Patents

Literature

135 results about "Roundness error" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

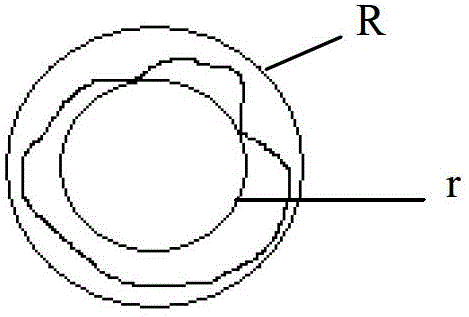

An example of a more complex roundness error is called lobing, which is an unintended form error from a centerless grinding operation. Roundness callouts on drawings have no reference to a datum, asroundness does not relate to the cross -section’s location on the part. is the 3D version of roundness.

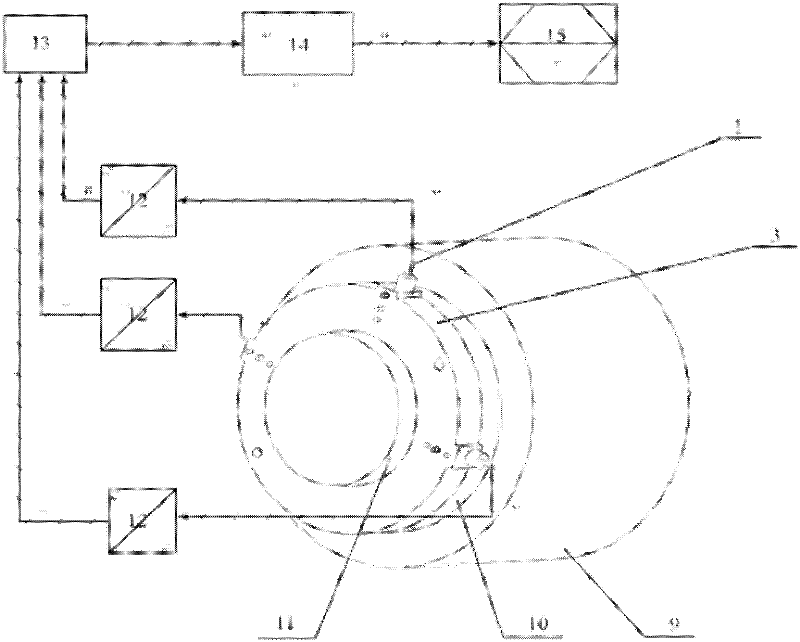

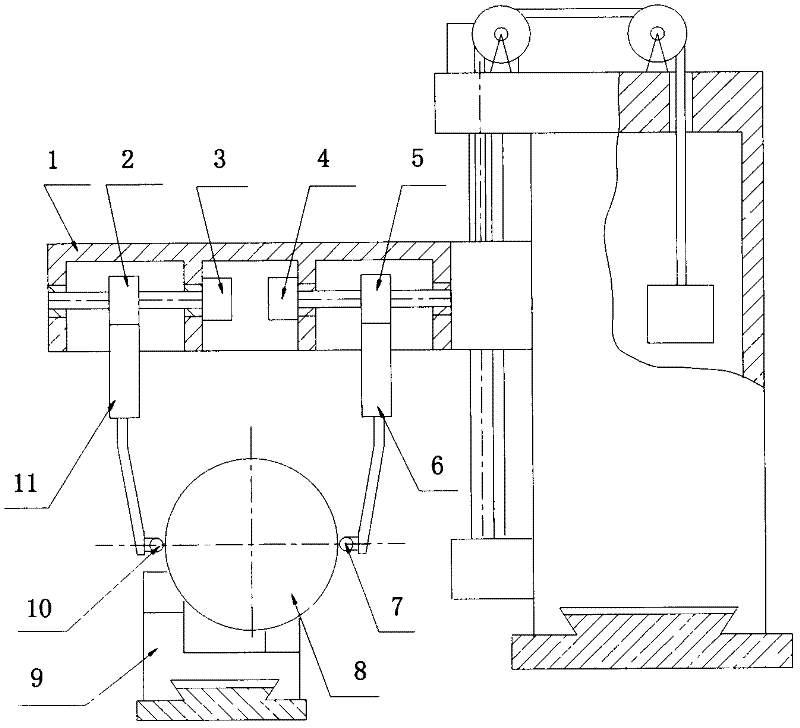

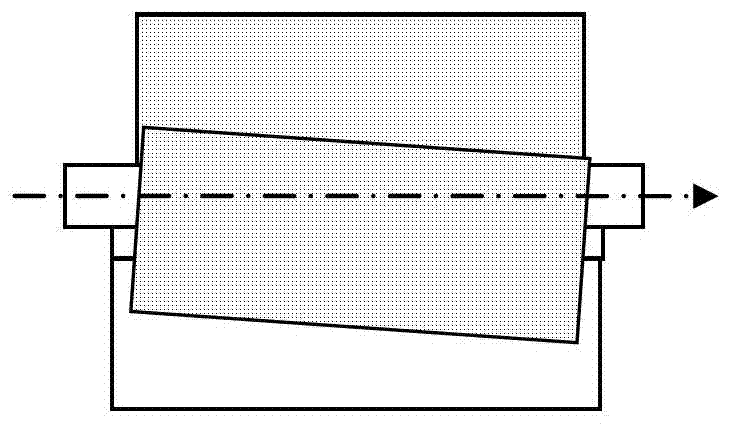

Online monitoring device for radial rotation accuracy of main shaft

ActiveCN102501137AReal-time online monitoringAccurate rotation accuracyMeasurement/indication equipmentsSeparation technologyData acquisition

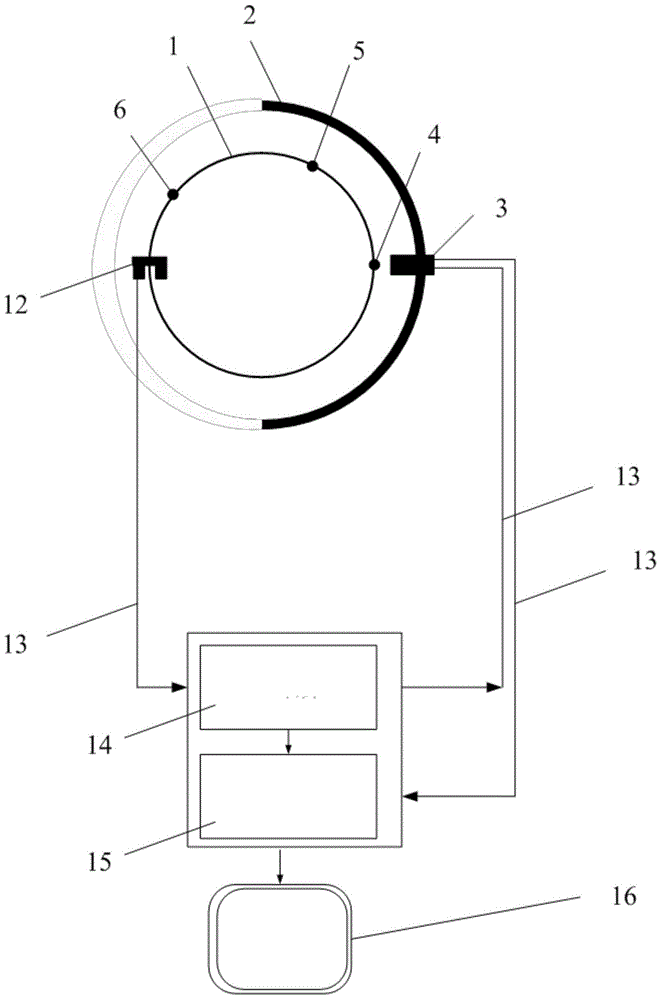

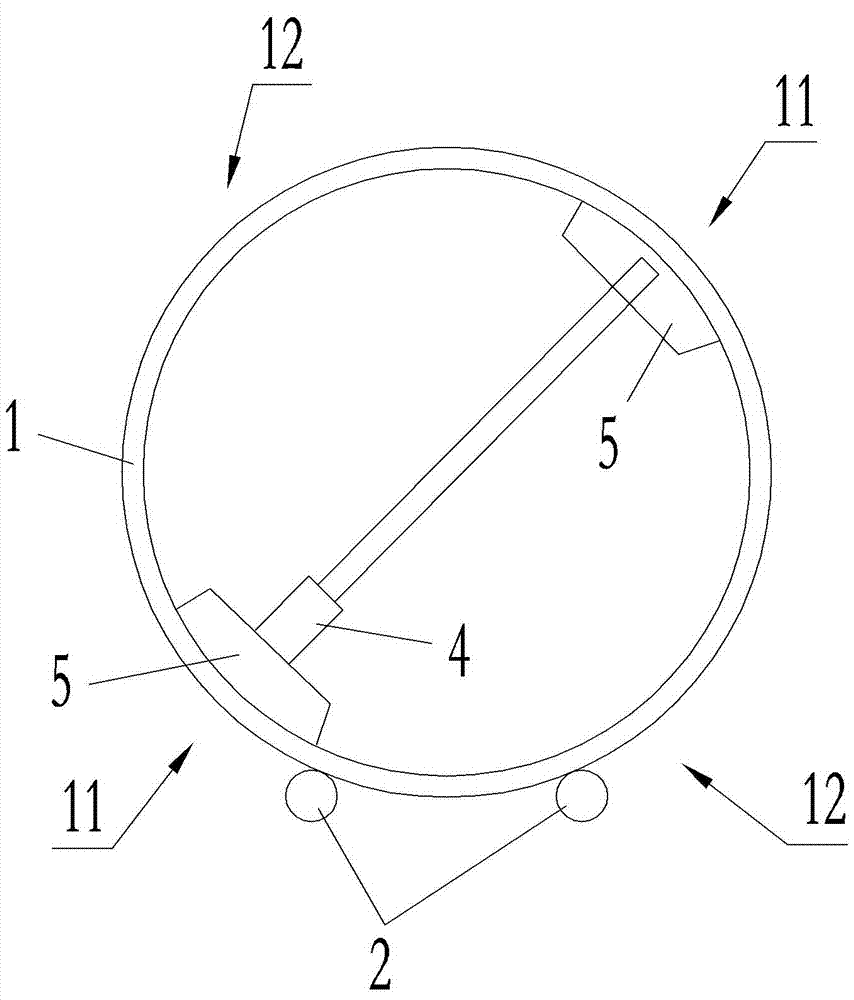

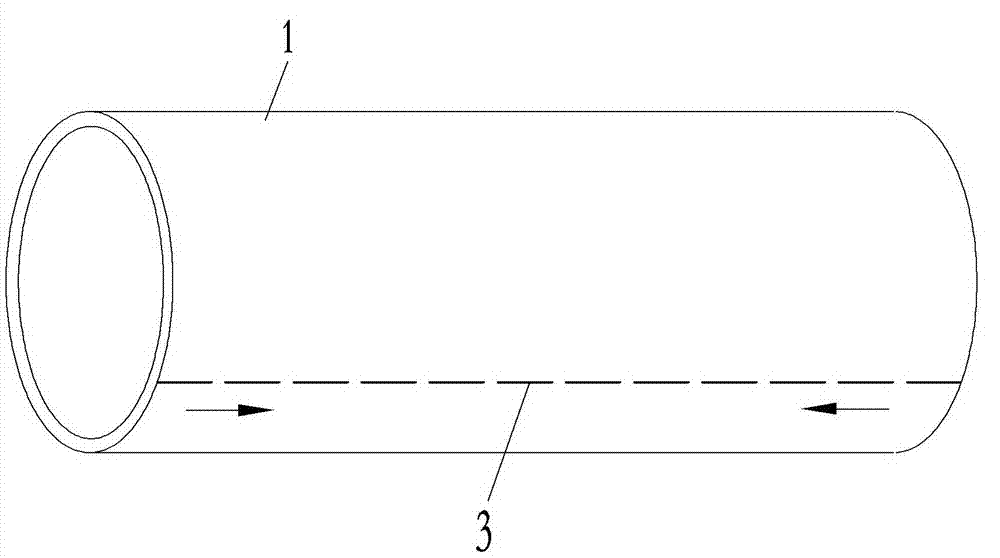

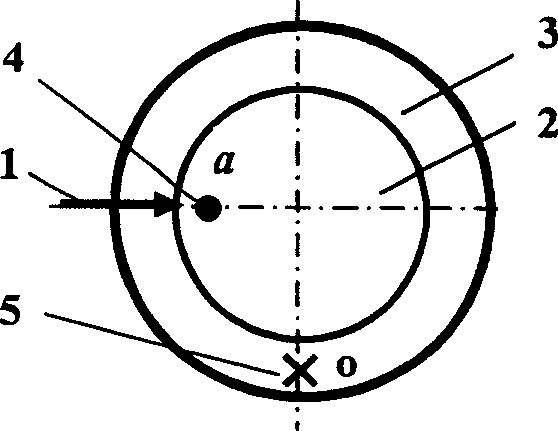

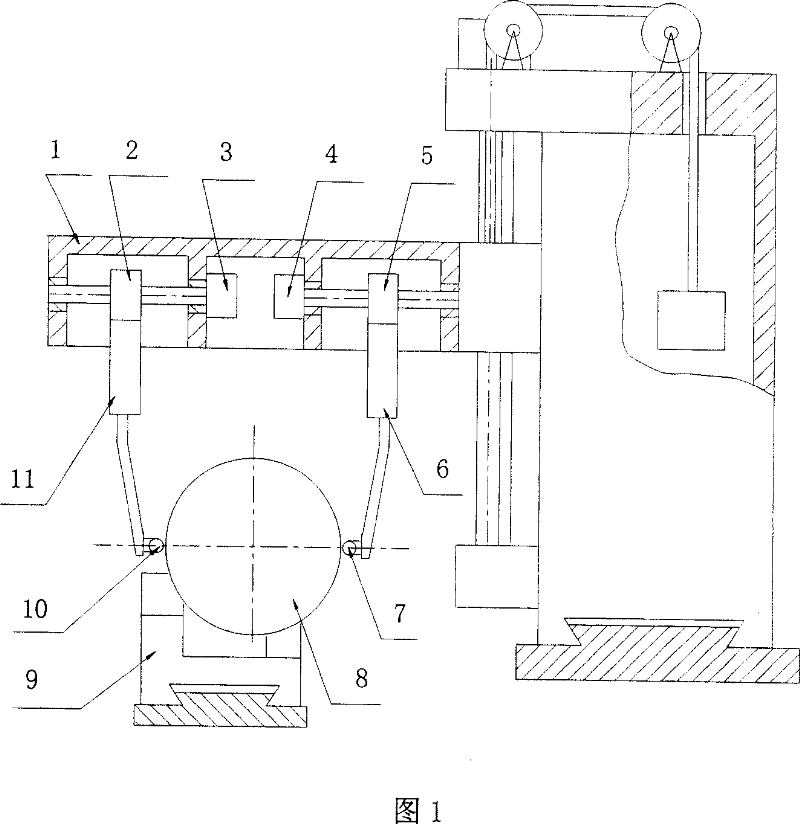

An online monitoring device for the radial rotation accuracy of a main shaft is disclosed, wherein a monitoring ring is installed at the radial measuring position of the main shaft; three eddy-current displacement sensors are installed on the monitoring ring; the proximitors of the eddy-current displacement sensors are connected with the terminal board of a data acquisition board card; the data acquisition board card is connected to an industrial computer via a PCI (peripheral component interconnection) slot; when the main shaft is in a rotating state, the eddy-current displacement sensors convert the measured voltage signal to a standard voltage signal via the proximitors; the analog signal is converted to a digital signal via a signal conditioning circuit module and an A / D (analog / digital) conversion module on the data acquisition board card, and then the digital signal enters into the industrial computer; the radial displacement signal of the main shaft is obtained by signal acquisition and analysis software; the roundness error of the main shaft is separated out by applying a three-point error separation technology, thereby obtaining the rotation error of the main shaft; and finally the analysis result of the rotation accuracy of the main shaft is displayed. The online monitoring device for the radial rotation accuracy of a main shaft has the advantages of being high in accuracy and convenient in adjustment.

Owner:XI AN JIAOTONG UNIV +1

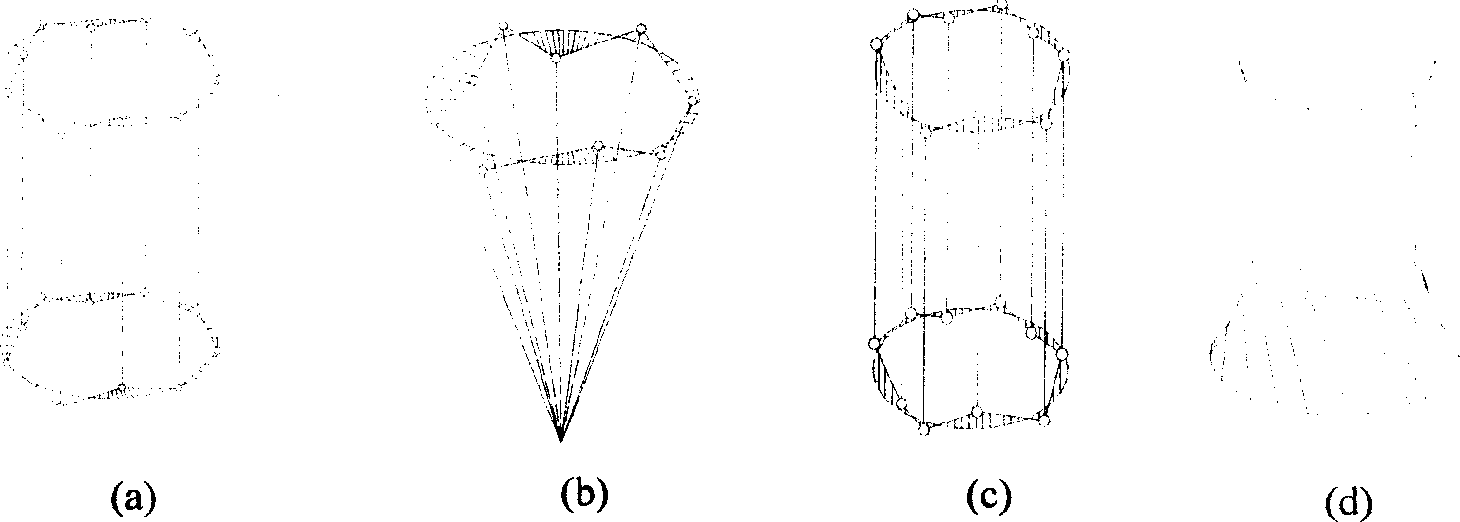

Self-separation method and device for spatial error of superprecise revolution reference

ActiveCN1527022AGood effectReduce axial sizeMechanical counters/curvatures measurementsMotion errorComputer science

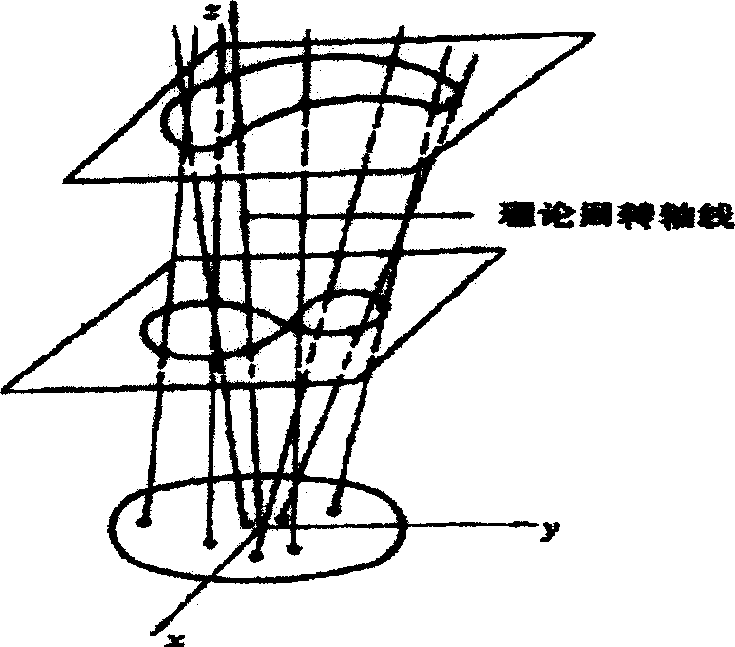

The present invention belongs to the field of precise instrument manufacture and measurement technology, and is especially self-separation method and device for spatial error of super-precise revolution reference. The method of Z-direction section-by-section separation of super-precise revolution reference spatial motion error can meet the requirement of high precision cylindricity instrument to reduce spatial revolution error. The self-separation device for spatial error of super-precise revolution reference is developed by means of integrating roundness error separating system and cylindricity instrument revolution main shaft system. The bench revolving single-transposition small-angle error separation method is adopted in realizing the section-by-section separation of spatial revolution motion error of cylindricity instrument revolution main shaft, so as to reach the aim of reducing the effect of the spatial revolution motion error on measurement result.

Owner:HARBIN INST OF TECH

Method and device for measuring main shaft rotary errors with capacity of installation eccentricity separation

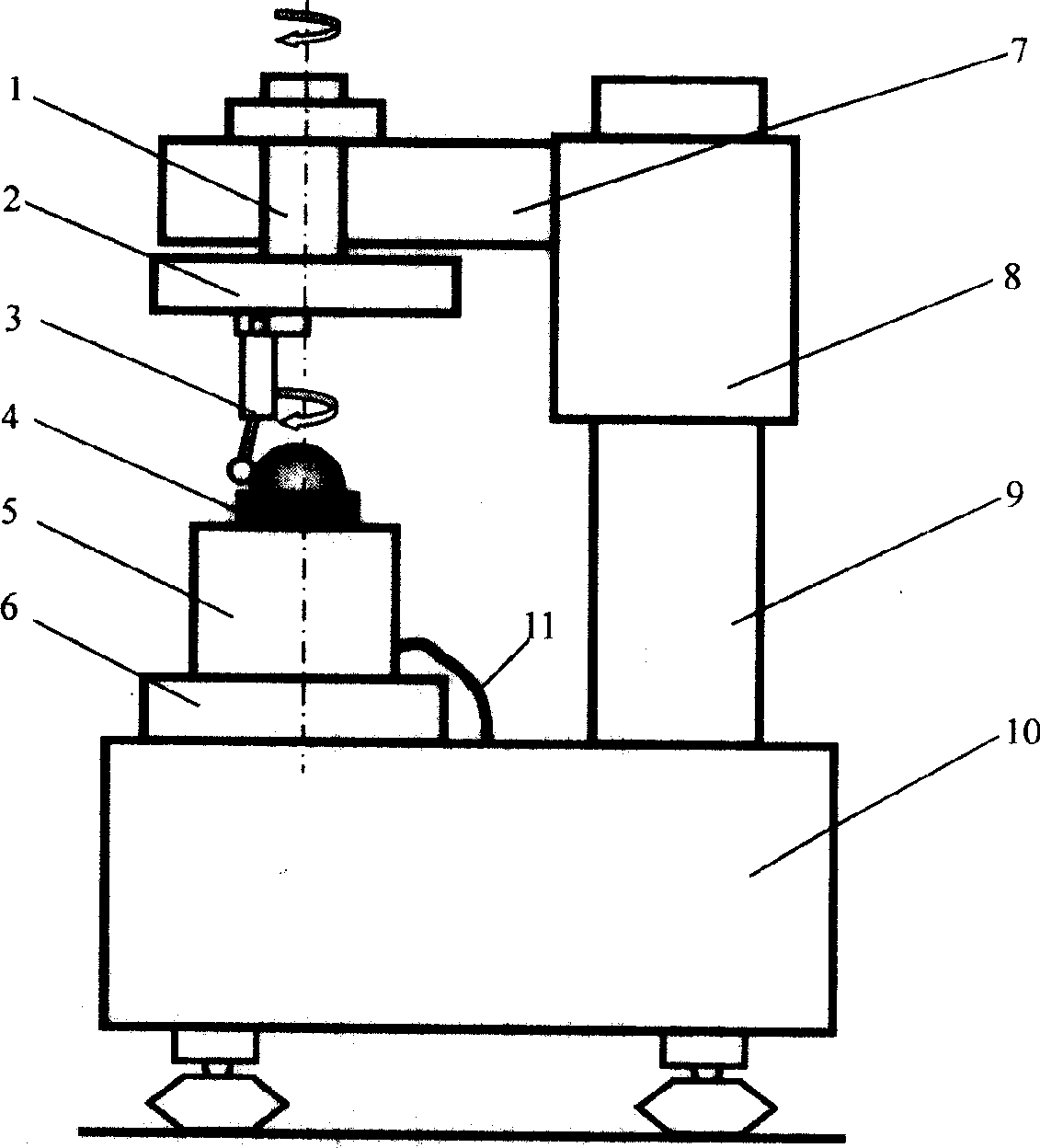

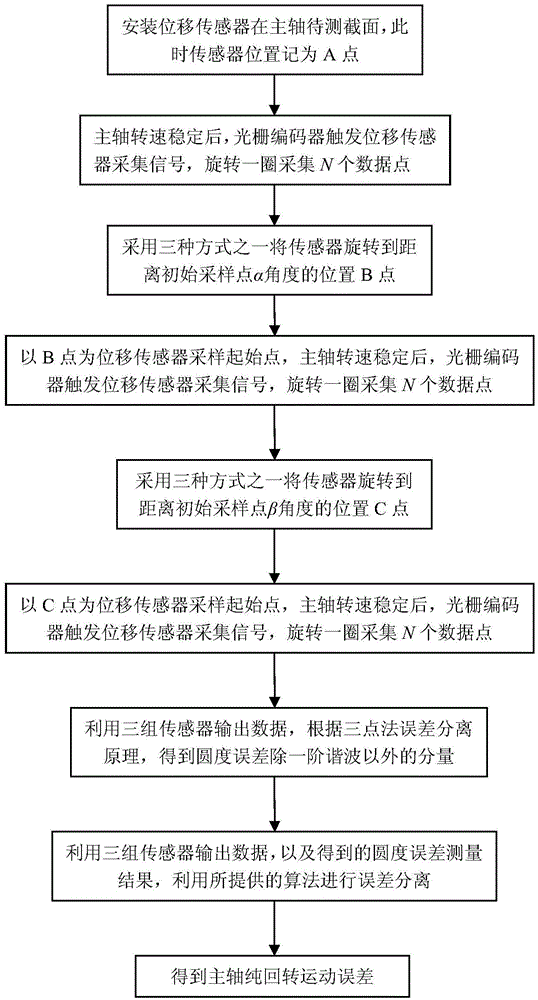

The invention discloses a method and device for measuring main shaft rotary errors with the capacity of installation eccentricity separation. The device comprises a displacement sensor installation clamping device, a displacement sensor, a grating encoder, a signal cable, a data processor and a computer. According to the measurement process, measurement is conducted by the displacement sensor according to three selectable modes with three different positions of the external profile of a main shaft serving as sampling starting points, other components, except for first-order harmonic waves, of main shaft roundness errors are obtained on the basis of the three-point method principle, secondary separation is conducted according to the provided algorithm, installation eccentricity is separated from the rotary errors, and therefore a pure rotary movement error value of the main shaft is obtained. On one hand, the roundness errors of the profile of the main shaft and eccentric errors of installation of a standard ball and the sensor are separated from the rotary movement errors of the main shaft, so that the separation operand is small. On the other hand, only one displacement sensor is adopted and measurement errors caused by a sensor performance difference because of three sensors adopted in a common three-point method error separation technology are avoided.

