Follow measuring method of crankshaft connecting rod roundness

A technology of a crankshaft connecting rod and a measuring method is applied in the directions of grinding machine parts, workpiece feed motion control, machine tools designed for grinding workpiece rotating surfaces, etc. and other problems, to achieve the effect of simple structure, good economy and convenient measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

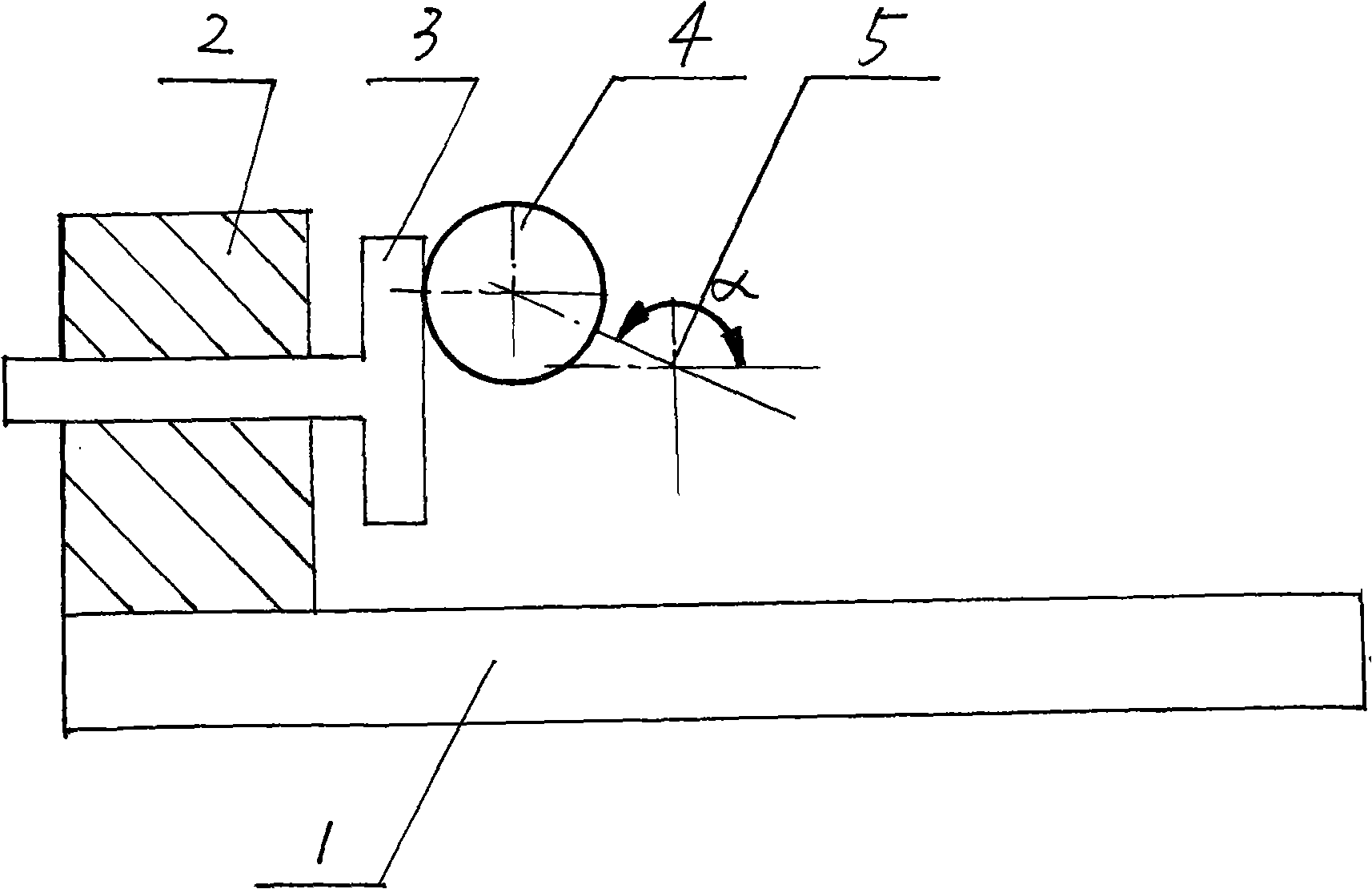

[0008] Such as figure 1 As shown, a follow-up measurement method for crankshaft connecting rod neck roundness is characterized in that:

[0009] A. Install the measuring head 3 on the wheel frame guide rail 1 from the measuring head seat 2, and the vertical surface of the measuring head is close to the outer surface of the connecting rod journal 4 of the crankshaft 5 to be tested;

[0010] B. Select a crankshaft connecting rod neck test piece, rotate the crankshaft 5, and move the grinding wheel frame guide rail 1 synchronously when the crankshaft rotates, drive the measuring head base to move horizontally, measure the horizontal moving distance of the measuring head 3 online, and this distance is the test The roundness error of each angle of the connecting rod neck measured online includes the fixed roundness error and the actual test roundness error caused by the movement error of the wheelhead guide rail and the crankshaft rotation angle error. Roundness error of connectin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com