Patents

Literature

31results about How to "Improve axial tensile strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

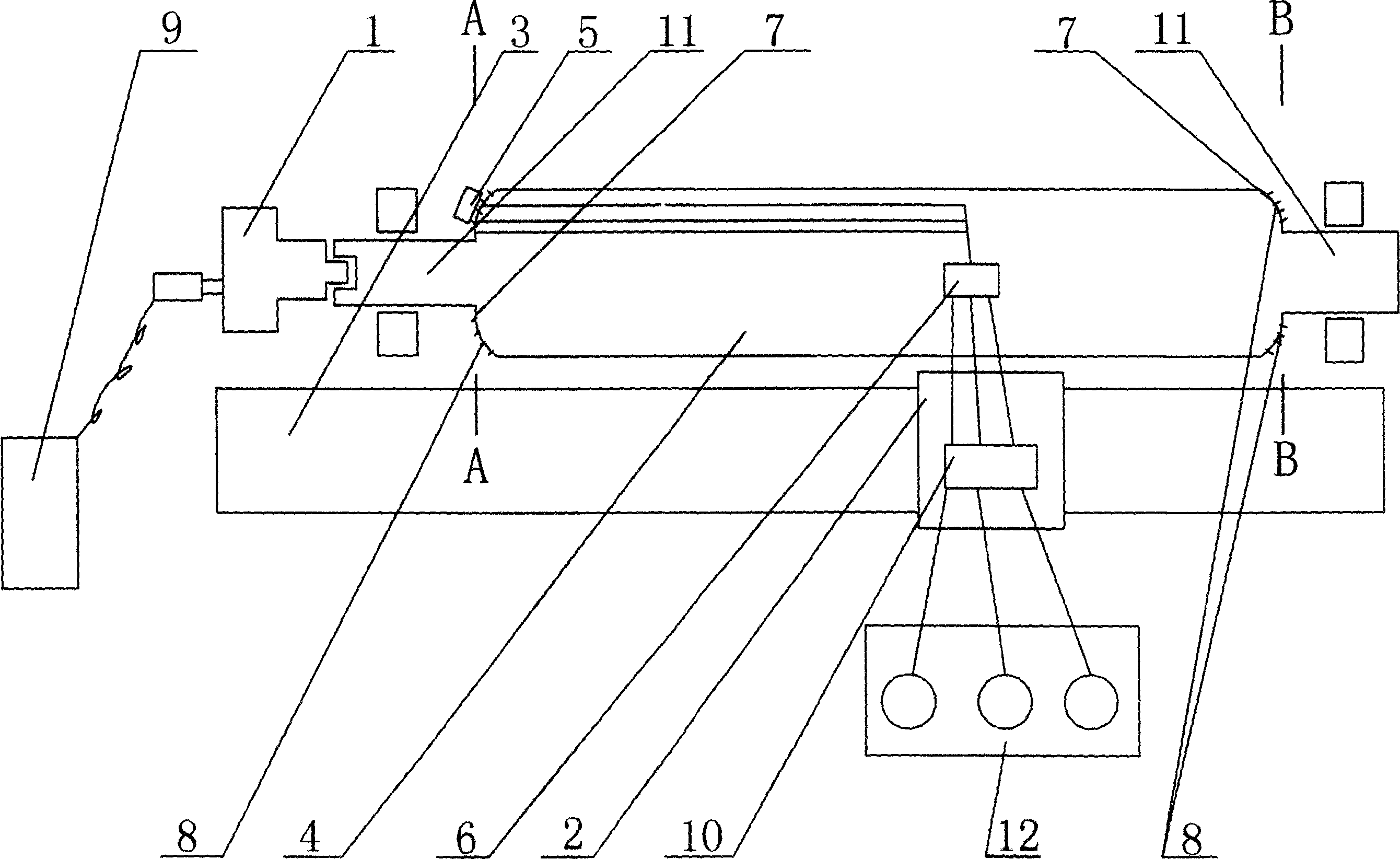

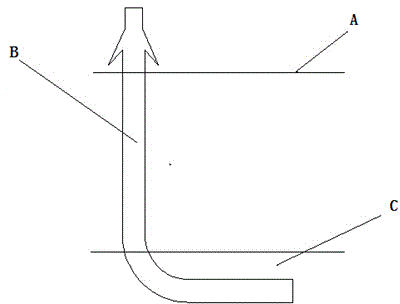

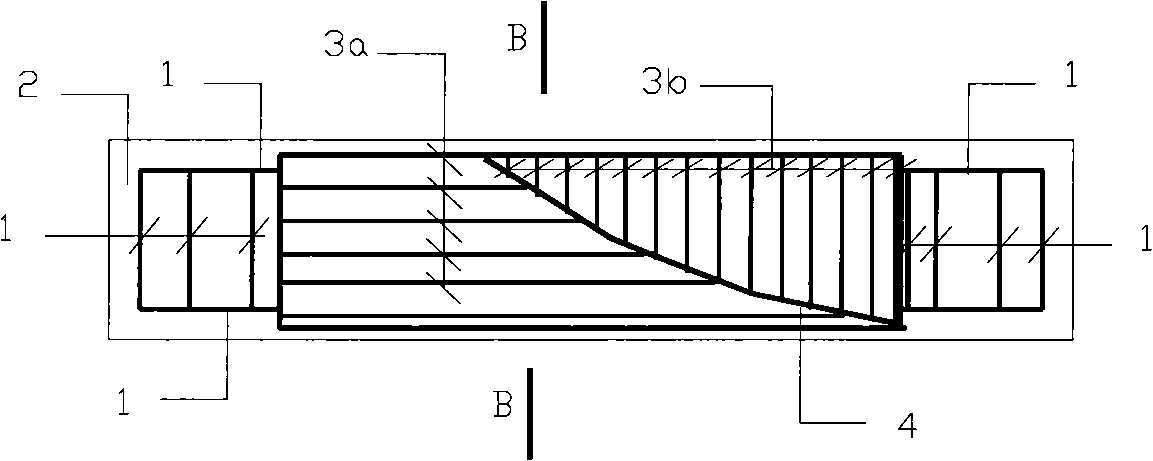

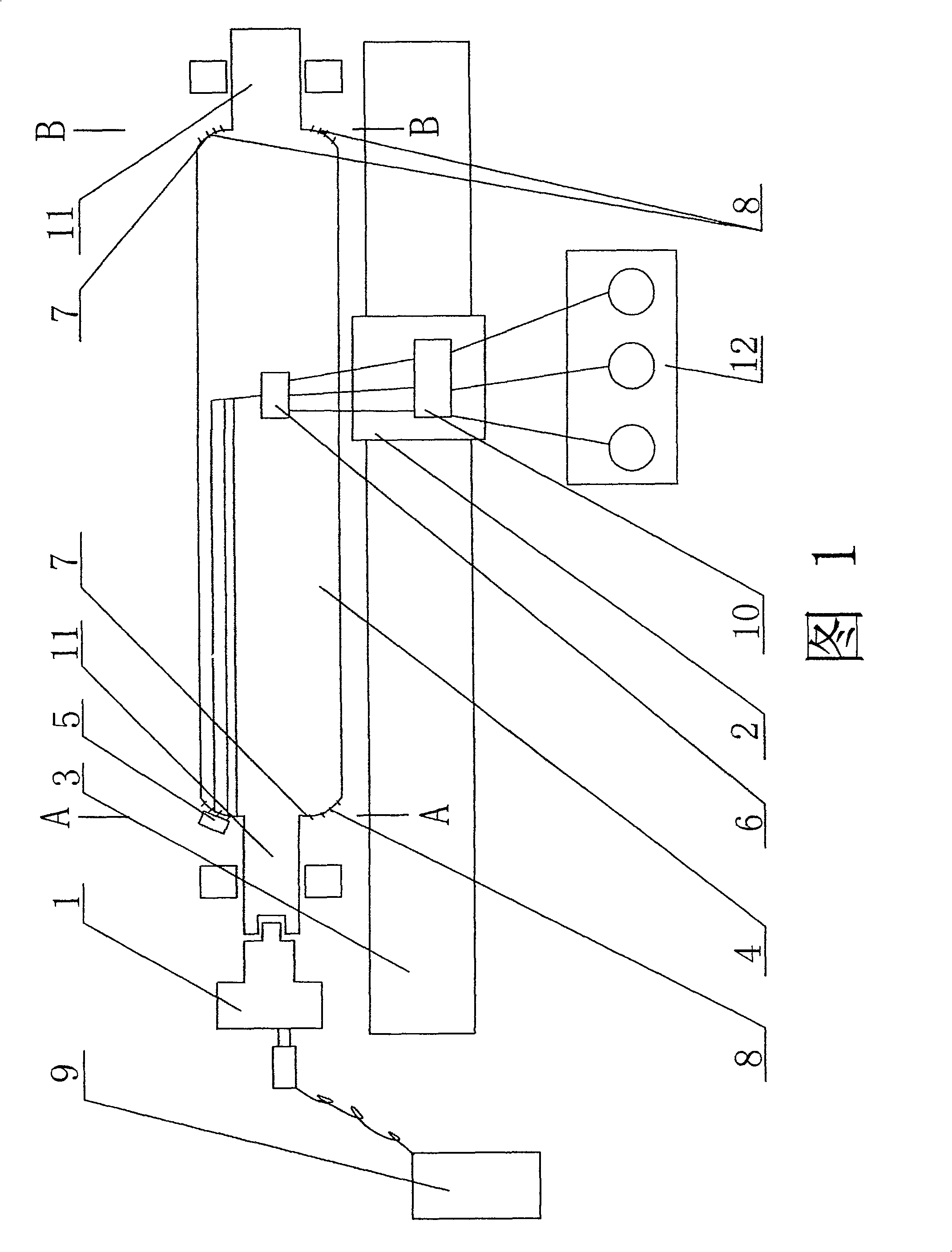

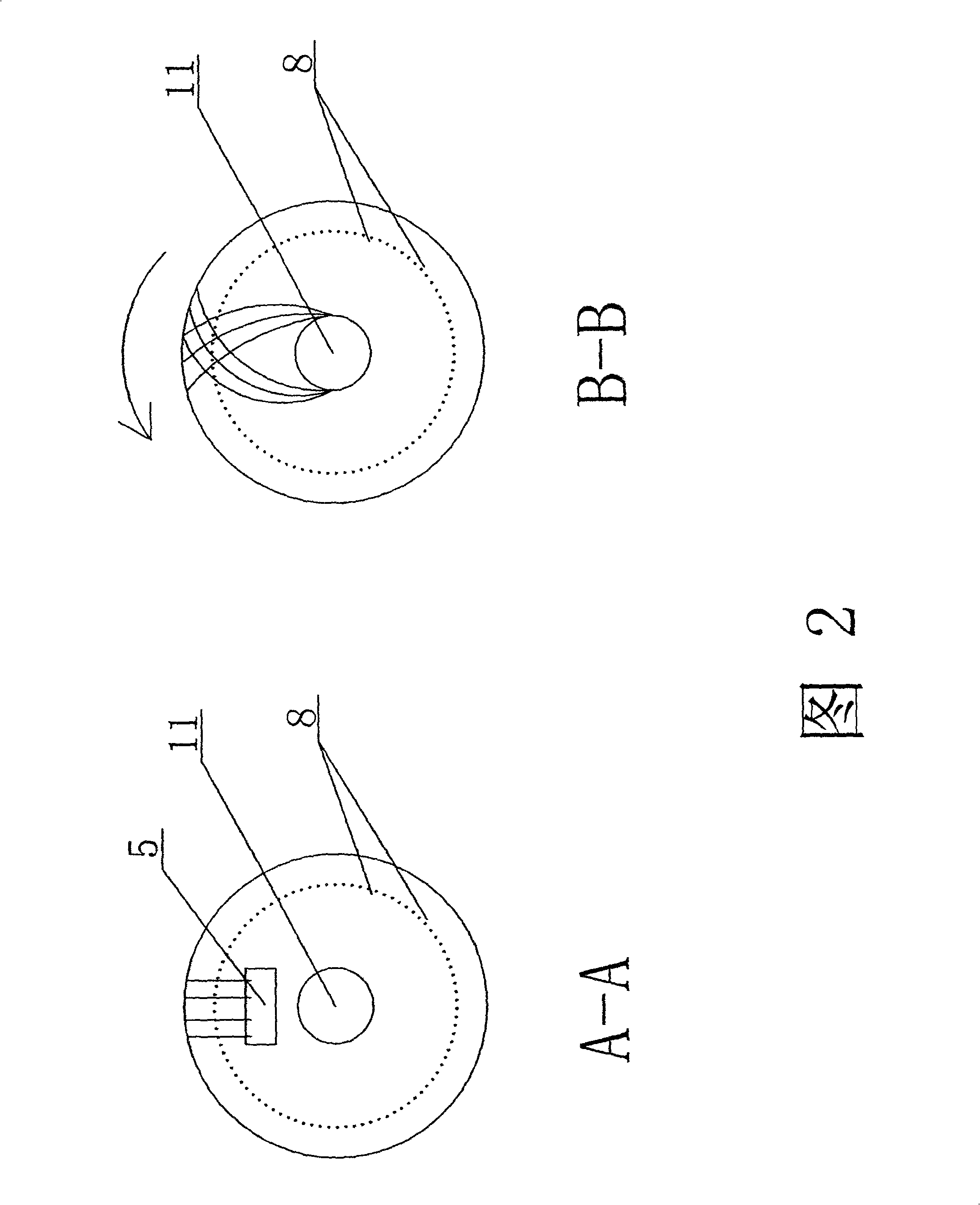

Continuous axial fiber arrangement method and its equipment

InactiveCN1850496AReduce dosageImprove axial tensile strengthTubular articlesIt equipmentConductor Coil

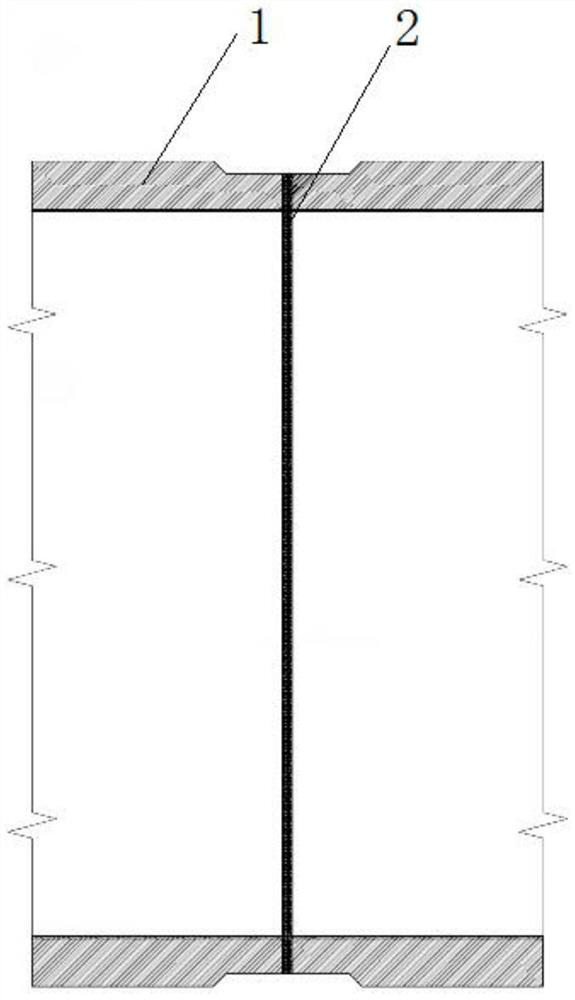

An arrangement method of the continuous axial fiber and the special device is about the fiber which winds the glass steel tube. In the process of the glass steel tube, the continuous axial fibrous zone is arranged out of the pipe except the toroidal fiber, so the tension direction of the fiber is same as the axial stress of the pipe instead of the reciprocal cross winding, so it can solve the problem of the axial low strength of the pipe and it improves the production efficient by the special production device.

