Rotary part arc trimming algorithm and control system using same

A technology of arc and parts, which is applied in the field of arc trimming algorithm and control system of rotary parts, can solve the problems of low efficiency, high cost, long trimming time, etc., and achieve the effect of reducing cost and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to make the present invention more comprehensible, preferred embodiments are described in detail below with accompanying drawings.

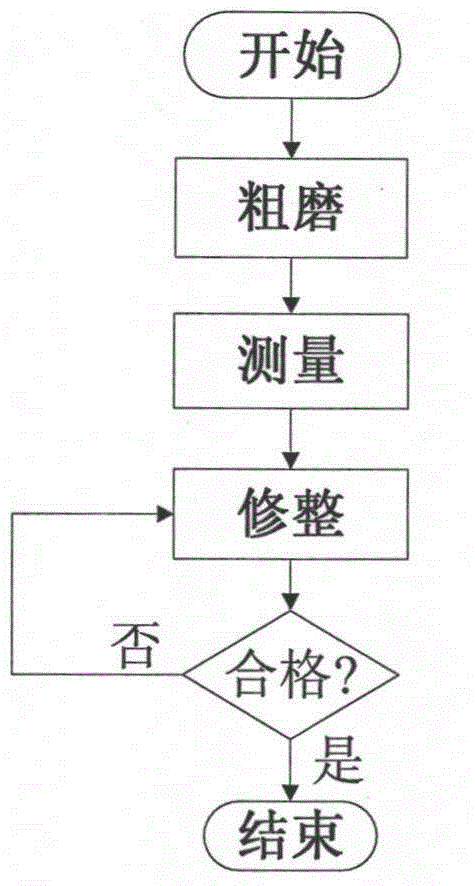

[0041] like figure 1 As shown, it is the basic principle based on the arc trimming algorithm of a rotary part disclosed in the present invention. After the workpiece has been roughly ground, the original contour error is measured, trimmed according to the error, and then measured and trimmed until the workpiece The accuracy meets the requirements.

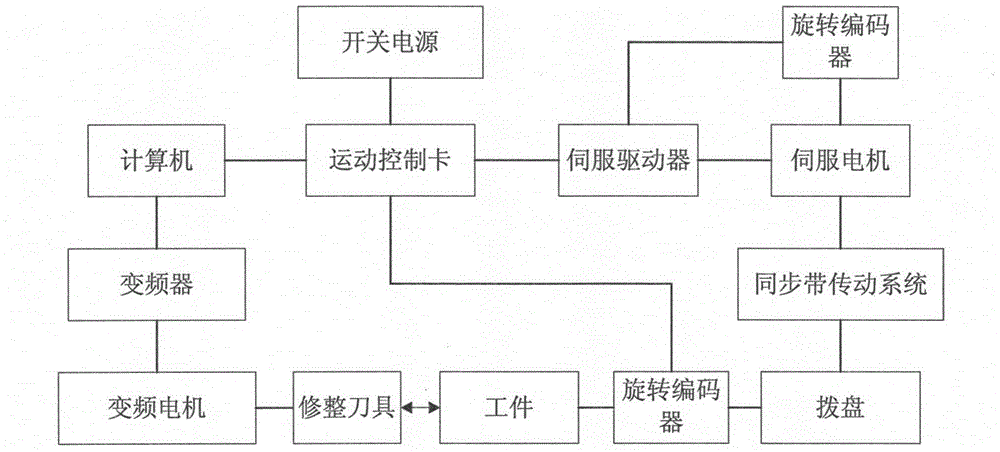

[0042] The arc trimming algorithm of rotary parts provided by the present invention can run on such figure 2 In the control system shown, the system includes a computer running the algorithm for arc trimming of rotary parts. The computer is connected to a frequency converter and a motion control card. The frequency converter is connected to a variable frequency motor. The workpiece is driven to rotate by the dial, and the rotary encoder records the number of rotations of the workpie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com