respectively arranged on inner periphery of the flue gas introduction pipeline and the inner periphery at top of the first eddy flow catalytic reaction chamber; when flue gas is introduced into the flue gas introduction pipeline, the flue gas and ammonia gas injected by the eddy flow atomizing nozzle are mixed, and a mixture enables spiral sinking along circumference of the first eddy flow catalytic reaction chamber from up to down in a tangent circle mode, under effect of a cyclone, and then the mixture enable spiral rise along circumference of the second eddy flow catalytic reaction chamber from down to up in the tangent circle mode. Under prerequisite that high efficiency denitration is ensured, catalyst amount is less, operation of technical means is simple and easy, compared with the prior art, a denitrating tower structure is simple, cost of the apparatus is low, denitration efficiency is high, energy consumption is low, escapement ratio of ammonia is reduced, denitration cost is greatly reduced, and economic benefit is obviously increased.

Owner:SOUTH CHINA UNIV OF TECH

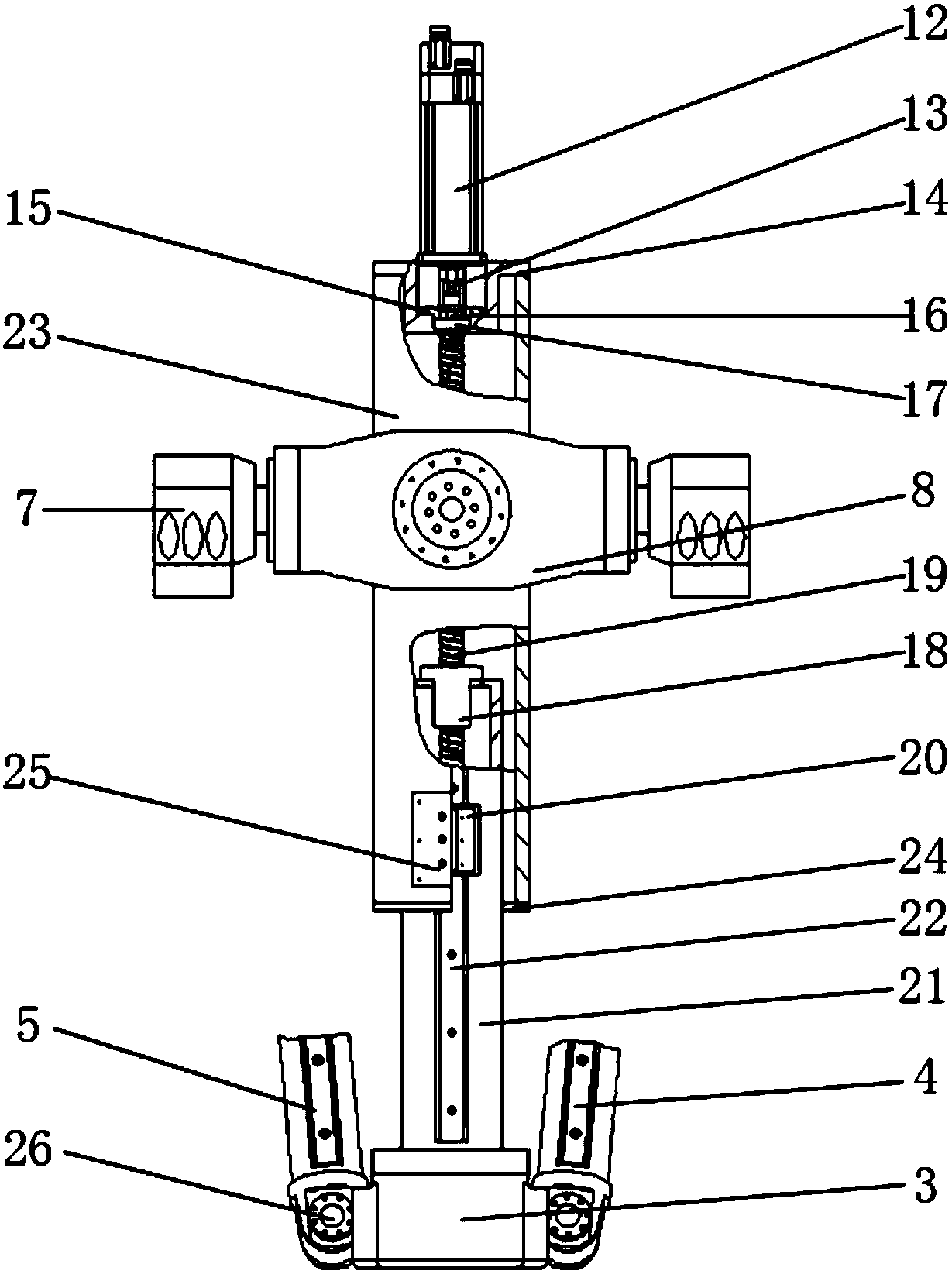

Weight clamping mechanical gripper for metrological verification work

The invention provides a weight clamping mechanical gripper for metrological verification work. The weight clamping mechanical gripper comprises an alternating current servo motor, a speed reduction gear, a double-rotation direction screw rod, screw rod nuts, connecting pressure plates, a first clamp, a second clamp, linear guide tracks and linear bearings, wherein the alternating current servo motor is connected with the double-rotation direction screw rod through the speed reduction gear, two screw rod nuts are matched and connected onto the double-rotation direction screw rod, the two screw rod nuts are nested in middle holes in the first connecting pressure plate and the second connecting pressure plate, and the side surfaces B of the first connecting pressure plate and the second connecting pressure plate are respectively connected with the left angle bracket-shaped first clamp and the right angle bracket-shaped second clamp; the two linear guide tracks are arranged on two sides of the double-rotation direction screw rod in parallel, the linear bearing are assembled on the linear guide tracks respectively, and the linear bearings are nested in an upper hole and a lower hole in the first connecting pressure plate and the second connecting pressure plate. The weight clamping mechanical gripper provided by the invention has the advantages of simple structure, high reliability and high convenience in control, and can efficiently complete weight clamping and handling tasks in the weight metrological verification process.

Owner:ZHENJIANG MEASUREMENT VERIFICATION TEST CENT +1

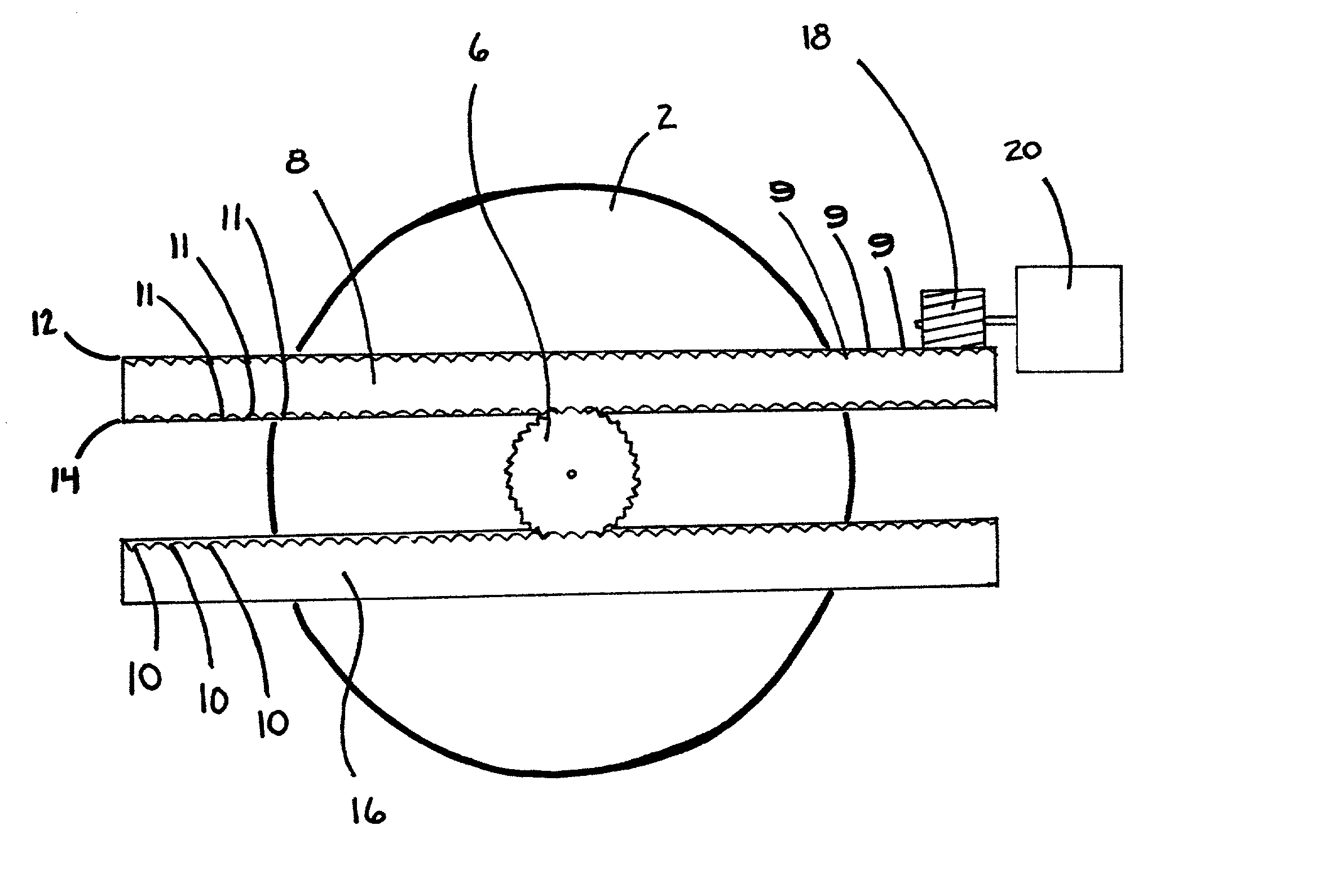

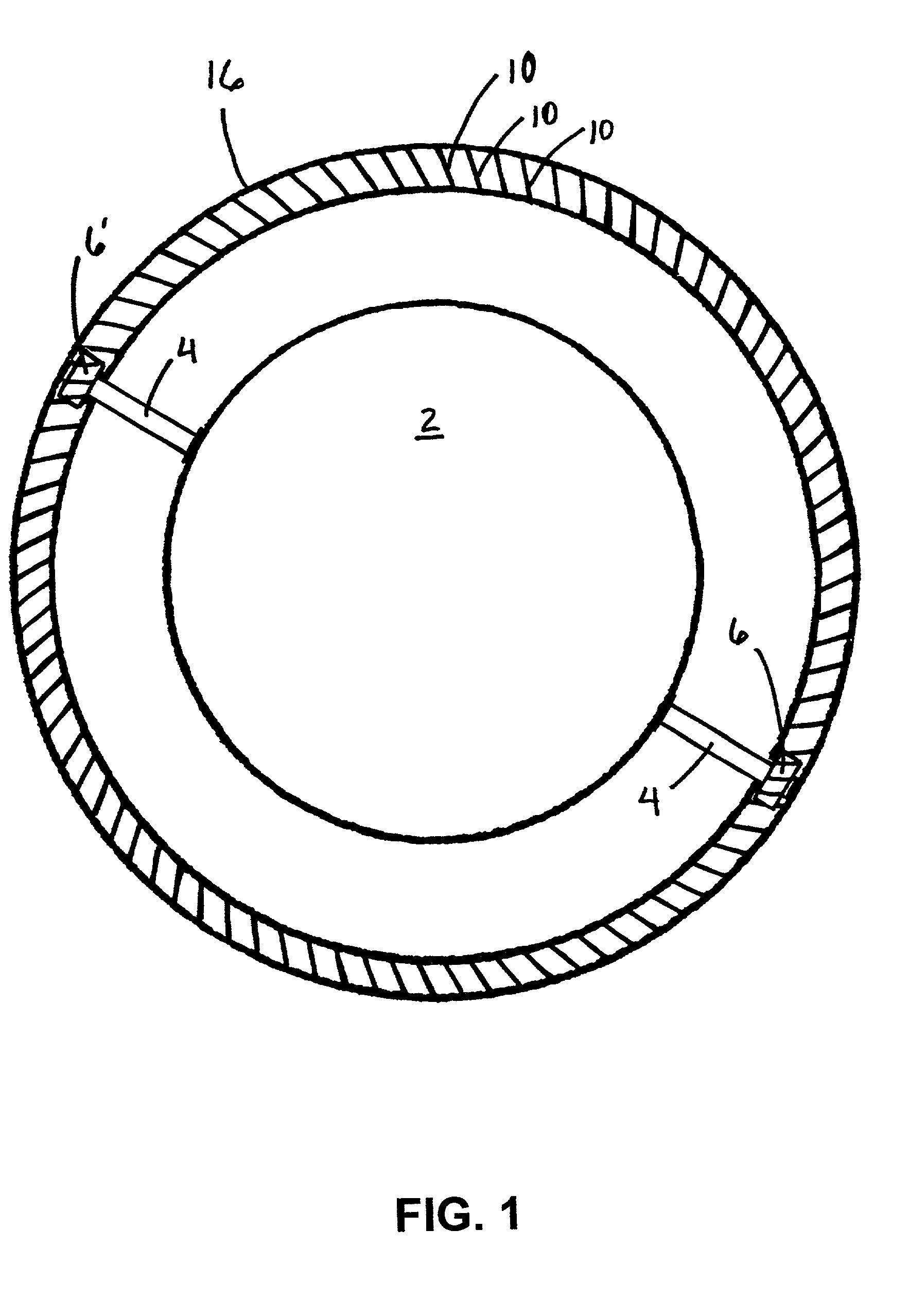

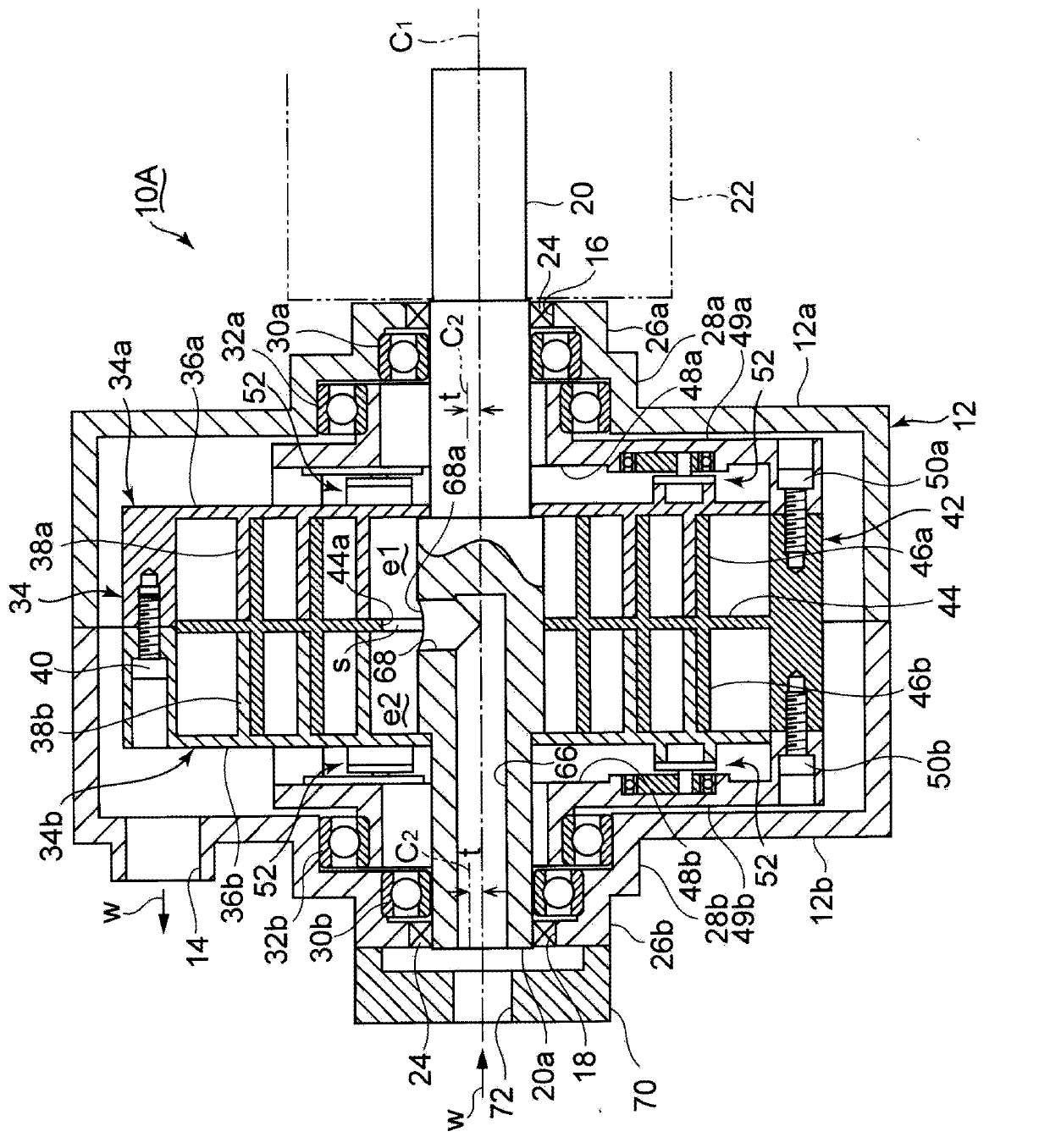

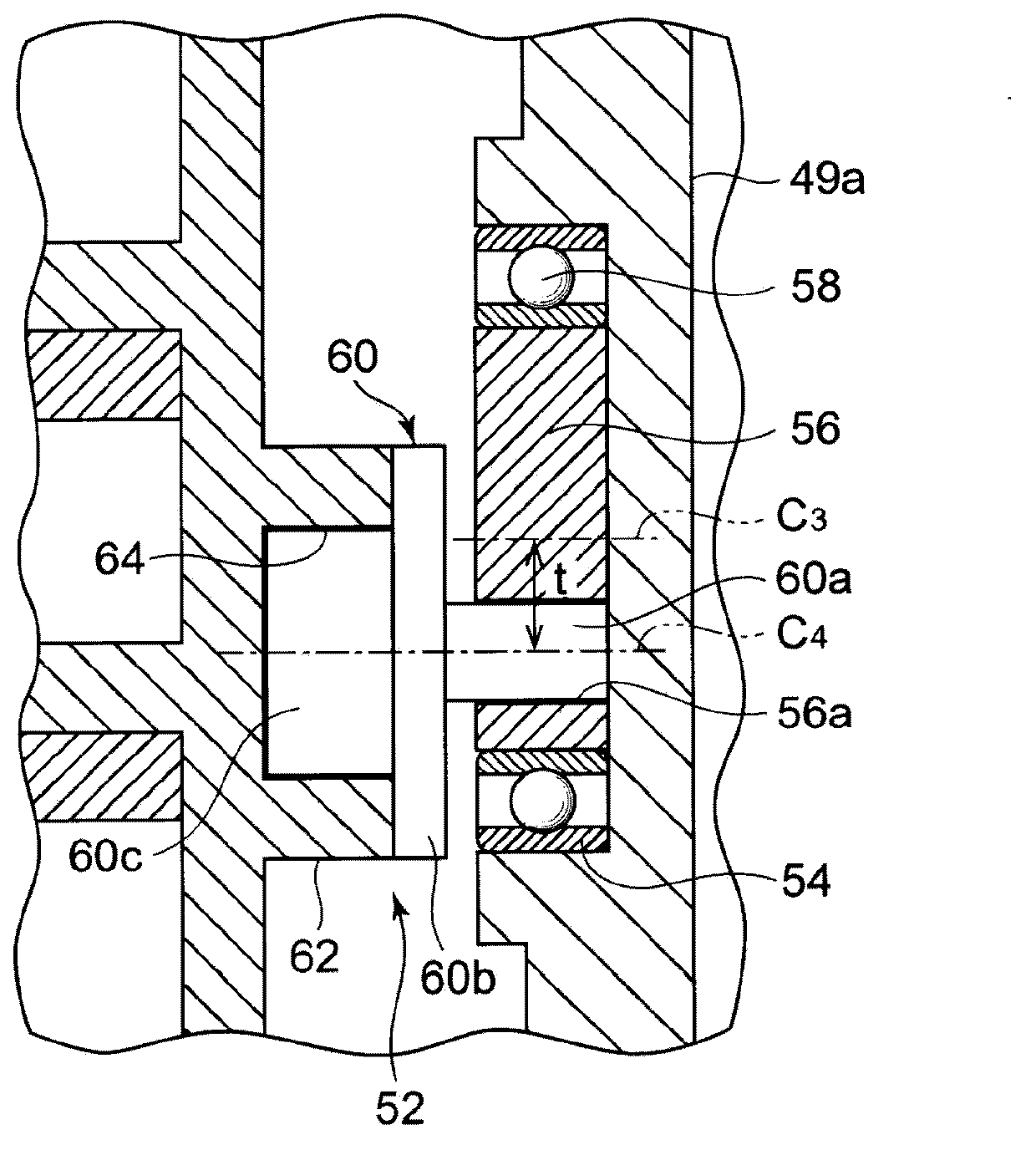

Bi-axial rotating magnetic therapeutic device

A device for applying a time-varying magnetic field to a human or animal body for therapeutic purposes comprising magnetic unit that is made to rotate about two separate axes at the same time. housed within non-magnetic components, which insrotatably housed in a nonmagnetic free moving member, which itself may rotating about an axis oblique to the axis of rotation of the magnet. The device may be held in the operator's hand or attached to his or her clothing, and is powered by a small electric motor that drives the gears necessary to produce the separate rotary movements. One axis of rotation is in the direction of a rod mounted to the magnet, and the other axis is along an imaginary line that runs through the center of the magnet body, roughly perpendicular to the rod. The two rotational movements of the magnet produce both a time-varying field of magnetic flux density and a time-varying field of angular flux displacement.

