Patents

Literature

1283results about "Elongated constructional elements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Connecting device for profiled bars with grooves

A connecting device for connecting at least two profiled bars that are essentially perpendicular to one another and have grooves, in conjunction with sliding blocks, one plate connector unit is fastened to the end of a first profiled bar and anchored in a groove in the second profiled bar by way of screw units they extend in recesses in the plate connector unit. The geometry of the screw head of the screw unit is configured such that it centers the screw unit within the groove in the first profiled bar and the engages with a centering effect in the groove in the second profiled bar.

Owner:FMS FORDER UND MONTAGE SYST SCHMALZHOFER

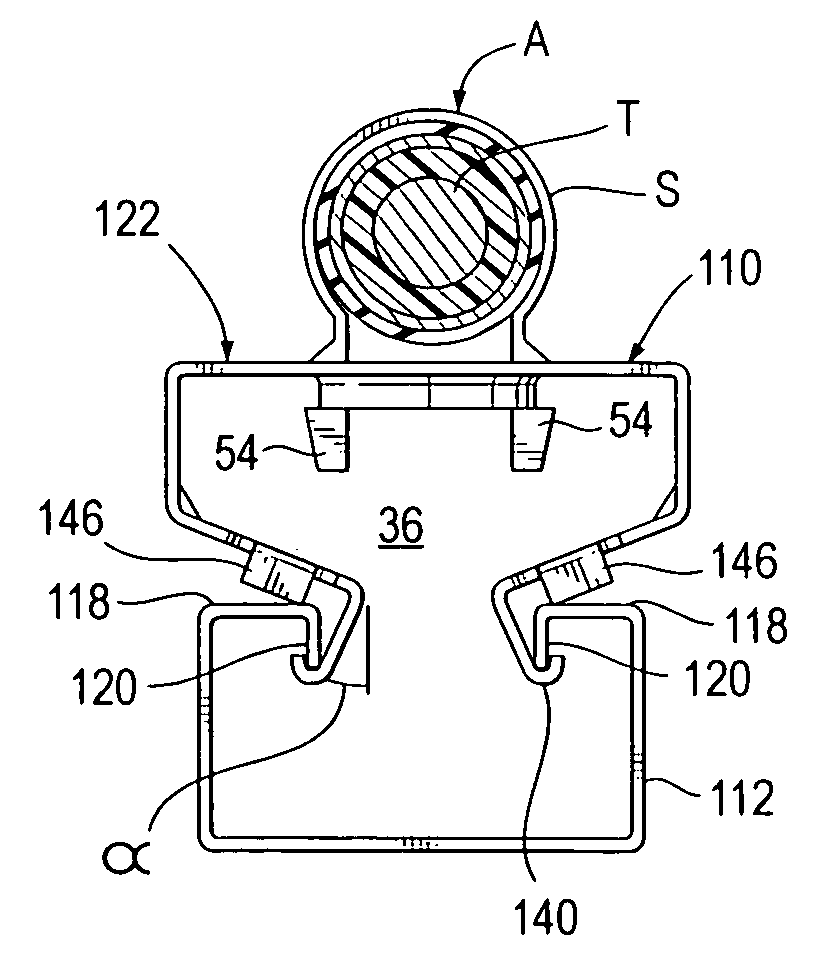

Anchor rail adapter and hanger and method

Owner:COMMSCOPE TECH LLC

Anchor rail adapter and hanger and method

Owner:ANDREW CORP

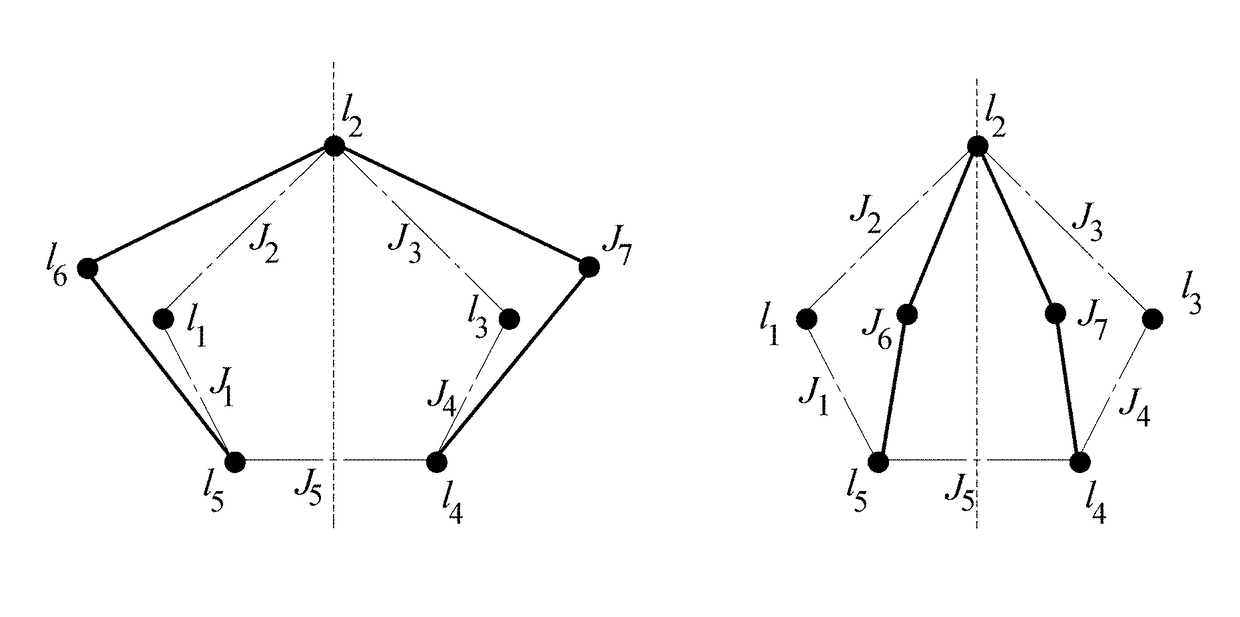

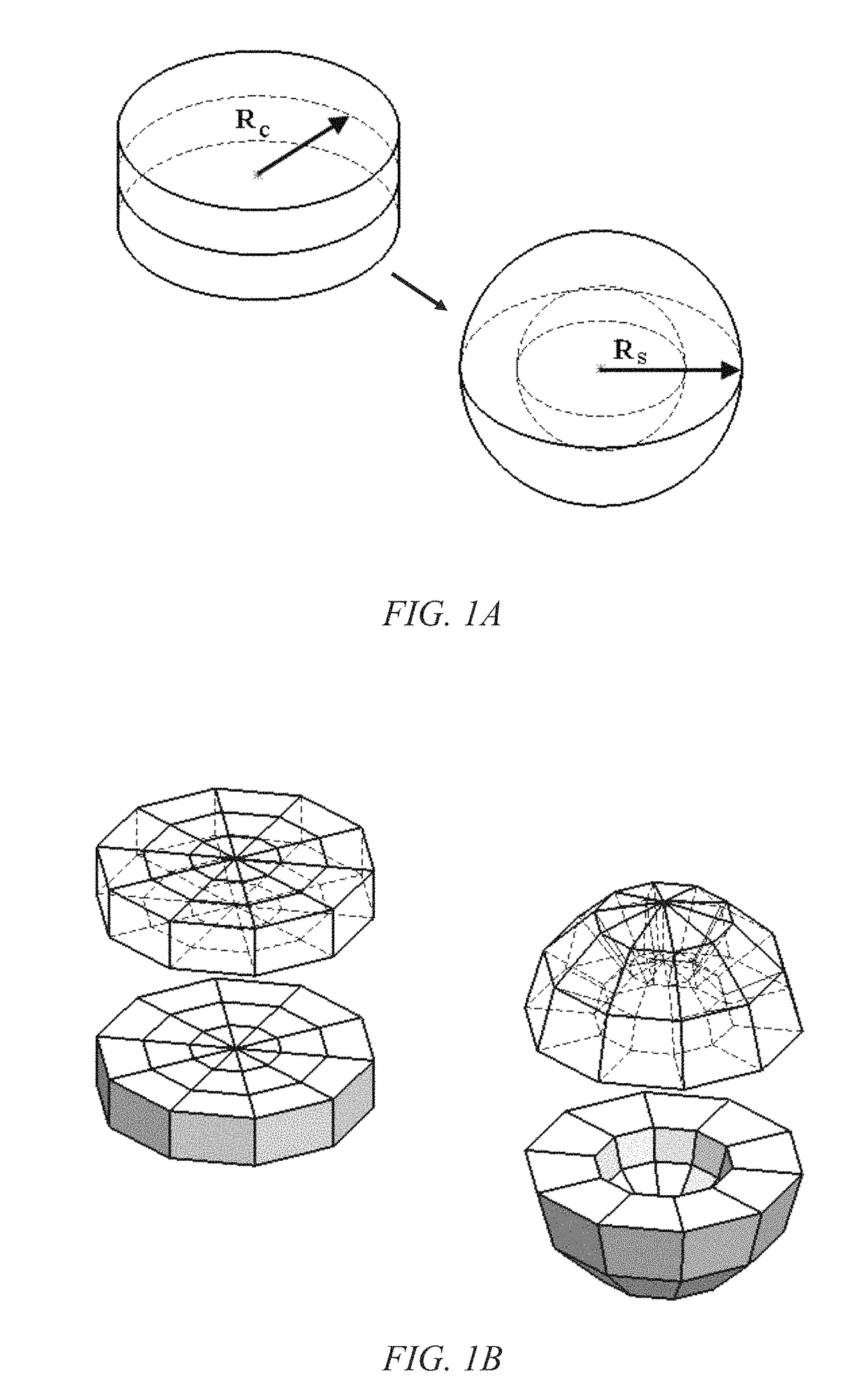

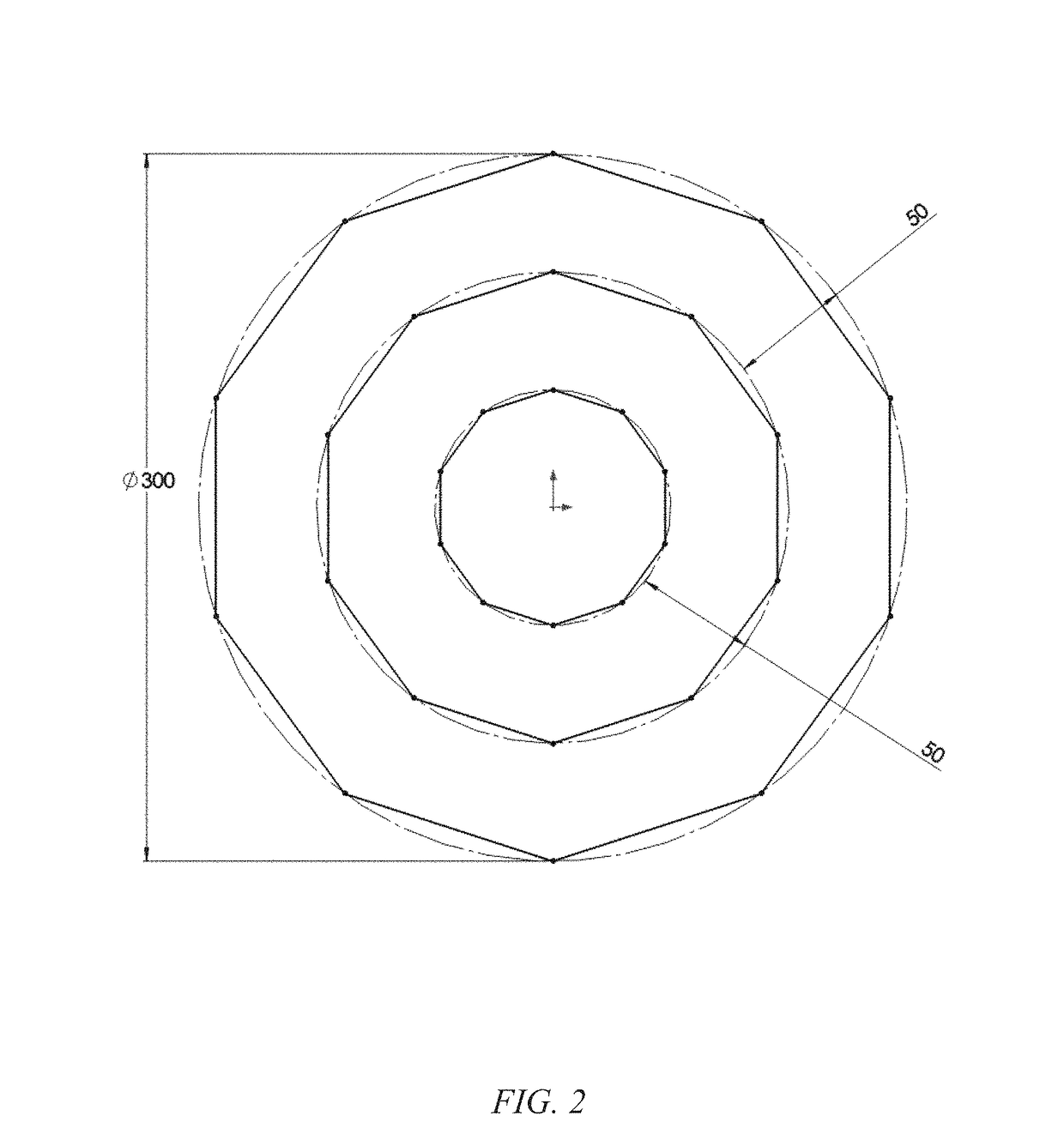

Shape-morphing space frame apparatus using unit cell bistable elements

ActiveUS9783977B2Facilitate behaviorSufficient flexibilityElongated constructional elementsExtraordinary structuresMorphingCompliant mechanism

Unit cell bistable elements, and particular arrangements thereof, that can transform or morph a structure from one shape to another. In certain embodiments, the current invention includes unit cell bistable elements, and particular arrangements and uses thereof, that can transform or morph a structure from one shape to another. In an embodiment, the current invention provides a method / ability to transform any four-bar compliant mechanism into a bistable compliant mechanism. It is an object of the current invention to facilitate structures morphing from one specific shape to another specific shape using unit cell bistable elements.

Owner:UNIV OF SOUTH FLORIDA

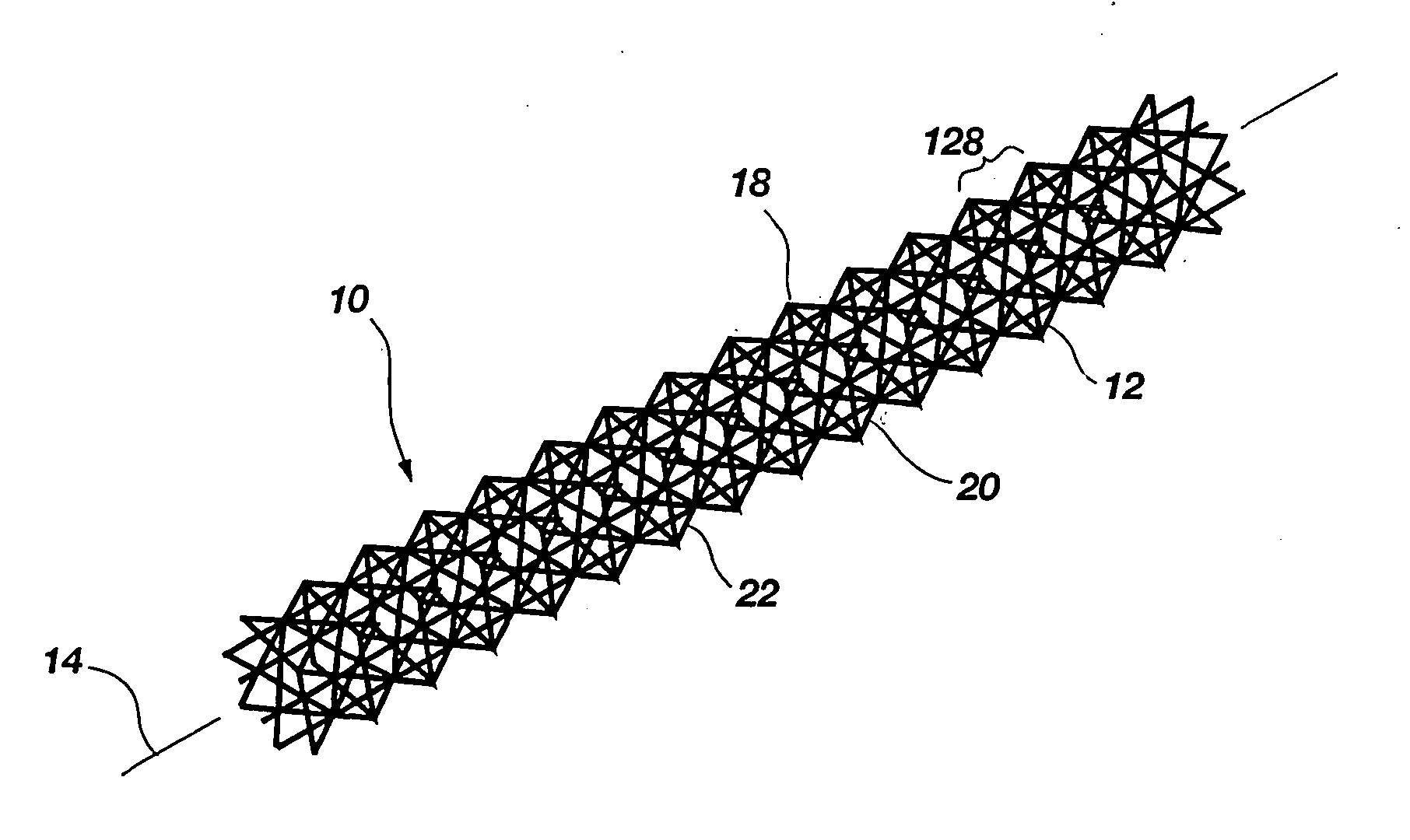

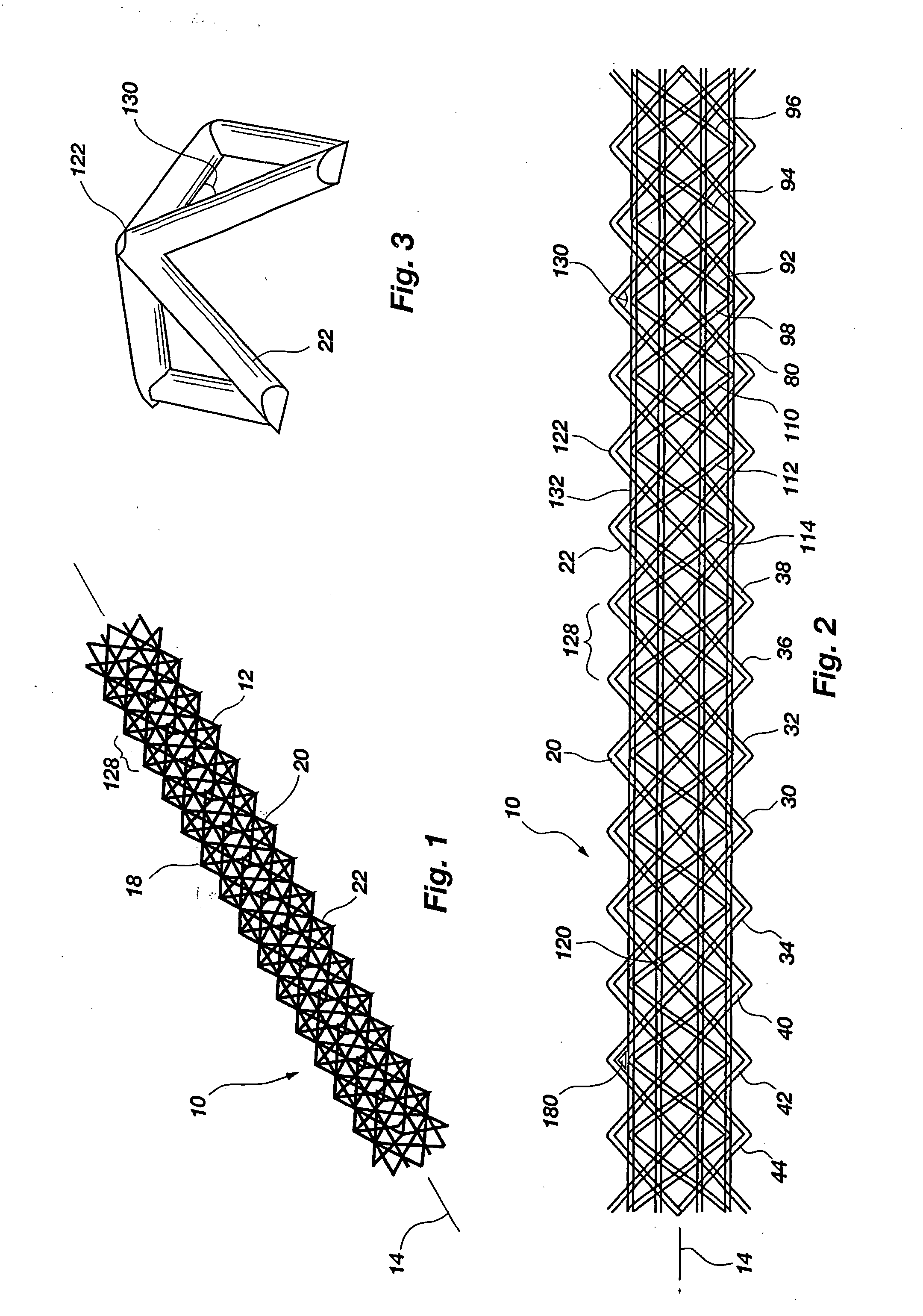

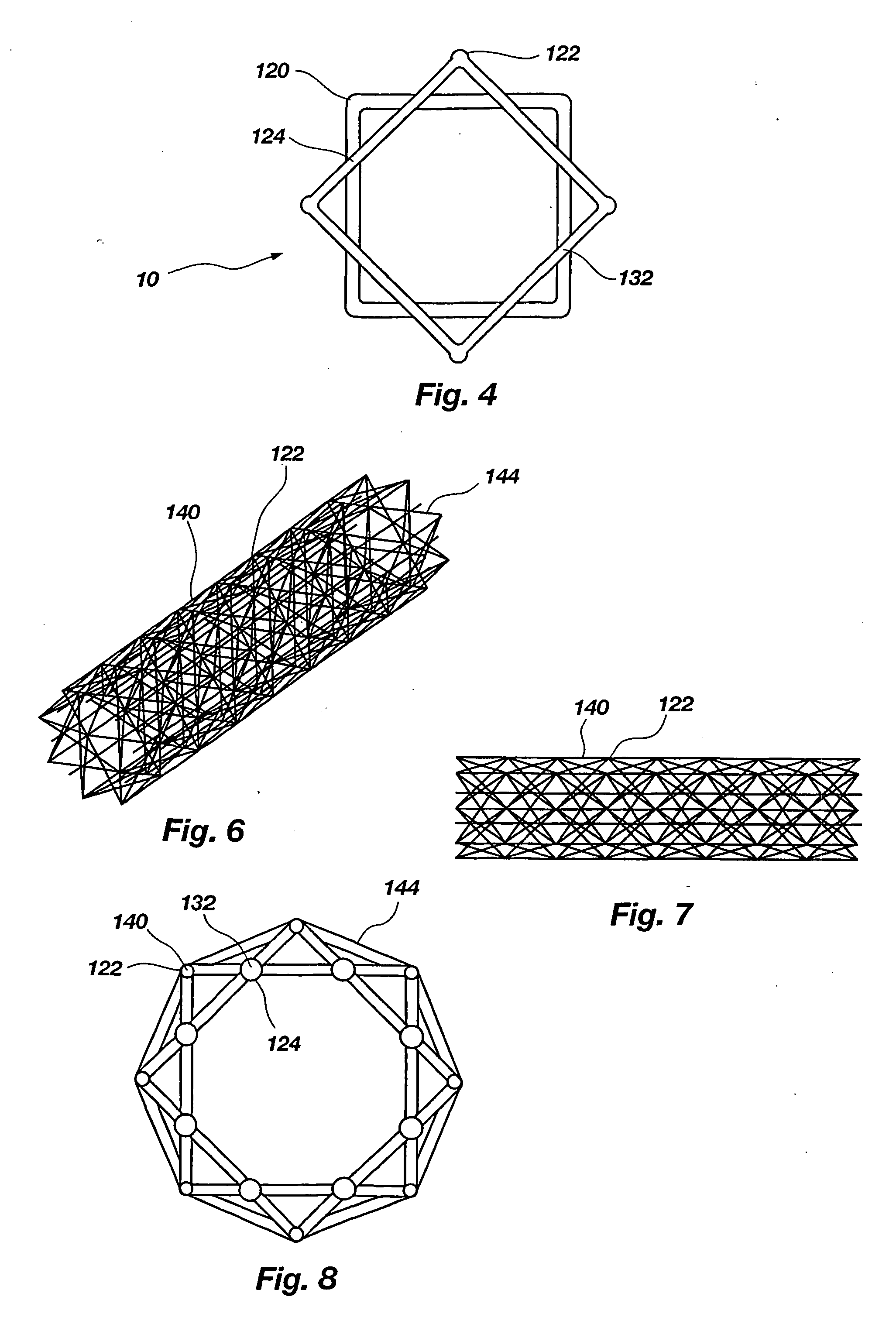

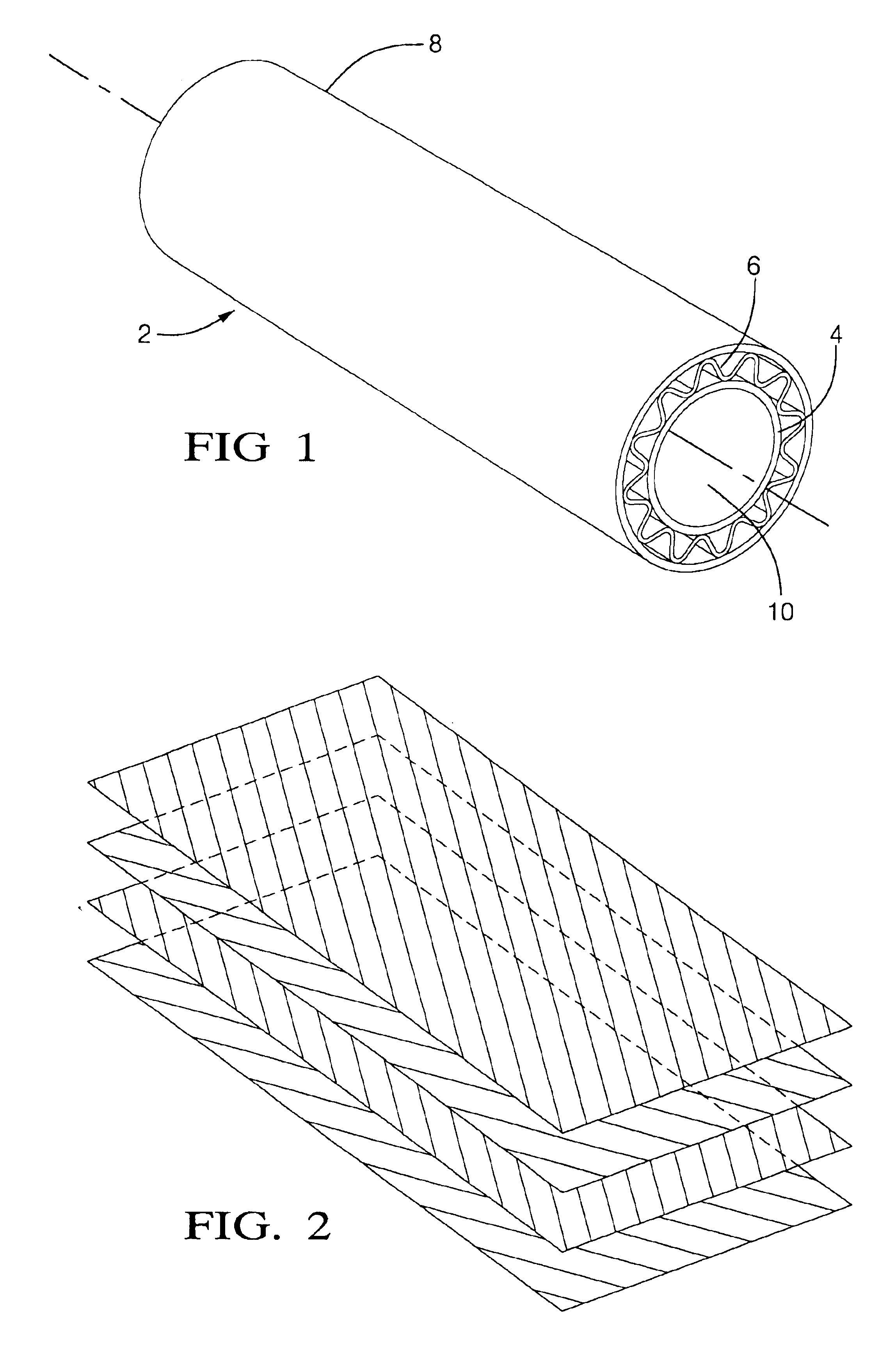

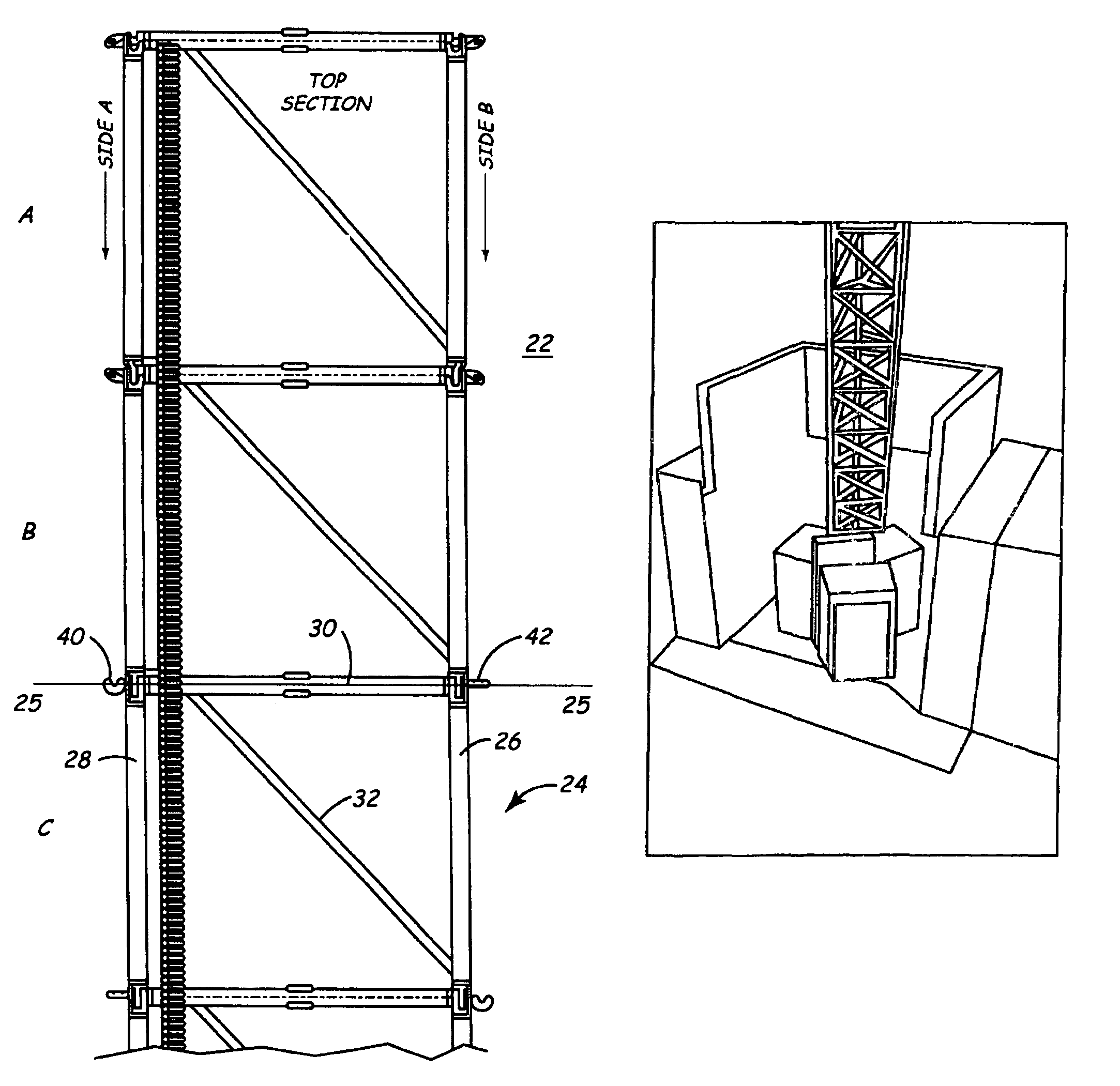

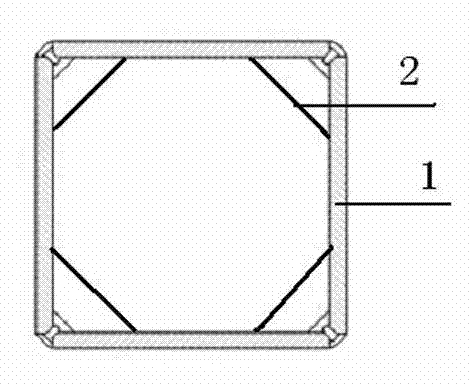

Iso-truss structure

InactiveUS20050115186A1Improved performance characteristicsReduced strengthTravelling sacksTruss-type bridgeSquare cross sectionAngular orientation

An iso-truss structure (10) includes at least two helical components (30, 32) and at least one reverse helical component (34) attached thereto with opposing angular orientations. Each helical and reverse helical component preferably includes at least four elongate, straight segments (22) rigidly connected end to end in a helical configuration forming a single, substantially complete rotation about a common axis (14) forming a first square cross section. The structure may further include at least two rotated helical components (80, 92) and at least one rotated reverse helical component (98) which are rotated with respect to the helical and reverse helical components forming a second square cross section, rotated with respect to the first. The structure may be straight, curved, flexible, or form angles.