Owner:河北正通玻璃钢有限公司

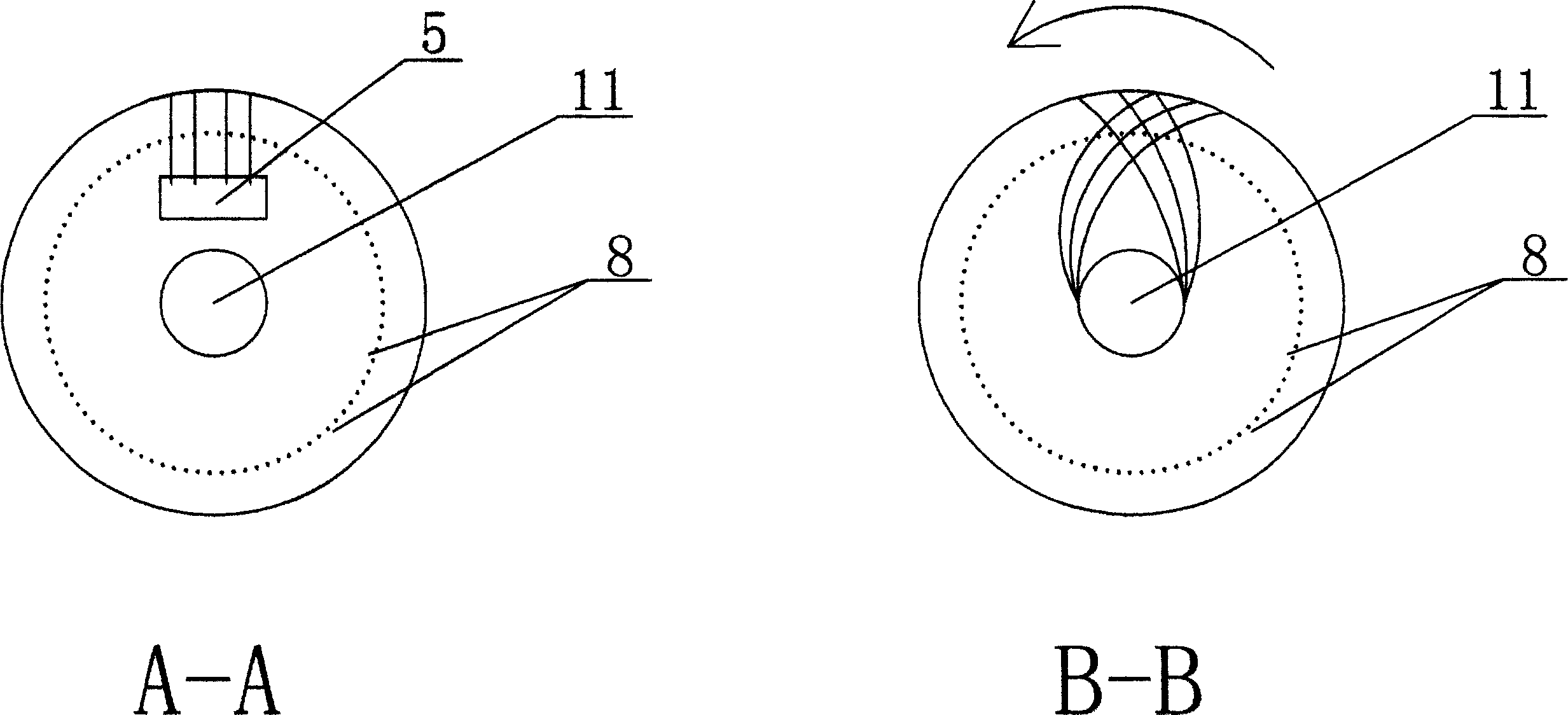

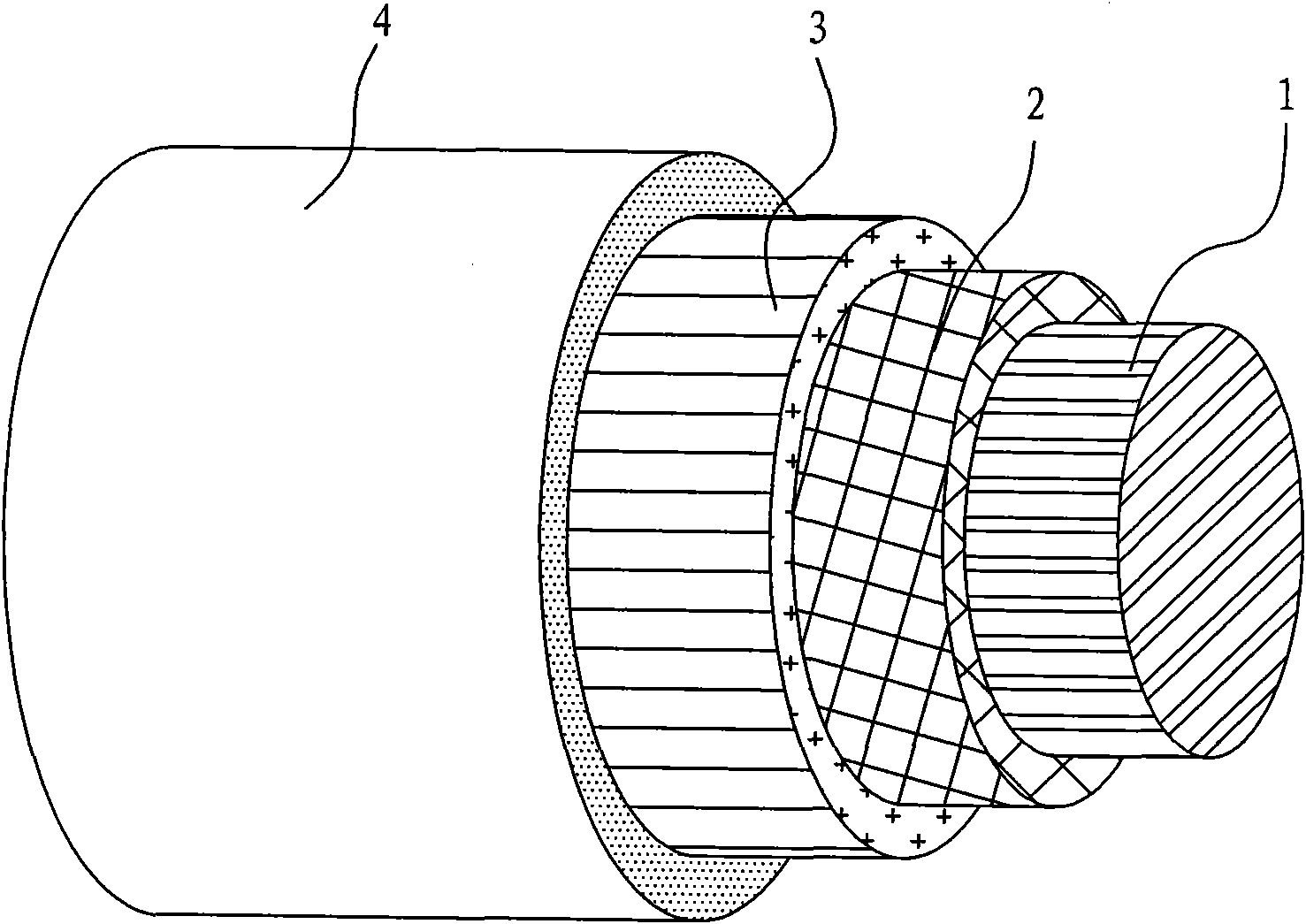

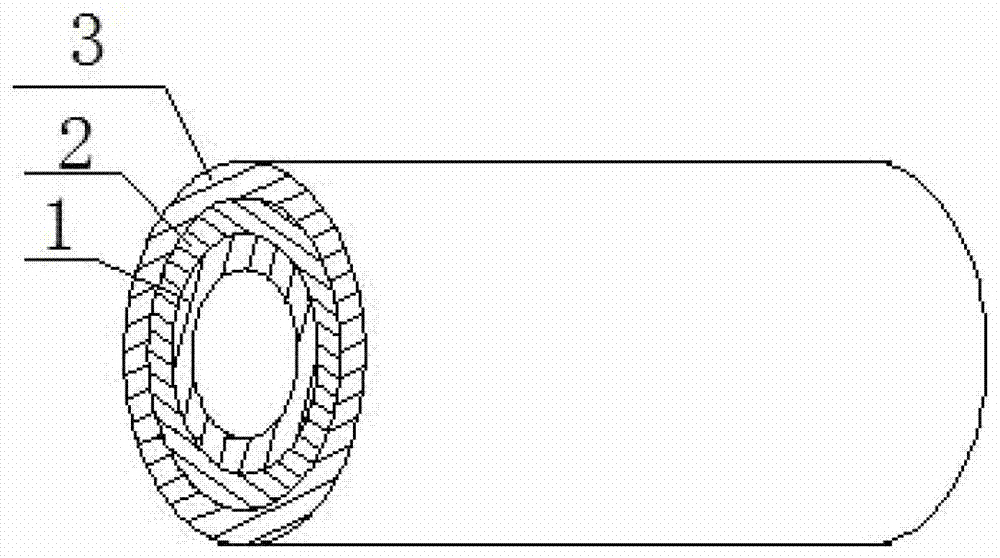

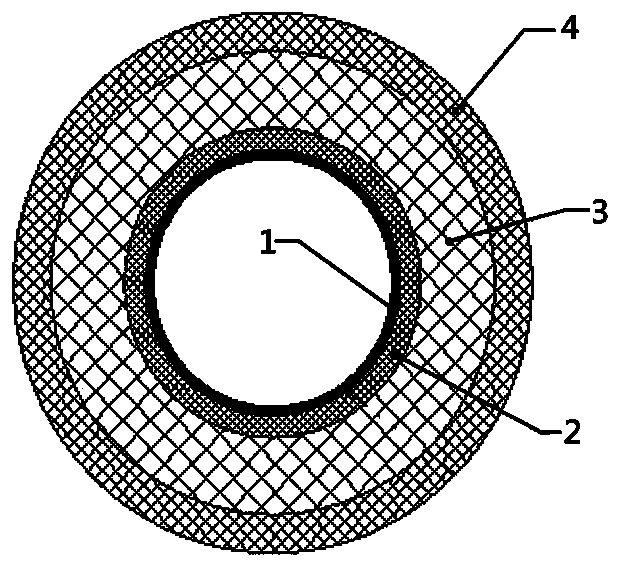

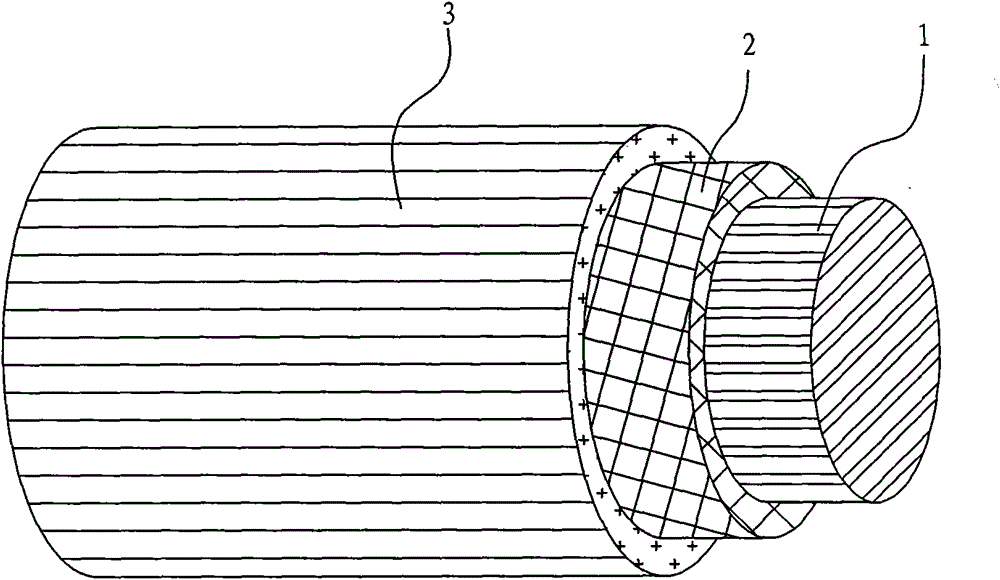

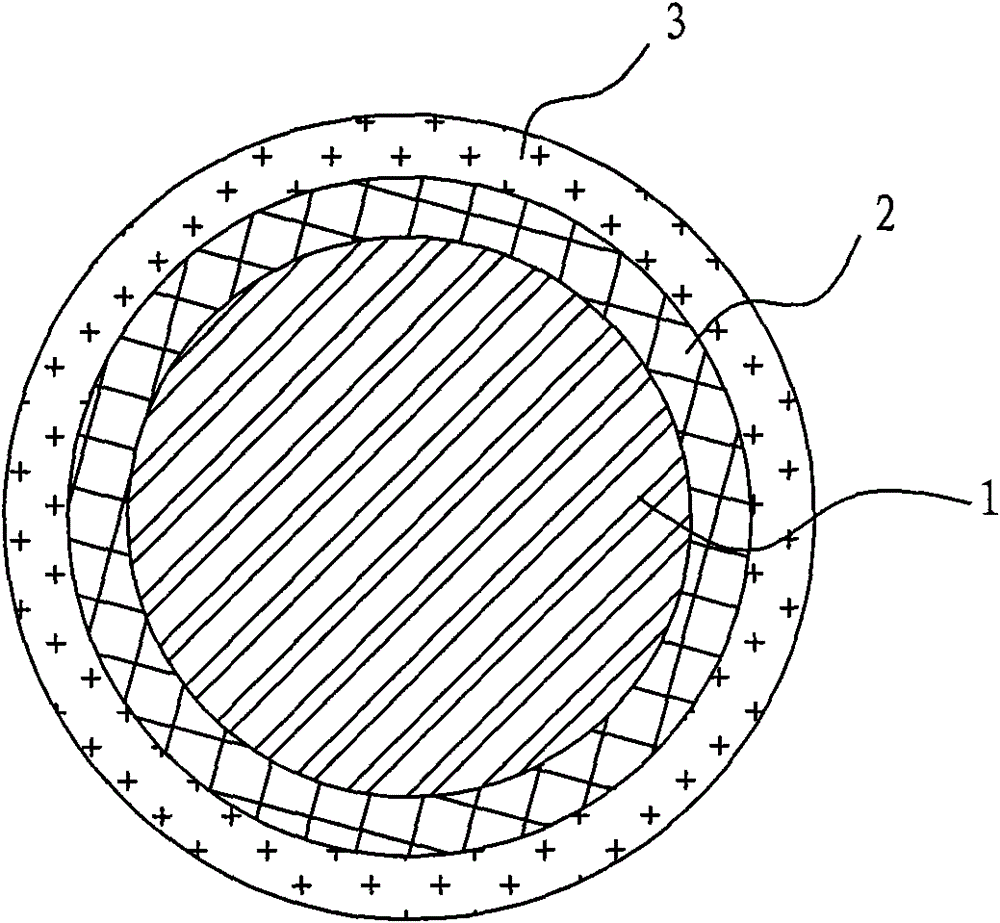

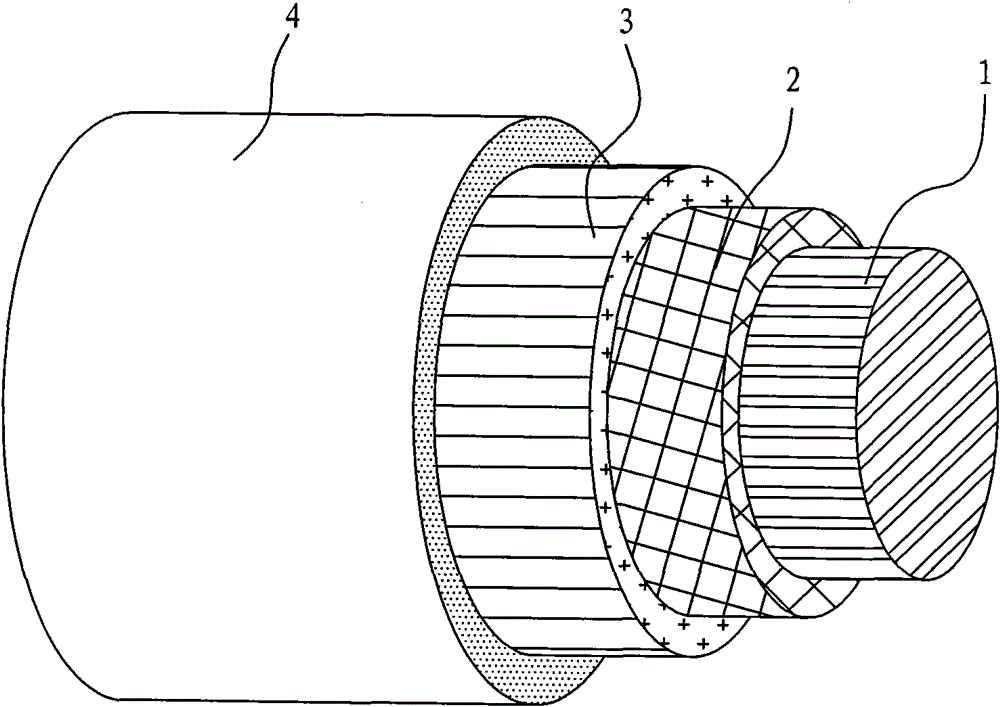

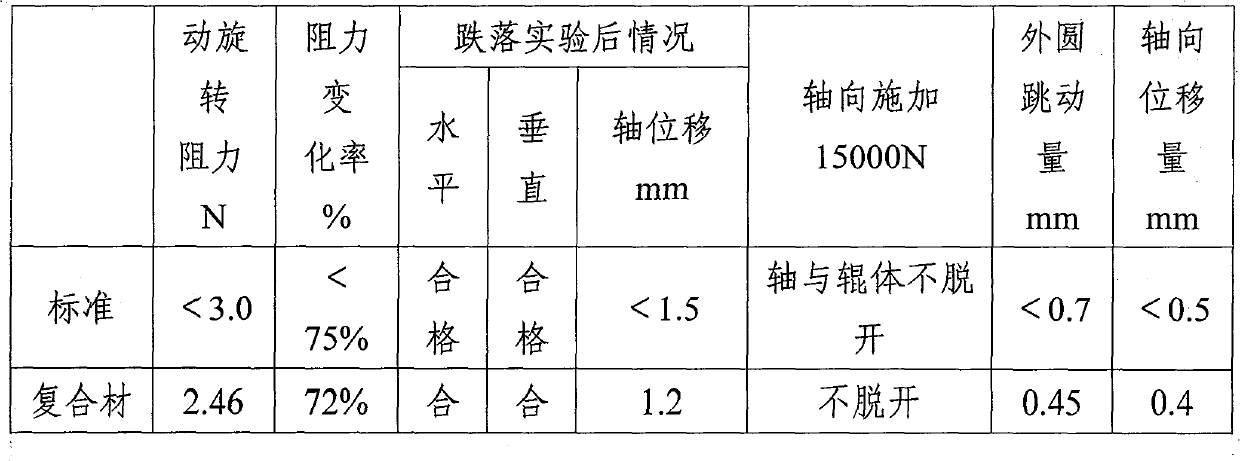

Composite core used for reinforced cable and reinforced cable

InactiveCN102110491AExtended syncNot easy to fall offNon-insulated conductorsInsulated cablesOptoelectronicsFiber

The invention relates to a composite core used for a reinforced cable. The composite core comprises an inner core, a structural layer and an outer layer, wherein the inner core comprises fibers and thermosetting resins; the structural layer comprises a fiber sleeving and the thermosetting resins; the fiber sleeving is formed by braiding a plurality of fibers or spirally winding the fibers along the axial direction of the inner core; and the outer layer comprises fibers arranged along the length direction of the composite core and the thermosetting resins. The composite core provided by the invention has the following beneficial effects: the outer layer is added outside the structural layer and the continuous fibers arranged along the length direction of the composite core are added to theouter layer; and the added outer layer wholly covers the structural layer 2 and provides protection to the fiber sleeving in the structural layer 2, under the condition that the composite core is subjected to great tension, the stretch and extension rates of the outer layer 3 and the inner core 1 are basically the same and the extension quantities of the outer layer 3 and the inner core 1 are synchronous, and the structural layer is tightly squeezed by the inner core and the outer layer so that the structural layer in the middle is not easy to drop or separate, thus effectively overcoming thedefect that the composite core adopts the fiber sleeving structure.

Owner:JIANGSU JIATAI TECH MATERIAL

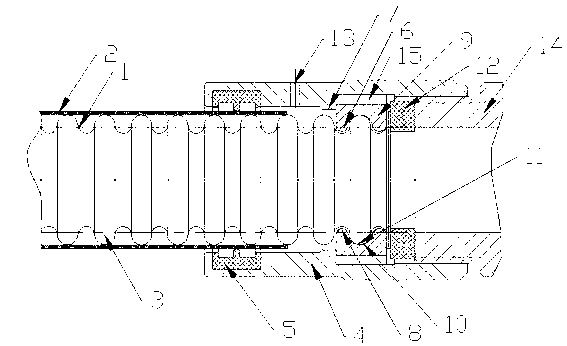

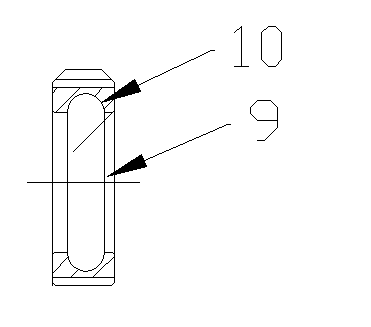

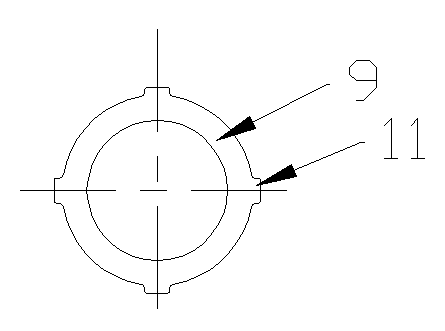

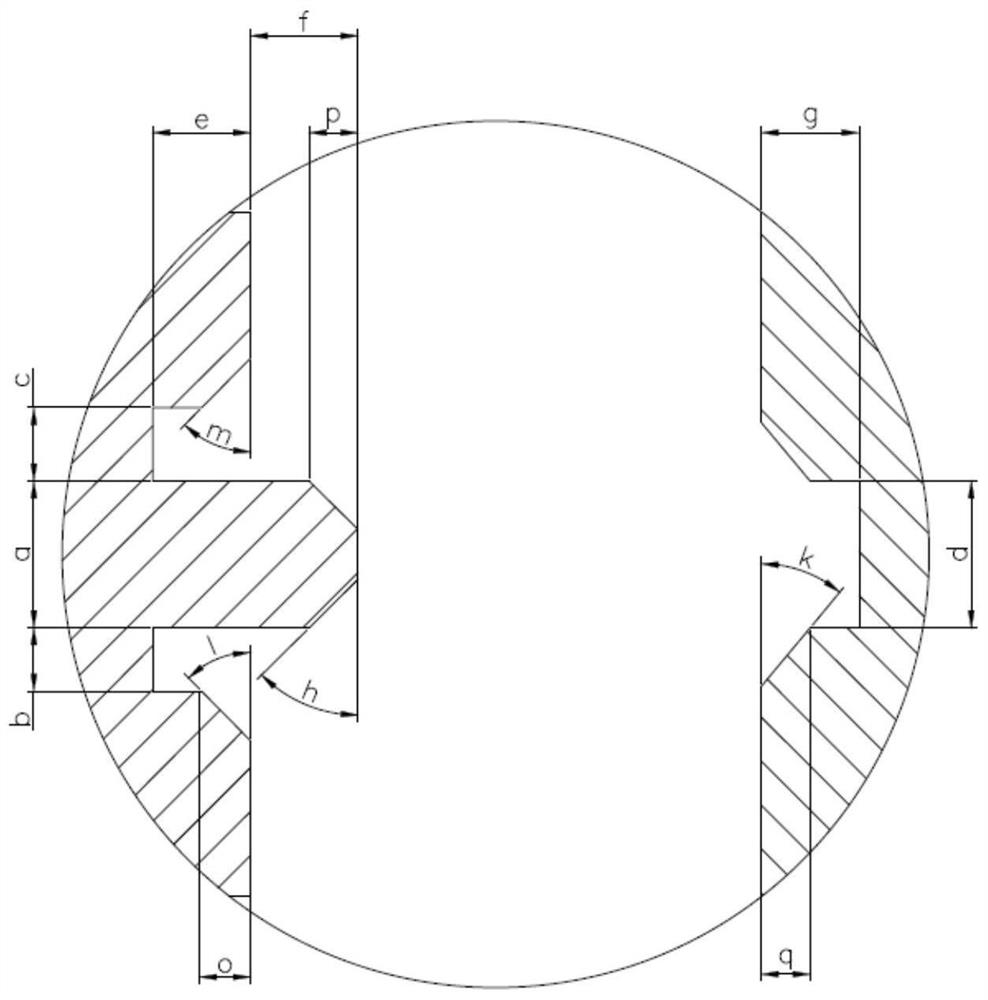

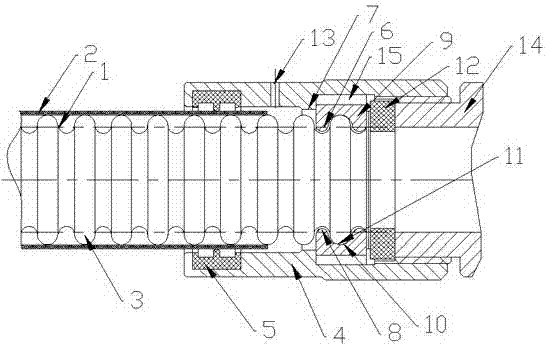

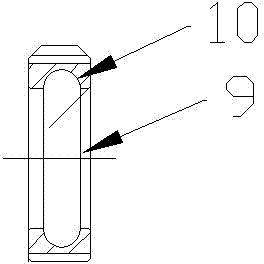

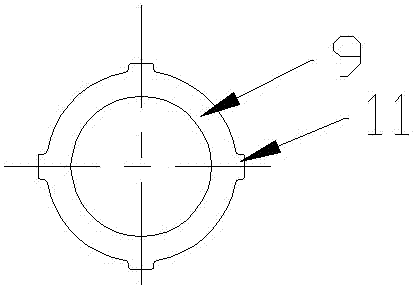

Stainless steel corrugated hose connecting devicefor fuel gas transportation

ActiveCN103104768AImprove sealingHigh strengthHose connectionsStructural engineeringMechanical engineering

The invention discloses a stainless steel corrugated hose connecting device for fuel gas transportation. The stainless steel corrugated hose connecting device for the fuel gas transportation comprises a corrugated hose and a plastic protective sleeve which is arranged on the corrugated hose in a sleeved mode. A plurality of gas-guiding grooves are evenly formed in the plastic protective sleeve. A straight through seat is arranged outside the plastic protective sleeve in a sleeved mode. A sealing ring is arranged between one end of the straight through seat and the plastic protective sleeve. Threads are formed in an inner circle of the other end of the straight through seat. A tool withdrawal groove is formed at the bottom of the threads. Four concave grooves are formed in the threads. A clamping ring is arranged on one side of the tool withdrawal groove, wherein the clamping ring is a metal ring which is divided into two pieces. A ditch groove is formed in an inner circle of the clamping ring. The ditch groove is matched with the corrugated appearance of the corrugated hose. Four bosses are arranged on an outer circle of the clamping ring. The bosses enter the tool withdrawal groove of the bottom of the threads through the four concave grooves, located at the place of the threads, of the straight through seat. A sealing mat is arranged on one side of the clamping ring. The stainless steel corrugated hose connecting device for the fuel gas transportation has the advantages of being convenient to install, high in axial tensile strength and good in sealing property. The stainless steel corrugated hose connecting device for the fuel gas transportation saves inner space and enables a corrugated hose with a larger outer diameter to be capable of adopting standard pipe threads.