Owner:NYUU MAGUNETEIKUSU

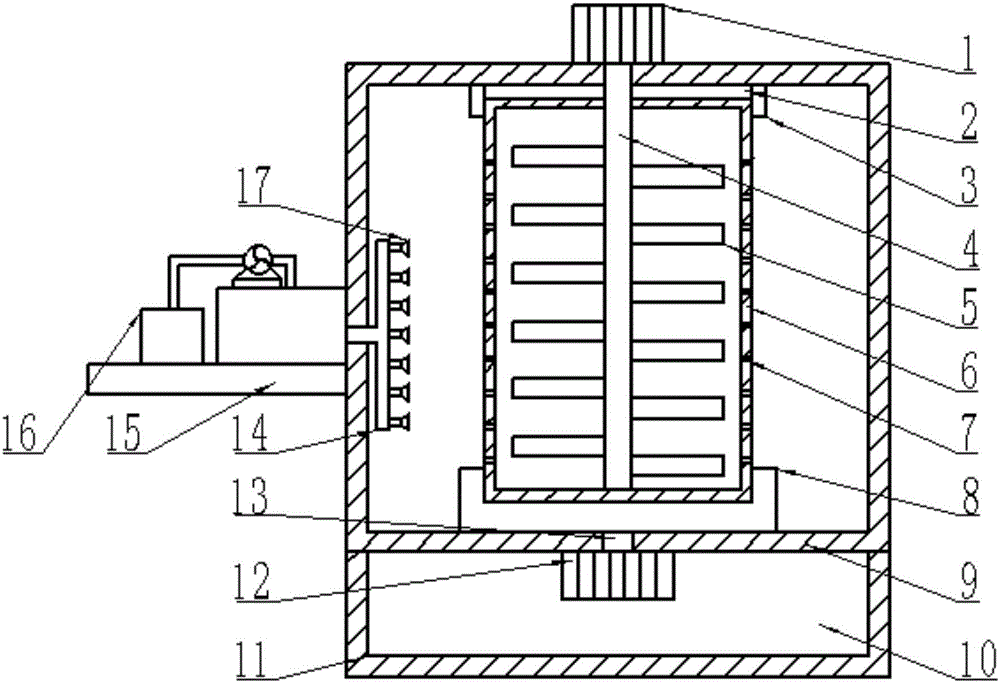

Double-rotation mixing and drying device for traditional Chinese medicinal materials

InactiveCN106766765ADry evenlyWell mixedDrying gas arrangementsDrying machines with non-progressive movementsEngineeringAir blower

The invention provides a double-rotation mixing and drying device for traditional Chinese medicinal materials. The double-rotation mixing and drying for the traditional Chinese medicinal materials comprises a stirring device, a box body, a motor cavity, a base and a filtering and drying device. The stirring device comprises a first motor and a second motor. The first motor is fixed to the upper end of the box body. The lower end of the first motor is provided with a stirring shaft. The second motor is fixed to the lower end of the box body and located in a motor cavity. A rotating shaft is arranged at the upper end of the second motor. A rotating drum seat is connected to the upper end of the rotating shaft. A supporting seat is arranged at the left end of the box body. The filtering and drying device are fixed to the supporting seat. The filtering and drying device comprises a filtering box, a first air inlet pipe, an air blower, a second air inlet pipe and an electric heating box. A filter layer and a dehumidifying layer are arranged in the filtering box. An electric heating wire bearing plate and an air outlet pipe are arranged inside the electric heating box. The electric heating wire bearing plate is arranged in the middle of the electric heating box. The electric heating wire bearing plate is provided with an electric heating wire and air guide holes. By the adoption of the double-rotation mixing and drying device for the traditional Chinese medicinal materials, mixing is convenient, uniform and rapid, and drying is uniform and efficient.

Owner:HENAN SHUIJINGTOU CULTURAL MEDIA CO LTD

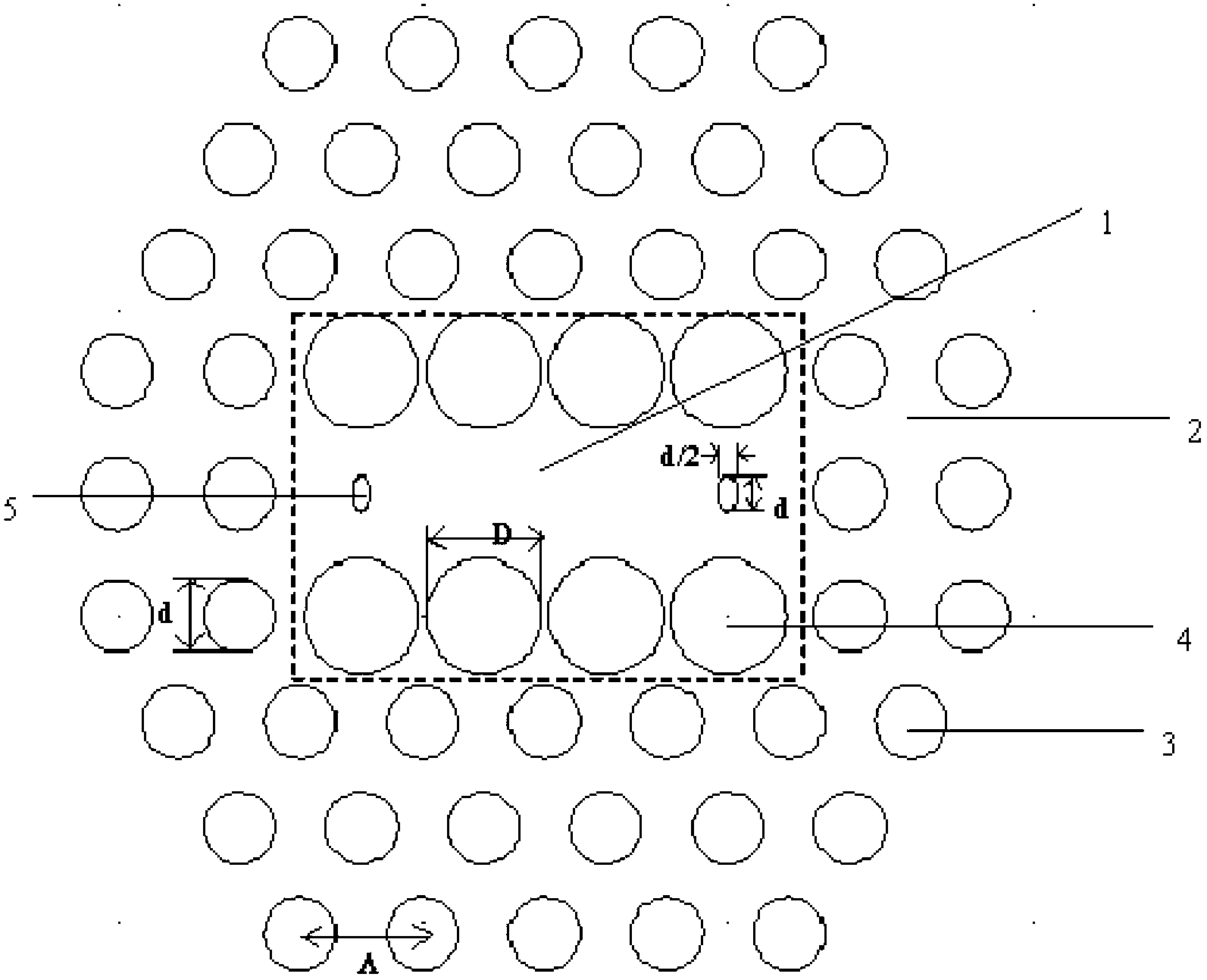

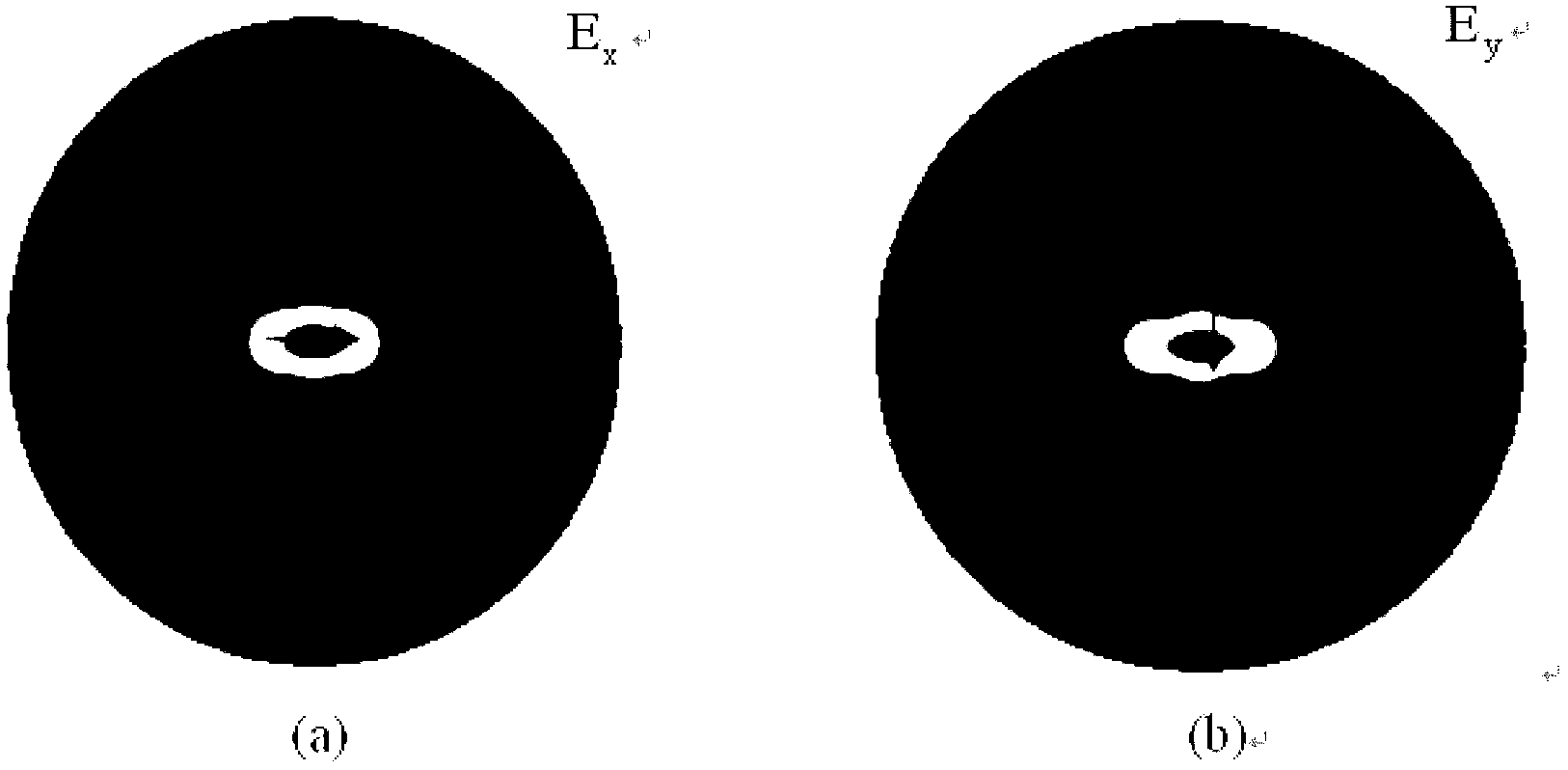

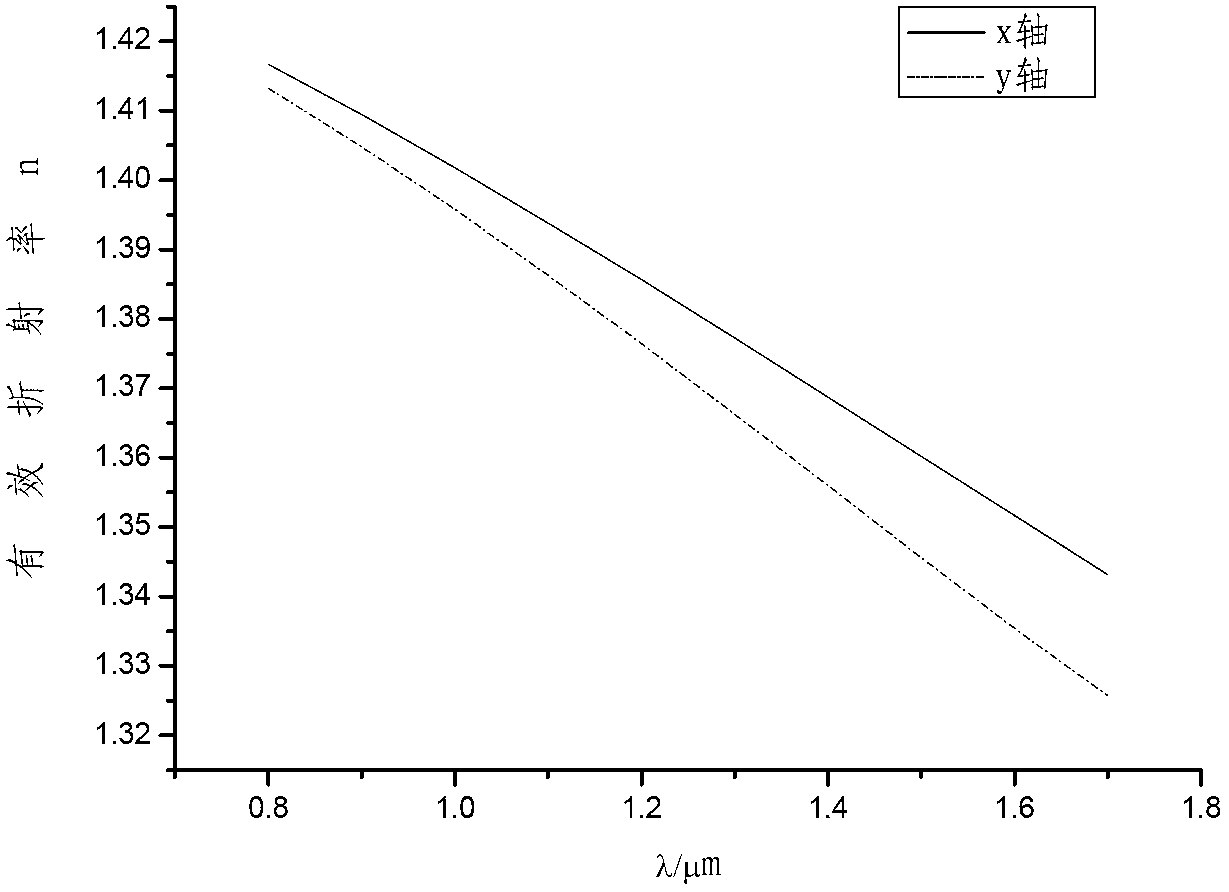

High double-refraction photonic crystal fiber (PCF)

InactiveCN102854562ASimple structureHas double rotational symmetryOptical fibre with polarisationOptical fibre with multilayer core/claddingPolarization-maintaining optical fiberEngineering