Owner:ISOTRUSS IND LLC

Contoured crushable composite structural members and methods for making the same

Owner:DELPHI TECH INC

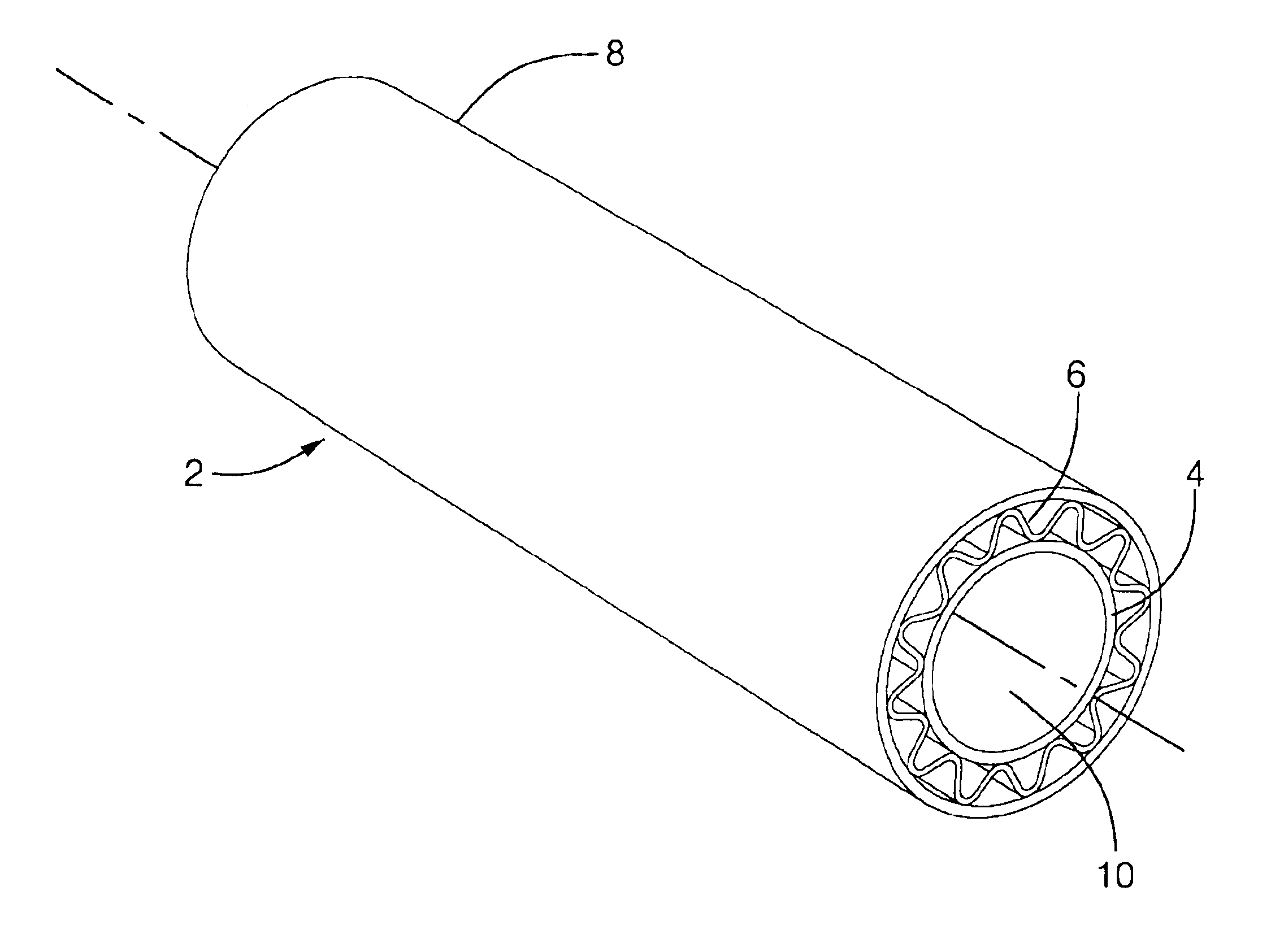

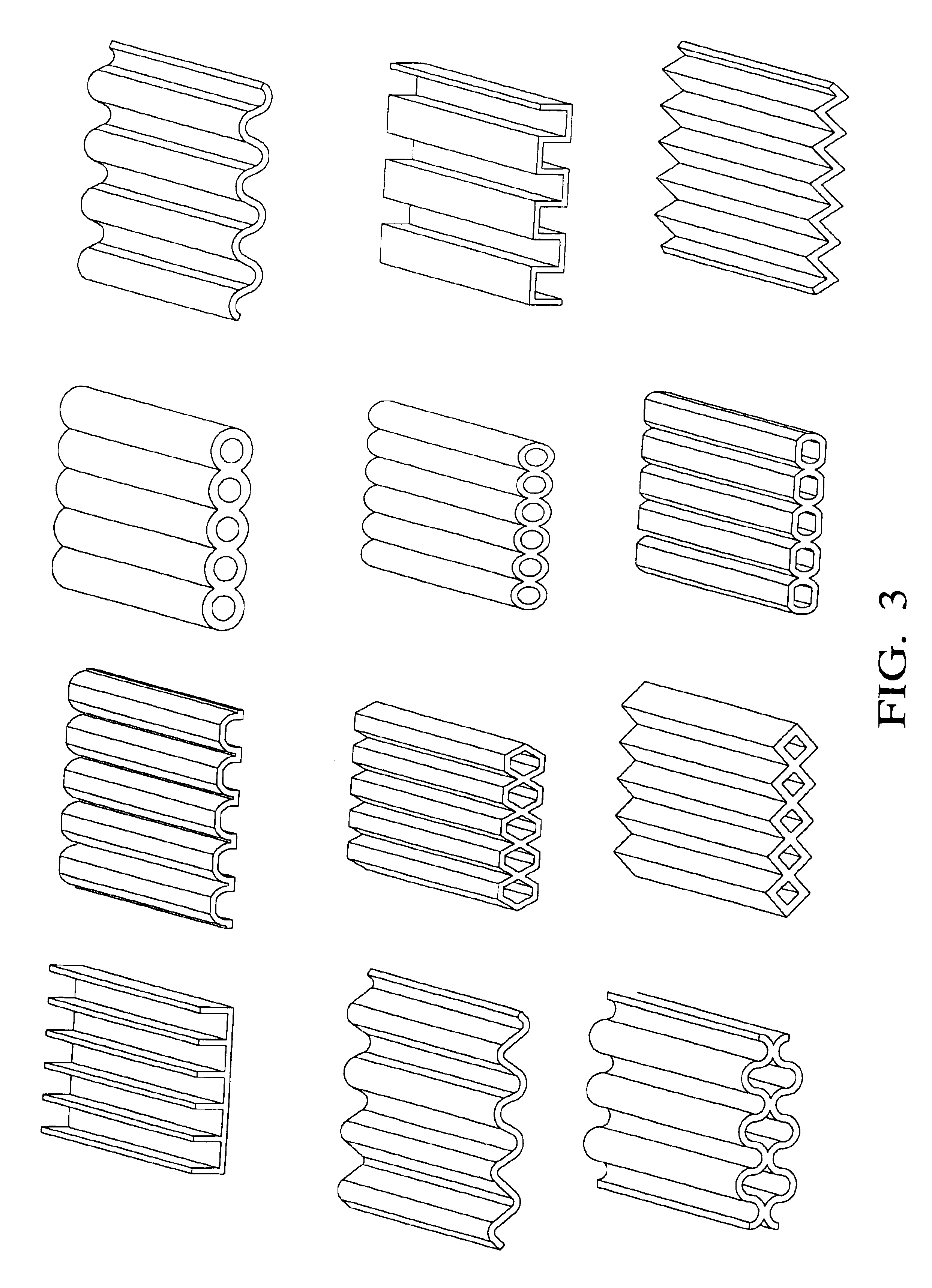

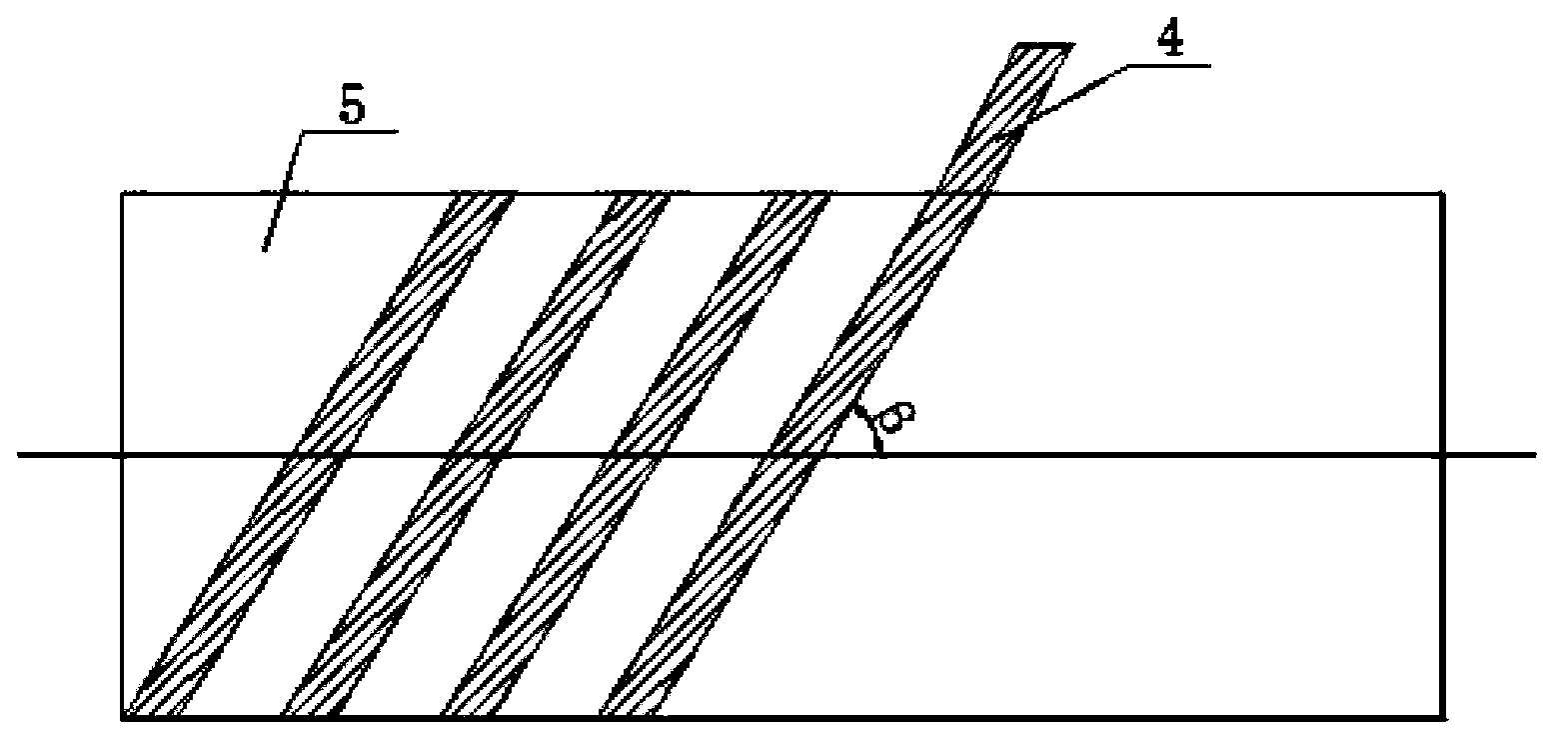

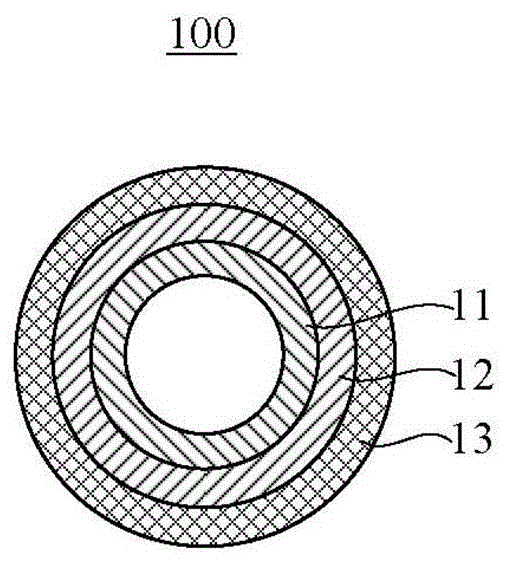

Composite wound thermoplastic glass-reinforced-plastic pipe and production method thereof

ActiveCN103791174AIncrease hoop tensile strengthImprove axial tensile strengthElongated constructional elementsRigid pipesGlass fiberThermoplastic elastomer

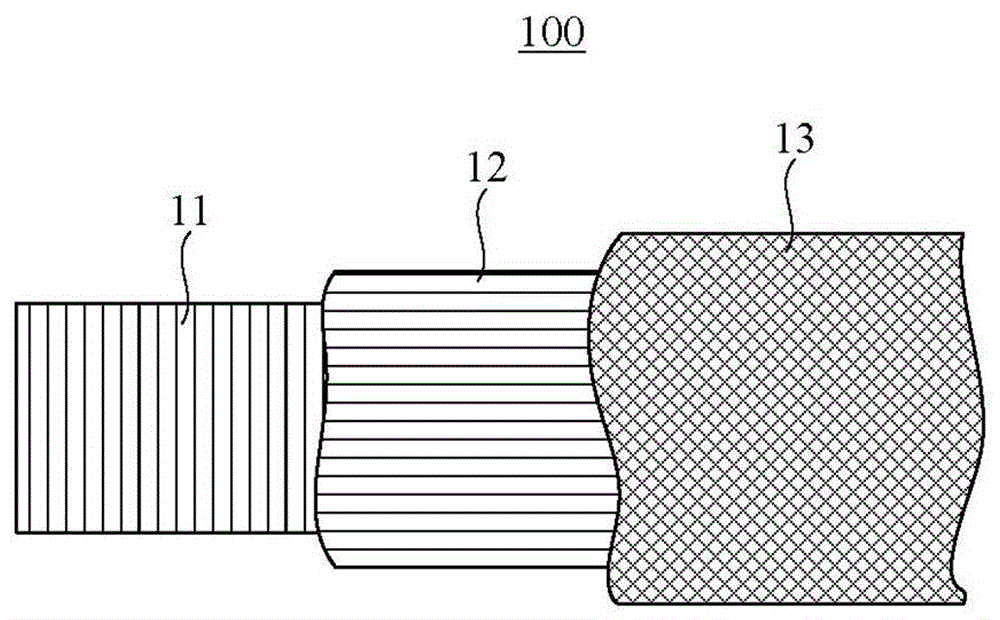

The invention relates to a composite wound thermoplastic glass-reinforced-plastic pipe and a production method thereof. The pipe comprises an inner layer, a middle layer and an outer layer. The inner layer is a circumferentially-wound continuous fiberglass-reinforced thermoplastic prepreg tape layer. The middle layer is a spirally-wound continuous fiberglass-reinforced thermoplastic prepreg tape layer. The outer layer is a circumferentially-wound continuous fiberglass-reinforced thermoplastic resin prepreg tape layer. Compared with the prior art, the composite wound thermoplastic glass-reinforced-plastic pipe has high circumferential tensile strength and high axial tensile strength, and the requirements for traction pipes in trenchless construction can be met. Not changing the width of the continuous fiber-reinforced thermoplastic resin composite prepreg tape but adjusting the winding process and changing the winding angle is required in the winding process of the composite wound thermoplastic glass-reinforced-plastic pipes, the whole winding process is continual, and production efficiency is high.

Owner:HEFEI GENIUS NEW MATERIALS

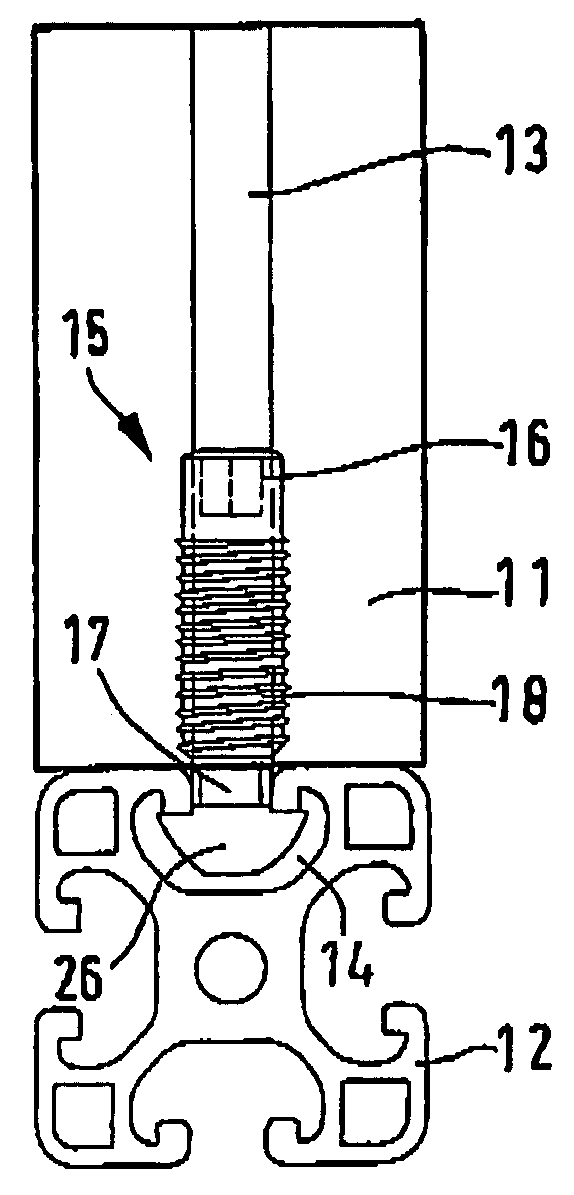

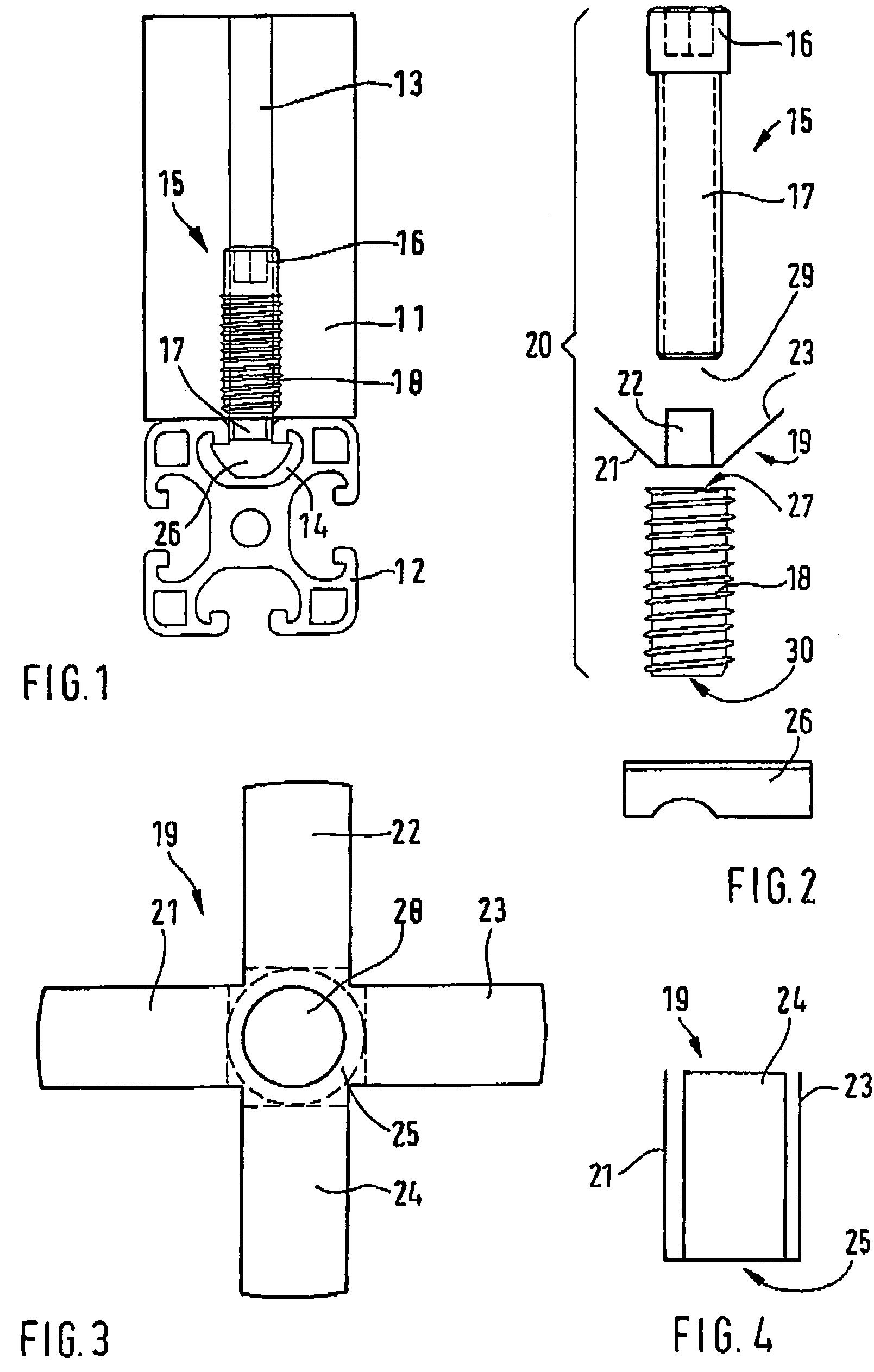

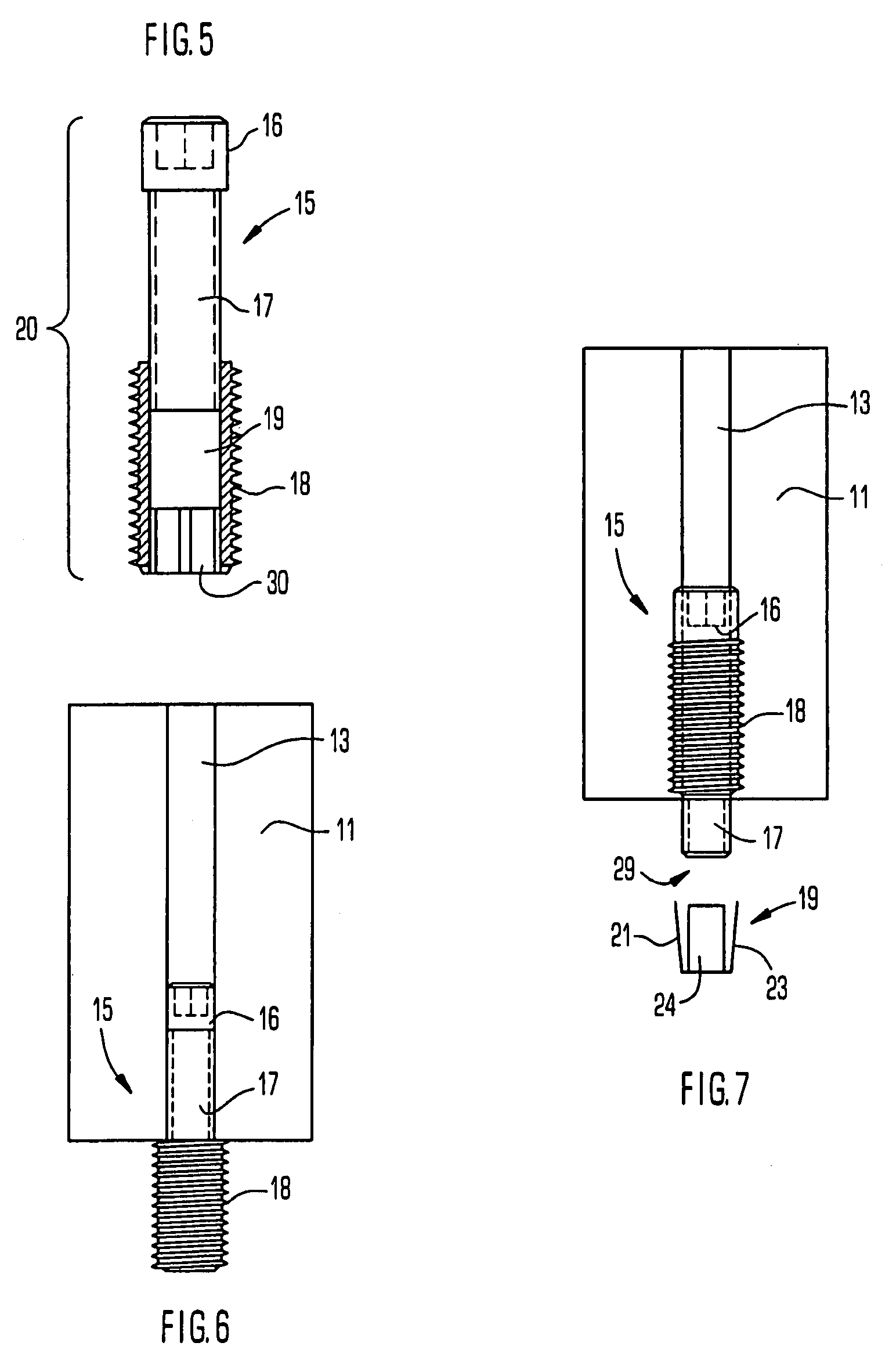

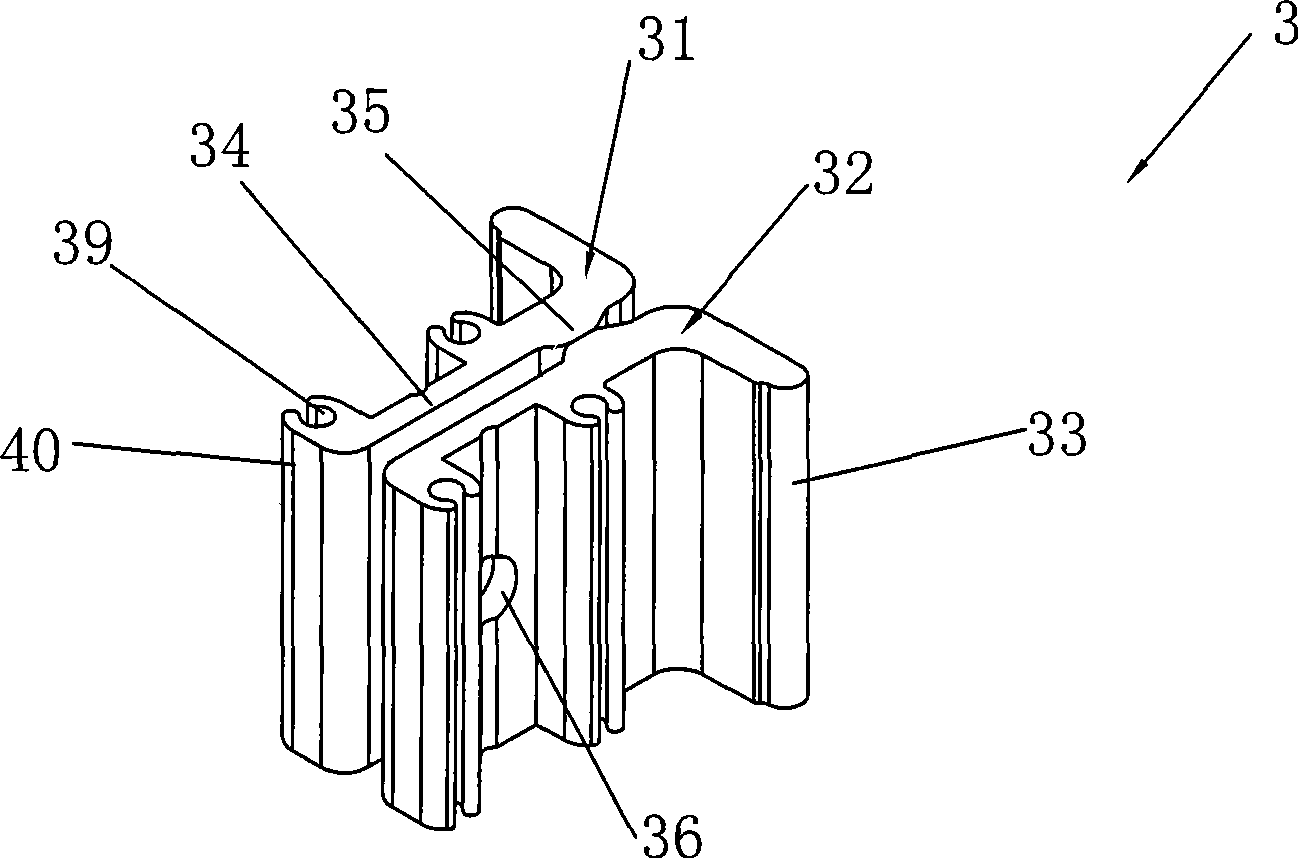

Connector system

InactiveUS7293935B2Prevents any undesirable displacementProcedure is complicatedElongated constructional elementsRod connectionsThrust bearingEngineering

A connector system that provides a profile connection having two profiled rods that are to be connected to one another and that each comprise at least one undercut, longitudinally oriented profile groove. The connector system may include a connecting screw with a screw head and a screw shaft as well as a threaded sleeve. The connecting screw is dimensioned such that it passes through the threaded sleeve and with part of its shaft, by way of the sleeve, can be engaged with a thrust bearing piece in the profile groove of the second profiled rod. The connecting screw is fixed in the threaded sleeve by a releasable anchoring element so as to be ready for installation. Thus, an assembly unit is created that can be screwed as a whole into the profile groove of the first profiled rod.

