Patents

Literature

456 results about "Linkage (mechanical)" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A mechanical linkage is an assembly of bodies connected to manage forces and movement. The movement of a body, or link, is studied using geometry so the link is considered to be rigid. The connections between links are modeled as providing ideal movement, pure rotation or sliding for example, and are called joints. A linkage modeled as a network of rigid links and ideal joints is called a kinematic chain.

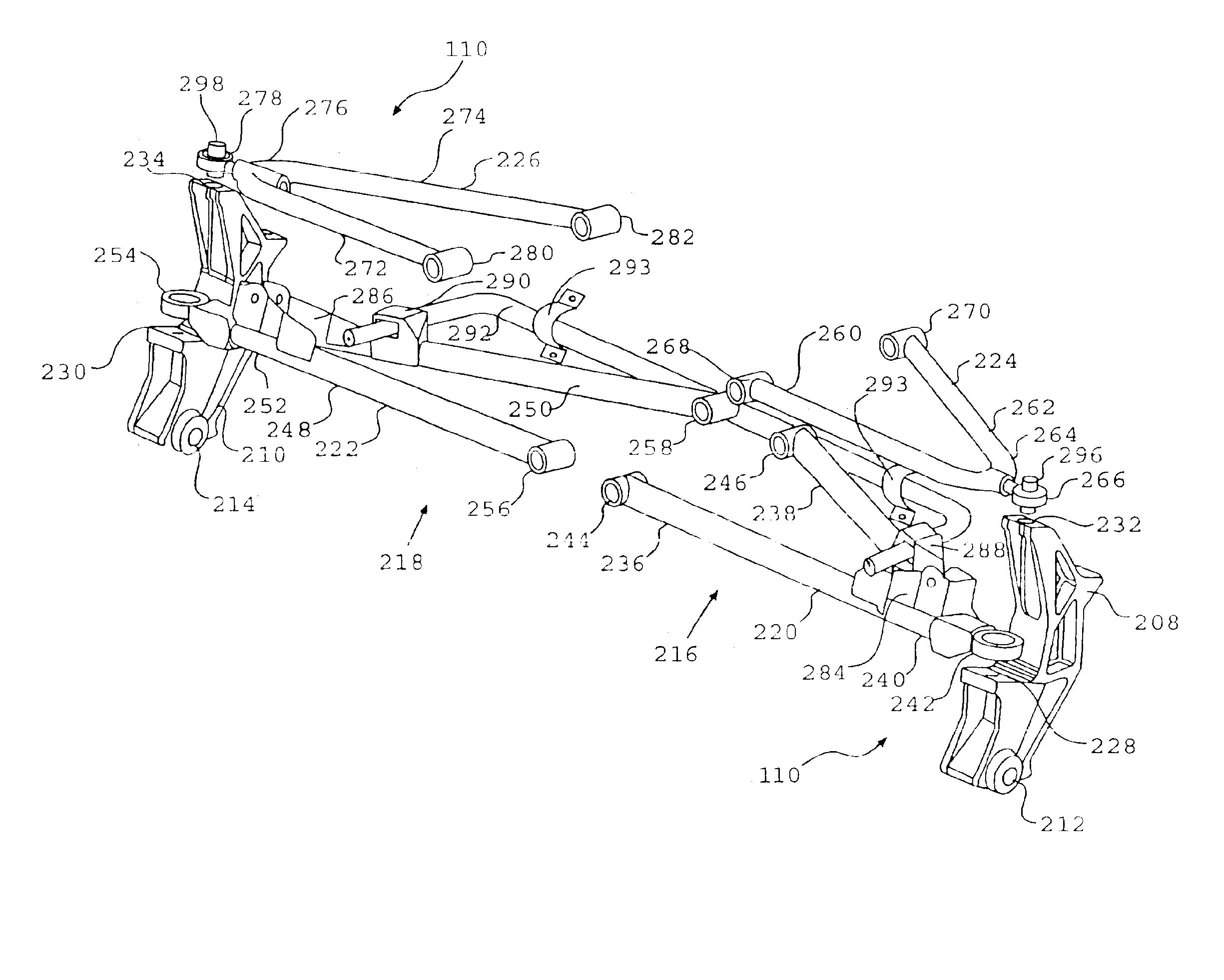

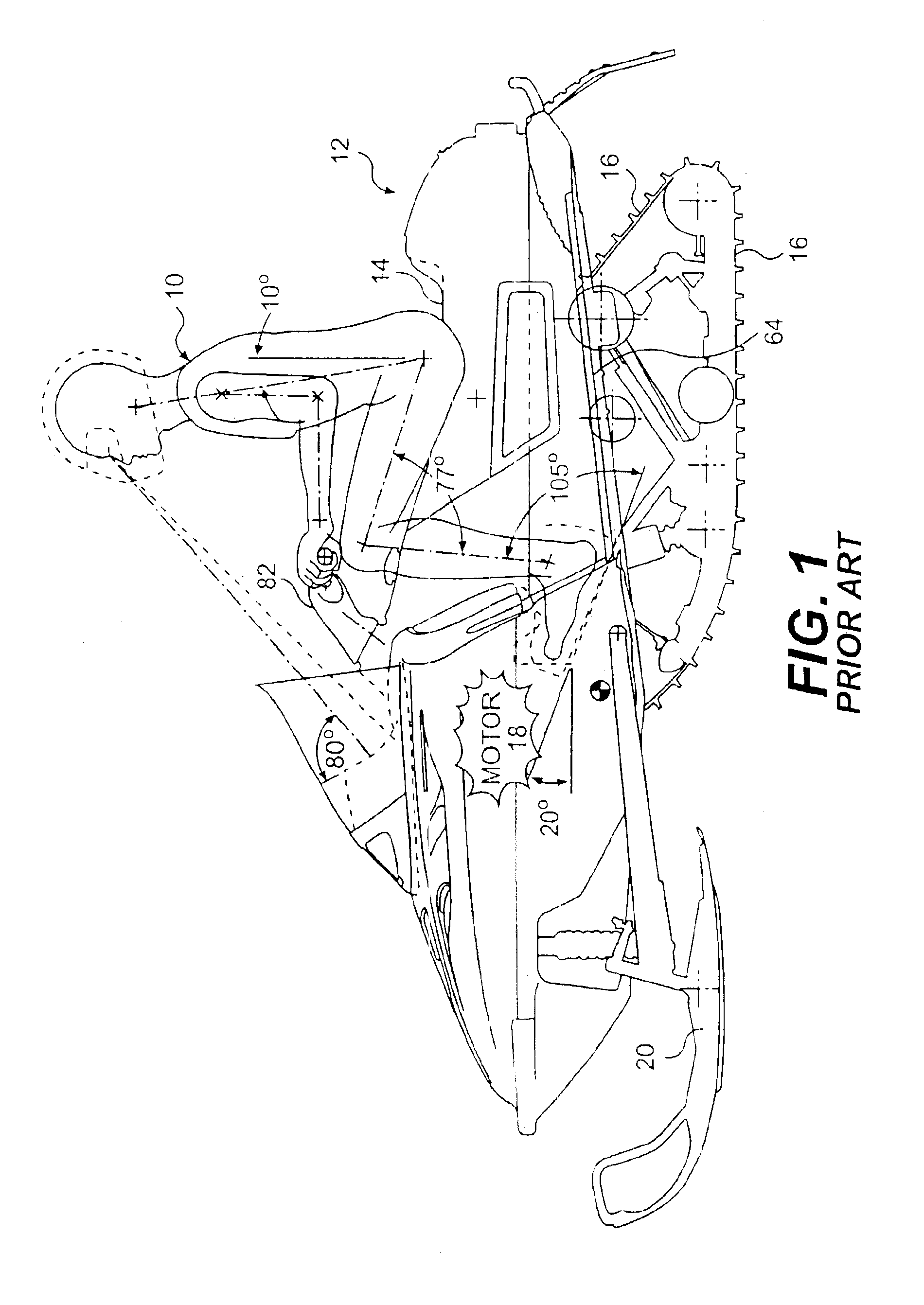

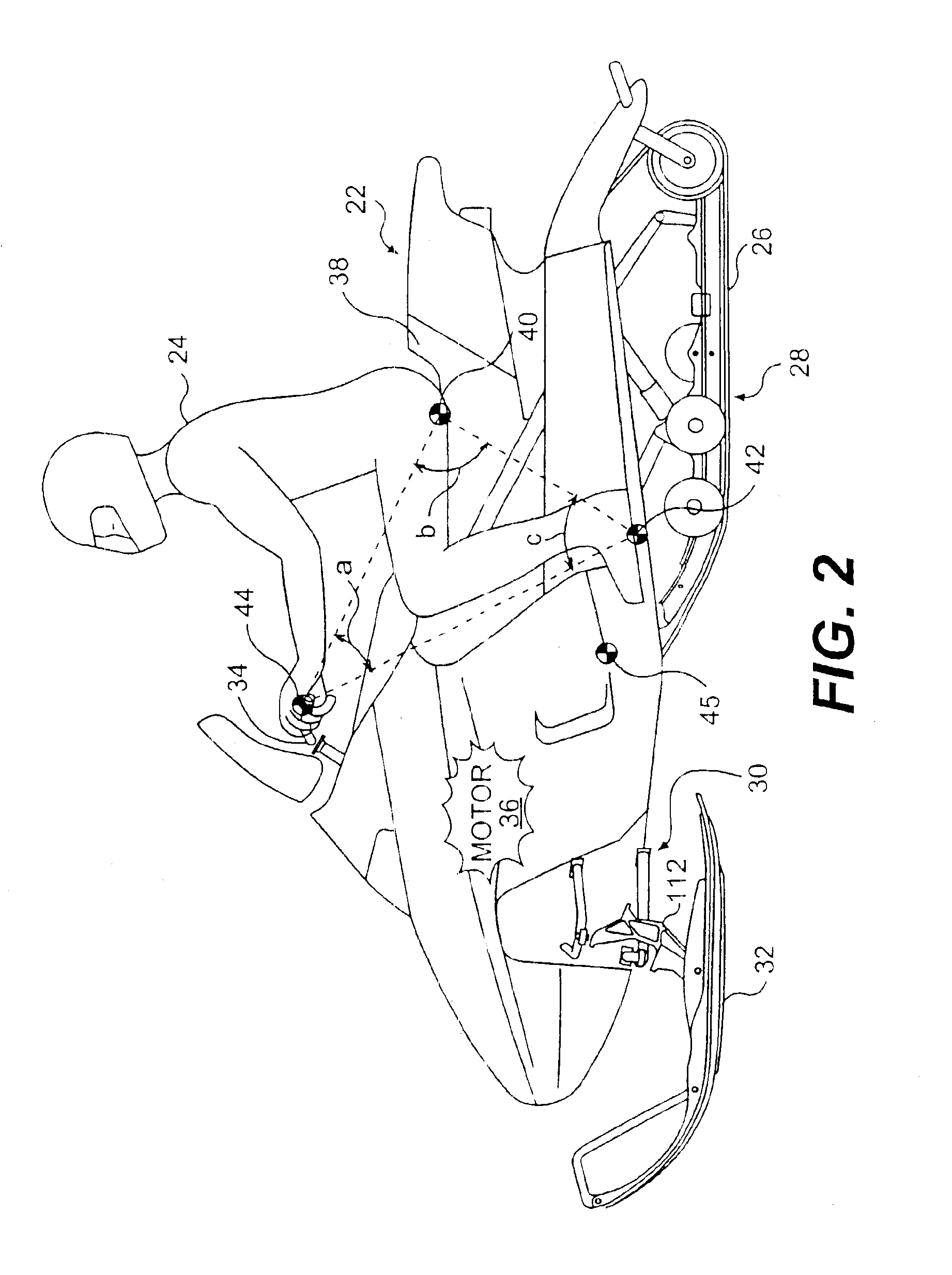

Front suspension with three ball joints for a vehicle

Owner:BOMBARDIER RECREATIONAL PROD INC

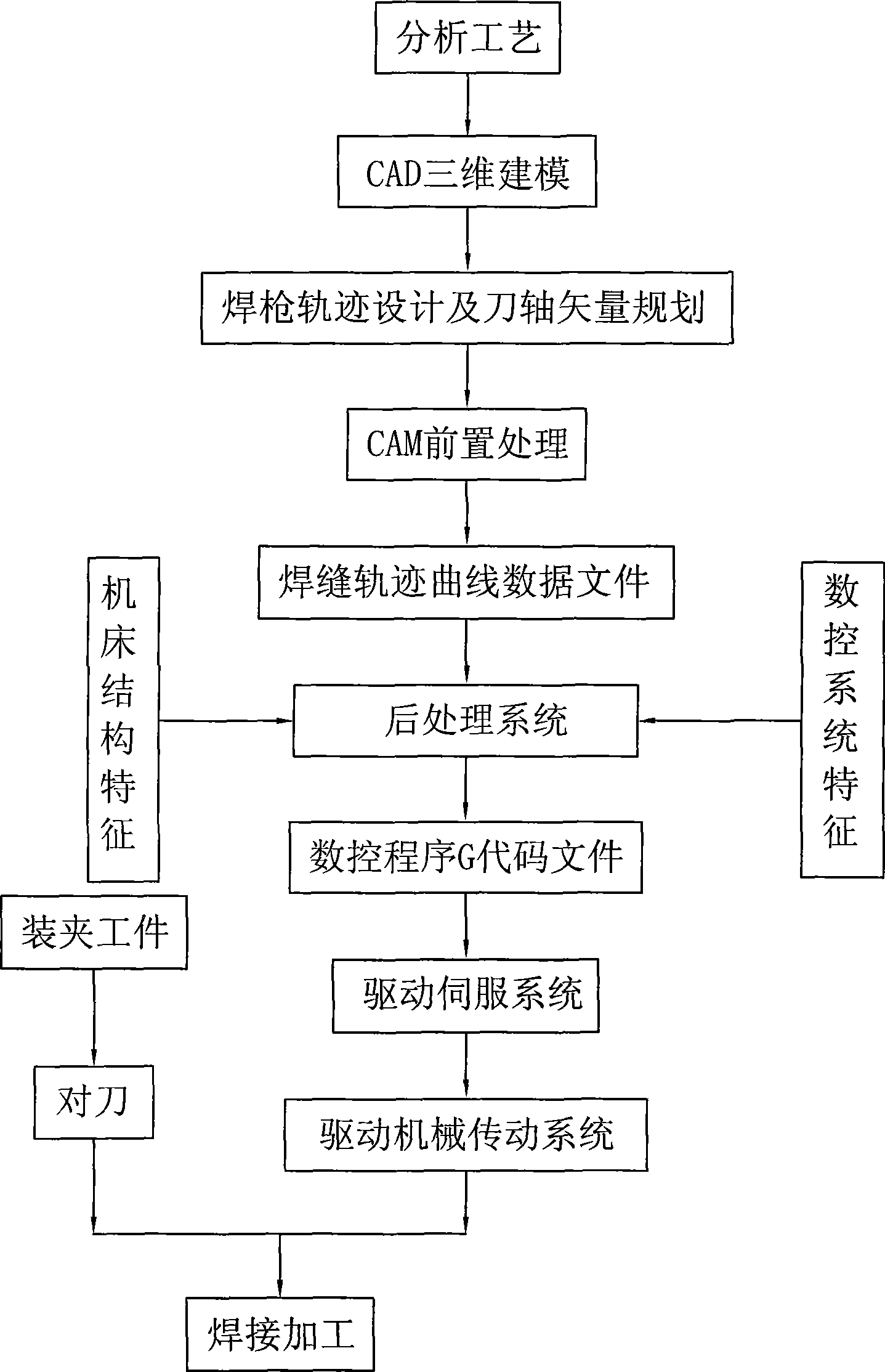

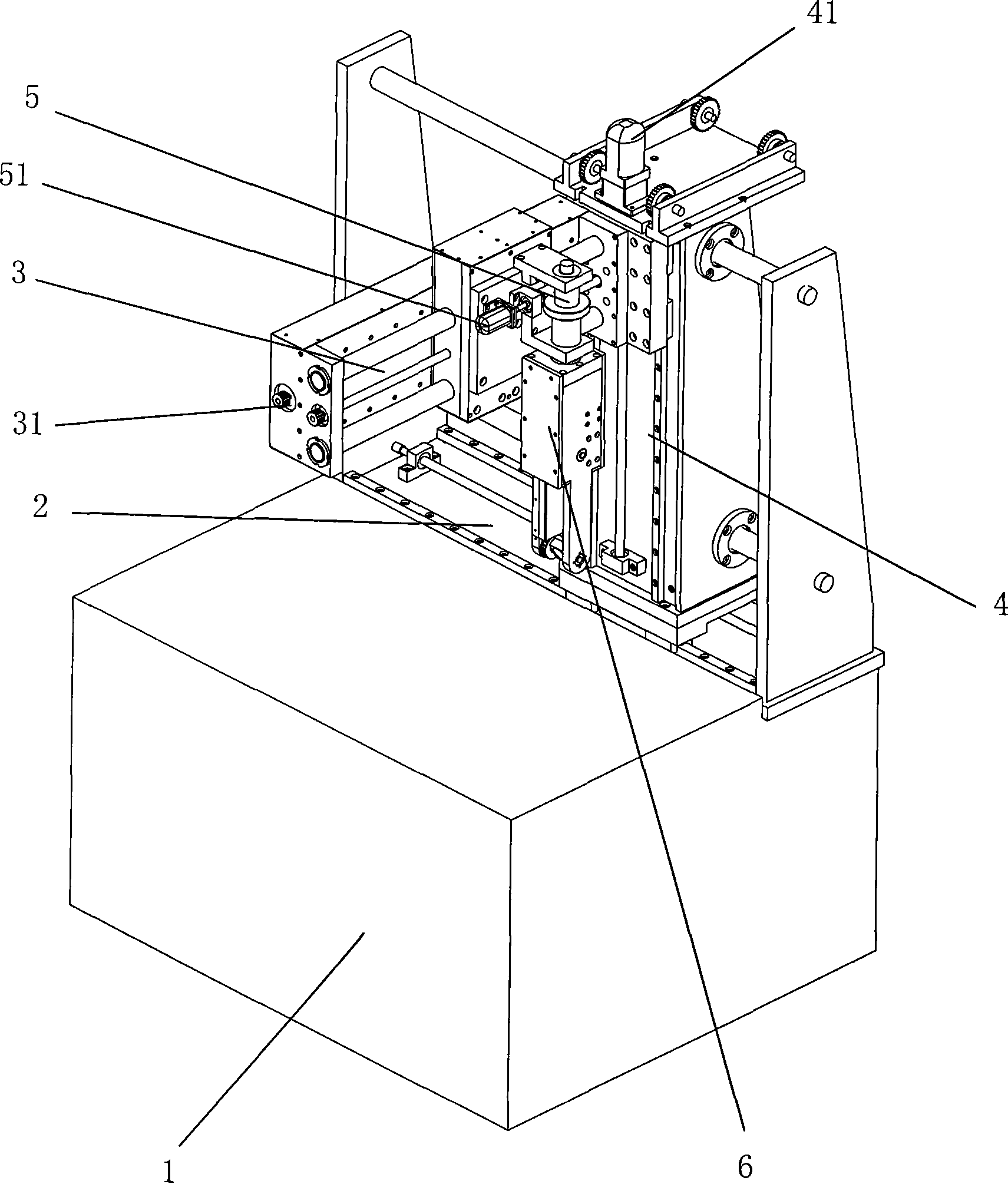

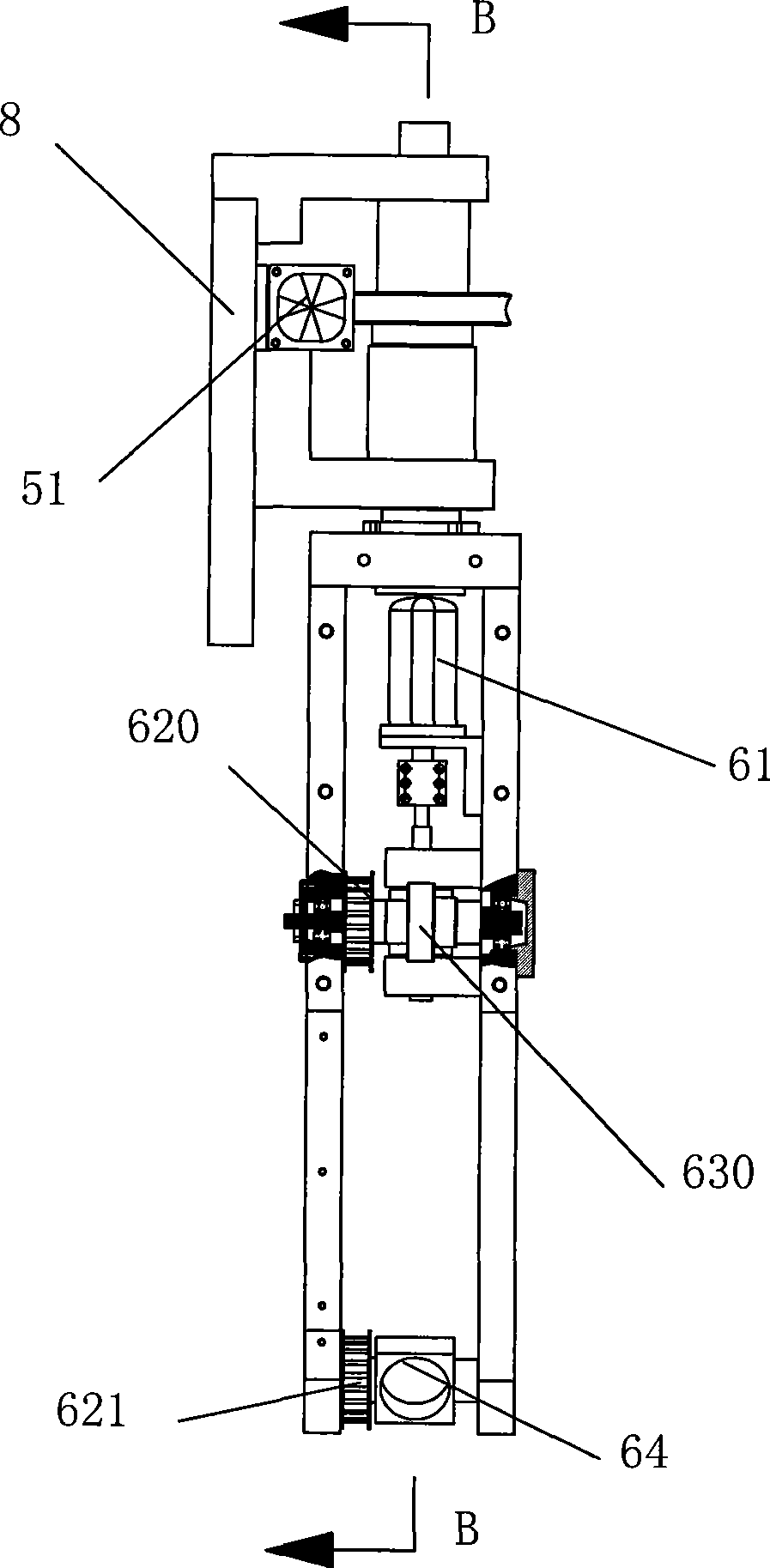

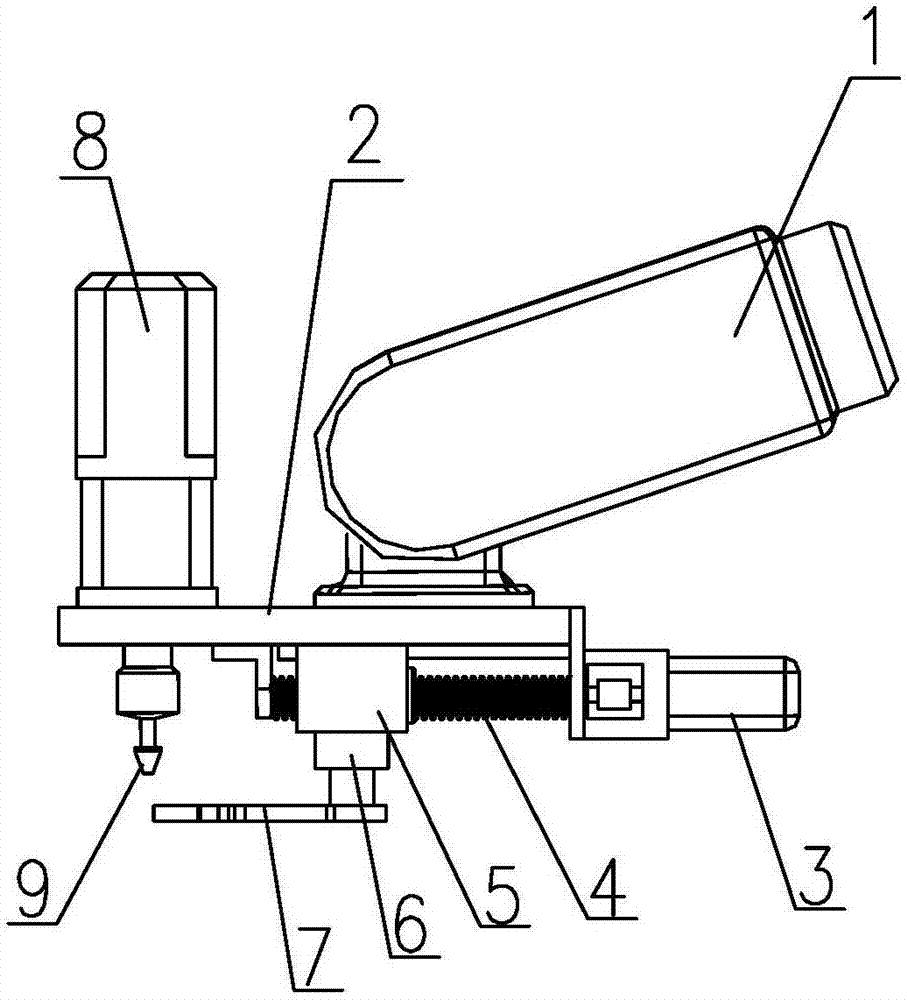

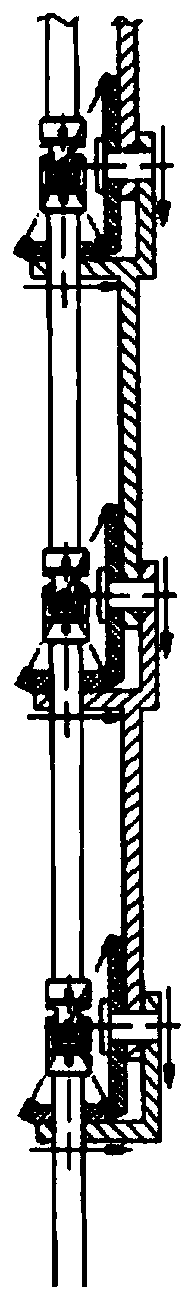

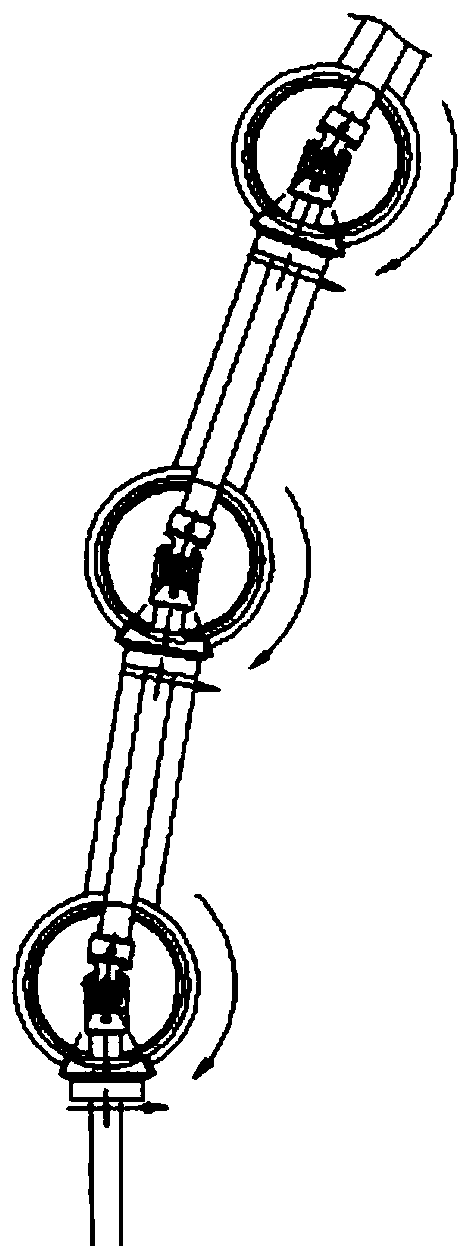

5-shaft linkage numerical control bonding machine and welding process control method thereof

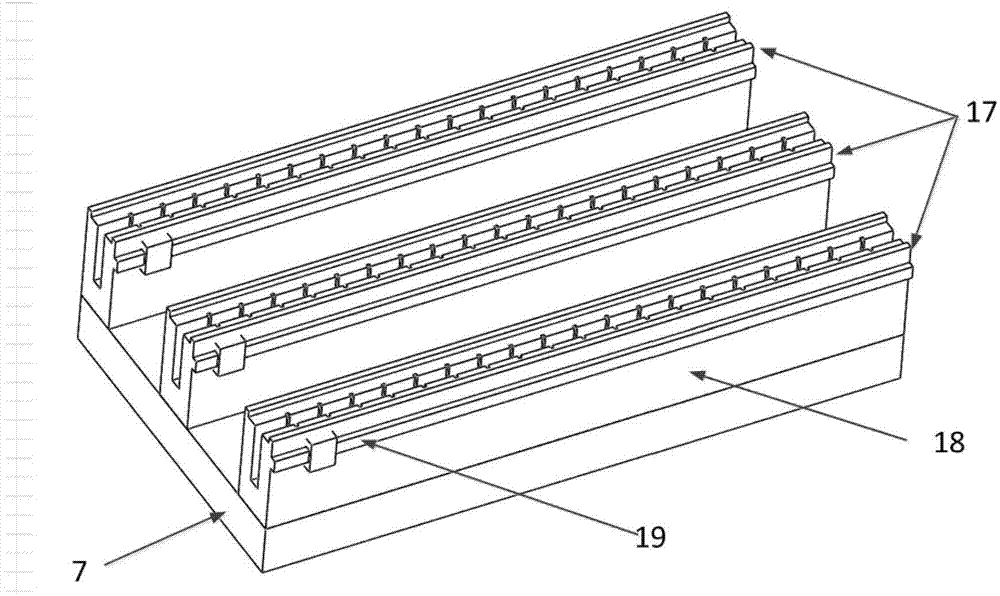

InactiveCN101376198AGuaranteed translationIncrease the itineraryWelding/cutting auxillary devicesArc welding apparatusRotational axisEngineering

The invention relates to a five-axis linkage numerical control welding machine and the welding technique control method thereof. The welding technique control method comprises the following steps: adopting CAD / CAM to build a welding workpiece model; planning and outputting the specific welding spot sequence data; and then carrying out a coordinate conversion and generating a G-code numerical control program file by applying a specific machine tool kinematical formula. The mechanical transmission system ensures the five-axis linkage according to the converted specific welding-spot data, so as to optimize the position between the welding gun and the welding spot while welding, ensure that the welding product has the advantages of good quality uniformity, high repeatability precision, good movement and power performance, etc.; the mechanical transmission system includes three linear movement guide rails X, Y and Z which drive the welding guns to work, and two rotating shafts which drive the welding guns to rotate, wherein the linear movement guide rails can ensure that the rotating shafts can move transversely in any position in the working space, and the two rotating shafts which drive the welding guns to rotate can ensure that the welding guns can perform a 360-degree rotation round the welding spot, therefore, the welding machine and the control method thereof have the advantages of large machine tool stroke, no dead area, high generality, high suitability, etc.

