Composite core used for reinforced cable and reinforced cable

A composite material core and cable technology, which is applied in the direction of insulating cables, cables, circuits, etc., can solve the problems that the effect of the transverse fibers of the fiber casing is not fully utilized, the tensile strength of the composite core is reduced, and the quality is not suitable for control, so as to achieve tensile strength. And high elastic modulus, improve fatigue strength and fatigue resistance, not easy to fall off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

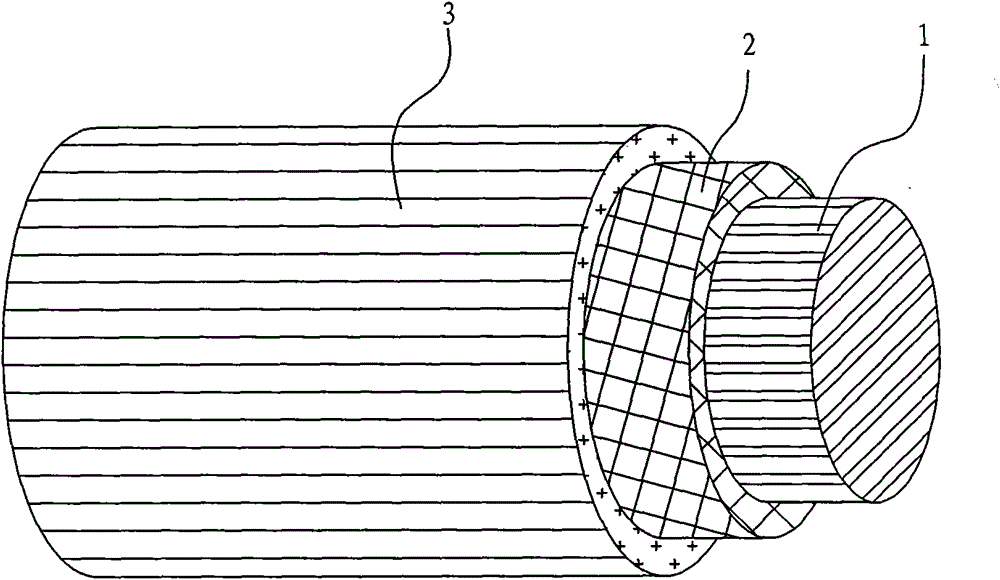

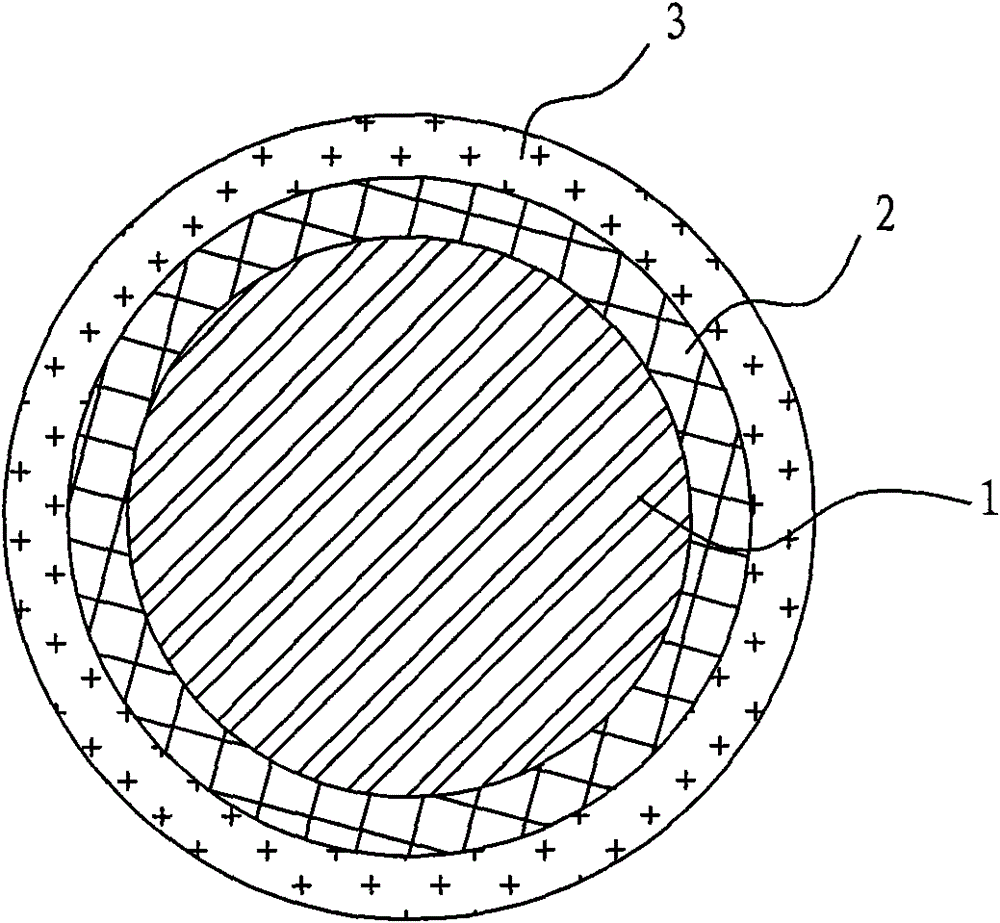

Embodiment 1

[0052] Embodiment 1: The inner core 1 uses 72 carbon fibers of 12K, the fiber diameter is 7 microns, and the tension is controlled with an adjustable tension frame, so that the tension of the carbon fibers is basically the same; the structural layer 2 is braided with 24 bundles of glass fibers. The glass fibers are 90 pieces and 4 strands; a 24-spindle horizontal braiding machine is used; 28 1200Tex glass fibers are used for the outer layer 3, and modified epoxy resin is used as the thermosetting resin, and the glass transition temperature Tg is about 210 °C. Curing agent, imidazole accelerator. Proportion of epoxy resin: modified epoxy resin: modified anhydride: 1-methylimidazole: zinc stearate=100:100:2:2. The sum of the fiber weights of the carbon fibers in the inner core 1, the fiber braided tubes in the structural layer 2 and the glass fibers in the outer layer 3 accounts for about 80% of the total weight of the composite core.

[0053] Use this ratio to select materials...

Embodiment 2