Owner:HANGZHOU WANQUAN METAL HOSE

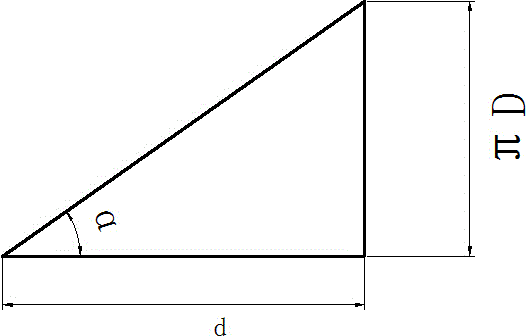

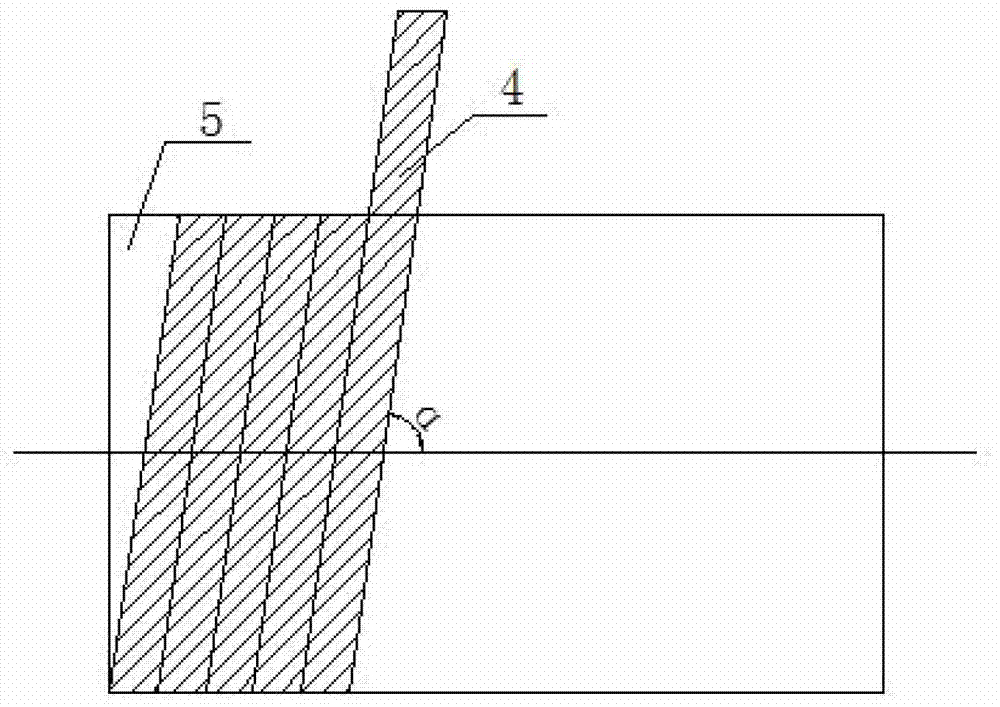

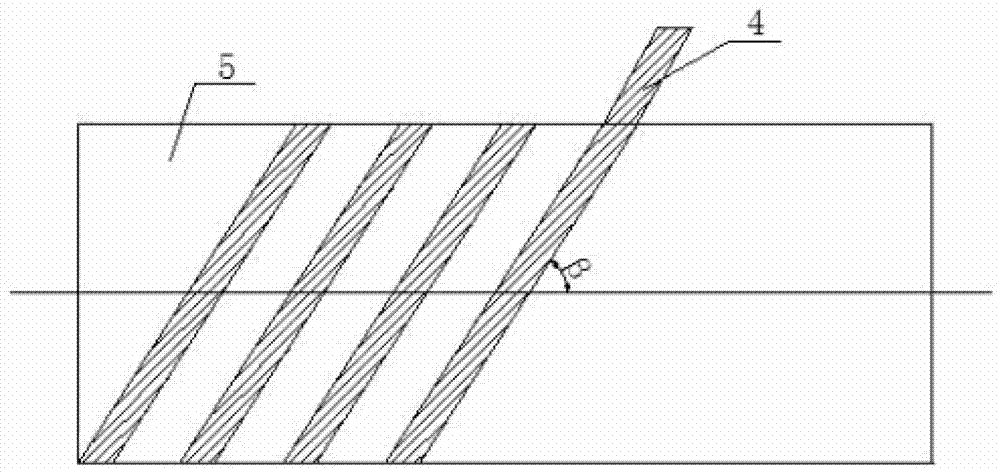

Method for preparing coalbed gas pipeline by adopting double-angle alternating winding technology

The invention discloses a method for preparing a coalbed gas pipeline by adopting a double-angle alternating winding technology. The method comprises the following steps: designing parameters; preparing a resin glue solution; processing a mold; alternately winding and molding; carrying out segmented heating curing; demolding and driving a piton; and fabricating threads. The method is reasonable in design of a whole process, and strong in maneuverability, and can be applied to production of coalbed gas pipelines with different sizes and strength requirements; and the prepared pipeline is excellent in quality. According to the angle alternating winding technology for large-angle and small-angle winding, the tensile strength of the pipeline in the axial direction can be effectively increased by small-angle winding; the defects of circumferential strength can be compensated by large-angle winding, thus the circumferential strength and the failure strength are not greatly weakened when the axial strength of the pipeline is increased; the operating requirements of the coalbed gas pipeline are achieved under the condition that the thickness of the wall is not greatly increased; the production cost is relatively low; the production efficiency is relatively high; and a plurality of defects of the prior art can be overcome.

Owner:LIANYUNGANG ZHONGFU LIANZHONG COMPOSITES GRP

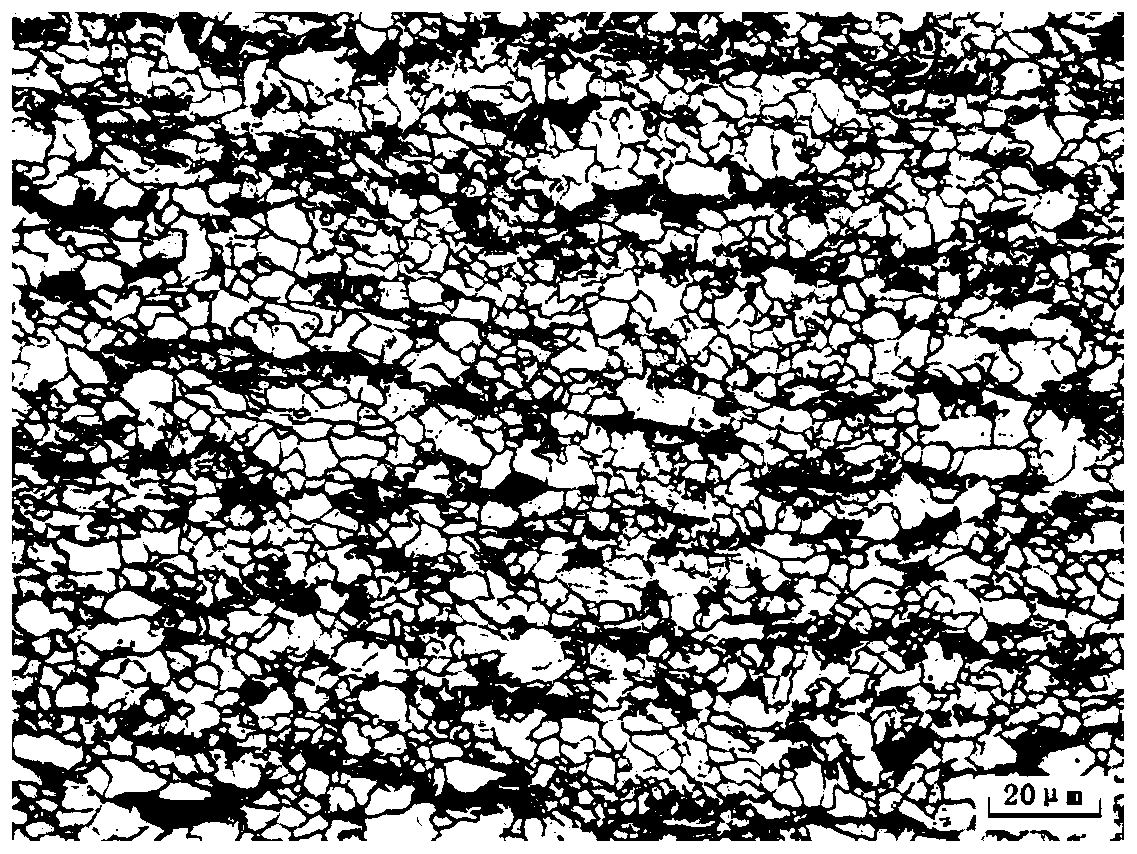

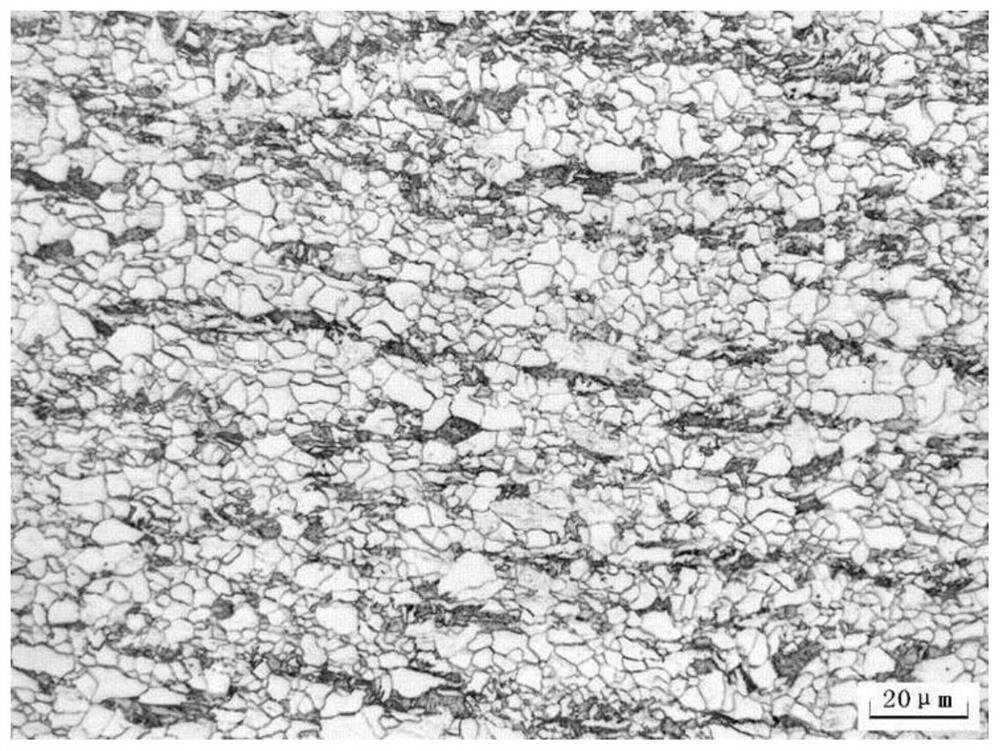

Marine high-strain welded steel pipe based on double-phase structure and preparing method thereof

ActiveCN110000517AWith mechanical propertiesCorrosion resistanceArc welding apparatusDouble phaseHigh intensity

The invention discloses a marine high-strain welded steel pipe based on a double-phase structure and a preparing method thereof. The marine high-strain welded steel pipe is made by a wide and thick steel plate having the double-phase structure, the steel grade of the high-strain welded steel pipe is L485MO, the thickness is larger than or equal to 25.4mm, the width of the steel plate is pi(1-epsilon)D-2t, D refers to the outer diameter of the steel pipe, t refers to wall thickness, epsilon refers to a cold expanding rate, the radius-to-thickness ratio is smaller than or equal to 30, the yield-to-strength ratio Rt0.5 / Rm is smaller than or equal to 0.85, A is larger than or equal to 25%, and UEL is larger than or equal to 7%. The manufactured steel pipe has the characteristics of high strength, high tenacity, high strain capability, low yield-to-strength ratio, low strain aging influence, H2S corrosion resistance, large wall thickness, small radius-thickness ratio, high diameter precision, small outer diameter error and small out-of-roundness error, can fully meet the technical requirements of marine service on the high-strain thick-walled delivery steel pipe, can be used for deep-sea oil and gas exploitation and saves marine development cost.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Reinforced concrete precast member containing steel plate

InactiveCN101265738AImprove shear resistanceImprove tensile propertiesLoad-supporting elementsEpoxySheet steel

The invention relates to a reinforced concrete prefabricated part containing a steel plate, and belongs to building structure members. The prefabricated part comprises a plurality of steel bars and an external concrete protective layer with enough thickness thereof. The prefabricated part is characterized by further comprising the steel plate composed of the steel plate and epoxy group pasted resin. The steel plate consisted of the steel plate and epoxy group pasted resin can be positioned in the concrete protective layer, the steel plate thereof is fixed on the steel bars or adhered to the surface of the concrete protective layer. Compared with the prior art, since the steel plate has the advantages of higher axial tensile strength, smaller strength-weight ratio, high durability, corrosion resistance and high aging and fatigue resistance, the adopted reinforced concrete prefabricated parts containing steel plates are capable of adhering together to the concrete protective layer by means of the epoxy group pasted resin in the positions subject to damage or crack of the prefabricated parts, thereby improving partial shearing, tension and fatigue resistance of the prefabricated parts, improving the ductility of the members, increasing the bearing capacity of the members and satisfying the use security obviously.

Owner:周昕毅

Rock wool-containing liquid rubber spray coating

InactiveCN102329569AImprove fire performanceImprove insulation effectUnspecified rubber coatingsConjugated diene hydrocarbon coatingsPolymer scienceSpray coating

The invention discloses a rock wool-containing liquid rubber spray coating, and relates to the technical field of spray coatings. The liquid rubber spray coating containing rock wool powder modified by a vacuum process comprises a component A and a component B, wherein the component A is anionic liquid rubber asphalt emulsion; the component B is a coagulant solution; the component A has the solid content of liquid rubber asphalt emulsion of 50-75 weight percent, and comprises the following components in percentage by mass: 1 to 35 percent of rubber emulsion, 10 to 50 percent of asphalt emulsion, 0.01 to 2 percent of anionic dispersing agent, 0.01 to 2 percent of anionic surfactant, and 1 to 60 percent of the rock wool powder modified by the vacuum process; and the component B is an aqueous solution at the concentration of 3-18 percent, which is prepared by mixing calcium chloride and composite aluminum-iron polymer in percentage by mass. The liquid rubber spray coating has high fireproof performance and can achieve good heat preservation effect.