Owner:吕家琪

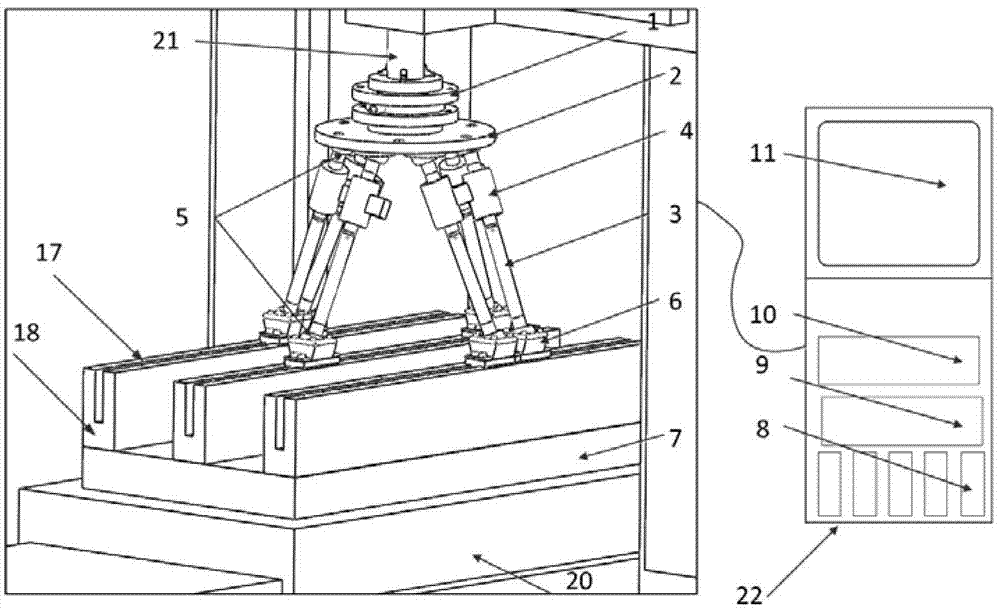

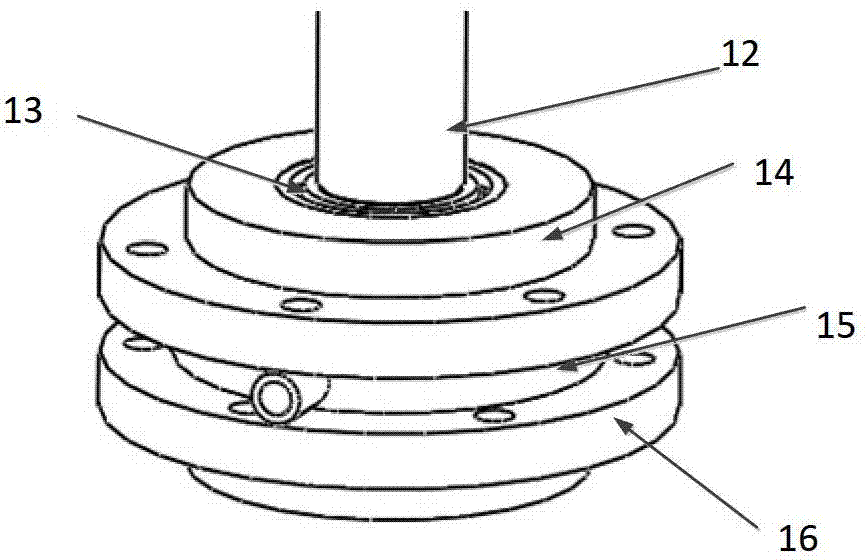

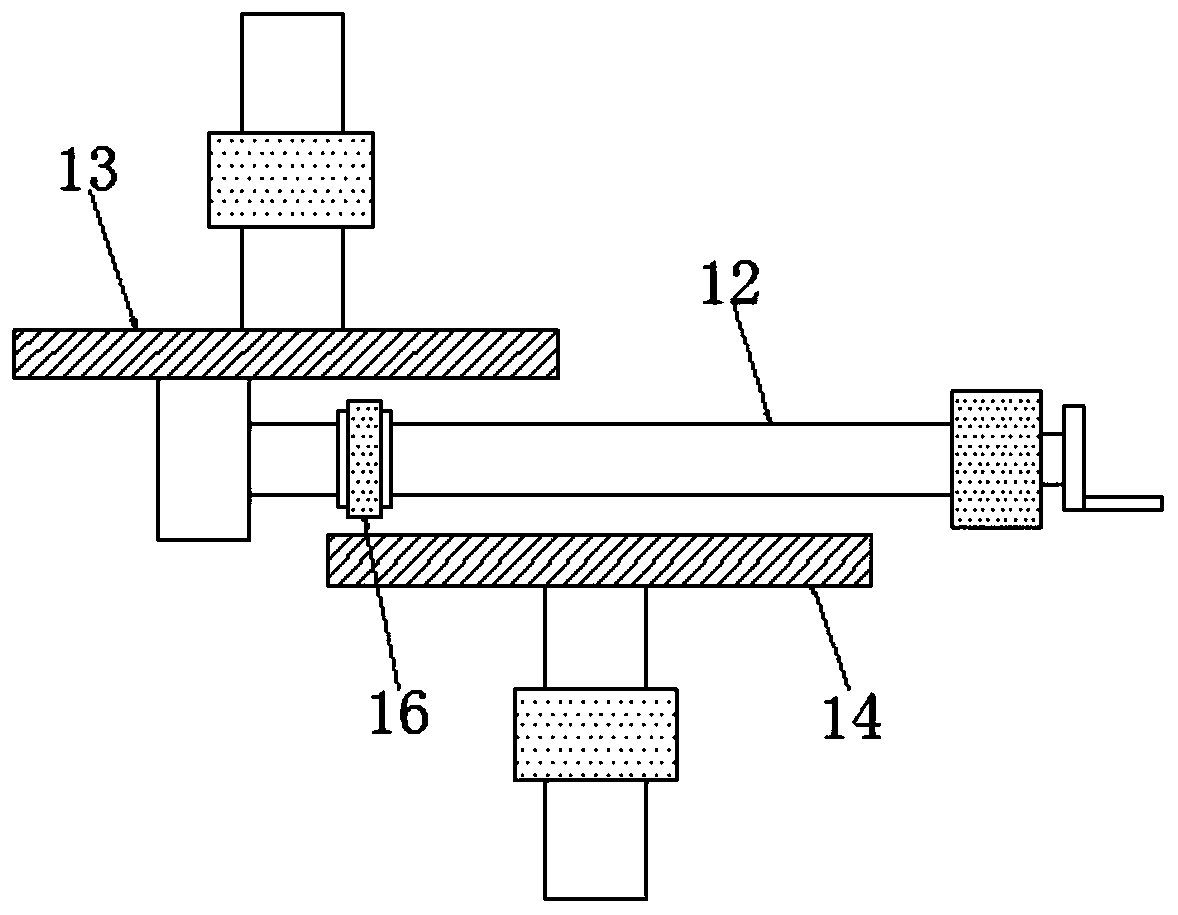

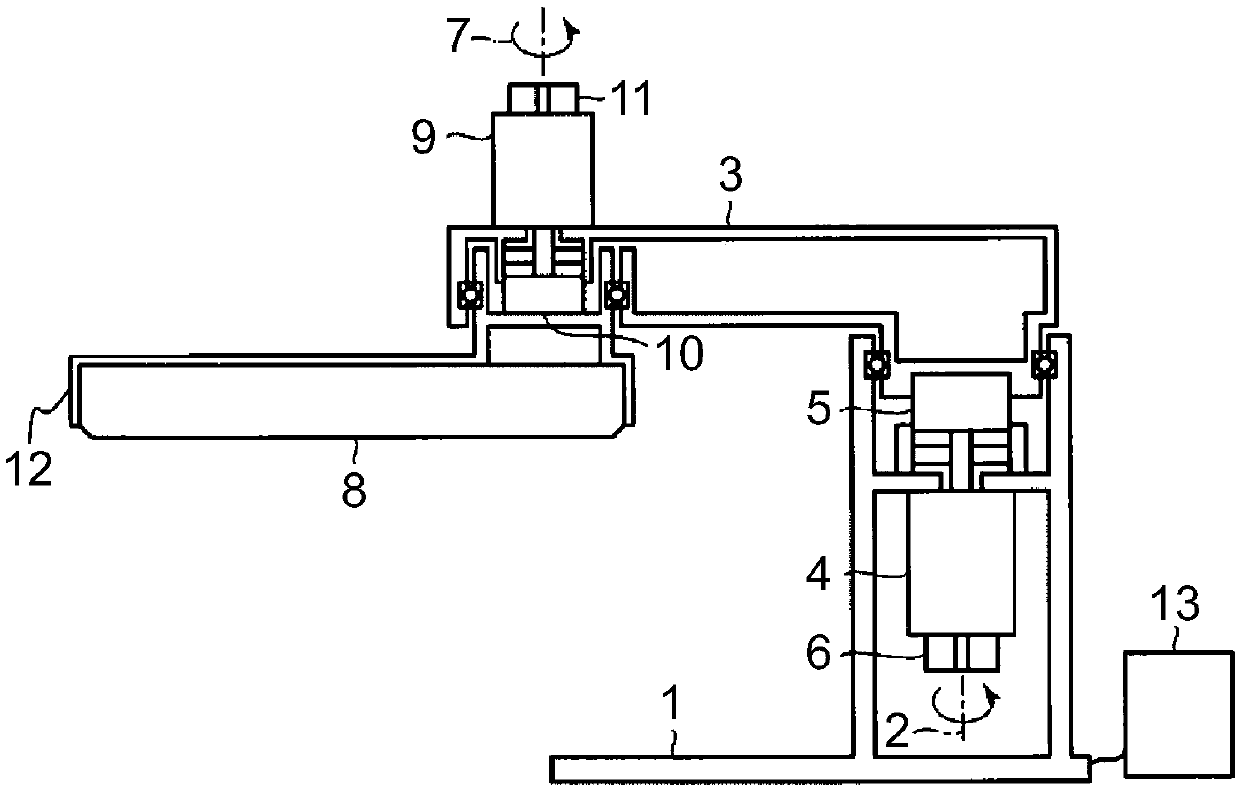

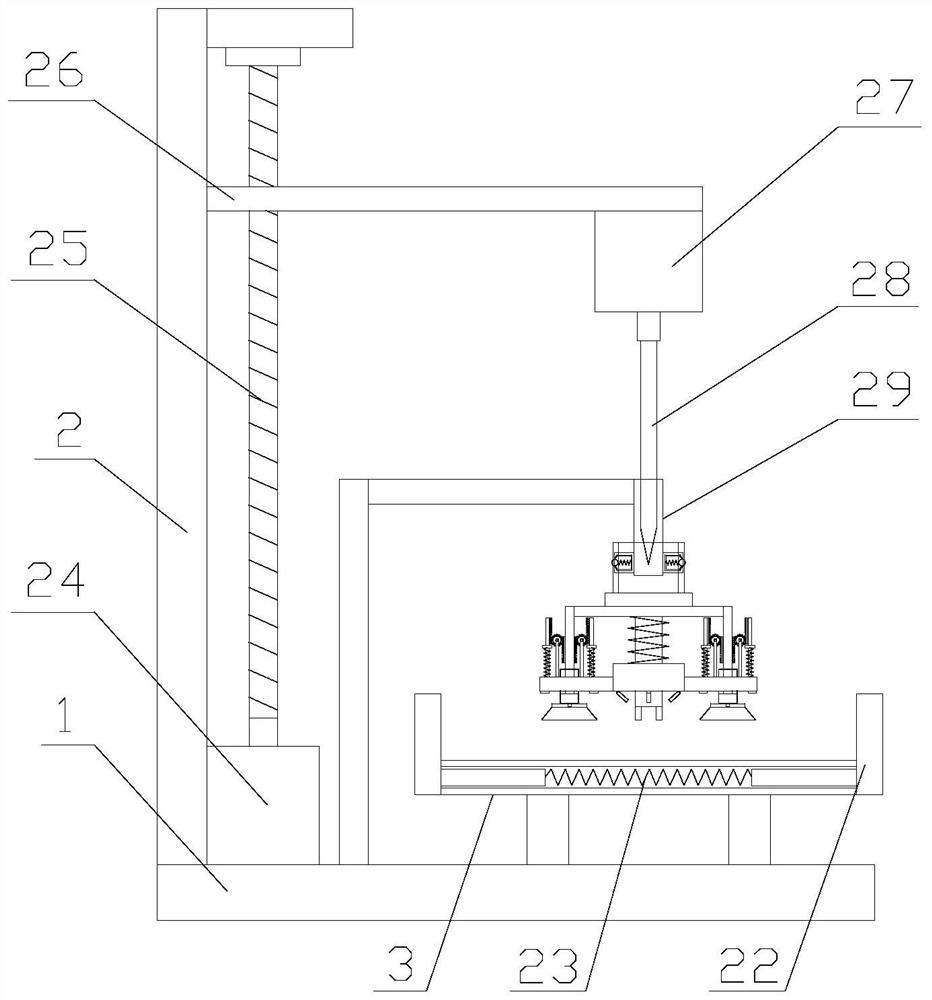

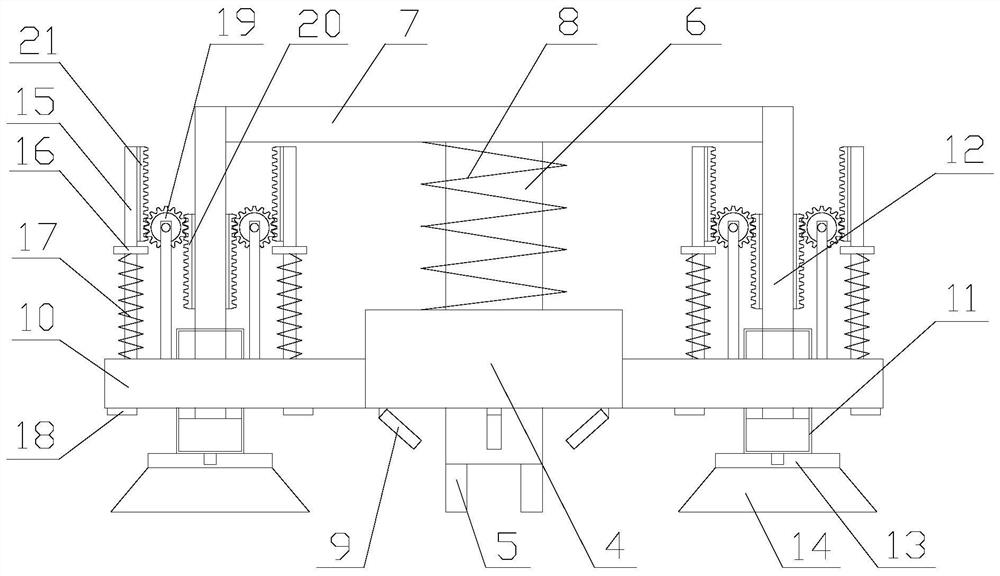

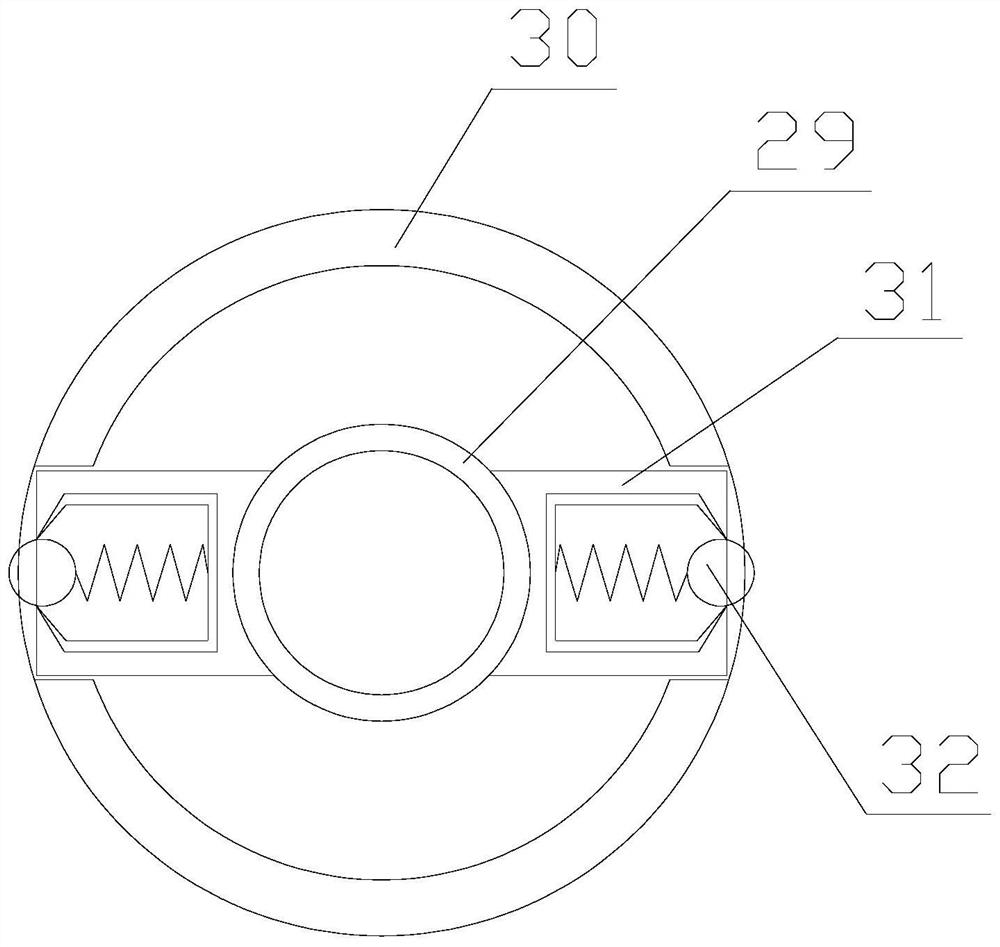

Five-axis linkage loading test device and loading test method for machine tool

InactiveCN102866030AAvoid cuttingLow costStructural/machines measurementAutomotive engineeringMovement control

The invention discloses a five-axis linkage loading test device for a machine tool. The device consists of a following loading mechanism mechanical part and a measurement and control system. The following loading mechanism mechanical part applies a load to a spindle through an interface of the spindle of the machine tool. The measurement and control system is used for realizing servo motor control, mechanism motion control, load calculation and signal processing functions of the following loading mechanism mechanical part. The five-axis linkage loading test method for the machine tool comprises the five major steps of: 1, measuring load data; 2, establishing a load spectrum; 3, organizing tool path data; 4, performing hardware solidification of the data; and 5, calibrating and correcting a database. The device and the method are universal and widely applicable to various types of tests in the reliability of the machine tool, and have practical significance and reference value for the research and development of high-performance load simulators in China.

Owner:BEIHANG UNIV

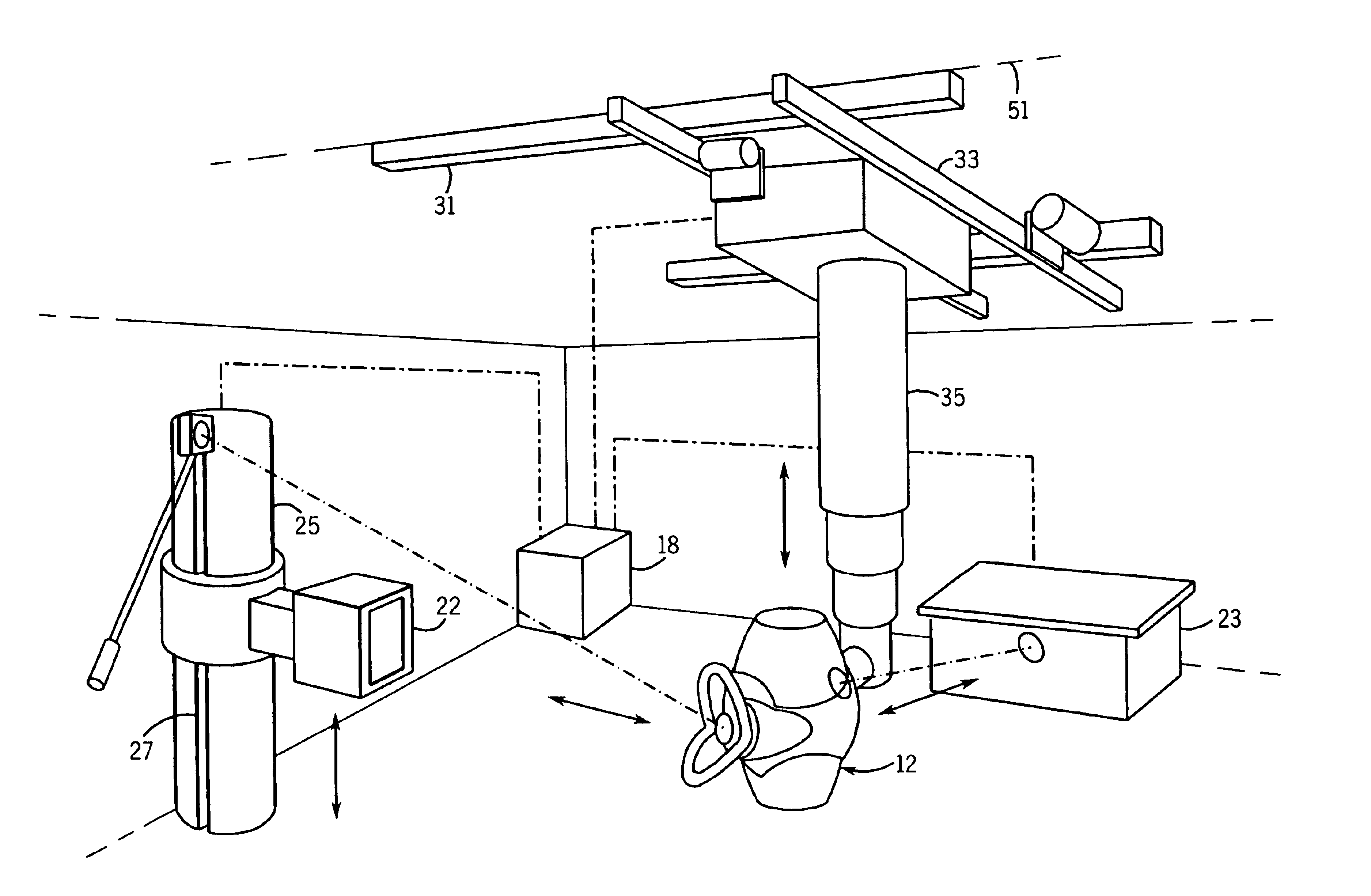

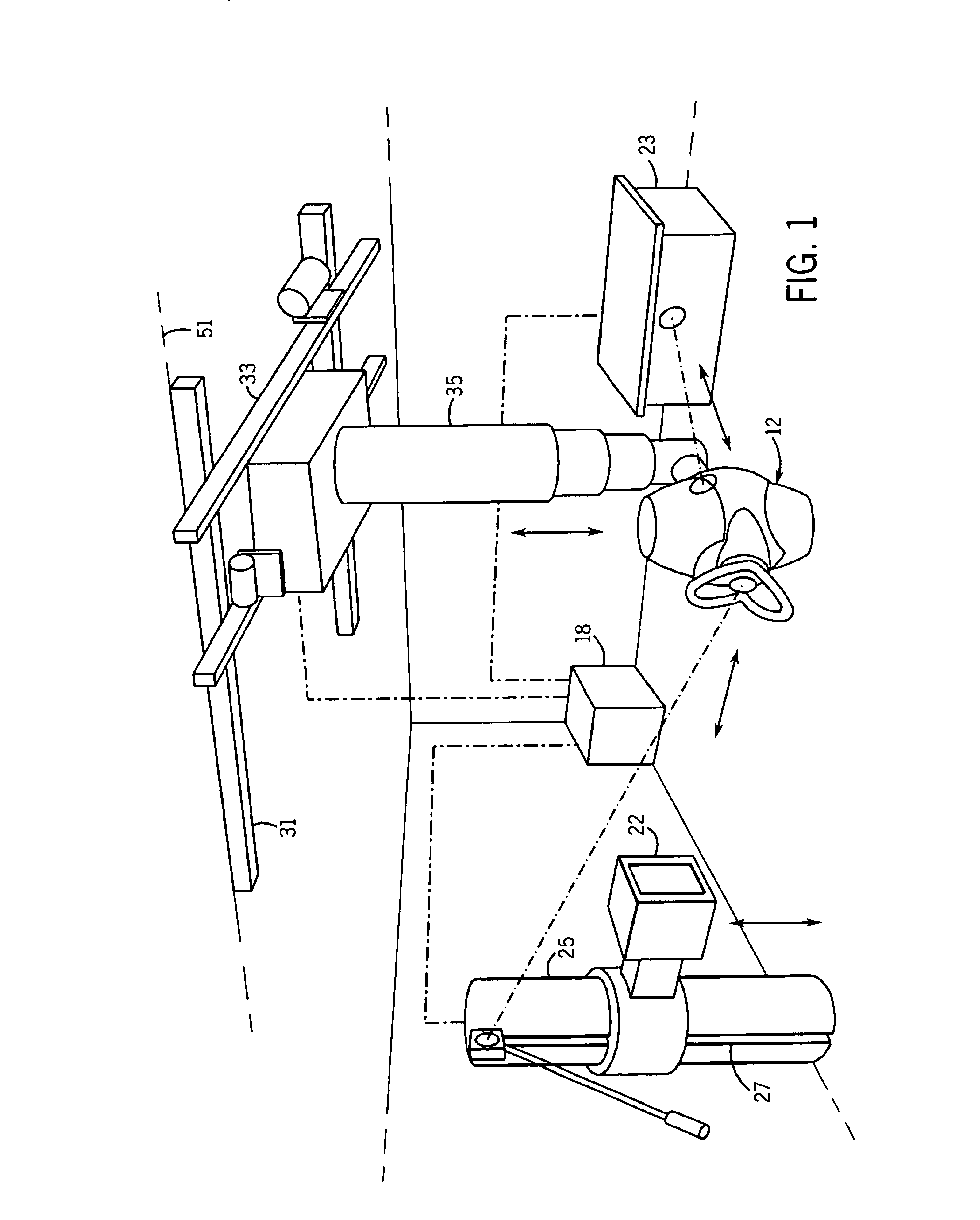

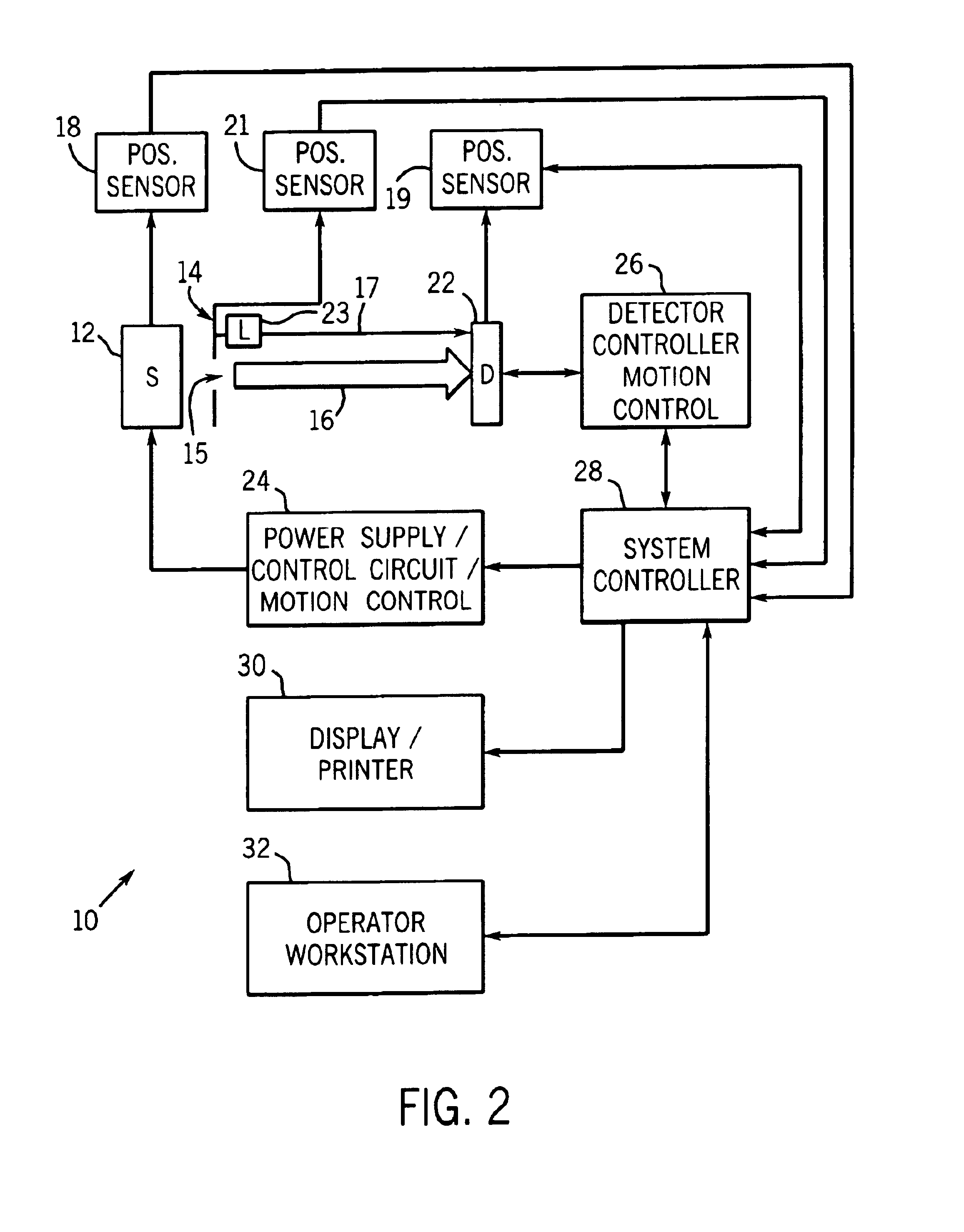

Method and apparatus for aligning an X-ray source and detector at various source to image distances

InactiveUS6935779B2Prevent cropping and misalignmentRadiation beam directing meansX-ray apparatusX-rayEXAMINATION ROOM

A digital radiographic imaging system includes an offset table for determining mechanical and structural offsets which would, if not corrected, misalign the source and detector during use. The method can correct for inaccuracies in mechanical linkages, examination rooms and other mounting structures, and “drift” induced during use of the system.

Owner:GE MEDICAL SYST GLOBAL TECH CO LLC

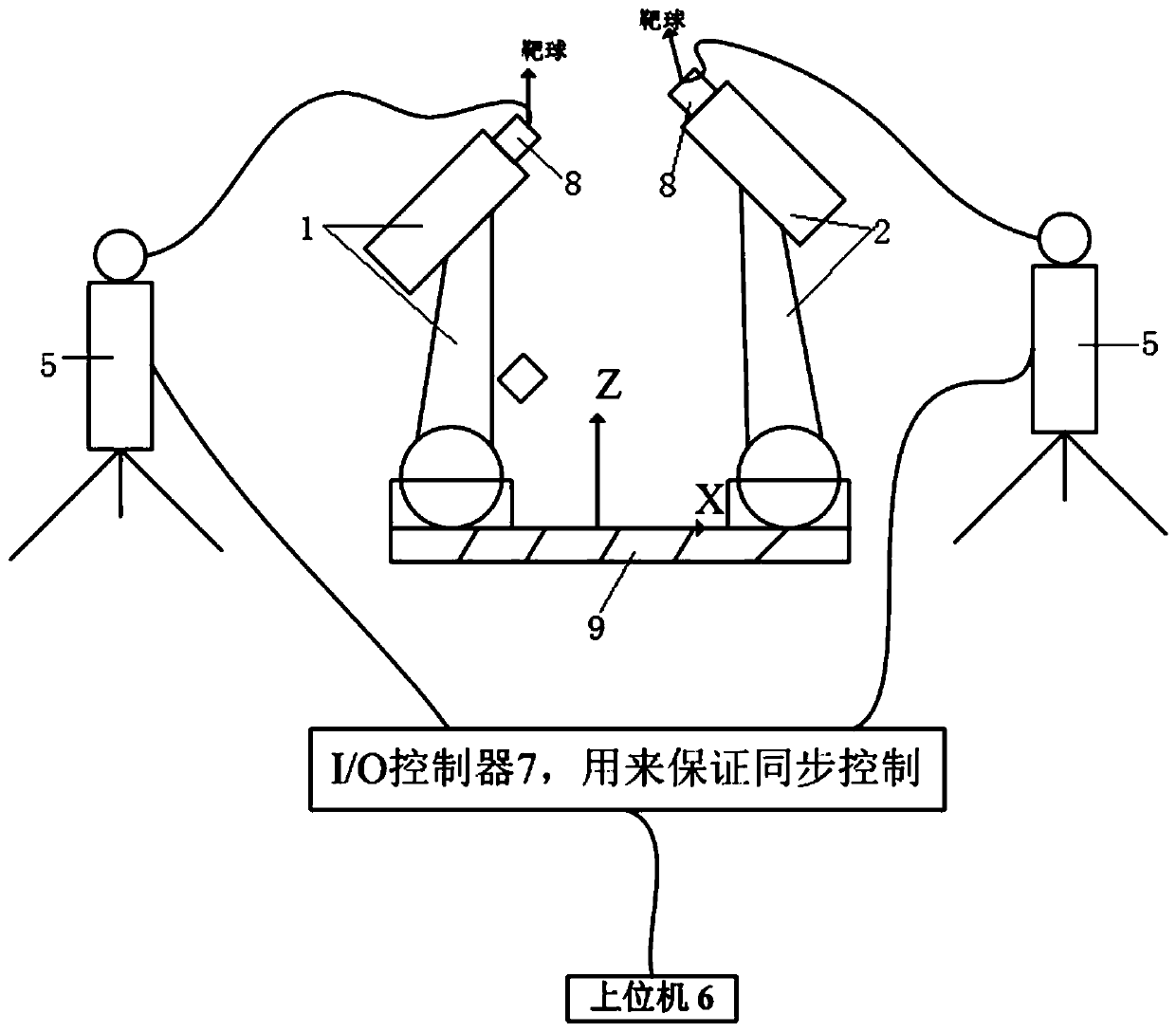

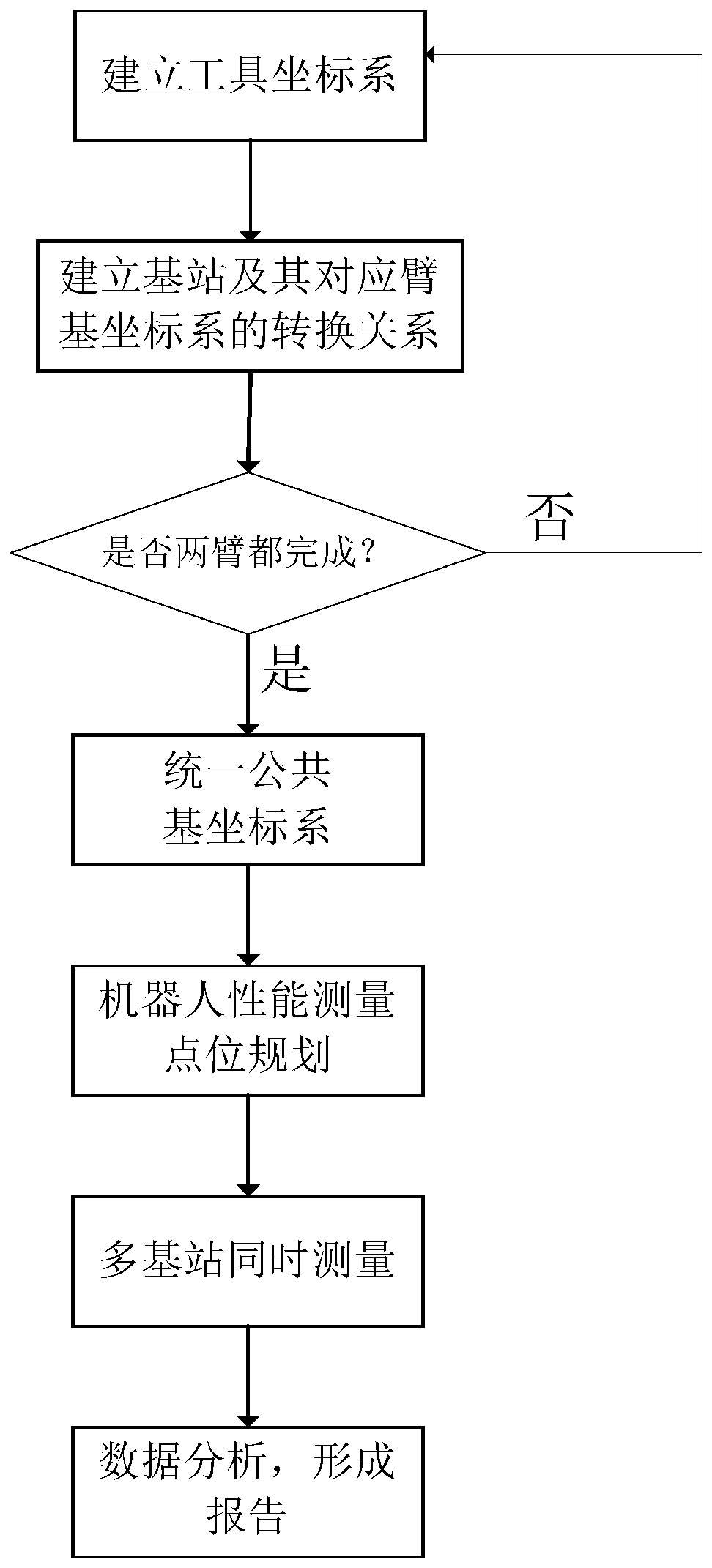

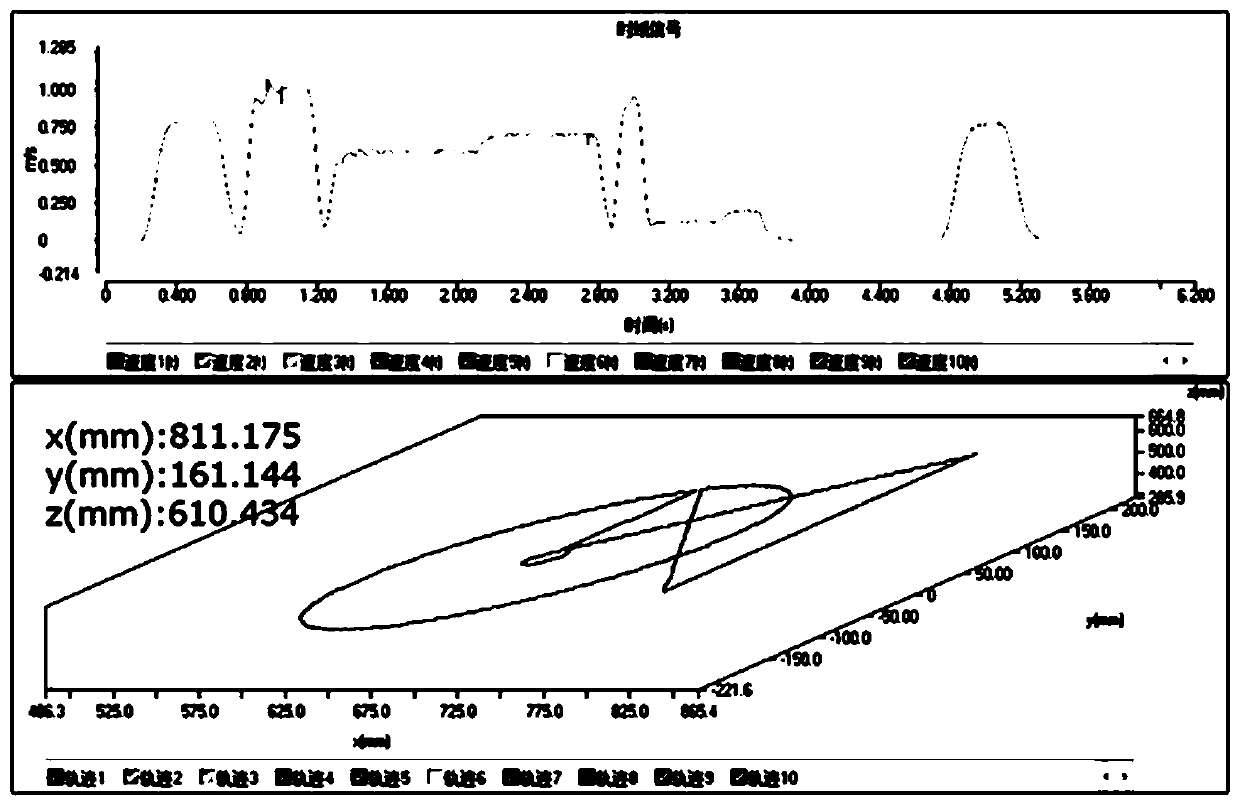

Double-arm robot performance measuring method based on multiple laser trackers

ActiveCN110370314AHigh measurement accuracyThe testing process is simpleManipulatorMeasurement precisionAccuracy and precision

The invention discloses a double-arm robot performance measuring method based on multiple laser trackers. The double-arm robot performance measuring method based on the multiple laser trackers comprises the following steps that (1-1) a double-arm robot tool coordinate system is established; (1-2) a coordinate conversion relation between base coordinate systems of the laser trackers and base coordinate systems of mechanical arms is established; (1-3) a public base coordinate system is unified; (1-4) robot performance measurement point planning is performed; (1-5) the laser trackers and an I / O synchronization technology are used for simultaneously measuring a double-arm robot; and (1-6) and data processing is performed, and a test report is generated. The double-arm robot performance measuring method has the characteristics that two arms of the double-arm robot can be simultaneously measured, the linkage characteristics of the two-arm robot can be evaluated, the movement points of the two arms do not need to be aligned in timing sequence, the measurement precision is high, and the test process is simple.