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

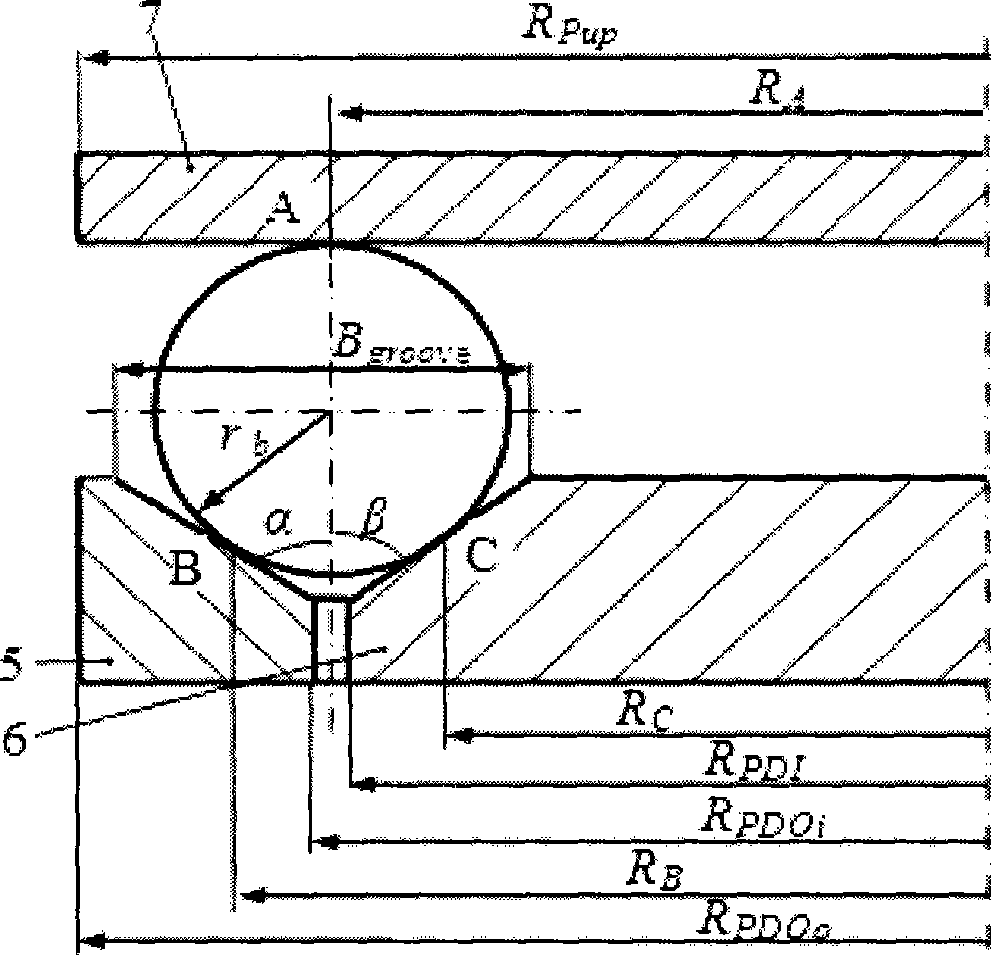

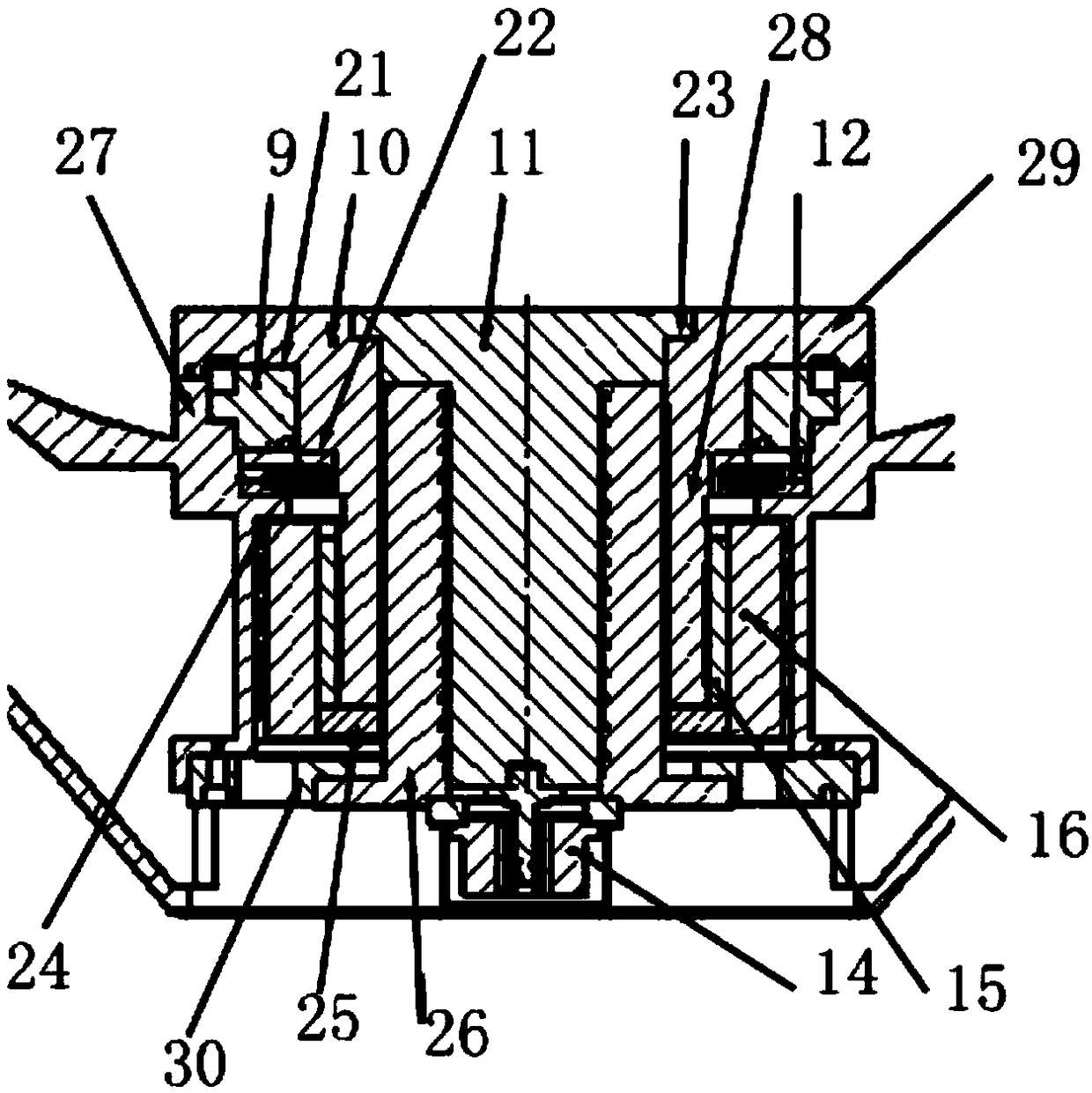

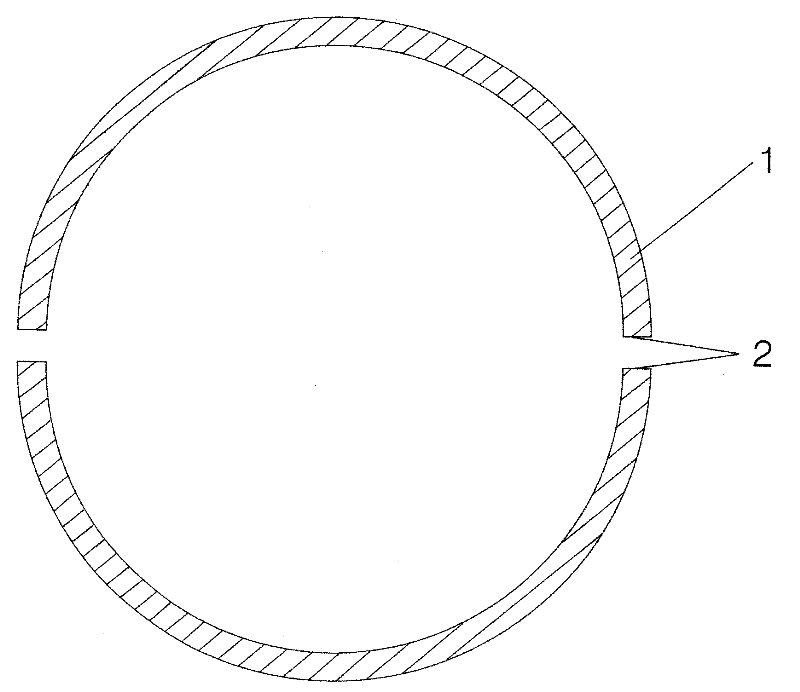

High-precision ball double-rotation V-shaped groove efficient grinding unit

InactiveCN101518886AImprove grinding precisionImprove grinding efficiencyLapping machinesDrive motorEngineering

A high-precision ball double-rotation V-shaped groove efficient grinding unit comprises a stand, a grinding pan device and a load pressurizing device which are arranged on the stand. The grinding pan device comprises an upper grinding pan, the upper end of the upper grinding pan is provided with the load pressurizing device; the high-precision ball double-rotation V-shaped groove efficient grinding unit also comprises a lower grinding inner pan and a lower grinding outer pan which are coaxially arranged, the lower grinding inner pan is embedded in the lower grinding outer pan, the tapered grinding surface at the outer side of the lower grinding inner pan and the tapered grinding surface at the inner side of the lower grinding outer pan form a V-shaped groove structure, the lower grinding inner pan is arranged on the stand, the upper grinding pan is arranged on a rotating shaft which is connected with an upper grinding pan drive motor, and the lower grinding outer pan is arranged on a main shaft which is connected with a lower grinding outer pan drive motor. The invention has simple structure, low processing cost and higher processing precision and processing efficiency.

Owner:ZHEJIANG UNIV OF TECH +1

Temperature compensated balance wheel/hairspring oscillator

ActiveCN1985103ACompensation for thermal driftFrequency stabilisation mechanismWound springsEngineeringDouble rotation

The invention relates to mechanical watch oscillators comprising an assembly consisting of a spiral and a temperature compensated balance. Said spiral is embodied in a quartz substrate whose section is selected in such a way that the drifts of the spiral and of the balance associated therewith are thermally compensated. The substrate section can be embodied in the form of a section of single or double rotation. Said invention is used for horology.

Owner:CSEM CENT SUISSE DELECTRONIQUE & DE MICROTECHNIQUE SA RECH & DEV

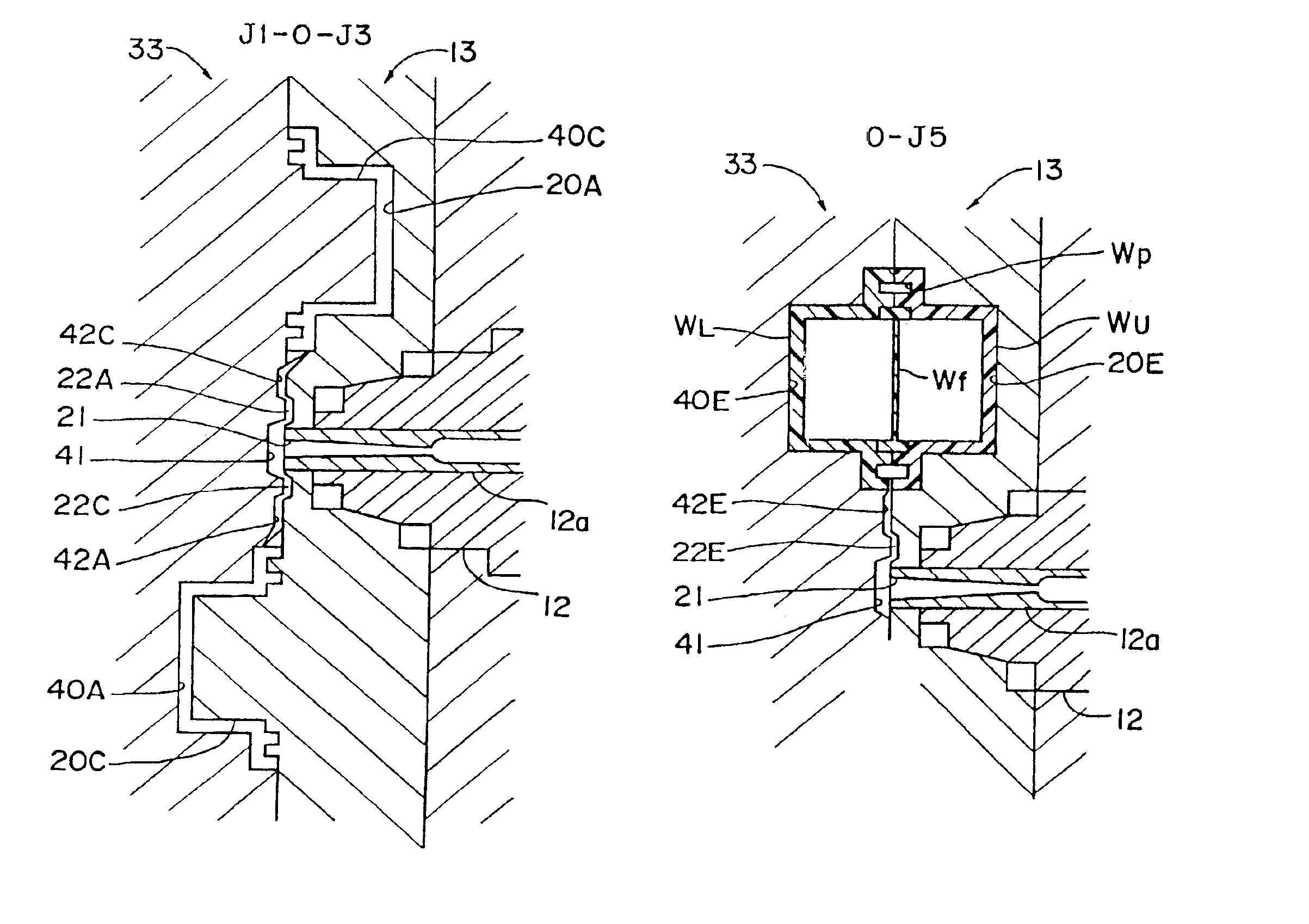

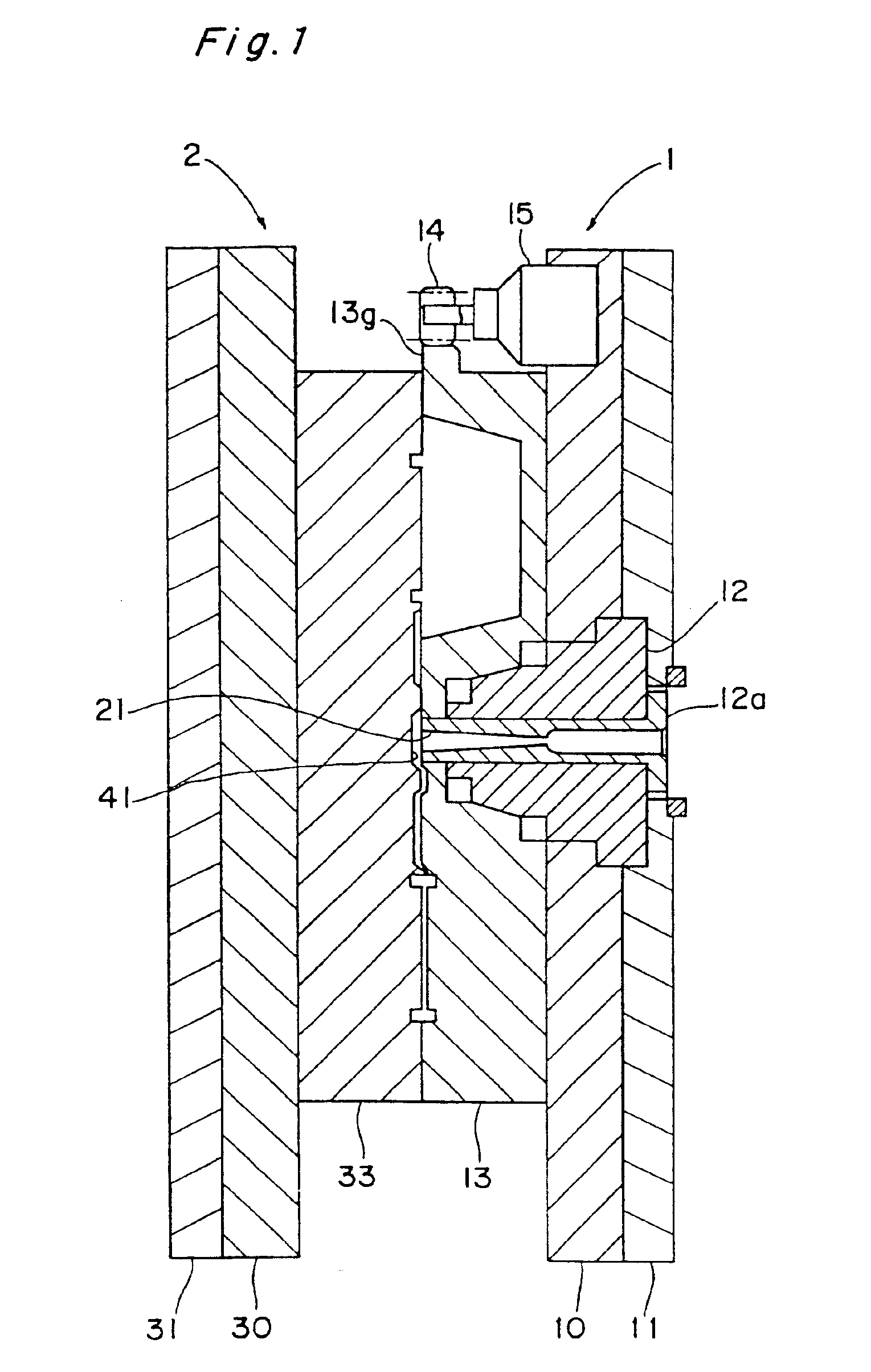

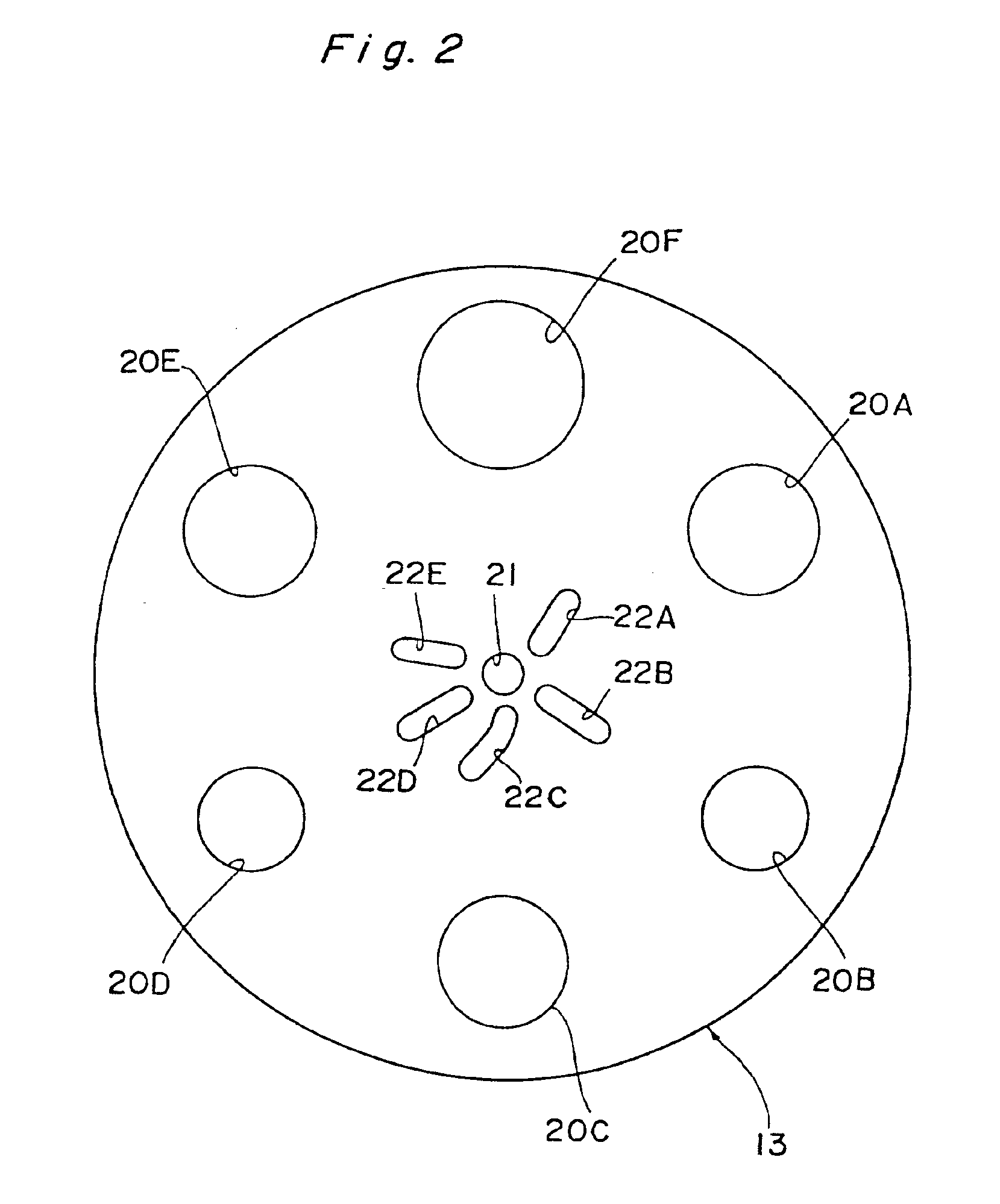

Apparatus for manufacturing synthetic resin hollow member incorporating an intermediate element therein

InactiveUS6981860B2High bonding strengthImprove sealing propertiesSemi-permeable membranesTailstocks/centresClose relativesShell molding

Method and apparatus for manufacturing a synthetic resin-made hollow member incorporating an intermediate element are provided which enable operations of molding half bodies, abutting and joining the half bodies together, and molding an intermediate element in a series of steps, and which eliminate the necessity of such a manual work as may otherwise be required in incorporating the intermediate element into the half bodies. A pair of rotary injection molding dies are used which can be opened and closed relative to each other and are rotatable relative to each other over an angle of 60° for each turn, each die having a half body molding section including one male molding portion and two female molding portions in the direction of rotation for each rotational run over an angle of 120°, each die also having an intermediate element molding portion provided between specified half body molding portions in the direction of each rotational run over an angle of 120°. In each two rotational runs of the molding dies, a series of steps is carried out including first injection for molding a pair of half bodies and an intermediate element, molded product setting for matching two half bodies with the intermediate element set in place and abutting the two half bodies against each other, and second injection for injecting melted resin onto the abutting portions and joining the two half bodies, whereby a hollow member with the intermediate element set between the two half bodies can be obtained.

