Scarfweld type steel grating and processing method thereof

A processing method and technology for steel grating, applied in the field of steel grating manufacturing, can solve the problems of difficult application of flat steel and high thickness tolerance requirements of cross bars, and achieve the effect of reducing selection requirements, simplifying processing equipment, and reducing precision requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

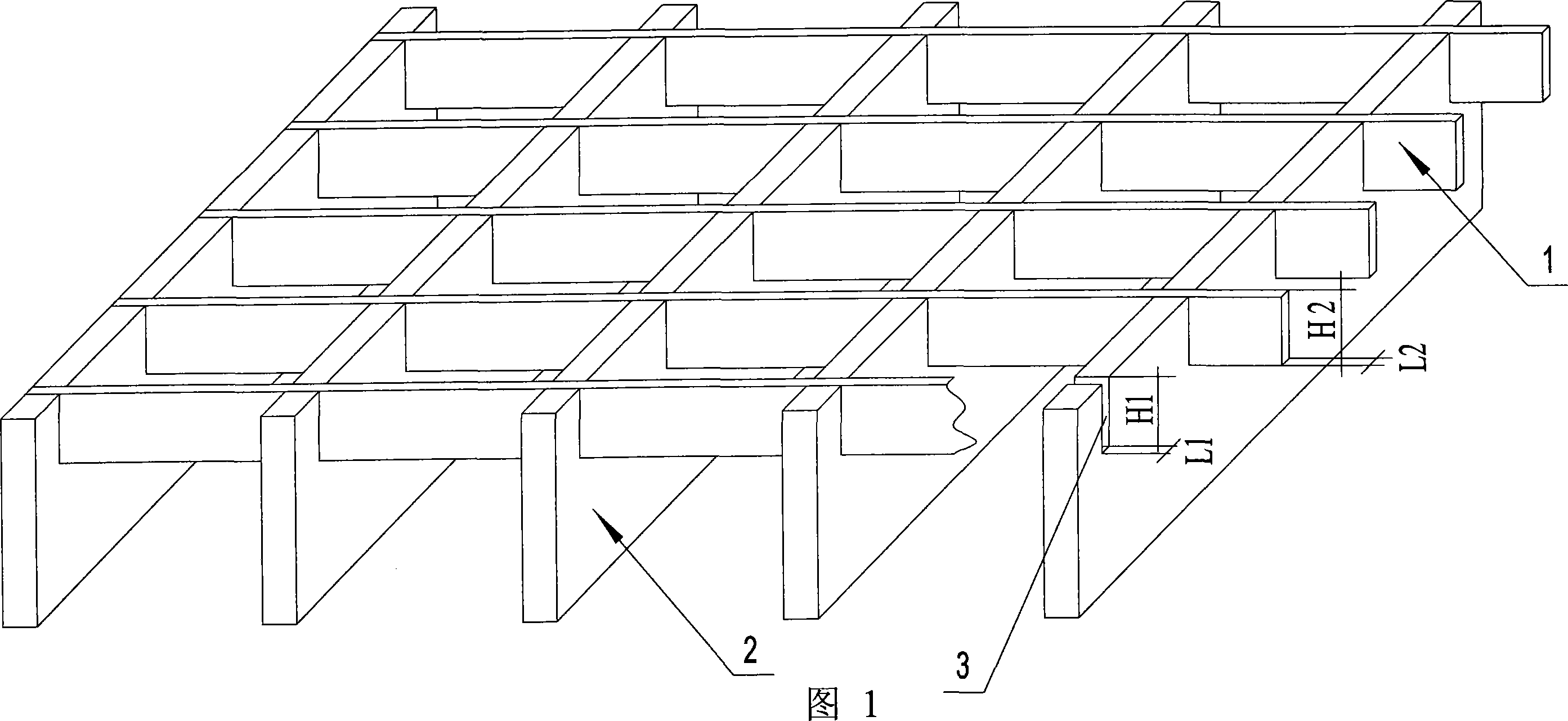

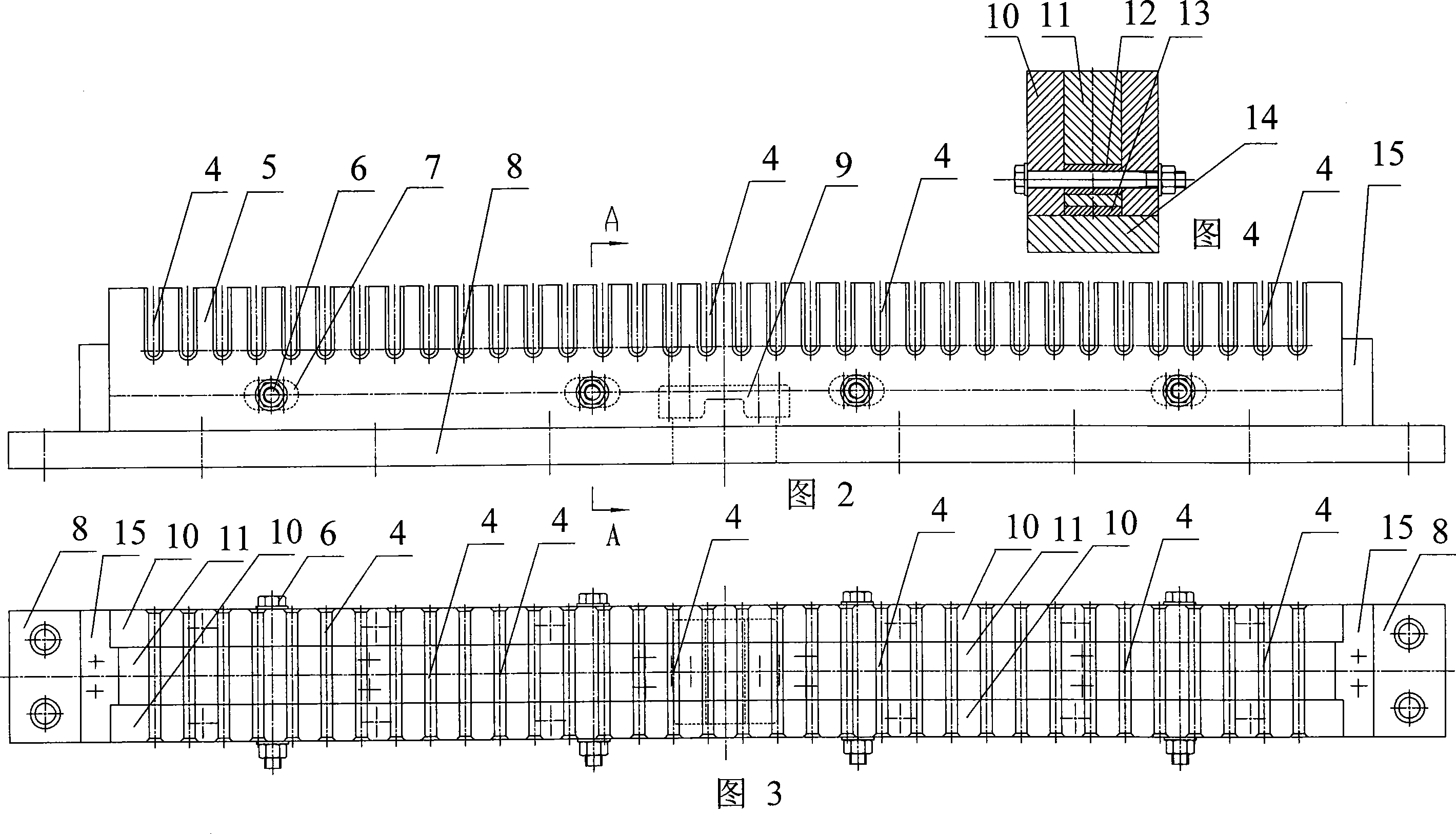

[0016] As shown in the figure: the embedded welded steel grating includes a load-bearing flat steel 2 and a cross bar 1. Several grooves 3 are set on the load-bearing flat steel 2, and the cross bar 1 is embedded in the groove 3, and the load-bearing flat steel 2 Welded together with crossbar 1. During manufacture, the width L1 of the groove 3 is greater than the thickness L2 of the crossbar 1, and the depth H1 of the groove 3 is smaller than the height H2 of the crossbar 1. After the crossbar 1 falls into the groove 3, the upper surface of the crossbar 1 is higher than the bearing The upper plane of the flat steel 2, and then apply welding current and pressure between the cross bar 1 and the load-bearing flat steel 2, and weld and flatten the cross bar 1 and the load-bearing flat steel 2 through the welding method of resistance welding to make an embedded Welded steel grating. The cross bar is flat steel or strip.

[0017] Processing method of the present invention is as fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com