Owner:BAND RICHARD +1

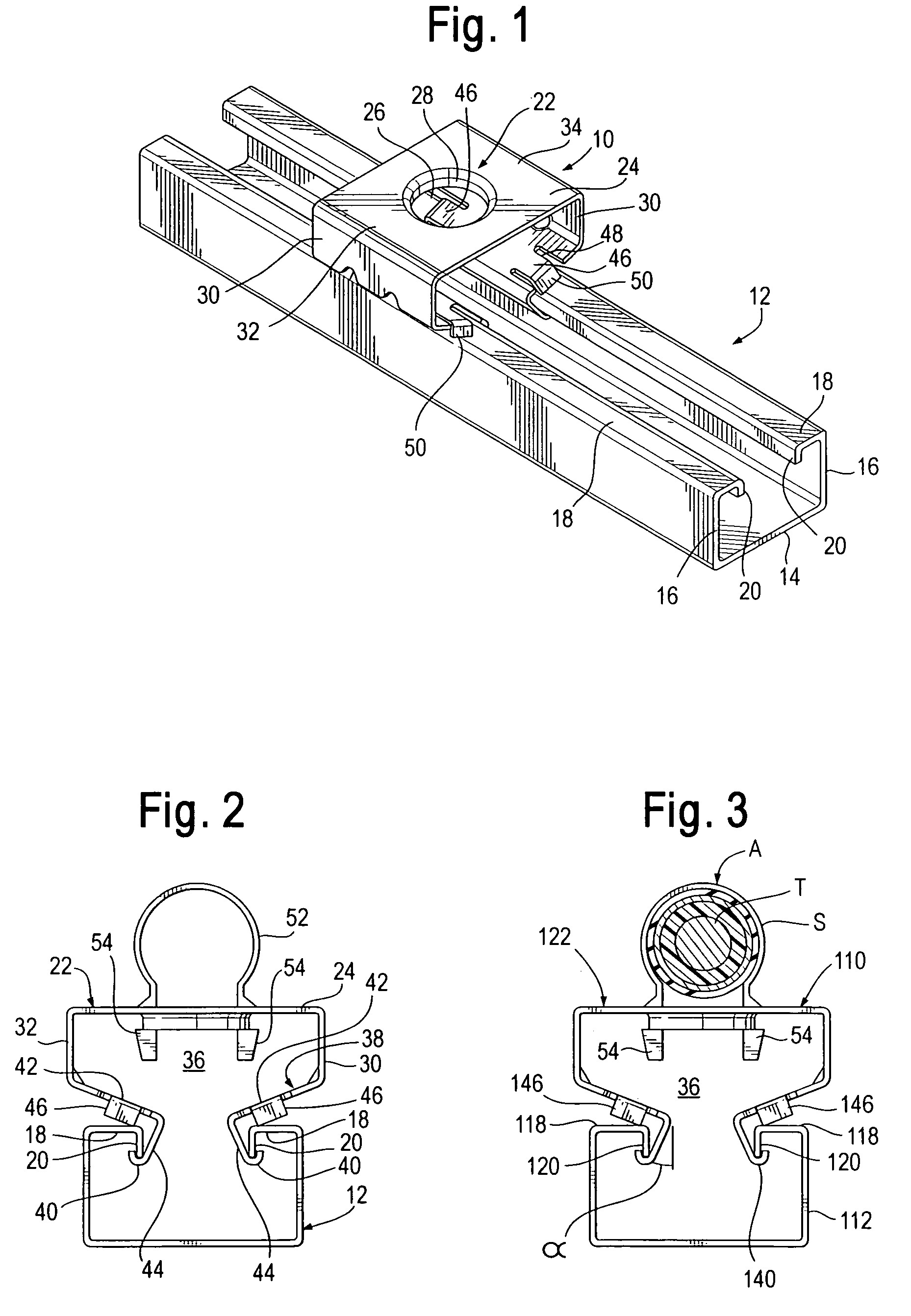

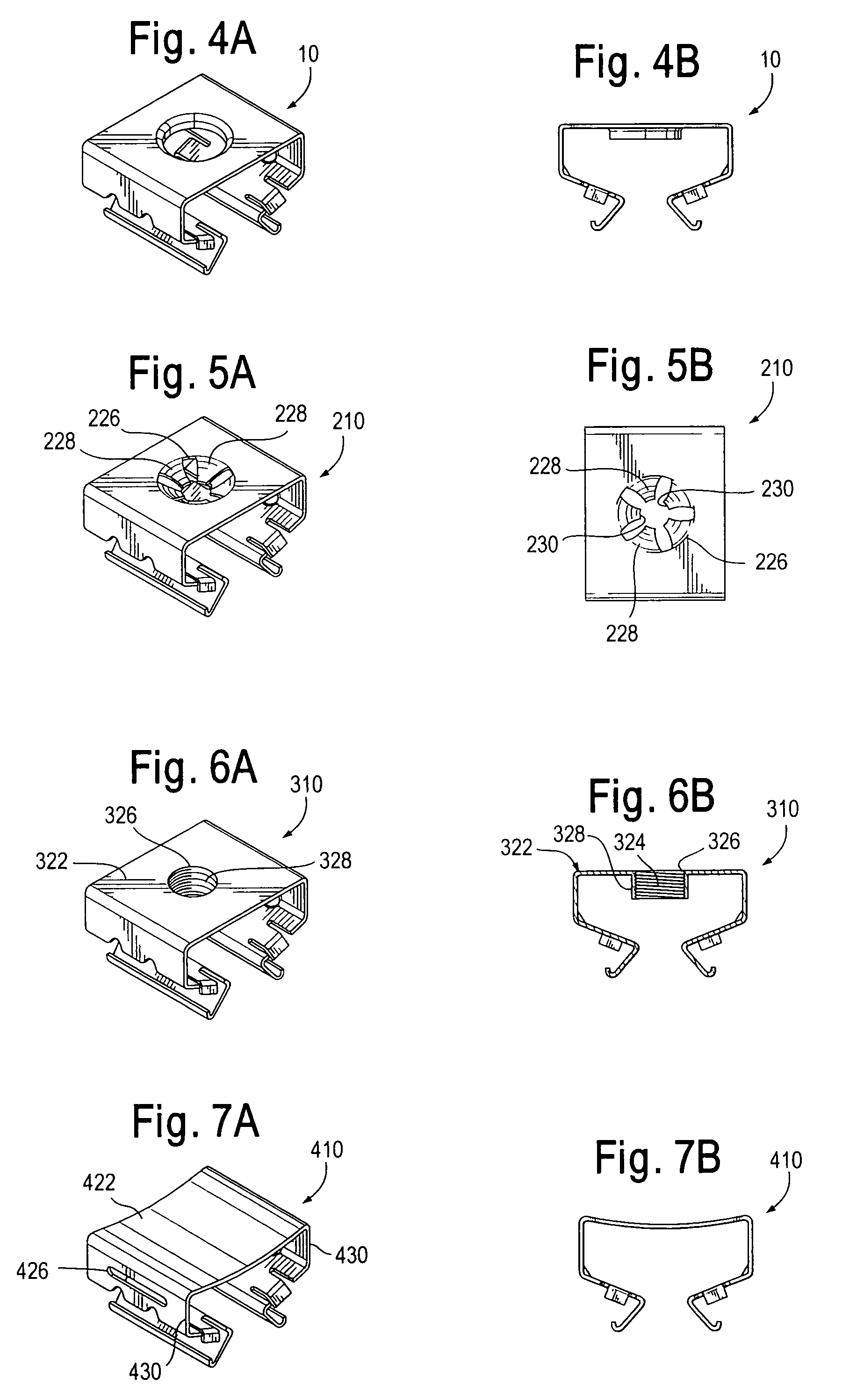

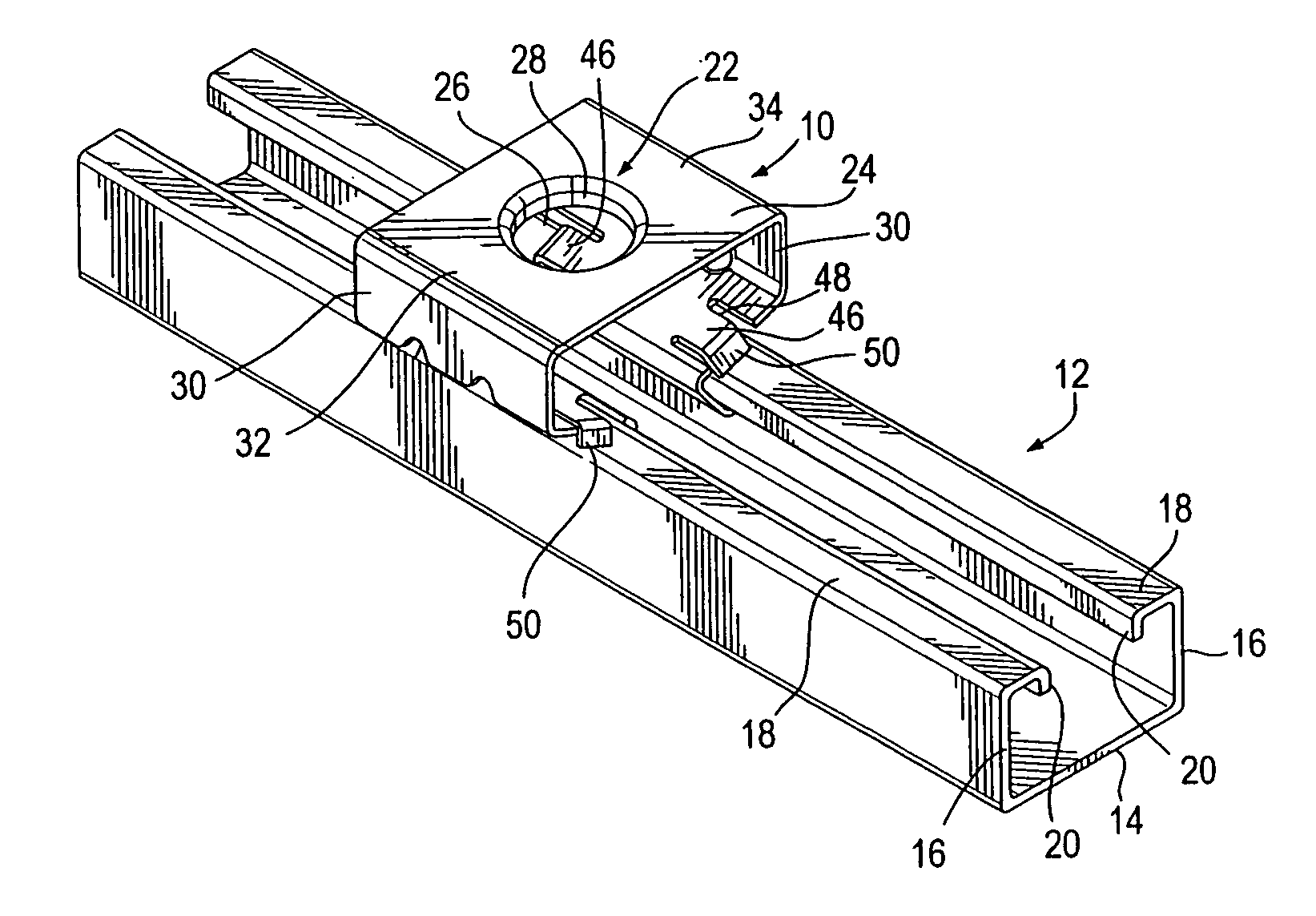

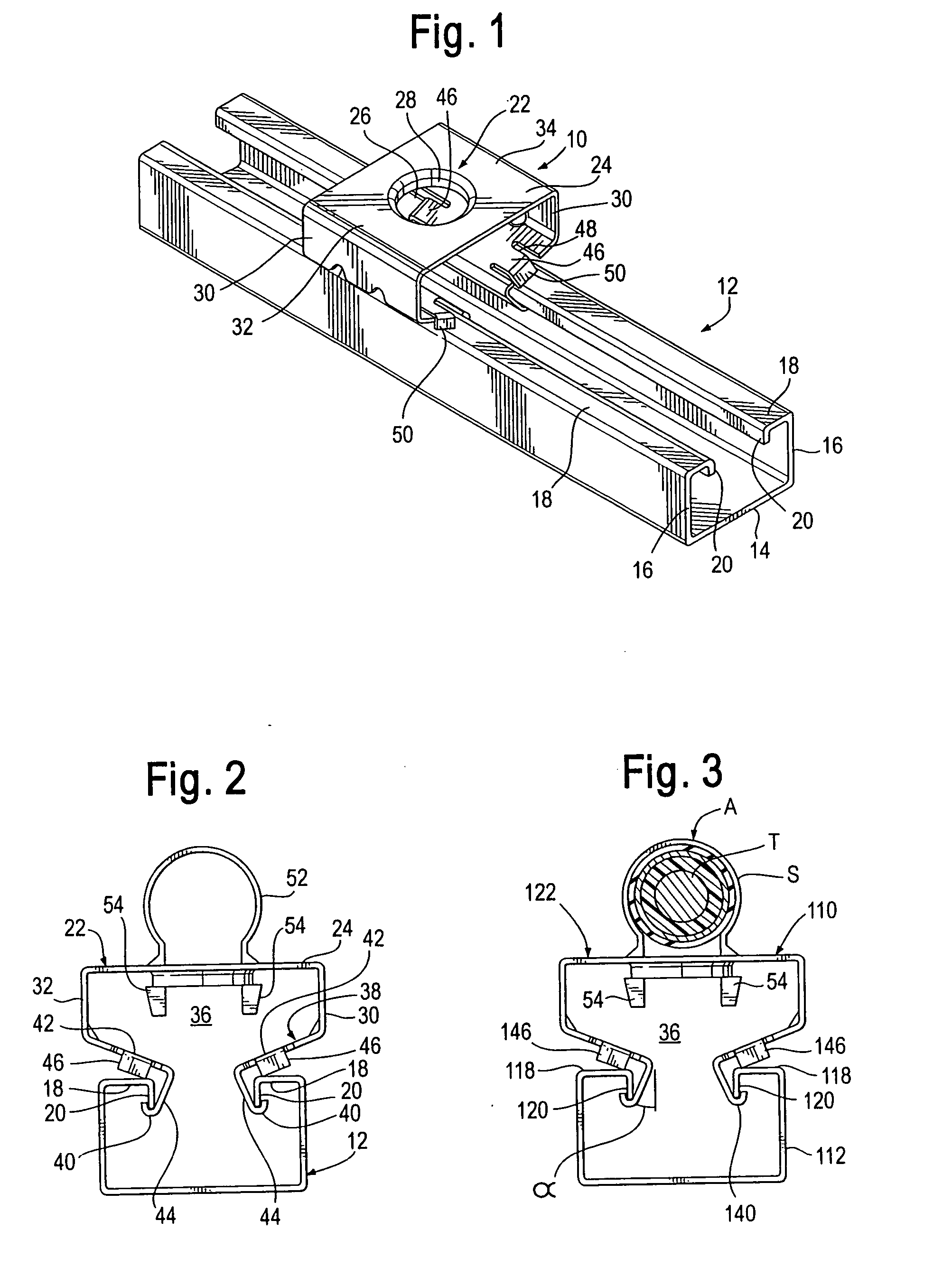

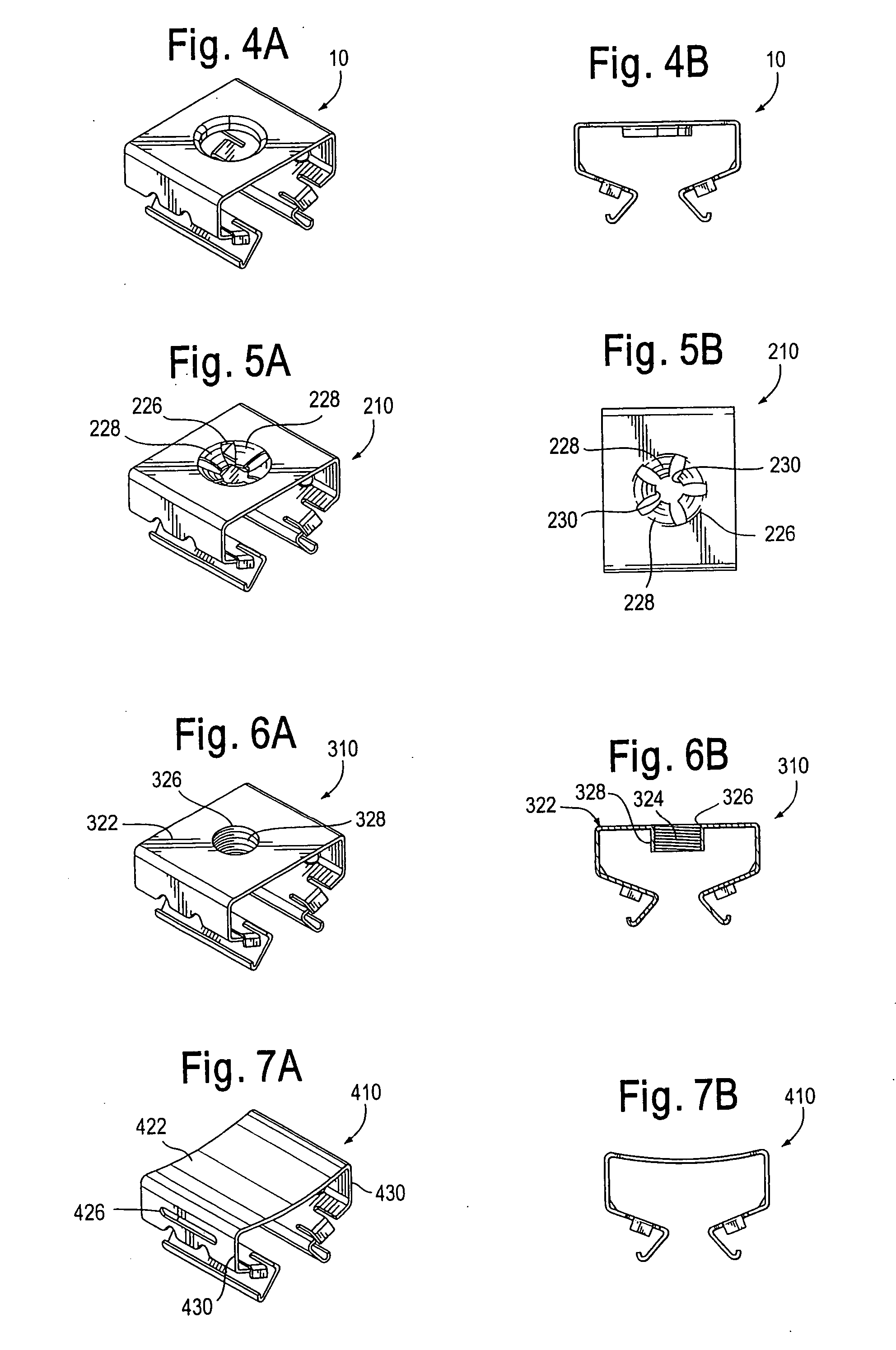

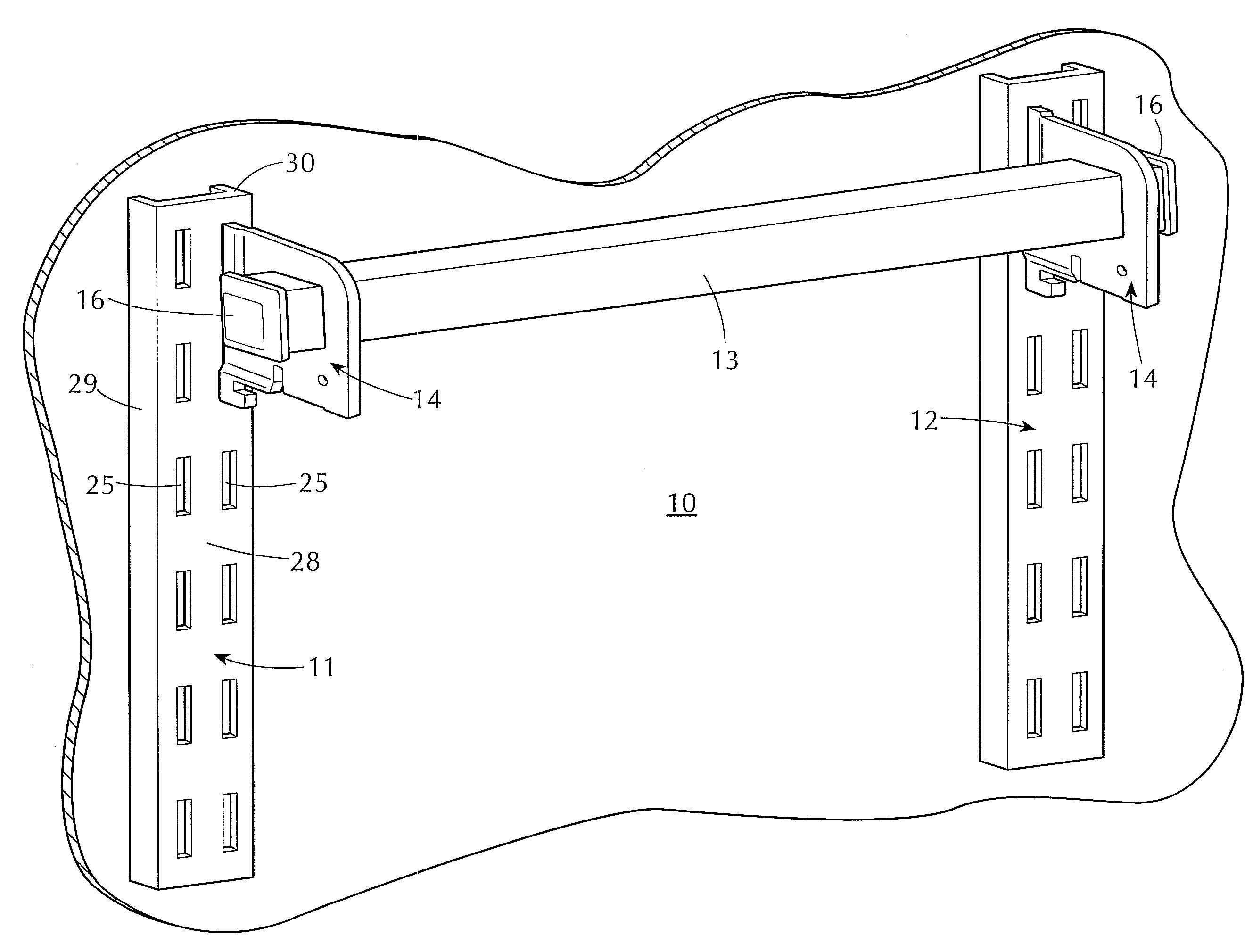

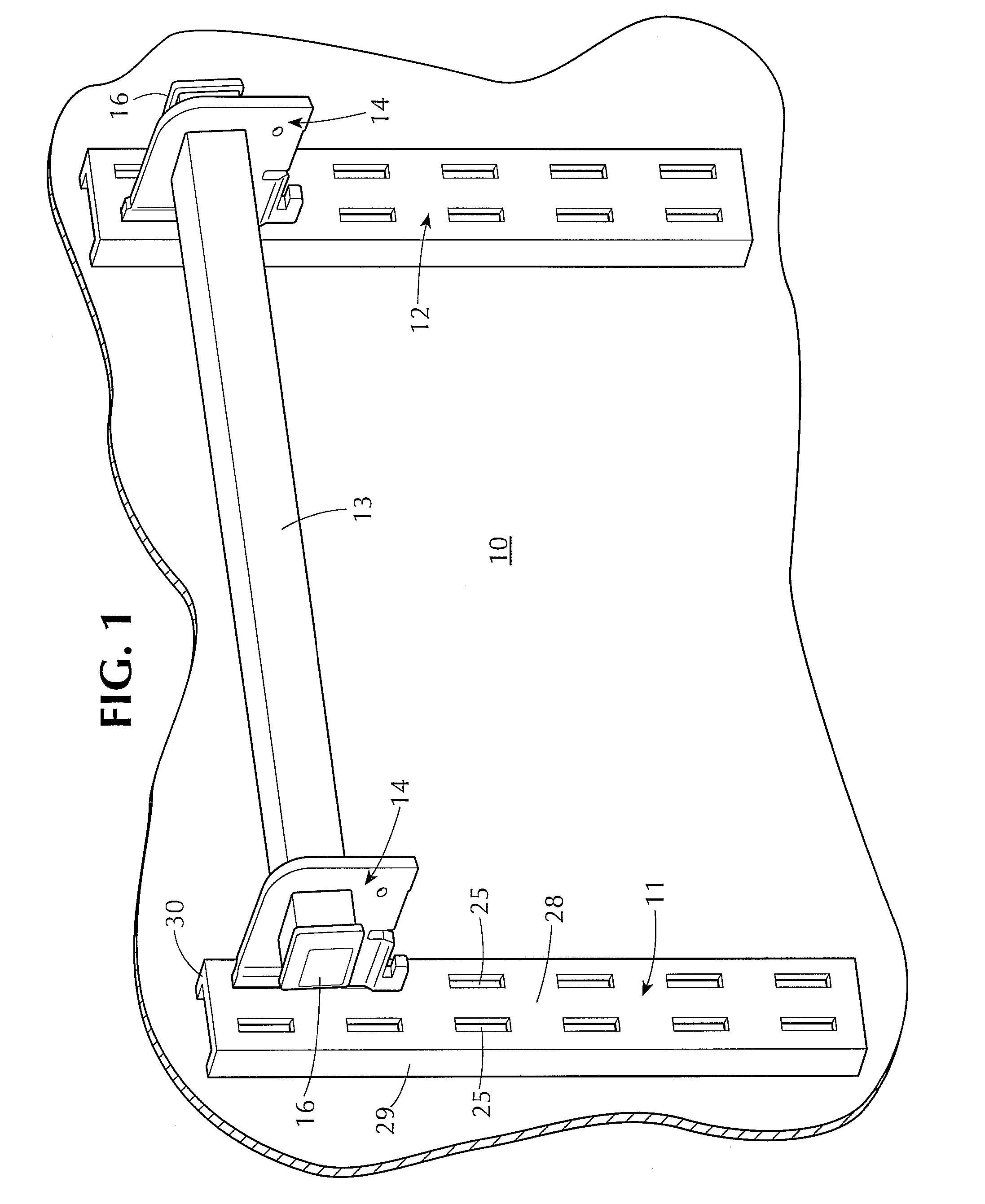

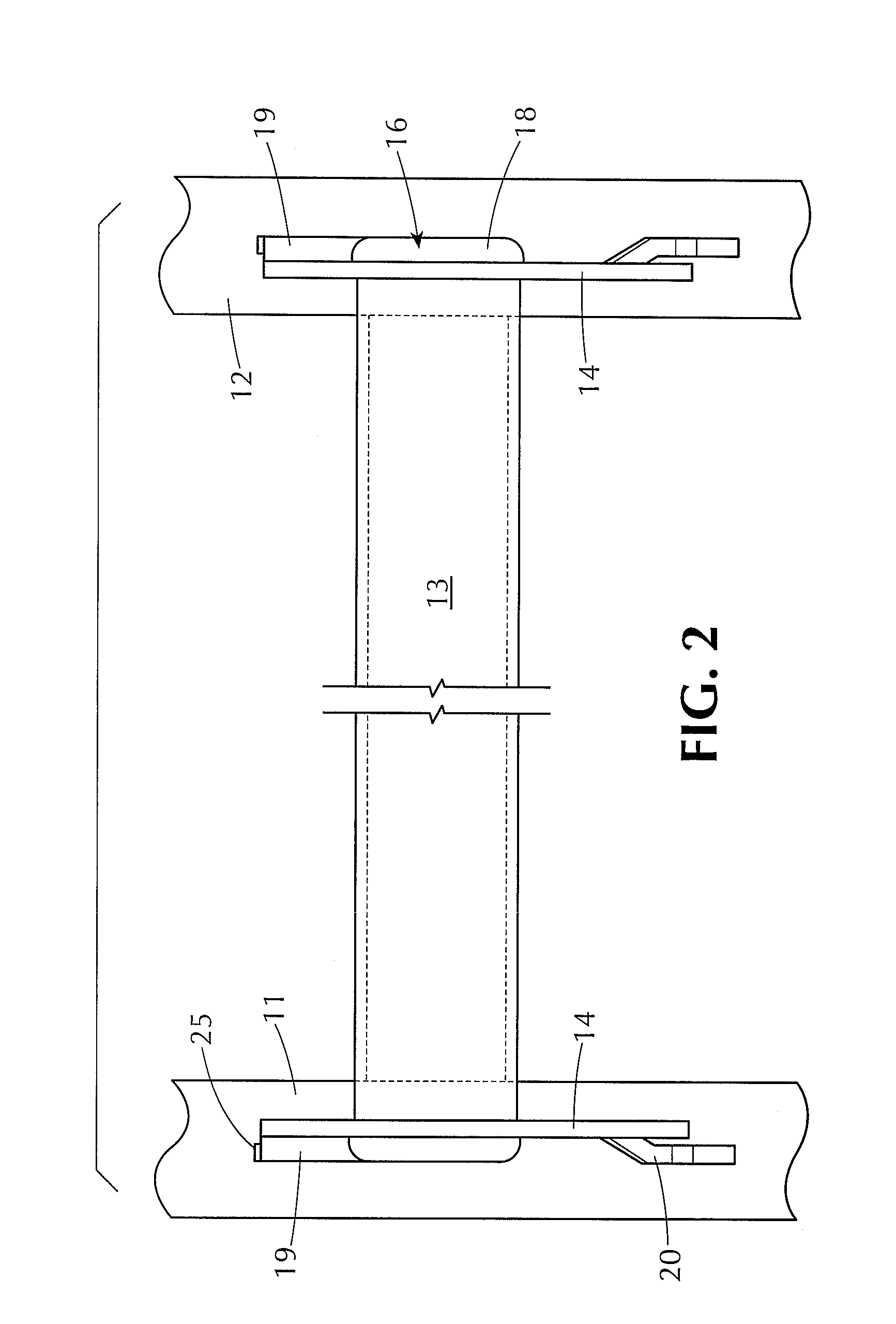

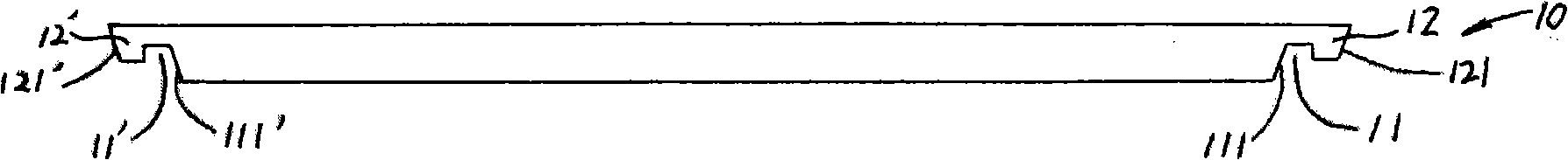

Display bar assembly for merchandising displays

ActiveUS20080203040A1Easy to installIncrease widthCandle holdersLighting support devicesMechanical engineeringEngineering

A display bar assembly for mounting on spaced apart slotted uprights on a merchandising gondola or the like. A tubular display bar of polygonal cross section is fitted with a pair of mounting brackets, which are slideable along the bar to enable spacing of the mounting brackets to agree with the spacing between the slotted uprights, which can be somewhat variable. The mounting brackets are formed with openings which closely and non-rotatably receive the display bar and are provided with hooks which engage slots in the uprights. Flanged end plugs are received tightly in each end of the display bar to prevent removal of the slideable brackets, such that the display bar and brackets form a permanent assembly. The mounting brackets may have multiple slot-engaging hooks for installation on uprights of different thicknesses in different rotary positions of the assembly. Where necessary to maintain a predetermined orientation of the display bar, the display bar can be formed with an axially limited portion of reduced cross section, enabling the mounting brackets, when positioned thereat, to be rotationally reoriented relative to the display bar.

Owner:TRION IND

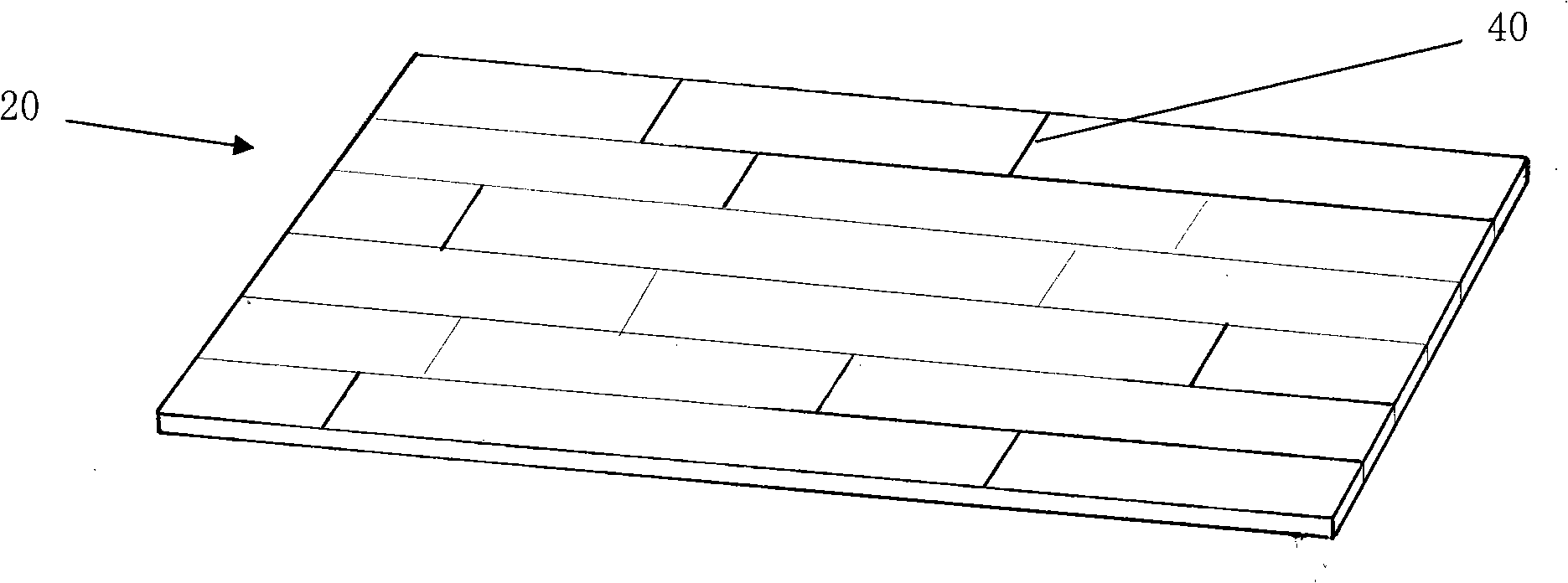

Seamless long bamboo sectional material

InactiveCN101294653ANovel structureWith horizontal pulling effectElongated constructional elementsWood treatment detailsEngineeringStructural engineering

Owner:SHANGHAI YUNSHENG BAMBOO & WOOD PROD

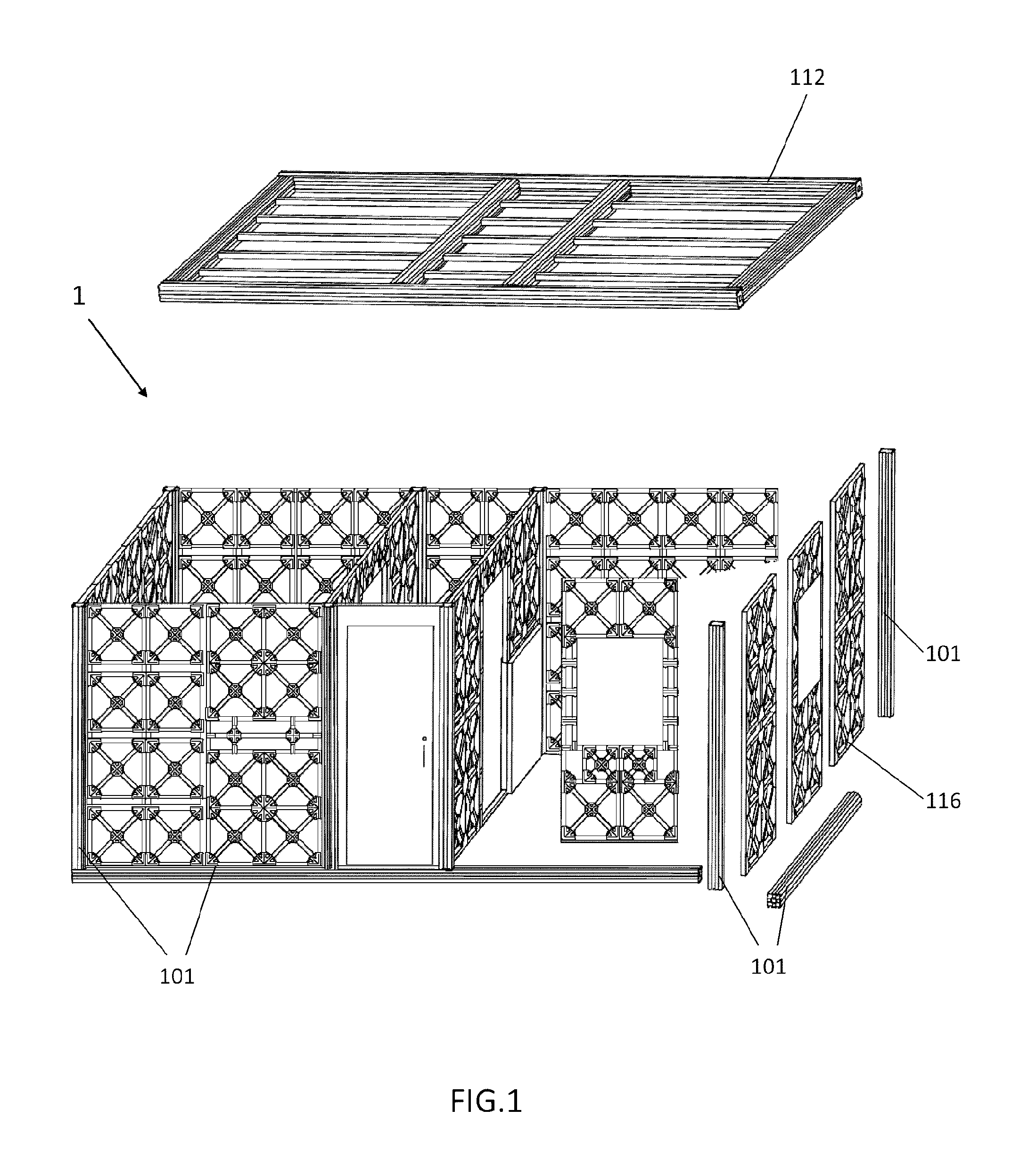

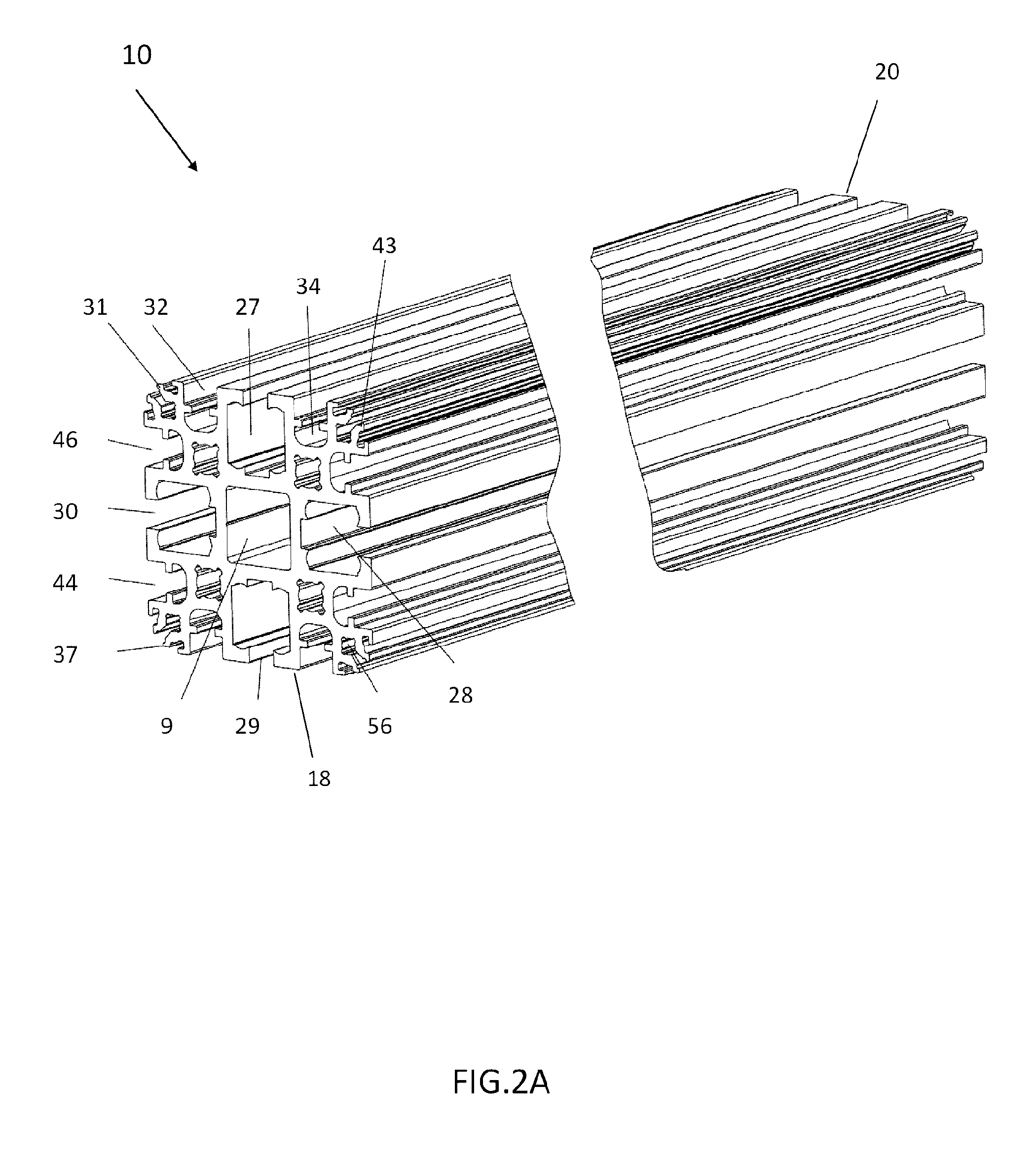

Quick connect structural system

A kit for an easy quick connect structural system for constructing framework structures comprising a plurality of elongate rectangular prism frame members is provided. The frame members incorporate custom design features which provide structural strength, facilitate assembly and expansion of the framework structure and allow ease of attachment and securing of accessories. These design features include a corner groove, a central hollow longitudinal chamber, at least one sub-trade chamber, at least one outer main channel, stub-nosed channels, and claw assembles flanking each corner groove. There is provided a plurality of snap-in connectors designed and configured to mate with the frame members such that the frame members can be secured in various arrangements with respect to each other. There is further provided custom reinforcement brackets designed and configured to securely bind together a selection of the plurality of the frame members.

