Machined terminal structure capable of preventing explosion of copper wire

A technology of mechanical processing and terminal structure, which is applied to the device for reducing stress at the connection of wires, parts of the connection device, electrical components, etc. It can solve the problems of easy exposure of wire cores and easy breakage of wire cores, so as to prevent bending and damage , prevent fracture, increase toughness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

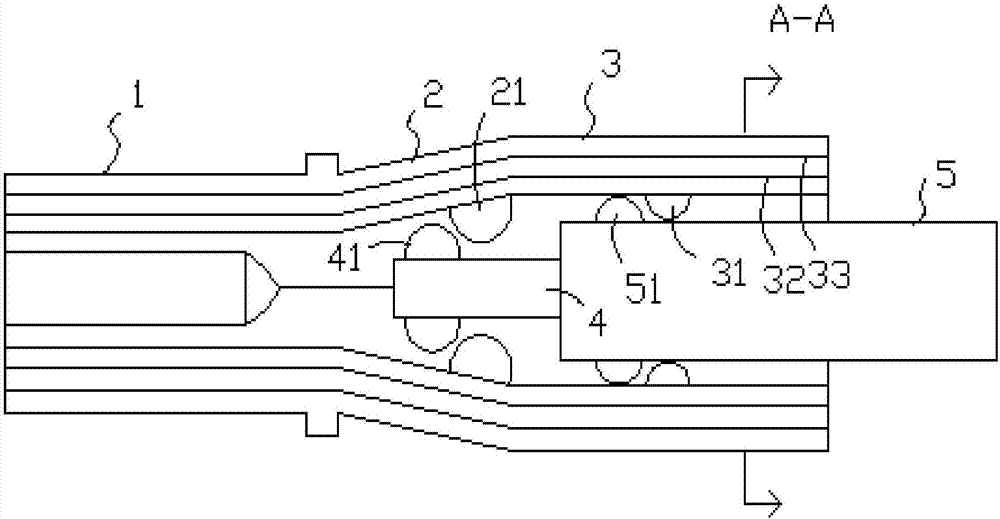

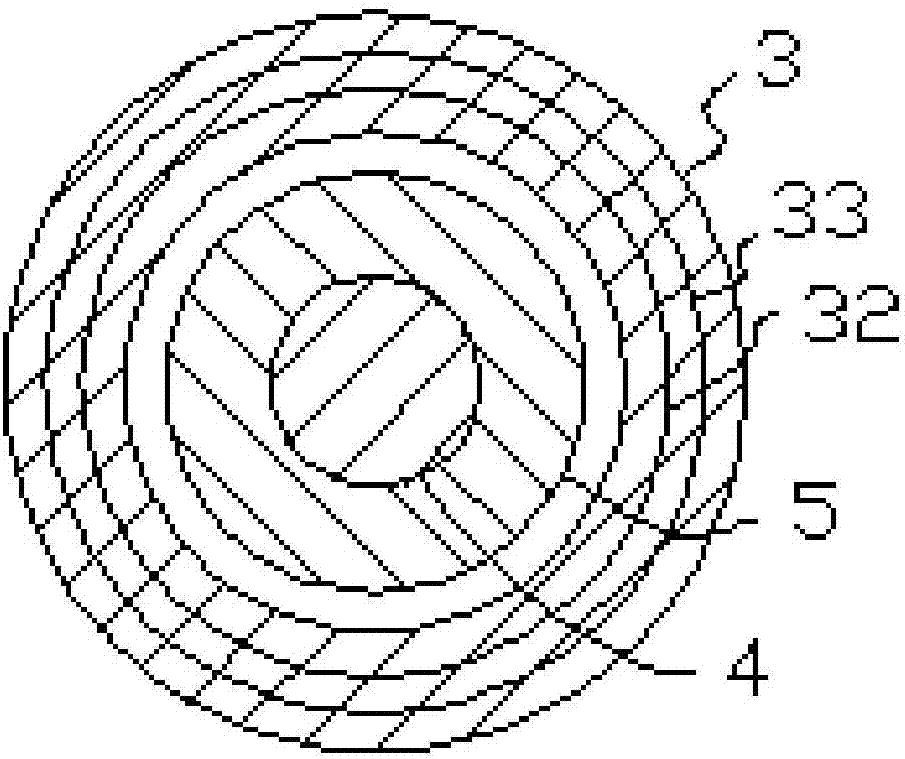

[0013] Such as figure 1 , figure 2 As shown, a mechanically processed terminal structure that can prevent copper wires from being exposed, the structure includes a cable plug 1, and the right side of the cable plug 1 is sequentially provided with a connecting part 2 and a wrapping part 3 integrally formed by mechanical stamping. An aluminum foil layer 32 is provided inside the side walls of the connecting part 2 and the wrapping part 3 , and a steel wire layer 33 is provided outside the aluminum foil layer 32 . When in use, the integrally formed connecting part and wrapping part by mechanical stamping has the advantages of high overall strength and is not easy to be bent and damaged, and the aluminum foil layer can increase the axial tensile strength of the connecting part and wrapping part, and the steel wire rope can increase the strength of the connecting part and wrapping part. The internal toughness can effectively prevent the wire core from being broken due to excessiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com