Owner:GENERAL ENG RES INST CHINA ACAD OF ENG PHYSICS

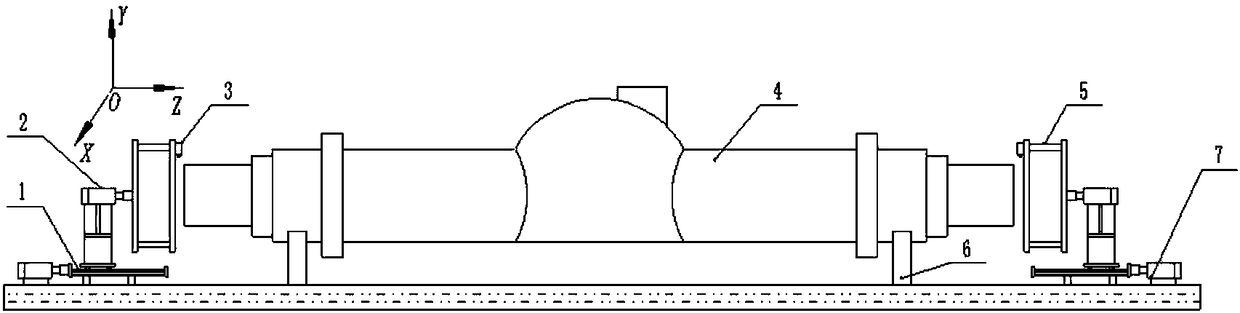

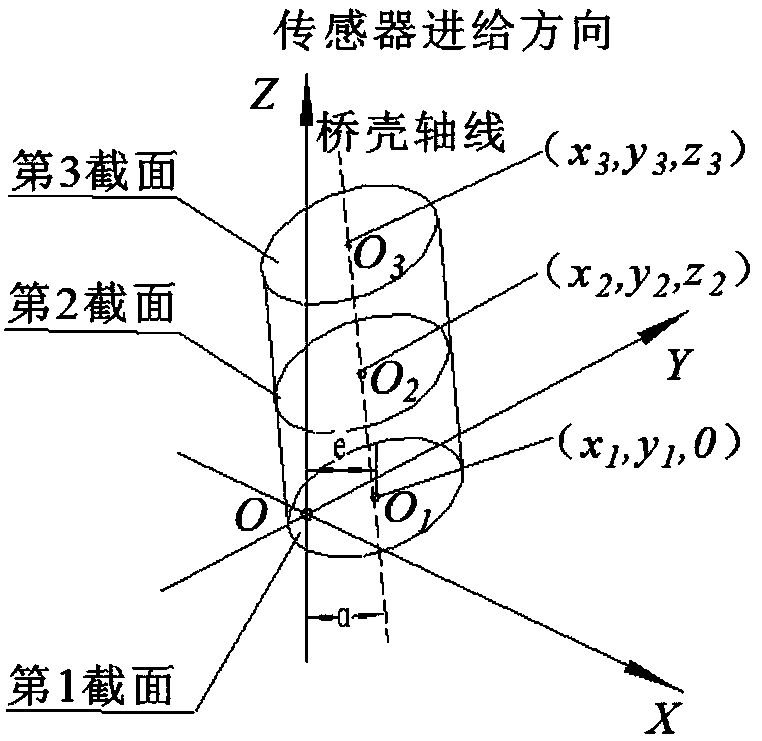

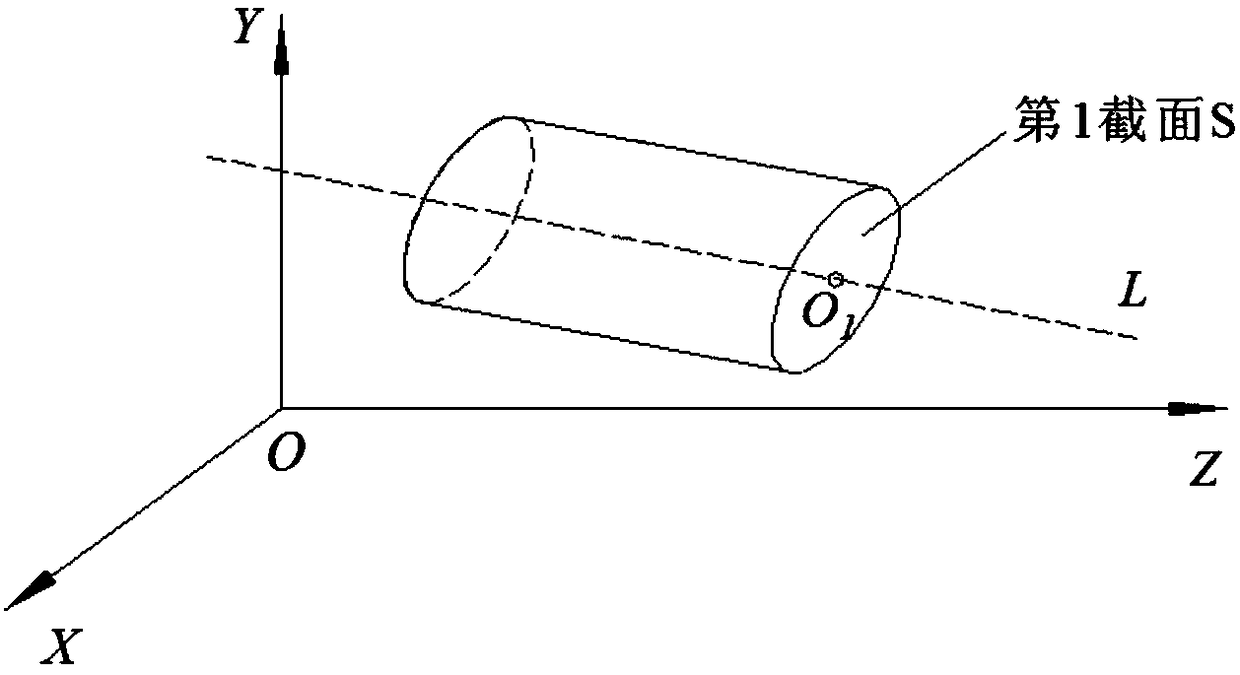

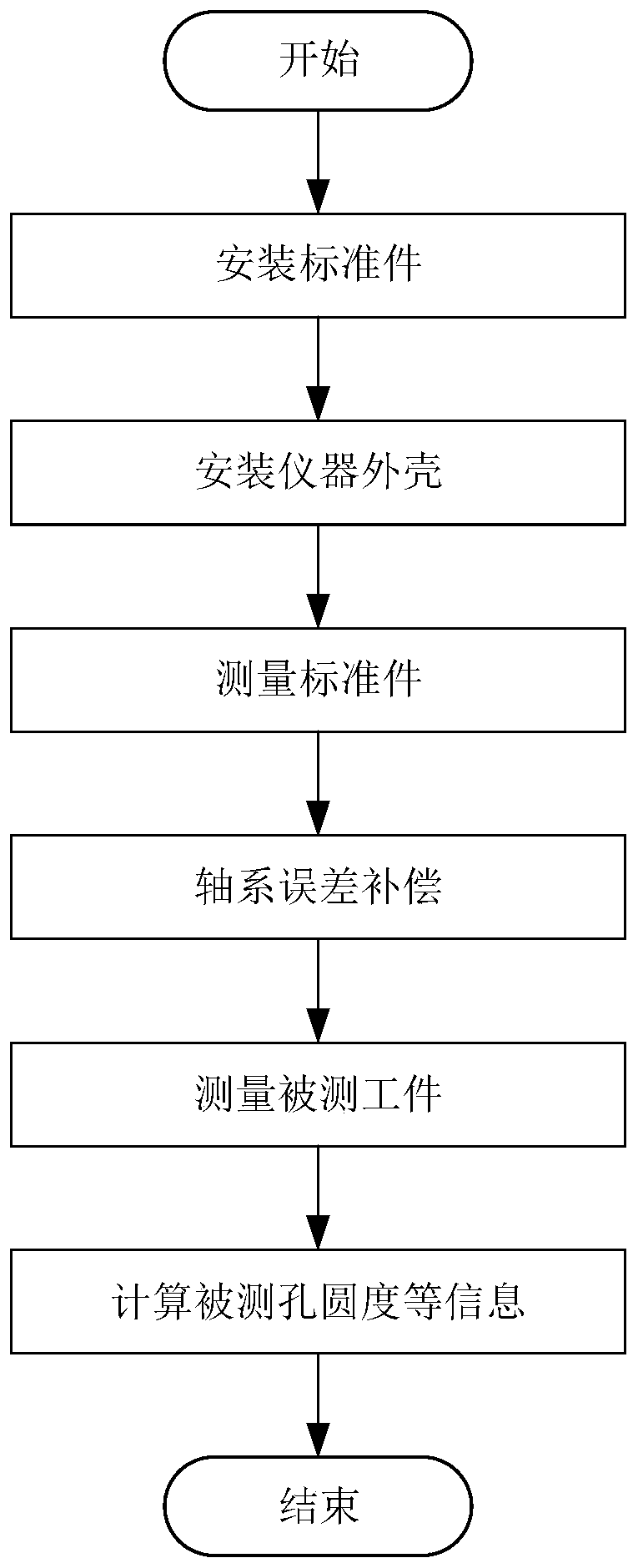

Workpiece axis positioning error compensation method for axle housing roundness and cylindricity detecting device

ActiveCN108253906AImprove detection accuracyAdapt to ultra-precision machining requirementsUsing optical meansEngineeringPosition error

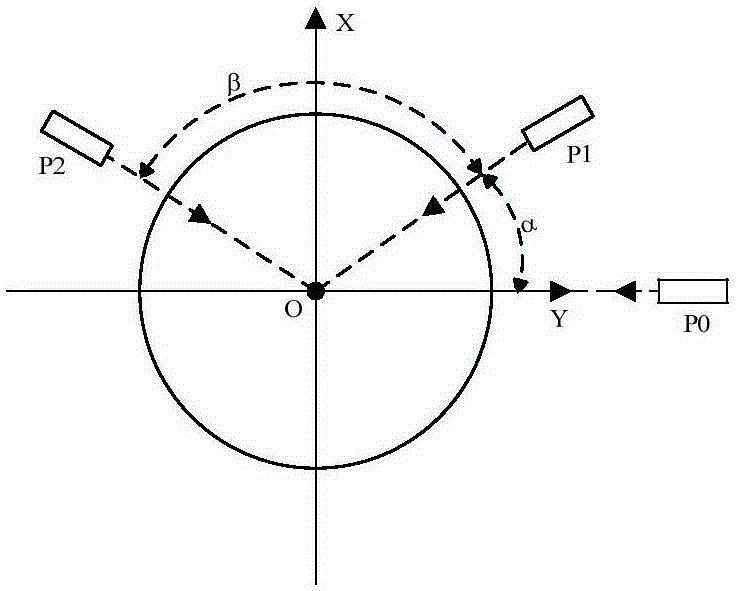

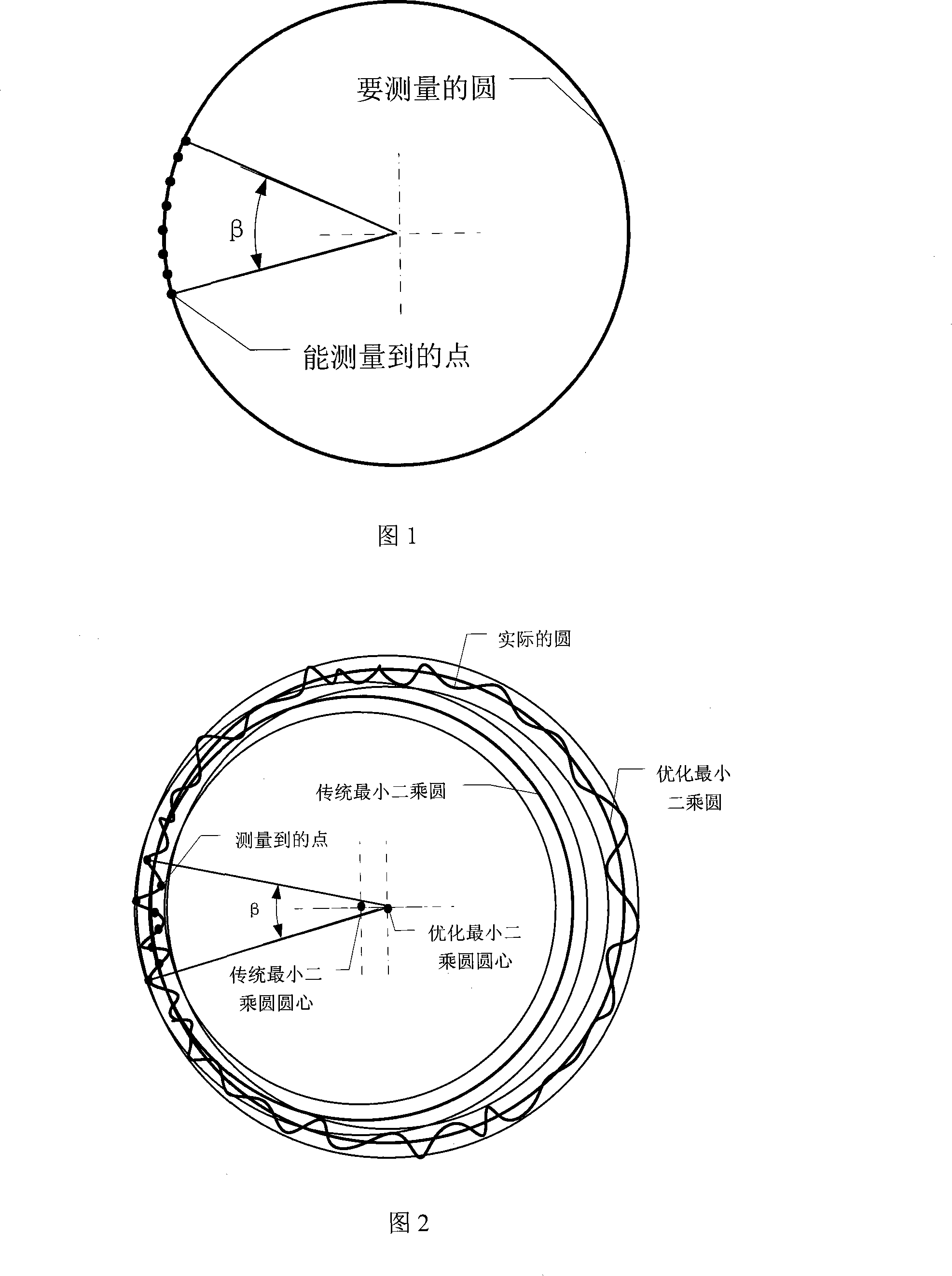

The invention discloses a workpiece axis positioning error compensation method for an axle housing roundness and cylindricity detecting device and belongs to the field of detection. The method is characterized in that an axle housing positioning model is built, a first section, a second section and a third section are arranged on the model, and the second section and the third section are used tocorrect the first section step by step. The method specifically includes: a target section uses O as the benchmark to perform spatial translation on a circle contour where O1 is located, performing axis eccentricity compensation to obtain a section S1 after eccentricity correction, and an axis L and the section S1 are rotated a theta degree along a Z axis to obtain a section S2; the axis L and thesection S2 are rotated an alpha degree along a Y axis to allow the axis L to coincide with the Z axis so as to obtain a section S3; the section S3 and the axis L are reversely rotated theta degrees to obtain the section S4; error evaluation is performed on the section S4 to obtain real roundness errors with workpiece axis positioning eccentricity inclination errors being removed, and a constraintcondition beta is provided. The workpiece axis positioning error compensation method can compensate roundness errors and cylindricity errors caused by workpiece axis positioning eccentricity and workpiece axis positioning inclination, increase axle housing detection precision and meet ultra-precision machining requirements.

Owner:QILU UNIV OF TECH

Tracking method of on-line measuring roundness error and machine tool main axle error

InactiveCN1927535ASolve the problem of online measurement of roundness errorSimple calculationAutomatic control devicesMeasurement/indication equipmentsTime domainSystem error

The invention relates to a method for online tracking and measuring the roundness error and the machine tool main spindle error. It measures the tracking roundness and the diameter making use of three displacement sensors in the online measuring device, and transforms the time-domain signal is collected when measuring into frequency domain signal then analyses the signal. It separates the roundness error coming from the eccentric rotations from system error online, so achieves online measure of the roundness error and system error and enhances the measurement accuracy.

Owner:SHANGHAI UNIV

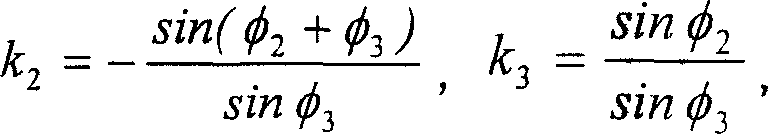

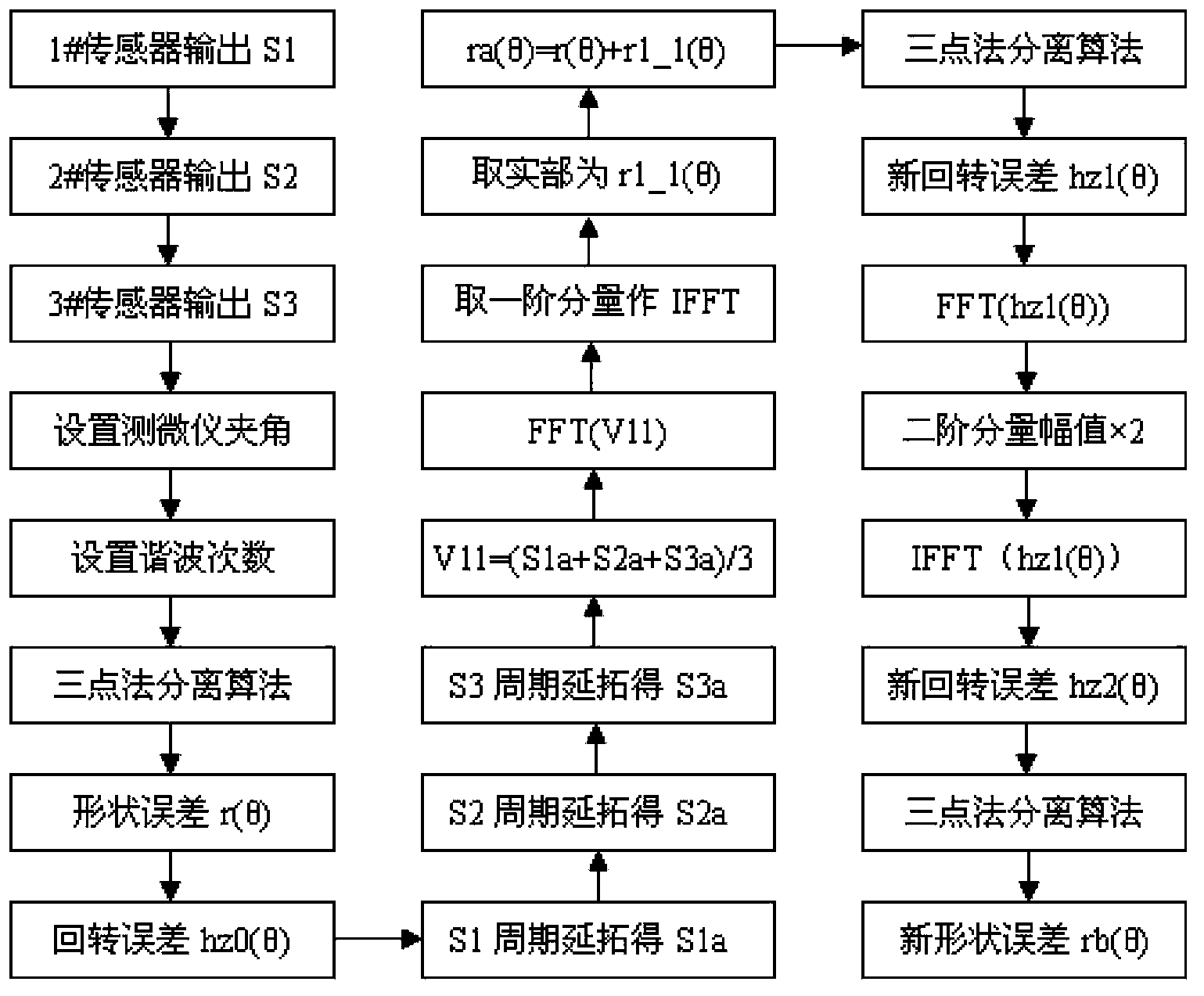

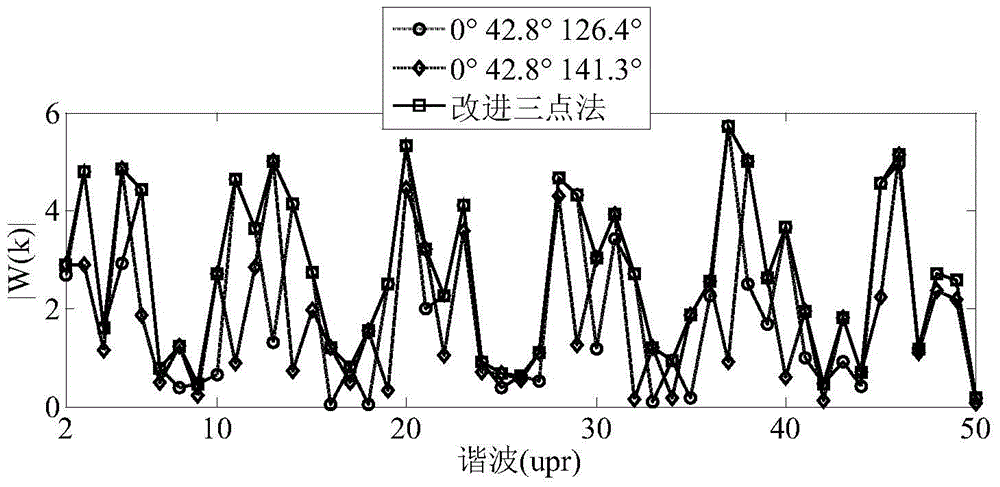

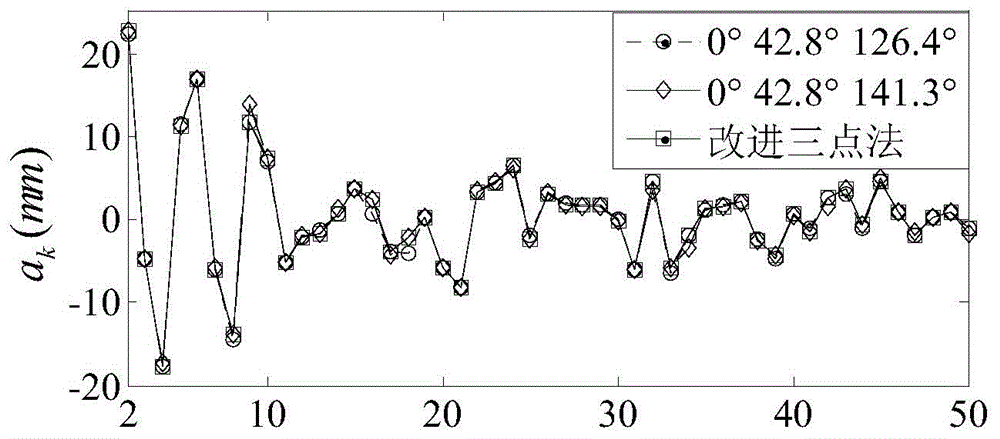

Improved three-point method turning error and roundness error calculation method

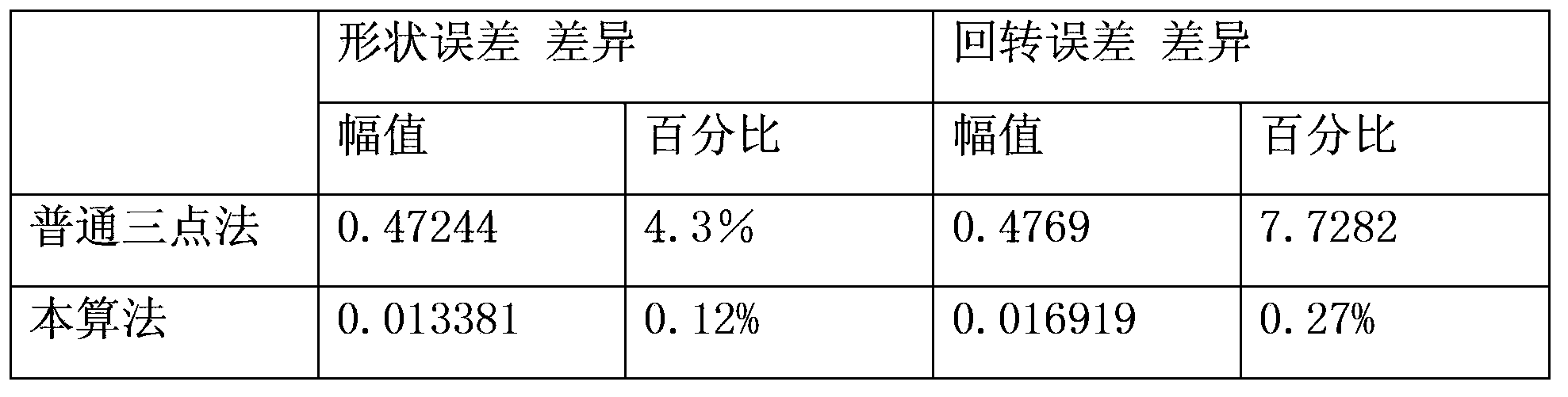

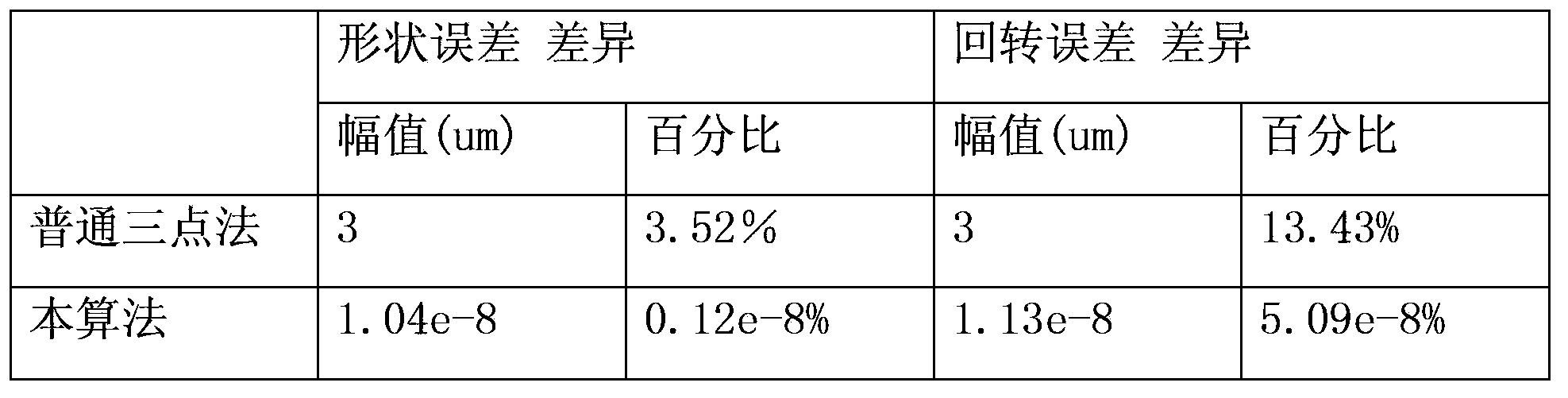

ActiveCN103363921ASolve the defect that the first-order component of the shape error cannot be obtainedImprove separation precisionUsing optical meansMeasurement precisionOrder of magnitude

The invention discloses an improved three-point method turning error and roundness error calculation method, which comprises the following steps of: translating and carrying out weighted average on three sensor signals, and carrying out frequency domain filtering to effectively obtain a one-order component of a form error. According to the method, the separation precision of the form error and the turning error can be obviously improved, and a surface is simulated; under the condition that the sensor is free from the noise interference, the separation precision of the form error and the turning error can be 10-8 orders of magnitude; and the measurement precision of the turning error and the roundness error can be effectively improved.