Owner:E6 XTRUSION STRUCTURES

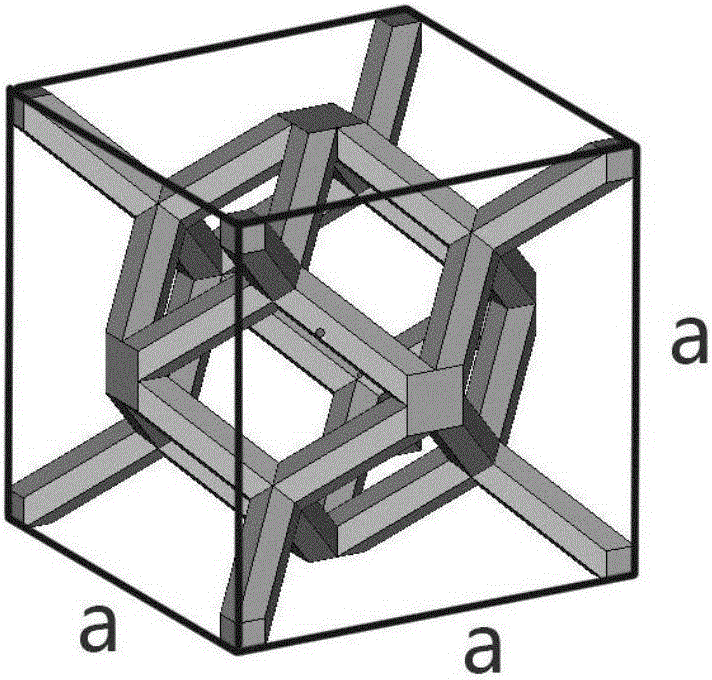

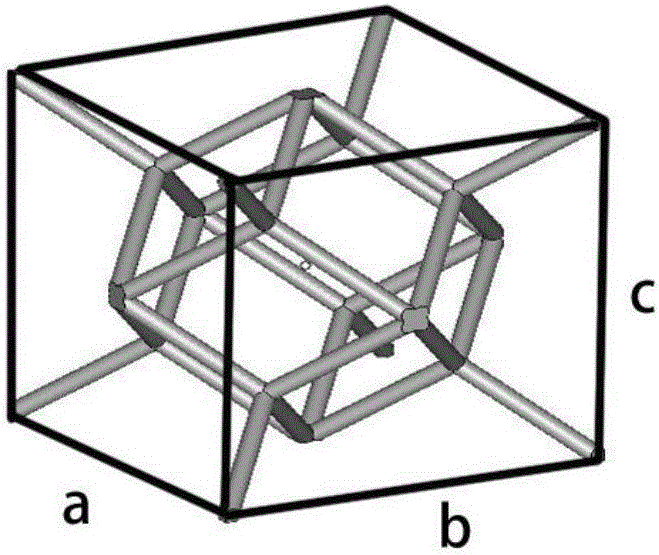

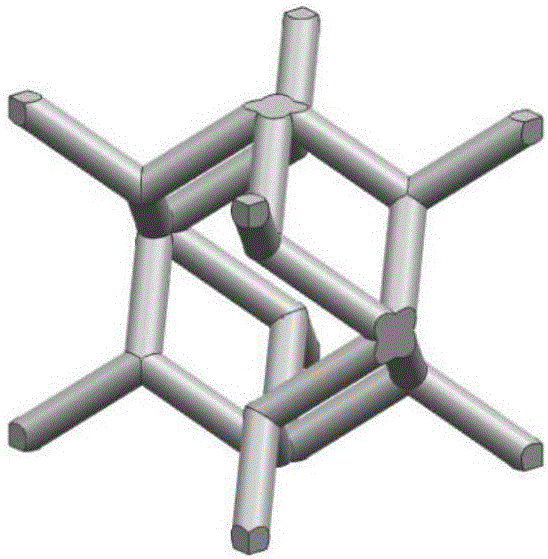

Hollow-out unit body used for metal 3D printing and part comprising hollow-out unit bodies

ActiveCN106247159ASmooth transitionMeet actual load requirementsElongated constructional elementsJoint implantsDodecahedronDiagonal

The invention discloses a hollow-out unit body suitable for the metal 3D printing technology. The hollow-out unit body comprises a main structure and an extension structure. The main structure comprises a dodecahedron structure formed by main rib strips serving as the edges. The extension structure comprises extension rib strips extending outwards from the directions of the body diagonals of a dodecahedron. The included angle between each main rib strip and the projection plane is theta, and theta is larger than or equal to 30 degrees but smaller than or equal to 90 degrees. The invention further discloses a metal part comprising the hollow-out unit body. The hollow-out unit body is of a self-supporting structure and suitable for metal 3D printing forming process conditions. Weight reduction of the unit body structure exceeds 90% maximally. A hollow-out weight reduction structure formed by the unit bodies through size changing, direction changing, density changing and other array modes is good in isotropy and high in weight reduction ratio, and the reliability of the part is improved.

Owner:XIAN BRIGHT ADDTIVE TECH CO LTD

X-ray fluuorroscopy device

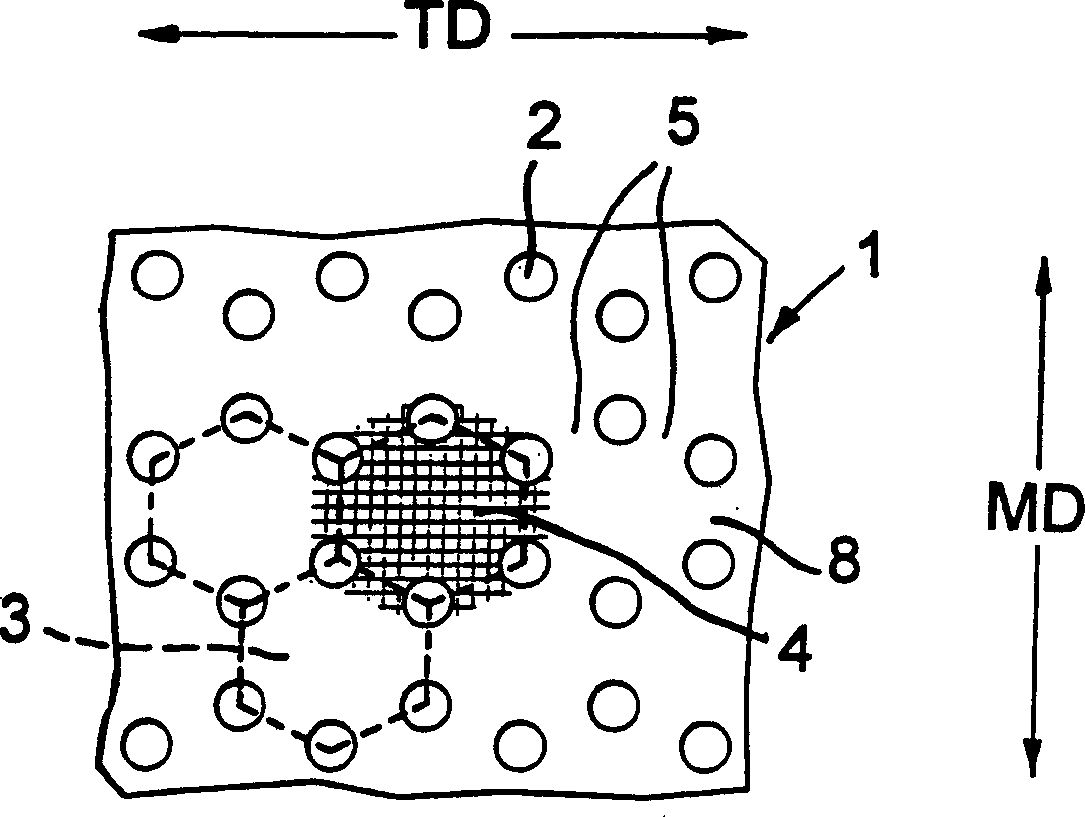

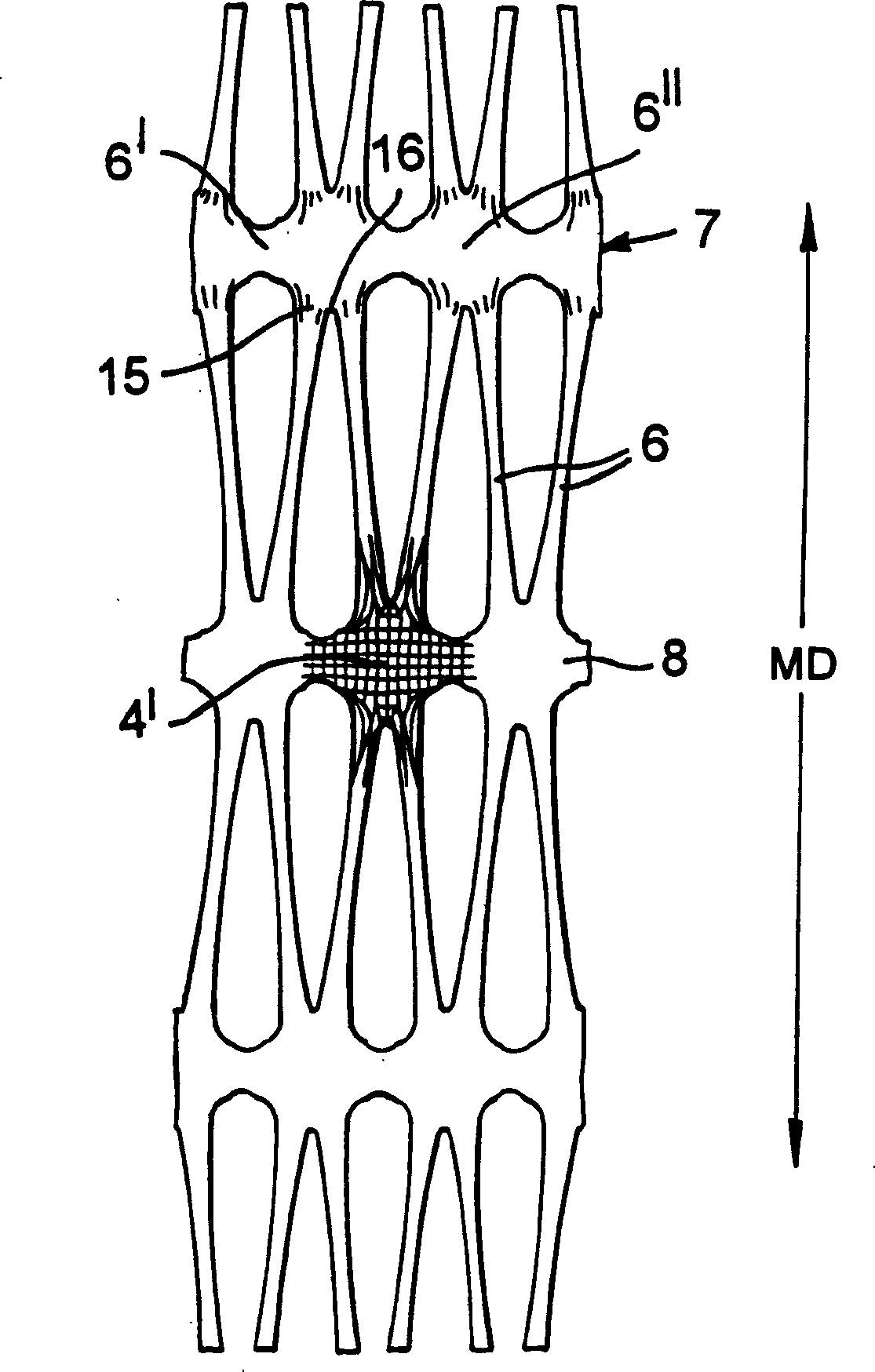

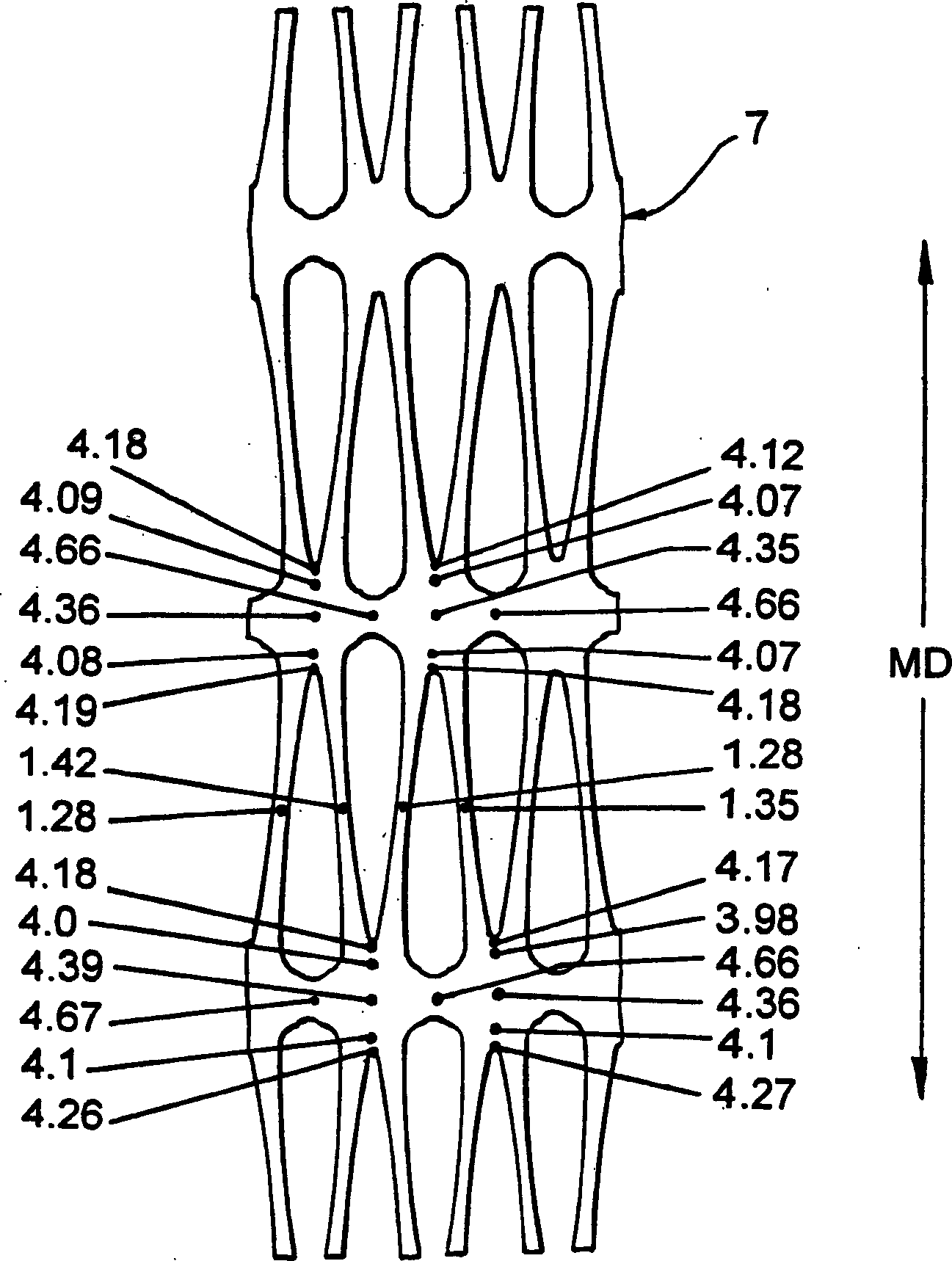

To make an oriented plastics material geogrid in which oriented strands form triangular meshes with a junction at each corner and six of the strands meet at each junction, a plastics material sheet starting material has holes in an array of hexagons, opposite holes of each hexagon being aligned in the machine direction, and the starting material is stretched first in the machine direction and secondly in the transverse direction. In the eventual geogrid, the centre portions of the hexagons in the starting material form the junctions. The centres of the junctions are slightly biaxially oriented, but at the edges of the junctions, the orientation of the edge of substantially each strand runs around the edge of the respective junction and into the edge of the next strand. During the second stretch, restraint can be applied in the first stretch direction and discontinued before the material is allowed to relax in the second stretch direction.

Owner:TENSAR TECH

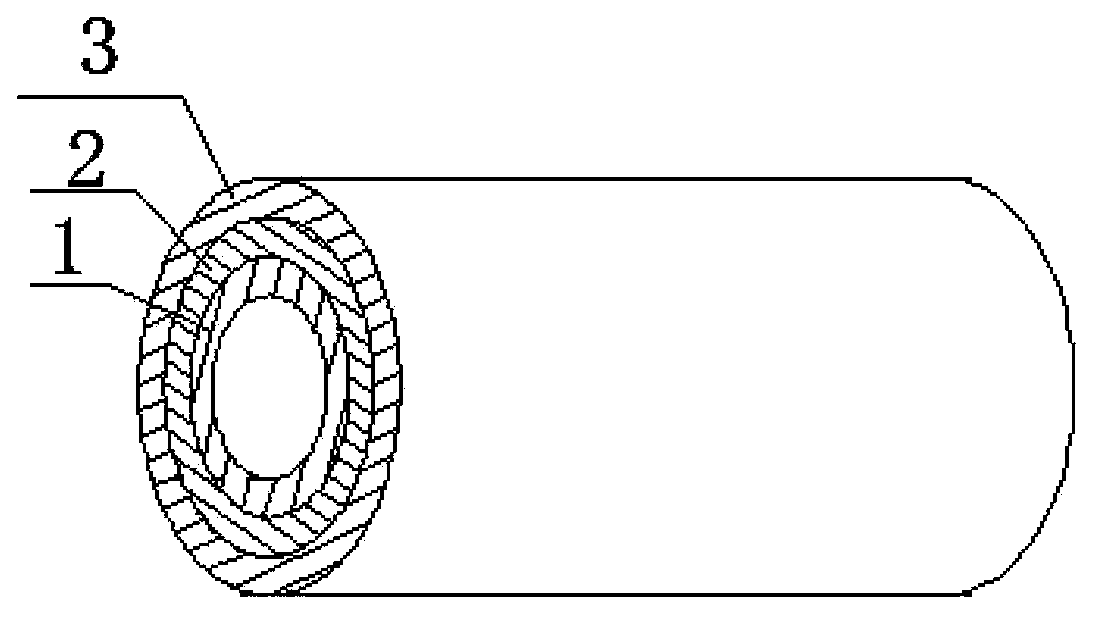

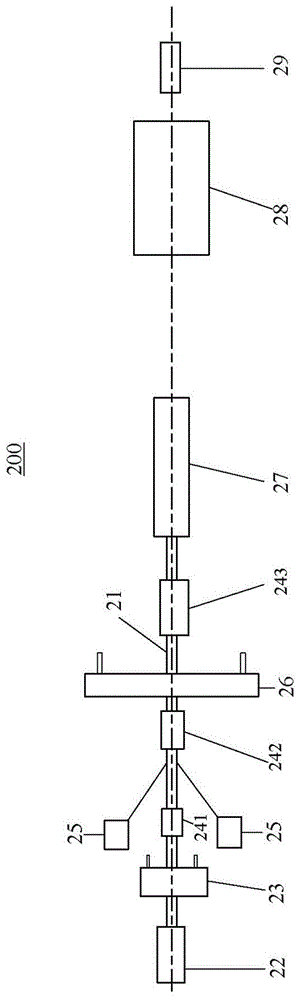

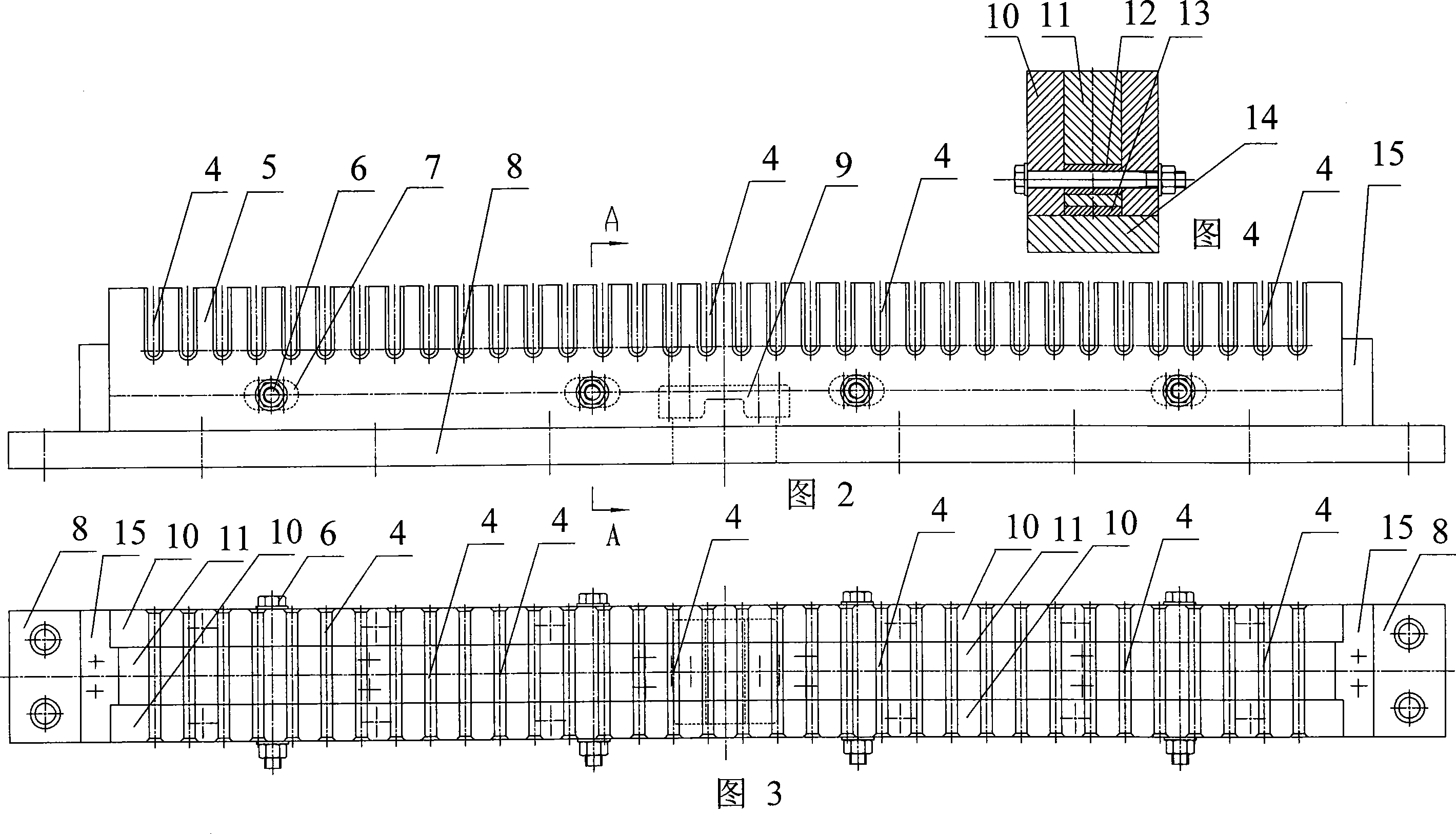

Pultrusion pipe and manufacturing method and equipment thereof

InactiveCN105952981AFacilitate continuous productionIncrease productivityElongated constructional elementsRigid pipesEngineeringForming processes

The invention provides a pultrusion pipe. The pipe wall of the pultrusion pipe at least comprises at least one of a circumferential fiber reinforcing layer and an axial fiber reinforcing layer, and a two-dimensional fiber braided layer braided and formed on the outermost layer. At least one layer in the pipe is of a continuous structure in the circumferential direction. The invention further provides a manufacturing method and equipment of the pultrusion pipe. The pipe manufactured through the manufacturing method is braided or wound or arranged layer by layer, and the problems that the numerical content of prepreg is high, a layering phenomenon is likely to happen between the layers in the forming process, and the anti-impact performance is poor do not exist between the layers. At least one layer in the pipe is of the continuous structure in the circumferential direction, no seam or fault exists, and the mechanical performance is excellent and stable. In addition, when the outer layers are wound or arranged, uniform pressure can be formed on the inner layers, interlayer bonding is enhanced, and the problem that the circumferential strength of a traditional pultrusion product is low is effectively solved.

Owner:SZ DJI TECH CO LTD

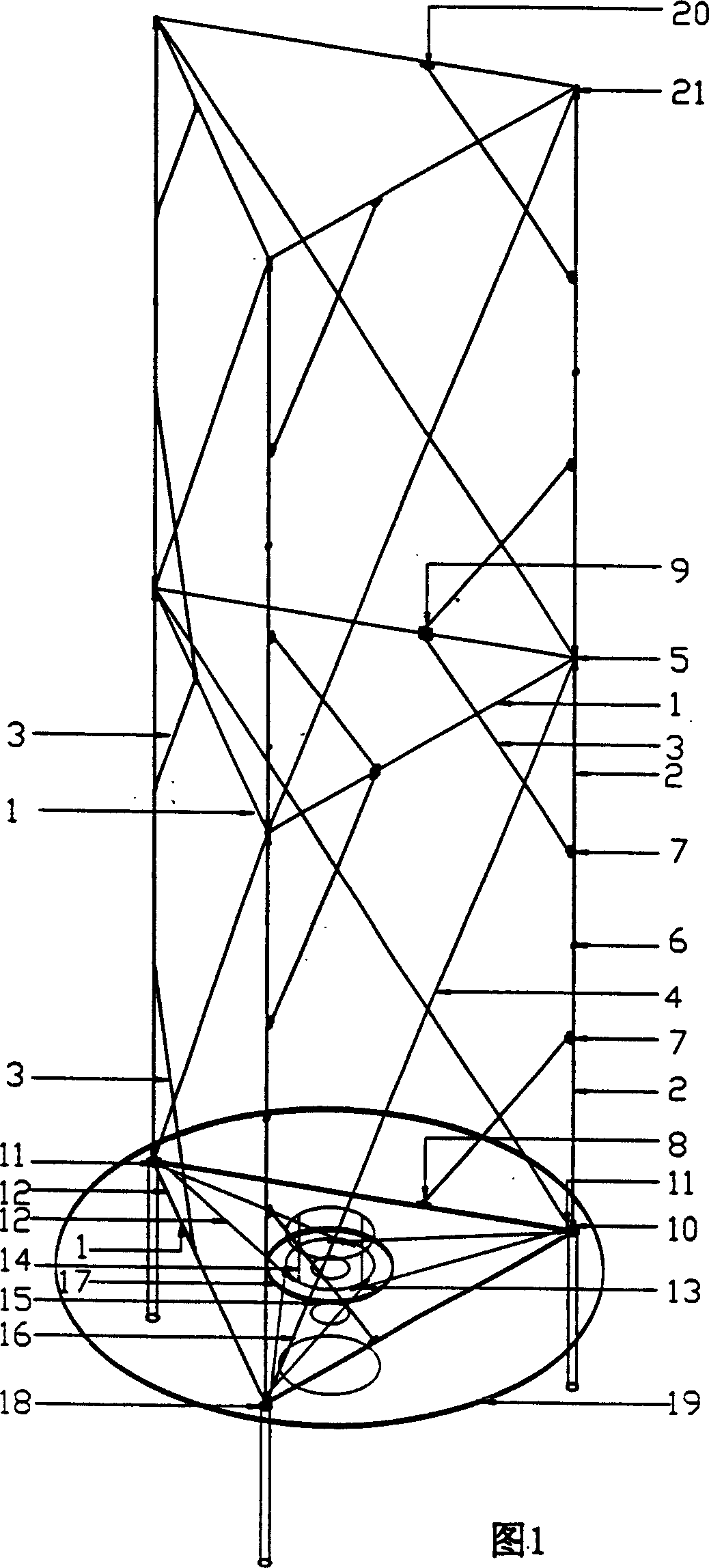

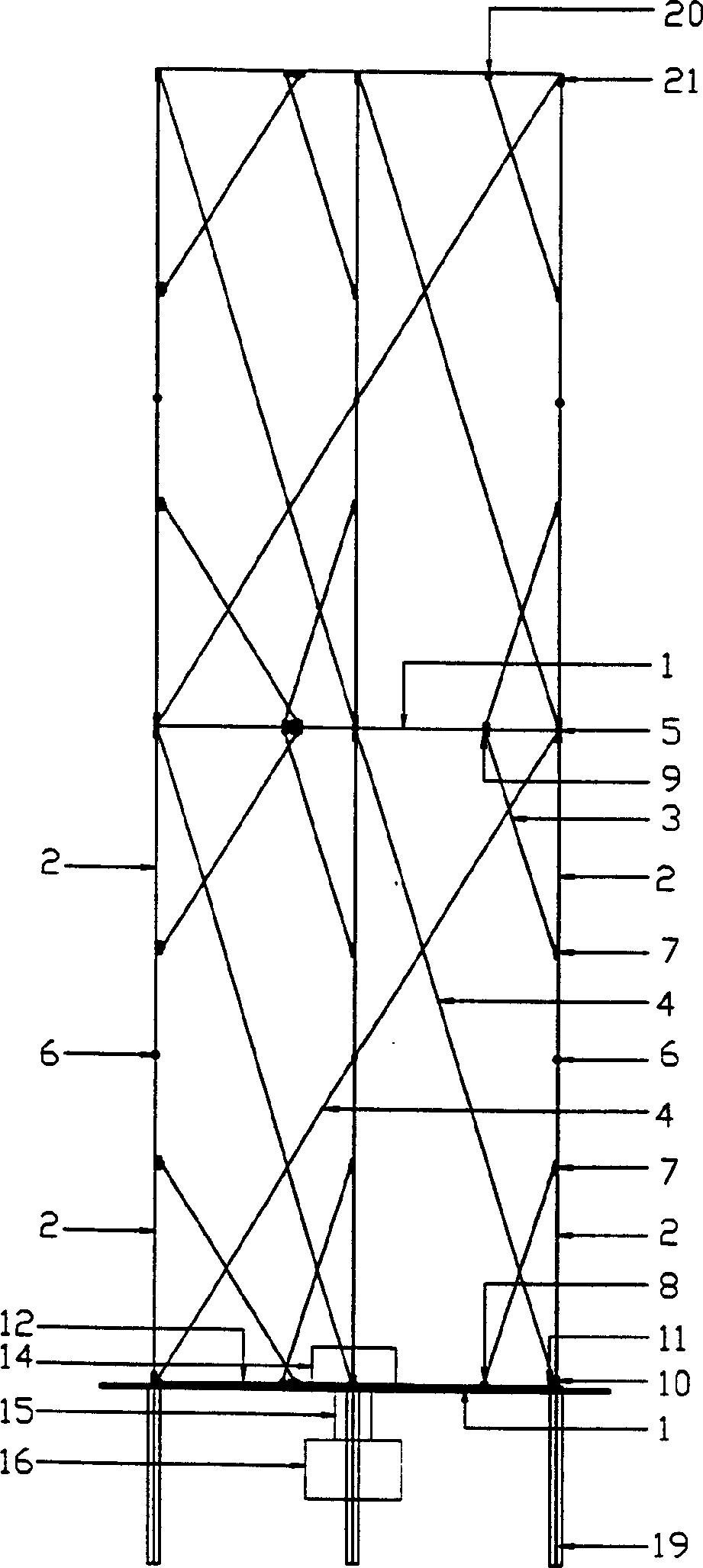

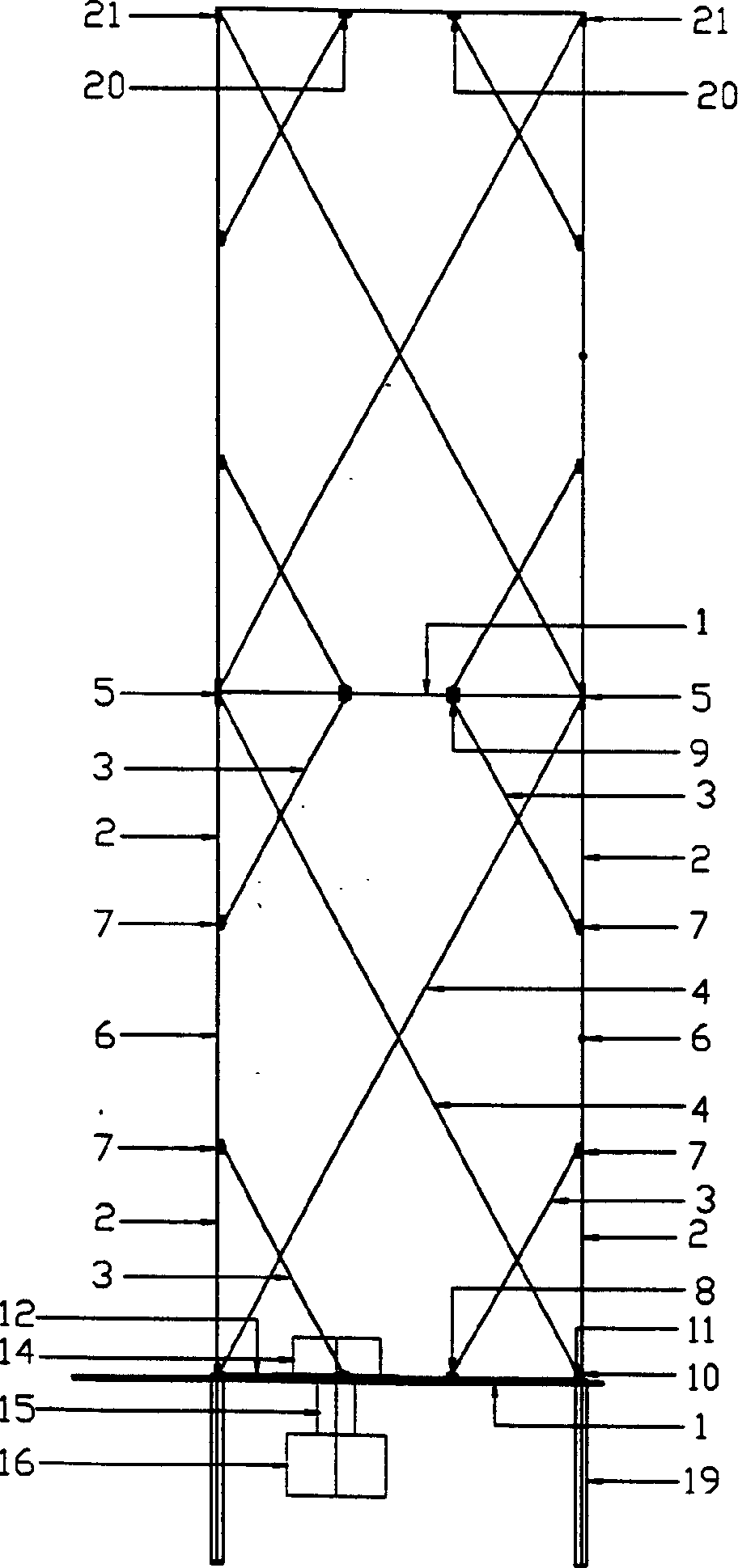

High-rigidity synchronously spreading folded space extension arm

InactiveCN1474069AImprove structural rigiditySimple organizationElongated constructional elementsRod connectionsDrive shaftEngineering

The high-rigidity synchronously spreading folded space extension arm consists of folded truss units capable of being expanded repeatedly and being spread, driving system, power supply system and supporting space platform. The folded truss units are basic units to constitute the extension arm and are connected mutually via standard triangular joints; the driving system is inside the triangular space in the bottom of the extension arm and is connected to the supporting space platform and to the power supply system through the transmission shaft. The truss structure in triangular prism form of the present invention has geometrical stability, high structural rigidity and high unit repeatability, and may be spread and folded synchronously in high precision. The present invention may be used in large communication satellite, electronic reconnaissance satellite and space station platform.

