Activated carbon desulfurization and denitrification conveying rotary valve

A technology of desulfurization and denitrification and activated carbon, which is applied in the field of environmental engineering, can solve the problems of large consumption of activated carbon, achieve the effects of improving emissions, improving environmental protection, and improving sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the examples.

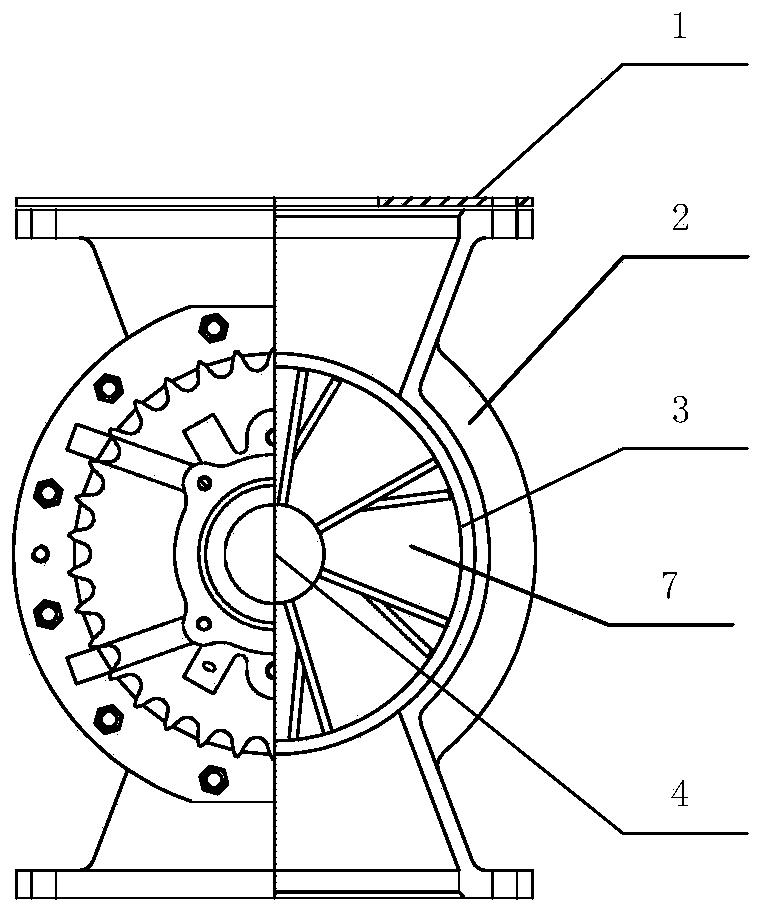

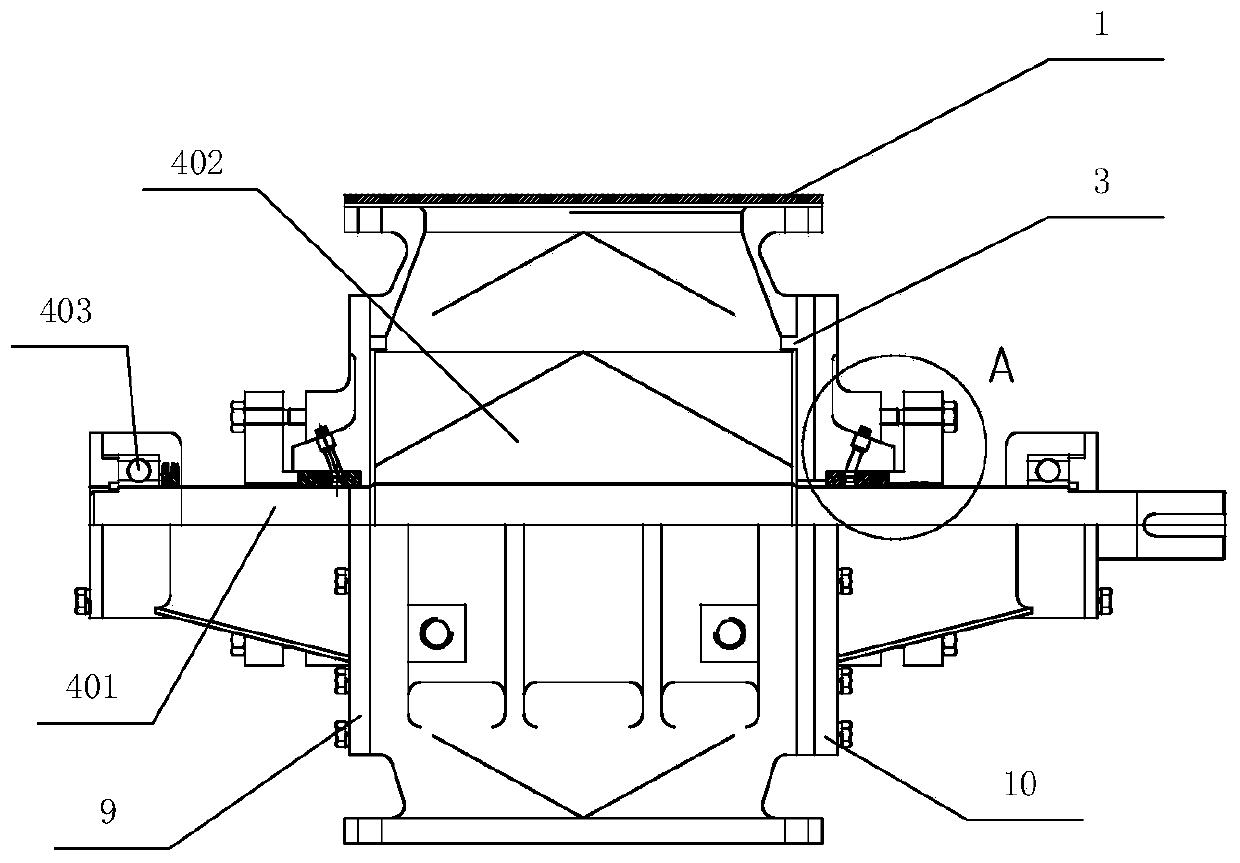

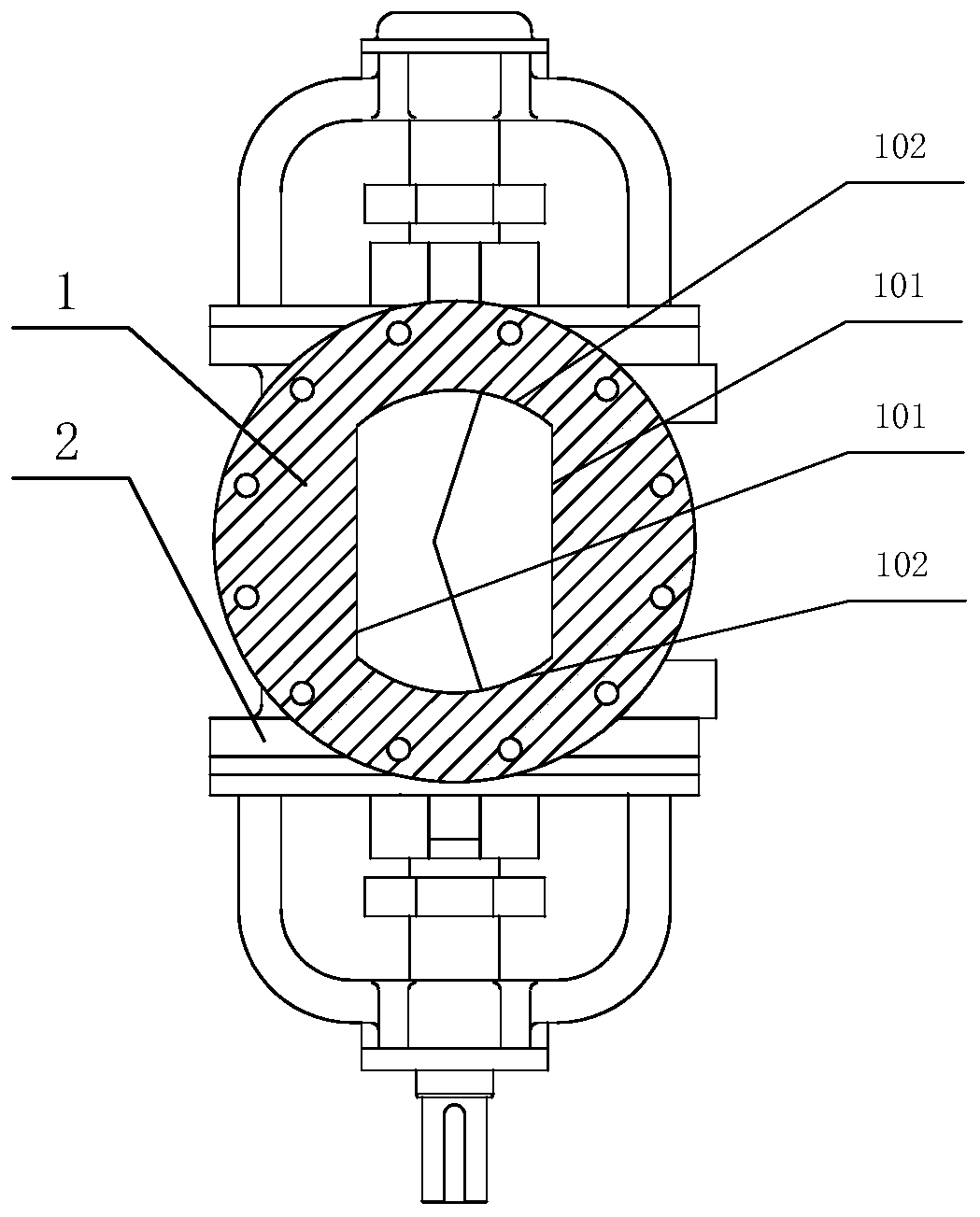

[0027] like Figure 1-4 and Figure 7-8 Shown is an embodiment of an activated carbon desulfurization and denitrification delivery rotary valve of the present invention, figure 1 It can be seen from the figure that the rotary valve of this embodiment is provided with a valve body 2, a cylindrical inner cavity 7 is arranged in the valve body 2, a feed port 12 is arranged on the valve body 2, and right end caps are respectively arranged on both sides of the valve body 2. 10 and the left end cover 9, the valve body 2 is in sealing connection with the right end cover 10 and the left end cover 9, the right end cover 10 and the left end cover 9 are provided with a rotor 4 for rotation, the rotor 4 includes a main shaft 401 and a valve disc 402, the main shaft 401 runs through the right end cover 10 and the left end cap 9, the main shaft 401 is rotatably connected with the right end cap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com