Owner:GENERAL ENG RES INST CHINA ACAD OF ENG PHYSICS

Method for correcting tubular structure diameter distortion by flame

The invention discloses a method for correcting tubular structure diameter distortion by flame. The method includes that before heating, radial outward pushing force is applied on the inner wall of a tubular structure area with a negative roundness error value to enable an additional stress to radially outwardly act on the area with the negative roundness error value in advance, and simultaneously stress radially inwardly acting on a tubular structure area with roundness error larger than tolerance is generated in the tubular structure area, so that when an area is heated, deformation of the heated area can be accelerated, roundness of a tubular structure can be corrected, correction amount can be well controlled, number of heating time is decreased, period for integral correcting work is shortened, and the situation about tubular structure scrapping caused by over times of heating is avoided.

Owner:GUANGZHOU WENCHONG SHIPYARD CO LTD

Single-transposition roundness fault separating method

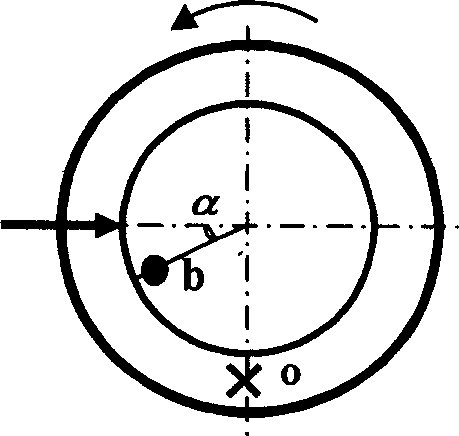

A method for separating roundness error of single transposition includes selecting proper transposition angle a for carrying out single small angle transposition in relevant angle to rotation major axis and realizing complete harmonic separation of z(n) and g(n) as in scope of 1-100 upr harmonic wave by measuring workpiece error g(n) and major axis transposition error z(n) before and after workpiece transposition as well as utilizing quick. Fourier series transform and harmonic analysis.

Owner:HARBIN INST OF TECH

Roundness error evaluation method based on variable-metric chaotic simulated annealing algorithm

The invention relates to a roundness error evaluation method based on a variable-metric chaotic simulated annealing algorithm. The roundness error evaluation method comprises the following steps of: taking the simulated annealing algorithm as optimizing coarse searching first, and then taking the high efficiency of a chaos optimization algorithm as optimizing fine searching to ensure that the optimizing process is concise and efficient. Because the optimizing result of the simulated annealing algorithm is independent of an initial value, an actual globally optimal area is searched by adopting the simulated annealing algorithm, and the chaos optimization algorithm is excellent in execution efficiency and is suitable for carrying out fine searching in the globally optimal area, thereby searching a globally optimal solution, and therefore fewer iterations are obtained in the optimization process; and meanwhile, the chaotic mapping xtin=cos (1 / xtin2) provided by the invention can better realize chaotic optimizing, the [a1, i+1, b1, i+1] and [a2, i+1, b2, i+1] are ceaselessly decreased according to the solution space variation in the execution process, and therefore the optimizing process ceaselessly approaches to the globally optimal solution.

Owner:HUAQIAO UNIVERSITY

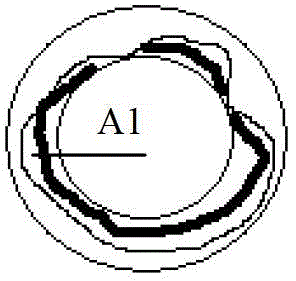

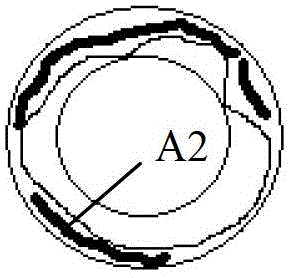

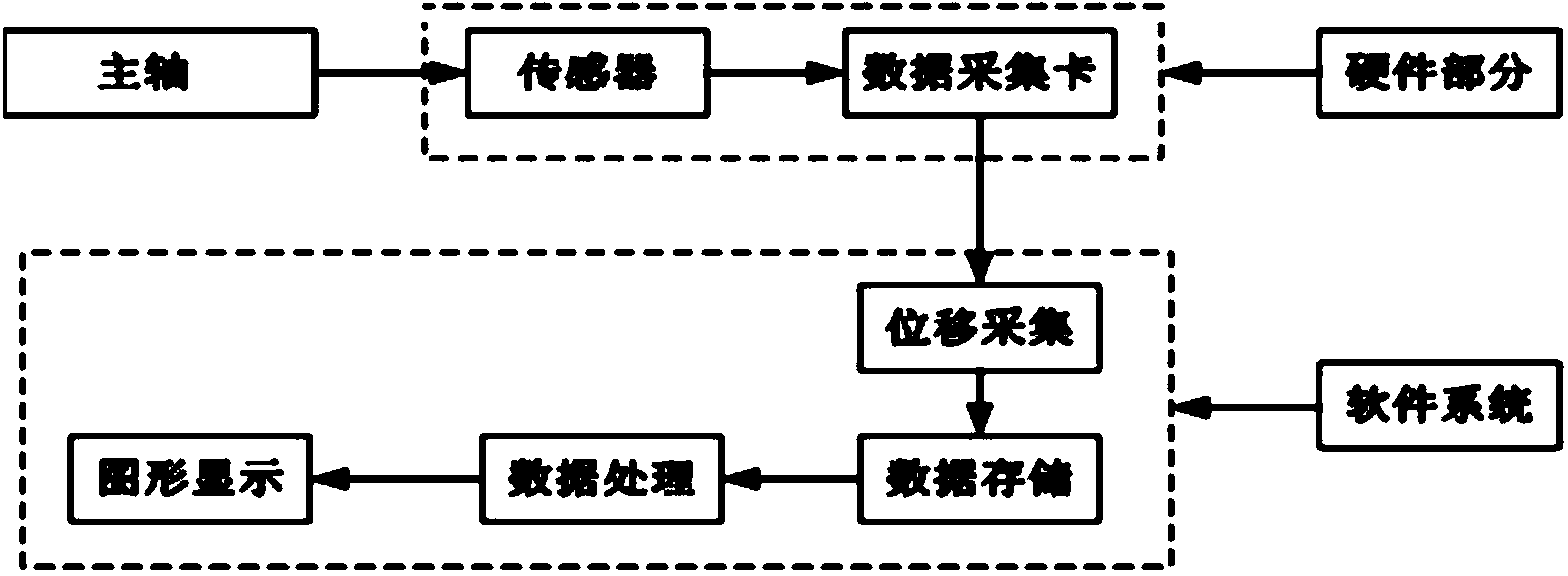

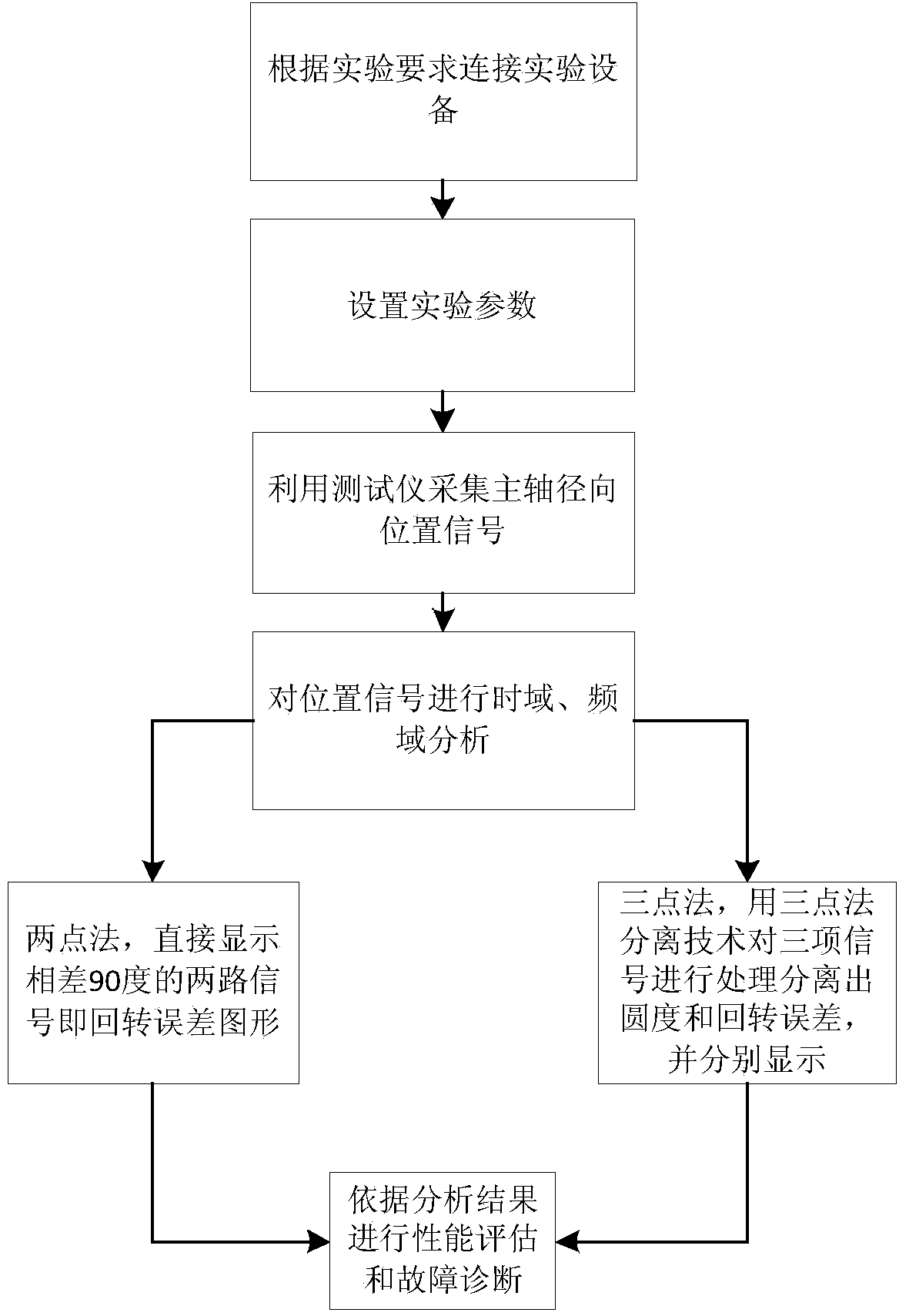

Testing and analyzing system for rotating errors of main shaft

InactiveCN104227501AFast and accurate roundness errorThe testing process is simpleMeasurement/indication equipmentsSoftware testing/debuggingAxial displacementSoftware system

The invention discloses a testing and analyzing system for rotating errors of a main shaft. The testing and analyzing system comprises a hardware part and a software part, wherein the hardware part comprises a bracket or magnetic stand, laser displacement sensors, signal connecting wires, a signal adapter plate and a signal acquisition card, wherein the bracket or magnetic stand is fixedly arranged on the main shaft; the laser displacement sensors and the bracket or magnetic stand are connected to acquire axial displacement runout of the main shaft; the signal output end of each laser displacement sensor is connected with the input end of the signal acquisition card through the signal connecting wire and the signal adapter plate; the signal adapter plate is used for outputting more than two laser displacement sensors according to a unified format; a software system is arranged on a computer; the computer communicates with the output end of the signal acquisition card by using testing software, acquires a displacement signal of each laser displacement sensor, then performs analysis processing on a filtering algorithm and a separation algorithm and separates and displays roundness error and rotating error. According to the testing and analyzing system disclosed by the invention, the roundness error and the rotating error of the main shaft can be acquired quickly and accurately; the testing is simple and practical.

Owner:XI AN JIAOTONG UNIV

Sensor mounting adjustment system and laser leveling reference device

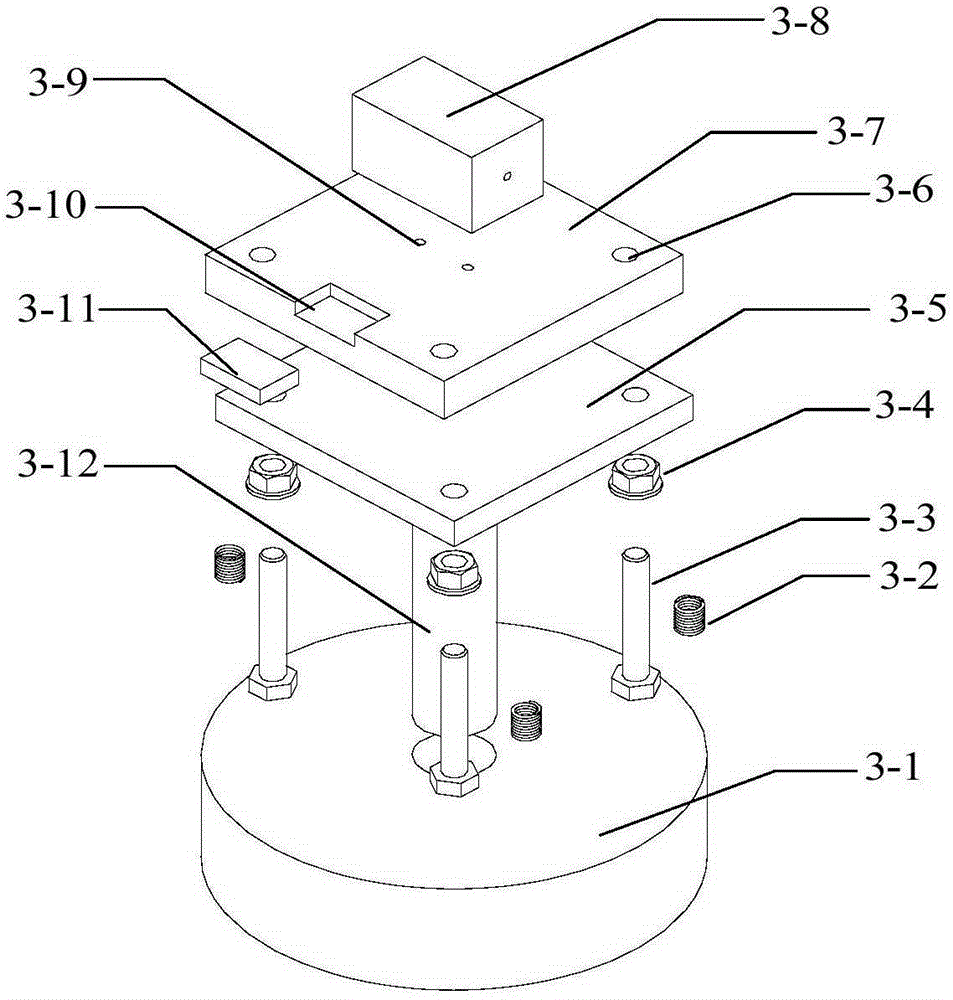

ActiveCN105223969AImprove efficiencyHigh precisionControl using feedbackMultiple sensorReference device

The invention relates to a sensor mounting adjustment system and a laser leveling reference device. The sensor mounting adjustment system comprises at least three sensor mounting adjustment devices and a laser leveling reference device for mounting a laser. Each sensor mounting adjustment device is provided with a height adjustment part for adjusting level of a sensor fixing seat and a level alignment mechanism. The level alignment mechanism comprises a target positioning hole arranged on a front mounting plate and a target reticle arranged on a rear mounting plate. The connection line between the target positioning hole and the target reticle is arranged parallelly with the sensor. The laser leveling reference device of the invention is provided with at least three height adjustment parts arranged at intervals around the circumferential direction for adjusting level of the sensor fixing seat. According to the system and the device of the invention, horizontal coplane and concentric mounting of measurement axes of multiple sensors can be quickly realized, efficiency and precision of mounting and positioning of the sensor are improved, and the roundness error measurement precision and the rotation error measurement precision can be further ensured.

Owner:HENAN UNIV OF SCI & TECH

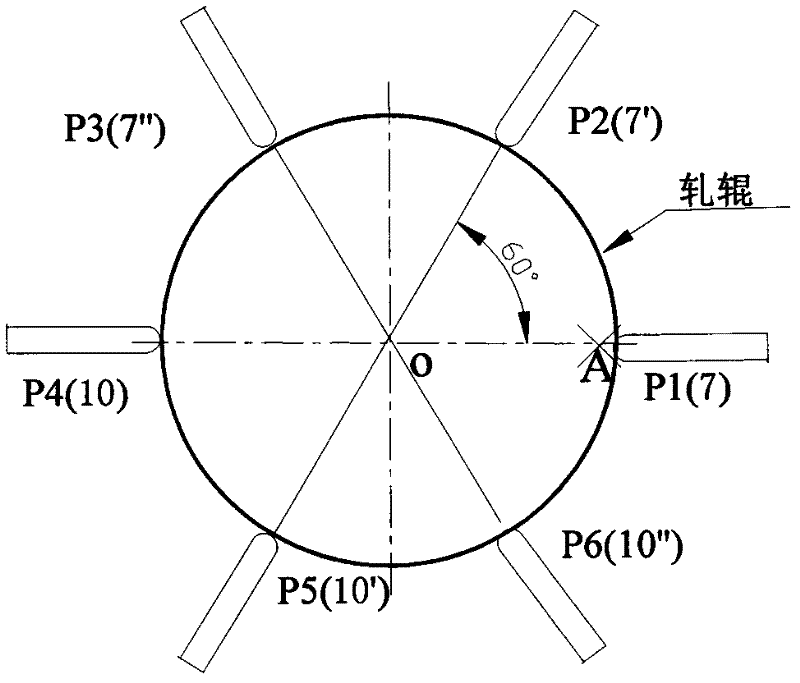

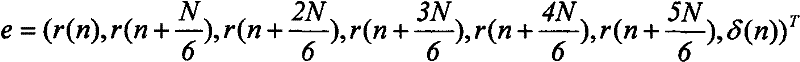

Method for measuring error of roller roundness and kinematic error of machine tool main axle using antipodal two points six positions

InactiveCN101033936ASolve the problem of roundness error on-machine measurementSimple calculationUsing electrical meansTime domainMotion error

The invention relates to a method about diametrical two points and six level measuring roll roundness error and machine tool spindle error., it makes the analysis when time-finite signal collected by two displacement sensors which are set according to diametrical method during six different displacement measuring changes into frequency domain, it makes separation of roundness error of roll which makes eccentric rotatoexercise and spindle motion error, and it realizes measures online about roundness error of roll and spindle motion error, thus, it improves the precision of measuring.

