Square tube two-way synchronous bending machining device for mechanical equipment production and assembly

A technology of production assembly and two-way synchronization, which is applied in the field of mechanical processing, can solve the problems of consistency, the square tube is easy to get stuck between the fixed wheel and the bending wheel, and the bending length at both ends of the square tube cannot be guaranteed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

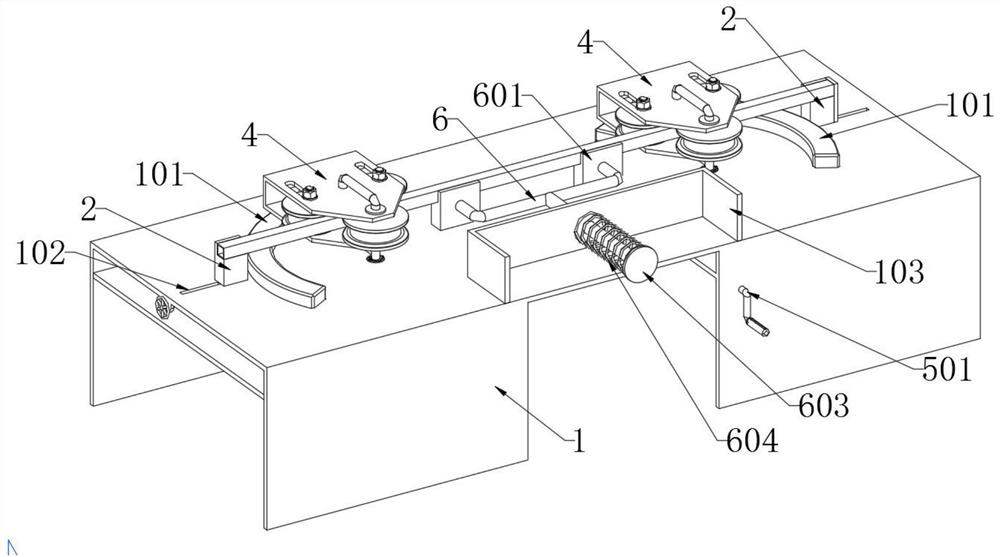

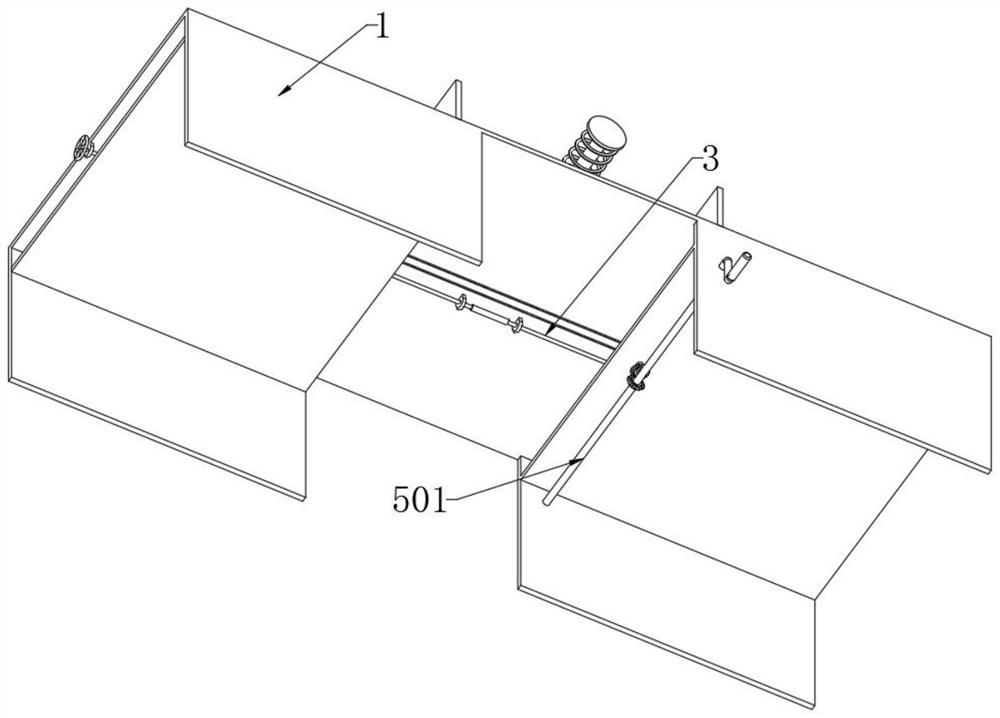

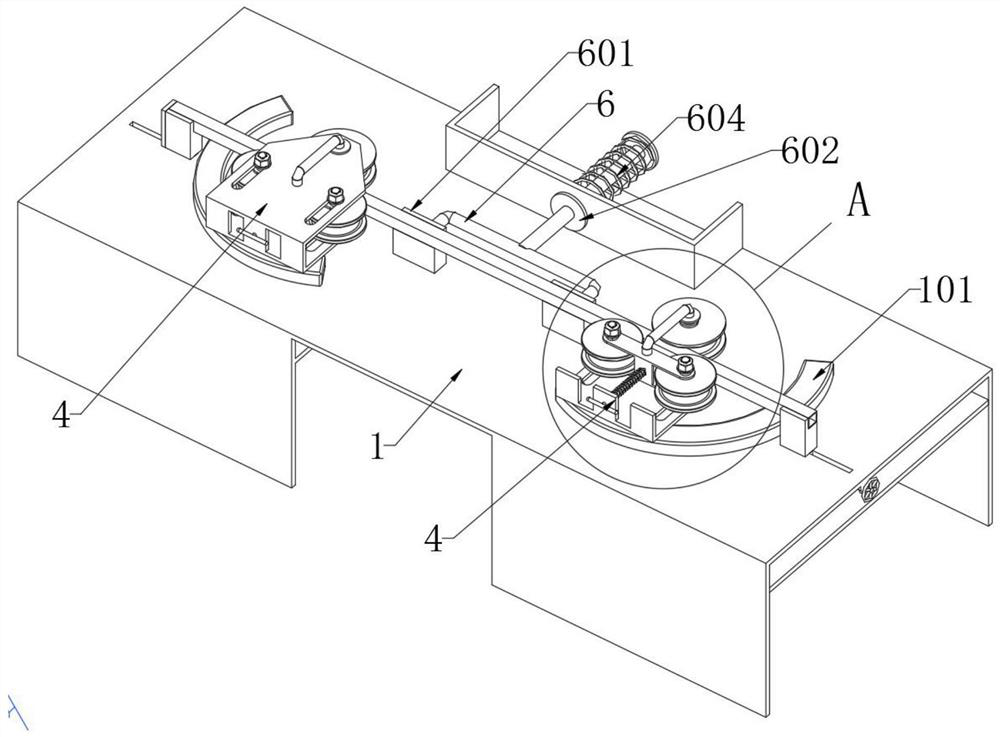

[0036] as attached figure 1 to attach Figure 10 Shown:

[0037] The invention provides a two-way synchronous bending processing device for square tubes used in the production and assembly of mechanical equipment, including a bending mechanism 4, a driving mechanism 5, and a discharge push rod 6; the bending mechanism 4 is provided with two groups, which are respectively rotated and installed on the processing platform 1, and the bottom side of the bending mechanism 4 are equipped with arc backing plates 101, the arc backing plates 101 are symmetrically installed on the two ends of the processing platform 1, and the outer sides of the arc backing plates 101 are respectively slidably installed There is an L-shaped support frame A2, and the L-shaped support frame A2 is slidably installed in the adjustment groove A102 through the clamp plate 201 at the bottom. The bottom of the clamp plate 201 is also connected with a threaded cylinder 2011, and the threaded cylinder 2011 is res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com