Rectangular winding glass fiber reinforced plastic

A fiberglass and rectangular technology, applied in the direction of glass/slag layered products, coatings, layered products, etc., can solve the problems of low rigidity, high construction requirements, large deformation, etc., and achieve high strength, high interlayer bonding strength, light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

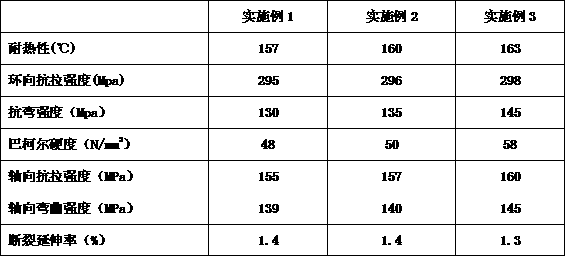

Embodiment 1

[0043]A rectangular winding FRP, the FRP is sequentially provided with a FRP inner lining layer, a FRP winding layer and an FRP outer protective layer from the inside to the outside, and the FRP inner lining layer includes a grid cloth layer, a glass fiber surface felt layer through the inner lining Layers of slurry are soaked and bonded. The FRP winding layer is composed of multi-layer winding layers and non-alkali cloth at intervals. Bonded; the winding layer includes long-cut glass fibers impregnated with toughening slurry, chopped glass fibers impregnated with reinforcing slurry, and roving impregnated with reinforcing slurry for textile winding Winding layer; the non-alkali cloth is the non-alkali cloth impregnated with the reinforcing slurry.

[0044] The inner liner slurry is made of the following raw materials in parts by weight: 80 parts of vinyl resin, 80 parts of epoxy vinyl ester resin, 5 parts of curing agent, 6 parts of accelerator, 20 parts of glycerin, 16 parts...

Embodiment 2

[0079] A rectangular winding FRP, the FRP is sequentially provided with a FRP inner lining layer, a FRP winding layer and an FRP outer protective layer from the inside to the outside, and the FRP inner lining layer includes a grid cloth layer, a glass fiber surface felt layer through the inner lining Layers of slurry are soaked and bonded. The FRP winding layer is composed of multi-layer winding layers and non-alkali cloth at intervals. Bonded; the winding layer includes long-cut glass fibers impregnated with toughening slurry, chopped glass fibers impregnated with reinforcing slurry, and roving impregnated with reinforcing slurry for textile winding Winding layer; the non-alkali cloth is the non-alkali cloth impregnated with the reinforcing slurry.

[0080] The inner liner slurry is made of the following raw materials in parts by weight: 90 parts of vinyl resin, 60 parts of epoxy vinyl ester resin, 10 parts of curing agent, 2 parts of accelerator, 30 parts of glycerin, 10 par...

Embodiment 3

[0115] A rectangular winding FRP, the FRP is sequentially provided with a FRP inner lining layer, a FRP winding layer and an FRP outer protective layer from the inside to the outside, and the FRP inner lining layer includes a grid cloth layer, a glass fiber surface felt layer through the inner lining Layers of slurry are soaked and bonded. The FRP winding layer is composed of multi-layer winding layers and non-alkali cloth at intervals. Bonded; the winding layer includes long-cut glass fibers impregnated with toughening slurry, chopped glass fibers impregnated with reinforcing slurry, and roving impregnated with reinforcing slurry for textile winding Winding layer; the non-alkali cloth is the non-alkali cloth impregnated with the reinforcing slurry.

[0116] The inner liner slurry is made of the following raw materials in parts by weight: 88 parts of vinyl resin, 70 parts of epoxy vinyl ester resin, 5 parts of curing agent, 4 parts of accelerator, 25 parts of glycerin, 13 part...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com