Owner:DAIKYONISHIKAWA CORP

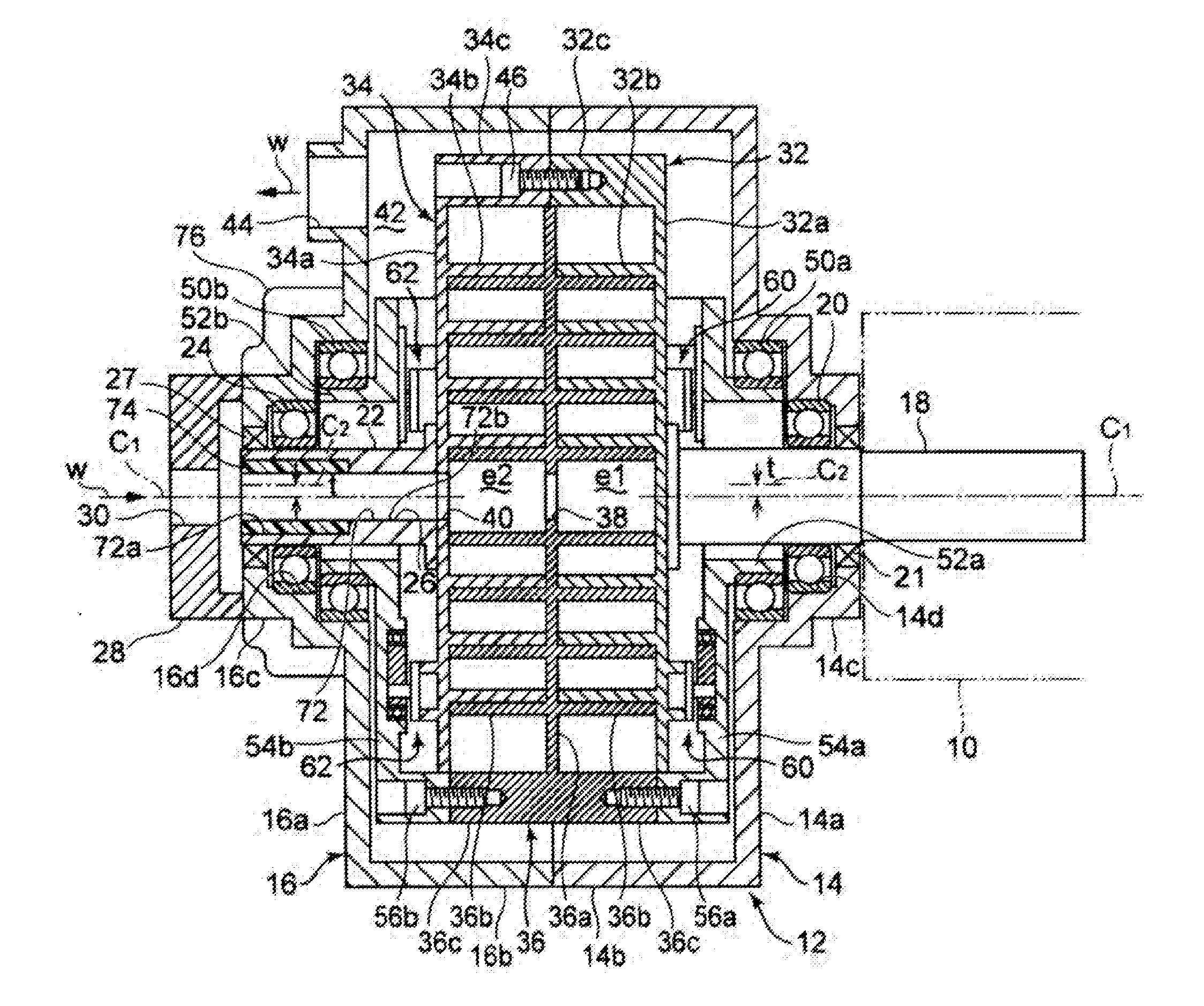

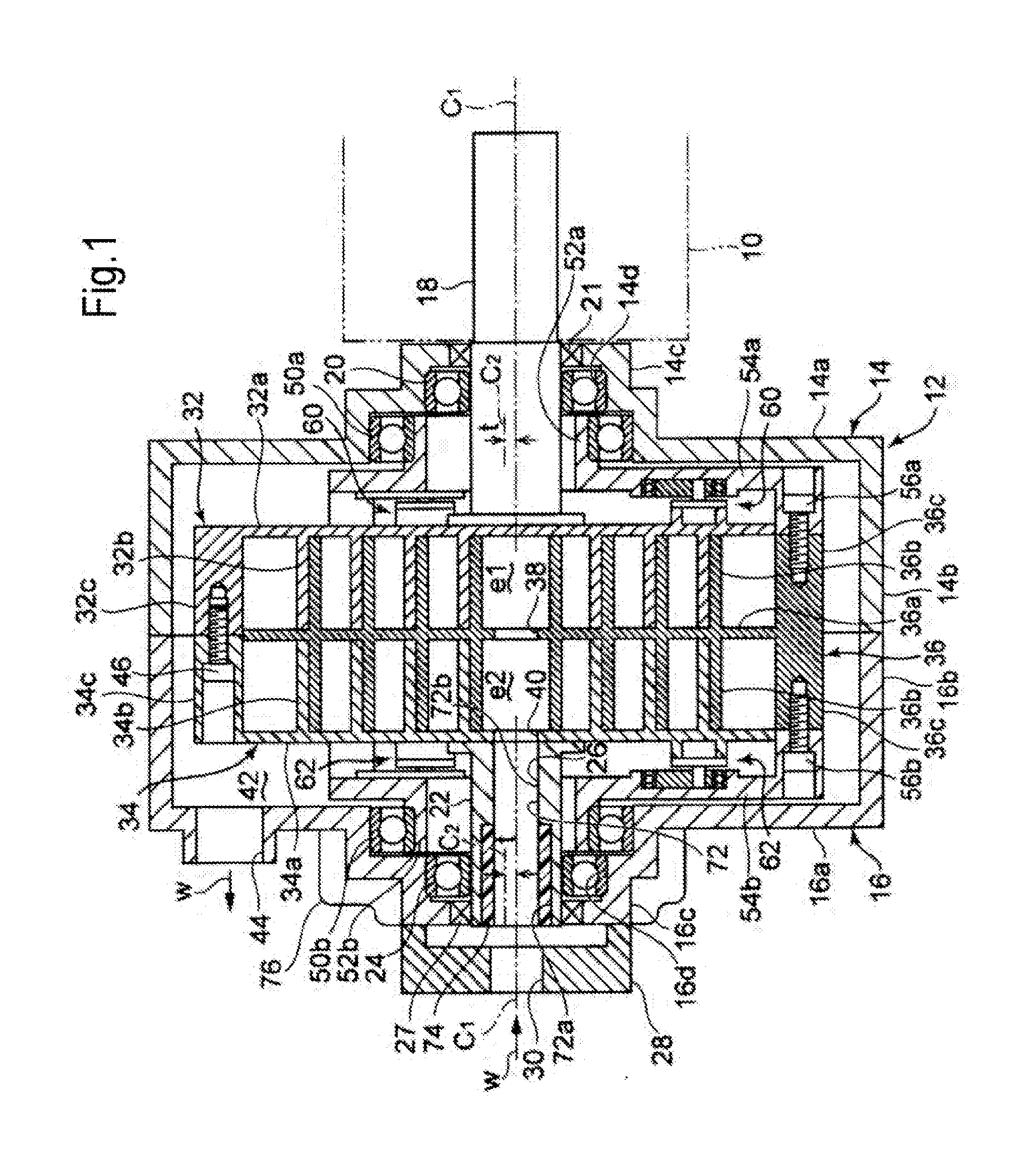

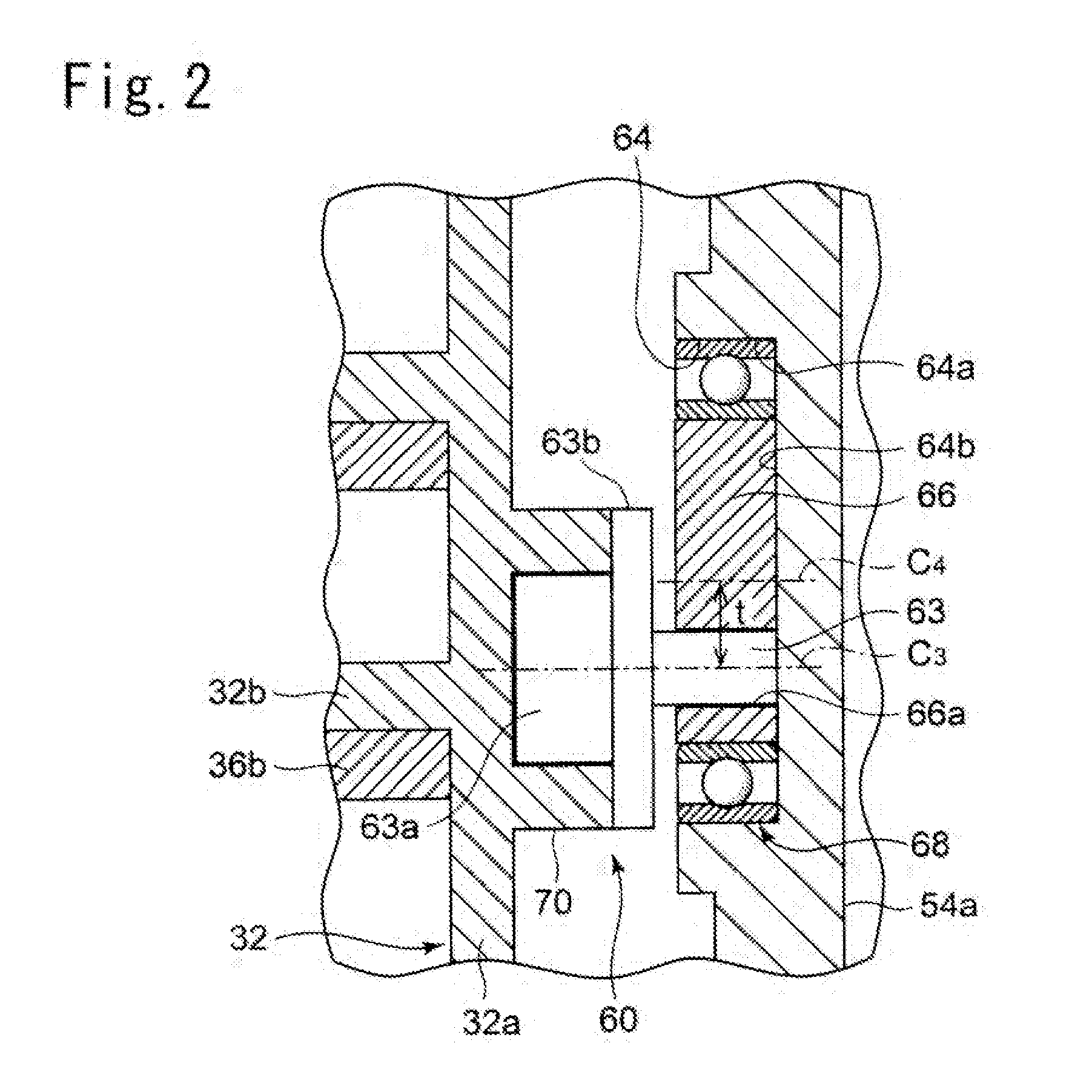

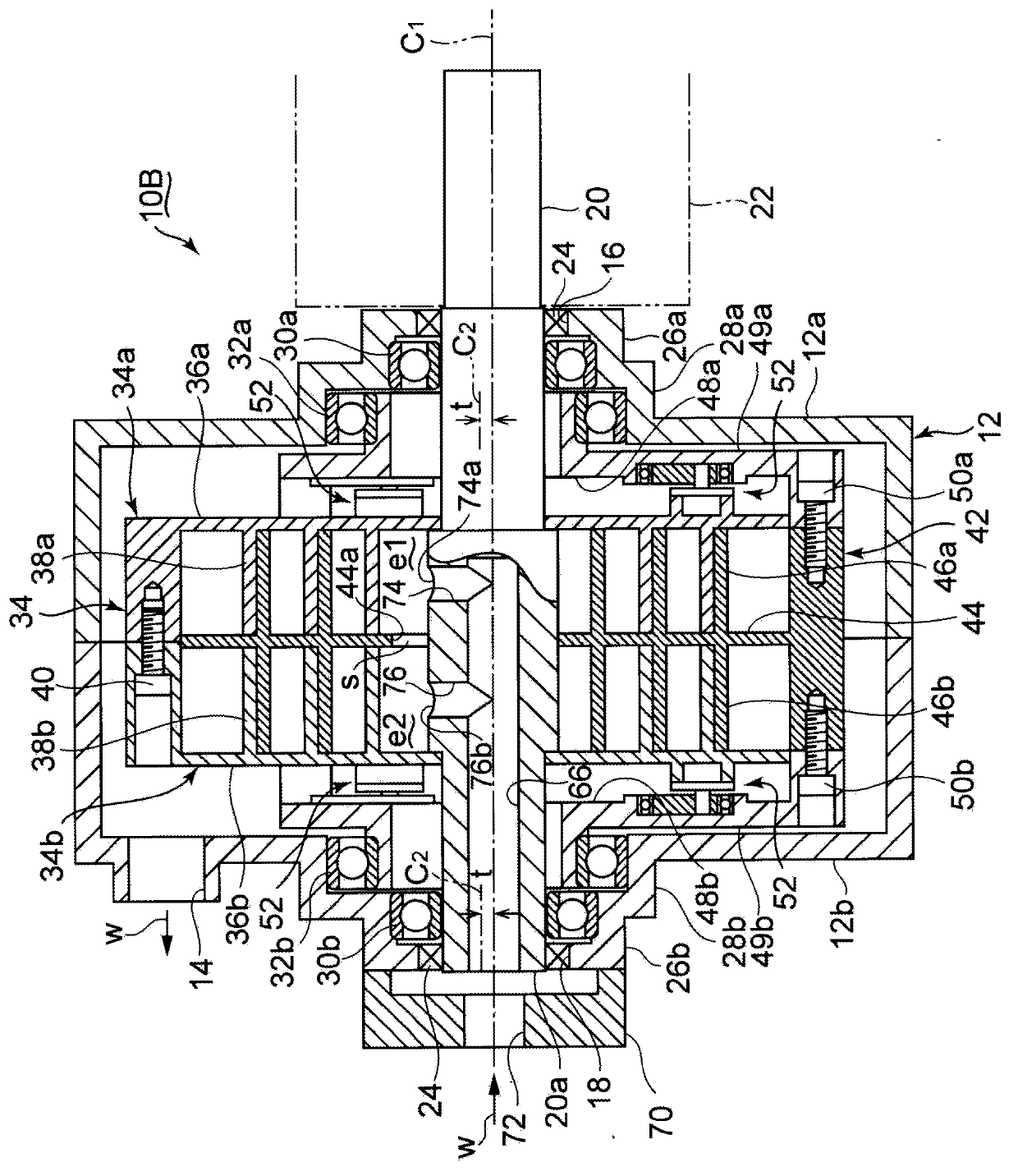

Double rotation type scroll expander and power generation apparatus including same

ActiveUS20130309116A1Improve heat resistanceExtend your lifePump componentsEngine of arcuate-engagement typeEngineeringDouble rotation

A double rotation type scroll expander that expands steam includes a first drive scroll, a second drive scroll, a driven scroll, a rotation mechanism that supports the driven scroll rotatably, and a revolving mechanism that couples the driven scroll to the first drive scroll and the second drive scroll to be capable of revolving relative thereto. The revolving mechanism includes: a plurality of metal revolving pins provided respectively between a first drive end plate of the first drive scroll and a first driven arm of the rotation mechanism and between a second drive end plate of the second drive scroll and a second driven arm of the rotation mechanism; and a plurality of metal revolving discs provided in relation to the respective revolving pins and disposed such that respectively corresponding revolving pins are coupled thereto eccentrically.