Owner:大连美宸特环保节能产品有限公司

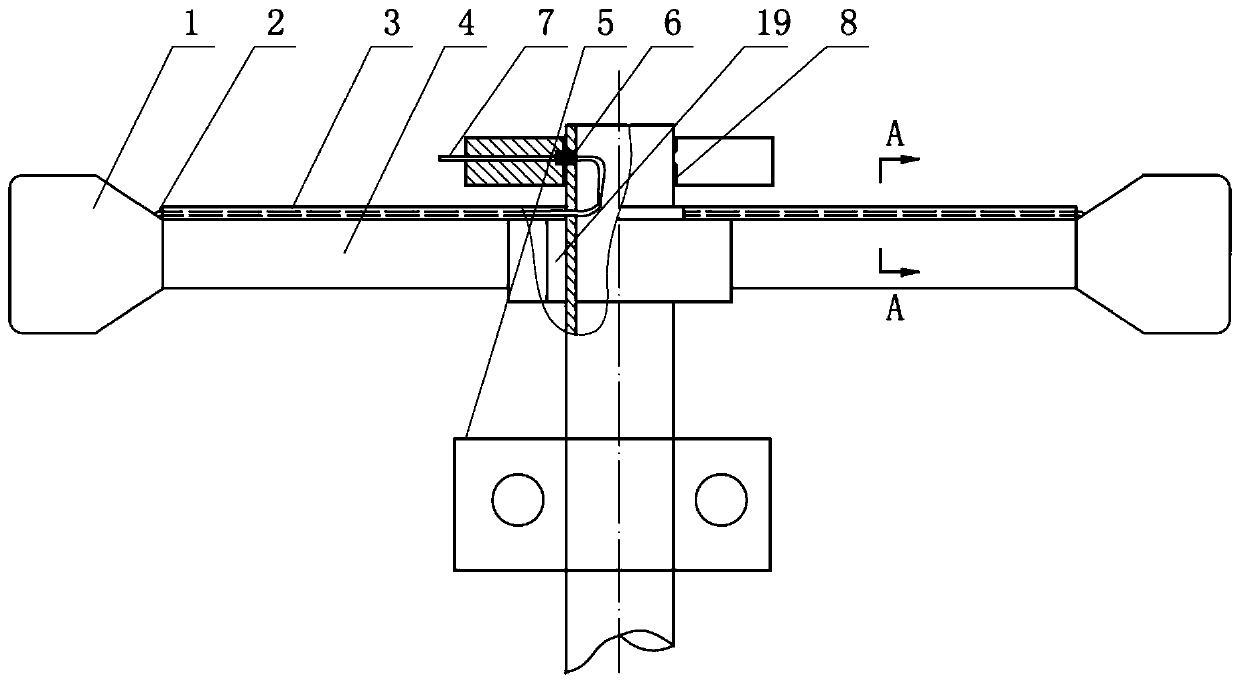

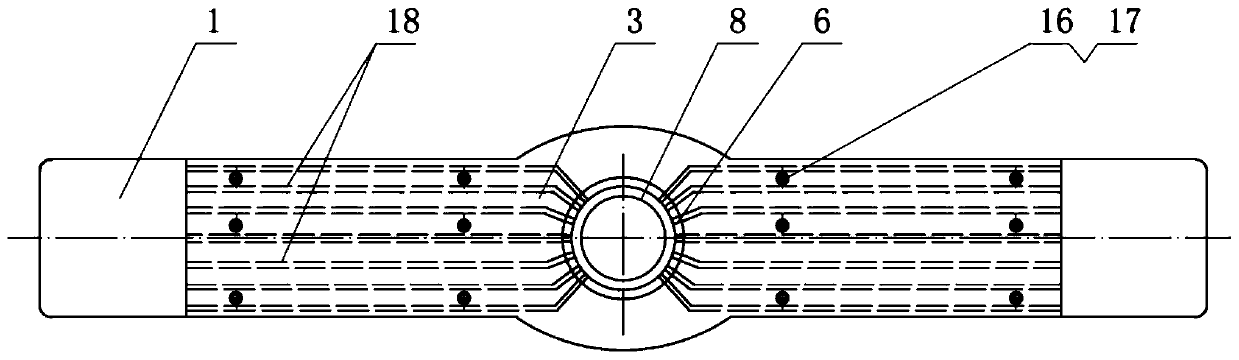

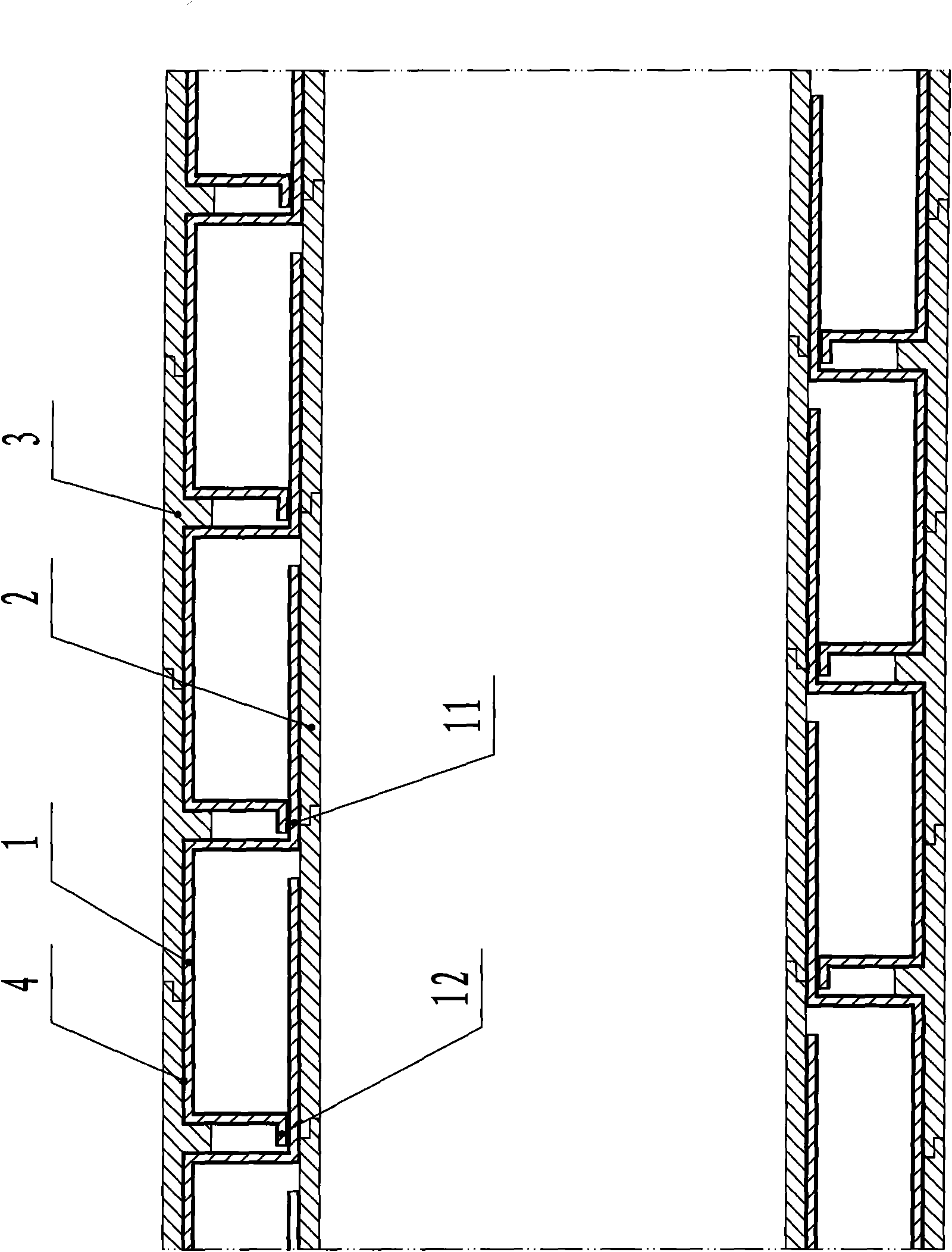

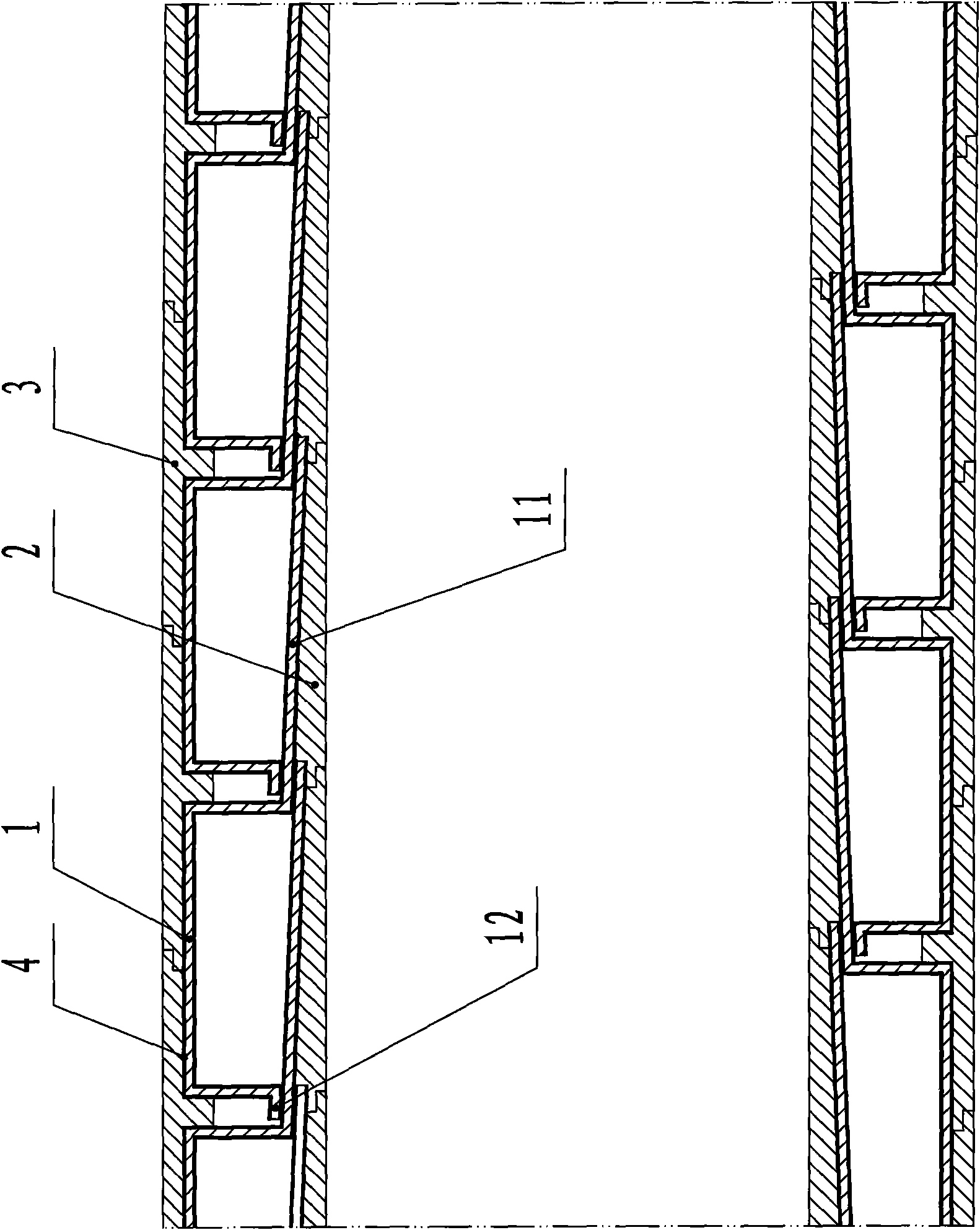

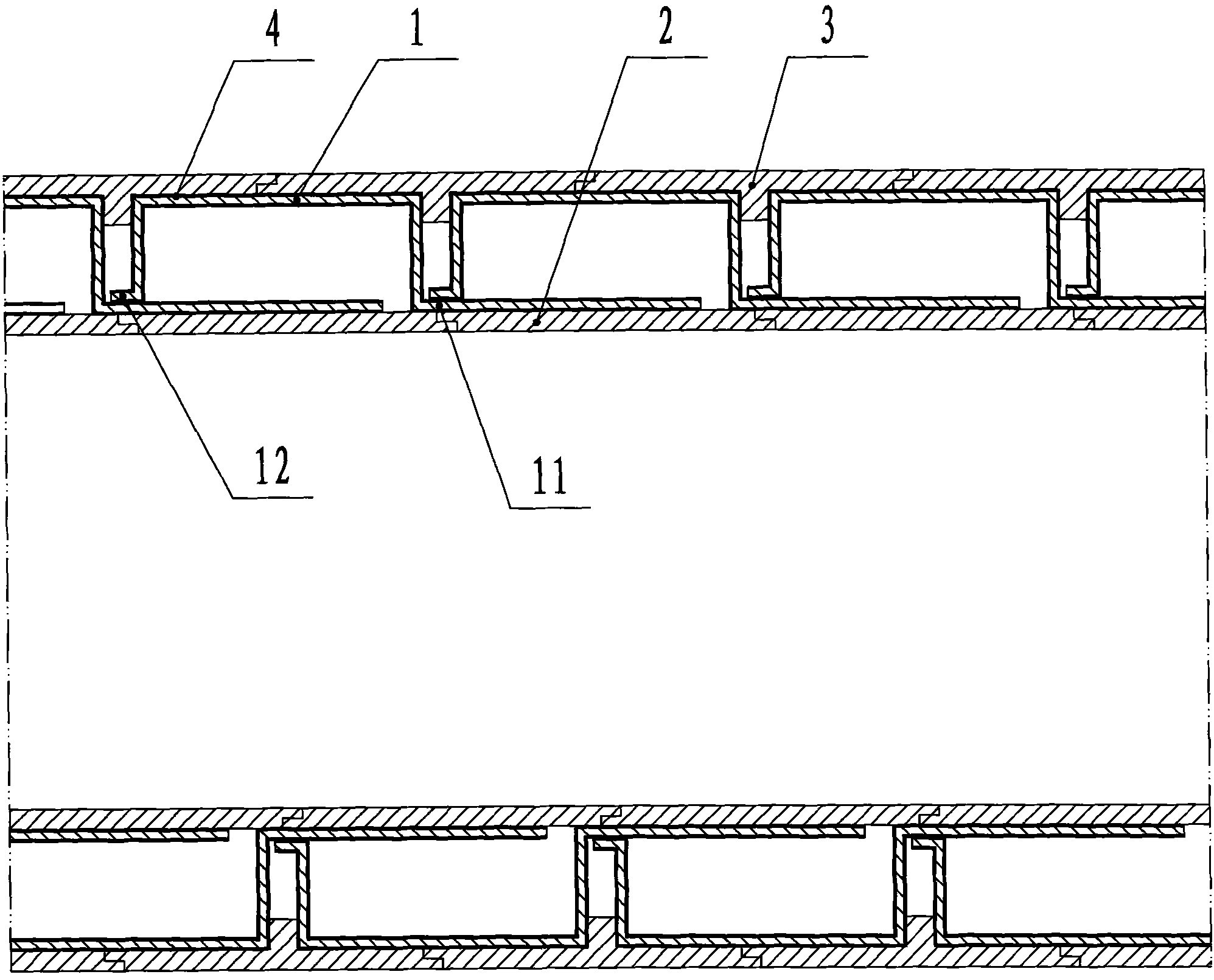

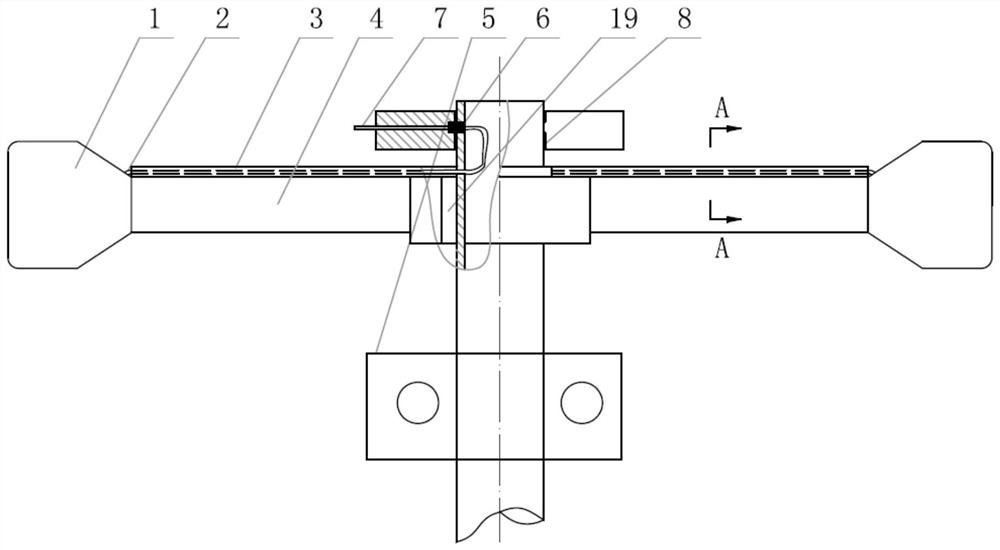

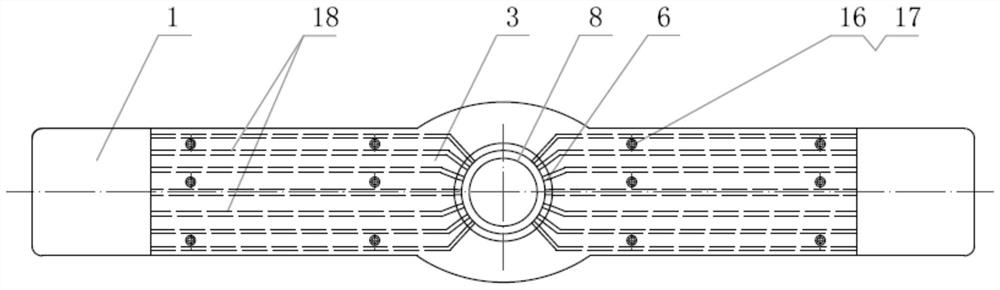

Structure for reinforcing signal data pipeline of hypergravity centrifuge

The invention discloses a structure for reinforcing a signal data pipeline of a hypergravity centrifuge. The reinforcing structure is installed on the high-speed rotating arm of the hypergravity centrifuge. The reinforcing structure is installed on the top surface of the high-speed rotating arm. Various pipelines are fixed in the reinforcing structure. The reinforcing structure comprises structural units which are symmetrically arranged on the upper side and the lower side of each pipeline and reinforcing carbon fiber composite layers which are arranged outside the structural units. The structural units on the upper side and the lower side wrap the upper sides and the lower sides of the pipelines respectively. The inner concave parts of the structural units between every two adjacent pipelines are filled up by the reinforcing carbon fiber composite layers. The structural units and the reinforcing carbon fiber composite layers are formed by stacking multiple carbon fiber composite material layers of different fiber arrangements. The signal data line reinforcing structure can overcome the huge pulling force caused by the high-speed rotation of the hypergravity centrifuge in the usingprocess, and prevents the signal data line from being thrown out and broken under the high-speed operation of the centrifuge. The signal data line is fixed firmly and has simple structure.

Owner:ZHEJIANG UNIV

Reinforced concrete prefabricated part with reinforced plasticity

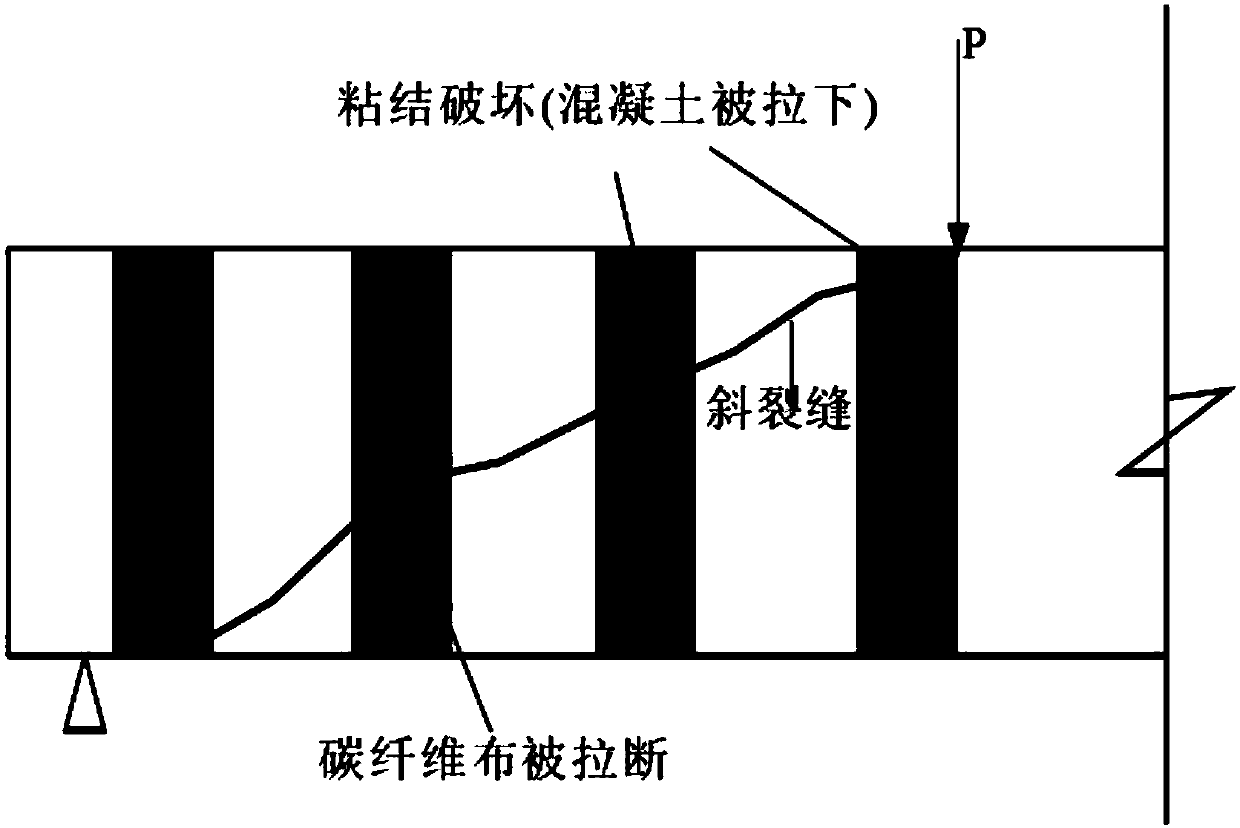

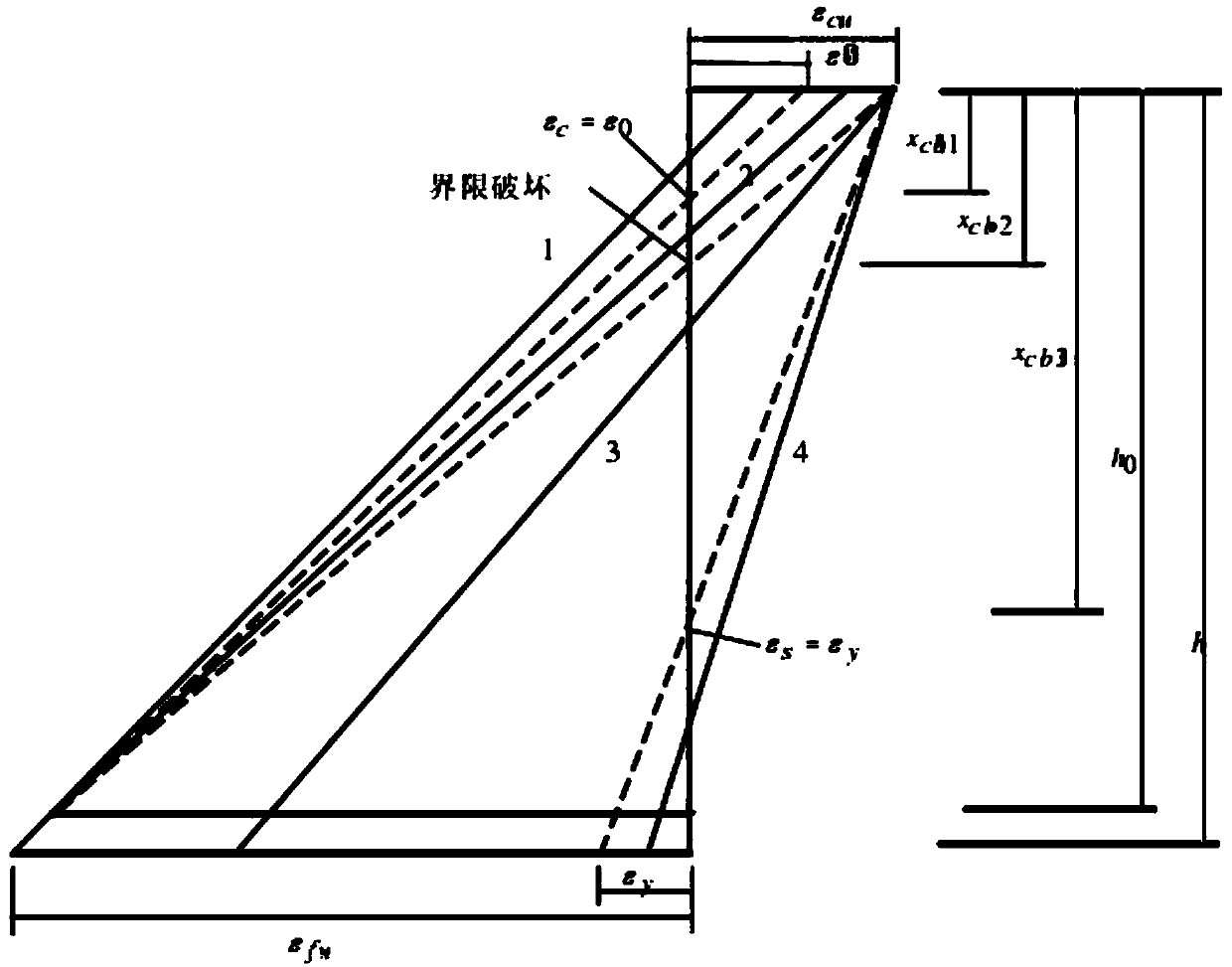

InactiveCN107575039AImprove axial tensile strengthLow strength to weight ratioBuilding repairsRebarReinforced concrete

The invention discloses a reinforced concrete prefabricated part with reinforced plasticity. The reinforced concrete prefabricated part is provided with a plurality of steel bars and a concrete protective layer with sufficient thickness and at the exteriors of the steel bars. The reinforced concrete prefabricated part is characterized in that the reinforced concrete prefabricated part further comprises a carbon fiber reinforced plasticity part consisting of carbon fiber cloth and epoxy bonded resin. The reinforced concrete prefabricated part is characterized in that the carbon fiber reinforcedplasticity part consisting of the carbon fiber cloth and the epoxy bonded resin is placed in the concrete protective layer, the carbon fiber cloth is fixed on the steel bars, and the reinforced concrete prefabricated part with the carbon-containing reinforced plasticity aims to solve deficiencies in the prior art, has the high crack resistance, and meets urgent requirements of use safety for a hydraulic structure in society.