[0054] Embodiment 2: The inner core 1 uses 36 12K carbon fibers with a fiber diameter of 7 microns, and uses an adjustable tension frame to control the tension so that the carbon fiber tension is basically consistent; Fiber braiding, each bundle of glass fibers is 120 two strands; a 16-spindle horizontal braiding machine is used; 20 600Tex basalt fibers are used for the outer layer 3, and epoxy resin is used as the thermosetting resin, and the glass transition temperature Tg is about 180°C. Use acid anhydride curing agent and imidazole as accelerator. Proportion of epoxy resin: modified epoxy resin: methyltetrahydrophthalic anhydride: 1-methylimidazole: zinc stearate = 100:90:1.5:2. The sum of the fiber weights of the carbon fibers in the inner core 1 and the basalt fibers in the structural layer 2 and the basalt fibers in the outer layer 3 accounts for about 70% of the total weight of the composite core.

[0055] Use this ratio to select materials to manufacture a composite ...

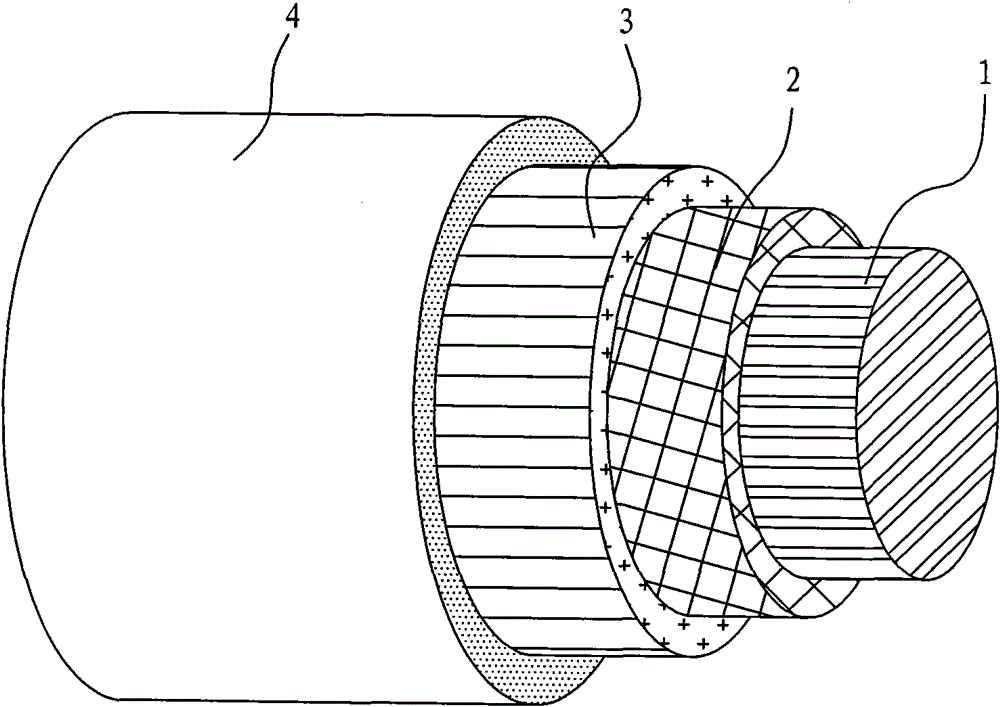

Embodiment 3

[0056] Example 3: The inner core 1 uses 75 12K carbon fibers with a fiber diameter of 7 microns, the structural layer 2 uses 24 bundles of basalt fibers to weave, each bundle of fibers is 90 four strands, and the outer layer 3 uses 100 Kevlar49 aramid fibers. The second structure layer 2' uses 36 bundles of glass fiber to weave, each bundle of glass fiber is 80 pieces and 6 strands, the second outer layer 3' uses 40 1200Tex glass fibers, and uses an adjustable tension frame to control the tension, so that carbon fiber, aramid fiber The tension of the fiber and the glass fiber is basically the same; the thermosetting resin is epoxy resin, the glass transition temperature Tg is about 200 ℃, and the acid anhydride curing agent and imidazole are used as accelerators. Epoxy resin ratio: modified epoxy resin: modified anhydride: 1-methylimidazole: zinc stearate: 12-14 alkyl glycidyl ether = 100:100:1.6:2:5. The sum of the fiber weights of the carbon fibers in the inner core 1, the b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com