Owner:ANEST IWATA CORP

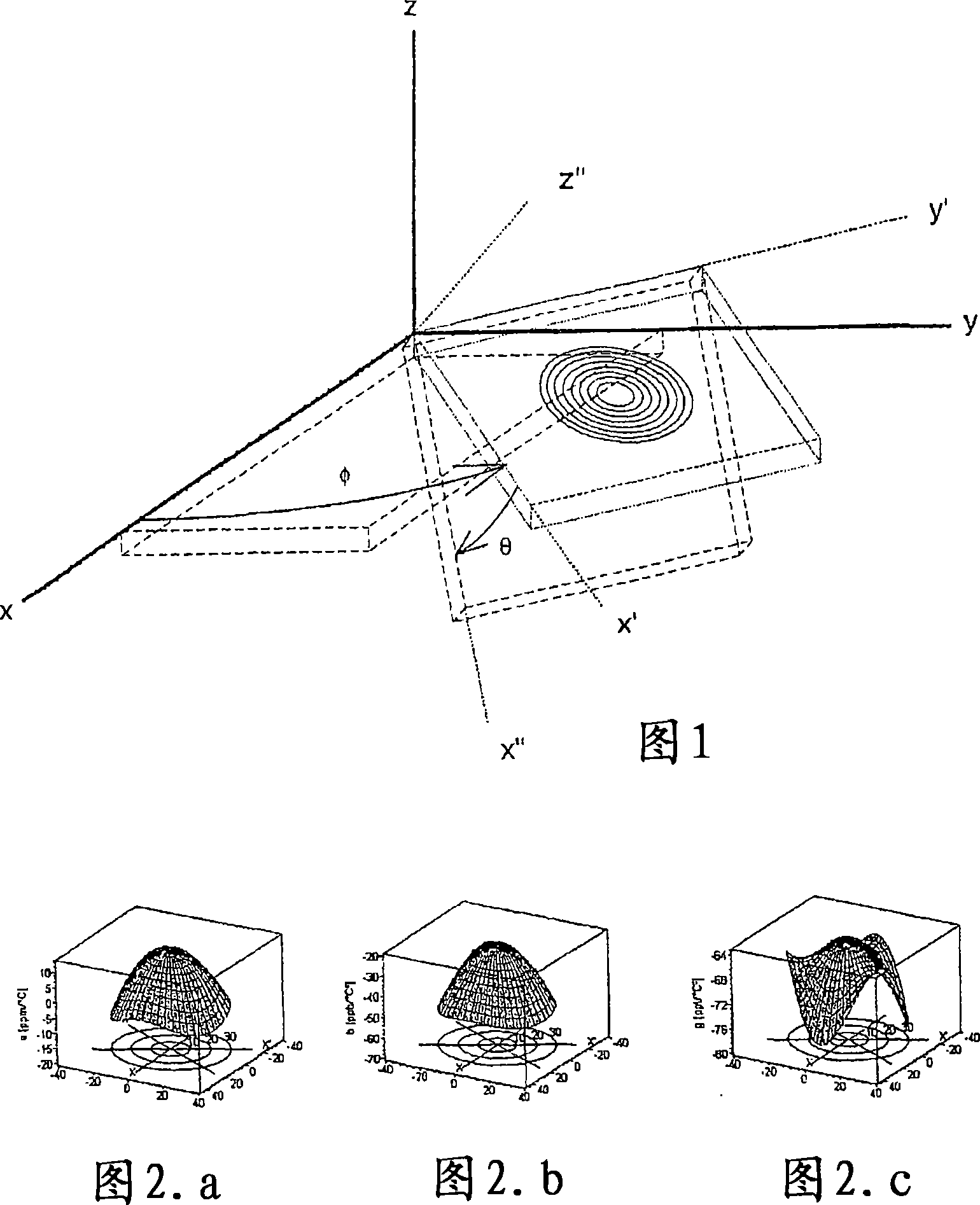

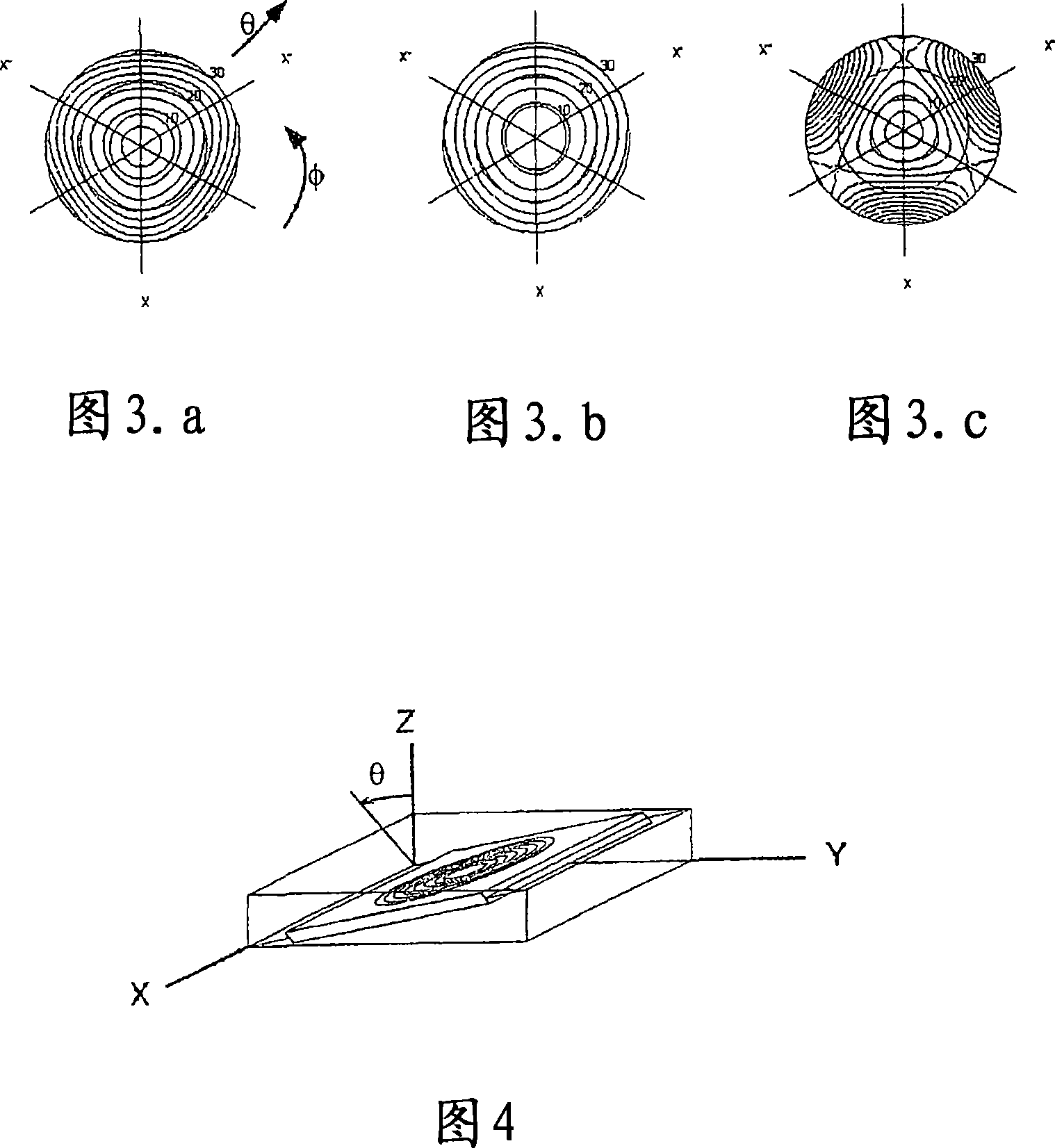

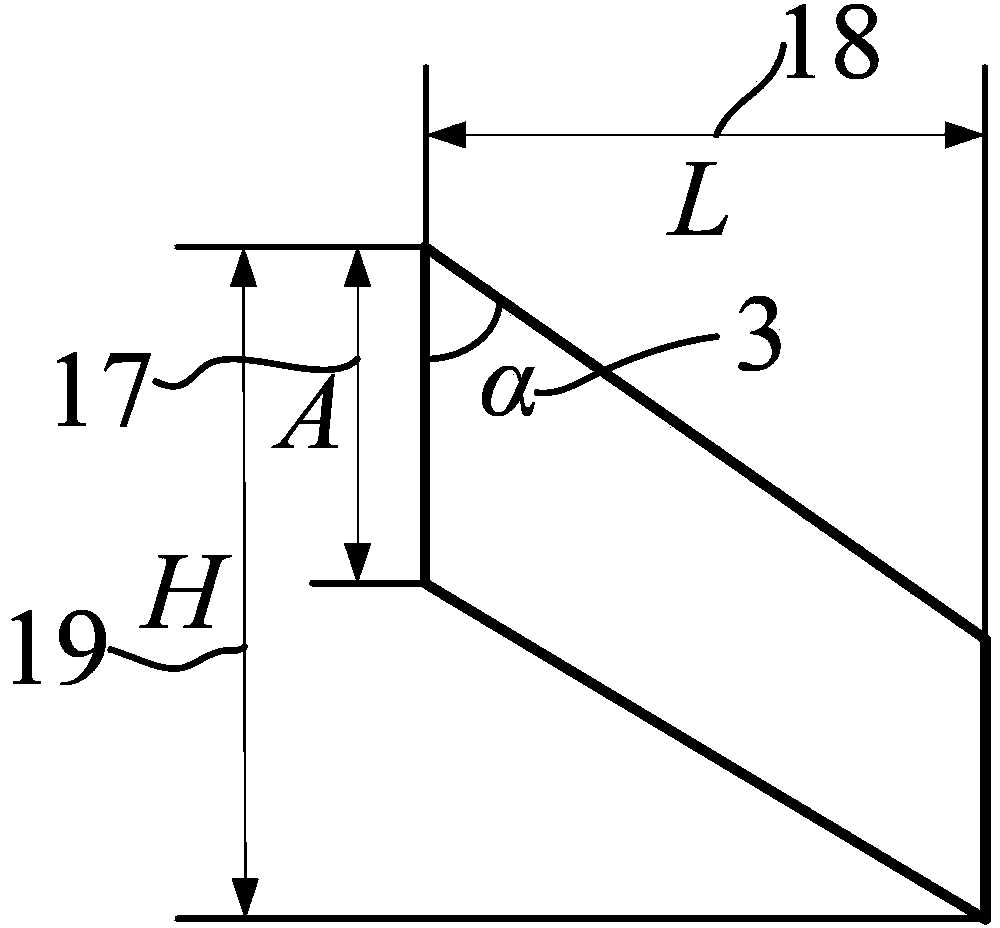

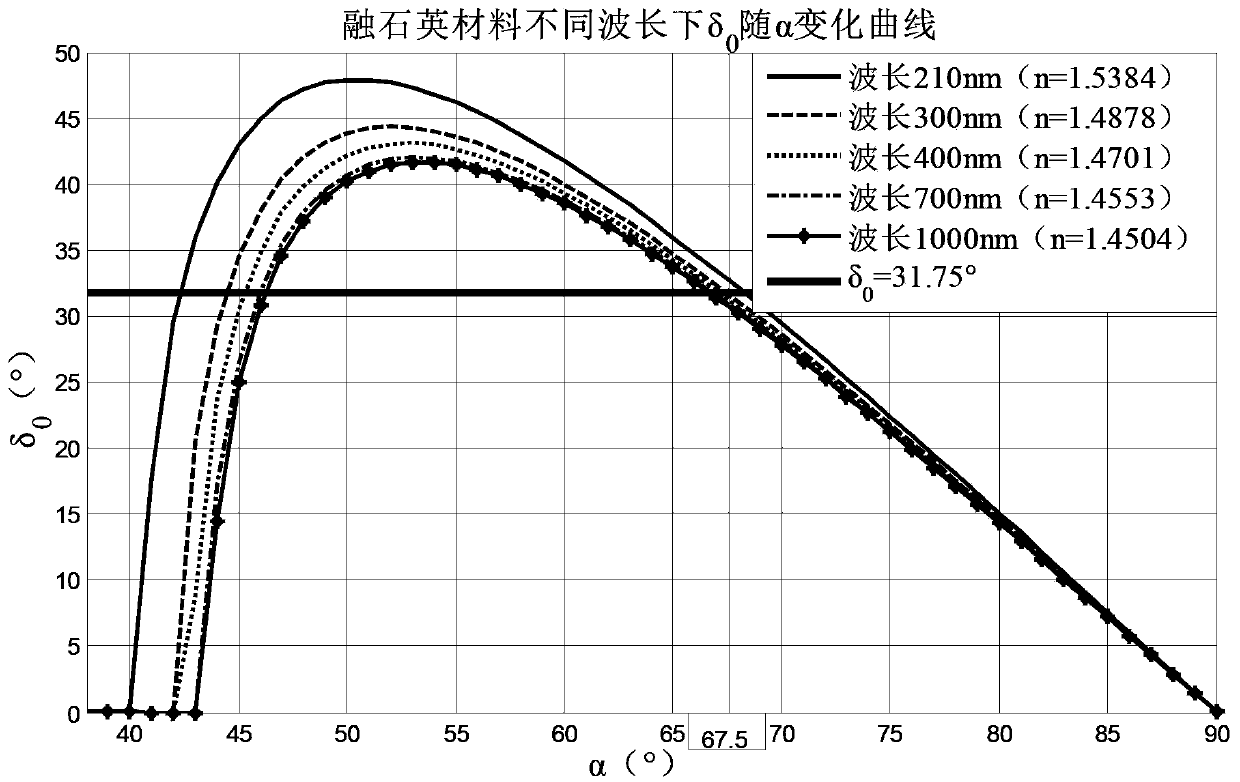

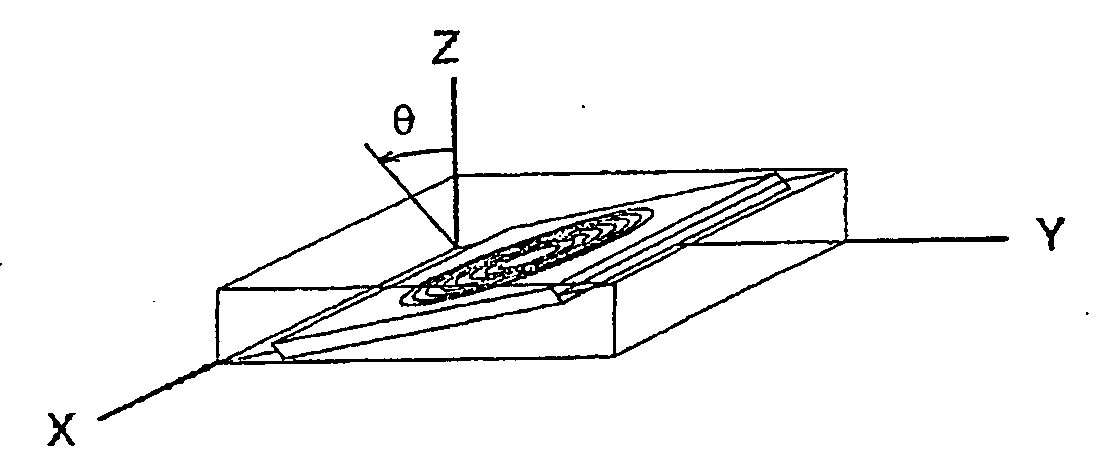

Fresnel prism phase retarder for double-rotation compensator ellipsometer

ActiveCN103424881ASatisfy the amount of phase delayFulfil requirementsPolarisation-affecting propertiesOptical elementsPhase retardationRefractive index

The invention discloses a Fresnel prism phase retarder for a double-rotation compensator ellipsometer. The Fresnel prism phase retarder consists of two rhombic prisms, and oblique bottom surfaces of one ends of the two rhombic prisms are bound to each other to form a symmetrical structure. The prism materials with corresponding refractive index are selected and oblique angles of the rhombic prisms are determined, an incident beam is emitted into the rhombic prism perpendicularly through the oblique bottom surface of the other end of one of the rhombic prisms, subjected to total reflection twice sequentially through the opposite two sides, emitted into the other rhombic prism through the binding surface of the two rhombic prisms, and further, subjected to total reflection twice through the two sides of the rhombic prism sequentially so as to be emitted out, so that the phase retardation required by the double-rotation compensator Mueller matrix type ellipsometer can be acquired. The phase retarder has good achromatism within bands of ultraviolet light, visible light and infrared light, is insensitive to the incident angle of the light beam, is convenient to process, can be used as a rotary compensator of the double-rotation compensator Mueller matrix type ellipsometer, and can meet the requirements of the double-rotation compensator Mueller matrix type ellipsometer to the broad spectrum band and the 127-degree phase retardation.

Owner:HUAZHONG UNIV OF SCI & TECH

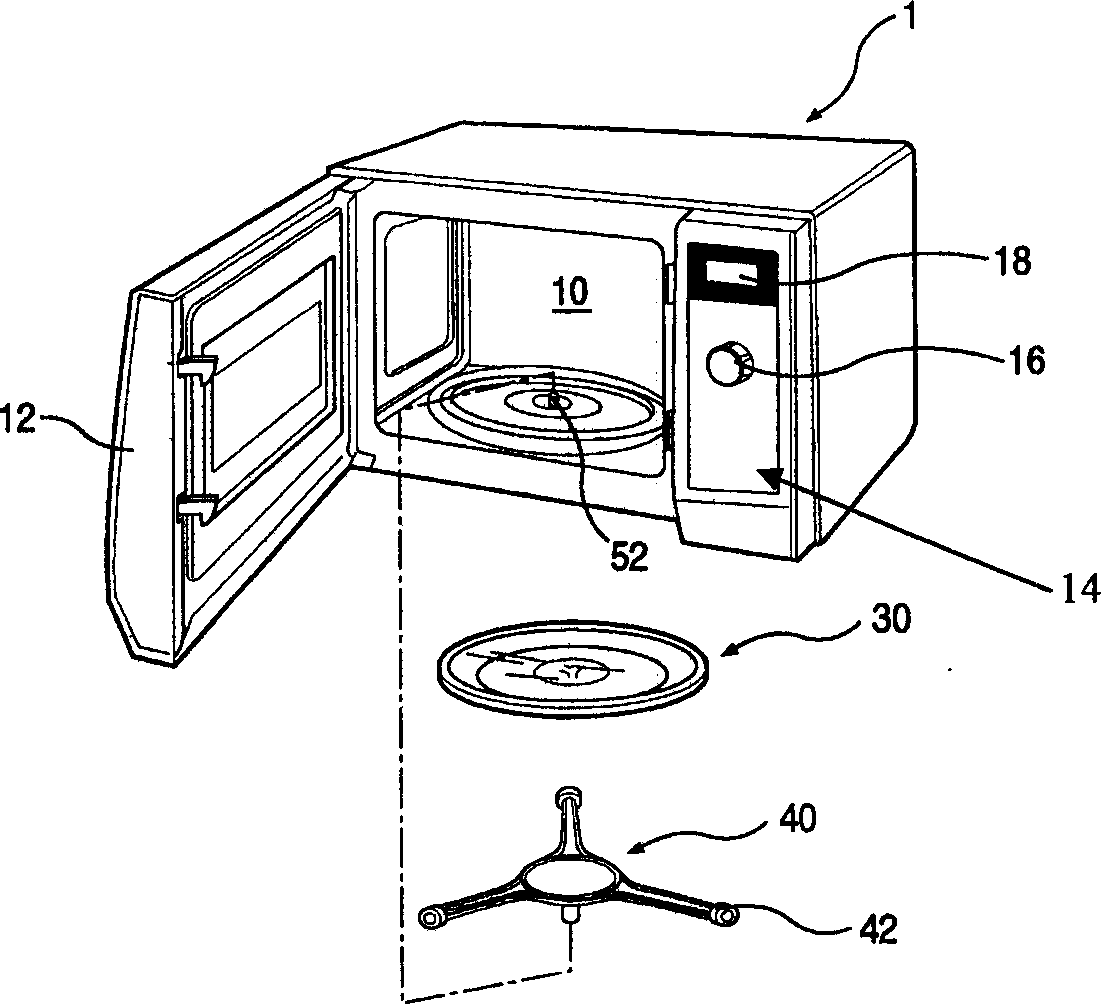

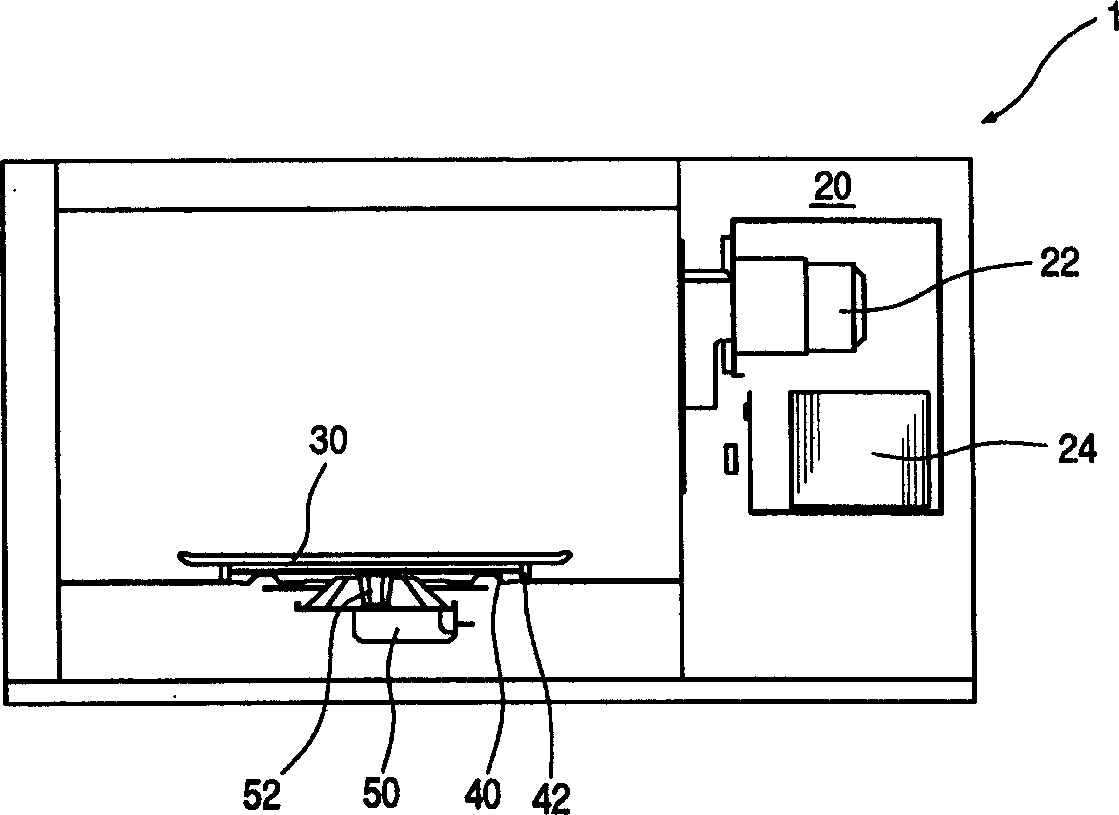

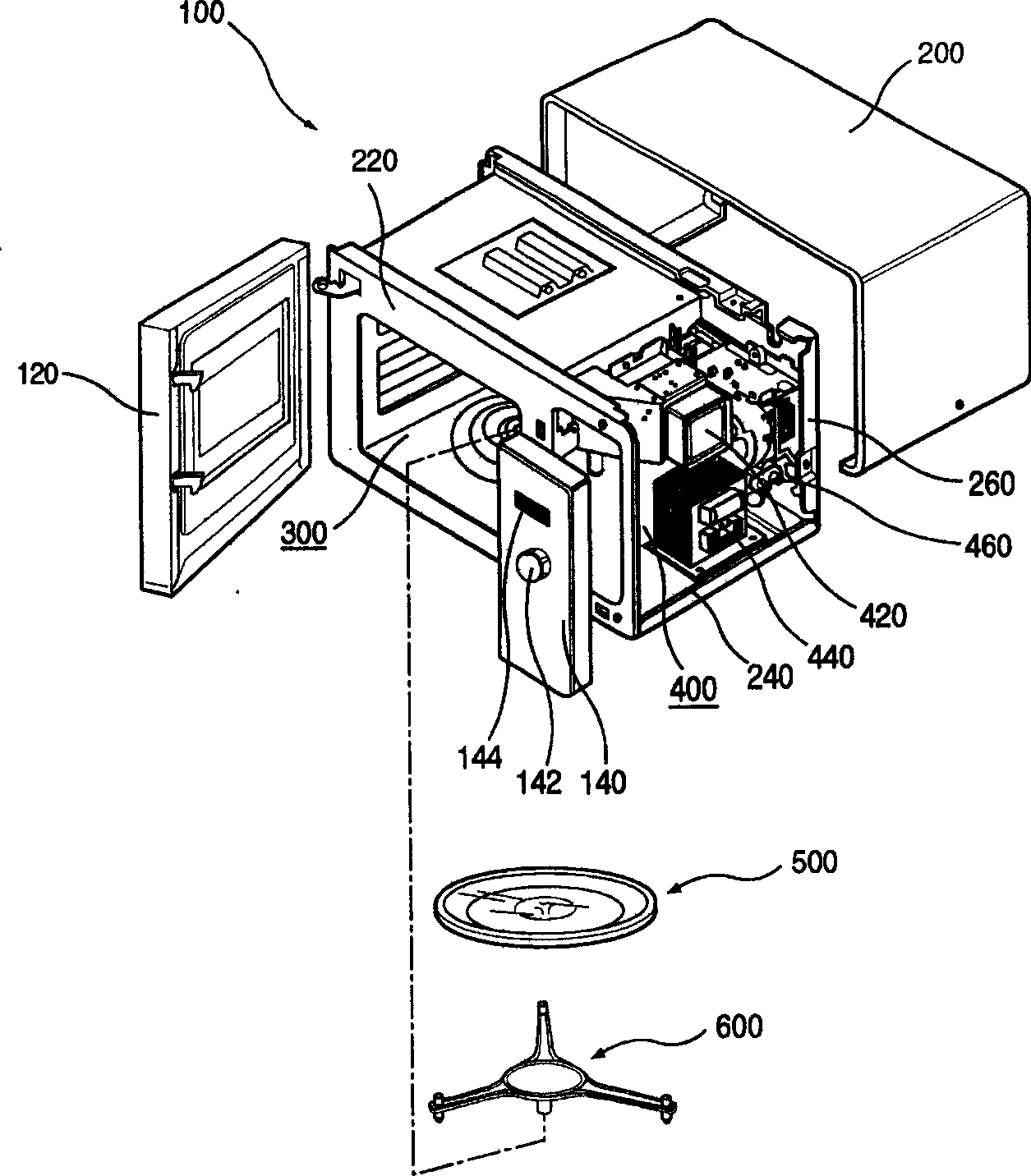

Microwave oven rotary disc assembly

InactiveCN1888572APrevent the phenomenon of microwave concentrationImprove cooking qualityDomestic stoves or rangesStoves/ranges shelves or racksMicrowave ovenDrive shaft