Owner:徐州金盟新型建材有限公司

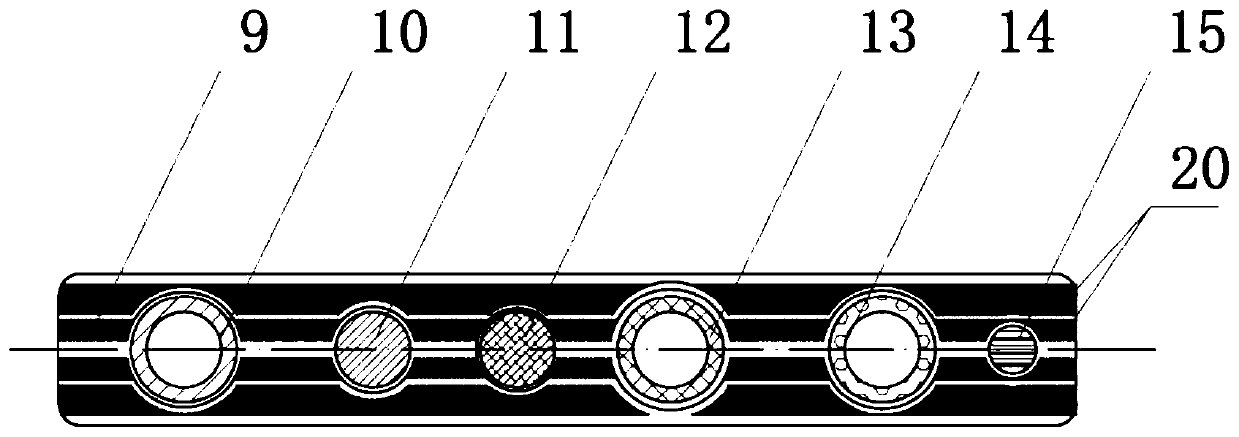

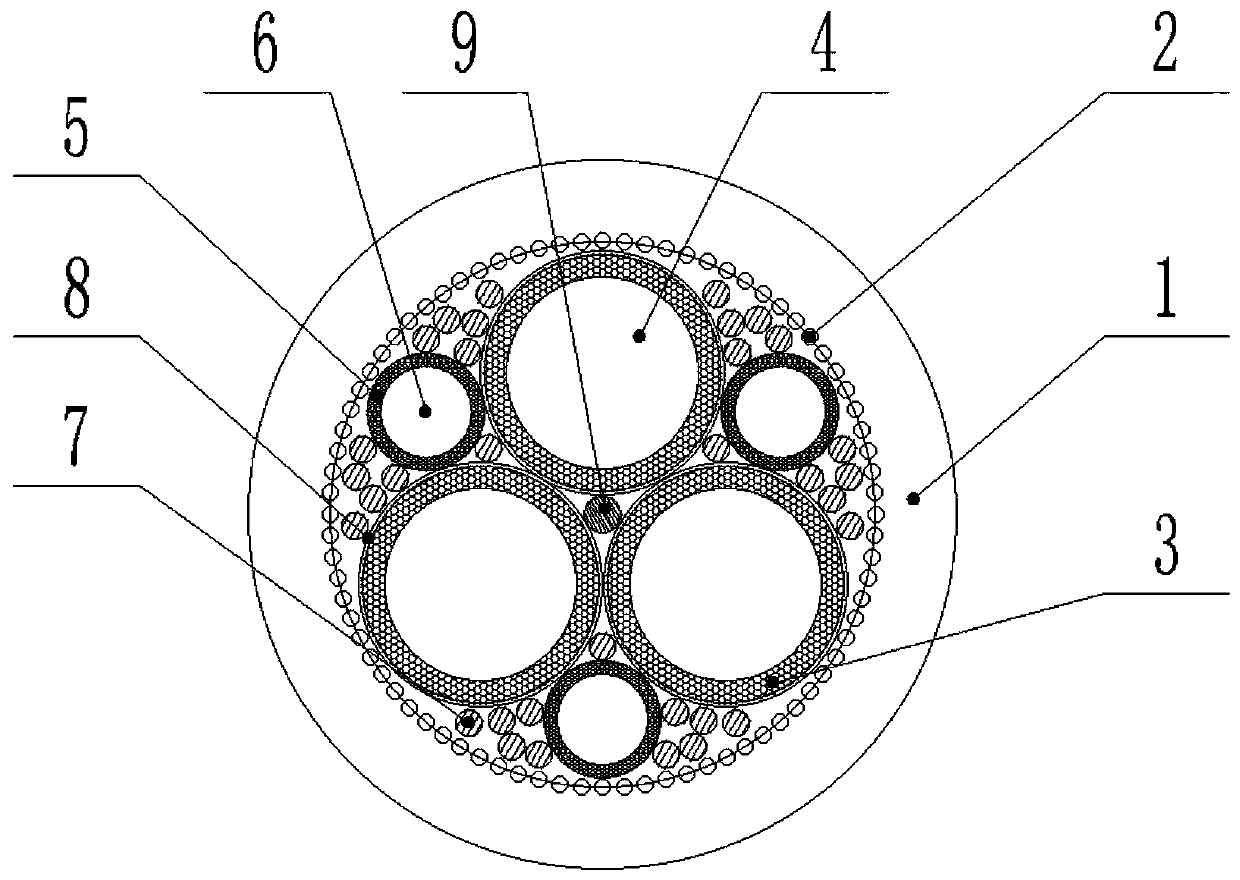

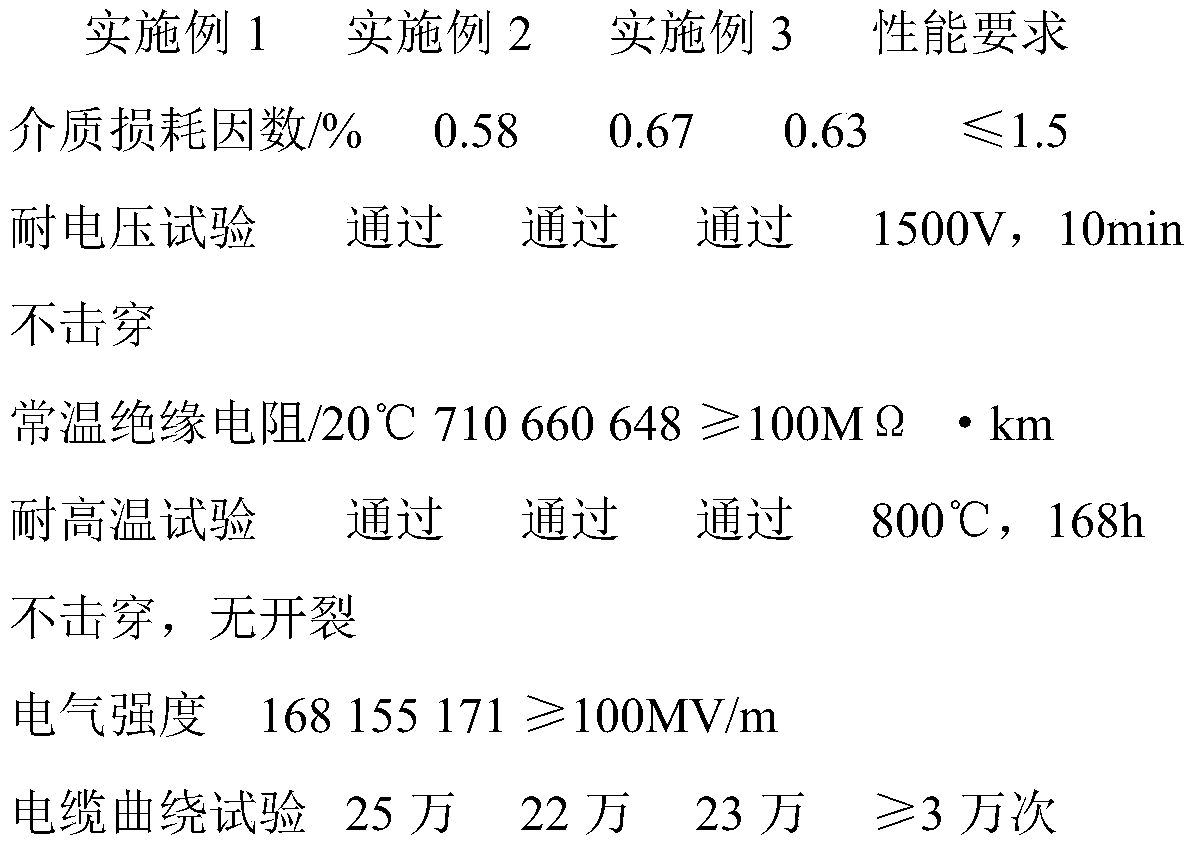

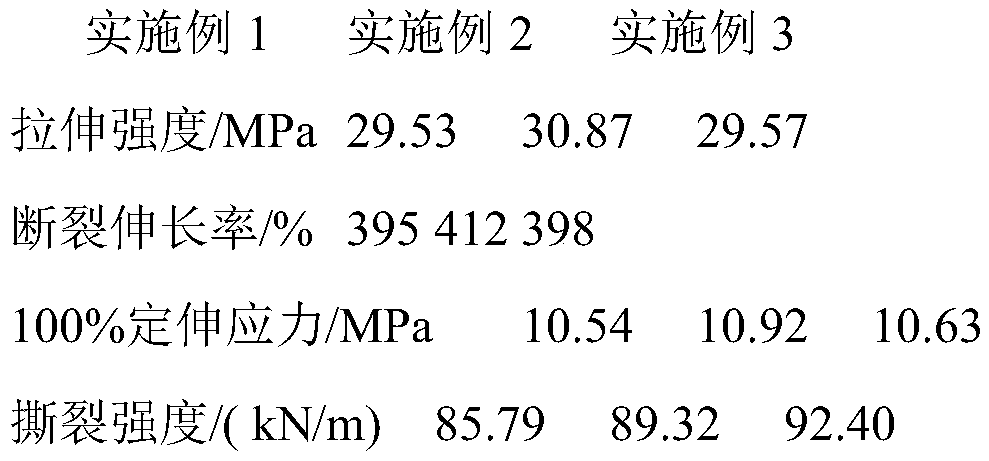

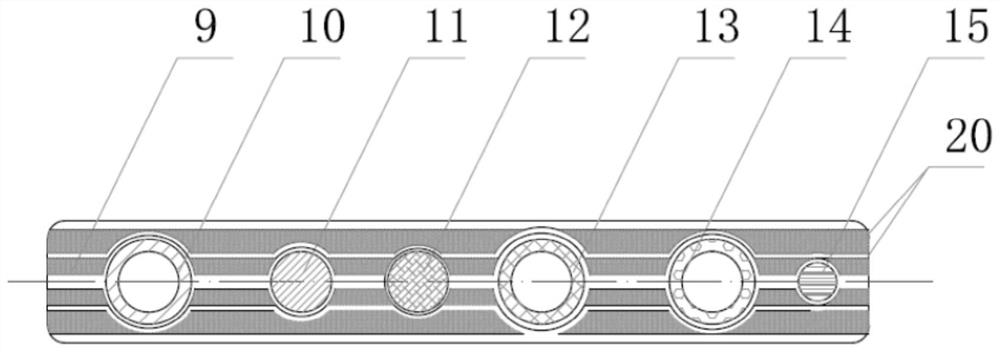

Nuclear power dragging abrasion-resistant cable

InactiveCN110808117AImprove axial tensile strengthImprove flexibilityFlexible cablesFlexible conductorsMasterbatchElectrical conductor

The invention discloses a nuclear power dragging abrasion-resistant cable, comprising an outer sheath, a shock-absorbing sheath, three main wires, three ground wires, multiple filler bars, and a cablecore. The outer sheath is made of a composite chain extender block modified TPU and abrasion-resistant masterbatch. The outer sheath tightly wraps the outer side of the shock-absorbing sleeve. The shock-absorbing sleeve is made of a reinforced natural rubber material. The main wires each include a main wire conductor and a main wire insulation sleeve tightly wrapping the outer side the main wireconductor. The outer periphery of each main wire is provided with an aluminum-plastic composite film. The ground wires each include a ground wire conductor and a ground wire insulation sleeve tightlywrapping the outer side of the ground wire conductor. The cable core is disposed at the center. The main wires are twisted along the cable core in an equilateral triangle with a pitch ratio of 8 to 10. The filling bars fill gaps between the main wires and the ground wires. The filling bars inside the cable can relieve shock multiple times so as to further alleviate the stress, reduce friction damage, improve the structural reliability of the cable, prolong the service life, and achieve higher safety.

Owner:湖南华菱线缆股份有限公司

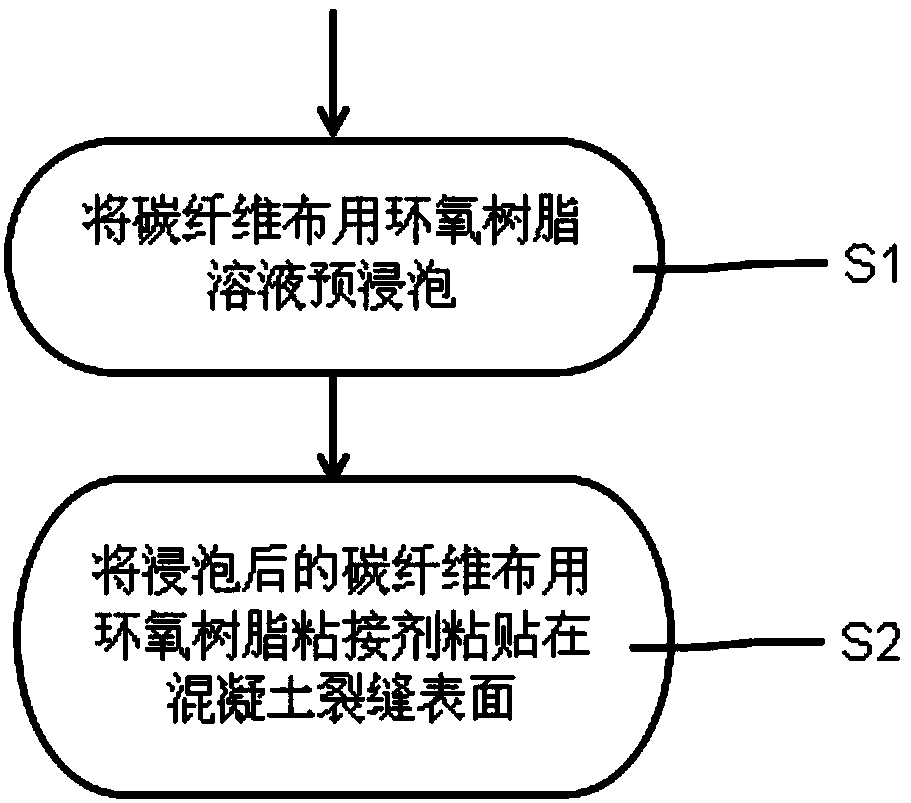

Carbon fiber structure reinforcement method

InactiveCN110219473AImprove axial tensile strengthHigh tensile strengthBuilding repairsEpoxyCarbon fibers

The invention belongs to the technical field of structural damage detection and reinforcement, and particularly relates to a carbon fiber structure reinforcement method. Before pasting a carbon fibercloth, the carbon fiber cloth is pre-soaked with an epoxy resin solution, the carbon fiber cloth after immersion is pasted on the surface of a concrete crack with an epoxy resin adhesive, and the carbon fiber cloth is pasted in the direction of the tension or in the direction perpendicular to the cracks. The carbon fiber structure reinforcement method solves the problem that in the prior art, thestrength, rigidity, stability and durability of a structure and a member cannot be well improved in the prior art, and has the beneficial technical effects of improving the strength, rigidity, crack resistance and elongation of the structure and being good in anti-seismic effect and better in reinforcement effect.

Owner:王伟

Continuous axial fiber arrangement method and its equipment

InactiveCN100446965CReduce dosageImprove axial tensile strengthTubular articlesIt equipmentConductor Coil

An arrangement method of the continuous axial fiber and the special device is about the fiber which winds the glass steel tube. In the process of the glass steel tube, the continuous axial fibrous zone is arranged out of the pipe except the toroidal fiber, so the tension direction of the fiber is same as the axial stress of the pipe instead of the reciprocal cross winding, so it can solve the problem of the axial low strength of the pipe and it improves the production efficient by the special production device.

Owner:河北正通玻璃钢有限公司

Steel-band reinforced steel plastic composite wound pipe

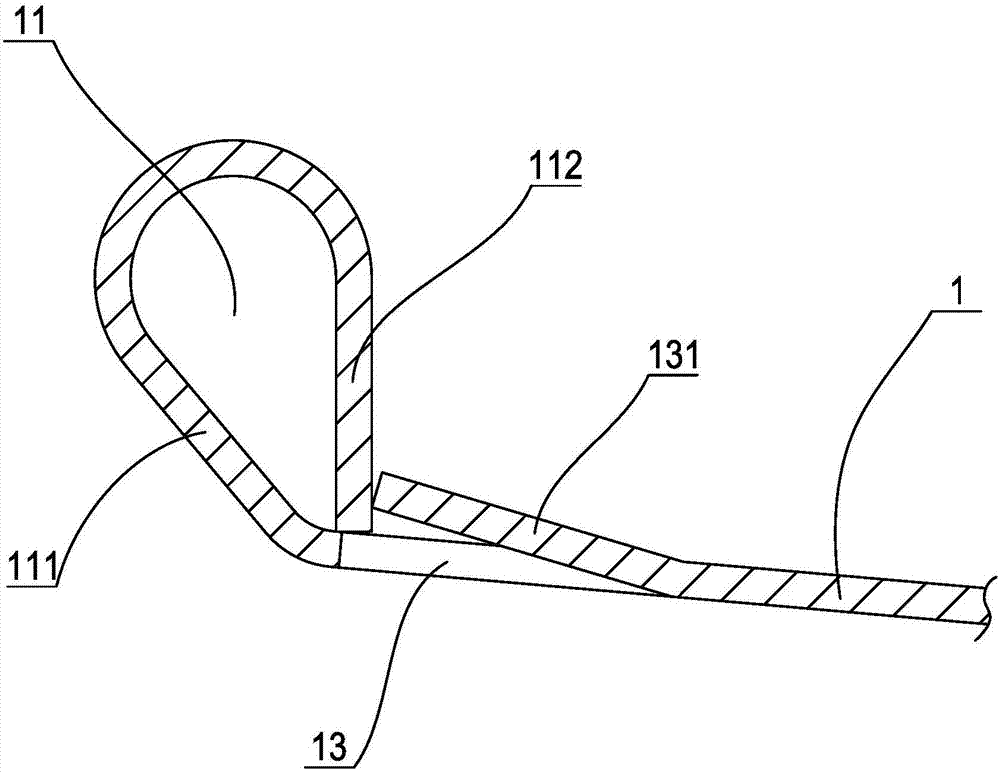

InactiveCN101876384AEasy to wrapReduce consumptionRigid pipesAgricultural irrigationChinese characters

The invention discloses a steel-band reinforced steel plastic composite would pipe comprising a pipe wall skeleton formed by winding a formed steel band. The internal surface and the external surface of the pipe wall skeleton are respectively wound by plastic tapes to form the internal wall and the external wall of the composite would pipe; the surface of the external wall is a smooth surface; the cross section of the formed steel band comprises a long leg and a short leg and is in a shape like a Chinese character ji; and in the axial cross section of the pipe wall skeleton, the short leg of the formed steel band is overlapped on the long leg of the adjacent formed steel band. The invention is suitable for water drainage and sewage engineering of municipal facilities, industry, civil use and public buildings and can also be applied to fields of long-distance water transportation, agricultural irrigation and the like.

