Anti-shaking synchronizing mechanism for slide rails

A synchronous mechanism and anti-shaking technology, which is applied in applications, household appliances, mechanical equipment, etc., can solve the problems of slide rail shaking, affecting the feel, precision error, etc., and achieve the effect of smooth sliding, improved feel, and improved transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

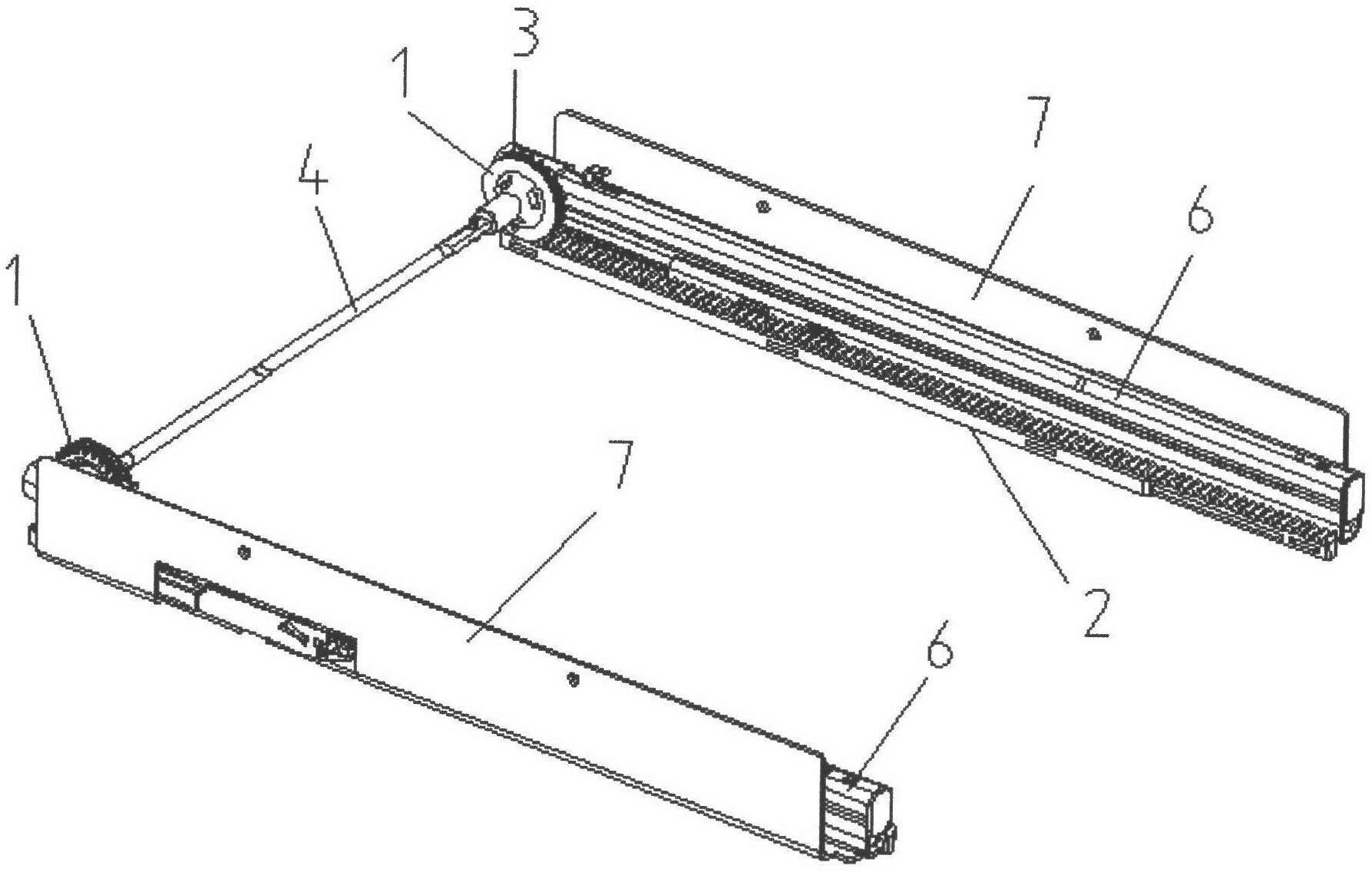

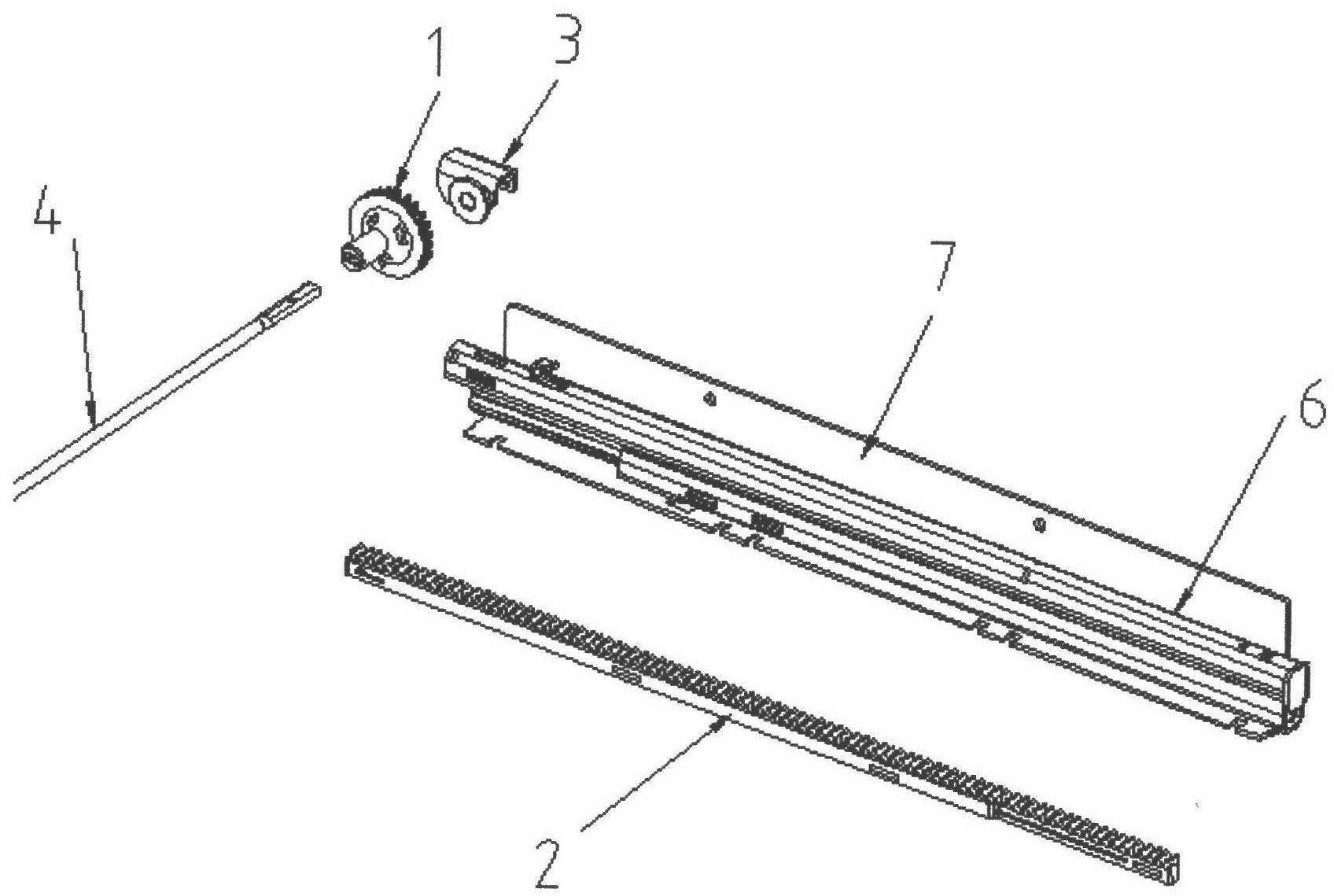

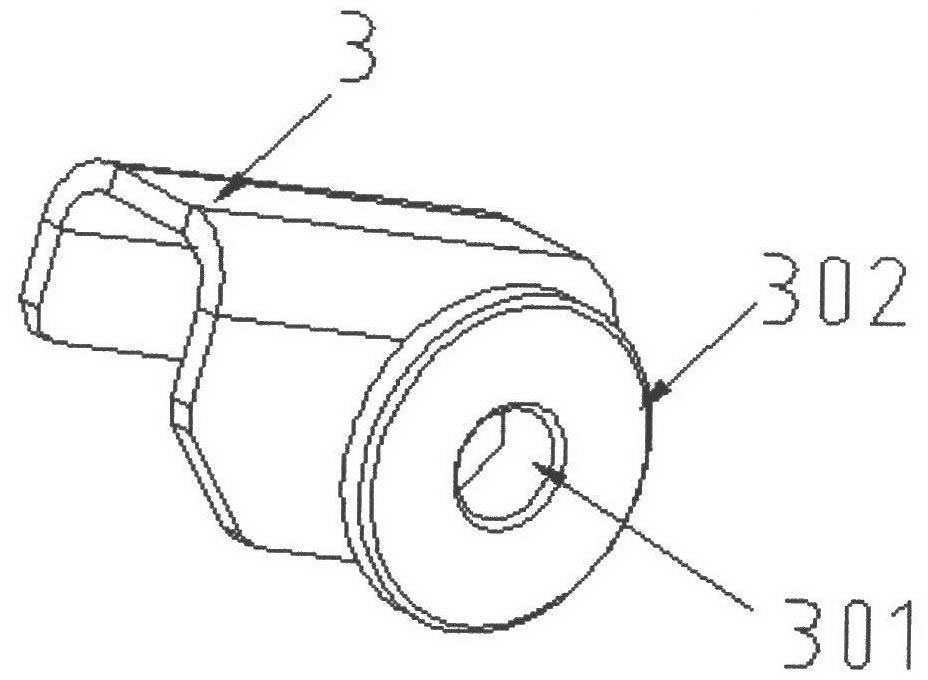

[0035] refer to figure 1 , figure 2 As shown, a kind of anti-shake synchronization mechanism for slide rails includes a pair of slide rail brackets 7 arranged in parallel and a pair of slide rails 6 arranged on the pair of slide rail brackets 7, and the two slide rails An anti-sway synchronous mechanism is arranged between the brackets 7; the anti-sway synchronous mechanism includes a long rod-shaped connecting rod 4, and the connecting rod 4 spans between the pair of slide rail brackets 7. The two ends of the rod 4 are respectively connected with gears 1, and the gears 1 on both sides are movably connected to the corresponding slide rails 6 respectively, and meshed with the rack 2 arranged on the slide rail bracket 7, the rack 2 2 The installation direction is consistent with the push-pull direction of the slide rail 6, and the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com