A tray assembly of microwave oven comprises a tray putting the heated food, a tray motor under the tray, a rotation shaft between the tray and the tray motor. The invention also includes a rotating machine combined with the bottom of the tray motor capable of making the integral tray motor rotate in a certain radius, so the tray can carry out a double-rotation taking the drive shaft of the tray motor and the revolving shaft of the rotating machine as the centre.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

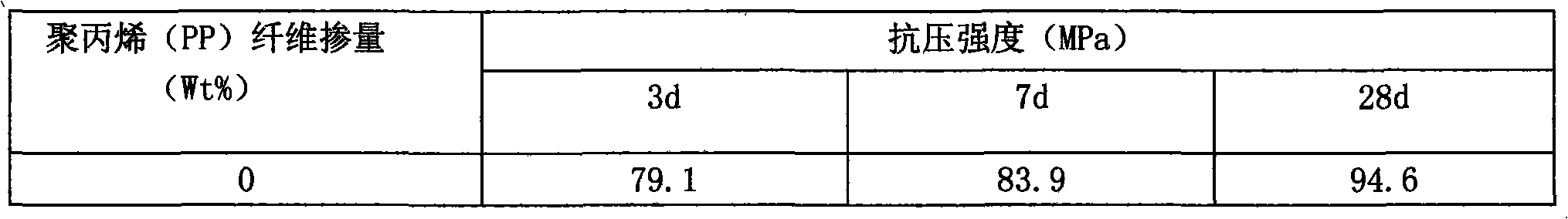

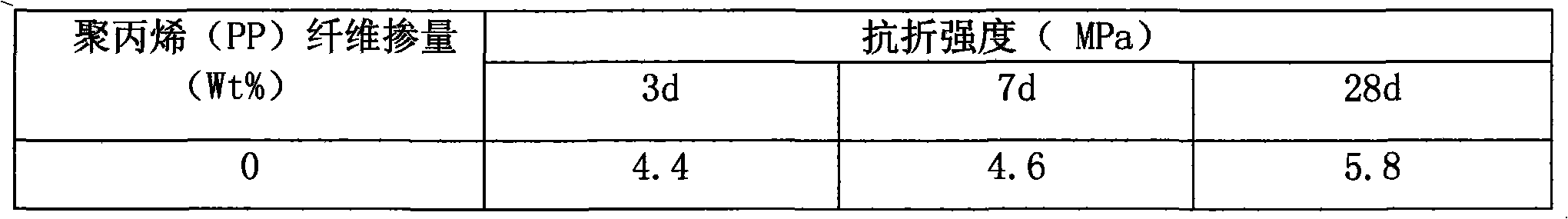

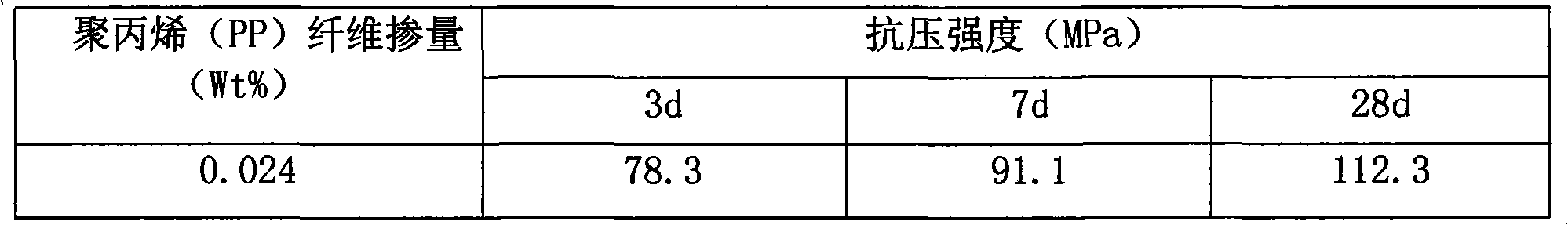

Polypropylene fiber reinforced inorganic polymer composite material and preparation method thereof

InactiveCN101570424AControl plastic shrinkageControl shrinkageSolid waste managementCement productionPolymer scienceSlag

The invention discloses a polypropylene fiber reinforced inorganic polymer composite material and a preparation method thereof. Polypropylene beam-like monofilament fiber and sodium silicate are added in slag, and the mixture is excited by the sodium silicate to prepare the composite material; the adding amount of the polypropylene beam-like monofilament fiber is 0.024 to 0.06 percent of the weight of the slag; and the adding amount of sodium silicate is 11 percent of the weight of the slag. The preparation method comprises the following steps: dispersing the polypropylene beam-like monofilament fiber in the formula ratio in the slag at the room temperature; putting the mixture in a double-rotation double-speed purified paste stirrer for stirring; adding a water solution of sodium silicate in the mixture and evenly stirring the mixture to form an evenly mixed paste, wherein the ratio of water to the slag is 0.31; and forming the paste , putting the paste in a standard curing box for curing, and testing the compressive strength and the flexural strength of the paste. Compared with the slag inorganic polymer, the maximum flexural strength of the composite material at 28d is increased by 5.4 MPa, and the maximum compressive strength of the composite material at 28dis increased by 17.7 MPa. The preparation process has the advantages of easy operation, unnecessary heating and no three-waste emission, so the preparation process is a green preparation process.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

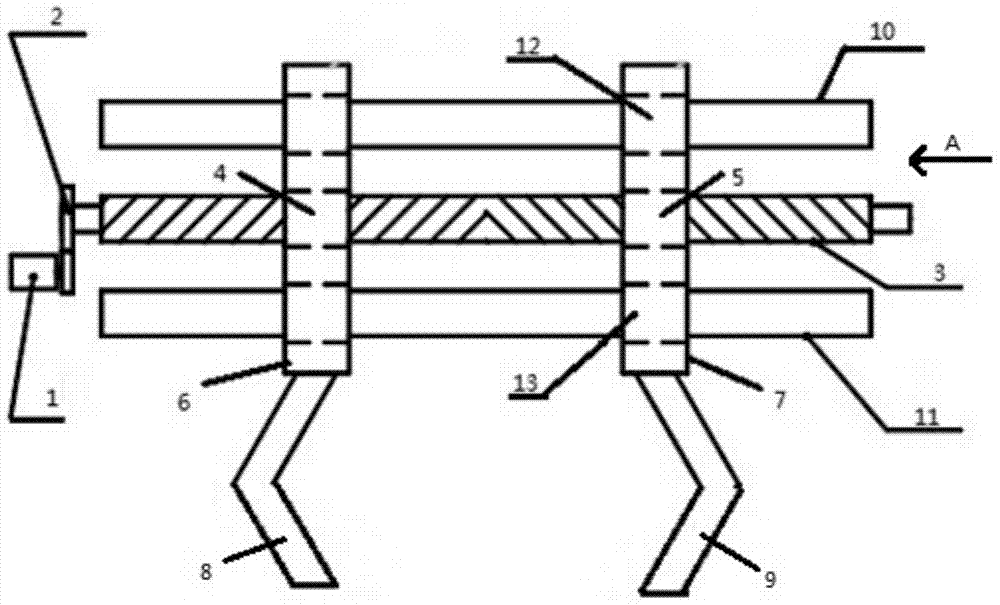

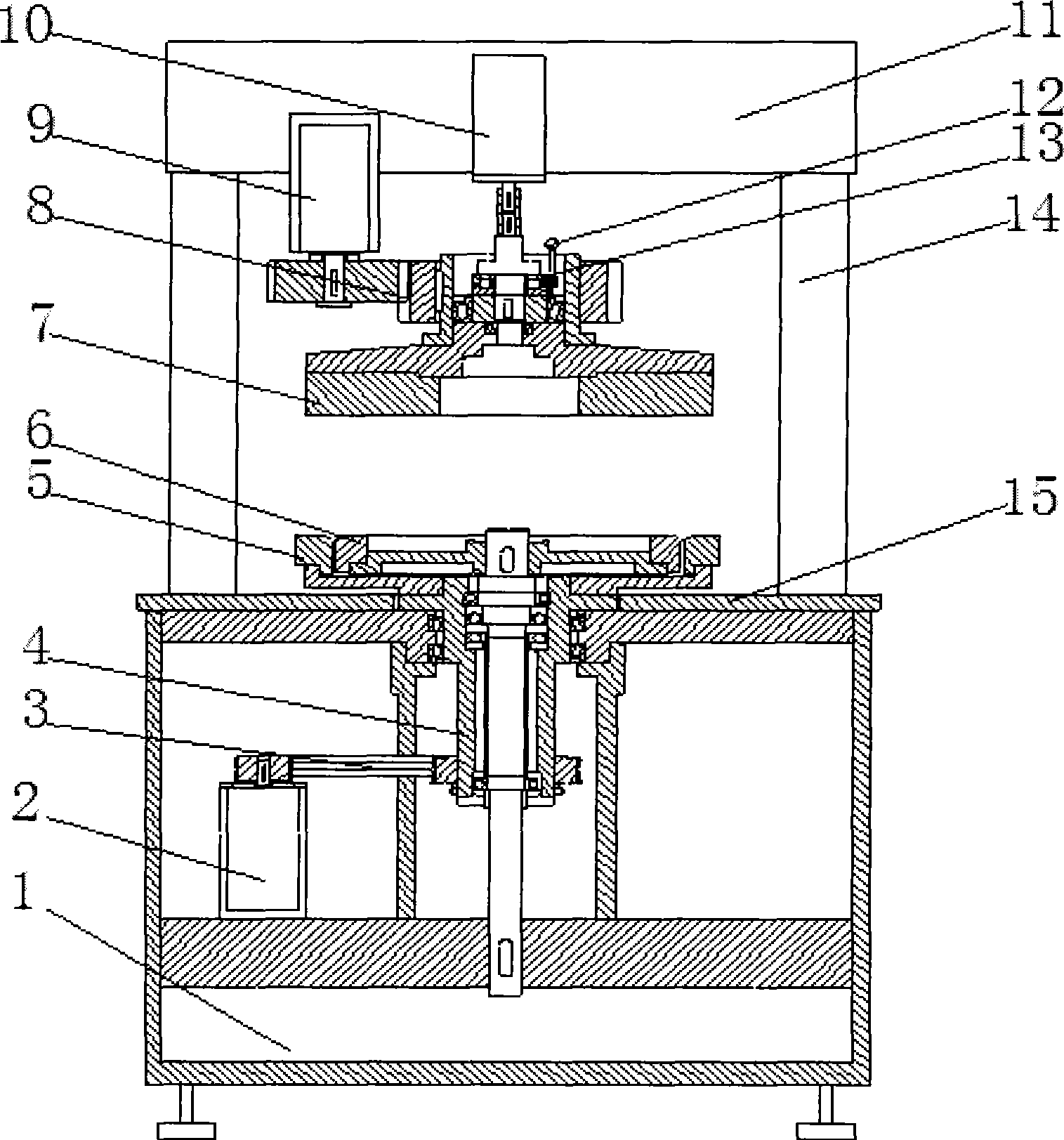

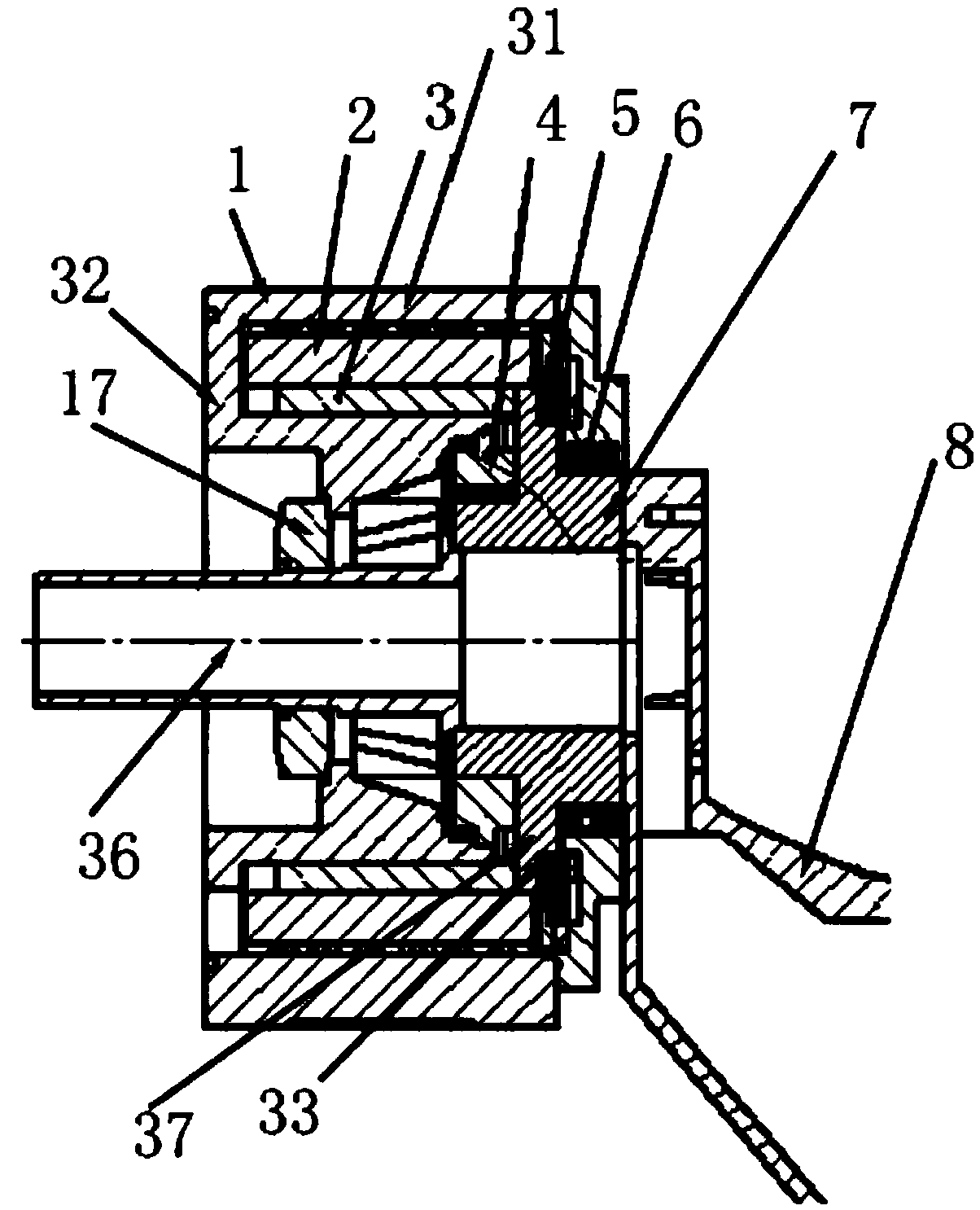

Double-rotation-shaft precision workbench

PendingCN108620898ARealize processingHigh positioning accuracyLarge fixed membersRotary stageRotational axis

The invention relates to a double-rotation-shaft precision workbench. The double-rotation-shaft precision workbench comprises a rotation workbench capable of rotating along a B axis, the lower portionof the rotation workbench is arranged in a swinging basket body, and the two ends, away from the rotation workbench, of the swinging basket body are fixed to an A-axis main shaft capable of rotatingalong an A axis. The outer edge of the A-axis main shaft is connected with a first torque motor, wherein the first torque motor can drive the A-axis main shaft to rotate, and accordingly the swingingbasket body can be driven to do the rotation movement along the A axis. The outer side of a rotation shaft of the rotation workbench is connected with a second torque motor, wherein the second torquemotor can drive the rotation shaft to rotate, and accordingly the rotation workbench can be driven to do the rotation movement along the B axis. The double-rotation-shaft workbench is arranged along the A axis and the B axis, the torque motors are adopted for direct drive, the rotation coordinate axis of a horizontal machining center has high positioning precision, and since the torque motors areadopted for direct drive, the inner space can be sufficiently utilized, the height of a rotation table is reduced, and the whole rotation table structure is more compact.

Owner:SHANGHAI SMARTSTATE TECH CO LTD

Temperature Compensated Balance-Spiral Oscillator

ActiveUS20080008050A1Assembly is smallEscapementsFrequency stabilisation mechanismDouble rotationMechanical watch

The invention relates to mechanical watch oscillators comprising an assembly consisting of a spinal and a temperature compensated balance. The spiral is embodied in a quartz substrate whose section is selected in such a way that the drifts of the spiral and of the balance associated therewith are thermally compensated. The substrate section can be embodied in the form of a section of single or double rotation.

Owner:CSEM CENT SUISSE DELECTRONIQUE & DE MICROTECHNIQUE SA RECH & DEV

Scroll expander

InactiveCN103375174AImprove sealingPrecise positioningEngine of arcuate-engagement typeRotary piston pumpsPre expansionDrive shaft

Owner:ANEST IWATA CORP

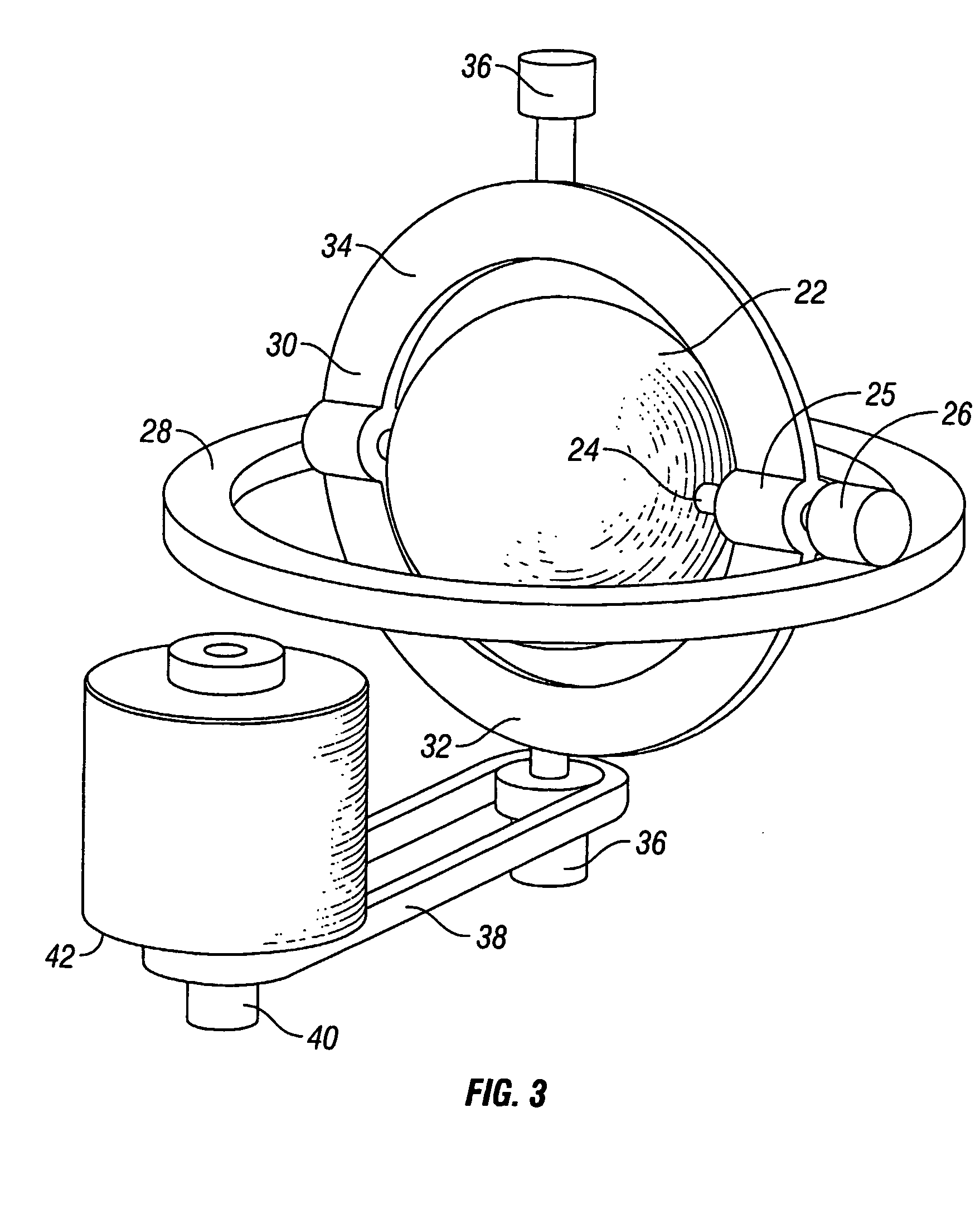

Fabrication method of seamless rear projection spherical screen and device thereof

ActiveCN102162988AUniform thicknessImprove the projection effectProjectorsEngineeringSpherical shaped

The invention relates to a fabrication method of a seamless rear projection spherical screen and a device thereof. The fabrication method is characterized in that a reaction-type resin is injected into a hollow die by a double-rotation forming method so that the reaction-type resin can react and be cured on the inner side surface of a spherical die to form a base; and an optical projector is fabricated on the base by the same method. The method and the device can be used for fabricating the seamless rear projection spherical screen by simple operation, and the products have good uniformity.