Owner:SHANGHAI JIAO TONG UNIV

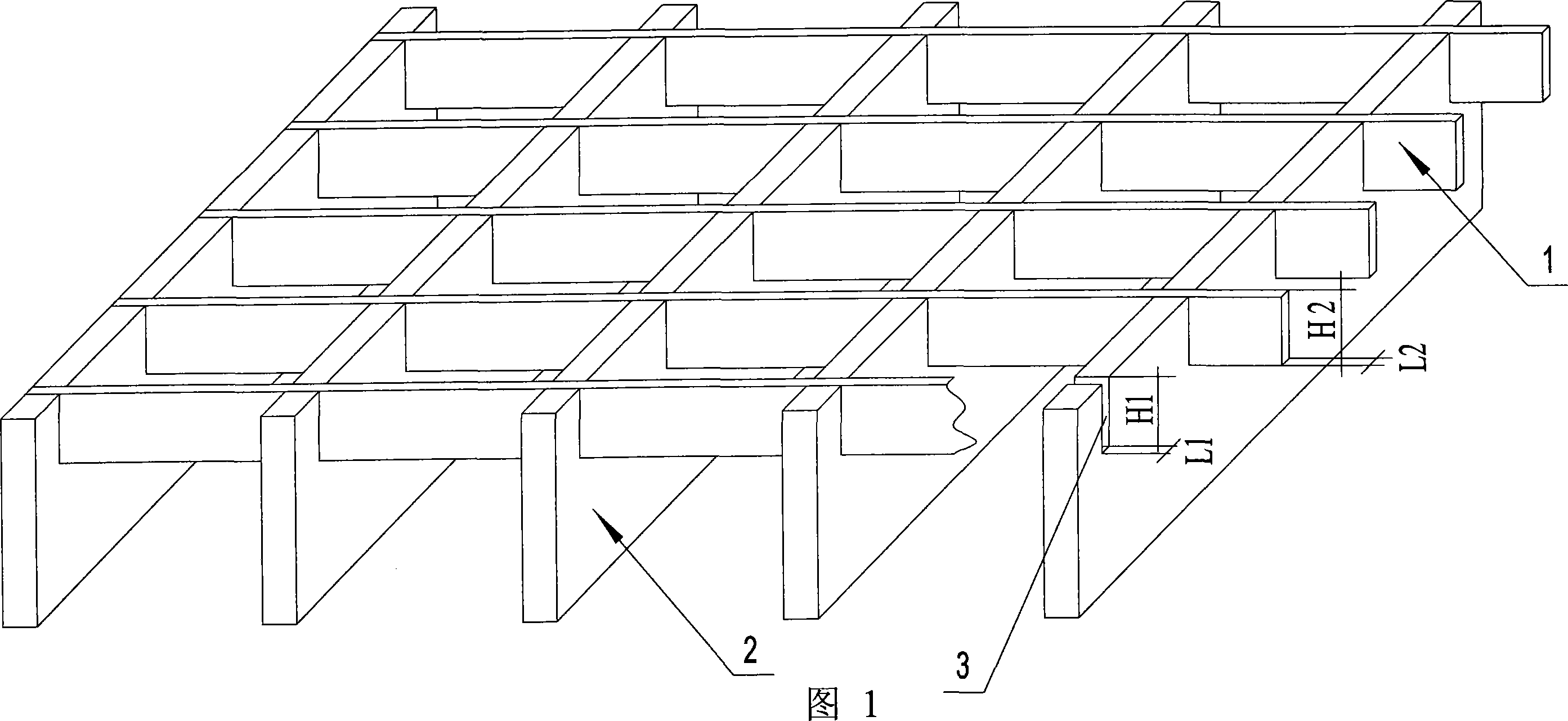

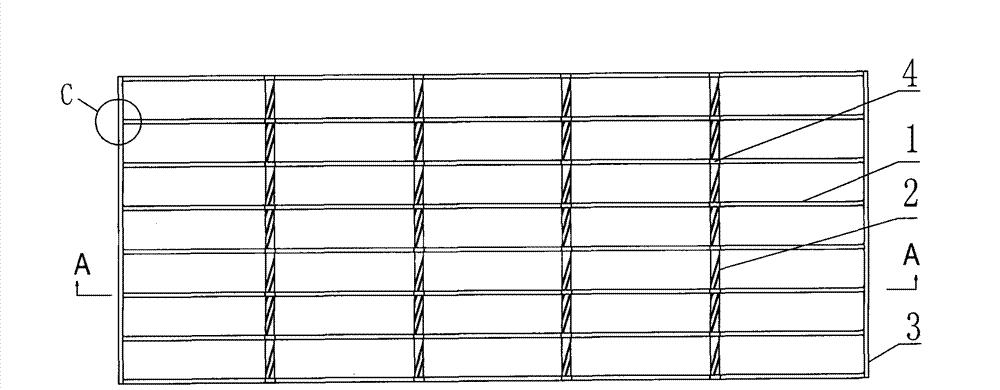

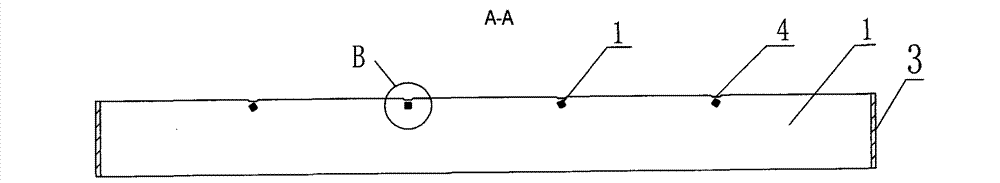

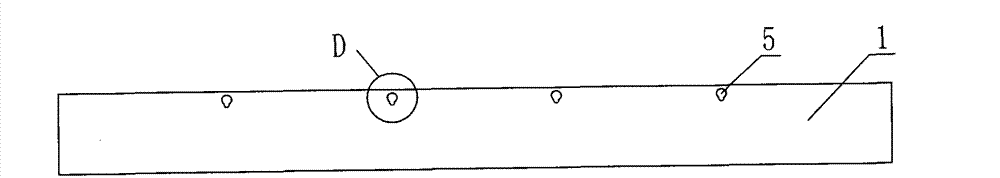

Scarfweld type steel grating and processing method thereof

InactiveCN101191581AEasy to embedReduced precision requirementsElongated constructional elementsResistance welding apparatusElectrical resistance and conductanceGrating

The invention relates to the steel grid plate manufacture technical field, in particular to a scraf welding type steel grid plate and the processing method thereof. According to the technical proposal provided by the invention, the scraf welding type steel grid plate comprising a bearing flat steel and cross bars is characterized in that: a plurality of grooves are arranged on the bearing flat steel, and the cross bars embedded in the grooves are welded with the bearing flat steel. The width of each groove L1 is larger than the thickness of each cross bar L2, and the depth of each groove H1 is smaller than the height of each cross bar H2, thereby enabling the upper surface of each cross bar to be above the upper plane of the bearing flat steel after each cross bar is felled into each groove. Then a welding current and pressure is applied between the cross bars and the bearing flat steel, the cross bars and the bearing flat steel are welded firmly and flattened through a resistance welding method, and finally the scraf welding type steel grid plate is manufactured. The invention has easy production, lower requirements on raw material and simple processing equipment.

Owner:WUXI WEIHUA ELECTRIC WELDING MFG +1

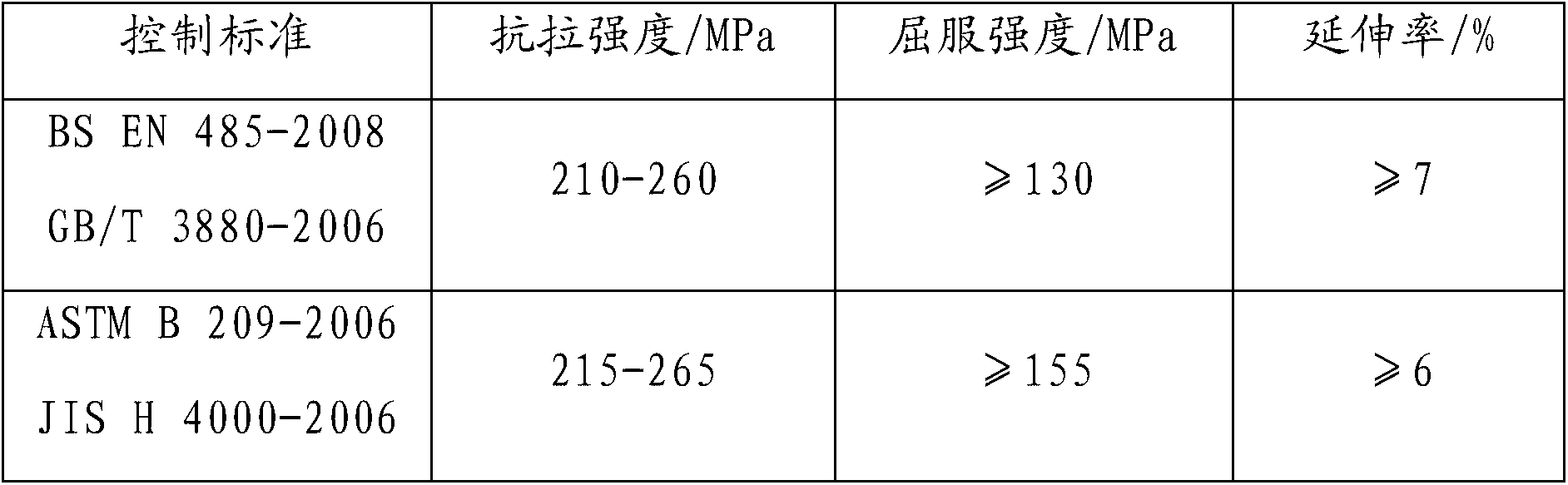

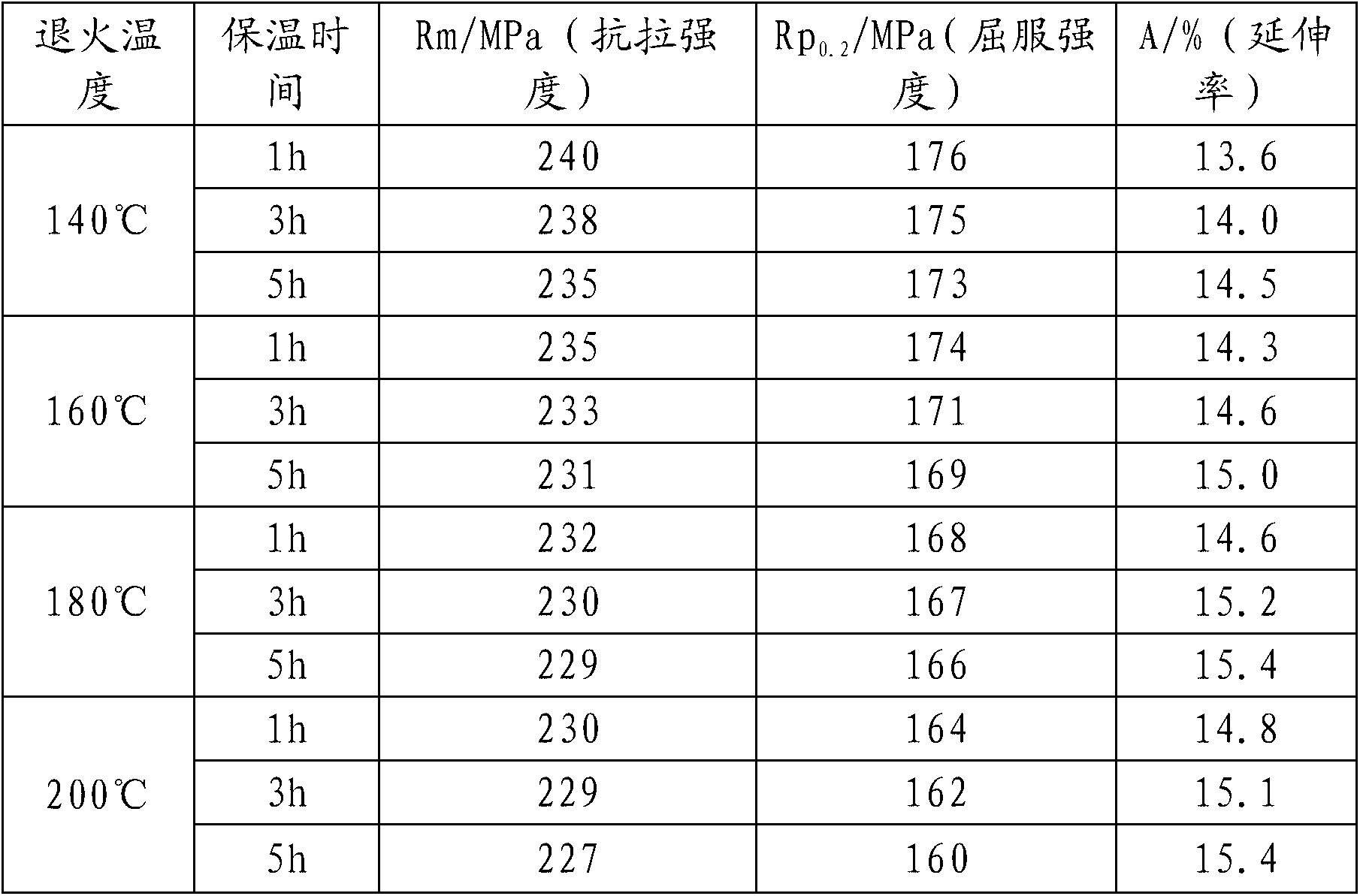

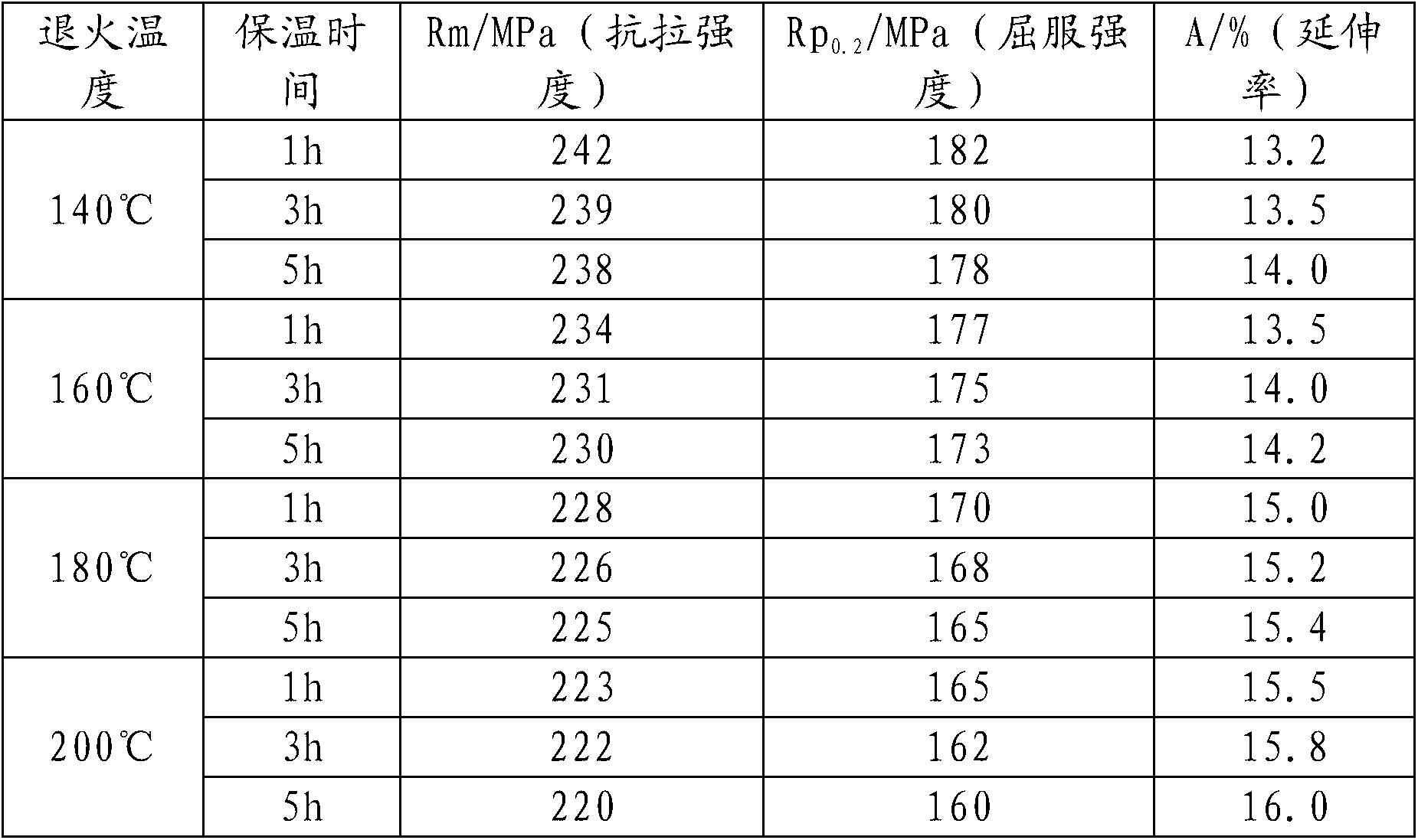

Production method of 5052-H32 aluminum alloy plate-strip

ActiveCN103008342AComplete annealingEliminate intermediate annealing processElongated constructional elementsTemperature control deviceIngotMachining

The invention discloses a production method of a 5052-H32 aluminum alloy plate-strip. The production method mainly comprises the following steps: casting, saw-cutting, face-milling, heating, hot rolling, cold rolling, stable annealing and finishing, wherein in the hot rolling step, the finish rolling temperature of hot rough rolling is controlled at 370-450 DEG C, the finish rolling temperature of hot fine rolling is 320-350 DEG C, and the thickness of a hot rolling ingot can be determined according to the requirement on the thickness of a finished product; and in the cold rolling step, the thickness of the finished product can be achieved by performing cold rolling once, and the total machining rate is 20-45%. According to the production method disclosed by the invention, for a finished 5052-H32 product with the thickness of not less than 1.1mm, full annealing and intermediate annealing process steps of the hot rolling ingot can be eliminated, the production cycle can be shortened and the production cost can be reduced.

Owner:ALUHOUSE TECHGD CO LTD

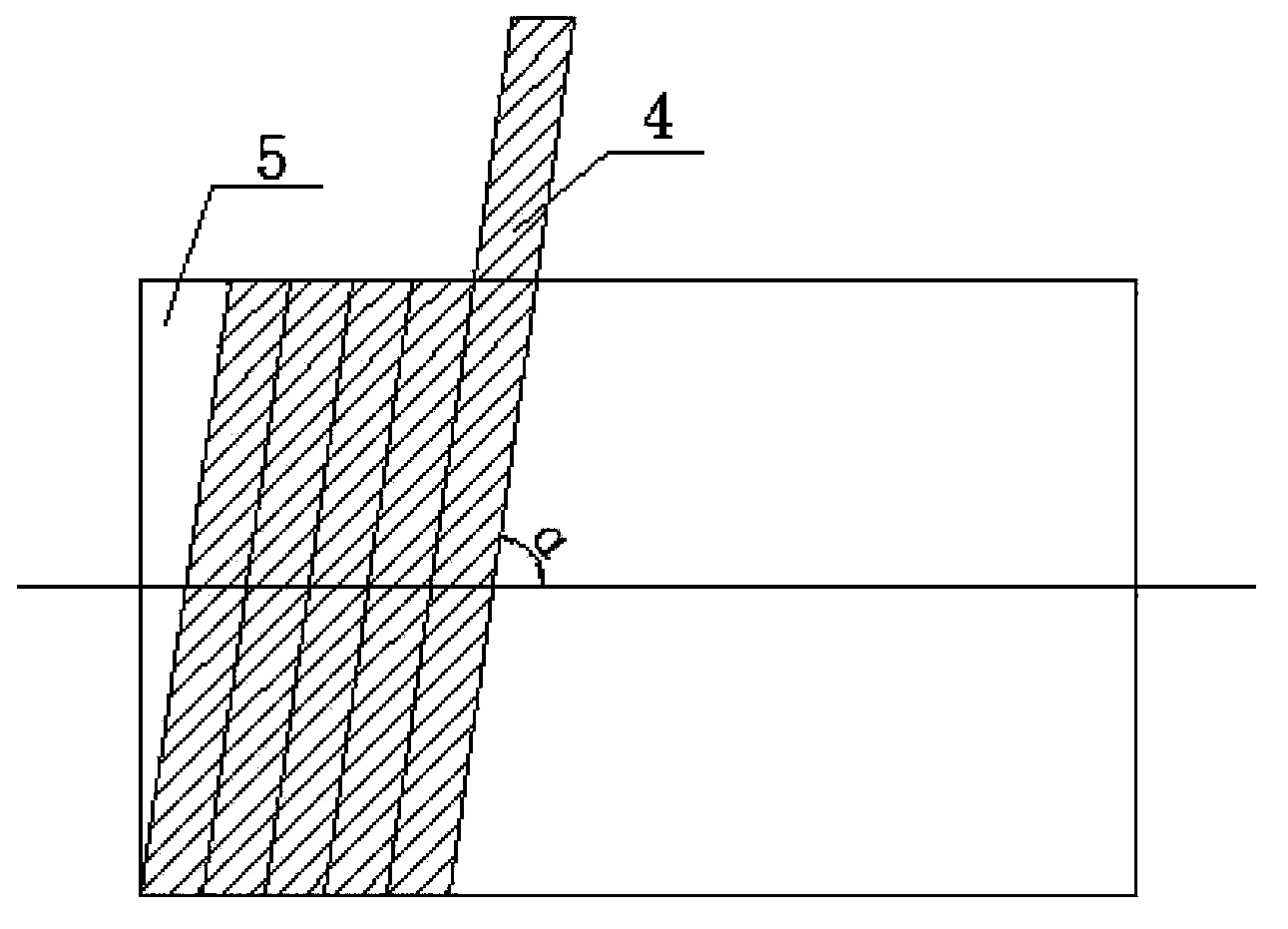

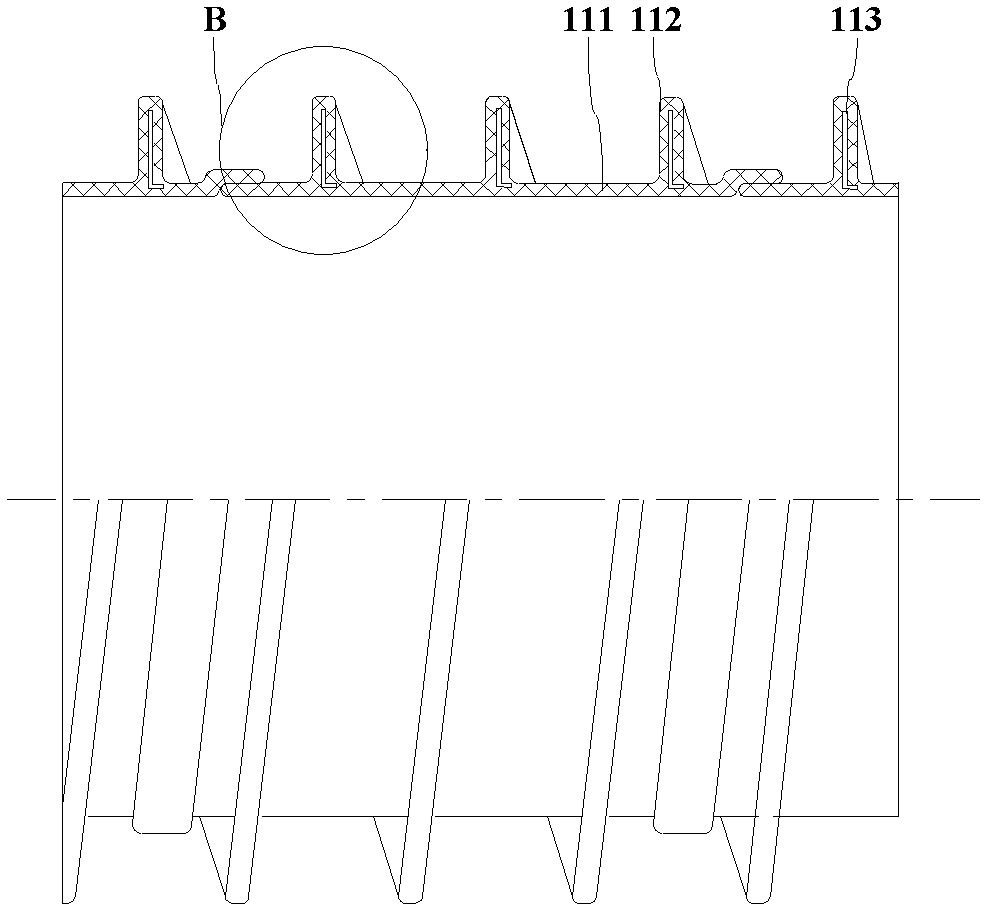

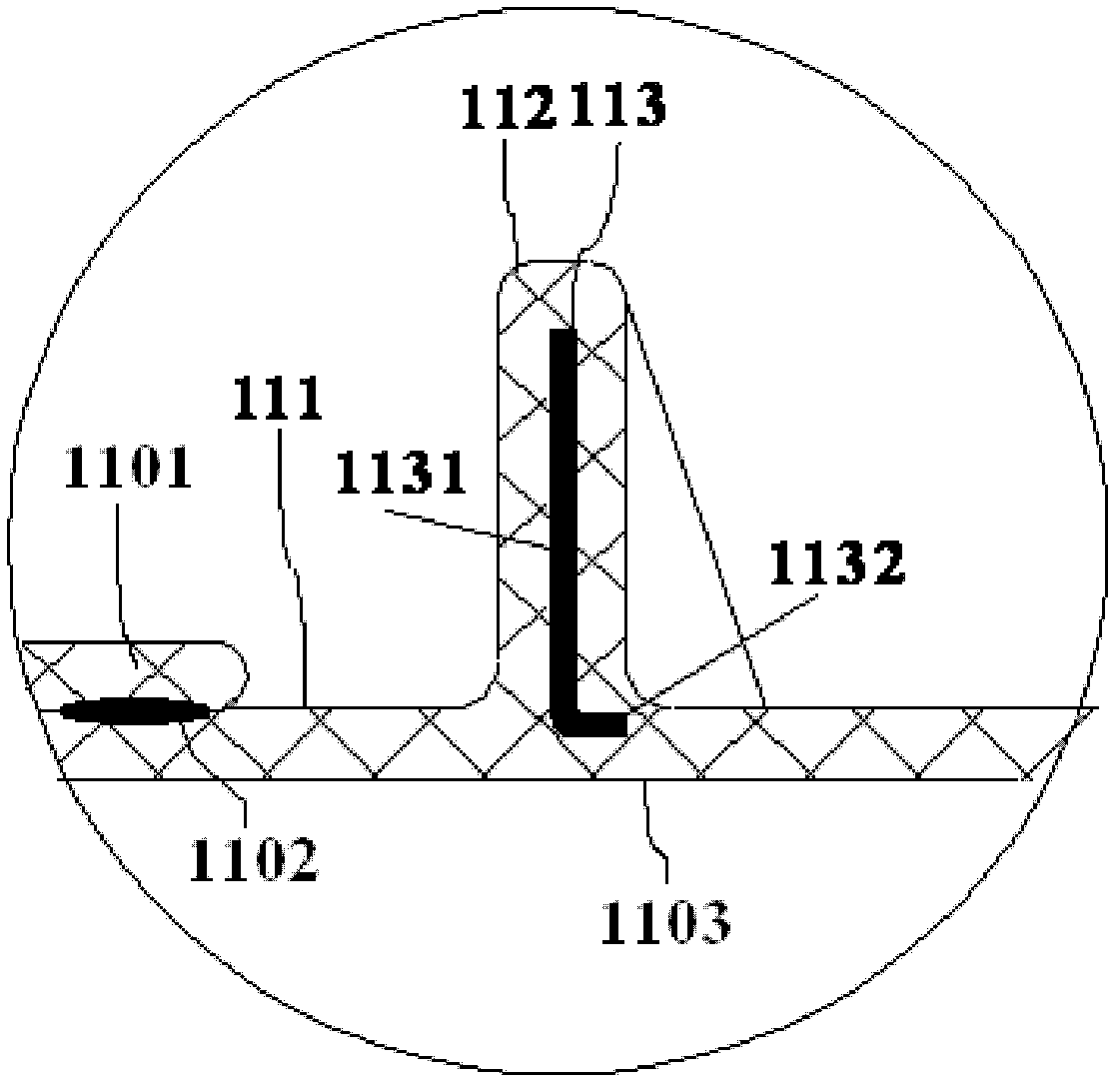

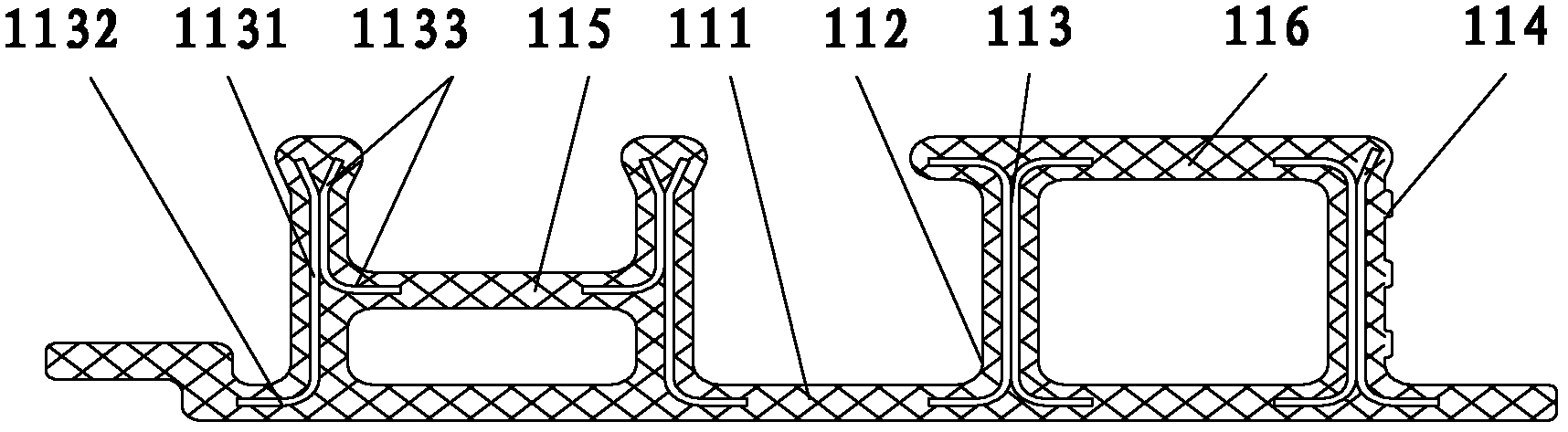

Reinforced thermoplastic composite structure wall-pipe pipe workpiece and strip material and complete set of production devices thereof

ActiveCN102305344AReduce consumptionLow costElongated constructional elementsFlexible pipesCompound structureEngineering

The invention discloses a reinforced thermoplastic composite structure wall-pipe strip material, which comprises a base plate, a reinforcing rib integrated with the base plate, and a reinforcing sectional material integrated with the reinforcing rib or simultaneously integrated with the base plate and the reinforcing rib, wherein the reinforcing sectional material is extruded and compounded with a thermoplastic material layer of the reinforcing rib, or simultaneously extruded and integrated with a thermoplastic material layer of the base plate and the reinforcing rib, and is completely coated by the thermoplastic material layer. The reinforced thermoplastic composite structure wall-pipe strip material can significantly improve the ring stiffness of a pipe workpiece. The invention also discloses a reinforced thermoplastic composite structure wall-pipe pipe workpiece, which is provided with smooth and flat inner walls and spirally surrounding reinforced thermoplastic composite reinforced structure outer walls with separation distances. The invention also discloses a complete set of production devices of reinforced thermoplastic composite structure wall-pipes for producing the reinforced thermoplastic composite structure wall-pipe strip material. By the production device, the continuous production of the reinforced thermoplastic composite structure wall-pipe strip material and the reinforced thermoplastic composite structure wall-pipe pipe workpiece can be synchronously realized and the production efficiency can be improved.