Owner:杭州亿恒科技有限公司

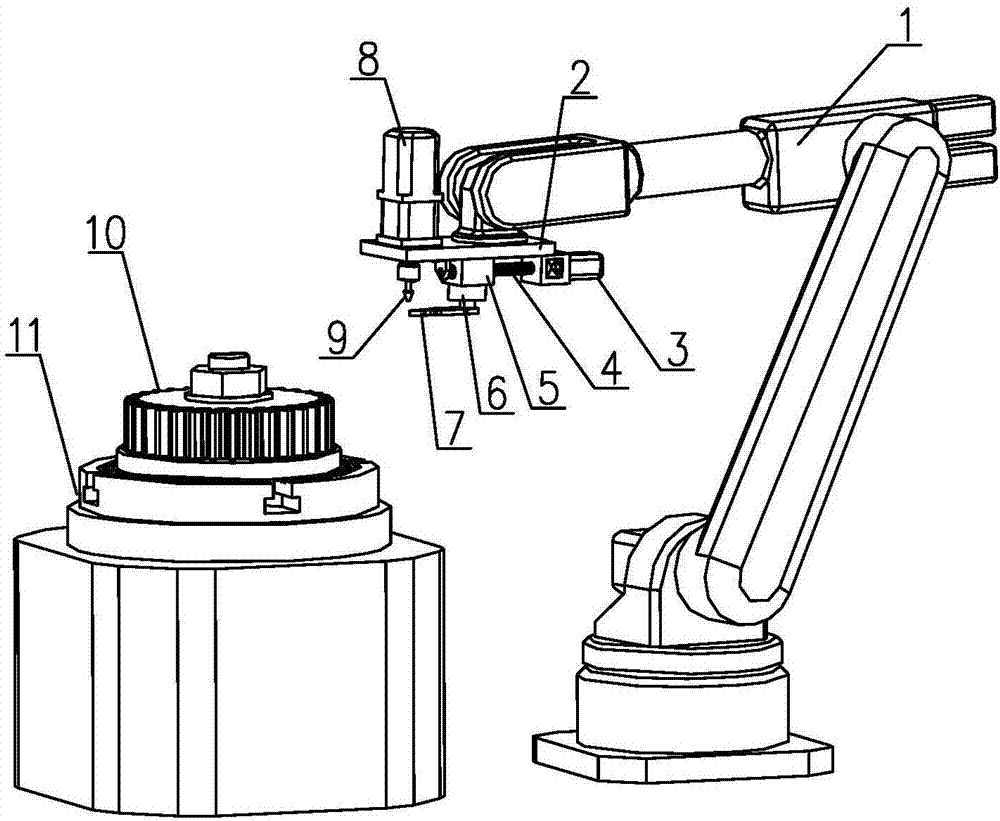

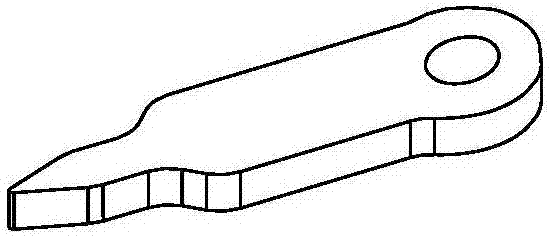

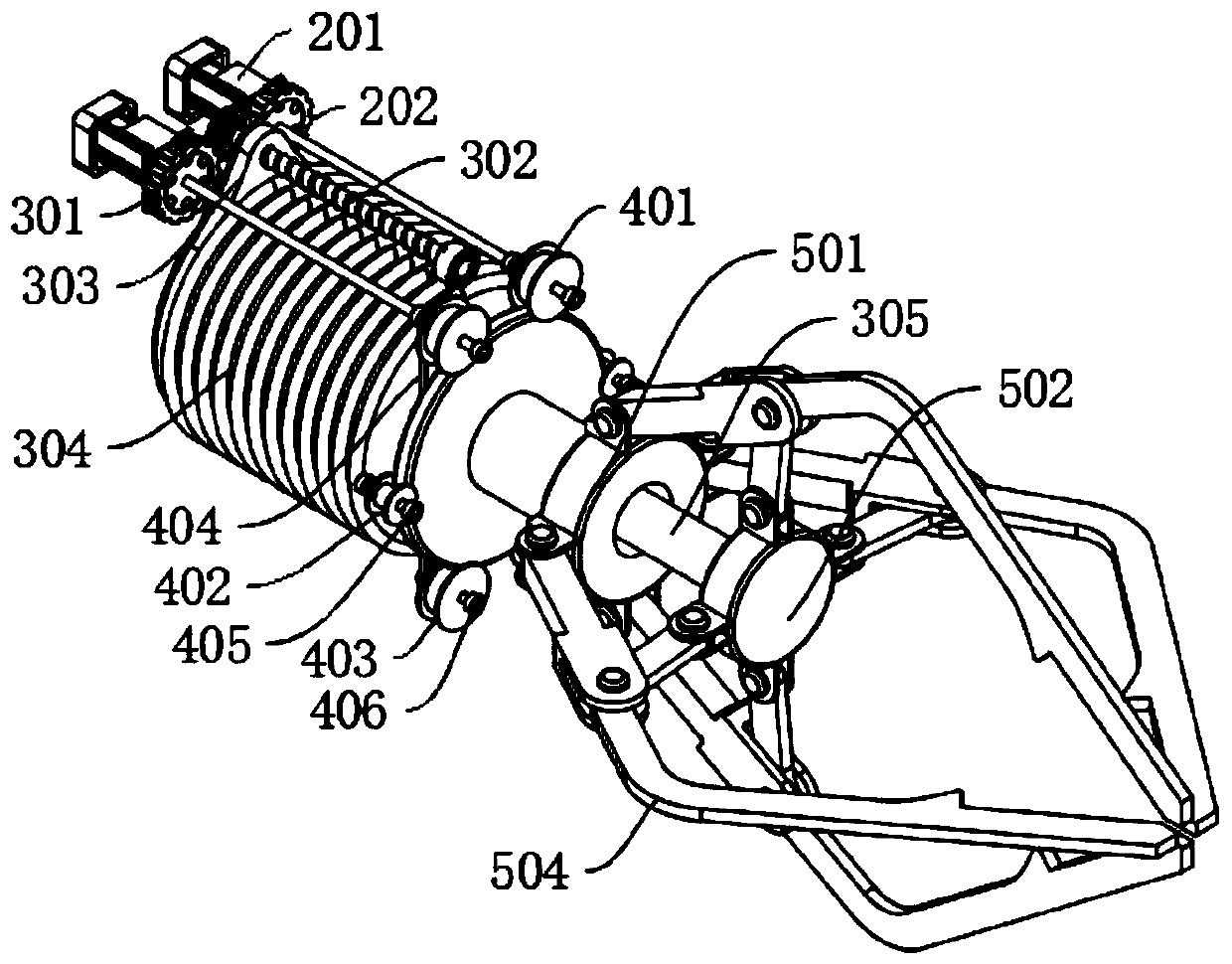

Mechanical hand for carrying out chamfering polishing on end face of gear and polishing method thereof

PendingCN107876904AControllable contact forceImprove machining accuracyManipulatorGear teethRobot handContact pressure

The invention provides a mechanical hand for carrying out chamfering polishing on the end face of a gear. A probe at the tail end of the mechanical hand and a polishing head are arranged to be an integrated linkage whole, a master controller enables the probe to make contact with the gear at the set contact pressure value, and the probe is arranged to be a sensor which monitors the contact pressure value in real time. The master controller adjusts the contact pressure value at the next moment. The displacement path of the probe is the polishing path of the polishing head. The invention furtherprovides a polishing method of the mechanical hand for carrying out chamfering polishing on the end face of the gear. The method comprises the steps that 1, the probe makes contact with the edge of the gear at the set contact pressure value; 2, when the gear is rotated, a force sensor feeds the real-time contact pressure value of the probe and the gear back to the master controller; 3, the position of the probe at the next moment is adjusted to enable the probe to be in tight fit with the gear, and copying description is carried out the gear contour; and 4, the polishing head and the probe are in integrated linkage, and the copied contour described by the probe is converted to be the polishing path of the polishing head. The contact force of the probe and the surface of the gear is controllable, the machining precision is high, and polishing quality is good.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

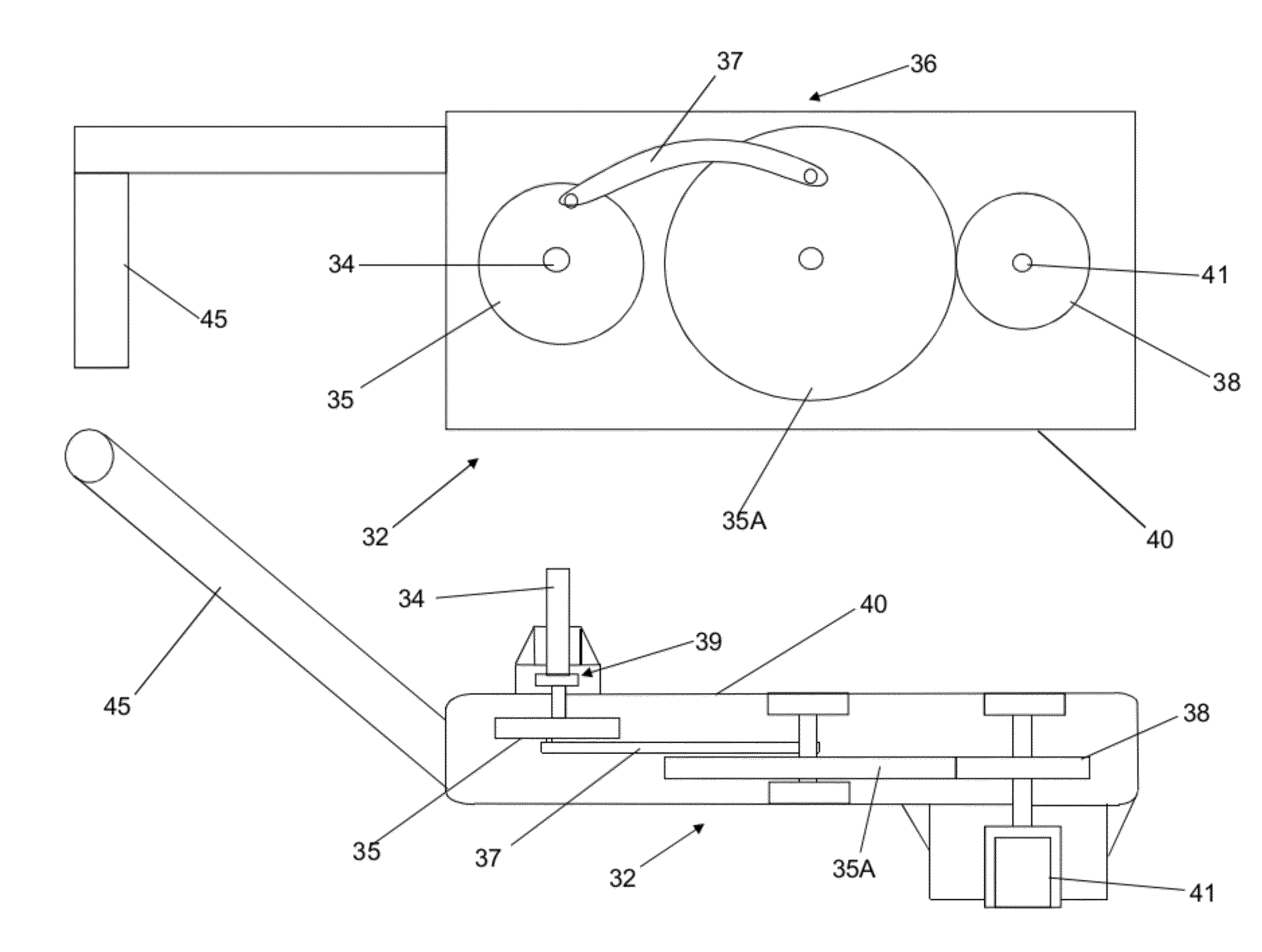

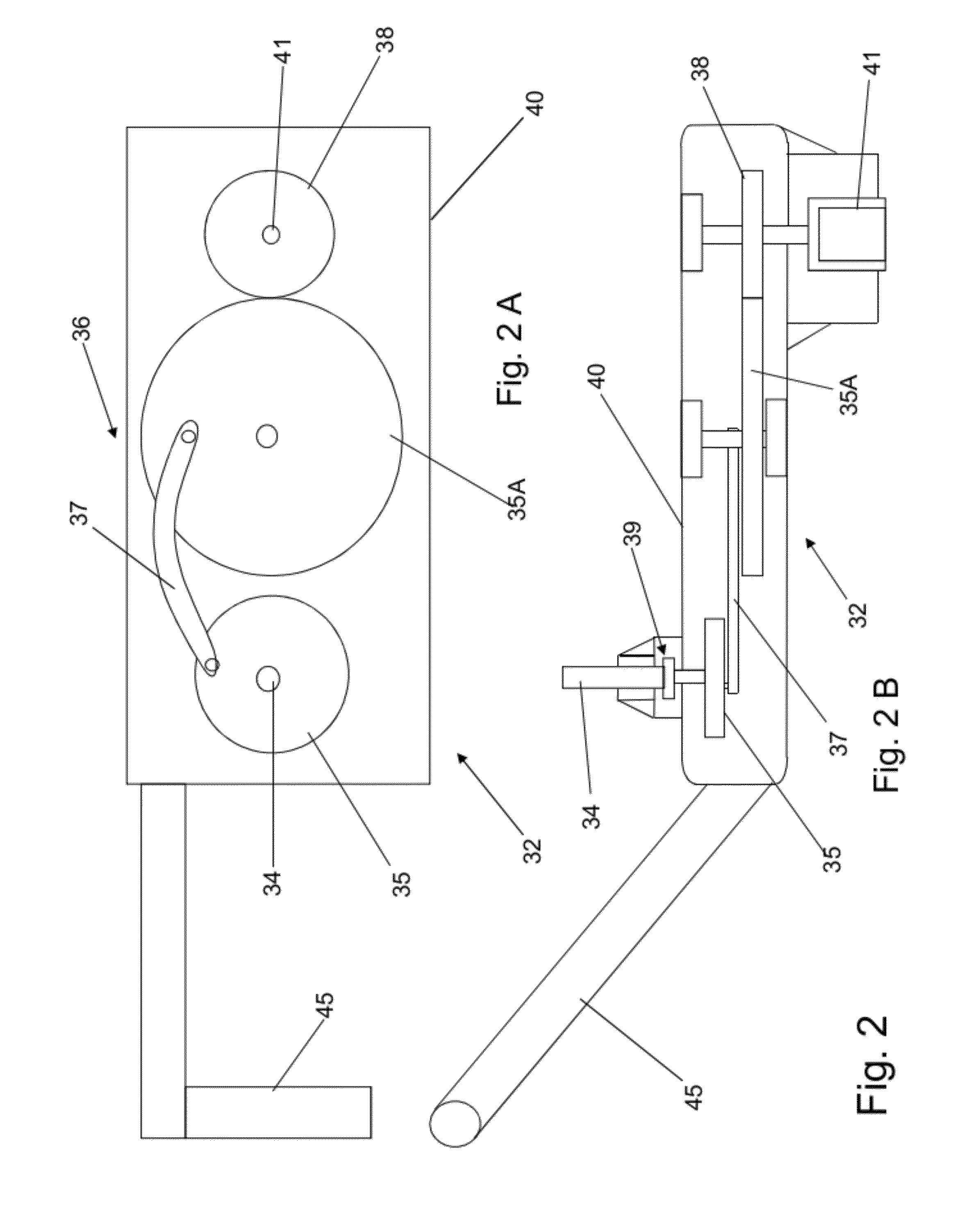

Oscillating device and process for drilling holes in soft materials

A simple mechanical device that converts the rotary motion of a drill motor to an oscillating / reciprocating or into a continuous motion. The device is for use in operations with soft, fibrous materials such as surgical needs, carpets, fiber based materials, and soft woods. The device drills a close tolerance hole with drive shafts in line or offset to the driven shaft. A general reciprocating drive system is comprised of a reciprocating drive device; a turning drive device such as a drill; a drive structure member such as a gear, plate or the like; a reciprocation configuration such as the eccentric linkage; a device encasement; a means for connecting the members to an encasement; a control mechanism for reciprocating or continuous rotation; a driven output connector such as a tool chuck; and a drill bit with at least 3 flutes.

Owner:SMITH RONALD D +1

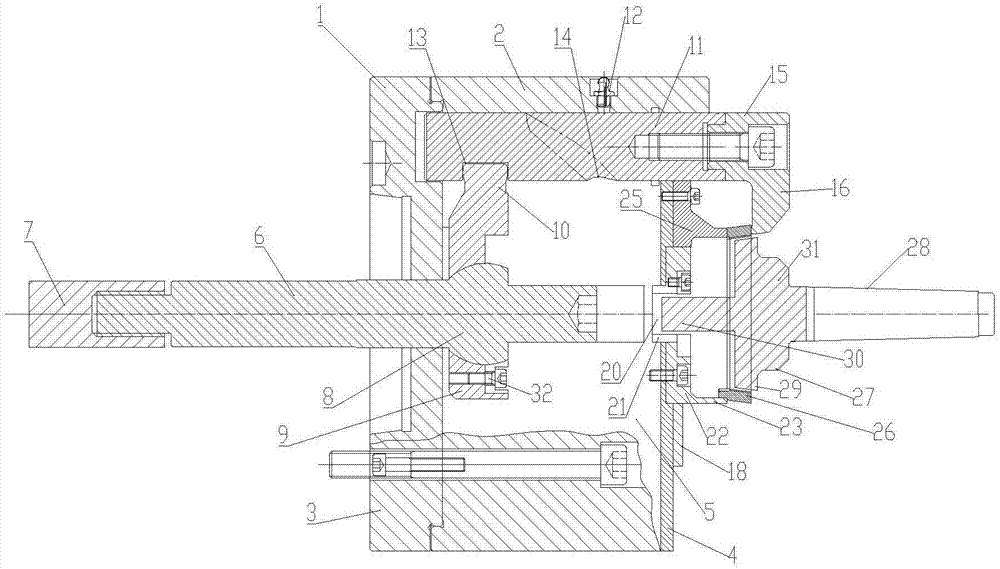

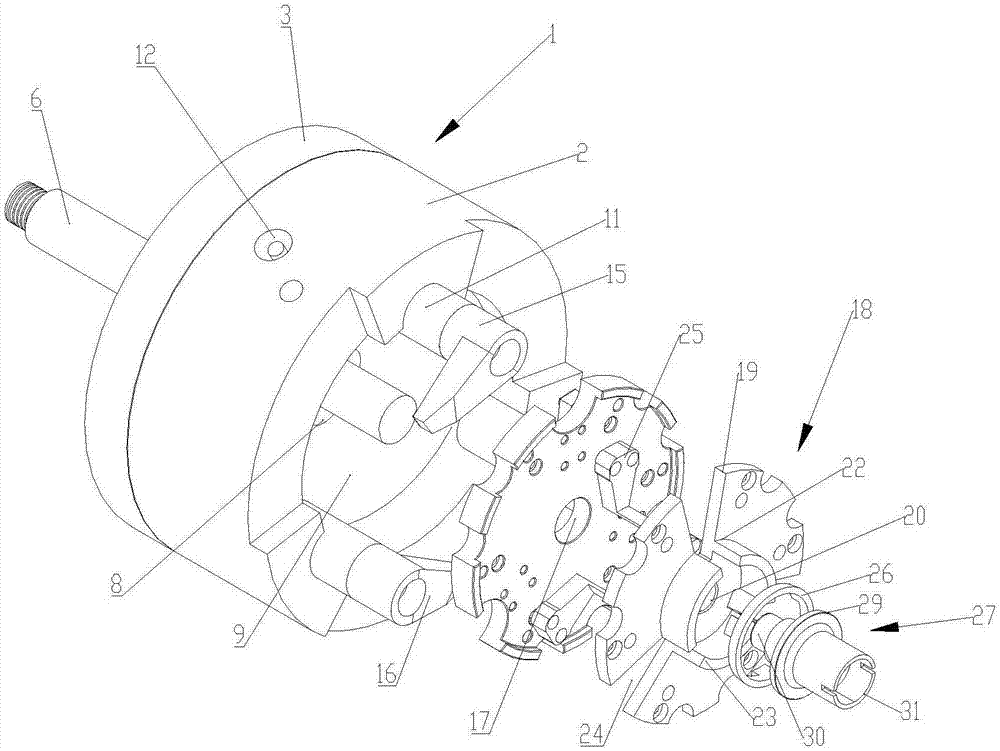

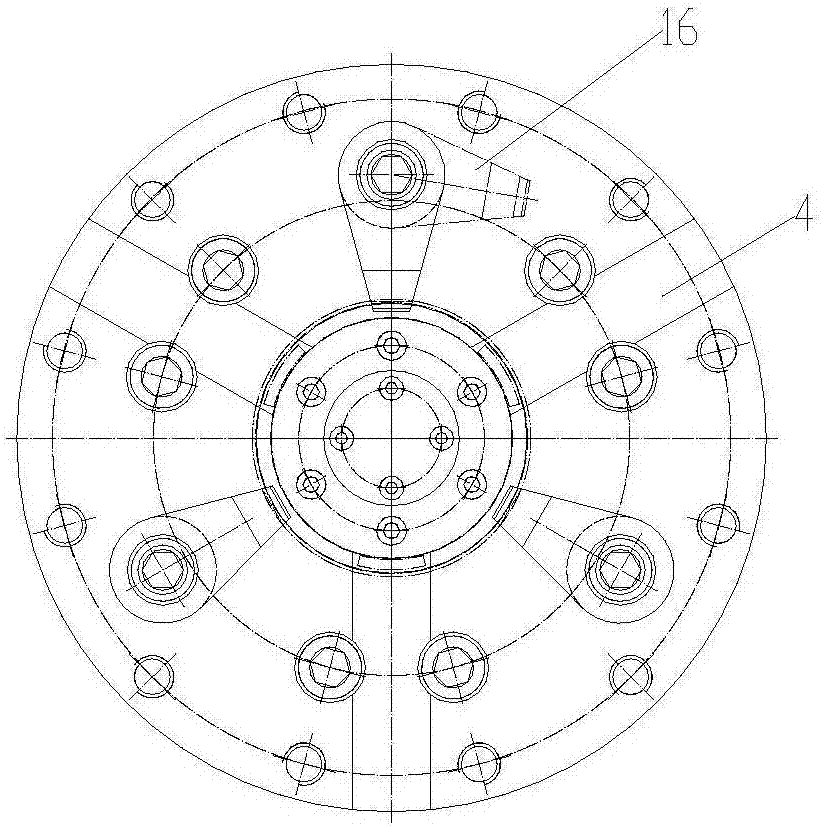

Synchronizer gear ring inner ring machining composite clamp

PendingCN107336040AEasy loadingGuaranteed coaxiality stabilityPositioning apparatusMetal-working holdersSynchronizerLinkage (mechanical)

Owner:WUHAN KYOWA SYNCHRONIZER RING

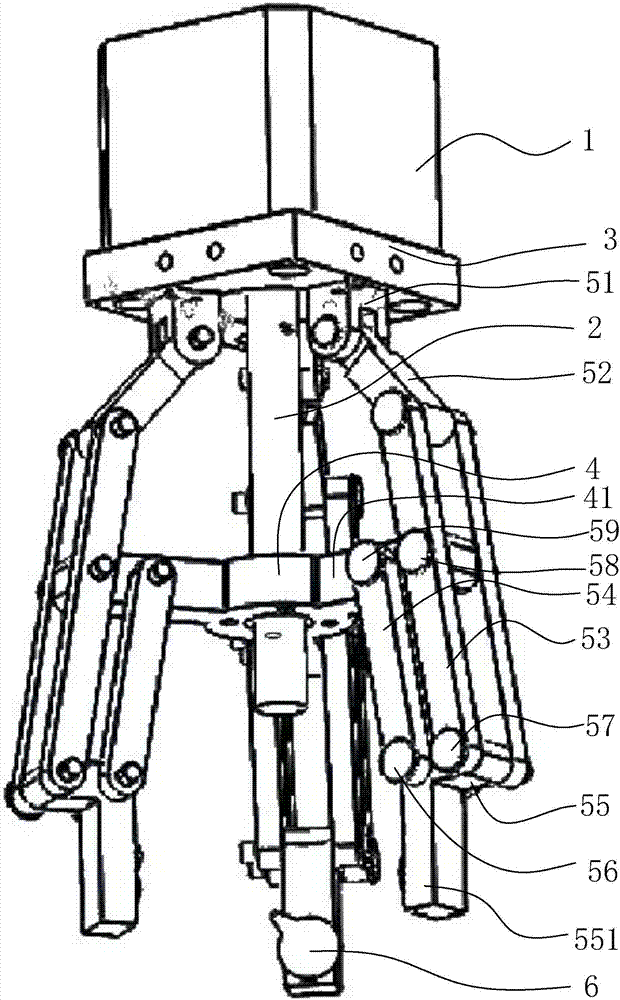

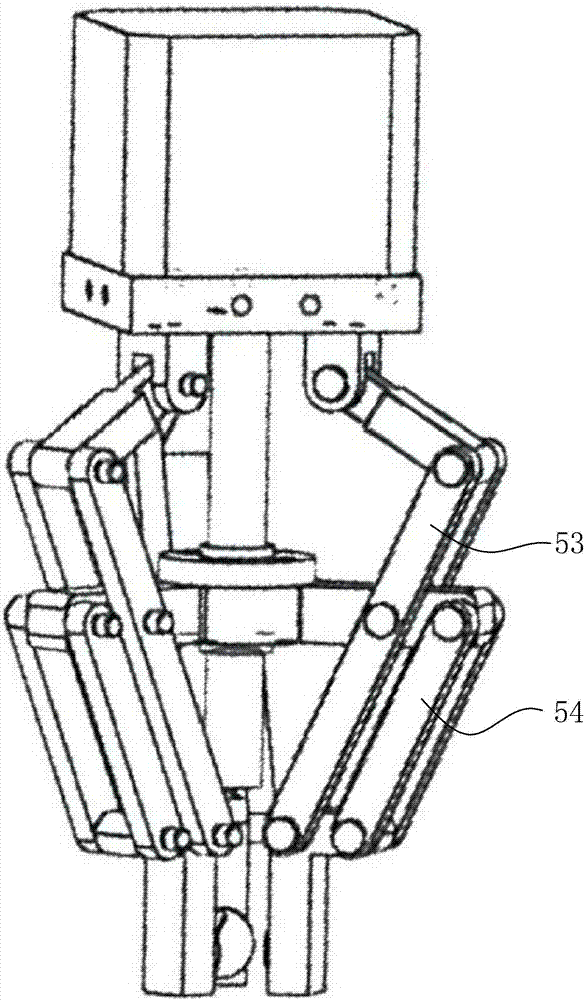

Mechanical paw

The invention discloses a mechanical paw. A driving module can drive a lead screw to rotate. In the rotating process of the lead screw, a servo lead screw nut will move up and down, and therefore the included angle formed between a first rod and a second rod is changed. According to the principle of parallelogram, a linkage rod connected with a third rod will produce displacement in the horizontal direction, and therefore clamping is achieved. Due to the fact that each driving component is of a simple connection rod structure, reliability is quite high, the service life is quite long, transmission of the servo lead screw nut and the driving lead screw is quite precise, and therefore the mechanical paw can achieve accurate clamping. Meanwhile, the servo lead screw nut and the driving lead screw can achieve the effects of reducing the speed and increasing torque and clamping force. Accordingly, the problems that an existing mechanical paw is large in size and high in weight as the existing mechanical paw needs to be additionally provided with a speed reducing mechanism is avoided.

