Header of cane harvester

A technology for harvesters and headers, which is applied to harvesters, harvesters, agricultural machinery and implements, etc., can solve the problems of affecting the efficiency of sugarcane harvesting, increasing harvesting costs, poor terrain adaptability, etc., to reduce equipment maintenance and maintenance cost, increase the efficiency of sugarcane harvesting, and improve the effect of terrain adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

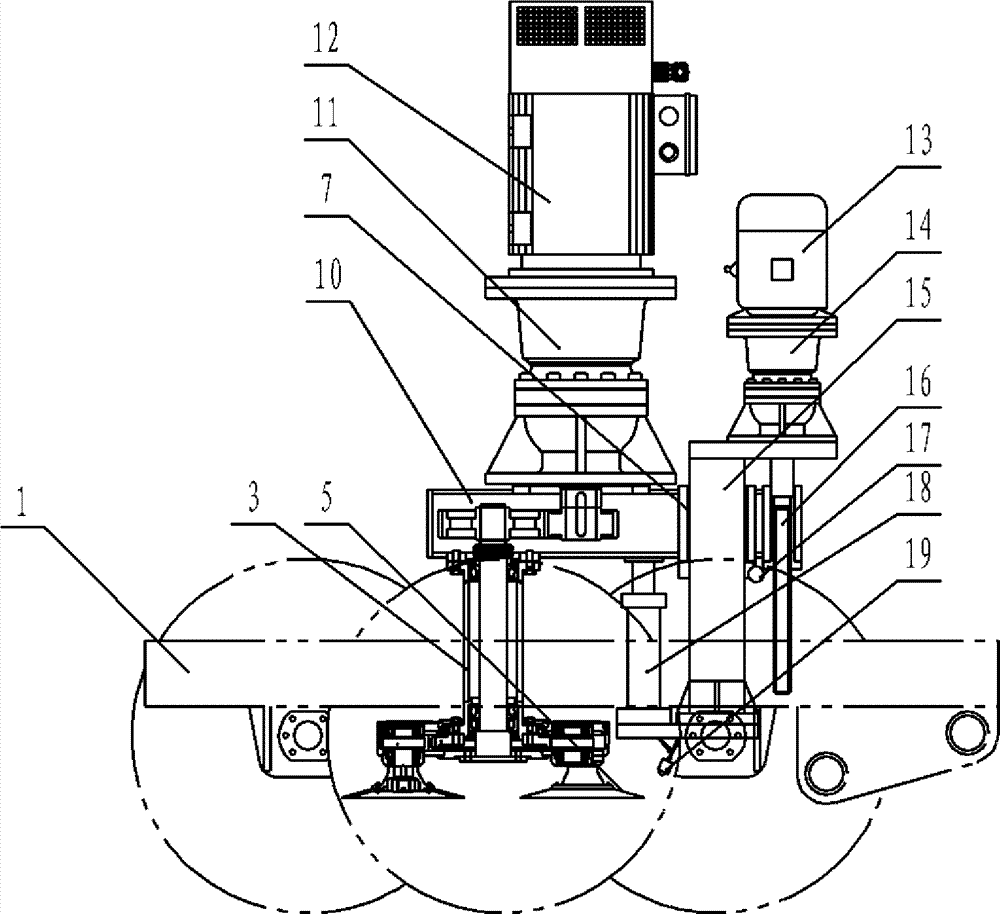

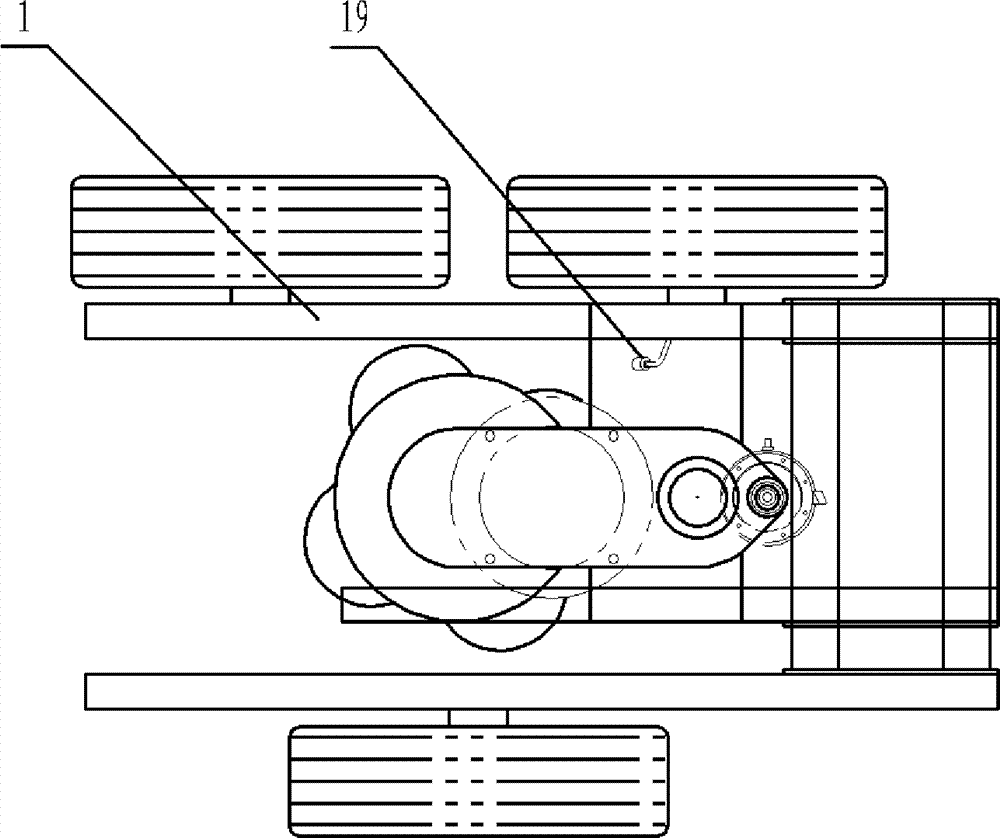

[0012] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

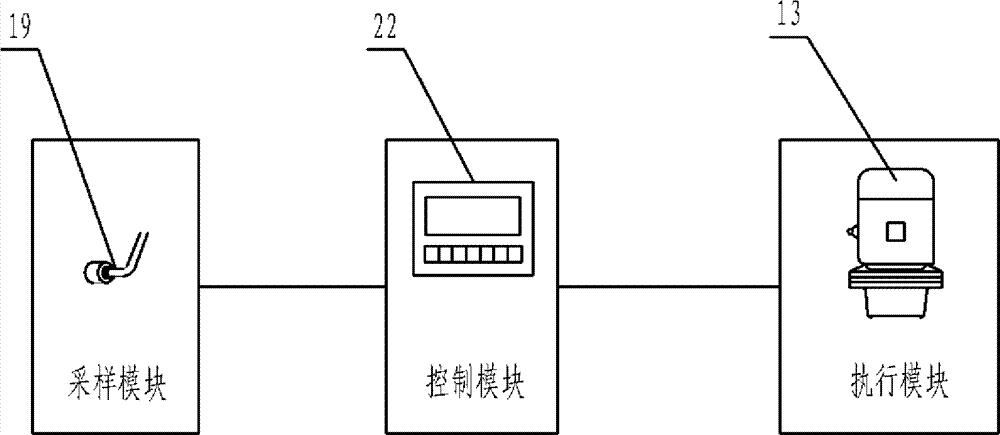

[0013] figure 1 , figure 2 Shown embodiment of the present invention 1 sugarcane harvester header includes terrain imitation wheel frame 1, is installed on the column 15 on the terrain imitation wheel frame 1, is enclosed within the lift slide block 7 on the column 15, lifts slide block 7 One side is connected with the screw pair 16 that is connected between the upright column 15 and the lifting slider 7, the screw rod of the screw screw pair 16 is connected with the lifting motor 13 connected by the reduction mechanism 14 and the bottom of the lifting slider 7, close to the wire The electric lifting mechanism that the brake 17 etc. that the screw mandrel place of rod pair 16 is installed constitutes. The other side of the lifting slider 7 is connected with a gearbox 10, a main motor 12 installed on the upper end of the gearbox 10 and a main reducer 11, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com