Owner:华瀚管道系统科技有限公司

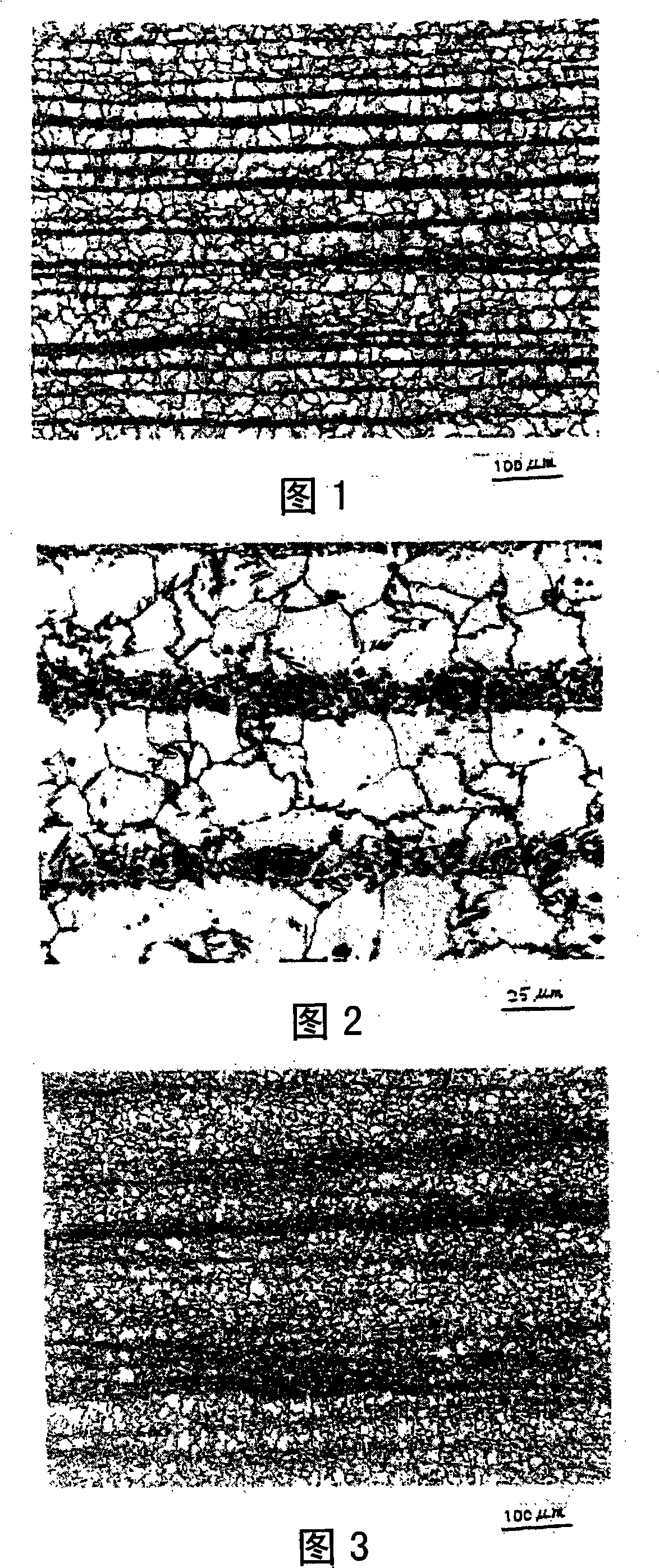

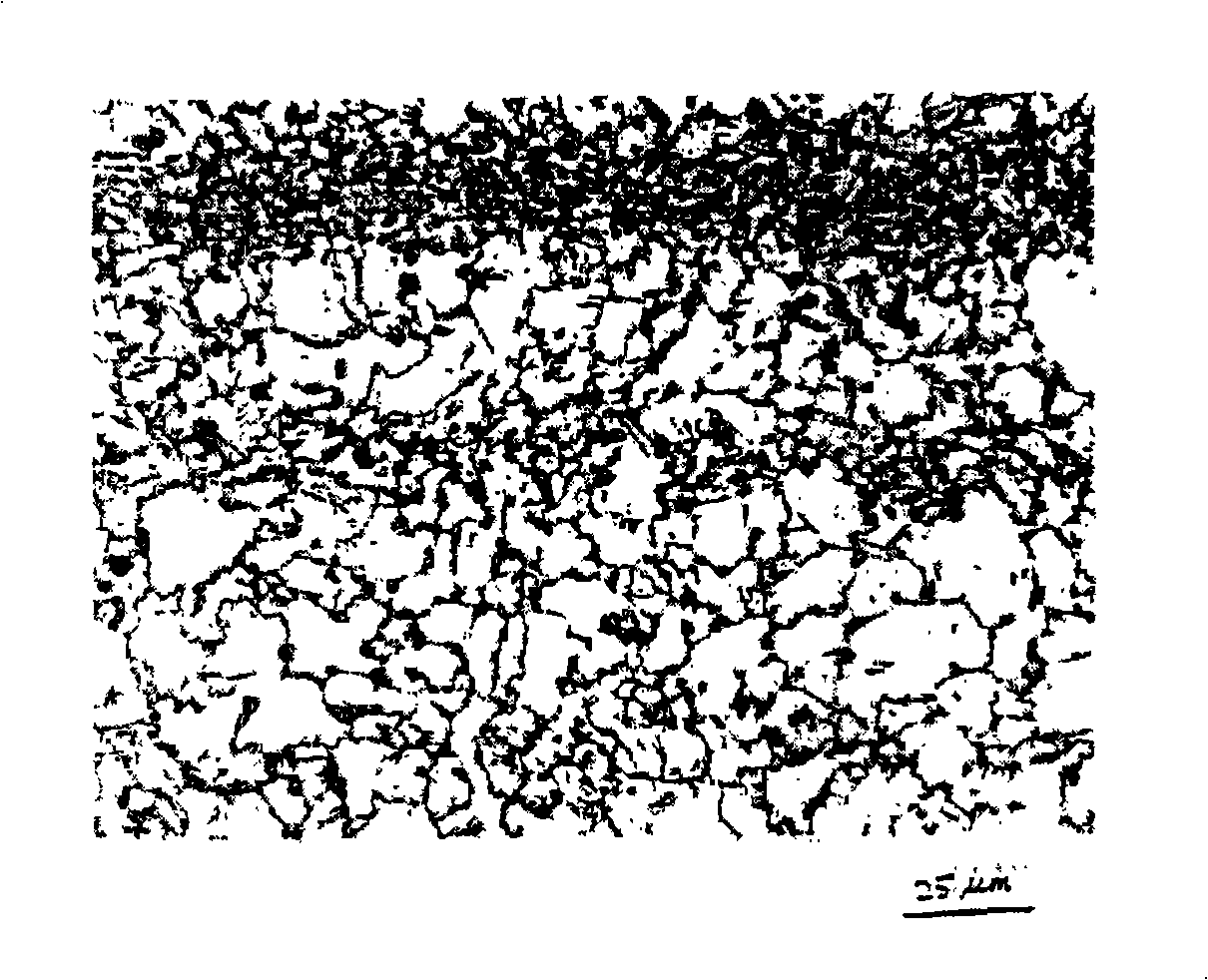

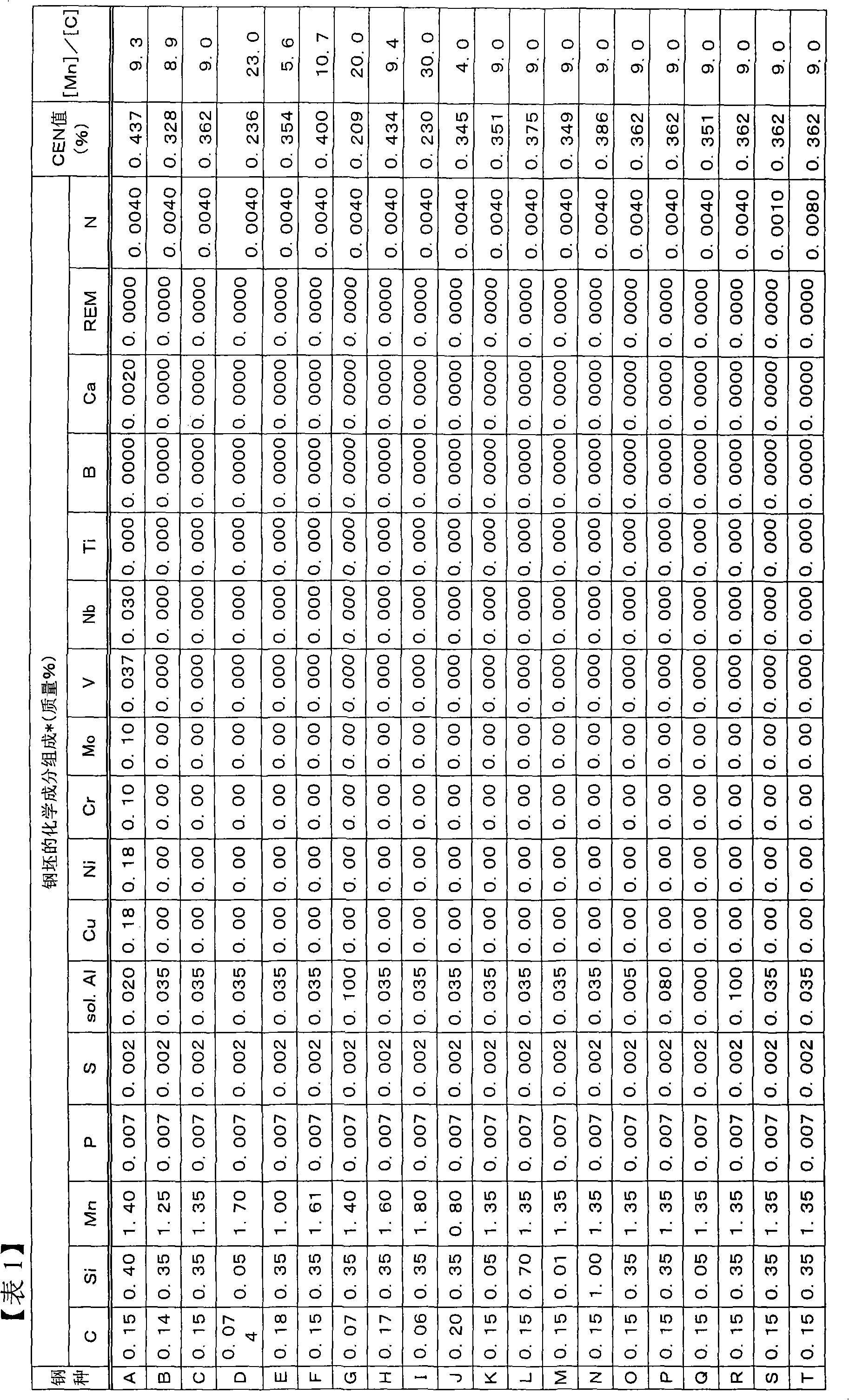

High-tension steel with excellent weldability and plastic deformation ability

The steel in the invention has specified chemical composition with the CEN valve specified by the following formula (1) in the specified range; the microscopic constitution composition of the steel is 65-85 volume% multilateral ferrite phase, 5-20 volume% strip pearlite phase, 3-15 volume% granulose tempered martensite phase existed in grain boundary ferrite; and the average equivalent circle diameter of the multilateral ferrite phase is 10-40 [mu]m. CEN=[C]+A(c).{[Si] / 24+[Mn] / 6+[Cu] / 15+[Ni] / 20+([Cr]+[Mo]+[Nb]+[V]) / 5}...(1); wherein, A(c)=0.75+0.25.tanh{20[C] -0.12}, [C], [Si], [Mn], [Cu], [Ni], [Cr], [Mo], [Nb] and [V] respectively represent content (mass%) of C, Si, Mn, Cu, Ni, Cr, Mo, Nb and V. According to the composition, like suiting for cold-forming round steel pipe, although the steel plate is exerted on strong processing (bending processing, tensile processing, compressing processing etc.) and does not execute SR processing, the tensile ratio is stable below 85% and has excellent toughness and weldability to be high-tension steel with tensile strength above 490 MPa.

Owner:KOBE STEEL LTD

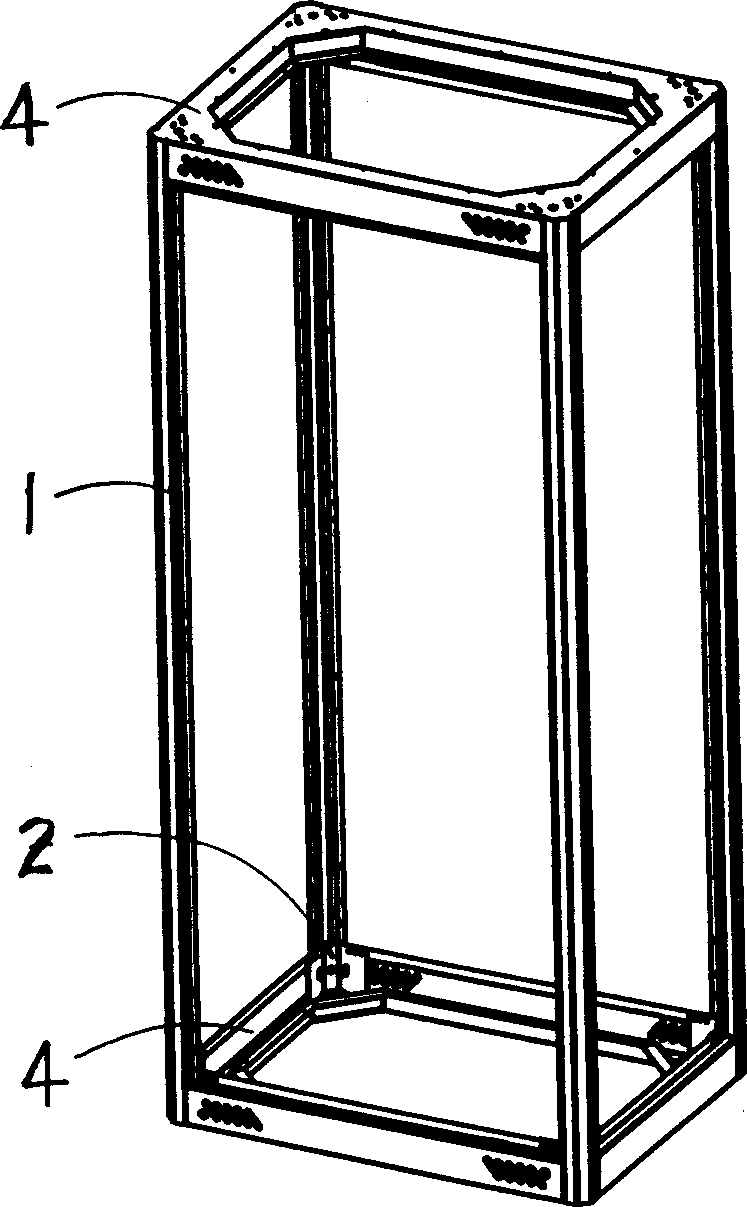

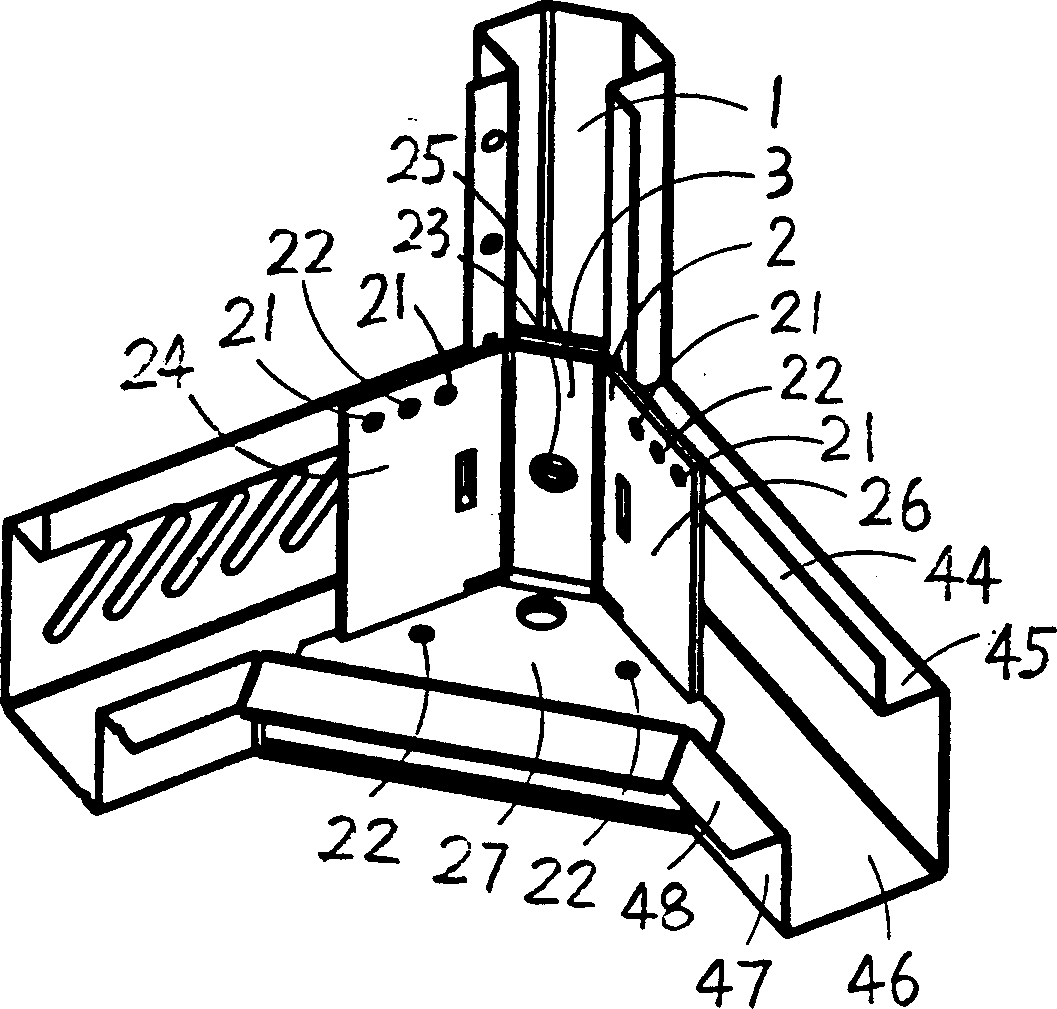

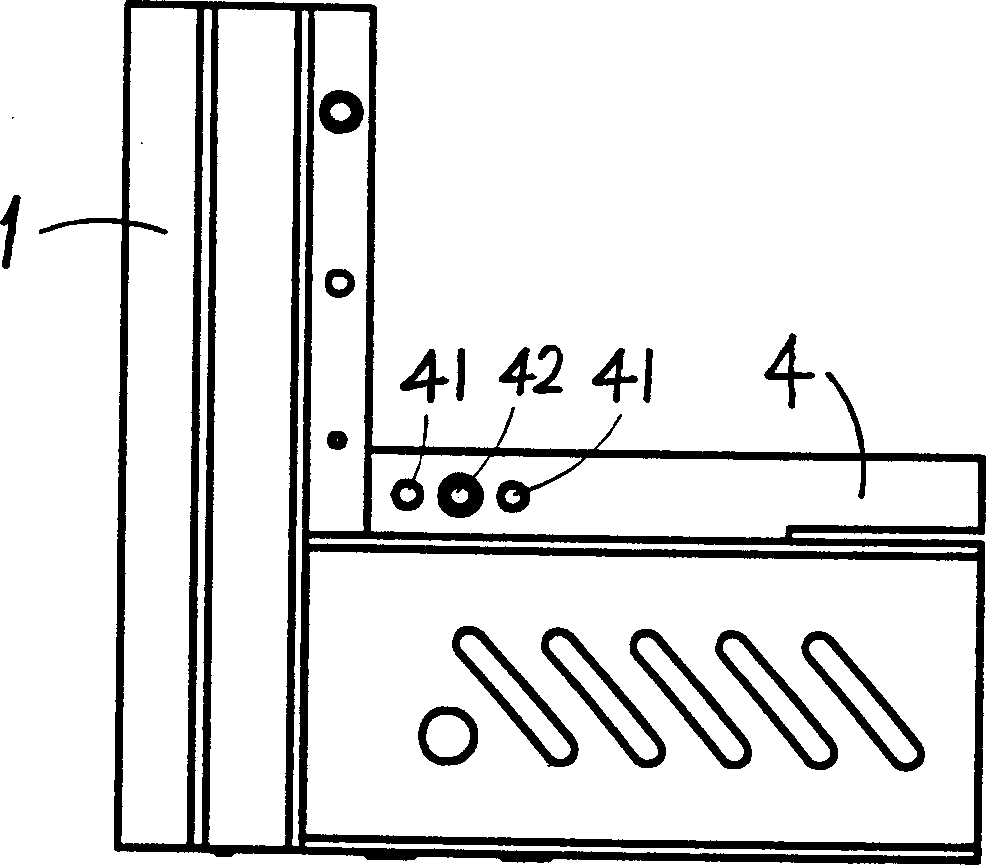

Assembling type rack frame structure

InactiveCN1450297AEasy to shipDoes not affect normal useElongated constructional elementsDismountable cabinetsMetal sheetEngineering

The present invention relates to a machine cabinet frame structure, in particular, it relates to a frame assembled by using upper and lower base seats and four corner upright columns, and the structure of every frame corner is made up by adopting corner upright column, corner connecting blocks, corner inner fastening blocks and base seat and directing, positioning, mounting and fixing the above-mentioned four metal sheet members. The above-mentioned metal members having good university and interchangibility, so that said invention can assemble various rectangular machine cabinets with different sizes.

Owner:上海惠亚电子有限公司

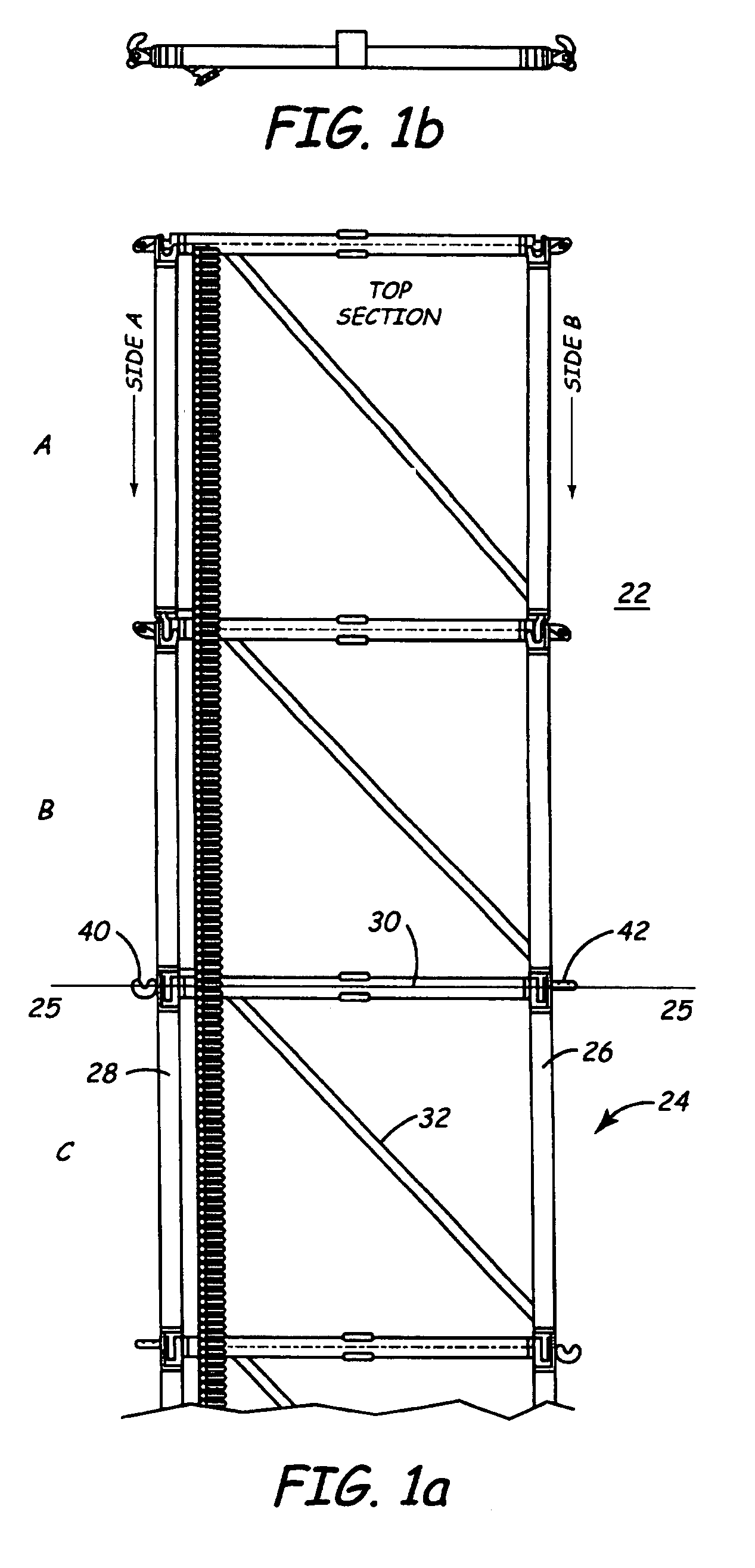

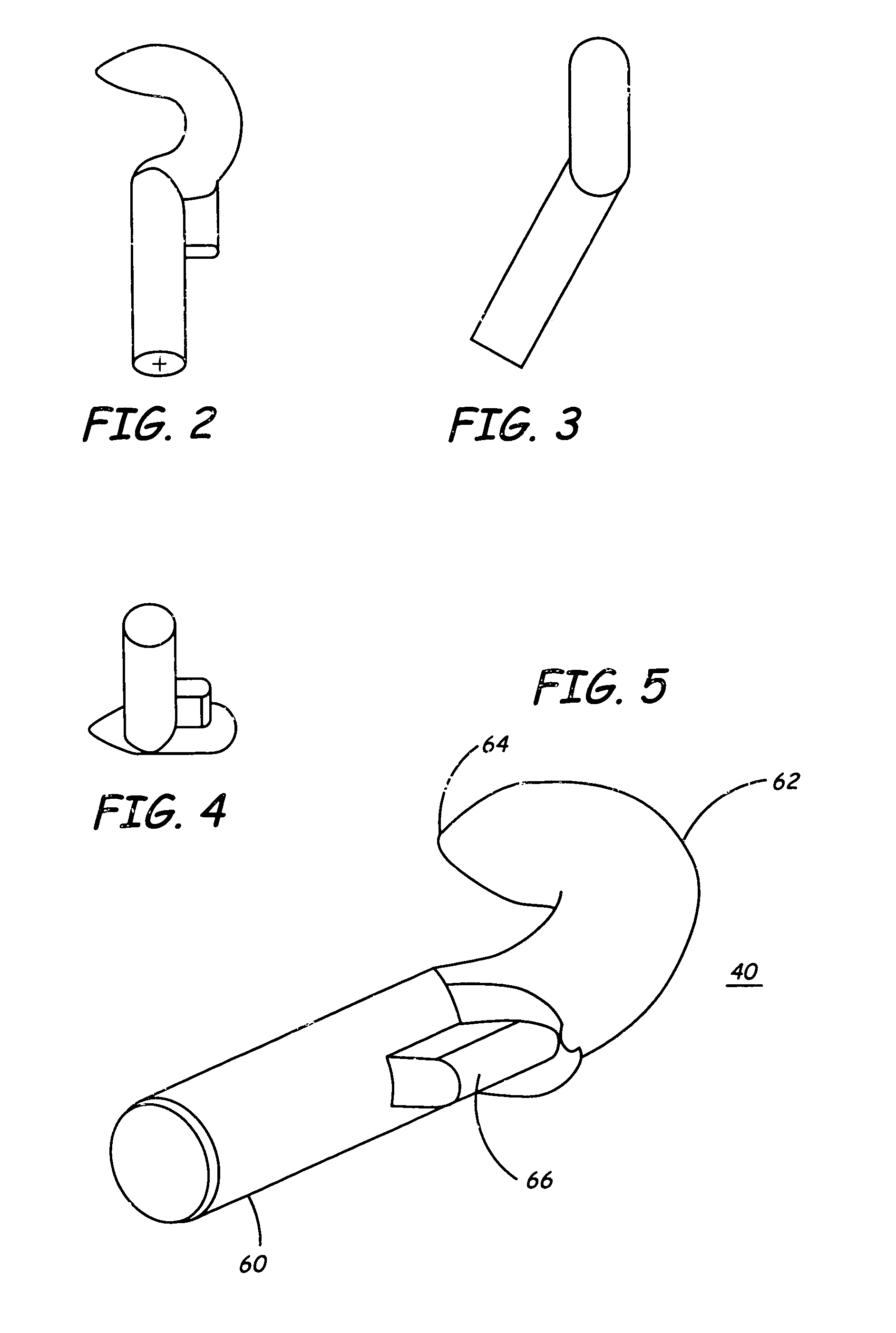

Retractable column and method of forming

InactiveUS7310915B2Increase resistanceImprove stabilityElongated constructional elementsLifting devicesEngineeringTower