Owner:FOSHAN UNIVERSITY

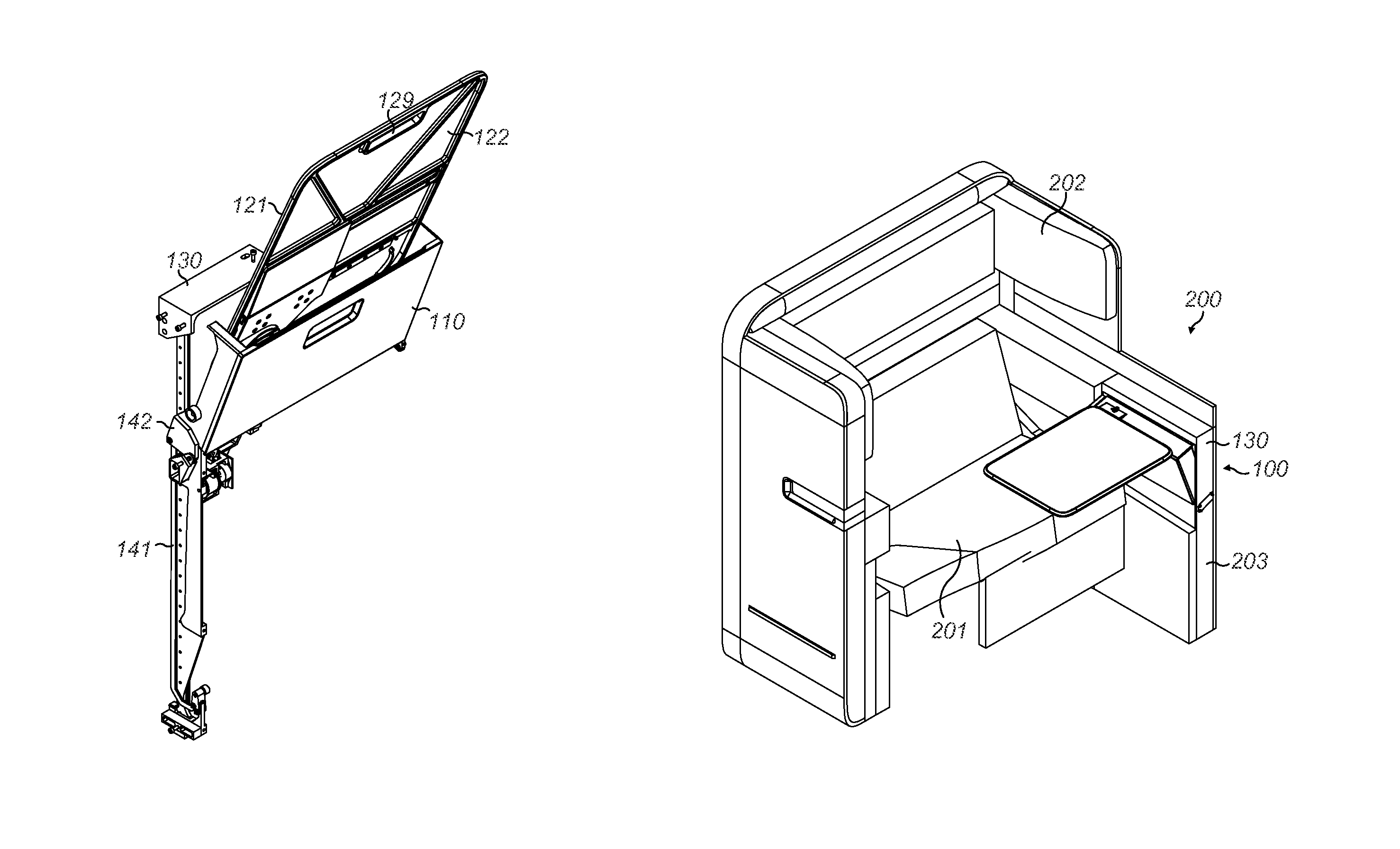

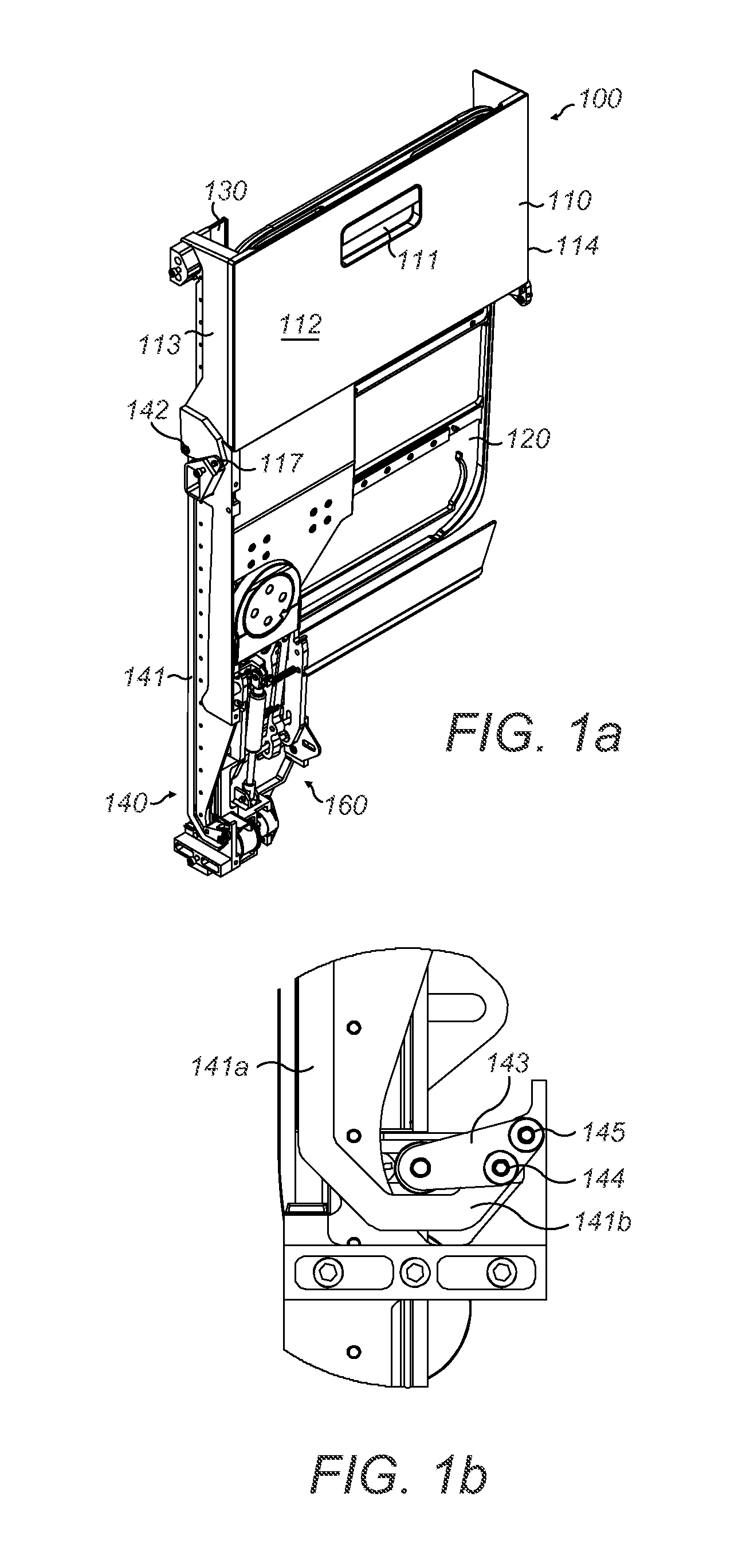

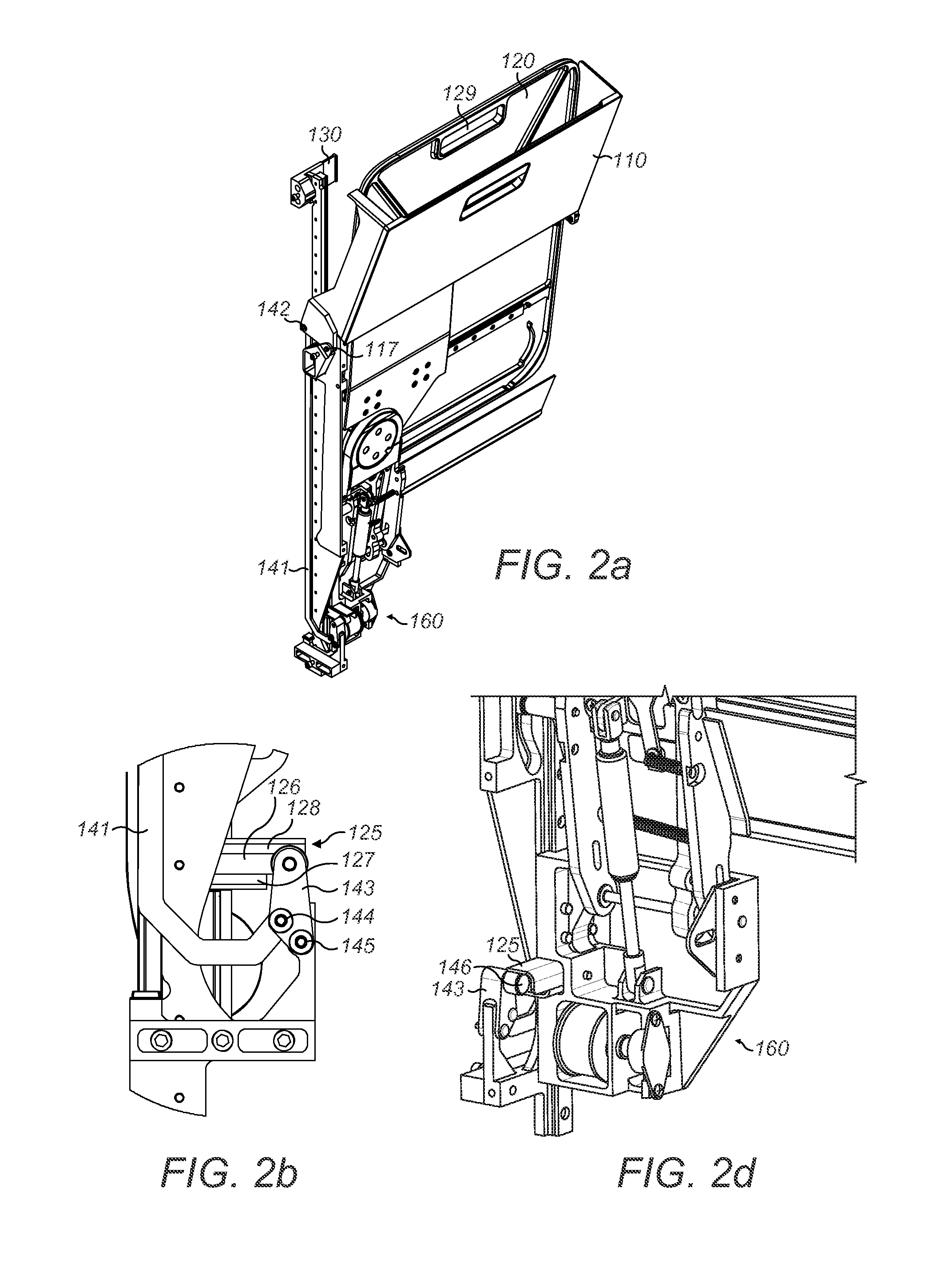

Table arrangement

ActiveUS9481464B2Stowage is easy and quick and simplerVehicle arrangementsSeating arrangementsLinkage (mechanical)Structural engineering

Owner:SAFRAN SEATS GB LTD

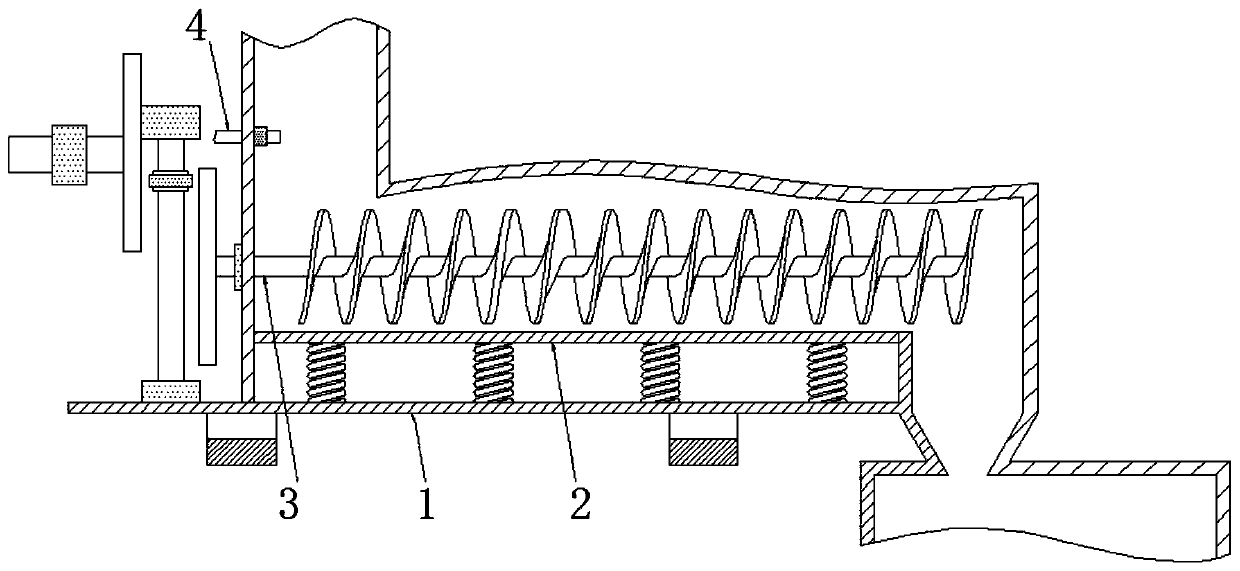

Device for changing rotating speed based on gravity variations to prevent feeding machine from being blocked

InactiveCN110817298AAvoid cloggingAvoid failureConveyorsPackagingExternal energyLinkage (mechanical)

The invention relates to the technical field of mechanical equipment, and discloses a device for changing the rotating speed based on gravity variations to prevent a feeding machine from being blocked. The device comprises a supporting plate. Due to the cooperative use of a threaded stud, a first sliding block, a small rotating wheel and a transverse rod, the conveying speed is increased, a blocked feeding pipe is automatically dredged, the phenomenon that a machine breaks down due to the fact that the machine cannot run normally is avoided, and the service life period of the device is prolonged. Due to the cooperative use of a baffle, a connecting rod and a connecting block, when a bearing plate descends to drive the baffle to be closed, the blocked feeding pipe can be automatically closed, and conveying burdens of the feeding pipe are relieved. Due to cooperative use of the baffle and the connecting rod, consequent reactions are in linkage, the linkage of the whole device is improved, and operation is easier and more convenient. Dredging can be performed by means of gravity variations of the bearing plate, and no other external energy needs to be supplied, so that the whole device is more intelligent and more environmentally friendly, and the using cost is lower.

Owner:吴金花

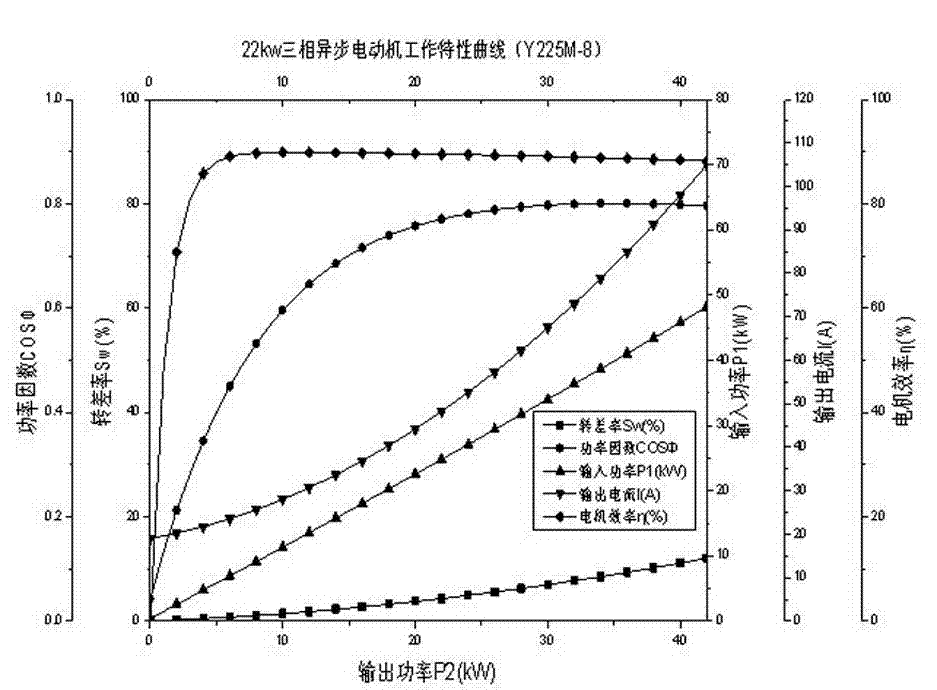

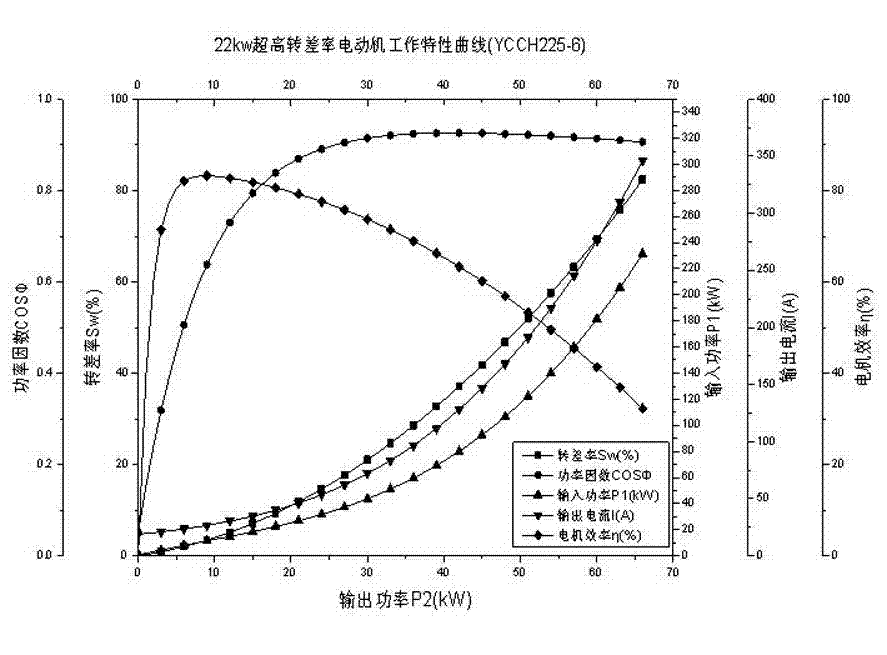

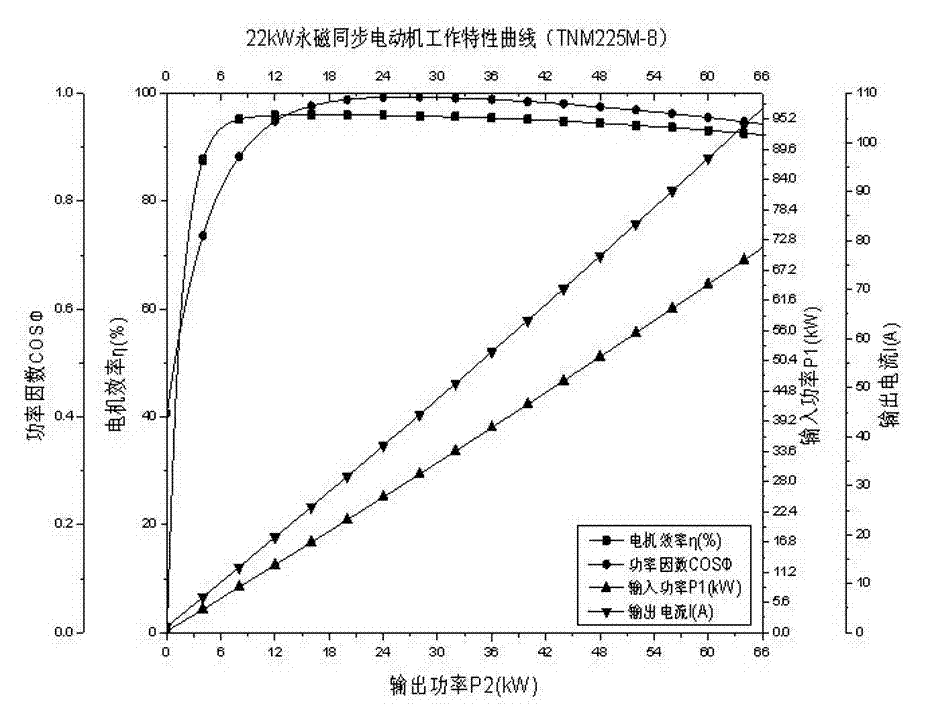

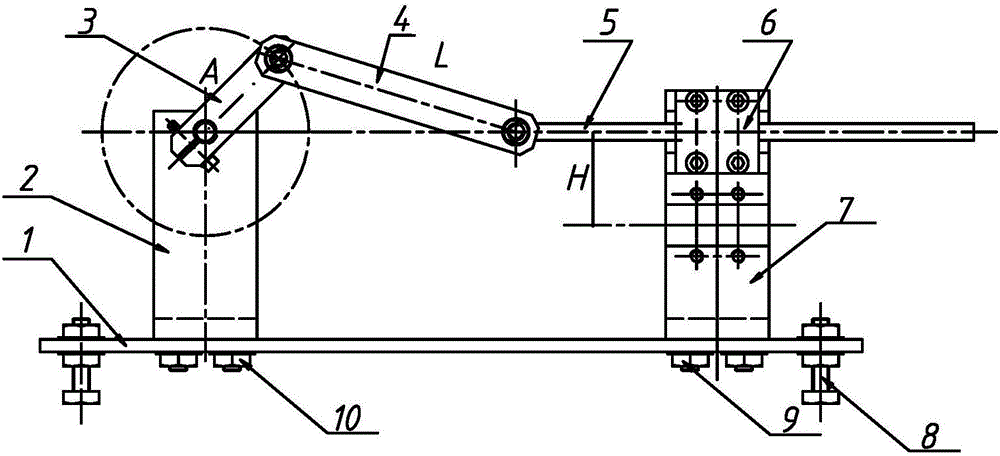

Reasonable matching method of walking beam type pumping unit and electromotor

InactiveCN103500247AImprove universalityIncrease profitAerodynamics improvementSpecial data processing applicationsThree phase asynchronous motorControl engineering

The invention relates to a reasonable matching method of a walking beam type pumping unit and electromotors. The method comprises the steps that firstly, a pumping unit database is built; secondly, an electromotor database is built; thirdly, a rod tube database is built; fourthly, four-bar linkage movement calculation is conducted on the pumping unit; fifthly, polished rod loads of a rod pumped well are calculated; sixthly, the torque of a reduction gearbox is calculated; seventhly, input end parameters of the driving electromotor are calculated; eighthly, the seventh step is repeated, and calculation is conducted on input end parameters of each one of a three-phase asynchronous electromotor, a double-power electromotor, a high slip electromotor and a permanent-magnet synchronous electromotor; ninthly, reasonable matching is conducted on the matched rod pumped well and the electromotor, calculation results of the eighth step are compared with a standard configuration electromotor scheme, and after screening based on constraint conditions is conducted, the scheme having the highest comprehensive electricity-saving ratio is the optimized electromechanical reasonable matching scheme. The method is beneficial to improving the power utilizing rate and efficiency of a driver electromotor, improving the current situation of 'big Mara trolleys', and achieving energy saving and emission reduction.

Owner:NORTHEAST GASOLINEEUM UNIV

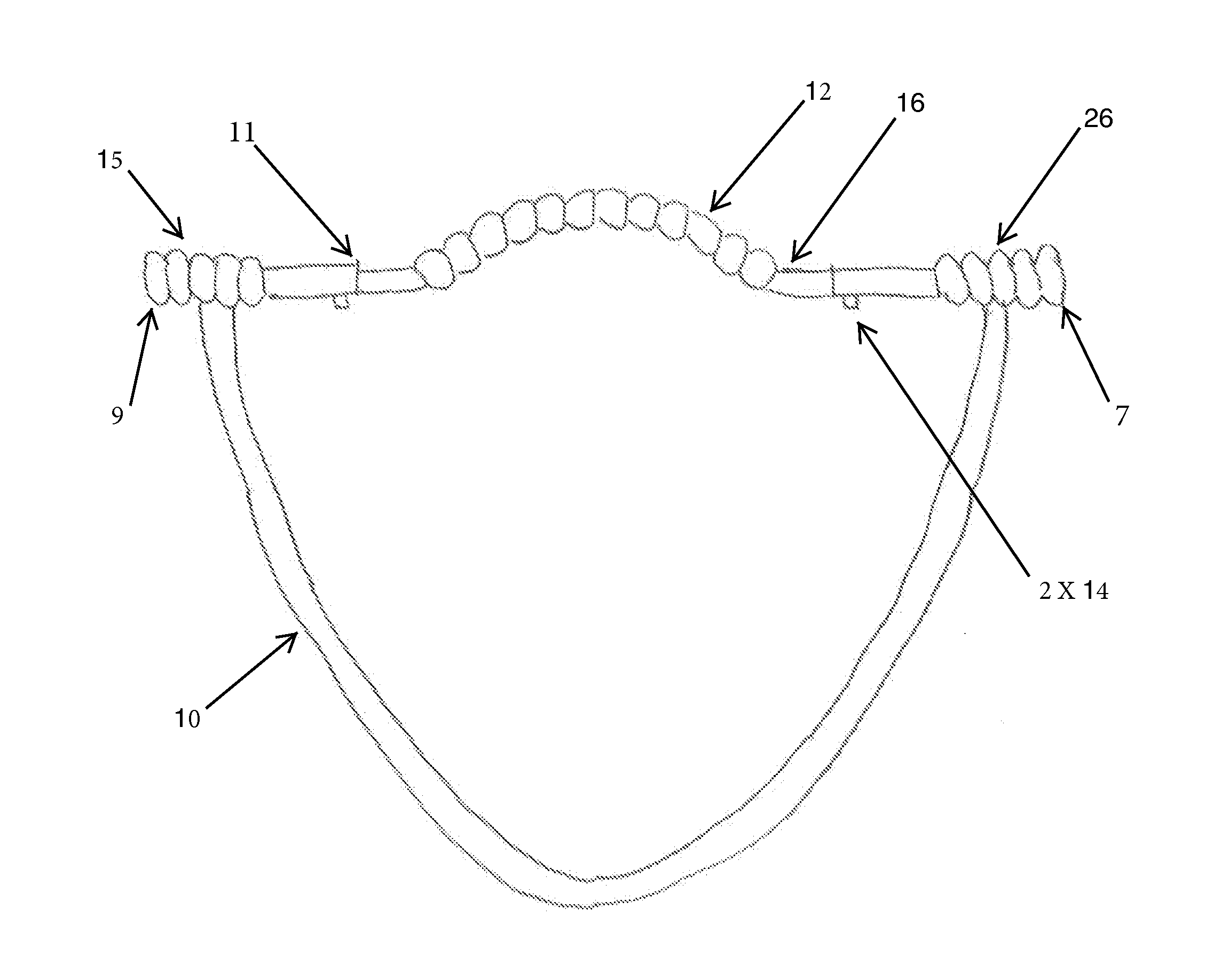

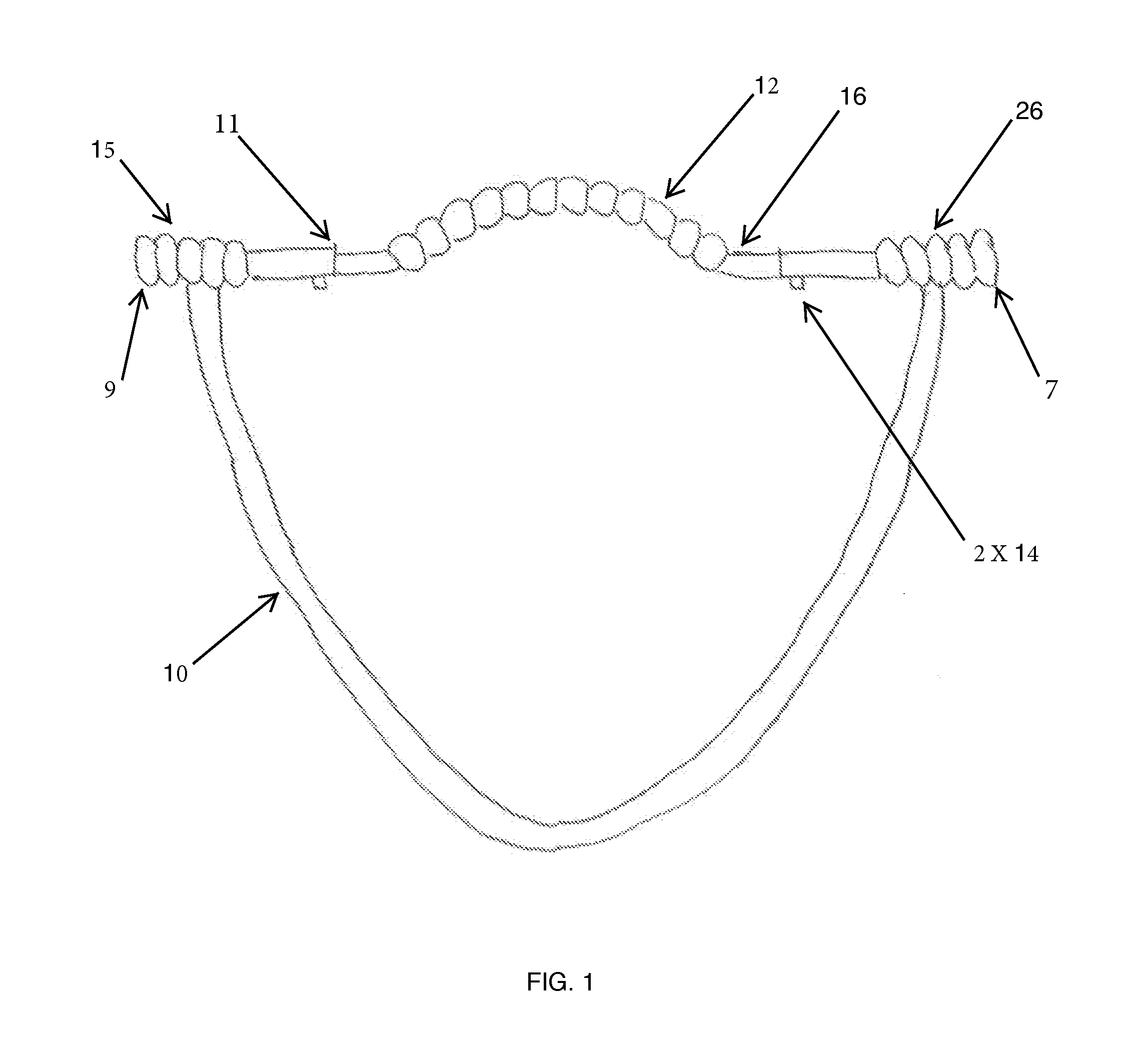

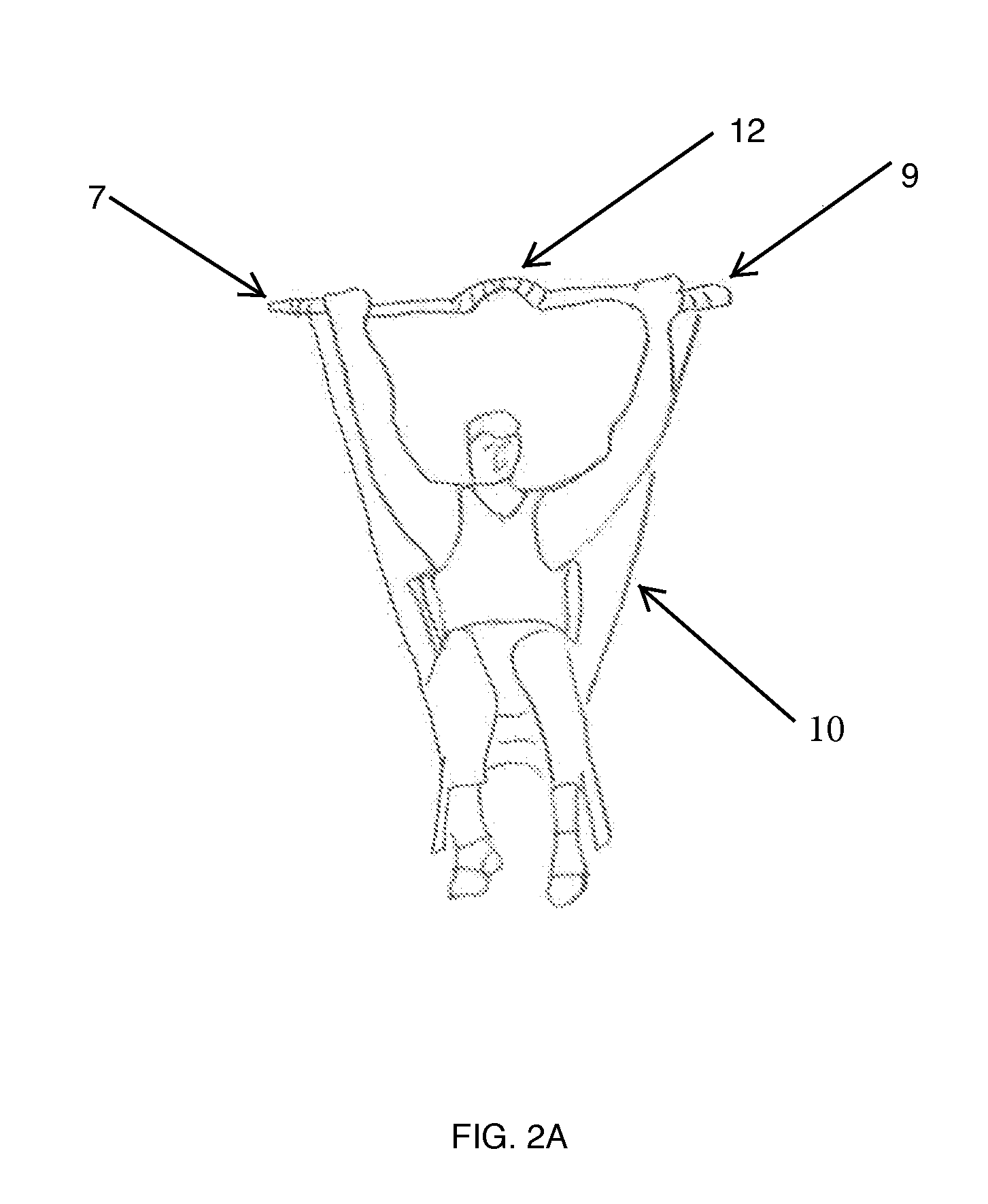

Apparatus for Multi-purpose Exercise

InactiveUS20160074692A1Effectively withstand concentrated stressReduce exposureResilient force resistorsMovement coordination devicesEngineeringAerobic exercise

The apparatus according to this invention involves connection of a tubular bar (7, 9) with gripping features for the hands and behind the neck, to a tension resistant elastic rope for performing various aerobic exercises. The tension resistant rope is guided through to an opening in the tubular bar (60) which then joins to a newly designed retainer (30). The retainer includes a hole (40) for the elastic rope to feed through. As part of the retainer assembly, a fastener (32) is used to couple the elastic rope to the retainer. The improvement of the retainer features an extruded rectangular cut (41) allowing a lightweight and more robust mechanical linkage between the elastic rope and the tubular handle.

Owner:WAYS OF WELLNESS

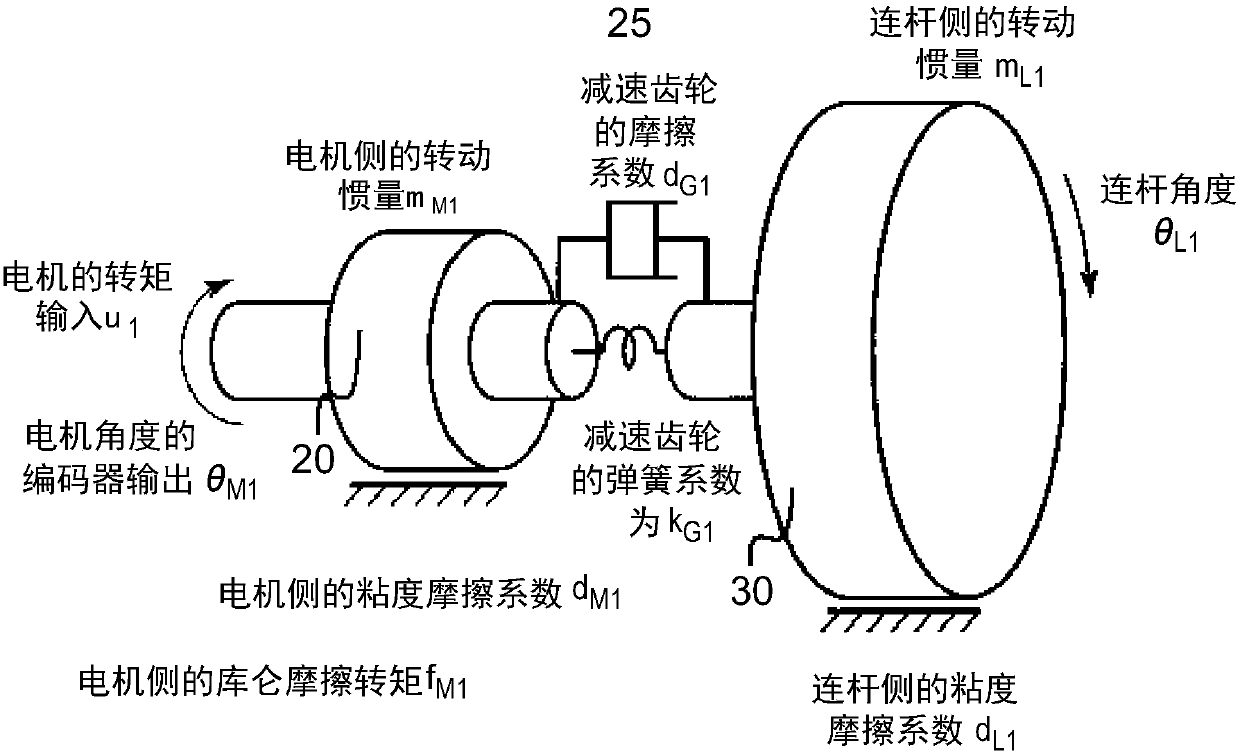

Robot control device, a robot control method, and a picking device

The invention relates to a robot control device, a robot control method, and a picking device. According to one embodiment, the robot control device is used for a mechanical arm including a linkage rod and a motor used for rotationally driving the linkage rod. The robot control device includes a derivation part. The derivation part derives a first estimated value including a variation of a rotation angle of the link and a second estimated value including a variation of a rotation angle of the motor, based on an angular velocity and a current reference value of the motor. Furthermore, the derivation part derives an external force generated to the robot arm, based on a difference between the first estimated value and the second estimated value.