Owner:SHAZHOU PROFESSIONAL INST OF TECH

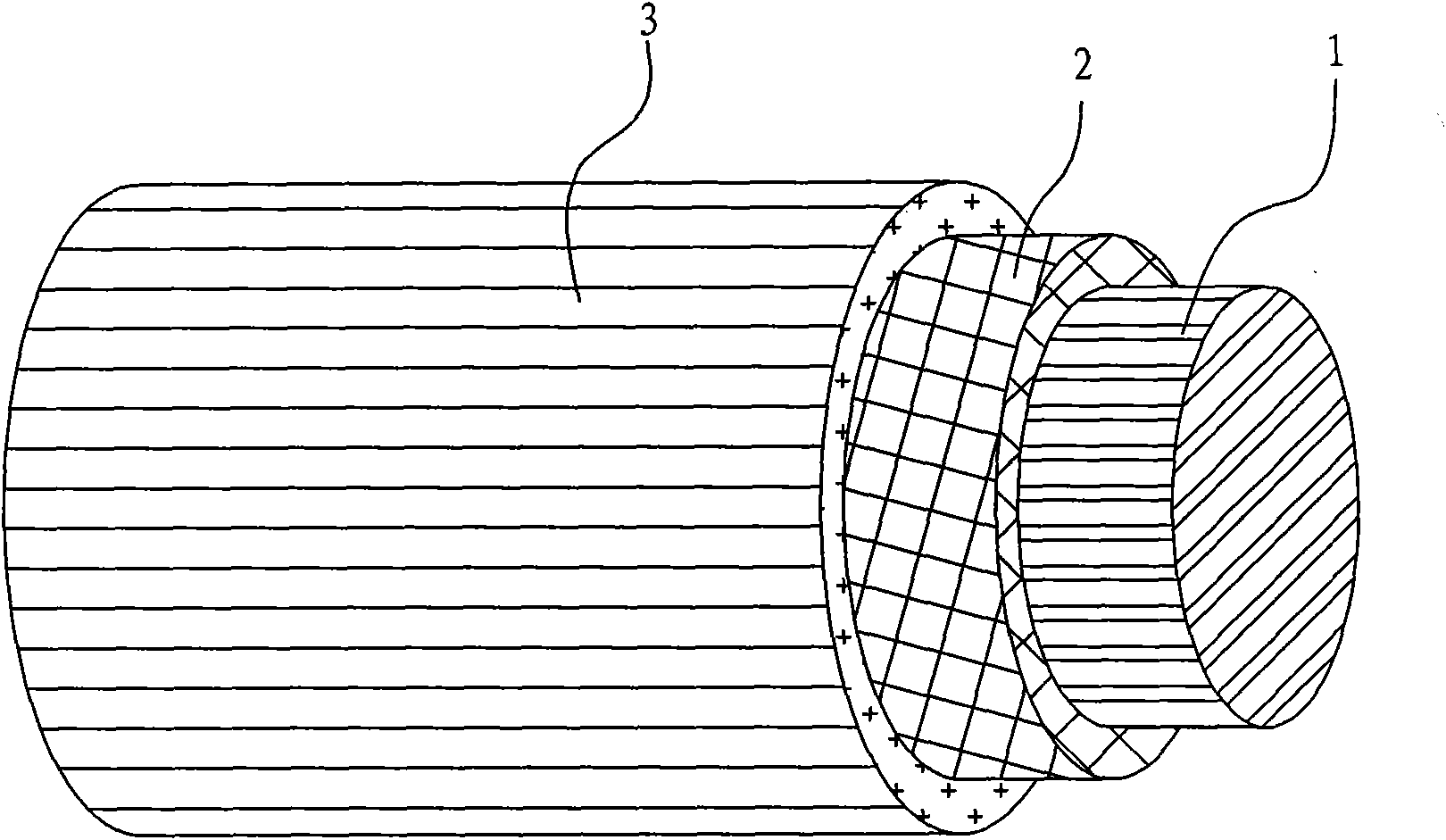

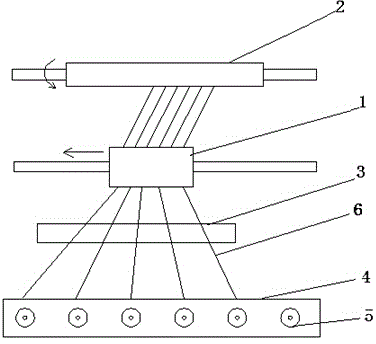

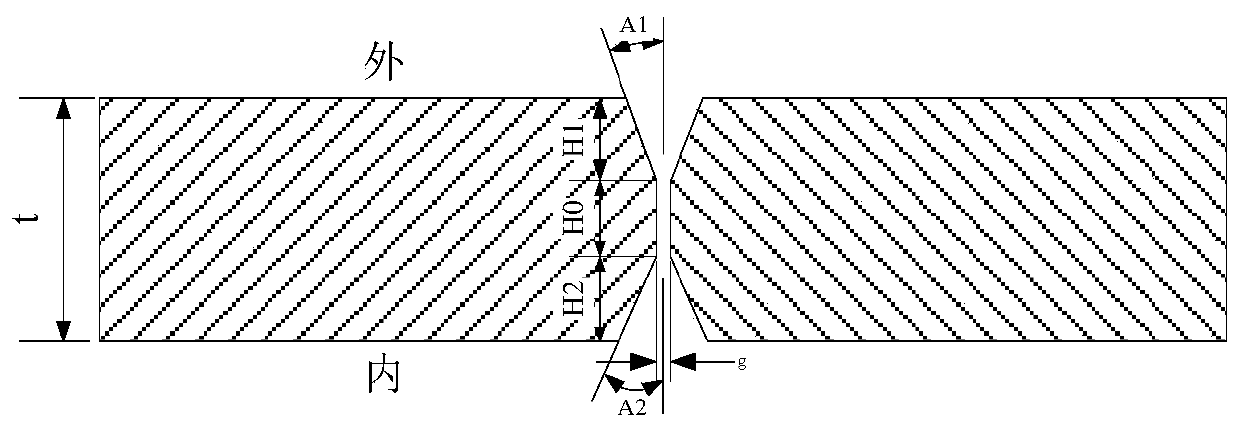

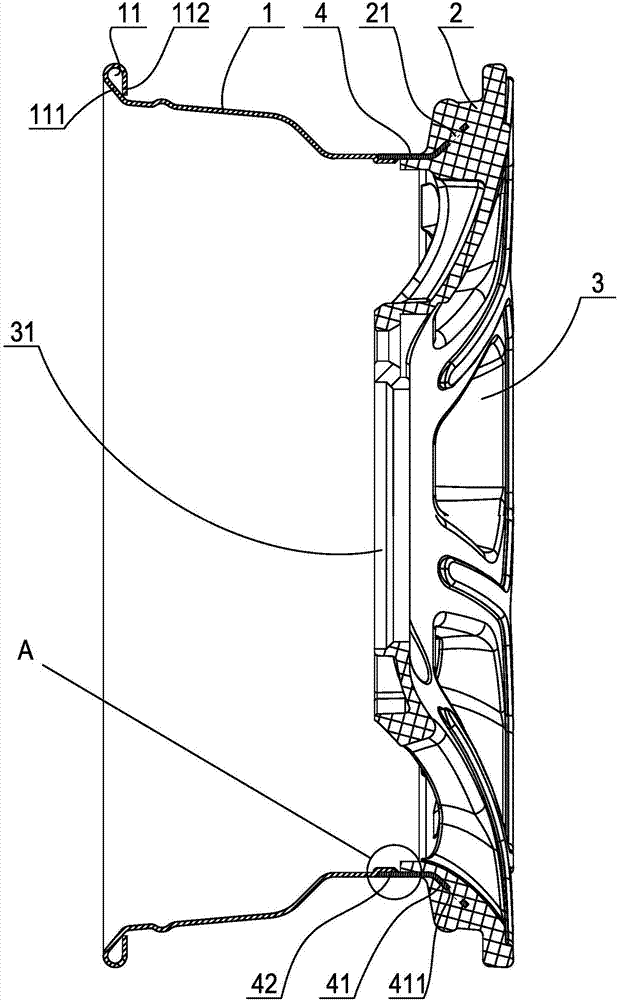

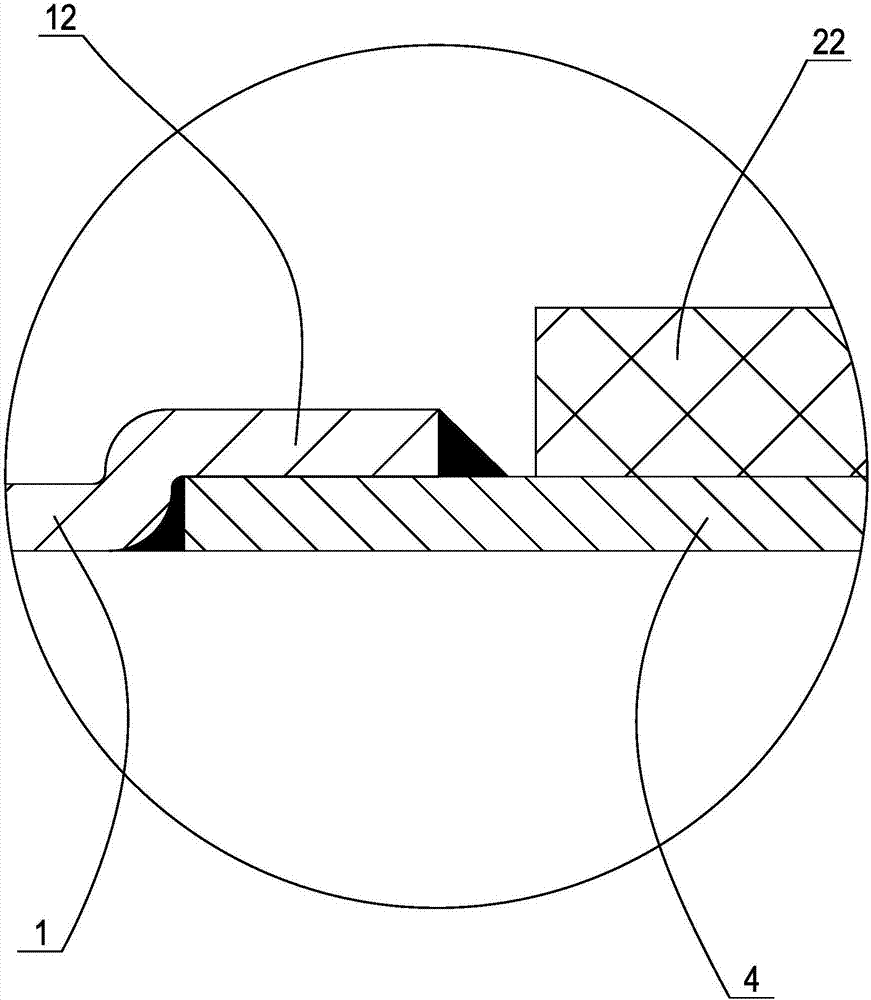

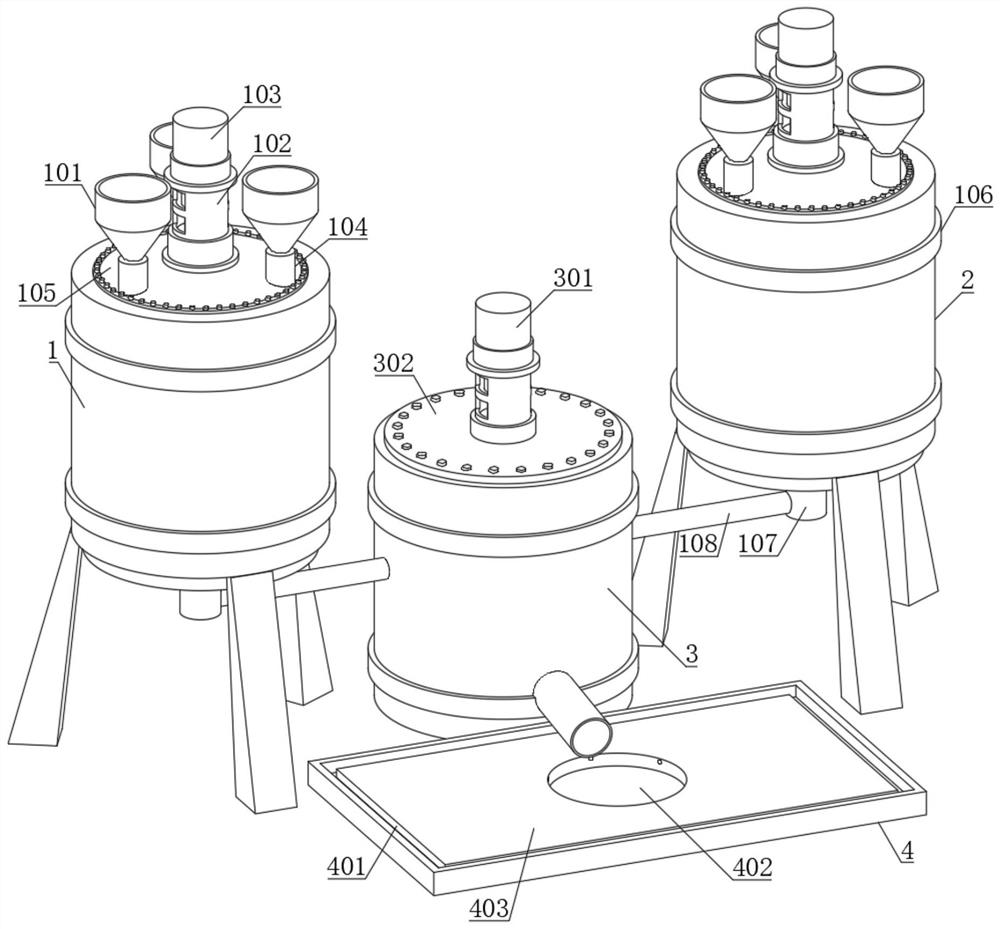

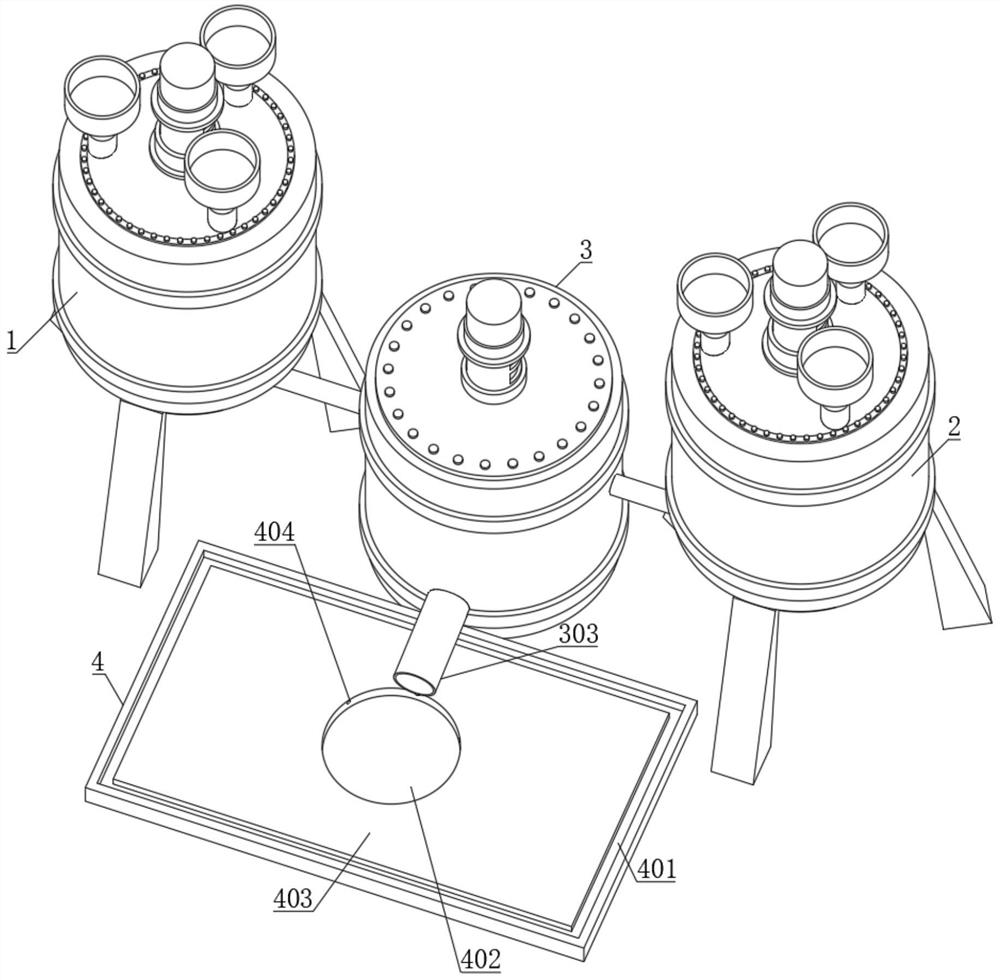

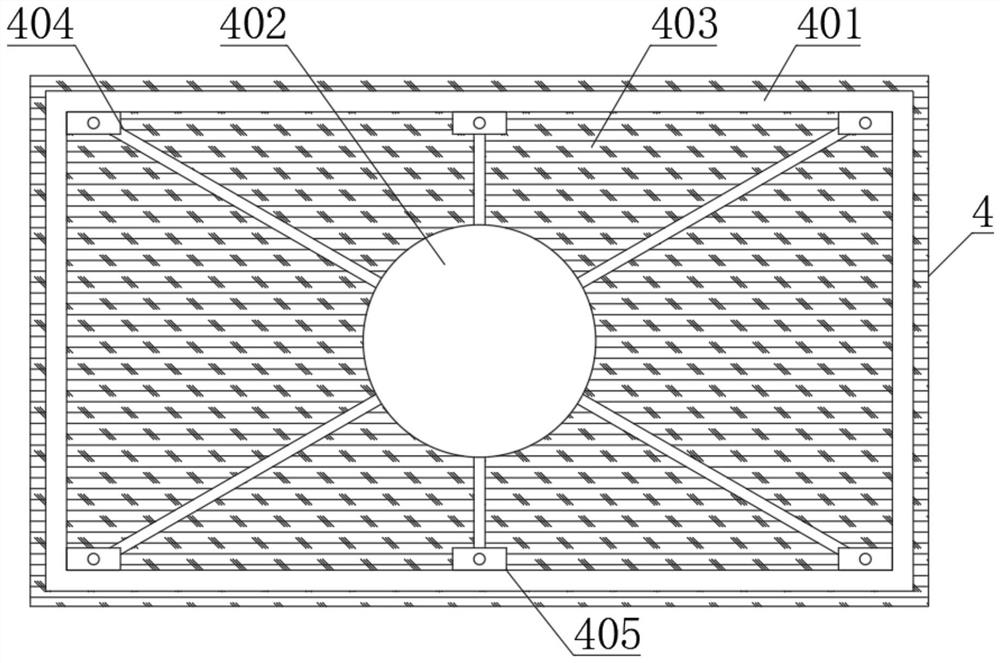

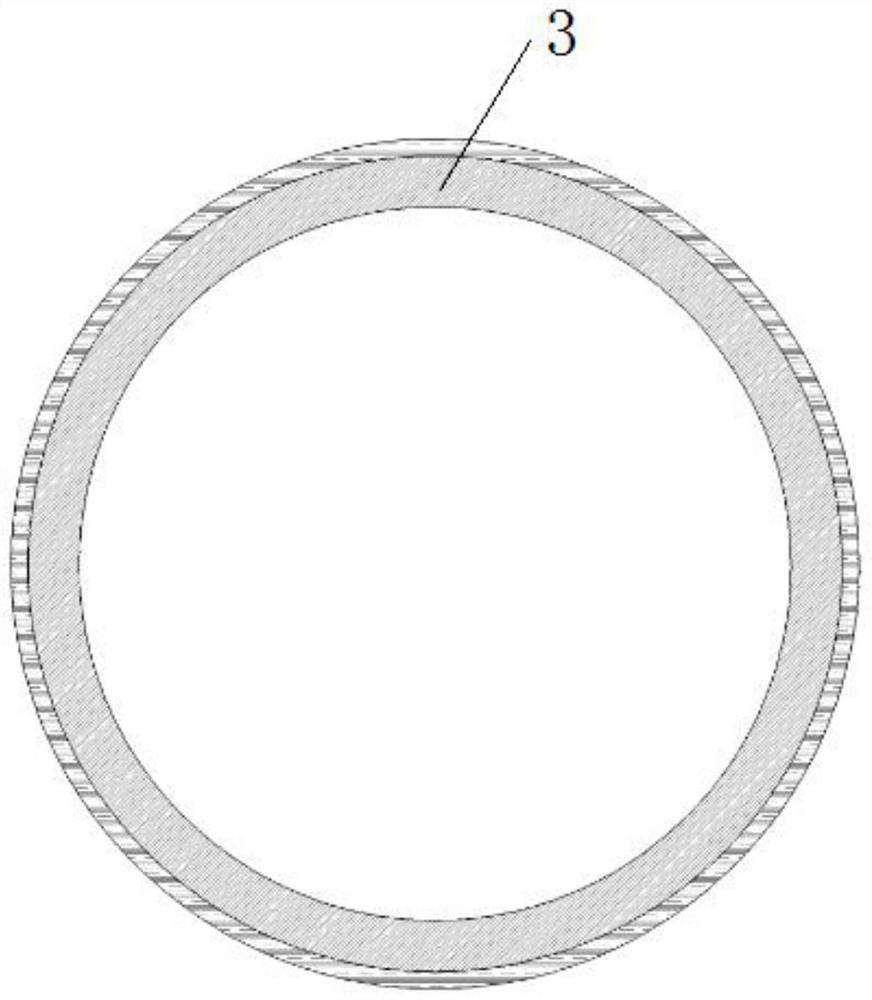

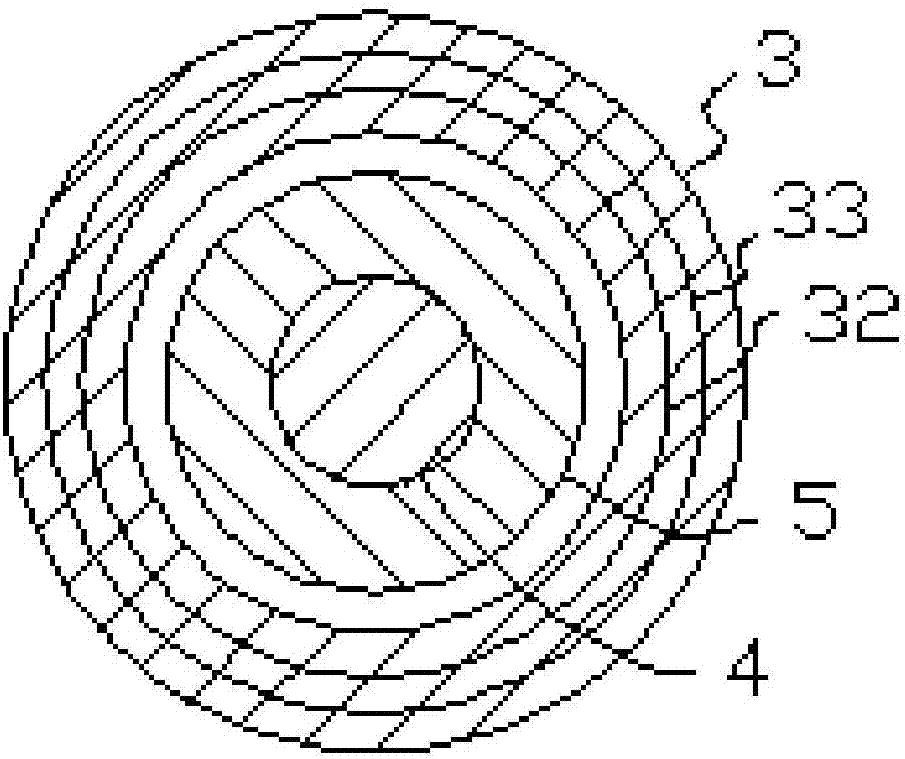

A composite winding thermoplastic fiberglass steel pipe and its preparation method

ActiveCN103791174BIncrease hoop tensile strengthImprove axial tensile strengthElongated constructional elementsRigid pipesGlass fiberEngineering

The invention relates to a composite winding thermoplastic glass steel pipe and its preparation method. The pipe is composed of an inner layer, a middle layer and an outer layer, wherein the inner layer is a continuous glass fiber reinforced thermoplastic prepreg tape layer wound in a hoop direction, and the middle layer is a spiral Winding continuous glass fiber reinforced thermoplastic prepreg tape layer, the outer layer is hoop wound continuous glass fiber reinforced thermoplastic resin prepreg tape layer. Compared with the prior art, the present invention not only has a higher hoop tensile strength, but also has a higher axial tensile strength, which can meet the requirements for pulling pipes in trenchless construction; the composite winding of the present invention During the winding process of thermoplastic FRP pipes, it is only necessary to adjust the winding process and change the winding angle, without changing the bandwidth of the continuous fiber reinforced thermoplastic resin composite material prepreg tape. The entire winding process is continuous and the production efficiency is high.

Owner:HEFEI GENIUS NEW MATERIALS

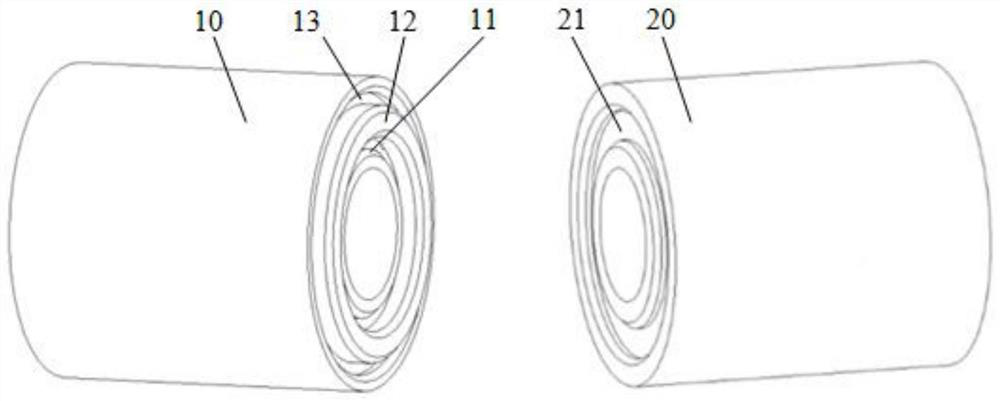

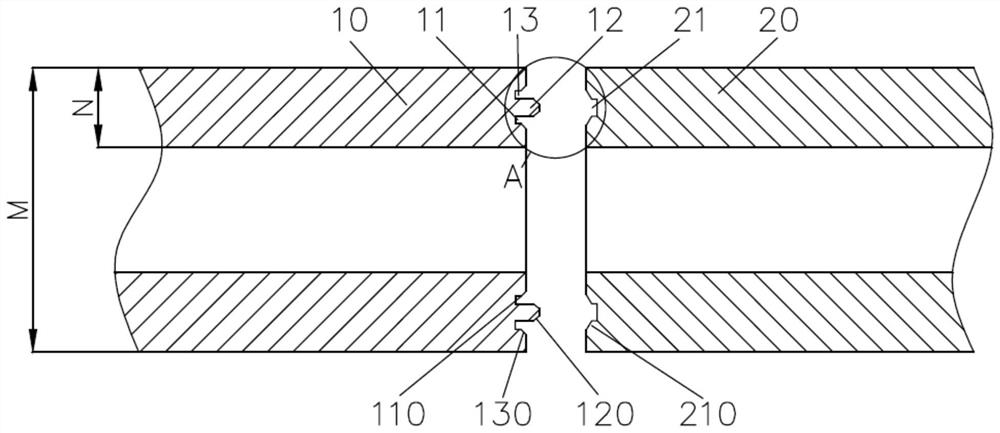

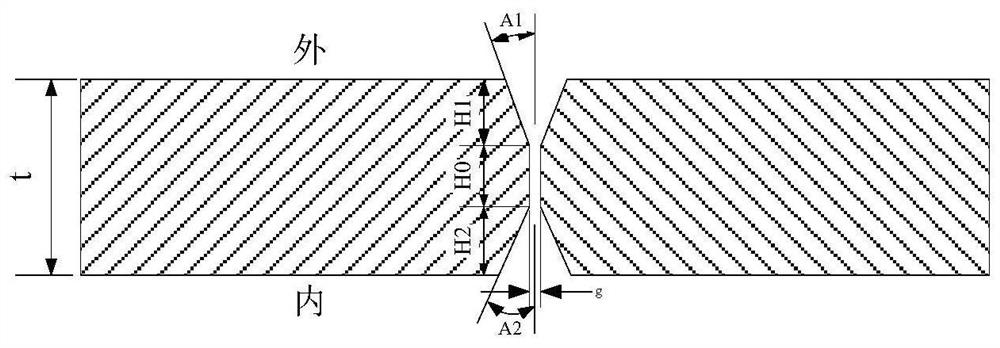

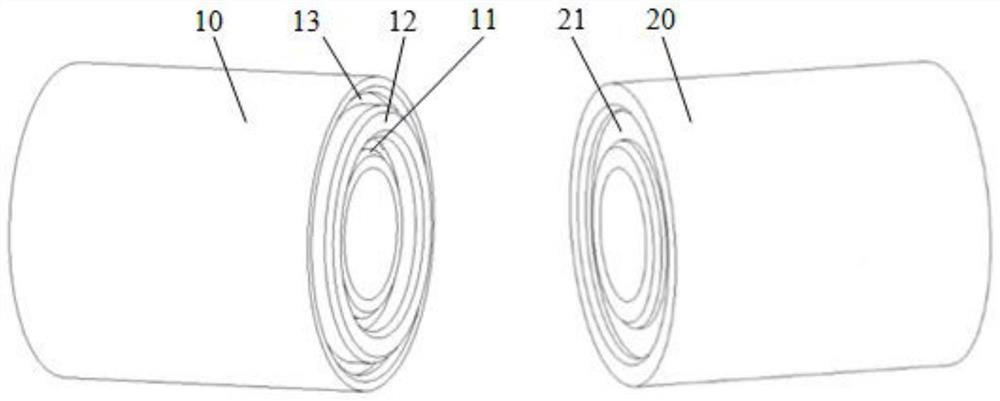

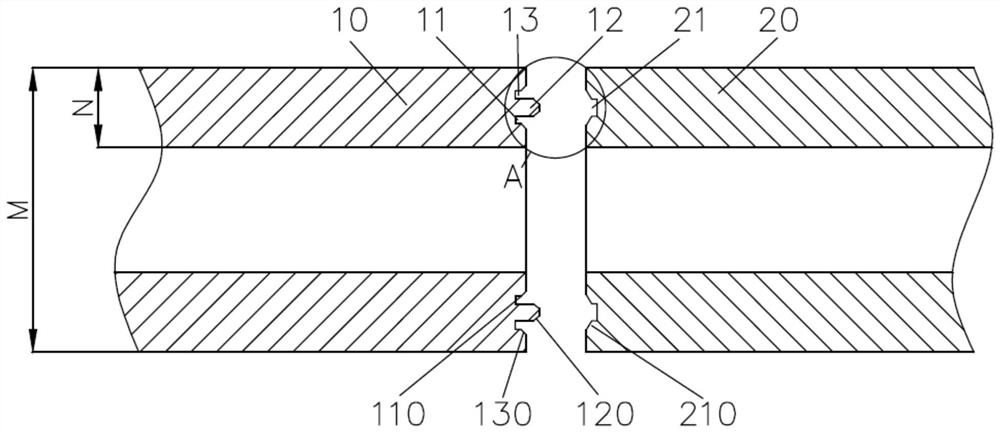

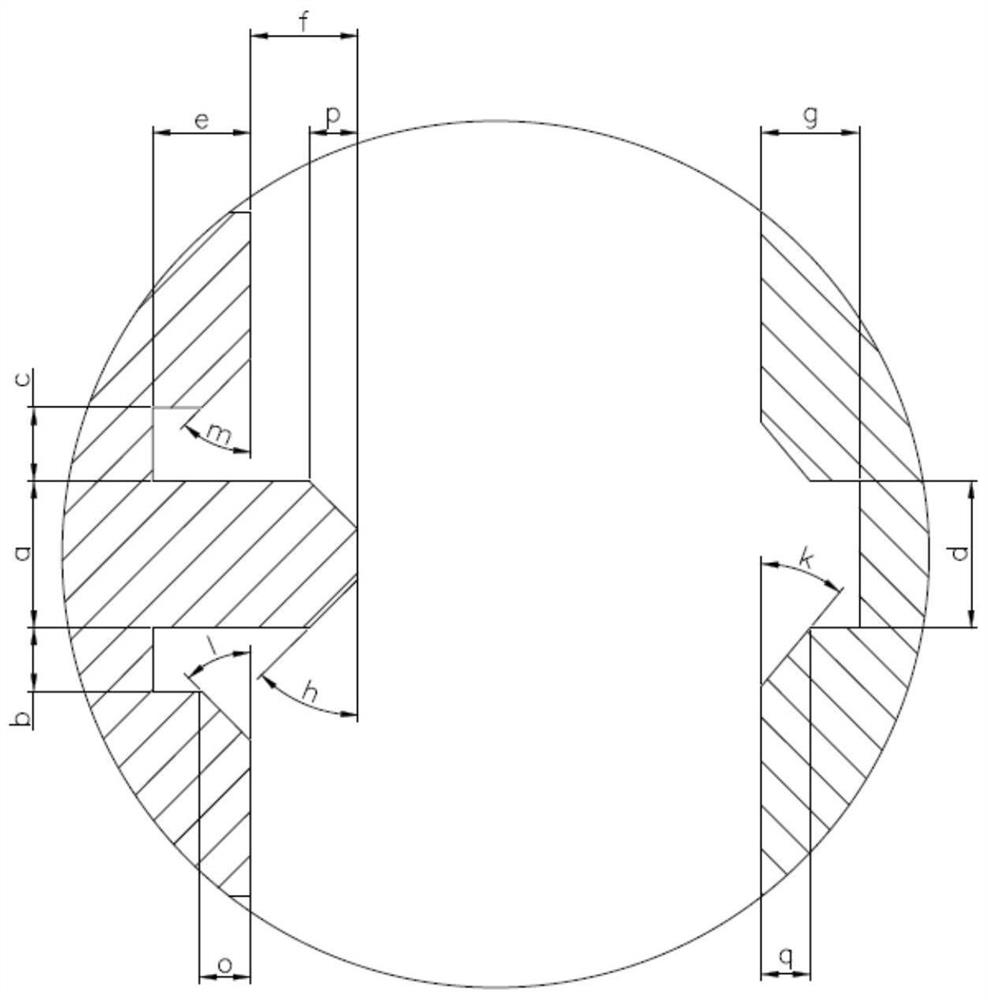

Large-size aluminum-steel reaction auxiliary heating and toughening friction welding method