Owner:TOWER SOLUTIONS

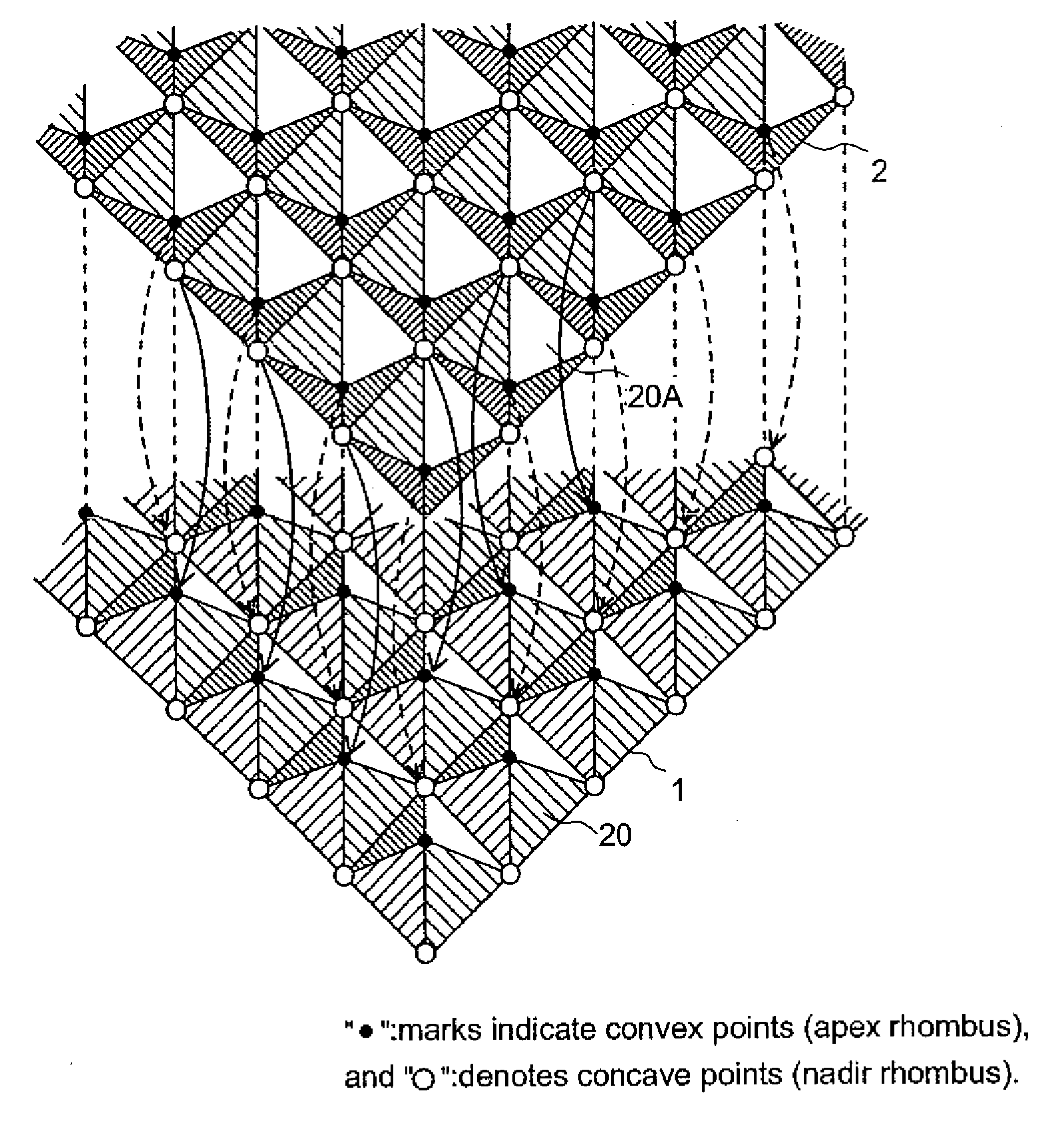

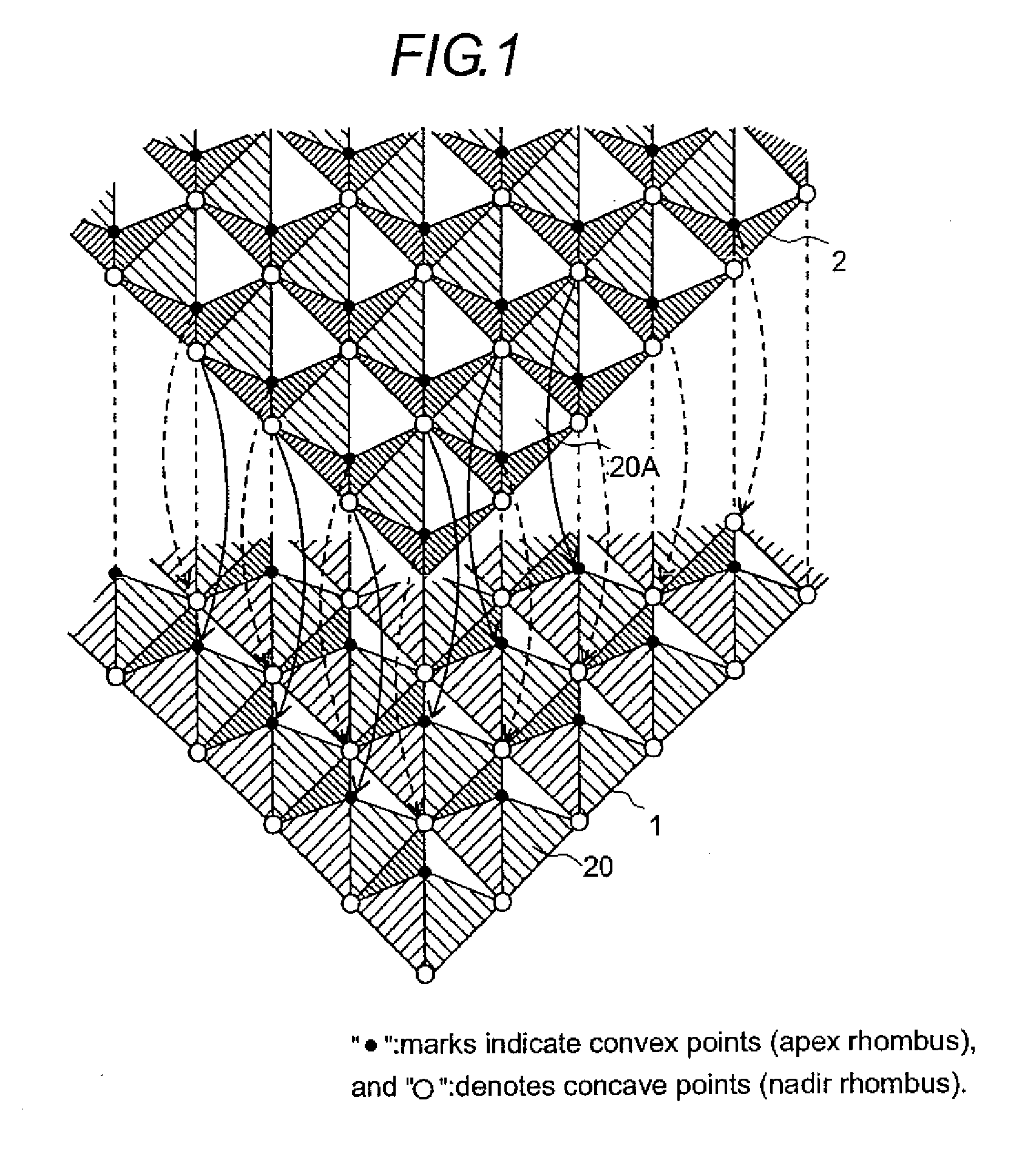

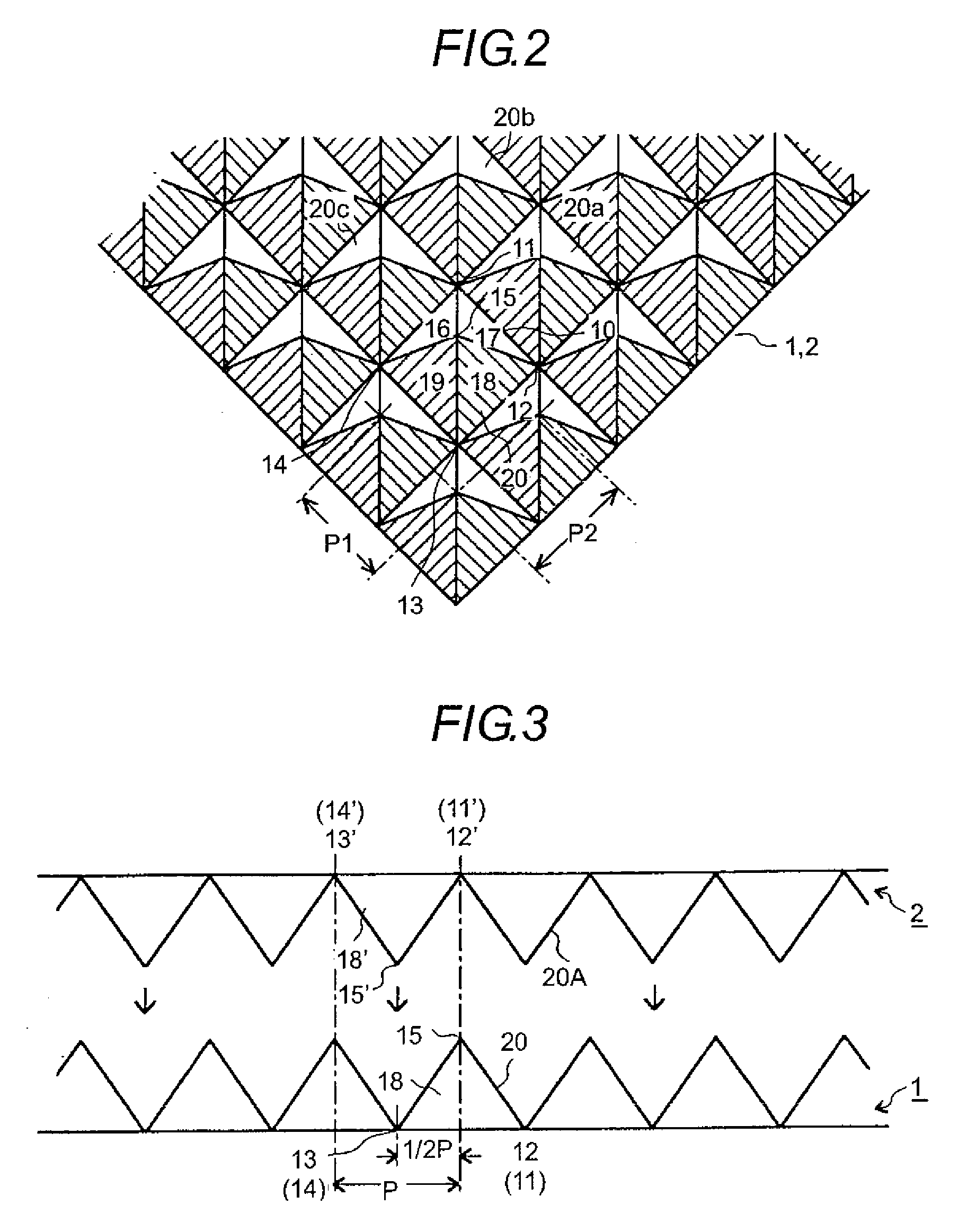

Space truss structure surface slab assembly

An apex rhombus is delimited over the center point of a square, which is delimited by plotting four nadir rhombuses on the same plane, and each of the nadir rhombuses and the apex rhombus are jointed to form a group of pyramidal surfaces equipped with four planar slopes having substantially the same height in a pyramidal form. Two pyramidal surface slabs are assembled, each composed of pyramidal surfaces around one pyramidal surface, each sharing one nadir rhombus, adjacent each other, and arranged in a grid pattern at an equal pitch in plural directions. The pyramidal surfaces arranged in a grid pattern are each displaced by one-half pitch in a specific direction, such that the apex rhombus of one of the pyramidal surface comes in contact with the nadir rhombus of the other pyramidal surface, whereby the two pyramidal surfaces are placed one on the other.

Owner:SHOJI BUNICHI

Phenolic glass reinforced plastic grille

The invention discloses a phenolic glass reinforced plastic grille which is formed by pulling and extruding ordinary alkali-free glass fiber yarns, a continuous glass fiber mat and phenolic resin andusing 1-10 microns aluminum hydroxide as a filler, wherein the temperature of a pulling and extruding mould is set to be 220-250 DEG C, and the weight ratio of the aluminum hydroxide to the phenolic resin is 0.05-0.3:1. The invention has the advantages that production raw materials have low price and easy to obtain; the price of the ordinary alkali-free glass fiber yarns is 1 / 5-1 / 15 of that of high-strength glass fiber yarns, thereby reducing the cost greatly and obtaining products with stronger competitive power; and the phenolic glass reinforced plastic grille has the property of 927 DEG C high-temperature ablation resistance. The invention passes USCG authentication of level 2 (USCG Level 2) of America.

Owner:CHINAGRATE COMPOSITES STRUCTURE NANTONG

Steel grating, using device and production method

InactiveCN102853245AReduce consumptionReduce manufacturing costElongated constructional elementsGratingArchitectural engineering

The invention discloses a steel grating, a using device and a production method. The steel grating comprises flat bars and cross rods. Each flat bar is provided with a through hole, the cross rods penetrate through corresponding through holes of the flat bars, and an indentation groove is arranged at the top end of each flat bar. One portion of each indentation groove corresponding to the lower cross rod forms an extrusion pit, a left protrusion and a right protrusion are respectively formed on two sides of each extrusion pit, and the outer wall of the through hole of each flat bar is clamped between the left protrusion and the right protrusion; or one portion of each indentation groove corresponding to the lower cross rod is provided with a clamping groove and the outer wall of the through hoe of each flat bar is clamped in each clamping groove. The production device of the steel grating comprises a press head and a first slot template. The production method of the steel grating includes that: the through holes of the flat bars are processed; the flat bars are inserted into flat bar grooves of the first slot template; the cross rods penetrate through the corresponding through holes of the flat bars and are positioned through baffles; and a press provided with the press head exerts pressure at the top end of the through holes of the flat bars. According to the steel grating, the using device and the production method, large special welding devices are not needed, massive consumption of electric energy is saved, the manufacture cost is low and the process is simple and practical.

Owner:李百宁

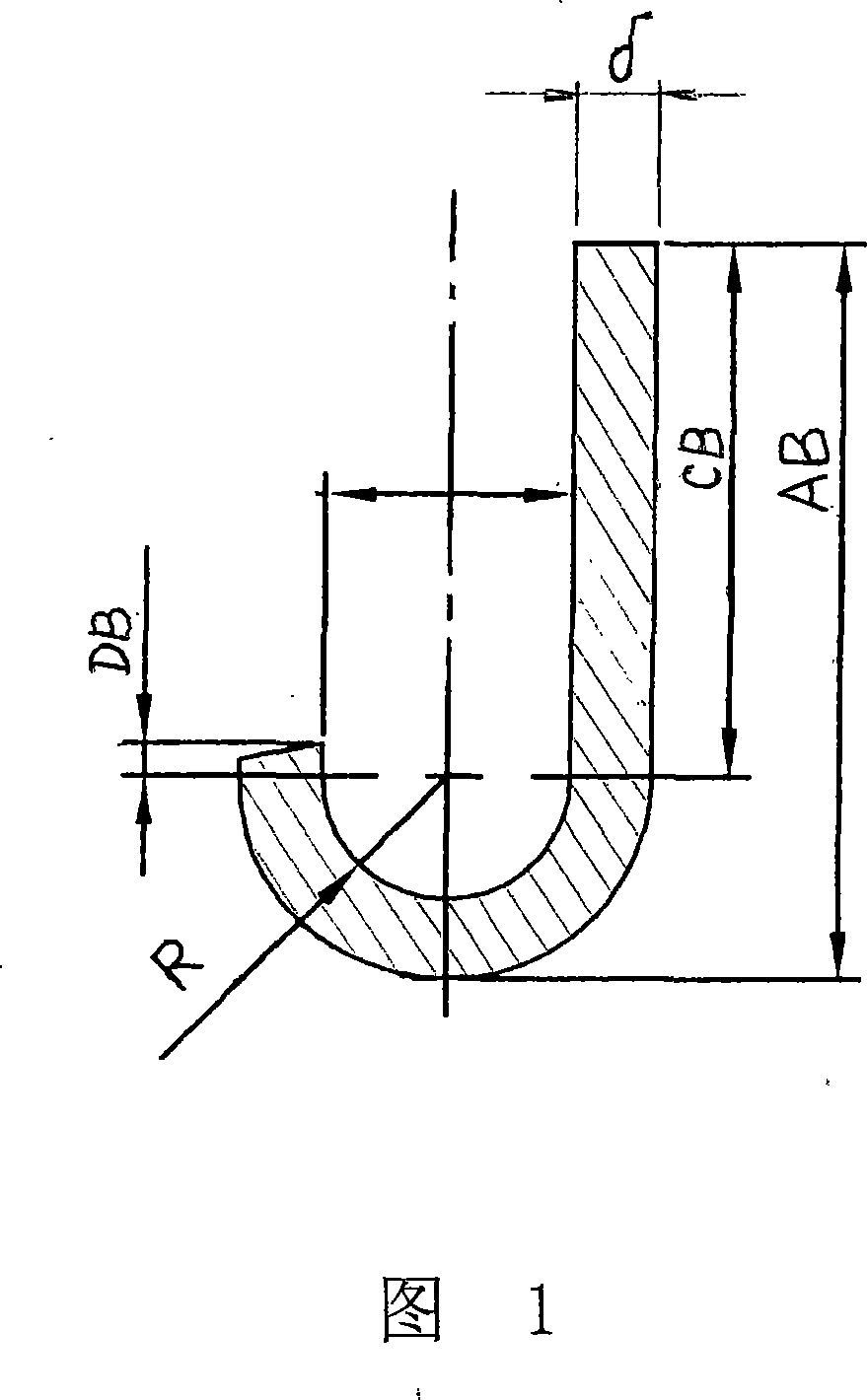

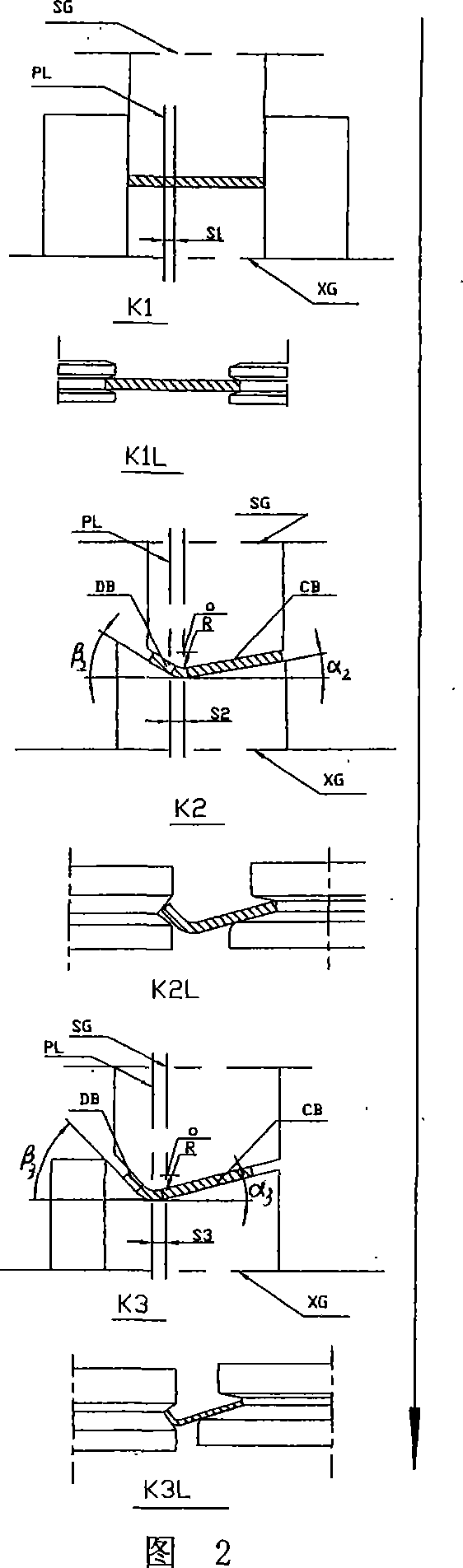

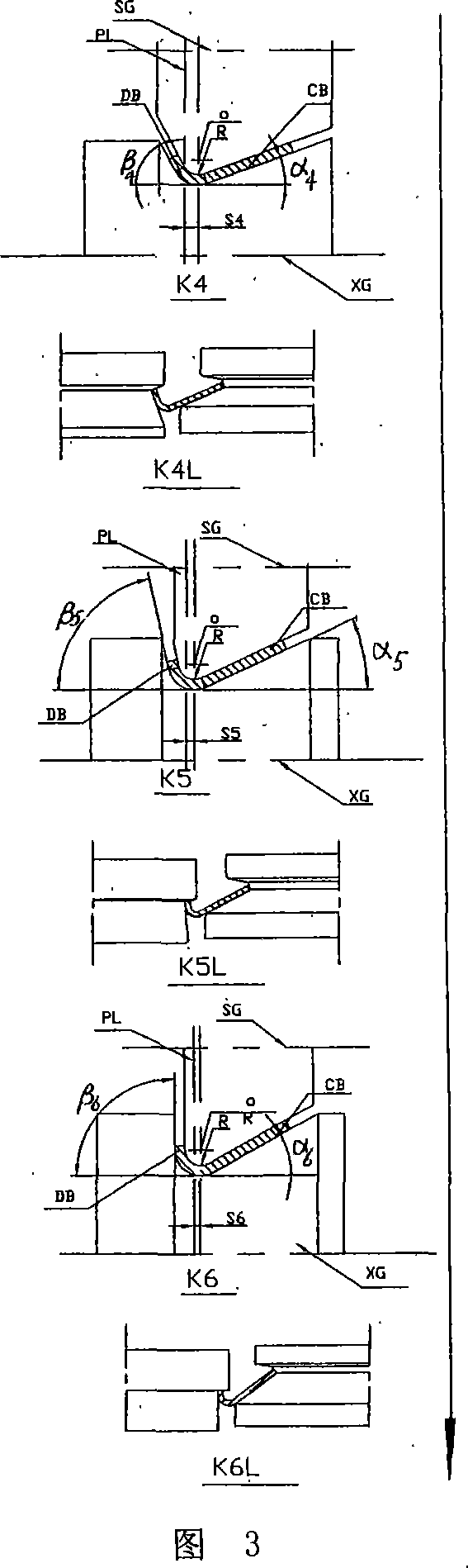

J-shape cold bend steel steel and rolling technology

InactiveCN101067470ADegree of reductionMinimize the difference in calenderingElongated constructional elementsMetal rolling arrangementsMetallurgyDistortion

The invention relates to a J shape cooled steel structure and the rolling process. The structure has the asymmetry length and the ration of the thickness and inner arc radius can reach above 80%. The technology scheme is to roll the steel by the roller continuously until the steel changing the shape, the rolling distortion process is divided into 12 times. It uses the up / down binate plain-barrel roll, the matched leading vertical roller, the three rollers frame and two straightening machines to make straight. The short lift angle is bigger than the long side in rolling process. The arc center departures the rolling line from big to 0. the steel of the invention has the asymmetry arc lengths which is above 16 times and reach to the difference +-0.1 to assure the quality.

Owner:上海佳冷冷弯科技股份有限公司

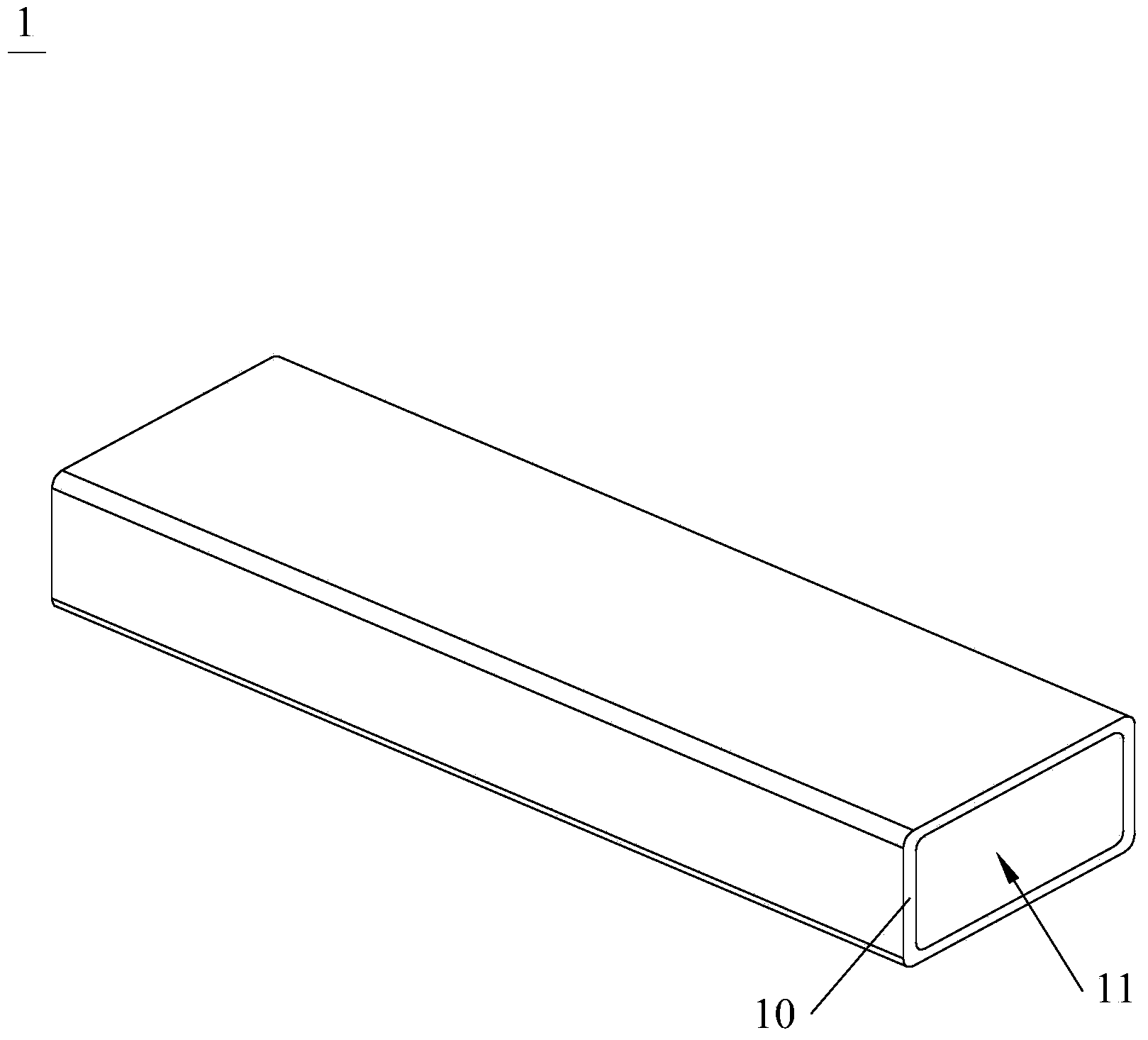

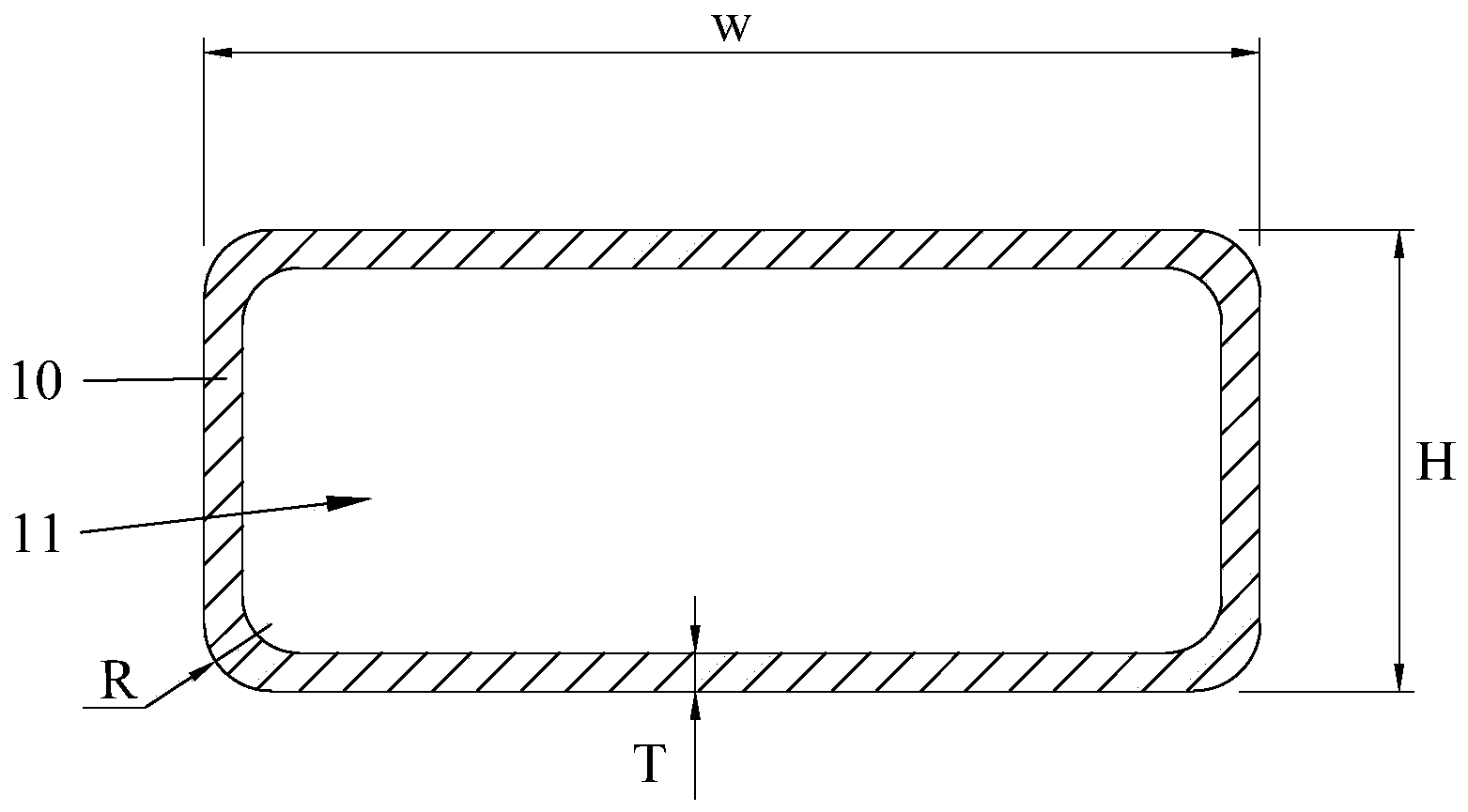

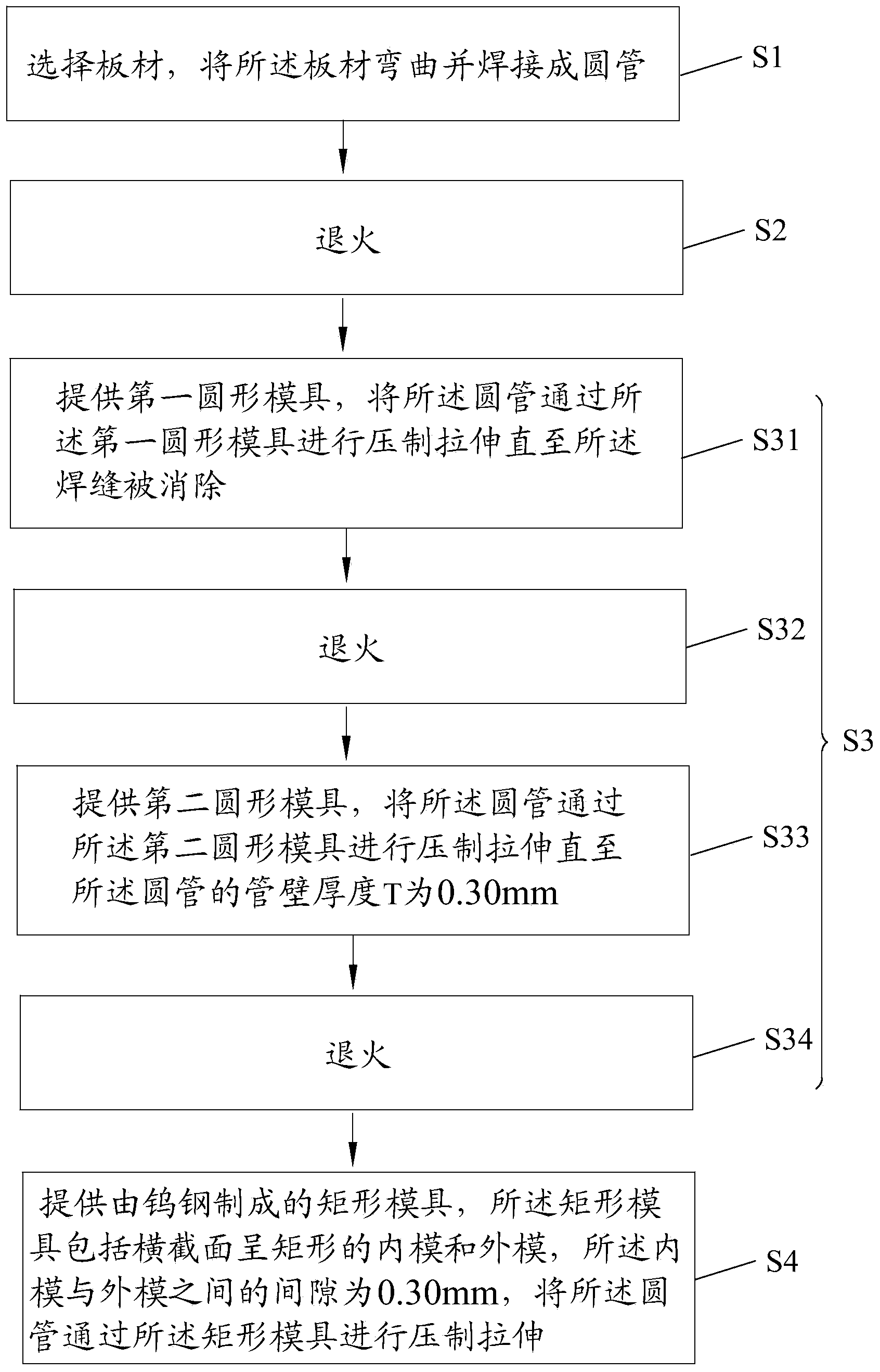

Rectangular pipe and production process thereof

InactiveCN103752644AEliminate weldsElongated constructional elementsCouplings bases/casesManufacturing engineeringSeries production

The invention discloses a rectangular pipe. The rectangular pipe comprises a pipe wall with the uniform thickness, wherein the pipe wall is defined in a closed mode to form an inner cavity; the outer contour of the rectangular pipe and the section of the inner cavity are rectangular; the thickness of the pipe wall is 0.30-0.35mm. According to the rectangular pipe, the size requirement of a universal serial bus (USB) interface on thickness is met, so that a seamless USB shell can be formed by using cutting and related processes. Correspondingly, the invention also discloses a production process for producing the rectangular pipe. According to the process, the rectangular pipes can be produced in batches.