Owner:KK TOSHIBA

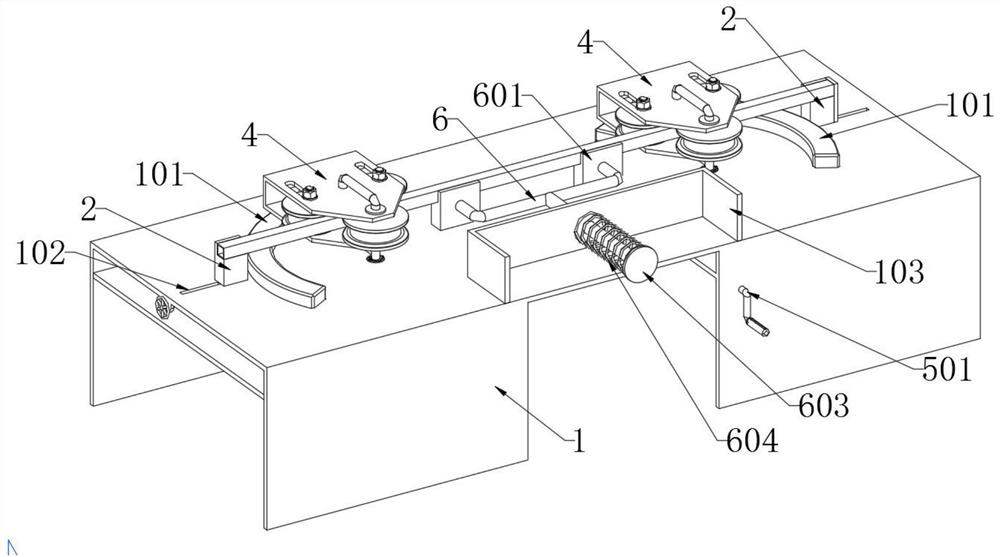

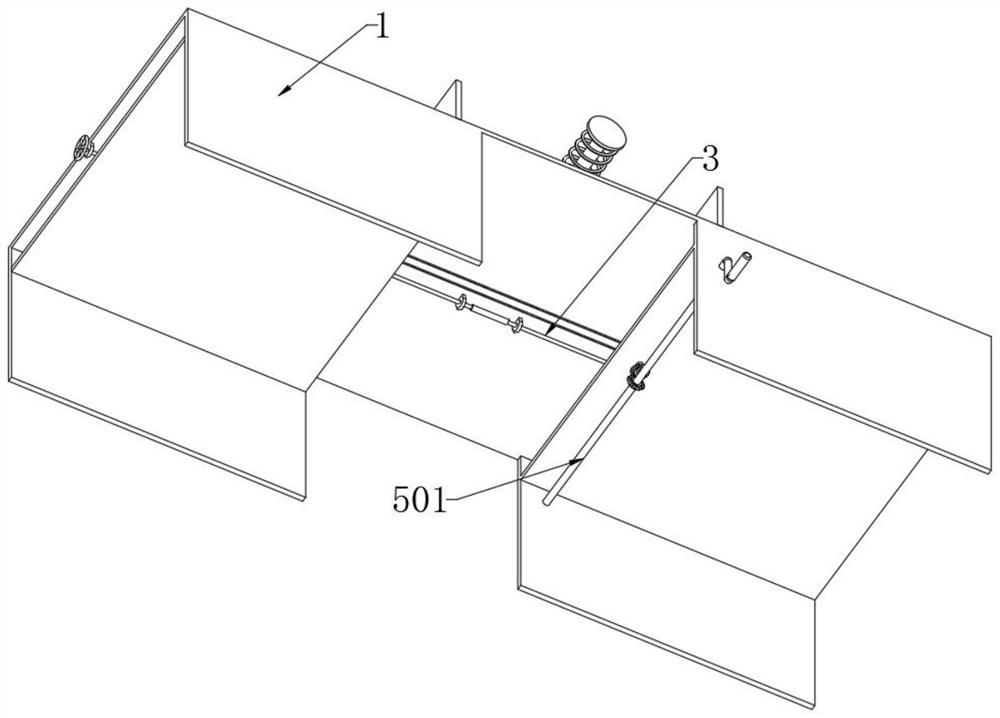

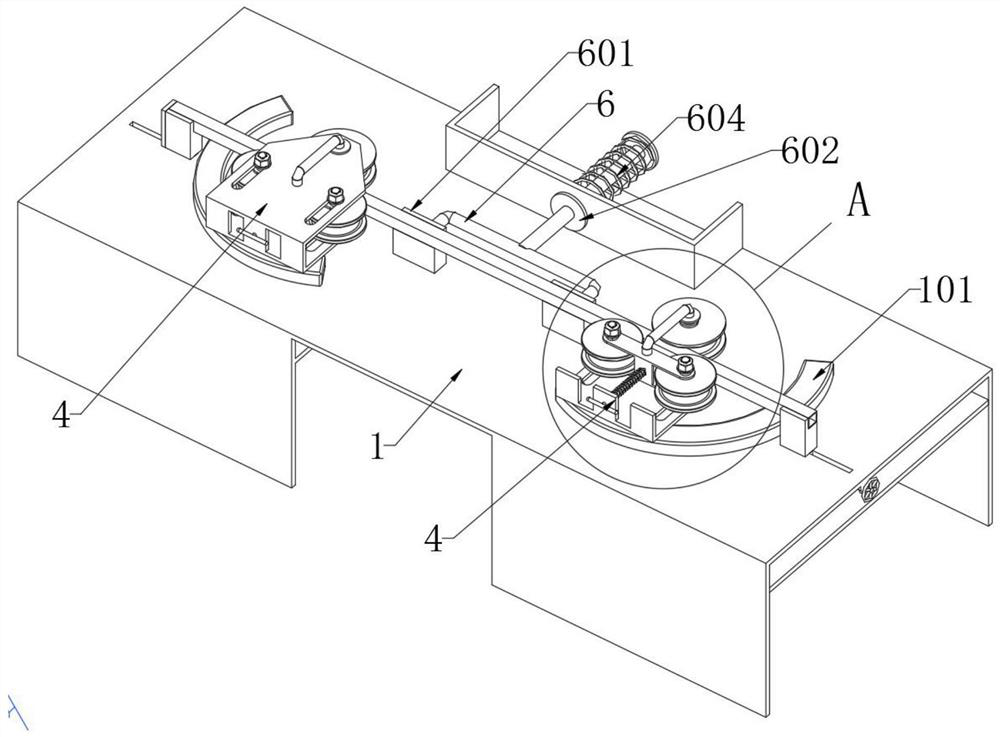

Hardware workpiece punching device capable of automatically pushing materials

InactiveCN112775267AReduce usageEasy to moveShaping toolsMetal-working feeding devicesComputer hardwarePunching

The invention relates to a hardware workpiece punching device capable of automatically pushing materials. The device comprises a base, a support rod, a cross rod, an operation table, a raw material box, a punching mechanism and a material pushing mechanism, wherein the hardware workpiece punching device capable of automatically pushing the materials realizes continuous punching of a workpiece through the punching mechanism, and realizes automatic intermittent material pushing of the workpiece through the material pushing mechanism, compared with an existing punching device, through linkage of the material pushing mechanism and the punching mechanism, the device achieves online material pushing and punching of the workpiece, efficiency is improved, a pure mechanical mechanism is adopted for linkage, use of electronic elements such as a sensor is avoided, stability of the device is improved, the service life of the device is prolonged, meanwhile, operation of the punching mechanism and the material pushing mechanism is achieved through one output end, energy is saved, compared with an existing material pushing mechanism, movement of rolling wheels is limited, damped and lubricated through a rolling unit, a buffering unit and a lubricating unit, a push rod moves more stably, and the better material pushing effect is achieved.

Owner:南京鸿音工程技术有限公司

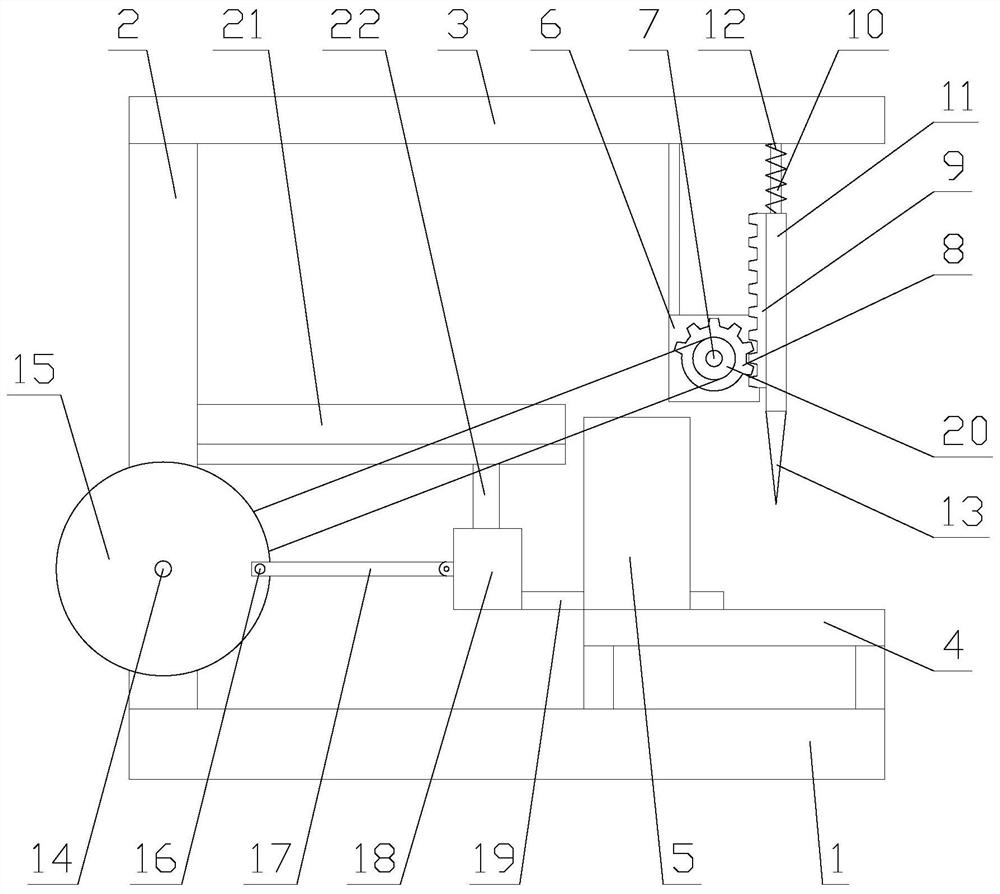

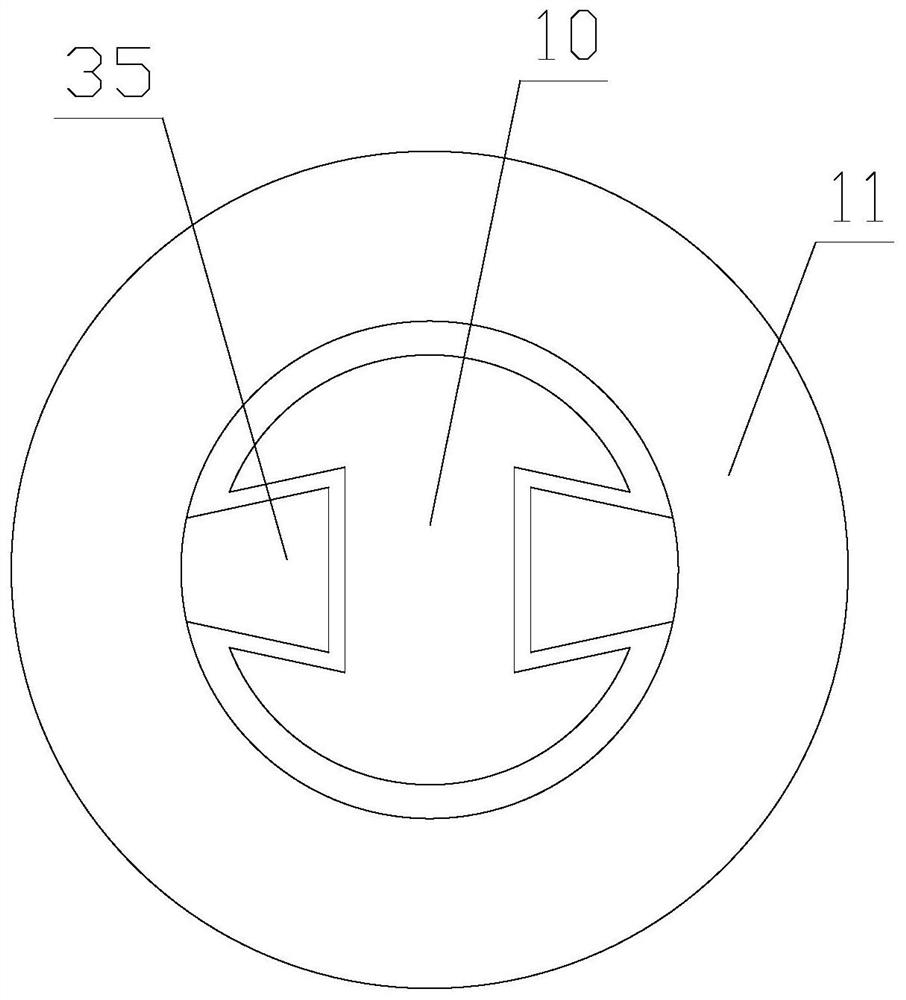

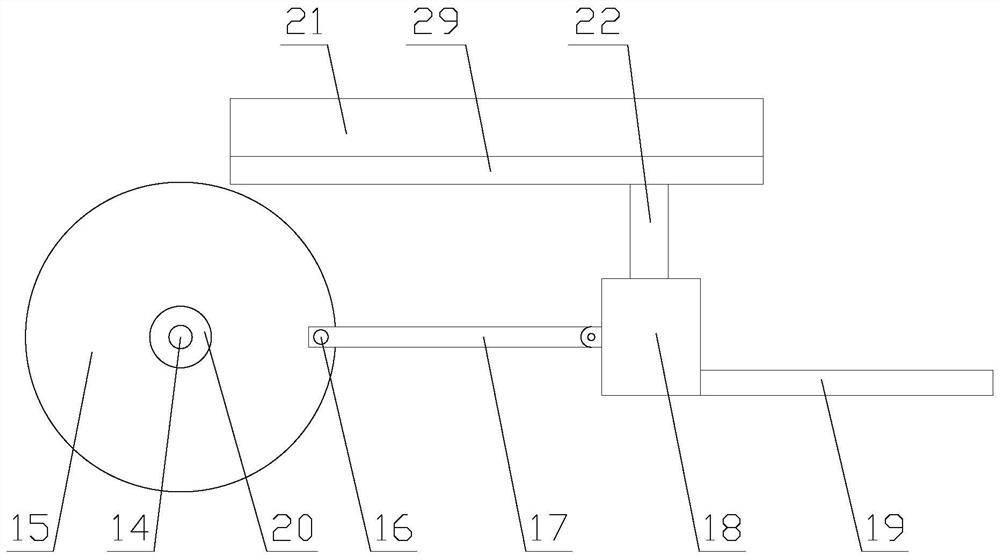

High-precision punching device with calibration function

InactiveCN111745738AWith calibration functionReduce usageMetal working apparatusPunchingLinkage (mechanical)

The invention relates to a high-precision punching device with a calibration function. The device includes a base, a support rod, an operation table, a punching mechanism, a calibration mechanism, anda clamping mechanism. According to the high-precision punching device with the calibration function, the calibration of a punching point and a drill can be achieved through the calibration mechanism,the clamping can be achieved through the clamping mechanism, and the punching can be achieved through the punching mechanism. Compared with an existing punching device, through coordination of the calibration mechanism and the clamping mechanism, the punching device make the punching point and the drill of a work piece keep alignment all the time, and the punching precision is improved. Comparedwith an existing calibration mechanism, the calibration mechanism adopts a purely mechanical mechanism to achieve determining and fixation of the punching point, a sensor is prevented from using, andthe service life is improved. Through linkage of determining assemblies and absorption assemblies, the fixation can be finished during determining, the better locating effect can be achieved, meanwhile through linkage of clamping assemblies and the absorption assemblies, a sucker absorbs the work piece well, and the absorption effect can be improved.

Owner:SHENZHEN LVYUAN HUIZHI TECH CO LTD

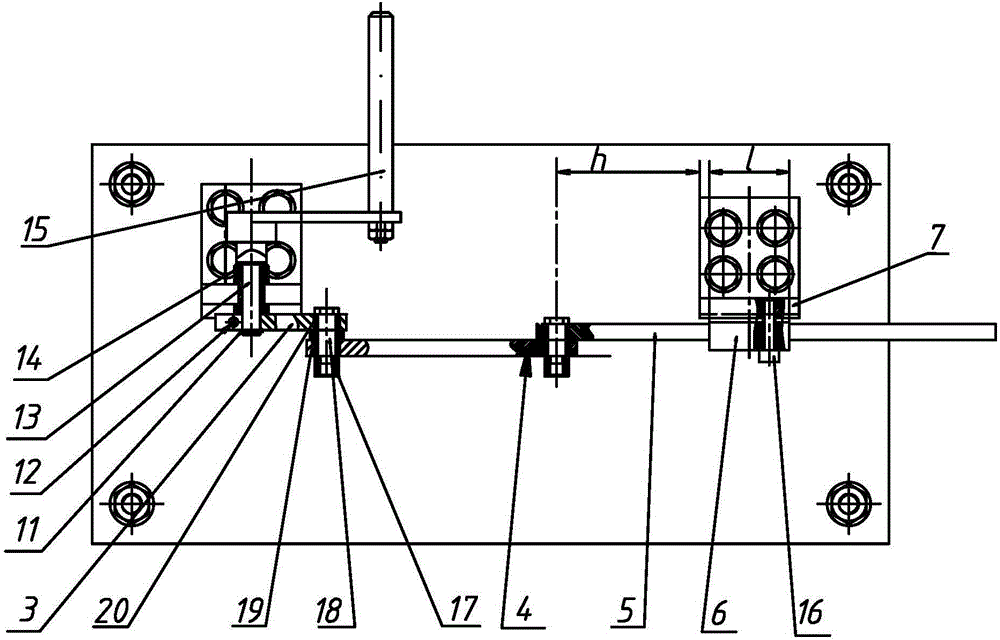

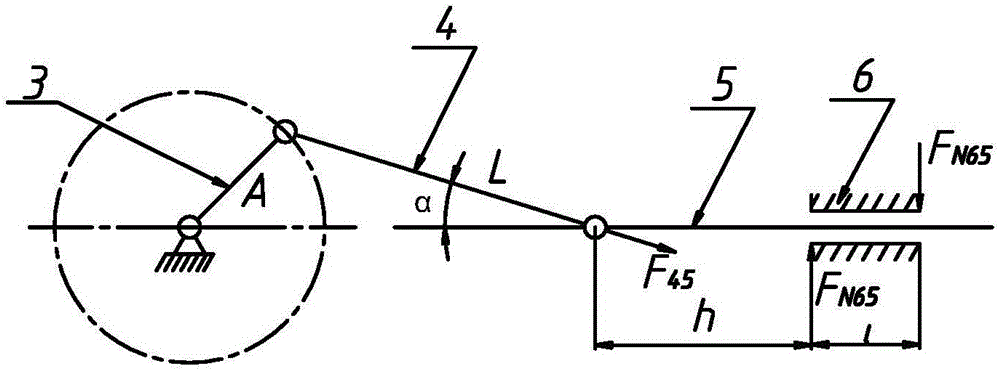

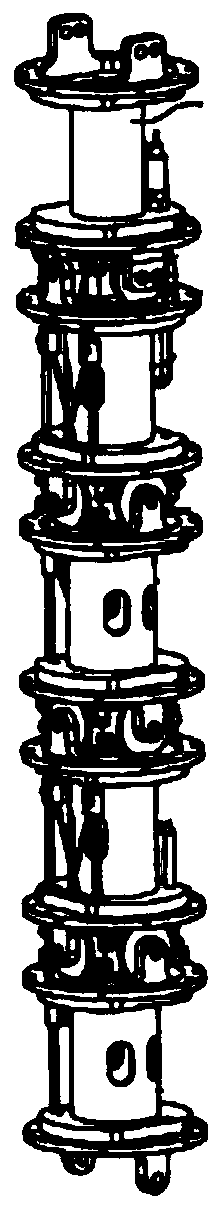

Linkage mechanism experimental system

InactiveCN106448414ADeepen understandingHelp to understandEducational modelsKinematic pairEngineering

The invention discloses a linkage mechanism experimental system which comprises a supporting platform, a crank support and a guide rail support, wherein cranks, connecting rods, slide blocks and slide block guide rails are sequentially arranged between the crank support and the guide rail support; a crankshaft is driven by a hand shank. Three cranks of different lengths, five connecting rods of different lengths and two slide block guide rails of different lengths are arranged in the system disclosed by the invention, and the slide block guide rails can be fixed in two positions of different heights by virtue of threaded holes of different heights in the guide rail support so as to be selected during assembling. The system disclosed by the invention is used for allowing students to select member sizes, assemble centered or biased crank slide bar (slide block) mechanisms, detect displacement errors and personally perceive mechanical properties of the mechanisms according to the specified slide bar (slide block) travel and other requirements. The experimental system disclosed by the invention contributes to allowing the students to cognize and understand the influences of kinematic pair structures and member sizes on mechanism motion output, the influences of kinematic accuracy and movement pair clearances on the mechanism motion accuracy, the influences of the member sizes on the mechanical properties of the mechanisms and the like.

Owner:TIANJIN POLYTECHNIC UNIV

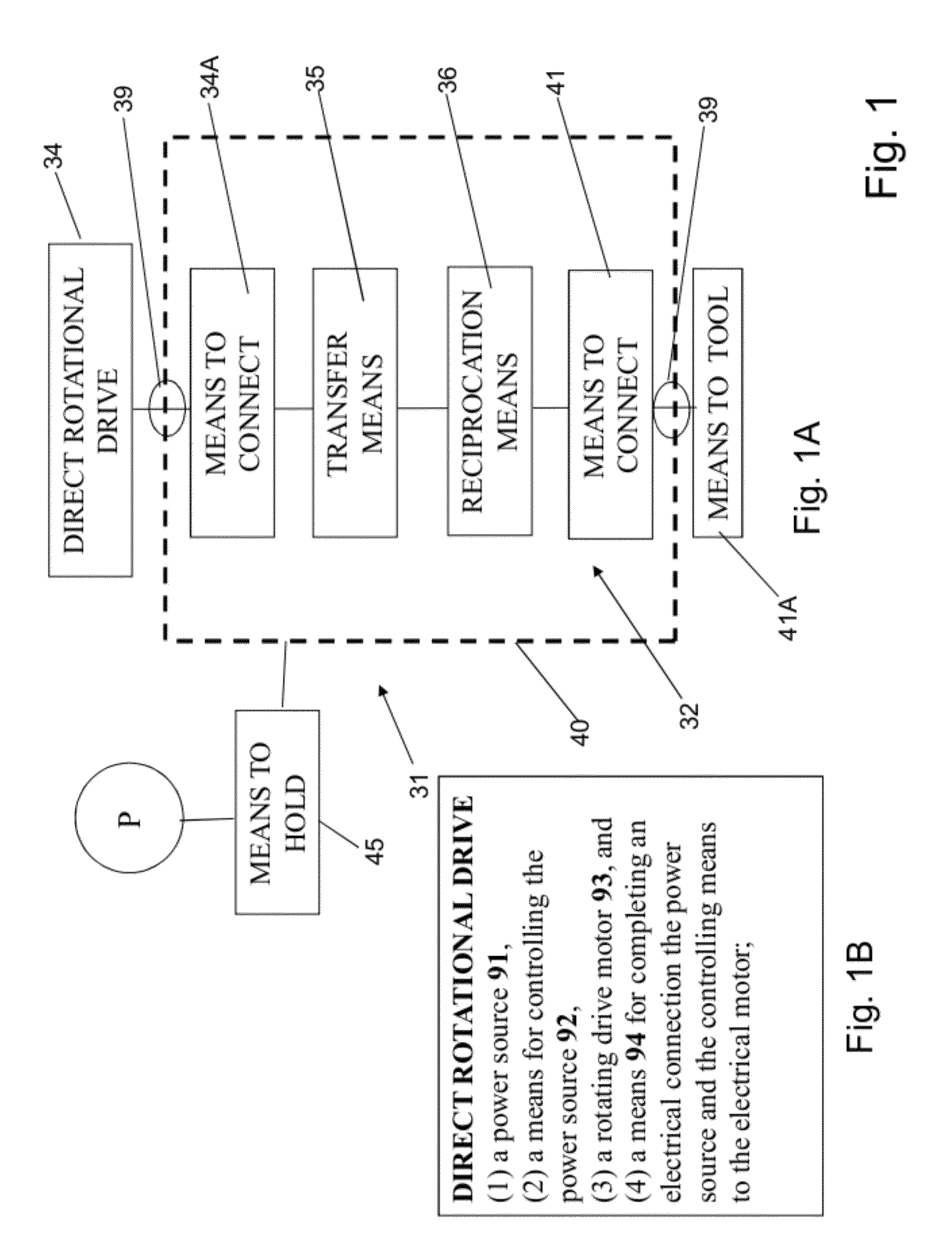

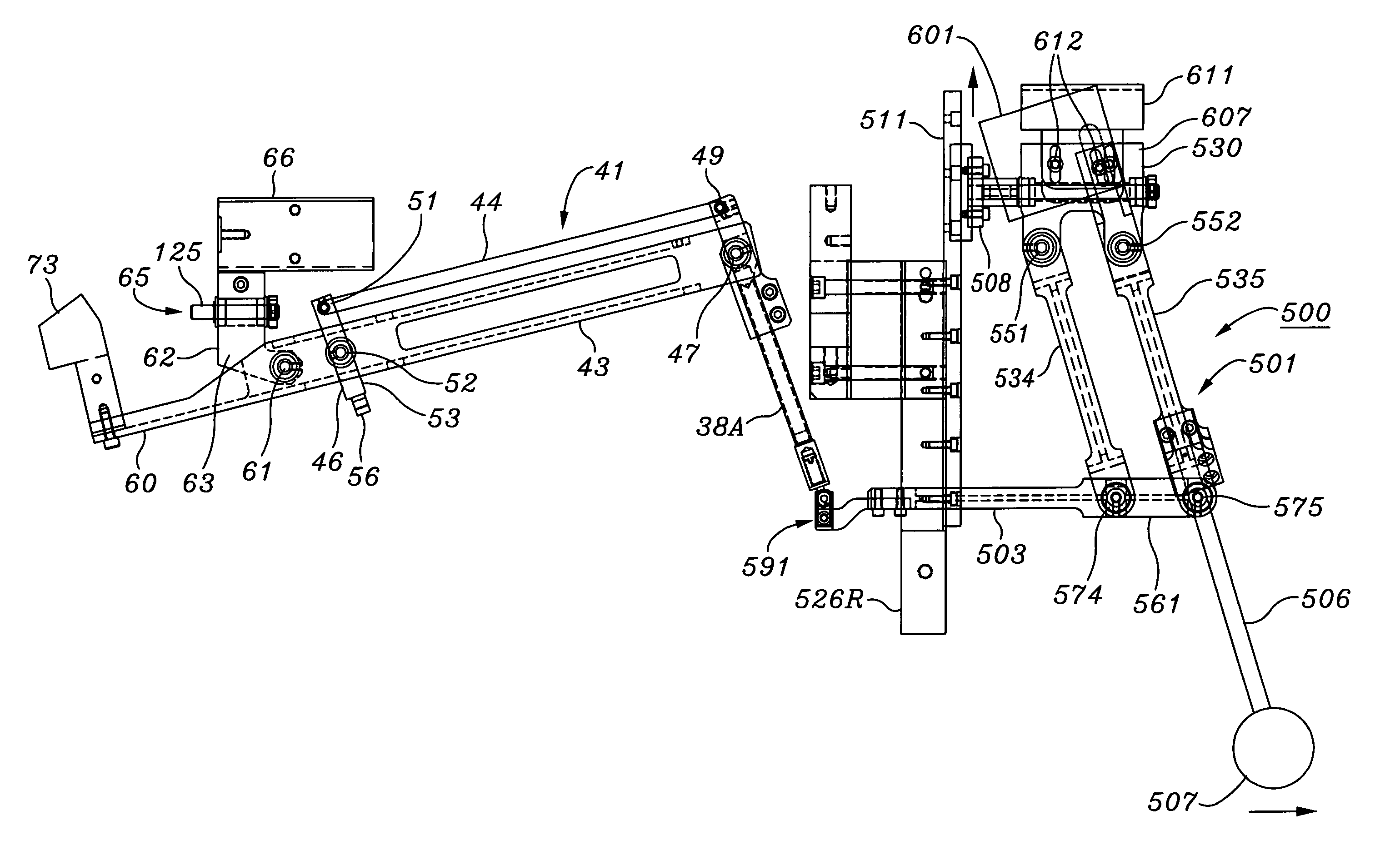

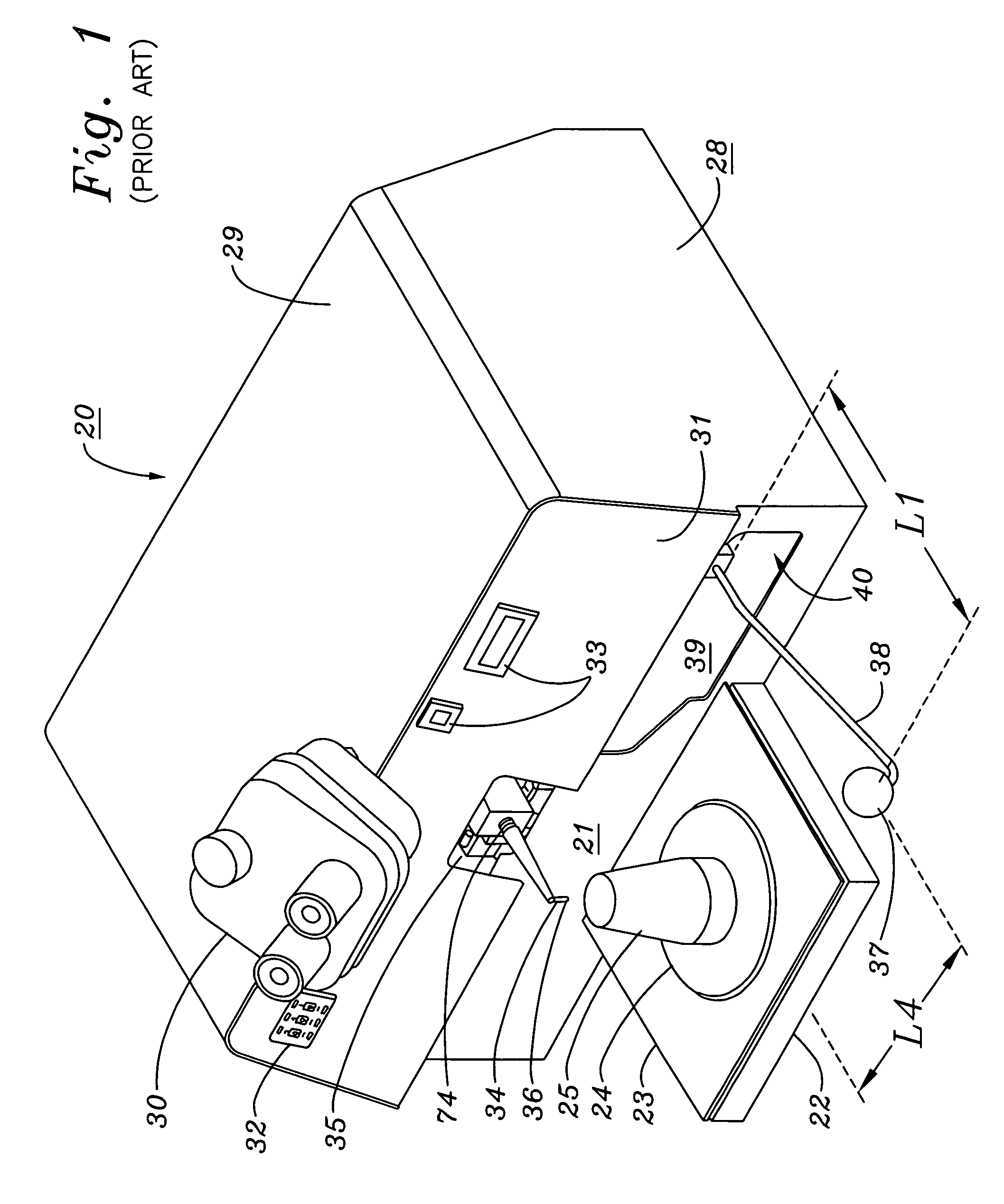

Auxiliary control apparatus for micro-manipulators used in ultrasonic bonding machines

ActiveUS7493191B1Increase in sizeImprove performanceWelding/cutting auxillary devicesFeeding apparatusInput controlEngineering

