Compound glass steel tube and its preparing method

A glass steel pipe, layer composite technology, applied in the direction of pipes, rigid pipes, pipeline protection, etc., to achieve the effects of increased axial tensile strength, good heat resistance, and good heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

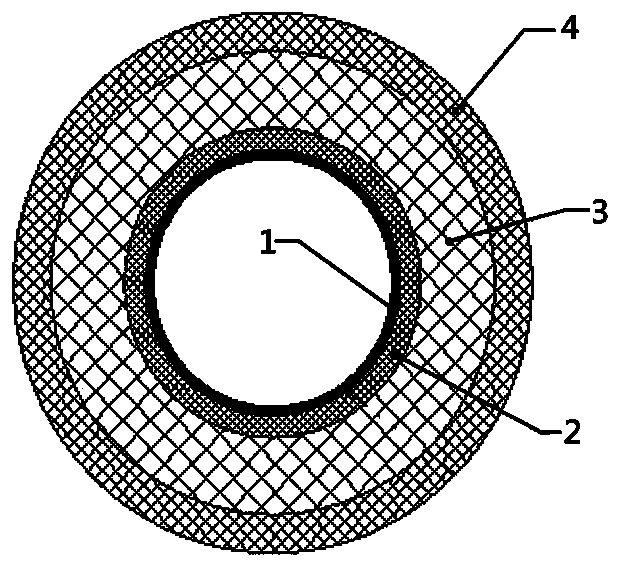

[0036] Such as figure 1 , the present invention is the lining layer 1, the toughening layer 2, the reinforcement layer 3 and the protection layer 4 from the inside to the outside, and each layer is a composite structure formed by different reinforcing materials and slurries:

[0037] a) Make the lining layer on the pipe body mold:

[0038] Weigh 100kg of E51 epoxy resin, 30kg of acetone, and 7kg of methyl ethyl ketone peroxide (No. 5 curing agent), fully stir and mix, and make a lining slurry for later use;

[0039] Brush a layer of 0.1mm thick inner lining slurry on the pipe body mold coated with mold release agent, wind a layer of polyester cloth with a mesh grid with a thickness of δ=0.1mm and a width of 20-30cm, repeat this The steps are operated 3 times to make a 0.6mm thick lining layer.

[0040] b) Make a toughening layer on the surface of the inner liner:

[0041] Add 4kg of methyl ethyl ketone peroxide into 100kg of 189# unsaturated polyester resin and stir, and af...

Embodiment 2

[0053] a) Make the lining layer on the pipe body mold:

[0054] Weigh 100kg of E44 epoxy resin, 50kg of acetone, and 8kg of dibenzoyl peroxide curing agent, fully stir and mix, and make a lining slurry for subsequent use;

[0055] Brush a layer of 0.2mm thick inner lining slurry on the pipe body mold coated with mold release agent, wind a layer of polyester cloth with a mesh grid with a thickness of δ=0.13mm and a width of 20-30cm, repeat this The steps are operated twice to make a 0.66mm thick lining layer.

[0056] b) Make a toughening layer on the surface of the inner liner:

[0057] The dibenzoyl peroxide of 3kg is added in the 189# unsaturated polyester resin of 100kg and stirs, and after the reaction is stable, add the diethylaniline promotor of 2kg, fully stir and mix, make toughening slurry for subsequent use;

[0058] Coat a layer of polyurethane adhesive with a thickness of 0.1mm on the surface of the inner lining layer;

[0059] Brush a layer of toughening slurry...

Embodiment 3

[0069] a) Make the lining layer on the pipe body mold:

[0070] Weigh 100kg of E51 epoxy resin, 35kg of acetone, and 7.2kg of cyclohexanone peroxide curing agent, fully stir and mix, and make a lining slurry for subsequent use;

[0071] Brush a layer of 0.5mm thick inner lining slurry on the pipe body mold coated with mold release agent, wind a layer of polyester cloth with a mesh grid with a thickness of δ=0.15mm and a width of 20-30cm, repeat this The step is operated 3 times to make a 1.95mm thick lining layer.

[0072] b) Make a toughening layer on the surface of the inner liner:

[0073] Add 2kg of methyl ethyl ketone peroxide into 100kg of 189# unsaturated polyester resin and stir, add 2kg of diethylaniline accelerator after the reaction is stable, fully stir and mix, and make a toughening slurry for subsequent use;

[0074] Coat a layer of polyurethane adhesive with a thickness of 0.1mm on the surface of the inner lining layer;

[0075] Brush a layer of toughening sl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com