Owner:陈皆得 +1

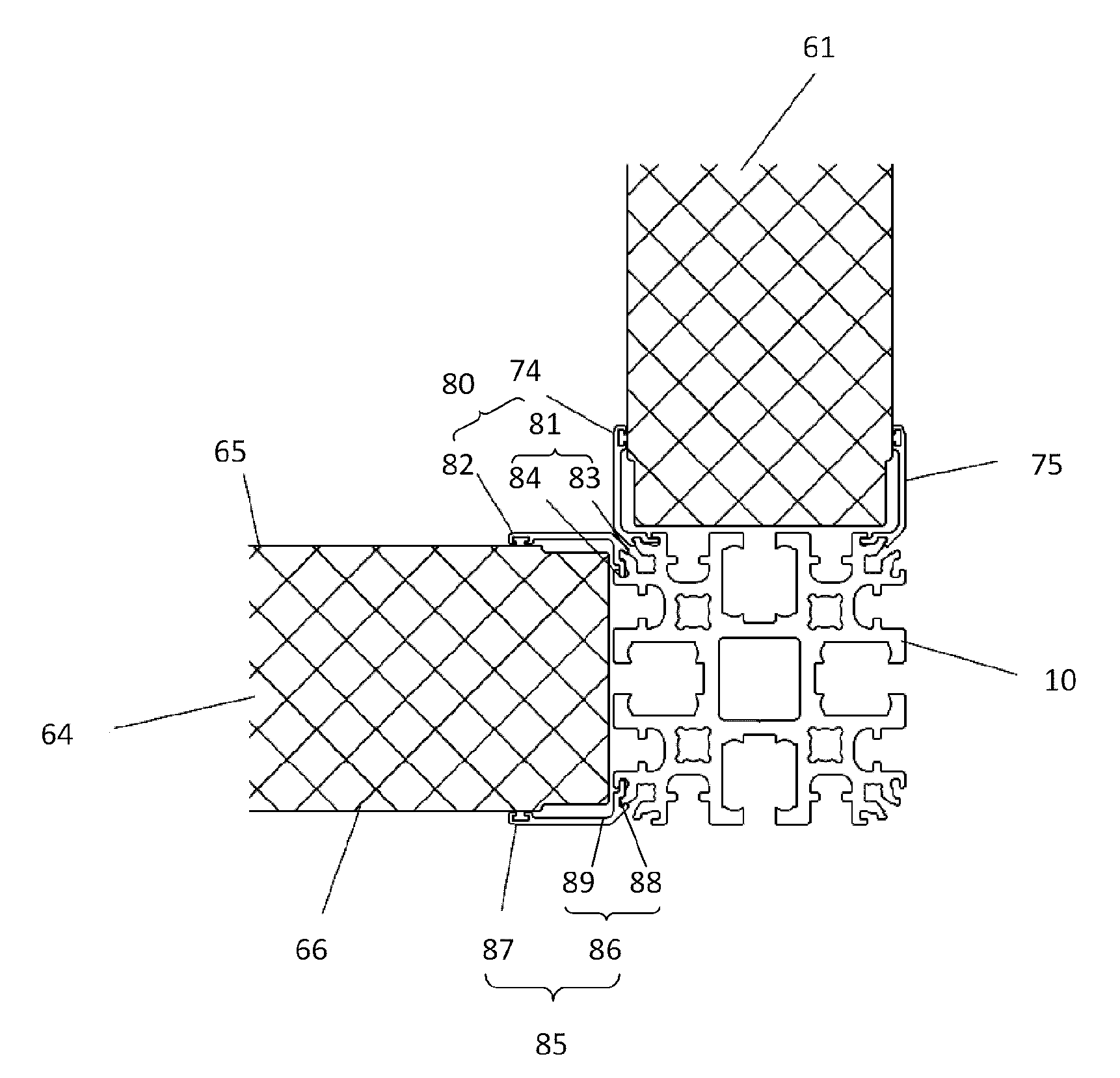

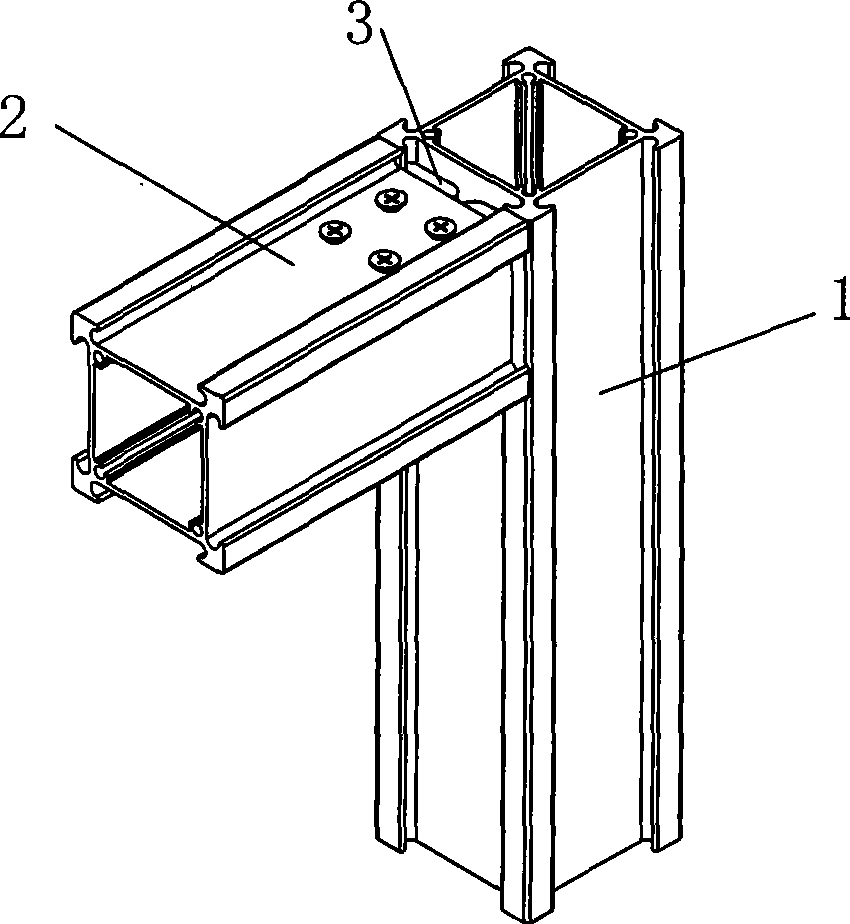

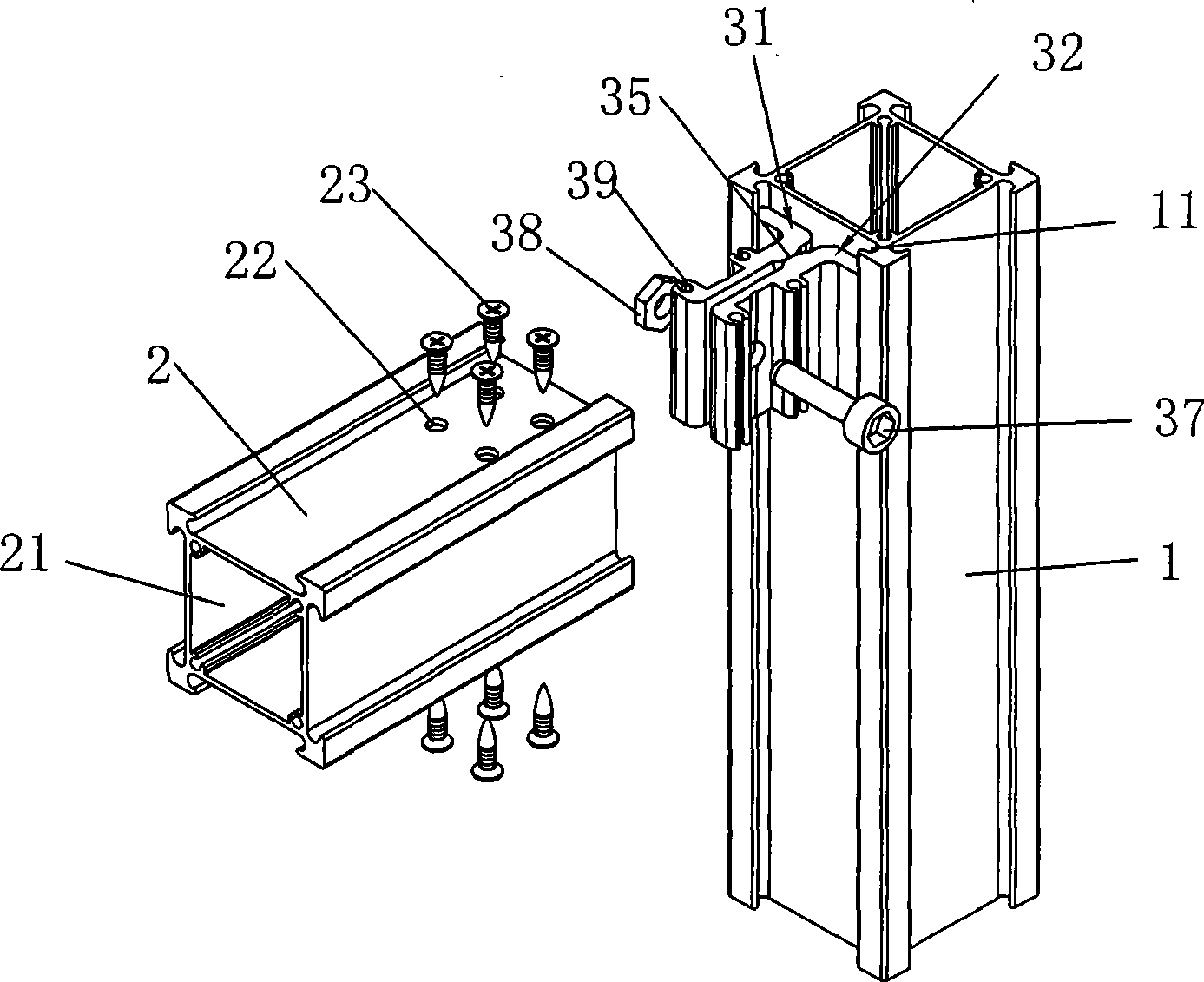

Section bar connection device and section bar apparatus with the same

InactiveCN101498399AFirmly connectedGuaranteed tensile strengthElongated constructional elementsRod connectionsRight flankUltimate tensile strength

Owner:深圳市迪威司国奥家具有限公司

Small-section square girder and welding process thereof

ActiveCN102773590AResolve the breakSolve Weld CrackingElongated constructional elementsArc welding apparatusShear capacityWelding deformation

The invention discloses a small-section square girder and welding process thereof, belonging to welding technology and capable of solving the problem of low welding quality in case of small manual welding space. The small-section square girder has four girder plates with widths of 200-220mm and lengths smaller than or equal to 10m in paired arrangement to form a box-shaped inner cavity, in which are arranged reinforcement rib plates, flanges are welded at two ends of the girder plates, and inside and outside fillets are present between the girder plates and between the girder plates and the flanges. In welding, a to-be-welded part is cleaned before welding, a run-on plate and a run-off plate are assembled and welded, welding is carried out by use of an automatic welding cart, an inner cavity and an exposed welding seam alternate welding sequence is adopted during welding, an inner cavity backing welding seam is firstly formed, the backing welding seam for an exposed welding seam is then formed after the back gouging is strictly performed, the inner cavity and the exposed welding seam are sequentially formed, and a back-step welding method is adopted. According to the invention, welding deformation is controlled within an allowable range, torsion resistance and shearing resistance of the small-section square girder are improved, and stability and reliability of the girder are ensured.

Owner:SHANXI PINGYANG IND MACHINERY

HDPE (high-density polyethylene) double-wall corrugated pipe with high ring stiffness

InactiveCN102786730AIncreased ring stiffnessStrong water absorptionElongated constructional elementsLow-density polyethyleneAcrylic resin

The invention discloses an HDPE (high-density polyethylene) double-wall corrugated pipe with high ring stiffness. The HDPE double-wall corrugated pipe comprises the following raw materials in parts by weight: 47 to 49 parts of high-density polyethylene, 17 to 19 parts of high modulus propene polymer (PP), 3 to 5 parts of attapulgite, rigidity-reinforcing and tenacity-reinforcing master batch and the like. Due to the adoption of the formula of the HDPE double-wall corrugated pipe, the ring stiffness of the HDPE double-wall corrugated pipe can be greatly improved; due to the adoption of the attapulgite in the formula, the HDPE double-wall corrugated pipe has high water absorptivity and slurry making property; and due to the adoption of modified acrylic resin which has certain cohesiveness, the machining property is high.

Owner:SINOMACH GENERAL MACHINERY SCIENCE & TECHNOLOGY CO LTD

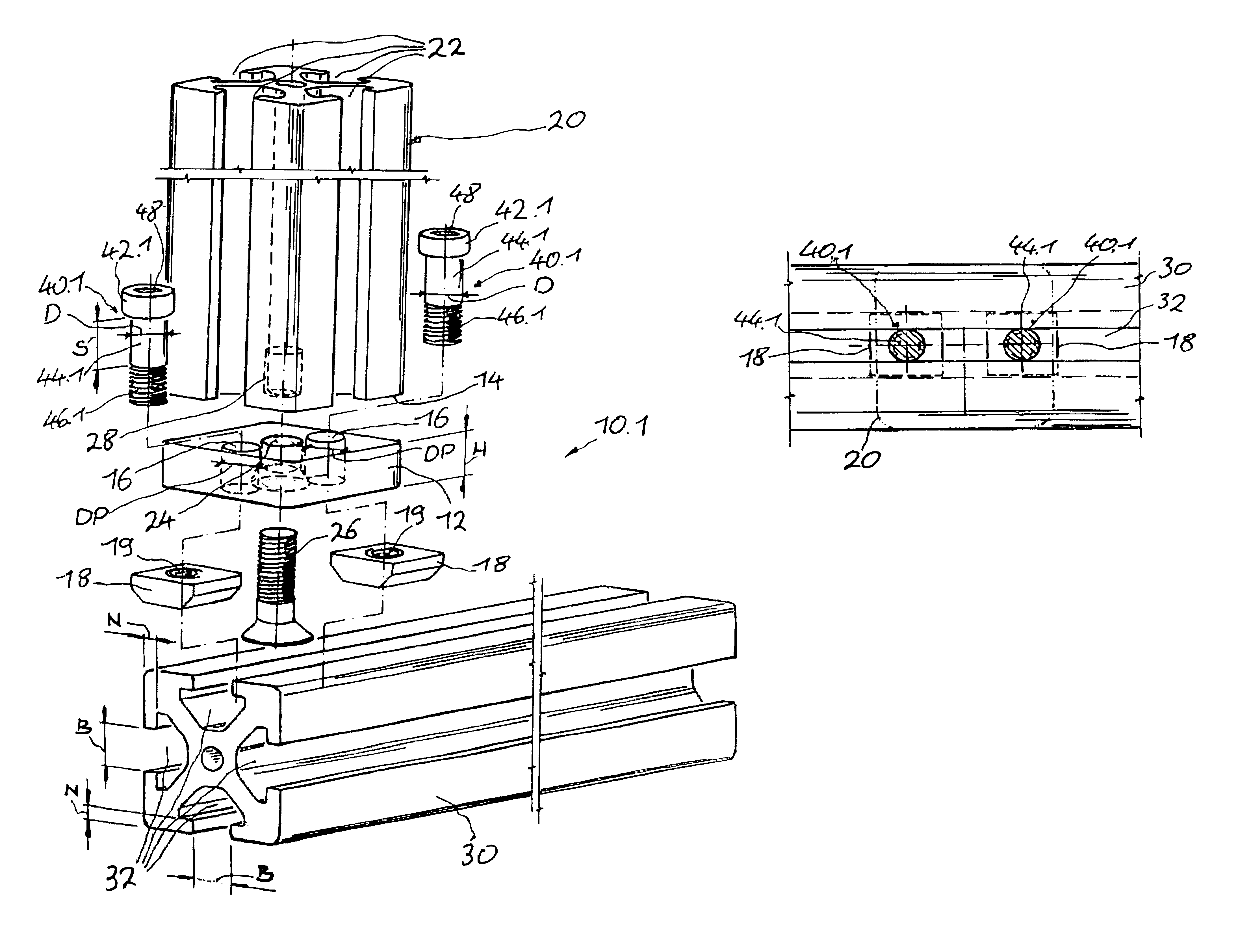

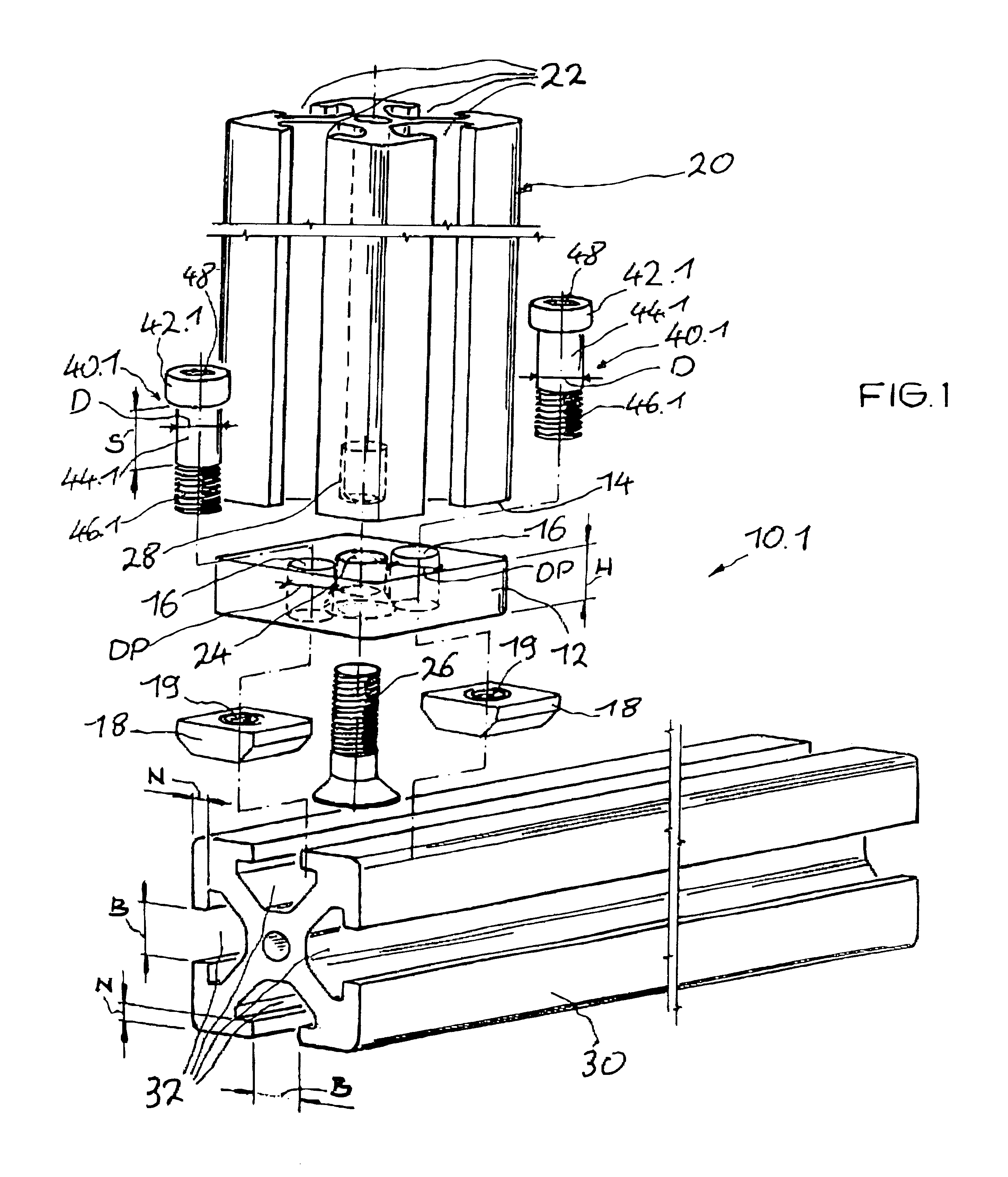

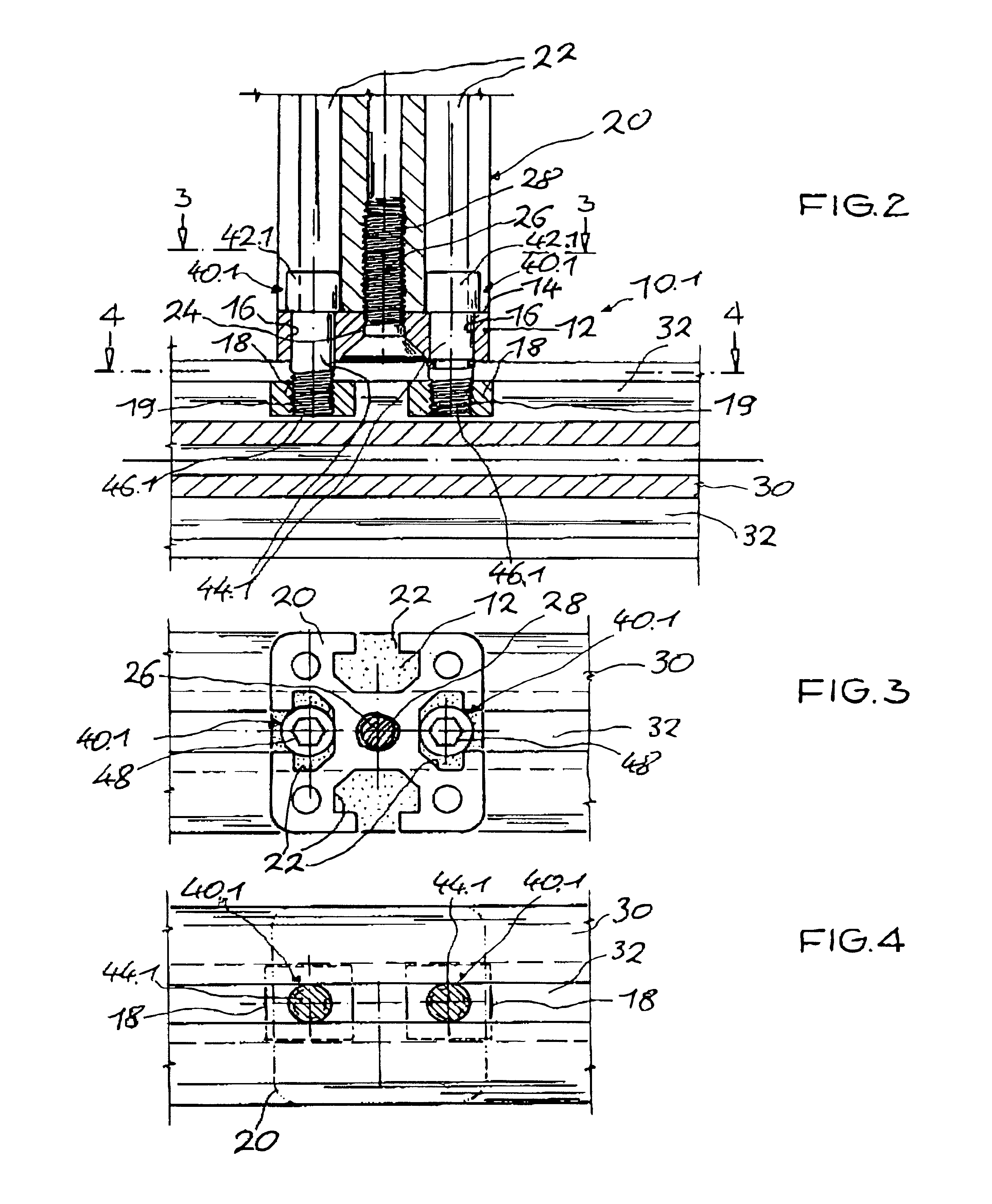

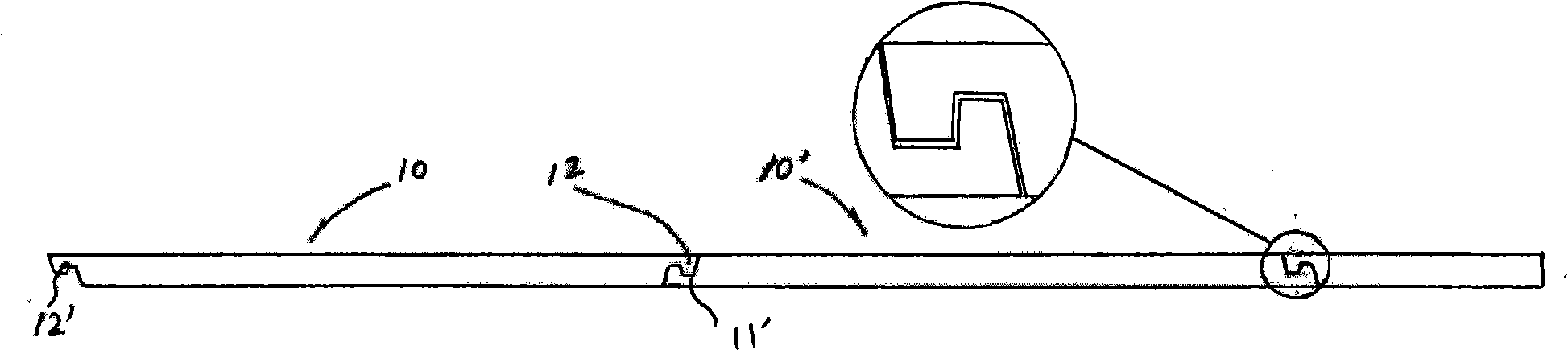

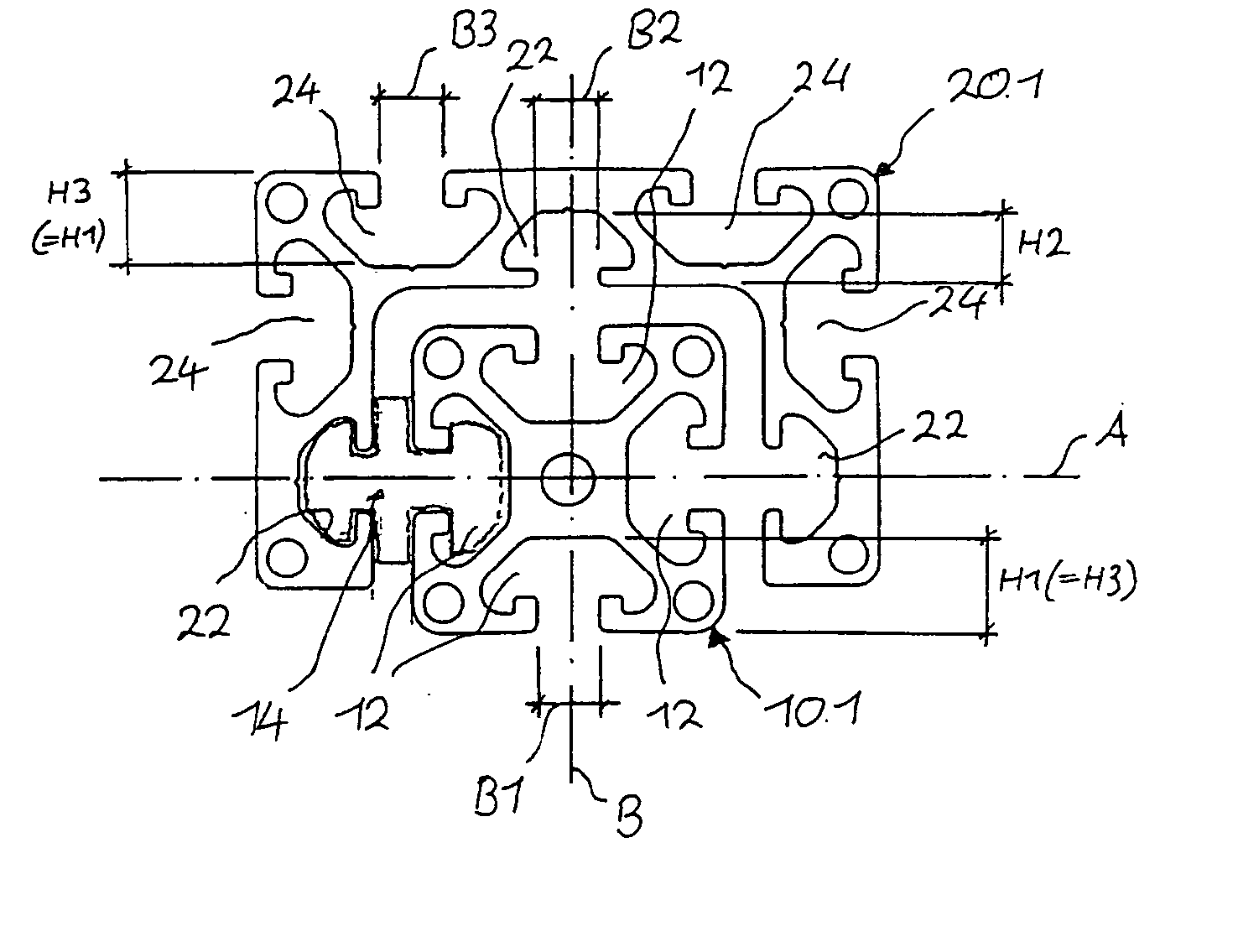

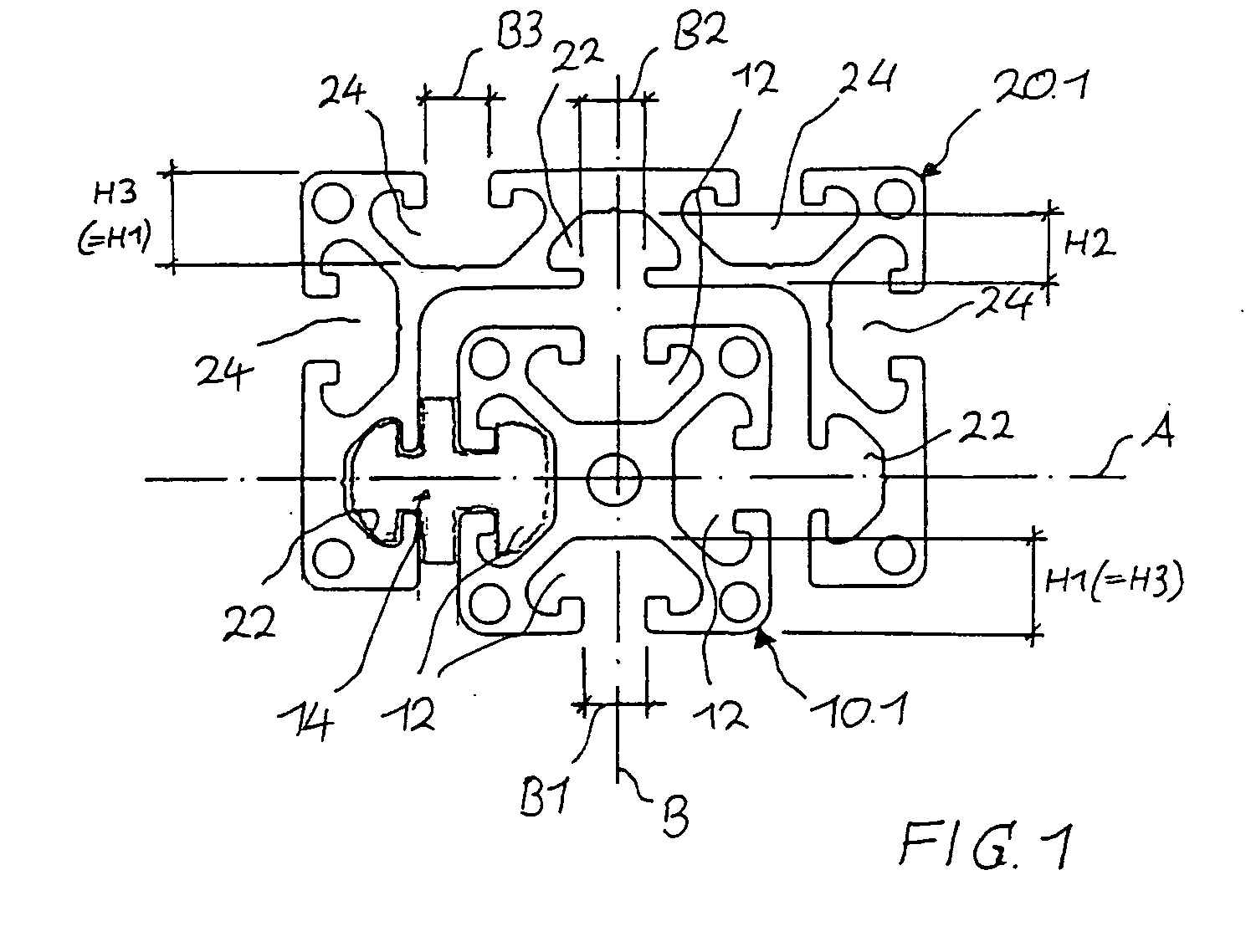

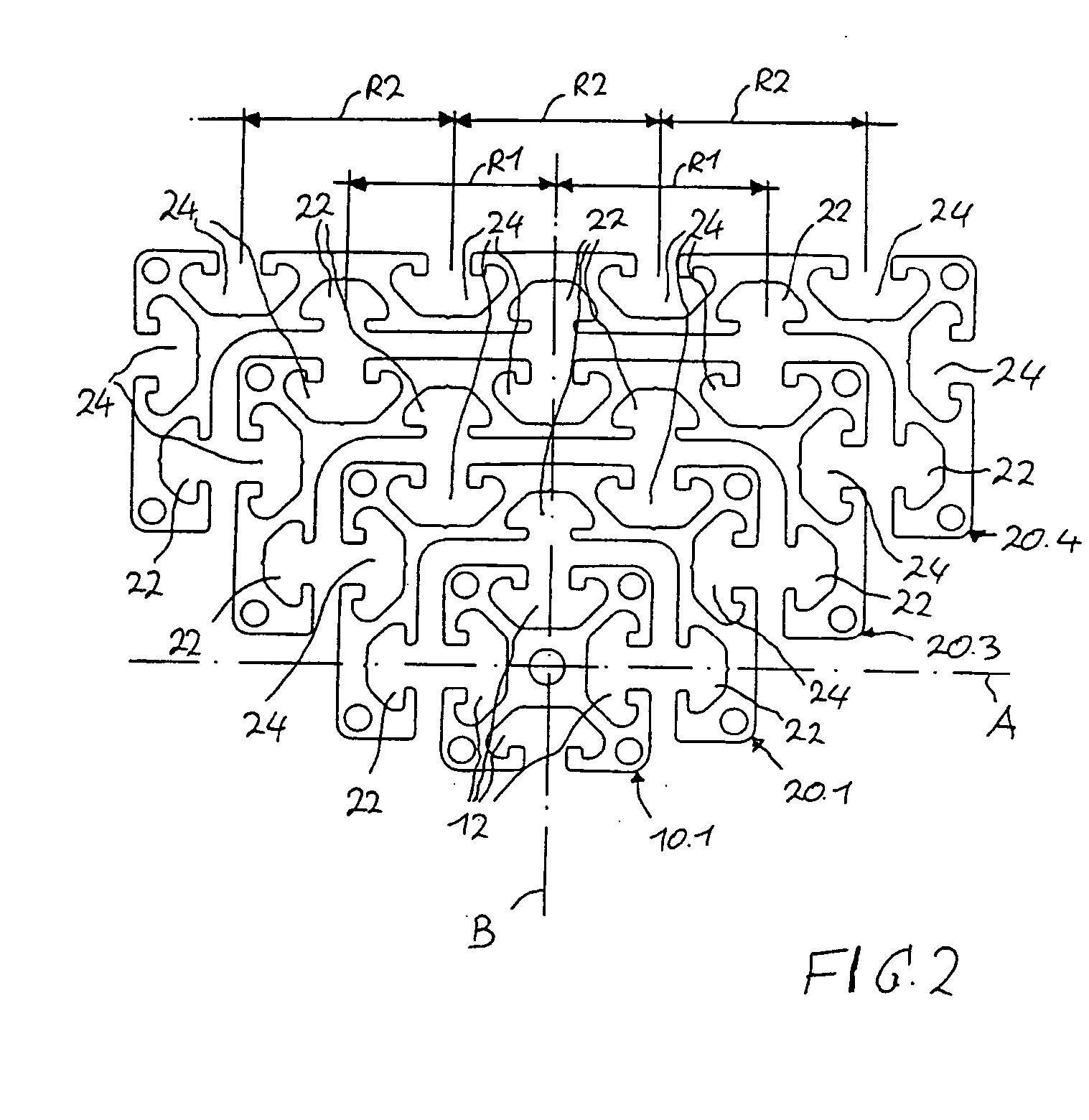

Slider system for a profiled bar

InactiveUS20040096129A1Linear bearingsElongated constructional elementsMechanical engineeringLight metal

A slider system for a profiled bar (10.1), especially a bar of extruded light metal, which, is provided in predefined cross-sectional system axes (A, B) with an undercut longitudinal groove (12) on a respective side or at least one outer side having a predefined width (B1). At least one slider profile section (20.1) is connected to the profiled bar and is able to be displaced in the direction of said profiled bar. The invention is characterized in that at least one slider profile (20.1) having at least one undercut inner longitudinal groove (22) which is arranged on one of the cross-sectional system axes (A, B) when the slider profile (20.1) is connected to the profiled bar, and by at least one sliding guide profile (14) which engages with the longitudinal groove (12) of the profiled bar (10.1) and the corresponding opposite inner longitudinal groove (12) of the slider profile (20.1) from the rear.

Owner:FMS FORDER UND MONTAGE SYST SCHMALZHOFER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com