Formula of highly anti-fatigue automobile brake chamber rubber diaphragm material

A technology of automobile brake and rubber diaphragm, applied in the field of automobile brake air chamber rubber diaphragm, can solve the problem of low fatigue resistance and other problems, and achieve the effects of strong rigidity, good chemical resistance and small wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

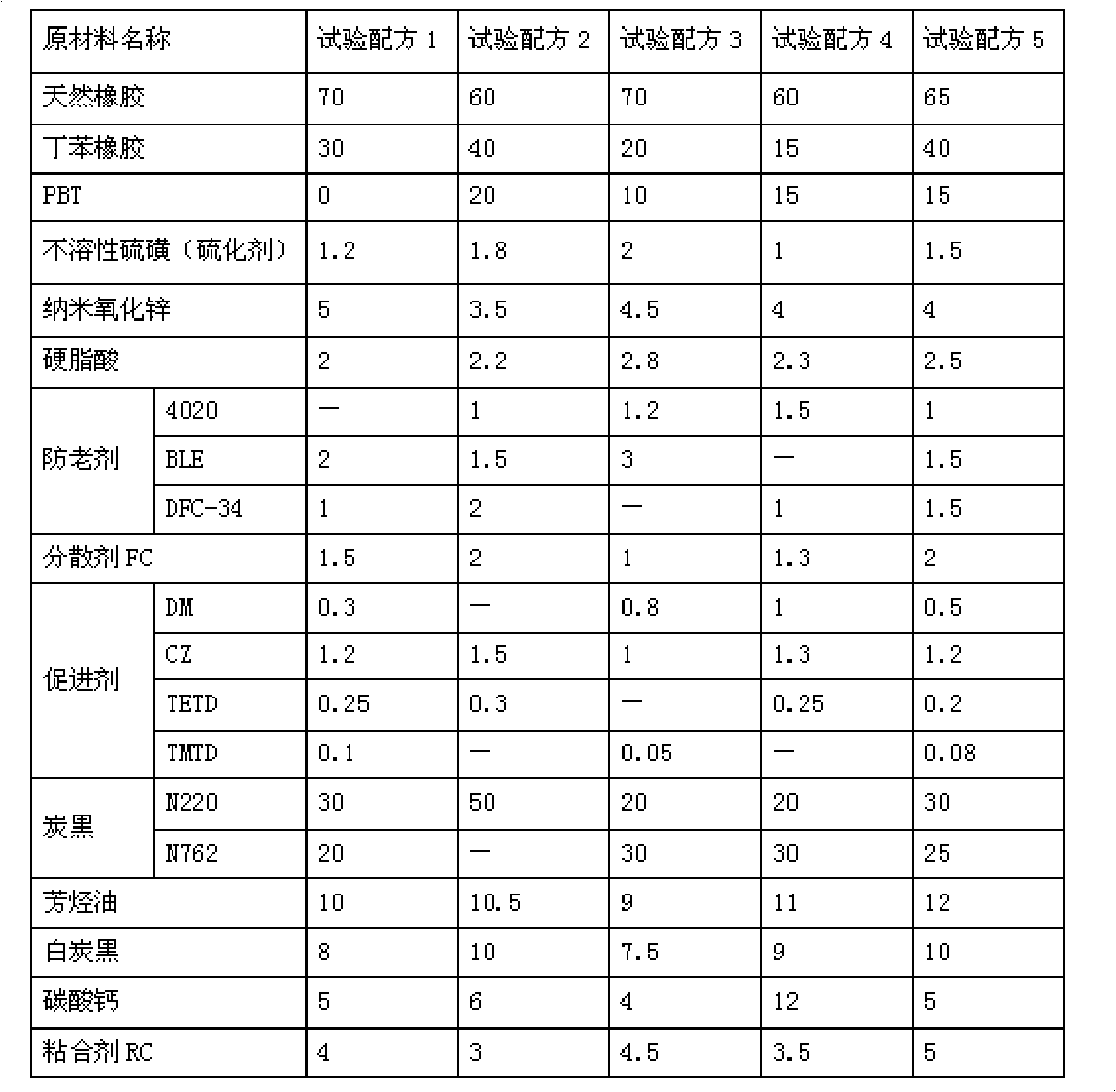

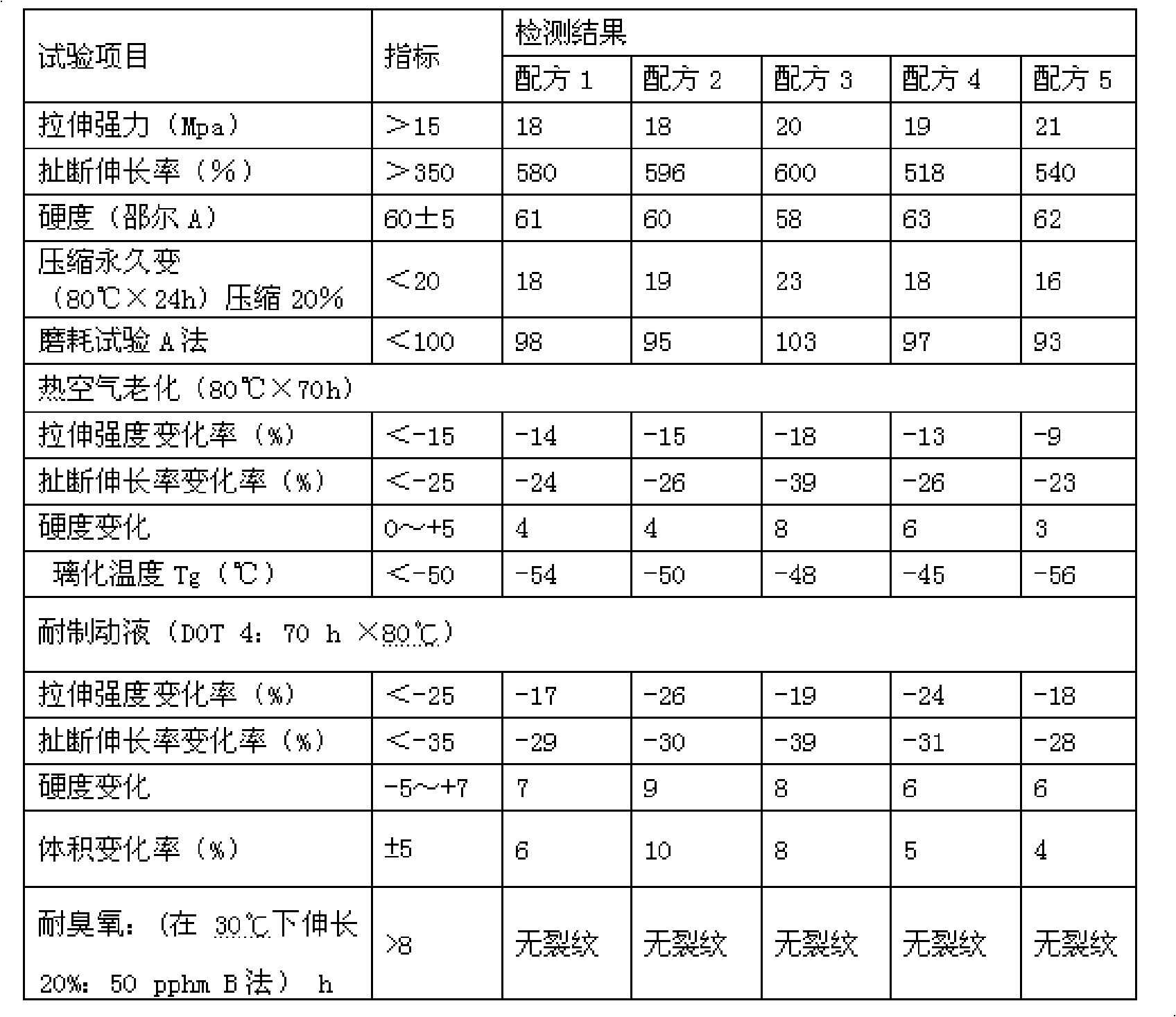

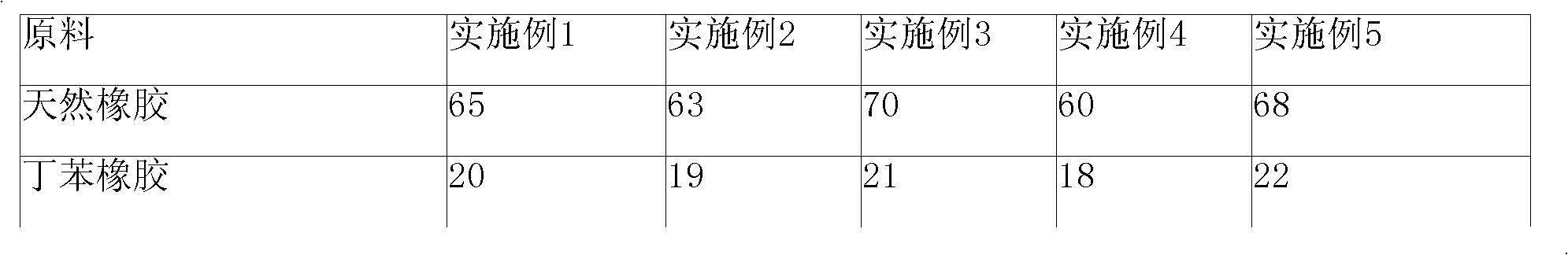

[0025] Raw materials: according to the proportioning of the following embodiments, the prescription is carried out: (unit: kilogram)

[0026]

[0027]

[0028] Preparation method: take the blending system of natural rubber, styrene-butadiene rubber and PBT as the main body, add auxiliary materials, and use a high-temperature internal mixer for two-stage mixing. The details are as follows:

[0029] 1. Preplasticization of PBT

[0030] Weigh the PBT and dispersant according to the formula in the above table, stir them evenly, put them in an oven, and plasticize at 160°C for 2 hours to fully disperse the PBT and achieve the purpose of pre-plasticization.

[0031] 2. Plasticizing of PBT

[0032] Raise the temperature of the rollers of the double-roller mill to 150-160°C, reduce the roller distance, add pre-plasticized PBT powder, and then start plasticating until the PBT is a uniform transparent film, then make five triangular bags for the next sheet, Go to the next step o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com