ActiveCN113967784AGrain refinementImprove toughnessNon-electric welding apparatusFriction weldingUltimate tensile strength

The invention provides a large-size aluminum-steel reaction auxiliary heating and toughening friction welding method. According to the method, two-way embedded structure design is conducted on a welding joint of an aluminum component (20) and a steel component (10), and a welding auxiliary layer is arranged at the welding joint. According to the two-way embedded structure design, specifically, an annular steel inner groove (11), an annular steel boss (12) and an annular steel outer groove (13) are sequentially machined in the to-be-welded face of the steel component (10) from a center shaft to the outside, and an annular aluminum groove (21) is machined in the to-be-welded face of the aluminum component. The welding auxiliary layer comprises a reaction transition layer (51), a reinforcing and toughening layer (52) and a reaction auxiliary heating layer (53). The method effectively solves the problems that in the welding process of the steel component and the aluminum component, a large number of brittle intermetallic compounds are likely to be generated, the stress of a welded joint is large, the strength of the welded joint is low, and toughness is poor, friction welding between the large-size aluminum component and the large-size steel component is achieved, the welding efficiency is high, and the welding quality is good.

Owner:NO 59 RES INST OF CHINA ORDNANCE IND

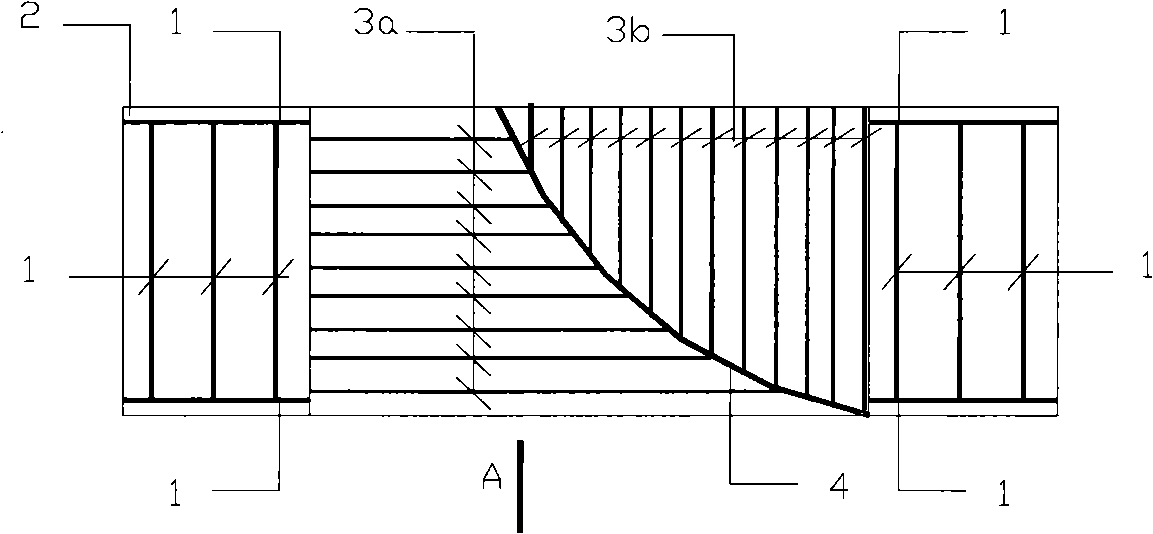

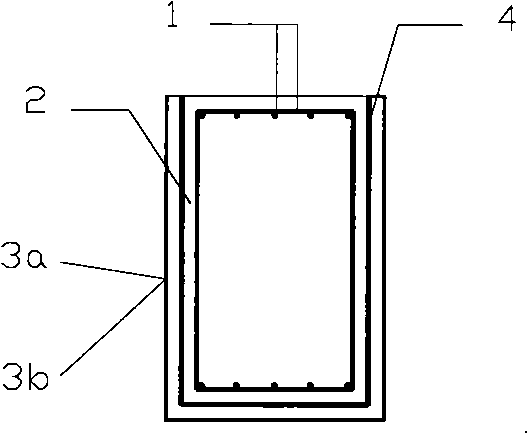

Rectangular winding glass fiber reinforced plastic

ActiveCN110605873AStrong rigidityImprove corrosion resistanceSynthetic resin layered productsGlass/slag layered productsGlass fiberFiber

The invention relates to rectangular winding glass fiber reinforced plastic. The glass fiber reinforced plastic is sequentially provided with a glass fiber reinforced plastic lining layer, a glass fiber reinforced plastic winding layer and a glass fiber reinforced plastic outer protective layer from inside to outside; wherein the glass fiber reinforced plastic lining layer comprises a gridding cloth layer, and a glass fiber surface felt layer, and is formed in a soaking and boding manner through a linking slurry material; the glass fiber reinforced plastic winding layer is formed by combininga plurality of winding layers and alkali-free cloth in an up-down staggered mode at intervals; the glass fiber reinforced plastic outer protective layer comprises glass steel wire cloth, and the polyester surface felt layer is formed by soaking and bonding protective slurry. The winding layer is formed by weaving and winding long-cut glass fibers soaked by toughening slurry, short-cut glass fiberssoaked by reinforcing slurry and coarse gauze soaked by reinforcing slurry; the alkali-free cloth is alkali-free cloth soaked by the reinforced slurry. The invention discloses rectangular winding glass fiber reinforced plastic, which is manufactured by adopting a continuous winding process technology and has high interlayer bonding strength, so that the overall strength and rigidity of a glass fiber reinforced plastic pipe are stronger.

Owner:JIANGSU SHENJIANG ENVIRONMENT TECH

Iron-aluminum composite steel ring and manufacturing method thereof

ActiveCN107214270AHigh strengthUniform strengthMetal-working apparatusCompression moldingManufacturing cost reduction

The invention discloses an iron-aluminum composite steel ring and a manufacturing method thereof. The iron-aluminum composite steel ring comprises a left ring body, a right ring body and a center plate. The left ring body is produced by press forming process, the right ring body and the center plate are produced by aluminum alloy compression molding process, the right ring body is internally provided with a transition ring body; the transition ring body comprises an embedding section and a welding section, wherein the embedding section is connected with the right ring body, and the welding section extends out of the right ring body; when the right ring body and the center plate are produced by compression molding, the transition ring body is served as an embedding piece of a compression molding mold, so that the embedding section located at the right end of the transition ring body is embedded in the right ring body; a shaft sleeve is connected with the right end of the left ring body and the welding section extended out of the right ring body of the transition ring body, and the left ring body and the welding section of the transition ring body are connected and integrated through a welding process; a roll rim is arranged on the edge of the left end of the left ring body, wherein the roll rim turns and rolls towards the circumferential surface of the outer side of the left ring body. According to the iron-aluminum composite steel ring and the manufacturing method thereof, not only can strength of a vehicle rim be guaranteed, and is production efficiency significantly improved to reduce the manufacturing cost, but also the quality grade can be effectively improved to adapt the requirement of high-quality vehicle.

Owner:ZHEJIANG FENGCHI MECHANICAL

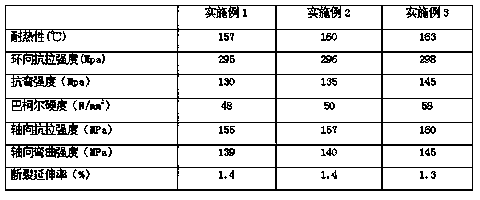

Fast curing epoxy resin system for glass fiber pultrusion frame and preparation method of fast curing epoxy resin system

PendingCN114573951AGood alkali resistanceHigh compressive strengthChemical/physical/physico-chemical stationary reactorsGlass fiberGlycidyl ethers

The invention discloses a fast curing epoxy resin system for a glass fiber pultrusion frame and a preparation method of the fast curing epoxy resin system, and belongs to the field of glass fiber processing. The invention relates to a fast curing epoxy resin system for a glass fiber pultrusion frame and a preparation method of the fast curing epoxy resin system. Comprising the following components in parts by weight: 50-75 parts of polybutadiene epoxy resin, 50-75 parts of glycidyl ether type epoxy resin, 15-30 parts of modified toughening particles, 8-12 parts of a curing agent, 30-40 parts of liquid crystal epoxy resin, 25-30 parts of B144 epoxy resin, 10-20 parts of inorganic whiskers, 15-20 parts of a dendritic polymer and 20-25 parts of a high polymer waterproof emulsion. By adding the high polymer waterproof emulsion and the dendritic polymer, the wear-resistant effect of an epoxy resin system is efficiently improved, mechanical connection is facilitated, glass fiber preparation work is carried out, and the working quality is effectively improved.

Owner:上海顺海精密机械有限公司

Axial plate type integrated welding technology for pipes

InactiveCN112091462AEnhanced axial tensile strengthIncreased ring stiffnessWelding/cutting auxillary devicesAuxillary welding devicesStructural engineeringPipe

The invention discloses an axial plate type integrated welding technology for pipes. A metal heating plate is fixed between the welding end surfaces of the two pipes, the pipes are fully fused on theshaft end surfaces after being electrified, heated and pressurized, the pipes are axially fused into a whole, the strength of pipe bodies can be achieved, the areas of the welding end surfaces are increased, the axial tensile strength of pipe connection openings can be enhanced, and the ring stiffness of the pipe connection openings can also be improved. According to the axial plate type integrated welding technology for the pipes, the problem that when the pipes with relatively-thick pipe walls and relatively-large pipe weights are connected, the condition that the tensile strength of the connecting positions is low occurs easily is solved, the problem that the welding surfaces of the pipes are torn due to dragging by large-tonnage ships is solved in the field of marine pipeline laying, and the axial plate type integrated welding technology is suitable for general popularization and use.

Owner:HEBEI TONGTAO PIPE CO LTD

A rectangular winding fiberglass

ActiveCN110605873BStrong rigidityImprove corrosion resistanceSynthetic resin layered productsGlass/slag layered productsPolyesterGlass fiber

The invention relates to rectangular winding glass fiber reinforced plastic. The glass fiber reinforced plastic is sequentially provided with a glass fiber reinforced plastic lining layer, a glass fiber reinforced plastic winding layer and a glass fiber reinforced plastic outer protective layer from inside to outside; wherein the glass fiber reinforced plastic lining layer comprises a gridding cloth layer, and a glass fiber surface felt layer, and is formed in a soaking and boding manner through a linking slurry material; the glass fiber reinforced plastic winding layer is formed by combininga plurality of winding layers and alkali-free cloth in an up-down staggered mode at intervals; the glass fiber reinforced plastic outer protective layer comprises glass steel wire cloth, and the polyester surface felt layer is formed by soaking and bonding protective slurry. The winding layer is formed by weaving and winding long-cut glass fibers soaked by toughening slurry, short-cut glass fiberssoaked by reinforcing slurry and coarse gauze soaked by reinforcing slurry; the alkali-free cloth is alkali-free cloth soaked by the reinforced slurry. The invention discloses rectangular winding glass fiber reinforced plastic, which is manufactured by adopting a continuous winding process technology and has high interlayer bonding strength, so that the overall strength and rigidity of a glass fiber reinforced plastic pipe are stronger.

Owner:JIANGSU SHENJIANG ENVIRONMENT TECH

Machined terminal structure capable of preventing explosion of copper wire

InactiveCN107959164AHigh strengthNot easy to bend and breakRelieving strain on wire connectionCouplings bases/casesCopper wireEngineering

The invention relates to a machined terminal structure capable of preventing explosion of a copper wire. The machined terminal structure comprises a cable plug; the right side of the cable plug is provided with a connection part and a wrapping part which are integrally formed through mechanical stamping; an aluminum foil layer is arranged inside the sidewalls of the connection part and the wrapping part; and the outer side of the aluminum foil layer is provided with a steel wire layer. When the machined terminal structure is used, the connection part and the wrapping part which are integrallyformed through mechanical stamping have the advantages of high overall strength and low possibility of being bent and damaged; the aluminum foil layer can increase the axial tensile strength of the connection part and the wrapping part, the steel wire layer can increase the toughness of the connecting part and the wrapping part, and therefore, the problem of the fracture of a wire core caused by an excessively large bending angle can be effectively prevented; first bosses and second bosses can cooperate with each other so as to effectively fix and limit the position of the wire core, so that the fracture of the internal wire core caused by the pulling of a cable can be prevented; and third bosses and fourth bosses can effectively cooperate with each other, so that the problem of the exposure of the wire core (copper wire) caused by rubber sheath shrinkage can be prevented.

Owner:ZHONGSHAN FENGSHEN ELECTRICAL APPLIANCE CO LTD

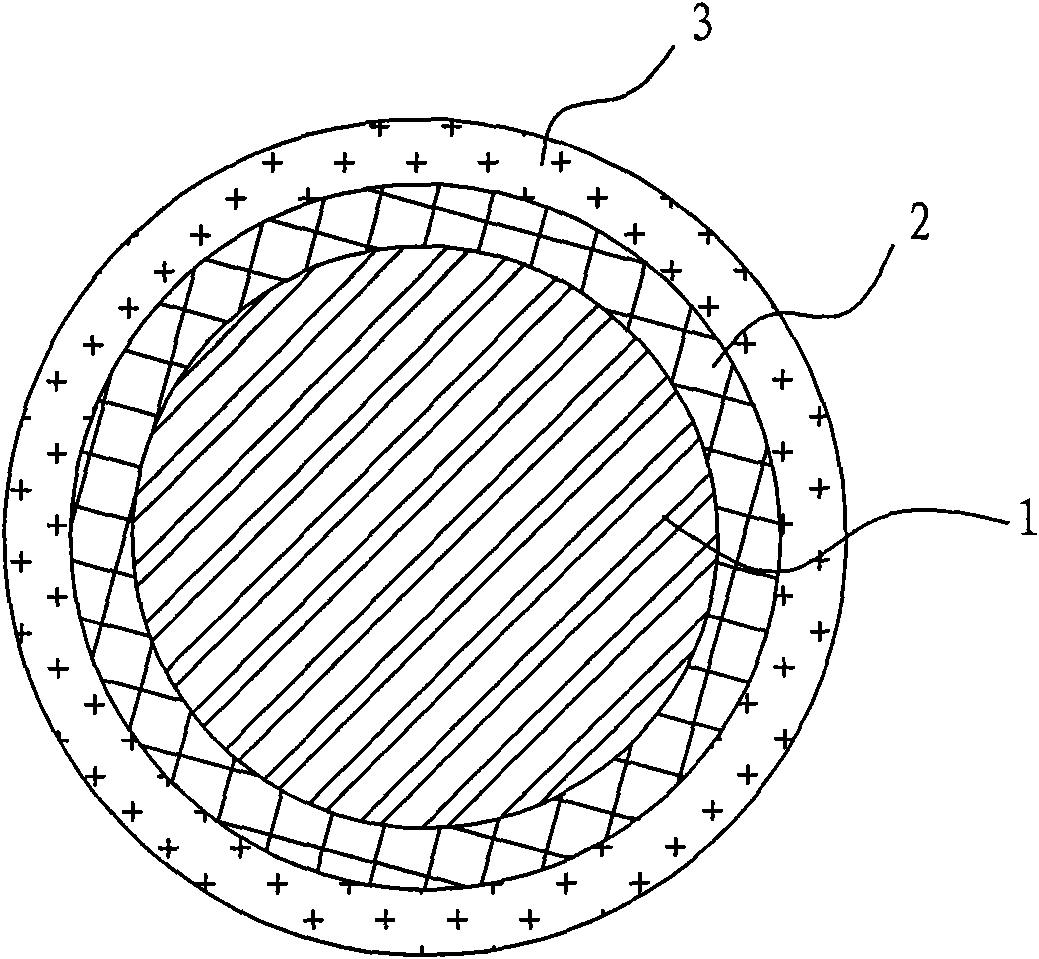

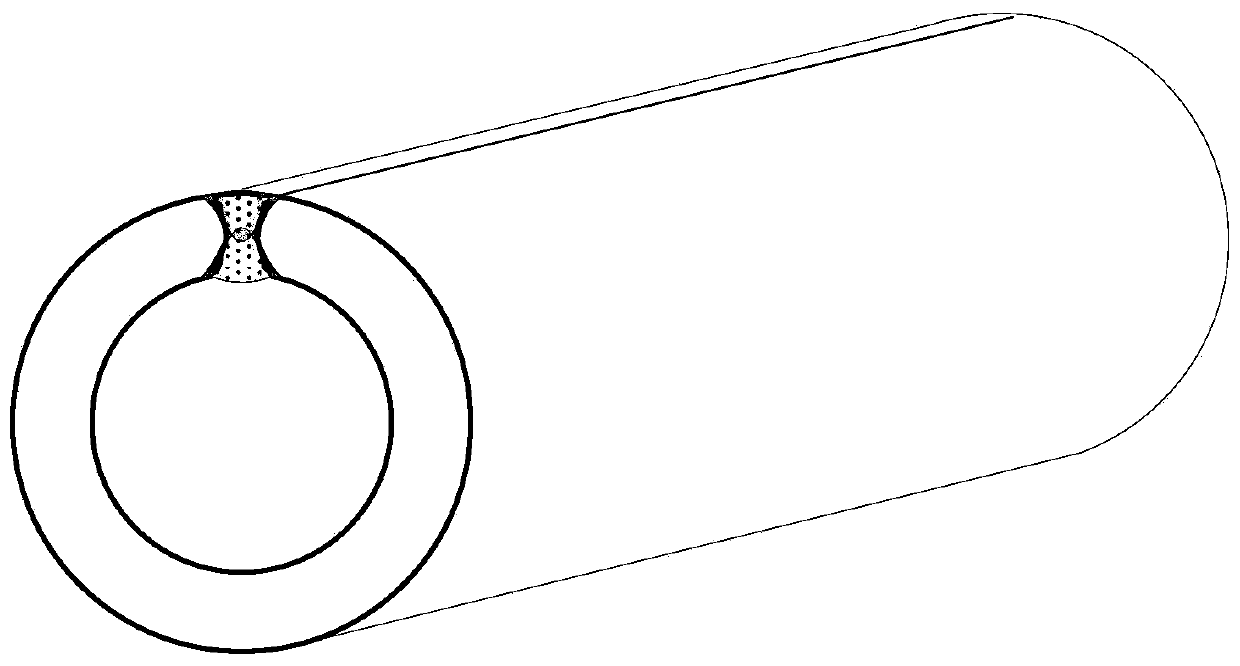

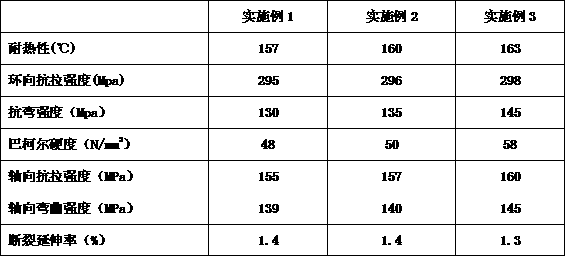

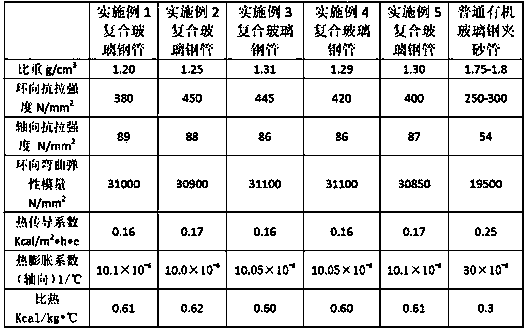

Compound glass steel tube and its preparing method

InactiveCN103292055BLow average specific gravityHigh strengthRigid pipesPipe protection against damage/wearGlass fiberHeat resistance

The invention discloses a compound glass steel tube. The tube wall of the compound glass steel tube is a four-layer compound structure comprising a lining layer, a toughening layer, a strengthening layer and a protecting layer sequentially from inside to outside. The lining layer is 0.6-2mm in thickness, the toughening layer is 0.6-2mm in thickness, the strengthening layer is 4-6mm in thickness, and the protecting layer is 0.6-2mm in thickness. The compound glass steel tube has the advantages of light weight: the average specific gravity of the compound glass steel tube is 30% lighter than that of normal glass fiber reinforced plastic; high strength: annular tensile strength and axial tensile strength of the compound glass steel tube are improved greatly and elasticity modulus is increased by 60%; good heat resistance: the axial heat expansion coefficient of the compound glass steel tube is 10x10<-6> / DEG C.