Owner:CHANGSHU INSTITUTE OF TECHNOLOGY

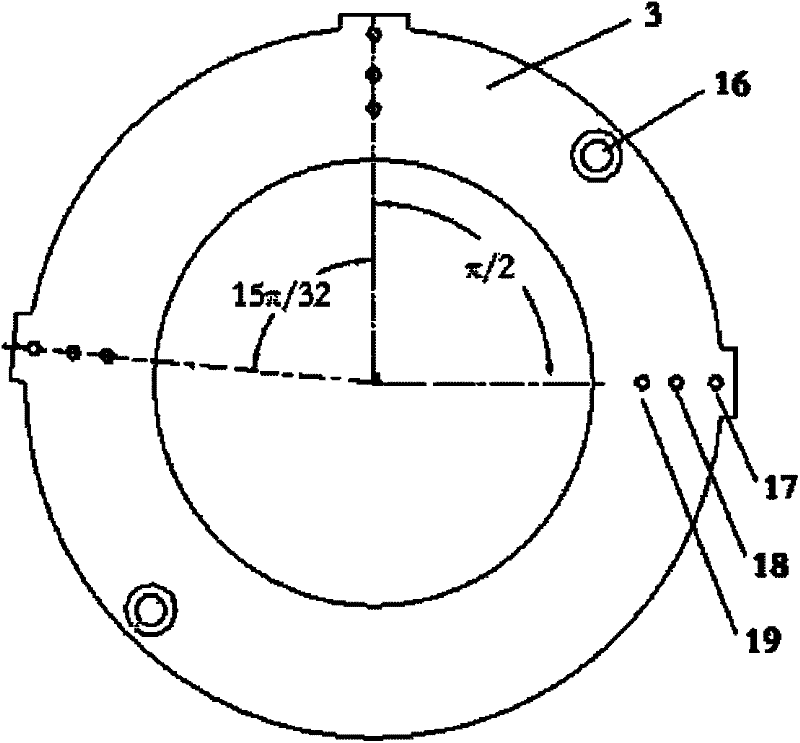

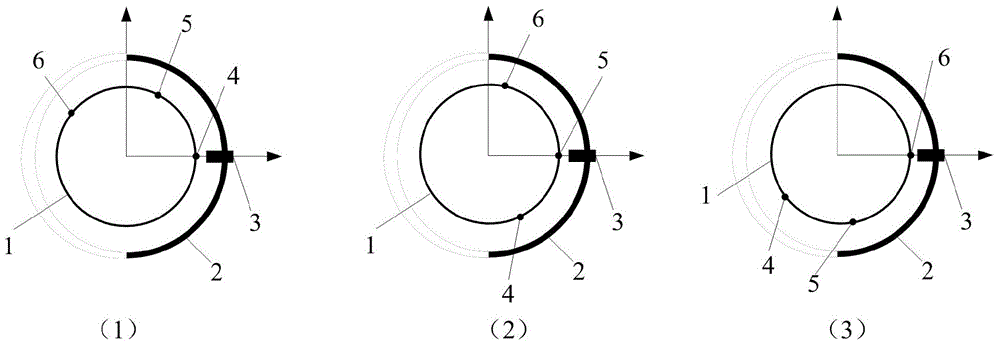

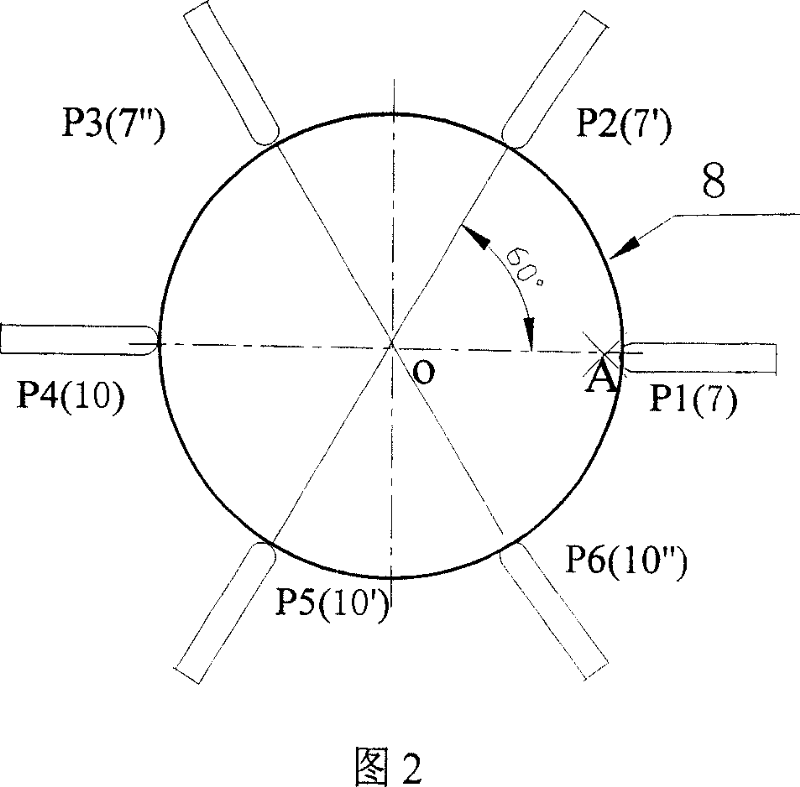

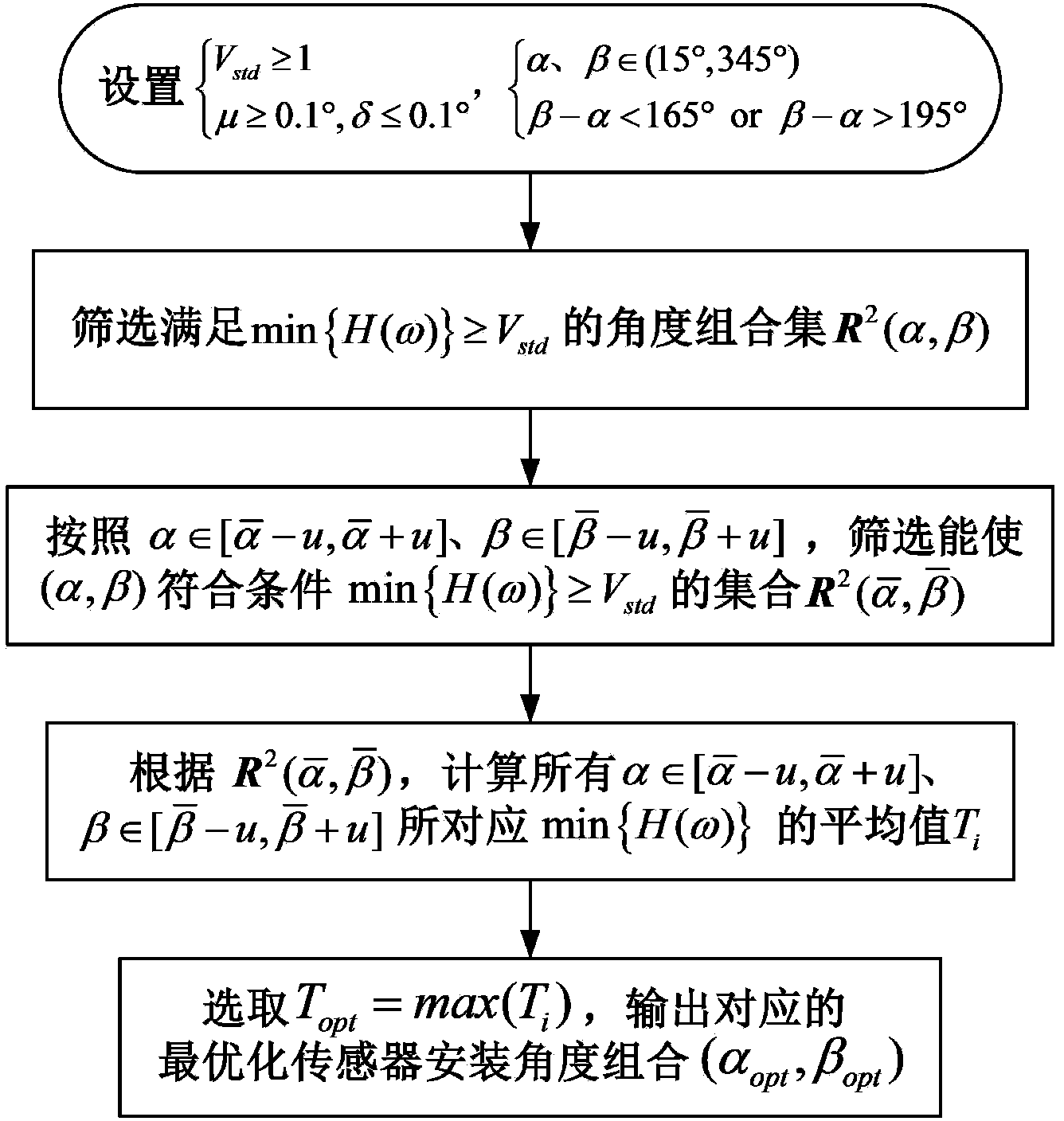

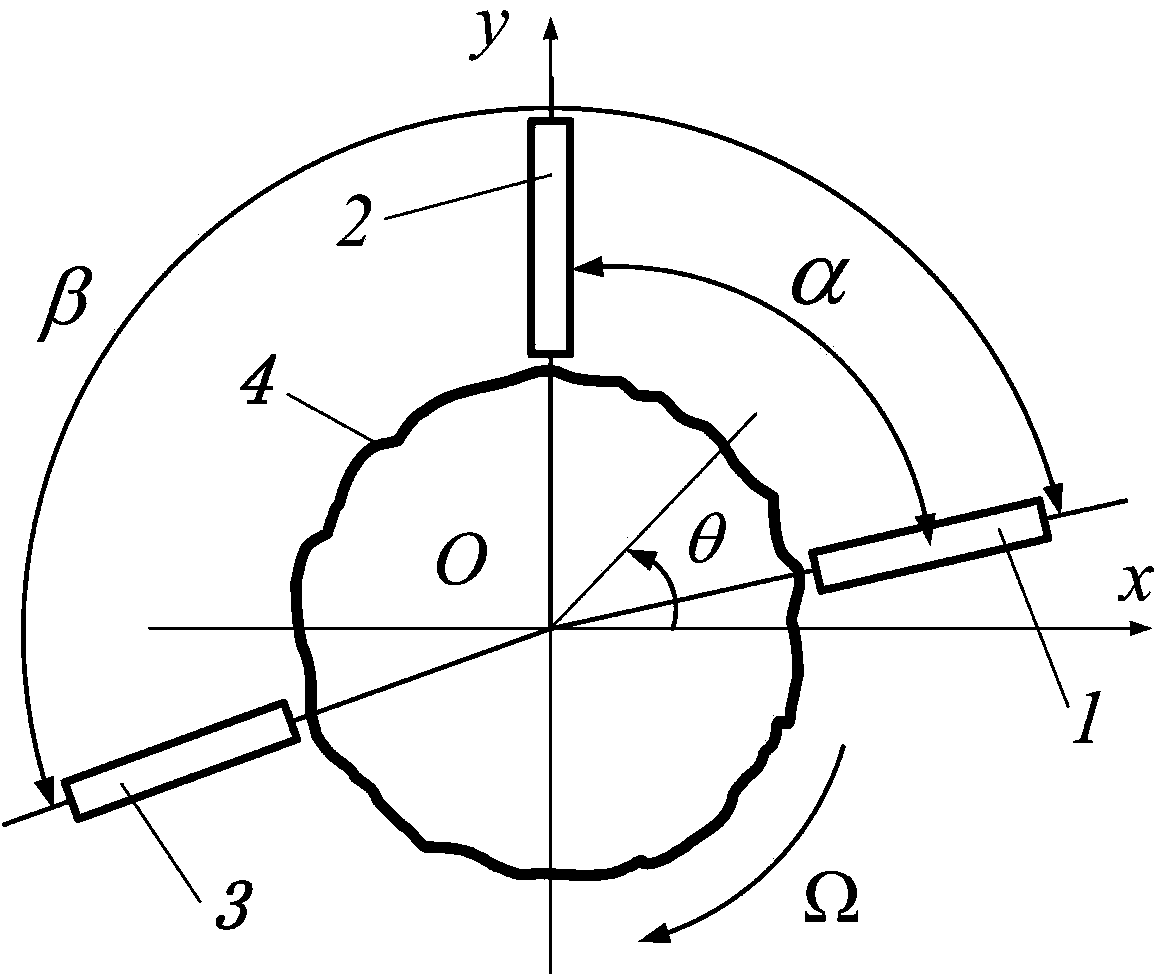

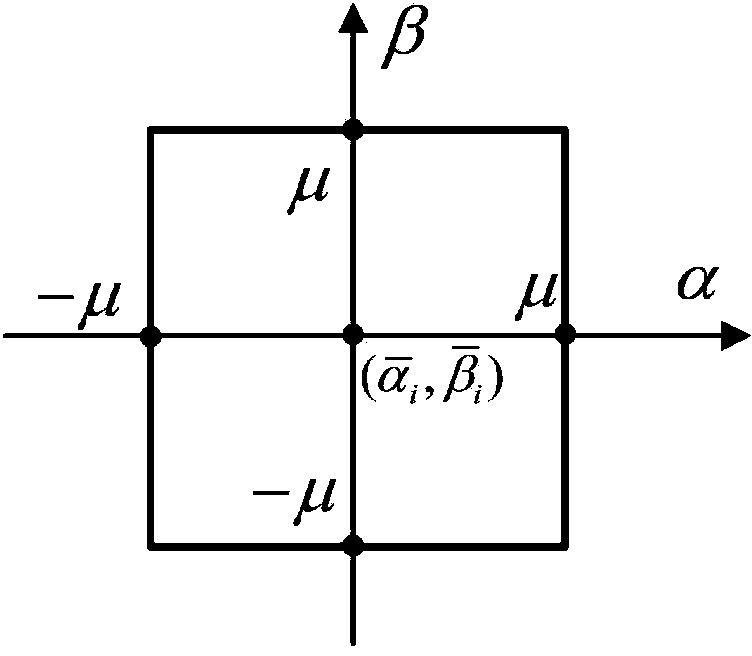

Sensor mounting angle selecting method for three-point method roundness error isolation technology

ActiveCN104374353AAvoid precision lossAngle selection cycle is shortMeasurement devicesHarmonicEngineering

The invention belongs to the field of precision revolution body high-precision measuring and particularly relates to a sensor mounting angle selecting method for a three-point method roundness error isolation technology. On the basis of the three-point method roundness error isolation technology, the character of a weight function during an isolation process is combined, a specific value is not used as a selecting target of a sensor mounting angle any longer, under the condition of a range where certain errors are allowed, angle combination sets which accord with the preset condition are screened, and then the best sensor mounting angle combination is obtained by comparing. Compared with a traditional angle selecting method, the phenomenon of weight function harmonic suppression caused by sensor mounting errors is effectively controlled, and when a sensor mounting angle deviates from a preset angle slightly, the precision of an error isolation process can still be guaranteed. A complex data post-processing step is of no need, an angle selecting cycle is short, an implementation process is simple, a deducing process is simple, and computer programming can be well achieved.

Owner:XIDIAN UNIV

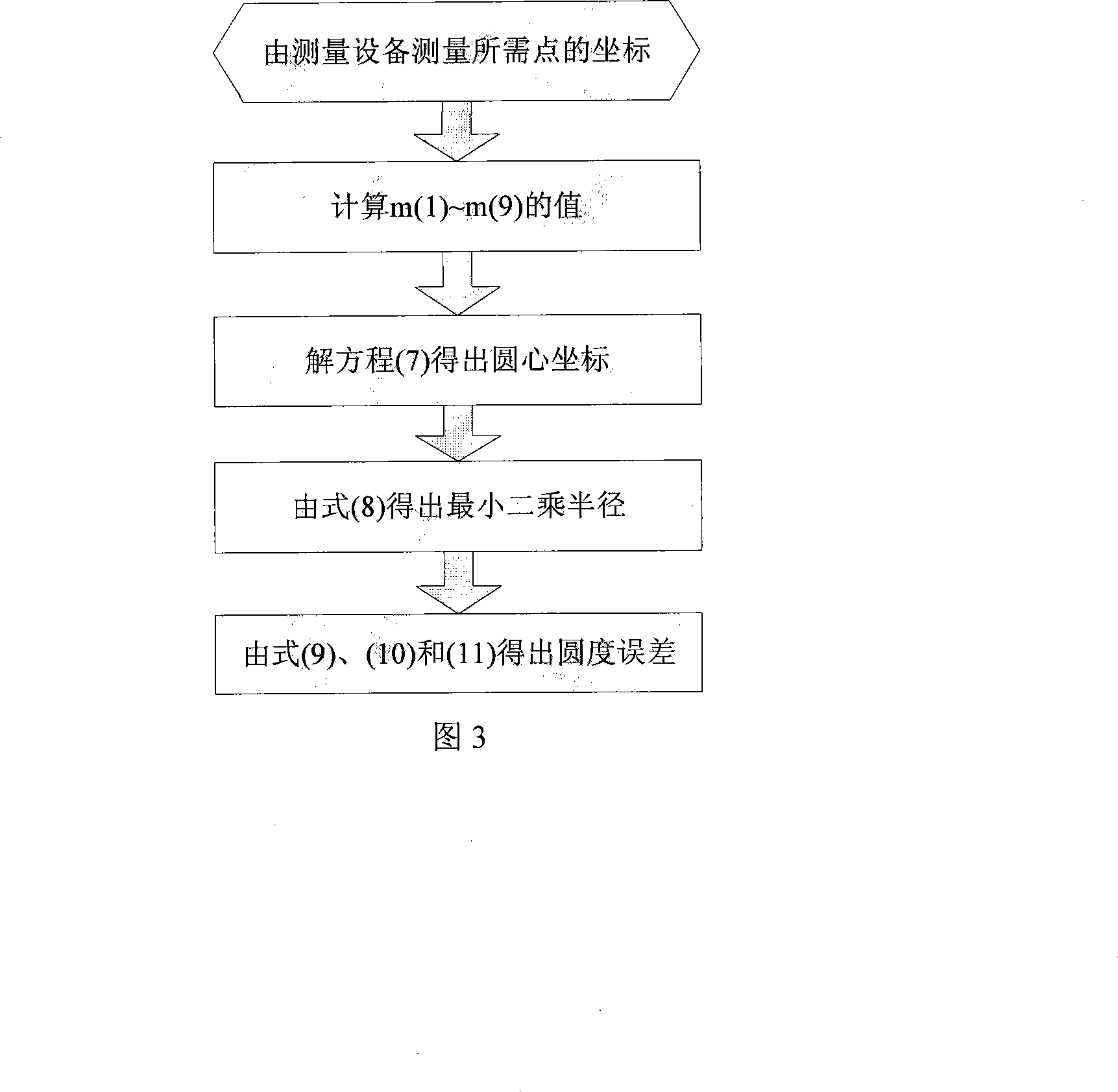

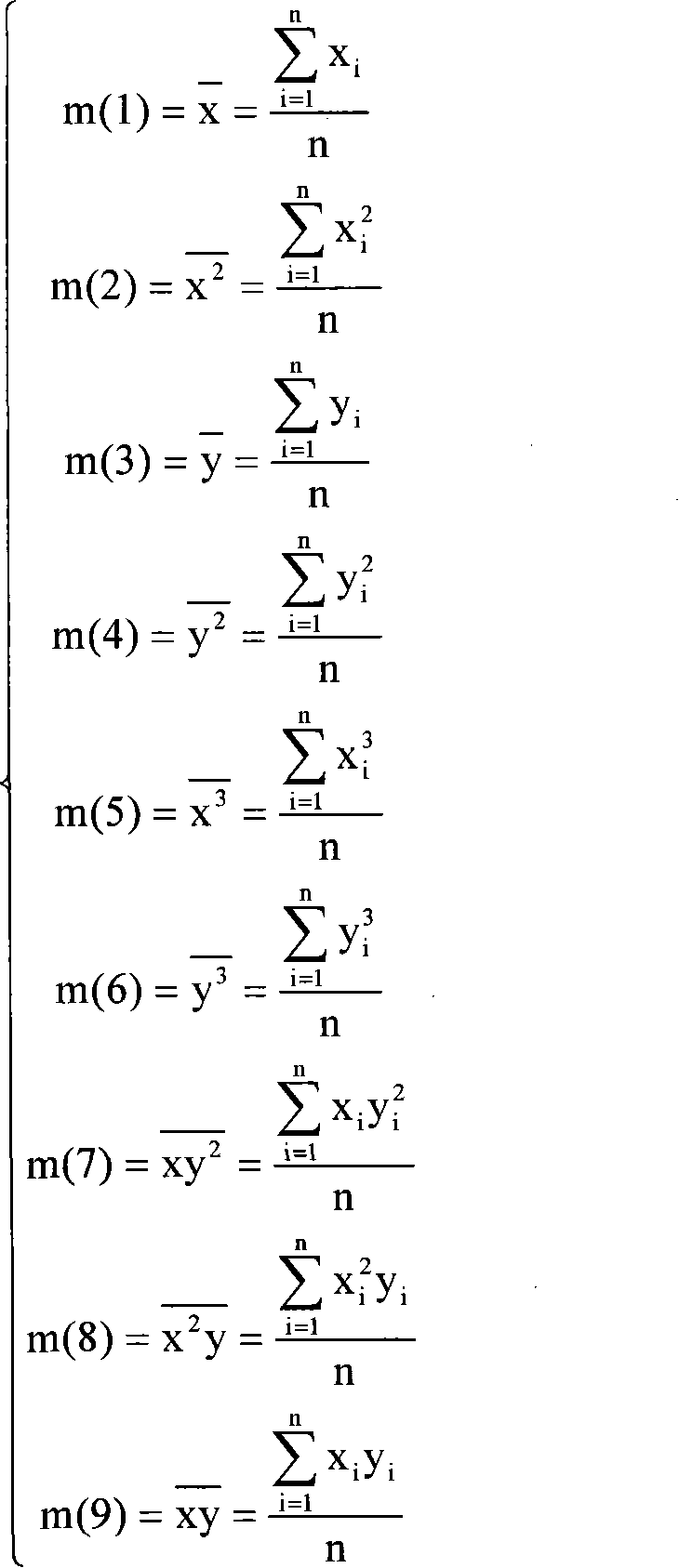

Optimized least square appraisement method for roundness of minor segment circular arc

InactiveCN101196394AHigh precisionImprove reliabilityMeasurement devicesLeast squaresRoundness error

The invention relates to an optimal least square evaluation method of small arc roundness, which assesses the central coordinate of circle through measuring the coordinates of a plurality of measuring points on a small part of arc and then gets the least square radius through the obtained central coordinate of circle, and finally gets the roundness error of circle. The invention can correctly find the center of the circle, thus the fitting circle can reflect the real situation of the circle better to improve the precision and reliability of counting.

