Five-axis linkage loading test device and loading test method for machine tool

A technology of five-axis linkage machine tool and loading test device, which is applied in measurement devices, testing of machine/structural components, instruments, etc., can solve the problems of low measurement efficiency, large waste of resources, large consumption of time and materials, etc. Avoid cutting, high real-time, cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

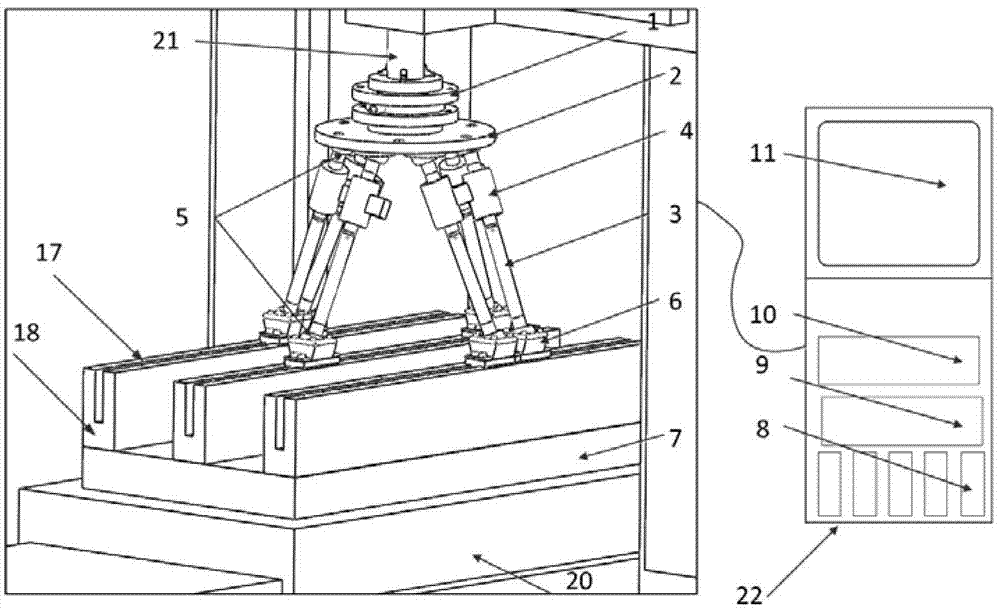

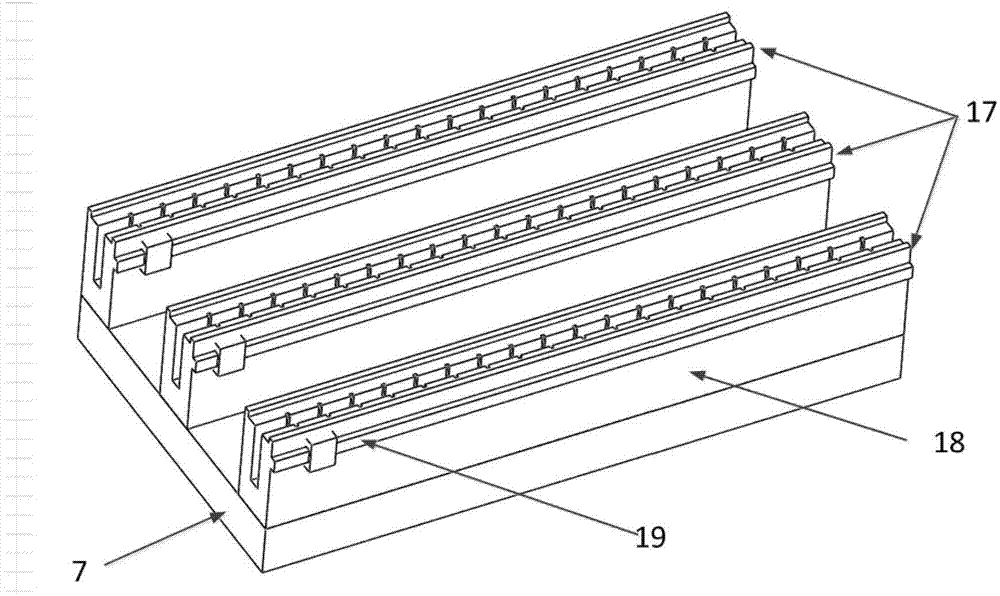

[0075] The five-axis linkage machine tool loading test device can carry out follow-up loading on the gantry milling machine, such as Image 6 shown. Fix the parallel loading device 23 on the workbench 20 of the machine tool 24 , adjust the position of the workbench 20 and the pose of the parallel loading device 23 , and connect the interface 1 between the loading mechanism and the spindle with the machine tool spindle 21 .

[0076] During actual loading, first, the industrial control computer 11 issues a mechanism initialization command to enable and initialize the mechanism motion controller 9, motor servo driver 8, linear motor 6 and signal compensation and processing device 10, and check and confirm the state of the parallel loading mechanism; after that Start the machine tool spindle 21 and make the machine tool move along the specified tool path; under the action of the control system, the parallel loading device performs follow-up loading on the tested machine tool 24 ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com