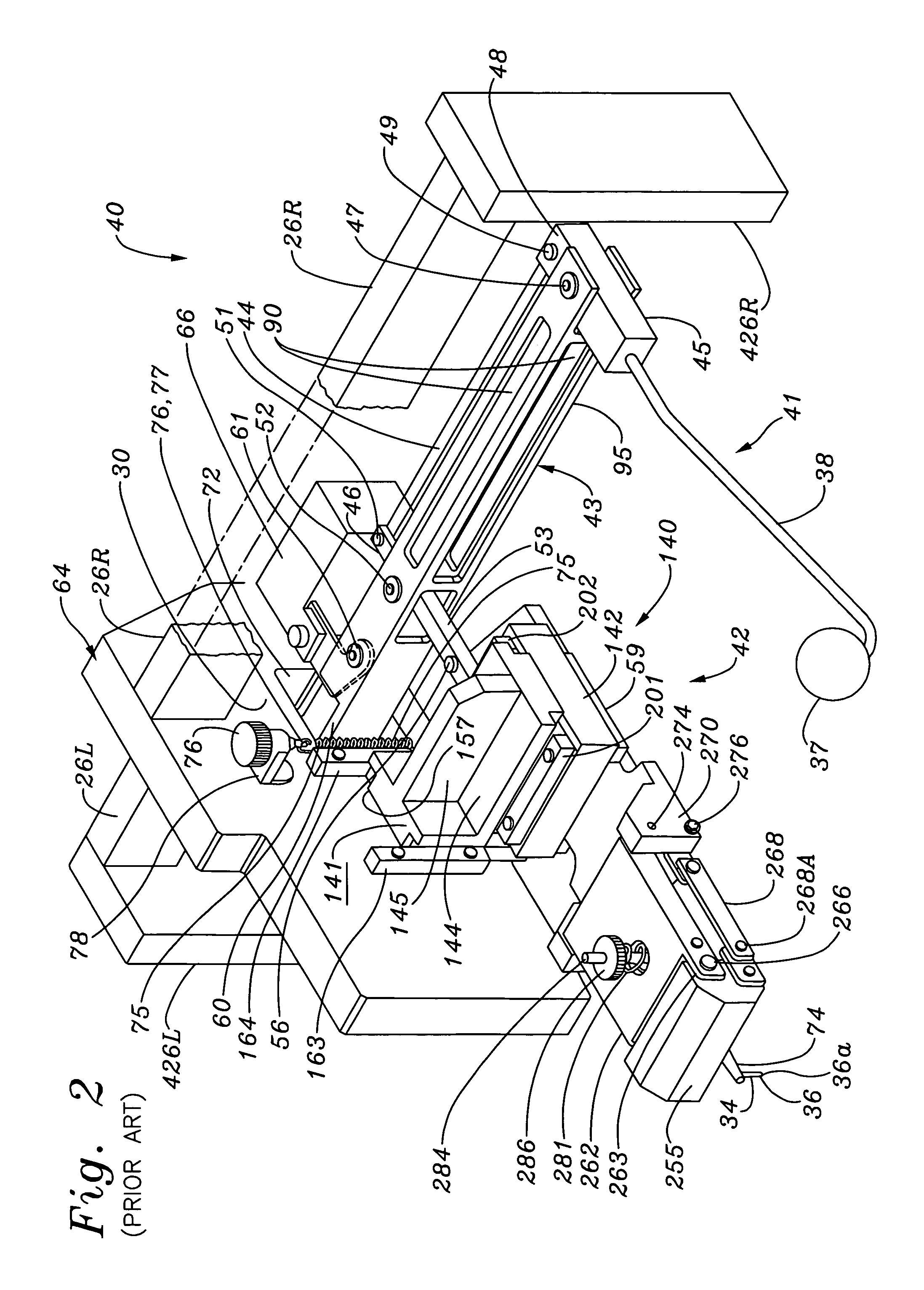

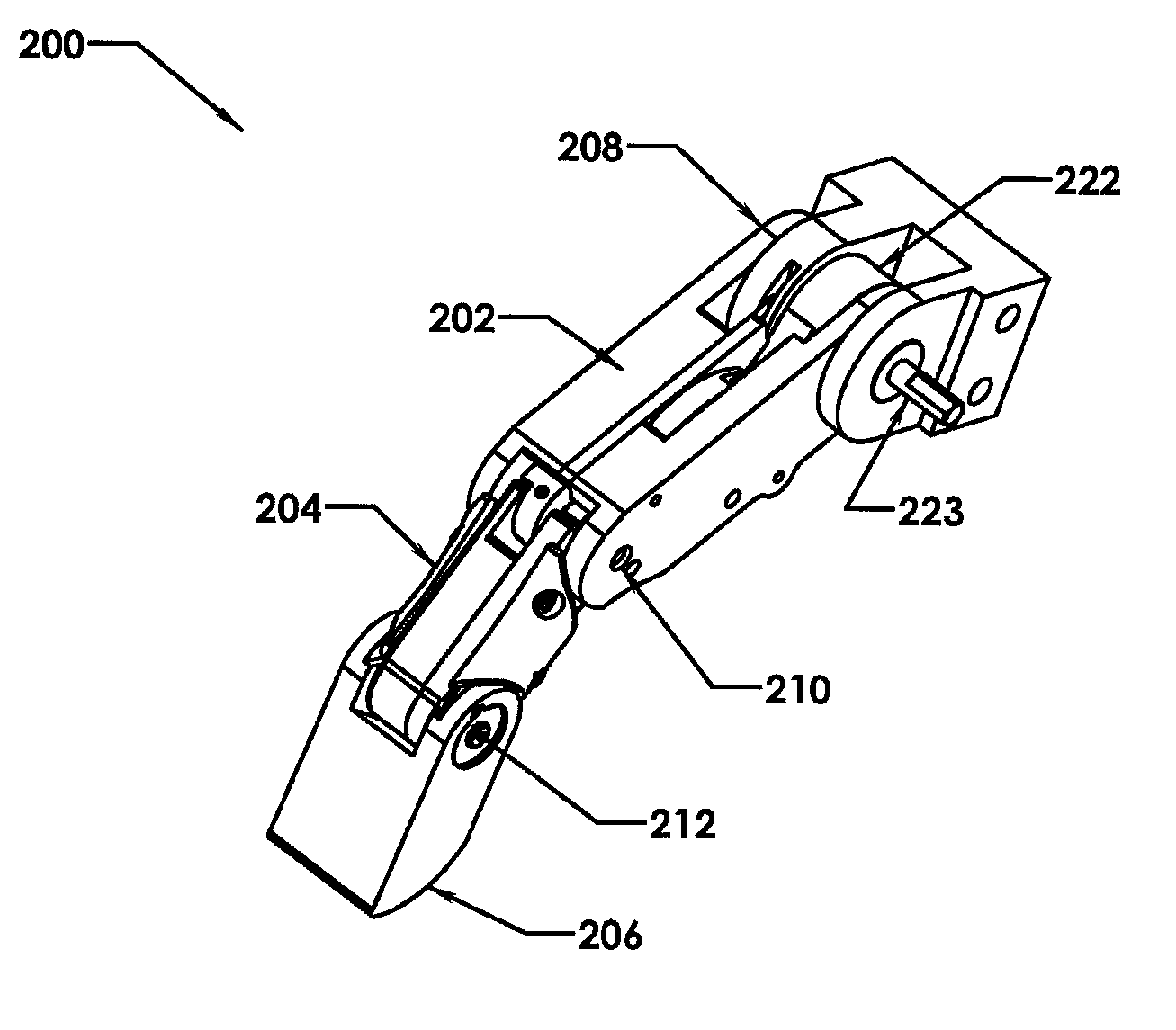

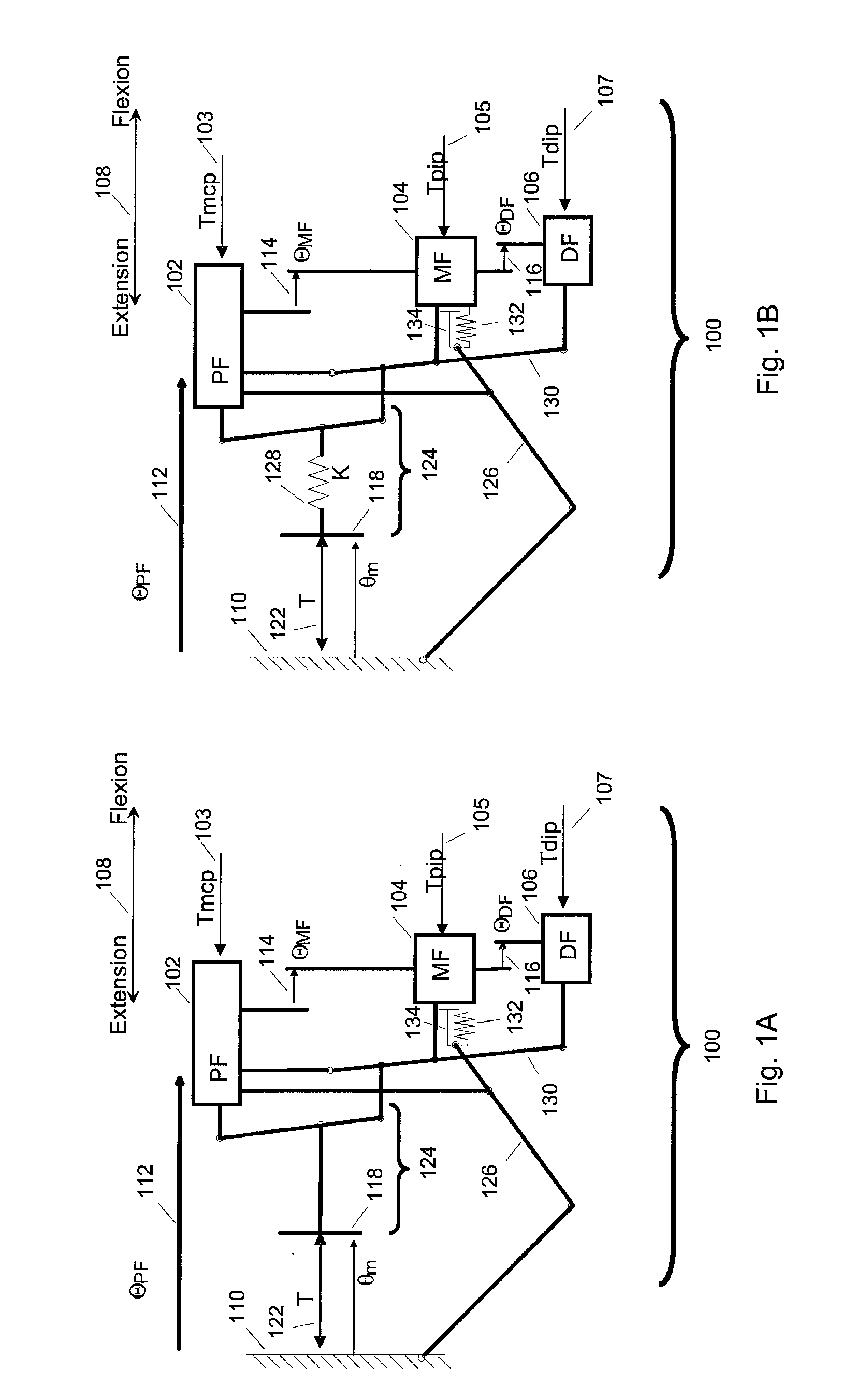

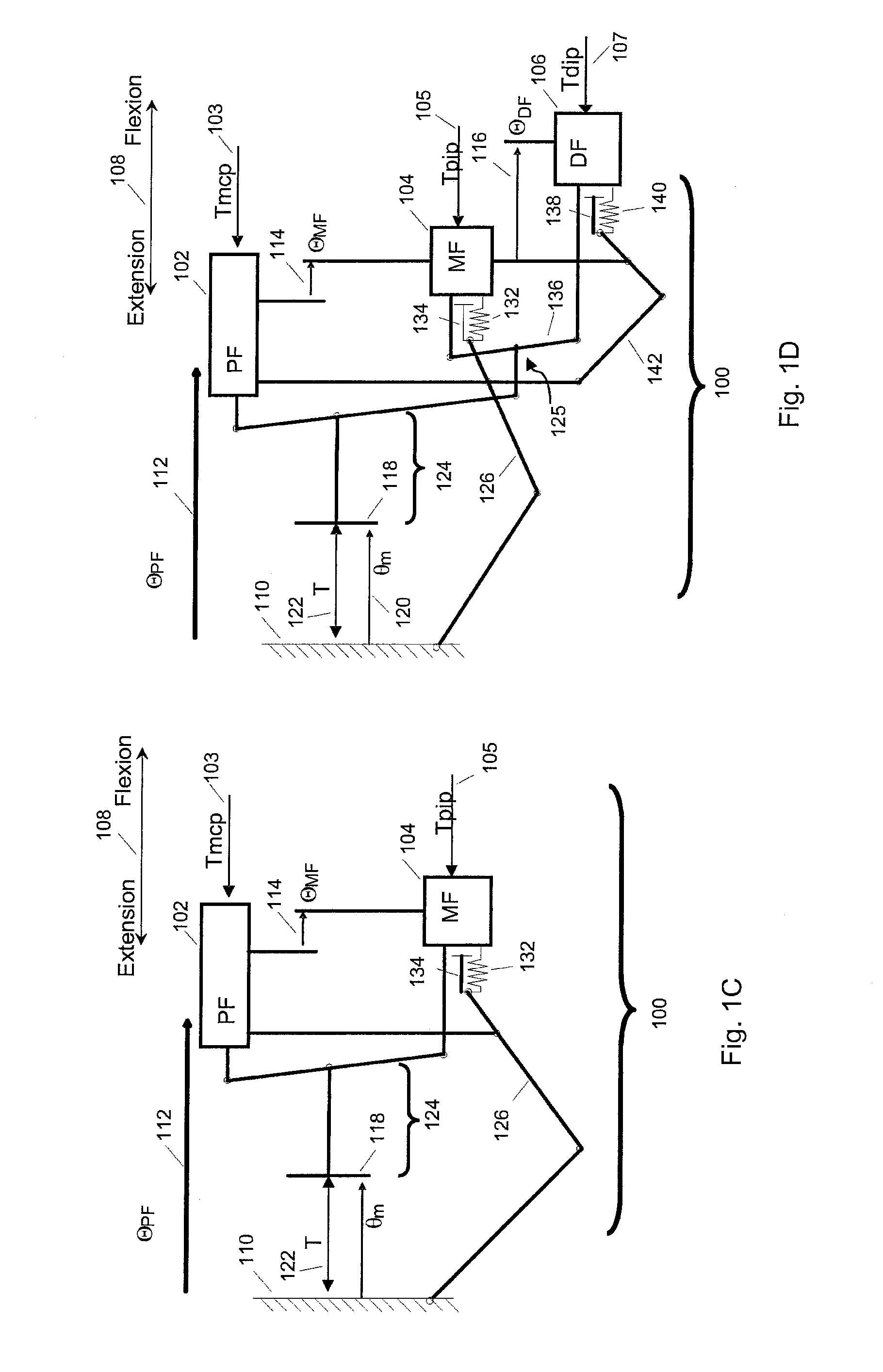

An auxiliary control apparatus mechanically couples forces exerted on a manually operable auxiliary hand control knob to an input member of a micro-manipulator of the type used to move a point of an object such as an ultrasonic bonding tool tip relative to a workpiece in scaled ratios of motions at an end of the micro-manipulator input member. The apparatus includes a 4-bar parallelogram linkage which is mounted to a structural support member of a micro-manipulator, and which includes a rear laterally disposed lateral linkage bar pivotably connected to inner and outer parallel longitudinally disposed linkage bars which are pivotably coupled at front ends thereof to a front laterally disposed linkage bar. An input control arm protrudes downwardly from and forward of the outer longitudinal linkage bar, and a connector arm protrudes laterally inwardly from an inner end of the front lateral linkage bar, inwardly of the inner longitudinal linkage bar; the inner lateral end of the connector arm is pivotably connected to a forward end of the micro-manipulator input member. The rear lateral linkage bar is pivotably mounted onto a pivot axle which protrudes laterally outwards from a trolley block rollably mounted on a fore-and-aft disposed linear bearing guide rail mounted to an outer longitudinal surface of the support structure. Motions of the hand control knob in fore-and-aft left and right, and up and down directions cause corresponding motions of the micro-manipulator input control member and tool tip.

Owner:MILLER CHARLES F

One motor finger mechanism

Owner:HDT EXPEDITIONARY SYST INC

Substance taking and releasing device having mechanical arm

InactiveCN111483802AEasy to moveFlexible and reliable extractionConveyor partsLogistics managementLinkage (mechanical)

The invention provides a substance taking and releasing device having a mechanical arm. The substance taking and releasing device having the mechanical arm comprises a linear driver connected with themechanical arm, a drawing device connected with the linear driver and clamping jaws which are arranged on two sides of the linear driver and are used for clamping two sides of a logistics object, wherein the linear driver is used for driving the drawing device to perform expanding and contracting movement, and the clamping jaws are linked with the linear driver; and when the linear driver is contracted, the clamping jaws are closed up, and when the linear driver is extended, the clamping jaws are opened. According to the substance taking and releasing device having the mechanical arm disclosed by the invention, the advantages of a sucker and the advantages of the clamping jaws are combined; to the logistics object stored in a narrow space, the drawing device is driven by the linear driverto extend and adsorb the object, besides, the linkage relationship between the drawing device and the linear driver is utilized, when the substance taking and releasing device having the mechanical arm is contracted, two sides of the logistics object are further clamped by the clamping jaws, and the logistics object is taken out, so that the logistics object in the narrow space can be flexibly and reliably taken out, and after contraction, much work space cannot be occupied, and the moving of the mechanical arm is convenient.

Owner:CAINIAO SMART LOGISTICS HLDG LTD

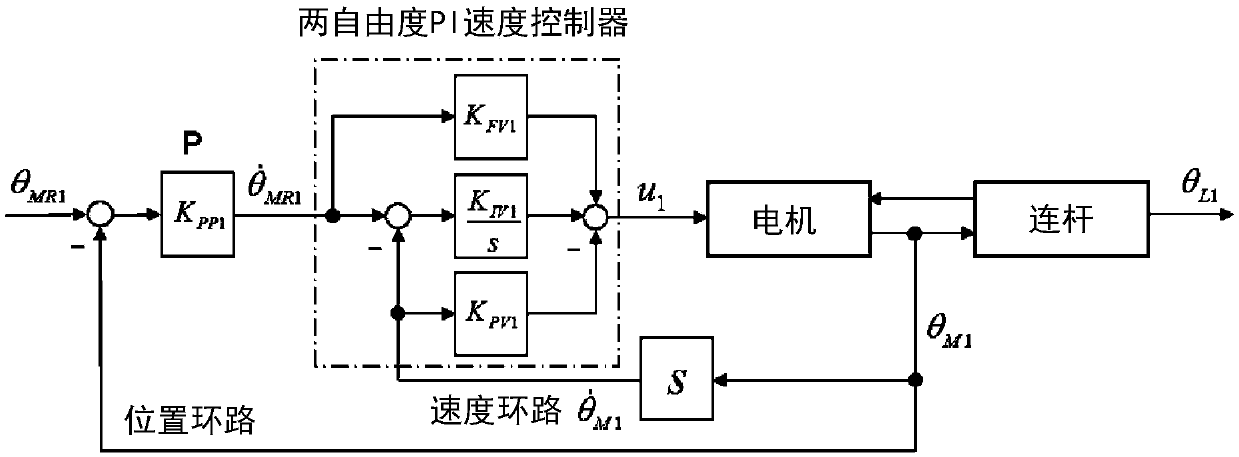

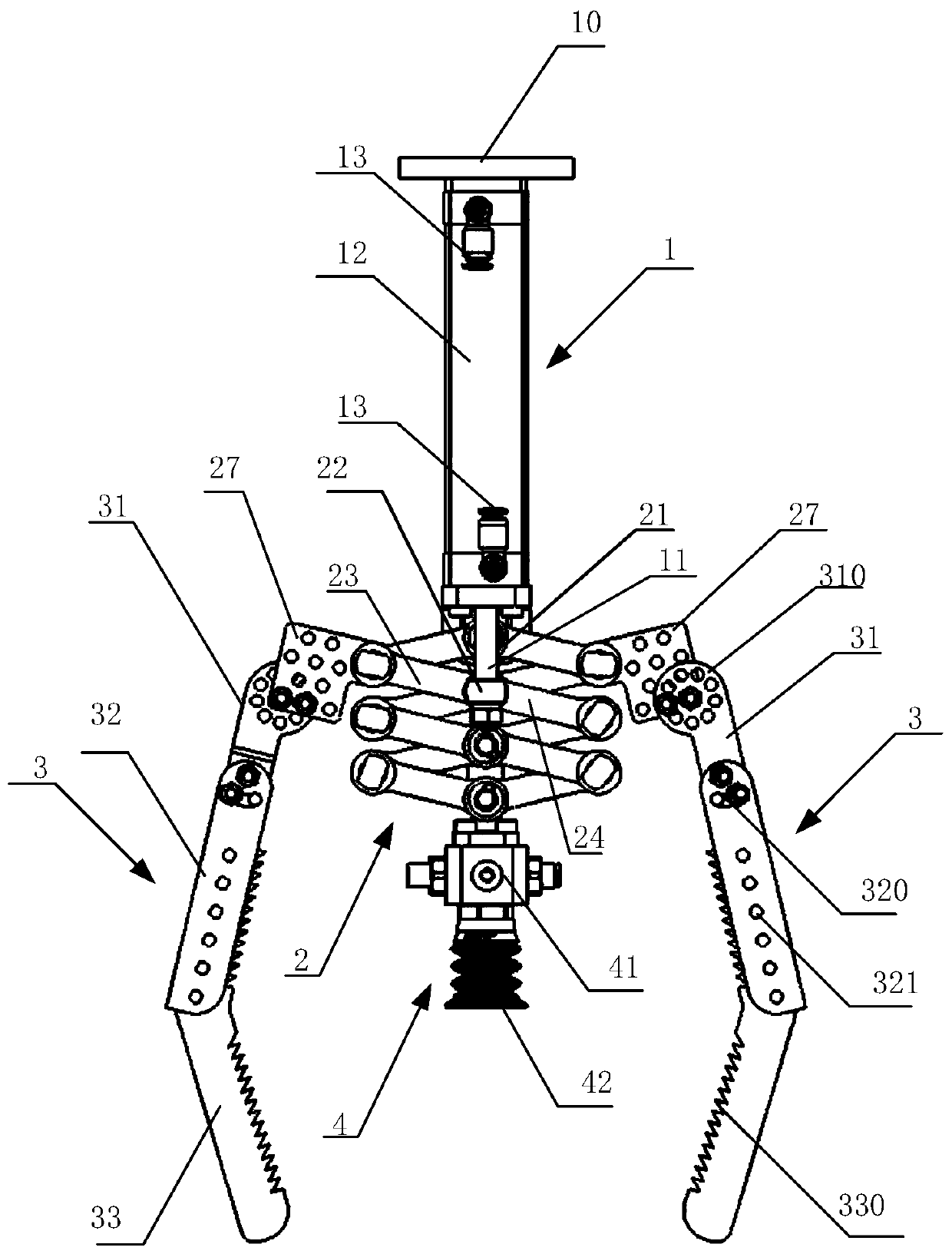

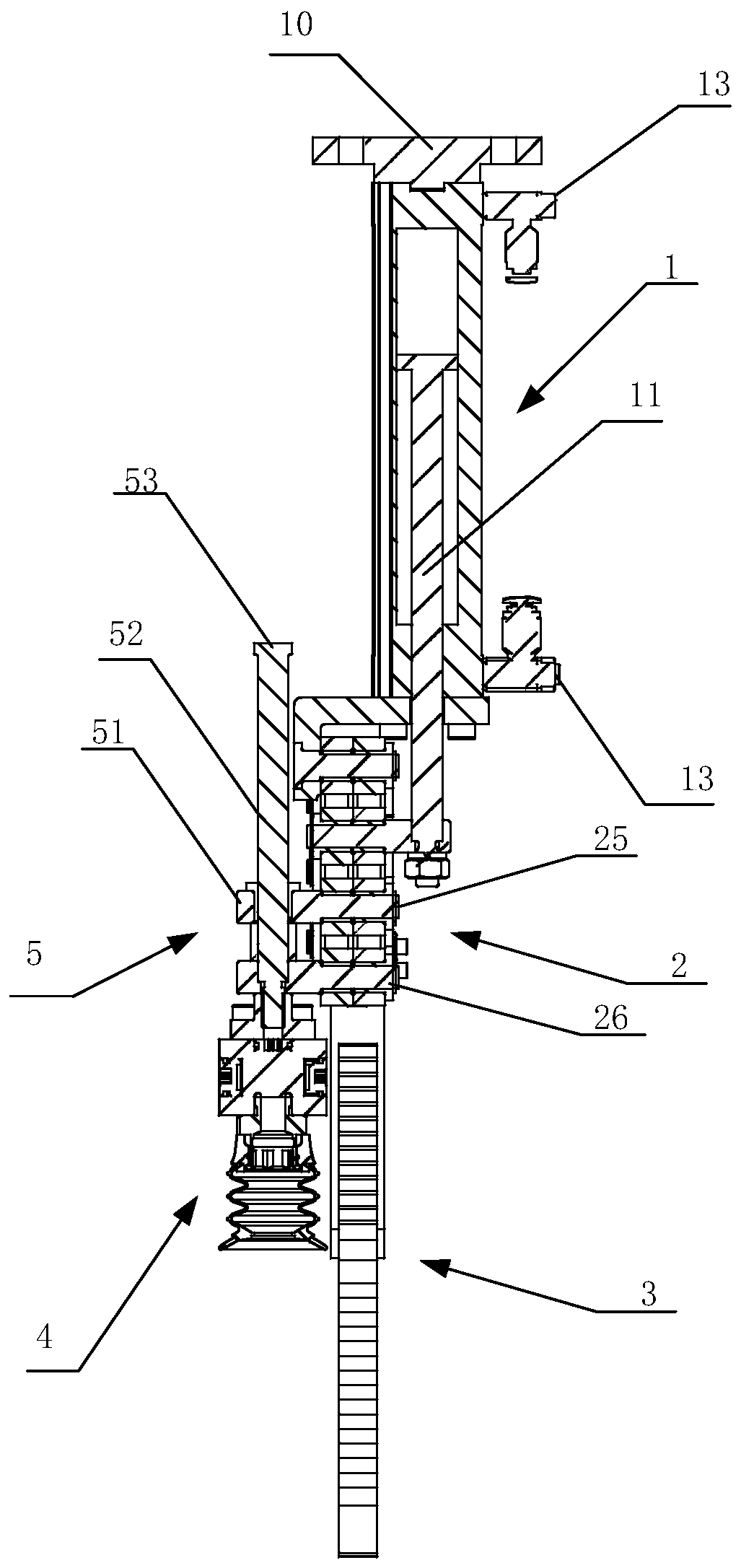

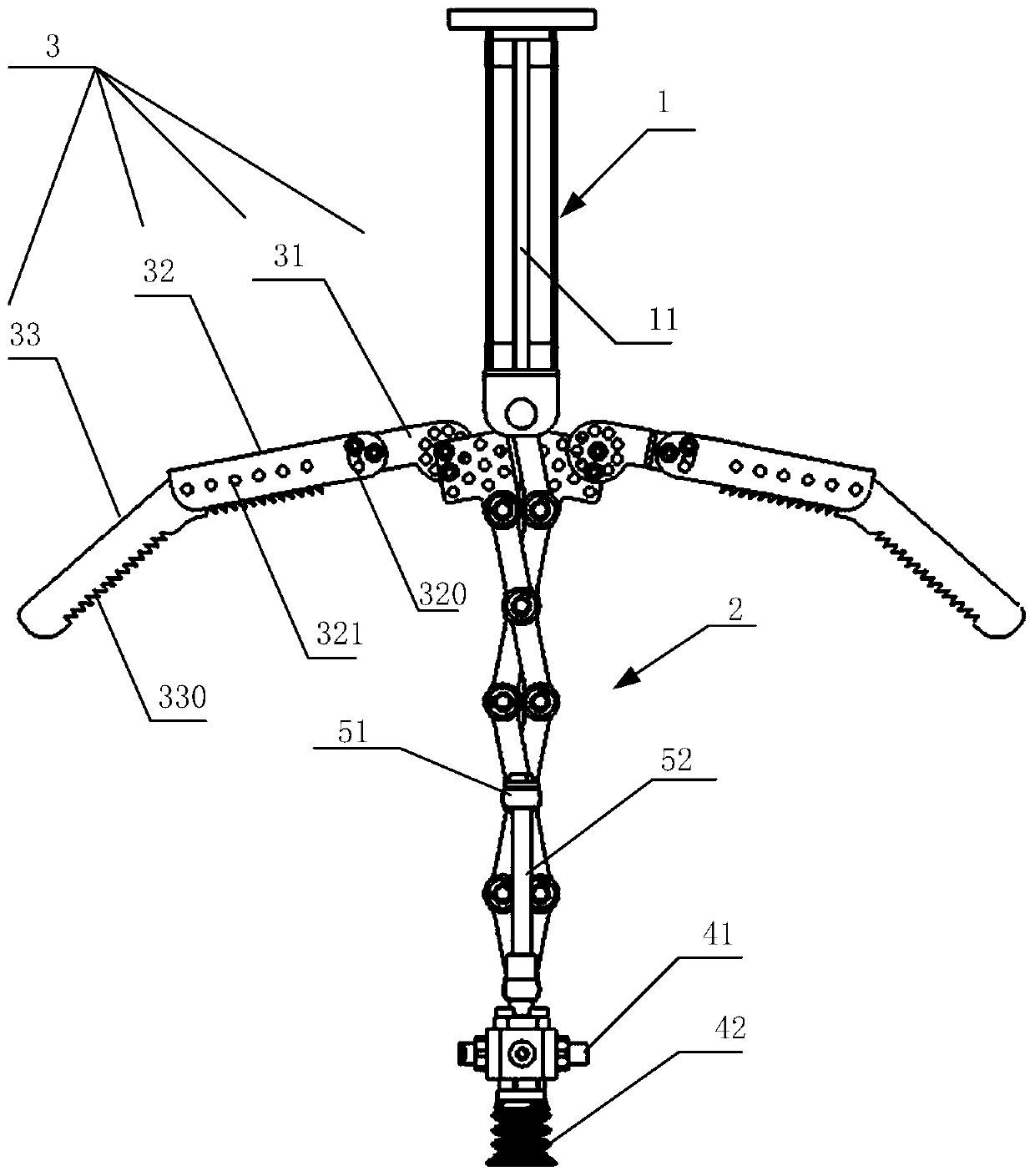

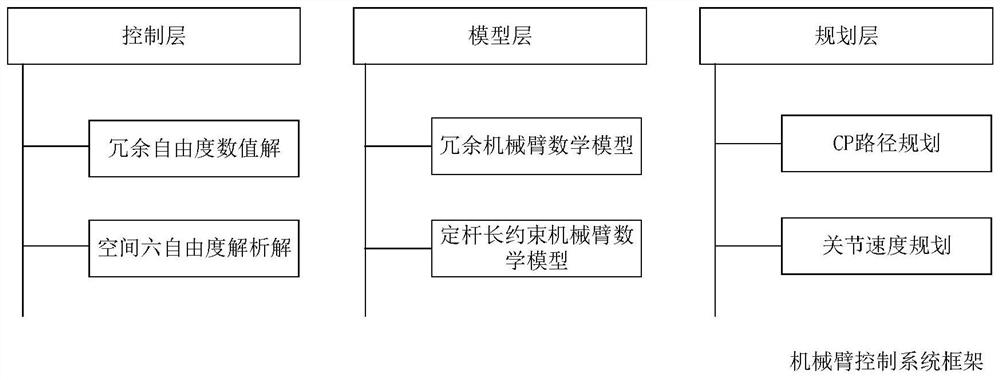

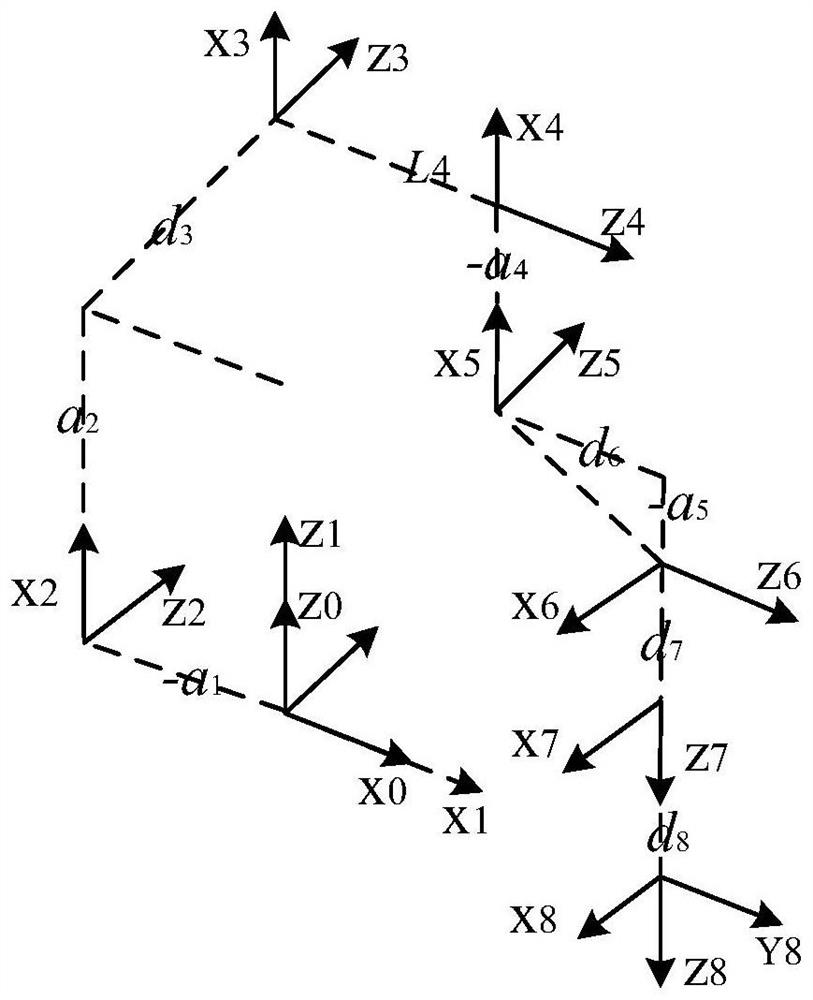

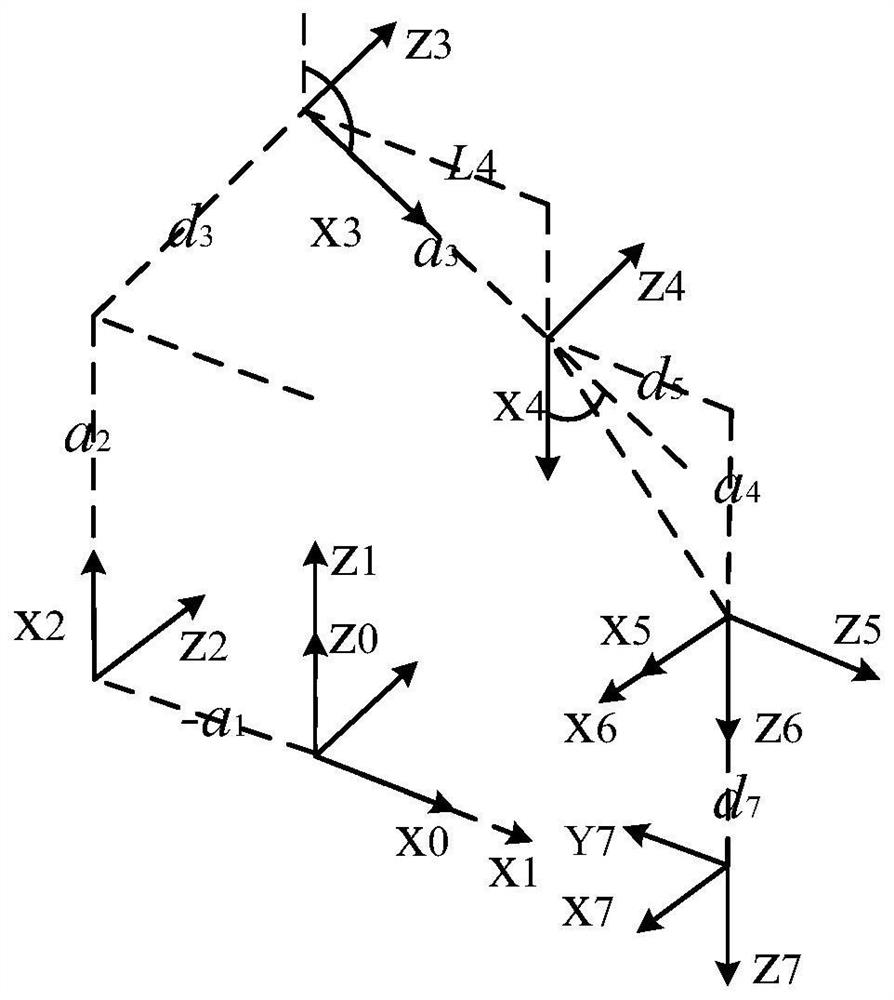

Mechanical arm multi-joint linkage control method

ActiveCN111993414AImprove versatilityGood precisionProgramme-controlled manipulatorMathematical modelControl system

The invention discloses a mechanical arm multi-joint linkage control method. The control method comprises the following steps that firstly, a mechanical arm control system frame is constructed, and the control system frame comprises a control layer, a model layer and a planning layer; secondly, a mechanical arm fixed base coordinate system, a coordinate system of a plurality of arm support jointsand a mathematical model of the plurality of arm support joints under different configurations are arranged on the model layer; then, a kinematics inverse solution algorithm of a mechanical arm underdifferent configurations is constructed on the control layer based on the mathematical model of the plurality of arm frame joints and the use working condition of the mechanical arm; and finally, a trajectory function of each arm support joint of the mechanical arm is planned on the planning layer based on the kinematics inverse solution algorithm. The control method and the control system framework can be popularized to general engineering machinery to realize high-precision and intelligent control of the engineering machinery.