Owner:SHANGHAI UNIV

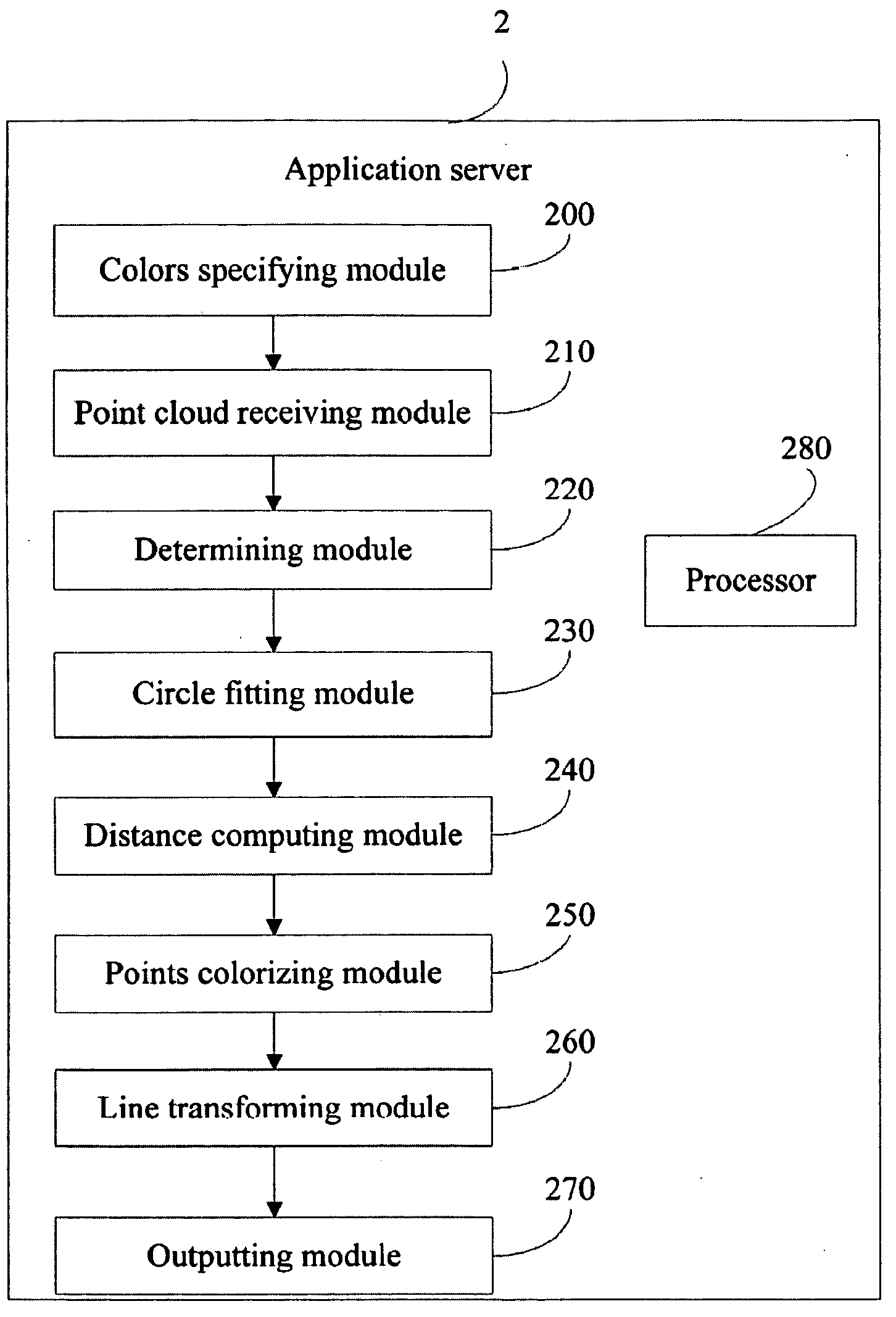

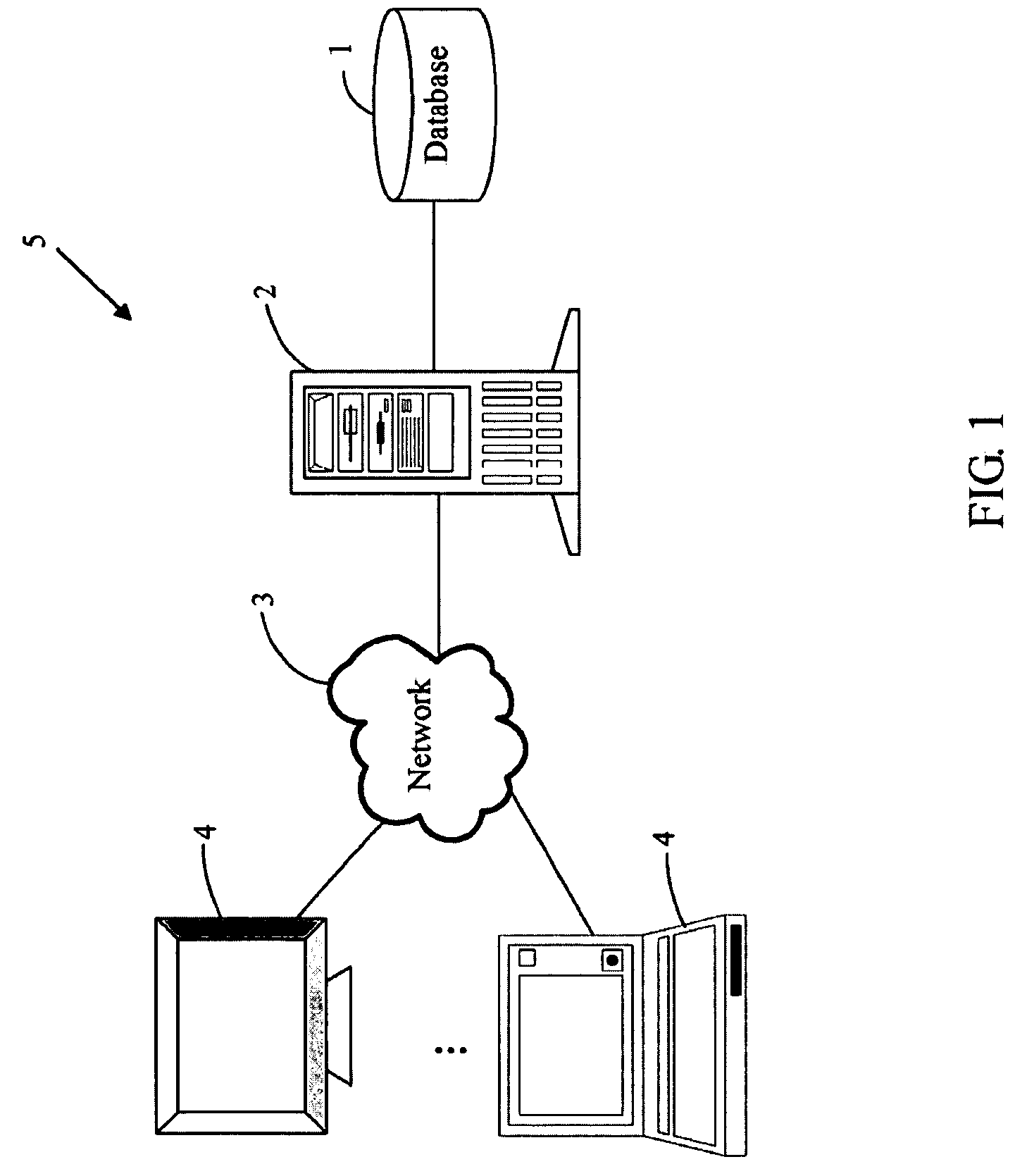

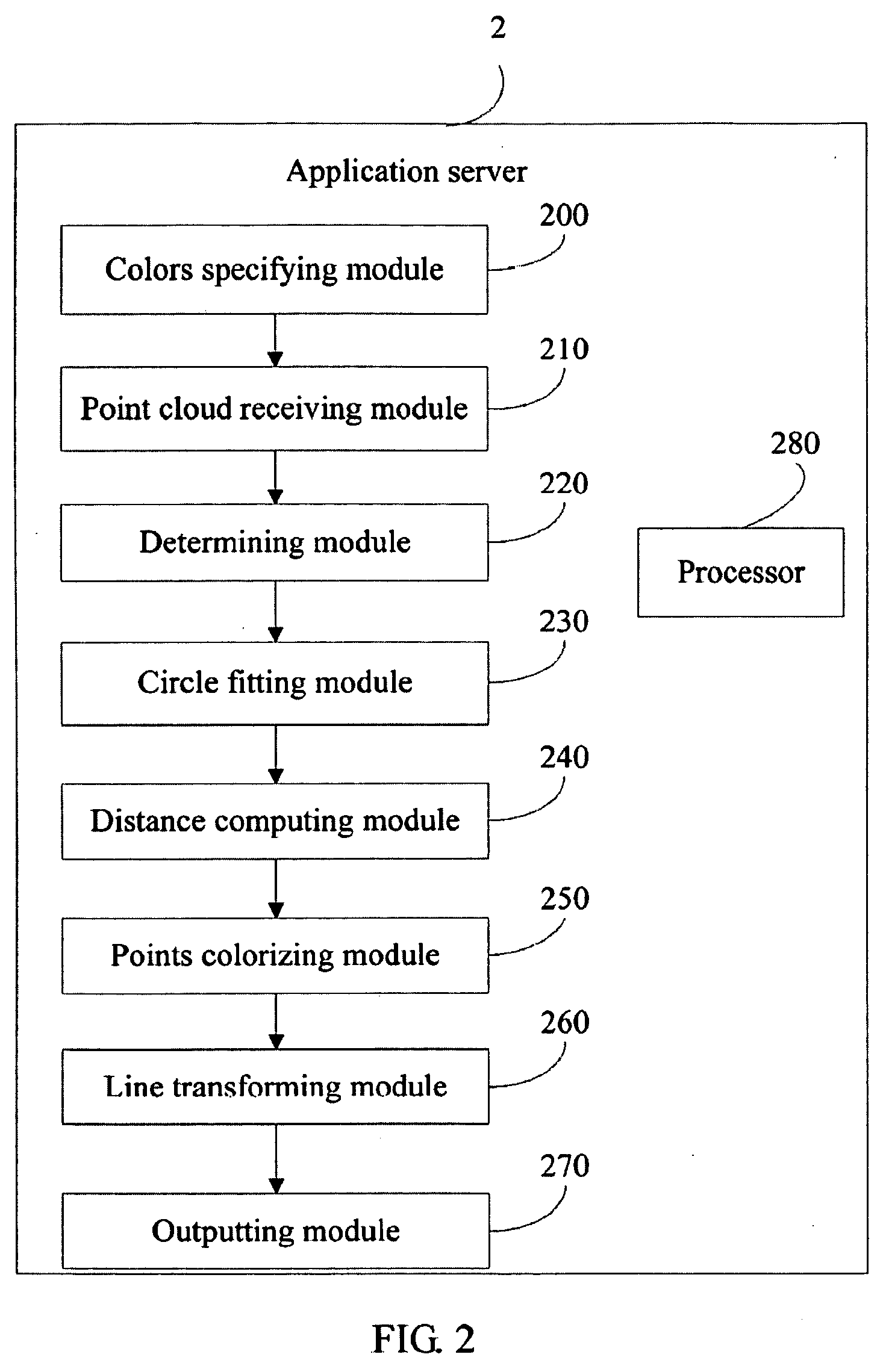

System and method for computing and displaying a roundness error of an object

A method and system for computing and displaying a roundness error of an object specifies different colors that respectively represents an error range of points. The method and system receives a point cloud of the object and fits a circle based on the point cloud. The method and system computes an error of each point in the point cloud by computing a distance between the each point and the circle, colorizes the points in the point cloud according to the errors and the specified colors, and generates and outputting a graphic roundness error analysis report.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

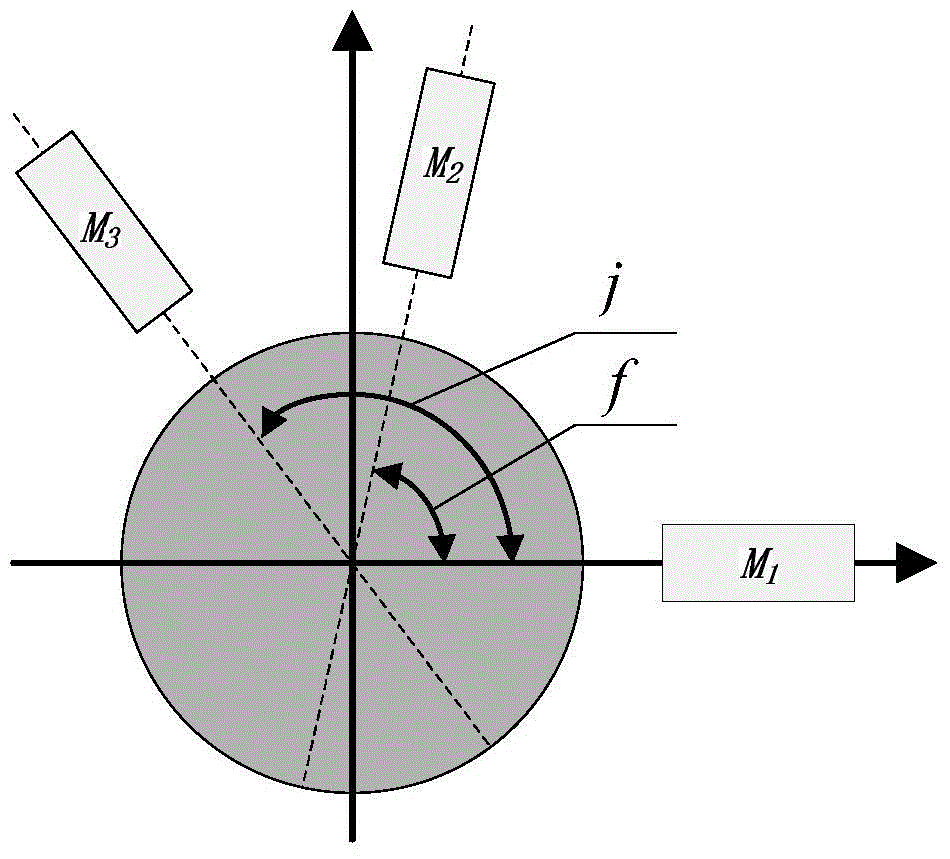

Improved three-point method for turning error and roundness error measurement

The invention relates to an improved three-point method for turning error and roundness error measurement. The method includes the following steps that: three displacement sensors are distributed at different angular positions so as to measure the radial run-out of a detection bar, and a high-frequency data acquisition system is utilized to record the measurement results of the sensors, and a three-point error separation technology is utilized to calculate the Fourier coefficients of harmonic waves of roundness error; the second sensor and / or third sensor is re-installed at different angles, the three-point method is repeated to perform measurement for many times, so that each Fourier coefficient can obtain a plurality of estimated values; a Fourier coefficient which is calculated through a transfer matrix of which the determinant is maximum is a most accurate Fourier coefficient estimated value; and the roundness error can be calculated through composite calculation based on the most accurate Fourier coefficient estimated value. With the method of the invention adopted, the accuracy of the estimation of each harmonic wave can be improved, and therefore, the accuracy of whole roundness error measurement can be improved.

Owner:XI AN JIAOTONG UNIV

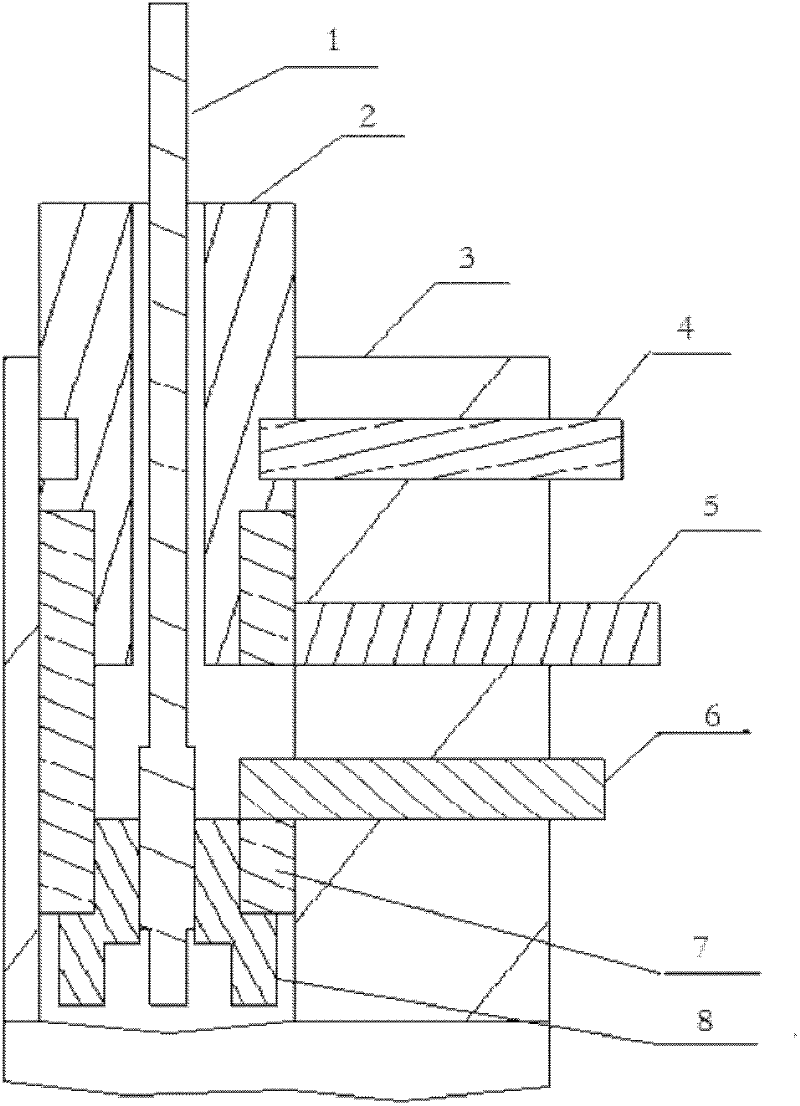

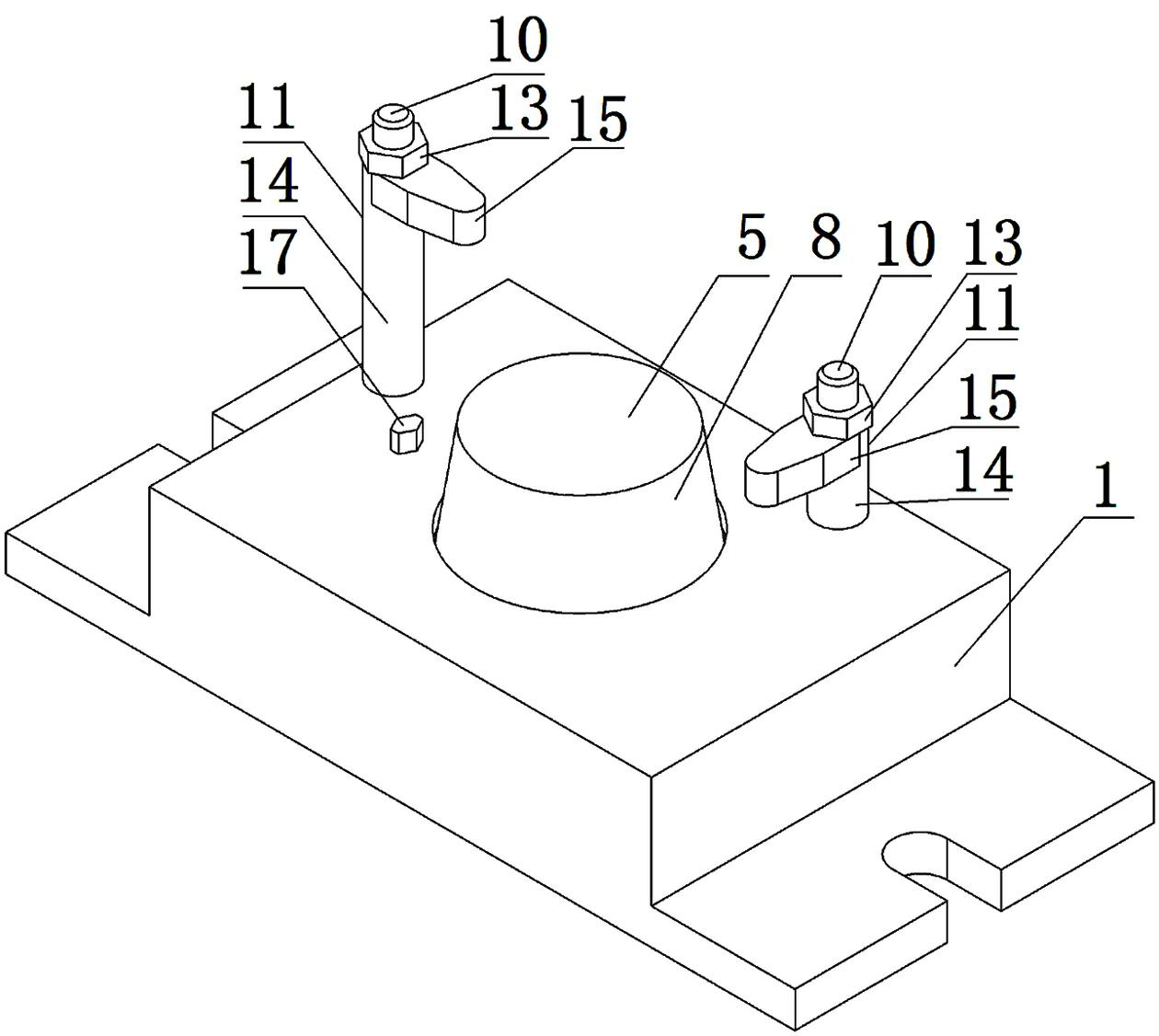

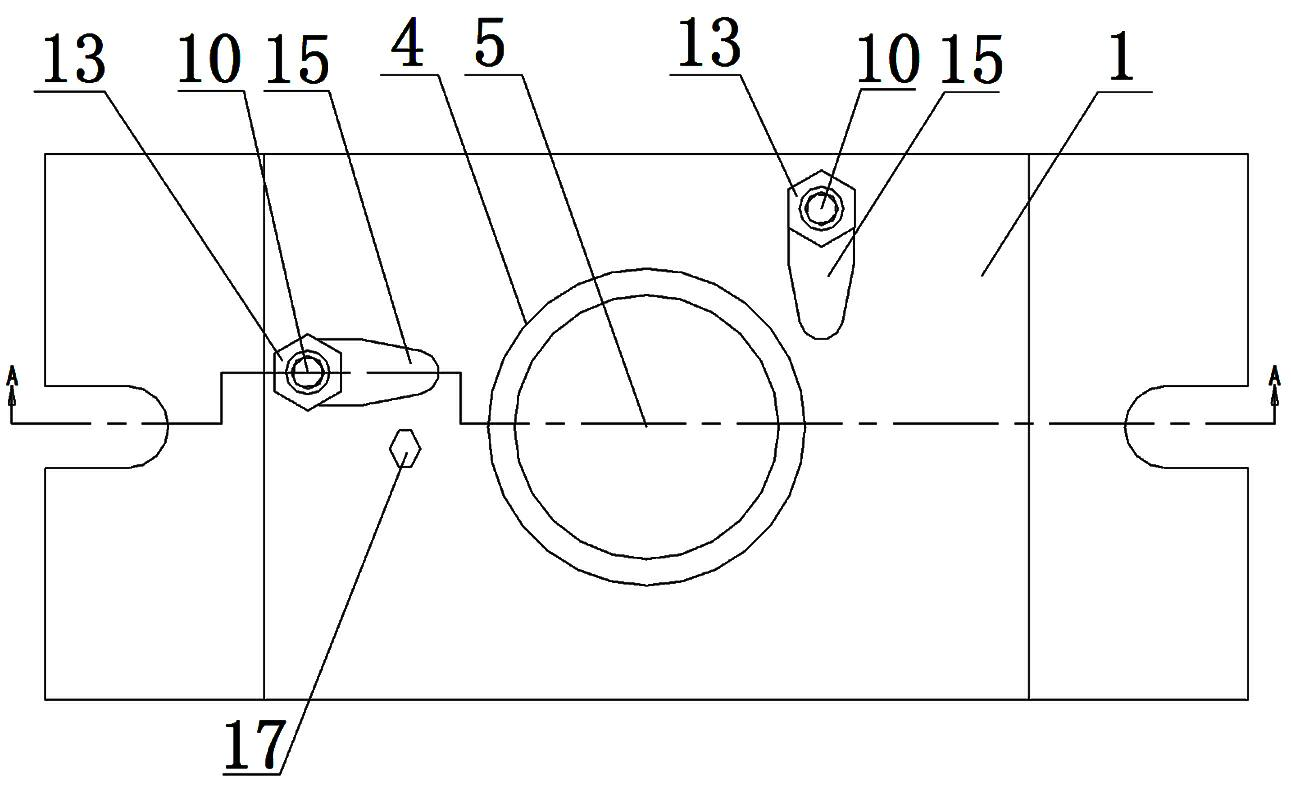

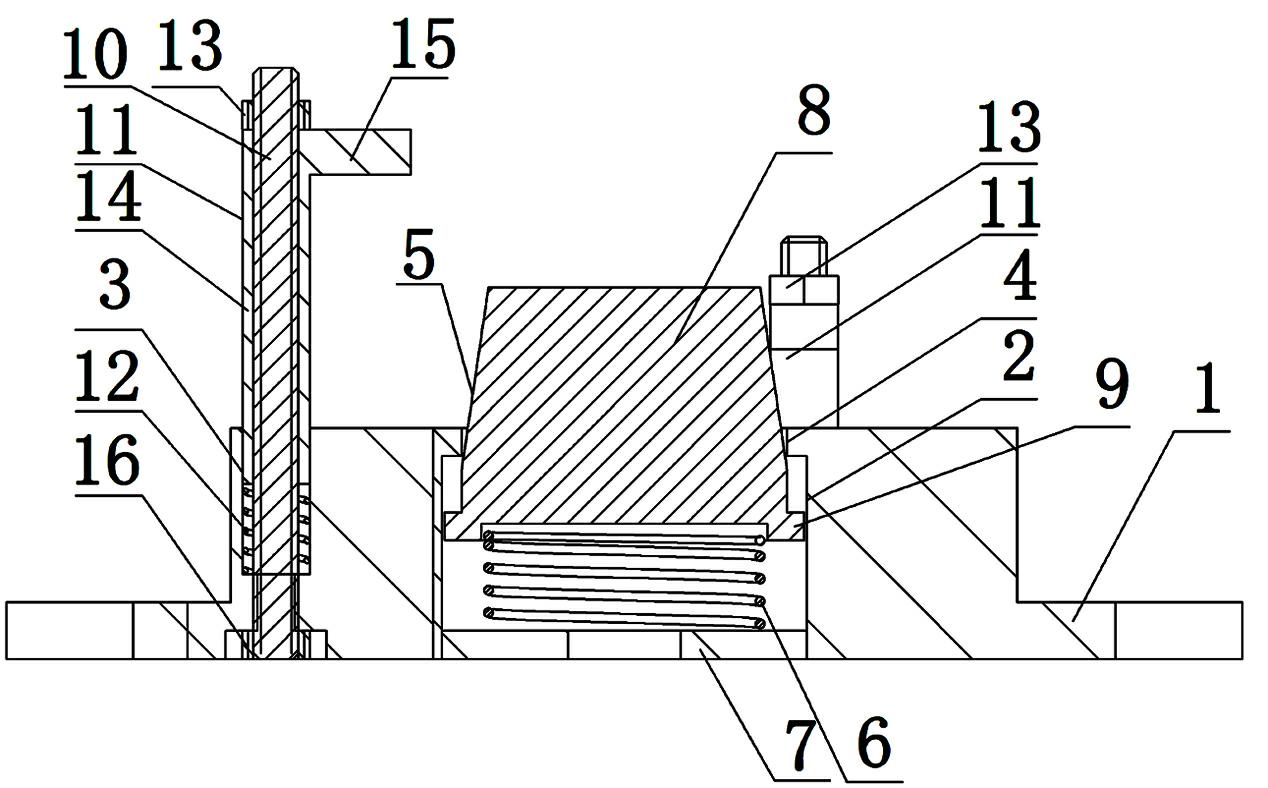

Mechanical processing positioning device

InactiveCN102490037AWide range of positioningOvercome sizePositioning apparatusMetal-working holdersEngineeringMachining

The invention disclose a mechanical processing positioning device, which comprises a base (1), an adjusting support assembly and an adjustable clamping mechanism, wherein the adjusting support assembly comprises a cylindrical taper pin (5), a compression spring A (6) and a screw plug (7), the cylindrical taper pin (5) is arranged in an inner cavity (2), the adjustable clamping mechanism comprises an adjusting screw rod (10), a press plate (11) and a compression spring B (12), the press plate (11) and the compression spring B (12) are sheathed outside the adjusting screw rod (10), and the adjusting screw rod (10) penetrates through a through hole (3) arranged on the base (1) and is fixed by a locking screw bolt (16). The mechanical processing positioning device has the beneficial effects that the diameter of the large end of a cone front part (8) is greater than the diameter of a blank hole, the wider positioning range is realized, the cylindrical taper pin (5) is tightly matched with the blank hole by the adjusting support assembly via the extension and retraction of the compression spring A (6), the influence of size and roundness errors of the blank hole can be overcome, the matching clearance is eliminated, and the positioning error is greatly reduced.