Owner:WUXI XIKE NETWORK TECH

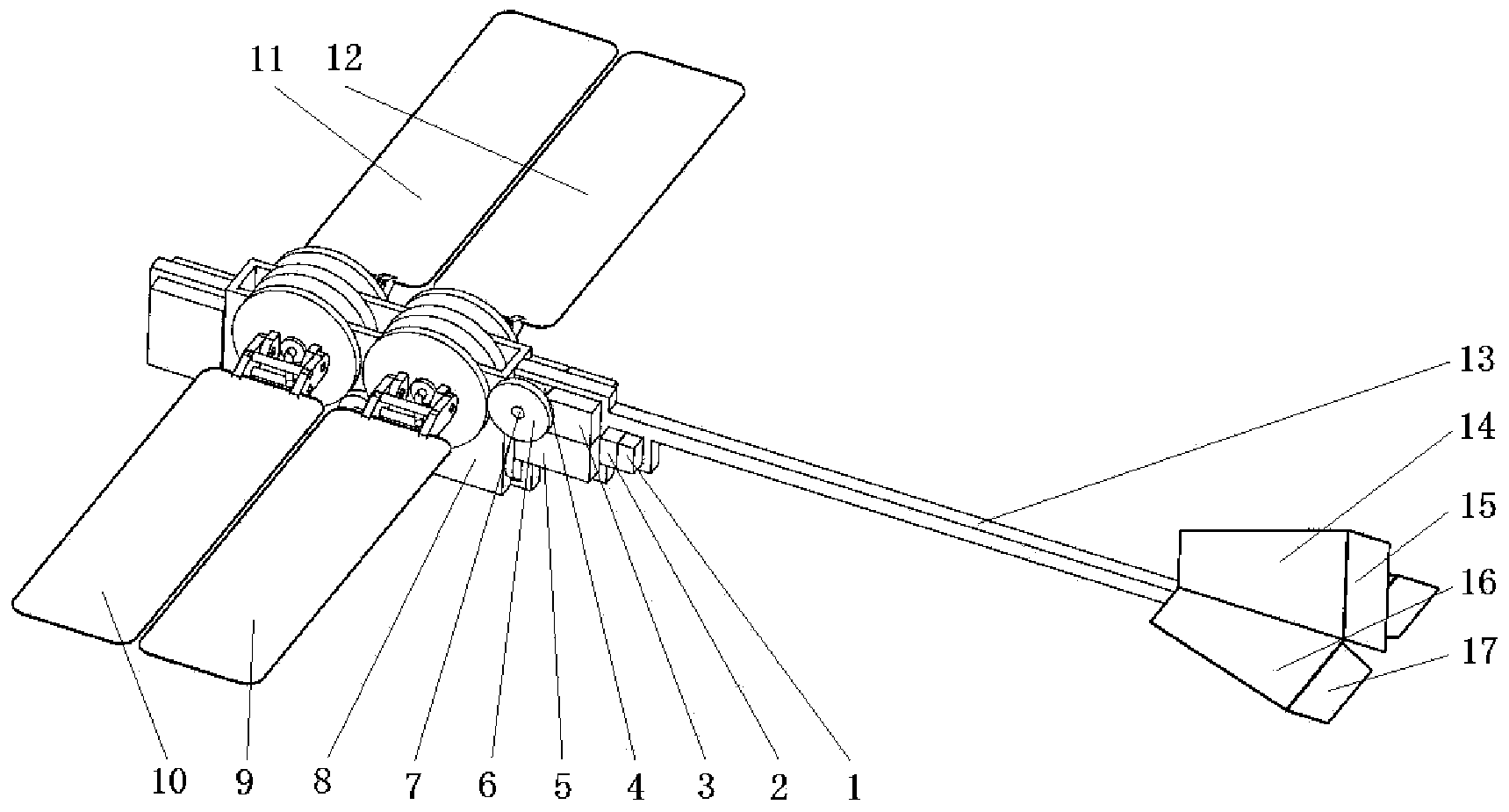

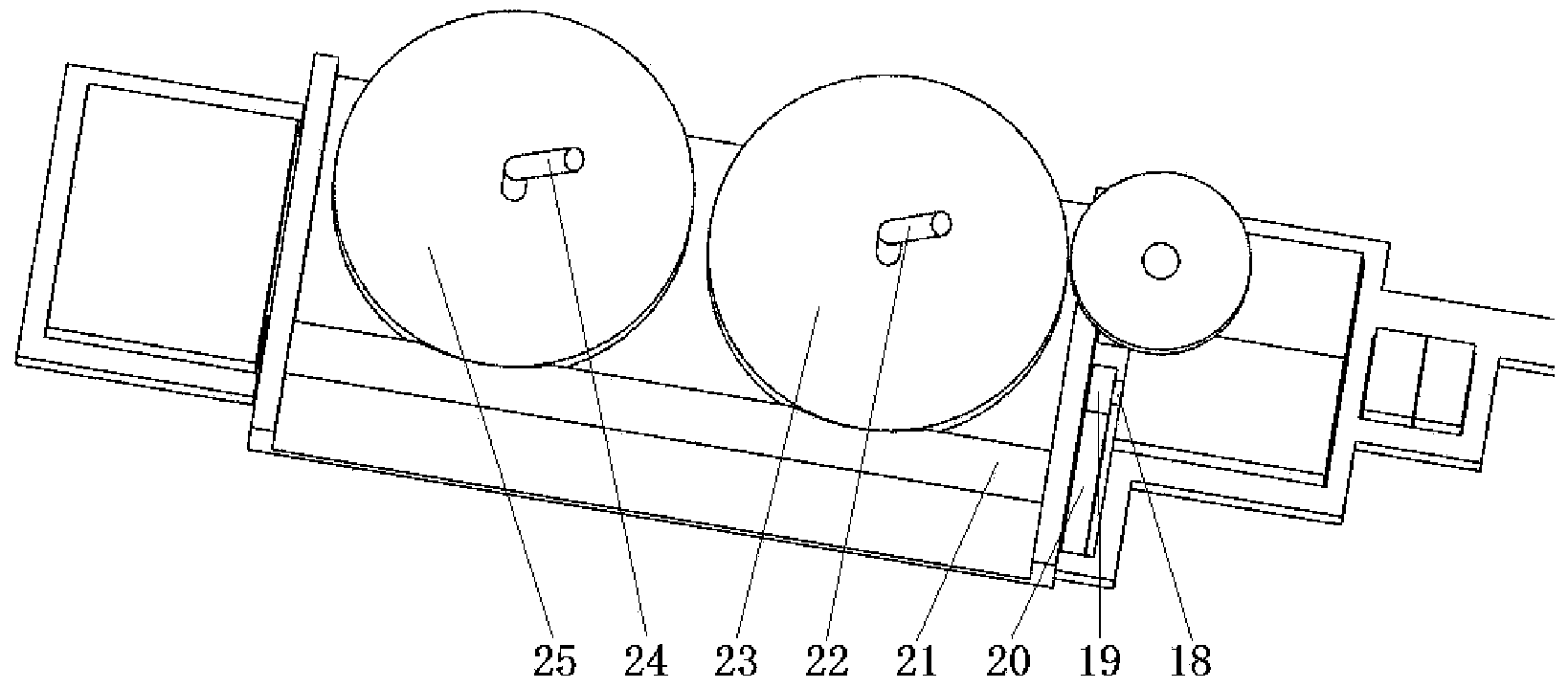

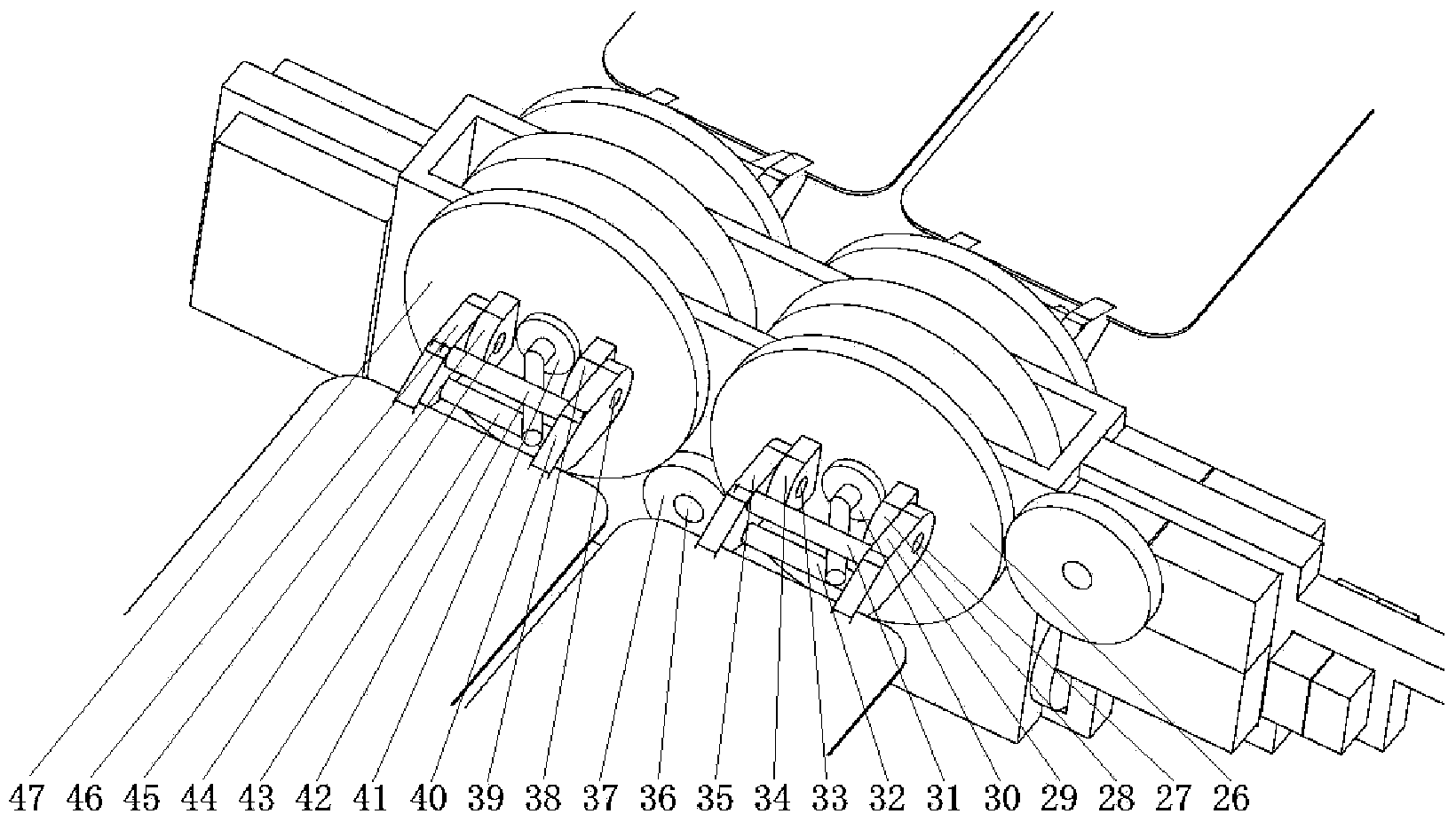

Miniature insect-like double-rotation flapping wing air vehicle

The invention relates to a miniature insect-like double-rotation flapping wing air vehicle. The miniature insect-like double-rotation flapping wing air vehicle comprises a rack, a flapping-wing rotary transmission system, a left-side front-rear flapping system, a right-side front-rear flapping system and a tail-wing system, wherein a motor b drives a left-side front flapping wing, a left-side rear flapping wing, a right-side front flapping wing and a right-side rear flapping wing to flap at high frequency by a gear b, a gear c, a worm, a front turbine, a rear turbine, a front two-end corner shaft and a rear two-end corner shaft. A motor a drives the left-side front flapping wing, the left-side rear flapping wing, the right-side front flapping wing and the right-side rear flapping wing to move in a rotating manner by a gear a, a gear f, a gear d, a gear e, a transmission shaft, a gear h, a gear g and a gear i. Compared with the prior art, the miniature insect-like double-rotation flapping wing air vehicle has the advantages that each flapping wing can move in a rotating manner; the transmission of the turbines and the worm has self-locking performance; complete symmetry of flapping of the left-side flapping wing and the right-side flapping wing is realized by the turbines and the worm; and a flapping mechanism formed by the two-end corner shafts and cylindrical supporting rods is simple in structure and flexible in flapping.

Owner:SHANGHAI UNIV OF ENG SCI

Bi-axial rotating magnetic therapeutic device

A device for applying a time-varying magnetic field to a human or animal body for therapeutic purposes comprising a magnetic body housed in a free-moving member, which is itself housed within the device. The device is powered by a small electric motor that drives the free-moving member and magnetic body to rotate about a axis of first rotation. The magnetic body is further caused to rotate about a axis of second rotation through angular forces imparted on it either mechanically or magnetically. Mechanical angular force is imparted by a gear and tooth arrangement or other similar tactile interaction with a roller member. Magnetic angular force is imparted by stationary magnets as the magnetic body rotates past them. The two rotational movements of the magnetic body are oblique to one another and produce both a time-varying field of magnetic flux density and a time-varying field of angular flux displacement.

Owner:ARDIZZONE VINCENT

Method for reduction and decomposition of phosphogypsum with yellow phosphorus tail gas

InactiveCN101492177AEmission reductionRealize comprehensive utilizationCarbon compoundsSulfur compoundsReductive decompositionFurnace temperature

The invention relates to a method for reducing and decomposing ardealite by tail gas of phosphor. The method comprises that: the naturally dried ardealite is put into a reductive decomposition furnace and filled with the tail gas of phosphor for reaction, and the furnace temperature is controlled to be between 700 and 1,000 DEG C, and the reaction time is between 10 and 50 minutes. The obtained furnace gas in which the content of the sulfur dioxide in percentage by volume is more than or equal to 15 percent is used as a material gas for the double-rotation double-suction acid preparation process; and the content of CaO, namely a solid product is more than or equal to 70 weight percent and is used as a cement material.

Owner:KUNMING UNIV OF SCI & TECH

Few-joint over-constrained five-freedom-degree parallel serial robot

ActiveCN107671845ASimple structureReduce the number of jointsProgramme-controlled manipulatorKinematicsEngineering

An over-constrained few-joint five-freedom-degree parallel serial robot mainly comprises a fixed platform, erect type vertical frames, a single-rotation-pair rotation frame, a double-rotation-pair rotation frame, a movable platform, a work platform, three branch chains the same in structure and a two-freedom-degree posture adjusting head. The work platform is arranged in front of the fixed platform, and the erect type vertical frames which are symmetrically arranged are arranged on the two sides of the fixed platform correspondingly. The three branch chains are arranged between the two erect type vertical frames and the movable platform, and the two-freedom-degree posture adjusting head is arranged at the lower end of the movable platform. A two-rotation and one-motion three-freedom-degreeparallel mechanism is formed by the erect type vertical frames, the movable platform and the three branch chains. The over-constrained few-joint five-freedom-degree parallel serial robot is simple instructure, the integral rigidity of the structure is improved, the control difficulty is lowered, the kinematics analysis is simple, and the dynamic response is good. Through combination of a two-freedom-degree swinging head and the movable platform, the work space of a machine tool is enlarged, the sensitivity of the machine tool is improved, and error accumulation caused by the component machining error and the assembling error is effectively avoided.