Owner:BEIJING XUANYU INTELLIGENT TECH CO LTD

Dual-purpose mechanical arm for intelligent manufacturing

The invention discloses a dual-purpose mechanical arm for intelligent manufacturing, and belongs to the technical field of intelligent manufacturing mechanical arms. According to the dual-purpose mechanical arm for intelligent manufacturing, a dual-motor mechanism is arranged in a driving mechanism to drive overall device driving, and a servo motor on one side is started to rotate backwards to drive an air inlet driving mechanism; due to the fact that a ratchet wheel is arranged in the upper end of a linkage mechanism, the linkage mechanism is not driven to rotate at this moment, a movable chassis is driven to move, and a grabbing claw is driven to open; then after the mechanical arm is moved to a designated spot, a servo motor on the other side is started to rotate backwards, the air inlet driving mechanism is driven to move, the movable chassis is driven to move, and the grabbing claw is driven to grab designated articles; and after the grabbing claw is closed at an idle state, a cross screwdriver is formed at the front end, and screw mounting work can be conducted.

Owner:姜超

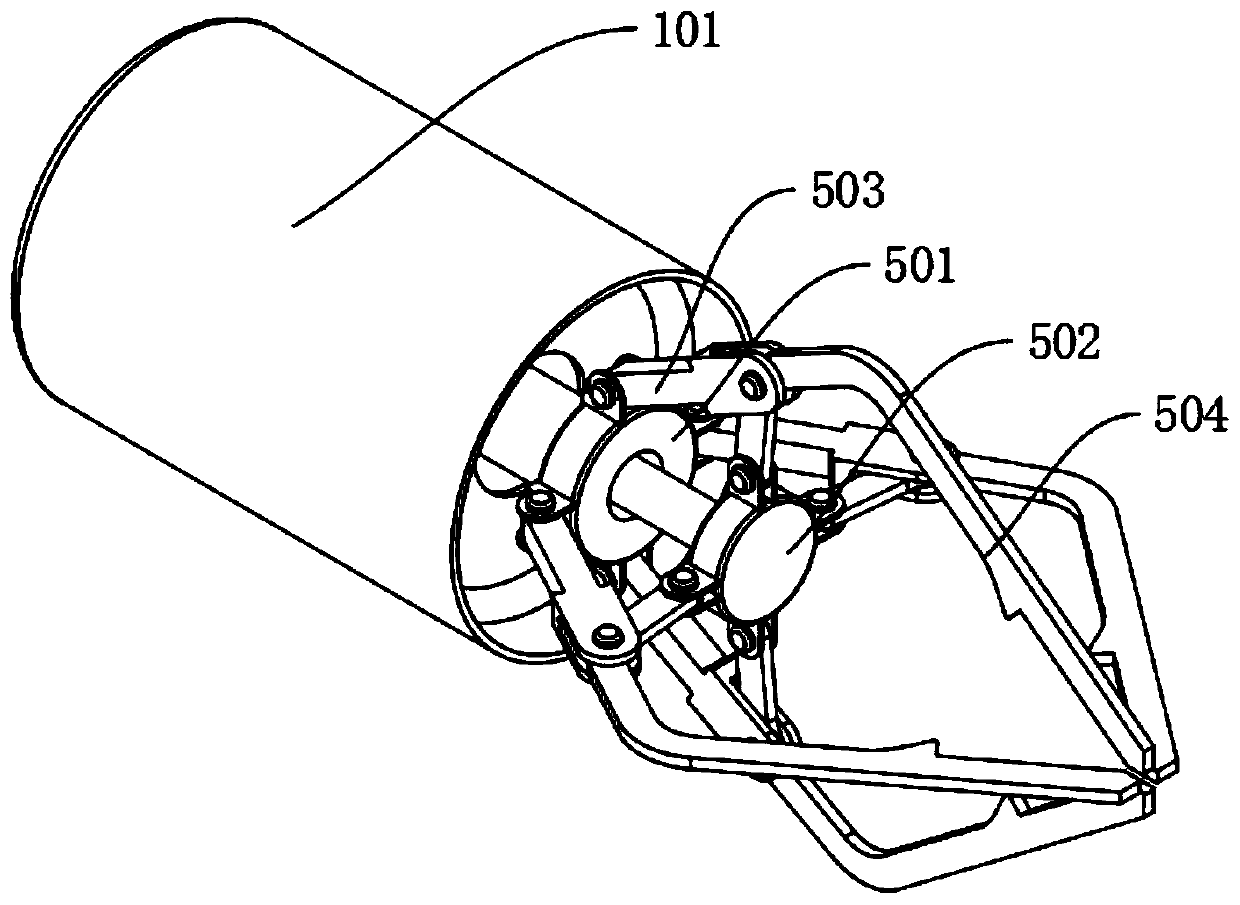

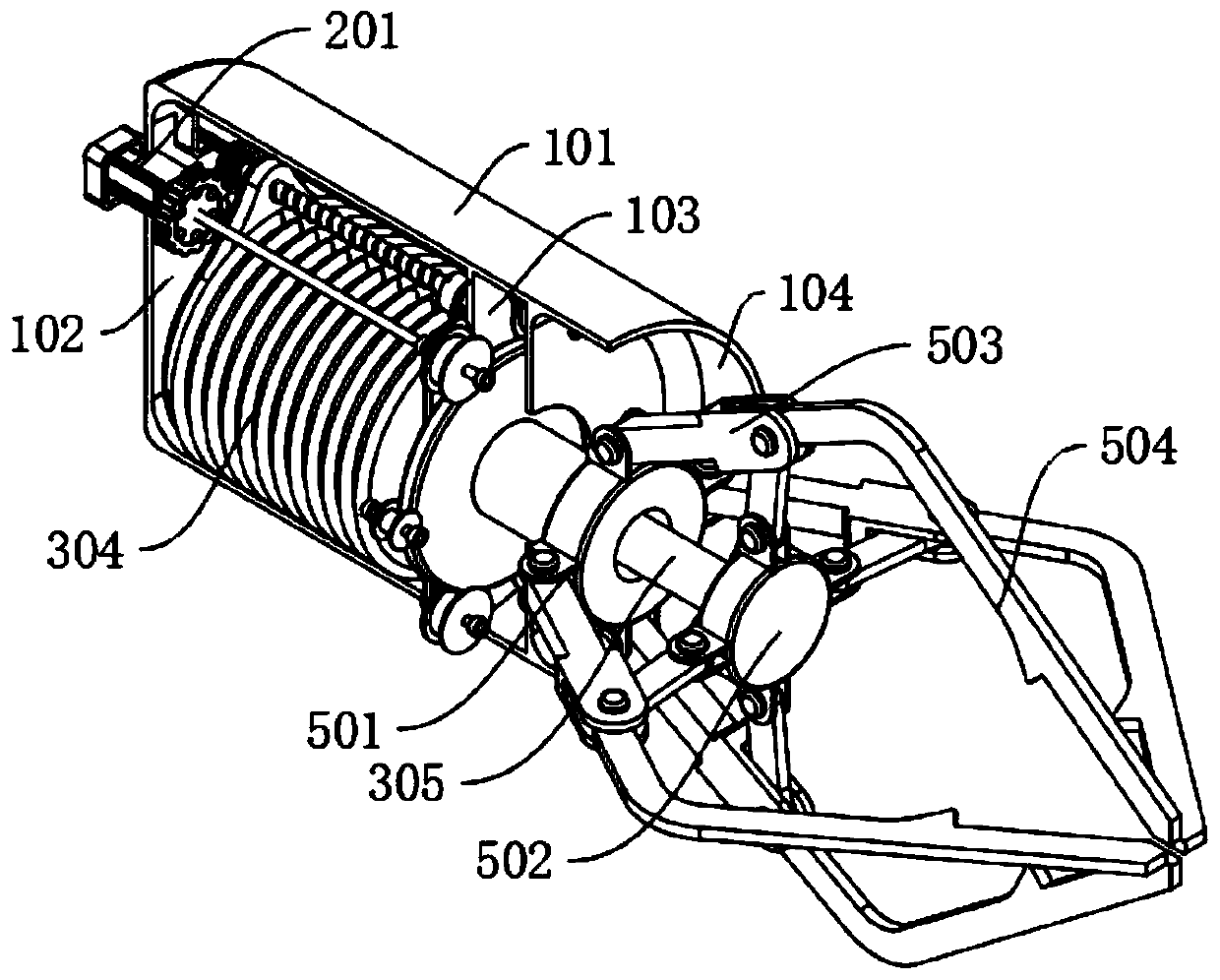

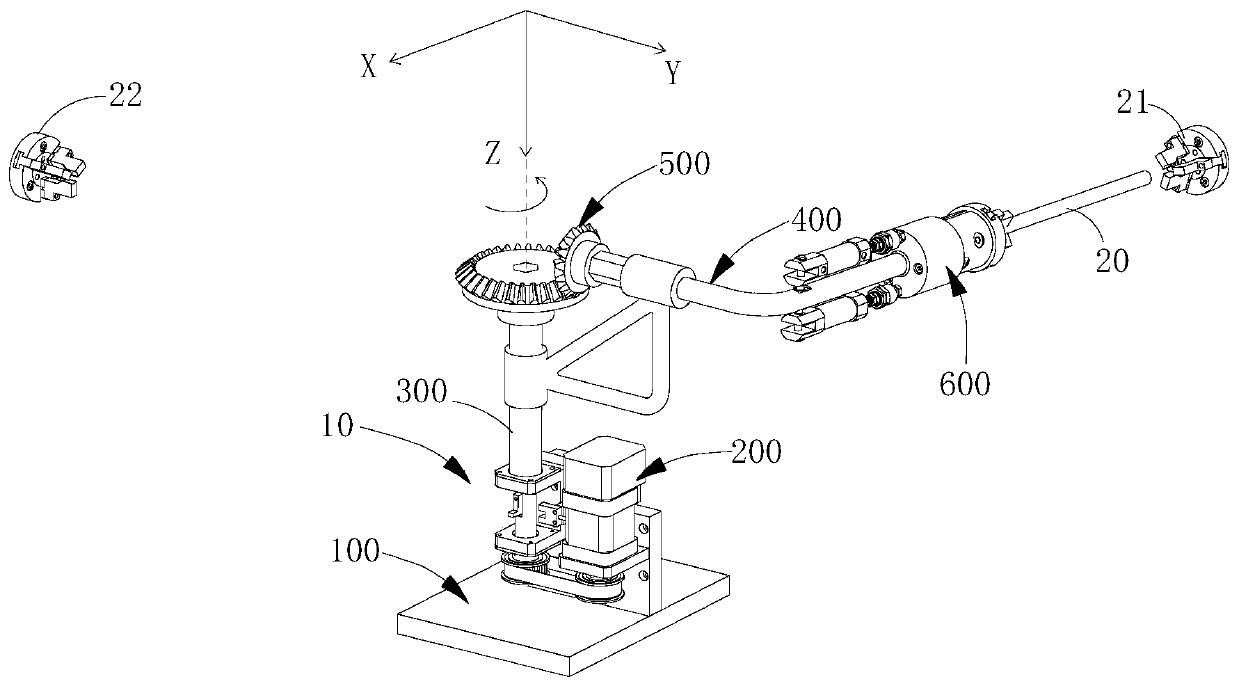

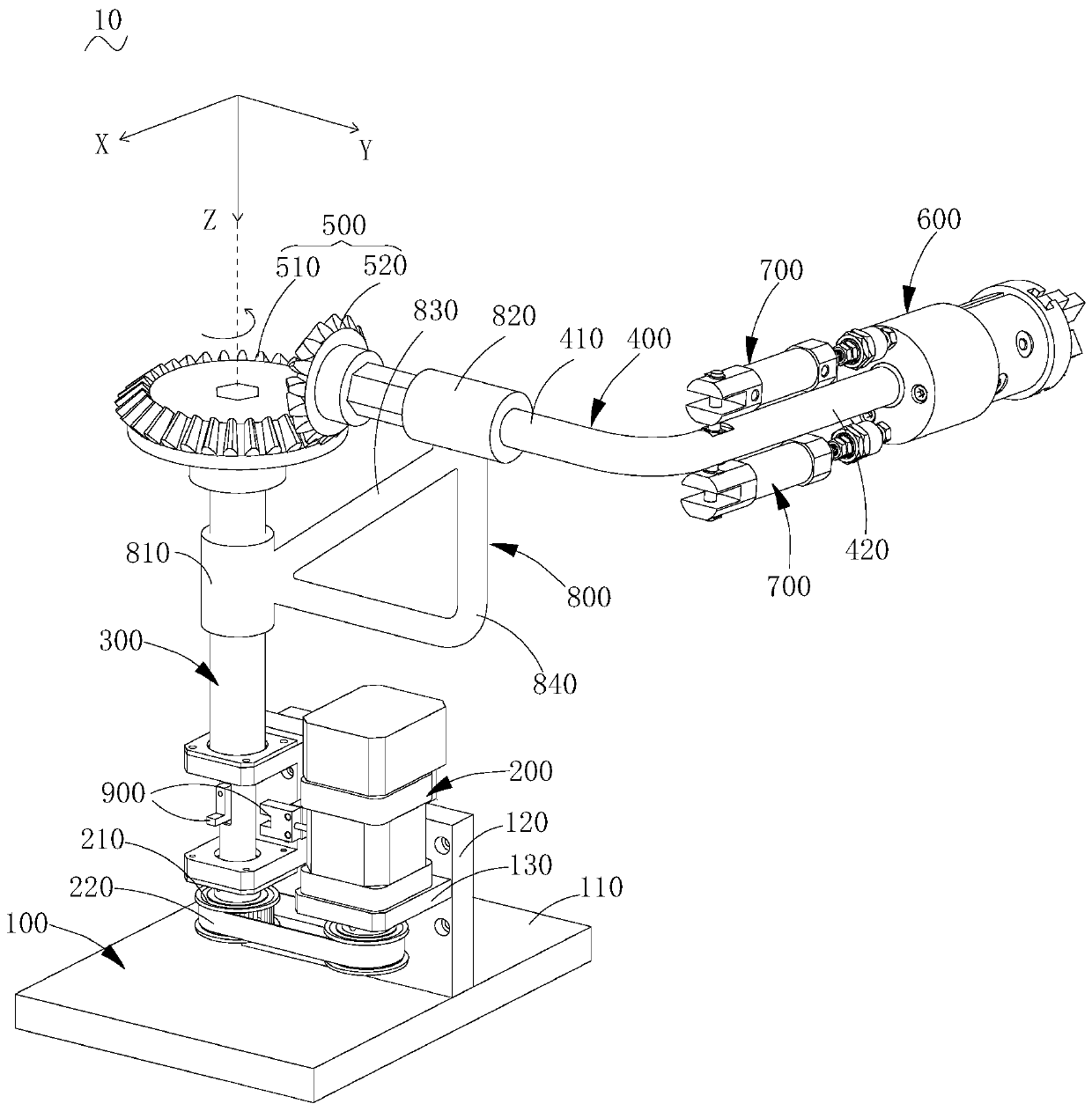

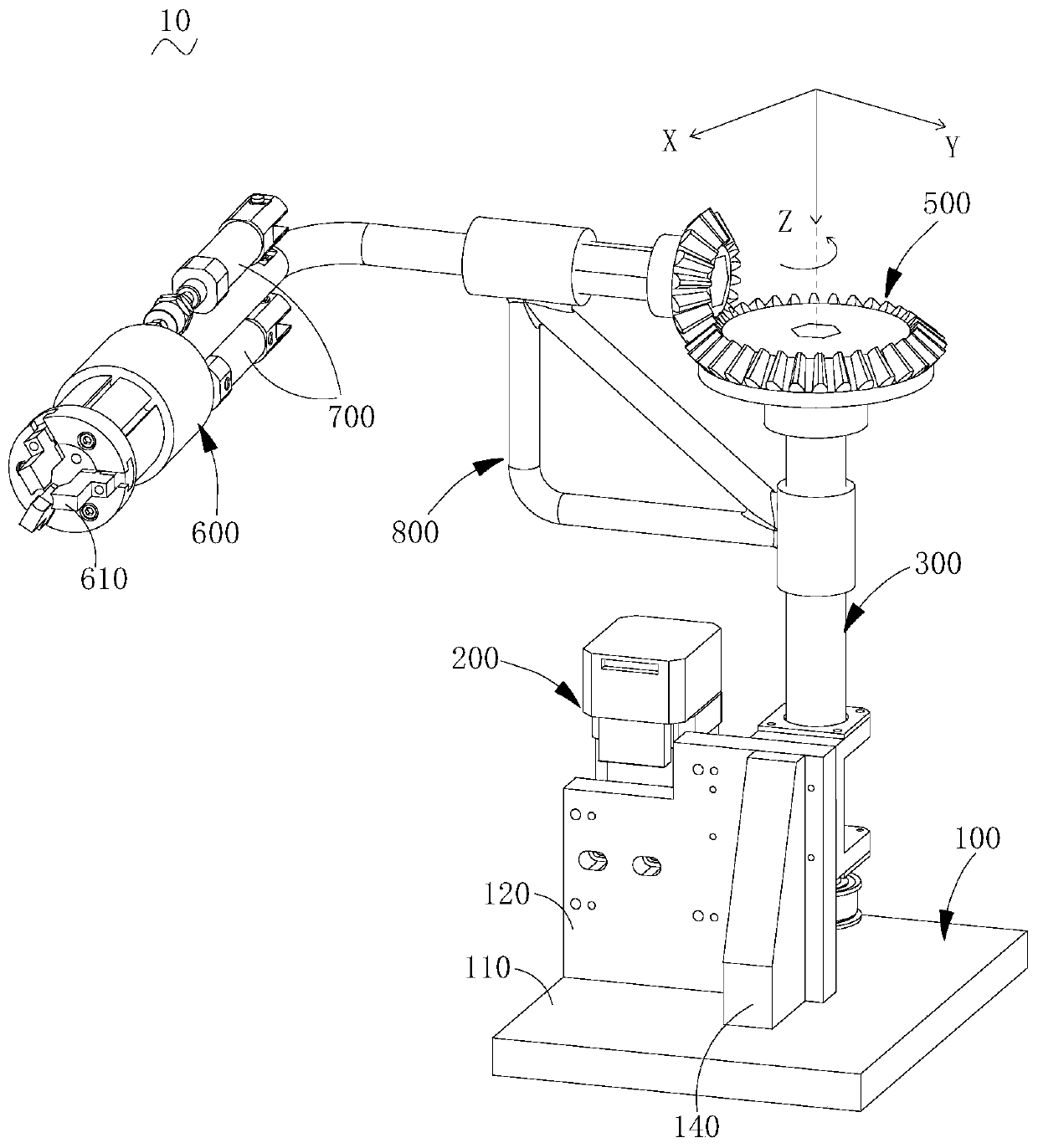

robotic arm

ActiveCN107097219BSimple structureEasy to debugProgramme-controlled manipulatorGripping headsDrive shaftClassical mechanics

Owner:GUANGDONG EVERWIN PRECISION TECH

Square tube two-way synchronous bending machining device for mechanical equipment production and assembly

InactiveCN112157150ASame lengthSmooth rotationMetal-working feeding devicesPositioning devicesGear driveGear wheel

The invention provides a square tube two-way synchronous bending machining device for mechanical equipment production and assembly. The square tube two-way synchronous bending machining device comprises arc-shaped base plates; L-shaped supporting frames A are further slidably mounted at the outer sides of the arc-shaped base plates correspondingly, the L-shaped supporting frames A are slidably mounted in adjusting grooves A through clamping plates at the bottoms of the L-shaped supporting frames A, threaded cylinders are further connected to the bottoms of the clamping plates, and adjusting screw rods are inserted into the threaded cylinders in a penetrating manner and engaged with the threaded cylinders correspondingly; and a driving mechanism is installed at the inner side of a machiningplatform and is in transmission connection with tube bending linkage gears on the tube bending mechanisms, the front end of a discharging push rod is of a U-shaped structure and is connected with twosets of L-shaped supporting frames B, and the rear end of the discharging push rod is connected with an inner baffle, then penetrates through a U-shaped frame and is sleeved with a reset spring. theadjusting screw rods drive the two L-shaped supporting frames A to conduct synchronous sliding adjustment so that the bent lengths of the two ends of a square tube can be kept consistent all the time,the bent square tube can be pushed out by pushing an outer baffle and the L-shaped supporting frames B, and the square tube returns under the action of the reset spring and the inner baffle after being loosened.

Owner:林召怀

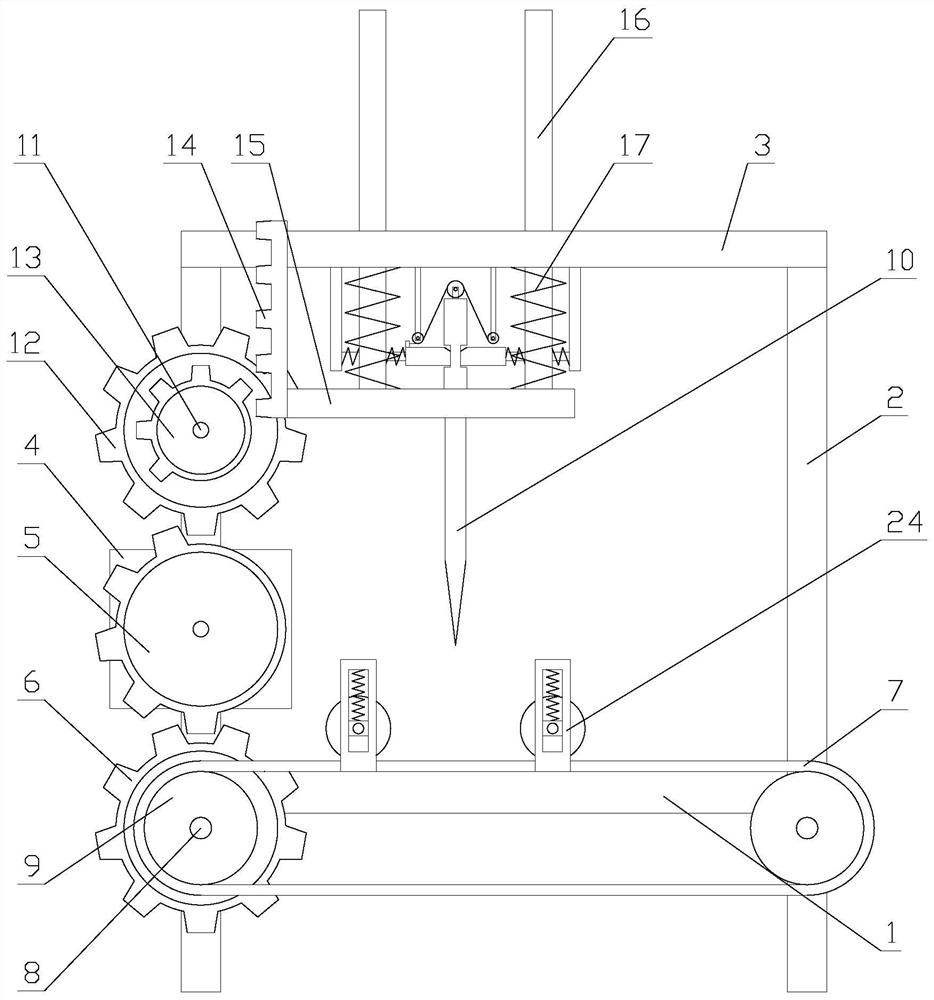

Automatic continuous punching device for metal plate

InactiveCN113102612ARealization of continuous punchingRealize online punchingPerforating toolsMetal-working feeding devicesPunchingLinkage (mechanical)

The invention relates to an automatic continuous punching device for a metal plate. The automatic continuous punching device for the metal plate comprises a base, a supporting rod, a cross rod, a driving mechanism, a conveying mechanism and a punching mechanism, the conveying mechanism is arranged on the base, and the punching mechanism is arranged above the conveying mechanism. According to the automatic continuous punching device for the metal plate, the conveying mechanism and the punching mechanism are driven by the driving mechanism to intermittently operate, continuous punching of workpieces is achieved, and compared with an existing punching device, the automatic continuous punching device has the advantages that operation of the conveying mechanism and the punching mechanism is achieved through one output end, energy is saved, meanwhile, linkage is adopted by the conveying mechanism and the punching mechanism, online punching of the workpieces is achieved, the linkage adopts a pure mechanical structure, the stability of the device is improved, and the service life of the device is prolonged. Compared with an existing punching mechanism, the mechanism adopts the mechanical structure to replace air cylinder driving, the stability is improved, meanwhile, the movement of a movable rod is buffered and positioned through a positioning assembly, the device runs more stably, and the practicability is improved.