Owner:成都恒高机械电子有限公司

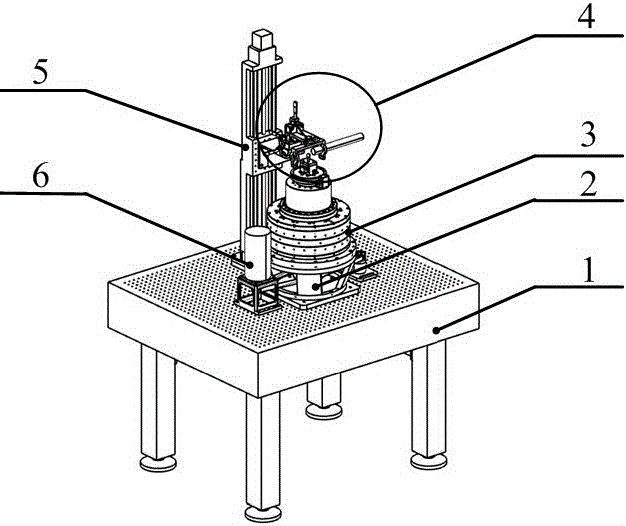

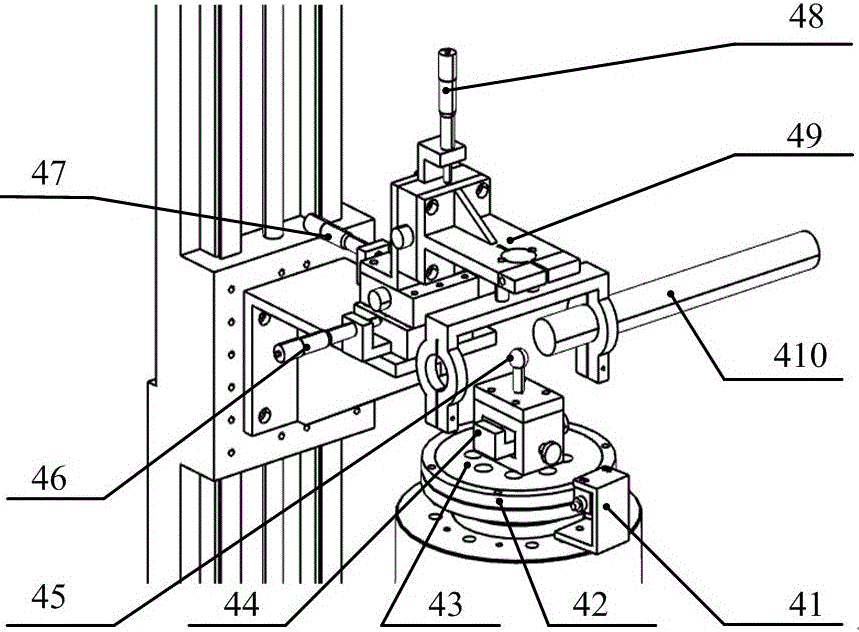

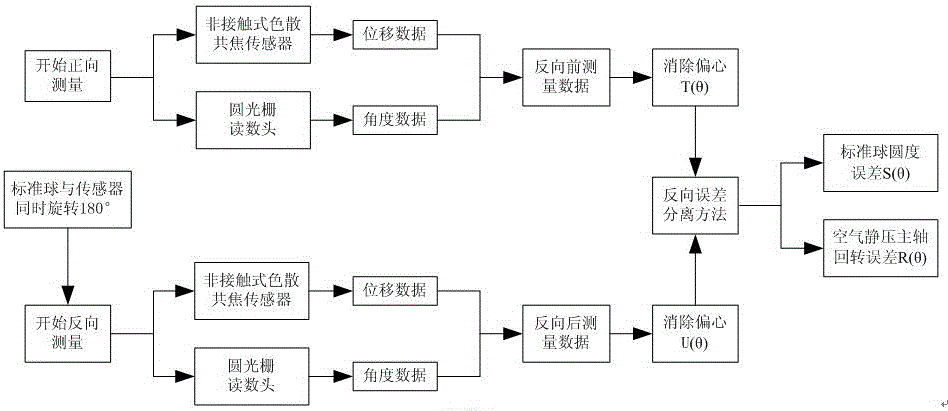

Rotation error measuring apparatus of aerostatic spindle

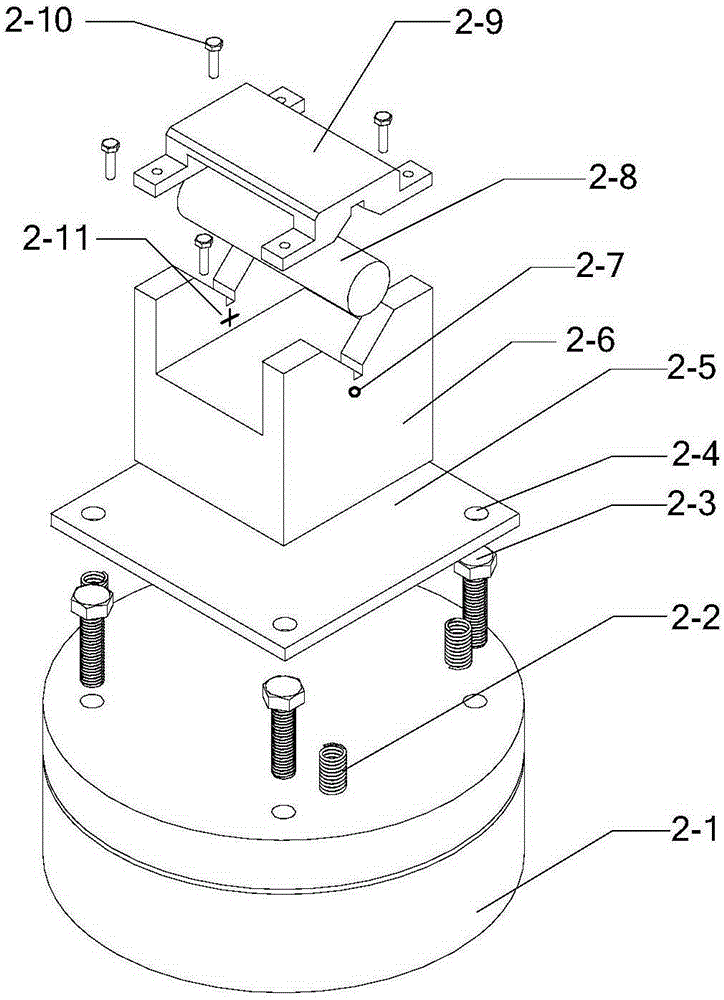

ActiveCN106556367AHigh measurement accuracyAccurate separationMeasurement devicesGratingAngular degrees

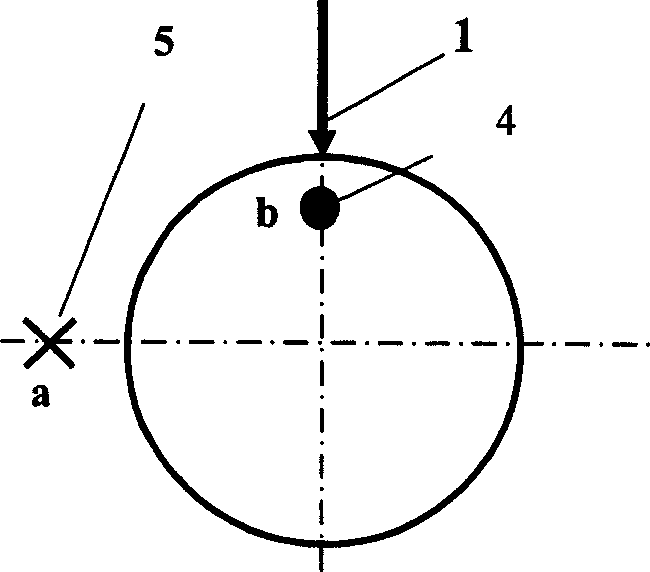

The invention provides a rotation error measuring apparatus of an aerostatic spindle. A left-right differential thread mechanism, a front-rear differential thread mechanism, and an up-down differential thread mechanism of the apparatus are used for guaranteeing the distance between the equator line of a standard ball and a non-contact displacement sensor is 70 [mu]m to 80 [mu]m, a standard ball installation seat is used for realizing submicron eccentric adjustment of the standard ball and the rotation axis of the aerostatic spindle, a sensor installation support is used for realizing 180-degreee rotation positioning of the non-contact displacement sensor before and after reverse measurement, an index plate is used for realizing 180-degree rotation positioning of the standard ball before and after reverse measurement, and a circular grating and a reading head are used for realizing strict equivalence of angles corresponding to sampling points of measuring data before and after reverse direction. According to the rotation error measuring apparatus of the aerostatic spindle, the rotation errors of the aerostatic spindle and the roundness errors of the standard ball can be accurately separated, and the measuring precision of the rotation errors of the aerostatic spindle is improved.

Owner:INST OF MACHINERY MFG TECH CHINA ACAD OF ENG PHYSICS

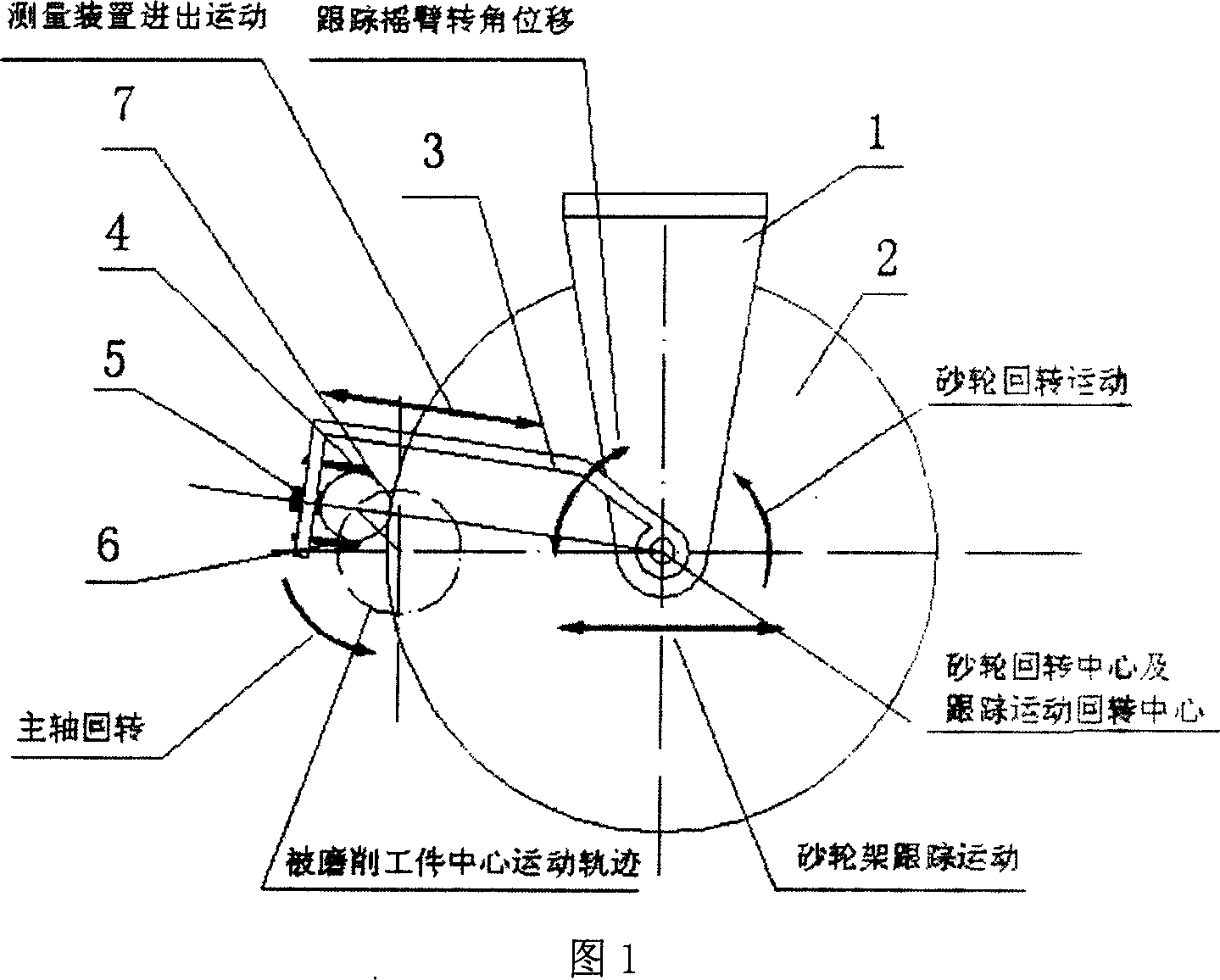

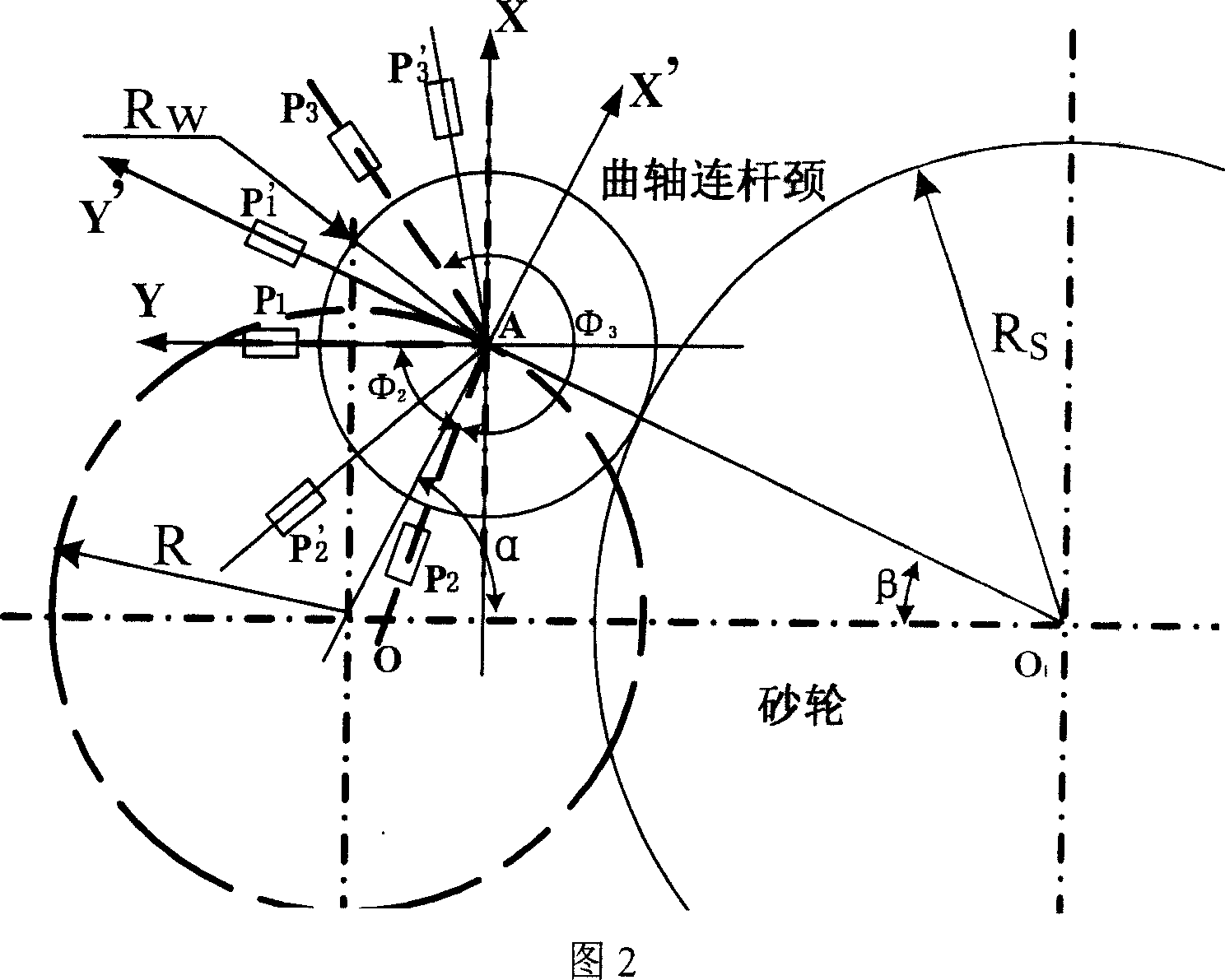

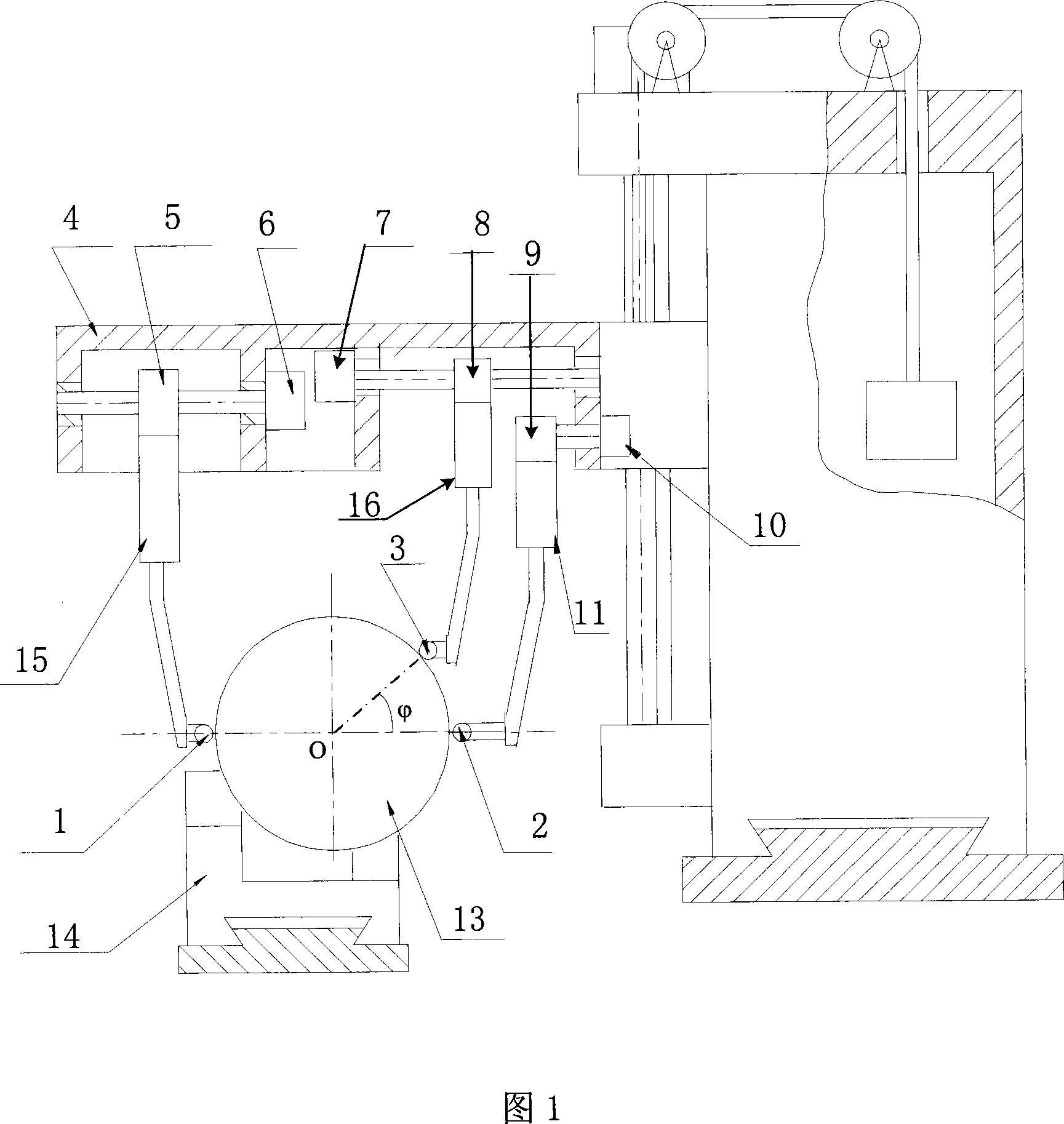

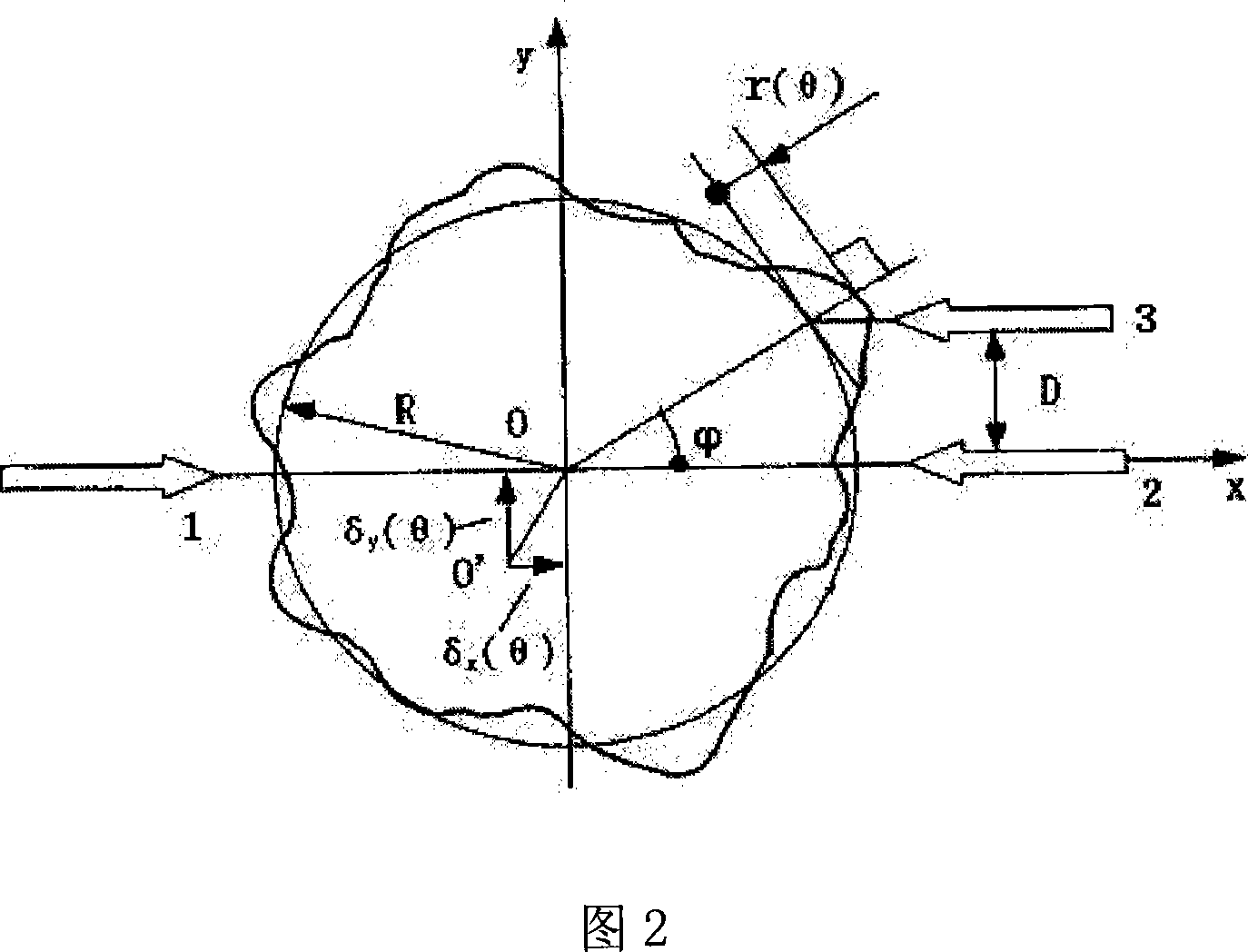

Follow measuring method of crankshaft connecting rod roundness

InactiveCN101279438AMeasurement roundness error eliminationSimple structureRevolution surface grinding machinesGrinding feed controlVertical planeEngineering

The invention belongs to the field of the mechanical processing, in particular to a follow measurement method for roundness of a crankshaft pin, which is characterized in that a measuring head is arranged on a grinding carriage guide rail, and the vertical plane of the measuring head leans tightly against the external surface of the crankshaft pin to be measured; a crankshaft pin specimen is selected, and an on-line measurement roundness error at various angles of the connecting rod journal specimen is measured on line; the actual roundness error is deducted from the measured roundness error of the specimen so as to obtain fixed roundness error of the measuring system; the data about the fixed roundness error are input into the measuring system, the workpieces are arranged, and the actual roundness error of the connecting rod journal workpiece can be obtained by automatically subtracting the fixed roundness error of the workpiece from the measuring roundness error of the workpiece, and the numeral system carries out another machining to eliminate the workpiece roundness error, according to the correction program data of the actual roundness error of the workpiece. The follow measurement method of the invention adopts single-point measurement, thus having the advantages of simple structure, convenient measurement, being scientific and rational and having good economy.