Owner:YANSHAN UNIV

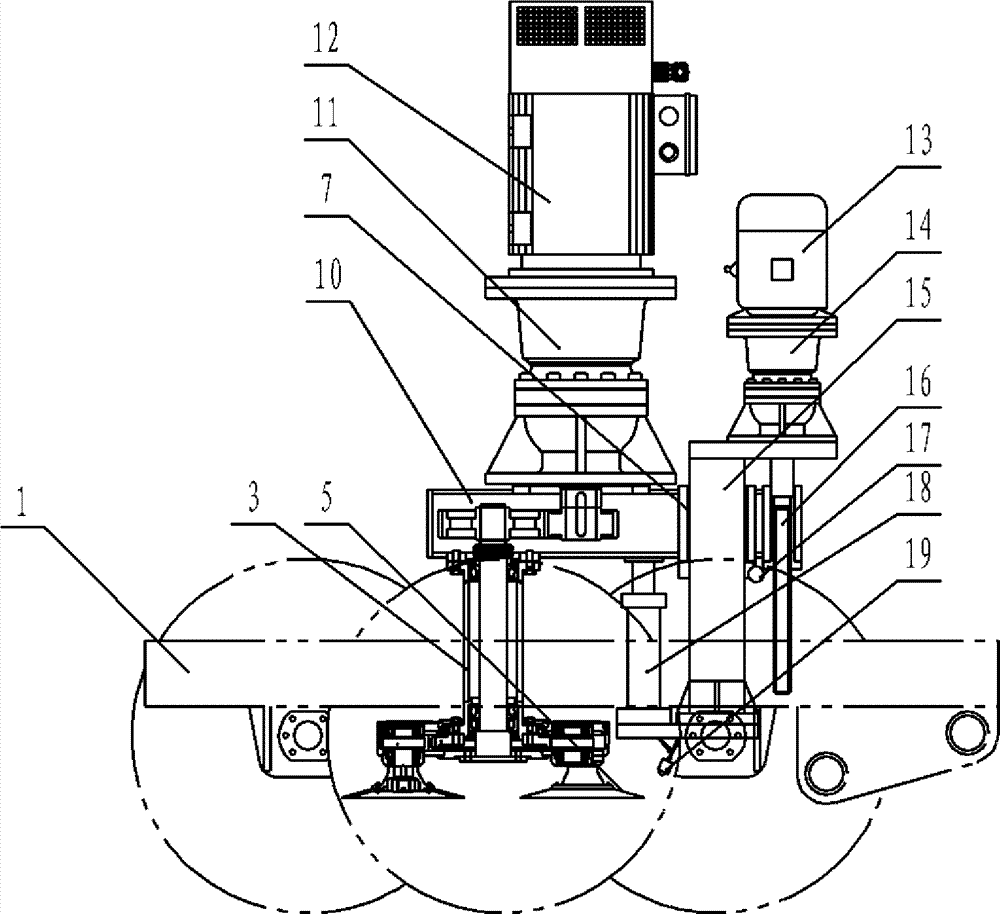

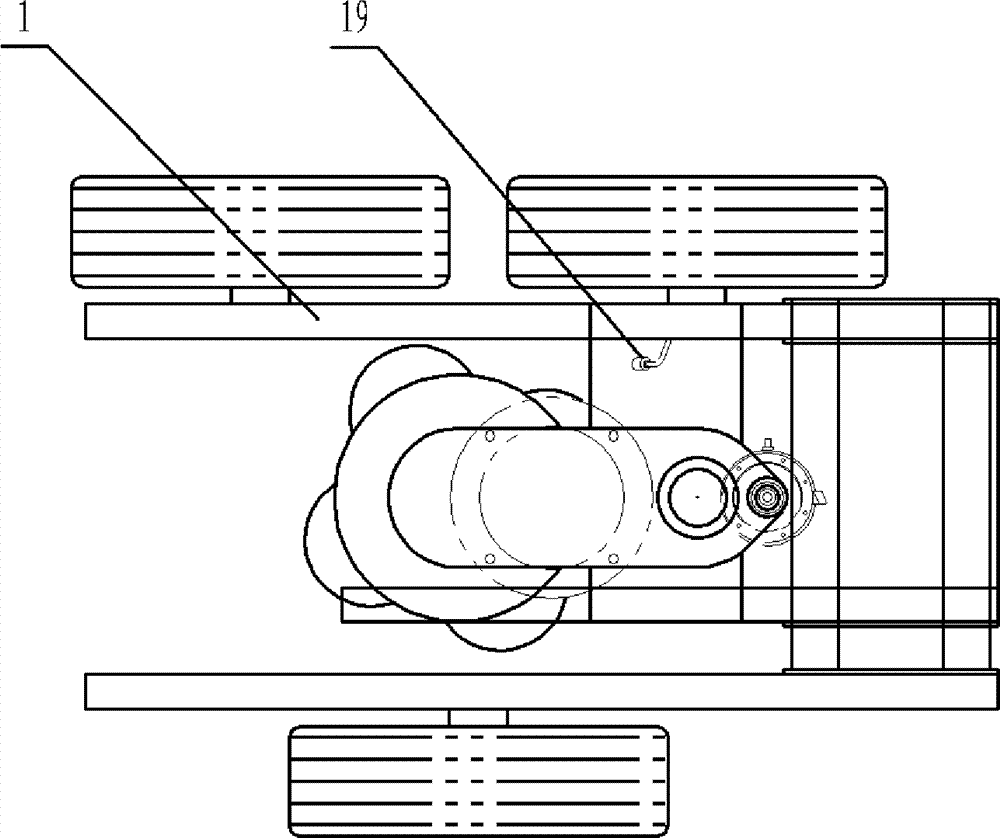

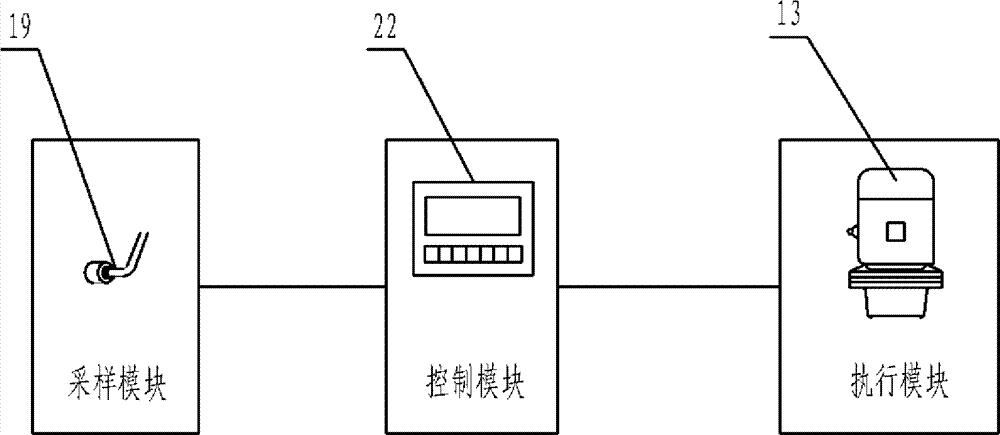

Header of cane harvester

The invention discloses a header of a cane harvester, which comprises a machine frame, an upright post mounted on the machine frame, and a lifting slider thereof, wherein an electric lifting mechanism is connected to one side of the lifting slider, the electric lifting mechanism is formed by a lead screw pair connected between the upright post and the lifting slider, and a lifting motor connected with the lead screw pair through a retarding mechanism. A cutter equipped with a main motor and a double rotation cutter blade plate is connected to the other side of the lifting slider, and a balance cylinder for balancing the weight is mounted between the machine frame and the cutter. A cutter lifting sensor is further mounted at the lower part of the machine frame, so as to form a cutter height automatic adjusting system comprising the cutter lifting sensor, a lifting controller, the electric lifting mechanism and the like. Therefore, the system can be used for adjusting the height of the cutter in real time according to the actual condition of harvest topography. Compared with the prior art, the header of the cane harvester, provided by the invention, solves the problems that the header of the conventional cane harvester is weak in topography adaptability, low in harvesting efficiency, and higher in harvesting cost.

Owner:朱季华

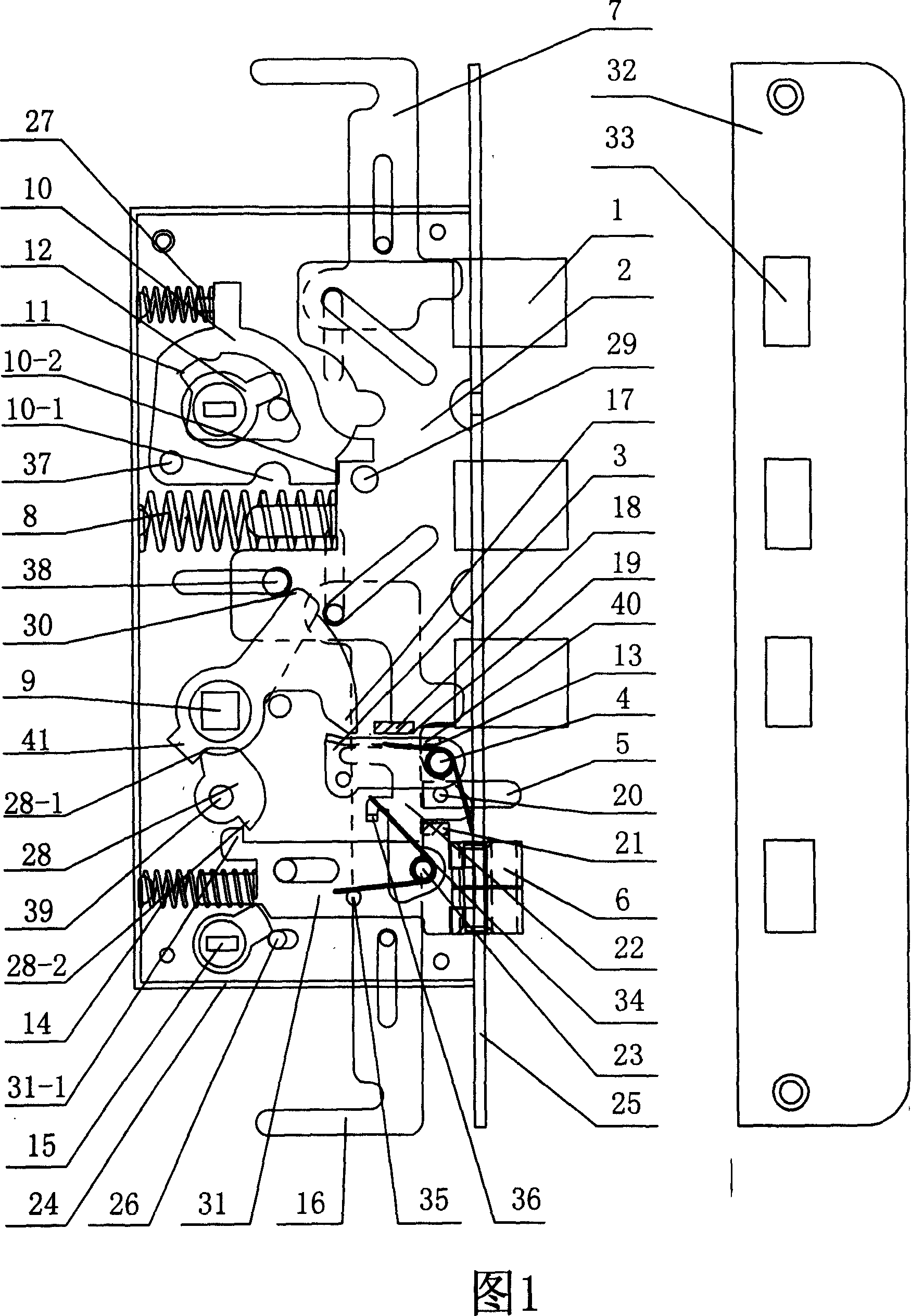

Automatic locking antitheft lock

This invention relates to an automatic lock anti-theft lock body, including lock-frames, body panels and the main lock bolt. Main lock bolt board sets up the main lock block and the main lock bolt plate slider, with the rotary blades on the block and only retreat plectrum. Tongue and double-rotation function tongue fixation connect with the function of the tongue plate locking activities roof block access shaft; locking block with the top activities locking control slip of tongue axis next, functional tongue plate fitted with locking control of the match slip of tongue slip of tongue positioning deduction. On the control plate with the Shaft control plate, plate and the main control board tongue positioning machine was linking deduction. Tongue pull double-block through a double-axle pin tongue Next, double tongue pull with the first block on top of the second block and the top block, Top with second piece of tongue function block top plate connecting match, the first block with the top block Plectrum top mutual linking. The beneficial effect of the invention is: closed automatically lock, simple structure and easy installation; because components are relative little, transmission components are the entire plate production, it is high reliability.

Owner:夏士林

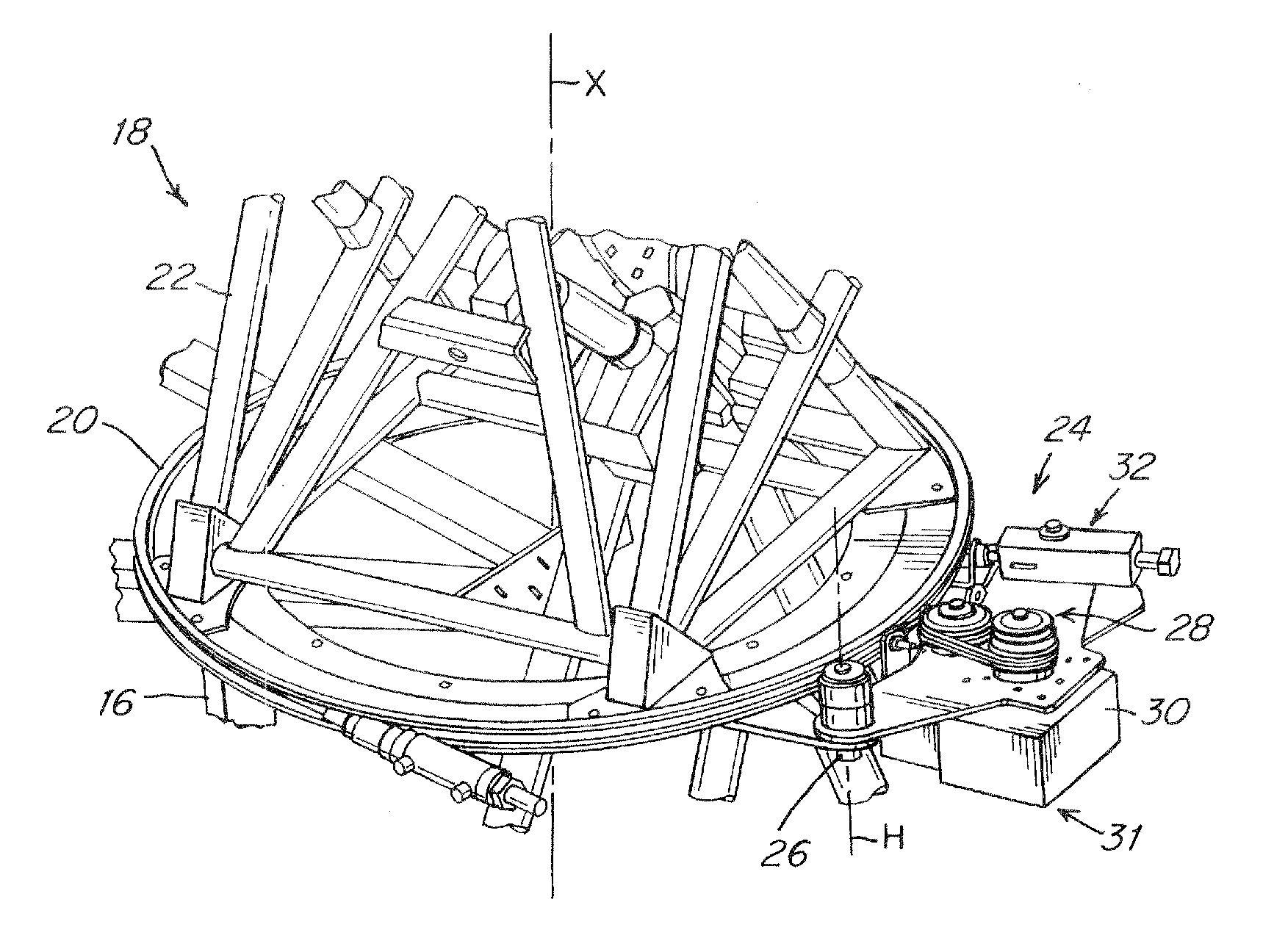

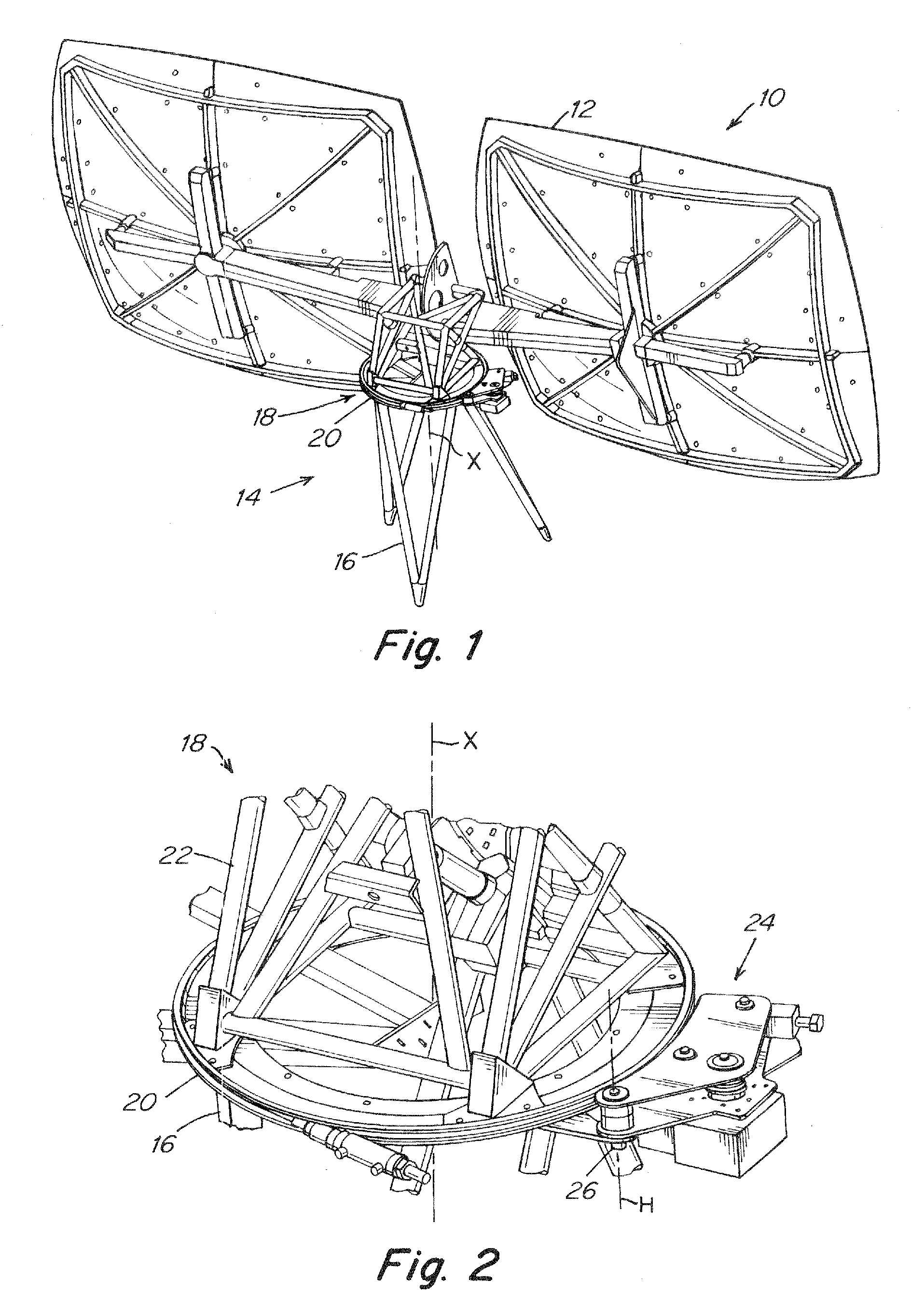

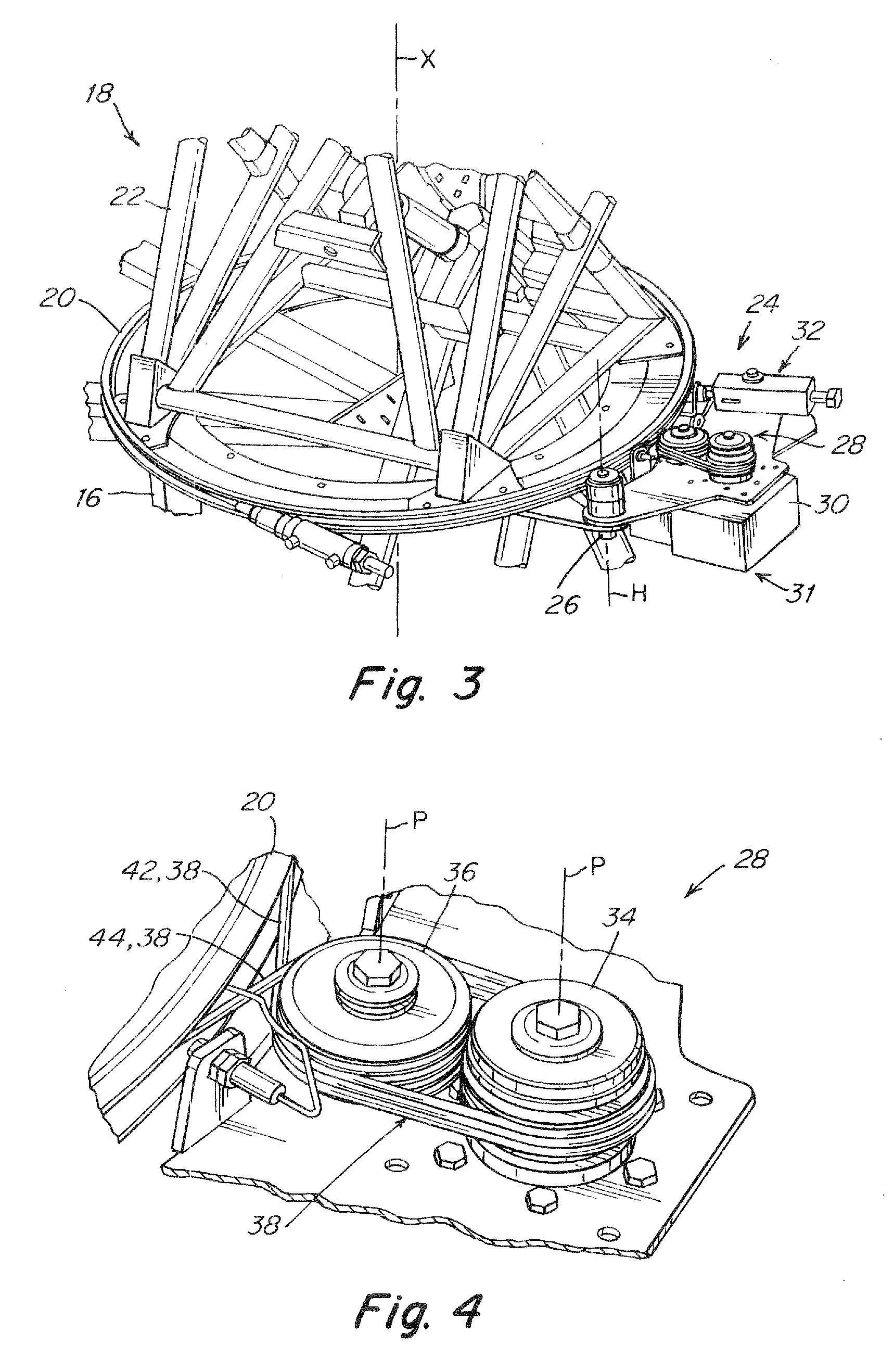

Orientation system and method

InactiveUS20120316017A1High positioning accuracyStable positionSolar heating energySolar heat devicesEngineeringDouble rotation

A system and a method for orientation of a ring by rotation, including a cable engaging the ring which rotates about a ring axis, a motor assembly providing a first rotation reduction, and a stretcher for stretching the cable. The system has at least one proximal pulley and at least one distal pulley rotating about a pulley axis each pulley having grooves configured for receiving the cable therein. The ring is rotated by the motor assembly and the pulley assembly is configured to provide a second reduction of rotation to the ring relative to motor rotation, whereby the ring is driven via at least a double reduction of rotation relative to rotation of the motor, and the cable, the plurality of pulleys, and the ring provide a one-way mechanism.

Owner:DOTAN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com