Owner:深圳市迅成科技有限公司

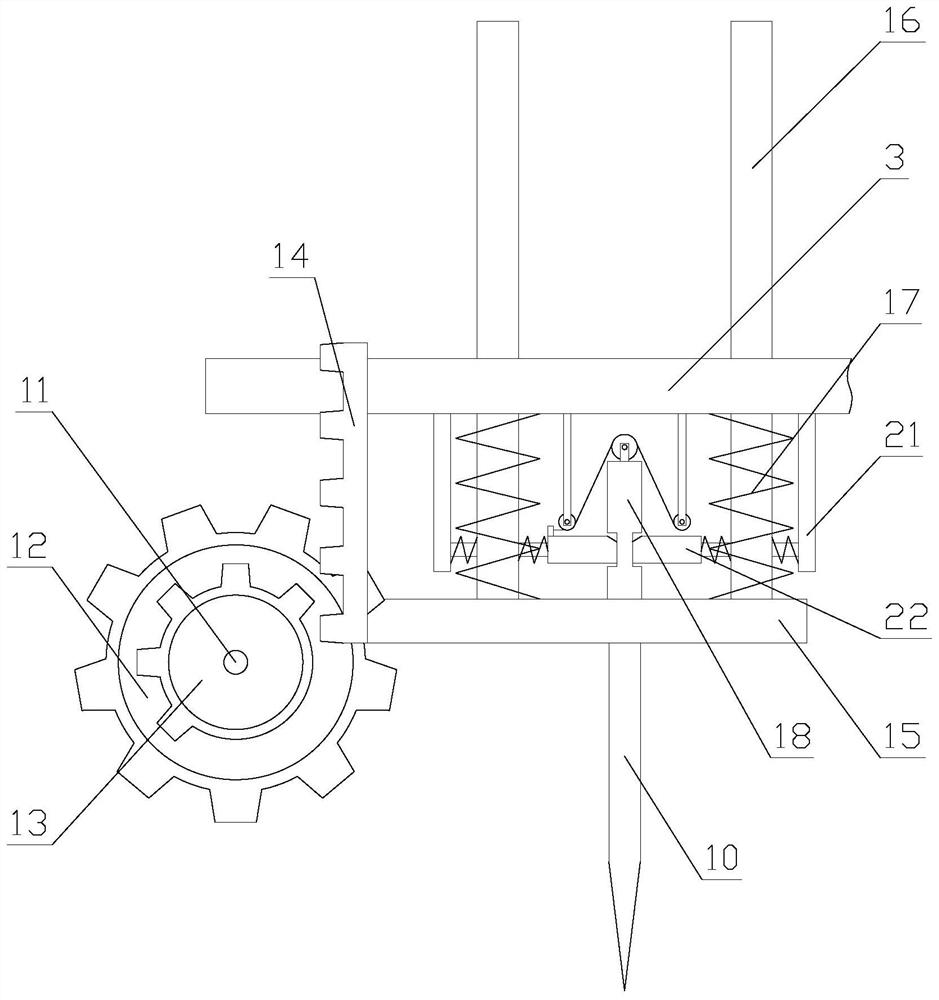

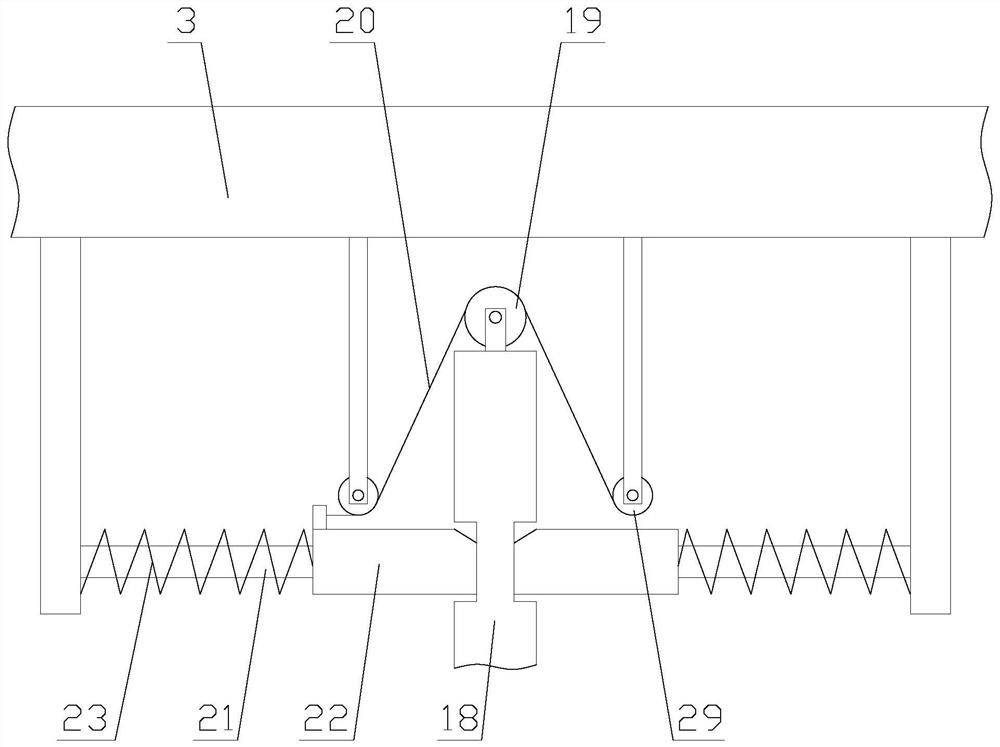

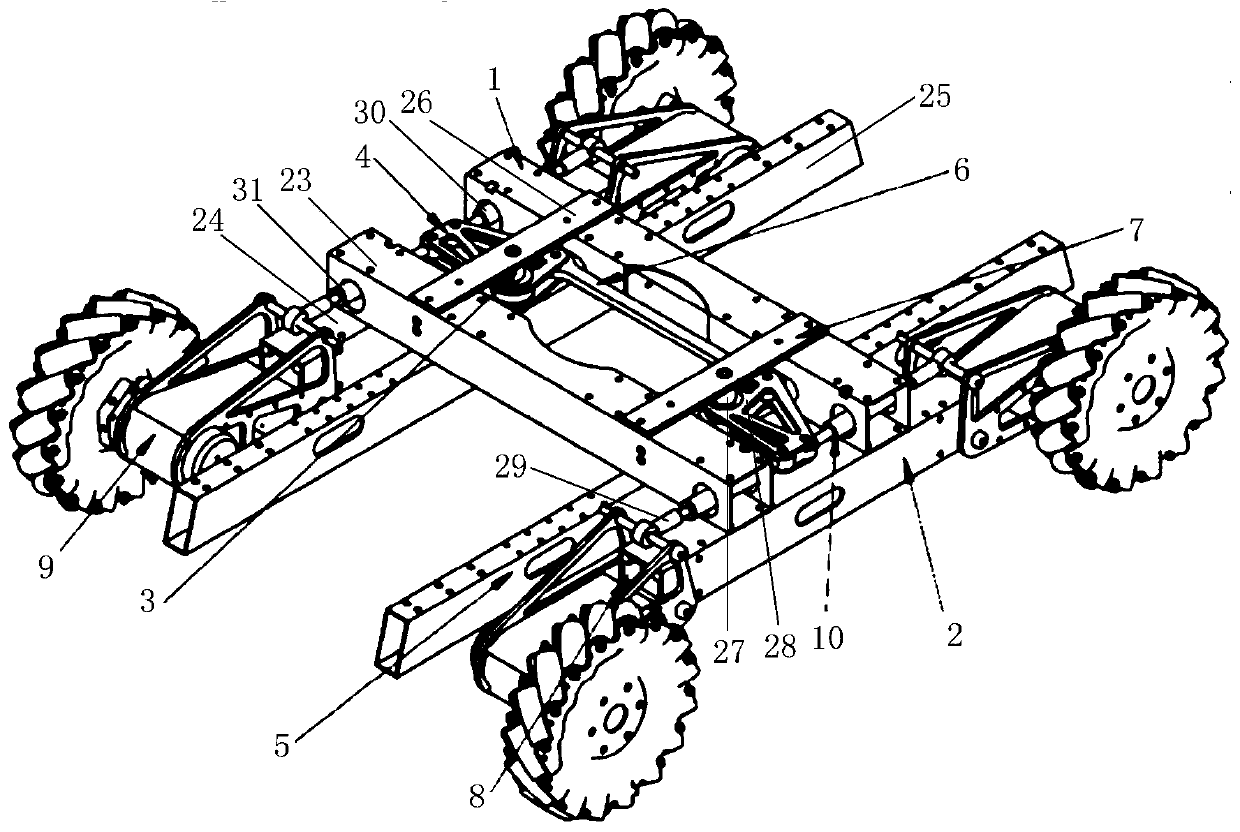

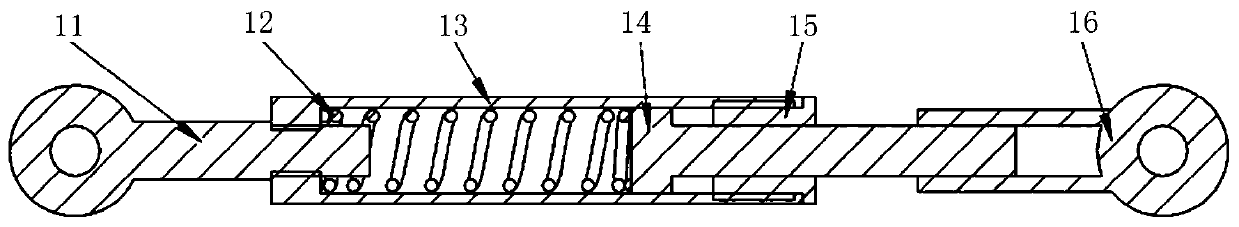

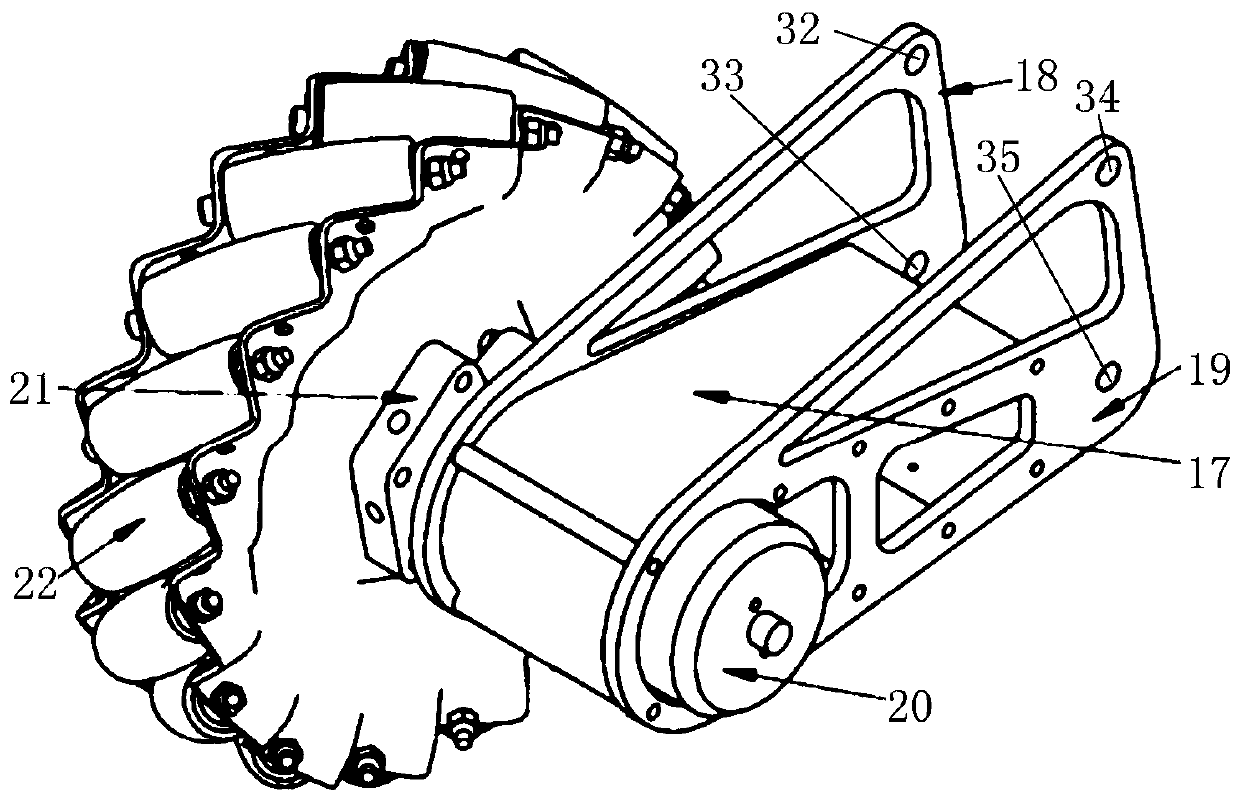

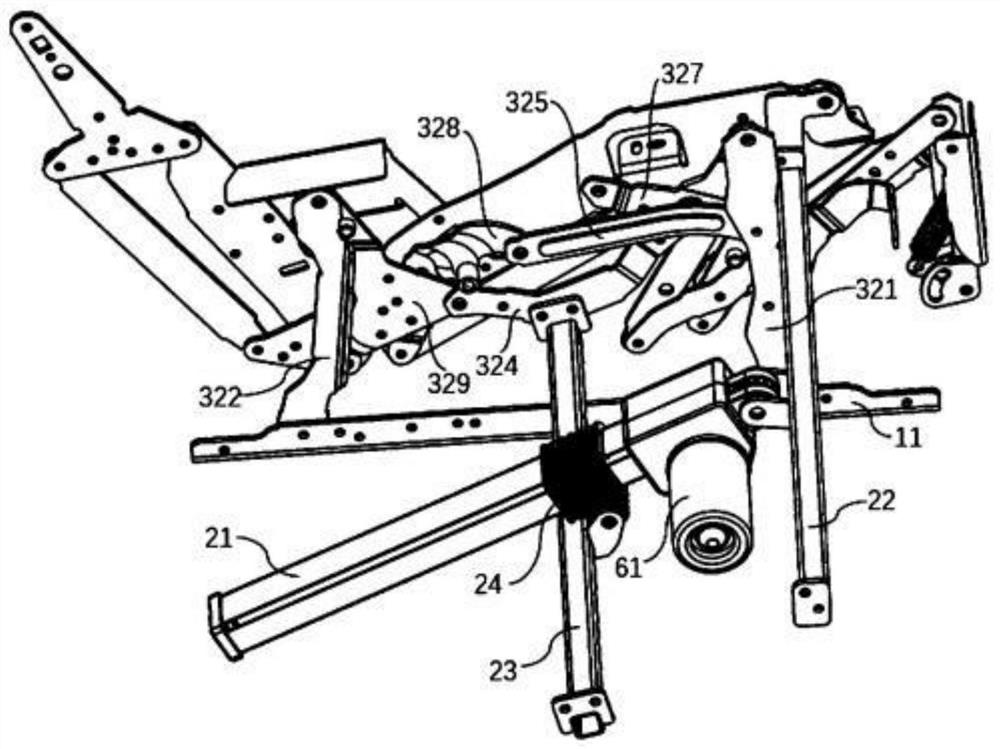

Self-adaptive suspension chassis system based on mechanical connecting rod mechanism

ActiveCN111267569ASolve shakingSolve the tilt phenomenonInterconnection systemsResilient suspensionsLinkage (mechanical)Control theory

The invention provides a self-adaptive suspension chassis system based on a mechanical connecting rod mechanism, and belongs to the technical field of robot chassis. The self-adaptive suspension chassis system comprises a completely non-independent connecting rod suspension, a chassis frame and four Mecanum wheel sets; the completely non-independent connecting rods are suspended on the chassis frame; and a connecting rod type spring damping device is arranged on the completely non-independent connecting rod suspension, wherein the two Mecanum wheel sets are symmetrically installed on one sideof the chassis frame and connected with the completely non-independent connecting rods in a suspended mode through the connecting rod type spring damping devices respectively, and the other two Mecanum wheel sets are symmetrically installed on the other side of the chassis frame and connected with the completely non-independent connecting rods in a suspended mode through the connecting rod type spring damping devices respectively. The connecting rod type spring damping device is adopted, so that the system can adapt to various special terrains, the phenomena of shaking and inclining caused bythe fact that the adjacent wheels move in the same direction during speed changing and turning are effectively avoided, and the system is high in impact resistance, stable in connection and high in practicability.

Owner:SHANGHAI JIAO TONG UNIV

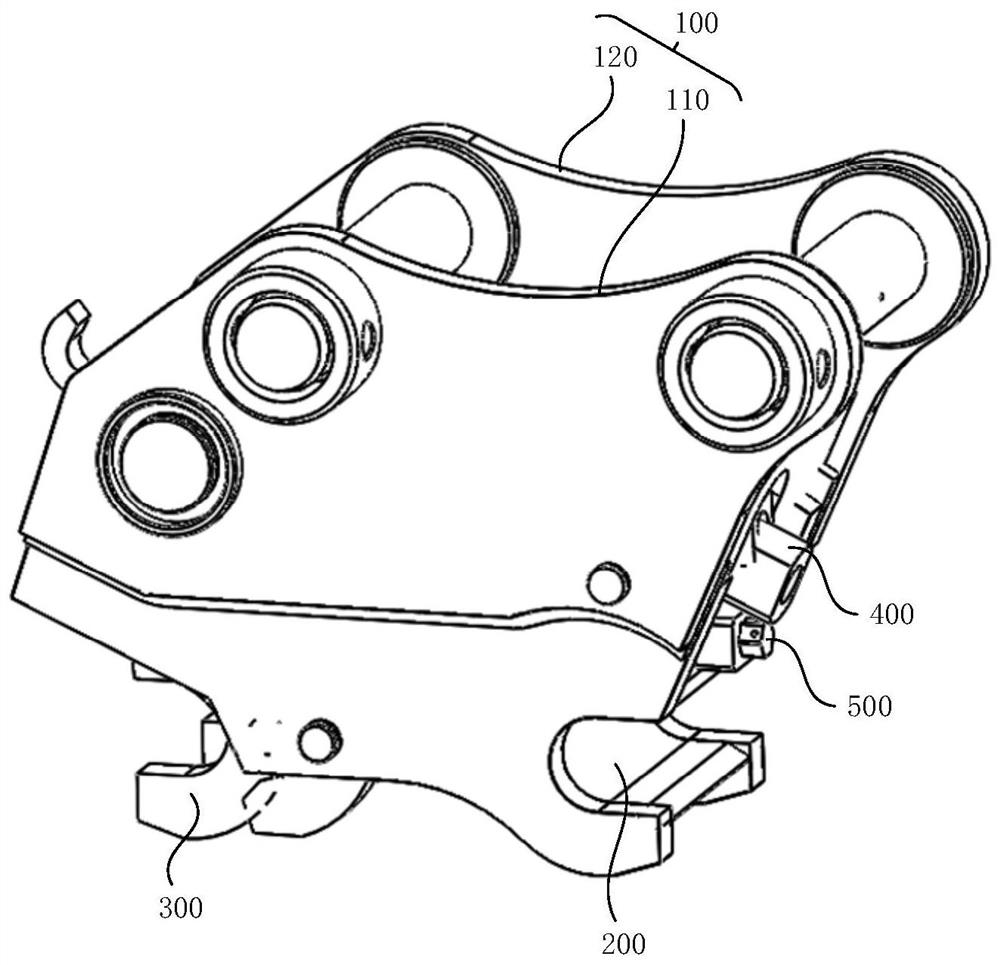

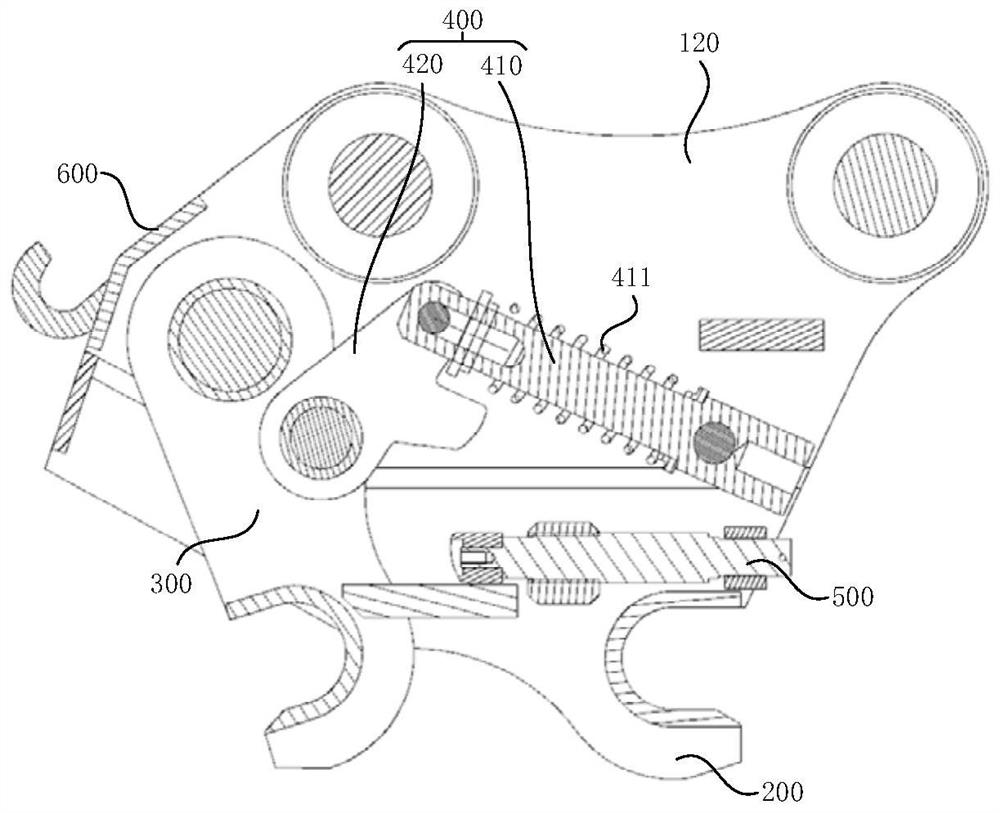

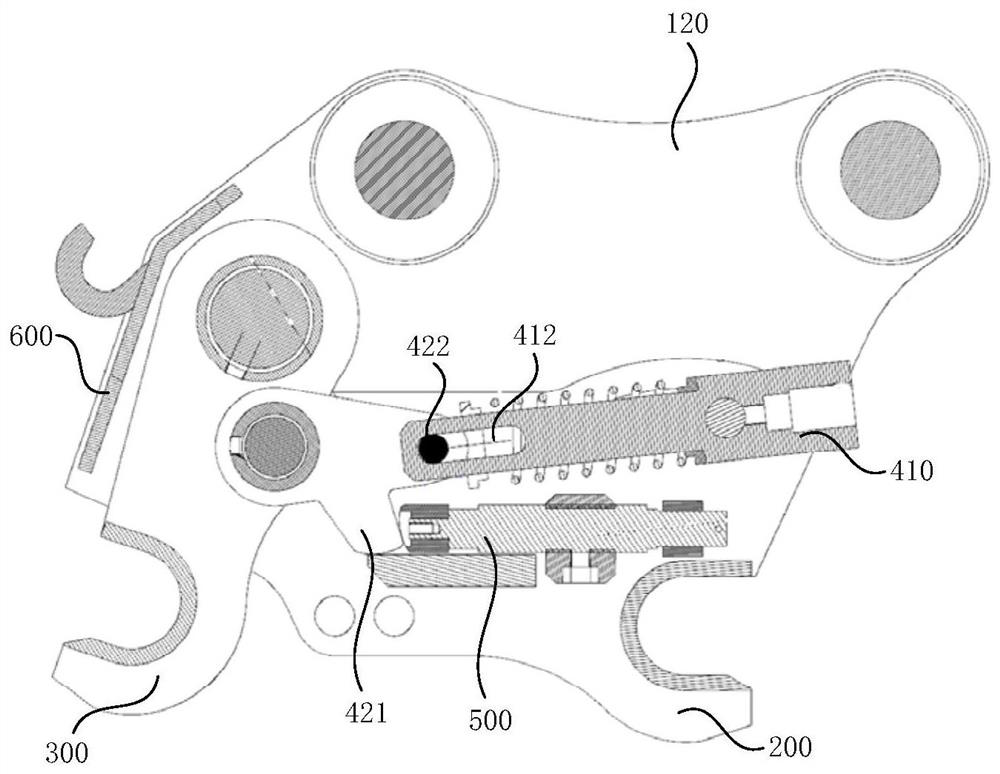

Connecting device and excavator

ActiveCN112267501AQuick releaseReduce the difficulty of replacementMechanical machines/dredgersControl engineeringConnection - action

The invention provides a connecting device and an excavator, and relates to the technical field of engineering machinery. The connecting device comprises a rack, an action mechanism, a main hook, a lock hook and a lock catch piece; the main hook is fixedly connected to the rack; the action mechanism comprises a driving piece and a linkage piece; the driving piece and the lock hook are rotationallyconnected with the rack separately; the driving piece is rotationally connected to the lock hook through the linkage piece; the driving piece drives the linkage piece to drive the lock hook to rotatein the direction away from or close to the main hook to be matched with the main hook to be connected with or separated from the accessory; and the lock catch piece is used for abutting against the action mechanism to lock the action mechanism when the lock hook is in the state of being connected with the accessory. According to the invention, the lock hook in the connecting device is matched with the main hook and the accessory in a moving mode to be detachably connected, and the accessory can be rapidly disassembled by operating the lock catch piece and the driving piece so that the accessory replacement difficulty can be reduced, and meanwhile the accessory replacement efficiency can be improved. The mechanical connection mode can effectively simplify a hydraulic control structure in the prior art, and the problem that a hydraulic system is complex in arrangement is avoided.

Owner:SANY HEAVY MACHINERY

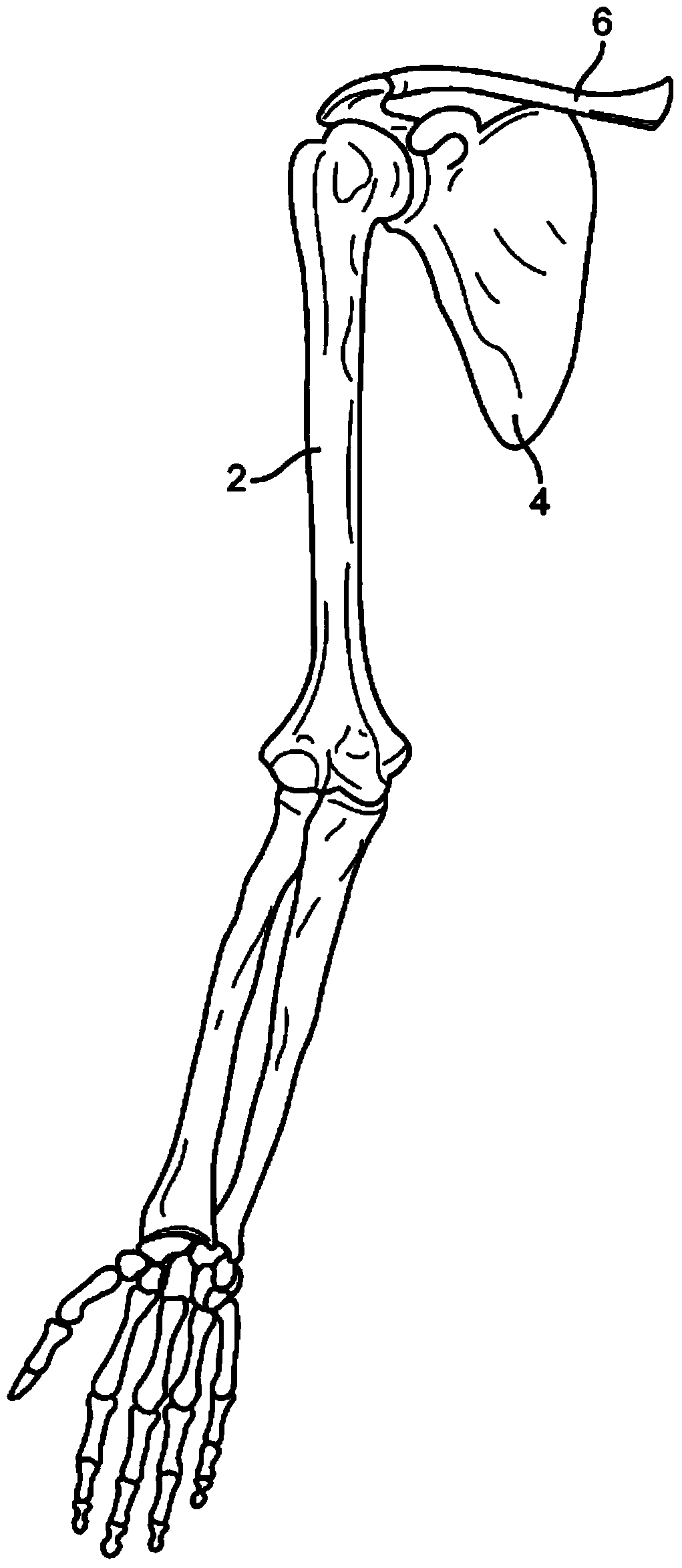

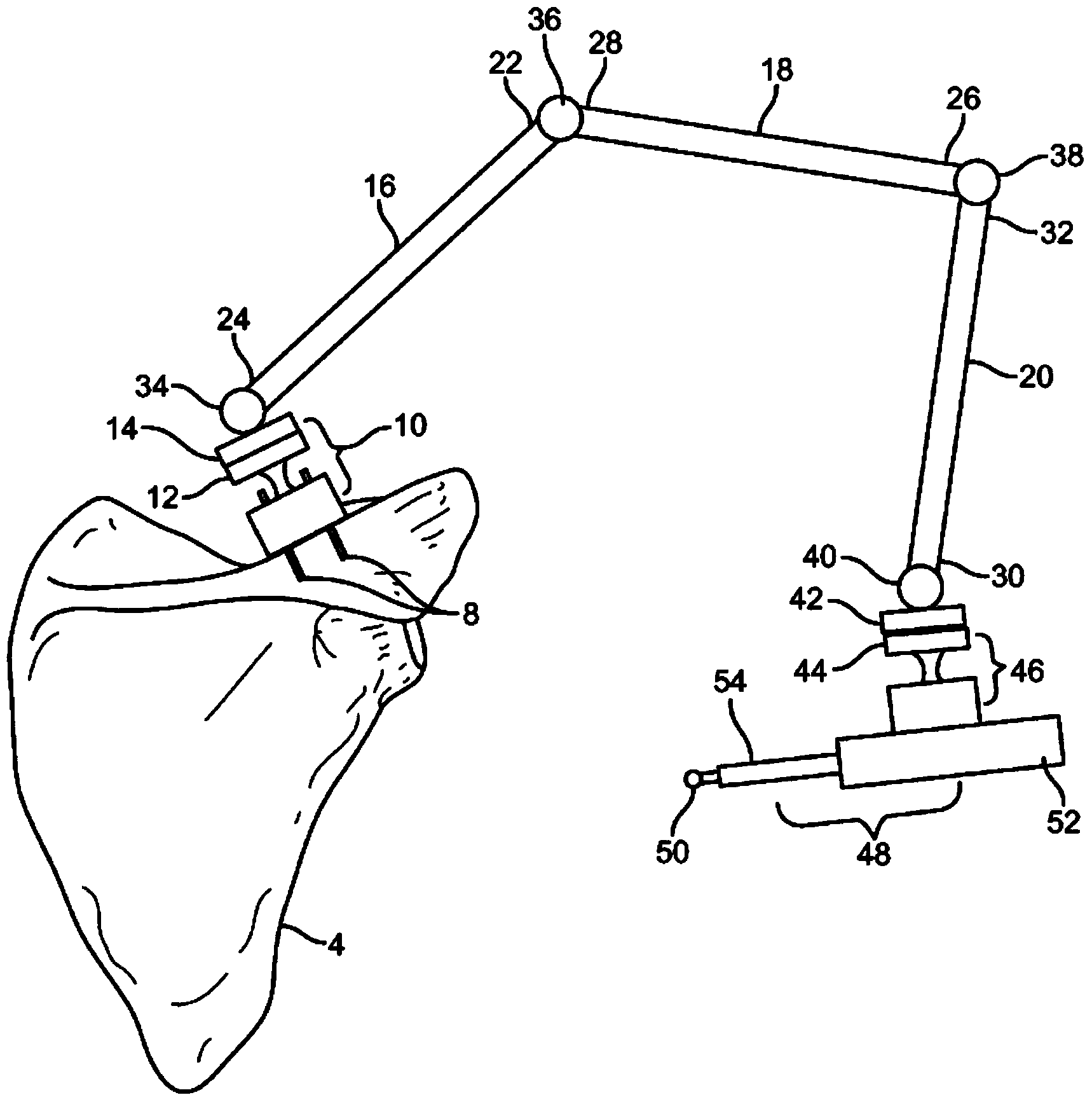

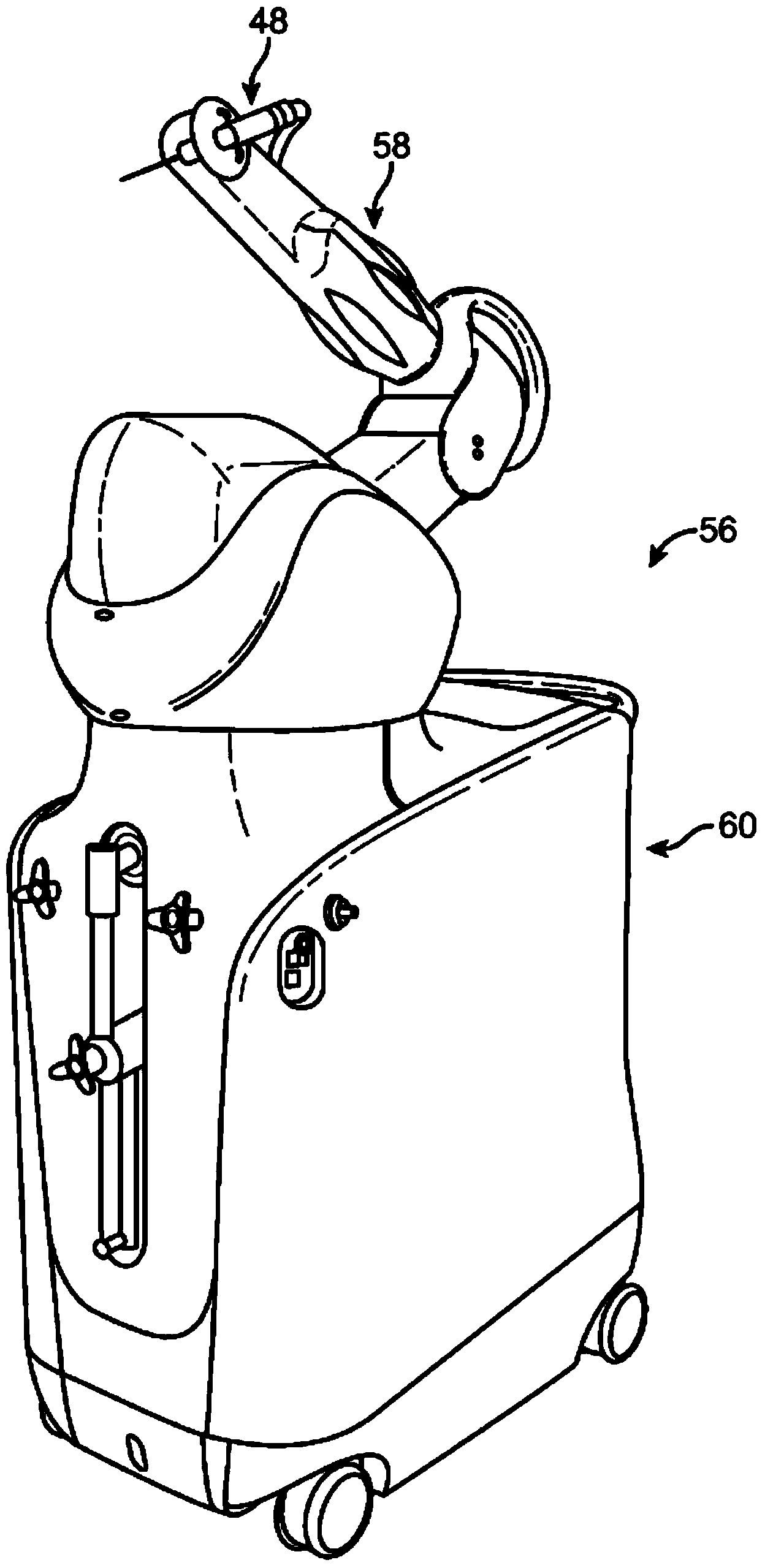

System for surgical tool tracking

Systems and methods for robotic surgery are disclosed. In one embodiment, a system comprises a controller configured to control actuation of at least one servo motor; a surgical instrument configured to be movable in a workspace controlled, at least in part, by actuation of the at least one servo motor; and a mechanical tracker linkage coupled between the elongate instrument and a portion of skeletal anatomy of a patient, the tracker linkage comprising one or more joints associated with one or more joint rotation sensors and being configured to send joint signals to the controller; wherein the controller controls positioning of the instrument based at least in part upon the joint signals received from the mechanical tracker.

Owner:MAKO SURGICAL CORP

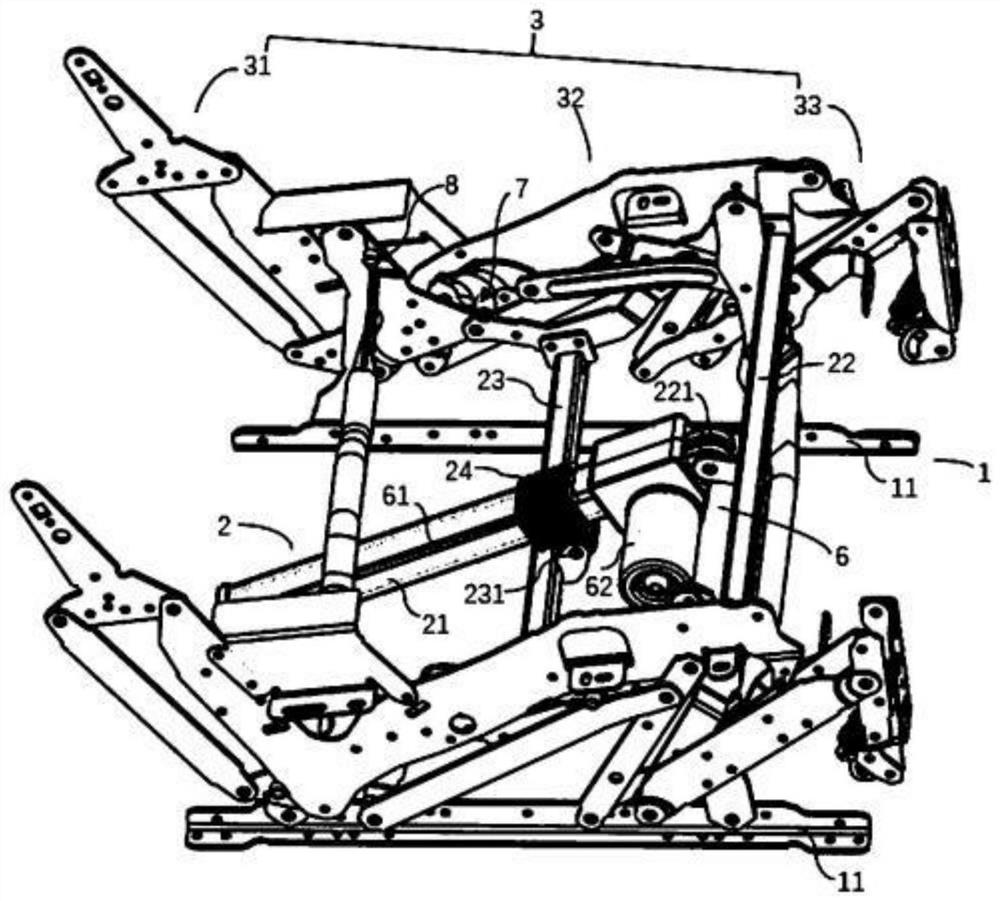

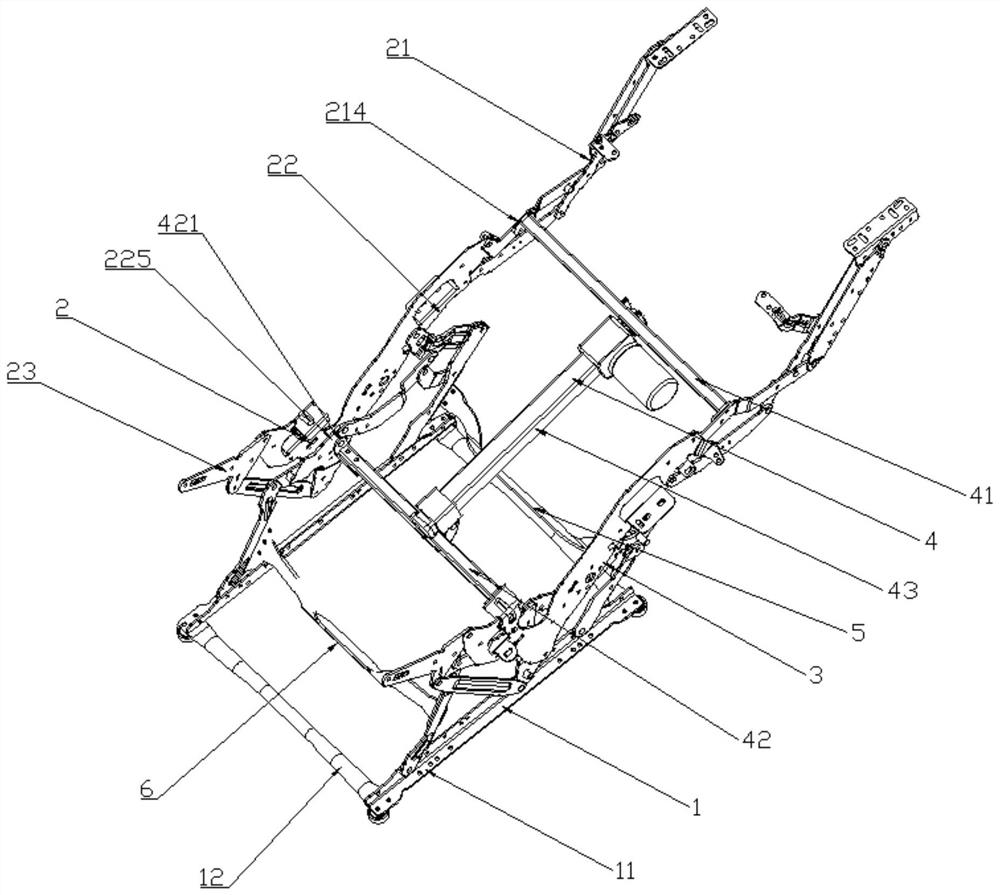

Novel motor-driven mechanical stretching device

PendingCN112545236AGuaranteed linkage functionSimple structureSofasCouchesElectric machineryLinkage (mechanical)

The invention discloses a novel motor-driven mechanical stretching device. The improved novel motor-driven mechanical stretching device comprises a left side component and a right side component whichare symmetrical, the left side component comprises a leg stretching mechanism, a seat plate linkage mechanism and a backrest mechanism, the seat plate linkage mechanism comprises a front mounting piece, one end of the front mounting piece is pivoted to the front portion of a bottom connecting rod, the other end of the front mounting piece is pivoted with a first front rotating piece, the middle of the front mounting piece is pivoted with a second front rotating piece, the other end of the second front rotating piece is pivoted with a side connecting rod piece, the front end of the side connecting rod piece is pivoted with the middle of the first front rotating piece, the rear end of the side connecting rod piece is pivoted with a rear rotating piece which is pivoted with a rear mounting piece, the other end of the rear mounting piece is pivoted to the rear end of the bottom connecting rod, and the rear rotating piece and the front rotating piece I are pivoted with an assembling side plate simultaneously. The problems that an existing seat plate linkage mechanism is complex in structure, large in number of parts, high in manufacturing cost and high in clamping stagnation risk are solved.

Owner:沙剑波

Flexible robotic arm and system assembly

ActiveCN108942906BConvenient and flexible engineering application designReduce the number of speciesProgramme-controlled manipulatorJointsRobotic armClassical mechanics

Disclosed is a flexible mechanical arm, comprising multiple arm lever joint segments (11, 12, 13) and corresponding central blocks (21, 22), wherein each arm lever joint segment is connected to the central block by means of a rotary connection mechanism to form a unit of an arm lever main body; and a plurality of units form the arm lever main body. The flexible mechanical arm further comprises linkage ropes (51, 52), wherein the linkage between adjacent arm lever joint segments and between adjacent central blocks is realized by means of the linkage ropes; and at least part of the linkage rope is S-shaped. In the solution, the method with a modularized unit and the stress state of a linkage process of the linkage rope are more rational than the existing technical solutions, and the linkage accuracy thereof is higher.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com