Owner:潘旭华

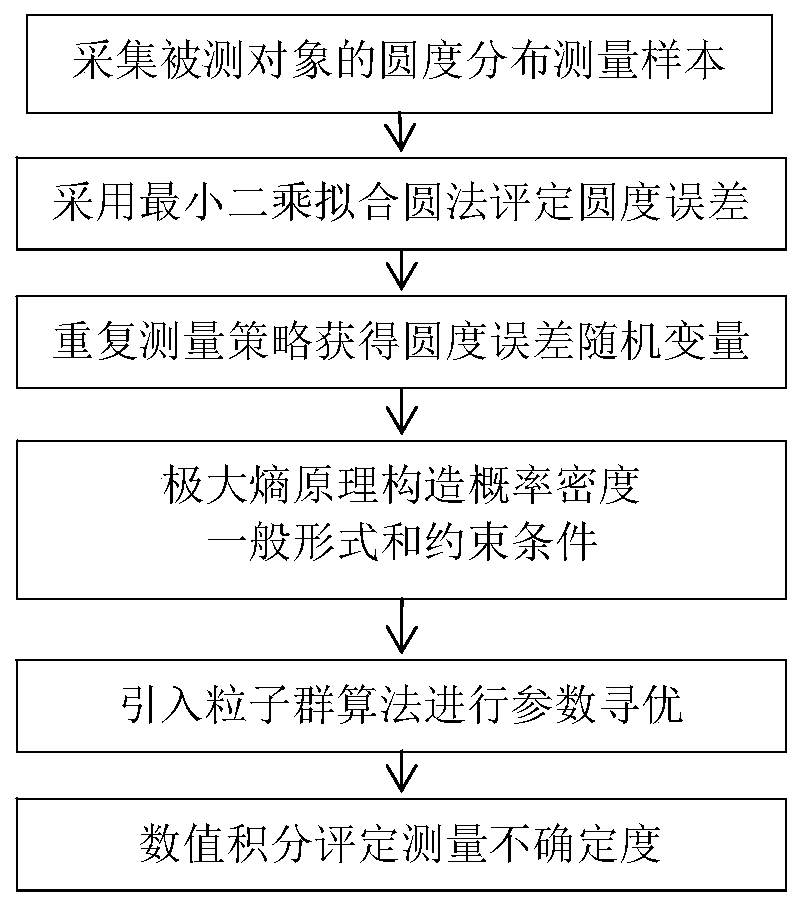

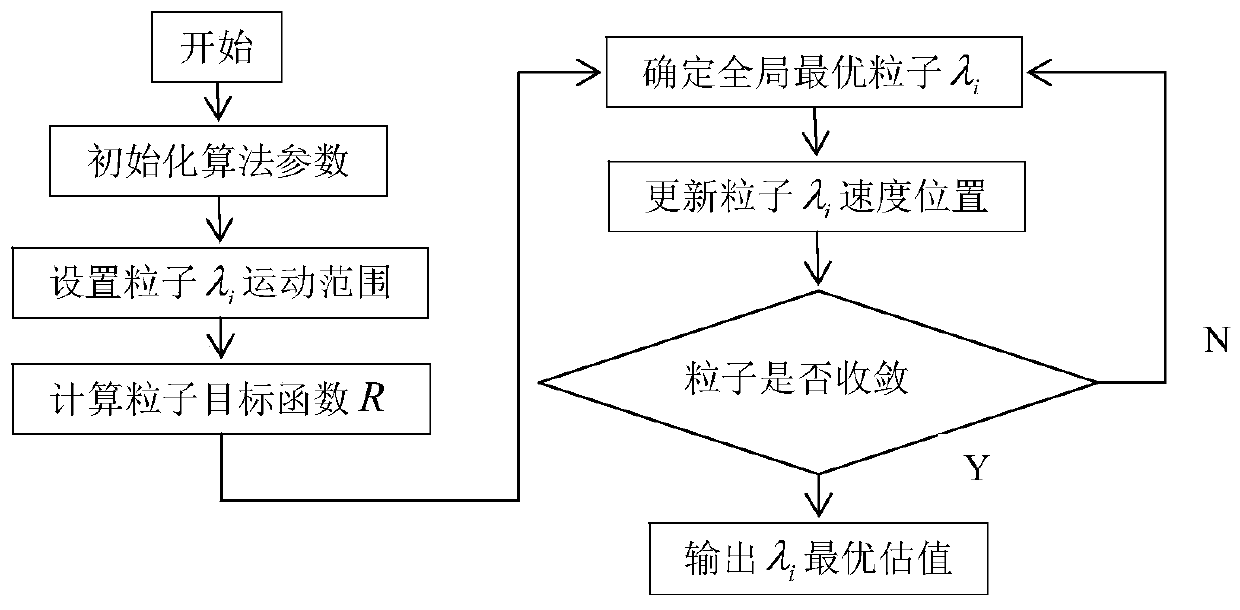

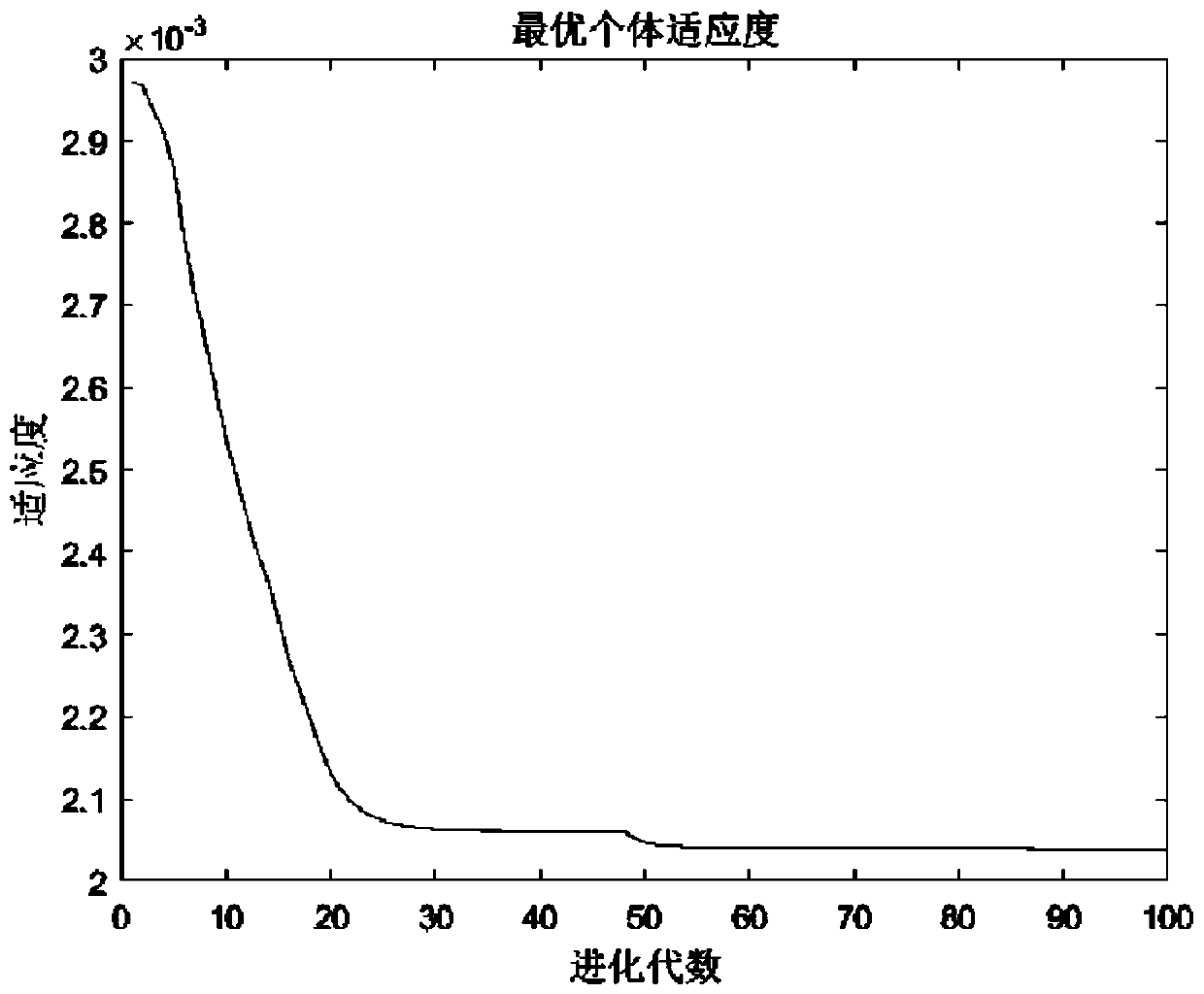

Roundness uncertainty evaluation method based on probability density function estimation

PendingCN110543618ARealize intelligent evaluation of measurement uncertaintyGuaranteed measurement accuracyComplex mathematical operationsSmall sampleFast algorithm

The invention provides a roundness uncertainty evaluation method based on probability density function estimation, and the method comprises the steps: carrying out the roundness sampling of a measuredobject, and obtaining a group of measurement point data; fitting a circle according to the measurement point data, and calculating a roundness error; acquiring a plurality of groups of measurement point data to obtain a plurality of roundness errors, and taking the roundness errors as a group of random variables; establishing a random variable probability density function, a sample origin momentgenerated through random variable calculation replacing a theoretical origin moment for mathematical change, and constructing constraint conditions of probability density; taking the origin moment ofthe sample as a condition, taking a probability density constraint condition as an objective function, and obtaining a probability density function of the roundness error; and performing numerical integration on the probability density function to calculate the standard deviation of the probability density so as to realize uncertainty evaluation of roundness measurement. The roundness error measurement uncertainty evaluation method can realize roundness error measurement uncertainty evaluation of small samples, and has the characteristics of fast algorithm convergence and stable calculation numerical value.

Owner:SHANGHAI INST OF TECH

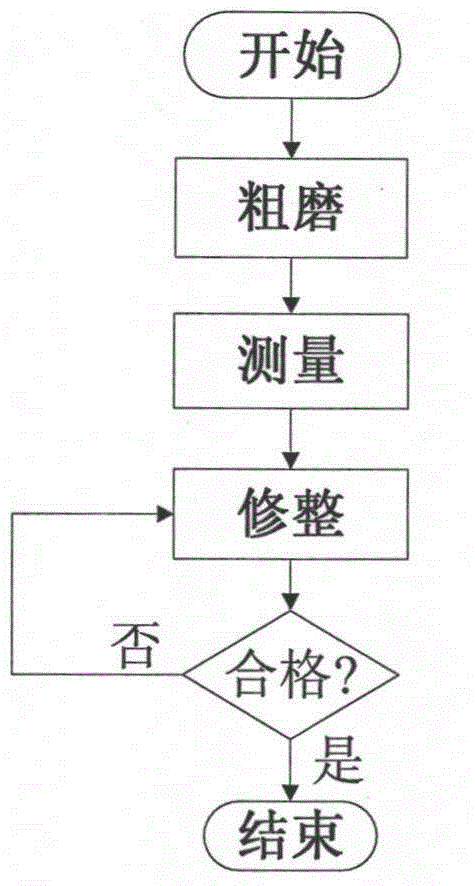

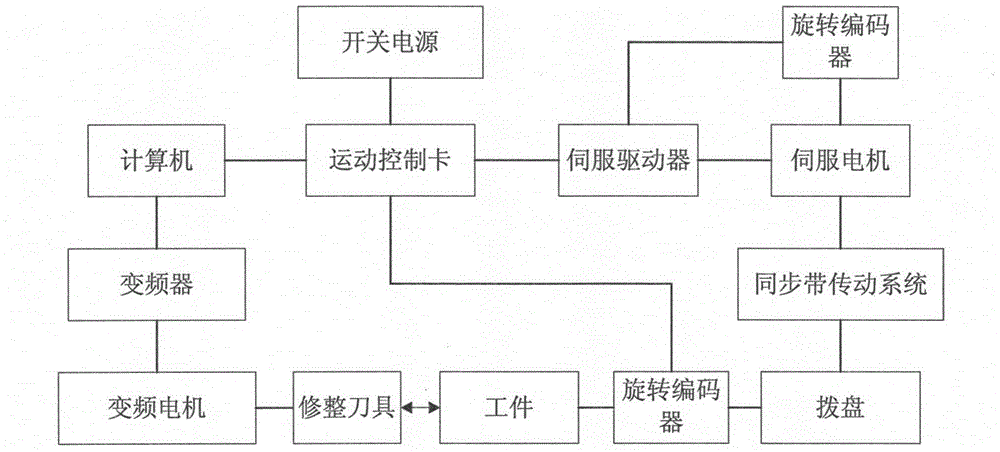

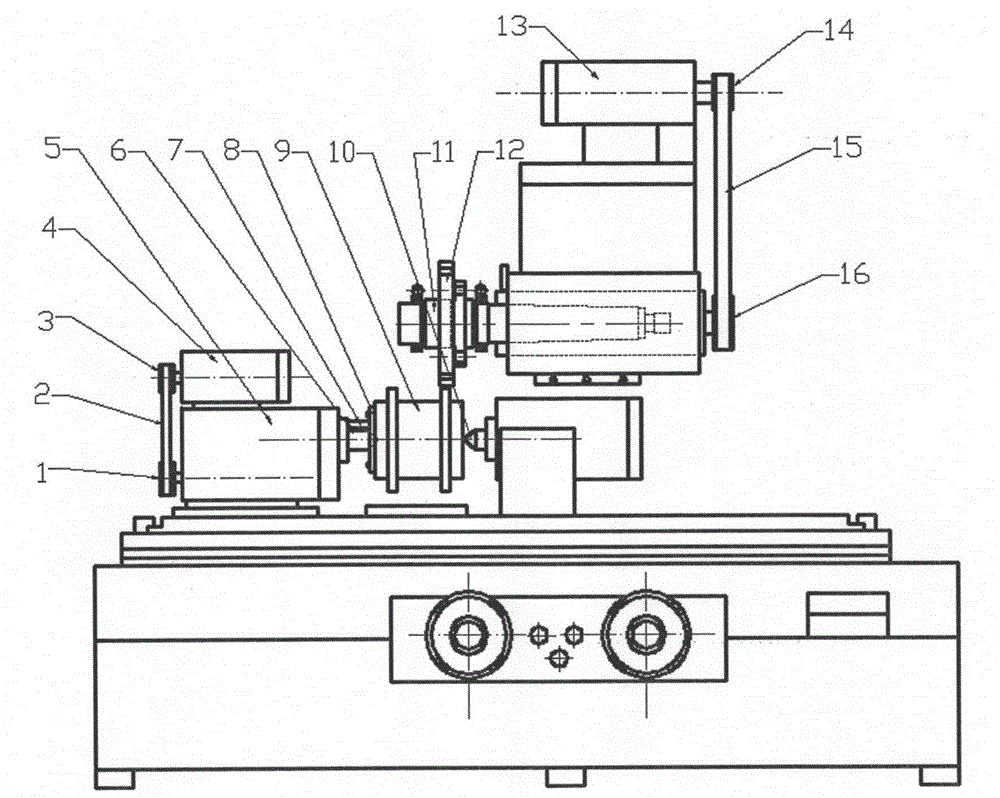

Rotary part arc trimming algorithm and control system using same

InactiveCN104400649ALow costOperational intelligenceGrinding feed controlGrinding machinesElectric machineControl system

The invention provides a rotary part arc trimming algorithm. The rotary part arc trimming algorithm is characterized by comprising the steps that parameters are initialized; roundness measurement is carried out; a roundness error is evaluated; angular speeds of trimming joints are determined; the motor rotating speed control pulse number which should be input for controlling the motor rotation is obtained, an indexing angle alpha is converted into a control angle of the motor, and then the control angle of the motor is converted into a corresponding motor angle control pulse number; and the motor controls a trimming tool to complete trimming of a workpiece to be trimmed according to the motor rotating speed control pulse number and the motor angle control pulse number. According to the other technical scheme, the invention provides a rotary part arc trimming control system using the rotary part arc trimming algorithm. According to the invention, on the premise that rotary part arc trimming cost is reduced, the roundness error can be rapidly converged; and the rotary part arc trimming algorithm and the rotary part arc trimming control system have the beneficial effects of being low in cost, high in efficiency and intelligentized.

Owner:DONGHUA UNIV

Diameter and parallel multiple-position measurement method for roller roundness error and machine tool principal axis movement error

InactiveCN101055165ASolve the problem of roundness error on-machine measurementEasy to implementElectric/magnetic contours/curvatures measurementsUsing electrical meansTime domainEngineering

The invention relates to a method for diameter and parallel multi-bit measuring roller roundness error and machine spindle motion error, including two displacement sensor diameter disposed on the periphery of the measurement section of the measured roller, one of which used as reference position sensor, while another as measurement sensor with one parallel setting displacement sensor, keeping relative movement with roller surface on different measurement position through roller multi-displacement, obtaining the redundant information of the detected section surface of the roller, establishing corresponding multi-bit roundness error separation equation, and converting the time domain signal in the collected redundant information to the frequency domain signal and analyzing, separating on-machine the roundness error of eccentric rotating motion roller and motion error of the main spindle, thereby realizing the measurement and separation of roller roundness and machine spindle motion error. The invention which is easy to be applied is capable of solving the roundness error online measurement problem of eccentric rotating motion roller, and can be extended to the online measurement and separation of the roundness error of common spindle part and machine spindle motion error.

Owner:SHANGHAI UNIV +1

Strength-strengthening method for use in super-thin complicated part processing

InactiveCN101069949AMeet lightweight requirementsReduce processing deformationPositioning apparatusMetal-working holdersAlloyUltimate tensile strength

The invention belongs to mechanical cool-working technology, which relates to an intensity enhancing method to process ultra-thin complex parts. The invention casts low melting point alloy outside the parts to process ultra-thin (<= 0.5mm) complex cavity parts. It can process ultra-thin products with different shapes to meet the lightweight requirements. It has small processing distortion and the roundness errors of the processed holes are controlled within 0.007mm. It has high processing precision and can realize multi-surface process with one clamping, which can guarantee the correlating size precision. The shapes of the workpieces can be designed as cuboids to facilitate the clamping and positioning.

Owner:中国航空工业第一集团公司第六一三研究所

Method for separating and handling thermal error, roundness error and turning error of main shaft of machine tool

ActiveCN105234745AAchieve separationHigh precisionMeasurement/indication equipmentsElectricityEngineering

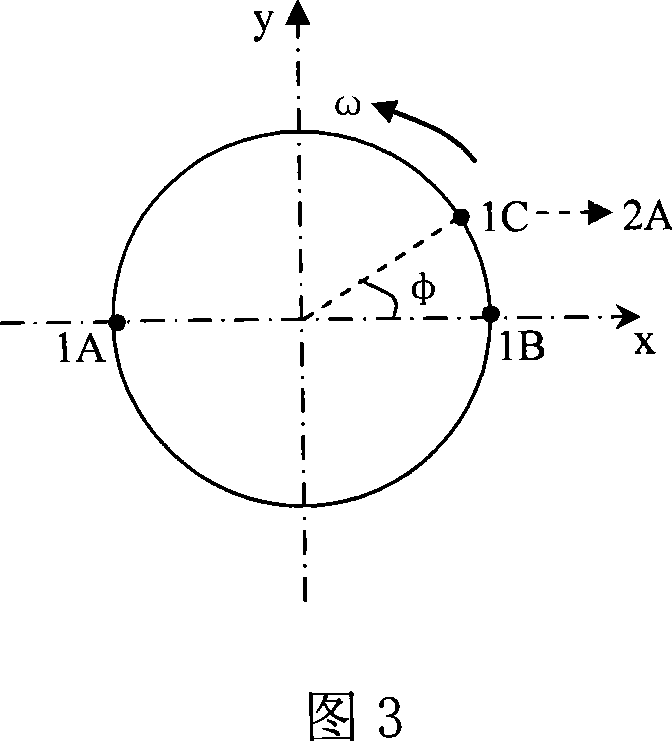

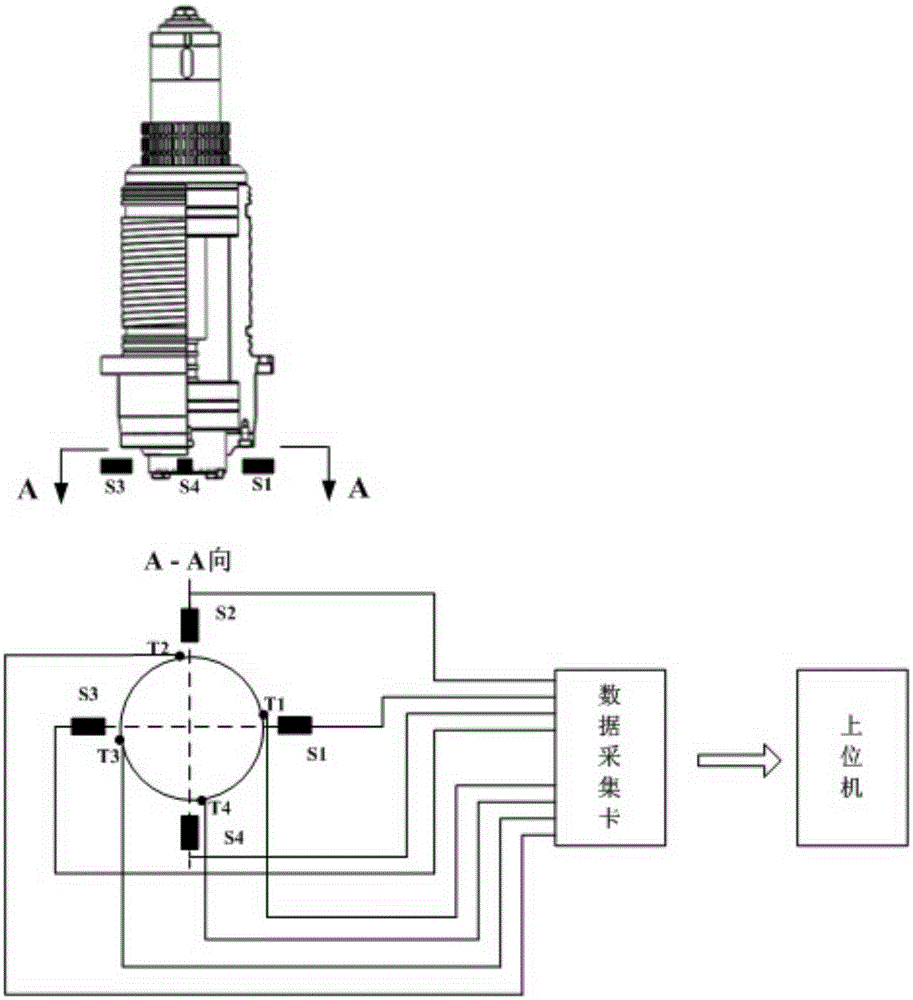

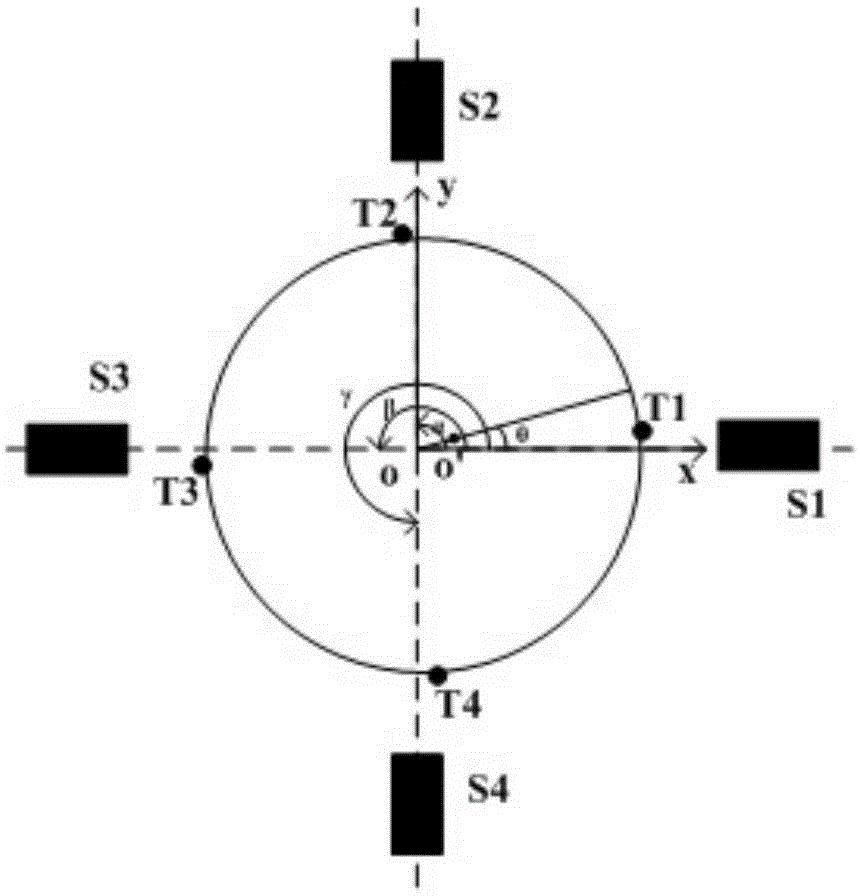

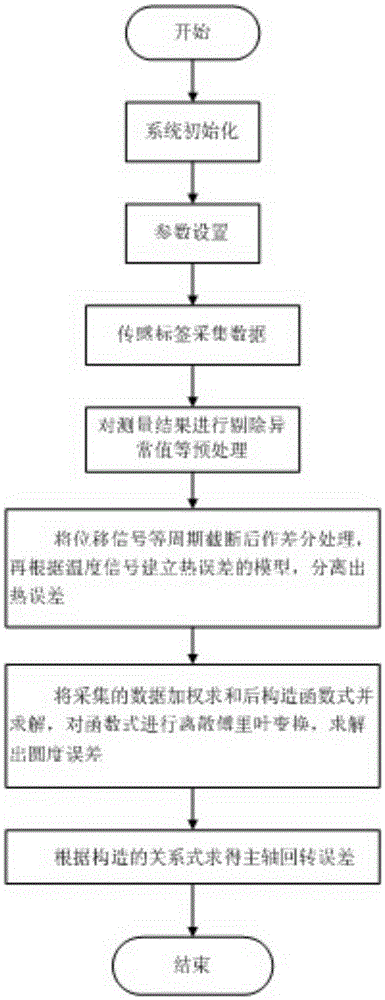

The invention discloses a method for separating and handling the thermal error, roundness error and turning error of a main shaft of a machine tool. The method comprises the steps of circumferentially uniformly distributing four temperature sensors and four electrical vortex sensors in the radial direction of the main shaft; setting the sampling time of the sensors according to the rotating speed of the main shaft, and acquiring the temperature and radial displacement signals of the main shaft of the machine tool; performing equivalent-cycle truncation for the radial displacement signals of the main shaft, and then carrying out differentiating to obtain the radial thermal displacement error of the main shaft, building a thermal error model through a least-square method, and then separating out the thermal error from the radial displacement error; performing weighted summation for the radial displacement signals of the main shaft, acquired by the four electric vortex sensors, so as to build a function relational expression, and then separating out the roundness error of the main shaft through discrete Fourier transform; subtracting the roundness error and the thermal error from the measured data, so as to separate out the turning error of the main shaft. The method achieves the separating of the radial thermal error, the roundness error and the turning error of the main shaft of the machine tool. Compared with the common three-point error separating method, the method has the advantage that the separating precision is improved.

Owner:NANTONG GUOSHENG INTELLIGENCE TECH GRP CO LTD

Method for carrying out diameter two-point six-transposition measurement on roundness error of large-scale shaft part and kinematic error of machine tool spindle

InactiveCN102506800ASolve the problem of roundness error on-machine measurementSimple calculationMeasurement devicesMeasurement/indication equipmentsTime domainEngineering

The invention relates to a method for carrying out diameter two-point six-transposition measurement on a roundness error of a large-scale shaft part and a kinematic error of a machine tool spindle. According to the method, a time domain signal acquired in the measuring process of six different transpositions according to two displacement sensors which are diametrically arranged is transformed into a frequency domain to be analyzed, and the roundness error of the large-scale shaft part which takes the eccentric rotating motion is separated from the kinematic error of the spindle by a machine, so that the on-line measurement of the roundness error of the large-scale shaft part and the motion of the spindle is realized and the measurement accuracy is improved.