Owner:河北华强科技开发有限公司

Stainless steel corrugated hose connection device for gas transmission

The invention discloses a stainless steel corrugated hose connecting device for fuel gas transportation. The stainless steel corrugated hose connecting device for the fuel gas transportation comprises a corrugated hose and a plastic protective sleeve which is arranged on the corrugated hose in a sleeved mode. A plurality of gas-guiding grooves are evenly formed in the plastic protective sleeve. A straight through seat is arranged outside the plastic protective sleeve in a sleeved mode. A sealing ring is arranged between one end of the straight through seat and the plastic protective sleeve. Threads are formed in an inner circle of the other end of the straight through seat. A tool withdrawal groove is formed at the bottom of the threads. Four concave grooves are formed in the threads. A clamping ring is arranged on one side of the tool withdrawal groove, wherein the clamping ring is a metal ring which is divided into two pieces. A ditch groove is formed in an inner circle of the clamping ring. The ditch groove is matched with the corrugated appearance of the corrugated hose. Four bosses are arranged on an outer circle of the clamping ring. The bosses enter the tool withdrawal groove of the bottom of the threads through the four concave grooves, located at the place of the threads, of the straight through seat. A sealing mat is arranged on one side of the clamping ring. The stainless steel corrugated hose connecting device for the fuel gas transportation has the advantages of being convenient to install, high in axial tensile strength and good in sealing property. The stainless steel corrugated hose connecting device for the fuel gas transportation saves inner space and enables a corrugated hose with a larger outer diameter to be capable of adopting standard pipe threads.

Owner:HANGZHOU WANQUAN METAL HOSE

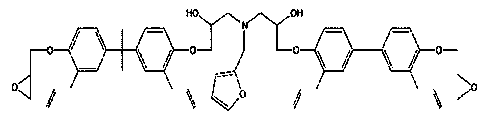

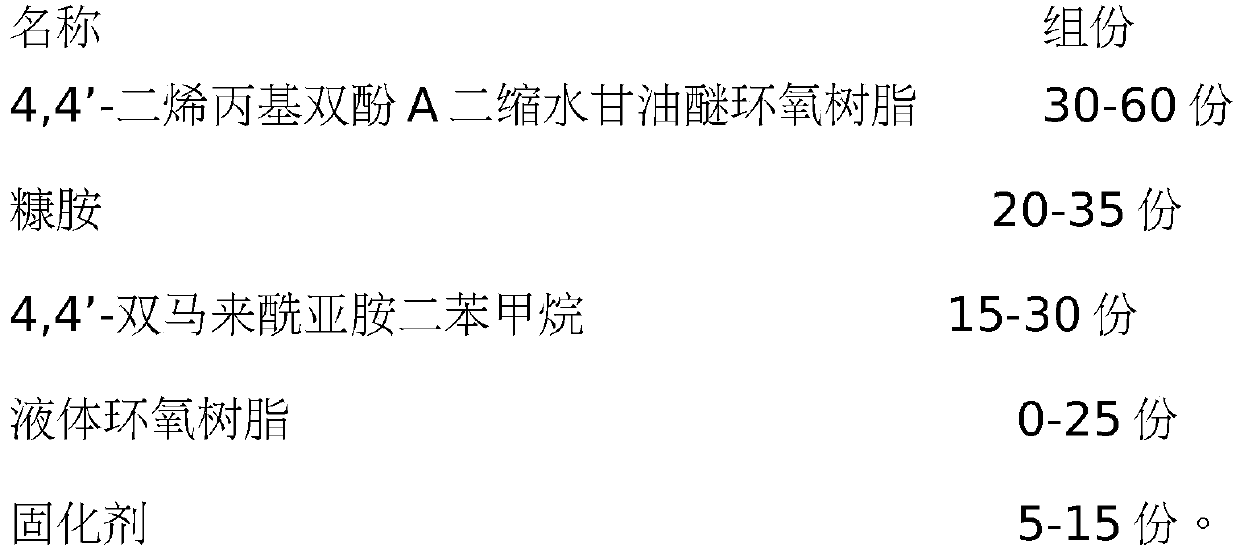

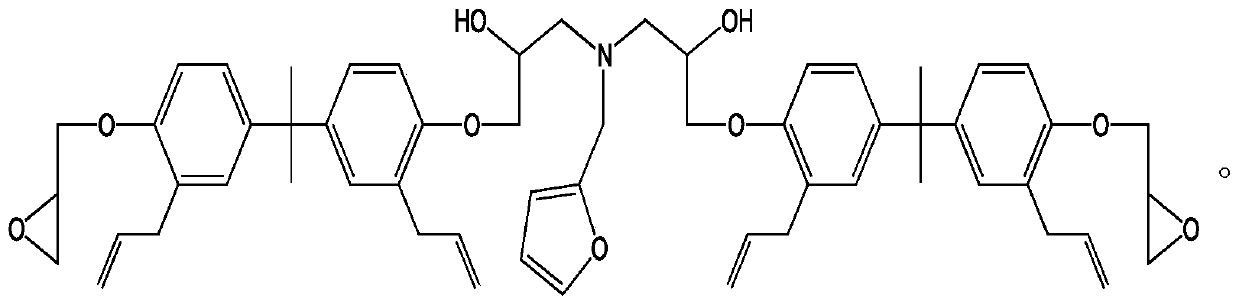

A reversible repair functional matrix resin for pultrusion and preparation method thereof

InactiveCN104194269BMeet the requirements of pultrusion processImprove axial tensile strengthDiphenylmethaneFuran

The invention discloses a reversible repair functional matrix resin for pultrusion and a preparation method of the matrix resin. The matrix resin is prepared from the following raw materials in parts by weight: 30-60 parts of 4,4'-diallylbisphenol A diglycidyl ether epoxy resin, 20-35 parts of furfuryl amine, 15-30 parts of 4,4'-bismaleimide diphenylmethane, 0-25 parts of liquid epoxy resin and 5-15 parts of curing agent. The preparation method comprises the following steps: dissolving the 4,4'-diallylbisphenol A diglycidyl ether epoxy resin in a formula amount into a solvent, slowly adding the furfuryl amine into a reaction container for reacting, adding the 4,4'-bismaleimide diphenylmethane, liquid epoxy resin and curing agent, reacting and mixing for a hour, performing reduced pressure distillation to remove the solvent, and cooling. The reversible repair functional matrix resin for pultrusion and the preparation method of the matrix resin disclosed by the invention have the beneficial effects that the matrix resin has good molding manufacturability, the molecular structure contains furan and imide structures, the heating and repairing functions of the prepared composite material can be realized by virtue of a Diels-Alder reversible reaction, and the matrix resin also has the advantages of high strength and high heat resistance.

Owner:HAIAN INST OF HIGH TECH RES NANJING UNIV

A Structure for Strengthening the Signal and Data Pipeline of Ultragravity Centrifuge

The invention discloses a structure for reinforcing a signal data pipeline of a hypergravity centrifuge. The reinforcing structure is installed on the high-speed rotating arm of the hypergravity centrifuge. The reinforcing structure is installed on the top surface of the high-speed rotating arm. Various pipelines are fixed in the reinforcing structure. The reinforcing structure comprises structural units which are symmetrically arranged on the upper side and the lower side of each pipeline and reinforcing carbon fiber composite layers which are arranged outside the structural units. The structural units on the upper side and the lower side wrap the upper sides and the lower sides of the pipelines respectively. The inner concave parts of the structural units between every two adjacent pipelines are filled up by the reinforcing carbon fiber composite layers. The structural units and the reinforcing carbon fiber composite layers are formed by stacking multiple carbon fiber composite material layers of different fiber arrangements. The signal data line reinforcing structure can overcome the huge pulling force caused by the high-speed rotation of the hypergravity centrifuge in the usingprocess, and prevents the signal data line from being thrown out and broken under the high-speed operation of the centrifuge. The signal data line is fixed firmly and has simple structure.

Owner:ZHEJIANG UNIV

Composite core used for reinforced cable and reinforced cable

InactiveCN102110491BHigh tensile strengthSolve the problem of no transverse fiber reinforcementNon-insulated conductorsInsulated cablesFiberOptoelectronics

The invention relates to a composite core used for a reinforced cable. The composite core comprises an inner core, a structural layer and an outer layer, wherein the inner core comprises fibers and thermosetting resins; the structural layer comprises a fiber sleeving and the thermosetting resins; the fiber sleeving is formed by braiding a plurality of fibers or spirally winding the fibers along the axial direction of the inner core; and the outer layer comprises fibers arranged along the length direction of the composite core and the thermosetting resins. The composite core provided by the invention has the following beneficial effects: the outer layer is added outside the structural layer and the continuous fibers arranged along the length direction of the composite core are added to theouter layer; and the added outer layer wholly covers the structural layer 2 and provides protection to the fiber sleeving in the structural layer 2, under the condition that the composite core is subjected to great tension, the stretch and extension rates of the outer layer 3 and the inner core 1 are basically the same and the extension quantities of the outer layer 3 and the inner core 1 are synchronous, and the structural layer is tightly squeezed by the inner core and the outer layer so that the structural layer in the middle is not easy to drop or separate, thus effectively overcoming thedefect that the composite core adopts the fiber sleeving structure.

Owner:JIANGSU JIATAI TECH MATERIAL

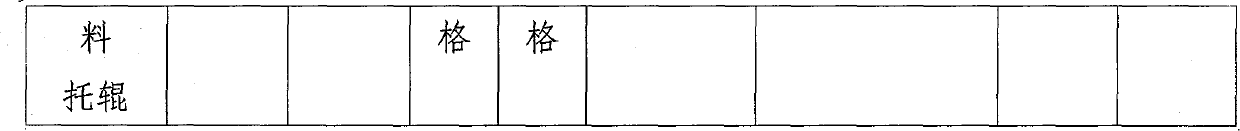

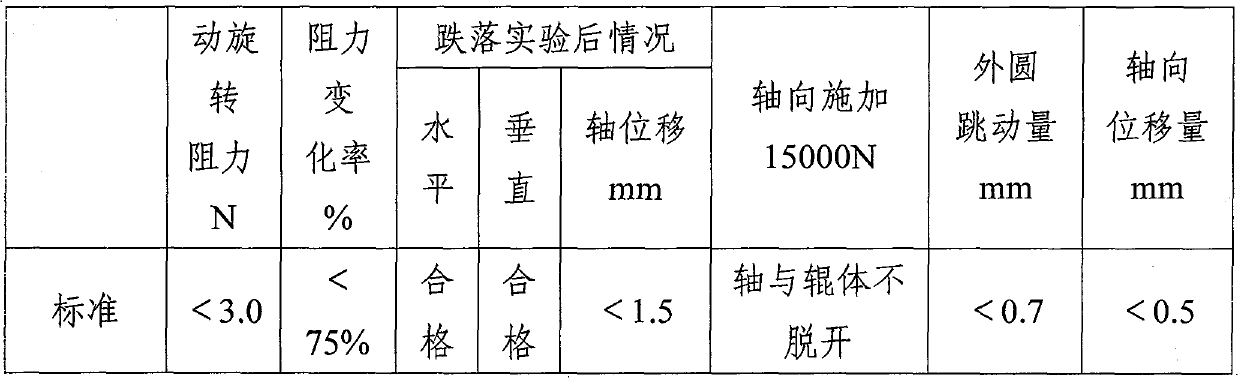

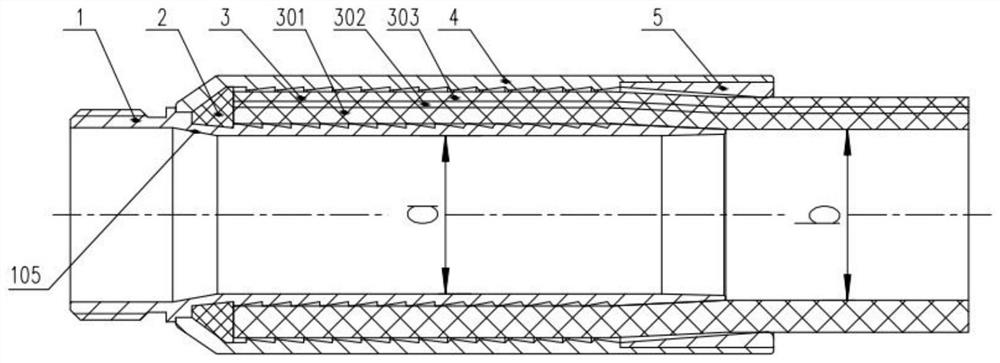

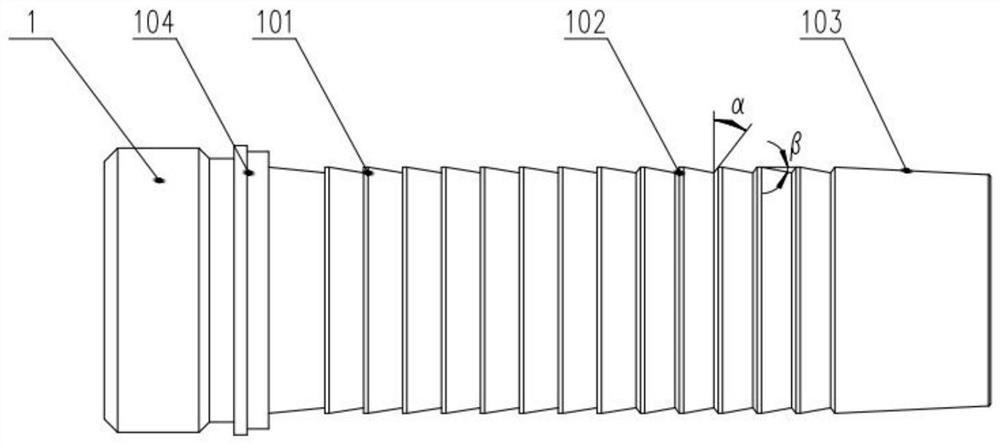

Glass/aluminum-base composite material support roller

The invention discloses a idler roller prepared by glass / aluminum matrix composite, comprising two bearings, two bearing chocks, a roller and an axis, the bearing chock and the roller are prepared by glass / aluminum matrix composite, the components of the glass / aluminum matrix composite and the weight percentage of each component are that: glass 7-30%, Aluminum 64-90%, crystal silicon 3-6%, the sum of the three is 100%. The glass / aluminum matrix composite idler roller, which is processed by the preparation technology of secondary hot extrusion and drawing, has the advantages of good comprehensive properties, i.e. low density, good conductivity, higher intensity and stiffness than rubber and plastic idler rollers and good anti-wear properties, more wear-resistance than the rubber and plastic idler rollers, not only greatly saving the energy consumption, reducing the cost, but also avoiding the occurrence of safety accident.

Owner:上海华威环保技术有限公司

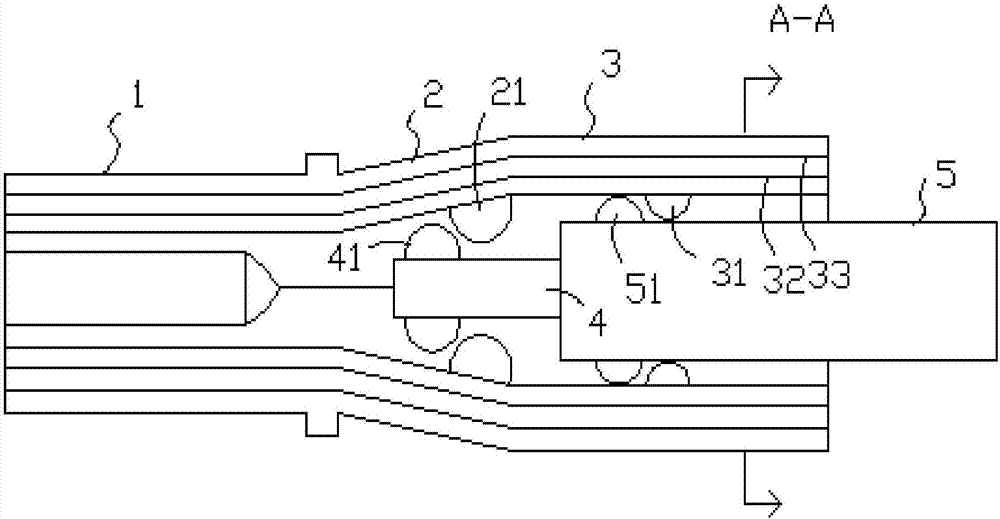

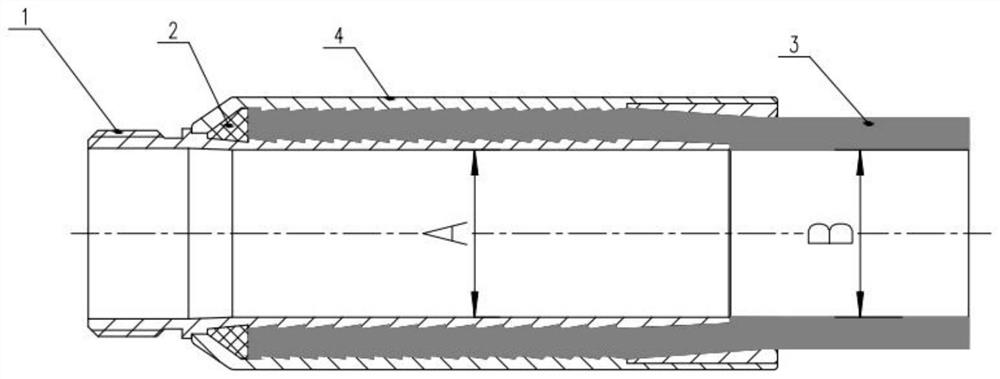

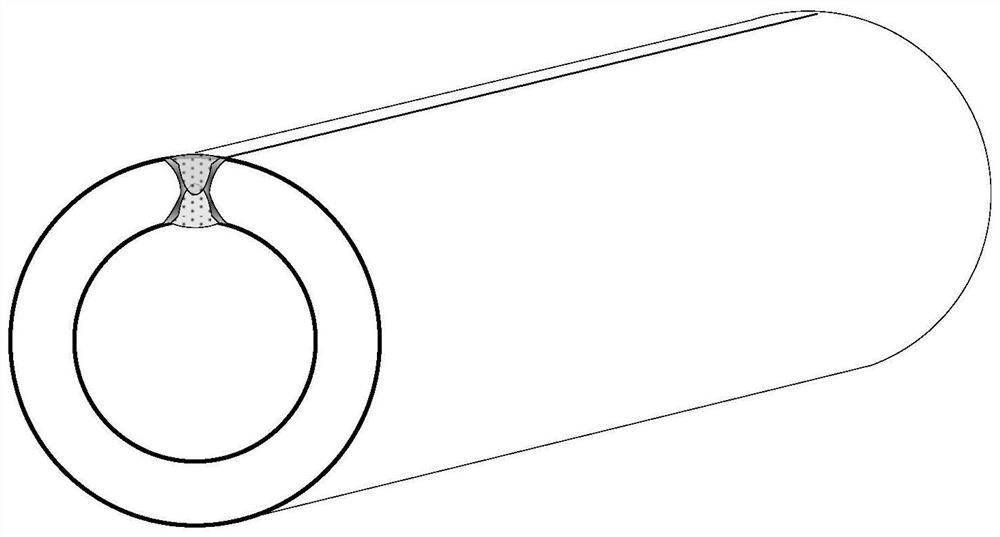

Composite pipe full-bore high-pressure connecting structure and connecting method thereof

PendingCN114877151AEasy to operateImprove sealingPipe connection arrangementsPipe fittingEngineering

The invention discloses a composite pipe full-bore high-pressure connecting structure and a connecting structure thereof. The composite pipe full-bore high-pressure connecting structure comprises a pipe fitting core pipe, a pipe fitting outer sleeve arranged on the periphery of the pipe fitting core pipe and a composite pipe arranged between the pipe fitting outer sleeve and the pipe fitting core pipe. A set of outer ring teeth are arranged on the outer surface of the pipe fitting core pipe in the axial direction, a set of inner ring teeth corresponding to the outer ring teeth are arranged on the inner surface of the pipe fitting outer sleeve in the axial direction, a conical surface structure is arranged at one end of the pipe fitting core pipe, and the composite pipe is inserted between the pipe fitting outer sleeve and the pipe fitting core pipe from one end of the conical surface structure of the pipe fitting core pipe. And the section, wrapping the pipe fitting core pipe, of the composite pipe forms a flaring section. According to the connecting structure, only internal expansion is needed, the internal expansion mold is pulled out of the pipe fitting core pipe, the pipe fitting core pipe is expanded outwards, plastic deformation occurs, and internal expansion is completed. Complicated processes such as external buckling are not needed, and connection operation is convenient.

Owner:LINHAI WEIXING NEW BUILDING MATERIALS CO LTD

A high-strain welded steel pipe for marine use based on a dual-phase structure and its preparation method

ActiveCN110000517BHigh strengthEnhance resilienceArc welding apparatusMarine engineeringDouble phase

The invention discloses a marine high-strain welded steel pipe based on a double-phase structure and a preparing method thereof. The marine high-strain welded steel pipe is made by a wide and thick steel plate having the double-phase structure, the steel grade of the high-strain welded steel pipe is L485MO, the thickness is larger than or equal to 25.4mm, the width of the steel plate is pi(1-epsilon)D-2t, D refers to the outer diameter of the steel pipe, t refers to wall thickness, epsilon refers to a cold expanding rate, the radius-to-thickness ratio is smaller than or equal to 30, the yield-to-strength ratio Rt0.5 / Rm is smaller than or equal to 0.85, A is larger than or equal to 25%, and UEL is larger than or equal to 7%. The manufactured steel pipe has the characteristics of high strength, high tenacity, high strain capability, low yield-to-strength ratio, low strain aging influence, H2S corrosion resistance, large wall thickness, small radius-thickness ratio, high diameter precision, small outer diameter error and small out-of-roundness error, can fully meet the technical requirements of marine service on the high-strain thick-walled delivery steel pipe, can be used for deep-sea oil and gas exploitation and saves marine development cost.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

A large-size aluminum-steel reaction-assisted thermal toughening friction welding method

ActiveCN113967784BGrain refinementImprove toughnessNon-electric welding apparatusFriction weldingUltimate tensile strength

Owner:NO 59 RES INST OF CHINA ORDNANCE IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com