Owner:TIANJIN UNIV OF TECH & EDUCATION TEACHER DEV CENT OF CHINA VOCATIONAL TRAINING & GUIDANCE

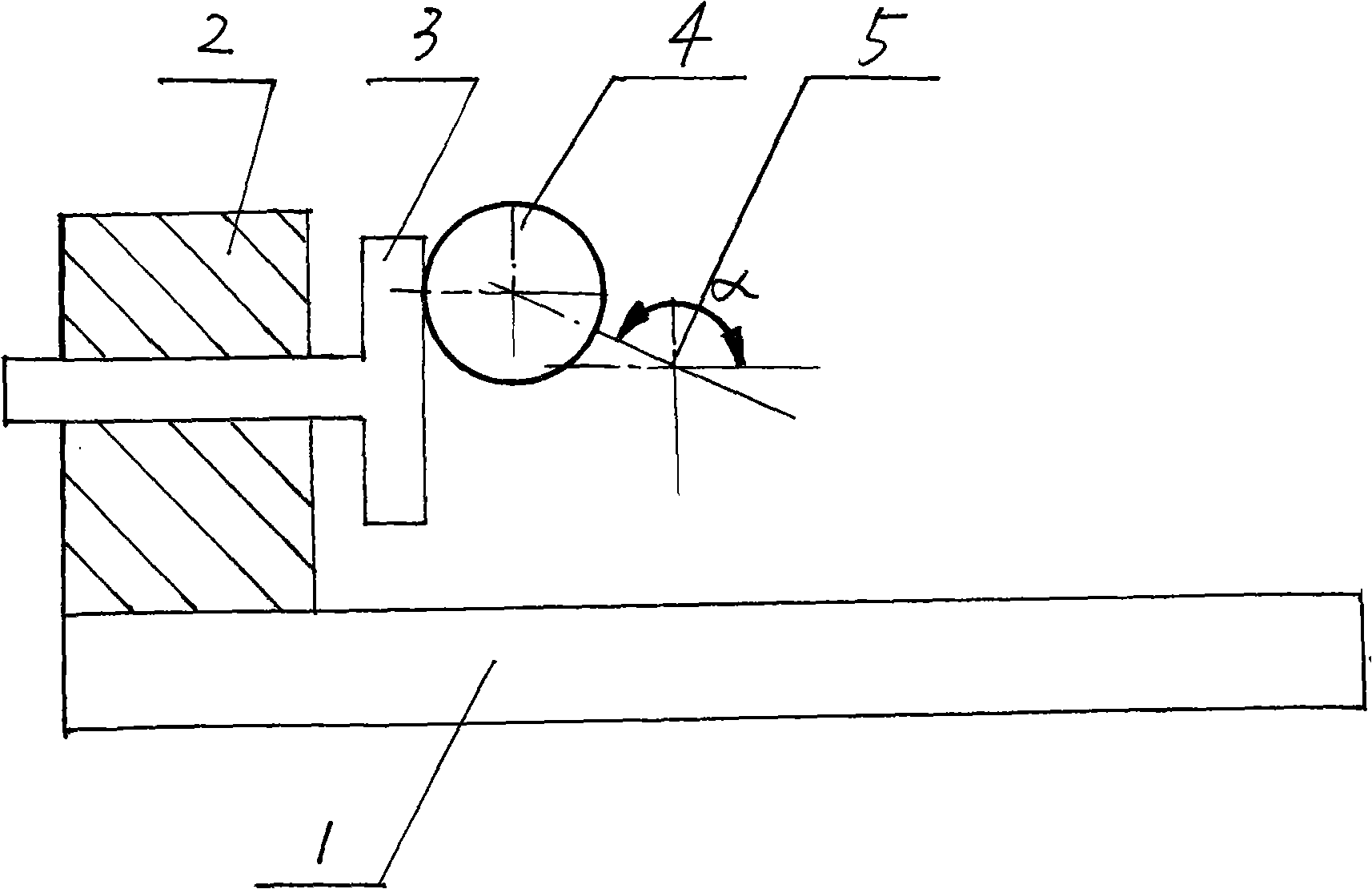

Bar centerless grinding technology and special knife board adjusting device thereof

InactiveCN102773776ASimple structureEasy to debug and maintainRevolution surface grinding machinesEngineeringMachining

The invention relates to a bar centerless grinding technology and a special knife board adjusting device thereof; the bar centerless grinding technology comprises the following steps of: firstly carrying out rough machining on a bar so as to enable the workpiece allowance to be between 0.3mm and 0.5mm, the roundness error is below 0.10mm and the straightness accuracy is within 1mm / m; the bar centerless grinding technology and the special knife board adjusting device thereof disclosed by the invention can efficiently eliminate or reduce the original roundness error of a bar blank, thereby controlling the roundness error of a workpiece finished product, improving the product percent of pass and saving the production cost; the whole process flow is simple in process and easy to operate; and the special knife board adjusting device is simple in structure, and convenient to debug and maintain.

Owner:BAOSTEEL DEV CO LTD

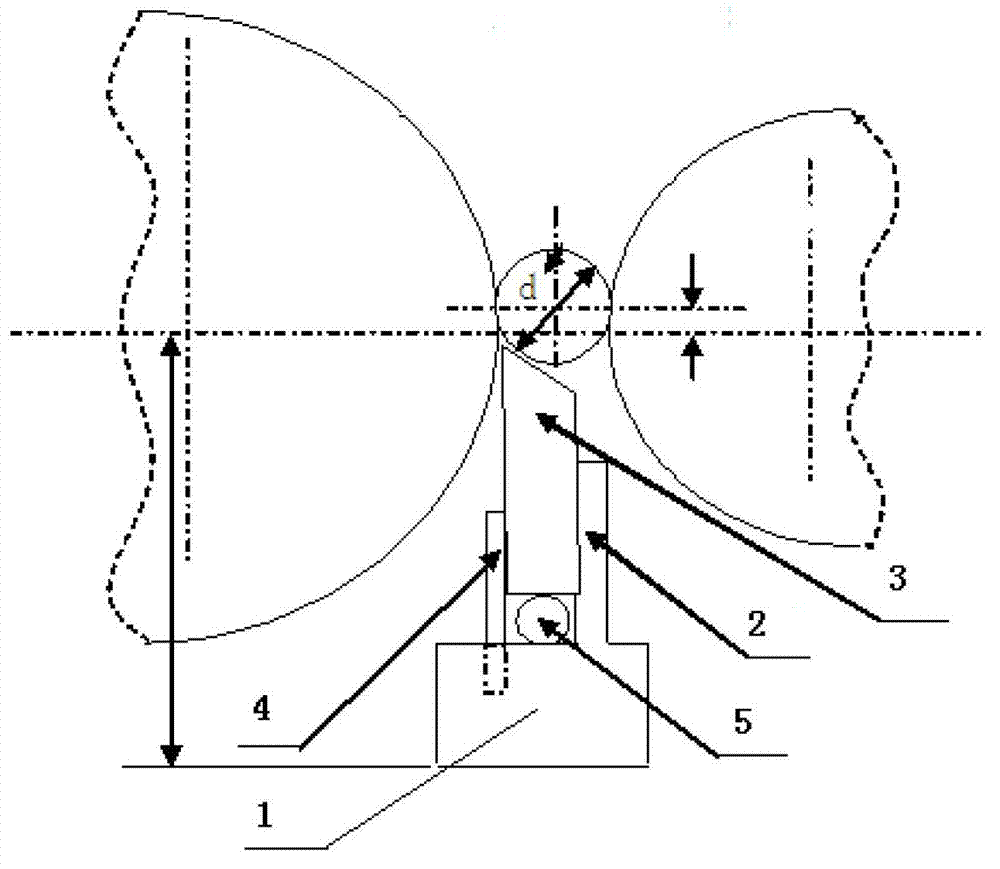

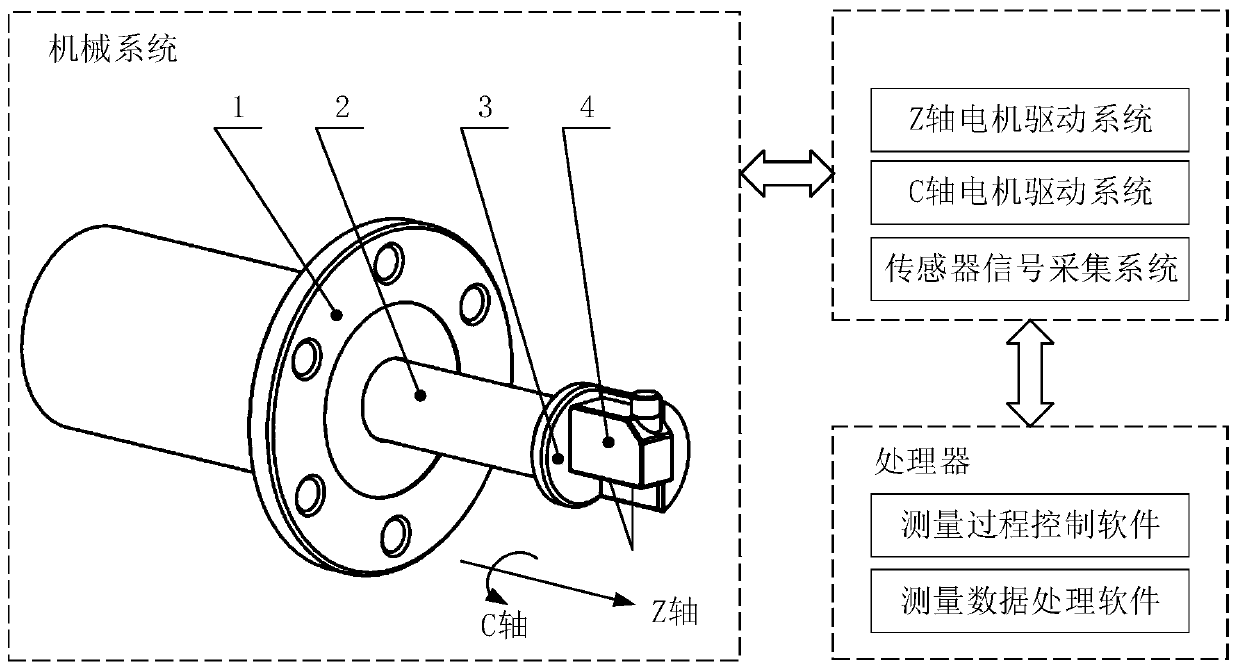

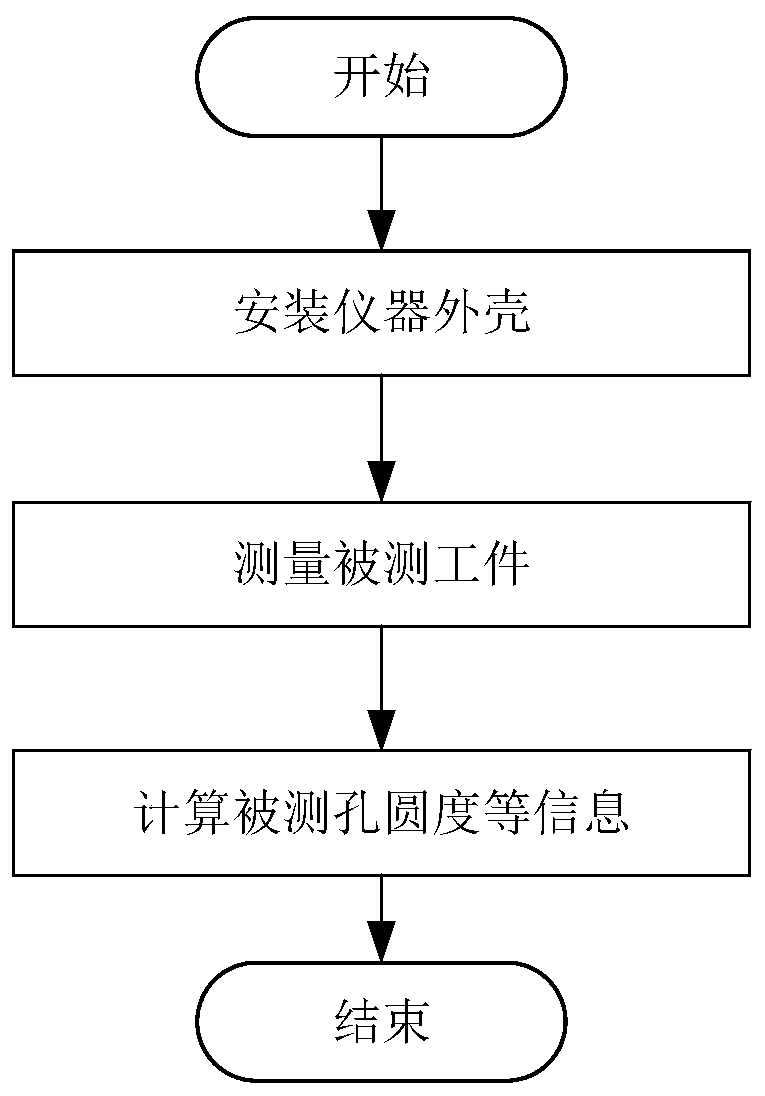

Device and method for measuring roundness of inner hole of large-sized part

ActiveCN110470242AReduce volumeSolve the problem of in-situ measurement of inner hole roundnessUsing optical meansMeasurement deviceEngineering

The invention belongs to the field of precision testing and relates to a device and method for measuring the roundness of the inner hole of a large-sized part. According to the method, an instrument main shaft provided with non-contact displacement sensors is controlled to move along a Z axis to a set position in the inner hole of a to-be-measured workpiece, and then to rotate at least one circlealong a C axis; the readings of the sensors of the to-be-measured workpiece which are distributed at M sampling points on the inner hole of the to-be-measured workpiece, and the corresponding angulardisplacement data of the C axis are recorded in the rotating process of the instrument main shaft; least square circle fitting is performed according to the readings of the sensors of the to-be-measured workpiece at the M sampling points and the corresponding angular displacement data of the C axis, so that the center of a first least square circle can be obtained; distances between the M samplingpoints to the center are calculated, the difference value of the maximum value and minimum value of the distances is adopted as the roundness error of the inner hole of the to-be-measured workpiece;and therefore, the measurement of the roundness of the inner hole of the to-be-measured workpiece is realized, and the problem that the roundness of the inner hole of a large-sized key part is difficult to measure is solved.

Owner:贵阳新天光电科技有限公司

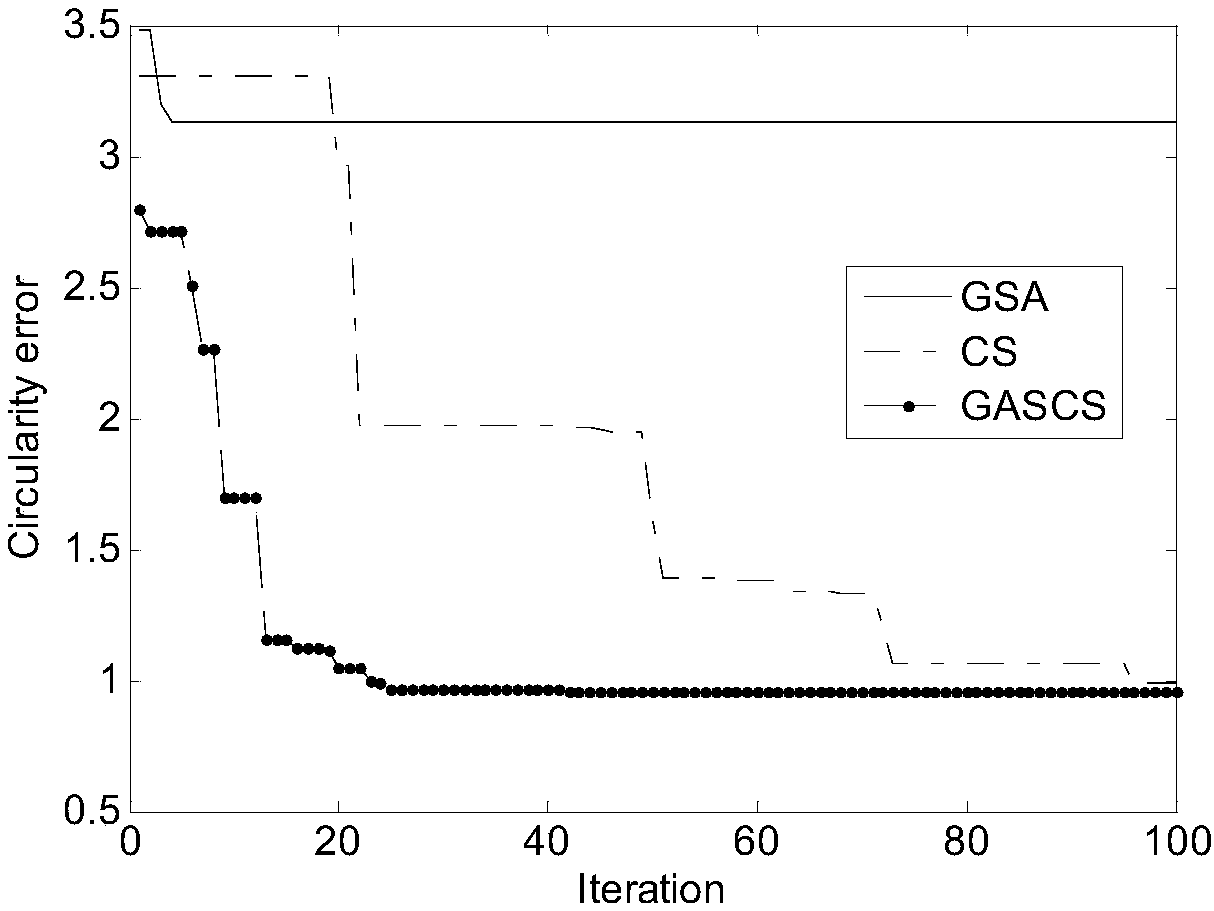

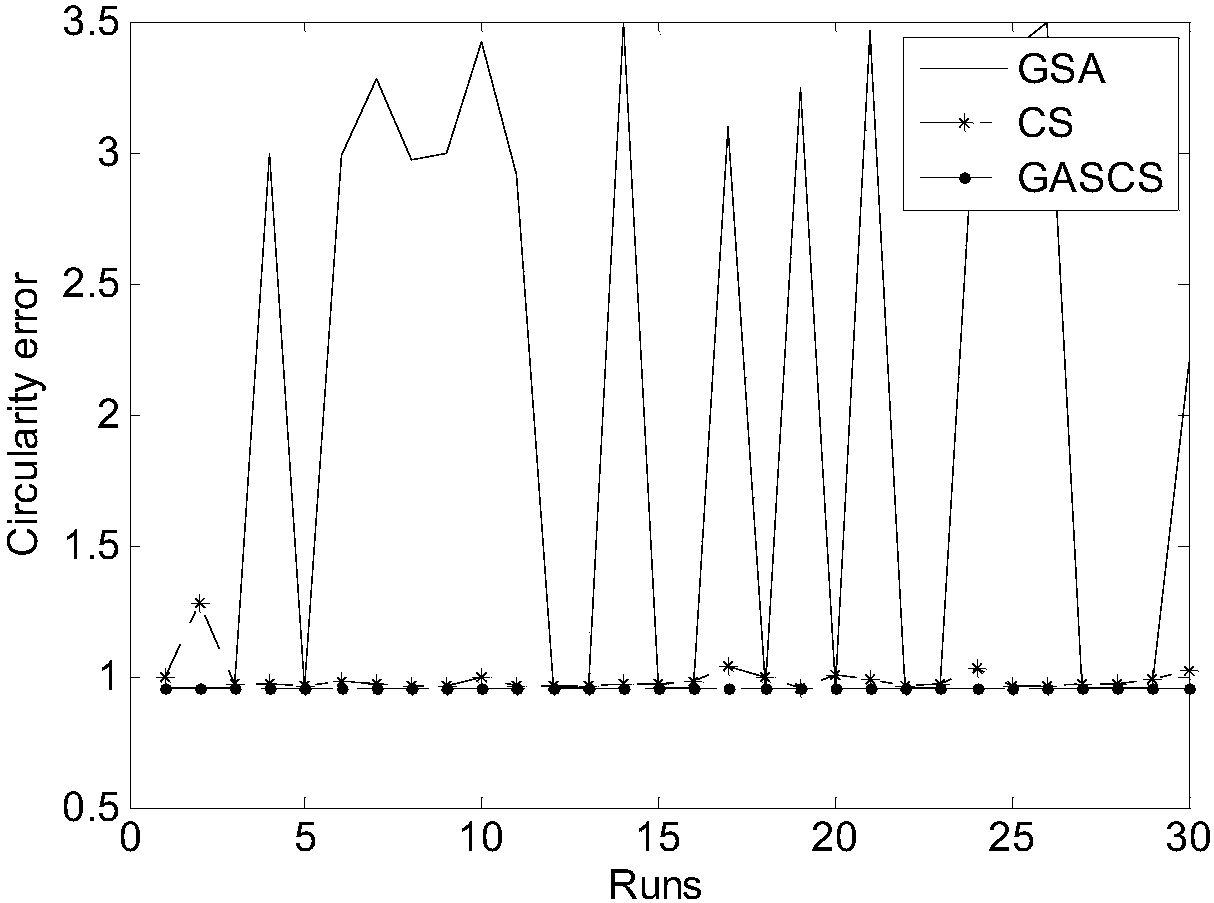

Roundness error evaluating method based on gravitational acceleration cuckoo algorithm

ActiveCN107747930AAvoid hysteresisImprove efficiencyMeasurement devicesArtificial lifeCuckooHysteresis phenomenon

Disclosed is a roundness error evaluating method based on a gravitational acceleration cuckoo algorithm. Based on gravitational search, the characteristics of global optimal information can still be perceived without learning the change of external environmental factors. Cuckoo nests are endowed with different individual masses, and the cuckoo nests obey the law of gravitation in the optimizationprocess. Acceleration search is carried out on Levy flight random walk and preferential random walk in the cuckoo algorithm based on the gravity among optimization individuals to get the update locations of corresponding cuckoo parasitic nest individuals. Under the action of gravity, the global search ability and the local search ability of the cuckoo algorithm are balanced, the hysteresis phenomenon due to the fact that the algorithm gets into a local extreme point at the end of execution is avoided, and the global search efficiency and convergence precision of the algorithm are improved. Theroundness error E to be optimized can quickly tend to be a stable optimal value. The ideal centers Xmin(1) and Xmin(2) of two concentric circles are calculated, and thus, the area between the two concentric circles is the minimum.

Owner:HUAQIAO UNIVERSITY

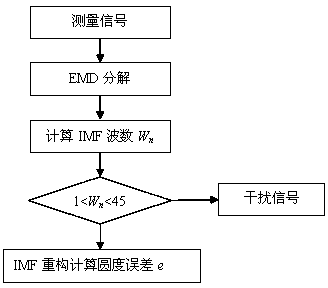

Roundness error evaluating method based on EMD (empirical mode decomposition)

ActiveCN104034299AAccurate removalImprove anti-interference abilityMeasurement devicesDecompositionComputer science

The invention discloses a roundness error evaluating method based on EMD. The method comprises performing angle sampling on a workpiece within one circle to obtain radius data of the workpiece, performing EMD on the radius data to decompose the radius data into a plurality of intrinsic mode functions (IMF) and a residual component from high frequency to low frequency, removing interference signal components through wave numbers; performing reconstitution through residue IMF to obtain surface shape error signals and further to calculate roundness errors. The roundness error evaluating method based on EMD is high in anti-interference performance, self-adapting, higher in analysis precision compared with traditional methods, rapid and convenient in the entire analysis process and easy to master by users.

Owner:浙江知多多网络科技有限公司

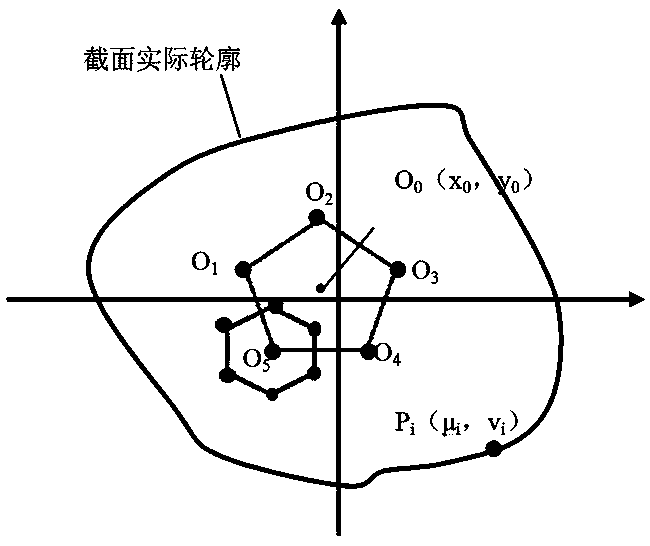

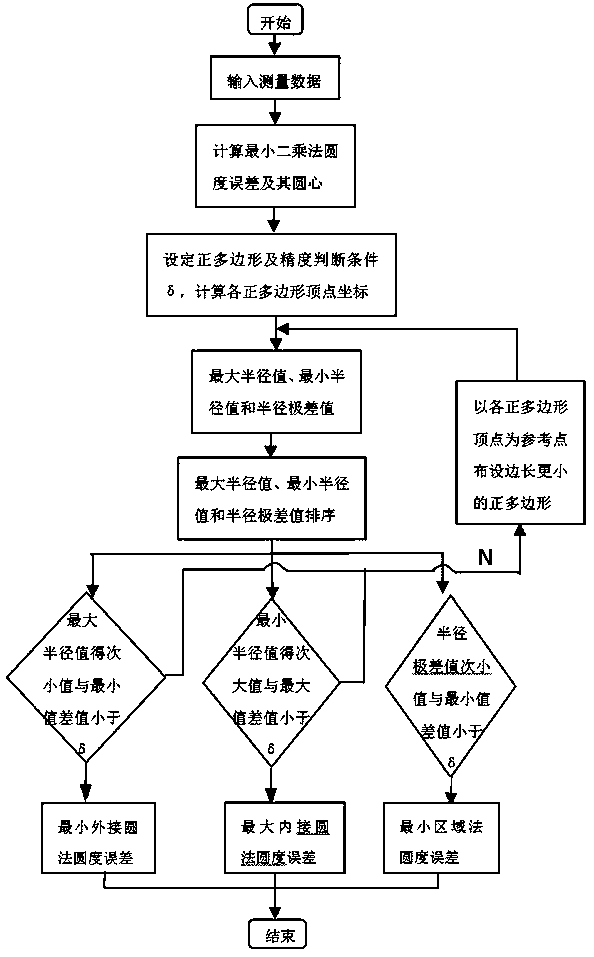

Novel circularity error evaluation algorithm

ActiveCN108871256AAccurate assessment meetsThe principle of the method is simpleMeasurement devicesManufacturing computing systemsMeasurement pointMeasuring instrument

The present invention belongs to the technical field of measurement tools, and especially relates to a novel circularity error evaluation algorithm. The algorithm takes a least-square center of a revolution body workpiece section as a reference point, a certain value (such as the least-square circularity error of the section or the estimated circularity error) is taken as a side length to construct a regular polygon, a plurality of vertexes of the regular polygon are orderly used as the centers to calculate the radius values from each vertex to all the measurement points, find out the maximumradius, the minimum radius and a range value of the radius when each vertex is the center and the corresponding center coordinate points are determined according to the definition of the circularity error evaluation algorithm (the minimum region method, the minimum circumscribed circle method and the maximum inscribed circle method) so as to obtain the required circularity error. The method is simple in principle and easy to implement and high in universality, circularity error evaluation software is easily installed on roundness measuring equipment, a coordinate measuring machine and other roundness precision measuring instruments with computers, the accurate evaluation of the circularity error can be met and the novel circularity error evaluation algorithm can be applied to the evaluation of other form and position errors in the practical engineering.

Owner:湖北爱默思智能检测装备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com